Page 1

Special timber handling

machines from Liebherr

Page 2

1

2

3

Special timber handling

machines from Liebherr

Wheel loaders

In recent years, Liebherr has become a com-

1

2

plete provider of timber handling equipment to

the timber industry. An industrial lift arm relevant to this

sector is available for all L 514 - L 580 wheel loaders as

an alternative to the standard lift arm, with no effect on

price. Wheel loaders with special grapples and buckets

for the timber industry are being used more and more

often, in the same way as special solutions like the

LogHandler.

Material handling machines

Liebherr timber material handlers are especially

designed for log handling operations. Mainly used in saw mills, timber yards and paper mills for

perfect performance with high mobility and versatility.

The new design and it´s advance engine and drive train

technology are an integrated part of the Liebherr material handler.

Electric material handling machines

Liebherr electric material handling machines are

3

quick change system, the comprehensive range of working tools enables material handling machines to achieve

a high degree of flexibility and diversity. The quiet electric

drive system and the reliability of the hydraulic components reduce the machine's maintenance costs considerably. Maintenance costs are minimised and at the same

time, any downtime of the material handling machines is

reduced. The product range of electric machines from

Liebherr produces very little noise. In operation, it generates 4 to 5 dB less than a comparable machine with a

diesel engine.

multi-functional. Combined with the Liebherr

Special timber handling machines from Liebherr

2

Page 3

4

6

5

Crawler tractors

Intensive co-operation with experienced clients

4

handling has led to the development and implementation

of numerous application-specific options for crawler tractors. The highest level of reliability, low operating costs

and high production performance are the result and help

to increase the client's competitiveness.

5

handlers are ideal for demanding timber handling operations. The telescopic handlers are available in four versions with lift heights of 10 to 13 metres and lift capacities

of between 4.1 t and 5.0 t.

in the fields of wood chip handling and biomass

Telescopic handlers

With their outstanding lifting performance and

excellent manoeuvrability, Liebherr telescopic

Reachstackers

Reachstackers are among the most flexible

6

nals. In addition, the LRS 645 LH offers new opportunities

in specialised goods handling. The Liebherr LogHandler

has been specially developed for use in timber handling

and is the ideal device when mobility and material handling performance are critical.

material handling equipment in container termi-

Special timber handling machines from Liebherr

3

Page 4

1

1

In recent years, Liebherr has become a complete provider of timber handling equipment to the

timber industry. An industrial lift arm relevant to this sector is available for all L 514 - L 580 wheel

loaders as an alternative to the standard lift arm, with no effect on price.

Wheel loaders with special grapples and buckets for the timber

industry are being used more and more often, in the same

way as special solutions like the LogHandler.

Wheel loaders

Special timber handling machines from Liebherr

4

Page 5

Performance

The Liebherr driveline allows different orientation for the

Liebherr diesel engine. In the wheel loaders L 524 - L 556

the diesel engine is rotated through 90° and mounted

transverse to the direction of travel, in the L 566 - L 580

it is mounted lengthways in the rear, with the output shaft

facing backwards. Compared to conventionally driven

wheel loaders, the operating weight is much lower, the

tipping load is higher, and more material can be moved

each operating hour.

Reliability

All material handlers have been subjected to intense

endurance testing and fulfill Liebherr's standard of

superior quality, even under the most extreme conditions.

Its well-developed concept and proven quality make

Liebherr wheel loaders the benchmark for reliability.

Comfort

The ultra-modern cab design with advanced ergonomics,

continuously variable Liebherr driveline for uninterrupted

tractive force, Liebherr ride control - installed as

standard on the L 550 - L 580 models, optimum weight

distribution and easy service access thanks to unique

engine installation position lead to extraordinary overall

comfort.

Economy

Compared to conventional transmission systems, the

hydrostatic driveline with Liebherr Power Efficiency

achieves a reduction in fuel consumption for wheel

loaders of up to 25%. This reduces operating costs and

environmental pollution.

Special timber handling machines from Liebherr

5

Page 6

Wheel loaders L 524 - L 580

overview

LED headlight packages

(optional)

• Fluff trap for radiator (optional)

• Large-mesh radiator (optional)

• Reversible fan drive (optional)

Rear area monitoring camera

via Liebherr display

(L524 - L542: optional /

L 550 - L 580 as standard)

Liebherr Power

Effi ciency (LPE)

as standard

Special timber handling machines from Liebherr

6

Joystick steering or

2-in-1 steering (optional)

Page 7

LIKUFIX quick-hitch

(L 524 - L 542) (optional)

Comprehensive range of

special equipment for timber handling

The optional industrial lift arm

including standard quickhitch for parallel guide and

industrial equipment

Special tyres for

timber-related operations

Special timber handling machines from Liebherr

7

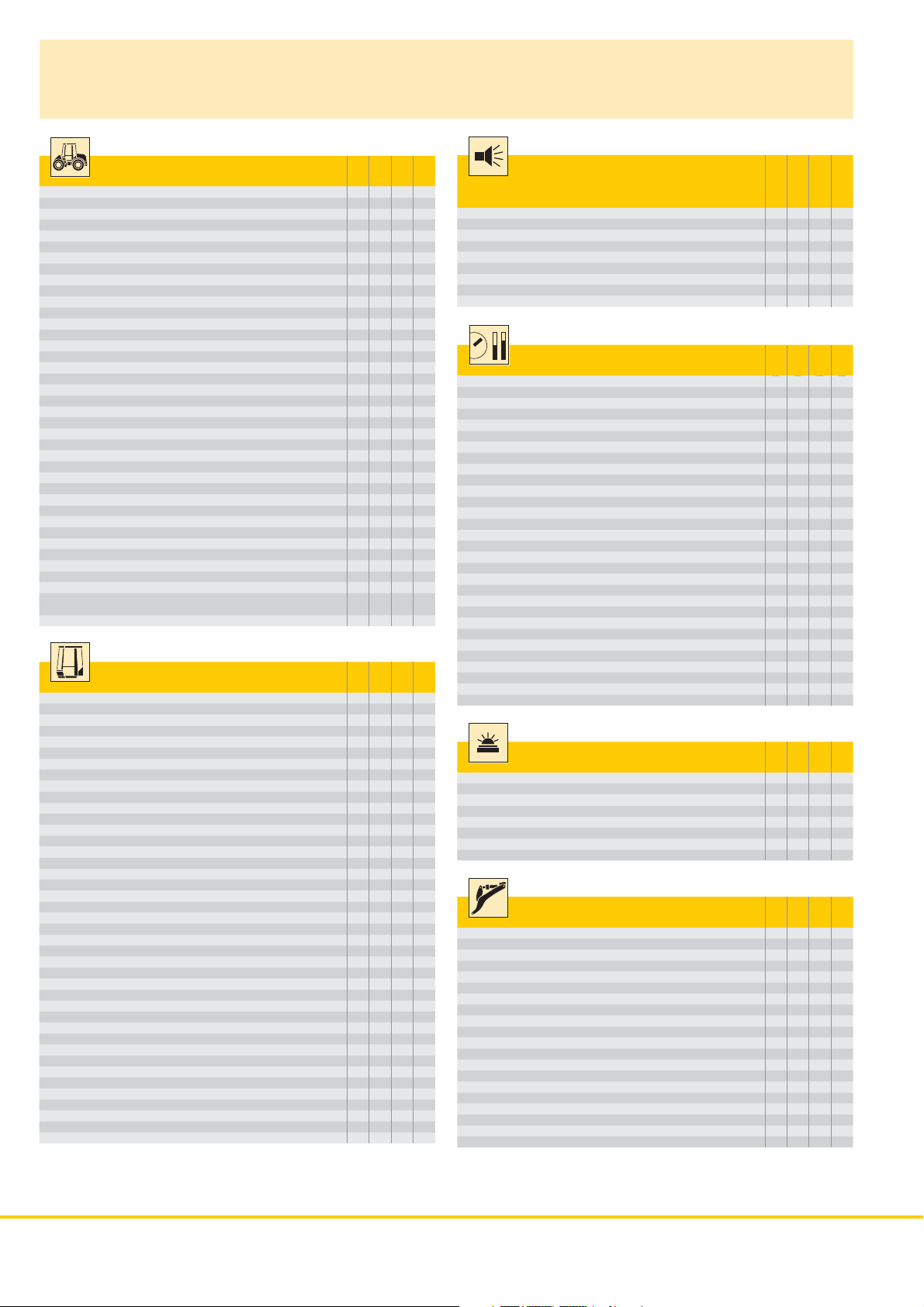

Page 8

Technical data

L 524 - L 542

L 524 L 528 L 538 L 542

L 524 L 528 L 538 L 542

Diesel engine

Design

Cylinder inline

Fuel injection process ______ electronic Common Rail high-pressure injection

Max. output according to

DIN/ISO 3046

at RPM 2,000 2,200 2,000 2,000

Max. torque

at RPM 1,600 1,600 1,600 1,600

Displacement

Bore/Stroke

Air cleaner system

Electrical system

Operating voltage

Battery

Alternator

Starter

Engine

_______________________

_________________________

_________________

_____________

______________

__________

______________

_________________

_____________________

__________________

__________________

kW 90 100 115 120

Nm 480 492 615 645

litres 4.5 4.5 4.5 4.5

mm 106/127 106/127 106/127 106/127

__________

V/A 24/100 24/100 24/100 24/100

V/kW 24/7.8 24/7.8 24/7.8 24/7.8

4045HFL92 4045HFL93 4045HFL93 4045HFL93

water-cooled with exhaust turbo charging, externally

cooled exhaust gas recirculation and diesel particulate

filter

4 4 4 4

Dry air filter with main and safety element,

pre-cleaner, service indicator on LCD display

V 24 24 24 24

Ah 2 x 135 2 x 135 2 x 135 2 x 135

The exhaust emissions are below the limits in Stage IIIB / Tier 4i.

L 524

1,000

900

800

700

600

500

400

Torque (Nm)

300

200

100

0

800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400

rpm

Torque

Output

180

150

120

90

60

30

0

Output (kW)

L 528

1,000

900

800

700

600

500

400

Torque (Nm)

300

200

100

0

800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400

rpm

Torque

Output

180

150

120

90

60

30

0

Output (kW)

L0011L0010

L 538

1,000

900

800

700

600

500

400

Torque (Nm)

300

200

100

0

800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400

rpm

Torque

Output

180

150

120

90

60

30

0

Output (kW)

L0012

L 542

1,000

900

800

700

600

500

400

Torque (Nm)

300

200

100

0

800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400

rpm

Torque

Output

180

150

120

90

60

30

0

Output (kW)

L0013

Special timber handling machines from Liebherr

8

Page 9

Technical data

L 524 - L 542

Travel Drive

Stepless hydrostatic travel drive

Design

Filtering system

Control

Travel speed range

Speed range A1-2

Speed range A1-3

The quoted speeds apply with the tyres that are

_________________________

______________

________________________

________________

Swash plate type variable flow pump and two variable

axial piston motors in closed loop circuit and axle

transfer case. Direction of travel is reversed by changing the flow-direction of the variable-displacement

pump

Suction return line filter for closed circuit

By travel and inching pedal. The inching pedal makes

it possible to control the tractive and thrust forces

steplessly at full engine speed. The Liebherr joystick

is used to control forward and reverse travel

Speed range 1

standard equipment on the loader.

