Page 1

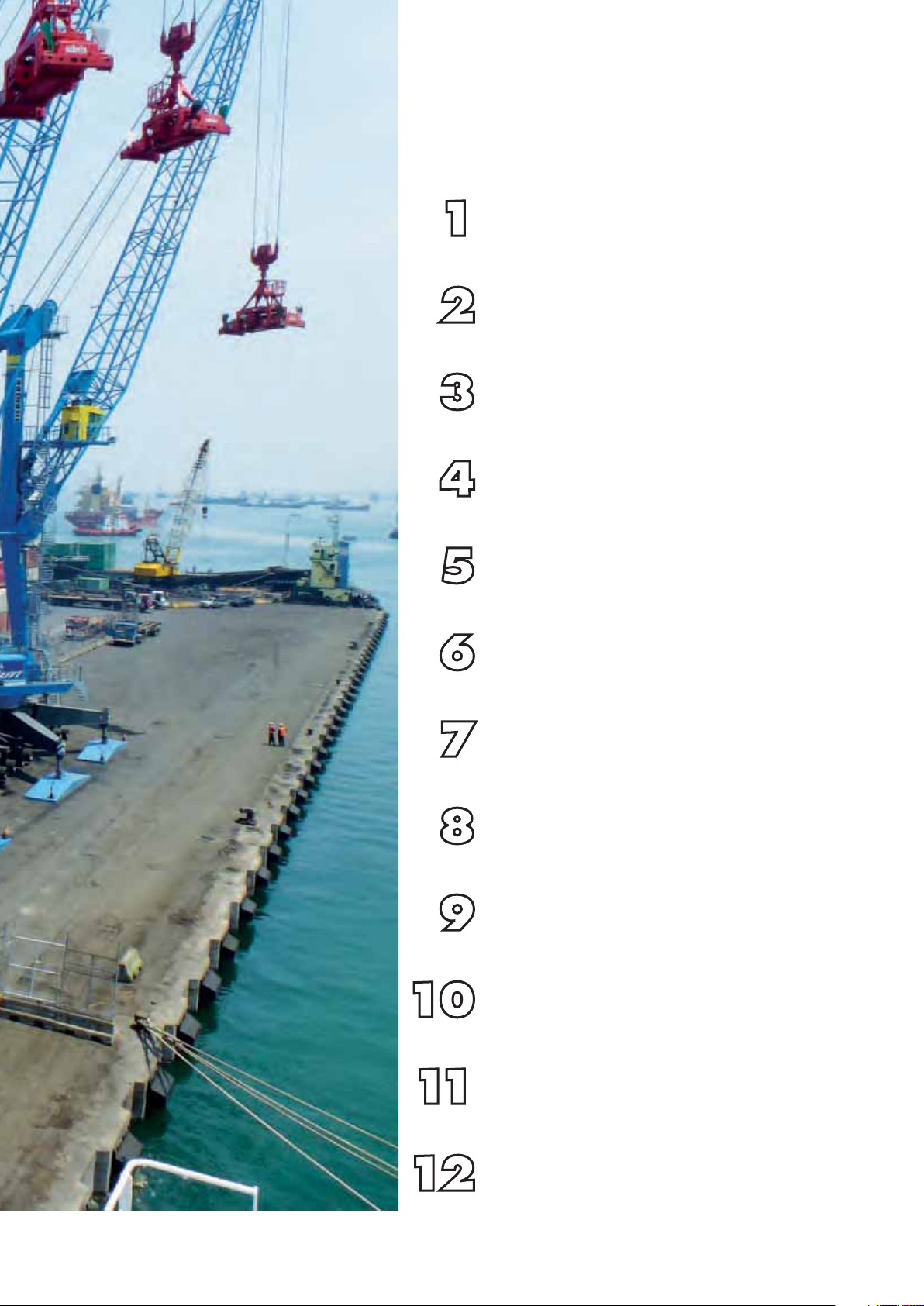

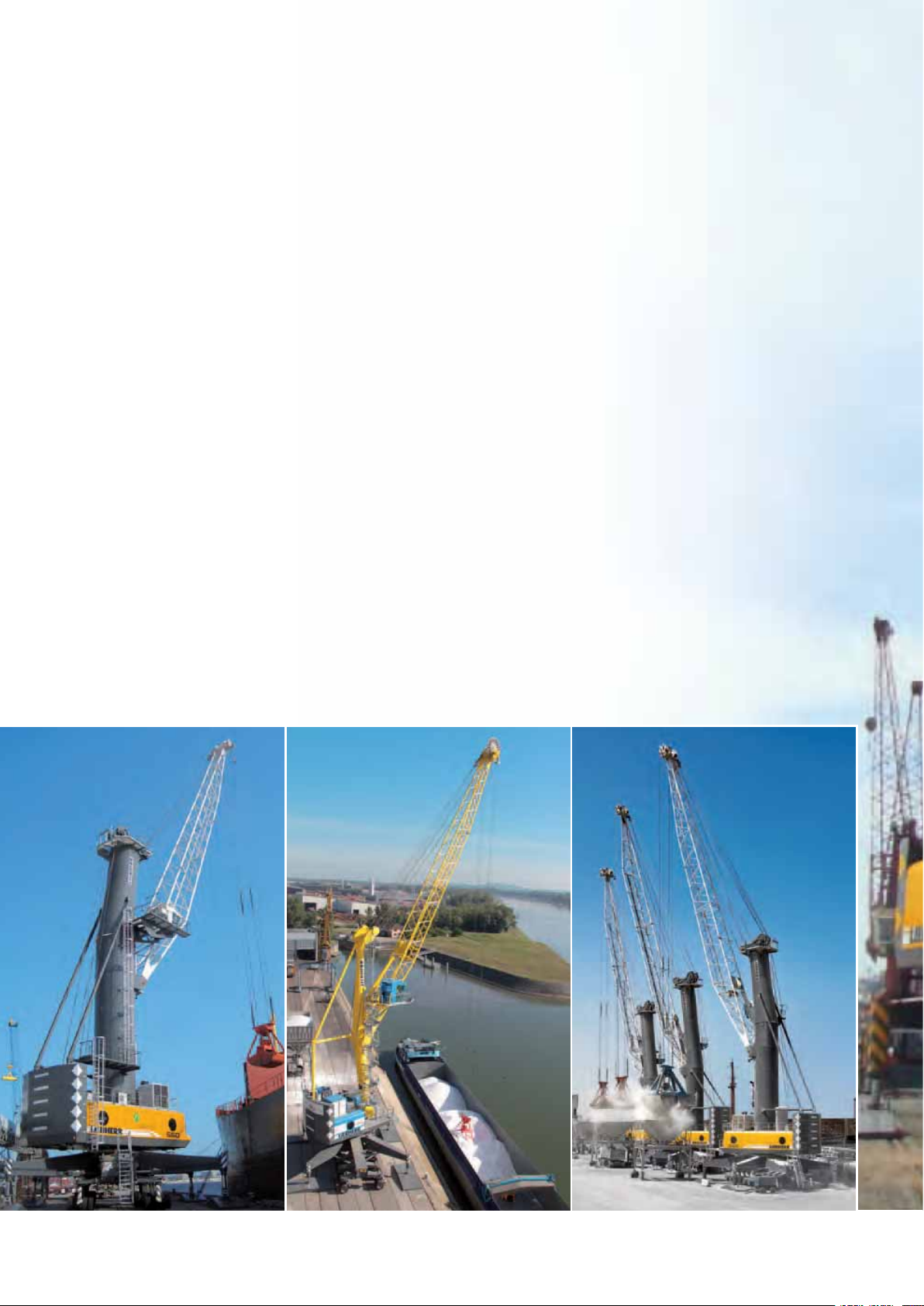

LHM Mobile

Harbour Cranes

Page 2

LHM 420 AKR

2

Page 3

Table Of Contents

1

Product Range ................................................................. 4

