Page 1

MAN GUIDE 103

TGE - Body

Page 2

The MAN TGE is a completely new commercial vehicle development. One of the most important goals

in the development of the TGE was to meet the increased requirements for vehicle safety, comfort, and

the optimization of payload and packing dimensions. For the car body, these goals are achieved by

using a modular body concept with a uniform front end, the increased application of adhesive technology and the use of more body panels of highest material grades. With the TGE, MAN is using higheststrength hot-formed body panels for the first time. Thanks to the completely new development, a large

number of different derivatives in 2 wheelbases, 3 vehicle lengths and 3 roof heights can be realised in

closed and open superstructures.

In addition, the Group's internal business unit “NC - Customized Solution”

offers numerous bodies and conversions such as box bodies, flat beds with

and without tarpaulins and three-way

tippers directly ex works.

Technical status January 2018

m103_160

The new design is based on the design

of the 6th-generation Transporter series

and relies on a consistently aerodynamic basic shape that is implemented

throughout all derivatives.

This chapter of the MAN TGE Guide

series shows you the special features of

the MAN TGE in terms of bodywork and

occupant protection.

2

Page 3

taBle of contents

4 IntroductIon

6 Body structure

12 Body repaIrs

6

14 Body assemBly

30 aerodynamIcs

14

30

32

32 InterIor equIpment

40 occupant protectIon

47 Glossary

40

The MAN TGE Guide teaches the basics of design and function for sales and after-sales of new vehicle models, new

vehicle components or new technologies.

The MAN TGE Guide is not a sales manual nor a repair guide! Specified values are for the sake of easy understanding

only and refer to the data status valid at the time the MAN TGE Guide was created.

The contents are not updated.

Please use the appropriate technical literature for customer advice, maintenance and repair work.

Note

Reference

3

Page 4

IntroductIon

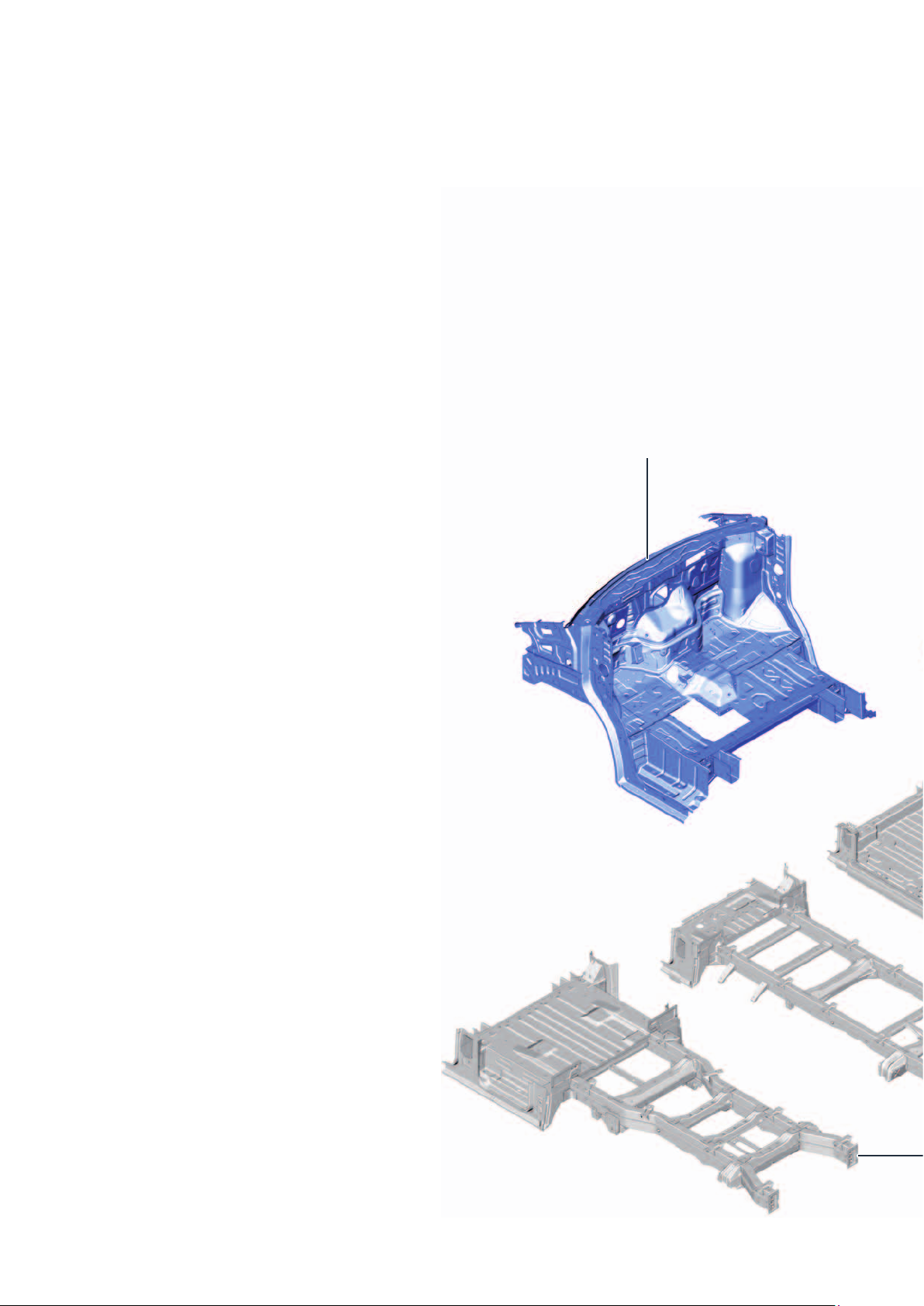

The modular design of the MAN TGE

An important goal in the development of the body structure was the creation of as many identical parts as possible. Thus, the body structure is based on a modular concept. The numerous derivatives and variants, such as

different wheelbases and roof heights, must be produced with high synergy effects.

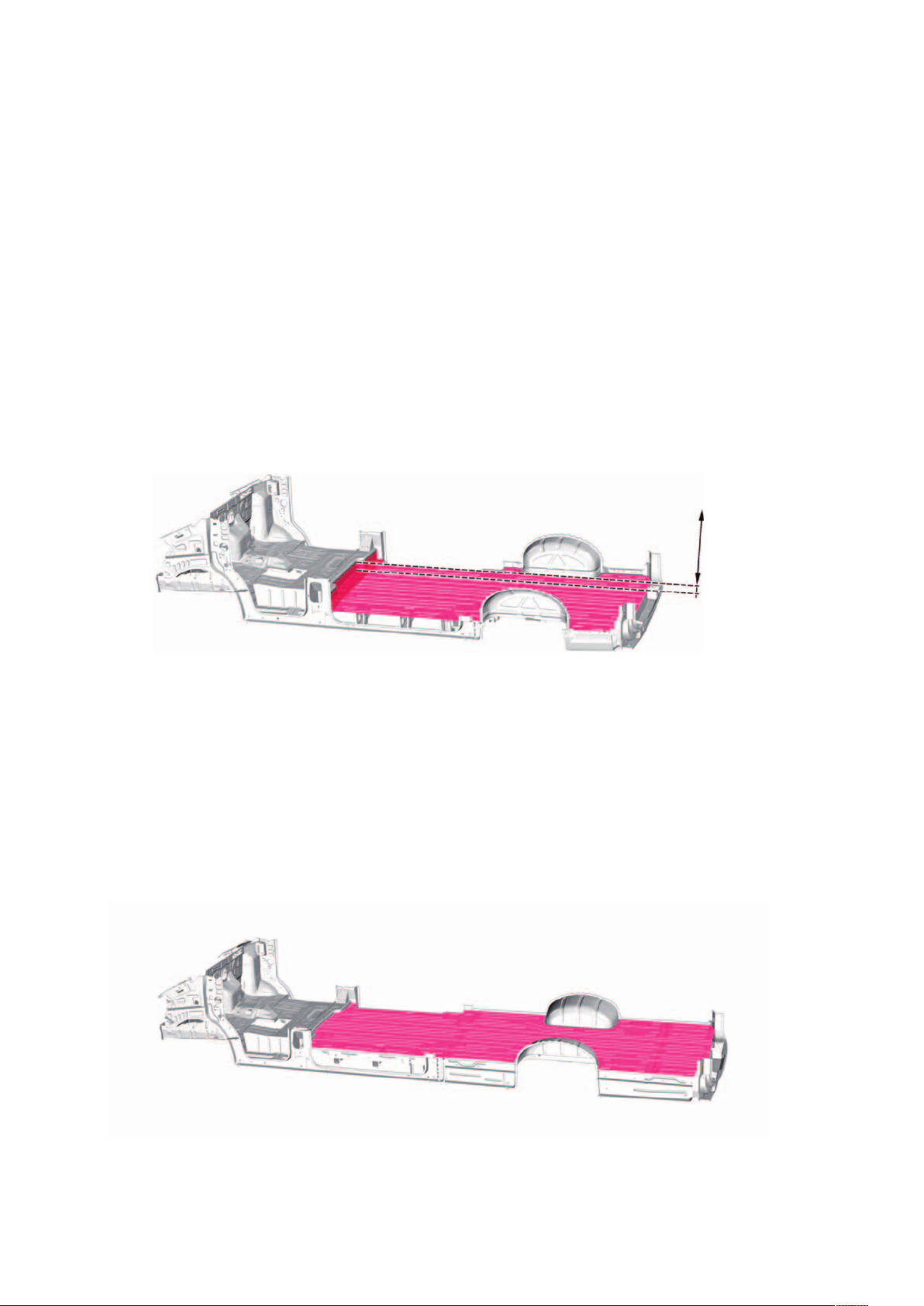

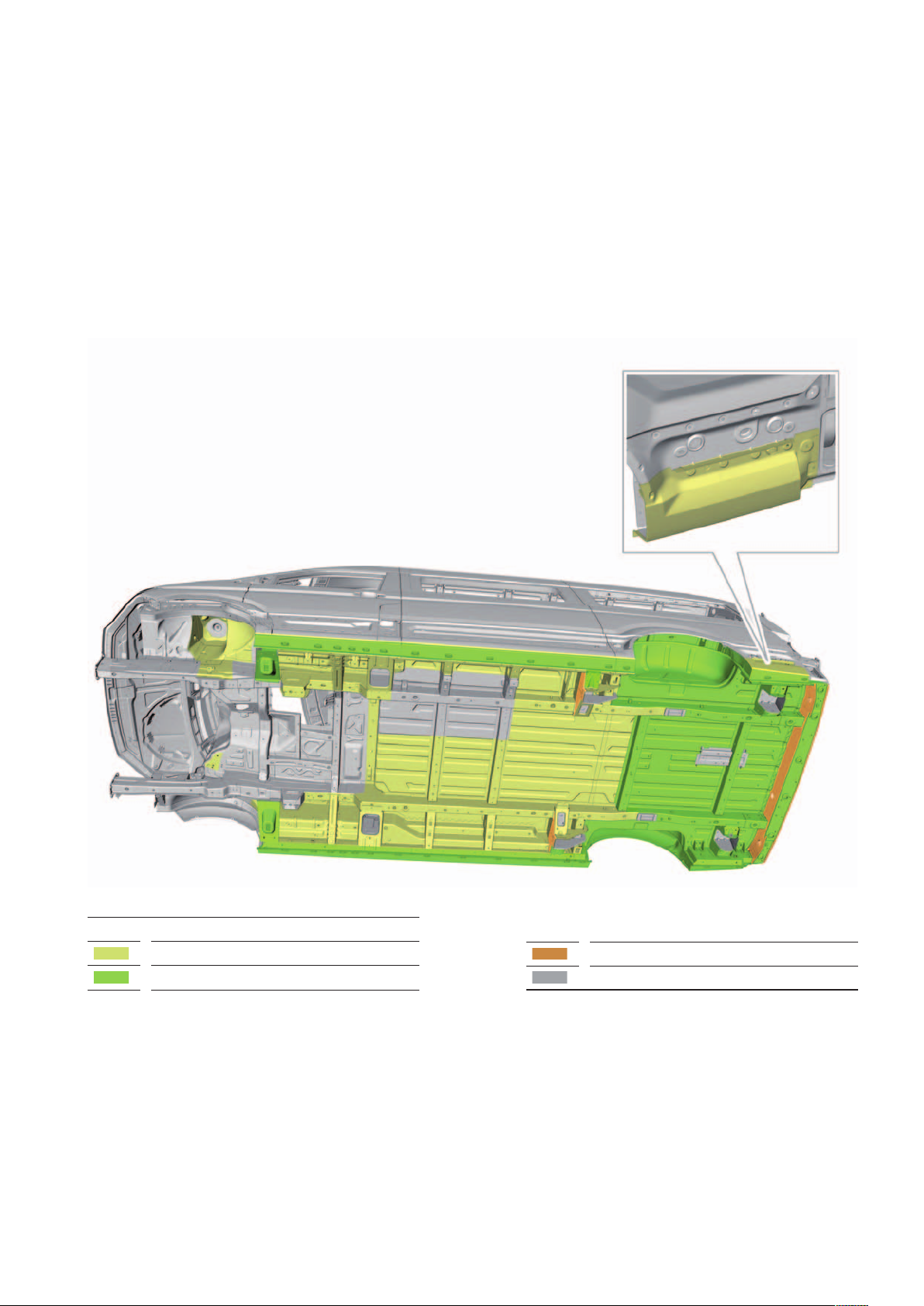

The floor structure in the front area of the MAN TGE is

the same for all vehicle variants.

The front end consists of the front side members, the

inner mudguards, the spray wall area, the lower area of

the A-pillars and the floor assembly in the area of the

driver's cab.

There are clear differences in the rear section with

regard to the floor assembly, the floor plates, the side

members, the wheel arches, the ladder frame and the

corresponding connecting parts and reinforcements.

Their design and layout is determined by the following

factors:

Uniform front vehicle

(enlarged image)

Type of drive

Wheelbase

Rear overhang

Type of superstructure

Single or dual tyres on the rear axle

Some examples of the modular structure can be seen

in the picture on the right.

4

Page 5

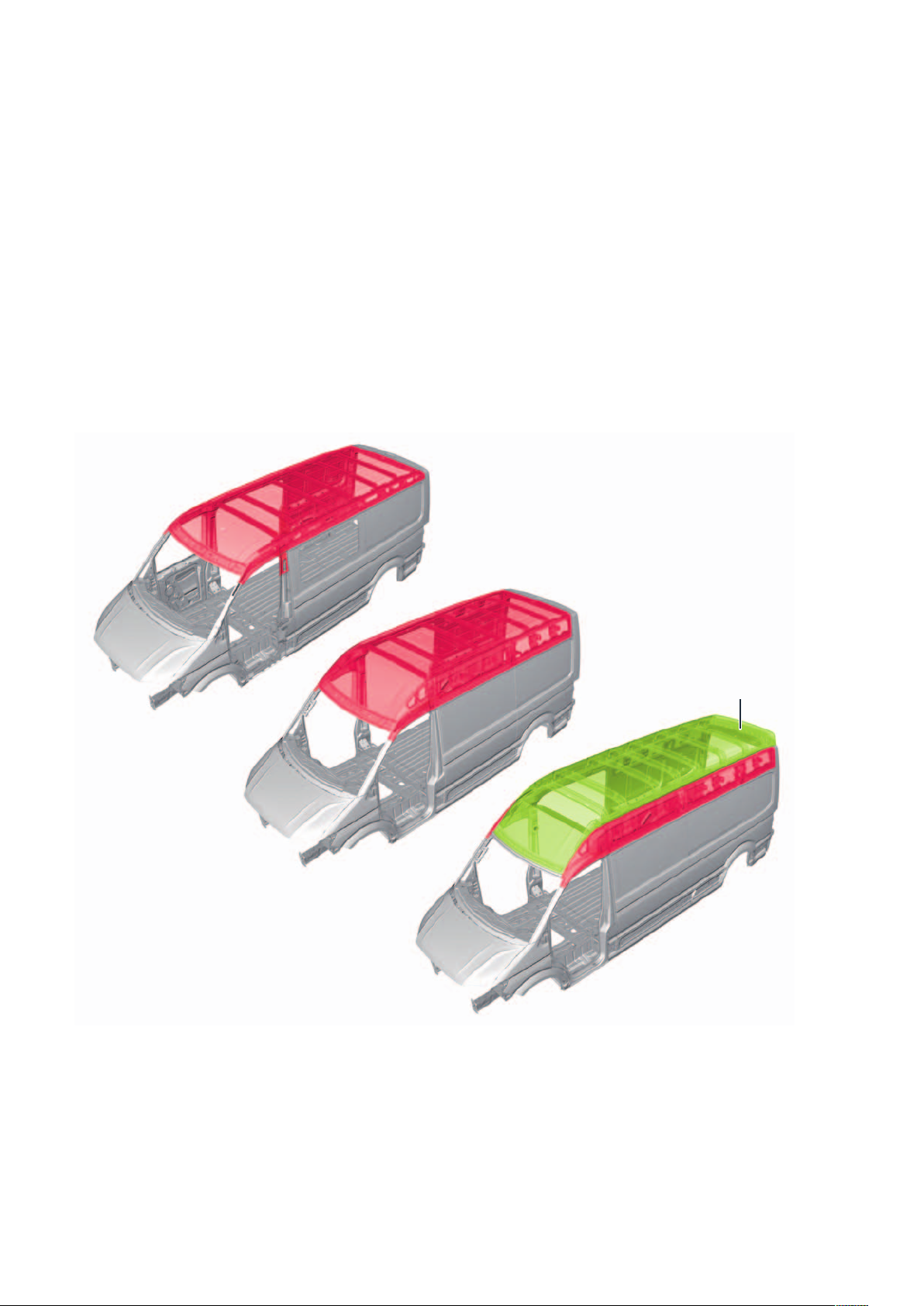

Superstructure of closed panel van,

long wheelbase with super high roof

Superstructure of fully glazed panel van,

short wheelbase with high roof

m103_110

Ladder frame for single cabin

Ladder frame for double cabin with

increased space for dual tyres

Superstructure of partially glazed panel van,

short wheelbase with normal roof

Floor assembly for panel vans

5

Page 6

Body structure

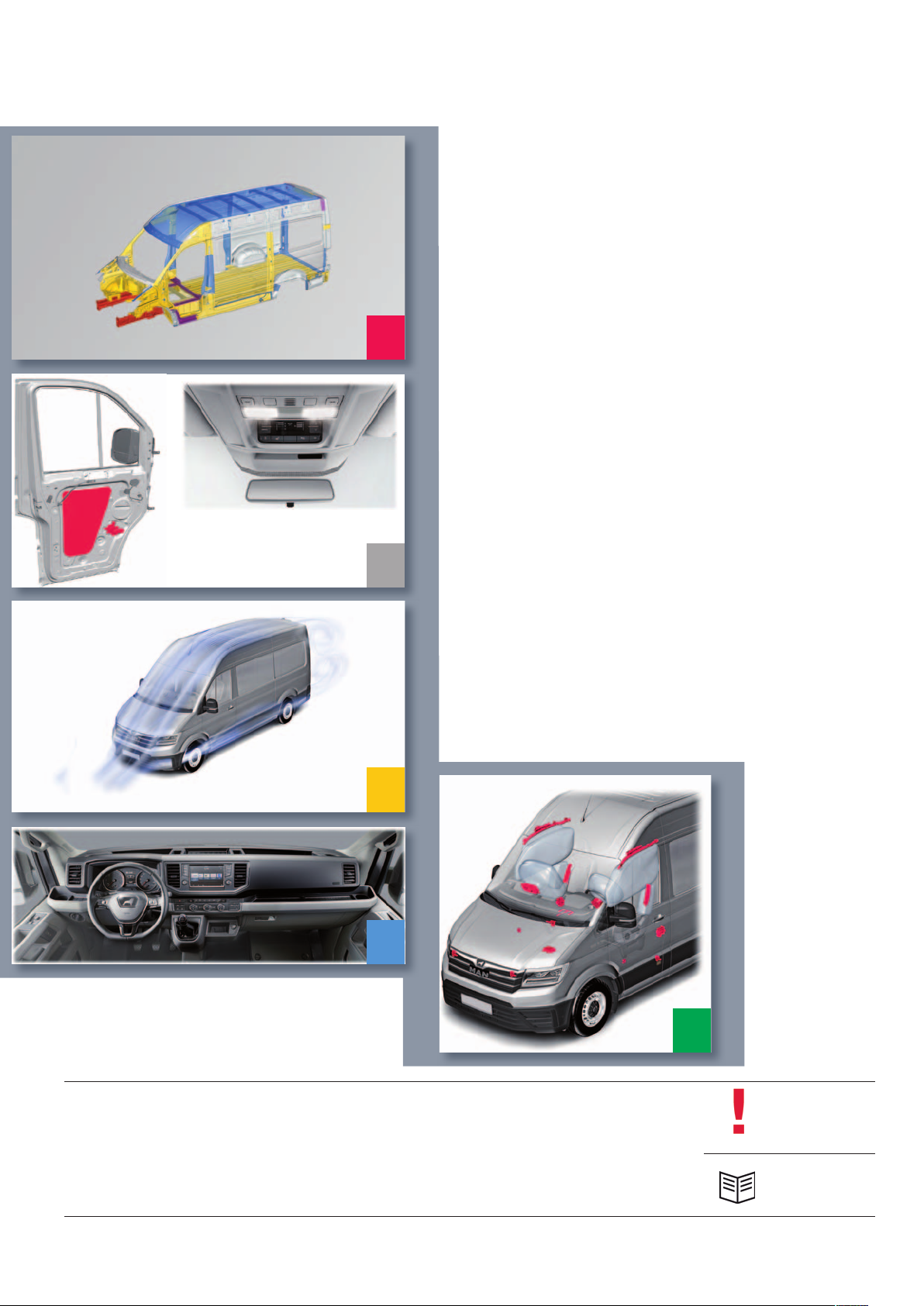

The body structure

In addition to the modular structure, the

development of the new body structure

was focused on achieving high crash

safety with low weight and optimizing

aerodynamics.

By achieving these goals, the MAN TGE

has been optimized in terms of payload,

economy and crash safety.

1*

Legend: Strength of steel sheets

(yield strength “Re”)

< 160 MPa soft

< 220 MPa high-strength

< 420 MPa higher-strength

< 1000 MPa highest-strength

> 1000 MPa highest-strength hot worked

m103_161

The attachments not shown, such as

doors, bonnet, mudguards, and side

panels are made of soft body sheet

<160MPa.

* Legend see page 7

6

Page 7

The increase in strength and weight reduction are achieved by the following design measures:

Geometrical lightweight construction

Increasing use of high-strength and

highest-strength hot-formed steels

3

Targeted use of modern processes in

the production of steel sheets, e. g.

hot forming, bake hardening and

tailored blank technology

4

Load-appropriate application of

joining processes such as resistance

spot welding, laser soldering, laser

welding and bonding

5

Legend

1

2

3

2

Rear roof corner reinforcement area

(shown in graphic m103_161 on page 6)

Reinforcement area for A-pillar base and

sills

Wheel arch area

Note

Hot-formed sheets must be treated separately during repair.

For more information, see the relevant service literature.

6

m103_162

4

5

6

Front transverse wall area

Area of longitudinal member reinforcement

in the driver's cab

End part area

7

Page 8

Floor structure on closed body

The closed bodies of the MAN TGE are available with two different floor structures depending on the drive concept.

Vehicles with front-wheel drive

In these vehicles it was possible to

lower the loading floor by 100 mm

compared to the driving space level, as

no installation space is required for the

cardan shaft.

Floor structure (loading floor -100 mm)

Example: short wheelbase

This results in advantages such as

100 mm greater interior height

a resulting larger loading volume

a correspondingly lower entry height

for vehicles with sliding doors and

rear doors.

-100 mm

m103_111

Vehicles with all-wheel and rear-wheel drive

These vehicles have a continuous

loading floor at the level of the driving

area.

Floor structure (loading floor at driver's cab level)

Example: long wheelbase with overhang

The resulting installation space is

required for the installation of the cardan

shaft and the rear axle drive.

m103_112

8

Page 9

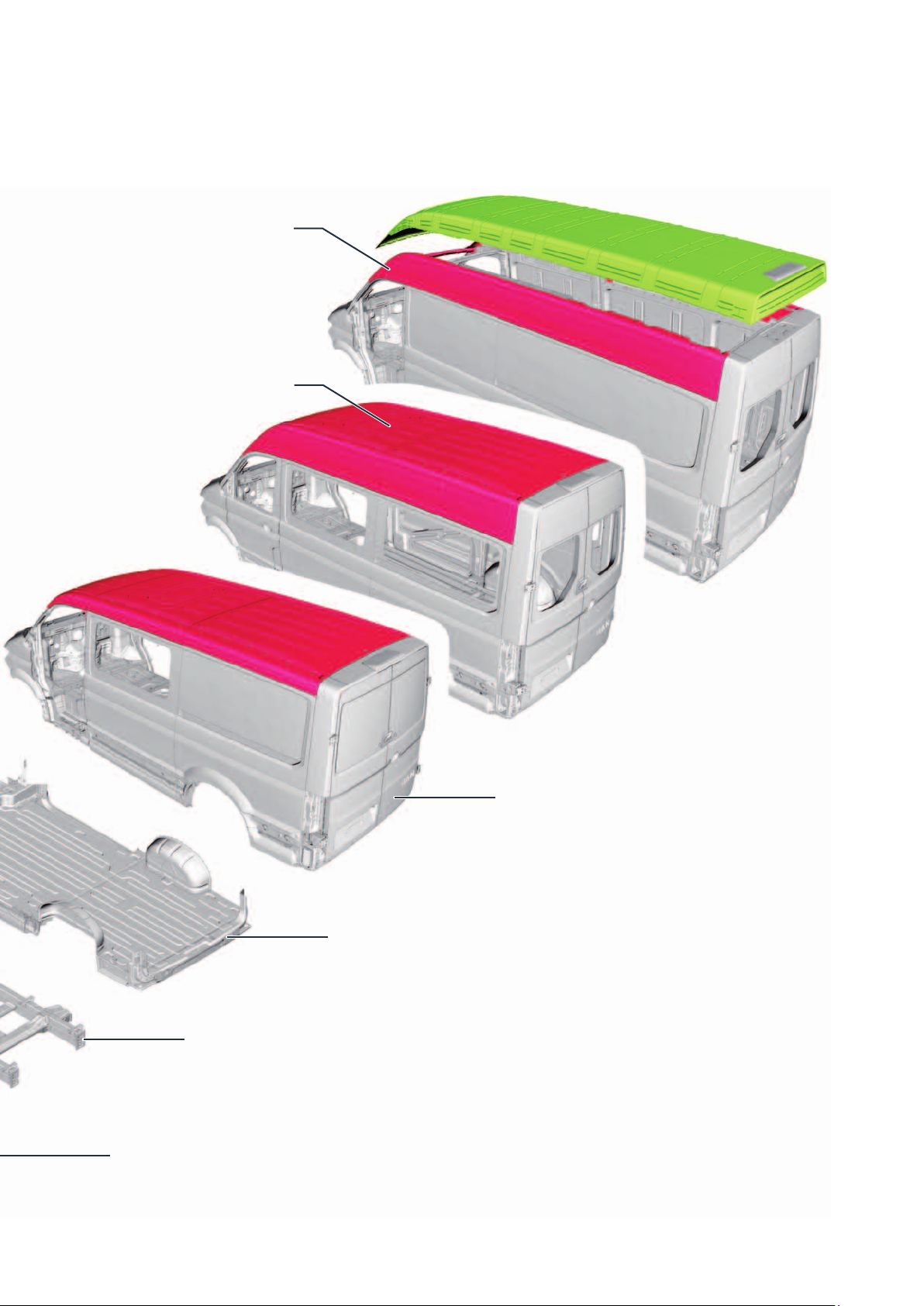

Roof variants on closed superstructure

The normal roof and the high roof are

made of sheet steel.

Transverse roof crossmembers reinforce

the roof.

The super high roof is made of polyester. Transverse roof crossmembers are

laminated into the polyester roof for

stabilization. In addition, a reinforcing

frame is integrated in the roof.

Roof height 1

Normal roof (H2*)

Roof height 2

High roof (H3*)

Thesuper high roof is connected to the

body by bonded and screwed connections. After assembly, the resulting gap

between the body and the polyester

roof element is sealed with joint seal.

Roof height 3

Super high roof (H4*)

Polyester roof

m103_113

* These parameters are explained in the “MAN GUIDE 101 TGE Fundamentals” on page 9.

9

Page 10

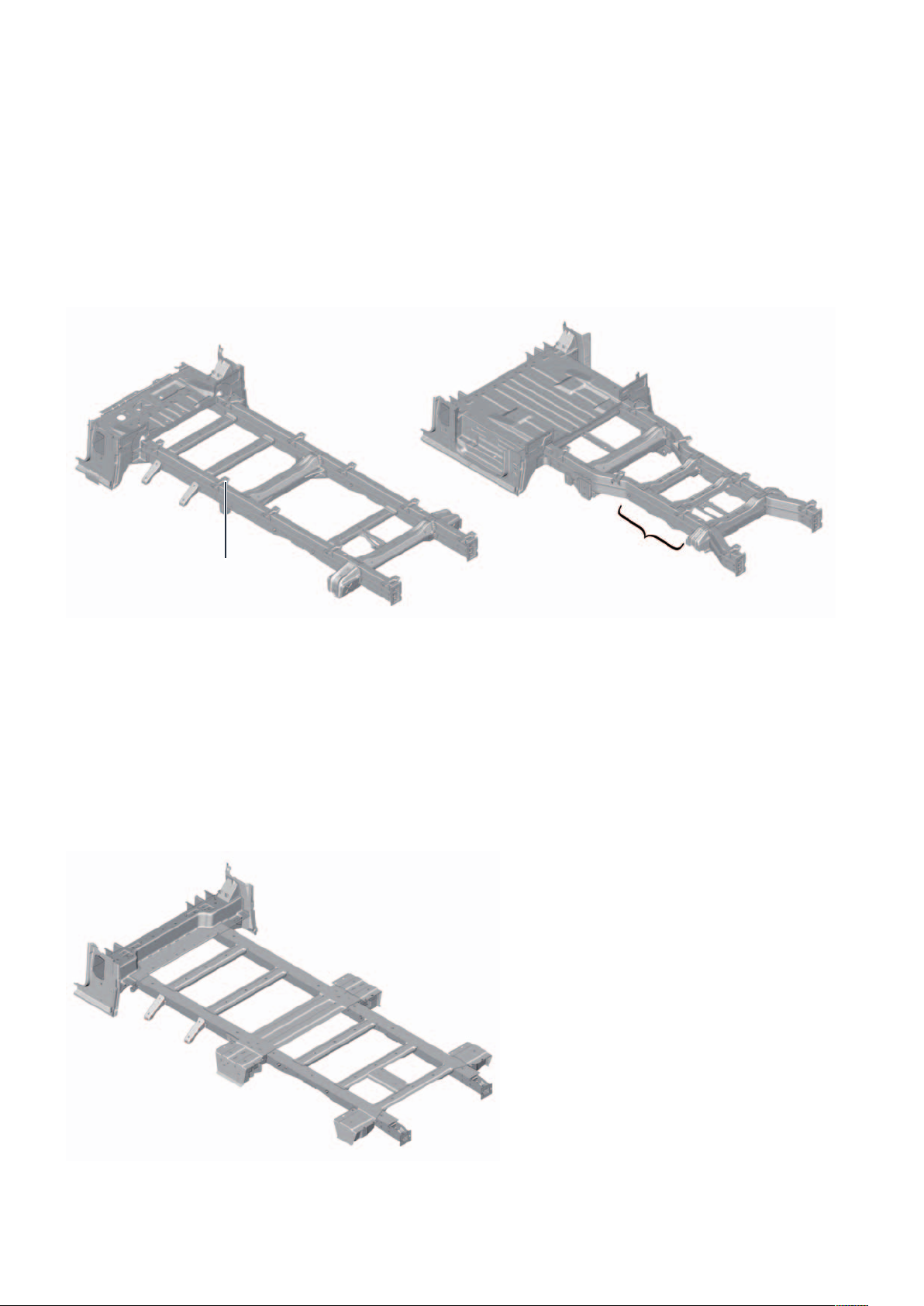

Open vehicle superstructure with ladder frame

Vehicles with 3.5 t and 5.0 t have different ladder frames. These are adjusted to the respective

payload and the tyres used.

Ladder frame 3.5 t Ladder frame 5.0 t

Space for

Space for

dual tyres

dual tyres

A flat frame is available for the use of

special superstructures (e. g. motor

homes). It is based on the deep base

frame (without base plate) of the Crafter

Flat frame 3.5 t

panel van and is about 193.5 mm lower

than the ladder frame for the open

superstructure.

m103_163

The flat frame is optionally available in

conjunction with an axle widened by

about 200 mm.

10

m103_164

Page 11

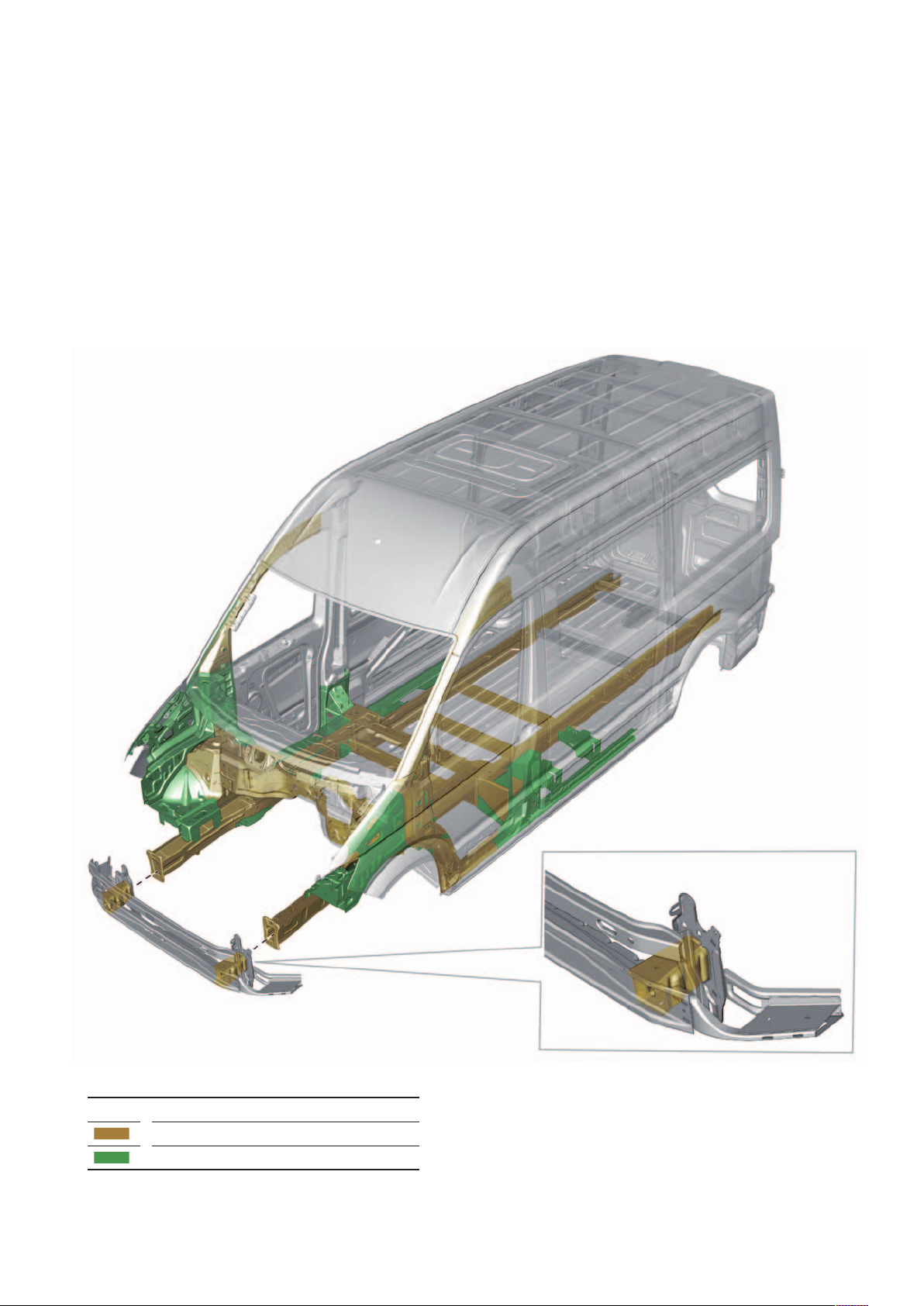

Load paths in the body structure

To absorb high energies in a front or

side crash, certain components of the

body structure are designed accordingly

and made of steels with specially

selected strengths (shown in brown).

Inthe event of a crash, the energy

absorbed can thus be reduced in a

defined manner through targeted deformations. Other selected areas of the

body structure have a supporting

function (shown in green). They have the

task of stabilizing the driver's cab in the

event of a front or side crash.

Legend

m103_165

Components for high loads

Components for support functions

11

Page 12

Bodywork repaIr

The joining processes

Different joining processes are used in the MAN TGE for design reasons, such as resistance spot welding, laser

soldering, laser welding, and bonding technology.

The paint structure

The MAN TGE is available with solid or metallic paint. Both paint variants finally receive a clear varnish top coat.

