Page 1

MAN GUIDE 107

TGE - The 8-speed automatic gearbox

Page 2

The gearbox variants in the TGE

In addition to the 6-speed manual gearbox described in the TGE GUIDE 105, the TGE can also be equipped with an

8-speed automatic gearbox. It is a consistent further development of the well-known 6-speed automatic gearbox from

AISIN AW CO., LTD. of Japan.

Technical status April 2019

2

m107_039

Page 3

table of contentS

4 IntroductIon

6 Selector lever

10 Gearbox deSIGn

18 valve body

4

20 oIl Supply

22 Gearbox manaGement

34 ServIce

10

20

35 teSt your knowledGe

22

The MAN TGE Guide teaches the basics of design and function for sales and after-sales of new vehicle models, new

vehicle components or new technologies.

The MAN TGE Guide is not a sales manual nor a repair guide! Specified values are for the sake of easy understanding

only and refer to the data status valid at the time the MAN TGE Guide was created.

The contents are not updated.

Please use the appropriate technical literature for customer advice, maintenance and repair work.

Note

Reference

3

Page 4

IntroductIon

The features of the 8-speed automatic gearbox

The new 8-speed automatic gearbox from Aisin is characterised by the following technical features:

Auxiliary hydraulic pump 1 for gearbox oil V475 for assuring the oil supply in start/stop operation

Torque converter with starter ring gear

Two additional electric pressure control valves for gears 7 and 8

An additional clutch on the Lepelletier planetary gearbox for gears 7 and 8

Design of one of the two brakes as a band brake

m107_016

Note

The exact technical design of the 8-speed automatic

gearbox depends on the engine of the respective vehicle

model.

4

Page 5

The technical data for the 8-speed automatic gearbox

Manufacturer

Gearbox code

Gearbox features

Maximum torque

ATF specification for gearbox oil

Filling quantity gear oil

Filling quantity bevel box

AISIN AW CO., LTD. Japan

AQ 450

8-speed automatic gearbox with single Lepelletier planetary gearbox

450Nm

G 055 540 A2

7.65 litres at a change interval of 200,000 km

0.86 litres lifetime filling

The drive train in the TGE

The diverse applications of the TGE mean there are also several variants of power transmission in

its drive concept. The spectrum ranges from front-wheel drive with manual gearbox to four-wheel

drive with 8-speed automatic gearbox including a Generation 5 four-wheel drive coupling and

electronic differential lock.

Power transmission

Gearbox

6-speed manual

gearbox

8-speed automatic

gearbox

This booklet presents the design and function of the 8-speed automatic gearbox with its components for front and

four-wheel drive.

Engine Type of drive Four-wheel drive

coupling

2.0 l TDI with 75 kW Front-wheel

drive

2.0 l TDI with 103 kW Front-wheel

drive and

four-wheel

drive

2.0 l TDI with 130 kW Front-wheel

drive and

four-wheel drive

2.0 l TDI with 103 kW Front-wheel

drive

2.0 l TDI with 130 kW Front-wheel

drive

2.0 l TDI with 130 kW Four-wheel

drive

No No

Generation 5 bevel

box and four-wheel

drive coupling

Generation 5 bevel

box and four-wheel

drive coupling

No No

No No

Generation 5 bevel

box and four-wheel

drive coupling

Differential lock

Electrical differential

lock (optional)

Electrical differential

lock (optional)

Electrical differential

lock (optional)

5

Page 6

Selector lever

The selector lever may differ in appearance from one vehicle to another. The operation and function

are the same for all vehicles with this automatic gearbox.

Design of the selector lever module

The selector lever module is made up of the following main components:

The selector mechanism

The selector lever with bellows

The selector lever position display Y6

The selector lever locked in position “P” switch F319

Plug connection C for selector lever

position display Y6

The selector lever lock solenoid N110

The Tiptronic switch F189

Switch for selector lever gate detection F257

Mechanical, manual emergency release

Selector lever

Electronics of

the selector

mechanism

6

Selector lever cable

Selector lever electronics

with switch for Tiptronic F189

Connector A to the vehicle

wiring harness for the gearbox

Emergency release

Selector housing

Selector mechanism

m107_042

Page 7

How the selector lever module works

The selector lever operates the selector slide in the

valve body and the multifunction switch via the

selector lever cable and a relay lever. The selector

lever module has both mechanical and electrical

functions.

Relay lever

Selector lever cable

Multifunction switch

Shaft to selector slide

Mechanical functions

Actuation of the parking lock

Actuation of the selector slide of the hydraulic

control unit

Actuation of the multifunction switch in the gearbox

Electrical functions

Ignition key withdrawal lock

Control of the display unit for selector lever position

(via gear control unit)

Tiptronic function

Selector lever lock (P/N lock)

Further electrical elements of the switching operation

Multifunction switch

The multifunction switch is connected to the selector

mechanism via a cable.

In the multifunction switch, the mechanical movement

of the cable is converted into electrical signals according to the selector lever position and transmitted to

the control unit for the automatic gearbox.

Selector lever locked in position “P” switch F319

The switch is operated by the selector lever in the “P”

position. It then sends a signal “selector lever in

position P” to the control unit for steering column

electronics.

The control unit needs this signal to control the ignition

key withdrawal lock.

m107_014

Switch for selector lever gate detection F257

The switch recognises the position of the selector lever

and thus the driver‘s wish. The signal is compared with

that of the multifunction switch and checked for

plausibility.

Tiptronic switch F189

The switch detects the Tiptronic gate as well as “Tip +”

and “Tip -”. The signal is sent via analogue line to the

gearbox control unit.

7

Page 8

Selector lever

Selector lever lock

The selector lever lock is engaged when the ignition is switched on and in the P and N positions

during vehicle operation. When the ignition key is removed, the lock is engaged in the P position.

The locking mechanism enables the selector lever to be locked both when the selector lever lock

solenoid N110 is deenergised (position P) and when the solenoid is energised (position N).

Lock in selector lever position P

If the solenoid N110 is deenergised, the locking lever automatically

engages in the P latch in the selector mechanism as soon as the

selector lever is brought into position P. This movement of the locking

lever is supported by a spring in the solenoid N110.

