Page 1

Mack

Natural Gas

®

Mack® Natural Gas

(LEU / MRU)

Mack® Natural Gas

(LEU / MRU)

21607699

21607699 21607699

© Mack Trucks, Inc. 2010

Printed in U.S.A.

September 2010

Page 2

Foreword

TheinformationinthismanualappliestovehiclesbuiltJanuary2010

andlater .Pleasekeepthismanualinthevehicleatalltimes.

ThisHandbookonlyappliestoLEUandMRUmodelsequippedwith

naturalgasengines.Formodelsequippedwithdieselengines,please

refertoMackT erraProSeriesOperator’sHandbook.

Note:Illustrationsinthismanualareusedforreferenceonlyandmay

differslightlyfromtheactualvehicle.However,keycomponents

addressedinthisdocumentarerepresentedasaccuratelyaspossible.

TheNationalHighwayTrafcSafetyAdministration(NHTSA)and

MACKTrucks,Inc.shouldbeinformedimmediatelyifyoubelieve

thatthevehiclehasadefectthatcouldcauseacrash,injuryordeath.

ContactNHTSAbycallingtheAutoSafetyHotlineat1(888)

327-4236,bywritingtoNHTSA,U.S.DepartmentofTransportation,

Washington,DC20590,byTTYat1(800)424-9153,orvisittheir

websiteatwww.nhtsa.dot.gov.

MackTrucks,Inc.

Greensboro,NCUSA

Ordernumber:PV776-21607699

©2010MackTrucks,Inc.,Greensboro,NCUSA

Allrightsreserved.Nopartofthispublicationmaybereproduced,

storedinretrievalsystem,ortransmittedinanyformsbyanymeans,

electronic,mechanical,photocopying,recordingorotherwise,without

thepriorwrittenpermissionofMackTrucks,Inc.

Page 3

Contents

OPERATOR’SHANDBOOKCUMMINS-WESPORTISL-GNA TURALGAS

ENGINE.......................................................................................................................1

INTRODUCTION..........................................................................................................1

TOTHEOWNER........................................................................................................1

AboutThisHandbook..............................................................................................1

SafetyInformation.........................................................................................................2

INSTRUMENTSANDCONTROLS...........................................................................15

CABINTERIOR..........................................................................................................15

MethaneDetector/AlarmSystem.............................................................................19

OPERATION..................................................................................................................20

LIQUIDNATURALGASSYSTEM..........................................................................20

LNGTank................................................................................................................20

LNGFueling............................................................................................................23

COMPRESSEDNATURALGASSYSTEM..............................................................26

CNGFueling............................................................................................................26

MAINTENANCEANDLUBRICATION....................................................................27

MAINTENANCEINTRODUCTION.........................................................................27

DAILYLNG/CNGFUELSYSTEMCHECKS..........................................................27

BEFOREPERFORMINGMAINTENANCEONTHELNGORCNGTANKS

ORFUELSYSTEM....................................................................................................29

RemovingPressureBeforeWorkingontheEngineFuelSystem...........................29

RemovingPressureBeforeWorkingontheTanks..................................................30

MovingaV ehicleUsingAuxiliaryFuel..................................................................30

ENGINEMAINTENANCE........................................................................................32

AirFilter...................................................................................................................32

AirInletSystemDucts,HosesandClamps.............................................................34

Chassis-MountedChargeAirCooling(CMCAC).......................................................34

FuelSystem..............................................................................................................35

COOLINGSYSTEM...................................................................................................36

RadiatorPressureCap..............................................................................................37

Thermostat...............................................................................................................37

FederalEmissions..........................................................................................................39

FEDERALEMISSIONREQUIREMENTS................................................................39

TamperingwithGaseousEmissionControlSystemsProhibited............................39

GaseousEmissionControlSystemsW arranty.........................................................40

GASEOUSEMISSIONSCONTROLSYSTEMWARRANTYFEDERAL

EMISSIONREQUIREMENTS...................................................................................41

ItemsNotCoveredbytheEmissionControlSystemsWarranty.............................41

EmissionControlSystemsWarranty—California.................................................42

EMISSIONSCONTROLSYSTEMWARRANTY—CALIFORNIA......................44

ProceduresforHandlingEmissionsControlSystemWarranty...............................44

ELECTRICAL...............................................................................................................46

Page 4

.....................................................................................................................................46

CircuitBreakerandRelayPanel..............................................................................46

Page 5

INTRODUCTION1

TOTHEOWNER

AboutThisHandbook

ThishandbookisreferredtoastheCummins-WesportISL-G™NaturalGasEngine

Handbook.ItcoversallNaturalGasEnginemodels.Keepthishandbookwiththe

vehicleatalltimestoensurethateachownerand/oroperatorwillhaveaccesstoall

pertinentinformationrelatingtotheoperationandhandlingofthisvehicle.

Thissupplementwaspreparedtoprovidethedriverwithallrelevantinformation

concerningthenaturalgasengine,itscharacteristicsanditspotentialhazardsifnot

maintainedproperly .Pleasereaditthoroughly;payparticularattentiontoadvisory

labelsthathavebeenincludedtodrawattentiontoimportantissuesofoperatorsafety

andoverallperformance.

Informationandillustrationsinthishandbookarebasedonthelatestproductionusage

atthetimeofprintingandaresubjecttochangewithoutpriornotice.

Refertoyourvehicle’sOperator’sHandbookforadditionalvehicleinformation.

Page 6

2SafetyInformation

ImportantSafetyInformationforAll

OperatorsofNaturalGasV ehicles

Althoughformalcerticationisnotcurrentlyrequired-fromanoperational,safety

andliabilityperspective-itmaybedesirableforpersonnelhandlingLNG/CNG

equipmenttocarryawrittencerticateattestingtosuchtraining.Itistheresponsibility

oftheownerandoperatorofanyLNG/CNGfacilityorequipmenttohaveproper

safetytrainingbeforeoperatingLNG/CNGequipment.Informationconcerning

properLNG/CNGsafetytrainingisavailablethroughthemanufacturerofLNG/CNG

vehiclesandequipment.Ifyouareunsureaboutyourqualicationsforoperating,

refuelingorrecognizingandrespondingtopotentiallydangerousemergency

situationsthatcouldariserelatedtotheoperatingofanLNG/CNGvehicle,contact

yourimmediatesupervisororcallMACKOneCall™CustomerSupportSystem

at1-800-866-1177.

ThescopeofthishandbookisnottocoverallsituationsrelatedtoLNG/CNGsafety.

EffectivesafetytrainingprogramsarerequiredatallLNG/CNGvehiclefacilitiesto

ensurethesafetyofpersonnel,protectpropertyandmaintainfacilityperformance

requirements.FamiliarizingallpersonnelwithbasicLNG/CNGinformationwill

allowthemtomakewell-informedsafetyjudgments.Asafetyprogramatthefacility

shouldinclude:

1Scheduledequipmentinspections

2Operationalsafetyprocedures

3Personneltrainingandcertication

4Emergencyresponseproceduresandperiodicpracticedrills

5Emergencyresponsecommunityinteraction

DANGER

Donotoperate,occupyorrefuelan

LNG/CNGvehicleifyouareunsure

ofyourqualicationsforoperating,

refuelingorrecognizingandresponding

topotentiallydangerousemergency

situationsthatcouldariserelatedto

LNG/CNGvehiclesandequipment.

Page 7

SafetyInformation3

Althoughthishandbookcontainssafetyinformationthatmaybeusedinconjunction

withasafetytrainingprogram,itisnottobeviewedasasafety-trainingmanual.The

safetyinformationcontainedinthismanualisforreferenceandrecallofinformation

alreadycoveredinanongoingsafetyprogram.Onlysafetytrainingandperiodic

practicedrillscanadequatelytrainoperatorsandlocalemergencypersonnel(suchas

redepartments,medicalemergencyunitsandpolicedepartments)forsafelyhandling

potentiallydangeroussituationsinthecommunityproximatetoLNG/CNGfacilities

andLNG/CNGvehicleoperation.

DANGER

Itisrecommendedthatpersonnelnever

enteravaporcloud.Ifthevaporignites,

theycouldbeseverelyburned.Inhaling

thevaporcancausebreathingproblems

orasphyxiation.

Page 8

4SafetyInformation

PropertiesofLNG:

LiqueedNaturalGas/Methane(LNG)isacolorless,odorlessgasorliquid.

Atambienttemperatures,theproductisagas,butatcryogenic(super-cooled)

temperaturesitisaliquidorheavygasthatmaytravelalongtheground,riseasit

warmsandvaporizes,andbecometrappedunderanyclosed-inspace.

PropertiesofCNG:

CompressedNaturalGas/Methane(CNG)isacolorless,odorless(sulfur)gas.Itis

compressedat2400to3600poundspersquareinchandstored/usedinspecially

designedcylinders.

NormalMethaneVenting

Themethanefueltanksautomaticallyventtoreleasepressurewhenthevehicleis

parkedforsometime.Duringventingahissingsoundmaybeheard.Thefrequency

anddurationofthisventingwillvarydependingontankpressureandambient

temperature.Itwillcontinuetoventuntilthetruckisoperatedagain,therebydropping

thepressure,oruntilthetank(s)isempty .

PrimaryLNGTankVentPiping

Fromthefactory,theventpipingfromtheprimaryLNGtankventsisattachedtothe

intakestackbydisposableplasticstraps.Thepipingshouldberemovedfromthe

intakestackandplumbedupandoverthebodybythebodyinstallersasshownin

thefollowingillustration.Formoreinformation,seethesectiontitled"LNGT ank

PressureV ents"intheOPERATIONsectionofthismanual.

CAUTION

Itisimportanttokeeptheprimary

pressureventfreeofblockagedueto

ice,snowordebris.

