Page 1

CH-9101 Herisau/Switzerland

Tel. ++41 71 353 85 85

Fax ++41 71 353 89 01

Internet www.metrohm.ch

E-Mail info@metrohm.ch

752 Pump Unit

Pump Unit752

POWER

REMOTE PUMP

ON ON

OFFOFF

MetrohmMetrohm

8.752.1013 Instructions for Use

1.10.1998 / dö

Page 2

Table of contents

Table of contents

1 Introduction............................................................................................1

1.1 Instrument description.............................................................................1

1.2 Parts and controls..................................................................................... 2

1.3 Information about the Instructions for Use..........................................4

1.3.1 Organization ..................................................................................4

1.3.2 Notation and pictograms............................................................... 5

1.4 Safety notes ...............................................................................................6

1.4.1 Electrical safety..............................................................................6

1.4.2 General precautionary rules.......................................................... 6

2 Installation..............................................................................................7

2.1 Setting up the instrument........................................................................ 7

2.1.1 Packaging......................................................................................7

2.1.2 Check ............................................................................................7

2.1.3 Location......................................................................................... 7

2.1.4 Arrangement of the instruments....................................................7

2.2 Mains connection......................................................................................8

2.2.1 Setting the mains voltage..............................................................8

2.2.2 Fuses.............................................................................................9

2.2.3 Mains cable and mains connection ..............................................9

2.2.4 Switching the instrument on/off..................................................... 9

2.3 Connection to the IC System ................................................................10

2.3.1 Electrical connection to the 732 IC Detector............................... 10

2.3.2 Connection of the suppressor module .......................................10

3 Operation................................................................................................15

3.1 Manual Operation....................................................................................15

3.2 Operation via 732 IC Detector...............................................................15

4 Troubleshooting.............................................................................17

4.1 Insufficient or non-existing flow rate...................................................17

4.2 Leaking of tubing nipples......................................................................17

4.3 Air bubbles in pump circuit...................................................................18

4.4 Exchanging the pump tubing................................................................18

5 Appendix..................................................................................................19

5.1 Technical data..........................................................................................19

5.2 Standard equipment ...............................................................................21

5.3 Optional accessories..............................................................................21

5.4 Warranty and conformity.......................................................................22

5.4.1 Warranty ......................................................................................22

5.4.2 EU Declaration of conformity ......................................................23

5.4.3 Certificate of conformity and system validation .......................... 24

5.5 Index..........................................................................................................25

752 Pump Unit I

Page 3

Table of contents

List of figures

Fig. 1: Front of the 752 Pump Unit ............................................................................... 2

Fig. 2: Rear of the 752 Pump Unit................................................................................ 3

Fig. 3: Setting the mains voltage.................................................................................. 9

Fig. 4: Connection 752 Pump Unit – 732 IC Detector................................................ 10

Fig. 5: Connections at suppressor module................................................................ 11

Fig. 6: Installing pump tubings................................................................................... 12

752 Pump UnitII

Page 4

1 Introduction

1.1 Instrument description

The 752 Pump Unit is a 2-channel peristaltic pump which can be used

to pump two solutions simultaneously. It is particularly suitable for operating the suppressor module in the 2.733.0X30 IC Separation Center

by supplying regeneration and rinsing solutions. This application is described in detail in these Instructions for Use.

The 752 Pump Unit can either be operated manually by means of the

on/off switch for the pump or remotely controlled via the remote interface.

1.1 Instrument description

752 Pump Unit 1

Page 5

1 Introduction

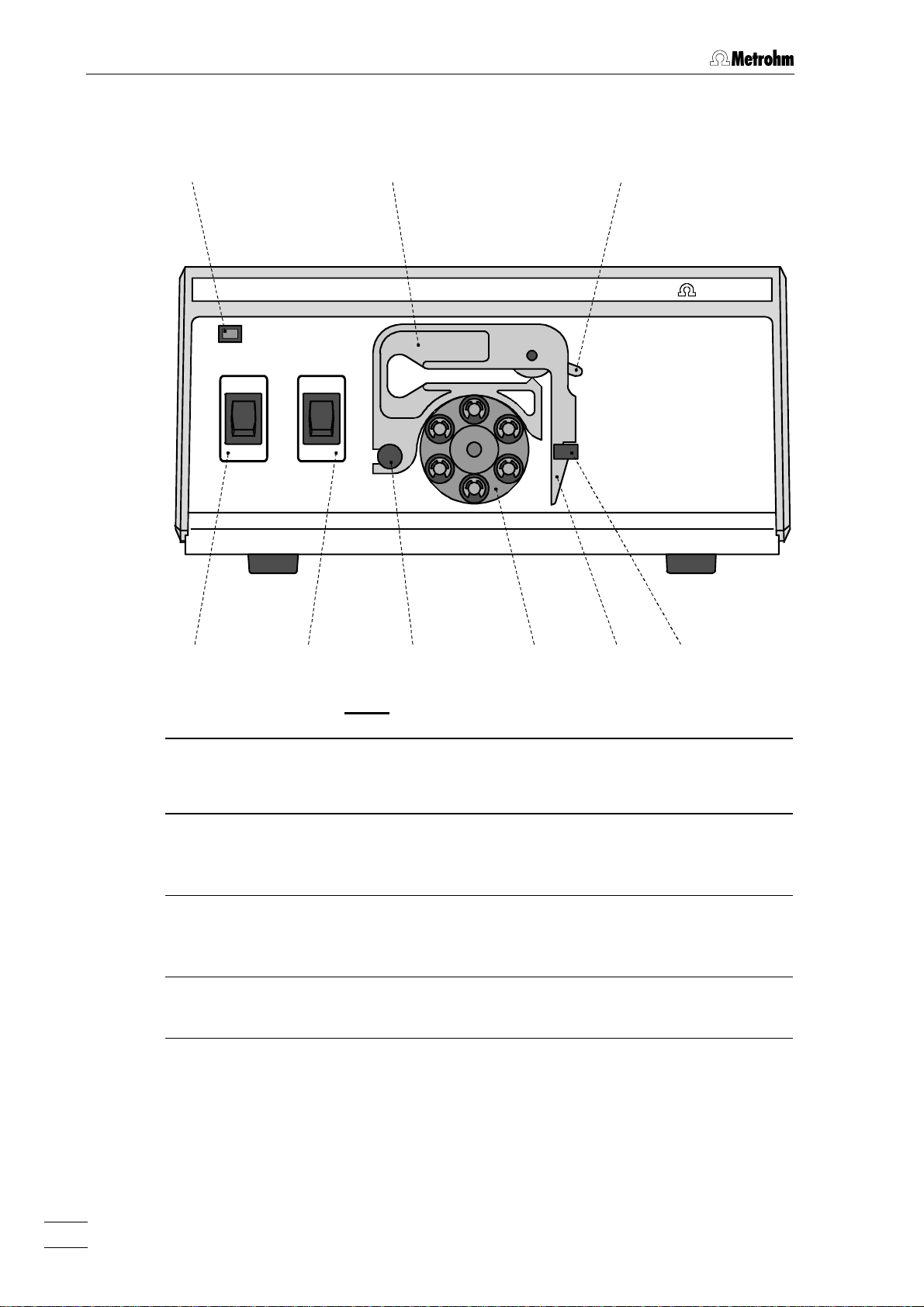

1.2 Parts and controls

33 44 55

Pump Unit752

POWER

REMOTE PUMP

ON ON

OFFOFF

22 11 668899 77

Fig. 1: Front of the 752 Pump Unit

MetrohmMetrohm

11 Pump ON/OFF

On/Off switch for the pump

(manual operation mode)

