Page 1

CH-9101 Herisau/Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

EMail sales@metrohm.ch

Internet http://www.metrohm.ch

748 DH Sample Changer

Instructions for Use

8.748.1003

99.01 mst, ti

Page 2

Contents

Contents

1 Introduction..............................................................................................................2

1.1 Overview....................................................................................................................... 2

1.2 Sample arm positions .................................................................................................. 4

1.2.1 Positions in the XY-direction ................................................................................. 4

1.2.2 Positions in the Z-direction.................................................................................... 4

2 Sample changer start-up.........................................................................................5

2.1 Mains voltage, mains connection................................................................................ 5

2.2 Sample Changer setup................................................................................................ 6

2.2.1 Setting up the basic instrument ............................................................................ 6

2.2.2 Installation of rinsing accessories......................................................................... 7

2.3 Equipping the titration head......................................................................................... 8

2.4 Sample racks................................................................................................................ 9

2.5 Sample Changer start up............................................................................................. 9

2.6 Adjusting Sample Changer.......................................................................................... 9

3 Operation via RS232 Interface ..............................................................................11

3.1 General rules .............................................................................................................. 11

3.1.1 Tree of commands .............................................................................................. 11

3.1.2 Triggers................................................................................................................ 11

3.2 Remote control commands ....................................................................................... 12

3.2.1 Overview .............................................................................................................. 12

3.2.2 Description of the remote control commands.................................................... 13

3.3 Properties of the RS 232 Interface............................................................................. 16

4 Troubleshooting, remedying faults ......................................................................17

4.1 Troubleshooting ......................................................................................................... 17

4.2 TiNet error messages................................................................................................. 18

4.3 Readjust Sample Changer......................................................................................... 19

5 Appendix.................................................................................................................20

5.1 Technical specifications............................................................................................. 20

5.2 Sample Changer methods......................................................................................... 21

5.3 Pin assignment of I/O sockets "Auxiliary" .................................................................. 22

5.4 Warranty and certificates............................................................................................ 23

5.4.1 Warranty............................................................................................................... 23

5.4.2 Certificate of Conformity and System Validation................................................ 24

5.5 Scope of delivery, accessories .................................................................................. 26

Index ..........................................................................................................................29

748 DH Sample Changer

Page 3

1 Introduction

1.1 Overview

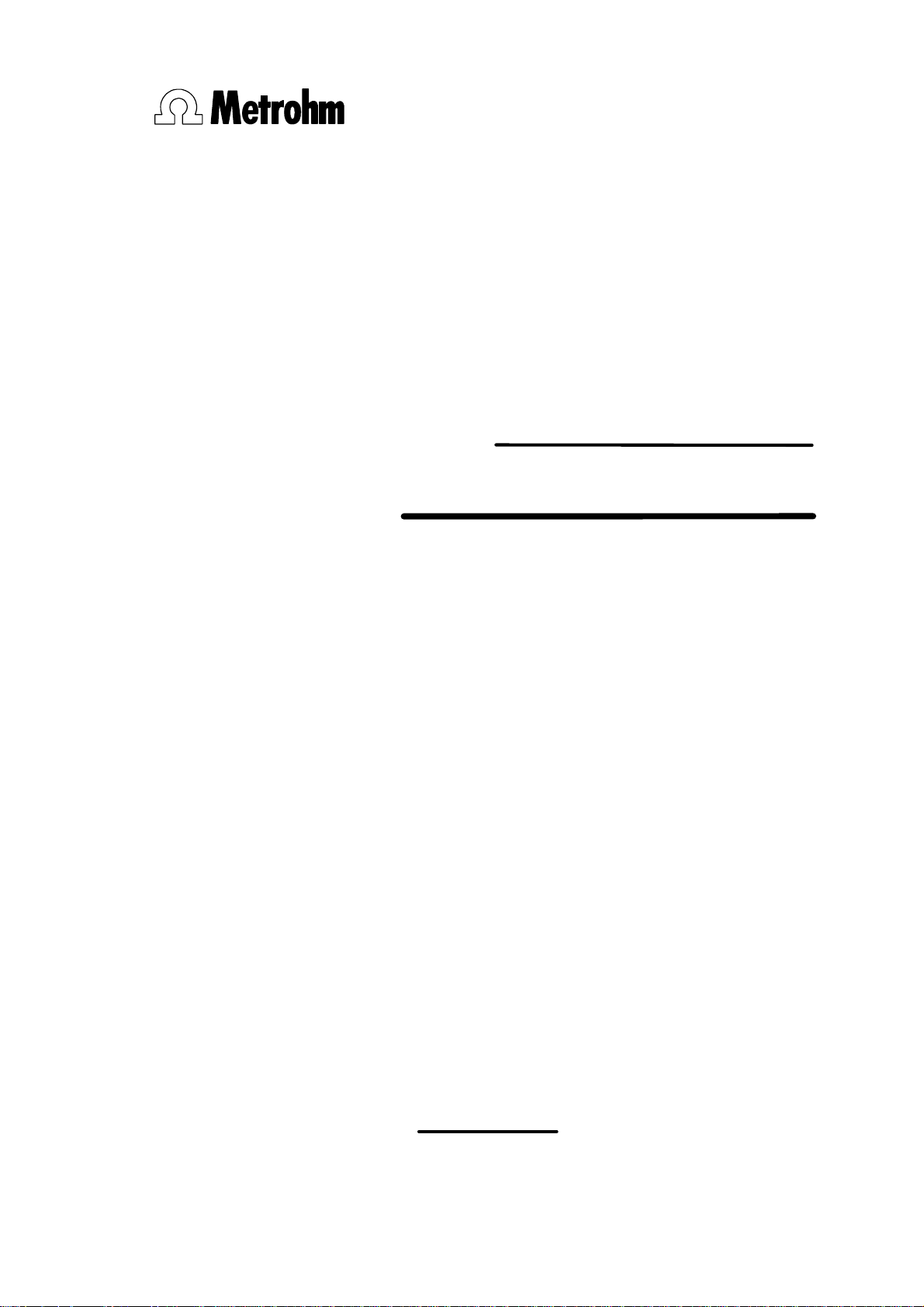

Instrument front panel:

1

2

3

1.1 Overview

4

5

6

Instrument rear panel:

8

9

10

7

748 DH Sample Changer

11 13 14

12

15

16

1

Page 4

1.1 Overview

Instrument front panel:

1 6.2053.010 cable/tubing clamps

2 Control cable

assembly see page 6.

