Operating instructions

Washer-disinfector

G 7827 / G 7828

To avoid the risk of accidents or

damage to the machine it is

essential to read these instructions

before it is installed, commissioned

and used for the first time.

G

M.-Nr. 06 190 350

Contents

Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Warning and safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Opening and closing the lift door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Automatic mobile unit recognition (AWK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mobile unit coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting mobile unit coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Areas of application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Loading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Laboratory glassware (LG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Surgical instruments (OP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Anaesthetic equipment (AN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Baby bottles (BC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating theatre shoes (OS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Transfer trolley for loading and unloading the machine . . . . . . . . . . . . . . . . . . . . 27

Dispensing liquid chemical agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preparing the DOS dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fill the containers with the relevant agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Venting the dispensing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dispensing system maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

External Dispensing systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Master switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

To change operating level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Starting a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Programme sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Switching off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

To change or cancel a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

To interrupt a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2

Contents

Data transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the filters in the wash cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the fine filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the flat filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the filters for the circulation pump. . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drying unit (TA) - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Changing the coarse filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Changing the fine filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maintenance of optional report printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Renewing the paper roll. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Renewing the colour ribbon cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Steam/Electro or Electro/Steam conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Technical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Special features - OXIVARIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Description of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Areas of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Connecting the H

Disposal of your old appliance or machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

solution container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2O2

3

Description of the machine

This Miele washer-disinfector is

capable of cleaning a wide range of

medical and laboratory products, and

disinfecting them either thermally in

temperatures up to 95 °C or chemothermally in temperatures up to 65 °C

with the addition of a suitable chemical

agent in accordance with general

standards of hygiene and those

required for the containing of

epidemics.

Medical products include e. g. surgical

and minimally invasive instruments,

instruments and utensils used in

anaesthetics and intensive care, etc.

Laboratory products include e.g. wide

and narrow necked flasks, conical

flasks, measuring cylinders, pipettes,

beakers, Petri dishes etc.

Follow medical and laboratory product

manufacturer’s instructions on how to

process their items by machine. The

DESIN vario TD programme provides

optimum protection for rigid fibre

optics, patient systems and surgical

motor systems which have been

declared by their manufacturers as

being suitable for machine processing.

Optional drying with sterile filtered hot

air is also available.

Areas of application:

surgical instruments,

–

minimally invasive instruments which

–

can be processed shortly after use,

anaesthetic and intensive care

–

instruments,

baby bottles and teats,

–

stainless steel and aluminium

–

containers (including anodised

aluminium),

operating theatre shoes,

–

– laboratory products used in research

and production as well as in all areas

of analysis and specimen taking,

including micro-biology and

biotechnology.

Instruments should preferably be

cleaned and then thermally disinfected

using the DESIN vario TD programme.

The parameters for thermal disinfection

in accordance with prEN ISO 15883-1

are 80 °C (+ 5 °C, - 0 °C) with a 10 min.

holding time or 90 °C (+ 5 °C, - 0 °C)

with a 5 min. holding time for the

inactivation of HBV.

4

Description of the machine

In the U.K. reference should be made

to your local infection control officer for

guidelines of disinfection temperatures

and holding times at temperature in

accordance with HTM 2030.

In Germany, the parameters for

disinfection of a temperature of 93 °C,

with a holding time of 10 minutes,

correspond to effective areas A and B.

These have been adopted into the

official list for disinfection of instruments

in washer-disinfectors and

decontamination units, according to

section 3.2 § 18 IfSG by the Robert

Koch Institute (RKI) in Berlin (Institute

for Infectious diseases and

non-communicable illnesses).

The effective areas are defined as

follows:

A = Suitable for the destruction of

vegetative bacteria, including

myco-bacteria, fungi and fungal

spores.

B = Suitable for inactivating viruses

(including HBV and HIV).

The cleaning programme must be

chosen according to the type of soiling

and product requiring processing in

order to ensure that disinfection is

carried out correctly, no residues are

left behind and that subsequent

sterilisation can take place. Medical

devices are best reprocessed using the

DESIN vario TD programme, or the

OXIVARIO programme where

applicable.

This washer-disinfector is programmed

to carry out the final rinse with mains

water or AD water (aqua destillata =

purified or de-ionised water (VE), H

O

2

pure, demineralised water, aqua

purificata or distilled water where the

application requires this standard).

