Page 1

Page 2

03/10

I

CONTENTS

DESCRIPTION PAGE

INTRODUCTION 1

NOTES FOR EASY CONSULTATION 1

SPECIFICATIONS 2

MAIN COMPONENTS 3

IDENTIFICATION DATA: CHASSIS N° / ENGINE N° 3

ANTI-TAMPERING PLATE 3

TIRES 4

PRESSURE 4

FUEL TANK 5

FRONT LUGGAGE COMPARTMENT 5

REAR-VIEW MIRROR 5

HELMET COMPARTMENT 6

LUGGAGE HOOK 6

INSTRUMENT BOARD 6

HANDLEBAR CONTROLS 7

RIGHT HAND CONTROL (FIG. 17) 7

LEFT HAND CONTROL (FIG. 18) 7

CHECKS BEFORE USE 7

MAINTENANCE TABLE 8

TRANSMISSION OIL 8

ENGINE OIL 9

LUBRICANT TABLE 10

SPARK PLUG 10

THROTTLE FREE PLAY ADJUSTMENT 10

CHECKING THE PADS AND DISC OF THE FRONT BRAKE (CONDITION AND WEAR) 11

CHECKING THE REAR BRAKE 11

HEADLIGHT 11

FRONT TURN INDICATOR 11

TAIL LAMP (WITH STOP LIGHT) 12

FUSES 12

BATTERY (12V - 5Ar) 13

BATTERY RECHARGING 13

FAIRING 14

DISMANTLING THE FRONT HANDLEBAR COVER 15

REPLACING THE HEAD LIGHT BULB 15

DISMANTLING THE REAR HANDLEBAR COVER 16

DISMANTLING THE FRONT SHIELD 16

DISMANTLING THE SIDE COVERS 17

DISMANTLING THE TAIL LIGHT ASSY 17

DISMANTLING THE REAR HANDLE 18

DISMANTLING THE HELMET COMPARTMENT 19

DISMANTLING THE FAIRING 19

BATTERY BOX 20

DISMANTLING THE FOOT BOARD 21

DISMANTLING THE LOWER SHIELD AND INNER SHIELD 21

REPLACING THE PARK LIGHT AND TURN INDICATORS BULBS 22

DISMANTLING THE FRONT MUDGUARD 22

FRONT WHEEL 24

DISMANTLING THE FRONT WHEEL 25

DISMANTLING THE FRONT BRAKE CALLIPER 25

DISMANTLING THE BRAKE DISC 25

FRONT RIM CHECK (WHEEL REMOVED) 26

CHECKING THE FRONT WHEEL SPINDLE 26

Page 3

03/10

II

DISMANTLING THE BRAKE PAD SET 26

FRONT FORK 28

DISMANTLING THE FORK 29

REPLACING CAPS AND STEERING CONES 29

DISMANTLING THE FORK 30

OIL LEVEL CHECK 30

MAIN IGNITION SWITCH 31

REAR WHEEL AND SHOCK ABSORBER 31

DISMANTLING THE REAR WHEEL 32

DISMANTLING THE BRAKE SHOES 32

DISMANTLING THE SHOCK ABSORBER 32

CHECKING THE BRAKE HUB 33

CHECKING BRAKE SHOES 33

CHECKING THE SHOCK ABSORBER 33

DISMANTLING THE MAIN STAND 34

REMOVING THE ENGINE FROM THE CHASSIS 34

CHECKING THE END COMPRESSION PRESSURE 39

ENGINE DISMANTLING 40

DISMANTLING THE CLUTCH COVER 40

DISMANTLING THE ASSY PRIMARY PULLEY 41

DISMANTLING THE REAR CLUTCH ASSY 41

DISMANTLING THE STARTER MOTOR 42

DISMANTLING THE ETC INTAKE MANIFOLD 42

DISMANTLING THE AIR CONVEYORS 42

DISMANTLING THE VALVE COVER 43

DISMANTLING THE SECONDARY AIR VALVE 43

DISMANTLING THE ROTOR 44

DISMANTLING THE STATOR AND PICK-UP 45

DISMANTLING THE CHAIN TENSIONER 45

DISMANTLING THE HEAD 46

DISMANTLING THE ROCKER ARMS 47

DISMANTLING VALVES AND VALVE STEM SEALS 47

DISMANTLING THE CYLINDER 48

DISMANTLING THE PISTON 49

DISMANTLING THE OIL SUMP 49

DISMANTLING THE OIL PUMP 50

DISMANTLING THE RIGHT CRANK CASE 51

DISMANTLING THE CRANK SHAFT 51

CHECK CONNECTING ROD ASSEMBLY 51

DISMANTLING THE TRANSMISSION COVER 52

ASSEMBLY 53

CRANKCASE ASSEMBLY 53

ASSEMBLE THE OIL SUMP 54

ASSEMBLING THE STATOR AND PICK-UP 55

ASSEMBLING THE PISTON RINGS 56

ASSEMBLING THE PISTON 56

ASSEMBLING THE CYLINDER 57

ASSEMBLING THE HEAD 57

TIMING 58

HEAD CYLINDER TIGHTENING 58

CHECKING TIMING 59

VALVE TIMING ADJUSTMENT 59

VARIOUS INTERVENTIONS 60

DISMANTLING THE STARTING SYSTEM 60

ASSEMBLING THE STARTING SYSTEM 60

DESCRIPTION PAGE

Page 4

03/10

III

REPLACING CENTRIFUGAL ROLLERS 61

DISMANTLING THE CLUTCH ASSY 61

ASSEMBLING THE CLUTCH ASSY 62

DISMANTLING THE CARBURETTOR 62

DISMANTLING THE STARTER 62

DISMANTLING THE VALVE 63

DISMANTLING THE FLOAT, NEEDLE AND JET 64

REMOVE THE IDLE SCREW AND IDLING ADJUSTING SCREW 65

CYCLE TIGHTENING TORQUES 66

ENGINE TIGHTENING TORQUE 67

TIGHTENING TORQUE (GENERIC TABLE) 68

FRAME DIMENSION CHECKS 68

ELECTRICAL PART LOCATION 69

SWITCH CHECKS 71

CHECK FUEL LEVEL GAUGE 71

CHECK FUEL LEVEL SENSOR 72

IGNITION 72

HT COIL 72

SPARK PLUG CAP 72

STATOR (POWER 70W) 72

WIRING DIAGRAM 73

DESCRIPTION PAGE

Page 5

03/10

1

INTRODUCTION

- MALBO Line makes on-going efforts to perfect all its

vehicles as well as the manuals supplied with them.

- MALBO Line reserves the right to modify its models

without notice; therefore, kindly check if the vehicle

meets your expectations before purchasing it.

- All MALBO Line vehicles are designed and built with

their common use in mind: therefore, any special use

of MALBO Line vehicles is excluded unless expressly

approved in writing by MALBO Line.

- The vehicle observes the emission limits provided

for by the European directive for motorcycles.

- Exclusively refuel your vehicle with: UNLEADED PET-

ROL.

The muffler irradiates heat even after the engine has just

been turned off. We therefore recommend you to carefully read the following instructions:

- Always allow the engine and muffler to cool down be-

fore any maintenance operation, in order to avoid hot

surfaces.

- Make sure you do not park nor stop your vehicle on

grass, paper, deadleaves or other easily inflammable

materials.

- The passenger should get on and off the vehicle from

the opposite side of the muffler, in order to avoid hot

surfaces.

NOTES FOR EASY CONSULTATION

For a quick and easy interpretation, symbols have been

used to highlight situations requiring extra attention,

practical advice or just information.

ATTENZION! Tips and precautions regarding

the safety of the rider (motorcycle user) and the

maintenance of vehicle integrity.

IMPORTANT! Subject matter for which you

must pay special attention.

Page 6

03/10

2

SPECIFICATIONS

MALBO Line reserves the right to modify the specifica-

tions at any time without prior notice.

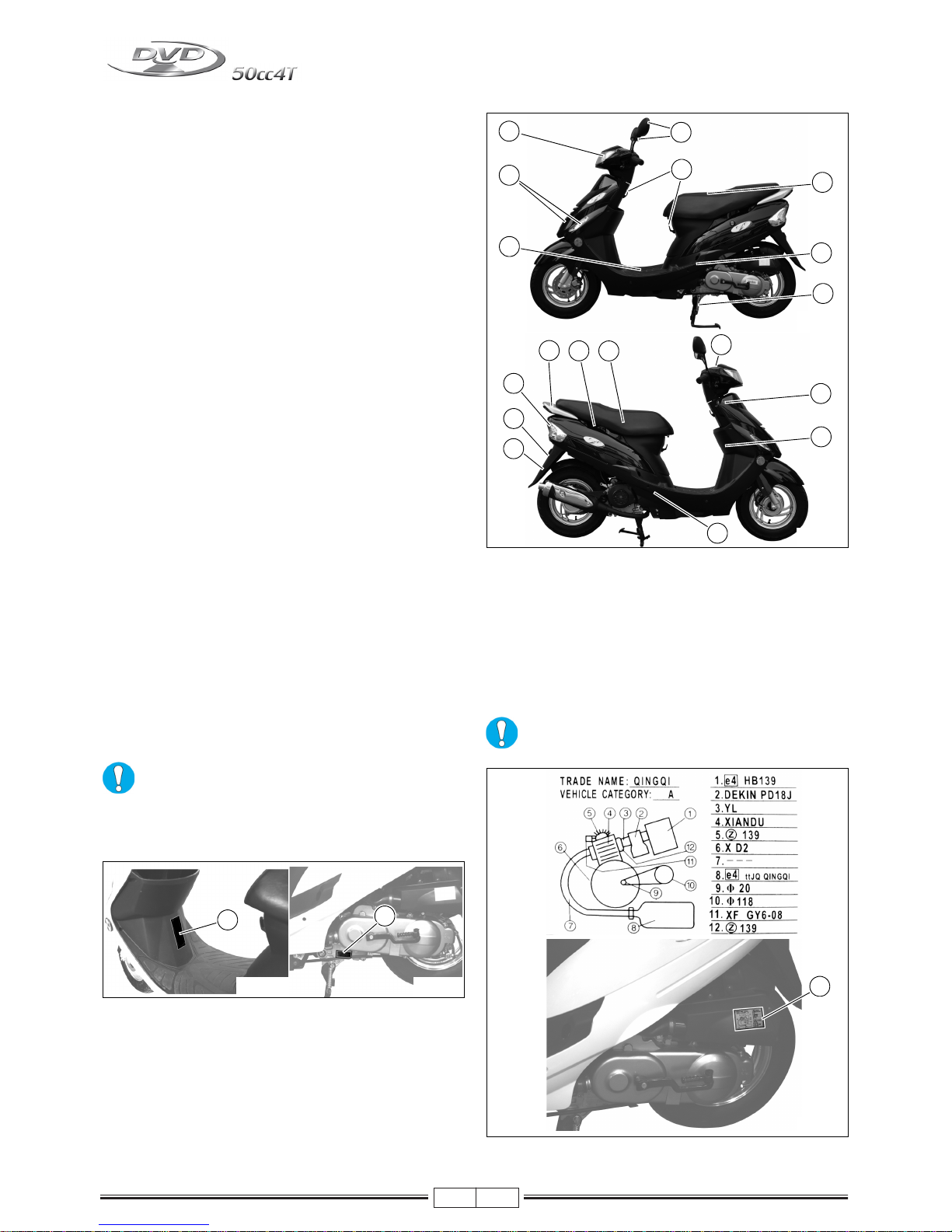

Dimensions

Wheel base (A-Fig. 01) m .....................................1,200

Max. length (B-Fig. 01) m ......................................1,640

Max. width (C-Fig. 01) m ......................................0,685

Max. height (D-Fig. 01) m ......................................1,075

Kerb weight kg ...........................................................85

Max. load with rider, passenger and luggage Kg .....160

Capacity

Engine oil cm

3

........................................................ 800*

Transmission oil cm

3

.............................................. 120*

Fuel tank capacity (reserve) l .......................... 6,0 (1,5)*

Engine: single-cylinder - 4-stroke

Type ................................................................ 139QMB

Cylinders ......................................................................1

Bore x stroke mm ........................................ Ø 39 x 41,4

Capacity cm

3

..............................................................49

Compression ratio ..............................................10,5 : 1

Cooling ............................................................forced air

Starting system ...................electrical and/or kickstarter

Lubrication system ........................... by wet crank case

Spark plug

Type ....................... NGK CR7HSA - A7RTC - LDA7TC

Transmission

Primary: automatic speed variator by V-belt.

Final: by gears.

Automatic centrifugal dry clutch.

Fuel system

Automatic starter

Fuel: unleaded petrol.

*Indicative Value

Ignition

Electronic.

Brakes

Front brake:

disk type, Ø 155 mm

transmission and hydraulic calipers.

Rear brake:

drum Ø 110 mm

mechanical transmission.

Chassis

High resistance tubular steel frame.

Suspensions

Front: hydraulicall fork Ø 26 mm.

Rear: Swinging engine with hydraulic shock absorber

featuring helical spring.

Battery

12V, 5Ah, maintenance-free.

Tires

Front: .........3.50 - 10 42J (tubeless)

Rear: .........3.50 - 10 42J (tubeless)

It is possible to use tires with load-capacity and

speed indexes that are higher than or identical

to those indicated.

It is however necessary for the speed indexes

to be identical for both tires.