Page 9

SafetyInformation5

C0032249

Page 10

6SafetyInformation

MethaneLeaks

Duringthedailywalkaround,inspecttheoutsideoftheLNGfueltankforfrost.

FrostedLNGtank(s),otherthanattheshroudarea*,indicatesthattheinnertank

isleakingintotheoutertank.Theappearanceofavaporcloudaccompaniedbya

hissingnoisemayalsoindicateamethaneleak.Aleakrequiresserviceonthetank(s)

beforethevehiclecanbeoperated.

*Rearfueltankdoorandplumbingxtures.

WARNING

Donotoperateavehiclewhichhasa

methaneleak.

RapidPressureRise

TherearethreemaincausesofrapidpressureriseonLNGsystems;overlling,fuel

systemleaksormalfunctionsandlossofvacuum.Aproperlyfunctioning,properly

lledLNGfuelsystemshouldbuildlessthan15psig/day.Anysystembuildingmore

than40psig/dayneedstroubleshootingtondthecause.

VacuumLoss

TotalvacuumlossisanunusualeventforanLNGtank(resultinginfrostingtheentire

shell),howeverthevacuumwillslowlydecaywithtimeasgassesdiffuseoutof

thetankmaterials.Thiswillshowupovertimeasamorerapidpressurerisetime,

eventuallyexceeding40psig/day.Oncethevacuumhasdecayedtothispoint,the

tankwillneedtobere-evacuatedbyacompetentmaintenancefacility.

Page 11

SafetyInformation7

METHANEDETECTOR/ALARMSYSTEM

Note:Thefollowinginformationappliestoequipmentlocatedonthevehicle

only.Separatemethanedetector/alarmsystemsshouldbeinstalledinfacilitiesthat

frequentlyhousenaturalgasvehicles.Inaddition,hand-heldmethanedetector/alarm

devicesshouldbeusedwhenworkingonnaturalgasvehicleswithnon-functioning

ordisconnectedmethanedetector/alarmsystemsandwherenoauxiliarymethane

detector/alarmsystemisinstalled.

Note:Consultyourlocalrecodeand/or

reinspectortomakesuethatadequate

Themethanevapordetectionsystemutilizestwosensorstoidentifymethanevapors;

onelocatedinthecabcompartmentandonelocatedintheenginecompartmentof

thevehicle.Thesystemoperateswithbothavisualandanaudiblealarmtowarn

theoperatorofpotentialdanger.Thealarmsaretriggeredattracelevels(20%LEL

[LowerExplosiveLimit])andatsignicantlevels(50%LEL)ofvaporconcentration.

Thesystemandsensoroperationisconstantlymonitored.Aninternalrelaycontrols

twoindicatorlamps(1greenand1red)thatcanbeseenthroughthewindshield.The

greenlampwillgooutandtheredlampwillilluminate15secondsafterasignicant

levelofmethanehasbeendetected.Themethanedetectoralsohasapassto-test

buttonthatcanbeusedtotesttheindicatorlampsandtheaudiblealarm.

detectionandpreventionmeasuresarein

place.

Page 12

8SafetyInformation

BeforeEnteringtheVehicle

Greenandredmethanedetectorremoteindicatorlampsareeasilyviewedthrough

thewindshieldandshouldalwaysbecheckedbeforeenteringthevehicle.(See

illustration.)

W0059509

Page 13

DANGER

WHENAPPROACHINGTHECAB

TOENTER:Donotopenthevehicle

doorsiftheREDLAMPISON!Donot

openthevehicledoorsiftheALARM

ISSOUNDING!Donotopenthe

vehicledoorsiftheGREENLAMP

isNOTON!Iftheindicatorlampis

red,ifthealarmissoundingorifthe

greenlampisNOTON,itisunsafeto

openthevehicledoorsbecauseeven

staticelectricitycanigniteconcentrated

methanefumesinanenclosedarea.

Immediatelyimplementthefollowing

procedure:*Removeallpersonnelfrom

thearea.Turnoffelectricalcircuitsand

sourcesofignitionintheimmediate

area.ManuallyturnofftheFuelShutOffValveoneachfueltanktoprevent

furthergasleakage.Waituntilthegas

hasdissipatedandthealarmsituation

hascleared.Itisnowsafetoopenthe

vehicledoorsandwindowstoventthe

vehicle.Donotoperatethevehicleuntil

thesourceoftheleakhasbeenrepaired.

SafetyInformation9

Note:Whenthebatteryisdisconnected,themethanedetector/alarmsystemwillnot

operatesothegreenlightswillnotbeon.Themethanedetector/alarmsystemis

poweredbythebatteryandisactiveatalltimesunlessthebatteryisdisconnectedor

thefuseisblown.

Hand-heldmethanedetector/alarmdevicesshouldbeusedwhenworkingonnatural

gasvehicleswithanonfunctionalordisconnectedmethanedetector/alarmsystemand

wherenoauxiliarymethanedetector/alarmsystemisinstalled.

Page 14

10SafetyInformation

DANGER

Intheeventofanalarmwhileoperating

thevehicle,immediatelyopenthe

cabwindows,safelystopthevehicle,

shutdowntheengineandturnoffthe

ignition.Exitthecabandleavethe

doorsandwindowsopentoventthe

vehicle.ManuallyturnofftheFuel

Shut-OffV alveoneachfueltankto

preventfurthergasleakage.Waituntil

thegashasdissipatedandthealarm

situationhascleared.Donotoperate

thevehicleuntilthesourceoftheleak

hasbeenrepaired.

Note:Foradditionalinformation,refertoandintheINSTRUMENTSAND

CONTROLSsectionofthishandbook.

CAUTION

AMGaDSIIIPlusisapropane,CNG

(CompressedNaturalGas)andLNG

(LiquidNaturalGas)detectoronly.

However,becausethesensorsdetect

allhydrocarbonvapors,analarmmay

betriggeredbytheuseofchemicals

suchascleaners,paint,polish,lacquer,

etc.Donotexposesensorstoliquids

orchemicalsunnecessarily.When

usingsuchsubstances,keepthevehicle

wellventilatedanddonotallowdirect

contactwiththesensors.Forcleaning

andmaintenanceoftheGasDetection

System,refertotheAMGaDSIIIPlus

Owner’sManualsuppliedwiththe

vehicle.

Page 15

SafetyInformation11

PotentialHazardAssociateswithLNG/CNG:

Skin/Eyes

LNGisstoredatcryogenictemperatures(low-temperaturestate,startsatorbelow

-240°F(about-150°C)andCNGisstoredinspeciallydesignedtanksunder

extremelyhighpressure.Therefore,properlyinsulatedsafetyglovesandeye

protectionsuchasgogglesorafaceshieldshouldbewornwhenworkingwithor

aroundLNG/CNGaswhenrefueling.Ifsuper-cooledliquidorgascomesintocontact

withtheskinoreyes,seeaphysicianimmediately.

WARNING

COVEREYESANDEXPOSEDSKIN.Accidentalcontactoftheeyesorskin

withLNGmaycauseafreezinginjurysimilartoaburn.Protecttheeyesand

covertheskinwheneverthepossibilityofcontactwithsuper-coldmetals,liquids

orgasexists.

Page 16

12SafetyInformation

Inhalation

LNG/CNGisnottoxic,butcancauseasphyxiationinconcentrationorinenclosed

areasbecauseitreducestheoxygenavailableforbreathing.Forthisreason,methane

detectorsarelocatedintheenginecompartmentandinsidethecab.Thesedetectors

willtriggeranalarminsidethecabifmethaneconcentrationgoesaboveasafelevel.

Thesedetectorsarealwaysactivewhetherthevehicleisonoroff,aslongasthebattery

isconnectedandthefuseisinplaceandnotblown.Ifovercomebyvapor,removethe

individualfromexposureandcallaphysicianimmediately.Ifbreathingisirregularor

hasstopped,startresuscitation(iftrainedinCPR)andadministeroxygenifavailable.

DANGER

KEEPTHEEQUIPMENTAREA

WELLVENTILATED.Although

LNG/CNGisnon-toxic,itcancause

asphyxiationinaconnedareawithout

ventilation.Anyatmospherethatdoes

notcontainenoughoxygenforbreathing

cancausedizziness,unconsciousness,

orevendeath.LNG,beingcolorless,

odorlessandtasteless,cannotbe

detectedbyhumansenses.Eventhough

CNGissulfurized,thesmellmay

gounnoticedonsomevehicles,such

asarefusetruck.Withoutadequate

ventilation,naturalgaswilldisplace

theoxygenandgivenowarningthat

anon-lifesupportingatmosphereis

present.StoreLNG/CNGinawell

ventilatedarea.

IfvehiclesequippedwithanLNGenginemustbeparkedorworkedonindoorsfor

shortperiodsoftime,pipingfromtheprimaryLNGtankventpipetotheoutsideof

thebuildingshouldbeprovided.See"PrimaryLNGT ankVentPiping"attheendof

theSAFETYsection.De-fuelingorremovaloftheLNGtank(s)isrecommendedfor

vehiclesstoredindoorsforlongperiodsoftime.

Separatemethanedetector/alarmsystemsshouldbeinstalledinfacilitiesthat

frequentlyhouseLNG/CNGvehicles,consultlocalcodesandordinancestoensure

compliance.Inaddition,handheldmethanedetector/alarmdevicesshouldbeused

whenworkingonLNG/CNGvehicleswithnon-functioningordisconnectedmethane

detector/alarmsystemandwherenoauxiliarymethanedetector/alarmsystemis

installed.

Note:DuetothecryogenicstateofLNGfuel,itcannotbeodorized,therefore,itwill

notsmelllikeCNGorpipelinegasinahome.