____________________________

________________________

________________________

0 – 6.0 km/h

0 – 16.0 km/h

0 – 40.0 km/h

Axles

Four-wheel drive

___________________________

Front axle

___________________________

Rear axle

Differentials

Reduction gear

Track width

_________________________

________________________

_____________________

Fixed

Centre pivot, with 10° oscillating angle to each side.

470 mm in height can be driven over (with all four

wheels remain in contact with the ground)

Automatic limited-slip differentials with 45% locking

action in both axles

Planetary final drive in wheel hubs

1,960 mm with all types of tyres (L 524, L 528)

1,900 mm with all types of tyres (L 538, L 542)

Brakes

Wear-free service brake

Parking brake

The braking system meets the requirements of the EC guidelines 71/320.

___________

______________________

Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator

brake system with wet multi-disc brakes located in

the differential housing (two seperate brake circuits)

Electro-hydraulically actuated spring-loaded disc

brake system on the front axle

Steering

______________________________

Design

Articulation angle

Emergency steering

__________________

_______________

„Load-sensing“ swash plate type variable flow pump

with pressure cut-off and flow control. Central pivot

with two double-acting steering cylinders

40° (to each side)

Electro-hydraulic emergency steering system

Attachment Hydraulics

______________________________

Design

_____________________________

Cooling

____________________________

Filtration

______________________________

Control

___________________________

Lift circuit

___________________________

Tilt circuit

L 524 L 528 L 538 L 542

____________________

Max. flow

Max. pressure

__________________

„Load-Sensing“ variable axial piston pump with

output and flow control, and pressure cut-off in the

control block

Hydraulic oil cooling using thermostatically controlled

fan and oil cooler

Return line filter in the hydraulic reservoir

„Liebherr joystick“ with hydrostatic servo control

Lifting, neutral, lowering

and float position controlled by Liebherr joystick with

detent; automatic hoist kick out optional

Tilt back, neutral, dump

automatic bucket return to dig

l/min. 105 141 223 223

bar 315 330 350 350

Attachment

Geometry can be chosen

____________________________

Bearings

Cycle time at nominal load

ZK PK ZK PK ZK PK ZK PK

Lifting

Dumping

Lowering (empty)

__________________________

______________________

_________

_________

________

_____________

Powerful Z-bar linkage with one tilt cylinder,

hydraulic quick-hitch – optional equipment;

Parallel linkage with two tilt cylinders, hydraulic

quick-hitch – standard equipment

Sealed

L 524 L 528 L 538 L 542

6.6 s 6.6 s 5.4 s 5.4 s 5.3 s 5.3 s 5.3 s 5.3 s

1.8 s 3.5 s 1.8 s 3.5 s 1.6 s 3.5 s 1.6 s 3.5 s

4.0 s 4.0 s 4.0 s 4.0 s 4.0 s 4.0 s 4.0 s 4.0 s

Operator‘s Cab

______________________________

Design

Liebherr Operator‘s seat

Cab heating and ventilation

On elastic bearing on rear section, soundproof

ROPS/FOPS cab. Operator‘s door with optional fold-

out window, 105° opening angle, ventilation opening

on the right side, front windscreen made of com-

pound safety glass, green tinted as standard, side

windows made of single-pane safety glass,

grey tinted, continuously adjustable steering column

and joystick control as standard, heated rear window

(ESG)

ROPS roll over protection per EN/ISO 3471/

EN 474-1

FOPS falling objects protection per EN/ISO 3449/

EN 474-1

__________

6 way adjustable seat with lap belt, vibration damping

and suspension adjustable for the operator‘s weight

(mechanically sprung)

_______

Operator‘s cab with 4-level air control, cooling water

heating, defroster and air conditioning with electronic

valve control, as well as electronic fresh/recirculated

air control, filter system with pre-filter, fresh air filter

and recirculated air filter, easily replaced, air condition

automatic air conditioning system optional

Noise Emission

L 524 L 528 L 538 L 542

ISO 6396

L

(inside cab)

pA

2000/14/EG

(surround noise)

L

WA

_______________

_________

69 dB(A) 69 dB(A) 69 dB(A) 69 dB(A)

101 dB(A) 101 dB(A) 102 dB(A) 102 dB(A)

Capacities

L 524 L 528 L 538 L 542

Fuel tank

(plastic design)

Fuel tank

(steel version, optional)

Engine oil

(inclusive filter change)

Transmission

Coolant

Front axle/wheel hubs

Rear axle/wheel hubs

Hydraulic tank

Hydraulic system, total

___________________

___________

___________

______________________

____________________________

____________

_____________

____________________

___________

l 205 205 205 205

l 220 220 220 220

l 14.7 20.5 20.5 20.5

l 3.8 3.8 3.8 3.8

l 38 38 38 38

l 16.3/2.6 16.3/2.6 16.3/2.6 16.3/2.6

l 15/2.6 15/2.6 15/2.6 15/2.6

l 110 110 110 110

l 170 170 180 180

/

Special timber handling machines from Liebherr

9

Page 10

H

L 524 - L 542

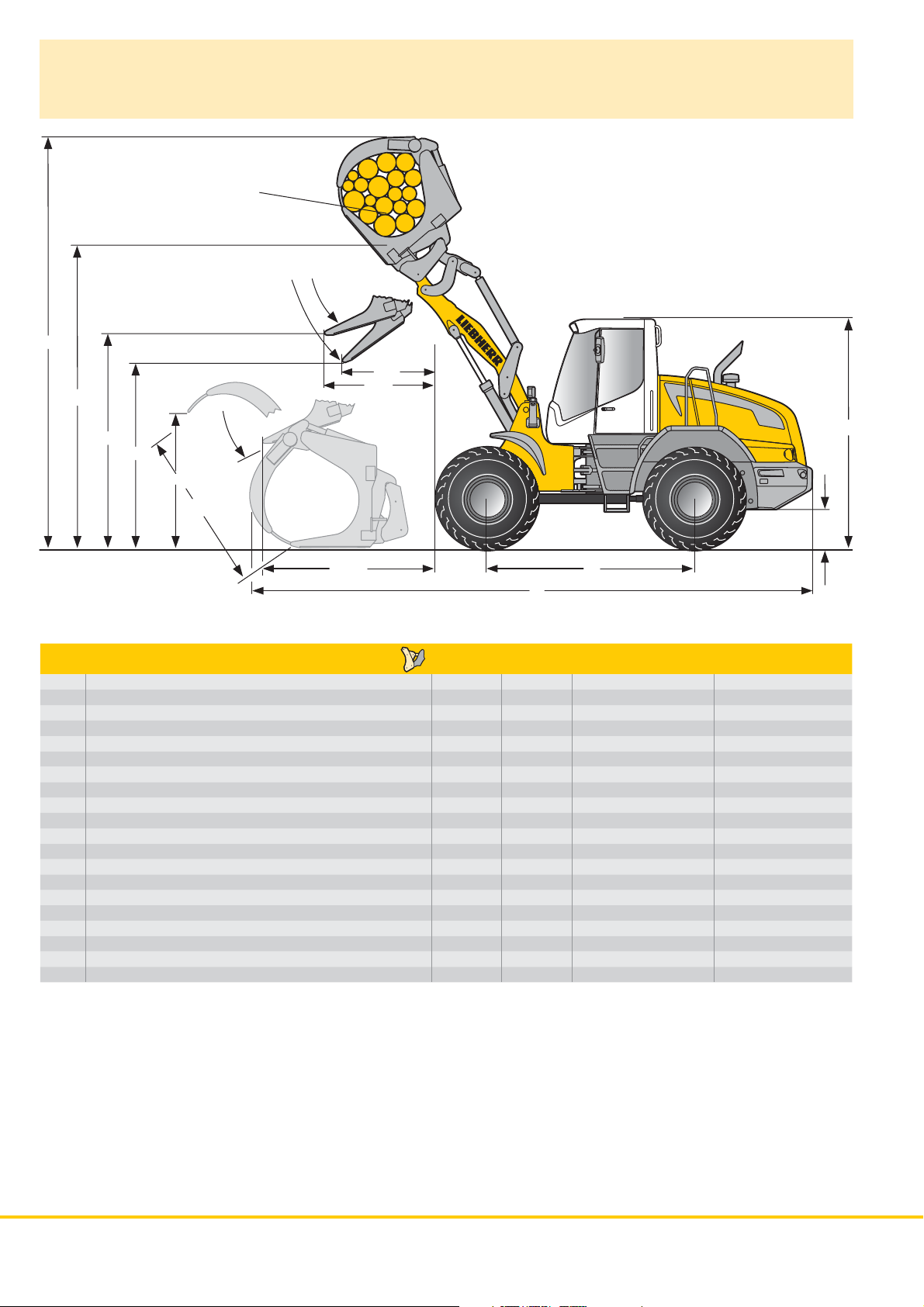

Log Grapple

Q

20°

45°

E

I

A

F 45

F 20

C 1

20°

F max.

L0008.01

K

L

L 524 L 528 L 538 L 542

2

1.3 1.3 1.3 1.8 1.3 1.8

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

A 20

A 45

C

Log Grapple

Geometry PK PK PK PK PK PK

A20 Discharge height at 20° mm 3,380 3,380 3,435 3,340 3,435 3,340

A45 Discharge height at 45° mm 2,895 2,895 2,950 2,835 2,950 2,835

C Max. grapple opening in loading position mm 1,795 1,795 1,795 2,325 1,795 2,325

C1 Max. grapple opening mm 2,075 2,075 2,075 2,580 2,075 2,580

E Max. height mm 5,790 5,790 5,845 6,100 5,845 6,100

F20 Reach at max. lifting height at 20° discharge mm 1,585 1,585 1,500 1,610 1,500 1,610

F45 Reach at max. lifting height at 45° discharge mm 1,275 1,275 1,185 1,255 1,185 1,255

F max. Max. reach mm 2,485 2,485 2,400 2,500 2,400 2,500

H Height above cab mm 3,200 3,200 3,250 3,250 3,250 3,250

I Manipulation height mm 4,240 4,240 4,295 4,375 4,295 4,375

J Ground clearance mm 460 460 490 490 490 490

K Wheelbase mm 2,850 2,850 2,975 2,975 2,975 2,975

L Overall length mm 7,760 7,760 7,980 8,110 7,980 8,110

Width over tyres mm 2,460 2,460 2,490 2,490 2,490 2,490

Q Grapple diameter m

Grapple width mm 1,600 1,600 1,600 1,600 1,600 1,600

Payload * kg 3,880 4,470 5,010 4,450 5,390 4,800

Operating weight * kg 11,800 12,450 13,460 13,860 13,860 14,260

Tyre sizes mm

* The figures shown include the above tyres, all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tyres and optional

equipment will change the operating weight and payload. (Tipping load, articulated at 40° according to ISO 14397-1)

