Page 1

Engineering tools

Engineer

Configuring drives_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Software Manual DE

Ä.PE8ä

13473623

L

Page 2

Target group

This documentation is intended for all persons who want to use the »Engineer«

engineering software to parameterise, configure and diagnose field devices and control

systems.

Screenshots/application examples

All screenshots provided in this documentation are application examples. Depending on

the firmware version of the Lenze devices and installed engineering tools (here: Lenze

»Engineer«), the representation may differ from the actual screen display.

Information regarding the validity

The information in this documentation is valid for the following Lenze software:

Software From version

»Engineer« 2.19

Document history

Version Description

2.12 10/2013 TD11 Updated contents for the »Engineer« V2.19 software version

2.11 11/2012 TD11 Updated contents for the »Engineer« V2.17 software version

2.10 05/2012 TD11 Updated contents for the »Engineer« V2.16 software version

2.9 11/2011 TD11 Updated contents for the »Engineer« V2.15 software version

2.8 04/2011 TD11 Updated contents for the »Engineer« V2.14 software version

2.7 11/2010 TD11 Updated contents for the »Engineer« V2.13 software version

2.6 04/2010 TD11 Updated contents for the »Engineer« V2.12 software version

2.5 10/2009 TD11 Updated contents for the software version »Engineer« V2.10 SP3

2.4 08/2009 TD11 Updated chapter: Managing cam data with the »Cam Manager«

2.3 04/2009 TD11 Optimised structures, update of dialog boxes & extension by new functions

of »Engineer« V2.10:

• Data logger

• Compare and copy parameter sets

2.2 11/2008 TD11 Extended by new functions of »Engineer« V2.9:

• L-force Loader Export, optimised menu control, device data update and

establishing an online connection.

• New chapter "Handling catalogues".

2.1 07/2008 TD11 Extended by new functions: User motors, Cam Manager, Cam Editor

2.0 10/2007 TD16 First edition

( 272)

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

1.1 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

1.2 Definition of notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3 User interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.1 Toolbar _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

3.2 Project view bar: Filtering the project tree _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

3.3 Project structure (project tree) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

3.3.1 History of the preselected elements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

3.3.2 General editing functions in the project view _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

3.3.3 Shortcuts in the project view _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

3.3.4 Project root _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

3.4 Workspace _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

3.4.1 Displaying parameter values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

3.5 Status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

3.6 Monitor: Monitoring parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

3.6.1 Show monitor window: Accept parameters/type of presentation _ _ _ _ _ _ _ _ _ _ _ _ _ 24

3.6.2 Adapt monitor window: Show parameters graphically (instruments) _ _ _ _ _ _ _ _ _ _ _ 25

3.6.3 Adapt monitor window: Present parameters graphically (list) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

3.7 Create _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.8 User menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.9 Messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.10 Wizards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

3.11 Options for the representation/project memory location _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

4 Getting started: creating a project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

4.1 Creating a new project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

4.1.1 Creating a new project (selecting a component from the catalogue) _ _ _ _ _ _ _ _ _ _ _ _ 32

4.1.2 Creating a new project (starting the search for devices connected) _ _ _ _ _ _ _ _ _ _ _ _ 34

4.1.3 Creating an empty project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

4.2 Opening the project file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

4.3 Updating projects while opening them: Adapting project file from previous version _ _ _ _ _ _ _ _ 39

4.4 Updating catalogues _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

4.5 Project properties _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

4.6 Save a project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

4.7 Managing projects in a packed archive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

4.7.1 Saving an archive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

4.7.2 Open an archive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

5 Mapping the system structure in the »Engineer« project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

5.1 Modularising with system modules and axes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

5.1.1 Inserting system modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

5.1.2 Inserting an axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

5.2 Inserting components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

5.2.1 Inserting controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

5.2.2 Inserting application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

5.2.3 Inserting device modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

5.2.4 Inserting controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

5.2.5 Inserting a motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

5.2.6 Inserting an I/O system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

5.2.6.1 System 1000 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

5.2.6.2 Compact I/O system IP20 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

5.2.6.3 Modular I/O system IP20 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

3 Lenze · Engineer · 2.13 EN - 10/2014

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.7 Inserting a power supply module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

5.2.8 Inserting the remote maintenance _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 66

5.3 Inserting a gearbox _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

5.4 Inserting a device detected online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

5.5 Insert from referential project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

5.6 Replace component _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

5.7 Documentation - Add project details _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

5.8 Protecting safe parameters - project-related password entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 74

6 Establishing an online connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

6.1 Build project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

6.2 Going online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

6.2.1 Setting the communication path _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 79

6.2.1.1 Diagnostic adapter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

6.2.1.2 CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 81

6.2.1.3 Ethernet / Ethernet IPC _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

6.2.1.4 PROFIBUS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 84

6.2.1.5 PROFINET _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

6.2.1.6 Gateway controller -> CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

6.2.1.7 Gateway controller -> EtherCAT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

6.2.1.8 Gateway Controller -> EtherCAT ADS (Beckhoff) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

6.2.1.9 Gateway Siemens - STEP 7 Communication Server (available by call in STEP 7) 89

6.2.2 Checking the serial number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

6.2.2.1 Communication path is currently being used by another device _ _ _ _ _ _ _ _ 94

6.2.2.2 Communication path is currently being used by another device _ _ _ _ _ _ _ _ 95

6.2.2.3 Switching off the serial number check _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

6.3 Going offline _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

6.4 System bus configurator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

6.5 PROFINET address configurator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

6.6 EtherNet / IP addresses configurator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

7 Device functions with active online connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 98

7.1 Options _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 99

7.2 Controlling an inverter: Enable/inhibit, start stop application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

7.2.1 Enable controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

7.2.2 Inhibit controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

7.2.3 Start application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

7.2.4 Stop application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

7.3 Application and parameter set transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

7.3.1 Download program to device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

7.3.2 Download parameter set to device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 105

7.3.3 Upload parameter set _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

7.3.4 Save parameter set _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

7.4 Optical tracking - device identification within the machine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

7.5 Manual control of the motor direction of rotation: Rotating the axes manually _ _ _ _ _ _ _ _ _ _ 109

7.6 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 110

7.7 Data logger _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 111

7.7.1 User interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 112

7.7.1.1 Data logger toolbar _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 112

7.7.1.2 Diagram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 113

7.7.1.3 Vertical settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

7.7.1.4 Trigger/cursor settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

7.7.1.5 Horizontal settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

7.7.1.6 Recording settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

4 Lenze · Engineer · 2.13 EN - 10/2014

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.7.2 Operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 116

7.7.2.1 Selecting the variables to be recorded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 116

7.7.2.2 Defining the recording time/sampling rate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 117

7.7.2.3 Defining the trigger condition _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 118

7.7.2.4 Using the time axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

7.7.2.5 Starting/stopping recording _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

7.7.2.6 Adjusting the representation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 120

7.7.2.7 Reading individual measured values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 121

7.7.2.8 Comparing peak values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 121

7.7.3 Data records _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

7.7.3.1 Commenting a data record _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

7.7.3.2 Saving/exporting a data record _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 123

7.7.3.3 Loading/importing data records _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 124

7.7.3.4 Closing the data record _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 125

7.7.3.5 Deleting a data record in the project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 125

7.7.3.6 Overlay function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

7.7.3.7 Copying a data record to the clipboard _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

7.8 Oscilloscope _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 127

8 Defining the system functionality _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

8.1 Representation in the project view _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

8.2 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

8.3 General notes with regard to the procedure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 131

8.4 Parameterising & configuring the devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

8.5 Assigning an application to the device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 133

8.6 Parameter setting in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 134

8.6.1 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 134

8.6.2 Working in the parameter list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

8.6.3 Altering a parameter offline _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 136

8.6.4 Altering parameters online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

8.6.4.1 Resetting parameters to the default setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 138

8.6.4.2 Accepting the parameter settings of the device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 138

8.6.5 Accepting parameter settings in the device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 139

8.6.6 Comparing parameter sets _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 139

8.7 Copying parameter sets _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 143

8.8 Configuring the terminal assignment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

8.8.1 Changing the terminal assignment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

8.8.2 Setting the gain & offset of the analog terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

8.8.3 Setting the active level of the digital terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

8.8.4 Displaying the actual status of the terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

8.9 Parameterising the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 146

8.9.1 Working in the "Application parameters" tab _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 146

8.9.1.1 Going directly to a parameter dialog _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 148

8.10 Function block editor (FB Editor) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

8.10.1 Connecting FBs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 151

8.10.2 Navigating within the FB Editor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 153

8.10.3 Printing the function block interconnection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 154

8.11 Port editor (ports) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

8.11.1 Overview: Variable types for ports _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

8.11.1.1 "Simple" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

8.11.1.2 "Record" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

8.11.1.3 "Array" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

8.11.1.4 Record or Simple? _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 160

Lenze · Engineer · 2.13 EN - 10/2014 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.11.2 Adding a port _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 162

8.11.2.1 Defining port with "Simple" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

8.11.2.2 Defining a port with "Record" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

8.11.2.3 Define a port with "Array" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 165

8.11.2.4 Defining element variables for "Record" variable type _ _ _ _ _ _ _ _ _ _ _ _ _ 166

8.11.2.5 Defining the interface and process data object _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

8.11.3 Renaming a port _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 169

8.11.4 Deleting a port _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 169

8.12 User menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 170

8.12.1 Configuring the user menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 171

8.12.2 Transferring the parameter selection to other controllers (in-project) _ _ _ _ _ _ _ _ _ _ _ 172

8.13 Inserting & configuring a machine application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

8.13.1 Inserting a machine application with a port interconnection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

8.13.2 Port interconnection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 175

8.13.2.1 Carrying out assignments _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 175

8.13.2.2 Cancelling assignments _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 176

8.13.3 Connecting ports within the machine application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 177

8.13.4 Adding ports as an external interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 179

8.13.5 Defining the type of connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 179

8.13.5.1 Automatic connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 180

8.13.5.2 Manual connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 180

8.13.5.3 Specifying the procedure for assigning the COB-IDs _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

8.13.5.4 Mixed connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 182

8.14 Creating an interconnection via the electrical shaft _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 182

8.14.1 Fixed synchronisation of the tools with regard to each other _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

8.14.2 Synchronisation of the tools with a material _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 184

8.14.3 Virtual master/real master _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 185

8.14.4 Establishing an interconnection via an electrical shaft _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 186

8.14.4.1 Adding placeholders to the interconnection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 190

8.14.4.2 Assigning an axis to a placeholder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 191

8.14.4.3 Cancelling existing assignments _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 193

8.14.4.4 Reusing the "Electrical shaft" object _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 193

8.14.5 Measuring systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 194

8.14.5.1 Unlimited/limited/modulo traversing range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 196

8.14.5.2 Creating/editing/deleting measuring systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 199

9 Inserting & configuring a network _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 202

9.1 Separation of the application and the network _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

9.1.1 Application level _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

9.1.2 Network level _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 205

9.2 Inserting a network _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 207

9.3 ETHERNET Powerlink network _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 210

9.3.1 Nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 210

9.3.1.1 Inserting nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 212

9.3.1.2 Node settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 214

9.3.1.3 Removing nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 214

9.3.2 Settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 215

9.3.3 Product features _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 215

9.3.4 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 215

9.4 CAN network _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 216

9.4.1 Nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 216

9.4.1.1 Inserting nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 218

9.4.1.2 Node settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 219

9.4.1.3 Removing nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 220

9.4.2 Settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 221

6 Lenze · Engineer · 2.13 EN - 10/2014

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.4.3 Synchronisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 223

