Page 1

EDSMF2191IB

.M\}

Ä.M\}ä

L−force Communication

Communication Manual

POWERLINK

EMF2191IB

Communication module

Page 2

Contentsi

1 About this documentation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Device− and application−specific safety instructions 11. . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Product features 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connections and interfaces 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Protective insulation 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Data for POWERLINK communication 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Cycle time 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Processing time in the inverter 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Dimensions 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installation 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Mechanical installation 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical installation 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Wiring according to EMC (CE−typical drive system) 24. . . . . . . . . . . . . . . . .

5.2.2 Network topology 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 POWERLINK 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Operation in the standard Ethernet 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 POWERLINK connection 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Specification of the Ethernet cable 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 Voltage supply 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

EDSMF2191IB EN 2.0

Page 3

Contents i

6 Commissioning 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Setting the node address 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Configuration via the "Automation Studio" 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Initial switch−on 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Diagnostics 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Appendix 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Index table 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Index 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSMF2191IB EN 2.0

3

Page 4

About this documentation1

0Fig. 0Tab. 0

1 About this documentation

Contents

This documentation exclusively describes the EMF2191IB (POWERLINK) communication

module.

Note!

This documentation supplements the mounting instructions supplied with the

function/communication module and the documentation of the used

standard device.

The mounting instructions contain safety instructions which must be

observed!

The features and functions of the communication module are described in detail.

Examples illustrate typical applications.

Furthermore this documentation contains the following:

ƒ Safety instructions that must be observed.

ƒ Key technical data relating to the communication module

ƒ Information on versions of Lenze standard devices to be used.

ƒ Notes on troubleshooting and fault elimination

The theoretical correlations are only explained in so far as they are necessary for

comprehending the function of the communication module.

This documentation does not describe the software of an original equipment

manufacturer. No responsibility is taken for corresponding information given in this

manual. Information on how to use the software can be obtained from the documents of

the host system (master).

All brand names mentioned in this manual are trademarks of their respective companies.

Tip!

Detailed information about POWERLINK can be found on the website of the

"Ethernet POWERLINK Standardisation Group":

http://www.ethernet−powerlink.org

4

EDSMF2191IB EN 2.0

Page 5

About this documentation 1

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking and remote service of a machine.

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

Validity information

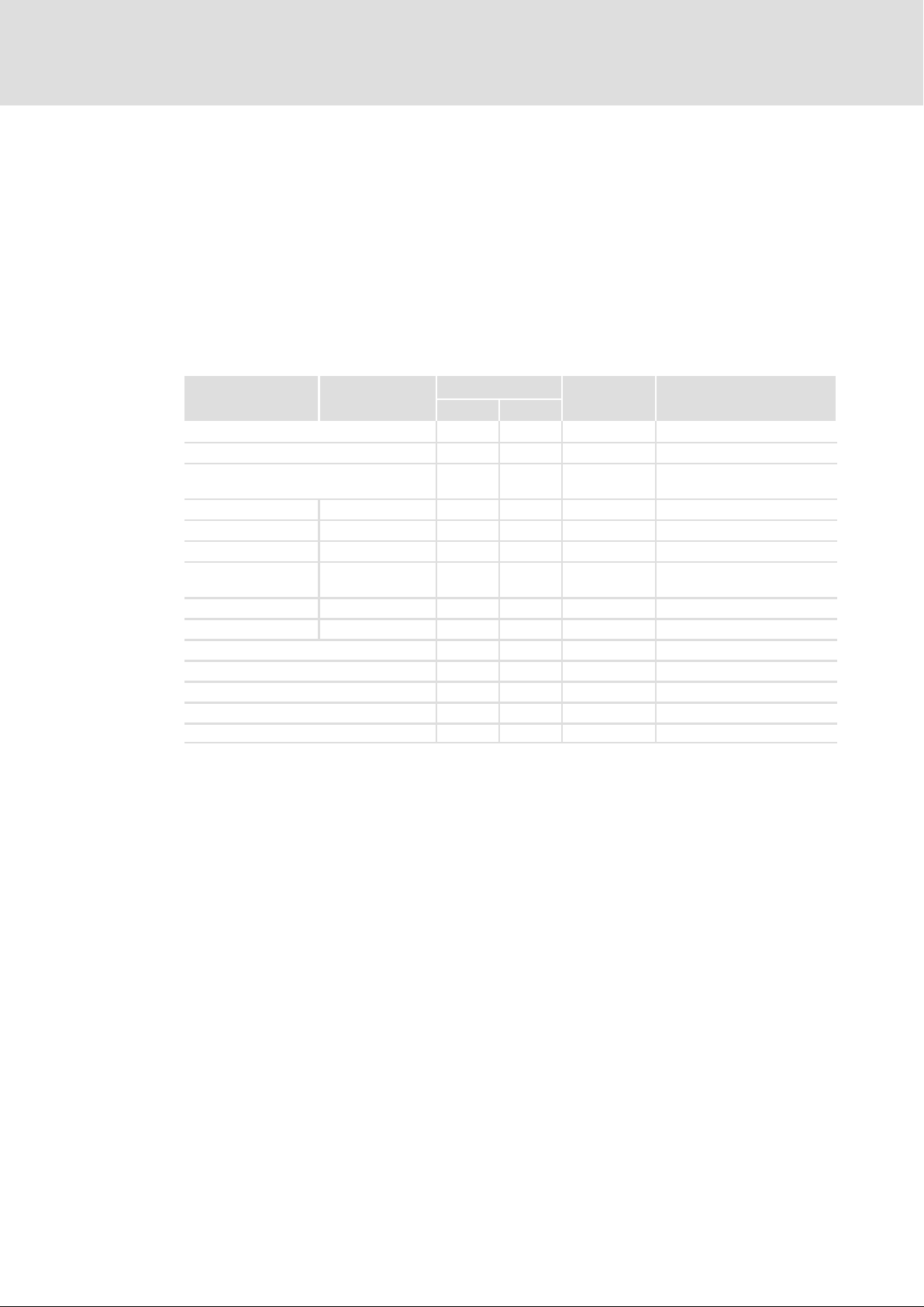

The information in this documentation applies to the following devices:

Extension module Type designation From hardware version From software version

POWERLINK

communication module

EMF2191IB VA 1.0

EDSMF2191IB EN 2.0

5

Page 6

1

About this documentation

Document history

1.1 Document history

Version Description

1.0 05/2008 TD00 First edition

2.0 09/2013 TD17 l Corrected information on cycle times ( 19)

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e−mail us to:

feedback−docu@Lenze.de

Thank you for your support.

Your Lenze documentation team

l New chapter structure

6

EDSMF2191IB EN 2.0

Page 7

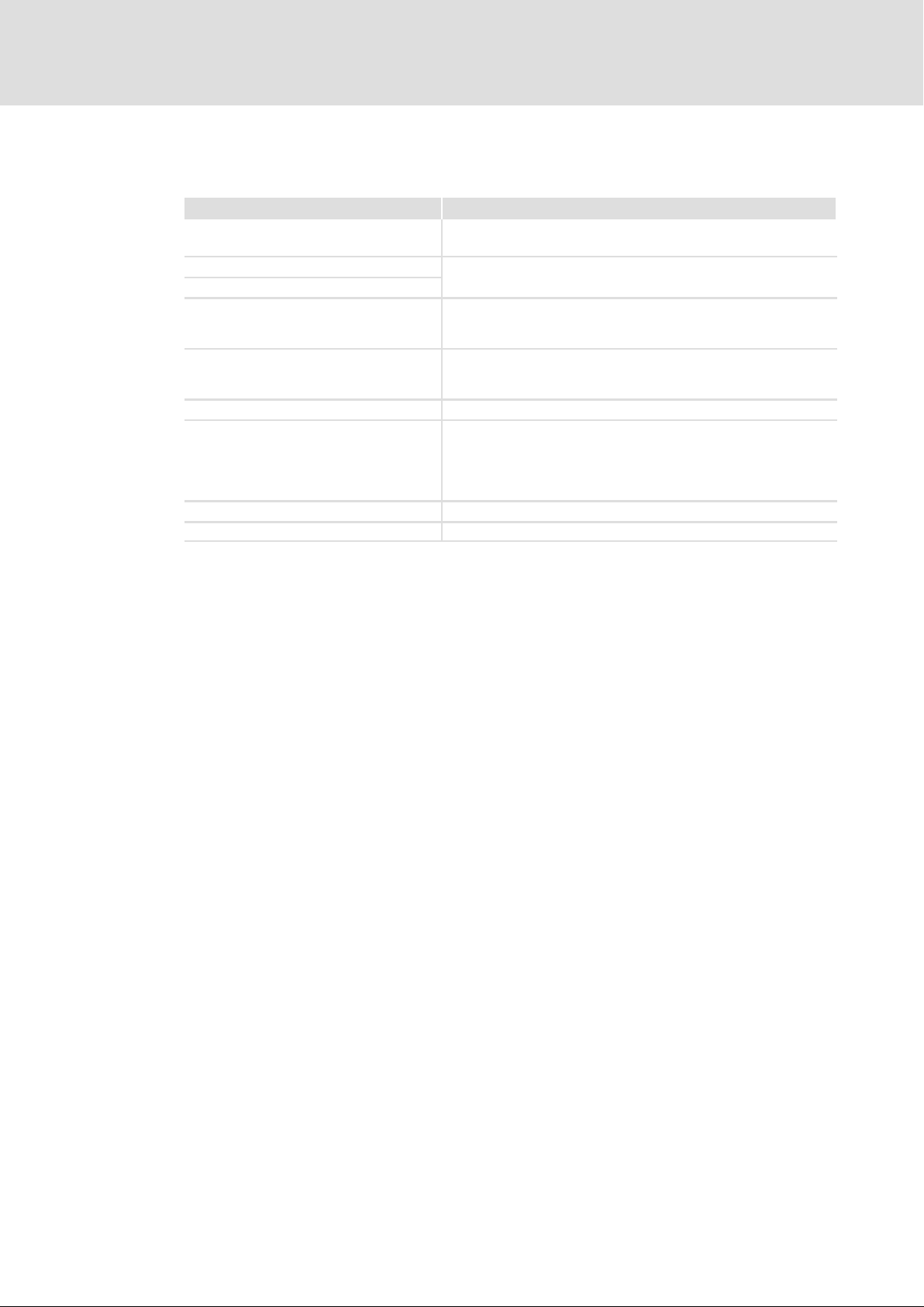

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Decimal Standard notation Example: 1234

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

l Nibble

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

Documentation reference Reference to another documentation with

About this documentation

Conventions used

Point In general, the decimal point is used.