PK = Parallel linkage with hydraulic quick-hitch

J

Special timber handling machines from Liebherr

10

Page 11

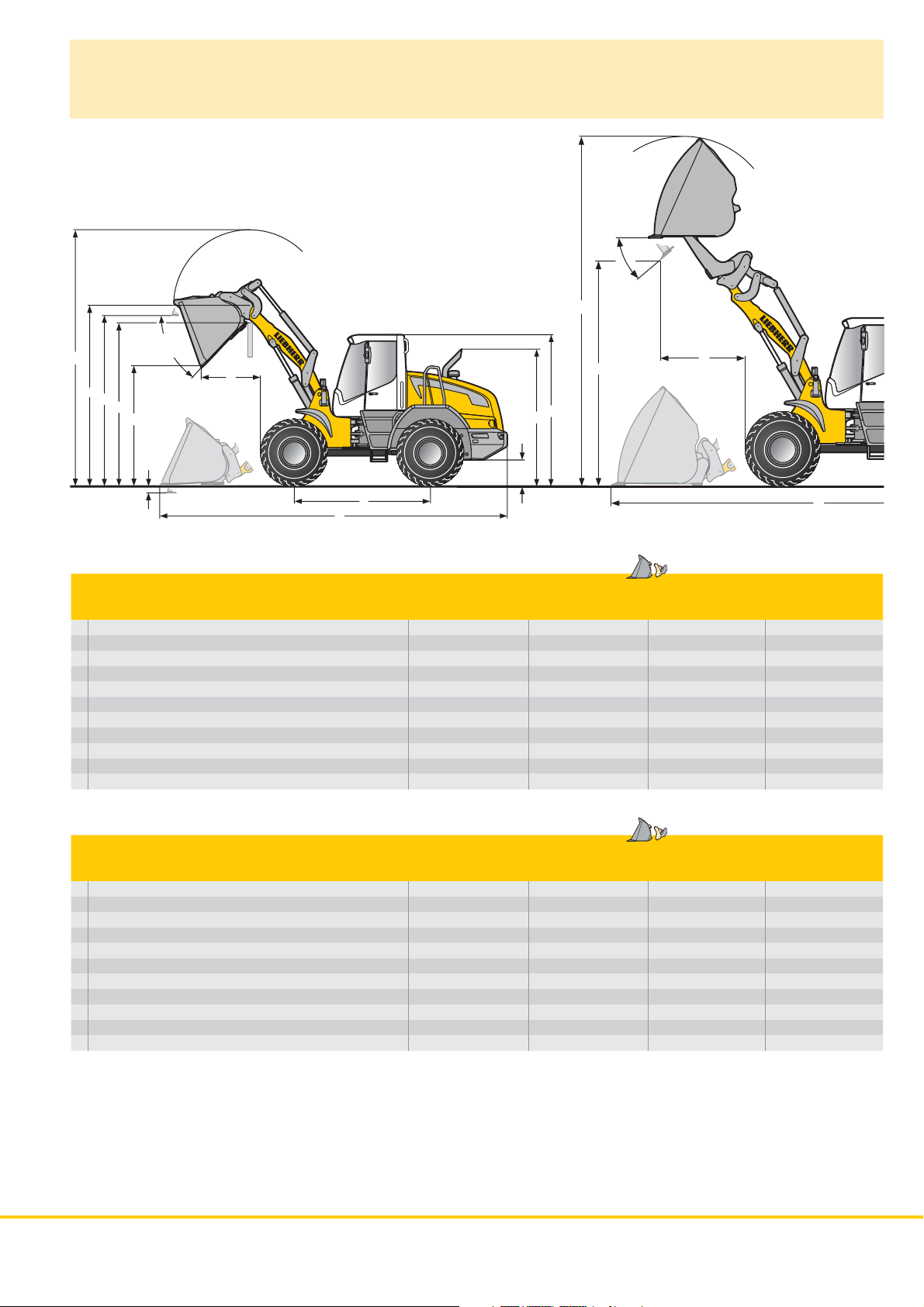

L 524 - L 542

Light Material Bucket High-Dump Bucket

PK 40º

PK-HL 35º

E

PK 45º

C

B

A

PK-HL 45º

F

H

I

A

E

D

F

L0007.01

G

Light Material Bucket

with Bolt-On Cutting Edge

Bucket capacity m

Bucket width mm 2,750 2,750 2,750 2,750 2,750 2,750 2,750 2,750

Specific material weight t/m

A

Dumping height at max. lift height mm 2,230 3,050 2,185 2,980 2,185 2,960 2,135 2,855

K

L

L 524 L 528 L 538 L 542

STD HL STD HL STD HL STD HL

3

5.5 4.0 6.0 4.5 6.5 5.0 7.0 5.5

3

0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

J

L0008.01

L

E Max. operating height mm 5,670 5,950 5,450 6,050 5,925 6,140 5,980 6,250

F Reach at max. lift height mm 1,630 1,355 1,680 1,425 1,650 1,404 1,700 1,505

L Overall length mm 7,930 8,265 8,000 8,365 8,250 8,635 8,320 8,780

Tipping load, straight * kg 7,330 5,760 8,340 6,610 9,400 7,600 10,060 8,090

Tipping load, articulated at 40° * kg 6,470 5,090 7,370 5,840 8,300 6,700 8,870 7,130

Operating weight * kg 12,200 12,400 12,900 13,100 13,950 14,150 14,420 14,630

Tyre sizes 17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

High-Dump Bucket

with Bolt-On Cutting Edge

Bucket capacity m

Bucket width mm 2,700 2,500 2,700 2,700 2,700 2,700 2,950 2,700

Specific material weight t/m

A

Dumping height at max. lift height mm 4,479 5,260 4,457 5,260 4,480 5,269 4,417 5,246

3

3

L 524 L 528 L 538 L 542

STD HL STD HL STD HL STD HL

5.0 3.5 5.5 4.0 6.0 4.5 6.7 5.0

0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

E Max. operating height mm 6,500 6,915 6,630 6,975 6,755 7,085 6,820 7,160

F Reach at max. lift height mm 1,639 1,468 1,666 1,468 1,613 1,446 1,600 1,479

L Overall length mm 7,839 8,357 7,874 8,357 8,094 8,612 8,194 8,652

Tipping load, straight * kg 6,845 5,180 8,030 6,050 9,260 7,050 9,800 7,620

Tipping load, articulated at 40° * kg 6,040 4,570 7,090 5,340 8,160 6,220 8,640 6,720

Operating weight * kg 12,650 12,800 13,330 13,490 14,320 14,540 14,930 15,050

Tyre sizes 17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

* The figures shown include the above tyres, all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tyres and optional

equipment will change the operating weight and tipping load. (Tipping load, articulated at 40° according to ISO 14397-1)

STD = parallel linkage

HL = parallel linkage, high lift version

Special timber handling machines from Liebherr

11

Page 12

L 524 - L 542

Equipment

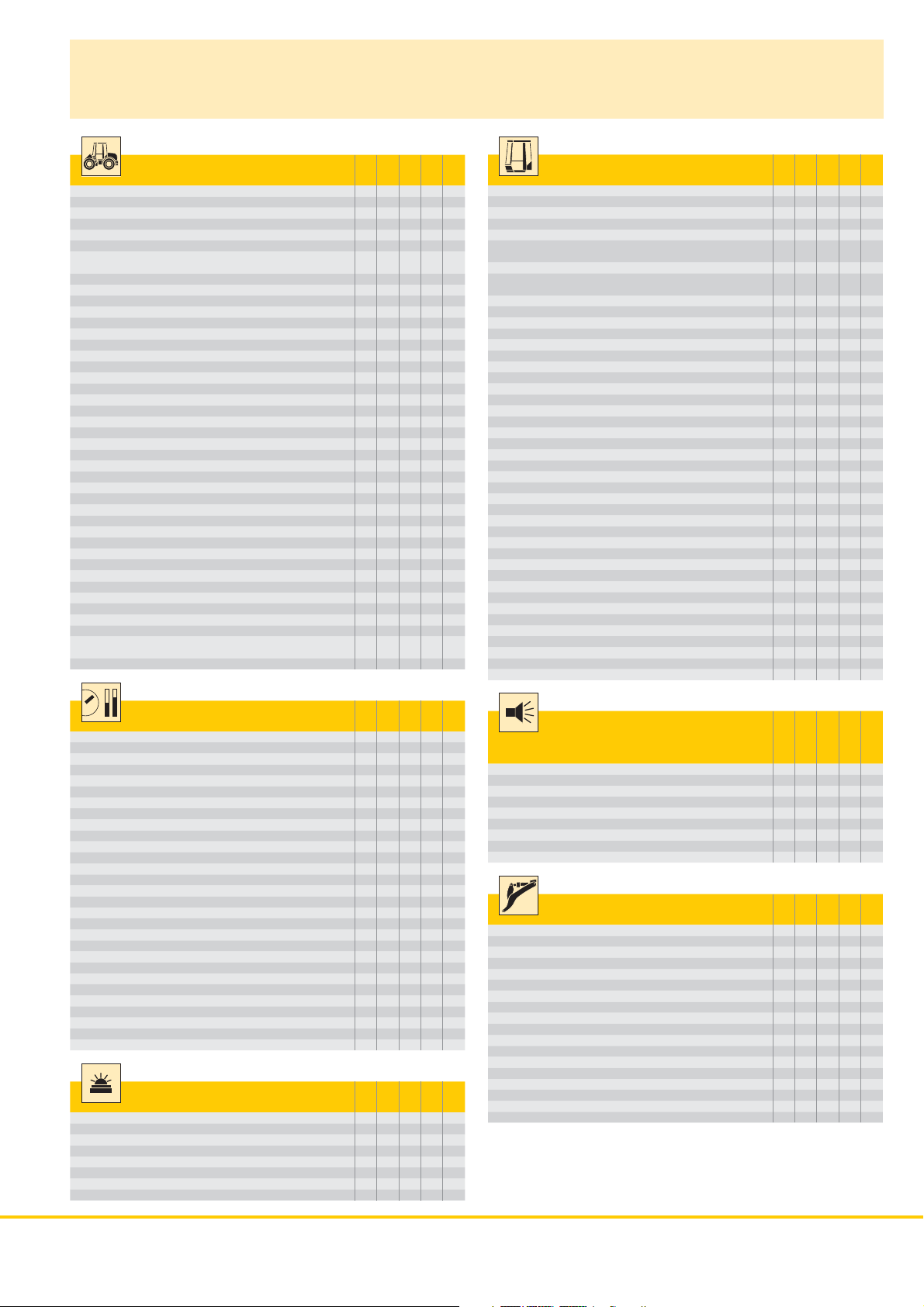

Basic Machine

Crash protection, rear

Access to facilitate windscreen cleaning

Exhaust pipe – stainless steel

Automatic central lubrication system

Battery master switch

Diesel particle filter

Electronical theft protection

Electronic tractive force regulation for difficult ground conditions

Automatic travel mode

Speed range selection

Driver identification (in conjunction with electronic theft lock)

Ride control

Parking brake

Fluff trap for radiator

Speed limitation, 20 km/h

Speed limitation V

Large-mesh radiator

Pre-heat system for cold starting

Combined inching-braking system

Fuel tank steel version

Multi-disc limited slip differentials in both axles

LiDAT (Liebherr Data Transfer System) – one year free of charge

Liebherr biodegredable hydraulic oil

Reversible fan drive

Air cleaner system with pre-filter

Emergency steering system

Reversing obstruction detector

Back-up alarm audible / visual

Tail lights, single version

Rear area monitoring camera (integrated in dispay unit)

Headlights front, single version (on front-chassis) – halogen

Lockable doors, service flap and engine hood

Widening for fender and rear mudguard (steel design)

Rubber widening for rear mudguards

Air pre-cleaner Top-Air

Hazard warning lights

Toolbox with toolkit

Weighing device for approved or non-approved weighing

(integrated in dispay unit)

Towing hitch

max

Operator’s Cab

Storage box

Armrest, adjustable

Exterior mirror, tiltable

Exterior mirror, heated

Fold-out window (operator‘s door)

