Page 1

Machine for

LH 120 M

Industrial Applications

li tr on ic

Operating Weight: 139,900 – 152,500 kg

Engine Output: 400 kW / 543 HP

`

Page 2

Technical Data

Engine

Rating per ISO 9249

�������������������������������

Model

���������������������������������

Type

Bore/Stroke

Displacement

Engine operation

Harmful emissions values

������������������������������

Cooling

Air cleaner

����������������������������

Fuel tank

Engine idling

Electrical system

Voltage

Batteries

Alternator

�������������������������������

Option

����������������

�������������������

�����������������

�������������������

���������������������������

������������������������

������������������������

�����������������������

����������������������

Hydraulic System

Hydraulic pump

for attachment

and travel drive

Max. flow

Max. pressure

Hydraulic pump

regulation and control

Hydraulic pump

for swing drive

Max. flow

Max. pressure

Hydraulic tank

Hydraulic oil filter

Hydraulic oil filter

Hydraulic oil cooler

MODE selection

S (Sensitive)

E (ECO)

P (Power)

P+ (Power-Plus)

����������������

����������������������

�����������������

��������������

����������������

����������������������

�����������������

����������������������

�������������������

�������������������

�����������������

��������������������

�������������������

������������������������

����������������������

���������������

Hydraulic Controls

Power distribution

Servo circuit

Attachment and swing

Driving and steering

Additional functions

������������������

����������������

Swing Drive

���������������������������������

Drive

Transmission

Swing ring

Swing speed

Swing torque

Brake

������������������������

���������������������������

������������������������

������������������������

��������������������������������

400 kW (543 HP) at 1,800 RPM

Liebherr D9508 according to stage IIIA / Tier 3

8 cylinder V-engine

128/157 mm

16.16 l

4-stroke diesel

Common-Rail

turbo-charged and after-cooled

reduced emissions

����������

in accordance with 97/68/EG stagee IIIA

water-cooled with integrated motor oil cooler

dry-type air cleaner with pre-cleaner, primary

and safety elements

3,350 l

sensor controlled

24 V

4 x 170 Ah/12 V

three phase current 28 V/140 A

Liebherr particle filter

four Liebherr variable flow, swashplate pumps

4 x 309 l/min.

350 bar

Positive Control multi-circuit hydraulic system for

independent and demand controlled dosing via the

hydraulic pumps; sensor-controlled

reversible, variable flow, swashplate pump, closed-loop

circuit

483 l/min.

280 bar

1,240 l

1,845 l

3 main return filters with integrated partial micro filtra-

tion (5 μm), 1 high pressure filter for each main pump

cooling system, consisting of a cooling unit for water

and charge air and a 2

with an infinitely variable, thermostatically controlled fan

drive system

adjustment of engine and hydraulic performance via

amode pre-selector to match application, e.g. for

especially economical and environmentally friendly

operation or for maximum material handling and

heavy-duty jobs

for precision work and lifting through very sensitive

movements

for especially economical and environmentally friendly

operation

for maximum digging power and heavy duty jobs

for highest performance and for very heavy duty

applications, suitable for continuous operation

via control valves in single block with integrated safety

valves

��������

with electro-hydraulic pilot control and proportional

operating joysticks

switchable slewing gear (torque or speed control)

����������

with electro-hydraulic pilot control and proportional

operating joystick

proportional control, proportionally acting transmitters

on the joysticks for additional hydraulic functions

Liebherr swashplate motor in a closed system with

integrated brake valve

Liebherr planetary reduction gear

Liebherr, sealed single race ball bearing swing ring,

internal teeth

0 – 5.5 RPM stepless

280 kNm

holding brake (spring applied – pressure released)

nd

cooler for hydraulic oil, each

Uppercarriage

���������������������������������

Type

Operator’s Cab

����������������������������������

Cab

Operator’s seat Standard

�����������

Operator’s seat Comfort (Option)

Operator’s seat Premium (Option)

Control system

Operation and displays

Air-conditioning

Noise emission

ISO 6396

2000/14/EC

���������������������

������������

���������������������

����������������������������

�������������������������

Undercarriage

���������������������������������

Type

���������������������������������

Drive

Travel speed

Axles

Position of wheelsets

Option

Steering programs

Service brake

Holding brake

Stabilization

������������������������

��������������������������������

���������������

�������������������������

������������������

�����������������������

�����������������������

�������������������������

Attachment

���������������������������������

Type

Hydraulic cylinders

Bearings

�����������������

�����������������������������

Complete Machine

Lubrication

Steps system

��������������������������

�����������������������

slewing platform made from high-strength steel plate,

designed for the toughest requirements

spacious operator cabin with profiled design, excellent

view on working area, access from behind, fixed front,

roof and base panel made of bullet proof glass, front

screen with electrical heating, shock-absorbing suspension, sounddamping insulating, sliding window on left

side, sun shadings on all relevant windows, folding seat

forinstructor

air cushioned operator’s seat with headrest, lap belt,

seat heater, manual weight adjustment, adjustable seat

cushion inclination and length and mechanical lumbar

vertebrae support

���

in addition to operator’s seat standard: lockable hori-

zontal suspension, automatic weight adjustment,

adjustable suspension stiffness, pneumatic lumbar

vertebrae support and passive seat climatisation with

active coal

��

in addition to operator’s seat comfort: active elec tronic

weight adjustment (automatic readjustment), pneumatic

low frequency suspension and active seat climatisation

with active coal and ventilator

joysticks with arm consoles and swivel seat

large high-resolution operating unit, selfexplanatory,

colour display with touchscreen, video-compatible,

numerous setting, control and monitoring options,

e.g.air conditioning control, fuel consumption, machine

and tool parameters

standard air conditioning, combined heating-cooling

unit, fast de-icing and demisting at the press of a button,

air vents can be operated via a menu; recirculated air

and fresh air filters can be easily replaced

LpA (inside cab) = 70 dB(A)

LWA (surround noise) = 108 dB(A)

torsion-resistant box design made from high-strength

steel plate, designed for the toughest requirements

per powered wheelset one Liebherr swashplate motor

with integrated brake valves acting on both sides

0 – 7.8 km/h stepless

0 – 4.2 km/h stepless (creeper speed)

wheelsets with suspended 40 t axles, with slewing drive

rotating around the vertical axis, hydraulic cylinder for

leveling

6 steering axles, 2 powered and braked, for leveling

and axle load distribution, interconnected by hydraulic

8 steering axles, 2 powered and braked, for leveling

and axle load distribution, interconnected by hydraulic

front wheel, rear wheel and all-wheel steering,

move to the side in crab steering possible

two circuit travel brake system with accumulator;

maintenance-free, wet and backlash-free disc brake

wet, maintenance-free multi disc brakes

x-shaped 4 point support with 4 folding arms, one

vertically positioned support cylinder per folding arm,

support plates with ball-and-socket joint, removable

high-strength steel plates at highlystressed points

forthe toughest requirements. Complex and stable

mountings of attachment and cylinders

Liebherr cylinders with special seal system.

Shock absorption

sealed, low maintenance

central lubrication system for uppercarriage and

attachment, automatically

central lubrication system for undercarriage,

automatically

undercarriage ascent via ladders (Standard)

undercarriage ascent via ladders and platforms

(HighRise)

