Page 1

LNC-Lathe Series

Prr

P

o

o

grr

g

a

a

m

m

mii

m

Leading Numerical Controller

n

n

g

g

M

M

a

n

n

u

u

a

2007/12 Ver:V04.00.003

all

a

LNC Technology Co., Ltd.

LNC Technology Co., Ltd. 1

Page 2

Page 3

LNC Lathe

Table of Content

Table of Content

1 G-CODE FUNCTION TABLE....................................................................1

2 GENERAL M-CODE FUNCTION TABLE.................................................5

3 SYNTAX OF G CODE...............................................................................7

G00: Positioning in rapid....................................................................................................................7

G01: Linear interpolation....................................................................................................................9

G02, G03: Circular interpolation (cw./ccw.).......................................................................................10

Direct pattern making.......................................................................................................................12

G04: Dwell.......................................................................................................................................23

G09: Exact stop................................................................................................................................24

G10: Data setting.............................................................................................................................25

G20, G21: Inch \ mm input................................................................................................................27

G22, G23: Stored stroke check ON / OFF.........................................................................................28

G27: Reference position return check...............................................................................................29

G28: 1st reference position return.....................................................................................................30

G29: From 1st reference position return............................................................................................31

G30: 2nd,3rd,4th, reference position return.......................................................................................32

G31: Skip function............................................................................................................................34

G33: Thread cutting..........................................................................................................................36

G34: Variable Thread Pith Threading................................................................................................38

Continuous Threading......................................................................................................................40

G40, G41, G42: Tool nose radius compensation...............................................................................45

G53: Machine coordinate system......................................................................................................47

G54 ~ G59: Selection of work coordinate system..............................................................................49

G61, G64: Exact stop mode / Cutting mode......................................................................................51

G65: User macro simple call.............................................................................................................52

G66: User macro modal call.............................................................................................................54

G67: User macro modal call cancel..................................................................................................55

G68: Mirror image for double turrets ON...........................................................................................56

G69: Mirror image for double turrets OFF.........................................................................................56

G70: Finishing Cycle........................................................................................................................58

LNC Technology Co., Ltd. I

Page 4

LNC Lathe

G-Code Function Table

G71: Stock removal in turning...........................................................................................................59

G72: Stock removal in facing............................................................................................................61

G73: Pattern repeating.....................................................................................................................63

G74: End face peck drilling cycle (Z axis).........................................................................................65

G75: Outer diameter / Internal diameter drilling cycle (X axis)...........................................................66

G76: Multiple thread cutting cycle.....................................................................................................67

G77: Outer diameter/internal diameter cutting cycle..........................................................................69

G78: Taper thread cutting cycle........................................................................................................70

G79: End face turning cycle..............................................................................................................75

G80: Canned cycle for drilling cancel................................................................................................76

G83: Face drilling cycle....................................................................................................................77

G84: Face tapping cycle...................................................................................................................81

G85: Face boring cycle.....................................................................................................................83

G87: Side drilling cycle (X axis)........................................................................................................85

G88: Side tapping cycle (X axis).......................................................................................................89

G89: Side boring cycle (X axis).........................................................................................................92

G187: Side drilling cycle (Y axis)......................................................................................................94

G188: Side tapping cycle (Y axis).....................................................................................................98

G189: Side boring cycle (Y axis).....................................................................................................100

G90, G91: Absolute / Incremental programming..............................................................................102

G92: Coordinate system setting or max. spindle speed setting........................................................103

G94, G95: Feed per minute (mm/min), Feed per revolution (mm/rev)..............................................104

G96, G97: Constant surface speed control ON / OFF.....................................................................105

G98, G99: Intial point return / R point return....................................................................................106

4 AUXILIARY FUNCTION (M CODE)......................................................107

5 MACRO.................................................................................................112

5.1 Macro program introduction.....................................................................................................112

5.2 User macro call.......................................................................................................................113

5.3 Difference between macro program call (G65) and general subprogram call (M98)..................118

5.4 MACRO function list................................................................................................................119

5.5 Variable...................................................................................................................................120

5.6 Mathematics command............................................................................................................130

5.7 Logic command.......................................................................................................................131

II LNC Technology Co., Ltd.

Page 5

Table of Content

5.8 Compare command.................................................................................................................132

5.9 Procedures control command..................................................................................................133

5.10 Function..................................................................................................................................134

5.11 Note........................................................................................................................................136

LNC Lathe

LNC Technology Co., Ltd. III

Page 6

Page 7

LNC Lathe

G-Code Function Table

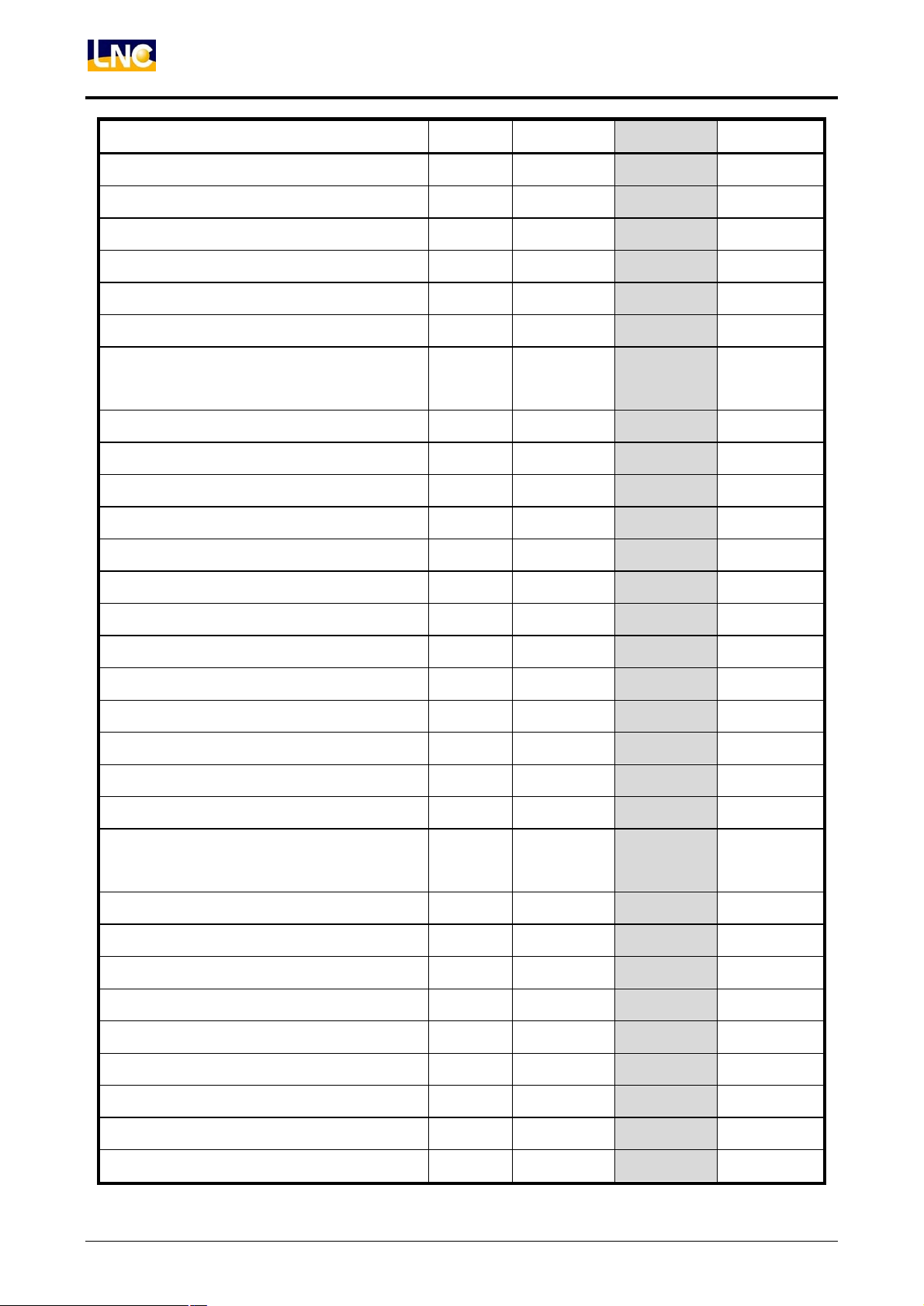

1 G-Code Function Table

Function Group TYPE A TYPE B TYPE C

Positioning in rapid 01 G00 G00 G00

Linear interpolation 01 G01 G01 G01

Circular interpolation (cw.) 01 G02 G02 G02

Circular interpolation (ccw.) 01 G03 G03 G03

Dwell 00 G04 G04 G04

Exact stop 00 G09 G09 G09

Data setting 00 G10 G10 G10

ARC Plane Setting 02 G17~19 G17~19 G17~19

input in inch 06 G20 G20 G70

input in mm 06 G21 G21 G71

Stored stroke check ON 09 G22 G22 G22

Stored stroke check OFF 09 G23 G23 G23

Reference position return check 00 G27 G27 G27

1st reference position return 00 G28,G29 G28,G29 G28,G29

2nd,3rd,4th, reference position return 00 G30 G30 G30

Skip function 00 G31 G31 G31

Thread cutting 01 G32 G33 G33

Variable Thread Pith Threading 01 G34 G34 G34

Tool nose radius compensation Cancel 07 G40 G40 G40

Tool nose radius compensation Left 07 G41 G41 G41

Tool nose radius compensation Right 07 G42 G42 G42

Machine coordinate system 00 G53 G53 G53

Selection of work coordinate system 14 G54 ~G59 G54 ~ G59 G54 ~ G59

Exact stop mode 15 G61 G61 G61

Cutting mode 15 G64 G64 G64

User macro simple call 00 G65 G65 G65

User macro modal call 12 G66 G66 G66

User macro modal call cancel 12 G67 G67 G67

Mirror image for double turrets ON 16 G68 G68 G68

LNC Technology Co., Ltd. 1

Page 8

LNC Lathe

Outer diameter / Internal diameter drilling cycle

Coordinate system setting or max. spindle

G-Code Function Table

Function Group TYPE A TYPE B TYPE C

Mirror image for double turrets OFF 16 G69 G69 G69

Finishing Cycle 00 G70 G70 G72

Stock removal in turning 00 G71 G71 G73

Stock removal in facing 00 G72 G72 G74

Pattern repeating 00 G73 G73 G75

End face peck drilling cycle (Z axis) 00 G74 G74 G76

00 G75 G75 G77

(X axis)

