Page 1

EDSMF2192IB

.K:ö

Ä.K:öä

L−force Communication

Communication Manual

EtherCAT®

EMF2192IB

Communication module

Page 2

Contentsi

1 About this documentation 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Device− and application−specific safety instructions 11 . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Product features 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connections and interfaces 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Protective insulation 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Communication time 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Dimensions 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Mechanical installation 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical installation 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Wiring according to EMC (CE−typical drive system) 22 . . . . . . . . . . . . . . . . .

5.2.2 Network topology 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 EtherCAT connection 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Specification of the Ethernet cable 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Voltage supply 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Synchronisation of the standard device 29 . . . . . . . . . . . . . . . . . . . . . . . . .

2

EDSMF2192IB EN 3.1

Page 3

Contents i

6 Commissioning 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Configuring the host system (master) 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Installing device description files 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Automatic device detection 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Configuring process data 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 Defining the cycle time 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.5 Address allocation 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.6 Specifying the station alias 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Synchronisation with "Distributed clocks" (DC) 33 . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Preparation / installation 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 DC configuration in the master 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 DC configuration in the standard device (slave) 34 . . . . . . . . . . . . . . . . . . . .

6.3.4 Behaviour of the Lenze EtherCAT nodes during start−up 35 . . . . . . . . . . . .

6.4 Initial switch−on 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Data transfer 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 EtherCAT frame structure 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 EtherCAT datagrams 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 EtherCAT state machine 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Process data transfer 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Parameter data transfer 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Connection establishment between master and slave 42 . . . . . . . . . . . . . . . . . . . . . .

9.2 Reading and writing parameters 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Reading parameters (expedited upload) 44 . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Writing parameters (expedited download) 48 . . . . . . . . . . . . . . . . . . . . . . .

9.3 SDO abort codes 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Diagnostics 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 LED status displays 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Emergency requests / emergency messages 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Appendix 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Implemented CoE objects 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Codes 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Product codes of the Lenze standard devices 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Index 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSMF2192IB EN 3.1

3

Page 4

About this documentation1

0Fig. 0Tab. 0

1 About this documentation

Contents

This documentation only contains descriptions for the EMF2192IB communication

module (EtherCAT).

Note!

This documentation supplements the mounting instructions supplied with the

communication module and the documentations for the standard devices

used.

The mounting instructions contain safety instructions which must be

observed!

The features and functions of the communication module are described in detail.

Examples illustrate typical applications.

Furthermore this documentation contains the following:

ƒ Safety instructions that must be observed.

ƒ Key technical data relating to the communication module

ƒ Information on versions of Lenze standard devices to be used.

ƒ Notes on troubleshooting and fault elimination

The theoretical correlations are only explained in so far as they are necessary for

comprehending the function of the communication module.

This documentation does not describe the software of an original equipment

manufacturer. No responsibility is taken for corresponding information given in this

manual. Information on how to use the software can be obtained from the documents of

the host system (master).

All brand names mentioned in this manual are trademarks of their respective companies.

Tip!

Detailed information on EtherCAT can be found on the website of the

EtherCAT Technology Group:

http://www.EtherCAT.org

4

EDSMF2192IB EN 3.1

Page 5

About this documentation 1

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking and remote service of a machine.

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

Validity information

The information given in this documentation is valid for the following devices:

Extension module Type designation From hardware version

EtherCAT communication

module

EMF2192IB VA 1.0

upwards

From software version

upwards

EDSMF2192IB EN 3.1

5

Page 6

1

1.1 Document history

About this documentation

Document history

Version Description

1.0 10/2009 TD17 First edition

2.0 09/2010 TD14 General revision

3.0 06/2011 TD17 General revision

3.1 11/2012 TD17 EtherCAT® is a registered trademark by Beckhoff Automation GmbH,

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e−mail us to:

feedback−docu@Lenze.de

Thank you for your support.

Germany.

Your Lenze documentation team

6

EDSMF2192IB EN 3.1

Page 7

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Decimal Standard notation For example: 1234

Hexadecimal 0x[0 ... 9, A ... F] For example: 0x60F4

Binary

l Nibble

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

About this documentation

Conventions used

Point In general, the decimal point is used.

For instance: 1234.56

In quotation marks

Point

For example: ´100´

For example: ´0110.0100´

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

1

EDSMF2192IB EN 3.1

7

Page 8

1

About this documentation

Terminology used

1.3 Terminology used

Term Meaning

EtherCAT® EtherCAT® is a real−time capable Ethernet system with top performance.

Standard device

Controller

»Global Drive Control« /

»GDC«

»Engineer«

»PLC Designer«

»TwinCAT« EtherCAT configuration software by Beckhoff Automation GmbH, Germany

Code Parameter used for controller parameterisation or monitoring. The term is usually

Subcode If a code contains several parameters, the individual parameters are stored under

Lenze setting

Basic setting

HW Hardware

SW Software

ESI EtherCAT Slave Information (device description file in XML format)

CoE CANopen over EtherCAT

I−1600.20 CoE index (hexadecimal representation)

DC "Distributed clocks" for EtherCAT synchronisation

PDO Process data object

SDO Service data object

"Hot connect" This feature enables the slave nodes to be coupled/decoupled during operation.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

Lenze controllers with which the communication module can be used.

12

Lenze PC software which supports you in "engineering" (parameterisation, diagnostics

and configuration) throughout the whole life cycle, i.e. from planning to maintenance

of the commissioned machine.

called "index".

"subcodes".

This manual uses a slash "/" as a separator between code and subcode (e.g. "C118/3").

The term is usually called "subindex".

This setting is the default factory setting of the device.

l In the example: Index 0x1600, subindex 0x20

8

EDSMF2192IB EN 3.1

Page 9

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

About this documentation

Notes used

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

1

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

EDSMF2192IB EN 3.1

9

Page 10

2

Safety instructions

General safety information

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order

to prevent serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety information

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ For Lenze drive components ...

... only use permitted accessories.

... only use original manufacturer spare parts.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

10

EDSMF2192IB EN 3.1

Page 11

Device− and application−specific safety instructions

2.2 Device− and application−specific safety instructions

ƒ During operation, the communication module must be securely connected to the

standard device.

ƒ With external voltage supply, always use a separate power supply unit, safely

separated in accordance with EN 61800−5−1 in every control cabinet ("SELV" /

"PELV").

ƒ Only use cables that comply with the given specifications ( 25).

Documentation for the standard device, control system, system/machine

All the other measures prescribed in this documentation must also be

implemented. Observe the safety instructions and application notes stated in

this manual.

2.3 Residual hazards

Safety instructions

2

Protection of persons

ƒ If the controllers are used on a phase earthed mains with a rated mains voltage

³ 400 V, protection against accidental contact is not ensured without implementing

external measures. (See chapter "4.2", 17)

Device protection

ƒ The module contains electronic components that can be damaged or destroyed by

electrostatic discharge.

EDSMF2192IB EN 3.1

11

Page 12

3

Product description

Application as directed

3 Product description

3.1 Application as directed

The communication module ...

ƒ is a device intended for use in industrial power systems.

ƒ is only to be used in EtherCAT networks.

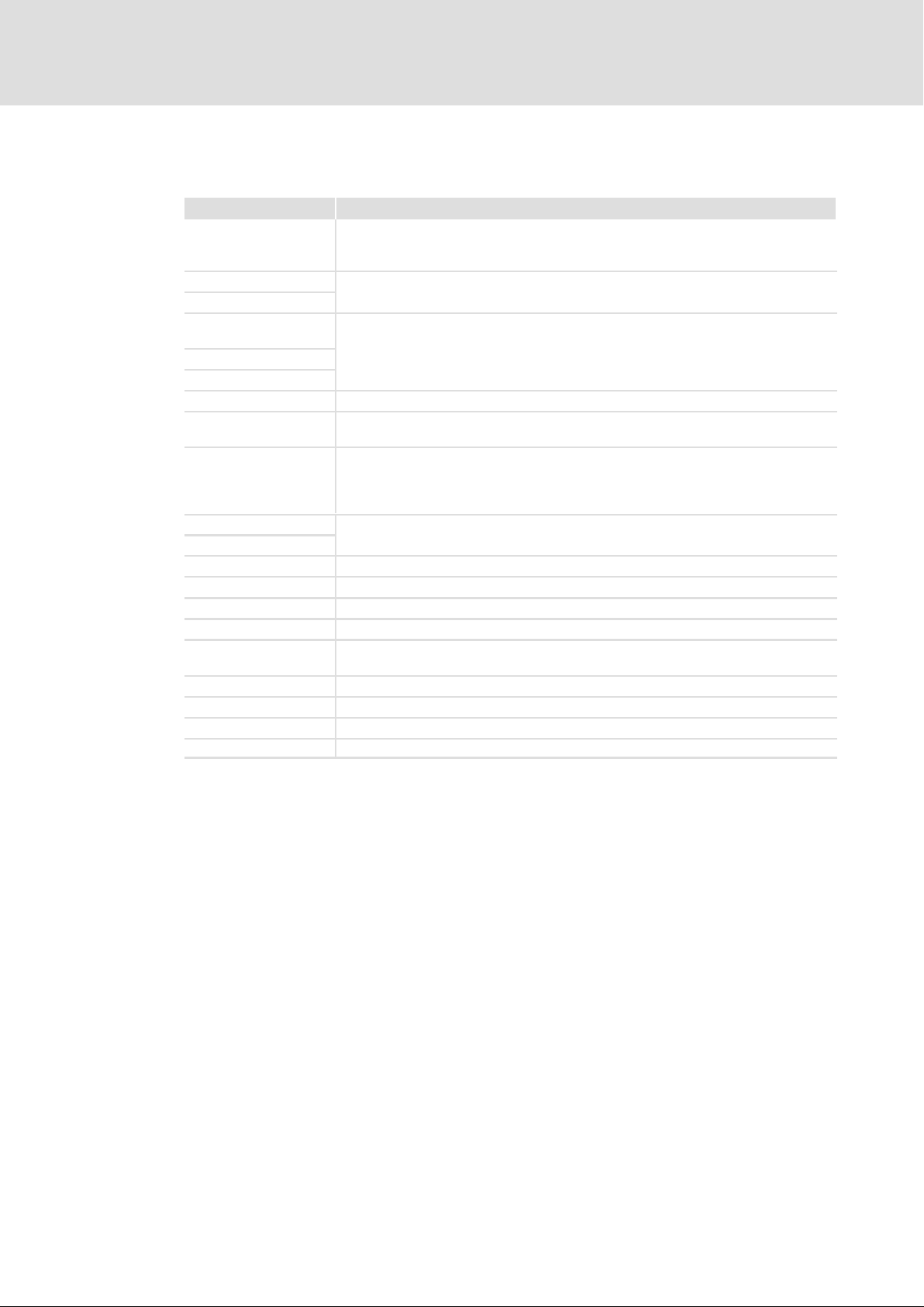

ƒ can be used in connection with the following standard devices (nameplate data):

Device type Design

82EVxxxxxBxxxXX ³ Vx ³ 1x 8200 vector

82CVxxxxxBxxxXX ³ Vx ³ 1x 8200 vector, cold plate

82DVxxxKxBxxxXX ³ Vx ³ 1x 8200 vector, thermally

EPL 10200 E ³ 1x ³ 1x Drive PLC

33.93xx xE. ³ 2x ³ 1x Vxxx 9321 − 9332 vector

33.938X xE. ³ 1x ³ 0x 9381 − 9383 vector

33.93xx xC. ³ 2x ³ 1x Vxxx 9321 − 9332, vector with cold

33.93xx EI / ET ³ 2x ³ 1x Vxxx 9300 Servo PLC

33.93xx CI / CT ³ 2x ³ 1x Vxxx 9300 Servo PLC, cold plate

ECSxSxxxx4xxxxXX ³ 1A ³ 7.0 ECSxS "Speed & Torque"

ECSxPxxxx4xxxxXX ³ 1A ³ 7.0 ECSxP "Posi & Shaft"

ECSxMxxxx4xxxxXX ³ 1A ³ 7.0 ECSxM "Motion"

ECSxAxxxx4xxxxXX ³ 1A ³ 7.0 ECSxA "Application"

ECSxExxxx4xxxxXX ³ VA ³ 5.0 ECSxE power supply module

1) Operating system software versions of the controllers

Version

HW SW

Variant Explanation

1)

separated

plate design

Any other use shall be deemed inappropriate!