3 Cable/tubing holder

4 Sample arm

5 Splash protection

6 Sample rack

for 48 x 250 mL beakers

or

for 136 x 75 mL beakers

7 Connection for waste tubing

2

748 DH Sample Changer

Page 5

Instrument rear panel:

8 Holder for control cable

9 Sockets for control cable

10 Mains switch

11 Connection for mains cable

Mains voltage adjustment: see page 5.

In networks where the mains voltage is subject to strong HFinterference the Sample Changer should be operated with an additional

mains filter, e.g. Metrohm 615 mains filter.

12 Remote sockets for I/O lines

The beaker detector is plugged into remote socket 1.

Remote sockets 2 and 3 can be used for connecting external instruments. The lines can be activated from TiNet (see TiNet Instructions for

Use).

1.1 Overview

13 RS232 interface

for connecting a computer

14 Stirrer connection and setting the stirrer speed

Rod stirrer 722

Supply voltage: 10 VDC (I ≤ 200 mA)

15 Voltage adjustment for pump

see page 5

16 Connection for rinsing tubing

with 6.1808.050 tubing nozzle

748 DH Sample Changer

3

Page 6

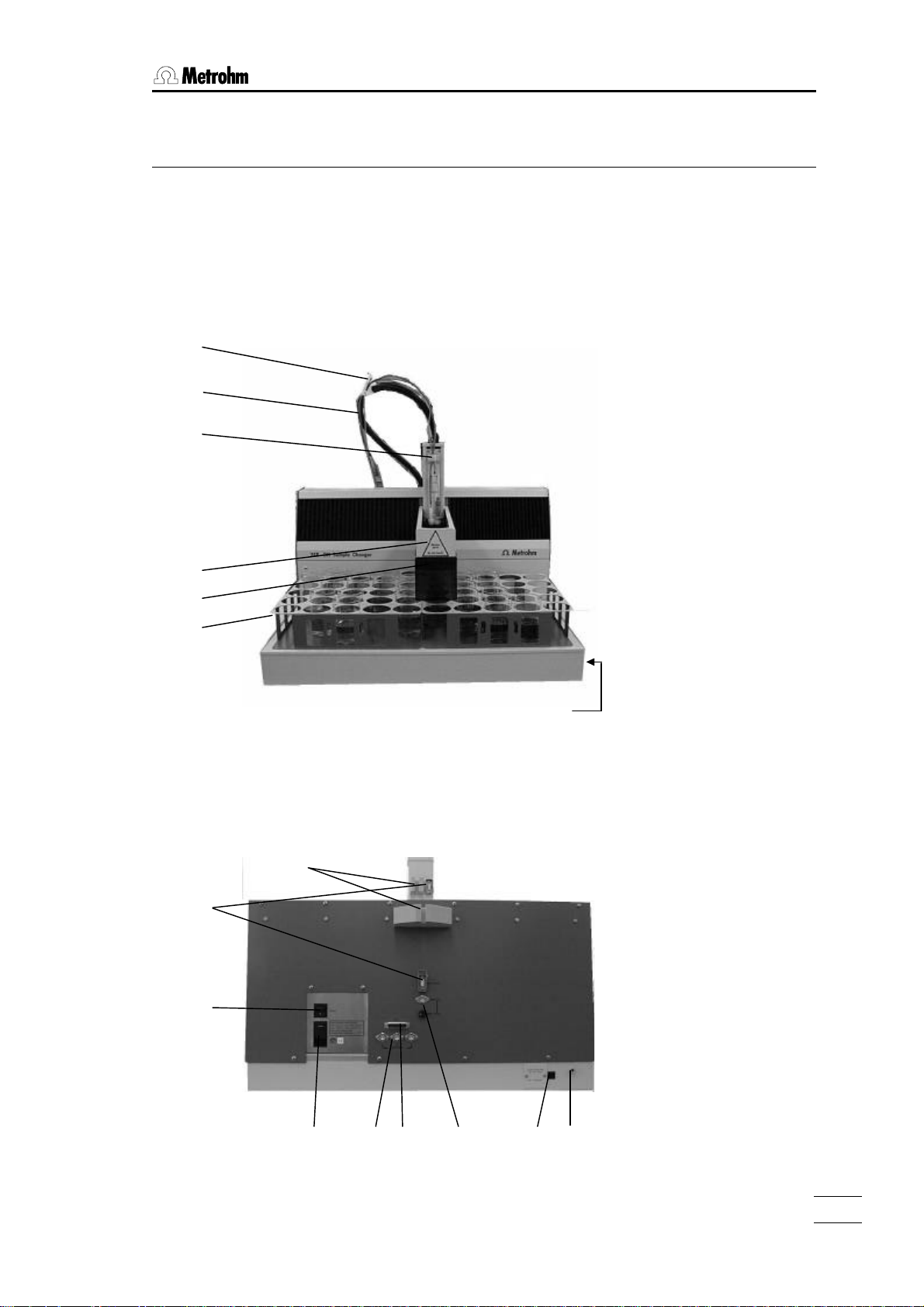

1.2 Overview

Y-

1.2 Sample arm positions

The sample arm is moved in both the XY-direction (rack positions) as

well as in the Z-direction.

1.2.1 Positions in the XY-direction

Left-hand rack Right-hand rack

1 Wash Soak Home

X-direction

direction

The sample arm is moved so that it only moves above samples which

have already been titrated (i.e. positions which have already been visited).

1.2.2 Positions in the Z-direction

The positions in the Z-direction are set in the TiNet configuration. They

are given in mm: measurements are made from the tower; the zero

point is 15 mm below the upper edge.

The positions in the Z-direction depend on both the type of rack used

and on the sample head fittings.

Working position

Position during titration/measurement.

The beaker detector should stand on the beaker rim.

Take care that electrodes, stirrer and buret tips are sufficiently immersed.

Rotation position, movement position

Position during the movement of the sample arm in the XY-direction.

Take care that electrodes, stirrer and buret tips are raised higher than

the beaker rims.

Rinsing position

Position during rinsing in the wash beaker.

Take care that electrodes, stirrer and buret tips are well located in the

rinsing spray of the wash beaker.

4

748 DH Sample Changer

Page 7

2.1 Mains voltage, mains connection

2 Sample changer start-up

2.1 Mains voltage, mains connection

Check that the voltage set on the instrument corresponds

to your mains voltage. If this is not the case then the mains

voltage must be altered:

1. Remove the mains cable.

2. Carefully open the compartment above the mains cable

with a screwdriver.

