Page 1

REPAIR INSTRUCTIONS,

PART 1

1.

Assémb e lhe slii'ener

wilh ñN lasl6n€c. Do NOT

plale

NO'E

fh6 6ngin6 siilf€ning fame

f4tene6 are ONE TIME USE

lasleóers musl be installed.

The aváilable lool, 9994649, cañ ba usd io

hold slifening lEme iñ

lnsrallthe oil

cfo$o@r

Using a lorque w rench, lighle¡ lhe alaching

fasl€néB in s€quénc6 amording lo

pfé$uB pipé

p¡pe

bet)€ tofqu+l¡ghtenlng the

Oil Pump Pipes and

lnslallation

aíachlnq

ONLY N&

posillon

wfile

and lh6

Stráiner

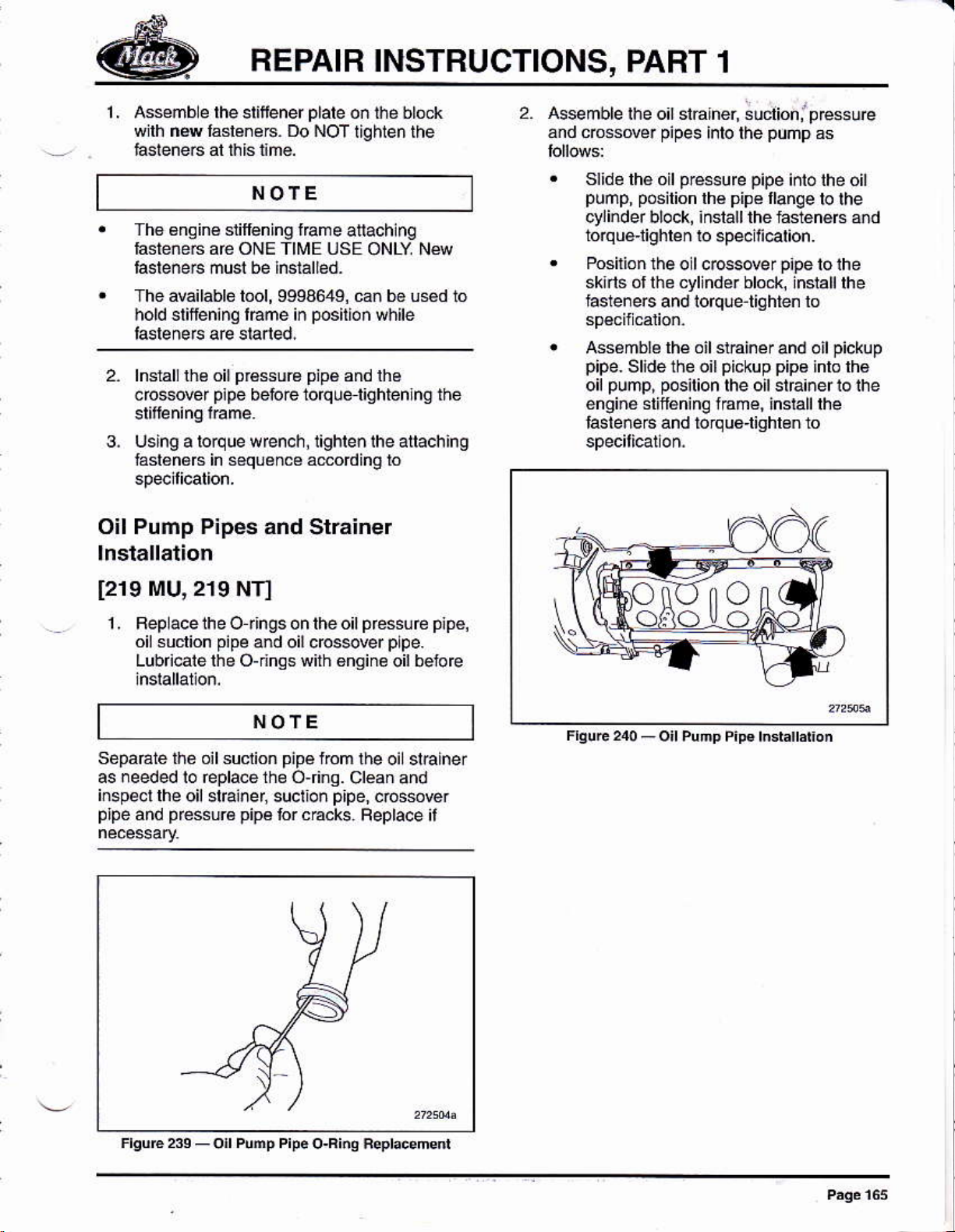

2. Asemblelhe

8nd ccsové¡

slide thé oil

punp, posilion

ct4inder block, ¡nslall the lasténéfs

torqué'lighren

Posilion

sklrls óf lhe cyllnder blo¿*,

hsteneE and lorqüetighten to

¡6s¿mblé lhé otl slrainér

pipe-

Slidé the oil

pump, posirion

oil

én9in6 stif€ning fÉmé, insrall rhe

IasteñéE and bJqué'lighlen lo

oi¡ siáher, ;udioni

pipes

inlo lhe

pessure pipe

lhé

to 6pe6ili@tion.

lhe o I ccsder

púñp

pipé

llanqe

p¡pe

and oil

pickup

rhe oil srfa¡ner ro ihe

pip€

pEs6u@

as

inlo lhe oit

lo lhe

and

lo ihe

lnstall the

pickup

inlo lh€

[219

MU,219

NT]

1, Bepacelheo t¡ngsonlheol

oi! suclion

Lubricate the O-dngswith 6ngine

sépaÉte th¿ oil suclion

as needed lo Éplace the o,finq.

iñspect

prpe

lhe oil stEi¡er, suclion

pr6ssuré

and

pipe

and oil dosever

NOTE

pipé

pipá

ror c€cks.

l¡om

p¡pe,

pressúfe pipé,

plpe.

oilbetoe

!hé oil stEiner

cléan and

cos$@r

Feplace il

o

o

o

o

Page 2

FEPAIR INSTBUCTIONS, PART

1

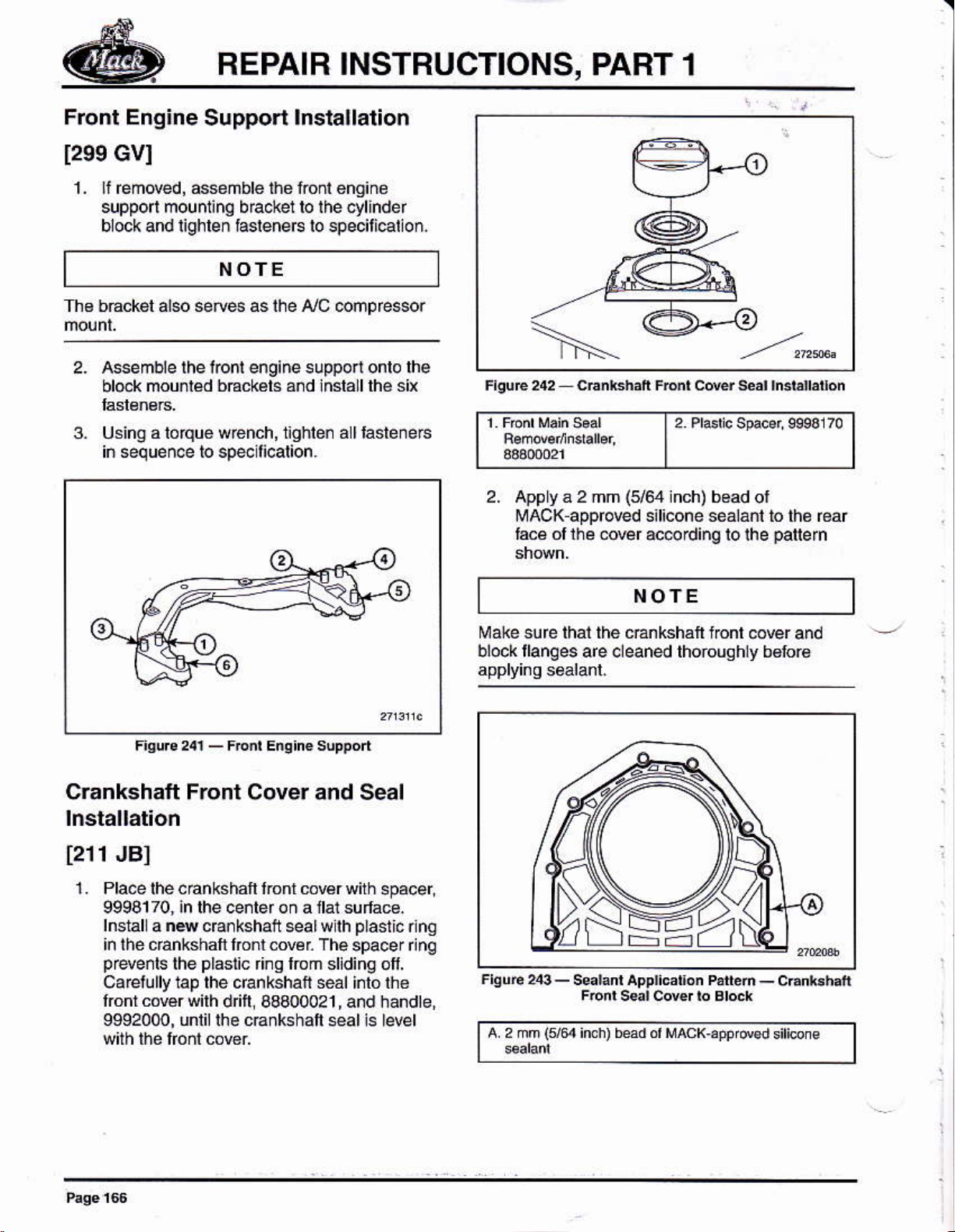

Front Eng¡ne

1299

Gvl

Support lnsta¡lation

1- ¡l €m@d, dsenbte the loni enqiñé

suppo mounring bfaokel ro rhe

block and lishleñ hsleneB lo specili€llo¡.

qlindef

NOTE

Tho bdckél also setu4 as lhe ¡/C @ñpre$or

2. Assemble lhe lon¡ engine suppo.! onlo lhe

moudád bBckéts a¡d iñslaLlthé sit

bl@k

3. Using a lolque wénch, tghle¡ all lasteneA

iñ sequen@ ro sp6ilicarion.

Pr6r.

l2

2. Apply á 2 mm

lvAcK approred sal¡cone seálañl to thé r6ar

lácé

lhé der

ol

(5/g

lnch) bead

ac@ding to the

sp*ar stes 170

ot

patern

Crankshatt Front Cover and Seal

lnstallatlon

[211

JBl

1. Pla@ lhe cánkshaft lronl cowr wftn

9998170, in lhe cenler oñ a llal sufface.

lnstal

¡n lhe cánkshalt lrcnt mr The

prryenls

carelully lap the crankshatt seát intó lhe

lronr co€r with

9992000, unlii lhe

a

ns

cErkshaft seal wllh

plás1ic

the

fing lrcm

d tl, 68400021

cEnkshaft *d ls le@l

plasl¡c

spacer ¡ng

sljding olf'

and handte,

,

6pacer.

rlng

NOTE

Make sure lhai the cÉnksháft lonl

block tlanges are cleaned thoroughly b6lor6

a 2 mm

(re

inch) bead o' MAcK¡ppr@3

@ver and

siticone

Page 3

REPAIR

INSTBUCTIONS, PART

1

3. Within 20 minulés

inslall lhe font wer to the éngine bl@k.

Cenle.lhe cEnkshaf lóñl 6v€r againsl rhe

c.anksháf

lnrall lhe

4.

usinq lhe

font @wr Note that the6 a¡€

For éarliéf typé

lnstallal¡on ¡ñstructioñs ápply:

lnsla

ll Ih e bo¡is wiihoui 1¡ghGñh g lh em

Using a stEighrédgé

the cder is flush wilh the leer édaé

ol sealanl appl¡calion,

pl4lic

fiñg.

(a),

rhe

tol¡Nirg

ru e, make sure

ol

F.uE245-FE6vdrÓiquós¿qenc8

5. RemoE the

hub. Dn@ in lh6 cÉnkshaft

48400021

d ft bónoms

plaslic

ring fom the crankshan

sea wilh dr¡ll,

and handle, 9992000, unlil lhe

,

against the c€nkshatt.

For lárér

rype

(B),

the iolrowlng

irsl¿llát¡on inslructoN

lnslallthe bolls in bolh boh ho es lhal

gn

al

Tiohtén by hand so lhállhe

lúed,

cove¡

lhé

lo lhe @@t

lnsiallihe remaininq bo[s.

NOTE

For lho laler

smallerand lhe righr-hánd hole

change

5. Us¡ng a torque wén.h

capscrews iñ sequonc6á@dinq

lvpé @ver, the tef hand hol€ is

lows

a

the laler mrer io bé coreclly

lighlen the

apply:

posltun.

cder is

is ovat. Thts

lo

Page 4

BEPAIB INSTRUCTIONS,

PART 1

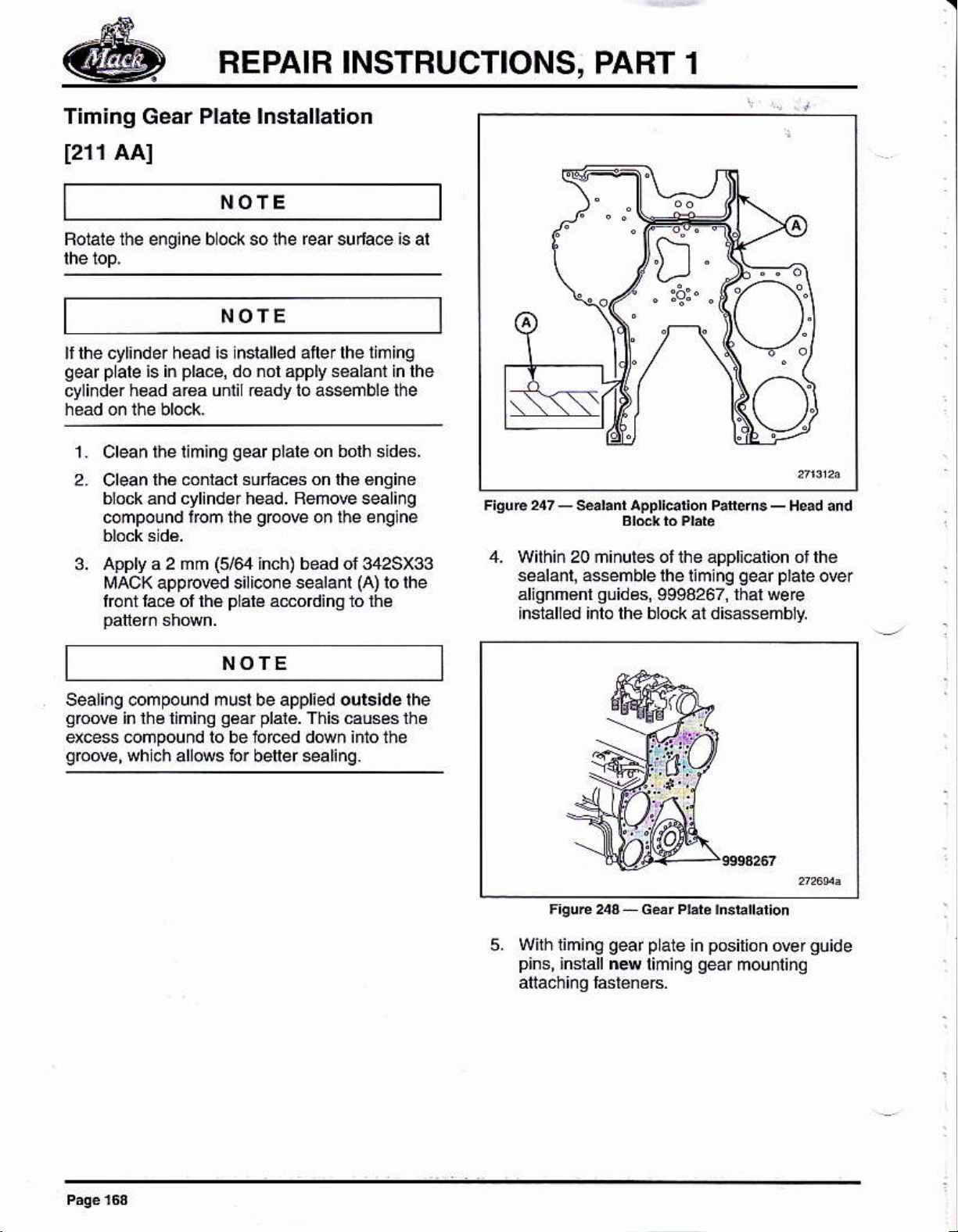

Tim¡ñg

1211

AAI

Gear

Plate lnstallation

NOfE

Roiale the engine b ock so the rear sur'a@ is al

NOTE

fthe cyr¡nder head is lnsralled atrer lhe riminq

geaf plale

cylinder

h€ad ár€a uniil Éády lo as*mble lhe

1. Clean lhe limino

Clean lhé @ñlacl

blockánd cylinde¡heád. Bém@ealing

compolnd fom rhe

Apply

3.

MACK appr@d sili@ne sealanl

lronl laÉ of lhé

i6 in

2 mm

a

pla@,

6/e

do nol apply séáhfn in lhe

qear plale

sulácés on lh€ €nqine

grcoE

inch) bead ol 342SX33

plal€

on bolh sidés.

on rhe englne

(A)

adording lo lhé

lo lhe

4. with¡¡ 20 ñinutes ol ihe appli€iion ot lhe

sealanl¡ assemblelhel¡ming

¿lianm€nl

lnsialied lnlo lhe bloók at disassembly.

quides,

9998267,

gear p¡aie

lhal wee

orer

NOTE

Sealióg @mpound musl be applied ours¡de the

aoM

excess @npound lo be iofced down lffo the

sb@,

in lhe limino

whicn

a[@5 b¡ betersalinq.

oáá¡

plalé.

This causés lhé

Wilhliming

5.

pins.

gear p

inslall n4

ate iñ

liminq

posilion

qea.