uppercarriage with platform left and right and

crossover possibility

parts hot-dip galvanised, nonskid surface

2 LH 120 M Litronic Machine for Industrial Applications

Page 3

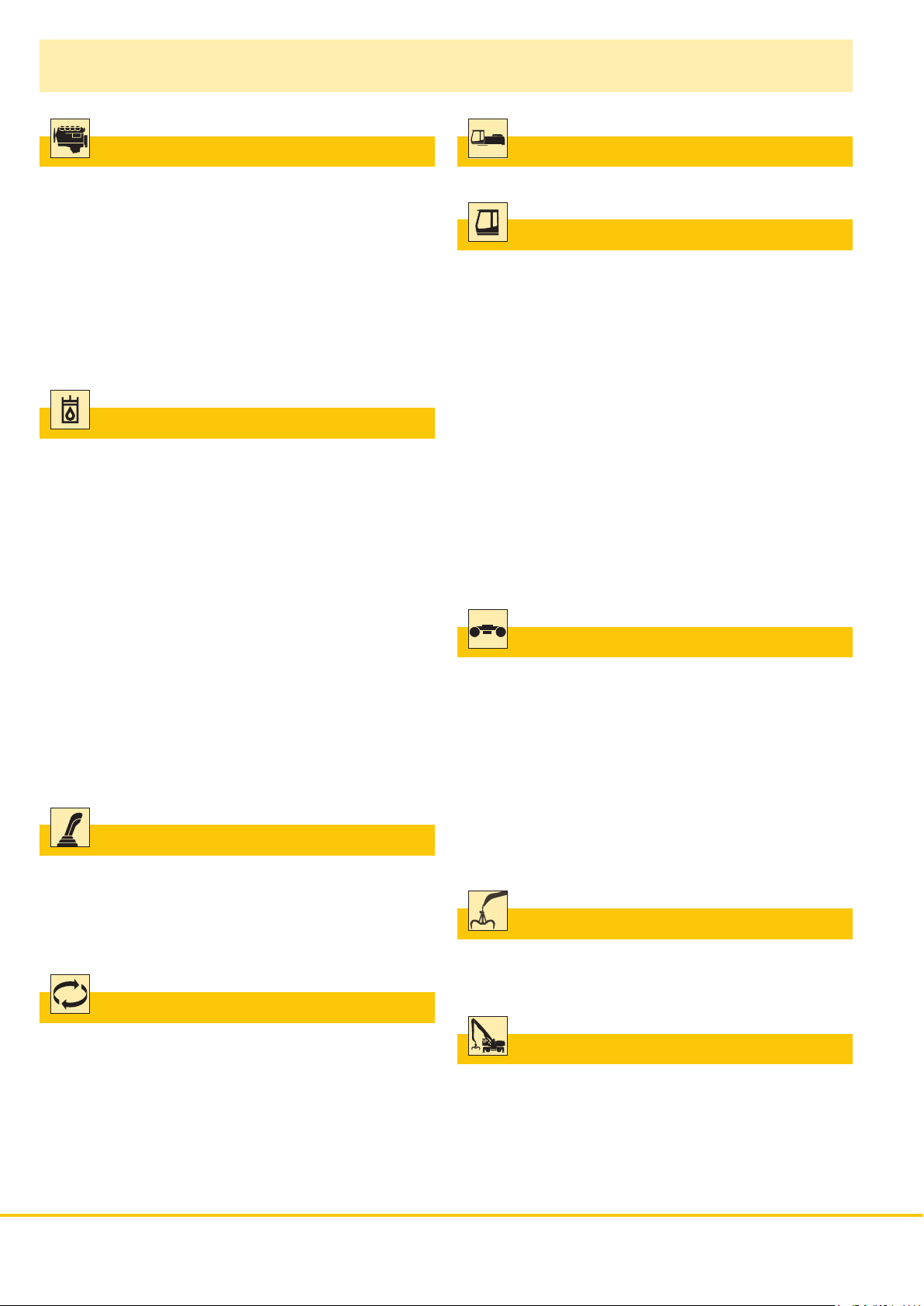

Dimensions

A2

E

D

A1

A

W

L4L3

8050

10686

11486

L1

L2

U

X

V

5050

3000

800

H

K

Q

N

S

B

B1

8500

11500

3000

800

8500

9300

H0290

C

Q1

H0289

without Turret Turret

turret mm 1.20 m mm 2.00 m mm

A 4,814 4,814 4,814

A1 5,220 5,220 5,220

A2 6,115 6,115 6,115

B 5,500 5,500 5,500

B1 – 5,796 5,796

C 8,854 10,054 10,854

D 4,912 4,912 4,912

E 5,020 5,020 5,020

H 6,323 7,523 8,323

K 3,568 4,768 5,568

L1 2,100 2,100 2,100

L2 2,000 2,000 2,000

L3 2,000 2,000 2,000

L4 2,100 2,100 2,100

N 1,700 1,700 1,700

Q 1,431 1,431 1,431

Q1 406 406 406

S 3,800 3,800 3,800

U 11,137 11,137 11,137

E = Tail radius

without Turret Turret

turret 1.20 m 2.00 m

Industrial-Type Angled Mono Boom 15.00 m

and Industrial Stick

m 12.00 13.50 12.00 13.50 12.00 13.50

V mm 11,000 10,350 11,050 10,200 11,150 10,500

W mm 7,950 9,800 8,700 9,950 9,250 10,450

X mm 21,400 21,100 22,100 21,400 21,350 21,450

Industrial-Type Angled Mono Boom 13.50 m

and Industrial Stick

m 10.50 12.00 10.50 12.00 10.50 12.00

V mm 11,050 10,450 11,150 10,600 11,200 10,550

W mm 7,750 9,250 8,600 9,800 9,100 10,100

X mm 19,950 19,800 19,900 20,000 19,850 20,050

Industrial-Type Straight Mono Boom 13.50 m

and Industrial Stick

m 10.50 12.00 10.50 12.00 10.50 12.00

V mm 11,750 11,250 12,200 11,500 12,950 11,350

W mm 7,000 8,750 7,900 9,000 8,700 9,000

X mm 20,000 19,800 20,000 19,950 20,100 20,050

LH 120 M Litronic Machine for Industrial Applications 3

Page 4

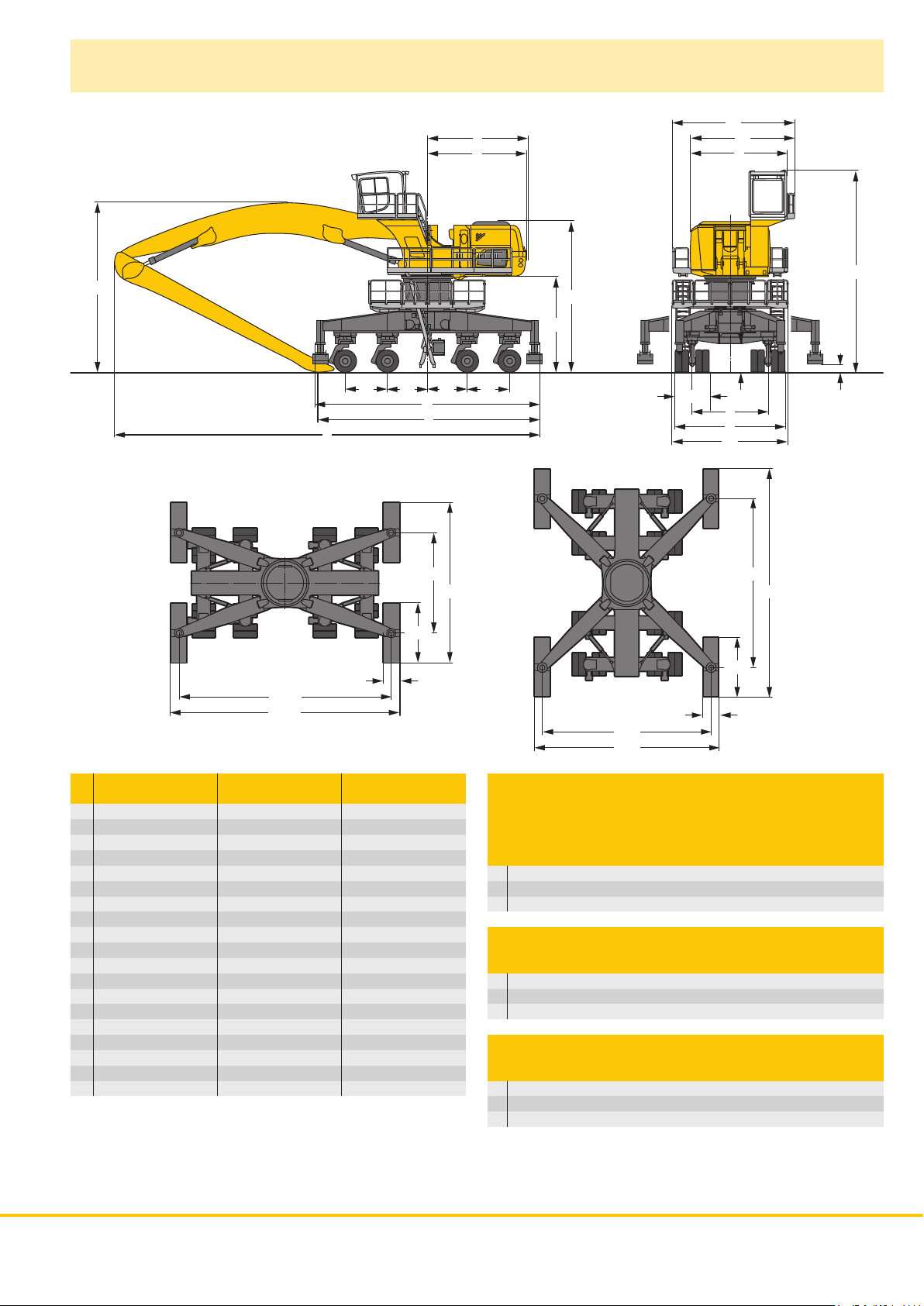

Industrial Attachment

with Industrial-Type Angled Mono Boom 15.00 m

H0292

Attachment Envelope

Kinematic variant 3D

1 with industrial straight stick 12.00 m

2 with industrial straight stick 13.50 m

3 with industrial straight stick 12.00 m and clamshell model GMZ 50

4 with industrial straight stick 13.50 m and clamshell model GMZ 50

Operating Weight

The operating weight includes basic machine with 4 point outriggers,

turret 2.00 m, rigid cab elevation, 32 solid tires and industrial attachment with industrial-type angled mono boom 15.00 m

with clamshell model GMZ 50/6.00 m

shells for loose material Weight

and industrial straight stick 12.00 m 151,900 kg

and industrial straight stick 13.50 m 152,500 kg

100

-10

-20

-30

32

30

28

90

26

80

24

22

70

20

60

18

16

50

14

40

12

10

30

8

10

6

4

10

2

0

0

-2

-4

-6

-8

-10

-12

mft

1

2

3

4

18202224262830

16 14 12 10 8 6 4 2 0

60708090 50 40 30 20 10 0

3

VarioLiftPlus

Hole C

Hole D

Hole 3

H0313

3D

Version 3D

VarioLiftPlus: Variable boom mounting positions for optimized lift capacities

with a different working range

3D

3C

Kinematic Variant 3D:

Increased lift capacities below ground level

and when working at large outreach

Kinematic Variant 3C:

Altered range curve with additional reach

depth, e.g. for unloading from ships

4 LH 120 M Litronic Machine for Industrial Applications

Page 5

Lift Capacities

with Industrial-Type Angled Mono Boom 15.00 m (Kinematic Variant 3D)

Industrial Stick 12.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m 25.5 m

m Undercarriage m

4 pt. outriggers down

27.0

4 pt. outriggers down

25.5

4 pt. outriggers down

24.0

4 pt. outriggers down

22.5

4 pt. outriggers down

21.0

4 pt. outriggers down

19.5

4 pt. outriggers down

18.0

4 pt. outriggers down

16.5

4 pt. outriggers down

15.0

4 pt. outriggers down

13.5

4 pt. outriggers down

12.0

4 pt. outriggers down

10.5

4 pt. outriggers down

9.0

4 pt. outriggers down

7.5

4 pt. outriggers down

6.0

4 pt. outriggers down

4.5

4 pt. outriggers down

3.0

4 pt. outriggers down

1.5

4 pt. outriggers down

0

4 pt. outriggers down

– 1.5

4 pt. outriggers down

– 3.0

4 pt. outriggers down

– 4.5

4 pt. outriggers down

– 6.0

4 pt. outriggers down

– 7.5

4 pt. outriggers down

– 9.0

4 pt. outriggers down

– 10.5

10.6* 10.6* 10.0* 10.0* 13.8

10.9* 10.9* 9.3* 9.3* 16.0

10.8* 10.8* 10.1* 10.1* 8.8* 8.8* 17.7

10.7* 10.7* 9.9* 9.9* 9.4* 9.4* 8.5* 8.5* 19.1

10.6* 10.6* 9.9* 9.9* 9.3* 9.3* 8.7* 8.7* 8.2* 8.2* 20.4

10.6* 10.6* 9.8* 9.8* 9.2* 9.2* 8.7* 8.7* 8.2* 8.2* 8.1* 8.1* 21.4

10.6* 10.6* 9.9* 9.9* 9.2* 9.2* 8.7* 8.7* 8.2* 8.2* 7.9* 7.9* 22.3

10.7* 10.7* 9.9* 9.9* 9.3* 9.3* 8.7* 8.7* 8.2* 8.2* 7.8* 7.8* 7.6* 7.6* 23.1

11.8* 11.8* 10.9* 10.9* 10.1* 10.1* 9.4* 9.4* 8.8* 8.8* 8.2* 8.2* 7.8* 7.8* 7.5* 7.5* 23.8

12.1* 12.1* 11.1* 11.1* 10.2* 10.2* 9.5* 9.5* 8.8* 8.8* 8.3* 8.3* 7.8* 7.8* 7.4* 7.4* 7.3* 7.3* 24.3

13.8* 13.8* 12.4* 12.4* 11.3* 11.3* 10.4* 10.4* 9.6* 9.6* 9.0* 9.0* 8.4* 8.4* 7.9* 7.9* 7.4* 7.4* 7.2* 7.2* 24.7

16.2* 16.2* 14.3* 14.3* 12.8* 12.8* 11.6* 11.6* 10.6* 10.6* 9.8* 9.8* 9.1* 9.1* 8.5* 8.5* 7.9* 7.9* 7.5* 7.5* 7.2* 7.2* 25.1

29.9* 29.9* 23.8* 23.8* 19.8* 19.8* 17.0* 17.0* 14.9* 14.9* 13.2* 13.2* 11.9* 11.9* 10.8* 10.8* 10.0* 10.0* 9.2* 9.2* 8.6* 8.6* 8.0* 8.0* 7.5* 7.5* 7.1* 7.1* 25.3

22.7* 22.7* 32.8* 32.8* 25.5* 25.5* 20.9* 20.9* 17.8* 17.8* 15.4* 15.4* 13.6* 13.6* 12.2* 12.2* 11.1* 11.1* 10.1* 10.1* 9.3* 9.3* 8.7* 8.7* 8.1* 8.1* 7.6* 7.6* 7.1* 7.1* 25.5

5.8* 5.8* 17.3* 17.3* 27.1* 27.1* 22.0* 22.0* 18.5* 18.5* 16.0* 16.0* 14.0* 14.0* 12.5* 12.5* 11.3* 11.3* 10.3* 10.3* 9.5* 9.5* 8.8* 8.8* 8.2* 8.2* 7.6* 7.6* 7.1* 7.1* 7.1* 7.1* 25.5

4.0* 4.0* 9.9* 9.9* 20.8* 20.8* 22.9* 22.9* 19.2* 19.2* 16.5* 16.5* 14.4* 14.4* 12.8* 12.8* 11.5* 11.5* 10.5* 10.5* 9.6* 9.6* 8.9* 8.9* 8.2* 8.2* 7.6* 7.6* 7.1* 7.1* 25.5

4.3* 4.3* 8.2* 8.2* 14.7* 14.7* 23.6* 23.6* 19.7* 19.7* 16.9* 16.9* 14.7* 14.7* 13.1* 13.1* 11.7* 11.7* 10.6* 10.6* 9.7* 9.7* 8.9* 8.9* 8.3* 8.3* 7.6* 7.6* 7.1* 7.1* 25.4

5.2* 5.2* 8.1* 8.1* 12.8* 12.8* 20.8* 20.8* 20.1* 20.1* 17.2* 17.2* 15.0* 15.0* 13.3* 13.3* 11.9* 11.9* 10.8* 10.8* 9.8* 9.8* 9.0* 9.0* 8.3* 8.3* 7.6* 7.6* 7.1* 7.1* 25.2

6.3* 6.3* 8.6* 8.6* 12.3* 12.3* 18.3* 18.3* 20.3* 20.3* 17.4* 17.4* 15.2* 15.2* 13.4* 13.4* 12.0* 12.0* 10.8* 10.8* 9.8* 9.8* 9.0* 9.0* 8.3* 8.3* 7.5* 7.5* 7.1* 7.1* 24.8

7.3* 7.3* 9.3* 9.3* 12.4* 12.4* 17.3* 17.3* 20.3* 20.3* 17.4* 17.4* 15.2* 15.2* 13.5* 13.5* 12.0* 12.0* 10.8* 10.8* 9.8* 9.8* 9.0* 9.0* 8.2* 8.2* 7.4* 7.4* 7.2* 7.2* 24.4

10.1* 10.1* 12.8* 12.8* 17.0* 17.0* 20.1* 20.1* 17.3* 17.3* 15.1* 15.1* 13.4* 13.4* 12.0* 12.0* 10.8* 10.8* 9.7* 9.7* 8.8* 8.8* 8.0* 8.0* 7.2* 7.2* 23.9

13.4* 13.4* 17.2* 17.2* 19.6* 19.6* 17.0* 17.0* 14.9* 14.9* 13.2* 13.2* 11.8* 11.8* 10.6* 10.6* 9.5* 9.5* 8.6* 8.6* 7.7* 7.7* 7.2* 7.2* 23.3

17.7* 17.7* 18.9* 18.9* 16.5* 16.5* 14.5* 14.5* 12.9* 12.9* 11.5* 11.5* 10.3* 10.3* 9.2* 9.2* 8.2* 8.2* 7.4* 7.4* 22.1

15.7* 15.7* 13.9* 13.9* 12.3* 12.3* 11.0* 11.0* 9.8* 9.8* 8.9* 8.9* 19.2

Industrial Stick 13.50 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m 25.5 m

m Undercarriage m

4 pt. outriggers down

27.0

4 pt. outriggers down

25.5

4 pt. outriggers down

24.0

4 pt. outriggers down

22.5

4 pt. outriggers down

21.0

4 pt. outriggers down

19.5

4 pt. outriggers down

18.0

4 pt. outriggers down

16.5

4 pt. outriggers down

15.0

4 pt. outriggers down

13.5

4 pt. outriggers down

12.0

4 pt. outriggers down

10.5

4 pt. outriggers down

9.0

4 pt. outriggers down

7.5

4 pt. outriggers down

6.0

4 pt. outriggers down

4.5

4 pt. outriggers down

3.0

4 pt. outriggers down

1.5

4 pt. outriggers down

0

4 pt. outriggers down

– 1.5

4 pt. outriggers down

– 3.0

4 pt. outriggers down

– 4.5

4 pt. outriggers down

– 6.0

4 pt. outriggers down

– 7.5

4 pt. outriggers down

– 9.0

4 pt. outriggers down

– 10.5

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface. These capacities

can be slewed through 360° with the undercarriage in the transverse position. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic

elements, or the maximum permissible lifting capacity of the load hook.

In accordance with the harmonised European Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe

fracturesafety valves, an overload warning device, a load hook and a lift capacity chart.