Page 17

SafetyInformation13

Flammability

SinceLNGisextremelyammable,thetank(s)shouldbegroundedwhenfueling,to

avoidcreatingsparksfromstaticelectricity.Keepanysourceofignition,suchasalit

cigarette,farawayfromLNG/CNGtanksandfuelingareas.

WARNING

KEEPAWAYFROMFLAMEOR

SPARK.

Naturalgasisammable.Smoking,

openames,andgeneralpurpose

electricalequipmentshallbeprohibited

wherenaturalgasisstoredorhandled.

Pressure

TheLNG/CNGfuelsystemsarepressurizedsystems.Therefore,automaticand

manualsafetyvents,reliefvalvesandshutoffpointsareinstalledthroughoutthe

systemtopreventexcesspressurefrombuilding.

WARNING

REMOVEPRESSURE.Alwaysempty

theLNG/CNGfueltank(s)andremove

anypressureonthesystempriorto

removingpartsorcomponentsofthe

tankforrepair.

ReleasesorSpills

Duringareleaseorspill,shutoffandeliminateallignitionsources.Ifdesired,stop

thesourceofthereleaseorspill.Keeppeopleaway.Minimizebreathingvapors.

Absolutelyavoidskincontact.V entilateconnedspaces.Nodisposalmethodis

necessary,norshoulditbeattempted,becauseextremelyrapidevaporationofthe

naturalgaswilltakeplace.Ifaspillisindangerofigniting,useawaterspray(donot

usesolidstreamsofwater)todirectgas-airmixturesawayfromignitionsources

Ifaspillhasignited,usewatertokeepre-exposedcontainersandequipmentcool

andtoprotectpersonnelwhomayhavetostopthesourceoftheleak.Ifitisdesirable

toextinguishthere,usedrychemical,carbondioxideorhalogenatedextinguishing

agents.

Page 18

14SafetyInformation

SPECIFICSAFETYINFORMATIONREGARDINGTHEINSTRUMENTS

ANDCONTROLS,THEOPERATION,ANDTHEMAINTENANCEOFTHE

CHASSISWILLBECOVEREDINYOUROPERA TOR’SHANDBOOK.

CabEntry/Exit

AsdescribedinyourOperator’sHandbook,followtheThree-LimbContactRule

toenterandexityourvehicle.

DANGER

Beforeopeningeithervehicledoor,

alwayslookthroughthedriverside

windowatthemethanealarmbox

locatedoninstrumentpanel(MRU

andLEU).DoNOTopenthedoorifa

redalarmlightisonorifyouhearthe

audiblealarmsounding.DoNOTopen

thedoorifthegreenlightisnotON.

Page 19

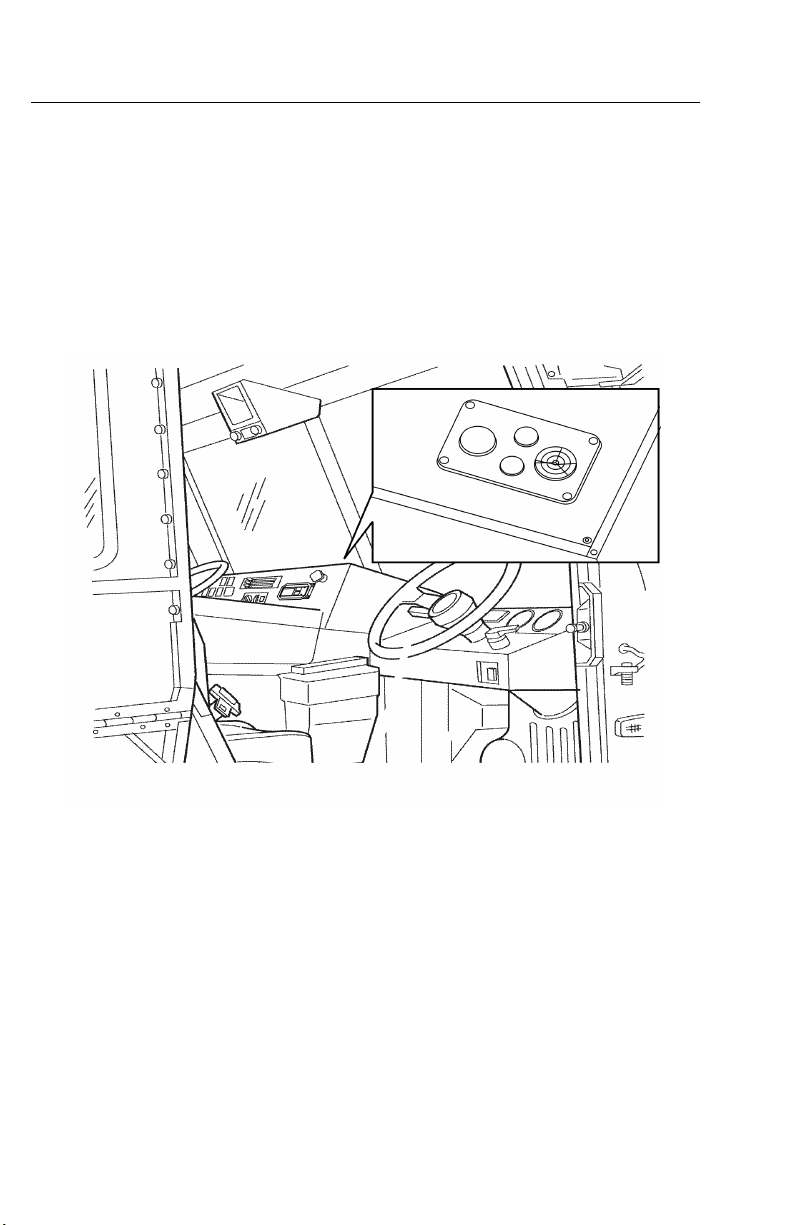

INSTRUMENTSANDCONTROLS15

CABINTERIOR

Belowyouwillseehowthemethanedetector/alarmsystemisarrangedonatypical

LEUinstrumentpanel:(Theexactlayoutmaydifferfromyourtruck,butthegas

detectionsystemwilllookthesame.)

1.GasDetectionSystem—Seebelowfordetaileddisplayinformation

W0059510

Page 20

16INSTRUMENTSANDCONTROLS

1.PowerOnIndicator(Green)6.RelayOn/OffIndicator

2.SignicantAlarmIndicators(Red)7.RelayResetButton

3.TraceSensorAlarmIndicators

(Amber)

4.AudibleAlarmSilenceButton9.SensorFaultIndicators

5.AlarmSilencedIndicator

8.SystemT estButton

C0032252

Page 21

INSTRUMENTSANDCONTROLS17

1PowerOnIndicator(Green)—ThisgreenLEDshouldalwaysbeon.Nopower

on/offswitchisprovidedforthisunitasitshouldbeonatalltimes.

Note:Whenthebatteryisdisconnected,themethanedetector/alarmsystemwill

notoperatesothegreenlightwillnotbeon.Themethanedetector/alarmsystemis

poweredbythebatteryandisactiveatalltimesunlessthebatteryisdisconnected

orthefuseisblown.Hand-heldmethanedetector/alarmdevicesshouldbeused

whenworkingonnaturalgasvehicleswithanon-functioningordisconnected

methanedetector/alarmsystemandwherenoauxiliarymethanedector/alarm

systemisinstalled.

DANGER

WHENAPPROACHINGTHECABTOENTER:

DonotopenthevehicledoorsiftheREDLAMPISON!Donotopenthe

vehicledoorsiftheALARMISSOUNDING!Donotopenthevehicledoorsif

theGREENLAMPisNOTON!

IftheindicatorlampisRED,ifthealarmissoundingorifthegreenlampis

NOTON,itisunsafetoopenthevehicledoorsbecauseevenstaticelectricity

canigniteconcentratedmethanefumesinanenclosedarea.Immediately

implementthefollowingprocedure:*

Removeallpersonnelfromthearea.

Turnoffelectricalcircuitsandsourcesofignitionintheimmediatearea.

ManuallyturnofftheFuelShut-OffV alveoneachfueltanktopreventfurther

gasleakage.Waituntilthegashasdissipatedandthealarmsituationhas

cleared.Itisnowsafetoopenthevehicledoorsandwindowstoventthevehicle.

Donotoperatethevehicleuntilthesourceoftheleakhasbeenrepaired.

*Dependingonlocalordinancesorcompanypolicy,itmayberecommendedthat

emergencypersonnelbecontactedtoimplementtheseprocedures

DANGER

theeventofanalarmwhileoperatingthevehicle,immediatelyopenthecab

windows,safelystopthevehicle,shutdowntheengineandturnofftheignition.

Exitthecabandleavethedoorsandwindowsopentoventthevehicle.Manually

turnofftheFuelShut-OffValveoneachfueltanktopreventfurthergasleakage.

Waituntilthegashasdissipatedandthealarmsituationhascleared.Donot

operatethevehicleuntilthesourceoftheleakhasbeenrepaired.

2SignicantSensorAlarmIndicators(Red)—IlluminationoftheredLED

for"Zone1"(cabcompartment)or"Zone2"(enginecompartment)indicates

thesystemhasdetectedgasfumesinconcentrationsabove50%oftheLower

ExplosiveLimit(LEL)andanaudiblehornwillsound.

Page 22

18INSTRUMENTSANDCONTROLS

3.T raceSensorAlarmIndicators(Amber)—IlluminationoftheamberLEDfor

"Zone1"(cabcompartment)or"Zone2"(enginecompartment)indicatesthesystem

hasdetectedagasconcentrationabove20%oftheLEL.Thisisacautionarysituation.

Correctivemeasuresshouldbetakenassoonaspossible—includingopeningthe

vehiclewindowsandreturningthevehicleforservice—toidentifyandcorrectthe

sourceofthemethaneleak.

4.AudibleAlarmSilenceButton—Presstosilencetheaudiblealarm.

