Page 1

PHANTOM F 12 MAX

A

WORKSHOP MANUAL

CHASSIS

Page 2

Page 3

A

09.03 3

INTRODUCTION

CHAPTER

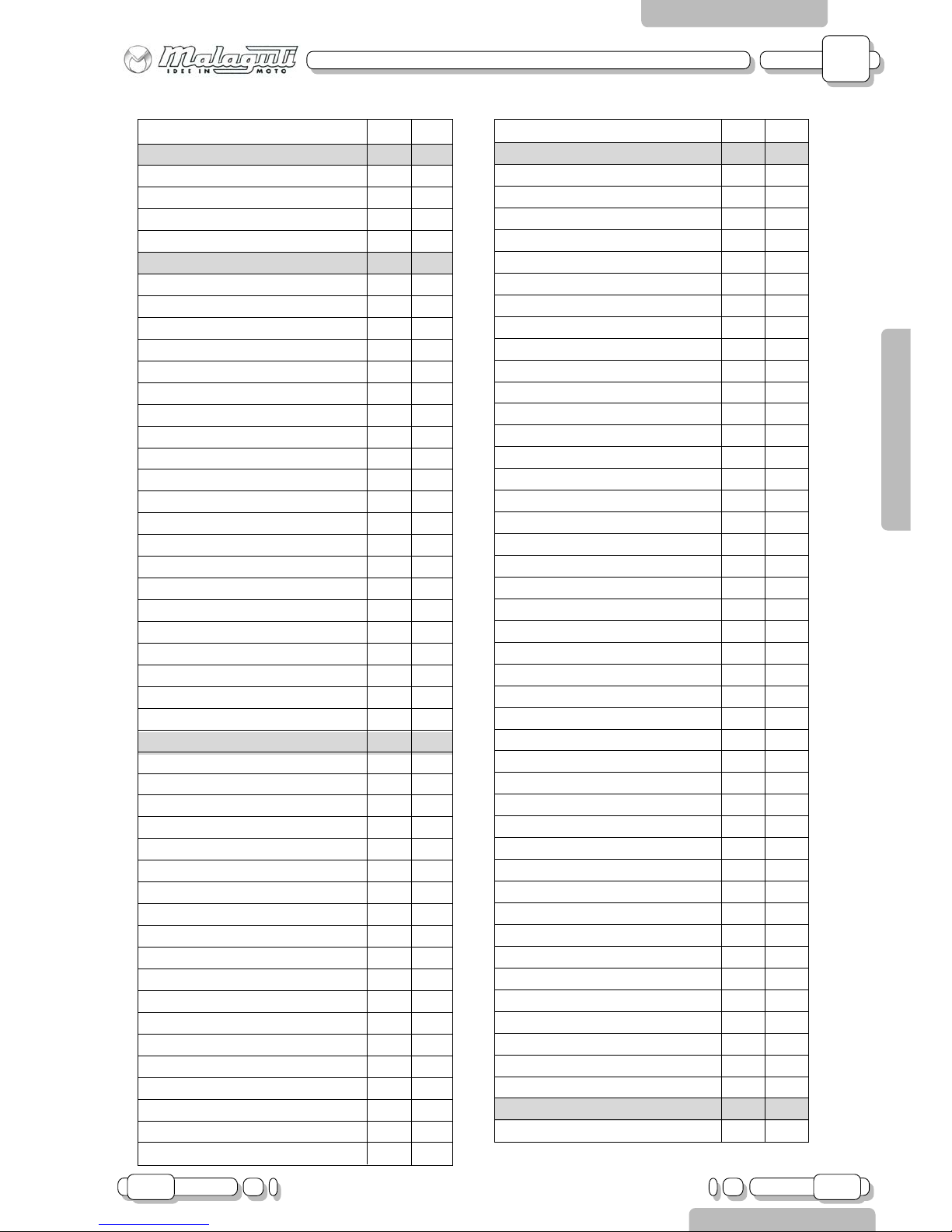

PAGEISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

SP

INTRODUCTION 1 44

Notes for easy consultation 1 5

Abbreviations 1 6

General work procedures 1 6

Editing symbols 1 9

GETTING TO KNOW YOUR VEHICLE 2 10

Specifications 2 10

Unpacking 2 12

Appearance check 2 12

Registration data 2 12

VIN Label 2 12

Anti-tampering label 2 12

Main components 2 13

Controls 2 14

Start switch/keys 2 14

Stands 2 15

Display 2 15

Tires 2 16

Fuel tank 2 16

Coolant 2 17

Engine oil 2 17

Transmission oil 2 19

Brake fluid 2 20

Adjustment of engine idling speed 2 20

Shock absorber adjustment 2 21

Fuses 2 21

Checking the shape of the chassis 2 22

DISASSEMBLY 3 23

Front handlebar cover 3 23

Instrument board 3 24

Handlebar upper fairing 3 25

Left control 3 25

Right control 3 26

Front wing 3 27

Speedometer sensor 3 27

Front brake calipers 3 27

Front wheel 3 29

Front brake disc 3 29

Front fairing 3 30

Headlights 3 31

Front indicators 3 32

Headlight guard 3 33

Horn 3 34

Coolant container 3 34

Seat 3 34

Passenger’s seat 3 35

Seat lock 3 35

TABLE OF CONTENTS

SP

DISASSEMBLY 3 23

Battery 3 36

Helmet compartment 3 36

Handle cover 3 38

Rear handle 3 38

Seat lock 3 38

Tail lamps 3 39

Rear indicators 3 39

Number plate light 3 40

Nameplate holder 3 40

Side casings 3 40

Rear cowling 3 41

Rear reflector 3 42

Tail section 3 42

Starter relays 1/2 3 43

Flashlight (125 cc only) 3 44

Regulator 3 44

Control unit 3 45

Fuel probe 3 46

Strut 3 47

Footboard 3 48

Lower fairing 3 49

Fuel filter 3 52

Fuel pump 3 52

Fuel tank 3 52

Radiator 3 53

Radiator fan 3 56

Rear shock absorbers 3 57

Air filter box 3 58

Muffler 3 60

Rear wing 3 62

Transmission cooling sleeve 3 63

Rear calipers 3 63

Rear wheel 3 65

Rear disc 3 66

Engine 3 66

Centre stand 3 72

Side stand 3 73

Side stand switch 3 73

Engine fixing plate 3 74

Switch with key 3 75

Handlebar 3 76

Fork 3 76

Stem-wheel holder assembly 3 77

ASSEMBLY 4 79

Chassis torque wrench settings 4 79

Page 4

A

4 09.03

INTRODUCTION

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

INTRODUCTION

• This Workshop Manual describes the main electrical/mechanical checks, the essential checks and the as-

sembly of components supplied disassembled in order to deliver a brand new motorcycle (the sequence of

operations is not binding).

• It is essential to follow the instructions with great care. Work carried out carelessly or, worse still, work that has

not been accomplished, can cause injuries and damage or, in the less serious cases, tiresome complaints.

Note:

These manuals provide the necessary information and instructions for routine maintenance and servicing. Some

information has been given to us by the engine manufacturers. We therefore decline all responsibility for any error,

omission or misrepresentation.

MALAGUTI reserves the right to make any changes and modifications hereto it deems necessary without prior

notice.

For further information and details, please contact the Malaguti S.p.A. Service Division.

MANUAL UPDATES

• Updated pages of this publication will be delivered by us (in a reasonable time) already punched and therefore

ready to be incorporated in the Manual. The superseded sheets should not be removed from the manual as they

remain applicable to the servicing of pre-modified vehicles.

• The table of contents will be duly updated in the event that new pages are inserted, which render the consulta-

tion of the manual difficult.

• IMPORTANT! The Workshop Manuals are to be considered as essential tools to be properly kept up-to-date so

as to maintain their “validity” over time.

Page 5

A

09.03 5

INTRODUCTION

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

X

W

Z

Y

(RH PAGE)

P A GE LA Y OUT

Y Chapter

X Section title

W Page N°

Z Date of issue

NOTES FOR EASY CONSULTATION

MODIFIED PAGES

• Modified pages shall bear the same number as those in the previous edition /pre-modified ones, followed by the

letter M, with the date of issue appearing in the appropriate box.

• Modified pages may contain new illustrations; in this case, the added illustration (or illustrations) will bear the

number of the illustration on the former page, followed by a letter.

ADDITIONAL PAGES

• Any additional pages shall bear the last number of the section to which they belong, followed by the letter A and

the date of issue.

ILLUSTRATIONS

• This manual describes disassembly of 125 cc and 200

cc versions; the illustrations will bear indications as to

which version of the vehicle is illustrated, in order to distinguish the sequences.

Illustration n°

Version

ILLUSTRATIONS

Page 6

A

6 09.03

INTRODUCTION

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

F Figure

Cs Tightening torque

P Page

Pr Paragraph

S Section

Sc Diagram

T Table

V Screw

EDITING SYMBOLS

• Symbols have been provided for quick and easy reference (see page 9), identifying situations requiring

utmost attention or providing practical suggestions or simple information.

• These symbols may appear next to a text (in which case they refer solely to the text itself), next to a figure

(in which case they refer to the topic illustrated in the figure and to the relative text), or at the top of the page

(in which case they refer to all the topics dealt with in the page).

Note:

The meaning of the symbols should be duly memorised as their scope is to avoid having to repeat basic technical

concepts or safety recommendations. They are therefore to be considered as veritable “memory tags”. In case of

any doubt as to their meaning, consult the page in which they are fully described.

ABBREVIATIONS

Note:

the letter V in the illustrations refers to retaining or adjusting screws. The number following this letter refers to the

number of the same type of screw in the unit or component described and illustrated. Letters not followed by a

number indicate a single screw. In case of different screws being referred to in the illustration, the letter V is

followed by a number and a small letter. For instance: (V4a).

Unless otherwise specified, units and components are reassembled by proceeding in the reverse order of removal.

GENERAL WORK PROCEDURES

• The advice, recommendations and warnings given hereafter are aimed at ensuring maximum work safety as

well as at considerably reducing the risk of accidents, personal injury, equipment damage and idle times. They

should therefore be strictly adhered to.