Fig. 01

Page 7

03/10

3

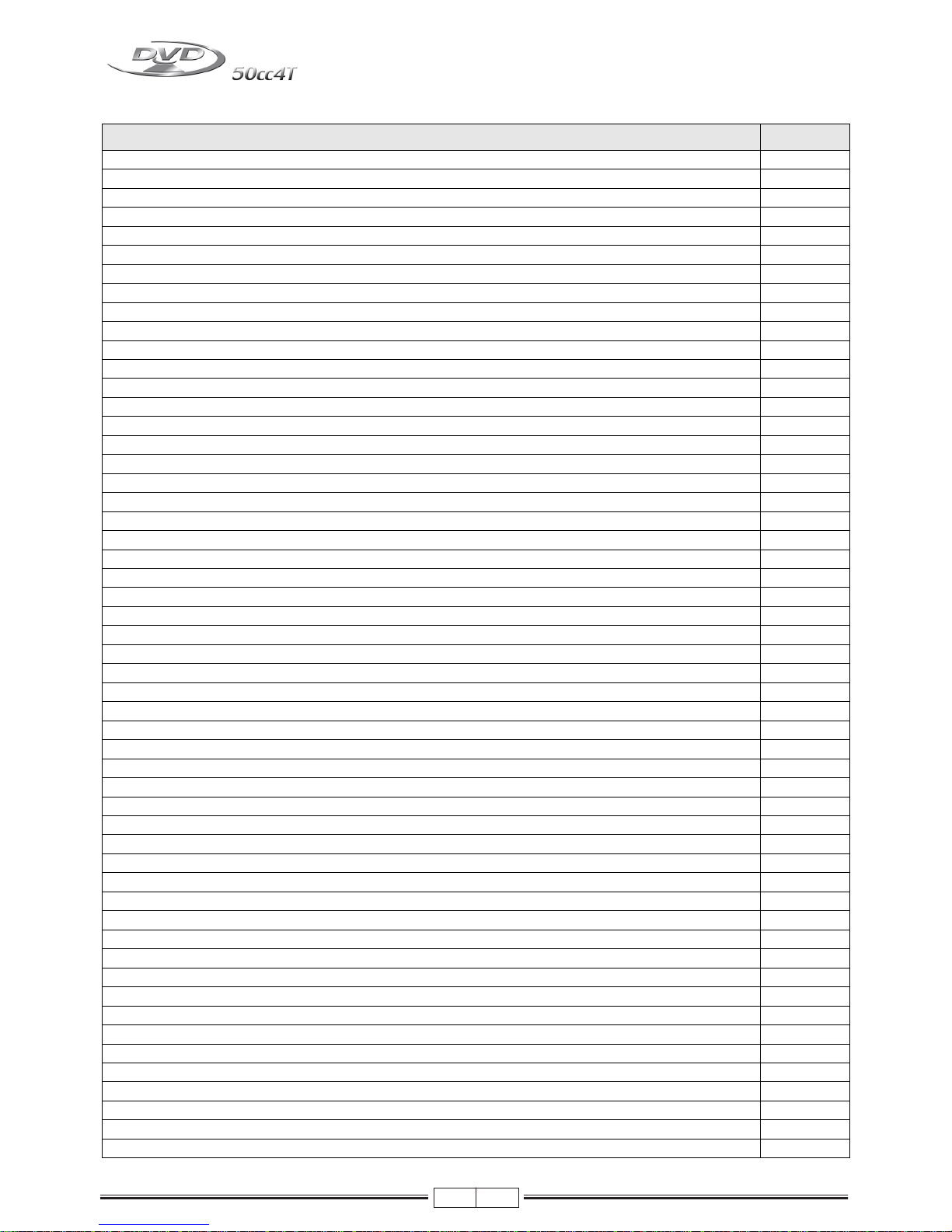

MAIN COMPONENTS

1 - Headlight

2 - Front turn indicator

3 - Passenger footboard

4 - Centre stand

5 - Battery - Protection fuses

6 - Helmet compartment

7 - Tail lamp

8 - Number plate holder

9- Muffler

10 - Luggage hooks

11 - Front luggage compartment

12 - Ignition key

13 - Mirror

14 - Instrument board

15 - Twin seat

16 - Fuel tank cap

17 - Passenger handles

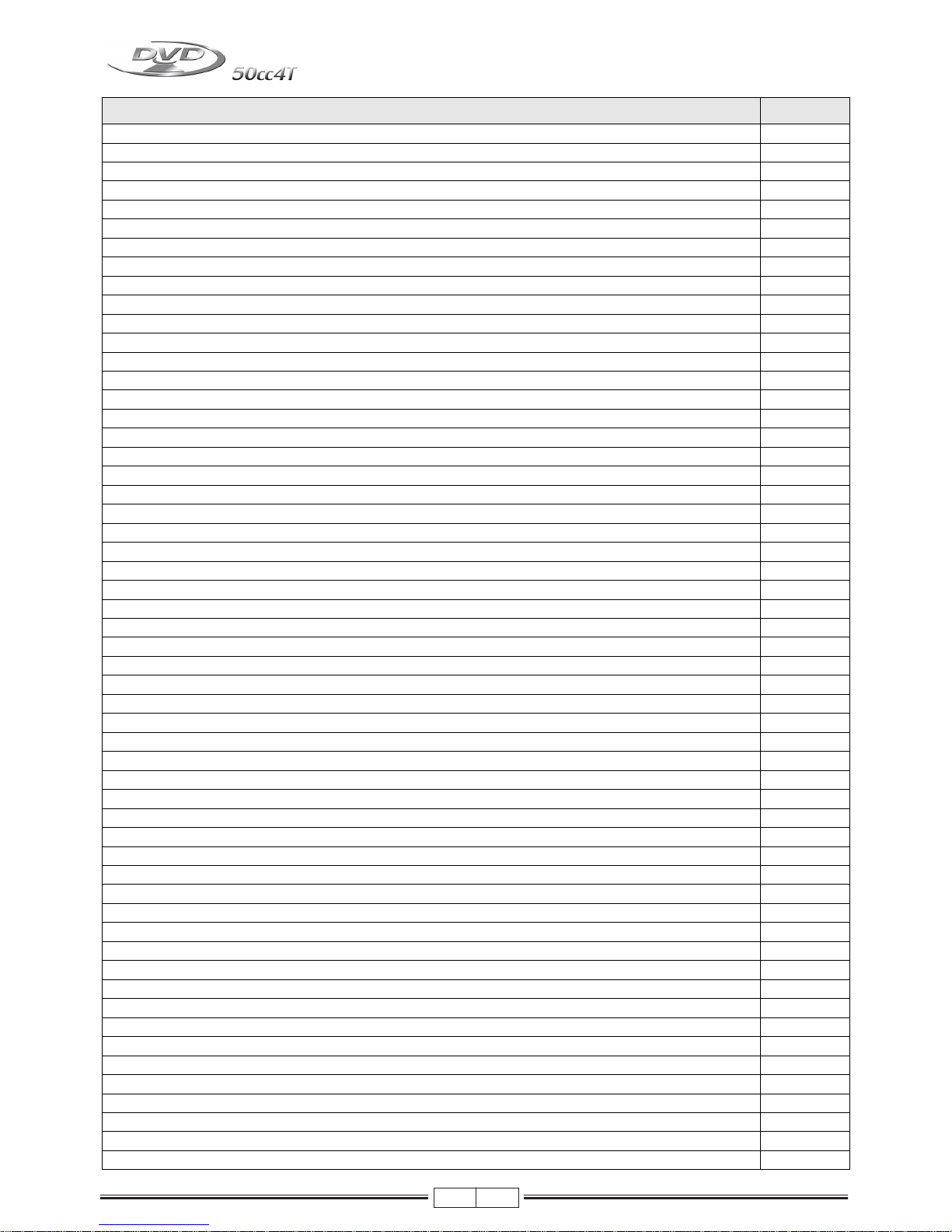

IDENTIFICATION DATA: CHASSIS N° /

ENGINE N°

- The type approval and vehicle numbers (VIN) are

stamped on the vehicle’s chassis in the positions

shown in the photos (A-Fig. 04).

- Engine identification data are visible on the left engine

crankcase (B-Fig. 05).

Altering identification data will be punished according to the law.

- When ordering spare parts, also quote the vehicle

identification data.

ANTI-TAMPERING PLATE

An anti-tampering plate (C-Fig. 06), bearing all vehicle

identification data required by Directive 97/24/CE

Chap. 7, is fitted on the filter box. If you have the filter box

replaced, make sure the plate is fitted too.

This label must be neither removed nor

changed.

10

13

1

2

5

6

3

4

11

12

14

7

8

9

17

16 15

3

Fig. 03

Fig. 02

A

B

Fig. 05Fig. 04

C

Fig. 06

Page 8

03/10

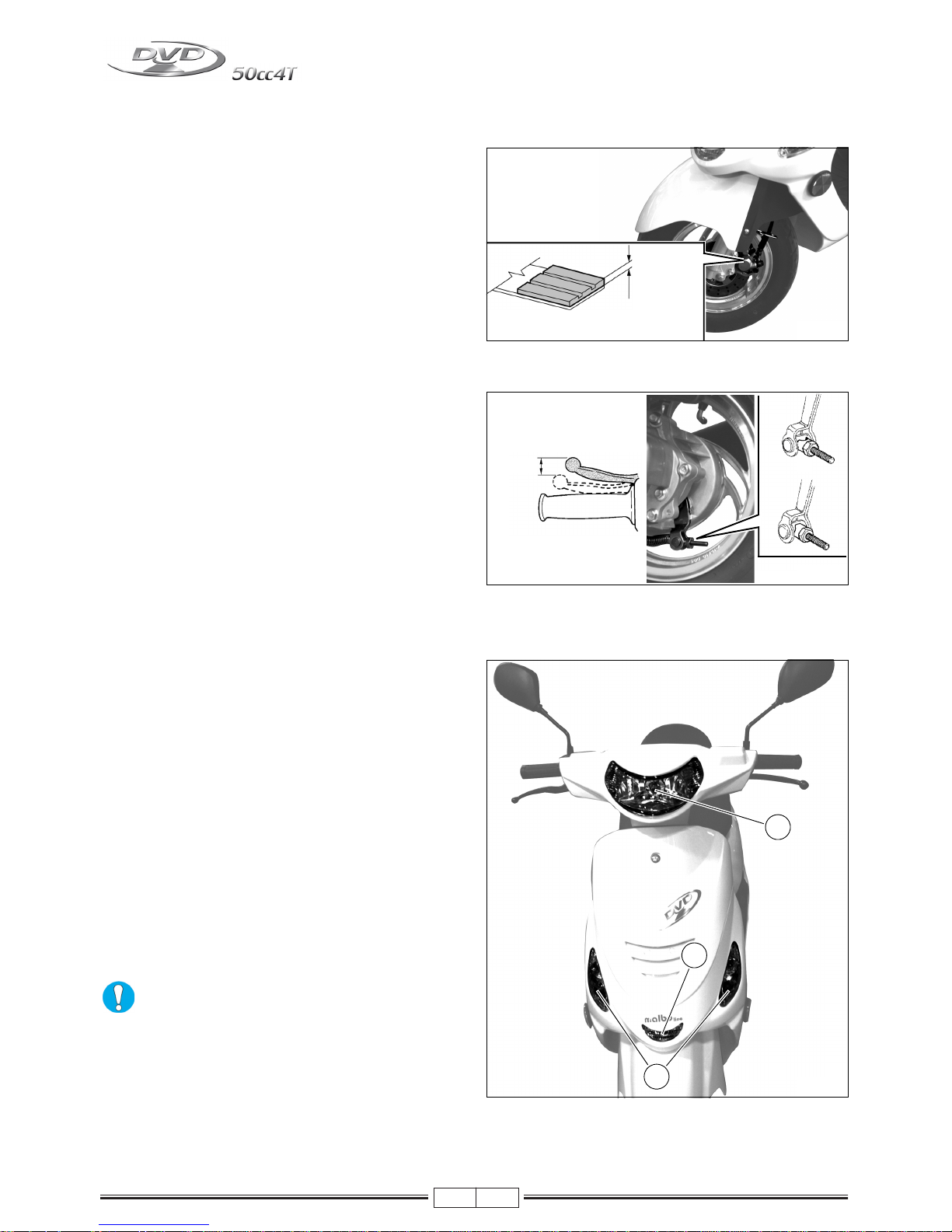

4

TIRES

Type: Tubeless (without inner tube)

It is possible to use tires with load-capacity and

speed indexes that are higher than or identical

to those indicated.

It is however necessary for the speed indexes

to be identical for both tires.

USE ONLY HOMOLOGATED TIRES.

Check the tire conditions (before every journey): if they

are broken (cracked) or cut, have them replaced as soon

as possible.

“T.W.I.” marks are provided all around the tire side walls.

These correspond to tire wear indicators, which are situated in the tire’s tread; if there is no difference between

the thickness of these indicators and the tread depth itself, the tire must be replaced.

Minimum tread depth (front and rear) is 2 mm

(Fig. 08).

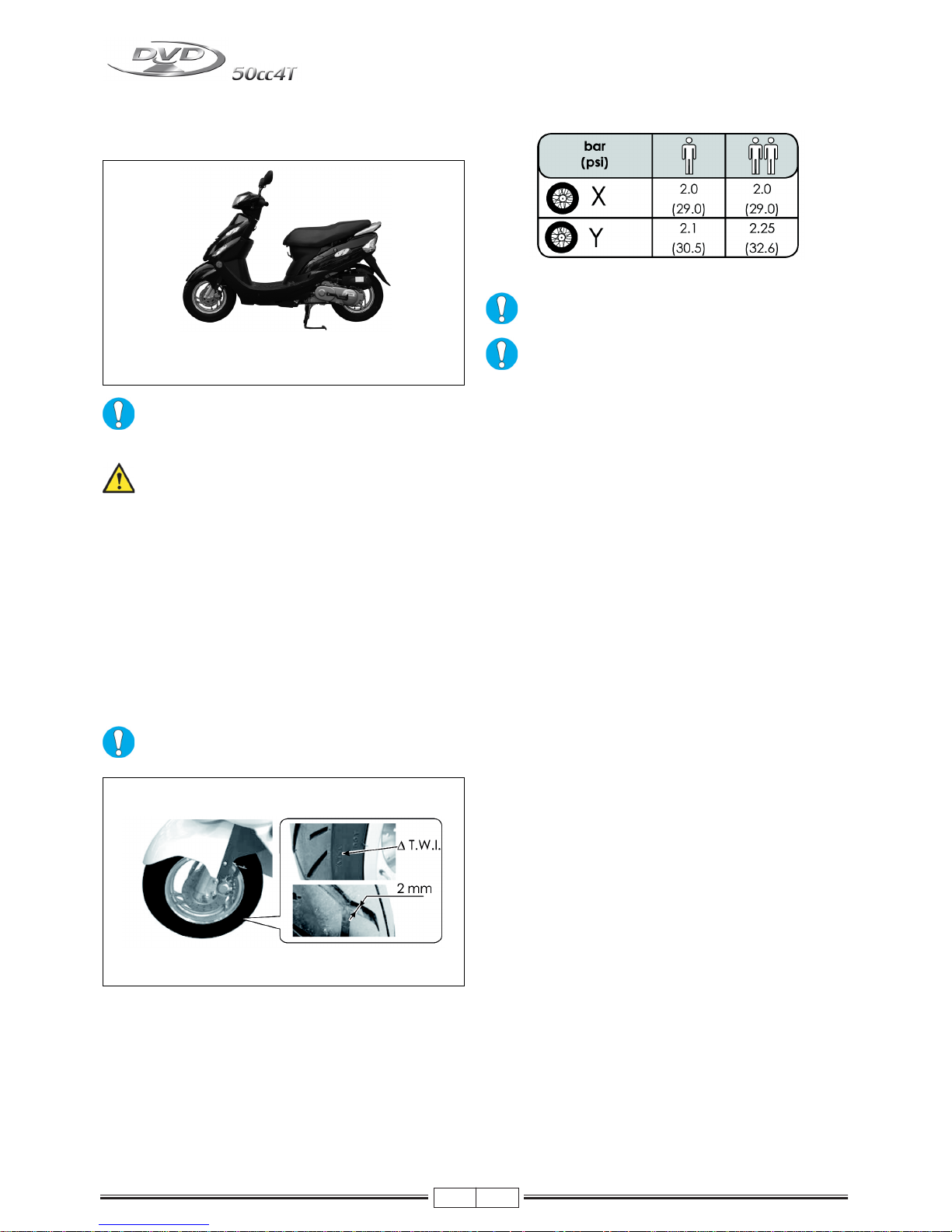

PRESSURE

The pressure of tires must be adjusted while

the tire is at ambient temperature.

Pressure differing from that indicated can lead

to higher fuel consumption, irregular wear of

the tire, impaired vehicle performance and riding conditions.

X

3.50-10 42J

Y

3.50-10 42J

Fig. 07

Fig. 08

Page 9

03/10

5

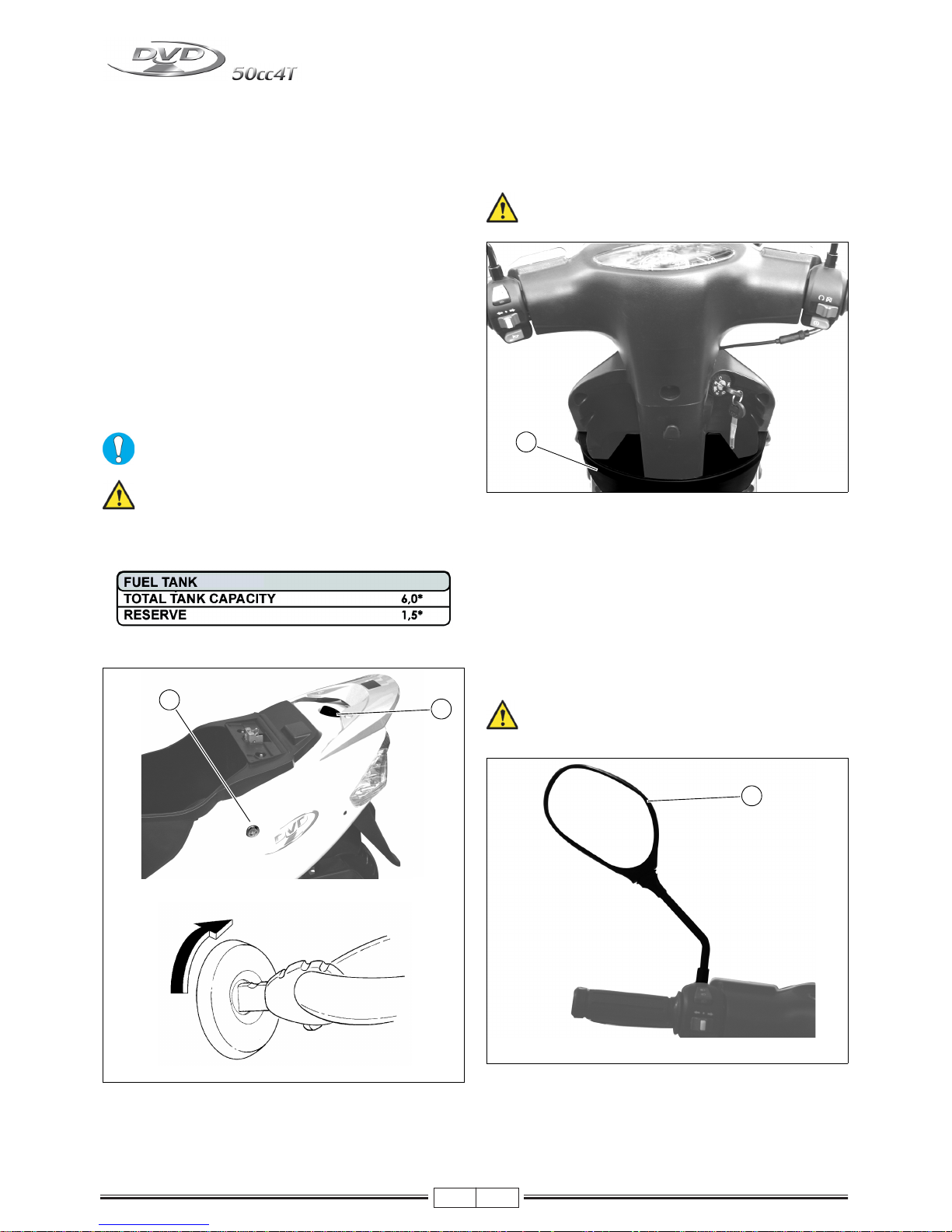

FUEL TANK

To gain access to the fuel tank, proceed as follows:

- Place the vehicle on the centre stand.