8.9* 8.9* 14.1

9.9* 9.9* 8.2* 8.2* 16.3

9.5* 9.5* 7.9* 7.9* 7.7* 7.7* 18.1

9.3* 9.3* 8.8* 8.8* 7.6* 7.6* 7.3* 7.3* 19.6

9.2* 9.2* 8.7* 8.7* 8.2* 8.2* 7.1* 7.1* 21.0

9.2* 9.2* 8.6* 8.6* 8.1* 8.1* 7.7* 7.7* 6.9* 6.9* 22.1

9.2* 9.2* 8.6* 8.6* 8.1* 8.1* 7.6* 7.6* 7.2* 7.2* 6.8* 6.8* 23.1

9.2* 9.2* 8.6* 8.6* 8.1* 8.1* 7.6* 7.6* 7.2* 7.2* 6.7* 6.7* 23.9

9.3* 9.3* 8.6* 8.6* 8.1* 8.1* 7.6* 7.6* 7.2* 7.2* 6.8* 6.8* 6.6* 6.6* 24.6

10.1* 10.1* 9.4* 9.4* 8.7* 8.7* 8.2* 8.2* 7.7* 7.7* 7.2* 7.2* 6.8* 6.8* 6.6* 6.6* 25.2

10.3* 10.3* 9.5* 9.5* 8.8* 8.8* 8.2* 8.2* 7.7* 7.7* 7.3* 7.3* 6.9* 6.9* 6.5* 6.5* 6.4* 6.4* 25.8

11.6* 11.6* 10.6* 10.6* 9.7* 9.7* 9.0* 9.0* 8.3* 8.3* 7.8* 7.8* 7.3* 7.3* 6.9* 6.9* 6.5* 6.5* 6.4* 6.4* 26.2

13.3* 13.3* 12.0* 12.0* 10.9* 10.9* 9.9* 9.9* 9.1* 9.1* 8.5* 8.5* 7.9* 7.9* 7.4* 7.4* 6.9* 6.9* 6.5* 6.5* 6.3* 6.3* 26.5

15.7* 15.7* 13.8* 13.8* 12.4* 12.4* 11.1* 11.1* 10.2* 10.2* 9.3* 9.3* 8.6* 8.6* 8.0* 8.0* 7.5* 7.5* 7.0* 7.0* 6.6* 6.6* 6.3* 6.3* 26.7

29.4* 29.4* 23.3* 23.3* 19.3* 19.3* 16.5* 16.5* 14.4* 14.4* 12.8* 12.8* 11.5* 11.5* 10.4* 10.4* 9.5* 9.5* 8.7* 8.7* 8.1* 8.1* 7.5* 7.5* 7.1* 7.1* 6.6* 6.6* 6.2* 6.2* 26.8

24.9* 24.9* 32.2* 32.2* 25.0* 25.0* 20.4* 20.4* 17.3* 17.3* 14.9* 14.9* 13.2* 13.2* 11.8* 11.8* 10.6* 10.6* 9.7* 9.7* 8.9* 8.9* 8.2* 8.2* 7.6* 7.6* 7.1* 7.1* 6.6* 6.6* 6.2* 6.2* 26.9

7.9* 7.9* 19.1* 19.1* 26.4* 26.4* 21.4* 21.4* 18.0* 18.0* 15.5* 15.5* 13.6* 13.6* 12.1* 12.1* 10.9* 10.9* 9.9* 9.9* 9.0* 9.0* 8.3* 8.3* 7.7* 7.7* 7.2* 7.2* 6.7* 6.7* 6.2* 6.2* 26.9

5.9* 5.9* 11.4* 11.4* 22.1* 22.1* 22.2* 22.2* 18.6* 18.6* 15.9* 15.9* 13.9* 13.9* 12.3* 12.3* 11.1* 11.1* 10.0* 10.0* 9.2* 9.2* 8.4* 8.4* 7.8* 7.8* 7.2* 7.2* 6.7* 6.7* 6.3* 6.3* 26.8

5.9* 5.9* 9.5* 9.5* 15.9* 15.9* 22.8* 22.8* 19.0* 19.0* 16.3* 16.3* 14.2* 14.2* 12.6* 12.6* 11.3* 11.3* 10.2* 10.2* 9.3* 9.3* 8.5* 8.5* 7.8* 7.8* 7.2* 7.2* 6.7* 6.7* 6.3* 6.3* 26.6

6.3* 6.3* 9.2* 9.2* 13.7* 13.7* 21.6* 21.6* 19.4* 19.4* 16.6* 16.6* 14.4* 14.4* 12.7* 12.7* 11.4* 11.4* 10.3* 10.3* 9.3* 9.3* 8.5* 8.5* 7.8* 7.8* 7.2* 7.2* 6.6* 6.6* 6.3* 6.3* 26.3

7.0* 7.0* 9.3* 9.3* 12.9* 12.9* 18.8* 18.8* 19.6* 19.6* 16.7* 16.7* 14.6* 14.6* 12.9* 12.9* 11.5* 11.5* 10.3* 10.3* 9.4* 9.4* 8.6* 8.6* 7.8* 7.8* 7.2* 7.2* 6.5* 6.5* 6.3* 6.3* 25.9

7.7* 7.7* 9.8* 9.8* 12.8* 12.8* 17.6* 17.6* 19.5* 19.5* 16.8* 16.8* 14.6* 14.6* 12.9* 12.9* 11.5* 11.5* 10.3* 10.3* 9.4* 9.4* 8.5* 8.5* 7.7* 7.7* 7.0* 7.0* 6.3* 6.3* 25.4

10.3* 10.3* 13.0* 13.0* 17.2* 17.2* 19.3* 19.3* 16.6* 16.6* 14.5* 14.5* 12.8* 12.8* 11.4* 11.4* 10.3* 10.3* 9.3* 9.3* 8.4* 8.4* 7.6* 7.6* 6.8* 6.8* 6.4* 6.4* 24.8

10.9* 10.9* 13.4* 13.4* 17.2* 17.2* 18.9* 18.9* 16.3* 16.3* 14.3* 14.3* 12.6* 12.6* 11.3* 11.3* 10.1* 10.1* 9.1* 9.1* 8.2* 8.2* 7.3* 7.3* 6.4* 6.4* 6.3* 6.3* 24.2

17.5* 17.5* 18.2* 18.2* 15.8* 15.8* 13.9* 13.9* 12.3* 12.3* 10.9* 10.9* 9.8* 9.8* 8.7* 8.7* 7.8* 7.8* 6.9* 6.9* 6.8* 6.8* 22.6

15.1* 15.1* 13.2* 13.2* 11.7* 11.7* 10.4* 10.4* 9.3* 9.3* 8.2* 8.2* 19.5

LH 120 M Litronic Machine for Industrial Applications 5

Page 6

Industrial Attachment

with Industrial-Type Angled Mono Boom 13.50 m

90

80

70

60

50

40

30

20

10

-10

-20

-30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

0

-2

-4

-10

-12

-6

-8

mft

1820222426

607080 50 40 30 20 10 0

1

2

3

4

16 14 12 10 8 6 4 2 0

H0312

Attachment Envelope

Kinematic variant 3D

1 with industrial stick 10.50 m

2 with industrial stick 12.00 m

3 with industrial stick 10.50 m and grapple model GMM 120

4 with industrial stick 12.00 m and grapple model GMM 120

Operating Weight

The operating weight includes basic machine with 4 point outriggers,

rigid cab elevation, 32 solid tires and industrial attachment with

industrial-type angled mono boom 13.50 m

with grapple model GMM 120-5/3.00 m

semi-closed tines Weight

and industrial stick 10.50 m 140,950 kg

and industrial stick 12.00 m 141,500 kg

3

VarioLiftPlus

Hole C

Hole D

Hole 3

H0313

3D

Version 3D

VarioLiftPlus: Variable boom mounting positions for optimized lift capacities

with a different working range

3D

3C

Kinematic Variant 3D:

Increased lift capacities below ground level

and when working at large outreach

Kinematic Variant 3C:

Altered range curve with additional reach

depth, e.g. for unloading from ships

6 LH 120 M Litronic Machine for Industrial Applications

Page 7

Lift Capacities

with Industrial-Type Angled Mono Boom 13.50 m (Kinematic Variant 3D)

Industrial Stick 10.50 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m 25.5 m

m Undercarriage m

4 pt. outriggers down

27.0

4 pt. outriggers down

25.5

4 pt. outriggers down

24.0

4 pt. outriggers down

22.5

4 pt. outriggers down

21.0

4 pt. outriggers down

19.5

4 pt. outriggers down

18.0

4 pt. outriggers down

16.5

4 pt. outriggers down

15.0

4 pt. outriggers down

13.5

4 pt. outriggers down

12.0

4 pt. outriggers down

10.5

4 pt. outriggers down

9.0

4 pt. outriggers down

7.5

4 pt. outriggers down

6.0

4 pt. outriggers down

4.5

4 pt. outriggers down

3.0

4 pt. outriggers down

1.5

4 pt. outriggers down

0

4 pt. outriggers down

– 1.5

4 pt. outriggers down

– 3.0

4 pt. outriggers down

– 4.5

4 pt. outriggers down

– 6.0

4 pt. outriggers down

– 7.5

4 pt. outriggers down

– 9.0

4 pt. outriggers down

– 10.5

12.8* 12.8* 11.7* 11.7* 12.5

13.1* 13.1* 10.9* 10.9* 14.6

12.8* 12.8* 12.1* 12.1* 10.3* 10.3* 16.2

12.6* 12.6* 11.9* 11.9* 11.4* 11.4* 9.9* 9.9* 17.6

12.6* 12.6* 11.9* 11.9* 11.3* 11.3* 10.8* 10.8* 9.7* 9.7* 18.7

12.7* 12.7* 11.9* 11.9* 11.3* 11.3* 10.7* 10.7* 10.1* 10.1* 9.6* 9.6* 19.7

12.9* 12.9* 12.0* 12.0* 11.3* 11.3* 10.8* 10.8* 10.3* 10.3* 9.5* 9.5* 20.5

14.2* 14.2* 13.1* 13.1* 12.3* 12.3* 11.5* 11.5* 10.9* 10.9* 10.3* 10.3* 9.9* 9.9* 9.5* 9.5* 21.1