12

EDSMF2192IB EN 3.1

Page 13

3.2 Identification

L

Type

Id.-No.

Prod.-No.

Product description

Identification

3

E82AF000P0B201XX

Type code 33.2192IB VA 1.0

Device series

Hardware version

Software version

2192ECAT013

EDSMF2192IB EN 3.1

13

Page 14

3

Product description

Product features

3.3 Product features

ƒ Interface module for the EtherCAT communication system to the AIF slots of the

Lenze device series 8200 vector, 9300, and ECS ( 12)

ƒ Support of the EtherCAT slave functionality

ƒ External 24V supply for maintaining the EtherCAT network if the standard device

fails

ƒ Support of the "Distributed clocks" (DC) functionality for synchronisation via the

fieldbus

ƒ PDO transfer with CoE (CANopen over EtherCAT)

ƒ Access to all Lenze parameters with CoE (CANopen over EtherCAT)

Front panel connector elements

ƒ Two sockets (RJ45) for the connection to EtherCAT

ƒ 2−pin plug connector for the external supply of the communication module

ƒ 3−pin plug connector (electrically isolated) for the synchronisation of the standard

device

Front panel LED status displays

ƒ Voltage supply of the communication module

ƒ Connection from the communication module to the EtherCAT bus system

ƒ Connection from the communication module to the standard device

ƒ Bus state according to EtherCAT specification

14

EDSMF2192IB EN 3.1

Page 15

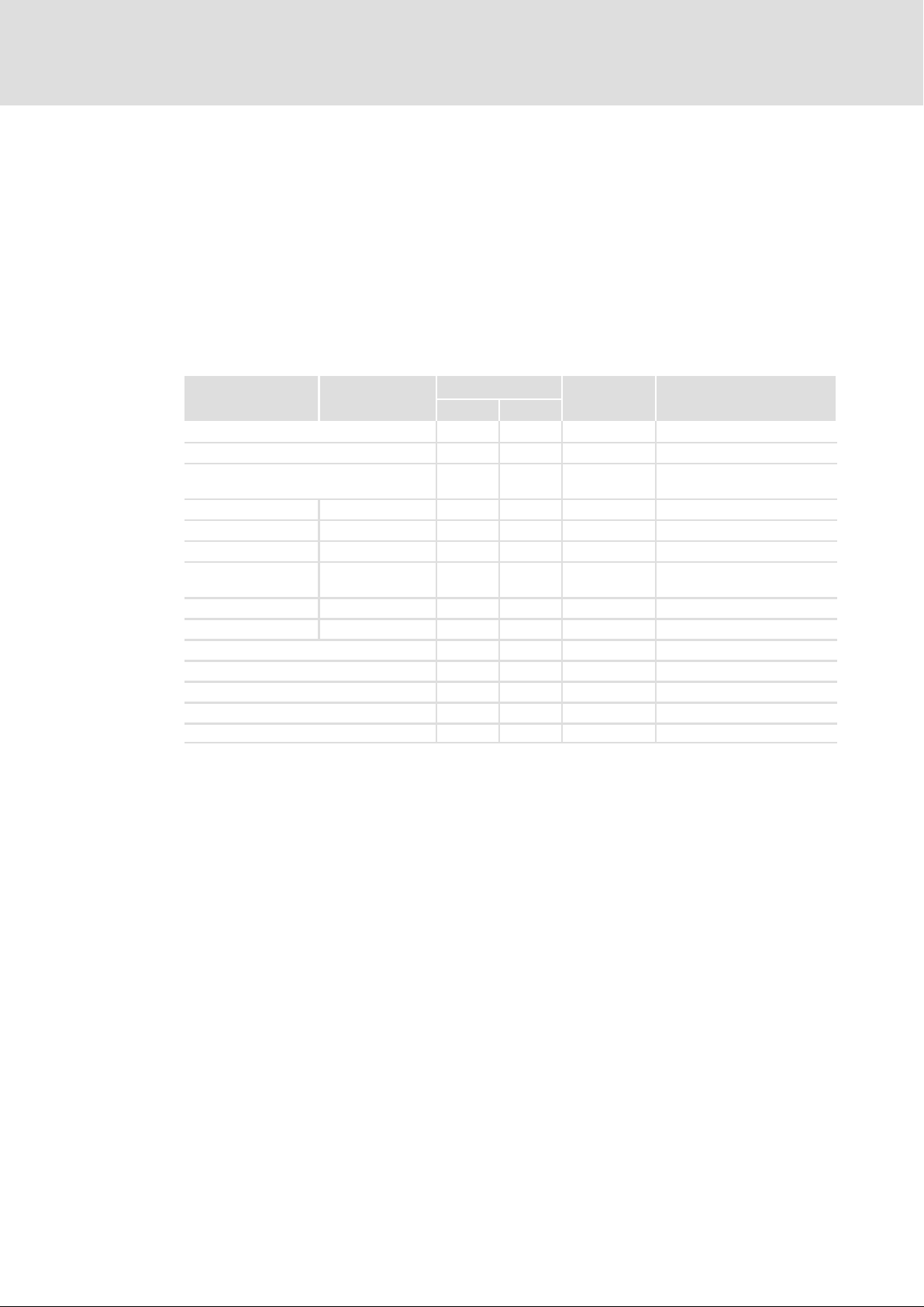

3.4 Connections and interfaces

Fig. 3−1 EMF2192IB (EtherCAT) communication module

Legend for the illustration

Pos. Description

...

LED status displays

53

Connection to the external voltage supply (24 V) of the communication module

l Plug connector with screw connection, 2−pin

27

Connection to EtherCAT synchronisation

l Plug connector with screw connection, 3−pin

29

EtherCAT output (OUT)

l RJ45 socket in accordance with IEC 60603−7

24

EtherCAT input (IN)

l RJ45 socket in accordance with IEC 60603−7

24

Nameplate

13

Product description

Connections and interfaces

3

2192ECAT001B

EDSMF2192IB EN 3.1

15

Page 16

4

Technical data

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

Area Values

Order designation EMF2192IB

Communication profile EtherCAT

Supported device profile and

mailbox protocol

Communication medium S/FTP (Screened Foiled Twisted Pair, ISO/IEC 11801 or EN 50173), CAT 5e

Interface for communication RJ45, standard Ethernet (acc. to IEEE 802.3), 100Base−TX (Fast Ethernet)

Network topology Line, switch

Node type EtherCAT slave

Number of nodes max. 65535 (in the entire network)

Cable length between two

EtherCAT nodes

Cycle times 1 ms or an integer multiple of 1 ms,

Vendor−ID 0x3B

Product−ID depending on the standard device used

Revision−ID depending on the main software version of the EtherCAT module

Baud rate 100 Mbps, full duplex

Voltage supply

Conformities, approvals

CANopen over EtherCAT (CoE)

max. 100 m (typical)

max. 15 ms when "Distributed clocks" (DC) are used

External supply via separate external power supply unit

l Terminal "+": U = 24VDC(20.4 V − 0%... 28.8 V+ 0%)

l Terminal "−": Reference potential for external voltage supply

CE

I = 140 mA

Documentation for Lenze series of devices 8200 vector, 9300 and ECS

Here you can find the ambient conditions and the electromagnetic

compatibility (EMC) specifications applying to the communication module.

16

EDSMF2192IB EN 3.1

Page 17

4.2 Protective insulation

Danger!

Dangerous electrical voltage

If Lenze controllers are used on a phase earthed mains with a rated mains

voltage ³ 400 V, protection against accidental contact is not ensured without

implementing external measures.

Possible consequences:

ƒ Death or serious injury

Protective measures:

ƒ If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged device modules, ...

– a double isolating distance must exist.

– the components to be connected must be provided with the second

isolating distance.

Technical data

Protective insulation

4

Insulation between bus and ... Type of insulation

(in accordance with EN 61800−5−1)

l Earth reference / PE Functional insulation

l With external supply Functional insulation

l Power stage

– 8200 vector Reinforced insulation

– 9300 servo inverter Reinforced insulation

– 93xx servo position controller Reinforced insulation

– 93xx servo register control Reinforced insulation

– 93xx servo cam profiler Reinforced insulation

– 9300 vector / Servo PLC Reinforced insulation

– ECS devices Reinforced insulation

l Control terminals

– 8200 vector Functional insulation

– 9300 servo inverter Basic insulation

– 93xx servo position controller Basic insulation

– 93xx servo register control Basic insulation

– 93xx servo cam profiler Basic insulation

– 9300 vector / Servo PLC Basic insulation

– ECS devices Basic insulation

EDSMF2192IB EN 3.1

17

Page 18

4

Technical data

Communication time

4.3 Communication time

Processing times in the controller

The parameter data and process data are independent of each other.

Processing times Parameter data Process data

Processing time within the

controller

Additional times outside

the controller

l Approx. 30 ms + a tolerance of 20 ms

for parameters within the controller

l In the case of some codes the

processing time can be longer. (See

documentation for the controller)

l In the case of ECS devices the

processing time depends on the

application loaded (duration of the

system task).

l Communication transmission times

l Communication processing times of the transmitting node

l Time for 8200 vector: approx. 3 ms +

tolerance of 2 ms

l Time for devices of the 9300 series:

approx. 2 ms + tolerance of 1 ms

(depending on the basic cycle time in

each case)

l Time for ECS devices:

– In synchronous operation a

minimum of 1 ms (AIF

communication) or according to

the fastest task

– Otherwise 1 ms + task cycle time

l A synchronisation depends on the

controller used ( 61) and has to be

configured accordingly ( 33 et

seqq.).

