Lexicon mpx500 Service Manual

MPX 500

24-Bit Dual Channel

Processor

Service

Manual

MPX 500 Service Manual

Copyright © 1999 Lexicon, Inc.

All Rights Reserved

Lexicon Inc. 3 Oak Park Bedford, MA 01730-1441 Tel (781) 280-0300 Customer Service Fax (781) 280-0499

Lexicon Part # 070-14399 Rev 0

Printed in the United States of America

MPX 500 Service Manual

MPX 500 Service Manual

Lexicon

Table of Contents

Chapter 1 Reference Documents, Required Equipment............................. 1-1

Reference Documents............................................................................................................................. 1-1

Required Equipment................................................................................................................................ 1-1

Tools .................................................................................................................................................... 1-1

Test Equipment.................................................................................................................................... 1-1

Chapter 2 General Information ................................................................... 2-1

Periodic Maintenance .............................................................................................................................. 2-1

Ordering Parts ......................................................................................................................................... 2-1

Returning Units to Lexicon for Service .................................................................................................... 2-1

Chapter 3 Specifications............................................................................. 3-1

Chapter 4 Performance Verification............................................................ 4-1

Diagnostics: ............................................................................................................................................. 4-1

Setup: ...................................................................................................................................................... 4-1

I/O Tests:................................................................................................................................................. 4-1

Analog In To Analog Out Level Test: ................................................................................................... 4-1

Frequency Response Test: ..................................................................................................................... 4-1

Analog In To Analog Out Frequency Test:........................................................................................... 4-1

THD+N Test: ........................................................................................................................................... 4-2

Analog In To Analog Out THD+N Test:................................................................................................ 4-2

Crosstalk Tests:....................................................................................................................................... 4-2

Analog In To Analog Out Crosstalk Test:............................................................................................. 4-2

Dynamic Range Tests: ............................................................................................................................ 4-2

Analog In To Analog Out Dynamic Range Test: .................................................................................. 4-2

Digital I/O Functionality............................................................................................................................ 4-2

MIDI Functionality:................................................................................................................................... 4-3

Footswitch Functionality: ......................................................................................................................... 4-3

Listening Test: ......................................................................................................................................... 4-4

Setup.................................................................................................................................................... 4-4

Verify Clean Audio ............................................................................................................................... 4-4

Shock Test ........................................................................................................................................... 4-4