Operator’s package

Operator‘s seat (mechanically sprung)

Operator’s seat – air sprung with/without seat heating

Fire extinguisher 2 kg

Cup holder

Rear window heater

Horn

Joystick steering

Floor mat

Clothes hook

Air conditioning system (manual)

Automatic air conditioning system

Storage box with cooling function

Steering column, height-adjustable

Steering column, adjustable

Liebherr joystick control – adjustable

Premium Display, Touchscreen (display unit)

Radio set

Provision for radio including loudspeaker

Interior rear-view mirror

Amber beacon

Soundproof ROPS/FOPS cab

Wash/wipe system for windscreen and rear window

Headlights rear, single or double version – halogen/LED

Headlights front, double version – halogen

Headlights front, double version – LED

Headlights front, single version – XENON

Protective ventilation system

Windscreen guard

Sun visor

Sunblind front/rear

Dust filter system

Plug 12 V

First aid kit

Hot water heater with defroster and recirculated-air system

Wide angle mirror

• = Standard, + = Option, - = not available

524

528

538

528

538

542

542

++ ++

••••

++ ++

++++

••••

••••

++++

••••

••••

••••

++ ++

++++

••••

++++

++ ++

••••

++++

••••

••••

++++

••••

••••

++++

++++

••••

••••

++++

++++

••••

++ ++

••••

••••

++ ++

++ ++

++ ++

••••

++++

++++

••••

524

••••

••••

••••

++ ++

++ ++

••••

••••

++++

++++

••••

••••

••••

++++

••••

••••

++++

++ ++

++++

++ ++

••••

••••

++ ++

++++

++++

••••

++++

••••

••••

++++

••••

++++

++++

++++

++++

••••

++ ++

++++

••••

++++

••••

++++

Audible

Warnings for

Quick-hitch, opened

Coolant level

Charge air/fuel temperature too high

Steering system / braking system

Engine oil pressure

Reversing obstruction detector

Back-up alarm

Service codes

Overheating of coolant, fuel, hydraulic oil

Display unit

Working hydraulics lockout

Automatic central lubrication system

Battery charge

Operating voltage

Timer for hours of operation

Indicator light / Hazard warning lights / High beam

Brake accumulator pressure

Date/outside temperature

Diesel particle filter

Rev. Counter

Speed range indicator

Driver identification

Travel speed

Travel direction

Parking brake

Gear level

Heater / Air conditioning

Hydraulic oil temperature

Joystick steering

Fuel level

Fuel consumption

Coolant temperature

Reversible fan drive

Engine oil pressure

Emergency steering system

Service codes

System and function settings

Time

Weighing device

Tractive force regulation

Warning symbols for

Battery charge

Brake accumulator pressure

Diesel particle filter

Air cleaner blockage

Engine oil pressure

Emergency steering system

Reversing obstruction detector

Engine overspeed

Equipment

Working hydraulics lockout

Automatic hoist kick out – adjustable

Automatic bucket return to dig – adjustable

Fork carrier and lift forks

High-dump bucket

Log Grapple

Hydraulic quick-hitch – Z-bar linkage

Hydraulic servo control of working hydraulics

Tilt cylinder protection

Loading buckets with and without teeth, or bolt-on cutting edge

Country-specific versions

Light material bucket

LIKUFIX

Parallel linkage including quick-hitch

Parallel linkage including quick-hitch – High Lift version

Load holding valves

Float position

Z-bar linkage

3rd hydraulic control circuit

3rd and 4th hydraulic control circuits

524

528

538

528

528

528

528

538

538

538

538

542

542

542

542

542

••••

••••

••••

••••

••••

++ ++

++ ++

••••

••••

524

524

••••

++++

••••

++++

••••

••••

••••

++++

••••

••••

••••

++++

••••

••••

••••

++++

••••

••••

++++

••••

++++

••••

++++

++++

••••

••••

++++

••••

++++

••••

524

••••

••••

••••

••••

••••

••••

++ ++

••••

524

••••

++++

••••

++++

++++

++++

++++

••••

++++

++++

++++

++++

++++

++++

++++

++++

••••

••••

++++

++++

Special timber handling machines from Liebherr

12

Page 13

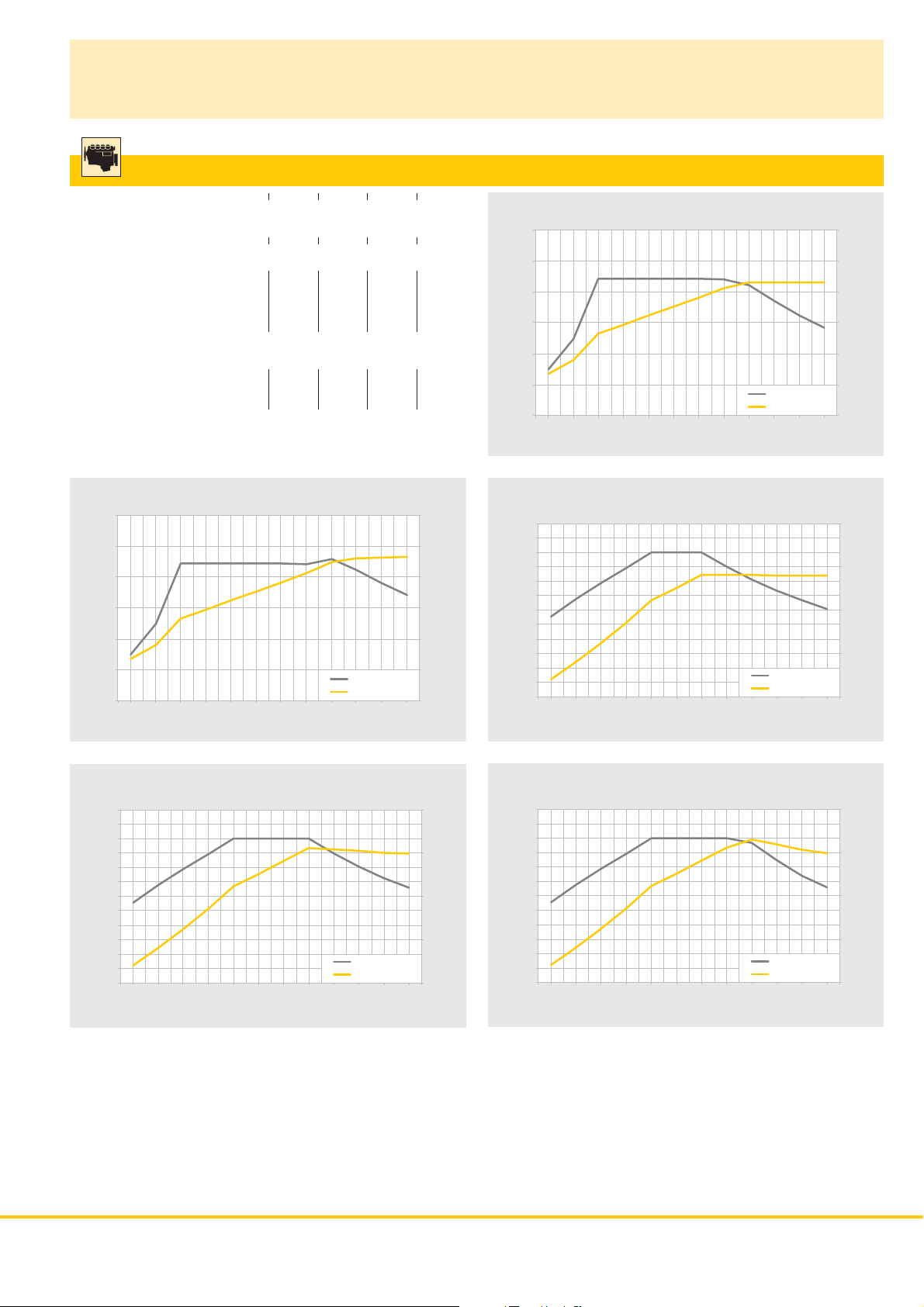

Technical data

L 550 - L 580

L 550 L 556 L 566 L 576 L 580

Liebherr diesel engine

Design

Cylinder inline

Fuel injection process

Max. output

to ISO 9249

at RPM 1,500 1,500 1,300 1,400 1,500

Max. torque

at RPM 1,300 1,500 1,300 1,200 1,100

Displacement

Bore/Stroke

Air cleaner

Electrical system

Operating voltage

Battery

Alternator

Starter motor

Engine

_________________________

__________________________

_____________

_________________

_______

_______________

____________________

__________

______________

____________________

__________

__________________

__________

kW 129 140 190 205 215

Nm 843 857 1,400 1,400 1,400

litres 7.01 7.01 10.52 10.52 10.52

mm 122/150 122/150 122/150 122/150 122/150

Ah 2 x 140 2 x 140 2 x 180 2 x 180 2 x 180

V/A 28/100 28/100 28/100 28/100 28/100

V/kW 24/7.8 24/7.8 24/7.8 24/7.8 24/7.8

D934 A7 D934 A7 D936 A7 D936 A7 D936 A7

water-cooled with 2-stage turbo charging, externally

cooled exhaust gas recirculation and diesel particle

filter

4 4 6 6 6

electronic Common Rail high-pressure injection

Dry type with main and safety element, pre-cleaner,

service indicator on the display

V 24 24 24 24 24

The exhaust emissions are below the limits in Stage IIIB/ Tier 4i.

L 556

1,000

900

800

700

Torque (Nm)

600

500

400

700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800

rpm

Torque

Output

180

150

120

90

60

30

0

Output (kW)

L 550

1,000

900

800

700

Torque (Nm)

600

500

400

700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800

rpm

L 566

1,600

1,500

1,400

1,300

1,200

1,100

1,000

900

Torque (Nm)

800

700

600

500

400

700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800

rpm

Torque

Output

Torque

Output

180

150

120

90

60

30

0

250

200

150

100

50

Output (kW)

L0015

Output (kW)

L0019L0018

L 576

1,600

1,500

1,400

1,300

1,200

1,100

1,000

900

Torque (Nm)

800

700

600

500

400

700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800

rpm

Torque

Output

250

200

150

100

50

Output (kW)

L0020

L 580

1,600

1,500

1,400

1,300

1,200

1,100

1,000

900

Torque (Nm)

800

700

600

500

400

700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800

rpm

Torque

Output

250

200

150

Output (kW)

100

50

L0021

Special timber handling machines from Liebherr

13

Page 14

Technical data

L 550 - L 580

Travel Drive

Stepless hydrostatic travel drive

Design

Filtering system

Control

Travel speed range

Speed range 2 and A2

Speed range A3

The quoted speeds apply with the tyres that are

_________________________

______________

________________________

________________

Swash plate type variable flow pump and two

varia ble axial piston motors in closed loop circuit

with one axle transfer case. Direction of travel in reversed by changing the flow-direction of the

variable-displacement pump

Suction return line filter for closed circuit

By travel and inching pedal. The inching pedal makes

it possible to control the tractive and thrust forces

steplessly at full engine speed. The Liebherr joystick

is used to control forward and reverse travel

Speed range 1

____________________________

___________________

__________________________

0 – 10.0 km/h

0 – 20.0 km/h

0 – 40.0 km/h

standard equipment on the loader

Axles

Four-wheel drive

___________________________

Front axle

____________________________

Rear axle

L 550 L 556 L 566 L 576 L 580

Height of obstacles which

can be driven over

With all four wheels remaining in contact with the

Differentials

Reduction gear

Track width

_________________________

_____________________

_________________________

Fixed

Centre pivot, with 13° oscillating angle to each side

______

mm 460 460 490 490 490

ground

Automatic limited-slip differentials

Planetary final drive in wheel hubs

2,000 mm with all types of tyres (L 550, L 556)

2,230 mm with all types of tyres (L 566, L 576, L 580)

Brakes

Wear-free service brake

Parking brake

The braking system meets the requirements of the EC guidelines 71/320.

