Miele G 7835 CD Operating instructions

Installation and operating instructions

Washer-Disinfector

G 7835 CD

To avoid the risk of personal injury or

damage to the appliance,

it is essential that

you read these operating instructions

before installation and use.

en-CA

M.-Nr. 07 776 530

Contents

Safety instructions and warnings ....................................4

Proper use .....................................................4

Symbols on the appliance .........................................8

Intended Use .....................................................9

Description of the appliance........................................11

Electronic controls .................................................12

Opening and closing the door ......................................14

Electric door lock ..................................................14

How to use the emergency door release................................14

Water softener ...................................................15

Setting the water softener ...........................................16

Salt indicator .....................................................16

Filling the salt reservoir .............................................16

Automatic mobile unit recognition (AWK).............................18

Mobile unit coding .................................................18

Holder with mobile unit coding .....................................19

Setting the mobile unit coding .....................................19

Applications .....................................................21

Protein testing ....................................................21

How to load the machine ............................................22

Spring-loaded adapter for the water line................................23

How to adjust the upper basket.......................................23

OR Instruments (OP) ...............................................24

Ophthalmological instruments ........................................25

Anesthesia instruments (AN) .........................................26

Baby bottles (BC) .................................................27

OR shoes (OS)....................................................28

Laboratory equipment (LG) ..........................................29

Chemical process ................................................30

Adding liquid detergents and neutralizers ............................35

Prepare the dispensing system .......................................35

Adding liquid detergents and neutralizers ............................36

Priming the dispensing system .......................................37

Servicing the dispensing system......................................37

External dispensing systems .........................................37

2

Contents

Operating the machine ............................................38

How to switch on ..................................................38

Changing the operating level ........................................38

Starting a program.................................................39

Program sequence ................................................40

Turning off .......................................................41

Cancelling a program ..............................................41

Interrupting a program..............................................42

Data transfer.....................................................43

Caring for the appliance ...........................................44

Routine maintenance ...............................................44

Process validation .................................................44

Routine checks ...................................................44

Cleaning the filters in the wash cabinet.................................45

Cleaning the coarse filter .........................................45

Cleaning the flat and micro-fine filters ...............................46

Cleaning the spray arms ............................................47

Cleaning the control panel...........................................48

Cleaning the front of the appliance ....................................48

Cleaning the wash cabinet ..........................................48

Cleaning the door seal..............................................48

Mobile units, baskets and inserts .....................................49

Servicing the drying unit ............................................50

Changing the coarse filter ........................................50

Changing the fine filter ...........................................51

Troubleshooting..................................................52

Temperature sensor................................................52

Cleaning the filters in the water inlet ...................................53

Cleaning the non-return valve and drain pump...........................54

Customer service.................................................55

Installation ......................................................56

Electrical connection..............................................58

Plumbing........................................................59

Technical data ...................................................62

Disposing of an old appliance ......................................63

3

Safety instructions and warnings

To avoid injury, please follow these

This appliance complies with all

applicable safety laws and

regulations. However, inappropriate

use can lead to personal injury and

property damage.

Read the operating instructions

carefully before using this machine.

This will help keep you safe and

avoid damage to the machine.

Keep these instructions in a safe

place.

Proper use

This machine is intended only for the

~

purposes specified in the operating

instructions. Any other uses,

conversions and modifications are not

allowed and can be dangerous.

The cleaning and disinfection

processes described here apply only to

those instruments, medical products

and labware that are specifically

designed by the manufacturer to be

re-used. Follow the product

manufacturer's instructions.

Miele will not be held liable for damage

caused by incorrect use or operation of

any kind.

This machine is intended exclusively

~

for use in interior locations.

The installation of this appliance in

~

non-stationary locations must be

performed by a qualified installer or

service agency in strict accordance

with national and local safety

regulations and standards.

instructions!

The machine must be installed,

~

maintained and repaired by a Miele

Service Technician. For best

compliance with Good Laboratory

Practice and regulations governing the

use of medical products, a Miele Ser

vice and Repair Contract is

recommended. Repairs by unqualified

persons could be very dangerous!

Do not install the machine in an area

~

where there is a risk of explosion or

freezing.

The electrical safety of this machine

~

is only assured if it is connected to a

properly installed grounding system. It

is imperative that this basic safety

requirement is met. If there is any

doubt, have the electrical system

checked by a qualified electrician.

The manufacturer will not be held liable

for damages resulting from an

inadequate grounding system (e.g.

electric shock).

A damaged or leaking machine is

~

dangerous. Turn off the machine imme

diately at the power switch and call the

Miele Service Department.

Machine operators must be trained

~

on a regular basis. Untrained personnel

must not be allowed access to the

machine or its controls.

-

-

4

Safety instructions and warnings

Take care when handling

~

processing chemicals (detergents,

softeners, neutralizers, rinsing agents,

etc.). These may contain irritant or

corrosive ingredients.

Observe the applicable safety

regulations! Wear protective gloves and

goggles! Always follow the

manufacturer's safety instructions and

material safety data sheets when using

processing chemicals.

The machine is only designed for

~

use with water and the recommended

processing chemicals. NEVER use

organic solvents or flammable liquids.

These could cause an explosion or

damage to rubber and plastic

components, which results in leaks.

The water in the machine is not safe

~

to drink!

Do not stand, sit or lean on the

~

machine door when open. The

appliance might tip over or be

damaged.

Take care when loading standing

~

items with sharp pointed ends. Position

them in the machine so that you will not

hurt yourself or create a danger for

others.

When operating this machine,

~

beware of the high temperatures

involved. If you bypass the electrical

lock to open the door, there is the

danger of scalding and heat or

chemical burns. If disinfectants have

been used, there is also a risk of

inhaling toxic vapors.

