Page 1

Accessories

Remote

Maintenance

EthernetCAN

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

EMF2180IB

Communication Manual EN

Ä.ObBä

13466533

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.1 General safety instructions and application notes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.2 Device and application-specific safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2.3 Residual hazards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

3 Product description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.1 Application as directed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.2 Identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.3 Connections and interfaces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

4 Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

4.1 General data and operating conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

4.2 Protective insulation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.3 Dimensions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

5Installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

5.1 Mechanical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

5.1.1 Mounting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

5.1.2 Dismounting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

5.2 Electrical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

5.2.1 Communication via Ethernet and CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

5.2.2 Connecting the CAN bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

5.2.2.1 Assignment of the 9-pin Sub-D plug connector _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5.2.2.2 Specification of the CAN bus cable _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5.2.3 Bus cable length (CAN) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

5.2.3.1 Total cable length _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

5.2.3.2 Segment cable length _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

5.2.3.3 Checking the use of repeaters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

5.2.4 Connecting the Ethernet cable _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

5.2.4.1 Ethernet cable specification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2.4.2 Pin assignment and use of the Ethenet cable _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

5.2.5 Voltage supply _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

6 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

6.1 Commissioning with the Lenze "System bus configurator" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

6.1.1 Installing/updating software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

6.1.2 Configuring the communication module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

6.1.3 After completing the configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

6.2 Commissioning with the web server _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

6.2.1 Assigning a fixed IP address _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

6.2.2 Assigning a dynamic IP address _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

6.2.3 Entering user name and password _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

6.2.4 Firmware update ("FW update") _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

6.2.5 Displaying Ethernet states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

6.2.6 Displaying alarms and events _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

6.3 Before initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

6.4 Initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.4.1 Signalling sequence of the LEDs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.4.2 LED signalling in compliance with DR303-3 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

2 Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

7.1 Access to the inverter codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

7.2 Data transfer via CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

7.3 Data transfer via Ethernet _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

8Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

8.1 Error: Cause and remedy _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

8.2 LED status displays for the communication module and for CAN communication _ _ _ _ _ _ _ _ _ 50

8.3 LED status displays for Ethernet communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

9 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

10 Implemented CANopen objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 66

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 3

Page 4

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Contents

This documentation exclusively describes the EMF2180IB communication module (EthernetCAN).

Note!

This documentation supplements the mounting instructions supplied with the

communication module and the "Remote maintenance" manual.

The mounting instructions contain safety instructions which must be observed!

The features and functions of the communication module are described in detail.

Typical applications are illustrated by means of examples.

The theoretical context is only explained as far as it is required for understanding the function of

the communication module.

This documentation does not describe any software provided by other manufacturers. No warranty

can be given for corresponding data provided in this documentation. For information on how to use

the software, please refer to the host (PLC, IO Controller) documents.

All product names mentioned in this documentation are trademarks of their corresponding owners.

"Remote maintenance" communication manual

Here you'll find some further information about remote maintenance scenarios.

4 Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 5

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Target group

This documentation is intended for all persons who plan, install, commission and maintain the

networking and remote servicing of a machine.

Tip!

Current documentation and software updates with regard to Lenze products can be found

in the download area at:

www.lenze.com

Validity

The information given in this documentation is valid for the following devices:

Extension module Type designation From hardware

version

Communication module EthernetCAN EMF2180IB 1x 1x

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the communication module and the software version of the engineering tools installed

(e.g. »Engineer«), the screenshots in this documentation may differ from the actual screen

representation.

From software

version

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 5

Page 6

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Document history

Version Description

1.0 11/2004 TD06 First edition

2.0 03/2005 TD06 • Update for the system bus configurator V1.2

• Lenze codes supplemented

3.0 04/2009 TD16 Publication as online help for the Lenze »Engineer«

4.0 09/2012 TD06 Commissioning with the web server supplemented

5.0 07/2014 TD17 • New layout

• General corrections

6

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 7

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Notation of numbers

Decimal Standard notation Example:1234

Decimal separator Point The decimal point is used throughout this documentation.

for example: 1234.56

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Text

Version information Blue text colour All information that applies to from a certain software

Program name " " The Lenze PC software »Engineer«...

Control element bold The OK button... / the Copy command... / the Characteristics

Sequence of menu

commands

Hyperlink Underlined

Symbols

Page reference ( 9) Optically highlighted reference to another page. In this

Step-by-step instructions

In quotation marks

Point

Example: ’100’

Example: ’0110.0100’

version of the device onwards are marked accordingly in this

documentation.

Example: This function extension is available from software

version V3.0 onwards!

tab... / the Name input field...

If several commands are required to execute one function,

the single commands are separated by an arrow: Select the

Open command to...

File

Optically highlighted reference to another topic. It is

activated with a mouse-click in this online documentation.

online documentation activated via mouse-click.

Step-by-step instructions are identified by a pictograph.

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 7

Page 8

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

Code Parameter which serves to parameterise and monitor the drive. In normal usage,

Subcode If a code contains several parameters they are stored in so-called "subcodes".

Use DHCP The "Dynamic Host Configuration Protocol" (DHCP) is a communication protocol

Engineering PC The Engineering PC and the Engineering tools installed serve to configure and

Engineering tools Lenze software solutions for the configuration and commissioning of Lenze

Inverter Generic term for Lenze frequency inverter, servo inverter

FW Firmware

HW Hardware

SW Software

the term is usually referred to as "Index".

In the documentation, the slash "/" is used as a separator between the code and

the subcode (e.g. "C00118/3").

In everyday language, the term is also referred to as "subindex".

providing for the assignment of the network configuration to cients by a server.

parameterise the system.

The Engineering PC communicates with the controller via Ethernet.

devices.

The EMF2180IB communication module is configured via the "System bus

configurator", which is part of the following Engineering tools:

• »Engineer«

• »Drive Server«, from version 1.1 onwards

• »Drive PLC Developer Studio« (DDS), from version 2.2 onwards

• »Global Drive Control« (GDC), from version 4.7 onwards

• »Global Drive Loader« (GDL), from version 2.2 onwards

Commissioning

( 32)

8

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 9

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

This documentation uses the following signal words and symbols to indicate dangers and

important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure troublefree operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to other documentation

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 9

Page 10

2 Safety instructions

2.1 General safety instructions and application notes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order to prevent

serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during operation.

2.1 General safety instructions and application notes

Danger!

If the following basic safety measures are disregarded, severe injuries to persons and

damage to material assets may result.

Lenze drive and automation components ...

• must only be used as directed.

Application as directed

• must never be commissioned if it displays any signs of damage.

• must never be modified technically.

( 12)

• must never be commissioned if it is not fully mounted.

• must never be operated without the required covers.

• during and after operation can have live, moving and rotating parts, depending on their degree

of protection. Surfaces can be hot.

The following applies to Lenze drive components ...

• only use the accessories approved.

• Only use genuine spare parts supplied by the manufacturer of the product.

Observe all specifications contained in the enclosed documentation and related documentation.

• This is the condition for safe and troublefree operation and the achievement of the specified

product features.

• The specifications, processes, and circuitry described in this document are for guidance only and

must be adapted to your own specific application. Lenze does not take responsibility for the

suitability of the process and circuit proposals.

