Page 1

MAN GUIDE 101

TGE basics

Page 2

With its new TGE, MAN is joining the world of transporters for the first time. What started in the past at

7.5 tons, now begins at maximum permissible weight

of 3.0 tons. Using the new TGE, MAN transfers the

usually customer-focussed truck business to the

category of delivery trucks. The TGE from MAN is a

light commercial vehicle which - flanked by its big

brothers - inspires users with enthusiasm who have

performed professional work with heavy trucks for a

long time. Excellent TGE sales consultants will always

provide a customized solution.

MAN as a full-range offerer

up to 18.4 cubic metres of loading space

engines from 75 kW to 130 kW

standard safety by emergency brake assistants

service and use around the clock

For example, MAN identifies the target groups in the

logistic and construction area. Also, sectoral requirements from handicraft and passenger transportation

businesses can be future applications of the light

“truck” from the MAN Truck & Bus company. All applications have the following in common: Thanks to the

lowest c

its class as well as the lowest maintenance and repair

costs, the best Total Cost of Ownership (TCO) of the

new MAN TGE is inspiring.

-value of 0.33 and the lowest consumption of

W

In addition to the panel van and the glazed estate car,

the chassis with their single-compartment and twincompartment cabs increase the offer of body types.

Two wheelbases, three roof heights and three vehicle

lengths are options. Always available: the loading

space illuminated by LED lamps.

Also, there are lots of drive types. Depending on the

maximum permissible gross weight, front-wheel or

rear-wheel and all-wheel drives are possible, optionally

coupled with a 6-speed manual gearbox or an

8-speed automatic transmission. 2.0L engines with

75kW / 102 HP, 90 kW / 122 HP, 103 kW / 140 HP,

and 130 kW / 177 HP are available.

With its standard emergency brake assist (EBA), MAN

considerably contributes to road-traffic safety. To this

effect, distance sensors review critical distances to the

vehicle in the front, helping reduce the stopping distance. In addition, the integrated city emergency brake

function automatically decelerates the vehicle at low

speeds and thus reduces one of the most frequent

causes of accidents. The adaptive cruise control

system provides great convenience on long highway

distances. The fatigue detection system and the

multi-collision brake have been designed for the safety

of everybody.

m001_002

2

Page 3

CONTENTS

4 INTRODUCTION

14 VEHICLE BODY

16 POWER UNITS

14

22 POWER TRANSMISSION

30 RUNNING GEAR

16

38 ELECTRICAL SYSTEM

22

52 HEATING AND AIR

CONDITIONING

59 RADIO, TELEPHONE AND

NAVIGATION

38

52

The MAN TGE Guide teaches the basics of design and function for sales and after-sales of new vehicle models, new

vehicle components or new technologies.

The MAN TGE Guide is not a sales manual and not a repair guide! The specified values are for the sake of ease of

understanding only and refer to the data status valid at the time the MAN TGE Guide was created.

The contents are not updated.

For customer advice, maintenance and repair work, please use the appropriate technical literature.

59

Note

Reference

3

Page 4

INTRODUCTION

Die Trucknology Generation

With the newly developed MAN TGE, MAN Truck & Bus is now for the first time making its commercial vehicle expertise in the

range from 3.0 to 41 tons (50 tons) available to all customers, as a full-range supplier.

The TGX, TGS, TGM and TGL series offer the customer the optimum vehicle base for individual transport solutions with total

weights from 7.49 to 41 tons (50 tons) and engine outputs from 150 hp to 640 hp. The MAN TGE now rounds this off between

3.0 and 5.5 tons total weight and an engine output of 105 hp to 175 hp and three drive variants.

MAN TGX To be successful in international long-

distance traffic, to shift up a gear in terms of transport

performance and to put the brakes on costs. This is what

the MAN TGX stands for, setting the standard for maximum

energy efficiency, reliability and economy with its exhaust

gas-optimized engines of up to 640 hp.

MAN TGS The MAN TGS is uniquely versatile:

Whether for heavy-duty local transport, on construction sites,

in municipal transport or as a specialist for special tasks, the

xxx is a versatile truck that is perfectly tailored to every sector

of industry.

MAN TGM In distribution traffic and also in

medium-heavy traction traffic, the MAN TGM is heavily

involved. With tonnages of between 13 and 26 tons and a

first-class payload, it offers economical transport solutions

for construction sites.

MAN TGL The MAN TGL is the solution for fresh

produce, construction, municipal use, furniture transport,

trade and industry. The 7.49 to 12 ton trucks are very

manoeuvrable and combine maximum payload with

dynamic driving characteristics.

The MAN TGE with its powerful commercial vehicle roots is ideally

equipped to meet the diverse challenges of the transporter market from 3.0 to 5.5 tons.

The MAN TGE always offers the right solution for tough everyday working conditions, be

it in the forest, on the construction site or in the confusing urban jungle. With its outstanding driving comfort, numerous assistance systems and a driver‘s cab at passenger car

level, it is the new benchmark in the transporter segment.

MAN TGE

4

Page 5

The production site

Since the laying of the foundation stone

in November 2014, Europe‘s most

modern plant of this kind has been built

in Wrzesnia, a city with around 30,000

inhabitants about 50 kilometres east of

Poznan, in just 23 months.

The production of the MAN TGE began

here on April 3, 2017, of which 100,000

units per year are to be produced by up

to 3,000 employees, together with the

identical VW Crafter.

In addition to the production halls for

vehicle assembly, a modern paint shop

and a supplier park with logistics areas

were built on the site. The development

of the supplier network and the service

sector has also created numerous new

jobs in the vicinity of the plant.

m001_216

m001_217

m001_215

5

Page 6

The product features of the MAN TGE

The following overview shows the 25 most important unique selling propositions and „Best in Class“ characteristics.

The safest transporter in its class thanks to versatile equipment and assistance

systems:

Emergency brake assistant as standard

Automatic Post-Collision Braking System

Automatic Distance Control (ACC)

Trailer manoeuvring assist

Lane departure warning

Lane change assistant with parking assistant

Cornering light

Headlights in LED technology

Side wind assistant

ESC with combination stabilization

Most comfortable driver‘s workplace:

Well designed storage compartment concept

Ergonomic seats with optional massage function

230 V socket in the cab

Innovative media systems

Clear displays and instruments

m001_004

Economy to the limit:

State-of-the-art engine-gearbox configurations

Streamlined body shape

Lightweight construction in every detail

Integration into fleet management systems

Versatile solution for every application:

Front, rear and all-wheel drive

Manual and automatic transmissions

Three possible vehicle lengths

Three possible roof heights

Four different body shapes

Universal floor with preparations for built-in

components

Optional longitudinal and transverse rails in the loading floor

Rear end free from technical equipment for various conversion

solutions

m001_005

6

Page 7

The notable characteristics of the MAN TGE

Vehicle front in striking MAN family

design

Modern workstation with ergonomic control panel and clearly

arranged instruments

LED headlights

Adjustable driver and front

passenger seats – also as

swing seat and AGR seat

(with seal of approval from the

campaign for healthy backs)

with electrical lumbar support

Loadspace with universal floor and a

wide variety of installation options

Tail light clusters with connecting character line

m001_082

7

Page 8

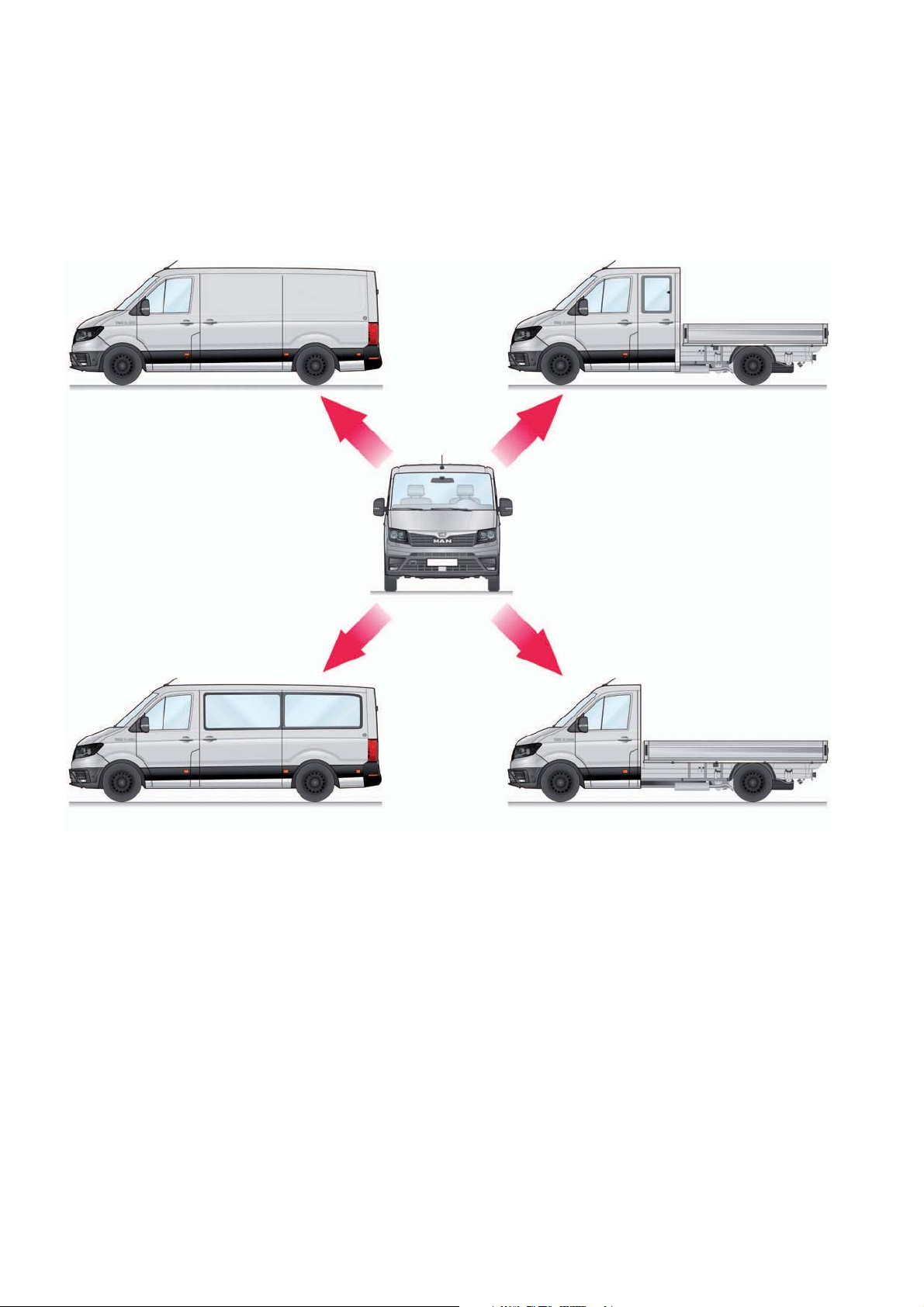

Derivatives

Panel van Double cab

Window van Single cab

The MAN TGE has an extensive range

of models to choose the vehicle best

suited to customer requirements. In

total, there is a choice of 69 body and

powertrain variants.

The four basic variants panel van,

window van and platform van with

single or double cab meet the highest

demands in their respective customer

segments.

The individual body shapes can be

further customized with different wheel

bases and roof heights.

