Page 1

MAN GUIDE 102

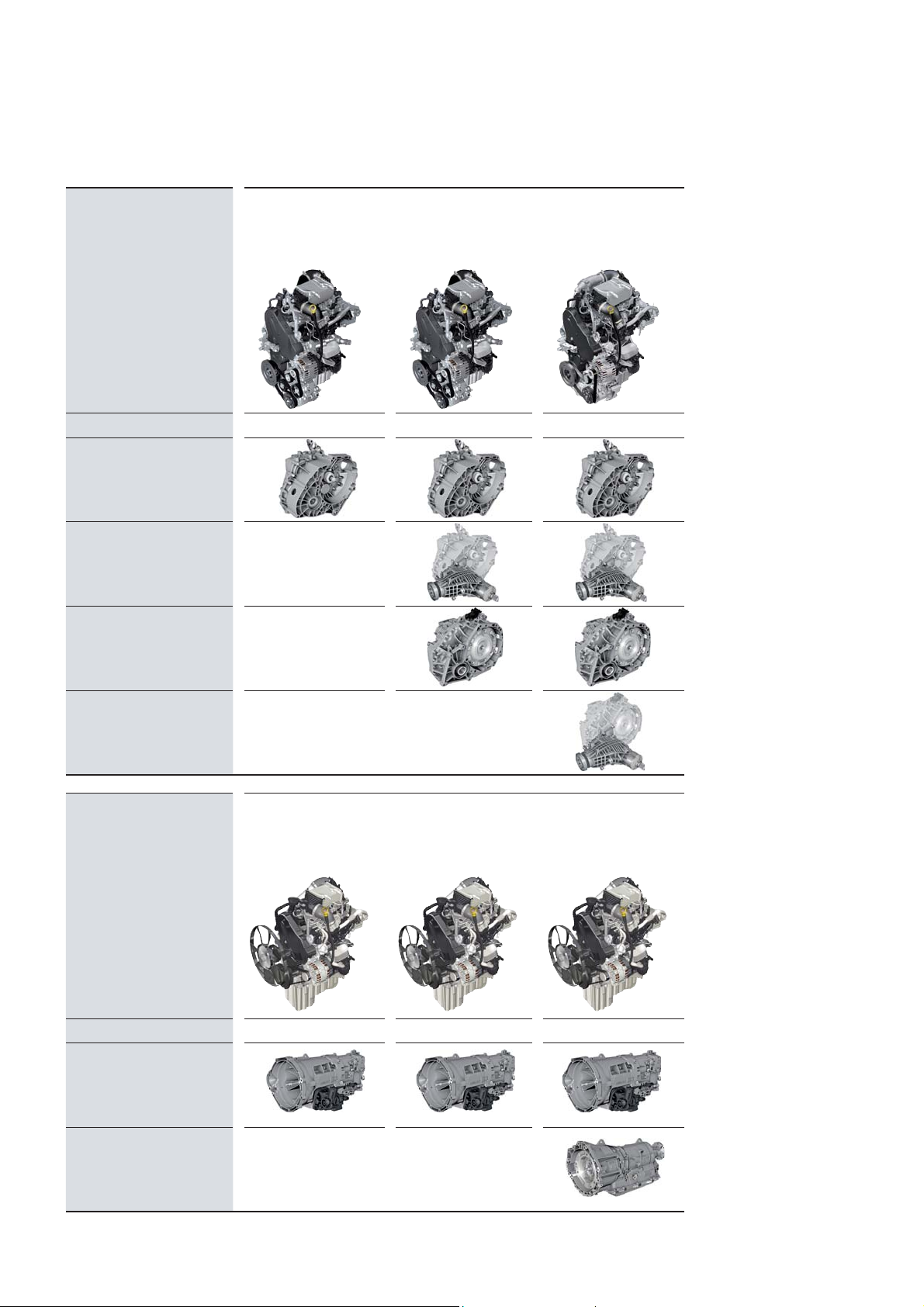

TGE Engine

Page 2

In the MAN TGE, only 2.0-litre turbo diesel engines from the VWnutz modular diesel construction kit are used.

The use of a uniform engine geometry with many identical parts creates high synergy effects and reduces manufacturing and

maintenance costs.

Transverse installation Longitudinal installation

The engines of the MAN TGE have been

specially designed for commercial

vehicles to meet the high requirements

in terms of mileage, driving resistance,

driving profi le and service life. Adjustments were made, for example, to the

intercooling, the cylinder head, the

intake manifold, the EGR cooler, the

turbochargers and the oil pan. The

installation position is adapted to the

commercial vehicle design. Depending

on the drive concept used, the engines

are installed transversely or longitudinally - an absolute special feature within

a vehicle series. In addition, transversely

installed engines are installed at an

angle of 8° to the front in order to make

optimum use of the available installation

space. Longitudinally installed engines

have a larger oil pan and an increased

oil quantity. Engines with one or two

turbochargers are used.

m002_002

A total of up to four power stages are

available, ranging from 75 kW to

130kW. The after-treatment of the

exhaust gases is carried out by an SCR

system for nitrogen oxide reduction.

Additional options, e. g. different

generators and compressors, are

possible with the accessory drive used.

2

Page 3

TABLE OF CONTENTS

4 INTRODUCTION

10 GEARBOX

14 ENGINE MECHANICS

4 10

23 OIL SYSTEM

26 COOLING SYSTEM

2314

26

33 ENGINE MANAGEMENT

50 EXHAUST SYSTEM

58 SERVICE

50

The MAN TGE Guide teaches the basics of design and function for sales and after-sales of new vehicle models, new

vehicle components or new technologies.

The MAN TGE Guide is not a sales manual nor a repair guide! Specifi ed values are for the sake of easy understanding

only and refer to the data status valid at the time the MAN TGE Guide was created.

The contents are not updated.

Please use the appropriate technical literature for customer advice, maintenance and repair work.

Hint

Reference

3

Page 4

INTRODUCTION

2.0l Turbo diesel - 75 kW - DAUB

Technical features

Transverse installation

Liquid-cooled intercooler

High pressure exhaust gas recirculation

Delphi Common Rail direct injection

Liquid-cooled injector for reduction agent

Injectors with solenoid valve

Single-piston high-pressure pump

(mono turbocharger)

m002_009

Technical data

Engine designation 2.0 l Turbo diesel

75 kW

Engine identifi cation DAUB

Cubic capacity 1968 cm

Engine design 4-cylinder in-line engine

Valves per cylinder 4

Bore 81.0 mm

Stroke 95.5 mm

Compression ratio 15.5: 1

Max. power

at 1/min

Max. torque

at 1/min

Engine management Delphi DCM6.2

Fuel DIN EN 590

Charge Mono turbocharger

3250 – 3500

300 Nm

1400 – 2250

3

75 kW

Torque and power diagram

500 100

400 80

300 60

200 40

Torque [Nm]

100 20

00

1000 2000 3000 4000

Torque [1/min]

Torque Power

Power [kW]

Exhaust gas recirculation yes

Exhaust emission

standard

1)

4

1)

EU6 plus: Light duty homologation <2840 kg reference weight (roller test bench)

EU6 plus

Page 5

2.0l Turbo diesel - 90 kW - DASA

Technical features

Longitudinal installation

Liquid-cooled intercooler

High pressure exhaust gas recirculation

Delphi Common Rail direct injection

Liquid-cooled injector for reduction agent

Injectors with solenoid valve

Single-piston high-pressure pump

(mono turbocharger)

m002_010

Technical data

Engine designation 2.0 l Turbo diesel

90 kW

Engine identifi cation DASA

Cubic capacity 1968 cm

Engine design 4-cylinder in-line engine

Valves per cylinder 4

Bore 81.0 mm

Stroke 95.5 mm

Compression ratio 15.5: 1

Max. power

at 1/min

Max. torque

at 1/min

Engine management Delphi DCM6.2

Fuel DIN EN 590

Charge Mono turbocharger

3250 – 3500

300 Nm

1400 – 2250

3

90 kW

Torque and power diagram

500 100

400 80

300 60

200 40

Torque [Nm]

100 20

00

1000 2000 3000 4000

Torque [1/min]

Torque Power

Power [kW]

Exhaust gas recirculation yes

Exhaust emission

standard

1)

1)

EURO VI: Heavy duty homologation >2380 kg reference weight (engine test bench)

EURO VI

5

Page 6

2.0l Turbo diesel - 103 kW - DAUA / DASB

Technical features

DAUA - transverse installation

DASB - longitudinal installation

Liquid-cooled intercooler

High pressure exhaust gas recirculation

Delphi Common Rail direct injection

Liquid-cooled injector for reduction agent

Injectors with solenoid valve

Single-piston high-pressure pump

(mono turbocharger)

m002_011

Technical data

Engine designation 2.0 l Turbo diesel

103 kW

Engine identifi cation DAUA / DASB

Cubic capacity 1968 cm

Engine design 4-cylinder in-line engine

Valves per cylinder 4

Bore 81.0 mm

Stroke 95.5 mm

Compression ratio 15.5: 1

Max. power

at 1/min

Max. torque

at 1/min

Engine management Delphi DCM6.2

Fuel DIN EN 590

Charge Mono turbocharger

103 kW

3500 – 3600

340 Nm

1600 – 2250

3

Torque and power diagram

500 125

400 100

300 75

200 50

Torque [Nm]

100 25

00

1000 2000 3000 4000

Torque [1/min]

Torque Power

Power [kW]

Exhaust gas recirculation yes

Exhaust emission

standard

1)

6

1)

EU6 plus: Light duty homologation <2840 kg reference weight (roller test bench)

EU6, EU6 plus

Page 7

2.0l Turbo diesel - 130 kW - DAVA / DAWA

Technical features

DAVA - transverse installation

DAWA - longitudinal installation

Liquid-cooled intercooler

High pressure exhaust gas recirculation

Delphi Common Rail direct injection

Liquid-cooled injector for reduction agent

Injectors with solenoid valve

Double-piston high-pressure pump

(bi-turbocharger)

m002_012

Technical data

Engine designation 2.0 l Turbo diesel

130 kW

Engine identifi cation DAVA / DAWA

Cubic capacity 1968 cm

Engine design 4-cylinder in-line engine

Valves per cylinder 4

Bore 81.0 mm

Stroke 95.5 mm

Compression ratio 15.5: 1

Max. power

at 1/min

Max. torque

at 1/min

Engine management Delphi DCM6.2

Fuel DIN EN 590

Charge Bi-turbocharger

130 kW

410 Nm

1500 – 2000

3

3600

Torque and power diagram

500 150

400 120

300 90

200 60

Torque [Nm]

100 30

00

1000 2000 3000 4000

Torque [1/min]

Torque Power

Power [kW]

Exhaust gas recirculation yes

Exhaust emission

standard

1)

EURO VI: Heavy duty homologation >2380 kg reference weight (engine test bench)

1)

EU6 plus: Light duty homologation <2840 kg reference weight (roller test bench)