Page 7

A

09.03 7

INTRODUCTION

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

F. 1

F. 3

F. 2

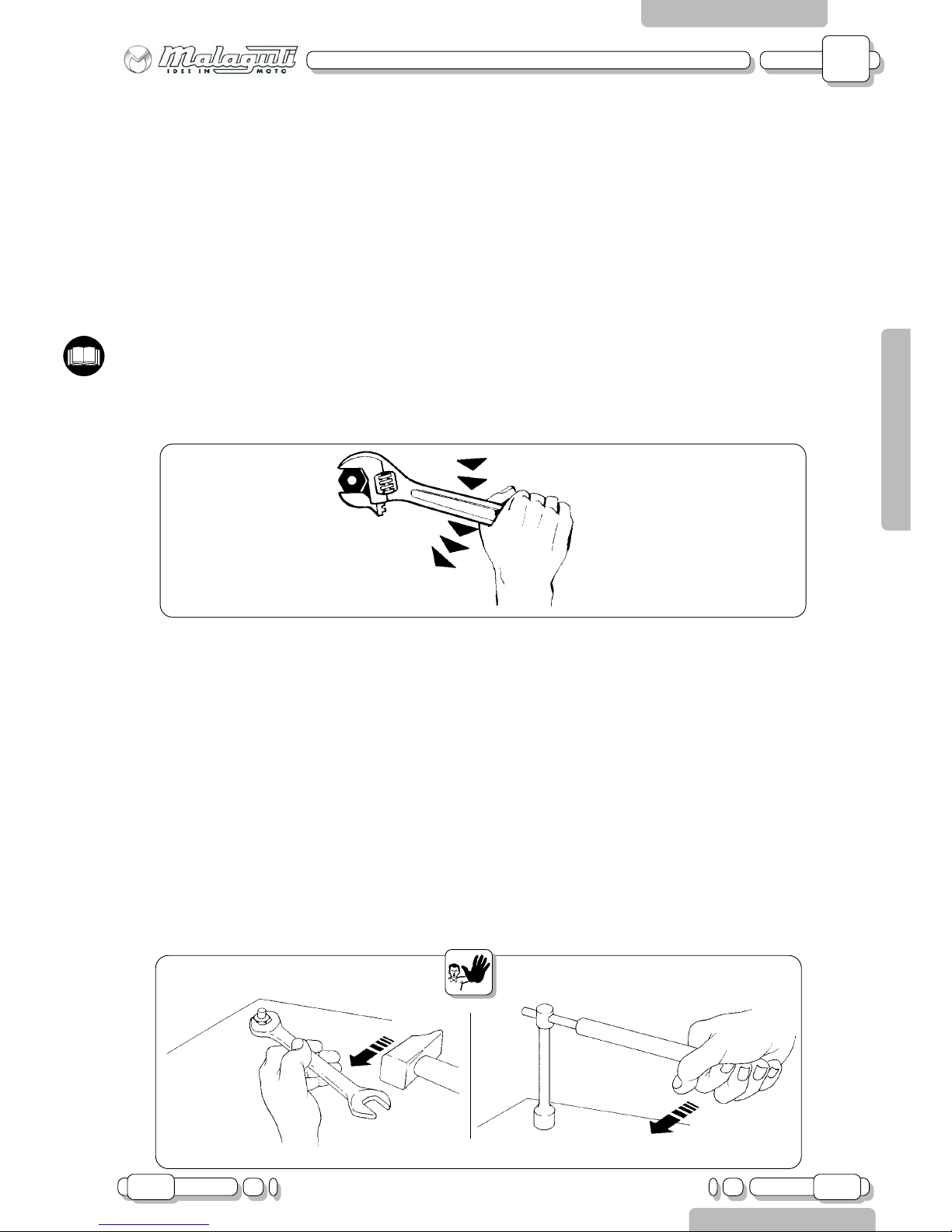

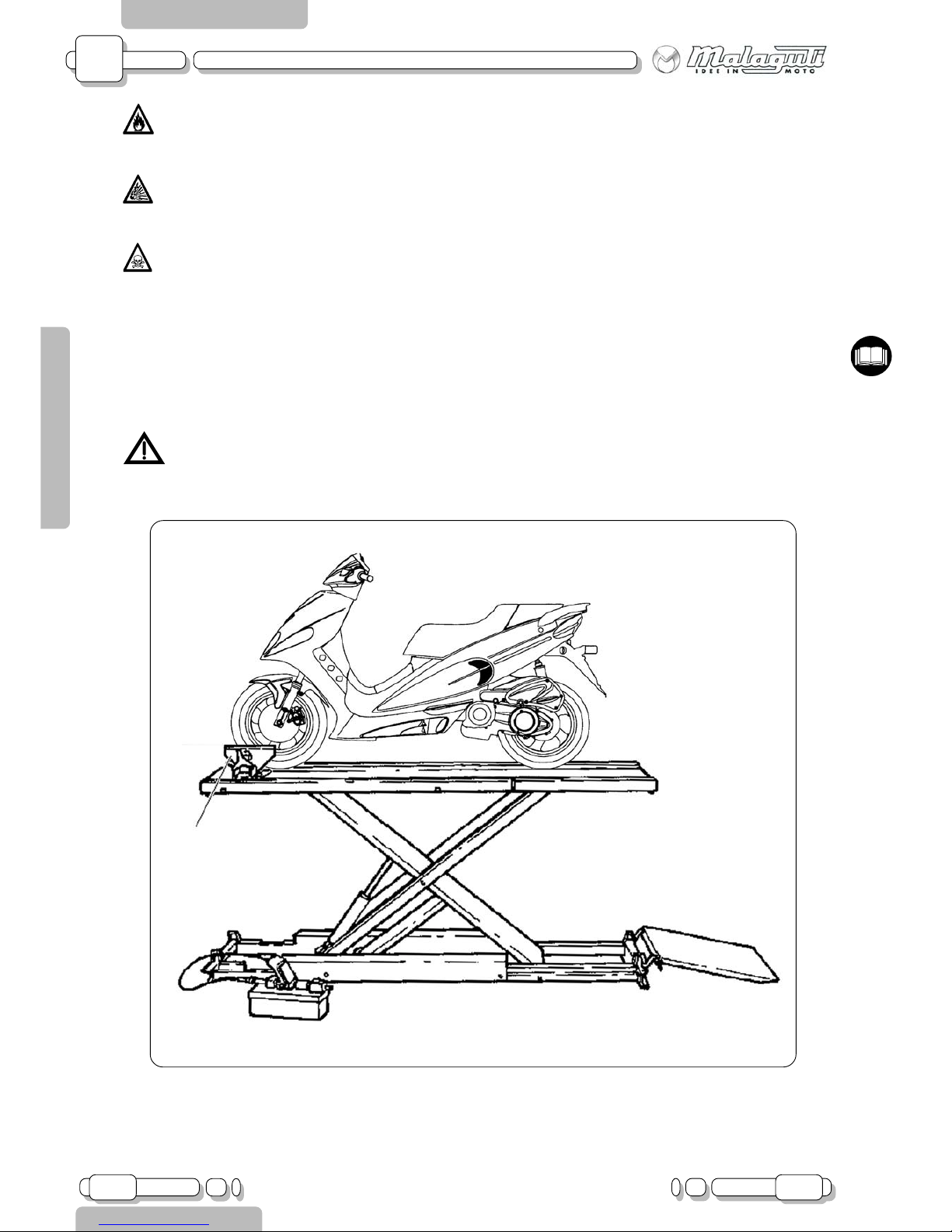

ADVICE:

• Only use quality tools and equipment.

• Only use equipment conforming to EU Directives for lifting the vehicle.

• During operations, always keep tools and equipment at hand, possibly laying them out according to the sequence in which they are to be used. Absolutely avoid putting them on the vehicle itself, out-of-sight or in poorly

accessible places.

• Always keep the work area clean and tidy.

• When tightening screws or nuts, start with the larger diameter or inner fasteners, and tighten them in progressive “pulls” in accordance to a “criss-cross” pattern.

• Preferably use open-end box wrenches by “pulling” and not “pushing”.

• Adjustable wrenches (F. 1) should only be used in case of emergency, i.e. when a properly sized wrench is not

available. they should preferably not be used as the movable jaw tends to open thus risking damaging or not

properly tightening the bolt to the correct torque. In any case, when using an adjustable wrench, take care to

proceed as shown in Figure 1.

• Except for occasional customers, always make out and deliver to the customer a work sheet specifying the

operations performed, with notes as to any future checks eventually required.

RECOMMENDATIONS:

• Before carrying out any operation on the vehicle, wait for all parts to cool down.

• For operations requiring two mechanics, make sure that the various steps to be performed by each of them are

clearly defined and coordinated beforehand.

• Make sure that each component has been properly fitted before proceeding with the next one.

• Lubricate all parts (where applicable) before reinstalling them.

• Gaskets, O-rings, circlips and split pins must be replaced at every refitting.

• The torque settings specified in the manuals refer to the “final torque”, which must be attained progressively by

steps.

• Loosen and tighten aluminium alloy parts (covers) only after the engine has fully cooled down.

• Only use screwdrivers with sizes suitable to the screws to be loosened or tightened.

• Work in a comfortable position and ensure that the vehicle is stable.

• Never use a screwdriver as a lever or chisel.

• Never use pincers to loosen or tighten screws or nuts because, in addition to not providing a sufficient clamping

force, they may also damage the screw head or nut hexagon.

• Never tap the wrench with a hammer or other similar tools to loosen or tighten screws and nuts (F. 2).

• Never attempt to increase the lever arm by fitting a tube into the wrench (F. 3).

Page 8

A

8 09.03

INTRODUCTION

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

F. 4

A

Never use open flames for any reason.

Never leave open containers or containers not suitable for holding fuel in passageways, close to heat

sources, etc

Never use petrol to clean the vehicle or the floor of the workshop. Always use low flash point solvents to

clean the vehicle components.

Never suck from or blow into the fuel pipe.

When welding, make sure that there are no flammable liquids in the vicinity. Always remove the tank, even

if completely empty, and disconnect the negative cable (-) from the battery.

Never leave the engine running in closed or poorly ventilated areas.

Before any servicing, make sure that the motorbike is perfectly stable.

The front wheel should preferably be anchored to the equipment (A - F 4) integral with the lifting board.

Page 9

A

09.03 9

INTRODUCTION

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 1

A - CHASSIS

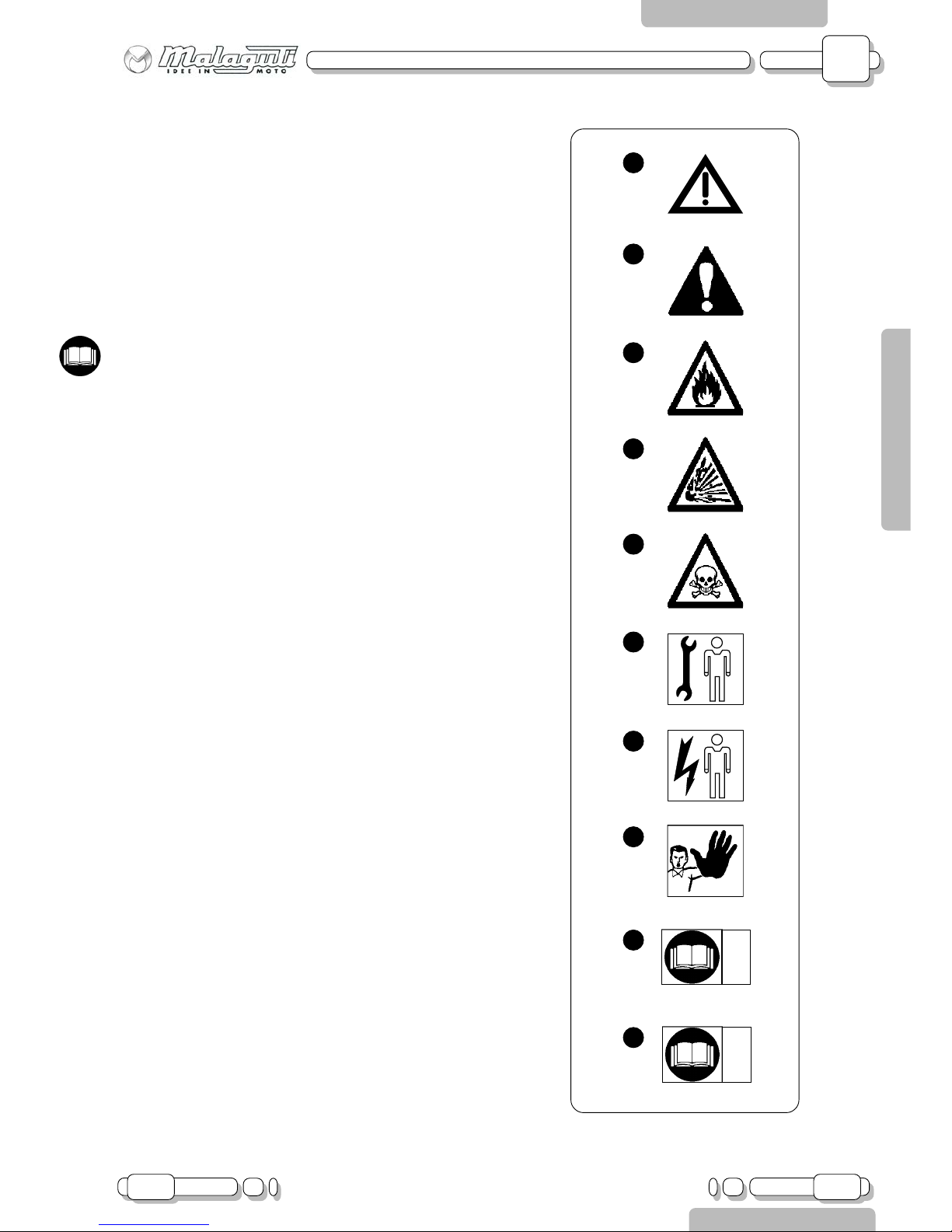

R

M

L

H

F

A

B

D

C

I

G

E

EDITING SYMBOLS

A) CAUTION! Recommendations and precautions regarding rider

safety and motor vehicle integrity.

B) WARNING! Situations entailing the risk of personal injury to

maintenance or repair mechanics, other workshop personnel or

third parties, or damage to environment, vehicle or equipment.

C) FIRE HAZARD

Indicates operations which may constitute a fire hazard.

D) RISK OF EXPLOSION

Indicates operations which may constitute a risk of explosion.

E) TOXIC FUMES

Indicates a possibility of intoxication, inflammation or corrosion.

F) MECHANICAL MAINTENANCE

Operations to be performed only by an expert mechanic.

G) ELECTRICAL MAINTENANCE

Operations be performed only by an expert electrical/electronic

technician.

H) NO! Operations to be absolutely avoided.

I) ENGINE WORKSHOP MANUAL

Indicates information which may be obtained by referring to said

catalogue.

L) SPARE PARTS CATALOGUE

Indicates information which may be obtained by referring to said

catalogue.

Page 10

A

10 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

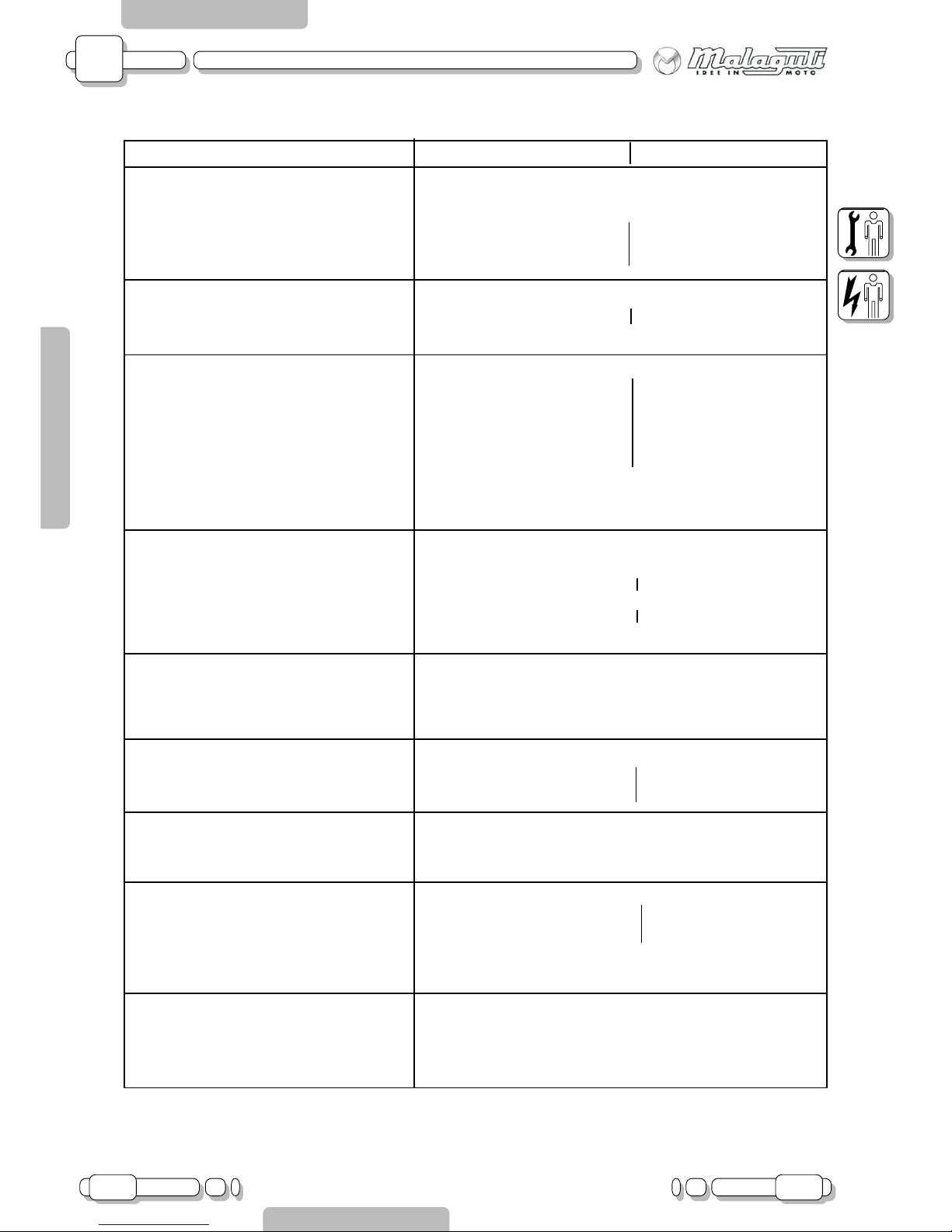

SPECIFICATIONS

125 cc

200 cc

Dimensions:

Max. length

Max. width

Max. height 1210 mm 1280 mm

Wheel base 1400 mm 1410 mm

Weight:

kerb weight 139 kg 143 kg

maximum load

Engine:

Type single cylinder, 2 valves single cylinder, 4 valves

Cylinder type 3M5 M244M

Displacement 124 cm

3

198 cm

3

Bore x stroke 53.7 x 54.8 mm 72.0 x 48.6 mm

Compression ratio 11: 1 11.5: 1

Starting system

Lubricating system

Ignition system

Type of oil:

Engine oil

Total amount 1.4 L 1000 cc

Transmission oil

Total amount 0.14 L 150 cc

Brake fluid

Fuel:

Type

Fuel tank capacity

Reserve amount

Carburettor:

Type 5XL WVF7 - KEI HIN/CVK30

Manufacturer TEIKEI Walbro

Chassis:

Frame

Spark plug:

Type NGK CR8EB NGK CR8EB

CHAMPION RG6YC

Manufacturer

Electrode gap

Cooling system

Type

Recommended fluid

Mode:

1980 mm

760 mm

170 kg

electrical starter

wet sump

electronic

Q8 CLASS 10W-40

Q8 T35 - 80W

Q8 BRAKE FLUID DOT 4

unleaded petrol

9.5 L

3 L

single tubular steel frame split at

the footboard level

NGK

0.6 ~ 0.7 mm

liquid cooled

Q8 TOP FLUID

Page 11

A

09.03 11

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 2

A - CHASSIS

GETTING TO KNOW YOUR VEHICLE

SECTION 2

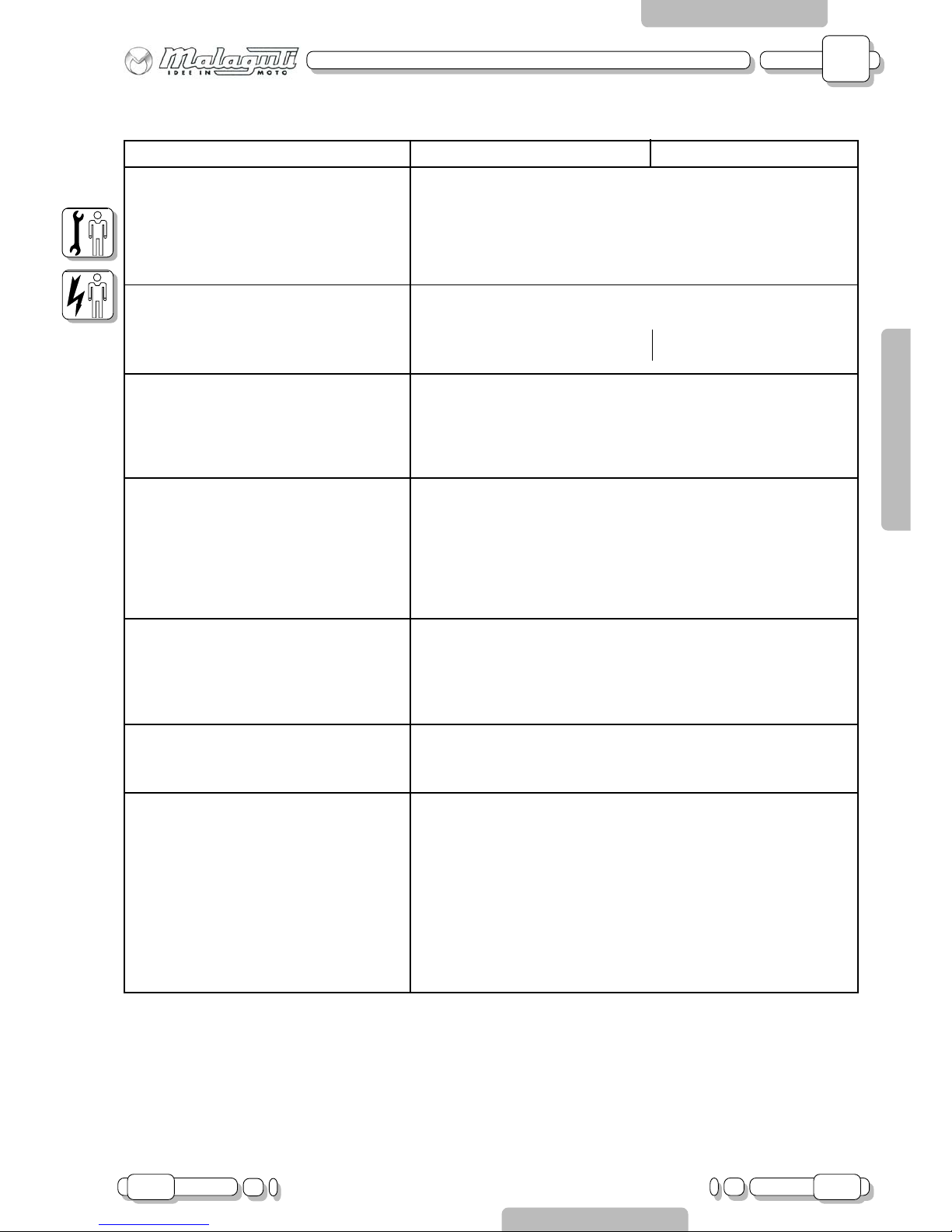

Transmission:

Type

Primary reduction system

Clutch

Tires:

Type

Front 130/70-13 57P 130/70-13 57S

Rear 130/60-18 63P 140/60-13 63S

Tire pressure (ambient temperature):

Front 0 ~ 90 kg

Rear 0 ~ 90 kg

Front 90 kg ~ max. load

Rear 90 kg ~ max. load

Brakes:

Front

Calipers

Operation

Rear

Calipers

Operation

Suspensions:

Front

Max. stroke

Rear

Max. stroke

Electrical equipment:

Battery capacity

Horn

Lights

Low beam

High beam

Front parking light

Front/rear - right/left turn indicators

Instrument board lights

Stop light

Rear parking light

Number plate

125 cc 200 cc

automatic speed variator, by V-belt,

one speed

gear type

dry, centrifugal and automatic

tubeless

2.3 bar

2.3 bar

2.3 bar

2.3 bar

hydraulic disk type, Ø220 mm

hydraulic

right hand

hydraulic disk type, Ø220 mm

hydraulic

left hand

telescopic-hydraulic fork with two stanchions Ø 33

90 mm

2 hydraulic shock absorbers with adjustable spring preload

82 mm

12V 9 Ah

12V

halogen, 12V - 65W HB3

halogen, 12V - 55W H3

12V - 3W

12V 10W

LED

12V - 16W - 2 Pcs

12V - 2.3W - 10 Pcs

12V - 5 W

Page 12

A

12 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

F.1i

F.2i

A

A

125 cc200 cc

B

C

MARCHIO DI FABBRICA: MALAGUTI S.P.A.

CATEGORIA DEL VEICOLO: (*)

1 -

---------------------

2 -

---------------------

3 -

---------------------

4 -

----------------------

5 -

----------------------

6 -

-----------------------

7 -

-----------------------

8 -

-----------------------

9 -

------------------------

10 -

---------------------

11 -

----------------------

12 - ----------------------

F.3i

F.4i

UNPACKING

• Unpack the motorcycle following the instructions printed on the pack, which must be disposed of in accordance

to the laws in force.

APPEARANCE CHECK

• Make sure all plastic components have been correctly fitted. In particular check the vehicle for scratches, marks,

etc.

REGISTRATION DATA

ENGINE REGISTRATION NUMBER

Engine registration data (A - F.1i) are on the left engine crankcase.

VEHICLE REGISTRATION NUMBER

To access the vehicle registration number, open the centre hatch, using the ignition keys, and remove the

cover (B - F. 2i).

VIN LABEL

The vehicle’s VIN label is applied to the front of the vehicle, on the right hand side, under the upper fairing

(C - F.3i)

ANTI-TAMPERING LABEL

Anti-tampering label (only for version 125 cc.) - (F. 4i). The anti-tampering label is located inside the

helmet holder. It bears all the registration data requested by Directive 97/24/CE.

If you have replaced your helmet holder, make sure the new component features this label.

When ordering spare parts, also quote the vehicle or engine registration data.

This label must be neither removed nor changed.

Page 13

A

09.03 13

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 2

A - CHASSIS

GETTING TO KNOW YOUR VEHICLE

SECTION 2

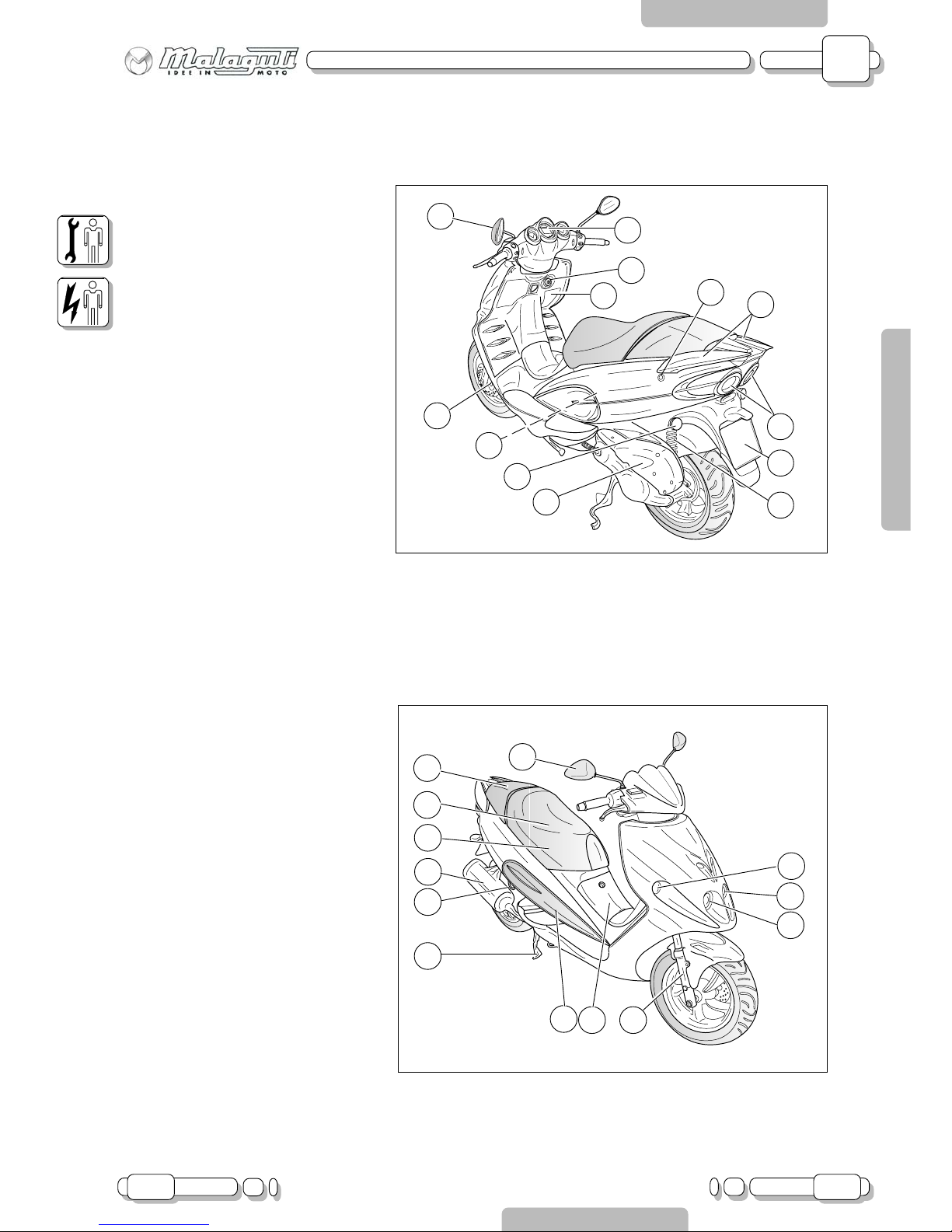

F.5i

F.6i

15a

24

22

14

20

17

16

25

21

23

1819

15b

4

1

2

7

8

13

9

5

11

10

12

3

6

MAIN COMPONENTS

(Left hand side)

1. Digital instrument board

2. Switch with key

3. Front ticket holder

4. Front disc brake calipers

5. Carburettor

6. Rear turn indicators

7. Tail light

8. Nameplate holder

9. Air filter

10. Seat lock

11. Left hand rear view mirror

12. Passenger’s handle

13. Adjustable shock absorbers

MAIN COMPONENTS

(Right hand side)

14. Right hand mirror

15a. High beam headlight

15b. Low beam headlight

16. Front turn indicators

17. Helmet holder

18. Fork

19. Fuel tank cap

20. Muffler

21. Battery

22. Anti-theft hook

23. Centre stand

24. Spark plug

25. Seat

Page 14

A

14 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

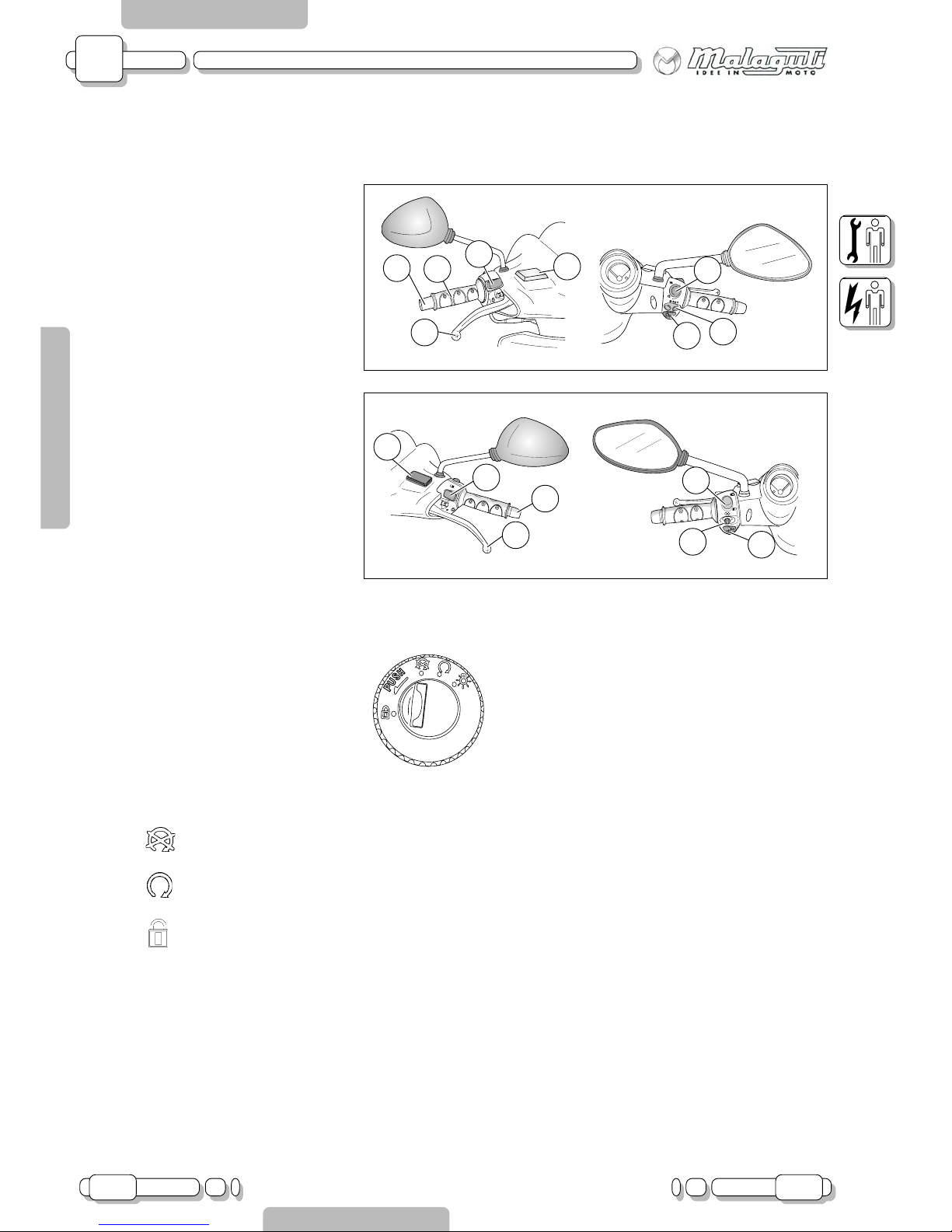

F.9i

26

29

27

28

30

31

32

33

40

39

38

36

37

35

34

F.7i

F.8i

CONTROLS

Right hand controls

26. Front brake lever

27. Counterweight

28. Throttle grip

29. MODE button

30. Front brake oil tank

31. Electrical starter button

32. Light switch

33. Emergency switch, engine

stop

Left hand controls

34. Rear brake oil tank

35. “Flash” lever, high beam lights

36. Rear brake lever

37. Counterweight

38. Light switch

39. Turn indicator switch

40. Horn button

START SWITCH/KEYS

• The main switch controls the ignition circuit and steering lock.