@rguide

mounl¡no

Page 5

REPAIR INSTRUCTIONS,

PART

1

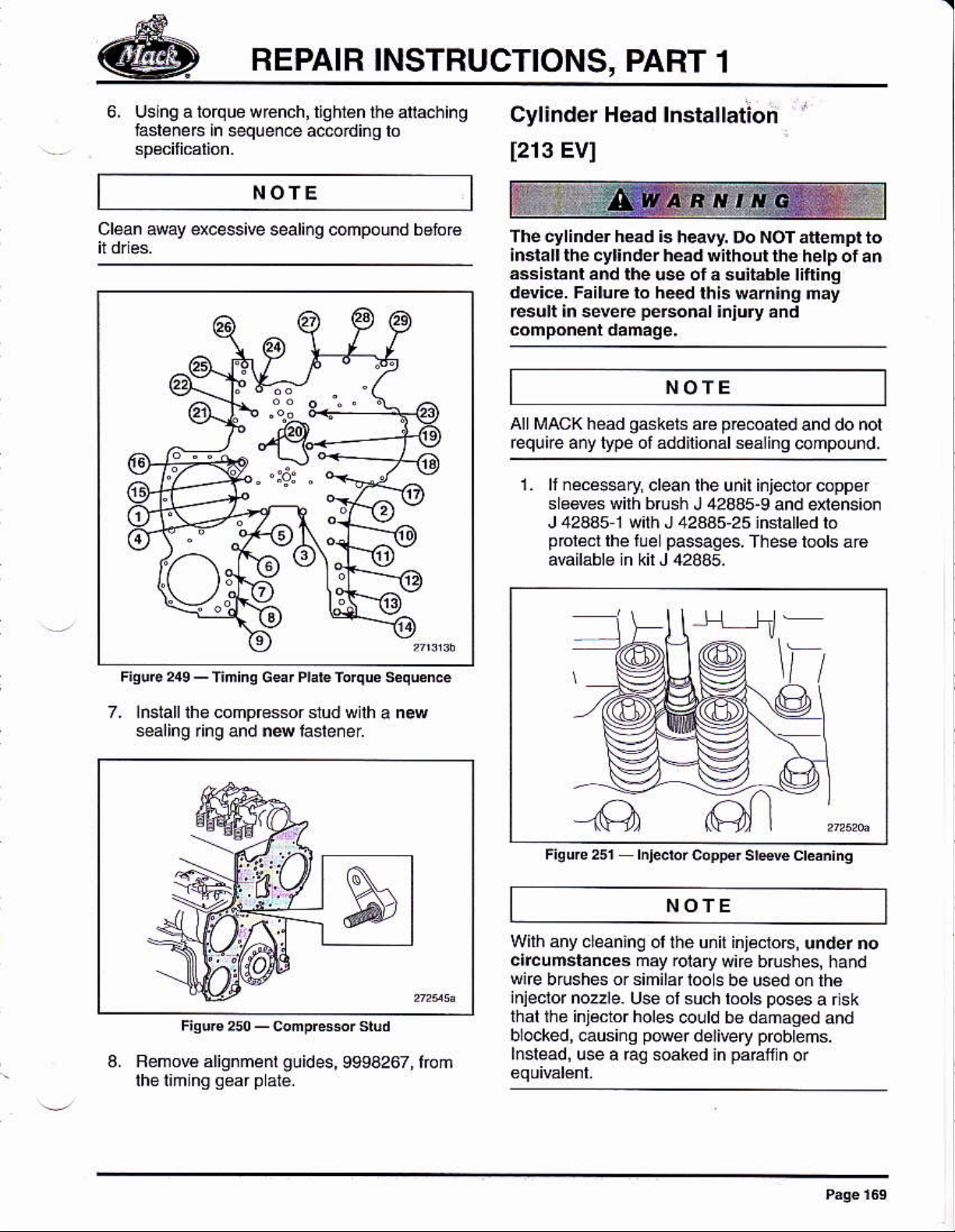

6. Uslng a iorque wénch, tighián

lasléneF in sequen@ ace¡di¡g lo

lhé afia.hing

NOfE

Cl@n away excessive sealing compóund betoré

Cyl¡nder Head lnslallation

[213

The cylind€r h€ad

¡mtatt lñe cyt¡ndér héád wiihout

áasisiánt

dd¡@. FsiluEto h*d

r6ult ln sevée

EVI

b heavy. Do NOT alléñpl to

and lhe us ol a suit¿blé ¡ifi¡nq

thls warnlng may

personal

¡ñjury ánd

the hetp ot ar

NOTE

all lr¡acK héad

g*k¿ts

equire añy lypé ot áddnional s6¿ling

1. lrnéc¿ssary

sle6v€s wilh brush

J 42445 1 w¡th J 42445-2 5 :nslalled lo

pfolécr

aúilábl€ in kil J 4245.

clean lhe unit injetorcopper

lhe fue

paseges.

pÉ@ated

arc

J 428a5-9 and extens¡on

fhess bols á16

and do not

compound,

7. lnslall the compressr slud wnh

sealing ring and n4lasle¡el

a. Rémore alignment

guides,

9994267, Ióm

a

new

Fieure 2sr hj*br

c¡pFr srp{e cr¿án¡nq

NOTE

Wilh any

c¡tcuñsláncea may

wife brushés orsimilarl@s

inieclor

thal the inj¿clor holes

b ocked, eusinq

lnslead, use a Éq soak€d ¡n

cleaninc ol lhé unit iniéctoB,

@lary wúe brushes¡

nozle. Usé ol such rools

@uld be &maged

p@er

delivery

u¡der no

hand

be used óñ th€

poses

probrems.

páEf

a ns k

and

n

or

Page 6

REPAIR INSTRUCTIONS, PABT 1

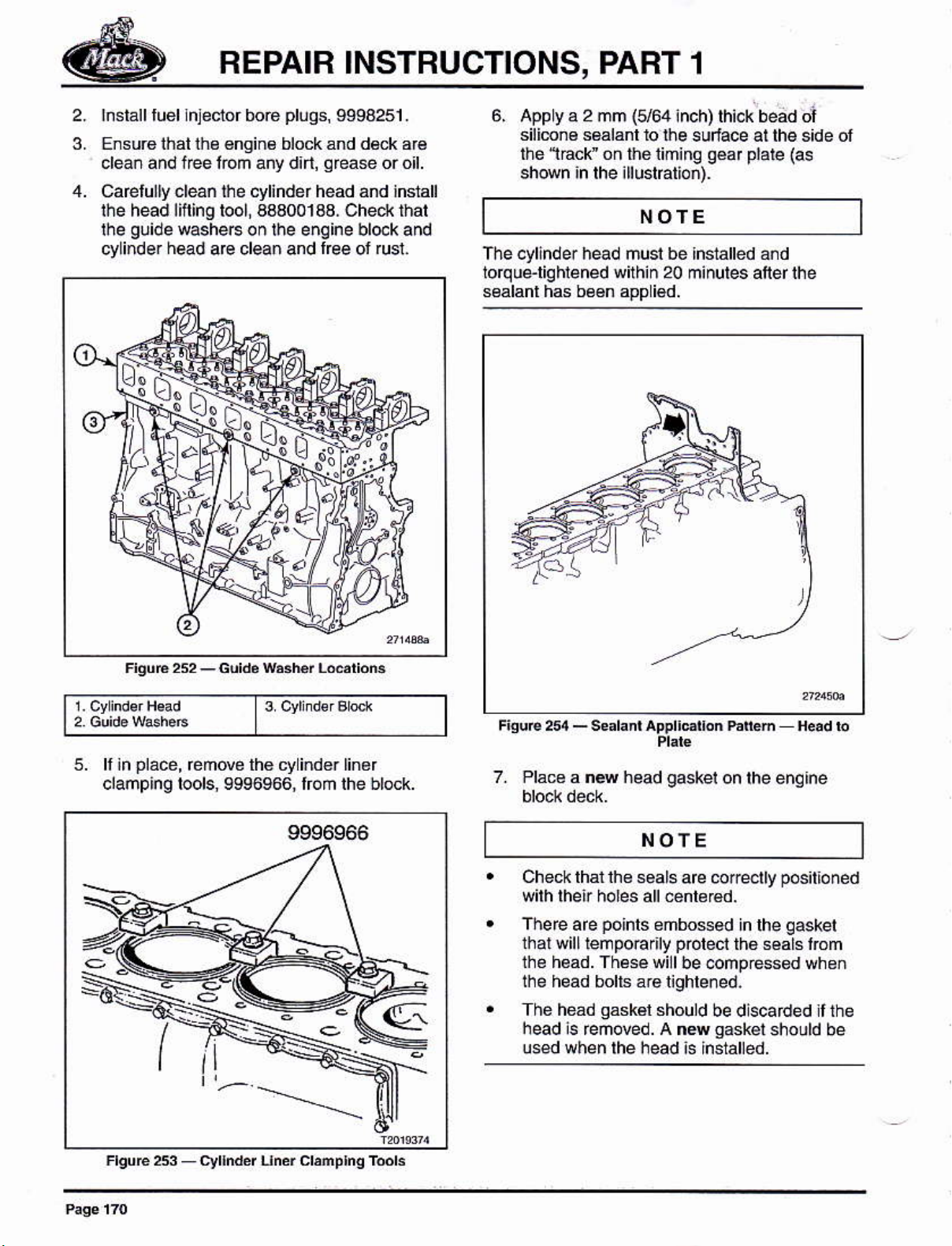

2. lnsiall fuél lnlector boé

Ensuro thal ths €ngin€ block ánd dtrk

clean and iree lom any dirt,

Caelú¡ly ¿léáñ rhe cylindd head and indall

the head lifting tool a3a001aa. ched< that

guide

ihe

cyli.de.

washeF on lhe e¡qine bl@k and

head

aE clean and

plúqs,

lree

9994251 .

qfeae

or rusi.

ffi

*fl3fi

ar€

or ol.

6,

App y a

silimn6 s6álánl 10

thé 1ácr ón thé liminq

sh@n in lhe illuslalioñ).

2

mm

(164

üe sudace at tho s¡de ol

NOTE

Tlre cylinder nead musl be

ioq ue-liq hrened

sealanl hs be6n app i€d.

wilhin

20

¡nch) lh¡ck bead cil

géar plate

{as

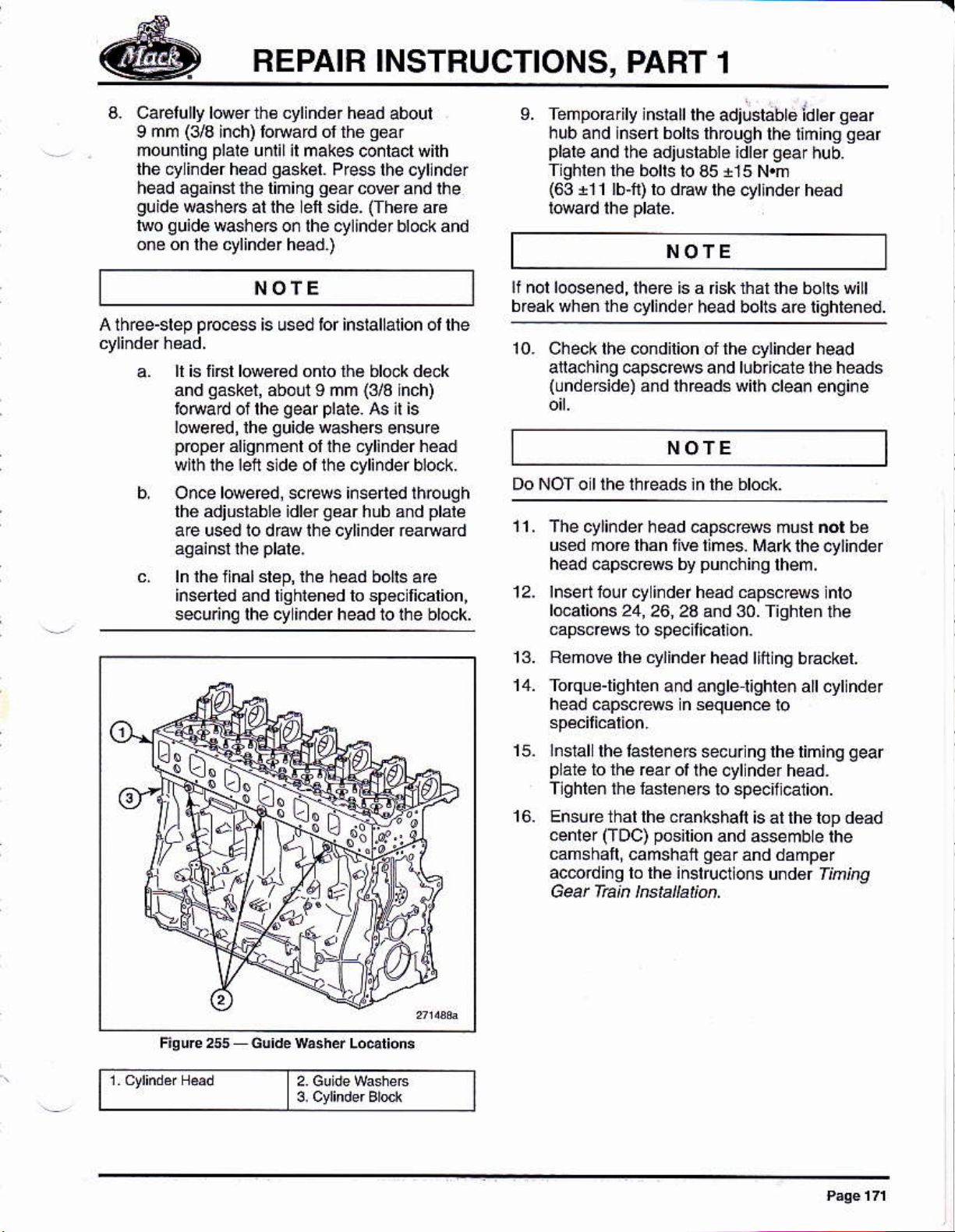

5. ll in

Place,

clañping lools, 9s96966, Iom

éñde thé cy ind€r

9996966

FlquE253_cy[ddln¿rcl,mplnqTml3

FiguB254_€e¡l¿nlApplldl.nh¡MH¿adb

a ns head

gaskel

on lhe enq¡ne

NOIE

Check that lh€

wilh lheir ho¡es all €ñt¿Bd.

There

lhal will lempoErfy

thé h€ad. Th66e wi I

the head bolls a.€ lighlened.

The héád

head is Emoved. A nN

u6ed whén rhé héád is lñ$ánéd

are

seals are coreotly

pohls

gásk€l

embo$ed

polect

be @mpÉss€d wheñ

should

be dlscaded ilthe

sasker

pos¡l¡oned

qasket

in lhe

th6 s€als ióm

should be

Page 7

REPAIB INSTRUCTIONS,

PABT 1

a. Caelllly lowerñ€ cylndér hsd

mm (3ts

I

mou¡ling

the cylind€r h€ad

head againl lhe liniñg

guide

guide

lwo

on6 on lhé cylinder head.)

inch) lotuad ol thé

plale

unlilil makes co¡lácl wilh

gaskel.

washeB ar rhe efi side.

Pfe$ lhe cyllnder

g6ar

corer and

w$he6 or lhe ctlinder block and

ÑOTE

A th@-slep

prcce$

ll is li6l l@e@d onro lhe bl@k dek

qásket,

and

bNad oi rhe

Iowered,lhe

pópd

wirh rhe bn slde ol the cyl¡ndef block.

O¡ce lweed, screG i¡serled lhouqh

thé adiustáblé idlér

is used tor inslallalion ol lhe

about I ñm

geaf plare.

quide

washeB

alignñé¡l ol lhe cyliñdér héad

qéar

a€ used io draw lhe cyliñder Éafrard

ln lh6lnalsláp,lhe head

inserted and tighlgn€d lo sp€cllicalion,

securinq lhe cy ¡rdef head io ihe block.

aboul

qéár

(Ih€f€

(3/3

hch)

A5 ¡r is

ensu¡e

hub ánd

bot6 are

lhe

a€

plalé

L TeñpoÉrry rnsrall

hub a¡d lnsért bolr€

plare

and rhe adjlstábra idre.

Tighléñ lhé

(63

i11 lb-ñ) lo dÉw

bolts b a5 +15 N.m

rhe adjosrablo idr€r

lhrough the lim¡ng

gear

the 6ytlnder head

q€ar

hub.

NOTE

h@d botts aÉ tightened.

10. Check the úndilion of lhé cfinder head

anachi¡g €pscf4s and lub¡l€te the heads

(undé6idé)

añd rh€áds with

crean engine

NOTE

Dó NoT o r rhé rhreáds in thé hr6rr<

11,

The cylinder head cap*rews ñust ñot bé

used ñ016 lhan fi@

head @pscBm by

12. lnsert lour cy indér h€ad capsc€ws

l@alions

mpsc@ws

24, 26, 2a a¡d 30. Tighlen

to specil¡cation.

times. Mark the cylinder

punchi¡g

lhem,

lnto

lhe

qear

ffi

13. Remo€ lhé cylinde r

14. Torque-lighlen

head cap*rews ñ s¿quén.e

lnslal

15.

p

lhe lasle¡e 6 secur ñg lhé liminq

á16 to thá rear

¡ghleñ lhs lásle¡eF

Ensure that lhé c€nkshalt

cenre¡

camshalli

(Toc) posilion

ác6rdi¡q ro ihé inslrucl

a nd angtet¡ghten att cyt ñdé I

oi lhe cyl nder h€ad.

camshail

head llfr ing b racksl.

io

to specifcal¡on.

is át th6 lop d€ad

and 4sembe the

géar

ánd dámper

ons und€r Itnt4g

gear

Page 8

REPAIR INSTRUCTIONS, PABT 1

Camshatt lnstallation

1213

Thé cáñ3hált ¡s h4vy. Do NoT álléñpl to

CHI

¡nsláll lhé cañsh¿ll wilhórd thé hélp ol ar

ássistant or thé use ol a sulable flting

de!¡ce. Falture to heed thls

resut ¡n severe

peBon.l

war¡¡ng máy

injury ánd

ll rcmov6d, iñslaLlthe canshati bear¡ng

saddlesiolhe odginal

lap lhe bea ng saddles onlo

using a soit-la.€d haññé¡ until lully sealed.

lnsenlh6 €mshafi low6r bearings and

2,

appry aceñefous c@1n9 ol clean engine oil

lo lhe camshaí

3,

Make suré

lowér beárlng saddle. The beaf¡ng insefls ai

béarlngs.

lhe¡€ b a b¿áing insrt on each

lhe No. 7 camshat

posilions.

jouhal

Ca€lully

guide pins

th e

haw lnlégEl

6,

lnslalllhe camshai uppe¡ b€aring

iñto lhé.ánshafr bea ñg caps, ¡úbricále thé

inseds

beannls añd l¡siall lhe beariñg caps lo lhe

respeclive bea¡ing saddles. Use a soflaced

mallet tó séal thó b6áriñg €ps d$ th6

lnsen and hand i¡gh1en lhe dhaust slde

beari¡g cap

bolts

and lighien lo

spd¡licalion. Fjnal liohl€nina lo lh€

speil¡ed lofque %lue wlll be done laler

when rhe rccker arm shafi is insralled.

3,

¡¡stallrhe bearing ep

r€qukád) al lh¿ numbér7ánd lhe number

p¡ess

i@r

(1wo

bea ñq €ps ás sh@n in lh8 illuslÉlion.

1

4. C ean and inspect the canshalt usinq

solwnl and comp@sed a¡r

Lower

5

lhe

lifiing lool, 45109034. Folalé lhe

bY hand io énsure tho emshaft is nol

b¡¡ding on the l@er beár¡no saddlés.

ihe camshafl caretully into

lower

bearlnq edd es and €move lhe

place

camshaft

on

NOTE

fhe lootis used when adlústing thétimtng

backlash when

lhe ocker shafi assembly is ¡ot

g€ar

Page 9

REPAIR INSTRUCTIONS,

PART 1

Timinq Gear Train lnstallatlon

NOfE

Apply á liQhr coal

DO NOI ovdlightú thé Mlkg awé

lastenets when instalkg añy ol the

t¡n¡ng

qeat

ol clean engine oil lo all

^caurroN

géaÉ

tak. oveñjgl,ten¡ng the hstaets

an @M sriwad fh@ds i¡ lhé ct4indd blúk.

1. As*ñbl6 á r4 o dnq on lhe chnkshafr

2. Apply a l¡lm ol ol io lhe O ring and ssemble

lhé chnksháí

Leaw two fáléneÉ lo6e

luming lhe cEnkshatl wilh

gáar

on lh€ c€nkshal hub.

NOTE

pa¡ts

ln the

3. Assembb rhé adiusrábré i¿b;

Figurc

and laslereG

3.adjGbbre dsGs

260), hub, bushins, lhrusl washer

plate.