All works on and with Lenze drive and automation components must only be carried out by qualified

personnel. According to IEC 60364 or CENELEC HD 384 these are persons who ...

• are familiar with installing, commissioning and operating the product.

• have the qualifications necessary for their occupation.

10

• know and are able to apply all regulations for the prevention of accidents, directives and laws

that apply to the location of use.

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 11

2 Safety instructions

2.2 Device and application-specific safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Device and application-specific safety instructions

• During operation, the communication module must be firmly connected to the inverter.

• Only use cables that meet the listed specifications.

Specification of the CAN bus cable

Ethernet cable specification ( 27)

• Decouple your Ethernet home network from the system network for Ethernet-capable Lenze

devices, in order to prevent Ethernet communication faults.

Connecting the Ethernet cable

• Before switching on the mains voltage, check ...

• the entire wiring for completeness, short circuit and earth fault:

• whether the bus system is terminated through a bus terminating resistor at the first and last

physical bus station.

Connecting the CAN bus

( 21)

( 22)

( 26)

Documentation for the inverter, control system, system/machine

All the other measures prescribed in this documentation must also be implemented.

Observe the safety instructions and application notes contained in this manual.

2.3 Residual hazards

Device protection

• The communication module contains electronic components which may be damaged or

destroyed by electrostatic discharge.

Installation

• To prevent the RJ45 socket from being damaged, insert or remove the Ethernet cable connector

straight (at a right angle) into or from the socket.

Connecting the Ethernet cable

• Observe the following to prevent any damage to the plug-on terminal strips and contacts:

• Wire the plug-on terminal strips first, then plug them on.

• Plug-on terminal strips that are not assigned must also be plugged on.

Voltage supply

( 17)

( 26)

( 30)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 11

Page 12

3 Product description

3.1 Application as directed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Product description

3.1 Application as directed

The communication module ...

• by remote maintenance is used for parameterisation or programming, commissioning and

diagnostics of the applicable Lenze devices;

• is suitable

and parameter data;

• is a device intended for use in industrial power systems;

• should only be used under the operating conditions prescribed in this documentation.

Any other use shall be deemed inappropriate!

Application range

The communication module can be used with the following Lenze devices:

• Servo Drives 9400

• 9300 servo inverter

• 9300 vector

• 9300 Servo PLC

• ECS servo system

• 8200 motec motor inverter

• 8200 vector frequency inverter

•Drive PLC

• 82XX frequency inverter

• starttec motor starter

• Terminal extension 9374

• Control / display unit (EPM-HXXX)

for the transmission of IEC61131 programs, application data (such as profile data)

12

• I/O system IP20 (EPM-TXXX)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 13

3 Product description

E82AF000P0B201XX

L

Type

Id.-No.

Prod.-No.

Ser.-No.

MAC

3.2 Identification

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.2 Identification

The type designation, hardware version and software version of a communication module are

indicated on its nameplate:

1 "33.2180IBxxyy" type designation:

• 33.2180IB: device series

• xx: hardware version

• yy: software version

2180FEW099

[3-1] Identification data

3.3 Connections and interfaces

[3-2] EMF2180IB communication module (EthernetCAN)

2180FEW001D

A ... D LED status displays for the communication module

and for CAN communication ( 50)

E Ethernet connection

RJ45 socket with 2 LED status displays

F CAN connection

9-pole Sub-D plug connector

G Voltage supply

4-pole plug connector with spring connection

H PE connection

When it is plugged in, the communication module is

automatically connected to the DIN rail.

The DIN rail must be connected to PE!

I, K LED status displays for Ethernet communication

( 52)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 13

Page 14

4Technical data

4.1 General data and operating conditions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Technical data

4.1 General data and operating conditions

Range Values

Order designation EMF2180IB

Communication media (system) CAN (ISO 11898)

Ethernet (100 Base TX, IEEE802.3u)

Number of nodes at the CAN bus Max. 100

Baud rate • For communication via CAN

•20 kbit/s

•50 kbit/s

•125 kbit/s

•250 kbit/s

•500 kbit/s

• 1000 kbps

• For communication via Ethernet

• 10 Mbps

•100 Mbits/s

Voltage supply (external) via

separate power supply unit

18 ... 30 V DC, max. 100 mA (in compliance with IEC/EN 61131-2)

Conformity and approval

CE See hardware manual of the used Inverter.

UL See hardware manual of the used Inverter.

EAC TP TC 020/2011

(TR ZU 020/2011)

TP TC 004/2011

(TR ZU 004/2011)

Operating conditions Values Deviations from standard

Climatic conditions

Storage 1 K3 to IEC/EN 60721-3-1 - 10 °C ... + 60 °C

Transport 2 K3 to IEC/EN 60721-3-2 - 10 °C ... + 70 °C

Operation 3 K3 to IEC/EN 60721-3-3 - 0 °C ... + 60 °C

Enclosure of the plugged

communication module

Degree of pollution 2 to IEC/EN 61800-5-1

Electromagnetic compatibility of

technical means

On safety of low voltage equipment

IP20

Eurasian Conformity

TR CU: Technical Regulation of Customs Union

14

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 15

4Technical data

4.2 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Protective insulation

[4-1] Protective insulation according to EN 61800-5-1

Connection Type of insulation

E Ethernet Functional insulation

F CAN bus Functional insulation

G Voltage supply No insulation

2180FEW001F

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 15

Page 16

4Technical data

aa

e

4.3 Dimensions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Dimensions

A Mounting rail

a 117 mm

b 103 mm

e 22.5 mm

2180FEW001B

[4-2] Dimensions

16

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 17

5 Installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Installation

Stop!

Electrostatic discharge

Electronic components within the communication module can be damaged or destroyed

by electrostatic discharge.

Possible consequences:

• The communication module is defective.

• Fieldbus communication is not possible or faulty.

Protective measures

Before touching the module, be sure that you are free of electrostatic charge.

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 17

Page 18

5 Installation

5.1 Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.1 Mechanical installation

5.1.1 Mounting

2181FEW002B

[5-1] Mounting

Switch off voltage supply (1) and attach communication module to DIN rail (2 ... 4).

18

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 19

5 Installation

5.1 Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.1.2 Dismounting

[5-2] Dismounting

Unlock communication module (1) and remove from DIN rail (2, 3).

2181FEW001E

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 19

Page 20

5 Installation

(CAN on board)

CAN

Ethernet

Servo Drives 9400

9400

9400

9400

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2 Electrical installation

Documentation for inverters, the control system, system/machine

Observe the notes and wiring instructions contained in this documentation.

5.2.1 Communication via Ethernet and CAN

[5-3] Communication via Ethernet and CAN

Installation steps

Step Position Additional information

1. Establish a connection to the CAN bus:

Plug "EWZ0046" Sub-D plug (see accessories) into the

communication module.

2. Connect the following components via Ethernet with

each other:

• Communication module

• Engineering PC

• Servo Drive 9400

• Other Ethernet nodes

3. Connect voltage supply to the plug connector. G Voltage supply

F Connecting the CAN bus

E

L

S

Connecting the Ethernet cable

( 26)

( 30)

2180FEW008

( 21)

20

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 21

5 Installation

L

EWZ0046

O

F

F

O

N

OFF

ON

ON

OFF

ð

ð

ð

ð

OUTIN IN IN

On

Off

On

120 120

120

L

EWZ0046

L

EWZ0046

L

EWZ0046

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.2 Connecting the CAN bus

2180FEW001K

The CAN bus must be terminated with resistors (120 ) between CAN-low and CAN-high.

