Page 1

MAN GUIDE 106

The eTGE

Page 2

The high-voltage components and the technologies used for the remaining subassemblies guarantee safe and comfortable

mobility. The electric motor boasts a power output of 100 kW and develops a maximum torque of 290 Nm from a standstill.

Depending on the vehicle payload, route and driving profile, the real range is approx. 120 km. According to the NEDC, the range

is 173 km. In the new, more challenging WLTC, the range is 110 / 114 km. The nominal energy of the lithium-ion high-voltage

battery is 35.8 kWh. The recuperation, i.e. the braking energy recovery, has been adapted for the eTGE with three-phase drive.

Under certain circumstances, the three-phase current drive can cause a deceleration when in alternator mode. The power and

control electronics for the electric drive supplies the energy generated to the high-voltage battery. Withthe eTGE, MAN is paving

the way for sustainable, future-proof mobility.

Technical status April 2019

2

m106_002

Attention! Dangerous electric voltage!

The eTGE is a battery-driven electric vehicle. It features a high-voltage system with a rated voltage

of 323 volts. This voltage level can be fatal. Only qualified employees may perform work on this

vehicle. The minimum qualification required is an electrically instructed person.

Page 3

taBle of contents

4 IntroductIon

6 Body

8 Power transmIssIon

10 HeatIng and aIr condItIonIng

16 drIver assIst systems

4

18 HIgH-voltage system

30 electrIcal system

8

38 InfotaInment

41 servIce

43 test your knowledge

18

38

The MAN TGE Guide teaches the basics of design and function for sales and after-sales of new vehicle models, new

vehicle components or new technologies.

The MAN TGE Guide is not a sales manual nor a repair guide! Specified values are for the sake of easy understanding

only and refer to the data status valid at the time the MAN TGE Guide was created.

The contents are not updated.

Please use the appropriate technical literature for customer advice, maintenance and repair work.

Note

Reference

3

Page 4

IntroductIon

The eTGE

The electric van is based on the TGE 2017. Like the versions with diesel engines, the new eTGE

isalso equipped with state-of-the-art assistance and comfort systems.

Because the battery is integrated in the underbody, the charging volume of the electric version

withjust under 10.7 m

The payload of the eTGE is approx. 1.0 tonne at a gross vehicle weight of 3.5 tonnes.

3

remains at the level of the conventional models with rear-wheel drive.

m106_004

4

Page 5

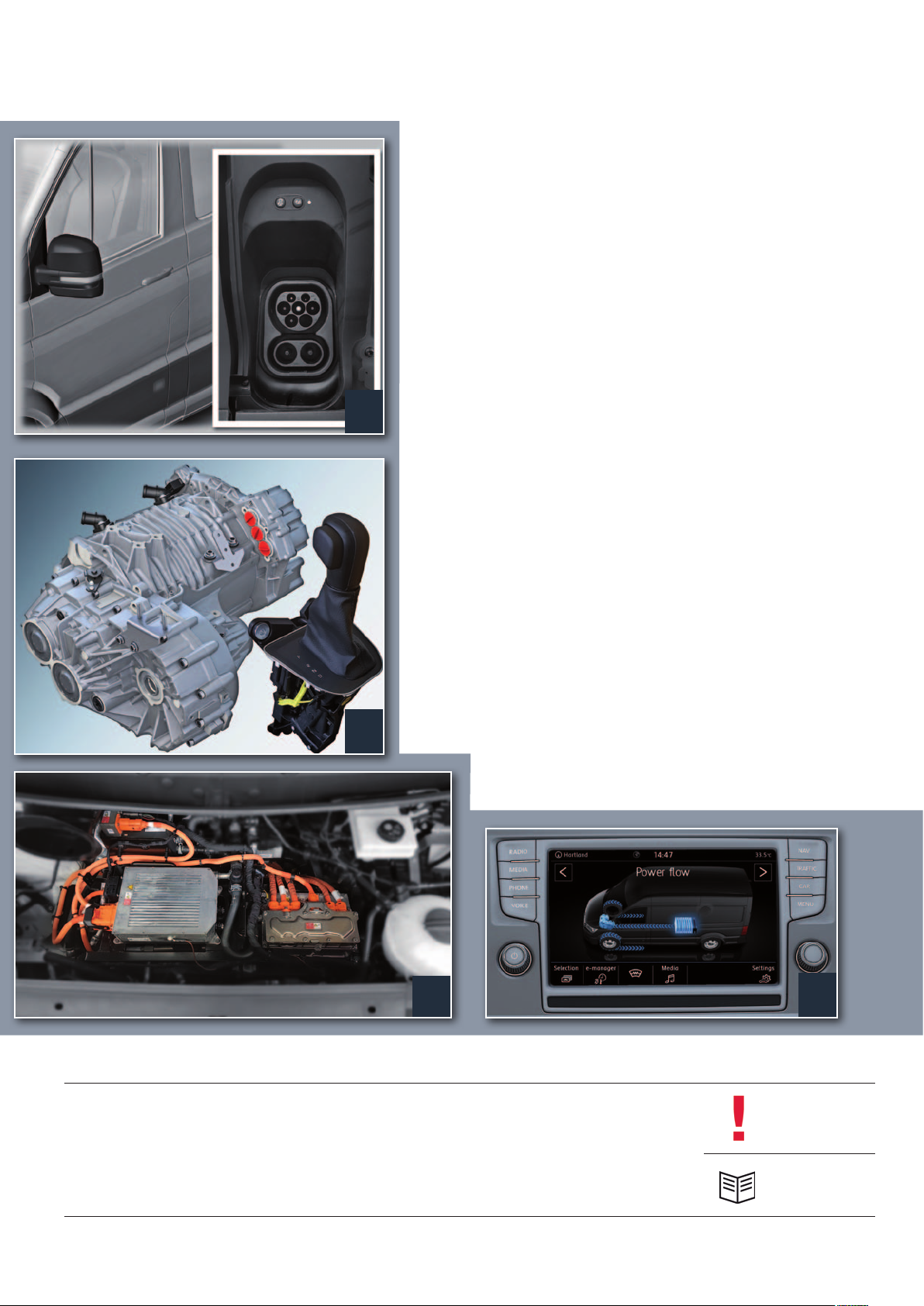

The characteristic features of the eTGE

eTGE emblems in the front grille, on the side panels, in front

of the wheel arches and at the rear left of the wing door at

the height of the tail light

e-specific displays in MAN Media Van Advanced

Instrument panel with e-specific displays

Charging socket behind the tank cap

m106_005

5

Page 6

Body

Body structure

The body structure is based on the vehicle body

featured in the TGE 2017. In order to do justice to

crash safety requirements, the necessary changes to

the geometry were implemented in the underbody, and

additional components have been utilised.

Battery frame

Key

Body changes specifically for the eTGE

6

Page 7

Underbody

The underbody has been extended, which allows

installation of the high-voltage battery, also allowing

thestricter impact requirements this involves to be

satisfied. In the lateral areas, additional crash elements

are installed between the high-voltage battery and the

sill panels. A support frame is located under the middle

of the underbody, which serves as protection for the

high-voltage battery from below. To protect against

dirt, and to improve the drag coefficient, the front of

the underbody features an underbody impact guard

and there are 4underbody covers in the middle.