Multiple thread cutting cycle 00 G76 G76 G78

Outer diameter/internal diameter cutting cycle 01 G90 G77 G20

Taper thread cutting cycle 01 G92 G78 G21

End face turning cycle 01 G94 G79 G24

Canned cycle for drilling cancel 10 G80 G80 G80

Face drilling cycle 10 G83 G83 G83

Face tapping cycle 10 G84 G84 G84

Face boring cycle 10 G85 G85 G85

Side drilling cycle (X axis) 10 G87 G87 G87

Side tapping cycle (X axis) 10 G88 G88 G88

Side boring cycle (X axis) 10 G89 G89 G89

Absolute programming 03 - G90 G90

Incremental programming 03 - G91 G91

00 G50 G92 G92

speed setting

Feed per minute (mm/min) 05 G98 G94 G94

Feed per revolution (mm/rev) 05 G99 G95 G95

Constant surface speed control ON 02 G96 G96 G96

Constant surface speed control OFF 02 G97 G97 G97

Intial point return 11 - G98 G98

R point return 11 - G99 G99

Side drilling cycle (Y axis) 10 187 187 187

Side tapping cycle (Y axis) 10 188 188 188

Side boring cycle (Y axis) 10 189 189 189

2 LNC Technology Co., Ltd.

Page 9

Function Group TYPE A TYPE B TYPE C

(Note)The TYPE is A, B or C to decide on the Pr153, default is TYPE B.

LNC Lathe

G-Code Function Table

LNC Technology Co., Ltd. 3

Page 10

Page 11

General M-Code Function Table

2 General M-Code Function Table

M Code Function Remark

M00 Program stop CNC

M01 Optional stop CNC

M02 End of program CNC

M03 Spindle CW

M04 Spindle CCW

M05 Spindle stop

LNC Lathe

Txx Auto tool change

xx:Tool no.

M08 Coolant ON

M09 Coolant OFF

M10 Chuck clamp

M11 Chuck unclamp

M30 Program rewind CNC

M98 Calling of subprogram CNC

M99 End of subprogram CNC

LNC Technology Co., Ltd. 5

Page 12

Page 13

Y Z

3 Syntax of G code

G00: Positioning in rapid

Format:

Argument:

G00 X___ Y___ Z___ C___;

LNC Lathe

Syntax of G code

X__ Y__ Z__

C__

Action:

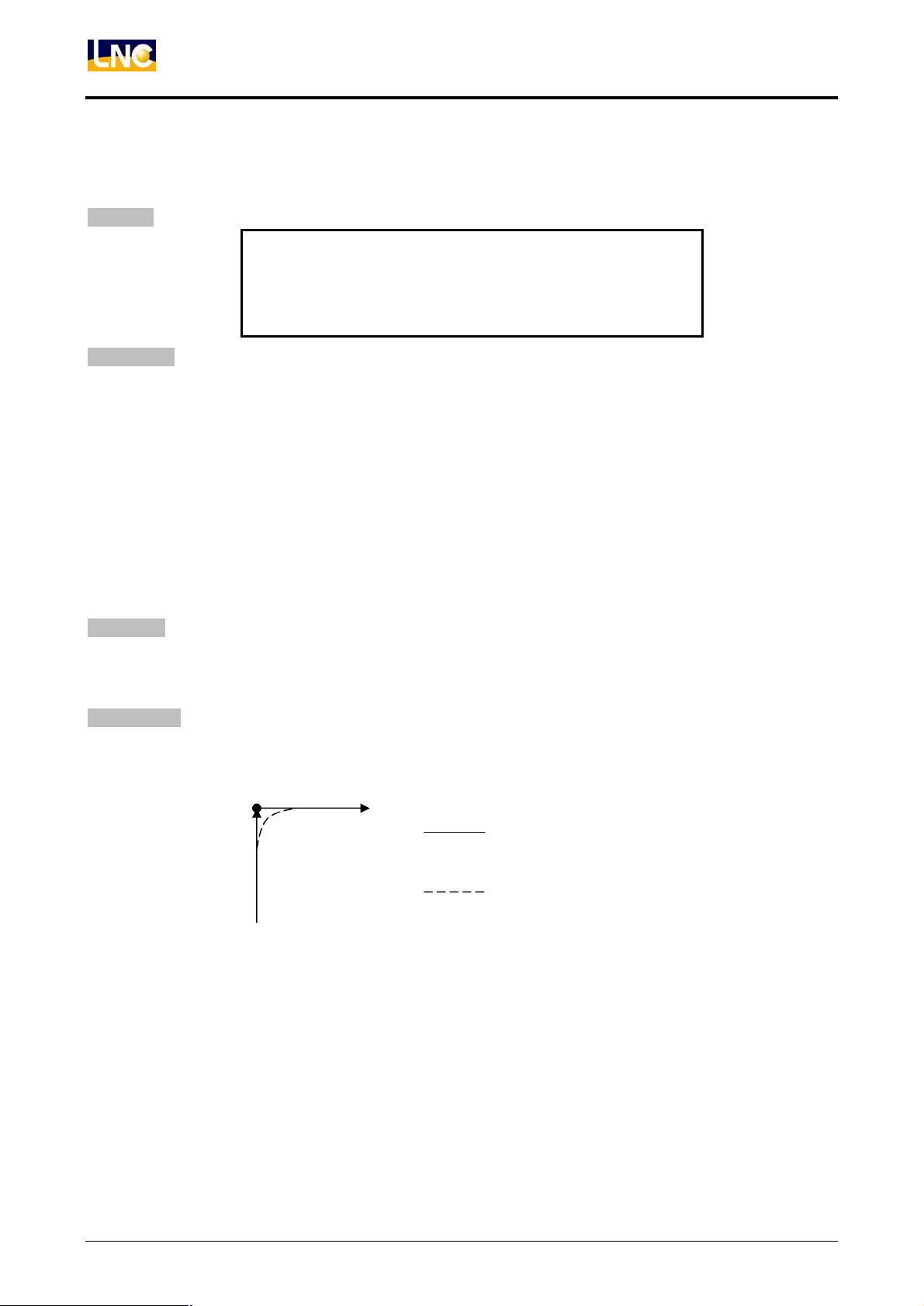

The function of G00 command is to make the tool move to the position of the specified coordinate

rapidly.

When using G00, the speed of moving is not descided by the format of F__, but by setting values of

parameter 1000 ~ 1003. Meanwhile, the rapid traverse adjustment knob can be used to adjust the

percentage of speed. (F0, 25%, 50%, 100%)

Illustration:

: For G90, the coordinate of an end point in absolute command.

For G91, the coordinate of an end point in Incremental command.

Target

Start

X

Tool path

Note:

Regarding G00 movement command, the movement of each servo axis is independent. The

movement speed of each axis is specified by parameters respectively. Operators should be

especially careful lest the tool may collide with the workpiece.

LNC Technology Co., Ltd. 7

Page 14

LNC Lathe

axis does not exceed

Moving speed of each axis does not exceed

Moving speed of each axis does not exceed

Syntax of G code

Methods of determing G00 simultaneously interpolated feed rate

None dry run

mechanism

Dry run mechanism

paremeter 0083 is 0

Dry run mechanism

paremeter 0083 is 1

Remark 1 Under this condition, Override depends on rapid traverse percentage.

Remark 2 Under this condition, Override depends on cutting feed percentage.

G00 command or commands with same

function under MEM, MDI modes

Moving speed of each

respectively set G00 speed (Remark 1)

respectively set JOG speed (Remark 2)

respectively set G00 speed

G00, G53 command of PMC axis function

Moving speed of each axis does not

exceed respectively set G00 speed

C23 is OFF: Moving speed of each axis

does not exceed respectively set JOG

speed

C23 is ON: Moving speed of each axis

does not exceed respectively set G00

speed

Moving speed of each axis does not

exceed respectively set G00 speed

8 LNC Technology Co., Ltd.

Page 15

G01: Linear interpolation

Format:

Argument:

X___, Z___ : For G90, the coordinate of an end point in absolute command.

U___, W___ : For G90/G91, the coordinate of an end point in Incremental

F___ : Feedrate.

Action:

G01 depends on the interpolation feed rate specified by F code, starts from current tool position, to

Syntax of G code

G01 X(U)___ Z(W)___ F___;

For G91, the coordinate of an end point in Incremental command.

command.

LNC Lathe

cut in a linear path to the end. Axes which are not specified do not move. Actual cutting feed can be

adjusted by the continuous feed rate adjustment knob at any time (0%-150%).

Max interpolation feed rate of G01 is specified by system parameter 1004. Acc/Dec time of G01 is

specified by system parameter 0014.

Illustration:

G91 G92 X100. Z100.;

G01 X10. Z10. F50;

(100,100)

G90 G92 X100. Z100.;

G01 X10. Z10. F50;

(110,110)

(100,100)

G92 X100. Z100.;

G01 U10. W10. F50;

(110,110)

(100,100)

G90 G92 X100. Z100.;

G01 X10. F50;

(100,100)

(10,10)

(10,100)

LNC Technology Co., Ltd. 9

Page 16

LNC Lathe

Syntax of G code

G02, G03: Circular interpolation (cw./ccw.)