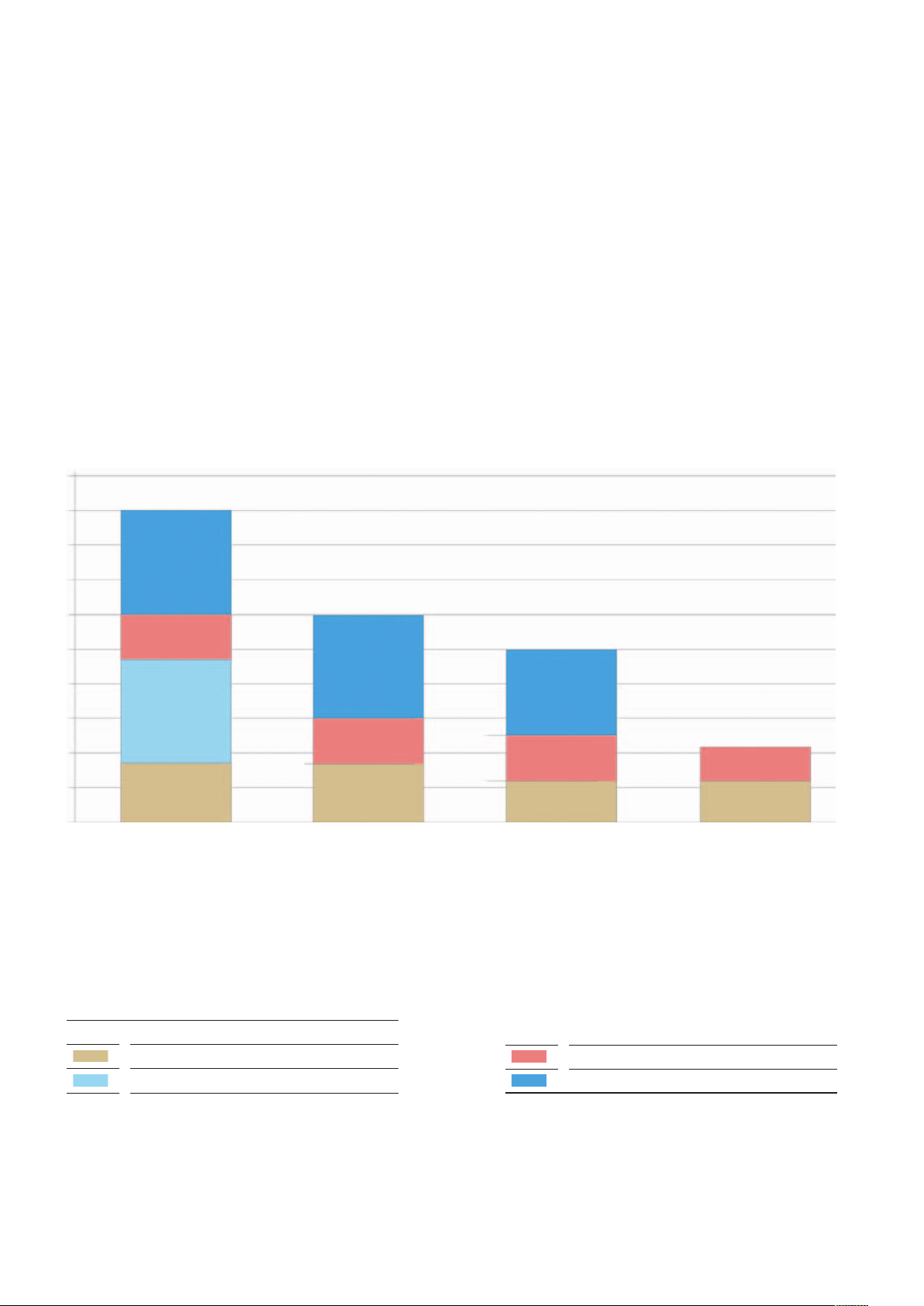

Minimum coating thickness values

Legend

12

Outer region

Visible, unobstructed

areas above the

main sill flange

Cathodic dip painting

Primer

Door interiors

Entrance areas for

defined exterior

colours

Load compartment

floor, uncladded

Bottom and wheel

arch

Base coat

Clear lacquer

Load compartment,

uncladded

Side panels

Roof

m103_166

Page 13

The corrosion protection

The underbody, the front and rear wheel

arches and the outer panels of the sill

are preserved with underbody protection in layer thickness values between

400μm to 1000μm.

The layer thickness values can deviate

upwards (maximum 2000μm).

The exterior body panel behind the rear

wheel arches is sealed with underbody

protection in the visible area. The PVC

Example - closed superstructure

underbody protection is applied directly

to the cathodic dip painting. Cavities and

mounting surfaces, e. g. for the leaf

spring support, are PVC-free. All seams

and folds on the underbody are sealed

with joint seal.

Legend

~ 400μm

~ 700μm

All cavities in the lower part of the body

and on the add-on parts are treated

with cavity wax.

The layer thickness of the cavity wax is

> 30μm. The cavities of the doors are

preserved to a height of 80 mm. The

body of the MAN TGE is galvanised

except for the hot-formed sheets and

some reinforcements inside the body. All

doors, the bonnet and the mudguards

m103_167

~ 1000μm

Cathodic dip painting

are hot-dip galvanised. The remaining

galvanized sheets are electro-galvanized.

13

Page 14

Body assemBly

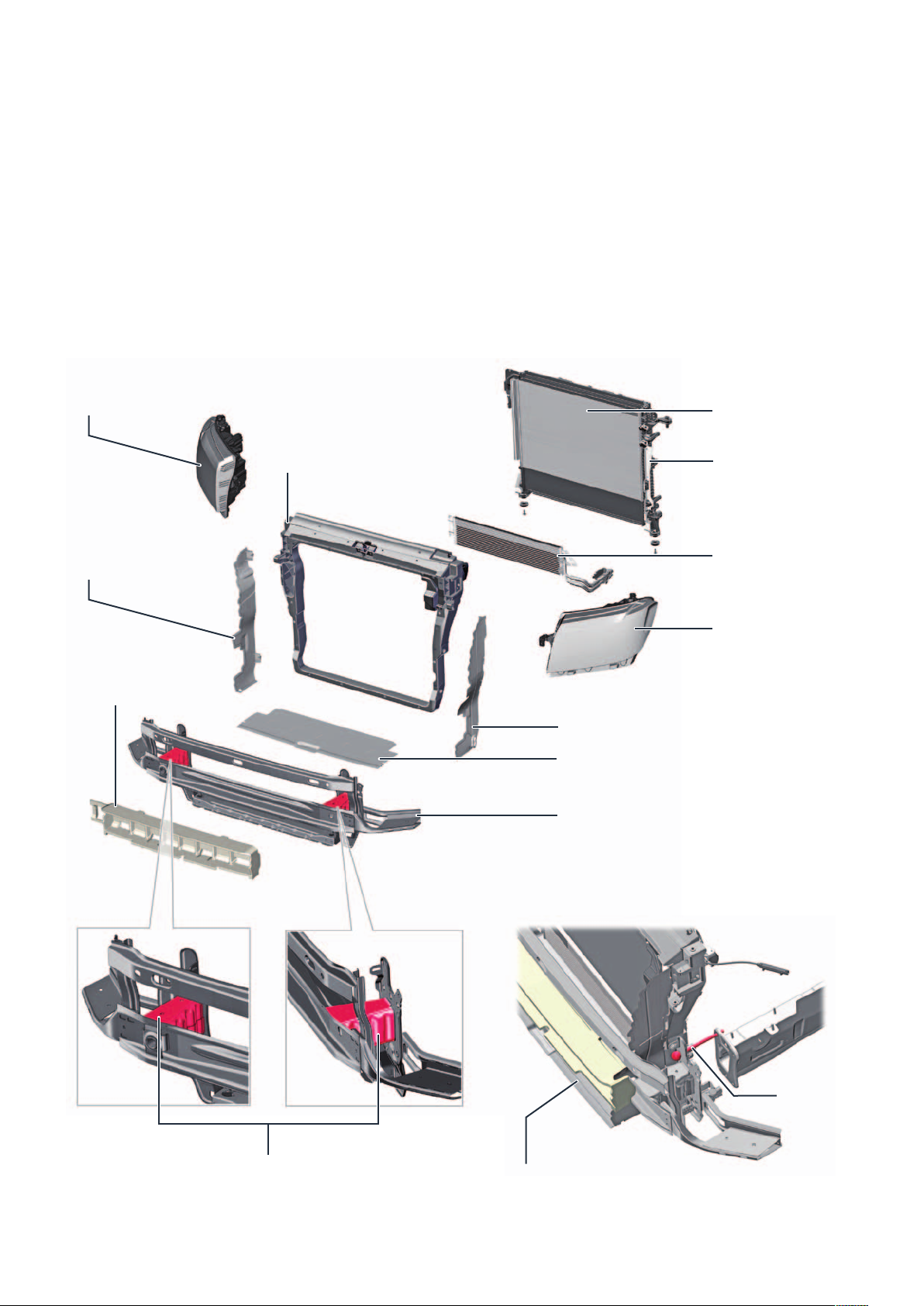

The front-end

The mounting support is made of sheet

steel and serves to accommodate the

radiator, the additional oil cooler and the

condenser of the air conditioning

Right headlamp

Mounting support

Right airflow

system. A reinforcement for the step is

incorporated in the mounting support.

The deformation element serves for

absorbing crash energy in the event of a

frontal impact. The front end can be

brought into service position with the

T10093 guide rods to improve accessibility.