18

EDSMF2192IB EN 3.1

Page 19

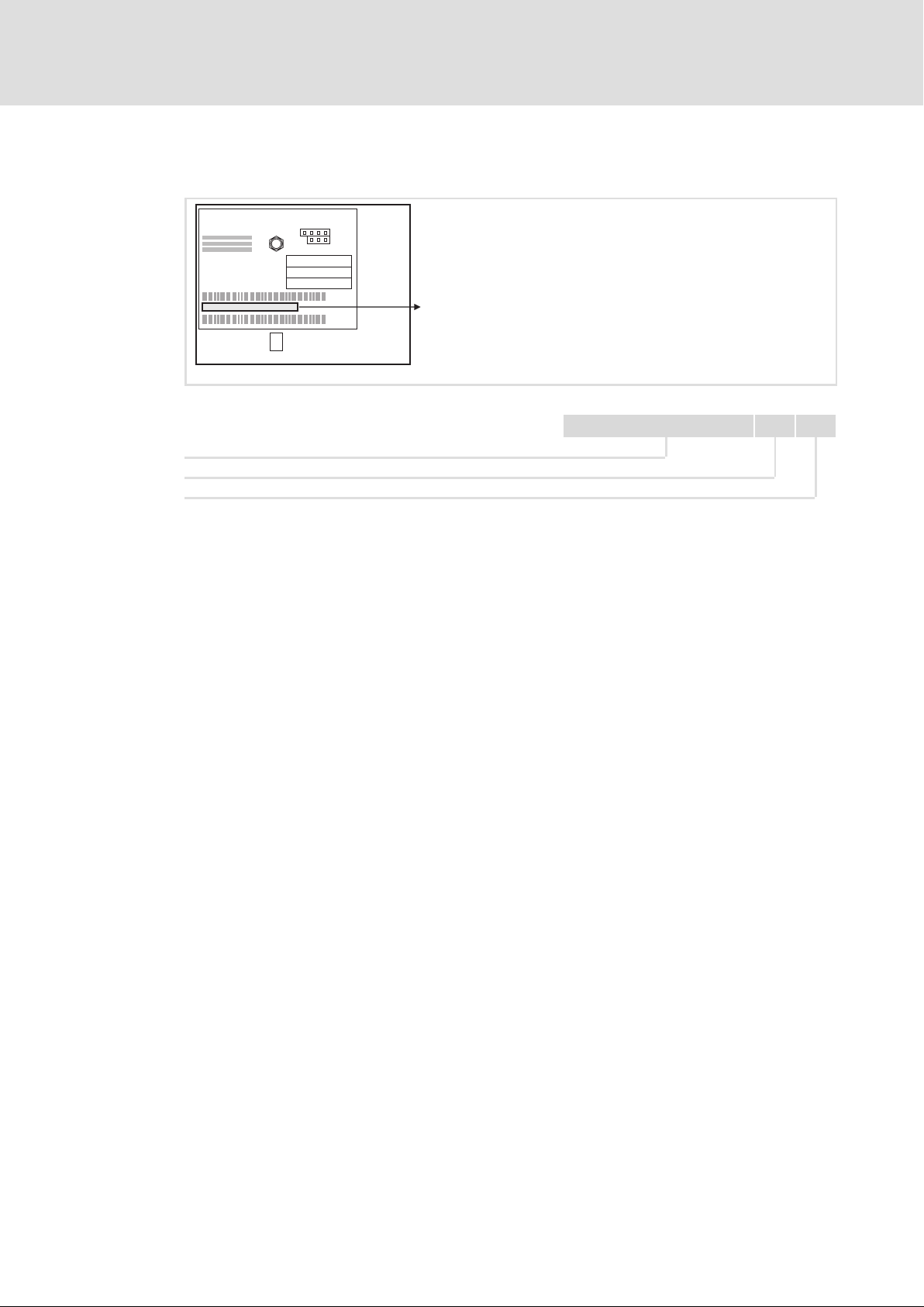

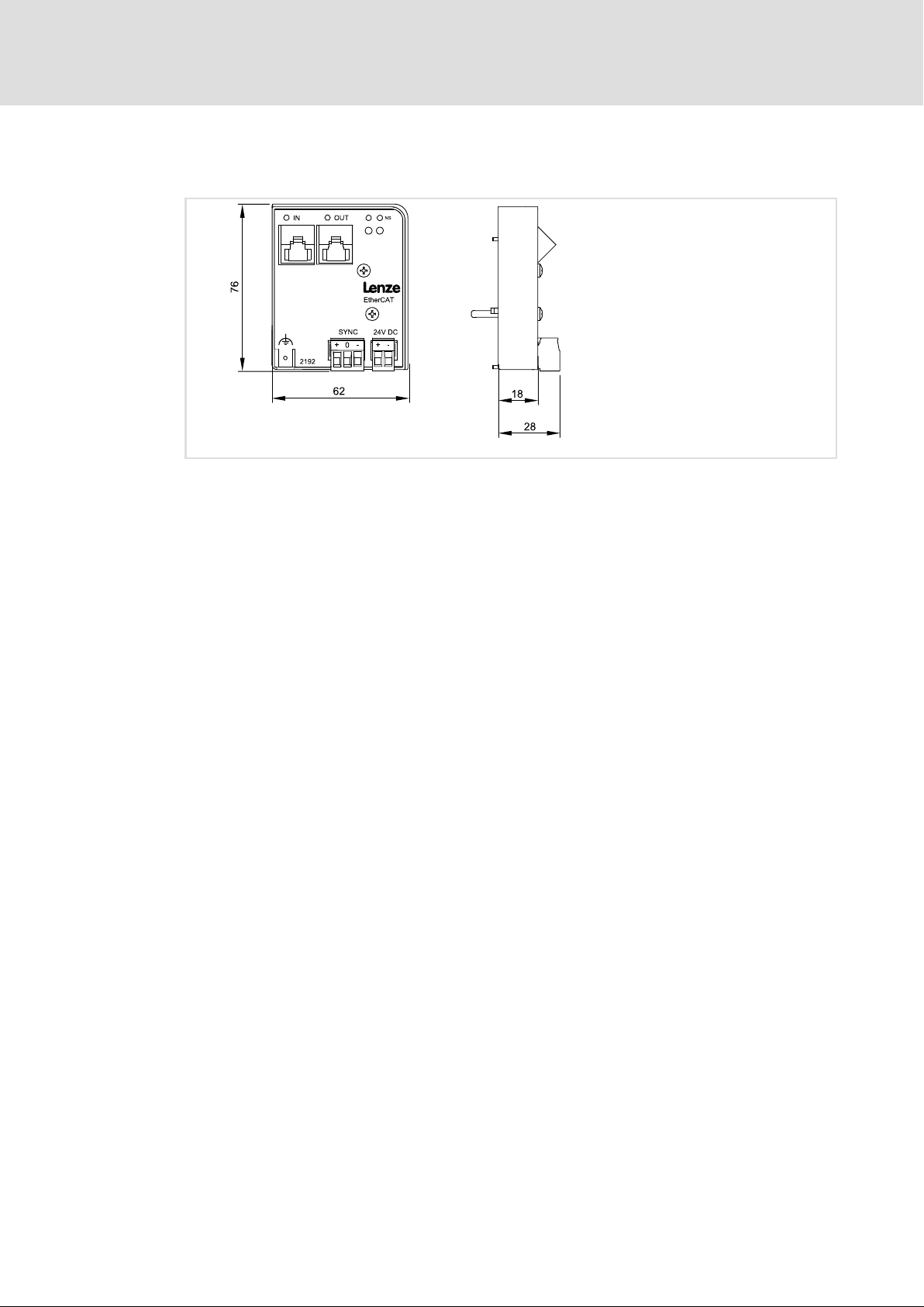

4.4 Dimensions

All dimensions in mm

Technical data

Dimensions

4

2192ECAT001B

EDSMF2192IB EN 3.1

19

Page 20

Installation5

5 Installation

Danger!

Inappropriate handling of the communication module and the standard device

can cause serious personal injury and material damage.

Observe the safety instructions and residual hazards described in the

documentation for the standard device.

Stop!

The device contains components that can be destroyed by electrostatic

discharge!

Before working on the device, the personnel must ensure that they are free of

electrostatic charge by using appropriate measures.

20

EDSMF2192IB EN 3.1

Page 21

5.1 Mechanical installation

Fig. 5−1 Attaching the communication module

ƒ Plug the communication module onto the standard device (here: 8200 vector).

ƒ Tighten the communication module to the standard device using the fixing screw in

order to ensure a good PE connection.

Installation

Mechanical installation

5

2102LEC014

Note!

For the internal supply of the communication module by the 8200 vector

frequency inverter the jumper has to be adjusted within the interface opening

(see illustration above).

Observe the notes ( 27).

EDSMF2192IB EN 3.1

21

Page 22

5

5.2 Electrical installation

5.2.1 Wiring according to EMC (CE−typical drive system)

Installation

Electrical installation

Wiring according to EMC (CE−typical drive system)

For wiring according to EMC requirements observe the following points:

Note!

ƒ Separate control cables/data lines from motor cables.

ƒ Connect the shields of control cables/data lines at both ends in the case of

digital signals.

ƒ Use an equalizing conductor with a cross−section of at least 16mm

(reference:PE) to avoid potential differences between the bus nodes.

ƒ Observe the other notes concerning EMC−compliant wiring given in the

documentation for the standard device.

Wiring procedure

2

1. Comply with bus topology, thus do not use stubs.

2. Observe notes and wiring instructions in the documents for the control system.

3. Only use cables that comply with the given specifications ( 25).

4. Observe notes for the voltage supply of the module ( 27).

22

EDSMF2192IB EN 3.1

Page 23

Installation

Electrical installation

Network topology

5

5.2.2 Network topology

An EtherCAT frame is transmitted by a pair of conductors from the master to the slaves. The

frame is forwarded from slave to slave until it has passed through all devices. Finally the

last slave sends the frame back to the master by a second pair of conductors. Thus,

EtherCAT always creates a logic ring topology, irrespective of the topology selected.

Line topology

Fig. 5−2 Line topology

M Master

SD Slave Device

ƒ The devices are interconnected successively.

ƒ For correct operation it is necessary that the Ethernet sockets IN and OUT are

assigned correctly.

Plug the incoming cable into the IN socket and the ongoing cable into the OUT

socket.

M

IN

SD

INOUT

SD

INOUT

SD

E94AYCET006

ƒ The direction of data transmission is from the master to the slaves.

Tip!

The termination of the last node is effected automatically by the slave.

