Page 1

Material handling machine

LH 120 C

Job Report

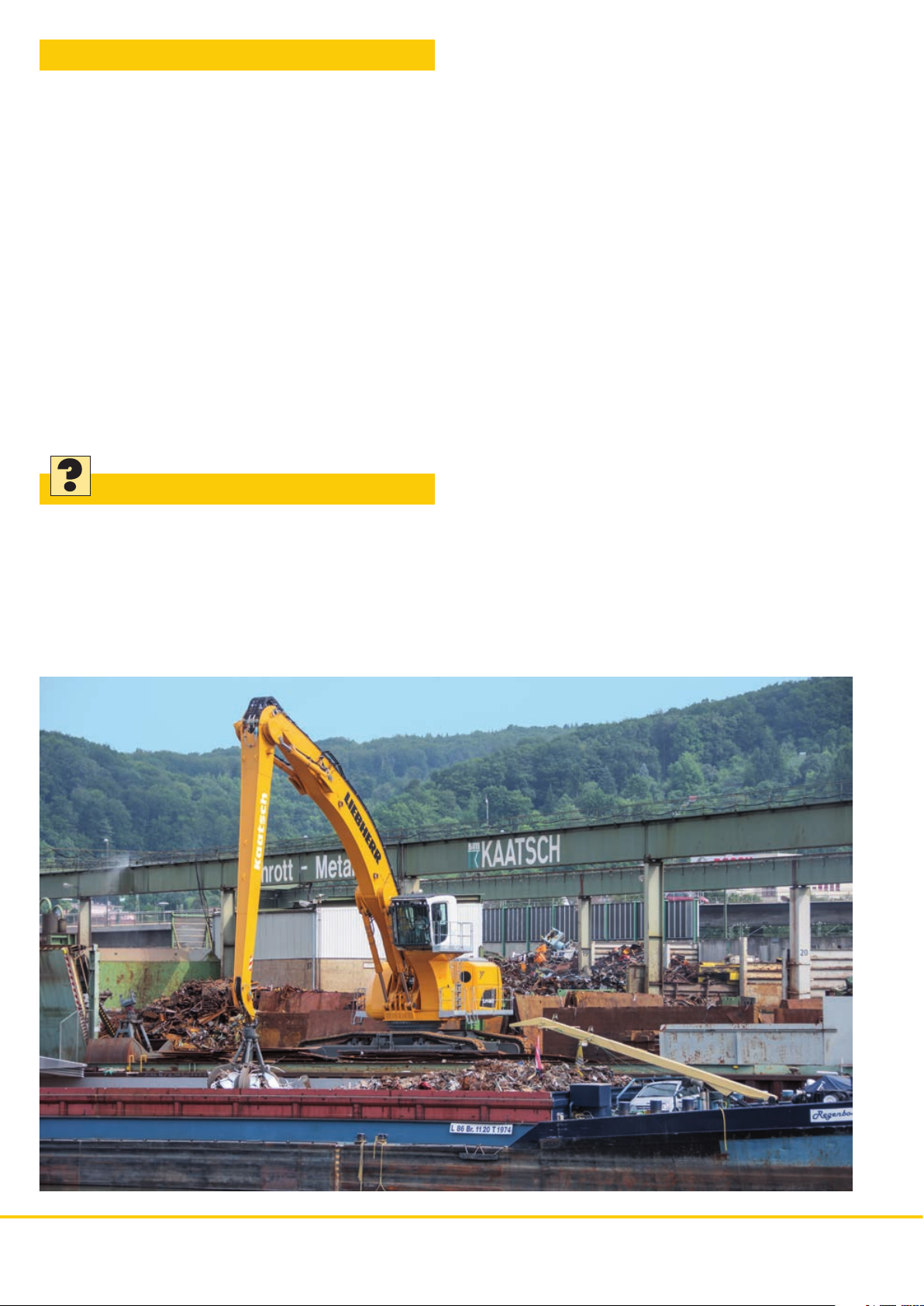

The LH 120 C Litronic material

handling machine in action

at Schrott- und Metallhandel

M. Kaatsch GmbH

Page 2

Situation

Scrap recycling protects raw material resources, saves energy

and protects the environment. To ensure that the recycling

process can be carried out economically the old materials must

be collected, sorted and treated correctly so that they can be

used as secondary raw materials. Schrott- und Metallhandel

M. Kaatsch GmbH is a waste disposal contractor with a highly

modern range of machinery and an extensive infrastructure which

enables it to make a significant contribution to this process.

The company is one of the most important and largest handling

companies for scrap and metals in Southern Germany. When it

was founded in 1952 by Margarete Kaatsch, M. Kaatsch Schrottund Metallhandel was the first step in a successful company

history bridging several generations. From humble beginnings

with a horse and cart, the company’s willingness to accept new

production techniques meant that it developed into a handling

company with its own port facilities and into a healthy, growing

business. In the hands of Managing Director Hermann Wager

and Scholz AG in Esslingen since 1988, Kaatsch GmbH has

developed into a modern recycling company. The small scrap and

metal storage facility from the 1950 has expanded not only in the

form of the company’s own fleet of vehicles but also with rail and

Task

Scrap is a mass volume material which means that transporting

it by waterway is an economical solution. An inland waterway

vessel on the River Neckar to date has had an average cargo

capacity of around 1250 tonnes. This corresponds to around 60

truckloads. The vessels are becoming increasingly larger and

they now have a capacity of up to 2000 tonnes of scrap. Since

the time when they are tied up costs money, the objective is to

load and unload these vessels as quickly as possible.

quay facilities. Since 1982 the company’s site has been extended

with environmental and bulk goods storage buildings and sound

protection systems to comply with environmental regulations.