Format:

G02

G03

Argument:

X___, Z___ : For G90, the coordinate of an end point in absolute command.

For G91, the coordinate of an end point in Incremental command.

U___, W___ : For G90/G91, the coordinate of an end point in Incremental

command.

R___ : Arc radius. (R>0, Arc<=180°. R<0. Arc>180°)

I___ : Xp axis distance from start point to the center of an arc. Xp is a

I__K__

Z(W)__X(U)__

R__

;F__

Action:

component in X direction.

K___ : Zp axis distance from start point to the center of an arc. Zp is a

component in Z direction.

F___ : Feedrate.

Pay attention to current tool position. The end point and the center of circle should be in the same

circle. If not, the controller emits an error signal INT 132. When R___, I___, and K___ of the

program are all written-in, system will depends only on the setting of R___.

System parameter 132 (XRC) defines if X (U) position is radius-specified or diameter-specified.

Radius-specified (XRC=1) and diameter-specified (XRC=0) differ in 2 times of the actual movement

amount of X axis. E.g. The movement amount of radius-specified U-10 is equal to

diameter-specified U-20.

End point

+X

G

0

3

Starting point

+X

G

0

2

G

0

3

I

Centre

K

+Z

Centre

+Z

10 LNC Technology Co., Ltd.

Page 17

Illustration:

The following 4 figures have the same cutting path of a clockwise cutting of a 1/4 circle, and the

radius is 5.

LNC Lathe

Syntax of G code

(In radius programming)

G91 G92 X100. Z100.;

G02 X-5. Z5. I-5. K0. F50;

(100,100)

(In diameter programming)

G91 G92 X100. Z100.;

G02 X-10. Z5. I-5. K0. F50;

(100,100)

(90,100)

(90,100)

(In radius programming)

G90 G92 X100. Z100.;

G02 X95. Z105. I-5. K0. F50;

(100,100)

(90,100)

(In diameter programming)

G90 G92 X100. Z100.;

G02 X90. Z105. I-5. K0. F50;

(100,100)

(90,100)

LNC Technology Co., Ltd. 11

Page 18

LNC Lathe

Syntax of G code

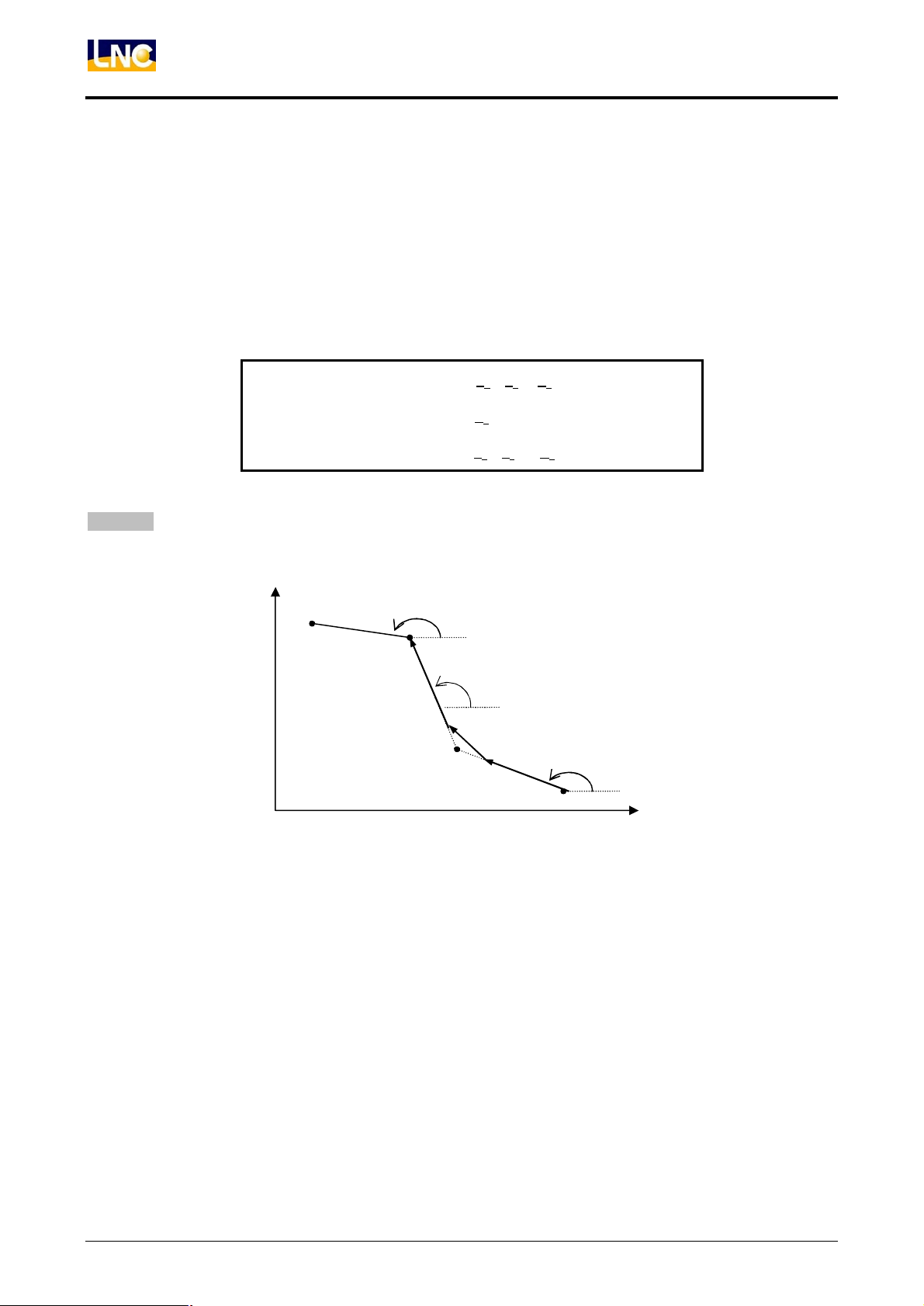

Direct pattern making

In order to make the manufacturing of workpieces easier, the controller provides functions of making corner

chamfering (,C_), corner rounding (,R_) and angle of straight line (A_).

1. Chamfering “,C_”

Continuous 2 blocks of command. In the 1st block, C_ sets up chamfer length between the 2 blocks. It is

applicable also when the previous and next blocks are circular commands.

Format:

G01

G02

G03

G01

G02

G03

C__; , Z__X__

Z__;X__

Example:

X

X

(80,10)

End point of

1st block

,C_

Z

(80,40)

C10

(20,40)

Z

G00 X20.0 Z40.0

G01 X80.0,C10.0 F100.0

G01 Z10.0

12 LNC Technology Co., Ltd.

Page 19

LNC Lathe

Z

Syntax of G code

2. Corner Rounding “,R_”

Continuous 2 blocks of command. In the 1st block,,R_ sets up the radius of the rounding corner linking the

2 blocks. It is applicable also when the previous and next blocks are circular commands.

Format:

G01

G02

G03

G01

G02

G03

R__; , Z__X__

Z__;X__

X

Example:

G00 X20.0 Z0.0

G02 X20.0 R10.0,R3.0 F100.0

X

(20,0)

,R_

R10

(20,20)

Z

(20,30)

G01 Z30.0

LNC Technology Co., Ltd. 13

Page 20

LNC Lathe

Syntax of G code

3. Angle of Straight Line ”A_”

When applying linear interpolation command G01, only the positions of X_ or Z_ and the angle of the line

A_ can be specified. The actual position of the corresponding end point will be calculated by the controller.

It is especially convenient when the manufacturing drawing provides only coordinates of X or Z directions

and angles.

Format:

Wherein A_ angle is calculated from the horizontal direction (Z axis). A positive value of A represents

a counterclockwise direction, and vice versa.

G01

X__

Z__

A__;

Example:

X

A+

X

(X, Z)

(10,10)

27°

Z

X

A-

(X, Z)

Z

(20, ??)

Z

G00 X10.0 Z10.0

G01 X20.0 A27.0 F100.0

14 LNC Technology Co., Ltd.

Page 21

LNC Lathe

?