22 Remote ON/OFF

On/Off switch for remote control

via remote interface

33 Power on lamp

Lights up when instrument is

switched on

44 Tubing cartridge

For 6.1826.050 Pump tubing

55 Contact pressure lever

For adjusting the contact pressure

66 Holding clamp

For locking the tubing cartridge into

place

77 Snap-action lever

For releasing the tubing cartridge

88 Pump drive

Roller head with contact rollers

99 Mounting pin

For attaching the tubing cartridge

752 Pump Unit2

Page 6

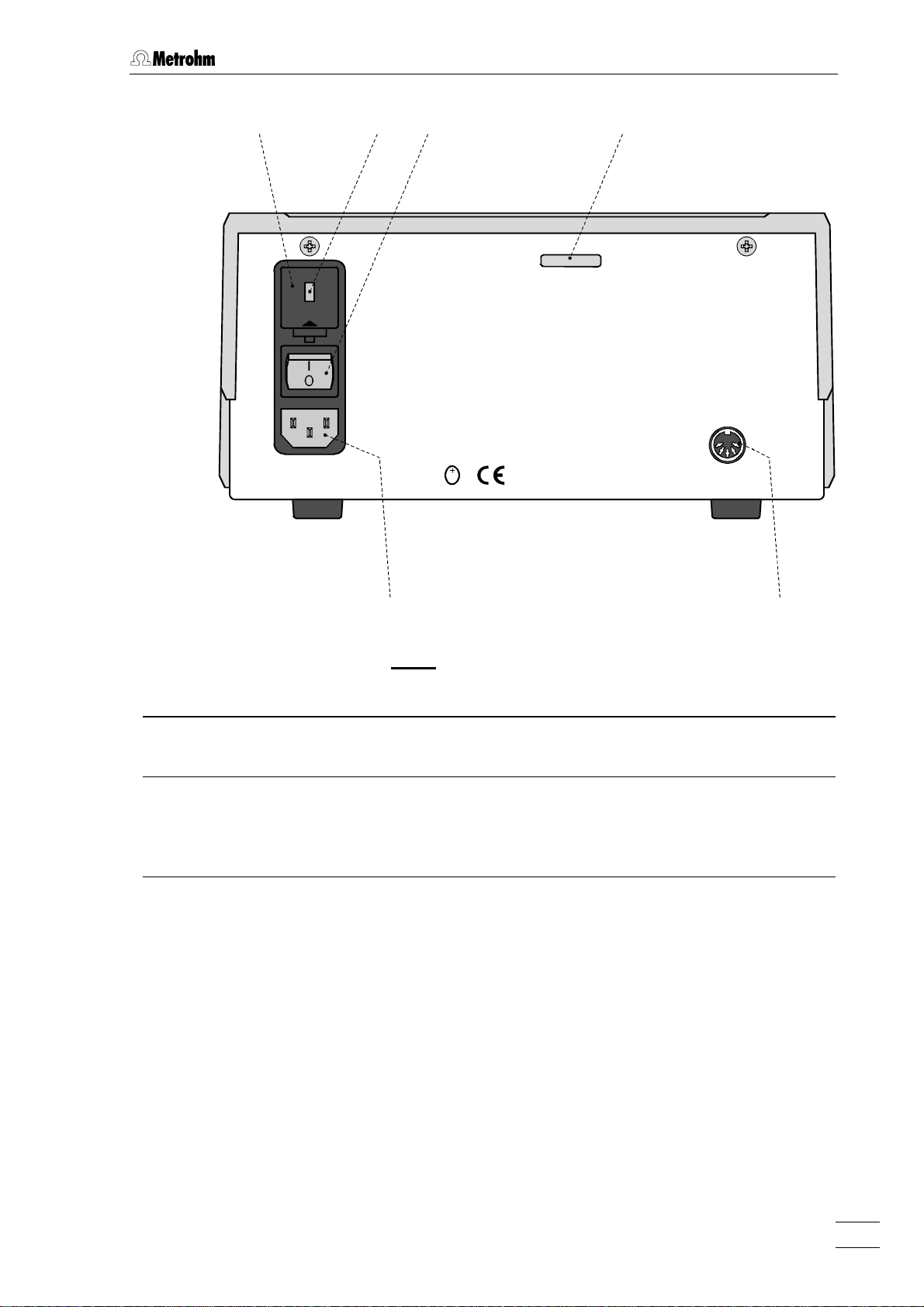

1.2 Parts and controls

1010

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

f=50-60 Hz

S=12 VA

115V: 110-120V:

230V: 220-240V:

Type 1.752.0010 Nr.

Fuse

0,2A(T)

0,1A(T)

S

131312121111

Remote

Pump

Made by Metrohm Herisau Switzerland

1515 1414

Fig. 2: Rear of the 752 Pump Unit

1010 Fuse holder

Changing the fuses, see section 2.2

1111 Voltage selection insert with

display of voltage

1212 Mains switch

For switching the instrument on/off:

I = ON 0 = OFF

1313 Serial number

1414 Remote interface

Remote I/O lines for connection of

external devices (e.g. 732 IC Detector)

1515 Mains connection plug

Mains connection, see section 2.2

752 Pump Unit 3

Page 7

1 Introduction

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 752 Pump Unit into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instruments.

1.3.1 Organization

These 8.752.1013 Instructions for Use for the 752 Pump Unit provide

a comprehensive overview of the startup procedure, operation, fault

rectification and technical specifications of these instruments. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instruments, parts and controls

and safety notes

Section 2 Installation

Attachment of accessories, connection to IC system

Section 3 Operation

Manual operation and operation via 732 IC Detector

Section 4 Maintenance – Faults

Maintenance, fault rectification

Section5 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments please use either

the Table of contents or the Index at the back.