16.2* 16.2* 14.7* 14.7* 13.5* 13.5* 12.5* 12.5* 11.7* 11.7* 11.0* 11.0* 10.4* 10.4* 9.9* 9.9* 9.5* 9.5* 21.7

19.3* 19.3* 17.1* 17.1* 15.4* 15.4* 14.0* 14.0* 12.9* 12.9* 12.0* 12.0* 11.2* 11.2* 10.5* 10.5* 10.0* 10.0* 9.6* 9.6* 22.1

24.4* 24.4* 20.7* 20.7* 18.1* 18.1* 16.1* 16.1* 14.5* 14.5* 13.3* 13.3* 12.3* 12.3* 11.4* 11.4* 10.7* 10.7* 10.1* 10.1* 9.6* 9.6* 22.4

46.6* 46.6* 33.8* 33.8* 26.8* 26.8* 22.3* 22.3* 19.1* 19.1* 16.8* 16.8* 15.1* 15.1* 13.7* 13.7* 12.6* 12.6* 11.6* 11.6* 10.9* 10.9* 10.2* 10.2* 9.6* 9.6* 9.6* 9.6* 22.6

10.5* 10.5* 35.3* 35.3* 29.1* 29.1* 23.8* 23.8* 20.2* 20.2* 17.6* 17.6* 15.7* 15.7* 14.1* 14.1* 12.9* 12.9* 11.9* 11.9* 11.0* 11.0* 10.3* 10.3* 9.7* 9.7* 9.6* 9.6* 22.7

5.9* 5.9* 15.2* 15.2* 31.1* 31.1* 25.2* 25.2* 21.2* 21.2* 18.3* 18.3* 16.2* 16.2* 14.5* 14.5* 13.2* 13.2* 12.1* 12.1* 11.2* 11.2* 10.4* 10.4* 9.7* 9.7* 9.6* 9.6* 22.7

5.8* 5.8* 11.5* 11.5* 22.0* 22.0* 26.3* 26.3* 22.0* 22.0* 19.0* 19.0* 16.7* 16.7* 14.9* 14.9* 13.5* 13.5* 12.3* 12.3* 11.3* 11.3* 10.5* 10.5* 9.7* 9.7* 9.6* 9.6* 22.6

6.8* 6.8* 10.9* 10.9* 17.9* 17.9* 27.0* 27.0* 22.7* 22.7* 19.5* 19.5* 17.1* 17.1* 15.2* 15.2* 13.7* 13.7* 12.5* 12.5* 11.4* 11.4* 10.5* 10.5* 9.7* 9.7* 22.4

8.0* 8.0* 11.3* 11.3* 16.7* 16.7* 26.3* 26.3* 23.0* 23.0* 19.8* 19.8* 17.3* 17.3* 15.4* 15.4* 13.8* 13.8* 12.6* 12.6* 11.5* 11.5* 10.5* 10.5* 9.8* 9.8* 22.1

12.1* 12.1* 16.5* 16.5* 24.2* 24.2* 23.1* 23.1* 19.9* 19.9* 17.4* 17.4* 15.5* 15.5* 13.9* 13.9* 12.5* 12.5* 11.4* 11.4* 10.3* 10.3* 9.8* 9.8* 21.7

13.0* 13.0* 16.9* 16.9* 23.5* 23.5* 22.9* 22.9* 19.8* 19.8* 17.4* 17.4* 15.4* 15.4* 13.8* 13.8* 12.4* 12.4* 11.2* 11.2* 9.9* 9.9* 9.8* 9.8* 21.1

17.6* 17.6* 23.6* 23.6* 22.4* 22.4* 19.4* 19.4* 17.1* 17.1* 15.1* 15.1* 13.5* 13.5* 12.1* 12.1* 10.7* 10.7* 9.8* 9.8* 20.5

21.5* 21.5* 18.7* 18.7* 16.5* 16.5* 14.6* 14.6* 12.9* 12.9* 11.5* 11.5* 11.3* 11.3* 18.2

Industrial Stick 12.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m 25.5 m

m Undercarriage m

4 pt. outriggers down

27.0

4 pt. outriggers down

25.5

4 pt. outriggers down

24.0

4 pt. outriggers down

22.5

4 pt. outriggers down

21.0

4 pt. outriggers down

19.5

4 pt. outriggers down

18.0

4 pt. outriggers down

16.5

4 pt. outriggers down

15.0

4 pt. outriggers down

13.5

4 pt. outriggers down

12.0

4 pt. outriggers down

10.5

4 pt. outriggers down

9.0

4 pt. outriggers down

7.5

4 pt. outriggers down

6.0

4 pt. outriggers down

4.5

4 pt. outriggers down

3.0

4 pt. outriggers down

1.5

4 pt. outriggers down

0

4 pt. outriggers down

– 1.5

4 pt. outriggers down

– 3.0

4 pt. outriggers down

– 4.5

4 pt. outriggers down

– 6.0

4 pt. outriggers down

– 7.5

4 pt. outriggers down

– 9.0

4 pt. outriggers down

– 10.5

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface. These capacities

can be slewed through 360° with the undercarriage in the transverse position. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic

elements, or the maximum permissible lifting capacity of the load hook.

In accordance with the harmonised European Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe

fracturesafety valves, an overload warning device, a load hook and a lift capacity chart.

10.3* 10.3* 12.8

11.9* 11.9* 9.5* 9.5* 14.9

11.3* 11.3* 9.3* 9.3* 8.9* 8.9* 16.7

11.1* 11.1* 10.6* 10.6* 8.8* 8.8* 8.5* 8.5* 18.1

10.9* 10.9* 10.4* 10.4* 10.0* 10.0* 8.3* 8.3* 19.4

10.9* 10.9* 10.4* 10.4* 9.9* 9.9* 9.5* 9.5* 8.1* 8.1* 20.4

11.0* 11.0* 10.4* 10.4* 9.9* 9.9* 9.5* 9.5* 8.7* 8.7* 8.0* 8.0* 21.3

11.1* 11.1* 10.5* 10.5* 9.9* 9.9* 9.5* 9.5* 9.1* 9.1* 7.9* 7.9* 22.0

12.1* 12.1* 11.3* 11.3* 10.6* 10.6* 10.1* 10.1* 9.6* 9.6* 9.1* 9.1* 8.3* 8.3* 7.9* 7.9* 22.6

12.5* 12.5* 11.6* 11.6* 10.9* 10.9* 10.2* 10.2* 9.7* 9.7* 9.2* 9.2* 8.8* 8.8* 7.9* 7.9* 23.1

14.1* 14.1* 12.9* 12.9* 11.9* 11.9* 11.1* 11.1* 10.4* 10.4* 9.8* 9.8* 9.3* 9.3* 8.8* 8.8* 8.0* 8.0* 23.5

16.5* 16.5* 14.8* 14.8* 13.4* 13.4* 12.3* 12.3* 11.4* 11.4* 10.6* 10.6* 10.0* 10.0* 9.4* 9.4* 8.9* 8.9* 8.1* 8.1* 23.8

23.8* 23.8* 20.2* 20.2* 17.6* 17.6* 15.6* 15.6* 14.0* 14.0* 12.8* 12.8* 11.8* 11.8* 10.9* 10.9* 10.2* 10.2* 9.6* 9.6* 9.0* 9.0* 8.3* 8.3* 24.0

46.0* 46.0* 33.3* 33.3* 26.3* 26.3* 21.8* 21.8* 18.7* 18.7* 16.4* 16.4* 14.6* 14.6* 13.2* 13.2* 12.1* 12.1* 11.2* 11.2* 10.4* 10.4* 9.7* 9.7* 9.1* 9.1* 8.6* 8.6* 8.5* 8.5* 24.1

13.2* 13.2* 37.0* 37.0* 28.6* 28.6* 23.3* 23.3* 19.7* 19.7* 17.2* 17.2* 15.2* 15.2* 13.7* 13.7* 12.4* 12.4* 11.4* 11.4* 10.6* 10.6* 9.8* 9.8* 9.2* 9.2* 8.6* 8.6* 8.6* 8.6* 24.1

8.4* 8.4* 17.2* 17.2* 30.4* 30.4* 24.6* 24.6* 20.7* 20.7* 17.9* 17.9* 15.7* 15.7* 14.1* 14.1* 12.8* 12.8* 11.7* 11.7* 10.8* 10.8* 10.0* 10.0* 9.3* 9.3* 8.6* 8.6* 24.0