: all electrical contacts are disconnected.

: contacts are connected. The engine can start.

: the steering lock is on.

KEYS

The vehicle is supplied with two keys featuring a code number, which have the following functions:

• Providing the ignition contact

• Turning the lights on.

• Locking the steering system.

• Opening the hatch of the fuel cap compartment.

STEERING LOCK

Locking: turn the handlebar all the way to the right or left, push the key in and turn it counter-clockwise.

Disengaging: turn the key clockwise.

Page 15

A

09.03 15

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 2

A - CHASSIS

GETTING TO KNOW YOUR VEHICLE

SECTION 2

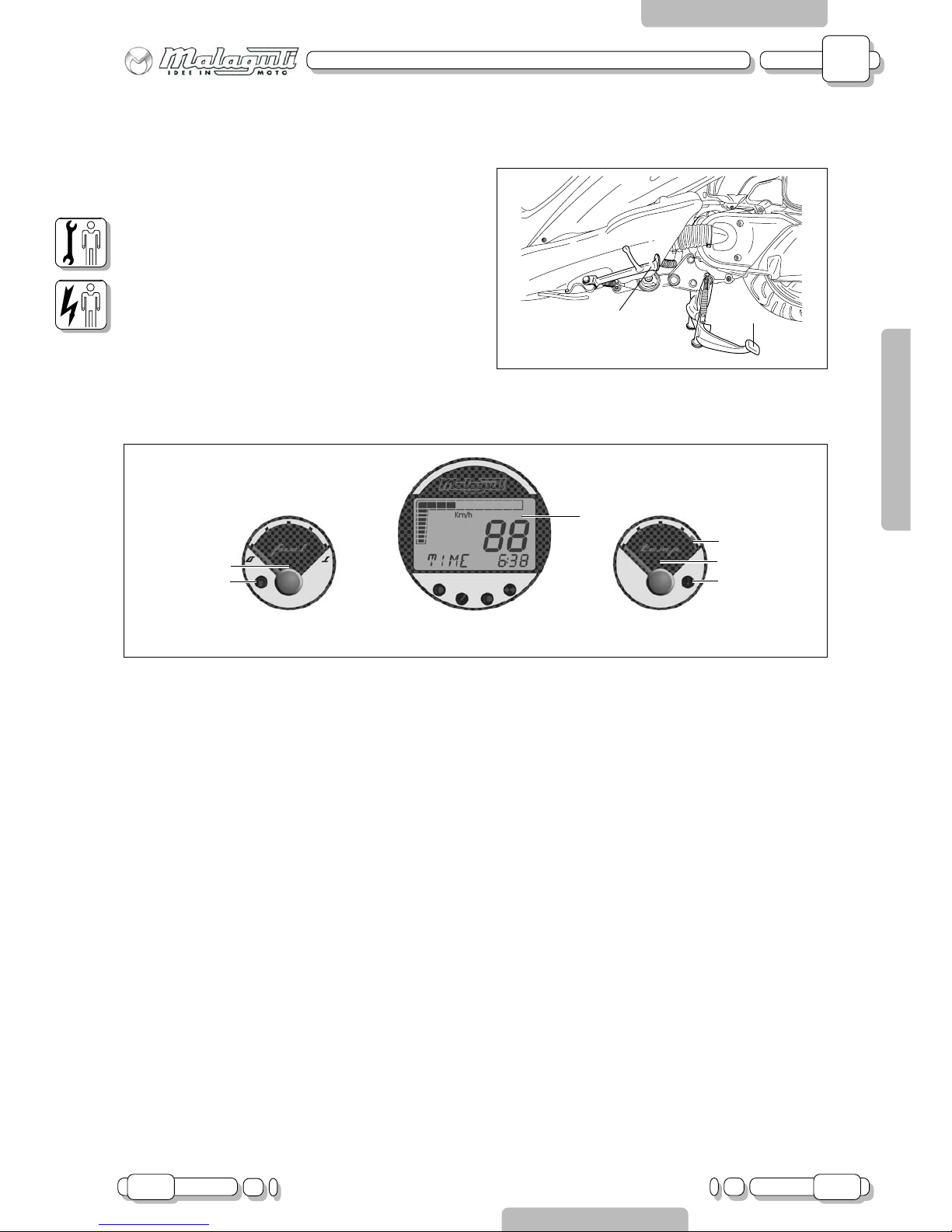

F.10i

F.11i

B

A

C

2

B

1

A

6

4

73

5

STANDS

Make sure the centre stand (A - F. 10i) and the side

stand (B - F. 10i) are correctly fitted and that they move

correctly. Check the spring holding the side stand in

place on a regular basis.

DISPLAY

1- Coolant temperature indicator

The red notch (A) and the activation of the red warning light (B) mean that the liquid is too hot, owing to a fault

in the cooling circuit or to a shortage of coolant. Bring the vehicle to an immediate stop.

2- Fuel level indicator

The warning light (C) comes on to indicate that the reserve amount has been reached.

3- Green low beam indicator light

4- Blue high beam indicator light

5- Green turn indicator light

6- Multifunction digital instrument board

7- Not controlled

Page 16

A

16 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

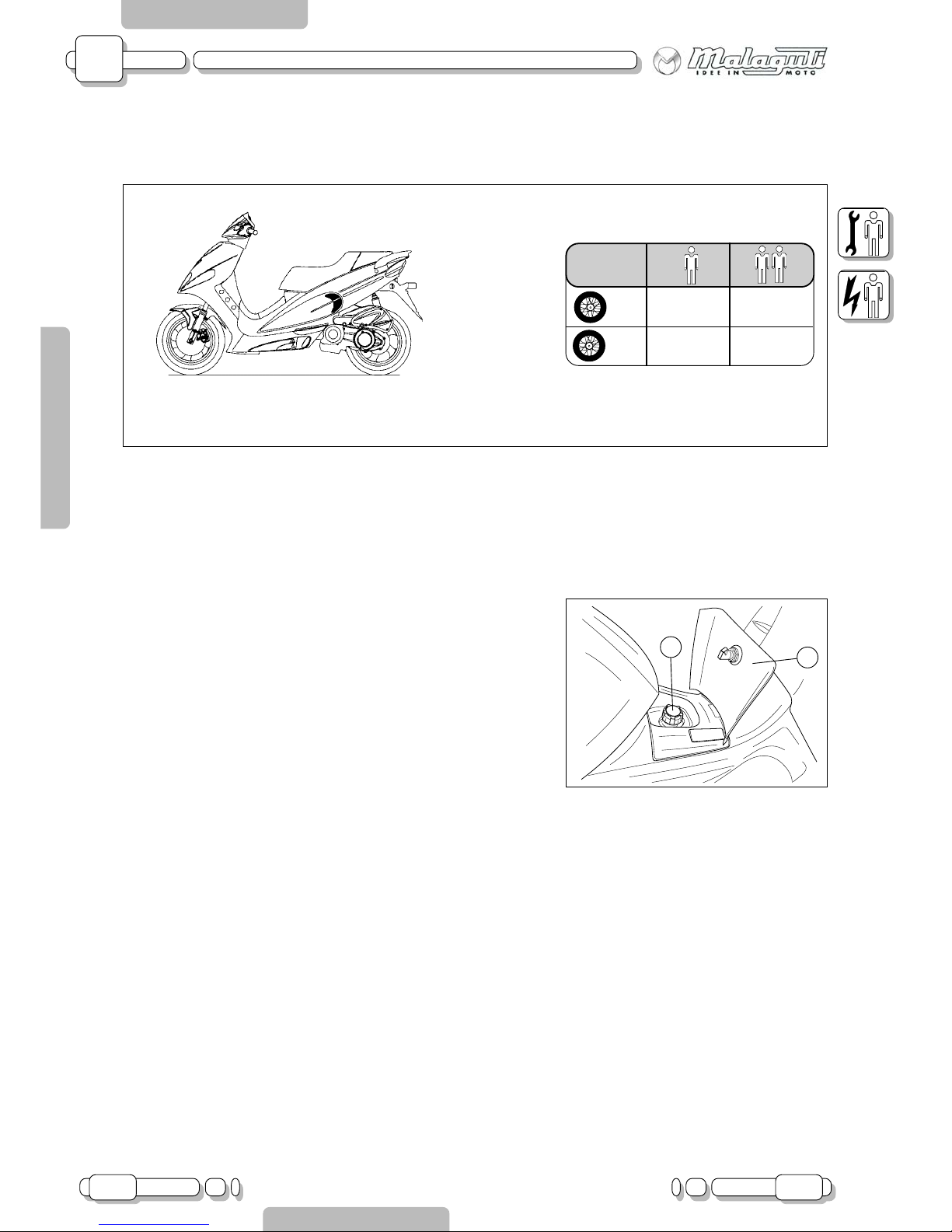

bar

(psi)

2,3 2,3

(33,4) (33,4)

2,3 2,3

(33,4) (33,4)

X

Y

X

Y

F.13i

F.12i

B

A

TIRE PRESSURE CHECK

Tire pressure must be checked when the tires are cold.

FUEL TANK

Open the hatch (A - F. 13i) with the starter key, unscrew the cap (B F. 13i) and fill the tank. Immediately wipe off spilled fuel.

Use unleaded petrol.

Fuel tank capacity:

Total: 9.5 L

Reserve amount: 3 L

Page 17

A

09.03 17

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 2

A - CHASSIS

GETTING TO KNOW YOUR VEHICLE

SECTION 2

F.14i

F.15i

1

A

Max

Min

A

F.16i

1

2

3

A

COOLANT

CHECK

To gain access to the coolant tank (1 - F. 14i), for

engine cooling, remove the cover by loosening the

screw (A - F. 14i).

The coolant level must be checked on a cold engine

since the level varies with engine temperature. The

level of coolant must fall within the maximum and

minimum notches on the tank.

If the level is low, add coolant.

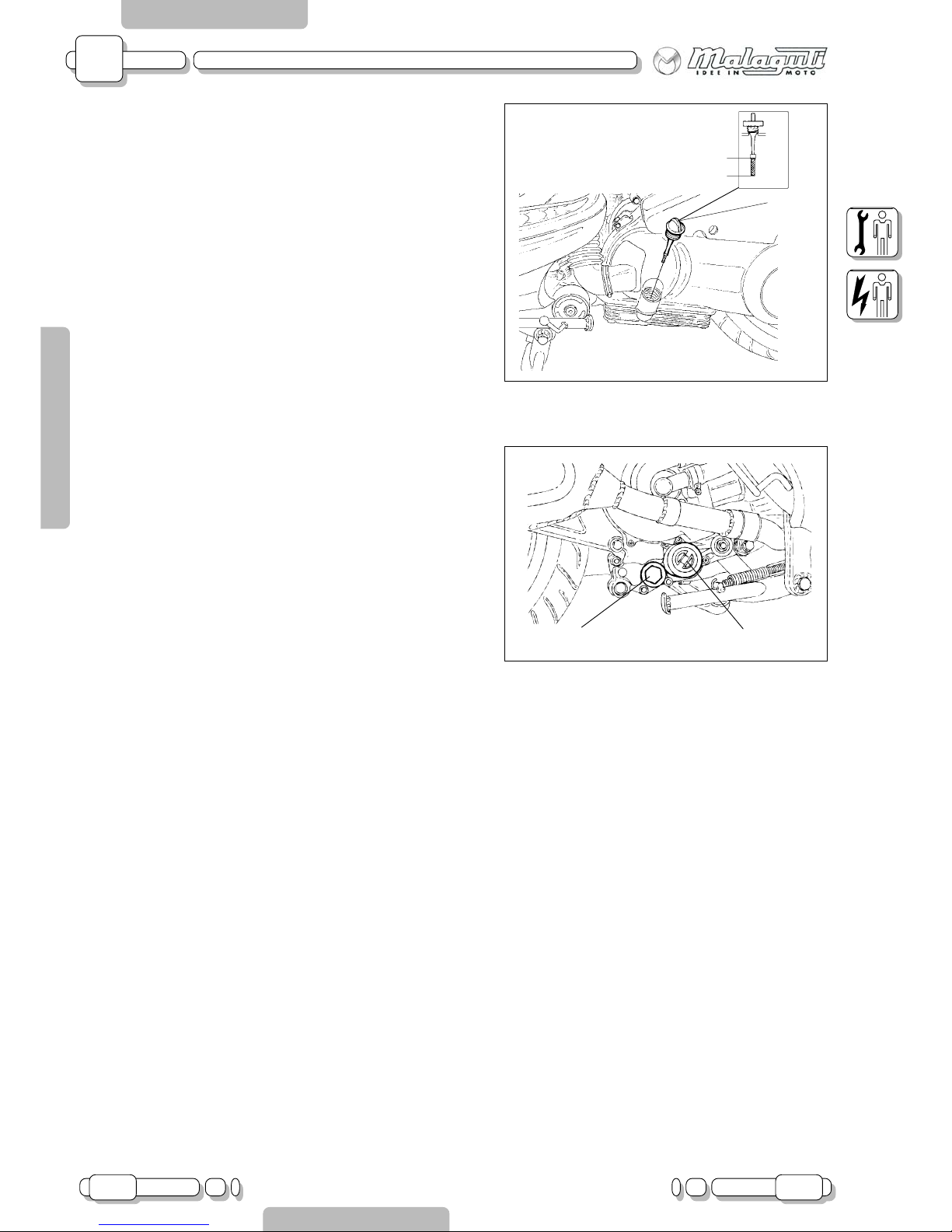

ENGINE OIL, 125 cc

CHECK

Put the scooter on its centre stand and warm up the

engine. Stop the engine and wait a few minutes for

the oil level to stabilise before checking.