If toxic chemicals may be present in

~

the wash cabinet (e. g. aldehydes in

the disinfectant), the door seal and, if

applicable, the steam condenser must

regularly be checked for soundness.

Opening the washer door during a

program interruption is particularly

dangerous when toxic chemicals are

present.

If you are exposed to toxic vapors or

~

processing chemicals, consult the

manufacturer's material safety data

sheets for emergency procedures.

Always allow baskets, inserts and

~

the washload to cool down. Empty any

water from hollow items into the wash

cabinet.

After drying with the drying unit,

~

leave the door open at first to allow the

items, baskets and inserts to cool

down.

Do not touch the heating elements

~

when you open the door during or at

the end of a program. They remain hot

for quite a few minutes after the

program has ended and can cause

burns.

NEVER hose down the machine or

~

the immediate vicinity, e.g., with a water

hose or pressure washer.

Before servicing the machine,

~

disconnect it from the power supply.

5

Safety instructions and warnings

The following points should always

be observed to assist in maintaining

quality standards when processing

medical devices and critical items, to

protect patients and to avoid damage

to property.

If the machine is being used for

~

decontamination ordered by the

authorities, the steam condenser and

its connections to the wash

compartment and outlet discharge

must be disinfected in the event of

repairs or replacements.

Only authorized persons may

~

interrupt a program, and only in

exceptional cases.

It is the responsibility of the operator

~

to routinely check that the required

cleaning and disinfection standards are

being met. Therefore, the processes

need to be thermoelectrically tested on

a regular basis and process results

checked and documented. For

thermo-chemical processes, additional

testing is required using chemical or

biological indicators.

For thermal disinfection, the

~

appropriate temperatures and holding

times, as required by microbiological

and public health standards and

guidelines, must be used to achieve the

required degree of infection control.

Disinfection programs that use a

~

chemical disinfectant at moderate

temperatures (for example 65 °C or

below) do NOT fulfill the requirement for

mandatory decontamination under

Section 18 of the IfSG. These programs

should only be used when the items in

question are temperature-sensitive. The

disinfection parameters are based on

the trials carried out by the disinfectant

manufacturer. Always observe their

specifications for handling, application

conditions and efficacy. The operator is

responsible for the use of any such

thermo-chemical processes.

OR shoes should only be cleaned

~

and disinfected in a machine that has

been installed for that purpose.

Under certain circumstances, the

~

processing chemicals can damage the

appliance. Consult Miele Customer Service for recommendations. For

concerns involving possible damage to

the appliance or materials, please

consult a Miele Application Specialist.

Pre-treating (e.g. with cleaning

~

agents or disinfectants), some types of

soiling and the interaction of certain

processing chemicals can cause

foaming. Suds can have an adverse

effect on the results obtained.

The process must be set so that no

~

foam escapes the wash compartment.

Escaping foam impairs the safe

operation of the machine.

The process must be checked

~

regularly in order to detect any

foaming.

6

Safety instructions and warnings

In order to prevent damage to the

~

machine and any accessories through

processing chemicals or dirt as well as

any interaction between them, see the

instructions in the section Chemical

process.

Even when a certain processing

~

chemical is recommended, the

appliance manufacturer takes no

responsibility for the effect of such

chemicals on the material of the items

to be treated.

Note that formulation changes, storage

conditions, etc. that are not disclosed

by the manufacturer may alter the

cleaning results obtained.

When using processing chemicals,

~

it is essential that the manufacturer’s

instructions are followed. Use the

processing chemicals only for the

applications intended by the

manufacturer to avoid possible

chemical reactions (such as explosive

oxyhydrogen gas reactions).

For critical applications, where very

~

high processing-quality requirements

have to be met, it is strongly

recommended that all process-related

factors (cleaning agents, water quality,

etc.) be discussed in advance with

Miele's Application Specialist.

The mobile units, baskets and

~

inserts must only be used for their

specific applications.

Hollow items must be positioned for full

exposure to wash water.

Empty all containers and hollow

~

utensils before loading them.

Ensure that no acid or solvent

~

residues, especially hydrochloric acid

or chloride solutions, get inside the

wash cabinet. This also applies for

corrosive ferrous material. Solvents

combined with contaminants

(especially from hazard class A1)

should be present in trace amounts

only.

To avoid corrosion damage, make

~

sure the stainless steel housing does

not come into contact with

solutions/steam containing hydrochloric

acid.

Whenever work is conducted on the

~

tap water network, the water supply line

to the machine must be cleared of air.

Failure to do so can result in damage to

the machine.

Please be sure to follow the

~

installation instructions in this manual

and in the separate installation manual.

For applications that demand

~

especially stringent cleaning and

rinsing, (e.g., chemical analysis,

special industrial processes, etc.) the

operator must perform quality control

on a regular basis to ensure the

required standard.

7

Safety instructions and warnings

Accessories

Whatever the application, only Miele

~

accessories should be connected to

this machine. Consult a Miele

Application Specialist for details on the

type of equipment to use.

Only Miele mobile units, baskets

~

and inserts should be used. If Miele

accessories are altered in any way, or

equipment from another manufacturer

is used, Miele cannot ensure the

cleaning and disinfection results.

Damage or injury caused in this way

are excluded from the warranty.

Only use processing chemicals that

~

are approved by their manufacturer for

the application involved. Any negative

effects on items and the machine itself

are the liability of the manufacturer of

the processing chemicals.

Symbols on the appliance

Caution:

Comply with the Operating

Instructions!

Disposing of your old appliance

Old appliances may be

~

contaminated from exposure to blood

or other body fluids and must therefore

be decontaminated before disposal.

For safety and environmental

protection, be sure to drain/remove all

processing chemical residue. (Comply

with safety regulations and wear

protective eyewear and gloves.)

Remove or destroy the door latch, to

prevent children from locking

themselves inside. The appliance can

now be sent for disposal through the

proper resource recovery facilities.