The EWZ0046 Lenze system connector with an integrated terminating resistor complies with the

DS102-1 recommendation of the CiA CAN user organisation. The system connector is not contained

in the scope of supply of the communication module.

2181FEW004

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 21

Page 22

5 Installation

1

6

5

9

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.2.1 Assignment of the 9-pin Sub-D plug connector

View Pin Assignment

1-

2CAN-LOW

3CAN-GND

4-

5-

6-

7CAN-HIGH

8-

9-

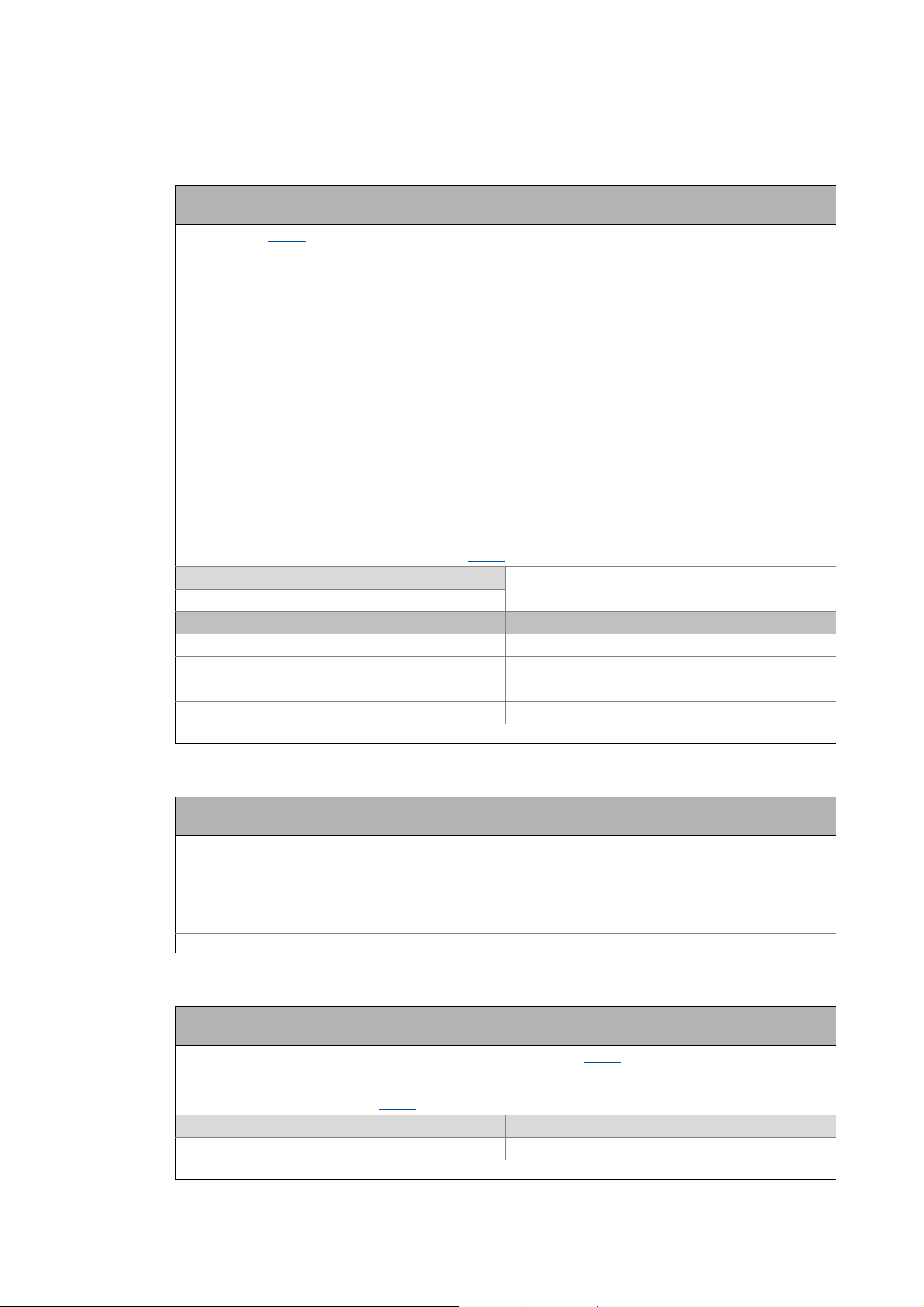

5.2.2.2 Specification of the CAN bus cable

We recommend the use of CAN cables according to ISO 11898-2:

CAN cable according to ISO 11898-2

Cable type Twisted in pairs with shield

Impedance 120 (95 ... 140 )

Cable resistance/cross-section

Cable length 300 m:

Cable length 301 ... 1000 m:

Signal propagation delay 5 ns/m

70 m/m / 0.25 ... 0.34 mm

40 m/m / 0.5 mm

2

2

(AWG20)

(AWG22)

22

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 23

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.3 Bus cable length (CAN)

Note!

• It is absolutely necessary to comply with the permissible cable lengths.

• If the total cable lengths of the CAN nodes differ for the same baud rate, the smaller

value must be used to determine the max. cable length.

• Observe the reduction of the total cable length due to the signal delay of the

repeater.Checking the use of repeaters

5.2.3.1 Total cable length

The baud rate also determines the total cable length.

Baud rate [kbps] Max. bus length [m]

10 8075

20 4012

50 1575

125 600

250 275

500 112

800 38

1000 12

( 25)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 23

Page 24

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.3.2 Segment cable length

The segment cable length is determined by the cable cross-section used and by the number of

nodes. Repeaters divide the total cable length into segments. If no repeaters are used, the segment

cable length is identical to the total cable length.

Max. number of

nodes per segment

2 240 m 430 m 650 m 940 m

5 230 m 420 m 640 m 920 m

10 230 m 410 m 620 m 900 m

20 210 m 390 m 580 m 850 m

32 200 m 360 m 550 m 800 m

63 170 m 310 m 470 m 690 m

100 150 m 270 m 410 m 600 m

Cable cross-section (can be interpolated)

0.25 mm

(AWG 24)

2

0.50 mm

(AWG 21)

2

0.75 mm

(AWG 19)

2

1.00 mm

(AWG 18)

2

Example: Selection help

Given

Total cable length to be

implemented

Number of nodes 63

Results

Max. possible baud rate 250 kbit/s

Required cable cross-section

(interpolated)

Cable cross-section of standard CAN

cable

200 m

(derived from the table Total cable length

0.30 mm

(derived from the table Segment cable length

0.34 mm

Specification of the CAN bus cable

2

(AWG23)

2

(AWG22)

( 23))

( 22)

( 24))

24

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 25

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.3.3 Checking the use of repeaters

Compare the values derived from tables Total cable length ( 23) and Segment cable length ( 24).

• If the sum of the segment cable lengths is smaller than the total cable length to be

implemented, either repeaters must be used or the cable cross-section must be increased.

• If the use of repeaters reduces the max. possible total cable length so much that it is smaller

than the total cable length to be implemented, then the cable cross-section must be increased

or less repeaters must be used or the baud rate must be decreased.