2

3

4

5

Structure Overview ................................................. 6

Modularity Redefined ......................................... 7

Applications ..................................................................... 8

Practical Solutions ..................................................14

6

7

8

9

10

Undercarriage ..............................................................16

Slewing Platform ........................................................ 20

Tower and Boom .......................................................... 24

Driver Comfort ............................................................. 26

Environmental Record ............................................. 28

11

12

Production and Transportation ...............30

Liebherr Service Worldwide ........................32

3

Page 4

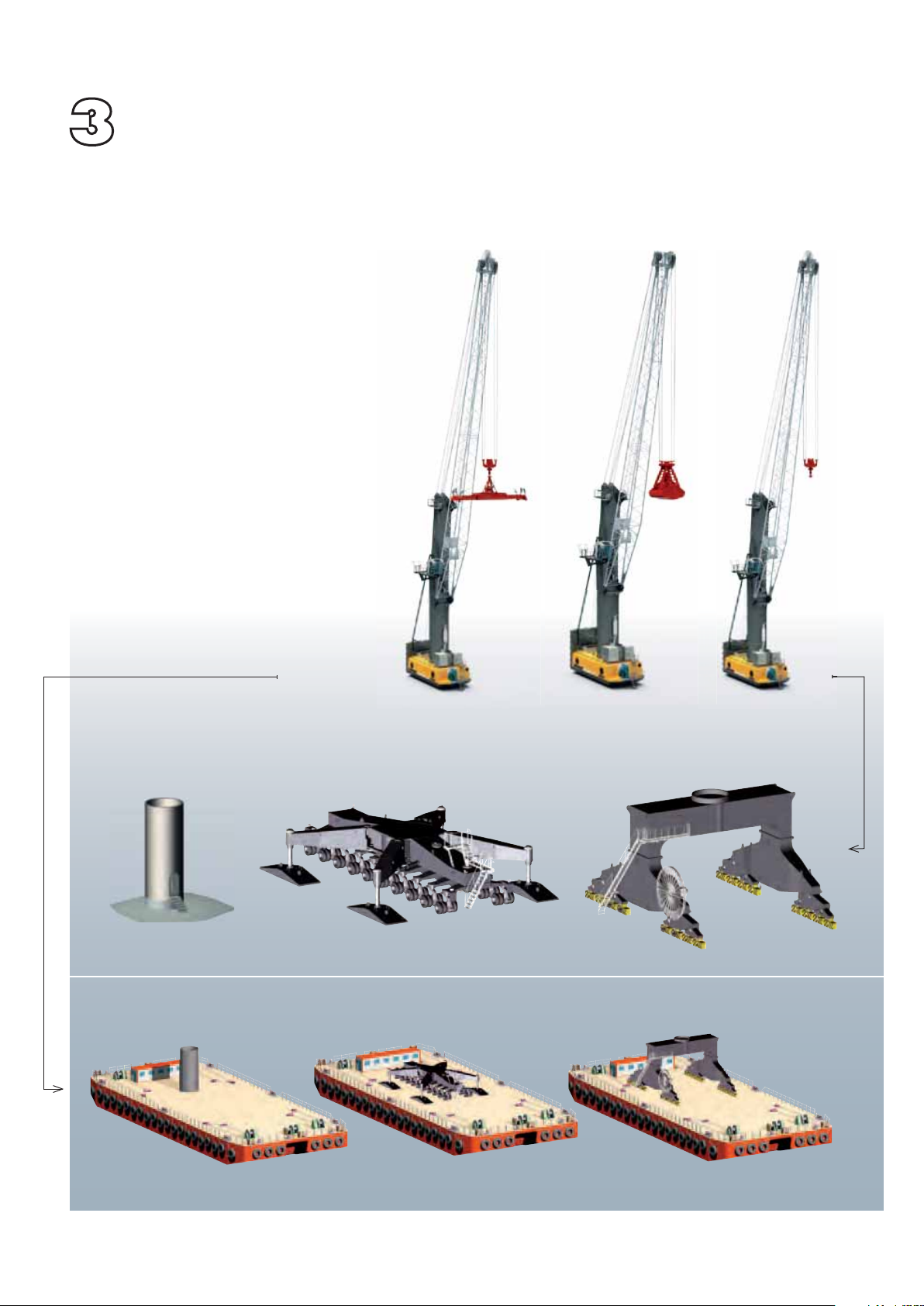

1

Through many years of experience and technology strictly orientated towards customer requirements, a range of

products has been created which sets new standards in innovation, quality, mobility and flexibility.

Product Range

The LHM’s extreme flexibility makes it a universal allrounder and key asset for handling everything, from containers to bulk goods, general cargo and even heavy lifts

up to 208 tonnes. Short delivery times, comparatively

low costs for transport and erection as well as minimised

operating and maintenance costs favour the LHM. It can

be used in practically all areas of the harbour where crane

capacity is required. Comprehensive basic equipment

and easy transportation guarantee a high resale value

and underline its flexibility as an investment.

LHM 600

Radius: 58 m

Max. capacity: 208 t

LHM 420

Radius: 48 m

Max. capacity: 124 t

LHM 550

Radius: 54 m

Max. capacity: 144 t

Capesize Post Panamax

4

Page 5

LHM 280

Radius: 40 m

Max. capacity: 84 t

LHM 120

Radius: 30 m

Max. capacity: 42 t

LHM 180

Radius: 35 m

Max. capacity: 64 t

Application:

Optimum

Panamax Handymax Feeder Coaster

Additional

5

Page 6

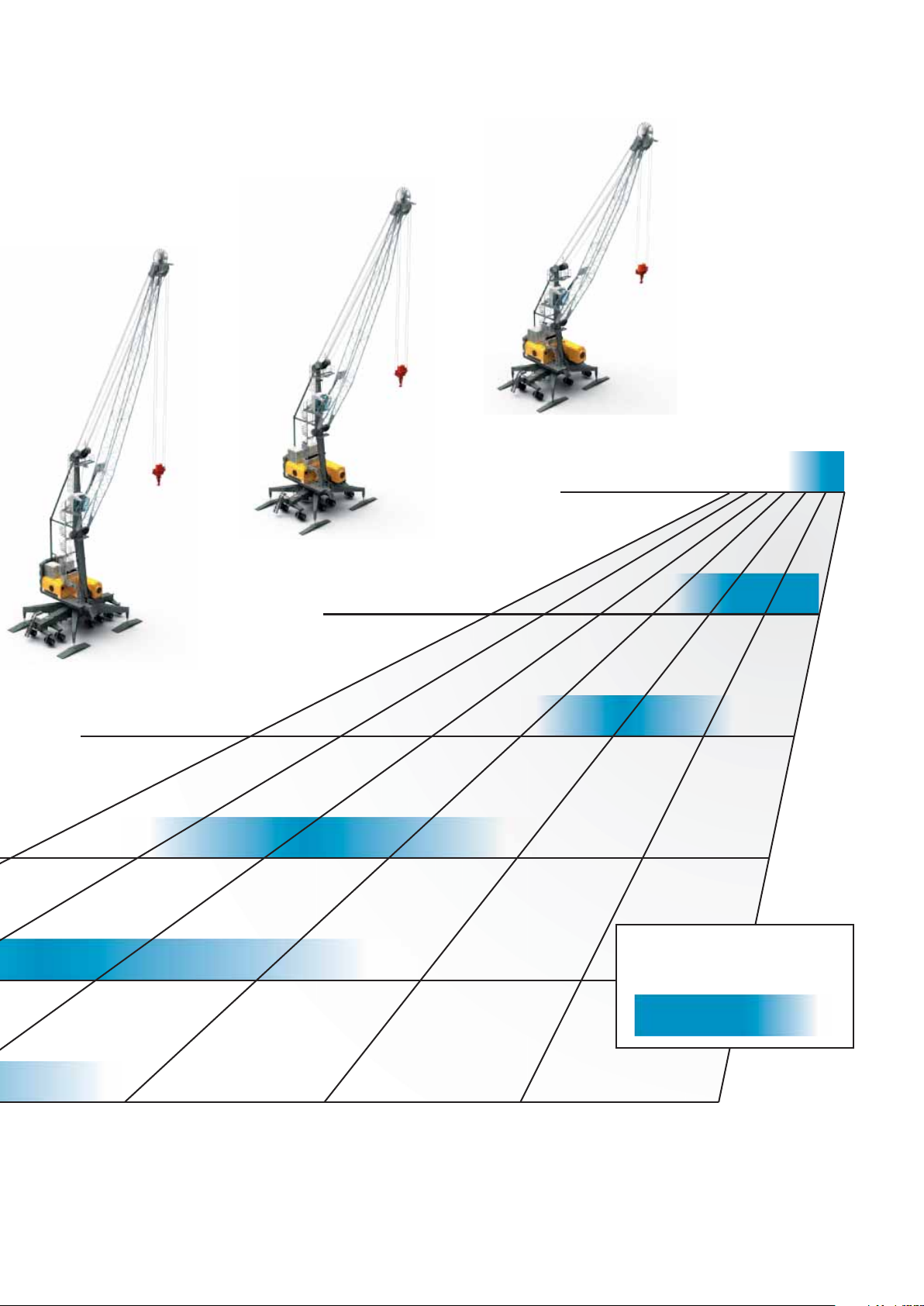

2

Liebherr mobile harbour cranes use the most advanced design,

engineering and production technology and consist of the following main constructional groups:

Structure Overview

Optimized boom lengths

(for practical applications)

Closed tower design

(with weatherproof access to tower cab)

PACTRONIC

(hybrid drive system)

Winches

(application-oriented

configurations)

Undercarriage

(with integrated diesel tank

and additional access in

middle section)

®

Tension luffing cylinder

(for more safety during operation)

Tower extension 4.8 m

(for higher boom fulcrum point

and cabin height, optional)

Motorisation

(diesel engines with different ratings

depending on purpose and crane size)

Slewing Platform

(GFRP = Glass-Fibre

Reinforced Plastic)

6

Page 7

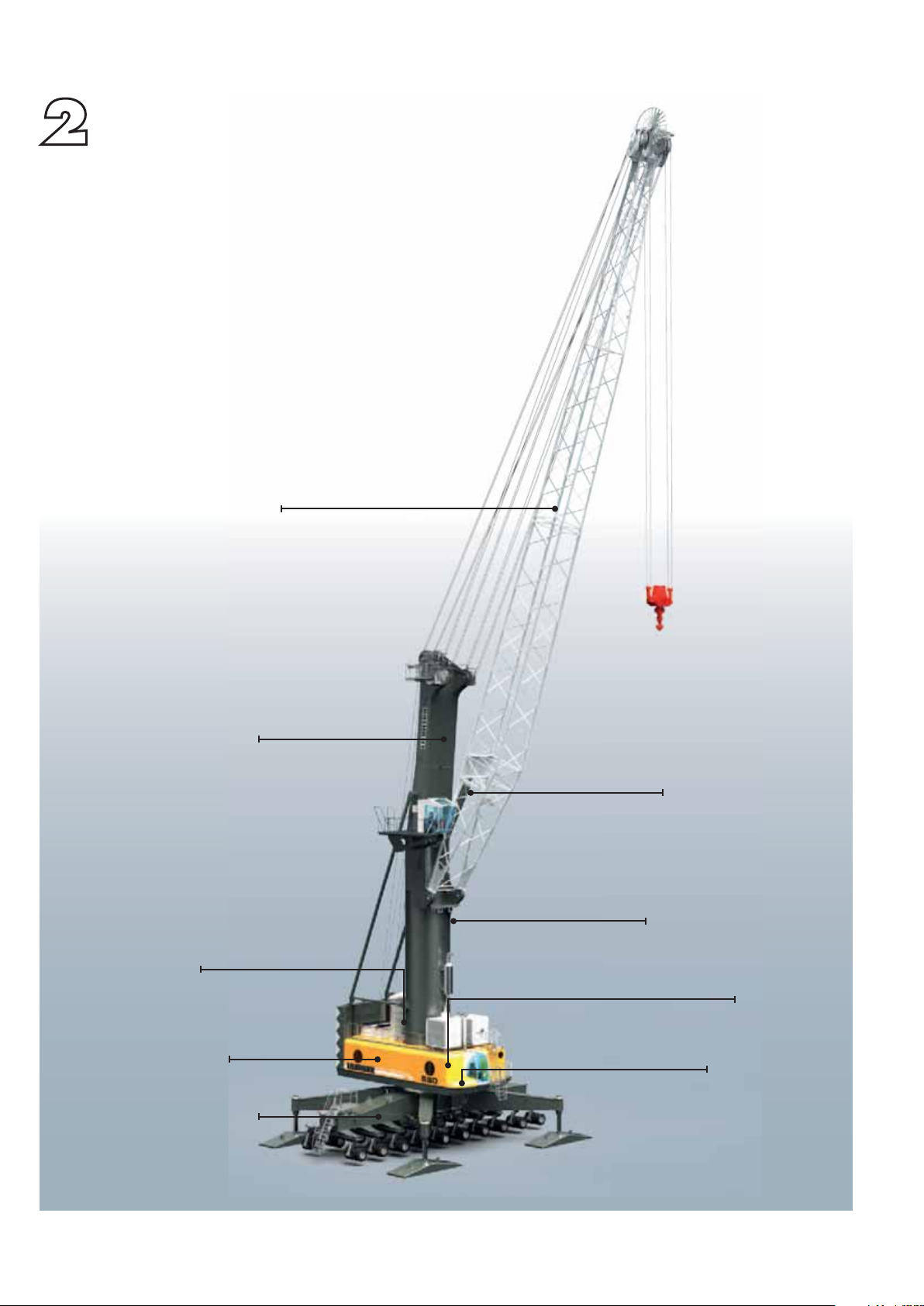

3

The Liebherr mobile harbour crane concept as a whole is characterized by an outstanding