9.4.4 CAN objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 225

9.4.5 Product features _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 225

9.5 Process data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 226

9.5.1 Packing ports into process data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 227

10 Application examples _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 228

10.1 Interconnection of an I/O terminal with a 9400 HighLine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 228

10.2 PROFIBUS nodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 230

11 Catalogue management in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 232

11.1 General information about catalogues _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 232

11.2 Catalogue packages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 233

11.3 Installation of catalogues _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 233

11.4 Use of catalogues in projects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 233

11.4.1 Relationship between project and catalogues _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 233

11.4.2 Characteristics of the elements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 234

11.5 Management of catalogue versions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 236

11.5.1 Objects of versioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 236

11.5.2 Procedure for the provision of new versions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 236

11.6 Particularities of the user motor catalogue _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 237

12 Error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 238

12.1 Application Connection Generator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 238

12.2 PortLogic generator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 241

12.3 CAN generator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 243

12.3.1 Addresses _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 243

12.3.2 Baud rate and MMT master _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 244

12.3.3 Synchronisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 245

12.3.4 COB-ID _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 246

12.3.5 Ports and PDO _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 248

12.4 Communication entity generator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 249

12.4.1 Standard (9300 servo + 9300 ServoPLC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 249

12.4.2 Compact (8200) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 252

12.4.3 9400 On board _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 253

12.4.4 I/O system IP20 (modular and compact) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 255

12.4.5 9400 PROFIBUS module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 255

13 Menu reference - Overview of the menu commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 257

13.1 "File" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 258

13.2 "Edit" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 259

13.3 "Insert" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 260

13.4 "View" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 260

13.5 "Online" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 260

13.6 "Application data" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 262

13.7 "Tools" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 263

13.8 "?" menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 263

13.9 "Project tree/project element" context menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 265

Lenze · Engineer · 2.13 EN - 10/2014 7

Page 8

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

14 Appendix _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 266

14.1 Export data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 266

14.1.1 Export applications to a Lenze package (LPK file) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 267

14.1.2 Export device description to a Lenze package (LPK file) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 268

14.1.3 Export parameters to a »L-force Loader« (LFL) file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 269

14.1.4 Export parameter values of the devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 269

14.1.4.1 Export all device parameters /Export individual parameters across devices _ _ 270

14.1.4.2 Export the parameter values of a single device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 271

14.2 Managing cam data with the »Cam Manager« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 272

14.2.1 Adding/editing/deleting products _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 273

14.2.2 Adding/editing/deleting tracks _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 275

14.2.3 Import data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 276

14.2.4 DSD export _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

14.2.5 Displaying project information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 278

14.3 Creating cam data with the »Cam Editor« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 279

14.3.1 User interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 280

14.3.2 Creating curves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 283

14.3.2.1 Step 1: Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 283

14.3.2.2 Step 2: Entering curves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 285

14.3.2.3 Step 3: Triggering automatic connection of segments _ _ _ _ _ _ _ _ _ _ _ _ _ 287

14.3.2.4 Step 4: Adapting acceleration for points _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 288

14.3.2.5 Step 5: Generating an interpolation point table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

14.3.2.6 Creating cams _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 290

14.3.2.7 Creating position markers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 292

14.4 User motors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 293

14.4.1 Creating user motors from controller settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 293

14.4.2 Saving a user motor to the user motor catalogue _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 296

14.4.3 Inserting the user motor into the project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 297

14.4.4 Modifying/supplementing motor default values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 299

14.4.5 Transferring default values to the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 300

14.4.6 Deleting/exporting/importing user motors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 302

15 Glossary _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 305

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

8 Lenze · Engineer · 2.13 EN - 10/2014

Page 9

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation contains information about the Lenze »Engineer«.

The »Engineer« is a Lenze engineering tool for different types of devices and is used for

parameterising, configuring and diagnosing Lenze devices (such as controllers, motors, I/O systems)

as well as machine control systems.

Short overview

Chapter Contents

Safety instructions

User interface ( 13) ...describes the user interface structure in the »Engineer«

Getting started: creating a project

( 30)

Establishing an online connection

( 75)

Device functions with active online

connection ( 98)

Defining the system functionality

( 128)

Inserting & configuring a network

( 202)

( 12) ...contains safety instructions which have to be observed if you want to

commission a controller or a system by means of the »Engineer«.

...describes how to create a project in the »Engineer«.

... describes how to establish an online connection to one or several

devices.

... describes how to execute the control functions of a device and a

parameter set/program transfer between the device and the

»Engineer«.

...describes the diagnostics options when an online connection has been

established to the device.

...describes how to define the functionality of your entire system in the

»Engineer«.

...describes how to add networks to the project and configure them to

ensure the communication between the devices of the system.

Lenze · Engineer · 2.13 EN - 10/2014 9

Page 10

About this documentation

Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Highlighting Examples/notes

Spelling of numbers

Decimal separators Point The decimal point is generally used.

For example: 1234.56

Text

Version information Text colour blue All pieces of information that only apply to or from a specific

Program name » « »Engineer«...

Window italics The Message window... / the Options dialog box...

Variable names Setting bEnable to TRUE...

Control element bold The OK button ... / The Copy command ... / The Properties tab

Sequence of menu

commands

Shortcut <bold> Use <F1> to open the online help.

Hyperlink underlined

Symbols

Page reference ( 10) Reference to further information: Page number in PDF file.

Step-by-step instructions

software version of the inverter are highlighted

correspondingly in this documentation.

Example: This function extension is available from software

version V3.0!

... / The Name input field ...

If several commands must be used in sequence to carry out a

function, the individual commands are separated by an

arrow: Select File

If a shortcut is required for a command to be executed, a "+"

has been put between the key identifiers: With

<Shift>+<ESC> ...

Reference to further information: Hyperlink to further

information.

Step-by-step instructions are marked by a pictograph.

Open to...

10

Lenze · Engineer · 2.13 EN - 10/2014

Page 11

About this documentation

Definition of notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Definition of notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Structure of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and informs how to prevent dangerous situations)

Pictograph Signal word Meaning

Danger! Danger of personal injuries through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of material damage

Application notes

Reference to an imminent danger that may result in death or serious personal

injury unless the corresponding measures are taken.

Reference to an imminent danger that may result in death or serious personal

injury unless the corresponding measures are taken.

Indicates a potential danger that may lead to material damage unless the

corresponding measures are taken.

Pictograph Signal word Meaning

Note! Important note to ensure troublefree operation

Tip! Useful tip for easy handling

Reference to another document

Lenze · Engineer · 2.13 EN - 10/2014 11

Page 12

Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller or

system using the »Engineer«.

Read the documentation supplied with the controller or the individual components of

the system carefully before you start to commission the devices with the »Engineer«!

The device documentation contains safety instructions which must be observed!

Danger!

If required, systems with integrated controllers have to be equipped with additional

monitoring and protective equipment in accordance with the safety regulations valid in

each case (e.g. law on technical equipment, regulations for the prevention of accidents),

so that an impermissible operating status does not endanger persons or equipment.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by the

moving machine parts.

Stop!

If you change parameters in the »Engineer« while the controller is connected online, the

changes will be directly accepted by the controller!

An incorrect parameterisation can result in unpredictable motor movements. By an

unintentional direction of rotation, too high speeds or jerky operation, powered

machine parts can be damaged!

12 Lenze · Engineer · 2.13 EN - 10/2014

Page 13

User interface

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 User interface

Note!

Different licence levels are available for the Engineering tools of Lenze. Depending on

the licence level used, the functional range varies on the user interface. Current

information can be found at:

The user interface is principally divided into the following areas:

http://www.Lenze.com

Title bar/available licence level Tabs (context-dependent)

Parameterising & configuring the devices

Menu commands

Menu reference - Overview of the menu commands

( 257)

Toolbar

Project view bar: Filtering the project tree

Project structure (project tree)

Getting started: creating a project

( 15) Status information ( 23)

( 17) Monitor: Monitoring parameters ( 24) /

( 18)

( 30)

Workspace

Create

User menu

without illustration: Wizards

( 21)

( 27) /

( 170) / Messages ( 27)

( 132)

( 28)

Lenze · Engineer · 2.13 EN - 10/2014 13

Page 14

User interface

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Tip!

In order to increase the workspace

view bar

• Alternatively the settings of the Project view bar 3 can be executed via the menu

on the left side or mask them out.

command ExtrasOptions in the Environment tab. Options for the representation/

project memory location ( 29)

, you can reduce the size of the buttons of the project

14 Lenze · Engineer · 2.13 EN - 10/2014

Page 15

User interface

Toolbar

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

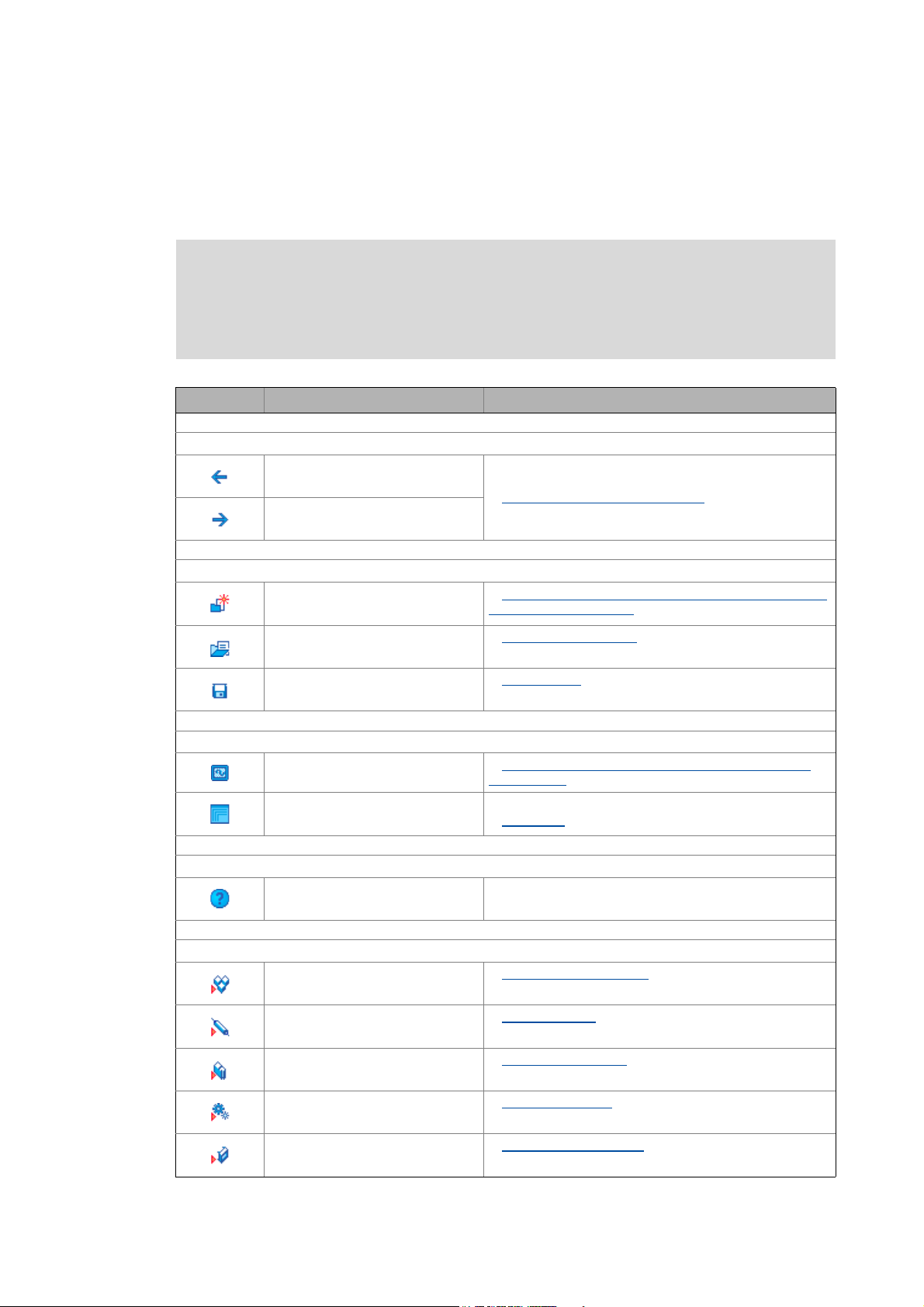

3.1 Toolbar

Via the Toolbar frequently used functions can be accessed without the need to use the menu

commands.

Note!

Depending on the project context, different icons can be activated or are deactivated

(greyed out).

• Some icons, for instance, are only available when a controller is selected.