• The use of a further repeater is recommended as ...

•service interface

Advantage: trouble-free connection during bus operation is possible.

• calibration interface

Advantage: the calibration/programming unit remains electrically isolated.

Example

Given

Total cable length to be

implemented

Number of nodes 32

Cable cross-section 0.50 mm

Baud rate 125 kbit/s

Repeater used Lenze repeater EMF2176IB

Reduction of the max. total cable

length per repeater (EMF2176IB)

450 m

30 m

2

(AWG 20)

Results

Max. possible total cable length 600 m

(see table Total cable length

Max. segment cable length 360 m

(see table Segment cable length

Comparison The max. segment cable length is smaller than the total cable length to be

implemented.

Conclusion A repeater must be installed at the determined max. segment cable length

of 360 m.

Results with 1 repeater

Max. possible total cable length 570 m

(Reduction of the Total cable length

Sum of the segment cable lengths 720 m

Comparison Both the possible total cable length and the segment cable lengths are larger

than the total cable length to be implemented.

Conclusion 1 repeater is sufficient to implement the total cable length of 450 m.

( 23))

( 24))

( 23) by 30 m)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 25

Page 26

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.4 Connecting the Ethernet cable

Note!

• Decouple your Ethernet house network from the system network for Ethernetcapable Lenze devices in order to prevent EthernetCAN communication faults.

Further information about this can be obtained from the "Ethernet in the industrial

application" manual.

• To prevent the RJ45 socket from being damaged, insert or remove the Ethernet cable

connector straight (at a right angle) into or from the socket.

2181FEW004A

[5-4] Ethernet connection

26

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 27

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.4.1 Ethernet cable specification

Ethernet cable in compliance with IEEE 802.3

Ethernet standard Standard Ethernet (in accordance with IEEE 802.3), 100Base-TX (Fast

Cable type S/FTP (Screened Foiled Twisted Pair), ISO/IEC 11801 or EN 50173, CAT 5e

Damping 23.2 dB (for 100 MHz and 100 m each)

Crosstalk damping 24 dB (for 100 MHz and 100 m each)

Return loss 10 dB (100 m each)

Surge impedance 100

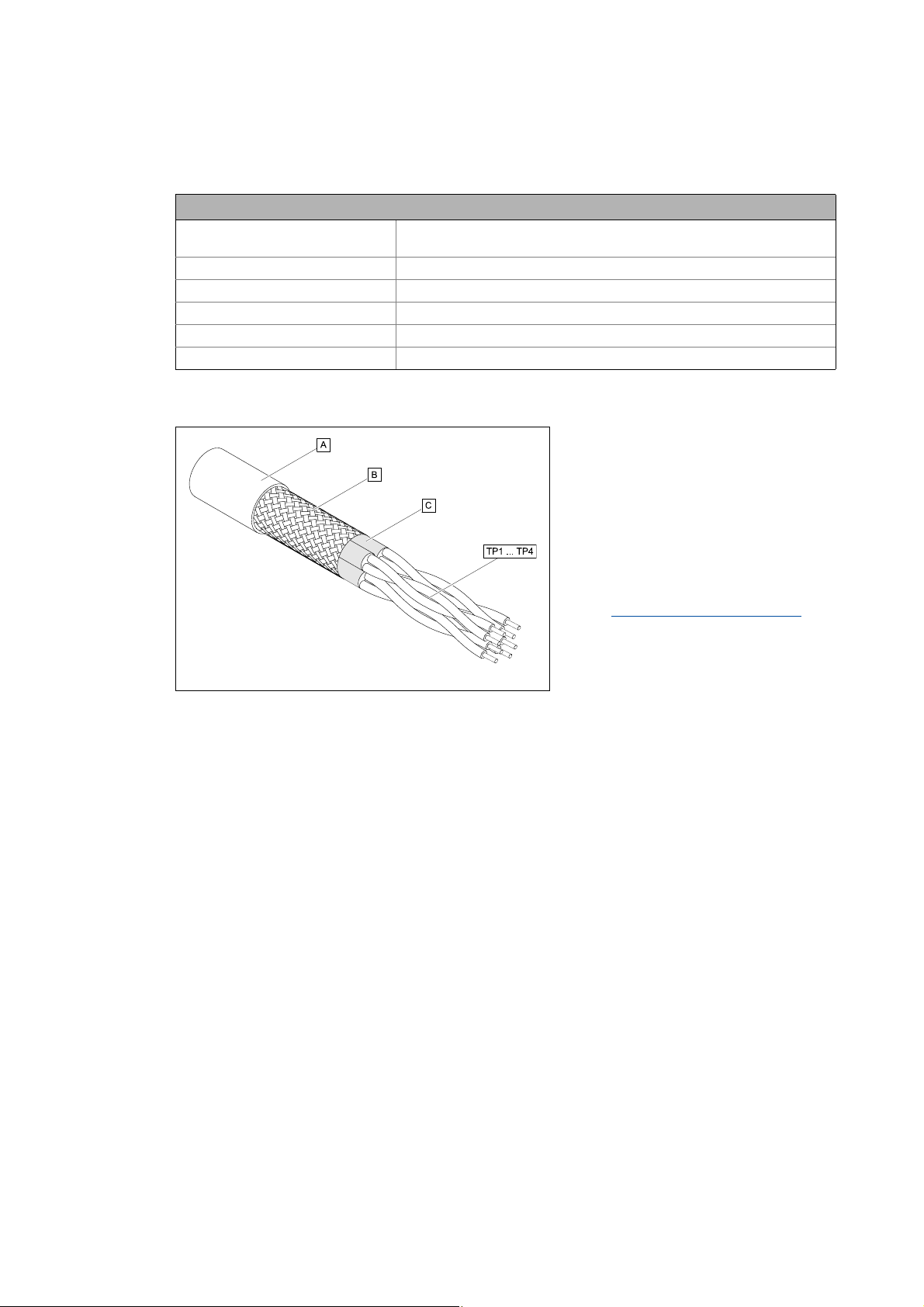

Structure of the Ethernet cable

Ethernet)

a Cable insulation

[5-5] Structure of the Ethernet cable (S/FTP, CAT 5e)

E94YCEP016

B Braid

C Foil shielding

TP1

Twisted core pairs 1 ... 4

...

Colour code of the Ethernet cable

TP4

( 28)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 27

Page 28

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Colour code of the Ethernet cable

Note!

Wiring and colour code are standardised in EIA/TIA 568A/568B.

In accordance with the industrial standard, the use of 4-pin Ethernet cables is

permissible. The cable type only connects the assigned pins 1, 2, 3 and 6 to one another.

E94YCEI004A

[5-6] Ethernet plug in accordance with EIA/TIA 568A/568B

Pair Pin Signal EIA/TIA 568A EIA/TIA 568B

3 1 Tx + white / green white / orange

2 Tx - Green orange

2 3 Rx + white / orange white / green

1 4 blue blue

5 white / blue blue / white

2 6 Rx - orange Green

4 7 white / brown white / brown

8brown brown

28

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 29

5 Installation

1Tx+ Tx+1

2Tx- Tx-2

3Rx+ Rx+3

44

55

6Rx- Rx-6

77

88

1Tx+ Tx+1

2Tx- Tx-2

3Rx+ Rx+3

44

55

6Rx- Rx-6

77

88

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.4.2 Pin assignment and use of the Ethenet cable

100BaseTX - CrossOver Cable 100BaseTX - Standard Patch Cable

The "100BaseTX - CrossOver Cable" is used for direct

coupling of the Engineering PC with the communication

module.