The water quality is of particular

importance for applications requiring

analytically clean laboratory glassware.

The type of chemical agents used will

depend on the analysis or analytical

methods being used.

Optional extras

– Drying unit (TA)

– Steam condenser (DK)

– Report printer (PRT)

– OXIVARIO kit

Water softener

If the mains water hardness level is

more than 70 mg/l (4°d), a water

softening system should be provided

on-site, such as the Miele G 7897

"Aqua-Soft system" which is effective up

to approx 720 mg/l (40°d).

5

Guide to the machine

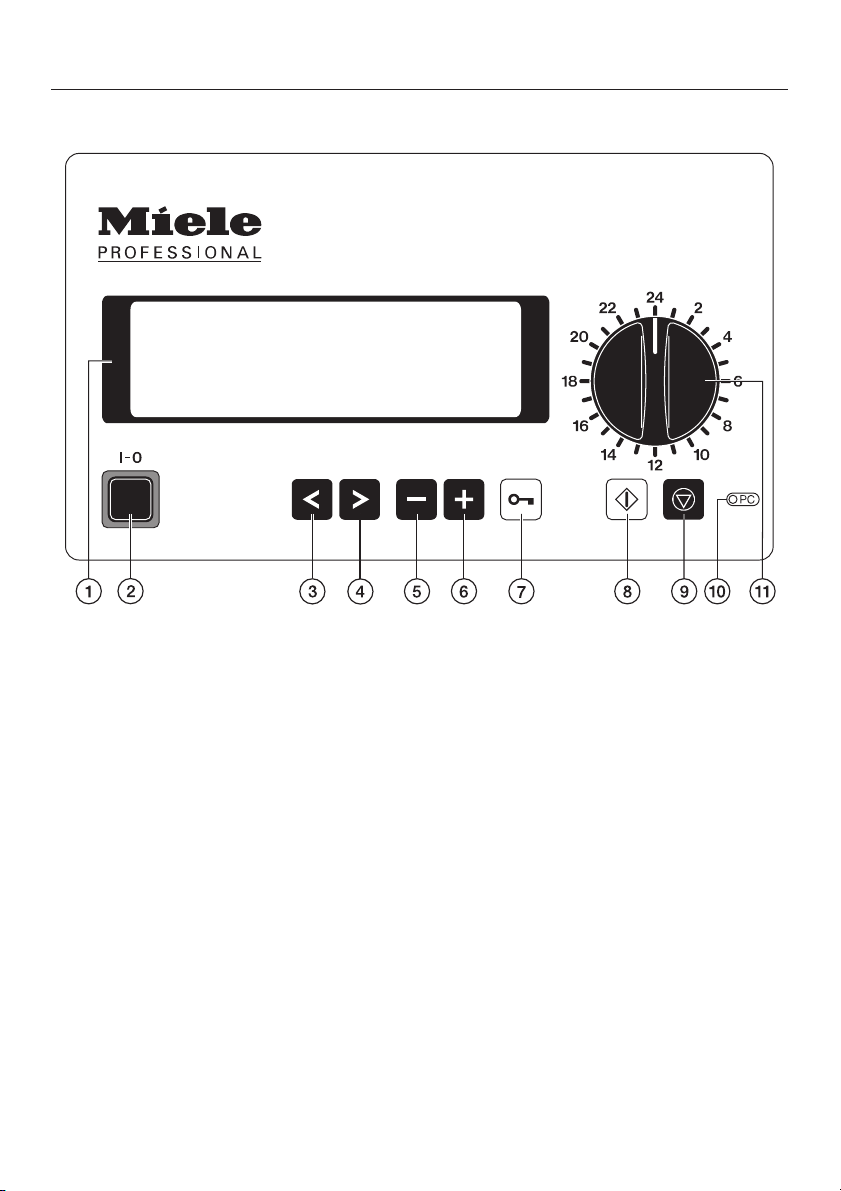

Electronic controls

a Display

with screen saver;

i.e. background lighting switches off

automatically after 15 mins.

