LNC Technology LNC-Lathe Programming Manual

LNC Technology Co., Ltd. 1

Leading Numerical Controller

LNC-Lathe Series

P

P

r

r

o

o

g

g

r

r

a

a

m

m

m

m

i

i

n

n

g

g

M

M

a

a

n

n

u

u

a

a

l

l

2007/12 Ver:V04.00.003

LNC Technology Co., Ltd.

LNC Lathe

Table of Content

LNC Technology Co., Ltd. I

Table of Content

1 G-CODE FUNCTION TABLE....................................................................1

2 GENERAL M-CODE FUNCTION TABLE.................................................5

3 SYNTAX OF G CODE...............................................................................7

G00: Positioning in rapid....................................................................................................................7

G01: Linear interpolation....................................................................................................................9

G02, G03: Circular interpolation (cw./ccw.).......................................................................................10

Direct pattern making.......................................................................................................................12

G04: Dwell.......................................................................................................................................23

G09: Exact stop................................................................................................................................24

G10: Data setting.............................................................................................................................25

G20, G21: Inch \ mm input................................................................................................................27

G22, G23: Stored stroke check ON / OFF.........................................................................................28

G27: Reference position return check...............................................................................................29

G28: 1st reference position return.....................................................................................................30

G29: From 1st reference position return............................................................................................31

G30: 2nd,3rd,4th, reference position return.......................................................................................32

G31: Skip function............................................................................................................................34

G33: Thread cutting..........................................................................................................................36

G34: Variable Thread Pith Threading................................................................................................38

Continuous Threading......................................................................................................................40

G40, G41, G42: Tool nose radius compensation...............................................................................45

G53: Machine coordinate system......................................................................................................47

G54 ~ G59: Selection of work coordinate system..............................................................................49

G61, G64: Exact stop mode / Cutting mode......................................................................................51

G65: User macro simple call.............................................................................................................52

G66: User macro modal call.............................................................................................................54

G67: User macro modal call cancel..................................................................................................55

G68: Mirror image for double turrets ON...........................................................................................56

G69: Mirror image for double turrets OFF.........................................................................................56

G70: Finishing Cycle........................................................................................................................58

LNC Lathe

G-Code Function Table

II LNC Technology Co., Ltd.

G71: Stock removal in turning...........................................................................................................59

G72: Stock removal in facing............................................................................................................61

G73: Pattern repeating.....................................................................................................................63

G74: End face peck drilling cycle (Z axis).........................................................................................65

G75: Outer diameter / Internal diameter drilling cycle (X axis)...........................................................66

G76: Multiple thread cutting cycle.....................................................................................................67

G77: Outer diameter/internal diameter cutting cycle..........................................................................69

G78: Taper thread cutting cycle........................................................................................................70

G79: End face turning cycle..............................................................................................................75

G80: Canned cycle for drilling cancel................................................................................................76

G83: Face drilling cycle....................................................................................................................77

G84: Face tapping cycle...................................................................................................................81

G85: Face boring cycle.....................................................................................................................83

G87: Side drilling cycle (X axis)........................................................................................................85

G88: Side tapping cycle (X axis).......................................................................................................89

G89: Side boring cycle (X axis).........................................................................................................92

G187: Side drilling cycle (Y axis)......................................................................................................94

G188: Side tapping cycle (Y axis).....................................................................................................98

G189: Side boring cycle (Y axis).....................................................................................................100

G90, G91: Absolute / Incremental programming..............................................................................102

G92: Coordinate system setting or max. spindle speed setting........................................................103

G94, G95: Feed per minute (mm/min), Feed per revolution (mm/rev)..............................................104

G96, G97: Constant surface speed control ON / OFF.....................................................................105

G98, G99: Intial point return / R point return....................................................................................106

4 AUXILIARY FUNCTION (M CODE)......................................................107

5 MACRO.................................................................................................112

5.1 Macro program introduction.....................................................................................................112

5.2 User macro call.......................................................................................................................113

5.3 Difference between macro program call (G65) and general subprogram call (M98)..................118

5.4 MACRO function list................................................................................................................119

5.5 Variable...................................................................................................................................120

5.6 Mathematics command............................................................................................................130

5.7 Logic command.......................................................................................................................131

LNC Lathe

Table of Content

LNC Technology Co., Ltd. III

5.8 Compare command.................................................................................................................132

5.9 Procedures control command..................................................................................................133

5.10 Function..................................................................................................................................134

5.11 Note........................................................................................................................................136