Switch topology

M

M

IN IN

SD

Fig. 5−3 Switch topology

M Master

S Switch

SD Slave Device

The wiring can also be carried out in a star structure via an appropriate switch. For this,

observe the additional runtimes.

S

SD

E94AYCET007

EDSMF2192IB EN 3.1

23

Page 24

5

Installation

Electrical installation

EtherCAT connection

5.2.3 EtherCAT connection

You can use a standard Ethernet patch cable for connection to the communication module

(see "Ethernet cable specifications" ( 25)).

Note!

Plug/remove the Ethernet cable plug vertically into/from the socket to make

sure that the RJ45 socket will not be damaged.

Pin assignment

RJ45 socket PIN Signal

E94AYCXX004C

1 Tx +

2 Tx −

3 Rx +

4 −

5 −

6 Rx −

7 −

8 −

Tip!

The EtherCAT interfaces are equipped with an auto−MDIX function. This

function adapts the polarity of the RJ45 interfaces such that independently of

the polarity of the opposite EtherCAT interface and the cable type used

(standard patch cable or crossover cable) a connection is established.

24

EDSMF2192IB EN 3.1

Page 25

Installation

Electrical installation

Specification of the Ethernet cable

5

5.2.4 Specification of the Ethernet cable

Note!

Only use cables complying with the below specifications.

Specification of the Ethernet cable

Ethernet standard Standard Ethernet (in accordance with IEEE 802.3), 100Base−TX (Fast

Cable type S/FTP (Screened Foiled Twisted Pair, ISO/IEC 11801 or EN 50173), CAT 5e

Damping 23.2 dB (at 100 MHz and per 100 m)

Crosstalk damping 24 dB (at 100 MHz and per 100 m)

Return loss 10 dB (per 100 m)

Surge impedance 100 W

Design of the Ethernet cable

Ethernet)

Fig. 5−4 Design of the Ethernet cable (S/FTP, CAT 5e)

A Cable insulation

B Braid

C Foil shielding of the core pairs

TP1 ... TP4 Twisted core pairs 1 ... 4

E94YCEP016

EDSMF2192IB EN 3.1

25

Page 26

5

Installation

Electrical installation

Specification of the Ethernet cable

Colour code of Ethernet cable

Note!

Wiring and colour code are standardised in EIA/TIA 568A/568B.

You can use 4−pin Ethernet cables in accordance with the industrial standard.

The cable type only connects the assigned pins 1, 2, 3 and 6 with each other.

Fig. 5−5 Ethernet plug in accordance with EIA/TIA 568A/568B

Pair Pin Signal EIA/TIA 568A EIA/TIA 568B

3

2 3 Rx + White/orange White/green

1

2 6 Rx − Orange Green

4

1

2 Tx − Green Orange

4 Not assigned Blue Blue

5 Not assigned White/blue Blue/white

7 Not assigned White/brown White/brown

8 Not assigned Brown Brown

Tx + White/green White/orange

E94YCEI004A

26

EDSMF2192IB EN 3.1

Page 27

Installation

Electrical installation

Voltage supply

5

5.2.5 Voltage supply

Internal voltage supply

Note!

Internal voltage supply has been selected in the case of standard devices with

an extended AIF interface opening (e.g. front of 8200 vector). The area shown

on a grey background in the graphic marks the jumper position.

ƒ By default, this is not supplied internally in the standard device.

ƒ For internal voltage supply place the jumper on the position indicated

below.

In the case of all other device series (9300, ECS), voltage is always supplied

from the standard device.

(Only external voltage supply possible.)

Lenze setting

Internal voltage supply

External voltage supply

Note!

Always use a separate power supply unit in every control cabinet and safely

separate it according to EN 61800−5−1 ("SELV"/"PELV") in the case of external

voltage supply and larger distances between the control cabinets.

The external voltage supply of the communication module ...

ƒ is required if communication via the fieldbus is to be continued when the supply of

the device fails.

ƒ is provided via the 2−pin terminal strip with screw−type connection (24 V DC):

Terminal Description

+ External voltage supply

U = 24VDC(20.4 V − 0%... 28.8 V +0%)

I = 85 mA

− Reference potential for external voltage supply

ƒ The parameters of a standard device disconnected from the mains cannot be

accessed.

EDSMF2192IB EN 3.1

27

Page 28

5

Installation

Electrical installation

Voltage supply

Terminal data

Area Values

Electrical connection Plug connector with screw connection

Possible connections

Tightening torque 0.5 ... 0.6 Nm (4.4 ... 5.3 lb−in)

Stripping length 6 mm

rigid:

flexible:

2

1.5 mm

without wire end ferrule

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

28

EDSMF2192IB EN 3.1

Page 29

Installation

Electrical installation

Synchronisation of the standard device

5

5.2.6 Synchronisation of the standard device

The synchronisation of the standard device via the EtherCAT fieldbus ˘ if it is supported ˘

can be carried out via the 3−pin plug connector with screw connection (sync).

Note!

ECS servo system

ƒ For the ECS axis modules, a synchronisation with operating system software

version ³ 8.3 is possible.

ƒ For the ECS power supply module a synchronisation is not supported.

Wire ...

ƒ terminal "0" to the corresponding sync input of the standard device (see

documentation of the standard device).

ƒ the sync supply to the 24V supply of the communication module or the standard

device.

EtherCAT-

Sync

W

Opto

0

2192ECAT002

Terminal Description

+ External sync supply (SELV/PELV)

U = 24VDC(20.4 V − 0%... 28.8 V +0%)

0 Sync output

(t = 150 ms, I

− Reference potential for external sync supply

= 10 mA at 24 V)

max

On 61 you’ll find an overview of the Lenze standard devices which support a

synchronisation.

EDSMF2192IB EN 3.1

29

Page 30

6

Commissioning

Before switching on

6 Commissioning

During commissioning, system−dependent data as e.g. motor parameters, operating

parameters, responses and parameters for fieldbus communication are selected for the

controller.

In Lenze devices, this is done via codes. The codes are stored in numerically ascending order

in the Lenze controllers and in the plugged−in communication/function modules.

In addition to these configuration codes, there are codes for diagnosing and monitoring

the bus devices.

6.1 Before switching on

Stop!

Before switching on the standard device with the communication module for

the first time, check the entire wiring for completeness, short circuit and earth

fault.

30

EDSMF2192IB EN 3.1

Page 31

6.2 Configuring the host system (master)

For communication with the communication module, first the host system (master) must

be configured.

For configuring EtherCAT networks. a configuration software is always required for the

host system (master), e.g.:

ƒ Lenze »PLC Designer«

ƒ »TwinCAT« by the company Beckhoff

These are software systems for programming control programs, EtherCAT configuration,

real−time execution and diagnostics.

ƒ The basic parameters of the communication module are stored in the internal

configuration memory and can be used by the master for the node detection.

ƒ During the search for nodes (fieldbus scan) the corresponding device descriptions of

the Lenze device family are used.

Commissioning

Configuring the host system (master)

Installing device description files

6

6.2.1 Installing device description files

The current XML device description file Lenze_AIF−Vxzz−ddmmyy.xmlrequired for the

EMF2192IB (EtherCAT) communication module can be found on the in the download area

under:

http://www.Lenze.com

Wildcard in the file name "Lenze_AIF−Vxzz−ddmmyy.xml"

x Major version of the XML device description file used

zz Minor version of the XML device description file used

dd Day

mm Month

yy Year

6.2.2 Automatic device detection

ƒ For an error−free integration of the EtherCAT slaves into a master configuration it is

required to select the correct Lenze device in the EtherCAT configuration software.

ƒ An EtherCAT node is clearly identified via the configuration software by the product

code (identical with the CoE object I−1018.2), the manufacturer’s identification mark

(0x3B) and the main software version of the communication module.

EDSMF2192IB EN 3.1

ƒ In order that the configuration software selects the configuration from the device

description file specific to the Ether−CAT nodes, the product code is automatically set

in the identity object and updated after switch−on or each application download.

ƒ During the initialisation, the product code is transmitted to the EtherCAT master.

With this identification, the master can adopt the corresponding settings from the

device description.

31

Page 32

6

6.2.3 Configuring process data

6.2.4 Defining the cycle time

6.2.5 Address allocation

Commissioning

Configuring the host system (master)

Configuring process data

ƒ The process data configuration is defined during the initialisation phase of the

master (PDO mapping).

ƒ The process data configuration predefined application−specifically in the device

description files and can be adapted by the user if required.

The process data objects (PDO) are transmitted cyclically between the EtherCAT master

and the slaves (controllers). The cycle time is set using the EtherCAT configuration

software.

Usually, the EtherCAT nodes are addressed via a permanent 16−bit address defined by the

EtherCAT master. At the start, this address is assigned to each node by the master

depending on the physical sequence in the EtherCAT network. The address is not saved and

gets lost after the device is switched off.

Additionally there is the possibility of allocating a fixed station alias address

(chapter 6.2.6).

6.2.6 Specifying the station alias

By means of the station alias, a permanent address is assigned to the EtherCAT slave.

ƒ For this, carry out the setting via the 0x58C5 object or code C1850 > 0.

ƒ In addition, specify the use of the fixed addressing on the master.

Note!

ƒ The station alias must only be set if the node is a member of a "hot connect"

group.

ƒ The station alias must be non−ambiguous and may only be assigned once in

the EtherCAT network.

ƒ Use the same station alias in the EtherCAT master and the slave.