7.8* 7.8* 13.2* 13.2* 23.4* 23.4* 25.7* 25.7* 21.5* 21.5* 18.5* 18.5* 16.2* 16.2* 14.4* 14.4* 13.0* 13.0* 11.9* 11.9* 10.9* 10.9* 10.1* 10.1* 9.3* 9.3* 8.7* 8.7* 23.8

8.2* 8.2* 12.2* 12.2* 19.1* 19.1* 26.4* 26.4* 22.1* 22.1* 18.9* 18.9* 16.6* 16.6* 14.7* 14.7* 13.3* 13.3* 12.0* 12.0* 11.0* 11.0* 10.1* 10.1* 9.3* 9.3* 8.7* 8.7* 23.5

9.0* 9.0* 12.2* 12.2* 17.5* 17.5* 26.7* 26.7* 22.4* 22.4* 19.2* 19.2* 16.8* 16.8* 14.9* 14.9* 13.4* 13.4* 12.1* 12.1* 11.0* 11.0* 10.1* 10.1* 9.2* 9.2* 8.8* 8.8* 23.1

9.8* 9.8* 12.6* 12.6* 17.0* 17.0* 24.6* 24.6* 22.5* 22.5* 19.4* 19.4* 16.9* 16.9* 15.0* 15.0* 13.4* 13.4* 12.1* 12.1* 11.0* 11.0* 10.0* 10.0* 8.9* 8.9* 8.9* 8.9* 22.6

13.2* 13.2* 17.1* 17.1* 23.6* 23.6* 22.3* 22.3* 19.2* 19.2* 16.8* 16.8* 14.9* 14.9* 13.3* 13.3* 12.0* 12.0* 10.8* 10.8* 9.7* 9.7* 8.9* 8.9* 22.0

17.5* 17.5* 23.5* 23.5* 21.8* 21.8* 18.9* 18.9* 16.5* 16.5* 14.6* 14.6* 13.0* 13.0* 11.6* 11.6* 10.4* 10.4* 9.1* 9.1* 9.1* 9.1* 21.1

23.9* 23.9* 20.9* 20.9* 18.2* 18.2* 15.9* 15.9* 14.1* 14.1* 12.5* 12.5* 11.1* 11.1* 10.6* 10.6* 18.5

LH 120 M Litronic Machine for Industrial Applications 7

Page 8

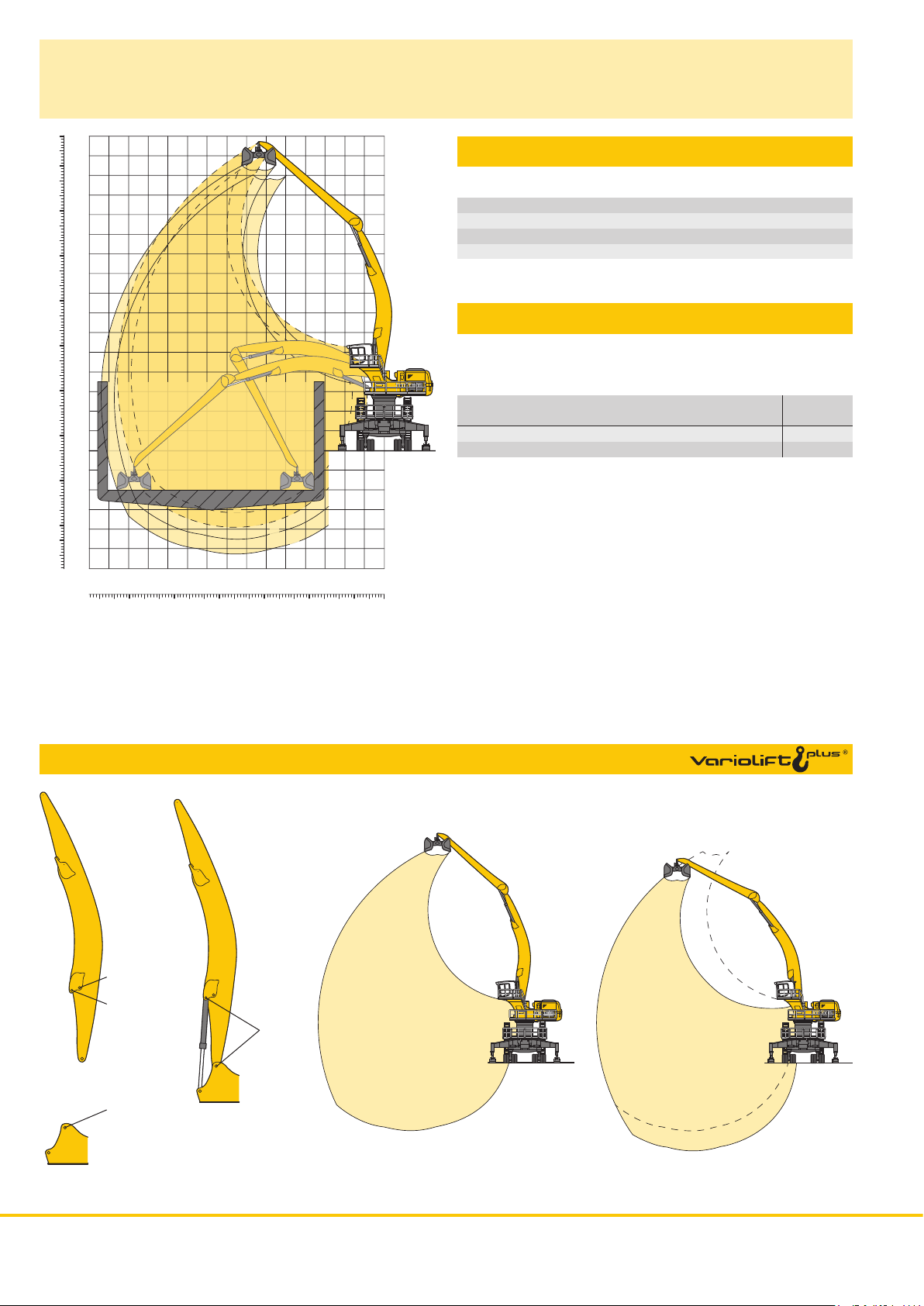

Industrial Attachment

with Industrial-Type Straight Mono Boom 13.50 m

H0311

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 10.50 m

2 with industrial stick 12.00 m

3 with industrial stick 10.50 m and grapple model GMM 120

4 with industrial stick 12.00 m and grapple model GMM 120

Operating Weight

The operating weight includes basic machine with 4 point outriggers,

rigid cab elevation, 32 solid tires and industrial attachment with

industrial-type straight mono boom 13.50 m

with grapple model GMM 120-5/3.00 m

semi-closed tines Weight

and industrial stick 10.50 m 139,900 kg

and industrial stick 12.00 m 140,500 kg

90

80

70

60

50

40

30

20

10

-10

-20

-30

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

0

-2

-10

-12

-4

-6

-8

mft

182022242628

60708090 50 40 30 20 10 0

1

2

3

4

16 14 12 10 8 6 4 2 0

3

VarioLiftPlus

Hole A

Hole B

Hole 2 Hole 3

H0314

Version 2A

VarioLift

Plus: Variable boom mounting positions for optimized lift capacities

with the same working range with a different working range

2A

3B

3A

Kinematic Variant 2A:

Increased lift capacities above ground level

Kinematic Variant 3B:

Kinematic Variant 3A:

Altered range curve with additional reach

depth, e.g. for unloading from ships

Increased lift capacities below ground level

and when working at large outreach

8 LH 120 M Litronic Machine for Industrial Applications

Page 9

Lift Capacities

with Industrial-Type Straight Mono Boom 13.50 m (Kinematic Variant 2A)

Industrial Stick 10.50 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m 25.5 m

m Undercarriage m

4 pt. outriggers down

27.0

4 pt. outriggers down

25.5

4 pt. outriggers down

24.0

4 pt. outriggers down

22.5

4 pt. outriggers down

21.0

4 pt. outriggers down

19.5

4 pt. outriggers down

18.0

4 pt. outriggers down

16.5

4 pt. outriggers down

15.0

4 pt. outriggers down

13.5

4 pt. outriggers down

12.0

4 pt. outriggers down

10.5

4 pt. outriggers down

9.0

4 pt. outriggers down

7.5

4 pt. outriggers down

6.0

4 pt. outriggers down

4.5

4 pt. outriggers down

3.0

4 pt. outriggers down

1.5

4 pt. outriggers down

0

4 pt. outriggers down

– 1.5

4 pt. outriggers down

– 3.0

4 pt. outriggers down

– 4.5

4 pt. outriggers down

– 6.0

4 pt. outriggers down

– 7.5

4 pt. outriggers down

– 9.0

4 pt. outriggers down

– 10.5

18.0* 18.0* 7.4

18.4* 18.4* 15.5* 15.5* 14.4* 14.4* 10.9

18.3* 18.3* 16.0* 16.0* 12.7* 12.7* 13.4

19.7* 19.7* 18.1* 18.1* 15.9* 15.9* 12.7* 12.7* 11.6* 11.6* 15.3

19.4* 19.4* 17.5* 17.5* 15.6* 15.6* 12.3* 12.3* 10.9* 10.9* 16.9

19.4* 19.4* 17.4* 17.4* 15.8* 15.8* 14.3* 14.3* 11.3* 11.3* 10.4* 10.4* 18.2

19.4* 19.4* 17.4* 17.4* 15.7* 15.7* 14.3* 14.3* 13.0* 13.0* 10.1* 10.1* 19.3

19.4* 19.4* 17.4* 17.4* 15.7* 15.7* 14.3* 14.3* 12.9* 12.9* 11.7* 11.7* 9.8* 9.8* 20.3

