Page 1

Mobile Harbour Crane

LHM 120

Page 2

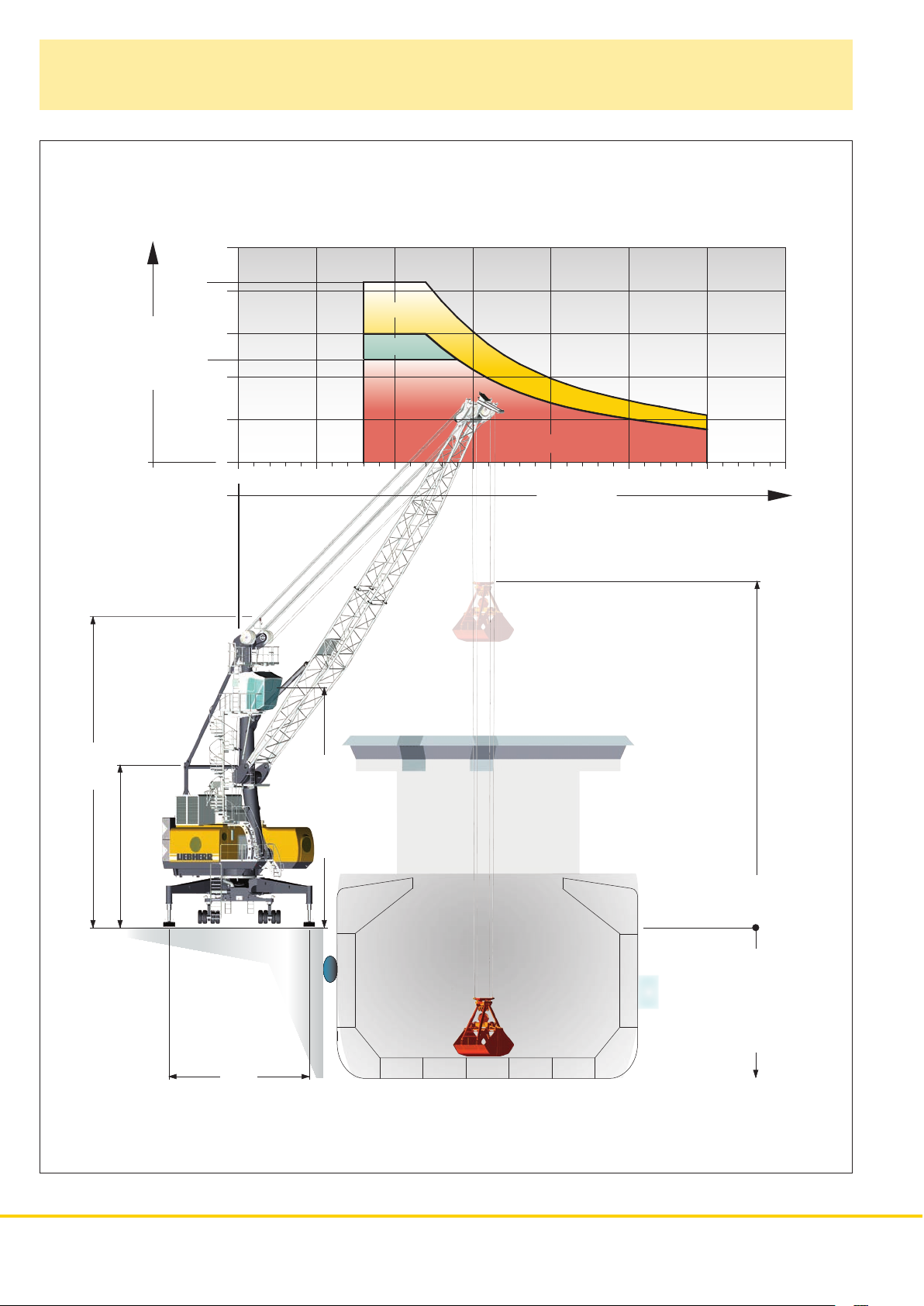

Main dimensions

Bulk operation

Load diagram

50

42

40

30

24

Capacity (t)

20

10

0

0

5 10

on the ropes

motor grab

15

4-rope grab

20

Outreach (m)