32

EDSMF2192IB EN 3.1

Page 33

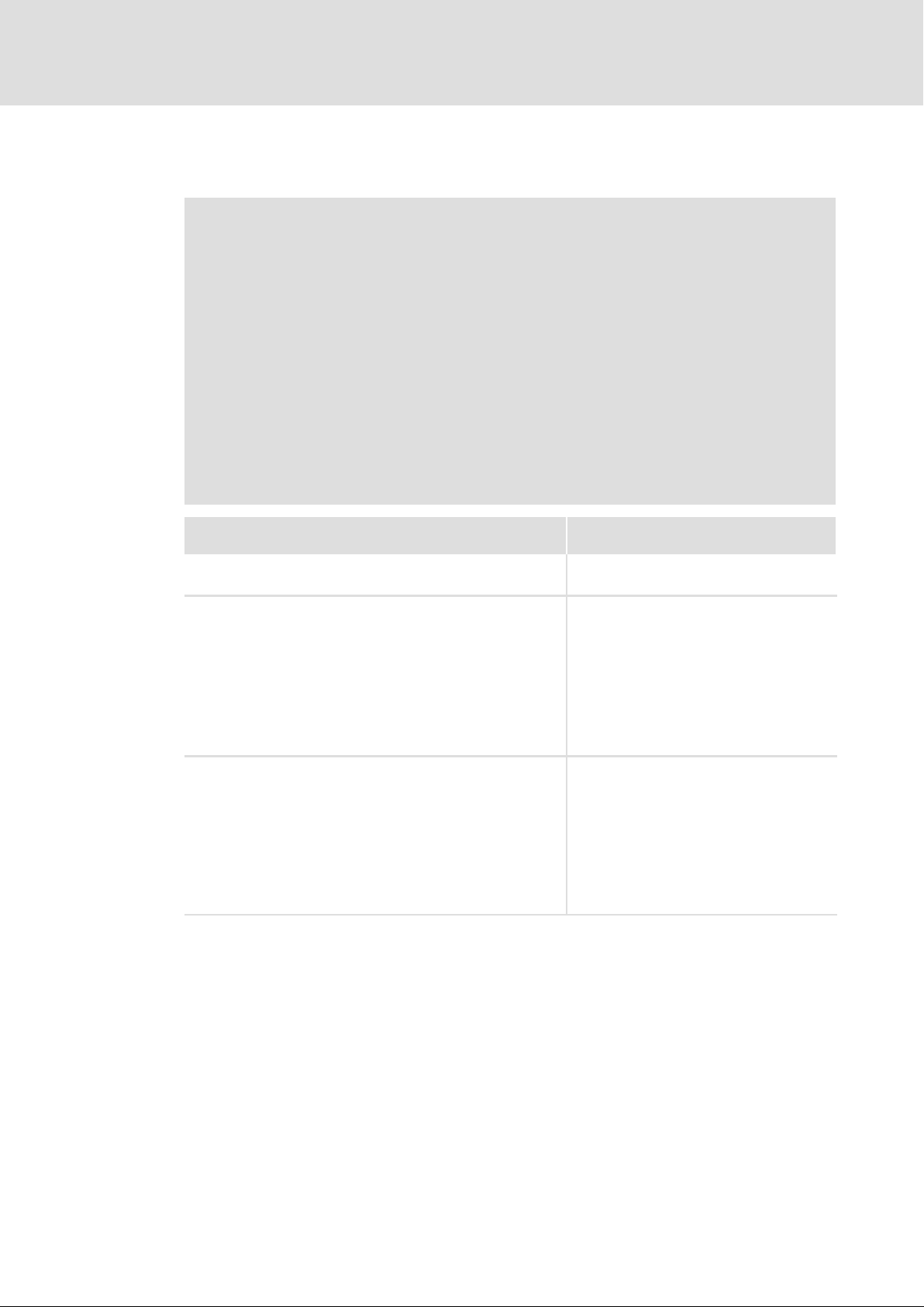

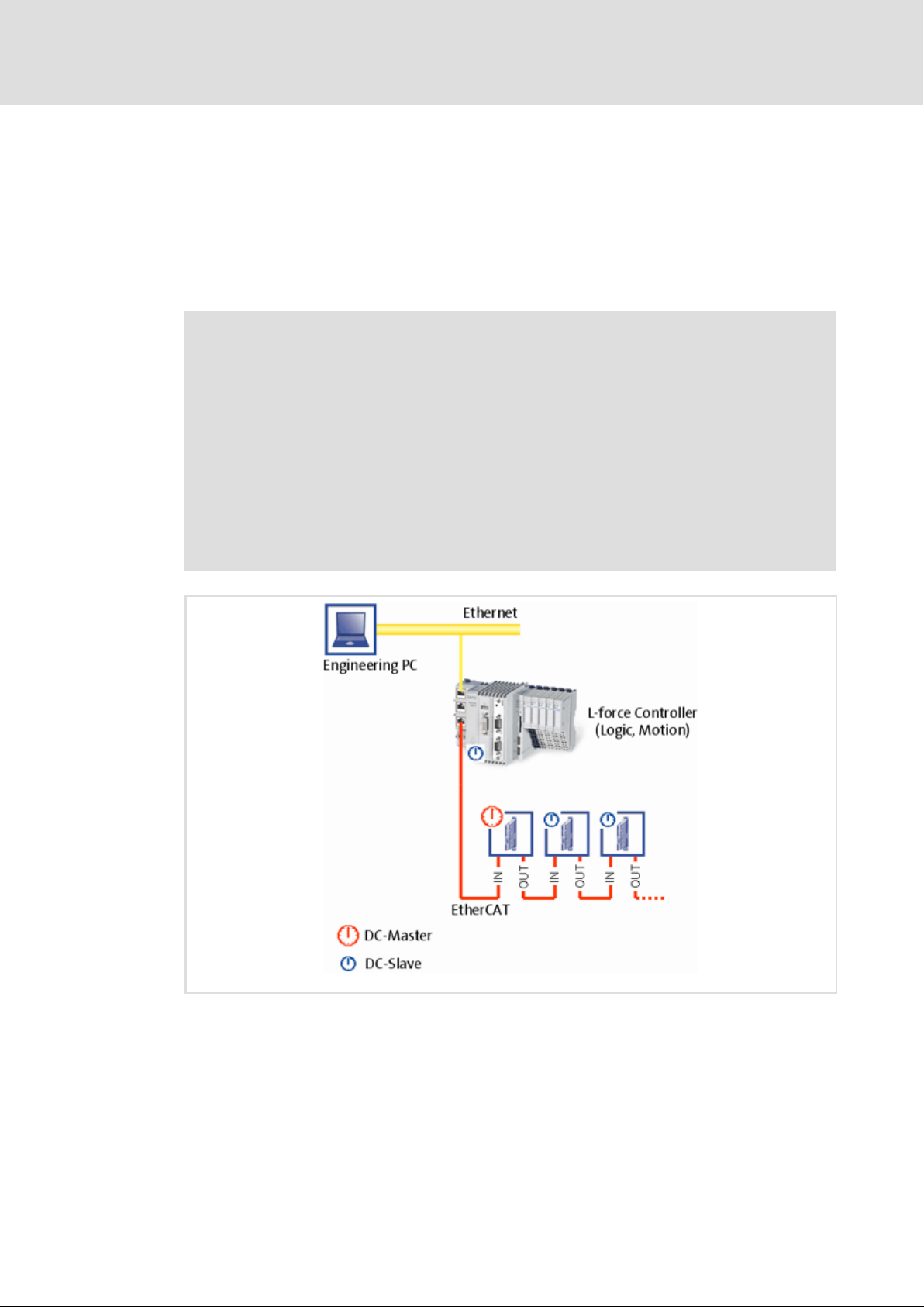

Synchronisation with "Distributed clocks" (DC)

6.3 Synchronisation with "Distributed clocks" (DC)

The "Distributed clocks" (DC) functionality enables an exact time adjustment for

applications where several auxiliary axes carry out a coordinated movement at the same

time. The data is accepted synchronously with the PLC program. With the DC

synchronisation, all slaves are synchronised with a reference clock, the so−called "DC

master".

Note!

ƒ Motion applications always require DC synchronisation.

ƒ DC synchronisation can also be used for logic applications.

ƒ Some slaves do not support the DC functionality.

– In order to be able to use the DC functionality, the first slave connected to

the EtherCAT master (e.g. L−force Controller) must be DC master−capable.

– In the arrangement of the slaves following then, DC−capable and

non−DC−capable devices can be mixed.

ƒ The first EtherCAT node after the EtherCAT master must be the DC master

which provides the exact time to the other EtherCAT nodes (incl. EtherCAT

master).

Commissioning

6

2192ECAT020

Fig. 6−1 Distributed clocks (DC)

The settings for DC synchronisation are made using the EtherCAT configuration software.

( 31).

EDSMF2192IB EN 3.1

33

Page 34

6

Commissioning

Synchronisation with "Distributed clocks" (DC)

Preparation / installation

" EtherCAT control technology" communication manual

Here you’ll find detailed information on the EtherCAT configuration and

commissioning of Lenze devices in the EtherCAT network.

6.3.1 Preparation / installation

Note!

Lenze devices without an external sync terminal input do not support DC

synchronisation.

Connect the sync terminal block of the EtherCAT communication module to the voltage

supply and the corresponding input terminal of the standard device (see 29 and the

documentation for the standard device).

6.3.2 DC configuration in the master

ƒ The use of the DC synchronisation is deactivated in the device description ( 31) by

default.

ƒ Parameterise the DC synchronisation in the EtherCAT configuration software.

ƒ Specify the synchronisation cycle time in the master. It significantly complies with

the processing time of the master and slaves.

6.3.3 DC configuration in the standard device (slave)

ƒ In order to be able to use the DC synchronisation via EtherCAT in the standard

device, select the "AIF" sync source with standard device code C1120.

ƒ Set the cycle time of the standard device in milliseconds with code C1121.

ƒ Depending on the standard device, it may be required to also select a corresponding

operating mode and control interface for EtherCAT communication via code.

Information on this can be found in the documentation for the standard device.

34

EDSMF2192IB EN 3.1

Page 35

Synchronisation with "Distributed clocks" (DC)

Behaviour of the Lenze EtherCAT nodes during start−up

6.3.4 Behaviour of the Lenze EtherCAT nodes during start−up

If the DC synchronisation is used, the communication module first changes to the

"Operational" state if the standard device has adapted its phase position to the DC signal.

This process can take several seconds.

Note!

ƒ If the communication module does not change to "Operational", there

possibly is an error in the configuration or the EtherCAT wiring.

ƒ The communication module compares the cycle time specified by the

EtherCAT master to the cycle time of the standard device set in C1121. The

synchronisation cycle time in the master has to be equal to the cycle time of

the standard device.

ƒ Moreover it is checked whether the selection of the sync source in the

standard device code C01120 is correct.

ƒ Further information can be gathered from the master as status information

or an emergency message.

Commissioning

6

EDSMF2192IB EN 3.1

35

Page 36

6

Commissioning

Initial switch−on

6.4 Initial switch−on

Switch on the drive and check its readiness for operation by means of the diagnostic LEDs

on the front of the communication module.

ƒ Red diagnostic LEDs must not be lit.

ƒ The following signalling should show:

LED

Pos. Colour Status

green

green on

green

blinking

on

The EtherCAT state machine controls the LED.

blinking

on

Description

l The EtherCAT connection has been established.

l Data communication of the EtherCAT connection is active.

The communication module is supplied with voltage and is connected to the

standard device.

"Pre−operational" or "Safe−operational" state active.

The communication module is in the "Operational" status.

36

EDSMF2192IB EN 3.1

Page 37

7 Data transfer

With EtherCAT, data is transmitted in "EtherCAT frames". The EtherCAT nodes only take

the data determined for them while the EtherCAT frame passes through the device.

Output data are entered in the frame the same way during the passage. Read and write

accesses are only executed in a small section of the total EtherCAT frame, the datagrams.

Thus, a frame does not need to be received completely before being processed. Processing

starts as early as possible.

EtherCAT transmits process data, parameter data, configuration data and diagnostic data

between the host system (master) and the controllers connected to the fieldbus (slaves).

The data is transmitted via corresponding communication channels depending on their

time−critical behaviour

(see chapter "Process data transfer" ( 41) and chapter "Parameter data

transfer" ( 42).