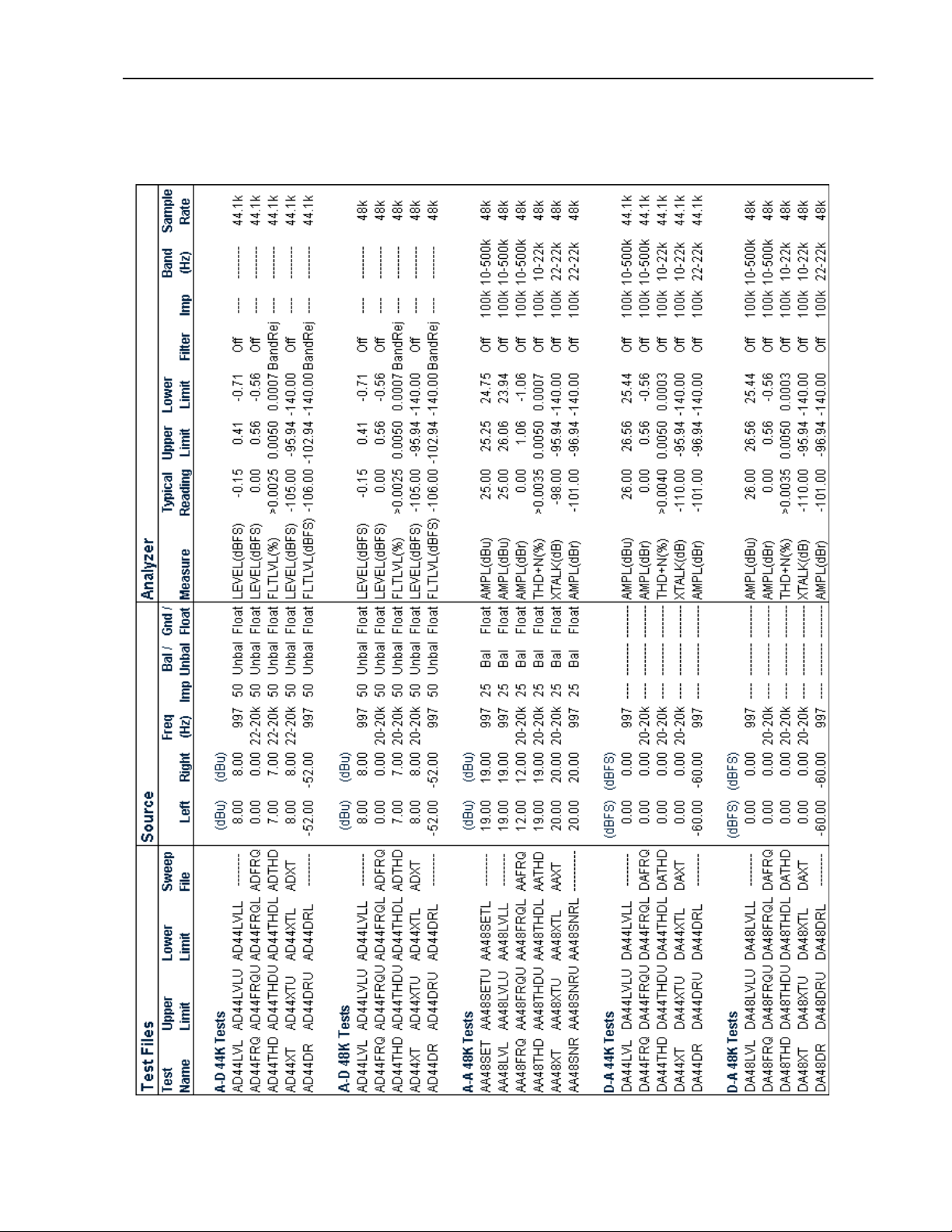

Lexicon Audio Precision ATE Summary .............................................................................................. 4-5

Chapter 5 Troubleshooting ......................................................................... 5-1

Check the Lexicon web site for the latest software and information:................................................ 5-1

Diagnostics .............................................................................................................................................. 5-1

Power Up Diagnostics.......................................................................................................................... 5-1

Error Indication..................................................................................................................................... 5-1

Test Descriptions ................................................................................................................................. 5-2

#1 ROM Test : .................................................................................................................................. 5-2

#2 SRAM Test: ................................................................................................................................. 5-2

#3 WCS Test: ................................................................................................................................... 5-2

#4 INT Test:...................................................................................................................................... 5-2

#5 ADF Test: .................................................................................................................................... 5-2

#6 EEPROM Test:............................................................................................................................ 5-2

Extended Diagnostics .......................................................................................................................... 5-3

#1 ROM Test : .................................................................................................................................. 5-4

#2 SRAM Test: ................................................................................................................................. 5-4

#3 WCS Test: ................................................................................................................................... 5-5

#4 INT Test:...................................................................................................................................... 5-5

#5 ADF Test: .................................................................................................................................... 5-5

#6 EEPROM Test:............................................................................................................................ 5-5

#7 DRAM Test:................................................................................................................................. 5-5

#8 Switch Test:................................................................................................................................. 5-5

MPX 500 Service Manual

Footswitches: ....................................................................................................................................5-5

Front Panel Switches: .......................................................................................................................5-6

#9 Encoder Test:...............................................................................................................................5-6

#10 MIDI Test:...................................................................................................................................5-7

#11 LCD Test: ...................................................................................................................................5-7

#12 Exit Test: ....................................................................................................................................5-7

#13 Initialize Test: .............................................................................................................................5-7

#14 Unused:......................................................................................................................................5-7

#15 Unused:......................................................................................................................................5-7

#16 Burn In Test:...............................................................................................................................5-7

General Troubleshooting and Service Notes............................................................................................5-8

Power Supply........................................................................................................................................5-8

Front Panel Knobs ................................................................................................................................5-8

Lexichip Replacement ..........................................................................................................................5-8

Chapter 6 Theory of Operation ................................................................... 6-1

Schematic walkthrough ............................................................................................................................6-1

Sheet 1 (INPUT) ...................................................................................................................................6-1

Sheet 2 (DAC) ......................................................................................................................................6-1

Sheet 3 (LEXICHIP3, ROM/RAM, uPROC) ..........................................................................................6-1

Sheet 4 (ENCODERS)..........................................................................................................................6-2

Sheet 5 (MIDI, DIGITAL AUDIO OUT)..................................................................................................6-2

Sheet 6 (DISPLAY DRIVER) ................................................................................................................6-3

Sheet 7 (POWER SUPPLY) .................................................................................................................6-3

Additional Sheets 1 each (SW#1, SW#2) .............................................................................................6-3

Chapter 7 - Parts List.................................................................................. 7-1

Chapter 8 Schematics and Drawings ......................................................... 8-1

Lexicon

Chapter 1 Refe rence Documents, Required Equipment

Reference Documents

MPX 500 User Guide - Lexicon P/N 070-14116 or latest revision

Required Equipment

Tools

The following is a minimum suggested technician's tool kit required for performing disassembly, assembly

and repairs:

• Clean, antistatic, well lit work area.