752 Pump Unit4

Page 8

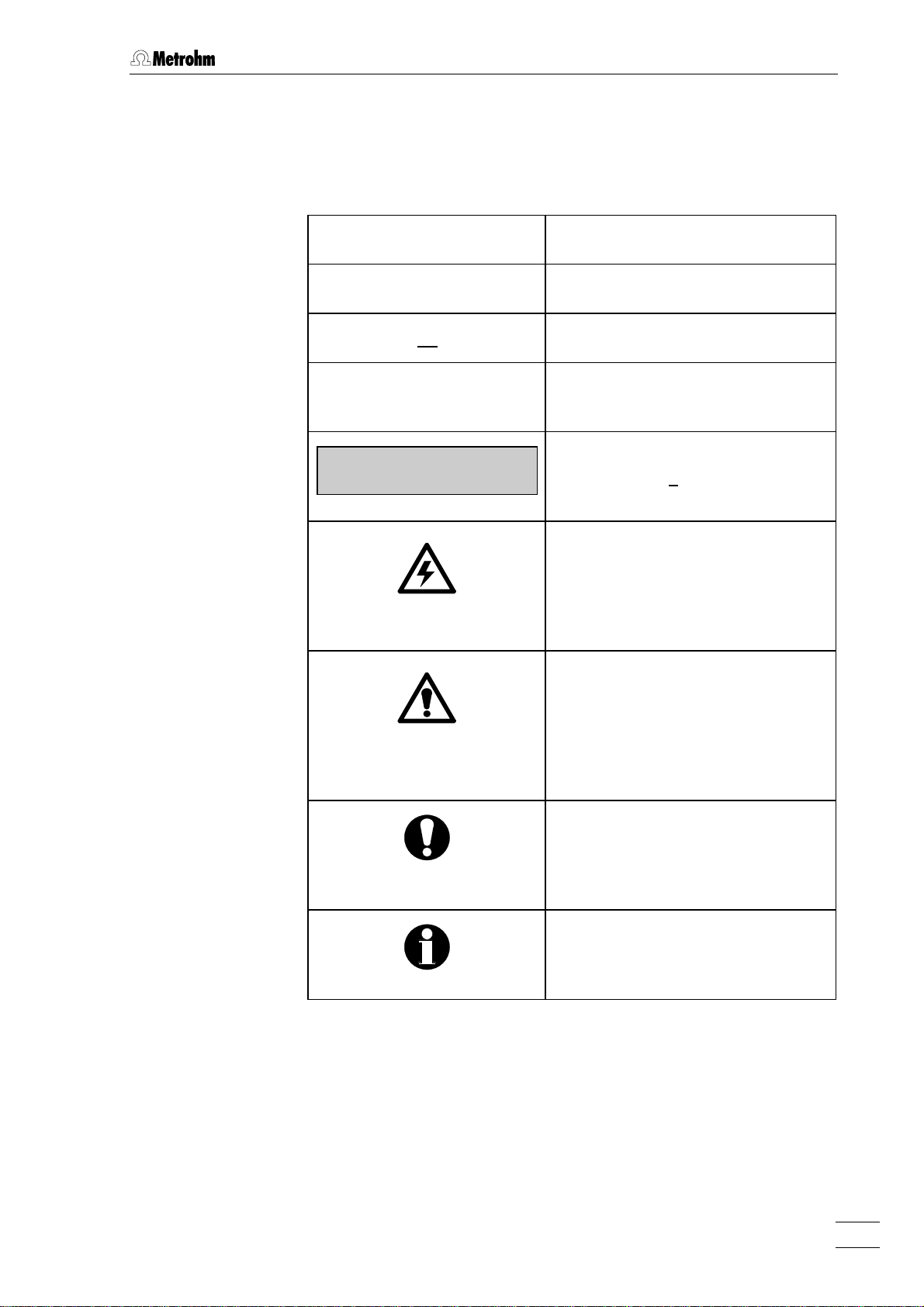

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

<PUMP> Switch or key

1515 Part or control of 752

8989 Part or control of 732/733

"range" Parameter or entry value

1.3 Information about the Instructions for Use

at 732 IC Detector

>PARAM/detector

range: 1.00 mS/cm

Display

Text in display 11 of the 732 IC

Detector

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. First read the associated

directions before you continue.

Comment

This symbol marks additional information and tips.

