Page 1

CH-9101 Herisau/Switzerland

Tel. ++41 71 353 85 85

Fax ++41 71 353 89 01

Internet www.metrohm.ch

E-Mail info@metrohm.ch

750 Autosampler

2.750.0020 Instrument version

8.750.1023 Instructions for Use

23.02.2000 / dö

Page 2

Table of contents

Table of contents

1 Introduction............................................................................................1

1.1 Instrument description.............................................................................1

1.2 Theory of operation ..................................................................................2

1.3 Control elements.......................................................................................4

1.4 Information on the Instructions for Use................................................6

1.4.1 Organization.................................................................................... 6

1.4.2 Notation and pictograms ................................................................7

1.5 Safety notes ...............................................................................................8

1.5.1 Electrical safety ...............................................................................8

1.5.2 General precautionary rules............................................................ 8

2 Installation..............................................................................................9

2.1 Setting up the instrument........................................................................ 9

2.1.1 Packaging .......................................................................................9

2.1.2 Check..............................................................................................9

2.1.3 Location...........................................................................................9

2.2 Connection to IC system........................................................................10

2.2.1 750 Autosampler as "Master"........................................................10

2.2.2 732 IC Detector as "Master".......................................................... 11

2.2.3 Connection to 762 with «IC Net»................................................... 12

2.2.4 Tubing connection ........................................................................14

2.3 Mains connection....................................................................................15

2.3.1 Check fuses ..................................................................................15

2.3.2 Mains cable and mains connection.............................................. 16

2.3.3 Switching the instrument on/off ....................................................16

2.4 Initial checkout ........................................................................................17

3 Operation............................................................................................... 19

3.1 Fundamentals of operation ...................................................................19

3.1.1 Display and instrument dialog...................................................... 19

3.1.2 Overview of key functions............................................................. 20

3.2 System settings.......................................................................................23

750 Autosampler

3.3 Manual rinsing.........................................................................................26

3.4 Manual injection......................................................................................26

3.5 Methods ....................................................................................................28

3.6 Method procedure...................................................................................34

3.7 Priority sample.........................................................................................35

3.8 Remote control........................................................................................36

I

Page 3

Inhaltsverzeichnis

4 Notes – Maintenance – Faults...................................... 39

5 Appendix ................................................................................................ 49

4.1 Operating information............................................................................ 39

4.1.1 Loading sample vials.................................................................... 39

4.1.2 Sample preparation ...................................................................... 39

4.1.3 Operating parameters................................................................... 40

4.2 Maintenance and servicing ................................................................... 41

4.2.1 General information ...................................................................... 41

4.2.2 Transfer needle replacement........................................................ 41

4.2.3 Sample preparation ...................................................................... 42

4.3 Remedying malfunctions....................................................................... 43

4.3.1 Non-reproducible injections ......................................................... 43

4.3.2 Missed injections.......................................................................... 44

4.4 Error messages.......................................................................................45

4.4.1 Entry error messages.................................................................... 45

4.4.2 System error messages................................................................ 47

4.4.3 Remote control error codes.......................................................... 48

5.1 Technical data .........................................................................................49

5.2 Interfaces.................................................................................................. 51

5.2.1 Contact closure strips................................................................... 51

5.2.2 RS232 interface............................................................................. 53

5.3 Standard equipment............................................................................... 54

5.4 Optional accessories.............................................................................. 55

5.5 Warranty and conformity....................................................................... 56

5.5.1 Warranty........................................................................................ 56

5.5.2 EU Declaration of conformity........................................................ 57

5.5.3 Certificate of conformity and system validation............................ 58

5.6 Index.......................................................................................................... 59

List of figures

Fig. 1: Autosampler 750 ............................................................................................... 1

Fig. 2: Positive displacement sample injection ............................................................2

Fig. 3: Displacement volume versus needle position .................................................. 3

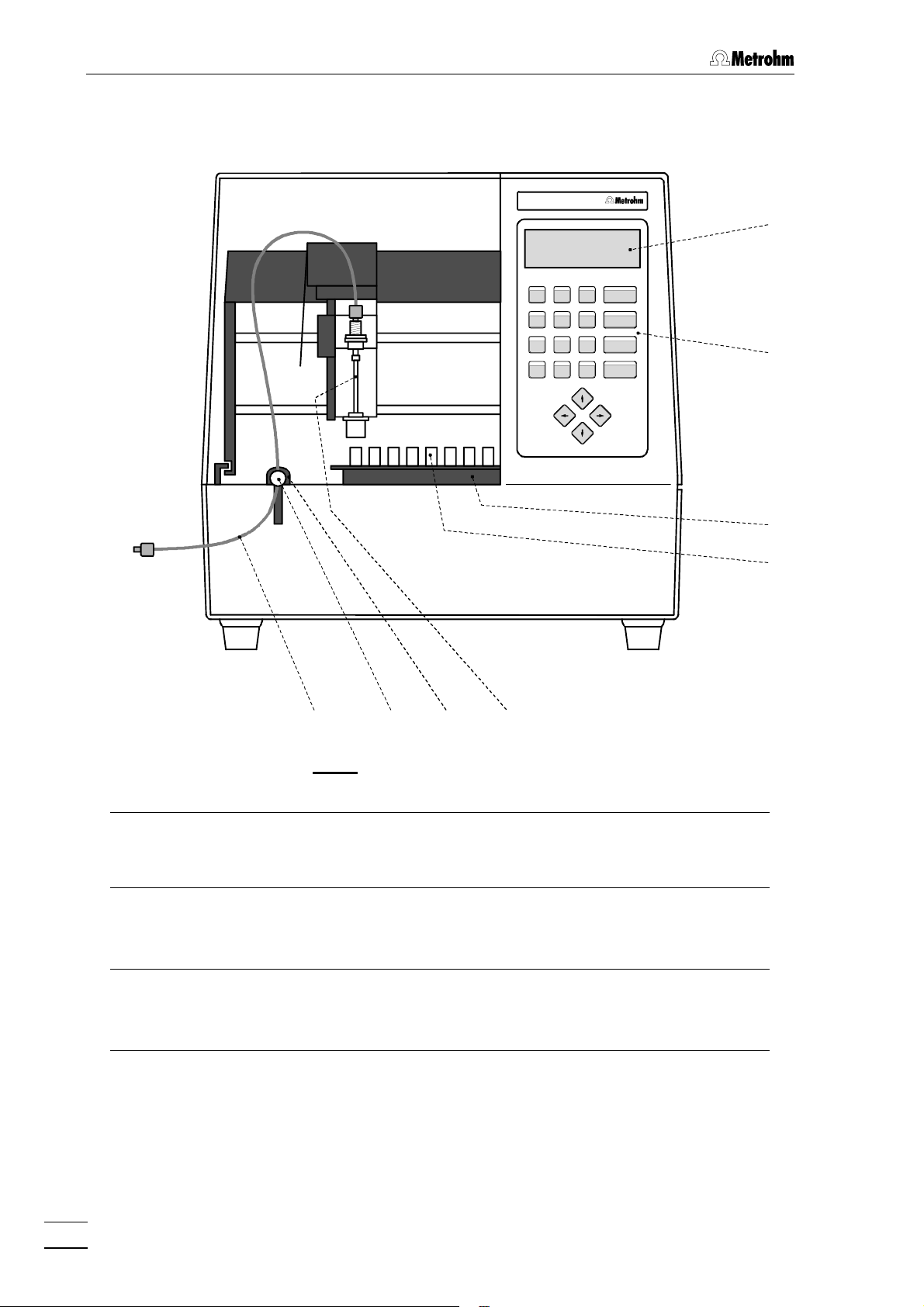

Fig. 4: Front of 750 Autosampler.................................................................................. 4

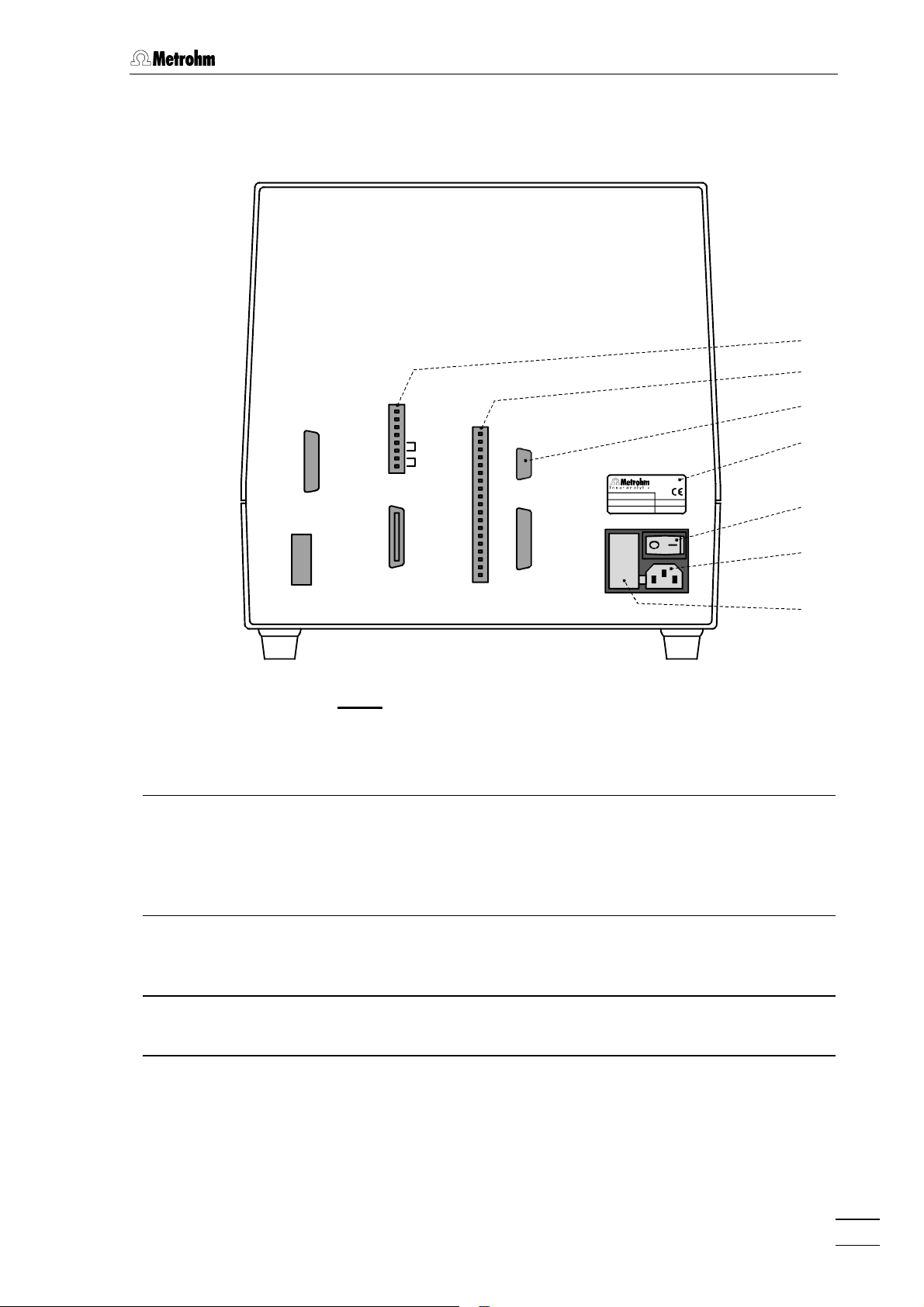

Fig. 5: Rear of 750 Autosampler................................................................................... 5

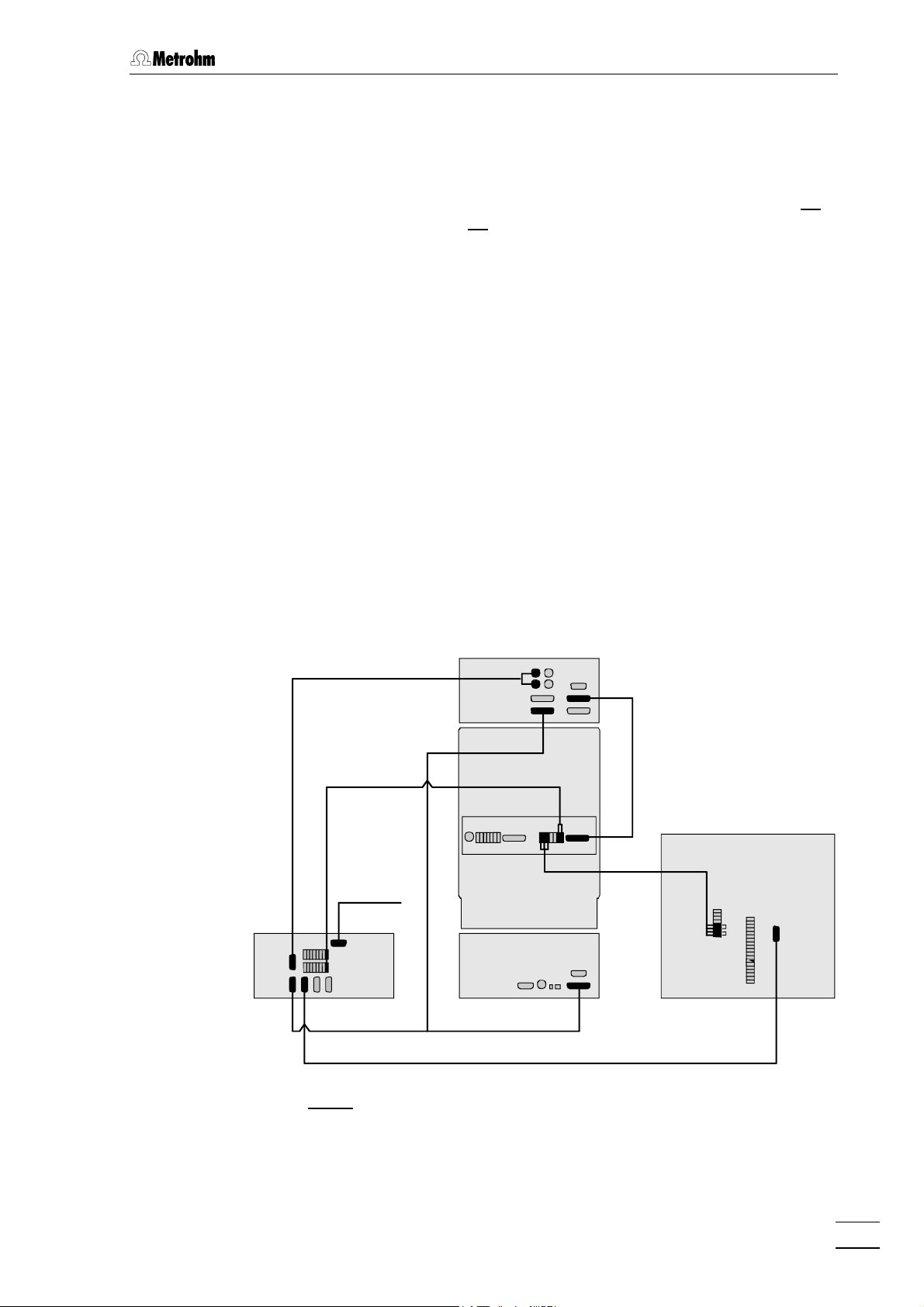

Fig. 6: Connection of 750 Autosampler to 732/733 ................................................... 11

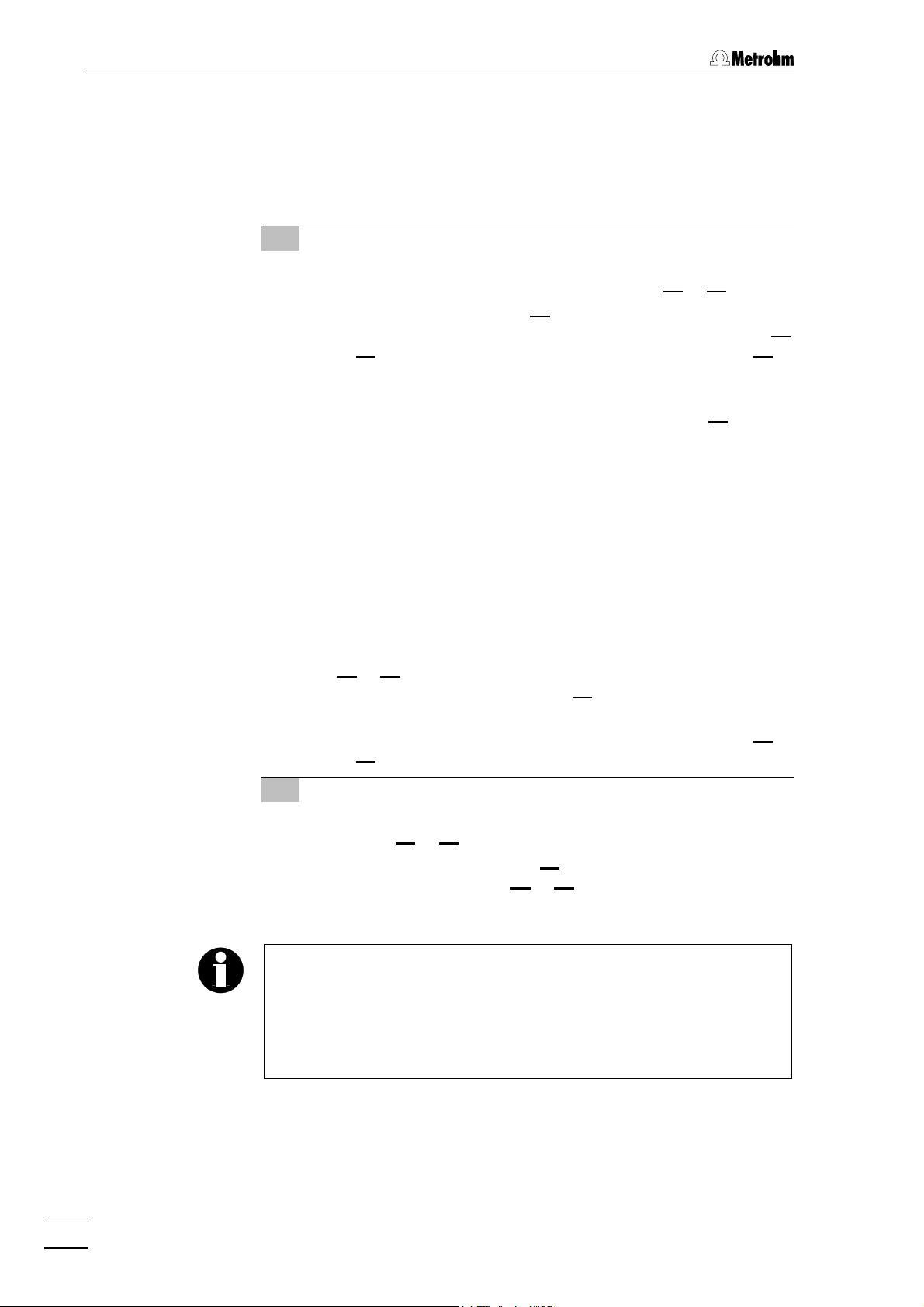

Fig. 7: Connection of 750 Autosampler to 732/733 and 762 ..................................... 13

Fig. 8: Keypad ............................................................................................................ 20

Abb. 9: Manual sample filtering ................................................................................... 39

Fig. 10: Sample filtering with FilterCaps....................................................................... 40

Fig. 11: Transfer needle replacement........................................................................... 51

Fig. 12: Valve control .................................................................................................... 57

Fig. 13: Inputs/outputs.................................................................................................. 51

II

750 Autosampler

Page 4

1 Introduction

1.1 Instrument description

The 750 Autosampler is a microcomputer-operated sampling/controller system designed to be used with the ion chromatographic instruments 732 IC Detector and 733 IC Separation Center. It has a capacity of up to 128 samples, which are transferred automatically into

the sample loop of the 733 IC Separation Center.

The 750 Autosampler performs up to four, fixed loop injections per vial

at user-selectable time intervals. All operating parameters are entered

from the front panel. Additionally, the instrument can be controlled remotely either by an externally programmable contact closure or through

the RS232 connector located on the rear panel.

1.1 Instrument description

750 Autosampler

Fig. 1: 750 Autosampler

1

Page 5

1 Introduction

Sample

Needle

Cap

Sample vial

Valve

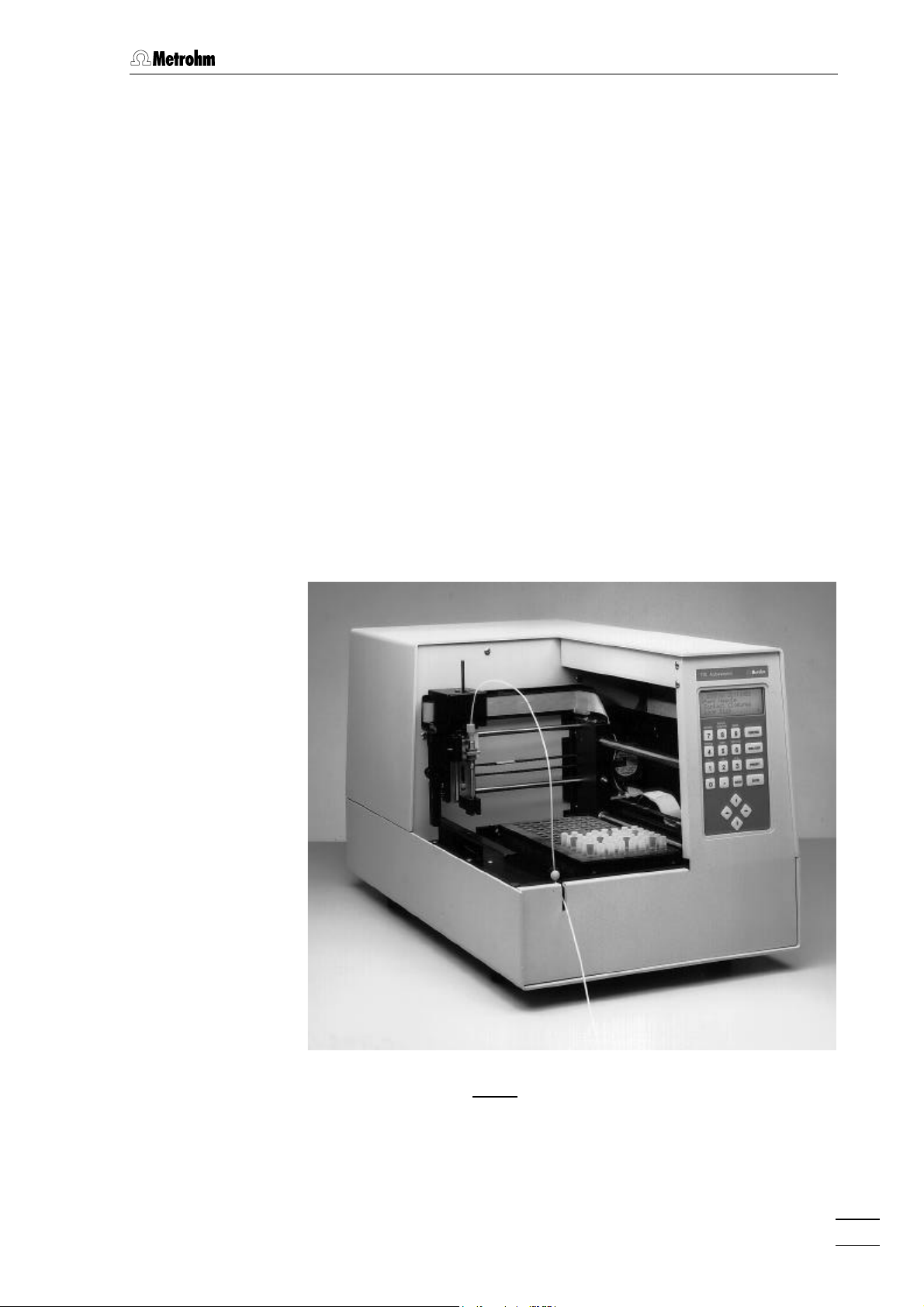

1.2 Theory of operation

Displacement principle

The 750 Autosampler operates using the positive displacement principle of sample transfer. This sample transfer process into the sample

loop of the 733 IC Separation Center is illustrated in Fig. 2. When an injection is initiated, the hollow transfer needle 55 descends into the vial.

The needle tip punctures the polyethylene cap of the sample vial. The

opening into the needle is located on the side to minimize plugging by

cap material as the cap is punctured. The needle continues downward

until the pushrod contacts the area around the puncture in the cap

which forces the cap down into the vial. The piston action of the cap

pressurizes the sample and forces it up through the needle and the

transfer tubing 88 that is connected to the needle. From the transfer

tubing, the sample flows through the injection valve and sample loop

with the excess passing on through the waste tube to a waste container.

Column

Rinsing by air bubbles

The air bubble (minimum 150 µL), which is always present at the top of

a properly filled and capped vial, precedes the sample stream through

the plumbing. The bubble disrupts the laminar flow of the fluid in the

tubing while pushing out the previous sample and solvent. This effect,

in addition to the large excess volume of sample, helps to minimize

sample carryover.

A B C D

Eluent

Waste

RUN FILL/LOAD

INJECT

RUN

Fig. 2: Positive displacement sample injection

2

750 Autosampler

Page 6

1.2 Theory of operation

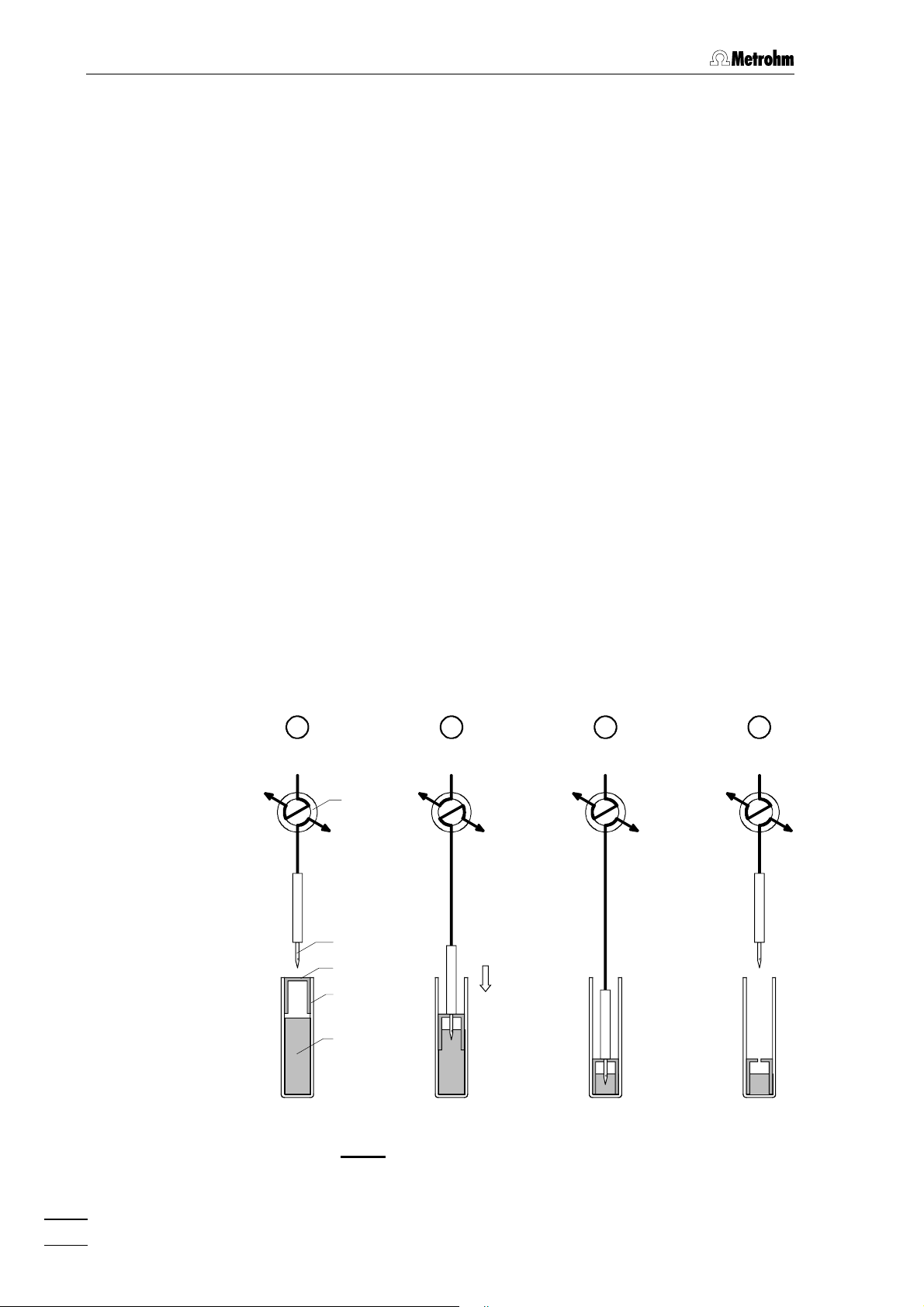

Number of injections

The number of injections per sample with the 750 Autosampler depends on the sample loop size. With sample loops > 10 µL max. 3,

with sample loops ≤ 10 µL max. 4 injections are possible. Fig. 3 details

the needle position and displacement volume at the sample delivery

action. Care should always be taken that the injection volume is at least

three times greater than the volume of the sample loop. This is why only

a maximum of 2 injections per sample should be made with 100 µL

loops; the minimum sample volume is 300 µL for 1 and 600 µL for 2 injections. For sample loops with a volume ≤ 10 µL up to 4 injections per

sample are possible. The minimum sample volume required is 150 µL

for 1, 300 µL for 2, 450 µL for 3 and 600 µL for 4 injections.

Rinsing

Rinsing will be necessary for highly concentrated samples or for samples that may absorb in the tubing or in the injection valve. Rinse vials

are filled with eluent or other suitable solvent. The Rinse process is

shown in Fig. 3. Rinse vials can be used either after each vial (every

even numbered or odd numbered vial) or at programmed vial intervals.

There are two types of Rinses, the Normal Rinse and the Quick Rinse.

The Normal Rinse occurs after all the injections have been made from

the sample vial and the run time has elapsed. A Quick Rinse occurs

immediately after an injection and is used in applications where the

sample solution must not be left in the needle, transfer tubing or valve

for whatever reason. Only one injection per vial can be programmed

when using a Quick Rinse.

Injection

1

2

3

4

1 Injection

per vial

2.65 cm

730

µL

2 Injections

per vial

1.63 cm

450

µL

1.02 cm

280

µL

3 Injections

per vial

1.63 cm

450

µL

0.51 cm

140

µL

0.51 cm

140

µL

4 Injections

per vial Rinse

1.12 cm

310

µL

0.51 cm

140

µL

0.51 cm

140

µL

0.51 cm

140

µL

2.65 cm

730

µL

750 Autosampler

Fig. 3: Displacement volume versus needle position

3

Page 7

1 Introduction

1.3 Control elements

750 Autosampler

MANUAL

METHOD

8 9

7

5 6

4

1

2 3

0

.

11

RINSEINJECTION

FUNCTION

REM/LOCTEMPSYSTEM

RUN/STOP

F3F2F1

PRIORITY

CLEAR

ENTER

22

88

Fig. 4: Front of the 750 Autosampler

11 Display (LCD)

comprising 4 lines each of

20 characters

22 Keypad

with function, numeric and cursor

keys (details see chap. 3.1.2)

33

44

556677

55 Transfer needle

66 Holder for transfer tubing

33 Sample rack (6.2041.600)

77 Holder stopper

for 128 sample vials

44 Sample vial

6.2743.000 sample vial (PP) or

6.2413.000 sample vial (glass)

88 Transfer tubing

6.1803.000 PTFE capillary for the

connection of the 750 Autosampler

with the injector of the 733 IC

Separation Center

4

750 Autosampler

Page 8

1.3 Control elements

1010

99

BCD

INJECT

LOAD

IEEE

EXT PWR

CONTROL

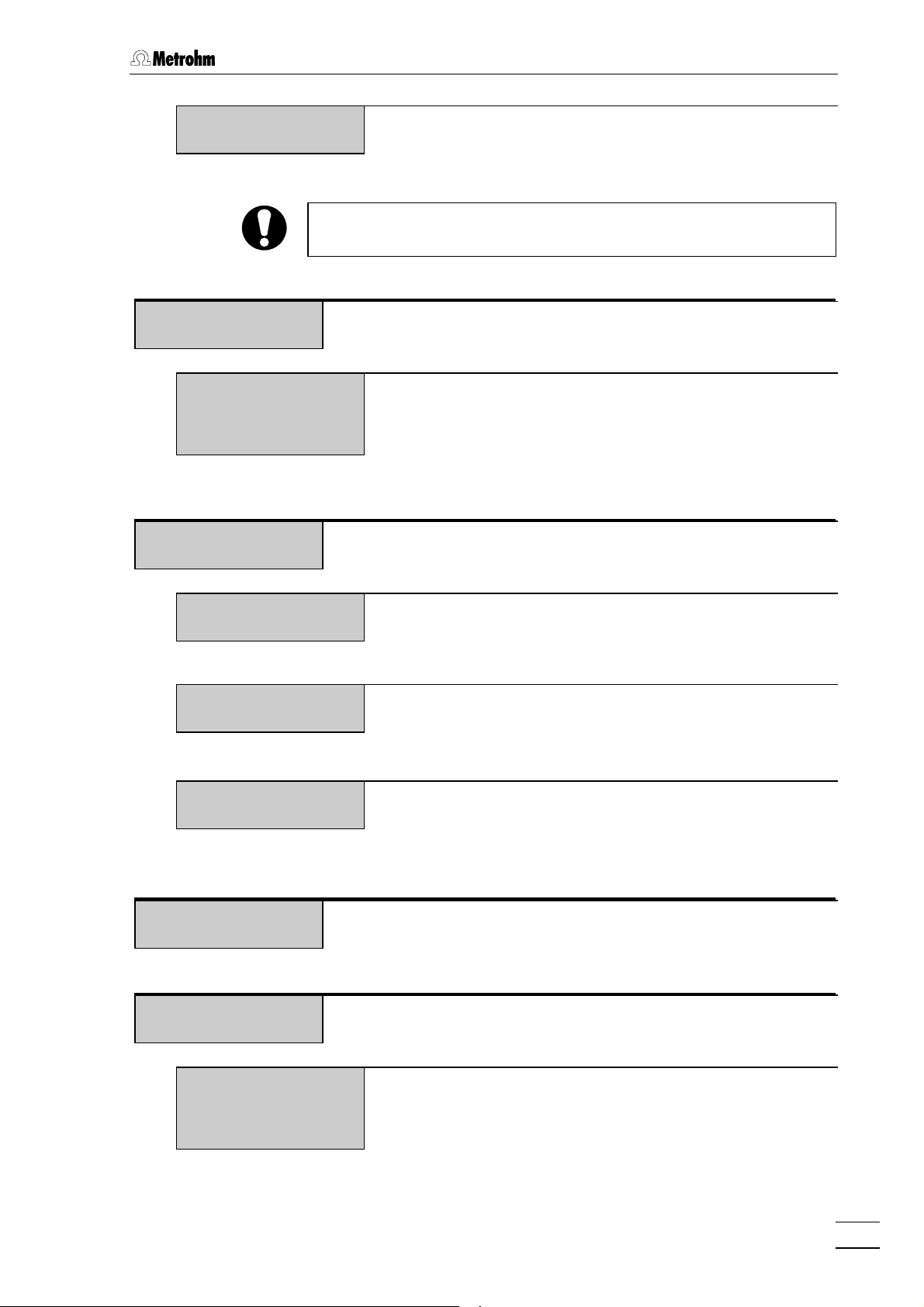

Fig. 5: Rear of the 750 Autosampler

99 Contact closure strip for valve

control

details see chap. 5.2.1

RS-232

PRINTER

Type:

Nr.:

U:

1313 Mains switch

switch to switch the instrument on

and off:

OFF

Switzerland

Hz

f:

VA

V

S:

I = ON 0 =

1111

1212

1313

1414

1515

1010 Contact closure strip for external

control

details see chap. 5.2.1

1111 RS232 interface

details see chap. 5.2.2

1212 Model plate

with instrument and serial number,

mains voltage, mains frequency,

power consumption

750 Autosampler

1414 Mains connection plug

mains connection see chap. 2.3

1515 Fuse cassette

changing the fuses, see chap. 2.3.1

5

Page 9

1 Introduction

1.4 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 750 Autosampler into operation. The Instructions for Use contain

information and warnings which must be heeded by the user to assure

safe operation of the instrument.