For instance: 1234.56

0b[0, 1]

Point

Example: ´0b0110´

Example: ´0b0110.0100´

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

additional information

For example: EDKxxx = see

documentation EDKxxx

1

EDSMF2191IB EN 2.0

7

Page 8

1

About this documentation

Terminology used

1.3 Terminology used

Term Meaning

EPSG Ethernet Powerlink Standardisation Group

Inverter

Standard device

Slave (CN) Controlled Node

Master (MN) Managing Node

Node ID POWERLINK node address

MAC address

(MAC ID)

HW Hardware

SW Software

User organisation which defines POWERLINK.

Inverter, the communication module can be used with ( 12).

POWERLINK node which is a slave in the real−time Ethernet

POWERLINK.

POWERLINK node which has the master function in the real−time

Ethernet POWERLINK.

Media Access Control address

The MAC address is unequivocal worldwide. The MAC address is

represented by six bytes in hexadecimal form the single bytes

being separated by dots. The first three bytes refer to the

manufacturer, the other bytes serve to identify the device.

8

EDSMF2191IB EN 2.0

Page 9

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

About this documentation

Notes used

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

1

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

EDSMF2191IB EN 2.0

9

Page 10

2

Safety instructions

General safety information

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order

to prevent serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety information

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ For Lenze drive components ...

... only use permitted accessories.

... only use original manufacturer spare parts.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

10

EDSMF2191IB EN 2.0

Page 11

Device− and application−specific safety instructions

2.2 Device− and application−specific safety instructions

ƒ During operation, the communication module must be securely connected to the

standard device.

ƒ With external voltage supply, always use a separate power supply unit, safely

separated in accordance with EN 61800−5−1 in every control cabinet (SELV/PELV).

ƒ Only use cables that meet the given specifications. ( 30)

Documentation of the standard device, control system, and plant/machine

All the other measures prescribed in this documentation must also be

implemented. Observe the safety instructions and application notes contained

in this manual.

2.3 Residual hazards

Safety instructions

2

Protection of persons

ƒ If controllers are connected to phase−earthed system with a rated mains voltage

400 V, external measures need to be implemented to provide reliable protection

against accidental contact. (see chapter "4.2", 18)

Device protection

ƒ The communication module contains electronic components that can be damaged

or destroyed by electrostatic discharge.

EDSMF2191IB EN 2.0

11

Page 12

3

Product description

Application as directed

3 Product description

3.1 Application as directed

The communication module ...

ƒ is a device intended for use in industrial power systems;

ƒ can only be used in POWERLINK networks;

ƒ can be used together with the following standard devices (nameplate data):

Device type Design

82EVxxxxxBxxxXX Vx 1x 8200 vector

82CVxxxxxBxxxXX Vx 1x 8200 vector, cold plate

82DVxxxKxBxxxXX Vx 1x 8200 vector, thermally

EPL 10200 E 1x 1x Drive PLC

33.93XX xE. 2x 1x Vxxx 9321 − 9332 vector

33.938X xE. 1x 0x 9381 − 9383 vector

33.93XX xC. 2x 1x Vxxx 9321 − 9332, with cold plate

33.93XX EI / ET 2x 1x Vxxx 9300 Servo PLC

33.93XX CI / CT 2x 1x Vxxx 9300 Servo PLC, cold plate

ECSxSxxxx4xxxxXX 1A 6.0 ECSxS "Speed & Torque"

ECSxPxxxx4xxxxXX 1A 6.0 ECSxP "Posi & Shaft"

ECSxMxxxx4xxxxXX 1A 6.0 ECSxM "Motion"

ECSxAxxxx4xxxxXX 1A 2.3 ECSxA "Application"

ECSxExxxx4xxxxXX VA 3.0 ECSxE power supply module

1) operating system software versions of the controllers

Version

HW SW

Variant Explanation

1)

separated

version

Any other use shall be deemed inappropriate!

12

EDSMF2191IB EN 2.0

Page 13

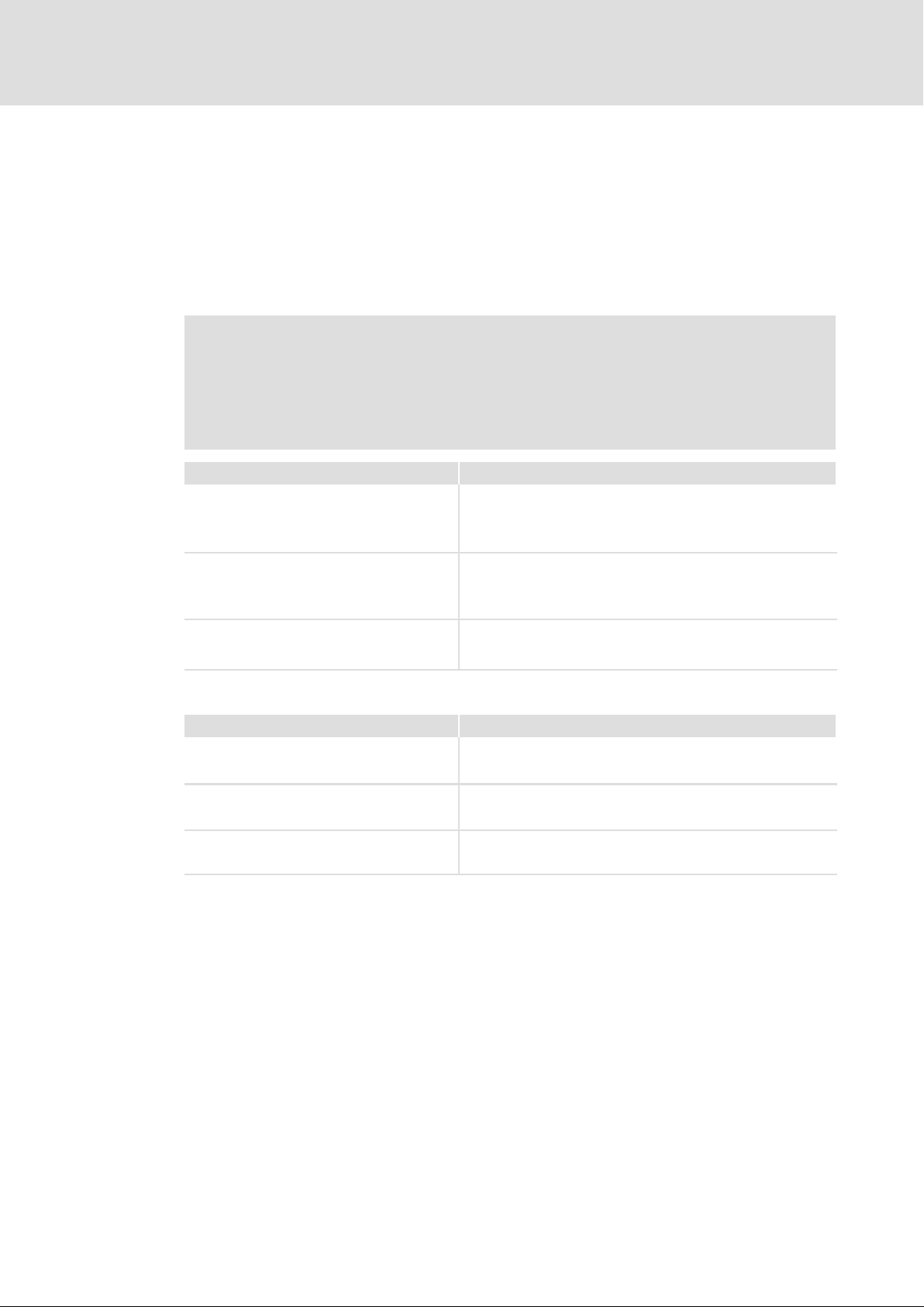

3.2 Identification

L

Type

Id.-No.

Prod.-No.

MAC-ID

Product description

Identification

3

E82AF000P0B201XX

Device series

Hardware version

Software version

2191EPL013

33.2191IB VA 10

EDSMF2191IB EN 2.0

13

Page 14

3

Product description

Product features

3.3 Product features

ƒ Powerful and real−time capable communication system for motion and general

applications. Real time Ethernet with the Ethernet POWERLINK V2 communication

profile.

ƒ Communication module for the AIF slot of the frequency inverters 8200 vector, 9300

vector and ECS servo system.

ƒ Support of the Ethernet POWERLINK slave functionality (controlled node).

ƒ Very short slave (Controlled Node) response times for optimal network performance.

ƒ Integrated Ethernet hub (double) for easily setting up line topologies without any

additional components.

ƒ External 24V supply for maintaining the POWERLINK communication in case the

device fails.

ƒ Use of max. 3 PDO crosslinks for master (managing node) or slave (controlled node)

to create systems with "distributed intelligence".