752 Pump Unit 5

Page 9

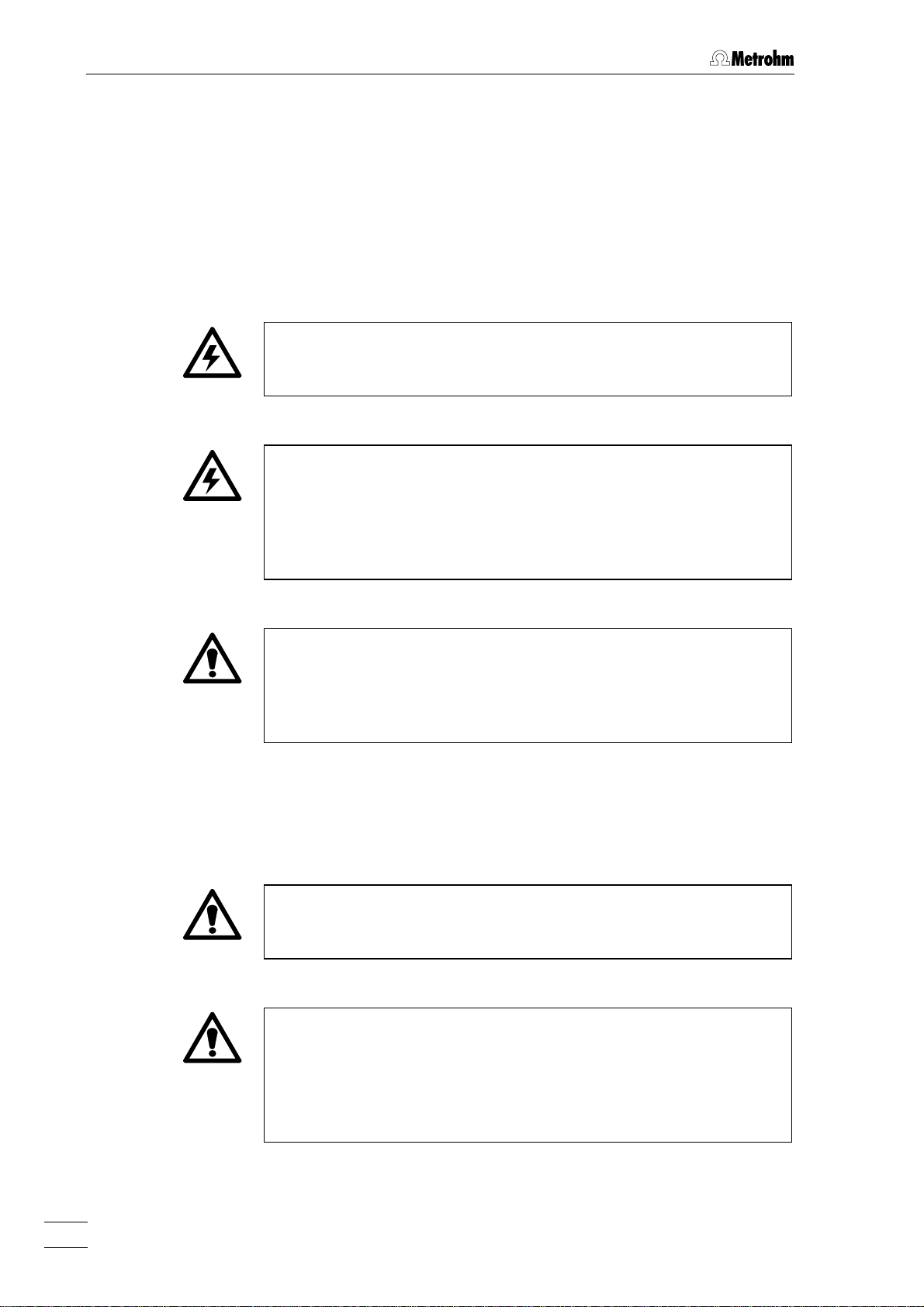

1 Introduction

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 752 Pump Unit is assured

in the context of the specifications IEC 1010-1 (protection class 1, degree of protection IP40), the following points should be noted:

• Mains connection

Setting the mains voltage, checking the mains fuse and the mains

connection must be effected in accordance with the instructions in

section 2.2.

• Opening the 752 Pump Unit

When the 752 Pump Unit is connected to the power supply the instrument must neither be opened nor should parts be removed from

it, otherwise there is a danger of coming into contact with components which are live. Always disconnect the instrument from all voltage

sources before you open it and ensure that the mains cable is

disconnected from mains connection 1515 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 752 Pump Unit, you should earth yourself and any tools you

are using by touching an earthed object (e.g. housing of the instrument or a radiator) to eliminate any static charges which exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all pump tubings and all input and output lines periodically for

possible leaks. Follow the relevant instructions regarding the handling

of flammable and/or toxic solvents and their disposal.

• Regular exchange of pump tubings

Pump tubings are consumable material and must be replaced from

time to time (see section 4.4). Suitable measures must be taken so

that any leak which might occur in the pump tubing or connections

during unattended operation will cause no damage (placing the

instrument at the bottom, collection device for any liquid which may

leak out).

752 Pump Unit6

Page 10

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 752 Pump Unit is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The actual instrument

is packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they can assure

damage-free transport of the instrument.

2.1.2 Check

2.1 Setting up the instrument

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 5.2). In the case of transport damage, see

instructions in section 5.4.1 "Warranty".

2.1.3 Location

Position the instruments in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive

atmosphere and contamination by chemicals.

2.1.4 Arrangement of the instruments

In one-channel operation with suppressor module (2.733.0X30 IC

Separation Center), the 752 Pump Unit, 709 IC Pump, 733 IC Separation Center and 732 IC Detector are best stacked on top of one another

in this order.

The 752 Pump Unit should always be placed at the bottom of the

instrument stack so that any leaks which may occur in the pump

tubing or connections cannot cause damage to the other instruments

by leakage of corrosive liquids (e.g. H2SO4).

752 Pump Unit 7

Page 11

2 Installation

2.2 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with the mains voltage set wrongly and/or

wrong mains fuse there is a danger of fire!

2.2.1 Setting the mains voltage

Before switching on the 752 Pump Unit for the first time, check that the

mains voltage set on the instrument (see Fig. 3) matches the local

mains voltage. If this is not the case, you must reset the mains voltage

on the instrument as follows:

Disconnect mains cable

1

Disconnect mains cable from mains connection plug 1515 of the

752 Pump Unit.

Remove fuse holder

2

Using a screwdriver, loosen fuse holder 1010 and take out com-

pletely.

Change mains voltage

3

Completely remove voltage selection insert 1111 by hand, rotate it

through 180° and reinsert it. The required mains voltage (115 or

230 V) must now be visible from the front.

Check fuses

4

Carefully take both fuses out of fuse holder 1010 and check their

specifications:

100……120 V 0.2 A (slow-blow) Metrohm-No. U.600.0009

220……240 V 0.1 A (slow-blow) Metrohm-No. U.600.0006

Insert fuses

5

Change both fuses if necessary and reinsert in fuse holder 1010.

Install fuse holder

6

Push fuse holder 1010 back into the opening of 752 Pump Unit by

hand until it clicks into place properly.

752 Pump Unit8

Page 12

1111

2.2 Mains connection

100 – 120 V220 – 240 V

1010 Fuse holder

2.2.2 Fuses

1010

230

115

1111 Voltage selection

insert with display

1212

of voltage

1212 Mains switch

1515

1515 Mains connection

plug

Fig. 3: Setting the mains voltage

Two fuses 0.2 A/slow-blow for 100…120 V or 0.1 A/slow-blow for

220…240 V are installed in the fuse holder 1010 of the 752 Pump Unit as

standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, proceed as described in section 2.2.1.

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables:

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 1515 of the 752 Pump

Unit (see Fig. 3).

2.2.4 Switching the instrument on/off

The 752 Pump Unit is switched on and off using mains switch 1212. When

the instrument is switched on lamp 33 lights up.

752 Pump Unit 9

Page 13

2 Installation

2.3 Connection to the IC System

2.3.1 Electrical connection to the 732 IC Detector

In order to allow remote control via 732 IC Detector the 752 Pump Unit

must be connected to the "Remote" connection of the 732 IC Detector

with the 6.2143.200 cable as shown in Fig. 4. To allow the remote control to operate, switch 22 "REMOTE" on the front of the 752 Pump Unit

must be set to "ON".

If a second, additional instrument (e.g. 752, 753, 754) is to be connected to the Remote interface of the 732 IC Detector then the

6.2143.220 cable (available as an option) should be used to connect

the 752 Pump Unit instead of the 6.2143.200 cable.

732

752

Fig. 4: Connection 752 Pump Unit – 732 IC Detector

2.3.2 Connection of the suppressor module

The Metrohm Suppressor Module MSM built into the 2.733.0X30 IC

Separation Center is described in detail in section 2.8.3 of the 732/733

Manual. The 752 Pump Unit is used to supply regeneration and rinsing

solutions to the suppressor module. To avoid contamination of the

suppressor module by foreign particles or bacterial growth, it is advantageous to install an in-line filter between the 752 Pump Unit and the

inlet capillaries of the suppressor module. The two 6.2821.100 Filter

units PEEK (see section 2.6.3 of the 732/733 Manual) supplied with

the 2.733.0X30 IC Separation Center are eminently suitable for this purpose.