EU6, EU6 plus,

EURO V/VI

7

Page 8

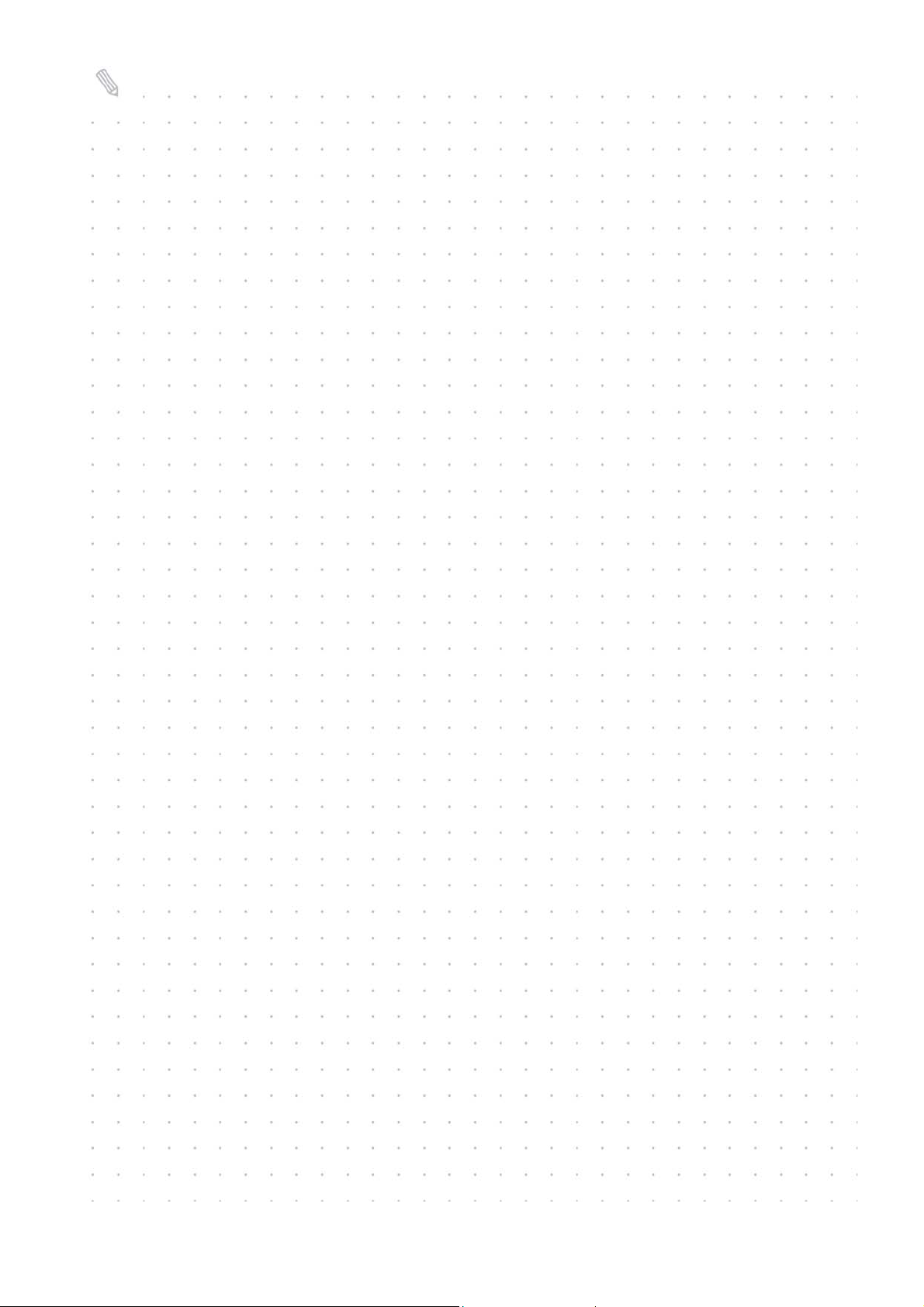

The engine-gearbox combinations

Transverse installation 2.0 l Turbo diesel

75 kW

DAUB

6-speed

manual gearbox

0AX front wheel drive

6-speed

manual gearbox

0AX all-wheel drive

8-speed

automatic gearbox

09Q front wheel drive

2.0 l Turbo diesel

103 kW

DAUA

2.0 l Bi-turbo diesel

130 kW

DAVA

8-speed

automatic gearbox

09Q all-wheel drive

Longitudinal installation 2.0 l Turbo diesel

90 kW

DASA

6-speed

manual gearbox

0F6 rear wheel drive

8-speed

automatic gearbox

0DR rear-wheel drive

2.0 l Turbo diesel

103 kW

DASB

2.0 l Bi-turbo diesel

130 kW

DAWA

8

Page 9

9

Page 10

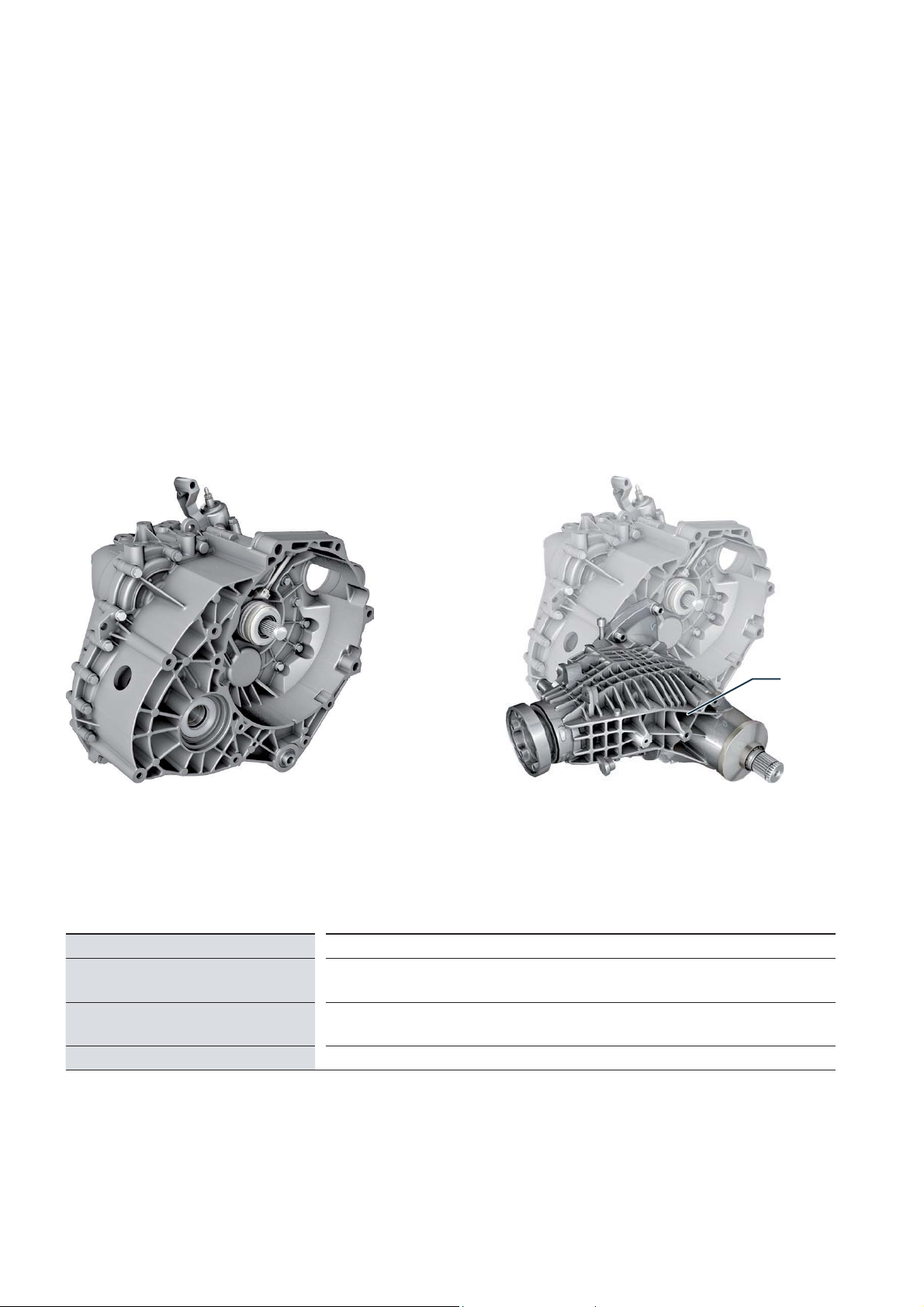

GEARBOX

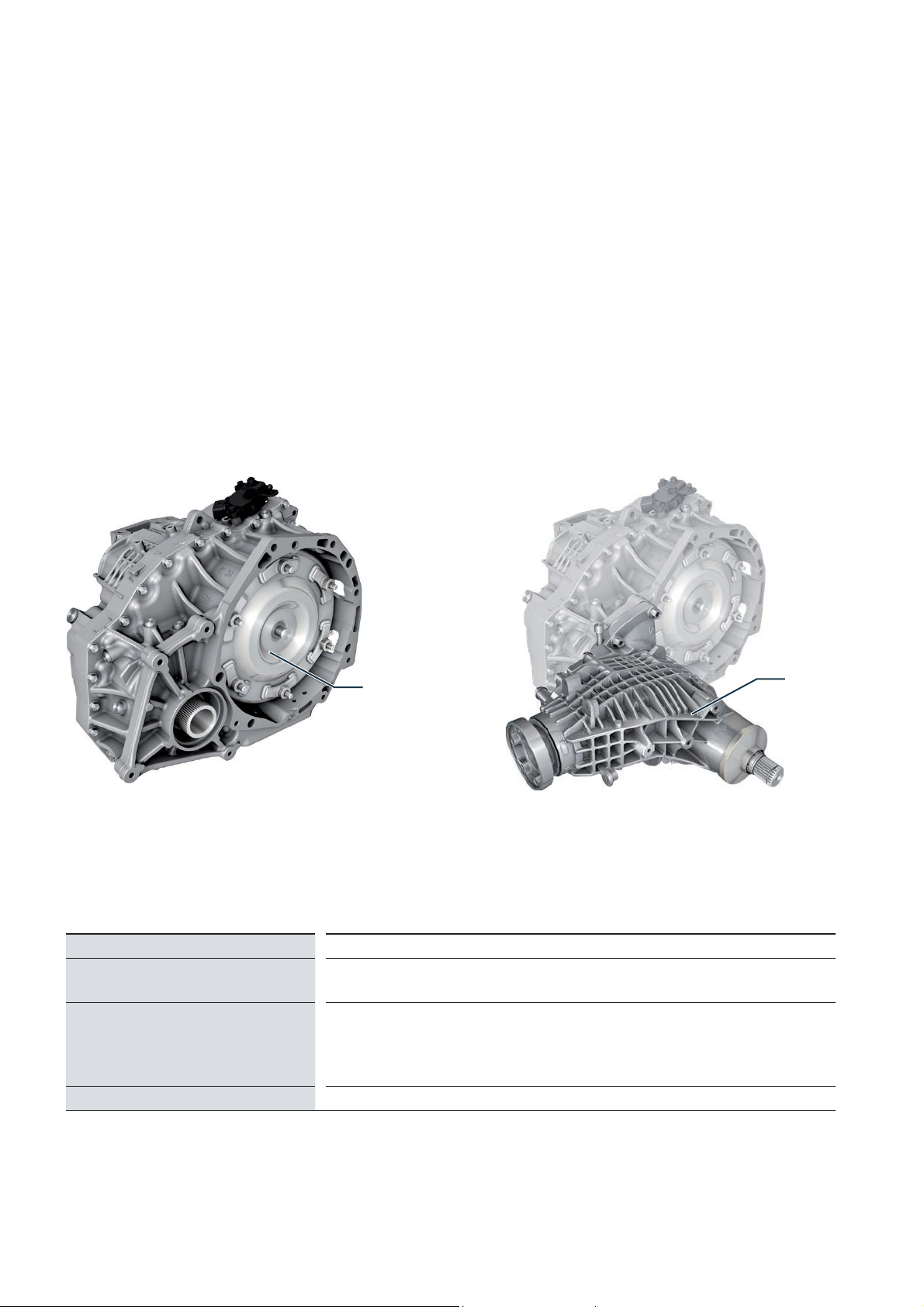

6-speed manual transmission 0AX transverse installation

This transmission is used in front wheel

drive or 4x4 four-wheel drive vehicles.

For use in the MAN TGE, it was

adapted with respect to gear ratios and

to the installation space-specifi c

conditions.

In the MAN TGE, it is used both for

front wheel drive, and with a

fl ange-mounted angle drive

for 4x4 all-wheel drive.

Front-wheel drive All-wheel drive 4x4

Angle drive

Developer/Manufacturer

Gearbox designation

Gearbox characteristics

Torque

m002_080 m002_081

Volkswagen AG

MQ500-6A/-6F

In service code: 0AX

6-speed manual transmission with four shafts and cable control for front-wheel or

all-wheel drive in transverse installation

410 Nm

10

Page 11

6-speed manual transmission 0F6 longitudinal installation

The newly developed manual transmission is used in rear-wheel drive vehicles.

For the MAN TGE it has been designed

with a correspondingly robust layout.

This applies, for example, to the design

of bearings and synchronization.

A gearbox-side power take-off is available as an option.

Developer/Manufacturer

Gearbox designation

Gearbox characteristics

Torque

m002_082 m002_083

Power take-off

ZF Friedrichshafen AG

ML410-6H

In service code: 0F6

2-shaft manual transmission with single and multiple synchronized speeds.

The gearbox consists of a drive shaft in conjunction with a coaxial output shaft,

a countershaft and a reverse shaft for reverse gear.

The power take-off is driven by the countershaft.