Crash elements

m106_006

7

Page 8

Power transmIssIon

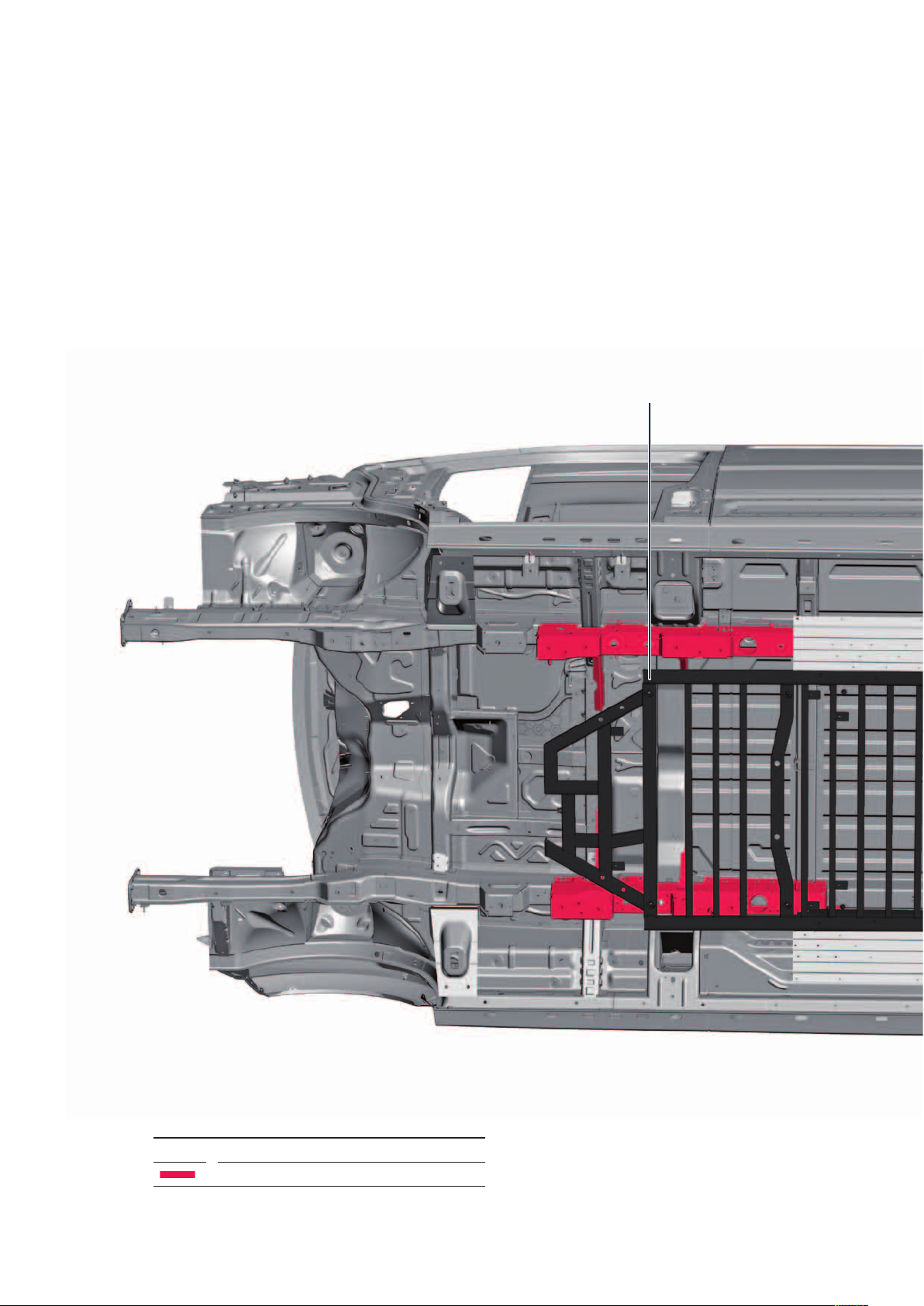

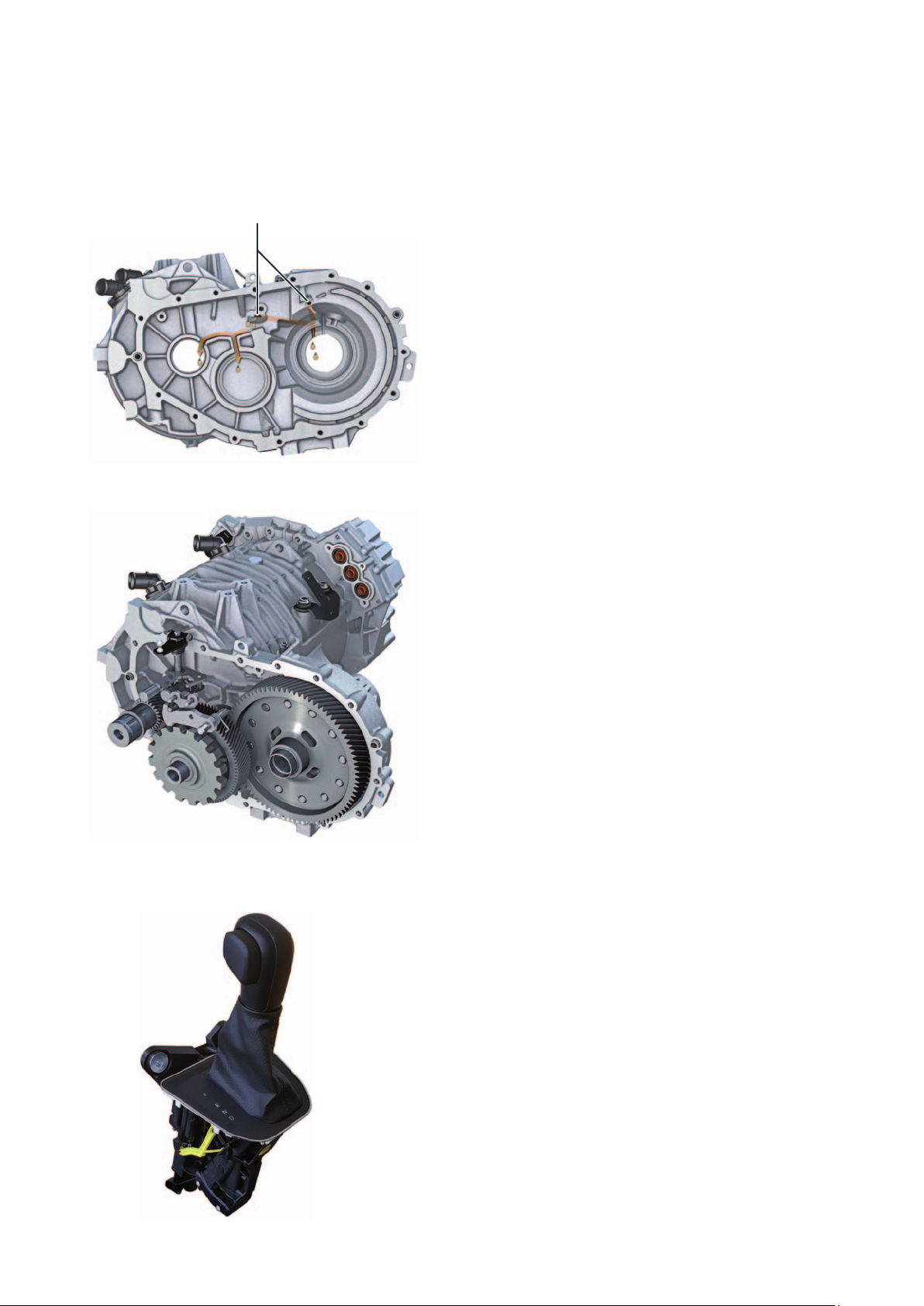

The 0MD 1-speed transmission

The 1-gear drive 0MD of the eTGE consists of proven

components of the group. Thereby, all components,

especially the lubrication in the gearbox, were optimally

designed to fulfil the high requirements in the

commercial vehicles sector.

Three-phase current drive VX54

1-speed transmission

0MD

Technical data

Transmission designation

Number of gears

Transmission stages

Transmission ratios

Max. input torque

Max. input speed

Weight (with oil)

Oil volume

Driveshafts

m106_007

0MD

1

2

Level 1: 3.192 (Z1 = 26; Z2 = 83)

Level 2: 3.609 (Z3 = 23; Z4 = 83)

290 Nm

12,000 rpm

32.2 kg

1.5 l

Splined connection

8

Page 9

Oil supply system

Oil holes

m106_009

The 1-speed gearbox 0MD of the eTGE uses splash

lubrication. To ensure permanent lubrication, the final

drive gear runs in the oil sump. This requires an

appropriate design of the gearbox housing to ensure

lubrication, cooling and oil distribution. Lubrication of

the bearings for the drive shaft, drive shaft and axle

drive is ensured on the gearbox and motor housing

side by 2transverse bores and grooves behind the

bearing shells.

Other necessary measures:

Reinforced tapered roller bearings

Reinforced and larger parking lock

Reinforced toothing of the drive gears

Reinforced differential

Selector lever

m106_008

The 1-gear gearbox 0MD and the selector lever E313

are connected by a cable. This mechanical connection

is used only to activate the parking lock. The mechanical and electrical components of the selector lever are

installed in the housing of the selector lever E313. The

locking mechanism for the selector lever E313 is

provided by the selector lever lock solenoid N110. In

the event of a defect or a power failure, the selector

lever E313 remains locked. The manual emergency

release is located on the left of the selector mechanism. To unlock the selector lever lock, pull the locking

lever backwards and press the selector lever lock

button at the same time.