For unlocking, the solenoid N110 is energised, which means the

solenoid pulls the locking lever out of the P latch.

Lock in selector lever position N

Solenoid N110 is activated if the selector lever is in position N. The

solenoid then pushes the locking lever with its upper hook into the N

latch and the selector lever locks. The solenoid N110 is switched off

to release. The weight of the locking lever causes it to drop down and

release the selector lever again.

Locking lever

Selector lever

lock solenoid

N110

Locking lever

P latch

Selector mechanism

m107_025

N latch

Selector lever

lock solenoid

N110

Note

In the event of a defect or a power failure, the selector

lever remains locked. In this case, a locked selector lever

can be unlocked mechanically.

8

Selector mechanism

m107_026

Page 9

The mechanical, manual emergency release of the P latch

The locking lever for the emergency release is located on the right of

the selector mechanism.

To unlock the selector lever lock, pull the locking lever backwards and

press the selector lever lock button at the same time.

Locking lever

m107_025

Selector mechanism

The ignition key withdrawal lock

The ignition key withdrawal lock prevents the ignition key from being

turned back to the withdrawal position if the parking lock is not

engaged.

It functions electromechanically and is controlled by the steering

column electronics control unit J527.

The control unit for steering column electronics detects the position

of switch F319. If the switch is open, the selector lever is in “P”, the

solenoid for ignition key withdrawal lock N376 is not energised. The

ignition key can be removed.