1.4.1 Organization

These 8.750.1023 Instructions for Use for the 750 Autosampler provide a comprehensive overview of the installation, startup procedure,

operation, fault rectification and technical specifications of the instrument. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instruments, control parts

and safety notes

Section 2 Installation

Installation of the 750 Autosampler, connection to

IC Separation Center 733, initial checkout

Section 3 Operation

Detailed description of the operation and

explanation of functions of all keys

Section 4 Notes – Maintenance – Faults

Notes on operation, maintenance,

fault rectification, diagnostic tests

Section 5 Appendix

Technical data, interfaces, standard equipment,

options, warranty, declarations of conformity, index

To find the required information on the instruments, you will find it an

advantage to use either the Table of contents or the Index at the

back.

6

750 Autosampler

Page 10

1.4.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

<PARAM> Key

"Run Time" Parameter or entry value

55 Control element of 750

8484 Control element of 732/733

1.4 Information on the Instructions for Use

(see chap. 1.3)

(see Instructions for Use 732)

1414 Control element of 762

READY

SELECT A FUNCTION

(see Instructions for Use 762)

Display

Text in display 11 of the 750 Auto-

sampler

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

750 Autosampler

Caution

This symbol marks important information. First read the associated directions before you continue.

Comment

This symbol marks additional information and tips.

7

Page 11

1 Introduction

1.5 Safety notes

1.5.1 Electrical safety

While electrical safety in the handling of the 750 Autosampler is assured

in the context of the specifications IEC 1010-1 (protection class 1, degree of protection IP20), the following points should be noted:

• Mains connection

Setting the mains voltage, checking the mains fuse and the mains

connection must be effected in accordance with the instructions in

section 2.3.

• Opening the 750 Autosampler

When the 750 Autosampler is connected to the power supply the

instrument must neither be opened nor should parts be removed from

it, otherwise there is a danger of coming into contact with components which are live. Always disconnect the instrument from all voltage

sources before you open it and ensure that the mains cable is

disconnected from mains connection plug 1414 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 750 Autosampler, you should earth yourself and any tools

you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

1.5.2 General precautionary rules

• Handling of solvents

Check all tubing of the IC system periodically for possible leaks.

Follow the relevant instructions regarding the handling of flammable

and/or toxic solvents and their disposal.

8

750 Autosampler

Page 12

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 750 Autosampler is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The actual instrument

is packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they can assure

damage-free transport of the instrument.

2.1.2 Check

2.1 Setting up the instrument

2.1.3 Location

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 5.3). In the case of transport damage, see

instructions in section 5.5.1 "Warranty".

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals. The Autosampler should be located as close as possible to the IC system to minimize dead volume.

When not in use the instrument should always be covered with the

6.2742.010 dust cover.

750 Autosampler

9

Page 13

2 Installation

2.2 Connection to IC system

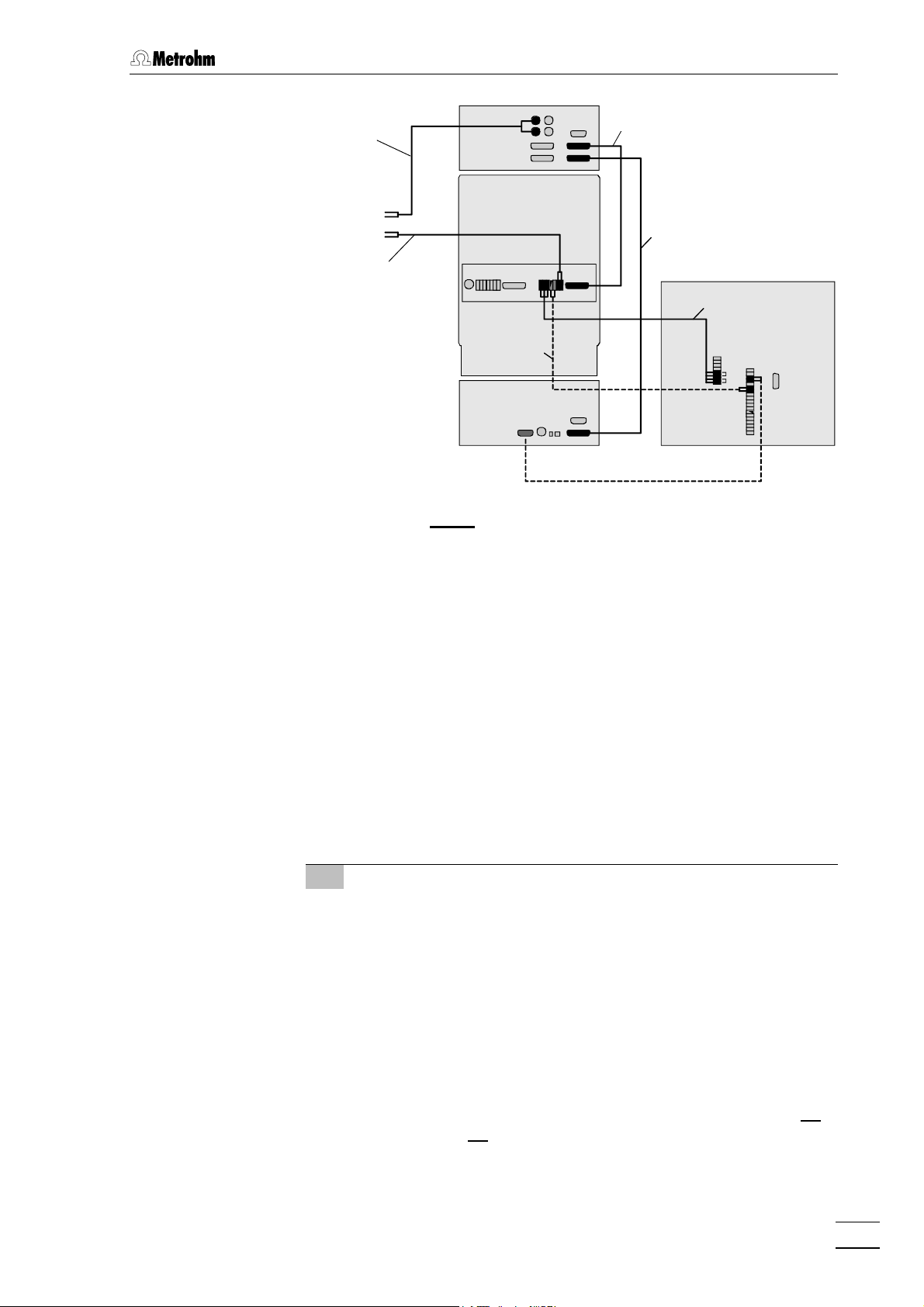

2.2.1 750 Autosampler as "Master"

When an IC system consisting of 732 IC Detector, 733 IC Separation

Center, and 709 IC Pump is operated with the 750 Autosampler as

"Master" the command to start the next injection after the analysis time

"Run Time" has elapsed will be given by the Autosampler itself. In this

case the 750 Autosampler is connected to the 733 IC Separation Center with the 6.2128.100 cable as shown in Fig. 6. In addition the 709 IC

Pump can be connected to the 750 Autosampler in such a way that

when the pump stops the Autosampler will also be automatically

stopped (important for unattended continuous operation).

Electrical connection 750 – 733

1

• Connect 6.2140.020 connector plug to contact closure strip 99

of the 750 Autosampler.

• Connect one end of the 6.2128.100 cable to the connections

"LOAD NO", "LOAD COM", "INJECT NO" and "INJECT COM"

on the connector plug inserted in the contact closure strip 99.

The four cable ends are appropriately inscribed with "LOAD

NO" (green), "LOAD COM" (yellow), "INJECT NO" (brown) and

"INJECT COM" (white).

• Connect the other end of the 6.2128.100 cable to the con-

nections "Ground", "Fill" and "Inject" on the terminal block 3838

(valve A) or 4646 (valve B) of the 733 IC Separation Center. The

three cable ends are appropriately inscribed with "GND"

(white), "FILL" (green) and "INJECT" (brown).

Electrical connection 750 – 709 (optional)

2

• Connect 6.2140.010 connector plug to contact closure strip

1010 of the 750 Autosampler.

• Connect jumper P12 to the control interface of the 709 IC

Pump in such a way that the contacts at outputs 3 and 4 will

be closed when the pump has stopped (see chap. 5.2 of the

709 Instructions for Use).

• Use 6.2134.070 cable (option) to connect outputs 3 and 4 of

the control interface on the 709 IC Pump with connection

"REMOTE STOP INPUT" and "GND" on contact closure strip

1010 of the 750 Autosampler.

Settings with 750 Autosampler as "Master"

The following settings are recommended for operating the IC system

with 750 Autosampler as "Master":

• 750 Autosampler: "Run Time" ≥ 3.0 min

• 732 IC Detector: operation without program or

with "Inject" program

10

750 Autosampler

Page 14

2.2 Connection to IC system

Cable 732/Evaluation

System (analog signal)

Evaluation system

Cable 732/Evaluation

system (start signal)

732

733

6.2115.070

709

6.2125.090

6.2125.060

6.2134.070

750

6.2128.100

INJECT

LOAD

Fig. 6: Connection of 750 Autosampler at 732/733

2.2.2 732 IC Detector as "Master"

When an IC system consisting of 732 IC Detector, 733 IC Separation

Center, and 709 IC Pump is operated with the 732 IC Detector as

"Master" the 750 Autosampler sample change procedure will be started

by a signal from the 733 IC Separation Center. The Autosampler must

be connected to the 733 IC Separation Center with two cables as

shown in Fig. 6. In addition the 709 IC Pump can be connected to the

750 Autosampler in such a way that when the pump stops the Autosampler will also be automatically stopped (important for unattended

continuous operation).

Electrical connection 750 – 733

1

• Connect 6.2140.020 connector plug to contact closure strip 99

and 6.2140.010 connector plug to contact closure strip 1010of

the 750 Autosampler.

• Connect one end of the 6.2128.100 cable to the connections

"LOAD NO", "LOAD COM", "INJECT NO" and "INJECT COM"

on the connector plug inserted in the contact closure strip 99.

The four cable ends are appropriately inscribed with "LOAD

NO" (green), "LOAD COM" (yellow), "INJECT NO" (brown) and

"INJECT COM" (white).

• Connect the other end of the 6.2128.100 cable to the con-

nections "Ground", "Fill" and "Inject" on the terminal block 3838

(valve A) or 4646 (valve B) of the 733 IC Separation Center. The

three cable ends are appropriately inscribed with "GND"

(white), "FILL" (green) and "INJECT" (brown).

750 Autosampler

11

Page 15

2 Installation

• Connect one end of the 6.2115.070 cable (option) to the

connections "EXTERNAL INJECT INPUT" and "GND" on the

connector plug inserted in the contact closure strip 1010.

• Connect the other end of the 6.2115.070 cable to the con-

nections "Pos. Fill" on the terminal block 3838 (valve A) or 4646

(valve B) of the 733 IC Separation Center so that COM and

GND are connected.

Electrical connection 750 – 709 (optional)

2

• Connect jumper P12 to the control interface of the 709 IC

Pump in such a way that the contacts at outputs 3 and 4 will

be closed when the pump has stopped (see chap. 5.2 of the

709 Instructions for Use).

• Use 6.2134.070 cable (option) to connect outputs 3 and 4 of

the control interface on the 709 IC Pump with connection

"REMOTE STOP INPUT" and "GND" on contact closure strip

1010 of the 750 Autosampler.