410 Nm

11

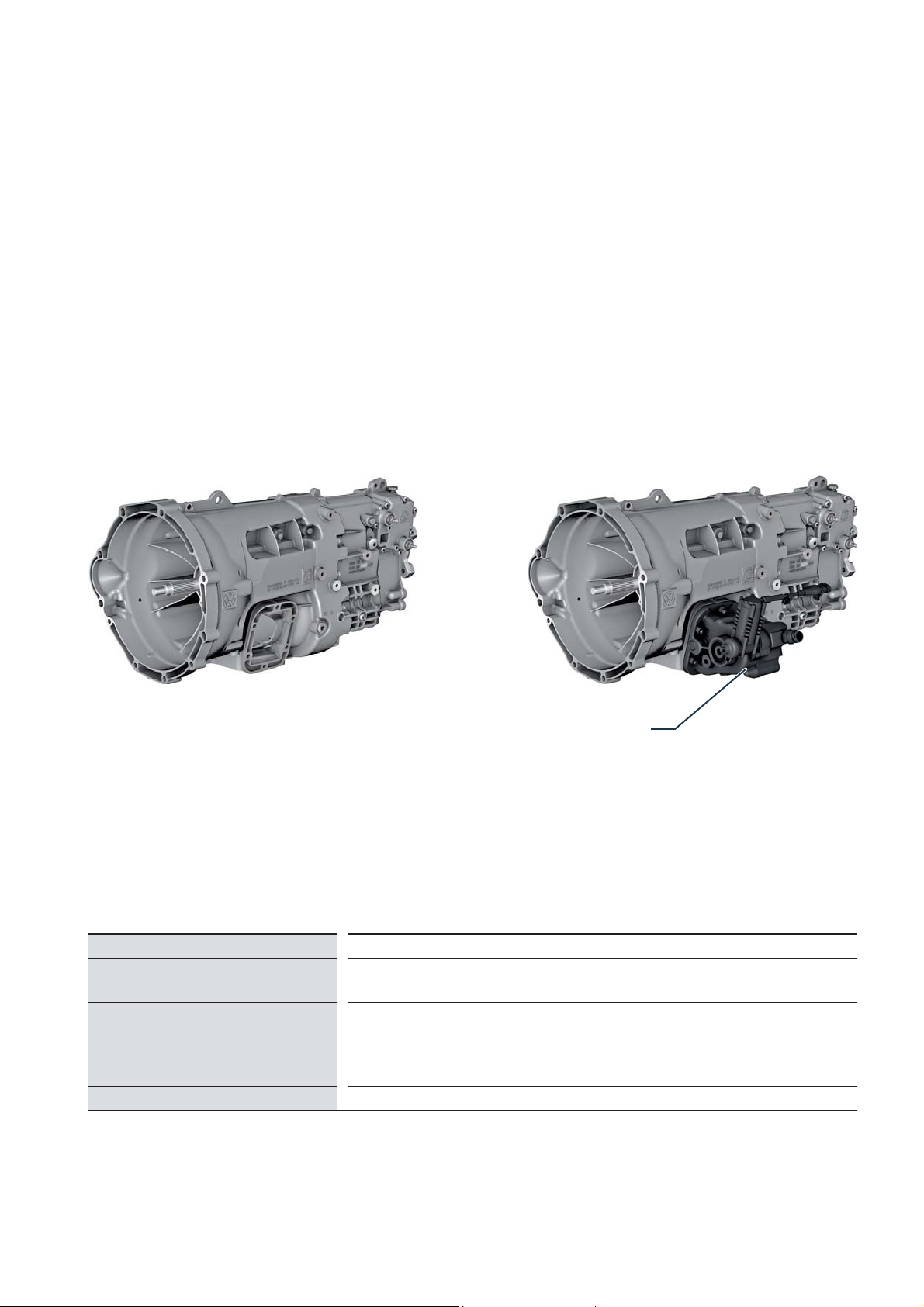

Page 12

8-speed automatic transmission 09Q transversal installation

The newly developed automatic transmission is used in front wheel drive or

4x4 four-wheel drive vehicles.

For use in the MAN TGE, care was

taken to ensure a robust design of the

converter, gearbox housing, differential

and parking lock. In all-wheel drive

vehicles, the drive to the rear axle is

provided by a fl ange-mounted angular

drive.

Front-wheel drive All-wheel drive 4x4

Torque converters

Angle drive

Developer/Manufacturer

Gearbox designation

Gearbox characteristics

Torque

m002_078 m002_079

AISIN AW CO., LTD Japan

AQ450-8A/-8F

In service code: 09Q

Electro-hydraulically controlled 8-speed planetary gearbox

(stepped automatic transmission) with hydrodynamic torque converter and slipcontrolled torque converter lock-up clutch for front or all-wheel drive in transverse

installation

410 Nm

12

Page 13

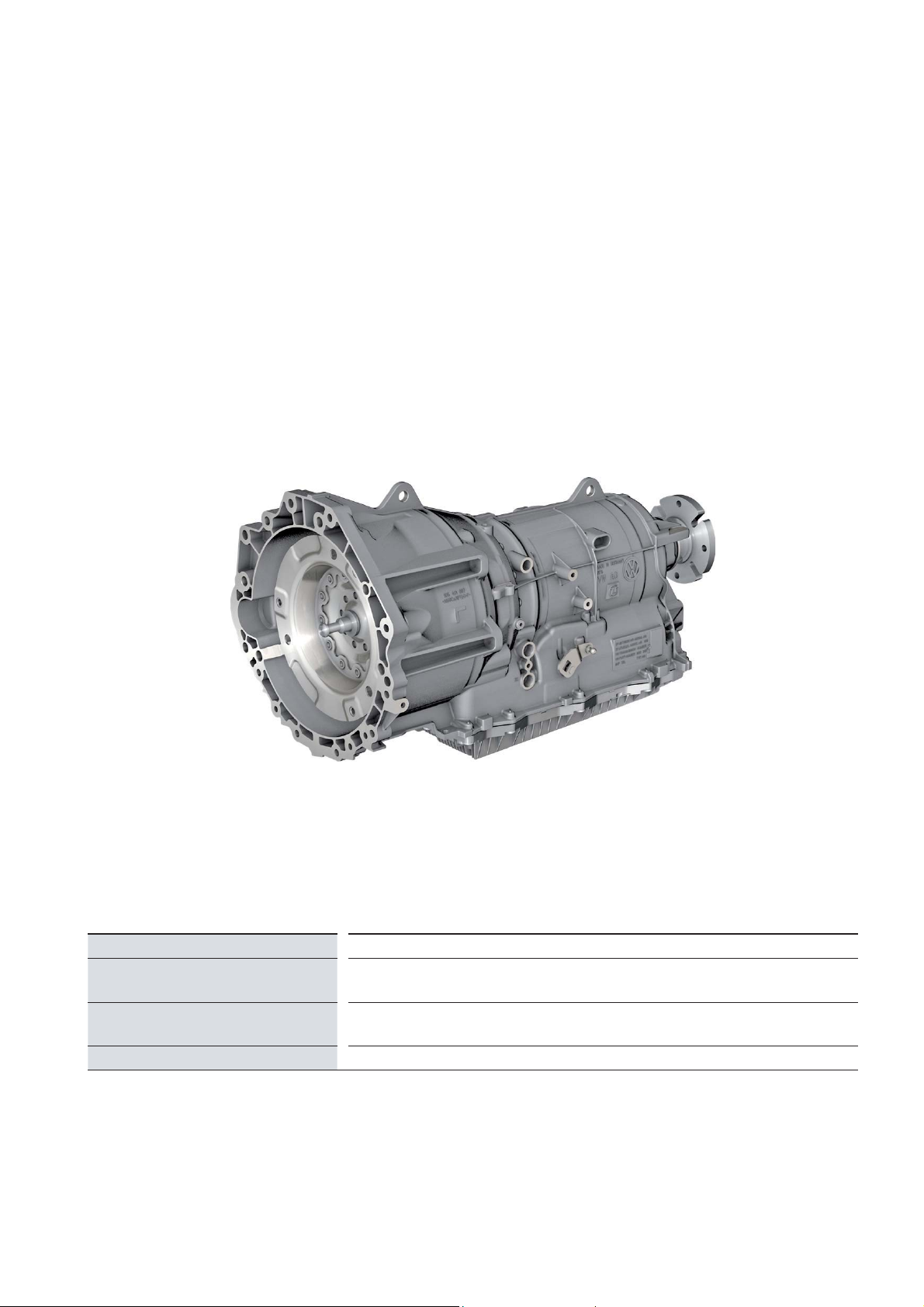

8-speed automatic transmission 0DR longitudinal installation

The newly developed automatic transmission is used in rear-wheel drive

vehicles. For the MAN TGE it has been

designed with a correspondingly robust

layout.

This concerns e. g. the transducer and

the planet set. In addition, the gearbox

housing, lining plates, plate supports

and the parking lock are reinforced.

Developer/Manufacturer

Gearbox designation

Gearbox characteristics

Torque

m002_084

ZF Friedrichshafen AG

AL550-8H

In service code: 0DR

Electro-hydraulically controlled 8-speed planetary gear with hydrodynamic

torque converter with slip-controlled torque converter lock-up clutch

410 Nm

13

Page 14

ENGINE MECHANICS

The cylinder block

The cylinder block of the EA288 engine

is made of grey cast iron. This is an alloy

of cast iron with lamellar graphite. The

cylinder block has deep-seated screw

threads for long cylinder head screws.

This achieves a good force fl ow distribution in the structure of the cylinder block

as well as a balanced pressure distribution over the entire circumference of the

cylinder head gasket.

The design of the cooling ducts in the

cylinder block ensures good cooling of

the webs between the cylinders.

14

m002_020

Page 15

The crank drive

Crankshaft

Due to the high mechanical load, a

forged crankshaft with fi ve bearings is

used in the 2.0l TDI engine. Instead of

the usual eight counterweights, this

Pistons and conrods

The pistons of the EA288 engine have

no valve seat pockets. This design of

the pistons reduces the dead space

and improves the swirl formation of the

crankshaft has four counterweights to

compensate the rotating inertia forces.

This reduces the load on the crankshaft

intake air in the cylinder. The pistons

have an annular cooling channel into

which oil is injected via piston nozzles

bearings. The toothed belt wheel for

driving the oil pump is shrunk on the

crankshaft.

for cooling the piston ring zone. The

connecting rods are designed as

cracked tapered connecting rods.

m002_021

15

Page 16

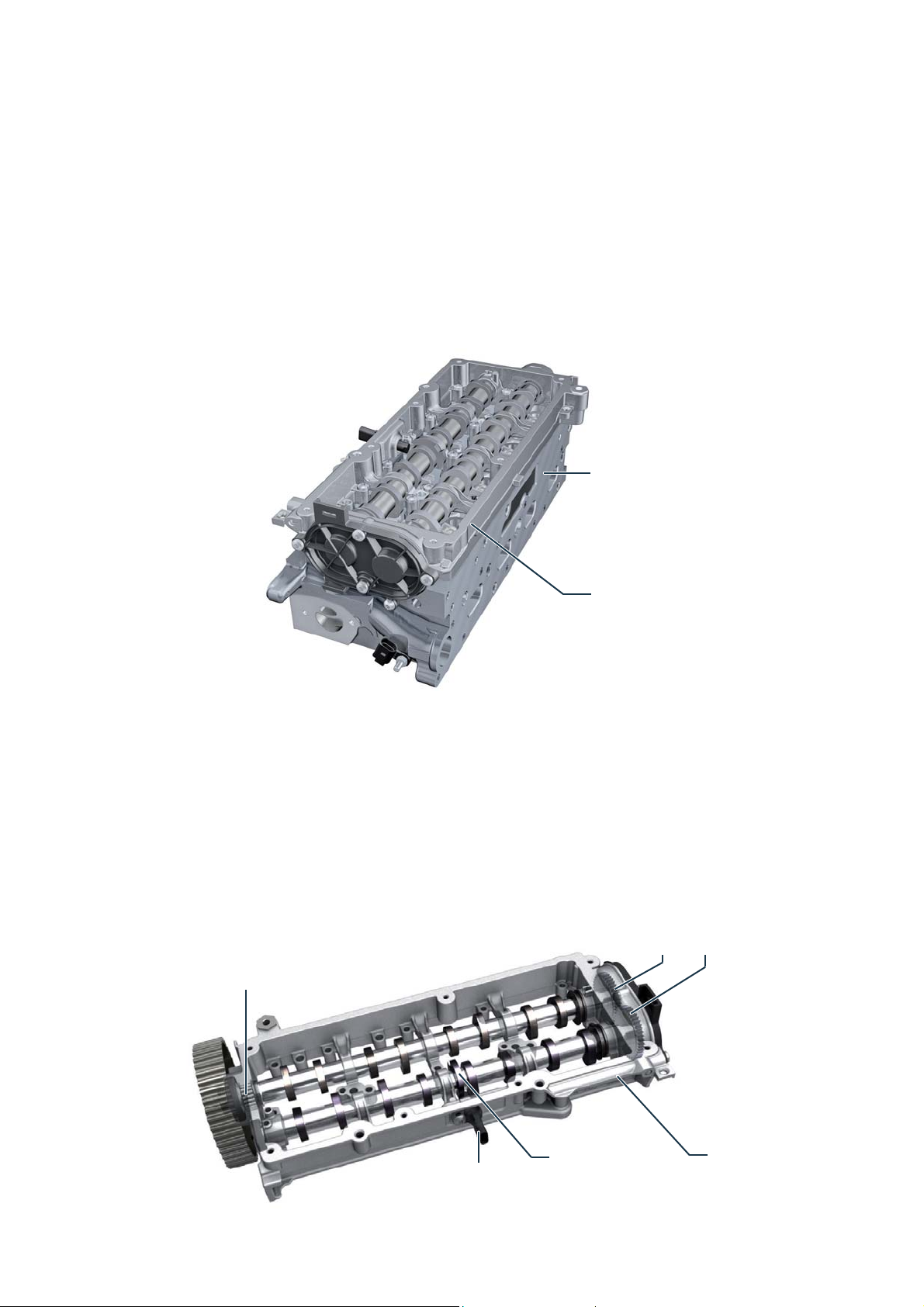

The cylinder head

The cylinder head is made of an aluminium alloy.