In addition to the standard body

shapes, the following derivatives are

also available for extensive customeroriented special configurations:

Carriage with flat frame chassis

Cowl panel

Platform

m001_218

8

Page 9

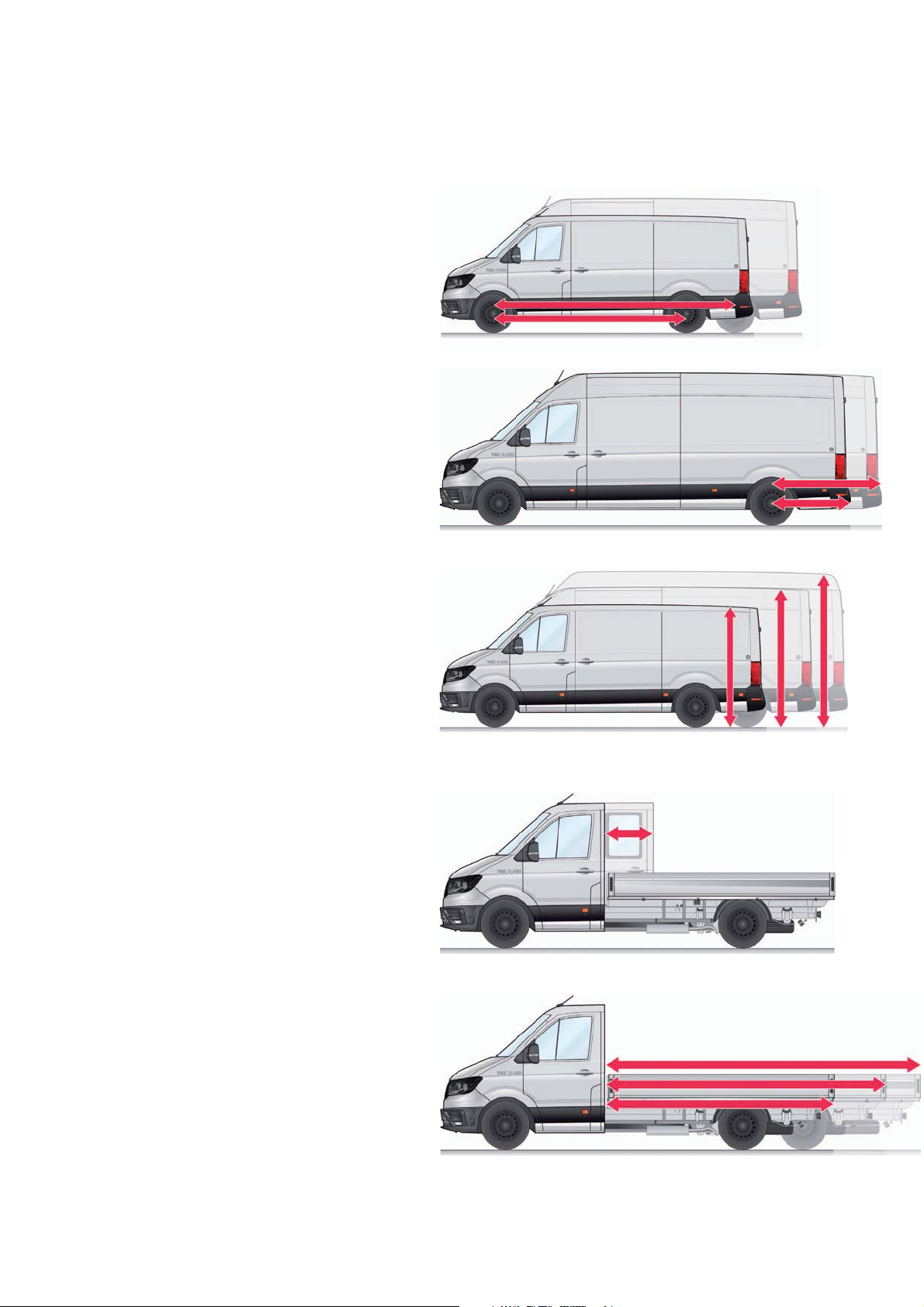

Dimension variants

Wheelbases

Two wheelbases are available.

Standard wheelbase: 3640 mm (L3)

Long wheelbase: 4490 mm (L4/L5)

Rear overhangs

Two rear overhang lengths are available

for the long wheelbase.

Long: 1346 mm (L3/L4)

Extra long : 1901 mm1) (L5)

Roof heights (panel van, window van)

Three roof heights are available.

m001_219

m001_220

Normal roof: 2355 / 2390 mm2) (H2)

High roof: 2590 / 2625 - 2637mm 2) (H3)

Super high roof: 2798 / 2830 - 2835

1), 2)

mm (H4)

Cabs (platform van, chassis)

Two cab sizes are available for the transport of additional

persons:

Single cab with maximum seat configuration 2+1

Double cab with maximum seat configuration 6+1

Platform lengths

Ex factory, three platform lengths are available with single cab (SC) and a further

platform length for double cab (DC).

m001_221

m001_222

Standard single cab: 3500 mm

Long single cab: 4300 mm

Extra long single cab: 4700 mm

Standard double cab: 2700 mm

Long double cab: 3500 mm

1)

Not with window van.

2)

Single/twin tyres

m001_223

9

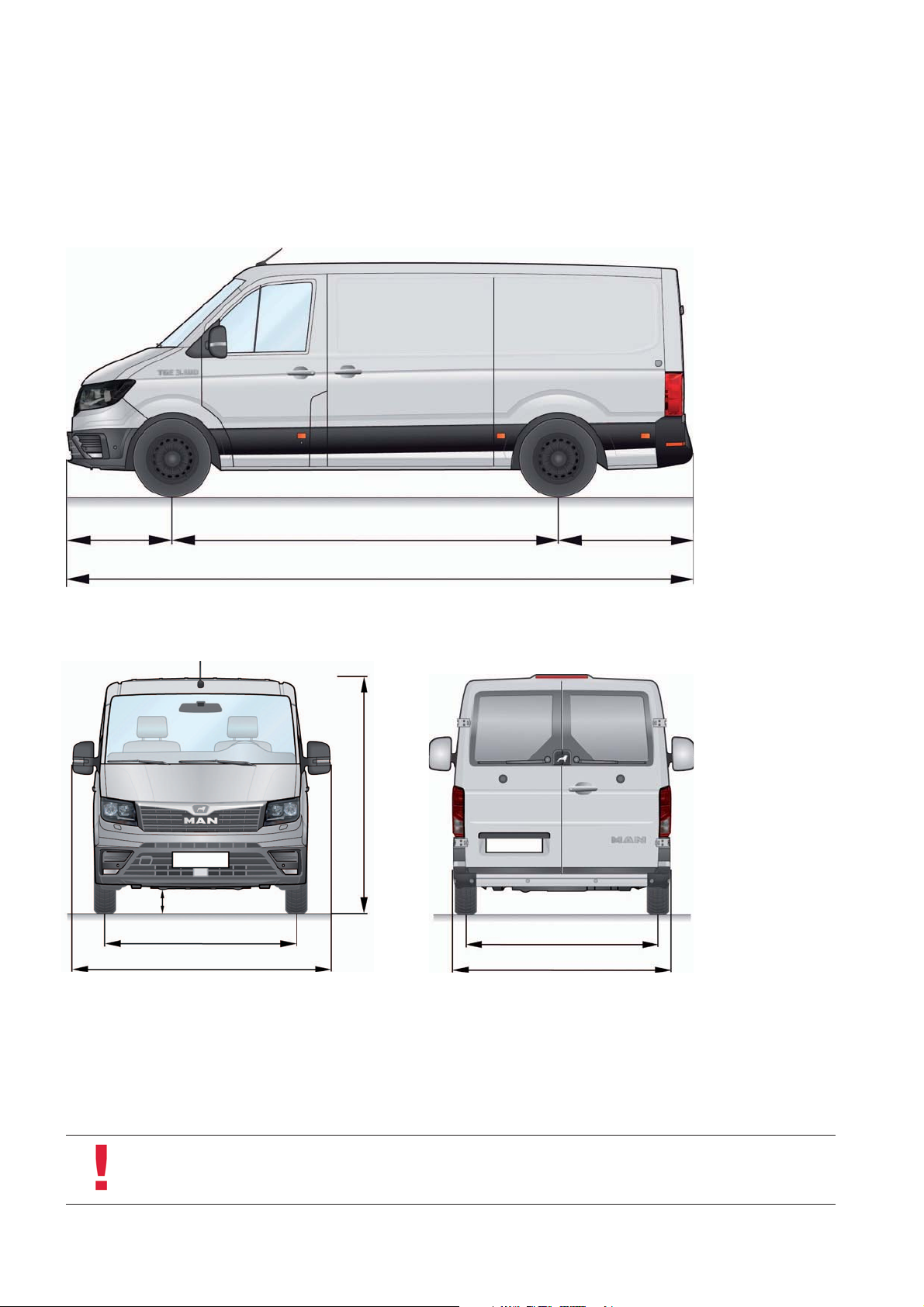

Page 10

Technical data

Panel van, window van

3640 – 44901000 1346 – 1901

5986 – 7391

m001_224

210 / 214

1773

2425 – 2427

All figures are in millimetres.

Note

The illustrations only show selected variants and their dimensions/dimension areas. For the complete technical data

for the entire model range, please refer to the current sales literature.

10

2355 – 2835

1)

1)

1)

m001_008

m001_225

1766 – 1788 / 1601

2040 / 2069

1)

Single/twin tyres

Page 11

Single cab, double cab

1000 3640 – 4490 1514 – 1914

3500 – 4700

6204 – 7404

m001_226

2321 – 2352 2305 – 2327

2700 – 3500

1000 3640 – 4490 1514 – 1564

6204 – 7004

m001_227

All figures are in millimetres.