Settings with 732 IC Detector as "Master"

The following settings are recommended for operating the IC system

with 732 IC Detector as "Master":

• 750 Autosampler: "Run Time" = 0.0 min

• 732 IC Detector: operation with cycle program with

command "valve A/B = fill" at time

"0.0 min".

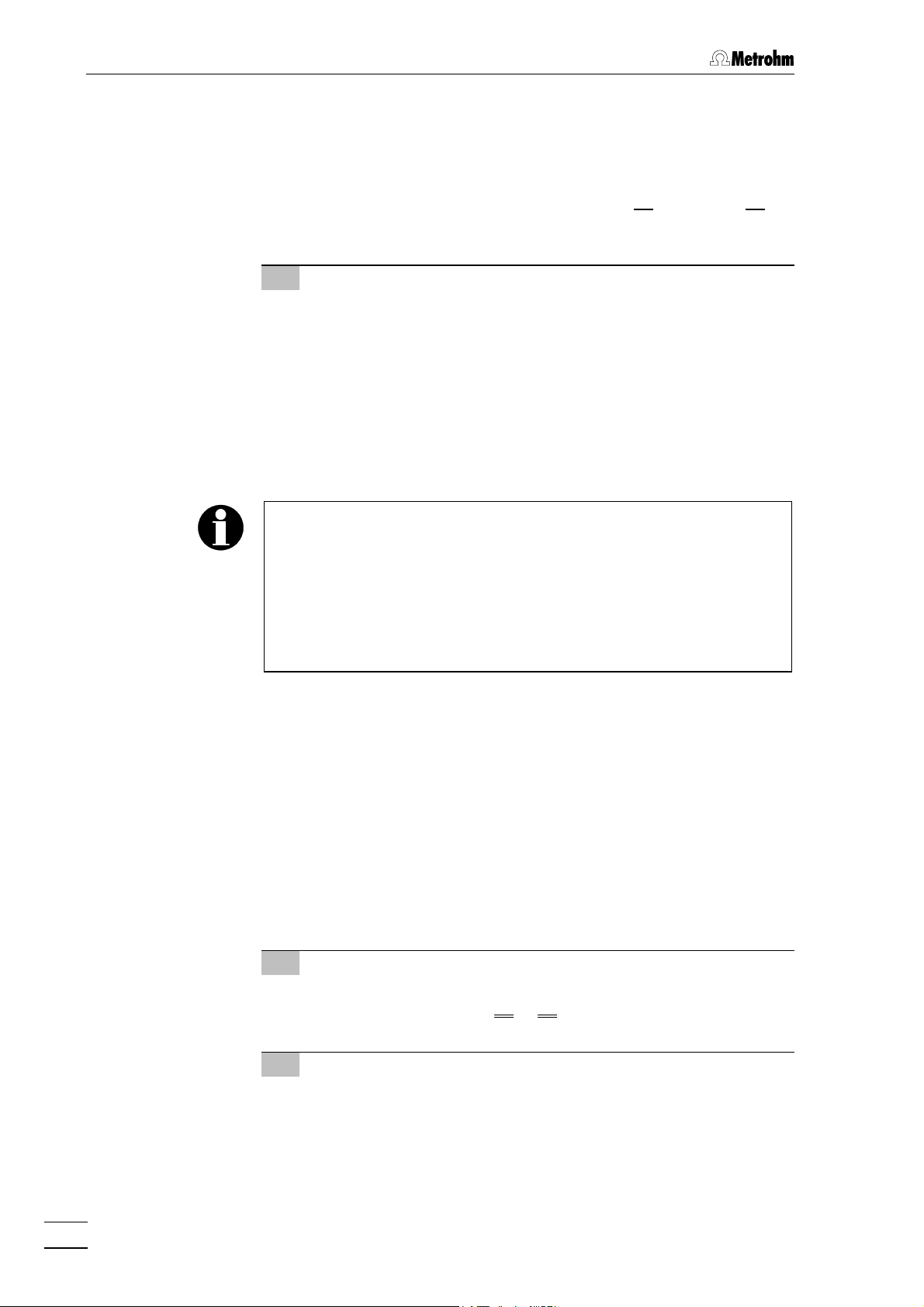

2.2.3 Connection to 762 with «IC Net»

When a modular IC system consisting of 732 IC Detector, 733 IC

Separation Center, 709 IC Pump, and 762 IC Interface is operated with

the PC software «IC Net» as "Master" the 750 Autosampler sample

change procedure will be started by a signal from the 733 IC Separation Center. The Autosampler must be connected to the 762 IC Interface using the 6.2134.000 cable and to the 733 IC Separation Center

using the 6.2128.100 as shown in Fig. 7.

Electrical connection 750 – 762

1

• Connect RS232 interface 1111 at the 750 Autosampler to one of

the RS232 interfaces 1414 or 1818 at the 762 IC Interface using

the 6.2134.000 cable.

12

Electrical connection 750 – 733

2

• Connect 6.2140.020 connector plug to contact closure strip 99

of the 750 Autosampler.

• Connect one end of the 6.2128.100 cable to the connections

"LOAD NO", "LOAD COM", "INJECT NO" and "INJECT COM"

on the connector plug inserted in the contact closure strip 99.

750 Autosampler

Page 16

2.2 Connection to IC system

The four cable ends are appropriately inscribed with "LOAD

NO" (green), "LOAD COM" (yellow), "INJECT NO" (brown) and

"INJECT COM" (white).

• Connect the other end of the 6.2128.100 cable to the con-

nections "Ground", "Fill" and "Inject" on the terminal block 3838

(valve A) or 4646 (valve B) of the 733 IC Separation Center. The

three cable ends are appropriately inscribed with "GND"

(white), "FILL" (green) and "INJECT" (brown).

732

6.2128.130

733

6.2125.090

(732)

6.2115.070

750

6.2128.100

6.2134.100

PC

6.2134.090

709762

6.2134.000

INJECT

LOAD

Fig. 7: Connection of 750 Autosampler at 732/733 and 762

750 Autosampler

13

Page 17

2 Installation

2.2.4 Tubing connection

For transferring the sample from the 750 Autosampler to the injection

valve of the 733 IC Separation Center the following tubing connections

must be made:

Tubing connection 750 – injection valve

1

• At the 733 IC Separation Center, loosen the rotary nipple

screwed onto the interior side of connection 2222 or 2828.

• Take PTFE suction tubing 8888 (see Fig. 16 and Fig. 17 of the

732/733 Instructions for Use) completely out of connection 2222

or 2828 and unscrew from connection "1" of injection valve 6868.

• Cut transfer tubing 88 (6.1803.000 PTFE capillary tubing of 750

accessories) to the shortest possible length between the

needle of the 750 Autosampler and injection valve 6868 of the

733 IC Separation Center.

• Remove the cover from transfer needle 55 of the 750 Auto-

sampler and screw one end of transfer tubing 88 to this con-

nection with the aid of a 6.2744.010 PEEK compression fitting.

• Remove holder stopper 77 from holder 66 and pull 6.1803.000

PTFE capillary tubing so far through the opening of holder

stopper 77 that the tubing length between needle connection

and the holder stopper is about 30 cm. Then press holder

stopper 77 fully back into holder 66.

• Pull the other end of the transfer tubing 88 through the opening

2222 or 2828 of the 733 IC Separation Center and screw onto

connection "1" of injection valve 6868 using a 6.2744.010 PEEK

compression fitting.

• Retighten rotary nipple on the interior side of connection 2222

or 2828 to fix the capillary tubing.

14

Tubing connection injection valve – waste

2

• Insert 6.2744.020 coupling (from 733 accessories) into con-

nection 2121 or 2727 of the 733 IC Separation Center.

• Screw PTFE suction tubing 8888 onto the 6.2744.020 coupling

attached to connection 2121 or 2727 and lead it into the waste

container.

In the case of the 2.733.0X20 IC Separation Center with two injection

valves, it is possible to fill both sample loops from the same 750

Autosampler. For this, connection "1" of valve A (outlet of the sample

loop) must be connected to connection "2" of valve B (inlet of the

sample loop) using a 6.1803.000 PTFE Capillary tubing cut to the

appropriate length.

750 Autosampler

Page 18

2.3 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with the mains voltage set wrongly and/or

wrong mains fuse there is a danger of fire!

2.3.1 Check fuses

The selection of mains voltage (100, 120, 220 or 240 V) and mains frequency (50 or 60 Hz) is made automatically by the 750 Autosampler

according to the mains voltage and frequency used. Nevertheless, before the 750 Autosampler is switched on for the first time a check

should be made as to whether the correct fuses for the intended mains

supply have been inserted in the instrument. Proceed as follows:

Disconnect mains cable

1

Disconnect mains cable from mains connection plug 1414 of the

750 Autosampler (see Fig. 5).

2.3 Mains connection

Remove fuse cassette

2

Using a screwdriver, loosen fuse cassette 1515 alongside the

mains connection plug 1414 and take out completely.

Remove fuse holder

3

Lift up the spring clip on the upper side of fuse cassette 1515 and

remove the fuse holder completely from the fuse cassette.

Check fuses

4

Carefully take the two fuses out of the fuse holder and check

their specifications:

100……120 V 2 A (rapid-action, with low rup-

turing capacity, 3AG)

230……240 V 1.25 A (rapid-action, with low rup-

turing capacity, 5××20 mm)

Insert fuses

5

Change fuses if necessary and reinsert in fuse holder.

Install fuse holder

6

Push the fuse holder into fuse cassette 1515 until the spring clip

clicks into position.

750 Autosampler

Insert fuse cassette

7

Completely reinsert fuse cassette 1515 in 750 Autosampler.

15

Page 19

2 Installation

2.3.2 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 1414 of the 750 Auto-

sampler (see Fig. 5).

2.3.3 Switching the instrument on/off

The 750 Autosampler is switched on and off using mains switch 1313.

When the instrument is switched on display 11 lights up.

16

750 Autosampler

Page 20

2.4 Initial checkout

Initial checkout will prove the general operation of the instrument and

show that no shipping damage or installation problem exists which

would prevent normal operation. To carry out this checkout the 750

Autosampler must be connected to the 733 IC Separation Center as

described in chap. 2.2 and correctly connected to the mains supply as

described in chap. 2.3.

For the initial checkout a standard chromatogram for the separation

column used in the 733 IC Separation Center should be recorded. In

order to do this a sample vial 44 filled with at least 500 µL of a suitable

standard ion solution should be placed in position 1 of sample rack 33;

then proceed step by step as follows:

Switch on 750 Autosampler

1

Switch on 750 Autosampler with mains switch 1313. The following

screen will be displayed after powerup and initialization:

2.4 Initial checkout

READY

SELECT A FUNCTION

Select "MANUAL INJECTION"

2

Press the <MANUAL INJECTION> key (<FUNCTION> +

<8>). The following screen will appear:

MANUAL INJECTION

àà

Sample Vial 1

Needle Depth POS 1

Run Injection ââ

Enter sample vial position

3

Press the <1> key and then press the <ENTER> key. The

screen will now change to:

MANUAL INJECTION

Sample Vial 1

àà

Needle Depth POS 1

Run Injection ââ

750 Autosampler

Enter needle depth

4

Press the <→> key two times and then press the <ENTER>

key. This results in the following display:

MANUAL INJECTION

Sample Vial 1

Needle Depth POS 3

àà

Run Injection ââ

17

Page 21

2 Installation

Start injection

5

Press the <ENTER> key. The 750 Autosampler will make an

injection from the vial at position 1. Afterwards the following

display will appear:

MANUAL INJECTION

COMPLETED

Select "SYSTEM"

6

Press the <SYSTEM> key (<FUNCTION> + <4>). The following screen will appear:

SYSTEM SETTINGS

àà

Park Needle

Contact Closures

Loop Size ââ

Park needle

7

Press the <ENTER> key. The transfer needle will be withdrawn

from the sample vial and moved back to its parking position in

the back left-hand corner. The following display then reappears:

READY

SELECT A FUNCTION

If any difficulties should occur during the initial checkout then proceed

as described in chap. 4.3.