m106_010

9

Page 10

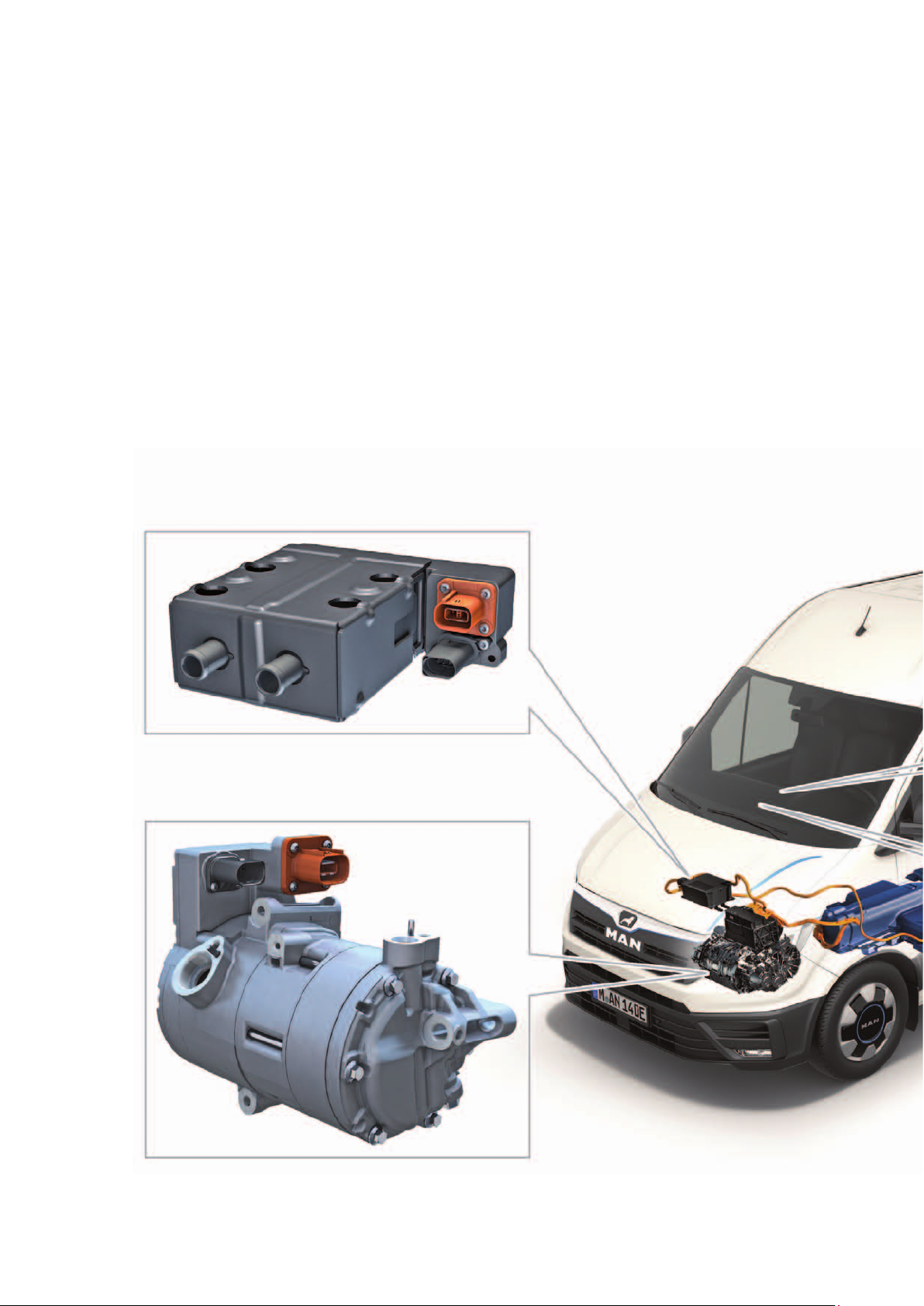

HeatIng and aIr condItIonIng

Overview of components

A 2-zone Climatronic is installed as series standard.

The interior air conditioning of the vehicle is carried out

entirely with a heat pump system via the operating

states “cooling” and “heating”. For cooling, the

refrigerant circuit is switched on in the same way as for

a normal air conditioning system. The system can

switch from cooling to heating via the modified control

of the expansion and shut-off valves. The hot

refrigerant coming from the compressor is passed over

the heating condenser and gives off its heat there to

the air flowing through, which heats the interior. The

Climatronic control unit J255 controls and monitors the

temperature sensors and the air and temperature flaps

in the interior. The thermal management control unit

J1024 controls, regulates and manages the expansion

valves, shut-off valves, high voltage heating (PTC)

Z115, electric air conditioning compressor and

refrigerant pressure and temperature senders.

High-voltage heater (PTC) Z115

Electrical air conditioner compressor V470

10

Page 11

The high-voltage heating (PTC) Z115 and the electric

air conditioning compressor V470 operate on demand

from the air conditioning control unit for heating/

cooling. The set temperature request is sent via CAN

bus to the thermal management control unit J1024.

The e-Manager can be used to program the auxiliary

air conditioning with three departure times (timer).

e-Manager

Climatronic control unit J255

m106_011

11

Page 12

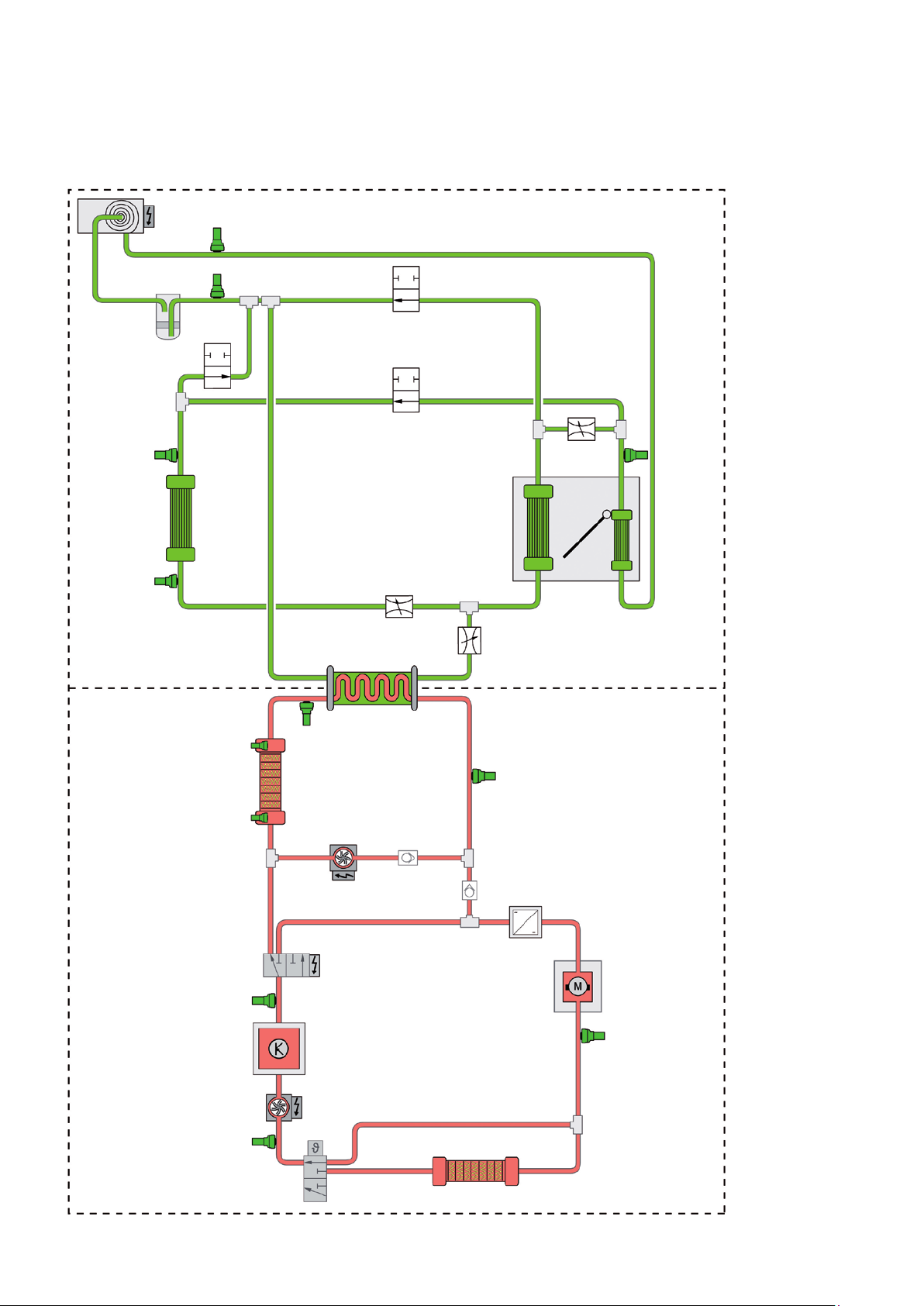

HeatIng and aIr condItIonIng

System overview

V470

G395

1

G827

2

G828

Refrigerant circuit

Coolant circuit

N643

G829

N642

N696

N636 G826

3

4

5

N637 N638

6

G785

N632

G789

JX1

V508

G83

9

G110

Z115

V509

G787

8

10

8

AX4

VX54

G788

m106_064

7

12

Page 13

Key

AX4

Charging unit 1 for high-voltage battery

G83 Radiator outlet coolant temperature

sender

G110 Air conditioning system coolant tempera-

ture sender

G395 Refrigerant pressure and temperature

sender 1

G785 Temperature sender in the high-voltage

heater (PTC)

G787

Temperature sender after heat exchanger

G788 Temperature sender after electric drive

motor

G789 Temperature sender after power and

control electronics for electric drive

G826 Refrigerant pressure and temperature

sender 2

G827 Refrigerant pressure and temperature

sender 3

G828 Refrigerant pressure and temperature

sender 4

G829 Refrigerant pressure and temperature

sender 5

JX1 Power and control electronics for electric

drive

N632

N636

N637

N638

N642

N643

N696

V470

Coolant changeover valve 1

Refrigerant expansion valve 1

Refrigerant expansion valve 2

Refrigerant expansion valve 3

Refrigerant shut-off valve 4

Refrigerant shut-off valve 5

Refrigerant shut-off valve 1

Electrical air conditioner compressor

V508 Coolant circulation pump before power

and control electronics for electric drive

V509 Coolant circulation pump before high-vol-

tage heater (PTC)