22.0* 22.0* 19.5* 19.5* 17.5* 17.5* 15.7* 15.7* 14.2* 14.2* 12.9* 12.9* 11.7* 11.7* 10.0* 10.0* 9.6* 9.6* 21.1

22.2* 22.2* 19.6* 19.6* 17.5* 17.5* 15.8* 15.8* 14.2* 14.2* 12.9* 12.9* 11.6* 11.6* 10.4* 10.4* 9.5* 9.5* 21.7

24.7* 24.7* 22.5* 22.5* 19.8* 19.8* 17.6* 17.6* 15.8* 15.8* 14.2* 14.2* 12.8* 12.8* 11.6* 11.6* 10.3* 10.3* 9.1* 9.1* 22.3

25.4* 25.4* 26.6* 26.6* 22.9* 22.9* 20.0* 20.0* 17.7* 17.7* 15.8* 15.8* 14.2* 14.2* 12.8* 12.8* 11.5* 11.5* 10.2* 10.2* 8.8* 8.8* 8.6* 8.6* 22.7

28.3* 28.3* 32.5* 32.5* 27.2* 27.2* 23.2* 23.2* 20.2* 20.2* 17.8* 17.8* 15.8* 15.8* 14.1* 14.1* 12.7* 12.7* 11.3* 11.3* 10.1* 10.1* 8.7* 8.7* 8.1* 8.1* 23.0

57.4* 57.4* 42.3* 42.3* 33.4* 33.4* 27.6* 27.6* 23.4* 23.4* 20.2* 20.2* 17.7* 17.7* 15.7* 15.7* 14.0* 14.0* 12.5* 12.5* 11.2* 11.2* 9.8* 9.8* 8.4* 8.4* 7.6* 7.6* 23.2

6.7* 6.7* 38.6* 38.6* 33.7* 33.7* 27.7* 27.7* 23.4* 23.4* 20.1* 20.1* 17.6* 17.6* 15.5* 15.5* 13.8* 13.8* 12.3* 12.3* 10.9* 10.9* 9.5* 9.5* 8.1* 8.1* 7.1* 7.1* 23.3

2.4* 2.4* 11.6* 11.6* 33.2* 33.2* 27.3* 27.3* 23.1* 23.1* 19.8* 19.8* 17.3* 17.3* 15.2* 15.2* 13.5* 13.5* 11.9* 11.9* 10.5* 10.5* 9.1* 9.1* 7.6* 7.6* 6.5* 6.5* 23.4

2.5* 2.5* 8.2* 8.2* 19.4* 19.4* 26.4* 26.4* 22.4* 22.4* 19.3* 19.3* 16.8* 16.8* 14.8* 14.8* 13.0* 13.0* 11.5* 11.5* 10.0* 10.0* 8.6* 8.6* 7.0* 7.0* 5.9* 5.9* 23.3

3.7* 3.7* 7.9* 7.9* 15.3* 15.3* 24.9* 24.9* 21.3* 21.3* 18.4* 18.4* 16.1* 16.1* 14.1* 14.1* 12.4* 12.4* 10.8* 10.8* 9.4* 9.4* 7.9* 7.9* 6.2* 6.2* 5.3* 5.3* 23.1

5.2* 5.2* 8.7* 8.7* 14.4* 14.4* 22.8* 22.8* 19.8* 19.8* 17.2* 17.2* 15.1* 15.1* 13.2* 13.2* 11.6* 11.6* 10.0* 10.0* 8.6* 8.6* 7.0* 7.0* 5.1* 5.1* 4.5* 4.5* 22.8

9.9* 9.9* 14.7* 14.7* 20.2* 20.2* 17.8* 17.8* 15.7* 15.7* 13.8* 13.8* 12.0* 12.0* 10.5* 10.5* 9.0* 9.0* 7.5* 7.5* 5.8* 5.8* 4.3* 4.3* 22.1

15.6* 15.6* 17.0* 17.0* 15.4* 15.4* 13.7* 13.7* 12.1* 12.1* 10.6* 10.6* 9.1* 9.1* 7.7* 7.7* 6.1* 6.1* 4.7* 4.7* 20.7

13.4* 13.4* 12.5* 12.5* 11.3* 11.3* 10.0* 10.0* 8.7* 8.7* 7.4* 7.4* 6.0* 6.0* 5.4* 5.4* 18.5

Industrial Stick 12.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m 25.5 m

m Undercarriage m

4 pt. outriggers down

27.0

4 pt. outriggers down

25.5

4 pt. outriggers down

24.0

4 pt. outriggers down

22.5

4 pt. outriggers down

21.0

4 pt. outriggers down

19.5

4 pt. outriggers down

18.0

4 pt. outriggers down

16.5

4 pt. outriggers down

15.0

4 pt. outriggers down

13.5

4 pt. outriggers down

12.0

4 pt. outriggers down

10.5

4 pt. outriggers down

9.0

4 pt. outriggers down

7.5

4 pt. outriggers down

6.0

4 pt. outriggers down

4.5

4 pt. outriggers down

3.0

4 pt. outriggers down

1.5

4 pt. outriggers down

0

4 pt. outriggers down

– 1.5

4 pt. outriggers down

– 3.0

4 pt. outriggers down

– 4.5

4 pt. outriggers down

– 6.0

4 pt. outriggers down

– 7.5

4 pt. outriggers down

– 9.0

4 pt. outriggers down

– 10.5

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface. These capacities

can be slewed through 360° with the undercarriage in the transverse position. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic

elements, or the maximum permissible lifting capacity of the load hook.

In accordance with the harmonised European Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe

fracturesafety valves, an overload warning device, a load hook and a lift capacity chart.

16.4* 16.4* 7.4

16.6* 16.6* 14.2* 14.2* 12.8* 12.8* 11.2

16.4* 16.4* 14.5* 14.5* 11.8* 11.8* 11.2* 11.2* 13.8

16.1* 16.1* 14.4* 14.4* 12.0* 12.0* 10.2* 10.2* 15.8

17.1* 17.1* 15.8* 15.8* 14.2* 14.2* 11.8* 11.8* 9.5* 9.5* 17.5

16.8* 16.8* 15.3* 15.3* 13.8* 13.8* 11.2* 11.2* 9.0* 9.0* 18.9

16.8* 16.8* 15.3* 15.3* 13.9* 13.9* 12.7* 12.7* 10.2* 10.2* 8.6* 8.6* 20.1

16.8* 16.8* 15.2* 15.2* 13.9* 13.9* 12.6* 12.6* 11.5* 11.5* 8.6* 8.6* 8.4* 8.4* 21.1

16.8* 16.8* 15.2* 15.2* 13.9* 13.9* 12.6* 12.6* 11.5* 11.5* 10.4* 10.4* 8.2* 8.2* 21.9

18.8* 18.8* 16.9* 16.9* 15.3* 15.3* 13.9* 13.9* 12.6* 12.6* 11.5* 11.5* 10.4* 10.4* 8.7* 8.7* 8.0* 8.0* 22.7

18.9* 18.9* 17.0* 17.0* 15.3* 15.3* 13.9* 13.9* 12.6* 12.6* 11.5* 11.5* 10.4* 10.4* 9.2* 9.2* 7.9* 7.9* 23.3

20.5* 20.5* 19.2* 19.2* 17.1* 17.1* 15.4* 15.4* 13.9* 13.9* 12.6* 12.6* 11.4* 11.4* 10.3* 10.3* 9.2* 9.2* 7.9* 7.9* 23.8

22.1* 22.1* 19.4* 19.4* 17.2* 17.2* 15.4* 15.4* 13.9* 13.9* 12.6* 12.6* 11.3* 11.3* 10.2* 10.2* 9.1* 9.1* 7.8* 7.8* 7.6* 7.6* 24.2

23.6* 23.6* 22.5* 22.5* 19.6* 19.6* 17.3* 17.3* 15.5* 15.5* 13.9* 13.9* 12.5* 12.5* 11.3* 11.3* 10.1* 10.1* 9.0* 9.0* 7.7* 7.7* 7.2* 7.2* 24.5

23.1* 23.1* 27.6* 27.6* 26.8* 26.8* 22.8* 22.8* 19.8* 19.8* 17.4* 17.4* 15.5* 15.5* 13.8* 13.8* 12.4* 12.4* 11.1* 11.1* 9.9* 9.9* 8.8* 8.8* 7.5* 7.5* 6.8* 6.8* 24.7

56.9* 56.9* 41.9* 41.9* 33.0* 33.0* 27.2* 27.2* 23.0* 23.0* 19.8* 19.8* 17.4* 17.4* 15.4* 15.4* 13.7* 13.7* 12.2* 12.2* 10.9* 10.9* 9.7* 9.7* 8.5* 8.5* 7.2* 7.2* 6.3* 6.3* 24.8