Unscrew the dipstick from the engine crankcase (A F. 15i).

Clean the dipstick and put it back into its seat but do

not screw it in place.

By means of this operation, you will check the

oil level.

The level must be between the MIN and MAX marks

on the dipstick (F. 15i). If the level is low, add oil.

Put the dipstick back into its seat and screw it in

place.

REPLACEMENT

Warm the engine up for a few minutes.

Stop the engine, put an oil pan under it and remove

the dipstick; remove the drainage cap (A - F. 16i),

and let the oil flow out.

Clean the oil filtering net (1 - F. 16i) with solvent.

Check the “O-ring” (3 - F. 16i) and replace it if it is

damaged; refit the “O-ring”, the compression

spring (2 - F. 16i), the oil filter and the drainage cap.

Page 18

A

18 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

A

Max

Min

F.17i

A

B

F.18i

ENGINE OIL, 200 cc

CHECK

Park the scooter on flat ground and place it on its centre

stand. Start the engine and let it run until it reaches operating temperature; turn off the engine and wait 5-10 minutes to enable the oil to flow into the sump.

Unscrew the dipstick (A - F. 17i) from the engine crankcase and clean it; now fit it back into its seat and screw

it firmly in place.

Remove the cap-dipstick and make sure the oil level falls

within the MIN and MAX marks illustrated in F.17i.

If the level is low, add oil.

After checking, refit the cap and dipstick and screw firmly

in place.

REPLACEMENT

Warm up the engine for a few minutes; stop the engine

and put an oil pan under the casing in correspondence

with the cap (A-F. 18i).

Remove the drainage cap and the dipstick and let the oil

flow out.

Clean the filtering net with compressed air, check the state

of the cap’s O-ring and, if damaged, replace it.

Remove the cartridge filter with O-ring (B-F. 18i) and replace it with a new one.

Before fitting the new cartridge filter, lubricate the relative

O-ring and screw in place, tightening by hand.

Refit the filtering net and the cap with O-ring.

Fill the engine with oil, refit the cap-dipstick and screw

firmly in place.

Run the engine to charge the new filter and lubricating

circuit. Stop the engine and, after 5 minutes, check the oil

level. If necessary, fill up to the MAX level mark.

Page 19

A

09.03 19

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 2

A - CHASSIS

GETTING TO KNOW YOUR VEHICLE

SECTION 2

F.19i

A

B

B

F.20i

A

MIN

MAX

F.21i

B

F.22i

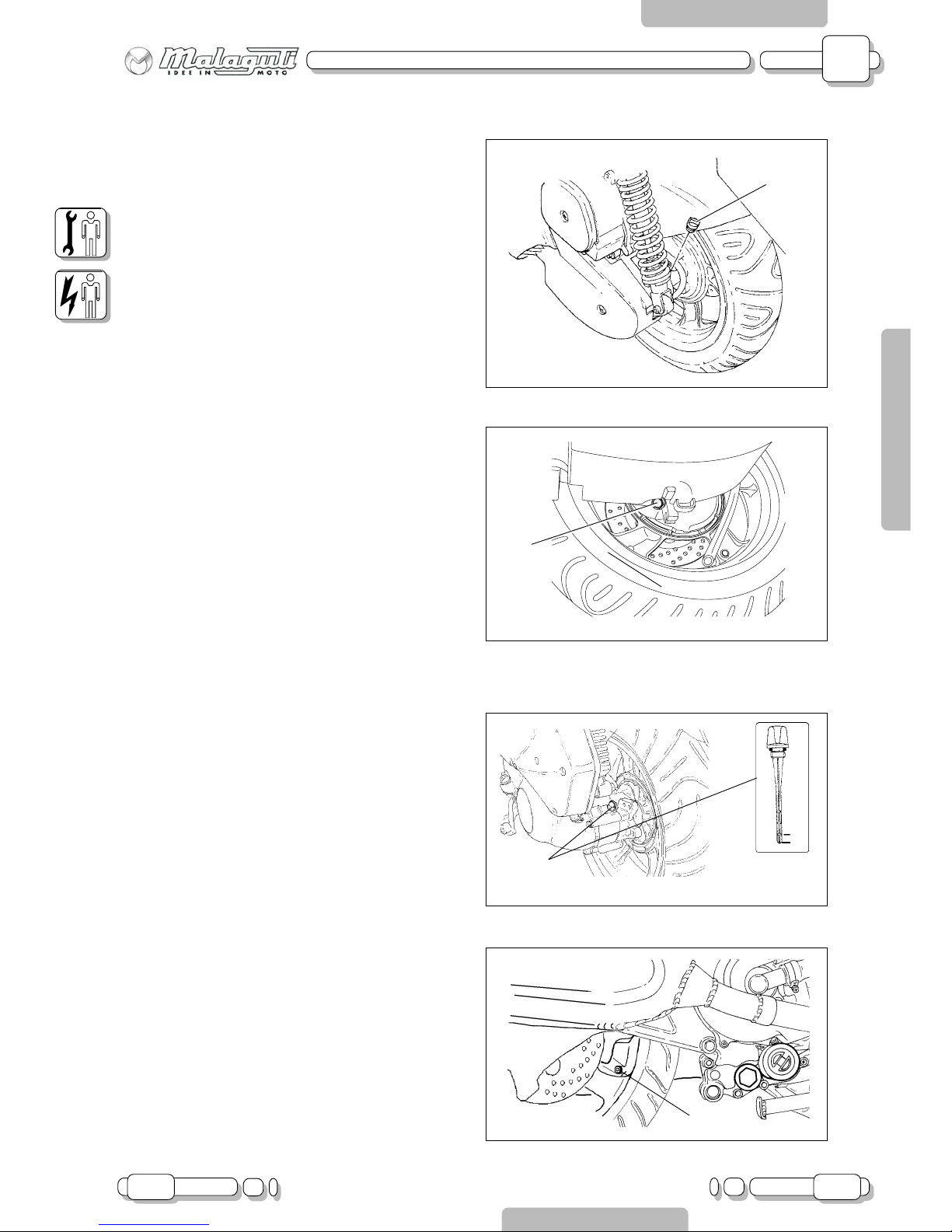

TRANSMISSION OIL, 125 cc

CHECK

Place the scooter on its stand.

Put a container under the engine crankcase, remove

the oil filling bolt (A - F. 19i) and the drainage cap to

drain out the oil (B - F. 20i); refit the drainage cap and fill

the crankcase with the recommended type of oil.

Start the engine and let it warm up for a few minutes.

While it is warming up, check for oil leakage. If oil is

leaking, immediately turn off the engine and locate the

cause.

REPLACEMENT

Place the scooter on its stand.

Put a container under the engine crankcase, remove

the oil filling bolt (A - F. 19i) and the drainage cap to

drain out the oil (B - F. 20i); let the oil flow into a suitable container (pay attention to avoid scorching).

Close the drainage cap and add new oil. You can now

close the filling cap.

TRANSMISSION OIL, 200 cc

CHECK

Park the scooter on flat ground and place it on its centre stand.

Unscrew the dipstick (A- F. 21i), clean it and screw it

back into place. Take it out again and make sure the oil

level is between the MAX and MIN notches.

If the level is low, top up to the MAX notch.

REPLACEMENT

Park the scooter on flat ground and place it on its centre stand.

Unscrew the dipstick (A- F. 21i), clean it, screw it back

into place then put a container under the engine crankcase and unscrew the drainage screw (B-F.22i), paying

attention to the gasket.

Let the oil flow into the container (pay attention to avoid

scorching).

Refit the drainage cap and gasket and fill with new oil.

Refit the cap and dipstick (A-F.21i).

Page 20

A

20 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

F.23i

MIN

A

S

F.24i

B

S

BRAKE FLUID

CHECK

The visual check should be made through the sight glass

(S) of the tanks: (A - F.23i - front brake) (B - F.24i - rear

brake), with the scooter parked on flat ground and perfectly upright.

The oil should be at 3 mm from the bottom edge of the

sight glass.

Top up by removing the covers (A - B), after loosening

the fixing screws.

REPLACEMENT

If the fluid features traces of dirt, debris or water, it must

be replaced.

A soft and spongy feeling in the brake lever can indicate

the presence of air in the circuit. Contact an authorised

service centre at once.

ADJUSTMENT OF ENGINE IDLING SPEED

Engine idling speed must be adjusted every time it

seems irregular.

To perform a correct check, start the engine and warm

it up to its operating temperature. Let it run idle and

check speed.

Open and close the throttle several times to make sure

that idling speed is maintained stable.

Page 21

A

09.03 21

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

SECTION 2

A - CHASSIS

GETTING TO KNOW YOUR VEHICLE

SECTION 2

F.25i

3

2

1

A

A

F

P

F.26i

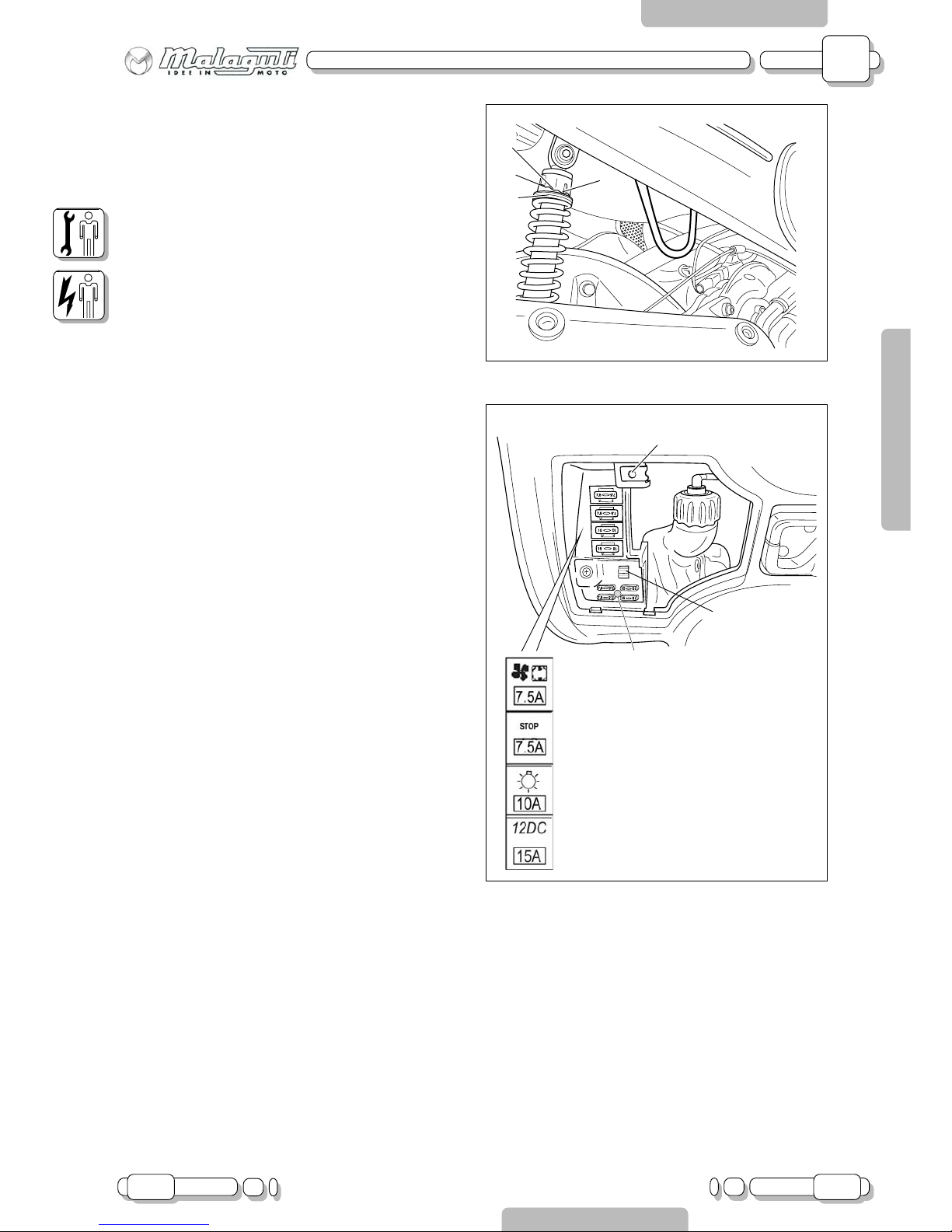

SHOCK ABSORBER ADJUSTMENT

The shock absorbers are equipped with a spring preload

ring nut, with which it is possible to adjust the scooter’s

behaviour depending on the load carried, how the scooter

is driven and where.

The adjustment is made by means of the key fitted to

the ring nut (A - F. 25i); turn it clockwise to increase

the spring preload.

FUSES

The electrical equipment includes four fuses protecting

the main components against faults. These are located

in the glove compartment (Fig. 26i). An illustration of

the protected component is placed next to each fuse.

To replace a fuse, remove the screw (A) to open the left

hand hatch; using the pliers supplied (P- F.26i) remove

the blown fuse and replace with another having the same

capacity.

Spare fuses (F - F.26i) are under the pliers (P).

If you have used the spare fuse, provide another spare

of identical capacity.

Page 22

A

22 09.03

CHAPTER

PAGE ISSUE

ENGLISH

SECTION 2

GETTING TO KNOW YOUR VEHICLE

A - CHASSIS

CHASSIS

SECTION 2

F.27i

A

A= 1220mm 2mm

+

-

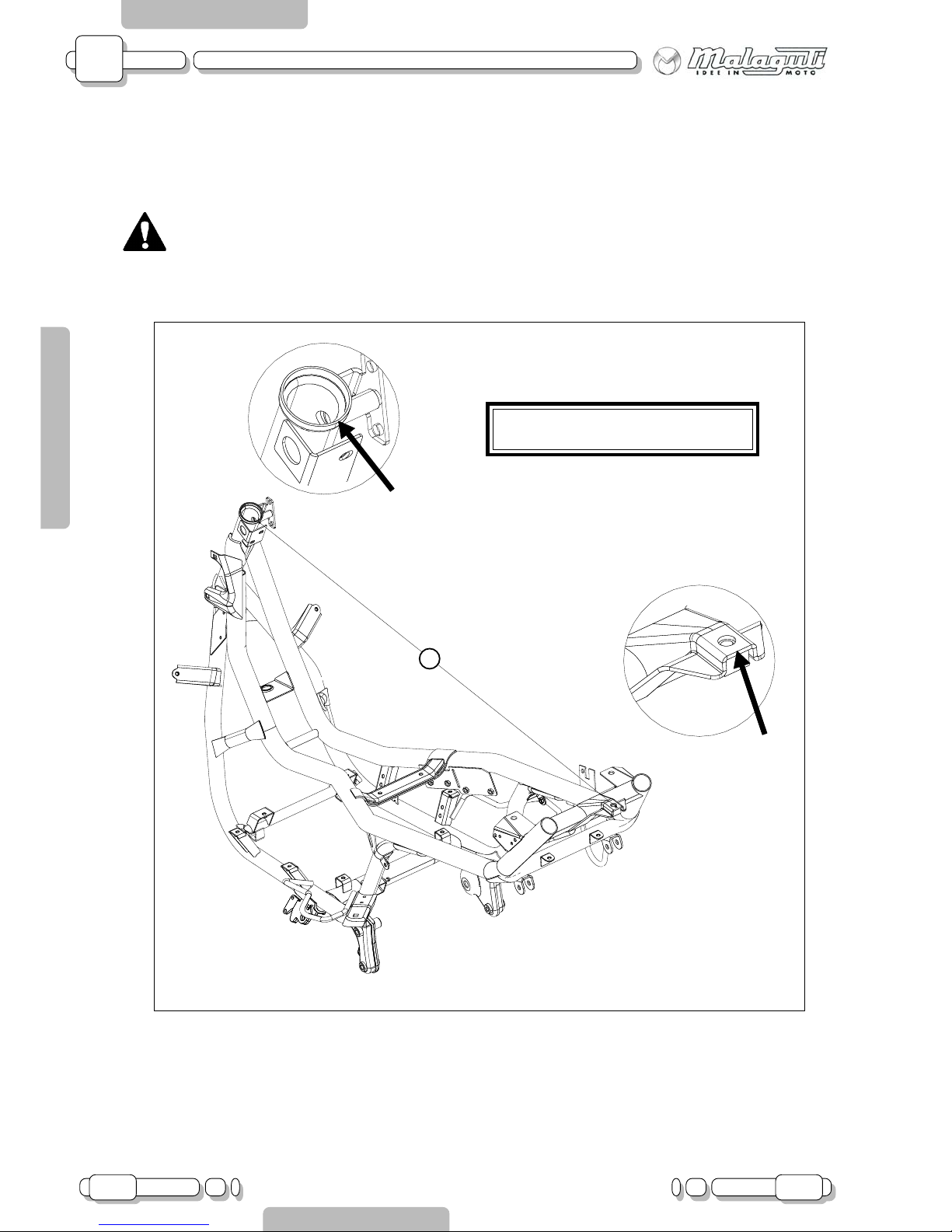

CHECKING THE SHAPE OF THE CHASSIS

If your scooter has had an accident and you believe that the chassis is deformed, it is essential to perform a check

on its shape before providing any further repair and setting up work.

The checking value (A - F.27i) must be 1220 mm with a tolerance of ± 2 mm.

Never deform the chassis to obtain the original “A” measure.

Page 23

A

09.03 23

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F. 1

F. 2

F. 3

F. 1/b

V1

V4

A

B

A

REMOVING THE FRONT HANDLEBAR COVER

Undo the centre screw (V1 - F.1) which is accessed by removing the cover (A - F.1b).

Undo the side screws (V4 - F.2).

Pull the handlebar cover up (A - F. 3) along with the

instrument board. Pay attention in order not to

damage the instrument board connector cable (B F.3).

Page 24

A

24 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F. 4

F. 5

A

B

B

A

C

D

E

F

V4

REMOVING THE INSTRUMENT BOARD

• (Remove front handlebar cover)

Pull out the connector (B - F. 4), by pressing the

tab (A - F. 4).

Undo the screws (V4 - F.4) and detach the instrument board from the front handlebar cover.

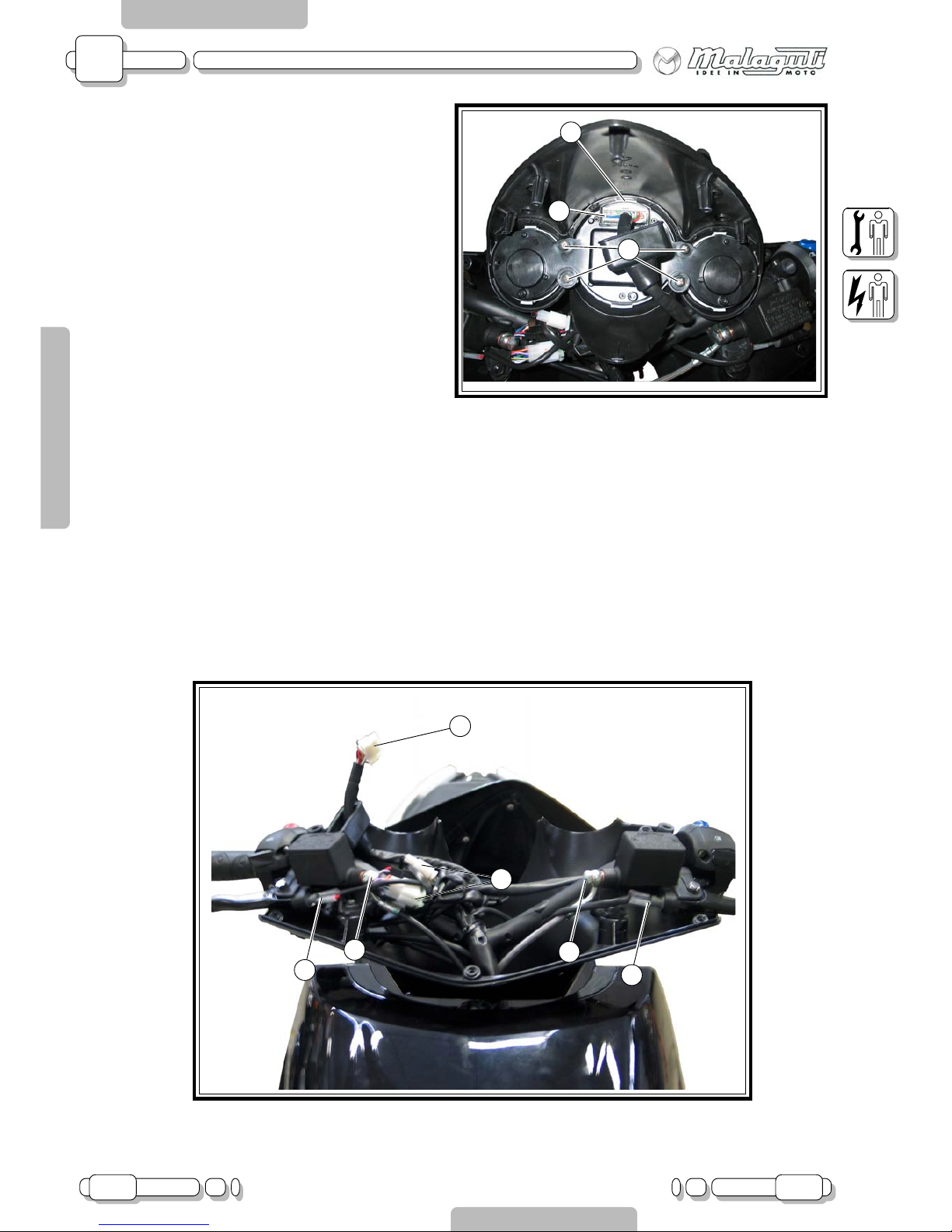

COMPONENTS ACCESSED BY REMOVING THE FRONT HANDLEBAR COVER

By removing the front handlebar cover, you gain access to the following components:

• Instrument board cables (A)

• Connector for the handlebar controls (right/left) (B)

• STOP switch, right hand control (C)

• STOP switch, left hand control (D)

• Coupling for the rear brake pump (E)

• Coupling for the front brake pump (F).

Page 25

A

09.03 25

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F. 7

F. 6

V5

V

V2

A

B

V2a

REMOVING THE HANDLEBAR UPPER FAIRING

• (Remove front handlebar cover)

Undo the screws (V5 - F.6).

REMOVING THE LEFT CONTROL

• (Remove front handlebar cover)

Undo the screw (V - F.7) and remove the counterweight.

Undo the screws (V2 - F.7) and remove the left

control.

Caution!!! To reduce friction during

knob removal and refitting, use compressed air.

Detach the fast-ons of the stop switch wiring (A F.7).

Undo the hydraulic transmission screw (B - F.7),

paying attention to oil leaks.

Loosen the screws (V2a - F.7) and remove the rear

brake pump.

Caution!!! When refitting, remember

to replace the copper gaskets and to

bleed using the relevant equipment.

Page 26

A

26 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F. 8

F. 9

V

V2a

V2

A

B

C

D

V

V2a

V2

A

B

C

200 cc

125 cc

REMOVING THE RIGHT CONTROL

125 cc VERSION

• (Remove front handlebar cover)

Disconnect the opening (A - F.8) and closing (B. F.8) of the throttle cable.

Undo the screw (V - F.8) and remove the counterweight.

Undo the screws (V2 - F.8) and remove the throttle

control.

Caution!!! To reduce friction during

knob removal and refitting, use compressed air.

Detach the fast-ons of the stop switch wiring (C F.8).

Undo the hydraulic transmission screw (D - F.8),

paying attention to oil leaks.

Loosen the screws (V2a - F.8) and remove the front

brake pump.

Caution!!! When refitting, remember

to replace the copper gaskets and to

bleed using the relevant equipment.

REMOVING THE RIGHT CONTROL

200 cc VERSION

• (Remove front handlebar cover)

Disconnect the throttle cable (A - F.9).

Undo the screw (V - F.9) and remove the counterweight.

Undo the screws (V2 - F.9) and remove the throttle

control.

Caution!!! To reduce friction during

knob removal and refitting, use compressed air.

Detach the fast-ons of the stop switch wiring (B F.9).

Undo the hydraulic transmission screw (C - F.9),

paying attention to oil leaks.

Loosen the screws (V2a - F.9) and remove the front

brake pump.

Caution!!! When refitting, remember

to replace the copper gaskets and to

bleed using the relevant equipment.

Page 27

A

09.03 27

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.10

F. 11

F.12

V

V2

V2

V2a

V

REMOVING THE FRONT WING

Undo the front (V2 - F.10) and rear (V2a - F.10)

screws and remove the wing by pulling it through

the fork, taking care to prevent it getting scratched.

Caution!!! This operation is symmetrical.

REMOVING THE SPEEDOMETER SENSOR

Undo the screw (V - F.11), paying attention not to

lose the spacer.

Caution!!! When refitting, use a thickness gage to make sure that the gap

between the sensor and disc is 1÷2

mm; on the contrary, provide a shim

near the spacer.

REMOVING THE FRONT CALIPERS

Undo the screws (V2 - F.12), undo the hydraulic

transmission screw (V - F.12) and detach the hydraulic transmission from the pliers.

Caution!!! When refitting, put the long

screw in the top fitting and replace

the gasket of the hydraulic transmission screw.

Page 28

A

28 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.13

2 mm

CHECKING THE FRONT BRAKE PADS FOR

WEAR

• Check the discs for wear. If they are worn or

scratched, have them ground.

If they are particularly damaged or a thinner

than 2 mm, replace them.

REPLACING THE FRONT CALIPERS

Empty the hydraulic circuit and drain fluid into a

special container so that it may be disposed of in

accordance to the laws in force concerning waste

disposal.

Caution!!! When removing the calipers,

pay special attention to prevent damage to the oil duct, disc and brake pads.

Caution!!! Minimum thickness of the

pads is 2 mm (F. 13).

After working on the braking system, make sure

that the brake fluid pipe is not twisted, that the

discs and pads are not soiled with oil or grease

and that all screws and fittings are firmly wrenched

in place.

Caution!!! A spongy feeling in the brake

lever or a change in its free play mean

that the braking circuit is faulty.

Page 29

A

09.03 29

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.16

F.14

F.15

V6

A

A

B

B

C

REMOVING THE FRONT WHEEL

• (Remove speedometer sensor and front cali-

pers)

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

Unscrew the lock nut (A - F.14) fastening the wheel

pin, whilst holding the pin head in place with an

Allen wrench.

Remove the wheel pin, whilst paying attention to

the spacers:

- the long one (A - F.15).

- two short ones (B - F.15).

Remove the wheel assembly.

Caution!!! Do not operate the brake

lever after removing the wheel, since

the pads would come into contact with

each other.

Caution!!! When refitting, make sure

to refit the spacers and grease the

wheel pin (C - F.15).

REMOVING THE FRONT DISC

• (Remove speedometer sensor, front calipers

and front wheel)

Loosen the screws (V6 - F.16)

Caution!!! When reassembling, replace the screws and apply a high

strength thread locker.

Page 30

A

30 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.18

F.19

F.17

V10V10

F.19/a

V

REMOVING THE FRONT UPPER FAIRING

• (Remove front wheel and front wing)

Remove the centre foot rest fitted to the lower fairing (paying attention not to damage the tabs).

Caution!!! This operation is symmetrical.

Undo the screws (V10 - F.18).

Undo the screw (V - F.19/a) under the strut.

Page 31

A

09.03 31

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.20

B

A

F.22

F.21

V4

A

V4

A

B

C

Disconnect the two connectors (A-B - F.20) of the

front light cables.

Remove the upper fairing by pulling it through the

fork, taking care to prevent it getting scratched.

Position the upper fairing upside down, with its

painted side facing upwards.

REMOVING THE HEADLIGHTS

Caution!!! There is no need to remove

the upper fairing; it can be placed on

the front wing covered beforehand

with scratch-proof material.

