Page 1

EDSMF2178IB

.Li|

Ä.Li|ä

L−force Communication

Communication Manual

CANopen

EMF2178IB

Communication module

l

Page 2

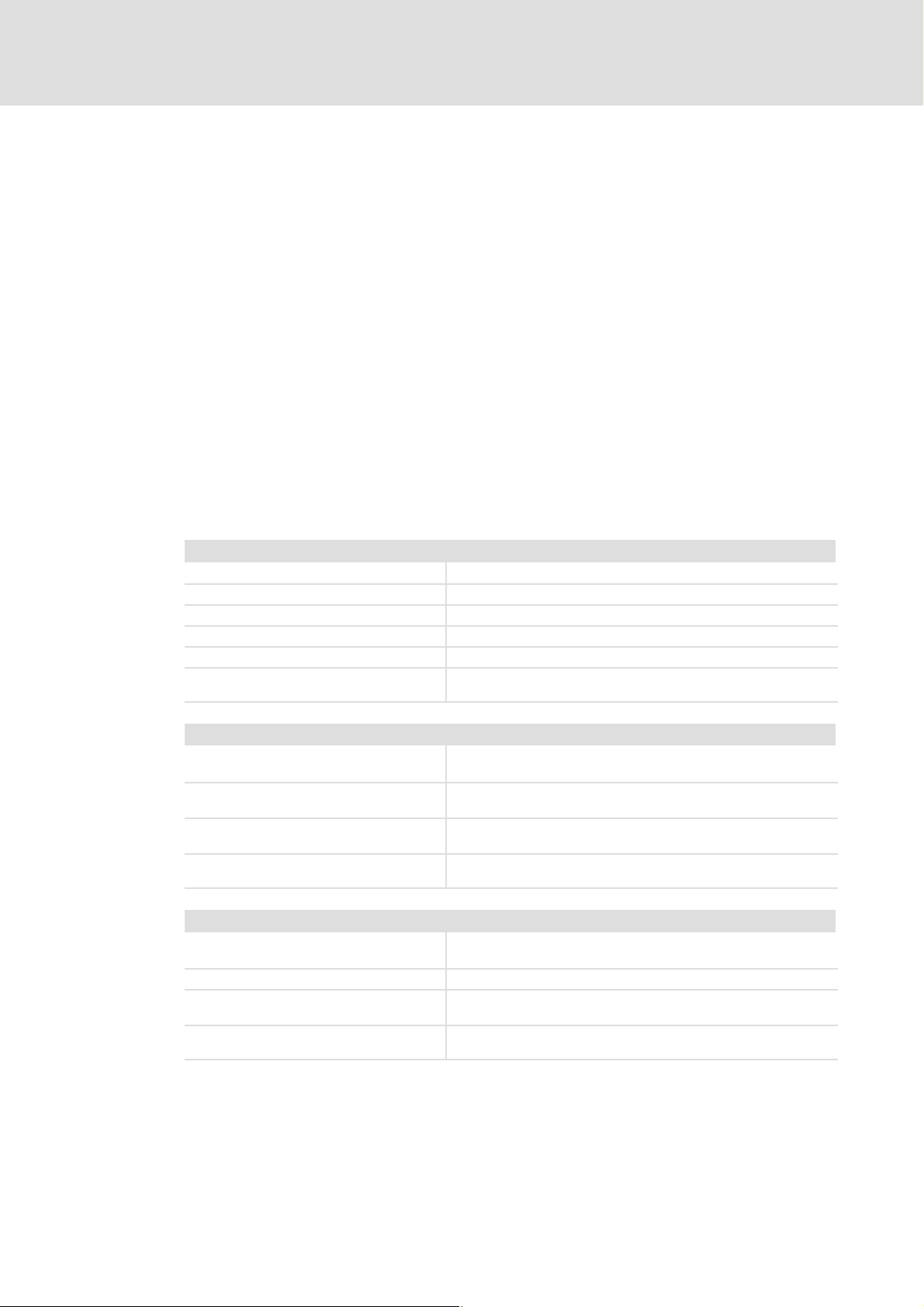

Contentsi

1 About this documentation 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Device− and application−specific safety instructions 12 . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Product features 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connections and interfaces 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Protective insulation 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Communication time 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Dimensions 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installation 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Mechanical installation 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical installation 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Wiring according to EMC (CE−typical drive system) 23 . . . . . . . . . . . . . . . . .

5.2.2 Wiring with a host (master) 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Wiring system bus (CAN) 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Specification of the transmission cable 26 . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Bus cable length 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Voltage supply 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Installing EDS files 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Setting node address and baud rate 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Initial switch−on 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Enable drive via the communication module 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

l

EDSMF2178IB EN 3.0

Page 3

Contents i

7 Replacing the EMF2172IB communication module (CAN) 39 . . . . . . . . . . . . . . . . . . . . . . . .

8 Data transfer 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Structure of the CAN telegram 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 CAN communication phases / network management (NMT) 45 . . . . . . . . . . . . . . .

9 Process data transfer 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Available process data objects 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Configuring process data channel 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Cyclic process data objects 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 Process data signals of Lenze controllers 52 . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Mapping in CANopen objects (I−160x, I−1A0x) 65 . . . . . . . . . . . . . . . . . . . . .

10 Parameter data transfer 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Access to the codes of the controller 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Lenze parameter sets 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Parameter sets for 8200 vector controller 71 . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Parameter sets for controller 93XX 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Structure of the parameter data telegram 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Error codes 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Examples of parameter data telegram 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 Special features for parameter setting of the drive controller 81 . . . . . . . . . . . . . . .

10.6.1 8200 vector controller 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.2 9300 Servo PLC / Drive PLC / ECS 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Monitoring 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Heartbeat Protocol 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Node Guarding Protocol 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Emergency telegram 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Diagnostics 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Measures in case of troubled communication 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 LED status displays 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSMF2178IB EN 3.0

l

3

Page 4

Contentsi

13 Implemented CANopen objects 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Reference between CANopen object and Lenze code 91 . . . . . . . . . . . . . . . . . . . . . . .

13.2 Overview 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.1 I−1000: Device type 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.2 I−1001: Error register 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.3 I−1003: Error history 97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.4 I−1005: COB−ID SYNC message 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.5 I−1006: Communication cycle period 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.6 I−1008: Manufacturer’s device name 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.7 I−100A: Manufacturer software version 100 . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.8 I−100C: Guard time 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.9 I−100D: Life time factor 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.10 I−1010: Store parameters 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.11 I−1011: Restore default parameters 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.12 I−1014: COB−ID emergency object 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.13 I−1015: Emergency inhibit time 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.14 I−1016: Consumer heartbeat time 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.15 I−1017: Producer heartbeat time 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.16 I−1018: Module device description 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.17 I−1029: Error behaviour 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.18 I−1200/I−1201: Server SDO parameters 107 . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.19 I−1400 ... I−1402: Receive PDO communication parameters 109 . . . . . . . . .

13.2.20 I−1600 ... I−1602: Receive PDO mapping parameters 111 . . . . . . . . . . . . . . .

13.2.21 I−1800 ... I−1802: Transmit PDO communication parameters 112 . . . . . . . .

13.2.22 I−1A00 ... I−1A02: Transmit PDO mapping parameters 114 . . . . . . . . . . . . . .

14 Codes 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Overview 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 Communication−relevant Lenze codes 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Important controller codes 144 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Index 149 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

l

EDSMF2178IB EN 3.0

Page 5

0Fig. 0Tab. 0

1 About this documentation

Contents

This documentation exclusively contains descriptions of the EMF2178IB communication

module (CANopen).

) Note!

This documentation supplements the mounting instructions supplied with the

function/communication module and the documentation of the used

standard device.

The mounting instructions contain safety instructions which must be

observed!

The features and functions of the communication module are described in detail.

Examples illustrate typical applications.

About this documentation 1

Furthermore this documentation contains the following:

ƒ Safety instructions that must be observed.

ƒ Key technical data relating to the communication module

ƒ Information on versions of Lenze standard devices to be used.

ƒ Notes on troubleshooting and fault elimination

The theoretical correlations are only explained in so far as they are necessary for

comprehending the function of the communication module.

This documentation does not describe the software of an original equipment

manufacturer. No responsibility is taken for corresponding information given in this

manual. Information on how to use the software can be obtained from the documents of

the host system (master).

All brand names mentioned in this manual are trademarks of their respective companies.

I Tip!

For further information visit the homepage of the CAN user organisation CiA

(CAN in Automation): www.can−cia.org.

© 2013 Lenze Drives GmbH, Postfach 10 13 52, D−31763 Hameln

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Drives

GmbH.

All information given in this documentation has been selected carefully and complies with the hardware and software described.

Nevertheless, discrepancies cannot be ruled out. We do not take any responsibility or liability for any damage that may occur.

Necessary corrections will be included in subsequent editions.

EDSMF2178IB EN 3.0

l

5

Page 6

About this documentation1

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking and remote service of a machine.

I Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

Validity information

The information given in this documentation is valid for the following devices:

ƒ EMF2178IB communication modules (CANopen) as of version 1x.2x.