Hand llohi€n lhé

adlus* rd!¿r &ár

ráñden Puñr

t6

FisuE e

o¡ the

-

I Gd,

7.Af

|

hec<f D,ñe

b@loem

Df 6

3 in

FiguÉ259_cEnk3hliGsrlaHubtrséñbly

4,

Chéck l¡al lhe @mshatl is

posilioned

at

Page 10

REPAIB INSTRUCTIONS, PART

1

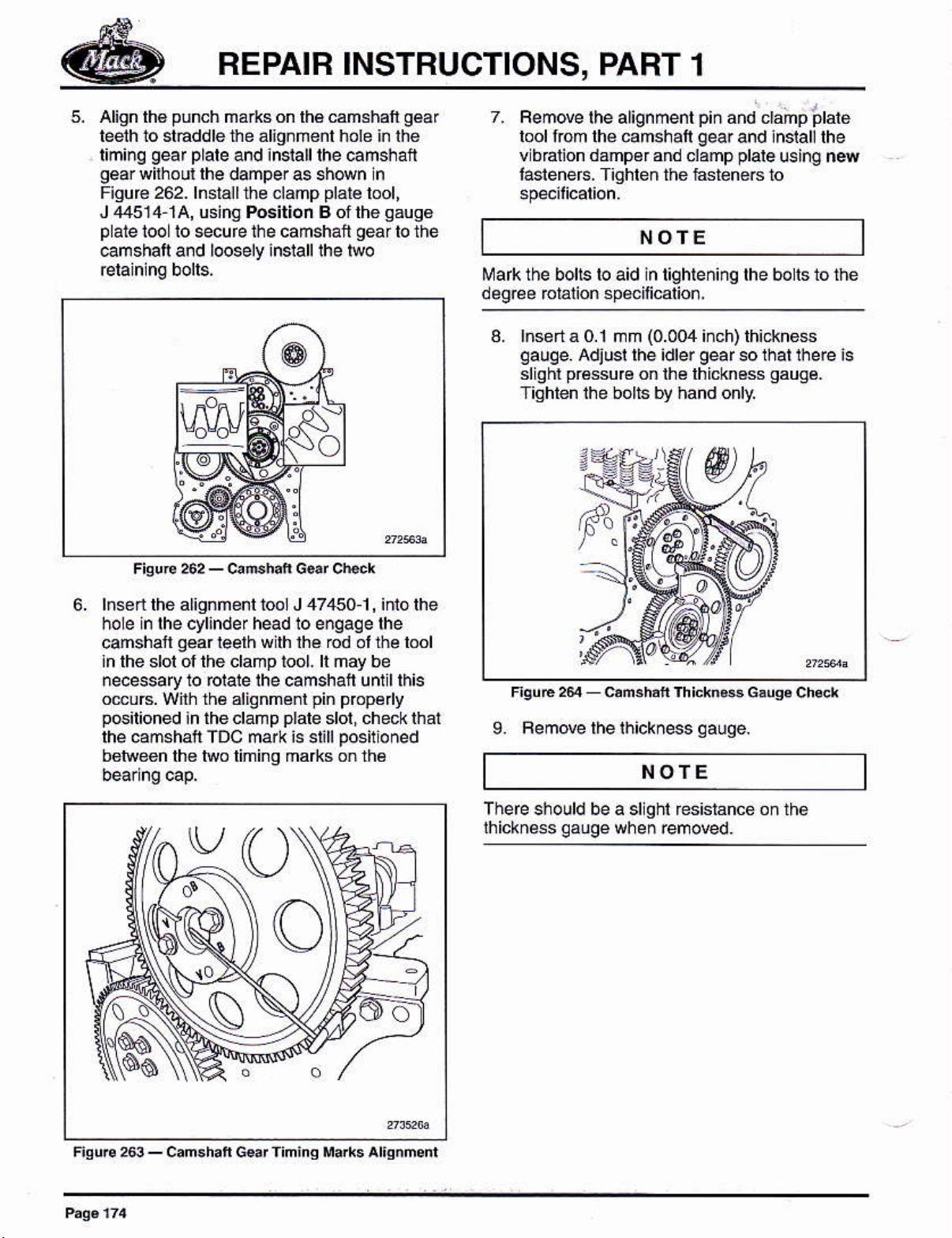

Align lh€

leeth 10 sláddle the al¡gnmenl hole in lhe

riming

gear

Figur€ 262- lnslall

J 4451,1-1?\, using f¡ositior B of th6

p

ate 1oo lo scufe the camshait

punch

geaf plare

wirhoú lhe

márks on lhá camshaft

and inrallrhe camshan

peras

d

1ie

clamp

shan n

plate

geá¡

géa¡

lool,

gaugé

to the

úmshalr and loosely inrall the rwo

7

Femove

lool from

v bdl¡on dampgrand clamp

lasleners- T¡ghlén thé lastenec io

lhe aliqnmenl

camshatr

rhé

pln

¿nd cl¿mpplare

gear

and lnsrall rhe

plale

using n4

NOfE

Mafk the bolrs ro aid ln righrening rhe borts 10 thé

degr¿e rclalion

a. hselta0.1 mm

gauqe.

slighr

Tiqhten ihe bolts bV hand onht

sp&ilicalion.

(0.004iñch)thickhess

Adjur rhe idler

pr€ssu€

onlhé lhickn6ss

geaf

so thar thele is

gaugé.

6. lnsed the alignmenl lool J 47,150.1, iñió lhe

hole in lhe cyl¡nde r hed 10 engaq e lhe

cúshatl

in the slol of the clamp tool- ll may be

necessafy to forare rhe camshafr unul rhis

gear

omuB. Wilh lh6 alignménl

p6ilioned

lhe camshail TDC mark is sl¡ll

¡n theclanp

bo¡reen lh€ lwo limi¡g mafts on lh6

¡eelh

w lh lhe ód

pin prcpé y

plale

sloi, checkihat

po6ilioned

l¡e lool

ol

9. Femde lhelhickness

t'¡oTE

a sllghl resislance on th6

qauqe.

F¡4uÉ263_can.h¡fG.¡l'in¡iqlla*s^liqnmnl

Page 11

REPAIR INSTRUCTIONS,

PABT

1

10. lnslall the J

thé timang

asainsl ¡¡a

adluslablé idl6r

'V66

,1451,1,5

oear

adjusrab e idler

plate-

q6a¡

clamp

S6re the hotd-down

doés

asémbly tool 10

gear

s the

nol rctaie.

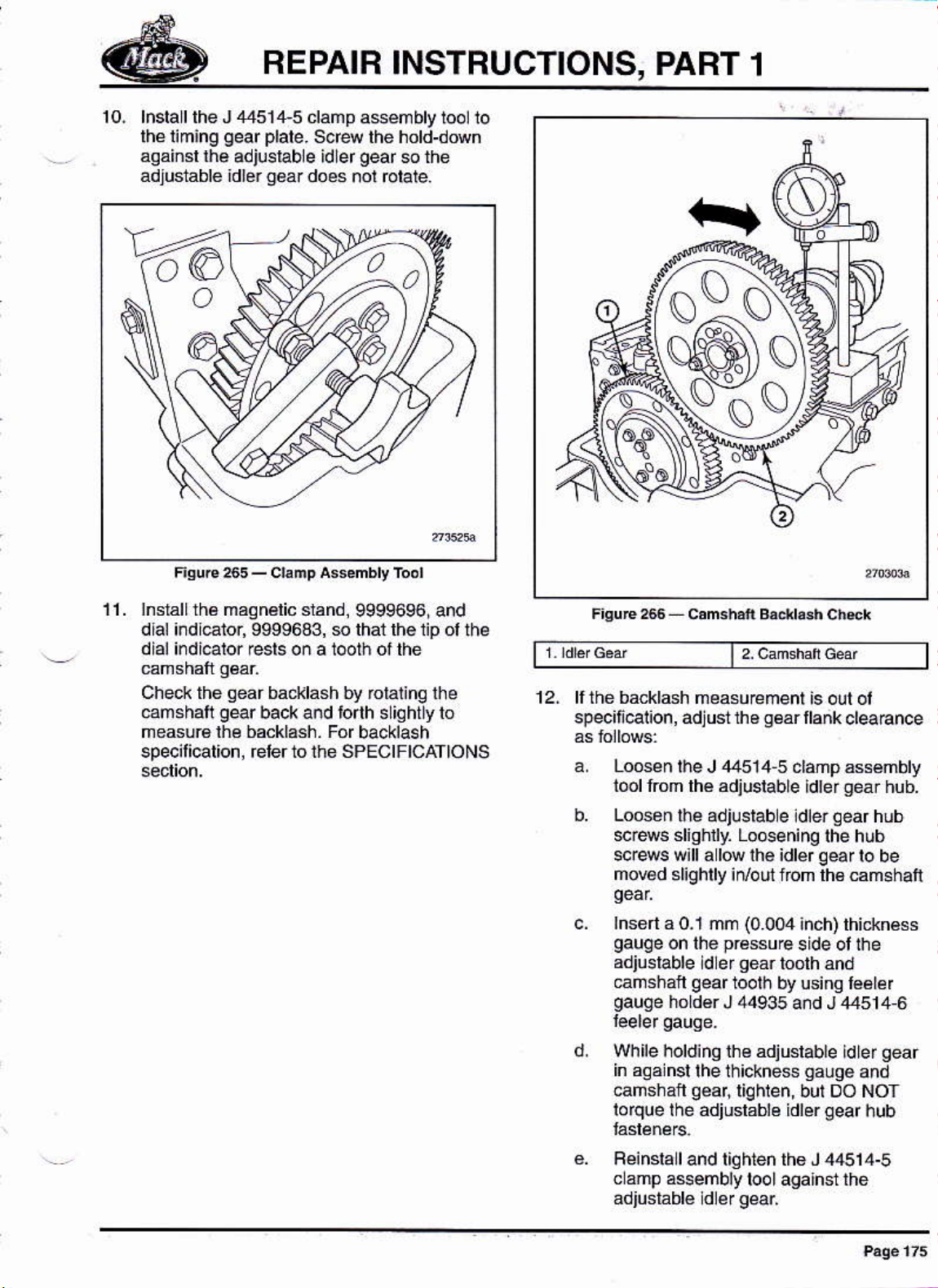

11. lnsrallrhá maqnálic sránd,

dlal i¡dl€tor, 9999643, $ that lhe 1ip ol

dial irdi€lor resls o¡ a 1@th ol thé

Ched< the

@mshati

measuÉ lhé backlash. For

specilicatton, éler to ihe SPEctFtcATtoNS

qear

bacJilash by rotalinq lhe

g€r

back and torrh s iChtly ro

9999696, and

backlash

th¿

12- ll thé backldh

specif@lion, adjust th6

Loós¿n

iool rrom rhé ádjustable

Loossn

lhe J 44514 5 ddp ássémbly

r¡¿ adjustab e ¡d¡er

$r4s slighlly. LoGening

sc@s w¡llalúihé idlérqearlo

mov€d

¡nsert

gauge

adjusrable

cañshafl

gauge

Wh ile holdino th€ adjuslable

in aoa nsl

ۖshaft

lorque lhé adjuslablé idler

slighlly irvoui nom lh€ ám6haÍ

a 0.1 mm

on lhe

hóldér J 44935

measurement is olt ol

llank

sۇr

(0.0er

prássue

qéár

ld er

qear

toolh

loolh by using lۇler

a¡d J

the th¡ckne$

géar,liqhlen,

cleaBnce

gear

ldrer

Oear

the hub

inch) thicknése

side ol the

and

,t4514,6

ld le r

qauoe

but DO NOT

ged

hub.

hub

be

gear

and

hub

Fein6lall and tiqhien th6 J 44514-5

c 5mp a$embly

tool against the

Page 12

REPAIR INSTRUCTIONS,

PART 1

I Remove thé leeler

adjustabe dler

g.

Fecheck

spécilied b@klashallained¡ repla@

6ach adiuslablé idlér

with ns and lighlen the scrows to

spe¡licarion one ar a rime so rhe

anained backlash is nol d¡slurbed.

lhe backl4h, Wilh lhe

gáuq€

gear

and camshán

aear

13. rnsiarlthe inrermediare idle¡

gearsel

(2)

to lhe timing

gear plare,

from lhé

hub M.ew

(double

idLer)

us

nq

15,

Tiqhten lhe inlemediale

ér)

id

mounl¡ng bo¡ls in seque.ce to

seá6ál

(doutlé

16. lnslalllheauxiliaryidlergearonlothétiñino

17. Bemovelhobea

45109204.

Unit

1221

lnjector lnstallation

GPI

og

cap

pre$

tools,

NOfE

€used, il

1. f not

pr*

sleeve, J 42435-25, a¡d clean the unll

injeclor mppér dé4é

ously

pericrñed,

wilh

musl

be lited

insla I

lhe

app@priale

lo lhe

prol€clive

FisuE 2t rnkrdúr. ¡dr$

|

14. Checklhalnté idlér

the markinqs on the crankshafi

gearmarking

(eude

6 r eñtumpDre

rdre4 G¿'rd

allg¡s with

leelh.

oeár

ir

Frquc te uñn hEdor

Afér cleaning

the inside sulace ollhe

bonom sulace wh6ré lhe injeotor

Any

¡emainir

and musl bé

indicaton ol a discrepancy

aboul súlabilityoflhe sleere lor réuse,

lhe @pper deM, carelully inspe.t

g

contaminalion is u

removed. Also, if lher6 is any

coo@r sreeve creaninq

NOTE

sleeve, espécs ly lhé

seat is ocaled.

na.ce

lhal ra¡ses conceh

olabte

repta@ il

Page 13

FEPAIR INSTRUCTIONS,

PART 1

Betore

rsquiréd to

Berc're doing ar'y c éaning, rhe injelor

inlel and oullel

connec¡or opening musl be covered lo

prdé¡l

pfo@ss-

¡¡sialled ¡n lhe lnlecior Relérto'uNlT

INJEoToF oLEANING'on

3.

Ren@ lhe boe

9S94251.

FiquÉ 270

1 uni¡ lnlsdo' Prcrdion

Busing añ i.jector, cle inq

€nsure suilability tor éuse.

ports

ánd lh6 el€crical

dnlminarion lrom

Also, lh€ré musl

proieolion

Unft rn¡dor Borc PEr€dion sre#

-

lhe cl4ning

no Lower

be

pag6

deM,

lr.'rnirlnlebeE

js

tuel

o{ing

244 lor

0

FsuE 21

Somé ea

orjginal design copp€r déms with iniegEl

y pbduclion

laised bead ar rhe bonom or rhe copper sr66vé.

rhis désign doés NOT

between lhe ¡njecior tip 5nd the

These oriqinal Eised¡ead d6lon copD6r

sledescan b€ idénrir

gbove

The curent

@pper sle4esi wh¡ch reqúi€ me

sásher) ár lhé

lwo

al all around ih8 upp¿r circumie¡ence,

prod

groov€

áround th¿ uppér circunle¡en@

hFdor Nde G*H

ÑOTE

MP3

engines ced lhe

gaskel

use a

@pper slewe,

ed by a single

uclion 'flal-botom'

gask€t (llat

iniécrór rip¡ can be identmed by

washeD

llat

groo@,

design

orno

ol

4. lnlallñ6w O{ings on lhe

.

Upper nnS larSé dlamelor, viol¿l

.

Lower ring smalldlañ6i6r, violál

Lubr¡€¡e

5.

inj¿cror boré wilh

hstarr a ñe inieclio¡ noz

washer)

push

seated againsr lhé bofiom

NOT

secure lhe

ñust bé inslalled

pojections

ot lhis

boih Ojlngs and fis cyl nd¿r head

clean eng¡ne o¡1.

on the i¡jéclor, usinq hand

il

@. lhe l¡p and down uñii it is fully

géas6

use

gaskel

or any olher

gaskel

(srippé6)

to lhe ¡¡jetor the

dry Three sñal

on rhe inside dlameler

rctaiñ il to ih€ injéclor during

injecloras

unil

gaskel

e

ot the injecror Do

{ital

lorce to

nale a¡ lo

gskér

F¡sur€2 copF.

srd.

tshwn

¡snmd ror

Page 14

BEPAIB INSTBUCTIONS,

PABT 1

NOTE

A rwied

rubber maling for impMd séaling was

implemenled ln

2003. Serul.e replacement

rubber coaling, DO NOT remove lhe rubber

The

g4kel

qaskel

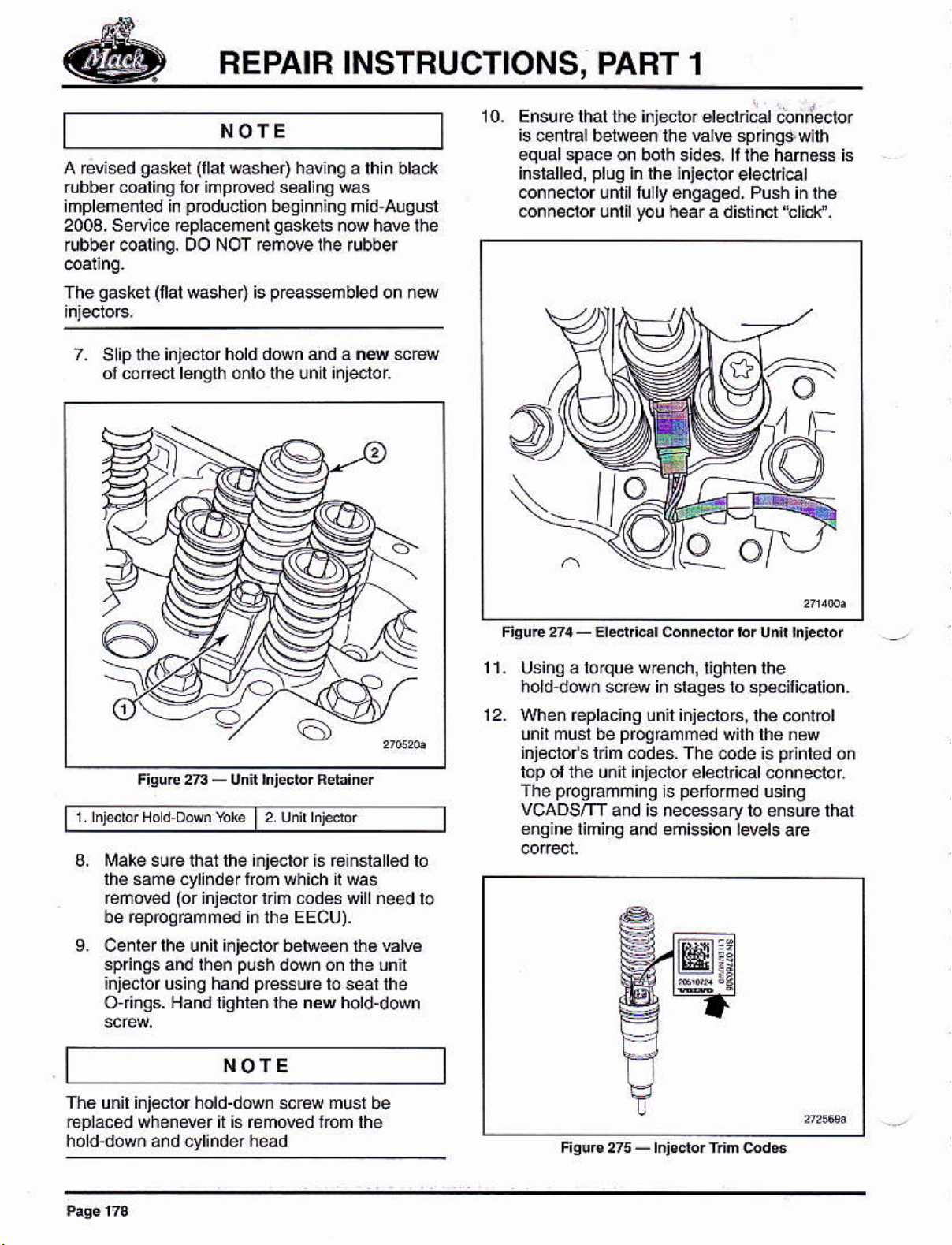

7, SLip lhe injécior hold

of cor€ct l6ñoth oñlo lhe lnll ¡nieolol

pbductlon

(llal

washer) is

(llal

washeo havinq a lhln blac(

begln¡lng ñld-auqusl

qaskels

p€assembled

d@n and á n4 srew

n@ have ihe

on new

10. Ensure rhar thé i¡jdtor érécld€r

is @ntEl betreen thé hh€ springd

€qual

@nnector únlll tully enqag¿d. Push in

space on borh sides. ll rhe hañess is

insiállod,

@nnec!o. unlil

pluq

in lhé ¡njecior

you

electrical

hear a diliñct'tlicl\¡.

o

@nllecbr

wilh

the

Fiore2n-Unft ¡nidorRd¡iner

1 nltuf Nod DM %k

Make sue that lhe inletor ts einstatted lo

same cylinderfom

lhé

reñóred

be rep@gEmmed h ihe EEcu).