9.1* 9.1* 40.6* 40.6* 33.2* 33.2* 27.2* 27.2* 22.9* 22.9* 19.7* 19.7* 17.2* 17.2* 15.2* 15.2* 13.5* 13.5* 12.0* 12.0* 10.7* 10.7* 9.4* 9.4* 8.2* 8.2* 6.8* 6.8* 5.8* 5.8* 24.8

4.9* 4.9* 13.8* 13.8* 32.6* 32.6* 26.8* 26.8* 22.6* 22.6* 19.4* 19.4* 16.9* 16.9* 14.9* 14.9* 13.1* 13.1* 11.6* 11.6* 10.3* 10.3* 9.0* 9.0* 7.7* 7.7* 6.3* 6.3* 5.3* 5.3* 24.7

4.8* 4.8* 10.1* 10.1* 21.1* 21.1* 25.8* 25.8* 21.9* 21.9* 18.8* 18.8* 16.4* 16.4* 14.4* 14.4* 12.7* 12.7* 11.2* 11.2* 9.8* 9.8* 8.5* 8.5* 7.2* 7.2* 5.5* 5.5* 4.8* 4.8* 24.6

5.6* 5.6* 9.6* 9.6* 16.8* 16.8* 24.3* 24.3* 20.8* 20.8* 17.9* 17.9* 15.6* 15.6* 13.7* 13.7* 12.0* 12.0* 10.5* 10.5* 9.2* 9.2* 7.8* 7.8* 6.4* 6.4* 4.6* 4.6* 4.1* 4.1* 24.3

6.7* 6.7* 10.0* 10.0* 15.6* 15.6* 22.3* 22.3* 19.2* 19.2* 16.7* 16.7* 14.6* 14.6* 12.8* 12.8* 11.2* 11.2* 9.7* 9.7* 8.3* 8.3* 7.0* 7.0* 5.4* 5.4* 3.5* 3.5* 23.9

10.9* 10.9* 15.6* 15.6* 19.7* 19.7* 17.3* 17.3* 15.1* 15.1* 13.2* 13.2* 11.6* 11.6* 10.1* 10.1* 8.7* 8.7* 7.3* 7.3* 5.9* 5.9* 4.2* 4.2* 3.7* 3.7* 22.8

16.2* 16.2* 16.7* 16.7* 14.9* 14.9* 13.2* 13.2* 11.6* 11.6* 10.1* 10.1* 8.7* 8.7* 7.4* 7.4* 6.0* 6.0* 4.4* 4.4* 4.1* 4.1* 21.3

13.1* 13.1* 12.0* 12.0* 10.8* 10.8* 9.5* 9.5* 8.3* 8.3* 7.0* 7.0* 5.7* 5.7* 4.9* 4.9* 18.9

LH 120 M Litronic Machine for Industrial Applications 9

Page 10

Choice of Cab Elevation

H0291

and Cab Protection

D

Rigid Cab Elevation

without Turret

B 7,867 mm

C 8,854 mm

D 2,329 mm

Rigid Cab Elevation

C

B

with Turret 1.20 m

B 9,067 mm

C 10,054 mm

D 2,329 mm

Rigid Cab Elevation

with Turret 2.00 m

B 9,867 mm

C 10,854 mm

D 2,329 mm

More rigid and hydraulically adjustable cab elevations

are available on request.

Standard Front Guard Top Guard Top and

Front Guard

10 LH 120 M Litronic Machine for Industrial Applications

Page 11

Variety of Tools

Shells for loose material with

Shells for Loose Material

cutting edge (without teeth)

Clamshell Model GMZ 50

Cutting width of shells mm 1,400 1,600 1,800 2,000 2,200 2,400

Capacity m

Weight kg 2,950 3,100 3,250 3,400 3,550 3,700

Clamshell Model GMZ 120

Cutting width of shells mm 1,800 2,000 2,400 2,800 3,200

Capacity m

Weight kg 3,104 3,241 3,515 3,789 4,063

Multiple

Tine Grapples

Grapple Model GMM 120-5 (5 tines)

Capacity m

Weight kg 2,500 2,570 2,640 2,700 2,840 2,900 3,010 3,140 2,950 3,145 3,300 3,465

3

3.50 4.00 4.50 5.00 5.50 6.00

3

4.50 5.00 6.00 7.00 8.00

open tines semi-closed tines closed tines

3

1.70 2.00 2.50 3.00 1.70 2.00 2.50 3.00 1.70 2.00 2.50 3.00

Wood Grapples

Grapple Model GMH 50

Claw width mm 1,000 1,000

Size m

Height of grapple, closed mm 2,680 2,735

Weight kg 2,400 2,550

2

2.80 3.20

Crane Hook with Suspension

Max. load t 32

Weight kg 180

Magnet Devices/Lifting Magnets

Generator kW 30

Electromagnets with Suspension

Power kW 22

Diameter of magnet mm 1,900

Weight kg 5,090

LH 120 M Litronic Machine for Industrial Applications 11

Page 12

Equipment

Undercarriage

6 wheelsets •

8 wheelsets +

Support plates, variants +

Axle load monitoring •

Working lights on undercarriage, LED •

Individual plate control •

Steering programs, variants •

Plate control, plate retraction monitoring •

Tyres, variants +

Warning beacons •

Turret 1,200 mm +

Turret 2,000 mm +

Access monitoring •

Uppercarriage

Maintenance-free swing brake lock •

Generator +

Main battery switch for electrical system •

Maintenance-free HD-batteries •

Hydraulic operable engine hood •

Walk-in engine bay •

Warning beacon on uppercarriage +

Hydraulic operable side hood on the right •

Tool equipment, extended •

Hydraulics

Shut-off valve between hydraulic tank and pump(s) •

Extra hydr. control for hydr. swivel +

Accumulator for controlled lowering of the attachment

with the engine shut down •

Hydraulic drive for generator +

Electronic pump regulation •

High-pressure filter per working pump •

Liebherr hydraulic oil from – 20 °C to + 40 °C •

Liebherr hydraulic oil, biologically degradable +

Liebherr hydraulic oil, specially for warm or cold regions +

Magnetic rod in hydraulic tank •

Bypass filter +

Preheating hydraulic oil +

Additional hydraulic circuits +

Engine

Turbo charger •

Common rail injection •

Fuel tank 3,000 l •

Automatic idling •

Liebherr particle filter +

Reversible fan drive, fully automatic +

Air filter with automatic dust ejector •

Preheating fuel +

Preheating coolant +

Preheating engine oil +

• = Standard, + = Option

* = optionally extendable after one year

Cab lights rear, halogen •

Cab lights rear, LED 1000 lumen +

Cab lights rear, xenon +

Cab lights front, halogen •

Cab lights front, LED 3000 lumen +

Cab lights front, xenon +

Mechanical hour meters, readable from outside the cab •

Storage and literature tray •

Operator’s seat Standard •

Operator’s seat Premium +

Driving alarm +

Fire extinguisher •

Air conditioning •

Joystick steering •

Dome light •

Cab elevation, hydraulic +

Cab elevation, rigid (variants) +

Electric cooler +

LiDAT Plus (extended Liebherr data transfer system) * •

7” colour multifunction display with touchscreen •

Bullet proof glass (front, roof and bottom window) •

Proportional control •

Radio Comfort (control via display) •

Warning beacon on cab +

All tinted windows •

Top guard +

Front guard +

Sun blind •

Auxiliary heating, adjustable (week time switch) +

Flashing light (xenon) +

Electronic immobilizer +

Washer-wiper for front, roof and bottom window •

Boom lights, 2 pieces, halogen •

Boom lights, 2 pieces, LED 3000 lumen +

Boom lights, 2 pieces, xenon +

Stick lights, 4 pieces, halogen •

Stick lights, 4 pieces, LED 3000 lumen +

Stick lights, 4 pieces, xenon +

Boom shutoff, ascending +

AutoLift +

Pressure warning mechanism hoist cylinder +

Height limitation and stick shutoff, electronically +

Boom cylinder cushioning +

Stick camera (with separate monitor), bottom side, with protection +

Liebherr line of tools +

Liebherr equipment program +

Pipe fracture safety valves hoist cylinders •

Pipe fracture safety valve stick cylinder •

Hydraulic quick coupler for grapple +

Retract stick without pressure •

Overload warning device +

Cylinders with shock absorber •

Refuelling systems +

Lubrication

Special coating

Monitoring

Operator’s Cab

Attachment

Complete Machine

Central lubrication system for uppercarriage and attachment,

automatically •

Central lubrication system for undercarriage, automatically •

Single-coloured, grey parts excepted +

Single-coloured, grey parts included (except power train) +

Multicoloured (except power train) +

Rear view monitoring with camera •

Options and/or special attachments, supplied by vendors other than Liebherr, are only to be installed with the

knowledge and approval of Liebherr in order to retain warranty.

Printed in Germany by Typodruck RG-BK-RP LHB/VF 11626299-1-03.13_enGB All illustrations and data may differ from standard equipment. Subject to change without notice.

Liebherr-Hydraulikbagger GmbH

Liebherrstraße 12, D-88457 Kirchdorf/Iller

+49 7354 80-0, Fax +49 7354 80-72 94

www.liebherr.com, E-Mail: info.lhb@liebherr.com

www.facebook.com/LiebherrConstruction

Loading...

Loading...