14

EDSMF2191IB EN 2.0

Page 15

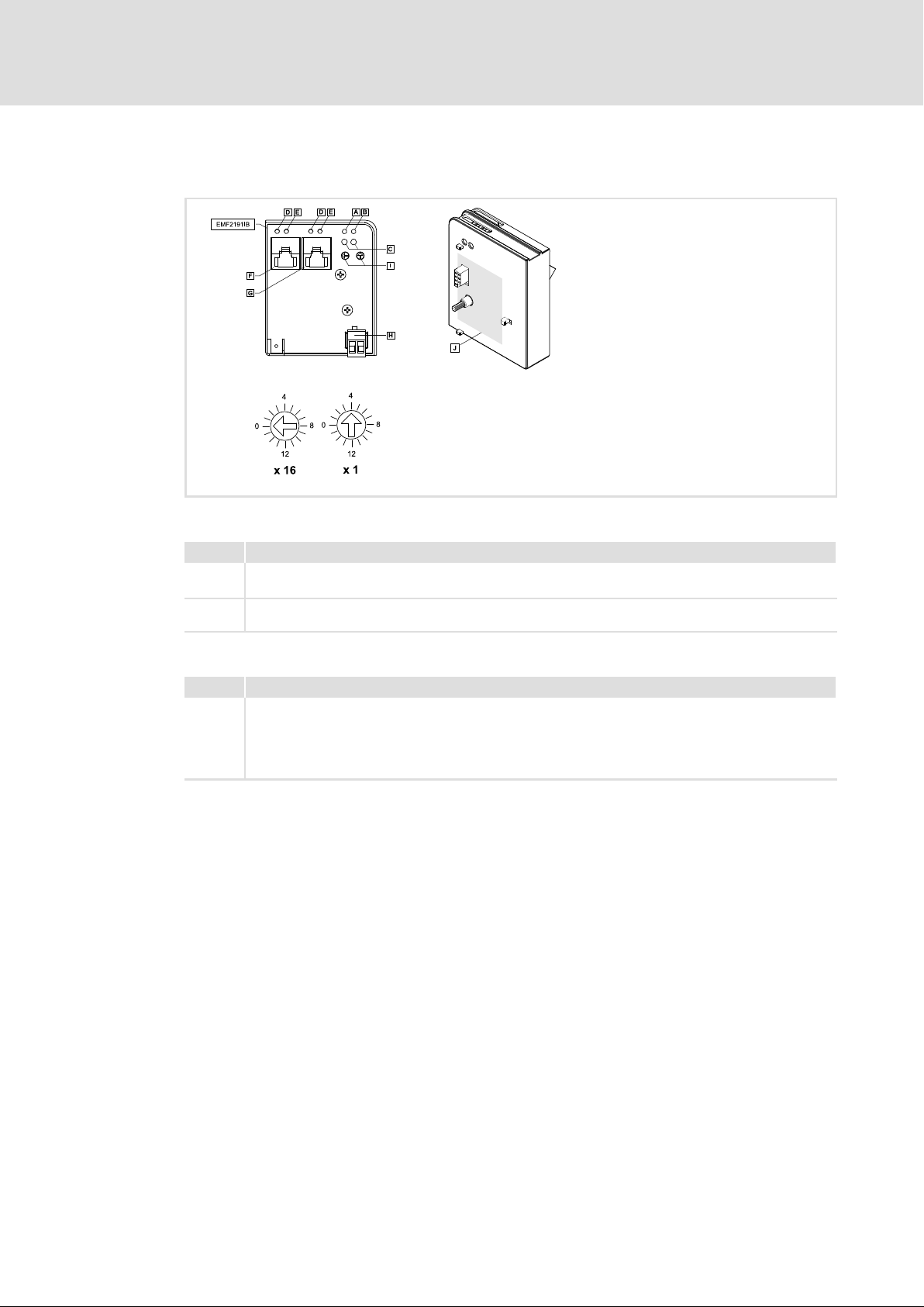

3.4 Connections and interfaces

Product description

Connections and interfaces

3

2191EPL001B

Connections

Pos. Description

Connection to external supply of the communication module

POWERLINK connection

Version: RJ45 socket according to IEC 60603−7

Version: Connector with screw connection, 2−pole

Switch

Pos. Description

Switches for addressing the nodes

l Left switch: Setting with factor 16

l Right switch: Setting with factor 1

The addition of both products results in the node address (node ID)

Node ID = 254 (the node ID is obtained from a DHCP server)

EDSMF2191IB EN 2.0

15

Page 16

3

Product description

Connections and interfaces

Displays

LED

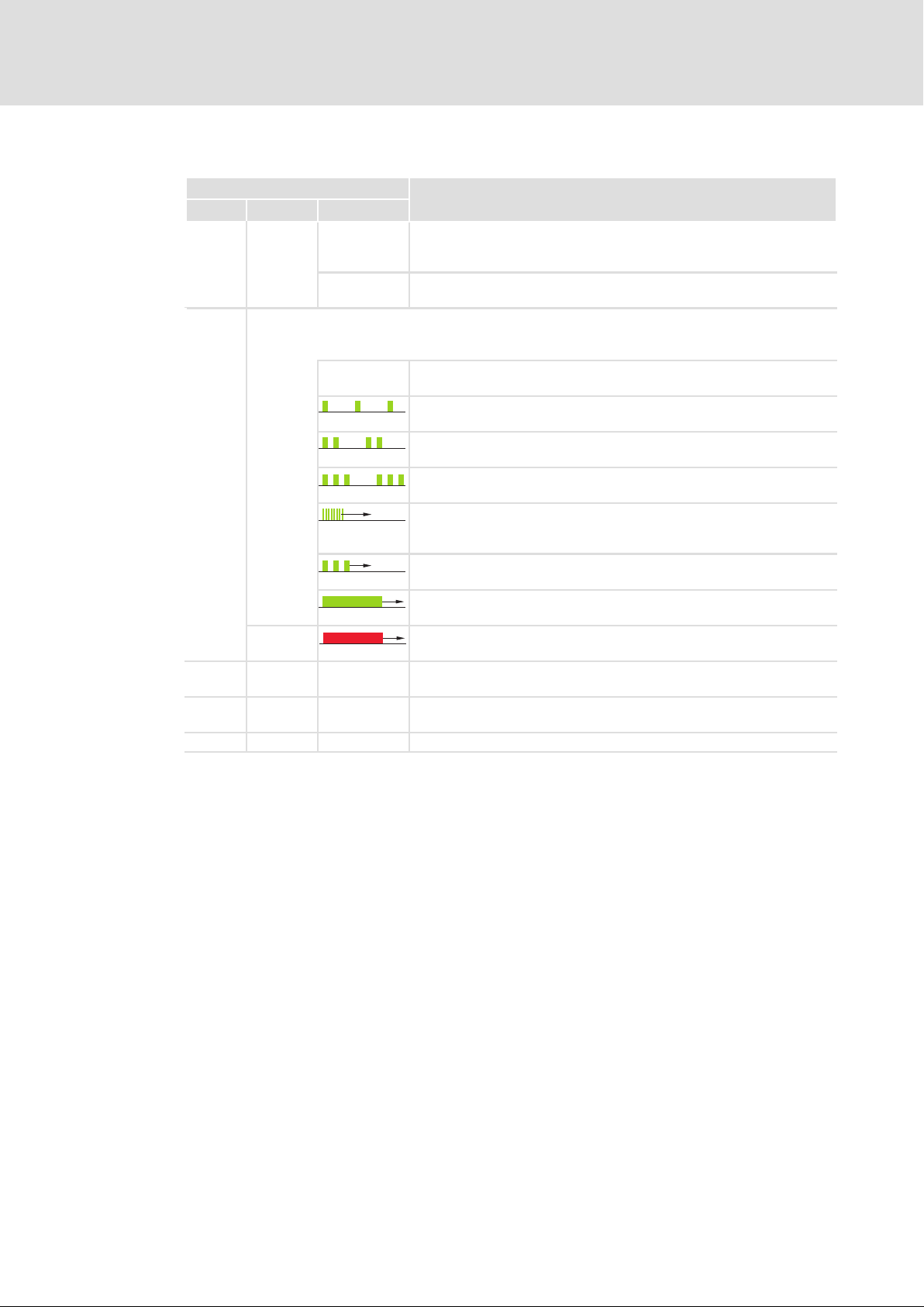

Pos. Colour Condition

green

green

Red ERROR

Red On The red and green drive LED indicates the operating status of the

green blinking Depending on the connection state, the data is transmitted or received

yellow on Ethernet connection is available (LINK).

off The communication module is supplied with voltage, but has no

on The communication module is supplied with voltage and is connected to

The NMT state machine triggers the two−colored LED:

l Green: Display of status messages

l Red: Display of error messages

Off NMT_GS_OFF, NMT_GS_INITIALISATION,

Description

connection to the basic device (basic device is either switched off, in the

initialisation phase, or not available).

the standard device.

NMT_CS_NOT_ACTIVE / NMT_MS_NOT_ACTIVE

NMT_CS_PREOPERATIONAL_1 / NMT_MS_PREOPERATIONAL_1

(LED flashes once within a second.)

NMT_CS_PREOPERATIONAL_2 / NMT_MS_PREOPERATIONAL_2

(LED flashes twice within a second.)

NMT_CS_READY_TO_OPERATE / NMT_MS_READY_TO_OPERATE

(LED flashes three times within a second.)

NMT_CS_BASIC_ETHERNET

(LED is blinking with a frequency of 10 Hz or depending on the

connection state)

NMT_CS_STOPPED

(LED is blinking with a frequency of 2.5 Hz.)

NMT_CS_OPERATIONAL / NMT_MS_OPERATIONAL

(LED is lit permanently.)

(LED is lit permanently. An error has occurred.)

standard device (see documentation of the standard device).

(ACTIVITY).