Cenler lhe un¡l ¡njector ben@en tha Elvé

9.

sp nqs

inj¿clor using

O rings. Hand lighlén lhé nil hold-down

(or

inieclor lrim óds will need

and rhen

hand

2 udrhFdr

I

which il Ms

plsh

down on the lnf

pre$¡re

lo seal lhe

NOTE

lo

Fioue274-Erd c¡rconn*brbrunnh,¿dór

11. Using á lorqué

hold dowñ scéw in daqés to speflicarion.

12_ When Éplacjhg lnil ini€clo6,

unil musl be

injécro/s ldm

lop olthé unit injector élécl

prcgrammi¡O

The

vCADSm

8ñqiné limina

w€nch, l¡ghlen lhe

lhe @nlol

prcqrammed

@des, The code is

silh lh6 .s

plnled

cal.onneotol

péfom€d

ls

and is ne@ssary lo ensub lhál

and emission levels aé

6inq

:3

:E

on

Thé unil ini€clor hold-down

roplac6d when€vér il is rcmMd l.om lhé

hold doM áñd cylinder head

scra

musl

be

Fisure ¿5

rnjedq frm ed6

-

Page 15

BEPAIR INSTRUCTIONS,

PART 1

NOTE

Due to the Enginé El&lronic

(EECU)

nemssary

PaÉmetórs

enq¡ne ielaled mmponents.

EECU lo leárn the nd @ñpon€nts

behavioi After sedcinq ¡s coñp ete,

pelon

ll rBinstallinq an in¡eclor inlo lhe sané

ocatioñ, rcprooámm nq is not Équned.

sell learn¡ng Épábrity, it is

lo es1 ¡eahed EECU

aftér s¿ruicing

lhé "L¿a¡néd Dala

Cónlol Unit

some

This dlM lhe

Fesef

13. Fepear rhe insrallarion sreps tor the

valve Yoke

t213

NVI

(Br¡dqe)

lnstallalion

NOfE

l6ated

in

yokes

tüáke sufé rhal

Rocker Arm

on

rheir rcspeclive úd€

lhey afe

Shattand Engine Brake

lnstallat¡on

[213

LPI

1. Oillhé vál€

2.

Using lhe lilling toot, a5109250, and an

Gsislanr,

posl¡on

yokés

placé

on ihe inboard sido ol lhe camshaft

and lh¿ camshaÍ

lhe

shall

wilh fockef

NOTE

enq¡ne bÉke, ihe exhaust

an inleg@ ulve

pbpery

lobes

arms in

pisron.

and

yokes

Uséd

Yokes belng returñed 10 seflicé musl bé inslalled

in lhe

same cylinder ¡ocalion lroñ which they

1

, Lubri€le ihe ilp ol a valve stem wilh a small

dop olc éan éngine

2. LubriBr6 lhe

ol clean e.glne oil¡n each o¡e.

have éslablishéd

oil.

yoké

so.*ets with a smatt drop

wear

patterns.

Fsu,€22 Fodersh¿fi

a*ñbthdár'dór

t,

3. Femo@

tlghlen lhe mker

lime, *dy across lhe

lhe

tüake sur€ lhal the rocker

pfoper¡y

béai¡gcaps.

ongin€ bEké, ¡em@

bands oflie slaps) secufi¡g

lhe titling bot. Then,

arm shatt boils á Inb

shail does nol bmme dislórred bént .r

NOTE

arm shan is sealed

guide

ln ihe

On engines equjpped wilh

dowels

lhe fesiáinls

IDB

Fódef

a*mb y

shar

i¡statt and

enti€ shatt so thal

ol the oamsháft

an

(rubbef

lhe exhaust Mker

al a

Page 16

REPAIR INSTRUCTIONS, PART 1

7. Torqué-lighlgn and

camshaft beadng €p añd óckér

anqle-lighlen all

an

shal

bo[6 in sequence a@rdlno 10 spédfcaton.

NOfE

The bohs have llmired reusabrr¡g and must be

(A)

ma¡kéd

iñslalled i¡ sedice. Bolls wilh lour

when remNd he been lighlened live i¡mes

wilh a

punch

áách limé lhey

punch

ae

márks

Lub.icalé lhé ó.k€r arm bl é8.

lnsen

5,

F¡gúre 279) lhóuqh the shafl, camshan

bearing cap6 and

üe bng

lasleneG

inlo

(Nos.

lhe ctlinder head.

8-20

in

g.

Feplace

6nsine b@ke

eno¡ne báke) oro now adaDier

lhe O{lng al the botlom ot lh€

conrrcl€@

(¡f

equ¡pped w¡rh

NOfE

On eñgines withoul th¿

adapter is used ¡¡

is mounlád in

head ánd is installed

enqine b6ke cofrtrolvdB in sléps S rhrough 13.

fhe

adapler

the eme localioñ on lh€ cytinder

p@¡des

engine bEke, an o¡t ltow

place

ol the oil mnl@l valre. lt

in lhe same mannerasthé

oll to the bckor

shaft-

Page 17

REPAIR

INSTRUCTIONS, PART 1

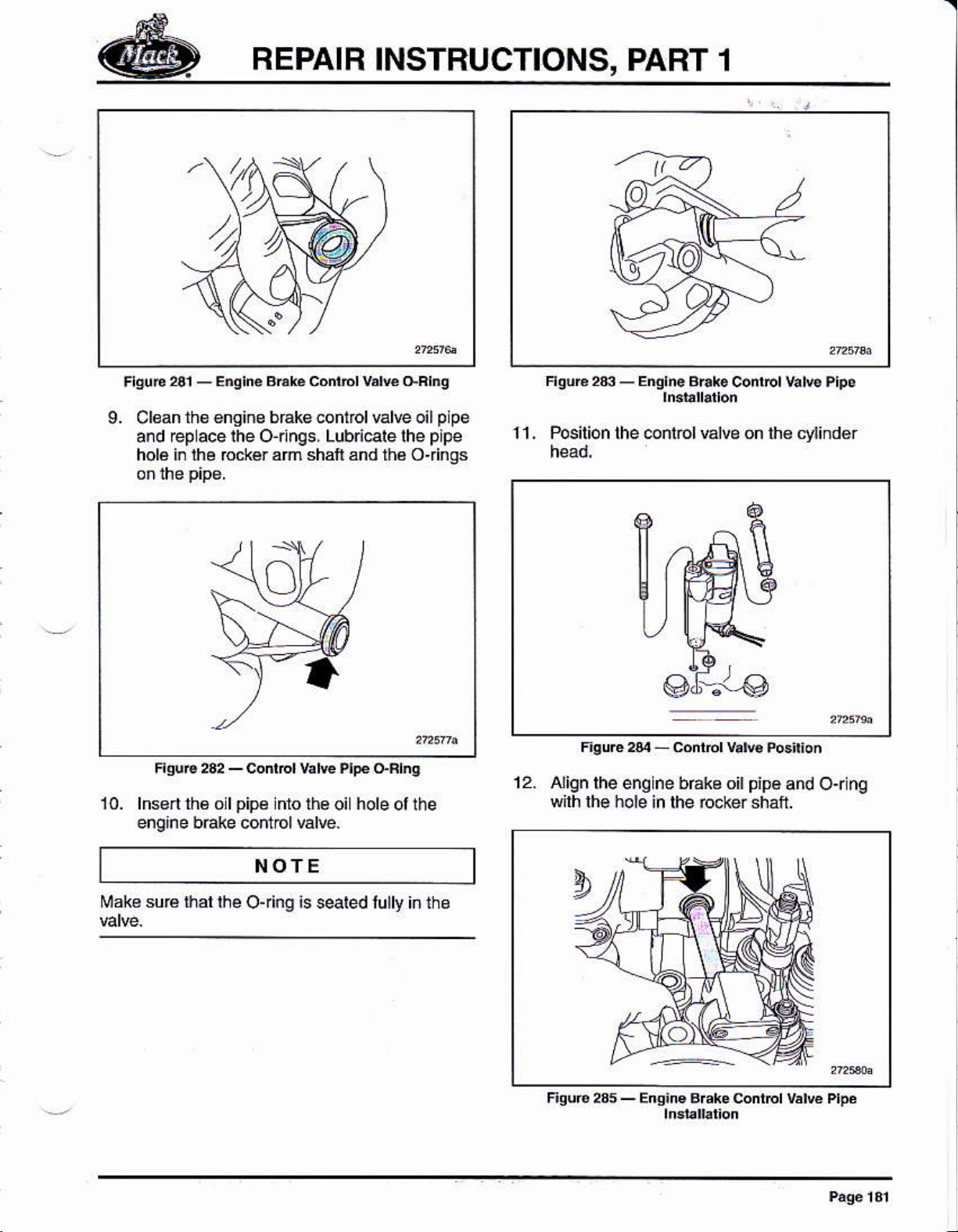

9. Clean

aód @p ace lhe O-nngs, Lubn@le lhe

holá i¡ lhe b.*ér am shaii and lhá Oiings

l0- lnsn ñ6 o lpip€ lnlo lhe

engine bÉke cofrtol valre.

ths €nsins brák€ control valÉ oil

holeollhe

oi

NOTE

plpe

pipe

1 1 . Pos¡tion lhe @ntol válvg on lh€ cylind€r

12.

Align lhe englne bÉke oil

wilh lhé holé in rhé ró.i€r sh.fr

pipe

and Or nq

Mak6 suÉ ihár lhe

Ojing is s@ted lully iñ ihe

Page 18

REPAIR INSTBUCTIONS, PART 1

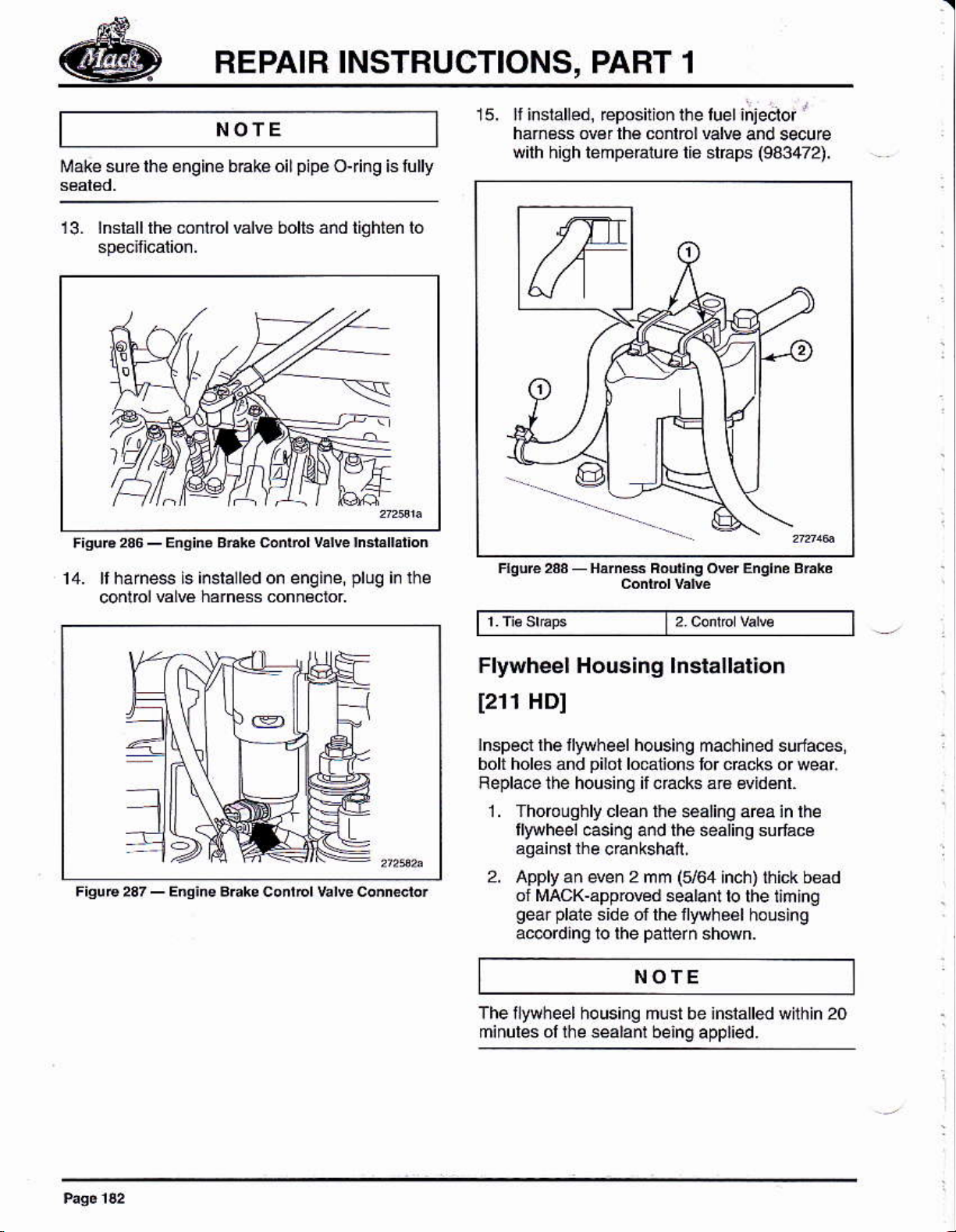

NOTE

surerhe enqine bake oil

¡¡ak€

13. lnsrállrh6 mnlrolválve bolts añd tighten lo

pipe

ojing is

lully

15. ll

inslalled,

hám€ss ov€r lhé conlrol vdre

qilh

high lehperature tie stráps

eposition rhe

luel

injecior

'

and secure

(943472).

14. rrharnes isinsralledon enqine,

conlbl

EIE harnéss conn€cror

plug

irlhe

Flyürheel Housing lnstallat¡on

f211

lnspecl lhe llyrheel housi¡g

bolt hole! ánd

Feplace the housing il .acks á16 widénl.

HDI

pilot

lo€1ions

1. Thoro!

llywheel

aqáinsl rhe

2. Apply

ol MAcK-app¡owd sealant

gear plaié

ac@rding to the

qhly

clean tho sealing a€a

€sinq and the sealinq suláco

crankshall,

an even 2 mm

side ol the fyrheel

patterñ

ma.hi¡ed suriáces

cEcks

lor

(164

inch) lhick bead

to the liming

or wear,

in lhe

holsing

shówn.

NOTE

The llywheel ho using mu st be inslalled whh in 20

minules

ol

lhe

sealanl

being appl¡ed.

Page 19

REPAIR

INSTRUCTIONS, PART 1

NOTE

F¡q!rc2s9_Flwt¡élfi.Gi.qs€al,i'Ap.ljolion

NOfE

Be

sure lo apply beads oi salanl around the

holos in the bo$6s ás sh¡M inthé

qEphic,

li ihe enQlne Msorg

gear

idler

bé u

bolts, lhe llyNh€61 housing may need

pdaled

lo block l¡re dler

plugandw6herfrcm pluq

followinq

prccedu

nally buill wllh lhe onger

qear

boll hole w lh

kii21090322. Uselhe

ré lo thr€ad lhé hole

a. Using a 3/4 16 UNF x 11.5 lap, lhroad

lhe hol¿ indicáled in Fig!re290,

b. Apply lh€ad locling .ómpound

(Loclrle@

üreads ol lhe

c. lnÉerr rhe

ro spécilicalion.

2z or €qu €len1l

p

uq,

plug

wirh washef and tiqhren

and

ro

rh€

to

a

nslall

femporari

llyryhee hoLs¡ng

y

irstall

glide pins

in lhe l$o lower

mouding holes i¡lhéliminq

3. Wlhin 20 ñinuiés ol lhe application ol lhe

séalanl,

the

4. lnsrl and hánd-t

Femow the te

a$emble the tlylvheel h ousinq de r

quid8

pins

ín lh€nminq

ghlén

the á¡aching

quide pins

plale.

oéar

áñd inslalt lh€

bolls.

5. Using a lolqu¿

bolls in sequ€nc€ ac@din

Femove any ex€s

6

lnsIalllhe limi¡g

7.

housing bohs

wrench, liqhten thé atla¿hinq

gear plate

(ilem

NOfE

llem

1 s€úés lh6

pump

h6m 3 smures

ilyryheel housing and

i¡slallálion inló thé chassis

mounling

and is not insia

lhe rear engine mounl lo lhé

g

lo specif .a1lon.

sealanl.

to the iywheet

2 in

Figúre 291).

powér

sleering and tuet

led al this

will be instalt upoñ

Page 20

REPAIR INSTBUCTIONS, PART 1

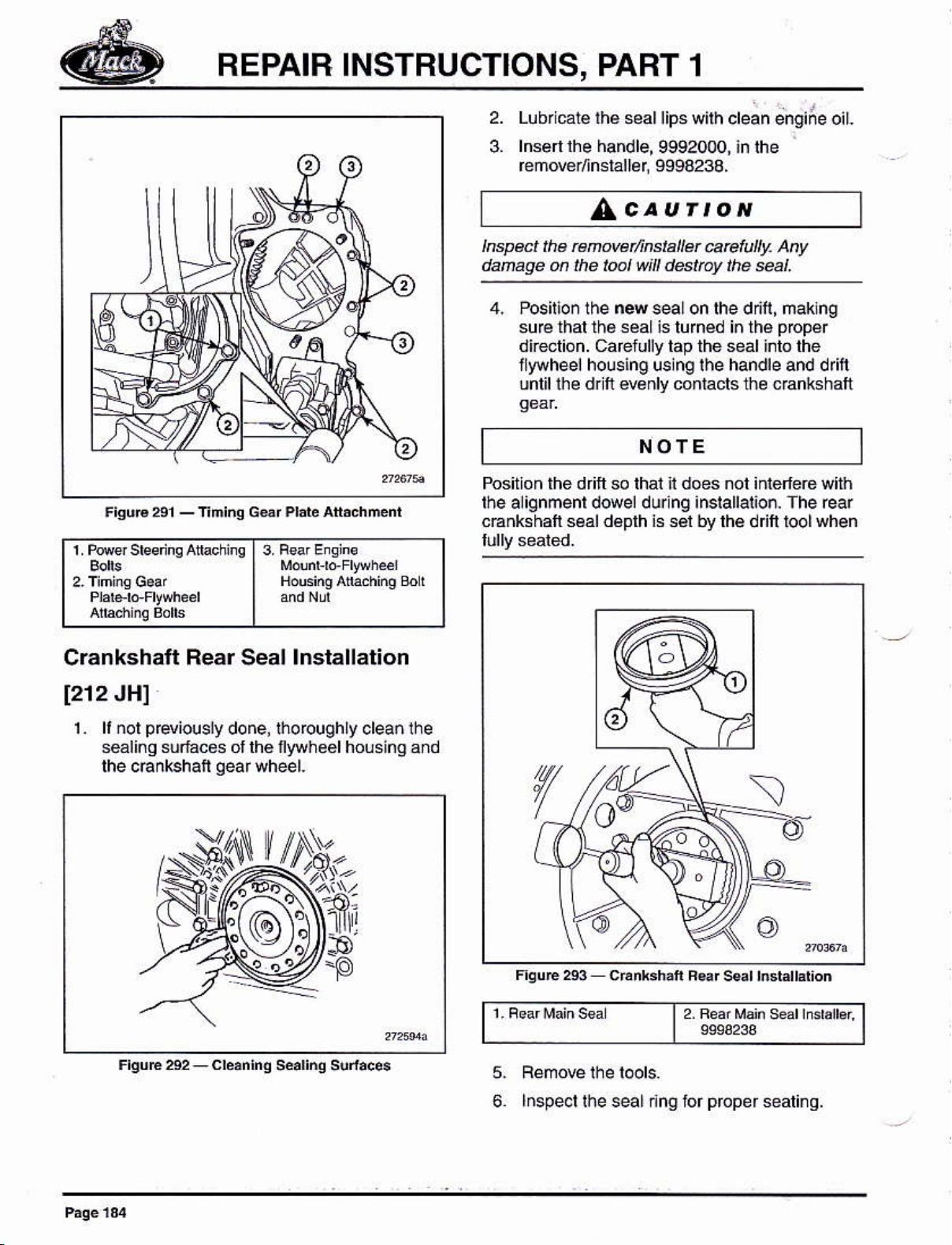

Lubricaté lhe seallips

2.

wilh clean engiÁe oil.