11

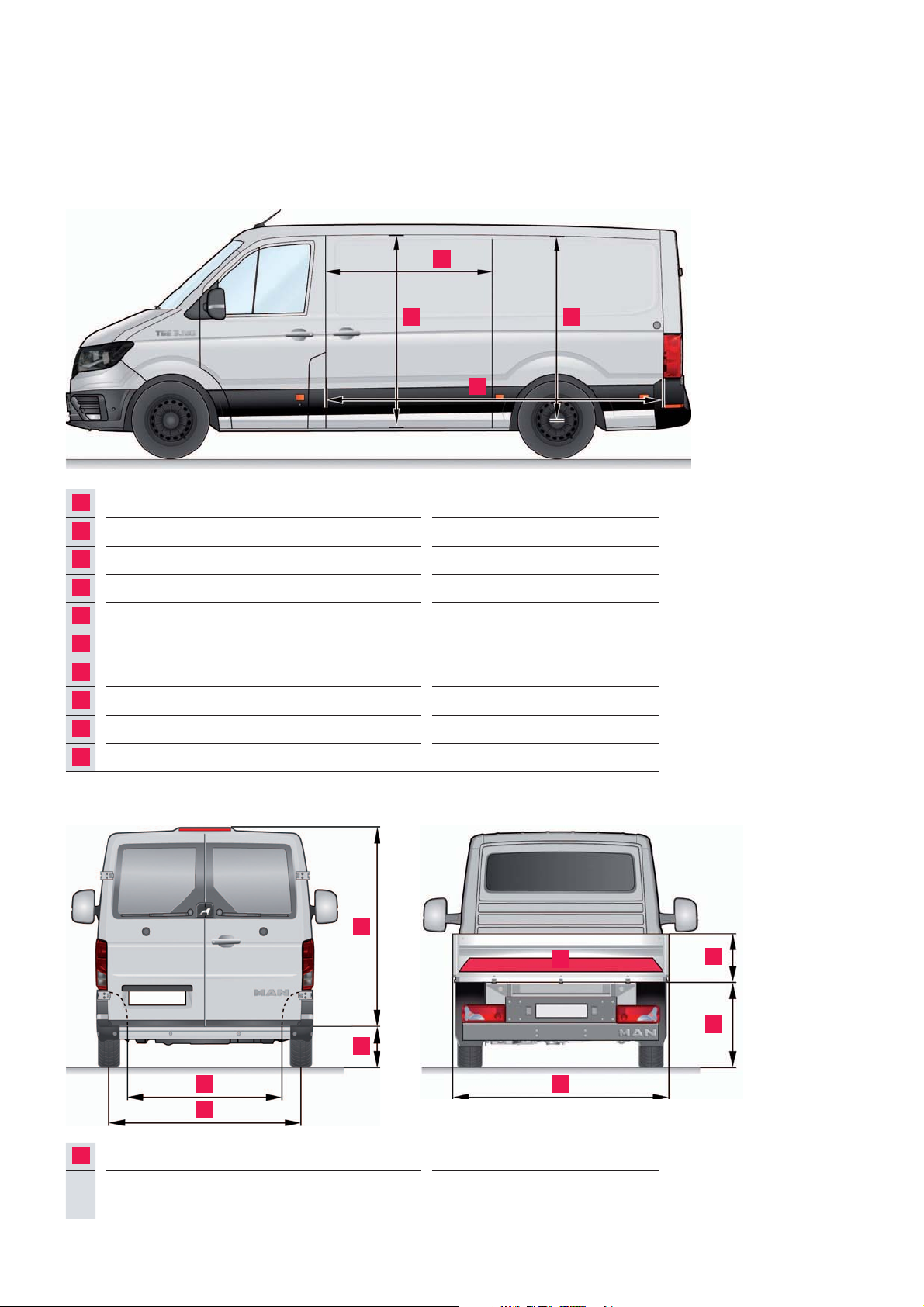

Page 12

Load compartment measurements

B D

A

Sliding door width 1311

B

Sliding door height 1430 – 1587 / 1668 – 1822

C

Maximum loadspace length 3201 – 4606

D

Maximum loadspace height 1568 – 2196

E

Height of rear wing door 1451 – 1605 / 1684 – 1840

F

Loading height/loadsill 570 – 725 / 1000 – 1050

G

Maximum loadspace width 1832

H

Width between wheel housings 1375 – 1380 / 1030

I

Maximum platform height 400

J

Maximum platform width external 2098

A

C

m001_228

1)

5)

1)

2)

3)

All figures are in

millimetres for vehicles

with front-wheel drive.

1)

Normal roof / High roof,

Super high roof

2)

Panel, window / platform

3)

Single / twin tyres

4)

Front and four-wheel drive /

rear-wheel drive

5)

incl. 15 cm subfloor storage

compartment

Window van, panel van Flatbed

E

F

H

G

K

Maximum loadspace area 5,16 – 8,99 m

m001_012

Maximum trailer weight 3000 / 3500 kg

Gross vehicle weight 3500 – 5500 kg

K

I

F

J

m001_229

2

4)

12

Page 13

The vehicle concept

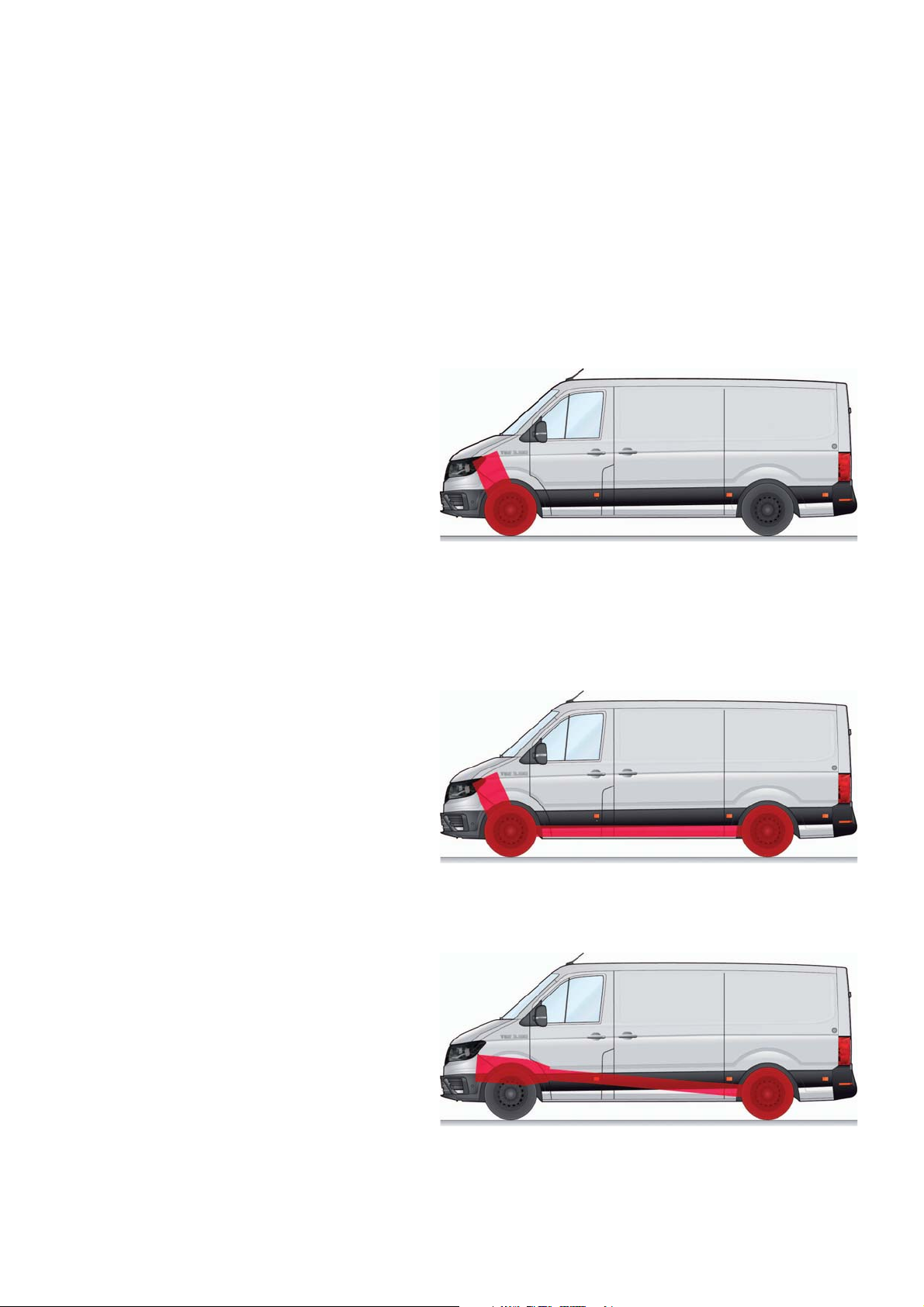

Drive system types

Prior to the development of the MAN

TGE, intensive customer surveys were

conducted and market requirements

Front-wheel drive

The drive unit is installed transversally.

Features are:

low loadspace floor (about -100 mm),

thereby increasing the loadspace

volume and reducing the loadsill

height

Rear end without drive technology

Driveline with reduced weight

(approx. 100 kg less), lower fuel

consumption

Applications include courier and

logistics services, joiners/plumbers/

glaziers, etc. and rescue services.

All-wheel drive 4x4

were taken into account in the design

process.

For the first time, three types of drive are

used in the MAN TGE and VW Crafter.

m001_230

The drive unit is installed transversally.

Features are:

Electronically controlled multi-plate

clutch

Optimum traction

Particularly suitable for regions with

poor weather conditions or roads

Applications include the building trade

and forestry as well as the police and

military.

Rear wheel drive

The drive unit is in inline installation.

Features are:

Good traction for high loads

Higher gross vehicle weight rating

possible (up to 5.5 t)

Single or twin tyres at rear

Use of auxiliary drives on the gearbox

(e.g. for body manufacturer) possible

Applications include service vehicles

and mobile workshops with heavy

built-in components as well as special

bodies.

m001_231

m001_232

13

Page 14

VEHICLE BODY

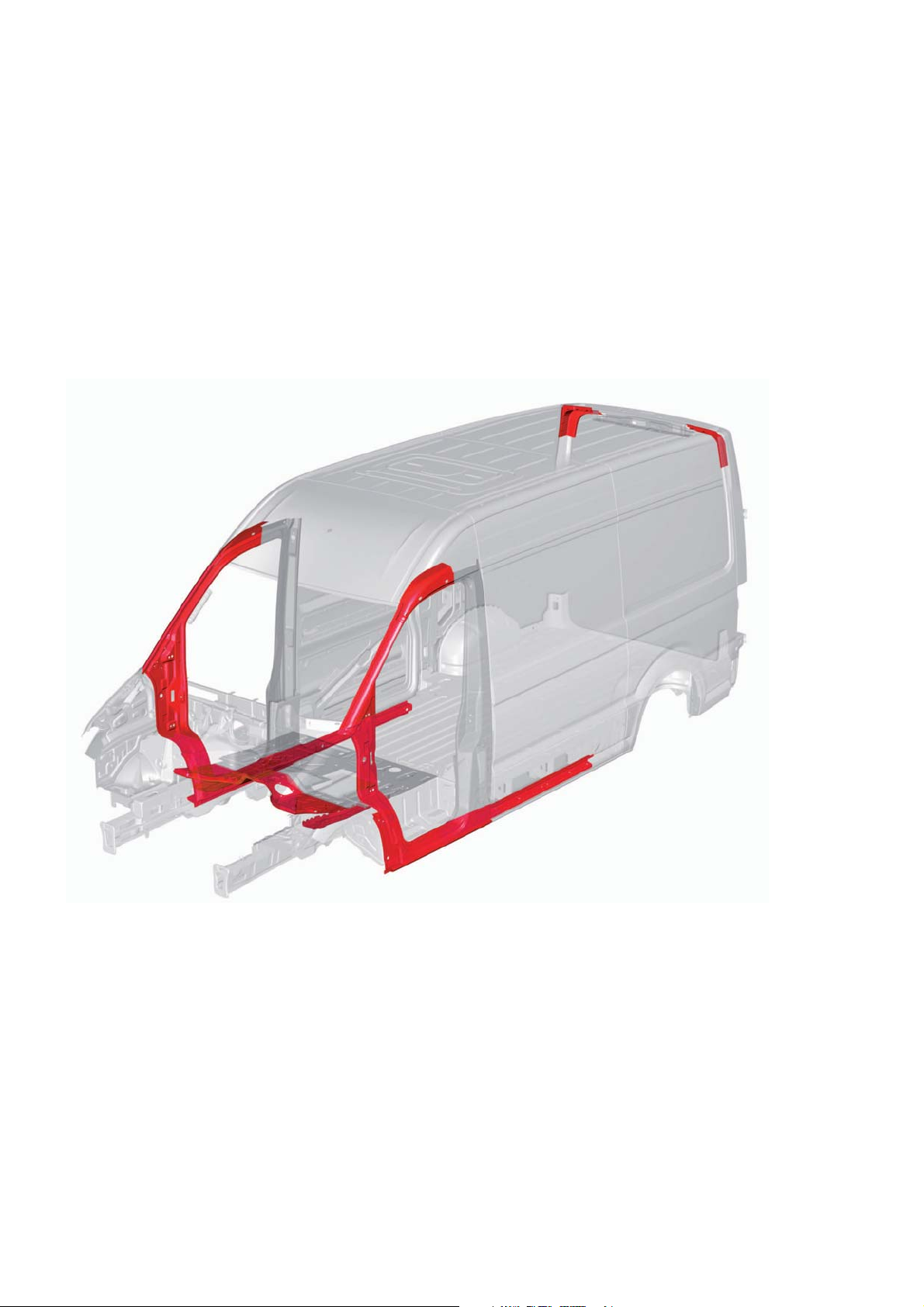

Body structure

The body of the MAN TGE has been

completely redesigned. In addition to

the modular design, the developers

focused on optimizing weight and

aerodynamics as well as crash safety.

These goals were achieved, among

other things, by the use of higheststrength hot-formed steels. Compared

to conventional steels, these are considerably stronger at a similar weight and

thus make the MAN TGE lighter and

safer.