- Take the ignition key out of the ignition barrel and insert it into the lock on the left hand side of the seat (A-

Fig. 09).

- Open seat by turning ignition key clockwise (Fig. 10).

- Remove the cap (B-Fig. 09) and fill the tank.

- After refuelling, immediately remove any possible traces of fuel from the vehicle body, since fuel may deteriorate the vehicle’s outer surfaces.

- The quantity of fuel, as well as a low fuel level, are displayed by the corresponding indicator on the right

hand side of the instrument board (5-Fig. 16).

- Use UNLEADED PETROL.

Important: do not overfill the fuel tank. Overflowing fuel may damage the vehicle.

Petrol is extremely inflammable; avoid approaching the fuel filler - also during filling with lit cigarettes or naked flames (for instance

matches). Danger of fire!

*Indicative value in litres

FRONT LUGGAGE COMPARTMENT

This is located at the centre of the lower fairing (AFig. 11). It can be used for storage small and light ob-

jects.

It is advisable not to leave any documents or

valuables inside these compartments.

REAR-VIEW MIRROR

The left hand rear view mirror must be fitted to the handlebar, in its special seat and firmly secured in place.

Adjust the visual angle of the mirror, while you are sat in

riding position on the vehicle in riding order, by turning

the mirror until you obtain the best conditions of visibility

(P-Fig. 12).

Objects that are visible in the mirror are actually closer

than they seem.

Do not adjust rear-view mirror while driving. Always wait to stop at a traffic light, for example.

A

B

Fig. 10

Fig. 09

A

Fig. 11

P

Fig. 12

Page 10

03/10

6

HELMET COMPARTMENT

- This is located under the seat. The helmet compartment can contain a Jet helmet. Some types of helmet

may not fit into the compartment. Before purchasing

your helmet, make sure it fits into the compartment.

- To gain access to the helmet compartment, put the vehicle on its stand; take the ignition key out of the switch

block and insert it into the lock on the left hand side of

the seat (Fig. 13).

The helmet compartment can be used to carry

light objects. They shall be stored in such a

way as not to compromise the vehicle’s stability while riding. Do not store objects which are

not temperature resistant (lighters, inflammable liquids, perishable goods, etc.). Do not

leave documents or valuables inside the helmet compartment.

LUGGAGE HOOK

The vehicle is fitted with two luggage hooks (G-Fig. 15)

on which you can hang small objects or bags. One of the

hooks is located at the centre of the lower fairing, the other is in centre position, under the seat. They must be

used only for holding light and stable loads.

Never use these hooks for loads that alter your

riding position or put the vehicle’s stability at

risk. The load must never protrude from the

sides of the vehicle.

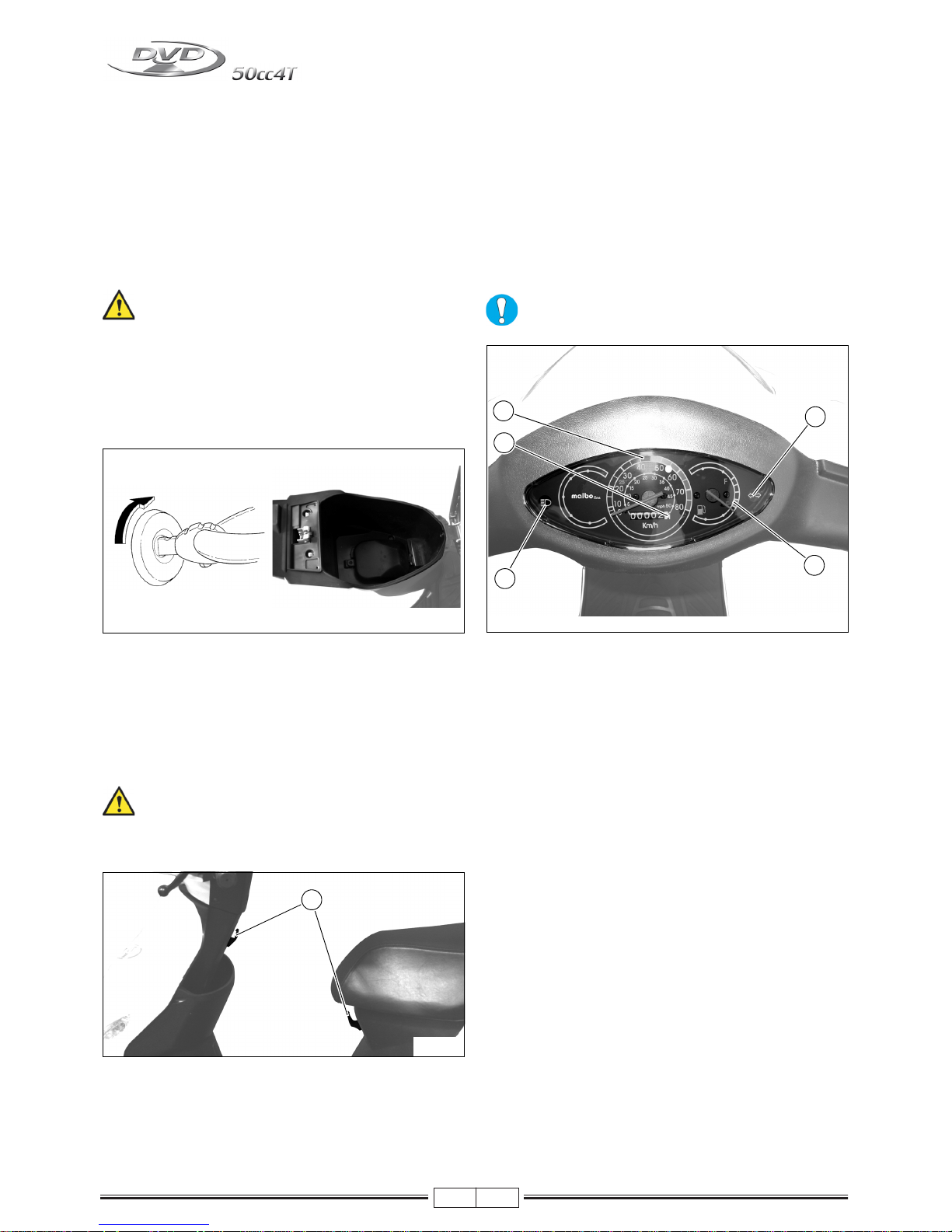

INSTRUMENT BOARD

1- Analogue instruments, Speedometer

This indicates the current speed in kmh or mph.

2- Odometer

This indicates the total distance travelled in km.

3 - Green turn indicator light

4 - Blue high beam indicator light

5- Fuel level indicator

This displays the level of fuel in the tank.

Red zone: reserve - REFUEL!!

To prevent damage, avoid washing instruments with pressurised system.

Fig. 14Fig. 13

G

Fig. 15

3

5

1

2

4

Fig. 16

Page 11

03/10

7

HANDLEBAR CONTROLS

RIGHT HAND CONTROL (FIG. 17)

1) Throttle grip

2) Front brake lever

3) Engine stop:

right = Position - Engine stop

left = Position - Engine starting

4) Electric starter button.

LEFT HAND CONTROL (FIG. 18)

1) Rear brake lever

2) Horn button.

3) Turn indicator switch.

4) Button for turning off indicator lights

5) Light switch:

high beam

low beam

PASSING High beam “flash” lever

CHECKS BEFORE USE

4

1

2

3

Fig. 17

1

5

4

2

3

Fig. 18

Part Check

Fuel Enough fuel

Transmission oil - Engine oil Level within limits specified. Check for leaks

Tires Check pressure/wear/damage

Nuts, screws, bolts Check tightness

Steering Free movement from one end to the other

Front/Rear brakes Working properly and not worn; if necessary, adjust or replace

Throttle Operation should be smooth, if necessary lubricate or adjust

Lights and indicators Proper working conditions

Stand Operation of stand and return springs

Loads

Make sure loads and accessories (e.g. rear case) are firmly secured to

vehicle

Page 12

03/10

8

MAINTENANCE TABLE

NOTE - Maintenance operations should be performed more frequently if the vehicle is used in rainy weather, in dusty

places or on rough terrain.

Due to their simplicity, checks featuring an asterisk CAN also be carried out by technicians not authorised by MALBO Line or MALAGUTI, but under their direct responsibility.

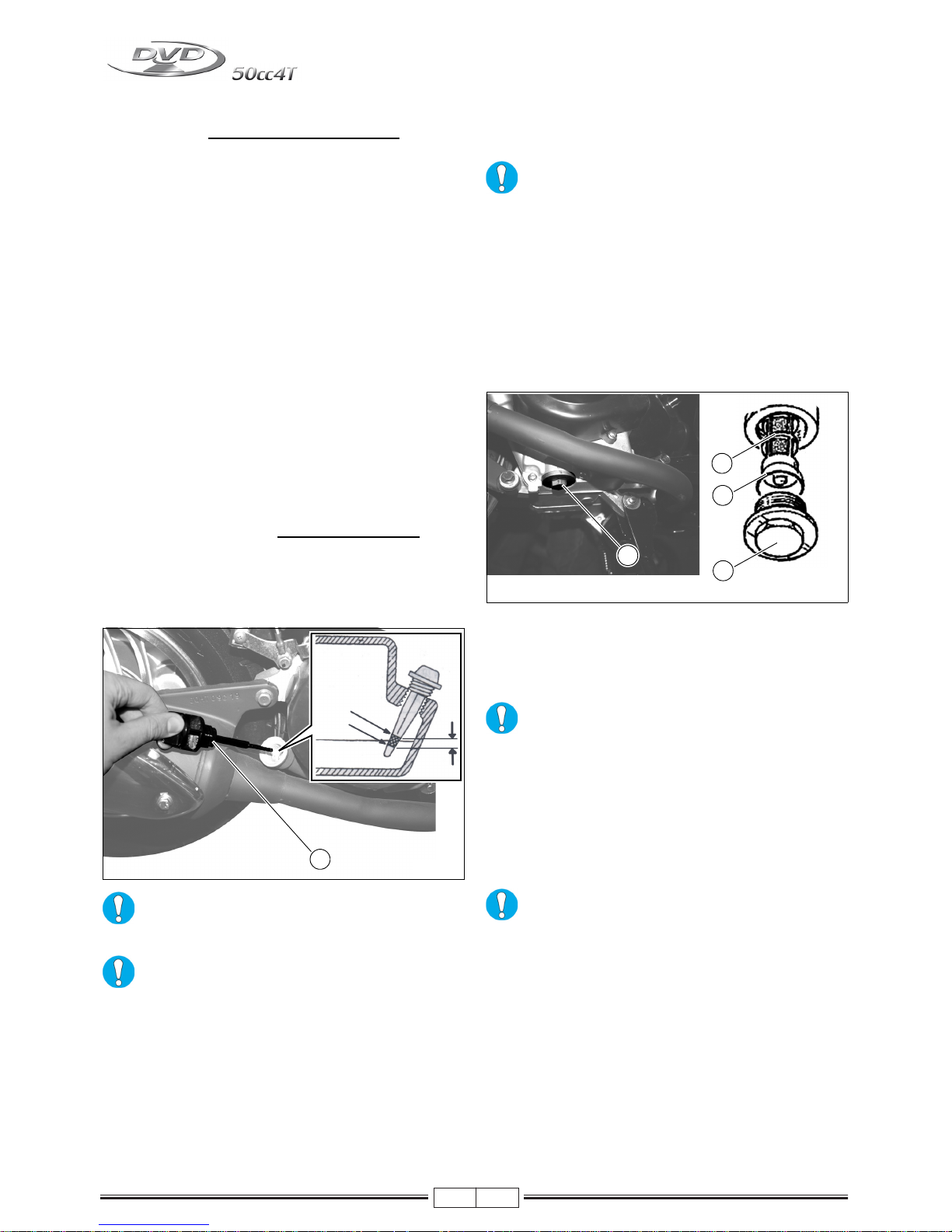

TRANSMISSION OIL

Checking level/topping up every 5,000 km/3,120

miles or 12 months

1 - Park the vehicle on a level surface on its centre

stand.

2 - Unscrew the dipstick (A-Fig. 19)

3 - If necessary, top up until it overflows.

4 - Refit and tighten the oil filling screw. Recommended

oil: Q8 T35 - 80W

Renew after the first 500/1,000 km (312/624 mi) and

every 10,000 km (6,240 mi) or 24 months

1 - Park the vehicle on a level surface on its centre

stand.

2 - Put a container under the drain cap.

3 - Remove the oil filler screw (A-Fig. 19).

4 - Unscrew the oil drainage screw (B-Fig. 19) and

drain out the entire oil content.

5 - Clean the drainage screw and refit it.

6 - Fill with new oil of the recommended type until you

notice oil overflowing.

Recommended oil: Q8 T35 - 80W

Capacity: 120 cc.

7 - Refit the oil filler screw and wrench in place.

Perform this operation with the engine off and

cold.

Prevent foreign matters from getting into transmission crankcase during checks or oil changes. Prevent oil dripping on tires or wheels.

A

B

Fig. 19

Page 13

03/10

9

ENGINE OIL

Check oil level EVERY 500 KM (310 MILES)

As far as four-stroke engines are concerned, engine oil is

used to lubricate distribution components, base bearings

and the thermal unit. An insufficient oil quantity or use

a poor quality oil can seriously damage the engine.

In all four-stroke engines, deterioration of the oil and a

certain consumption are to be considered normal. Consumption, in particular, strictly relates to conditions of usage (oil consumption increases if the vehicle is used with

the throttle fully open).

To prevent trouble, check the oil level more frequently with respect to the indications given in the MAINTENANCE TABLE, especially before long journeys.

Checking the oil level

This check should be performed when the engine is cold,

as described below:

1 - Park the vehicle on flat ground and put it on its cen-

tre stand.

2 - Stop the engine and wait a few minutes for the oil to

stabilise.

3 - Unscrew the cap/dipstick (A-Fig. 20), dry it with a

clean cloth and refit it, without wrenching it

.

4 - Remove the cap/dipstick and make sure the level

falls between the MAX and MIN notches; if neces-

sary, top up with Q8 CLASS 10W40 oil.

5 - Refit the cap/dipstick (A-Fig. 20).