VX54

Z115

Three-phase current drive

The high-voltage heater (PTC)

1

2

3

4

5

6

Dryer

Condenser

Evaporator

Temperature flap

Heat condenser

Heat exchanger for heat condenser

7 Internal temperature sender in the high-

voltage heater (PTC)

8

9

10

Non-return valve

Thermostat

Cooler

Refrigerant circuit

Coolant circuit

13

Page 14

HeatIng and aIr condItIonIng

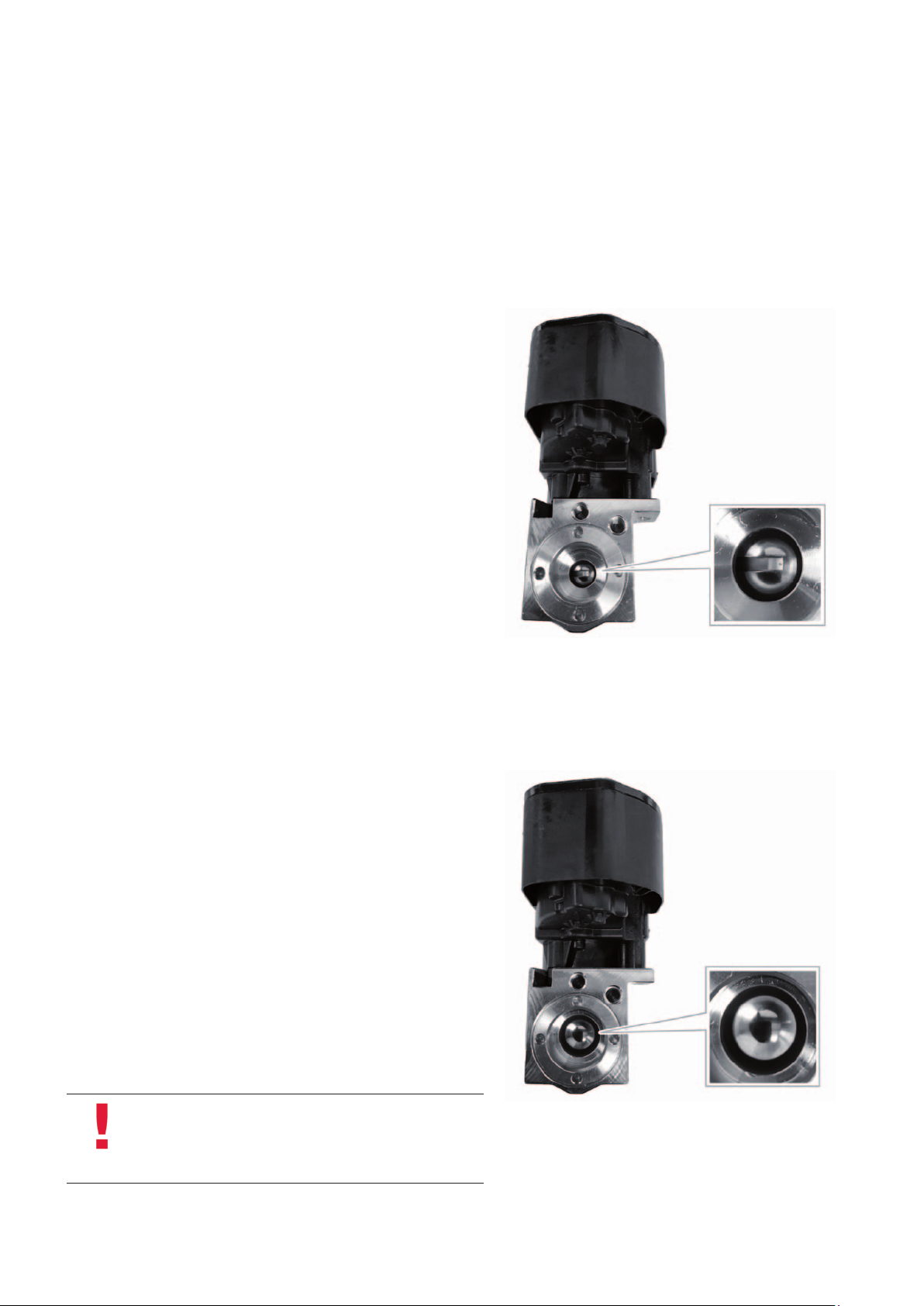

Expansion valves and shut-off valves

The refrigerant circuit has three expansion valves and three shut-off valves.

Expansion valve

The expansion valves are designed as ball valves with a V-shaped

control edge increasing in size. The expansion valves are actuated by

the thermal management control unit J1024 as and when required.

The electric valve is controlled so as to take any position between 0%

(closed) and 100% (fully open). The expansion valves are all identical

in design and are connected to the thermal management control unit

via a LIN bus.

The refrigerant flows through the N637 (EXV2) in one direction or the

other according to the function (heating or cooling).

Coolant

The shut-off valves have been designed as ball valves. They are all

identical in design and are connected to the thermal management

control unit via a LIN bus. The valves can be 0% (closed) or 100%

(fully open).

m106_070

14

Note

When a valve is replaced, it must be readdressed via the

diagnostic software in the thermal management control

unit J1024.

m106_071

Page 15

Heat exchanger

The heat exchanger is the link between the refrigerant circuit and the coolant circuit.

It is required in some operating conditions for re-evaporation of the refrigerant.

Connections for

coolant lines

m106_067

Air conditioning system coolant temperature sender G110

Task and function

The air conditioning system coolant temperature sender G110

measures the current coolant temperature before the heat exchanger

and sends this information to the thermal management control unit

J1024. If the measured waste heat temperature of the water-cooled

high-voltage components is not sufficient to re-evaporate the

refrigerant, the PTC heating element Z115 is activated to increase

thetemperature in the refrigerant circuit.

Connections for

refrigerant lines

m106_068

15

Page 16

drIver assIst systems

Overview of the driver assist systems

Available driver assist systems

Cruise control system (CCS)

Speed limiter

Parking aid (PDW)

Rain/light sensor

Area monitoring system

(Front Assist) with

City Emergency Brake

Main beam assist

(FLA)

Side wind assist

(ESC function)

Lane departure warning

(Lane Assist)

Automatic Post-Collision Braking

SystemArea

16

Page 17

Note

You will find further information on the driver assist

systems in MAN GUIDE 104

“TGE - Driver Assist Systems”.

Hill Start Assist Optical 360° parking system

(OPS) with flank protection

Reversing camera

(Rearview Camera System)

Traffic sign detection

(Sign Assist)

Driver Alert System

(DAS)

m106_013

Tyre Pressure Monitoring System

(TPMS)

17

Page 18

HIgH-voltage system

The high-voltage system at a glance

The components of the high-voltage system have been installed to save space, ensuring there are

no limitations imposed on the room available, along with operation.

High-voltage heater

(PTC)

Z115

Charging unit 1 for high-voltage

battery

AX4

Power and control electronics

for electric drive

JX1

Electrical air conditioner

compressor

V470

18

Three-phase current drive

VX54

Page 19

Charging socket 1 for high-voltage battery charging UX4,

230volt alternating current voltage, 400volt alternating

current voltage and 400volt direct current voltage

m106_069

Crash element

High-voltage battery 1

AX2

Attention! Dangerous electric voltage!

Please note that work on the electric vehicle may be carried out only by qualified personnel.

Improper handling of the high-voltage equipment may lead to life-threatening situations.

AC voltages of 25 volts or more and DC voltages of 60 volts or more are dangerous for humans.

Therefore, please observe the safety information in the service literature, the vehicle diagnostic

tester and on the vehicle itself.

19

Page 20

HIgH-voltage system

Three-phase current drive VX54

Design

The three-phase current drive VX54 includes:

The electric drive motor V141

The drive motor temperature sender G712

The drive motor rotor position sender 1 G713

2 coolant connections and

the 3 phase connections.

The electric drive motor V141 is comprised of a rotor

and stator.

m106_021

Drive motor rotor

position sender 1 G713

Drive motor

temperature sender

G712

Technical data

Maximum output

Maximum torque

Max. motor speed

Weight including gearbox

Efficacy

100 kW

290 Nm

12,000 rpm

~106 kg

up to 94 %

3 phase connections Electric drive motor

V141

Torque and power diagram

[Nm]

300

250

200

150

Motor housing

m106_022

Coolant connectionsRotorStator

[kW]

100

80

60

20

100

50

0

40

20

0

2000 6000 10000 [rpm]

m106_023

Page 21

Power and control electronics for

electric drive JX1

The power and control electronics for electric drive JX1

are installed at the front of the motor compartment. It

controls the energy flow from high-voltage battery 1

AX2 to the three-phase drive VX54 and sets the required (motor or generator) torque for the three-phase

current drive. Furthermore, the power and control

electronics for electric drive JX1 backs up the 12-volt

vehicle electrical system via the integrated voltage

converter A19.

Fitting location

The power and control electronics for electric drive JX1

are installed at the left of the motor compartment.