Locking pin

m107_055

9

Page 10

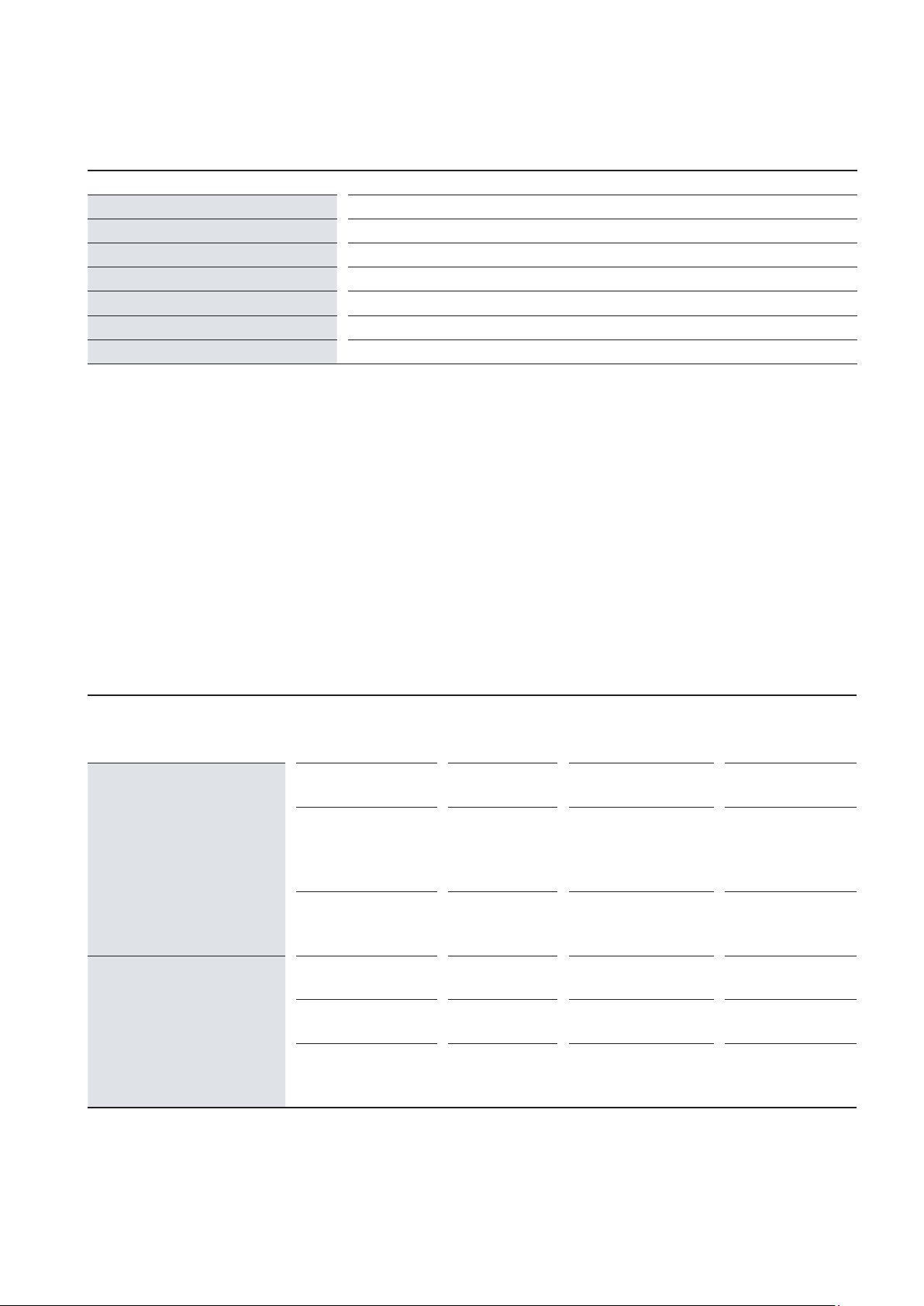

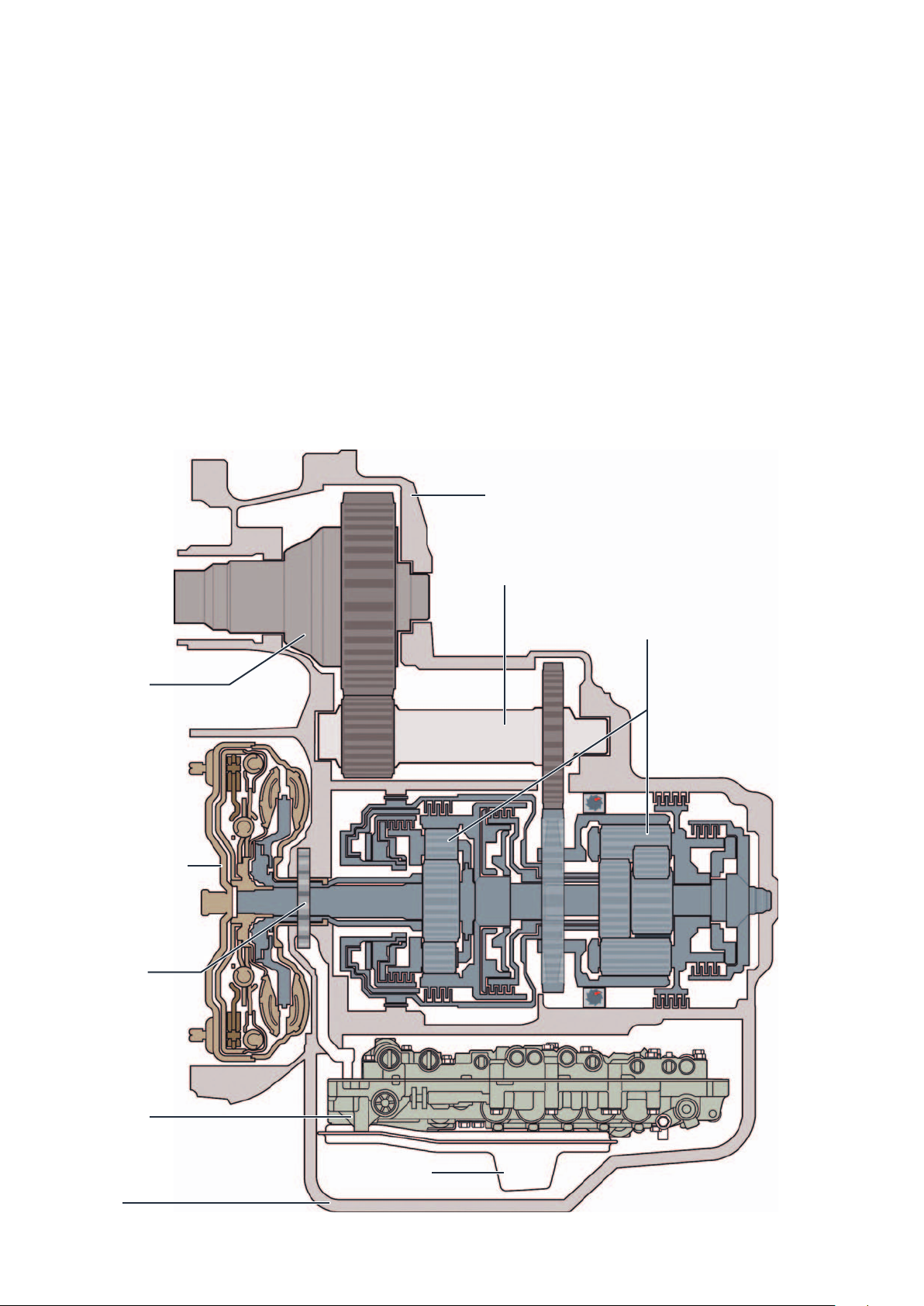

Gearbox deSIGn

The gearbox at a glance

The gearbox is divided into the following main

assemblies:

The torque converter with torque converter lock-up

clutch

− for front-wheel drive without centrifugal pendulum

− for four-wheel drive with centrifugal pendulum

The ATF oil pump

Differential

The planetary gearbox

The valve body

The transfer box (only for four-wheel drive)

The automatic gearbox control unit (in the engine

compartment)

Gearbox housing

Intermediate shaft

Planetary gearbox

Torque converter

ATF pump

Valve body

Sump

10

Oil filter

m107_002

Page 11

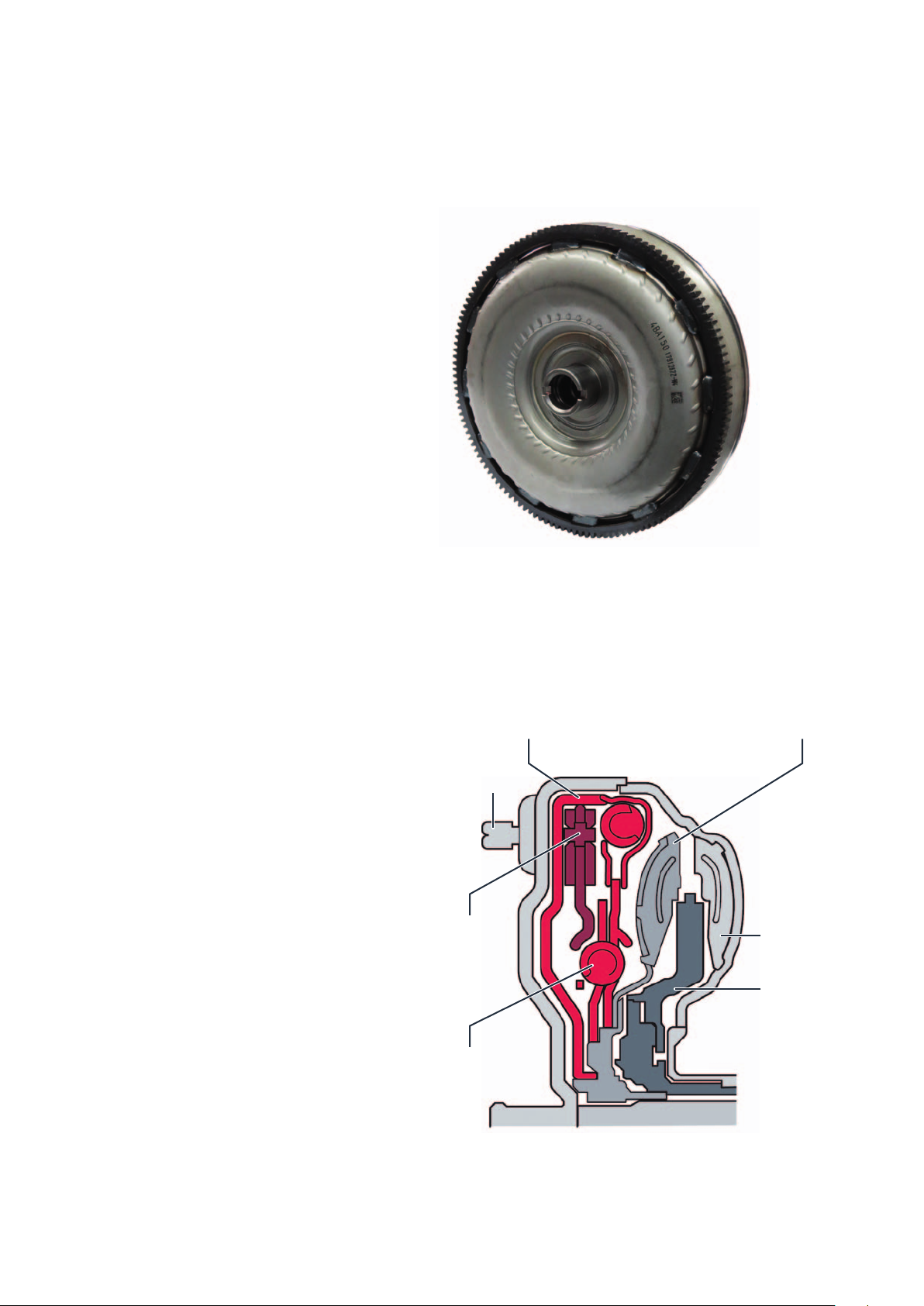

Torque converter

The hydromechanical torque converter is a fluid

coupling. It serves as a driving off element and boosts

the torque in the conversion range. Alongside the

turbine wheel, pump wheel and stator, a torque

converter lock-up clutch is fitted in the torque

converter. The torque converter of the fourwheel

driveversion of the TGE has what are referred to as

centrifugal pendulums to compensate for torsional

vibrations in the engine more efficiently.

During operation, their inertia causes them to oscillate

in the opposite direction to the engine oscillations, thus

largely compensating for them. The torque converter is

connected to the various engines via a driving plate

with six studs, which are permanently connected to

the torque converter.

m107_043

Alongside the turbine wheel, pump wheel and stator, a

torque converter lock-up clutch is fitted in the torque

converter.

An optimised torsional damper is used in the torque

converter of the TGE. In addition, torque converters in

four-wheel drive vehicles have integrated centrifugal

pendulums. Torsion dampers and centrifugal

pendulums reduce the transmission of torsional

vibrations from the engine to the drive train.

Torque converter lock-up clutch

Stud

Centrifugal

pendulum

absorbers

Torsional damper

Turbine

Pump impeller

Stator

m107_018

11

Page 12

Gearbox deSIGn

The planetary gearbox

Like its predecessors, this automatic gearbox also has

two planetary gear sets arranged one behind the other.

The first planetary gear set is a single planetary

gearbox.

The second planetary gear set is a double planetary

gearbox based on the Ravigneaux principle. This

special arrangement of the two different planetary gear

sets is called a Lepelletier planetary gearbox.

The first planetary gear set makes it possible to drive

the second planetary gear set at two different speeds.

Due to this special design, it is possible to implement

amaximum of 9 gears (10 minus 1). This means that

gearboxes with this design have an extremely wide

range of applications from 5-speed automatic gearboxes to the 8-speed automatic gearbox described

here. They differ essentially only in the number of

clutches and brakes required to implement the

respective number of gears.

m107_044

m107_056

12

Single planetary gear set Double planetary gear set

according to Ravigneaux

Planetary gearbox according to Lepelletier

Page 13

The single planetary gear set

From the torque converter, the drive torque of the

engine passes from the gearbox input shaft via the

planetary gear carrier PT1 to this planetary gearbox.

The sun gear S1 is permanently connected to the ATF

oil pump via a plug connection. This means it cannot

m107_045

rotate freely. The planetary gear carrier PT1 has five

planetary gears for transmission to the annulus H1.

The single planetary gearbox is integrated into the

gearbox via theclutches K1, K3 and K4 as well as the

brake B1.

Planetary gear

carrier PT1

Input shaft

Sun gear S1

Brake B1 Annulus H1

Clutch K4 Clutch K3 Clutch K1

m107_022

13

Page 14

Gearbox deSIGn

The double planetary gear set according to Ravigneaux

The clutches K1, K3 and K4 on the single planetary

gearbox and the clutch K2 on the Ravigneaux

planetary gearbox transmit the engine torque to this

double planetary gearbox. This is done either from the

gearbox input shaft via the single planetary gear set

described above to the sun gears S2 or S3 or via the

clutch K2 directly from the gearbox input shaft to the

planetary gear carrier PT2.

The two sun gears S2 and S3 can rotate at different

speeds. On the planetary gear carrier there are three

planetary gears of different lengths P2a and P3a. The

short planetary gears P2a engage in the sun gear S2

and the annulus H2 and the long planetary gears P3a

engage in the annulus H2 and via inner planetary gears

P3b on the sun gear S3. The double planetary gear set

is integrated into the gearbox via the clutch K2, the

brake B2 and the freewheel.

Output to

differential

Connection K3 and K4

with sun gear S2

Input shaft

Connection K1 with

sun gear S3

m107_047

Annulus H2 Brake B2

Planetary gear carrier PT2

Intermediate shaft

(turbine shaft)

14

m107_023

Sun gear S2 Sun gear S3 Clutch K2

Page 15

The brakes

Brake B1

Brake B1 is a band brake. It is connected to the

gearbox housing and is operated hydraulically by

means of a control piston via the valve body.

Brake B1 is controlled using the automatic gearbox

pressure regulating valve 2. The return movement is

performed using a spring.

When applied, it holds the sun gear S2, when K4 is

closed it holds the planetary gear carrier PT1, when K3

is closed it holds the annulus H1 and when K1 is

closed it holds the sun gear S3.

m107_027

Brake B1

Brake B2

Brake B2 is designed as a multi-disc brake. It is

connected to the gearbox housing.

When the solenoid valve 1 N88 is energised, the

hydraulic oil pressure compresses the discs of the

brake.

The planetary gear carrier PT2 is held in this way.

m107_029

B1 PT1 H1 S2 S3

m107_028

Brake B2

B2 PT2

m107_030

15

Page 16

Gearbox deSIGn

The clutches

The clutches K1, K2, K3 and K4

The electric solenoid valves inside the valve body open

or close the clutches. The clutches fulfil the following

functions when closed:

Clutch K1 connects the annulus H1 with the sun

gear S3.

Clutch K2 connects turbine shaft to the planetary

gear carrier PT2.

Clutch K3 connects the annulus H1 with the sun

gear S2.

Clutch K4 connects the planetary gear carrier PT1

to the sun gear S2.

16

m107_031

Clutch K4 Clutch K3 Clutch K1 Clutch K2

Page 17

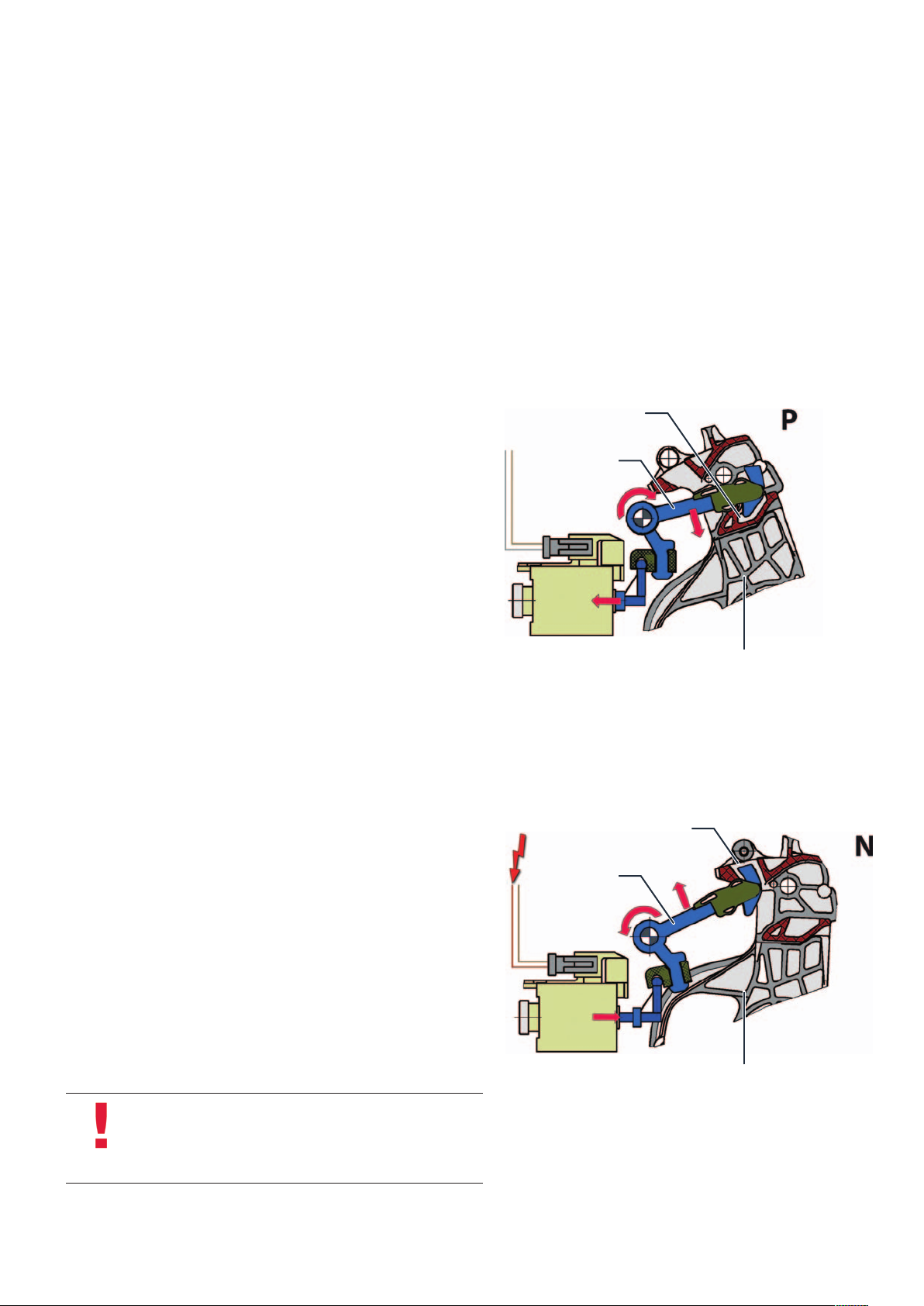

Parking lock

In order to protect the parking lock against

unnecessary mechanical wear, a new display concept

has been implemented in the TGE to prevent misuse

ofthe parking lock.

In this context, misuse means using the parking lock

as a service brake.

This means that the parking lock is engaged when the

vehicle is rolling in order to bring the vehicle to a

standstill. The parking lock serves exclusively to secure

the vehicle against rolling away and is only allowed to

be engaged when the vehicle is stationary.

The display concept works with two warning levels.

Warning level 1

m107_050

An acoustic warning tone of priority level 2 sounds.

The display of the dash panel insert shows the

adjacent warning message for six seconds.

Warning level 2

An acoustic warning tone of priority level 1 sounds.

The display of the dash panel insert shows the

adjacent warning message for six seconds.

In addition, the central warning lamp lights up red.

The display of this warning level repeats itself with

each engine start.

Warning level 2 cannot be reset. The gearbox must

berenewed.

Only engage P

when stationary!

Wear of the

parking lock!

m107_052

Parking lock

damaged by misuse.

Use handbrake.

Workshop!

m107_053

17

Page 18

valve body

The valve body at a glance

The valve body is screwed into the gearbox housing

from below. The clutches and brakes of the gearbox

are actuated by means of hydraulic valves, so-called

shift valves, inside the valve body. The shift valves are

controlled by electrically operated solenoid valves,

which in turn are controlled by the automatic gearbox

control unit J217. In addition to the shift valves, the

valve body controls the torque converter and the

various pressures in the gearbox, e.g. main, control,

converter and lubricating pressure.

To achieve the required oil pressure in start-stop

operation, an auxiliary hydraulic pump 1 for gearbox oil

V475 is installed in the valve body.

Solenoid valve 2 N89 (solenoid valve)

Pressure regulating valve 1 for automatic

gearbox N215 (falling characteristic)

Selector slide

Gearbox oil temperature sender G93

The valve body contains the following components:

The mechanically operated selector slide valve

Two electrically controlled solenoid valves

(3/2-way valves)

Six electric pressure regulating valves with

increasing characteristic curve (pressure increases

with increasing control current)

One electric pressure regulating valve with falling

characteristic (pressure decreases with increasing

control current)

The gearbox oil temperature sender G93

The electric auxiliary hydraulic pump 1 for gearbox

oil V475

Solenoid valve 1 N88 (solenoid valve)

Pressure regulating valve 3 for automatic

gearbox N217 (rising characteristic)

Auxiliary hydraulic

pump1 for gearbox oil

V475

Pressure regulating

valve 8 for automatic

gearbox N510

(rising characteristic)

Pressure regulating

valve 6 for automatic

gearbox N371

(risingcharacteristic)

m107_019

Pressure regulating valve 5 for automatic

gearbox N233 (rising characteristic)

18

Pressure regulating valve 4 for automatic

gearbox N218 (rising characteristic)

Pressure regulating valve 2 for automatic

gearbox N216 (rising characteristic)

Page 19

Solenoid valves

Gears

P R N 1 2 3 4 5 6 7 8

Solenoid valve 1 N88 – – – X – – – – – – –

Solenoid valve 2 N89 – – – – X X – – – – –

Pressure regulating valve 1 for

automatic gearbox N215

Pressure regulating valve 2 for

automatic gearbox N216

Pressure regulating valve 3 for

automatic gearbox N217

Pressure regulating valve 4 for

automatic gearbox N218

Pressure regulating valve 5 for

automatic gearbox N233

Pressure regulating valve 6 for

automatic gearbox N371

Pressure regulating valve 8 for

automatic gearbox N510

The pressure regulating valve 1 modulates the main oil pressure of the gearbox

depending on of the accelerator pedal value.

– – – – X – – – – – X

– – – X X X X X – – –

– – – – – – – X X X X

– X – – – X – – – X –

– – – – – – X – X – –

The pressure regulating valve 8 modulates the oil pressure for the torque converter

lock-up clutch depending on the shift strategy.

Clutches

Gears

P R N 1 2 3 4 5 6 7 8

Clutch K1 – – – X X X X X – – –

Clutch K2 – – – – – – – X X X X

Clutch K3 – X – – – X – – – X –

Clutch K4 – – – – – – X – X – –

Brakes/freewheel

Gears

P R N 1 2 3 4 5 6 7 8

Brake B1 – – – – X – – – – – X

Brake B2 – X – X* – – – – – – –

Gliding – – – X – – – – – – –

– = Valve switched off, clutch open, brake not applied

X = Valve switch on, clutch closed, brake applied

X* = Only closed in Tiptronic mode in 1st in certain driving situations to use the

engine braking effect

19

Page 20

oIl Supply

The ATF oil pump

In the case of vehicles with internal combustion

engines, the mechanical ATF pump (Automatic

Transmission Fluid) is exclusively responsible for the

supply of hydraulic oil to the gearbox during normal

driving. It draws the ATF oil from the oil sump, builds

up the oil pressure and supplies the valve body with

the hydraulic fluid required for the gear changes.

m107_054

The ATF oil pump is an internal geared wheel pump

(duocentric oil pump). It is driven directly by the engine

via the converter housing by the converter hub. Here,

m107_012

the drive lugs of the pinion of the ATF oil pump engage

in two grooves on the converter hub.

20

Page 21

Auxiliary hydraulic pump 1 for gearbox oil V475

The electric oil pump is required for vehicles with

start-stop system. It maintains the oil pressure in the

gearbox during the stop phase. This allows the vehicle

to move off immediately after the engine starts without

any loss of comfort.

After the internal combustion engine has started again

and the mechanical oil pump has built up the required

oil pressure, the auxiliary hydraulic pump 1 for gearbox

oil is switched off.

m107_020

m107_021

21

Page 22

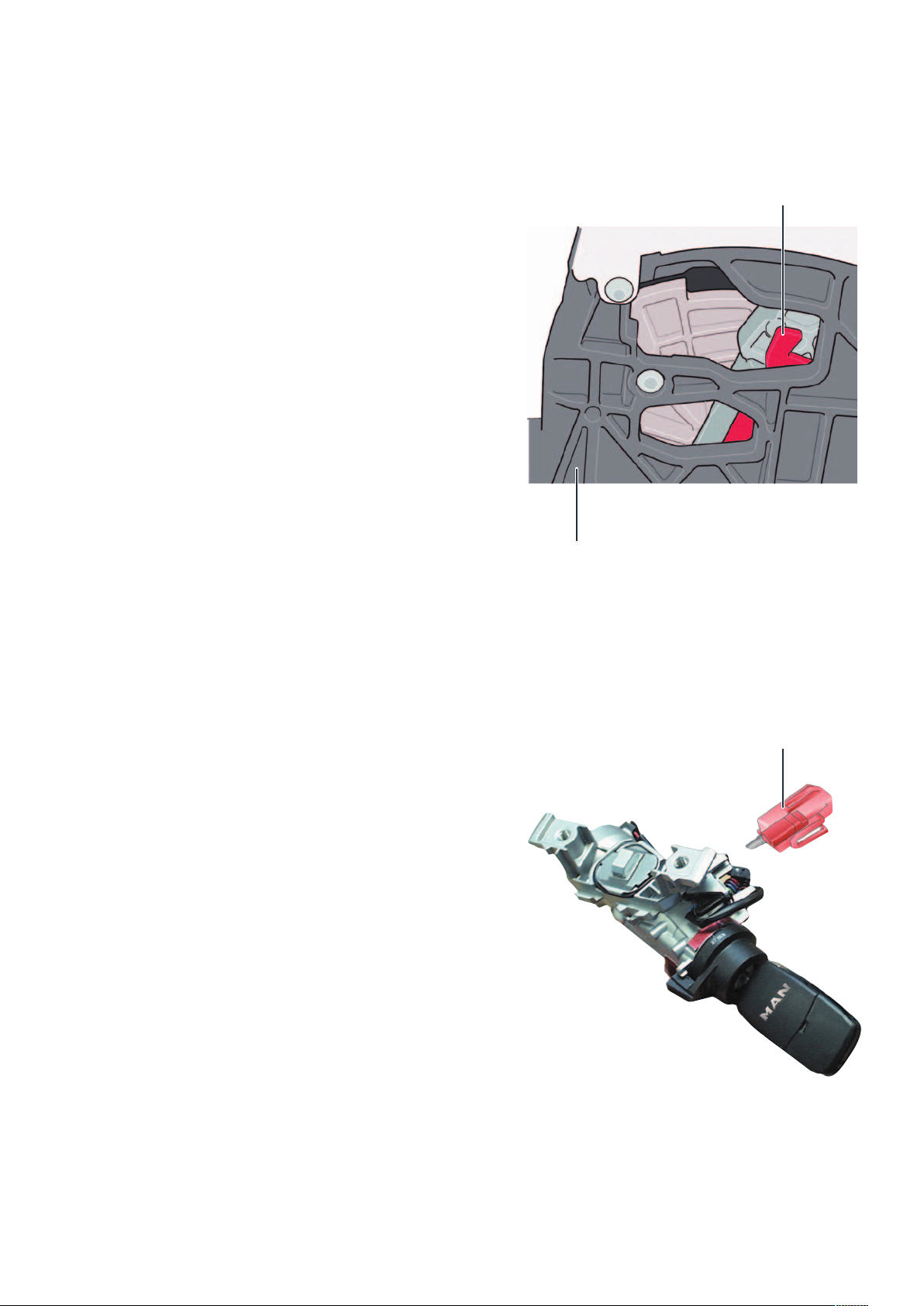

Gearbox manaGement

System overview

Sensors

Reversing switch

F41

Gearbox position switch

F305

Selector lever locked in position P switch

F319

Multifunction switch

F125

On-board power

supply control unit

J519

Tiptronic switch

F189

Gearbox oil temperature sender

G93

Gearbox input speed sender

G632

Selector lever sensors

control unit

J587

Data bus diagnostic

interface J533

Automatic gearbox

control unit

J217

Control unit in dash

panel insert

J285

22

Gearbox output speed sender

G195

Page 23

Engine control unit

J623

Actuators

Selector lever lock solenoid

N110

Solenoid for selector lever lock P

N380

Selector lever position display

Y6

Steering column

electronics control

unit J527

Solenoid valve 1

N88

Solenoid valve 2

N89

Pressure regulating valve 1 for automatic gearbox N215

Pressure regulating valve 2 for automatic gearbox N216

Pressure regulating valve 3 for automatic gearbox N217

Pressure regulating valve 4 for automatic gearbox N218

Pressure regulating valve 5 for automatic gearbox N233

Pressure regulating valve 6 for automatic gearbox N371

Pressure regulating valve 8 for automatic gearbox N510

Auxiliary hydraulic pump 1 for gearbox oil

V475

m107_038

23

Page 24

Gearbox manaGement

The automatic gearbox control unit J217

The automatic gearbox control unit J217 is located in

the engine compartment at the front left under the

battery console of the additional battery.

It is connected to the diagnostic interface for data bus

via the powertrain CAN bus.

The automatic gearbox control unit directly controls

the solenoid valves in the valve body.

The information from the sensors in the gearbox is also

transmitted directly. For this reason, the control unit is

connected to the on-board electrical system and the

gearbox via a 52-pin plug.

The VAS adapter cable 1598/48 is available for static

and dynamic measurements on the system.

The manufacturer of the control unit is also AISIN AW

Japan. The update programming is possible with the

VAS 5051.

The dynamic shift program DSP is integrated in the

control unit. This shift program evaluates the driving

resistance (e.g. for driving on hilly terrain), the route

profile (e.g. for windy roads) and the driving style,

amongst other factors, to determine the gearshift

points.

24

m107_037

Page 25

The torque characteristics

The torque curves of the individual gears are shown in

the following highly simplified cross-section of the

gearbox. The illustration of the valve body shows

1st gear

PT1

which solenoid valves are activated for the respective

gear.

H1

K1

H2

P2

P3

S3

B2

PT2

Clutch K1 and freewheel F

The gearbox input shaft transmits the engine torque to

the planetary gear carrier PT1 of the single planetary

gear set. The planetary gears P1 roll around supported

on the fixed sun gear S1 and drive the annulus H1.

Clutch K1 connects the planetary gear carrier H1 to

the sun gear S3 and, in this way, transfers the torque

to the double planetary gear set. The freewheel blocks

the planetary gear carrier PT2. From the sun gear S3,

the torque is transferred to the planetary gears P3.

Supported by the planetary gear carrier PT2, the

torque is transferred to the annulus H2.

Annulus H2 is connected to the gearbox output shaft.

N88

N217

In certain driving situations, the braking effect of the

engine can be used by selecting 1st gear in Tiptronic

mode.

Using the engine braking effect in 1st gear is made

possible by closing the brake B2.

Brake B2 blocks the planetary gear carrier PT2

similarly to the freewheel. Unlike the freewheel F,

however, the brake B2 holds the planetary gear carrier

PT2 in both directions of rotation.

m107_003

25

Page 26

Gearbox manaGement

2nd gear

B1

PT1

H1

N217

K1

N89

N216

P2

H2

P3

S3

PT2

m107_004

Clutch K1 and brake B1

As with the first gear, the engine torque is introduced

into the double planetary gear set by the annulus H1 of

the single planetary gear set. Clutch K1 connects the

annulus H1 to the sun gear S3 for this purpose.

26

Brake B1 blocks the sun gear S2. From the sun gear

S3, the torque is transferred to the planetary gears P3.

Planetary gears P2 roll around the sun gear S2 and,

together with the planetary gears P3, drive annulus H2.

Page 27

3rd gear

K3

PT1

H1

K1

N89

P2

S2

H2

P3

S3

PT2

Clutches K1 and K3

As before, the clutch K1 connects the annulus H1 to

the sun gear S3.

Clutch K3 additionally connects the annulus H2 to the

large sun gear S2.

N217

N233

m107_005

Planetary gears P2 and P3 are blocked by K1 and K3.

Planetary gear carrier PT2 now rotates together with

the sun gears S2 and S3.

The torque is thus transmitted via the planetary gear

carrier PT2 to the annulus H2.

27

Page 28

Gearbox manaGement

4th gear

K4

PT1

H1

N217

K1

P2

S2

H2

P3

S3

N371

PT2

m107_006

Clutches K1 and K4

Once again, the clutch K3 connects the annulus H1 to

the sun gear S3 and, in this way, transfers the torque

to the double planetary gear set.

Clutch K4 connects the planetary gear carrier PT1 to

the sun gear S2 and also transfers the torque to the

double planetary gear set, although with different input

speeds.

28

Sun gear S3 is driven more slowly than the sun

gearS2. Planetary gears P2/P3 roll around the fasterrotating sun gear S2 and drive the annulus H2.

Page 29

5th gear

PT1

H1

N217

K1

N218

P2

H2

P3

S3

K2

PT2

m107_007

Clutches K1 and K2

Clutch K1 connects the annulus H1 to the sun gear S3

and, in this way, transfers the torque to the double

planetary gear set. The clutch K2 connects the turbine

shaft to the planetary gear carrier PT2 and thereby

transfers the torque to the double planetary gear set in

the same way.

Together with the planetary gear carrier PT2, planetary

gears P2 and P3 drive the annulus H2.

29

Page 30

Gearbox manaGement

6th gear

K4

PT1

H1

N217

P2

S2

H2

P3

N371

K2

PT2

m107_008

Clutches K2 and K4

The turbine shaft drives the planetary gear carrier PT1

of the single planetary gear set and the outer disc

carrier of the clutch K2. The clutch K4 connects the

planetary gear carrier PT1 to the sun gear S2 and, in

this way, transfers the torque to the double planetary

gear set.

The clutch K2 connects the turbine shaft to the

planetary gear carrier PT2 and thereby transfers the

torque to the double planetary gear set in the same

way.

30

Sun gear S2 transfers the torque to the planetary

gears P2. The torque is transferred to the planetary

gears P3 via the planetary gear carrier PT2. Together

with the planetary gears P2, the planetary gears P3

drive the annulus H2.

Page 31

7th gear

K3

H1

H2

K2

PT1

N218

N233

P2

S2

P3

PT2

m107_009

Clutches K2 and K3

The turbine shaft drives the planetary gear carrier PT1

of the single planetary gear set and the outer disc

carrier of the clutch K2. Planetary gear carrier PT1

drives the planetary gears P1, which roll around

supported on the fixed sun gear S1 and thus drive the

annulus H1.

Clutch K3 connects the annulus H1 to the sun gear S2

and, in this way, transfers the torque to the double

planetary gear set.

The clutch K2 connects the turbine shaft to the

planetary gear carrier PT2 and, in this way, likewise

transfers the torque to the double planetary gear set.

The planetary gears P2, which are jointly driven by sun

gear S2 and planetary gear carrier PT2, drive the

annulus H2 along with the permanently connected

outer planetary gears P3a.

31

Page 32

Gearbox manaGement

8th gear

B1

PT1

H1

N218K2N216

P2

S2

H2

P3

PT2

m107_010

Clutches K2 and brake B1

Brake B1 blocks the sun gear S2. Clutch K2 connects

the turbine shaft to the planetary gear carrier PT2 of

the double planetary gear set and, in this way,

transfers the torque to the double planetary gear set.

32

The long planetary gears P3 roll around the stationary sun

gear S2 and, together with the planetary gears P2, drive

the annulus H2. The clutches K1 and K3 are open.

The single planetary gear set is not part of the power flow.

Page 33

Reverse gear

K3

H1

B2

H2

PT1

N233

P2

S2

P3

N510

PT2

m107_011

Clutches K3 and brake B2

The turbine shaft drives the planetary gear carrier PT1

of the single planetary gear set. The planetary gear

carrier PT1 drives the planetary gears P1, which roll

around supported on the fixed sun gear S1.

The annulus H1 is driven in this way.

Clutch K3 connects the annulus H1 to the sun gear S2

and, in this way, transfers the torque to the double

planetary gear set. In the double planetary gear set,

brake B2 blocks the planetary gear carrier PT2.

From the sun gear S2, the torque is transferred to the

planetary gears P2 and P3. Supported by the

planetary gear carrier PT2, the torque is transferred

tothe annulus H2, which is connected to the output

shaft. Annulus H2 is thereby driven against the

direction of engine rotation.

33

Page 34

ServIce

Special tools

Special tools

Designation

T10173

Setting gauge

30-211A

Support bridge

Tool Use

To set the multifunction switch

m107_040

Holds the torque converter in position

when the engine and gearbox are

separated.

m107_041

Towing

Note

If the TGE with 8-speed automatic gearbox has to be

towed, the 50/50 rule must be strictly observed. This

means that it is only allowed to be towed at a maximum

speed of 50 km/h over a maximum distance of 50 km.

34

Page 35

teSt your knowledGe

Which answers are correct?

One or several of the given answers may be correct.

1. An automatic gearbox according to Lepelletier essentially consists of:

a) A double Lepelletier planetary gear set and a single Ravigneaux planetary gear set

b) An upstream single planetary gear set and a Ravigneaux double planetary gear set

c) Two single Lepelletier planetary gear sets

2. Which statement is correct?

a) The entire planetary gearbox has a multi-disc brake and a band brake.

b) The entire planetary gearbox has two band brakes.

c) The entire planetary gearbox has two multi-disc brakes.

3. What is new about the parking lock in the 8-speed automatic gearbox of the TGE?

a) There are no new features on the parking lock.

b) A new display concept has been developed intended to prevent the misuse of the parking

lock as a service brake.

c) The parking lock is mechanically designed in such a way that it cannot be used as a service

brake.

4. The auxiliary hydraulic pump 1 for gearbox oil V475 is:

a) Screwed onto the gearbox housing from the outside.

b) Screwed onto the left longitudinal member under the cabin, separately from the gearbox.

c) Integrated in the valve body.

Answers:

1. b); 2. a); 3. b); 4. c)

35

Page 36

MAN Truck & Bus SE

Dachauer Straße 667

80976 München

www.mantruckandbus.com

MAN Truck & Bus – A company of the MAN group

Loading...

Loading...