18

750 Autosampler

Page 22

3 Operation

3.1 Fundamentals of operation

3.1.1 Display and instrument dialog

The LCD display 11 on the 750 Autosampler consists of 4 lines each with

20 characters. After the Autosampler has been switched on and initialized the following display appears:

READY

SELECT A FUNCTION

This screen is called the main screen. It is always displayed any time

the instrument is idle. Note that the line "SELECT A FUNCTION" flashes.

3.1 Fundamentals of operation

Methods, system settings, and other functions consist of a menu of

parameters which can be edited for different sample requirements. The

complete parameter menu, in many instances, cannot be shown on the

display at one time due to the available number of display lines. For example, a typical menu has the following appearance:

MANUAL INJECTION

Sample Vial 1

àà

Needle Depth<POS 3>

Run Injection ââ

The first line always shows the title of the selected function. Parameters

which can be edited with the numerical and/or cursor keys are shown

beneath. If the arrows "áá" or "ââ" appear at the right-hand side this indi-

cates that the cursor keys <áá> and <ââ> can be used to scroll

through the menu. In most menus the last entry is "Exit" (return to basic

condition).

An arrow pointing to the right "àà" on the left-hand side shows the pa-

rameter which can currently be edited. Each parameter requires either

a numerical entry or the selection of a value from an existing list.

Numerical parameter values are entered either directly with the numerical keys, or the <àà> and <ßß> keys are used to increase or decrease

the value step by step. The <CLEAR> key is used to delete an incorrect entry. When the required value for the parameter is shown it must

be confirmed. This is done with the <ENTER> key or by changing to

the next or previous parameter with the <áá> or <ââ> keys.

If a numerical entry is made which is outside the range possible for that

parameter the Autosampler will issue a warning alarm, followed by the

display of the following error message:

750 Autosampler

19

Page 23

3 Operation

Numeric keys

ERROR

Value out of range

Enter value between

## - ####

where # and ## are the appropriate range limits. The error message will

remain on the display until the <CLEAR> key is pressed.

Parameter lines which contain the characters "<" and/or ">" (e.g. "NONE>")

on either side of the parameter value indicate that a selection must be

made from a discreet menu of items. Pressing either the <àà> or <ßß>

key allows scrolling through the selection list. When the desired selection is displayed, press either the <ENTER>, <áá> or <ââ> key to

confirm the selection.

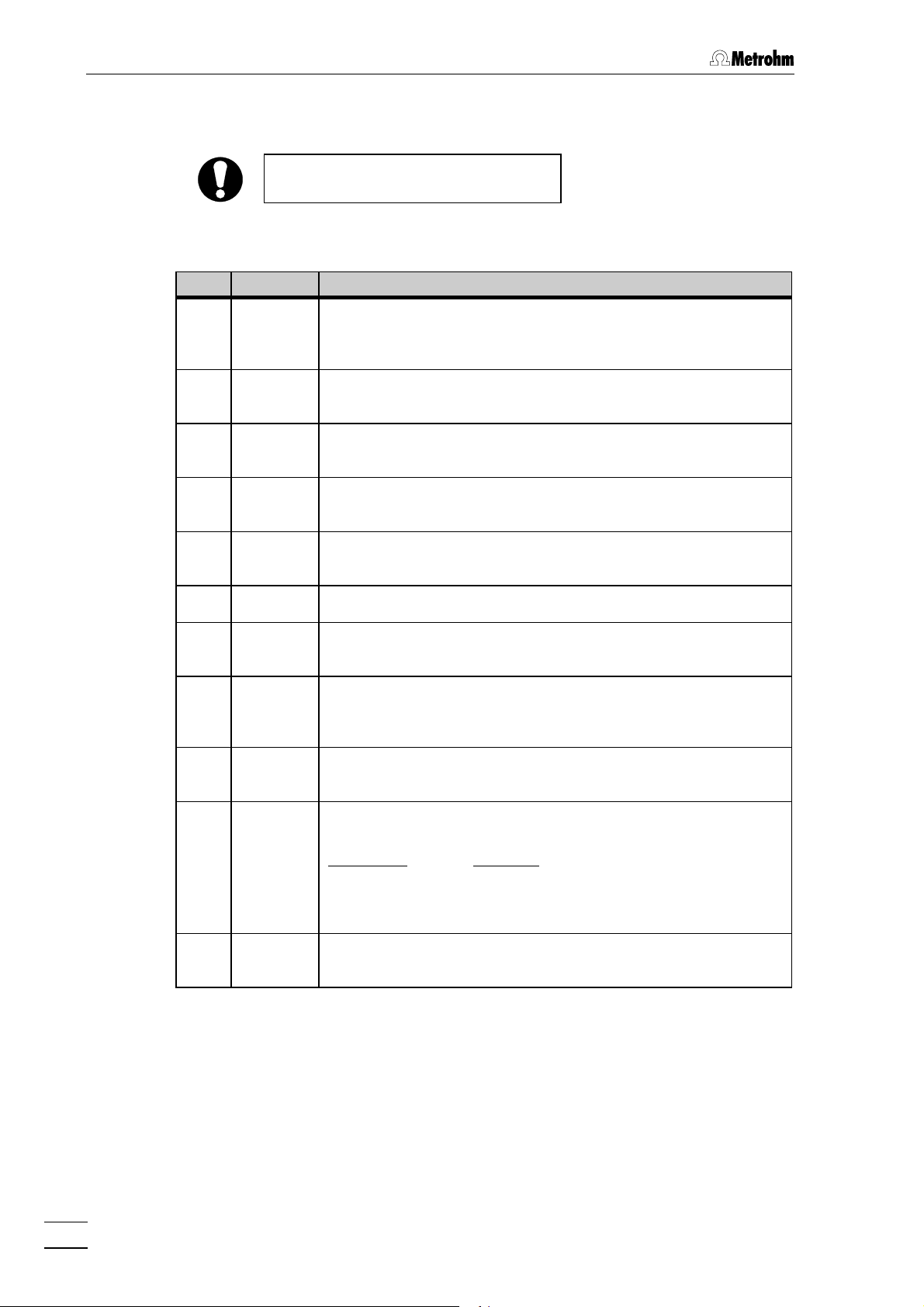

3.1.2 Overview of key functions

METHOD

MANUAL

RINSEINJECTION

8 9

7

4

1

0

REM/LOCTEMPSYSTEM

5 6

2 3

.

F3F2F1

CLEAR

Fig. 8: Keypad

FUNCTION

RUN/STOP

Main function keys

PRIORITY

ENTER

Cursor keys

20

The keypad of the 750 Autosampler contains 4 main function keys, 12

numerical keys (incl. <CLEAR>) and 4 cursor keys. In the basic condition the functions given above the numbers can also be activated by

pressing the <FUNCTION> key and the corresponding numeric key.

The following table provides a brief overview of the different functions of

the individual keys of the 750 Autosampler. You will find more detailed

information on the key functions in sections 3.2…3.8.

750 Autosampler

Page 24

Keys of 750 Autosampler

Key Normal function Function with <FUNCTION>

3.1 Fundamentals of operation

FUNCTION

RUN/STOP

PRIORITY

ENTER

METHOD

7

Function key

• Selection of a function in combi-

nation with the corresponding

numeric key.

Run/Stop key

• If no method runs:

Selection and start of a method.

• If a method runs:

Stop of the running method.

Key for priority sample

• Interruption of a running method

and injection of a priority sample.

Enter key

• Confirmation of entered parame-

ter.

Numeric entry 7

• Numeric entry of number "7".

–

–

–

–

Method

• Selection of method menu for

editing or deleting methods.

MANUAL

INJECTION

8

RINSE

9

SYSTEM

4

TEMP

5

REM/LOC

6

Numeric entry 8

• Numeric entry of number "8".

Numeric entry 9

• Numeric entry of number "9".

Numeric entry 4

• Numeric entry of number "4".

Numeric entry 5

• Numeric entry of number "5".

Numeric entry 6

• Numeric entry of number "6".

Manual injection

• Selection of the "MANUAL

INJECTION" menu for injections to be made from a

specified sample vial.

Rinse

• Rinsing of the transfer needle

and the injection valve with a

rinsing solution.

System parameters

• Selection of the menu for

system settings.

No function

• The <TEMP> function is not

available.

Remote control

• Selection of the menu for the

remote control (Local/RS232).

750 Autosampler

21

Page 25

3 Operation

Key Normal function Function with <FUNCTION>

F1

1

F2

2

F3

3

0

.

CLEAR

Numeric entry 1

• Numeric entry of number "1".

Numeric entry 2

• Numeric entry of number "2".

Numeric entry 3

• Numeric entry of number "3".

Numeric entry 0

• Numeric entry of number "0".

Point

• Entry of decimal point ".".

Delete/reset

• Deletion of an entered parameter

and/or resetting to default value.

No function

• The <F1> function is not

available.

No function

• The <F2> function is not

available.

No function

• The <F3> function is not

available.

Shipping position

• Transfer needle is moved to

the shipping position.

–

"Escape"

• Exit from parameter menus

and return to standby mode.

Cursor key <á>

• Moves the display cursor up a

line.

Cursor key <â>

• Moves the display cursor down a

line.

Cursor key <ß>

• Decrements numerical parameter

values.

• Moves the display one selection

item to the left.

Cursor key <à>

• Increments numerical parameter

values.

• Moves the display one selection

item to the right.

"Escape"

• Exit from parameter menus

and return to standby mode.

–

–

–

22

750 Autosampler

Page 26

3.2 System settings

3.2 System settings

SYSTEM

By pressing the <SYSTEM> key (<FUNCTION> + <4>) the system

settings menu appears. The system settings are global parameters

which affect the operation of the Autosampler, but are not required to

4

be programmed for each sample or method. The following screen

results:

SYSTEM SETTINGS

Park Needle

Contact Closures

Loop Size

Needle Setup

Key Beep

Time/Date

Injection Valve

Exit

Status

The individual menu points are selected by pressing the <áá> and

<ââ> keys. The individual inquiries of a menu point are accessed using

the <ENTER> key and exited by pressing simultaneously the

<FUNCTION> + <CLEAR> keys. The following listings show all dialog items which appear under <SYSTEM>. The values shown in the

displays are the default values, the possible entry values or ranges are

shown below the display.

System settings

Park transfer needle in home position

Enter contact closure times

Specify injection loop

Specify needle settings

On/off switching of the audible beep

Set date/time

without function for 750 Autosampler

Return to standby mode

Status display

SYSTEM SETTINGS

à

Park Needle

SYSTEM SETTINGS

à

Contact Closures

Park transfer needle in home position

After confirmation of this command with <ENTER> the transfer

needle is moved to the left rear of the instrument to provide easy

access to the sample rack.

Contact closure times

On the 750 Autosampler there is the possibility of producing four

signals in the form of a contact closure on contact closure strip 1010

for controlling external instruments:

Injection Automatic contact closure at output "START" for every

injection triggered by the Autosampler.

Event 1 Contact closure after a time laid down in the method

at output "T1".

Event 2 Contact closure after a time laid down in the method

at output "T2".

Event 3 Contact closure after a time laid down in the method

at output "T3".

Both signals are produced not only as "normal open" (between

outputs NO – COM) but also as "normal closed" (between outputs

NC – COM).

Entry of <ENTER> opens the following menu:

750 Autosampler

23

Page 27

3 Operation

CLOSURE DURATIONS

à

Injection 1

1…32000 s

CLOSURE DURATIONS

à

Event # 1

1…32000 s

CLOSURE DURATIONS

à

Exit

SYSTEM SETTINGS

à

Loop Size

Contact closure time for "START"

Input of contact closure time for the signal to be produced at

output "START" when the injection valve is switched to the

"INJECT" position.

Contact closure time for "T1", "T2" or "T3"

Entry of contact closure time for the signal to be produced at

output "T#". The signal output is made according to the time

laid down in the method "Event# Time".

Return to "SYSTEM SETTINGS" menu

Loop size

Size of the loop at the injection valve at the 733 IC Separation

Center. By pressing <ENTER> the following screen is displayed:

Enter Loop Size

10µµL

(Four injs/vial)

SYSTEM SETTINGS

à

Needle Setup

NEEDLE SETUP

à

Depth

Enter Needle

position for ONE

injection per vial.