25 30 35

19.6 m

Boom fulcrum

10.1 m

9 m

Eye level 15.2 m

Coastal Bulk Carrier

Above quay max. 34 m

(depending on grab)

Below quay 13 m

2 LHM 120

Page 3

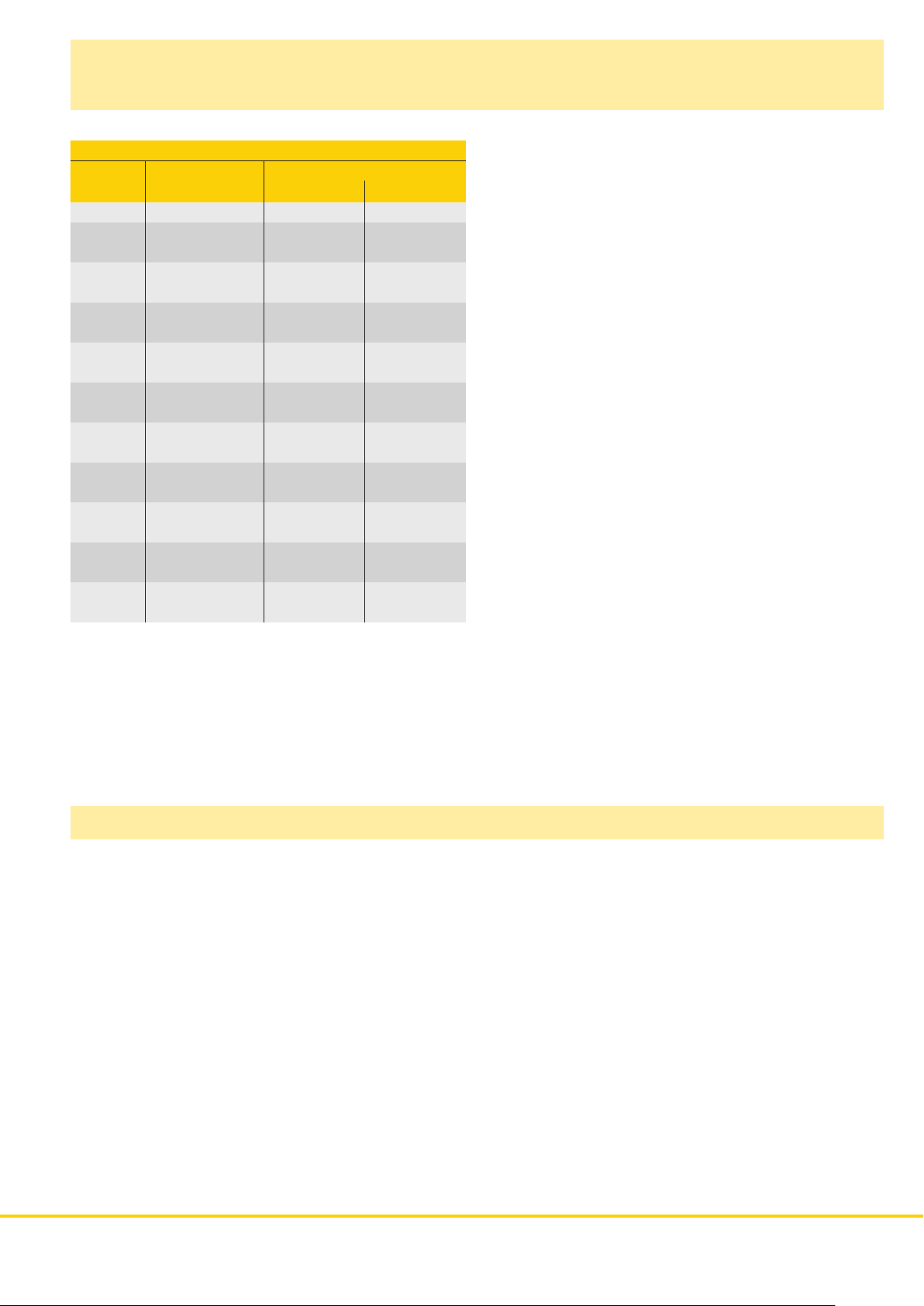

Bulk operation

Maximum crane capacity 42 t

Hook operation Grab operation

Outreach on the ropes 4-rope grab motor grab

(m) (t) (t) (t)