16

EDSMF2191IB EN 2.0

Page 17

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

Field Values

Order designation EMF2191IB

Communication profile Ethernet POWERLINK V2

Interface RJ45, Fast Ethernet Mode MII (according to IEEE 802.3)

Communication medium TP (100BaseTX, Cat5e)

Cable length max. 100 m between 2 nodes / hubs

Total extension Number of nodes x 100 m

Network topology Tree, star, line

Transmission mode Half duplex

Type of node Slave (CN, Controlled Node)

Node address Max. 239

Conformities, approvals l CE

l cUL

Baud rate 100 Mbps

Voltage supply External supply via separate power supply unit

+V =

−

24VDC(20.4 V − 0%... 28.8 V+ 0%)

I =

140 mA

Reference potential for external voltage supply

Technical data

4

Documentation for Lenze series of devices 8200 vector, 9300 and ECS

Here you can find the ambient conditions and the electromagnetic

compatibility (EMC) specifications applying to the communication module.

EDSMF2191IB EN 2.0

17

Page 18

4

Technical data

Protective insulation

4.2 Protective insulation

Danger!

Dangerous electrical voltage

If Lenze controllers are used on a phase earthed mains with a rated mains

voltage 400 V, protection against accidental contact is not ensured without

implementing external measures.

Possible consequences:

ƒ Death or serious injury

Protective measures:

ƒ If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged device modules, ...

– a double isolating distance must exist.

– the components to be connected must be provided with the second

isolating distance.

Insulation between bus and ... Type of insulation

(in accordance with EN 61800−5−1)

l Earth reference / PE Functional insulation

l With external supply Functional insulation

l Power stage

– 8200 vector Reinforced insulation

– 9300 servo inverter Reinforced insulation

– 93xx servo position controller Reinforced insulation

– 93xx servo register control Reinforced insulation

– 93xx servo cam profiler Reinforced insulation

– 9300 vector / Servo PLC Reinforced insulation

– ECS devices Reinforced insulation

l Control terminals

– 8200 vector Functional insulation

– 9300 servo inverter Basic insulation

– 93xx servo position controller Basic insulation

– 93xx servo register control Basic insulation

– 93xx servo cam profiler Basic insulation

– 9300 vector / Servo PLC Basic insulation

– ECS devices Basic insulation

18

EDSMF2191IB EN 2.0

Page 19

4.3 Data for POWERLINK communication

Field Values

Jitter synchronisation information approx. 1 s

Total cycle times Slave (CN): 1, 2, 3 60 ms

Buffer size

Frame size Max. asynchronous telegram size (MTU): 1518 bytes

SDO communication method UDP/IP

Number of RPDOs 3

RPDO user data per application (all

RPDOs)

Number of TPDOs 1

TPDO user data per application max. 32 objects with a total of max 64 bytes

Delay time

Tx−iso: max. 92 bytes (64 bytes of PDO user data)

Rx−iso: max. 328 bytes (300 bytes of PDO user data)

max. 32 objects with a total of max 64 bytes

T

− T

PReq

T

− T

SoA

Technical data

Data for POWERLINK communication

l The module can be operated with a minimum cycle of

1 ms.

l In multiplex mode, a minimum cycle of 200 sec is

supported if the data is accepted on the millisecond.

: 1900 ns

PRes

: 1900 ns

ASnd

4

EDSMF2191IB EN 2.0

19

Page 20

4

Technical data

Data for POWERLINK communication

Cycle time

4.3.1 Cycle time

The cycle time of the communication system is the time in which all process data between

the master (managing node) and the slaves (controlled nodes) are exchanged.

It depends on the data of the communication system and can be calculated as follows e. g.

for a baud rate of 500 kbps:

t

+ 3, 35 @ 10*3(n ) 48 ) 3 BK) ) 0, 24 L ) 0, 2

zykl

The following diagram shows the relation between cycle time and number of connected

fieldbus nodes. The given values refer to the connection of Lenze inverters (e.g. 82xx) with

48 bits (1 parameter data word + 2 process data words).

Cycle time

[ms]

12

t

cycl

n Sum of all data bits in the POWERLINK network

BK Number of bus terminals

L Length of the remote bus cable [km]

Cycle time [ms]

10

8

6

4

2

1

10

Number of nodes

Fig. 4−1 Relationship between cycle time and number of nodes

20

30 40

4.3.2 Processing time in the inverter

There are no interdependencies between parameter data and process data.

Processing times Parameter data Process data

Processing time inside the

inverter

Additional times outside

the inverter

l For controller−internal parameters

approx. 30 ms + a tolerance of 20 ms

l Some codes may have a longer

processing time (see documentation

of the inverter)

l Communication transfer times

l Communication processing times of the transmitting node

50 60

l There is no synchronisation between

the communication module and the

inverter.

l Times of 8200 vector/motec,

starttec: Approx 3 ms + a tolerance of

2 ms

l Times of 9300 / ECS: Approx. 2 ms +

a tolerance of 1 ms (each being

independent of the basic cycle time)

20

EDSMF2191IB EN 2.0

Page 21

4.4 Dimensions

All dimensions in mm

Technical data

Dimensions

4

2191EPL001B

EDSMF2191IB EN 2.0

21

Page 22

Installation5

5 Installation

Danger!

Inappropriate handling of the communication module and the standard device

can cause serious personal injury and material damage.

Observe the safety instructions and residual hazards described in the

documentation for the standard device.

Stop!

The device contains components that can be destroyed by electrostatic

discharge!

Before working on the device, the personnel must ensure that they are free of

electrostatic charge by using appropriate measures.

22

EDSMF2191IB EN 2.0

Page 23

5.1 Mechanical installation

Fig. 5−1 Attaching the communication module

ƒ Plug the communication module onto the standard device (here: 8200 vector).

ƒ Tighten the communication module to the standard device using the fixing screw in

order to ensure a good PE connection.

Installation

Mechanical installation

5

2102LEC014

Note!

For the internal supply of the communication module by the 8200 vector

frequency inverter the jumper has to be adjusted within the interface opening

(see illustration above).

Observe the notes ( 32).

EDSMF2191IB EN 2.0

23

Page 24

5

5.2 Electrical installation

5.2.1 Wiring according to EMC (CE−typical drive system)

Installation

Electrical installation

Wiring according to EMC (CE−typical drive system)

For wiring according to EMC requirements observe the following points:

Note!

ƒ Separate control cables/data lines from motor cables.

ƒ Connect the shields of control cables/data lines at both ends in the case of

digital signals.

ƒ Use an equalizing conductor with a cross−section of at least 16mm

(reference:PE) to avoid potential differences between the bus nodes.

ƒ Observe the other notes concerning EMC−compliant wiring given in the

documentation for the standard device.

Wiring procedure

2

1. Comply with bus topology, thus do not use stubs.

2. Observe notes and wiring instructions in the documents for the control system.

3. Only use cables that comply with the given specifications ( 30).

4. Observe notes for the voltage supply of the module ( 32).

24

EDSMF2191IB EN 2.0

Page 25

Installation

Electrical installation

Network topology

5

5.2.2 Network topology

IP routing

IT integration (NAT)

Access protection

Ethernet

Protected segment (machine system)

EPL

router

Hub

max. 100 m

max. 100 m

Hub

Detailed information on this topic can be found in the Ethernet POWERLINK

brochure "Real−time Industrial Ethernet is reality"

EDSMF2191IB EN 2.0

25

Page 26

5

Installation

Electrical installation

POWERLINK

5.2.3 POWERLINK

POWERLINK network segment

Note!

Standard Ethernet nodes are not permitted in the POWERLINK network

segment.

In order to use the real−time capability of the POWERLINK technology, the POWERLINK

nodes must be interconnected in a separate network segment.

In accordance with the POWERLINK rules, only the network master (managing node)

controls the access of the slaves (controlled nodes) to the network. The network master is

the only node that transmits autonomously. All other nodes (controlled nodes) only

transmit when they are entitled to transmit by the master.

Non−POWERLINK nodes (e.g. PCs) typically violate these rules by sending frames

independently of the master. These frames interfere with the cyclic frame exchange of the

POWERLINK nodes and prevent the real−time capability of the POWERLINK.

Connection to the standard Ethernet network

The connection to an external standard Ethernet network is carried out via an Ethernet

POWERLINK router.

These infrastructure component separates the network traffic in the POWERLINK network

segment from the one in the standard Ethernet. The handling of the frames depend on

their direction:

ƒ Standard Ethernet −−−> POWERLINK network segment

Only frames that are addressed to nodes in the POWERLINK network segment are

forwarded. The forwarding takes place in the asynchronous area of the POWERLINK

cycle.

ƒ POWERLINK network segment −−−> Standard Ethernet

Only asynchronous frames that are not addressed to nodes in the POWERLINK network

segment are forwarded.

26

EDSMF2191IB EN 2.0

Page 27

Installation

Electrical installation

POWERLINK

Topologies in the POWERLINK network segment

Note!

The use of class 1 hubs and switches inside the POWERLINK network segment

is not permitted.

Inside the segment only Ethernet hubs may be used as infrastructure elements. The hubs

must meet the requirements on class 2 repeaters acc. to IEEE 802.3u.

For this purpose, Lenze offers the dual hub integrated into the communication module and

the separate eight−fold hub, type E94AZCEH.

Class 1 hubs and switches are not permissible since they have considerably longer delay

times for the frame forwarding and a bigger jitter. Both sizes reduce the real−time

capability and dynamics.

The cable length between both nodes is limited to 100 m.

The topology rules (IEEE802.3u) required for controlling the collisions may be violated in

the POWERLINK network segment since according to the POWERLINK access order, frame

collisions are prevented. This enables a structure of lines and any hybrid forms between

star and line topology.

5

Recommended topology

For an easy configuration and due to many possible topology variants we recommend to

create networks according to the following rules:

1. Create slave groups with up to 10 nodes

2. Connect groups in star shape to the master (managing node).

3. For more than 2 groups: Use external 8−port hubs, e.g. Lenze hub E94AZCEH.

Exception: For maximally 2 groups, these are directly connected to the two ports of the

communication module.

Master

Hub

1. slave group

2. slave group

Fig. 5−2 Star topology for 1 to 2 slave groups

EDSMF2191IB EN 2.0

4. Connect slave groups to the master via one external hub each.

– For max. 7 slave groups one hub is sufficient.