In the case of machines with a tank

system, the water in the tank must first

be removed.

The manufacturer will not be held

liable for damage caused by failure

to comply with the safety instructions

and warnings.

Caution:

Danger of electric shock!

8

Intended Use

Miele washer-disinfectors are designed

to clean, rinse, disinfect

(thermal/thermochemical) and dry

re-usable medical devices, laboratory

equipment and instrumentation.

Whatever items are being processed,

always comply with the particular

manufacturer's instructions (EN ISO

17664).

Typical applications include:

surgical instruments,

–

endoscopic instruments,

–

– intensive care and anesthesiology

equipment,

– baby bottles and nipples,

– OR shoes,

or

– laboratory equipment for research

and production,

– laboratory equipment for analytical

and preparation applications,

–

microbiology and biotechnology

labware.

Labware can include anything from

evaporation dishes to centrifuge tubes.

In this operating manual, the general

term labware is used to cover a range

of equipment and items.

For standardized results, it is preferable

to machine-wash lab instruments and

equipment.

When disinfection is required to protect

staff and/or patients, the preference is

for thermal disinfection, e. g., with the

DESIN vario TD process.

According to the A

concept described

0

in EN ISO 15883-1, thermal disinfection

occurs at 80°C (+ 5 °C, - 0 °C) with

10 min holding time (A

600), or at 90°C

0

(+ 5 °C, - 0 °C) with 5 min holding time

(A

3000), depending on the

0

disinfection result required. The

efficacy standard A

3000 includes the

0

inactivation of HBV.

Regional and/or other official directives

may apply (e. g., §18 of the IfSG for

Germany).

The cleaning parameters should always

be optimally matched to the type of

soiling and labware involved.

The processing chemicals used also

should be matched to the particular

cleaning needs / analysis / analytical

methods involved.

9

Intended Use

For re-usable items to be safe for

continued use, the cleaning result must

meet certain minimum standards for

disinfection, sterilization and residue

levels.

Re-usable medical products are best

cleaned with the DESIN vario TD

process.

Also important for acceptable cleaning

results is the use of suitable loading

accessories (mobile carts, modules,

inserts). See the section on

"Applications" for examples.

The washer-disinfector is designed to

rinse with tap water or processed water

(e.g., distilled water, pure water,

deionized water, demineralized water)

depending on the quality required for

your application(s). The water quality

selected is especially important for

labware intended for analytical uses.

Under EN ISO 15883, this

washer-disinfector is suitable for

process validation.

10

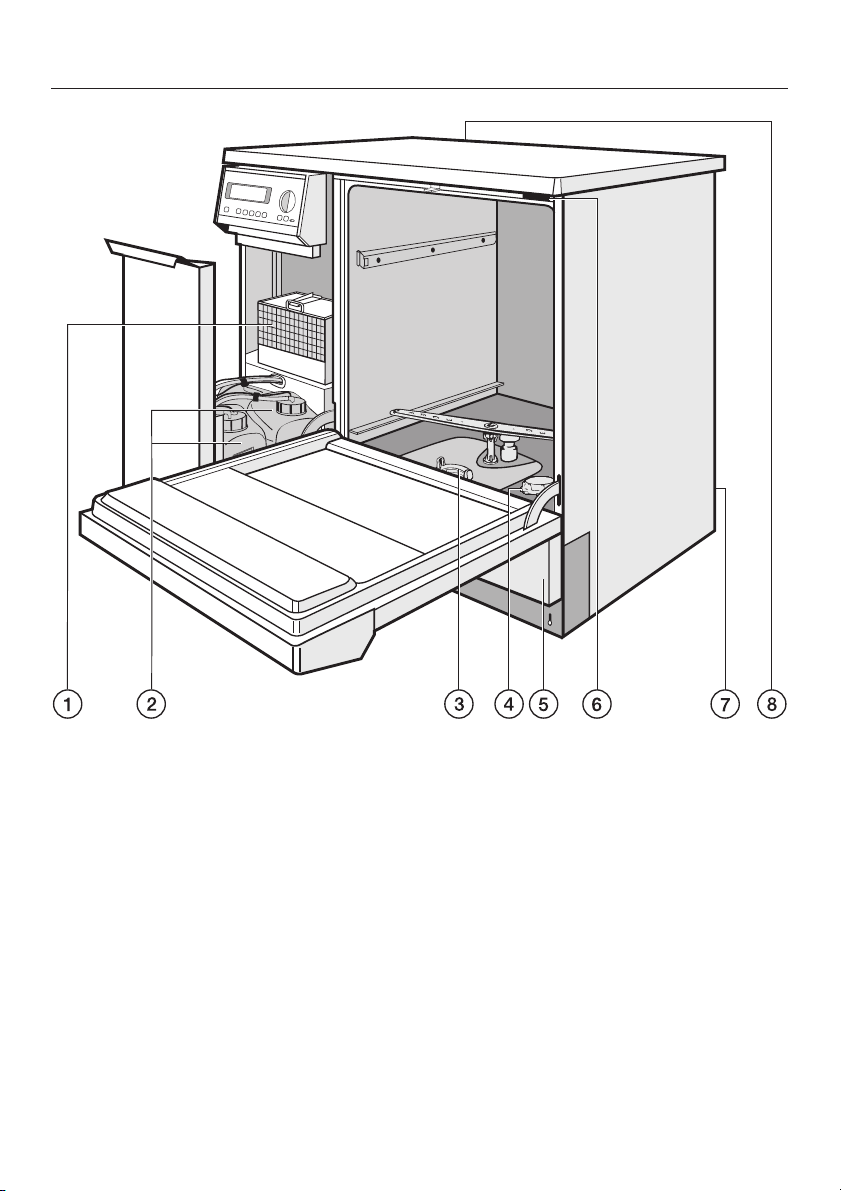

Description of the appliance

a Drying unit (TA)

b Dispenser for neutralizer (red) and

liquid detergent (blue)

c Filter combination

d Reservoir for regenerating salt

(water softener)

e Service panel

f Sensor access for validation

On the rear side of the appliance:

g Connection for DOS Module K 60

"Dispensing pump for neutralizer"