6

l

EDSMF2178IB EN 3.0

Page 7

1.1 Document history

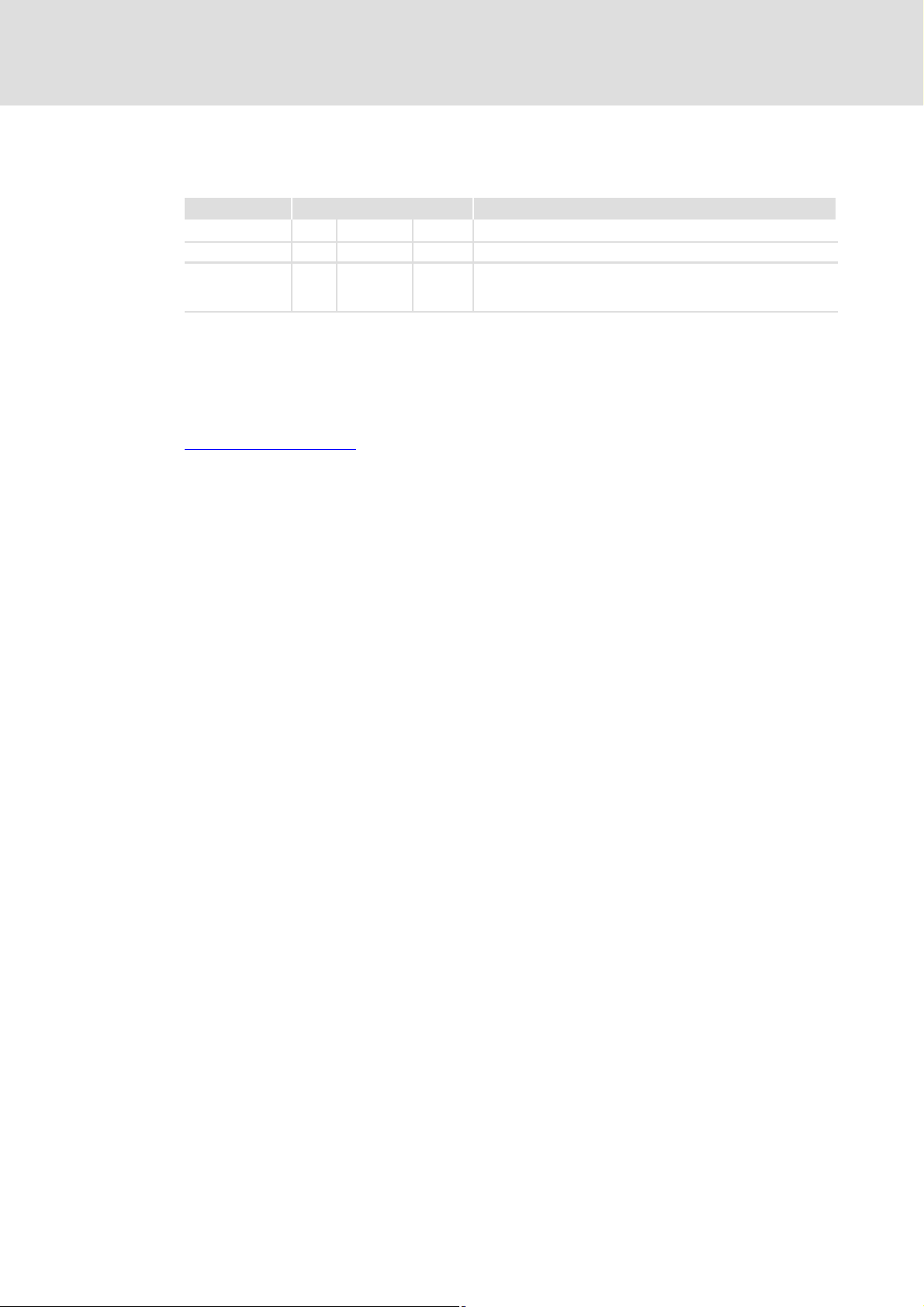

Material no. Version Description

− 1.0 01/2008 TD17 First edition

13127634 2.0 07/2011 TD17 General revision

.Li|

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e−mail us to:

feedback−docu@Lenze.de

Thank you for your support.

Your Lenze documentation team

3.0 06/2013 TD17 l New chapter "Replacing communication module

About this documentation

Document history

EMF2172IB (CAN)" (^ 39)

l General updates

1

EDSMF2178IB EN 3.0

l

7

Page 8

1

About this documentation

Conventions used

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Decimal Standard notation Example: 1234

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

l Nibble

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

Documentation reference , Reference to another documentation with

Point In general, the decimal point is used.

For instance: 1234.56

0b[0, 1]

Point

Example: ´0b0110´

Example: ´0b0110.0100´

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

additional information

For example: , EDKxxx = see

documentation EDKxxx

8

l

EDSMF2178IB EN 3.0

Page 9

1.3 Terminology used

Term Meaning

Standard device

Drive

»Global Drive Control« /

»GDC«

Code Parameter which serves to parameterise and monitor the controller. In normal speech,

Subcode If a code contains more than one parameter, these parameters are stored in

Lenze setting

Basic setting

HW Hardware

SW Software

PDO Process data object

SDO Service data object

About this documentation

Terminology used

Lenze controllers that can be used with the communication module.

^ 13

PC software from Lenze which supports you in "engineering" (parameter setting,

diagnosing, and configuring) during the entire life cycle, i.e. from planning to

maintenance of the commissioned machine.

the term is usually called "Index".

"subcodes".

In this documentation a slash "/" is used as a separator between code and subcode

(e.g. "C00118/3").

In normal speech, the term is also called "Subindex".

These are settings the device is preconfigured with ex works.

1

EDSMF2178IB EN 3.0

l

9

Page 10

1

1.4 Notes used

About this documentation

Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Application notes

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

10

l

EDSMF2178IB EN 3.0

Page 11

2 Safety instructions

) Note!

It is absolutely vital that the stated safety measures are implemented in order

to prevent serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety information

} Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

Safety instructions

General safety information

2

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ For Lenze drive components ...

... only use permitted accessories.

... only use original manufacturer spare parts.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

EDSMF2178IB EN 3.0

l

11

Page 12

2

2.2 Device− and application−specific safety instructions

Safety instructions

Device− and application−specific safety instructions

ƒ During operation, the communication module must be securely connected to the

standard device.

ƒ With external voltage supply, always use a separate power supply unit, safely

separated in accordance with EN 61800−5−1 in every control cabinet (SELV/PELV).

ƒ Only use cables that meet the given specifications. (¶ 26)

, Documentation of the standard device, control system, and plant/machine

All the other measures prescribed in this documentation must also be

implemented. Observe the safety instructions and application notes contained

in this manual.

2.3 Residual hazards

Protection of persons

ƒ If controllers are connected to phase−earthed system with a rated mains voltage

³ 400 V, external measures need to be implemented to provide reliable protection

against accidental contact. (see chapter "4.2", ^ 18)

Device protection

ƒ The communication module contains electronic components that can be damaged

or destroyed by electrostatic discharge.

12

l

EDSMF2178IB EN 3.0

Page 13

3 Product description

3.1 Application as directed

The communication module ...

ƒ enables communication with Lenze controllers over the CAN bus with the CANopen

communication profile.

ƒ is a device intended for use in industrial power systems.

ƒ can be used in conjunction with the following Lenze controllers:

Product description

Application as directed

3

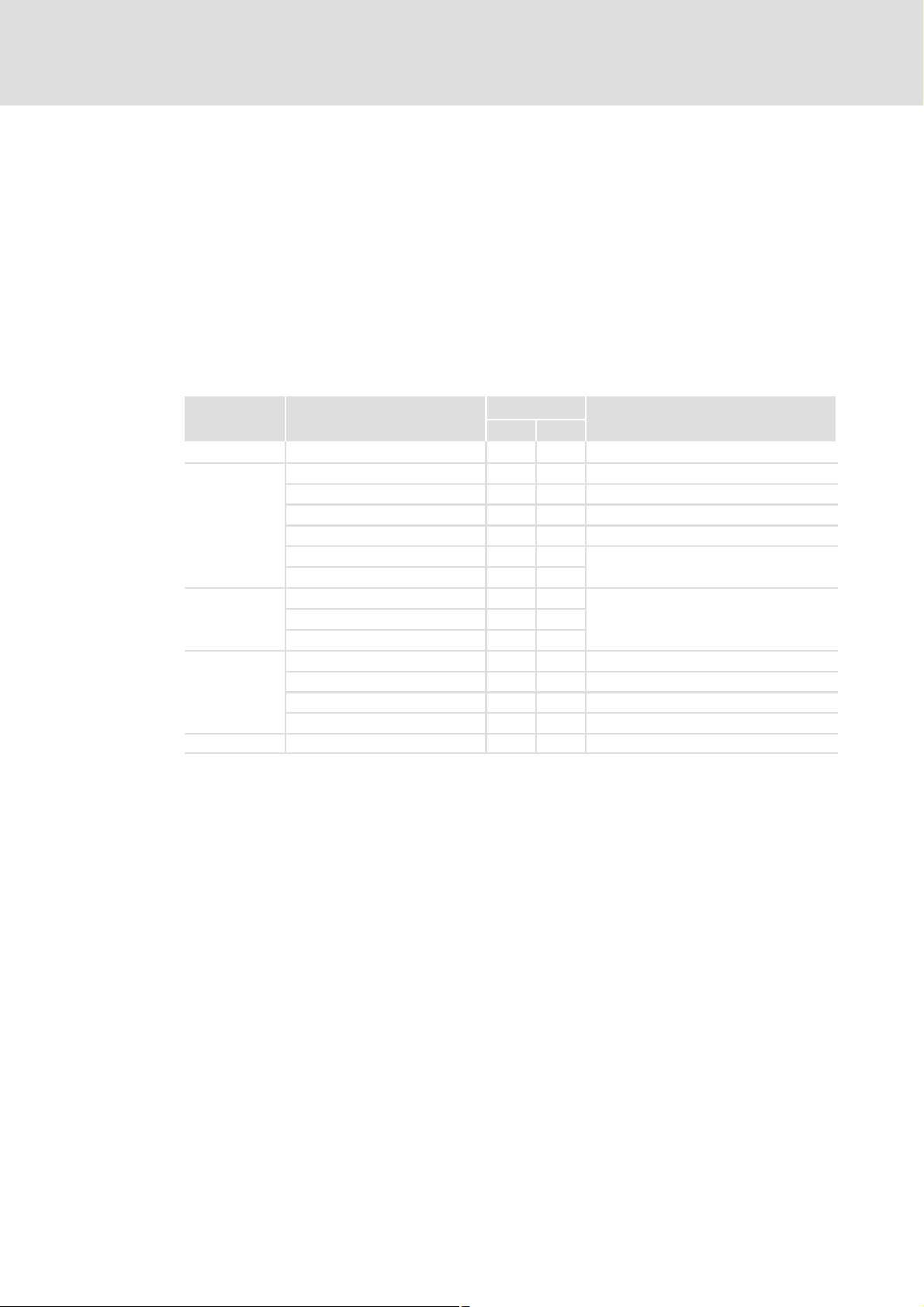

Series Device type

8200 vector E82xVxxxKxBxxxXX Vx 1x 8200 vector frequency inverter

9300

9300 vector

ECS servo

system

Drive PLC EPL10200−xI ... EPL10203−xI 1x 8x Drive PLC

1) Operating system software versions of the controllers

EVS9321−xS ... EVS9332−xS 2x 1x Servo inverter

EVS9321−xK ... EVS9332−xK 2x 1x Servo cam profiler

EVS9321−xP ... EVS9332−xP 2x 1x Servo position controller

EVS9321−xR ... EVS9332−xR 2x 1x Servo register controller

EVS9321−xI ... EVS9332−xI 2x 8x

EVS9321−xT ... EVS9332−xT 2x 8x

EVF9321−xV ... EVF9333−xV 2x 1x

EVF9335−xV ... EVF9338−xV 1x 0x

EVF9381−xV ... EVF9383−xV 1x 0x

ECSxSxxxC4xxxxXX 1A 6x "Speed and Torque"

ECSxPxxxC4xxxxXX 1A 6x "Posi and Shaft"

ECSxMxxxC4xxxxXX 1A 6x "Motion"

ECSxAxxxC4xxxxXX 1A 6x "Application"

Version

HW SW

Explanation

1)

9300 servo PLC

9300 vector frequency inverter

Any other use shall be deemed inappropriate!

EDSMF2178IB EN 3.0

l

13

Page 14

3

Product description

Identification

3.2 Identification

L

Type

Id.-No.

Prod.-No.

Ser.-No.

E82AF000P0B201XX

Type code W 33.2178IB 1x 2x

Series

Hardware version

Software version

99371BC013

14

l

EDSMF2178IB EN 3.0

Page 15

3.3 Product features

ƒ Attachable communication module for the basic Lenze devices 8200 vector, 93XX,

9300 Servo PLC, Drive PLC, ECSXX

ƒ Front DIP switches for setting the ...

– CAN node address (max. 127 nodes)

– baud rate (10, 20, 50, 125, 250, 500 and 1000 kbit/s)

ƒ Bus expansion without repeater up to 7450 m

ƒ Topology: Line terminated at both ends (R = 120 W)

ƒ Simple connection through plug−on screw terminals

ƒ Together with a 9300 Servo PLC, additional CANopen application profiles can be

implemented.

Product description

Product features

3

EDSMF2178IB EN 3.0

l

15

Page 16

3

Product description

Connections and interfaces

3.4 Connections and interfaces

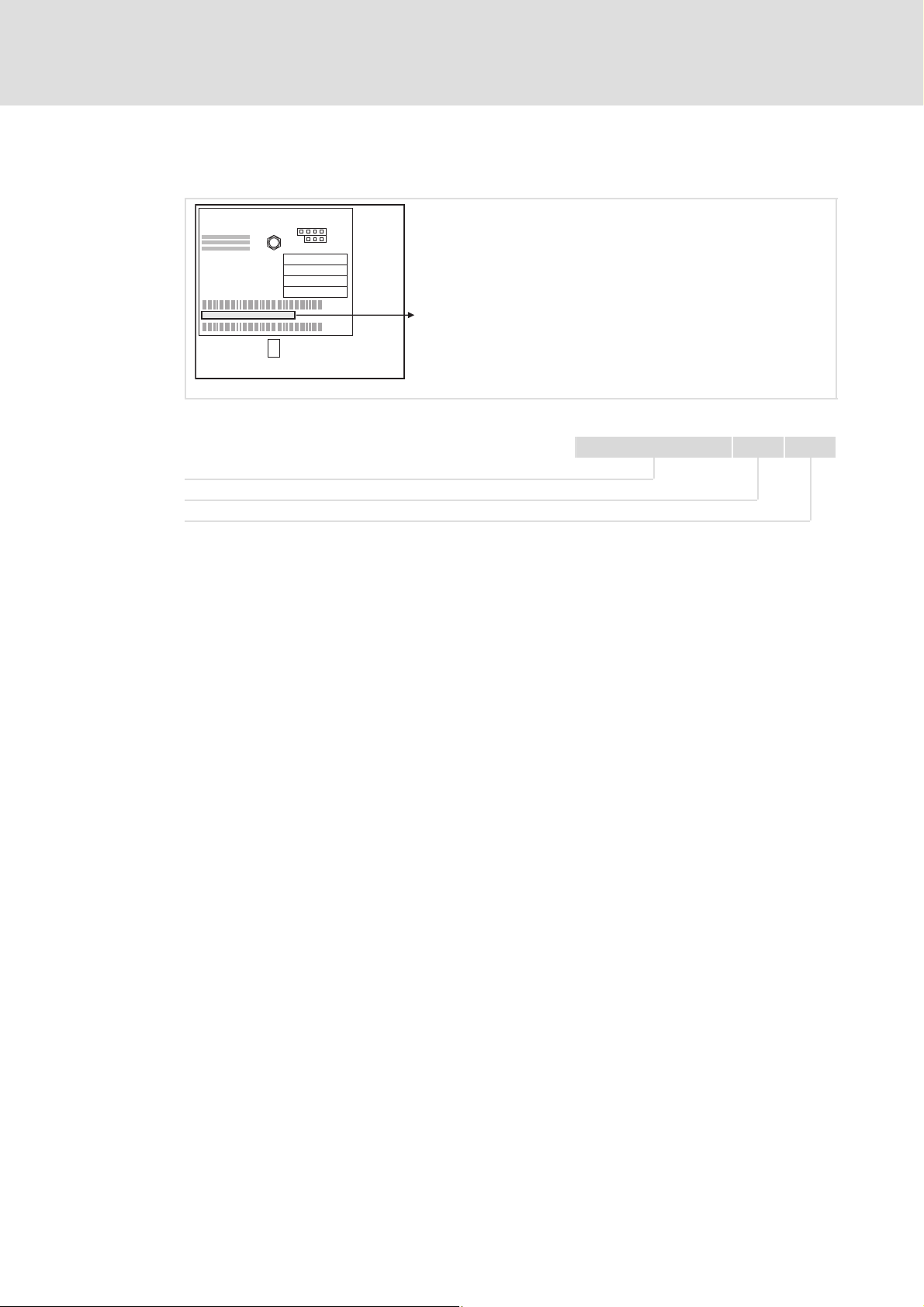

EMF2178IB

6

5

Address Bd

GND

CAN_L

0

L

CANopen

CAN_H

SHLD

1

2

3

V+

4

2178

2178CAN003

Legend for fold−out page

Pos. Description Detailed

0 Connection status to standard device (two−colour LED)

1 Connection status to fieldbus (two−colour LED)

2 Operating status of standard device (green and red Drive LED)

3 Fixing screw

4 Plug connector with double screw connection, 5−pole ^ 24

5 PE shield cable connection

6 DIP switches for setting the

l node address (switches 1 ... 7)

l baud rate (switches 8 ... 10)

8 Nameplate ^ 14

information

^ 89

^ 33

2102LEC007

16

l

EDSMF2178IB EN 3.0

Page 17

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

Field Values

Order designation EMF2178IB

Communication media DIN ISO 11898

Network topology Line terminated at both ends (R = 120 W)

Communication profile CANopen, DS301 V4.01

Node addresses Max. 127

Cable length Max. 7450 m (depending on the baud rate, ^ 27)

Baud rate [kbit/s] 10, 20, 50, 125, 250, 500, 1000

Voltage supply

Internal or external supply possible for basic devices: 8200 vector / 93XX /

9300 Servo PLC / Drive PLC / ECSXX

(also see ^ 30)

External supply via separate power supply unit:

V+: V = 24 V DC ± 10 %

I = 100 mA

GND:

Reference potential for external voltage supply

Technical data

4

, Documentation for Lenze series of devices 8200 vector, 9300 and ECS

Here you can find the ambient conditions and the electromagnetic

compatibility (EMC) specifications applying to the communication module.