• (1) #1 Phillips tip screwdriver

• (1) T9 Torx screwdriver

• (1) 3/16" Hex socket nut driver

• (1) 5/16" Hex socket, full hollow, nut driver with plastic insert (to prevent Front Panel scratches)

• (1) 15mm Hex socket nut driver

• Solder: 63/37 - Tin/Lead Alloy composition, low residue, no-clean solder.

• Magnification glasses and lamps

• SMT Soldering / Desoldering bench-top repair station

Test Equipment

The following is a minimum suggested equipment list required to perform the proof of performance tests.

• Amplifier with speakers or headphones.

• Cables: (dependent on your signal source)

• Audio Input cable (balanced) with shield and a XLR or ¼ “ plug on one end and an

appropriate connector on the opposite end for connection to the Low Distortion Oscillator.

• Audio Output cable (balanced) with shield and a XLR or ¼ “ plug on one end and an

appropriate connector on the opposite end for connection to the Distortion Analyzer.

• (1) MPX 500 Power Cord (choose accordingly):

CORD,POWER,NA/IEC,SVT,VW-1,10A, N. AMER Lexicon P/N 680-09149

•

CORD,POWER,IEC, 6A, 2M, EURO Lexicon P/N 680-08830

•

CORD,POWER,IEC, 5A, 2M, UK Lexicon P/N 680-10093

•

CORD,POWER,IEC, 6A, 2M, ITALY Lexicon P/N 680-10094

•

CORD,POWER,IEC, 6A, 2M, SWISS Lexicon P/N 680-10095

•

CORD,POWER,IEC, 6A, 2M, AUSTRALIA Lexicon P/N 680-10096

•

CORD,POWER,IEC, 6A, 2M, JAPAN Lexicon P/N 680-10097

•

CORD,POWER,IEC, 6A, 2M, UNIVERSAL Lexicon P/N 680-10098

•

• (1) Low Distortion Oscillator with Single-ended or balanced output , <100 ohms output

impedance, < 0.005% THD.

• (1) analog Distortion Analyzer and Level Meter with single-ended or balanced input, switchable

30Hz highpass filter or audio bandpass (20-20kHz) filter

• (1) 100 MHz oscilloscope

1-1

Lexicon

Chapter 2 Gene ral Information

Periodic Maintenance

Under normal conditions the MPX 500 requires minimal maintenance. Use a soft, lint-free cloth slightly

dampened with warm water and mild detergent to clean the exterior surfaces of the connector box.

Do not use alcohol, benzene or acetone-based cleaners or any strong commercial cleaners. Avoid

using abrasive materials such as steel wool or metal polish. It the unit is exposed to a dusty environment, a

vacuum or low-pressure blower may be used to remove dust from the unit's exterior.

Ordering Parts

When ordering parts, identify each part by type, price and Lexicon Part Number. Replacement parts can be

ordered from:

LEXICON, INC.

3 Oak Park

Bedford, MA 01730-1441

Telephone: 781-280-0300; Fax: 781-280-0499; email: csupport@lexicon.com

ATTN: Customer Service

Returning Units to Lexicon for Service

Before returning a unit for warranty or non-warranty service, consult with Lexicon Customer

Service to determine the extent of the problem and to obtain Return Authorization. No equipment

will be accepted without Return Authorization from Lexicon.

If Lexicon recommends that a MPX 500 be returned for repair and you choose to return the unit to Lexicon

for service, Lexicon assumes no responsibility for the unit in shipment from the customer to the factory,

whether the unit is in or out of warranty. All shipments must be well packed (using the original packing

materials if possible), properly insured and consigned, prepaid, to a reliable shipping agent.

When returning a unit for service, please include the following information:

• Name

• Company Name

• Street Address

• City, State, Zip Code, Country

• Telephone number (including area code and country code where applicable)

• Serial Number of the unit

• Description of the problem

• Preferred method of return shipment

• Return Authorization #, on both the inside and outside of the package

Please enclose a brief note describing any conversations with Lexicon personnel (indicate the name of the

person at Lexicon) and give the name and telephone daytime number of the person directly responsible for

maintaining the unit.

Do no include accessories such as manuals, audio cables, footswitches, etc. with the unit, unless

specifically requested to do so by Lexicon Customer Service personnel.