LNC Lathe

G-Code Function Table

LNC Technology Co., Ltd. 1

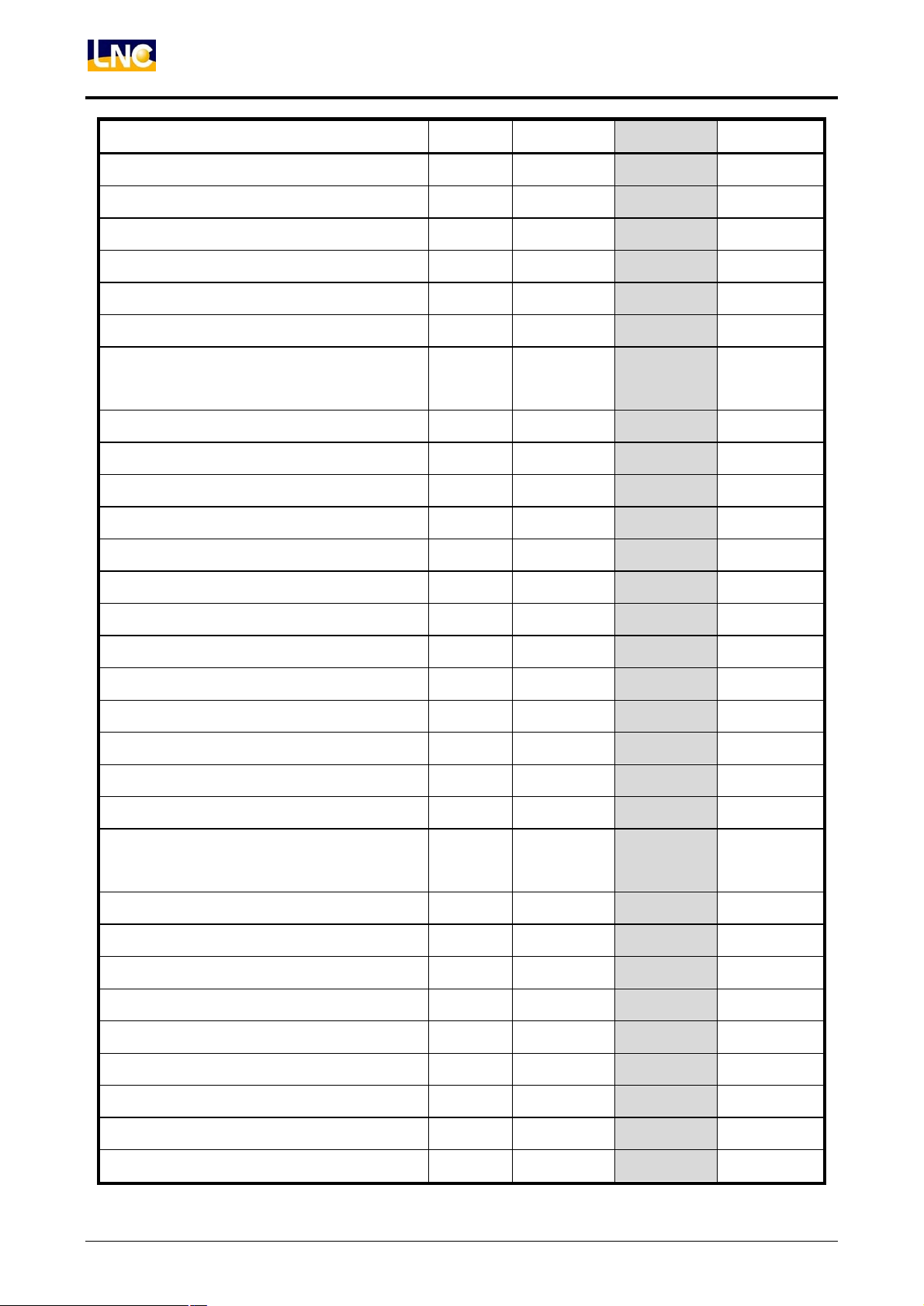

1 G-Code Function Table

Function Group TYPE A TYPE B TYPE C

Positioning in rapid 01 G00 G00 G00

Linear interpolation 01 G01 G01 G01

Circular interpolation (cw.) 01 G02 G02 G02

Circular interpolation (ccw.) 01 G03 G03 G03

Dwell 00 G04 G04 G04

Exact stop 00 G09 G09 G09

Data setting 00 G10 G10 G10

ARC Plane Setting 02 G17~19 G17~19 G17~19

input in inch 06 G20 G20 G70

input in mm 06 G21 G21 G71

Stored stroke check ON 09 G22 G22 G22

Stored stroke check OFF 09 G23 G23 G23

Reference position return check 00 G27 G27 G27

1st reference position return 00 G28,G29 G28,G29 G28,G29

2nd,3rd,4th, reference position return 00 G30 G30 G30

Skip function 00 G31 G31 G31

Thread cutting 01 G32 G33 G33

Variable Thread Pith Threading 01 G34 G34 G34

Tool nose radius compensation Cancel 07 G40 G40 G40

Tool nose radius compensation Left 07 G41 G41 G41

Tool nose radius compensation Right 07 G42 G42 G42

Machine coordinate system 00 G53 G53 G53

Selection of work coordinate system 14 G54 ~G59 G54 ~ G59

G54 ~ G59

Exact stop mode 15 G61 G61 G61

Cutting mode 15 G64 G64 G64

User macro simple call 00 G65 G65 G65

User macro modal call 12 G66 G66 G66

User macro modal call cancel 12 G67 G67 G67

Mirror image for double turrets ON 16 G68 G68 G68

LNC Lathe

G-Code Function Table

2 LNC Technology Co., Ltd.

Function Group TYPE A TYPE B TYPE C

Mirror image for double turrets OFF 16 G69 G69 G69

Finishing Cycle 00 G70 G70 G72

Stock removal in turning 00 G71 G71 G73

Stock removal in facing 00 G72 G72 G74

Pattern repeating 00 G73 G73 G75

End face peck drilling cycle (Z axis) 00 G74 G74 G76

Outer diameter / Internal diameter drilling cycle

(X axis)