EDSMF2178IB EN 3.0

l

17

Page 18

4

Technical data

Protective insulation

4.2 Protective insulation

{ Danger!

Dangerous electrical voltage

If Lenze controllers are used on a phase earthed mains with a rated mains

voltage ³ 400 V, protection against accidental contact is not ensured without

implementing external measures.

Possible consequences:

ƒ Death or serious injury

Protective measures:

ƒ If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged device modules, ...

– a double isolating distance must exist.

– the components to be connected must be provided with the second

isolating distance.

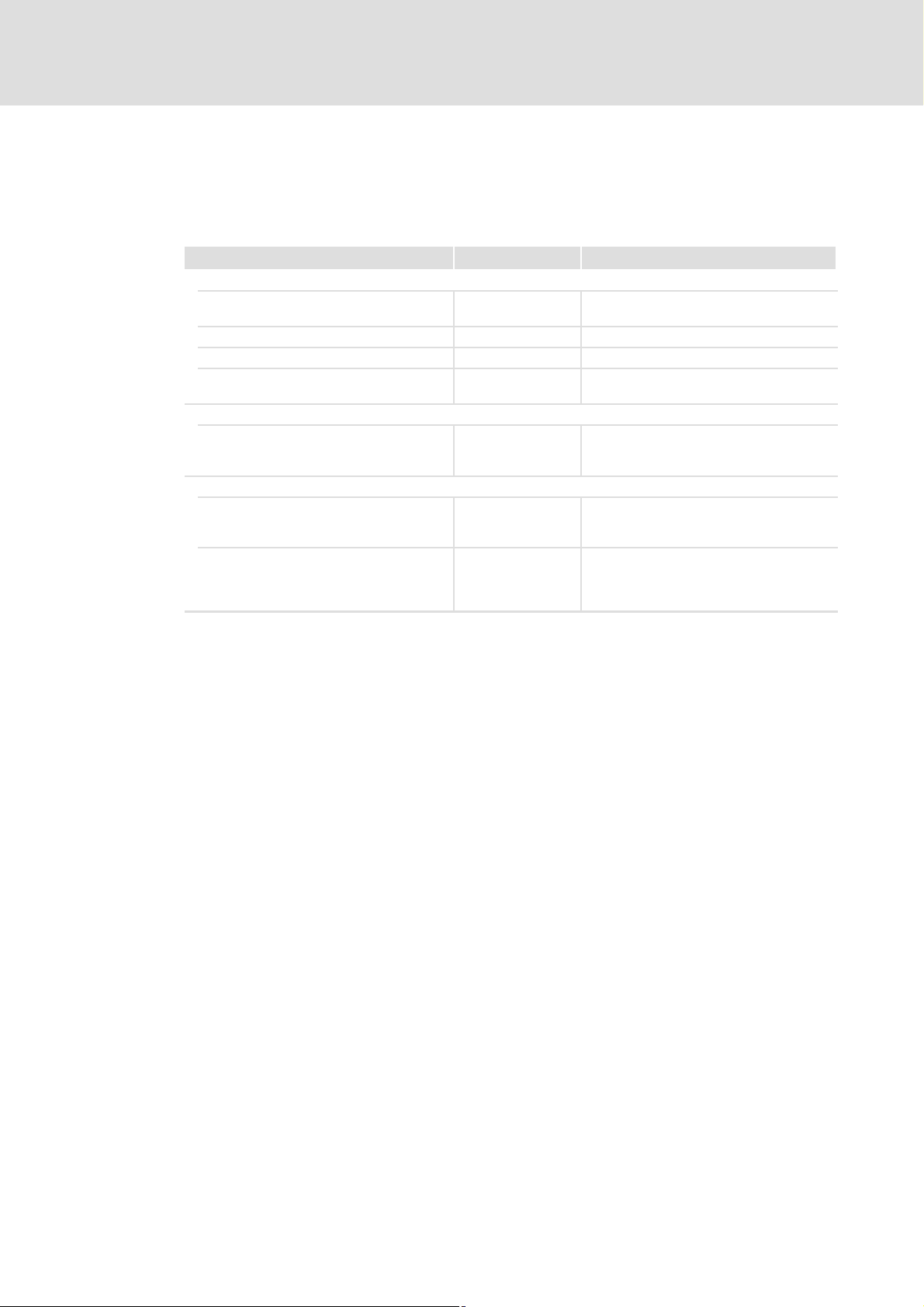

Protective insulation between the bus and ... Type of insulation according to EN 61800−5−1

Reference earth / PE Functional insulation

External supply No functional insulation

Power section

l 8200 vector Double insulation

l 9300 vector, Servo PLC Double insulation

l Drive PLC Double insulation

l ECSXX Double insulation

Control terminals

l 8200 vector

(with internal supply, ^ 30)

l 8200 vector

(with external supply, ^ 30)

l 9300 vector, Servo PLC Basic insulation

l Drive PLC Basic insulation

l ECSXX Basic insulation

No functional insulation

Basic insulation

18

l

EDSMF2178IB EN 3.0

Page 19

4.3 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The CAN bus communication times depend on ...

ƒ the processing time in the controller (see documentation of the controller)

ƒ Telegram runtime

– baud rate

– telegram length

ƒ the data priority

ƒ the bus load

Processing time in the controller

Technical data

Communication time

4

, Documentation for the controller

Here you can find information on the processing times in the controller.