2-1

Chapter 3 Spec ifications

Analog Inputs

Connectors: XLR/TRS balanced

Impedance: 50k balanced; 25k unbalanced

A/D Dynamic Range: 1058dB, typical

Levels: +20 to +8dBu full scale

Resolution: 24-Bit Sigma-Delta Conversion

Analog Outputs

Connectors: XLR/TRS balanced

Impedance: <600

D/A Dynamic Range: 101dB, typical

Levels: +26dBu balanced; +20dBu unbalanced

Resolution: 24-Bit Sigma-Delta Conversion

Frequency Response: 20Hz-20kHz ±1dB

Crosstalk: -96dB @ 1kHz

THD: <0.5%, 20Hz-20kHz

Digital Audio Interface

Connectors: Coaxial RCA; S/PDIF (IEC-958, CP-340)

Lexicon

System Sample Rates

Internal Clock and S/PDIF Input: 44.1kHz, 48kHz

Display: 150 x 32 LCD, Backlit

Footswitch: Tip/Ring/Sleeve phone jack for Bypass and Tap (optional)

MIDI Interface: Connectors: IN, OUT/THRU

System Specifications

Power Requirements: 90-250V 50-60Hz; 12.5W; 3-pin IEC Connector

RFI/ESD: FCC Class B; European EMC Directive 89/336/ECC

Environment: Operating Temperature: 32°-104°F (0°-40°C); Relative Humidity: 95% non-condensing

Dimensions: 19"W x 1.75"H x 5.5"D (483x45x140.25mm)

Weight: 3 lbs (1.4kg)

3-1

Lexicon

Chapter 4 Perfo rmance Verification

This section describes a quick verification of the operation of the MPX 500 and the integrity of its analog

and digital audio signal paths.

Diagnostics:

The MXP 500 contains two types of Diagnostics: Power Up Diagnostics, and Extended Diagnostics. Each

of these will be described fully in Chapter 5: Troubleshooting. When the MPX 500 is powered on, the Power

up Diagnostics run automatically to verify proper operation of its internal systems. The Power Up

Diagnostics consist of the following tests:

ROM Test

SRAM Test

WCS Test

INT Test

ADF Test

EEPROM Test

Setup:

1. Turn on the MPX 500 and wait for the Power Up Diagnostics cycle to finish.

2. Enter System Mode by pressing the System button.

3. Use Edit Knob 1 to select the following System Parameters and Edit Knob 3 to set the parameter as

noted:

3.1. Output Level: 0dB

3.2. Input Source: Analog Stereo

3.3. Clock Source: Internal 44.1k

3.4. Bypass Mode: Dry

4. Press the System button to return to the previous running mode.

5. Turn the Program Select Knob to Program #1.

6. Press the Bypass button on the front panel and verify that the button LED lights.

7. Connect a (balanced) audio cable between the Low Distortion Oscillator and the MPX 500 Left Input.

8. Connect a (balanced) audio cable between the MPX 500 Left output and the Distortion Analyzer.

9. Set the Distortion Analyzer to measure Vrms.

10. Turn the Input Trim knob fully clockwise.

I/O Tests:

These tests will verify the audio performance of the MPX 500's audio input and output circuitry

Analog In To Analog Out Level Test:

1. Apply a 1kHz sinewave signal to the MPX 500 Left Input @ 1.946Vrms.

2. Adjust the Input Trim knob and measure the output for a level between 15.46 and 13.78Vrms.

3. Move the cables to the Right Input/Output connections and repeat step 2.

Frequency Response Test:

These tests will verify the frequency response specifications of the Left and Right analog inputs to the Left

and Right analog output signal paths of the MPX 500.

Analog In To Analog Out Frequency Test:

1. Disable all Filters on the Distortion Analyzer

2. Apply a 1kHz sinewave signal to the MPX 500 Left Input @ 3.083Vrms

4-1

MPX 500 Service Manual

3. Connect the Left Output to the Distortion Analyzer.

4. Set the Analyzer for a 0dB reference (@1kHz).

5. Sweep the Oscillator from 20Hz to 20kHz and verify the level to be within +/- 1.0dBr through out the

sweep.

6. Move the cables to the Right Input/Output connections and repeat step 4 & 5.

THD+N Test:

These tests will verify the THD+N specifications of the MPX 500's Left and Right input to output circuitry.

Analog In To Analog Out THD+N Test:

1. Apply a 1kHz sinewave signal to the MPX 500 Left Input @ 6.904Vrms.

2. Connect the Left Output to the Distortion Analyzer.

3. Set the Distortion Analyzer to measure THD.

4. Enable the Low pass filters on the Analyzer (30kHz, 20kHz).

5. Verify the Left output, THD+Noise level on the Analyzer is < 0.005%.

6. Move the cables to the Right Inputs/Outputs connections and repeat step 5.

Crosstalk Tests:

These tests will verify the crosstalk specifications of the MPX 500's Left and Right input to output circuitry.

Analog In To Analog Out Crosstalk Test:

1. Apply a 1kHz sinewave signal to the MPX 500 Left Input @ 7.746Vrms.

2. Connect the Right Output to the Distortion Analyzer.

3. Enable the Low pass filters on the Analyzer (30kHz, 20kHz).

4. Sweep the Oscillator from 20Hz to 20kHz and verify the level to be >.245mVrms throughout the sweep.

5. Move the Input cable to the Right side and the Output cable to the Left and repeat step 4.

Dynamic Range Tests:

These tests will verify the Dynamic Range specifications of the MPX 500's Left and Right input to output

circuitry.

Analog In To Analog Out Dynamic Range Test:

1. Apply a 1kHz sinewave signal to the MPX 500 Left Input @ 7.746Vrms.

2. Connect the Left Output to the Distortion Analyzer.

3. Set the Distortion Analyzer for a 0dB reference

4. Remove the Input cable from the Left input.

5. Enable the Low pass filters on the Analyzer (30kHz, 20kHz).

6. Verify the Noise level at the Left Output is > -97dBr (.218mVrms); (-101 dBr typical).

7. Connect the 1kHz-sinewave signal to the Right Input of the MPX 500.

8. Move the Left Output cable to the Right Output.

9. Set the Distortion Analyzer for a 0dB reference.

10. Remove the Input cable from the Right input.

11. Enable the Low pass filters on the Analyzer (30kHz, 20kHz).

12. Verify the Noise level at the Right Output is > -97dBr (-101 dBr typical).

Repeat Tests @ 48K

Select Internal 48k Clock Source from System mode and repeat all of the above tests.

Digital I/O Functionality

This test will verify that the MPX 500 will pass a valid S/PDIF digital audio signal through its digital input and

output circuitry.

4-2

Lexicon

1. Connect a Digital signal (CD player, DAT, or effects box) to the S/PDIF input jack on the back of the

MPX 500.

2. Connect the S/PDIF output of the MPX 500 to a D/A device (M300) for conversion back to an analog

signal.

3. Connect the analog output of the D/A device (M300) to your amplifier with speaker output. Be sure to

turn the volume down on the amplifier.

4. Turn the volume up on your amplifier to a comfortable listening level and verify audio at the output and

that it is free and clear of any audio defects (pops, clicks, static, etc.).

MIDI Functionality:

This test will verify that the MIDI Input and MIDI Output/Thru circuits are working.

The test will transmit data out of the MIDI OUT jack and will attempt to read the data through the MIDI IN

jack.

Midi functionality is tested through the extended diagnostics of the MPX 500.

To enter the Extended Diagnostics, power on the unit while pressing down & holding the BYPASS button

on the front panel of the MPX 500. When the EDIT LED is lit, the BYPASS button can be released. After it

is released, the EDIT LED will go out and the LCD Display will indicate the first test, # 1 ROM. Turn the

Program Knob CW until test # 10 Midi test is displayed.

Connect a 5 Pin Male DIN to 5 Pin Male DIN Cable (also known as a MIDI cable) between the MIDI IN jack

and the MIDI OUT jack.

Press the Program Knob once to execute the test.

When the test is executed, the LCD Display will indicate the test is “Running…”, followed by the Pass/Fail

status of the test.

To exit the test, press the Program Knob.

Footswitch Functionality:

Footswitch functionality is performed through the extended diagnostics of the MPX 500.

To enter the Extended Diagnostics, power on the unit while pressing down & holding the BYPASS button

on the front panel of the MPX 500. When the EDIT LED is lit the BYPASS button can be released. After it is

released, the EDIT LED will go out and the LCD Display will indicate the first test, # 1 ROM. Turn the

Program Knob CW until test # 8 Switch test is displayed.

To perform this test, a Dual stereo style footswitch must be plugged into the Footswitch jack on the back of

the MPX 500 using a ¼ tip/ring/sleeve cable.

Press the Program Knob once to execute the test.

Press the LEFT FOOTSWITCH (Ring). The BYPASS LED will light and the LCD Display will indicate

“BYPASS”. The remaining LEDs will be off. When the LEFT FOOTSWITCH is released, the BYPASS LED

will go off.