The following components are made

from hot-formed steel:

Front roof side members

Sill panel reinforcement

Corner reinforcement on the rear roof

m001_083

A-pillar bottom part

Front bulkhead

Longitudinal member reinforcement

for driver‘s cab

14

Page 15

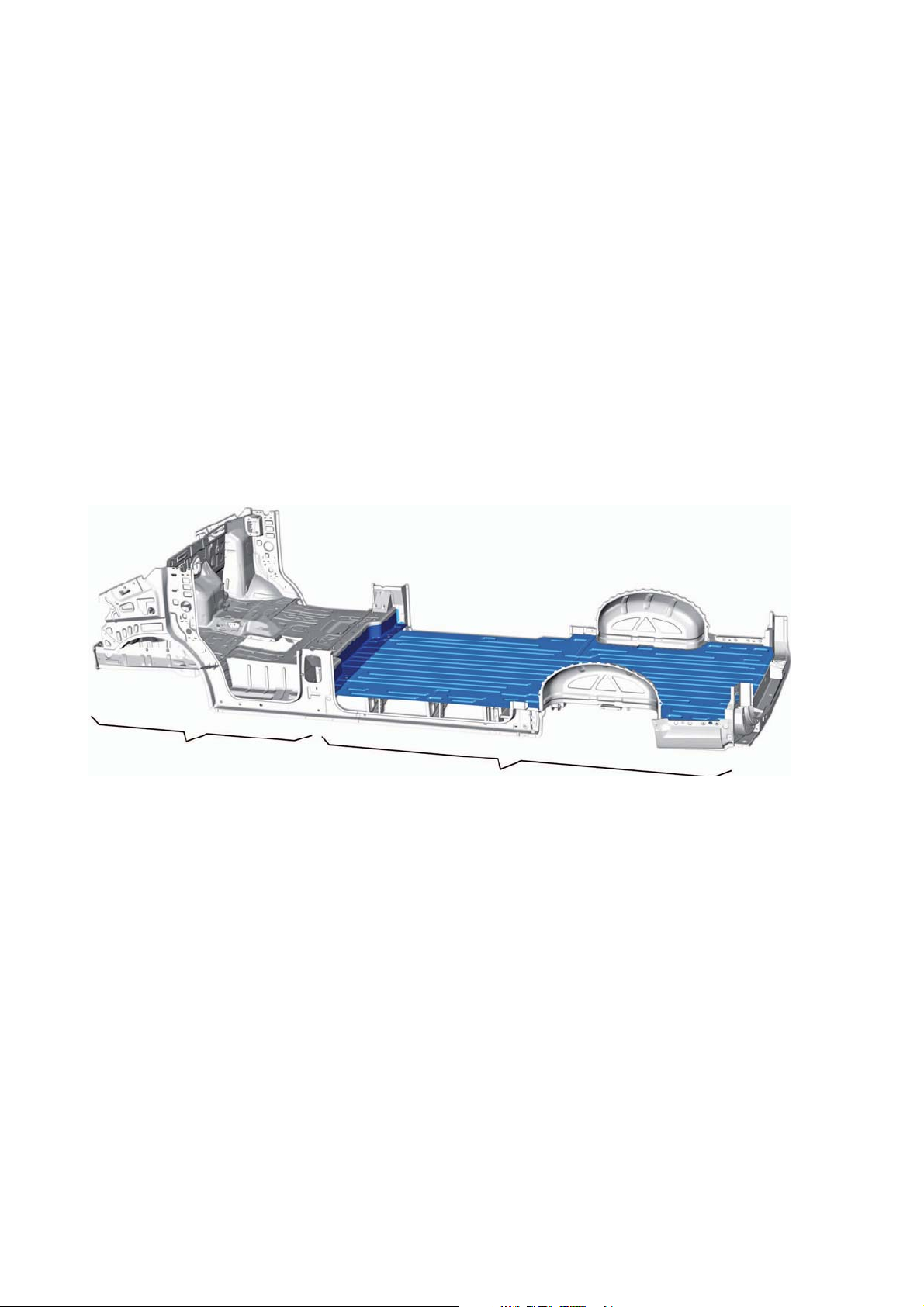

Modular structure

Use of as many identical parts as

possible was an important goal during

development of the body structure. The

objective was to allow the numerous

derivatives and variants such as different

wheelbases and roof heights to be

manufactured with great synergy

effects.

Vehicle front end the

same for all variants

Floor structure

The floor structure of the MANTGE is

the same for all variants in the vehicle

front end area. At the rear end, however,

there are significant differences regarding the floor panel, longitudinal

members, wheel housings and the

corresponding connecting parts as well

Vehicle rear end different depending on

the variant, in this case short wheelbase

with low loadspace floor (-100 mm)

as reinforcements. Their configuration

and design are determined by the

following factors:

Type of drive

Wheelbase

Rear overhang

m001_084

Type of body

Single or twin tyres on the rear axle

15

Page 16

POWER UNITS

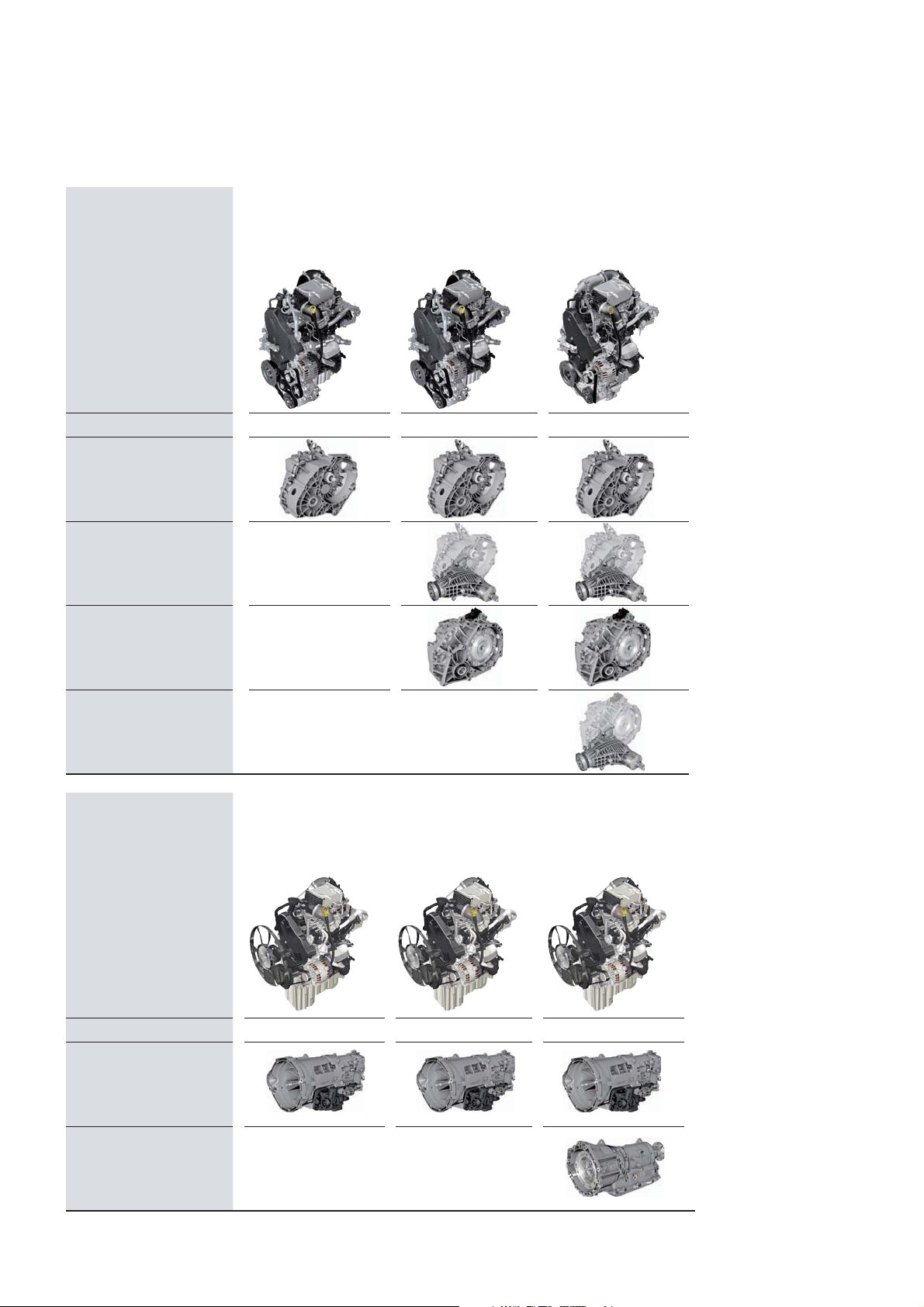

Engine/gearbox combinations

Transverse

installation

6-speed

Manual gearbox

0AX front-wheel drive

6-speed

Manual gearbox

0AX four-wheel drive

8-speed

Automatic gearbox

09Q front-wheel drive

2.0l Turbo diesel

75 kW

DAUB

2.0l Turbo diesel

103 kW

DAUA

2.0l Biturbo diesel

130 kW

DAVA

8-speed

Automatic gearbox

09Q four-wheel drive

Longitudinal

installation

6-speed

Manual gearbox

0F6 rear-wheel drive

8-speed

Automatic gearbox

0DR rear-wheel drive

2.0l Turbo diesel

90 kW

DASA

2.0l Turbo diesel

103 kW

DASB

2.0l Biturbo diesel

130 kW

DAWB

16

Page 17

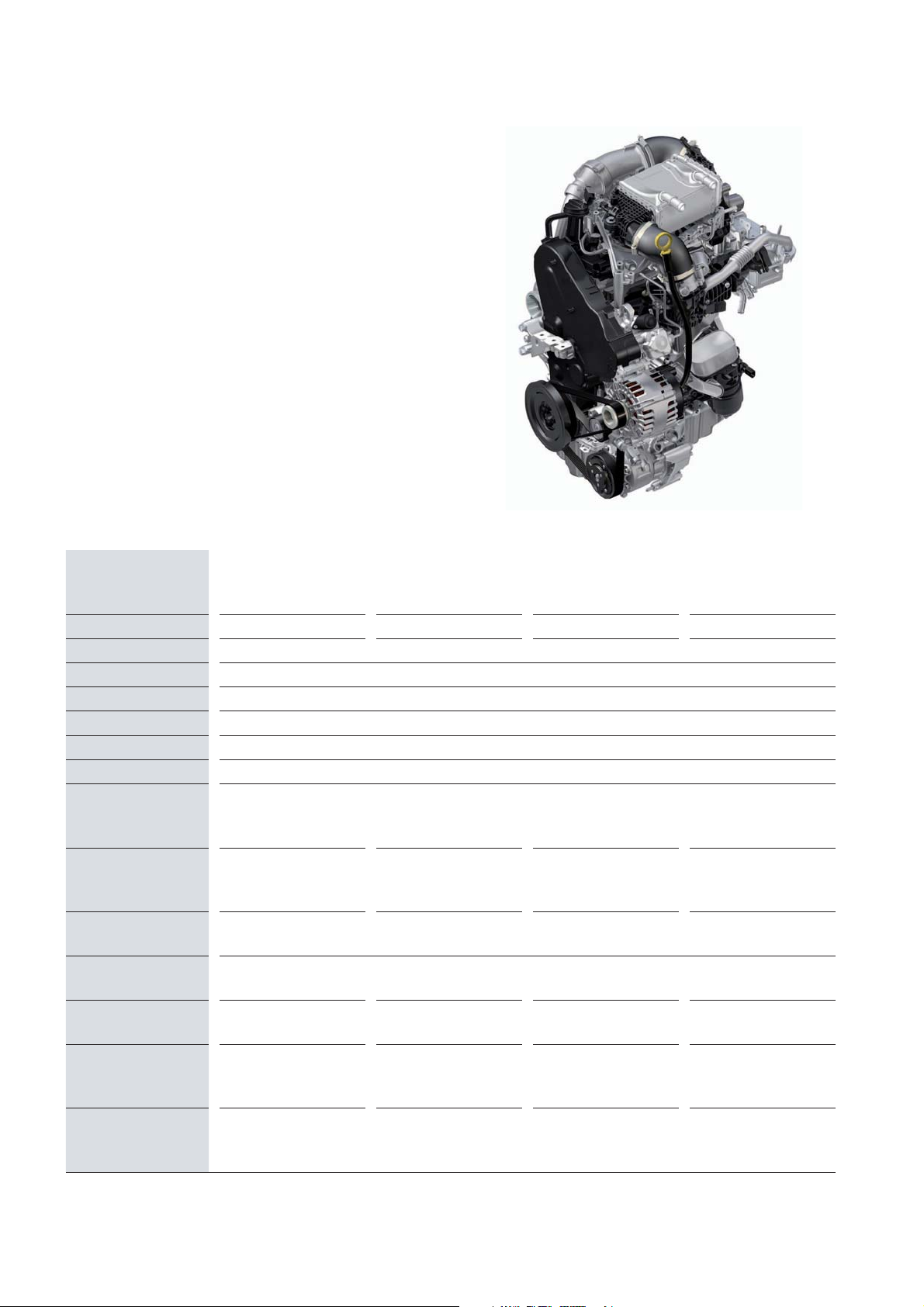

The 2.0 l turbo diesel engines

In the MAN TGE, only 2.0-litre turbo diesel engines from the MDBnutz modular diesel construction kit are used. The use of a

uniform engine geometry with many identical parts creates high synergy effects and reduces manufacturing and maintenance

costs.