1 Pore¡ sbs'inq Aturrinq

BsarE¡qhs

13.

Mdún, ro Fr!}hel

I

ándNú

|

lnsenlhe handle,

3.

f emover/inslaller 9994233.

9992000, in lhe

AcaurloN

|repe.x lhe rcnNét/¡rstalü

@elully.

datuae ú lhe loal \|¡I d4ttay lhe ffi|.

4. Posilion lhe n4 seal on lhe dn'f, mak ng

sufé thal thé séaL !s luméd i¡ rhé

dkelióñ. cafelully tap the seal into lhe

llyohe el housing uslng ihe handle and d ritl

unlil lhe dr fi e€nly conlacls th¿ cEnkshalt

NOTE

Position the drift so lhat it does ¡ot iñierleG with

rhe alignmenr dowel durlng insrallarioó. The rear

cEnkshaft seal déplh is sél by lhe

d l loolwhen

y

At

pppér

Crankshatt

[212

JH]

1. li ¡ol

sealinq súlaces ol lhe Íyryheel housing and

lhe cÉnkshaf

Rear

p

€viously done, lho

Seal

qearwheel.

lnstallation

rough

ly clean lhe

5.

lnspecl

t2

lhe seal inO ior

Féáf Mañ s¿ar

proper

sealinq.

mratb.

Page 21

FEPAIR

INSTBUCTIONS, PART

1

Flywheel and Pilot Bearing

lnstallation

1212VCl

AcaurroN

AtÍerre ¡fackg,

balance hol6 ón tÉ ctutd1 Bida @]JJ¡6

rcbalañ¡ns by a Mch¡he shop.

vehicles

On

üansmiss on, il may bé néc€ssary 10 insláll

dllferenl componenls lo ihe fywheel relalnlng

hsleneB Feter io lhe Automalic Tbnsmi$¡on

D vé Arsngeménl Assémbly lnslruclions¡

1.

Clean lhe sulace in lhe

flywheél li6 llush ágái¡st lhé c€nkshafi

anyíy hel úth dt¡¡led

NOTE

pped

equ

w¡lh an aulomallc

pla.es

5-902,

where lhe

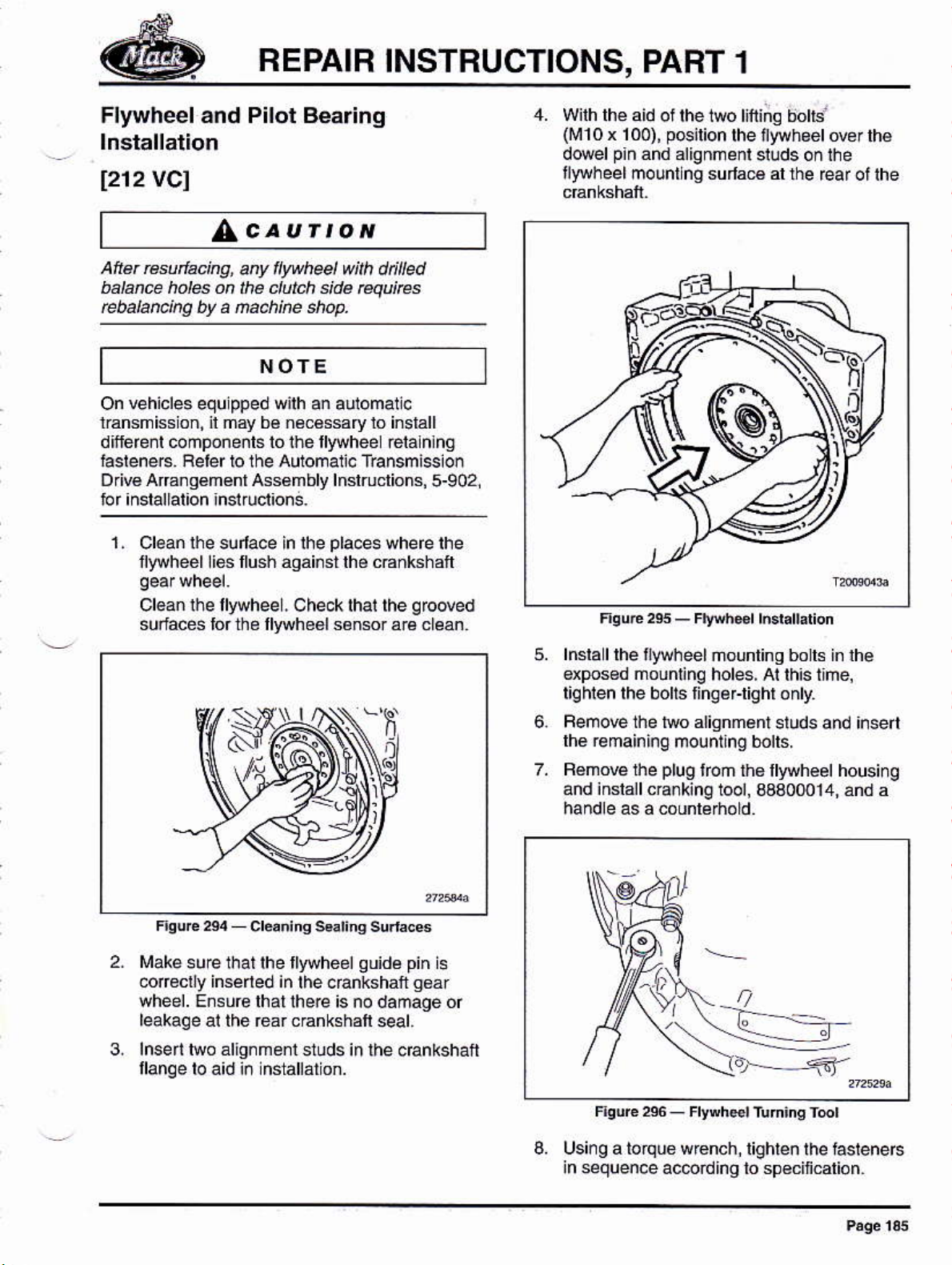

4. Wilh lhé

(rü10x

dowetp¡n and atignment

f'ryheel mountlng surla€ al

aid of lhe 1wo lifiñg bohs'

pcirion

100),

7

rhe iyvhgérowr lhé

studs onlhe

the ear ot the

\+

)

Cl€an rhe tlywheel, Ch4klhal lhe

surfaces lor the llyuh66l sénsor ará cléan

lüake

su€lhallhe fywheelguidá

@fecl¡y inséled in

wheel. Ensure lhalihe@

leakaqe ai thé éa¡ canksháft seal.

3.

lnserihro áliqnmenl

llanqe to a¡d ¡ñ nstattátio¡.

lhe eEnkshafr

is no damaqe of

sluds in lhe oEnkshan

qroded

pin

i6

gۇr

Fqué 2es

lnsla I

dposed mounlinq

liqhlen lhe bolts liñg¿Flighr only,

6.

Femove the two alignmant

lhe re

BémoE the

and inslall cE¡king1ool,

lhe ¡ywheel nounling bo ls in lhe

main ing mou nting bolts.

F¡Éh*r

-

holes, Ai lh¡s t¡me,

plug

lroñ ths llyryhéel housinq

I

ó,--5'

r.d.lldioñ

studs and ¡nsert

3aa00014, ánd a

8, Using a to¡quo w€nch,

in sequence ac@rdino

Page 22

BEPAIB INSTBUCTIONS, PART 1

,AcauÍtoN

Do tut ¡lghten aqa@nt úM seq@nüatty.

Dokg@@nre

Fa¡luté to h@d th¡s

¡t ¡n meven lwee¡ allgnñút.

@ut¡@ @n @lt ¡n se!ere

@

plug.

n{

cEnking

pllol

lool, lnsérihe

bearing in lh6llywhoel

9.

FemoBlh¿

Using lool asembly, 9991S01 and 9992564,

inslalla

AcauÍtoN

Fot lh¡s eng¡¡e, llo shap ing ¡s Eqúircd on lhe

pilot

b@ n9. Do Nof subs¡¡tute

lhal do nal beat lhe @tred

awliB¡ion. Fzilute tc, h@d ds aú¡¡on ñay

Esu¡t k sete ens¡re danase.

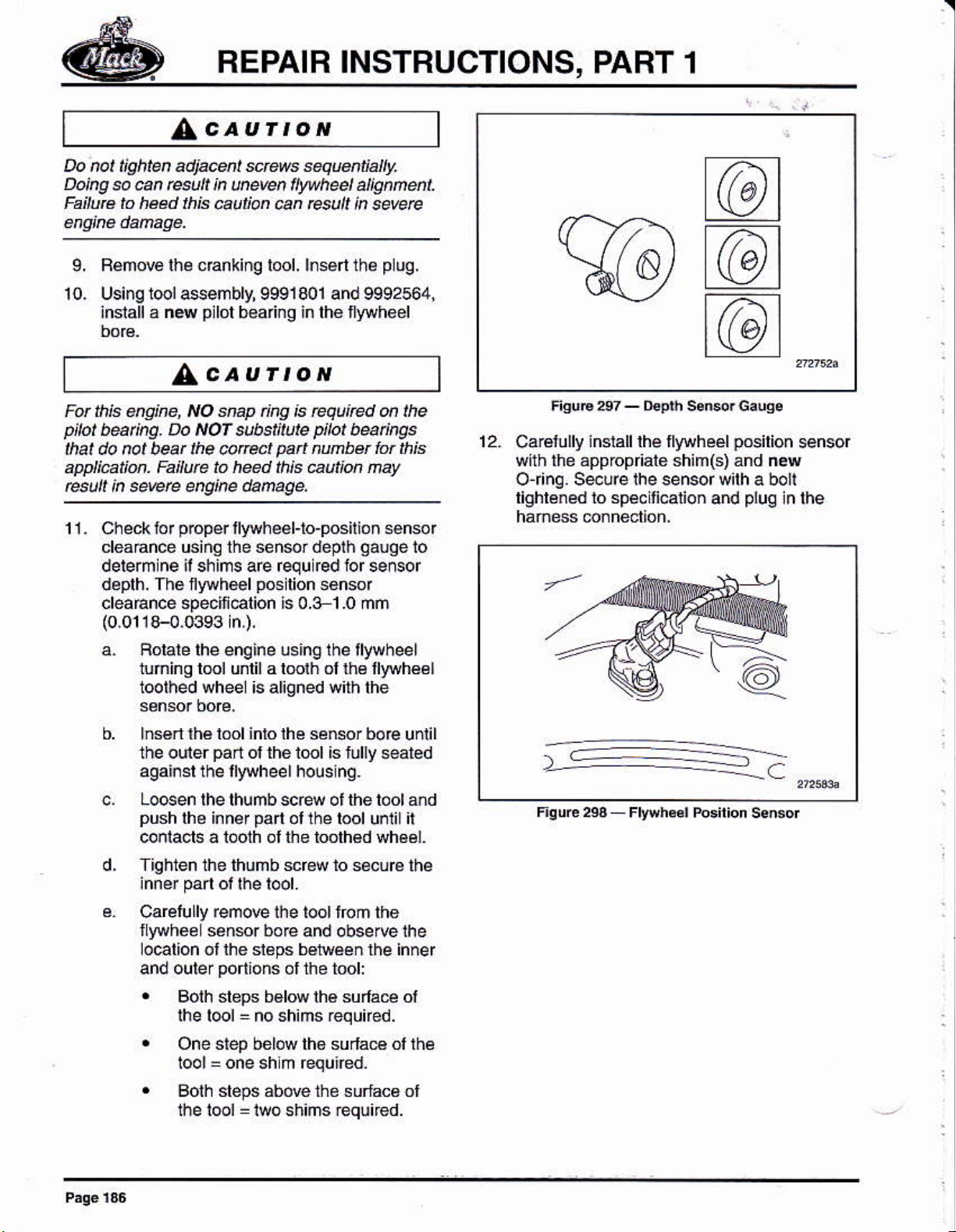

11.

éck

Ch

cleadñcé using the sénsrdelh

delermlne ¡l shims are ¡equ red ior sereor

déplh. Th6 nywhel

cleaÉnce specii€l¡on ls 0.3 1.0 mñ

(0.0118-0,0393

to r

p@pér

llywh€el-lo-positió

pos

n,),

a. Boiare rhe enqine using the lllrvheel

tuñinq lml unlil a lmlh ol ths fwhéél

loolhed wheél is al¡gned with lhe

p¡bt

pan

nunbü bt ¡f'¡s

lion sonsor

b@n@s

ñ senso r

gaooe

lo

@

t@t

FisuF 24

12.

Cárélully

with ihe approp ale shim(s) and new

Or¡nq. S@ure the sensor with a boli

lighléned io spécmcaion

-

jnslalllhe

@'

llywh éél

s€No. Galsa

and

pósilion

plug

sensor

in lhe

b. hs6n ú€ bol inro lhe sener

the ouiér

asainsr the llywheel housinq.

Locen lhelhumbscÉw ol the tool and

pushlhe

conlacls á toolh ol lhe loolh€d wh6¿1.

Tighten the thúmb screw to sécurc

Ca@lully remow ihe lool irom the

llywhoeL sensr bore

ocation ol fte sl6ps béiween rhe inner

and outer

.

.

.

pa¡i

ol the i@l is lully s€ated

inn¿¡pa ót

portlons

Bolh steps bdN lhé suffa@ ol

Ihe l@l

One step bélow th6 surlaÉ ol rhé

Iool = one sh m Équiéd.

Boih slePs abó@ the surfac6 ol

the l@l : iwo shiñs reqúúed.

no shims ¡equned.

=

the lool unli

and observe the

ol the tool:

bo@ until

il

lh¿

Page 23

Pan lnstallaiion

Oil

BEPAIR INSTRUCTIONS,

PABT 1

I21r

NBI

lhe

(0.079

llyvhee¡

plale,

inch) wide béad oi

houslngand lhel¡htho

Alsq appya 2 mm

1 , Apply a 2 mm

lrAcK-apprcred s€lant ar thé *ams

be¡reen

g6ar

mounling

(0.079

seams belweeh thetmlng

plale

inch) wid€ béad ol sáálánl al rhe

and lhe enqine bock.

Aeár

mounling

3. For

plasl¡c pañ

pan

seal inlolhe

Check thal the séal lo@lnq

prcperlyáliqned

holeson

lie mounÍnqfanqé.

appli.alions, ¡nslá I rhs oil

gb@

and seal€d

ol the ollpañ.

tabs a€

jnrh€

locali¡g

2. Applv a 2 mm

MACK approled sealant lo lh€ seam

belwéén lhé lro¡l seál ¿over ánd the blo.k

(0.079inch)

bead oi

Page 24

REPAIB INSTBUCTIONS,

PART f

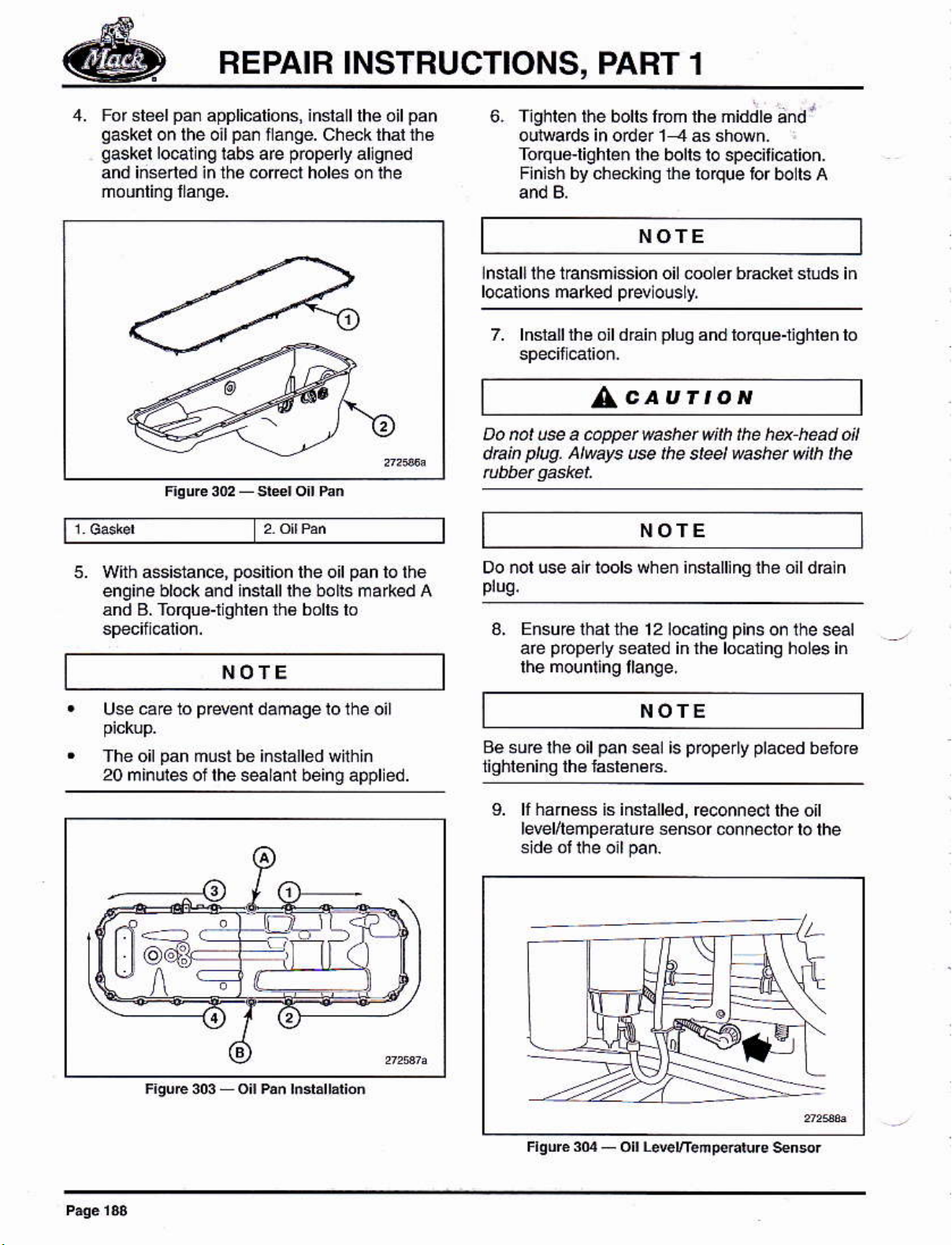

4. For steelpan applicalions, inslalllhe oilpan

qaskel

qaskel

iñsened

and

on lhe oil

lo@1

pán

ilange. check thal tha

ng labs are

.or¿cl

in the

properly

hds on lhe

allgned

6. ¡ghreñ rhe borrs lóm lhé mid;b

dd

l

oul@ds in oder 1 -4 as shówh-

Torqu&lighle¡

Flnish bv ch€ckino the loque

rhe bolrs ro specillcatióñ.

tor bolts A

NOTE

lnsiall lhe tbnsñission oil .oo 6r bEckér studs iñ

l@arions marked

7. lnslalllhe oil dráin

prwlously,

pluq

and lorqué-nghlen lo

LcauÍtoN

Do not u@ a @ppet washet with

ptug.

dta¡n

At$ys

u@ the steel

NOTE

5. Wilh assistance,

engine block and ¡nsrallrhe bolrs ma*ed A

ánd B. Tofquo-r

pGitbn

qhl€n

the of

rh6 bolls lo

pan

NOTE

ca€

Use

The oil

20 minules of lhe sealanl being appled.