The "100BaseTX - Standard Patch Cable" is used in

conjunction with hubs and switches.

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 29

Page 30

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.5 Voltage supply

2181FEW001G

[5-7] Communication via the diagnostic interface (only for Servo Drives 9400)

Handling of pluggable terminal strips

Stop!

Observe the following to prevent any damage to the plug-on terminal strips and

contacts:

• Wire the plug-on terminal strips first, then plug them on.

[5-8] Use of pluggable terminal strip with spring connection

• Plug-on terminal strips that are not assigned must also be plugged on.

E82ZAFX013

30

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 31

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Terminal data

Range Values

Electrical connection Plug connector with spring connection

Possible connections rigid:

2.5 mm2 (AWG 12)

flexible:

without wire end ferrule

2

2.5 mm

with wire end ferrule, without plastic sleeve

2.5 mm

with wire end ferrule, with plastic sleeve

2.5 mm

Bare end 10 mm

(AWG 12)

2

(AWG 12)

2

(AWG 12)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 31

Page 32

6 Commissioning

6.1 Commissioning with the Lenze "System bus configurator"

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Commissioning

6.1 Commissioning with the Lenze "System bus configurator"

Via the "System bus configurator", the EMF2180IB communication module is configured for

communication with the fieldbus nodes and the Lenze Engineering tools.

The "System bus configurator" is part of the following Lenze Engineering tools:

• »Engineer«

• »Drive Server«, from version 1.1 onwards

• »Drive PLC Developer Studio« (DDS), from version 2.2 onwards

• »Global Drive Control« (GDC), from version 4.7 onwards

• »Global Drive Loader« (GDL), from version 2.2 onwards

Note!

Some of the Engineering tools mentioned offer alternative communication paths for

CAN. In this case, always select the "OPC" communication path.

Tip!

6.1.1 Installing/updating software

We recommend always using the most recent version of the Lenze Engineering tools.

Current software updates for the Engineering tools and information about the system

requirements can be found in the ”Download” area at:

www.lenze.com

How to install or update the Lenze Engineering tools:

1. Download the corresponding file from the Download area of the Lenze homepage to your

Engineering PC.

2. Start the installation program by double-clicking the file downloaded.

3. Follow the further instructions of the installation program.

32

After having carried out the installation successfully, you can open the "System bus configurator"

via the MS Windows® start menu under:

All Programs Lenze Communication System bus configurator

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 33

6 Commissioning

6.1 Commissioning with the Lenze "System bus configurator"

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.1.2 Configuring the communication module

Before communication with the communication module can be established, you have to carry out

settings for the following parameters:

•CAN parameters

The CAN parameters are saved in the communication module and contain specific data for the

CAN bus such as the baud rate, parameter data channel, or time-out.

• Parameters for access to the communication module

The communication module is an Ethernet node. Each Ethernet node has 2 addresses: a MAC

address and an IP address.

The MAC address serves to unambiguously identify a device worldwide. Observe the MAC

address entry on the nameplate of the communication module. The MAC address is hard-coded

in the device and cannot be changed. If an Ethernet connection to the communication module

has already been established, the MAC address can be read out online.

The IP address is a logical address which must be adapted to the corresponding Ethernet

network.

How to configure the communication module:

1. Open the "System bus configurator" via the MS Windows® start menu under:

All Programs Lenze Communication System bus configurator

2. Click the Add button and select the "EMF2180IB" communication module from the list.

3. Click the Settings tab.

4. Enter the CAN parameters.

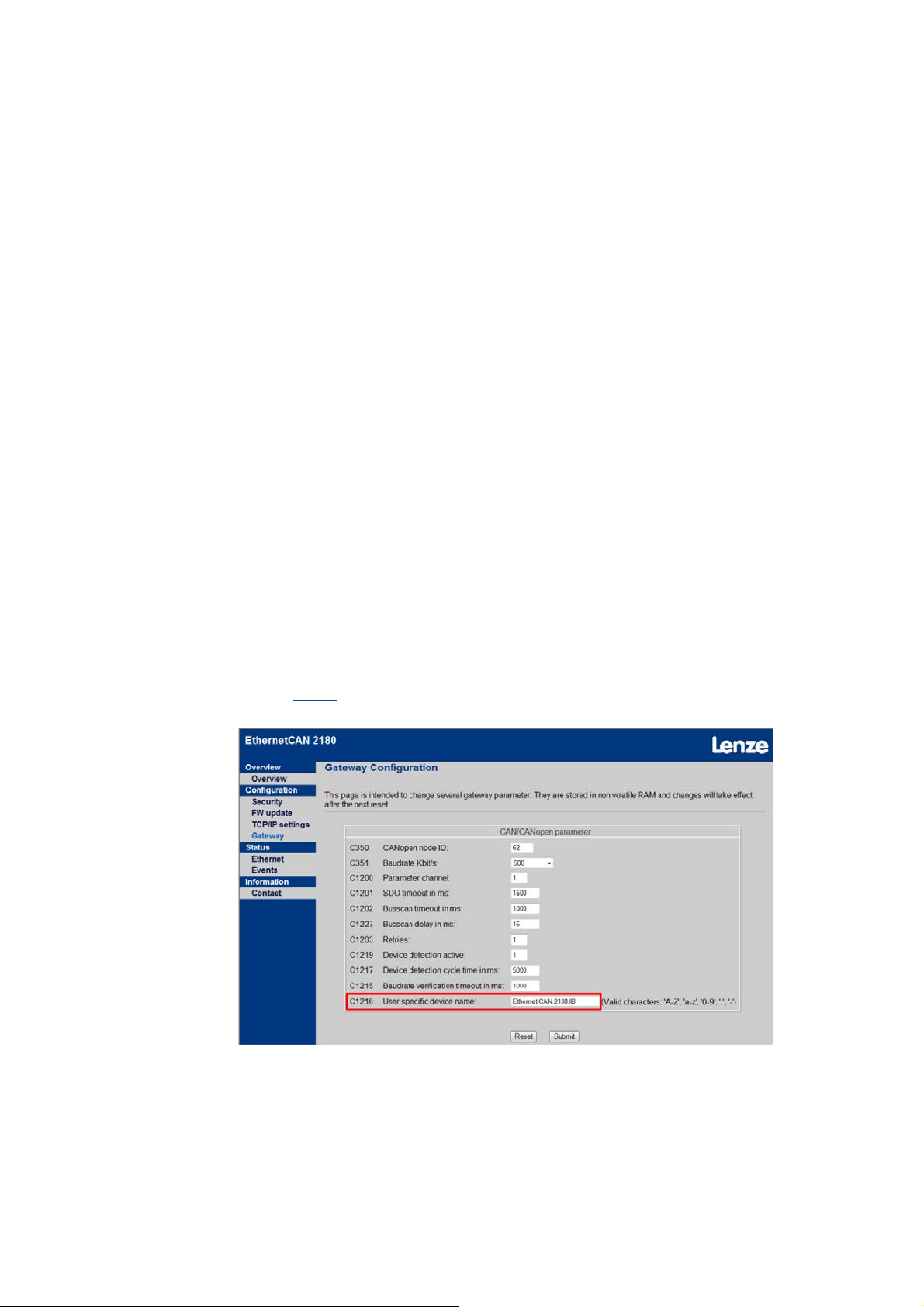

The following function is available from version 1.7 onwards!