Technical data

Voltage range

Maximum current

12 V charge current

Frequency

Weight

250 – 430 V

450 A

120 A

9 – 10 kHz

10.5 kg

2 connections for the

high-voltage battery

m106_024

m106_053

1 connection for the charging unit

3 connections for the electric drive motor

(three-phase current drive VX54)

1 signal connector for the

12-volt vehicle electrical system

2 coolant/low-temperature

connections up to max. 65 °C

Connection for the charging cable to

the 12-volt vehicle electrical system

21

Page 22

HIgH-voltage system

Design

The power and control electronics for electric drive JX1 are comprised of several integrated

components. All components are controlled by the electric drive control unit J841. The following

components are installed:

Key

1

2

3 Discharge resistor for the intermediate

4

5

Electric drive control unit J841

Intermediate circuit capacitor 1 C25

circuit capacitor 1 C25

Voltage converter A19

DC/AC converter for drive motor A37

1

High-voltage + (HV+)

4

Vehicle voltage + (NV+)

Vehicle voltage - (NV-)

5

22

High-voltage - (HV-)

2 3

V141

m106_052

Page 23

The coolant circuit

To protect against excessively high temperatures, the

three-phase drive VX54, the charger 1 for high-voltage

battery AX4 and the power and control electronics for

electric drive JX1 are cooled by the coolant circuit. The

coolant temperature amounts to as much as 65°C and

is electronically monitored and regulated by the motor

control unit J623.

The thermostat opens from a coolant temperature of

approx. 30 °C, thereby opening the flow through the

cooler. By controlling the shut-off valve N632, the

coolant circuit is divided into two circuits. The large

coolant circuit is also used for cooling the electrical

components and the small coolant circuit is used for

re-evaporation of the refrigerant in the heat exchanger.

Representation of the coolant circuit

The diagram gives an overview of the components of

the coolant circuit.

1

2

Z115

G785

N632

G789

JX1

V508

G83

G110

Small

Coolant circuit

V509

Large

Coolant circuit

4

G787

3

3

AX4

VX54

G788

5

m106_066

Key

AX4

G83 Radiator outlet coolant temperature

G110 Air conditioning system coolant tempera-

G785 Temperature sender in the high-voltage

G787

G788 Temperature sender after electric drive

G789 Temperature sender after power and

JX1 Power and control electronics for electric

N632

V508 Coolant circulation pump before power

V509 Coolant circulation pump before high-

VX54

Z115

1

2 Internal temperature sender in the high-

3

4

5

Charging unit 1 for high-voltage battery

sender

ture sender

heater (PTC)

Temperature sender after heat exchanger

motor

control electronics for electric drive

drive

Coolant changeover valve 1

and control electronics for electric drive

voltage heater (PTC)

Three-phase current drive

The high-voltage heater (PTC)

Heat exchanger for heat condenser

voltage heater (PTC)