Q)(

pr*nl

lo

pan

must bo iñstallod wilhin

damagelolhe oil

to thé

Do nol use alr lools wheñ inslallingihe oild€in

3. Ensurá

popery

aré

rhal ihé 1 2 localinq

seabd inlh6l@alino holes in

pins

on the seal

NOTE

aé suré lhé

oil

pan

seal is

L lf harnBs is inslalled, reconnect

level/leñpe¡alure sensor mnñe.lor

properly pláced

lhe ott

bslirr€

lo lhe

Page 25

REPAIR

INSTRUCTIONS, PART 1

Oil F¡ller P¡peand D¡pstick Pipe

lnstallation

1 . lnsla I a nw O r ng on lhs oil lill lube ánd

inslalllhe

lneallrhé oilfi

tube to lhe s¡de oftheollpan.

lrube lasrenerc and rlghrenlo

2. lnstall a new O dng on lhe dlpsnck tube,

rhen nsrall rhe iube and secu fe wnh lhe

laslen€r lnsláll rhe dipslick.

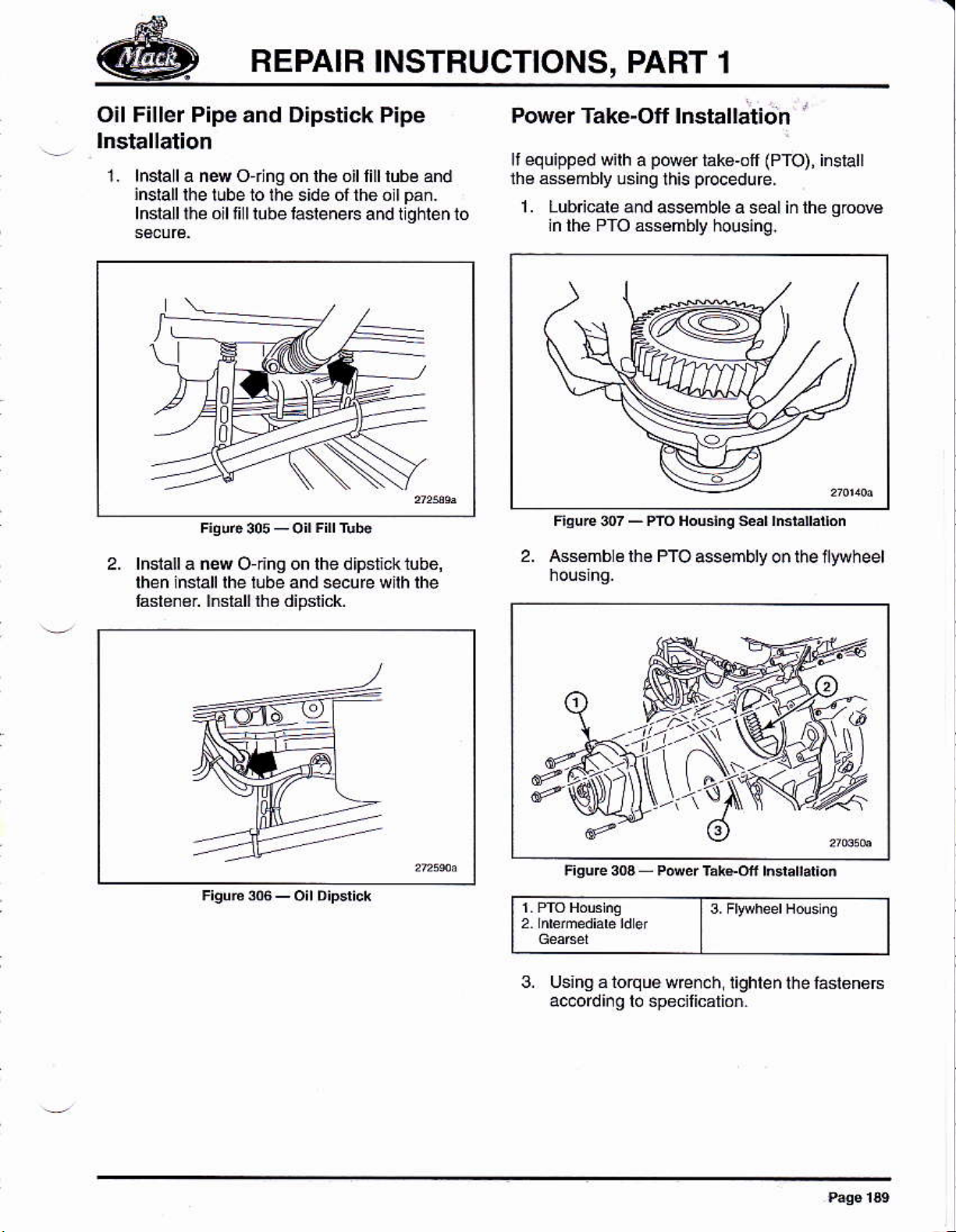

Power Take-Off lnstallation

equipped

li

the asámbly

1 . Lubicale

ln the PfO ássémbly housing.

wilh a

2. ¡Gsmb ¿ lhe PTO

ptuer

lsing this

and Nemble a seal iñ lhe

iakg'off

pbcedure.

ssembry o¡ the llywheel

(PTO),

'

inslall

qrcM

3. Fwheer Hds nq

3. Usingalorquewrcnch

ac.ord ¡. o lo specilicalio¡.

lighlen lhe lasteners

Page 26

REPAIR INSTRUCTIONS, PART 1

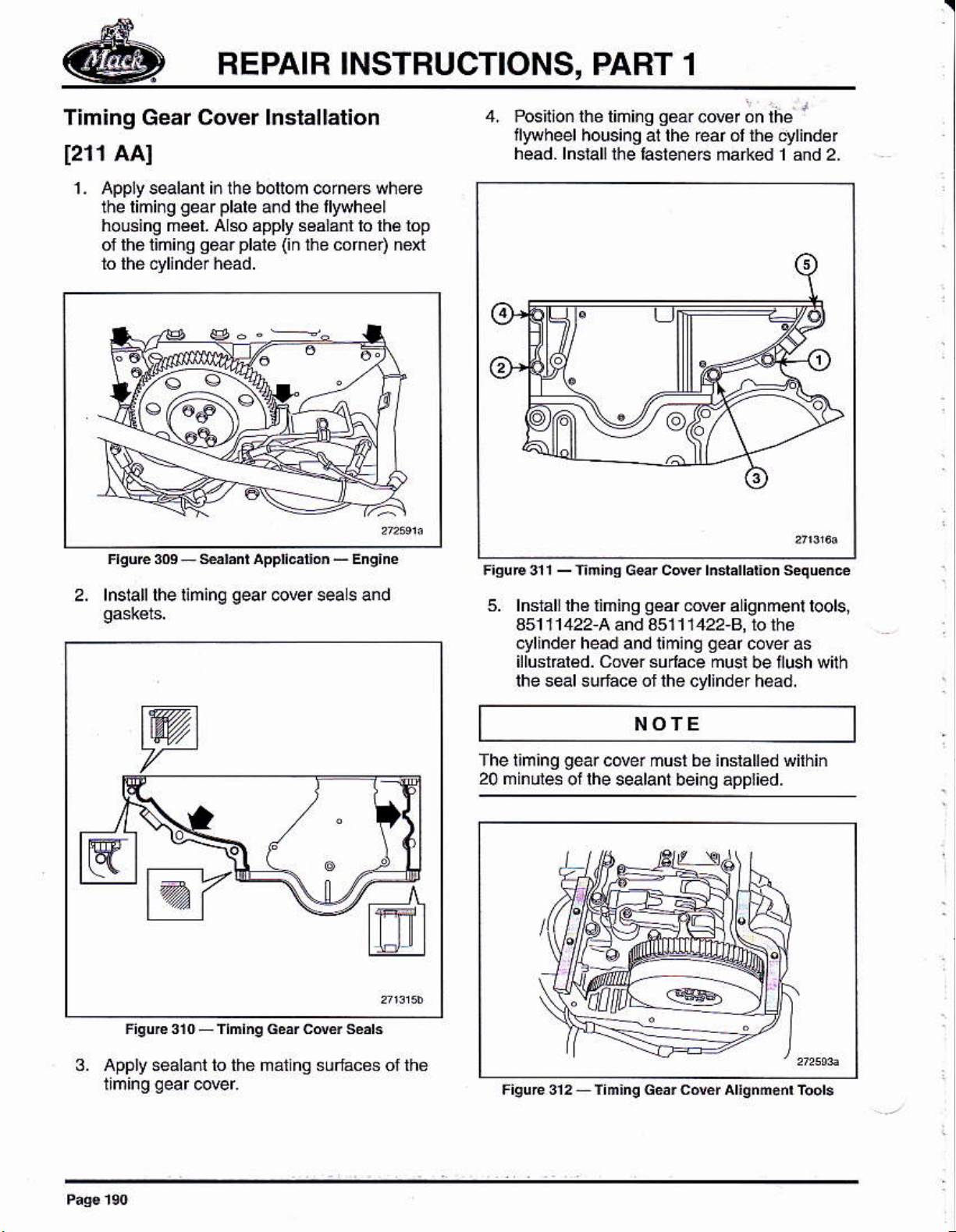

Timing Gear Cover lnslallation

1211

AAI

1 . Apply sealanl in the botlom corneÉ wheÉ

the limirg

houing mééI. Als apply s6ala.l lo lh6 lop

of th6 liming

to thé cylinder héad.

gear plale

geár plale (in

and lhe llywheel

t¡_Le corner) next

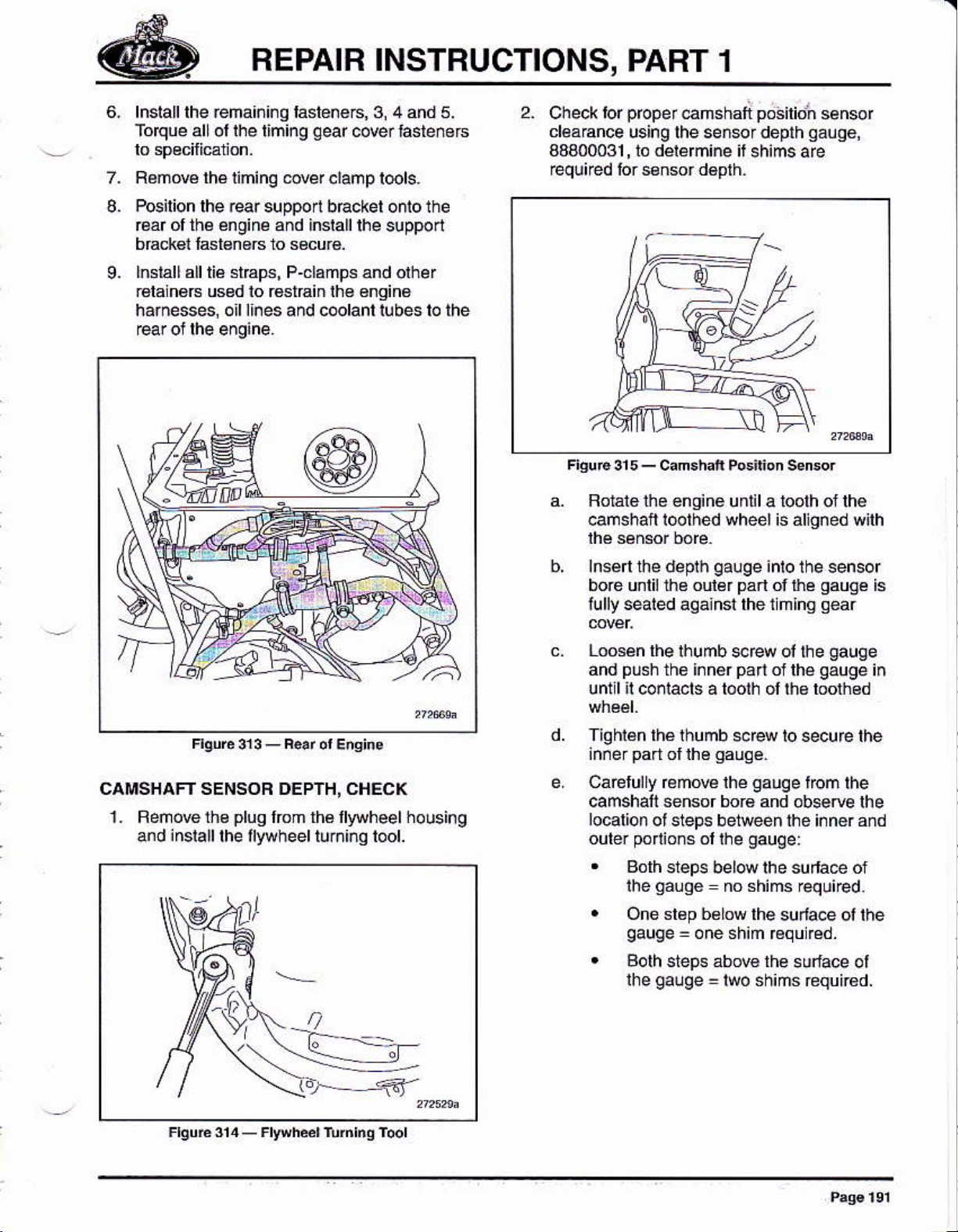

4. Posftlon ihe liñi¡g

go¿¡

cowr on

fyvheel housi¡g al the rear ól th6

héad. lnsiall rhé f¿sré¡eE márkéd 1 and 2

I

lhe

q/lindér

2, lnsrall rhe riminq

qeaf

@Er sea s and

5. lnstall lh€ nming

451 11422 A and 351 1 1422-8, to lhe

cylinder

illusrral€d. CNér suda.e must

lhe seal sulace of lhe cylinder head.

head

qéar

órer

and liming

qed

NOTE

fhe liming

20 mindes

gear

cover must b6 inslalled wilhin

ol lhe sealant bei¡q ápptied.

ignment

a

cover as

be l¡ush with

toolsj

3. Apply sealáñt to the matlng súóces of the

Page 27

BEPAIB INSTRUCTIONS,

PART 1

lnslalllhe fema¡nl¡q faslené6,3, 4 áñd 5.

Toque all ol rhe liming

Rémów lhé liming

Posilion

8.

Éár ófth¿ énginé

lhe @r supporl brackel onto the

gear

cMr lasten6rs

@@r .lamp l@ls.

inlalllhe

and

supporl

brrck l l'srsnáB ió s¡.x¡.

lnstallalltiá sl€p3. P-clampl

9.

¡6lain€B Esd lo r6slrain lh€ €ngin6

harnesses, o¡l l¡nes and c@lanl lubes lo lhe

and olher

2.

Check tor

cléa€nce

43400031,ló délBñiñe it

required lor ssn$r déplh.

prcper

using lhe senerdeplh

a. Fotát6 lhe éngine

@mshai i@thed wheél is aliqned uilh

enshai

unlil a loolh of lhe

póaito'n

qáuqé,

shims are

sensor

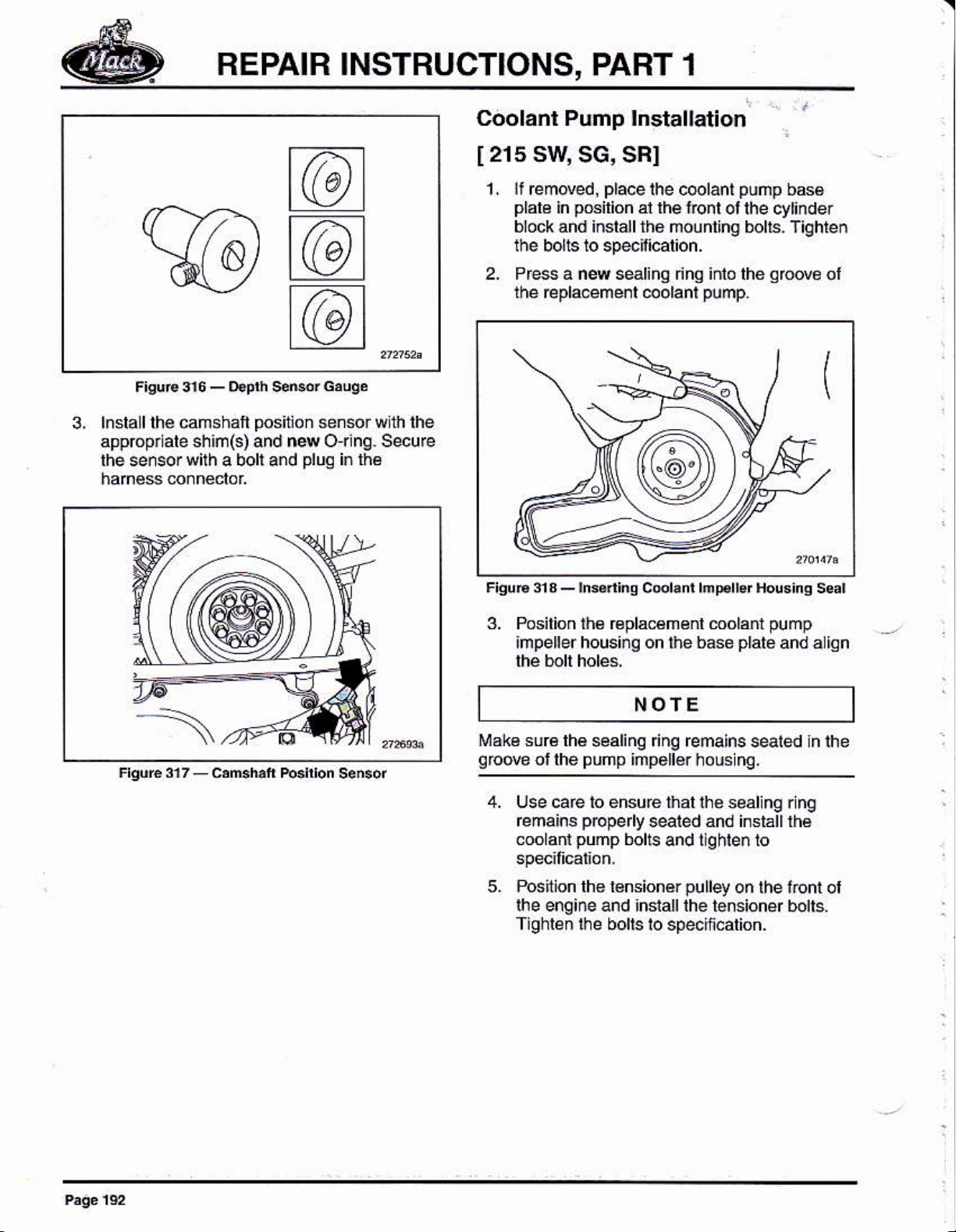

CAMSHAFT SENSOB DEPTH, CHECK

1. Beñ@ lhs

inslall

and

plug

lom lh6llyuheel holsing

lhe fywheel lur¡¡¡q lool.

b, lnse lhe depih

boé unlil ü6 oulér

lully seated aqahsi the nhhq

c. Looeén lhe

and

until il coólacfs a tooih d ln€ loolhod

Tigr'ién rhe thumb

Ca€lulry réño€ lhé

camshaf señsor bor€ and

localion

outer

.

.

.

thó i¡n€rpa oflhégaugéin

Púsh

ot steps belweén ihe inn6r áñd

pódionsol

Bolh

sleps bel@ lhe sula@ of

gauq6

ihe

Oño slsp b¿low

qauge

Borh steps abM lhe

gauqe

lhe

qauqe

lhumb $r4 ol lhe

inlo lhe sensor

pán

ol tre

$f4 io *curc the

gauge

gauge:

rhe

no shims required.

=

lhe su¡la@ ol lhe

oné shim €qunéd.

=

lwo shims equi6d.