Condenser

Radiator

Additional oil cooler

Left

headlamp

Foam part

m103_115

Left air flow

Bottom separation part

Bumper crossmember

Front-end service position

Guide bar

T10093

14

Deformation element

Service position

Front-end pulled forward about 100 mm

m103_114

Page 15

The front bumper

The front bumper essentially consists of

3 components, the bumper cover, the

radiator grille and the panel. These are

connected to each other exclusively via

Cover for

step

Supporting member

clip connections. The step and fog

lights are integrated in the bumper

cover.

Bumper crossmember Reinforcement for step

The panel is fitted as standard on the

MAN TGE in a painted version, and is

also available as a robust grained

version as an option.

Radiator grille

Chrome trim

Step

Bumper cover

Panel ACC sensor support

(clipped from behind in the lower

part of the bumper cover)

Step Cover for

step

Supporting member

m103_116

15

Page 16

The rear bumper

The rear bumper is constructed in three

parts to improve ease of repair. The

middle section of the bumper can

Three-piece bumper

optionally be designed as a step.

Thestep is reinforced by a frame part.

Vehicles with steps are not available in

combination with trailer hitch.

Bumper middle section with step

Frame part to reinforce the step

m103_117

16

m103_118

Page 17

The door concept

Driver/passenger doors

The driver/passenger doors of the MAN

TGE consist of an outer panel and an

inner panel. These are constructed in

one piece. All internal components are

installed via a large mounting opening.

The door foil closes the mounting

opening.

Pressure sensor

G780

Door foil

m103_119

Exterior mirrors

The door mirror is connected to the door with two screw connections. The clip on the mirror base cover and the

sliding carriage serve as a mounting aid.

Dismantling position:

Sliding carriage open

Mirror base

Sliding carriage

Mounting position:

Sliding carriage locked in

place

Door panel

m103_120

17

Page 18

Sliding door

When fitted, sliding doors are installed

as standard on the body side opposite

the steering wheel side. The MAN TGE

is optionally available as a double loader

with a sliding door fitted on the left and

right.

Top stop

The door is guided by rollers in the top,

middle and bottom guide rails. For the

different roof heights, the sliding doors

are available in two door heights, one

for the normal roof and one for the high

roof and super high roof. For doors with

increased thermal insulation, e. g. in

Picture shows door of high roof

Upper

roller guide

Outside handle

(concealed)

refrigerated vehicles, there is a different

version of the central roller guide with

large lift-out. This means that the open

sliding door is about 25 mm further

away from the side panel of the body in

the rear area.

Bottom stop

Centre roller

guide (normal

lift-out)

Door lock

(concealed)

Centre roller

guide (large

lift-out)

Pivot

Lower roller

guide

18

m103_121

Page 19

Rear doors

The rear doors are designed as double

doors. The maximum opening angle for

both rear doors is 180°, optionally 270°

(standard for extra long vehicles). In this

case, magnetic stops are used to hold

Picture shows door of high roof

6 3 5 3 6

1

9

2

1

the open doors securely. On the sliding

door side, the opening angle is slightly

smaller in order to avoid collisions with

the sliding door. The right double door

always opens first. There are two differ-

Legend

1

2

1

3

4

5

6

7

8

2

9

10

1

11

ent door heights, one for the normal

roof and one for high and super high

roof.

Hinge

Door-stay

Rotary latch lock

Lower lock

Seal

Guide key

Guide ring

Door lock (concealed)

Inside operation

Stop (bottom left picture)

Magnetic stop (bottom left picture)

8 7 7 4

Rear door with magnetic stop - closed Rear door with magnetic stop - 270 degrees open

m103_122

1110

m103_123 m103_124

19

Page 20

Door handle with locking cylinder

The door handles in the MAN TGE are particularly ergonomic and equipped with innovative safety features. The driver's door

and the rear wing door are fitted with locking cylinders.

The images show the door handle of the left-hand drive driver door

Anti-theft screw Slide

Locking cylinder Door knob

Bearing support

m103_125

Locking cylinder Cap (cap with hole)

The door handle is guided in the bearing

support. The tappet of the door handle

engages in the reversing lever in the

bearing support. To operate the door

Tappet

Bowden cable

lock, the tappet moves the reversing

lever, which in turn operates the

Bowden cable to the door lock. The

locking cylinder is mechanically locked

Reversing lever

m103_126

via the slide of the bearing support and

secured with an anti-theft screw. The

cap serves to protect the locking cylinder.

20

Page 21

Door handle without locking cylinder

Filling parts (cap without hole) are fitted on the front passenger door and the sliding door instead of locking cylinders.

The images show the door handle of the sliding door on the right

Bearing support

Filling part

(cap with hole)

Door knob

m103_127

Filling part

(cap without hole)

Slide

Reversing lever

Tappet

Bowden cable

The design and function of the door

handle are basically the same as for the

door handle with locking cylinder. The

only thing missing is the locking cylinder

m103_128

with its anti-theft screw. The design of

the slider has been adapted with

respect to its shape. The filling piece

replaces the missing locking cylinder

and is mechanically secured by the slide

of the bearing support.

21

Page 22

The lights

Interior lamps

2 lights at the roof gallery

There are 2 lights on the underside of

the roof gallery for the driver and the

passenger.

Lights in the load compartment

m103_168

Depending on the respective country

setting, there are different lights in the

load compartment.

Incandescent lamp above the rear door

The other variant is equipped with

4LED lights in the roof crossmembers.

One version has one incandescent lamp

each above the rear and side door.

m103_169 m103_170

Incandescent lamp above the side door

22

m103_171

Page 23

Tail lights with closed vehicle superstructures

The tail lights are attached using 2 screw connections and 2 clip nut connections.

The external connection of the rear

lights is a clip nut connection. In the

support plate for the clip nut, the outer

plate of the side part and the corner

plate of the D-pillar overlap.

To prevent water ingress, the mounting

hole for the clip nut is covered with a

self-adhesive sealing foil (zinc foil).

After dismantling the tail light, the

sealing foil must be checked for

damage and replaced if necessary.

m103_129

m103_130

Screws Clip nut

Side part D-pillar

m103_131

Sealing foil

Mounting hole for clip nut

Note

Further information on the rear lights with closed vehicle superstructures can be found in the corresponding service

literature.

23

Page 24

Raised brake light

The raised third stop light can optionally be equipped with an additional reversing camera. The housing of the brake light is

fastened to the roof crossmember with eight metal clips and two screw connections. The metal clips and screws are accessible

through the openings on the underside of the roof crossmember.

Third brake light without reversing camera

Reversing camera

m103_132

Third brake light with reversing camera

Metal clips

Screw

Brake light power supply

Line for video signal

from the camera

Camera power supply

24

m103_133

Screw

Page 25

Side marker lights

Depending on the model, side marker lights in LED technology are installed in the MAN TGE. These are integrated into the side

protectors of the closed vehicle.

Side marker lights

In open vehicles, the first side marker light is integrated in the side protector. The other

side marker lights are mounted on a support on the superstructure.

m103_134

Side marker lights

m103_135

25

Page 26

The side protectors

The side protectors protects the lower part of the body

against external damage.

The ultrasound sensors for the side protection and the

side marker lights are integrated into the side protectors, too.

Adhesive area

Cable passageway Double-sided adhesive tape Side protectors

Side marker light

Top clip row

Centering pins

Bottom clip row

m103_136

Ultrasound sensorScrews

The side protectors are generally clipped and additionally bonded with double-sided adhesive tape at the upper edge.

They are additionally secured with screw connections to the driver, passenger and sliding doors. The protectors do not have any

direct contact with the body except on the adhesive surface. The adhesive prevents relative movements between body and side

protectors and thus avoids corrosion and damage to paintwork. Ultrasound sensors and side marker lights are attached to the

side protectors with double-sided adhesive tape. The screw connections on the side protectors serve to protect against theft.

This prevents easy disassembly and blocks access to the vehicle via body openings in the doors.

26

Page 27

The glazing

The windscreen, the rear windows and the side windows are bonded. Sliding windows for closed vehicles and hinged windows

for the double cabin are offered as options.

Sliding window in the side panel

m103_137

Heated windscreen

The windscreen heater helps to defrost the windscreen and only works with running engine.

Ground terminals

m103_172

Heating wires shown

symbolically

Connection for

left heating panel

Connection for

right heating panel

m103_138

27

Page 28

The trailer hitch

The trailer hitch for the MAN TGE is available in two different versions:

with rigid ball head

as a variable variant with the “Varioblock” system by the company Rockinger

With the variable variant, a detachable ball head or a jaw coupling can be attached to the hitch. The maximum towing capacity

of the MAN TGE is 3500 kg. Vehicles with rigid and variable trailer hitches can be equipped with a side step.

Version with rigid ball head Variant with variable coupling

Step

Rigid ball head

Hitch Jaw coupling

m103_140

The roof rack

The guide rails for the roof rack are bolted to the body roof

and reinforced from the inside with another bolted profile

piece in the area of the D-pillar. The connection points are

fitted as standard. This means that the guide rails for the

roof rack can always be retrofitted.

Adapter

Rigid ball head

m103_140

Guide rail

m103_141m103_173

Possible roof loads:

Normal roof up to max. 300 kg

High roof to max. 150 kg

28

Reinforcement on

the D-pillar

Page 29

The pre-assembly stages for special

superstructures

Complete open chassis without platform bodies are offered to body and conversion manufacturers. Furthermore, incomplete

chassis are offered allowing an economic individualization. There are two types of incomplete chassis: cowl and platform.