Four valves are installed per cylinder.

The valve arrangement is the classic

design, i. e. the inlet valves are located

on the inlet side and the outlet valves on

the outlet side. The valve is actuated by

roller cam followers with compensating

elements.

The combustion chamber pressure

transmitter for cylinder 3 G679 is integrated in the glow plug for this cylinder

and screwed into the cylinder head like

the other glow plugs. In order to

increase service life, the head of the

EA288Nutz has been improved in terms

of thermal management compared to

the basic engine.

Cylinder head

Camshaft housing

Camshaft housing

The camshafts are fi rmly and inseparably integrated into a closed bearing

frame by means of a thermal joining

process. This process enables a very

rigid design of the camshaft bearings

with low weight. In order to reduce

friction, the fi rst bearing, most loaded by

Needle roller bearing

m002_022

the toothed belt drive, is a needle roller

bearing. The encoder wheel for Hall

sensor G40 ins located on the inlet

camshaft. The signal from the Hall

sensor enables the engine control unit

to detect the current position of the

camshafts.

Both camshafts are driven by only one

drive wheel.

The intake camshaft is driven by a spur

gearing from the exhaust camshaft.

This design improves the service life of

the timing belt.

Spur gearing

16

Hall sensor G40

Encoder wheel

m002_023

Bearing frame with

cam shafts

Page 17

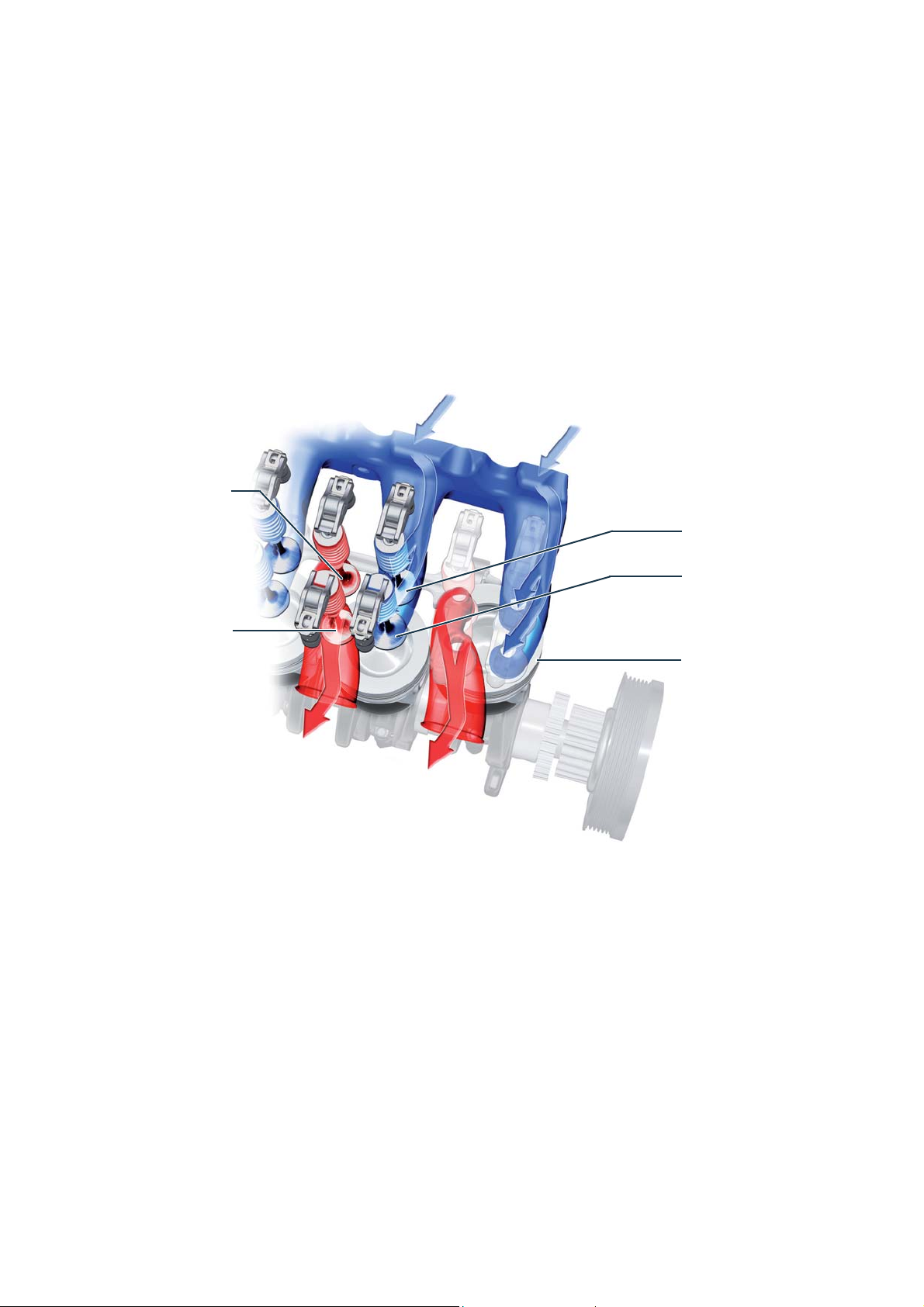

Valve arrangement

In order to meet future exhaust emission

standards, the valve arrangement is

rotated with respect to the longitudinal

axis of the engine. As a result, the inlet

and outlet channels for each cylinder

First exhaust valve

Cylinder 2

Second outlet valve

Cylinder 2

are arranged one after the other in fl ow

direction.

The camshafts thus operate one intake

and one exhaust valve per cylinder. The

Intake air

valve arrangement is designed in a way

that the inlet and outlet ducts achieve a

maximum fl ow rate with good swirl

effect.

First inlet valve

Cylinder 2

Second inlet valve

Cylinder 2

Cylinder 1

Exhaust gas

m002_028

17

Page 18

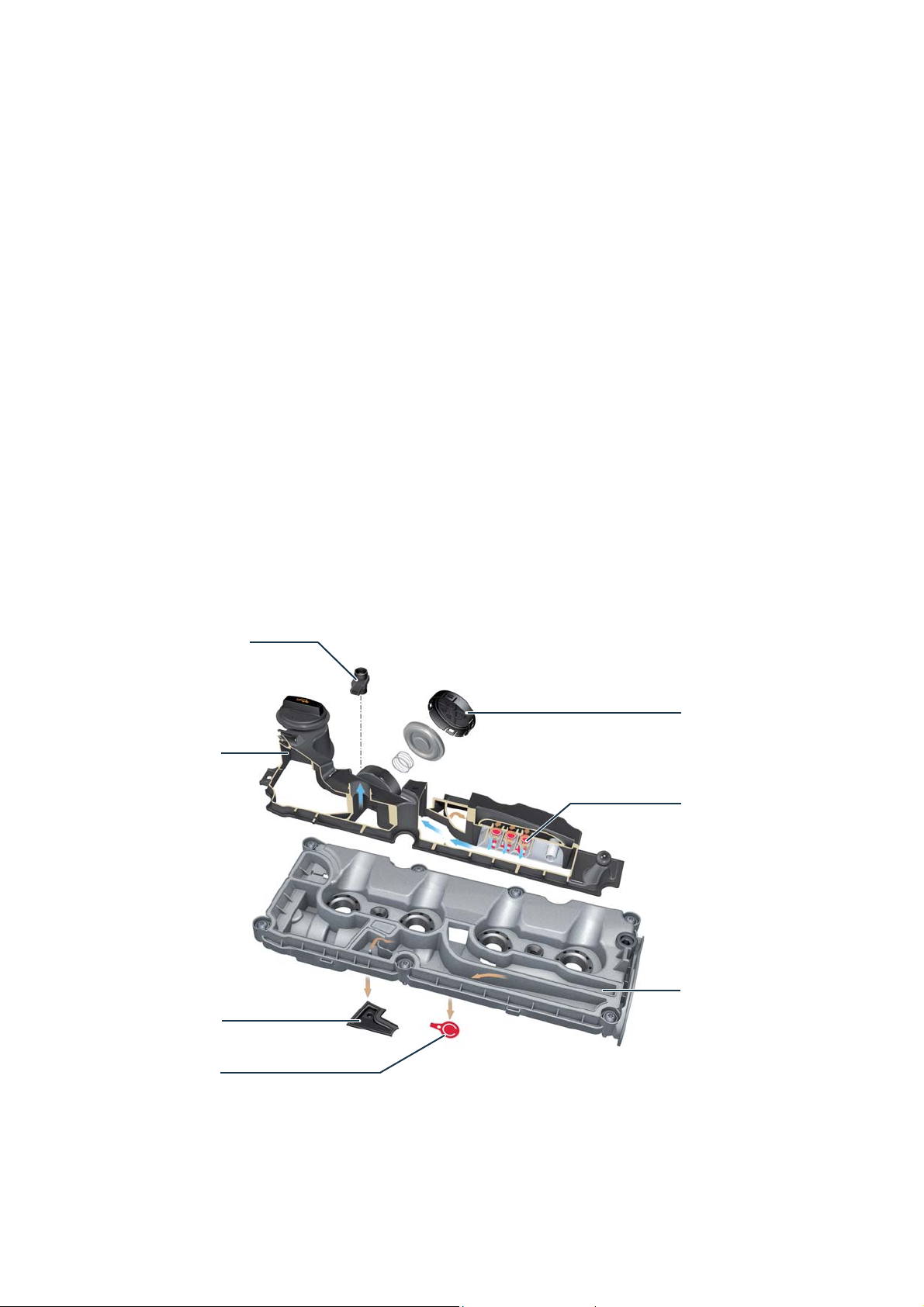

The crankcase ventilation

The components of the crankcase

ventilation system are integrated into the

cylinder head cover, in addition to the oil

fi ller neck and the pressure accumulator

for the engine's vacuum system. The air

currents occurring in combustion

engines between piston rings and

cylinder walls, the so-called blow-by

gases, are returned to the intake area

For countries with a cold climate, the crankcase ventilation is equipped with a heating resistor. The heating resistor prevents

freezing of the line connection from the cylinder head cover to the intake manifold in case of low outside temperatures.

Heating resistor for

crankcase ventilation

via the crankcase ventilation. This

avoids environmental pollution caused

by oil-containing gases. For effective oil

separation, crankcase ventilation is

performed in several stages. First of all,

the blow-by gases from the crankshaft

and camshaft space are transferred to a

calming volume of the cylinder head

cover.

There, the larger oil droplets settle on

the walls and drip into the cylinder head.

Subsequently, the oil-containing gases

are separated off by a cyclone separator.

The purifi ed gases are fed to the suction

pipe via the pressure control valve and

are then lead to the combustion.

Vacuum tank

Oil return from

fi ne oil separator

Gravity valve

for oil return fl ow

Pressure regulator

Fine oil separation

(cyclones)

Calming volume

m002_024

18

Page 19

The toothed belt drive

The components of the control drive are

driven by a toothed belt from the crankshaft. Starting from the crankshaft, the

toothed belt runs to the tension pulley,

via the camshaft drive wheel to the drive

wheel of the high-pressure pump of the

common-rail injection system and the

drive wheel of the coolant pump. The

return pulleys ensure a bigger wrap

angle of the toothed wheels by the

toothed belt. The toothed belt was

reinforced due to the increased loads.

Camshaft drive wheel

Return pulley

High pressure pump

drive wheel

Tension pulley

Coolant pump drive wheel

Return pulley

Toothed belt wheel of crankshaft

The toothed belt is stretched four times per

crankshaft revolution due to the actuation of a

double-piston high-pressure pump.

In order to keep the load on the timing belt low, a

bi-oval toothed belt wheel is installed on the

crankshaft. The bi-oval toothed belt wheel

changes the transmission ratio and thus counteracts the stretching of the toothed belt.

Crankshaft toothed belt wheel

m002_025

Large diameter

Small diameter

m002_026

19

Page 20

Oil and vacuum pump drive

The oil pump and the vacuum pump are

integrated in one housing. The pump

housing is screwed to the underside of

the cylinder block. The pumps have a

common drive shaft and are driven by a

toothed belt from the crankshaft. The

maintenance-free toothed belt runs

directly in the oil and is only tensioned

by the centre distance of the toothed

belt wheels.

Drive via crankshaft

Cylinder block Oil pump

20

m002_027

Vacuum pump

Page 21

Drive of auxiliary units

In order to meet the diverse customer

requirements, an auxiliary unit drive is

used which can be expanded on a

modular basis. In addition to the usual

units, such as generator and air-conditioning compressor, it is also possible to

drive an auxiliary air-conditioning compressor or an additional generator.

This allows to provide the required

energy for vehicles with superstructures,

such as camper vans or refrigerated

boxes, e. g. for air conditioning, cooling,

or for the drive of electrically operated

auxiliary units.

