Operating and Installation

Instructions

Medium capacity

Glassware Washer

G 7825 / G 7826

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en - US, CA

M.-Nr. 07 776 870

Contents

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Function of the laboratory glassware washer. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Guide to the laboratory glassware washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Automatic mobile unit recognition (AWK). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mobile unit coding .................................................16

Setting mobile unit coding ........................................17

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Process validation .................................................19

Protein detection ..................................................19

Laboratory glassware (LG) ..........................................21

Transfer cart for loading and unloading the machine ......................22

Adding of liquid detergents and neutralizers . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Priming the DOS dispensers .........................................24

Filling the containers with the relevant detergent or neutralizer ............25

Priming the liquid dispensing systems .................................26

Dispensing system maintenance......................................26

External Dispensing systems.........................................26

Effects of Processing Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Turning on .......................................................32

Door lock ........................................................32

Opening the door..................................................32

Closing the door ..................................................32

Changing the operating level ........................................33

Starting a program.................................................34

Program sequence ................................................35

Turning off .......................................................35

Cancelling a program ..............................................36

Interrupting a program..............................................37

Serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

Contents

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Routine checks ...................................................40

Cleaning the filters in the wash cabinet.................................41

Cleaning the fine filter ............................................41

Cleaning the flat filter ............................................41

Cleaning the filter system of the circulation pump ......................41

Cleaning the spray arms ............................................42

Cleaning the control panel...........................................43

Cleaning the exterior ...............................................43

Cleaning the wash cabinet ..........................................43

Cleaning the door seal..............................................43

Mobile units, baskets and inserts .....................................44

Report printer (Option)..............................................45

Replacing the print paper ...........................................45

Replacing the ribbon cartridge .......................................45

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Steam/Electro or Electro/Steam conversion .............................48

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Caring for the environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3

IMPORTANT SAFETY INSTRUCTIONS

Please pay attention to the following

This machine conforms to current

safety requirements. However,

inappropriate use can lead to

personal injury and property

damage. Read the operating

instructions carefully before using

this machine.

The manufacturer cannot be held

responsible for damage caused by

non-observance of these Important

Safety Instructions.

WARNING - To reduce the risk of fire,

electric shock or injury:

Use

This machine is not intended for any

~

purpose that is not indicated in the

operating instructions. Conversions,

modifications, and other unintended

uses are considered to be dangerous.

Follow the product manufacturer's

instructions. Miele will not be held liable

for damage caused by incorrect use of

any kind.

The installation of this unit in non

~

stationary locations (e.g. ships) must be

performed by a qualified installer or

service agency in strict accordance

with national and local safety

regulations and standards.

notes to maintain safe procedures.

The machine should be

~

commissioned and maintained only by

a Miele Service Technician. Repairs by

unqualified persons could be

dangerous.

Do not install the machine in an area

~

where a danger of explosion or freezing

may be present.

Be certain this labwasher is properly

~

installed and grounded by an

authorized technician. To guarantee the

electrical safety of this machine,

continuity must exist between the

machine and an effective grounding

system. It is imperative that this basic

safety requirement be met. If there is

any doubt, have the electrical system

checked by a qualified technician. The

manufacturer cannot be held

responsible for damage or injury

caused by the lack, or inadequacy, of

an effective grounding system

(e.g. electric shock).

A damaged machine is dangerous.

~

Turn off the machine immediately at the

power switch and call the Miele Service

Department.

Personnel operating the machine

~

should be trained regularly. Children

and untrained personnel must not be

allowed access to the machine or its

controls.

,

Mount on non-combustible floors

only!

4

IMPORTANT SAFETY INSTRUCTIONS

Take care when handling

~

processing chemicals (detergents,

softeners, neutralizers, etc.). These may

contain irritant or corrosive ingredients.

Wear protective gloves and goggles.

With all chemical agents the

manufacturer’s safety conditions must

be observed.

The lab washer is only designed to

~

operate with water and the

recommended processing chemicals.

The machine must NOT be operated

with organic solvents or flammable

liquids. This may cause an explosion or

damage to rubber and plastic

components, which in turn allows liquid

substances to leak out.

Do not stand, sit or lean on the

~

opened machine door.