3. Remove the voltage selection drum.

4. If necessary change the fuse: remove the parts marked

with "⇒" and insert the fuses for the corresponding voltage which are given on the rear panel of the instrument.

5. Rotate the voltage selection drum so that the correct

voltage appears at the front (when the compartment is

closed this voltage will appear in the window).

6. Close the compartment again.

Set mains voltage for pump

1. Screw off the cover for the pump voltage setting (foldout page, position 15).

2. Adjust the tumbler switch so that your approximate

mains voltage appears:

220...240 V: switch display 230 V

100...120 V: switch display 115 V

3. Change the fuse if necessary.

4. Screw on the cover again so that the marking with the

set voltage is on the outside.

The mains cable supplied with the instrument is a 3-core

cable fitted with a plug with an earthing pin. If a different

plug must be used then the yellow/green lead must be

connected to the protective earth. Any break in the earthing

inside or outside the instrument can turn it into a hazard.

When the instrument is opened or if parts of it are removed

then certain components may be live if the instrument is still

connected to the mains. This means that the mains cable

must always be unplugged when certain adjustments are

made or when parts are replaced.

748 DH Sample Changer

The cable should only be plugged in and unplugged when

the instrument is switched off.

5

Page 8

2.2 Sample Changer setup

2.2 Sample Changer setup

2.2.1 Setting up the basic instrument

Attaching the

control cable:

Fastening the titration head,

sample arm from below:

Important:

Do not lift the sample changer by the sample arm.

Check the delivery immediately on receipt for completeness and transport damage.

Setup

1. Attach control cable to sample arm: insert the white

sleeve with the washer in the cable holder and screw

the holding ring tight (with 1.5 mm Allen key).

Insert cable and secure with clip.

2. Attach and insert the control cable on the rear panel

of the sample changer in the same way.

3. Clip 6.2053.010 cable clamps onto the control cable.

4. Remove splash protection: screw off the 2 sidemounted Phillips screws and carefully pull off plastic

panel.

5. Screw the titration head into the titration head holder

of the sample arm from below (3 mm Allen key)

6. Lead the beaker detector cable through the cable

holder and through the cable clamps to the rear panel

of the sample changer.

7. Connect the beaker detector cable to remote socket

"Auxiliary 1".

8. Reattach splash protection: set place plastic part in

position and screw on again.

6

748 DH Sample Changer

Page 9

2.2.2 Installation of rinsing accessories

1. Screw 6.1808.050 tubing nozzle for the rinsing tubing

onto the rear panel of the Sample Changer (fold-out

page, Position 16).

2. Attach the rinsing tubing (thin 6.1801.120 PVC tubing)

to the tubing nozzle. Use tubing clamps to attach

tubing firmly.

3. Pull the nut of the small opening of the canister over

the rinsing tubing.

4. Push the other end of the rinsing tubing onto

6.1828.000 connection nipple and screw it tight.

5. Push 6.1812.010 PTFE tubing onto the other end of

the connection nipple (heat up tubing end, hold tubing firmly with abrasive paper) and screw it tight.

6. Screw rinsing tubing onto the rinsing canister and fill

the rinsing canister with rinsing solution (water).

7. Push 6.1801.130 PVC tubing onto the right-hand side

of the Sample Changer (fold-out page, Position 7).

8. Attach other end of tubing to 6.1828.010 tubing nozzle.

9. Screw tubing nozzle onto the waste canister.

2.2 Sample Changer setup

Important

• The waste tubing must not sag.

• Do not seal the canister hermetically (pressure com-

pensation, backwater in the wash beaker!).

• Regularly check the filling levels of the rinsing and

waste canisters!

• The rinsing device is only suitable for use with aqueous solutions.

If you have to rinse with organic solvents then you can

clean the inserts by "immersion in a rinsing beaker".