When checking the oil level, make sure the vehicle is upright; slight tilting may alter the readings.

If you need to check the level when the engine

is warm, remember that the level line will be

lower. It is best to wait at least 10 minutes from

stopping the engine in order to have a correct

reading

Topping up

Before topping up, check the oil level and in no case

allow the level to rise above the MAX notch.

Never allow the level to rise above the MAX

mark! Excessive internal pressure can impair

performance and cause malfunctioning or

damage to the engine.

Change engine oil and clean the filtering net every

2,500 km/1,560 miles or 6 months

1 - Warm the engine up for a few minutes.

2 - Stop the engine and put an oil container under the

engine.

3 - Remove the drainage plug of the filtering net (A-

Fig. 21-22) and the dipstick, then let oil flow out.

4 - Clean the filtering net (C-Fig. 22) with a suitable

solvent and blow dry with compressed air.

5 - Refit the filtering net, a new O-ring (B-Fig. 22) and

the drain cap.

Make sure the O-ring is correctly seated.

6 - Tighten the drain cap at the requested torque set-

ting: Tightening torque: 25-28 Nm/2.5-2.8 kgm

7 - Fill the engine with 800 cc of Q8 CLASS 10W40 oil

and top up if necessary. Refit the dipstick.

8 - Run the engine and let it warm up; check for any

leaks. If leaks are noted, stop the engine and locate

their cause.

Letting the engine run with an insufficient

amount of lubricant or with the wrong types of

lubricant causes wear to moving parts and can

in the long run cause serious damage.

A

Max

Min

Fig. 20

A

C

B

A

Fig. 22Fig. 21

Page 14

03/10

10

LUBRICANT TABLE

NOTE - The vehicle’s life depends also on the care devoted to lubricating it.

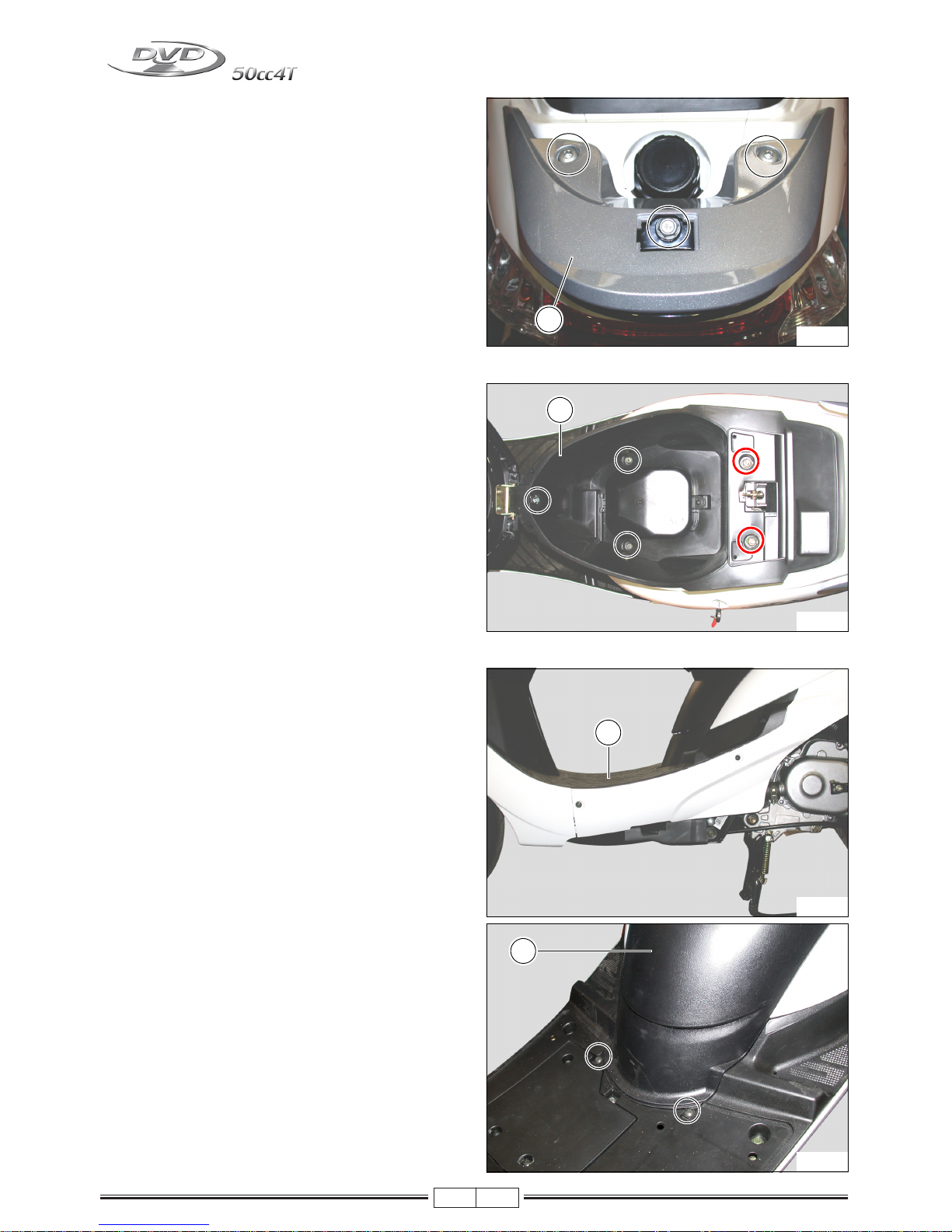

SPARK PLUG

Replace every 5,000 km (3,120 mi)

The spark plug is an essential component:

1 - Proper care of the plug is important for maintaining

the engine in perfect working order.

2 - For maintenance, remove the centre partition under

the seat (P-Fig. 23) , by unscrewing the three fixing

screws (V-Fig. 24) (2 on the footboard and one

inside the helmet compartment) and raising the bot-

tom profile (with the aid of a screwdriver) sealed

onto the two teeth of the footboard. Carefully

remove the cap by turning it clockwise and anti-

clockwise alternatively (C-Fig. 24); now, unscrew

the spark plug using the special wrench supplied

with the vehicle (all operations on the spark plug

must be performed when the engine is cold).

3 - Examine the spark plug conditions after a reasona-

bly long drive (10-15 km) and after letting the

engine cool down (at least 10-15 minutes), since

the sediments and the colour of the insulator can

provide useful information about the heat rating of

the spark plug, carburetion, lubrication and general

conditions of the engine. A light brown colour of the

insulator, around the central electrode, indicates

good working order.

4 - After disassembling the spark plug, suitably clean

the electrodes and the insulator using a metal

brush. Adjust the electrode gap using a filler gauge:

the gap should range from 0,5 ÷ 0,6 mm.

5 - Blow onto it so as to prevent possible residues from

entering the engine, then refit it, by wrenching until

finger tight. Then, using the special spark plug

wrench, wrench it to the recommended torque

wrench setting: 17.5 Nm / 1.75 kgm.

Spark plugs with a heat rating differing from

the recommended one may seriously damage

the engine.

It is imperative that any spark plug exhibiting

cracks on the insulator or corroded electrodes

be replaced.

THROTTLE FREE PLAY ADJUSTMENT

Check that the throttle grip idle stroke is 1-3 mm (measured on the end of the throttle grip).

0,5в0,

Fig. 24Fig. 23

V

P

C

Page 15

03/10

11

CHECKING THE PADS AND DISC OF THE

FRONT BRAKE (CONDITION AND WEAR)

1 - We recommend you to check the front pads and disc

every 2,500 km (1,560 mi).

2 - The minimum thickness of the brake lining shall not

be less than 2 mm (Fig. 25). Check the thickness of

the brake pads as illustrated in Fig. 26.

3 - If the thickness of the pads is close to the lowest per-

mitted limit or if they are damaged, have them

replaced immediately.

CHECKING THE REAR BRAKE

- Check whether the lever’s stroke is as illustrated in

Fig. 27. The idle stroke of the lever is approximately 10

mm.

- To adjust the rear brake, turn the adjuster under the en-

gine, as illustrated in Fig. 28.

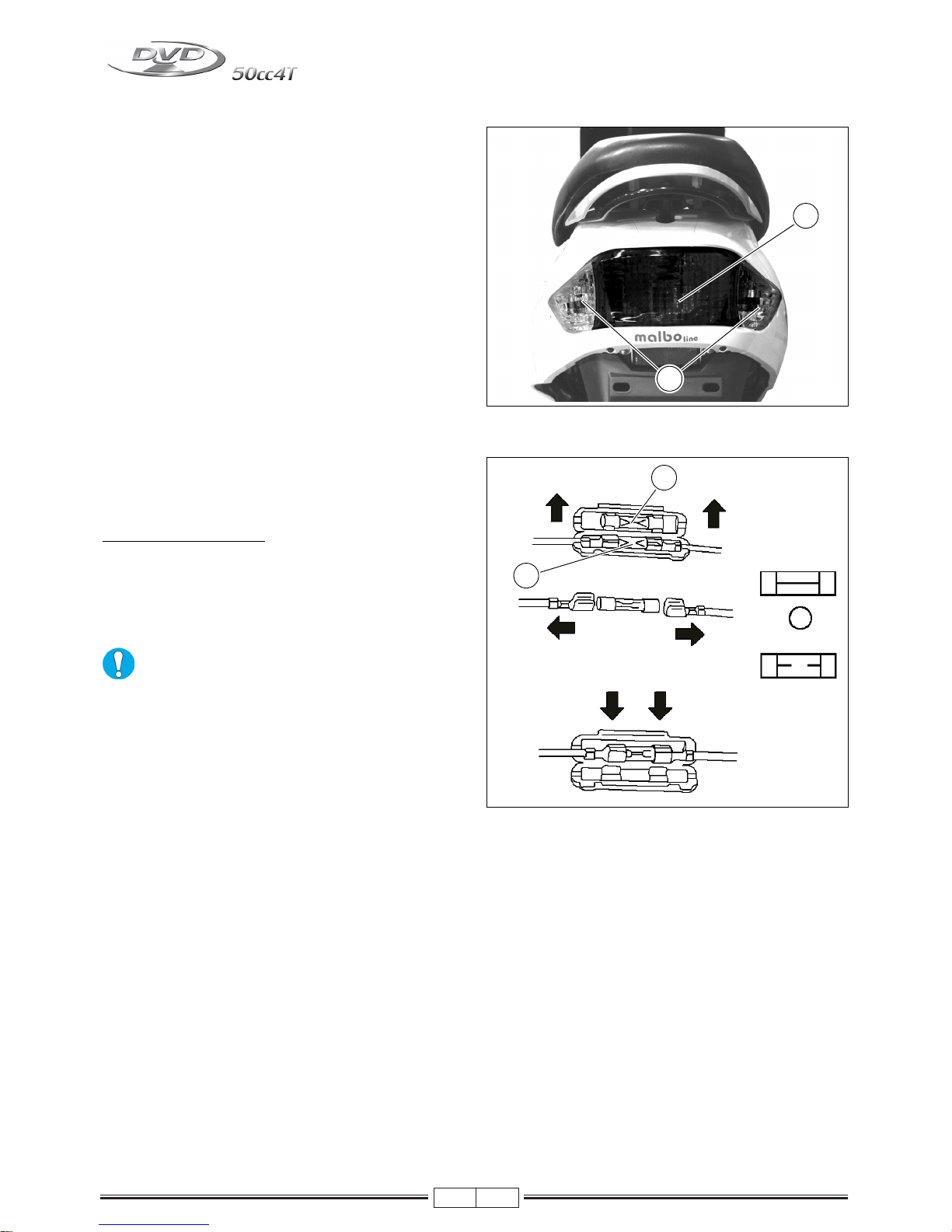

HEADLIGHT

To increase visibility at night, quartz (halogen) type headlights are fitted.

- Low beam / high beam (A-Fig. 29)

Bulb 12V - 25/25W

- Parking light bulb (B-Fig. 29)

Bulb 12V - 5W

NOTE - We advise you to check if the replaced bulb works

properly before refitting the headlight unit definitively.

FRONT TURN INDICATOR

- Front turn indicator (C-Fig. 29)

Orange lamp 12V - 10W

The rate at which the turn indicator warning light

on the instrument board flashes will increase to

signal that one of the four indicators is not working.

MIN. 2mm

Fig. 26Fig. 25

Fig. 28Fig. 27

NO

OK

10 mm

Fig. 29

B

A

C

Page 16

03/10

12

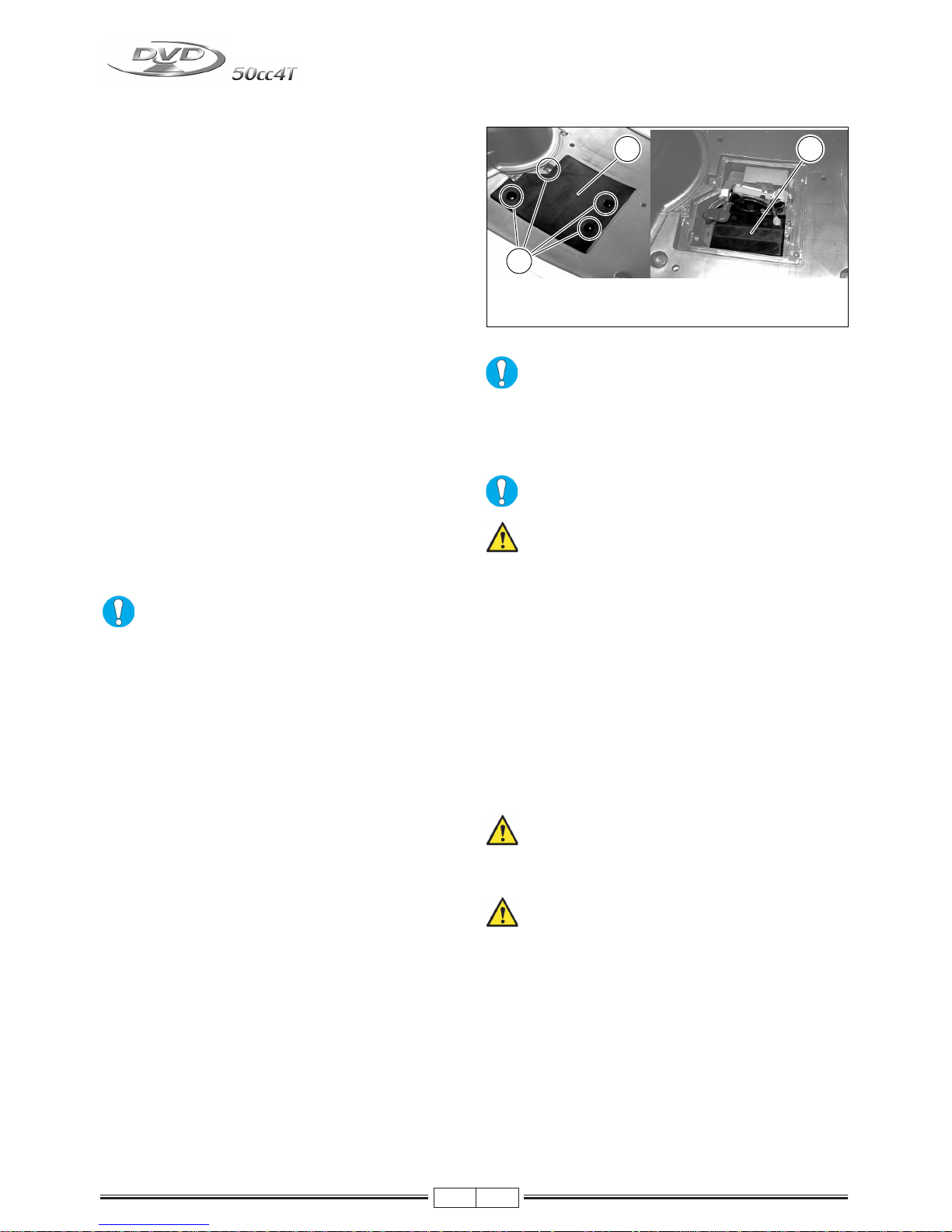

TAIL LAMP (WITH STOP LIGHT)

- Parking/Stop light (B-Fig. 30)

Bulb 12V - 21W/5W

- Rear turn indicator (E-Fig. 30)

Bulb 12V - 10W (R10W)

NOTE - Visually check if the stop light works properly, by

pulling one of the two brake levers.