Press any button to switch the

display back on again.

b On/Off button (I-0)

c Cursor button: left

Moves the cursor to the left:

- to the previous menu point

- to the previous parameter

- to the previous input position

d Cursor button: right

Moves the cursor to the right:

- to the next menu point

- to the next parameter

- to the next input position

6

e Minus button

– Selects programmes from position

24 upwards

– Scrolls back page by page in

menus

– Is used for entering numbers and

letters

– Alters pre-settings e.g. service

parameters

f Plus button

– Selects programmes from position

24 upwards

– Scrolls forward page by page in

menus

– Is used for entering numbers and

letters

– Alters pre-settings e.g. service

parameters

g Door switch

Guide to the machine

h Start button

– Starts programmes

– Activates input mode

– Confirms activated values and

settings

– Confirms menu points for entry

into the relevant sub-menu

i Stop button

– Cancels a programme

– Exits from input screen without

saving

– Exits from menu screen

j Service interface

kProgramme selector

Selects programme places 1-23

7

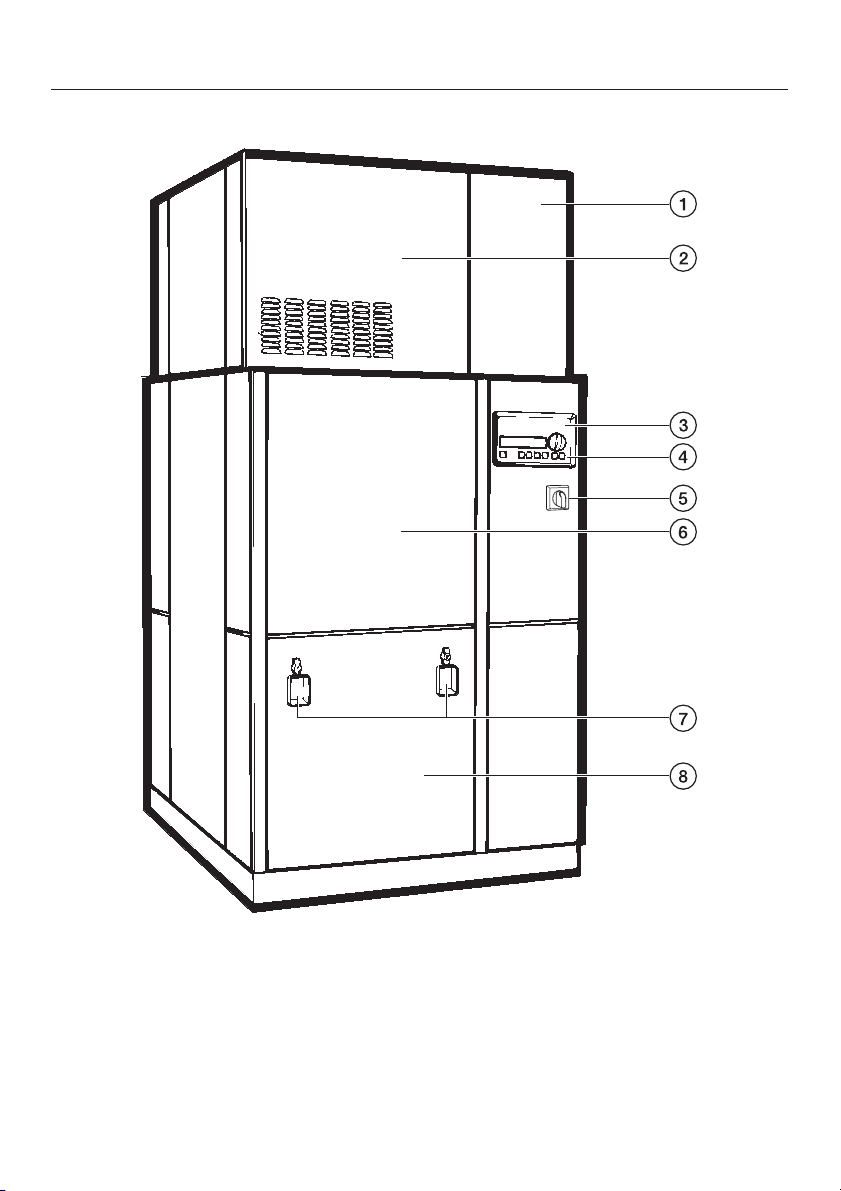

Guide to the machine

Unclean side

a Hot air drying unit TA *)

b Steam condenser DK *)

*) behind top housing (optional)

c "Profitronic" electronic controls (see

also "Programming manual")

d Controls

8

e Master switch (with "emergency

cut-off function" for service work)

f Lift door (closed)

g Docking facility for the "Mieltransfer"

trolley.

h Service panel

Unclean side

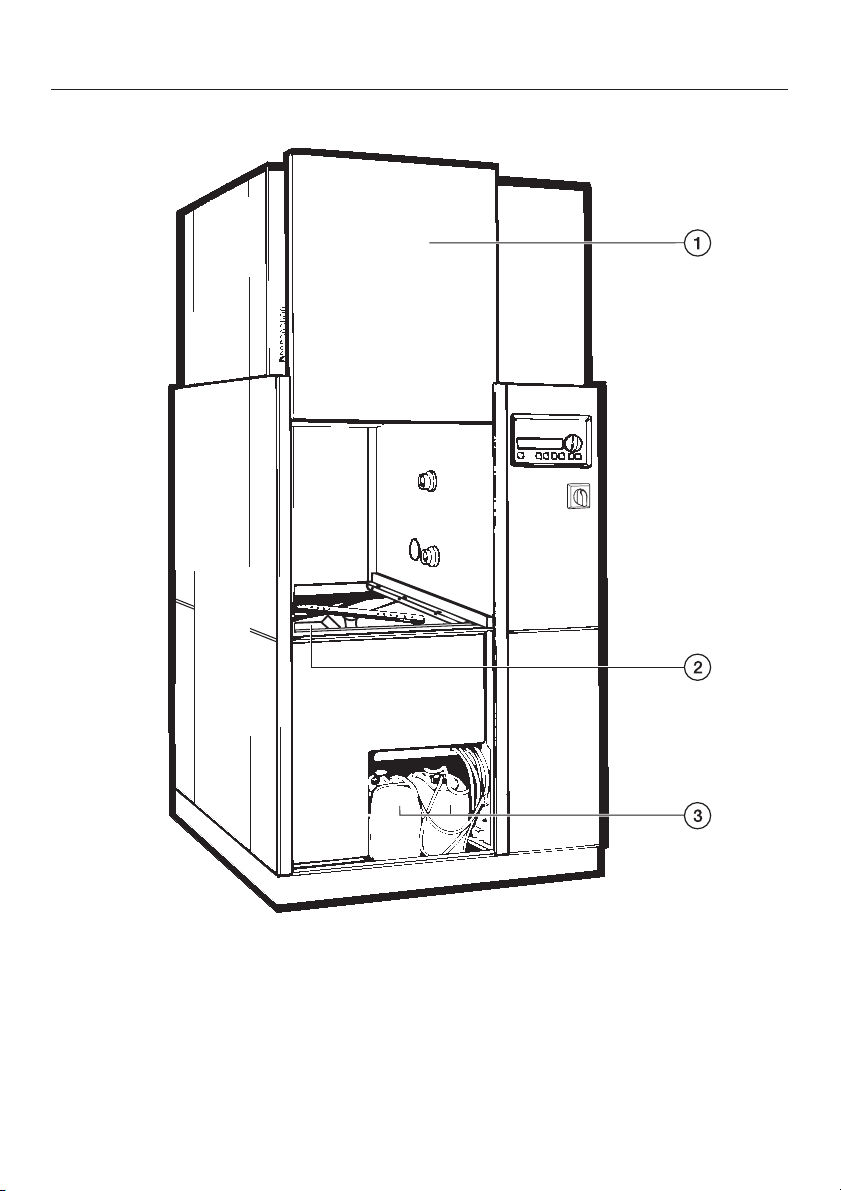

Guide to the machine

a Lift door (open)

b Filter combination

c Containers for dispensing systems

DOS 1 - DOS 4

9

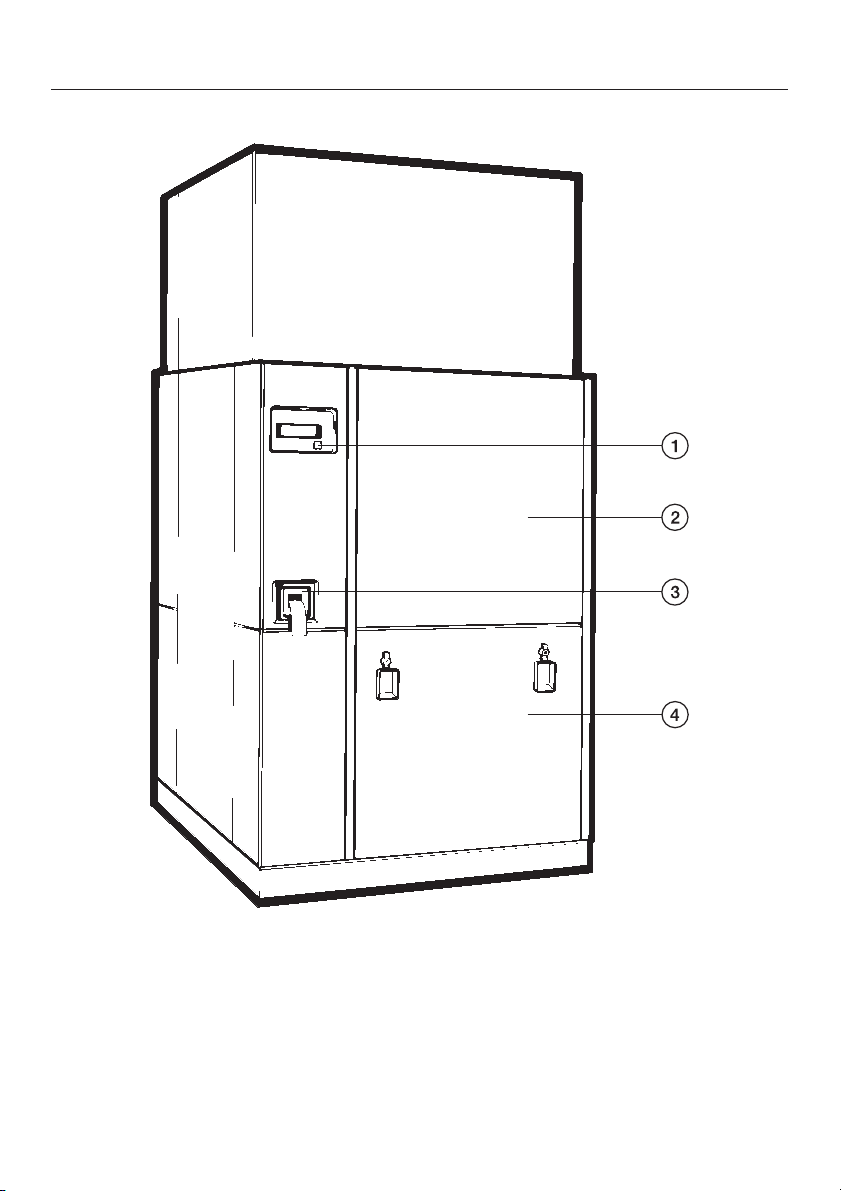

Guide to the machine

Clean side (G 7828 only )

a Door release

b Lift door (closed)

c Printer (optional)

G 7827: on the unclean side

10

d Service panel with docking facility for

the "Mieltransfer" trolley.

Warning and safety instructions

This machine complies with all

relevant legal safety requirements.

Incorrect use can lead to personal

injury and damage to property.

Read these operating instructions

carefully before starting to use this

machine. This way you will avoid the

risk of accidents and damage to the

machine.

Keep these instructions in a safe

place for reference, and pass them

on to any future user.

Correct use

This washer-disinfector is designed

for commercial use and for

specialised applications only, as

described in these operating

instructions. Alterations or conversions

to the machine or using it for purposes

other than those for which it was

designed are not permitted and could

be dangerous.

This machine must only be used for

cleaning and disinfecting instruments

or medical products and laboratory

ware if the manufacturer has stated that

they are suitable for machine

processing. Manufacturer’s cleaning

and maintenance instructions for

instruments etc. must also be

observed.

The manufacturer cannot be held liable

for damage caused by improper or

incorrect use of the machine.

This equipment may only be used

in mobile installations such as

ships, aircraft etc. if a risk assessment

of the installation has been carried out

by a suitably qualified engineer.

Please pay attention to the following

notes to avoid injury and damage.

The machine should be

commissioned and then

maintained only by a Miele authorised

and trained service technician. To

ensure compliance with the Medical

Devices Directive a Miele service

contract is recommended. Repairs and

other work by unqualified persons

could be dangerous.

Do not install the machine in an

area where there is any danger of

explosion or of freezing conditions.

The electrical safety of this

machine can only be guaranteed if

connected to a correctly installed

earthing system on site. It is most

important that this basic safety

requirement is tested regularly, and

where there is any doubt the electrical

system should be inspected by a

qualified electrician.

The manufacturer cannot be held liable

for damage or injury caused by the lack

of or inadequacy of an effective

earthing system (e.g. electric shock).

11

Warning and safety instructions

A damaged machine is a safety

hazard. Switch off at the mains

immediately and call the Miele Service

Department or an authorised and

trained Miele Service Dealer.

Personnel operating the machine

should be trained regularly.

Untrained personnel must not be

allowed access to the machine or its

controls.

This machine is not a toy! To avoid the

risk of injury never allow children to play

on or near the machine, or to operate it.

Take care when handling

chemicals such as cleaning agent,

neutralising agent, rinsing agent etc.

These may contain irritant or corrosive

ingredients. Do not use organic

solvents as these could cause an

explosion.

Follow all relevant safety procedures

carefully. Wear protective gloves and

goggles. With all chemical agents, the

manufacturer’s safety instructions must

be observed.

The water in the machine must not

be used as drinking water.

Be careful when sorting items with

sharp pointed ends and

positioning them in the machine that

you do not hurt yourself or create a

danger for others. Sharp knives etc.

should be placed in baskets with the

pointed ends facing downwards.

When using this machine in the

higher temperature ranges be

especially careful not to scald or burn

yourself or come into contact with

irritant substances when opening the

door. Where disinfecting agents are

used there is a danger of inhaling toxic

fumes. Baskets, inserts and utensils

must be allowed to cool down before

they are unloaded. Any water remaining

in containers could still be very hot.

Empty them into the wash cabinet

before taking them out.

After using the hot air drying unit

open the door to allow everything

in the cabinet from the load itself to the

mobile units, modules and inserts to

cool down.

Do not touch the heating elements

(under the wide area filter) during

or directly after the end of a

programme. You could burn yourself.

The elements remain hot for some time

after the end of the programme.

If the boiler has been programmed

to "BOILER READY", be particularly

careful of hot water and steam when

opening the door. Danger of burning or

scalding. The inlet to the wash cabinet

is located, as viewed from the unclean

side, underneath the basket runner on

the left hand side.

Steam heating is permissible up to

a pressure of 1000 kPa (10 bar).

This corresponds to a water steam

temperature of 179 °C.

12

Never clean the machine or near

vicinity with a water hose or a high

pressure hose.

Warning and safety instructions

The machine must be

disconnected from the mains

electricity supply before any

maintenance or repair work is carried

out. Do not reconnect it until the

maintenance or repair work has been

successfully completed.

The following points should be

observed to assist in maintaining

quality standards for processing

medical instruments and sensitive

laboratory glassware, and to avoid

injury to patients or damage to

equipment.

If the machine is being used for

disinfection in accordance with

official regulations on the control of

epidemics, the steam condenser and

its connections to and from the wash

cabinet must be cleaned and

disinfected whenever any repairs are

carried out or parts replaced.

For decontamination in

accordance with official

regulations, the programme must not

be interrupted by pressing the I-0

button to switch off after START has

been pressed. Interrupting any other

programmes should also be avoided as

this will reduce cleaning, disinfection

and the final rinse results. If it is opened

the programme should be completely

repeated.

The standard of cleaning and

disinfection in the disinfection

programmes must be routinely

confirmed by the user. The process

should be regularly monitored using

thermo-electrical, chemical or

bio-indicators, and this should be fully

documented.

For thermal disinfection, use

temperatures and temperature

holding times to achieve the required

infection prophylaxis in accordance

with current health and safety

regulations.

Disinfection programmes which

use a chemical disinfecting agent

at moderate temperatures such as

65 °C or lower are not recognised by

§18 IfSG for disinfection. They should

only be used for items which cannot

withstand the higher temperatures used

by thermal disinfection. The range of

effective disinfection is based on claims

made by the producer of the

disinfecting agent. Their instructions on

handling, use and effectiveness must

be observed. The use of chemothermal disinfection procedures is the

responsibility of the operator.

If there are toxic or chemical

substances in the suds solution

(e.g. aldehyde in the disinfecting agent)

you must be particularly vigilant of the

risks these carry should you need to

interrupt a programme and open the

door. The door seals and correct

functioning of the steam condenser

should be regularly monitored.

13

Warning and safety instructions

Theatre (OP) shoes should only be

cleaned and disinfected in a

machine installed specifically for this

purpose.

Only use chemical agents

formulated for special processes

and approved by Miele for use with this

machine. Use of unsuitable agents

could adversely affect the components

of the machine. Any resultant damage

would invalidate the machine

guarantee.

Pre-treatments with cleaning or

disinfecting agents can create

foam, as can certain types of soiling

and chemical agents. Foam can have

an adverse effect on the disinfection

and cleaning process.

Where a chemical additive is

recommended on technical

application grounds (e.g. a cleaning

agent), this does not imply that the

manufacturer of the machine accepts

liability for the effect of the chemical on

the items being cleaned.

Please be aware that changes in

formulation, storage conditions etc.

which may not be publicised by the

chemical manufacturer, can have a

negative effect on the cleaning result.

When using cleaning agents and

specialised products it is essential

that the manufacturer’s instructions are

followed. Only use the product for the

application described by the

manufacturer, to avoid any material

damage or the occurrence of strong

chemical reactions.

The machine is designed for

operation with water and additive

chemical agents only. Organic solvents

must not be used in this machine, as

there is the danger under certain

circumstances of fire or explosion.

Although this is not the case with all

organic solvents, other problems could

arise with their use, for example

damage to rubber and synthetic

materials.

In critical applications where very

stringent requirements have to be

met, it is strongly recommended that all

the relevant factors for the process,

such as chemical agents, water quality

etc. are discussed with the Miele

Application Technology specialists.

If cleaning and rinsing results are

subject to particularly stringent

requirements (e.g. chemical analysis,

specialised industrial processes etc.), a

regular quality control test must be

carried out by the user to ensure that

the required standards of cleanliness

are being achieved.

Mobile units, modules and inserts

should only be used for the

purpose they are designed for.

Hollow instruments must be thoroughly

cleaned, internally and externally.

Empty any containers or utensils

before arranging them in the

machine.

14

Warning and safety instructions

Do not allow any remains of acids

or solvents, and in particular

hydrochloric acid or chloride solutions,

to get into the wash cabinet. Similarly

avoid any materials with a corrosive

effect. The presence in compounds of

any solvents should be minimal

(especially those in hazard class A1).

Ensure that solutions or steam

containing hydrochloric acid do not

come into contact with the steel outer

casing of the machine, to avoid any

corrosion damage.

Please follow the advice on

installation in these instructions

and the separate Installation

Instructions.

Using accessories

Only use genuine Miele

accessories with this machine.

Consult Miele on the type and

application of such equipment.

Only use Miele mobile units,

baskets and inserts in this

machine. Using accessories made by

other manufacturers, or making

modifications to Miele accessories can

result in unsatisfactory cleaning and

disinfecting results, for which Miele

cannot be held liable. Any resultant

damage would also invalidate the

machine guarantee.

Disposal of your old machine

Before throwing an old machine

away it must first be made

unusable. Disconnect from the mains

and cut off the cable as close to the

machine as possible.

Please note that the machine may have

contamination from blood or other

bodily fluids in it and must be

decontaminated before disposal.

For environmental and safety reasons

ensure the machine is completely

drained of any residual water, chemical

residues and cleaning agent. Observe

safety regulations and wear safety

goggles and gloves.

Make the door lock inoperable, and

block or disable the door in such a way

that children cannot accidentally shut

themselves in the cabinet. Then make

appropriate arrangements for the safe

disposal of the machine. For tank

system machines ensure that any water

is emptied out of the tank before it is

moved.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these Warning

and Safety instructions.

15

Opening and closing the lift door

The lift door can only be opened when:

the electricity supply to the machine

–

is switched on,

the red ("emergency cut out") master

–

switch is in the I-ON position,

the I-0 On-Off button is pressed in

–

and

a cleaning or disinfection programme

–

is not in progress.

The door on the clean side (G 7828)

can only be opened if:

– DESIN (disinfection) programmes

have been correctly completed,

or

– if the Door interlock has been

activated, i.e. DOOR MECH. has

been set to one of the following

parameters:

- INTERLOCK,

- DOOR CLEAN+INTERLOCK,

- DOOR UNCL.+INT.LOCK.

(see "Machine function - Door

mechanism" in the programming

manual).

To open the lift door

Press the 5 door button. The lift door

^

rises.

Do not touch the heating

,

elements under the wide area filter

during or directly after the end of a

programme. You could burn

yourself. They remain hot for some

time after the programme has

finished.

If the boiler has been programmed

to "BOILER READY", be particularly

careful of hot water and steam when

opening the door. Danger of burning

or scalding. The inlet to the wash

cabinet is located, as viewed from

the unclean side, underneath the

basket runner on the left hand side.

To close the lift door

^ Press the 5 door button. The lift door

lowers itself.

16

Loading...

Loading...