– For more than 7 slave groups, use further hubs.

– The groups can be distributed on the hubs just as you like.

27

Page 28

5

5.2.4 Operation in the standard Ethernet

Installation

Electrical installation

Operation in the standard Ethernet

Note!

Operation in the standard Ethernet does not permit any real−time

communication.

The communication module can be operated in the standard Ethernet for a basic

parameter setting provided that the following applies:

1. Operation of the module in slave mode:

– Network address 239

– IP address: 192.168.100.<EPL address>

2. Real time operation must not be carried out.

3. No integration of a master (EPL address 240) into the standard Ethernet network.

More notes on wiring

ƒ Do not wire, if possible, more than 9nodes in succession in a network line.

28

EDSMF2191IB EN 2.0

Page 29

Installation

Electrical installation

POWERLINK connection

5

5.2.5 POWERLINK connection

You can use a standard Ethernet patch cable for connecting the communication module

to the fieldbus (see "Ethernet cable specifications" ( 30)).

Note!

Plug/remove the Ethernet cable plug in a straight manner (at right angles)

into/from the socket to make sure that the RJ45 socket will not be damaged.

Pin assignment

RJ45 socket PIN Signal

E94AYCXX004C

1 Tx +

2 Tx −

3 Rx +

4 −

5 −

6 Rx −

7 −

8 −

Tip!

The POWERLINK interfaces feature an auto MDIX function. This function

adjusts the polarity of the RJ45 interfaces so that a connection is established

irrespective of the polarity of the opposite POWERLINK interface, and

irrespective of the type of cable used (standard patch cable or crossover cable).

EDSMF2191IB EN 2.0

29

Page 30

5

Installation

Electrical installation

Specification of the Ethernet cable

5.2.6 Specification of the Ethernet cable

Note!

Only use cables complying with the below specifications.

Ethernet cable specifications

Ethernet standard Standard Ethernet (according to IEEE 802.3), 100base TX (fast Ethernet)

Cable type S/FTP (Screened Foiled Twisted Pair), ISO/IEC 11801 or EN 50173, CAT 5e

Damping 23.2 dB (at 100 MHz and per 100 m)

Crosstalk damping 24 dB (at 100 MHz and per 100 m)

Return loss 10 dB (per 100 m)

Surge impedance 100

Design of the Ethernet cable

Fig. 5−3 Design of the Ethernet cable (S/FTP, CAT 5e)

A Cable insulation

B Braid

C Foil shielding of the core pairs

TP1 ... TP4 Twisted core pairs 1 ... 4

E94YCEP016

30

EDSMF2191IB EN 2.0

Page 31

Colour code of Ethernet cable

Note!

Wiring and colour code are standardised in EIA/TIA 568A/568B.

You can use 4−pin Ethernet cables in accordance with the industrial standard.

The cable type only connects the assigned pins 1, 2, 3 and 6 with each other.

Installation

Electrical installation

Specification of the Ethernet cable

5

Fig. 5−4 Ethernet plug in accordance with EIA/TIA 568A/568B

Pair Pin Signal EIA/TIA 568A EIA/TIA 568B

3

2 3 Rx + White/orange White/green

1

2 6 Rx − Orange Green

4

1

2 Tx − Green Orange

4 Not assigned Blue Blue

5 Not assigned White/blue Blue/white

7 Not assigned White/brown White/brown

8 Not assigned Brown Brown

Tx + White/green White/orange

E94YCEI004A

EDSMF2191IB EN 2.0

31

Page 32

5

Installation

Electrical installation

Voltage supply

5.2.7 Voltage supply

Internal voltage supply

Note!

Internal voltage supply has been selected in the case of standard devices with

an extended AIF interface opening (e.g. front of 8200 vector). The area shown

on a grey background in the graphic marks the jumper position.

ƒ By default, this is not supplied internally in the standard device.

ƒ For internal voltage supply place the jumper on the position indicated

below.

In the case of all other device series (9300, ECS), voltage is always supplied

from the standard device.

(Only external voltage supply possible.)

Lenze setting

Internal voltage supply

External voltage supply

Note!

In the case of an external voltage supply and for greater distances between

the control cabinets, always use a separate power supply unit (SELV/PELV) that

is safely separated in accordance with EN 61800−5−1 in each control cabinet.

The external voltage supply of the communication module ...

ƒ is required if communication via the fieldbus is to be continued when the supply of

the device fails.

ƒ is provided via the 2−pin terminal strip with screw−type connection (24 V DC):

Terminal Description

+ External voltage supply

U = 24VDC(20.4 V − 0%... 28.8 V +0%)

I = 85 mA

− Reference potential for external voltage supply

ƒ The parameters of a standard device disconnected from the mains cannot be

accessed.

32

EDSMF2191IB EN 2.0

Page 33

Electrical installation

Terminal data

Area Values

Electrical connection Plug connector with screw connection

Possible connections

Tightening torque 0.5 ... 0.6 Nm (4.4 ... 5.3 lb−in)

Stripping length 6 mm

rigid:

flexible:

2

1.5 mm

without wire end ferrule

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

Installation

Voltage supply

5

EDSMF2191IB EN 2.0

33

Page 34

6

Commissioning

Before switching on

6 Commissioning

During commissioning, system−dependent data as e.g. motor parameters, operating

parameters, responses and parameters for fieldbus communication are selected for the

controller.

In Lenze devices, this is done via codes. The codes are stored in numerically ascending order

in the Lenze controllers and in the plugged−in communication/function modules.

In addition to these configuration codes, there are codes for diagnosing and monitoring

the bus devices.

6.1 Before switching on

Stop!

Before switching on the standard device with the communication module for

the first time, check the entire wiring for completeness, short circuit and earth

fault.

34

EDSMF2191IB EN 2.0

Page 35

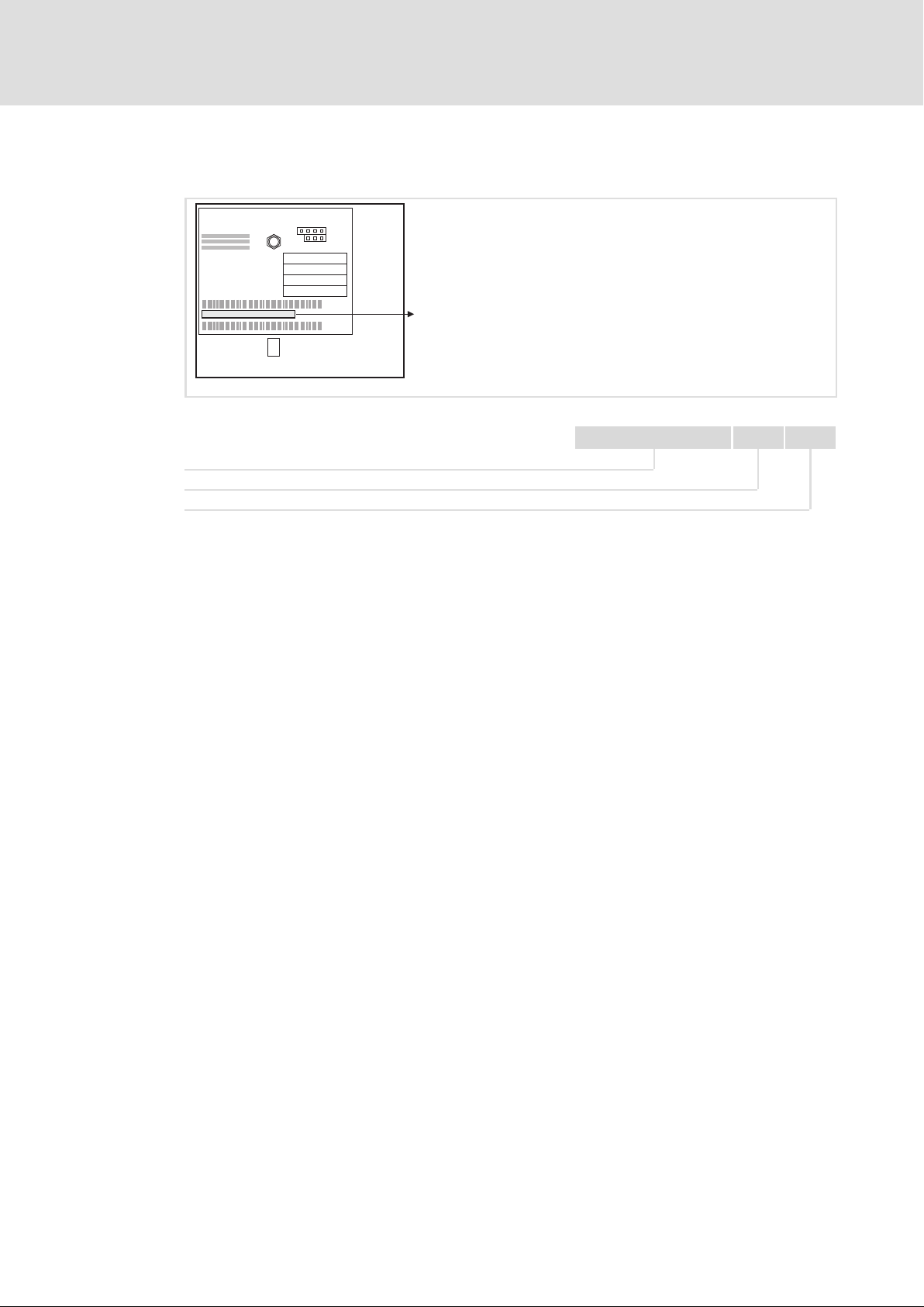

6.2 Setting the node address

Note!

ƒ Use different node addresses for several networked inverters.

The Lenze setting for the node address (node ID) has the value ’4’:

– link switch in position ’0’

– right switch in position ’4’

ƒ Switch the voltage supply of the inverter/communication module off and

on again to activate changed settings.