Icon/button Menu command Function

History of the operating steps (back/next)

- One step forwards or backwards in the history of the

-

previously selected elements.

History of the preselected elements

( 19)

Managing projects

New project...

File

File

Open...

Save

File

Configure user interfaces

- Adapt monitor window: Show parameters graphically

- Maximise or minimise workspace

Call context help

- Display online help in the context of the selected device

Inserting project elements

Insert

System module

Axis

Insert

Updating projects while opening them: Adapting project

file from previous version ( 39)

Opening the project file

Save a project

(instruments) ( 25)

Workspace

Inserting system modules

Inserting an axis

( 42)

( 21)

( 38)

( 47)

( 48)

Component

Insert

Gearbox

Insert

Device module

Insert

Lenze · Engineer · 2.13 EN - 10/2014 15

Inserting components

Inserting a gearbox

Inserting device modules

( 51)

( 67)

( 57)

Page 16

User interface

Toolbar

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Icon/button Menu command Function

InsertApplication

Inserting application

( 55)

Network

Insert

Machine application

Insert

Going online/offline

OnlineGo online

Online

Go offline

Online

Optical location

Manual control

Online

- Commissioning wizard for guided commissioning of

Device functions with active online connection

OnlineEnable controller

Inserting a network

Inserting a machine application with a port

interconnection ( 174)

Establish a connection to a device

Going online

Break the connection to a device

Going offline

Device search function (signalling via device LEDs)

Optical tracking - device identification within the machine

( 107)

Manual control (available depending on the device)

• Can only be activated if one

device supports this function. Manual control of the

motor direction of rotation: Rotating the axes manually

( 109)

controllers of the 8400 device series

• ... is available in case there is an active online connection

to the device. Going online

Enable device (cancel controller inhibit)

Enable controller

( 207)

( 77)

( 96)

device is selected and the

( 100)

Safety instructions ( 12)

Inhibit controller

Online

Online

Start application

Safety instructions ( 12)

Stop application

Online

Application / parameter transfer

Online

Download program

Online

Download parameter set

Online

Upload parameter set

Online

Save parameter set

Inhibit device (set controller inhibit)

Inhibit controller

Start application in the device

Start application

Stop application in the device

Stop application

Download application to the device

Download program to device

Download parameter set to the device

Download parameter set to device

Upload parameter set

Upload parameter set

Save parameter set in the device safe against mains failure

Save parameter set

( 101)

( 101)

( 101)

( 103)

( 105)

( 106)

( 107)

16

Lenze · Engineer · 2.13 EN - 10/2014

Page 17

User interface

Project view bar: Filtering the project tree

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Icon/button Menu command Function

Build project (compile)

Build project

Tools

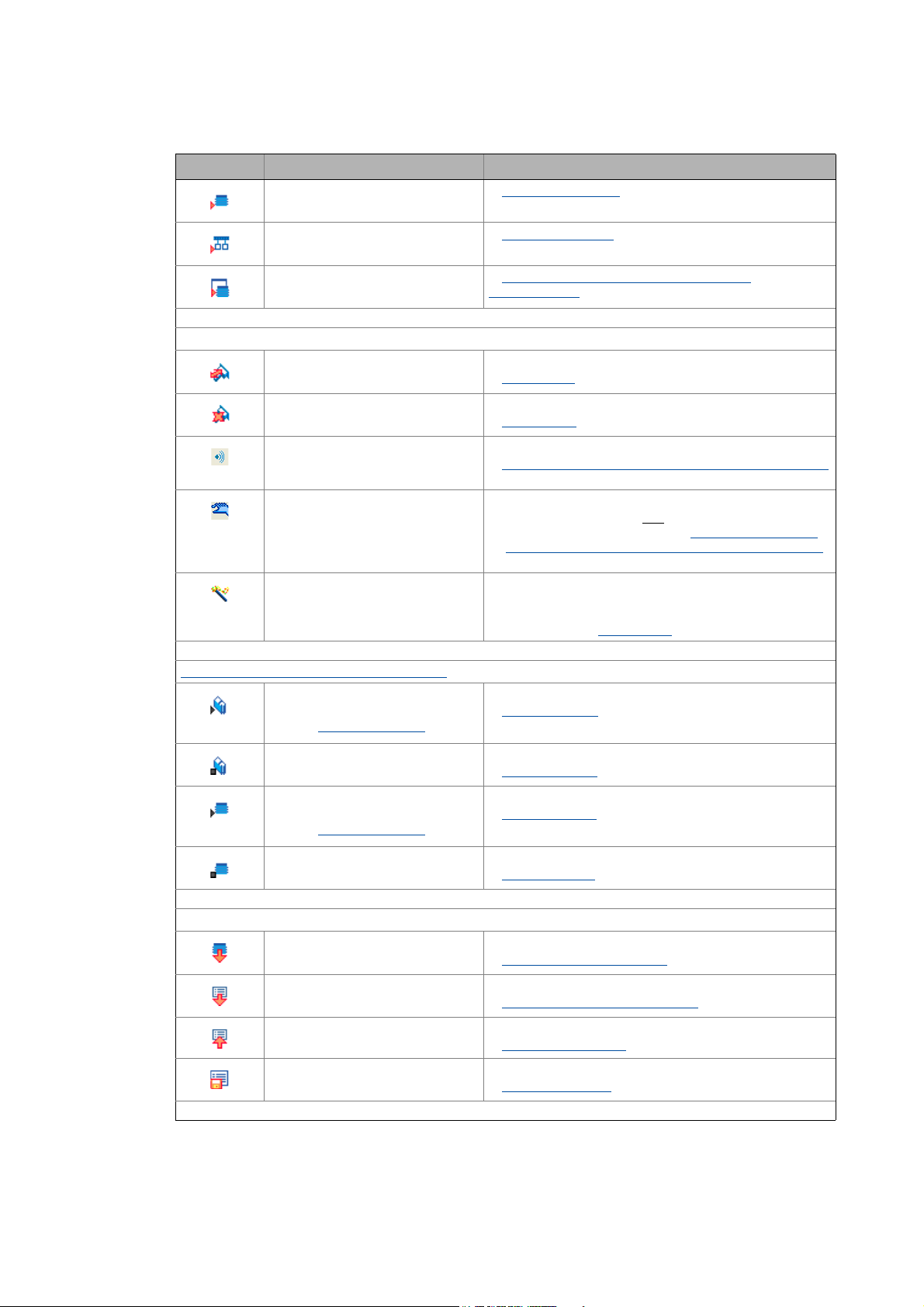

3.2 Project view bar: Filtering the project tree

Via the following buttons/icons in area of the application window you can filter the view of the

Project tree:

Button Representation in the project tree

Show Project tree in the Project view.

• This button serves to show all

•All

project elements can be edited.

Build project (individual project elements or whole project).

Build project ( 76)

available project elements.

Project

Devices

Network

Applications

Note!

Filter Project tree in the Device view

• The project tree only shows the root element and the devices inserted.

Details (like for example interfaces) are masked out.

Filter project tree in the Network view

• The project tree only shows the root element and the networks inserted.

Filter Project tree in the Application view

• The project tree only shows the root element and the applications that

are inserted in the project.

In order to be able to completely edit the project, you have to be in the Project view

(Project button in the Project view bar).

• Depending on the button selected in the Project view bar, the available icons in the Toolbar, the

elements shown in the Project view, and the Workspace change.

Lenze · Engineer · 2.13 EN - 10/2014 17

Page 18

User interface

Project structure (project tree)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Representing the project view bar in a reduced size/masking it out

Tip!

In order to increase the workspace, you can use the context menu (right-hand mouse

button) to reduce the size of the buttons in the project view bar or mask them out.

Alternatively, the settings of the project view bar can be executed via the menu command