Data transfer 7

EDSMF2192IB EN 3.1

37

Page 38

7

Data transfer

EtherCAT frame structure

7.1 EtherCAT frame structure

EtherCAT frames have the following structure:

Ethernet header Ethernet data FCS

48 bits 48 bits 16 bits 11 bits 1 bit 4 bits 48 ... 1498 bytes 32 bits

Destination Source EtherType

Ethernet header

The Ethernet header contains the following information:

ƒ Target address of the EtherCAT frame (destination)

ƒ Source address of the EtherCAT frame (source)

ƒ Type of EtherCAT frame (EtherType = 0x88A4)

Ethernet data

Frame header

Length Reserved Type

Datagrams

The Ethernet data contain the following information:

ƒ Length of the datagrams within the EtherCAT frame (length)

ƒ A reserved bit (reserved)

ƒ Type of datagrams within the EtherCAT frames (type)

ƒ EtherCAT datagrams (datagrams)

FCS

ƒ Checksum of the EtherCAT frame

38

EDSMF2192IB EN 3.1

Page 39

7.2 EtherCAT datagrams

EtherCAT datagrams have the following structure:

Data transfer

EtherCAT datagrams

7

EtherCAT

Command header

10 bytes Max. 1486 bytes 2 bytes

EtherCAT command header

The EtherCAT command header contains the following information:

Command to be executed

Addressing information

Length of the data area (Data)

Interrupt field

Data

The data area contains the data of the command to be executed.

WKC

The working counter is evaluated by the master for monitoring the execution of the

command.

Data WKC

EDSMF2192IB EN 3.1

39

Page 40

7

Data transfer

EtherCAT state machine

7.3 EtherCAT state machine

Before communication via EtherCAT is possible, the fieldbus passes through the EtherCAT

status machine during power−up. The following illustration shows the possible state

changes from an EtherCAT slave view:

Init

Pre-Operational

Safe-Operational

Operational

E94AYCET009

Fig. 7−1 EtherCAT state machine

Status Description

Init l Initialisation phase

l No SDO/PDO communication with the slaves

l The device detection is provided by a fieldbus scan.

Pre−operational l The fieldbus is active.

l The SDO communication (mailbox communication) is possible.

l No PDO communication

Safe−operational l The SDO communication (mailbox communication) is possible.

l PDO communication:

– The input data is transmitted to the master and evaluated.

– The output data is the "Safe" status. They will not be transmitted to the standard

device.

Operational l Normal operation:

– SDO communication

– PDO communication

– Fieldbus synchronisation successful (if used)

40

EDSMF2192IB EN 3.1

Page 41

8 Process data transfer

ƒ The process data are transmitted by means of "EtherCAT datagrams" ( 39) via the

CoE process data channel.

ƒ By means of the process data the controller is operated.

ƒ The transmission of process data is time−critical.

ƒ Process data are transmitted cyclically between the host system (master) and the

controllers (slaves) (permanent exchange of current input and output data).

ƒ The master can directly access the process data. In the PLC for instance, the data are

directly stored in the I/O area.

ƒ Process data are not stored in the controller.

ƒ Process data, for instance, are setpoints, actual values, control words and status

words.

Process data transfer 8

EDSMF2192IB EN 3.1

41

Page 42

9

Parameter data transfer

Connection establishment between master and slave

9 Parameter data transfer

Parameter data are transmitted via the fieldbus as SDOs (Service Data Objects). The SDO

services allow for the writing and reading access to the object directory.

ƒ Via the SDO channel, access to all implemented CoE objects ( 55) and Lenze codes

( 57) is enabled with the CoE protocol.

ƒ When a "CiA402" technology application is used in the controller, the access to all

implemented CANopen CiA402 objects is enabled.

ƒ The transmission of parameter data usually is not time−critical.

ƒ Parameter data for instance are operating parameters, diagnostic information,

motor data.

9.1 Connection establishment between master and slave

Basically a master can always request parameter requests from a slave if the slave is at

least in the "Pre−operational" state.

E94AYCET008

Fig. 9−1 Data communication via the SDO channel

42

EDSMF2192IB EN 3.1

Page 43

9.2 Reading and writing parameters

Parameters ...

ƒ are set, for instance, for one−time system settings or if materials are changed within

a machine.

ƒ are transmitted with a low priority.

In the case of Lenze controllers, the parameters to be changed are contained in codes or in

the case of the CANopen device profile "CiA402" as device profile objects.

Indexing of the Lenze codes

If they are accessed via a communication module, the codes of the controller are addressed

by the index.

The index for Lenze codes is settled in the manufacturer−specific range of the object

directory between 8192 (0x2000) and 24575 (0x5FFF).

The index number for a code results as follows:

Parameter data transfer

Reading and writing parameters

9

Conversion formula

Index (dec) Index (hex)

24575 − Lenze code 0x5FFF − (Lenze code)

hex

Example for C0001 (operating mode):

Index (dec) Index (hex)

24575 − 1 = 24574 0x5FFF − 0x0001 = 0x5FFE

Structure of a mailbox datagram

In a datagram, mailbox data are transferred within an EtherCAT frame. The data area of the

mailbox datagram has the following structure:

Mailbox

Header

6 bytes 2 bytes 1 byte 2 bytes 1 byte 4 bytes 1 ... n bytes

CoE

Header

SDO control

byte

Index Subindex

Data Data

EDSMF2192IB EN 3.1

43

Page 44

9

Parameter data transfer

Reading and writing parameters

Reading parameters (expedited upload)

9.2.1 Reading parameters (expedited upload)

1. The master transmits "Initiate Domain Upload Request".

2. The slave acknowledges the request with a positive response ("Initiate Domain

Upload Response").

In the event of an error the slave responds with "Abort Domain Transfer".

Note!

In the case of jobs for the controller, please make sure that you convert the

code into an index ( 43).

SDO Upload Request

Detailed breakdown of the data for an "SDO Upload Request":

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value / description

Length

Address WORD 2 bytes Station address of the source if an EtherCAT master is the instructing

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x02: SDO Request

Reserved

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is read.

Command specifier 3 bits (5 ... 7) 0x02: Upload Request

Index WORD 2 bytes Index of the object

Subindex BYTE 1 byte Subindex of the object

Reserved DWORD 4 bytes 0x00

WORD 2 bytes 0x0: Length of the mailbox service data

WORD

WORD

BYTE

party.

Station address of the target if an EtherCAT slave is the instructing

party.

6 bits (0 ... 5) 0x00: Reserved

...

0x03: Highest priority

9 bits (0 ... 8) 0x00

4 bits (0 ... 3) 0x00

0x01: The complete object is read.

0x00 or 0x01 if "complete access" = 0x01.

44

EDSMF2192IB EN 3.1

Page 45

Parameter data transfer

Reading and writing parameters

Reading parameters (expedited upload)

SDO Upload Expedited Response

An "SDO Upload Expedited Response" takes place if the data length of the parameter data

to be read amounts to up to 4 bytes.

Detailed breakdown of the data for an "SDO Upload Expedited Response":

9

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value / description

Length

Address WORD 2 bytes Station address of the source if an EtherCAT master is the instructing

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x03: SDO Response

Size indicator

Transfer type 1 bit (1) 0x01: Expedited transfer

Data set size 2 bits (2, 3) 0x00: 4 bytes data

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is read.

Command specifier 3 bits (5 ... 7) 0x02: Upload Response

Index WORD 2 bytes Index of the object

Subindex BYTE 1 byte Subindex of the object

Data DWORD 4 bytes Data of the object

WORD 2 bytes 0x0A: Length of the mailbox service data

party.

Station address of the target if an EtherCAT slave is the instructing

party.

WORD

WORD

BYTE

6 bits (0 ... 5) 0x00: Reserved

...

0x03: Highest priority

9 bits (0 ... 8) 0x00

1 bit (0) 0x01: Size of the data in "data set size"

0x01: 3 bytes data

0x02: 2 bytes data

0x03: 1 byte data

0x01: The complete object is read.

0x00 or 0x01 if "complete access" = 0x01.

EDSMF2192IB EN 3.1

45

Page 46

9

Parameter data transfer

Reading and writing parameters

Reading parameters (expedited upload)

SDO Upload Normal Response

An "SDO Upload Normal" takes place if the data length of the parameter data to be read

amounts to ³ 4 bytes.

Detailed breakdown of the data for an "SDO Upload Normal Response":

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value [hex] / description

Length

Address WORD 2 bytes Station address of the source if an EtherCAT master is the instructing

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x03: SDO Response

Size indicator

Transfer type 1 bit (1) 0x00: Normal transfer

Data set size 2 bits (2, 3) 0x00

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is read.

Command specifier 3 bits (5 ... 7) 0x02: Upload Response

Index WORD 2 bytes Index of the object

Subindex BYTE 1 byte Subindex of the object

Complete size DWORD 4 bytes Total data length of the object

Data BYTE n − 10 bytes Data of the object

WORD 2 bytes n ³ 0x0A: Length of the mailbox service data

party.

Station address of the target if an EtherCAT slave is the instructing

party.

WORD

WORD

BYTE

6 bits (0 ... 5) 0x00: Reserved

...

0x03: Highest priority

9 bits (0 ... 8) 0x00

1 bit (0) 0x01

0x01: The complete object is read.

0x00 or 0x01 if "complete access" = 0x01.

46

EDSMF2192IB EN 3.1

Page 47

Parameter data transfer

Reading and writing parameters

Reading parameters (expedited upload)

Example

The transmitted response structure in case of an upload to the index 0x5FD8 (standard

value of C00039/1 = 0x0FA0) contains the following data:

9

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value [hex] / description

Length

Address WORD 2 bytes 0x00

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x03: SDO Response

Size indicator

Transfer type 1 bit (1) 0x01: Expedited transfer

Data set size 2 bits (2, 3) 0x02: 2 bytes data

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is read.

Command specifier 3 bits (5 ... 7) 0x02: Upload Response

Index WORD 2 bytes 0xD8: Index low byte of the object

Subindex BYTE 1 byte 0x01

Data DWORD 2 bytes 0x0FA0

WORD 2 bytes 0x0A: Length of the mailbox service data

WORD

WORD

BYTE

6 bits (0 ... 5) 0x00: Reserved

9 bits (0 ... 8) 0x00

1 bit (0) 0x01: Length of the data in "Data set size"

0x5F: Index high byte of the object

EDSMF2192IB EN 3.1

47

Page 48

9

Parameter data transfer

Reading and writing parameters

Writing parameters (expedited download)

9.2.2 Writing parameters (expedited download)

1. The master transmits "Initiate Domain Download Request".

2. The slave acknowledges the request with a positive response ("Initiate Domain

Download Response").

In the event of an error the slave responds with "Abort Domain Transfer".

Note!

In the case of jobs for the controller, please make sure that you convert the

code into an index ( 43).

SDO Download Expedited Request

A "SDO Download Expedited Request" takes place if the data length of the parameter data

to be written amounts to up to 4 bytes.