8-11 42.0 24.0 30.0

12 42.0 24.0 29.9

13 37.7 24.0 26.8

14 33.8 24.0 24.1

15 30.5 21.7 21.7

16 27.5 19.6 19.6

17 25.1 17.8 17.8

18 23.0 16.3 16.3

19 21.2 15.0 15.0

20 19.6 13.9 13.9

21 18.2 13.0 13.0

22 17.1 12.2 12.2

23 16.1 11.5 11.5

24 15.2 10.8 10.8

25 14.4 10.2 10.2

26 13.7 9.7 9.7

27 13.0 9.2 9.2

28 12.3 8.7 8.7

29 11.6 8.3 8.3

30 11.0 7.8 7.8

Weight ramshorn hook 1.5 t

Weight rotator 1.5 t

Professional bulk handling – Turnover up to 550 t per hour

The powerful hydrostatic transmission and advanced Liebherr electronics ensure short, productive working cycles

during bulk handling.

• During grab operation, hoisting, slewing, and luffing are

driven simultaneously at maximized speed to achieve the

highest (possible) turnover.

• During grab filling, features such as automatic lowering

and hoisting guarantee the optimum filling level of the

grab.

• The slack rope monitoring system ensures extended lifetime of the ropes and increases operational safety.

• Reverse power is returned to the drive process through

closed loop hydraulics which results in reduced fuel

consumption.

®

• The Cycoptronic

anti-sway system automatically

compensates for all rotational swing, transverse and

longitudinal sway of the load at maximum speeds.

• To provide safe and stress-free working conditions for

®

the operator, Liebherr offers the Cycoptronic

®

teach-in

feature, a semi-automatic system, which pilots

including

the crane from the vessel hatch to the quay without any

sway. Especially for bulk operation into hoppers, the teach-

®

system increases turnover and ensures consistent

in

turnover rates during the entire ship unloading.

• Liebherr technology is absolutely resistant to all types of

dust and dirt due to the closed hydraulic system and an

electronic system which is military proven and tested.

• The airflow needed for cooling hydraulic and engine

systems is routed external from the main machinery

house. This helps keep the engine room clean and free

of debris.

LHM 120 3

Page 4

Main dimensions

General cargo operation

Load diagram

50

42

40

36

30

on the ropes

19.6 m

Capacity (t)

20

10

0

semi-automatic spreader 20´

0

5 10

15

20

Outreach (m)

25 30 35

4 LHM 120

10.1 m

Boom fulcrum

Eye level 15.2 m

Above quay max. 34 m

Coastal Vessel

Below quay 13 m

9 m

Page 5

General cargo operation

Maximum crane capacity 42 t

Hook operation Capacity under spreader

Outreach on the ropes

(m) (t) (t) (t)

8-11 42.0 36.0 36.0

12 42.0 36.0 36.0

13 37.7 34.9 33.6

14 33.8 31.0 29.7

15 30.5 27.7 26.4

16 27.5 24.7 23.4

17 25.1 22.3 21.0

18 23.0 20.2 18.9

19 21.2 18.4 17.1

20 19.6 16.8 15.5

21 18.2 15.4 14.1

22 17.1 14.3 13.0

23 16.1 13.3 12.0

24 15.2 12.4 11.1

25 14.4 11.6 10.3

26 13.7 10.9 9.6

27 13.0 10.2 8.9

28 12.3 9.5 8.2

29 11.6 8.8 7.5

30 11.0 8.2 6.9

Weight rotator 1.5 t

Weight semi-automatic spreade r 1.3 t (20 ft), 2.6 t (40 ft)

semi-

automatic 20´

semi-

automatic 40´

General cargo up to 42 tonnes

The LHM displays its unique versatility and flexibility especially in general cargo handling with continuously changing

operating appliances and handling methods.

• Changing from one lifting device to another requires only

minutes.

• Special controls & individually pre-selectable lifting methods

– no modification delay.