5.AlarmSilencedIndicator—Illuminatestoindicatetheaudiblealarmhasbeen

silenced.

6.RelayOn/OffIndicator—IfthereisaSIGNIFICANTalarmdetectedfor15

seconds,the"RelayEngaged"LEDwillgoon.Theremotewindshield-visiblegreen

lampwillgooutandtheremotewindshield-visibleredlampwillilluminate.

7.Relay(Shutdown)ResetButton—Onlyafterthemethanegashasclearedand

thealarmsareoff,maytheinternalrelayberesetbypressingthe"ShutdownReset"

button.AfterpressingtheShutdownResetbutton,the"RelayEngaged"LEDgoesoff.

8.SystemT estButton—Pressingthebuttonwillcausethesystemtoperforma

self-testofallelectricalandsensorfunctionsandsimulateanalarmcondition.The

systemreturnstonormalwhenthetestbuttonisreleased.

9.SensorFaultIndicators—IfeitherSensorFaultlightremainsilluminated

orilluminatesintermittently ,adisconnectedorfaultysensorisindicatedinthe

correspondingzone.Zone1indicatesthecabcompartmentsensorandZone2

indicatestheenginecompartmentsensor.Donotoperatethevehicleuntilaqualied

personcorrectsthiscondition.

CAUTION

AMGaDSIIIPlusisapropane,CNG(CompressedNaturalGas)andLNG(Liquid

NaturalGas)detectoronly .However,becausethesensorsdetectallhydrocarbon

vapors,analarmmaybetriggeredbytheuseofchemicalssuchascleaners,paint,

polish,lacquer,etc.Donotexposesensorstoliquidsorchemicalsunnecessarily .

Whenusingsuchsubstances,keepthevehiclewellventilatedanddonotallow

directcontactwiththesensors.ForcleaningandmaintenanceoftheGasDetection

System,refertotheAMGaDSIIIPlusOwner’sManualsuppliedwiththevehicle.

Page 23

INSTRUMENTSANDCONTROLS19

MethaneDetector/AlarmSystem

Inadditiontothemethanedetectorlocatedinthecab,thereisanothermethane

detectorlocatedinthe"doghouse"underthecabasshowninthefollowingillustration.

Themethanealarm/detectionsystemrunsoffthebatteryandisactiveatalltimes

unlessthebatteryisdisconnected.

C0032253

DANGER

Ifthebatteryisdisconnected,the

methanedetector/alarmsystemwillnot

operate.

FrostedLNGtank(s),otherthanaroundtheareaoftherearfueltankdoorand

plumbingxtures,indicatesthattheinnertankisleakingintotheoutertank.The

appearanceofavaporcloudaccompaniedbyahissingnoisemayalsoindicatea

methaneleak.Aleakingconditionrequiresserviceonthetank(s)beforethevehicle

canbeoperated.

DANGER

Intheeventthemethanealarmred

lightcomesonandthealarmsounds,

thecabwindowsshouldimmediately

beopened,thevehicleshouldbesafely

stoppedandturnedoff,andpersonnel

shouldexitthecab.Followsafety

precautionsintheSAFETYsectionof

thismanual.

WARNING

DoNOToperateavehiclewhichhasa

methaneleak.

Page 24

20OPERATION

LIQUIDNATURALGASSYSTEM

LNGTank

ThereareoneortwoLNGtanks.Theyaremountedononeorbothsidesofthetruck

withtheplumbingcomponentsaccessibleinsidetherearofeachtank.TheLNGfuel

tankis,forsimplicityofexplanation,designedlikeavacuum(Thermos™)bottle

whichcanwithstandpressuresupto230psi,orwhatevermaximumpressureisposted

onthemanufacturer’slabel(seeillustration).

1.RearofTank(Shroud)withDoor

Closed

2.Maximum-PressureLabelinPounds

perSquareInch(psi)

3.Manufacturer’sLabel6.LiqueedNaturalGasSymbol

4.FuelT ankFillFitting

5.TankSafetyLabel

C0032254

Page 25

1.FillConnectiontoSecondFuelTank6.FuelShut-OffValve

2.ManualVent7.ExcessFlowValve

3.FuelTankPressureGauge8.FuelT ankFillFitting

4.TankManufacturer’sManual(Inside

9.FuelGaugeSendingUnit

BottomhalfofTankDoor)

5.EvacuationPlug(DoNotRemove)10.FuelTankLevelProbe

OPERATION21

C0032255

Page 26

22OPERATION

1FillConnectiontoSecondFuelTank—Whenfueling,LNGwillenterthe

secondvesselthroughthisconnectingpipe.

2ManualV ent—ThisvalveisclearlymarkedwithOPENandCLOSEdirectional

arrows.Itisnormallykeptclosed,butmaybeopenedtobleedthetankorincertain

fuelingsituationswhicharedescribedinthesection"LNGFueling."

Note:Thereisnormallynoneedtomanuallyventthetank.Thevesselisprotected

fromover-pressurizationbyseveralautomaticsafetyreliefvalves.

3FuelT ankPressureGauge—Eachtankhasaseparatepressuregauge.The

normaloperatingpressureofthetanksisapproximately120psiorhigher.Normal

procedureistorefuelonadailybasisoreachtimethevehicleistakenintoactive

service.

4TankManufacturer’sManual—Locatedinsidethebottomhalfofthetankdoor.

Asthelabelindicates,thismanualshouldbereadentirelybeforeoperatingthetank.

5EvacuationPlug(DoNotRemove)—TheLNGfueltankisequippedwithan

outerjacketevacuationplugthatwillpopopenifthereisalossofvacuum.The

lossoftheevacuationplugindicatesaninnervesselleak.Theevacuationplugis

protectedfromtheenvironmentandtamperingbyaplasticcap.Donotremovethe

plasticcaporevacuationplug.

6FuelShut-OffValve—ThisvalveisclearlymarkedwithOPENandCLOSE

directionalarrows.Duringnormaloperation,thevalveshouldremainfullyopento

allowfueltoreachtheengine.Closethisvalvetoshutofffueltotheengine.

Note:Ifthereismorethanonetank,bothtankvalvesmustbeturnedofftoshut

offfueltotheengine.

7ExcessiveFlowValve—Restrictsexcessfuelowintheeventofafuelline

breakage.

8FuelT ankFillFitting—FillingtheLNGvehiclefueltanksisdonethrougha

singlehoseconnectedtothelltting.Instructionsonllingthefueltanksare

underthesection"LNGFueling."

9FuelGaugeSendingUnit—Receivessignalsfromthetankprobeandconverts

themintovaluescompatiblewiththefuelgauge.Thesendingunitissealedand

non-adjustable.

10FuelTankLevelProbe—Sensesthefuellevelinthetank.

Duringthedailywalkaroundinspection,ifyouseeanysignsofamethaneleaksas

previouslymentionedintheSAFETYsectionofthishandbook,openthetankdoor.If

theEvacuationPlughaspoppedout,thetankmustbeservicedbeforeoperating.

Page 27

OPERATION23

LNGT ankPressureReliefV alves

Periodicallypressurewillbeharmlesslyreleasedthroughtheprimaryreliefvalveas

thefuelheatsupandexpandsduetoambientoutsidetemperature.LiquidLNGin

thetankscanbeaslowas-260°F(-177°C).BecausesmallamountsofLNGare

convertedintolargeamountsofnaturalgas,pressuresmayrapidlyincreaseifameans

ofreliefisnotprovided.

Theprimaryandsecondarypressureventsarelocatedinsidethefueltankdoor.The

primaryventisconnectedtopipingwhichshouldbeattachedtothebodyofthe

truckfacingtowardtherearofthevehicle,awayfromthepassengercompartment.

Onlytheprimaryreliefvalveispipedaway.Thesecondaryreliefvalveshouldbe

leftwiththefactoryinstalledplasticcapinplace.Refertothetankmanufacturer’s

manualformoredetails.

Fromthefactory,theventpipingfromtheprimaryLNGtankventisattachedtothe

intakestackbydisposableplasticstraps.Thepipingshouldberemovedfromthe

intakestackandplumbedupandoverthebodybythebodyinstallersasshowninthe

illustrationattheendoftheSAFETYsectioninthishandbook.

CAUTION

Itisimportanttokeeptheprimarypressureventfreeofblockageduetoice,snow

ordebris.

LNGFueling

Normalprocedureistorefuelthetanksonadailybasisoreachtimethevehicleis

takenintoactiveservice.Thenormaloperatingpressureineachtankisapproximately

120psiorhigher.Ifthepressureislow,say90psi,thevehicleisprobablylowon

fuel.Asaresult,itwillbelowinpowerandmayeventuallyrunoutoffuel.

Note:CompleteandsafeinstructionsonLNGfuelingshouldbeobtainedfromthe

tankmanufacturer’smanualandfromtheassistanceofpersonnelwhoareexperienced

inLNGfueling.

WARNING

COVEREYESANDEXPOSEDSKIN.

Accidentalcontactwiththeeyesorskin

maycauseafreezinginjurysimilarto

aburn.Protecttheeyesandcoverthe

skinwheneverpossiblecontactwith

supercooledmetals,liquidsorgases

exists.

Page 28

24OPERATION

DANGER

KEEPTHEEQUIPMENTAREA

WELLVENTILATED.Although

LNG/CNGisnon-toxic,itcancause

asphyxiationinaconnedareawithout

ventilation.Anyatmospherethat

doesnotcontainenoughoxygen

forbreathingcancausedizziness,

unconsciousness,orevendeath.LNG,

beingcolorless,odorlessandtasteless,

cannotbedetectedbyhumansenses.

Withoutadequateventilation,natural

gaswilldisplacetheoxygenandgive

nowarningthatanon-lifesupporting

atmosphereispresent.StoreLNGina

wellventilatedarea.