Press the RIGHT FOOTSWITCH (TIP). The TAP LED will light and the LCD Display will indicate “TAP”. The

remaining LEDs will be off. When the RIGHT FOOTSWITCH is released, the TAP LED will go off.

To exit the test, press the Program Knob.

4-3

MPX 500 Service Manual

Listening Test:

Setup

1. Connect an audio cable between the output of the Low Distortion Amplifier and the MPX 500 Left and

Right Inputs.

2. Connect two audio cables between the headphone amplifier inputs and the MPX 500 Left and Right

outputs.

3. Set the headphone amplifier volume control to its lowest level.

4. Set the oscillator for 220Hz sinewave at 100mVrms.

5. Power on the MPX 500 and turn the program knob to the # 1 program Small Plate

Verify Clean Audio

1. Load Program # 1 Small Plate.

2. Set the reverb time to 2.04 seconds or greater, the Mix to 100% and Bypass to Off.

3. Put on headphones and set the headphone amplifier volume to a comfortable listening level.

4. Sweep the input knob over the entire range and verify that no pops, clicks, distortion, or static noises

are heard when turning the knob.

Shock Test

1. Lift one side of the MPX 500 four inches off the work surface and drop

2. Verify that no audio or display intermittence is caused by this action.

NOTE: To prevent damaging the unit, keep one side of the unit touching the work surface at all times.

4-4

Lexicon Audio Precision ATE Summary

Lexicon

4-5

Lexicon

Chapter 5 Trou bleshooting

Check the Lexicon web site for the latest software and information:

http://www.lexicon.com

The Lexicon Support Knowledgebase:

http://www.lexicon.com/kbase/kbase.asp

Diagnostics

The MXP 500 contains two types of Diagnostics: Power Up Diagnostics, and Extended Diagnostics. Each

of these is described in this chapter.

Power Up Diagnostics

On Normal power up, the MXP 500 will automatically execute a set of tests that comprise the Power Up

Diagnostics. All front panel LEDs will be turned on for approximately 200ms, and then the MPX 500 will

attempt to run the following sequence of tests. The tests have been designed to take less than 10 seconds.