FUSES

The electrical equipment includes a fuse protecting the

main components against faults. It is located close to the

battery (F-Fig. 31).

REPLACING THE FUSE

To replace the fuse, just open the battery compartment, extract the blown fuse and replace it with one of the same capacity. Inside the fuse box, you will find a spare fuse (S-

Fig. 31). Check that the fuse you are using has the same

amperage of the fuse you are replacing.

Do not replace the fuse with one having a higher

capacity, as it could seriously damage the electrical equipment and cause a fire on the vehicle in

the event of a short circuit.

Fig. 30

B

E

Fig. 31

F

S

Page 17

03/10

13

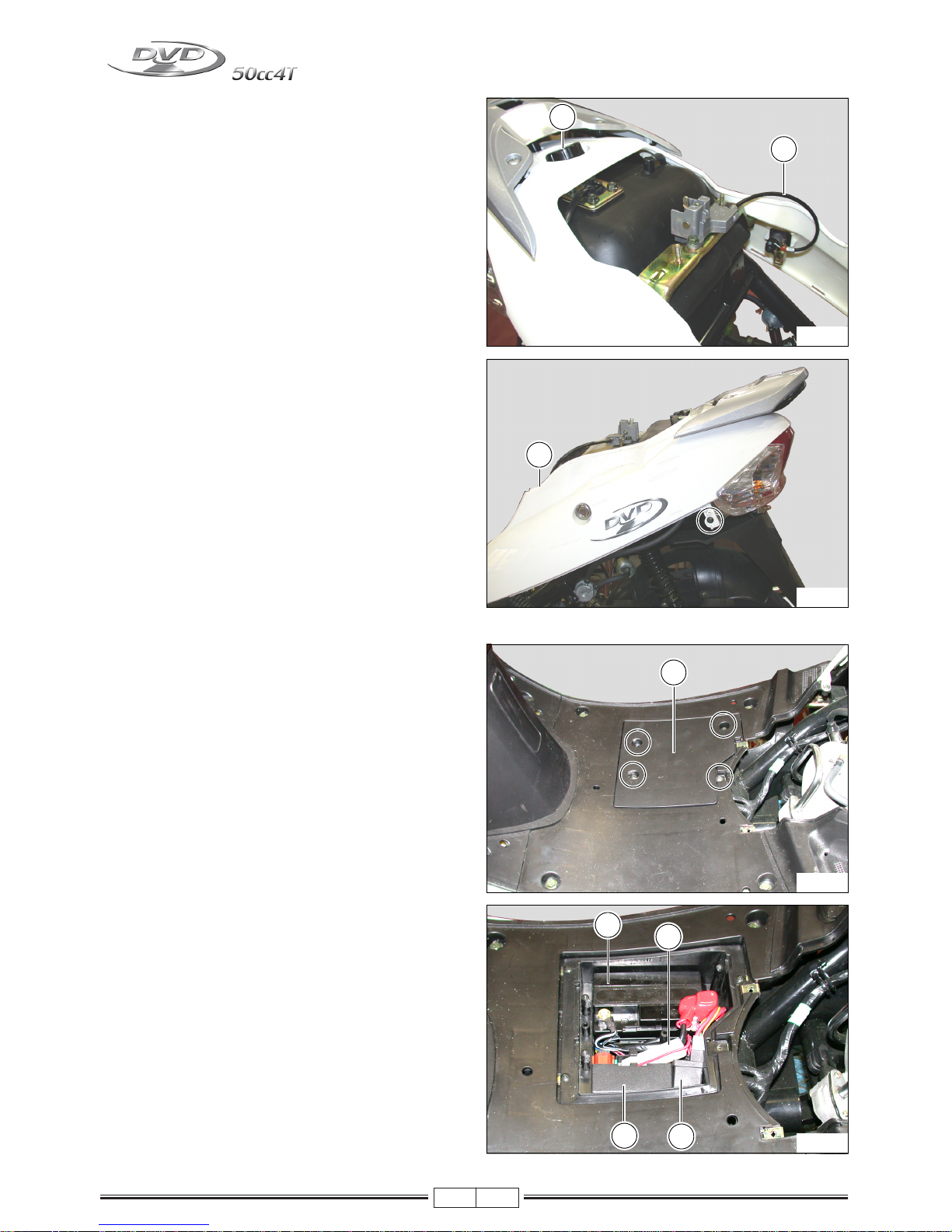

Battery (12V - 5Ar)

The battery compartment is located in the front section of

the vehicle.

Fitting battery

(operation performed before delivery)

To fit battery, proceed as follows:

- Take a previously charged battery.

- Remove the rubber mat.

- Loosen the four screws (V-Fig. 32) and remove the battery cover (C-Fig. 33).

- Remove the 10A general protection fuse.

- Insert the battery (B-Fig. 33) and make sure it is correctly seated.

- Connect the battery wiring:

- positive pole (+) to the RED - RED/BLUE cables

- negative pole (-) to the BLACK cables.

- Wrench down the battery terminals.

- Refit the 10A general protection fuse previously removed.

- Check that the battery and the wiring harness are correctly installed.

- Refit the battery cover and the rubber mat.

NEVER invert the cable connections.

Do not use the vehicle if the battery has not

been fitted correctly and connected to its cables.

This may cause failures and short circuit of the electrical

system and its components.

If the battery remains flat it will be seriously

damaged.

We advise you to use protective gloves and

goggles while removing the battery from its

compartment, for example to recharge the battery.

BATTERY RECHARGING

- To perform this operation, it is recommended to take

the battery out of its compartment.

- Disconnect the cables.

- It is good practice to recharge with amperage of 1/10

with respect to that of the charged battery.

- Refit the battery, being careful to connect the positive

cable (red) to the + pole and the negative cable (black)

to the - pole.

- Wrench down the battery terminals.

- The battery must always be kept completely charged.

During winter or when the vehicle is not used, charge

the battery at least once a month.

Danger of explosion! Never use open flames

(lighters, matches, etc.) to check the battery liquid level.

The battery contains sulphuric acid, which is

highly toxic. Avoid any contact with eyes, skin

or clothes.

Fig. 33Fig. 32

BC

V

Page 18

03/10

14

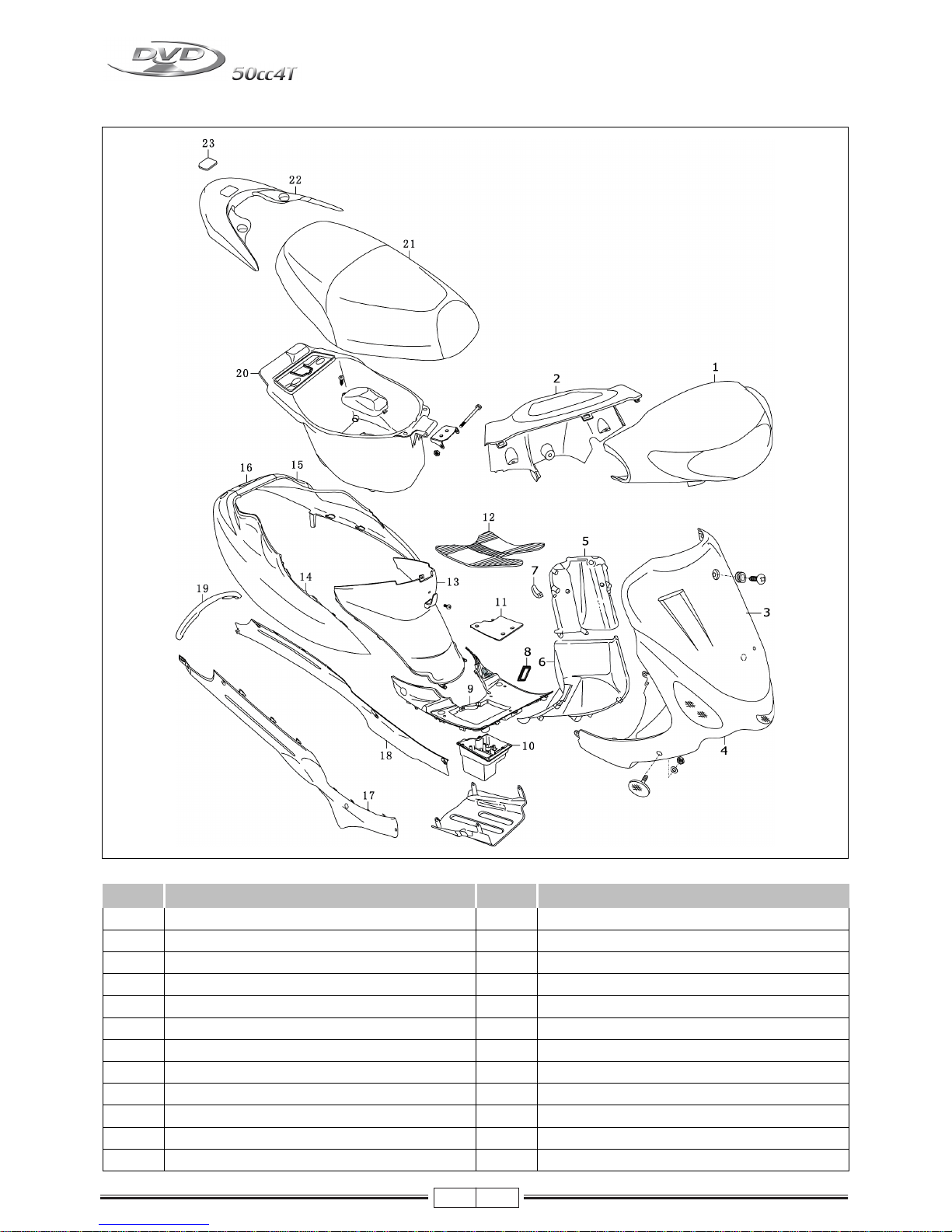

FAIRING

Fig. 01

Nr. Item Nr. Item

1 Handlebar cover (front) 14 Rear fairing r/h

2 Handlebar cover (rear) 15 Rear fairing l/h

3 Front shield 16 Central fairing

4 Shield (lower) 17 Side cover r/h

5 Inner shield (upper) 18 Side cover l/h

6 Inner shield (lower) 19 Central fairing

8 VIN number cover 20 Helmet compartment

9 Foot board panel 21 Seat

10 Battery box 22 Rear handle

11 Battery cover 23 Plug

12 Mat set

13 Side cover mounting

Page 19

03/10

15

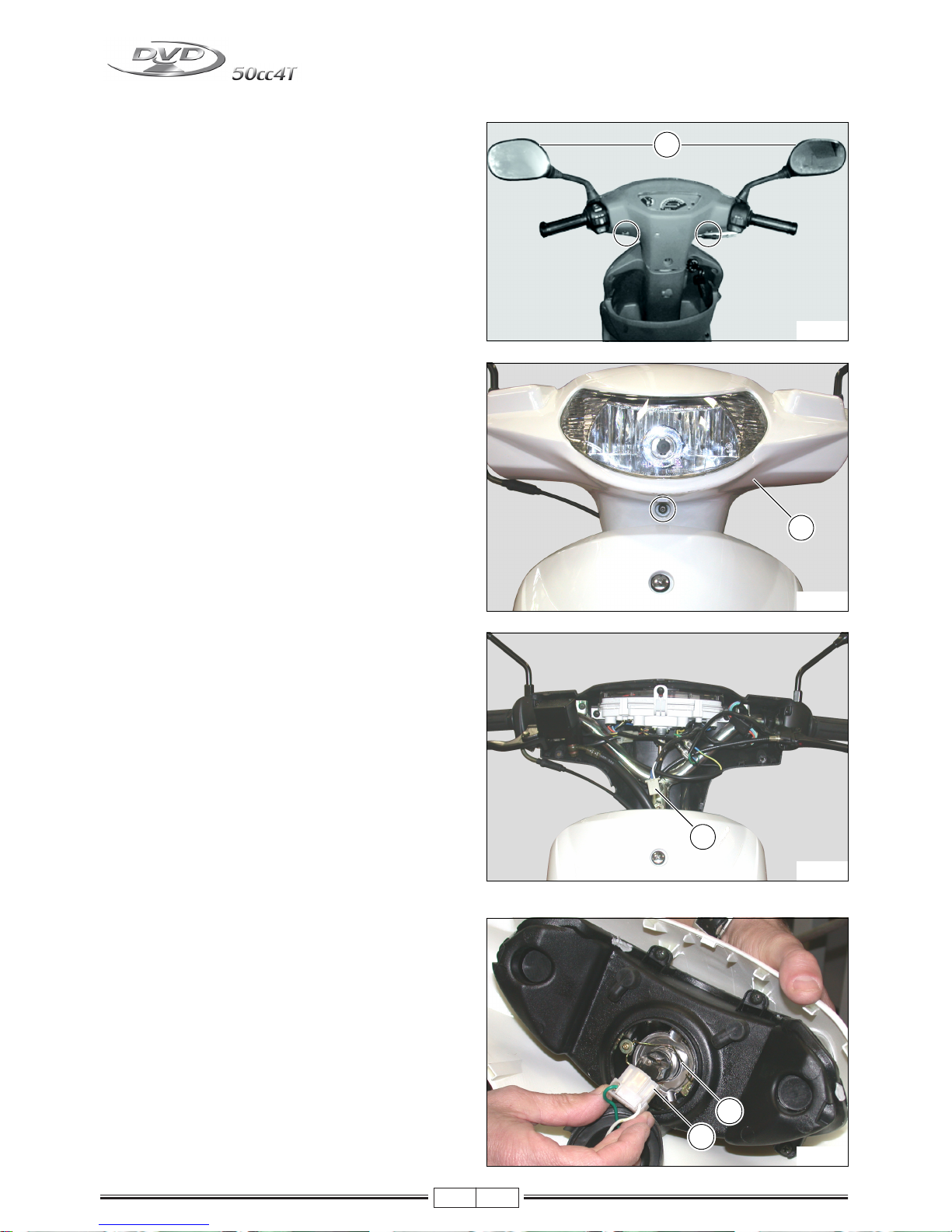

DISMANTLING THE FRONT HANDLEBAR COVER

- Remove the RIGHT and LEFT mirrors (1)

- Remove the front handlebar cover (2).

- Disconnect the connector (3).

REPLACING THE HEAD LIGHT BULB

- Disconnect the connector (1) and replace the light

bulb (2).