(white) and "Dispensing pump for

chem. disinfectant" (green)

h Serial interface

(upper left, behind cover plate)

11

Description of the appliance

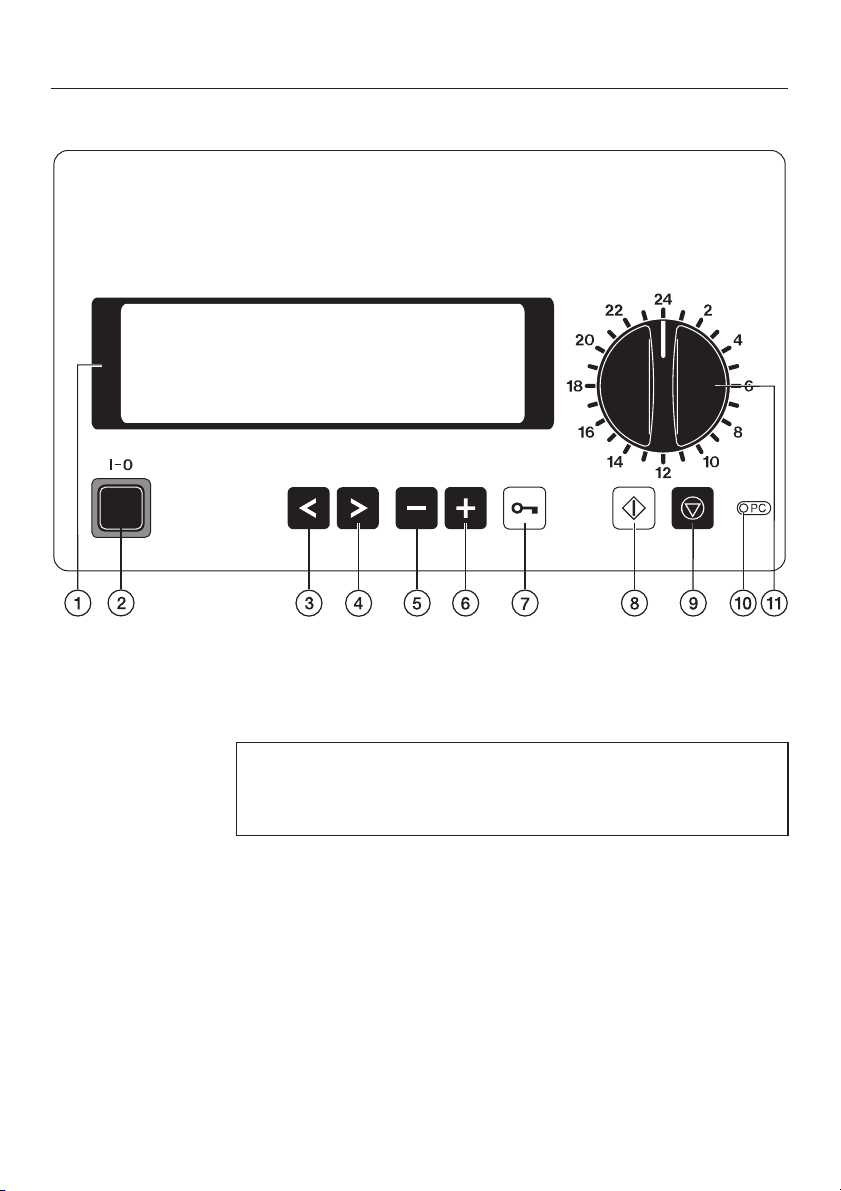

Electronic controls

12

a Display

with screen saver (background light switches off

automatically after 15 minutes, press any key to turn the

background light on again)

Fault messages during operation are shown in the display.

See the "Programming manual" for a table of all the fault

messages.

b ON/OFF button I-0

c Cursor button left 1

moves the cursor to the left:

– to the previous menu

– to the previous parameter

– to the previous input location

Description of the appliance

d Cursor button right 2

moves the cursor to the right:

– to the next menu

– to the next parameter

– to the next input location

e Minus button 3

– Program selection for program slots 24 and above

– page back through the Menus

– Enter letters and numerals

– Change default settings, e.g. service parameters

f Plus button 4

– Program selection for program slots 24 and above

– page forward through the Menus

– Enter letters and numerals

– Change default settings, e.g. service parameters

g Door switch 5

h Start button 6

– Starting a program

– Activate the programming mode

– Confirm the values and settings

– Confirm the Menu items to enter the corresponding

Sub-Menu

i Stop button 7

– Cancelling a program

– Leave the programming mode without saving

– Leave the Menu

j Optical interface 8 (for Miele service technicians)

k Program selector

Selecting programs 1-23

13

Opening and closing the door

Electric door lock

The machine is equipped with an

electric door lock.

The door can only be opened when

the washer-disinfector is connected

–

to the power supply,

the "ON/OFF" I-0 button is pressed

–

and

no wash or disinfection program is

–

running.

Opening the door

^ Press the door 5 button, grip the

door handle and pull open the door.

Do not touch the heating

,

elements when you open the door at

the end of a program. They remain

hot for quite a few minutes after the

program has ended and can cause

burns.