modularity regarding customer and port requirements.

The undercarriage is a patented Liebherr mobile

harbour crane chassis where the number

of individually mounted sets of four wheels

each can be easily adapted to comply with

the most stringent quay load restrictions.

Alterna-tively, the basic undercarriage concept can be re placed by a portal or a barge.

Different applications call for different configurations of winches and drive systems

(power packs) to conform to all variants

of professional cargo handling.

Tower extension, boom variants with

different radii and increased lifting

capacity on request (S-version) complement the modular concept of the

Liebherr mobile harbour crane.

Modularity Redefined

7

Page 8

4

The range of Liebherr mobile harbour cranes is suited exactly to the demands of the ship, port and transport

industries. Liebherr offers an optimum solution for every type of vessel, for every cargo and every size of port or

stevedore.

Applications

Container Handling

Due to strikingly short acceleration times of all crane

motions, which are precisely and accurately monitored

by the Litronic® control system, Liebherr emphasize their

peak position in container handling. The outreach and

load capacity are suitable to be used on a wide array of

vessels, from coaster vessels to super post-panamax

container liners.

The crane can be fitted with various types of spreaders

(fixed or telescopic) connected to the rotator. Manual,

semi or fully automatic telescopic spreaders are available

for all regular container sizes between 10’ and 48’.

s¬ 4HE¬,IEBHERR¬HYDROSTATIC¬DRIVE¬IS¬THE¬MOST¬RELIABLE¬AND¬

highest performing drive system for mobile harbour

cranes. Independent closed loop hydraulic systems utilize the minimum number of components to guarantee

highly responsive, smooth and precise operation while

maximizing operational safety

s¬ ,IEBHERRS¬ PATENTED¬ #YCOPTRONIC® (cycle optimizing

electronic crane control system) allows for direct load

positioning and aids the crane driver in mastering his

task. With Cycoptronic® turnover, safety and the confidence of the operator will be improved

s¬ 3AFETY¬4HE¬LUFlNG¬CYLINDER¬IS¬POSITIONED¬ABOVE¬THE¬LAT-

tice boom. This eliminates any damage to the cylinder

that can occur through swinging loads or highly stowed

rows of containers on board the vessel

LHM 600 Tecondi LHM 500 GemportLHM 280 SIA Rigas Universalais Terminals

8

Page 9

LHM 550 Portuaria Lirquen

9

Page 10

Bulk Handling

The optimised interaction between powerful hydrostatic transmission and advanced Liebherr electronics ensures short,

productive working cycles in bulk handling. Independent of whether using a motor grab or a four-rope grab, all important

handling parameters such as the volume to be lifted with each grab, the opening/closing and hoisting speeds, simultaneous functions, winch synchronisation etc. are optimized using specially developed Liebherr electronics.

s¬ $URING¬GRAB¬OPERATION¬HOISTING¬SLEWING¬AND¬LUFlNG¬ARE¬

driven simultaneously at maximized speed to achieve

the highest (possible) turnover

s¬ $URING¬GRAB¬lLLING¬FEATURES¬SUCH¬AS¬AUTOMATIC¬LOWERING¬

and hoisting guarantee the optimum filling level of the

grab

s¬ 4HE¬ SLACK¬ ROPE¬ MONITORING¬ SYSTEM¬ ENSURES¬ EXTENDED¬

lifetime of the ropes and increases operational safety

s¬ 2EVERSE¬POWER¬IS¬RETURNED¬TO¬THE¬DRIVE¬PROCESS¬THROUGH¬

closed loop hydraulics which results in reduced fuel

consumption

s¬ 4HE¬#YCOPTRONIC® anti-sway system automatically com-

pensates for all rotational swing, transverse and longitudinal sway of the load at maximum speeds

s¬ 4O¬PROVIDE¬ SAFE¬ AND¬ STRESSFREE¬ WORKING¬ CONDITIONS¬ FOR¬

the operator, Liebherr offers the Cycoptronic® inclucing

Teach- In® feature, a semi-automatic system, which pilots the crane from the vessel hatch to the quay without

any sway. Especially for bulk operation into hoppers, the

Teach- In® system increases turnover and ensures consistent turnover rates during the entire ship unloading

LHM 550 SSA Marine Gulf LHM 280 CCI de Colmar et du Centre-Alsace LHM 550 AGAM

10

Page 11

LHM 180 TMB

11

Page 12

Project Cargo and Heavy Duty

Safety and precision are the most important criteria when

lifting heavy goods. The hydrostatic drive concept in connection with closed hydraulic circuits guarantees immediate system reaction times for rapid and safe working

cycles.

Depending on the type, Liebherr mobile harbour cranes

can lift up to a maximum of 208 tonnes. The endurance

and stability required especially for this kind of cargo handling has been strongly considered as a basic concept.

The unique Liebherr cruciform support base creates stability. The arising forces are diverted to the surface of the

pier via the shortest routes.

s¬!BSORPTION¬OF¬ALL¬STATIC¬AND¬DYNAMIC¬DEMANDS¬RESULTING¬

from travelling and operation of the crane

s¬ 2EDUCTION¬OF¬STRESS¬ AND¬ STRAIN¬ON¬ALL¬SUPPORTING¬PARTS¬

and undercarriage to a minimum

s¬ )NCREASED¬ SAFETY¬WHICH¬ENHANCES¬ THE¬DRIVERS¬COMFORT¬

and consequently improves productivity

General Cargo

The LHM displays its unique versatility and flexibility

especially in general cargo handling with continuously

changing operating appliances and handling methods.

s¬ #HANGING¬ FROM¬ ONE¬ LIFTING¬ DEVICE¬ TO¬ ANOTHER¬ REQUIRES¬

only minutes

s¬ 3PECIAL¬ CONTROLS¬ AND¬ INDIVIDUAL¬ PRESELECTABLE¬ LIFTING¬

methods – no modification delay

s¬ !UTOMATIC¬ RECOGNITION¬ AND¬ PRESELECTION¬ OF¬ THE¬ LIFTING¬

device through Liebherr Litronic

®

control system

LHM 180 Port Sochi Imeretinskiy LHM 500 Port of Washington LHM 280 Esbjerg Havn

12

Page 13

LHM 600 RHB

13

Page 14

5

Liebherr develops and produces special designs and solutions to meet particular requirements

outside the norm, supplemented by a wide variety of lifting appliances and equipment.