Basic drive AC drive

Generator

(different power

levels)

For a engine with generator, an elastic

belt is used exclusively as V-ribbed belt.

For all other variants, the V-ribbed belt is

tensioned with a belt tensioner.

Generator

(different power

levels)

Auxiliary drive

m002_085 m002_086

Generator

(different power

levels)

AC compressor

Additional generator

(in 180-Aversion)

AC compressor

Generator

(different power

levels)

AC compressor

Auxiliary air conditioning compressor

m002_087 m002_088

21

Page 22

QUESTIONNAIRE

Which answer is correct?

One or more answers of the given ones can be correct.

1. How many counterweights does the crankshaft of the EA288Nutz have?

a) 4

b) 6

c) 8

2. Where does the control unit get the camshaft position signal from?

a) Inductive encoder on the camshaft sprocket

b) Hall sensor at the outlet camshaft

c) Hall sensor at the inlet camshaft

3. Which components are integrated in the crankcase ventilation?

a) Inlet valve, drain valve, positioner

b) Cyclone separator, pressure regulator, gravity valve

c) Glow pin, oil spray nozzle, pressure limiter

4. How many valve pockets do the pistons of the EA288 engine have?

a) 4

b) There are none.

c) 2

5. Which statement about the camshaft housing is correct?

a) The camshaft housing is inseparably integrated into the cylinder head.

b) The camshafts can be replaced individually.

c) The camshafts are inseparably integrated into a closed bearing frame.

d) The camshafts can only be replaced completely with the bearing frame.

22

Solutions: 1) a, 2) c, 3) b, 4) b, 5) c

Page 23

OIL SYSTEM

The oil supply

The oil pressure generated by the

engine oil pump is used to adjust the

camshaft. The oil pump can adjust its

delivery volume in two pressure stages

to the operating conditions of the

engine. In addition, it is driven by the

Oil pressure switch

F1

crankshaft via a maintenance-free

toothed belt. It supplies crank drive,

valve train, high-pressure and lowpressure exhaust turbochargers with

suffi cient engine oil.

The piston accumulator ensures that

there is suffi cient oil volume in the low oil

pressure stage for fast adjustment of

the vane adjuster even during engine

operation.

Oil pressure switch

for reduced oil pressure F378

Oil pressure control

The oil pressure is controlled via two pressure stages.

The change from the low pressure stage with a small

fl ow rate at 2.0-2.3 bar to the high pressure stage with

a large fl ow rate at 3.3-3.8 bar takes place at a speed

of 3000 rpm.

Hint

In order to improve the running-in behaviour of the new engine, the oil pump has been switched to the high oil

pressure stage for the fi rst 1000 km. After the installation of new parts such as engine, engine section, cylinder

head, camshaft housing and exhaust turbocharger, the oil pressure control must be adjusted to the high oil pressure

level for 1,000 km.

The high oil pressure level must be set with the vehicle diagnostic tester.

m002_029

High pressure level

3,3-3,8 bar

Low pressure level

2,0-2,3 bar

Pressure requirement

m002_030

3000 l/min

23

Page 24

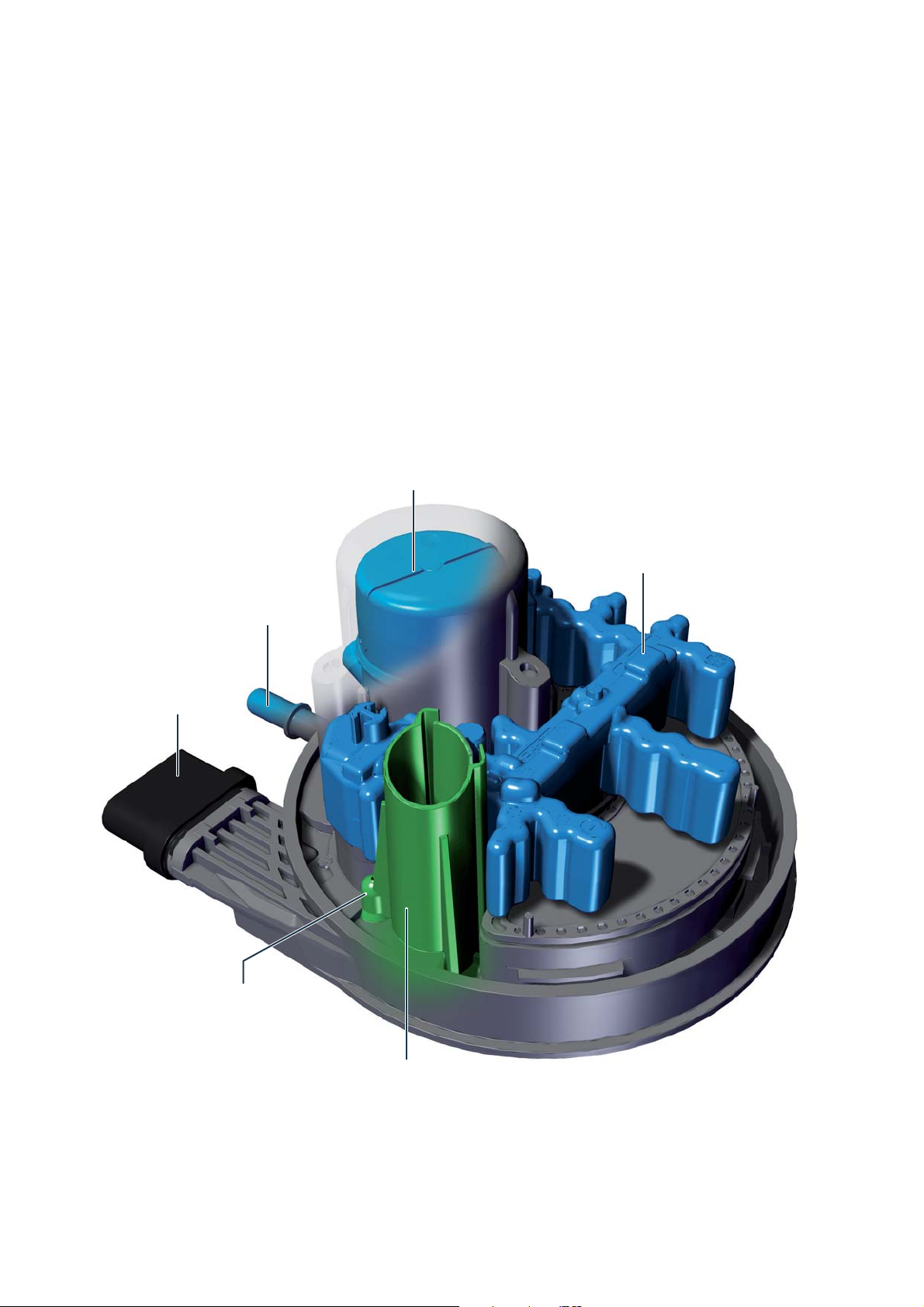

Construction of the oil and vacuum pump

Flutter valves

Housing cover

Housing

Drive wheel with

housing cover

Oil pump

The oil pump is a volume-fl ow-controlled vane pump in which the delivery

characteristics of the pump can be

changed by means of an eccentrically

Vane pump

mounted adjusting ring.

The position of the rotating adjustment

ring changes the delivery volume of the

Vacuum pump

Regulating piston

Check valve

m002_031

pump, thus adapting the pump's drive

power to the operating conditions of the

engine.

Vacuum pump

The vacuum pump draws in air from the

brake booster and the engine's vacuum

system via vacuum lines and transfers it

to the cylinder block via the fl utter

24

valves. The extracted air then passes as

blow-by gas through the crankcase

ventilation into the intake manifold and

is fed to the combustion chamber. The

oil used to lubricate the vacuum pump

is fed into the oil pan via the fl utter

valves from the working chamber of the

vacuum pump.

Page 25

25

Page 26

COOLING SYSTEM

The thermal management

The cooling system of the EA288 engine

is controlled by a thermal management

system. The thermal management

serves for the optimum distribution of

the available engine heat, taking into

account the heat and cooling requirements of the interior, engine and transmission.

1

2 3 4

4

5

The thermal management quickly heats

up the engine in the warm-up phase

after a cold start. The heat fl ows generated in the engine are directed to the

components of the cooling system in a

targeted and demand-oriented manner.

The rapid heating of the coolant and the

optimal use of the available heat in the

cooling system mainly reduces internal

engine friction, which contributes to the

reduction of fuel consumption and

exhaust emissions.

In addition, a comfortable air conditioning of the passenger compartment is

achieved.

16 17

76

4

15

18

3

20

Legend

1

2 2/3-way venting valve

3

4

5 2/3-way valve

6

26

Coolant compensation tank

(thermostatically controlled)

Throttle

Check valve

(thermostatically controlled)

Shut-off valve for coolant of heating

system N279

7

8

9

10

11

12 2/3-way valve

Coolant pump for high-temperature circuit

V467

Cooler for exhaust gas recirculation

Pre-cooler for exhaust gas recirculation

Coolant pump

Coolant thermostat

(thermostatically controlled)

Page 27

4

8 4

10

19

22

4

21

23

11 12

4

25

9

4

13

3

14

3

13

14

15

16

17

18

19

24

Pump for exhaust gas recirculation cooler

V400

Temperature sensor

Coolant circulation pump V50

Heat exchanger

Rear heat exchanger

Auxiliary water heating

Engine oil cooler

26

m002_032

20

21

22

23

24

25

26

Coolant regulator

Intercooler

Intercooling pump V188

Reduction agent injection valve N474

Radiator for low-temperature circuit

Check valve

Main radiator

27

Page 28

High-temperature circuit

When the engine is cold, the

coolant circulates from the coolant

pump (10) via the oil cooler (19), the

cylinder head, the cylinder block and

the heat exchanger (16). The 2/3-way

bleed valve (6) is open. It closes at a

coolant temperature of 49 °C. When the

engine has reached operating temperature, the coolant thermostat (11) opens

1

3 4

4

2

5

4

15

at 92 °C. The coolant pump for hightemperature circuit V467 (7) is controlled

depending on the heating requirement

and the coolant temperature. The

heating requirement is sensed via the

control unit of the air conditioning

system. The control is performed by the

engine control unit. The pump for the

exhaust gas recirculation cooler V400

6

7

(13) is controlled by the engine control

unit via a PWM signal with a fl ow rate of

70% after the ignition is switched on. It

runs permanently over all operating

areas. In case of higher EGR cooling

requirements, the control is increased to

100% fl ow rate.

4

4

9

8

10

12

11

3

13

14

16 172018

Legend

1

Coolant compensation tank

2 2/3-way venting valve

(thermostatically controlled)

3

4

5

Throttle

Check valve

2/3-way valve

(thermostatically controlled)

6 Shut-off valve for coolant of heating

system N279

19

25

4

26

m002_034

7 Coolant pump for high-temperature circuit

V467

8

9

10

11

Cooler for exhaust gas recirculation

Pre-cooler for exhaust gas recirculation

Coolant pump

Coolant thermostat

12 2/3-way valve

(thermostatically controlled)

28

Page 29

Low-temperature circuit

The liquid-cooled intercooling enables a

regulation of the air temperature in the

intake manifold to a set point that meets

the requirements. The intercooling

temperature is controlled by the engine

control unit via the activation of the

1

2

intercooling pump V188 (22). The

reference variable for the control is the

intake manifold temperature after the

intercooler. The intercooling coolant

circuit is connected to the engine

cooling circuit for the purpose of fi lling

and venting via a check valve (4) and a

throttle (3). There is no connection to

the engine cooling circuit during operation. The reduction agent injection valve

N474 (23) is integrated in the lowtemperature circuit.

13 Pump for exhaust gas recirculation cooler

V400

14

15

16

17

18

19

Temperature sensor

Coolant circulation pump V50

Heat exchanger

Rear heat exchanger

Auxiliary water heating

Engine oil cooler

Hint

Observe the repair guide when refi lling the coolant.

3 4

22

21

23

24

m002_033

20

21

22

23

24

25

26

Coolant regulator

Intercooler

Intercooling pump V188

Reduction agent injection valve N474

Radiator for low-temperature circuit

Check valve

Main radiator

29

Page 30

Coolant regulator

The coolant regulator is a 3/2-way valve, operated via a wax element. Depending on the coolant temperature, the coolant

regulator switches between the large and the small cooling circuit. This allows the engine to reach its operating temperature

more quickly.

Warm-up phase

During the engine's warm-up phase, the coolant fl ow

from the cylinder block to the main water cooler is

blocked by the large disc of the coolant regulator. The

coolant fl ows directly into the small cooling circuit via

the coolant pump. Due to with the stagnant coolant –

with the coolant pump switched off – the engine

reaches its operating temperature faster. When the

coolant pump is switched on, it is ensured that a

suffi cient amount of coolant fl ows through the cylinder

head and exhaust gas recirculation cooler during the

engine's warm-up phase.