Transverse installation Longitudinal installationtion

m001_140 m001_141

The engines of the MAN TGE have been

specially designed for commercial

vehicles to meet the high requirements

in terms of mileage, driving resistance,

driving profile and service life.

Adjustments were made, for example,

to the intercooling, the cylinder head,

the variable-length intake manifold, the

EGR cooler, the turbochargers and the

oil pan.

The installation position is adapted to

the commercial vehicle design.

Depending on the drive concept used,

the engines are installed transversely or

longitudinally - an absolute special

feature within a vehicle series.

In addition, transversely installed

engines are installed at an angle of 8° to

the front in order to make optimum use

of the available installation space.

Longitudinally installed engines have a

larger oil pan and an increased oil

quantity.

Engines with one or two turbochargers

are used. A total of up to four power

stages are available, ranging from 75

kW to 130 kW. The after-treatment of

the exhaust gases is carried out by an

SCR system for nitrogen oxide reduction. Additional options, e. g. different

generators and compressors, are

possible with the accessory drive used.

17

Page 18

Technical data

The engine is part of the engine series EA288nutz and

is installed in this design – beside the MAN GTE – only

in the VW Transporter and Crafter. The engine is

available in the EU6 plus and EURO VI exhaust emission standards, depending on the application.

Technical features

Liquid-cooled charge air cooler

High-pressure exhaust gas recirculation

Delphi common rail direct injection

Liquid-cooled injector for reducing agent

Injectors with solenoid valve

Single-plunger high-pressure pump (monoturbo),

double-plunger high-pressure pump (biturbo)

m001_052

Motor designation 2.0 l Turbo diesel

75 kW

Engine code DAUB DASA DAUA / DASB

Capacity 1968 cm

Type 4-cylinder in-line engine

Valves per cylinder 4

Bore 81.0 mm

Stroke 95.5 mm

Compression ratio 15.5 : 1

Maximum output

at rpm

Max. torque

at rpm

Engine management Delphi DCM6.2

Fuel DIN EN 590 DIN EN 590 DIN EN 590 DIN EN 590

Forced induction Mono turbo Mono turbo Mono turbo Biturbo

75 kW

at 3250 – 3500

300 Nm

at 1400 – 2250

2.0 l Turbo diesel

90 kW

90 kW

at 3250 – 3500

300 Nm

at 1400 – 2250

2.0 l Turbo diesel

103 kW

1)

3

103 kW

at 3500 – 3600

340 Nm

at 1600 – 2250

2.0 l Biturbo diesel

130 kW

DAVA / DAWA

130 kW

at 3600

410 Nm

at 1500 – 2000

Exhaust gas

recirculation

Emission standard

1)

Longitudinal/transversal

2)

EU6 plus: Light duty homologation <2840 kg reference weight (roller test bench)

EURO VI: Heavy duty homologation >2380 kg reference weight (engine test bench)

18

yes yes yes yes

2)

EU6 plus EURO VI EU6, EU6 plus EU6, EU6 plus,

EURO V/VI

Page 19

Ancillary drive

An ancillary drive with modular expansion capability is used in response to

the wide variety of customer requirements. In addition to the usual units

such as an alternator and air conditioner

compressor, it is also possible to drive

an additional air conditioner compressor

or additional alternator. In vehicles with

bodies such as camper vans or refrigerated vans, this allows the required form

of energy to be provided, e.g. for air

conditioning, cooling or driving electrically operated ancillaries.

An elastic belt alone is used as the poly

V-belt in an engine with alternator. In all

other variants, the poly V-belt is tensioned using a belt tensioner.

Basic drive Air conditioning drive

Alternator

(various

power levels)

Alternator

(various

power levels)

Air conditioner

compressors

Additional drive

m001_053 m001_054

Alternator

(various

power levels)

Air conditioner

compressors

Additional

alternator

(in 180 A version)

Alternator

(various

power levels)

Air conditioner

compressors

Additional air

conditioner

compressor

m001_055 m001_056

19

Page 20

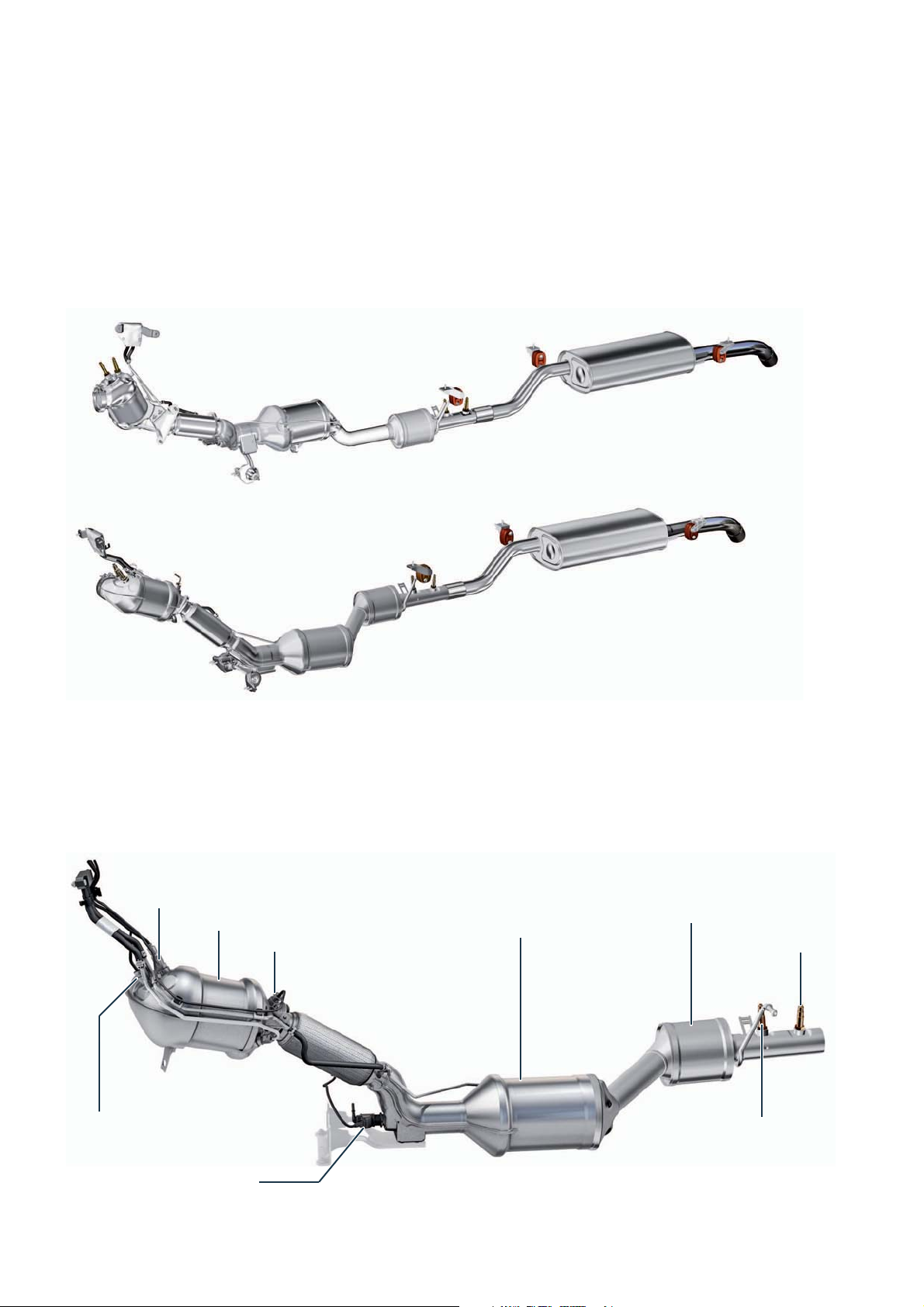

Exhaust system

The exhaust system of the MANTGE is available in various variants. Its structure depends on the engine or body variant, for

example.

Inline installation, EU6

Transverse installation, EU6

m001_058

Exhaust gas treatment

In vehicles with SCR system (EU6 exhaust standard), there is a lambda probe (oxygen sensor) in the front part of the exhaust

pipe as well as three temperature sensors, the injector for reducing agent as well as the corresponding catalytic converters.

Lambda probe

Oxidising catalytic converter

Temperature sensor 3

Temperature sensor 2

Diesel particulate filter

with SCR coating

Trap catalytic converter

Particle mass sensor

sensor

NO

x

20

Injector for reducing

agent N474

m001_060

Page 21

Reducing agent tank

In addition to the fuel tank with a capacity of about 75 litres, there is a tank

with a capacity of about 18 litres of

reducing agent (AdBlue). The reduction

agent consumption depends on the

individual driving style, the operating

temperature of the system and the

ambient temperature.

The tank for reducing agent is replenished via the filler neck for reducing

agent under the fuel filler neck, and is

sealed by a blue tank cap. The tank for

reducing agent is located on the underbody ahead of the fuel tank. A compensation volume has been integrated in

the top part of the vent in order for the

reducing agent flowing in at high speed

to be filled.

m001_061

Fuel filler neck Filler neck for reducing agent

Body

Control unit for reducing

agent heating

J891

Breather diaphragm

Breather line Filler pipe

Expansion section

Filler line

Reducing agent tank

Pump module with:

Heating

Sender for reducing agent tank G697

Filter

m001_062

21

Page 22

POWER TRANSMISSION

Overview

The diverse drive concept means there

are also several variants of power

transmission. The range extends from

straightforward front-wheel drive with

Rear final drive 0AY

manual gearbox through to four-wheel

drive and rear-wheel drive with an

auxiliary drive on the gearbox for additional working implements. In vehicles

with front or four-wheel drive, the

gearbox is installed transversely

whereas vehicles with rear-wheel drive

have an inline gearbox installation.

Electronically controlled multi-disc clutch /

5th generation four-wheel drive coupling

Rear final drive

Vehicles with rear-wheel drive are equipped with rear

axle drive 0HA. Vehicles with all-wheel drive 4x4, on

the other hand, are equipped with a rear axle drive with

four-wheel drive coupling

m001_191

m001_190

Final drive 0HA Rear final drive with four-wheel drive coupling

22

Page 23

Selector mechanism

The gears are changed using a joystick gearshift on

the dash panel. In vehicles with manual gearbox, a

gearshift recommendation is shown on the display of

the instrument cluster.