ExtrasOptions in the Environment. Options

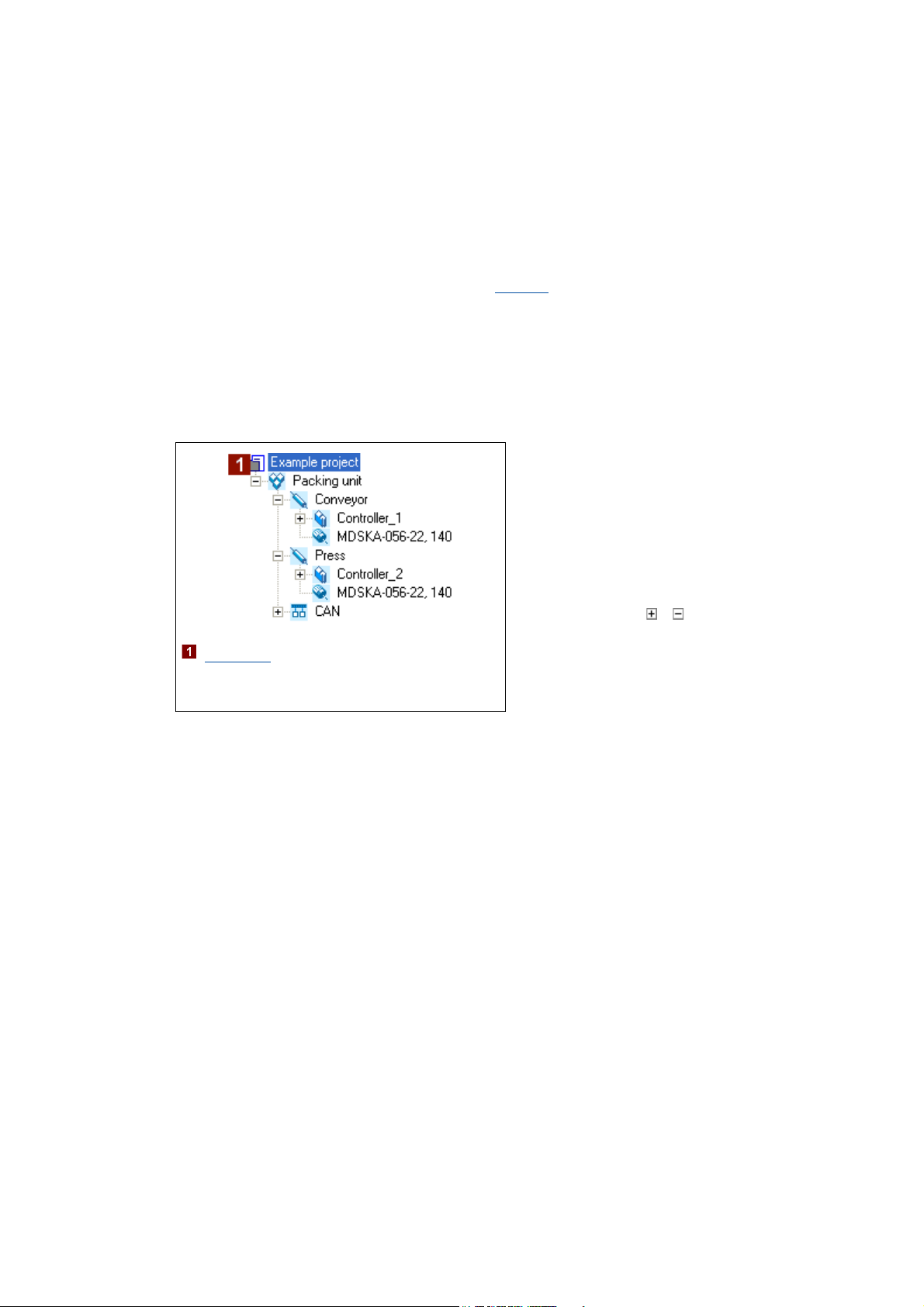

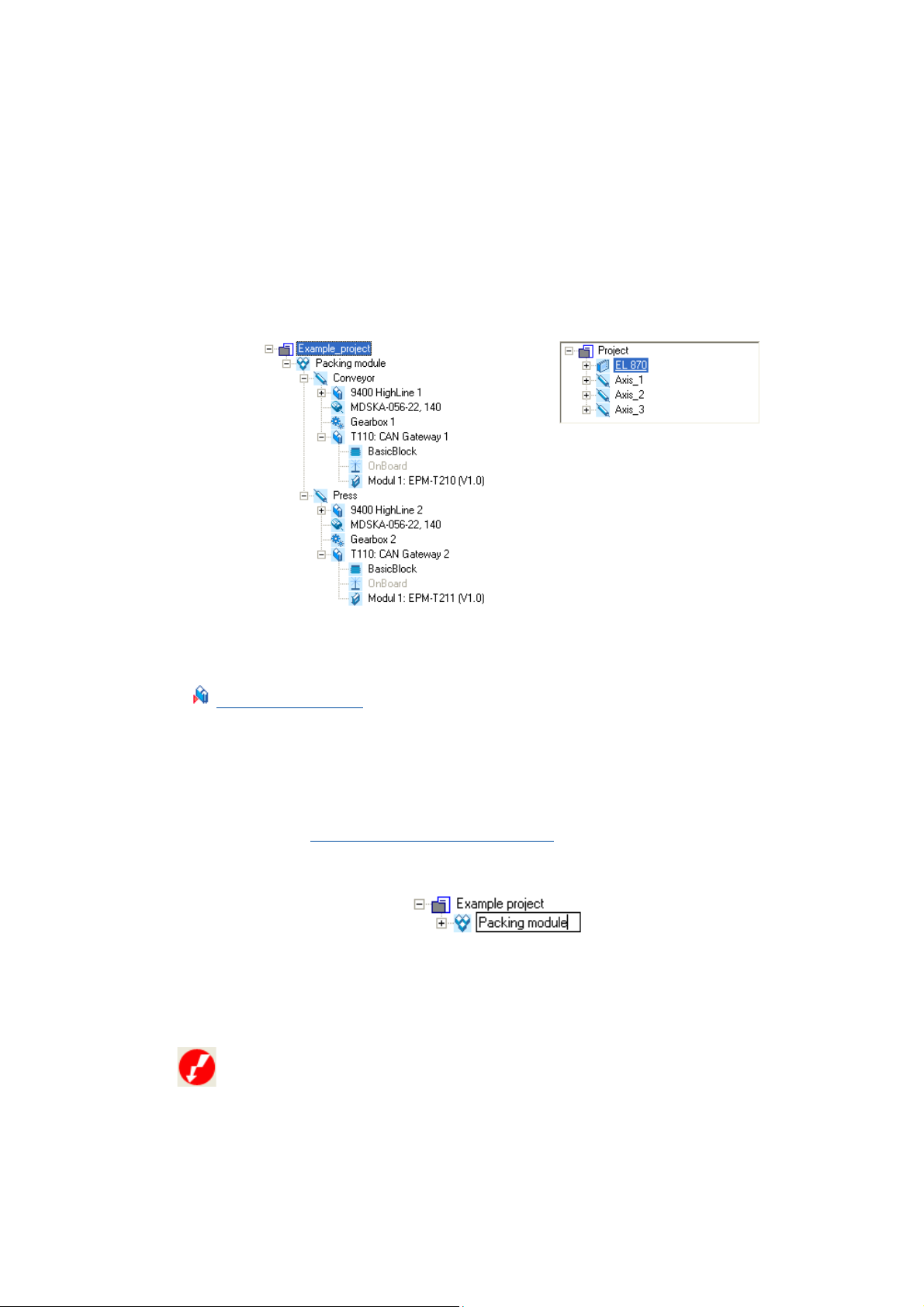

3.3 Project structure (project tree)

Similar to the folder view in the Windows Explorer, the project structure shows the individual

machine components in the form of a tree topology:

( 99)

• If you select a project element and then

change to the workspace, the project

element is still shown on a grey

background and is underlined at the same

time.

• Like this you can clearly see which

project element the active workspace

belongs to.

• By clicking the / icons, sub-elements

can be shown / hidden.

[3-1] Example for the hierarchical representation of the project structure in the Project tree

: Project root

•In the workspace, the properties and

settings of the currently selected element/

device are shown and can be edited there.

Tip!

You can alter the width and height of the Project view by using the mouse pointer to shift

the screen divider between the Project view and the Workspace or between the Project view

and the Message window.

By clicking with the right-hand mouse button, you can open a Context menu containing

functions relevant to the elements.

18

Lenze · Engineer · 2.13 EN - 10/2014

Page 19

User interface

Project structure (project tree)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3.1 History of the preselected elements

All elements selected in the Project view during project processing are stored in a "history".

Note!

The history is emptied automatically when the project is closed, i.e. the history is always

empty when you open a project.

The / buttons in the Toolbar jump to the project element selected previously / next.

Tip!

If the Project tree contains multiple devices, use to return to the component edited last

(e.g. a controller).

• If you click the arrow, , next to the / buttons, a selection list including the elements

selected last is available.

• Every entry is provided in the following form: "project name: element name".

3.3.2 General editing functions in the project view

The following processing functions apply to all elements in the Project view.

Drag element (cut & paste)

Duplicate element (copy & paste) ( 20)

Delete element ( 20)

Rename element ( 20)

Drag element (cut & paste)

1. Select the element to be shifted including all subelements.

2. Click and hold the element with your left mouse button and drag it to the desired position. The

current position of the element is displayed in one of the following manners:

• Highlighting the respective element:

The element to be shifted becomes the sub-element of the highlighted element. This behaviour

corresponds to the following command chain: EditCut, and then EditPaste.

( 19)

Lenze · Engineer · 2.13 EN - 10/2014 19

Page 20

User interface

Project structure (project tree)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• Element representation as horizontal bar:

The shifted element is positioned as desired between the two adjacent elements. The order of

elements of the same level can be changed in the Project tree:

or

1. Select the element to be shifted including all subelements.

2. Select menu command EditCut.

3. Select the element into which the element cut before is to be pasted.

4. Select menu command EditInsert.

Duplicate element (copy & paste)

1. Select the element which is to be copied including all subelements.

2. Select menu command EditCopy.

3. Select the element into which the element copied before is to be pasted.

4. Select menu command EditInsert.

Delete element

1. Select the element to be deleted including all subelements.

2. Select menu command EditDelete or press the <Del> button in order to delete the element

selected.

Rename element

1. Select the element to be renamed.

2. Select menu command EditRename or press the <F2> function key.

3. Enter new name.

4. Press the <input key> to accept the new name.

3.3.3 Shortcuts in the project view

20

Tip!

As an alternative to directly selecting elements with the help of the mouse pointer, you can

use keyboard shortcuts (for example, if you are running »Engineer« on a notebook). This

enables faster movement within the Project view in order to select elements for editing.

You can use the following shortcuts for navigating within the Project view if an element is focused

on in the Project view:

Lenze · Engineer · 2.13 EN - 10/2014

Page 21

User interface

Workspace

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Shortcut Function

<PG UP> Browsing upwards in the Project tree.

<PG DN> Browsing downwards in the Project tree.

<UP ARROW> Selection of the next element up.

<DOWN ARROW> Selection of the next element down.

<LEFT ARROW> Depending on the symbol shown in front of the element:

/ Selection of the higher-level/lower-level element in the hierarchy.

<RIGHT ARROW Depending on the symbol shown in front of the element:

/ Selection of the higher-level/lower-level element in the hierarchy.

<BACKSPACE> Selection of the higher-level element in the hierarchy in each case.

<POS1> Selection of the first project element.

<END> Selection of the last (shown) project element.

Tip!

In order to focus on an element in the Project view, click on a project element or press the

<Tab> key until you reach the desired element.

3.3.4 Project root

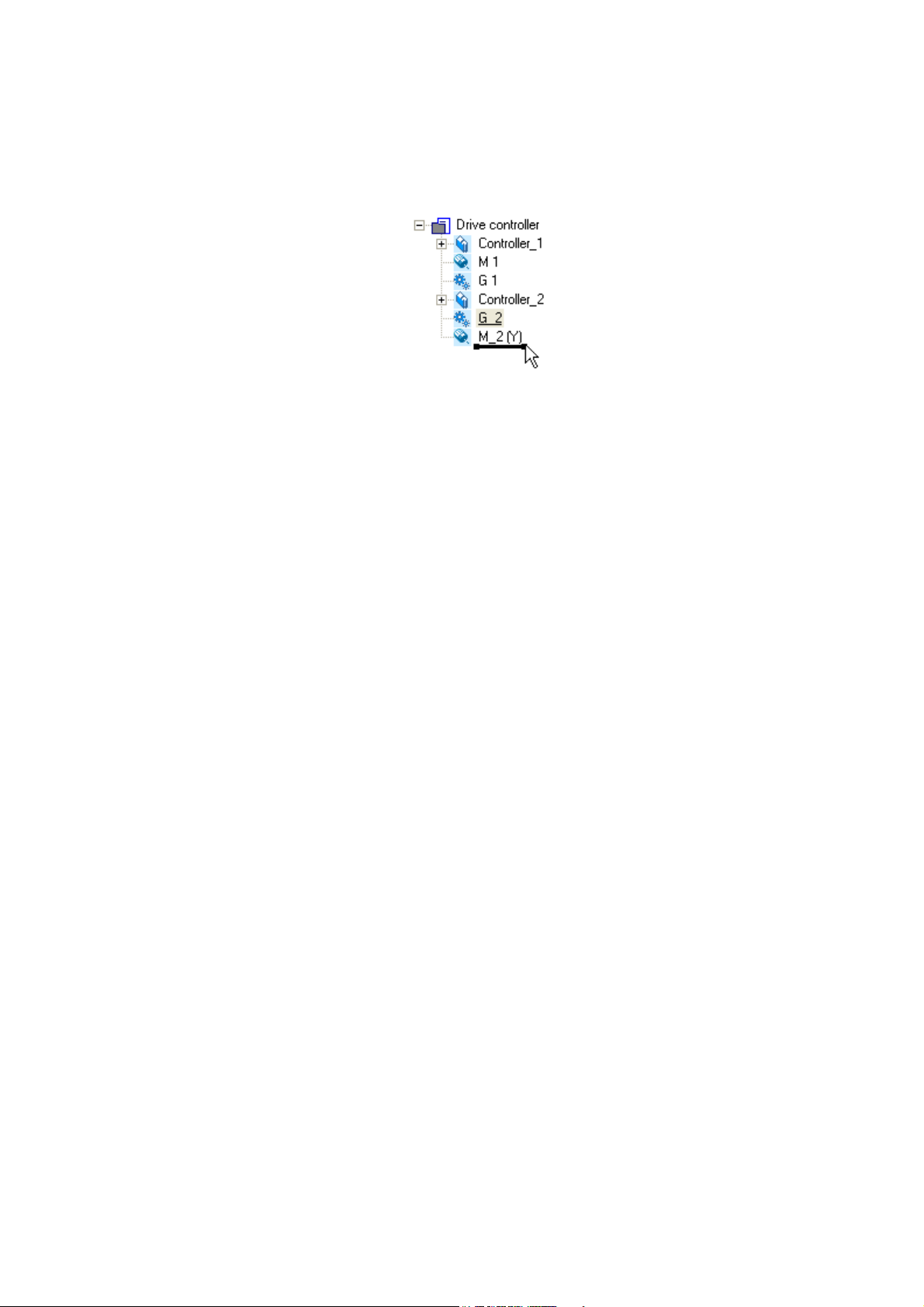

The project root is the topmost element in the Project tree (root element). The name

corresponds to the file name of the project.

• If the project root is selected, the tabs including general project properties are visible in the

workspace.

Tab Function

Components Tabulates all components inserted into the project.

Applications Tabulates all applications inserted into the project.

Data logger The data logger serves to record the temporal course of parameter values

Documentation Provides the opportunity to enter detailed information on the project and

Protection Settings for protecting the safe configuration

• The properties of the respective component are visible (device type,

firmware version, communication path) as well as the structural

integration in the form of system modules/axes.

• The assignment to system modules/axes is visible.

and display it as a line diagram. Data logger

• Note: For using this function, an online connection to the desired device

is required!

the projected machine plant.

• Notes and file attachments can be added to each project element.

Documentation - Add project details

• Assign a project-related password for protecting the safe configuration

(tab Safe configuration, safe parameters. Protecting safe parameters -

project-related password entry ( 74)

( 111)

( 71)

3.4 Workspace

The workspace (area ) has various tabs which show the properties and settings of the project

element currently selected in the project tree. A project element can be for instance a device: Servo

Drives 9400 HighLine.