Z X

Syntax of G code

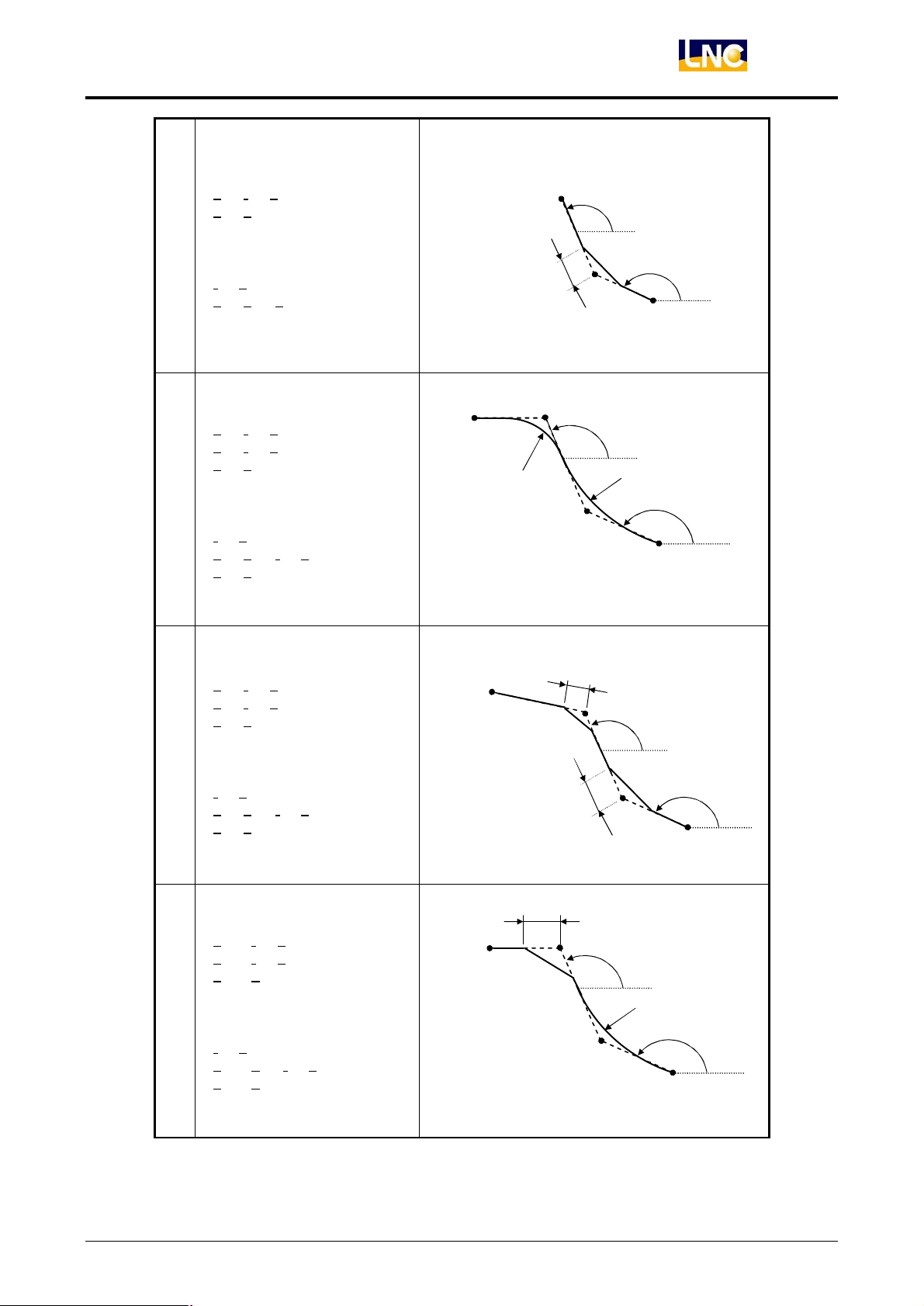

4. Geometric input function

In a manufacturing drawing, it is often that angles are provided, but not correct cutting positions; or that

only the size of corner or round corner is provided when making a corner. Therefore the calculation of the

coordinates of the intermediate point can be inconvenient when transforming the data to linear and

circular cutting command while compiling a manufacturing program. This function makes compiling

programs more easily, and help avoid calculation errors.

l Type 1

Intersection point of 1st and 2nd blocks is unknown

Angles of 1st and 2nd blocks are known

End point coordinates are known

Format:

N01 G01 Aa

1

N02 G01 Xx3 Zz3 Aa2

a

N01

1

a

2

N02

(x1, z1)

(x3, z3)

LNC Technology Co., Ltd. 15

Page 22

LNC Lathe

X

Z

a2

a1 ?

Syntax of G code

Example:

G00 X0.0 Z0.0

G01 A30.0

G01 X10.0 Z30.0 A-45.0

Coordinates of intermediate point are unknown

-45°

l Type 2

Format:

30°

(10,30)

Intersection point of 1st and 2nd blocks is unknown

Angles of 1st and 2nd blocks are known

End point coordinates are known

Corner of 1st and 2nd blocks is chamfer or fillet

N01 G01 Aa1,Cc1 (,Rr1)

N02 G01 Xx3 Zz3 Aa2

X

(z3,z3)

N02

C1 or r1

N01

(z1,z1)

Z

16 LNC Technology Co., Ltd.

Page 23

X

a2

a1 ?

a3

l Type 3

Format:

Either X_ or Z_ of the intersection point of 1st and 2nd blocks is known

Intersection point of 2nd and 3rd blocks is unknown

Coordinates of end point of 3rd block are known

Angles of 1st, 2nd and 3rd blocks are known

N01 G01 Xx2(Zz2) Aa1

N02 G01 Aa2

N03 G01 Xx4 Zz4 Aa3

LNC Lathe

Syntax of G code

(z4,z4)

N03

N02

(z2,z2)

N01

Z

LNC Technology Co., Ltd. 17

Page 24

LNC Lathe

X

C1 or r1

a2

a1 ?

a3

Syntax of G code

l Tyep 4

Intersection point of 1st and 2nd blocks is known

Intersection point of 2nd and 3rd blocks is unknown

Coordinates of end point of 3rd block is known

Angles of 1st, 2nd and 3rd blocks are known

Corner of 1st and 2nd blocks is chamfer or fillet

N01 G01 Xx2(Zz2) Aa

1

Format:

(z4,z4)

N02 G01 Aa

N03 G01 Xx4 Zz

N03

N02

(z2,z2)

2

4 Aa3

N01

Z

18 LNC Technology Co., Ltd.

Page 25

a2

?

X

l Type 5

Intersection point of 1st and 2nd blocks is unknown

Intersection point of 2nd and 3rd blocks is known

Coordinates of end point of 3rd block are known

Angles of 1st and 2nd blocks are known

Corner of 1st and 2nd blocks is chamfer or fillet

Corner of 2nd and 3rd blocks is chamfer or fillet

N01 G01 Xx2 Zz2 ,Cc

1

(,Rc1)

LNC Lathe

Syntax of G code

N02 G01 Aa

N03 G01 Xx3 Zz

2

3 Aa1

Format:

(z4,z4)

(z3,z3)

N03

C2 or r2

N02

C1 or r1

a

1

N01

Z

Note:

1. The following G codes can not be in the same block with geometric input commands, or be used to

input pattern size of continuous shapes.

a. G codes of Group 00 (excluding G04)

b. G02, G03, G90, G92, G94 of Group 01

2. Only be effective under MEM Mode

3. Fillet command can not be used in thread-cutting blocks.

4. When applying G01 X_ A_, if angle value is 0∘±1, 180∘±1, then the command is ineffective.

5. When applying G01 Z_ A_, if angle value is 90∘±1, 270∘±1, then the command is ineffective.

6. If the angle between 2 lines is within +1∘, chamfering and filleting will be ignored.

LNC Technology Co., Ltd. 19

Page 26

LNC Lathe

2

, Z2

A

1

R

Syntax of G code

Table of usages of geometric commands

1

X2 (Z2_) A

A1

2

X3 Z3 A2

Command Illustration

(X2, Z2)

(X1, Z1)

(X3, Z3)

A

2

(X2, Z2)

A

(X1, Z1)

A

1

X2 Z2 ,R1

X3 Z3

3

or

A1 ,R1

X3 Z3 A2

(X3, Z3)

(X

A

2

)

(X1, Z1)

20 LNC Technology Co., Ltd.

Page 27

LNC Lathe

Syntax of G code

X2 Z2 ,C1

X3 Z3

4

or

A1 ,C1

X3 Z3 A2

X2 Z2 ,R1

X3 Z3 ,R2

X4 Z4

5

or

A1 ,R1

X3 Z3 A2 ,R2

X4 Z4

(X4, Z4)

R

2

(X3, Z3)

C

1

(X3, Z3)

(X2, Z2)

A

2

(X2, Z2)

A

2

A

(X1, Z1)

R

1

(X1, Z1)

1

A

1

X2 Z2 ,C1

X3 Z3 ,C2

X4 Z4

6

or

A1 ,C1

X3 Z3 A2 ,C2

X4 Z4

X2 Z2 ,R1

X3 Z3 ,C2

X4 Z4

7

or

A1 ,R1

X3 Z3 A2 ,C2

X4 Z4

(X4, Z4)

(X4, Z4)

C

2

(X2, Z2)

C

2

C

1

(X3, Z3)

(X3, Z3)

A

2

(X2, Z2)

A

2

R

1

(X1, Z1)

A

(X1, Z1)

A

1

1

LNC Technology Co., Ltd. 21

Page 28

LNC Lathe

Syntax of G code

R

2

(X3, Z3)

A

X2 Z2 ,C1

X3 Z3 ,R2

X4 Z4

(X4, Z4)

8

or

A1 ,C1

X3 Z3 A2 ,R2

C

1

(X2, Z2)

A

1

(X1, Z1)

X4 Z4

22 LNC Technology Co., Ltd.

Page 29

G04: Dwell

Format:

Argument:

X___ : Specify a time. Unit: sec. Range: 0.001 ~ 99999.999.

P___ : Specify a time. Unit: ms. No decimal poiint. Range: 1 ~ 99999999.

Action:

Dwell action; set up dwell time after G04; when the time is over, next block will be executed

automatically.

G04 X___;

G04 P___;

LNC Lathe

Syntax of G code

Example:

G04 X100.;------------------------------------------------------- 100 sec

G04 P100;---------------------------------------------------------0.1 sec

G04;------------------------------------------------------ Exact stop (G09)

LNC Technology Co., Ltd. 23

Page 30

LNC Lathe

;

Syntax of G code

G09: Exact stop

Format:

Argument:

G09 is a command used along with the exact stop of cutting. When using G09, system checks

positioning degrees after executing every positioning command. After making sure statuses of

positioning comply with settings, system continues executing next block. Therefore, if cutting

positioning exists between blocks, there might be a little interruption due to the demanding of the

precision of positioning point. Speed is sacrificed for a higher shape precision. The degree of

__01G

09G

__02G

__03G

precision is specified by parameters 0006 ~ 0009. The function of G09 only takes effect within its

block.

Example:

G91 G09 G01 Y100. F200.;-------------------------------------------------------------------------------------- (1)

G01 X100.;----------------------------------------------------------------------------------------------------------- (2)

Illustration:

(2)

Tool path in G09

(1)

Tool path in non-exact stop

24 LNC Technology Co., Ltd.

Page 31

:

:

:

:

G10: Data setting

Format 1:

Format 2:

Format 3:

Argument of format 1:

P___ : No. of compensation.