1

Fig. 02

2

Fig. 03

3

Fig. 04

1

2

Fig. 05

Page 20

03/10

16

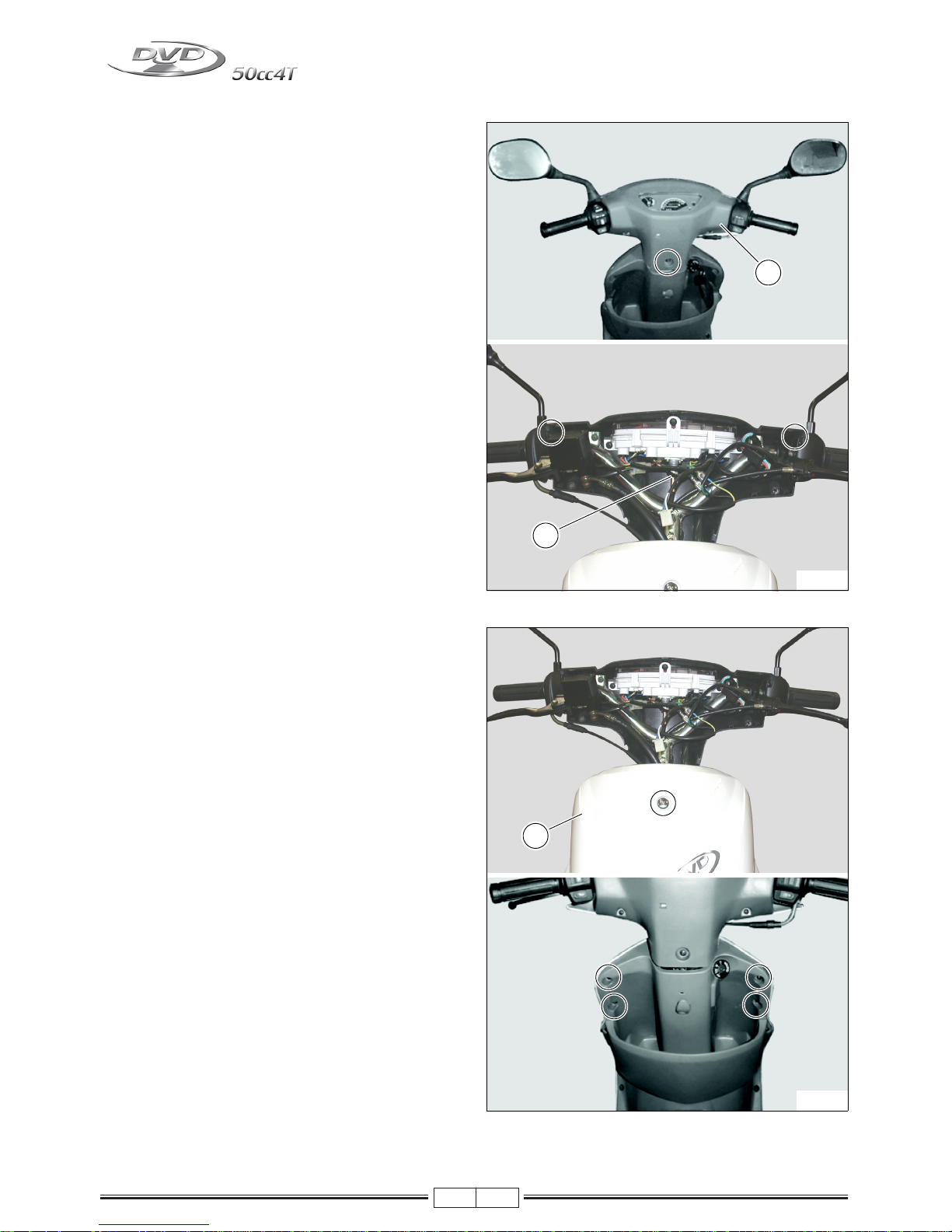

DISMANTLING THE REAR HANDLEBAR COVER

- Remove the rear handlebar cover (1).

- Remove the speedometer cable (2).

DISMANTLING THE FRONT SHIELD

- Remove the front shield (3).

2

1

Fig. 06

3

Fig. 07

Page 21

03/10

17

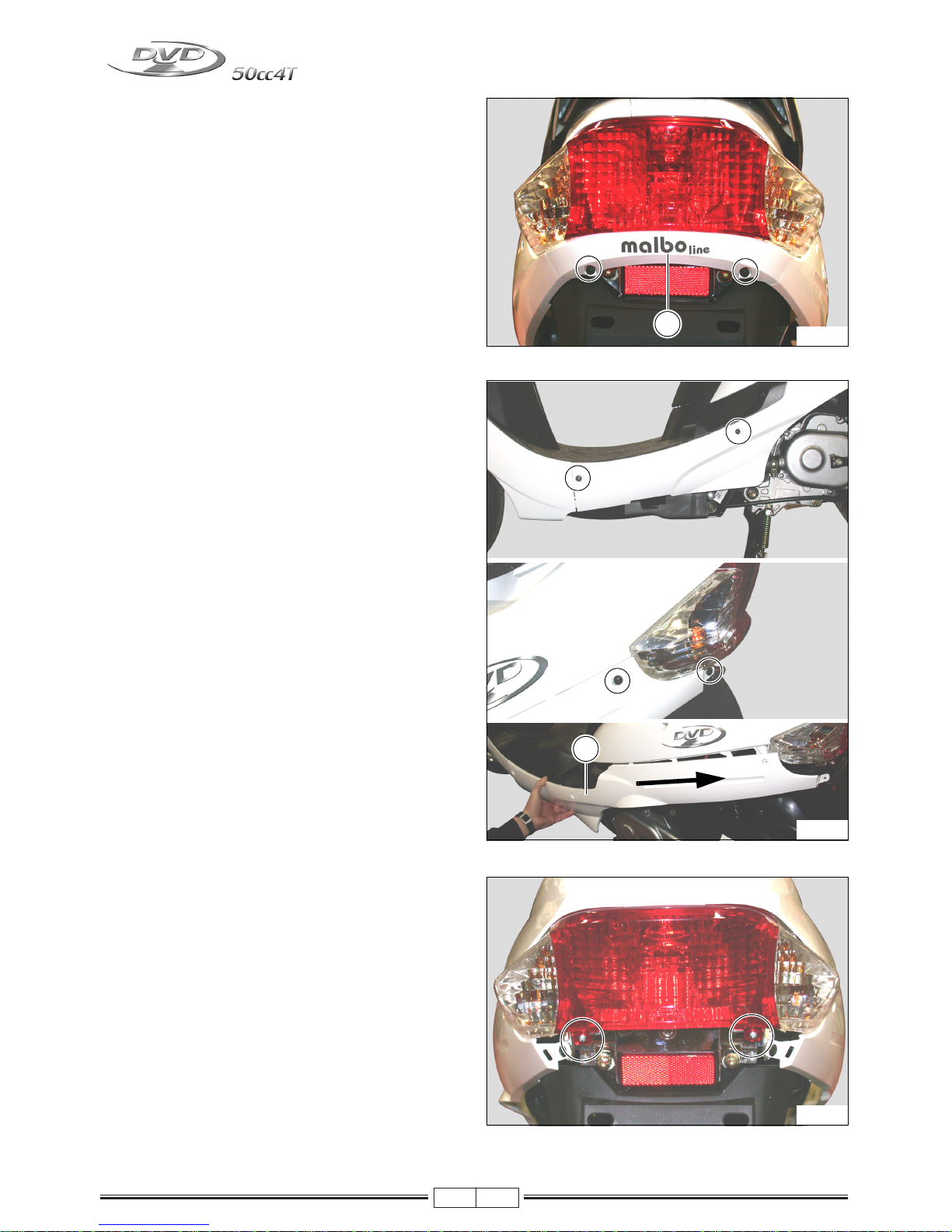

DISMANTLING THE SIDE COVERS

- Remove the central fairing (1).

- Remove the right and left side covers (2).

DISMANTLING THE TAIL LIGHT ASSY

- Unscrew the tail glass screws.

1

Fig. 08

2

Fig. 09

Fig. 10

Page 22

03/10

18

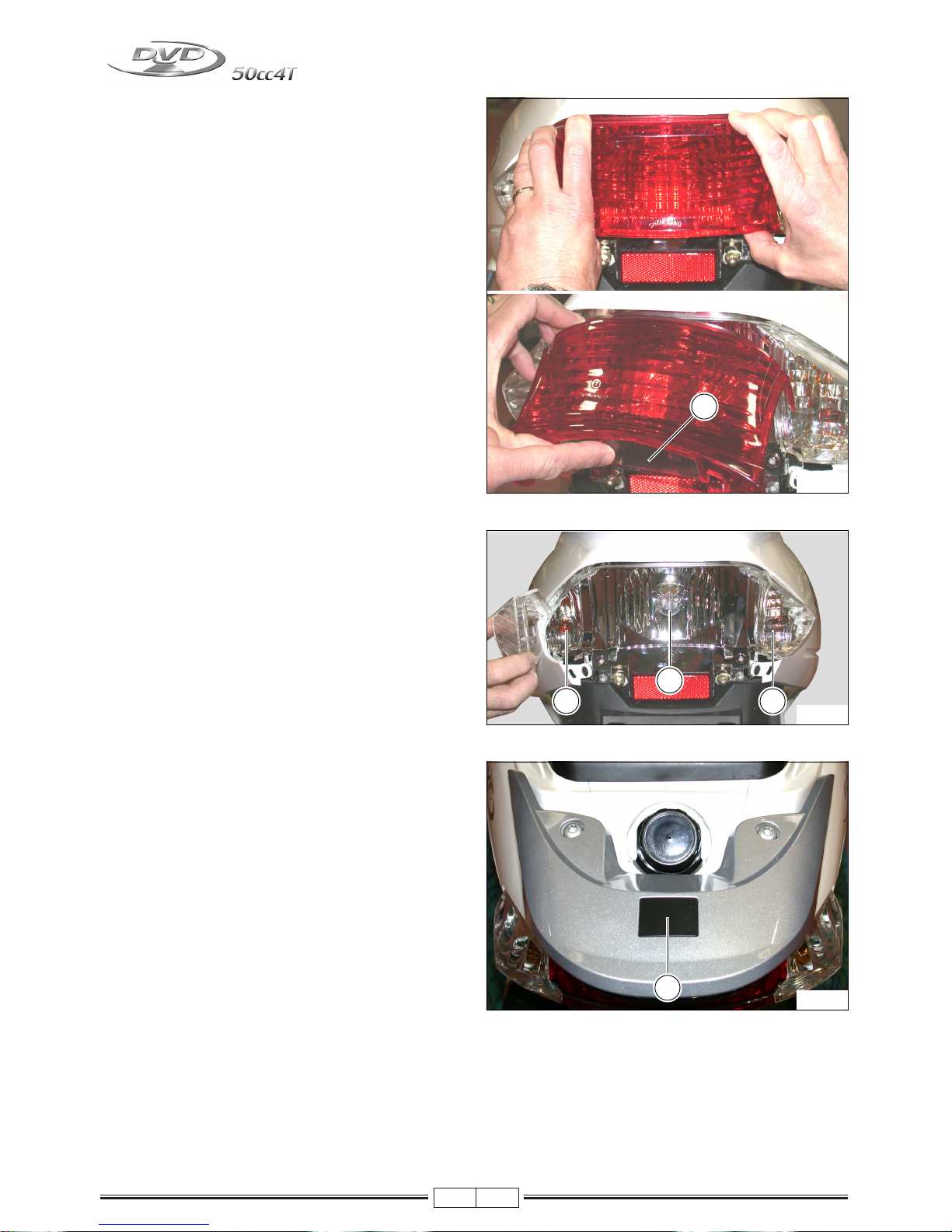

- Release the tail cover glass by slighting pushing your

thumbs on the illustrated points.

NOTE - Be careful not to push too hard on the point (1); the

glass could break.

- Tail light bulb (2).

- Turn indicator light bulbs (3).

DISMANTLING THE REAR HANDLE

- Remove the plug (1).

1

Fig. 11

2

3

3

Fig. 12

1

Fig. 13

Page 23

03/10

19

- Remove the rear handle (2).

DISMANTLING THE HELMET COMPARTMENT

- Open the seat.

- Unscrew the illustrated screws and nuts.

- Remove the helmet compartment (1).

DISMANTLING THE FAIRING

- Remove the mat set (1).

- Remove the side cover mounting (2).

2

Fig. 14

1

Fig. 15

1

Fig. 16

2

Fig. 17

Page 24

03/10

20

- Unscrew the fuel tank cap (3).

- Before removing the fairing, release the seat opening

cable (4).

- Remove the fairing (5).

BATTERY BOX

- Remove the battery cover (1).

- Remove the battery (2).

- Remove the 10 Ampere fuse box holder (3).

- Remove the CDI unit (4).

- Remove the starter relay (5).

4

3

Fig. 18

5

Fig. 19

1

Fig. 20

2

4

5

3

Fig. 21

Page 25

03/10

21

DISMANTLING THE FOOT BOARD

- Remove the battery (see specific chapter).

- Remove the foot board (1).

DISMANTLING THE LOWER SHIELD AND INNER SHIELD

- Remove the ignition barrel cover (1).

- Remove the bag handle hook (2).

- Remove the screws and remove the inner shield (3) and

lower shield (4).

NOTE - Before removing the lower shield (4), remove the

front wheel and front mudguard as indicated in the

specific chapters.

1

Fig. 22

1

Fig. 23

2

3

4

Fig. 24

Page 26

03/10

22

REPLACING THE PARK LIGHT AND TURN INDICATORS BULBS

- Pack light bulb (1).

- Turn indicator light bulb (2).

DISMANTLING THE FRONT MUDGUARD

- Release the two front mudguard halves (wheel side and

shield side).

- Remove the wheel as indicated in the specific chapter.

- Release the two mudguard halves (wheel and shield

sides) from the bracket (1).

1

2

Fig. 25

Fig. 26

1

Fig. 27

Page 27

03/10

23

- Remove the rear part (2) and front part (3).

2

3

Fig. 28

Page 28

03/10

24

FRONT WHEEL

Fig. 29

Nr. Item Nr. Item

1 Front rim 7 Brake disc

2 Front tyre (Tubeless) 8 Bolt M8x24

3 Spacer 9 Spacer front brake

4 Bearing 6002 (ø15x32x9) 10 Nut M12

5 Bearing 6003 (ø17x35x10) 11 Front wheel spindle

6 Oil seal 12 Speedo drive

Page 29

03/10

25

DISMANTLING THE FRONT WHEEL

Check perfect vehicle stability, positioned on the

main stand.

- Disconnect the speedometer cable (2).

- Unscrew the nut (1).

DISMANTLING THE FRONT BRAKE CALLIPER

- Unscrew the front brake calliper screws (3).

- Lift the vehicle using the lift and remove the wheel.

DISMANTLING THE BRAKE DISC

- Unscrew the 3 illustrated screws and remove the brake

disc.

1

Cs - N*m

53

2

1

Fig. 30

3

Cs - N*m

26

3

Fig. 31

V3

Cs - N*m

23

Fig. 32

Page 30

03/10

26

FRONT RIM CHECK (WHEEL REMOVED)

Check front rim oscillation (Radial and Axial) and make

sure it does not exceed the service limit. If oscillation was

caused by the bearing, the rim may be reused after replacing the bearing. Otherwise, replace with a new rim.

Oscillation limit = 2.0 mm

CHECKING THE FRONT WHEEL SPINDLE

Check front shaft oscillation with a centesimal gauge and

replace it if it exceeds the service limit.

Measurement instrument: Micrometer

Linearity limit: 0,25 mm

DISMANTLING THE BRAKE PAD SET

Do not pull the brake lever before installing the pad

set.

- Remove the screw (4).

- Rotate the calliper away from the cover.

- Remove the calliper cover.

Fig. 33

Fig. 34

4

Cs - N*m

26

4

Fig. 35

Page 31

03/10

27

When reassembling:

- Mount the springs (5) as indicated.

- Mount the pad set (6) facing them in the indicated directions (flat side (7) facing towards the cover).

When reassembling the pad set, fully push the

piston into its housing.

After reassembling, pull the brake lever several

times to position the pad set in contact with the

brake disk.

5

6

7

Fig. 36

Page 32

03/10

28

FRONT FORK

Grease parts Nr. 8, 9, 10, 11, 12, 13, 26.

Tighten parts Nr. N. 3, 4, 15, 17, 29 to the specified tightening torque.

Fig. 37

Nr. Item Nr. Item

1 Handlebar 17 Plug

2 Bolt 18 O-Ring

3 Nut 19 Spring

4 Bolt 20 Piston tube

5 Screw 21 Seeger

6 Lock nut 22 Return spring

7 Lock washer 23 Fork tube

8 Adjustable cone 24 Dust seal

9 Steering ball cages N° 26 (ø 5/32) 25 Seeger

10 Upper washer 26 Oil seal

11 Lower washer 27 R/h fork leg assy

12 Steering ball cages (lower) N° 29 (ø 5/32) 28 Copper washer

13 Steering cone 29 Screw

14 Bottom yoke

15 Screw

16 L/h fork leg assy

Page 33

03/10

29

DISMANTLING THE FORK

- Remove the handlebar cover.

- Unscrew screw (1) and screw (2).

- Remove the front wheel.

- Remove the front mudguard.

- Remove the calliper.

- Remove the front shield

- Slide the handlebar off the fork tube.

- Unscrew the steering lock nut (3).

- Slide off the lock washer (4).

- Unscrew the adjustable cone (5).

- Slide out the fork, being careful of ball cages.

REPLACING CAPS AND STEERING CONES

- Using a wrench, remove the steering caps.