Practical Solutions

LPS 600 Eren

14

Page 15

LPS 280 Vanino Commercial Sea Port

LPS

The Liebherr Portal Crane LPS is an efficient combination of space-saving portal undercarriage (mounted

on rails) and a flexible mobile harbour upper carriage.

Customer-specific requirements such as permissible

quay and rail loadings, track gauges, clearance heights

are individually adapted.

Particularly on narrow quays, individual portal solutions

permit railway trains and road trucks to travel below the

portal.

LBS

In its floating crane concept, Liebherr combines state

of the art technology and over 30 years of experience

in the mobile harbour crane field with the expertise of

established barge manufacturers.

Liebherr floating cranes can be used for transhipment

and midstream operation between ocean-going vessels and river barges on different types of waterways,

including those having no or few quays. In addition, the

LBS solution allows direct cargo transfer from ship to

shore; especially when quays have reached capacity

limits.

This floating crane concept, based on many years of

experience in designing and operating floating cranes

and other transhipment units for various environmental

conditions throughout the world, is conceived for midstream operation in ports and sheltered waters, on rivers and in coastal waters; for ship to ship as well as ship

to shore handling. Based on the Liebherr mobile harbour crane series, the LBS models are precisely tailored

to meet individual requirements and manufactured according to a uniform design principle combined with

purpose-built barges as customer specific solutions.

15

Page 16

Undercarriage –

6

Varying design and construction methods of quays and terminals throughout the world have led Liebherr to a

unique undercarriage design. Having turned away from a fixed axle concept, individually mounted sets of four

wheels each enable movement in all directions.

Individual Wheel Sets

During steering operation all driven wheel sets are individually controlled and steerable. At every wheel set a

sensor indicates the actual wheel position to the electronic control system. The steering can be operated either from the tower cabin or the operator’s cabin on the

slewing platform.

s¬ /PTIMAL¬ACCESSIBILITY¬FOR¬AN¬EASE¬OF¬MAINTENANCE

s¬ )NDIVIDUALLY¬STEERABLE¬AXLE¬SETS¬REDUCE¬TYRE¬WEAR

s¬ $IFFERENT¬ARRANGEMENTS¬WITH¬VARYING¬NUMBERS¬OF¬

driven wheel sets allow for an inclination of up to 10 %

The Ultimate Travelling System

Tyres

The tyres correspond to those used for heavy goods

vehicles making requisition of spares economical and

time-saving. Standard tyres means that customers can

purchase locally from any dealer.

s¬ /PTIMAL¬AVAILABILITY¬¬NO¬DELIVERY¬BOTTLENECKS

s¬ (IGHEST¬ TYRE¬ LIFE¬ TIME¬ DUE¬ TO¬ LOWEST¬ TYRE¬ LOADING¬

(below 6 t/tyre) and individually steerable wheel sets

s¬ /PTION¬FOAM¬lLLED¬TYRES¬FOR¬SCRAP¬HANDLING

Individual wheel sets and industrial truck tyres

16

Page 17

Outstanding Mobility

Liebherr mobile harbour cranes are characterised by

their outstanding mobility. Due to the system of independent and individually steerable wheel sets (no additional infrastructure e.g. rails or power supply are required) and a very short undercarriage not only are the

smallest turning circles possible but also longitudinal

and diagonal movements of up to 135°. The LHM can

travel in all directions, whether straight ahead, backwards, sideways diagonally or even turn around variable

centre points, knowing no limits.

s¬ %SPECIALLY¬ AT¬ NARROW¬QUAYS¬ AND¬ TERMINALS¬ THE¬ABOVE¬

mentioned manoeuvrability is a decisive advantage

for the positioning of the crane

s¬ 3MALLER¬TURNING¬CIRCLE¬ALLOWS¬BETTER¬ACCESS¬TO¬QUAYS

s¬ 3IDE¬TRAVELLING¬TO¬BYPASS¬OBSTACLES¬AND¬TO¬MOVE¬

between bollards

s¬ &ASTEST¬POSSIBLE¬POSITIONING¬AT¬NARROW¬SITES

s¬ -INIMUM¬TYRE¬WEAR¬AND¬TEAR¬n¬HIGHER¬LIFE¬TIME

s¬ ,ESS¬DIESEL¬CONSUMPTION

Movement in any possible direction

17

Page 18

Hydraulic Load Distribution

The modular undercarriage concept allows further reduction of quay loads by installing additional wheel sets

to comply with the most stringent quay load restrictions.

During travelling hydraulic suspension guarantees optimum pressure distribution on uneven ground and

avoids overloading of the individual wheel sets and of

the quay structure.

Independent linked suspension causes lower loads onto quay structure

Liebherr undercarriage – optimal accessibility from every direction

18

Page 19

X-shaped Support Base

The operational position of the crane can be adapted

to the quay requirements on the basis of an X-shaped

stabiliser arrangement (quadratic and rectangular support is possible) and different sizes of supporting pads

depending on the condition of the quay. A special

Liebherr feature is the very solid propping system with

four swing-out arms forming a cruciform propping configuration. Stresses and strains occurring during handling operation are thereby transmitted via the shortest

route through the centre of the chassis onto the outriggers and further to the ground.

s¬ 2EDUCTION¬OF¬TORSION¬STRAIN¬IN¬THE¬UNDERCARRIAGE

s¬ ,IFETIME¬ENHANCEMENT¬OF¬THE¬SLEWING¬BEARING¬

and the chassis

s¬ /PTIMISED¬VERTICAL¬STABILITY¬DURING¬OPERATION

s¬ -AINTENANCE¬FREE¬OUTRIGGERS¬OF¬XSHAPED¬SUPPORT¬BASE

s¬ &LEXIBILITY¬OF¬THE¬XSHAPED¬SUPPORTING¬BASE¬NEEDS¬LESS¬

space to pass narrow areas

State of the art: X-shaped support base

19

Page 20

7

The slewing platform is designed to house the diesel-hydraulic power pack, the winches,

the counterweight, the slewing gears and the electric control cabinet.

Slewing Platform

Machinery House

The front part of the slewing platform contains the

diesel-hydraulic power pack. This machinery house is

sound insulated and fully protected against any kind of

corrosion using Glass-Fibre Reinforced Plastic (GFRP).