The automatic gearbox selector lever has a Tiptronic

manual shifting mode. The Tiptronic gear selector lever

has the normal arrangement of speeds as in an automatic transmission in the left row, with a connection to

a second parallel row on the right. In this second row,

shifting is performed one step up (+) or down (-) by

pressing the selector lever. The current selector lever

position is shown on the display of the instrument

cluster.

Selector lever

position display unit

m001_114

Interlock button on

selector lever

Selector lever

position display unit

Selector mechanism via cable

8-speed automatic gearbox 09Q

Final drive gear

m001_072

23

Page 24

The gearboxes

6-speed manual gearbox 0AX

This transmission is used in front wheel

drive or 4x4 four-wheel drive vehicles.

Front-wheel drive All-wheel drive 4x4

For use in the MAN TGE, it was

adapted with respect to gear ratios and

to the installation space-specific conditions.

In the MAN TGE, it is used both for front

wheel drive, and with a flange-mounted

angle drive for 4x4 all-wheel drive.

Final drive

gear

Developer/manufacturer

Transmission designation

Gearbox features

Torque

m001_045 m001_046

Volkswagen AG

MQ500-6A/-6F im

Service code: 0AX

6-speed manual gearbox with four shafts and cable operation for front or fourwheel drive in transverse installation

410 Nm

24

Page 25

8-speed automatic gearbox 09Q

The newly developed automatic transmission is used in front wheel drive or

4x4 four-wheel drive vehicles.

Front-wheel drive All-wheel drive 4x4

For use in the MAN TGE, care was

taken to ensure a robust design of the

converter, gearbox housing, differential

and parking lock.

In all-wheel drive vehicles, the drive to

the rear axle is provided by a flangemounted angular drive.

Final drive

gear

Developer/manufacturer

Transmission designation

Gearbox features

Torque

m001_047 m001_048

AISIN AW CO., LTD Japan

AQ450-8A/-8F

Service code: 9Q

Electrohydraulically controlled 8-speed planetary gearbox (automatic rangechange

gearbox) with hydrodynamic torque converter and limited-slip torque converter

lock-up clutch for front or four-wheel drive in transverse installation

410 Nm

25

Page 26

6-speed manual gearbox 0F6

The newly developed manual transmission is used in rear-wheel drive vehicles.

For the MAN TGE it has been designed

with a correspondingly robust layout.

This applies, for example, to the design

of bearings and synchronization. A

gearbox-side power take-off is available

as an option.

Developer/manufacturer

Transmission designation

Gearbox features

Torque

m001_138 m001_049

PTO

ZF Friedrichshafen AG

ML410-6H

Service code: 0F6

2-shaft manual gearbox with single and multi-synchronised gear stages. The

gearbox comprises an input shaft in conjunction with a coaxial output shaft, as well

as a layshaft and a reverse shaft for reverse gear. The auxiliary drive is driven via

the layshaft.

410 Nm

26

Page 27

8-speed automatic gearbox 0DR

The newly developed automatic transmission is used in rear-wheel drive

vehicles.

For the MAN TGE it has been designed

with a correspondingly robust layout.

This concerns e. g. the converter and

the planetary gear set.

In addition, the gearbox housing, lining

plates, plate supports and the parking

lock are reinforced.

Developer/manufacturer

Transmission designation

Gearbox features

Torque

m001_050

ZF Friedrichshafen AG

AL550-8H

Service code: 0DR

Electro-hydraulically controlled 8-speed planetary gearbox with hydrodynamic

torque converter and torque converter lock-up clutch with controlled slip

410 Nm

27

Page 28

Four-wheel drive coupling

The four-wheel drive coupling in the

rear-wheel drive corresponds to the

5thgeneration of electrohydraulically

controlled four-wheel drive couplings.

It is available either with or without a

differential lock in the MAN TGE.

The differential lock is operated using an

electrically driven actuator.

Four-wheel

drive coupling pump

V181

m001_075

Final drive, here without

differential lock

5th generation four-wheel

drive coupling

Propshafts

Depending on the wheelbase, different

propshafts are used in vehicles with rear

or four-wheel drive. In a short wheel-

Four-wheel drive control

unit J492

base, a propshaft with a universal joint

transmits the drive force to the rear axle,

whereas in a long wheelbase there is a

Short wheelbase

propshaft with two universal joints,

which is also configured in two parts.

Long wheelbase

28

m001_074

Page 29

PTO

An auxiliary drive on the gearbox side is used if high

power is required over a longer period. The manual

gearbox 0F6 (only in vehicles with rear-wheel drive) can

optionally be equipped with an auxiliary drive for driving

additional external devices, such as:

Hydraulic pumps, e.g. for crane/tipper

External underfloor generators

Compressors, e.g. for high-pressure washers

Drain flushing pumps

The auxiliary drive is activated by an electric shift

cylinder. The power is taken off at the side of the

gearbox. The auxiliary drive is available in three different variants:

Power take-off without flange

Auxiliary drive with flange

Auxiliary drive with four-hole adapter sleeve, e.g. for

axial piston pumps

Optionally, the auxiliary drive can be equipped with

additional gear oil cooler for higher power output. In

this case, the transmission has a higher oil quantity.

Observe the notes in the repair instructions and the

assembly guidelines.

Return pipe

Gear oil cooler

Oil temperature controller

(Thermostat)

Shift cylinder for

auxiliary drive

Feedback switch

Supply pipe

m001_135

Intake line

Gear oil pump

Flange for connection

to the manual gearbox

Operation

The auxiliary drive is switched on by button E225. The

optional working speed governor can be engaged

using button E261 when the auxiliary drive is switched

on.

Switch-on conditions:

Road speed = 0 km/h

Parking brake applied

Neutral detected

Engine running (max. 1040 rpm)

Press button E225 and hold it for 2 to 5 seconds

The auxiliary drives is engaged if the clutch is

depressed within 10 seconds following activation

using button E225.

Switch-off condition: press clutch

Power take-off without flange Output shaft

Switch module on left

next to the steering wheel

Button for working

speed governor

E261

Button for auxiliary drive

E225

m001_081

m001_076

29

Page 30

RUNNING GEAR

Overview of the chassis

The overview shows important running gear equipment of the MANTGE that is fitted as standard and optionally. The different

drive concepts mean there have also been corresponding adaptations in the running gear.

Running gear

Technical features

Three-point assembly mountings with

subframe

McPherson strut front suspension

Rear axle as rigid axle with leaf

springs in four variants

16-inch disc brake system front and

rear

17-inch disc brake system front and

rear with 5.5 t

Brake system ESC/ABS 9.2

McPherson suspension struts

in vehicles with rear-wheel drive,

single or twin tyres are an option on

the rear axle

Electromechanical power steering

30

Electromechanical power steering

Drive assembly carrier

Page 31

Disc brake system rear

Rigid axle with leaf springs

(for front-wheel drive)

Parking brake

with folding actuating lever

m001_139

31

Page 32

Overview of the driver assist systems

Available driver assist systems

With about 20 assistance systems, the MAN TGE is the best in its class.

It is the only transporter equipped with the emergency brake assistant as standard; thus, it makes an important contribution to

general road safety.

A special highlight are the various parking

assistants from the side protection via the

parking steering assistance to the trailer range

assistant.

.

Automatic Distance Control (ACC) Main beam assistant

Emergency brake assistant (series))

Automatic Post-Collision Braking

System (series)

Main beam assistant

Automatic Distance Control (ACC))

Trailer manoeuvring assist

Side wind assistant

Speed control system incl. speed

limitation system

Parking assistant

Tire pressure control system

Rain/light sensor

Driver Alert System (DAS)

Park assist steering

Lane departure warning (Lane Assist)t

Traffic sign detection (Sign Assist)

Lane change assistant

Flank protection

Reversing camera (Rearview Camera

System)

Assist system for reversing out of

parking spaces (Rear Cross Traffic

Alert)

Hill Start Assist

Side wind assistant

Assist system for reversing out of

parking spaces (Rear Cross Traffic

Alert)

32

Page 33

Automatic Post-Collision Braking

System

Optical 360° parking system (OPS)

with flank protectionz

Lane departure warning Lane change assistant

Trailer manoeuvring assist

m001_233

Traffic sign detection (Sign Assist)

Hill Start Assist Reversing camera (Rearview

Park assist steering

Camera System)

33

Page 34

Front axle

The front axle in the MAN TGE has a

drive assembly carrier to which the

transverse links are connected. The

drive assembly carrier is bolted to the

body via several mounting points. The

anti-roll bar is located ahead of the axle

McPherson suspension

struts

Electromechanical power steering

and is connected via coupling rods to

the McPherson suspension struts

Coupling rod Anti-roll bar Drive assembly carrier Transverse link

Trim on the transverse left

The aerodynamic package includes underbody paneling and aerodynamic trims at the transverse links. The

clipped-in trims contribute to reducing the drag coefficient and provide protection against stone chippings.

m001_063

34

m001_122

Page 35

Rear axle

A rigid axle with leaf springs is used as

the rear axle in the MANTGE. Depending on the drive type, this has a continuous steel tube (front-wheel drive), a

rear final drive or a four-wheel drive

coupling.

In vehicles with front-wheel drive,

there are two different variants

depending on the height of the body

floor.

For vehicles with rear-wheel drive,

there are two different variants

depending on whether they are

equipped with single or twin tyres.

A four-wheel drive coupling of the fifth

generation is used in vehicles with

four-wheel drive.

Front-wheel drive All-wheel drive 4x4

m001_064 m001_065

Tear-wheel drive with single tyres Rear-wheel drive with twin tyres

m001_066

m001_067

35

Page 36

Brakes

Front brake

The MANTGE‘s front axle is fitted with a 16-inch or

17-inch floating caliper disc brake system with ventilated brake discs. The various double-piston brake

calipers are used depending on equipment:

Front or four-wheel drive: 48 mm

Rear-wheel drive 16-inch: 52 mm

Rear-wheel drive with 5.5 t and 17-inch: 52 mm

Rear brake

Two different versions of the 16-inch brake system and

one of the 17-inch brake system are fitted on the rear

axle.

Vehicles with four-wheel, front-wheel or rear-wheel

drive with single tyres have a 16-inch floating caliper

disc brake with ventilated brake discs and a brake

piston with a diameter of 48 mm.

Vehicles with rear-wheel drive and twin tyres have a

16-inch floating caliper disc brake with ventilated

brake discs and two brake piston with a diameter of

44 mm each. From 5.5 t gross vehicle weight rating

onwards, a 17-inch brake system is fitted with the

same piston diameters.

m001_071

m001_069

Parking brake

Due to the different brake systems on the rear axle,

there are also two different kinds of parking brake:

In vehicles with four-wheel, front-wheel or rear-wheel

drive with single tyres, the parking brake acts

directly on the disc brake.

In vehicles with rear-wheel drive and twin tyres, the

parking brake acts on an internal drum brake which

is integrated in the disc brake. The parking brake is

configured as a duo servo brake in this case.

36

m001_070

Page 37

Electromechanical power steering system

The MAN TGE features electromechanical power steering with axle-parallel

drive (APD). Power steering is provided

as required depending on the vehicle

speed, the steering moment applied by

the driver, the current steering angle and

Bosch APD steering

Adjusting unit for front/rear

and tilt adjustment

the engine speed. Electromechanical

power steering offers many advantages

compared to hydraulic steering.

One major advantage is that when this

steering is used, it is also possible to fit

driver assist systems such as the Park

Assist system, trailer manoeuvring assist

and lane departure warning. In addition,

it is possible to achieve a measurable

consumption advantage compared to

vehicles with conventional power steering.