Operating temperature

Coolant from

cylinder block

Connection to

coolant pump

Coolant regulator

Connection to

main radiator

m002_035

Coolant from

cylinder block

At a coolant temperature of about 92 °C, the large disc

of the coolant controller starts to open and thus integrates the main radiator into the large cooling circuit.

At the same time, the small disc of the coolant regulator blocks the direct path to the coolant pump.

Connection to

coolant pump

Coolant regulator

Connection to

main radiator

m002_036

30

Page 31

Coolant temperature sensor G62

The coolant temperature sensor is screwed into the cylinder head near the combustion chamber.

This arrangement enables the engine control unit to determine the engine temperature, independent of the coolant fl ow rates which depend on the operating point.

Signal use

The engine control unit requires the coolant temperature sensor signal as a correction value for

calculating the injection amount, the boost pressure and the exhaust gas recirculation amount.

Thesignal is also used to switch the switchable coolant pump on and off.

Effects of signal loss

If the signal fails, the engine control unit calculates a fi xed replacement value. The switchable

coolant pump remains permanently switched on.

Electronically controlled coolant pumps

Coolant pump for high-temperature circuit V467

The coolant pump for high-temperature circuit is an electronically controlled centrifugal pump with

brushless drive. It draws the coolant from the heat exchanger and delivers it to the combustion

engine. For this purpose, the pump is controlled with a PWM signal as required

by the engine control unit.

Coolant circulation pump V50

The pump for coolant circulation is an electronically controlled centrifugal pump with brushless

drive. It draws in the coolant from the heat exchanger via a check valve and delivers it to the

auxiliary water heating. For this purpose, the pump is controlled with a PWM signal as required by

the engine control unit.

Intercooling pump V188

The intercooling pump is an electronically controlled

centrifugal pump with brushless drive. It draws the

coolant from the intercooler cooling circuit and

conveys it to the intercooler. For this purpose, the

pump is controlled with a PWM signal as required by

the engine control unit.

m002_037

31

Page 32

32

Page 33

ENGINE MANAGEMENT

Injection system

The TGE uses a common rail injection

system made by the company Delphi. It

provides a maximum injection pressure

of 2000 bar.

The 2.0 litre TDI engine 130 kW with

bi-turbo unit is fi tted with a doublepiston high-pressure pump. The rail also

differs in volume and weight.

Injection system with

single-piston high-pressure pump

Since the return lines of the injectors are

connected to the fuel supply, there is a

pressure of 4-6 bar.

Injection system with

double-piston high-pressure pump

m002_038

In addition to the design of the high-pressure pump, the systems differ in the design of the high-pressure accumulator (fuel rail),

in the number of high-pressure pipes and in the size of the bore of the injection nozzles used.

Hint

When replacing the injectors, make sure that you use the injectors specifi ed for the performance variant in MANTIS

(MAN Parts Information System). The different injection nozzles differ only in the bore diameter and can be distinguished externally only by the part number.

33

Page 34

Injection system with single-piston

high-pressure pump

Single-piston high-pressure pump

The high-pressure pump is driven by the

toothed belt drive.

The pressure piston is actuated by a ram

mounted in a roller.

The fuel metering valve N290 is integrated

in the high-pressure pump. The compressed fuel is transferred at a pressure of

up to 2000 bar via a high-pressure pipe to

the high-pressure storage tank.

The maximum pump capacity is 0.42 cm

Drive shaft

3

/r.

Quantity metering valve

Pump head

Pressure piston

High-pressure connection

Fuel fl ow

Fuel return

m002_039

Pump casing

High-pressure accumulator

The high-pressure reservoir has a volume of

12.3 cm

high-pressure pump via a high-pressure line

and slightly shorter than the high-pressure

reservoir of the double-piston high-pressure

pump. The control valve for fuel pressure

N276 and the fuel pressure sensor G247

are screwed into the high-pressure reservoir.

3

. It is connected to the

Control valve for fuel pressure

N276

High-pressure connections

to the injectors

Return

High-pressure accumulator

High pressure connection to

the single-piston high-pressure

pump

Fuel pressure sensor

G247

m002_040

34

Page 35

Overview

7

6

10

4

5

9

2

3

1

9

9

9

8

m002_041

Legend

1

2

3

4

5

6

7

8

9

10

Fuel pump

Fuel tank

Fuel fi lter

Single-piston high-pressure pump

Fuel temperature sensor G81

Fuel pressure sensor G247

High-pressure accumulator (rail)

Control valve for fuel pressure N276

Injection valves N30, N31, N32, N33

Valve for fuel metering N290

Special features

High pressure pump with single piston and one high pressure output

One high-pressure fuel line between pump and high-pressure accumulator

High pressure accumulator with one high-pressure connection

8-hole injector nozzles with 700 ml

High fuel pressure up to 2000 bar

Fuel supply pressure 4.0-6.0 bar

Fuel return pressure from the

injection valves 4.0-6.0 bar

Fuel return pressure 0-0.3 bar

35

Page 36

Injection system with double-piston

high-pressure pump

Double-piston high-pressure pump

This high-pressure pump is also operated

by the toothed belt drive. In contrast to the

single-piston high-pressure pump, the

pressure pistons are actuated by a slider.

The fuel metering valve N290 is integrated

in the high-pressure pump. The compressed fuel is transferred at a pressure of

up to 2000 bar via a high-pressure pipe to

the high-pressure storage tank.

The maximum pump capacity is 0.7 cm

3

/r.

Drive shaft

Pump casing

Pump head

Pressure piston

Quantity metering valve

High-pressure connection

Fuel fl ow

Fuel return

High-pressure connection

m002_042

High-pressure accumulator

The high-pressure accumulator has a

volume of 18 cm

high-pressure pump

via two high-pressure lines and slightly

longer than the

high-pressure accumulator of the singlepiston high-pressure pump. Here too, the

control valve for fuel pressure N276 and the

fuel pressure sensor G247 are screwed into

the high-pressure reservoir.

3

. It is connected to the

Control valve for fuel pressure

N276

High-pressure connections

to the injectors

Return

High-pressure accumulator

High pressure connection to

the

single-piston high-pressure

pump

Fuel pressure sensor

G247

m002_043

36

Page 37

Overview

7

6

10

4

5

9

2

3

1

9

9

9

8

m002_044

Legend

1

2

3

4

5

6

7

8

9

10

Fuel pump

Fuel tank

Fuel fi lter

Double-piston high-pressure pump

Fuel temperature sensor G81

Fuel pressure sensor G247

High-pressure accumulator (rail)

Control valve for fuel pressure N276

Injection valves N30, N31, N32, N33

Valve for fuel metering N290

Special features

Double-piston high-pressure pump with two high-pressure outputs

Two high-pressure fuel lines between pump and high-pressure accumulator

High pressure accumulator with two high-pressure connections

8-hole injectors with 900 ml

High fuel pressure up to 2000 bar

Fuel supply pressure 4.0-6.0 bar

Fuel return pressure from the

injection valves 4.0-6.0 bar

Fuel return pressure 0-0.3 bar

37

Page 38

The injectors

In the two fuel systems, the only difference between the injectors is the bore diameter

of the injection channels. Structure and functionality are identical.

Structure and functionality

A data carrier is located on the head side of the injection valves. A 20-digit correction value for the injection

valves is embossed on this data carrier. The correction

value is determined on a test bench during the production for each injection valve.

It describes the injection behaviour of this unique

injector.

The injectors are fi xed by clamping claws in the

cylinder head. The have the task to inject the correct

amount of fuel into the combustion chambers at the

right time. For this, they are controlled by the engine

control unit.

If the solenoid valve is not actuated, the pressure ratios

at the nozzle needle and in the control chamber are

the same. The injection nozzle remains closed. If the

solenoid valve is actuated, the switching valve opens

the fuel return fl ow and the pressure in the control

chamber is reduced. Now the injection starts. In order

to stop the injection process, the solenoid coil is not

actuated. The switching valve closes the return fl ow,

the pressure in the control chamber rises and the

nozzle needle spring closes the nozzle needle.

Connection to the

high pressure accumulator (rail)

Connection to the

fuel return

Electrical connection

Switching valve spring

Solenoid

Switching valve

Nozzle needle

spring

Nozzle needle

m002_045

38

Page 39

Actuation phases

Characteristic diagram of the actuation phases

The engine control unit requires the input of

the correction value from the head side of the injection

valve in order to individually control the actuation

of this injection valve in the entire map range and to

correct it over the entire correction range. This enables

a precise control of the injection quantities. This helps

to reduce fuel consumption and exhaust emissions as

well as to smoothen the engine operation.

One of the main measurement variables are the signals

from the two knock sensors.

Valve closed and

nozzle needle closed

m002_047

Valve opened and

nozzle needle closed

[A]

Valve opened and

nozzle needle opened

m002_048 m002_049

Control current

m002_046

[μs]

m002_050 m002_051 m002_052

The solenoid valve is actuated.

The control current increases to about

23 A at a voltage of 12 V.

The injection valve remains closed in

this phase.

The switching valve lifts out of its seat.

The control current is regulated to the

holding current of about 9 A.

In this phase, the nozzle needle also

begins to lift.

The nozzle needle is open and the

injection takes place. The injection

quantity is determined by the duration of

the actuation.

39

Page 40

QUESTIONNAIRE

Which answer is correct?

One or more answers of the given ones can be correct.

1. What is the maximum injection pressure for EA288Nutz engine?

a) 1800 bar

b) 2500 bar

c) 2000 bar

2. At what temperature does the coolant regulator start to open?

a) 92 °C

b) 85 °C

c) 87 °C

3. How many pressure stages does the oil pressure control have?

a) 1

b) 2

c) 3

4. What is the fuel pre-pressure for the common rail system?

a) 3-4 bar

b) 4-6 bar

c) 1-2 bar

5. Which is the pressure in the return line of the injector?

a) 0-0.3 bar

b) 4-6 bar

c) 1-2 bar

40

Solutions: 1) c, 2) a, 3) b, 4) b, 5) b

Page 41

The pre-heating system

The 2.0-litre TDI engine with commonrail injection system has a diesel quickstart pre-heating system.

This system allows the diesel engine to

start immediately under all climatic

conditions.

Long pre-heating times are no longer

necessary and the starting process is

comparable to that of a gasoline engine.

Advantages of the pre-heating system

Engine start comparable to that of a gasoline engine at temperatures down to -24 °C

Extremely short heating-up time. The glow plug reaches temperatures of up to 1000 °C in 2 seconds.

Controllable temperatures for pre- and afterglow.

Self-diagnosis capability.

Component of the Euro on-board diagnostic pre-heating system

System overview

Engine speed sensor

G28

Coolant temperature sensor

G62

On-board control unit

J519

Engine control unit

J623

Control unit for automatic glowing time

J179

Diagnostic interface

for data bus J533

Control unit in panel

insert J285

Indicator lamp for

pre-heating time K29

Glow plug 1 Q10

Glow plug 2 Q11

Glow plug 3 Q12

Glow plug 4 Q13

m002_053

41

Page 42

Function

Preheating

The steel glow plugs are controlled in a

phase-shifted way by the engine control

unit via the control unit for automatic

glowing time J179, using a pulse width

modulated signal (PWM). The voltage at

Afterglow

For afterglow, the switch-on time of the

on-board power supply voltage in the

PWM duty cycle is set in such a way

that an effective voltage of 4.4 V results.

Afterglow is carried out up to a coolant

the individual glow plug is set via the

duty cycle of the PWM pulses.

A maximum voltage of 11.5 V is available for a quick start at an outdoor

temperature of less than 24 °C. This

temperature of 24 °C after starting the

engine and for a maximum of 5 minutes.

Afterglow helps to reduce hydrocarbon

emissions and combustion noise during

the warm-up phase. In vehicles with a

ensures that the glow plug heats up to

over 1000 °C within a very short time

(max. 2 seconds). This reduces the

preheating time for starting the engine.

start-stop system, the afterglow process

is not interrupted when the engine stop

function is active. This avoids frequent

temperature changes and thus protects

the material of the steel glow plug.

Phase-shifted control of the glow plugs

In order to relieve the on-board power

supply voltage during the glow phases,

the glow plugs are controlled in a

phase-shifted way. The falling signal

edge always controls the next glow

plug.

Glow plug

Cylinder 1

Cylinder 2

Cylinder 3

Cylinder 4

Time (s)

m002_054

42

Page 43

Cylinder pressure controlled combustion control

In order to achieve a precise fuel injection control, the engine management

takes into account the pressure curve in

the cylinder during combustion.

The engine control unit receives information about the actual pressure curve

in the cylinder from the combustion

chamber pressure transmitter for cylinder 3 G679.

This sensor is integrated in the housing

of the glow plug on cylinder 3.

The cylinder pressure controlled combustion control system is capable of

adjusting the injection timing and thus

the combustion pressure profi le to the

different exhaust gas recirculation rates,

fuel qualities and component tolerances

over the lifetime of the engine. A software model in the engine control unit

calculates the pressure curve for each

cylinder from the signal from the combustion chamber pressure sensor for

cylinder 3 G679 and the signal from the

engine speed sensor G28. Correction

values for the injection time and the

actuation time of the injection valve are

determined in accordance with the

deviations from the nominal/actual

comparison.