00 G75 G75 G77

Multiple thread cutting cycle 00 G76 G76 G78

Outer diameter/internal diameter cutting cycle 01 G90 G77 G20

Taper thread cutting cycle 01 G92 G78 G21

End face turning cycle 01 G94 G79 G24

Canned cycle for drilling cancel 10 G80 G80 G80

Face drilling cycle 10 G83 G83 G83

Face tapping cycle 10 G84 G84 G84

Face boring cycle 10 G85 G85 G85

Side drilling cycle (X axis) 10 G87 G87 G87

Side tapping cycle (X axis) 10 G88 G88 G88

Side boring cycle (X axis) 10 G89 G89 G89

Absolute programming 03 - G90 G90

Incremental programming 03 - G91 G91

Coordinate system setting or max. spindle

speed setting

00 G50 G92 G92

Feed per minute (mm/min) 05 G98 G94 G94

Feed per revolution (mm/rev) 05 G99 G95 G95

Constant surface speed control ON 02 G96 G96 G96

Constant surface speed control OFF 02 G97 G97 G97

Intial point return 11 - G98 G98

R point return 11 - G99 G99

Side drilling cycle (Y axis) 10 187 187 187

Side tapping cycle (Y axis) 10 188 188 188

Side boring cycle (Y axis) 10 189 189 189

LNC Lathe

G-Code Function Table

LNC Technology Co., Ltd. 3

Function Group TYPE A TYPE B TYPE C

(Note)The TYPE is A, B or C to decide on the Pr153, default is TYPE B.

LNC Lathe

General M-Code Function Table

LNC Technology Co., Ltd. 5

2 General M-Code Function Table

M Code Function Remark

M00 Program stop CNC

M01 Optional stop CNC

M02 End of program CNC

M03 Spindle CW

M04 Spindle CCW

M05 Spindle stop

Txx Auto tool change

xx:Tool no.

M08 Coolant ON

M09 Coolant OFF

M10 Chuck clamp

M11 Chuck unclamp

M30 Program rewind CNC

M98 Calling of subprogram CNC

M99 End of subprogram CNC

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 7

3 Syntax of G code

G00: Positioning in rapid

Format:

G00 X___ Y___ Z___ C___;

Argument:

X__ Y__ Z__

C__

:

For G90, the coordinate of an end point in absolute command.

For G91, the coordinate of an end point in Incremental command.