G10 P 1~30 X_ (U_) Z_ (W_) R_ (C_) Q_;

G10 P 101~130 X_ (U_) Z_ (W_) R_ (C_) Q_;

G10 P 154~159 X Z

LNC Lathe

Syntax of G code

P1~30 are the values of no. 1~30 tool wear compensation.

X___

Z___

U___

W___

Q___ : Tool type. Types are shown below figure.

R___ : The value of tool nose wear compensation. (Absolute)

C___ : The value of tool nose wear compensation. (Increment)

Argument of format 2:

P___ : No. of compensation.

P101~130 are the values of no. 1~30 tool length compensation.

X___

Z___

U___

W___

:

The value of tool wear compensation of X axis. (Absolute)

The value of tool wear compensation of Z axis. (Absolute)

:

The value of tool wear compensation of X axis. (Increment)

The value of tool wear compensation of Z axis. (Increment)

:

The value of tool length compensation of X axis. (Absolute)

The value of tool length compensation of Z axis. (Absolute)

:

The value of tool length compensation of X axis. (Increment)

The value of tool length compensation of Z axis. (Increment)

Q___ : Tool type. Types are shown below figure.

R___ : The value of tool nose wear compensation. (Absolute)

C___ : The value of tool nose wear compensation. (Increment)

Argument of format 3:

P___ : No. of compensation.

P154~159 are the values of G54~G59 coordinate.

X___ : The value of X axis coordinate.

LNC Technology Co., Ltd. 25

Page 32

LNC Lathe

Syntax of G code

Z___ : The value of Z axis coordinate.

Illustration:

Q=2

Q=7

Q=6Q=1

Q=0,9

Q=8Q=3

Tool type(Q__)

Q=5

Q=4

26 LNC Technology Co., Ltd.

Page 33

G20, G21: Inch \ mm input

Format:

Argument:

G20 : Inch input, minimum 0.0001inch.

G21 : mm input, minimum 0.001mm.

These commands should be used alone in their respective block without any other command, and

they have to be at the beginning of programs, i.e. before the setting of coordinate system.

When converting unit, pay attention to the following items:

G20;

G21;

LNC Lathe

Syntax of G code

(1) Recover workpiece coordinates to basic system.

(2) Cancel tool compensation.

(3) System-related parameters should be meanwhile adjusted to be in accordance with new unit.

LNC Technology Co., Ltd. 27

Page 34

LNC Lathe

nternal travel forbidden

Syntax of G code

G22, G23: Stored stroke check ON / OFF

Format:

Argument:

X___ Z___andI___ K___: Marks travel range. Machine coordinates. Refer to example.

Action:

G23 is used to cancel tool-stored travel check.

Execute G22 command after manual home returing. Once it’s set, the tool can not enter

travel-forbidden area specified by G22, or a system warning will occur.

G22 X___ Z___ I___ K___;

G23;

“MOT 9009 X axis over G22 soft limit(+)”

“MOT 9010 X axis over G22 soft limit(-)”

“MOT 9013 Z axis over G22 soft limit(+)”

“MOT 9014 Z axis over G22 soft limit(+)”

In manual mode, users can move spindle in the opposite direction to cancel warning. In auto mode,

besides the aforementioned warning, system warning ”MOT 4058 Over soft limit” will also be

emitted, and NC stops moving, then users have to click RESET button to cancel warning status.

G22-specified forbidden area can be either internal ro external, and it can be specified by system

parameter 0071.

Illustration:

(X,Z)

(X,Z)

28 LNC Technology Co., Ltd.

(I,K)

I

area

P0071 be set to 1. P0071 be set to 0.

(I,K)

External travel

forbidden area

Page 35

G27: Reference position return check

Format:

Argument:

X___, Z___ : For G90, the reference position in absolute command.

For G91, the reference position in Incremental command.

U___, W___ : For G90/G91, the reference position in Incremental command.

Action:

When program finishes an execution cycle, and is at the end point or back to the reference position,

users can perform a position return check in order to make sure the correctness of current real

position. This command can check if system returns to the reference position. If it is back to the

reference position, the reference position indication light will be alight, and the next block will be

executed. If it is not at the reference position, system will emit a warning signal “MOT 4046

reference position return failure”.

G27 X(U)___ Z(W)___;

LNC Lathe

Syntax of G code

If X__ or U__ axis is specified in command, then X axis will perform return and check. If it is not

specified, X axis will not move. It is the same as with Z or W axes.

Cancel all compensations before using command G27.

Illustration:

◎Failure ◎Success

(Turn on the power, then return reference position)

G92 X100. Z100.; G92 X100. Z100.;

(Reference position be set to (100,100))

G00 U-30. W40.; G00 U-30. W40.;

G00 W80.; G00 W80.;

G27 U20. W-70.; G27 U30. W-120.;

(ALARM) (Normal)

Zero point

(100,100)

Zero point

(100,100)

0

0

(70,140)

System ALARM

G

G00

2

7

(70,220)

G

0

0

(70,140)

G

2

7

G00

(70,220)

G

Failure Success

LNC Technology Co., Ltd. 29

Page 36

LNC Lathe

Syntax of G code

G28: 1st reference position return

Format:

Argument:

X___Z___ : For G90, the intermediate position in absolute command.

For G91, the intermediate position in Incremental command.

U___W___ : For G90/G91, the intermediate position in Incremental command.

Action:

System reserves G28-specified coordinates of the intermediate point for later G29 to use.

In manufacturing program, use G28 command to control tool to travel through specified intermediate

G28 X(U)___ Z(W)___;

point, and then automatically return to 1st reference position (machine home). Before executing G28,

users have to manually perform home return process lest system warning”MOT 4018 no home

return after system start” will be emitted.

When argument X___ is not specified, X axis does not perform the process of 1st reference position

return, and so do the other axes. However, if there is not any argument of axis direction specified, all

axes will perform the process of 1st reference position return.

Illustration:

+X

Zero point

(100,80)

Zero point

+X

(50,50)Starting point (50,50)Starting point

+Z

G90 G28 X100. Z80.;

30 LNC Technology Co., Ltd.

G91 G28 X0. Z0.;(no passing through

intermediate point)

+Z

Page 37

G29: From 1st reference position return

Format:

Argument:

X___Z___ : For G90, the target position in absolute command.

For G91, the target position in Incremental command.

U___W___ : For G90/G91, the target position in Incremental command.

Action:

G29 command is used only after G28. After executing G28, tool stops on 1st reference position, and

then G29 can control tool to move from 1st reference position through G28-specified intermediate

point to destination position.

G29 X(U)___ Z(W)___;

LNC Lathe

Syntax of G code

Illustration:

G00 X50. Z50.;------------------------------------------------------------------------------------------------------ (A)

G90 G28 X100. Z100.;---------------------------------------------------------------------------------- (A→B→R)

G29 X50. Z180.;------------------------------------------------------------------------------------------ (R→B→C)

+X

A(50,50)

Zero point

R

B(100,100)

C(50,180)

+Z

LNC Technology Co., Ltd. 31

Page 38

LNC Lathe

Syntax of G code

G30: 2nd,3rd,4th, reference position return

Format:

Argument:

P__ : P2~4: 2nd, 3rd, 4th reference position return.

X___, Z___ : For G90, the intermediate position in absolute command.

For G91, the intermediate position in Incremental command.

U___, W___ : For G90/G91, the intermediate position in Incremental command.

Action:

Z(W)__;X(U)__ 432 P G30

This command is used to perform 2nd, 3rd and 4th reference position return process. The tool will

move from current position through specified intermediate point to 2nd, 3rd and 4th reference

positions.

The offset amount between 2nd reference position and machine home point can be specified by

parameter 1022 ~ 1025; offset amount between 3rd reference position and machine home point can

be specified by parameter 1026 ~ 1029; and offset amount between 4th reference position and

machine home point can be specified by parameter 1030 ~ 1033.

Before executing G30, users have to manually perform home return process lest system

warning”MOT 4018 no home return after system start” will be emitted..

When argument X___ is not specified, X axis does not perform the process of reference position

return, and so do the other axes. However, if there is not any argument of axis direction specified, all

axes will perform the process of reference position return.

32 LNC Technology Co., Ltd.

Page 39

Illustration:

LNC Lathe

Syntax of G code

+X

(50,50)Starting point

G90 G30 P2 X100. Z80.;

P2

(100,80)

+Z

+X

P2

(50,50)Starting point

G91 G30 P2 X0. Z0.;(no passing

through intermediate point)

+Z

LNC Technology Co., Ltd. 33

Page 40

LNC Lathe

Syntax of G code

G31: Skip function

Format:

Argument:

X___, Z___ : For G90, the coordinate of an end point in absolute command.

U___, W___ : For G90/G91, the coordinate of an end point in Incremental

P___ P1~P4.designate skipsignal source. If P_ is not specified, the default

F___ : Feed rate of G31 block. The specified is only effective in this block. If

G31 X(U)___ Z(W)___ P___ F___;

For G91, the coordinate of an end point in Incremental command.

command.

value is P1.

Action:

it’s not specified, the value of parameter 1042 will be the feed rate of

the block.

This command has the same function of G01. But if a skip signal is triggered duting the execution,

the block will cease working, and program will move to the next block.

Incremental mode

+X

G31 target

Skip

Programming path

Actual path

G31 start

+Z

34 LNC Technology Co., Ltd.

Page 41

Note:

LNC Lathe

Syntax of G code

Absolute mode

+X

G31target

Skip

Programming path

Actual path

G31start

+Z

1. When G31 skip signal is triggered, system saves coordinate value of the break point to system

macro variables, as the following table shows. But before G31 skip signal is triggered, these

variables are destination position coordinates of G31 command. Besides, if absolute coordinate

was once used to redesignate absolute coordinate, e.g. G92 (G50 in lathe A type), the saved

absolute coordinate will not include the offset made by G92.