Lenze · Engineer · 2.13 EN - 10/2014 21

Page 22

User interface

Workspace

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Tip!

The representation of the tabs in the workspace depends on the selected project element /

device type.

You can alter the width and height of the Workspace by using the mouse pointer to move

the screen divider between the Project view and the Workspace or between the Workspace

and the Message window as required.

Parameterising & configuring the devices

3.4.1 Displaying parameter values

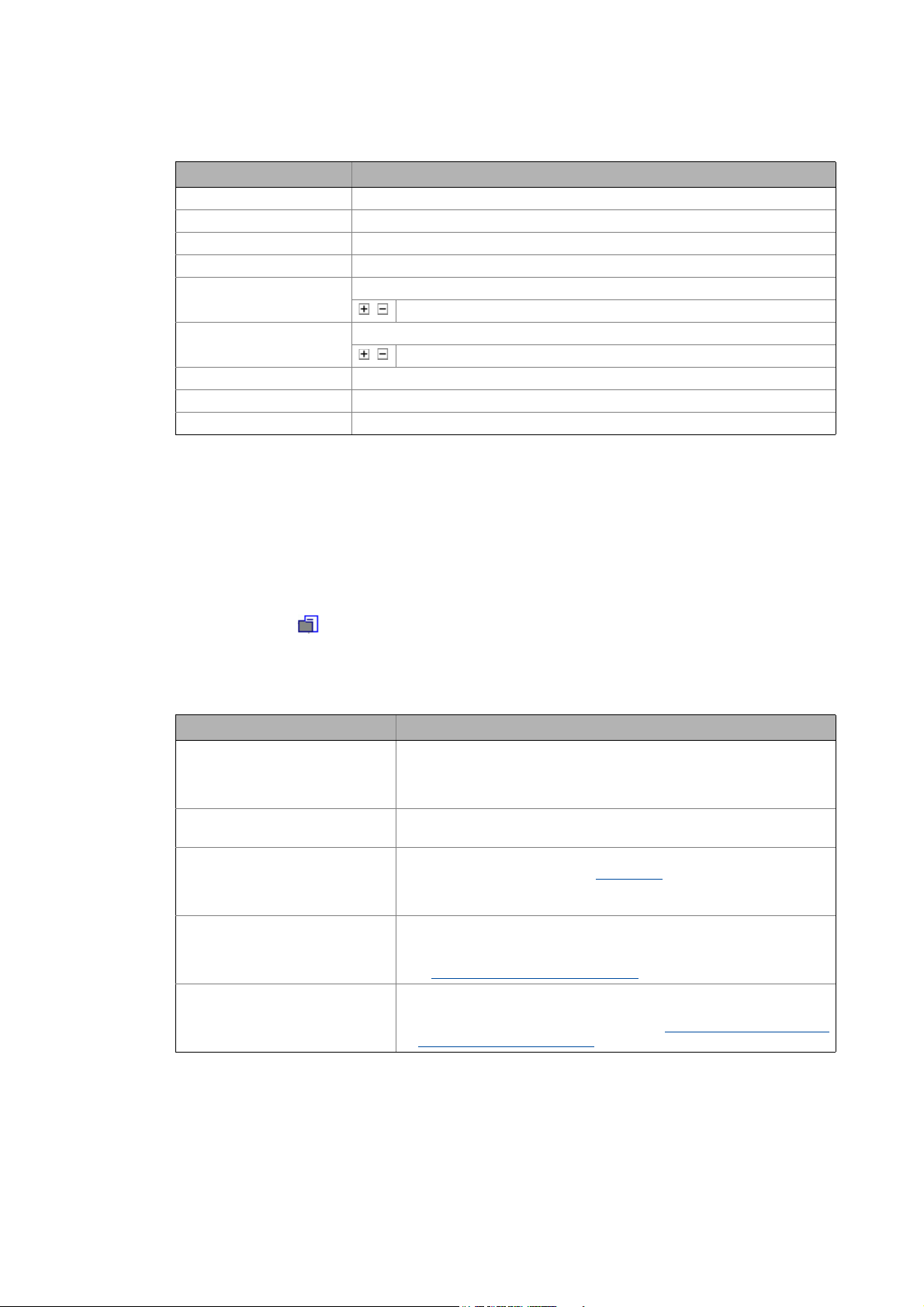

Device parameter settings shown in the workspace of the »Engineer« (e.g. in the Parameters tab for

a device) are displayed with different background colours with the following meaning:

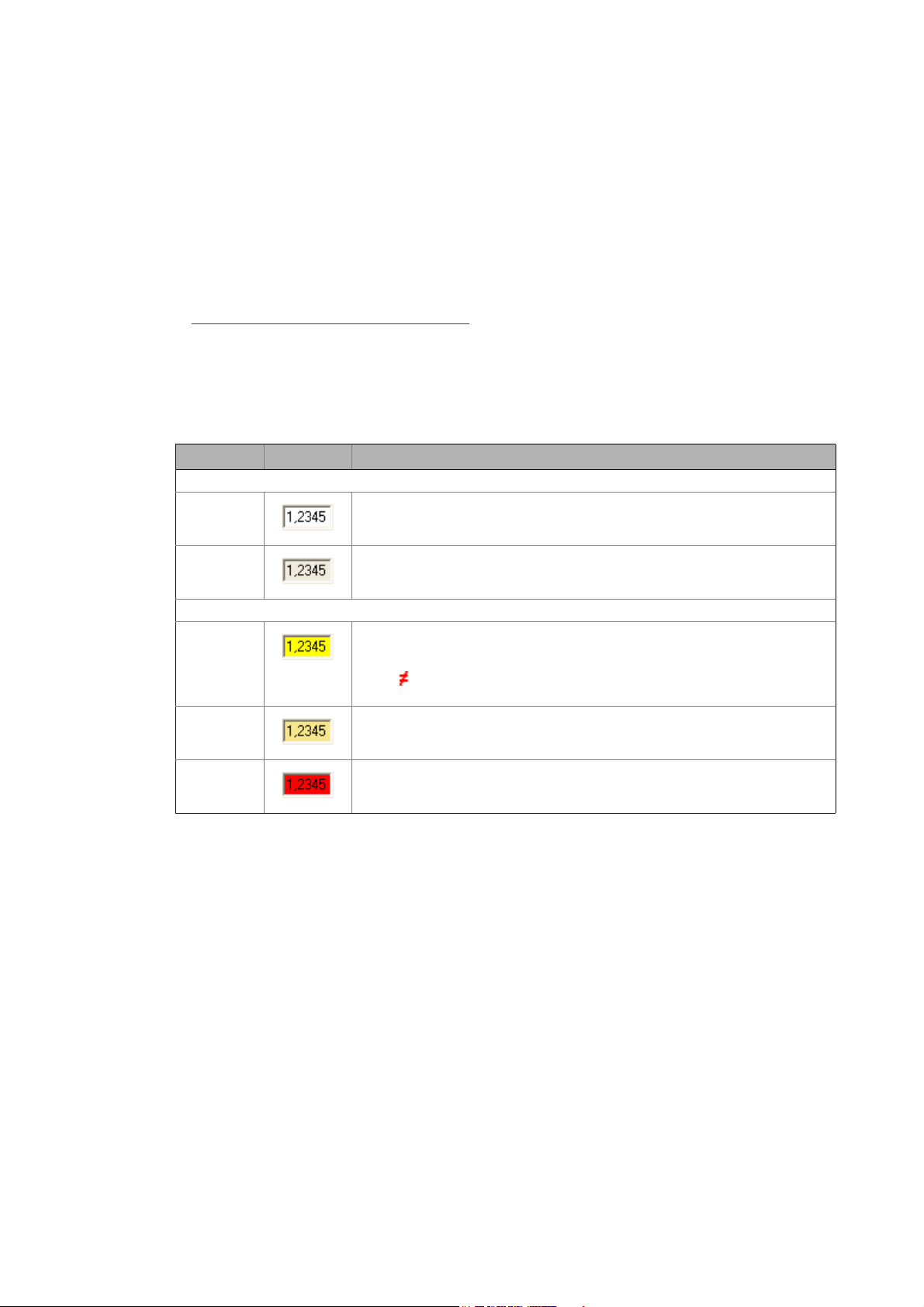

Colour Example Meaning

Offline representation

White Offline parameter

Light grey Offline display parameter

Online representation

Yellow Online parameter (value can be changed)

Pale yellow Online display parameter (read only)

Red Communication error (time-out)

( 132)

• The device is not connected "online" with the »Engineer«. The "offline" parameter

value set in the project is displayed.

• So-called "display parameters" are parameters which are only used to show

status information and actual values and which feature a read-only access.

• The device is connected "online" with the »Engineer«. The current parameter

value of the device is displayed.

• The symbol in front of a parameter value indicates that the value in the device

differs from the parameter value set in the project.

• The device is "online", i.e. connected to »Engineer«. The current parameter value

of a display parameter of the device is shown.

• Communication to a device is interrupted, the online parameter could not be

read out of the device within a certain time.

22

Lenze · Engineer · 2.13 EN - 10/2014

Page 23

User interface

Status information

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

If you edit a parameter value in an input field, you can see from the colour of the text whether the

altered value has already been integrated into the project or the device and is within the valid range.

Colour Example Meaning

Black Parameter value that is within the valid range and that has already been integrated

into the project or device.

Blue Altered parameter value that has not yet been integrated into the project or the

Red Changed parameter value which is outside the valid range.

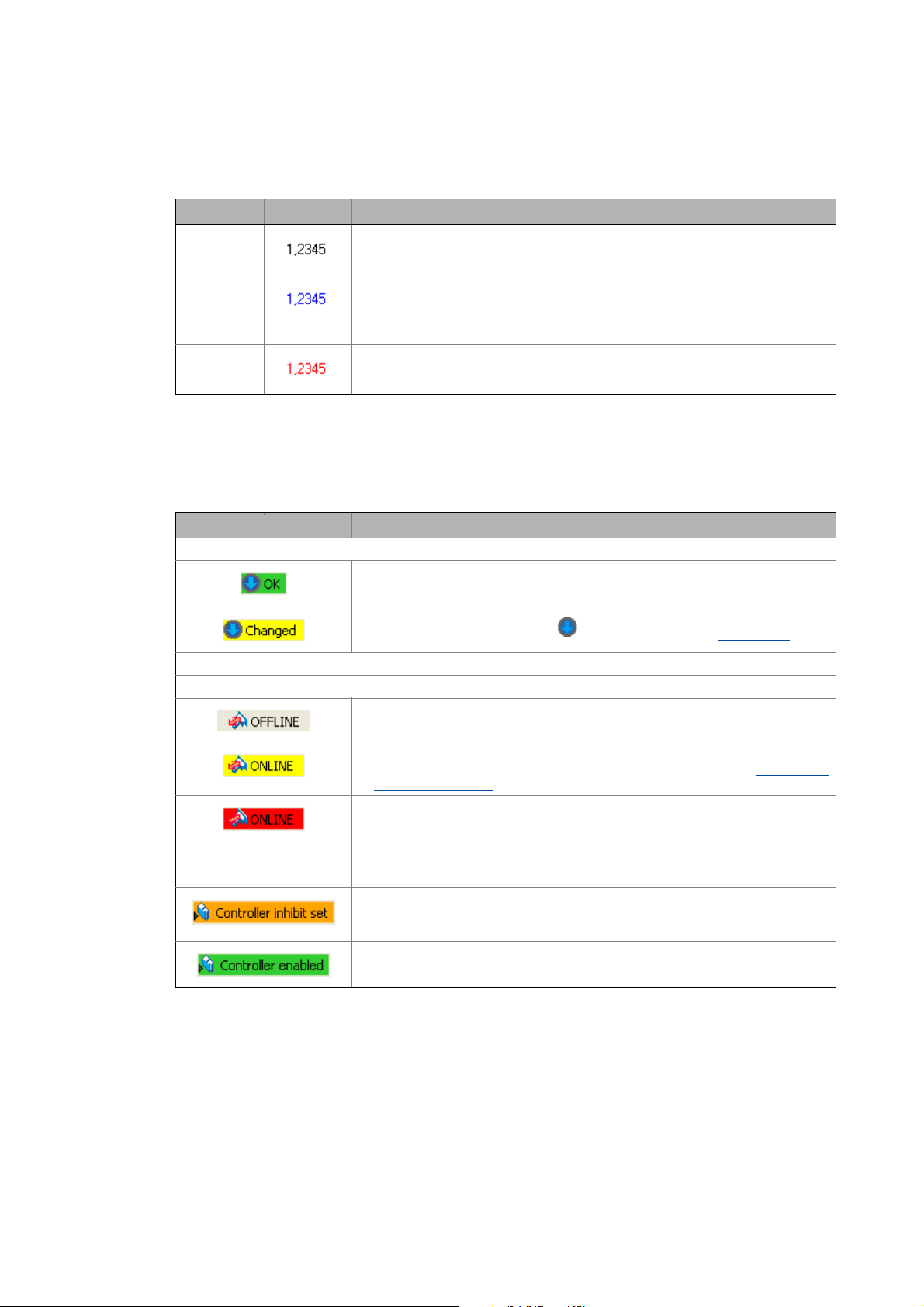

3.5 Status information

Information on the status of the project and devices/applications.