Connection of the suppressor module to the 752 Pump Unit is carried

out as described in section 2.8.6 of the 732/733 Manual . The most important points are repeated here; underlined numbers #### refer to op-

erating elements in the 732/733 Manual:

6.2143.200

Connect column to injector

1

see section 2.8.6 of 732/733 Manual

Rinse column

2

see section 2.8.6 of 732/733 Manual

752 Pump Unit10

Page 14

2.3 Connection to the IC System

Eluent

H2O

Detector

Waste

Waste

H

SO

8989 Suppressor inlet

capillary for eluent

8989

94949090

1

2

3

9191

9393

9292

Fig. 5: Connections at suppressor module

Connect column to suppressor module

3

• Cut inlet capillary 8989 marked with "Eluent" of suppressor

module 9595 (see Fig. 17 in 732/733 Manual) to the desired

length using a sharp cutting tool (e.g. razor blade).

• Screw inlet capillary 8989 to outlet end of separating column 7676

using a 6.2744.014 Compression fitting.

9090 Suppressor inlet

capillary for H2SO

9191 Suppressor outlet

capillary for H2SO

9292 Suppressor outlet

capillary for H2O

9393 Suppressor inlet

capillary for H2O

9494 Suppressor outlet

capillary for eluent

4

4

Fix column

4

• Insert one or two column holders 8484 (6.2027.030, 6.2027.040

or 6.2027.050) in mounting rails 8383 and fasten separating

column in the column holder.

Connect suppressor module to detector block

5

• Cut outlet capillary 9494 marked with "Detector" of suppressor

module 9595 to the desired length using a sharp cutting tool

(e.g. razor blade).

• Screw outlet capillary 9494 marked with "Detector" to coupling

9696 using a 6.2744.014 Compression Fitting.

• Screw inlet capillary 8282 of detector block 8181 to other end of

coupling 9696.

Fix connection suppressor – detector block

6

• Insert one of the column holders 8484 (6.2027.030, 6.2027.040

or 6.2027.050) in mounting rail 8383 and fasten coupling 9696 in

the column holder.

Attach pump tubings to 752 Pump Unit

7

• Loosen both tubing cartridges 44 from the holding clamp 66 by

pressing down snap-action lever 77 and remove from mount-

ing pin 99 on Pump Unit 752 (see Fig. 1).

752 Pump Unit 11

Page 15

2 Installation

1616 1717 1818 1919 44 55 1919 1717 9090//939377 20202020 1616 2020 2222 2323 20202121

Fig. 6: Installing pump tubings

44 Tubing cartridge 2020 PEEK compression fitting

(6.2744.010)

55 Contact pressure lever 2121 Connector (6.2824.110) with filter

77 Snap-action lever 2222 Housing for 6.2824.100 Filter unit

PEEK

1616 PTFE tubing (6.1803.020) 2323 Connector

1717 Coupling (6.2744.030) 9090 Suppressor inlet capillary for

H2SO

4

1818 Pump tubing (6.1826.050) 9393 Suppressor inlet capillary for H2O

1919 Stopper (white-yellow)

• Press contact pressure lever 55 on both tubing cartridges

down as far as it will go.

• Insert a length of pump tubing 1818 (6.1826.050) into each of

the tubing cartridges as shown in Fig. 6. The white-yellow

stopper 1919 must click into the corresponding holder on the

left-hand side of the tubing cartridge.

• Place the tubing cartridges on mounting pin 99 and press

down on the right-hand side until snap-action lever 77 clicks

into position on holding clamp 66. Take care that no kinks are

formed in the pump tubing.

Suppressor connection 2: H2SO

8

4

• Loosen rotary nipple screwed onto the interior side of connection 2727. Pull inlet capillary 9090 marked with "H2SO4" (see

Fig. 17 of 732/733 Manual) by hand out of the opening of

connection 2727 as far as required. Retighten nipple on the in-

terior side of connection 2727 to fix inlet capillary 9090.

752 Pump Unit12

Page 16

2.3 Connection to the IC System

• Attach inlet capillary 9090 using compression fitting 2020

(6.2744.014) to the connector 2323 (see Fig. 6) of the filter unit

PEEK (see section 2.6.3 of 732/733 Manual).

• Attach a piece of PTFE tubing 1616 cut to the required length

using a compression fitting 20 20 (6.2744.014) to the connector

2121 with filter at the other end of the filter unit PEEK.

• Attach the other end of the PTFE tubing 1616 using a compres-

sion fitting 2020 (6.2744.014) to the coupling 1717 (6.2744.030)

and mount it on the outlet end of the first length of pump

tubing 1818.

• Mount a coupling 17 17 (6.2744.030) to the inlet end of the first

length of pump tubing 1818. Attach a piece of the PTFE tubing

1616 (6.1803.020) cut to the required length using a compression fitting 2020 (6.2744.014) to the other end of this coupling.

• Immerse the other end of the aspirating tubing in a vessel

containing regeneration solution (normally 20 mmol/L H2SO4)

and fix in place.

• Pull outlet capillary 9191 marked with "Waste" of the suppressor

module through the rear panel opening 4343, lead it to a suffi-

ciently large waste container and fix it in place.

Suppressor connection 3: H2O

9

• Loosen rotary nipple screwed onto the interior side of connection 2828. Pull inlet capillary 9393 marked with "H2O" (see

Fig. 17 of 732/733 Manual) by hand out of the opening of

connection 2828 as far as required. Retighten nipple on the in-

terior side of connection 2828 to fix inlet capillary 9393.

• Attach inlet capillary 9393 using compression fitting 2020

(6.2744.014) to the connector 2323 (see Fig. 6) of the second

filter unit PEEK (see section 2.6.3 of 732/733 Manual).

• Attach a piece of PTFE tubing 1616 cut to the required length

using a compression fitting 20 20 (6.2744.014) to the connector

2121 with filter at the other end of the filter unit PEEK.

• Attach the other end of the PTFE tubing 1616 using a compres-

sion fitting 2020 (6.2744.014) to the coupling 1717 (6.2744.030)

and mount it on the outlet end of the second length of pump

tubing 1818.

• Mount a coupling 17 17 (6.2744.030) to the inlet end of the

second length of pump tubing 1818. Attach a piece of the PTFE

tubing 1616 (6.1803.020) cut to the required length using a

compression fitting 2020 (6.2744.014) to the other end of this

coupling.

• Immerse the other end of the aspirating tubing in a vessel

containing rinsing solution (normally dist. H2O) and fix in

place.

• Pull outlet capillary 9292 marked with "Waste" of the suppressor

module through the rear panel opening 4343, lead it to a suffi-

ciently large waste container and fix it in place.