To remove the low beam headlight, undo the screws

(V4 - F.21).

To gain access to the light bulb, remove the lamp

socket (A - F.21), by turning it 15° anti-clockwise.

To remove the high beam headlight, undo the screws

(V4 - F.22).

To access the bulb, remove the rubber cap (A F.22), disconnect the cable (B - F.22) and act on

the clips (C - F.22).

Page 32

A

32 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.23

F.24

F.25

A

V2

V2

A

A

To access the parking light bulbs, remove the

lamp sockets (A - F.23).

To remove the entire headlight assembly, undo the

screws (V2 - F.24) and unscrew the light adjustment knob (A - F.24).

Caution!!! When refitting the adjustment knob, install all parts in the right

sequence.

To adjust the beam, act on the knob (A) as follows:

- tighten to raise the beam

- loosen to lower the beam

REMOVING THE FRONT INDICATORS

Caution!!! There is no need to remove

the upper fairing; it can be placed on

the front wing covered beforehand

with scratch-proof material.

Undo the screws (V2 - F.25).

To gain access to the light bulb, remove the lamp

socket (A - F.25), by turning it 15° anti-clockwise.

Caution!!! This operation is symmetrical.

Page 33

A

09.03 33

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.26

F.27

V4

A

B

C

D

E

F

G

H

REMOVING THE HEADLIGHT GUARD

Caution!!! There is no need to remove

the upper fairing; it can be placed on

the front wing covered beforehand

with scratch-proof material.

Loosen the screws (V4 - F.26) and remove the

guard.

COMPONENTS THAT CAN BE ACCESSED BY REMOVING THE UPPER FAIRING

By removing the upper fairing, you can gain access to the following components:

• Horn (A)

• Fuse carrier (B)

• Coolant container (C)

• Fork (D)

• Radiator (E)

• Switch with key (F)

• The fan’s thermal switch (G)

• Ring nuts of the steering system (H)

Page 34

A

34 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.30

A

F.28

F.29

V

V2

A

B

HORN

Caution!!! There is no need to remove

the upper fairing; it can be placed on

the front wing covered beforehand

with scratch-proof material.

Undo the screw (V - F.28) and disconnect the cables.

Caution!!! Refit components in the

right sequence.

COOLANT CONTAINER

• (Remove upper fairing)

Undo the screws (V2 - F.29).

Loosen the clamp (A - F.29) and remove the pipe.

Loosen the clamp (B - F.29) and remove the pipe.

REMOVING THE SEAT

Release the seat with a wrench (A - F.30) and tip

it over.

Page 35

A

09.03 35

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

D2

F.32

V2

F.31

F.33

A

V2

Unscrew the nuts (D2 - F.31), remove the seat

and position it with the stuffing facing upwards.

REMOVING THE PASSENGER’S SEAT

Undo the screws (V2 - F.32) and remove the passenger’s seat by pulling it out from the front side.

Caution!!! The level of electrolyte in

the battery can be checked through

the sight glass under the passenger’s

seat, thus avoiding removal.

REMOVING THE SEAT LOCK

• (Remove passenger’s seat)

Remove the nut covers (A - F.33) and undo the

screws (V2 - F.33).

Page 36

A

36 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.36

V2

A

F.34

F.35

A

B

C

A

Release the cable from the lock by unhooking

the spring (A - F.34).

REMOVING THE BATTERY

• (Remove passenger’s seat)

Detach the cables (A-B - F.35) from their terminals.

Carefully lift the battery and before actually pulling

it out of its compartment, release it from the exhaust pipe (C - F.35).

Caution!!! Refit the battery, making

sure that the exhaust pipe is connected, that it is coming out of the battery

compartment and that is not bent,

clogged or twisted.

REMOVING THE HELMET HOLDER

• (Remove battery, seat and passenger’s seat)

Undo the screws (V2 - F.36).

Caution!!! With the helmet holder fitted, the carburettor can be adjusted

through the hole (A - F.36).

Page 37

A

09.03 37

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.37

V2

A

B

C

A

C

B

F.38

Undo the screws (V2 - F.37).

Raise the helmet holder and pull out battery cables (A-B - F.37), exhaust pipe (C - F.37) and seat

lock cable.

Caution!!! When refitting, take care to

put the exhaust pipe, battery cables

and seat lock cable back into their

openings.

COMPONENTS THAT CAN BE ACCESSED BY REMOVING THE HELMET HOLDER

By removing the helmet holder, you can gain access to the following components:

• Fuel probe (A)

• Carburettor (B)

• Control unit connector (C)

Page 38

A

38 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.40

F.41

V2

V3

L

A

B

F.39

V2

REMOVING THE HANDLE COVER

• (Remove seat, passenger’s seat and helmet

holder)

Undo the screws (V2 - F.39), remove the cover and

pull it out from the rear side after disengaging its

hooks.

REMOVING THE REAR HANDLE

• (Remove seat, passenger’s seat, helmet hold-

er and handle cover)

Undo the screws (V3 - F.40).

Undo the screws (V2 - F.40).

Remove the rear handle.

Caution!!! The handle features four

threaded holes for fastening the luggage container or rack.

REMOVING THE SEAT LOCK

• (Remove seat, passenger’s seat and helmet

holder)

Remove the spring (A - F.41) and pull out the cable

(B - F.41).

Pull the tab (L - F-41) downwards and remove the

barrel.

Page 39

A

09.03 39

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.42

V2

A

B

F.43

F.44

V3

V

V1

A

REMOVING THE TAIL LAMPS

• (Remove seat, passenger’s seat, helmet hol-

der, handle cover and rear handle)

Undo the screws (V2 - F.42).

Remove the clamp (A - F.42) and detach the connector (B - F.42).

Undo the screws (V3 - F.43) and release the snap

locks.

To access the bulb of the stop light, remove the

centre lamp socket by turning it 45° clockwise.

To access the 5 bulbs of the parking lights, remove the relative lamp sockets.

Caution!!! Test operation, before refitting removed parts.

REMOVING THE REAR INDICATORS

Undo the screw (V - F.44).

Remove the glass cover and detach the lamp socket cables.

Undo the fixing screw (V1 - F.44).

Remove the cover (A - F.44) and take out the lamp.

Caution!!! This operation is symmetrical.

Caution!!! Test operation, before refitting removed parts.

Page 40

A

40 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.47

F.46

V

V3

F.45

V

REMOVING THE NUMBER PLATE LIGHT

Undo the screw (V - F.45).

To access the light bulb, remove the lamp socket

whilst paying attention not to damage the cables.

Caution!!! Test operation, before refitting removed parts.

REMOVING THE NUMBER PLATE HOLDER

Remove the number plate by undoing the four

screws or rivets.

Undo the screws (V3 - F.46).

Caution!!! Do not use glue, two-sided

adhesive tape, etc. to refit the number

plate.

REMOVING THE SIDE CASINGS

Undo the screw (V - F.47).

Remove the side casing by pulling out from the

front so that it detaches from its snap locks.

Caution!!! This operation is symmetrical.

Page 41

A

09.03 41

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.48

C

A

B

F.49

V4

F.50

V

COMPONENTS THAT ARE ACCESSED BY REMOVING THE RIGHT SIDE CASING

By removing the side casing, you can gain access to the following components:

• Regulator (A)

• Control unit (B)

• Weights (C)

REMOVING THE REAR COWLING

• (Remove seat, passenger’s seat, helmet hol-

der, handle cover, rear handle and side casings)

Detach the cable of the tail lamp.

Undo the screws (V4 - F.49) on the right and left.

Undo the screw (V - F.50), by releasing the shock

absorber plaque.

Caution!!! This operation is symmetrical.

Raise and release the rear cowling from its hooks

by pulling its front side open. Pay attention not to

scratch the plastic.

Page 42

A

42 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.53

V2

F.51

F.52

V2

V2

REMOVING THE REAR REFLECTOR

Undo the screws (V2 - F.51) and remove the reflector by pulling it outwards.

REMOVING THE TAIL SECTION

• (Remove seat, passenger’s seat, helmet hol-

der, handle cover and rear handle)

Undo the screws (V2 - F.52) on both sides.

Undo the screws (V2 - F.53), release the snap locks

on the top side of the tail and remove the tail section.

Page 43

A

09.03 43

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.55

B

A

F.54

B

A

C

D

P

C

COMPONENTS THAT ARE ACCESSED BY REMOVING THE REAR COWLING

By removing the rear cowling, you can gain access to the following components:

• Starter relay 1 (A)

• Starter relay 2 (B)

• Flashlight (C - 125 cc only)

• Fuel pump (D)

REMOVING STARTER RELAYS 1/2

• (Remove side casings and rear cowling)

- 1st relay (A - F.55): release from the chassis by

pulling upwards, then detach the connector (C F.55).

- 2nd relay (B - F.55): take out of the relay holder (P

- F.55).

Page 44

A

44 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.56

A

125 cc

F.57

V2

125 cc

A

F.58

200 cc

A

V2

F

M

M

REMOVING THE FLASHLIGHT

125 cc VERSION ONLY

• (Remove side casings and rear cowling)

Disconnect the connector (A - F.56) and release

the flashlight from the chassis.

REMOVING THE REGULATOR

125 cc VERSION

• (Remove side casings and rear cowling)

Detach the connector (A - F.57)

Undo the screws (V2 - F.57).

Caution!!! When refitting, fasten the

weights (M - F.57) firmly in place.

REMOVING THE REGULATOR

200 cc VERSION

• (Remove side casings and rear cowling)

Detach the connector (A - F.58)

Undo the screws (V2 - F.58).

Caution!!! When refitting, fasten the

weights (M - F.58) firmly in place and

check the condition of the 15 A fuse (F

- F.58).

Page 45

A

09.03 45

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.61

200 cc

B

F.59

A

125 cc

F.60

125 cc

F.57

G

A

REMOVING THE CONTROL UNIT

125 cc VERSION

• (Remove side casings and rear cowling)

Remove the clamps and detach the connector (A F.59).

Take the control unit out of its rubber protection (G

- F.60).

REMOVING THE CONTROL UNIT

200 cc VERSION

• (Remove side casings and rear cowling)

Remove the rubber protection (A - F.61), release

the connector (B - F.61) and cut the clamps holding the wires in place.

Page 46

A

46 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.63

A

200 cc

V2

F.62

F.64

V4

Undo the screws (V2 - F.62).

Caution!!! The flashlight is built into

the control unit.

REMOVING THE FUEL PROBE

• (Remove seat, passenger’s seat and helmet

holder)

Detach the connector (A - F.63) and cut the clamps

that hold the wires in place.

Undo the screws (V4 - F.64) and remove the probe.

Page 47

A

09.03 47

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.65

F.66

F.67

F.65/b

A

V2

V

V

REMOVING THE STRUT

Place the scooter on its centre stand.

Remove the rubber mat on the footboard (A - F.65).

Undo the screws (V2 - F.65/b).

Undo the screw (V - F.66).

Undo the screw (V - F.67).

Carefully pull the strut towards the front.

Caution!!! When refitting remember

that the V - F.66/67 screws are longer

than the V2 - F.65/b screws.

These operations are symmetrical.

Page 48

A

48 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

A

T

B

V2

V3

125 cc

125 cc

125 cc

F.68

F.69

F.70

REMOVING THE FOOTBOARD

125 cc VERSION

• (Remove side casings, rear cowling and strut)

Undo the screws (V3 - F.68) on both sides.

Undo the screws (V2 - F.69) to release the footboard from the secondary air valve.

Open the tank’s hatch (A - F.70), unscrew the cap

(T - F.70) and remove the gasket (B - F.70).

Pull the footboard upwards.

Caution!!! After removing the footboard, screw the tank’s cap back on.

Page 49

A

09.03 49

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.73

A

A

T

B

V3

200 cc

F.71

200 cc

F.72

REMOVING THE FOOTBOARD

200 cc VERSION

• (Remove side casings, rear cowling and strut)

Undo the screws (V3 - F.71) on both sides.

Open the tank’s hatch (A - F.72), unscrew the cap

(T - F.72) and remove the gasket (B - F.72).

Pull the footboard upwards.

Caution!!! After removing the footboard, screw the tank’s cap back on.

REMOVING THE LOWER FAIRING

• (Remove side casings, rear cowling, strut, foot-

board and upper fairing)

Detach cables (A - F.73) from fuses.

Caution!!! When reassembling, fasten

the fast-ons as follows:

- 15 A fuse BLUE/RED - LIGHT BLUE

- 7.5 A fuse YELLOW-BLUE

- 7.5 A fuse WHITE/GREY - BLUE

- 10 A fuse GREEN/RED - BLUE

Page 50

A

50 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.76

F.75

V2

A

F.74

V

Undo the screw (V - F.74) under the footrest.

Caution!!! This operation is symmetrcal.

Undo the screws (V2 - F.75) of the luggage hook.

Remove the cover (A - F.76) of the switch with key

by turning it 1/4 of a turn clockwise.

Remove the lower fairing, by pulling it carefully

downwards.

Page 51

A

09.03 51

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.77

A

B

C

E

D

COMPONENTS THAT ARE ACCESSED BY REMOVING THE STRUT, FOOTBOARD AND THE LOWER FAIRING

By removing the strut, footboard and lower fairing, you can gain access to the following components:

• 15 A recharge fuse (A)

• Side stand switch (B)

• Radiator fan (C)

• Tank (D)

• Petrol filter (E)

Page 52

A

52 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.79

A

B

C

V2

F.78

B

A

F.80

V2

REMOVING THE FUEL FILTER

• (Remove side casings, rear cowling, strut and

footboard)

CAUTION!!!

Make sure the tank is empty.

Loosen clamp A (F.78), clamp B (F.78) and take

the petrol filter off its support.

Caution!!! When refitting, avoid narrow bends of the pipes.

REMOVING THE FUEL PUMP

• (Remove side casings, rear cowling, strut and

footboard)

Detach the fuel inlet pipe (A - F.79), the fuel outlet

pipe (B - F.79) and the vacuum pipe (C - F.79).

Undo the screws (V2 - F.79).

Caution!!! When refitting, connect the

pipes in their correct position.

REMOVING THE FUEL TANK

• (Remove side casings, rear cowling, strut, foot-

board and lower fairing)

CAUTION!!!

Make sure the tank is empty.

Before emptying the tank, wait for the

engine to cool down. Use a manual

pump.

Release the petrol filter and disconnect the probe

connector.

Undo the screws (V2 - F.80) on both sides.

Shift the tank towards the rear side to enable the

front fixing tabs to move beyond the coupling. You

can now pull the tank out from the front side.

Caution!!! When refitting, perform

above operations in reverse order.