Detailed breakdown of the data for an "SDO Download Expedited Request":

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value / description

Length

Address WORD 2 bytes Station address of the source if an EtherCAT master is the instructing

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x02: SDO Request

Size indicator

Transfer type 1 bit (1) 0x01: Expedited transfer

Data set size 2 bits (2, 3) 0x00: 4 bytes data

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is written.

Command specifier 3 bits (5 ... 7) 0x01: Download Request

Index WORD 2 bytes Index of the object

Subindex BYTE 1 byte Subindex of the object

Data DWORD 4 bytes Data of the object

WORD 2 bytes 0x0A: Length of the mailbox service data

WORD

WORD

BYTE

party.

Station address of the target if an EtherCAT slave is the instructing

party.

6 bits (0 ... 5) 0x00: Reserved

...

0x03: Highest priority

9 bits (0 ... 8) 0x00

1 bit (0) 0x01: Size of the data in "data set size"

0x01: 3 bytes data

0x02: 2 bytes data

0x03: 1 byte data

0x01: The complete object is written.

0x00 or 0x01 if "complete access" = 0x01.

48

EDSMF2192IB EN 3.1

Page 49

Parameter data transfer

Reading and writing parameters

Writing parameters (expedited download)

SDO Download Normal Request

An "SDO Download Normal Request" takes place if the data length of the parameter data

to be written amounts to ³ 4 bytes.

Detailed breakdown of the data for an "SDO Download Normal Request":

9

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value / description

Length

Address WORD 2 bytes Station address of the source if an EtherCAT master is the instructing

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x02: SDO Request

Size indicator

Transfer type 1 bit (1) 0x00: Normal transfer

Data set size 2 bits (2, 3) 0x0

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is written.

Command specifier 3 bits (5 ... 7) 0x01: Download Request

Index WORD 2 bytes Index of the object

Subindex BYTE 1 byte Subindex of the object

Complete size DWORD 4 bytes Total data length of the object

Data BYTE n − 10 bytes Data of the object

WORD 2 bytes 0x0A: Length of the mailbox service data

party.

Station address of the target if an EtherCAT slave is the instructing

party.

WORD

WORD

BYTE

6 bits (0 ... 5) 0x00: Reserved

...

0x03: Highest priority

9 bits (0 ... 8) 0x00

1 bit (0) 0x01

0x01: The complete object is written.

0x00 or 0x01 if "complete access" = 0x01.

EDSMF2192IB EN 3.1

49

Page 50

9

Parameter data transfer

Reading and writing parameters

Writing parameters (expedited download)

SDO Download Response

Detailed breakdown of the data for an "SDO Download Response":

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value / description

Length

Address WORD 2 bytes Station address of the source if an EtherCAT master is the instructing

Channel

Priority 2 bits (6, 7) 0x00: Lowest priority

Type 4 bits (8 ... 11) 0x03: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x00

Number

Reserved 3 bits (9 ... 11) 0x00

Service 4 bits (12 ... 15) 0x03: SDO Response

Size indicator

Transfer type 1 bit (1) 0x00

Data set size 2 bits (2, 3) 0x00

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is read.

Command specifier 3 bits (5 ... 7) 0x3: Download Response

Index WORD 2 bytes Index of the object

Subindex BYTE 1 byte Subindex of the object

Reserved DWORD 4 bytes 0x00

WORD 2 bytes 0x0A: Length of the mailbox service data

party.

Station address of the target if an EtherCAT slave is the instructing

party.

WORD

WORD

BYTE

6 bits (0 ... 5) 0x00: Reserved

...

0x03: Highest priority

9 bits (0 ... 8) 0x00

1 bit (0) 0x00

0x01: The complete object is read.

0x00 or 0x01 if "complete access" = 0x01.

50

EDSMF2192IB EN 3.1

Page 51

Parameter data transfer

Reading and writing parameters

Writing parameters (expedited download)

Example

The transmitted request structure in case of a download from the index 0x1600 contains

the following data:

9

SDO frame

area

Mailbox Header

CANopen Header

SDO

Data field Data type / length Value [hex] / description

Length

Address WORD 2 bytes 0x0

Channel

Priority 2 bits (6, 7) 0x0: Lowest priority

Type 4 bits (8 ... 11) 0x3: CANopen over EtherCAT (CoE)

Reserved 4 bits (12 ... 15) 0x0

Number

Reserved 3 bits (9... 11) 0x0

Service 4 bits (12 ... 15) 0x2: SDO request

Size indicator

Transfer type 1 bit (1) 0x01: Expedited transfer

Data set size 2 bits (2, 3) 0x00: 4 bytes data

Complete access 1 bit (4) 0x00: The entry addressed with index and subindex is written.

Command specifier 3 bits (5 ... 7) 0x01: Download Request

Index WORD 2 bytes 0x00: Index low byte of the object

Subindex BYTE 1 byte 0x01: Subindex of the object

Data DWORD 4 bytes 0x5C930110

WORD 2 bytes 0xA: Length of the mailbox service data

WORD

WORD

BYTE

6 bits (0 ... 5) 0x0: Reserved

9 bits (0 ...8) 0x0

1 bit (0) 0x01: Size of the data in "data set size"

0x16: Index high byte of the object

EDSMF2192IB EN 3.1

51

Page 52

9

Parameter data transfer

Reading and writing parameters

SDO abort codes

9.3 SDO abort codes

If an SDO request is evaluated negatively, a corresponding error code is output.

Index [hex] Description

0x00000000 No error

0x05030000 The status of the toggle bit has not changed.

0x05040000 SDO protocol time−out

0x05040001 Invalid or unknown specification symbol for the client/server command

0x05040002 The data block length is too great.

0x05040005 The space in the main memory is not sufficient.

0x06010000 Access to object not supported

0x06010001 Read access to a write−protected object

0x06010002 Write access to a write−protected object

0x06020000 Object is not listed in the object directory.

0x06040041 An object cannot be mapped into the PDO.

0x06040042 The number and/or length of the mapped objects would exceed the PDO length.

0x06040043 General parameter incompatibility

0x06040047 General internal device incompatibility

0x06060000 Access has failed because of hardware errors.

0x06070010 Wrong data type or parameter length.

0x06070012 Incorrect data type (The parameter length is too big)

0x06070013 Wrong data type (parameter length is too small).

0x06090011 Subindex does not exist.

0x06090030 The value range for parameters is too large (only for write access).

0x06090031 The parameter value is too high.

0x06090032 The parameter value is too low.

0x06090036 The maximum value is lower than the minimum value.

0x08000000 General error

0x08000020 Data cannot be transferred to the application or stored in the application.

0x08000021 Due to local control, data cannot be transferred to the application or stored in the

0x08000022 Data cannot be transferred to or saved in the application because of current device state.

0x08000023 Dynamic object directory generation has failed or no object directory available.

application.

52

EDSMF2192IB EN 3.1

Page 53

10 Diagnostics

The LEDs on the front are provided to the communication module for the purpose of fault

diagnostics.

10.1 LED status displays

Diagnostics

LED status displays

10

Fig. 10−1 LEDs of the communication module

LED

Pos. Colour Status

green

green

green

red on

red

green

blinking

on

off The communication module is not supplied with voltage.

blinking

on

The EtherCAT state machine controls the two−colored LED (red/green):

l Status messages are shown in green.

l Error messages are shown in red.

off The communication module is not active on the fieldbus or is in the "Init"

blinking

on

Description

l The EtherCAT connection has been established.

l Data communication of the EtherCAT connection is active.

The communication module is supplied with voltage, but has no connection to

the standard device (standard device is switched off, in the initialisation

phase, or not available.)

The communication module is supplied with voltage and is connected to the

standard device.

status.

"Pre−operational" or "Safe−operational" state active.

The communication module is in the "Operational" status.

An error has occurred in the communication module.

The red and green drive LED indicates the operating status of the standard

device (see operating instructions of the standard device).

2192ECAT001B

EDSMF2192IB EN 3.1

53

Page 54

10

Diagnostics

Emergency requests / emergency messages

10.2 Emergency requests / emergency messages

Emergency messages are sent once to the EtherCAT master if the error status of the

controller/communication module changes, i.e. ...

ƒ if an error of the controller/communication module occurs;

ƒ if an error of the controller/communication module is omitted.

An "Emergency Request" on the fieldbus consists of the "Mailbox Header", "CANopen

Header" and the Emergency message:

Mailbox Header CANopen

Header

6 bytes 2 bytes 8 bytes

Emergency Message

Structure of the emergency message

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Emergency

error code

Low Byte High Byte Low Byte High Byte

Error

register

(I−1001)

Reserved error code

(Device)

Low Word High Word

Low Byte High Byte Low Byte High Byte

Example: The AIF connection to the standard device has been lost (error code "0x31").

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Emergency

error code

0x00 0x10 0x01 0x00 0x00 0x00 0x00 0x31

ƒ Bytes 1 and 2 indicate that an error has occurred.

ƒ Byte 3 indicates the contents of the error register (I−1001).

ƒ Bytes 5 ... 8 indicate the corresponding error code.

Error

register

(I−1001)

Reserved Error code

(Device)

Possible error codes (overview)

54

No.

(Byte 8)

0x10 EMCY_BAD_SYNC_INPUT The sync source specified in code C1121 of the standard

0x11 EMCY_BAD_SYNC_CYCLETIME The sync cycle time specified by the master cannot be used.

0x12 EMCY_BAD_SYNC_CYCLE_GG The specified sync cycle time from code C1122 of the

0x13 EMCY_CANT_SYNC Synchronisation of the standard device is not possible.

0x14 EMCY_SYNC_LOST EtherCAT has lost the synchronisation.

0x31 EMCY_AIF_LOST The AIF connection to the standard device has been lost.

0x32 EMCY_AIF_UNKNOWN_GG The standard device is unknown.

Designation Meaning

device is incorrect.

standard device cannot be used.