• Automatic recognition and pre-selection of the lifting device

through Liebherr Litronic

®

control system.

• The hydrostatic drive concept in connection with closed

hydraulic circuits guarantees immediate system reaction

times for rapid and safe working cycles.

• The luffing cylinder also uses a closed hydraulic circuit,

assuring accuracy without vibration.

LHM 120 5

Page 6

Undercarriage

9 m

9 m

5.5 m

0.8 m

5.4 m

Mobility

• Outstanding mobility and manoeuvrability

• Curves at any possible radii and even slewing

on the spot

longitudinally

diagonally

Modular propping system

• Minimised stress and strain of undercarriage due to cruciform support

base which directs the load path from boom tip to quay

• Modular system allows further reduction of quay loads by installing

additional axle sets

• Easy adaptation to various sizes of support pads and bases

Optional wheel sets

sideways

curves

slewing on the spot

Hydraulic load distribution

• Hydraulic suspension avoids overloading of individual wheel sets

Standard trailer tyres making requisition of spares economical and

time-saving

Increased lifetime of tyres due to individually steerable wheel sets

Schematic diagram

6 LHM 120

Optimum pressure distribution and

adaption of wheel sets on uneven surfaces

Page 7

Technical data

Capacity and Classification

Capacity Classification

Grab operation < 19 t A8

Grab operation < 24 t A7

General cargo < 30 t A6

Heavy lift 42 t A4

Main dimensions

Min. to max. outreach 8—30 m

Height of boom fulcrum 10 .1 m

Tower cabin height (eye level) 15.2 m

Overall height (top of tower) 19.6 m

Overall length of undercarriage 12.6 m

Overall width of undercarriage 5.4 m

Propping arrangements

Standard supporting base 9 m x 9 m

Standard pad dimension 4 x 5.5 m x 0.8 m

Standard supporting area of pads 4.4 m2

Optional size of supporting pads and bases on request

Quay load arrangements

Uniformly distributed load 1.17 t / m2

Max. load per tyre 5.2 t

Due to a unique undercarriage design its parameters (pad sizes,

supporting base and number of axle sets) can easily be adapted to

comply with the most stringent quay load restrictions.

Weight

Total weight approx. 124 t

Working speeds

Hoisting / lowering 0 — 90 m/min

Slewing 0 — 1.6 rpm

Luffing 0 — 67 m/min

Travelling 0 — 5.4 km/h

Optional equipment

1. Cycoptronic

2. Teach-In - semi-automatic point to point system

3. Sycratronic® - synchronizing crane control system

4. Vertical Line Finder - diagonal pull preventing system

5. Dynamic anti-collision system

®

- anti-sway system

Hoisting heights

Above quay at minimum radius 34 m

Above quay at maximum radius

Below quay level 13 m

11. Video monitoring system

12. Radio remote control

13. Autopropping undercarriage

14. Cyclone air-intake system for the engine

15. Low temperature package

15 m

6. Lidat® - basic package

7. Lidat® - tele service package

8. Lidat® - turnover package

9. SCULI - crane analyzer with various features

10. Economy software - for optimised fuel consumption

16. Customer-specific painting & logo

17. Additional (driven) axle sets

18. Axle sets equipped with foamed tyres

19. Different supporting bases and pad sizes

20. And many more as per customers´ requirements

LHM 120 7

Page 8

Practical solutions

Liebherr develops and produces special designs and solutions to meet

customer-specific requirements

• The Liebherr Portal Crane, LPS, is an efficient combination

of a space-saving portal (mounted on rails) and the proven

mobile harbour crane concept. Particularly on narrow quays,

individual portal solutions permit (railway) trains and (road)

trucks to travel below the portal.

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41-725

Fax: +43 50809 41-447

mobile.harbour.crane@liebherr.com

www.liebherr.com

• Liebherr Fixed Slewing Cranes (LFS) are an efficient

combination of a mobile harbour crane upper carriage and a

fixed pedestal. LFS cranes provide an economical and spacesaving solution for the installation on quaysides and jetties,

especially where room for manoeuvring is limited and low

ground pressure is essential.

LHM 120 —10097934—06/2012—Subject to change without notice.

Loading...

Loading...