752 Pump Unit 13

Page 17

2 Installation

Startup of 752 Pump Unit

10

• Set switch <REMOTE> 22 on 752 Pump Unit to "OFF".

• Switch on 752 Pump Unit with mains switch 1212 and set switch

<PUMP> 33 to "ON".

• Adjust the contact pressure for both tubing cartridges: press

contact pressure lever 55 upwards until the solutions just start

to be drawn in. Then press the contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

• Check all capillaries between the 752 Pump Unit, the sup-

pressor module and the waste container for escaping liquid. If

liquid escapes anywhere the corresponding compression fitting must be tightened further or changed.

Pump tubings are consumable material with a lifetime which depends

on the contact pressure. This is why the tubing cartridges should be

raised completely by loosening snap-action lever 77 on the right-hand

side if the pump is to remain switched off for a considerable length of

time (the set contact pressure remains unchanged).

752 Pump Unit14

Page 18

3 Operation

3.1 Manual operation

The 752 Pump Unit cannot be manually operated unless the installation has been carried out properly as described in section 2 (mains

connection, attaching the pump tubing, connection to the IC system).

Switch instrument on/off

The 752 Pump Unit is switched on and off using mains switch 1212

on the rear of the instrument (see Fig. 2):

I Instrument switched on

0 Instrument switched off

3.1 Manual operation

POWER

After the instrument has been switched on the power lamp 33

lights up to show that the instrument is ready for use.

Switch off remote control

REMOTE

ON

OFF

In order to allow manual operation the remote control must be

switched off.

ON Remote control switched on

OFF Remote control switched off

Switch pump on/off

PUMP

ON

OFF

The drive of Pump Unit 752 is switched on and off with the switch

<PUMP>:

ON Pump switched on

OFF Pump switched off

3.2 Operation via 732 IC Detector

The 752 Pump Unit cannot be remotely operated via the IC Detector

unless the installation has been carried out properly as described in

section 2 (mains connection, connection cable 732 – 752, attaching

the pump tubing, connection to the IC system).

Switch instrument on/off

The 752 Pump Unit is switched on and off using mains switch 1212

on the rear of the instrument (see Fig. 2):

I Instrument switched on

0 Instrument switched off

POWER

752 Pump Unit 15

After the instrument has been switched on the power lamp 33

lights up to show that the instrument is ready for use.

Page 19

3 Operation

REMOTE

ON

OFF

Switch on remote control

In order to allow remote operation via 732 IC Detector the remote

control must be switched on.

ON Remote control switched on

OFF Remote control switched off

Automatic pump switch-on when the 732 IC

Detector is switched on

In order to start up the drive of the 752 Pump Unit automatically

when the 732 IC Detector is switched on alterations must be

made to the basic settings (Setup, see section 4.4.1 of 732/733

Manual). The remote output lead 1 must be set to 1 (on, active,

0 V):

>SETUP/output

remote 10000000

When the 732 IC Detector is switched off the pump is also

switched off.

Switch pump on/off in a program

In the 732 IC Detector the <PROGRAM> key can be used to

create time programs with a maximum of 20 program steps (see

section 4.7.1 of 732/733 Manual). The pump can be switched on

or off at any program step by setting the remote output lead 1 to

1 (on, active, 0 V) or 0 (off, inactive, open) respectively:

Switch on:

Switch off:

>PROGRAM/edit XXX.X min

remote 1TTTTTTT

>PROGRAM/edit XXX.X min

remote 0TTTTTTT

Switch pump on/off at an event

In the 732 IC Detector the <EVENT> key can be used to

program a maximum of 4 different events (see section 4.7.3 of

732/733 Manual). The pump can be switched on or off at any

event by setting the remote output lead 1 to 1 (on, active, 0 V) or

0 (off, inactive, open) respectively:

Switch on:

EVENT YY-MM-DD HH:MM:SS

remote 1TTTTTTT

Switch off:

EVENT YY-MM-DD HH:MM:SS

remote 0TTTTTTT

752 Pump Unit16

Page 20

4.1 Insufficient or non-existing flow rate

4 Troubleshooting

4.1 Insufficient or non-existing flow rate

If the 752 Pump Unit is supplying insufficient liquid or no liquid at all

then this can be remedied by proceeding as follows:

Set contact pressure correctly

1

• Press contact pressure lever 55 on the tubing cartridge down

as far as it will go.

• Press contact pressure lever 55 upwards until the solution just

starts to be drawn in. Then press contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

Exchange the pump tubing

2

• If the delivery performance is still not satisfactory then the

pump tubing must be exchanged (see section 4.3).

• After the pump tubing has been exchanged press contact

pressure level 55 on the tubing cartridge down as far as it will

go.

• Press contact pressure level 55 upwards until the solution just

starts to be drawn in. Then press contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

Check the connections

3

• If the delivery performance is still not satisfactory even with

the new pump tubing then the connections must be checked.

• Loosen the first connection after the tubing cartridge in the

supply direction. If liquid is still flowing here then retighten the

connection and release the following connection and so on.

• Replace the connection at which liquid transport ceases or

exchange the connection pieces.

• If liquid transport ceases after the Filter unit PEEK, replace

filter 2121 (6.2824.110; see Fig. 6).

• If liquid transport ceases after the suppressor module then

this should be exchanged.

4.2 Leaking of tubing nipples

If liquid is leaking from the tubing nipples then these must be tightened

up further. If the fault cannot be cured in this way then the tubing nipples must be replaced.

752 Pump Unit 17

Page 21

4 Troubleshooting

4.3 Air bubbles in pump circuit

If air bubbles can be seen in the pump circuit then the aspirating tubing

must be immersed completely in the liquid. If this has no effect then the

connections must be checked (see section 4.2).

4.4 Exchanging the pump tubing

Pump tubings are consumable material with a limited lifetime and

should be exchanged at regular intervals (approx. every 2 weeks under

continuous use).

The working life of pump tubing depends to a considerable extent on

the contact pressure. This is why the contact pressure must be correctly set as described in section 2.3.2. If the pump is to remain

switched off for a lengthy period of time the tubing cartridges should be

raised completely by loosening snap-action lever 77 on the right-hand

side (the set contact pressure remains unchanged).

As the pump is always operated on the same side the pump tubings

6.1826.050 supplied can be used on both sides. To exchange a pump

tubing proceed as follows:

Remove old pump tubing

1

• Press contact pressure lever 55 on the tubing cartridge down

as far as it will go.

• Release tubing cartridge 44 from holding clamp 66 by pressing

down snap-action lever 77 and remove from mounting pin 99

on the 752 Pump Unit (see Fig. 1).

• Remove old pump tubing.