Via code C1216

communication module:

or the web interface, you can assign an alphanumeric name to the

2180FEW016

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 33

Page 34

6 Commissioning

6.1 Commissioning with the Lenze "System bus configurator"

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5. Enter the MAC address of the nameplate or identify it online.

6. Enter the desired IP address and transfer it to the communication module online.

Afterwards an automatic reset is carried out by the communication module, which may

take some seconds (observe LEDs).

7. When the communication module is ready for operation again, change to the General tab.

8. Click the Diagnostics tab.

An attempt is made to establish a connection to the communication module. First, a

comparison is made, checking whether the CAN parameters configured are identical to

those in the device. If this is not the case, an adjustment is carried out.

9. Then search the CAN bus for nodes connected.

10. Confirm the confirmation prompt with Yes, or select No to abort the diagnostics process.

34

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 35

6 Commissioning

6.1 Commissioning with the Lenze "System bus configurator"

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.1.3 After completing the configuration

Communication with Lenze Engineering tools

When the configuration of the communication module has been completed successfully, the Lenze

Engineering tools can communicate via the communication module. The Lenze Engineering tools

only carry out the selection of the bus system to be used.

All system bus-specific settings as well as the selection of the communication module are

exclusively carried out via the "System bus configurator".

Note!

For some older program versions of the Lenze Engineering tools, settings for "Interrupt"

and "I/O address" can still be made, which, for the EMF2180IB communication module,

are irrelevant.

Communication with nodes

If the communication module can communicate successfully with the corresponding nodes, the

CAN node addresses of the nodes found are listed in the Device status field.

The communication module itself answers with its CAN node address or with "0" if it doesn't have

a CAN node address (depending on the setting in C0350

the communication module itself are not visible on the CAN bus.

Communication failed

If there is no communication with the nodes, a corresponding error message is output.

). The data frames for communication with

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 35

Page 36

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2 Commissioning with the web server

Commissioning via the integrated web server is an alternative to commissioning with the "System

bus configurator".

The integrated web server makes it possible to configure the communication module by means of

a simple web browser.

The following function is available from version 1.7 onwards!

When the DHCP function is activated, the DHCP server automatically assigns an IP address to the

communication module.

If an invalid combination of IP address and subnet mask is detected, an error message is output via

the web page:

2180FEW019

In this case, the two values (IP address, subnet mask) will not be saved in the EEPROM of the

communication module.

The gateway IP is only valid if it is inside the user's own network (exception: gateway IP ’0.0.0.0’).

36

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 37

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

The following function only applies to version <1.7!

Prerequisite for commissioning via web server:

• The IP address of the communication module must have been assigned by the "System bus

configurator" before.

• The IP address must be within the range that can be addressed by the Engineering PC

connected.

If one of the preconditions is not met, the IP address has to be changed using the "System bus

configurator":

2180FEW017

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 37

Page 38

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.1 Assigning a fixed IP address

Note!

The Lenze standard setting of the IP address is ’0.0.0.0’. With this (invalid) IP address, the

communication module at the start automatically finds its own IP address in the range

of ’169.254.xxx.xxx’ according to the standardised APIPA process.

Start your web browser and then enter the communication module's IP address that is known to you

as URL (instead of "xxx.xxx.xxx.xxx"):

2180FEW010

The web interface of the communication module will appear. Here you can carry out all further

settings.

2180FEW011

38

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 39

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.2 Assigning a dynamic IP address

By corresponding configuration, the communication module can also dynamically obtain the IP

address by the DHCP server.

For this, activate the "Use DHCP" checkbox under the TCP/IP settings:

Note!

Since the procedure for the dynamically assigned IP address is not found in industrial

environments very often, its use is not recommended.

Ethernet communication manual

Here you'll find more information about the configuration of an Ethernet network.

2180FEW013

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 39

Page 40

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

The following function is available from version 1.7 onwards!

You can activate DHCP in the »Engineer« via code C1228

So far, this has only been possible via a checkbox on the "TCP/IP Settings" page of the web interface.

A static IP configuration that has already been configured is maintained after the activation of

DHCP. Even after the deactivation of DHCP and

configuration is still valid.

subsequent mains switching or reset, the static IP

:

2180FEW018

40

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 41

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.3 Entering user name and password

All settings that can be carried out under "Configuration" are protected by a combination of a user

name and a password. The Lenze standard setting is:

•User name: Lenze

• Password: Lenze

The user name and password can be changed as often as desired. The entries are case-sensitive.

Via the Submit button, the data that have been altered are written to the EEPROM of the

communication module. They are only active after the next restart.

6.2.4 Firmware update ("FW update")

Note!

This page is only used for Lenze-internal purposes and cannot be accessed freely.

2180FEW012

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 41

Page 42

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.5 Displaying Ethernet states

These states are displayed:

• Current transfer rate (10/100 Mbit/s)

• Transmission mode (half/full duplex)

• MAC ID of the EMF2180IB communication module

• Static parameters of the Ethernet connection

2180FEW014

42

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 43

6 Commissioning

6.2 Commissioning with the web server

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.6 Displaying alarms and events

After the communication module has been started, alarms and events are recorded and displayed

in a list.

Events are classified by severity into:

• Error

• Warning

•Info

The list also contains the time when the alarm or the event occurred.

Note!

The list is deleted every time the communication module is restarted.

Date and time are only correct if a "time server" is configured. Without configuration of

the "time server", the computation of time always starts with the restart of the

communication module on 01.01.1970 at 0:00 h.

2180FEW015

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 43

Page 44

6 Commissioning

6.3 Before initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3 Before initial switch-on

Stop!

Before switching on the mains voltage, check ...

• the entire wiring for completeness, short circuit and earth fault:

• whether the bus system is terminated by means of a bus terminating resistor at the

first and last physical bus station.

Connecting the CAN bus

Automatic address allocation and detection of the baud rate

The EMF2180IB communication module is provided with the following functions:

• Automatic address assignment

• Automatic detection of the baud rate

( 21)

These functions are used to prevent failures due to an incorrectly set node address and baud rate.

Note!

In the Lenze standard setting, these functions are not activated.

For this, observe the information relating to codes ...

• C0350

• C0351

(CAN node address)

(CAN baud rate)

44

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 45

6 Commissioning

6.4 Initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4 Initial switch-on

6.4.1 Signalling sequence of the LEDs

[6-1] LEDs on the front of the communication module

Signalling sequence after switch-on:

1. Initialisation phase of peripherals starts:

•LED D (voltage supply, green) is lit.

2. After the CAN controller initialisation:

•LED C (RUN-LED, green) is blinking.

3. Ethernet connection is established:

•LED I is lit.

•LED A shows the baud rate of the Ethernet connection (10 Mbps or 100Mbps).

•When LED A is blinking, the communication module is currently determining the IP address.

Communication via Ethernet is only possible when this process has been completed.

Now, the device is ready for operation.