Winch Frame

The winches are located within the rear part of the slewing platform. Various winches are available according to

crane variants and application.

s¬ -AXIMUM¬SAFETY¬AND¬RELIABILITY¬WITH¬

minimum components

s¬ !LL¬COMPONENTS¬ARE¬STANDARDISED¬AND¬UNIFORM¬

throughout the LHM Series which reduces repair costs

s¬ &IRST¬CLASS¬AND¬PRACTICALLY¬MAINTENANCEFREE¬HYDRAULIC¬

components for enormous cost savings and

long-term endurance

s¬ /PTIMAL¬ACCESSIBILITY¬TO¬ALL¬COMPONENTS¬AND¬SIMPLIlED¬

maintenance

s¬ 3IMPLE¬AND¬EASY¬TRAINING¬OF¬PERSONNEL

Middle Section

The middle part of the slewing platform accommodates

the base section of the tower, the slewing gears, the

generator and access stairs to the tower cab.

A Liebherr triple row roller bearing connects the slewing platform with the undercarriage allowing for unlimited rotation in both directions. Slewing gear units are

placed around the slew-ring bearing according to crane

variants and application. Due to the round tower design

the load is already distributed over 360 degrees when

it arrives at the slew-ring resulting in longer life time of

components as well as the steel structure.

Winch room – axial piston motors and rope drum Middle section – generator, slewing gears and access stairs to tower cab

20

Page 21

Machinery house – diesel engine and splitter gearbox

21

Page 22

Electric Switch Compartment

Situated on the right side of the slewing platform is the

electric switch compartment, containing the in-house

designed Liebherr Litronic

CAN-Bus 2-line).

s¬ !VAILABILITY¬OF¬SPARE¬PARTS¬¬YEARS

s¬ !LL¬UPGRADES¬ARE¬DOWNWARD¬COMPATIBLE

s¬ %ASE¬OF¬MAINTENANCE¬n¬NO¬ADDITIONAL¬SOFTWARE¬

specialist required

s¬ 3UITABLE¬FOR¬CORROSIVE¬ENVIRONMENT¬SPECIAL¬COATING¬

of all cards, saltspray tested)

s¬ $ESIGNED¬AND¬TESTED¬FOR¬MARITIME¬ENVIRONMENT¬

(military standard)

s¬

Spacious arrangement for optimal service accessibility

®

crane control system (VME-

Cooling and Ventilation System

The cooling system for the engine water and the engine

charge as well as the hydraulic oil cooler are situated

outside on top of the slewing platform (for working conditions above 50°C). The cooling air flow is completely

conducted outside the machinery room: for such reason it is not possible to contaminate the diesel engine

and other hydraulic components with dust particles.

In addition Liebherr technology is absolutely insusceptible to all sorts of dust and dirt due to the closed hydraulic system and an electronic system which is military

proven and tested.

Slewing platform and outside located coolers

Electric switch compartment: CPU – Liebherr Litronic

22

®

crane control system

Page 23

Drive Concept - Advantages Of Liebherr Hydrostatic Power Transmission

The Liebherr hydrostatic drive is undeniably the most

reliable and high performing drive system for every mobile harbour crane due to rapid achievement of high performance, long-term durability, low maintenance costs

and a series of operation-specific advantages such as

outstanding acceleration and deceleration. This means

higher turnover in shorter periods and proven savings

for the customer.

The crane drive is diesel-hydraulic consisting of a splitter gear box feeding variable displacement axial piston

pumps for the hoisting, slewing and the luffing gear. In

an effort to reduce complexity, during travelling pumps

from other operations are used. The splitter gear box

can either be driven by a diesel motor or alternatively by

electric motors.

Closed hydraulic circuits technology for maximum performance and high efficiency is used. The independent,

closed circuits guarantee a highly responsive, smooth

and sensitive operation with a minimum of components,

maximising the operating safety even in continuous operation or high ambient temperatures (-40°C to +50°C).

s¬ )MMEDIATE¬AND¬SHORT¬SYSTEM¬REACTION¬TIMES¬FOR¬RAPID¬

and safe working cycles

s¬ !LL¬CRANE¬MOTIONS¬ARE¬APPLIED¬CONTINUOUSLY¬PRECISELY¬

and simultaneously with maximum speed and load

s¬ (IGH¬PERFORMANCE¬DENSITY¬REQUIRING¬A¬MINIMUM¬OF¬FUEL¬

and energy

s¬ &ASTER¬ACCELERATION¬AND¬DECELERATION¬TIMES¬DUE¬TO¬LOW¬

masses of inertia – higher turnover

s¬ #LOSED¬ LOOP¬ SYSTEMS¬ FROM¬ ¬K7¬ UPWARDS¬ REQUIRE¬

up to 75 % less hydraulic oil than open loop systems

s¬ $YNAMIC¬ BRAKING¬ IS¬ ACCOMPLISHED¬ BY¬ ATTEMPTING¬ TO¬

reverse the rotation of the pump. The pump and prime

mover constitute the dynamic brake

s¬ 5SE¬ OF¬ REVERSE¬ POWER¬ n¬ THE¬ LOWERING¬ ENERGY¬ IS¬ LED¬

back to the power pack (less fuel consumption)

s¬ #LOSED¬CIRCUITS¬ALLOW¬EASY¬FAULT¬lNDING¬AND¬DIAGNOSIS¬

due to separate circuits for each crane function

s¬ /NLY¬ONE¬DRIVE¬SYSTEM¬SIMPLIlES¬AND¬REDUCES¬SERVICE¬

and maintenance costs

Liebherr Diesel Engine, Type D9508 A7

23

Page 24

8

Tower and Boom

Tubular Tower Design

The submerged-arc welded pipe construction, a torsionally rigid design, is part of a unique stress-flow system

absorbing all static and dynamic demands and distributing the load as best as possible onto the slew ring bearing. The spiral staircase is well lit with handrails and kickplates, leading to the tower cabin. Access to the upper

tower platform and rope pulleys is also gained through

this route.

s¬ $ECREASE¬OF¬TORSIONAL¬STRAIN

s¬ ,OW¬STRESS¬FOR¬WELDING¬SEAMS

s¬ ,ONGER¬LIFETIME¬OF¬SLEWING¬GEARS¬AND¬UNDERCARRIAGE

s¬ 3AFE¬AND¬CONVENIENT¬ACCESS¬TO¬THE¬TOWER¬CABIN¬INSIDE¬

the tower

Luffing Cylinder

The cylinder rod is completely protected while in crane

parking position. Due to the fact that the luffing ram is a

tension cylinder, collisions between swinging loads and

the cylinder during crane operation are impossible.

s¬ -AINTENANCE¬FREE

s¬ ,ESS¬CORROSION

s¬ ,UFlNG¬CYLINDER¬IS¬PROTECTED¬AGAINST¬DAMAGE

s¬ .O¬RISK¬OF¬BUCKLING¬ONLY¬TENSION¬FORCE

Boom

The boom is of lattice construction featuring three main

chords and consisting of 2 sections (fulcrum section,

boom head). The boom head can be laid down on the

ground. Seamless high strength tubular steel ensures operation without difficulty down to -40°C.

s¬ -ORE¬STABILITY¬¬HIGH¬LEVEL¬OF¬STIFFNESS

s¬ 0RECISE¬CRANE¬MOVEMENT

s¬ 0IVOT¬POINT¬UP¬TO¬¬M

Tubular tower design: exterior view

24

Page 25

Cable drum and reel

Tubular tower design: interior view

Tension luffing cylinder

25

Page 26

9

The tower and optional slewing platform cabin are fully equipped allowing the operation of all crane functions including travel and supporting options. The design of the tower and the slewing platform cabin was driven by the needs for

visibility, comfort and operability.