Since 2004 Kaatsch has also operated a waste timber treatment

plant. Today the company in Plochingen has over 7,000 square

metres of production and storage space on which an average of

500,000 tonnes of material is handled every year.

The company site right on the railway intersection in Plochingen

with its own port facilities on the River Neckar is just about ideal

for transporting material by rail and water. Large quantities of the

treated scrap are loaded into vessels straight from the storage

site. The material then goes to supply steelworks in both Germany

and elsewhere with this valuable material by waterway which

protects the environment and saves energy.

A large number of Liebherr handling machines in various sizes

with mobile and crawler undercarriages is used for loading and

unloading trucks and railway wagons, for sorting the storing

scrap, feeding the 1,200 tonne scrap shears and for loading and

unloading ships.

This results in an increase in loading capacities. This also

reduces storage costs since the material is stored for as short

a time as possible. To achieve these objectives the company

decided to purchase a larger, more efficient handling machine.

The requirements for it were more grapple capacity and the

ability to get a greater reach and height range.

Page 3

Solution

A long term partnership has developed between Liebherr and

Kaatsch, a specialist in the recycling industry and a technology

leader in scrap recycling as a result of the latter’s good

experience with Liebherr machines. Kaatsch has been using a

fleet of 30 Liebherr handling machines with mobile and crawler

undercarriages for many years for sorting and handling scrap.

In close cooperation with Kaatsch, Liebherr designed and built

a handling machine perfectly tailored to the needs of a modern,

pioneering scrap and material trading company - the Liebherr

LH 120 C Litronic material handling machine which has been in

use since 2009 for loading and unloading vessels.

The machine, which weighs around 135 tonnes and develops

around 400 kW of power, is equipped with a 15 m industrialtype angled boom, a 12 m industrial-type stick and a grapple

with a capacity of 2.5 m³. This balanced industrial kinematic

ensures a maximum reach of 25.0 m to the centre of the grapple

and a maximum height range of 22.5 m with the grapple open.

In addition at maximum radius throughout the swivel range

of 360° the machine has a load of 7 tonnes on crane hook.

A large undercarriage with a square design provides excellent

stability and enables the user to take advantage of the maximum

handling capacity.

Coordinated components, the majority manufactured by

Liebherr, ensure that the machine is highly economical.

The multi-circuit hydraulic system and the Liebherr diesel engine

have been perfectly tailored to each other with reduced engine

speed and large flow cross-sections in the hydraulic hoses

and hydraulic components ensuring extremely low losses.

Other features such as the „Positive Control“ hydraulic system

ensure fast and precise working movements during the handling

process. Since superimposed operating cycles can be activated

individually but also in combination, this ensures excellent use of

energy. All these innovations are reflected in drastically reduced

fuel consumption.

The LH 120 C material handling machine allows modular,

driver-independent joystick programming. This feature makes it

possible to program individual settings on the machine for each

driver.

Two separate temperature-controlled fans ensure that the

hydraulic system, air, water and fuel are kept at their perfect

operating temperatures. The separate cooler system is

temperature-controlled and thus enhances the machines energy

efficiency. The „Retract arm without pressure“ function is a

major contributor to the machine’s efficiency. The fundamental

benefits of this include:

- Fuel savings - no increase in pressure

on the arm cylinder ring side

- Improved performance - the power saved

can be used for hoisting

- Higher hoist speed - the complete operating

cycle is around 10% faster

- Safety - due to the automatic braking

of the arm whilst it is being retracted

The LH 120 C material handling machine is LiDAT-capable

which means that the customer can record the machine’s

relevant operating data at any time, transfer them and evaluate

them accordingly. In addition LiDAT supplied service interval

information which helps to improve time management for

machine maintenance.

Page 4

Technical Data Equipment

LH 120 C Litronic

Operating weight

Engine type

Engine output

Emission stage

____________________________________________________________________________________________________________________________________________________________

________________________________________________________________

____________________________________________________________________________________

Liebherr D 9508, 8-Zylinder-V-Engine

400 kW / 543 PS at 1,800 min

_________________________________________________________________________________________________________________________________________________________________________________________________________

135

Tonnes

-1

IIIA

Undercarriage:

Track gauge

Wheelbase

Flat pads

_____________________________________________________________________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________________________________________________________________________________________

5.70 m

7.20 m

750 mm

Loading capacity

A Dutch inland vessel was loaded with 1,630 tonnes of scrap,

the equivalent of 2,500 m³ destined for a French steelworks

in approx. 5 hours. Loading straight from the port facility with

a swivel radius of 180° allowed the machine to achieve a loading

capacity of 300 tonnes per hour.

Industrial-type angled mono boom

Industrial-type stick

Grapple type

Max. reach

__________________________________________________________________________________________________________________________________________________________________________________________________________

Max. heap height

Max. load

________________________________________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________

15.0 m

12.0 m

GMM 120 with 2.5 m³

25.0 m

22.5 m

7

Tonnes

Liebherr-Hydraulikbagger GmbH

Liebherrstraße 12, D-88457 Kirchdorf / Iller

+49 7354 80-0, Fax +49 7354 80-72 94

www.liebherr.com, E-Mail: info.lhb@liebherr.com

www.facebook.com/LiebherrConstruction

Printed in Germany by Typodruck BK LHB 11658552-1.0-12.13_enGB Subject to technical modifications.

Loading...

Loading...