___________

______________________

Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator

brake system with wet multi-disc brakes

(two sepa rate brake circuits)

Electro-hydraulically actuated spring-loaded disc

brake system on the transmission

Steering

______________________________

Design

Angle of articulation

Emergency steering

_______________

_______________

“Load-sensing” swash plate type variable flow pump

with pressure cut-off and flow control. Central pivot

with two double-acting, damped steering cylinders

40° (to each side)

Electro-hydraulic emergency steering system

Attachment Hydraulics

______________________________

Design

_____________________________

Cooling

_____________________________

Filtering

______________________________

Control

___________________________

Lift circuit

___________________________

Tilt circuit

L 550 L 556 L 566 L 576 L 580

____________________

Max. flow

Max. pressure

Z-bar linkage

Industrial lift arm _______bar 350 380 380 380 380

______________

“Load-sensing” swash plate type variable flow pump

with output and flow control, and pressure cut-off in

the control block

Hydraulic oil cooling using thermostatically controlled

fan and oil cooler

Return line filter in the hydraulic reservoir

“Liebherr-Joystick” with hydraulic servo control

Lifting, neutral, lowering

and float positions controlled by Liebherr joystick

with detent

Tilt back, neutral, dump

Automatic bucket return to dig

l/min. 234 234 290 290 290

bar 330 360 350 350 380

Attachment

___________________________

Geometry

____________________________

Bearings

Cycle time at nominal load

Z-bar linkage

Lifting

Dumping

Lowering (empty)

Industrial lift arm

Lifting

Dumping

Lowering (empty)

__________________________

______________________

_____________

__________________________

______________________

_____________

Powerful Z-bar linkage with tilt cylinder and cast steel

cross-tube

Sealed

_______

L 550 L 556 L 566 L 576 L 580

5.5 s 5.5 s 5.5 s 5.5 s 5.5 s

2.3 s 2.3 s 2.0 s 2.0 s 2.0 s

2.7 s 2.7 s 3.5 s 3.5 s 3.5 s

5.5 s 5.5 s 5.5 s 5.5 s 5.5 s

3.5 s 3.5 s 3.0 s 3.0 s 3.2 s

2.7 s 2.7 s 3.5 s 3.5 s 3.5 s

Operator’s Cab

______________________________

Design

Liebherr Operator’s seat

Cab heating and ventilation

On elastic bearing on rear section, soundproof

ROPS/FOPS cab. Operator’s door with optional

sliding window, 180° opening angle, fold-out window

on right side with opening angle, front windscreen

made of compound safety glass, green tinted as

standard, side windows made of single-pane safety

glass, grey tinted, continuously adjustable steering

column and joystick control as standard, heated rear

window

ROPS roll over protection per EN/ISO 3471/

EN 474-1

FOPS falling objects protection per EN/ISO 3449/

EN 474-1

__________

6 way adjustable seat with lap belt, vibration

damping and suspension adjustable for the

opera tor’s weight (mechanically sprung)

_______

Operator’s cab with 4-level air control, cooling water

heating, defroster and air conditioning with electronic

valve control, as well as electronic fresh/recirculated

air control, filter system with pre-filter, fresh air

filter and recirculated air filter, easily replaced,

air con ditioning as standard

Noise Emission

L 550 L 556 L 566 L 576 L 580

ISO 6396

L

(inside cab)

pA

2000/14/EC

L

(surround noise)

WA

_______________

_________

68 dB(A) 68 dB(A) 68 dB(A) 68 dB(A) 68 dB(A)

104 dB(A) 104 dB(A) 105 dB(A) 105 dB(A) 105 dB(A)

Capacities

L 550 L 556 L 566 L 576 L 580

__________________________

Fuel tank

Engine oil

(including filter change)

Pump distribution gearbox

Transmission

Coolant

Front axle

Rear axle

Hydraulic tank

Hydraulic system, total

Air condition system R134a

_____________________

___________________________

_________________________

__________________________

___________________

l 300 300 400 400 400

__________

l 40 40 44 44 44

______

l 2.5 2.5 2.5 2.5 2.5

l 11.5 11.5 11.5 11.5 11.5

l 42 42 52 52 52

l 35 35 42 42 42

l 35 35 40 42 42

l 135 135 135 135 135

__________

l 245 245 265 265 265

___

g 1,250 1,250 1,250 1,250 1,250

Special timber handling machines from Liebherr

14

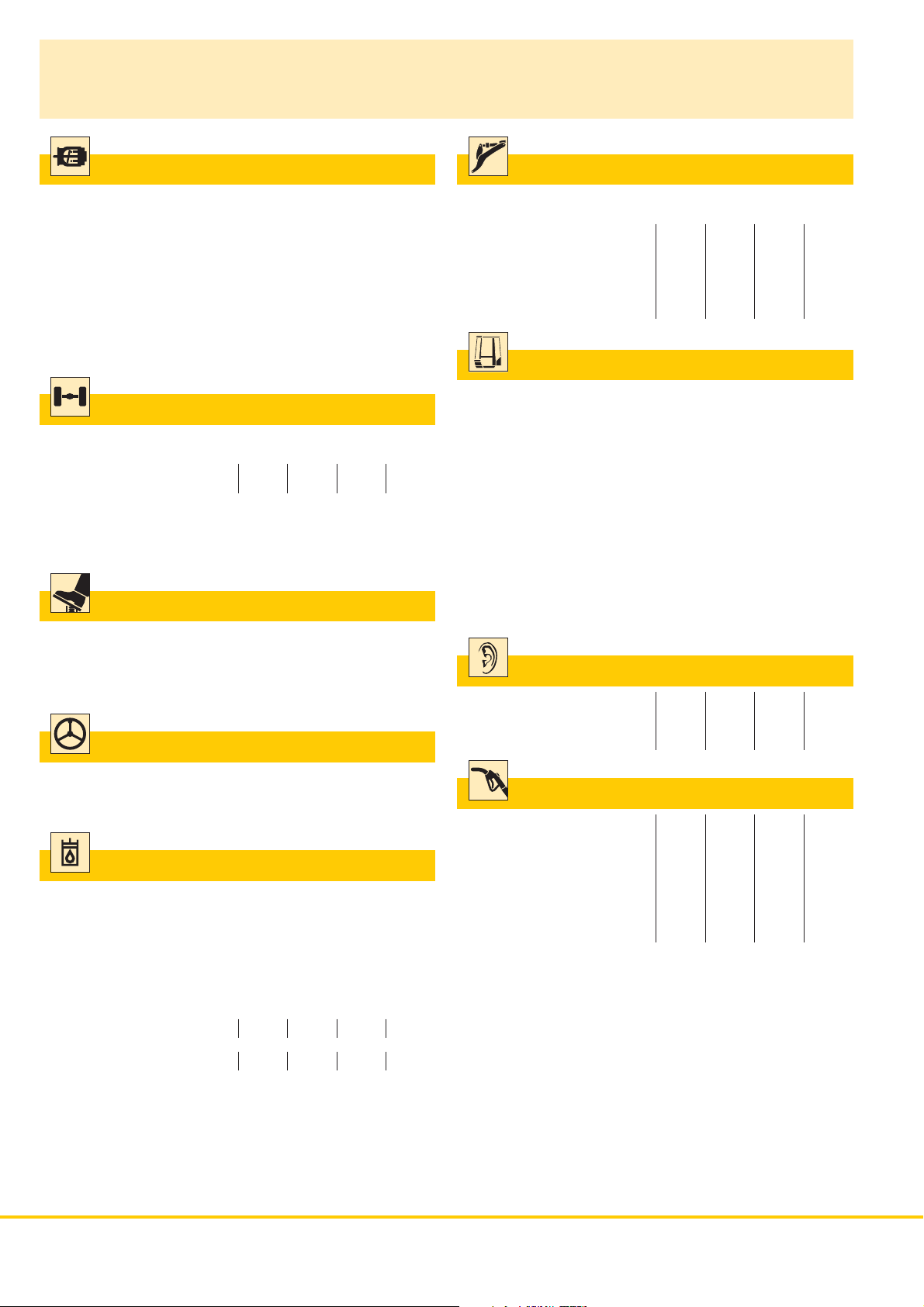

Page 15

Attachment

Log Grapple

Q

20º

45º

E

B

20º

F 45

F 20

A 20

A 45

C

C 1

L0051

KF max.

L

Log Grapple

Geometry

A20 Discharge height at 20° mm

A45 Discharge height at 45° mm

B Manipulation height mm

C Max. grapple opening in loading position mm

C1 Max. grapple opening mm

E Max height mm

F20 Reach at max. lifting height at 20° discharge mm

F45 Reach at max. lifting height at 45° discharge mm

F max. Max. reach mm

H Height above cab mm

I Height above exhaust mm

J Ground clearance mm

K Wheelbase mm

L Overall length mm

Width over tyres mm

Q Grapple diameter m

Grapple width mm

Payload * kg

Operating weight * kg

Tyre sizes

* The figures shown include the above tyres, all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tyres and optional

equipment will change the operating weight and payload. (Tipping load, articulated at 40° according to ISO 14397-1)

IND = Industrial lift arm with parallel guidance including hydraulic quick-hitch

L 550 L 556 L 566 L 576 L 580

IND IND IND IND IND

3,590 3,570 3,570 3,570 3,520

3,020 2,950 2,930 2,930 2,805

4,530 4,530 5,125 5,125 5,125

2,395 2,740 2,650 2,650 2,930

2,590 2,990 3,050 3,050 3,340

6,320 6,480 7,400 7,400 7,500

1,740 1,890 2,165 2,165 2,215

1,410 1,530 1,620 1,620 1,625

2,670 2,820 3,110 3,110 3,160

3,360 3,360 3,590 3,590 3,590

3,015 3,015 3,000 3,000 3,000

490 490 535 535 535

3,305 3,305 3,780 3,780 3,900

8,550 8,700 9,880 9,880 10,050

2,650 2,650 2,970 2,970 2,970

2

1.8 2.4 3.1 3.1 3.5

1,600 1,600 1,800 1,800 1,800

6,300 6,400 8,200 8,650 9,200

18,490 19,350 25,640 26,900 27,670

23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3 26.5R25 L3

I

J

H

Special timber handling machines from Liebherr

15

Page 16

L 550 - L 580

Light Material Bucket High-Dump Bucket

E

F

A

L0049

L

Light Material Bucket

Cutting tool BOCE BOCE BOCE BOCE BOCE BOCE BOCE

Bucket capacity m

Bucket width mm 3,400 3,400 3,400 3,400 3,700 4,000 4,000

Specific material weight t/m³ 0.5 0.5 0.5 0.5 0.45 0.45 0.45

A Dumping height at max. lift height mm 2,340 2,920 2,265 2,840 2,620 2,620 2,480