Bearing plate

Steering moment

sender G269

Locking lever

Universal joint

Steering racks

Electromechanical power

steering motor V187

m001_068

Power steering control unit J500 with

steering angle sender G85

(iLWS = internal steering angle sensor)

37

Page 38

ELECTRICAL SYSTEM

The power supply concepts

For the installation of consumers with high energy requirements, an additional battery can be installed in the MAN TGE.

In the engine compartment on the right

Earth connection for jump start

Jump-start terminall Second battery charging

circuit relay J713

38

Control unit 2 for

battery monitoring

J934

Second battery in the engine

compartment on the left

Battery master switch above

the accelerator pedal

Page 39

Different power supply concepts are available for the MANTGE. This means body manufacturers can select between several

ex-works solutions depending on the application. In addition to the basic equipment with one starter battery and one alternator (140, 180, 250 A), it is possible to select between further variants:

Variant 1

One alternator (140, 180, 250 A):

Second battery with isolator relay

Second battery with isolator relay and

battery monitoring

Variant 2

Two alternators (second alternator

180A, in each case can be combined

with 140A or 180A first alternator):

Second battery with battery monito-

ring

The battery monitoring

The battery monitoring includes second battery energy management. The second battery is monitored by means of an additional date module, the control unit 2 for battery monitoring J934, on the negative terminal of the second battery and the control

unit for special vehicles J608.

Most important highlights

Battery monitoring for starter and

second batteries

Vehicle responses to maximum

second battery charging as well as

body supply

Output of second battery status and

second battery data

Intelligent distribution of external

charging between starter and second

batteries

Emergency start preparation for

engine start from second battery if

the starter battery is insufficiently

charged

Battery monitor control unit J367

Starter battery underneath the driver’s

footwell

m001_125

39

Page 40

The installation locations and safety concept

The vehicle electrical system architecture is adapted to the specific requirements of commercial vehicles.

At the driver seat

230volt socket

with pure sine wave,

300watt continuous

power

SH fuses in the engine compartment on

the left

Fuses in the engine compartment

Starter battery underneath the driver’s

footwell

40

In the instrument panel

Relay carrier and fuse holder C (SC)

with onboard supply control unit J519

Under the driver seat

Relay carrier and fuse

holder B (SB) and D (SD)

Page 41

Residual current circuit breaker

On the rear side panel

230 volt supply

Starter battery underneath the driver’s

footwell

m001_133

Main fuses (SA) of the battery

41

Page 42

Networking concept

The networking concept is based on that of the

Modular Transverse Construction Kit (MQB) and has

been expanded and adapted for the MAN TGE. All

CAN bus systems in the MAN TGE have a transfer

speed of 500 kbit/s. The LIN buses have a speed of

19.2 kbit/s.

The data bus diagnostic interface J533 contains the

control system for several LIN buses and forms the link

between the individual CAN buses as usual.

Further LIN buses are connected to various control

units.

Legend

Powertrain CAN bus

Running gear CAN bus

CAN bus extended

Convenience CAN bus

Infotainment CAN bus

LIN bus

CAN bus line

LIN bus wire

A

Diagnostic CAN bus

CVBS Colour Video Blanking Synchronisation

signal

LVDS

MIB

SF

1)

Low-voltage differential signalling

Modular infotainment matrix CAN bus

Sensor fusion CAN bus

With left-hand drive vehicle; with righthand drive vehicle J388 connected to

J386 (LIN)

2)

Connection of J608 on the powertrain

CAN bus read only

3)

4)

R or J794 depending on equipment

Connection to J364 or J604

CX1

CX2

E857

EX21

G24

G85

G238

G273

G805

G823

H12

J104

J126

J217

J234

J285

J345

J350

J362

J364

J367

J386

J387

J388

Alternator with voltage regulator

Alternator 2 with voltage regulator

Additional display and operating unit 1

Heater and air conditioning controls

Tachograph

Steering angle sender

Air quality sensor

Interior monitoring sensor

Pressure sender for refrigerant circuit

Air humidity, rain and light sensor

Alarm horn

ABS control unit

Fresh air blower control unit

Automatic gearbox control unit

Airbag control unit

Control unit in dash panel insert

Trailer detector control unit

Control unit for hot air blower

Immobiliser control unit

Auxiliary heater control unit

Battery monitor control unit

Driver door control unit

Front passenger door control unit

Rear left door control unit

42

Page 43

m001_094

J389

J428

J446

J453

J492

J500

Rear right door control unit

Adaptive cruise control unit

Parking aid control unit

Multifunction steering wheel control unit

Four-wheel drive control unit

Power steering control unit

J502 Tyre Pressure Monitoring System control

unit

J519

J527

J533

J604

J608

J623

Vehicle electrical system control unit

Steering column electronics control unit

Data bus diagnostic interface

Auxiliary air heater control unit

Control unit for special vehicles

Engine control unit

J685 Display unit for front information display

and operating unit control unit

J791

J794

Park assist steering control unit

Control unit 1 for information electronics

J934

Control unit 2 for battery monitoring

J949 Emergency call module control unit and

communication unit

J1086

J1087

Control unit for blind spot detection

Control unit 2 for blind spot detection

J1144 Control unit for additional blower for air

conditioning

J1145 Control unit for additional blower 2 for air

conditioning

R

Radio

R64 Remote control receiver for auxiliary

heating

R189

R242

R368

Reversing camera

Front camera for driver assist systems

Camera for trailer manoeuvring assist

U13 DC/AC converter with socket,

12 V - 230V

Z35

Auxiliary air heater element

43

Page 44

The installation locations of the control devices

Some of the control units listed in this overview are optional or country-specific equipment. For reasons of clarity, not all of the

control units fitted in the vehicle can be shown.

Display unit for

control unit of the

front information

display and operating unit J685

Control unit for

distance control

J428

Control unit 1 for information

electronics J794

Trailer detection control

unit J345

Control unit for special

vehicles J608

Front passenger

door control unit

J387

Engine control unit

J623

Automatic gearbox control unit

J217

Control unit for ABS

J104

Emergency call

module control unit

and communication

unit J949

Data bus

diagnostic

interface

J533

Control

unit for

park

distance

control

J446

Onboard

supply

control unit

J519

44

Page 45

Information about the precise location description of the control units as well as instructions for installation and

removal can be found in the current service literature.

Front camera for driver

assist systems R242

Control unit for differential

lock J187/control unit for

four-wheel drive J492

Control unit for blind spot

detection

J1086

Reversing camera

R189

Driver door control unit

J386

Radio receiver for

auxiliary heater R64

Tyre Pressure Monitoring

System control unit J502

Camera for trailer

manoeuvring assist

R368

m001_234

Control unit 2 for blind

spot detection

J1087

45

Page 46

Lighting system

Headlights

Halogen headlights H7 and LED headlights can be selected for the MANTGE.

Headlight module H7

The headlight module has an H7 bulb

for the dipped beam. An H15 bulb is

used for the daytime running light and

main beam.

The H7 headlights are equipped with

manual headlight range control which

can be adjusted using a potentiometer

in the instrument panel.

Daytime running lights/

high beam

H15, 15/55 W

Dipped beam

H7, 55 W

Turn signal

H, 21 W

Side light

W, 5 W

m001_235

Headlight module with

LED technology

The light functions are provided by

LEDs, except for the turn signal. One

bulb is used for the turn signal.

The LED unit for the dipped/main beam

uses LED lens technology. The light is

emitted via a lens.

The LED unit for main beam emits the

light using a reflector.

In the headlight flasher, only the inner

LED module provided for the main

beam function is activated.

Main beam

LED

Daytime running/side lights

LED

Dipped beam/main beam

LED

m001_236

Turn signal

H, 21 W

46

Page 47

Tail lights

The rear lights (tail, brake, reflector and

reversing lights) are individually designed

and form a complete unit. In closed

bodies, the light functions except for the

High-level brake light

The high-level brake light is mounted on

the roof cross member above the wing

doors. It is configured with LED technology and has 30 LEDs.

rear fog light are configured with conventional bulb technology. An LED

module is used for the rear fog light.

In addition, high-level turn signals can

be mounted on the vehicle roof.

Tail light/brake light

2 x P 21 W

Reversing light

P 21 W

Turn signal

PY, 21 W

Additional light module

The front fog lights are fitted in the

bumper. They are also used as static

cornering lights.

Rear fog light

LED

m001_098

m001_099

Fog lights/cornering light

H11, 55 W

47

Page 48

The dash panel insert

Two variants of instrument clusters are

available for the MAN TGE. Both contain

the immobiliser control unit J362.

Multi-function display

This variant has a black/white segment

display with a maximum of 480display

segments.

A loudspeaker for playback of warning

signals is integrated in the instrument

cluster. The time can be set, or the trip

recorder can be reset, using a setting

knob.

Equally, the dial is used for calibrating

the tyre pressure monitoring system.

Depending on the equipment, one of

the two variants is used as a multifunction display (MFA):

Multi-function display

Multi-function display „Plus“

m001_090

Multi-function display

„Plus“

This variant has a black/white TFT

display as MFD with a dot matrix of

110x166pixels.

Compared to the instrument cluster with

MFD, it has an advanced display possibility as a precondition for fitting various

equipment items such as driver assist

systems.

48

m001_091

Page 49

The central locking

A locking concept is used in the MAN TGE which makes it possible to lock and unlock the doors of the loadspace and driver‘s

cab jointly as well as separately from one another.

Operation via the ignition key

Pressing the middle button on the

ignition key unlocks the loadspace while

the driver‘s cab is locked at the same

time. This is useful, for example, if you

are working on a building site and you

want to store your personal belongings

safely in the driver‘s cab.

Lock all vehicle doors

Unlocking loadspace/

locking driver‘s cab

Unlock all vehicle doors

Loadspace closing button

The button on the right next to the

steering wheel enables the doors of the

loadspace to be locked or unlocked if

the ignition is switched on.

The warning lamp in the button lights up

if the loadspace has been locked with

the button. The doors of the loadspace

can then only be unlocked and opened

from the inside, not from the outside.

Pressing the loadspace closing button

when the ignition is switched off causes

the loadspace to be locked.

In that case, it can no longer be opened

by pressing the loadspace button again.

This is useful, for example, if the

payload should be kept secure while the

driver‘s cab is open.

m001_100

m001_101

Loadspace closing button

49

Page 50

The control unit for special vehicles

As a result of the increasing requirements of the various bodies and their

signal diversities, the control unit for

special vehicles J608 has been developed for the MAN TGE.

It offers a wide range of functions as

well as analog and digital inputs/

outputs.

Fixed function

packages

Battery monitoring

Free

programmability

Interfaces

CIA447 / J1939

The control unit for special vehicles

J608 is available in the variants BASIC

and MAX.

In addition to the functions of the BASIC

control unit, the MAX control unit offers:

24 outputs

16 digital inputs

A connection for an automotive-

compatible USB cable

A WLAN module (with connection for

an external aerial to increase the

range)

A Bluetooth module

BASIC

MAX

Basic functions (excerpt)

Light: control of exterior lighting, taxi

alarm, additional exterior lighting

Engine: ignition bypass, starter

inhibitor, engine remote start/stop,

auxiliary drive

Note

A special department creates the configuration file for the controller for special vehicles. The configuration file is

integrated into the vehicle via the Offboard Diagnostic Information System.

8 analog inputs

Closing systems: CL status signals,

door status signals

Energy: terminal status, battery

status, overload protection

m001_152

50

Page 51

Immobiliser and component protection

The MANTGE is equipped with the 5th generation immobiliser and component protection.

Legend

J234

J285

J362

J428

J519

J533

J623

J949 Emergency call module control unit and

J794

The MAN TGE uses the immobilizer

system of the fifth generation.