- Using a chisel, slide off the steering cone (6).

Fig. 38

1

2

4

3

5

Fig. 39

6

Fig. 40

Page 34

03/10

30

Install the following new parts:

- Fork cone (7).

- Steering caps (8).

DISMANTLING THE FORK

- Lubricate the caps

- Install 26 ball cages (9) for the upper cap and 29 ball

cages (10) for the lower cap (ø 5/32).

- Insert the fork in the steering shaft.

- Install and tighten the adjustable cone (11).

- Loosen and re-tighten the adjustable cone.

- Position the lock washer (12).

- Install and tighten the steering lock nut (13).

OIL LEVEL CHECK

- Insert a stick or gauge and check that oil is 110 ±5 mm

from the upper edge of the rod (move the rod to end

stop).

If necessary, top up with oil: Q8 FORK OIL

8

7

Fig. 41

13

Cs - N*m

30

11

13

9

12

10

Fig. 42

Quantity per tube ~ 40 cc

Fig. 43

Page 35

03/10

31

MAIN IGNITION SWITCH

- Remove the front shield.

- Unscrew the fixing screws.

- Disconnect the connector.

- Remove the key switch (1).

REAR WHEEL AND SHOCK ABSORBER

1

Fig. 44

Fig. 45

Nr. Item Nr. Item

1 Rear rim 8 Nut M6

2 Rear tire 9 Washer

3 Brake shoes 10 Wheel nut

4 Spring 11 Shock absorber

5 Cam 12 Bolt M10x71

6 Brake lever 13 Nut

7 Bolt M6 x 28 14 Bolt M8x24

Page 36

03/10

32

DISMANTLING THE REAR WHEEL

- Remove the exhaust.

- Unscrew the nut (D).

- Remove the rear wheel.

DISMANTLING THE BRAKE SHOES

- Remove the rear wheel.

- Unscrew the screw (V).

- Remove the brake shoes (1) being careful not to damage the springs (M).

DISMANTLING THE SHOCK ABSORBER

- Remove the rear fairing.

- Remove the air filter.

- Unscrew the screws (V

2).

- Remove the rear shock absorber.

D

Cs - N*m

120

Fig. 46

D

1

Fig. 47

V

M

V2

Cs - N*m

29

Fig. 48

V2

Page 37

03/10

33

CHECKING THE BRAKE HUB

Check the INTERNAL DIAMETER of the brake hub and replace the rim if the INTERNAL DIAMETER exceeds wear

limits.

Wear limit: 120.7 mm

CHECKING BRAKE SHOES

Make sure brake shoes are not worn or damaged and replace the complete brake shoe set if necessary.

CHECKING THE SHOCK ABSORBER

Make sure the shock absorber does not leak and that it is

not damaged. Replace if necessary.

Fig. 49

Fig. 50

Fig. 51

Page 38

03/10

34

DISMANTLING THE MAIN STAND

Secure the vehicle so that it does not fall when the

main stand is removed.

- Remove the split pin (1).

- Remove the spring (2).

- Slide out the pin (3) and remove the main stand.

REMOVING THE ENGINE FROM THE CHASSIS

- Remove the helmet compartment (1).

1

Fig. 52

3

2

Fig. 53

1

Fig. 54

Page 39

03/10

35

- Remove the right and left side covers (2).

- Disconnect the carburettor starter connector (A) and

stator connector (B).

- Release the throttle cable (3), the fuel hose (4) and depression hose (5).

- Unscrew the filter box clamp (6).

2

Fig. 55

Fig. 56

A

B

5

4

6

3

Fig. 57

Page 40

03/10

36

- Disconnect the positive and negative starter motor cables (7).

- Remove the rear brake cable adjustment nut (8).

- Remove the filter case (9).

- Unscrew the rear shock absorber screw (10).

7

Fig. 58

8

Fig. 59

9

Fig. 60

10

Fig. 61

Page 41

03/10

37

- Slide off the spark plug cap (11).

- Remove the main stand (see specific chapter).

- Unscrew the nut (12), slide off the engine pin and remove the engine from the frame.

- Unscrew the screws (13).

- Unscrew the exhaust manifold screws (14) and remove

the exhaust.

11

Fig. 62

12

Fig. 63

13

Cs - N*m

24

13

13

Fig. 64

14

Cs - N*m

10

14

14

Fig. 65

Page 42

03/10

38

- Unscrew the nut (15) and remove the rear wheel.

15

Fig. 66

Page 43

03/10

39

CHECKING THE END COMPRESSION PRESSURE

- With the engine cold, remove the spark plug cap

- Remove the spark plug.

- Fit a compression testing pressure gauge in the spark plug seat with a spark plug fitting and tighten it.

- Run the engine using the starter motor and with the carburettor fully open, until the reading on the pressure gauge

is stable.

- If the pressure is normal, remove the device and reassemble the dismantled parts.

- If the pressure readings are below those indicated, check the rpm used for the test, if it is low, check the starter

system. If the number of rpm is perfect or slightly above, make sure the correct seal has been chosen for the cylinder base and check the seals of the thermal part ( elastic bands- valves etc...)

IF YOU HAVE A HARD TIME INSERTING THE PRESSURE GAUGE FITTING, DISCONNECT THE ENGINESWING ARM CONNECTION PIN AND PULL BACK THE ENGINE AS REQUIRED TO INSERT THE FITTING.

Technical specifications

Spark plug fitting

10 mm

Rpm

~ 800 rpm (starting speed).

Compression end pressure

14 ÷ 15 BAR

Page 44

03/10

40

ENGINE DISMANTLING

- Place the engine on a suitable support.

- Unscrew the engine oil tank cap (1).

- Unscrew the cap (2) and drain oil.

Note: the filtering net (3) must be cleaned and the

gasket replaced at each oil change.

DISMANTLING THE CLUTCH COVER

- Unscrew the 8 cover fixing screws.

- Remove the clutch cover.

- Remove the gasket.

- Remove the 2 bushes.

Replace the gasket each time the cover is dismantled.

2

Cs - N*m

20

Fig. 01

Fig. 02

V8

Cs - N*m

10

Fig. 03

Page 45

03/10

41

DISMANTLING THE PRIMARY PULLEY ASSY

- Unscrew the nut (1) and remove the washer (2).

- Remove the kick starter plate (3).

- Remove the fan (4).

- Remove the primary fixed half pulley (5).

- Remove the V-belt.

- Remove the clutch assy (6) and bush (7).

- Remove the washer (8).

- Dismantle the starter pinion unit assy (9).

DISMANTLING THE REAR CLUTCH ASSY

- Lock the clutch housing using the specific tool.

- Unscrew the nut (1).

- Dismantle the clutch housing and the rear clutch assy.

1

Cs - N*m

50

Fig. 04

Fig. 05

1

Cs - N*m

50

Fig. 06

Page 46

03/10

42

DISMANTLING THE STARTER MOTOR

- Remove the 2 fixing screws (1).

- Remove the starter motor (2) after disconnecting the

positive wire.

Check starter motor O-Ring conditions.

DISMANTLING THE ETC INTAKE MANIFOLD

- Unscrew the 2 intake manifold fixing nuts.

- Remove the intake manifold.

- Remove the two O-Rings.

If necessary, replace the O-Rings.

DISMANTLING THE AIR CONVEYORS

- Remove the 4 fixing screws (1).

- Remove the conveyor (2).

- Unscrew the fixing screw (3).

1

Cs - N*m

10

Fig. 07

1

Cs - N*m

10

Fig. 08

Fig. 09

Page 47

03/10

43

- Unscrew the 2 air conveyor fixing screws (4) on the

clutch side.

- Remove the air conveyors.

- Remove the gasket (5).

DISMANTLING THE VALVE COVER

- Unscrew the 4 fixing screws (1).

- Unscrew the 2 secondary air hose screws (2).

- Remove the valve cover with its gasket.

The gasket must be replaced at each dismantling.

DISMANTLING THE SECONDARY AIR VALVE

- Remove the secondary air filter.

- Unscrew the 2 screws (1).

- Unscrew the screw (2).

- Remove the air valve cover (3).

- Remove the air valve (4).

Fig. 10

1-2

Cs - N*m

10

Fig. 11

Fig. 12

Page 48

03/10

44

DISMANTLING THE ROTOR

- Unscrew the fan fixing screws (V

4).

- Remove the fan.

- Lock the rotor with the specific tool.

- Unscrew the nut (D).

Warning: using an unsuitable tool may deteriorate the magneto flywheel coils.

- Screw in the flywheel extractor (E) on the rotor (2) and

screw in the central screw until the rotor detaches.

V4

Cs - N*m

10

D

Cs - N*m

50

FLYWHEEL EXTRACTOR Code

64023700

Fig. 13

V4

Fig. 14

D

Fig. 15

E

Page 49

03/10

45

DISMANTLING THE STATOR AND PICK-UP

- Unscrew the 2 pick-up fixing screws (1) and two stator

fixing screws (2).

- Remove the stator and pick-up.

DISMANTLING THE CHAIN TENSIONER

- Unscrew the screw, O-Ring and chain tensioner

spring (1).

- Unscrew the 2 chain tensioner screws (2).

- Remove the chain tensioner and pull it by the lock

tab (A).

- Remove the gasket.

1

Cs - N*m

6

2

Cs - N*m

8

Fig. 16

1

Cs - N*m

8

2

Cs - N*m

10

Fig. 17

Fig. 18

Page 50

03/10

46

DISMANTLING THE HEAD

- Remove the spark plug.

- Manually rotate the engine shaft in the operating direction to correctly align the rocker arm with the cam (A).

- Loosen the 2 screws (1).

- Gradually loosen the four head nuts (2) in crossed order.

- Remove the 4 nuts, washers and 2 screws.

- Remove the valve rocker arm bracket (3).

- Remove the timing chain (4).

- Slide out the cam shaft (5).

- Remove the head, the head gasket (6) and 2 pins (7).

- Remove the timing chain sliding shoe (8) (located in the

cylinder on the exhaust side).

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Page 51

03/10

47

DISMANTLING THE ROCKER ARMS

- Remove the 2 rocker arm pins (1).

- Remove the intake (2) and exhaust (3) rocker arms.

DISMANTLING VALVES AND VALVE STEM SEALS

- Compress the valve spring using the specific tool.

- Remove the 2 valve stem halves (1).

- Decompress the spring and remove the tool.

Remove:

- Upper valve cup (2).

-Springs (3).

- Lower washer (4).

- Valve (5).

- Remove the second valve following the same procedure.

Fig. 23

Fig. 24

Fig. 25

Page 52

03/10

48

When one valve is removed, always replace the

relevant valve stem seals.

- Using a specific tool, install a new valve stem seal.

- Reassemble valves, springs (7) and 2 valve stem

halves (6) in the upper valve cup.

When reassembled, thoroughly grease the rocker

arm shafts, cams and contact points between the

rocker arm and valve to avoid jamming when the

engine is started (use Molykote type grease).

Valve stem seals must be lubricated.

DISMANTLING THE CYLINDER

- Remove the cylinder (1).

- Remove the base cylinder gasket (2) and 2 pins (3).

- Remove the timing chain sliding shoe (5) screw (4).

- Slide out the timing chain sliding shoe.

Fig. 26

Fig. 27

4

Cs - N*m

10

Fig. 28

Fig. 29

Page 53

03/10

49

DISMANTLING THE PISTON

- Remove one of the seals (1).

- Remove the piston pin.

- Remove the piston (2).

DISMANTLING THE OIL SUMP

- Unscrew the 4 screws (1) (85 mm).

- Unscrew the 4 screws (2) (100mm).

No tool is required to remove the oil sump.

- Remove the oil sump (3).

- Remove the 2 pins (4) and the gasket (5).

Fig. 30

1-2

Cs - N*m

10

Fig. 31

Fig. 32

Page 54

03/10

50

DISMANTLING THE OIL PUMP

- Lock the shaft.

- Unscrew the oil pump pinion nut (1).

- Remove the oil pump pinion (2).

- Unscrew the 3 oil pump screws (3).

- Remove the oil pump.

When the oil pump is removed, always replace the

2 O-Rings (3).

Before reassembling the oil pump, submerge it in

a container with specific engine oil.

3

Cs - N*m

10

Fig. 33

Fig. 34

Fig. 35

Page 55

03/10

51

DISMANTLING THE RIGHT CRANK CASE

- Remove the two O-Rings (1).

- Remove the oil pump pin (2).

- Remove the fixing screw (3).

- Remove the right crankcase (4).

- Remove the 2 pins.

- Remove the gasket.

DISMANTLING THE CRANK SHAFT

- Remove the crank shaft (1).

- Remove the timing chain, marking the rotation

direction (2).

CHECK CONNECTING ROD ASSEMBLY

- Check connecting rod axial play using a thickness

gauge.

- Maximum admitted connecting rod axial play must not

exceed: 0.55 mm.

3

Cs - N*m

10

Fig. 36

Fig. 37

Fig. 38

Page 56

03/10

52

- Eccentricity values read at the end of the crank shaft

must not exceed 0.10 mm.

- 35 mm transmission side (A).

- 27 mm flywheel side (B).

DISMANTLING THE TRANSMISSION COVER

- Drain oil through the drain cap (1).

- Fill and check oil level through the cap (2).

- Unscrew the 2 screws (3) (30 mm).

- Unscrew the screw (4) (35 mm).

- Unscrew the 3 screws (5) (40 mm).

- Remove the transmission cover.

- Remove the 2 pins and the gasket.

Fig. 39

2

Cs - N*m

12

3-4

5

Cs - N*m

12

Fig. 40

Fig. 41

Fig. 42

Page 57

03/10

53

- Remove the spacer (1) and idle gear assy (2).

- Remove the drive shaft assy (3).

- Remove the wheel axle (4).

- Remove the primary drive shaft (5).

ASSEMBLY

CRANKCASE ASSEMBLY

The oil seals must be replaced each time the

crankcase is dismantled.

- Replace crankcase oil seals.

- Mount the engine shaft and timing chain in the left crankcase.

Fig. 43

Fig. 44

Fig. 45

Page 58

03/10

54

- Mount the 2 pins (1).

- Assemble the gasket (2).

- Assemble the right crankcase with the left crankcase.

- Tighten the screw (3).

- Mount the oil pump pin (4) and 2 O-Rings (5).

- Assemble the oil pump.

- Tighten the 3 screws.

- Assemble the oil pump pinion (6).

- Assemble the gasket and 2 pins.

ASSEMBLE THE OIL SUMP

- Position the oil seal (1) using a suitable tool.

The oil seals must be replaced each time the

crankcase is dismantled.

Fig. 46

Fig. 47

Fig. 48

Fig. 49

Page 59

03/10

55

- Assemble the right crankcase (2).

- Tighten the 4 screws (3) (85 mm).

- Tighten the 4 screws (4) (100mm).

- Make sure the crank shaft freely rotates in the crankcase.

ASSEMBLING THE STATOR AND PICK-UP

- Position the stator as indicated.

- Tighten the 2 screws (1).

- Tighten the 2 screws (2).

Check correct woodruff key (3) position as indicated in the figure, before mounting.

- Position the rotor on the crank shaft.

- Lock the rotor with the specific tool.

- Position and tighten the rotor nut to the indicated tightening torque (Page 44 - Fig. 14).

3-4

Cs - N*m

10

Fig. 50

1

Cs - N*m

6

2

Cs - N*m

8

Fig. 51

Fig. 52

Page 60

03/10

56

ASSEMBLING THE PISTON RINGS

- Position the spring (1) (no assembly direction).

- Position the 2 piston rings (2) next to the spring, offsetting the two openings (no assembly direction).

- Position the piston ring (3) with reference "A" facing up.

- Position the upper piston ring (4) with reference "A" facing up.

ASSEMBLING THE PISTON

- Assemble the piston so that the "IN" reference is on the

intake side.

Piston pin circlips must be replaced each time

the piston is dismantled.

- Piston pin circlip opening (1) must face either up or

down, but never to the side.

Fig. 53

Fig. 54

Fig. 55

Page 61

03/10

57

ASSEMBLING THE CYLINDER

- Install a new base gasket and 2 pins on the crankcase.