Information Meaning

Project status

Device status

device.

• By pressing the <input key>, you accept the altered value.

• You can reject the change by pressing the <ESC> key.

• You can reject the change by pressing the <ESC> key.

All project information is up to date.

• The project element selected in the Project tree does not have to be updated.

The project contains unsaved changes.

• Build the project by pressing the button in the Toolbar. Build project

The device is offline.

• No online connection to the device.

( 76)

Active online connection to the device.

• The »Engineer« communicates with device via a bus connection. Establishing

an online connection ( 75)

Active online connection is interrupted.

• An established online connection between the device and the »Engineer« is

interrupted (communication error).

DDCMP:/ Device-dependent access path

• The access path depends on the respective bus connection.

The controller is inhibited.

• The controller inhibit is set. Move the mouse pointer over the status information

of the controller in the status line to display the source of the controller inhibit.

The controller is enabled.

Depending on the device connection used, more information can be displayed in the status line, as

for instance the application status or unsaved changed of the parameter set.

Lenze · Engineer · 2.13 EN - 10/2014 23

Page 24

User interface

Monitor: Monitoring parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

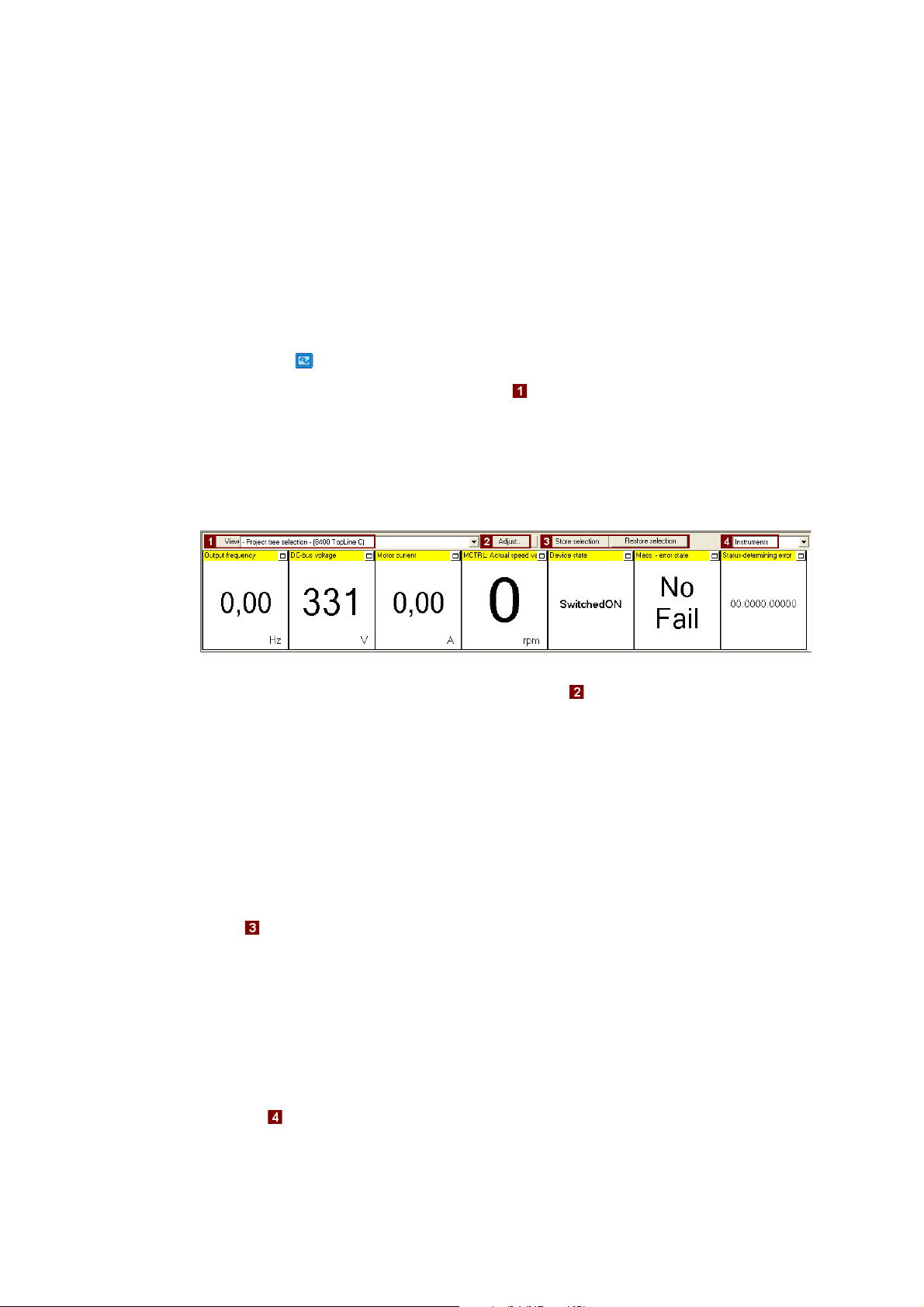

3.6 Monitor: Monitoring parameters

In the Monitor area below the project view and workspace, the parameters of a device to be selected

can be displayed as display parameters. This is reasonable, for instance, for monitoring certain

parameters for diagnostic purposes.

3.6.1 Show monitor window: Accept parameters/type of presentation

How to show the monitor window:

1. Click the Monitor tab at the bottom of the user window.

2. Select the desired monitor window in the View list field:

• -Project tree selection-: The monitor window always shows the parameters for device

currently marked in the project tree.

• System: Multi-device monitor window with your compiled parameters for several

devices of the automation system.

• Monitor window for a certain device. This leaves the focus on this device although a

different device has been marked in the project tree.

•The monitor window is preconfigured with display parameters. The display parameters visible

in the monitor window can be changed by clicking the Adjust button.

Tip!

Increase individual display parameter: By clicking the window symbol in the top right

display field, you show a display parameter across the entire width of the monitor window.

For reducing it again, click the displayed window icon . This serves to show all display

parameters again in the monitor window.

Using the parameter compilation for another device

Using the Store selection and Restore selection buttons, you can use the parameter compilation

of a monitor window for another device in the same project.

• After a monitor window has been created with device 1, click the Store selection button.

• Mark the desired device 2 in the project tree the application is to apply to as well.

•Click the Restore selection button to accept the parameter selection for the monitor window for

device 2.

Change type of presentation: Graphic or tabular

24

The list field changes the type of presentation: Graphic as Instruments or tabular as single-

column/two-column list.

Lenze · Engineer · 2.13 EN - 10/2014

Page 25

User interface

Monitor: Monitoring parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

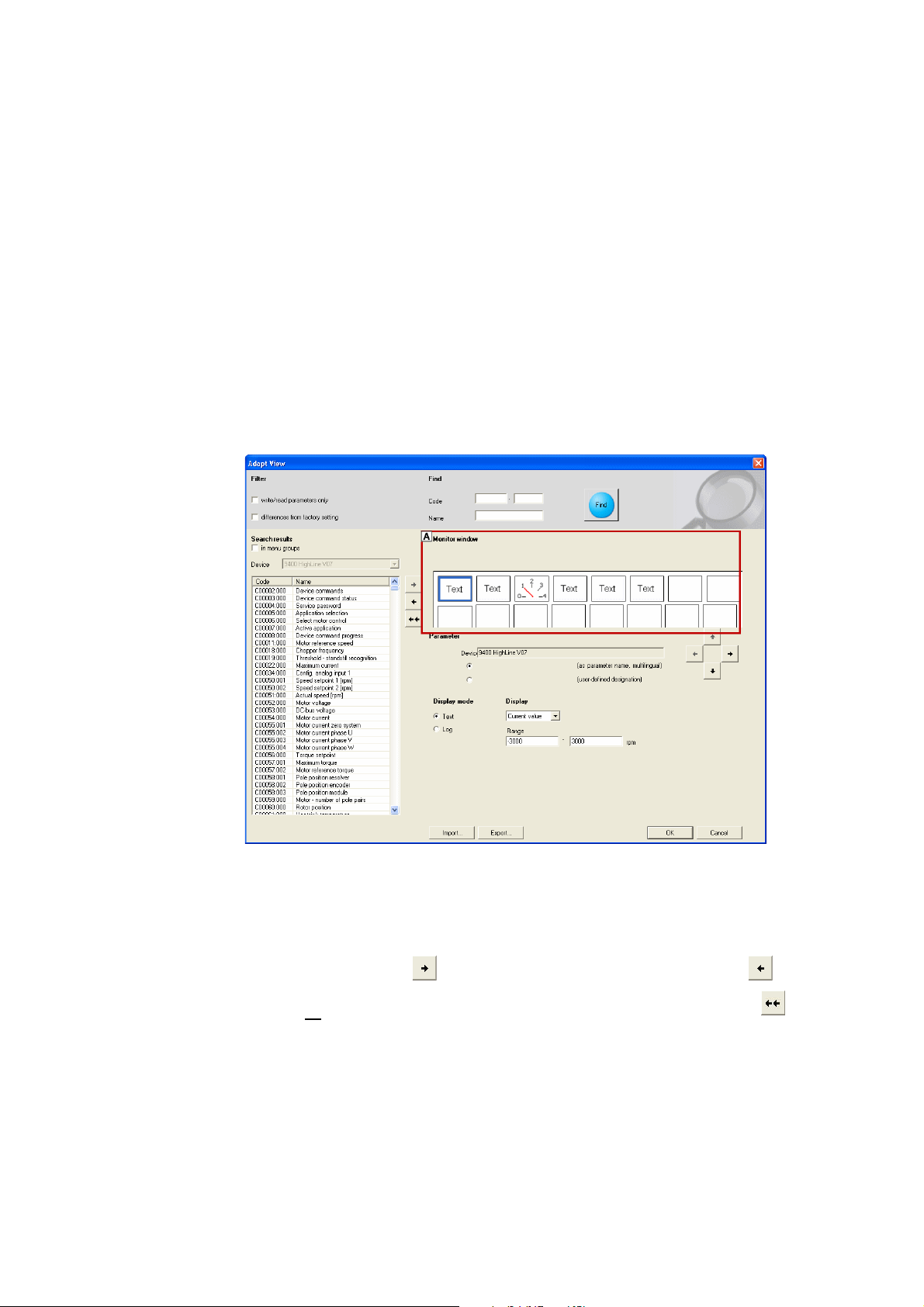

3.6.2 Adapt monitor window: Show parameters graphically (instruments)

The instruments option serves to present your requested parameters graphically.

Tip!

Any value from the parameter list (All parameters tab) of a device can be transferred to the

monitor window via right-click: Command: Add to monitor window

How to add the parameters to the monitor window:

1. Select the desired monitor window:

• Select the monitor window to be configured in the View list field (above the monitor

window.

2. Click the Adapt button:

• Click the display field you want to configure in the area. The currently selected display field is

highlighted by a blue frame.

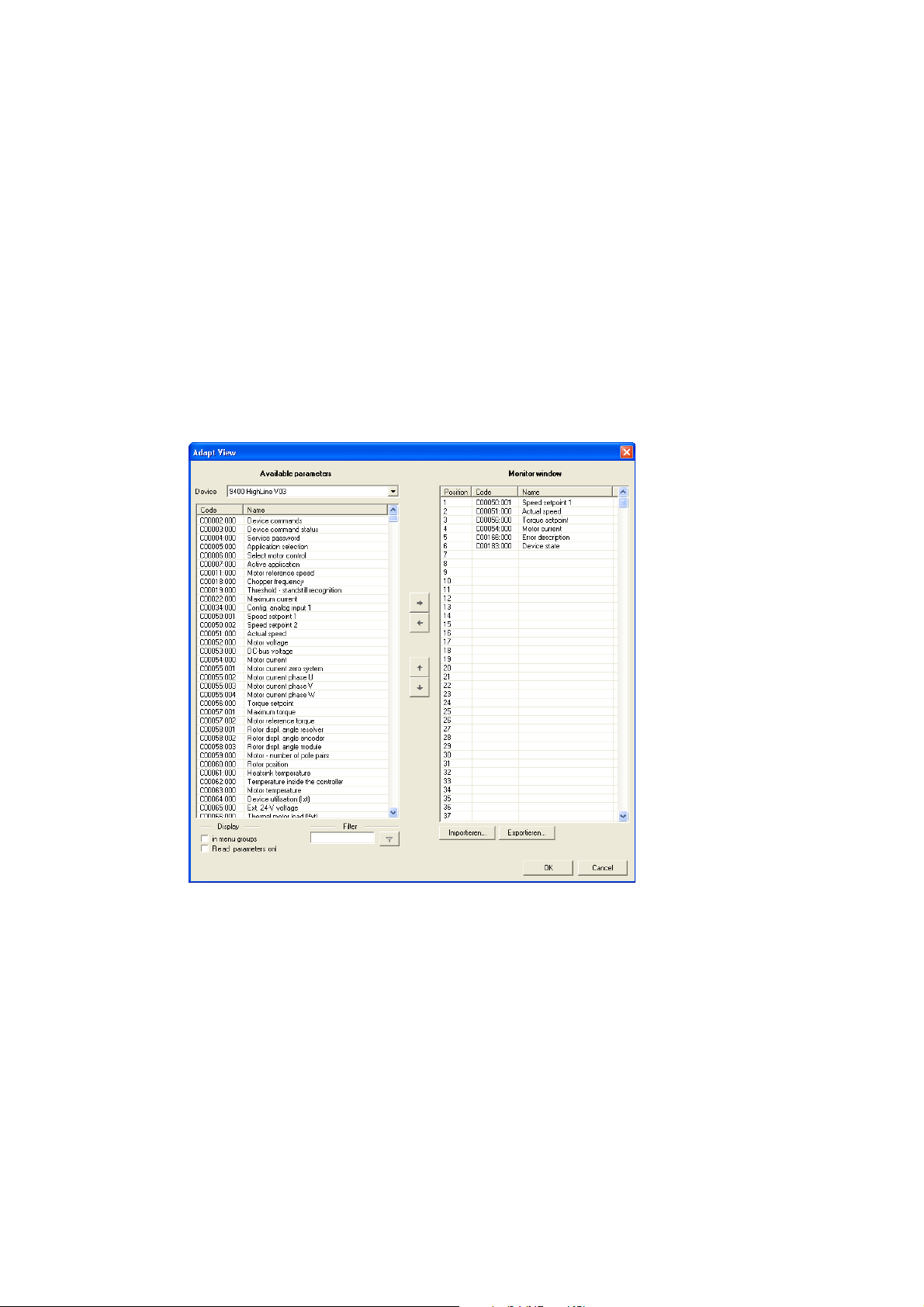

3. In the area , select the parameter from all parameters of the device ...

... to be displayed in the display field of the monitor window (area ).

...by clicking the arrow key /undoing the selection by using the arrow key . In order

to remove all

• In order that only certain parameters are visible in the area , activate the corresponding

filter options.

• Activate the in menu groups control field to arrange the parameters according to menu

groups.

4. Repeat the steps 1 to 4 to display more parameters in the display fields in area (one

parameter each per display field is possible).

parameters from the monitor window, use the double arrow key .

Lenze · Engineer · 2.13 EN - 10/2014 25

Page 26

User interface

Monitor: Monitoring parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5. In the field, the Import/Export buttons serve to import/export composed monitor views.

This serves, for instance, to use them in another »Engineer« project.

6. Press OK to transfer the selection to the monitor window.

3.6.3 Adapt monitor window: Present parameters graphically (list)

The instruments option serves to present your requested parameters in table form in the monitor

window.

How to add the parameters to the monitor window:

1. In the View list field, select the Monitor window to be configured.

2. Click the Adapt button to open the Adapt view dialog box.

3. Go to area and select the parameters to be transferred to the monitor window.

• Multi-selection of parameters shown one above the other: Hold down the <CTRL> key

and highlight the parameters.

• Multi-selection of individual parameters: Hold down the <SHIFT> key and highlight the

desired parameters individually.

• In order that only certain parameters are visible in the area, optionally activate the

corresponding filters .

• Activate the in menu groups control field to arrange the parameters according to menu

groups.

26

Lenze · Engineer · 2.13 EN - 10/2014

Page 27

User interface

Create

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4. Select the highlighted parameters (area ) by using the arrow key /undoing the

5. In the field, the Import/Export buttons serve to import/export composed monitor views.

6. PressOk to add the selection to the monitor window.

3.7 Create

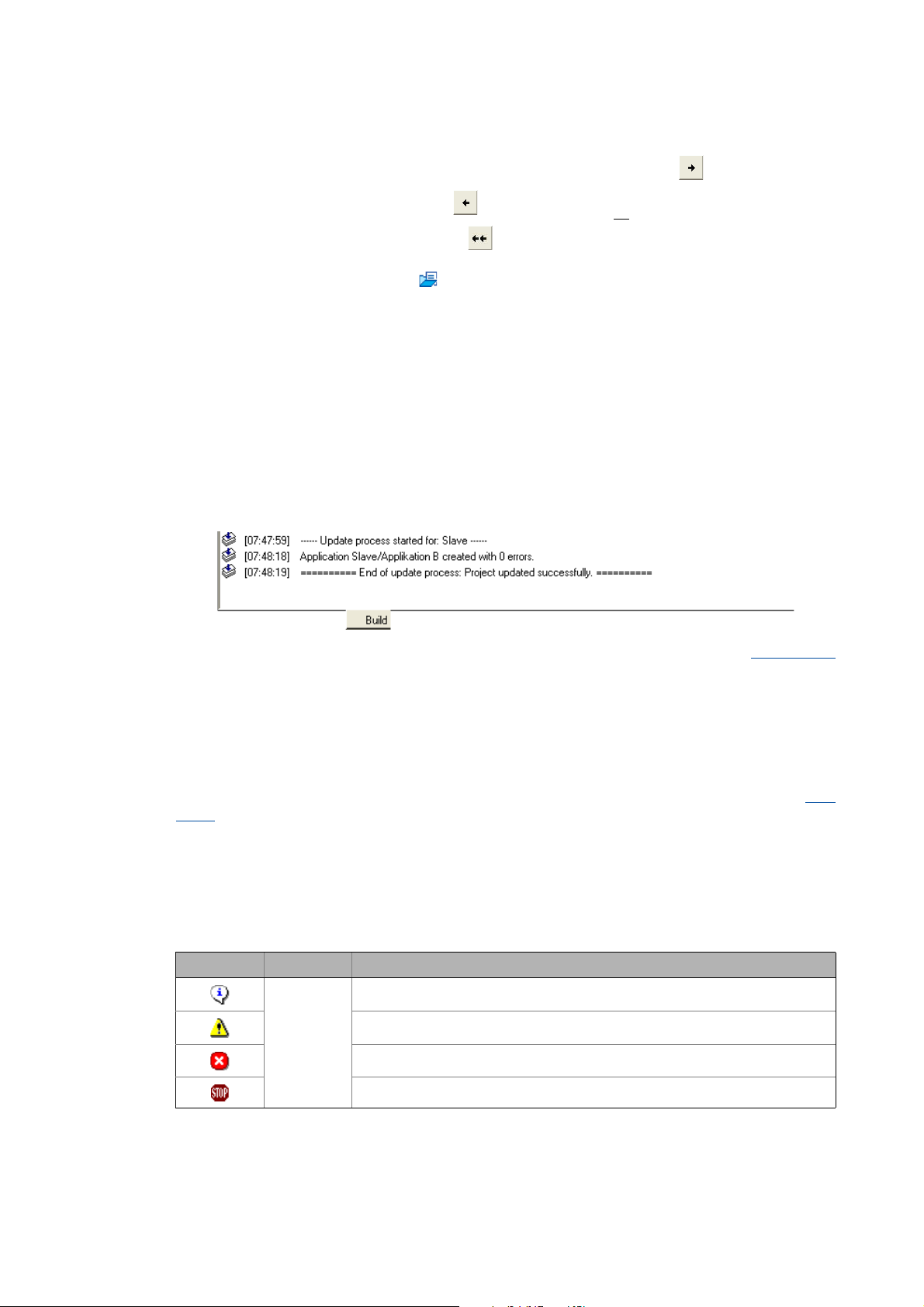

The Build tab shows information on the individual creation and updating processes. Build project

( 76)

selection by using the arrow key . In order to remove all

window, use the double arrow key .

As an alternative, press the button to open a GDC file which includes the required

parameter selection.

• Field shows the parameters selected for display.

•Press OK.

This serves, for instance, to use them in another »Engineer« project.

parameters from the monitor

3.8 User menu

The User menu tab shows the selection of parameters compiled by the user.

More information on how to create a user menu can be found in the following section: User

menu ( 170)

3.9 Messages

The Message window displays status and error messages relating to an executed program operation

or the current status of the program.

Icon Time stamp Text

Context menu

The following commands can be called in the message window via right-click:

[hh.mm.ss] Information text

Note

Error text

Program error text

Lenze · Engineer · 2.13 EN - 10/2014 27

Page 28

User interface

Wizards

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Command Function

Delete Delete all messages in the message window.

Display Submenu to select the elements to be displayed.

Copy list Copy all messages to the clipboard.

Copy message Copy the selected message to the clipboard.

Tip!

Using the mouse pointer, the height of the Message window can be changed by dragging

the screen divider between Workspace and Message window up or down.

3.10 Wizards

The »Engineer« is provided with several "wizards", e.g. for creating a project or setting up and

configuring a network.

• The wizards are structured as follows. Select step by step the desired settings:

•Area shows within which step of the wizard you are right now.

•Area contains the main dialog box for entering the data and selecting the desired options.

•Areadisplays further information and input requests for the respective step.