=

gauge

gear

gauge

fom the

obsetue lhe

suúce ot

is

(d,---

-5r

Page 28

REPAIB INSTRUCTIONS, PART 1

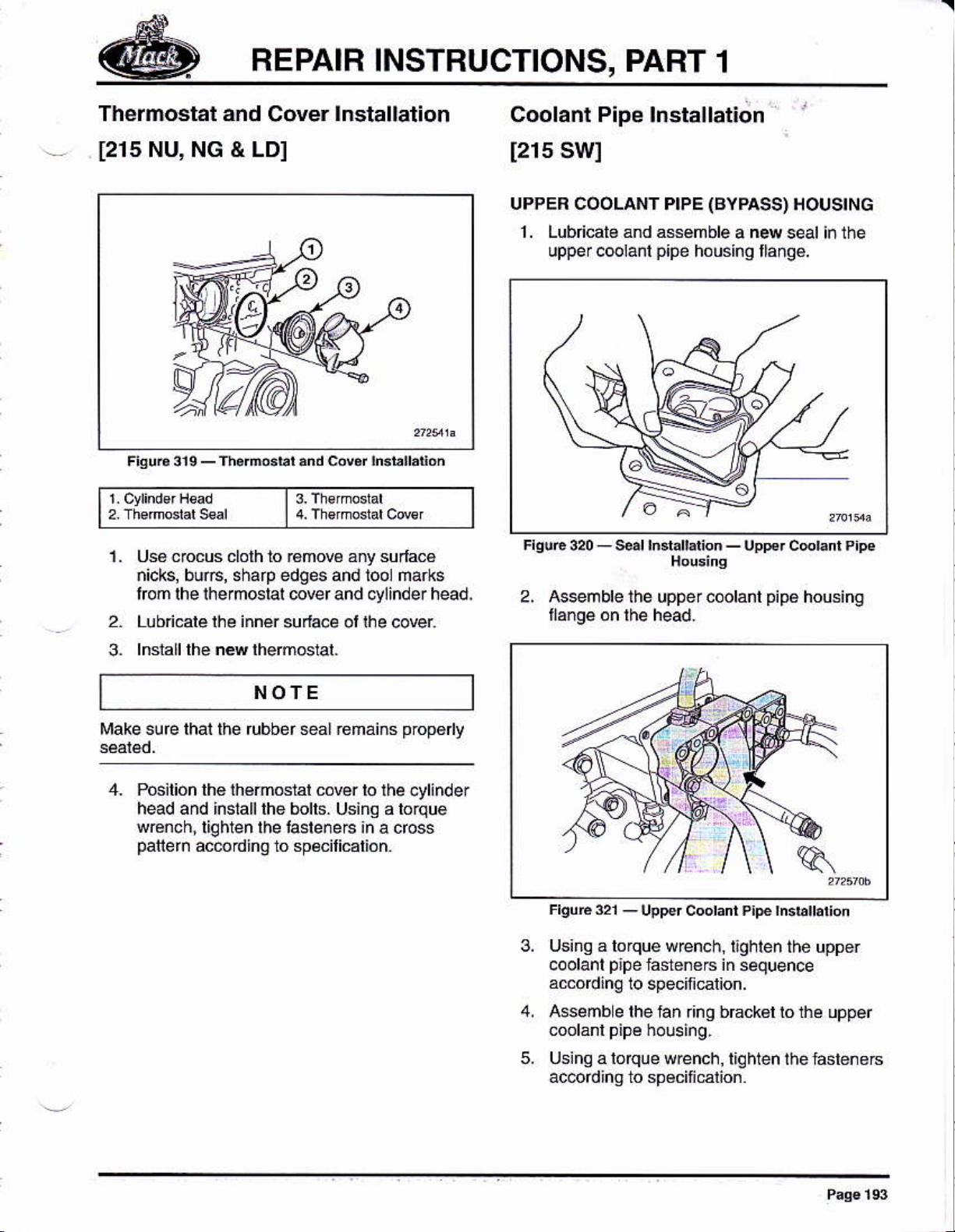

Coolanl Pump lnstallation

@

@

@

3, l.slall

appópnab shrñ(s) and n4 o¡ng. secufe

lhe sersor with a boll and

lhe camshaft

positlon

plug

señsor wlh lhe

in lhé

215 SW

[

remded,

l. lf

plale

block and install the mounling bolts.

the bolls to speoil¡@t¡on.

SG, SBI

posilion

in

placelhe

al rhe font

c@lánt

ot the cytinde¡

púñp

2. Prcss a ns selinq dhQ inlo lhe

repla.emenl

the

@olanl

pump.

b66

Tighleñ

grodé

ol

3. Posilion lh6 €placémérl coolani

hpellerhousing on the base

plalo

NOfE

¡rake sur6lhé

qbde

of the

sealinq ng reñains seaied h ihe

PUnP

imp6llérhous

nq.

4, lJse caE to éhsúre that ihe seal

@mains

mo ant

5. Poslion lh6 l6nsionér

lhe engine and ¡nsialllhe tension$ bolts.

Tlghlen

pbpeny

pump

lhe bolls lo speciñcation.

sealed and inslállrh6

bolts

and lighle¡ lo

pulley

on lhe f.ont of

pump

and a ion

ng r ng

Page 29

REPAIR

INSTRUCTIONS, PART

1

Thermostat and

[215

NU, NG & LD]

l

Ct,nderH€¿d

Uss cocus cloth 10 r€mow ány su¡lacé

nicks, buft, sharp edges añd lool ñarks

Cover

t

lnstallation

3.Th€,mo,Lar

fom lhe rhermoslal @ver and d/linder head.

Lubn.alé lh€ inner

suda.e ol lhe co@r

Coolant P¡pe lnstallation

[215

UPPEB COOLAI¡II PIPE (BYPASS)

SWI

1 . Lubricato ánd asémble

upper coolanl

p¡pe

housing lláng€.

uppercoolant

a

ñ4

Pipé

HOUSING

seal in the

housing

lnslall lhé néw lhémGral.

3-

NOTE

Make sure lhai the tubber *al remáins

4- Pcilioñ thé lh6moslal cóver lo

head and inslalllhe bolls. Using a lorque

w€nch,liqhien

paliem

acerding lo sp€cilicárión.

lhe lasleneE an a cross

lhe .ylinde¡

proD6

v

FrsuE o1

Using á lo

coolanl

aúoding

Asseñb e lhe lan r¡ng b6ck6l lo the upper

using

ac@rdinq to spéciñcalion

upper cooranr

-

que

wren. h, l¡ghlen thé upper

p¡pe

fa$enere in

lo specinatun.

loque

a

w@nch, liqhten thé lasteneE

p¡pé

hsbÍa

sequence

on

Page 30

REPAIR INSTRUCTIONS, PART 1

PUMP INLET HOUSING

1 Lubndeand assemble nssealing Íngs

on lhe

pump

inbr

pipe

ar r-he

2. Plae lhá inlel housing in

th6 uppereolantpipo and the

Replacé and lubficale á I sea lno o finos.

joinr

posil¡on

pump

wjlh

belweén

inlei.

rhe

Oil Coolerand Cooling Duct cover

[215

The oll coolor músl be atached

duct cover belo€ aftaohing the Ó@r b lhé

OIL COOLER

Dw' 2r9 EPI

the cooling

1o

INSTALLATION

1

Using a shálp

,

rubber sear

¡n lheoilcooler c@er,

Clean lhe

inspect for danage ló lhe *a inq sulfáce.

Ale, inspecl thecyllnderblocka¡d ensure

lheséaling

2. lnslall a nN lo¡med

pick,

carBlully remde lhe

(norded

cover of ány din, adhesives a¡d

sulae is clean

qasket)

il

notal€ady done.

'fon

and undamagéd.

g*kel

in lhe

the

grcove

g@ove

NOTE

ol

3. lnstall the Ma hsleneG and tiqhlen lo

specilicalión,

3ñd liqhbn to specifiatioñ.

Th€n,

housing trange 10 lhe

inslallrh¿ M10 faslen6r

NOTE

pump

flrsl

Apply a ñ ñimal ámouñt ol slicona saLant in lhs

grcove

sea!

as*nbly.

lo hold rhe seal in

lnslalllhé

mq

3. lnslallnq oil6lers6alng

bé¡reen

sealingojings nto

lhe oi cooler ahd covel lnslallrhe

wilhin

lhe

prace

20

O-nnqs

grooves

durng

minules ot

¡¡ the cover

Page 31

REPAIR

INSTRUCTIONS,

COOLING DUCT COVER ¡NSTALIAT¡ON

PABT 1

1. Feplace lhe Mler

lormed ¡ubber

Lubricále néw

2. Wilh assislance.

assembly h

gasket

gaslel

pláce.

NOTE

pump

sel the c@ling duct cder

inler

hbuslng

wlih a ñew

upo¡ i¡sta laton.

lnslalllhé uppé¡ éí

gsket,

5,

Using a lorque wrench, t¡qhien the tasteñers

iñ sequgncé amoding ro

lnslallrhe

cooler T¡qtfen tóténaB 1o spécilicalion

oi @derll@

speitiellon.

plate

over the oit

This mouñilng lo@l

3. Using lh€ ass€mb

the cover loeard lo cómp€ss lhé lomed

rubbé¡

the upper ¡iahl corner l4lener

gaskel

on is sloted lor¿dtúsrm€nr.

y

lool,

3a300022,

al lhe waler

pump

NOTE

A small

kéep fóm

lool fool is

p¡e.e

ol ñétál srock

deiormlng thé slamped

pressi¡g

aqainsl.

should be used b

cwer that the

push

inbr. hsla I

frsu6

3¿

coo¡ins oud ca$ adjudm¿ ródl

-

Page 32

REPAIR INSTRUCTIONS, PART

1

4. Adiusl 6wr as €qui€d

rówéf énrér lasrénéfs ró

NOTE

The uppér cenler mourninq location h6 á liqht€r

ldeÉñe than olher moúñ1iñ0 locaiions.

5. slart a I reñalnlhg m@r lastene6 ahd

lolqle üg}nen bsleners to speciti€lion,

Oil Filter Housing

[21e

EPI

L hsla I the ea¡

wlh a new

clamps in

cde¡, insla I lhe iasleneG and lighlen lo

gaskei.

posilion

lnstallalion

pipe

lo lhe oil @oler

Place lhé rálaining

on lhe oilmolerducl

cow¡

and

gasket

posil

on lhe rear

to the engi.é btock

pipe.

pipe

ear

lnslalllhe

3.

lnsrall rhe oil li[er housing onro rhé énsina

block

lnslall lhé fásl6nérs to rhe

fller hous¡ng. Toque the bolls to

lnstall the lont

lhéoi

fllerhousngandlheóil@o¡ercovei

p¡pe

wilh n4 seals belleeñ

Torqle lhe

n the olt

2. lnsialllwo allgnñenl

gskél

in

place

ard 10 aid in lhe alignmenl oi

pins

-),

to holdlho

pipes

7. hstáll all hárd

(molaff

and oil) lo lhá

ollcooler@rel Beplace and lubricate all

sealinq

O{in$, Alsq Bpla@ sealing

w6he6forlhe banio finino on lhé oil@oler

covei Tiqhlen banjo lili¡nqs to specifications.

Page 33

REPAIB INSTRUCTIONS,

PART 1

Exhaust

1214

Manifold lnstallat¡on

EGI

NOTE

The éxhaust manilold mounling laslene6

used lire l¡mes u¡less the mánffold ls béino

rcpla@d.lflhe manitold is being éplaced, use

can be

1, Clean lhe manilold mounling suriace on lhe

2. T¿mpoÉrily insláll án alignm6d slud at each

exhaust manfold fanqe bcal¡on on lhe

NOfE

This is don€ lo hold lhé manifold whil¿

the manifold

gaskels

lof ¡nslallal¡on ol lhe bons

posilioning

o

1. Múibrd s ds

4. Apply ánli-séizá.ompou¡d

and under ths h6áds or contacl

áll lhe mánilold laslé¡e6

(ftbl)

NOTE

2. cv ndsr Hd se

l

(wih

to the threads

sula@s ol

o' o

ae\

(_ll

,o

F'Urc3sAl¡gnm¿dPhh3bll¡lio.

3. lnsrall néw

wilhthe s€a

qaskéts

The

aid i¡ ¡nsla lation. Mak€ su@ lo

gaskel

lhe

gEphil¿

libn side

qakets

side

oñlo lhe

lacing

NOTE

ár€ malkéd "MANIFOLD

lMrd lhe exhaúst ñan told. The

gaskel

ol lhe

ój

l¡re

SIDEI 10

this side ol

da@

laces lhe cyllndar

Anli-s€izé hélps

cofosioñ and ¡€duces ficlion

inlended clamp load oñ the compo¡énl whe¡

qhléning

1

rhé

5. lnsiall lhe dhausl mániióld

alignmenl

in lhé low.

p¡nsen

@placed wnh ñounling lásleneF

p@nt

hsleneF to specifi€lion.

plns.

holes, Now lhe upper alignm¿nr

b6 émowd o¡e

iasiener oxidatioñ

lo help ach¡eve the

oEr lhe

l6tállfast€náE wilh

ala lme and

and the

spacers

NOTE

M¿ké surelhe

in themdilold

Exhaúst man lold laslene6

Tiqhlen

6.

lhe l¿s16n6rs lo

sp¡@É ¿r€ seated

siep bore hole

€n bB uséd

speciti€l¡on.

p@pe¡ y

loc¿xon.

up

Page 34

REPAIR INSTBUCTIONS, PART 1

Turbocharger lnslallat¡on

[214

SCI

Lcaurror,

Use oity ¡ev md aryove.t

w aB a¡t. oil 4d dhaust Mnectare ¡a

tuftnchatgú. Avaid the @ of *al¡ng d

Le

jakt

úrpoúds ar a|¡ l¡anged @nñec1¡ore.

fhopuoh

pañ¡des

¡nducled dutkg

te to

ha nd I i n

Aftét únpte¿ns úq¡he ea*ñt)ly, l¡¡l the

tutbocharyet ol

o¡l belote sbn¡N

ptace¿úe

ENG¡NE PBEPABA|ION

1.

tnspecl the i¡1ake ánd exhaust systems

leading to and

máke suG there is no foreign ñálelal

incudi¡g búiÍs and ooe lining fagments.

.lea¡tress ¡s rcqu¡ted. Sna

ñ úúse @vee b¡ü danage

h¡gh-speed opetut¡ü. Bé

plug

the inlal and últel

g

th e tu tuocha

undet Tutbocharyet ¡n ¡he

l@n

ry

paege

lha éNke. Befer ló the

lhe

gaskets

q.

wnh dean

AND

lurbochalgér lo

po¡/l'

at the

il

wh¡|e

eryke

z lnsrallrhe rurbochargertlanqe nurs and

spacers ro rh€ Bxhausr mán lold and

to¡qúe t¡ohien to specilletions.

NOTE

Clean the co¡iact suface oñ the *hausl

manifold,

Relaln the

lu¡bochaqe.

oil €lurn/d@ln back

polectl@

po

€ps @f the

s

lo keep deb'is and dúl

oulollho lurbdharger as

apply añi¡ se¡2e ófrpouñd to lhe théads

and under

the fasleneG. Anli-soiz€ h€lps

hstener ox dalio. @clon and redues

l clon ro help

load on the componont when lighlening

'aslene6

5,

lnstaf nee h

betweén

6,

Pósilion lhe lubocharqer and

aqainsl rh€ Bxhausr manilold.

lhe heads

achiwe lhe

to spec¡iielioñ.

gh

the tulbo fange and

or conl,aol sula@s ot

tempé¡á1uÉ

p pé

gngine

pt€wnl

¡ntended

gaskets

qhausl

gaskels

and

clamp

lhé

y

app

undér lhé conlá.i surláés ol lhe laslénérs

a¡i¡-se¡ze compound tó lhe théáds ánd

Page 35

REPAIR

INSTRUCTIONS, PART 1

a. lnstall the lúrb@hárg¿r oil

9.

(lower)

lnsral

gasket.

with a nN

the oil suppt

Totque-lighlen tho bolts lo

oaskel.

line (uppe4

E¡rrn

pipe

wilh a new

Exhaust Pressure covernortEPG)

lnstallation

gD

234

1. Lower lhe EPG housinq inlo

bétuéen

lhe exhaus!

p¡pe

2. lnsrall a nM hiqhreñpehtué

ho usin

g

and éxhausl

pipe.

posirion

and lurbocharqár

o6két

EPc

/AcauÍtoN

Pra-lill Ihé tutbodÉger w¡lh

S¡añlhg the eñgiñe wiktut oil

Ary" lubaúaget @ dmage lhe luúo.

cl@n úgjre oi¡.

pressure

and

a

3. Tighton lhe clamp

pipe

lo EPG housina.

atiaching lhe dhausi

Page 36

REPAIR INSTRUCTIONS,

PART

1

4. lnslalllhe dhausl clamp lom

EPGrorubocharger

lhe

Siarter lnslallation

1272

The staner is held ln

Nér sruds ireérléd in the bró.k rr á sr'd ii

DHI

plács

by nuls

1 . Using a loque wrcnch,

siuds a@ordhg lo spéciñcalion.

lighten repla@ñóñt

assembled

2. Asseñble lh€ süner on the sruds

in lhe

5. Con¡eclthea¡r súpoly li¡e to lhé EPG.

F.goÉ343_shghbra¡on

3. Using a torqu€ wEnch,

ac@d¡nq to spejlicarion.

lghten the nLns

Page 37

REPAIR

Air Compressor lñstallation

1261

CKI

INSTRUCTIONS, PAFT

2,

Asemble lhe alr coñprá;ior

moonring llange

ollhetimi¡q

1

on ine

géar plate.

1- lnsiall a nNseal inlhe

housinq hou¡lihg fl

ange.

alrcompEssor

3.

Using a lorque wrench, iighleh ihe atlaching

¡úls iñ two slages

aeodlnq lo specitlcatlóó.

Page 38

REPAIR

INSTRUCTIONS, PART

d

1

lnsláll1he cmlanl linás lo lhe

5.

lnslall the lubication tiñes to the an

Tandem Pump

(Fuel

and Power

Steering) lnstallat¡on

[231

AA,262 EBI

1-,nsiall

landeñ

a na OÍng in the

pump

mounlinq llange.

2- Assmble lh€ tándem

pump

ai

qrcove

on

lhe lttaheet

on the

LL)

F¡surc 7-r.nd.ñ

3, Using a b¡que wrcnch,

hsteneB accordinq tosp€cilicalion,

Punp

(Fuer

tighten the attachiñg

'nd

pú.r

srs nq)

Page 39

REPAIR

lnlet Manifold lnstallation

INSTBUCTIONS,

PAHT 1

[214

HD]

1. Usinq a 6haD

rubb€r sai (nolded

¡n the lntaké nañilóld, il nol alréady done.

Clean lhe úanifold ol arry din, adhésivos

and inspeci lor aw damaqe io the séarñq

su¡lace Also, nspecl lhe cylinder head and

ensu¡e

the

2. lnslall a ns rubbor s6ál

lnto the

gl@e

plck,

carelullv renove ths

qaske0

8€alinq sudace

ol lhe iffake man¡hld.

is

(mold€d

lrom the

clean and

s6k€t)

groove

NOTE

Apply a m i¡ imal amo unr ot sil¡cone seala nt in rhe

growe

s@l

a$eúbly. lnslalllhé ñáñilód wilhln 20 ñl¡utes

lo hold

lhe seal

nplacedu ng

Torqle-righren

s6q u€ nce lo sp ecifi@lio..

the

iniake

manilold bolts in

SeuBlhé 6noiné hamésslolhe inlake

ná¡ihld usi.g

l¡siáll rhé

ai l€mp€Elur6 sn.or localed

the inlake and *curelhe hahé* wlh li6

pdiously

eLeclrical con¡ecto. to the charge

r€mowd

on the lop oi

Posirio¡

3.

pGviou!¡y

molnt¡ng bolis with mounring

hold ihe man lold

alig nm€ rn

ma¡¡hld bolts wilh spáÉB.

the intake nanifotd onlo lhé lwo

imlalled

pins

aligrmenl

placé,

in

and install the ¡ema¡n¡no

NOfE

use f4 scf6m wllh mounling

¡nslall¡rg lhe ¡¡lake mañilold.

piós.

siarl hro

space6lo

ihen r6move lhe

spacefs when

(Bocr)

7

Using á torquo wench,

a€oding

io spec licaton.

sen$'

I

qhlen

the sensor

Page 40

REPAIR INSTRUCTIONS,

Englne Prehealer/Spacer

lnstallation

PART 1

[214

HL]

1. Cléán

intak€ ñdilold, ai

lhé lomd $aling sudae on

preheargr

or spac€r, and

2. Posilion lh6 inlál adepr€r and inlér áir

p¡ehearer

n4

$an $e bolls lo hold lh€ Gsémbly

using a 1o¡qué wreñch, tighten lhó lástgnéB

ió

a crcss

lnsrall rhe lan ñnq suppon bEcket mounr¡ng

fásl6ñ6r Torqu€-tqhl6n lhé boh ló

(rf

equ¡pped), of spacer brock w¡rh

gaskers

onro rhe inrake ñanilold, Nexl,

Figu65_l¡l3lAd¡pl€l

patlern

a@ordlng lo specitldlion.

rhé

lo lhé

EECU

t230

EKI

añd Cooler

lnstallation

NOfE

The sóquénc6 iñwhich lhá luél iinér

housing, luel lines and EECUar6asmbled

lhe engine depends on the

uséd. For €nginé slánds rhar

atáched lo th€ l€lt sid6 ol lhe

.omponenis cannol be ¡¡sialled unt¡laltd lhé

6ngiñé hás béé. Émw€d lrcm

Fuél lEsh lróm

EECU. Th6 mol6r

the luel lrcm the lank inló lhs lu6lpump.

the tank serves as @otant tor lh€

@nnets into lhe line cary¡nq

Vpe

use an adaplef

engine, lhese

ELve

ol enqhe sland

lhe fepa¡f sláñd.

on

plate

f equapped,

p€hearer

10 ths mounring surla@

man¡bld. conne.t and seué the

ground

and

postt

on añd iñstátt thé intél air

relay

bE ker

cables é marked al

(wlrh

on lhe

élay atrached)

inlake

pMér

NOTE

l¡ake sure the @olinq

1. PGilionlhe

insiall ihe ñóunling la6te¡e6.

plar€

EECU on the engine btok and

and EECU mat¡ng

Page 41

REPAIR

NOfE

INSTRUCTIONS,

4.