Commissioning

Setting the node address

6

E94YCEP001D

Fig. 6−1 Setting the node address

Each node has to be assigned to a unique address (node ID).

ƒ Valid address range for slave (controlled node): 1 ... 239

ƒ The corresponding IP address of the communication module results from the setting

of the two rotary switches.

IP address: 192.168.100.<Node ID>

(ValueNJLeftSwitchNj 16))(ValueNJRightSwitchNj) + NodeAddress

Example

ƒ Left rotary switch in position ’2’

ƒ Right rotary switch in position ’5’

(2 16))5 + 37

==> The node address is ’37’.

EDSMF2191IB EN 2.0

35

Page 36

6

6.3 Configuration via the "Automation Studio"

Commissioning

Configuration via the "Automation Studio"

The upgrade mechanism of the "Automation Studio" of the B & R company serves to establish an internet connection via which the necessary installation files are called.

After the upgrade, tick "display customised devices" in the hardware selection list to display the Lenze devices.

The following functions are available:

ƒ Adding Lenze devices to the hardware configuration

ƒ Setting node parameters (e.g. node ID)

ƒ I/O configuration (basic configuration settings of the controller)

ƒ Defining the I/O mapping (assignment of the process data objects of the controller

to the PLC objects)

The communication module is configured like a B & R device. The I/O configuration indicates the code which are compulsory for commissioning the inverter.

If further codes have to be written, library functions from the PLC project can be used. For

this purpose, you can find the "AsEPL" library in the "Library Manager". It provides the functions "EplSDOWrite" and "EplSDORead" which serve to read and write any parameters of

the device.

Indexing the Lenze codes

The index number is converted to a code as follows:

Conversion formula

Index (dec) Index (hex)

24575 − Lenze code 0x5FFF − (Lenze code)

Example of C0001 (operating mode):

Index (dec) Index (hex)

24575 − 1 = 24574 0x5FFF − 1 = 0x5FFE

Further information on the "Automation Studio" functions can be found in the

corresponding documentation.

36

EDSMF2191IB EN 2.0

Page 37

6.4 Initial switch−on

Switch on the inverter and check whether it is ready for operation using the diagnostic

LEDs at the front of the communication module.

ƒ Red diagnostic LEDs must not be on.

ƒ The following signalling should be visible:

LED

Pos. Colour Condition

green on The communication module is supplied with voltage and is connected to

green

green blinking Depending on the connection state, the data is transmitted or received

yellow on Ethernet connection is available (LINK).

Commissioning

Description

the standard device.

The NMT state machine triggers the two−colored LED:

l Green: Display of status messages

l Red: Display of error messages

NMT_CS_BASIC_ETHERNET

(LED is blinking with a frequency of 10 Hz or depending on the

connection state)

NMT_CS_OPERATIONAL / NMT_MS_OPERATIONAL

(LED is lit permanently.)

(ACTIVITY).

6

Initial switch−on

EDSMF2191IB EN 2.0

37

Page 38

Diagnostics7

7 Diagnostics

The LEDs on the front are provided to the communication module for the purpose of fault

diagnostics.

Displays

LED

Pos. Colour Condition

green

green

Red ERROR

Red On The red and green drive LED indicates the operating status of the

green blinking Depending on the connection state, the data is transmitted or received

yellow on Ethernet connection is available (LINK).

Description

off The communication module is supplied with voltage, but has no

connection to the basic device (basic device is either switched off, in the

initialisation phase, or not available).

on The communication module is supplied with voltage and is connected to

the standard device.

The NMT state machine triggers the two−colored LED:

l Green: Display of status messages

l Red: Display of error messages

Off NMT_GS_OFF, NMT_GS_INITIALISATION,

NMT_CS_NOT_ACTIVE / NMT_MS_NOT_ACTIVE

NMT_CS_PREOPERATIONAL_1 / NMT_MS_PREOPERATIONAL_1

(LED flashes once within a second.)

NMT_CS_PREOPERATIONAL_2 / NMT_MS_PREOPERATIONAL_2

(LED flashes twice within a second.)

NMT_CS_READY_TO_OPERATE / NMT_MS_READY_TO_OPERATE

(LED flashes three times within a second.)

NMT_CS_BASIC_ETHERNET

(LED is blinking with a frequency of 10 Hz or depending on the

connection state)

NMT_CS_STOPPED

(LED is blinking with a frequency of 2.5 Hz.)

NMT_CS_OPERATIONAL / NMT_MS_OPERATIONAL

(LED is lit permanently.)

(LED is lit permanently. An error has occurred.)

standard device (see documentation of the standard device).

(ACTIVITY).

38

EDSMF2191IB EN 2.0

Page 39

8 Appendix

8.1 Index table

Overview

The following objects specified by the Ethernet POWERLINK communication profile are

supported.

Tip!

The Ethernet POWERLINK specification contains details on the POWERLINK

communication profile and can be obtained from the Ethernet POWERLINK

Standardisation Group (EPSG):

http://www.ethernet−powerlink.org

Appendix

Index table

8

EPL index Subindex Index name More information

0x1000 NMT_DeviceType_U32 42

0x1001 ERR_ErrorRegister_U8 42

0x1003 ERR_History_ADOM −

0x1006 NMT_CycleLen_U32 42

0x1008 NMT_ManufactDevName_VS −

0x1009 NMT_ManufactHwVers_VS −

0x100A NMT_ManufactSwVers_VS −

0x1010 NMT_StoreParam_REC −

0x1011 NMT_RestoreDefParam_REC −

0x1018 1 ... 4 NMT_IdentityObject_REC 42

0x1020 CFM_VerifyConfiguration_REC −

0x1030 1 ... 9 NMT_InterfaceGroup_0h_REC 43

0x1101 1 Dia_NMTTelegramCount_REC 43

0x1400 1 ... 2 PDO_RxCommParam_00h_REC 43

0x1401 1 ... 2 PDO_RxCommParam_01h_REC 44

0x1402 1 ... 2 PDO_RxCommParam_02h_REC 44

0x1600 1 ... 20 PDO_RxMappParam_00h_REC 44

0x1601 1 ... 20 PDO_RxMappParam_01h_REC 45

0x1602 1 ... 20 PDO_RxMappParam_02h_REC 45

0x1800 1 ... 2 PDO_TxCommParam_00h_REC −

0x1A00 1 ... 20 PDO_TxMappParam_00h_REC 46

0x1C0A DLL_CNCollision_REC 46

0x1C0B DLL_CNLossSoC_REC 46

0x1C0C DLL_CNLossSoA_REC −

0x1C0D DLL_CNLossPReq_REC −

0x1C0E DLL_CNSoCJitter_REC −

0x1C0F DLL_CNCRCError_REC 47

0x1C10 DLL_CNLossOfLinkCum_U32 47

0x1C13 DLL_CNSoCJitterRange_U32 −

EDSMF2191IB EN 2.0

39

Page 40

8

Appendix

Index table

More informationIndex nameSubindexEPL index

0x1C14 DLL_LossOfFrameTolerance_U32 −

0x1E40 1 ... 5 NWL_IpAddrTable_0h_REC 48

0x1E4A 1 ... 3 NWL_IpGroup_REC −

0x1F50 PDL_DownloadProgData_ADOM −

0x1F51 PDL_ProgCtrl_AU8 −

0x1F52 PDL_LocVerApplSw_REC −

0x1F81 1 ... 64 NMT_NodeAssignment_AU32 49

0x1F82 NMT_FeatureFlags_U32 50

0x1F83 NMT_EPLVers_U8 50

0x1F8C NMT_CurrState_U8 51

0x1F8D 1 ... 64 NMT_MNPResPayloadList_AU32 51

0x1F93 1 ... 2 NMT_EPLNodeID_REC 51

0x1F98 1 ... 9 NMT_CycleTiming_REC −

0x1F99 NMT_CNBasicEthernetTimeout_U32 51

0x1F9A NMT_HostName_VSTR 52

0x1F9E NMT_ResetCmd_U8 52

40

EDSMF2191IB EN 2.0

Page 41

Appendix

Index table

How to read the index table

Model of an index table

Index Name

Subcode Lenze Values Data type

Access:

Meaning

Header Meaning

Index Number of the Ethernet POWERLINK index I−xxxx

Name Display text

8

Leading

columns

Subcode Number of the subcode

Lenze

Values

Data type

Footer Meaning

Access ro: The parameter can only be read (display code)

Meaning

Lenze setting ("Default" setting) of the code

à Display code

The code cannot be configured.

Minimum value [smallest increment/unit] Maximum value

In case of a display code the displayed values are specified.

l BITFIELD_8

l BITFIELD_32

l U8 8 bit value without sign

l U16 16 bit value without sign

l U32 32 bit value without sign

l U64 64 bit value without sign

l VS Visible String, string with specified length

rw: The parameter can be changed

EDSMF2191IB EN 2.0

41

Page 42

8

Appendix

Index table

I−1000:

EPL device type

Index

0x1000

Subcode Lenze Values Data type

−

EPL name

NMT_DeviceType_U32

U32

Access: ro

The object displays the device type of the node.

I−1001:

EPL error register

Index

0x1001

Subcode Lenze Values Data type

−

EPL name

ERR_ErrorRegister_U8

U8

Access: ro

The object contains currently pending errors arranged according to error classes. The bits

of the error register have the following meaning:

Bit Description

0 Generic error, signals an existing error message in the CN which can be read out via StatusResponse

1 Amperage

2 Voltage

3 Temperature

4 Communication error

5 Device profile−related error

6 Reserved (0)

7 Manufacturer−specific error

I−1006:

EPL cycle time

Index

0x1006

Subcode Lenze Values Data type

−11 ... [1 ms] ... 20 U32

EPL name

NMT_CycleLen_U32

Access: rw

The object contains the length of the EPL cycle in [s].

I−1018:

EPL identity object

Index

0x1018

Subcode Lenze Values Data type

1: VendorId_U32 0x59

2: ProductCode_U32 2191

3: RevisionNo_U32 0x00000000

4: SerialNo_U32

EPL name

NMT_IdentityObject_REC

U32

Access: ro

The object contains identification information on the communication module.

42

EDSMF2191IB EN 2.0

Page 43

I−1030:

EPL MAC address

Appendix

Index table

8

Index

0x1030

Subcode Lenze Values Data type

1: InterfaceIndex_U16

2: InterfaceDescription_VSTR EMF2191IB_1 VSTR

3: InterfaceType_U8 6 U8

4: InterfaceMtu_U32 1500 U32

5: InterfacePhysAddress_OSTR "00:0A:86:84:xx:xx" OSTR

6: InterfaceName_VSTR "IF1" VSTR

7: InterfaceOperStatus_U8 1 U8

EPL name

NMT_InterfaceGroup_0h_REC

0 U16

Access: ro for subcodes 1, 2, 3, 4, 5

and 7

Access: rw for subcode 6

The object contains information on the Ethernet interface. The subcode 5 contains the

MAC address. When the communication module is produced, the MAC address is assigned

unequivocally worldwide and provides addressing on the lowest level.

I−1101:

EPL telegram counter

Index

0x1101

Subcode Lenze Values Data type

1: IsochrCyc_U32 − − U32

EPL name

DIA_NMTTelegrCount_REC

Access: ro

Subcode 1 of the object contains a counter for POWERLINK cycles. The counter is started

with each power−on of the node at 0. An overflow occurs at 4.294.967.295.

I−1400:

EPL address : RPDO

Index

0x1400

Subcode Lenze Values Data type

100, 1 ... 240, 253, 254 U8

EPL name

PDO_RxCommParam_XXh_REC.NodeID_U8

Access: rw

Subcode 1 of the object contains the node address (node ID) of the transmitting node for

the PDO channel (n+1).

Values > ’0’ describe the origin of a PRes telegram. The value ’0’ is reserved for "PReq"

(cannot be used in systems with a Lenze Servo Drive 9400 as managing node).

The value is only valid if the corresponding object 0x160x has a value > ’0’.

EDSMF2191IB EN 2.0

43

Page 44

8

Appendix

Index table

I−1401:

EPL address : RPDO

Index

0x1401

Subcode Lenze Values Data type

100, 1 ... 240, 253, 254 U8

EPL name

PDO_RxCommParam_XXh_REC.NodeID_U8

Access: rw

Subcode 1 of the object contains the node address (node ID) of the transmitting node for

the PDO channel (n+1).

Values > ’0’ describe the origin of a PRes telegram. The value ’0’ is reserved for "PReq"

(cannot be used in systems with a Lenze Servo Drive 9400 as managing node).

The value is only valid if the corresponding object 0x160x has a value > ’0’.

I−1402:

EPL address : RPDO

Index

0x1402

Subcode Lenze Values Data type

100, 1 ... 240, 253, 254 U8

EPL name

PDO_RxCommParam_XXh_REC.NodeID_U8

Access: rw

Subcode 1 of the object contains the node address (node ID) of the transmitting node for

the PDO channel (n+1).

Values > ’0’ describe the origin of a PRes telegram. The value ’0’ is reserved for "PReq"

(cannot be used in systems with a Lenze Servo Drive 9400 as managing node).

The value is only valid if the corresponding object 0x160x has a value > ’0’.

I−1600:

EPL number of RPDO

Index

0x1600

Subcode Lenze Values Data type

000, 1 ... 32 U64

EPL name

PDO_RxMappParam_xxh_AU64.NumberOfEntries

Access: rw

The object describes the number of valid mapping entries for the PDO channel (n+1).

The value ’0’ inhibits the PDO channel. The sum of all mapping entries enabled via the

objects 0x160x must not exceed the value ’64’.

44

EDSMF2191IB EN 2.0

Page 45

I−1601:

EPL number of RPDO

Appendix

Index table

8

Index

0x1601

Subcode Lenze Values Data type

000, 1 ... 32 U64

EPL name

PDO_RxMappParam_xxh_AU64.NumberOfEntries

Access: rw

The object describes the number of valid mapping entries for the PDO channel (n+1).

The value ’0’ inhibits the PDO channel. The sum of all mapping entries enabled via the

objects 0x160x must not exceed the value ’64’.

I−1602:

EPL number of RPDO

Index

0x1602

Subcode Lenze Values Data type

000, 1 ... 32 U64

EPL name

PDO_RxMappParam_xxh_AU64.NumberOfEntries

Access: rw

The object describes the number of valid mapping entries for the PDO channel (n+1).

The value ’0’ inhibits the PDO channel. The sum of all mapping entries enabled via the

objects 0x160x must not exceed the value ’64’.

EDSMF2191IB EN 2.0

45

Page 46

8

Appendix

Index table

I−1A00:

EPL TPDO

Index

0x1A00

Subcode Lenze Values Data type

1 ... 32: ObjectMapping − see below U64

EPL name

PDO_TxMappParam_00h_AU64

Access: rw

The object describes the mapping for the TPDO channel. Subcode 0 describes the number

of valid mapping object entries. Subcodes 1 to 32 describe the mapping of the individual

objects.

The entry is structured as follows:

Byte Name Description

0, 1 Index EPL index of the mapped object

2 Subindex Subindex

3 Reserved

4, 5 Offset Offset, calculated from the start of the PDO user data [bits]

6, 7 Length Length of the mapped object [bits]

I−1C0A:

EPL CN: Telegr. collisions

Index

0x1C0A

Subcode Lenze Values Data type

1: CumulativeCnt_U32 − − U32

EPL name

DLL_CNCollision_REC

Access: ro

The object indicates the number of Ethernet collisions detected by the slave (controlled

node).

Each event is counted. Every single event is followed by an error message. No threshold

value management is implemented.

I−1C0B:

EPL CN: Loss of synchr.

Index

0x1C0B

Subcode Lenze Values Data type

1: CumulativeCnt_U32 − −

2: ThresholdCnt_U32 − −

3: Threshold_U32 1 0, 1, 2 etc.

EPL name

DLL_CNCollision_REC

U32

Access: see below

The slave (controlled node) expects SoC frames in time intervals which correspond to the

cycle time.

The object indicates the error counters for missing SoC frames.

46

EDSMF2191IB EN 2.0

Page 47

I−1C0F:

EPL CN: Frame error (CRC)

Appendix

Index table

8

Index

0x1C0F

Subcode Lenze Values Data type

1: CumulativeCnt_U32 − − U32

2: ThresholdCnt_U32 0 0, 1, 2, 3 ... U32

3: Threshold_U32 0 0, 1, 2, 3 ... U32

EPL name

DLL_CNCRCError_REC

Access:

Subcode 3: rw , otherwise ro

The object indicates the number of frame checksum errors detected by the slave

(controlled node).

I−1C10:

EPL CN: Link interruptions

Index

0x1C10

Subcode Lenze Values Data type

−−− U32

EPL name

DLL_CNLossOfLinkCum_U32

Access: ro

The object indicates the counter of the slave (controlled node) for Ethernet connection

interruptions.

Each event is counted. Every single event is followed by an error message. No threshold

value management is implemented.

EDSMF2191IB EN 2.0

47

Page 48

8

Appendix

Index table

I−1E40:

EPL IP address

Index

0x1E40

Subcode Lenze Values Data type

2

3

5 0xC0A864FE −

ƒ Subcode 2:

EPL name

NWL_IpAddrTable_0h_REC.Addr_IPAD

−

−

U32

Access: ro

The subcode contains the IP address of the communication module. It is derived

according to the following rule from the node address (node ID, I−1F93):

192.168.100.<I−1F93>

ƒ Subcode 3:

The subcode contains the IP subnet mask which limits the IP address range that can be

addressed directly (i.e. without using a gateway in the EPL segment of the routers). In

an EPL segment, the subnet mask is permanently assigned to the value

’255.255.255.0’ (0xFFFFFF00).

ƒ Subcode 5:

The subcode contains the IP address of the EPL router via which the EPL segment is

connected to the higher−level network.

The standard entry corresponds to the standard router address of the POWERLINK

specification:

192.168.100.254

Permissible entries replace the lowest−order byte of the standard entry with the EPL

address of the node which has the function of a router.

48

EDSMF2191IB EN 2.0

Page 49

I−1F81:

EPL node declaration CN

Appendix

Index table

8

Index

0x1F81

Subcode Lenze Values Data type

EPL name

NMT_NodeAssignment_AU32

see table U32

Access: rw

The object describes the slave (controlled node) and its properties.

The describing bit field has the following structure:

Relevance

Bit

0 (LSB) þ þ 0, 1 0 Node with this ID does not exist

1 þ þ 0, 1 0 Node with this ID is no CN

2 þ ¨ 1 0

3 þ þ 1 0 optional CN.

4 þ ¨ 0

5 þ ¨ 0 0 Application SW version verification is not required

6 þ ¨ 0, 1 0 Automatic application SW update is not allowed

7 − − 0 − Reserved

8 þ þ 0, 1 0 Isochronously accessed CN.

9 þ þ 0 0 Continuously accessed CN

10 ... 30 − − 0 − Reserved

31 (MSB) þ þ 0, 1 0 Bit 0 .. 30 inhibited

*)

Not permissible for Servo Drives 9400

MN CN

Lenze Value Description

1 Node with this ID exists

1 Node with this ID is a CN

*)

starting CNs are not automatically booted

1 starting CNs are automatically booted

1 obligatory CN.

0

1

1

1 Automatic application SW update is allowed

1 AsyncOnly CN, bit 9 irrelevant

1

1 Bit 0 .. 30 enabled

CN can be reset independently of the current state using the

NMTResetCommunication command

*)

CN must not be reset when being in the NMT_CS_OPERATIONAL state

*)

Application SW version verification is required

*)

Multiplex CN

EDSMF2191IB EN 2.0

49

Page 50

8

Appendix

Index table

I−1F82:

EPL feature flags

Index

0x1F82

Subcode Lenze Values Data type

−

EPL name

NMT_FeatureFlags_U32

U32

Access: ro

The object indicates the POWERLINK functions implemented by the slave (controlled

node).