2181FEW001H

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 45

Page 46

6 Commissioning

6.4 Initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4.2 LED signalling in compliance with DR303-3

Connection status to the CAN bus with the following signalling:

LEDs Description

off Connection to the master is available.

Green CANopen status ("Z")

Red CANopen error ("F")

Status display (LED) Explanation

Constantly red F: Bus-off

Flicker Automatic baud rate detection is active.

Blinking green every 0.2 s Z: Pre-operational, F: No errors

Blinking green every 0.2 s

1 x red blinking, 1 s OFF

Green blinking every 0.2 s

2 x red blinking, 1 s OFF

Constantly green Z: Operational, F: No errors

Z: Pre-operational, F: Warning limit reached

Z: Pre-operational, F: Node guarding event

Constantly green

1 x red blinking, 1 s OFF

Constantly green

2 x red blinking, 1 s OFF

Constantly green

3 x red blinking, 1 s off

Green blinking every second Z: Stopped, F: No errors

Green blinking every second

1 x red blinking, 1 s OFF

Green blinking every second

2 x red blinking, 1 s OFF

Z: Operational, error: Warning limit reached

Z: Operational, F: Node guarding event

Z: Operational, F: Sync message error

Z: Stopped, F: Warning limit reached

Z: Stopped, F: Node guarding event

46

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 47

7 Data transfer

7.1 Access to the inverter codes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer

The master (e.g. a PLC) and inverter communicate with each other by exchanging data frames via

the fieldbus. The user data area of the data frame either contains network management data,

parameter data, or process data.

Different communication channels are assigned to parameter and process data in the inverter.

Parameters are for instance operating parameters, motor data, or diagnostic information, which are

stored under a code in the Lenze inverters.

Normally, the transfer of parameters is not as time-critical as the transfer of process data.

7.1 Access to the inverter codes

Documentation for the inverter

Here you can find some detailed information on the codes and value ranges.

Via the communication module, a higher-level master (e.g. a PLC) can change the properties and the

response of each inverter integrated in the network.

In Lenze inverters, parameters to be changed are listed under codes.

Inverter codes are addressed via indexes when accessing the code through the communication

module.

The indexes for Lenze code numbers are between 16576 (0x40C0) and 24575 (0x5FFF).

Indexing of codes using the example of code C0001 (operating mode)

Decimal Hexadecimal

Index = 24575 - Lenze code number Index

Index = 24575 - 1 = 24574 Index = 0x5FFF - 0x1 = 0x5FFE

= 0x5FFF - Lenze code number [hex]

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 47

Page 48

7 Data transfer

(CAN on board)

CAN

Ethernet

Servo Drives 9400

9400

9400

9400

7.2 Data transfer via CAN

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2 Data transfer via CAN

[7-1] Parameter data transfer via CAN

2180FEW008

Parameter data are transmitted via the CAN bus as so-called "Service Data Objects (SDOs) and are

acknowledged by the receiver. The SDO enables read and write access to the object directory.

Indexes (e.g. I-1000

in the object directory. In order to be able to transfer SDOs, the information contained in the user

data must comply with the CAN-SDO protocol.

) provide for access to parameters and functions of the device, which are stored

CAN/CANopen communication manual

Here you'll find some detailed information relating to the CAN frame structure.

CANopen parameter channels

The communication module is provided with two parameter data channels.

In the Lenze standard setting, both channels are activated.

Note!

Compatibility with CANopen

Switch off the second parameter data channel via code C1200 in order to establish

compatibility with CANopen.

48

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 49

7 Data transfer

7.3 Data transfer via Ethernet

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.3 Data transfer via Ethernet

The Engineering PC and the communication module communicate via a proprietary protocol which

is based on TCP/IP. The port number '22080' is used for the communication module.

The port number may have to be cleared if a firewall or something similar is used.

Port '3677' is used to search for fieldbus nodes.

Port '80' is required to operate the web server.

Tip!

The search via Ethernet is only possible within one network. The frames are not

transmitted via routers.

Ethernet communication manual

Here you'll find some detailed information relating to the Ethernet data frame structure.

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 49

Page 50

8Diagnostics

8.1 Error: Cause and remedy

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8 Diagnostics

8.1 Error: Cause and remedy

Diagnostics Possible cause of error Remedy

Power LED (P) is not on. The device is not switched on. Check external voltage supply

Error LED (E) is on or blinking. CAN bus error Check CAN wiring.

Link LED is not on. Ethernet wiring error Check Ethernet wiring.

8.2 LED status displays for the communication module and for CAN communication

2180FEW001D

[8-1] LED status displays for the communication module and for CAN communication

LED Colour Status Description

B Yellow off Ethernet baud rate: 10 Mbps

on

Ethernet baud rate: 100 Mbps

blinking

The IP address is not assigned yet; it is currently being identified.

50

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 51

8Diagnostics

8.2 LED status displays for the communication module and for CAN communication

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

LED Colour Status Description

E

(Error)

Red off No error; the device is ready for operation.

on

"Bus off" state

The CAN controller is in the "Bus off" state.

"Diagnostic interface" operating mode

In this operating mode, the LED is lit if no device is connected.

blinking once

(single flash)

Warning limit is reached

At least one of the error counters of the CAN controller has reached or

exceeded the warning level (too many error frames).

blinking twice

(double flash)

Error control event

A guard event (NMT slave or NMT master) or heartbeat event (heartbeat

consumer) has occurred.

R

(Run)

blinking 3 times

(triple flash)

SYNC error

The sync message has not been received within the time configured for

the time monitoring of the communication cycle..

flickering

AutoBaud/LLS

The automatic detection of the baud rate or LSS services is/are executed.

(The LEDs E and R are flickering alternately red/green.)

Green off No communication

on

"Operational" state

The communication module is in the "Operational" state.

blinking

"Pre-operational" state

The communication module is in the "Pre-operational" state.

blinking once

(single flash)

"Stopped" state

The communication module is in the "Stopped" state.

flickering

AutoBaud/LLS

The automatic detection of the baud rate or LSS services is/are executed.

(The LEDs E and R are flickering alternately red/green.)

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 51

Page 52

8Diagnostics

8.3 LED status displays for Ethernet communication

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

LED Colour Status Description

P

(Power)

8.3 LED status displays for Ethernet communication

Green off The communication module is not supplied with voltage.

on

The communication module is supplied with voltage.

2180FEW001D

[8-2] LED status displays for Ethernet communication

LED Colour Status Description

A

(Link)

B

(Activity)

Green off No connection to Ethernet

on

Ethernet connection is available.

Green off No data transfer

on or

flickering

Data are transmitted or received.

52

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 53

9 Parameter reference

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Parameter reference

This chapter lists all parameters of the communication module in numerically ascending order.

C0002

C0093

C0099

Parameter | Name:

C0002 | Load default setting

C0002 shows the status of the device command executed last. C0150 can be used to enquire the current status of

the device control.

Selection list (Lenze setting printed in bold) Info

0Load Def. Load Lenze standard setting

• Only possible with controller inhibit and stopped user

program.

1 Load PS Load parameter set

• The parameter set stored in the memory module is

loaded.

• Only possible with controller inhibit and stopped user

program.

Read access Write access CINH PLC STOP No transfer

Parameter | Name:

C0093 | Device type

The display for the EMF2180IB communication module is "2180 0000".