Non-return valve

Thermostat

Cooler

Refrigerant circuit

Coolant circuit

23

Page 24

HIgH-voltage system

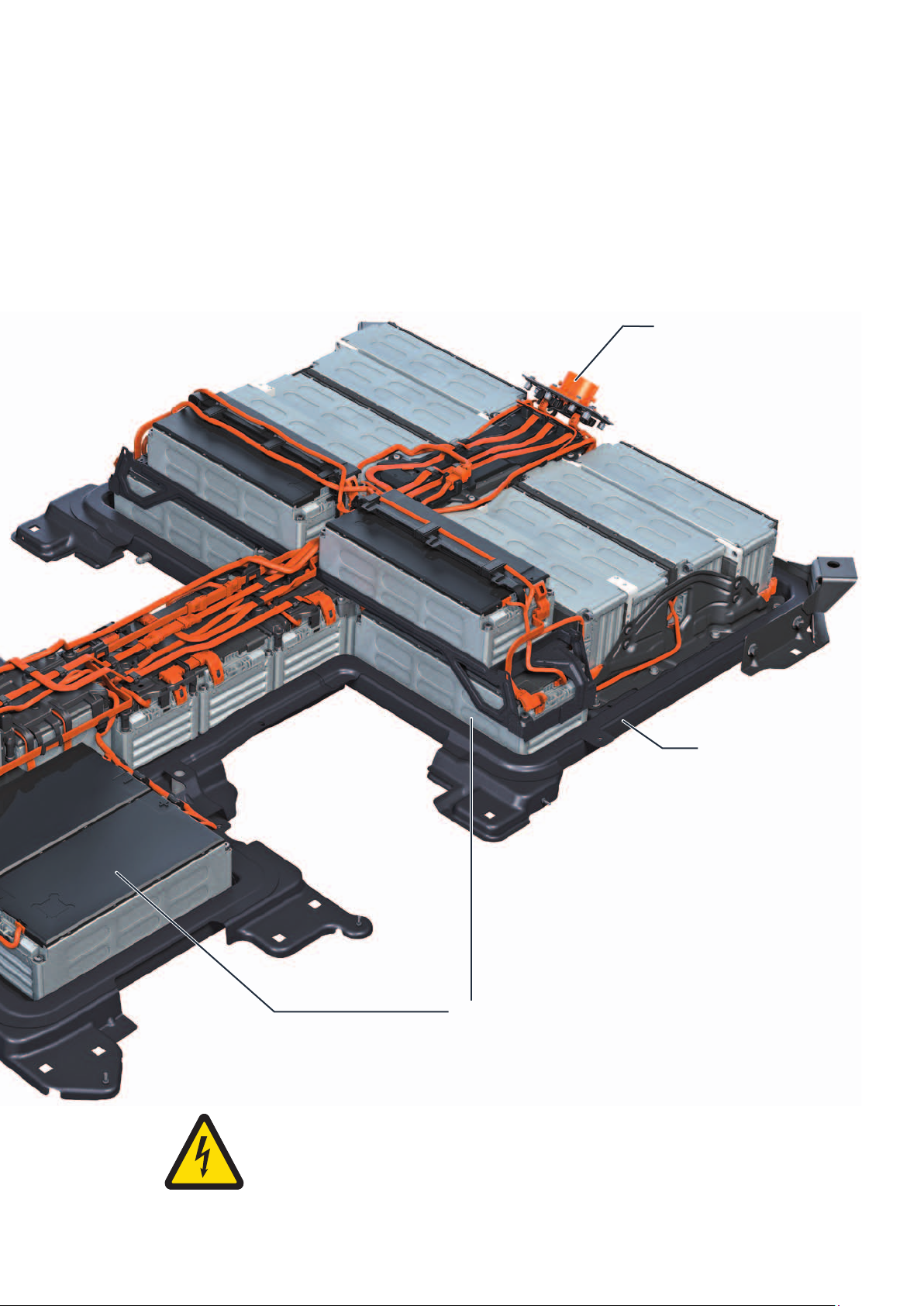

High-voltage battery 1 AX2

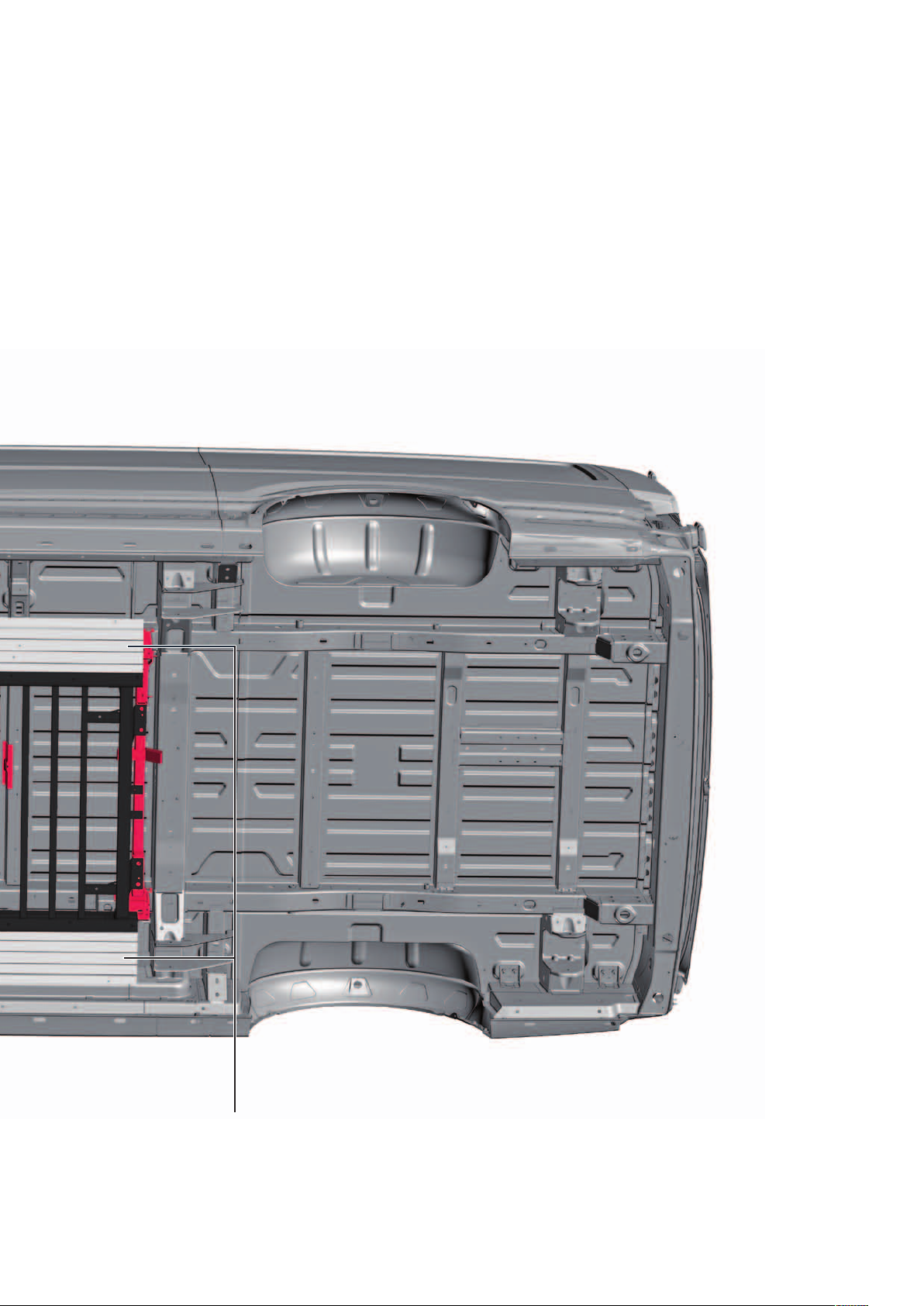

The high-voltage battery is installed under the vehicle and provides the energy needed for driving,

heating and cooling. Lithium-ion battery cells are used for storing the energy.

Technical data

Weight

Number of battery cells

Battery module

Nominal voltage

Nominal energy

Capacity

Temperature range

Switching unit for high-voltage battery SX6

with:

- Battery regulation control unit J840 and

- Module monitor control unit for batteries J497

344 kg

264 with 3.7 V

27

323 V

35,8 kWh

111 Ah

-25 °C to +55 °C

10 battery modules with 6 battery cells

as a slave modules

12 volt on-board power

system connection

High-voltage connection

24

Page 25

The battery regulation control unit J840, which has

been integrated into the switching unit for high-voltage

battery SX6, has the following functions:

Monitoring of the pilot line

Testing the crash signal

Master function for the module monitor control unit

for batteries J497

The module monitor control unit for batteries J497 has

the following functions:

Contactor controls

Regulating the charge level

Monitoring the isolation protection

Current measurements upstream and downstream

of the contactors

DC charging connection

for charging using DC current

Battery bottom part

m106_026

17 battery modules with

12 battery cells, subdivided into

8 master modules and

9 slave modules

Attention! Dangerous electric voltage!

Please note that maintenance work on the high-voltage battery may only be carried out by qualified

MAN high-voltage experts.

25

Page 26

HIgH-voltage system

Battery module

The eTGE has 27 battery modules connected in series.

8 master modules with 12 battery cells

9 slave modules with 12 battery cells

10 slave modules with six battery cells

The battery modules are comprised of the battery

cells. 3 battery cells configured in parallel are always

connected in series.

Master modules

Each master module can have up to 4 slave modules

connected to it. The master module controls the

charge level, and monitors the module temperature

and the cell voltage. The data are transmitted to the

module monitor control unit for batteries J497 using a

private data bus.

Battery cell configuration

(module with six battery cells)

Cell

m106_027

Master module with 12 battery cells

Slave modules

The slave modules register the cell voltage and temperature, and relay the data to the master module.

m106_028

Slave module with 12 battery cells

m106_029

26

Page 27

Charging unit 1 for high-voltage battery AX4

Charging unit 1 for high-voltage battery AX4 is responsible for converting the alternating current

sourced from the mains grid into direct current for charging the high-voltage battery 1 AX2. The

control unit for high-voltage battery charging unit J1050 has been integrated for control purposes.

A power distributor for the air-conditioning system has also been integrated.

Charging unit 1 for the high-voltage battery AX4 is housed in the motor compartment.

Fitting location

Charging unit 1 for high-voltage battery AX4 is housed

in the motor compartment on the right.

Technical data

Vehicle electrical system

connection for the control unit

Coolant Electrical

Air conditioner

compressor V470

High-voltage heater (PTC)

Z115

m106_054

Charging socket 1 for

high-voltage battery charging

UX4

High-voltage connector for

the power and control

electronics for electric drive

JX1

m106_030

Input alternating current voltage,

alternating current

Output direct current voltage, direct

current

Efficacy

Weight

100 – 400 V, 16 A/32A

220 - 450 V, 12 A

93 %

7.1 kg

27

Page 28

HIgH-voltage system

The charging connector

The charging socket 1 for high-voltage battery UX4 is the point connecting the vehicle with the

external source of power.

The charge plug includes the following contacts:

PP - Proximity

(max. rated current/wire cross-section)

CP - Control Pilot

(enable/cancel charging by the vehicle)

PLC – Power Line Communication

(communication with the charging station/charging

cable)

AC charge plug option

PLC

N CP PP L1

PE - Protected Earth

L1 - Phase 1

L2 - Phase 2

N - Neutral

+/-DC - DC current connection

DC charge plug option

PLC

CP PP

PE

PE L2

m106_031

High-voltage battery charging socket 1 UX4

Button module for battery charging EX32

m106_061

+/-DC

Charging indicator (LED)

Immediate charge button

Time-delay charge button

m106_032

28

Page 29

High-voltage wire routing

The following diagram provides an overview of how the high-voltage wires are routed to the highvoltage components.

Key

1

Three-phase current drive VX54

2 Power and control electronics for electric

drive JX1

3

4

5

Charging unit 1 for high-voltage battery AX4

High-voltage battery 1 AX2

High-voltage battery charging socket 1 UX4

3

DC 2 x 4 mm

6

2

DC 2 x 25 mm

7

6

7

Electrical air conditioner compressor V470

High-voltage heater (PTC) Z115

L1, L2

N

PE

AC 4 x 4 mm

DC 2 x 4 mm

2

2

2

AC

DC

5

2

AC 3 x 35 mm

4

DC 2 x 35 mm

2

2

1

m106_038

29

Page 30

electrIcal system

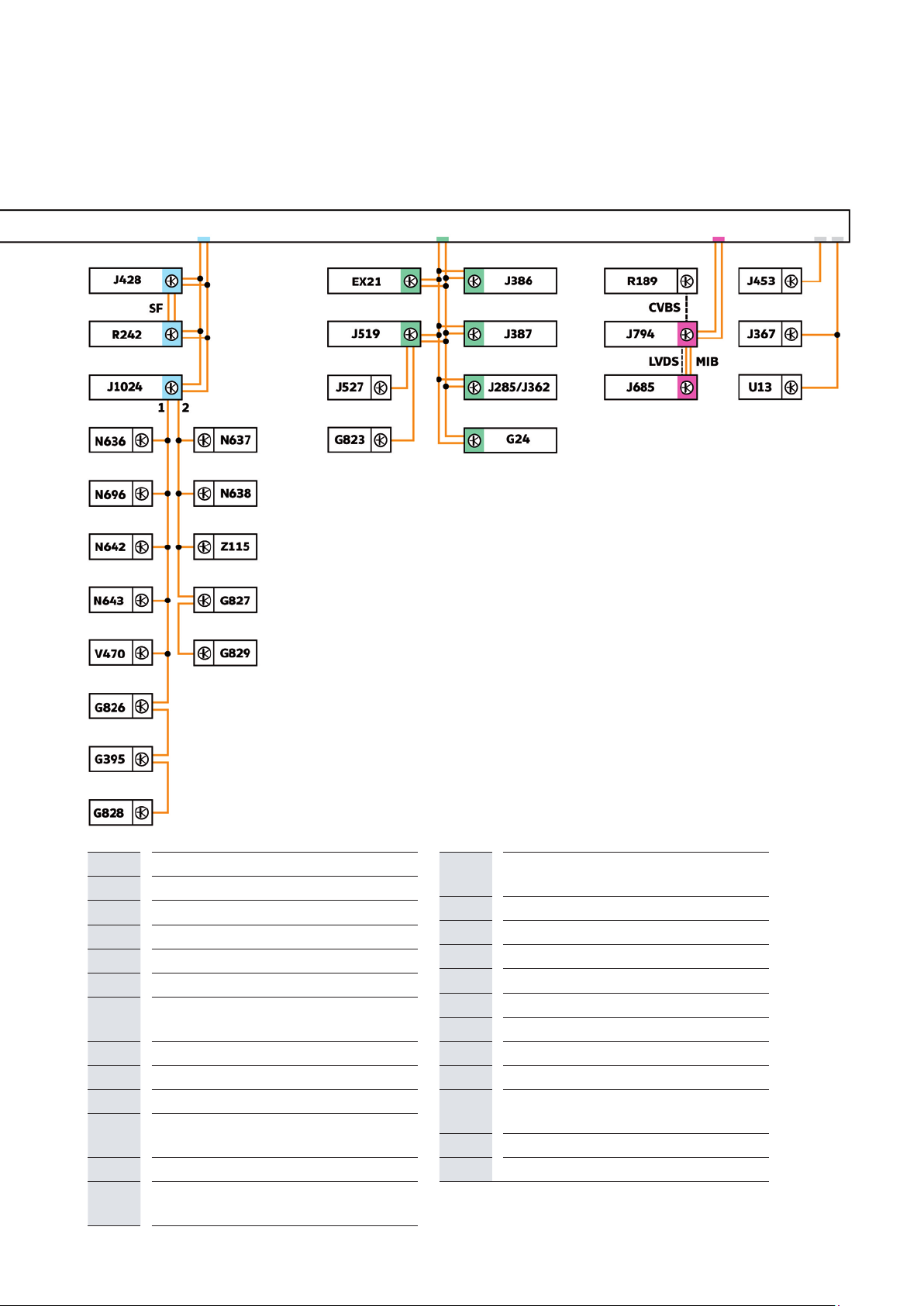

Networking concept

The networking concept is based on that of the MQB

and has been expanded and adapted for the eTGE.