The describing bit field has the following structure:

Relevance

Bit

0 ¨ þ Isochronous access is allowed Only AsyncOnly access

1 þ þ SDO via UDP/IP No SDO by UDP/IP

2 þ þ SDO via EPL ASnd

3 þ þ SDO integrated in PDO No SDO integrated in PDO

4 þ þ Support NMT Info Services No NMT Info Services

5 þ þ Support of extended NMT State Commands No extended NMT State Commands

6 þ þ Support of dynamic PDO mapping No dynamic PDO mapping

7 þ ¨ NMT services via UDP/IP No NMT services via UDP/IP

8 þ þ Configuration manager function No configuration manager function

9 þ þ Isochronous multiplex access is possible Only isochronous cyclic access is allowed

10 ¨ þ Address assignment via SW No address assignment via SW

11 þ ¨ Support of basic Ethernet mode of the master No support of basic Ethernet mode of the master

12 þ þ Device can be used as Powerlink to standard Ethernet

13 þ þ Device can be used as Powerlink to fieldbus router Device does not support any Powerlink to fieldbus

14 ... 31 − − Reserved (these bits are assigned to FALSE) −

MN CN

TRUE FALSE

(only MN for Servo Drives 9400)

router

No SDO via EPL ASnd

(only CN for Servo Drives 9400)

Device does not support any Powerlink to standard

Ethernet function

router function

I−1F83:

EPL version

Index

0x1F83

Subcode Lenze Values Data type

−

EPL name

NMT_EPLVers_U8

0x20 U8

Access: ro

The object describes the version of the Ethernet POWERLINK communication profile

implemented by the communication module.

The higher−order nibble describes the major version, the lower order nibble describes the

minor version. The implemented value corresponds to the EPL version 2.0.

50

EDSMF2191IB EN 2.0

Page 51

I−1F8C:

EPL communication status

Appendix

Index table

8

Index

0x1F8C

Subcode Lenze Values Data type

−

EPL name

NMT_CurrNMTState_U8

see table

Access: ro

The object contains the current NMT state.

I−1F8D:

EPL CN: Max. user data PRes RPDO

Index

0x1F8D

Subcode Lenze Values Data type

1 ... 100 36 bytes see description, unit: Byte U16

EPL name

NMT_PResPayloadList_AU16

Access: rw

This object defines the reserved user data length of the PRes frames.

Each subcode corresponds to a node with the same node ID. The node must have been

enabled via the object 0x1F81. The subcode describes the received PRes frames.

The value must be within the range of 36 ... 1490 bytes. The values are limit values for the

total sizes of the PDO mappings to be defined for received PRes frames.

I−1F93:

EPL device address

Index

0x1F93

Subcode Lenze Values Data type

−−1 .. 239 U8

EPL name

NMT_EPLNodeID_REC.NodeID_U8

Access: ro

The object contains the currently valid node address (node ID).

I−1F99:

EPL CN: Max. MN detection time

Index

0x1F99

Subcode Lenze Values Data type

− 5000000 s 0 ... 50000000 s U32

EPL name

NMT_CNBasicEthernetTimeout_U32

Access: rw

The object contains a time interval for a booting slave (controlled node) for detecting a

master (managing node). If a booting slave (controlled node) detects a master (managing

node) during the interval, it changes to NMT_CS_PREOPERATIONAL_1. If not, it changes to

"Basic Ethernet Mode".

EDSMF2191IB EN 2.0

51

Page 52

8

Appendix

Index table

I−1F9A:

EPL host name

Index

0x1F9A

Subcode Lenze Values Data type

−−see "naming convention" VS15

EPL name

NMT_Hostname_VSTR

Access: rw

The object contains a DNS−compatible device name. The length is limited to 15 characters.

Naming convention:

ƒ The device name ...

– starts with a letter;

– ends with a letter or a digit.

ƒ The device name consists of ...

– letters (A .. Z), upper or lower case,

– digits (0 .. 9),

– hyphen (−).

Note!

The device name must be unambiguous within the network domain.

I−1F9E:

EPL reset command

Index

0x1F9E

Subcode Lenze Values Data type

− see table U8

EPL name

NMT_ResetCmd_U8

Access: wo

The object initiates a reset of the node. The following reset commands are available:

Command Value Status transition

NMTInvalidService 0xFF (255) no function (default)

NMTResetNode 0x28 (40) NMT_GS_RESET_APPLICATION

NMTResetCommunication 0x29 (41) NMT_GS_RESET_COMMUNICATION

NMTResetConfiguration 0x2A (42) NMT_GS_RESET_CONFIGURATION

NMTSwReset 0x2B (43) NMT_GS_INITIALISING

When the reset has been executed, the object is automatically set to "NMTInvalidService".

Stop!

A reset command on a single node in the network can cause cycle and

monitoring errors.

52

EDSMF2191IB EN 2.0

Page 53

9 Index

Index 9

A

Address settings, 35

Application as directed, 12

Automation Studio, configuration, 36

B

Baud rate, 17

C

Cable specification, 30

CE−typical drive system, 24

Colour code of Ethernet cable, 31

Commissioning, 34

− Initial switch−on, 37

Communication medium, 17

Communication profile, 17

Configuration via the "Automation Studio", 36

Connection to the standard Ethernet, 26

Connections, 15

Cycle time, 20

D

Data for POWERLINK communication, 19

Definition of notes used, 9

Definitions, 8

Design of the Ethernet cable, 30

Device protection, 11, 22

Diagnostics, 38

E

Electrical installation, 24

EPL index

− 1C0B, 46

− I−1000, 42

− I−1001, 42

− I−1006, 42

− I−1018, 42

− I−1030, 43

− I−1101, 43

− I−1400, 43

− I−1401, 44

− I−1402, 44

− I−1600, 44

− I−1601, 45

− I−1602, 45

− I−1A00, 46

− I−1C0A, 46

− I−1C0F, 47

− I−1C10, 47

− I−1E40, 48

− I−1F81, 49

− I−1F82, 50

− I−1F83, 50

− I−1F8C, 51

− I−1F8D, 51

− I−1F93, 51

− I−1F99, 51

− I−1F9A, 52

− I−1F9E, 52

Ethernet cable specification, 30

Ethernet cable, colour code , 31

Ethernet cable, design, 30

Ethernet connection, 29

External voltage supply, 32

EDSMF2191IB EN 2.0

53

Page 54

Index9

H

Hardware version, type code, 13

I

I−1000: EPL device type, 42

I−1001: EPL error register, 42

I−1006: EPL cycle time, 42

I−1018: EPL identity object, 42

I−1030: EPL MAC address, 43

I−1101: EPL telegram counter, 43

I−1400: EPL address RPDO, 43

I−1401: EPL address RPDO, 44

I−1402: EPL address RPDO, 44

I−1600: EPL number of RPDO, 44

I−1601: EPL number of RPDO, 45

I−1602: EPL number of RPDO, 45

I−1A00: EPL TPDO, 46

I−1C0A: EPL CN: Telegr. collisions, 46

I−1C0B: EPL CN: Loss of synchr., 46

I−1C0F: EPL CN: Frame error (CRC), 47

I−1C10: EPL CN: Link interruptions, 47

I−1E40: EPL IP address, 48

I−1F81: EPL node declaration CN, 49

I−1F82: EPL feature flags, 50

I−1F83: EPL version, 50

I−1F8C: EPL communication status, 51

I−1F8D: EPL CN: Max. user data PRes RPDO, 51

I−1F93: EPL device address, 51

I−1F99: EPL CN: Max. MN detection time, 51

I−1F9A: EPL host name, 52

I−1F9E: EPL reset command, 52

Identification, 13

Indexing the Lenze codes, 36

Initial switch−on, 37

Installation, 22

− electrical, 24

− mechanical, 23

Interface, 17

Interfaces, 15

Internal voltage supply, 32

M

Mechanical installation, 23

N

Nameplate, 13

Network segment, 26

Network topology, 17

Notes, definition, 9

O

Operation in the standard Ethernet, 28

Order designation, 17

P

POWERLINK communication (technical data), 19

POWERLINK connection, 29

POWERLINK network segment, 26

Processing time, 20

Product description, 12

− application as directed, 12

Product features, 14

Protection of persons, 11

Protective insulation, 18

R

Residual hazards, 11

S

Safety instructions, 10

− application as directed, 12

− definition, 9

− device− and application−specific, 11

− layout, 9

Setting the node address, 35

Software version, type code, 13

Specification of the Ethernet cable, 30

Standard Ethernet connection, 26

Standard Ethernet operation, 28

Switch on, initial, 37

54

EDSMF2191IB EN 2.0

Page 55

Index 9

T

Technical data, 17

Terminal data, 33

Topologies in the POWERLINK network segment, 27

Transmission mode, 17

Type code, 13

− finding, 13

V

Validity of the documentation, 5

Voltage supply, 32

− internal, 32

Voltage supply: external, 32

W

Wiring according to EMC, 24

EDSMF2191IB EN 2.0

55

Page 56

F

(

Ê

ü

© 09/2013

Lenze Automation GmbH

Hans−Lenze−Str. 1

D−31855 Aerzen

Germany

+49(0)51 54 /82−0

+49(0)51 54 /82 − 28 00

Lenze@Lenze.de

www.Lenze.com

Service Lenze Service GmbH

Breslauer Straße 3

D−32699 Extertal

Germany

(

Ê

008000/ 2446877 (24 h helpline)

+49(0)5154/ 82−11 12

Service@Lenze.de

EDSMF2191IB § .M\} § EN § 2.0 § TD17

10987654321

Loading...

Loading...