GroundT ankandOpenFuelTank

FillFitting

DANGER

KEEPAWAYFROMFLAMEOR

SPARK.Naturalgasisammable.

Beforefueling,connectthefueltankto

thegroundcableatthefuelingstation.

Smoking,openames,andgeneral

purposeelectricalequipmentshallbe

prohibitedwhereliqueednaturalgas

isstoredorhandled.

C0032256

Page 29

ConnectFillHose

DANGER

Fuelingstationsandfuelingsituations

differ.DonotllanLNGtankwithout

rstgoingthroughtheprocedureswith

theassistanceofexperiencedpersonnel.

OPERATION25

C0032257

NormalFilling

FillingtheinnervesseloftheLNGvehiclefueltankisdonethroughasinglehose.

Whenthellhoseisconnectedtothefueltanklltting,LNGissuppliedata

pressurehigherthanthevehicletankpressure.Thellisautomaticallyterminated

whenthepressurereachesapresetvalueatthefuelingstation.Removethelling

hosefromthetting.

WarmTankFilling

TheLNGvehiclefueltankisconsideredtohaveawarminnervesseleitherpriorto

initialllingofthetank,orafterthetankhasbeenoutofserviceformorethantwo

weeks.Therecommendedprocedureforawarmtankllistollthevehicletank

withapproximately95liters(25gallons)ofLNGandallowittobuildpressure.This

willbegintocooltheinnervesselandbuildenoughpressuretoallowaleaktesttobe

performed.Thepressuremaynowbemanuallyventeddownandanormalfueling

sequencemaybedone.

Page 30

26OPERATION

COMPRESSEDNATURALGASSYSTEM

CNGFueling

RefertoFuelSystemInstallerforfueling/defuelingrequirements.

WARNING

COVEREYESANDEXPOSEDSKIN.

Accidentalcontactwiththeeyesorskin

maycauseafreezinginjurysimilarto

aburn.Protecttheeyesandcoverthe

skinwheneverpossiblecontactwith

supercooledmetalsorgasesexists.

DANGER

KEEPTHEEQUIPMENTAREA

WELLVENTILA TED.AlthoughCNG

isnon-toxic,itcancauseasphyxiation

inaconnedareawithoutventilation.

Anyatmospherethatdoesnotcontain

enoughoxygenforbreathingcan

causedizziness,unconsciousness,or

evendeath.EventhoughCNGis

odorized,undercertaincircumstances,

inarefusevehicleforexample,it

maynotbedetectedbyhumansenses.

Withoutadequateventilation,natural

gaswilldisplacetheoxygenandgive

nowarningthatanon-lifesupporting

atmosphereispresent.StoreCNGina

wellventilatedarea.

DANGER

KEEPAWAYFROMFLAMEOR

SPARK.Naturalgasisammable.

Beforefueling,connectthefueltankto

thegroundcableatthefuelingstation.

Smoking,openames,andgeneral

purposeelectricalequipmentshallbe

prohibitedwherecompressednatural

gasisstoredorhandled.

DANGER

Fuelingstationsandfuelingsituations

differ.DonotllaCNGtankwithout

rstgoingthroughtheprocedureswith

theassistanceofexperiencedpersonnel.

DANGER

Failureorimproperselectionor

improperuseofthisproductcancause

death,personalinjuryandproperty

damage,including,butnotlimited

toelectrocution,uidinjectionor

lossoflimbcausedbyhighpressure

leak,dangerouslywhippinghose,re

explosionorcontactwithsuddenly

movingorfallingobjects.

Page 31

MAINTENANCEANDLUBRICATION27

MAINTENANCEINTRODUCTION

ThishandbookcontainsmaintenanceinformationspecictotheNaturalGasV ehicle

andEngine.Forrecommendedlubricationchangeintervalsandproceduresfor

gearoils(transmission,rearaxlecarrier[s],frontdriveaxlecarrier,transfercase

andywheelPTO)orothermaintenanceschedulesorproceduresnotincludedin

thisportionofthehandbook,refertotheMaintenanceandLubricationManual

(21394653)oryourvehiclemodel’sOperatorHandbook.

DAILYLNG/CNGFUELSYSTEMCHECKS

CheckforMethaneLeaksorLossofVacuum

TheLNGandCNGfuelsystemsarepressurizedsystems.Anydamagetothefuel

deliverysystemmayresultinleaks.Allthetubingcarryingliquidorgasfuelfrom

thefueltankstothevaporizerarestainlesssteel.Thetubingfromthevaporizer

throughouttheremainderofthefueldeliverysystemisspecializedhighpressure

tubing.Anydamagetothissystemshouldberepairedassoonaspossible.

Duringthedailywalkaround,checkforanyleaksordamagetothefuelsystem.The

appearanceofavaporcloudaccompaniedbyahissingnoisemayindicateamethane

leak.Inspecttheoutsideofthefueltankforfrost(LNGonly).Afrostedtankindicates

thattheinnertankisleakingintotheoutertankortherehasbeenalossofvacuum.

Openthetankdoor;iftheEvacuationPlughaspoppedout,thetankmustbeserviced.

Aleakingconditionrequiresservicebeforethevehicleisoperated.

WARNING

Donotoperateavehiclewhichhasa

methaneleak.

Note:Somefrostingandsweatingisnormalaroundtheplumbingttingsinthe

shroudedendofthetank.

Page 32

28MAINTENANCEANDLUBRICATION

PrimaryLNGTankVentPiping

Fromthefactory,theventpipingfromtheprimaryLNGtankventsisattachedtothe

intakestackbydisposableplasticstraps.Thepipingshouldberemovedfromthe

intakestackandplumbedupandoverthebodybythebodyinstallers.

CAUTION

Itisimportanttokeeptheprimary

pressureventfreeofblockagedueto

ice,snowordebris.

CAUTION

IfLNGvehiclesmustbeparkedor

workedonindoorsforshortperiodsof

time,pipingfromtheprimaryLNGtank

ventpipetotheoutsideofthebuilding

shouldbeprovided.De-fuelingor

removaloftheLNG/CNGtanksis

recommendedforvehiclesstored

indoorsforlongperiodsoftime.

Page 33

MAINTENANCEANDLUBRICATION29

BEFOREPERFORMINGMAINTENANCEONTHE

LNGORCNGTANKSORFUELSYSTEM

Note:Separatemethanedetector/alarmsystemsshouldbeinstalledinfacilitiesthat

frequentlyhouseLNG/CNGvehicles.Inaddition,hand-heldmethanedetector/alarm

devicesshouldbeusedwhenworkingonLNG/CNGvehicleswithanon-functioning

ordisconnectedmethanedetector/alarmsystemandwherenoauxiliarymethane

detector/alarmsystemisinstalled.

CAUTION

Beforeperforminganymaintenanceon

theLNG/CNGtanksystem,refertothe

tankmanufacturer’soperationmanual.

WARNING

REMOVEPRESSURE.Before

workingontheLNG/CNGfuelsystem,

closethefuelvalvesoneachtankand

relievethepressureinthefuellineby

openingthedrainonthefuellterorby

runningtheengineuntilitstops.

TheLNG/CNGfuelsystemsare

pressurizedsystems.LNGwillboiland

causepressuretobuildinthesystem.

DoNOTallowLNGtobecometrapped

inpiping,asbetweentwoclosedvalves.

Itwillvaporizeandrapidlyincrease

pressure,burstingthepipe.

RemovingPressureBeforeWorkingontheEngine

FuelSystem

BeforeservicingtheLNG/CNGenginefuelsystem,removepressurefromthefuel

linesbyturningthevalvesoneachtanktotheOFFposition.Thiswillstopmorefuel

fromenteringthelinestotheengine.Allowtheenginetorununtilit"dies."

Page 34

30MAINTENANCEANDLUBRICATION

RemovingPressureBeforeWorkingontheTanks

Ifthefuellinesbetweenthetanksorthetanksthemselvesmustbeworkedon,the

systemmustbetotally"bled"offuel,includingthetanks.Withaminimumamount

offuelinthetanks,openthemanualventvalvesonthetanksuntilthetankpressure

gaugesreadzero.

Note:Ifpossible,trytoservicethetanksafterthevehiclehasusedmostofits

on-boardfuel.

WARNING

Neverbleedthetanksinanenclosed

area.Besuretherearenosourcesof

ignitioninthearea.

MovingaVehicleUsingAuxiliaryFuel

WhenLNGtanksarenotfueledorhavebeenremoved,thevehiclemaybemovedby

connectinganauxiliaryCNG(compressednaturalgas)tanktotheconnectionlocated

ontheleftsideframerailbehindthefrontinsideofthefueltankonthedriverside.

CAUTION

UseaCNGtankwithitsownpressure

regulator.Pressuremustnotexceed120

psigatauxiliarytankconnectionvalve

(seeillustration).

Page 35

MAINTENANCEANDLUBRICATION31

Turnthethree-wayvalvetoAUXtooperatethevehiclefromanauxiliarytank.

TurnthevalvetoONtooperatefromthemaintank(s)and,besuretoturnthevalveto

OFFwhenparkingthevehicle.

C0032260

1.Three-WayFuelValve3.FrontEdgeofFuelTank,DriverSide

2.AuxiliaryTankConnectionValve120psigmaximum

C0032261

Page 36

32MAINTENANCEANDLUBRICATION

ENGINEMAINTENANCE

AirFilter

ChecktheFilterMinderGaugedaily.TheFilterMinderGaugeistypicallymounted

directlyontheaircleanercanisterbehindthecab(MRUandLEU)asshowninthe

illustrationfollowing.Changethelterwhenthegaugeshows300mm(12in)of

waterortherestrictiongaugeredsignallocksinfullview.Regardlessofthegauge

reading,changetheelementatleastonceyearly.