Insert new pump tubing

2

• Insert the new pump tubing 1818 (6.1826.050) in the tubing

cartridge as shown in Fig. 6. The white-yellow stopper 1919

must click into the corresponding holder on the left-hand side

of the tubing cartridge.

• Place the tubing cartridge on mounting pin 99 and press down

on the right-hand side until snap-action lever 77 clicks into po-

sition on holding clamp 66. Take care that no kinks are formed

in the pump tubing.

Set contact pressure

3

• Press contact pressure lever 55 upwards until the solution just

starts to be drawn in. Then press contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

752 Pump Unit18

Page 22

5 Appendix

5.1 Technical data

Pump

Pump type 2-channel peristaltic pump with rotational speed

Pump capacity typically 0.5…0.6 mL/min with

Pressure max. 4 bar (0.4 MPa)

Pumpable liquids Clear liquids with no solid contents

Pump tubing material PVC (Tygon)

5.1 Technical data

of

20/min (50 Hz)

24/min (60 Hz)

6.1826.050 pump tubing

Mains connection

Mains voltage 115 V: 100...120 V ± 10 %

230 V: 220...240 V ± 10 %

Switchable with voltage selection insert in fuse

holder (see section 2.2.1)

Mains frequency 50...60 Hz

Power consumption 12 VA

Fuse 5 mm Ø, 20 mm length

100…120 V: 0.2 A (slow-blow)

220…240 V: 0.1 A (slow-blow)

Remote interface

Purpose

Remote control of pump (switching on/off)

Pin assignment

330

+5V

external752

Pin

current flows: on

current does not flow: off

2

+

-

5

Safety specifications

Construction / Testing According to IEC 1010 / EN 61010 / UL 3101-1,

protection class 1, degree of protection IP40

Safety directions The Instructions for Use include information and

warnings to which the user must pay attention in

order to assure safe operation of the instrument.

752 Pump Unit 19

Page 23

5 Appendix

Electromagnetic compatibility (EMC)

Emitted interference Standards met:

EN 55011, EN 55022, EN 50081-1

Immunity to interference Standards met:

IEC801-2/IEC1000-4-2 (class 4), IEC801-4/

IEC1000-4-4 (class 4), EN50082-1/2,

IEC1000-4-11/EN61000-4-11

Ambient temperature

Nominal operating range +5…+45°C

(at 20…80 % atmospheric humidity)

Storage, transport –40…+70°C

Housing

Material of cover Polyurethane rigid foam (PUR) with fire protection

for fire class UL94VO, CFC-free

Material of base Steel, enamelled

Dimensions

Width 260 mm

Height 129 mm

Depth 366 mm

Weight 4.2 kg (incl. accessories)

752 Pump Unit20

Page 24

5.2 Standard equipment

1.57

0.97

Subject to changes !

All dimensions are given in mm.

The 2.752.0010 Pump Unit includes the following parts:

Quant. Order No. Description

1 6.1803.020 PTFE capillary tubing

Length = 5 m

5.2 Standard equipment

2 6.1826.050 Pump tubing

made of PVC (Tygon); with 2 firmly

attached white-yellow stoppers;

i.d. = 0.57 mm, e.d. = 2.27 mm

1 6.2143.200 Connecting cable

Connecting cable 732 IC Detector –

752 Pump Unit

1 6.2122.0X0 Mains cable

to customer's specifications:

Cable socket Cable connector

Type IEC 320/C 13 Type SEV 12 (CH…) ...............................6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…)...........................6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) ......................6.2122.070

2 6.2744.014 PEEK compression fitting

For connection of 6.1831.010 PEEK

capillaries or 6.1803.020 PTFE capillaries.

Set of 2

150

400

25 pol.

2 m

26

1 6.2744.030 PEEK Coupling

Connection between 6.2744.010 PEEK compression fitting and 6.1826.0X0 pump tubing.

Set of 4

25

1 8.752.1013 Instructions for Use (English)

for 752 Pump Unit

5.3 Optional accessories

6.2143.220 Connecting cable

Connecting cable 732 IC Detector –

752 Pump Unit – 753 Suppressor Module

752 Pump Unit 21

Page 25

5 Appendix

5.4 Warranty and conformity

5.4.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In such cases the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which we are asked to carry out during the

warranty period for reasons other than material or manufacturing faults

will be invoiced. For parts manufactured by third parties, insofar as

these constitute an appreciable part of our instrument, the warranty

stipulations of the manufacturer in question apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

With regard to defects in material, construction or design as well as the

absence of guaranteed features, the purchaser has no rights or claims

except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

Lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedding

them in wood shavings or similar material, the parts must be packed in

a dustproof package (for instruments the use of a plastic bag is imperative). If open assemblies are enclosed in the scope of delivery that

are sensitive to electromagnetic voltages (e.g. data interfaces etc.)

these must be returned in the associated original protective packaging

(e.g. conductive protective bag). (Exception: assemblies with built-in

voltage source belong in a non-conductive protective packaging). For

damage which arises as a result of non-compliance with these instructions, no warranty responsibility whatsoever will be accepted by

Metrohm.

752 Pump Unit22

Page 26

5.4.2 EU Declaration of conformity

EU Declaration of Conformity

The METROHM AG company, Herisau, Switzerland hereby certifies, that the instrument:

752 Pump Unit

meets the requirements of EC Directives 89/336/EWG and 73/23/EWG.

5.4 Warranty and conformity

Source of the specifications:

EN 50081-1 Electromagnetic compatibility, basic specification

Emitted Interference

EN 50082-1/2 Electromagnetic compatibility, basic specification

Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement

and control equipment

Description of the instrument:

Two-channel peristaltic pump with remote control

Herisau, September 27, 1996

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

752 Pump Unit 23

Page 27

5 Appendix

5.4.3 Certificate of conformity and system validation

Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well as to the standard specifications for security and

to system validation issued by the manufacturing company.

Name of commodity: 752 Pump Unit

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

Principal technical information: Voltages: 100…120, 220…240 V

Frequency: 50…60 Hz

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

IEC801-2/IEC1000-4-2 (level 4), IEC801-4/IEC1000-4-4 (level 4),

IEC1000-4-11/EN 61000-4-11, EN55011, EN55022, EN50081-1,

EN50082-1/2 — Electromagnetic compatibility

IEC1010, EN61010, UL3101-1 — Security specifications

It has also been certified by the Swiss Electrotechnical Association (SEV), which

is member of the International Certification Body (CB/IEC).

The technical specifications are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for

quality assurance in design/development, production, installation and servicing.