Page 53

A

09.03 53

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.83

B

A

F.81

F.82

A

A

125 cc

125 cc

125 cc

REMOVING THE RADIATOR

125 cc VERSION

• (Remove upper fairing)

CAUTION!!!

Empty the radiator by putting a suitable container under it. Now open the

pipe clamp (A - F.81) and detach the

pipe from its coupling.

The radiator is installed on a Silentblock; to remove this, proceed as follows.

Disconnect the fan connector (A - F.82).

Disconnect the cables of the thermostatic fan (A F.83) and of the thermal switch when these are

warm (B - F.83).

Page 54

A

54 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.84

A

B

F.85

125 cc

125 cc

V2

Remove the two pipes, by unscrewing the clamps

(A/B - F.84).

Disengage and remove the radiator support plate

by loosening the screws (V2 - F.85).

Remove the radiator by pulling it downwards.

Page 55

A

09.03 55

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.88

A

F.86

F.87

A

A

200 cc

200 cc

200 cc

B

REMOVING THE RADIATOR

200 cc VERSION

• (Remove upper fairing)

CAUTION!!!

Empty the radiator by putting a suitable container under it. Now open the

pipe clamp (A - F.86) and detach the

pipe from its coupling.

The radiator is installed on a Silentblock; to remove this, proceed as follows.

Disconnect the fan connector (A - F.87).

Disconnect the cables of the thermostatic fan (A F.88).

Caution!!! Do not remove the drainage cap (B - F.88).

Page 56

A

56 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.89

A

B

F.90

200cc

F.91

V3

V2

200cc

A

Remove the two pipes, by unscrewing the clamps

(A/B - F.89).

Disengage and remove the radiator support plate

by loosening the screws (V2 - F.90).

Remove the radiator by pulling it downwards.

RADIATOR FAN

• (Remove radiator)

Detach the connector (A - F.90).

Undo the screws (V3 - F.91).

Remove fan by pulling it sideways.

Page 57

A

09.03 57

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.92

A

125 cc

F.93

F.94

200 cc

A

B

200 cc

B

A

B

F.94/b

REMOVING THE FRONT SHOCK ABSORBERS

125 cc VERSION

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

To remove the left shock absorber, unscrew the

top bolt (A - F.92) and the bottom bolt (B - F.92)

and remove the shock absorber by pulling it towards the rear side.

Caution!!! This operation is symmetrical.

REMOVING THE REAR SHOCK ABSORBERS

200 cc VERSION

• (Remove filter box and muffler)

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

To remove the right shock absorber, unscrew the

top bolt (A - F.93) and the bottom nut (B - F.93)

and remove the shock absorber by pulling it towards the rear side.

Undo the nut (B) and pull the shock absorber outwards, without moving the arm.

To remove the left shock absorber, unscrew the

top bolt (A - F.94) and the bottom bolt (B - F.94)

and remove the shock absorber by pulling it towards the rear side.

Caution!!! When refitting, check the

direction in which the shock absorb-

ers are fitted (F.94 /b).

Page 58

A

58 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.97

V2

F.96

A

A

B

F.95

125 cc

125 cc

125 cc

REMOVING THE AIR FILTER BOX

125 cc VERSION

• (Remove helmet holder)

Open the clamp (A - F.95) and disconnect the steam

recycling pipe (B - F.95).

Unscrew the clamp (A - F.96) and disconnect the

suction pipe.

Undo the screws (V2 - F.97).

Page 59

A

09.03 59

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.98

V

125 cc

F.99

F.100

200 cc

200 cc

A

B

A

Undo the screw (V - F.98) and remove the filter box

assembly, complete with its coupling.

REMOVING THE AIR FILTER BOX

200 cc VERSION

• (Remove helmet holder)

Open the clamp (A - F.99) and disconnect the

steam recycling pipe (B - F.99).

Unscrew the clamp (A - F.100) and disconnect the

suction pipe.

Page 60

A

60 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

V3

V2

F.103

F.102

F.101

125 cc

125 cc

200 cc

V2

Undo the screws (V2 - F.101) and remove the filter

box.

REMOVING THE MUFFLER

125 cc VERSION

CAUTION!!!

Before removing, make sure the muffler has cooled down.

Undo the screws (V2 - F.102) securing the exhaust

manifold in place.

Undo the screws (V3 - F.103) and remove the muffler with its guard.

Page 61

A

09.03 61

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.105

F.106

F.104

125 cc

G

200 cc

V2

200 cc

V3

The parts composing the exhaust assembly must

be disassembled as illustrated in F.104.

Caution!!! When refitting the muffler,

remember to replace part G.

REMOVING THE MUFFLER

200 cc VERSION

CAUTION!!!

Before removing, make sure the muffler has cooled down.

Undo the screws (V2 - F.105) securing the exhaust

manifold in place.

Undo the screws (V3 - F.106) and remove the muffler with its guard.

Page 62

A

62 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.107

200 cc

F.108

V2

125 cc

F.109

200 cc

V2

G

The parts composing the exhaust assembly must

be disassembled as illustrated in F.107.

Caution!!! When refitting the muffler,

remember to replace part G.

REMOVING THE REAR WING

125 cc VERSION

• (Remove muffler compartment)

Undo the screws (V2 - F.108).

Undo the screws (V2 - F.97- page 57), the screw

(V - F.98- page 58) and push the filter box aside to

enable removal of the wing.

REMOVING THE REAR WING

200 cc VERSION

• (Remove muffler compartment)

Undo the screws (V2 - F.109).

Undo the screws (V2 - F.101- page 59) and push

the filter box aside to enable removal of the wing.

Page 63

A

09.03 63

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F. 11 0

V3

A

F. 11 2

V2

V

125 cc

F. 111

125 cc

200 cc

A

V3

REMOVING THE TRANSMISSION COOLING

SLEEVE

125 cc VERSION

• (Remove strut)

Undo the screws (V3 - F.110).

Cut the clamp (A - F.110) and pull out the sleeve.

REMOVING THE TRANSMISSION COOLING

SLEEVE

200 cc VERSION

• (Remove strut)

Undo the screws (V3 - F.111).

Cut the clamp (A - F.111) and pull out the sleeve.

REMOVING THE REAR CALIPERS

125 cc VERSION

• (Remove muffler)

Undo the screws (V2 - F.112).

Loosen the hydraulic transmission screw (V - F.112)

and detach the pipe from the calipers.

Caution!!! When refitting, replace the

gasket of the hydraulic screw.

Page 64

A

64 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.113

F.114

2 mm

200 cc

V2

V

REMOVING THE REAR CALIPERS

200 cc VERSION

• (Remove muffler)

Undo the screws (V2 - F.113).

Loosen the hydraulic transmission screw (V - F.113)

and detach the pipe from the calipers.

Caution!!! When refitting, replace the

gasket of the hydraulic screw.

CHECKING THE REAR BRAKE PADS FOR

WEAR

• Check the discs for wear. If they are worn or

scratched, have them ground.

If they are particularly damaged or are thinner

than 2 mm, replace them.

Caution!!! Minimum thickness of the

pads is 2 mm (F. 114).

REPLACING THE REAR CALIPERS

Empty the hydraulic circuit and drain fluid into a

special container so that it may be disposed of in

accordance to the laws in force concerning waste

disposal.

Caution!!! When removing the calipers,

pay special attention to prevent damage to the oil duct, disc and brake pads.

After working on the braking system, make sure

that the brake fluid pipe is not twisted, that the

discs and pads are not soiled with oil or grease

and that all screws and fittings are firmly wrenched

in place.

Page 65

A

09.03 65

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F. 11 5

V2

A

125 cc

F. 11 6

200 cc

V1

A

V

V2

V

REMOVING THE REAR WHEEL

125 cc VERSION

• (Remove muffler, rear wing and rear calipers)

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

Disassemble the arm as follows:

Undo the bottom screw (V - F.115) of the right shock

absorber and turn it towards the rear side.

Undo the screws (V2 - F.115).

Caution!!! When refitting, put the long

screw in the top section and the short

screw in the bottom section (F.115).

Undo the nut (A - F.115) and remove the wheel.

Caution!!! When refitting, insert all

parts in the right order and grease

them.

REMOVING THE REAR WHEEL

200 cc VERSION

• (Remove muffler, rear wing and rear calipers)

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

Disassemble the arm as follows:

Undo the bottom screw of the right shock absorber (V - F.116) and turn it towards the rear side.

Undo the screws (V2 - F.116).

Undo the screw (V1 - F.116) and remove the support of the hydraulic transmission pipe.

Remove the split pin (A - F.116), remove the protection, unscrew the nut and remove the wheel.

Caution!!! When refitting, insert all

parts in the right order and grease

them.

Page 66

A

66 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.117

V6

F. 11 9

125 cc

A

F.118

125 cc

V

REMOVING THE REAR DISC

• (Remove rear wheel)

Undo the screws (V6 - F.117).

Caution!!! When reassembling, replace the

screws and apply a high strength thread locker.

ENGINE REMOVAL

125 cc VERSION

• (Remove seat, passenger’s seat, helmet hold-

er, air filter box, muffler, rear wing, rear calipers

and rear wheel)

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

Disengage the rear left shock absorber by undoing

the screw (V - F.118).

Disengage the transmission cooling sleeve (A F.119).

Page 67

A

09.03 67

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

B

A

A

F.121

F.122

125 cc

125 cc

F.120

B

A

125 cc

Remove the pipe for delivery to the radiator (A F.120), by unscrewing the clamp (B - F.120).

Remove the return pipe of the radiator (A - F.121)

by unscrewing the clamp (B - F.121).

Detach the flywheel connectors (A - F.122) and

cut all the cable fixing clamps.

Page 68

A

68 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.123

F.124

F.125

125 cc

A

B

125 cc

V2

125 cc

V

Detach the fast-on (A - F.123) and the pipe of the

fuel pump (B - F.123).

Disengage the carburettor from the engine by undoing the screws (V2 - F.124) and secure the carburettor to the chassis.

Undo the screw (V - F.125) and remove the support of the hydraulic transmission pipe.

Page 69

A

09.03 69

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.126

B

125 cc

F.127

F.128

200 cc

A

A

125 cc

Unscrew the nut (A - F.126).

Remove the pin (B - F.127).

Pull the engine out from the rear side.

ENGINE REMOVAL

200 cc VERSION

• (Remove seat, passenger’s seat, helmet hold-

er, air filter box, muffler, rear wing, rear calipers

and rear wheel)

CAUTION!!!

Before disassembly, hold the centre

chassis section to prevent the vehicle

falling over.

Disengage the transmission cooling sleeve (A F.128).

Page 70

A

70 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.129

F.130

F.131

200 cc

A

200 cc

A

B

V2

200 cc

A

C

B

Remove the connector (A - F.129) from the flywheel

cover.

Disengage the rear shock absorber by unscrewing

the bolt (A - F.130).

The shock absorber can also be disengaged by

removing the screws (V2 - F.130) that secure the

support (B - F.130) to the engine.

Remove the pipe for delivery to the radiator (A F.131), by unscrewing the clamp (B - F.131).

Detach the fast-on (C - F.131).

Page 71

A

09.03 71

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.132

F.133

F.134

200 cc

200 cc

200 cc

V

A

B

A

V2

A

Remove the pipe (A - F.132) .

Disengage the carburettor from the engine by undoing the screws (V3 - F.132) and secure the carburettor to the chassis.

Remove the radiator return pipe (A - F.133), by

unscrewing the clamp (B - F.133).

Undo the screw (V - F.133) and remove the support of the hydraulic transmission pipe.

Unscrew the nut (A - F.134).

Page 72

A

72 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

B

V

V

F.135

200 cc

F.136

125 cc

F.137

125 cc

A

Remove the pin (B - F.135) and pull the engine out

from the rear side of the vehicle.

REMOVING THE CENTRE STAND

125 cc VERSION

CAUTION!!!

Before disassembly, hold the vehicle

in place to prevent it falling over.

Undo the screw (V - F.136).

Undo the screw (V - F.137).

Remove the double spring (A - F.137) and hence

the stand.

Page 73

A

09.03 73

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.139

A

V

F.138

F.140

V2

200 cc

B

A

REMOVING THE CENTRE STAND

200 cc VERSION

CAUTION!!!

Before disassembly, hold the vehicle

in place to prevent it falling over.

Remove the double spring (A - F.138).

Unscrew the nut (B - F.138), remove the pin and

hence the stand.

REMOVING THE SIDE STAND

Remove the double spring (A - F.139).

Undo the screw (V - F.139).

Furthermore, check correct operation of the switch,

which should prevent engine ignition if the stand is

operated.

Caution!!! Do not tamper with this

safety device!

REMOVING THE SIDE STAND SWITCH

• (Remove seat, passenger’s seat and helmet

holder)

Undo the screws (V2 - F.140).

Page 74

A

74 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.143/b

F.141

A

F.142

A

125 cc

F.143

A

C

125 cc

V

B

125 cc

D

Disconnect the cables (A - F.141) and cut the cable clamps.

REMOVING THE ENGINE FIXING PLATE

125 cc VERSION

• (Remove seat, passenger’s seat, helmet hold-

er, handle cover, rear handle, side casings, tail

section and strut)

CAUTION!!!

Before disassembly, hold the vehicle

in place to prevent it falling over.

Remove the spring (A - F.142).

Undo the screw (V - F.143).

Remove the pin (A - F.143), by unscrewing the nut

(B - F.143/b).

Remove the pin (C - F.143), by unscrewing the nut

(D - F.143/b).

Page 75

A

09.03 75

CHAPTER

PAGEISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.146

A

V2

F.145

F.145/b

F.144

200 cc

A

200 cc

200 cc

A

V

B

C

D

REMOVING THE ENGINE FIXING PLATE

200 cc VERSION

• (Remove seat, passenger’s seat, helmet hold-

er, handle cover, rear handle, side casings, tail

section and strut)

CAUTION!!!

Before disassembly, hold the vehicle

in place to prevent it falling over.

Remove the spring (A - F.144).

Undo the screw (V - F.145).

Remove the pin (A - F.145), by unscrewing the nut

(B - F.145/b).

Remove the pin (C - F.145), by unscrewing the nut

(D - F.145/b).

REMOVING THE SWITCH WITH KEY

• (Remove handlebar cover, upper fairing and low-

er fairing)

Undo the screws (V2 - F.146) and disconnect the

cables (A - F.146).

Page 76

A

76 09.03

CHAPTER

PAGE ISSUE

CHASSIS

ENGLISH

DISASSEMBLY

A - CHASSIS

SECTION 3

F.148

V

F.147

A

B

F.149

A

REMOVING THE HANDLEBAR