Note:Asdamageorholesintheltermediumwillgiveaninaccuraterestriction

reading,changetheelementatleastonceyearlytopreventdust,dirtandotherharmful

contaminantsfromenteringtheengine.

CAUTION

Donotattempttocleantheairlter

elementwithcompressedairasthis

coulddamagetheltermediumand

possiblyresultinsevereenginedamage.

C0032262

Page 37

MAINTENANCEANDLUBRICATION33

Toproperlyinstallanewlterelement:

1Wipetheaircleanerhousingclean.

2Loosenthecoverretainingnutsandremovethelterelement.

3Inspectsealingareasfor"dirttracks"whichwouldindicatethatdusthasleaked

pasttheseal.Ifdirttracksarefound,thecausemustbedeterminedandcorrected.

4Thoroughlycleantheinsideoftheaircleanercanisterwithadampclothor

vacuumcleaner.

5Inspecttheinsideofthecanisterforrust.Ifrustispresent:

•Removetheaircleanercanisterfromthechassis.

•RemovealllooserustwithawirebrushorcoarseScotchBrite®pad.

•ThoroughlywashtheareawithPPGDX-440®,orequivalentwaxandgrease

remover.

•EtchandpreparewithPPGMetalPrep79(DX-579®),orequivalent.

•Rinsewithwateranddrythoroughly.

•TreattheareawithundilutedGalvaprepSGDX-520®,orequivalent.

•Rinsewithwateranddrythoroughly.

•PaintwithPPGDP40/401®,orequivalent.

•Reinstalltheaircleanercanisteronthechassis.

6Inspectthesealingareasofthehousingfordamage.Repairorreplaceasnecessary.

7UseMACKTrucks,Inc.,approvedreplacementelementsandgaskets.Makesure

thenewelementsandgasketsarenotdamaged.Besuretousenewgasketseach

timetheelementischanged.

8Reinstallthecoverandtorquetheretainingnutsevenlyat11N.m(8-10lb-ft).

9ResettheFilterMinderbypushinginthebutton.

Page 38

34MAINTENANCEANDLUBRICATION

AirInletSystemDucts,HosesandClamps

Every45daysor150hours,whicheveroccursrst,inspectallductsandhosesfor

signsofleakageorchang.Replacehoseandrepairorreplaceductswithholes.

Tightenclamps.

Chassis-MountedChargeAirCooling(CMCAC)

VehiclesequippedwithCMCACrequirethefollowingpreventivemaintenance:

•Daily—Removeallinsects,leavesandotherforeigndebrisfromthefrontalarea

byusingarmbristlebrushandsoapywater.

CAUTION

DonotuseacausticsolutiontocleanCMCAC.

•Every45daysofusageor150hours*—Checkallairductingandgasket

connections.Properhoseclamptorquingprocedureistotightenhoseclampnuts

untilspringisfullycompressed3.9to4.5N.m(35–40lb-in).

•Every180daysofusageor600hours*—Checkforcracks.Checkthemounting

bracketsforsecurityandcondition.Torquethemountsto41N.m(30lb-ft).Check

corensforexternaldamage,debrisorsaltcorrosion.Usearm,bristledbrushto

removedsaltcorrosion.Useairpressuretocleancoreblockageduetodebris.

*Whicheveroccursrst.

Page 39

MAINTENANCEANDLUBRICATION35

FuelSystem

WARNING

BeforeservicingtheLNG/CNGengine

fuelsystem,removepressurefromthe

fuellinesbyturningthevalvesoneach

tanktotheOFFposition.Thiswillstop

morefuelfromenteringthelinestothe

engine.Allowtheenginetorununtil

it"dies."

1.Engine-MountedFilterAdapter(For

clarity,thelterassemblyisshown

removedfromtheengine.)

2.FilterDrain6.ThreadedFilterRod

3.FilterCanister7.O-Ring

4.FilterRetainer

5.FilterElement

C0032264

Page 40

36MAINTENANCEANDLUBRICATION

•Afterallfuelhasbeenremovedfromthefuelsystem,opentheltercanister

drain[2]atthebottomofthelterunit.Allowanyaccumulatedwaterandany

remainingfueltodrain.

•Rotatetheltercanister[3]counterclockwisetoreleaseitfromthemounted

lteradapter[1].

•Removetheretainer[4]fromthebottomofthethreadedrod[6]thatholdsthelter

element.Pullstraightdownonthelterelementtoremoveitfromtherod.

•ReplacethecanisterbowlO-ring[7]ifthereareanysignsofdamageor

deterioration.Cleananylterdebrisfromtheadapter,canisterandretainer.

•LubricatetheO-ringverylightlywithcleanengineoilandreinstallitintheadapter

groove.Installthenewlterelementontotherodandhand-tightentheretainer

ontotherodtoholdthelterinplace.

•Reinstallandhand-tightenthecanisteroverthelterelement.

•Closethelterdrain.

•Openthevalvesoneachtanktoallowfueltore-enterthesystem.

•Starttheengineandcheckforleaks.

Note:Avaporcloudorhissingsoundnearthelterindicatesaleak.

CAUTION

UseofanythingotherthangenuineMACK/Cumminsltersmaycausedamage

andvoidtheenginewarranty.

COOLINGSYSTEM

Thecoolingsystemplaysanimportantroleinoverallengineperformanceby

keepingtheenginewithinthenormaloperatingtemperaturerange-hotenoughfor

efcientcombustion,andcoolenoughtopreventenginedamagefromoverheating.

Goodpreventivemaintenancepractices,alongwithmonitoringcoolingsystem

performance,goalongwayinpreventingenginedamagethatcouldresultfrom

coolingsystemproblems.Themaintenanceitemsandtestsoutlinedinthissection

shouldbeperformedattheintervalsspeciedtoensureoptimumperformancefrom

thecoolingsystem.

Page 41

MAINTENANCEANDLUBRICATION37

RadiatorPressureCap

AteveryCandDinspection,checktheconditionoftheradiatorcapgasket.Also,

pressuretestthecapusingasuitablecoolingsystemandradiatorcaptester.A16-psi

pressurecapiscurrentlyusedonallMACKTrucks,Inc.,modelchassis.

Thermostat

Checkthermostatoperation,particularlyduringcoldweather,tomakesurethe

thermostatclosesfully,doesnotallowanyleakageanddoesnotopentoosoon.Also,

thethermostatsealshouldbecheckedforleakage.Coolantleakingpastthethermostat

cancauseovercoolingandmayresultininsufcientcabheat.

Page 42

38MAINTENANCEANDLUBRICATION

Page 43

FederalEmissions39

FEDERALEMISSIONREQUIREMENTS

ThissectioncoverstherequirementoftheUnitedStatesCleanAirActwhichstates:

"Themanufacturershallfurnishwitheachnewmotorvehicleormotorvehicleengine

suchwritteninstructionsforthemaintenanceanduseofthevehicleorengineby

theultimatepurchaserasmaybereasonableandnecessarytoassuretheproper

functioningofemissioncontroldevicesandsystems."

Thissectionalsocoverstherequirementsoftheemissionsregulationspromulgated

undertheMotorV ehicleSafetyActinCanada.

TamperingwithGaseousEmissionControl

SystemsProhibited

TheFederalCleanAirActprohibitstheremovalorrenderinginoperativeofany

deviceorelementofdesigninstalledonorinamotorvehicleormotorvehicleengine

incompliancewithFederalEmissionRegulationsby:

1Anypersonpriortoitssaleanddeliverytotheultimatepurchaser,or

2Anymanufacturerordistributorafteritssaleanddeliverytotheultimatepurchaser,

or

3Anypersonengagedinthebusinessofrepairing,servicing,selling,leasing,or

tradingmotorvehiclesormotorvehicleenginesfollowingitssaleanddelivery

totheultimatepurchaser,or

4Anypersonwhooperatesaeetofmotorvehiclesfollowingitssaleanddelivery

totheultimatepurchaser.

Page 44

40FederalEmissions

GaseousEmissionControlSystemsWarranty

(SupplementtoStandardV ehicleWarranty)

MACKTrucks,Inc.warrantstotheoriginalandeachsubsequentpurchaserofa

MACKTrucks,Inc.,motorvehicleorCummins-WesportISL_Genginethatsuch

vehicleorengineisdesigned,builtandequippedsoastoconformatthetimeofsale

withallsuchUnitedStatesandCanadaFederalemissionsregulationsapplicableatthe

timeofmanufacture,andthatitisfreefromdefectsinmaterialsandworkmanship

whichwouldcauseittofailtomeetsuchregulationswithinaperiodofveyearsafter

deliveryofsuchvehicleorenginetotheoriginalpurchaseror,subjecttotheexclusions

setforthbelowforcomponentsnotmanufacturedbyMACKTrucks,Inc.,beforesuch

vehicleorthevehicleinwhichsuchenginehasbeeninstalled,hasbeenoperated480

000km(300,000miles)or10,800hoursofengineoperation,whicheverrstoccurs.

Equipmentsuchasturbochargers,injectionequipment,andchargeaircoolersnot

manufacturedbyMACKTrucks,Inc.areexcludedfromtheabovewarranty,butare

coveredbytheapplicablewarrantyoftherespectivemanufacturerineffectatthe

timeofdelivery;provided,however,thatinnocasewillanysuchcomponentbe

warrantedforlessthanveyearsafterdeliveryofthevehicleorenginetotheoriginal

purchaseror160000km(100,000miles)ofoperationofsuchvehicleorofthe

vehicleinwhichsuchenginehasbeeninstalled,or3,000hoursofengineoperation,

whicheverrstoccurs.