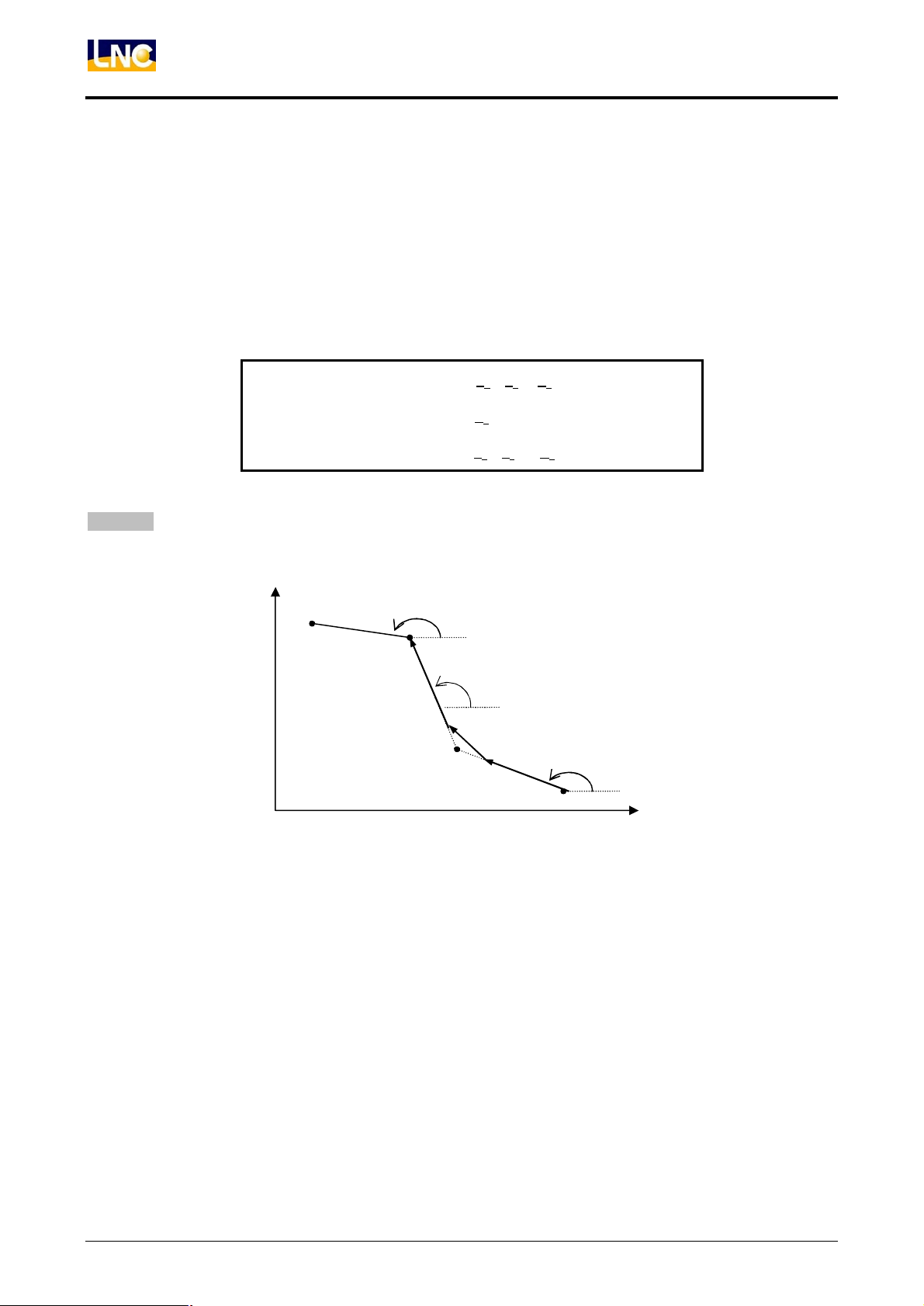

Action:

The function of G00 command is to make the tool move to the position of the specified coordinate

rapidly.

When using G00, the speed of moving is not descided by the format of F__, but by setting values of

parameter 1000 ~ 1003. Meanwhile, the rapid traverse adjustment knob can be used to adjust the

percentage of speed. (F0, 25%, 50%, 100%)

Illustration:

Note:

Regarding G00 movement command, the movement of each servo axis is independent. The

movement speed of each axis is specified by parameters respectively. Operators should be

especially careful lest the tool may collide with the workpiece.

X

Y

Z

Start

Target

Tool path

LNC Lathe

Syntax of G code

8 LNC Technology Co., Ltd.

Methods of determing G00 simultaneously interpolated feed rate

G00 command or commands with same

function under MEM, MDI modes

G00, G53 command of PMC axis function

None dry run

mechanism

Moving speed of each

axis does not exceed

respectively set G00 speed (Remark 1)

Moving speed of each axis does not

exceed respectively set G00 speed

Dry run mechanism

paremeter 0083 is 0

Moving speed of each axis does not exceed

respectively set JOG speed (Remark 2)

C23 is OFF: Moving speed of each axis

does not exceed respectively set JOG

speed

C23 is ON: Moving speed of each axis

does not exceed respectively set G00

speed

Dry run mechanism

paremeter 0083 is 1

Moving speed of each axis does not exceed

respectively set G00 speed

Moving speed of each axis does not

exceed respectively set G00 speed

Remark 1 Under this condition, Override depends on rapid traverse percentage.

Remark 2 Under this condition, Override depends on cutting feed percentage.

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 9

G01: Linear interpolation

Format:

G01 X(U)___ Z(W)___ F___;

Argument:

X___, Z___ :

For G90, the coordinate of an end point in absolute command.

For G91, the coordinate of an end point in Incremental command.

U___, W___ :

For G90/G91, the coordinate of an end point in Incremental

command.

F___ :

Feedrate.

Action:

G01 depends on the interpolation feed rate specified by F code, starts from current tool position, to

cut in a linear path to the end. Axes which are not specified do not move. Actual cutting feed can be

adjusted by the continuous feed rate adjustment knob at any time (0%-150%).

Max interpolation feed rate of G01 is specified by system parameter 1004. Acc/Dec time of G01 is

specified by system parameter 0014.

Illustration:

G90 G92 X100. Z100.;

G01 X10. Z10. F50;

(100,100)

(10,10)

G91 G92 X100. Z100.;

G01 X10. Z10. F50;

(100,100)

(110,110)

G92 X100. Z100.;

G01 U10. W10. F50;

(100,100)

(110,110)

G90 G92 X100. Z100.;

G01 X10. F50;

(100,100)

(10,100)

LNC Lathe

Syntax of G code

10 LNC Technology Co., Ltd.

G02, G03: Circular interpolation (cw./ccw.)

Format:

;F__

R__

I__K__

Z(W)__X(U)__

G03

G02

Argument:

X___, Z___ :

For G90, the coordinate of an end point in absolute command.