B Dump-over height mm 3,500 4,100 3,500 4,100 3,900 3,900 3,900

D Max. height of bucket pivot point mm 4,075 4,640 4,075 4,640 4,490 4,490 4,490

E Max. operating height mm 6,110 6,470 6,250 6,600 6,700 6,700 6,800

F Reach at maximum lift height mm 1,705 1,520 1,780 1,600 1,860 1,860 1,950

L Overall length mm 8,970 9,400 9,080 9,520 10,100 10,100 10,200

Tipping load, straight * kg 10,620 8,890 11,530 10,140 13,955 15,580 16,880

Tipping load, articulated at 40° * kg 9,365 7,870 10,160 8,950 12,310 13,740 14,950

Operating weight * kg 18,870 19,130 19,570 19,890 25,780 27,110 27,680

Tyre sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3 26.5R25 L3

L 550 L 556 L 566 L 576 L 580

STD HL STD HL STD STD STD

3

9.0 8.0 10.0 9.0 12.0 13.0 14.0

E

F

A

L

L0052

High-Dump Bucket

Cutting tool BOCE BOCE BOCE BOCE BOCE BOCE BOCE

Bucket capacity m

Bucket width mm 3,400 3,400 3,400 3,400 3,700 4,000 4,000

Specific material weight t/m³ 0.5 0.5 0.5 0.5 0.45 0.45 0.45

A Dumping height at max. lift height mm 4,450 4,800 4,610 4,950 4,840 4,840 4,780

B Dump-over height mm 3,500 4,100 3,500 4,100 3,900 3,900 3,900

D Max. height of bucket pivot point mm 4,075 4,640 4,075 4,640 4,490 4,490 4,490

E Max. operating height mm 6,900 7,200 7,150 7,500 7,490 7,490 7,650

F Reach at maximum lift height mm 1,800 1,580 1,860 1,650 2,140 2,140 2,060

L Overall length mm 9,000 9,400 9,100 9,550 10,200 10,200 10,300

Tipping load, straight * kg 9,880 7,950 10,615 9,370 12,500 13,875 14,915

Tipping load, articulated at 40° * kg 8,710 7,010 9,355 8,260 11,020 12,240 13,210

Operating weight * kg 19,270 19,530 19,980 20,040 26,080 27,410 27,980

Tyre sizes 23.5R25 L3 23.5R25 L3 26.5R25 L3 26.5R25 L3 26.5R25 L3

* The figures shown include the above tyres, all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. (Tipping load, articulated at 40°

according to ISO 14397-1)

STD = Industrial lift arm with parallel guidance including hydraulic quick-hitch

HL = Industrial lift arm with parallel guidance including hydraulic quick-hitch, High Lift

BOCE = Bolt-on cutting edge

Special timber handling machines from Liebherr

16

L 550 L 556 L 566 L 576 L 580

STD HL STD HL STD STD STD

3

8.5 7.5 9.5 8.5 11.0 12.0 13.0

Page 17

L 550 - L 580

Equipment

Basic Machine

Crash protection, rear

Access to facilitate windscreen cleaning

Exhaust pipe – stainless steel

Automatic central lubrication system

Battery master switch

Diesel particle filter

Electronic tractive force regulation for difficult ground

conditions

Electronical theft protection

Automatic travel mode

Speed range selection

Driver identification (in conjunction with electronic theft lock)

Ride control

Parking brake

Fluff trap for radiator

Speed limitation, 20 km/h

Speed limitation Vmax

Large-mesh radiator

Pre-heat system for cold starting

Combined inching-braking system

Mudguard extension

Multi-disc limited slip differentials in both axles

Noise suppression package

LiDAT (Liebherr Data Transfer System) – one year free of charge

Liebherr biodegredable hydraulic oil

Reversible fan drive

Air cleaner system with pre-filter

Emergency steering system

Reversing obstruction detector

Back-up alarm audible / visual

Tail lights, single version

Rear area monitoring camera (integrated in dispay unit)

Headlights rear, single version (on tail flap) – halogen

Headlights rear, single version (on tail flap) – LED

Headlights front, single version (on front-chassis) – halogen

Counterweight for road travel

Lockable doors, service flap and engine hood

Rubber widening for rear mudguards

Air pre-cleaner Top-Air

Hazard warning lights

Toolbox with toolkit

Weighing device for approved or non-approved weighing

(integrated in dispay unit)

Towing hitch

550

556

566

576

+++++

+++++

•••••

+++++

•••••

•••••

•••••

+++++

•••••

•••••

+++++

•••••

•••••

+++++

+++++

•••••

+++++

•••••

•••••

+++++

•••••

+++++

•••••

+++++

+++++

•••••

•••••

+++++

+++++

•••••

•••••

•••••

+++++

•••••

–––+–

•••••

+++++

+++++

•••••

•••••

+++++

•••••

580

Operator’s Cab

Storage box

Ashtray

Exterior mirror, tiltable and heatable

Operator’s package

Operator’s seat – mechanically sprung

Operator’s seat with active suspension, with seat climate

control and seat heating

Operator’s seat – air sprung with seat heating

Operator’s seat – horizontal side-to-side suspension with

control console moving as one

Fire extinguisher 2 kg

Cup holder

Rear window heater

Horn

Joystick steering

Floor mat

Clothes hook

Air conditioning system (manual)

Automatic air conditioning system

Storage box with cooling function

Steering column, height-adjustable

Steering column, adjustable

Liebherr joystick control – adjustable

Multi-lever control system

Premium Display, Touchscreen (display unit)

Radio set (CD/MP3)

Provision for radio including loudspeaker

Interior rear-view mirror

Amber beacon

Soundproof ROPS/FOPS cab

Wash/wipe system for windscreen and rear window

Headlights rear, double version – LED

Headlights rear, single version – halogen/LED

Headlights front, double version – LED

Headlights front, double version – halogen

Headlights front, single version - XENON

Sliding window

Protective ventilation system

Windscreen guard

Sun visor

Dust filter system

Plug 12 V

First aid kit

Wide angle mirror

2in1 steering system – changeable

550

556

566

576

•••••

•••••

•••••

•••••

•••••

+++++

+++++

+++++

+++++

•••••

•••••

•••••

+++++

•••••

•••••

•••••

+++++

+++++

+++++

•••••

•••••

+++++

•••••

+++++

+++++

•••••

+++++

•••••

•••••

+++++

+++++

+++++

•••••

+++++

+++++

+++++

+++++

•••••

+++ ++

•••••

+++++

+++++

+++++

580

Display unit

Working hydraulics lockout

Automatic central lubrication system

Battery charge

Operating voltage

Timer for hours of operation

Indicator light / Hazard warning lights / High beam

Brake accumulator pressure

Diesel particle filter

Rev. Counter

Speed range indicator

Driver identification

Travel speed

Travel direction

Parking brake

Gear level

Heater / Air conditioning

Hydraulic oil temperature

Joystick steering

Fuel level

Fuel consumption

Coolant temperature

Reversible fan drive

Engine oil pressure

Emergency steering system

Service codes

System and function settings

Time/date/outside temperature

Weighing device

Tractive force regulation

Warning symbols for

Battery charge

Brake accumulator pressure

Diesel particle filter

Air cleaner blockage

Engine oil pressure

Emergency steering system

Reversing obstruction detector

Engine overspeed

550

556

566

576

566

576

580

580

•••••

+++++

•••••

•••••

•••••

•••••

•••••

•••••

•••••

•••••

+++++

•••••

•••••

•••••

•••••

•••••

•••••

+++++

•••••

•••••

•••••

+++++

•••••

•••••

•••••

•••••

•••••

+++++

•••••

550

556

•••••

•••••

•••••

•••••

•••••

•••••

+++++

•••••

Audible

Warnings for

Quick-hitch, opened

Coolant level

Charge air/fuel temperature too high

Steering system / braking system

Engine oil pressure

Reversing obstruction detector

Back-up alarm

Overheating of coolant, fuel, hydraulic oil or gearbox oil

Overheating coolant, fuel, hydraulics or transmission fluid

Equipment

Working hydraulics lockout

Automatic hoist kick out – adjustable

Automatic bucket return to dig – adjustable

Fork carrier and lift forks

High Lift arms

High-dump bucket

Log Grapple

Hydraulic quick-hitch

Industrial lift arm including quick-hitch

Tilt cylinder protection

Loading buckets with and without teeth, or bolt-on cutting edge

Country-specific versions

Light material bucket

Load holding valves

Float position

Z-bar linkage

3rd hydraulic control circuit

3rd and 4th hydraulic control circuits

• = Standard, + = Option, – = not available

550

556

566

576

566

576

580

580

•••••

•••••

•••••

•••••

•••••

+++++

+++++

•••••

•••••

550

556

•••••

+++++

•••••

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

•••••

•••••

+++++

+++++

Special timber handling machines from Liebherr

17

Page 18

Wheel loader L 580 LogHandler

overview

Various

grapple versions

and sizes with

modular blade

systems

• Protective grille

for headlights

• Lamp carrier in

steel design

Optional Stump ram,

hydraulically lowered

Special timber handling machines from Liebherr

18

Page 19

Special kinematic for timber handling

• Piston rod protection

• Protective grille for front windscreen

mounted on lifting frame

• Five working area lights at front

• Automatic central lubrication system

Cab with roof window including sun blind

• Protective grille for cab roof window

• Washing system for cab roof window

• Fluff trap for radiator (optional)

• Large-mesh radiator (optional)

• Reversible fan drive (optional)

Liebherr control lever, electrohydraulically controlled, adjustable

using Liebherr touchscreen

Special tyres for timberrelated operations

Extension for fenders

and rear mudguards

Special timber handling machines from Liebherr

19

Page 20

Technical data

Engine

Diesel engine

Design

Cylinder inline

Combustion process

Rated output according

to ISO 9249

Max. torque

Displacement

Bore/Stroke

Air cleaner

Electrical system

Operating voltage

Capacity

Alternator

Starter motor

The exhaust emissions are below the limits in Stage IIIA / Tier 3.

_______________________

_________________________

_________________

_________

___________________

___________________

_________________

___________________

__________________________

____________

_______________________

______________________

_________________

D936L A6

Liebherr diesel engine, water-cooled, exhaust turbo

charged with intercooler

6

Unit pump (PLD) microprocessor controlled

230 kW at 2,000 RPM

1,320 Nm at 1,300 RPM

10.52 litres

122/150 mm

Dry type with main and safety element, pre-cleaner,

service indicator on LCD display

24 V

170 Ah

28 V/80 A

24 V/6.6 kW

Travel Drive

Stepless hydrostatic travel drive

Design

Filtering system

Control

Travel speed range

Speed range 2 and A2

Speed range A3

The quoted speeds apply with the tyres 775/65R29

________________________

_______________

________________________

________________

Swash plate type variable flow pump and two

variable axial piston motors in closed loop circuit with

one axle transfer case. Direction of travel in reversed

by changing the flow-direction of the variable-

displacement pump

Suction return line filter for closed circuit

By travel and inching pedal. The inching pedal makes

it possible to control the tractive and thrust forces

steplessly at full engine speed. The Liebherr joystick

is used to control forward and reverse travel

Speed range 1

____________________________

___________________

__________________________

0 – 10.0 km/h

0 – 20.0 km/h

0 – 30.0 km/h

Goodyear GP-4D

Axles

Four-wheel drive

___________________________

Front axle

____________________________

Rear axle

Height of obstacles which

can be driven over

Differentials

Reduction gear

Track width

_________________________

_____________________

_________________________

Fixed

Centre pivot, with 9° oscillating angle to each side

___________

520 mm

With all four wheels remaining in contact with the

ground

Automatic limited-slip differentials

Planetary final drive in wheel hubs

2,370 mm with all types of tyres

Brakes

Wear-free service brake

Parking brake

The braking system meets the requirements of the EC guidelines 71/320.