Themanufacturer’sobligationunderthiswarrantyislimitedtotherepairor

replacement,ashereinprovided,atitsoptionofanypartorpartsoftheemission

controlsystemofsuchvehicleorenginefoundtotheManufacturer’ssatisfactionto

bedefectiveuponexaminationbyit,providedthatsuchpartorpartsshallbereturned

totheManufacturer’sfactoryortoitsnearestauthorizedDistributororSubsidiary.

Page 45

FederalEmissions41

GASEOUSEMISSIONSCONTROLSYSTEM

WARRANTYFEDERALEMISSIONREQUIREMENTS

Thefollowingenginecomponentsarecoveredbythesupplementalemissionscontrol

systemwarrantypolicyasrequiredbytheFederalemissionsregulations.

ItemsNotCoveredbytheEmissionControl

SystemsWarranty

•Malfunctionscausedbymisuse,improperadjustments,modication,alteration,

tampering,disconnection,improperorinadequatemaintenance.

•Damageresultingfromaccident,actsofnatureorothereventsbeyondthecontrol

ofMACKTrucks,Inc.

•Inconvenience,lossofuseofthevehicle,orcommercialloss.

•Anyvehicleonwhichtheodometerhasbeenchangedsothatmileagecannot

bereadilydetermined.

Therepairorreplacementofdefectivepartsunderthiswarrantywillbemadewithout

chargeforpartsand,ifmadeatthemanufacturer’sfactory,Subsidiary,orauthorized

Distributor’splaceofbusiness,withoutchargeforlabor.

THISW ARRANTYISMADEEXPRESSL YINLIEUOFANYOTHER

WARRANTIES,EXPRESSEDORIMPLIED,INCLUDINGANYIMPLIED

WARRANTYOFMERCHANTABILITYORFITNESSFORAP ARTICULAR

PURPOSE,ANDOFANYOTHEROBLIGA TIONONTHEPARTOF

THEMANUFACTURER,INCLUDING,WITHOUTLIMITA TIONOFTHE

FOREGOING,CONSEQUENTIALANDINCIDENT ALDAMAGE.

Page 46

42FederalEmissions

EmissionControlSystemsWarranty—California

TheCaliforniaAirResourcesBoardandMackT rucks,Inc.arepleasedto

explaintheCaliforniaemissioncontrolsystemwarrantyonyournewmotorvehicle

engine.InCalifornia,newmotorvehicleenginesmustbedesigned,builtandequipped

tomeettheState’sstringentanti-smogstandards.MackTrucks,Inc.mustwarrantthe

emissioncontrolsystemonyourenginefortheperiodoftimelistedbelow;provided

therehasbeennoabuse,neglect,orimpropermaintenanceofyourengine.

Youremissioncontrolsystemmayincludepartssuchasthefuelcontrolsystem,

turbochargerassembly,electroniccontrolmoduleandotheremission-related

assemblies.

Whereawarrantableconditionexists,MackTrucks,Inc.willrepairyourengineatno

costtoyouincludingdiagnosis,parts,andlabor.

Manufacturer’sWarrantyCoverage

Ifanemission-relatedpartofyourengineisdefective,thepartwillbe

repairedorreplacedbyMackTrucks,Inc.Thisisyouremissioncontrol

systemDEFECTSWARRANTY.

Owner’sW arrantyResponsibilities

Asthemotorvehicleengineowner,youareresponsiblefortheperformanceofthe

requiredmaintenancelistedinthismanual.MackTrucks,Inc.recommendsthat

youretainallreceiptscoveringmaintenanceofyourvehicle,butMACKTrucks,

Inc.cannotdenywarrantysolelyforthelackofreceiptsorforyourfailuretoensure

theperformanceofallscheduledmaintenancelistedinothermanualswhichwere

suppliedwithyourvehicle(s).

YouareresponsibleforpresentingyourmotorvehicleenginetoaMACKTrucks,Inc.

dealerassoonasaproblemexists.Thewarrantyrepairsshouldbecompletedina

reasonableamountoftime,nottoexceed30days.

Asthemotorvehicleengineowner,youshouldalsobeawarethatMackTrucks,Inc.

maydenyyouwarrantycoverageifyourvehicleoraparthasfailedduetoabuse,

neglect,impropermaintenance,orunapprovedmodications.

Ifyouhaveanyquestionsregardingyourwarrantyrightsandresponsibilities,you

shouldcontacttheMackTrucks,Inc.WarrantyDepartmentatP.O.Box1801,

Allentown,P A18105,ortheCaliforniaAirResourcesBoardat9480TelstarAvenue,

ElMonte,California91731.

Page 47

FederalEmissions43

(SupplementtoStandardV ehicleWarranty)

(Applicableonlytovehiclesand/orenginescertiedforsaleandregisteredin

theStateofCalifornia)

MackTrucks,Inc.warrantstotheoriginalandeachsubsequentpurchaserofaMACK

TrucksInc.motorvehicleorCummins-W esportISL_Genginethatsuchvehicle

orengineisdesigned,builtandequippedsoastoconformatthetimeofsalewith

allStateofCaliforniaemissionsstandardsapplicableatthetimeofmanufacture,

andthatitisfreefromdefectsinmaterialsandworkmanshipwhichwouldcauseit

tofailtomeetsuchstandardswithinaperiodofveyearsafterdeliveryofsuch

vehicleorenginetotheoriginalpurchaser,orsubjecttotheexclusionssetforthbelow

forcomponentsnotmanufacturedbyMACKTrucks,Inc.,beforesuchvehicleor

thevehicleinwhichsuchenginehasbeeninstalled,hasbeenoperated480000km

(300,000miles)or10,800hoursofengineoperation,whicheverrstoccurs.

Equipmentsuchasturbochargers,injectionequipment,andchargeaircoolersnot

manufacturedbyMACKTrucks,Inc.areexcludedfromtheabovewarranty,butare

coveredbytheapplicablewarrantyoftherespectivemanufacturerineffectatthe

timeofdelivery;provided,however,thatinnocasewillanysuchcomponentbe

warrantedforlessthanveyearsafterdeliveryofthevehicleorenginetotheoriginal

purchaseror160000km(100,000miles)ofoperationofsuchvehicleorofthe

vehicleinwhichsuchenginehasbeeninstalled,or3,000hoursofengineoperation,

whicheverrstoccurs.

MACKTrucks,Inc.’sobligationunderthiswarrantyislimitedtotherepairor

replacement,ashereinprovided,atitsoptionofanypartorpartsoftheemissions

controlsystemofsuchvehicleorenginefoundtotheManufacturer’ssatisfactionto

bedefectiveuponexaminationbyit,providedthatsuchpartorpartsshallbereturned

totheManufacturer’sfactoryortoitsnearestauthorizeddealer .

Thiswarrantyshallnotapplytoanydefectswhicharisesolelyasaresultofaccident

orownerabuseorlackofrequiredmaintenance.

Therepairorreplacementofdefectivepartsunderthiswarrantywillbemadewithout

chargeforpartsand,ifmadeatMACKTrucks,Inc.’sfactoryorauthorizeddealer’s

placeofbusiness,orauthorizedrepairfacility,withoutchargefordiagnosisorlabor.

THISW ARRANTYISMADEEXPRESSL YINLIEUOFANYOTHER

WARRANTIES,EXPRESSEDORIMPLIED,INCLUDINGANYIMPLIED

WARRANTYOFMERCHANTABILITYORFITNESSFORAP ARTICULAR

PURPOSE,ANDOFANYOTHEROBLIGATIONORLIABILITYONTHEPAR T

OFMACKTRUCKS,INC.INCLUDING,WITHOUTLIMITATIONOFTHE

FOREGOING,CONSEQUENTIALANDINCIDENT ALDAMAGESSUCHAS

INCONVENIENCE,LOSSOFUSEOFTHEVEHICLE,COMMERCIALLOSS,

ETC.

Page 48

44FederalEmissions

EMISSIONSCONTROLSYSTEMWARRANTY—

CALIFORNIA

ProceduresforHandlingEmissionsControl

SystemWarranty

Thefollowingenginecomponentsarecoveredbythesupplementalemissionscontrol

systemwarrantypolicyasrequiredbytheCaliforniaCodeofRegulations.

1RepairsbyMACKTrucks,Inc.Dealers,Sub-DealersandServiceDealers

RepairscoveredbytheCaliforniaEmissionControlSystemsWarrantywillbe

performedbyanauthorizedMACKTrucks,Inc.repairfacilityathisplaceof

businesswithnochargeforpartsandlabor(includingdiagnosis),usingMACK

Trucks,Inc.partsforanypartoftheemissioncontrolsystemscoveredbythis

warrantyandfounddefective.

2InanEmergency

Inanemergency,whereanauthorizedMACKTrucks,Inc.facilityisnotavailable,

repairsmaybeperformedatanyavailableserviceestablishment,orbytheowner,

usinganyreplacementpart,withinthelimitationsofparagraphs4and5inthis

section.Anemergencyconditionexistsunderthissectionif,after30days,repairs

havenotbeencompletedorpartsarenotyetavailable.MACKTrucks,Inc.

willreimbursetheownerforsuchrepairsthatarecoveredunderthiswarranty,

includingdiagnosis,nottoexceedMACKTrucks,Inc.suggestedretailpricefor

partsreplacedandlaborchargesbasedonMACKTrucks,Inc.recommendedtime

allowanceandgeographicallyappropriatehourlylaborrate.Replacedpartsand

paidinvoicesmustbepresentedataMACKTrucks,Inc.facilityasaconditionof

reimbursementforemergencyrepairsperformedelsewhere.

3RepairsbyNon-MACKTrucks,Inc.Facilities

Ownersmayelecttohavemaintenance,replacement,orrepairofemissioncontrol

systemsperformedbyanyrepairfacility,andmayelecttousepartsotherthan

MACKTrucks,Inc.partswithoutinvalidatingthewarrantyonothercomponents,

butthecostofsuchserviceorpartswillnotbecoveredbyMACKTrucks,Inc.

underitswarranty .