ROM Test

SRAM Test

WCS Test

INT Test

ADF Test

EEPROM Test

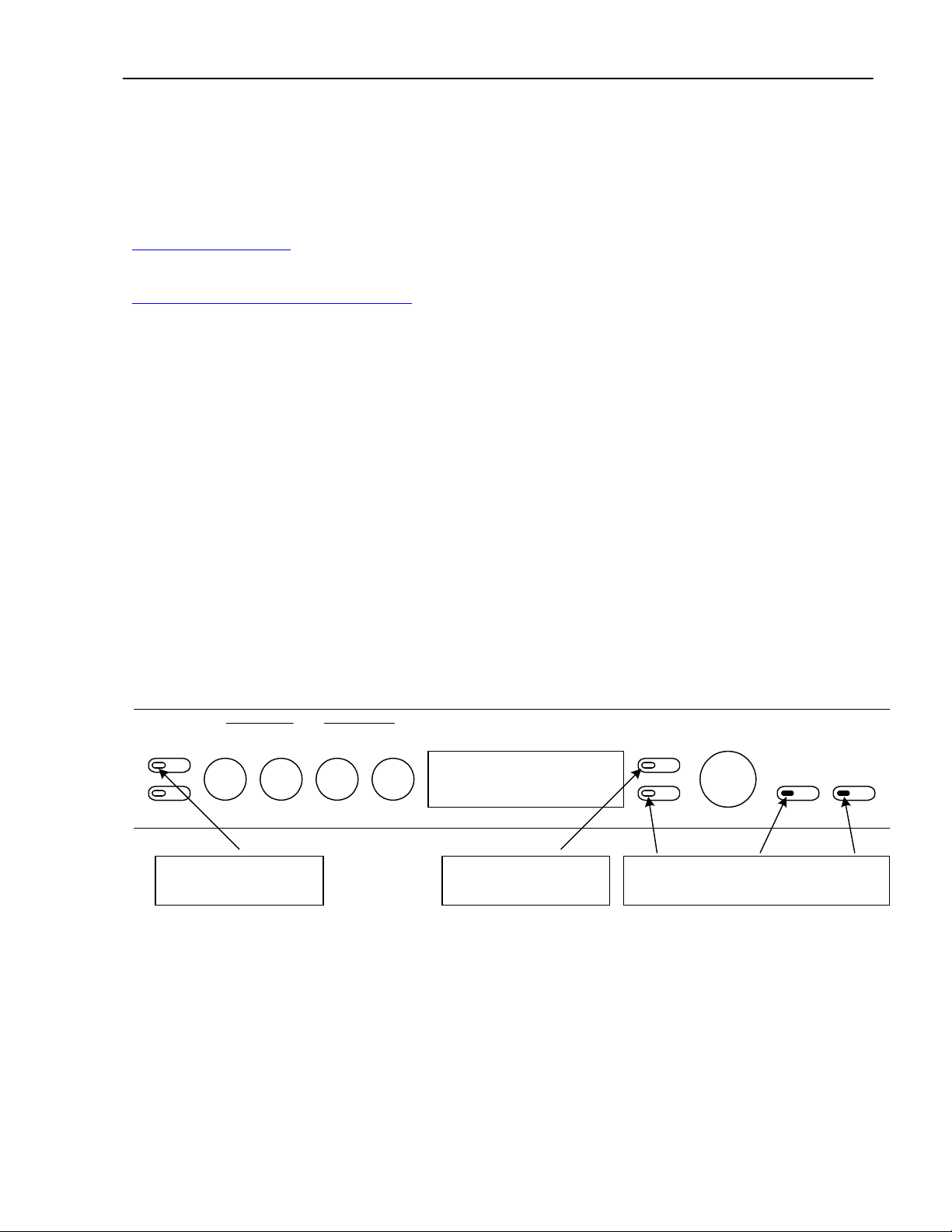

Error Indication

If any of the Power Up Diagnostics tests fail, the LOAD LED will be turned on. The error message will be

displayed on the front panel as shown in the example below. This will be true for all tests if an error occurs.

To continue to the next test after a failure is reported press BYPASS.

Edit

System

EDIT

12

LED indicates

when test has Passed

Edit

34

LOAD

LED indicates

when test has Failed

Load

Bypass

(MSB) (LSB)