- Position piston ring opening as follows.

- A. Upper seal piston ring opening

- B. Lower seal piston ring opening

- C. Upper piston ring opening.

- D. Lower piston ring opening

Lubricate the cylinder.

- Pass the timing chain through the cylinder slot.

- Manually compress piston rings and individually mount

them in the cylinder.

- Mount the timing chain sliding shoe, fitting it in the cylinder housing (A) on the exhaust side.

ASSEMBLING THE HEAD

- Position the 2 pins (1) and the cylinder head gasket (2)

on the cylinder.

- Pass the timing chain through the head slot.

Any intervention that requires head dismantling

requires always timing phase tuning.

Fig. 56

Fig. 57

Fig. 58

Page 62

03/10

58

TIMING

- Position the rotor on the crank shaft, making sure it correctly fits on the key.

- Turn the magneto flywheel (1) to position the "T" reference in front of the crankcase stud (2) (clockwise).

- Position the cam shaft pinion references as on the reference (3).

- Position the timing chain on the cam shaft pinion (5).

- Make sure the cam shaft references (3) are parallel to

the head level (4).

- Position the valve rocker arm bracket.

HEAD CYLINDER TIGHTENING

- This operation is performed in several steps:

- Slightly grease the stud bolts.

- Position the 4 washers.

- Snugly fit the 4 nuts (6) and 2 screws (7).

- Tighten the 4 nuts in crossed order.

- Tighten the 2 screws (7).

Fig. 59

Fig. 60

6

Cs - N*m

18

7

Cs - N*m

8

Fig. 61

Page 63

03/10

59

- Position the chain tensioner and 2 fixing screws (8).

- Position the spring (9).

- Position the screw (10) and gasket (11) (checking gasket conditions, replacing it if necessary).

CHECKING TIMING

- Rotate the crank shaft 2 turns in the engine rotation direction (clockwise).

- Turn the magneto flywheel (12) to position the "T" reference in front of the crankcase stud (13).

- Make sure the cam shaft references (14) are parallel to

the head level (15).

If references are not aligned, repeat the timing

procedure.

VALVE TIMING ADJUSTMENT

- Manually rotate the crank shaft in the operating direction

to correctly align the rocker arm with the cam (A).

- Loosen the rocker arm adjusting screw locknut (1).

- With a thickness gauge, adjust timing on each valve, using the rocker arm adjusting screw (2).

Timing:

•

0.10 mm intake.

• 0.10 mm exhaust.

- Lock the rocker arm adjusting screw.

- Tighten the locknut.

8

Cs - N*m

10

10

Cs - N*m

8

Fig. 62

Fig. 63

Fig. 64

Fig. 65

Page 64

03/10

60

VARIOUS INTERVENTIONS

DISMANTLING THE STARTING SYSTEM

- Unscrew the 8 clutch cover screws.

- Remove the gear cover.

- Remove the gasket.

- Remove the 2 pins.

Replace the gasket each time the cover is dismantled.

- Manually start the kick starter shaft (1), removing the

washer and pinion (2).

- Remove the kick starter screw (3).

- Remove the kick starter (4).

- Remove the seeger.

- Remove the washer, the kick starter shaft (1) and the

spring (5) from the gear cover.

- Remove the roller bearing (6).

ASSEMBLING THE STARTING SYSTEM

- Position the spring (1), hook the longer side on the cover

pin (A).

- Position the roller bearing (2).

- Position the kick starter shaft (3) in the previously

greased housing.

- Hook the other side of the spring (B) to the kick starter

shaft.

- Load the spring until the kick starter shaft is positioned

on the cover lock (C).

- Turn the cover, position the seeger and washer on the

kick starter shaft.

- Position the washer on the bush housing.

- Load the kick starter shaft about 1/8 a turn and position

the starter pinion (4).

- Position the starter spring (5) on the notch (D) protruding

from the cover.

V8

Cs - N*m

10

Fig. 66

Fig. 67

Fig. 68

Page 65

03/10

61

REPLACING CENTRIFUGAL ROLLERS

- Unscrew the 8 cover screws.

- Remove the gear cover.

- Remove the gasket.

- Remove the 2 pins.

Replace the gasket each time the cover is dismantled.

- Unscrew the nut (1) and remove the washer (2).

- Remove the kick starter plate (3) and fan (4).

- Remove the primary fixed half pulley (5).

- Remove the V-belt.

- Remove the clutch assy (6) and bush (7).

- Remove the washer (8).

- Remove the 3 plate (10) screws (9).

- Remove the plate (10).

- Remove the housing cap (11) and 3 dowels (12).

- Remove the 6 centrifugal rollers (13).

Centrifugal rollers must be replaced if abnormally

worn.

Assembly:

- Proceed in reverse dismantling order without greasing

the centrifugal rollers.

DISMANTLING THE CLUTCH ASSY

- Unscrew the 8 cover screws.

- Remove the clutch cover.

- Remove the gasket.

- Remove the 2 pins.

Replace the gasket each time the cover is dismantled.

- Lock the clutch housing using the specific tool.

- Unscrew the nut.

- Remove the clutch housing, rear clutch assy and fan

belt.

- Compress the rear clutch assy using the specific tool

and insert it in the clamp.

- Unscrew the nut (1).

- Decompress the specific tool.

1

Cs - N*m

50

Fig. 69

Fig. 70

Fig. 71

Page 66

03/10

62

- Remove the clutch assy (2), the spring holder cup (3),

spring (4) and pulley side cup.

- Slide out the guide pins (6).

- Separate the secondary fixed pulley (7) and secondary

mobile pulley (8).

ASSEMBLING THE CLUTCH ASSY

- After ensuring that the 2 oils seals (1-Fig. 73) and mobile pulley O-Rings (2) are in good conditions, grease

the 3 guide pins (6) and install parts in reverse dismantling order.

- Tighten the nut (1-Fig. 72).

DISMANTLING THE CARBURETTOR

DISMANTLING THE STARTER

- Remove the starter cover (1).

- Remove the screw (2) and starter plate (3).

- Remove the starter (4) marking its direction.

Fig. 72

1

Cs - N*m

50

Fig. 73

Fig. 74

Page 67

03/10

63

- Remove the 2 starter mounting screws (5).

- Remove the starter mounting and relevant gasket.

DISMANTLING THE VALVE

- Remove the 2 valve cover screws (1).

- Remove the valve cover (2).

- Remove the spring.

- Remove the needle, valve and diaphragm.

- Remove the needle lock (1) and relevant spring (2) rotating it ¼ a turn.

- Remove the needle and relevant washer (3).

The needle position is adjusted by the manufacturer and cannot be modified.

Fig. 75

Fig. 76

Fig. 77

Page 68

03/10

64

DISMANTLING THE FLOAT, NEEDLE AND JET

- Remove the 3 float chamber screws (1).

- Remove the float chamber (1) and relevant O-Ring.

- Remove the float (2), relevant float pin (3) and needle

(4).

- Remove the idle jet (5) (Ø 30).

- Remove the max jet (6) (Ø 78).

- Remove the atomizer (7).

Fig. 78

Fig. 79

Fig. 80

Page 69

03/10

65

Check the conditions of the needle and its housing (A).

Check chamber O-Ring conditions.

REMOVE THE IDLE SCREW AND IDLING ADJUSTING SCREW

- Turn the idle screw (1) clockwise, counting the number

of turns until stop.

This operation allows it to be replaced in the same

regulation position when reassembled.

- Turn the screw (2) clockwise, counting the number of

turns until stop.

This operation allows it to be replaced in the same

regulation position when reassembled.

- Clean the carburettor and parts with specific solvents.

- Spray all carburettor body ducts and its jets with compressed air.

Do not use metallic tools which could ruin ducts

or some elements.

Fig. 81

Fig. 82

Fig. 83

Fig. 84

Page 70

03/10

66

CYCLE TIGHTENING TORQUES

Fig. 85

Fig. 87

Fig. 89

Fig. 91

Fig. 86

Fig. 88

Fig. 90

Fig. 92

Page 71

03/10

67

ENGINE TIGHTENING TORQUE

Fig. 93

Fig. 94

Nr. Item Nm Kgm Figure

1 Front wheel spindle 53 5,3 85

2 Handlebar screw 49 4,9 86

3 Front fork nut 30 3,0 86

4 Handlebar positioning screw 25 2,5 86

5 Fork leg screw (botton yoke) 45 4,5 87

6 Brake pump jumper screw 10 1,0 88

7 Brake hose bolt 23 2,3 89

8 Caliper screw 26 2,6 90

9 Clamp drain valve 7,5 0,75 90

10 Front disc screw 23 2,3 90

11 Rear wheel nut 120 12 91

12 Shock absorber screw 29 2,9 92

13 Rear brake lever nut 11 1,1 93

14 Engine mount pivot 98 9,8 94

15 Engine pivot 80 8,0 94

Item Nm Kgm Figure

Cylinder head screw 10 1,0 -

Cam shaft nut 18 1,8 -

Rocker arm nut 10 1,0 -

Crankcase cover screw 10 1,0 -

Clutch housing nut 50 5,0 -

Clutch assy nut 50 5,0 -

Kick starter screw 10 1,0 -

Rotor nut 50 5,0 -

Stator screw 8 0,8 -

Page 72

03/10

68

TIGHTENING TORQUE (GENERIC TABLE)

FRAME DIMENSION CHECKS

If even slight frame deformation is suspected after an accident, check frame dimension.

Control quota A = 750 mm (tolerance ± 5 mm)

If a quota is found out of tolerance, replace the frame.

Deforming the frame to return the quota (A) to its

original settings is strictly prohibited.

Pick-up screw 6 0,6 -

Oil pump gear nut 10 1,0 -

Oil filter cap 20 2,0 -

Starter motor screw 10 1,0 -

Gear motor oil level screw 12 1,2 -

Gear motor crankcase screw 12 1,2 -

Oil pump screw 10 1,0 -

Crankcase screw 10 1,0 -

Cylinder stud bolt 25 2,5 -

Cooling fan screw 8 0,8 -

Intake manifold screw 10 1,0 -

Spark plug 18 1,8 -

Item Nm Kgm

M5 nut and bolt 4 0,4

M6 nut and bolt 9 0,9

M8 nut and bolt 12 1,2

M10 nut and bolt 26 2,6

M12 nut and bolt 39 3,9

Item Nm Kgm Figure

Fig. 95

Page 73

03/10

69

ELECTRICAL PART LOCATION

Legend

1 - Ignition switch

2 - Regulator

3- Horn

4 - Resistance

5- Relay

6 - Front stop switch

7 - Rear stop switch

8 - Right switch connector

9 - Left switch connector

5

1

2

3

4

Fig. 96

6

9

7

8

Page 74

03/10

70

Legend:

10 - Battery

11 - Fuse box holder (10 A)

12 - CDI unit

13 - Starter relay

14 - Fuel level gauge

15 - Fuel level gauge connector

16 - Tail light wiring connector

17 - Flywheel connectors

18 - HT coil

19 - Starter motor wire connector (+)

20 - Ground wire

18

17

19

10

12

13

11

20

Fig. 97

16

15

14

Page 75

03/10

71

SWITCH CHECKS

Engine stop button

Light switch

Indicator switch

Start

Horn

Front/rear brake switch

Main ignition switch

CHECK FUEL LEVEL GAUGE

- Disconnect the fuel level sensor connector (1).

- Bridge the White/Black wire with the Yellow/White

wire.

- Turn the key to "ON". The fuel level gauge should be po-

sitioned on the "F" symbol (FUEL). If the gauge remains

on "E", check Yellow/White wire and White/Black wire

(GROUND) continuity If necessary, replace the dashboard

NOTA - The White/Blue wire controls the fuel reserve

warning signal

Position

White/

Black

Red/

Black

- Off

- On

Position

White/

Blue

Blue White Black

High beam

Low beam

Passing

Position Orange Grey

Light

Blue

L

R

Position

Yellow/

Green

Yellow/

Red

Push

Position Black

Light

green

Push

Position Black

Green/

yellow

Off - lever idle

On - lever pulled

Position B-N VR VR R N

Key “OFF”

Key “ON”

1

Fig. 98

Page 76

03/10

72

CHECK FUEL LEVEL SENSOR

- Remove the helmet case.

- Disconnect the fuel level sensor connector.

- Remove the sensor (1) from the tank.

- Measure sensor resistance as per the table.

If the measured values are different, replace the

sensor.

IGNITION

Ignition type: Advance variable

HT COIL

SPARK PLUG CAP

STATOR (POWER 70W)

1

Fig. 99

Float position Resistance

"F" position 6-10 Ω

"E" position 90-100 Ω

F

E

Fig. 100

Resistance

Winding

Primary

0,45Ω ± 10%

at 25°C

Winding

Secondary

3KΩ ± 20%

at 25°C

Resistance 5KΩ ± 20%

Component Resistance

Pick-up (Blue/yellow wire) 153Ω ± 10%

Coil (Red/Black wire) 420Ω ± 10%

Light supply

(Yellow wire)

0,9 Ω

Battery charge

(White wire)

1 Ω

Battery charge voltage 14 ± 0,5V

Page 77

03/10

73

WIRING DIAGRAM

AZ

10

W

1010

W

5

W

AR

VR

VR

M/B

GL

B/N

35

35

AZ

B

VR

B

BL

B/N

VR

AZ

B/N

N

GL/V

LG

B/N

AR

B/N

B/N

GL

AR

AZ

N

GL/B

GL

BL

AR

AZ

N

GL/B

B/BL

B/BL

GL

GL/B

AR

N

B/N

GL/R

VC

AZ

N/R

GL/V

VC

GL

N/R

B/BL

GL/R

GL/B

AR

AZ

GL/V

GL

B/N

VR

B-N

OFF

ON

VR

R

N

N

G

R

B/N

R

L

AR

GR

AZ

N

B/

/

N

B

GL/

R

N/R

ON

0FF

GL/R

GL/V

N/R

B/N

/RN

NB/

NB

/

R

N

N

+

-

R

R

10A

R

GL/R

B/R

GL/V

R

B/N

B/N

LG/

BL

GL/N

/NB

N/R

N/R

N

N/R

N/R

GL/BL

GL/BL

GL

B

GL

GL

GL/BL

B

B

R

B/N

B/N

GL/N

G

L

/

N

+12V

/

BN

V

C

B/B

L

BLB

/

GL/B

G

L/B

L

G

/

N

B

/N

W

W

10

10

5

21

W

AZ

M

VR

GL/V

AR

AR

GL/V

B/N

GL

AZ

ON

0FF0FF

N

B

L

B

RA

GR

ZA

N

CV

B/B

L

B

BL

AR

GR

AZ

N

VC

VC

BL

B/BL

B

N

VR

GL

VR/N

VR

5

-

5W

GL

N

VR

W

VR

B

E

L

3 4 5 6

7

1

2

9

8

12

14

19

20

21

23

25

26 27 28 29

30 31

24

22

18

16

15

17

13

11

10

Fig. 101

Page 78

03/10

74

Colour legend Component legend

1 - Flasher relay

2 - Dashboard

3 - Left turn indicator

4 - Park light

5 - High/low beam

6 - Right turn indicator

7 - Stop switch

8 - Light switch

9- Passing

10 - High beam

11 - Low beam

12 - Indicators

13 - Horn

14 - Left switch

15 - Right switch

16 - Engine Stop

17 - Start

18 - Ignition switch

19 - Horn

20 - Fuel level sensor

21 - Flywheel

22 - CDI unit

23 - Regulator

24 - Battery

25 - Starter resistance

26 - Electric starter

27 - Left turn indicator

28 - Stop light

29 - Right turn indicator

30 - Coil

31 - Starter motor

Code Colour

AR Orange

AZ Light Blue

B White

B/N White/Black

B/BL White/Blue

B/R White/Red

BL Blue

GL Yellow

GL/B Yellow/White

GL/BL Yellow/Blue

GL/N Yellow/Black

GL/V Yellow/Green

GL/R Yellow/Red

GR Grey

M Brown

N Black

N/R Black/Red

R Red

VR Green

VC Light green

Loading...

Loading...