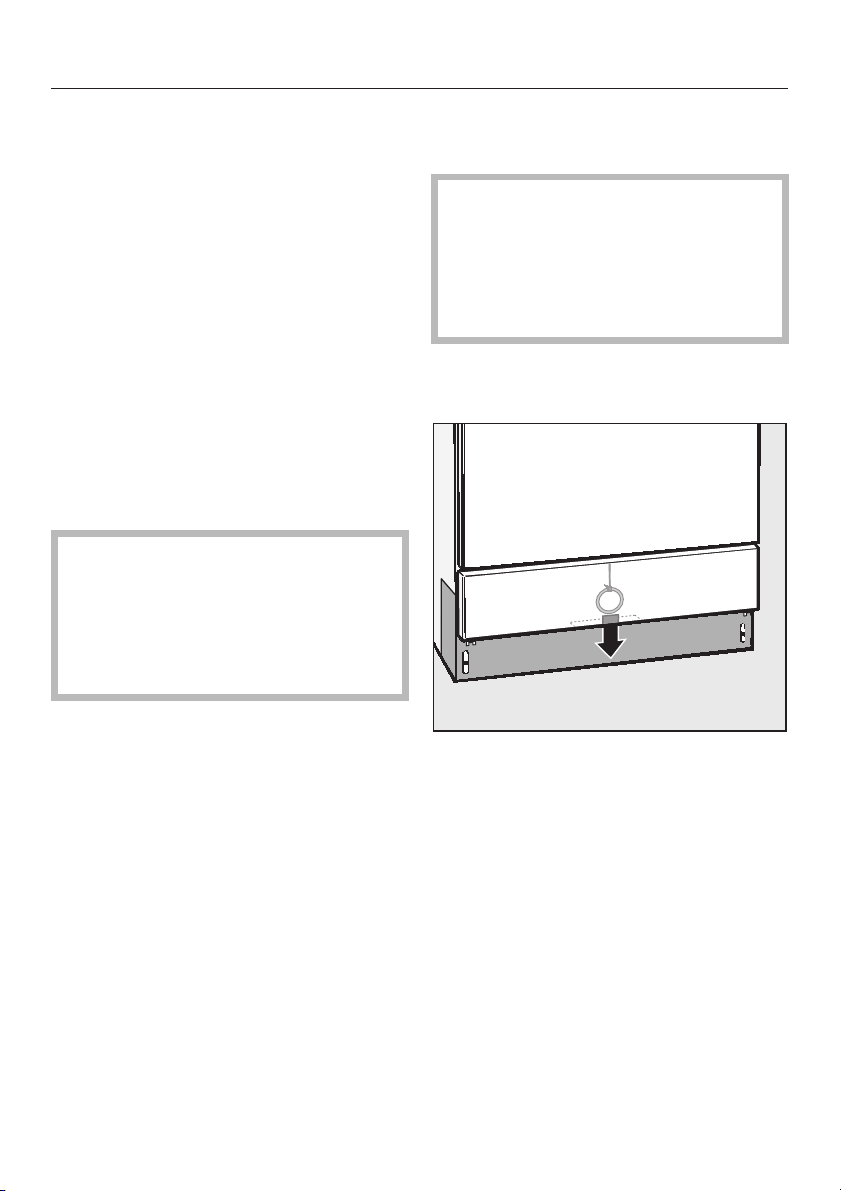

How to use the emergency

door release

The emergency release feature

should only be used when it is not

possible to open the door normally,

e.g. in the case of a power outage.

For all DESIN programs, please read

the "Important safety information".

Press the "ON/OFF" I-0 button to

^

switch off the machine.

How to close the door

^

Lift the door upward and push it until

it clicks shut.

14

^

Locate the ring for the emergency

release cable (at the bottom of the

machine, behind the service panel)

and pull the ring downward to open

the door.

Water softener

In order to provide good cleaning

results, the machine requires a supply

of soft water (water that is low in

calcium and magnesium). If hard tap

water is used, it can leave a white

mineral deposit build-up on the labware

and the machine itself.

Therefore, tap water with a hardness of

4 °d (0.7 mmol/l) or more must be

softened. The built-in water softener is

designed for this purpose.

In order to function properly, the

–

water softener requires a supply of

reactivation salt.

– The washer-disinfector must be

correctly programmed to match the

hardness of the tap water supply.

– Your local water authority will provide

information about the hardness of the

tap water in your area.

The factory default for the water

softener is set to a hardness of 19 °d

(3.4 mmol/l).

If the actual water hardness is

different (even if it is below 4 °d), the

factory default setting will need to be

changed using the electronic

control.

If the water hardness is known to

fluctuate (e. g., 8 - 17 °d), always

program for the highest value (in this

instance 17 °d).

The built-in water softener can be

programmed to settings from 1 °d to

60 °.

It is useful to make a note of the water

hardness so that you can provide the

service technician with this information

in the event of any service calls.

Please note the water hardness in the

space provided here:

°d

15

Water softener

Setting the water softener

Before using the machine for the first

time, the programming must be set to

the local water hardness(see

"Programming manual", "Operating

information / Regeneration").

Salt indicator

If the display shows NO SALT, the salt

reservoir needs to be filled.

The water softener is automatically

regenerated while the next program is

running.

The program display will show

REACTIVATION during this process.

Filling the salt reservoir

Only special, coarse-grained

reactivation salt*, with a grain size of

1-4 mm, should be used in this

machine.

*Available from your Miele dealer.

Do not use other types of salt, e.g. table

salt, agricultural or de-icing salt. These

could contain components which are

insoluble in water and could damage

the water softener. If in doubt, consult

Miele Technical Service.

The salt reservoir holds approximately

2.5 kg salt.

Inadvertently filling the salt

,

reservoir with detergent WILL

damage the water softener.

Before filling the reservoir, always

make sure that you are using

reactivation salt.

16

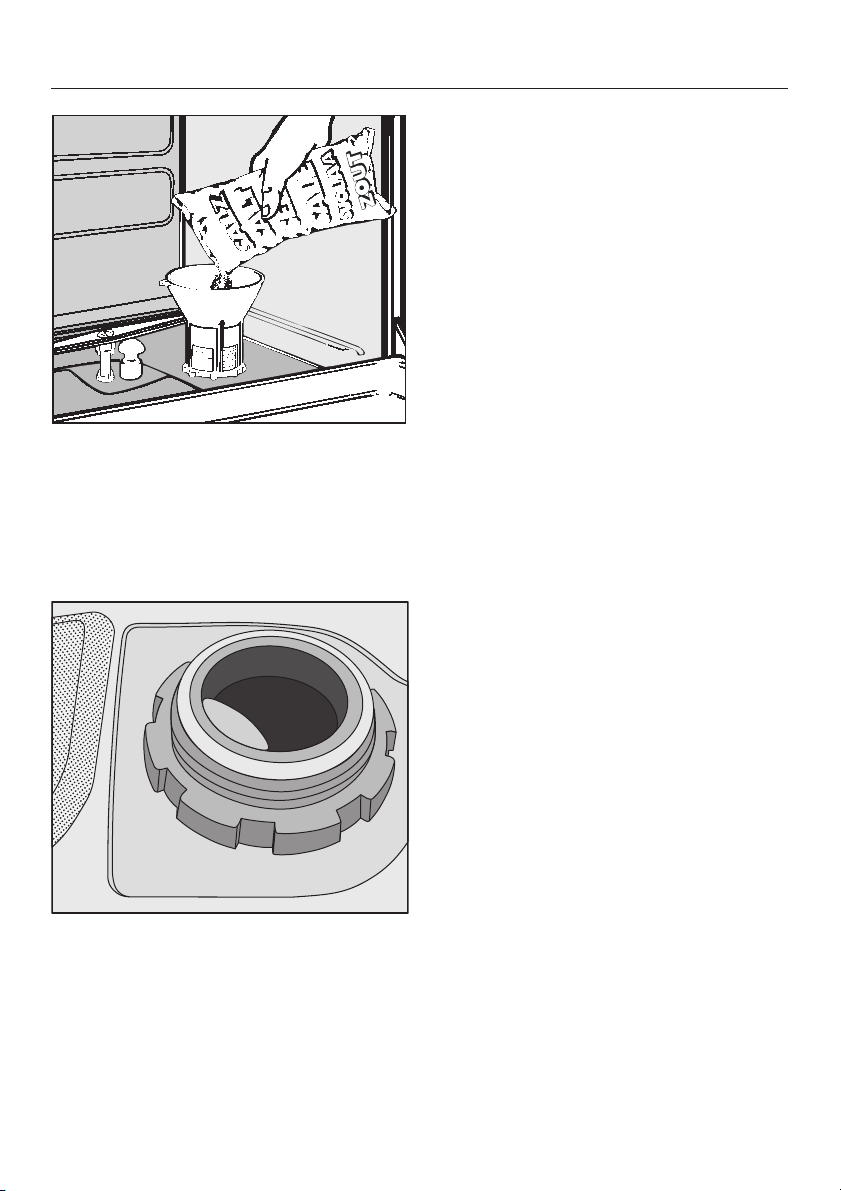

^

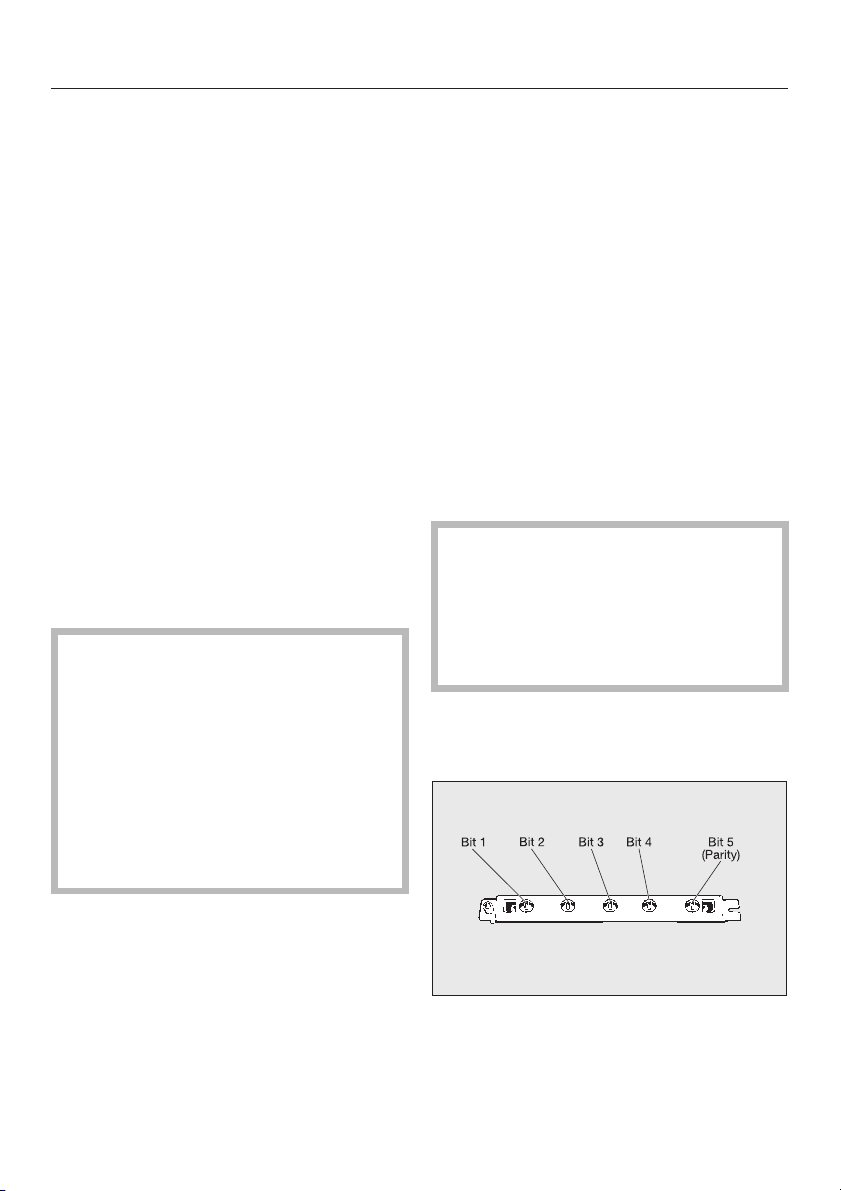

Remove the bottom basket from the

machine.