28

Lenze · Engineer · 2.13 EN - 10/2014

Page 29

User interface

Options for the representation/project memory location

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

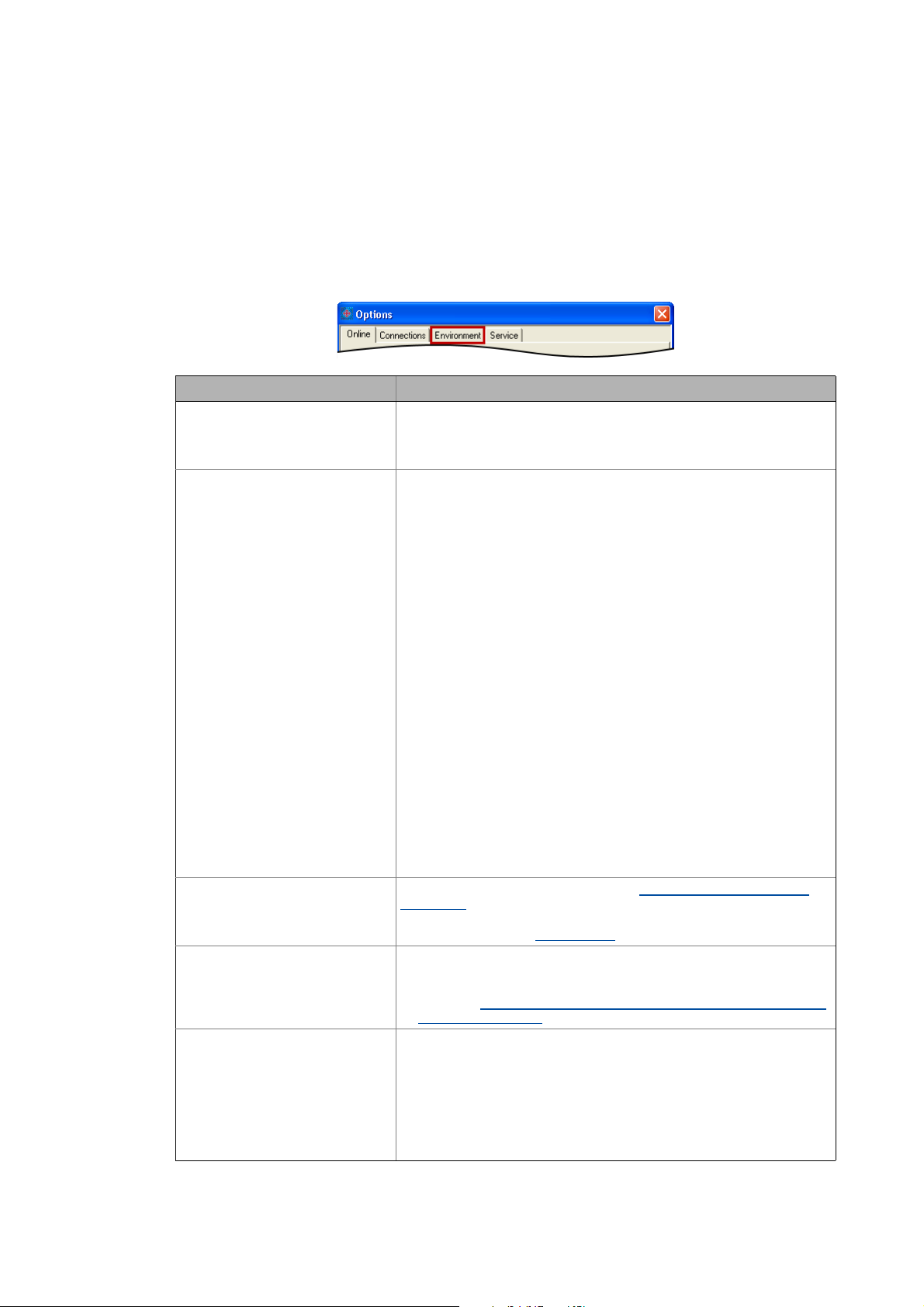

3.11 Options for the representation/project memory location

Via the ToolsOptions menu command you open the Options dialog box. In this dialog box you can

carry out general settings for the user interface in the Environment tab.

•In the Environment tab general settings can be edited.

• The settings are not a project property. Thus the settings are maintained for the following

»Engineer« projects.

Option Description

• Activate confirmation prompt

when deleting components

• Register external applications

automatically

Activate/deactivate confirmation prompt that is shown when components

are deleted.

• If this option is deactivated, the »Engineer« directly deletes the desired

component without a confirmation prompt.

Specifies that the »Engineer« automatically writes the required entries into

the Windows registry to start external programs.

• Like this the external program is registered for use in the »Engineer« and

can thus be called by the »Engineer«. Registration is effected in

accordance with the general Windows operating system standards.

• This option is activated by default.

• Change representation of the

Project view bar

• Standard memory location for

»Engineer« projects

• Representation of descriptive

texts

Example:

When a Servo Drive 9400 HighLine is updated, the »Engineer« calls the »PLC

Designer« to compile the program code which was previously created from

the function block interconnection.

On the Engineering PC several versions of »Engineer« and/or the »PLC

Designer« can be installed. When the option is activated, the »Engineer«

automatically ensures that the "suitable" (expected) »PLC Designer« version

is used for the compilation process.

Note:

If unexpected malfunction on your system occurs by thi s procedure, you can

deactivate this option.

For instance administrated access authorisation can prevent the »Engineer«

from writing into the registry.

In order to ensure that the external programs can be called by the

»Engineer«, you then have to make sure that after installing the »Engineer«

no other version of the program to be called by the »Engineer« has been

installed on your Engineering PC. Otherwise malfunction or an unexpected

response of the controller may result!

Specify the form of representation of the Project view bar: Filtering the

project tree.

•For instance, the Project view bar can be masked out to increase the size

of the Workspace. User interface

Specify the standard memory location for the creation of »Engineer«

projects

• The standard memory location can also be defined when a new project is

created. Updating projects while opening them: Adapting project file

from previous version ( 39)

Specify the type of representation of the descriptive texts.

• The standard setting is "simple and self-explanatory". By this the

respective descriptive text is reduced to the essential.

• "Formally more clearly" provides further information. Hence, the

descriptive texts are written in greater detail.

• The option for instance has a (device-independent) effect on all codes and

selection texts in the »Engineer«, which contain further descriptive texts.

• The option will become effective after an »Engineer« restart.

( 13)

Lenze · Engineer · 2.13 EN - 10/2014 29

Page 30

Getting started: creating a project

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Getting started: creating a project

Projects are created in the »Engineer« to show the machine/system concept in the project tree. In

this project file, all parameterisation and configuration settings of the automation system are

saved.

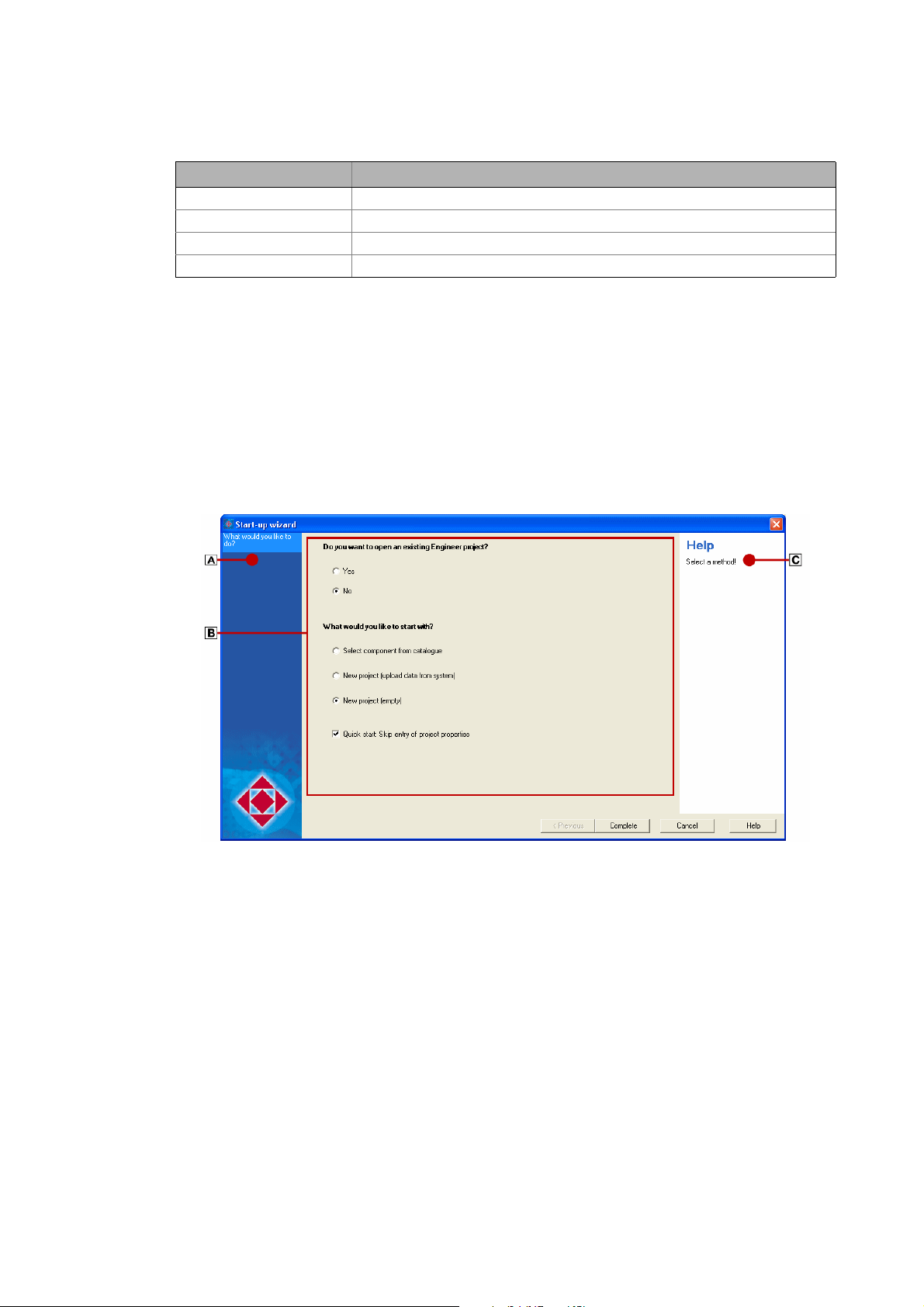

• When you start the »Engineer«, no project is loaded at first. The Start-up wizard enables ...

• ... you to open existing projects. Opening the project file

• ... you to create new projects. Updating projects while opening them: Adapting project file

from previous version ( 39)

( 38)

30 Lenze · Engineer · 2.13 EN - 10/2014

Page 31

Getting started: creating a project

Creating a new project

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1 Creating a new project

Create a new project using the Start-up wizard.

• Define the desired options for inserting components and project properties.

How would you like to start?

Step Option Function

What would you like to do?

• Select a component from the

catalogue

• Start the search for devices

connected

•Empty project

• Quick start guide: Skip entry of

the project properties (optionally)

Project properties

Create a project including

components from the selection lists

of the catalogues.

Creating a new project (selecting a

component from the catalogue)

( 32)

Search for devices that can be

accessed online to insert all

identified devices into the project

tree.

Creating a new project (starting

the search for devices connected)

( 34)

Creating an empty project

• Skip project properties

(properties/memory location). For

the time being the project is

named My Project and is stored at

the standard memory location.

• The quick start guide for instance

is helpful when you need projects

temporarily for testing purposes.

( 37)

Lenze · Engineer · 2.13 EN - 10/2014 31

Page 32

Getting started: creating a project

Creating a new project

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Step Option Function

Product features •Project name

•Project data

•Descriptive text

Memory location • Name of the project folder

• Memory location for projects

Project properties

The project properties entered in the Start-up wizard can be edited any time later on. Project

properties ( 41)

Memory location

An »Engineer« project includes a project file (*.afs format, ) as well as other directories and files

which are stored in a project directory.

• The name and path for the project directory can be selected in the Start-up wizard.

• The memory location can be changed later. Options for the representation/project memory

location ( 29)

Define desired properties in order to

be able to clearly identify the project.

Define desired memory location.

• Optionally a standard memory

location can be defined.

4.1.1 Creating a new project (selecting a component from the catalogue)

By this procedure you create a project with components (for example controller, I/O system, etc.).

The components are chosen from the selection lists of the catalogues in the »Engineer«.

• By means of this option you can go online with the inserted controller directly after having

created the project, in order to transfer e.g. parameters.

How to create a new project with components:

1. Click the icon or select the menu command FileNew to call the start-up wizard.

Step 1 - What would you like to do?

32

Lenze · Engineer · 2.13 EN - 10/2014

Page 33

Getting started: creating a project

Creating a new project

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2. Select the Select component from catalogue option.

3. Click the Next button.

4. Step 2 - Properties

Enter the corresponding properties of the project (name, order number etc.) in the input

fields.

• Enter desired Properties.

•The Name can be found later in the Project view as the name of the project element.

5. Click the Next button.

6. Step 3 - Memory location

As Project name the previously entered Project designation is suggested. If required,

correct the suggestion accordingly.

•The Project name at the same time is the name for the project directory to be created.