748 DH Sample Changer

7

Page 10

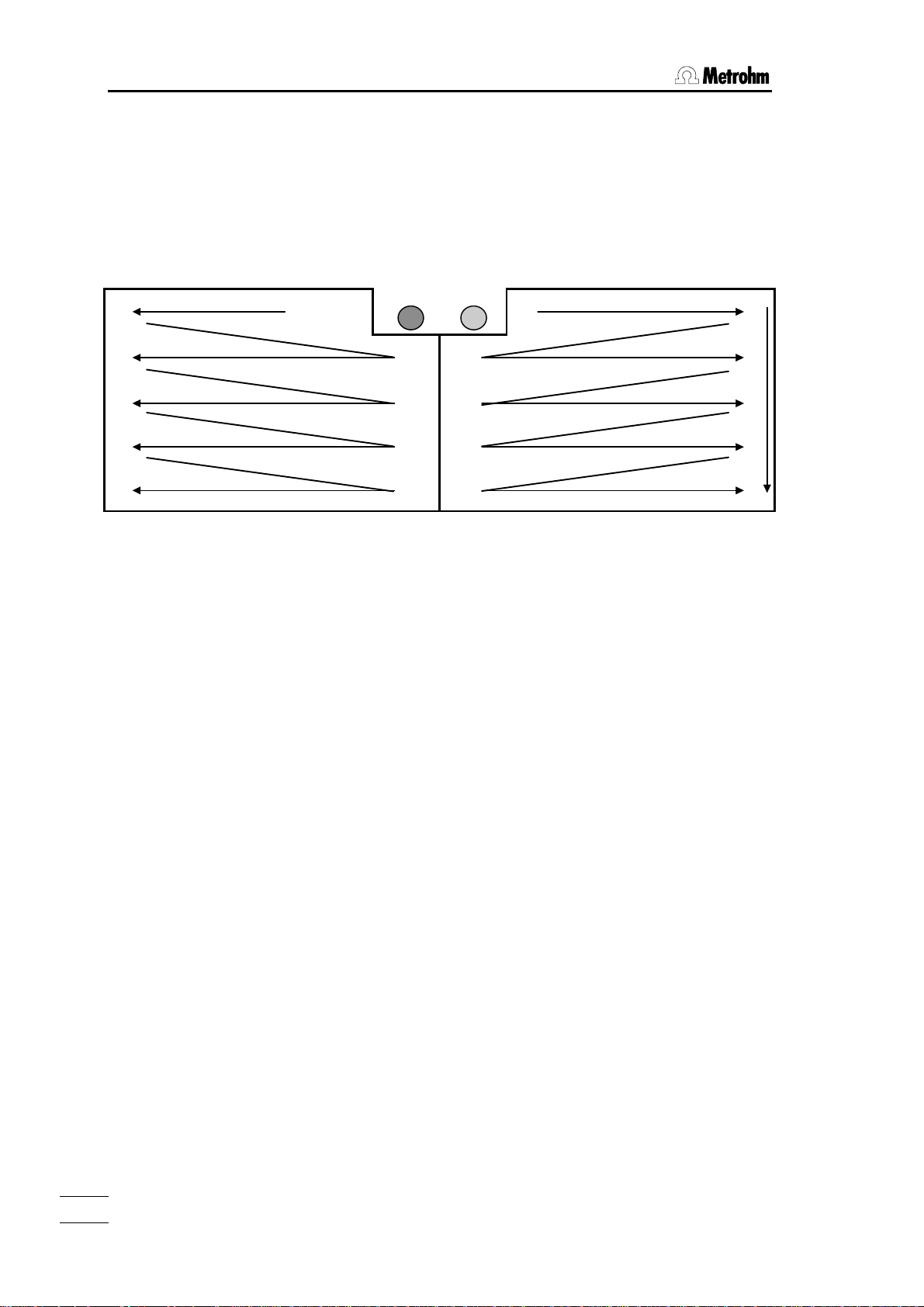

2.3 Equipping the titration head

titration head:

2.3 Equipping the titration head

6.1463.000 Macro

titration head:

Beaker detector

M10 screw threads for buret

tips

Stirrer

6.1463.010 Micro

Beaker detector

Stirrer

2.722.0020 Rod stirrer

1. Insert stirrer in titration head.

2. Lead stirrer cable through cable holder and through the

cable clamps to the rear panel of the Sample Changer.

3. Connect cable to stirrer socket "Mixer".

4. Push 6.1909.020 stirrer propeller onto the stirrer from

below.

5. The stirrer speed can be set with the rotary switch on the

rear panel of the Sample Changer.

Electrodes (see also page 27

6.1463.000 macro titration head: electrodes with SGJ 14/15

6.1463.010 micro titration head: micro electrodes, 6 mm di-

ameter.

1. Insert electrode into titration head.

2. Screw electrode cable (at least 2 m long) onto electrode

plug head and lead it through the cable holder and the

cable clamps to the rear panel of the Sample Changer.

3. Plug electrode cable into Titrator.

Buret tips

1. Insert buret tips into titration head and screw tight with

M10 screw threads.

2. Screw 6.1805.XXX tubing connection onto the buret tips.

3. Lead tubing through the tubing holder and the tubing

clamps to the rear panel of the Sample Changer.

4. Connect the other end of the tubing to the dosing unit

outlet. Use 6.1808.000 connection piece for connecting

to the dosing tubing if necessary.

Important

The cable and tubing should be led between the cable/tubing holder and the cable/tubing clamps in a curve so

Built-in buret tips

M10 screw threads for

electrodes or further buret

tips

that they are not subjected to stress when the titration head

is lowered!

Check length of cables and tubings as follows:

• Open Sample Changer window in the titration part of TiNet.

• Press button <Ctrl>.

• Move to "Home" position and lower the sample arm to

working position.

8

748 DH Sample Changer

Page 11

2.4 Sample racks

Place sample racks in position.

Place 6.1432.320 sample beaker in the soak position (see

page 4).

Use 6.2060.000 holders to carry the racks.

2.5 Sample Changer start up

Connect the RS232 interface of the Sample Changer with a

COM of the computer:

Cables:

25-pole / 9-pole, 3 m.............................................6.2125.110

25-pole / 25-pole, 3 m...........................................6.2125.060

Extension cable 25-pole / 25-pole, 3 m................ 6.2125.020

Extension cable 9-pole / 9-pole, 3 m.................... 6.2134.110

Start TiNet on the computer and configure the Sample

Changer; see TiNet Instructions for Use.

2.4 Sample racks

2.6 Adjusting Sample Changer

The offset settings for new instruments are determined by

Metrohm. Each Sample Changer is supplied with a document containing these data.

Entering the offset data in TiNet

1. Start the program "Iniedit.exe" from the TiNet bin directory.

2. Under "Various" you will find "Offset 748".

3. Enter the values for X and Y.

4. Press <Apply>.

5. Close the program "Iniedit.exe" and start TiNet (again).

748 DH Sample Changer

9

Page 12

Page 13

3 Operation via RS232 Interface

3.1 General rules

The DH Sample Changer has a remote control facility that allows its control

via TiNet. The parameters of the Sample Changer may be easily set by the

method editor of TiNet.

The following description offers special possibilities of low level control via

the transfer command of the calculation block of the TiNet method editor.

3.1.1 Tree of commands

The commands are hierarchically ordered with the following rules:

Rules Example

The root of the tree is designated by &.

The branches (levels) of a tree are marked with

a dot (.) when calling up an object.

3.1 General rules

Upper- or lowercase letters may be used. &STIRER.ON or &Stirer.On

An object can be assigned a value. Values are

marked at the beginning and end by quotes (").

They may contain ASCII characters or numerical values.

The current object remains valid until a new

object is called.

New objects can be addressed relative to the

old object:

A preceding dot leads forwards to the next level

in the tree.

More than one preceding dot leads one (or

several) level(s) backwards in the tree. n node

backwards require n+1 preceding dots.

If you want to jump back to the root, enter a

preceding &.

&Stirer.On"True"

&Init.SpeedXY"3"

&Stirer.On"True";..$G

Leads back from nod &Stirer.On to nod &Stirer

3.1.2 Triggers

$G Go Commands are executed with $G.

Example:

&Stirer.On"True" Sets command.

..$G Starts stirrer.

748 DH Sample Changer

11

Page 14

3.2 Remote control commands

3.2 Remote control commands

3.2.1 Overview

Object Description Input range Reference

& Root

à Stirer Stirrer control $G 3.2.2.1.

³ Ã .On Switching stirrer True, False ditto

³

à GoTo Go to position $G 3.2.2.2.

³ Ã .Vessel Designation of vessel special ditto

³

à GoAbove Go to position $G 3.2.2.3.

³ Ã .Vessel Designation of vessel special ditto

³

à GoIn Go into vessel $G 3.2.2.4.

³ Ã .Vessel Designation of vessel special ditto

³

à GoToHome Goes to home position $G 3.2.2.5.

³

à WashElectrodes Wash electrodes $G 3.2.2.6.

³ Ã .Times Number of wash cycles 1...9999 ditto

³

à SetCtrlLine Setting I/O line $G 3.2.2.7.

³ Ã .On Setting line True, False ditto

³ Ã .Line Selection of line 1...3 ditto

³

à WaitForInput Waiting for input on I/O line $G 3.2.2.8.