All CAN bus systems in the eTGE have a transfer

speed of 500kbit/s. The LIN buses have a speed of

19.2kbit/s.

The data bus diagnostic interface J533 contains the

control system for several LIN buses and forms the link

between the individual CAN buses as usual. Further

LIN buses are connected to various control units.

Due to the increased number of control units used for

the drive, the hybrid CAN bus is used in addition to the

powertrain CAN bus. This is a sub-bus (it is not connected to the data bus diagnostic interface J533) and

is used for communication between the individual

high-voltage components.

Key

Powertrain CAN bus

Hybrid CAN bus

Running gear CAN bus

CAN bus extended

Convenience CAN bus

Infotainment CAN bus

LIN bus

CAN bus line

LIN bus line

A

CVBS Colour Video Blanking Synchronisation

LVDS

MIB

SF

a

1

2

EX21

G24

G85

Diagnostic CAN bus

signal

Low voltage differential signalling

Modular infotainment matrix CAN bus

Sensor fusion CAN bus

Private CAN bus

LIN bus 1

LIN bus 2

Heater and air conditioning controls

Tachograph

Steering angle sender

G395 Refrigerant pressure and temperature

sender 1

G823

G826 Refrigerant pressure and temperature

G827 Refrigerant pressure and temperature

G828 Refrigerant pressure and temperature

G829 Refrigerant pressure and temperature

J104

J234

J285

J362

J367

J386

J387

J428

J446

J453

J497

Air humidity, rain and light sensor

sender 2

sender 3

sender 4

sender 5

ABS control unit

Airbag control unit

Control unit in dash panel insert

Immobiliser control unit

Battery monitor control unit

Driver door control unit

Front passenger door control unit

Adaptive cruise control unit

Parking aid control unit

Multifunction steering wheel control unit

Module monitor control unit for batteries

30

Page 31

m106_040

J500

J519

J527

J533

J587

J623

Power steering control unit

Onboard supply control unit

Steering column electronics control unit

Data bus diagnostic interface

Selector lever sensors control unit

Engine control unit

J685 Display unit for front information display

and operating unit control unit

J794

J840

J841

Control unit 1 for information electronics

Battery regulation control unit

Electric drive control unit

J966 Charge voltage control unit for high-

voltage battery

J1024

Thermal management control unit

J1050 Control unit for high-voltage battery

charging unit

Jxx*** Battery modules 0-26: J991 – J1002;

J1068; J1077 – J1085

N636

N637

N638

N642

N643

N696

R189

R242

Refrigerant expansion valve 1

Refrigerant expansion valve 2

Refrigerant expansion valve 3

Refrigerant shut-off valve 4

Refrigerant shut-off valve 5

Refrigerant shut-off valve 1

Reversing camera

Front camera for driver assist systems

U13 DC/AC converter with socket, 12 V -

230V

V470

Z115

Electrical air conditioner compressor

The high-voltage heater (PTC)

31

Page 32

electrIcal system

Fitting locations in the 12-volt vehicle electrical

system

Despite electrification of the drive and the integration of the high-voltage system this involves,

virtually all comfort components in the eTGE, except for the voltage supply, are supplied with

power by the 12-volt vehicle electrical system.

32

Vacuum pump V22 for brake booster in

the motor compartment on the right

Maintenance connector TW with instruction flag Fuse carrier SH on left in engine compartment

Page 33

In the dash panel

Relay carrier and fuse holder C

(SC) with onboard supply control unit J519

and instruction flag

Under driver seat, relay carrier

and fuse holder B (SB)

Battery under driver’s footwell Main fuses (SA) of the battery

m106_039

33

Page 34

electrIcal system

Maintenance plug TW

The maintenance connector TW is located in the motor

compartment and is marked with a warning sign. It is

on the one hand an electrical connection in the 12 volt

control circuit of the power contactors of the highvoltage battery, and on the other hand a component of

the safety line. If the maintenance connector TW is

opened, the safety line is opened and the 12 volt

control circuit of the contactors is interrupted. The

maintenance connector serves to disconnect the

voltage of the high-voltage system. Please use the

corresponding program in the vehicle diagnostic

systems for opening and disconnecting the highvoltage system proficiently. After opening, the

maintenance connector TW is secured against being

switched on again with the padlock T40262/1.

m106_055

Fuse carrier in the passenger compartment

The fuse for the voltage supply of the control current to

the contactors is marked with a warning sign.

m106_055

m106_057

34

m106_058

Page 35

Dash panel insert

The dash panel insert features the following e-specific

displays:

Power meter

Available power

Charge level of the high-voltage battery

Multifunction display (MFI) Current gear display

Power meter

The modified multifunction display (MFI) can display

the following additional information:

Constant display of the remaining range

Ready to drive with the display “READY”

Current power consumption

Average power consumption

Charging mode display

Speed

Available power Constant display

Charging mode display

Charge plug connected

Ready mode

of the remaining range

When charging is active, the indicator provides a

reading of the current charge level of the high-voltage

battery, and the charging station symbol flashes. The

driver door must be opened for this to occur.

m106_041

Charge state of the

high-voltage battery

m106_042

Remaining charge time Charging station symbol

35

Page 36

electrIcal system

Left-hand instrument dial

The left-hand instrument dial is comprised of the

Power meter

Power availability, and

Warning lamp for limited driving performance

The power meter (which displays the power output as

a percentage) shows the power demands. It is divided

into the categories power delivered, eco-friendly

driving, ready to drive, energy recovery, not ready to

drive and standby.

The “power availability” display shows the power

currently available.

If the indicator in the power availability instrument is

pointing to the red area, then there are considerable

restrictions to the drive power and comfort functions

are switched off. When this occurs, the warning lamp

for restricted vehicle performance (turtle) lights up in

the dash panel insert.

Energy recovery area/

energy recovery

(green section)

ready to drive

Power meter

Inactive state

Ready to drive/Ready

Not

Available power

Power delivered section

Eco-friendly driving

(blue section)

m106_043

Inactive state

When in standby mode, the indicators in both displays

point to the starting point of the scale, which is at the

lower left.

Warning lamp for restricted driving

performance

36

m106_044

Page 37

Ready mode

Availability of peak power

The ready-to-drive display is indicated both by

“READY” and by the indicator pointing to the

0position. In addition, an acoustic signal will sound

once. These displays appear when terminals S and 15

are active, and when terminal 50 is deactivated.

m106_045

If the indicator in the power availability instrument is in

the “max” section, then the maximum power is

available. The indicator in the power meter can deflect

up to 10 (= 100%) in the event of full load acceleration,

with the full power being available at all times.

The driving style determines how quickly the power

availability decreases in the white section.

Available power

m106_046

If the indicator in the power availability instrument is in

the “normal” section, then less than peak power is

available. The position of the indicator shows how

much power is available at most. The power meter

display (= power demanded) cannot exceed the

percentage currently shown by the power availability

instrument.

Display of the power availability

m106_047

37

Page 38

InfotaInment

MAN Media Van Advanced

MAN Media Van Advanced, a feature of the modular infotainment matrix (MIB), is installed as series

standard.

Touch-sensitive 8“ TFT colour display

Radio mode

Media mode

Telephone use

Voice operation

Rotary knob with push

button: on/off switch,

volume adjustment

Navigation mode

Traffic program function

Vehicle and system settings

Display of additional functions,

calls up set-up

m106_048

Rotary knob with push button:

menu settings, manual station settings,

SCAN function

MAN Media Van Advanced has been modified for use in an electric vehicle, and now features the

following additional functionalities:

e-specific displays, such as:

− Range monitor

− Energy flow display

− Energy recovery statistics

e-Manager

Note

You can find further information on the modular

infotainment matrix and the MAN Media Van Advanced in

MANGUIDE 101 “TGE basics”.