<POS 3>

POS1,POS2,POS3,POS4

1…100 µL

Entry of loop size

Entry of loop size in µL. In the bottom line the number of

possible injections per sample is displayed. For a volume of

≤ 10 µL the maximum is 4, for a volume > 10 µL a maximum

of 3 injections can be made.

Needle settings

By pressing <ENTER> the following menu is opened:

Depth Needle depth.

Pressure Pressure for needle lowering.

Needle depth

By pressing <ENTER> the following screen is displayed:

Entry of needle depth

Entry of the position to which the transfer needle is lowered

with 1 injection per sample. The positions correspond to the

following displacement volumes (see section 1.2):

POS1 310 µL POS3 590 µL

POS2 450 µL POS4 730 µL

24

If sample vessels closed with 6.2743.030 filter stoppers are used then

immersion depth "POS4" must not be selected.

750 Autosampler

Page 28

3.2 System settings

NEEDLE SETUP

à

Pressure Low>

SYSTEM SETTINGS

à

Key beep

Audible Key Feedback

Selection

<ON

SYSTEM SETTINGS

à

Time/Date

Pressure for needle lowering

The needle can be lowered either with "Low" pressure or with

Low,High

"High" pressure.

If sample vessels closed with 6.2743.030 filter stoppers are used then

pressure "High" must be selected.

On/off switching of an audible beep

By pressing <ENTER> the following screen is displayed:

Audible beep whenever a key is pressed

Switches acoustic signal each key a key is pressed on/off.

Switching is made by means of the <àà> or <ßß> cursor

keys.

ON,OFF

Date/time settings

By pressing <ENTER> the following screens are displayed:

Time/Date

à

02/23/00 03:31 AM

Time/Date

à

Set Date

Time/Date

à

Set Time

SYSTEM SETTINGS

à

Injection Valve

SYSTEM SETTINGS

à

Status

Display of date and time

Set date

By pressing <ENTER> a menu is opened for setting "Year",

"Month", and "Day".

Set time

By pressing <ENTER> a menu is opened for setting "Hour",

"Month", and "AM" or "PM".

Injection valve

Without function for 750 Autosampler.

Status display

By pressing <ENTER> the following screen is displayed:

Validated

709/50 S/N 03029

Version H1.00A1.00

<CLEAR> to Exit

750 Autosampler

Status display

Display of validation status, instrument type, serial number,

and program version number.

25

Page 29

3 Operation

3.3 Manual rinsing

RINSE

9

Enter Rinse Vial

# 1

1…128

This command allows the rinsing of the transfer needle, transfer tubing

and injection valve. When the <RINSE> key (<FUNCTION> + <9>)

is pressed, the following screen appears:

Position of rinsing solution

Entry of position of the rinsing solution on the sample rack. After

confirmation with <ENTER> the transfer needle moves to the

given rinsing vial and sinks down to its lowest position "POS4".

When the rinsing process has ended the instrument returns to its

basic condition. The transfer needle remains in the rinsing vial.

3.4 Manual injection

MANUAL

INJECTION

The <MANUAL INJECTION> key (<FUNCTION> + <8>) allows

manual injections of a user specified sample. When pressed, the

following screen is provided:

8

MANUAL INJECTION

Sample Vial 1

Needle Depth POS 1

Run Injection

Exit

The individual menu points are selected by pressing the <áá> and

<ââ> keys. The individual inquiries of a menu point are accessed using

the <ENTER> key and exited by pressing simultaneously the

<FUNCTION> + <CLEAR> keys. The following listings show all dialog items which appear under <MANUAL INJECTION>. The values

shown in the displays are the default values, the possible entry values

or ranges are shown below the display.

Manual injection

Position of sample vial

Needle depth

Run injection

Return to standby mode

MANUAL INJECTION

à

Sample Vial 1

26

1…128

Position of sample vial

Entry of the sample vial position on the sample rack for the desired

sample to be injected.

750 Autosampler

Page 30

3.4 Manual injection

MANUAL INJECTION

à

Needle Depth POS4

MANUAL INJECTION

à

Run Injection

Needle depth

Entry of the position to which the transfer needle is lowered at the

injection of the sample. The positions correspond to the following

displacement volumes (see also section 1.2):

POS1 310 µL POS3 590 µL

POS2 450 µL POS4 730 µL

If sample vessels closed with 6.2743.030 filter stoppers are used then

immersion depth "POS4" must not be selected..

Run injection

After confirmation with <ENTER> the injection valve is switched

to the "FILL" position, the transfer needle is moved to the given

sample vial and lowered to the selected position. When the sample loop has been filled the injection valve is returned to the

"INJECT" position. The following display appears while the injection is being carried out automatically:

MANUAL INJECTION

Vial # N

Needle Depth POS M

SAMPLE INJECTED

MANUAL INJECTION

COMPLETED

Manual injection running

The given sample position number N and the selected needle depth position M are displayed. When the valve has

switched to the "INJECT" position "SAMPLE INJECTED" is additionally shown in the bottom line for a short time, after which

the following display appears:

Manual injection completed

When the injection has been completed the transfer needle

remains in the sample vial. Further injections can now be

started from the same sample vial, for which a new immersion depth must be selected.

750 Autosampler

27

Page 31

3 Operation

3.5 Methods

METHOD

By pressing the <METHOD> key (<FUNCTION> + <7>) the method

menu appears. For the 750 Autosampler a method is understood as

being a program defined by the operator which proceeds automatically

7

after being started. A maximum of 10 methods with up to 128 program

steps each can be stored in the Autosampler. The <METHOD> key

opens the following menu:

METHOD MENU

Edit Method

Run Method

Copy Method

Delete Method

Display Method Use

Print Method

Exit

The individual menu points are selected by pressing the <áá> and

<ââ> keys. The individual submenus or inquiries of a menu point are

accessed using the <ENTER> key and exited by pressing simultaneously the <FUNCTION> + <CLEAR> keys. The following listings

show all dialog items which appear under <METHOD>. The values

shown in the displays are the default values, the possible entry values

or ranges are shown below the display.

Method menu

Enter or edit methods and steps

Execute the selected method

Copy steps from one method into another

Delete selected method

Shows which of the ten method blocks are filled

Print method

Return to standby mode

METHOD MENU

à

Edit Method

Enter Method Number

# N

EDIT METHOD # N

Edit Step

Append Step

Insert Step

Delete Step

Exit

Edit method

Allows a method to be edited by inserting, deleting and editing

program steps. After entering <ENTER> the following display

appears:

Select method

Enter the method number N which is to be edited. If the

selected method already contains program steps the following program step menu will appear after confirmation with

1…10

<ENTER>:

Program step menu

Edit program step

Append program step to the end of the method

Insert program step between two existing program steps

Delete selected program step

Return to method menu

The individual menu points are selected by pressing the

<áá> and <ââ> keys:

28

750 Autosampler

Page 32

3.5 Methods

EDIT METHOD # N

à

Edit Step

Enter Step Number

#M

METHOD N STEP M

à

Start Vial 1

METHOD N STEP M

à

Final Vial 1

Edit program step

Allows an already existing program step to be called

up and edited. The following display will appear after

entering <ENTER>:

Select program step

Entry of the number M of the program step

which is to be edited. After confirmation with

<ENTER> a menu with method number N and

1…128

program step number M in the title line and the

following 10 editable parameters for the program

steps will appear:

Start vial

Entry of the number of the first sample vial for the

1…128

sample series defined in this program step.

Final vial

Entry of the number of the last sample vial for the

1…128

sample series defined in this program step. If the

numbers of the first and last samples are identical then this program step applies only to this

single sample.

If the transfer needle is removed from the sample vial after an injection

then no further injections can be made from the same sample vial.

METHOD N STEP M

à

Injections <1>

0,1,2,3,(4),

SKIP,RINSE

Number of injections

The number of injections which are to be carried

out per sample vial for the sample series defined

in the program step. As well as the number of

injections (1…4 depending on loop volume) the

following values can also be selected with the

<àà> and <ßß> keys:

0 No injections are made. This step

can be used for programming timecontrolled events.

SKIP The sample series will be skipped.

RINSE The sample vials are only used for

rinsing.

If sample vials sealed with 6.2743.030 filter stoppers are used

then a maximum of only 3 injections per sample vial can be

carried out.

750 Autosampler

29

Page 33

3 Operation

METHOD N STEP M

à

Run Time 3.0

0.0,0.1…999.9 min

METHOD N STEP M

à

Event1 Time 0.0

0.0…999.9 min

Run time

Selects the run time (chromatographic analysis

time) between switching the injection valve to the

"INJECT" position and the start of a new injection

with the same or the next sample.

The minimum run time is 0.1 min. If 0.0 min is

entered the external injection start is activated.

The sample loop will only be filled and the injection started when a contact closure has been

made at the "EXTERNAL INJECT INPUT". The

run time will then be determined externally.

Time for event T1

Selects the time after which a signal in the form

of a contact closure will be produced at output

"T1".

The signal will only be produced if the selected

time is shorter or the same as the run time. If the

production of a signal is to be avoided for a

sample series then a time must be selected

which is longer than the run time.

METHOD N STEP M

à

Event2 Time 0.0

0.0…999.9 min

METHOD N STEP M

à

Event3 Time 0.0

0.0…999.9 min

METHOD N STEP M

à

Rinse Type NONE>

NONE,EVEN,ODD,

QR_E,QR_O

Time for event T2

Selects the time after which a signal in the form

of a contact closure will be produced at output

"T2".

The signal will only be produced if the selected

time is shorter or the same as the run time. If the

production of a signal is to be avoided for a

sample series then a time must be selected

which is longer than the run time.

Time for event T3

Selects the time after which a signal in the form

of a contact closure will be produced at output

"T3".

The signal will only be produced if the selected

time is shorter or the same as the run time. If the

production of a signal is to be avoided for a

sample series then a time must be selected

which is longer than the run time.

Rinse type

This parameter allows every second sample vial

to be programmed as a rinsing vial. The following options can be selected with the <àà> and

<ßß> cursor keys:

NONE No rinses. The vials are used as pro-

grammed.

30

750 Autosampler

Page 34

3.5 Methods

EVEN Every even numbered vial is used for

rinsing.

ODD Every odd numbered vial is used for

rinsing.

QR_E Every even numbered vial is a quick

rinse vial. The rinsing occurs immediately after the injection (possible

only with 1 injection per sample).

QR_O Every odd numbered vial is a quick

rinse vial. The rinsing occurs immediately after the injection (possible

only with 1 injection per sample).

METHOD N STEP M

à

Next Step

At end of method.

Add another step?

<ENTER> for Yes

<CLEAR> for No

<ENTER>,<CLEAR>

METHOD N STEP M

à

Previous Step

EDIT METHOD # N

à

Append Step

Next program step

Changes to next program step in the method. If

no further program step exists the following

display appears:

Add new program step

Decision as to whether a new program

step is to be added:

<ENTER> Add a new program step.

<CLEAR> Return to program step

menu.

Previous program step

Changes to previous program step in the

method.

Append program step

Allows the addition of a new program step at the end

of the selected method. After <ENTER> is pressed a

menu with the 10 editable parameters for the program

step appears (see under "

àà

Edit Step ").

750 Autosampler

EDIT METHOD # N

à

Insert Step

INSERT A STEP

Enter Step Number

#N

Insert program step

Allows the addition of a new program step between

two existing program steps. After <ENTER> is

pressed the following display appears:

Select program step

Entry of the number of the program step after

which the new program step is to be inserted.

After <ENTER> is pressed a menu with the 10

editable parameters for the program step appears (see under "

àà

Edit Step ").

31

Page 35

3 Operation

EDIT METHOD # N

à

Delete Step

METHOD MENU

à

Run Method

DELETE A STEP

Enter Step Number

#N

Delete Step # N?

<ENTER> to Delete

<CLEAR> to Abort

Running a method

Allows a method to be started. After <ENTER> is pressed the

following display appears:

Delete program step

Allows program steps to be deleted. After <ENTER>

is pressed the following display appears:

Select program step

Entry of the number of the program step which is

to be deleted. After <ENTER> is pressed the

following display appears:

Confirmation of deletion process

<ENTER> Delete selected program step N.

<CLEAR> Abort deletion process.