³ Ã .On Line state True, False ditto

³ Ã .Line Selection of line 1...3 ditto

³

à Init Setup of Sample Changer $G 3.2.2.9.

³ Ã .SpeedXY Speed in XY direction 0...5...7 ditto

³ Ã .SpeedXYFast Speed in XY direction 0...2...7 ditto

³ Ã .SpeedZ Speed in Z direction 0...3...7 ditto

³ Ã .SpeedZFast Speed in Z direction 0...7 ditto

³ Ã .SpeedZSlow Speed in Z direction 0...7 ditto

³

à StopAll Emergency stop $G 3.2.2.10.

³

à Assembly Basic assembly functions

³ Ã .GoToXYZ Go to postion $G 3.2.2.11.

³ ³ Ã .X X coordinate 0...630 ditto

³ ³ Ã .Y Y coordinate 0...272 ditto

³ ³ Ã .Z Z coordinate 0...120 ditto

³ ³ Ã .SpeedXY Speed in XY direction 0...3...7 ditto

³ ³ Ã .SpeedZ Speed in Z direction 0...3...7 ditto

³ Ã .PumpOn Switching on/off pump True, False, $G 3.2.2.12.

12

748 DH Sample Changer

Page 15

3.2 Remote control commands

3.2.2 Description of the remote control commands

3.2.2.1 Stirer $G

Stirer.On True, False

&Stirer.On"True";..$G Switching the stirrer on.

&Stirer.On"False";..$G Switching the stirrer off.

3.2.2.2 GoTo $G

GoTo.Vessel 1...XXX, Home, Soak, Wash

Makro command which moves to the predefined beaker using the speeds

from branch "Init" (see 3.2.2.9):

- Moves to shift position (set in TiNet configuration), SpeedZSlow

- Moves to beaker position, SpeedXY

- Moves to Z = 0 (as defined in the rack definition file

..\bin\PW74xDef\748*r.def of TiNet) position.

3.2.2.3 GoAbove $G

GoAbove.Vessel 1...XXX, Home, Soak, Wash

Makro command which moves to the predefined beaker (without dipping)

using the speeds from branch "Init" (see 3.2.2.9):

- Moves to shift position (set in TiNet configuration), SpeedZSlow

- Moves to beaker position, SpeedXY

748 DH Sample Changer

3.2.2.4 GoIn $G

GoIn.Vessel 1...XXX, Home, Soak, Wash

Makro command which moves to the lowest possible position in the predefined beaker using the speeds from branch "Init" (see 3.2.2.10):

- Moves to shift position (set in TiNet configuration), SpeedZSlow

- Moves to beaker position, SpeedXY

- Moves to lowest possible Z position, Zmax. (defined in the corresponding

rack definition file), SpeedZ

3.2.2.5 GoToHome $G

Makro command which moves to home position, readjusting the Sample

Changer and using the speeds from branch "Init" (see 3.2.2.9):

3.2.2.6 WashElectrodes $G

WashElectrodes.Times 1...9999

Makro command which moves to wash position position, washes the electrodes and uses the speeds from branch "Init" (see 3.2.2.9):

- Moves up to Z=0, SpeedZ

- Moves to wash position, SpeedXY

- Moves down to wash position, SpeedZ

- Switches pump on

- Moves down to lowest possible position Zmax, SpeedZSlow

- Switches pump off

13

Page 16

3.2 Remote control commands

Ø

- Stirrs during 3 s

- Moves up to Z=0, SpeedZFast

.Times: The number of washing cycles can be set. If the number is >1, the

following additional steps will be carried out (n times); the repetitive steps beginning at the marked position Ø in the sequence:

- Moves up to Z=0, SpeedZFast

- Switches pump on

- Moves down to Zmax., Speed Zslow

- Switches pump off

3.2.2.7 SetCtrlLine $G

A remote control line can be set. Select socket 1...3 and set line as follows:

&SetCtrlLine.On"True";..$G Sets an active line (0 V), see also page 20.

&SetCtrlLine.On"False";..$G Sets the line to inactive (5 V)

The beaker sensor is normally plugged into socket 1.

SetCtrlLine.On True, False

SetCtrlLine.Line 1...3

3.2.2.8 WaitForInput $G

WaitForInput.On True, False

WaitForInput.Line 1...3

The Sample Changer waits for an active line (with WaitForInput.ON"True") or

for an inactive line (with WaitForInput.ON"False"). No other commands are

worked off during this waiting time.

3.2.2.9 Init $G

Init.SpeedXY 0...5...7

Init.SpeedXYFast 0...2...7

Init.SpeedZ 0...3...7

Init.SpeedZFast 0...7

Init.SpeedZSlow 0...7

Sets the global speeds for all makro commands of the Sample Changer. A

small number means a high speed, i.e. 0 is the highest possible speed.

The speeds are only set if the init movement is carried out (command &Init

$G).

&Init $G moves to home position and Z=0.

3.2.2.10 StopAll $G

Emergency stop. Stops all commands immediatelay. May be used e.g. to set

remote control lines to inactive, or to stop stirrer or pump.

14

748 DH Sample Changer

Page 17

3.2 Remote control commands

3.2.2.11 Assembly.GoToXYZ $G

Assembly.GoToXYZ.X 0...630

Assembly.GoToXYZ.Y 0...272

Assembly.GoToXYZ.Z 0...120

Assembly.GoToXYZ.SpeedXY 0...3...7

Assembly.GoToXYZ.SpeedZ 0...3...7

Moves to the predefined position. The above speeds are only valid for Assembly commands.

The extreme positions which are still in the moving range of the Sample

Changer are given in the corresponding rack definition file

(..\bin\PW74xDef\748*r.def of your TiNet program).

You may enter higher valuesfor X, Y, and Z but the Sample Changer has to be

reinitialized after being moved to a position out of ist moving range.

3.2.2.12 Assembly.PumpOn True, False, $G

&Assembly.Pump"True";$G Switching the pump on.

&Assembly.Pump"False";$G Switching the pump off.

748 DH Sample Changer

15

Page 18

3.3 Properties of the RS 232 Interface

3.3 Properties of the RS 232 Interface

The DH Sample Changer is configured as DTE (Data Terminal Equipment).