^

Unscrew the salt reservoir cap.

Before filling the salt reservoir for the

first time fill the reservoir with

approximately 2.5 liters of water, so

that the salt can dissolve properly.

Once the washer-disinfector has

been operated, there will always be

enough water in the reservoir.

Place the funnel provided in place.

^

^ Carefully fill the reservoir with the

reactivation salt.

Some displaced water will run out - this

is normal.

Water softener

Immediately after this step, start the

^

REMOVE SALT program, to remove

any traces of salt from the inside of

the machine.

Note: There may be a delay of a few

minutes before the REMOVE SALT

program starts due to the reactivation

of the water softener.

^

Wipe any residual salt off the thread

and seal of the reservoir.

^

Screw the cap on securely.

17

Automatic mobile unit recognition (AWK)

In Operating level C, the automatic

mobile unit recognition (AWK) assigns

a properly coded mobile unit to one of

program slots 1 to 15.

The coding on the mobile unit and the

program slot with the corresponding

program must be matched up in the

electronic control.

To do so:

Before each mobile unit is used for

^

the first time, it needs to be properly

coded (see "Mobile unit coding"), and

assign the wash program for mobile

^

unit coding to the corresponding

program slot.

For instructions on how to change

program slots, refer to the

"Programming manual", under "System

function / Selector switch organization".

,

Before starting the program, it is

essential to check that the program

required for this mobile unit is the

one shown in the display.

Otherwise, inadequate cleaning and

disinfection could result.

Do NOT allow the programs for

mobile units with automatic

recognition (AWK, pre-set program

slots) to be used interchangeably.

Mobile unit coding

The automatic mobile unit recognition

feature assigns each mobile unit to a

program slot. For this to work, the

mobile units must be coded with a

magnetic strip (with a bit combination).

In operating level C, only the program

assigned to the corresponding program

slot is available for a given coded

mobile unit.

When a coded mobile unit is inserted

into the machine (make sure there are

no small parts stuck to the magnetic

strip) and the washer-disinfector door

closes, the automatic recognition unit

selects the assigned program.

Make sure that no metallic parts

,

or pieces are stuck to the magnetic

strip, in particular the underside.

Attached metallic objects can cause

the coding to be misread or

unreadable.

Use the 6 button to start the program.

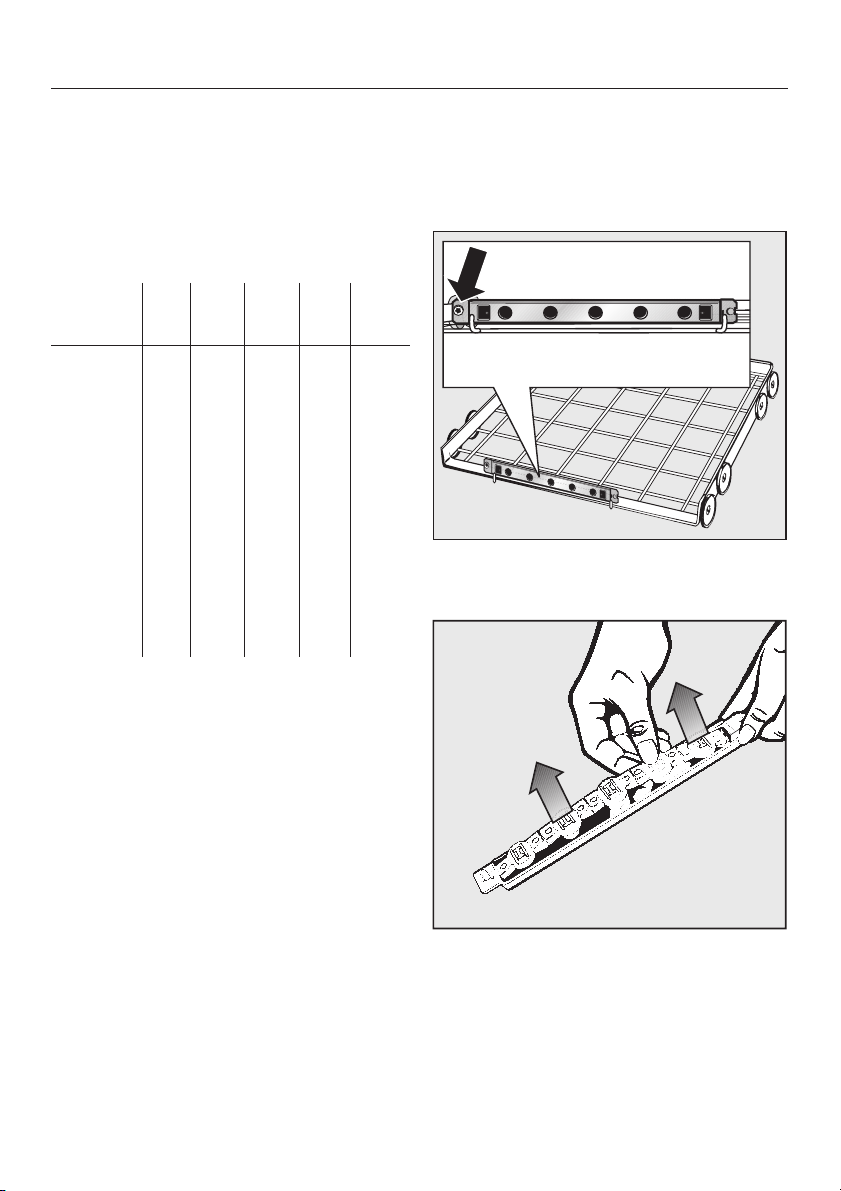

The coding includes 5 bits:

18

–

Bits 1 to 4 determine the mobile unit

code,

–

Bit 5 is for control purposes (parity

bit).