38

Page 39

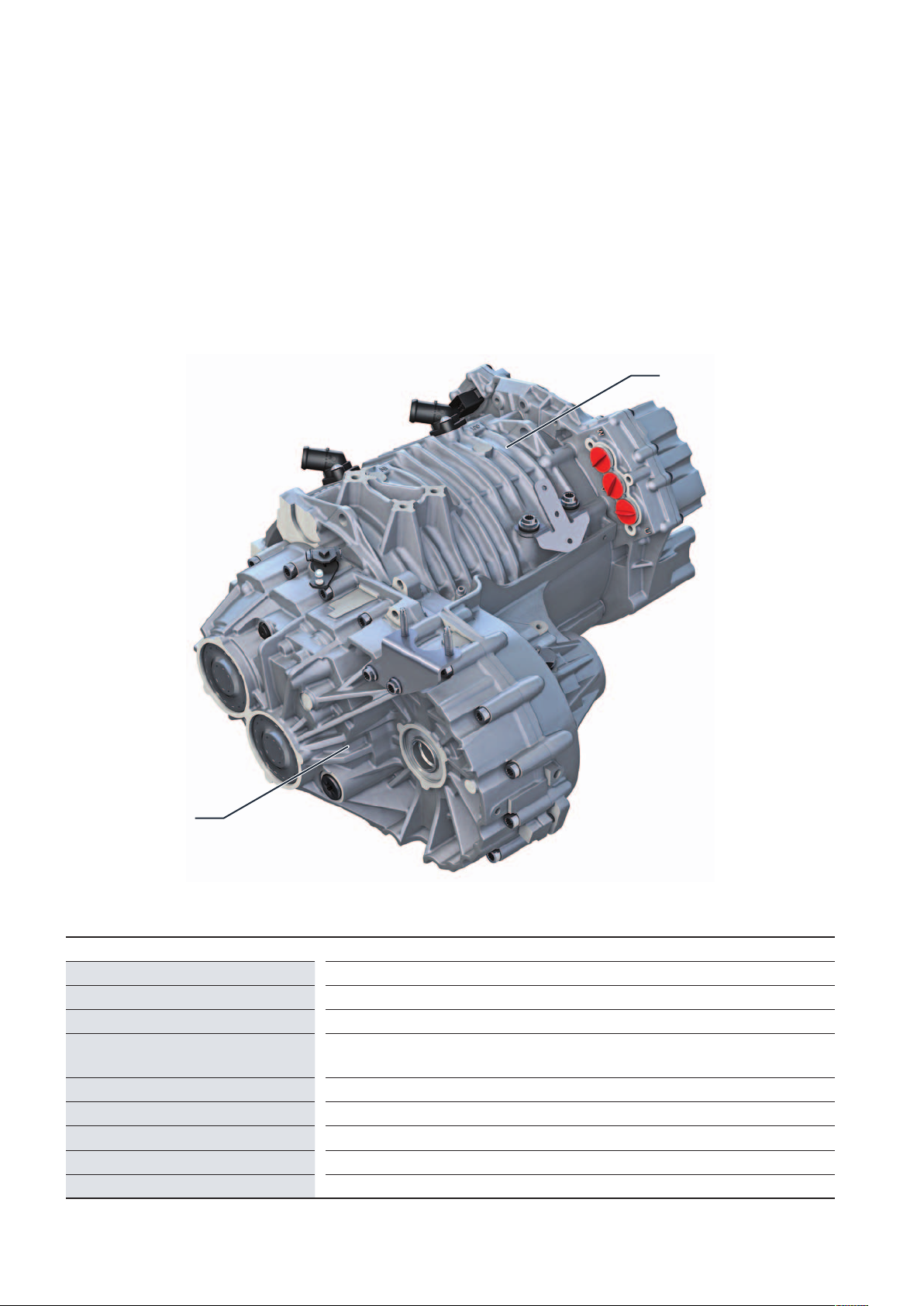

The e-specific displays

m106_049

m106_050

Range monitor

The operating range display shows the current vehicle

range in a diagram. Furthermore, the driver is informed

about the potential (additional range) which can be

utilised when convenience functions are switched off.

This function is activated by the data bus diagnostic

interface J533.

Energy flow display

The energy flow display uses an animated diagram to

represent the flow of energy between the electric

motor and the high-voltage battery when accelerating

or braking.

The current being discharged is shown using a blue

arrow, and green arrows pointing in the opposite

direction show that the high-voltage battery is being

charged when braking or using energy recovery. The

high-voltage battery shown indicates the charge level.

m106_051

Energy recovery statistics

The energy recovery statistics show the amount of

energy recovered since the journey began. To show

this, the energy recovered each minute is displayed

using a column graph.

39

Page 40

InfotaInment

Der e-Manager

The user can use the e-Manager function to program vehicle charging and air conditioning in

relation to departure times and charging locations. The following diagram provides an overview of

the setting options:

e-Manager

Departure time

Setting options:

Programming up to 3 departure

times:

time, weekdays

Departure time 1 - 3

Setting options:

Entering a new charging location or

selecting a saved one.

Configuring charging locations:

air conditioning,

maximum charge current,

upper battery charge limit,

off-peak current.

Charging location

Basic setting

Electric driving/charging

settings

Setting options:

Immediate charging:

maximum charge current

e-Manager settings:

interior temperature, allow air

conditioning using the battery, lower

battery charge limit

m106_059

40

m106_062

Page 41

The maintenance intervals

Inspections are time-dependent and mileage-dependent. The first inspection takes place after

30,000 km or 24 months, followed by every 12 months or 30,000 km after that, depending on

which comes first. The production control number VI9 refers specifically to an electric vehicle.

The brake fluid inspection intervals remain the same: for the first time after 3 years, followed by

every 2 years.

servIce

Inspection and

additional work

Note

Please observe the most recent information in the service

literature.

30,000 km or

24 months

60,000 km or

36 months

90,000 km or

48 months

Towing

Electric vehicles feature a fixed connection between the drive wheels and the three-phase current

drive (electric drive motor). This connection cannot be undone without mechanical work. If the

vehicle needs to be towed, there are 2 options:

1. Towing the vehicle with the high-voltage system intact

120,000 km or

60 months

Switch the ignition (terminal 15) to “On” and move the selector lever to the N position to allow

electric freewheel mode. The vehicle can now be towed for a maximum distance of 50 km at

50km/h using a rope or tow-bar.

Using a bar for towing is recommended for safety reasons.

2. Towing with a damaged high-voltage system

If it is not possible to activate the high-voltage system, the vehicle must be transported with the

front axle raised. Freewheel mode cannot be activated, which creates a risk of overheating.

The corresponding text message in the dash panel insert reads: “Towing damages electrical

system”. Vehicle wallet.

41

Page 42

servIce

The emergency start function

If the high-voltage battery has been discharged completely, there is still an option allowing the

eTGE to be restarted twice for a short distance:

1. For approx. 100 metres, after switching the ignition off and on

2. For approx. 50 metres, after switching the ignition off and on once again

3. No more emergency starts are possible.

Note

Also observe the information in the vehicle wallet!

The charging plug emergency release

The charging plug is locked and unlocked by the

actuator for high-voltage charging plug lock 1 F498. If

unlocking is not possible, emergency unlocking can be

initiated by pressing and holding the immediate charge

button in the button module for battery charging EX32

and simultaneously pressing the opening button on the

remote control. If emergency unlocking is still not

possible, the charging plug can be emergency

unlocked via a Bowden cable. By pulling the

emergency unlocking loop of the Bowden cable, the

mechanism of the actuator for high-voltage charging

plug lock 1 F498 is actuated directly and the locking

pin in the charging socket is pulled back. Now the

charging plug can be removed. The emergency release

loop of the Bowden cable can be found at the bottom

in the passenger compartment, behind the driver‘s

seat.

Emergency release loop

behind driver‘s seat

42

Page 43

test your knowledge

Which answers are correct?

One or several of the given answers may be correct.

1. What particular measure has to be considered when renewing a shut-off or expansion

valve?

a) After installation, the new valve must be adapted using the diagnostic tester.

b) There are no specifics to be considered.

c) After installation, a waiting period of 30 minutes must be maintained before the heat pump

system can be put back into operation. During this period, the valve is automatically adapted

to the thermal management control unit.

2. What are the functions of the three-phase drive VX54 in the eTGE?

a) Drive motor and alternator for high-voltage battery

b) Starter for the electric drive motor

c) Monitoring of activation by the power and control electronics for electric drive

3. On an eTGE, what is interrupted when the maintenance connector for high-voltage

system TW is opened?

a) Positive supply to the battery regulation control unit J840 and the pilot line

b) Positive cable to the power and control electronics

c) Voltage supply to the charging unit 1 for high-voltage battery AX4

4. The coolant circuit in the eTGE ...

a) is also used to heat the vehicle interior.

b) is only required to cool the high-voltage components.

c) is required to ensure cooling of the high-voltage components as well as for re-evaporation of

the refrigerant in the heat exchanger.

d) has no dedicated water pump. Circulation is assured by the air conditioner compressor.

Answers:

1. a); 2. a); 3. a); 4. c)

43

Page 44

MAN Truck & Bus SE

Dachauer Straße 667

80976 München

www.mantruckandbus.com

MAN Truck & Bus – A company of the MAN group

Loading...

Loading...