Telegram time

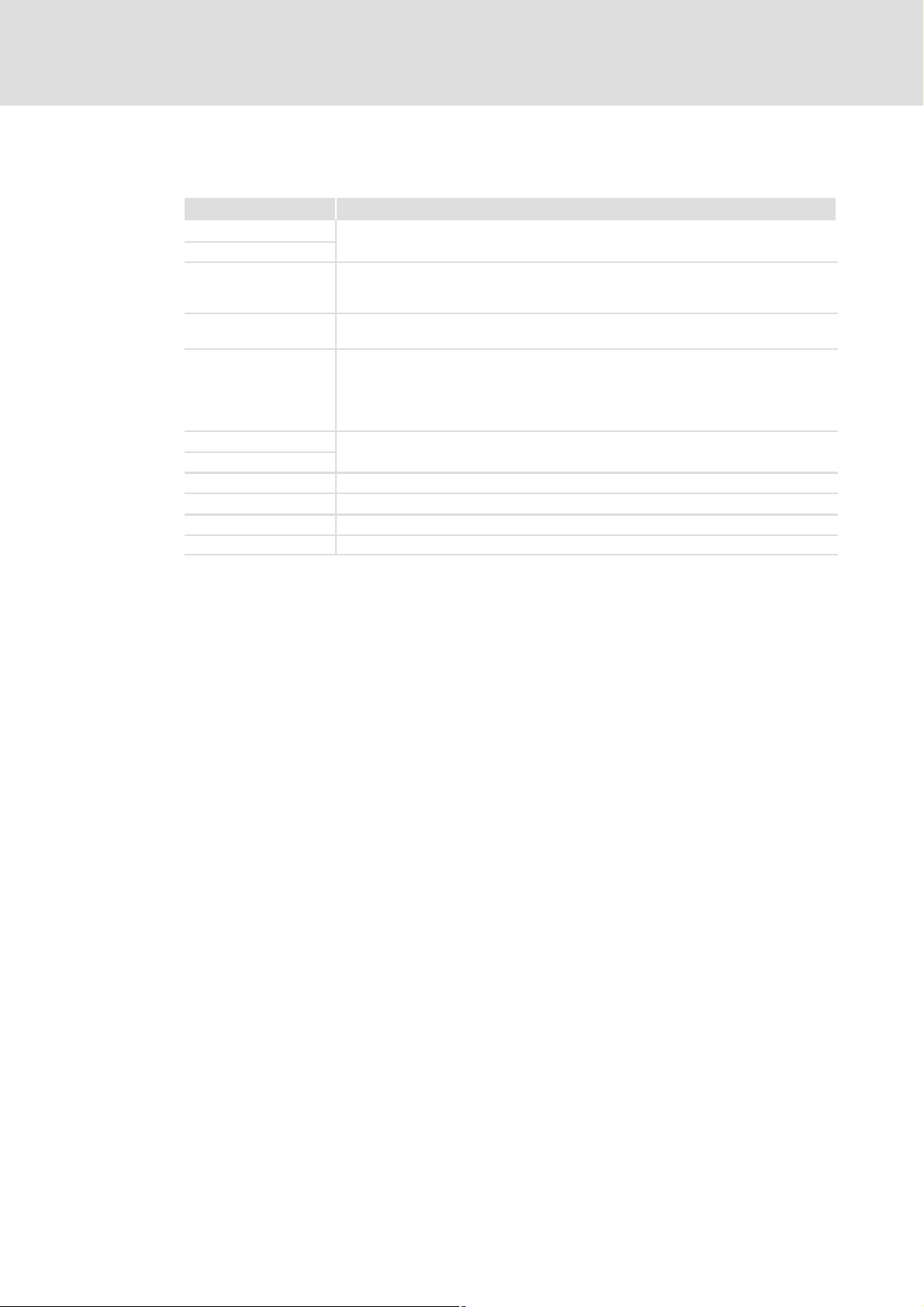

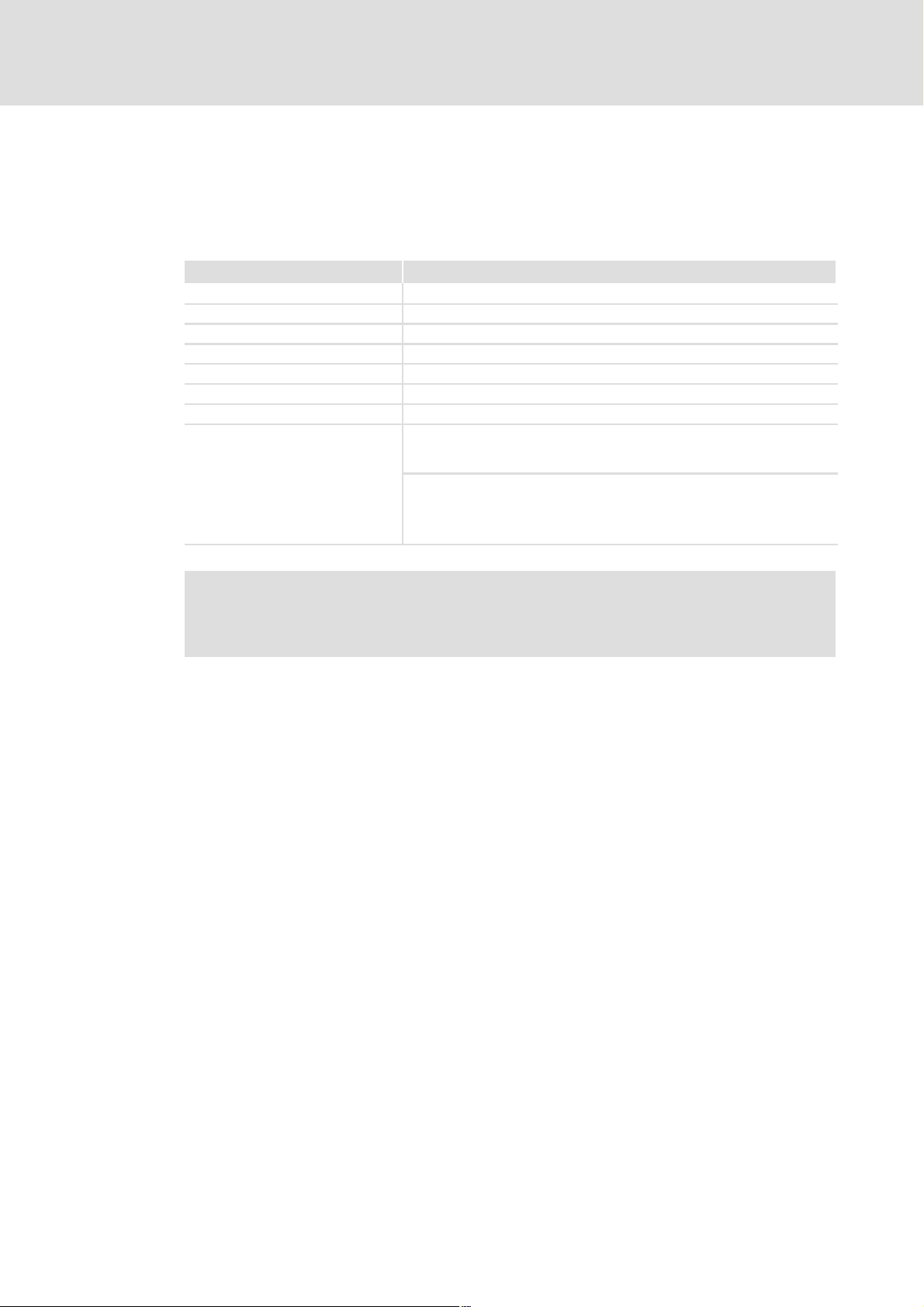

The telegram times depend on the baud rate and the telegram length:

Baud rate

[kbit/s]

0 bytes 2 bytes 8 bytes

10 5.44 7.36 13.12

20 2.72 3.68 6.56

50 1.09 1.47 2.62

125 0.44 0.59 1.05

250 0.22 0.29 0.52

500 0.11 0.15 0.26

1000 0.05 0.07 0.13

Telegram runtime

[ms]

EDSMF2178IB EN 3.0

l

19

Page 20

4

Technical data

Dimensions

4.4 Dimensions

Address Bd

GND

Fig. 4−1 Dimensions of the communication module (all dimensions in mm)

62

CAN_L

L

CANopen

CAN_H

SHLD

75

V+

2178

18

36

2178CAN003

20

l

EDSMF2178IB EN 3.0

Page 21

5 Installation

} Danger!

Inappropriate handling of the communication module and the standard device

can cause serious personal injury and material damage.

Observe the safety instructions and residual hazards described in the

documentation for the standard device.

( Stop!

The device contains components that can be destroyed by electrostatic

discharge!

Before working on the device, the personnel must ensure that they are free of

electrostatic charge by using appropriate measures.

Installation 5

EDSMF2178IB EN 3.0

l

21

Page 22

5

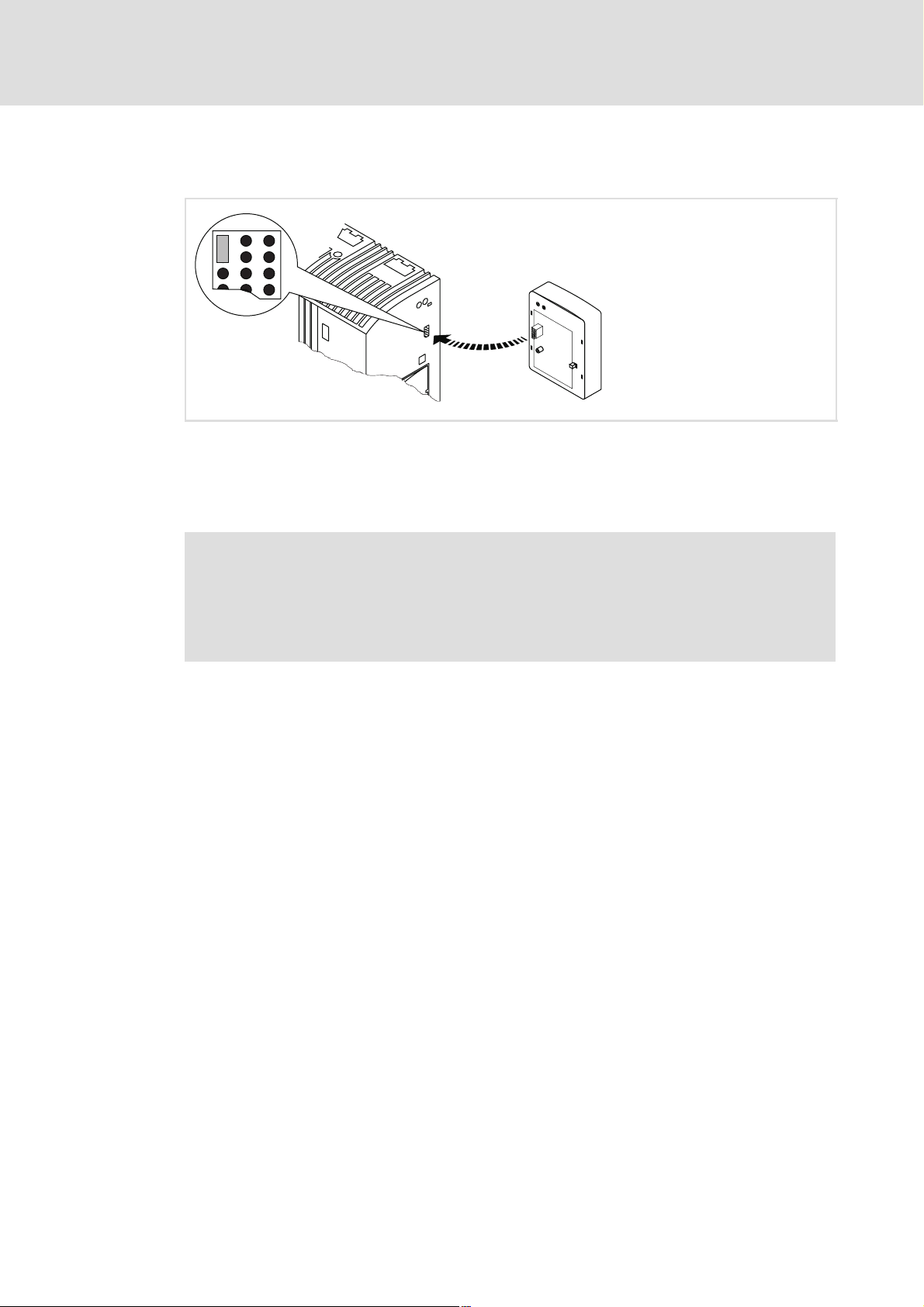

5.1 Mechanical installation

Installation

Mechanical installation

Fig. 5−1 Attaching the communication module

ƒ Plug the communication module onto the standard device (here: 8200 vector).