Lathe X Y Z 4th axis

Absolute coordinate of

P1

skip point

Machine coordinate of

skip point

Absolute coordinate of

P2

skip point

Machine coordinate of

skip point

Absolute coordinate of

P3

skip point

Machine coordinate of

skip point

Absolute coordinate of

P4

skip point

Machine coordinate of

skip point

$140 $141 $142 $143

$144 $145 $146 $147

$148 $149 $150 $151

$152 $153 $154 $155

$156 $157 $158 $159

$160 $161 $162 $163

$164 $165 $166 $167

$168 $169 $170 $171

2. The lock feature of P1~P4 break position in G31 can be specified by parameter G31 P1~4

signal source Local signal point serial numbers. Specified as 1~2: corresponding to 1st axis

card’s 1~2 Local Input, will save values in absolute position value recorder of each axis, and the

coordinate of break point can be obtained accurately. Specified as 3~8: corresponding to 1st axis

card’s 3~8 Local Input, for using software-specified lock action.

LNC Technology Co., Ltd. 35

Page 42

LNC Lathe

Syntax of G code

G33: Thread cutting

Format:

Argument:

X(U)___ : End point of X axis.(mm)

Z(W)___ : End point of Z axis.(mm)

F___ : Lead in longitudinal direction.(mm/rev)

G33 X(U)__ Z(W)__ F__; (Constant-lead thread cutting)

G33 X(U)__ Z(W)__ F__ Q__; (Mulitiple-thread cutting)

Example:

G33 X_ F_ ; Lead in direction of X axis.

G33 X_ Z_ F_; Lead in direction of X axis.(X_ > Z_)

Action:

G33 X_ Z_ F_; Lead in direction of Z axis. (X_ < Z_)

Q___ : Threading start angle. (Unit: 0.001deg. No decimal poiint. Range: 0 ~

360000)

1. F__ and Q__ are both norms. Once specified, there will be no need to input in later blocks.

2. In continuous G33 blocks, only the specified Q__ of the 1st G33 block is effective.

E.g.:

G33 W-10 F1 Q18000;----------------------------------------------------------Start angle is 180 degree

U-5 W-5 Q270000;------Due to continuous threading, the specified 270 degree is not effective

3. In G33 threading process, feed rate adjustment knob is not effective ( fixed to 100%).

In continuous G33 blocks, only the spindle turn around signal in the 1st block will be searched,

the signal will not be waited in later blocks.

E.g.:

G33 W-10 F1;------------------------------------------------------------------Wait for a turn around signal

U-5 W-10;---------------------------------------------------------------------------------------------Do not wait

U-10;---------------------------------------------------------------------------------------------------Do not wait

4. During threading, spindle speed can be adjusted, but it will result in threading error.

5. Because servo system follows the error, when threading, incomplete threads will occur at the

stard and end positions. In order to improve it, when perform threading, designate the length

of thread to be longer than actual necessity.

36 LNC Technology Co., Ltd.

Page 43

Example:

Self-defined departure angle and departure speed cutting (peroform cutting only once)

T0707;---------------------------------------------------------------------------------------------------Call for #7 tool

G00 X4.5 Z2.;----------------------------------------- X axis, Z axis rapidly move to cutting start position

G33 Z-12. F1;-------------------------------------------------------1st section of threading, thread pith 1mm

G33 X11.43 Z-14;-----------------------------------2nd section of threading, departure angle 60 degrees

G00 Z2;--------------------------------------------------------------------------------------Z axis rapid movement

M30;------------------------------------------------------------------------------------------------------Program ends

60°

LNC Lathe

Syntax of G code

G00

G

3

3

G33

ψ

5

1222

LNC Technology Co., Ltd. 37

Page 44

LNC Lathe

Syntax of G code

G34: Variable Thread Pith Threading

Format:

Argument:

X(U)___ : End point of X axis. (mm)

Z(W)___ : End point of Z axis. (mm)

F___ : Lead in longitudinal direction.(mm/rev)

Q___ : Threading start angle. (Unit: 0.001deg, no decimal poiint. Range: 0 ~

K___ : Lead per spindle revolution. (mm/rev)

G34 X(U)___Z(W)___ F___ Q___ K___

360000)

Increment in positive, and decrement in negative.

Action:

G34 has the same usage as G33 (excluding K___).

In continuous G34, K can be specified repeatly in every block (E.g. A lead which originally increase

gradually can turn to decrease gradually in the next block).

Example:

main program

T0707;----------------------------------------------------------------------------------------------------call for #7 tool

G0 X7.;-----------------------------------------------------------------------------------------move to start position

Z-5.;

G66 P0342 K0.1;------------------------------------------------Use G66 call for self-defined Macro O0342

X6.5;----------------------------------------------------------------------------------------------------------------1st cut

X6.25;--------------------------------------------------------------------------------------------------------------2nd cut

X6.04;--------------------------------------------------------------------------------------------------------------3rd cut

X5.9;----------------------------------------------------------------------------------------------------------------4th cut

X5.8;----------------------------------------------------------------------------------------------------------------5th cut

G67;------------------------------------------------------------------------------------------End self-defined Macro

G0 X20;

Z30;

M30;

subprogram

G33 U-2. F2;Use G33 thread pitch 4mm for approach (F=2mm is used to increase approach speed)

G34 W-15. K#11 F1;------------------------------------------------------variable lead thread cutting (K=0.1)

38 LNC Technology Co., Ltd.

Page 45

LNC Lathe

Syntax of G code

G33 U2 F4;Use G33 thread pitch 8mm for departure (F=4mmis used to increase departure speed)

G0 W15;--------------------------------------------------------------use G00 to rapidly return to start position

M99;-------------------------------------------------------------------------------------------------subprogram ends

W15

U2

W-15

U-2

ψ5

5153

LNC Technology Co., Ltd. 39

Page 46

LNC Lathe

Syntax of G code

Continuous Threading

command format 1: (continuous G33)

Action:

It is used to cut continuous threads. At the meantime, Z axis direction cutting amount or X axis

direction cutting amount both follow spindle revolve amount (please refer to the instruction on G33

argument F__).

Note:

1. Specified threading approach angle Q__ is only effective in the 1st block of continuous G33

blocks.

2. Thread pitch F__ can be specified in every block, and sothreads with variable thread pitch can be

made.

command format 2: (continuous G34)

G33 X(U)__ Z(W)__ F__ Q__;

G34 X(U)__ Z(W)__ F__ Q__ K__;

G33 X(U)__ Z(W)__ F__;

G33 X(U)__ Z(W)__ F__;

Action:

Note:

G34 X(U)__ Z(W)__ K__;

G34 X(U)__ Z(W)__ K__;

It is used for cutting continuous variable thread.

1. Designation of threading approach angle Q__ is only effective in the 1st block of continuous G34

blocks.

2. Designation of thread pitch F__ is only effective in the 1st block of continuous G34 blocks.

3. Thread increment K__ can be specified in every block.

40 LNC Technology Co., Ltd.

Page 47

command format 3: (combined G33, G34)

LNC Lathe

Syntax of G code

Action:

Achieve special thread cutting with features of continuous G33 and G34. G33 can change pitch in

continuous blocks, and G34 can change thread increment in continuous blocks, but start angle Q__

can still be specified in the 1st block only.

Example:

continuous thread cutting

main program

T0707;----------------------------------------------------------------------------------------------------call for #7 tool

G0 X12.;------------------------------------------------------X axis rapidly traverses to cutting start position

Z-5.;------------------------------------------------------------Z axis rapidly traverses to cutting start position

G66 P0332;-----------------------------------------------------------------------continuous call for subprogram

G33 X(U)__ Z(W)__ F__ Q__

G34 X(U)__ Z(W)__ F__ K__

G34 X(U)__ Z(W)__ K__

G33 X(U)__ Z(W)__ F__

X11.6;--------------------------------------------------------------------------------------------thread cutting 1st cut

X11.4;--------------------------------------------------------------------------------------------thread cutting 2nd cut

X11.1;--------------------------------------------------------------------------------------------thread cutting 3rd cut

X10.9;-------------------------------------------------------------------------------------------thread cutting 4th cut

X10.8;-------------------------------------------------------------------------------------------thread cutting 5th cut

G67;-------------------------------------------------------------------------------------cancel call for subprogram

G0 X20;--------------------------------------------------------------------------------------X axis rapidly traverses

Z30;-------------------------------------------------------------------------------------------Z axis rapidly traverses

M30;------------------------------------------------------------------------------------------------------program ends

subprogram

G33 U-7 F1;-----------------------------------------------------thread cutting approach thread pitch 1 mm

W-5;-----------------------------------------------------------------------------------------thread cutting 1st section

U5 W-10;--------------------------------------------------------------thread cutting 2nd section (taper section)

W-5;-----------------------------------------------------------------------------------------thread cutting 3rd section

U2;-------------------------------------------------------------------------------------------thread cutting departure

G0 W20;--------------------------------------------------------------------Z axisrapidly returns tostart position

M99;-----------------------------------------------------------------Return from subprogram to main program

LNC Technology Co., Ltd. 41

Page 48

LNC Lathe

Syntax of G code

multi-line continuous thread cutting

main program

T0707;----------------------------------------------------------------------------------------------------call for #7 tool

G0 X12.;------------------------------------------------------X axis rapidly traverses to cutting start position

Z-5.;------------------------------------------------------------Z axis rapidly traverses to cutting start position

G66 P0332 A0;-------------------------------------------------------------------continuous call for subprogram

X11.6;--------------------------------------------------------------------------------------------thread cutting 1st cut

X11.4;-------------------------------------------------------------------------------------------thread cutting 2nd cut

X11.1;-------------------------------------------------------------------------------------------thread cutting 3rd cut

X10.9;------------------------------------------------------------------------------------------thread cutting 4th cut