Driver Comfort

Tower Cabin

The crane operator’s cabin layout has been designed to

ergonomic principles and provides a comfortable, noisefree environment, essential for ensuring uninterrupted

concentration for the driver when operating the crane.

Any vibration is reduced to an unnoticeable minimum

through active swing equalisers.

An ergonomic driver‘s seat with adjustable armrests,

screen wipers and washer as well as air conditioning

allow the operator to work in all climatic environments.

Control desk, joy-sticks and monitor are ergonomically

arranged.

The window sections are constructed of tinted anti glare

toughened safety glass mounted in an innovative glass

frame design giving a clear view of the handled cargo

throughout the slewing circle and an unobstructed line of

sight between the boom tip and the vessel deck.

Control Meets Comfort

s¬ /PTIMAL¬FORWARD¬MOUNTED¬STANDARD

s¬ #ABIN¬HEIGHT¬n¬UP¬TO¬¬M

s¬ ¬¬GLASS¬PROPORTION¬SAFETY¬GLASS

s¬ 5NRESTRICTED¬AND¬RELIABLE¬VIEW¬OF¬WORKING¬SURROUNDINGS

s¬ )NTEGRATED¬,ITRONIC® screen (shows all the crane

functions on the monitor)

s¬ #LOSEDCIRCUIT¬VIDEO¬SYSTEM¬ON¬THE¬JIB¬HEAD¬

with coloured monitor in the cabin

s¬ !IR¬CONDITIONING¬STANDARD

s¬ .OISEINSULATED¬CABIN¬NOISE¬LEVEL¬WITHIN¬REQUIREMENTS¬

of 2000/14/EG)

s¬ !CTIVE¬SWING¬EQUALIZER

Slewing Platform Cabin

The cabin is mounted on the front part of the slewing

platform. This elevated position assures easy manoeuvrability in both directions, optimal view while travelling

and minimises safety hazard. As it is always facing the

load, it can be used by checkers in adverse conditions.

There are two different cabins available:

s¬ #ABIN¬EQUIPPED¬WITH¬IDENTICAL¬CONTROLS¬

to the tower cabin

s¬ #ABIN¬EQUIPPED¬WITH¬REMOTE¬CONTROL¬ONLY¬

for travelling operations

LHM 550 slewing platform cabinMaximum visibility range

26

Page 27

Optimal forward mounting of cabin

27

Page 28

10

With its headquarters located in an environmentally protected area, ecological issues have always been high on the

agenda for Liebherr-Werk Nenzing. The implementation of economy software, bio-degradable oils and special noise

insulation throughout its mobile harbour crane range are just a few examples of Liebherr’s ecological awareness.

Environmental Record

Eco-Control

The proven hydraulic drive system in combination with the

in-house developed “ECO-Control” achieves a notable

reduction of diesel consumption up to 25 % without any

impact on turn-over output. Once the designated speed of

the crane movement is achieved, the Litronic® crane control system automatically calculates the minimal required

rpm (revolutions per minute) for the diesel engine.

A further side effect is the low rpm of the hydraulic system,

which means longer lifetime of hydraulic pumps and components. In addition, the lowered engine rpm has a direct

impact on reduction of noise exposure.

Operating Liquids

Alternatively Liebherr mobile harbour cranes can be run

on bio-diesel to comply with local regulations and the

transition to alternative fuels in customer equipment fleets.

Liebherr developed biodegradable oil especially for

the Liebherr product line. In combination with spectrographic oils analysis techniques oil life time is extended

and keeps components such as pumps and motors for

ever longer lifetimes.

Due to the special design of the luffing gear (tension

cylinder in closed loop circuit) a minimal quantity of oil is

required.

Noise Insulation

The cooling system for the engine water and the engine

charge as well as the hydraulic oil cooler are equipped with

a specially designed cooling fan minimizing turbulences

and decreasing noise emissions. Furthermore, regulated

rpm guarantees higher lifetime, less required drive power

and a decrease of fuel consumption.

Elastic suspension of the winches guarantees an additional

reduction of vibrations and noise. With the optional attenuation package for the machinery as well as the winch room

a further reduction of sound pressure can be reached.

28

Page 29

Liebherr-Werk Nenzing

29

Page 30

11

A clearly defined company strategy guarantees that only top quality products are developed and built in the most

modern production facilities.

Production and Transportation

Liebherr-MCCtec Rostock

In order to further expand its position in the international

maritime market Liebherr has established an additional

production site for mobile harbour cranes in Rostock’s

harbour district on the German Baltic Coast in 2006.

The production facility in Rostock plays an important role

in the further growth and development of the international

market position of the LHM product division. Overall, the

Liebherr Group has four state-of-the-art production sites

for maritime cranes (Nenzing, Rostock, Killarney and

Sunderland).

Factory Testing

All LHM cranes are put through an intense factory testing

program, this means that every single crane is fully assembled and tested before delivery which results in an extraordinary quick commissioning. Under normal conditions

Liebherr mobile harbour cranes are assembled and ready

for operation within two weeks after delivery.

Fully Assembled Transportation

Thanks to direct access to the sea, Rostock is very well

situated in terms of the logistics of worldwide sales, especially when shipping large equipment. Ro-Ro shipment,

semi-erected or even fully as

means of transportation from the Rostock location.

When sent by barge and tug from the Rostock facility,

Liebherr mobile harbour cranes are ready for operation immediately after driving off from the barge and onto the quay.

sembled, are the standard

LHM production facility Liebherr-MCCtec Rostock

30

Page 31

Fully assembled transportation

31

Page 32

12

Over 10,000 mobile harbour, ship, offshore and gantry cranes as well as reachstackers are serviced by Liebherr’s maritime

division. The worldwide network of customer service centres guarantees the supply of spare parts and service throughout

the entire lifetime of all machines.

Liebherr Service Worldwide

Competence On Site Reliable Partnership

Speed and reliability have always been part of our service.

Liebherr fully understands the value of a quick response

for reduced downtime and immediate restoration of LHM’s

productivity. Qualified specialists will deal with any issue

without delay – if necessary, right around the clock.

Extensive know-how ensures first class and effective performance of all service and maintenance work, contributing to LHM’s availability and profitability. Liebherr combines

expertise with client’s experience to continuously optimise

products and services.

Logistics Service –

High Speed Organisation 24/7

For your LHM to function effectively, every operational

hour is vital.

is there for our clients around the clock, even on weekends

and public holidays.

The standardised Liebherr overnight distribution service

guarantees fast and safe delivery of the original parts to

their destination.