ƒ Tighten the communication module to the standard device using the fixing screw in

order to ensure a good PE connection.

2102LEC014

) Note!

For the internal supply of the communication module by the 8200 vector

frequency inverter the jumper has to be adjusted within the interface opening

(see illustration above).

Observe the notes (¶ 30).

22

l

EDSMF2178IB EN 3.0

Page 23

Wiring according to EMC (CE−typical drive system)

5.2 Electrical installation

5.2.1 Wiring according to EMC (CE−typical drive system)

For wiring according to EMC requirements observe the following points:

) Note!

ƒ Separate control cables/data lines from motor cables.

ƒ Connect the shields of control cables/data lines at both ends in the case of

digital signals.

ƒ Use an equalizing conductor with a cross−section of at least 16mm

(reference:PE) to avoid potential differences between the bus nodes.

ƒ Observe the other notes concerning EMC−compliant wiring given in the

documentation for the standard device.

Procedure for wiring

Installation

Electrical installation

5

2

1. Observe the bus topology, i.e. do not use stubs.

2. Observe notes and wiring instructions in the documents for the control system.

3. Only use cables corresponding to the listed specifications (¶ 26).

4. Observe the permissible bus cable length (¶ 27)

5. Connect bus terminating resistors of 120 W each (scope of supply):

– only to the physically first and last node

– between the terminals CAN−LOW and CAN−HIGH

.

EDSMF2178IB EN 3.0

l

23

Page 24

5

Installation

Electrical installation

Wiring with a host (master)

5.2.2 Wiring with a host (master)

{ Danger!

An additional electrical isolation is required if a safe electrical isolation

(reinforced insulation) to EN61800−5−1 is necessary.

For this purpose for instance an interface module for the master computer with an

additional electrical isolation can be used (see respective manufacturer information).

For wiring observe the electrical isolation of the supply voltage. The supply voltage is on the

same potential as the data bus.

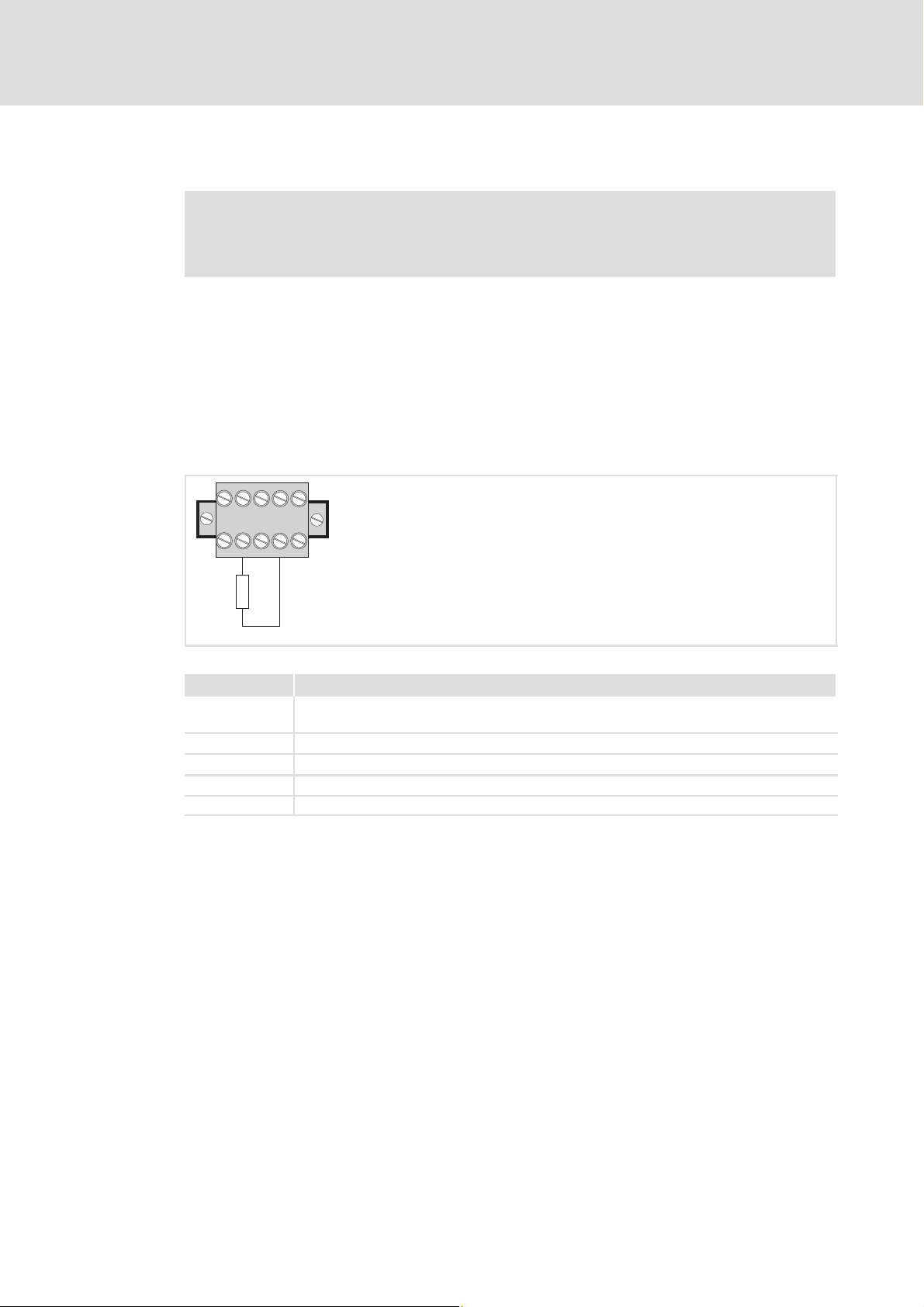

The 5−pole plug connector with double screw connection serves to

ƒ connect the bus (¶ 25);

ƒ effect the external voltage supply (¶ 30).

CAN_H

CAN_L

SHLD

GND

120W

V+

2178CAN003

Fig. 5−2 5−pole plug connector with double screw connection

Designation Explanation

GND Reference potential for external voltage supply

CAN−GND connection

CAN_L Data line / input for terminating resistor 120 W

SHIELD Shielding

CAN_H Data line / input for terminating resistor 120 W

V+ External voltage supply

24

l

EDSMF2178IB EN 3.0

Page 25

Installation

Electrical installation

Wiring system bus (CAN)

5

5.2.3 Wiring system bus (CAN)

Structure of a CAN bus system (example)

The CAN bus system is designed as a 2 conductor (twisted pair) shielded with additional

mass and termination at both ends of the line.

For sending and receiving data the following paths are available:

ƒ Max. three process data channels (PDO = Process Data Object)

– Process data are sent via the process data channel and are used for high−speed and

high−priority control tasks. Typical process data are, for instance, control words,

status words, setpoints and actual values of a standard device.

ƒ Two parameter data channels (SDO = Service Data Object)

– The parameters are transferred at lower priority than the process data and are set

or changed e.g. during commissioning or product change.

– The parameters are accessed via the parameter data channels of the EMF2178IB

communication module to the codes of the basic Lenze device or the

corresponding CANopen objects.

– With both parameter data channels, two masters can be connected to a standard

device. A PC (e.g. with the Lenze software "Global Drive Control") or an operator

terminal serve to change parameters directly at the standard device during

operation of a system connected to PLC. The second parameter data channel can

be reached under the set address (via DIP switch or C0009) with an offset of "64".

If, e.g., a PLC addresses the standard device with the address "1" and a second

commanding device the address "65", always the same standard device is

addressed.

– The second parameter channel is deactivated in the default state.

) Note!

ƒ The last telegram determines the parameter when a parameter is accessed

by two units (see CANopen objects 1200 and 1201 "Server SDO

Parameters".(¶ 107)).

ƒ Please observe the notes in the chapter 6Commissioning (¶ 33), if you do

not select the baud rate and address via the front DIP switches.