The RS 232 interface has the following technical specifications:

• Data interface according to the RS 232C standard

• RS232 parameters: 9600 baud

8 data bit

1 stop bit

no parity

SW handshake

• Control characters: C

• Cables 6.2125.060 25/25 pol

(ASCII DEC 13)

R

LF (ASCII DEC 10)

XON (ASCII DEC 17)

XOFF (ASCII DEC 19)

6.2125.110 25/9 pol

length: max. approx. 15 m

16

748 DH Sample Changer

Page 19

4.1 Troubleshooting

4 Troubleshooting, remedying faults

4.1 Troubleshooting

Problem Possible causes and remedies

Beaker detector does not respond

although no beaker is present.

Rack does not fit on Sample Changer. Loosen wash beaker from below the Sample

Rinsing solution does not enter the wash

beaker.

Rinsing solution is not discharged. • Waste tubing must not sag!

Sample arm contacts left or right side. Readjust Sample Changer, see page 19.

Stirrer does not rotate. • Increase stirrer speed. Turn

• Activate beaker detector in program part

"Configuration" of TiNet.

• Is the beaker detector correctly plugged into

the "Auxiliary 1" socket?

Changer, set rack onto Sample Changer and

screw wash beaker back in position.

• The rinsing canister must be open.

• Is the aspiration tubing sufficiently immersed

in the rinsing canister?

• Are all tubing connections tight?

• The waste canister must be open.

counterclockwise until maximum stirrer

speed is reached.

• Try switching on the stirrer in the Sample

Changer window of TiNet, program part

"Titration". If the stirrer rotates then it is

possible that your method does not contain

the command to switch the stirrer on.

• Is the stirrer connected correctly to the

"Mixer" socket?

748 DH Sample Changer

17

Page 20

4.2 TiNet error messages

4.2 TiNet error messages

Problem Possible causes and remedies

Invalid head position selected. A rack position has been selected which is not

contained in the rack definition file.

• Check the selected position.

• Have you selected the correct rack in the

TiNet configuration?

Selected command can't be executed. General communication problem. Exchange

the cable.

There is no beaker. (Position: X) In the TiNet configuration the beaker test is set

to "Display" and no beaker is present in the

given position.

Set the beaker test to "Move" if you want to

move to the next beaker automatically or to

"OFF" if you want to switch off the beaker test.

There is no reply from the Sample

Changer.

Transfer error: the target device cannot

receive data.

Communication interrupted?

• Try to initialize the Sample Changer with the

menu item "Commands, Initialize

instruments" in the titration part of TiNet.

• Reboot computer.

• Switch Sample Changer off/on, make sure

cable is well plugged in and try to initialize

again.

• Does the green lamp light up? If not, check

whether the mains cable is plugged in

correctly. If everything seems to be OK,

change the power supply fuses, see page 5.

• If the green lamp lights up and everything

appears to be OK then change the pump

fuse, see page 5.

• Exchange cable.

Errors if transfer commands from the

calculation block in the method editor are

used:

• Wrong path, value and/or trigger.

• Communication interrupted.

18

748 DH Sample Changer

Page 21

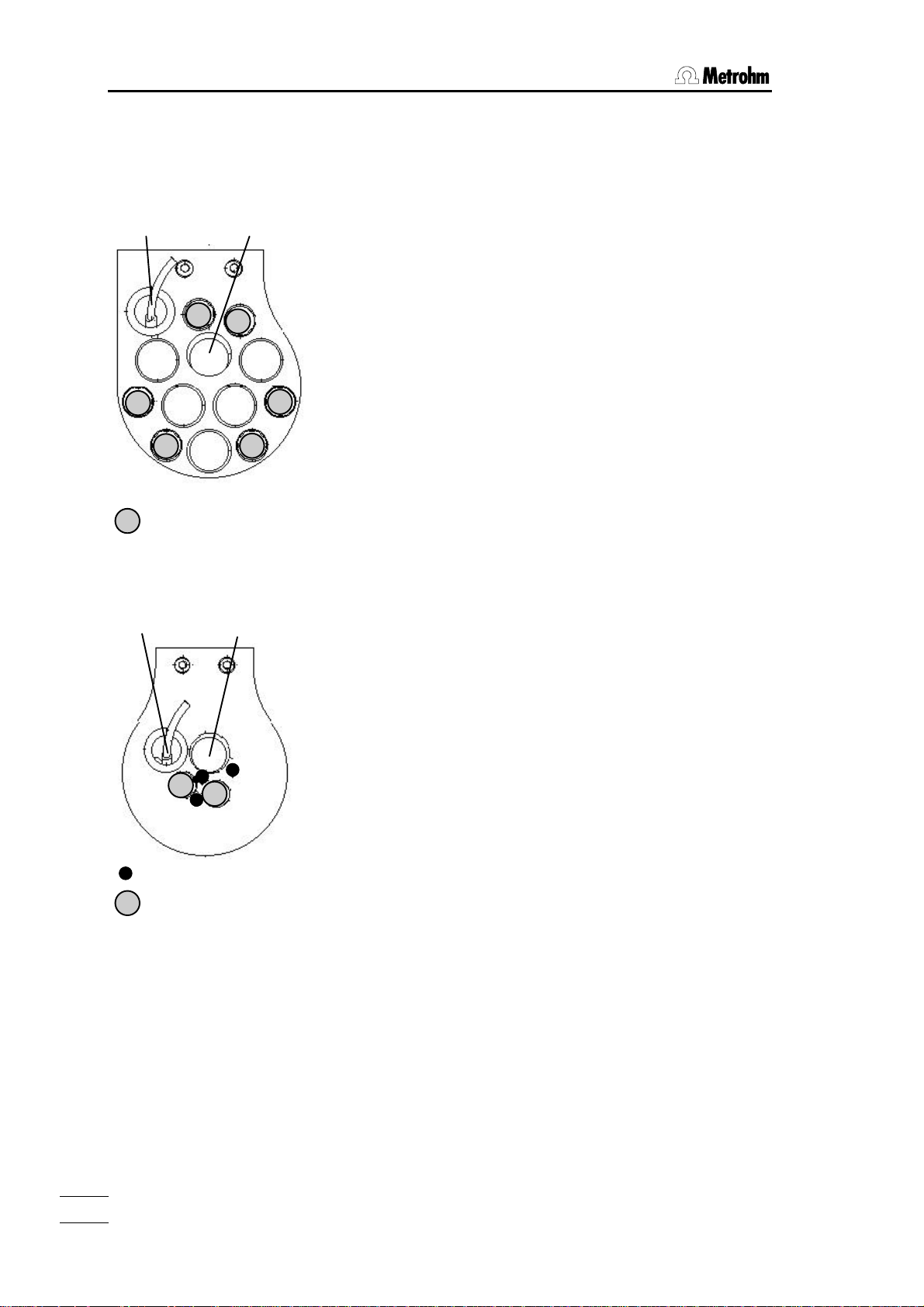

4.3 Readjust Sample Changer

4.3 Readjust Sample Changer

Sample arm from below

with position guide:

Centering ring over rack

bolt:

1. Load the test software from the Internet:

http://www.metrohm.ch

2. Remove the sample racks from the Sample Changer.

3. Install 6.2625.000 position guide on the sample arm instead of the titration head.

4. Place the centering ring over the right-hand side rack

bolt.