Cowl

An open chassis without roof and rear wall is called a cowl. This version favours conversion to delivery vehicles, mobile homes or

ambulances, for example.

m103_142

Platform

The platform lacks the complete upper body of the driver's cab as well as doors, bonnet, fenders, bumpers, headlights and

seats. This version favours, for example, the conversion to fully integrated delivery vehicles or motor homes.

m103_143

29

Page 30

aerodynamIcs

Aerodynamic optimization

The basic shape of the body was

radically optimized with regard to

aerodynamics. For example, the design

of the bumpers featuring a special air

duct creates an air curtain in the area of

Aerodynamically optimized parts:

Roof tapering

Rear tapering, lateral

Rear spoilers

A-pillar

Exterior mirrors

Bumpers

Step

the front wheels. The roof tapering in

connection with the lateral rear tapering

ensures an aerodynamically optimal air

flow on the outer contour of the body.

This form is also called the “fish belly”.

It is the best aerodynamic design

for a vehicle body. Special spoilers at

the rear of the vehicle provide an aerodynamically favourable flow interruption.

Targeted air guidance past the wheel

(air curtain)

Steps

The front bumper has two steps on the left and right.

These are used to climb up, for example to clear the

windscreen of snow and ice. The covers in front of

these are locked in the bumper and can be removed

to the front. The shape of the covers optimises the air

flow.

m103_144

30

CoverStep

m103_145

Page 31

The consumption optimization package

Underbody panelling

Flow losses on the underbody of a

vehicle play a significant role in

increased driving resistance.

The underbody of the MAN TGE has

been specifically designed with smooth

surfaces to minimise flow losses on the

underbody.

An almost complete smoothing of the

underbody has been achieved by

cladding. For vehicles equipped with the

efficiency package, underbody panels

are used which not only improve aerodynamics but also significantly reduce

interior noise. These underbody panels

are only available for front-wheel drive

vehicles. The aerodynamic package

also includes an additional spoiler on

the left and right transverse links.

Spoiler on

transverse link

m103_174

31

Page 32

InterIor equIpment

The storage concept

Dashboard

The workplace of the MAN TGE has been tailored to the driver. In addition to numerous storage and stowage compartments, it

offers connection options for mobile devices.

Cup holder Storage compartment

Storage compartment with

12 V socket

with USB port and

AUX IN connector

Storage compartment/

ashtray (hiking ashtray)

Centre

storage tray

12 V socket/ socket

Cigarette lighter

Storage tray with

12 V socket

illuminated, lockable,

chilled

Cup holder

m103_146

Storage trayGlove compartment

Door panel

Storage compartment with

bottle holder

Storage compartment with

support for warning triangle and first aid kit

32

Storage tray

m103_175

Page 33

Roof gallery

The roof gallery is optionally available with 2 spacious storage compartments and 2 DIN slots (if equipped with a second

evaporator, only 1 DIN slot is available).

Storage tray DIN slots Storage tray

m103_147

Side panels in the load compartment

Multi-part side panels made of plastic and plywood are optionally available in different heights.

m103_176 m103_177

Side panels made of plastic Side panels made of plywood

33

Page 34

The seat concept

Single seats in the driver's cab

Individual seats in different versions are available for the driver's cab.

Rigid

seat

Backrest angle adjustment • • • • • •

Longitudinal adjustment • • • • • •

Height adjustment • • • • •

Seat cushion angle adjustment • • • • •

Manual 2-way lumbar support •

Electric 4-way lumbar support • • • •

Comfort

seat

Comfort

“Plus”

seat

“ergo

Comfort”

seat

“ergo

Activ”

seat

Swivel seat

1 x armrest inside •

2 x armrest inside/outside • • • •

Suspension unit with

adjustable weight

Seat depth adjustment • •

Massage function •

Rotation function •

• •

34

Page 35

“ergoComfort” / ”ergoActive” seat

The “ergoComfort” and “ergoActive”

seats have been consistently developed to meet the physical needs of the

driver. By means of two coil springs

and a gas pressure damper a vertical

oscillation behaviour adaptable to the

body weight is generated. This ensures

comfortable and fatigue-free sitting,

Headrest adjustable in two heights

Hand wheel for adjusting the

backrest inclination (concealed)

Armrest, continuously

adjustable

especially on long trips or poor roads.

The feeling of well-being is enhanced by

the adjustment of a large number of

individual seating positions. The lumbar

support integrated in the backrest

relieves the spine. The seat is available

as “ergoComfort” (without massage

function) or “ergoActive” (with massage

function). The seat has already been

awarded the AGR seal (Aktion Gesunder Rücken, Healthy Back Campaign)

for its exceptionally good ergonomic

properties. The control unit for massage

function and lumbar adjustment is

located under the driver's seat.

Lumbar support with motor for

longitudinal adjustment of

driver seat lumbar support

V125 and motor for height

adjustment of driver seat

lumbar support V129

Handle for

mechanical

seat depth adjustment

Lever for

longitudinal seat

adjustment

Lever for

blocking the

vertical movement of

the suspension seat

Hand wheel for adjusting

the body weight on the

suspension seat

Key for

back massage function

(only with “ergoActive”)

Side airbag

2 coil springs

Gas pressure absorbers

Seat height adjustment lever

Control unit for massage function

Hand wheel for adjusting the

seat surface inclination

Switch for adjusting the driver's

seat lumbar support E176

m103_148

35

Page 36

Double passenger bench

In standard equipment, the seat cushions can be folded individually. Below is

a covered storage compartment inside

the seat frame. Optionally, the inner

backrest is also equipped with a folding

function. This offers further loading

possibilities. In addition, the backrest

has a writing surface for office work

(cup holder, writing surface, pen tray,

storage compartment for e. g. tablet

computer, mobile phone, etc. and

clipboard).

m103_184

Four-seater bench for double cabin

The double cabin is equipped with a four-seater bench in the passenger compartment in the second row of seats.

Features

Storage compartment under seat accessible from

above

Seat-integrated three-point safety belts for the two

middle seats

Flat headrests, height adjustable

Retaining strap for fixing the folded up seat cushions

Retaining

strap

36

m103_185

Page 37

Load compartment with closed vehicle superstructure

The load compartment offers a wide range of possible applications.

Universal floor

The universal floor is based on the

continuous wooden floor covering of the

MAN TGE. It allows the quick set-up of

vehicle installations without having to

adapt the loading floor. This is a prerequisite for the individual furnishing of the

load compartment – without any gluing

Structure

The universal floor consists of beech

hardwood veneer sealed with a non-slip

coating. There are numerous lockable

cut-outs that can be removed. Floor

or drilling. Shelving and cabinet systems

from various manufacturers can be

easily installed and removed in line with

customer requirements. If necessary,

the components can be removed

without leaving any residue.

adapters can then be screwed in at

these points, e. g. to accommodate

cabinet systems from different manufacturers.

m103_186

The universal floor is not bonded to the

vehicle and can therefore be easily

removed. Optionally the universal floor

can be equipped with lashing rails and

lashing eyes.

Lockable cut-outs for

floor adapters

Installation system

e. g. shelf

Lockable cut-out

Screw

Anchor

m103_149

Lashing rails

37

Page 38

Load securing

Closed vehicles can optionally be

equipped with lashing rails in the side

sections, the roof crossmembers, on

the floor and on the divider in order to

secure the load. The manufacturer's

lashing rails feature a specified “airline

profile” hole profile and are screwed to

the body with hexagon blind rivet nuts

with M6 thread.

The hexagonal holes for the blind rivet

nuts are standard on all vehicles and are

located centrally and at the top in the

side parts, in the roof crossmembers

and on the divider. The blind rivet nuts

Hexagon blind rivet nut

with outer hexagonal profile are pressed

into these hexagonal holes. The hexagonal profile prevents unintentional

twisting later when fastening screws are

tightened or loosened.

Legend

Lashing rail on the

dividers

Lashing rail on the side walls Lashing rail at the roof

Lashing rail on the floor

m103_150

38

Page 39

Roof rack in the load compartment

Ladders or pipes weighing up to 50 kg

per support bracket can be stowed on

the roof rack in the load compartment.

The roof rack consists of 2 support

Lashing rail at the roof crossmember

Roof crossmembers

brackets which are attached to the

outer lashing rails of the roof crossmembers. These can be positioned variably

in longitudinal direction. When not in

Connection of the support bracket to the lashing rail

use, the two carrying handles can be

retracted to save space. The support

brackets are equipped with fastening

options from the airline profile system.