EDSMF2178IB EN 3.0

l

25

Page 26

5

Installation

Electrical installation

Specification of the transmission cable

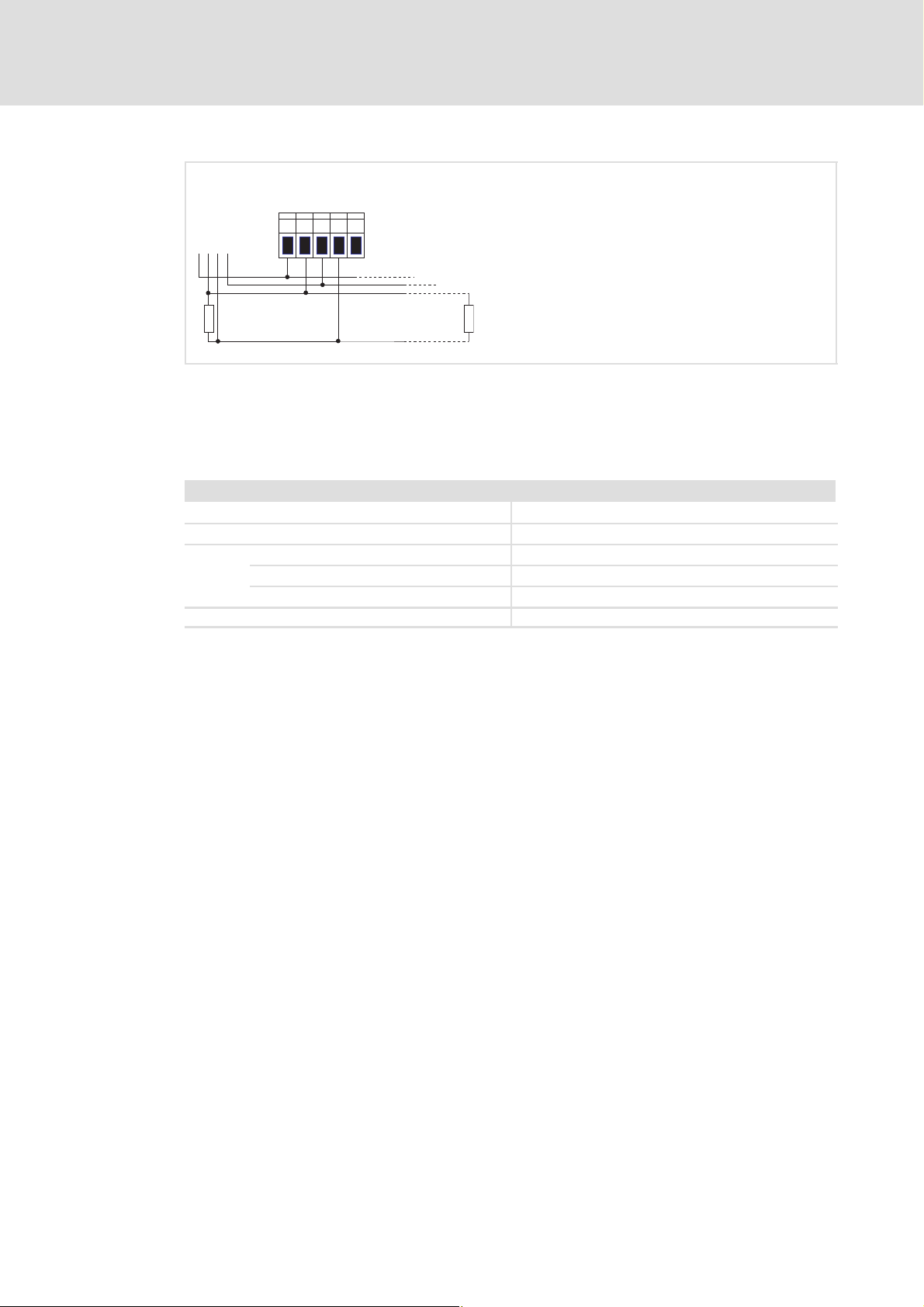

V+

SHLD

CAN_L

CAN

GND

LOW

+

HIGH

GND

CAN_H

EMF2178IB

GND

+

120 W

Fig. 5−3 Connection to the plug connector

5.2.4 Specification of the transmission cable

We recommend the use of CAN cables in accordance with ISO 11898−2:

CAN cable in accordance with ISO 11898−2

Cable type Paired with shielding

Impedance 120 W (95 ... 140 W)

Cable resistance/cross−section

Cable length £ 300 m £ 70 mW/m / 0.25 0.34 mm2 (AWG22)

Cable length 301 1000 m £ 40 mW/m / 0.5 mm2 (AWG20)

Signal propagation delay £ 5 ns/m

120 W

2178CAN002

26

l

EDSMF2178IB EN 3.0

Page 27

Installation

Electrical installation

Bus cable length

5

5.2.5 Bus cable length

) Note!

ƒ It is absolutely necessary to comply with the permissible cable lengths.

ƒ If the total cable lengths of the CAN nodes differ for the same baud rate, the

smaller value must be used to determine the max. cable length.

ƒ Observe the reduction of the total cable length due to the signal delay of the

repeater.

5.2.5.1 Total cable length

The baud rate determines the total cable length.

Baud rate [kbps] Max. bus length [m]

10 7450

20 3950

50 1550

125 630

250 290

500 120

1000 25

Tab. 5−1 Total cable length

EDSMF2178IB EN 3.0

l

27

Page 28

5

Installation

Electrical installation

Bus cable length

5.2.5.2 Segment cable length

The segment cable length is determined by the cable cross−section used and by the number

of nodes. Repeaters divide the total cable length into segments. If no repeaters are used,

the segment cable length is identical to the total cable length.

Max. number of

nodes per segment

2 240 m 430 m 650 m 940 m

5 230 m 420 m 640 m 920 m

10 230 m 410 m 620 m 900 m

20 210 m 390 m 580 m 850 m

32 200 m 360 m 550 m 800 m

63 170 m 310 m 470 m 690 m

100 150 m 270 m 410 m 600 m

Tab. 5−2 Segment cable length

Cable cross−section

(can be interpolated)

0.25 mm

(AWG24)

2

0.5 mm

(AWG21)

2

0.75 mm

(AWG19)

2

1.0 mm

(AWG18)

Example: Selection help

Given

Total cable length to be implemented 200 m

Number of nodes 63

Results

Max. possible baud rate 250 kbps

(derived from Tab. 5−1 Total cable length)

Required cable cross−section (interpolated) 0.30 mm2 (AWG23)

(derived from Tab. 5−2 Segment cable length)

Cable cross−section of standard CAN cable 0.34 mm2 (AWG22)

(see specification of the transmission cable ^ 26)

2

28

l

EDSMF2178IB EN 3.0

Page 29

5.2.5.3 Checking the use of repeaters

Compare the values derived from Tab. 5−1 Total cable length (¶ 27) and Tab. 5−2 Segment

cable length (¶ 28).

ƒ If the sum of the segment cable lengths is smaller than the total cable length to be

implemented, either repeaters must be used or the cable cross−section must be

increased.

ƒ If the use of repeaters reduces the max. possible total cable length so much that it is

smaller than the total cable length to be implemented, then the cable cross−section

must be increased or less repeaters must be used or the baud rate must be

decreased.

ƒ The use of a further repeater is recommended as ...

– service interface

Advantage: Trouble−free connection during bus operation is possible.

– calibration interface

Advantage: The calibration/programming unit remains electrically isolated.

Installation

Electrical installation

Bus cable length

5

Example

Given

Total cable length to be implemented 450 m

Number of nodes 32

Cable cross−section 0.50 mm2 (AWG 20)

Baud rate 125 kbps

Repeater used Lenze repeater EMF2176IB

Reduction of the max. total cable length per

repeater (EMF2176IB)

Results

Max. total cable length 630 m

Max. segment cable length 360 m

Comparison The max. segment cable length is smaller than the total cable

Conclusion A repeater must be installed at the determined max. segment

Results with 1 repeater

Max. total cable length 600 m

Max. segment cable length 720 m

Comparison Both the possible total cable length and the segment cable lengths

Conclusion 1 repeater is sufficient to implement the total cable length of 450

30 m

(see Tab. 5−1 Total cable length (^ 27))

(see Tab. 5−2 Segment cable length (^ 28))

length to be implemented.

cable length of 360 m.

(Reduction of the total cable length (^ 27) by 30 m)

are larger than the total cable length to be implemented.

m.

EDSMF2178IB EN 3.0

l

29

Page 30

5

Installation

Electrical installation

Voltage supply

5.2.6 Voltage supply

Internal voltage supply

) Note!

Internal voltage supply has been selected in the case of standard devices with

an extended AIF interface opening (e.g. front of 8200 vector). The area shown

on a grey background in the graphic marks the jumper position.

ƒ By default, this is not supplied internally in the standard device.

ƒ For internal voltage supply place the jumper on the position indicated

below.

In the case of all other device series (9300, ECS), voltage is always supplied

from the standard device.

(Only external voltage supply possible.)

Lenze setting

Internal voltage supply

External voltage supply

) Note!

In the case of an external voltage supply and for greater distances between

the control cabinets, always use a separate power supply unit (SELV/PELV) that

is safely separated in accordance with EN 61800−5−1 in each control cabinet.

The external voltage supply of the communication module ...

ƒ is required if communication via the fieldbus is to be continued in case the supply of

the standard device fails.

ƒ is carried out via the 2−pole plug connector with screw connection (24 V DC):

Terminal Description

V+ External voltage supply

V = 24VDC±10%

I = 100 mA

GND Reference potential for external voltage supply

ƒ The parameters of a basic device disconnected from the mains cannot be accessed.

30

l

EDSMF2178IB EN 3.0

Page 31

Electrical installation

Terminal data

Area Values

Electrical connection Plug connector with screw connection

Possible connections

Tightening torque 0.5 ... 0.6 Nm (4.4 ... 5.3 lb−in)

Stripping length 6 mm

rigid:

flexible:

2

1.5 mm

without wire end ferrule

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

Installation

Voltage supply

5

EDSMF2178IB EN 3.0

l

31

Page 32

6

Commissioning

Before switching on

6 Commissioning

During commissioning, system−dependent data as e.g. motor parameters, operating

parameters, responses and parameters for fieldbus communication are selected for the

controller.

In Lenze devices, this is done via codes. The codes are stored in numerically ascending order

in the Lenze controllers and in the plugged−in communication/function modules.