For G91, the coordinate of an end point in Incremental command.

U___, W___ :

For G90/G91, the coordinate of an end point in Incremental

command.

R___ :

Arc radius. (R>0, Arc<=180°. R<0. Arc>180°)

I___ :

Xp axis distance from start point to the center of an arc. Xp is a

component in X direction.

K___ :

Zp axis distance from start point to the center of an arc. Zp is a

component in Z direction.

F___ :

Feedrate.

Action:

Pay attention to current tool position. The end point and the center of circle should be in the same

circle. If not, the controller emits an error signal INT 132. When R___, I___, and K___ of the

program are all written-in, system will depends only on the setting of R___.

System parameter 132 (XRC) defines if X (U) position is radius-specified or diameter-specified.

Radius-specified (XRC=1) and diameter-specified (XRC=0) differ in 2 times of the actual movement

amount of X axis. E.g. The movement amount of radius-specified U-10 is equal to

diameter-specified U-20.

G

0

3

Centre

K

+X

G

0

3

I

+Z

Starting point

G

0

2

End point

Centre

+X

+Z

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 11

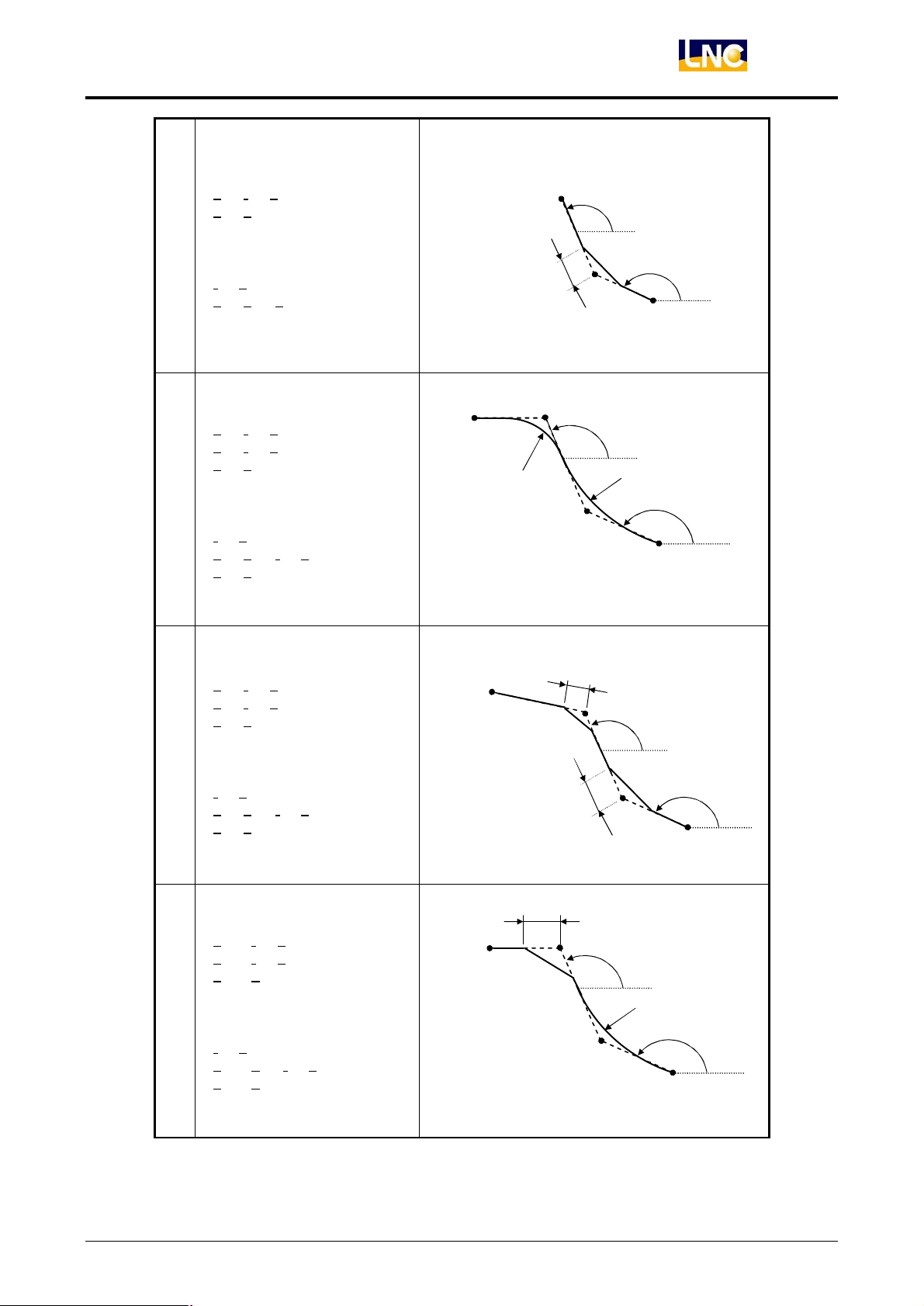

Illustration:

The following 4 figures have the same cutting path of a clockwise cutting of a 1/4 circle, and the

radius is 5.