Support bracket with airline profile

Support bracket

m103_151

39

Page 40

occupant protectIon

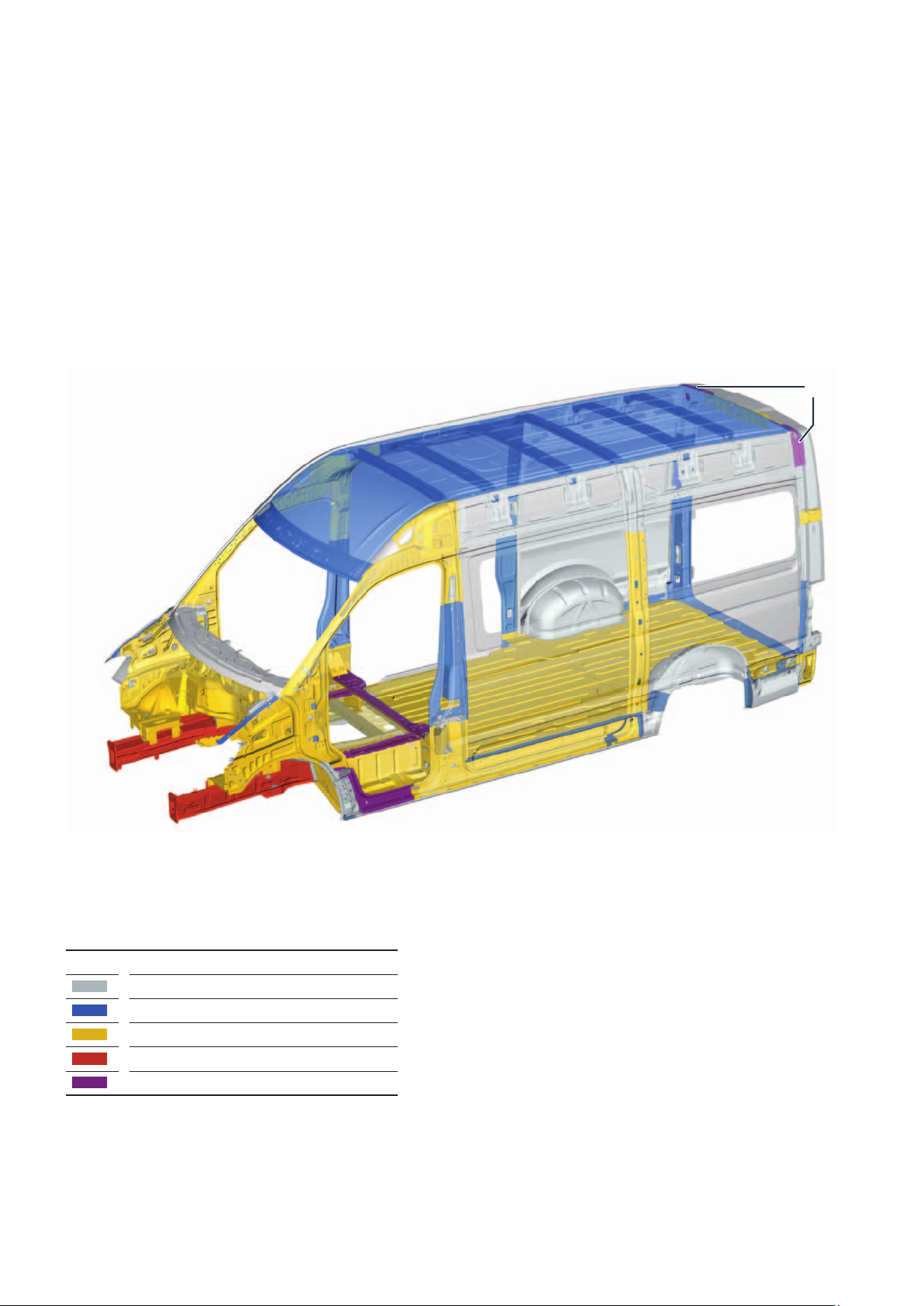

Occupant protection

Overview of safety systems

The following occupant protection is offered in the MAN TGE:

Driver airbag as standard

Passenger airbag for single seat/

double passenger bench, optional,

can be switched off

Side airbag, optional

Head airbag, optional

Only the driver airbag is standard equipment. The head airbag and the side

airbag are also available only on one

side, i. e. for the left or right side of the

vehicle. This allows the body manufacturer to customize the vehicles at low

cost.

In the glove compartment:

Key switch for deactivating

the airbag on the passenger

side E224

Head airbag

Passenger's side

Passenger side airbag

Front passenger side airbag

Seat belt with ball belt tensioner

Passenger's side

Seat occupancy sensor

on assenger side G128

Crash sensor for head and

side airbags

on passenger side G595

Pressure sensor for side airbag

on passenger side G781

Crash sensor for front airbag

on passenger side G284

40

Crash sensor for front airbag

on driver's side G283

Page 41

Crash sensors

The sensors for the front and side airbags are separate and work according to different principles.

Pilot light for passenger

front airbag K145

Head airbag on driver's side

Front airbag on driver's side

Side airbag on driver's side

Seat belt with

ball belt tensioner

on driver's side

Crash sensor for head and

side airbags

on driver's side G594

Pressure sensor for side airbag

on driver's side G780

Control unit for airbag J234

m103_152

41

Page 42

Crash sensor for front airbag G283/G284

The crash sensors for front airbags

G283 / G284 are acceleration sensors.

They are installed on the left and right

side of the front end and are located in

Crash sensor for front airbag on

driver's side G283

the front crumple zone of the vehicle.

Thus, the control unit for airbag J234

receives the signals from the two crash

sensors particularly early. This enables a

rapid detection of the severity of the

frontal impact. This results in a higher

level of protection for the occupants.

Crash sensor for front airbag

on passenger side G284

42

m103_153

Page 43

Pressure sensors for side airbags G780 and G781

In the MAN TGE, the G780 and G781

pressure sensors are used to detect a

side impact in the side doors; these are

particularly fast sensors. The sensors

are locked into the inner door panel.

The pressure sensors require a pressure

chamber inside the door. The pressure

chamber for the pressure sensor is

created by closing the mounting

opening with a door foil. For the pressure sensor to function correctly, the

door foil, the sealing plugs and the

sealing foils that close the pressure

chamber of the door must not be

damaged. In case of damage or after

dismantling these foils must therefore

always be replaced. The seals to be

checked are located on the inside and

outside of the door.

Pressure sensor

G780

In the event of a side impact, the outer

door panel is pressed in and an overpressure is created in the door due to

the reduction in volume. This pressure

increase is transmitted to a piezo

element in the sensor and a delay signal

is determined, depending on the pressure curve, within a certain period of

time. If the change in air pressure

exceeds a certain level, the sensor

transmits a corresponding signal to the

control unit for airbag J234. In control

unit J234, this pressure signal is evaluated with the signals from the corresponding side crash sensor in the door

entry at the B-pillar and, if necessary,

the airbag deployment of the side airbag

and the head airbag is started.

Door foil

m103_154

43

Page 44

Driver airbag

The driver airbag contains a single-stage pyrotechnic gas generator.

Airbag volume is

approx. 60 litres

m103_155

Cover

Airbag pack

Passenger airbag

A single-stage pyrotechnic gas generator is used in the passenger airbag. It is

installed under the dashboard and is

accessible via the glove compartment.

There are two airbag sizes due to the

different air volumes of the single front

Pyrotechnic gas

generator

passenger seat or double passenger

bench. The larger airbag is used for the

double passenger bench.

44

Passenger airbag

for single seat

Airbag volume

approx. 102 litres

Passenger airbag for

double passenger

bench

Airbag volume

approx. 165 litres

m103_156

Page 45

Head airbag

The head airbag contains a single-stage pyrotechnic gas generator. The head airbag is attached to the roof frame by means of

clip connections. The anti-twist marking must be visible and not twisted after installation.

Airbag volume

approx. 21 litres

Anti-twist marking

m103_157

Side airbag

A single-stage pyrotechnic gas generator is installed in the side airbag. The airbag is installed in the backrest frame of the following seats:

Driver's seat

Front passenger seat

Outer seat of the double passenger

bench

Airbag volume

approx. 15 litres

m103_158

45

Page 46

Safety belt equipment

The MAN TGE is equipped with the following belt systems:

Belt tensioner with force limiter

Always on driver's side

Passenger side, single seat with

passenger airbag

Outer seat of double passenger

bench with passenger airbag

The driver and front passenger seats as

well as the double passenger bench are

equipped with a seat belt reminder

system. For this purpose, the front

Belt tensioner (without force limiter)

Passenger side, single seat without

passenger airbag

passenger seat/double passenger

bench has a seat occupancy sensor

that works with a foil sensor. It is fixed

directly on the seat shell by means of

Standard retractor

(3-point automatic seat belt)

Passenger side, both seat belts on

double passenger bench without

passenger airbag

Passenger side, middle seat belt on

double passenger seat bench with

passenger airbag

clip connections. The application of seat

occupancy detection is market-dependent. The driver's seat is monitored by

an electric belt buckle.

46

Pyrotechnic belt tensioner

Seat occupancy sensor

Passenger side G128*

* market-dependent

m103_159

Page 47

Glossary

Bake hardening steels

Bake hardening steels are higher- and

highest-strength steels. The bake

hardening effect occurs when coldformed steels are heated up to around

150 °C - 200 °C. This results in a

structural transformation and an

increase in strength. During the production of the vehicle, the required temperature is reached during the paint

baking in the painting process.

Drag coefficient Describes a sheet metal blank which is

The drag coefficient, also known as the

cw value, is the decisive factor for drag

in addition to the cross-sectional area A

of a vehicle. It provides information on

how aerodynamic a vehicle is.

Highest-strength hot-formed steel

sheets

Highest-strength hot-formed steels are

significantly stronger than sheets of

conventional steels. By using these

sheets for the body, smaller material

cross-sections and thus also lower

body masses are possible. Together

with weight reduction, greater stability

and crash safety are achieved.

Highest-strength hot-formed sheets are

produced in the form-hardening

process. The body panel is heated up

to red heat (approx. 950 °C) before

pressing. During the pressing process,

the sheet is formed into its final shape.

The cooling during pressing causes a

structural change in the material structure, which gives the sheet its high final

strength.

KTL

KTL = Cathodic dip painting

Cathodic dip painting is an electrochemical painting process in which the

entire body is coated in an immersion

bath, thus providing continuous corrosion protection for the body. It takes

place in vehicle production after phosphating the bodywork.

Tailored blank

typically composed of different material

grades and/or sheet thickness values.

The different sheet thickness values are

produced by repeated rolling.

47

Page 48

MAN Truck & Bus AG

MAN Academy

Dachauer Straße 667

80976 München

www.mantruckandbus.com

MAN Truck & Bus – A company of the MAN group

Loading...

Loading...