___________

______________________

Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator

brake system with wet multi-disc brakes (two

sepa rate brake circuits)

Electro-hydraulically actuated spring-loaded brake

system on the transmission

Tyres

Dimensions/weight are calculated for loaders equipped with Goodyear 775/65R29

GP-4D L4 tyres.

Dimensions/weight when fitted with Michelin 800/65R29 XLD65 L3 tyres are amended to:

Operating weight

Vertical dimensions

____________

__________

+ 440 kg

+ 20 mm

Working hydraulics

______________________________

Design

______________________________

Cooling

_____________________________

Filtering

______________________________

Control

___________________________

Lift circuit

Turning circle

Grapple swing

Grapple rotation

Max. flow

Max. pressure

_______________________

______________________

____________________

___________________________

______________________

“Load-sensing” swash plate type variable flow pump

with output and flow control, and pressure cut-off in

the control block

Hydraulic oil cooling using thermostatically controlled

fan and oil cooler

Return line filter in the hydraulic reservoir

“Liebherr-Joystick” with hydraulic servo control

Lifting, neutral, lowering

Forwards, neutral, backwards

Automatic transport configuration

Forwards and backwards

360°

400 l/min.

320 bar

Attachment

___________________________

Geometry

____________________________

Bearings

Powerful and stable “LogHandler” lifting equipment

for optimum lifting heights. 360° rotating grapple tool

Sealed

Operator’s Cab

______________________________

Design

Liebherr Operator’s seat

Cab heating and ventilation

On elastic bearing on rear section, soundproof

ROPS/FOPS cab. Operator’s door with optional

sliding window, 180° opening angle, fold-out window

on right site with opening angle, front windscreen

made of compound safety glass, green tinted as

standard, side windows made of single-pane safety

glass, grey tinted, continuously adjustable steering

column and joystick control as standard, heatable

rear window

ROPS roll over protection per EN/ISO 3471/

EN 474-1

FOPS falling objects protection per EN/ISO 3449/

EN 474-1

__________

6 way adjustable seat with lap belt, vibration damping

and suspension adjustable for the opera tor’s weight

_______

Operator’s cab with 4-level air control, cooling water

heating, defroster and air conditioning with electronic

valve control, as well as electronic fresh/recirculated

air control, filter system with pre-filter, fresh air filter

and recirculated air filter, easily replaced, air

con ditioning as standard

Noise Emission

____________________________

ISO 6396

2000/14/EC

_________________________

LpA (inside cab) =

LWA (surround noise) =

69 dB(A)

105 dB(A)

Steering

______________________________

Design

Angle of articulation

Emergency steering

Special timber handling machines from Liebherr

20

_______________

_______________

“Load-sensing” swash plate type variable flow pump

with pressure cut-off and flow control. Central pivot

with two double-acting, damped steering cylinders

40° (to each side)

Electro-hydraulic emergency steering system

Capacities

__________________________________________________________________________________

Fuel tank

Engine oil (including filter change)

Pump distributor gears

Transmission

______________________________________________________________________________________

Coolant

____________________________________________________________________________________

Front axle

_____________________________________________________________________________________

Rear axle

Hydraulic tank

Hydraulic system, total

Air condition system R134a

____________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

_________________________________________________________

__________________________________________________________________

______________________________________________________________

350 l

43 l

2.5 l

11.5 l

52 l

58 l

50 l

135 l

300 l

780 g

Page 21

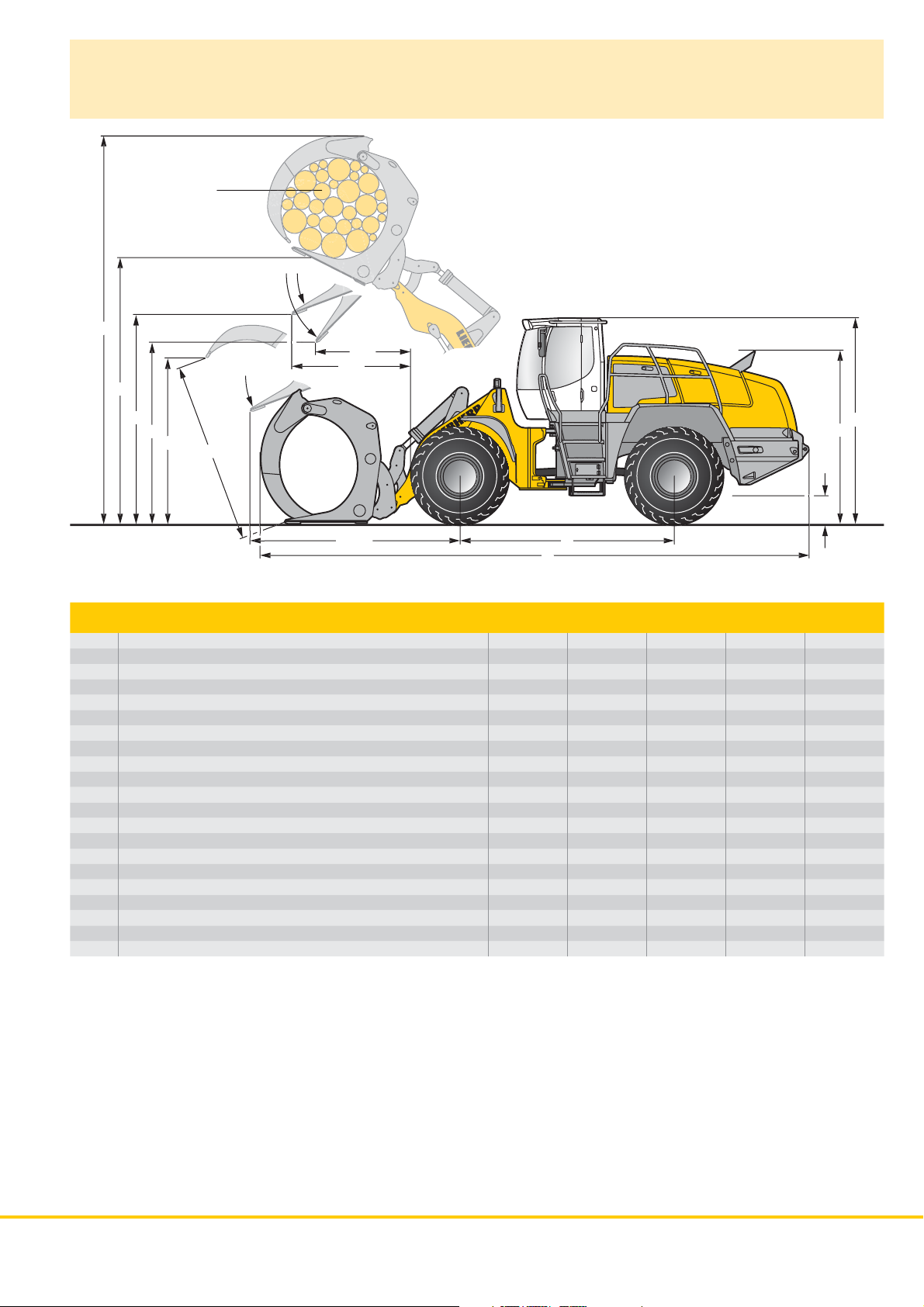

Dimensions

PP

EE

GG

BB

AA

CC

DD

Rotating Grapple, 360°

QQ

Z

MM

NN

FF

F max.F max.

KK

LL

L max.L max.

L0056 L0056 L0056

II

HH

JJ

L0056

3.2 m² 3.6 m² 3.8 m² 3.2 m² 3.6 m²

A Max. manipulation height with grapple closed mm 5,909 5,801 5,719 5,688 5,570

B Max. manipulation height with grapple open mm 6,354 6,304 6,266 6,244 6,192

C Manipulation height at max. outreach mm 2,409 2,301 2,219 2,188 2,070

D Lower manipulation area mm 824 932 1,014 1,045 1,163

E Max. height mm 9,120 9,120 9,120 9,120 9,120

F Outreach at max. lift height mm 2,675 2,675 2,675 2,675 2,675

F max. Max. outreach mm 3,970 3,970 3,970 3,970 3,970

G Height of grapple link mm 8,650 8,650 8,650 8,650 8,650

H Height above cab mm 3,590 3,590 3,590 3,590 3,590

I Height with grapple positioned longitudinally mm 5,050 5,050 5,050 5,050 5,050

Height when max. outreach is attained mm 6,730 6,730 6,730 6,730 6,730

J Ground clearance mm 580 580 580 580 580

K Wheelbase mm 3,700 3,700 3,700 3,700 3,700

L Overall length mm 10,207 10,290 10,304 10,125 10,197

L max. Max. Total length at max. outreach mm 12,559 12,642 12,656 12,477 12,549

Width over tyres mm 3,220 3,220 3,220 3,220 3,220

M Grapple opening mm 3,846 4,038 4,183 4,237 4,448

N Max. span with grapple open mm 4,403 4,622 4,771 4,300 4,517

P Height from top to top mm 2,741 2,849 2,931 2,962 3,080

Q Grapple cross-section mm 2,465 2,647 2,679 2,377 2,522

Grapple weight kg 2,328 2,349 2,336 2,384 2,442

Z Jaw width mm 1,000 1,000 870 1,000 870

Turning circle over lifting equipment with grapple positioned longitudinally

mm 6,830 6,900 6,950 6,830 6,900

Turning circle over external edge of tyres mm 6,725 6,725 6,725 6,725 6,725

Turning circle over inner edge of tyres mm 3,500 3,500 3,500 3,500 3,500

Max. payload with 40° angle of articulation * kg 8,650** 8,625** 8,635** 8,590** 8,350**

Max. payload with 37° angle of articulation * kg 8,800** 8,780** 8,790** 8,650** 8,490**

Operating weight * kg 33,450** 33,470** 33,450** 33,650** 33,850**

Tyre sizes 775/65R29 775/65R29 775/65R29 775/65R29 775/65R29

Goodyear Goodyear Goodyear Goodyear Goodyear

GP-4D GP-4D GP-4D GP-4D GP-4D

* The figures shown here are valid with tyres above, includes all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tyres

and optional equipment as well as chains or tie-down devices will change the operating weight and payload. The stump pusher encreases the

operating weight at 860 kg.