(In radius programming)

G91 G92 X100. Z100.;

G02 X-5. Z5. I-5. K0. F50;

(In radius programming)

G90 G92 X100. Z100.;

G02 X95. Z105. I-5. K0. F50;

(In diameter programming)

G91 G92 X100. Z100.;

G02 X-10. Z5. I-5. K0. F50;

(In diameter programming)

G90 G92 X100. Z100.;

G02 X90. Z105. I-5. K0. F50;

(100,100)

(90,100)

(100,100)

(90,100)

(100,100)

(90,100)

(100,100)

(90,100)

LNC Lathe

Syntax of G code

12 LNC Technology Co., Ltd.

Direct pattern making

In order to make the manufacturing of workpieces easier, the controller provides functions of making corner

chamfering (,C_), corner rounding (,R_) and angle of straight line (A_).

1. Chamfering “,C_”

Continuous 2 blocks of command. In the 1

st

block, C_ sets up chamfer length between the 2 blocks. It is

applicable also when the previous and next blocks are circular commands.

Format:

Z__;X__

G03

G02

G01

C__; , Z__X__

G03

G02

G01

Example:

G00 X20.0 Z40.0

G01 X80.0,C10.0 F100.0

G01 Z10.0

End point of

1st block

,C_

X

Z

C10

Z

X

(20,40)

(80,40)

(80,10)

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 13

2. Corner Rounding “,R_”

Continuous 2 blocks of command. In the 1

st

block,,R_ sets up the radius of the rounding corner linking the

2 blocks. It is applicable also when the previous and next blocks are circular commands.

Format:

Z__;X__

G03

G02

G01

R__; , Z__X__

G03

G02

G01

Example:

G00 X20.0 Z0.0

G02 X20.0 R10.0,R3.0 F100.0

G01 Z30.0

Z

X

,R_

X

(20,0)

(20,20)

(20,30)

R10

Z

LNC Lathe

Syntax of G code

14 LNC Technology Co., Ltd.

3. Angle of Straight Line ”A_”

When applying linear interpolation command G01, only the positions of X_ or Z_ and the angle of the line

A_ can be specified. The actual position of the corresponding end point will be calculated by the controller.

It is especially convenient when the manufacturing drawing provides only coordinates of X or Z directions

and angles.

Format:

A__;

Z__

X__

G01

Wherein A_ angle is calculated from the horizontal direction (Z axis). A positive value of A represents

a counterclockwise direction, and vice versa.

Example:

G00 X10.0 Z10.0

G01 X20.0 A27.0 F100.0

Z

X

(X, Z)

A-

Z

X

(X, Z)

A+

X

(10,10)

(20, ??)