The sequence and selection of the

adjustments to the individual compo-

Airbag control unit

Control unit in dash panel insert

Immobiliser control unit

Adaptive cruise control unit

Vehicle electrical system control unit

Data bus diagnostic interface

Engine control unit

communication unit

Control unit 1 for information electronics

nents of the immobilizer system are

determined by the FAZIT database

(vehicle information and central information tool).

m001_142

Powertrain CAN bus

CAN bus extended

Convenience CAN bus

Infotainment CAN bus

CAN bus line

Immobiliser participant

Component protection participant

This single-head automatic system used

for adapting the immobilizer system

therefore replaces all of the previous

decision-making options.

51

Page 52

HEATING AND AIR CONDITIONING

Overview

The MANTGE can be equipped with the following

systems (the illustration shows the maximum possible

range of equipment):

Heating and ventilation system as basic equipment

Manual air conditioning system “Climatic”

Automatic air conditioning system „Climatronic“

(two or three zones)

Air conditioning variants

The climate zones in the MANTGE can be divided up

as follows:

One-zone heating and ventilation system or air

conditioning

Two-zone air conditioning in the driver‘s cab on the

right/left

Two-zone air conditioning in the driver‘s cab/

passenger compartment

Three zone air conditioning in driver‘s cab on the

right/left and passenger compartment

Additional display and operating unit 1

Air conditioning unit for Climatronic

Air intake system

Capacitor

Supplementary equipment

Additional components can be fitted depending on

equipment:

Roof ventilator for air extraction or blow-in

Water auxiliary heater

Additional air heater (fuel-operated)

Additional air heater (PTC / in air conditioner)

Additional air conditioner compressor for body

manufacturer directly on the engine

Second heat exchanger for loadspace/passenger

compartment

Second evaporator for loadspace/passenger

compartment)

Heated steering wheel

Heated windscreen

Heated rear window

52

Air conditioner compressor

(transverse installation here)

Water auxiliary heater

Page 53

Second evaporator Air duct in the headliner

(window van only)

Temperature sensor in the loadspace

Front operating unit Supplementary air heater

(Fuel)

Note

The refrigerant in the additional refrigerant circuit does not have to be R134a or R1234yf. It is defined by the body

manufacturer according to the requirements of its body.

m001_038

Second heat exchanger

53

Page 54

The operating units

Heating and ventilation system

The control panel of the heating and fresh air system

has three dials and one switch module.

Manual air conditioning

system „Climatic“

The control panel of the manual air conditioning

system has the same design as that of the heating and

fresh air system. However, some function-related

elements are different.

Automatic air conditioning

system „Climatronic“

1

7

8 42

1

7

1

2

3

6

3

6

5

3 1114

4

m001_040m001_035m001_036

5

5

4

In this air conditioning system, different temperatures

can be set for the various climate zones independently

from one another. The blower stages and flap positions

are controlled fully automatically, as is the control of the

air blowing out of the nozzles and the interior temperature.

Key to the figures

1

Seat heating left

2

Heated rear window

3

Air recirculation mode

4

Seat heating right

5

Air distribution

6

Blower speed

7

Temperature

8

Air conditioning system operation

Temperature setting to „LO“,

9

maximum blower output, air distribution to the

nozzles

10

Temperature right

16

Synchronisation of the climate zones to the

11

driver‘s value

Automatic control of the blower, temperature

12

and air distribution depending on the

sunshine intensity, outside and inside

temperatures

Air conditioning regulation for passenger

13

compartment

Use of residual heat when the engine is warm

14

and ignition switched on, used for keeping the

interior of the vehicle warm

Defrost, windscreen heating as well as

15

maximum blower setting and air distribution

towards the windows

16

Temperature left

17

Interior temperature sensor

6 17

13

12 109 82 15

54

Page 55

Additional display and operating unit 1

In vehicles with heating and air conditioning system or with manual air conditioning system, the settings for the additional air

conditioning systems are made using the control panel in the roof console at the front.

Button for temperature selection

Instant heating

Continuous operation (air heating) Call up menu

Setting button

Confirm settings

m001_037

Climatronic equipped with allergen filter

A polyphenol coating has been added

to the dust and pollen filter with activated charcoal. This coating is a natural

product that has anti-inflammatory

properties and occurs in many plants. It

absorbs allergens and renders them

harmless. The yellow-coloured coating

makes the filter easy to distinguish from

conventional dust and pollen filters.

An air quality sensor G238 detects

pollutants in the ambient air. The air

conditioner compressor is activated or

Allergen filter

switched to recirculation mode depending on the pollution of the ambient air,

the interior and outside temperature and

the tendency of the windscreen to mist

up.

2

1

3

Legend

Fleece layer with antibacterial and

1

antiallergenic polyphenol coating

Activated charcoal layer to filter out odours

2

and gases

3

Fleece layer to filter out pollen and dust

Filtered air

m001_039

55

Page 56

Ventilation and air conditioning at rear

Air duct in the headliner

(only in window van)

Second evaporator

In vehicles with closed bodies, it may be

sensible to extend the air conditioning.

This can be in the form of a second

evaporator arranged above the driver‘s

cab and/or a second heat exchanger

fitted under the front passenger seat.

The refrigerant lines for the second

evaporator are routed upwards in the

B-pillar, thus providing the connection to

the vehicle air conditioning system. The

regulated air enters the passenger

compartment via an air duct in the

headliner.

The volume of air flowing out is controlled by the blower speed. The direc-

56

Air outlet in the floor of the

passenger compartment

tion of the air flow can be set using

adjustable vents. The air duct is deleted

in vehicles that are used for transporting

cooled goods such as foodstuffs or

pharmaceuticals. If the second heat

exchanger is fitted, the air is channelled

into the loadspace/passenger compart-

Second heat exchanger

ment via the footwell vents that are at

the level of the B-pillar. In the window

van, there is also an air duct running

under the floor which additionally has

two vents in the floor of the passenger

compartment.

Page 57

Ventilation of the loadspace via the roof ventilator

If explosives or strong-smelling substances are transported, it may be necessary to ventilate the loadspace. This is

done using two different ventilation

systems. Firstly, an electrical fan module

on the vehicle roof which can be operated using two buttons on the left next to

the steering wheel or mechanical venti-

Second evaporator

lation without an electrical fan in the roof

module, although in this case with an

extraction duct on the rear left in the

loadspace floor that is closed from

above by a ventilation grille.

Roof fans

m001_159

m001_118

Operation

m001_119

Ventilation Breather

57

Page 58

Supplementary heater and auxiliary heater

The Thermo Top Evo is used as the supplementary water heating system in the MANTGE. The supplementary air heating

system is the Airtronic M2 D4A which is used as an auxiliary heater and a supplementary heater. It is infinitely variably controllable. In addition, for the first time it is possible to use a system of flaps with an auxiliary heater to control the air distribution forwards and to the rear.

Water auxiliary heater Supplementary air heater

Air intake system

m001_160

m001_086

Heated steering wheel

Optionally, the MANTGE is equipped with a heated

steering wheel that features an incorporated PTC

heating mat. The heating output of the PTC pad is

elevated at the usual hand positions (3 o‘clock and

9o‘clock).

Heater unit Air vent

m001_120

58

Page 59

RADIO, TELEPHONE AND NAVIGATION

The radios and navigation systems

The MAN TGE will be equipped with a

new generation of radios and navigation

systems. These devices are from the

Modular Infotainment System (MIS) of

the second generation that is currently

used in models from Volkswagen Passenger Cars that are based on the

modular transverse matrix (MQB).

For the first time in a commercial

vehicle, the devices now enable vehicle

status information to be displayed and

vehicle functions to be configured

(Carmenu).

CAR button

m001_130

MAN Media Van

The radio “Media Van” is the entry-level

variant of the radio systems for the MAN

TGE.

Technical features

TFT monochrome display

370 x 98 px

Output power of 4 x 20 watt

AM/FM single tuner

MP3, WMA format support

SD card reader

AUX-IN connection

USB connection

Bluetooth interface for mobile tele-

phones (HFP, PBAP, A2DP, AVRCP)

Microphone

m001_127

USB connection

SD card reader

AUX-IN connection

59

Page 60

MAN Media Van Advanced

In the “Media Van Advanced” the

“display unit for front information display

and operating unit control unit J685”

and the “control unit 1 for information

electronics J794” are accommodated

in separate housings.

The “control unit 1 for information

electronics J794” is located in the glove

compartment.

The two components are connected by

the MIB CAN bus and a LVDS cable.

This strategy has also been implemented for the “Media Van Navigation”.

Technical features

Capacitive 8-inch TFT colour display

with touchscreen and proximity

sensors*, WVGA, 800 x 480 pixel

Output power of 4 x 20 watt

FM phase diversity, AM

CD drive

MP3, WMA, AAC, FLAC audio format

support

JPEG viewer

Bluetooth (HFP, A2DP, PBAP, AVRCP,

MAP, 2 mobile phones can be paired

simultaneously via HFP)

SD card reader

USB/AUX-IN connection (with Apple

support) in the storage compartment

of the dash panel above the steering

wheel

Voice control

Optional

DAB+

m001_128

m001_136

SD card reader

* Proximity sensors:

When a finger approaches the display, the virtual buttons are increased in size.

60

Page 61

MAN Media Van Navigation

The “Media Van Navigation” has a

navigation function. The navigation data

is not transferred to the navigation

system, but is called for dynamically,

which means the SD card with the

navigation data must always be left in

one of the two SD card readers of the

two SD card readers in the control unit

1 for information electronics.

One-shot destination entry

The navigation system can be operated

by voice input. The destination is

entered in a coherent spoken phrase

instead of sequential requests for the

address components.

Technical features

In addition to the features of the

Composition Media radio, this device

configuration has the following characteristics:

Second SD card reader

WLAN*

m001_129

m001_105

SD map reader 1 SD map reader 2

* In conjunction with Media Control

61

Page 62

The reversing camera

Fitting location

In the MANTGE, the reversing camera R189 is used and improves visibility to the rear when reversing. In vehicles with closed

bodies, it is attached on the roof above the rear doors and supplies a real video image of the area behind the vehicle. The reversing camera can be combined with the “Media Van Advanced” and “Media Van Navigation” radio or navigation systems.

Radio display

When terminal 15 is on and reverse

gear engaged, the video signal from the

camera is shown on the screen.

The screen shows the real video image.

The static help lines that overlay the

surrounding picture in the colour display

are applied by the screen and are used

for gauging distances better. The reversing camera R189 does not require

calibration.

m001_131

Reversing camera R189

Media Van Navigation display example

62

m001_132

Static lines

Page 63

Aerial systems

In the MANTGE, a rod aerial as well as exterior mirrors with integrated vehicle aerials are used. The illustrations show a rod

aerial and exterior mirrors with the maximum possible vehicle equipment.

Rod aerial

The rod aerial is bolted onto the roof above the driver‘s cab.

m001_110

Aerials in the exterior mirrors

LTE aerial for

telematics preparation

4)

GNSS1) aerial for

telematics preparation

UMTS aerial for control

unit for emergency

call module and

communication unit

J949

DAB aerial

4)

LTE aerial for storage compartment

with interface for mobile phone

5)

R265

Aerial

AM/FM

1)

GNSS

aerial

(GPS2) + LONASS3))

for navigation and

control unit for

emergency call

module and

communication unit

J949

m001_111

Aerial FM2

m001_112 m001_113

1)

GNSS: Global Navigation Satellite System, GNSS is a collective term for using existing and future global satellite systems

2)

GPS: Global Positioning System, also known as NAVSTAR GPS

3)

GLONASS: GLObal NAvigation Satellite System of the Russian Federation

4)

Telematics preparation: interface to fleet management systems

5)

It would be added at a later point

63

Page 64

MAN Truck & Bus AG

MAN Academy

Dachauer Straße 667

80976 München

www.mantruckandbus.com

MAN Truck & Bus – An enterprise of the MAN group

Loading...

Loading...