X10.8;------------------------------------------------------------------------------------------thread cutting 5th cut

G67;--------------------------------------------------------------------------------------cancelcall for subprogram

G66 P0332 A180000;--continuous call for subprogram, 2nd line of thread (start angle 180 degree)

X11.6;--------------------------------------------------------------------------------------------thread cutting 1st cut

X11.4;-------------------------------------------------------------------------------------------thread cutting 2nd cut

X11.1;-------------------------------------------------------------------------------------------thread cutting 3rd cut

X10.9;------------------------------------------------------------------------------------------thread cutting 4th cut

X10.8;------------------------------------------------------------------------------------------thread cutting 5th cut

G67;-------------------------------------------------------------------------------------cancel call for subprogram

G0 X20;--------------------------------------------------------------------------------------X axis rapidly traverses

Z30;-------------------------------------------------------------------------------------------Z axis rapidly traverses

M30;------------------------------------------------------------------------------------------------------program ends

subprogram

G33 U-7 F1 Q#1; approach, thread pitch 1 mm (#1 is thread approach position angle, inserted from

A__ to subprogram)

W-5;-----------------------------------------------------------------------------------------thread cutting 1st section

U5 W-10;---------------------------------------------------------------------------------thread cutting 2nd section

W-5;-----------------------------------------------------------------------------------------thread cutting 3rd section

U2;------------------------------------------------------------------------------------------------------------tool depart

G0 W20;------------------------------------------------------Z axis rapidly traverses (increment coordinate)

M99;-------------------------------------------------------------------return from subprogram to main program

42 LNC Technology Co., Ltd.

Page 49

sectional variable lead continuous thread cutting

main program

T0707;----------------------------------------------------------------------------------------------------call for #7 tool

G0 X12.;------------------------------------------------------X axis rapidly traverses to cutting start position

Z-5.;------------------------------------------------------------Z axis rapidly traverses to cutting start position

G66 P0332;-----------------------------------------------------------------------continuous call for subprogram

X11.6;--------------------------------------------------------------------------------------------thread cutting 1st cut

X11.4;-------------------------------------------------------------------------------------------thread cutting 2nd cut

X11.1;-------------------------------------------------------------------------------------------thread cutting 3rd cut

X10.9;------------------------------------------------------------------------------------------thread cutting 4th cut

X10.8;------------------------------------------------------------------------------------------thread cutting 5th cut

G67;--------------------------------------------------------------------------------------cancelcall for subprogram

G0 X20;--------------------------------------------------------------------------------------X axis rapidly traverses

LNC Lathe

Syntax of G code

Z30;----------------------------------------------------------------------------------------- Z axis rapidly traverses

M30;------------------------------------------------------------------------------------------------------program ends

subprogram

G33 U-7. F2.; -----------------------------------------------approach, thread pitch 2 mm

W-5. F1.25;-------------------------------------------------thread cutting 1st section, thread pitch 1.25 mm

U5. W-10. F1.5;---------------------------------------------thread cutting 2nd section, thread pitch 1.5 mm

W-5. F1.75;-------------------------------------------------thread cutting 3rd section, thread pitch 1.75 mm

U2. F2.;------------------------------------------------------------------------------departure, thread pitch 2 mm

G0 W20.;------------------------------------------------------------------Z axis rapidly returns to start position

M99;-------------------------------------------------------------------return from subprogram to main program

LNC Technology Co., Ltd. 43

Page 50

LNC Lathe

Syntax of G code

X11.6 1st cutting

X11.4 2nd cutting

X11.1 3rd cutting

X10.9 4th cutting

X10.8 5th cutting

W20

U2

ψ10

W-5

5

U

5

,

W

-

1

0

W-5

U-7

ψ5

10

5 5

44 LNC Technology Co., Ltd.

Page 51

G40, G41, G42: Tool nose radius compensation

Format:

LNC Lathe

Syntax of G code

Argument:

G40 : Tool nose radius compensation. (Cancel)

G41 : Tool nose radius compensation. (Left)

G42: : Tool nose radius compensation. (Right)

Action:

Blocks in which tool radius compensation value begins and cancels must be linear command ( G00

or G01), not arc command (G02 or G03).

Tool radius compensation can be divided into Type A and Type B, which is decided by parameter

0131.

Illustration:

G41: When face to tool movement direction,

tool shifts to the left for a radius.

G17

G18

G19

G40;

G41

G42

G42: When face to tool movement

direction, tool shifts to the right

for a radius.

LNC Technology Co., Ltd. 45

Page 52

LNC Lathe

Syntax of G code

Programming path

Actual tool path

TYPE A

Programming path

TYPE B

Actual tool path

Programming path

Actual tool path

Programming path

Actual tool path

46 LNC Technology Co., Ltd.

Page 53

G53: Machine coordinate system

Format:

LNC Lathe

Syntax of G code

Argument:

X___ : Tool traverses to machine coordinate of X axis.

Z___ : Tool traverses to machine coordinate of Z axis.

Action:

Machine home point is the fixed original position specified by a machine factory while producing

CNC machines. This coordinate system is fixed, and can not be changed. When designating G53

command and coordinate commands, tool traverses to the specified position on the basic machine

coordinate system. When tool returns to machine home point(0,0), the position of G53 is the original

position of the machine coordinate system.

G53 machine coordinate system is also called 00 coordinate system.

Note:

1. G53 command is only effective in the specified block.

G53 X__ Z__;

2. G53 is only effective in absolute value mode, not in incremental value mode.

3. Before G53 is specified, erase relevant tool radius, length or position compensation.

4. Befoire using G53 to set up coordinate system, manually set up a coordinate system based on

the returned position of reference position.

5. If G53 coordinate system has a set value, when executing G54~G59 coordinate system, an

offset occurs to G53 coordinate system’s set value.

Program Example :

G53 X20. Z20. ;-------------------------------------------------------------------(Move to machine coordinate)

G53 X10. Z50. ;-------------------------------------------------------------------(Move to machine coordinate)

LNC Technology Co., Ltd. 47

Page 54

LNC Lathe

Syntax of G code

+X

G53X20.Z20.

G53X10.Z50.

Zero point

+Z

Chuck

-X

48 LNC Technology Co., Ltd.

Page 55

G54 ~ G59: Selection of work coordinate system

Format:

LNC Lathe

Syntax of G code

Action:

G54;

G55;

G56;

G57;

G58;

G59;

The workpiece coordinate system adopts G54~G59 to represent 6 different coordinate systems.

Users can select among them according to manufacturing needs.

Each coordinate system’s original position offset can be set in〈OFFSET〉à〈coordinate system

setting〉; refer to operation manual for detailed instructions. Besides, it can also be set by G10

command, and please refer to G10 command for detailed instructions.

The relationship between each coordinate system is as the following: (default coordinate system

when system starts is G54 coordinate system)

G54

G54 Offset

00 Offset

Zero point

G55 Offset

00 Work coordinate

G59 Offset

G55

G56 Offset

G57 Offset

G59

G56

G58 Offset

G57

G58

LNC Technology Co., Ltd. 49

Page 56

LNC Lathe

Syntax of G code

Example:

G90 G54 G00 X100. Z100.;

G55 X100. Z100.;------------------------------------------------------------------------------------------------AàB

+X

100

+X

A(100,100)

G54

100

G53 Coordinate

+Z

100

+X

G55

B(100,100)

+Z

100

+Z

50 LNC Technology Co., Ltd.

Page 57

G61, G64: Exact stop mode / Cutting mode

Format:

LNC Lathe

Syntax of G code

Argument:

G61 : Exact stop mode

G64 : Cutting mode

Action:

G61’s function is the same as G09, while G09 is only effective in its block, G61 is effective ever

since it’s executed until G64 (general cutting ) is executed. G64 is the default system mode, unless

G61 is executed, system stays in G64 mode.

To cutting commands (G01/G02/G03), each axis’ positioning precision is set by parameter 0006 ~

0009; to rapid traverse (G00), each axis’ positioning precision is set by parameter 0800 ~ 0803.

Moreover, use parameter 0043 to define whether each axis’ correct positioning function is enabled.

Illustration:

G61;

G64;

Example:

G61 G91 G01 X100. F200.;---------------------------------------------------------------------Exact stop mode

Z100.;------------------------------------------------------------------------------------------------Exact stop mode

G64;-------------------------------------------------------------------------------------------------------Cutting mode

Tool path in G61

Tool path in G64

LNC Technology Co., Ltd. 51

Page 58

LNC Lathe

#2=3.0

Syntax of G code

G65: User macro simple call

Format:

Argument:

P__ : Number of the program to call. P9010 call file name O9010. If P_ is

L__ : Repetition count. (1 by default)

Besides P and L arguments, users can use other NC addresses (English letters excluding G, L, N, O,

P) to lead in arguments. The order of sequence does not matter. These argument values are

corresponding to local variables in called macro programs as the following charts:

Address

A #1

B #2

G65 P__ L__ <Argument…>;

inputted vacant, controller will have an alarm “INT 3111 Lack of file

name”.

Local

variable

Address

I #9

J #10

Local

variable

Address

T #20

U #21

Local

variable

C #3

D #4

E #5

F #6

H #8

O0001;

.

.

G65 P0008 L1 A2.0 B 3.0;

.

.

#1=2.0

K #11

M #13

Q #17

R #18

S #19

O0008;

#3=#1+#2;

G00 X#3;(G00 X5.0;)

M99;

V #22

W #23

X #24

Y #25

Z #26

M30;

52 LNC Technology Co., Ltd.

Page 59

LNC Lathe

Syntax of G code

In a G65 block, G65 must be prior to all arguments. G65 can do nested calls, the combination of

G65 and G66 can be up to the 4th level (excluding main program which is the 0th level), and each

level has its own local variables, as shown in the following charts:

Main program

(Level 0)

O0001;

..

#1=2.0

..

#1=1;

G65 P0002 A2.0;

..

..

M30;

Local variable

(Level 0)

#1

..

1 2 3 4 5

..

Macro

(Level 1)

O0002;

..

#1=3.0

..

..

G65 P0003 A3.0;

..

..

M99;

Local variable

(Level 1)

#1

..

..

Macro

(Level 2)

O0003;

..

#1=4.0

..

..

G65 P0004 A4.0;

..

..

M99;

Local variable

(Level 2)

#1

..

..

Macro

(Level 3)

O0004;

..

#1=5.0

..

..

G65 P0005 A5.0;

..

..

M99;

Local variable

(Level 3)

#1

..

..

Macro

(Level 4)

O0005;

..

..

..

..

..

..

M99;

Local

variable

(Level 4)

#1

..

..

..

#33

..

..

#33

..

..

#33

..

..

#33

..

..

#33

..

LNC Technology Co., Ltd. 53

Page 60

LNC Lathe

Call

O0008

After move end, call

O0008

Syntax of G code

G66: User macro modal call

Format:

Argument:

P__ : Number of the program to call. P9010 call file name O9010. If P_ is

L__ : Repetition count. (1 by default)

Besides P and L arguments, users can use other NC addresses (English letters excluding G, L, N, O,

P) to lead in arguments. The order of sequence does not matter. These argument values are

corresponding to local variables in called macro programs, and please refer to G65 for relevant

instructions.

Action:

The only difference between G66 and G65 is that G65 calls a macro program which is used for only

one time, but the macro programs called by G66 will be called every time when a motion block

finishes until G67 is used to cancel this mode.

G66 P__ L__ <argument…>;

inputted vacant, controller will have an alarm “INT 3111 Lack of file

name”.

O0001;

.

.

G66 P0008 L1 A 2.0 B3.0;

G91 G00 Y10.;

After move end, call O0008

O0008;

#3=#1+#2;

G91 G00 Z#3;

Z-#3;

Return O0001

M99;

Y10.;

Y10.;

After move end, call O0008

G67;

Y10.;

.

.

In a G66 block, G66 must be prior to all arguments. G66 can do nested calls. The combination of G65 and

G66 can be up to the 4th level (excluding main program which is the 0th level), but G66’s argument

(corresponding to macro program’s local variables) is only specified once in the block of G66, and it won’t be

respecified in following mode calls.

54 LNC Technology Co., Ltd.

Page 61

G67: User macro modal call cancel

Format:

LNC Lathe

Syntax of G code

Action:

G67;

G67 is applied to cancel the calling for G66 macro program mode.

LNC Technology Co., Ltd. 55

Page 62

LNC Lathe

X Z

Syntax of G code

G68: Mirror image for double turrets ON

G69: Mirror image for double turrets OFF

Format:

Action:

This G CODE group mode can be obtained through system variable $16.

Once enter G68 mode, users can only cancel it by G69, i.e. clicking RESET button will not change

this mode.

When users execute G68 command, NC will at first make an offset to the coordinate system of the

corresponding tool on the other side (the distance bwtween the two paired tools is specified by

system parameter #1099); latter on, the specified X axis command amount in the manufacturing

program will take Z axis as the center axis and be mirrored to the other side.

Illustration:

○

6

○

5

○

G68;

G69;

Tool A

4

1

○

2

3

○

○

ψ80

5

○

56 LNC Technology Co., Ltd.

4

○

ψ60

3

○

ψ40

2

○

1

○

140

Tool B

Page 63

LNC Lathe

Syntax of G code

…

T0101;--------------------------------------------------------------------------------------------------------------Tool A

G00X40.Z150.;-------------------------------------------------------------------------------------------------Path ○1

G01Z120.F0.1;-------------------------------------------------------------------------------------------------Path ○2

G68;---------------------------------------------------------------------Mirror image of X axis ON. B(-140mm)

T0202;--------------------------------------------------------------------------------------------------------------Tool B

G00X60.---------------------------------------------------------------------------------------------------------Path ○3

G01Z100.;-------------------------------------------------------------------------------------------------------Path ○4

G69;---------------------------------------------------------------------Mirror image of X axis OFF. A(140mm)

T0101;---------------------------------------------------------------------------------------------------------------Toll A

G00X80.;--------------------------------------------------------------------------------------------------------Path ○5

G01Z50.;--------------------------------------------------------------------------------------------------------Path ○6

…

LNC Technology Co., Ltd. 57

Page 64

LNC Lathe

Syntax of G code

G70: Finishing Cycle

Format:

Argument:

P__ : Sequence number of the first block for the program of finishing

Q__ : Sequence number of the last block for the program of finishing

Action:

It is used after G71, G72, G73 rough cutting cycles along with G70 command to perform precise

cutting to obtain desired size.

Please refer to G71 for examples.

shape.

shape.

G70 P__ Q__;

58 LNC Technology Co., Ltd.

Page 65

G71: Stock removal in turning

Format:

LNC Lathe

Syntax of G code

Argument:

U d : Depth of cut in X axis direction. (Radius designation) This value can

R e : Escaping amount. This value can be specified by the parameter

P ns : Sequence number of the first block for the program of finishing

Q nf : Sequence number of the last block for the program of finishing

U___ : Distance and direction of finishing allowance in X axis direction.

W___ : Distance and direction of finishing allowance in Z axis direction.

F___ : Feedrate.

T___ : Tool number.

G71 U d R e ;

G71 P ns Q nf U W F S T ;

be specified by the parameter (P1081).

(P1082).

shape.

shape.

Action:

Note:

S___ : Spindle speed.

1. Rapidly traverse (G00) to A position (start position) before cycle begins;

2. After executing G71 command, tool takes the set preserved precise cutting amount (X axis is

U/2, Z axis is W) as the offset amount;

3. Tool again traverses to Z axis for a distance of U(d), and traverse to outline surface;

4. Then depart in Z axis direction for a distance of e at 45∘, and X axis traverse in the opposite

direction until the adjacent position which is parallel to the start position;

5. Then depart in Z axis direction for a distance of U(d) to continue the next repeated cycle ;

6. As the last cycle ends, tool lathe cutting once along outline A'àB;

7. When finishes, tool rapidly traverses to A position, and waits for next cycle to start.

1. Outline path is specified by blocks between ns and nf, ranges from A position to A' position then

to B position.

2. F, S, T commands specified in blocks between nsànf are not effective, they can be effective

only when written in blocks of rough lathing cycle (G71).

3. Blocks between nsànf can not do subprogram call .

LNC Technology Co., Ltd. 59

Page 66

LNC Lathe

Syntax of G code

Illustration:

B

C

A

Δd

45°

e

ΔW

Δu/2

60 LNC Technology Co., Ltd.

Page 67

G72: Stock removal in facing

Format:

LNC Lathe

Syntax of G code

Argument:

W d : Depth of cut in Z axis direction. This value can be specified by the

R e : Escaping amount. This value can be specified by the parameter

P ns : Sequence number of the first block for the program of finishing

Q nf : Sequence number of the last block for the program of finishing

U___ : Distance and direction of finishing allowance in X axis direction.

W___ : Distance and direction of finishing allowance in Z axis direction.

F___ : Feedrate.

T___ : Tool number.

G72 W d R e ;

G72 P ns Q nf U W F S T ;

parameter (P1081).

(P1082).

shape.

shape.

Action:

Note:

S___ : Spindle speed.

1. Rapidly traverse (G00) to A position (start position) before cycle begins;

2. After executing G72 command, tool takes the set preserved precise cutting amount (X axis is

U/2, Z axis is W) as the offset amount;

3. Tool again traverses to Z axis for a distance of U(d), and traverse to outline surface;

4. Then depart in Z axis direction for a distance of R(e) at 45∘, and X axis traverse in the opposite

direction until the adjacent position which is parallel to the start position;

5. Then depart in Z axis direction for a distance of U(d) to continue the next repeated cycle ;

6. As the last cycle ends, tool lathe cutting once along outline A'àB;

7. When finishes, tool rapidly traverses to A position, and waits for next cycle to start.

1. Outline path is specified by blocks between ns and nf, ranges from A position to A' position then

to B position.

2. F, S, T commands specified in blocks between nsànf are not effective, they can be effective

only when written in blocks of rough lathing cycle (G72).

3. Blocks between nsànf can not do subprogram call .

LNC Technology Co., Ltd. 61

Page 68

LNC Lathe

Syntax of G code

Illustration:

Δu/2 Δd

ΔW

A'

A

e

B

C

45°

62 LNC Technology Co., Ltd.

Page 69

G73: Pattern repeating

Format:

LNC Lathe

Syntax of G code

Argument:

U i : Distance and direction of relief in X axis direction. (Radius

W k : Distance and direction of relief in Z axis direction. This value can be

R d : The number of division. This value can be specified by the parameter

P ns : Sequence number of the first block for the program of finishing

Q nf : Sequence number of the last block for the program of finishing

U___ : Distance and direction of finishing allowance in X axis direction.

W___ : Distance and direction of finishing allowance in Z axis direction.

G73 U i W k R d ;

G73 P ns Q nf U W F S T ;

designation) This value can be specified by the parameter (P1083).

specified by the parameter (P1084).

(P1085).

shape.

shape.

Action:

F___ : Feedrate.

S___ : Tool number.

T___ : Spindle speed.

G73 command is an outline forming rough lathing cycle which is used when the workpiece is a

welding or casting product with preliminary shapes, and with a size slightly bigger than precise

manufacturing, hence if using G71, G72 lathe command will result in generating many unnecessary

cutting path and the waste of time. Therefore, G73 (mixed-type outline rough cutting fixed cycle ) is

used to make repeated lathing which can move along workpiece’s indigenous outline, repeat cutting

for necessary times, and move for a suitable distance and depth in each cycle.

1. Traverse tool to A position (start position) before cycle begins;