5. Start the test software which you have loaded from the

Internet and follow the instructions which you will also

find there.

748 DH Sample Changer

19

Page 22

5.1 Technical specifications

5 Appendix

5.1 Technical specifications

Lift

Max. lift way 146 mm

Max. load 500 g

Sample position precision ± 2 mm

Sample racks 48 beaker, 250 mL

136 beaker, 75 mL

Material Light metal, powder coated

Pump

Capacity 0.33 L/min

Fuse for 100...120 V: T1.25A

for 220...240 V: T630mA L

Housing Al (antichromed) and stainless steel, powder coated

RS232 interface for PC connection

Input/output lines for beaker sensor and any other devices

Ambient temperature

Nom. operation range 0 ... 45 °C

Storage, transport – 25 ... 60 °C

Safety specifications

Designed and tested in accordance to IEC publication

1010-1, safety class I. This manual contains information

and warnings which have to be followed by the user to ensure safe operation and to retain the apparatus in safe

condition.

Mains connection

Voltage 100, 120, 220, 240 V ± 10 % (switchable)

Frequency 50 ... 60 Hz

Power consumption max. 190 VA

Fuses (2) for 100...120 V: T2A/120V

for 220...240 V: T1A/250V

Dimensions

Width 750 mm

Height 750 mm

Depth 600 mm

Weight, incl. accessories ca. 35.5kg

20

748 DH Sample Changer

Page 23

5.2 Sample Changer methods

Methods for TiNet and working with the 748 DH Sample Changer are

available at http://www.metrohm.ch

5.2 Sample Changer methods

748 DH Sample Changer

21

Page 24

5.3 Pin assignment of I/O sockets "Auxiliary"

5.3 Pin assignment of I/O sockets "Auxiliary"

external Function

Input

Output

Ground

0 V

+5 V

pin 2

pin 1 1 A

50 V

non-inductive

0 V

pin 5

22

5-pin DIN plug

No liability whatsoever will be accepted for damage caused by improper interconnection of instruments.

748 DH Sample Changer

Page 25

5.4 Warranty and certificates

5.4.1 Warranty

The warranty regarding our products is limited to rectification free of

charge in our workshops of defects that can be proved to be due to

material, design or manufacturing faults which appear within 12

months from the day of delivery. Transport costs are chargeable to

the purchaser.

For day and night operation, the warranty is valid for 6 months.

Glass breakage in the case of electrodes or other glass parts is not

covered by the warranty. Checks which are not a result of material or

manufacturing faults are also charged during the warranty period.

For parts of outside manufacture insofar as these constitute an appreciable part of our instrument, the warranty stipulations of the

manufacturer in question apply.

With regard to the guarantee of accuracy, the technical specifications in the Instructions for Use are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the purchaser has no rights or

claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment

or if the goods show signs of transport damage after unpacking, the

carrier must be informed immediately and a written damage report

demanded. Lack of an official damage report releases METROHM

from any liability to pay compensation.

If any instruments and parts have to be returned, the original packaging should be used if at all possible. This applies above all to instruments, electrodes, buret cylinders and PTFE pistons. Before

embedding in wood shavings or similar material, the parts must be

packed in a dustproof package (for instruments, use of a plastic bag

is imperative). If open assemblies are enclosed in the scope of delivery that are sensitive to electromagnetic voltages (e.g. data interfaces etc.) these must be returned in the associated original protective packaging (e.g. conductive protective bag). (Exception: assemblies with built-in voltage source belong in a non-conductive protective packaging). For damage which arises as a result of noncompliance with these instructions, no warranty responsibility whatsoever will be accepted by METROHM.

5.4 Warranty and certificates

748 DH Sample Changer

23

Page 26

5.4 Warranty and certificates

5.4.2 Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for

electrical appliances and accessories, as well as to the standard

specifications for security and to system validation issued by the

manufacturing company.

Name of commodity: 748 DH Sample Changer

System software: Stored in ROMs

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

This Metrohm instrument has been built and has undergone final type testing according to the standards:

Electromagnetic compatibility: Emission

EN50081-1/92, EN55022/class B,

EN55011/class B Generic emission

Electromagnetic compatibility: Immunity

IEC801-2/91, Static discharge

IEC801-3, IEC1000-4-3 Radiated rf electromag.field immunity

EN61000-3-2/95 Harmonic current

Security specifications

IEC1010 class1, EN61010 class1, UL3101-1

The technical specifications are documented in the instruction manual.

The system software, stored in Read Only Memories (ROMs) has

been validated in connection with standard operating procedures in

respect to functionality and performance.

The features of the system software are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS certificate of the quality system

ISO 9001 for quality assurance in design/development, production,

installation and servicing.

Herisau, October 14, 1998

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

24

748 DH Sample Changer

Page 27

5.4 Warranty and certificates

Ionenanalytik • Analyse des ions • Ion analysis • Análisis iónico

748 DH Sample Changer

EU Declaration of Conformity

The company Metrohm AG, Herisau, Switzerland, certifies herewith, that the following

instrument:

748 DH Sample Changer

meets the CE mark requirements of EU Directives 89/336/EWG and 72/23/EWG.

Source of specifications:

EN 50081-1 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control

equipment

Description of apparatus:

X,Y,Z Sample Changer with built-in rinsing pump, controlled by a PC via the RS232

interface.