Enter Method Number

# N

METHOD MENU

à

Copy Method

COPY METHOD

Copy FROM Method

# N

COPY METHOD

Copy TO Method

# M

Select method

Entry of the method number N which is to be started. After

confirmation with <ENTER> the selected method is carried

out exactly as if it has been started with the <RUN/STOP>

1…10

key (details see chap. 3.6).

Copy a method

Allows a method to be copied. After <ENTER> is pressed the

following display appears:

Source method

Entry of the method number N which is to be copied. After

confirmation with <ENTER> the following display appears:

1…10

Target method

Entry of the method number M which is to be overwritten

with the selected source method. After confirmation with

<ENTER> the method will be copied provided that the

1…10

target method is empty.

If the target method already contains program steps then the

following safety inquiry will appear:

32

750 Autosampler

Page 36

3.5 Methods

Method #

contains a program

<ENTER> to Overwrite

<CLEAR> to Abort

<ENTER>,<CLEAR>

METHOD MENU

à

Delete Method

Enter Method Number

# N

Delete Method # N?

<ENTER> to Delete

<CLEAR> to Abort

Overwrite confirmation

The selected target method already contains a program.

<ENTER> Overwrite confirmation.

<CLEAR> Return to method menu.

Delete a method

Allows a method to be deleted. After <ENTER> is pressed the

following display appears:

Select method

Entry of the method number N which is to be deleted. After

confirmation with <ENTER> the following display appears:

1…10

Confirmation of deletion process

<ENTER> Delete selected method N.

<CLEAR> Abort deletion process.

METHOD MENU

à

Display Method Use

PROGRAMMED METHODS

1 2 3 4 5 6 7 8 9 10

P - - - - - - - - -

Method storage display

After <ENTER> is pressed the following display appears:

Display of programmed methods

The occupation of the 10 possible places for methods in the

method memory is shown. The characters have the following

meaning:

P Memory place occupied by programmed method.

– Memory place free.

750 Autosampler

33

Page 37

3 Operation

3.6 Method procedure

A previously programmed method can be started by pressing

RUN/STOP

the <RUN/STOP> key or (as already described in chap. 3.5)

by selection of the menu item "Run Method" in the method

menu. In both cases the following display appears:

Enter Method Number

# N

1…10

METHOD STEP METHTIME

NN MM XXX.X

VIAL INJ RTIME

nnn m xxx.x

Select method

Entry of the method number N which is to be started.

After confirmation with <ENTER> the selected

method is started. While the program is running the

following display appears:

Status display for running method

While the program is running the following data are

displayed and continually updated:

METHOD Number NN of current method

STEP Number MM of program step

METHTIME Total elapsed time since method start

VIAL Number nnn of current vial

INJ Number m of current injection

RTIME Run time of current sample

When the last program step has been completed the

transfer needle is returned to the park position. The

following display appears:

METHOD

COMPLETED

METHOD STOPPED

<RUN/STOP> to Resume

<ENTER> to Abort

<FUNC-7> to Edit

Method completed

The selected method has been correctly completed.

The instrument is ready for a method to be restarted or

to return to the basic condition.

Method stopped

A running program can be stopped at any time with

the <RUN/STOP> key; the transfer needle remains in

its position and the display shown alongside appears.

The three following possibilities now exist:

<RUN/STOP> Continue method run.

<ENTER> Abort method.

<FUNC-7> Edit the current method, then re-

turn to this selection.

34

750 Autosampler

Page 38

3.7 Priority sample

By pressing the <PRIORITY> key a running method can be

PRIORITY

interrupted so that a single priority sample can be processed.

The priority sample can be assigned its own parameters

independently from those of the current method.

The priority sample has priority before the next sample, i.e. it

will be processed as soon as all injections from the current

sample vial have been completed. When the priority sample

has been processed the Autosampler returns to the program

step which would have followed had the priority sample not

interrupted the method run.

When the <PRIORITY> key is pressed during a running

method the following menu with parameters for the priority

sample appears (for parameter details see chap. 3.5):

3.7 Priority sample

PRIORITY SAMPLE

Priority Vial N

Injections 1

Run Time 3.0

Event1 Time 0.0

Event2 Time 0.0

Event3 Time 0.0

Run Sample

Exit

After the current method has been processed the priority

sample is started. The following display appears:

PRIORITY SAMPLE

VIAL INJ RTIME

nnn m xxx.x

Parameter menu for priority sample

Number of sample vial for priority sample

Number of injections (1…4)

Run time

Time for event T1

Time for event T2

Time for event T3

Triggers the start of the priority sample (carried out

automatically directly after current sample has been

processed)

Return to display of program status

Status display for priority sample

While the program is running the following data are

displayed and continually updated:

VIAL Number nnn of the sample vial with the

priority sample

INJ Number m of current injection

RTIME Run time for priority sample

750 Autosampler

When the priority sample has been completed the Autosampler returns to the running method and carries on with

the program step which would have followed had the

priority sample not interrupted the method run.

35

Page 39

3 Operation

3.8 Remote control

REM/LOC

By pressing the <REM/LOC> key (key <FUNCTION> + <6>) the

menu for switching between normal operation (Local) and remotecontrolled operation via the RS232 interface (Remote) appears. The key

6

REMOTE/LOCAL

Local

RS-232

IEEE-488

Exit

opens the following menu:

The individual menu points are selected by pressing the <áá> and

<ââ> keys. The individual inquiries of a menu point are accessed using

the <ENTER> key and exited by pressing simultaneously the

<FUNCTION> + <CLEAR> keys. The following listings show all dialog items which appear under <REM/LOC>. The values shown in the

displays are the default values, the possible entry values or ranges are

shown below the display.

Remote control/Normal operation

Normal operation

Remote control via RS232

Remote control via IEEE-488

Return to standby mode

REMOTE/LOCAL

à

Local

REMOTE/LOCAL

à

RS-232

Select Baud Rate

<4800>

300,600,1200,2400,

4800,9600,19200,

Select Parity

<None

Even,Odd,None

Switch to normal operation

After confirmation of this command with <ENTER> the instrument

is switched from operating under remote control via RS232 to

normal operation.

Switch to remote control via RS232

After confirmation of this command with <ENTER> the following

display appears:

Entry of baud rate

Entry of baud rate in bits/s for the RS232 interface. The value

entered here must also be set on the external controller. After

the baud rate has been confirmed with <ENTER> the following display appears:

38400

Entry of parity

Entry of parity for the RS232 interface. The value entered

here must also be set on the external controller. After the

parity has been confirmed with <ENTER> the following

display appears:

36

750 Autosampler

Page 40

3.8 Remote control

Select Data Bits

8

5,6,7,8

Select Stop Bits

1

REMOTE MODE

RS-232

1,2

Entry of data bits

Entry of data bits for the RS232 interface. The value entered

here must also be set on the external controller. After the

data bits have been confirmed with <ENTER> the following

display appears:

Entry of stop bits

Entry of stop bits in bits/s for the RS232 interface. The value

entered here must also be set on the external controller. After

the stop bits have been confirmed with <ENTER> the following display appears:

Instrument in remote control mode

The Autosampler 750 is completely controlled by the computer connected to the RS232 interface. The Autosampler

remains in this condition until it is switched to normal operation by the controller or the <REM/LOC> key is pressed.

Remote control via the RS232 interface is carried out with the

commands described in the following table.

750 Autosampler

37

Page 41

3 Operation

Summary of the remote control commands

Command Description

@GTV ###

@LDL #

@VLV LD/INJ

@RNP

@RVN

@RVP

@RDX

@RDY

@RDZ

Go to vial position ### :

0 Rest position at left front

1 … 128 Vial position on sample tray

Fill sample loop:

The transfer needle is lowered to position # (1 … 4).

Switch injection valve:

LD LOAD (switch injection valve to FILL position)

INJ INJECT (switch injection valve to INJECT position)

Read needle position:

The position (1 … 4) is put out.

Read vial number:

The position (1 … 128; HOME) is put out.

Read injection valve position:

The position (LOAD, INJECT) is put out.

Read x position:

The x position (0…760) is put out.

Read y position:

The y position (0…1000) is put out.

Read z position:

The z position (0…46) is put out.

@BZR $$$

@AUX 1 ON/OFF

@MSG ## "$$$"

Trigger acoustic signal $$$:

Set contact closure 1 ("T1") on or off.

Display at position ## (1…80; 1…20 = 1st line; 21…40 = 2nd line;

41…60 = 3rd line; 61…80 = 4th line) on the LCD display the message

"$$$...".

@LOC

# = digit 0 … 9; $ = any character

Return to normal operation (LOCAL).

CLK single short acoustic signal

ERR single long acoustic signal

ALM triple slow acoustic signal

PNC repeated slow acoustic signal

ON continuous signal

OFF switch off acoustic signal (PNC, ON)

38

750 Autosampler

Page 42

4.1 Operating information

4 Notes – Maintenance –

Faults

4.1 Operating information

4.1.1 Loading sample vials

Load the vial with sample to within ≈ 6 mm (1/4 in.) of the top and push

the polyethylene cap (cup side down) into the vial. The cap has two

sealing rings on its periphery. The cap should be pushed into the vial

so that both rings engage and remain so. The maximum volume of

sample is 800 µL, the minimum volume of sample is 300 µL using a

loop size > 20 µL and 150 µL using a loop size ≤ 20 µL.

Air trapped under the plastic caps is of no consequence. The first

stroke of the needle into the vial displaces enough liquid to force the air

completely through the injector valve loop and through the waste outlet

tube. Should any air remain in the vial, it will be above the needle

opening and will not enter the tubing. The first stroke also forces

enough sample through the tubing and loop to remove remnants of the

previous sample.

4.1.2 Sample preparation

It is important that samples be free of particulate matter which may plug

the needle or tubing. Metallic or gritty particles will cause damage to the

injection valve and may plug the chromatographic system. All samples

should be filtered therefore prior to filling the vials. This can be accomplished using a hand filtration device with a 0.45 µµm membrane filter

shown in Fig. 9.

750 Autosampler

Fig. 9: Manual sample filtering

39

Page 43

4 Notes – Maintenance – Faults

A further possible way of filtering samples is by means of the optional

6.2743.030 filter stoppers. These filter stoppers, which contain a

built-in filter unit, are fitted to the sample vials just like normal stoppers.

The way they work is shown in Fig. 10.

To injection valve

Filtered sample

Unfiltered sample

Fig. 10: Sample filtering with FilterCaps

FilterCaps were designed to free the chromatographer from the timeconsuming task of hand filtering samples. They can be used to free

samples from suspensions and particles. However, filter stoppers are

not suitable for filtering samples containing a large amount of solids as

this causes the filter to become blocked which also blocks the transfer

needle. Those samples which are difficult to filter manually with a membrane filter (see Fig. 9) should be centrifuged before filtration.

When working with filter stoppers the "POS4" setting for the needle

immersion depth "Needle Depth" must not be selected.

4.1.3 Operating parameters

Before samples can be injected all necessary instrument settings must

be made. The most important parameter is the retention time. The time

interval "Run Time" between individual injections must be sufficiently

long so that all substances are eluted before the next sample is injected. Moreover, it may be necessary to include further time for baseline analysis and evaluation with the evaluation system.

40

750 Autosampler

Page 44

4.2 Maintenance and servicing

4.2.1 General information

The 750 Autosampler was designed for years of maintenance-free use.

The X,Y,Z sample tray assembly is equipped with bushings and bearings made from materials chosen to minimize the need for lubrication.

The needle drive carriage position is recalibrated at powerup and with

the start of each method. Therefore, there are no user serviceable parts

in the X,Y,Z sample tray assembly or the needle drive carriage with the

exception of changing the transfer needle (see section 4.2.2).

4.2.2 Transfer needle replacement

If the transfer needle is blocked it must be replaced. Proceed as follows

(see Fig. 11):

4.2 Maintenance and servicing

Prepare Autosampler

1

• Stop any method which may be running by pressing

<RUN/STOP> and <ENTER>.

• Park the transfer needle 55 by pressing <SYSTEM> and "Park

Needle".

• Switch off instrument by means of mains switch 1313.

Remove old needle

2

• Hold connection screw 2121 with open-end spanner and un-