Page 1

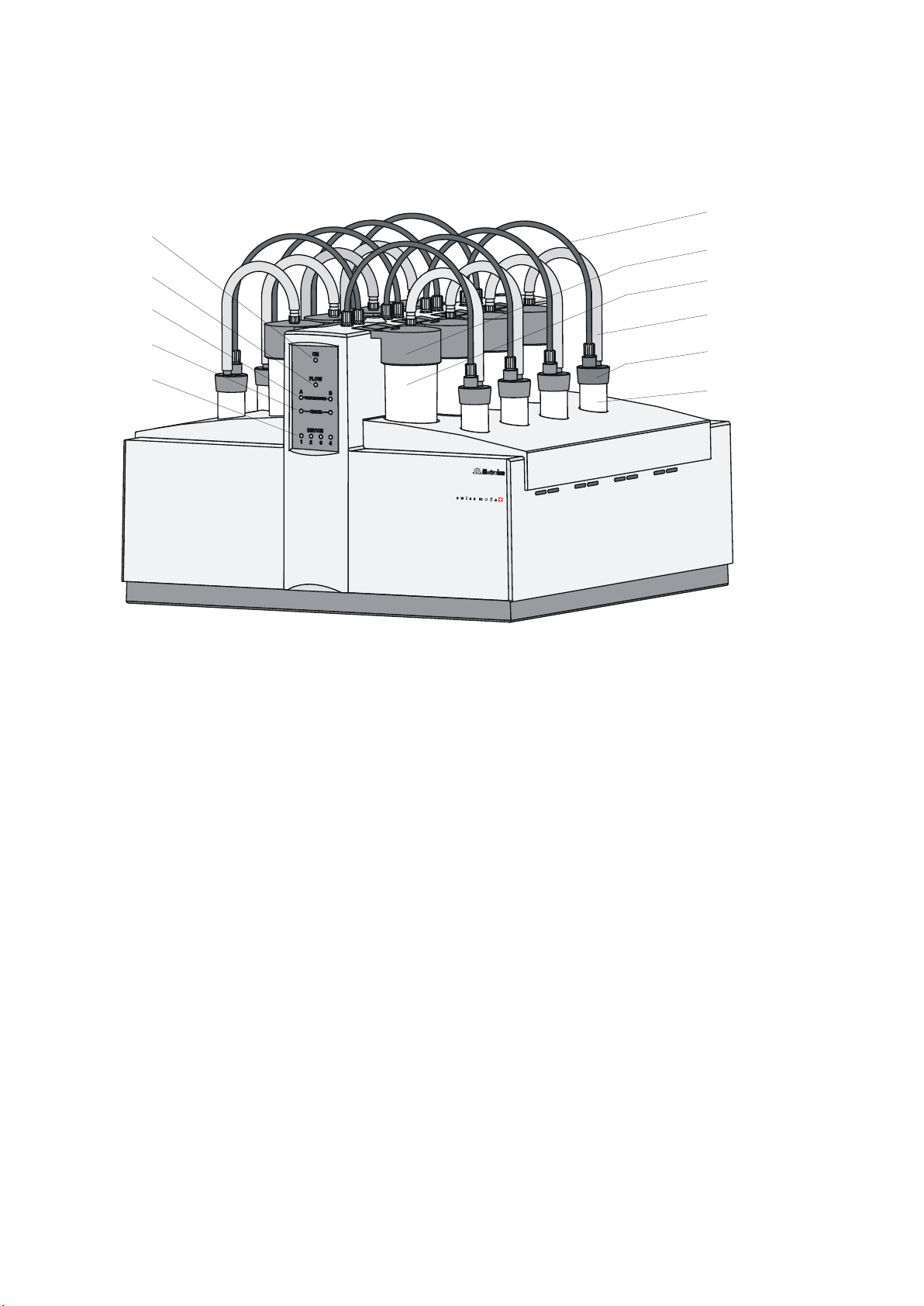

743 Rancimat

Manual

8.743.8003EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

743 Rancimat

Manual

8.743.8003EN 03.2009 jb/ars

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Rancimat method ................................................................. 2

1.3 About the documentation ................................................... 3

1.3.1 Symbols and conventions ........................................................ 3

1.4 Safety instructions ................................................................ 4

1.4.1 General notes on safety ........................................................... 4

1.4.2 Electrical safety ........................................................................ 5

1.4.3 Flammable solvents and chemicals ........................................... 6

1.4.4 Recycling and disposal ............................................................. 6

2 Overview of the instrument 7

3 Installation 10

Table of contents

3.1 Setting up the instrument .................................................. 10

3.1.1 Packaging .............................................................................. 10

3.1.2 Checks .................................................................................. 10

3.1.3 Location ................................................................................ 10

3.2 Mounting accessories ......................................................... 10

3.2.1 Mounting accessories for the internal air supply ..................... 10

3.2.2 Mounting accessories for the external air supply .................... 13

3.2.3 Equipping the reaction and measuring vessels ........................ 13

3.2.4 Inserting vessels / Establishing tubing connections ................. 16

3.2.5 Mounting the exhaust collection tube (optional accessories) .. 17

3.3 Mains connection ............................................................... 18

3.3.1 Checking the mains voltage ................................................... 18

3.3.2 Replacing fuses ...................................................................... 18

3.3.3 Mains cable and mains connection ........................................ 19

3.3.4 Switching the instrument on/off ............................................ 19

3.4 Connecting a PC ................................................................. 19

3.4.1 Connecting the 743 Rancimat and the PC .............................. 19

3.4.2 Installing the software ........................................................... 20

3.4.3 Carrying out basic settings ..................................................... 22

4 Operation 24

743 Rancimat

4.1 Fundamentals of operation ............................................... 24

4.1.1 Starting and exiting the program ........................................... 24

4.1.2 Terms .................................................................................... 25

4.1.3 Control window .................................................................... 25

4.1.4 Results window ..................................................................... 27

4.1.5 File types ............................................................................... 30

4.1.6 Context-sensitive menus ........................................................ 31

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.1.7 Mouse functions .................................................................... 31

4.1.8 Help ...................................................................................... 32

4.2 Instrument and Program Settings ..................................... 33

4.2.1 Establishing the instrument communication ........................... 33

4.2.2 Managing access rights ......................................................... 34

4.2.3 Timer ..................................................................................... 37

4.2.4 Gas flow control .................................................................... 39

4.2.5 Recording the temperature .................................................... 40

4.2.6 Optimizing program and database ......................................... 41

4.3 Program information ......................................................... 42

4.3.1 Instrument information .......................................................... 42

4.3.2 Status overview ..................................................................... 44

4.3.3 Displaying, filtering and deleting event overview .................... 45

4.4 Calibration functions .......................................................... 48

4.4.1 Determining cell constants ..................................................... 48

4.4.2 Determining Delta T .............................................................. 50

4.5 Methods .............................................................................. 55

4.5.1 Managing methods ............................................................... 55

4.5.2 Parameter description ............................................................ 60

4.6 Determinations ................................................................... 75

4.6.1 Preparing samples ................................................................. 76

4.6.2 Preparing the instrument and the accessories ......................... 79

4.6.3 Preparing the determination .................................................. 81

4.6.4 Starting the determination ..................................................... 83

4.6.5 Cleaning the instrument and accessories ................................ 83

4.6.6 Adjusting the method parameters during the determination .. 84

4.6.7 Stopping the determination manually .................................... 85

4.6.8 Status of the live curve ........................................................... 86

4.7 Results ................................................................................. 87

4.7.1 Determination overview ......................................................... 87

4.7.2 Determination and method data .......................................... 103

4.7.3 Graph and reevaluation ....................................................... 112

4.7.4 Extrapolation ....................................................................... 117

4.7.5 Recalculating a determination .............................................. 121

4.7.6 Printing and exporting data ................................................. 128

4.7.7 Program settings ................................................................. 135

4.7.8 Arranging windows ............................................................. 141

4.8 GLP functions .................................................................... 142

4.8.1 General information on GLP and validation .......................... 142

4.8.2 GLP monitoring ................................................................... 142

4.8.3 GLP status ........................................................................... 144

4.8.4 Carrying out GLP tests ......................................................... 145

4.8.5 GLP results .......................................................................... 156

■■■■■■■■

IV

743 Rancimat

Page 7

■■■■■■■■■■■■■■■■■■■■■■

5 Handling and maintenance 160

6 Troubleshooting 164

7 Technical specifications 170

Table of contents

5.1 General information ......................................................... 160

5.1.1 Care .................................................................................... 160

5.1.2 Maintenance by Metrohm Service ........................................ 160

5.2 Replacing the dust filter .................................................. 161

5.3 Regenerating or replacing the molecular sieve ............. 161

5.4 Self test when switching on ............................................ 162

5.5 Quality Management and validation with Metrohm .... 163

6.1 Problems ........................................................................... 164

7.1 General data ..................................................................... 170

7.2 Temperature regulation and measurement ................... 170

7.3 Conductivity measurement .............................................. 171

7.4 Gas flow regulation .......................................................... 171

7.5 GLP test set ....................................................................... 172

7.6 RS-232 interface ............................................................... 172

7.7 Mains connection ............................................................. 172

7.8 Safety specification .......................................................... 173

7.9 Electromagnetic compatibility (EMC) ............................. 173

7.10 Ambient temperature ...................................................... 173

7.11 Housing ............................................................................. 174

8 Conformity and warranty 175

8.1 Declaration of Conformity ............................................... 175

8.2 Quality Management Principles ...................................... 176

8.3 Warranty (guarantee) ....................................................... 177

9 Accessories 178

9.1 Scope of delivery .............................................................. 178

9.2 Optional accessories ........................................................ 185

743 Rancimat

Index 188

■■■■■■■■

V

Page 8

Table of figures

Table of figures

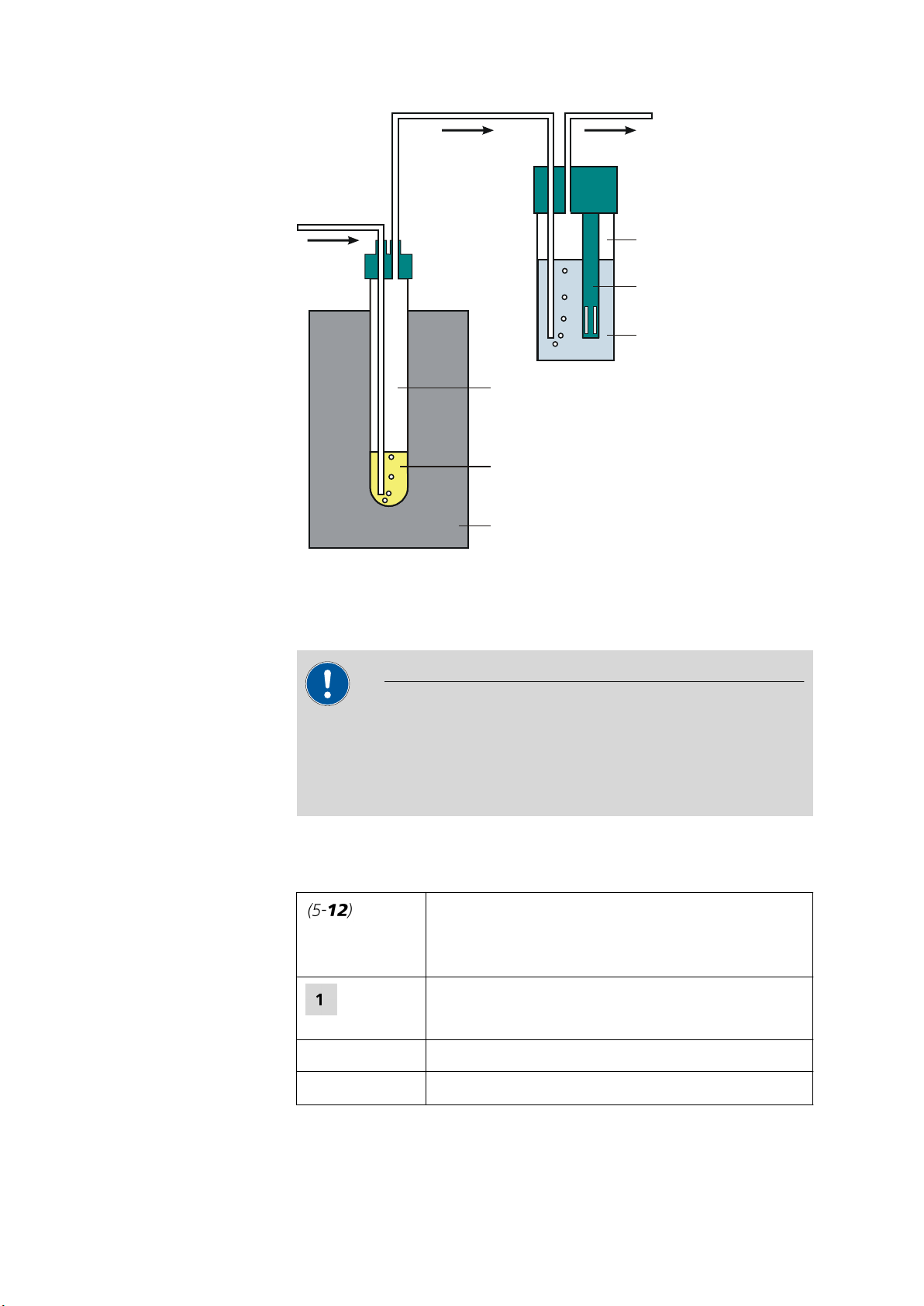

Figure 1 Measuring arrangement (schematic representation) ........................... 3

Figure 2 Front 743 Rancimat ........................................................................... 7

Figure 3 Rear 743 Rancimat ............................................................................ 8

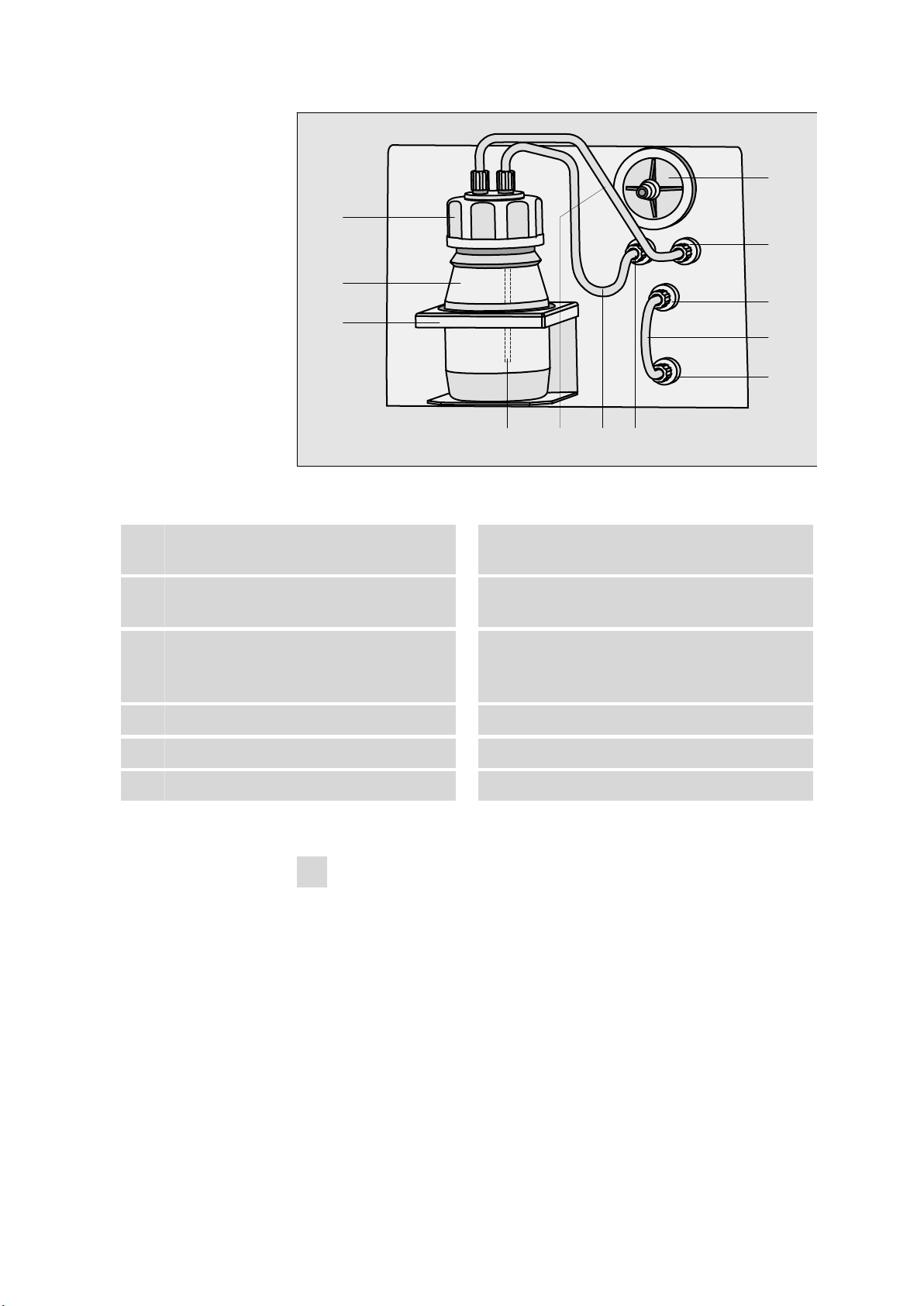

Figure 4 Mounting accessories for the air supply (rear of the instrument) ...... 11

Figure 5 Equipping the reaction and measuring vessels ................................. 14

Figure 6 Equipping the reaction vessel for determining Delta T ...................... 51

Figure 7 Accessories for GLP test Temperature ............................................ 145

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

VI

743 Rancimat

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 743 Rancimat is a PC-controlled measuring device for determining the

oxidation stability of samples containing oil and fat.

It is equipped with two heating blocks each with 4 measuring positions

(channels). Every block can be heated individually, i.e. 4 samples can each

be measured at 2 different temperatures or 8 samples at the same temperature. The measurements at the individual measuring positions can be

started individually for this.

Operation of the 743 Rancimat is realized completely via a PC connected

to the RS-232 interface using the control and evaluation program 743

Rancimat. Up to 4 instruments can be connected to each PC, hence

allowing a maximum of 32 samples to be analyzed. The evaluation algorithm of the PC program determines the break point of the Rancimat

curve fully automatically and hence the induction time. Besides the induc-

tion time, the so-called stability time, i.e. the time duration until attaining a defined conductivity change, can also be determined. In the case of

conductivity changes (stages) which do not have anything to do with the

autoxidation, the evaluation can be interrupted for definite time intervals.

The results determined can be processed further by computer. In particular, the induction times can be converted to the default temperatures of

the corresponding standards.

1 Introduction

Each Rancimat curve can also be evaluated manually. A PC-supported

tangential method is available for this, in which you can position the tangents anywhere on your curves. This makes evaluations possible in

extreme cases as well.

The results of the determinations are saved in a database together with

all methods and determination data. Determinations can be searched for,

sorted, filtered, exported and printed in the program part for the results

display. Besides the graphic display of single and multiple curves, recalculation with altered parameters and extrapolation of the results to a definite temperature is also possible.

GLP (Good Laboratory Practice) and instrument validation are becoming

increasingly important. The 743 Rancimat enables GLP tests for temperature, conductivity and gas flow measurement. You determine whether

and which tests have to be carried out. You can also specify the time

interval between the tests as well as the requirements regarding accuracy.

If the GLP function has been selected, each result report will receive a

comment stating whether the GLP tests have been fulfilled. Metrohm

743 Rancimat

■■■■■■■■

1

Page 10

1.2 Rancimat method

offers a GLP test set to carry out these tests (see Optional accessories,

page 185).

1.2 Rancimat method

The decay of vegetable and animal fats, which can be perceived in the initial stage through a deterioration of odor and taste (rancidity), is to a

great extent the result of chemical alterations caused by the effect of

atmospheric oxygen. These oxidation processes progressing slowly at

ambient temperatures are referred to as autoxidation. They start with

radical reactions on unsaturated fatty acids and undergo a process involving multiple stages resulting in diverse decomposition products, in particular peroxides as primary oxidation products and alcohols, aldehydes and

carboxylic acids as secondary oxidation products.

With the Rancimat method, the sample is exposed to an air flow at a

constant temperature between 50…220 °C (see Figure 1, page 3).

Highly volatile, secondary oxidation products (for the most part formic

acid) are transferred into the measuring vessel with the air flow, where

they are absorbed in the measuring solution (distilled water). Here the

conductivity is continuously registered. The organic acids can thus be

detected by increasing the conductivity. The time until occurrence of these

secondary reaction products is referred to as the induction time or induction period, which is a good indicator for the oxidation stability.

■■■■■■■■■■■■■■■■■■■■■■

The Rancimat method has been developed as an automated variant to the

extremely complex AOM (active oxygen method) for determining the

induction time of fats and oils. This method has become established

over the course of time and has been incorporated in various national and

international standards, e.g. AOCS Cd 12b-92 and ISO 6886.

■■■■■■■■

2

743 Rancimat

Page 11

■■■■■■■■■■■■■■■■■■■■■■

Reaction vessel

Sample

Heating block

Measuring

vessel

Conductivity

measuring cell

Measuring

solution

1 Introduction

Figure 1 Measuring arrangement (schematic representation)

1.3 About the documentation

Caution

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which have to be followed by the user in order to ensure

safe operation of the instrument.

1.3.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Method Dialog text, parameter in the software

Instruction step

Carry out these steps in the sequence shown.

743 Rancimat

File ▶ New

Menu or menu item

■■■■■■■■

3

Page 12

1.4 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

[Next] Button or key

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

1.4 Safety instructions

1.4.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

Hot reaction vessels

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

■■■■■■■■

4

Warning

The reaction vessels can become very hot.

Avoid any contact with the hot reaction vessels. Place these in the vessel holders provided for cooling down.

743 Rancimat

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

Flammable substances

Warning

The oven of the 743 Rancimat can be heated to 220 °C.

Flammable substances may ignite at these temperatures.

Adjust the maximum heating temperature of the oven to the sample

being examined.

Defective glass vessels

Warning

Caution with defective glass vessels.

An overflow of flammable samples into the heating block can be dangerous.

Check the glass vessels before each use.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the regulations IEC 1010-1 (protection class 1, degree of protection

IP20).

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Warning

Warning

743 Rancimat

■■■■■■■■

5

Page 14

1.4 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

1.4.3 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. laboratory

flue).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled fluids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.4.4 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

743 Rancimat

Page 15

■■■■■■■■■■■■■■■■■■■■■■

743

Rancimat

11

10

9

8

7

6

5

4

3

2

1

2 Overview of the instrument

2 Overview of the instrument

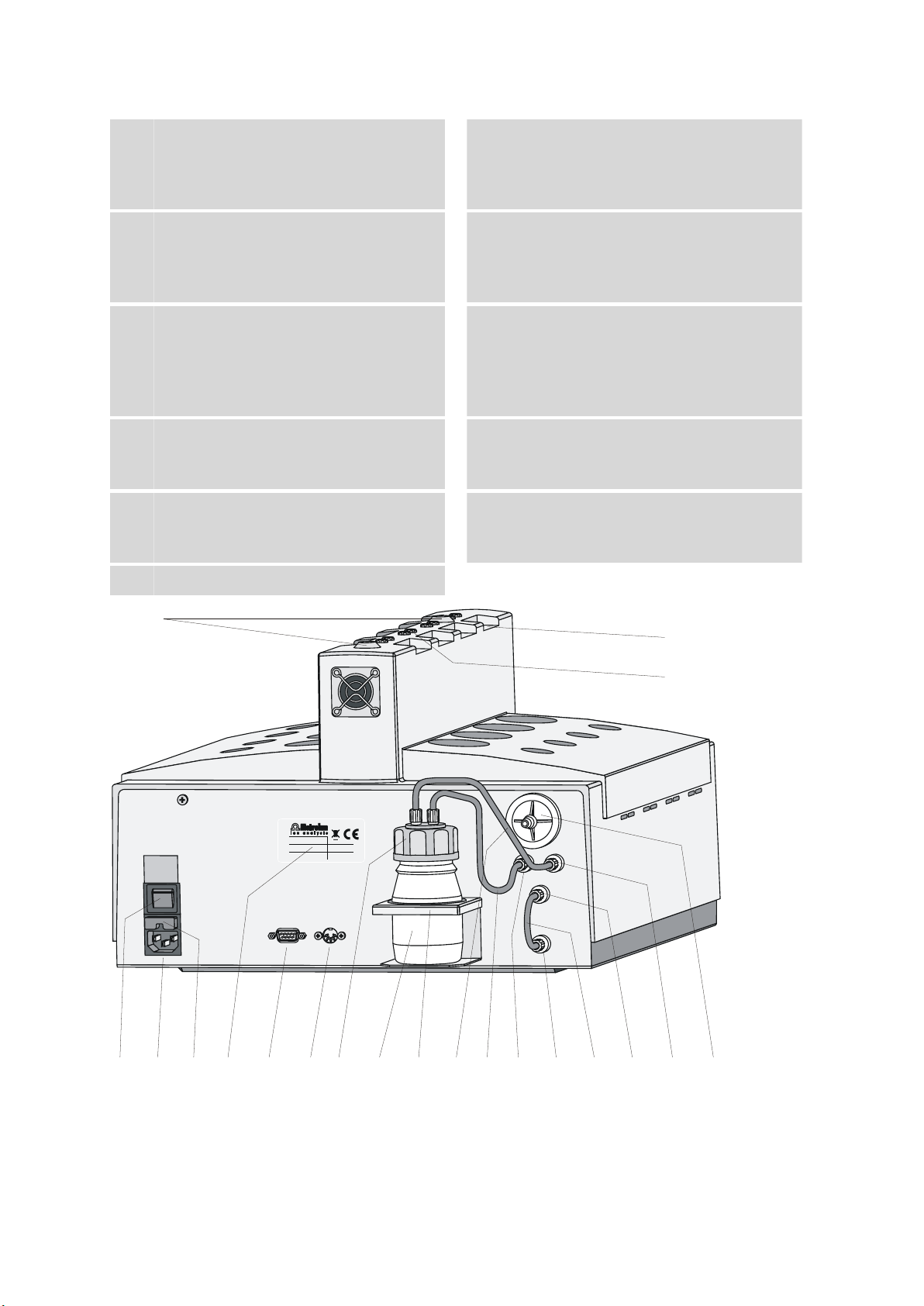

Figure 2 Front 743 Rancimat

743 Rancimat

■■■■■■■■

7

Page 16

■■■■■■■■■■■■■■■■■■■■■■

Molecular sieve flask

Filter

Air out

2

Air/N in

Pt 100

RS 232

WARNING - Fire Hazard -

with the same type and rating of fuse

For continued protection replace only

100-115V: 4A(TH)

Fuse

Made by Metrohm Herisau Switzerland

From

flask

To

flask

220-240V: 2A(TH)

Type:

Nr.:

U:

f:

S:

14

3

4

5

6

8 9 10

13 15

16

18 19 20

1

2

Pilot lamp

1

Lights up when the instrument is switched

on.

Temperature display

3

Flashes when the heating is switched on.

Lights up when the temperature has been

reached.

Instrument number display

5

Indicates the number of the instrument.

Lights up if the instrument is registered.

Flashes (all LEDs) if the connection to the PC

is interrupted.

Measuring vessel cover (6.0913.130)

7

Contains an integrated conductivity measuring cell.

Silicone tubing (6.1816.010)

9

For connecting the reaction vessel to the

measuring vessel.

Reaction vessel (6.1429.040)

11

Gas flow display

2

Flashes when the gas flow is switched on.

Lights up when the gas flow has been

reached.

Error display (red)

4

Lights up or flashes when a fault has occurred in the instrument (see Troubleshooting

Chapter).

FEP tubing 250 mm (6.1805.080)

6

For supplying air into the reaction vessel.

Measuring vessel (6.1428.100)

8

Reaction vessel cover (6.2753.107)

10

Figure 3 Rear 743 Rancimat

■■■■■■■■

8

743 Rancimat

Page 17

■■■■■■■■■■■■■■■■■■■■■■

2 Overview of the instrument

Collection tube holder

1

For fastening the optional exhaust collection

tube (6.2757.000).

Air supply connection

3

For connecting the FEP tubing 250 mm

(2-6).

Mains connection socket

5

For important information on the mains connection, see Chapter 3.3.

Type plate

7

Contains specifications concerning mains

voltage and serial number.

Pt100 connector

9

For connecting an external temperature sensor.

Drying flask (6.1608.050)

11

FEP tubing 250 mm (6.1805.080)

13

For supplying the air from the internal pump

to the drying flask.

Electrode connector

2

For connecting the conductivity measuring

cell integrated in the measuring vessel cover

(2-7).

Mains switch

4

For turning the instrument on and off.

I = ON / 0 = OFF.

Fuse holder

6

Replacing fuses, see Chapter 3.3.2.

RS-232 connector

8

For connecting the PC.

Drying flask cover (6.1602.145)

10

Cover for the drying flask.

Flask holder

12

For fastening the drying flask.

FEP tubing 250 mm (6.1805.080)

14

For supplying the air from the drying flask to

the reaction vessel (2-11).

"From Flask" connection

15

FEP tubing 130 mm (6.1805.010)

17

For connecting the Air out connection to

the Air/N2 in connection during normal

operation with the internal air pump.

"To Flask" connection

19

"Air/N2 in" connection

16

"Air out" connection

18

Dust filter (6.2724.010)

20

743 Rancimat

■■■■■■■■

9

Page 18

3.1 Setting up the instrument

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

■■■■■■■■■■■■■■■■■■■■■■

Place the instrument in a location of the laboratory suitable for operation

and free of vibrations, if possible protected from corrosive atmospheres

and contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

Note

In order to improve accessibility for the measuring positions, the instrument can be placed on the optionally available 6.2059.000 turning ring.

3.2 Mounting accessories

3.2.1 Mounting accessories for the internal air supply

The gas in the Rancimat is normally supplied using the internal air

pump, which sucks in laboratory air. For air supply and air purification,

the following accessories must be mounted on the rear of the Rancimat:

■■■■■■■■

10

743 Rancimat

Page 19

■■■■■■■■■■■■■■■■■■■■■■

Molecular sieve flask

Filter

Air out

2

Air/N in

From

flask

To

flask

8

9

10

12

11

1

2

3

654 7

3 Installation

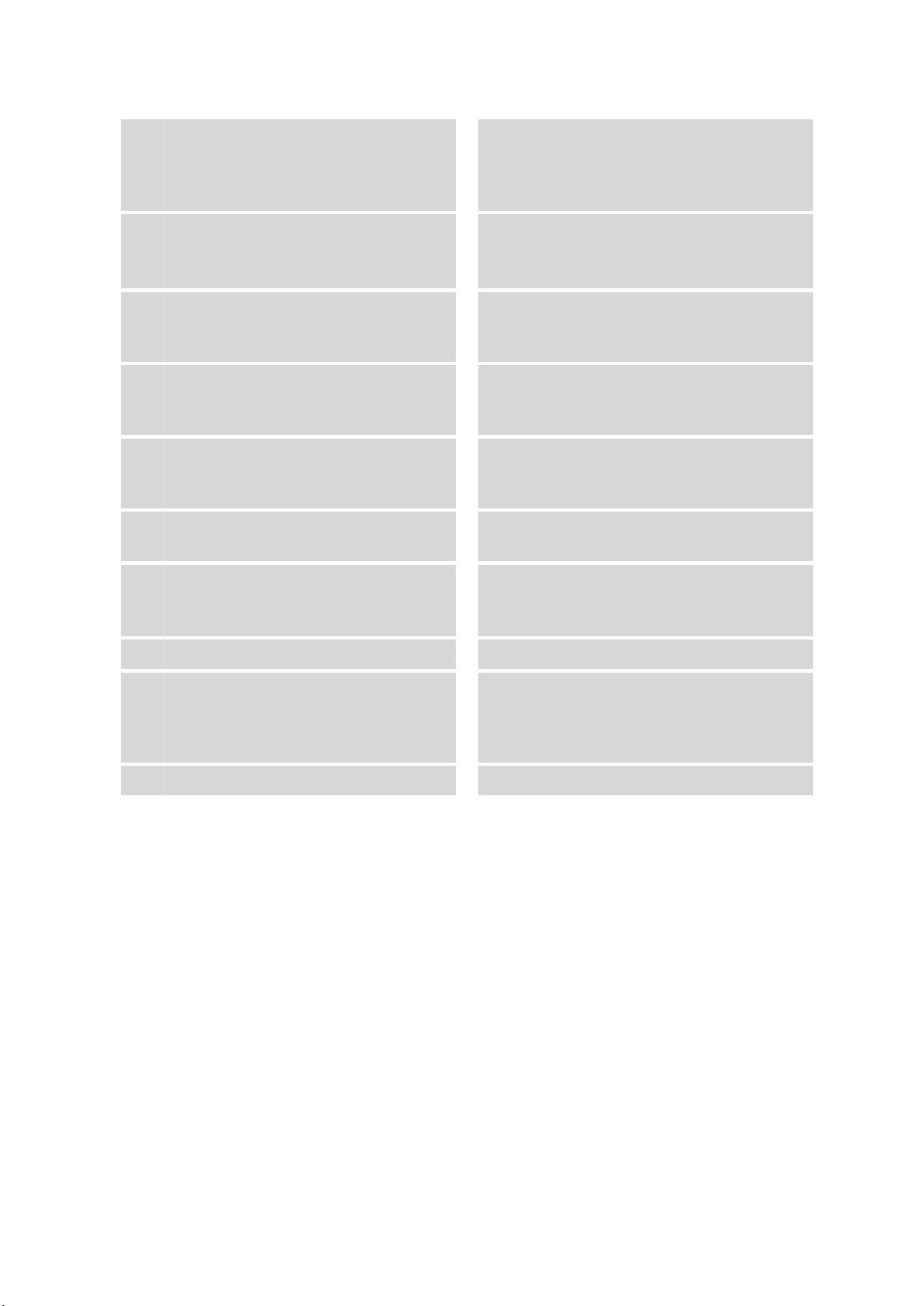

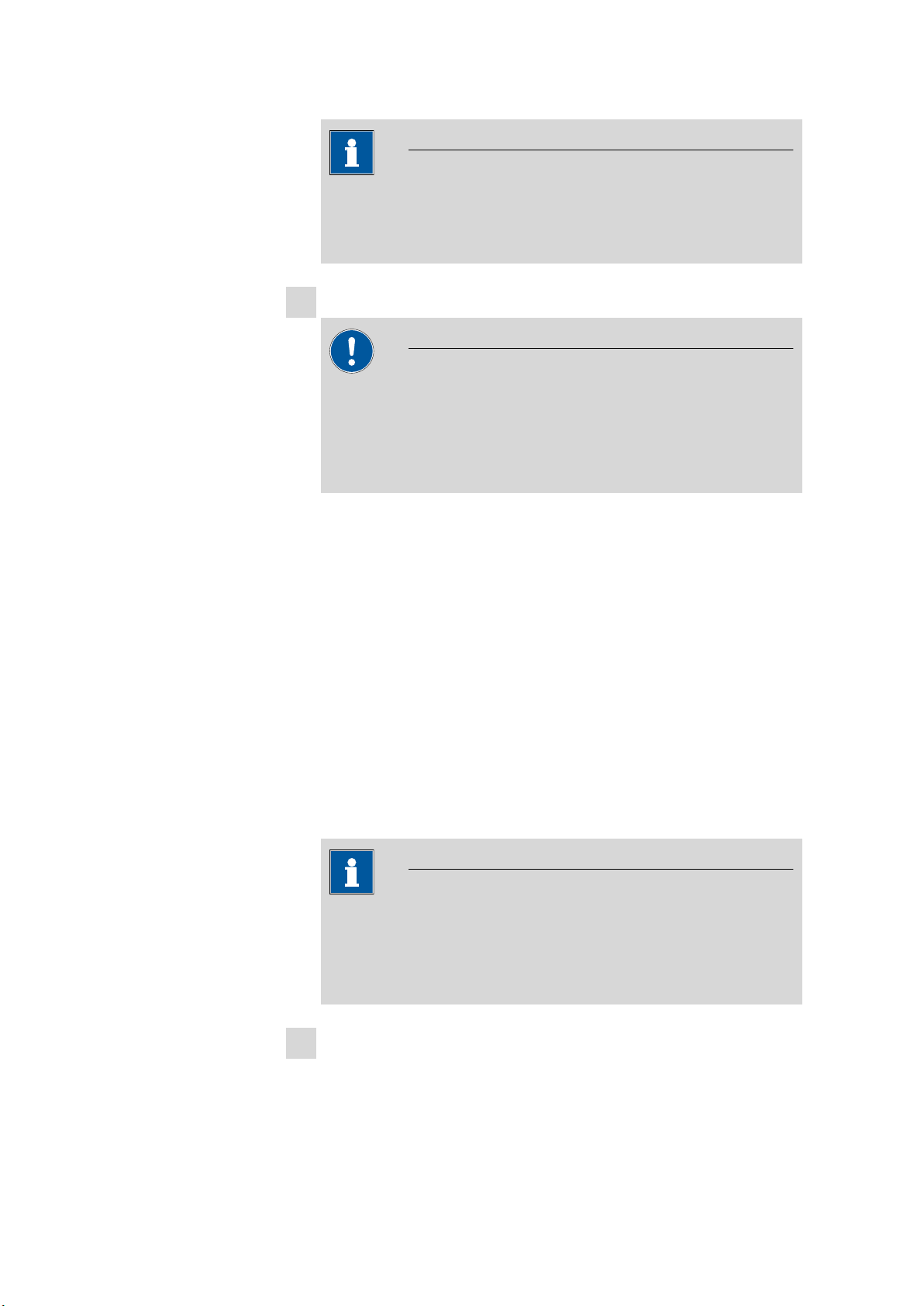

Figure 4 Mounting accessories for the air supply (rear of the instru-

ment)

Drying flask cover (6.1602.145)

1

Cover for the drying flask.

Flask holder

3

For fastening the drying flask.

FEP tubing 250 mm (6.1805.080)

5

For supplying the air from the internal pump

to the drying flask.

"From Flask" connection

7

"To Flask" connection

9

FEP tubing 130 mm (6.1805.010)

11

Mount the accessories for the air supply as follows:

1

Mount dust filter

■ Insert the dust filter (4-8) on the connection marked with Filter

■ If the laboratory air is heavily contaminated, a tubing for supply-

Drying flask (6.1608.050)

2

Filter tube (6.1821.040)

4

FEP tubing 250 mm (6.1805.080)

6

For supplying the air from the drying flask to

the reaction vessel (2-11).

Dust filter (6.2724.010)

8

"Air out" connection

10

"Air/N2 in" connection

12

on the rear of the Rancimat.

ing fresh air can be connected to the dust filter.

743 Rancimat

■■■■■■■■

11

Page 20

3.2 Mounting accessories

■■■■■■■■■■■■■■■■■■■■■■

Note

The dust filter serves for filtering the air sucked through the air

pump and must be replaced at periodic intervals (see Chapter 5.2,

page 161).

2

Mount drying flask

Caution

Do not fill the hot molecular sieve directly into the drying flask

after regeneration, as otherwise the plastic filter on the filter tube

will melt.

Wait until the molecular sieve has cooled down before filling.

■ Fill the molecular sieve into the drying flask (4-2).

■ Screw the filter tube (4-4) on the lower side of the drying flask

cover (4-1) into the opening marked (above) with a dot.

■ Screw the drying flask cover with mounted filter tube onto the

drying flask and insert in the flask holder (4-3) on the rear of the

Rancimat.

■ Screw the one end of the FEP tubing 250 mm (4-6) onto that

opening on the drying flask cover at the bottom of which the filter tube is located.

■ Screw the other end of the FEP tubing onto the From flask con-

nection (4-7) on the rear of the Rancimat.

■ Screw the one end of the second FEP tubing 250 mm (4-5) onto

the second opening on the drying flask cover.

■ Screw the other end of the second FEP tubing onto the To flask

connection (4-9).

■■■■■■■■

12

Note

The molecular sieve serves for adsorbing interfering oxidizing gases

as well as water from the sucked in air. You can regenerate it in

the drying oven at +140…+180 °C for 24 to 48 h (see Chapter

5.3, page 161).

3

Mount the FEP tubing for the supply air

■ Screw the one end of the FEP tubing 130 mm (4-11) onto the Air

out connection (4-10).

743 Rancimat

Page 21

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

■ Screw the other end of the FEP tubing onto the Air/N

nection (4-12).

3.2.2 Mounting accessories for the external air supply

If the laboratory air is heavily contaminated, an external gas supply with

synthetic air can be provided. For this, the corresponding accessories must

be mounted on the rear of the Rancimat.

Mount the accessories for the external air supply as follows:

1

Mount the FEP tubing

■ Screw the one end of the FEP tubing 130 mm (4-11) onto the

Air/N2 in connection (4-12) on the rear of the Rancimat.

■ Screw the tubing adapter M6 / olive (6.1808.020) onto the other

end of the FEP tubing.

2

Connect the gas supply

■ Mount the gas supply from the bomb with synthetic air onto the

tubing adapter M6 / olive (6.1808.020).

in con-

2

Note

With an external gas supply, the gas flow cannot be regulated in the PC

program. The gas flow must be set manually using the reducing valve

and the gas flow display (see Chapter 4.2.4, page 39).

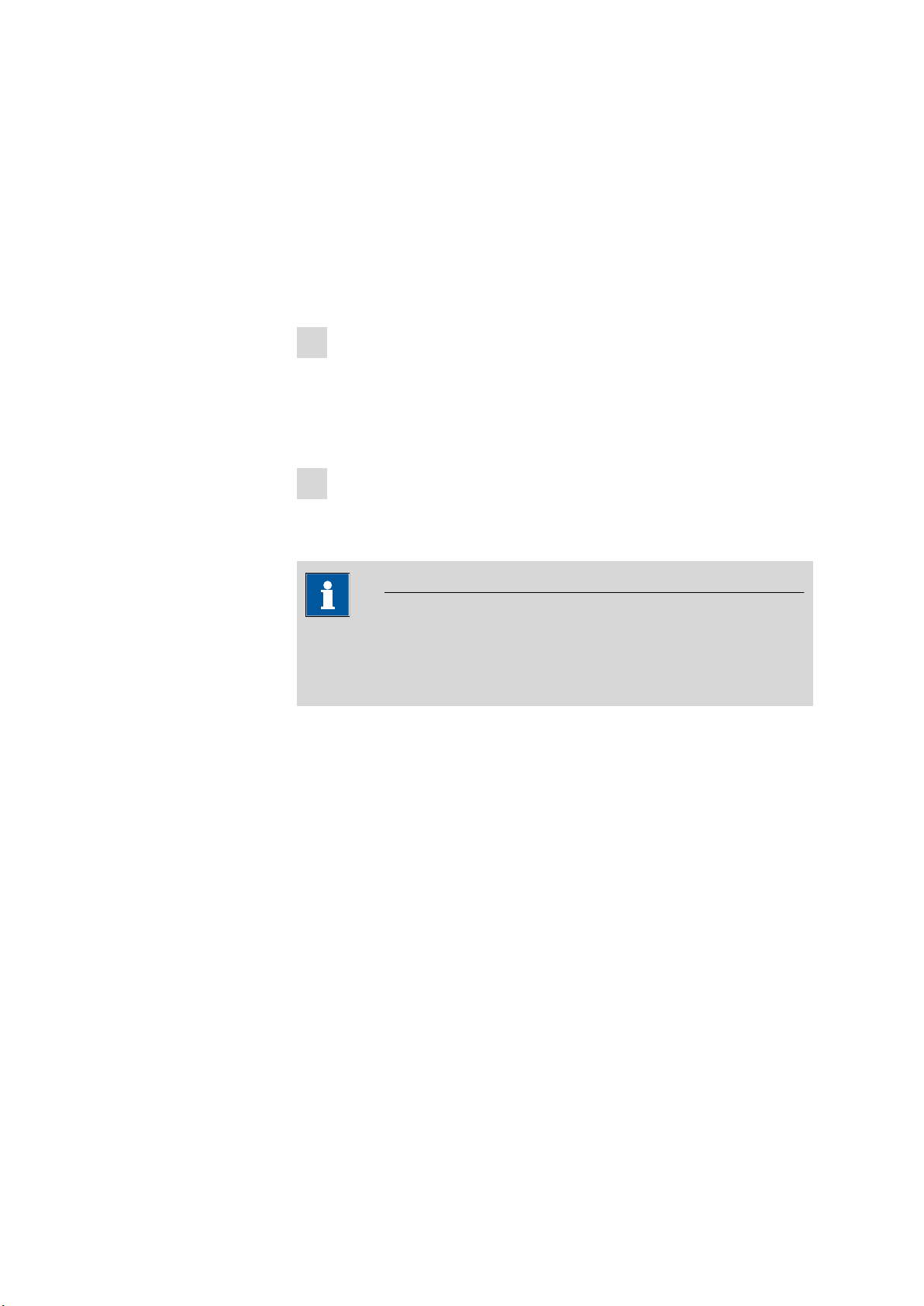

3.2.3 Equipping the reaction and measuring vessels

The following figure shows in detail, how the accessories parts for measuring the oxidation stability have to be mounted and connected to one

another.

743 Rancimat

■■■■■■■■

13

Page 22

3.2 Mounting accessories

2

1

3

4

5

6

7

8

9

10

20

16

12

11

13

14

15

17

18

19

■■■■■■■■■■■■■■■■■■■■■■

Figure 5 Equipping the reaction and measuring vessels

■■■■■■■■

14

743 Rancimat

Page 23

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

FEP tubing 250 mm (6.1805.080)

1

For supplying air into the reaction vessel.

Thread adapter M8 / M6 (6.1808.090)

3

Air tube (6.2418.100)

5

Connection

7

For connecting the thread adapter M8 / M6.

Foam barrier (6.1451.010)

9

Tubing adapter M8 / olive (6.1808.050)

11

For connecting the silicone tubing to the

opening In (5-13).

Opening "In"

13

For supplying the air to the measuring vessel.

Connector plug

15

Silicone tubing (6.1816.010)

2

For connecting the reaction vessel to the

measuring vessel.

Tubing connector

4

For connecting the silicone tubing.

O-ring (6.1454.040)

6

Reaction vessel cover (6.2753.107)

8

Reaction vessel (6.1429.040)

10

Opening "Out"

12

For removing the air from the measuring

vessel.

Labeling field

14

For entering the cell constant.

Measuring vessel cover (6.0913.130)

16

Contains integrated conductivity measuring

cell.

PTFE tube (6.1819.080)

17

For supplying the air to the measuring solution.

Protection ring

19

Proceed as follows to mount the measuring and reaction vessel:

1

Mount the measuring vessel cover

■ Insert the PTFE tube (5-17) from above into the opening In (5-13)

■ Screw the tubing adapter M8 / olive (5-11) into the opening In of

■ Place the measuring vessel cover (5-16) on the measuring vessel

2

Mount the reaction vessel cover

■ Insert the air tube (5-5) from below into the connection (5-7) of

■ Place the O-ring (5-6) over the upper end of the air tube.

■ Screw the thread adapter M8 / M6 (5-3) gently into the connec-

Electrode

18

Measuring vessel (6.1428.100)

20

of the measuring vessel cover.

the measuring vessel cover.

(5-20).

the reaction vessel cover.

tion (5-7) and, at the same time, press the air tube against the

thread adapter M8 / M6.

743 Rancimat

■■■■■■■■

15

Page 24

3.2 Mounting accessories

■ Now fix the air tube onto the reaction vessel cover by firmly pull-

■■■■■■■■■■■■■■■■■■■■■■

ing the thread adapter M8 / M6.

■ If determinations are carried out with highly foaming samples,

clamp the foam barrier (5-9) onto the air tube.

■ Place the reaction vessel cover on the reaction vessel.

Warning

The foam barrier can melt if it projects too deeply into the heating

block.

Ensure that the foam barrier (5-9) is at least 7 cm above the base of

the reaction vessel (5-10).

3.2.4 Inserting vessels / Establishing tubing connections

After you have assembled the reaction and measuring vessels, insert them

in the Rancimat and establish the tubing connections as follows:

1

Insert the measuring vessel

■ Fill the measuring vessel (5-20) with distilled water.

■ Place the measuring vessel cover on the measuring vessel.

■ Insert the measuring vessel into the openings provided on the

Rancimat. At the same time, carefully insert the connector plugs

(5-15) into the electrode connector (3-2).

■ Connect the white silicon tubing (5-2) to the tubing adapter

M8 / olive (5-11) of the measuring vessel cover.

2

Mount the tubings for the air supply

■ Screw the FEP tubings 250 mm onto the air supply connections

(3-3) of the Rancimat.

3

Insert the reaction vessel

■ Fill the reaction vessel (5-10) with the sample.

■ After reaching the required temperature, insert the reaction vessel

with the mounted reaction vessel cover in the openings provided

on the Rancimat.

4

Establish the tubing connections

■ Connect the white silicone tubing (5-2), which is fastened on the

measuring vessel cover, to the tubing connector (5-4) of the reaction vessel cover.

■■■■■■■■

16

743 Rancimat

Page 25

■■■■■■■■■■■■■■■■■■■■■■

■ Screw the FEP tubing 250 mm (5-1), which is fastened on the

tubing adapter M8 / olive (5-11) of the Rancimat, onto the thread

adapter M8 / M6 (5-3) of the reaction vessel cover.

Note

Instead of the measuring vessel 6.1428.100 made from polycarbonate,

the optionally available measuring vessel 6.1428.020 made from clear

glass can be used. In contrast to the polycarbonate vessel, the measuring vessel 6.1428.020 can also be cleaned with acetone.

3.2.5 Mounting the exhaust collection tube (optional accessories)

The optionally available exhaust collection tube 6.2757.000 can be mounted on the 743 Rancimat for targeted removal of the exhaust air. In addition to the exhaust collection tube, 8 silicone tubings 6.1816.010

(220 mm) also have to be ordered.

Proceed as follows to mount the collection tube:

1

Mount the exhaust collection tube

■ Insert the exhaust collection tube with both nozzles into the col-

lection tube holders (3-1) on the Rancimat in such a way that the

connection to the exhaust air removal is located to the rear.

2

Connect the measuring vessels

3 Installation

■ Screw the tubing adapter M8 / olive (5-11) into the opening Out

(5-12) of the measuring vessel cover.

■ Connect the one end of the silicone tubing (5-2) to the tubing

adapter M8 / olive.

■ Insert the other end of the silicone tubing into the corresponding

opening on the collection tube.

■ Seal the unused openings on the collection tube with the

enclosed plugs E.400.0010.

3

Connect the exhaust collection tube

■ Connect a suitable tubing to the connection of the exhaust collec-

tion tube and connect this to an active suction device (e.g. water

jet pump).

743 Rancimat

■■■■■■■■

17

Page 26

3.3 Mains connection

3.3 Mains connection

Warning

There is a risk of fire if the instrument is operated with an incorrect

mains fuse!

Follow the regulations below for the mains connection.

3.3.1 Checking the mains voltage

Before switching the 743 Rancimat on for the first time, check whether

the mains voltage indicated on the type plate (3-7) corresponds to the

mains voltage present. If this is not the case, please contact Metrohm

Service.

3.3.2 Replacing fuses

Two fuses 4 A (slow-acting) for 115 V or 2 A (slow-acting) for 230 V are

installed in the fuse holder (3-6) of the 743 Rancimat as standard.

■■■■■■■■■■■■■■■■■■■■■■

Warning

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is a risk of fire!

Proceed as follows to replace defective fuses:

1

Pull out the mains cable

■ Pull the mains cable out of the mains connection socket of the

Rancimat.

2

Remove the fuse holder

■ Use a screwdriver to loosen and completely pull out the fuse

holder (3-6) above the mains connection socket.

3

Replace fuses

■ Carefully take the defective fuses out of the fuse holder and

replace them with two new fuses suitable for the set mains voltage of the type TH (slow-acting, with high switching capacity):

– 115 V 4 A (TH) Metrohm No.: U.600.0022

– 230 V 2 A (TH) Metrohm No. U.600.0107

■■■■■■■■

18

743 Rancimat

Page 27

■■■■■■■■■■■■■■■■■■■■■■

4

Insert the fuse holder

■ Push the fuse holder back into the instrument until it latches into

place.

3.3.3 Mains cable and mains connection

Mains cable

The mains cable optionally supplied for the instrument

■ 6.2122.020 with plug SEV 12 (Switzerland)

■ 6.2122.040 with plug CEE(7), VII (Germany, …)

■ 6.2122.070 with plug NEMA 5-15 (USA, …)

is three-core and provided with a plug with grounding pin. If another plug

has to be mounted, the yellow/green conductor (IEC standard) must be

connected to the protective ground (protection class I).

Warning

3 Installation

Any interruption to the grounding within or outside the instrument can

make it dangerous!

Mains connection

Plug the mains cable into the mains connection socket of the Rancimat.

3.3.4 Switching the instrument on/off

The Rancimat is switched on and off using the mains switch. When

switching the instrument on, the pilot lamp ON lights up on the front of

the instrument auf.

3.4 Connecting a PC

3.4.1 Connecting the 743 Rancimat and the PC

Caution

Always switch the Rancimat and PC off before you connect the two

devices with the RS-232 cable 6.2134.100.

743 Rancimat

The PC program 743 Rancimat allows control of max. 4 instruments.

The following options are available for connecting the instruments to

serial PC interfaces:

■ Connection to integrated COM interfaces of the PC

■ Connection to an additional integrated interface expansion card

■■■■■■■■

19

Page 28

3.4 Connecting a PC

Connect the RS-232 interface of the Rancimat to the required serial COM

port on the PC using the RS-232 cable 6.2134.100 (9-pin/9-pin). For 25pin COM ports, the optional RS-232 cable 6.2125.110 (not in the scope of

delivery) or a commercially available adapter must be used.

3.4.2 Installing the software

3.4.2.1 System requirements

Operating system Windows 2000, Windows XP Professional, Win-

RAM 256 MB (Windows 2000 / Windows XP)

Processor Pentium III or higher

Memory approx. 20 MB for program files

RS-232 interface one free RS-232 interface (COM)

The windows user must have administrator rights in order to be able to

install 743 Rancimat.

■■■■■■■■■■■■■■■■■■■■■■

dows Vista

1 GB (Windows Vista)

3.4.2.2 Installing the program

Proceed as follows to install 743 Rancimat:

1

Start the installation program

■ Place the installation CD in the CD drive. The installation program

is started automatically.

If this option is deactivated on your computer, double click the file

Setup.exe.

Windows Vista: Select the option "Approve".

■ Click on 743.

2

Select the dialog language

■ Select the dialog language of the program.

■ Click on the [OK] button.

■ Click on the [Next >] button.

3

Accept the license agreement

■ Read through the license agreement and accept it with [Yes].

4

Define a target folder for the program

■ If required, choose another folder than the default target folder

for the program files. For that, click on the [Browse...] button.

■ Confirm the target folder with [Next >].

■■■■■■■■

20

743 Rancimat

Page 29

■■■■■■■■■■■■■■■■■■■■■■

5

Define the components of the program

■ Click on the [Next >] button.

6

Define a target folder for the program icon

■ Choose or enter the program folder of the Start menu in which

The program will be installed.

7

Complete the installation

■ Click on the [Finish] button after the successfully completed

The installation program will be exited.

3.4.2.3 Windows Vista

3 Installation

the program icon is to be inserted and confirm with [Next >].

installation.

Caution

If you run the software 743 Rancimat on a computer with Windows

Vista, you need a special update in order to be able to display the help.

Due to licensing reasons you have to download this file from a Microsoft web page. On the installation CD the link "Download Win-

Help.url" to the corresponding Microsoft web page can be found in

the folder "Vista Update for HLP help". Download the necessary

installation file and save it.

Proceed as follows to install the update:

■ Exit 743 Rancimat if you have started the software after the instal-

1

lation.

■ Start the installation file by double-clicking and follow the instruc-

tions of the installation program.

743 Rancimat

■■■■■■■■

21

Page 30

3.4 Connecting a PC

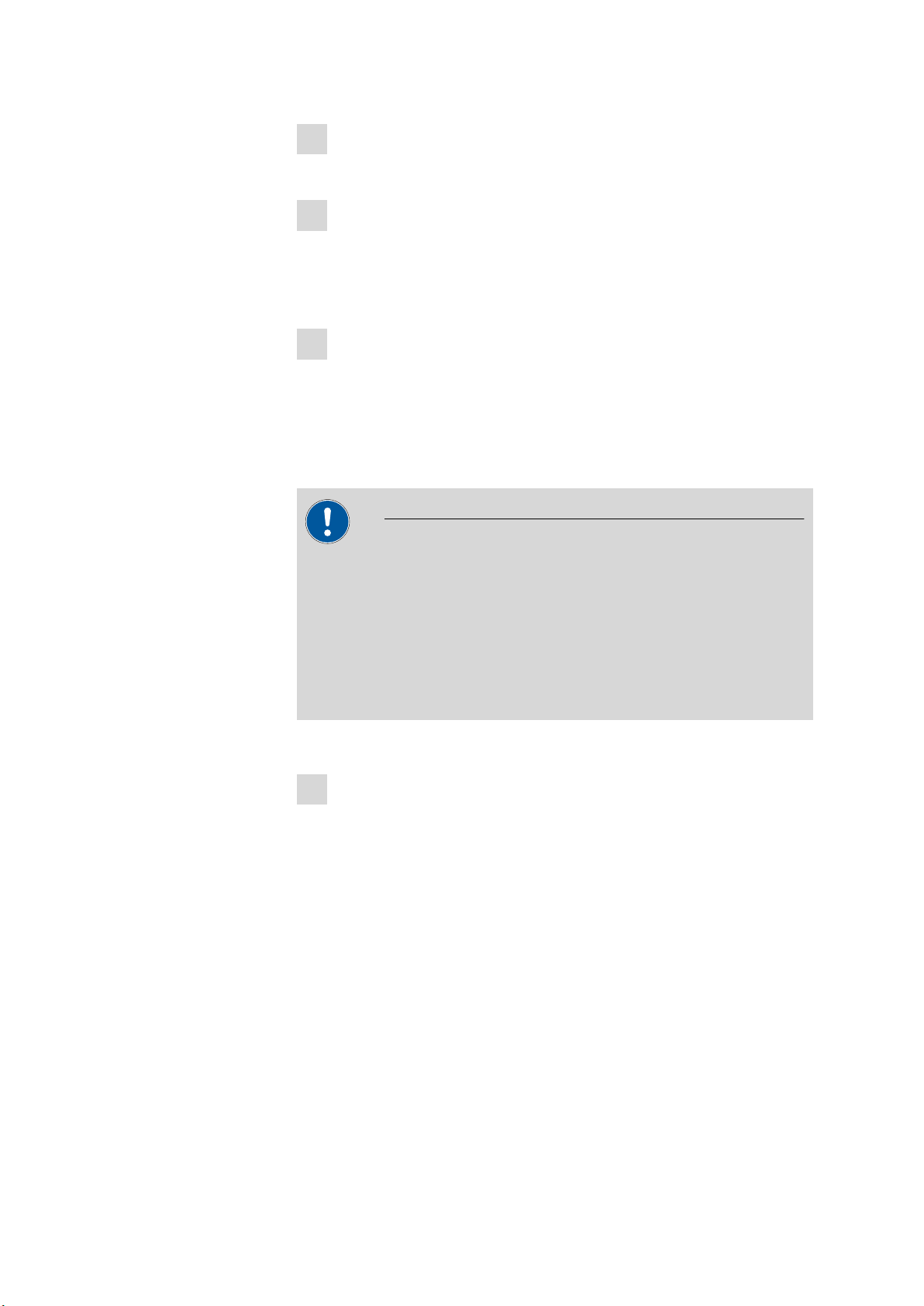

3.4.3 Carrying out basic settings

Setting the Administrator password

When starting the program for the first time, the Administrator password

must be set. Proceed as follows:

1

Switch on the instruments

■ Check whether the Rancimat is correctly connected to the PC (see

Chapter 3.4.1, page 19).

■ Switch on the Rancimat using the mains switch.

■ Switch on the PC.

2

Start program

■ In the Windows Start menu under Pro-

grams ▶ Metrohm ▶ Rancimat, click on the menu item Rancimat.

■■■■■■■■■■■■■■■■■■■■■■

The login window for the Administrator opens:

3

Set Administrator password

■ Do not enter a password, instead click on [OK].

■ Confirm the displayed message with [OK].

The following dialog window appears:

■■■■■■■■

22

■ Leave the Old password field empty.

■ Enter a new password for the Administrator in the New pass-

word field.

743 Rancimat

Page 31

■■■■■■■■■■■■■■■■■■■■■■

■ Reenter the password in the Confirm new password field and

confirm with [OK].

The dialog window Login opens again:

4

Log in as Administrator

■ Enter the Administrator password set before in the Password

field and confirm with [OK].

■ Confirm the message "There are no units configured yet!"

with [OK].

3 Installation

Establishing the device communication

Follow the instructions in Section 4.2.1.

1

743 Rancimat

■■■■■■■■

23

Page 32

4.1 Fundamentals of operation

4 Operation

This section describes the most important points for operation of the 743

Rancimat.

You can find more detailed information in the Online help of the software, which you can use to rapidly and easily call up the required information everywhere, via [F1].

4.1 Fundamentals of operation

4.1.1 Starting and exiting the program

Proceed as follows to start and exit the program:

Note

■■■■■■■■■■■■■■■■■■■■■■

If you are starting the program for the first time, you first have to set an

Administrator password (see Chapter 3.4.3, page 22).

1

Start program

■ In the Windows Start menu under Pro-

grams ▶ Metrohm ▶ Rancimat, click on the menu item Rancimat.

The following dialog window appears:

2

Log in

■ Select the required User.

■ Enter the Password and confirm with [OK].

3

Close program

■■■■■■■■

24

■ Click on the menu item File ▶ Exit or the symbol in the upper

right corner of the dialog window.

743 Rancimat

Page 33

■■■■■■■■■■■■■■■■■■■■■■

4.1.2 Terms

4 Operation

For opening and closing the Results window, see page 28.

Control window The main window 743 Rancimat Control is

called the control window. It contains all the

functions for monitoring and controlling the

Rancimats connected to the PC.

Method A method comprises all parameters for carrying

out and evaluating a determination.

Determination Determination refers to the automatic determi-

nation of the induction time and/or stability time

for a sample. In order to carry out a determination, a method suitable for the samples must be

selected.

Results The results of a determination are automatically

saved in the database Repos.mrd and can be

viewed in the Results window.

Reevaluation Reevaluation refers to the subsequent revision of

Recalculation The recalculation can be used to subsequently

Extrapolation Extrapolation can be used to convert the results

4.1.3 Control window

The dialog window 743 Rancimat Control serves for controlling the

devices, managing methods, displaying the live curves and accessing various program functions. The dialog window opens automatically when the

program is started.

Structure

The elements of the Control window are the menu bar, the toolbar, the

control panel and the status bar.

a determination, in particular the manual specification of the induction time using tangents.

recalculate results, formulas and standards.

measured at various temperatures to a required

target temperature. In addition, the factor for

converting the induction time to the standard

time can be determined.

743 Rancimat

■■■■■■■■

25

Page 34

4.1 Fundamentals of operation

■■■■■■■■■■■■■■■■■■■■■■

An image of the Rancimat is shown in the Control panel, which can be

used for starting, displaying and stopping determinations.

The following information is shown in the status bar:

■ a short description of the menu item highlighted in the menu bar

■ the registered user

■ the instrument status

Menus

The Control window contains the following main menus:

File Create new methods, open existing methods,

manage methods, open Results window, print,

new login, close program.

View Activate/Deactivate toolbar and status bar, dis-

play instrument information, change live parameters, display status overview, display event logging, select instrument.

Tools Manage cell constants, perform GLP tests, set

timer, set gas flow control, start all channels,

determine Delta T, record temperature, perform

service diagnosis.

■■■■■■■■

26

743 Rancimat

Page 35

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

Options Carry out general settings, set instrument config-

uration, manage access rights.

Help Call up program-specific Online help.

Symbols

New method

Open method

Method Manager

Print

Results Open Results window (see "Opening and closing the Results window", page

Create a new method (see Chapter 4.5.1, page 55).

Open an existing method (see Chapter 4.5.1, page 55).

Open, rename and delete methods (see Chapter 4.5.1, page 55).

Print results (see Chapter 4.7.6, page 128).

28).

Live parameters Display live parameters which can be changed for a current determination (see

Chapter 4.6.6, page 84).

Status overview Display status overview for the instruments connected (see Chapter 4.3.2, page

44).

Instrument information

GLP status

Instrument information (see Chapter 4.3.1, page 42).

Display GLP status (see Chapter 4.8.3, page 144).

Instrument 1…4

Start all channels

Block A

Start all channels

Block B

Help topics

Select instrument 1…4.

Start all channels of Block A (see Chapter 4.6.4, page 83).

Start all channels of Block B (see Chapter 4.6.4, page 83).

Call up the Online help.

4.1.4 Results window

The dialog window 743 Rancimat Results serves for displaying, outputting and recalculating results of the determinations recorded with the 743

Rancimat. The determination data is saved in database files *.mrd and

can be displayed in this dialog window in the form of overview tables and

curves. The Results window can also run if the Control window is closed.

743 Rancimat

■■■■■■■■

27

Page 36

4.1 Fundamentals of operation

■■■■■■■■■■■■■■■■■■■■■■

Opening and closing the Results window

Proceed as follows to open and close the Results window:

1

Open Results window

■ In the dialog window 743 Rancimat Control, click on the menu

item File ▶ Results... or the symbol .

When opening the Results window, the database Repos.mrd is

automatically loaded, in which all recorded determinations are saved

by default.

2

Close Results window

■ In the dialog window 743 Rancimat Results, click on the menu

item File ▶ Back or the symbol .

Structure

The elements of the Results window are the menu bar, the toolbar, the

subwindows (determination overview, live, single and multiple graphs)

and the status bar.

■■■■■■■■

28

743 Rancimat

Page 37

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

In the Results window subwindows with a determination overview, single,

multiple or live graphs can be opened.

Menus

The Results window contains the following main menus:

File Open database, print, close dialog window.

Edit Copy, select, delete content of the filter.

View View selection: determination overview, determi-

nation and method data, GLP.

Determination Search, sort, filter, display graphs, perform

extrapolation, perform recalculation, export

determinations, delete determinations.

Format Format determination overview.

Options Carry out general program settings.

Window Arrange subwindows.

Help Display program-specific Online help.

Print

Copy

Select fields for

determination overview

Display determination overview

Display all methods

and determination

data

Search

Ascending

Symbols

The toolbar of the Results window contains the following symbols:

Print results, curves and overview lists (see Chapter 4.7.6, page 128).

Copy data to clipboard.

Format determination overview (see Chapter 4.7.1, page 87).

Display determination overview (see Chapter 4.7.1, page 87).

Display all methods and determination data of the selected determination (see

Chapter 4.7.2, page 103).

Search in the database (see Chapter 4.7.1, page 87).

Sort column in ascending order (see Chapter 4.7.1, page 87).

Descending

Selection-based filter

743 Rancimat

Sort column in descending order (see Chapter 4.7.1, page 87).

Filter by selection (see Chapter 4.7.1, page 87).

■■■■■■■■

29

Page 38

4.1 Fundamentals of operation

■■■■■■■■■■■■■■■■■■■■■■

Special filter

Apply filter

Remove filter

Delete filter

Filter selection

Selection not in filter

Single graph

Multiple graph

Live graph with

reevaluation

Export to Word

Define filter (see Chapter 4.7.1, page 87).

Apply filter (see Chapter 4.7.1, page 87).

Remove filter (see Chapter 4.7.1, page 87).

Delete content of the filter (see Chapter 4.7.1, page 87).

Only display selected determinations (see Chapter 4.7.1, page 87).

Hide selected determinations (see Chapter 4.7.1, page 87).

Display single graph (see Chapter 4.7.3, page 112).

Display multiple graph (see Chapter 4.7.3, page 112).

Reevaluate live graph (see Chapter 4.7.3, page 112).

Export Determination overview to Word (see Chapter 4.7.6, page 128).

Export to Excel

Export measured values

Export determination

and method data

Tile vertically

Tile horizontally

Return to main program

4.1.5 File types

Export Determination overview to Excel (see Chapter 4.7.6, page 128).

Export measured values to a TXT file (see Chapter 4.7.6, page 128).

Export determination and method data to a TXT file (see Chapter 4.7.6, page

128).

Arrange subwindows on top of each other (see Chapter 4.7.8, page 141).

Arrange subwindows beside each other (see Chapter 4.7.8, page 141).

Close Results window and return to main program.

The following file types are generated by the program 743 Rancimat:

*.mrd Database file

This file contains the measured data and results

of the determinations. The file repos.mrd is

automatically saved in the directory Database.

When exporting databases, the memory location

can be freely selected.

■■■■■■■■

30

743 Rancimat

Page 39

■■■■■■■■■■■■■■■■■■■■■■

*.mel Event file

*.txt Text file

4.1.6 Context-sensitive menus

Many menu functions of the Program window can also be selected by

clicking with the right mouse button on the required dialog window or

element. The menu options opened depend on the active dialog window

or element selected.

4 Operation

This file contains a protocol of all events which

have occurred with the connected Rancimats.

The file *.mel is automatically saved in the Log

directory.

Measured values, determination and method

data as well as the data of the temperature log

can be saved in ASCII format as a TXT file. The

memory location can be freely selected, except

for the temperature log. This file is saved in the

Log directory.

4.1.7 Mouse functions

The standard functions for program control such as selecting menu items

and fields can be executed using the mouse.

It also serves for magnifying a curve sector (Zooming).

Zooming

Proceed as follows:

1

Drag zoom square

■ Place the cursor on the upper left corner of the sector to be mag-

■ Keeping the left mouse button pressed down, pull the cursor to

The cursor assumes the form of a magnifying glass.

2

Release mouse button

■ Release the mouse button in order to magnify the selected area

nified.

the lower right corner of the sector.

to the full size of the window.

743 Rancimat

■■■■■■■■

31

Page 40

4.1 Fundamentals of operation

3

Switch zoom off again

■ Right click in the graphs window.

The context-sensitive menu for graphs appears.

■ Click on the menu item Zoom Off.

■■■■■■■■■■■■■■■■■■■■■■

4.1.8 Help

You can call up help for the current topic anywhere with the symbol ,

the menu item Help ▶ Help topics or the key [F1].

Green text can be clicked on. This takes you to another help

topic.

Violet text marks menu items, parameters or buttons in the

program.

Blue text marks titles and important information.

■■■■■■■■

32

743 Rancimat

Page 41

■■■■■■■■■■■■■■■■■■■■■■

4.2 Instrument and Program Settings

4.2.1 Establishing the instrument communication

Up to four instruments can be controlled with the program 743 Rancimat. Configure the communication between your PC and the 743 Ranci-

mat as follows:

1

Select number of instruments connected

■ In the Control window, click on the menu item

Options ▶ Communication....

The following dialog window appears:

4 Operation

■ Enter the number of connected instruments and confirm with

[OK].

The following dialog window appears:

2

Select interface

■ Under COM port, select the serial interface of the PC to which

the instrument is connected.

743 Rancimat

■■■■■■■■

33

Page 42

4.2 Instrument and Program Settings

■ If a softswitch is used, activate the option Softswitch in use and

select the serial interface of the softswitch to which the instrument is connected under Softswitch port.

■ Confirm the entry with [OK].

3

Restart program

■ Close the program with the menu item File ▶ Exit.

■ In the Windows Start menu under Pro-

grams ▶ Metrohm ▶ Rancimat, click on the menu item Rancimat.

■ Enter the Administrator password and confirm with [OK].

The program is opened. The message Instr.#: Ready now appears

in the status bar for all connected instruments.

4.2.2 Managing access rights

The 743 Rancimat program offers extensive password protection, allowing each menu item to be provided with individual access rights.

■■■■■■■■■■■■■■■■■■■■■■

The dialog Users and groups manager, used to manage the access

rights, is only accessible to the Administrator. The Administrator himself is

not listed as a user, but has all access rights.

First of all, the access rights are given to different Groups. Then, individual Users can be assigned to a specific group.

Note

User lists are best created and passwords are best entered immediately

after the first program start.

■■■■■■■■

34

The setup for the users and their access rights is carried out in the following order:

1. Add a new group

2. Adjust rights for this group

3. Create users in this group

743 Rancimat

Page 43

■■■■■■■■■■■■■■■■■■■■■■

4 Operation

After having entered the access rights, the Login window for selecting the

user and entering the password appears each time the program is started.

All methods, determinations and reports are marked with the user name.

It is possible to change the user at any time with the menu item

File ▶ New login....

Adding a new group

In order to add a new group, proceed as follows:

1

Open Users and groups manager

■ In the Control window, click on the menu item

Options ▶ User permissions....

2

Create new group

■ Right click on an existing group to select the menu item Add

group....

■ Under Enter new group name enter the name for the group

and confirm with [OK].

Adjusting access rights for the group

Proceed as follows to set the access rights:

1

Open Users and groups manager

■ In the Control window, click on the menu item

Options ▶ User permissions....

2

Open Properties dialog

■ Right click on the relevant group whose access rights are to be

adjusted to select the menu item Properties....

The following dialog window appears:

743 Rancimat

■■■■■■■■

35

Page 44

4.2 Instrument and Program Settings

■■■■■■■■■■■■■■■■■■■■■■

3

Activate/Deactivate the rights

■ Click on the symbol to open the menu tree for the access

rights..

■ Activate or deactivate the required options by clicking on the sym-

bol .

■ Confirm the changes with [OK].

Adding a new user

Proceed as follows to add a new user:

1

Open Users and groups manager

■ In the Control window, click on the menu item

Options ▶ User permissions....

2

Create new user

■ Right click on an existing group to select the menu item Add

user....

■ Under Enter new user name enter the name for the user and

confirm with [OK].

■■■■■■■■

36

743 Rancimat

Page 45

■■■■■■■■■■■■■■■■■■■■■■

Deleting a user

Proceed as follows to delete an existing user:

1

Open Users and groups manager

■ In the Control window, click on the menu item

Options ▶ User permissions....

2

Delete user

■ Right click on the user to be deleted to activate the menu item

Delete user.

■ Confirm the message Do you really want to delete user

"user name"? with [Yes].

Deleting a group

Proceed as follows to delete an existing group:

1

Open Users and groups manager

■ In the Control window, click on the menu item

Options ▶ User permissions....

2

Delete group

■ Right click on the group to be deleted in order to select the menu

item Delete group.

■ Confirm the message Do you really want to delete group

"group name"? with [Yes].

4 Operation

4.2.3 Timer

743 Rancimat

The function Timer can be used to start the two heating blocks A and B,

independently of one another, automatically and at a time specified by

you. The Rancimat has to be switched on and the software must be running.

Two different examples will explain how to program the timer.

■■■■■■■■

37

Page 46

4.2 Instrument and Program Settings

Proceed as follows to automatically start the heating of block A at a specific time:

■■■■■■■■■■■■■■■■■■■■■■

Starting heating block A once automatically

1

Open dialog window

■ In the Control window, click on the menu item Tools ▶ Timer

function....

The following dialog window appears:

2

Set automatic start time

■ Under Start heating select the option Once.

■ Under Start at... enter the required time and date.

■ Confirm the entries with [OK].

Starting heating block B daily automatically at the same

time

Proceed as follows to automatically start the heating of block B on a specific day of the week, at a specific time:

1

Open dialog window

■ In the Control window, click on the menu item Tools ▶ Timer

function....

The following dialog window appears:

■■■■■■■■

38

743 Rancimat

Page 47

■■■■■■■■■■■■■■■■■■■■■■

2

Set automatic start time

■ Under Start heating select the option Daily.

■ Click on the button [Which days...].

The following dialog window appears:

4 Operation

■ Select the required day(s) and confirm with [OK].

■ Under Start at... enter the required time and confirm with [OK].

4.2.4 Gas flow control

The gas flow produced by the internal pump through the reaction vessels to the measuring vessels can be switched on and off manually and

displayed in a separate window.

Switching the gas flow on and off

Proceed as follows:

1

Switch on

■ Click on the menu item Tools ▶ Gas flow control ▶ Gas flow

2

Switch off

■ Click on the menu item Tools ▶ Gas flow control ▶ Gas flow

on.

off.

743 Rancimat

■■■■■■■■

39

Page 48

4.2 Instrument and Program Settings

Proceed as follows:

■■■■■■■■■■■■■■■■■■■■■■

Displaying the gas flow

1

Open dialog window

■ Click on the menu item Tools ▶ Gas flow control ▶ Display

gas flow....

The following dialog window appears:

Note

This option is only available if no determination is running.

4.2.5 Recording the temperature

The temperature can be recorded at any time for each individual heating

block.

The program writes the recorded measured values into a text file containing the following values:

t(s) Time in seconds.

Block [°C] Temperature measured in the heating block.

Ext. Sensor [°C] Temperature measured with the external tem-

The text file is saved under the name U#X-YYMMDD-hhmmss.txt in

the folder Log, # denoting the instrument number (1...4), X denoting the

block (A or B) and YYMMDD-hhmmss denoting the date and time when

the data logging started.

perature sensor.

■■■■■■■■

40

743 Rancimat

Page 49

■■■■■■■■■■■■■■■■■■■■■■

Switching the temperature log on and off

Proceed as follows:

1

Switch on the recording for block A or B

■ Click on the menu item Tools ▶ Temp. logging ▶ Block A on.

or

■ Click on the menu item Tools ▶ Temp. logging ▶ Block B on.

2

Switch off the recording for block A or B

■ Click on the menu item Tools ▶ Temp. logging ▶ Block A off.

or

■ Click on the menu item Tools ▶ Temp. logging ▶ Block B off.

4.2.6 Optimizing program and database

The data which the program Rancimat requires for displaying the Results

window is saved in the file Nachaus.prg. With the standard installation,

this file is located at C:\Program Files\Metrohm\Rancimat\Template. As

soon as the file is greater than 10 MB, you should optimize and compress the program, so that this file no longer has any superfluous data and

the program runs faster again.

4 Operation

The file size of the database Repos.mrd can make access to existing

determinations considerably slower. If you regularly work with the program and carry out a large amount of determinations, you should optimize the standard database Repos.mrd once a month.

Optimizing the program

Proceed as follows to optimize the program:

1

Quit program

■ Close the program Rancimat (see Chapter 4.1.1, page 24).

2

Optimize program

■ In the windows Start menu, click on the menu item Pro-

grams ▶ Metrohm ▶ Rancimat ▶ Optimize ▶ Program.

743 Rancimat

■■■■■■■■

41

Page 50

4.3 Program information

Optimizing the database

Proceed as follows to optimize the standard database:

1

Export database

■ Export determinations not currently required from the database

Repos.mrd into a newly created database (see "Exporting deter-

minations to another database", page 133).

■ Close the Results window and the program Rancimat (see Chap-

ter 4.1.1, page 24).

2

Optimize database

■ In the Windows Start menu, click on the menu item Pro-

grams ▶ Metrohm ▶ Rancimat ▶ Optimize ▶ Database.

4.3 Program information

■■■■■■■■■■■■■■■■■■■■■■

4.3.1 Instrument information

Displaying and printing the instrument information

Proceed as follows to display and print the instrument information of the

currently selected Rancimat:

1

Open dialog window

■ In the Control window, click on the menu item View ▶ Unit

information….

The following dialog window appears:

■■■■■■■■

42

743 Rancimat

Page 51

■■■■■■■■■■■■■■■■■■■■■■

2

Print instrument information

■ Click on the button [Print report…].

4 Operation

Serial number

Program number

Last maintenance

Last calibration

Unit operating hours

The status report is printed on the printer which is defined on your

PC as the default printer.

Meaning of the individual parameters

Serial number of the selected instrument.

Number of the EEPROM program of the selected instrument.

Date of the last maintenance with signature of the service technician who

has carried out the service work.

Date of the last instrument adjustment with signature and code of the

responsible body.

Number of hours during which the instrument was switched on.

Pump operating hours

743 Rancimat

Number of hours during which the internal pump was in operation.

■■■■■■■■

43

Page 52

4.3 Program information

The block Service diagnosis is password-protected and only accessible for trained service personnel.

4.3.2 Status overview

Displaying the status overview

Proceed as follows to display and adjust the status overview:

1

Open dialog window

■ In the Control window, click on the menu item View ▶ Status

The following dialog window appears:

■■■■■■■■■■■■■■■■■■■■■■

Note

overview.

Unit

Block

Channel

Method

2

Adjust and save column width

■ You can adjust the column width to the required size by dragging

the right field border with the mouse.

■ In the Control window, click on the menu item

Options ▶ Save settings now.

Meaning of the columns in the status overview

Instrument number (1…4).

Instrument block (A or B).

Channel (1…4).

Name of the method loaded.

■■■■■■■■

44

743 Rancimat

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Sample ID1

Status

Stab. time

Induc. time

4 Operation

Sample identification 1.

Status of the channel.

ready: No active measurement. The channel is ready for starting a determination.

running: Instrument is measuring.

finished: Determination finished. The channel is ready for starting a new

determination.

error: Communication error between instrument and PC.

Stability time determined.

Induction time determined.

Set temp.

Setpoint temperature (defined in the method).

Current temp.

Current block temperature.

4.3.3 Displaying, filtering and deleting event overview

Opening and saving the event log file

Proceed as follows to display and save all events of the Rancimats connected to the PC:

1

Open current log file

■ In the Control window, click on the menu item View ▶ Event

log overview.

The following dialog window appears:

743 Rancimat

■■■■■■■■

45

Page 54

4.3 Program information

■■■■■■■■■■■■■■■■■■■■■■

Note

You can find the meaning of the symbols and columns in the

event overview at "Meaning of the symbols and columns in the

event overview", page 47.

2

Update view

■ Click on the symbol or the menu item View ▶ Refresh to

view the current status of the log file.

3

Save log file

■ Click on the symbol or the menu item File ▶ Save as….

■ In the dialog window Save file as enter a file name and confirm

with [OK].

4

Open saved log file

■ Click on the symbol

■ In the dialog window Open, select the required file and confirm

or the menu item File ▶ Open….

with [OK].

Filtering entries in the event overview

Proceed as follows to filter the entries in the event file:

1

Filter the entries

■ Click on the required filter criterion (e.g.: date = "30.08.2006").

■■■■■■■■

46

743 Rancimat

Page 55

■■■■■■■■■■■■■■■■■■■■■■

■ Click on the symbol or the menu item Filter ▶ Selection

based filter.

Only entries with the date "30.08.2006" are displayed in the dialog

window.

2

Remove the filter again

4 Operation

■ Click on the symbol

or the menu item Filter ▶ Remove filter.

All entries are once again displayed in the dialog window.

Deleting entries from the event overview

Proceed as follows to delete certain entries from the event file:

1

Open dialog window

■ In the Control window, click on the menu item

Options ▶ Event log….

The following dialog window appears:

Type

Date

2

Delete entries

■ Enter the maximum age in days, which the entries are allowed to

have in the list. All older entries are deleted.

■ Confirm the entry with [OK].

Meaning of the symbols and columns in the event overview

- Information on correctly executed events.

- Indication of a special event.

- Error message for error event.

Date of the event. The format depends on the settings defined in Windows in Control Panel ▶ Country settings ▶ Date.

743 Rancimat

■■■■■■■■

47

Page 56

4.4 Calibration functions

Time

Time of the event. The format depends on the settings defined in Windows in Control Panel ▶ Country settings ▶ Time.

User

Name of the user logged in at the time of the event.

Unit

Instrument number (1…4).

Event

Description of the event.

4.4 Calibration functions

4.4.1 Determining cell constants

Only the change in conductivity is measured an evaluated during the

Rancimat measurement. As a result, the cell constants of the conductivity

measuring cells used in the Rancimat, which are normally in the range

from 1.00...1.20, only have to be entered exactly if the absolute con-

ductivity measured value is to be displayed correctly.

■■■■■■■■■■■■■■■■■■■■■■

The value also has to be entered before carrying out the GLP test "Conductivity". The cell constants can thereby be entered manually or deter-

mined automatically using a defined standard solution (see Optional

accessories, page 185).

Entering cell constants manually

Proceed as follows if you wish to enter the cell constants manually:

1

Open dialog window

■ Click on the menu item Tools ▶ Cell constants ▶ Manual....

The following dialog window appears:

■■■■■■■■

48

743 Rancimat

Page 57

■■■■■■■■■■■■■■■■■■■■■■

2

Enter cell constants

■ Enter the cell constants of the conductivity measuring cells for the

required channels and confirm with [OK].

Determining cell constants automatically

4 Operation

Proceed as follows if you wish to enter the cell constants automatically:

1

Open dialog window

■ Click on the menu item Tools ▶ Cell constants ▶ Automatic....

The following dialog window appears:

743 Rancimat

2

Select channels and define conductivity

■ Activate the check boxes of those channels, for which the cell

constant is to be determined.

■■■■■■■■

49

Page 58

4.4 Calibration functions

■■■■■■■■■■■■■■■■■■■■■■

■ Enter the conductivity of the standard used.

c(KCl) = 1 mmol/L can be used as a standard solution. This is

derived from the optionally available conductivity standard

6.2301.060 (KCl 0.1 mol/L) through dilution with distilled water. The

conductivity of this diluted solution is:

Temperature Conductivity

18 °C

19 °C

20 °C

21 °C

22 °C

23 °C

24 °C

25 °C

127 µS/cm

130 µS/cm

133 µS/cm

136 µS/cm

138 µS/cm

141 µS/cm

144 µS/cm

147 µS/cm

Alternatively, the conductivity standard 6.2324.000 (undiluted) can

be used.

3

Start determination and check the values

■ Click on [Start] to start the determination of the cell constant.

After the determination is finished, the dialog window Enter/Check

cell constants appears again.

If you wish to accept the displayed values, click [OK].

4.4.2 Determining Delta T

The temperature correction Delta T indicates the deviation of the current temperature of the sample from the temperature in the heating block

and belongs to the method as a parameter (see Chapter 4.5.2, page