27°

Z

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 15

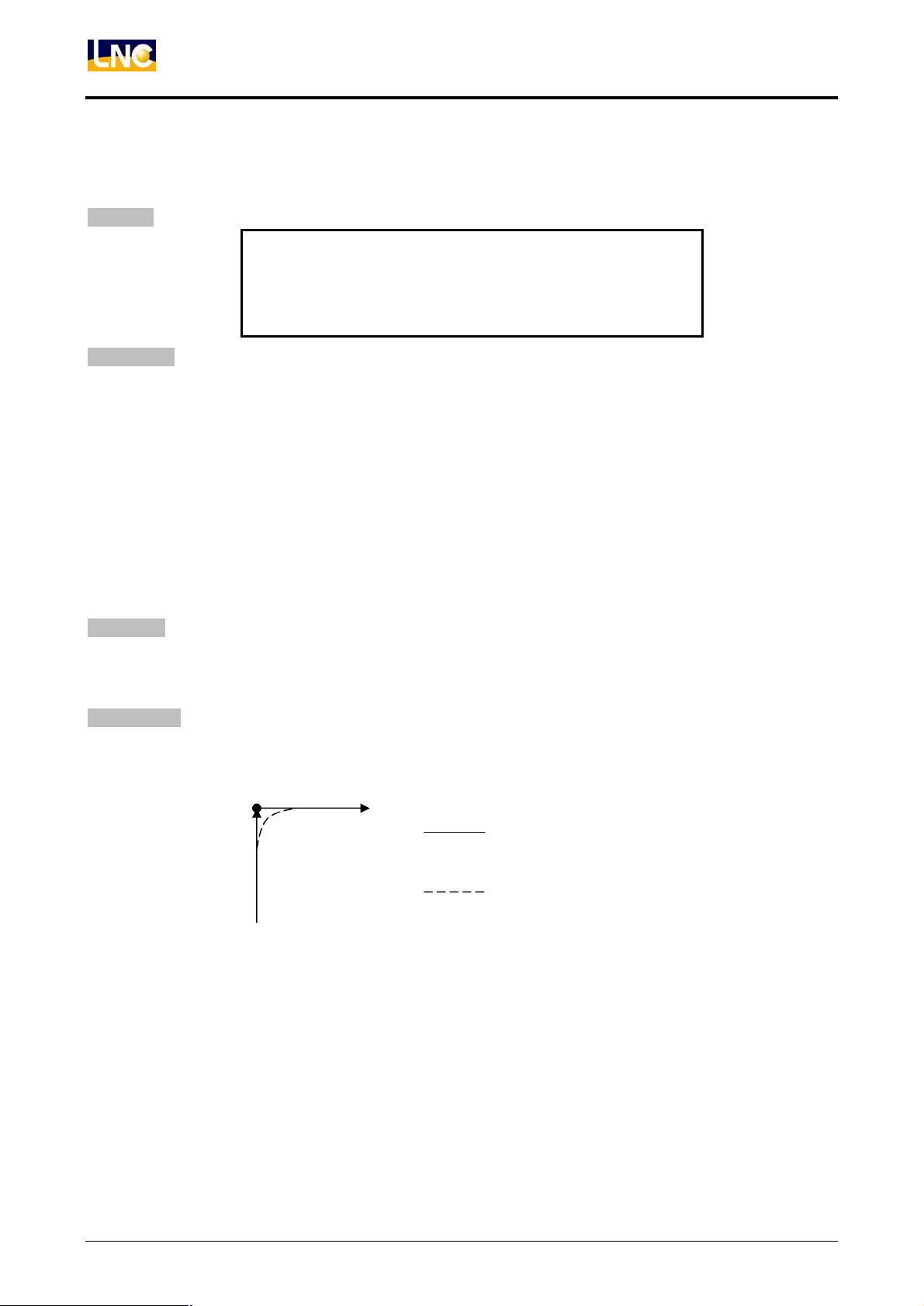

4. Geometric input function

In a manufacturing drawing, it is often that angles are provided, but not correct cutting positions; or that

only the size of corner or round corner is provided when making a corner. Therefore the calculation of the

coordinates of the intermediate point can be inconvenient when transforming the data to linear and

circular cutting command while compiling a manufacturing program. This function makes compiling

programs more easily, and help avoid calculation errors.

l Type 1

Intersection point of 1

st

and 2

nd

blocks is unknown

Angles of 1

st

and 2

nd

blocks are known

End point coordinates are known

Format:

N01 G01 Aa

1

N02 G01 Xx

3

Zz

3

Aa

2

a

1

a

2

?

(x3, z3)

Z

X

N01

N02

(x1, z1)

LNC Lathe

Syntax of G code

16 LNC Technology Co., Ltd.

Example:

G00 X0.0 Z0.0

G01 A30.0

G01 X10.0 Z30.0 A-45.0

l Type 2

Intersection point of 1

st

and 2

nd

blocks is unknown

Angles of 1

st

and 2

nd

blocks are known

End point coordinates are known

Corner of 1

st

and 2

nd

blocks is chamfer or fillet

N01 G01 Aa1,Cc1 (,Rr1)

N02 G01 Xx3 Zz3 Aa2

Format:

-45°

(10,30)

X

30°

Coordinates of intermediate point are unknown

Z

C1 or r1

a

2

a

1

?

(z

3

,z

3

)

N01

N02

(z

1

,z

1

)

Z

X

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 17

l Type 3

Either X_ or Z_ of the intersection point of 1

st

and 2

nd

blocks is known

Intersection point of 2

nd

and 3

rd

blocks is unknown

Coordinates of end point of 3

rd

block are known

Angles of 1

st

, 2

nd

and 3

rd

blocks are known

N01 G01 Xx2(Zz2) Aa1

N02 G01 Aa2

N03 G01 Xx4 Zz4 Aa3

Format:

Z

X

a

2

a

1

?

(z

2

,z

2

)

N01

N03

a

3

(z

4

,z

4

)

N02

LNC Lathe

Syntax of G code

18 LNC Technology Co., Ltd.

l Tyep 4

Intersection point of 1

st

and 2

nd

blocks is known

Intersection point of 2

nd

and 3

rd

blocks is unknown

Coordinates of end point of 3

rd

block is known

Angles of 1

st

, 2

nd

and 3

rd

blocks are known

Corner of 1

st

and 2

nd

blocks is chamfer or fillet

N01 G01 Xx

2

(Zz

2

) Aa

1

N02 G01 Aa

2

N03 G01 Xx

4

Zz

4

Aa

3

Format:

Z

X

C

1

or r1

a

2

a

1

?