EDSMF2192IB EN 3.1

Page 55

11 Appendix

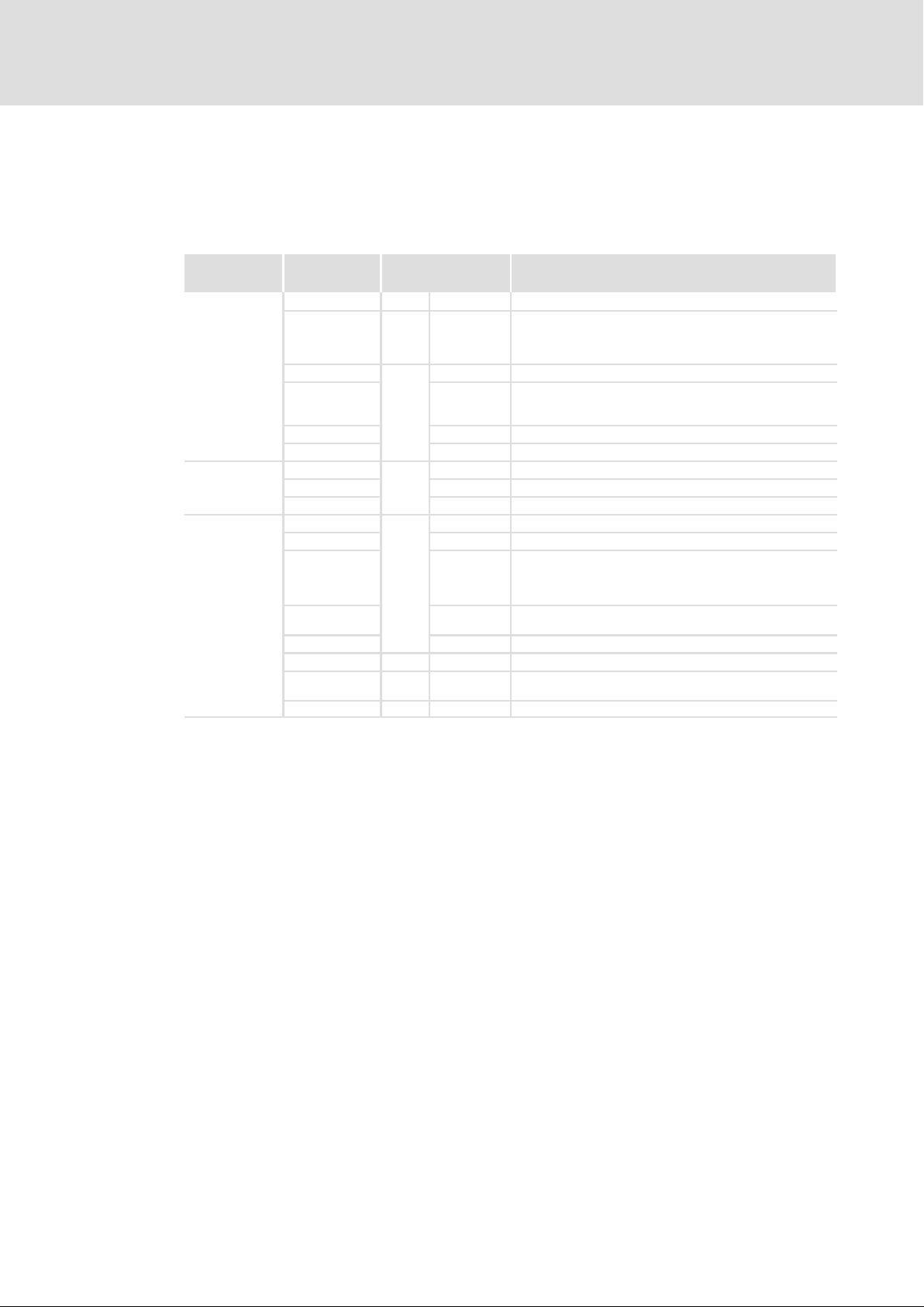

11.1 Implemented CoE objects

Lenze devices can be parameterised with Lenze codes and with the

manufacturer−independent "CoE objects". In order to obtain a complete

EtherCAT−compliant communication, only the CoE objects may be used for

parameterisation. The CoE objects described in this documentation are defined in the

"EtherCAT Specification, Part 6 ˘ Application Layer Protocol Specification".

Appendix

Implemented CoE objects

11

EDSMF2192IB EN 3.1

55

Page 56

11

Appendix

Implemented CoE objects

Index Index name Subindex Subindex name Data type Bits Access

0x1000 Device type − − UDINT 32 R

0x1008 Device name − − STRING(30) 240 R

0x1009 Hardware version − − STRING(2) 16 R

0x100A Software version − − STRING(30) 240 R

0x1018 Identity 0 Number of elements USINT 8 R

1 Vendor ID UDINT 32 R

2 Product code UDINT 32 R

3 Revision number UDINT 32 R

4 Serial number UDINT 32 R

0x1600 IO Outputs 0 Number of elements USINT 8 RW

1 … 32 Output Object 1 … 32 UDINT 32 RW

0x1800 IO Inputs 0 Number of elements USINT 8 RW

7 TxPDO−State BOOL 1 R

9 TxPDO−Toggle BOOL 1 R

0x1A00 IO Inputs 0 Number of elements USINT 8 RW

1 … 12 Input Object 1 … 12 UDINT 32 RW

0x1C00 Sync Man Communication

0x1C12 RxPDO Assignment 0 Number of elements USINT 8 R

0x1C13 TxPDO Assignment 0 Number of elements USINT 8 R

0x1C32 SM output parameter 0 Number of elements USINT 8 RW

0x1C33 SM input parameter 0 Number of elements USINT 8 RW

R: Read access only

RW: Read and write access

type

0 Number of elements USINT 8 R

1 Elements UDINT 32 R

1 Elements UDINT 32 R

1 Elements UDINT 32 R

1 Synchronization type UINT 16 RW

2 Cycle time / ns UDINT 32 RW

3 Shift time / ns UDINT 32 RW

4 Sync types supported UINT 16 R

5 Minimum cycle time / ns UDINT 32 R

6 Minimum shift time / ns UDINT 32 R

1 Synchronization type UINT 16 RW

2 Cycle time / ns UDINT 32 RW

3 Shift time / ns UDINT 32 RW

4 Sync types supported UINT 16 R

5 Minimum cycle time / ns UDINT 32 R

6 Minimum shift time / ns UDINT 32 R

56

EDSMF2192IB EN 3.1

Page 57

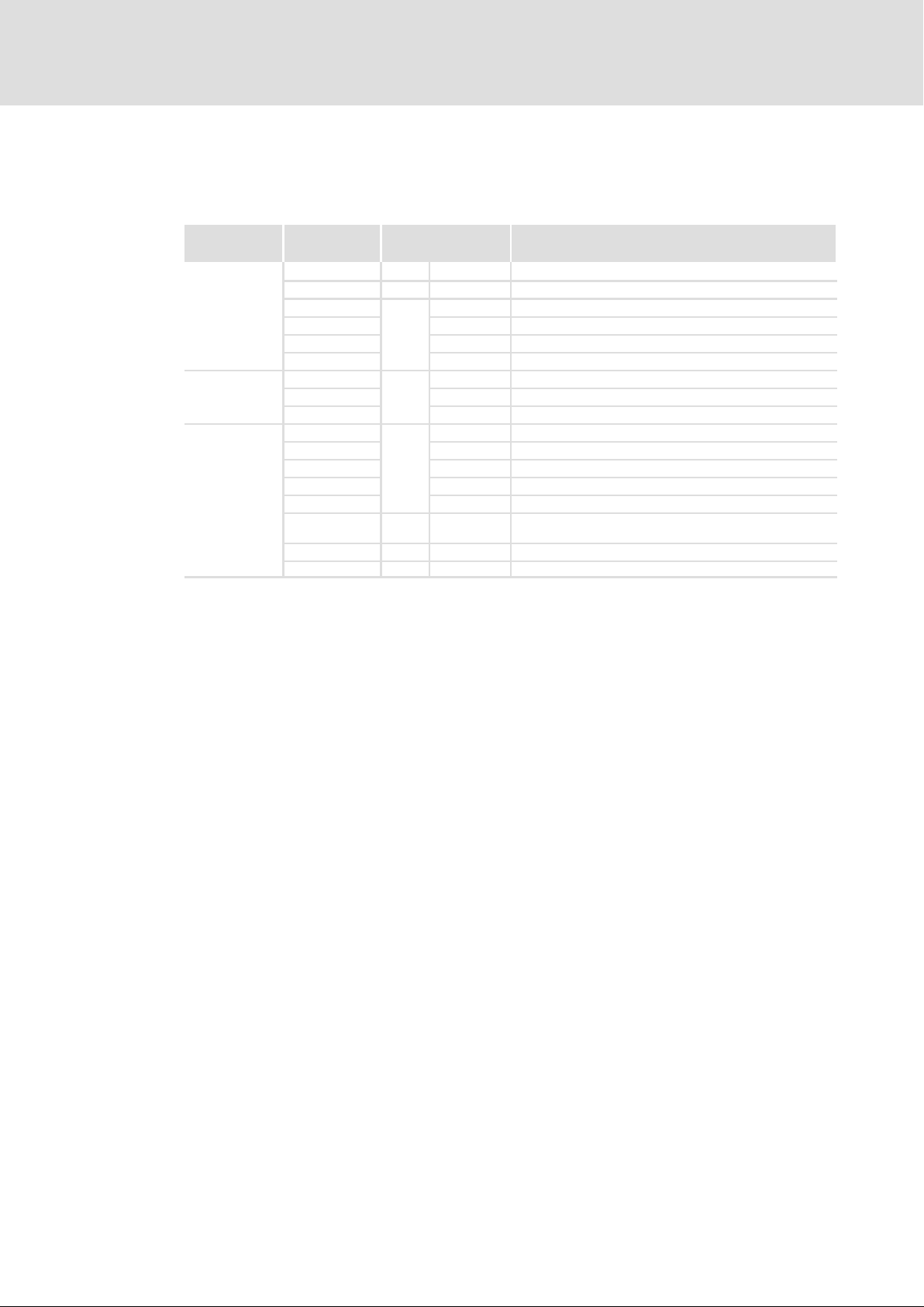

11.2 Codes

The objects specified in the table can be accessed via EtherCAT fieldbus. The objects are

implemented in the Lenze code structure. Writable codes are stored permanently and are

maintained after the communication module is switched off.

Tip!

Appendix

11

Codes

The codes are visible in the object directory of the EtherCAT configuration tool.

Object

Index

[hex]

0x58ED − C1810 − Software identification of the module R

0x58EC C1811 − Software creation date R

0x58E1 1 ... n C1822 1 ... n AIF input words (to the standard device) R

0x58E0 1 ... n C1823 1 ... n AIF output words (from the standard device) R

0x58DF 1 ... n C1824 1 ... n AIF input double words (to the standard device) R

0x58DE 1 ... n C1825 1 ... n AIF output double words (from the standard device) R

0x58D9 − C1830 − Bus status R

0x58C5 − C1850 − Station alias address RW

0x58A5 − C1882 − Response when exiting "Operational" RW

0x58A4 − C1883 − Monitoring time when exiting "Operational" RW

R: Read access only

RW: Read and write access

Subindex

Code Subcode Designation Access Information

58

58

58

58

58

59

59

59

59

60

EDSMF2192IB EN 3.1

57

Page 58

11

Appendix

Codes

Code description

Parameter

C1810

Name

Software identification of the module

The software ID of the communication module is shown here.

Display: "33S2192I_xy000" (xy = version x.y)

Parameter

C1811

Name

Software creation date

The software creation date ("mm dd yyyy") and the time ("hh:mm:ss") are shown here.

Example: "FEB 06 2008 09:23"

Parameter