Automatic mobile unit recognition (AWK)

Holder with mobile unit coding

15 different codes can be set. They are

assigned to program slots 1 to 15.

Go to "System function "Selector

organization" to assign the various

programs to the first 15 program slots.

Program

slot

10

11

12

13

14

15

Bit 1 Bit 2 Bit 3 Bit 4 Bit 5

0

1

2

3

4

5

6

7

8

9

0

0

I

I

0

I

I

0

0

0

I

I

0

I

I

0

0

0

I

I

0

I

I

0

0

0

I

I

0

I

I

Parity

bit

0

0

0

0

0

0

I

I

I

I

0

0

0

0

I

I

I

I

I

0

I

0

0

0

I

0

0

0

0

0

I

0

I

I

0

I

0

I

I

I

0

I

I

I

I

I

0

I

Setting the mobile unit coding

To set or modify the coding for a mobile

unit with automatic recognition (AWK),

follow these steps:

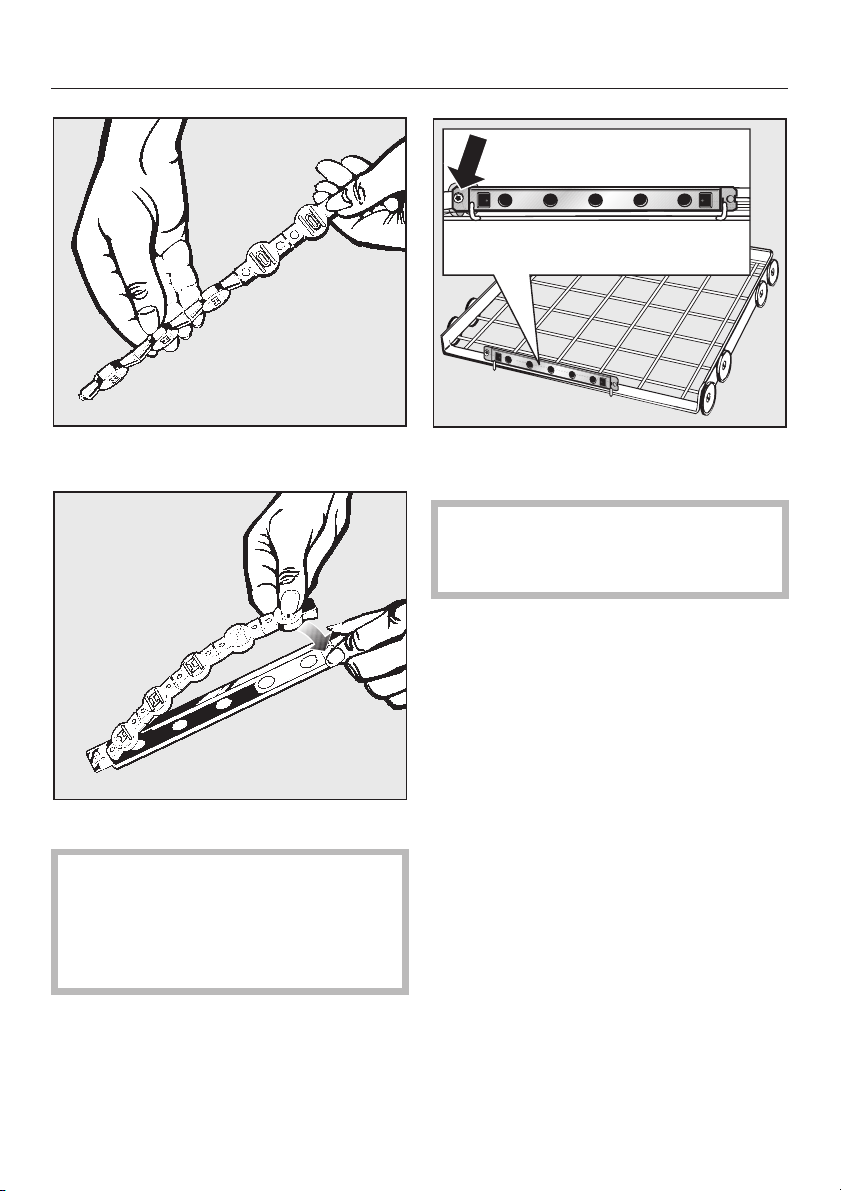

^ Unscrew the AWK rail (Allen key) and

remove it from the holder.

The sum of the coding must be an even

number.

If the sum of the coding is an odd

number, you will see the message

CHECK MOBILE UNIT RECOGNITION.

If the mobile unit coding equals 0, you

will see the message NO MOBILE UNIT

RECOGNITION. In both cases, no

program can be started. The mobile

unit recognition must be re-set.

^

Remove the magnetic strip from the

rail.

19

Automatic mobile unit recognition (AWK)

Set the coding for the program place.

^

Lay the rail in the holder and screw

^

into place.

The magnetic strip for washerdisinfector G 7835 and G 7836 must

contain gray magnets.

^

Set the magnetic strip in the rail.

The magnetic strip must be placed

in the rail in such a way that the set

bit coding according to the table is

visible through the round window in

the rail.

20

Loading...

Loading...