Do not touch the heating elements

~

during or directly after the end of a

program, burns could result. The

elements remain hot for some time after

the end of the program.

The water in the machine must not

~

be used as drinking water.

Be careful when sorting items with

~

sharp, pointed ends. Carefully position

these items in the machine, so that you

will not hurt yourself or create a danger

for other operators.

When using this machine regard the

~

high temperatures and be especially

careful not to scald or burn yourself.

When opening the door bypassing the

electrical lock, a danger of burning,

scalding and corrosion exist. Let mobile

units, inserts and cleaned items cool

before touching them. Any water which

may remain in containers will be very

hot and must be emptied into the wash

cabinet.

If toxic chemical substances can

~

form in the wash water during

processing (e.g. aldehydes in the

disinfection agent), the door seal and, if

applicable, the function of the steam

condensor must be checked regularly.

In that case, opening the lab washer

door during a program interruption can

be dangerous.

If you are exposed to toxic vapors or

~

processing chemicals, consult the

manufacturer's material safety data

sheets for emergency procedures.

Always allow mobile units, modules,

~

inserts, and loads to cool before

removing. Be sure to empty any water

from concave items into the wash

cabinet before removing.

After drying with the TA drying unit

~

open the door to allow the items and

inserts to cool.

5

IMPORTANT SAFETY INSTRUCTIONS

If the boiler has been programmed

~

to "BOILER READY", be particularly

careful of hot water and steam when

opening the door. Danger of burning or

scalding. The water inlet pipe to the

wash cabinet is located, as viewed

from the unclean side, underneath the

basket runner on the left hand side.

Steam heating is permissible up to a

~

pressure of 145 psi. This corresponds

to a water steam temperature of 354°F

(179 °C).

Never clean the machine or near its

~

vicinity with a water or high pressure

hose.

Avoid inhaling powder products.

~

They can cause burning in the mouth

and throat if swallowed, and can inhibit

breathing.

Before servicing, disconnect the

~

power supply by either removing the

fuse, unplugging the unit or manually

"tripping" the circuit breaker.

Whenever work is conducted on the

~

tap water network, the water supply line

to the washer must be cleared of air.

Failure to do so can result in damage to

the water softener.

The following points should be

observed to assist in maintaining

quality standards for critical labware

and to avoid damage to the loads

being cleaned.

For this type of cleaning, the

~

program must not be interrupted until

completion. In other words, the On/Off

Button must not be used. Interruptions

should also be avoided for all other

programs, such as during performance

testing, because this can negatively

affect the cleaning and rinsing results.

After any interruption, the program

should be restarted from the beginning.

Only use cleaning agents

~

formulated for special processes and

approved by Miele for use with this

machine. Use of unsuitable cleaning

agents could adversely affect the

components of the machine.

Use only Miele approved cleaning

~

agents with this machine. Use of

unsuitable cleaning agents could

adversely affect the components of the

machine. Damages resulting from using

unsuitable cleaning agents are not

covered by the warranty.

Pre-treatments with cleaning agents

~

can create suds, as can certain rinsing

agents. For pre-treatment and / or

cleaning, only use low-sudsing

detergents which have been approved

by Miele. Suds can have an adverse

effect on the cleaning process.

In critical applications where very

~

high requirements have to be met, it is

strongly recommended that all the

relevant factors for the process, such

as cleaning agent, quality of water, etc.

are discussed with the Miele

Applications Specialists.

6

IMPORTANT SAFETY INSTRUCTIONS

It is the responsibility of the operator

~

to routinely check that the required

cleaning standards are being met.

Therefore, results need to be regularly

tested and documented, both thermo

electrically and through inspection. For

thermo chemical processes, additional

testing is required using chemical or

biological indicators.

The performance of the cycles was

~

tested using Neodisher products. The

use of other products is not

discouraged but may not yield identical

results. Please be aware that changes

in formulation, storage conditions, etc.

which may not be publicized by the

chemical manufacturer can have a

negative effect on cleaning results. and

are not the responsibility of the machine

manufacturer.

The process must be set so that no

~

foam escapes the wash compartment.

Escaping foam jeopardizes the safe

operation of the lab washer.

The process must be checked

~

regularly in order to detect any

foaming.