Program

Store

Tap

5-1

MPX 500 Service Manual

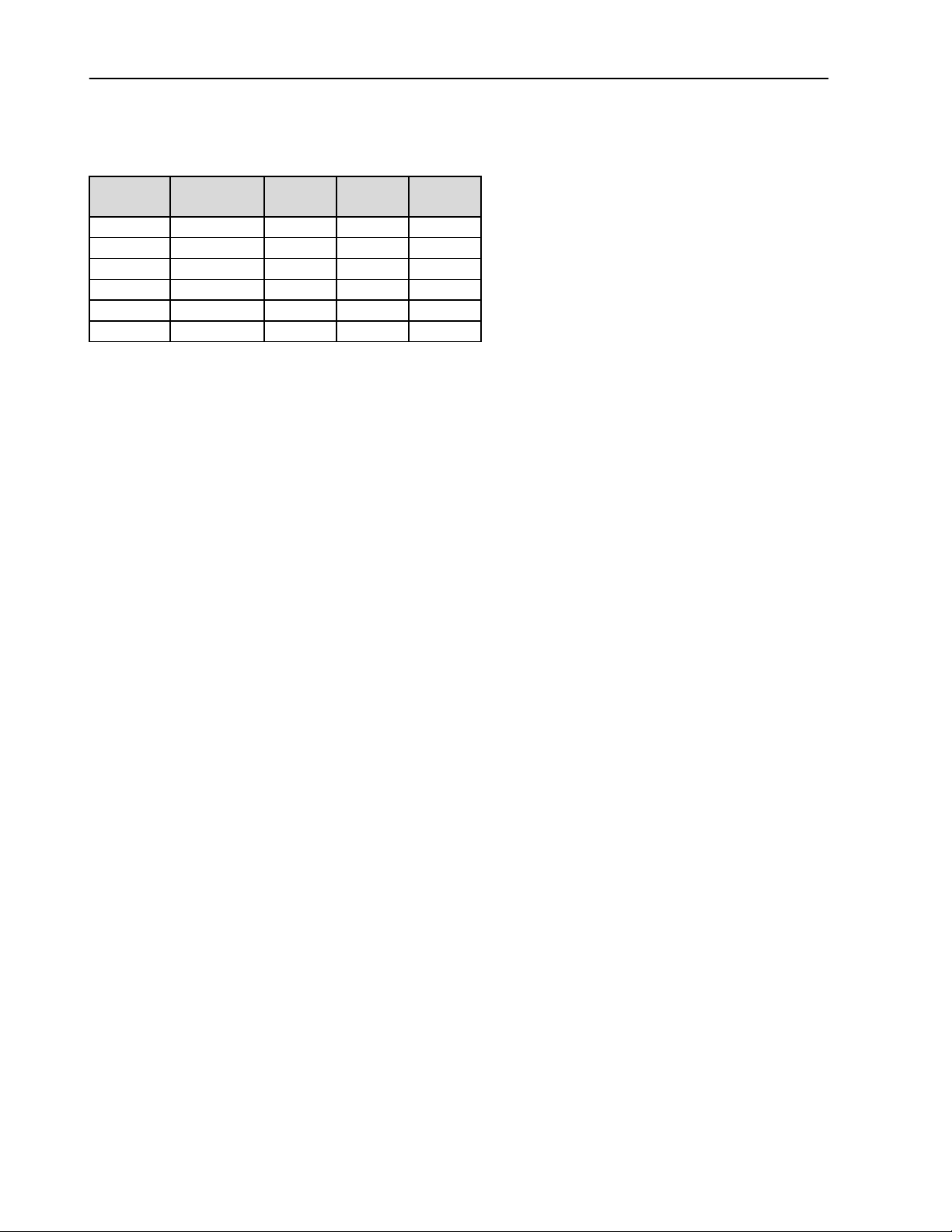

The table below displays the Power Up Diagnostic test code which the front panel will display before the

tests are executed.

Test

No.

Test

Name

BypassStore Tap

1ROM 001

2SRAM 010

3WCS 011

4INT 100

5ADF 101

6 EEPROM 1 1 0

0 = OFF

1 = ON

Test Descriptions

#1 ROM Test :

The ROM checksum, which is a byte size value, is located in the last location of each Bank. The test adds

the contents of the entire ROM including the check sum byte. The result should equal a 0 for the test to

pass.

#2 SRAM Test:

This test will verify the entire contents of the SRAM. The test first writes 00hex (000000000 binary) to all of

the memory locations, and then verifies this by reading back all the memory locations. The test will also

write/read the following patterns: 55hex (01010101 binary), AAhex (10101010 binary), and FFhex

(11111111 binary).

If what is written to all locations is read back, the test will pass.

#3 WCS Test:

This test will verify the program memory space of the Lexichip 3. The Ram (memory space) is first filled with

the value 55hex (01010101 binary), then each memory location is read back to confirm it contains the 55.

The memory space is then filled with AAhex (10101010 binary) and the memory is read back again. The

final test is the memory is filled with 0’s. If what is written to all locations is read back, the test will pass.

#4 INT Test:

This test will verify that the Lexichip 3 interrupt (INT/) is working and occurring at the proper time intervals.

The Lexichip 3 does this by providing this signal to the Z80’s maskable interrupt line. If the Z80 sees the

signal at the proper times the test will pass.

#5 ADF Test:

This test will verify that the Audio Data File in the Lexichip 3 is working properly. The Lexichip 3 Audio Data

File (ADF) is a fast synchronous 128-word SRAM that provides audio data buffering and storage for

external memory references, Serial I/O and the Host-to-Lexichip data port. ADF locations also function as

ARU Registers and as scratchpad memory.

#6 EEPROM Test:

This test will verify the functions of the EEPROM on the MPX 500.

First the test will verify that the EEPROM has been initialized properly. This is done by storing the software

version of the EPROM in the first five bytes of the EEPROM. Then the stored value is verified if correct

5-2

Lexicon

when the test is executed. If the stored value read from the first five bytes of the EEPROM is incorrect, the

EEPROM will be initialized.

Second, the test will read each byte in the User Register portion of the EEPROM and add them together to

calculate a checksum. This value is compared with the checksum value stored in the EEPROM itself. This

checksum will be recalculated each time a register is stored.

Extended Diagnostics

Extended Diagnostics are provided to help in troubleshooting specific functions in the MPX 500.

To enter the Extended Diagnostics, power on the unit while pressing down & holding the BYPASS button

on the front panel of the MPX 500. When the EDIT LED is lit, the BYPASS button can be released. After it

is released, the EDIT LED will go out and the LCD Display will indicate the test number and it name. The

Binary testcode will be displayed on the front panel (Bypass, Store, and Tap LEDs) as was described in the

Power Up Diagnostics section earlier in this chapter.

The following is a complete list of tests in the Extended Diagnostics.

ROM Test

SRAM Test

WCS Test

INT Test

ADF Test

EEPROM Test

DRAM Test

Switch Test

Encoder Test

MIDI Test

LCD Test

Exit Test

Init

Burn In Test

When each of these tests are run, they will display the test code and report an error the same way the

Power Up Diagnostic did. Unlike the power Up diagnostics however, each can be chosen individually by

turning the PROGRAM knob. Once a test is selected, execution of the test is done by pressing the Program

knob.

5-3

Loading...

Loading...