Herisau, October 14, 1998

748 DH Sample Changer

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance

25

Page 28

5.5 Scope of delivery, accessories

5.5 Scope of delivery, accessories

748 DH Sample Changer.............................................................................2.748.0010

including the following accessories:

1 Sample beaker, glass, 250 mL........................................................................... 6.1432.320

2 PE containers, 10 L ............................................................................................. 6.1621.000

1 PVC tubing 4/6, 2m ............................................................................................. 6.1801.120

1 PVC tubing 8/12, 2m........................................................................................... 6.1801.130

1 Tubing nozzle/outer M8 thread........................................................................... 6.1808.050

1 PTFE tubing, 4/6, 45 cm ..................................................................................... 6.1812.010

1 Connecting nipple for container .........................................................................6.1828.000

1 Tubing nozzle for container ................................................................................ 6.1828.010

3 Cable/tubing clamps........................................................................................... 6.2053.010

1 Set rack holders (2 items)................................................................................... 6.2060.000

1 Position adjustment tool ..................................................................................... 6.2625.000

1 Mains cable with cable socket type CEE(22), V

Cable plug to customer's specifications

Type SEV 12 (Switzerland...)............................................................................. 6.2122.020

Type CEE(7), VII (Germany...)........................................................................... 6.2122.040

Type NEMA/ASA (USA...).................................................................................. 6.2122.070

1 Instructions for Use for 748 DH Sample Changer.............................................. 8.748.1003

26

748 DH Sample Changer

Page 29

5.5 Scope of delivery, accessories

Options

Accessories to separate order and on payment of extra charge:

Titration heads, stirrer, buret tips

Macro titration head for 250 mL beakers...............................................................6.1463.000

Micro titration head for 75 mL beakers.................................................................. 6.1463.010

Rod stirrer, PP......................................................................................................... 2.722.0020

Nipple with M10 thread .......................................................................................... 4.658.0180

O-ring for nipple with M10 thread ..........................................................................E.301.0083

Tubing for buret tips

80 cm ............................................................................................................... 6.1805.110

150 cm ............................................................................................................... 6.1805.030

200 cm ............................................................................................................... 6.1805.530

Coupling bush for tubing with M6 threads ............................................................ 6.1808.000

Ball stopper for buret tips in SGJ 14/15................................................................. 6.1446.030

Electrodes

Electrode cable, G head, F plug, 2 m.................................................................... 6.2104.030

Electrode cable, G head, F plug, 3 m.................................................................... 6.2104.040

For 6.1463.000 titration head:

Combined pH glass electrode............................................................................... 6.0232.100

Ag Titrode ...............................................................................................................6.0430.100

Pt Titrode................................................................................................................. 6.0431.100

SGJ sleeve for electrodes without glass SGJ .......................................................6.1236.020

For 6.1463.010 titration head:

Combined micro pH glass electrode..................................................................... 6.0234.110

Micro Ag Titrode ..................................................................................................... 6.0433.110

Micro Pt Titrode ......................................................................................................6.0434.110

Please refer to Metrohm's Electrode Catalog for more information

Sample racks

Sample rack for 24 x 250 mL beakers, left ............................................................ 6.2041.540

Sample rack for 24 x 250 mL beakers, right.......................................................... 6.2041.560

Foil holder for rack with 250 mL beakers, left........................................................ 6.2041.550

Foil holder for rack with 250 mL beakers, right ..................................................... 6.2041.570

PE foil for rack with 250 mL beakers, 20 items .....................................................6.2749.080

Sample rack for 68 x 75 mL beakers, left .............................................................. 6.2041.620

Sample rack for 68 x 75 mL beakers, right............................................................ 6.2041.640

Foil holder for rack with 75 mL beakers, left.......................................................... 6.2041.630

Foil holder for rack with 75 mL beakers, right .......................................................6.2041.650

PE foil for rack with 75 mL beakers, 20 items .......................................................6.2749.090

Special racks on request

748 DH Sample Changer

27

Page 30

5.5 Scope of delivery, accessories

Beakers

Sample beaker, 250 mL, glass.............................................................................. 6.1432.320

Sample beaker, 200 mL, PP .................................................................................. 6.1453.220

Sample beaker, 250 mL, PP .................................................................................. 6.1453.250

Sample beaker, 75 mL, glass ................................................................................ 6.1432.210

PC connection

Cable 748 DH Sample Changer — PC (25/9 pins), 3 m ......................................6.2125.110

Cable 748 DH Sample Changer — PC (25/25 pins), 3 m ....................................6.2125.060

RS232 C extension cable (25/25 pins), 3 m.......................................................... 6.2125.020

RS232 C extension cable (9/9 pins), 3 m.............................................................. 6.2134.110

TiNet, program for titration control......................................................................... 6.6012.130

Various items

Cable 748 DH Sample Changer, Remote — Dosimat ......................................... 6.2121.020

28

748 DH Sample Changer

Page 31

Index

Page numbers in the green part are in italics. Page no. + ff means “and following pages“.

Index

A

Accessories................................................26

Adjustment .............................................9, 19

Appendix ..................................................20ff

Auxiliary, pin occupancy ............................22

Auxiliary socket...........................................22

B

Beaker detector........................................6, 8

Buret tips ................................................8, 27

C

Cables ........................................................28

CE-marks....................................................25

Certificates..................................................24

Comparative data...................................9, 19

Computer connection.............................9, 28

Computer connection.............................9, 28

Cover for sample racks ..............................27

E

Electrodes ..................................................27

Error messages from TiNet ........................18

F

Faults........................................................17ff

Foil for sample racks..................................27

Fuses............................................................5

G

Guarantee...................................................23

H

Home position ..............................................4

I

I/O leads, pin occupancy...........................22

ISO..............................................................24

M

Mains

cables....................................................26

connection ..............................................3

voltage.....................................................5

Movement position.......................................4

O

Offset data ............................................. 9, 19

Operation .....................................................9

Ordering designations ............................... 26

Overview....................................................... 2

P

Power

cables ................................................... 26

connection.............................................. 3

voltage .................................................... 5

Problems.................................................. 17ff

Pump, voltage adjustment........................... 5

R

Racks .....................................................9, 27

Rinsing position ........................................... 4

Rinsing ......................................................... 7

Rod stirrer................................................... 27

Rotating position.......................................... 4

RS232 interface.......................................... 16

RS232....................................................... 11ff

S

Sample beaker........................................... 28

Sample changer methods .........................21

Sample changer setup................................. 6

Sample positions .........................................4

Sample racks ......................................... 9, 27

Scope of supply......................................... 26

Setup.......................................................... 6ff

Soak position ...............................................4

Stirrer connection......................................... 3

Stirrer...................................................... 8, 27

T

Technical data............................................ 20

Titration head ............................................27

equipping................................................ 8

Transfer .................................................... 11ff

Tree ............................................................ 12

Troubleshooting......................................... 17

Tubing ........................................................ 27

748 DH Sample Changer

29

Page 32

Index

W

Warranty ..................................................... 23

Wash position............................................... 4

Washing .......................................................7

Waste canister.............................................. 7

Working position ..........................................4

XY

XY direction .................................................. 4

Z

Z direction ....................................................4

30

748 DH Sample Changer

Loading...

Loading...