Display range (min. value | unit | max. value)

-214748 214748

Read access Write access CINH PLC STOP No transfer Scaling factor: 10000

Data type: INTEGER_32

Index: 24573 = 0x5FFD

Data type: INTEGER_32

Index: 24482 = 0x5FA2

Parameter | Name:

C0099 | Software version

Display "x.y"

(x: major version, y: index)

Display range (min. value | unit | max. value)

0.0 100.0

Read access Write access CINH PLC STOP No transfer Scaling factor: 10000

Data type: INTEGER_32

Index: 24476 = 0x5F9C

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 53

Page 54

9 Parameter reference

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

C0150

C0200

C0202

Parameter | Name:

C0150 | Status word

The binary interpretation of the displayed decimal value reflects the bit statuses of the status word:

• Bit 0: Ready for operation

• Bit 1: Dial-up connection is available

• Bit 2: Internal error

Value is bit-coded:

Bit 0 Ready for operation

Bit 1 Reserved

... ...

Bit 15 Reserved

Read access Write access CINH PLC-STOP No transfer

Parameter | Name:

C0200 | Software ID

During initialisation, the manufacturer's product code is used to determine which device is connected as node.

The display for the EMF2180IB communication module is "33S2180F_10000".

Read access Write access CINH PLC-STOP No transfer

Parameter | Name:

C0202 | Software ID (octet)

In subcodes 1 ... 4, the corresponding octet of the manufacturer's product code is shown.

Display range (min. value | unit | max. value)

-2147483647 2147483647

Subcodes Info

C0202/1 1st octet

C0202/2 2nd octet

C0202/3 3rd octet

C0202/4 4th octet

Read access Write access CINH PLC-STOP No transfer

Data type: UNSIGNED_16

Index: 24425 = 0x5F69

Data type: VISIBLE_STRING

Index: 24375 = 0x5F37

Data type: INTEGER_32

Index: 24373 = 0x5F35

54 Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 55

9 Parameter reference

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

C0350

C0351

Parameter | Name:

C0350 | CAN node address

The node address can be set via the CAN bus using the code C0350.

If zero is used as address, the communication module does not have a node address of its own. It can then not be

addressed from the CAN bus (no parameter setting, node guarding, etc.), but only serves as a dial-in option for reading parameters via the CAN bus.

If the communication module is to have an address, after determination of the baud rate, check whether this

address is still free. Then an attempt is made to read the implemented CANopen object -1000. If this address is

already assigned to another node, another free address is selected automatically.

Note:

Node addresses in the range of 64 ... 127 can only be assigned if code C1200 is set to the value "0" (CANopen

conformity)

Changes that are made to the settings will be accepted after ...

• reconnection to the mains;

• a "Reset node" or "Reset communication" via the bus system;

• a "Reset node" via code C0358

Setting range (min. value | unit | max. value) Lenze setting

0 127 63

Read access Write access CINH PLC STOP No transfer

Parameter | Name:

C0351 | CAN baud rate

The baud rate over the CAN bus can be set using this code.

Prior to accessing the CAN bus, the baud rate used is determined by the communication module and is compared

with the baud rate configured.

If there is a difference between the two values, the baud rate determined is used. Code C1209

out the baud rate detected by the communication module.

If there is no data exchange on the CAN bus, the baud rate cannot be determined. The subsequent response of the

communication module depends on the selection configured in code C0351

Selection 0 ... 5

After a time-out that can be configured using code C1215

Selection 16 (automatic detection of the baud rate)

The communication module is not accessed by the bus until a baud rate has been detected.

Changes that are made to the settings will be accepted after ...

• reconnection to the mains;

• a "Reset node" command via the bus system;

• a "Reset node" via code C0358

Selection list (Lenze setting printed in bold)

0 500 kbit/s

1 250 kbit/s

2 125 kbit/s

3 50 kbit/s

4 1000 kbps

5 20 kbit/s

16 Autom. baud rate detection

Read access Write access CINH PLC STOP No transfer

.

:

, the CAN bus is accessed with the baud rate configured.

.

Data type: INTEGER_32

Index: 24225 = 0x5EA1

Data type: INTEGER_32

Index: 24224 = 0x5EA0

can be used to read

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 55

Page 56

9 Parameter reference

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

C0358

Parameter | Name:

C0358 | CAN reset node

After a reset any changes to communication parameters such as baud rate or node address are applied.

A "Reset node" can be activated by:...

• reconnection of the mains;

• a "Reset node" via the bus system;

• a "Reset node" via code C0358.

Selection list (Lenze setting printed in bold)

0No function

1CAN reset

Read access Write access CINH PLC STOP No transfer

Data type: INTEGER_32

Index: 24217 = 5E99

56 Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17

Page 57

9 Parameter reference

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

C0359

Parameter | Name:

C0359 | CAN bus status

This code displays the current operating status of the CAN controller. Here, the following states are distinguished:

Selection 0: "Operational"

In this state the bus system is fully functional.

Selection 1: "Pre-operational"

In this state only parameter data (codes) can be transferred via the bus system. It is not possible to exchange process

data. To change to the "Operational" state, a network management frame must be output on the bus.

A state change from "Pre-operational" to "Operational" can be made with the following actions:

• A drive is defined as master using the inverter code C0352. During mains connection, an automatic state change

for the whole drive system is performed after the boot-up time defined in C0356/1

• "Reset node" via code C0358

• With the "Reset node" binary input signal which can, for instance, be set via a terminal if inverter code C0364 is

configured accordingly (precondition: C0352 = 1).

• A network management message from a CAN master.

Selection 2: "Warning"

Incorrect frames have been received if the state is "Warning". The CAN node is now only involved in a passive way;

no more data are sent from the inverter.

The reason for this situation can be:

• A missing bus terminator

• Inadequate shielding

• Potential differences at the ground connection for the control electronics

• An excessively high bus load

• CAN node is not connected to the bus

Selection 3: "Bus Off"

The frequency of the erroneous frames has caused the CAN node to decouple from the bus. A change-over to "PreOperational" can be effected by ...

•a "TRIP reset";

• a "Reset node";

• reconnection to the mains.

Selection 4: "Stopped"

Only NMT frames can be received.

The state can be changed to "Pre-operational" by ...

• a "Reset node" via code C0358

• a "Reset node" via the bus system;

• reconnection to the mains.

Selection list (read only)

0 Operational

1 Preoperational

2 Warning

3 Bus Off

4 Stopped

Read access Write access CINH PLC-STOP No transfer

(precondition: C0352 = 1).

;

Data type: INTEGER_32

Index: 24216 = 0x5E98

Lenze · EMF2180IB communication module (EthernetCAN) · Communication Manual · DMS 5.0 EN · 07/2014 · TD17 57

Page 58

9 Parameter reference

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

C0360

C0361

Parameter | Name:

C0360 | CAN frame counter

All CAN frames of the CAN node that have been transmitted and received are counted.

The counters have 32 bits, i. e. when a value of 4294967295 is exceeded, the counting process starts again at 0.

Display range (min. value | unit | max. value)

-2147483647 2147483647

Subcodes Info

C0360/1 Number of frames transmitted

C0360/2 Number of frames received

Read access Write access CINH PLC-STOP No transfer

Parameter | Name:

C0361 | CAN bus load

Using this code the percentage total bus load can be determined. Erroneous messages are not taken into account

here.

Note: