Page 1

Service Training

Self-study Programme 370

The Crafter

Electrical system

Design and function

Commercial

Vehicles

Page 2

Innovations in automotive engineering are also taking

place in the commercial vehicle segment.

The Volkswagen Crafter is therefore fitted with

extensive electrical equipment and with electrical and

optical data bus systems.

In comparison with the predecessor model,

these systems enable familiar electrical

functions to be actuated in different ways and

new functions to be implemented.

This self-study programme is intended to explain

these functions and help you to understand

their interconnections better.

The self-study programme shows the design and

function of new developments.

The contents will not be updated.

2

S370_087

NEW Important

Note

For current testing, adjustment and repair

instructions, refer to the relevant

service literature.

Page 3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Vehicle electrical system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ignition lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Anti-theft system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Dash panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Convenience systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Tachograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Special control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Test yourself . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3

Page 4

Introduction

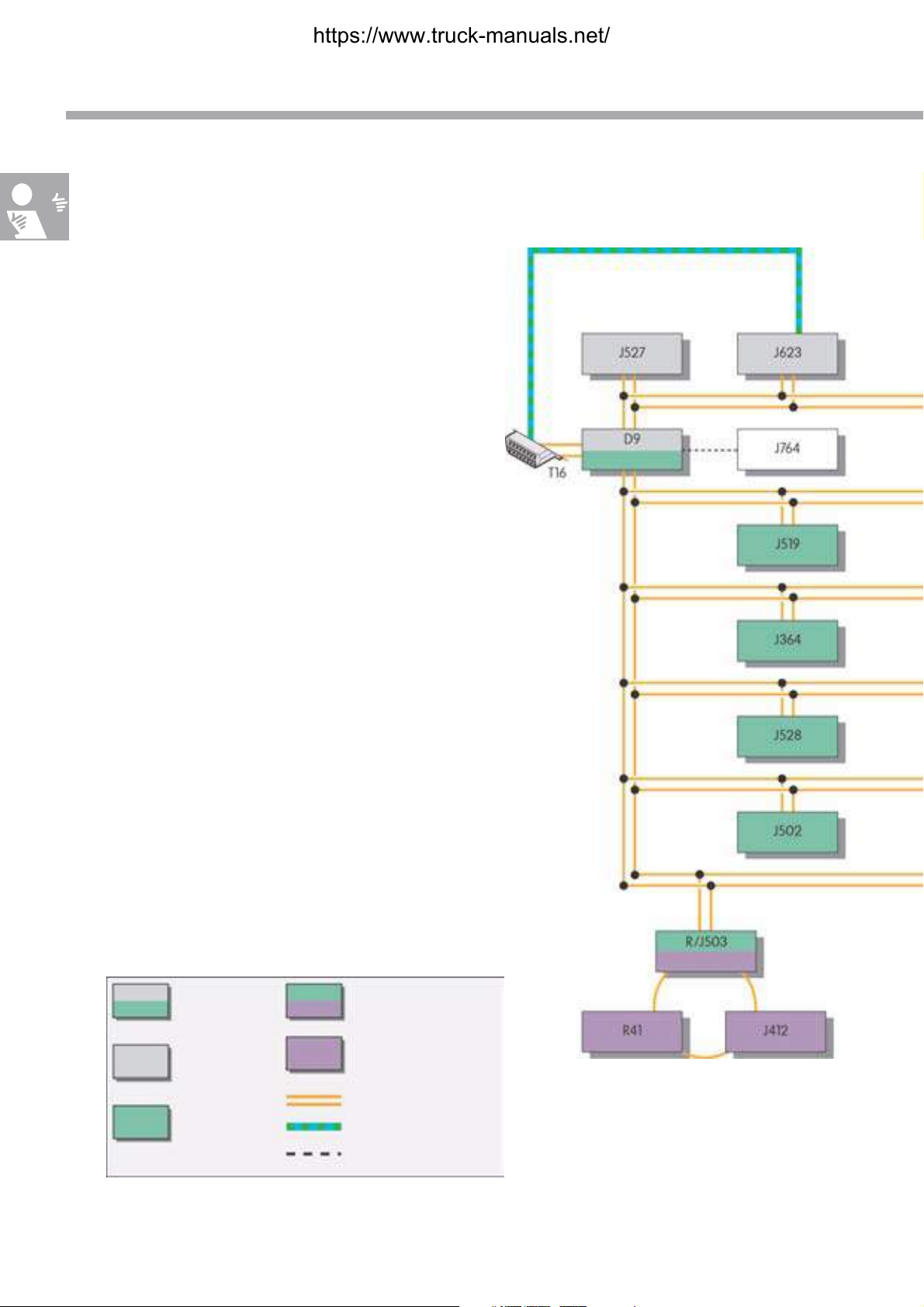

Data bus systems

Data bus networking

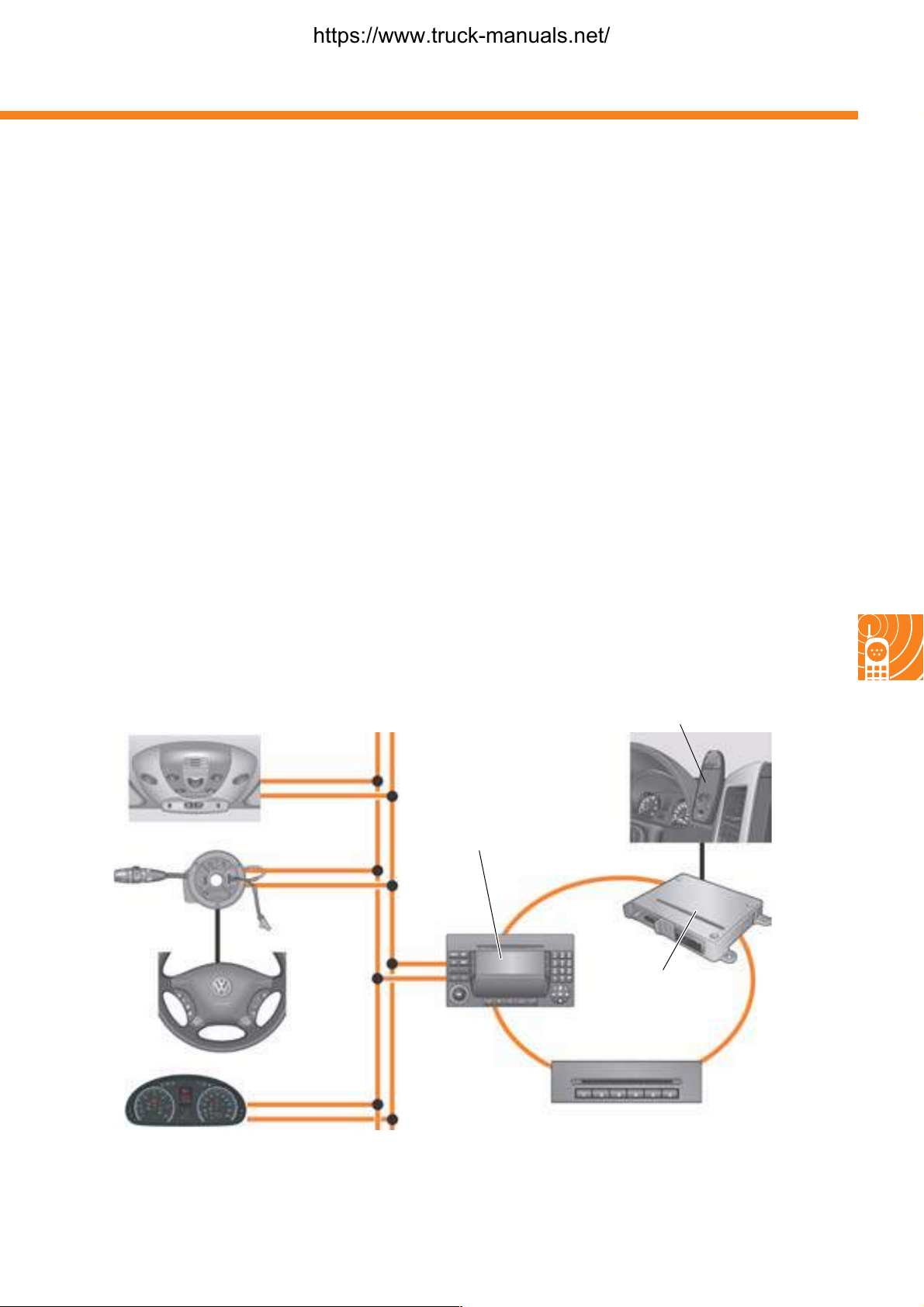

The Volkswagen Crafter's control units are networked

via the CAN data bus and the MOST data bus.

Networking enables data to be exchanged between

the individual control units.

Instead of using conventional (discrete) cable

connections, the data are transmitted via the data

buses in digital form as an electrical signal or

as a light signal. This makes it possible to make data

available to several control units.

The CAN data bus is sub-divided into three individual

systems, the CAN drive data bus, the CAN

convenience data bus and the CAN diagnostic data

bus.

All three bus systems are connected to each other via

the electronic ignition lock D9, and are therefore able

to exchange information.

Diagnostic

interface

CAN drive

data bus

CAN

convenience

data bus

MOST data bus

interface

MOST data bus

Data bus

K-wire

Serial data cable

S370_080

4

Page 5

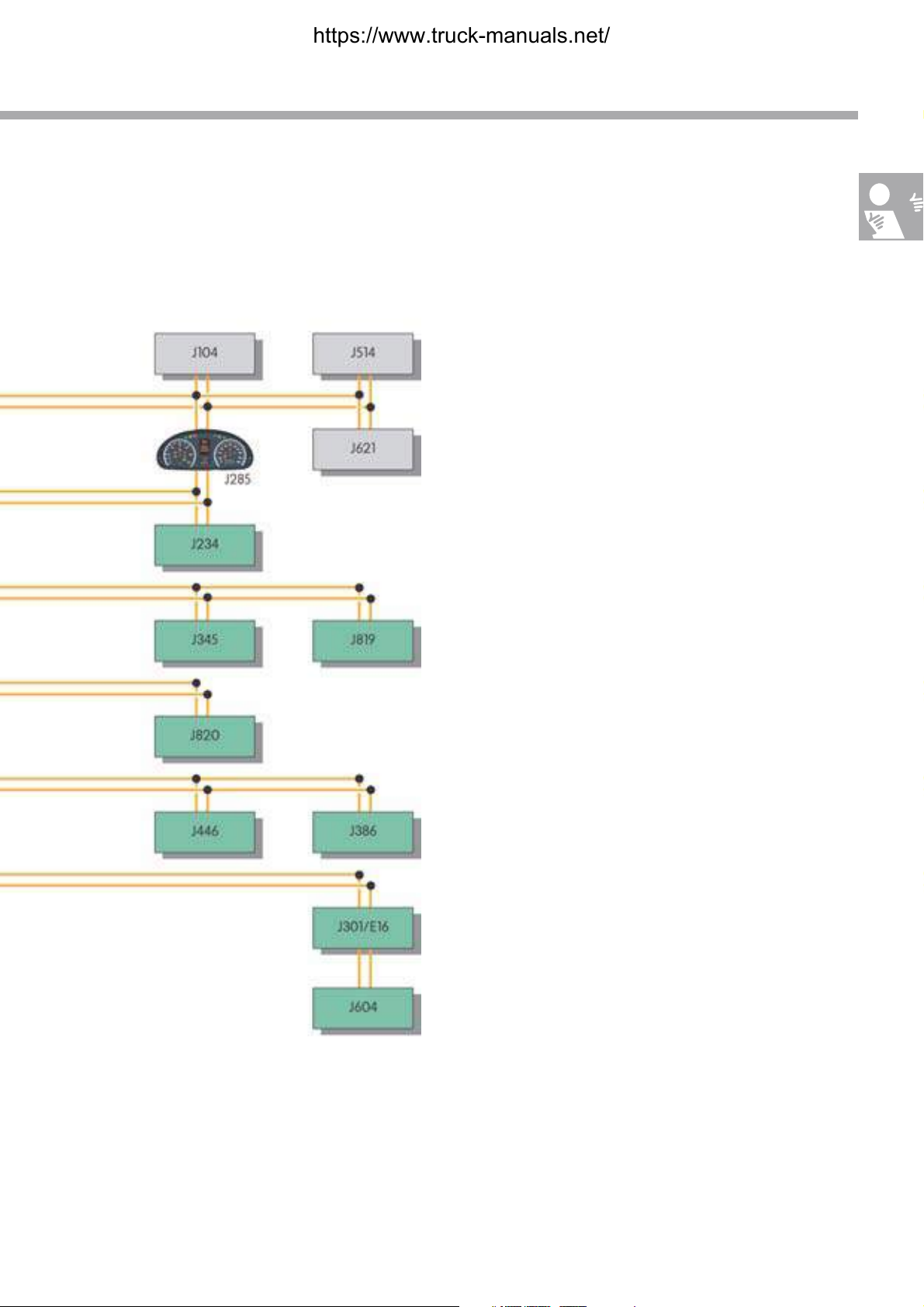

Legend

D9 Electronic ignition lock

E16 Heater/heat output switch

J104 ABS control unit

J234 Airbag control unit

J285 Control unit in dash panel insert

J301 Air conditioning system control unit

J345 Trailer detector control unit

J364 Auxiliary heater control unit

J386 Driver door control unit

J412 Mobile telephone operating electronics control unit

J446 Parking aid control unit

J502 Tyre pressure monitor control unit

J503 Control unit with display for radio and navigation

J514 Electronic manual gearbox control unit

J519 Onboard supply control unit

J527 Steering column electronics control unit

J528 Roof electronics control unit

J604 Auxiliary air heater control unit

J621 Tachograph control unit

J623 Engine control unit

J764 Electronic steering column lock control unit

J819 Control unit for middle of dash panel

J820 Control unit for programmable special functions

S370_001

R Radio

R41 CD changer

T16 16-pin connector (diagnostic connection)

5

Page 6

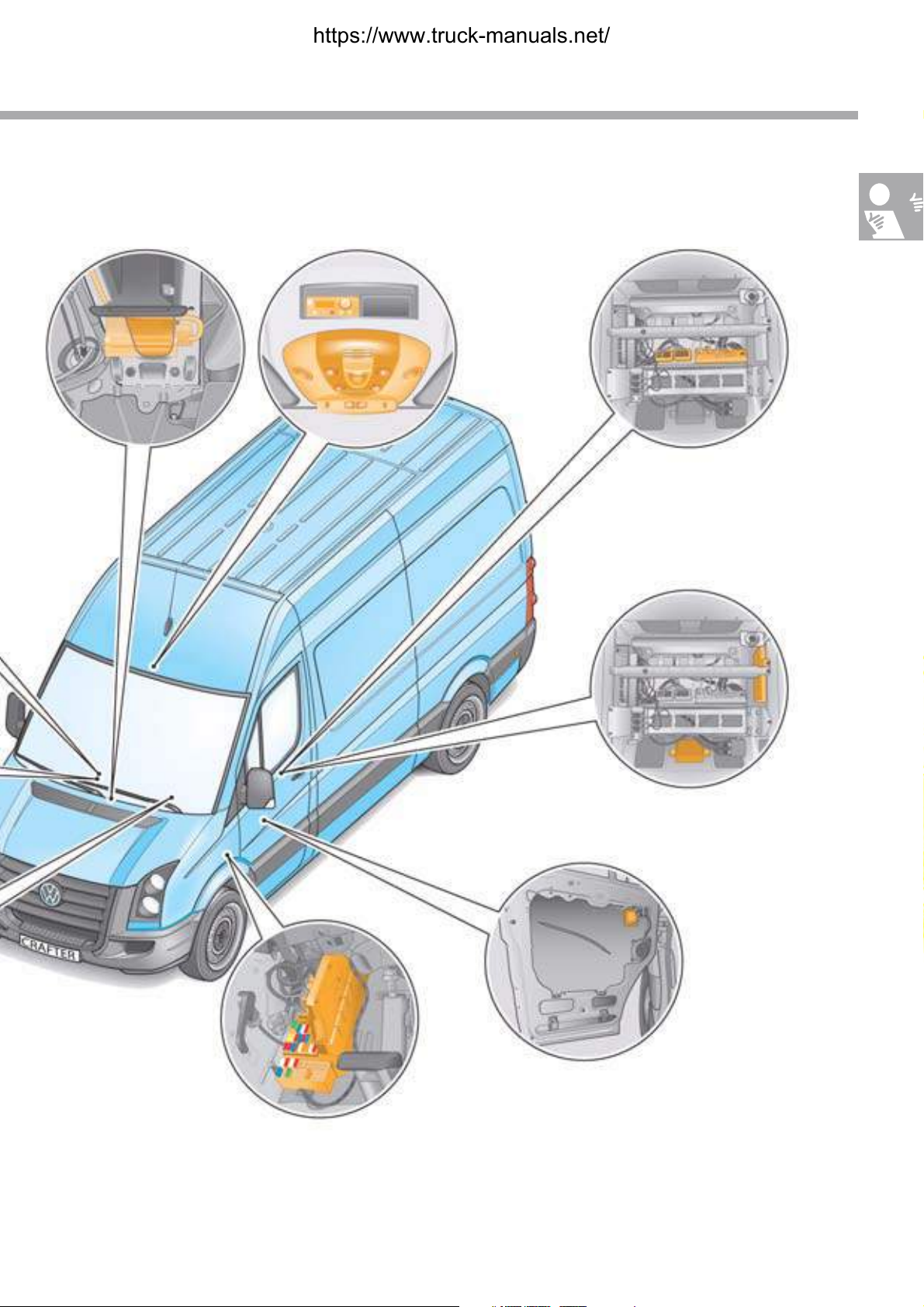

Introduction

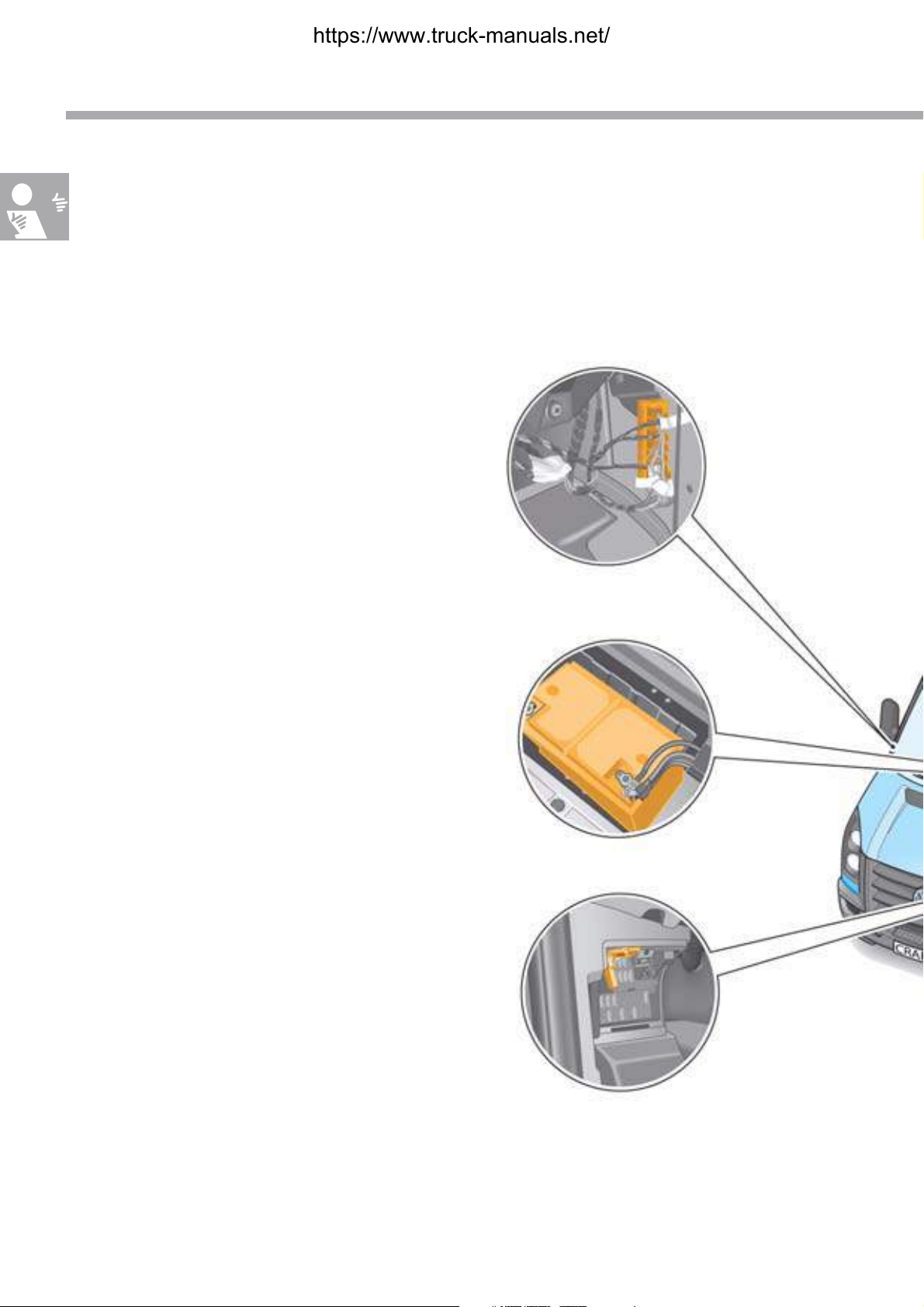

Installation locations of the electrical components

Overview of installation locations

The vehicle electrical system has a decentralised

structure; the fuse and relay installation locations are

therefore in different locations throughout the vehicle.

Junction boxes 2 and 3 for

bus systems,

on the right A pillar

Fuse holder (SA),

on right-hand side of battery, visible only following

removal

Connector (T16, diagnostic connection),

on the left A pillar

6

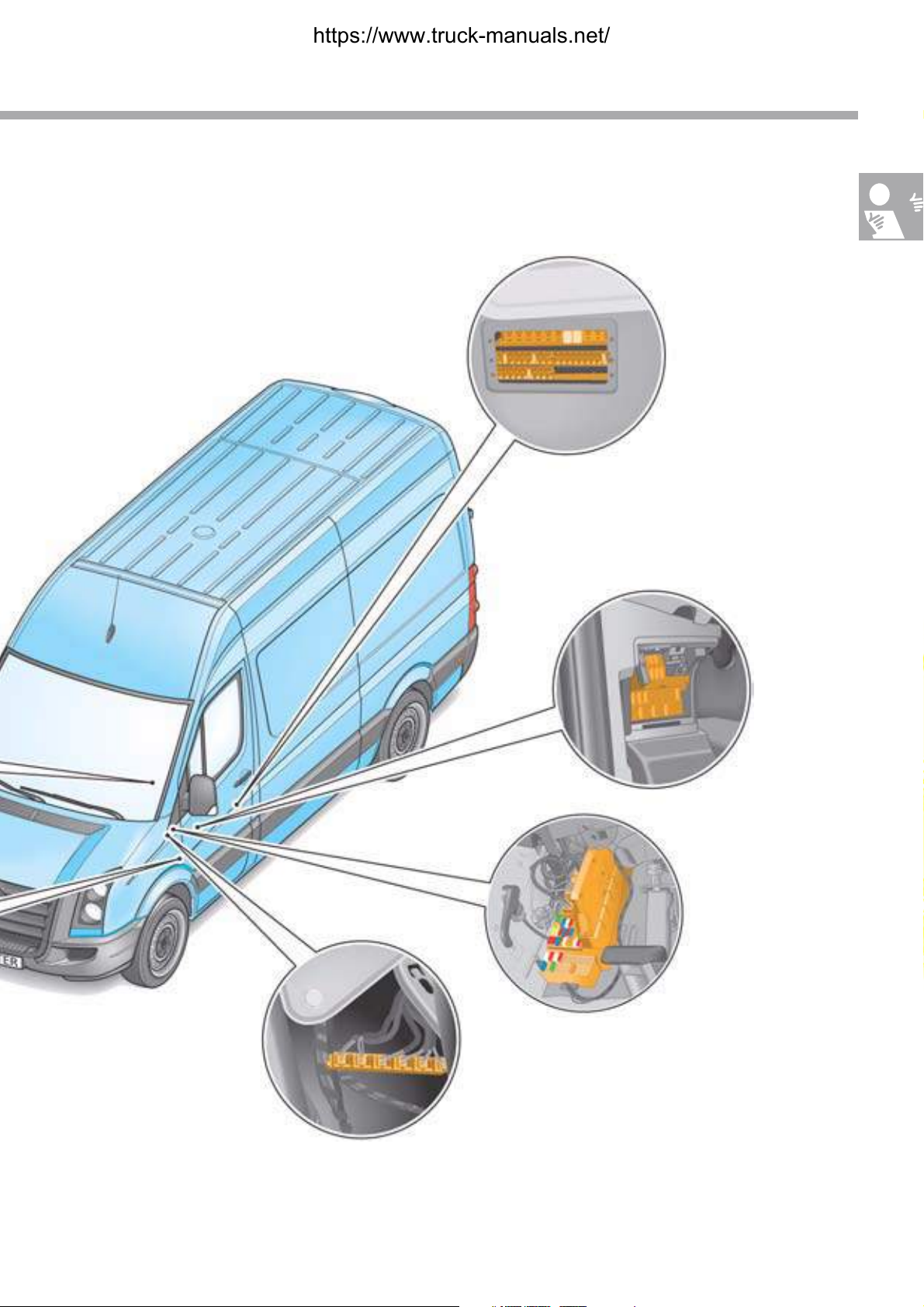

Page 7

Fuse holder D (SD),

beneath the driver's seat

Fuse holder B (SB),

left A pillar

Junction box 1 for bus systems,

beneath the front left dash panel

Fuse holder C (SC),

on the left A pillar

S370_002

7

Page 8

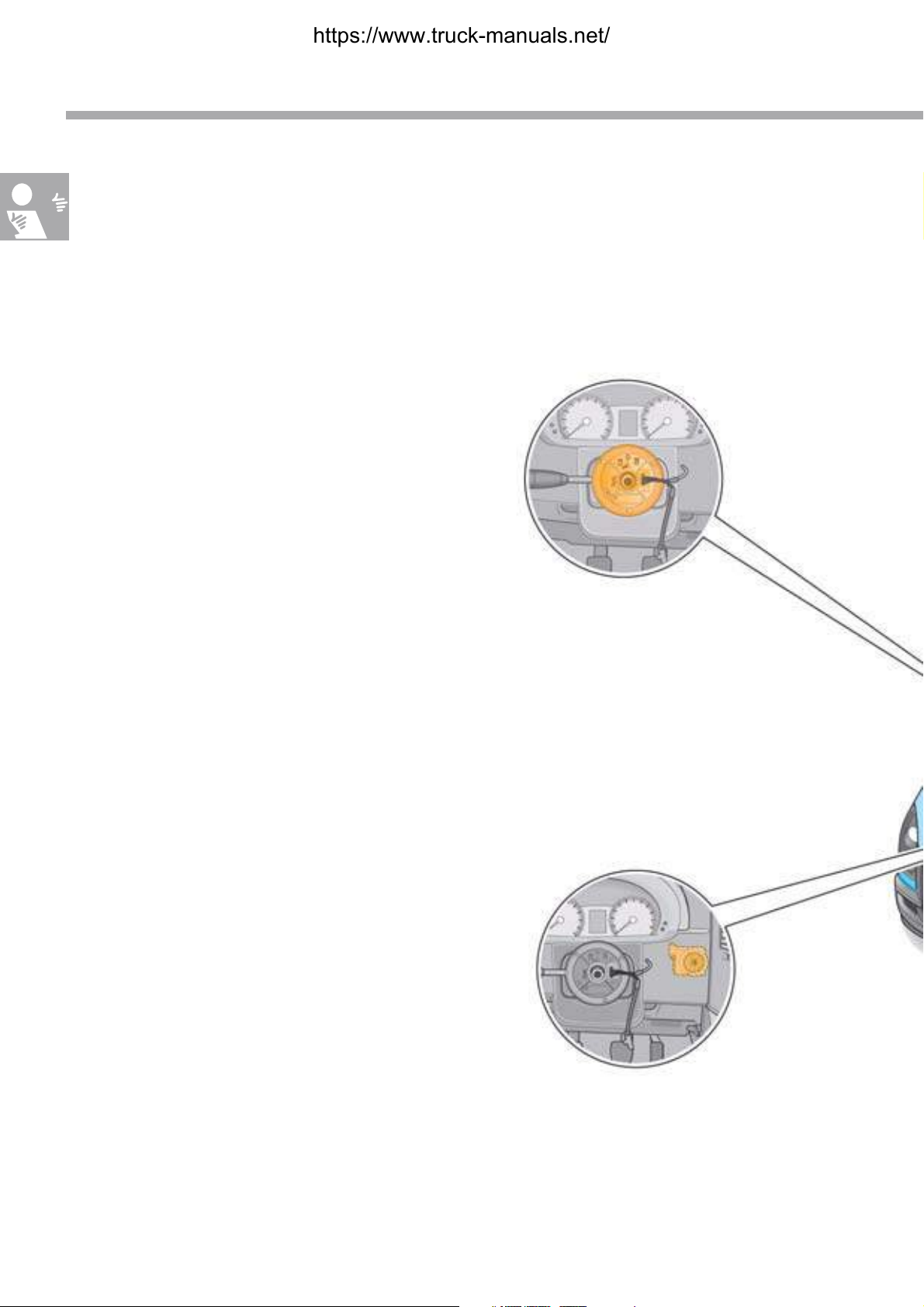

Introduction

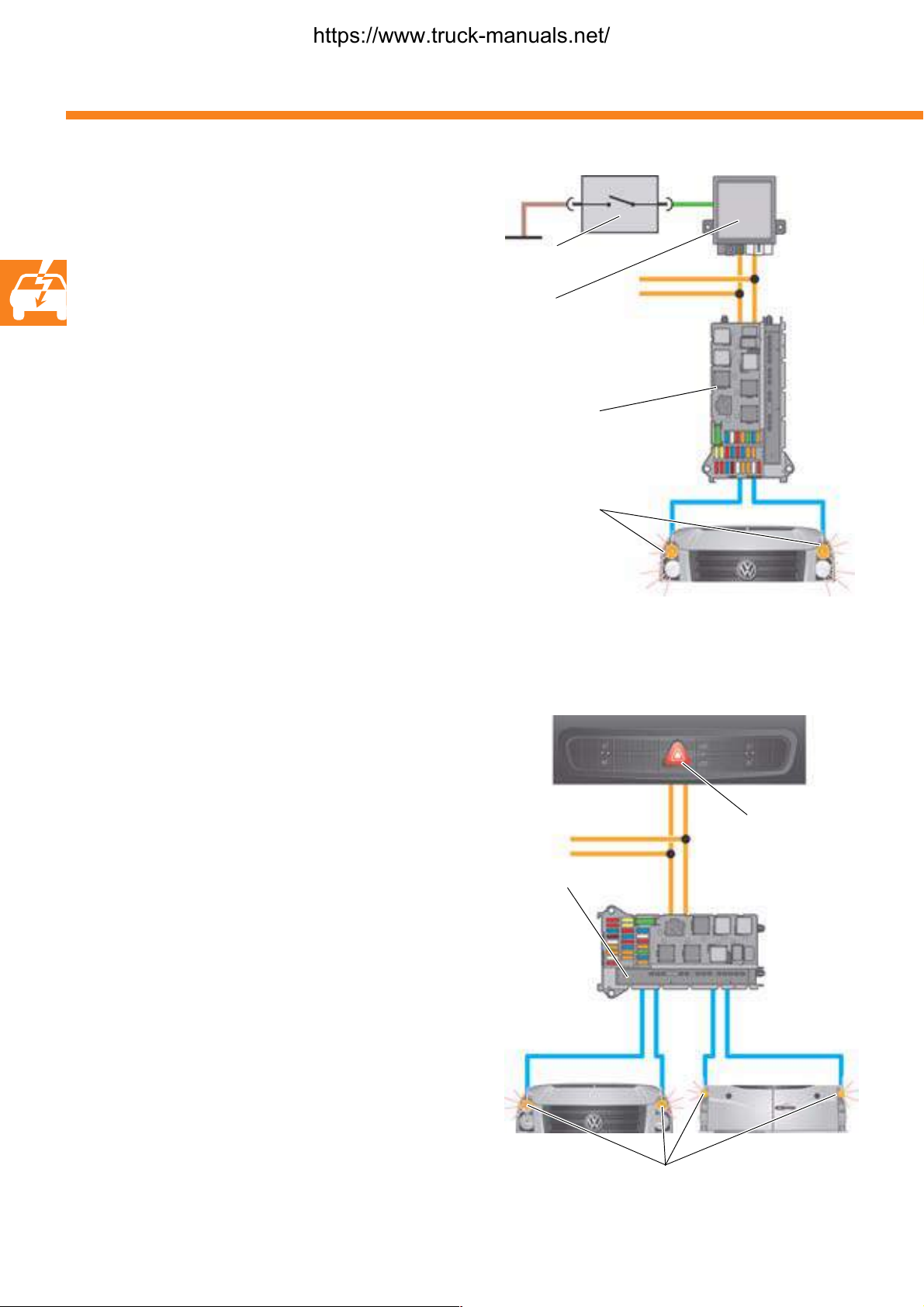

Installation locations of the control units in the CAN drive data bus

Control units and installation

locations

The adjacent illustration shows the control units which

take part in CAN drive data bus data communication

and their installation locations.

Data are transmitted at a speed of

500 kbit/s. Transmission is carried out via the

CAN high cable and the CAN low cable.

CAN high cables are green/white and the

CAN low cables are green.

To ensure reliable data transmission,

the CAN cables are twisted together.

The CAN drive data bus is not 1-wire-capable;

if a CAN cable fails, no data transmission is possible.

Steering column electronics control

unit J527,

on the steering column

Electronic ignition lock D9,

on the right next to the steering wheel

8

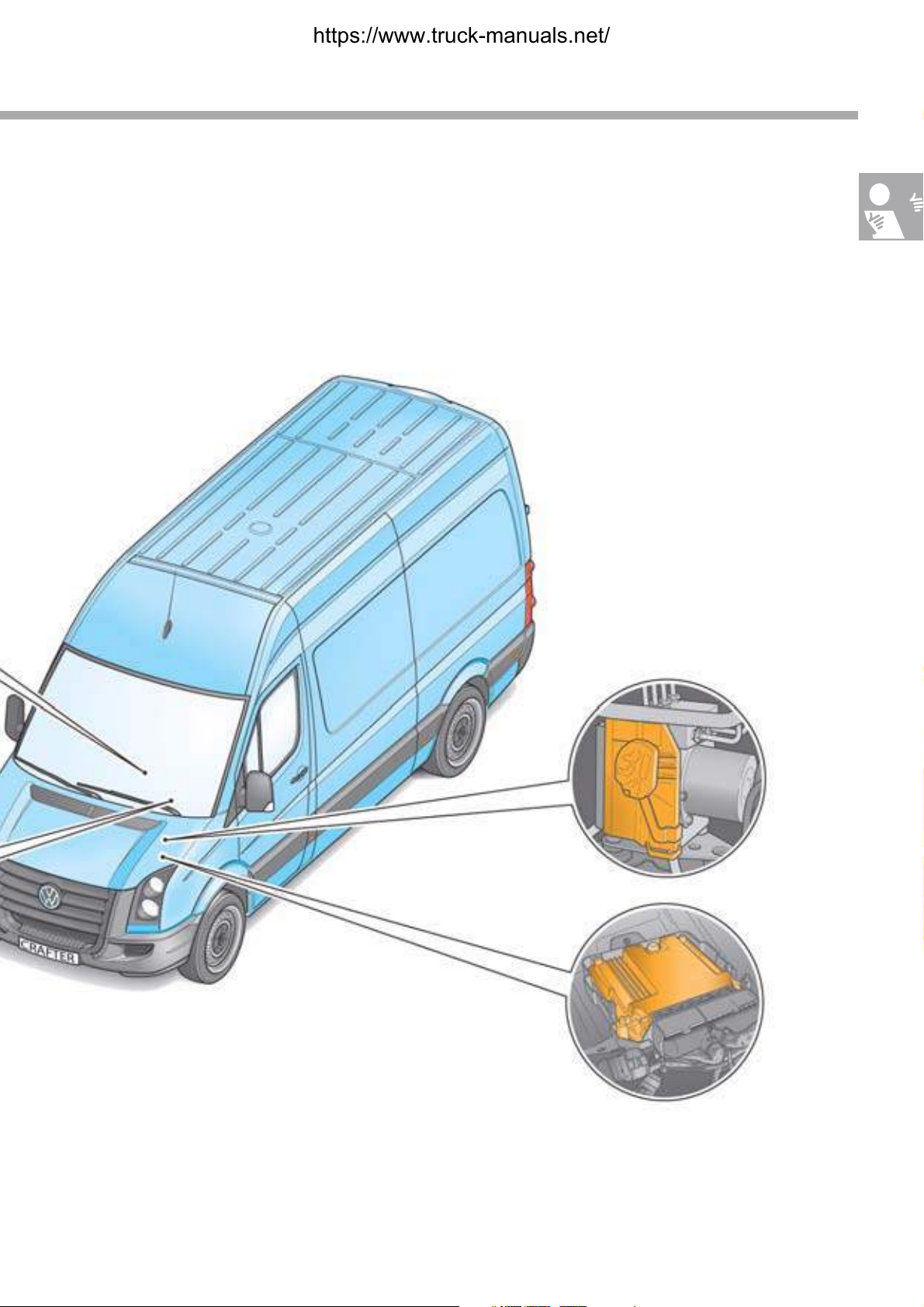

Page 9

ABS control unit J104,

on the left in the engine compartment

Engine control unit J623,

on the left in the engine

compartment

S370_004

9

Page 10

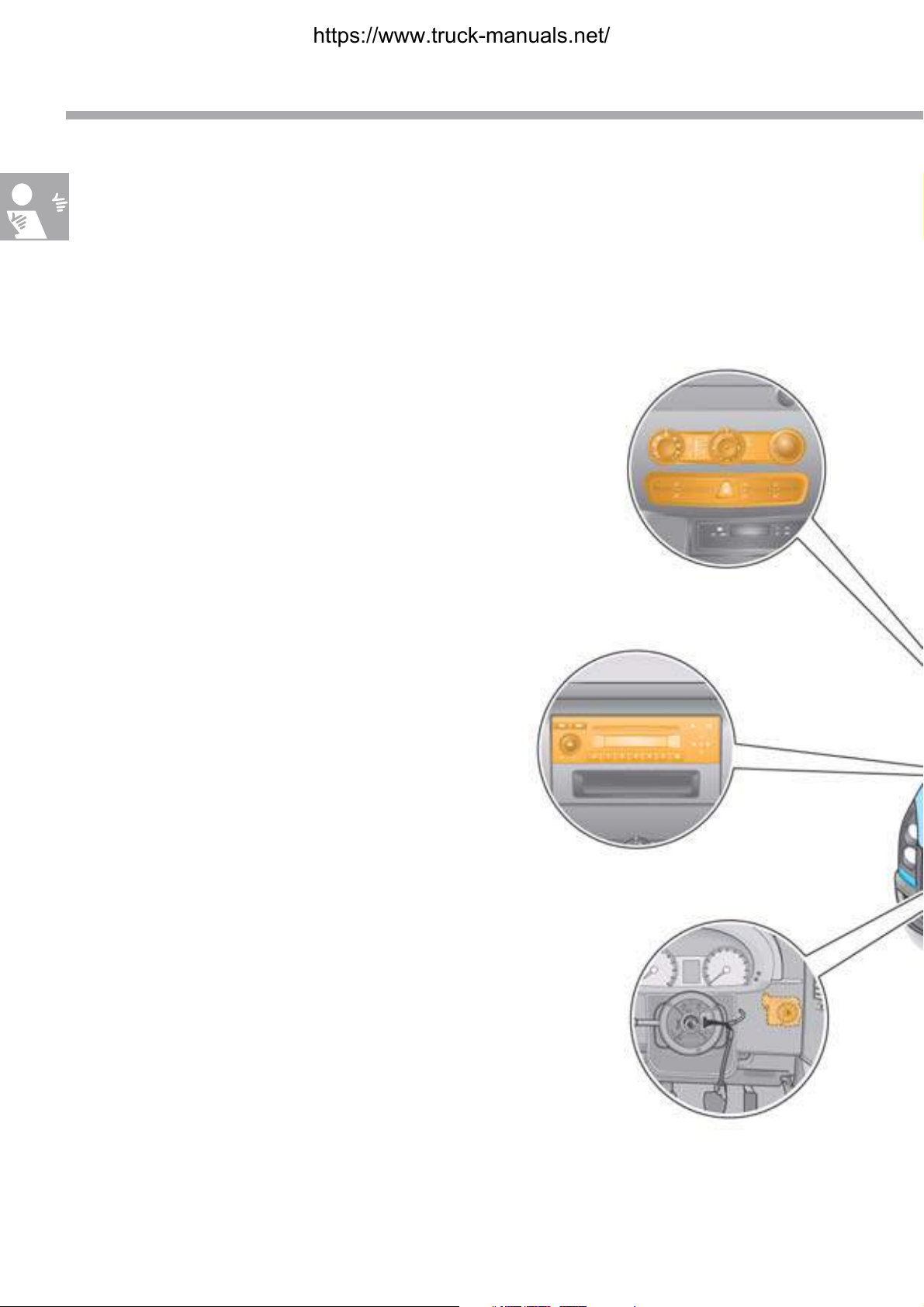

Introduction

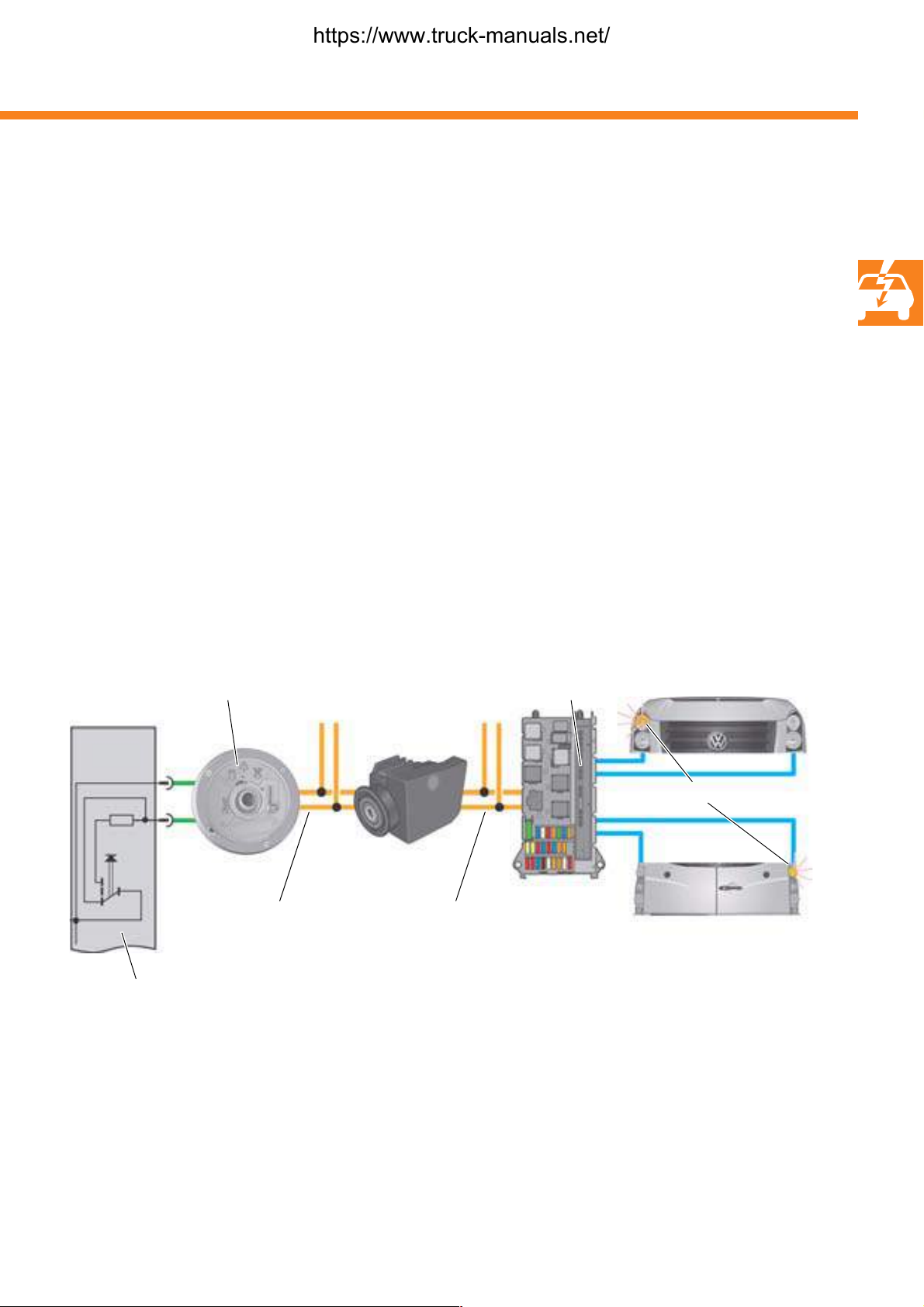

Installation locations of the control units in the CAN convenience

data bus

Control units and installation

locations

The adjacent illustration shows the control units which

take part in CAN convenience data bus data

communication and their installation locations.

Data are transmitted at a speed of

83.3 kbit/s. Transmission is carried out via the CAN

high cable and the CAN low cable.

CAN high cables are brown/red and the CAN low

cables are brown.

Air conditioning system control unit J301,

in centre of dash panel

To ensure reliable data transmission, the CAN

cables are twisted together.

The CAN convenience data bus is 1-wire-capable;

if a CAN cable fails, data transmission remains

possible.

Control unit for middle of dash panel J819,

in centre of dash panel

Radio R/control unit with display for radio and

navigation J503 *,

in centre of dash panel

10

* Acts as the interface for the MOST

infotainment data bus

Electronic ignition lock D9,

on the right next to the steering

wheel

Page 11

Airbag control unit J234,

beneath the centre console

Auxiliary heater control unit J364,

in moulded headlining near to the interior mirror

Roof electronics

control unit J528,

in moulded

headlining near to

the interior mirror

Trailer detector control

unit J345,

beneath the front left seat

Control unit for programmable

special functions J820,

beneath the front left seat

Parking aid control unit J446,

beneath the front left seat

Tyre pressure monitor control unit J502,

beneath the front left seat

Onboard supply control unit J519,

on the left A pillar

Driver door control unit J386,

in the front left door

S370_003

11

Page 12

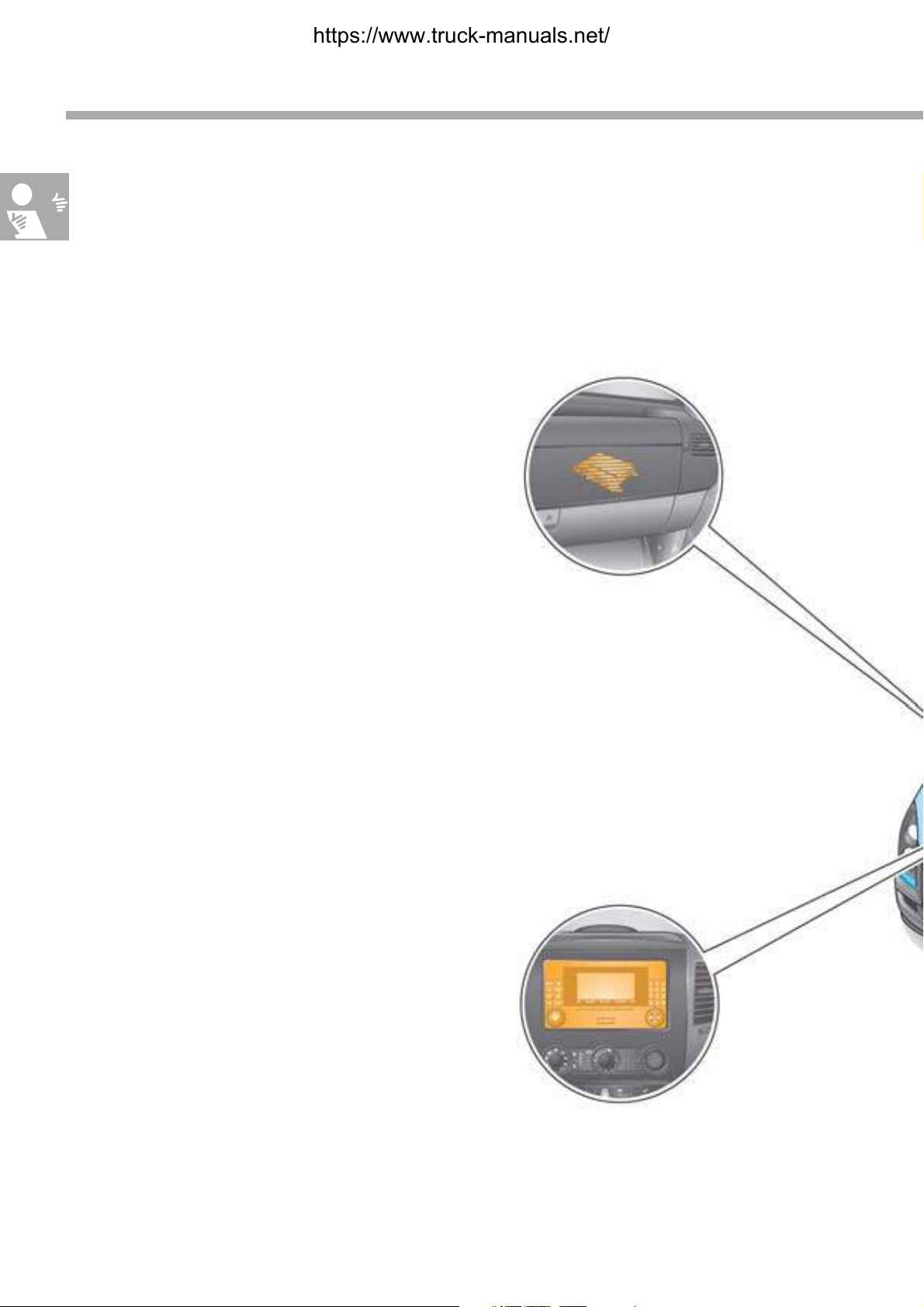

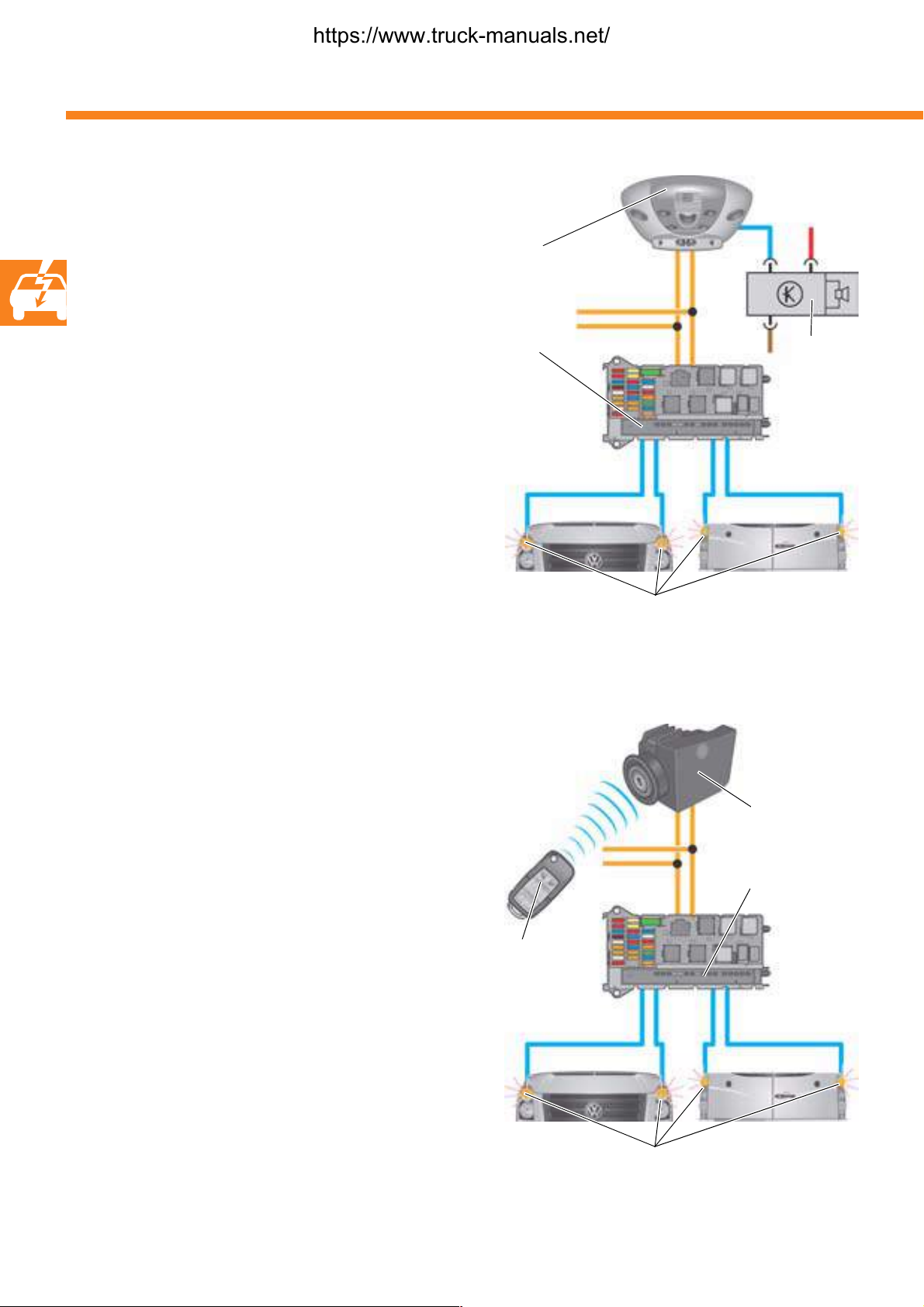

Introduction

Installation locations of the control units in the MOST infotainment

data bus

Control units and installation

locations

Besides the familiar CAN data bus systems,

the Volkswagen Crafter is also equipped with an

optical data bus system.

This data bus system has been named according

to the "Media Oriented Systems Transport" (MOST)

cooperation.

This co-operation has been established by various car

manufacturers, their suppliers and software

companies in order to implement a standardised

system for fast data transmission.

The optical MOST data bus is used to exchange data

between the radio/control unit with display for radio

and navigation, the CD changer and the mobile

telephone operating electronics control unit by means

of light waves.

In comparison with radio waves, light waves have

very short wavelengths, do not generate

electromagnetic interference waves, are

simultaneously insensitive to these and have

a significantly higher data transmission rate than

electronic data bus systems.

On routing, the radius of the fibre optical cable must

be at least 25 mm.

Mobile telephone operating

electronics control unit J412,

behind the glove box

12

Control unit with display unit for radio and

navigation J503/radio R,

in centre of dash panel

Page 13

CD changer R41,

centre of vehicle interior

S370_071

During diagnosis, please observe the

Guided Fault Finding instructions.

13

Page 14

Vehicle electrical system

Batteries

Equipment

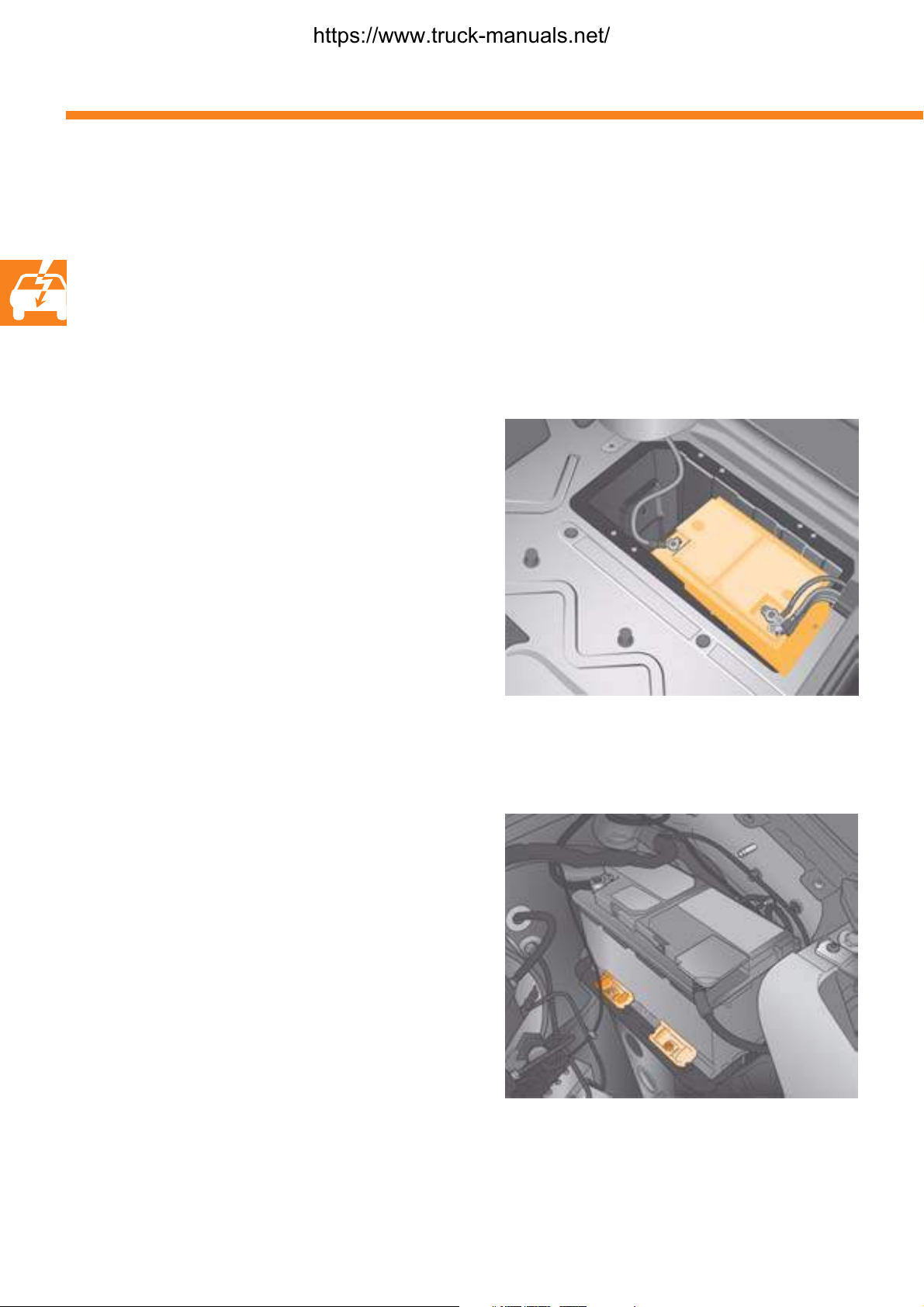

The Volkswagen Crafter can be optionally equipped

with a dual-battery vehicle electrical system; in this

case, a starter and a vehicle electrical supply battery

are installed.

Starter battery

The vehicle electrical system's standard 12 V vehicle

voltage is supplied by the maintenance-free starter

battery. The starter battery is installed in the covered

battery recess in front of the driver's seat (left-hand

drive vehicle) or the front passenger's seat (right-hand

drive vehicle).

A vent pipe emerges into the open air from the recess.

Vehicle electrical system battery

To supply high-current, body-side consumers,

a second battery, located on the left of the engine

compartment, is available in addition to the starter

battery (left-hand drive vehicles only). This second

battery is not intended as a starter battery.

By supplying the high-current consumers, it is instead

intended to protect the starter battery from discharge,

thereby maintaining the vehicle's ability to start.

S370_049

S370_050

14

Page 15

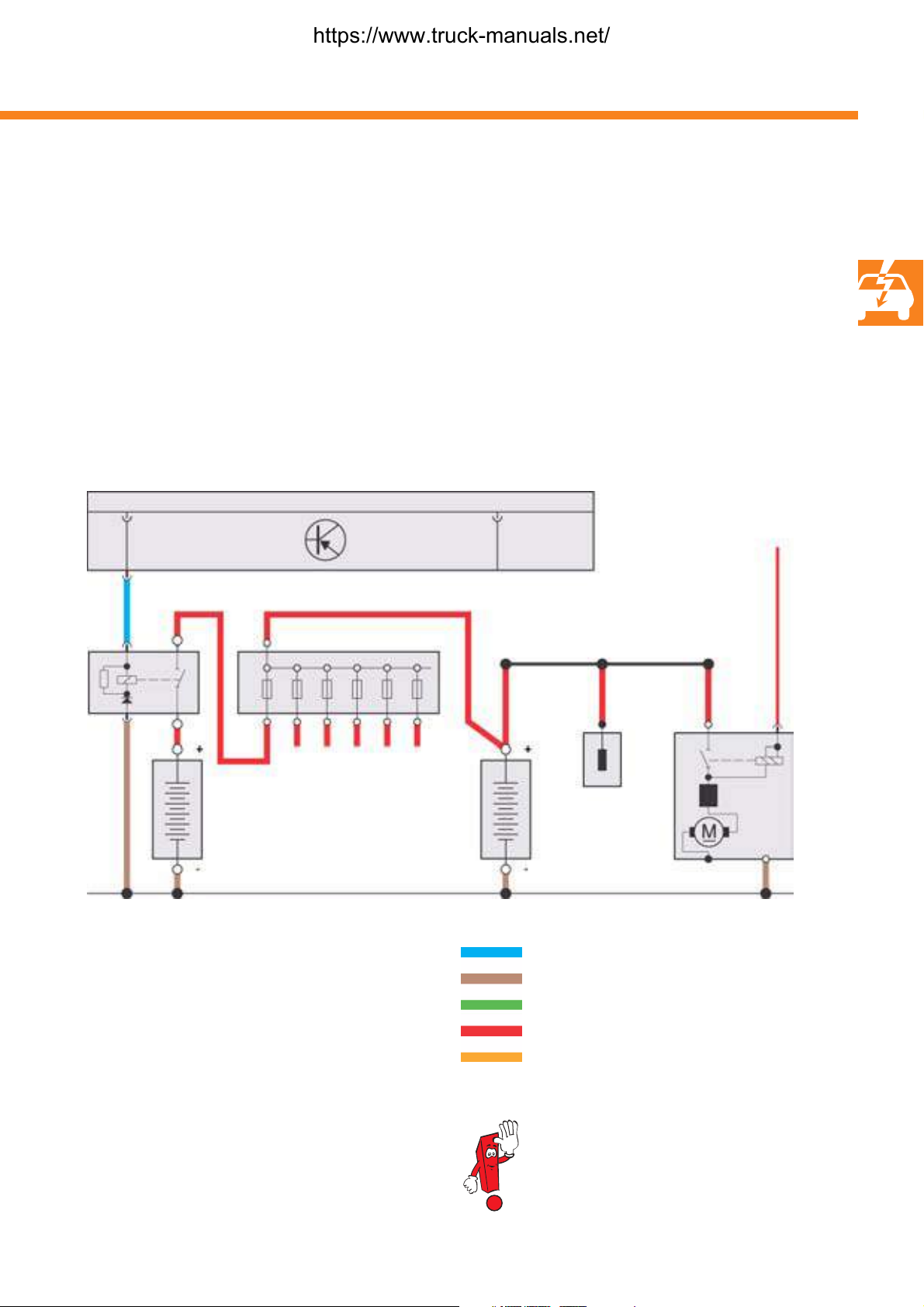

Functional diagram

The second battery A1 is only available in

combination with the battery isolation relay J7.

This prevents battery A from being drained by

consumers which are connected to the second battery.

At the same time, drainage of the second battery

by the standard consumers is prevented.

J7 SA

A1 A

Legend

ABattery

A1 Second battery

BStarter

J7 Battery isolation relay

J519 Onboard supply control unit

SA Fuse holder A

TV32 Jump start connection

J519

SSSSSS

TV32

B

S370_051

Signal output

Ground

Signal input

Positive

CAN data bus cable

The signal cable colours shown in the illustration

apply to all subsequent functional diagrams.

15

Page 16

Vehicle electrical system

Jump start connections

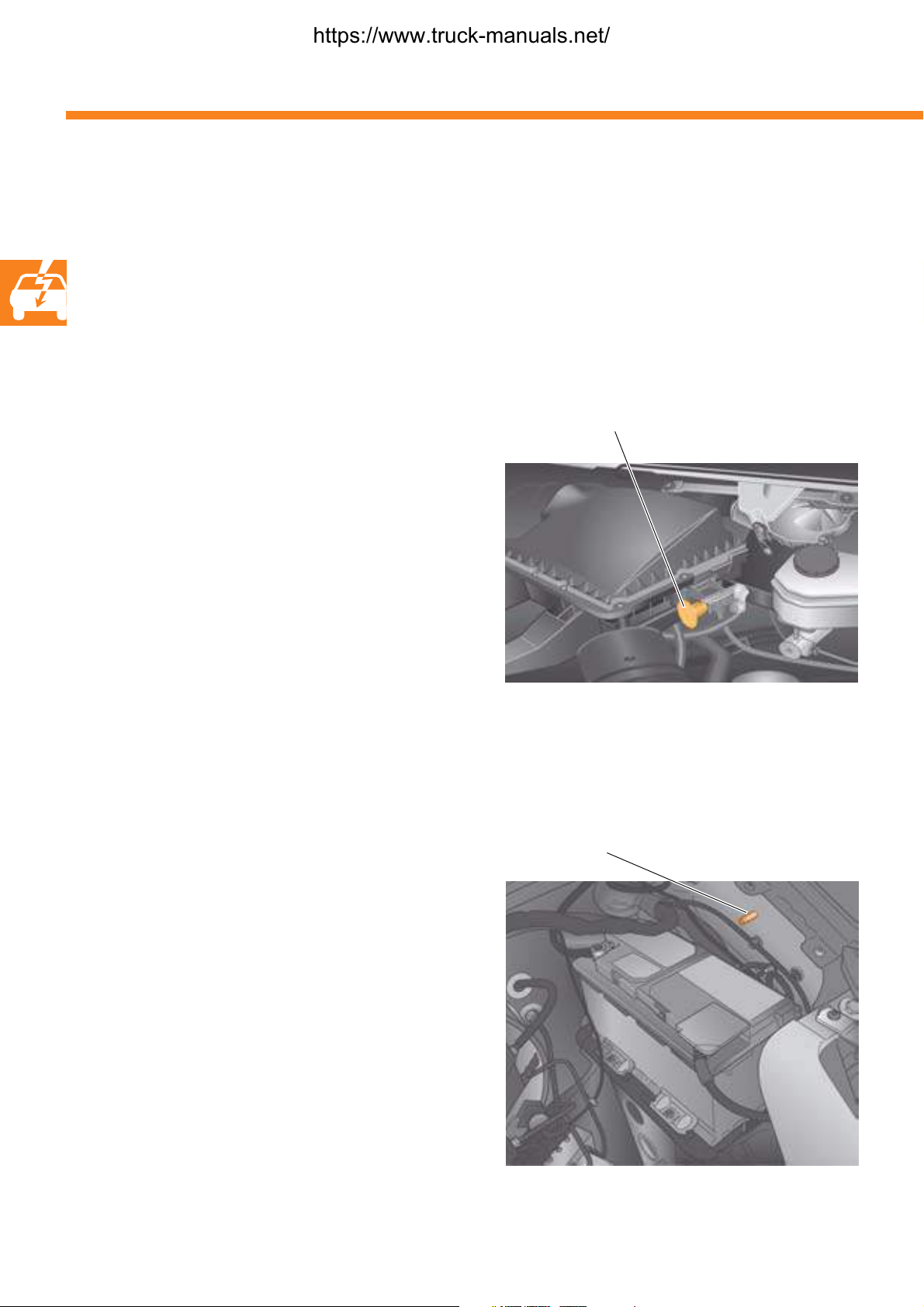

Equipment

The Volkswagen Crafter is equipped with a positive

and a negative connection for jump-starting and for

charging the battery.

Positive jump start connection

To connect a jump-starting cable or a battery charger,

a connection point for the positive cable is located on

the left-hand side of the air filter housing in the

engine compartment.

Negative jump start connection

Jump start connection

S370_052

Jump start connection

16

To connect a jump-starting cable or a battery charger,

a connection point for the negative cable is located

on the left-hand wing in the engine compartment.

S370_053

Page 17

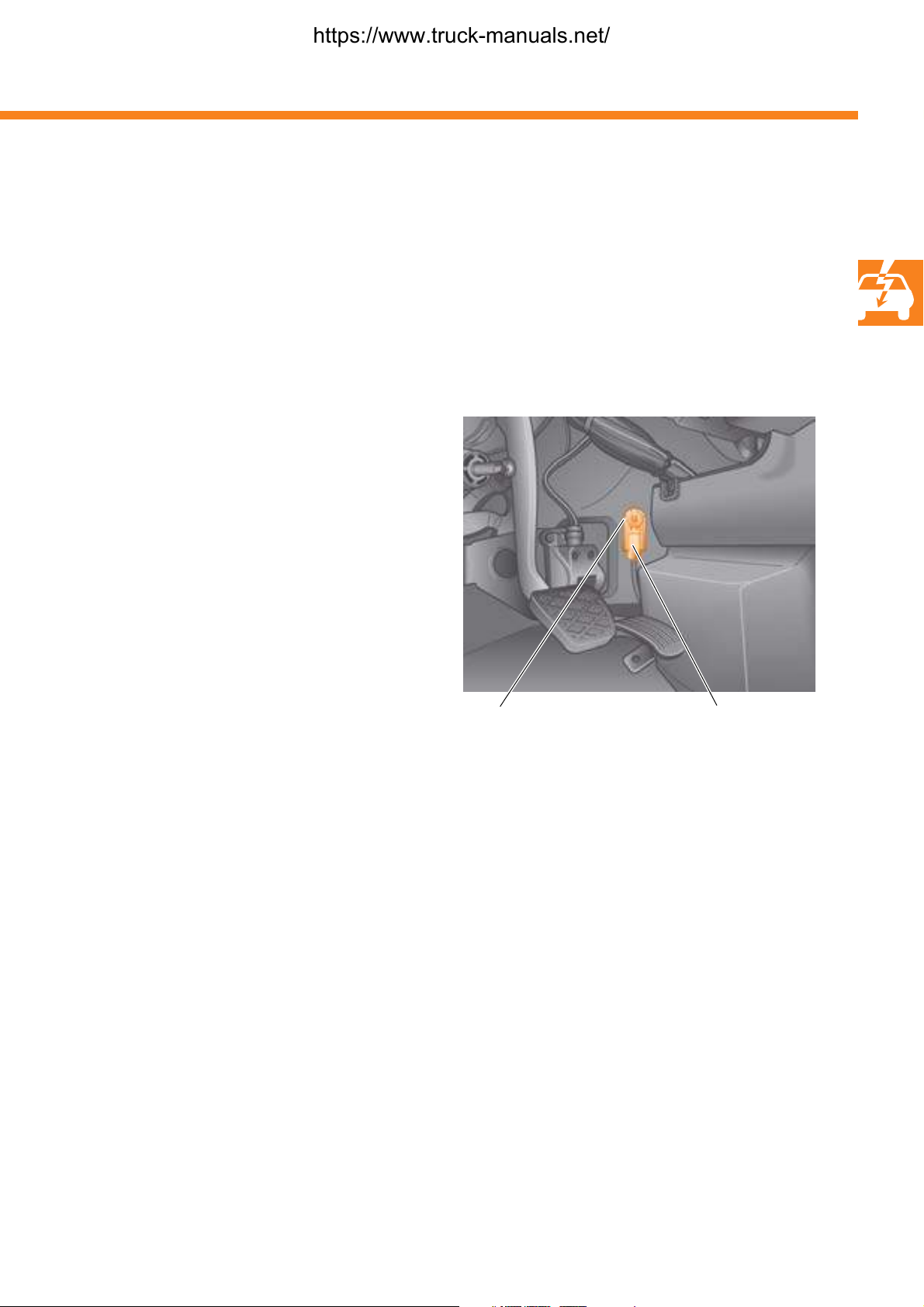

Negative main connection

The optional, main connection for the battery

negative cable is located on the right next to the

accelerator pedal.

The connection and the ground bolt can be separated

by pulling the red actuation tab.

This enables the battery to be isolated from the

vehicle electrical system if necessary or prescribed for

repair work.

Main connection Actuation tab

S370_054

17

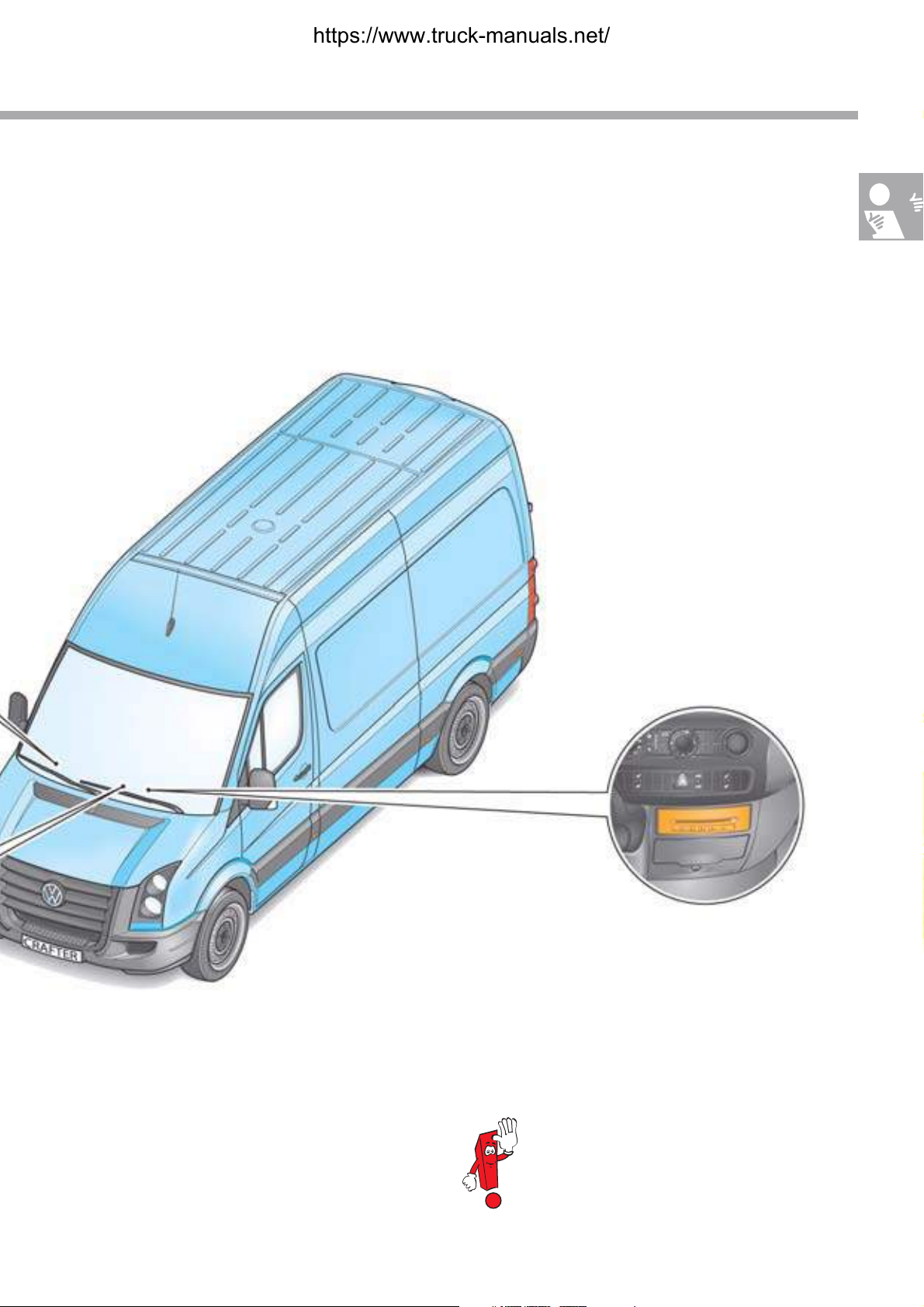

Page 18

Vehicle electrical system

Onboard supply control unit

Installation location

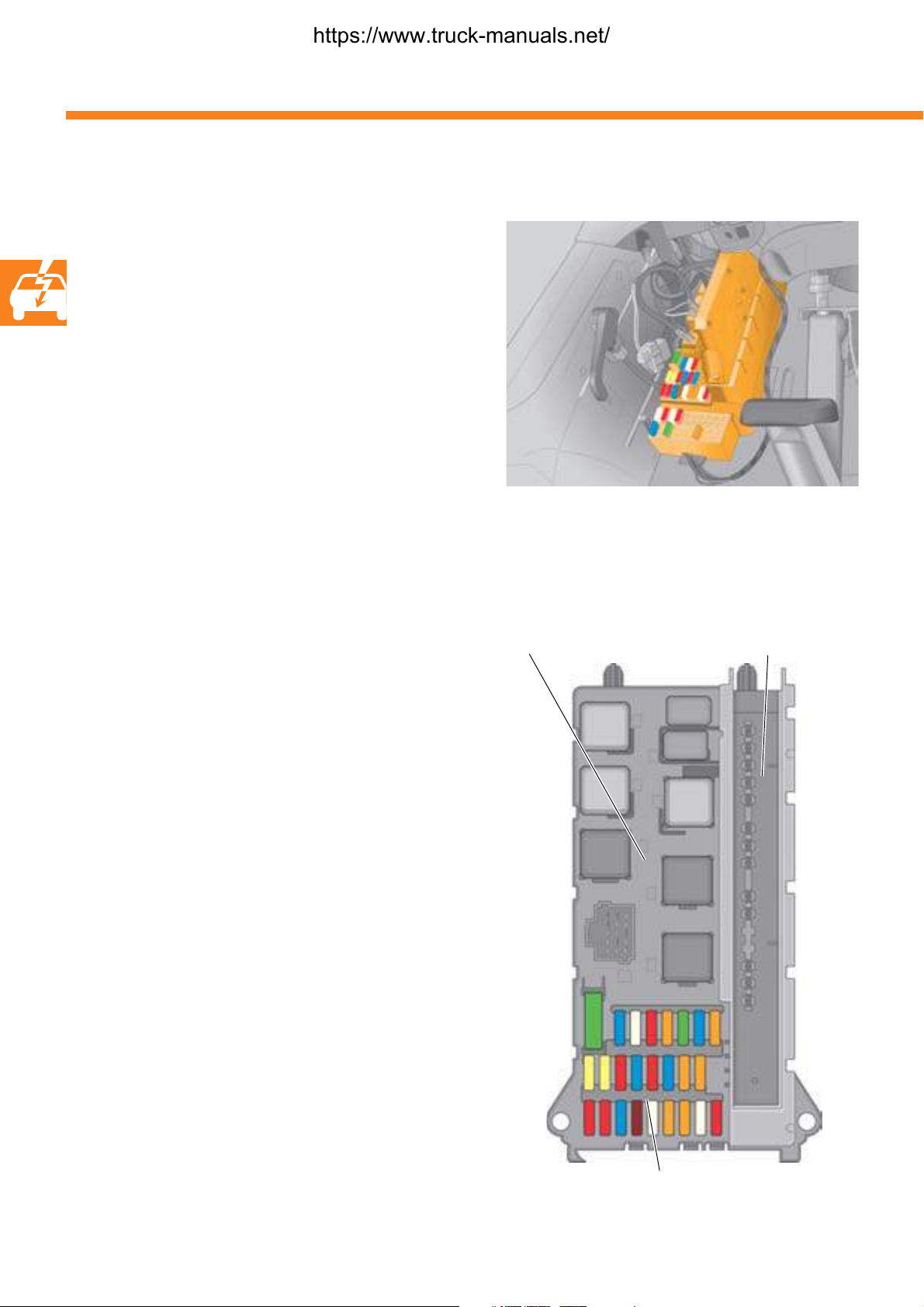

The onboard supply control unit (OBSCU) J519 is

located, together with the fuse and relay box, on

the left of the vehicle interior in the footwell beneath

the instrument panel.

Variants

It is available in the following variants:

-Standard

- Low line

-Mid line and

- High line

The different variants offer various functions.

Relay box

S370_006

Onboard supply control unit

18

Fuse box

S370_007

Page 19

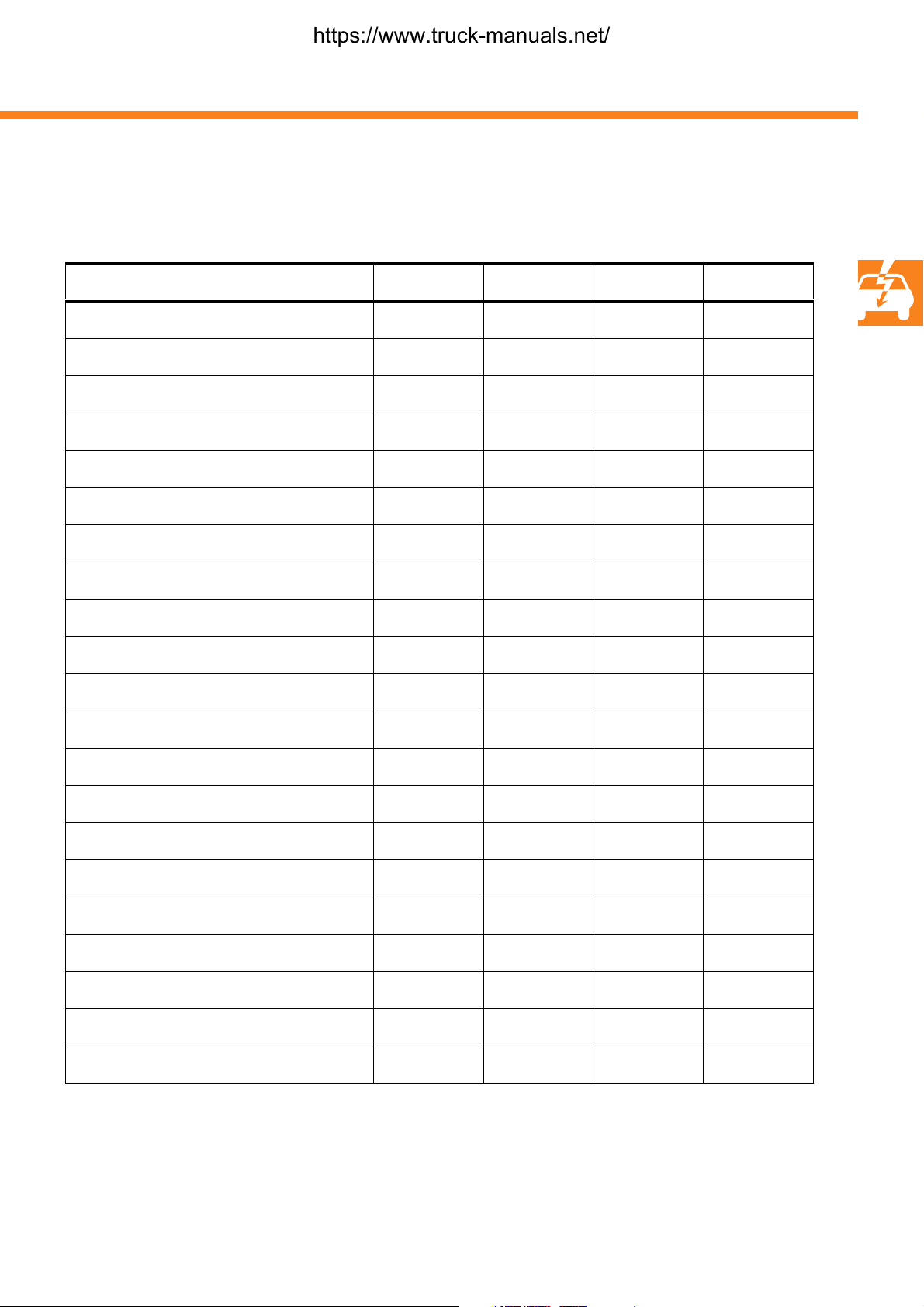

Functions

Function Standard Low line Mid-line High-line

Exterior light control system with bulb monitoringXXXX

High-level brake light X X

Fog lights XX

Turn signal actuation XXXX

Interior light control system XXXX

Interior convenience light X

Windscreen wiper and washer systemXXXX

Rear window wiper and washer system X X

Heated rear window X X

Heated windscreen X

Central locking: Sliding door, hinged rear door X X X

Central locking: 2nd sliding door X X

Rotary light switch input XXXX

Sensor signal and switch input XXXX

Vent windows X

Headlight washer system X X

Auxiliary turn signal module X X

Alarm function XXXX

ATA function XXXX

Central locking: Front passenger door XXXX

Window regulator: Front passenger door XXXX

19

Page 20

Vehicle electrical system

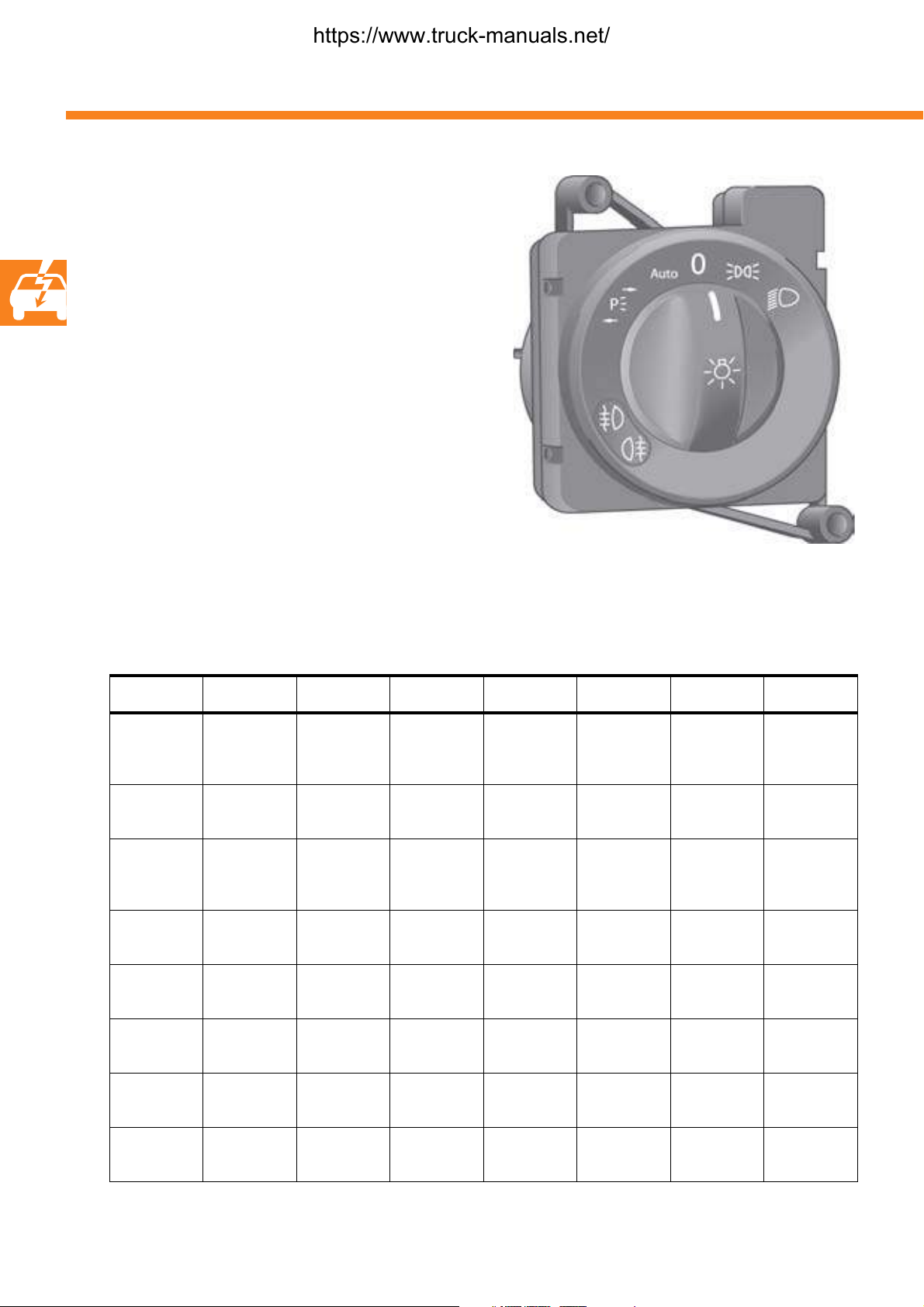

Light switch

Function

The light switch E1 is responsible for actuating the

exterior light functions. The onboard supply control

unit reads in the signals from the voltage-coded light

switch directly.

The signals for the turn signal and main beam

functions are transmitted from the steering column

electronics control unit via the CAN drive data bus

and the CAN convenience data bus.

S370_005

Variants

The light swicth is available in eight different variants.

Variant 1 Variant 2 Variant 3 Variant 4 Variant 5 Variant 6 Variant 7 Variant 8

Off Autom.

driving

lights

Side light Off Side light Off Right

Dipped

beam

Rear fog

light

Side light Dipped

Dipped

beam

Rear fog

light

Off Autom.

driving

lights

Side light Off Autom.

beam

Rear fog

light

Fog light Rear fog

Dipped

beam

light

Left parking

light

parking light

Side light Off Side light Off

Dipped

beam

Left parking

light

Right

parking light

driving

lights

Side light Dipped

Left parking

light

Right

parking light

Off Autom.

beam

Left parking

light

Right

parking light

driving

lights

Side light

20

Fog light Rear fog

light

Dipped

beam

Rear fog

light

Rear fog

light

Fog light Rear fog

Dipped

beam

light

Fog light

Page 21

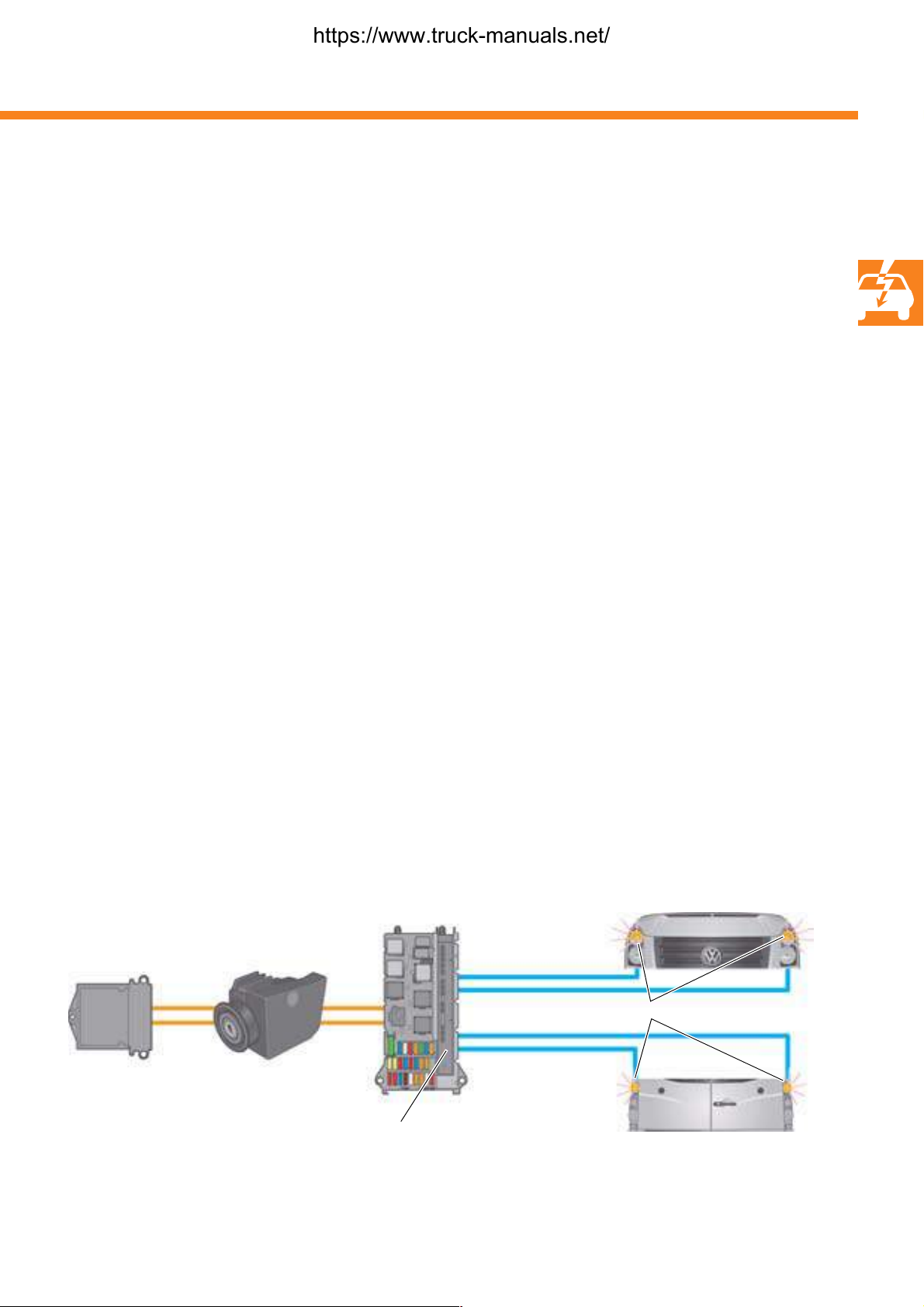

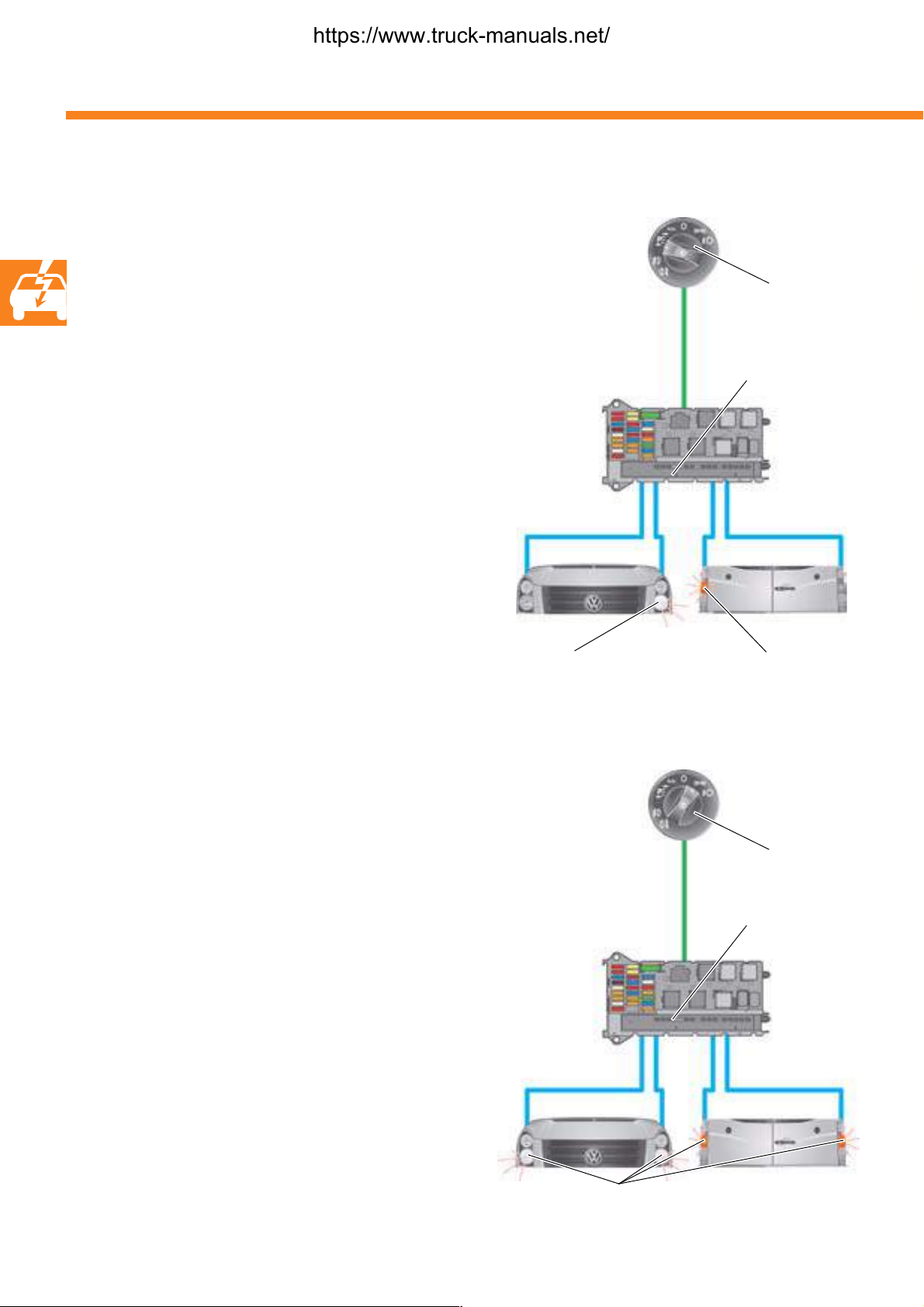

Turn signal control system

Function description

The onboard supply control unit is the master for the

turn signal function and carries out the various turn

signal functions. It receives all requests to actuate the

turn signals, prioritises these and is the only control

unit to implement a turn signal pulse on the CAN data

bus. All of the other involved control units evaluate

this turn signal pulse.

Turn signal actuation priority

The turn signals are actuated according to the

following piority:

● 1 Airbag hazard warning flashing

● 2 Special alarm flashing

● 3 Direction indication or hazard warning flashing

Airbag hazard warning flashing

In the event of airbag deployment, the airbag control

unit transmits a CAN message to the onboard supply

control unit. The hazard warning flashing function is

then triggered.

Electronic ignition lock D9

● 4 ATA alarm flashing

● 5 Central locking feedback flashing

This function is deactivated by actuating the hazard

warning lights button (E229) once or by switching the

ignition off, on and off again.

Airbag control

unit J234

Turn signal bulbs

Onboard supply control unit J519

S370_008

21

Page 22

Vehicle electrical system

Special alarm flashing

The control unit for programmable special functions

can request alarm flashing with a pre-specified on/off

phase from the onboard supply control unit.

Switch

Depending on the way in which the control unit for

programmable special functions is programmed, the

following lighting facilities can be actuated in the

event of special alarm flashing:

- Main beam,

- Fog lights and

-Turn signals

The special alarm flashing function is used,

e.g. in emergency vehicles.

Hazard warning flashing

The onboard supply control unit receives the hazard

warning flashing signal from the control unit for

middle of dash panel J819, which reads in the signals

from the hazard warning lights button E229. The

onboard supply control unit then actuates all turn

signals.

No bulb monitoring is carried out during hazard

warning flashing. The hazard warning flashing

function is always operational.

Control unit for

programmable special

functions

Onboard supply control unit

Bulbs

S370_009

Control unit for middle of dash panel

Hazard warning lights

button E229

Onboard supply control

unit J519

22

Turn signal bulbs

S370_010

Page 23

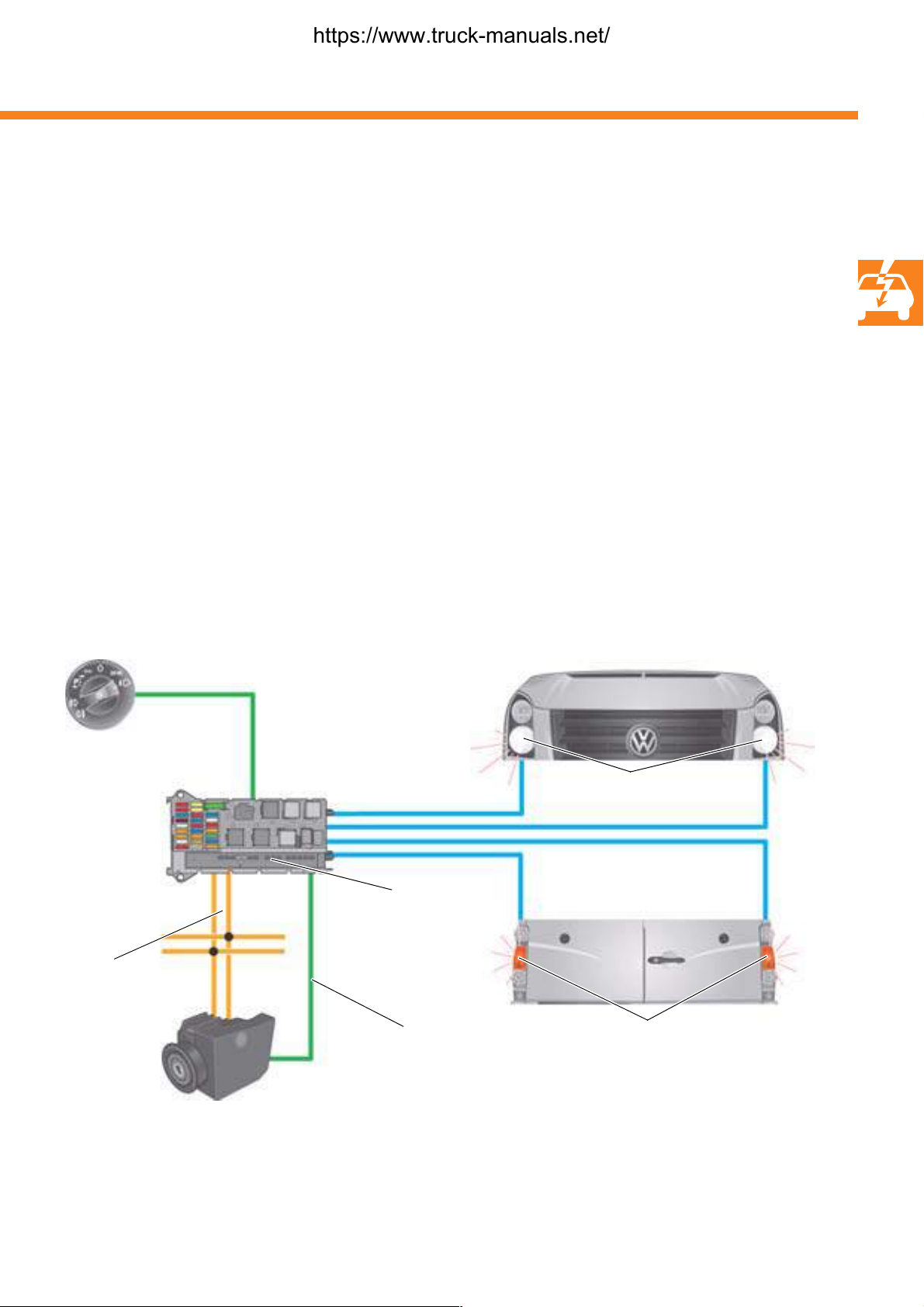

Direction indication

The signal for direction indication is received by the

onboard supply control unit from the steering column

electronics control unit J527, which reads in the signals

from the turn signal switch E2 in voltage-coded form.

The electronic ignition lock (EIL) D9 transfers the

signals from the CAN drive data bus to the CAN

convenience data bus. The onboard supply control

unit actuates the turn signal bulbs as requested.

During direction indication, the turn signal bulbs are

monitored for bulb failure.

The bulbs' flashing frequency is doubled in the event

of bulb failure. Actuation of the turn signal warning

lamps is carried out via the CAN convenience data

bus and the control unit in the dash panel insert. The

direction indication function is only active in the case

of "terminal 15 on".

Steering column electronics control unit J527

Turn signal switch E2

Onboard supply control unit J519

Turn signal bulbs, right

CAN drive data bus CAN convenience data bus

S370_011

23

Page 24

Vehicle electrical system

ATA alarm flashing

The ATA alarm flashing function is active if no

authorised key is located in the electronic

ignition lock (EIL).

The alarm is output via the alarm horn H12 and the

turn signals.

In this case, the roof electronics control unit transmits

a request to the onboard supply control unit via the

CAN convenience data bus. Bulb monitoring is not

carried out during ATA alarm flashing.

Roof electronics

control unit

Onboard supply control

unit

Alarm horn

Central locking feedback flashing

Unlocking the vehicle is indicated by all of the turn

signals' flashing twice. Locking the vehicle is indicated

by all of the turn signals' flashing once.

The request for central locking feedback flashing is

transmitted by the electronic ignition lock via the CAN

convenience data bus. This function is only active if no

authorised key is located in the electronic ignition

lock.

S370_012

Turn s i gnal s

Electronic

ignition lock

Onboard supply control

unit

Radio

remote control

24

S370_013

Turn s i gnals

Page 25

Special direction indication

The control unit for programmable special functions is

able to request direction indication from the onboard

supply control unit. The onboard supply control unit

handles this request like a request from the steering

column electronics control units, although these

requests have priority.

The control unit for programmable special functions

does not send a request, or ends its request, as soon

as it detects a request for direction indication from the

steering column electronics control unit.

Control unit for

programmable

special functions

Onboard supply control

unit

Special hazard warning flashing

The control unit for programmable special functions is

able, like the control unit for middle of dash panel,

to request hazard warning flashing from the onboard

supply control unit.

It withdraws its request as soon as it detects a request

from the control unit for middle of dash panel.

This function is deactivated either by the control unit

for programmable special functions or by actuating

the hazard warning lights button.

Turn sig n a l s

Control unit for programmable special functions

Hazard warning

lights button

Onboard

supply

control

unit

Control unit for

middle of dash

panel

S370_014

Turn sig n a l s

S370_015

25

Page 26

Vehicle electrical system

Lighting

Parking light

The left or right side light bulbs and the left or right

tail light bulbs are actuated by the onboard supply

control unit.

Light switch

The request to switch on the parking lights comes

directly from the light switch.

The parking light function is active if no authorised

key is located in the EIL.

Bulb monitoring is carried out when the parking light

function is on.

Side light and tail light

Onboard supply

control unit

S370_016

Left side light bulb Left tail light bulb

26

The left and right side and tail light bulbs are

actuated by the onboard supply control unit.

The request to switch on comes directly from the light

switch. The side and tail lights can also be switched on

if the ignition key has been removed, in which case an

acoustic signal is emitted.

Side light and tail light bulbs

Light switch

Onboard supply

control unit

S370_017

Page 27

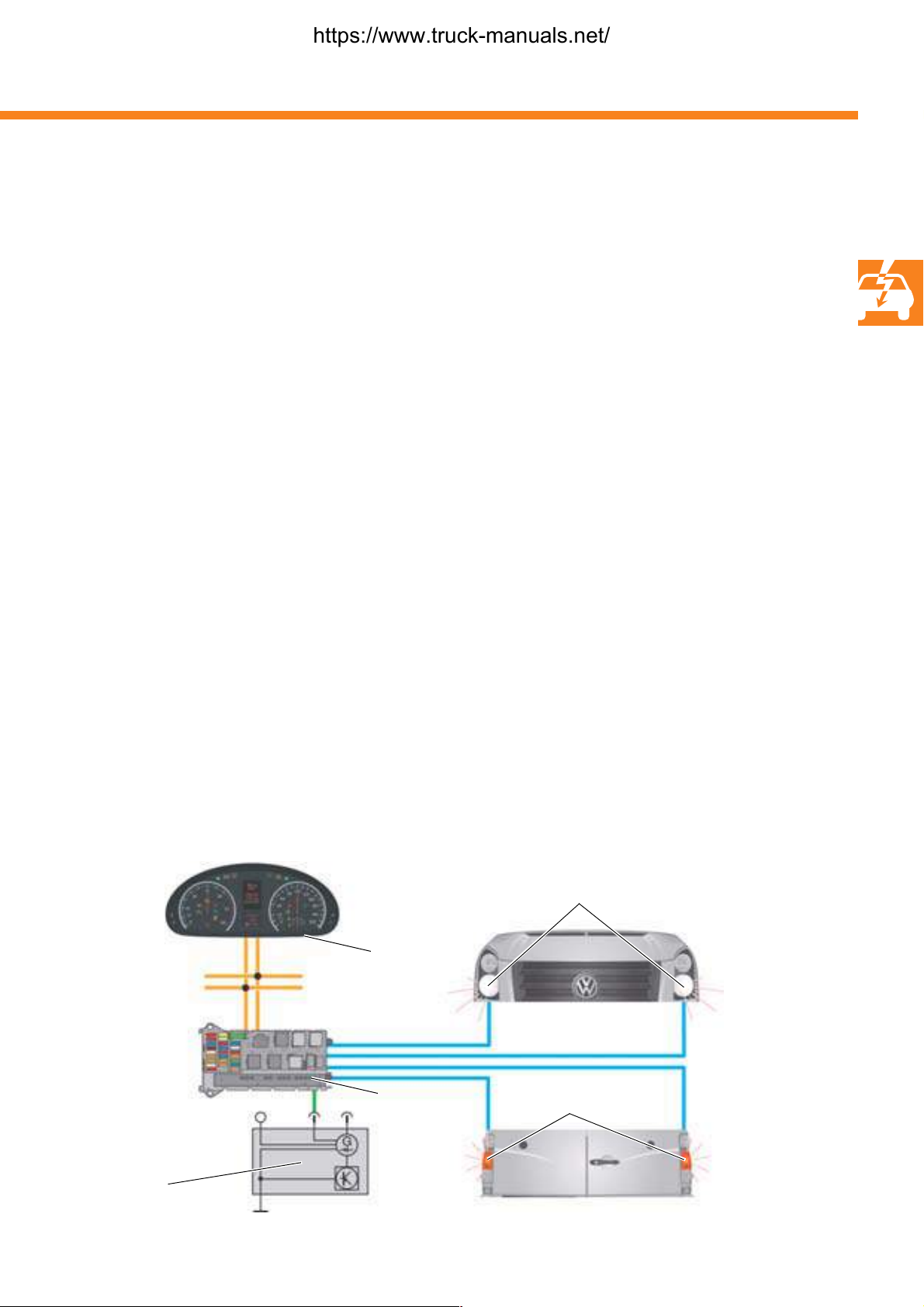

Dipped beam (driving lights)

The left and right dipped beam bulbs are actuated by

the onboard supply control unit.

The request to switch on comes directly from the light

switch. Dipped beam is switched on in the case of

"terminal 15 on" and when the switch is set to dipped

beam. The headlights, side lights, tail lights and

number plate lights are also switched on.

The side lights are switched on instead of dipped

beam in the case of "terminal 15 off".

Light switch

"Terminal 15 on"

via CAN data bus

Electronic ignition lock

Onboard supply control

unit

"Terminal 15 on" discrete

Dipped beam bulbs and

side light bulbs

Tail light bulbs

S370_018

27

Page 28

Vehicle electrical system

Automatic driving lights (option)

The automatic driving lights are controlled by the rain

and light sensor G397, which automatically switches

the driving lights on and off when the light switch is

set to the "Auto" position.

The roof electronics control unit reads in the signals

from the rain and light sensor, and sends a

corresponding message on the CAN convenience

data bus. The onboard supply control unit then

supplies the dipped beam headlight bulbs with

current.

Roof electronics control unit

Light switch Onboard supply

control unit

Rain and light sensor

Dipped beam bulbs and

side light bulbs

Tail light bulbs

S370_019

28

Page 29

Daylight driving lights (DDL)

The master for the daylight driving lights is the control

unit in dash panel insert, via which the following

functions are activated.

● Dipped beam

● Side lights

● Tail lig h t s

● Number plate lights

When the engine is running, "terminal 61 active" is

sent by the onboard supply control unit via the CAN

convenience data bus. The control unit in dash panel

insert then activates the daylight driving lights via the

onboard supply control unit.

The daylight driving light function can be activated

and deactivated via the control unit in dash panel

insert.

It cannot be deactivated in those countries in which

daylight driving lights are legally required!

The daylight driving lights are switched off when the

engine is switched off ("terminal 61 not active").

When the light switch is switched to the "side light" or

"dipped beam" position, the daylight driving lights

are also switched off, and the light function selected

at the light switch is active.

In countries in which daylight driving lights are legally

required, only the headlight flasher, not main beam, is

permissible when DDL is activated.

In countries in which the daylight driving lights can be

activated/deactivated by the user via the instrument

cluster, the headlight flasher and main beam are

permissible when DDL is activated. The logic for this is

contained in the control unit in dash panel insert

Alternator

Control unit in

dash panel insert

Onboard supply

control unit

Dipped beam bulbs and

side light bulbs

Tail light bulbs

S370_020

29

Page 30

Vehicle electrical system

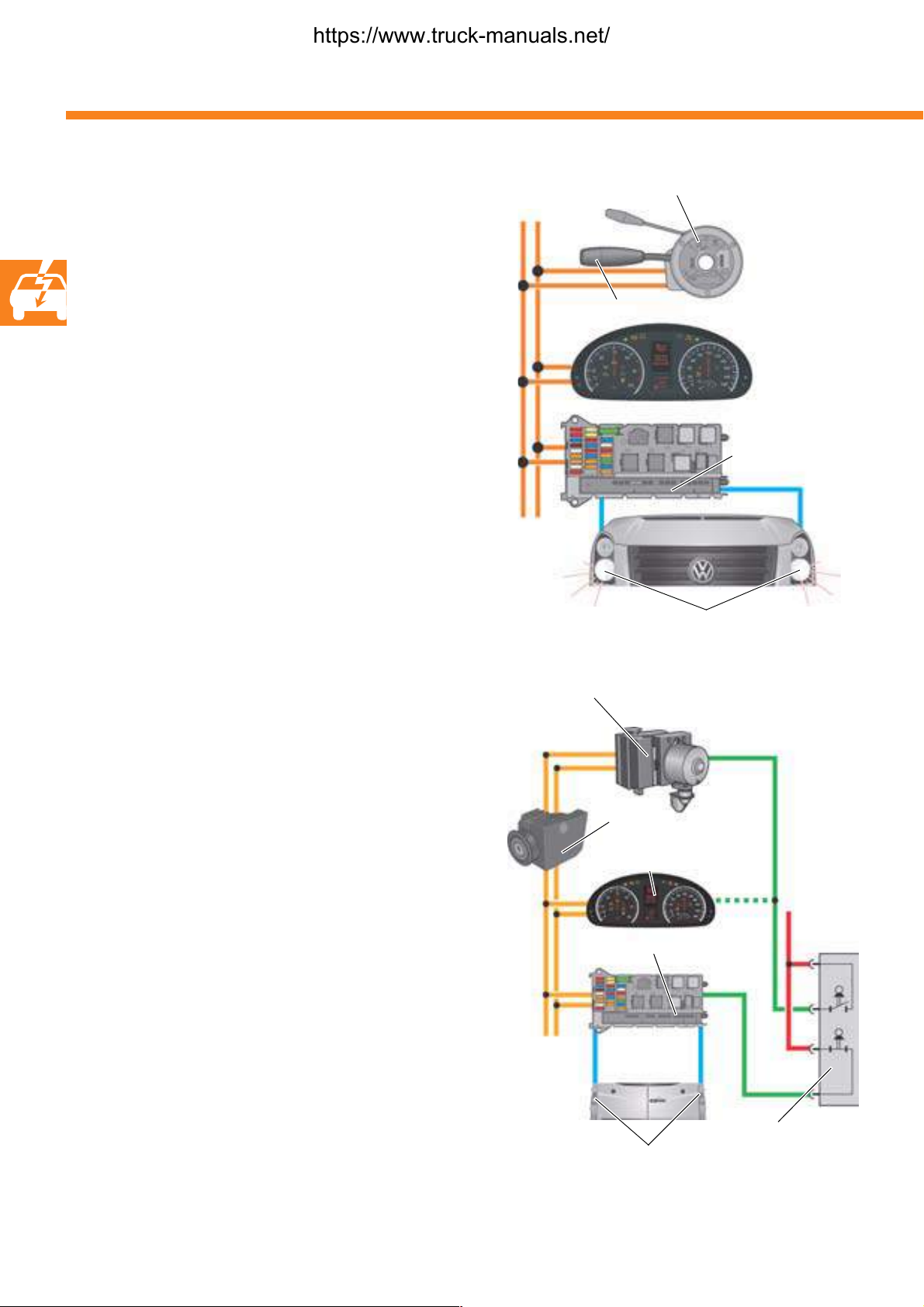

Main beam / headlight flasher

The steering column electronics control unit receives

the signals from the headlight dipper/flasher switch

E4 and, in the case of "terminal 15 on", sends

a corresponding message on the CAN convenience

data bus. The onboard supply control unit then

switches main beam or the headlight flashers on and

also sends a message on the CAN convenience data

bus, whereupon the control unit in dash panel insert

actuates the main beam warning lamp K1.

Steering column electronics control unit

Headlight dipper/flasher switch

Control unit in dash panel insert

Onboard supply

control unit

Main beam bulb

S370_021

Brake light

The brake light bulbs are actuated by the onboard

supply control unit via semi-conductors.

The request to switch on the brake lights comes

- in discrete form via brake light switch F and

- the CAN data bus via the electronic ignition lock

from the ABS control unit

- or, in vehicles without ABS, from the control unit in

dash panel insert, which reads in the information

from brake light switch F.

As soon as one of the two pieces of input information

requests brake light actuation, the brake lights are

switched on.

ABS control unit

Electronic ignition lock

Control unit in

dash panel insert

Onboard supply control unit

Brake light bulbs

Brake light switch

S370_022

30

Page 31

Reversing light

The reversing light bulbs are actuated by the onboard

supply control unit. The signals from the reversing light

switch F4 are read in by the onboard supply control

unit. The "terminal 15 on" terminal status of the

electronic ignition lock D9 is transmitted via the CAN

convenience data bus.

Electronic ignition lock

Onboard supply control unit

Reversing light switch

Reversing light bulbs

S370_026

31

Page 32

Vehicle electrical system

Emergency light

The objective of the emergency light function is to

avoid the failure of the vehicle's entire lighting system

due to a single fault in the control unit or implausible

signals from the light switch.

The emergency light function is only active in the case

of "terminal 15 on".

Dipped beam, the tail lights and side lights are

switched on in the event that the controller in the

onboard supply control unit fails.

The trailer tail lights are switched on in the event that

the controller in the trailer detector control unit fails.

On failure of one of the two controllers, the brake

lights are only activated via discrete signal inputs to

control units.

The emergency light function is activated in the event

of

● Implausible light switch statuses,

● Failure of the CAN data bus or

● Failure of the rain and light sensor.

Once the emergency light cause has disappeared,

the emergency light function is independently

deactivated.

The dash panel insert indicates the emergency light

function in the same manner as bulb failure.

Light switch

Onboard supply control unit

Electronic

ignition lock

Control unit in dash panel insert

ABS control unit

Front vehicle lights

Rear vehicle lights

Trailer detector

control unit

Trailer lights

S370_027

32

Page 33

Trailer lighting

The trailer detector control unit J345 controls all of the

lighting functions of a trailer connected to the vehicle.

Installation location

The trailer detector control unit is located on the righthand side beneath the front left seat.

Trailer detection

Trailer detection is carried out in purely electronic

form. To do this, the brake light and the left-hand

direction indicator are briefly supplied with current

whilst switched off.

Electronic

ignition lock

Onboard supply control

unit

S370_028

The voltage level which is established is used to

determine whether a trailer is connected. If a light is

detected, a trailer is regarded as detected.

CAN convenience data busCAN drive data bus

Trailer detector

control unit

ABS control unit

Control unit in

dash panel insert

Light switch

Brake light switch

Trailer lights

S370_029

33

Page 34

Vehicle electrical system

Windscreen wiper and washer system

Installation locations

Intermittent wiper switch E22

The switch is located in the steering column switch.

Intermittent wiper switch

S370_059

Wiper motor switch-over relay 1 J368 and wiper

motor switch-over relay 2 J369

The switch-over relays are located on the fuse and

relay box on the left-hand A pillar.

Wiper motor switch-over

relay 2

S370_060

Wiper motor switch-over

relay 1

34

Page 35

Wiping the windscreen

The windscreen wiper is activated via the intermittent

wiper switch E22.

Depending on the variant, the signals from the

intermittent wiper switch are read in by the steering

column electronics control unit (vehicles with ABS) or

the electronic ignition lock (vehicles without ABS) and

are sent on the CAN drive data bus and the CAN

convenience data bus.

CAN convenience data bus

The onboard supply control unit receives the signals

and actuates wiper motor switch-over relay 1 J368

and wiper motor switch-over relay 2 J369. The wipers

are switched on/off via wiper motor switch-over relay

1. Wiper motor switch-over relay 2 J369 is used to

switch between the first and second wiper stage.

The onboard supply control unit is the master for this

function.

J368

V

Legend

ABattery

E22 Intermittent wiper switch

J368 Wiper motor switch-over relay 1

J369 Wiper motor switch-over relay 2

J519

J369

S

A

J519 Onboard supply control unit

J527 Steering column electronics control unit

SFuse

V Windscreen wiper motor

J527

E22

S370_061

35

Page 36

Vehicle electrical system

Rain and light sensor

If the rain and light sensor G397 is installed and the

intermittent function is active, wiping is requested by

the sensor.

It is connected to the roof electronics control unit.

Data communication between the roof electronics

control unit and the onboard supply control unit takes

place via the CAN convenience data bus.

The rain and light sensor can be used to control the

interval times from "wipers off" to "continuous wiping

in stage 1 or 2".

Rain and light sensor G397

During rain sensor operation, the roof electronics

control unit acts as the master and the onboard

supply control unit as the slave.

This means that wiper control is carried out entirely by

the roof electronics control unit; the onboard supply

control unit only actuates wiper motor switch-over

relay 1 J368 and wiper motor switch-over relay 2 J369

when requested to do so by the roof electronics

control unit J528.

The "touch-wiping" and "washing" switch positions

are the exceptions.

Functional prerequisite

Communication between the onboard supply control

unit and the roof electronics control unit only takes

place if the "rain/light sensor" option has been

adapted as present in the variant coding in the EIL.

Light-emitting diode

Photo diodes

S370_084

If this is not the case, the onboard supply control unit

controls the "intermittent wiping" function as in

vehicles without a rain and light sensor.

36

Page 37

Speed reduction

At a vehicle speed of < 5 km/h, the wiper speed is

reduced.

Functional prerequisite:

● Intermittent function (rain and light sensor not

installed) or

● Stage 1 or

● Stage 2

Without rain and light sensor

The wiper speed is reduced by one stage,

- From stage 2 to stage 1,

- From stage 1 to intermittent with an interval

of 6 sec.

- From intermittent with an interval of 6 sec to

intermittent with an interval of 9 sec.

Speed reduction is withdrawn again under the

following conditions:

● Vehicle speed > 8 km/h

● Actuation of the windscreen wiper switch for

intermittent mode (intermittent, stage 1, stage 2,

except touch-wiping and washing)

With rain and light sensor

If the sensor is installed, no speed reduction takes

place.

The wiping speed or intermittent interval is adapted

by the sensor as required.

J528

G397

Legend

ABattery

E22 Intermittent wiper switch

G397 Rain and light sensor

J368 Wiper motor switch-over relay 1

J369 Wiper motor switch-over relay 2

CAN convenience data bus

J519

J368 J369

V

J519 Onboard supply control unit

J527 Steering column electronics control unit

J528 Roof electronics control unit

SFuse

V Windscreen wiper motor

J527

S

A

E22

S370_062

37

Page 38

Vehicle electrical system

Rear window wiper and washer system

Rear window wiper

Up to two rear window wipers may be installed.

The rear window wipers and the "rear window

washing" function are switched on and off via the

rear wiper switch E34.

The "wiping on reversing" function is automatically

switched on when reverse gear is engaged and

the windscreen wipers are active.

The onboard supply control unit is the master for these

functions and actuates both the windscreen washer

pump and the rear wipers. If the ignition (terminal 15)

is switched off whilst the rear wipers are active, the

rear wipers remain in their present position.

The rear wiper switch has the following settings:

● Wash-wipe function on with intermittent rear

wiping on

● Intermittent rear wiping on

● Intermittent rear wiping off

● Wash-wipe function on

J527

E34

Legend

A Battery

E34 Rear wiper switch

J329 Terminal 15 voltage supply relay

J519 Onboard supply control unit

CAN convenience data bus

J519

J329

S

SS

A

V92 V93

J527 Steering column electronics control unit

V92 Rear left wing door window wiper motor

V93 Rear right wing door window wiper motor

SFuse

S370_065

38

Page 39

Functions

Rear wiping with windscreen wipers

switched off

When the windscreen wipers are switched off, the

rear window wiping function is carried out in

intermittent mode with the standard interval time of

6 seconds.

Windscreen wipers set to stage 1 or 2

If the windscreen wiper switch for intermittent mode is

set to stage 1 or 2, rear wiper actuation is always

synchronised with the windscreen wipers, in which

case the rear wipers only wipe for a defined

percentage of the windscreen wiper cycle.

This percentage is speed-dependent.

Rear window wiping with windscreen

wipers set to "intermittent"

When intermittent windscreen wiping is switched on,

the rear window wiping function is dependent on the

presence of a rain and light sensor.

● Without sensor: Rear wiping is synchronised with

windscreen wiping

● With sensor: Rear wiping is carried out with the

standard interval time of 6 sec.

Rear door open

The wash-wipe function is interrupted when the

vehicle is stationary and the rear door is open, and is

continued when the rear door is closed.

● v < 80 km/h: Rear wipers wipe for 1/10 of the

windscreen wiper cycle.

● v > 80 km/h: Rear wipers wipe for 1/7 of the

windscreen wiper cycle.

39

Page 40

Vehicle electrical system

Heated windscreen

Function

An optional, heated windscreen may be installed; this

contains two heating elements (e. g. driver and front

passenger).

The heated windscreen is switched on and off via the

heated windscreen switch in the control unit for

middle of dash panel. The switch contains a function

indicator, which lights up when the heated windscreen

is switched on.

The maximum heating time is limited to 5 minutes.

The control unit for middle of dash panel is the master

for this function. The function request is forwarded

from the control unit for middle of dash panel to the

onboard supply control unit via the CAN convenience

data bus. The heated windscreen relay is actuated by

the onboard supply control unit.

Functional prerequisite

● Functional prerequisite for reading in the switch

and function indicator:

CAN data bus signal "terminal 61 on"

● Functional prerequisite for actuating the heated

windscreen:

CAN data bus signal "terminal 61 on"

● Idle speed stable:

The heated windscreen can only be actuated when

the engine is running at a stable speed

(approx. 800 rpm).

● Function abortion:

CAN data bus signal "terminal 61 off"

The functional prerequisite and function abortion link

takes place in the control unit for middle of dash

panel.

40

Switch for

heated windscreen

Control unit for middle of dash panel

Battery

CAN convenience data bus

Fuse

Heated

windscreen

Onboard supply control unit

Relay for heated windscreen

S370_072

Page 41

Heated rear window

Function

An optional, heated rear window may be installed.

In the case of rear wing doors, the heating wires for

the heated rear window in left wing door Z26 and the

heated rear window in right wing door Z27 are wired

in parallel.

In vehicles which are fitted with optional interior

monitoring, each heating wire is individually supplied

with current.

The heated rear window is switched on and off using

the heated rear window button E230 in the control

unit for middle of dash panel J819. The button

contains a function indicator, which lights up

continuously when the heated rear window is

switched on. A fault is displayed by the indicator's

flashing. The maximum heating time is limited to 15

minutes.

The control unit for middle of dash panel is the master

for this function. The heated rear window relay J9 and

the additional relay for heated rear window J109

(with interior monitor only) are located on fuse carrier

D beneath the driver's seat. Both relays are actuated

by the onboard supply control unit.

Functional prerequisite

The functional prerequisites correspond to those for

the heated windscreen.

Heated rear window button

Control unit for middle of dash panel

Battery

Heated rear

window in left

wing door

CAN convenience data bus

Fuse

Heated rear

window in

right wing

door

Onboard supply control unit

Heated rear window relay

S370_073

41

Page 42

Vehicle electrical system

Roof electronics control unit

General function

The roof electronics control unit J528 variants are

dependent on the various special equipment items

which are installed.

Depending on equipment, the control unit is

responsible for manual operation and dimming of the

interior light and reading lights plus actuation of the

rain and light sensor, anti-theft alarm system and

sliding roof. It additionally houses the microphone for

the hands-free system.

Installation location

The roof electronics control unit is located in the upper

centre of the vehicle behind the trim panel for the

interior lights and buttons.

S370_057

42

Page 43

Vari ants

Standard Low line

with ATA, without glass sliding roof

Interior lighting Interior lighting Interior lighting

Separately operable reading spotlights

for

driver and front passenger

Glasses compartment

Telephone hands-free microphone Telephone hands-free microphone Telephone hands-free microphone

Switch for interior light and

reading spotlights

Interior light on/off (button) Interior light on/off (button) Interior light on/off (button)

Door contact on/off (switch) Door contact on/off (switch) Door contact on/off (switch)

Driver reading spotlight on/off (button) Driver reading spotlight on/off (button) Driver reading spotlight on/off (button)

Front passenger reading spotlight on/

off (button)

Separately operable reading spotlights

for

driver and front passenger

Switch for interior light and

reading spotlights

Front passenger reading spotlight on/

off (button)

High-line

with ATA, with glass sliding roof

Separately operable reading spotlights

for

driver and front passenger

Switch for interior light and

reading spotlights

Front passenger reading spotlight on/

off (button)

ATA interior monitor sensors (optional) ATA interior monitor sensors (optional)

Electronics incl. interface for the

rain and light sensor

Electronics for ATA/IM and interface to

the alarm horn

CAN interface CAN interface

Electronics incl. interface for the rain

and light sensor

Electronics for ATA/IM and interface to

the alarm horn

Switch for sliding roof

Evaluation of sliding roof motor

Hall senders

43

Page 44

Vehicle electrical system

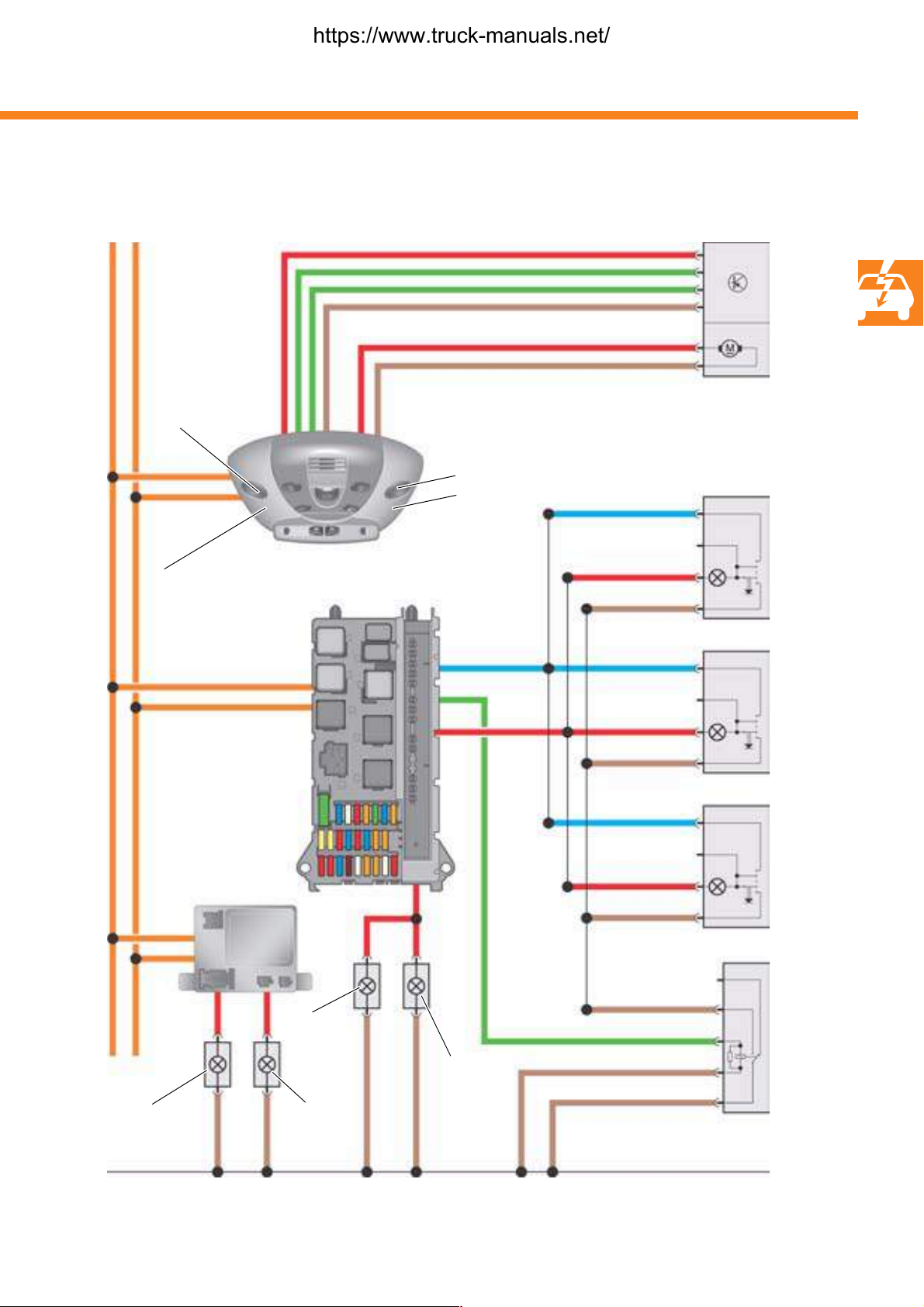

Actuation of the interior lights

General description

The interior lighting is switched on via an automatic

function (e.g. door open). If the interior illumination

switch is now actuated, the interior lighting is switched

off. It is only switched on again following further

actuation of the switch.

Actuation of the interior lights

The interior lights are sub-divided into two circuits.

The front circuit is influenced by the driver and front

passenger doors, the rear circuit by the left and right

sliding doors and the rear lid or rear door and the

interior illumination switch E599.

The following components are actuated by the roof

electronics control unit

- The front passenger reading light W13,

- The left interior light W16,

- The right interior light W17 and

- The driver side reading light W19.

The following components are actuated by the

onboard supply control unit

- The front interior light W1,

- The centre interior light W7 and

- The rear interior light W43.

Priorities

The following priorities apply to all front and rear interior light control system applications:

Priority Function

1 Special alarm and ATA alarm

2 Manual activation via button/switch

44

3 Automatic interior light control system (doors/sliding doors/rear door)

4 Automatic interior light control system (locking/unlocking/ignition)

Page 45

Functional example

Rear sliding roof control unit

Driver side

reading light

Left interior light

Rear sliding roof motor

Front passenger reading light

Right interior light

Roof electronics control unit

Onboard supply control unit

Front interior light

Centre interior light

Driver door control unit

Front

left

entry light

Rear left

entry light

Front

right

entry light

Rear interior light

Rear right

entry light

Interior light relay

S370_058

45

Page 46

Ignition lock

Electronic ignition lock

Installation location

The electronic ignition lock (EIL) D9 is located on the

right-hand side next to the steering wheel.

Variants

Different variants of the electronic ignition lock are

installed. The variant is dependent on the radio

frequency of the central locking system and the

presence of the steering column electronics control

unit.

Distinguishing features

● For vehicles with steering column electronics

control unit (vehicles with ABS/ESP) and radio

frequency of 433 MHz (Europe and other countries

which use this frequency).

● For vehicles without steering column electronics

control unit (vehicles without ABS/ESP) and radio

frequency of 433 MHz.

S370_030

● For vehicles with steering column electronics

control unit (vehicles with ABS/ESP) and radio

frequency of 315 MHz (Europe and other countries

which use this frequency).

● For vehicles without steering column electronics

control unit (vehicles without ABS/ESP) and radio

frequency of 315 MHz.

46

Page 47

Immobilizer and starting fucntions

● Mounting the ignition key

● Mounting the transponder coil for polling

the ignition key ID and transponder data

● Rotary lock inhibitor in the case of an unauthorised

key

● Immobilizer communication between the ignition

key, engine control unit J623 and electronic

steering column lock control unit J764

● Reading in the steering column switch signals when

no steering column electronics control unit

is installed.

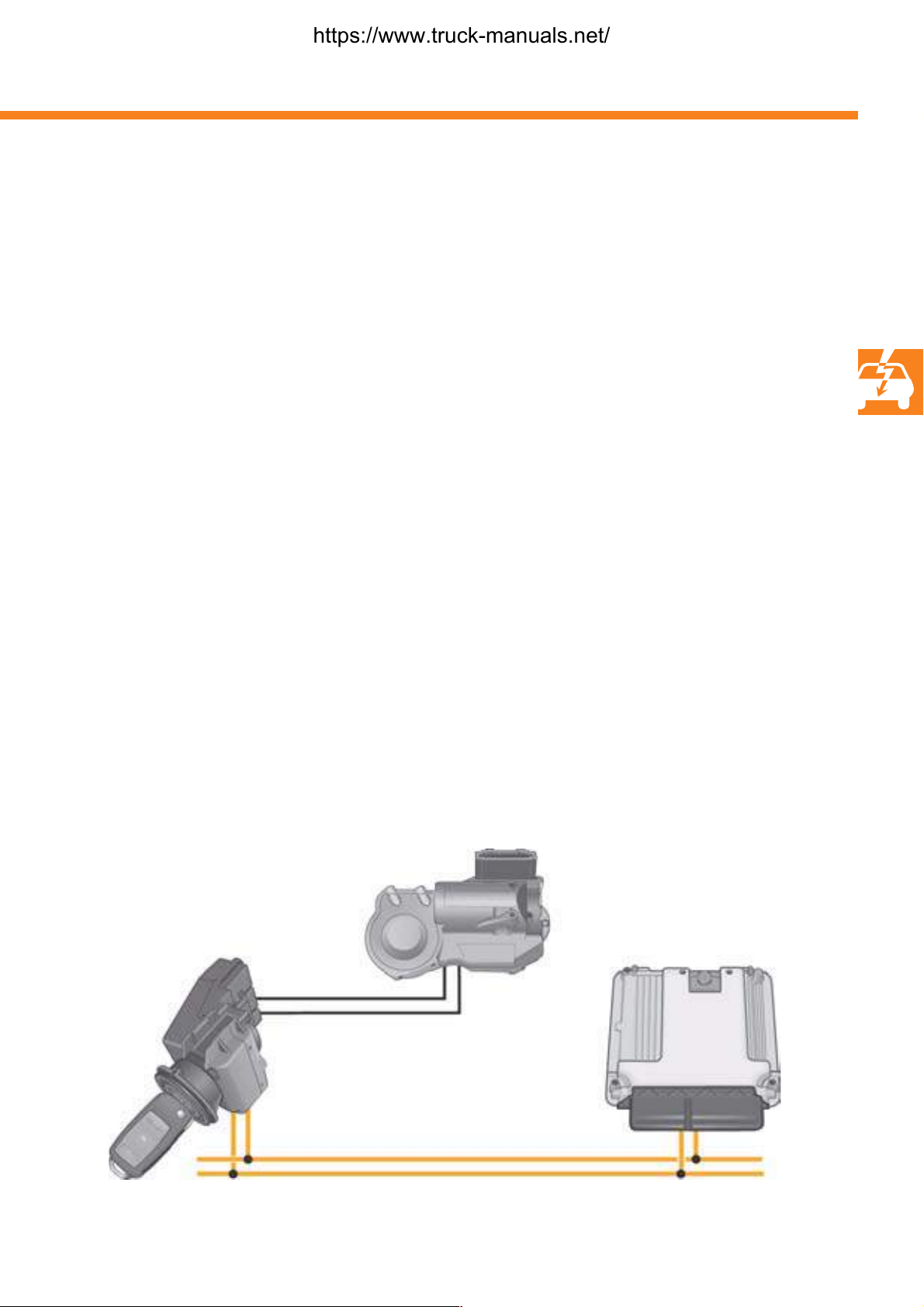

Starting

The vehicle is started via communication between the immobilizer in the electronic ignition lock with the ignition key,

the engine control unit and the electronic steering column lock control unit.

By inserting a key into the EIL, the electronics are activated and the key is supplied with energy (inductively) from

the EIL. The key is identified by means of bi-directional data exchange.

The "drive authorisation system" (DAS) in the EIL releases the control units via the CAN data bus. At the same time,

the mechanical lock (ESL, steering wheel lock) is released via a serial interface.

Key with transponder

Electronic steering column

lock control unit

Engine control unit

Electronic ignition lock

S370_055

47

Page 48

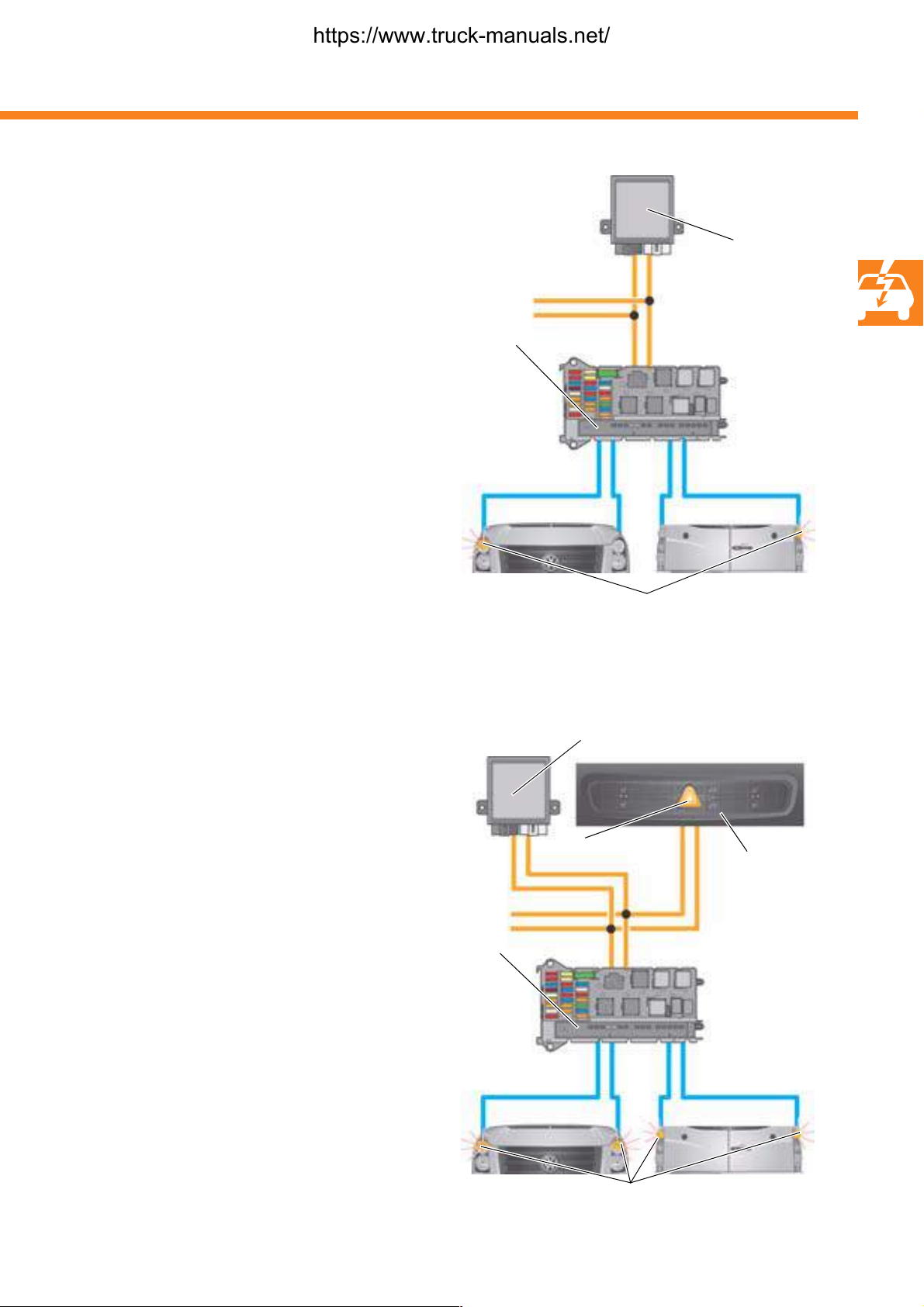

Ignition lock

Central locking system functions

The electronic ignition lock (EIL) is the master control

unit for all opening and closing functions.

The vehicle can also be locked via radio remote

control.

The HF receiver is integrated into the EIL. The HF

signals are decoded exclusively by the EIL.

The resulting actuation requests are then transferred

onto the CAN convenience data bus by the EIL and

are read in by the driver door control unit J386.

The driver door control unit actuates the driver door

central locking motor V56 directly.

The onboard supply control unit actuates

- The front passenger door central

locking motor V57,

- The right sliding door central locking motor V58,

- The left sliding door central locking motor V95 and

- The rear wing door central

locking motor V96,

when the driver door control unit sends

a corresponding message on the CAN convenience

data bus.

Key with

radio remote control

Electronic ignition lock

Driver door control unit

Onboard supply control unit

Driver door contact switch

Driver door central locking motor

Front passenger door contact switch

Front passenger door central

locking motor

Rear right door contact switch

Right sliding door central locking

motor

Rear left door contact switch

Left sliding door central locking

motor

Rear right door contact switch

Rear right central locking

switch

Rear wing door central locking

S370_056

motor

48

Page 49

Diagnostic interface function

Data bus systems are necessary due to the high

number of data which have to be transmitted in the

vehicle. The electronic ignition lock undertakes the

tasks of a networking gateway for data bus systems,

the principle task of which is to form the interface

between the various, independent data bus systems

in the vehicle. The electronic ignition lock is the

interface between the CAN drive data bus, the CAN

convenience data bus and the CAN diagnostic data

bus.

Amongst others, the following, logical signals are

transmitted on the CAN data bus systems by the EIL:

● Bus status signals for terminal 15 and terminal 50

● Transmission of diagnostic messages between the

VAS diagnostic tester and the individual

control units

● Wake-up signals on opening with the radio remote

control, on starting diagnosis and on insertion of

the ignition key

VAS 5 052

S370_074

49

Page 50

Anti-theft system

Electronic steering column lock (ESL)

Electronic steering column lock

control unit J764

The electronic steering column lock is actuated by the

electronic ignition lock (EIL). Locking, unlocking and

diagnosis are controlled via a serial data bus link with

the EIL. The control unit is located on the steering

column and is secured with "shear head bolts".

Electronic steering column lock

control unit

Actuation

The electronic steering column lock control unit is

connected to the voltage supply via the fuse holder on

the onboard supply control unit and to earth via the

right-hand earth point in the A pillar.

Onboard supply control unit

S370_064

The actuation signals for unlocking and locking are

transmitted by the EIL via a serial data cable in the

form of encrypted data to the electronic steering

column lock control unit.

Electronic steering column lock

control unit

50

CAN convenience data bus

Electronic ignition lock

Serial data bus cable

Final control for

steering column lock

S370_075

Page 51

Function

If the authorised ignition key is inserted into the

electronic ignition lock, the encrypted data are

transmitted to the electronic steering column lock via

the data cable.

If the data are recognised to be correct, the electric

motor is activated; it draws the locking bar out of the

locking ring on the steering spindle.

A terminal switch reports the released position to the

electronics. The release signal is only sent to the

electronic ignition lock when all data are recognised

as correct. The key can now be turned to position I, II

or III (position I without detent).

Before the key reaches position I, the electronic

steering lock's voltage supply is interrupted in the

electronic ignition lock.

This interruption is withdrawn when the ignition key is

turned to position 0 again.

When removing the ignition key in position 0, a signal

is sent to the electronic steering lock. The electric

motor moves the locking bar into the locking position,

in which it prevents the the locking ring from rotating.

Terminal switch

Steering tube

Locking bar

Worm gear drive

Electric motor

S370_063

51

Page 52

Anti-theft system

Anti-theft alarm system

Description

The anti-theft alarm system is available as an option.

Its functions are distributed amongst several control

units. The master function is undertaken by the roof

electronics control unit J528; it is linked to all of the

other involved control units via the CAN data bus.

Installation location

The roof electronics control unit is located in the

moulded headlining near to the interior mirror.

Variants

The anti-theft alarm system is available in the

following variants:

● Electronic immobilizer, with anti-theft alarm system

● Anti-theft alarm system, interior monitor and

towing sensor

● Anti-theft alarm system, interior monitor, back-up

horn (alarm horn) and towing sensor

S370_057

52

Page 53

Function

The ATA monitors the doors via the door contact

switches; the engine compartment is additionally

secured via the bonnet contact switch.

The signal from the

- Driver door contact switch F2 is read in

by the driver door control unit J386,

- Bonnet contact switch by the control unit in dash

panel insert J285.

The signals from the

- Front passenger door contact switch F3,

- Rear right door contact switch for sliding door or

side door F7,

- Rear left door contact switch for sliding door or

side door F176 and

- Rear right door contact switch F226 are read in by

the onboard supply control unit.

Activation of the ATA

The ATA can only be activated when the ignition is

switched off (terminal 15 off).

The radio remote control is used to lock the vehicle.

When all of the vehicle's doors are locked, the ATA

carries out a self-test and is activated. If not all of the

vehicle's doors are locked, the ATA cannot be

activated.

Deactivation of the ATA

The ATA is deactivated by unlocking the vehicle using

the radio remote control or via the detection of a valid

key in the EIL.

Successful locking or unlocking is acknowledged by

the turn signal lights' acknowledge signal.

Control unit in dash

panel insert

Bonnet

contact switch

Onboard supply control unit Roof electronics control unit Driver door control unit

Front passenger door

contact switch

Rear left door

contact switch

Rear right door

contact switch

Rear door

contact switch

Alarm horn

Fuse

Driver door contact

switch

S370_076

53

Page 54

Anti-theft system

Interior monitor (IM)

The interior monitor monitors the interior of the vehicle

and reacts if attempts are made to penetrate the

vehicle from the outside. The alarm which is triggered

is output optically via the turn signals and constantly

illuminated interior lights and acoustically via the

horn or the optional alarm horn.

Incompletely closed windows or sliding roofs

influence the sensitivity of the interior monitor.

Interior monitor

sensors

The passenger compartment is monitored by means

of ultrasonic sensors, whilst the rear window is

monitored using the heated rear window's heating

wire. An alarm is triggered as soon as the heating

wires are separated.

The interior monitor is activated approx. 40 seconds

after the vehicle has been locked.

Interior monitor

sensors

54

S370_024

Deactivation

If the interior monitor deactivation switch E183 is

actuated when terminal 15 is switched off and the IM

is not active, the interior monitor is deactivated until

terminal 15 is switched on again.

The warning lamp lights up for 5 sec. to confirm this.

S370_077

Page 55

Towing sensor

The vehicle inclination sender G384 is located in the

roof electronics control unit. The sender reports

a change in position as soon as the vehicle is raised

for towing or to unbolt the wheels, in which case the

roof electronics control unit triggers an alarm.

The towning sensor is activated approx. 20 seconds

after the vehicle has been locked.

Normal vehicle position Vehicle raised

Following ATA activation, the vehicle inclination

sender determines the relative resting position of the

vehicle (zero level). An alarm is triggered as soon as

the vehicle's position changes by an angle of more

than 0.8°.

Once the alarm has been triggered, the current angle

is taken over as the zero level.

Deactivation

If the deactivation button for vehicle inclination

sender E360 is actuated when terminal 15 is switched

off and the ATA is not active, the vehicle inclination

sender is deactivated until terminal 15 is switched on

again. The warning lamp lights up for 5 sec. to

confirm this.

S370_025

S370_023

55

Page 56

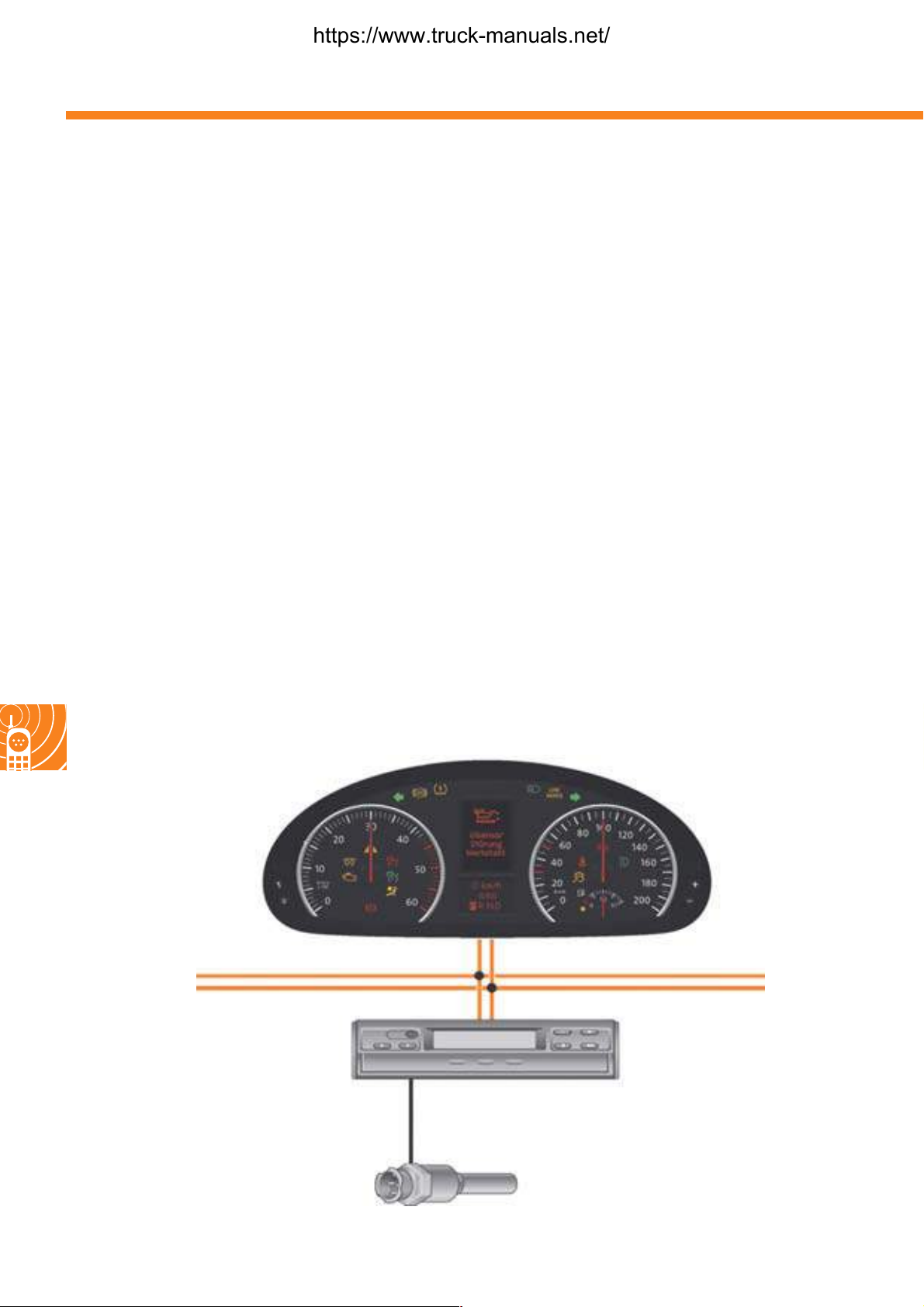

Dash panel

Control unit in dash panel insert

Variants

The control unit in dash panel insert J285 is available in

- Low line and

- High line variants.

Low line variant

Warning lamps

Rev. counter G5 Speedometer G21

Segmented display

The low line variant is equipped with:

Dial gauges

● Rev. counter G5

● Speedometer G21

Segmented display

● Fuel gauge

(bar scale)

● Odometer

● Trip o domet er

● Time

● Exterior temperature

● Menu displays

● Gear indicator for automated

Warni n g lamps

● Bulb failure

● Door open warning lamp

● TCS/ ESP/BAS

● Coolant temperature

● Coolant level

● Air filter soiled

● Washer fluid level

● Brake pad wear

● Engine start/stop

● Working speed governor

● ESP

● Reserve fuel

● Particulate filter

● Glow period warning lamp

● EOBD

● ABS

● Turn signals/hazard warning lights

● Main beam

● Brake fluid -

parking brake warning lamp

● Glowing

● Airbag

● Seat belt warning

manual gearbox

S370_066

56

Page 57

High line variant

Warni n g l a m p s

Rev. counter G5

Multi-function display, lower section

The high line variant is equipped

with:

Dial gauges

● Rev. counter G5

● Speedometer G21

● Fuel gauge G1

Lower display

● Time

● Gear indicator for automated

manual gearbox

● Exterior temperature indicator

● Speed

Multi-function display, upper section

Upper display

● Odometer

● Trip odometer

● Menu displays

● ESI display

Warn ing la m ps

● Glow period display

● ESP

● Left direction indicator

● ABS

● Tyre pressure warning lamp

● Main beam

● Right direction indicator

● Seat belt warning

S370_067

Speedometer G21

● Parking brake

● Daylight driving lights

● Brake lining, brake fluid, electronic

brake pressure distribution

● EOBD

57

Page 58

Dash panel

Menu display in low line variant

In the low line variant, the following menus can be

called up by actuating the "menu button" in the

segmented display:

● Read service date Actuate the menu button until the remaining distance

in kilometres or the remaining time in days is

displayed.

● Pre-select/set auxiliary heater activation time Actuate the menu button until the "auxiliary heater"

symbol is shown in the segmented display; a pre-set

starting time can then be selected with the

+ or - button.

● Set time Actuate the menu button until the hours display

flashes. The + and - buttons can then be used to set

the hour. The minutes display can then be set via the

reset button and the + and - buttons.

58

● Set date Actuate the menu button until the day display flashes.

The + and - buttons can then be used to set the day.

The month and year display can then be set via the

reset button and the + and - buttons.

Page 59

Menu display in high line variant

Multi-function buttons

The high line variant is equipped with multi-function

buttons in the steering wheel for controlling the

menus. The buttons can be used to select the menus

and to carry out the desired settings in the selected

menu.

S370_032

Menu selection

Starting from the basic mask, various setting and

information menus can be switched through in the

display during vehicle operation by changing the

display level with the multi-function buttons in the

steering wheel. These are shown exclusively in the

upper area of the display; the exterior temperature,

time, gear and gearbox programme are constantly

shown in the lower status area.

Only those functions whose systems are actually fitted

in the vehicle are run through. The precise procedure

is described in the operating instructions.

DOWN

UP

No

malfunction

Settings

Reset

Press reset

button

for 3 s

S370_031

59

Page 60

Convenience systems

Parking aid

Description

The Volkswagen Crafter can be optionally equipped

with an ultrasound-based parking aid at the front and

rear. The system can be manually deactivated using

a button.

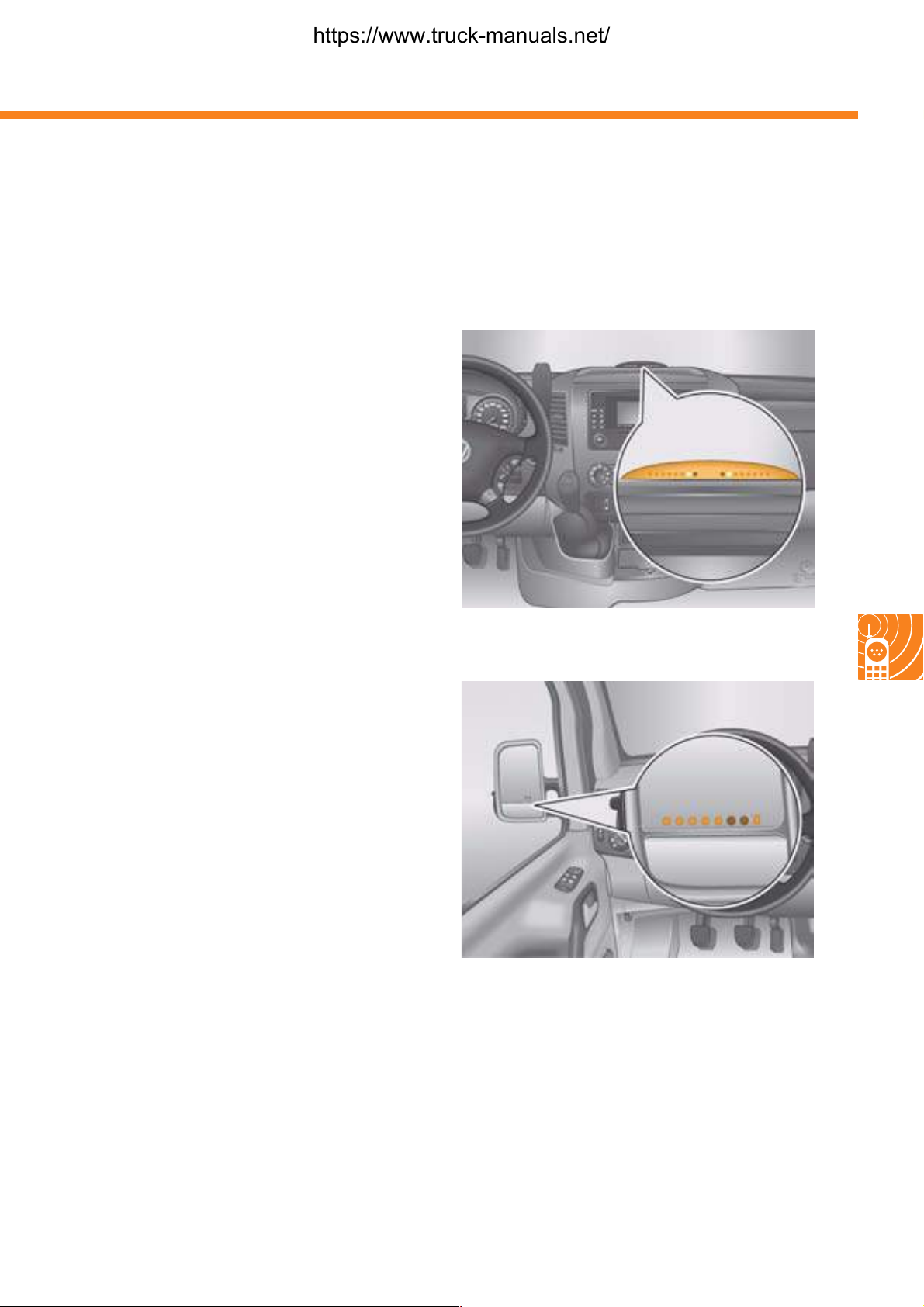

The parking aid displays are located on the

instrument panel and in the outside rear-view mirrors.

If the distance between the vehicle and an obstacle is

less than 40 cm, an acoustic warning is sounded.

Installation location

The parking aid control unit J446 is located on the

right-hand side beneath the front left seat.

Parking aid button E226

The button is located in the control unit for middle of

dash panel J819 and serves to switch the parking aid

off and on manually. The status is indicated via an

LED in the button.

LED illuminated: System off

LED not illuminated: System active

S370_034

S370_035

60

Page 61

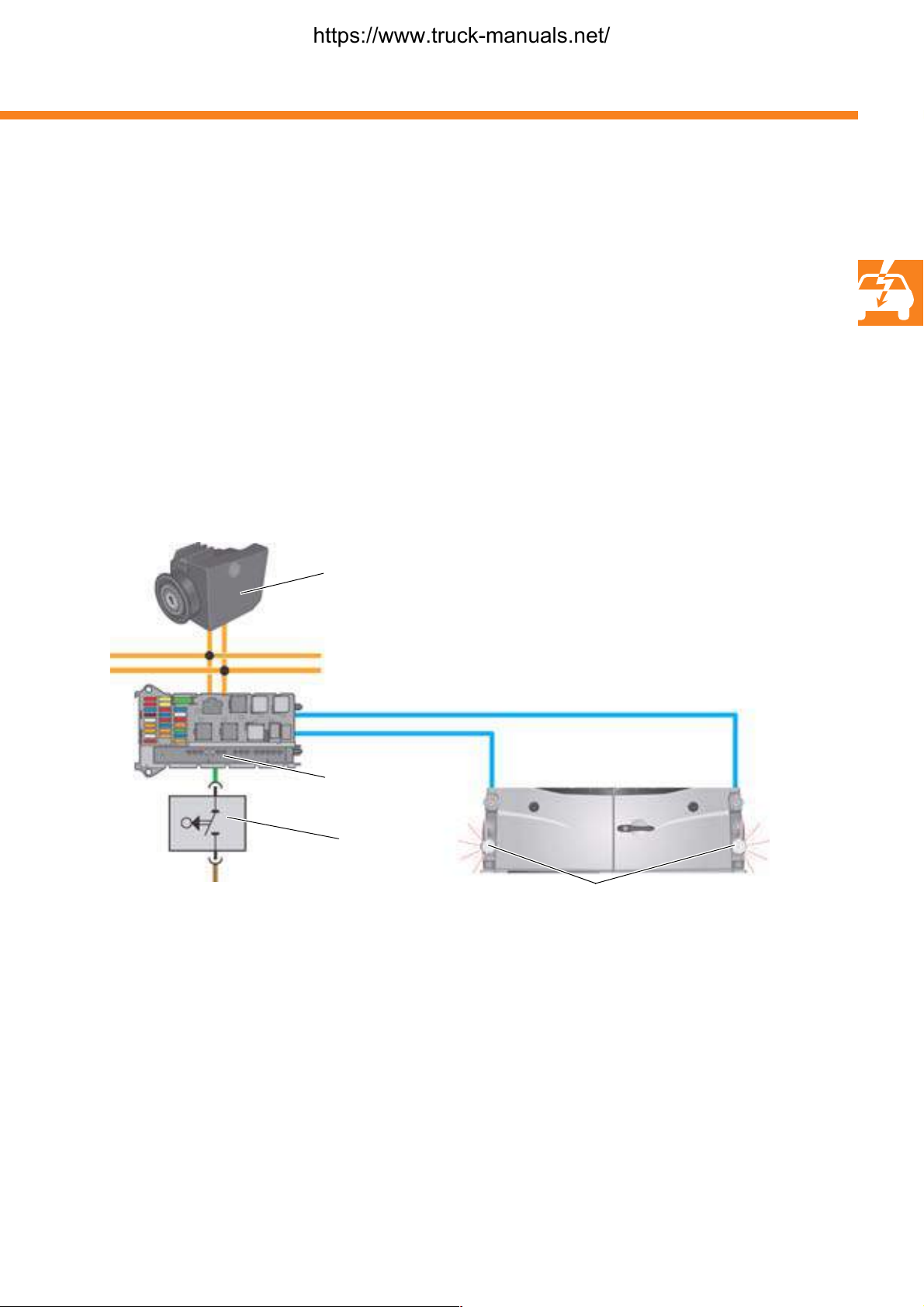

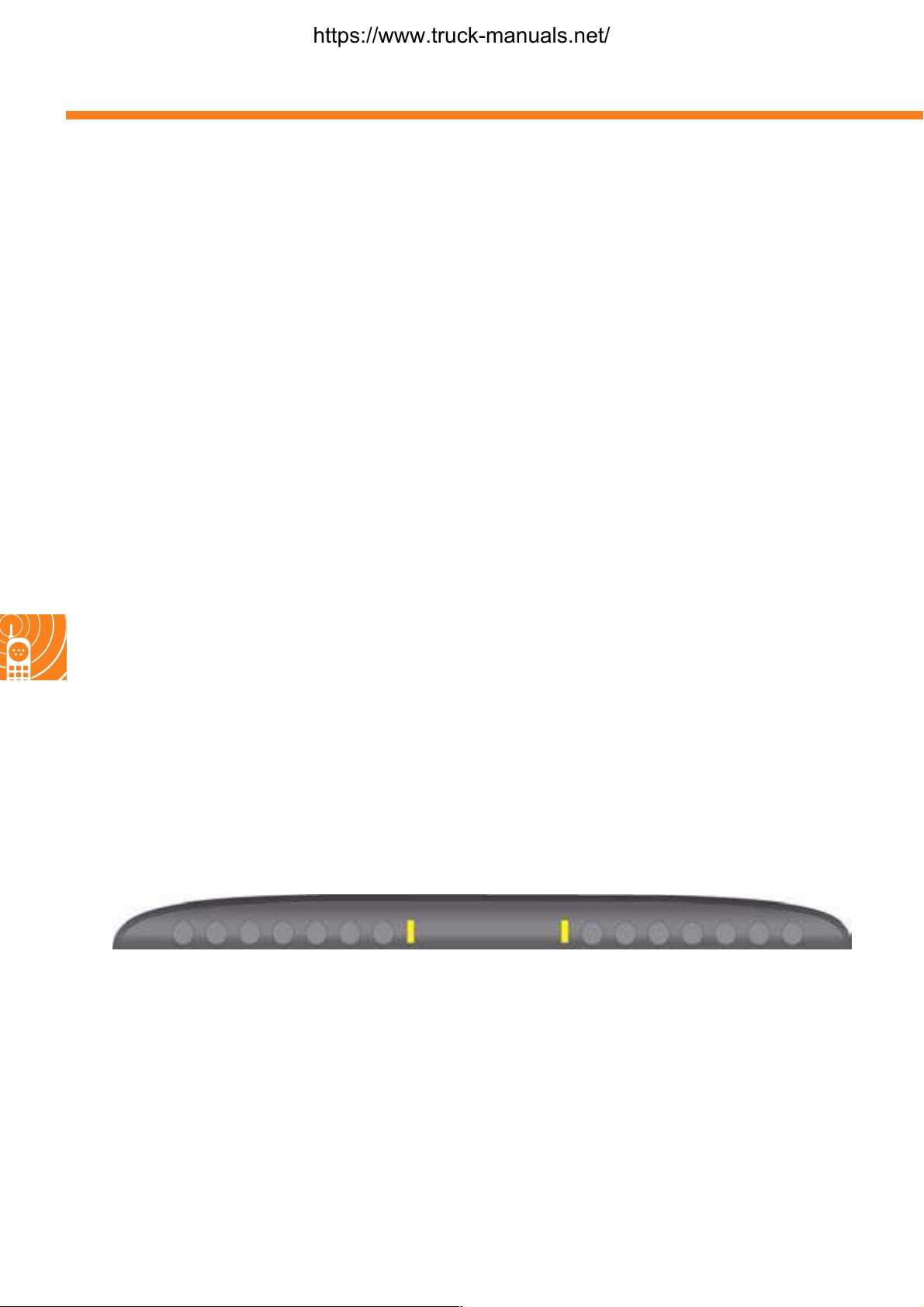

Warning displ ays

In the case of the parking aid, obstacles are displayed

using one double and two individual warning

elements.

The front left parking aid display Y13 and the front

right parking aid display Y14 for the front area are

positioned centrally on the instrument panel.

The control segments show the distance between the

sensors and the obstacle on the left and right sides of

the vehicle.

S370_036

The rear left parking aid display Y27 and the rear

right parking aid display Y28 for the rear area are

housed in the left and right outside rear-view mirrors

respectively.

S370_037

Displays

The warning display for each side of the vehicle is sub-divided into five yellow and two red segments.

When the yellow "ready" displays light up, the parking aid is ready to measure. If only the red segments light up,

a malfunction is present.

61

Page 62

Convenience systems

Functional check

After the ignition has been switched on, "terminal 15

on", the parking aid control unit J446 actuates all

parking aid displays for approx. 1 second.

The correct function of the system is optically

confirmed by the LEDs' lighting up.

Operational readiness

The system is ready to operate when the ignition has

been switched on, the parking brake has been

released and the vehicle speed is < 18 km/h.

In vehicles with a manual gearbox, the front and rear

display units are activated when reverse gear is

engaged.

The control unit, the sensors, the cables to the sensors,

the parking aid displays and the cables to the

displays are checked.

If reverse gear is not engaged, only the front display

units are active.

System activation is indicated by the rectangular,

yellow LEDs.

62

S370_039

Page 63

Activation of the functions:

Trailer operation

If a trailer is connected to the vehicle, the parking aid

is switched off. The presence of a trailer is detected

via the trailer detector control unit J345.

The trailer detector control unit makes this information

available on the CAN convenience data bus.

Vehicle stat ion ar y

Speed-dependent

The system is active until a speed of approx.

18 km/h is exceeded, after which it switches the

display units to stand-by.

The display units' and sensors' voltage supply

switches off completely on exceeding a speed of

approx. 40 km/h, and switches back on again when

the vehicle speed falls below approx. 40 km/h.

The warning elements are only switched on again

when the vehicle speed falls below 16 km/h.

Reverse gear engaged

The statuses of the handbrake warning switch F9 and

the wheel speed sensors are evaluated. If the value of

the wheel speed sensors does not change in three

successive measurements, no new, acoustic warnings

are emitted, but current ones are carried out to

completion.

All optical warnings are also suppressed. The parking

aid is activated again when the handbrake is released

or the vehicle moves off.

In vehicles with a manual gearbox, the front and rear

warning elements are active when reverse gear is

engaged. If reverse gear is not engaged, only the

front area is monitored (exception: Rolling-back

warning). If the vehicle is reversing and the steering

angle lies within a defined range, acoustic warnings

in the front area are suppressed. Optically, however,

the distances are displayed in full.

63

Page 64

Convenience systems

Detection range

Six sensors are mounted in the front bumper and four

in the rear bumper to detect obstacles. The two outer

sensors at the front additionally serve to protect the

corners vehicle front swivel range).

Four sensors in the rear bumper are sufficient, as the

corner area is covered by the side mirrors in this case.

S6

S5

S4

S3

S2

S1

Displaying obstacles

There is a left and right-hand detection range in front

of and behind the vehicle. The more the distance

decreases, the more segments are activated.

The vehicle corner measuring range starts at

a distance of 65 cm at the front and 100 cm at the

rear.

S4

S3

S2

S1

S370_033

The display range emcompasses 7 LEDs, in which case

5 yellow LEDs cover an obstacle distance of approx.

40 cm and 100 cm at the front and 180 cm at the rear.

The 30 cm to 40 cm range is depicted by 2 red LEDs.

64

Warning display Optical

front S1 and S6

1st segment, yellow < 100 cm < 180 cm

2nd segment, yellow < 85 cm < 100 cm

3rd segment, yellow < 65 cm < 70 cm < 100 cm < 100 cm

4th segment, yellow < 55 cm < 60 cm < 70 cm < 70 cm

5th segment, yellow < 45 cm < 50 cm < 50 cm < 50 cm

6th segment, red < 35 cm < 40 cm < 40 cm < 40 cm < 40 cm intermittent

7th segment, red < 25 cm < 30 cm < 30 cm < 30 cm Continuous

Optical

front S2 to S5

Optical

rear S1 and S4

Optical

rear S2 and S3

Acoustic sound

Page 65

Rolling-back warning

If the vehicle's rolling back is detected by the parking

aid when reverse gear is not engaged

(via evaluation of the wheel speed sensors), proximity

warning for the rear area is activated.

Minimum height of obstacles

Due to the particular physical characteristics of the

ultrasonic signals emitted by the sensors, the system

cannot always reliably detect obstacles which are

lower than the height at which the sensors are

installed (approx. 50 cm depending on load).

If an obstacle is located a maximum of 80 cm away,

all of the warning segments light up and the

continuous warning tone is sounded.

50 cm

The parking aid cannot replace the driver's attentiveness. The driver bears responsibility during parking

and similar driving manoeuvres.

50 cm

S370_038

65

Page 66

Convenience systems

Tyre pressure monitor

Function

The tyre pressure monitor serves to constantly monitor

the tyre inflation pressure during vehicle operation.

At certain intervals, the tyre pressure of each wheel is

recorded by the tyre pressure sensors G222 - G225

and is transmitted, via the front and rear tyre pressure

monitor aerials, R95 and R96, and a LIN data bus

link, to the tyre pressure monitor control unit J502.

Installation location

The tyre pressure monitor control unit J502 is located

in the centre under the left front seat.

In the event of pressure loss, a warning message is

indicated in the upper section of the multi-function

display and via the tyre pressure warning lamp K230.

66

S370_040

Page 67

Front and rear tyre pressure monitor

aerials R95 and R96

The front aerial is located in the engine compartment

next to the passenger compartment fan. The rear

aerial is located between the rear wheels. They

receive the tyre pressure sensor signals and forward

these to the tyre pressure monitor control unit via the

LIN data bus.

S370_078

Tyre pressure sensors

G222 - G225

The sensors are located in the wheel rims and transmit

data to the aerials via radio. Each sensor has an

individual serial number (ID), which is recorded by the

tyre pressure monitor control unit during calibration.

Based on this ID, the control unit is able to assign the

individual data to the wheels. Depending on the

country in which the system is used, the transmission

frequency is 315 MHz or 433 MHz.

S370_041

With regard to renewing batteries, please note the instructions in the electronic repair information

system (ELSA) or in the operating instructions.

67

Page 68

Convenience systems

Overview of the system

Front right tyre pressure

sensor G223

Dash panel

Front left tyre pressure

sensor G222

Front tyre pressure

monitor aerial R95

LIN data bus

CAN data bus

Rear right tyre pressure

sensor G225

Rear tyre pressure

monitor aerial R96

LIN data bus

Tyre pressure monitor

control unit J502

Rear left tyre pressure

sensor G224

S370_042

Calibration

The system automatically detects the new tyre inflation

pressures

after

- The tyre pressure has been increased,

- Wheels or tyres have been renewed or

- New wheels or tyres have been fitted.

Please refer to the electronic repair information system (ELSA) or the operating instructions for

the procedure for calibrating new tyre inflation pressures.

If automatic detection is not carried out, the system

can be re-calibrated in the dash panel.

The system initialisation time may take up to 15

minutes.

68

Page 69

Warnings

Soft warning

The operating status "soft warning" describes

a pressure loss in which operating safety is still

guaranteed. At the end of the journey,

a request for the driver to correct the tyre inflation

pressure at the next opportunity appears in the upper

section of the multi-function display. This message is

displayed for approx. 30 sec. when the ignition is

switched off ("terminal 15 off").

Hard warning

The operating status "hard warning" describes

a pressure loss in which operating safety is no longer

fully guaranteed. In the upper section of the multifunction display, the driver is requested, during

vehicle operation, to check the tyres.

A "hard warning" is triggered when one of the

following conditions is met:

The "soft warning" is triggered when the temperaturecompensated tyre pressure has fallen by more than

0.25 bar in comparison with the inflation pressure.

No single tyre is specified; all tyre pressures have to

be checked.

The warning is displayed until the ignition is switched

off (terminal 15 off).

If the ignition is switched off and on again, the tyre

pressure warning lamp is actuated immediately.

The warning in the upper section of the multi-function

display is active again after travelling for approx.

5min.

● The tyre pressure falls below 2.6 bar.

● The tyre pressure falls by 20% in comparison with

the inflation pressure (max. 0.5 bar).

In parallel with the "hard warning", the tyre pressure

warning lamp is actuated.

This actuation is only withdrawn following

re-activation of the system or when pressure

correction has been determined by the system.

In the case of the "hard warning" operating status,

the affected tyre is specified in the multi-function

display.

69

Page 70

Convenience systems

RCD 2001

Radio system RCD 2001 is equipped with an audio CD

drive and a CD changer connection. The radio unit

has a single FM and AM tuner and a TP/TA traffic

radio function.

The display is monochromatic and dimmable;

connection of a CD changer, a mobile telephone

operating electronics control unit or a telephone mute

switch via a discrete cable connection is possible. RCD

2001 is integrated into CAN data bus communication

via the CAN convenience data bus and is therefore

diagnosis-capable.

Four channels, which are wired depending on the

equipment which is fitted, are available as

loudspeaker outputs.

The HF connection is provided by a passive rod aerial