(z

2

,z

2

)

N01

N03

a

3

(z

4

,z

4

)

N02

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 19

l Type 5

Intersection point of 1

st

and 2

nd

blocks is unknown

Intersection point of 2

nd

and 3

rd

blocks is known

Coordinates of end point of 3

rd

block are known

Angles of 1

st

and 2

nd

blocks are known

Corner of 1

st

and 2

nd

blocks is chamfer or fillet

Corner of 2

nd

and 3

rd

blocks is chamfer or fillet

N01 G01 Xx

2

Zz

2

,Cc

1

(,Rc

1

)

N02 G01 Aa

2

N03 G01 Xx

3

Zz

3

Aa

1

Format:

Note:

1. The following G codes can not be in the same block with geometric input commands, or be used to

input pattern size of continuous shapes.

a. G codes of Group 00 (excluding G04)

b. G02, G03, G90, G92, G94 of Group 01

2. Only be effective under MEM Mode

3. Fillet command can not be used in thread-cutting blocks.

4. When applying G01 X_ A_, if angle value is 0∘±1, 180∘±1, then the command is ineffective.

5. When applying G01 Z_ A_, if angle value is 90∘±1, 270∘±1, then the command is ineffective.

6. If the angle between 2 lines is within +1∘, chamfering and filleting will be ignored.

Z

C1 or r1

a

2

a

1

(z

3

,z

3

)

?

N01

N03

(z

4

,z

4

)

N02

C2 or r2

X

LNC Lathe

Syntax of G code

20 LNC Technology Co., Ltd.

Table of usages of geometric commands

Command Illustration

1

X

2

(Z

2

_) A

2

A

1

X

3

Z

3

A

2

3

X

2

Z

2

,R

1

X

3

Z

3

or

A

1

,R

1

X

3

Z

3

A

2

(X

1,

Z

1

)

A

(X

2,

Z

2

)

(X

2,

Z

2

)

(X

1,

Z

1

)

A

2

(X

3,

Z

3

)

A

1

(X

2

,

Z

2

)

(X

1,

Z

1

)

A

1

(X

3,

Z

3

)

A

2

R

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 21

4

X

2

Z

2

,C

1

X

3

Z

3

or

A

1

,C

1

X

3

Z

3

A

2

5

X

2

Z

2

,R

1

X

3

Z

3

,R

2

X

4

Z

4

or

A

1

,R

1

X

3

Z

3

A

2

,R

2

X

4

Z

4

6

X

2

Z

2

,C

1

X

3

Z

3

,C

2

X

4

Z

4

or

A

1

,C

1

X

3

Z

3

A

2

,C

2

X

4

Z

4

7

X

2

Z

2

,R

1

X

3

Z

3

,C

2

X

4

Z

4

or

A

1

,R

1

X

3

Z

3

A

2

,C

2

X

4

Z

4

(X

2,

Z

2

)

(X

1,

Z

1

)

A

1

(X

3,

Z

3

)

A

2

C

1

(X

2,

Z

2

)

(X

1,

Z

1

)

A

1

(X

3,

Z

3

)

A

2

R

1

(X

4,

Z

4

)

R

2

(X

2,

Z

2

)

(X

1,

Z

1

)

A

1

(X

3,

Z

3

)

A

2

C

1

C

2

(X

4,

Z

4

)

(X

2,

Z

2

)

(X

1,

Z

1

)

A

1

(X

3,

Z

3

)

A

2

R

1

(X

4,

Z

4

)

C

2

LNC Lathe

Syntax of G code

22 LNC Technology Co., Ltd.

8

X

2

Z

2

,C

1

X

3

Z

3

,R

2

X

4

Z

4

or

A

1

,C

1

X

3

Z

3

A

2

,R

2

X

4

Z

4

(X

2,

Z

2

)

(X

1,

Z

1

)

A

1

(X

3,

Z

3

)

A

C

1

R

2

(X

4,

Z

4

)

LNC Lathe

Syntax of G code

LNC Technology Co., Ltd. 23

G04: Dwell

Format:

G04 X___;

G04 P___;

Argument:

X___ :

Specify a time. Unit: sec. Range: 0.001 ~ 99999.999.

P___ :

Specify a time. Unit: ms. No decimal poiint. Range: 1 ~ 99999999.

Action:

Dwell action; set up dwell time after G04; when the time is over, next block will be executed

automatically.

Example:

G04 X100.;------------------------------------------------------- 100 sec

G04 P100;---------------------------------------------------------0.1 sec

G04;------------------------------------------------------ Exact stop (G09)

LNC Lathe

Syntax of G code

24 LNC Technology Co., Ltd.

G09: Exact stop

Format:

;

__03G

__02G

__01G

09G

Argument:

G09 is a command used along with the exact stop of cutting. When using G09, system checks

positioning degrees after executing every positioning command. After making sure statuses of

positioning comply with settings, system continues executing next block. Therefore, if cutting

positioning exists between blocks, there might be a little interruption due to the demanding of the

precision of positioning point. Speed is sacrificed for a higher shape precision. The degree of

precision is specified by parameters 0006 ~ 0009. The function of G09 only takes effect within its

block.

Example:

G91 G09 G01 Y100. F200.;-------------------------------------------------------------------------------------- (1)

G01 X100.;----------------------------------------------------------------------------------------------------------- (2)

Illustration:

Tool path in non-exact stop

Tool path in G09

(1)

(2)

Loading...

Loading...