Uslng alorque sr6nch,lighteñ1hé

in séquence

PART 1

hstenere

adordinq to spéciÍcation.

i¡áke suÉ lhal rubber isolatoE

¡nsialled and thal lh€

Usi.q a

adording to specil ca1 on.

Assemblé lhe coo 6ron lh€ EECU. When

loque wrench,

pcilioning

snalgmund sl@p

unil s

properly

grcund

lhe module, ñake sureihallhe

al lhe uppef r¡stf oi ihe

secured ánd

áre corectty

sl@p is

riqhlen rhe fasieners

prcssád

gounded

in

10

Fuel L¡nes añd Filter

Housing

lnstallation

NOTE

Thesequencéinwhichthéluélf ltérhous¡¡q,

lines and EECU

depends on lh€

engine slands that lse án adápler

lo lhe láft side ol

cannol bé inst¿l sd uff I altér lhe

been removed lom lhe ¡epair sland.

areassembled on lhe enqiné

ol

Vpé

lhe engine,lhese componéñ1s

engine siand ced. For

plalé

ana.hed

engine has

tuet

NOfE

FisuEs

1,

Asemble lh€ tuél finer

2,

Using á lorquo w€nch.

Fü.r Firsf ¿nd HoG¡nq asñbt

acmding lo speciliEi on.

3. Allach

al lhe réaf

p¡pe

lhe

bellveen

a¡d the lilte.hous ng.

housing onlh6 btock.

t¡ghten the taslénerc

the s¡de ot the h€ád

Page 42

REPAIR INSTRUCTIONS, PART

1

Atach the

lnslalllhé iuél rélum liné

cyliñder h*d at lh€ lorn and lh€ lifter válw

lnsrallrhe line ro rhe b¡ock w¡rh P-clamps.

lnsrall lhe lue I relu

line

lo the bl@k with a

line

rn

be¡réen

con¡ect lng the

P-clamp,

rhe

liller Etue housing lo thé EECU ód¿i

lnsrall lh6 lu€l supply and ré1un I nes

belween lhe lue¡

L

U3ing

llttlnqs accordino to specif calio¡.

aloque wE¡6h,lighlen

pump

and thelillér

lhe bahlo

Lop.P,eure Fler

5.

súpp¡y

Pump

Crankcase Ventilation

1.

Clean lhe cankÉse venlilallon sepaáto¡

malinq sulacé o. lhe éngine

n4 rubber

aáskel

iffo {ré s6pa6ror

(Mounr€d

ro Poref

Separator

btock. lnstalt a

2. Assemble the sepaábr on lhe blóck

and

Page 43

BEPAIB INSTRUCTIONS,

PART

1

3. l.rsing a ioque w€nch, l¡ghlen lhe lasleneB

ac6rdi¡g

4. Assemble

ou el conneclor a¡d instal hose clámps.

lo

specif calion

lhe ouíel hose on lhe separalor

5. ljslng a torque wrench, liqhlBn the hc6

clamp

6. Assmblé 1¡e lnler hce

inlel and

in a iulu@ slep, lnsiattho* ctamps.

7.

Using a lorque wench, tlghlen the h66

clamp tasl€nerc ác@.ding

laslenerc

pr€pa€

ac@rding !o sp4¡l¡*¡on.

on the separator

fo¡ € re cov6r

connslion

lo sp4iti€lion.

1. Assémblé the

ánd I¿¡

.Enkshafl vibration'damper

puloyon

rhe

cÉñlshail hub Ging

NOTE

F¡duress.FanDvePu'le'.ndc

virüaion o¿npér

t2

c,¡nrshaft Hub

t3

Crankshaft Vibration Damper and

Fan

Pulley lnslallatlon

[212

RB,2'16'tA]

AcaurroN

When

to dañage llÉ fo6kg. Denls

hús¡ng

v¡b@üú

h*d ¡h¡s autim nay

lnspecllhe vibElion

llu d leaks in lhe outer housing. ll any

widénr, rhe

clos€ cloaEnce

¡nd lhe rolorinsids, denrs ór nrcks

conlact belween lhe two componenls.

will dele o¡ate lhe dampeñi¡q eftucl oJ rhé

handling a tbnton darpéL bé a6tul

ln the au¡er

s¡l¡ rcndq the danpet

danpe. @nnol be Epated. Failure to

re'u|t in see engine

damper lof dents, n¡cks or

dampermustbe reptac6d. Duelolhe

beñveen lhe damper housing

inefecfive. rhe

oi l¡ese are

nayeuse

Fluid loss

na¡

Using aloquewcnch,tghlenlhe

l6léneF in

a@odhg to sp6cilicalion.

3.

Asseñb e lh€ fonl

(FEPTO)

last6néc in

a@ordina ro

sequence in two stéps

engine

il equ¡pped. Tighrén rhe

sequencé in ldo sleps

spe.ilication.

p@er

ataching

láke of

atachlng

Page 44

BEPAIR INSTBUCTIONS, PART

A*emble

6.

compGssoron lhei

the allernalor and reriqeÉ;l

1

pads.

F¡qure 3@

-

FDnt

E

Po@ Tar.¡r

qiru

Alternator and Ref r¡gerant

Compressor

1271

C8,264

Assemble lhé allémalo. mouñrinq brackel

onlo lho cylind6r block. Ighlon ih6

Iastere6 a.cordang to spe¡licalion.

2,

ll ¡emoved and nol

á$émbl6lhé lronl énginé supporl mounling

báckel on lhe cy inder block. This brackel

pr@ldes

also

Using á lorque wBnch,lighlén

lor the b€ckei ánd ñou áccording lo

lf €mN¿d,

Using a lorqúe wrench,

ácordino to specf cár on.

lnstallation

DP1

ppiolsly

lhe mounlinq

assemb e the bett tensioñ idter

lighlen lhe lalene6

installed,

poinls

lhé

(FEProl

io¡ lhe

lasleneB

s. m 6mp,ésor

I

6. Mounr¡m Bccb| Fron'

|

Enané súppod

I

usinq alorque wrench, l¡ghlenlhelasleñefs

a€oding lo specmcatun.

ll a hárnBss is installéd. secuely

the eLectlical wi nqáslagg€ddu ng

L

Assemble lhe be I

and

compressor hubs, r reñóved.

pulleys

on lh€ állénaror

connect

Page 45

REPAIB INSTRUCTIONS,

Wiring Harness lnstallat¡on

wñqHafÉss

l3

PABT 1

1. Roule añd

engine s noled durlng di6a6sembly,

2. lnsén lhé unil injéclor

throqgh the holé l¡ the tlñlnq

pGition

the harnéss on fie

ponion

ol lhe h.me$

gear

housi¡g.

3. Connecl ihe hamess lo each iñiectóf.

4, Conneclthehamessiotheengiñébáké

mnlrcl valve t

Usinq hioh-lémpéÉlue wne

aliach ihe harness lo lhe cyLinder head.

previously

¡t nol

6.

wiring harness

valve. secure the hafn€ss lo lhé cónrfol

Blve as shown iñ Figué 363. i¡ák€ suro

thal lhé ham€s is

the boss al the lóp of the Elw assémbly.

lnslalléd.

Íes. 983472,

done, caelul

@er lhe engine brake control

pGilioned

y

ror,lo lhe

lo the s¡de of

/AcaurroN

Do Nof mute

lop oÍ the engine tuake

enough deatatu belween the valve

wive

@ver far lhe hatñess when rhe

insblled. fhe hatress

s¡de af the b6s ro awid da@ge

the hames o@¡ the bos at rhe

@nlrcl hlve. Therc ¡s nat

añd the

@ver

ñusl be

pós¡ioned

¡o the hahess.

is

¡ó lhe

2. cúLrclva €

|

ahe énernal

encGed in a@fdion lubinq. Th€rá afa séváEl

unils éách of which

permn

thai

allachmerl

CONNECTING THE EECU

L Ch€ck l¡\é lénsio.

p¡ns

podon

.o¡veniont st

lo the block in úrious localions.

úshq ihe tésl

ol lhe w

¡s tilled w¡lh end connecto6

ol lhe lermanal ¿on n6cto I

pins

ng hame6s is

jóininq

ging

n

¡

roól

kit 999000a.

a¡d

NOfE

ll

lerminal

2.

pins

are damaged

or coroded, ¡ep ace

Caelullyengagetheuppera¡dlowerwiring

haiñess connécroF

lhe connecloG are lalched

lo lhe EEcu. v€rify lhai

propedy

and

Ue aE to

aE sla¡qft an.l undanaged,

^caurroN

entute ¡hat the EECU teminat

pks

Page 46

REPAIR INSTRUCTIONS, PABT 1

3. lnslall lhe bolls

lo

secufe

lh6 wiing hafness

Cylinder Head

(Valve)

Cover

lnslallation

[211

JBI

1.

ean lhé

C

cylhder héad. The su¡la@s shóuld bó cléár

of a¡y di¡l or debrls and l¡ee ol any oil.

2. lnspecl lhe

@pla€mént

ñe

lhat I ¡s

@nrour

g6két

gaskel

is necéssary caEtully

gdk6t

intó the channel, ñákiño sué

propeny

of rhé chanñé|.

sáaling

lof damage. li

sllace ol lhe

*aled and tollds lhe

r

plácá

a

Cónnecl thé vanous le¡mináls as lagged al

di*ssembly lo áll ssnso6, rslays áñd

componenls such as ihe stailef, allernalof

and Élli96€nl cómprcssrámong olhé6.

Anach rh€ clamps lo hold lhe hamess

5.

on lhe

FlguEscyn.&fH*dcov¿lG'3k¿t

3. Appry a 2 mm

i0.079

séalanliolh¿ areawhere lhe liming @ver

ándlhecylinderhoad mééi. This

is on bolh s¡des of the cyli¡der héád.

Ca€lully

cylindsr h6ad and make

rema¡ns

posilion

pope y

¡nch) bead of MAoK

valve

lhe

séátéd.

cover on the

lhal

su€

paning

liné

lhe seal

Page 47

REPAIR

INSTRUCTIONS,

PART 1

4. lñstálllhé sp ngloaded

covei Tofqúe tlqhloñ lha

sequen@

io speoilication.

bolts ¡n lhe utve

@l€ cover bolts in

NOTE

The cyl¡nder head cdór musl b€

wilhin 20 mi¡utes ol lhe séálánl beinq

inlake

pov¡de

manitold. Torquerlghlen

e@n te¡sion on lhé

The boll springs

lnsla¡llh€ last€néB securino lhe

5.

venl¡bnon tube and bÉcket lo the vd@

cover and

lh€ fásl€néc lo specilicalion.

in$aned

c@nkcse

NOTE

l¡spetthecEnkcase ventllatión lubóOjing and

Fan Hub

[216

and Drive Beli lnstállation

AAI

1. Pla@ lhe iáñ hub bráckét

pos

lion

al lhe f@nl of ihe cylind$ héad

block. lnslalllhé

lighleó 10 sp4jfi calion.

mounting tasleneG and

a$embly ¡n

and

t1&€soryod€Bd

Puñe Bor'

I

Pláce lhe 1áñ

lens¡oneriñ

housing.

ll nor ¿keády

drire bsll i€nsioner

cylindef block. lnsralllhe l4te¡e6

Check lhe @nd¡llóñ of borh of rhé óridi¡sr

A/c/áltemalor

Check tor dry

@Place wilh nd b€lls I ány

P€rlhe

¡Llo/alterñalo¡ and lan/water

d ve and

posirion

lnslatt lh6 tasleners

done,

a¡d waier

cEcks or scuf marks ánd

ac@$ory rouling d8cal, bure

puñp

on lhe coohfn

pt¿c6 rhe

pGrlonon

m

pumpÍan

rssiomf

driw beh

pump

and l¡qhten ló

a@essory

th6

and

belrs.

ol these

lhe

pump

betts.

Page 48

REPAIR INSTRUCTIONS, PART 1

7. Using lool

/14392,

J

eay fom ihe ran and wátér

and insralllhe belt. Reléass lh€ lénsion

pry

lhe be¡l lens¡oner

pump

dnw beh

Removing Engine ftom Eng¡ne

Sland

and

6. Place a 1/2-¡nch Elchel or speclal lool

J4€92inlhéa@essoryd

nolch. lñs1álllh6 dfive belt by

lenslonef away fom lhe bell lo €li4e lhe

lénsion on lhé adiúste! ánd állow thé bélt lo

srip ó¡io ihe ¡l/c @npfes$r

Feleaé the léñsion and r¿move lhe tod .

vebelllánsionér

pryiñ0lhe

purréy.

t200

fhe

ñwr he exnise.l whíle

the stan !. Faitut¿ to u*

aDd ,allure to keep

in e¡iffi

EBI

qglre

ls very heaw an.¡ at@e úuüú

¡t is belng úfted lrcn

p*@I

pñpü

yoú

bo.,y ct@t ñay re tt

¡n¡ury

éqlipúent

ot.l@th ÍtE

úgíre shoúLt la d s¡r.rdúly ah¡ft

1. Atach

J 47033-6 and

a. S idé lhé

b Placelhe

c. Sl¡de thé réár lifting

d,

engine lifung ioo s J 47033-1,

4703a4

J

centerengine liftiñq barder

thé cylind€r head

cl4is

clévis lo

ey€s ánd s*ure

pin.

Connect thé c€nlé¡ lifiing

lhe chain on lhe hoisl.

l¡fing cha¡n toihe é¡giná tift

lifting bar and iñslalllh6

goll

on lhe floñt sectioñ ol lh€ 6ng ne

lifting bBckel

installth6

lo lhe cyl¡nde¡ héád áñd

pin

in

as lottows:

cwerard instal lhe

lhe chain lo th6

plare

inlo

pin.

lhe bai

out of

bar

the @nter

é. Torqué'lighlen litt ng

bracket hslene6

Page 49

REPAIB INSTRUCTIONS,

PART 1

U* on¡y the ch¿¡ns, ctév¡B dnd tiking

prov¡ded

úé ¡hé @ret

¿Iów lhé úg¡re to fa,

pet@nal

3.

wilh th* spec¡al tals. Fail* Io

sp@lal too¡ @nponents náy

@u.¡ng 4 @5

ln¡úry ú rlééth.

Supportlheweighl of th6 én9in6 usinq a

mobile ll@rcEnesuch as OfC 16.1313 or

equivalentcrane capable ot lifing lhe

€ngi¡é. Posilion th6 cEné and hook up ló

the bar as d6e as

slighrly ro apply rension rolhe chain.

With

€ngi¡e

fasleneBlrom the enq¡ne stánd.

Using theenlhe hoisl,

suitable supporr Éck or insiall rhe engine i¡

lhe @hicle

REPATR TNSTFUCIIONS,

the

w€ight,

lifting

(sée

pos

ble. Baiso lhe cnno

device now suppo ing rhe

@mov€

F¿o,h€ /rs¿tlrli¿, in lhe

the mou¡ling

pla@

lhe engine in a

PART 1 secrion).

pla¿e

1. r nól ak€ady don

oompo¡enls onlh6 éngine

p

ocedu fes cove red ea i6r in this

.

Enginewkins harné*

I

cfa¡kcase ventilát on lubing

.

EEC|Jandcoolinqplal6

Fuel l¡lter valve hóusing and luéllines

Cra.kcase venlilalion sepa€lor

e, asser; blé thd lottowjns

using lhe

6eclion.

F¡lters and Miscellaneous

Components

[219

This seclion coveG lnslallation ol lill6B ánd olhér

componenls thar might

a$embly opéaiions and to which nólhing is

EV,2t5 LDI

lnstallation

gel

in

lhe way 01 olher

NOfE

Ths sequ6nc¿ in which

housing, tuell¡nesá.d EECU ဠssembled

lh6 ¿nq né dépendsoñ

u@d. Fof engin€ slands thal

attached lo lhe len s¡dé of lh6 ánginé, rhese

cóñpoñ6¡ls cannol

engine h6 b$n fomoved t@m

the luell¡ller hl@

the lype ól6nQiné sland

use an adapler

be ¡nslalled uñti aft€flhe

lhe repa¡¡ siand.

on

p

até

i . Eno n6 w?iñq

Hamess

I

I

I

2. Assem ble thé fu ll-llów

lo

.onlacl

Assemblelhe

3.

contácr

assémble

contáó1Plus 3/4 lo 1

plus

3L/4lo I lurn.

Plus

bypasso nleránd

3/4 lo 1 lurñ.

lhe coolanl flteránd tghren 10

4. EECU

6.Cankasvéñúárón

s+¿mbr

oil tilte 6 and tig ht€n

Ughtenlo

lurn.

Page 50

REPAIR INSTRUCTIONS, PART 1

ENGINE INSTALLATION

Special Tools

General lnstructions

Détails

lfom one Éhicle to snolier This setioñ

gene@l guidelin6

oi

rhé

enqine

insla

Jor insralling an MPB enqine in

lalion

p.océdue

prdidos

NOTE

Belore insiafing lhe enqin6, mak8 su€

equipme¡t a@ inspecred lor sfety and

1. Positlon the vehiclo 0n a fat, lwel 6u.lace

Apply lhe

wheels.Obse@allsatelypreautións.

parklng

brako añd block ihe

Ery

NOfE

R6rer to th€ SPECIFICATIONS

lnirfrá¡oñ ¿boll lhe laslénéB mé.lioned

Some

sp€cilc sequence,

speciñed i¡ the lorquo sp€cili@tion

groups

ot

Paflens ol sequence are also

'aslene6

lnsrallation

Thé engine ¡3 obv¡ously

handle. Obta¡n a helper

l¡ftlng devlce to support il salély during

iBrállátion-

esú ir séveÉ

FailüE to hedthis r¿rniñg ñáy

p€bonal

and

section lor

musl be tlqhtened in a

seclion,

heavy and difñcult lo

prd¡de

a súitable

¡njury

be ou

Page 51

REPAIR INSTRUCTIONS,

PART 1

wh¡lé i.sratl¡ng

lhal ñay ktañée. such ae eng¡ne

@rnpúeñl' bhcke.ls, clanps and other

a¡tached to the lqñe and @b. Fá¡lurc to heetl

¡h¡B 6úim n6y

ghe

aúl other

1

Cryérlhé

^caurroN

the engke, wat h lot abstucl¡ús

and chassÉ

pañs

Esult

in

sevee danage to ¡he

@pú4ts.

valvé méchanism and

géarlÉin