4UseofNon-MACKTrucks,Inc.Parts

UseofreplacementpartswhicharenottheequivalentofMACKTrucks,Inc.

partsmayimpairtheeffectivenessofemissioncontrolsystems.Ifotherthan

MACKTrucks,Inc.partsareused,theownershouldobtainassurancesthatsuch

partsarewarrantedbytheirmanufacturertobetheequivalentofMACKpartsin

performanceanddurability.MACKTrucks,Inc.assumesnoliabilityunderthis

warrantywithrespecttopartsotherthanMACKTrucks,Inc.parts;however,the

useofnon-MACKTrucks,Inc.partsdoesnotinvalidatethewarrantyonother

componentsunlessnon-MACKTrucks,Inc.partscausedamagetowarrantedparts.

5MaintenanceandMaintenanceRecords

Thevehicleownerisresponsiblefortheperformanceofallrequiredmaintenance

speciedinthishandbook.MACKTrucks,Inc.willnotdenyawarrantyclaim

solelybecausethereisnorecordofmaintenance;however,MACKTrucks,Inc.

maydenyawarrantyclaimiffailuretoperformrequiredmaintenanceresultsinthe

failureofawarrantedpart.Receiptsorotherrecordscoveringtheperformance

Page 49

FederalEmissions45

ofscheduledmaintenanceshouldberetainedtoanswerquestionsthatmayarise

concerningmaintenance.Maintenancerecordsshouldbetransferredtosubsequent

ownersifthevehicleissold.

6ItemsNotCoveredbytheEmissionControlSystemsWarranty

•Malfunctionscausedbymisuse,improperadjustments,modication,alteration,

tampering,disconnection,improperorinadequatemaintenance.

•Damageresultingfromaccident,actsofnatureorothereventsbeyondthe

controlofMACKTrucks,Inc..

•Inconvenience,lossofuseofthevehicle,orcommercialloss.

•Anyvehicleonwhichtheodometerhasbeenchangedsothatmileagecannot

bereadilydetermined.

CAUTION

Intheeventthatdamageresultsfromunauthorizedadjustmentsasevidencedby

settingsotherthanasspecied,orbrokenfastenerseals,thecostofrepairingsuch

damageWILLNOTBECOVEREDunderwarranty.

CAUTION

Anyunauthorizedadjustmentscancauseseveredamagetotheengine.Intheevent

thatdamageresultsfromunauthorizedadjustments,asevidencedbysettingsother

thanspecied,orbrokenfastenerseals,thecostofrepairingsuchdamageWILL

NOTBECOVERED.

7CustomerAssistance

MACKTrucks,Inc.wishestoensurethattheCaliforniaEmissionControlSystem

Warrantyisproperlyadministered.Intheeventthatownersdonotreceivethe

warrantyservicetowhichtheybelievetheyareentitledundertheCalifornia

EmissionControlSystemsWarranty,theyshouldcontactthenearestMACK

Trucks,Inc.RegionalOfceforassistance.Theaddressandtelephonenumber

foreachRegionalOfceisintheMACKTrucks,Inc.DirectoryofSales,Parts

andServiceCenters.Ownersinneedofadditionalassistanceorinformation

concerningtheCaliforniaEmissionControlSystemsWarrantymayalsocontact:

MackTrucks,Inc.

WarrantyActivities

P.O.Box26259

Greensboro,NC27402–6115

Page 50

46ELECTRICAL

CircuitBreakerandRelayPanel

LEUSerieswithCNGEngine

C0032284

Page 51

LEUSerieswithLNGEngine

ELECTRICAL47

C0032285

Page 52

48ELECTRICAL

LEUSerieswithCNGEngine

CabCircuitProtection

#1—5A#2—20A#3—15A#4—25A

RearHazard

Lamps

#5—10A#6—10A#7—15A#8—20A

ParkBrake,

EmergencyStop

Lamps

#9-20A#10-15A#11-20A#12-10A

CBPosts

#13-10A#14-10A#15-5A#16-10A

Anti-LockBrake

System

#17-10A#18-5A#19-15A#20-15A

KysorControlAnti-LockBrake

#21-20A#22-20A#23-10A#24-10A

LHWiperMotorRHWiperMotorWiperControl,

#25-30A#26-15A#27-10A#28-15A

Heater

#29-10A#30-#31-#32-15A

HydraulicPump

ProtectionCircuit

#33-20A#34-#35-20A#36-

StopLamps

Headlamps(T ypeI

Breaker)

DomeLamps

Communication

Connector

Anti-LockBrake

System

System

PlowUp-Down

Solenoids

NoCircuitNoCircuitRearFloodLamp

NoCircuitClearanceLampsNoCircuit

MarkerLamps,

CabIDLamps,

Park&TailLamps

IgnitionSwitchCigarLighter,Horn

Spare

Spare

Gauges,Indicator

Lamp

WasherMotor

RearHopper

Lamps

DirectionalLamps,

Flasher

ParkBrakeApply

Solenoid

BodyBuzzer

WoodwardEngine

ECU

MasterLH-RH

Switch

AllisonHD

InterfaceCircuits

Page 53

ELECTRICAL49

CabCircuitProtection

#37-20A#38-#39-20A#40-15A

TailLampsNoCircuitBody,Ignition

Power

#41-15A#42-20A#43-#44-20A

HydraulicPump

Solenoid

#45-#46-15A#47-20A#48-10A

Spare

ReverseLamps,

BackUpAlarm

SynchroStart

NoCircuitAirDryer,Drain

Spare

ReserveFuelTank

Valve

AllisonHDControl

Unit

Page 54

50ELECTRICAL

LEUSerieswithLNGEngine

CabCircuitProtection

#1-15A#2-20A#3-15A#4-20A

Lighter,Horn

#5-20A#6-20A#7-20A#8-10A

Stop,ParkLampsHeadlampDRL

#9-20A#10-20A#11-10A#12-10A

ClearanceLampBatteryPowerFeed

#13-15A#14-10A#15-15A#16-20A

GaugePanelKysorW arningMirrorHeatAirDryer

#17-20A#18-10A#19-30A#20-20A

IgnitionPower

Feed

#21-20A#22-10A#23-10A#24-15A

LHWiperLH/RHControlMunciePTOMirrorMotor

#25-15A#26-#27-5A#28-15A

CNGEngine

Interface

#29-20A#30-15A#31-10A#32-

Power,Indicator

Lamps

#33-#34-30A#35-#36-

NoCircuitNeutral/Reverse

CBPost

(TypeIBreaker)

EngineBrake

NoCircuitABS,Ignition

J1708Diagnostic

Connection

Power

Radio,IgnitionDirectionalSignal

MarkerLamps

SpareSparePower,

Heater

Power

Spare,IgnitionNoCircuit

NoCircuitNoCircuit

Lamps

DomeLamps

IndicatorLamps

RHWiper

Automatic

Transmission

Page 55

ELECTRICAL51

CabCircuitProtection

#37-15A#38-#39-#40-

2-WayRadioNoCircuitD-Full,ABS,

Battery

#41-#42-#43-#44-15A

NoCircuitNoCircuitNoCircuitD-Basic,ABS,

#45-#46-20A#47-#48-10A

NoCircuit

BeaconLamps

NoCircuitAutomatic

NoCircuit

Battery

TransmissionECU

Page 56

52ELECTRICAL

MRUSeries

C0032286

Page 57

ELECTRICAL53

CabCircuitProtection

#1-5A#2-20A#3-15A#4-25A

AccessoryRelayHeadlampsMarkerLams,ID

Lamps

#5-10A#6-10A#7-10A#8-20A

StopLamps

#9-20A#10-15A#11-15A#12-

CB,RadioCommunication

#13-10,15,20A#14-10A#15-15A#16-

ABSABSSpareOpen

#17-10A#18-15A#19-10A#20-20A

KysorShutdownNGWoodward

#21-20A#22-20A#23-20A#24-10A

LHWiperRHWiper

#25-30A#26-10A#27-5A#28-15A

Heater,A/C

#29-15A#30-#31-10A#32-15A

IgnitionStud

#33-20A#34-30A#35-30A#37-20A

TrailerStopLampsReverse/Neutral

#38-20A#39-20A#40-#41-10A

BatteryStudTrailerABSPower

#42-15A#43-20A#44-20A#45-30A

Back-UpLamps

#46-20A#47-

Strobe

DomeLamps

Connection

ECU

SpareABS

Open

Power

BatteryBox,

IgnitionStud

Open

IgnitionSwitchHorn,CigarLighter

BatteryStud

Gauges

BatteryBox,

IgnitionStud

Automatic

Transmission

Cab&Trailer

ClearanceLamps

Open

AirDryerFuelHeater

DirectionalSignal

Flasher

Spare

MirrorHeat

Spare

HDAutomatic

Transmission

Spare

TrailerTailLamps

PTO,FanClutch

Page 58

54ELECTRICAL

1F1-5A—MPHSensor,TransmissionModulatorRelay,FuelGauge,PowerStud,

ElectronicMalfunctionIndicator,PowersFuse8

2F2-15A—CamSensor,Relay#1

3F3-35A—ManifoldAbsolutePressure,NaturalGasT emperature,EngineCoolant

Temperature,Pre-TurbinePressure,NGTP/TKTemperatureReturn,ExhaustBack

Pressure,Relay#2

4F4-15A—UEGOConnectionOxygenSensor,LowPressureLockoffSolenoid,

HighPressureLockoffSolenoid

5F5-15A—Governor,Wastegate

6F6-10A—IgnitionModule

7F7-3A—MethaneWarningDetector

8F8-1A—PoweredbyFuse1,FuelTankSendingUnit(LNGOnly)

Page 59

Loading...

Loading...