Advantages of cylinder pressure guided combustion control

Precise control of injection timing and injection quantities

Adjustment of injection quantity tolerances of the injectors over the running time

Stable and smooth engine running over all cylinders

Adjustment of the injection in case of ignition delay due to high exhaust gas recirculation rates and different fuel qualities

Control of challenging engine operating modes and mode changes, e. g. regeneration of the NOx storage catalyst or

regeneration of the diesel particulate fi lter, without infl uencing the driving characteristics.

Function

The measuring principle of the combustion chamber pressure transmitter for cylinder 3 G679 is based on a heating rod which

moves in axial direction and transfers the combustion pressure in the cylinder to a measuring diaphragm. This measuring

diaphragm is equipped with strain gauges that change their electrical resistance in case of deformation. An integrated electronic

evaluation system calculates an analog voltage signal from the resistance value – in relation to the measured cylinder pressure –

and transmits it to the engine control unit.

43

Page 44

Construction of glow plug 3 Q12 with combustion chamber pressure

transmitter for cylinder 3 G679

Electrical plug-in connection

Sensor plus

Sensor ground

Sensor signal

Electronic evaluation system

Glow plug plus

Diaphragm

Strain gauges

Axially movable heating element

Bellows

(sealing to combustion chamber)

Filament

Combustion pressure

m002_055

Signal use

The signal from the combustion chamber pressure sensor for cylinder 3 G679 is used by the engine control unit for calculating

the correction value for the fuel injection control.

Effects of signal loss

If the signal fails, there is no cylinder pressure controlled combustion control. This can lead to uneven engine running.

44

Page 45

The exhaust turbochargers

Mono turbocharger

The turbocharger is integrated in an

exhaust manifold module.

The turbocharger has adjustable guide

vanes that can infl uence the exhaust

gas fl ow to the turbine wheel. This has

the advantage that an optimum boost

pressure can be achieved over the

entire speed range of the engine. The

guide vanes are adjusted via a linkage

by negative pressure. The vacuum is

controlled by an electro-pneumatic

Vacuum actuator for guide vane adjustment

Vacuum connection

Turbocharger compressor

valve, the valve for boost pressure

limitation. The position sensor for the

boost pressure regulator G581 is integrated in the vacuum actuator of the

turbocharger. This position sensor is a

displacement sensor that enables the

engine control unit to determine the

position of the blades of the turbocharger. The EA288-TDI engine with

EU6 emissions standard has a lowpressure exhaust gas recirculation

system. Here, the exhaust gas is only

taken after the diesel particulate fi lter

and led to the compressor wheel of the

turbocharger. The entire exhaust gas

mass fl ow is thus maintained in front of

the turbocharger's turbine wheel. This

leads to a better response of the turbocharger; thus, higher boost pressures

and thus larger cylinder fi llings are

possible especially in partial load operation.

Operating lever for

guide vane adjustment

Exhaust gas turbine with

guide vane adjustment

Intake air from the air fi lter

Pulsation damper Connection of low pressure exhaust gas recirculation

The pulsation silencer arranged in the direction of fl ow to the intercooler reduces interfering noise in the charge air path.

Exhaust manifold

m002_056

Air control system

The higher demands on exhaust aftertreatment to be expected in future

require an extended control and regulation structure for the engine's air

system. The engine management

system of the EA288 diesel engine is

supported by the engine's air control

system. The air control system is based

on a model that calculates the conditions of the air system in all engine

operating states. All pressure values,

temperature values and mass fl ows are

determined in the intake air, charge air

and exhaust gas section of the engine.

These parameters are used for regulat-

ing the boost pressure, the cylinder

fi lling and the exhaust gas recirculation

rate. The advantage of this model is that

the engine's complex air control system

manages with a limited number of

sensors, despite a large number of

actuators.

45

Page 46

Bi-turbocharger

In the 2.0-litre TDI engines with 130 kW,

two turbochargers connected in series

generate the boost pressure, which

together form a bi-turbocharger unit.

Pressure box for

steering vane adjustment

High-pressure exhaust turbocharger

with adjustable guide vanes

Exhaust manifold

The intake air is pre-compressed at low

engine speeds by the low-pressure

exhaust turbocharger and is fi nally

compressed by the high-pressure

exhaust turbocharger

(two-stage operation). At high engine

speeds, only the low-pressure exhaust

turbocharger compresses the intake air

(single-stage operation).

Compressor bypass valve

Low pressure exhaust

turbocharger

Pressure box for wastegate valve

Pressure box for exhaust gas fl ap

m002_058

Special features of the exhaust turbocharger system with

bi-turbocharger unit

High pressure exhaust turbocharger with adjustable vanes with small turbine wheel and small compressor wheel.

This arrangement results in fast response at low engine speeds.

Low-pressure exhaust turbocharger with large turbine wheel and large compressor wheel. This arrangement results in high

boost pressure at high engine speeds. Consequently, high engine power is achieved at high engine speeds.

Compact construction: High- and low-pressure exhaust turbochargers are installed directly at the exhaust manifold.

46

Page 47

Air control system

In the 2.0-litre TDI bi-turbo engine, two

turbochargers connected in series

generate the boost pressure. The intake

air is pre-compressed at low engine

9

8

1

2

6

10

12

13

7

speeds by the low-pressure exhaust

turbocharger and is fi nally compressed

by the high-pressure exhaust turbocharger (two-stage operation). At high

11

14

15

5

18

engine speeds, only the low-pressure

exhaust turbocharger compresses the

intake air (single-stage operation).

16

17

19

Legend

1

2

3

4

5

6

7

8

9

10

11

12

13

20

4

3

Air fi lter

Airfl ow meter G70

Low pressure turbocharger compressor wheel

Booster pressure sensor 2 G447

Compressor wheel of the high pressure

exhaust turbocharger

Compressor bypass valve

Throttle valve control unit GX3

Booster pressure sensor G31

Intake air temperature sensor G42

Intercooler

Charge air temperature sensor after

intercooler G811

Actuator for exhaust gas recirculation GX5

Cooler for exhaust gas recirculation

23

21

22

24

m002_059

14

15

Exhaust gas temperature sensor 1 G235

Turbine bypass fl ap

16 Pressure box for exhaust gas fl ap with

position sensor 2 for boost pressure regulator

G580

17

18

Valve for turbine switching N529

Turbine wheel of the high-pressure exhaust turbocharger

19

Solenoid valve for boost pressure limitation N75

20 Pressure box for guide vane adjustment with

position sensor for boost pressure regulator G581

21

22

23

Wastegate valve

Pressure box for wastegate valve

Solenoid valve 2 for boost pressure limitation N274

24 Turbine wheel of the low-pressure exhaust turbo-

charger

47

Page 48

Exhaust gas recirculation module

The low-pressure exhaust gas recirculation module consists of the exhaust gas recirculation cooler and the actuator 2 for

exhaust gas recirculation V339. It is located between the diesel particulate fi lter and the compressor side of the turbocharger.

Due to the engine-close arrangement and the compact design, the fl ow losses in the exhaust gas return section are reduced to

a minimum.

Actuator 2 for exhaust gas recirculation V339

Exhaust gas pipe with cooling function for

cooler with longitudinally installed engine

48

Exhaust gas pipe without cooling function for

cooler with transversely installed engine

m002_065

Cooler for exhaust gas recirculation

Page 49

Cooler for exhaust gas recirculation

All recirculated exhaust gases are passed through the exhaust gas recirculation cooler. Due to the fact that the exhaust gases

are colder, a larger amount of exhaust gases can be supplied to the intake air. In addition, the components in the charge air

section are protected from excessively high exhaust gas temperatures.

Filter element

The low-pressure exhaust gas recirculation module consists of the exhaust gas recirculation cooler and the actuator 2 for

exhaust gas recirculation V339. It is located between the diesel particulate fi lter and the compressor side of the turbocharger.

Due to the engine-close arrangement and the compact design, the fl ow losses in the exhaust gas return section are reduced to

a minimum.

Actuator 2 for exhaust gas recirculation V339

The actuator 2 for the exhaust gas

recirculation V339 is controlled by the

engine control unit with a PWM signal

and actuates the throttle valve of the

exhaust gas recirculation system. The

position of the throttle valve, in conjunction with the position of the exhaust fl ap

in the exhaust fl ap control unit, adjusts

the pressure gradient from the exhaust

tract to the intake passage. The amount

of recirculated exhaust gases is regulated by the pressure gradient.

The higher the pressure gradient, the

greater the volume of recirculated

exhaust gases. Since a high pressure

drop occurs at high engine load, the

exhaust gas recirculation rate in this

operating state is controlled by the

actuator for exhaust gas recirculation.

The exhaust gas fl ap remains open for

this.

Effects of failure

If the actuator 2 for exhaust gas recirculation V339 fails, the throttle valve of the exhaust gas recirculation system is closed by a

spring. There is no exhaust gas recirculation.

Potentiometer 2 for exhaust gas recirculation G466

The potentiometer 2 for exhaust gas

recirculation G466 is integrated in the

actuator 2 for exhaust gas recirculation

V339. The signal determines the position of the actuator 2 for exhaust gas

recirculation V339. With this information

the engine control unit calculates and

controls the recirculated exhaust gas

volume.

Effects of failure

If the signal of potentiometer 2 for exhaust gas recirculation G466 fails, the exhaust gas recirculation is deactivated. The actuator

2 for exhaust gas recirculation V339 is no longer activated by the engine control unit and the throttle valve of the exhaust gas

recirculation system is closed by a spring.

49

Page 50

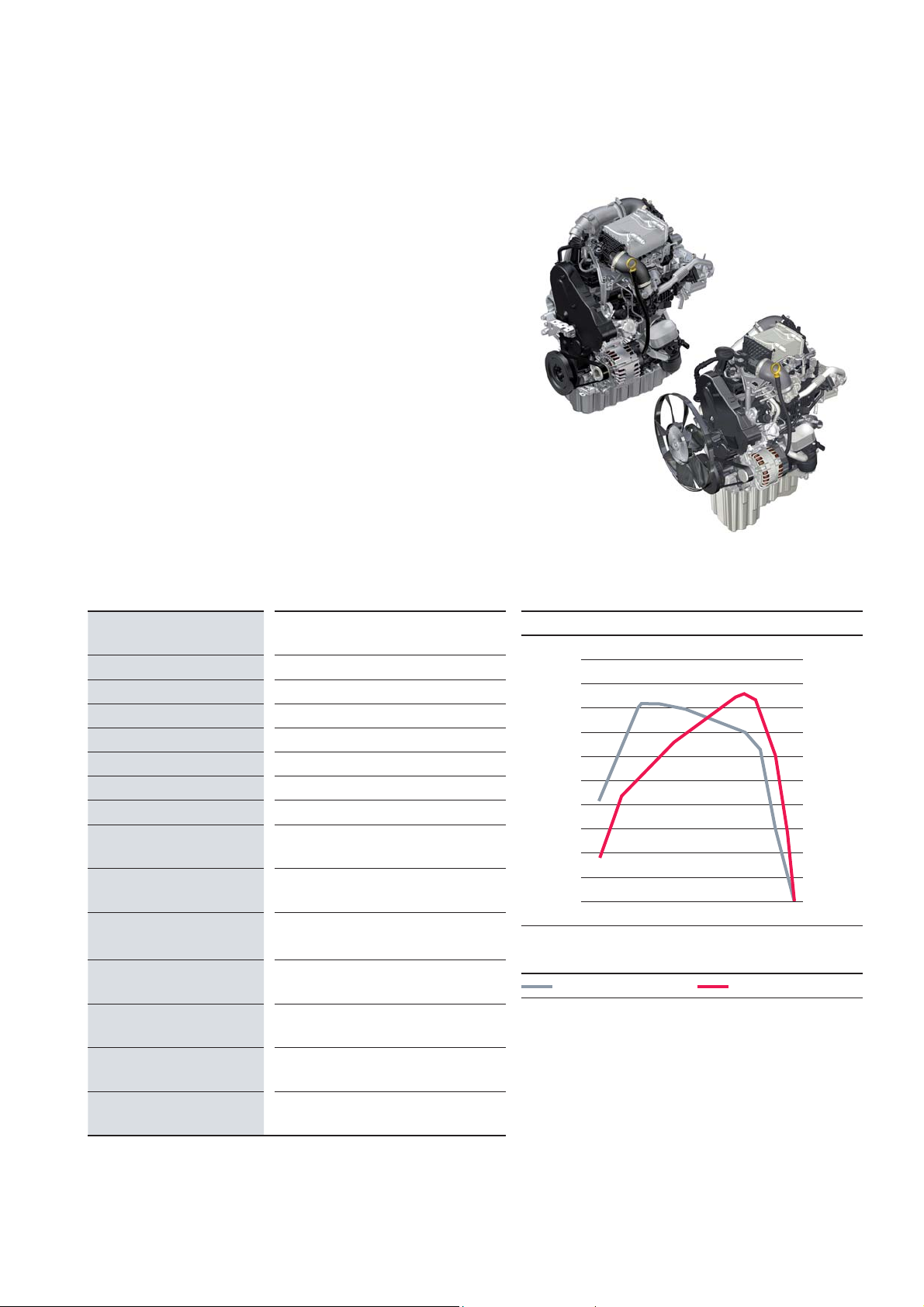

EXHAUST SYSTEM

The design of the exhaust gas aftertreatment system is identical for all

power levels of the

2.0l TDI engine in the MAN TGE. The

oxidation catalyst follows the respective

turbocharger system. With a corrugated

pipe as transition, the diesel particulate

fi lter with SCR blocking catalyst follows

as a module. The injection valve for

reduction agent N474 is installed into

this module. In addition to the exhaust

gas temperature sensors (G235, G448,

G495, G648) and the NO

(G687), a new sensor for detecting the

soot particle emission is installed downstream the SCR blocking catalyst

(particle sensor G784). The injection

valve for reduction agent is supplied

with reduction agent (AdBlue

reduction agent tank via the reduction

sensor

x

®

) from the

agent supply unit (GX19). The reduction

agent tank has a capacity of about 18

litres. The range is about 5200 km. In

addition to a level sensor, the feed

pump and the heating system, a quality

sensor is installed in the feed module to

monitor the quality of the reduction

agent (quality sensor for reduction agent

G849).