Liebherr original spare parts and service staff

s¬ 0REVENTIVE¬MAINTENANCE¬AND¬SAFETY¬CHECKS

s¬ 4AILORMADE¬SERVICE¬CONTRACTS¬FROM¬INSPECTION¬

agreements to full service contracts

s¬ #OMPREHENSIVE¬TRAINING¬FOR¬CUSTOMERS¬OPERATORS¬

service and maintenance personnel

s¬ 7ORLDWIDE¬CUSTOMER¬HOTLINE¬ROUNDTHECLOCK

s¬ )MPLEMENTATION¬OF¬TECHNICAL¬MODIlCATIONS¬AND¬

up-grades

s¬ 2EMOTE¬DIAGNOSES¬FOR¬FAULT¬ANALYSIS¬AND¬REPAIR

Organisation with high-speed guarantee

32

Page 33

Spare parts depot Rostock

33

Page 34

The Liebherr Group –

Partner For The Future

Today, Liebherr is among the leading manufacturers in the fields of hoisting technology and materials handling equipment. The name Liebherr stands for products and services. It has become a synonym for ideas and innovations.

Liebherr – A Family Enterprise

In family-operated companies, ownership merges with

active entrepreneurship. This results in characteristic

principles. Liebherr is both a family business and a corporation. This does not have to be a contradiction, as the

continuous success and steady growth prove.

To create top products, the development capacities and

production facilities must measure up to the highest

standards. This requires substantial investments. From

stable locations, Liebherr is following a solidly financed

expansion course. The profits made are almost entirely

retained within the Group. This provides ample scope

for extensive investments. The economic power of the

Liebherr Group is best shown by its unusually high equity

ratio of more than 50%. This sound economic basis

makes Liebherr highly independent in its strategic decisions, and it provides an important basis for future investment and innovation strategies. Offering high-quality

products and services which are aimed towards customers’ needs remains the benchmark.

34

Page 35

Mastering Key Technologies

In

view of the high quality that Liebherr demands of its

products, mastering key technologies internally and keeping core competencies in-house has always been of great

importance to the company. Therefore, Liebherr develops

and produces crucial components, such as the entire

propulsion and control technology, themselves. Further

examples are hydraulic components, slip ring elements,

and diesel engines. Here, Group suppliers are measured

against the best and most efficient external providers.

Decentralized And International,

Based On Tradition

Operating efficiently in manageable, self-dependent

units and aimin

always formed part of the basic business principles. Thus,

Liebherr regularly invests substantially in further marketing and service companies as well as in new production

sites. Entering and expanding into new markets means

being locally available to assure the customer receives full

and lasting manufacturer support.

While maintaining the proven decentralized organizational

form, a divisional company structure, whose international

expansion is being carried forward, was implemented

globally.

g strategically at emerging markets have

35

Page 36

Sunderland

Killarney

Rostock

Nenzing

Manufacturing Head Offices

Sales and Service Stations

Representative Offices

Sales and Service Stations:

Liebherr Algérie EURL

Zone Industrielle Lot No 4

Qued el Kerma, BP 540,

16305 Saoula/Alger, Algeria

Phone +213 21 55 93 04

Fax +213 21 55 60 54

Liebherr Brasil Guindastes e

Máquinas Operatrizes Ltda

Rua do Rócio, 288 – Salas 81/82

Vila Olímpia, 04552-000 Sao Paolo,

Brazil

Phone +55 11 3845 4181

Fax +55 11 3845 7268

Liebherr-Canada Ltd

1015 Sutton Drive

Burlington ON L7L 5Z8

Canada

Phone +1 905 319 92 22

Fax +1 905 319 66 22

Liebherr-Nenzing

Equipements SAS

Zone d’Activité

BP 80047

68127 Niederhergheim

France

Phone +33 389 863 325

Fax +33 389 863 334

Liebherr-Nenzing Service GmbH

Am Neuländer Baggerteich 1

21079 Hamburg

Germany

Phone +49 40 767 022 00

Fax +49 40 767 587 86

Liebherr India Private Limited

D-16/3 MICD, Ground Floor

TTC Industrial Area, Turbhe

Navi Mumbai – 400 703

India

Phone +91 22 4126 7500

Fax +91 22 4126 7599

Liebherr-EMtec Italia S.p.A.

Via dell’Industria, 8-12

24040 Lallio (BG)

Italy

Phone +39 035 69691 40

Fax +39 035 69691 49

Liebherr-Maritime Benelux B.V.

Beeldschermweg 2

3821 AH Amersfoort

Netherlands

Phone +31 33 4500 830

Fax +31 33 4500 899

Liebherr Maritime Benelux

Vaartkai 16

2170 Antwerp

Belgium

Phone +32 3 641 80 40

Fax +32 3 641 80 49

Liebherr Romania SRL

Bd. Aurel Vlaicu 186

900330 Constanta

Romania

Phone +40 241 878637

Fax +40 241 878627

Liebherr-Russland

1-ya Borodinskaya Str. 5

Office 302

121059 Moscow

Russian Federation

Phone +7 495 502 1734

Fax +7 495 933 7223

Liebherr Singapore Pte. Ltd.

8 Pandan Avenue

Singapore 609384

Singapore

Phone +65 6265 2305

Fax +65 6261 6485

Liebherr Africa (PTY) Ltd

2 Krishna Lane, Ivy Park

3600 Pinetown

South Africa

Phone +27 31 701 1381

Fax +27 31 701 1383

Liebherr Ibérica S.A.

C/ Argentina 15

Parcela 6 Sector 30D

Pol. Ind. Casarrubios

28806 Alcala de Henares

Spain

Phone +34 911 34 19 01

Fax +34 911 34 19 19

Liebherr-Machine Ticaret

Limited Sikereti

Cumhuriyet Mah. E-5 Yanyol No. 39

Yakacık, Kartal, Istanbul

Turkey

Phone +90 216 453 1000

Fax +90 216 671 1690

Liebherr Great Britain Ltd.

Stratton Business Park

Normandy Lane

Biggleswade, SG18 8QB

Great Britain

Phone +44 7725 704 797

Fax +44 1767 602 161

Liebherr Nenzing Crane CO.

11801 NW 100th Road, Suite 17

Miami, FL 33178

USA

Phone +1 305 889 0176

Fax +1 305 889 0655

Liebherr-Middle East FZE

Jebel Ali Free Zone (South)

Plot no: S 10508, 2540, Dubai

United Arab Emirates

Phone +971 4 8860 199

Fax +971 4 8860 323

www.liebherr.com

Printed in Germany by Schirmer. BK-RP. LWN 10448346 - 1.0-05.12

Pictures: Liebherr-Werk Nenzing GmbH, p. 30 (r.) RostockPort/Nordlicht

llustrations and data may differ from standard equipment. Subject to change without notice.

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing

콯 +43 50809 41-725, Fax +43 50809 41-447

www.liebherr.com, E-Mail: mobile.harbour.crane@liebherr.com

Loading...

Loading...