Herisau, September 27, 1996

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

752 Pump Unit24

Page 28

5.5 Index

5.5 Index

A

Air bubbles in pump circuit .................18

Ambient temperature........................... 20

Appendix .............................................19

Arrangement of the instruments............ 7

Aspirating tubing ....................... 12,13,18

Automatic pump switch-on ................. 16

C

Cable (6.2143.200)......................... 10,21

Cable (6.2143.220)......................... 10,21

Caution.................................................. 5

Certificate of conformity and

system validation............................. 24

Check .................................................... 7

Check the connections........................ 17

Column holder 8484

Installation ....................................... 11

Comment............................................... 5

Compression fitting 2020

Figure ..............................................12

Installation .................................. 12,13

Ordering designation....................... 21

Conformity........................................... 23

Connect column............................. 10,11

Connect suppressor module............... 11

Connection 2727

Installation of suppressor

inlet capillary.................................... 12

Connection 2828

Installation of suppressor

inlet capillary.................................... 13

Connection of the

suppressor module .........................10

Connection to the IC System............... 10

Connections at

suppressor module .........................11

Connector 2121

Connection of PTFE

tubing 1616 .................................... 12,13

Figure ..............................................12

Connector 2323

Connection of

inlet capillary 9090 .........................12,13

Connection of

inlet capillary 9393 ..............................13

Figure ..............................................12

Contact pressure................................. 14

Contact pressure lever 55

Adjust contact pressure ..................14

Figure ...........................................2,12

Install tubing cartridge..................... 18

Set contact pressure .......................17

Coupling 1717

Figure ..............................................12

Installation .................................. 12,13

Ordering designation....................... 21

Coupling 9696

Installation ....................................... 11

D

Declaration of conformity .................... 23

Degree of protection ........................ 6,19

Dimensions ......................................... 20

E

Earthing.............................................. 6,9

Electrical connection........................... 10

Electrical safety ..................................... 6

Electromagnetic compatibility............. 20

EMC .................................................... 20

Emitted interference ............................ 20

EU Declaration of conformity ..............23

Exchanging the pump tubing.............. 18

F

Filter unit PEEK (6.2624.100)

Connection at 752 Pump Unit.... 12,13

Fix column........................................... 11

Flow rate.............................................. 17

Front...................................................... 2

Fuse holder 1010

Change fuses.................................... 8

Figure ............................................. 3,9

Fuses............................................. 8,9,19

G

General precautionary rules.................. 6

H

H2O...................................................... 13

H2SO4.................................................. 12

Handling of solvents.............................. 6

Hazard................................................... 5

Holding clamp 66

Figure ................................................ 2

Install tubing cartridge................ 11,18

Housing............................................... 20

Housing 2222

Figure .............................................. 12

I

Immunity to interference...................... 20

Information about the Instructions for

Use.................................................... 4

Insert new pump tubing ...................... 18

Installation ............................................. 7

Installing pump tubings........................12

Instructions for Use (8.752.1013)...........4

Instrument description ...........................1

Insufficient flow rate .............................17

Introduction............................................1

L

Leaking of tubing nipples.....................17

Leaks..............................................6,7,17

Location .................................................7

M

Mains cable.......................................9,21

Mains connection...........................6,8,19

Mains connection plug 1515

Figure..............................................3,9

Mains connection...............................9

Mains frequency...................................19

Mains switch 1212

Figure..............................................3,9

Startup..............................................14

Switching the instrument on/off.....9,15

Mains voltage.......................................19

Malfunctions.........................................17

Manual operation .................................15

Mounting pin 99

Figure.................................................2

Install tubing cartridge ................11,18

MSM.................. see Suppressor module

N

Non-existing flow rate...........................17

Notation..................................................5

O

Opening the 752 Pump Unit ..................6

Operation .............................................15

Operation via 732 IC Detector..............15

Optional accessories ...........................21

Organization...........................................4

P

Packaging..............................................7

Parts and controls..................................2

Pictograms.............................................5

Pin assignment ....................................19

Power consumption .............................19

Power on lamp 33

752 Pump Unit 25

Page 29

5 Appendix

Figure ................................................2

Ready for use display................... 9,15

Precautionary rules................................6

Pressure ..............................................19

Protection class............................. 6,9,19

Protective earth...................................... 9

PTFE tubing 1616

Figure ..............................................12

Installation................................... 12,13

Ordering designation....................... 21

Pump capacity.....................................19

Pump drive 88

Figure ................................................2

Pump tubing 1818

Exchange.................................... 17,18

Figure ..............................................12

Installation................................... 11,12

Ordering designation....................... 21

Working life......................................18

Pump tubing material .......................... 19

Pump tubings

Precautionary rules............................ 6

Pump type ........................................... 19

Pumpable liquids................................. 19

R

Rear....................................................... 3

Rear panel opening 4343

Insert suppressor

outlet capillary.............................12,13

Regeneration solution..................... 12,13

Remote control via

732 IC Detector ...............................10

Remote interface 1414

Figure ................................................3

Technical data................................. 19

Rinse column....................................... 10

Rinsing solution ................................... 13

Suppressor inlet capillary 9393

Figure .........................................11,12

Installation ....................................... 13

Suppressor module............................. 10

Suppressor module 9595

Connection 1................................... 11

Installation ....................................... 11

Suppressor outlet capillary 9191

Figure ..............................................11

Installation .................................. 12,13

Suppressor outlet capillary 9292

Figure ..............................................11

Installation ....................................... 13

Suppressor outlet capillary 9494

Figure ..............................................11

Installation ....................................... 11

Switch 11 <PUMP>

Figure ................................................2

Function........................................... 15

Startup............................................. 14

Switch 22 <REMOTE>

Figure ................................................2

Function...................................... 15,16

Startup............................................. 14

Switch instrument on/off...................... 15

Switch off remote control..................... 15

Switch on remote control..................... 16

Switch pump on/off ............................. 15

Switching the instrument on/off............. 9

System validation ................................24

T

Technical data..................................... 19

Transport.......................................... 7,20

Transport damage............................ 7,22

Troubleshooting .................................. 17

Tubing cartridge 44

Figure ...........................................2,12

Install pump tubings........................ 11

Installation ....................................... 18

Tubing nipples..................................... 17

S

Safety directions.................................. 19

Safety notes...........................................6

Safety specifications............................ 19

Serial number 1313

Figure ................................................3

Set contact pressure ......................17,18

Setting the mains voltage................... 8,9

Setting up the instrument ......................7

Snap-action lever 77

Figure ...........................................2,12

Install tubing cartridge................11,18

Standard equipment............................ 21

Static charges........................................ 6

Stopper 1919

Figure ..............................................12

Install pump tubing.......................... 18

Storage................................................20

Suppressor inlet capillary 8989

Figure ..............................................11

Installation........................................ 11

Suppressor inlet capillary 9090

Figure .........................................11,12

Installation........................................ 12

V

Voltage selection insert 1111

Change fuses .................................... 8

Figure .............................................3,9

W

Warning................................................. 5

Warranty .............................................. 22

752 Pump Unit26

Loading...

Loading...