Exhaust gas aftertreatment

For vehicles with SCR system (exhaust gas standard EU6), the front exhaust pipe contains a lambda sensor, three temperature

sensors, the reduction agent injection valve and the corresponding catalysts.

Lambda sensor

Temperature sensor 2

Reduction agent

injection valve N474

Oxidation catalyst

Temperature sensor 3

Diesel particulate fi lter

with SCR coating

Blocking catalyst

Particle mass sensor

NO

sensor

x

m002_066

50

Page 51

Reduction agent injection valve N474

Location and task

The reduction agent injection valve N474 is installed

upstream of the module consisting of a diesel particulate fi lter and SCR blocking catalyst. It is integrated

into the low-temperature coolant circuit of the thermal

management system and has the task of introducing

the reduction agent into the exhaust gas stream in

metered quantities downstream of the oxidation

catalyst.

Location and task

Reduction agent

injection valve N474

m002_067

The reduction agent injection valve N474 is installed

upstream of the module consisting of a diesel particulate fi lter and SCR blocking catalyst. It is integrated

into the low-temperature coolant circuit of the thermal

management system and has the task of introducing

the reduction agent into the exhaust gas stream in

metered quantities downstream of the oxidation

catalyst.

Electrical

connection

Solenoid valve

Connection of reduction agent line

Cooling connections

m002_068

Effects of failure

In the event of a defective injection valve, only insuffi cient, too much or no reduction agent can be injected into the exhaust

system. The exhaust gas values can no longer be maintained. Depending on the type of fault, the exhaust gas warning light K83

(MIL) and the AdBlue

®

warning indicator which indicates a fault in the SCR system are switched on in the panel insert display.

51

Page 52

Reduction agent tank

In addition to the fuel tank with a capacity of about 75 litres, there is a tank with

a capacity of about 18 litres of reduction

agent (AdBlue

The consumption of reduction agent

depends on the individual driving style,

the operating temperature of the system

and the ambient temperature.

The reduction agent tank is fi lled via the

fi ller neck for reduction agent underneath the fuel fi ller neck and is closed

by a blue tank cap. The reduction agent

tank is located on the underbody in

front of the fuel tank. In order to be able

to absorb the reduction agent fl owing in

at a high fl ow rate, a compensation

volume has been integrated in the upper

part of the venting system.

®

).

m002_069

Fuel fi ller neck Reduction agent fi ller neck

Assembly

Control unit for

reduction agent heating

J891

Venting membrane

Venting pipe Filler neck

Compensating volume

Filling pipe

Reduction agent tank

52

Conveying unit for

reduction agent dosing system GX19

m002_070

Page 53

The conveying unit for the reduction agent

dosing system

Location and task

The following components are integrated in the conveying unit for reduction agent dosing system GX19:

Pump for reduction agent V437

Tank sensor for reduction agent G684

Heating for reduction agent tank Z102

Temperature sensor for reduction agent G685

Reduction agent quality sensor G849

Pump for reduction agent V437

Heating for

reduction agent tank Z102

Connection for

reduction agent line

Electrical connection

Temperature sensor for

reduction agent G685

Tank sensor for reduction agent G684

m002_071

53

Page 54

AdBlue® warning indicators for

reduction agent tank

Level warning stage 1

The fi rst prompt to refi ll reduction agent is displayed

when a range of 2400 km can be reached with the

remaining AdBlue

The engine control unit calculates the remaining range

based on the current amount of reduction agent in the

tank and the consumption of reduction agent.

Level warning stage 2

The warning increases when there is less of 1000 km

of remaining range. For this purpose, the warning is

displayed in yellow, supplemented by a warning triangle. The vehicle can only be driven for the displayed

remaining range. If no reduction agent is refi lled in

suffi cient quantity, the engine can no longer be started

after the remaining range has elapsed and the engine

has been switched off.

®

.

m002_072

Level warning stage 3

If there is no more AdBlue® in the reduction agent tank,

the warning symbol is displayed in red. Reduction

agent must be refi lled in order to be able to start the

engine again.

m002_073

m002_074

54

Page 55

QUESTIONNAIRE

Which answer is correct?

One or more answers of the given ones can be correct.

1. What temperature do the glow plugs reach within 2 seconds?

a) 1000 °C

b) 650 °C

c) 800 °C

®

2. What happens if the level of the reduction agent (AdBlue

a) Creep mode

b) Power reduction

c) No engine start possible

3. Which cylinder is used to measure the combustion chamber pressure?

a) 1st cylinder

b) 3rd cylinder

c) 4th cylinder

) is displayed as empty?

4. How is the mono turbocharger regulated?

a) by means of guide vane adjustment

b) by means of the wastegate valve

c) there is no regulation

5. What is the combustion chamber pressure sensor required for?

a) better cold start behaviour

b) combustion control

c) check of mechanical faults

6. How are the glow plugs activated?

a) approximately 12 V are applied at cold start

b) approximately 6 V are applied at cold start in order to relieve the battery

c) they are controlled with a PWM signal

Solutions: 1) a, 2) c, 3) b, 4) a, 5) b, 6) c

55

Page 56

System overview

Sensors

Engine speed sensor G28

Hall sensor G40

Airfl ow meter G70

Coolant temperature sensor G62

and coolant temperature sensor 3 G812

Coolant temperature sensor

at radiator output G83

Booster pressure sensor G31

and boost pressure transmitter 2 G447

Charge air temperature sensor upstream and

downstream the intercooler G810 and G811

Fuel temperature sensor G81

Fuel pressure sensor G247

Exhaust gas recirculation valve 1 GX5

Lambda sensor 1 upstream catalyst GX10

Exhaust gas temperature sensor 1-4

G235, G448, G495, G648

Differential pressure sensor G505

Heating for reduction agent line

(heating circuit 2) Z104

Heating for reduction

agent tank (heating circuit 1)

Z102

Control unit for

reduction agent

heating

J891

Control unit for NOx sensor 2

J881 with NOx encoder 2 G687

Temperature sensors 2 and 3 for

exhaust gas recirculation G690 and G949

Suction pipe encoder GX9

Encoder for variable-length intake manifold

position G513

Throttle valve control unit GX3

Knock sensor 1 and 2 G61 and G66

Position sensor for boost pressure regulator G581

and

position sensor 2 for boost pressure regulator G580

Sensor for reduction agent quality G849

Conveying unit for reduction agent

dosing system GX19

Tank sensor for reduction agent G684

Temperature sensor for reduction agent G685

Encoder for gearbox neutral position G701

Oil pressure switch for reduced oil pressure F378

Oil level and oil temperature sensor G266

Oil pressure switch F1

Control unit for sensor electronics

J849 with particle sensor G784

CAN

data bus

drive

Combustion chamber

pressure transmitter

for cylinder 3 G679

Accelerator pedal

module GX2

Brake light switch F

Clutch position encoder

G476

56

Page 57

Indicator lamp for

preheating time

K29

Actuators

Control unit for fuel pump J538

Fuel supply unit GX1

Fuel pump for pre-supply G6

Exhaust gas

warning light

K83

Indicator lamp for

diesel particulate

fi lter

K231

Control unit in the

panel insert

J285

CAN data bus

comfort

Diagnostic interface

for data bus J533

Injection valves for cylinders 1-4

N30, N31, N32, N33

Valve for fuel metering N290

Control valve for fuel pressure N276

Solenoid valve for boost pressure limitation N75

Solenoid valve 2 for boost pressure limitation N274

Reduction agent injection valve N474

Throttle valve control unit GX3

Diagnostic connector

Engine control unit J623

m002_075

Exhaust gas recirculation valve 1 GX5

Switching valve for exhaust gas recirculation

cooler N345

Intercooling pump V188

Pump for exhaust gas recirculation cooler V400

Coolant pump for high-temperature circuit

V467

Valve for oil pressure control N428

Lambda sensor 1 upstream catalyst GX10

Heating resistor for crankcase ventilation

N79

Control unit for automatic glowing time J179

Glow plugs 1-4 Q10, Q11, Q12, Q13

57

Page 58

SERVICE

Special tools

Denomination Part number Assembly

Hose clamp pliers VAG1275 08.04099-0009 Drive train

Offset screwdriver T10264 08.06125-9059 Engine

Puller T10055 80.99601-6065 Engine

Puller T10537 80.99601-6066 Engine

Puller T10443 80.99601-6067 Engine

Puller T10489 80.99601-6068 Engine

Frontend hook 3370 80.99602-0359 Chassis

Adapter plate T10103/1 80.99602-0360 Drive train

Cylinder screw T10103/2 80.99602-6049 Drive train

Spanner for union nut 3217 80.99603-0440 Fuel system

Multi-tooth adapter SW 17 3400 80.99603-0441 Engine

Wrench T10202 80.99603-0442 Fuel system

Plug insert SW 17 T10491 80.99603-0443 Exhaust system

Socket wrench SW 17 T40055 80.99603-0444 Fuel system

Plug insert XZN 10 T10385 80.99603-0446 Exhaust system

Lever T10468 80.99603-0447 Fuel system

Dismantling tool T40280 80.99603-0448 Chassis

Counterholder T10172A 80.99603-6040 Engine

Tool set T10395A 80.99603-6041 Exhaust system

Mounting sleeve T10377 80.99604-0534 Fuel system

Piston resetting device T10145 80.99604-6075 Brake system

Assembly tool T10146 80.99604-6076 Brake system

Mounting fi xture T10053 80.99604-6077 Engine

Mounting fi xture T10493 80.99604-6078 Engine

Pressure sensor VAG 1397B 80.99605-0308 Engine

Protective caps T10250 80.99605-6047 Chassis

58

Page 59

Special tools

Denomination Part number Assembly

Universal measuring device VW385 80.99605-6048 Drive train

Towing arm 3390 80.99606-0847 Engine

Chocks T10383 80.99606-0848 Chassis

Engine bracket 80.99606-5024 Engine / gearbox

Counterholder 3067 80.99606-5025 Engine

Catching device 10-222A 80.99606-6242 Engine / gearbox

Adapter 10-222A/23 80.99606-6243 Engine / gearbox

Dismantling and assembly device T10133C 80.99606-6245 Engine

Mounting fi xture T10134 80.99606-6246 Engine

Adapter VAG1274/8 80.99607-0257 Cooling system

Adapter VAG1274/9 80.99607-0258 Cooling system

Cable harness repair kit VAS 1978B 80.99607-6106 Electrical system

Test apparatus for charge air

systems

Adapter VAG 1687/10 80.99607-6110 Engine

Compression tester VAG 1763 80.99607-6111 Engine

Guide rods T10228 80.99608-6002 Chassis

Counterholder 3415/1 80.99615-0530 Engine

Adapter kit 3415/2 80.99615-0531 Engine

Positioning tool T10265 80.99617-0240 Chassis

Positioning pin T10492 80.99617-0241 Engine

Mandrel VW222A 80.99617-0242 Engine

Adapter VAS 6291A/4 80.99620-0034 Drive train

Filling device all-wheel clutch VAS 6291A 80.99620-6026 Drive train

Crankshaft stop T10490 80.99622-6039 Engine

Counterholder T50053 80.99622-6040 Chassis

Diagnostic cable VAS 5051/5A 80.99641-0115 Electrical system

VAG 1687 80.99607-6109 Engine

59

Page 60

MAN Truck & Bus

MAN Academy

Dachauer Straße 667

80976 München

www.mantruckandbus.com

MAN Truck & Bus – A company of the MAN group

Loading...

Loading...