In order to prevent damage to the

~

lab washer and any accessories

through processing chemicals or dirt as

well as any interaction between them,

see "Effects of Processing Chemicals".

When a chemical additive is

~

recommended, the manufacturer of the

machine takes no responsibility for the

effect of the chemical on the items

being cleaned.

The mobile units, baskets and

~

special inserts should only be used for

their specific applications. Instruments

with hollow parts must be flushed

through with wash water.

Empty any containers or utensils

~

before arranging them in the machine.

Do not allow any remains of acids,

~

solvents or corroding ferrous material,

and in particular hydrochloric acid or

chloride solutions to get into the wash

cabinet. Similarly avoid any materials

with a corrosive effect. The presence in

compounds of any solvents should be

minimal, (especially those in hazard

class A1).

To avoid any corrosion damage

~

ensure that solutions or steam

containing hydrochloric acid do not

come in contact with the stainless steel

casing of the machine.

Please follow the installation advice

~

in these instructions and the separate

Installation Instructions.

7

IMPORTANT SAFETY INSTRUCTIONS

Using accessories

Only genuine, Miele parts and

~

accessories should be used with this

machine, including Miele mobile units,

baskets and inserts.

Adequate cleaning results cannot

~

be guaranteed when non-Miele

accessories are used, or when Miele

accessories are altered. Damages

resulting from the use of unsuitable

accessories are not covered by the

warranty.

Please note the following symbols on

the machine:

Caution : See the Operating

Instructions!

Caution : Danger of electric

shock!

Disposal of an old machine

When discarding a lab washer,

~

disconnect it from the power supply

and cut off the power cord.

The old machine may be contaminated

by blood or other body fluids and must

be disinfected before disposal.

For environmental and safety reasons

ensure the machine is completely

drained of any residual water and

cleaning agent. (Observe safety

regulations and wear safety goggles

and gloves). Make the door lock

inoperative or remove the door

completely, so that children cannot

accidentally shut themselves in. Make

appropriate arrangements for the safe

disposal of the machine.

Machines with a tank system: remove

the water from the tank before

disposing the machine.

SAVE THESE

INSTRUCTIONS

8

Function of the laboratory glassware washer

The Miele G 7825 / G 7826 Glassware

Washing System is designed to provide

high-throughput glassware cleaning in

areas where space is at a premium.

This unit is ideal for cleaning both large

volumes of small items and difficult to

clean large items.

This high tech system has been proven

in hundreds of laboratories worldwide.

It features the user-friendly Profitronic

programming system for easy

programming, a fully modular basket

system for washload flexibility and an

automatic basket recognition system to

help eliminate user error.

Standard model

Serial interface

–

On-board liquid detergent

–

dispensing

Basket recognition

–

Available options

HEPA-filtered forced - air drying

–

Steam condenser (DK)

–

Report printer (PRT)

–

Dispensing systems DOS 2 and

–

DOS 4

9

Guide to the laboratory glassware washer

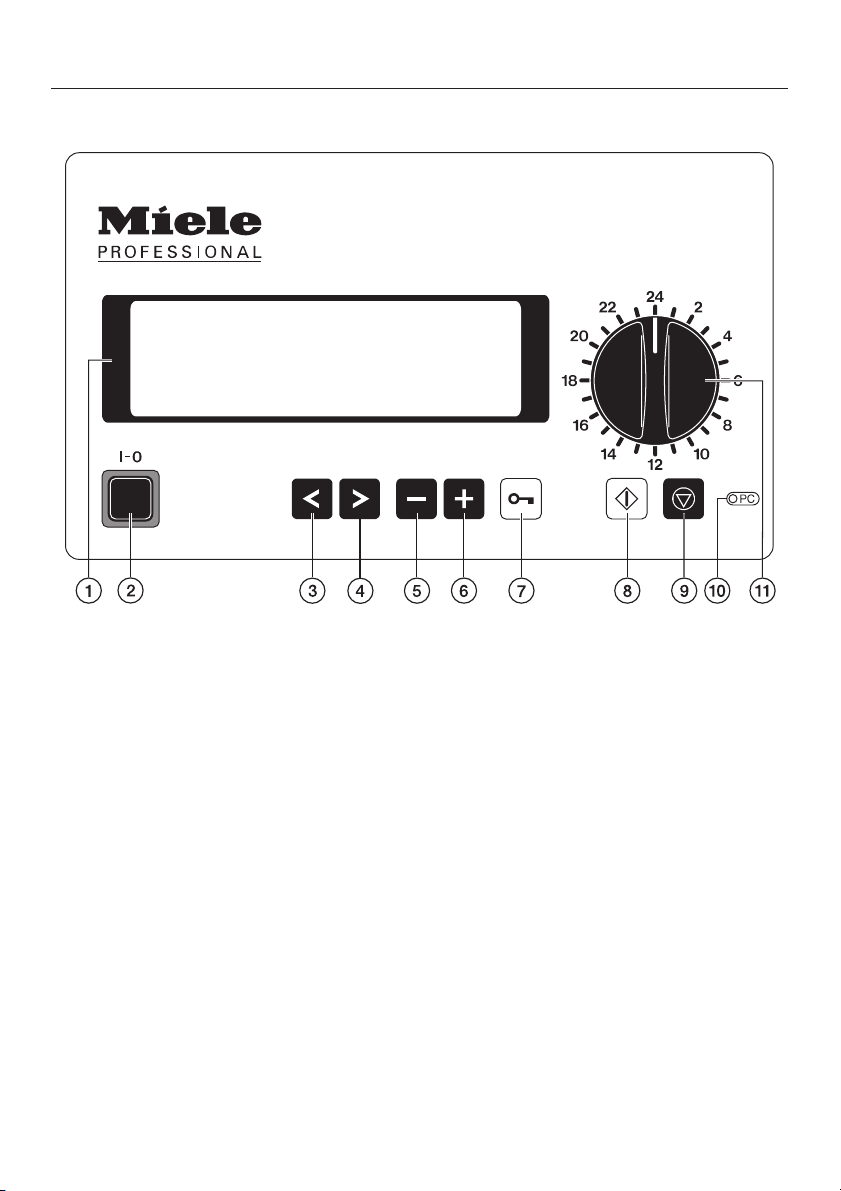

Electronic controls

10

Guide to the laboratory glassware washer

a Display

with screen saver

The background light turns off

automatically after 15 minutes.

Press any key to turn the background

^

light on again.

If an fault occurs during operation it

will be indicated in the display. See

"Messages" in the Programming

manual for more information.

b On/Off button (I-0)

c Cursor left 1

moves the cursor to the left:

– to the previous menu

– to the previous parameter

– to the previous input position

d Cursor right 2

moves the cursor to the right:

– to the next menu

– to the next parameter

– to the next input position

e Minus button 3

– program selection for programs

over 24

– scrolling back page-wise in menus

– entering numbers and letters

– changing default settings,

e.g. service parameter

f Plus button 4

– program selection for programs

over 24

– scrolling forward page-wise in

menus

– entering numbers and letters

– changing default settings,

e.g. service parameter

g Door button 5

h Start button 6

– Starting a program

– Activating insert mode

– Confirming settings

– Confirming menu points,

to get to the respective submenu

i Stop button 7

– Canceling a program

– Leaving the input screen

without saving

– Leaving a menu

j Optical interface 8

(for service technician)

k Program selector

Selecting programs 1-23

11

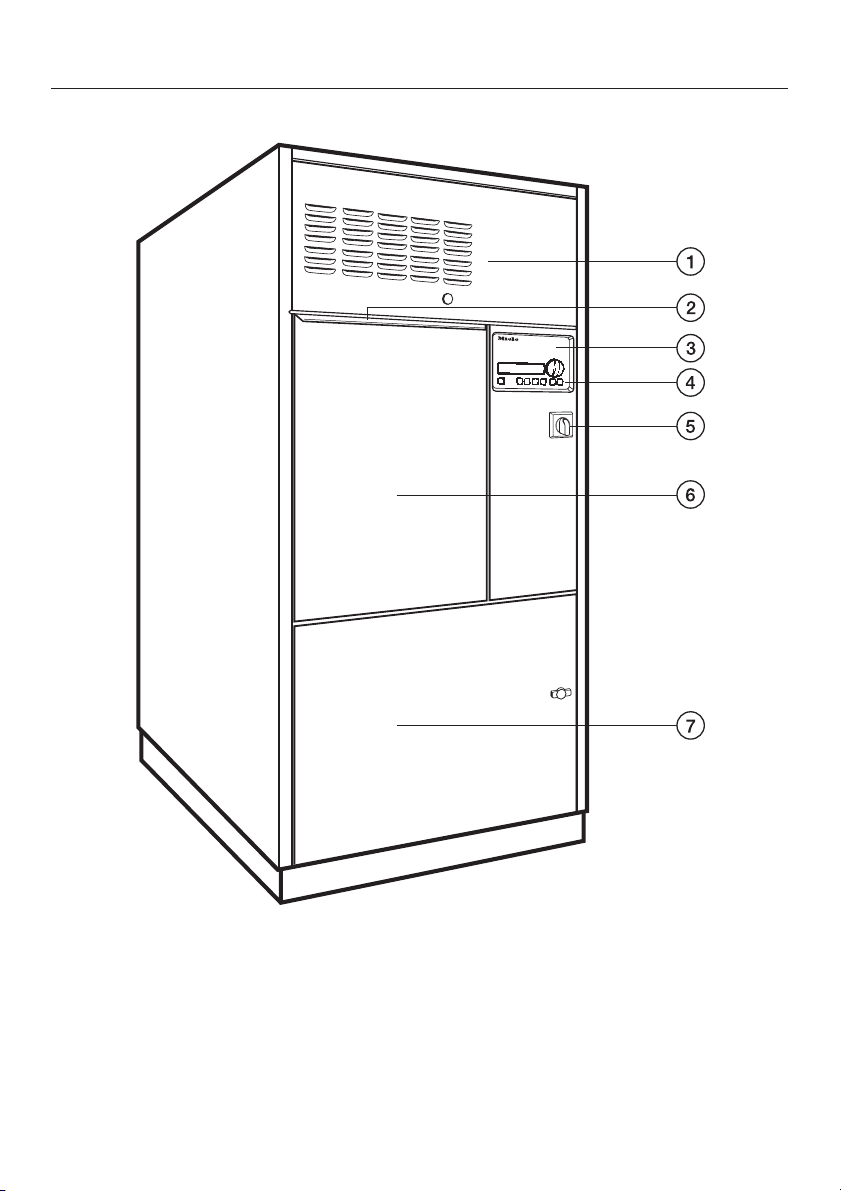

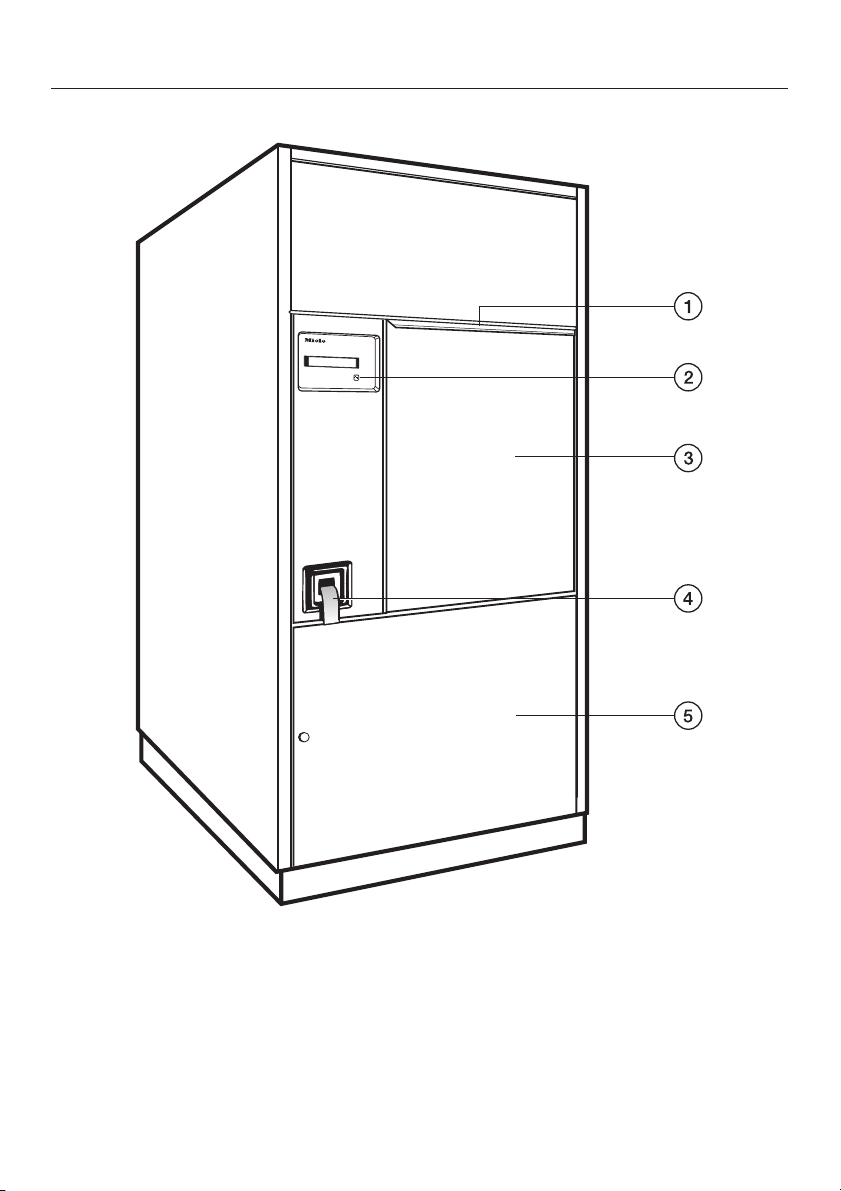

Guide to the laboratory glassware washer

Unclean side

a Drying unit (TA) (optional)

b Handle

c Electronic control "Profitronic"

(see "Programming manual")

d Controls

12

e Power switch (with "Emergency

cut-off" function for Service)

f Drop-down door (closed)

g Service panel

Unclean side

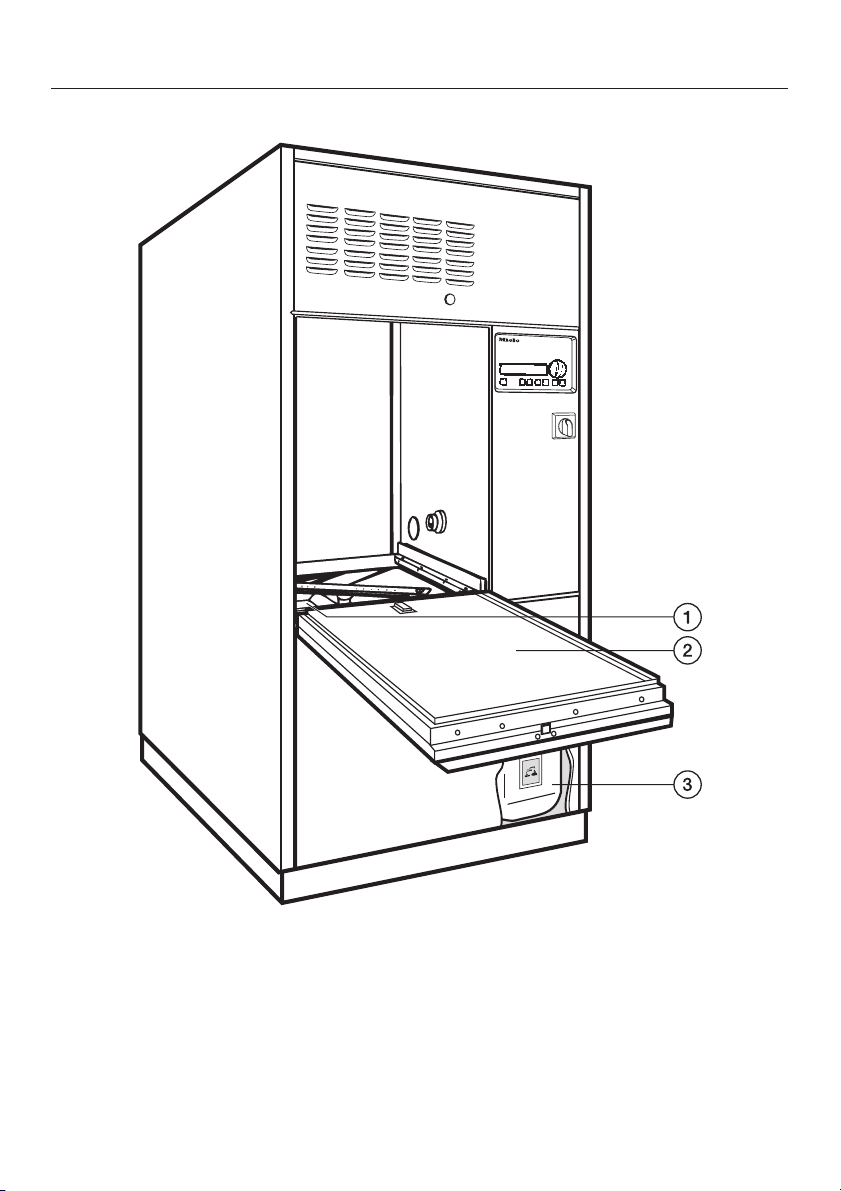

Guide to the laboratory glassware washer

a Filter combination

b Drop-down door (open)

c Containers for dispensing systems

DOS 1 / DOS 3

(optional DOS 2 / DOS 4)

13

Guide to the laboratory glassware washer

Clean side (G 7826 only)

a Handle

b "Door" button

c Drop-down door (closed)

14

d Printer (optional)

G 7825 on the unclean side

e Service panel

Opening and closing the door

The door can only be opened when:

the lab glassware washer is

–

connected to the electrical supply,

the red ("emergency cut-off") power

–

switch is in the I-ON position,

the I-0 On-Off button is pressed in,

–

and

no program is running.

–

The door on the clean side (G 7826)

can only be opened when:

DESIN (disinfection) programs have

–

been correctly completed.

or

– the "Door locking" function is active

(see "Machine function - Door

locking" in the "Programming

Manual").

Opening the door

Press the 5 door button, hold the

^

door handle and open the door.

Do not touch the heating

,

elements (under the wide area filter)

during or directly after the end of a

program, you could burn yourself.

If the boiler has been programmed

to "BOILER READY", be particularly

careful of hot water and steam when

opening the door. Danger of burning

or scalding. The water inlet pipe to

the wash cabinet is located, as

viewed from the unclean side,

underneath the basket runner on the

left hand side.

To close the door

^ Lift the door upwards and push until

it clicks shut.

15

Automatic mobile unit recognition (AWK)

In operating level C the AWK attributes

a fixed program place to a mobile unit

with valid coding.

Program places 1-15 are reserved for

the AWK automatic mobile unit

recognition.

The unit coding (on the mobile unit) and

the program place with the

corresponding program (in the

"Profitronic" electronic control unit) must

match.

Each mobile unit must be coded

^

before being used for the first time.

See "Mobile unit coding".

^ The wash program through which the

mobile unit is coded has to be

assigned to the relevant program

place.

Program place changes, see the

"System function - Selector switch

organization" section in the

Programming Manual.

Mobile unit coding

The automatic mobile unit recognition

feature assigns a program place to a

mobile unit. The mobile units must be

coded with a magnetic strip, via a bit

combination. In operating level C the

only program available for a coded

mobile unit is the one assigned to the

corresponding program place.

When a coded mobile unit is inserted in

the machine and the door closes, the

automatic mobile unit recognition

selects the assigned program. Be sure

no small items connect to the magnetic

strip.

^ Press 6 to start the program.

Important!

Before starting the program with the

"Start" button 6, check that the

program needed for this mobile unit

is displayed.

Otherwise insufficient wash results

may occur!

Always check that programs for

mobile units with AWK (on fixed

program places) are not exchanged.

16

The coding is made up of 5 bits:

–

Bits 1 to 4 define the mobile unit

code,

–

Bit 5 serves as a control (Parity-Bit).

Bit 6 controls the volume of water intake

and the circulation pump for mobile

units with side coupling. This setting

cannot be changed!

Mobile units without side coupling are

coded with tracks which do not contain

Bit 6!

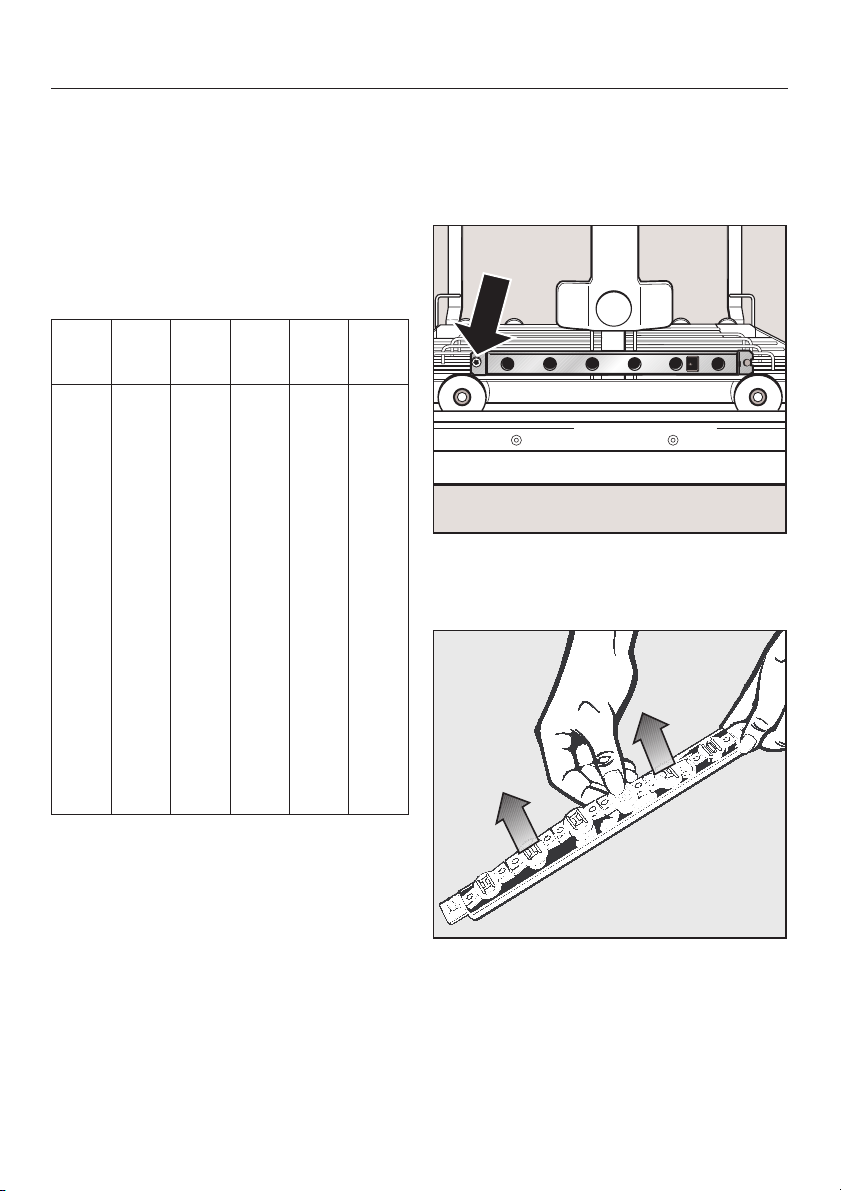

Automatic mobile unit recognition (AWK)

Mobile unit coding strip

15 different codes can be set. They are

assigned to program places 1 to 15.

Under "System function - Selector

switch organization" the matching

programs have to be put into the first

15 program places.

Prog.place

Bit 1 Bit 2 Bit 3 Bit 4 Bit 5

Parity-

Bit

-00000

1 l 000 l

20l00l

3l l000

400l0l

5l0l00

60 l l 00

7l l l0l

8000 l l

9l00l0

100l0l0

11l l0l l

12 0 0 l l 0

13l0lll

140llll

15llll0

Setting mobile unit coding

To set or alter the coding of a mobile

unit with automatic recognition (AWK)

proceed as follows:

^ Unscrew the track with an AWK (allen

wrench) and remove it from the

retainer.

The coded total must be an even

number. Bit 6 is not included in this

calculation.

If the coded total equals an odd number

the message CHECK MOBILE UNIT

RECOGNITION will appear. If the mobile

unit code equals 0, the message NO

MOBILE UNIT RECOGNITION will

appear. In both cases the program

cannot be started. The mobile unit

recognition must be reset.

^

Remove the magnetic strip from the

track.

17

Loading...

Loading...