** Data with rear tyres filled with water

L0056

Combination grapple; closes tip to tip

Heart-shaped grab with chain as stump holder; closes tip on tip

Special timber handling machines from Liebherr

21

Page 22

Equipment

Basic Machine

Exhaust pipe – stainless steel

Automatic central lubrication system

Battery master switch

Fuel particle filter

Electronic crowding force control

Electronical theft protection with/without driver identification

Automatic travel mode

Headlights

Ride control

Fluff trap for radiator

Large-mesh radiator

Pre-heat system for cold starting

Creep speed/Cruise control

Combined inching-braking system

Multi-disc limited slip differentials in both axles

Noise suppression package

LED lights on the rear flap

LiDAT Standard (Liebherr Data Transfer System)

LiDAT Plus (extended Liebherr Data Transfer System)

Liebherr travel gear

Liebherr bio degredable hydraulic oil

Air cleaner system with pre-filter

Reversible fan drive

Emergency steering system

Back-up alarm

Lockable doors, service flap and engine hood

Extension for fenders and rear mudguards

Toolbox with toolkit

Weighing device (integrated)

Towing hitch

Two working area lights at rear

Two tail lights

20 km/h speed limiting

Operator’s Cab

Storage box •

Lockable storage compartment •

Ashtray •

Roof window with protective grille and washing system •

Operator’s package •

Operator’s seat – adjustable in 6 ways •

Operator’s seat with active suspension, with seat climate control and seat heating +

Operator’s seat – air sprung with seat heating +

Fire extinguisher 2 kg +

Cup holder •

Five working area lights at front •

Height-adjustable steering column +

Horn •

Joystick steering +

Floor mat •

Clothes hook •

Air conditioning system •

Storage box with cooling function +

LED operating spotlight, front/rear +

Liebherr joystick control – adjustable •

Radio set +

Provision for radio including loudspeaker +

Rear view monitoring with camera +

Interior rear-view mirror •

Amber beacon +

Soundproof ROPS/FOPS cab with tinted safety glass front

windscreen, heatable rear window

Wash/wipe system for windscreen and rear window •

Sliding window +

Protective ventilation system +

Sun visor •

Dust filter system +

Plug 12 V •

First aid kit +

Adjustable steering column •

Hot water heater with defroster and recirculated-air system •

Wide angle mirror +

Xenon working lights front +

Two or four working area lights rear +

• = Standard, + = Option, - = not available

Instruments for

Timer for hours of operation

+

Flashing turn indicators

•

Diagnosis system

•

Rev. counter

+

Forward – reverse travel

•

Travel speed ranges and gear selected

+

High-beam headlights

•

Fuel reserve

•

Engine oil temperature

•

Reverse travel

+

Speedometer

+

Clock

•

Diesel engine pre-heat

•

Forward travel

•

•

+

•

+

+

+

Battery charge

•

Flow through emergency steering system

+

Parking brake

•

Hydraulic oil temperature

+

Air cleaner blockage

•

Engine oil pressure

+

Engine overheat

•

•

+

•

+

•

+

Overheat of hydraulic fluid

Engine oil pressure

Engine overheat

Emergency steering system

Warning lights for

Audible Warnings for

Function Keys for

Working lights rear

Working lights front

Electronic tractive force adaptation

Speed range selection

Headlights

Ride control

Parking brake

Blower

Heater

Air conditioning

Creep speed

Steering column switch for direction of travel

Mode switch

Amber beacon

Wash/wipe system for rear window

Road travel

Transport position (at operating lever)

Hazard warning flashers

Additional hydraulics

•

Rotating Grapple, 360°

Electro-hydraulic control of the working hydraulics

LogHandler lifting gear with protective grille for front windscreen

Modular blade system for grapple

Stump ram

Equipment

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

+

+

Special timber handling machines from Liebherr

22

Page 23

The Liebherr Wheel Loaders

Wheel Loader

L 506Compact L 507Stereo L 508Compact L 509Stereo L 514Stereo

Tipping load kg 3,450 3,712 3,850 4,430 5,680

Bucket capacity m

Operating weight kg 5,180 5,470 5,600 6,390 8,350

Engine output kW/HP 46/63 50/68 50/68 54/73 77/105

3

0.8 0.9 1.0 1.2 1.5

Wheel Loader

L 524 L 528 L 538 L 542 L 550

Tipping load kg 7,500 8,500 9,500 10,200 12,150

Bucket capacity m

Operating weight kg 10,400 10,900 12,800 13,400 17,300

Engine output kW/HP 90/122 100/136 115/156 120/163 129/175

3

2.1 2.3 2.6 2.8 3.2

L0009

L0009

L0009

L0009

Wheel Loader

L 556 L 566 L 576 L 580 L 586

Tipping load kg 13,550 15,750 17,500 18,500 20,430

Bucket capacity m

Operating weight kg 17,900 23,150 24,450 25,180 31,380

Engine output kW/HP 140/191 190/259 205/279 215/292 250/340

3

3.6 4.0 4.5 5.0 5.5

Environmental protection can help you earn money!

The Liebherr Standard Consumption Test –

easy to reproduce and practical.

The Liebherr Standard Consumption Test determines the number of loading cycles that can be carried out with 5 litres of diesel. The material is

taken from pile A and carried over a distance of 20 metres to point B. The

time needed for each working cycle should be 35 seconds. Discharge at

point B should take place from a height of 2.5 m. The working cycles

continue until the 5 litres of diesel in the external measuring tank have

been used up. The loader’s fuel consumption per operating hour is calculated as follows:

35

n=?

B

5

2,5 m

4

30

25

20

15

20 m

T ~ 35 sec.

A

3

2

1

Number of loading cycles

Values for the Liebherr Wheel Loaders

L 524: 2.1 m

L 528: 2.3 m

L 538: 2.6 m

L 542: 2.8 m

L 550: 3.2 m

L 556: 3.6 m

L 566: 4.0 m

L 576: 4.5 m

L 580: 5.0 m

L 586: 5.5 m

* Equipped with L5 tyres and 5.5 m3 HD bucket

** Wheel loader in practical customer applications (with individual

machine configurations).

3

3

3

3

3

3

3

3

3

3

400

Numbers of

working cycles

n = 47 2.8 8.5 7.1

n = 46 2.6 8.7 7.2

n = 39 2.7 10.3 8.5

n = 38 2.6 10.5 8.7

n = 31 2.8 12.9 10.9

n = 27 2.9 14.5 12.1

n = 22 3.2 18.2 15.1

n = 21 2.9 19.1 15.8

n = 20 2.8 20.0 16.2

n = 14 3.6 28.5* 20.5

Litres/

100 tons

Special timber handling machines from Liebherr

=

consumption

per hour

Litres/

hour

Ø Litres/

hour**

23

Page 24

2

2

Liebherr material handlers are specialists in timber yards and saw mills. The design and technology

of Liebherr timber machines are proven over many years of experience in fi eld operations and are

improved continuously based on customers demand and feedback. The rotating upper carriage, the

all-wheel steering or the high loading capacities – as well as the large reach at the same time – offer

advantages that optimize the timber handling operations of the customer. Liebherr, there is no better

way of handling logs.

Material handling machines

Special timber handling machines from Liebherr

24

Page 25

Performance

Impressive versatility and its all-around talents stands for

the new Liebherr material handler timber generation. All

wheel steering as a standard feature guarantees a high

maneuverability in all conditions at any yard profile. A

technical highlight of the LH 60 M Timber Litronic is the

Liebherr-developed dual motor drive unit. The new

Liebherr drive concept saves fuel and guarantees a

smooth and productive operation under all operating

conditions.

Higher efficiency with less consumption.

Reliability

The heavy duty undercarriage guarantees the required

stability for material handling and timber transportation.

The four wheel steering increases driving comfort and

improves directional stability. In combination with an

optimized drive technology, the key benefits for the

customer are a better handling performance combined

with the highest level of safety.

More quality for more reliability.

Comfort

Perfect driving characteristics at any time. The four

single tyres on Liebherr timber material handlers provide

an excellent driving comfort, thanks to the high damping behavior of the air filled tires. The mechanical components are well protected and a high ground clearance

is achieved. The fixed cab riser provides a higher eye

point and assures an exceptional all-around view for safe

operation.

More comfort for more performance.

Economy

Timber handlers have a high daily share in driving mode.

Liebherr timber machines are designed to meet these

demands and impress with low fuel consumption. The

diesel particulate filter takes care of the exhaust gases

after treatment. The service-friendly layout of the machine

guarantees short maintenance periods and a minimum of

maintenance costs.

Emissions and operating costs at a low level.

Special timber handling machines from Liebherr

25

Page 26

Material handling

machine overview

Equipment

specially designed

for timber handling

Working tools

available directly

from the manufacturer

Special timber handling machines from Liebherr

26

Page 27

Optional LED

headlights

Integrated protection

equipped as standard

New Liebherr

cockpit for more

space and comfort

Optional side area monitoring

Engine Emission

stage IIIB

Standard rear

area monitoring

Safe and

ergonomic

access system

Special timber handling machines from Liebherr

27

Page 28

Speed and high performance for

highly

The material handling machines for transport operations

With an attached dozer blade, routes on-site can be kept clear.

Another highlight of the Liebherr timber transport machines is the standard four wheel steering.

Machine model

Recommended equipment/grapple

combination. Other versions available on

request.

Equipment version GA 10 GA 11 GA 11

Operational weight (without grapple) kg approx. 27,800 approx. 35,100 approx. 42,900

Engine output kW (HP) 140 (190) 150 (204) 200 (272)

Standard grapple type*

Surface m

Weight kg 1,775 2,160 / 2,265 approx. 2,600

* Applicable for round log length of 4.0 m and dense softwood 0.8 t/m³

Transport operation

LH 35 M Timber

litronic

Blade

Four wheel steering

Transport operation

GM 20B GMH 50 / GMH 80 GMH 120

2

1.7 2.5 / 2.5 3.2

`

LH 50 M Timber

litronic

Blade

Four wheel steering

Transport operation

`

LH 60 M Timber

litronic

Blade

Four wheel steering

Transport operation

`

GMH 80

Features:

• Closes with overlap

• Sturdy, dual motor slewing drive

• Ideal timber clamp for work in sorting

plant as well as for timber transport

• Good single log handling

• Modular exchangeable claws

Special timber handling machines from Liebherr

28

Page 29

efficient material handling

The material handling machines for loading operations

With the 4 point outriggers, the machine is on secure footing in the whole working area.

Machine model

Recommended equipment/grapple

combination. Other versions available

on request.

Loading operation

LH 26 M

litronic

4 point

outriggers

Loading

operation

`

LH 30 M

litronic

4 point

outriggers

Loading

operation

`

LH 35 M

litronic

4 point

outriggers

Loading

operation

`

LH 40 M

litronic

4 point

outriggers

Loading

operation

`

LH 50 M

litronic

4 point

outriggers

Loading

operation

`

LH 60 M

litronic

4 point

outriggers

Loading

operation

`

LH 80 M

litronic

4 point

outriggers

Loading

operation

Equipment version GA 12 GA 12 GA 13 GA 14 GA 16 GA 18 GA 19

Operational weight (without grapple)

Engine output

Standard grapple*

Surface m

Weight kg 1,270 1,580 1,580 1,675 1,675 2,150

* Applicable for round log length of 4.0 m and dense softwood 0.8 t/m³

kg

approx. 24,500 approx. 26,900 approx. 31,300 approx. 36,800 approx. 42,100 approx. 57,700 approx. 74,100

kW (HP)

110 (150) 129 (175) 129 (175) 140 (190) 140 (190) 180 (244) 230 (313)

GM 10B GM 20B GM 20B GM 20B GM 20B GMH 80

2

0.8 1.0 1.0 1.3 1.3 1.6

GMH 80

2.2

2,230

GMH 50

Features:

• Sturdy, dual motor slewing drive

• Low installation height at discharge

height level

• Hydraulic hold-down device possible

• Modular exchangeable claws

`

Special timber handling machines from Liebherr

29

Page 30

Special machine LH 120 Litronic

The material handling machines for loading operations

The LH 120 Litronic impresses by exceptionally high material handling performance. The machine is available in different undercarriage versions.

Machine model

Recommended equipment/grapple

combination. Other versions available

on request.