In addition to these configuration codes, there are codes for diagnosing and monitoring

the bus devices.

6.1 Before switching on

( Stop!

Before you switch on the standard device with the communication module for

the first time, check

ƒ the entire wiring with regard to completeness, short circuit, and earth fault.

ƒ whether the bus system is terminated by a bus terminating resistor at the

physically first and last node.

6.2 Installing EDS files

The EDS files serve to implement the Lenze communication modules for the AIF and FIF

interfaces into the CANopen configuration software.

The single EDS files describe the implemented CANopen functions of the respective

communication module and the "on board" Lenze system bus (CAN).

I Tip!

The current EDS file required for configuring the EMF2178IB (CANopen)

communication module can be found in the download area on:

www.Lenze.com

32

l

EDSMF2178IB EN 3.0

Page 33

6.3 Setting node address and baud rate

The node address and the baud rate can be set via codes or via the DIP switches arranged

at the front:

ƒ Node address: Switches 1 ... 7 / code C1850/C2350

ƒ Baud rate: Switches 8 ... 10 / code C1851/C2351

The Lenze setting of all DIP switches is OFF.

) Note!

Settings via codes

ƒ In the Lenze setting ˘ Address switches 1 ... 7 = OFF ˘, the values are

accepted from the codes C1850/C2350 (node address) and C1851/C2351

(baud rate).

– Node addresses > 99 can only be set via DIP switch.

– The baud rates 10 kbps and 20 kbps can only be selected via DIP switch.

ƒ Writing the codes (e.g. with GDC via CAN) has a direct effect on the standard

device codes C0009 and C0126.

ƒ Acceptance of code changes by:

– Switching off and then on again the voltage supply;

– "Reset node" with C0358 = 1;

– Network management command "Reset Communication";

– Set C2120 (AIF control byte) = 1.

ƒ The codes are inactive if at least one address switch (1 ... 7) has been set to

ON position before a renewed mains connection.

Commissioning

Setting node address and baud rate

6

EDSMF2178IB EN 3.0

l

33

Page 34

6

Commissioning

Setting node address and baud rate

Node address setting

BdAddress

OPEN

OFF

ON

12345678910

Fig. 6−1 Address assignment via DIP switch

ƒ If several devices are connected to the CAN network, the node addresses must differ

from each other.

ƒ The desired node address results from the sum of the values of switches (1 ... 7) in

ON position.

Example

Switch Value

164OFF

2 32 OFF

3 16 ON

4 8 OFF

5 4 ON

6 2 ON

7 1 ON

Switch position Node address

16 + 4 + 2 + 1 = 23

) Note!

Switch off the voltage supply of the communication module, and then switch

it on again to activate the changed settings.

34

l

EDSMF2178IB EN 3.0

Page 35

Setting node address and baud rate

Baud rate setting

BdAddress

OPEN

OFF

ON

12345678910

Fig. 6−2 Baud rate setting

ƒ The baud rate must be the same for all CAN nodes.

ƒ The following baud rates can be set:

Commissioning

6

Baud rate [kbps]

8 9 10

10 ON ON OFF

20 ON OFF ON

50 OFF ON ON

125 OFF ON OFF

250 OFF OFF ON

500 OFF OFF OFF

1000 ON OFF OFF

Switch

) Note!

Switch off the voltage supply of the communication module, and then switch

it on again to activate the changed settings.

EDSMF2178IB EN 3.0

l

35

Page 36

6

6.4 Initial switch−on

Commissioning

Initial switch−on

) Note!

Do not change the setting sequence.

1. Switch on the standard device and, if necessary, the external voltage supply of the

communication module.

– The green LED 0 on the front of the communication module is lit.

– The status LED of the standard device (Drive LED) 2 must be lit or blinking. The

meaning of the signalling can be found in the standard device documentation.

2. You can now communicate with the drive, i. e.

– all parameters (SDO) can be read;

– all writable parameters (SDO) can be overwritten.

3. After a state change ("Operational") process data can be exchanged with the drive.

2172CAN000D

Fig. 6−3 LEDs of the communication module

36

l

EDSMF2178IB EN 3.0

Page 37

Enable drive via the communication module

6.5 Enable drive via the communication module

) Note!

ƒ During operation, the plugging of the communication module onto a

different controller may cause undefined operating states.

ƒ Observe the information on the CAN configuration and controller enable in

the documentation of the corresponding controller.

Enable the 8200 vector via the communication module

Step Procedure Comments

1. Set C0001 from

"0" to "3"

2. Assign 28 to HIGH level The terminal 28 (controller enable) is always active and must be assigned to

3. Assign input terminal

for QSP to HIGH level

4. The controller now accepts parameter data and process data.

Enable 93XX via the communication module

The Lenze parameter C0001 (operating mode) can be set with the GDC,

keypad XT or directly via CANopen.

Example for direct setting via CANopen:

Write (C0001 = 3)

l Index = 0x5FFE (resulting from: 0x5FFF − (C0001)

l Subindex: 0

l Value: 30000 (resulting from: C0001 = 3 x 10000)

HIGH level during CANopen operation. Otherwise the controller cannot be

enabled via CANopen.

The quick stop function (QSP) is always active. If QSP is configured to an

input terminal (Lenze setting: Not assigned), it must be assigned to HIGH

level during CANopen operation.

Commissioning

;)

hex

6

Step Procedure Comments

1. Set C0005 to th value

"xxx3"

2. Set C0142 = 0 See "Protection against uncontrolled restart" (^ 38).

3. Assign 28 to HIGH level The terminal 28 (controller enable) is always active and must be assigned to

4. Assign terminal E1 to

HIGH level

5. Connect terminal X5/A1

to

l X5/28 and

l X5/E1

6. The controller now accepts parameter data and process data.

The value "xxx3" of the Lenze parameter C0005 (control of the controller via

CANopen) can be set with the GDC, keypad XT or directly via CANopen.

Example for the first commissioning with the signal configuration "1013":

Write (C0005 = 1013)

l Index = 0x5FFA (resulting from: 0x5FFF − (C0005)

l Subindex: 0

l Value: 10130000 (resulting from: C0005 = 1013 x 10000)

HIGH level during CANopen operation. Otherwise the controller cannot be

enabled via CANopen.

If the signal configuration C0005 = 1013, the quick stop function (QSP) is

assigned to the digital input terminals E1 and E2 in connection with the

right/left change−over and thus always active.

Only affects the signal configuration C0005 = xx13

With this signal configuration the terminal A1 is switched as voltage

output.

hex

)

EDSMF2178IB EN 3.0

l

37

Page 38

6

Commissioning

Enable drive via the communication module

Enable ECSXX via the communication module

Step Procedure Comments

1. Select control interface

"AIF" via code.

2. Set C0142 = 0 See "Protection against uncontrolled restart" (^ 38).

3. Assign terminals X6/SI1

and X6/SI2 to HIGH

level

4. The controller now accepts parameter data and process data.

See documentation of the corresponding ECS controller.

The terminals X6/SI1 (controller enable/inhibit) and X6/SI2 (pulse

enable/inhibit) are always active and must be assigned to HIGH level during

CANopen operation. Otherwise, the controller cannot be enabled via

CANopen.

Protection against uncontrolled restart

) Note!

Establishing communication

If communication is to be established via an externally supplied

communication module, initially the standard device must also be switched

on.

After communication has been established, the externally supplied module is

independent of the power on/off state of the standard device.

Protection against uncontrolled restart

After a fault (e.g. short−term mains failure), a restart of the drive is not always

wanted and − in some cases − even not allowed.

The restart behaviour of the controller can be set in C0142:

ƒ C0142 = 0 (Lenze setting)

– The controller remains inhibited (even if the fault is no longer active).

– The drive starts up in a controlled manner by explicit controller enable:

93XX: Set terminal 28 to HIGH level.

ECSXX: Set terminals X6/SI1 and X6/SI2 to HIGH level.

ƒ C0142 = 1

– An uncontrolled restart of the drive is possible.

38

l

EDSMF2178IB EN 3.0

Page 39

Replacing the EMF2172IB communication module (CAN) 7

7 Replacing the EMF2172IB communication module (CAN)

Observe the following information when replacing the EMF2172IB (CAN) communication

module by EMF2178IB (CANopen):

ƒ The communication modules feature different plug connectors for connecting the

voltage supply and the system bus (CAN).

ƒ The DIP switches of the communication modules feature different assignments for

setting the CAN node address and the baud rate (¶ 40). Furthermore there are

different adjustable CAN address ranges:

Communication module CAN address range DIP switch

EMF2172IB (CAN) 1 ... 63 S4 ... S9

EMF2178IB (CANopen) 1 ... 127 S1 ... S7

ƒ Depending on the standard device used, the 2. SDO channel is activated via code

C1865/1 or C2365/1 (¶ 41).

Changing the wiring

The following illustration shows how you must carry out the previous wiring for the

EMF2178IB communication module now.

Address Bd

1 - 3

4 - 9

addressbaud

24 V DC

+

-

21

L

CAN

Low

GND

5

4

3

High

2172

6

L

CANopen

CAN_H

CAN_L

SHLD

GND

2

4

V+

2178

1

3

5

6

2178CAN010

EDSMF2178IB EN 3.0

l

39

Page 40

Replacing the EMF2172IB communication module (CAN)7

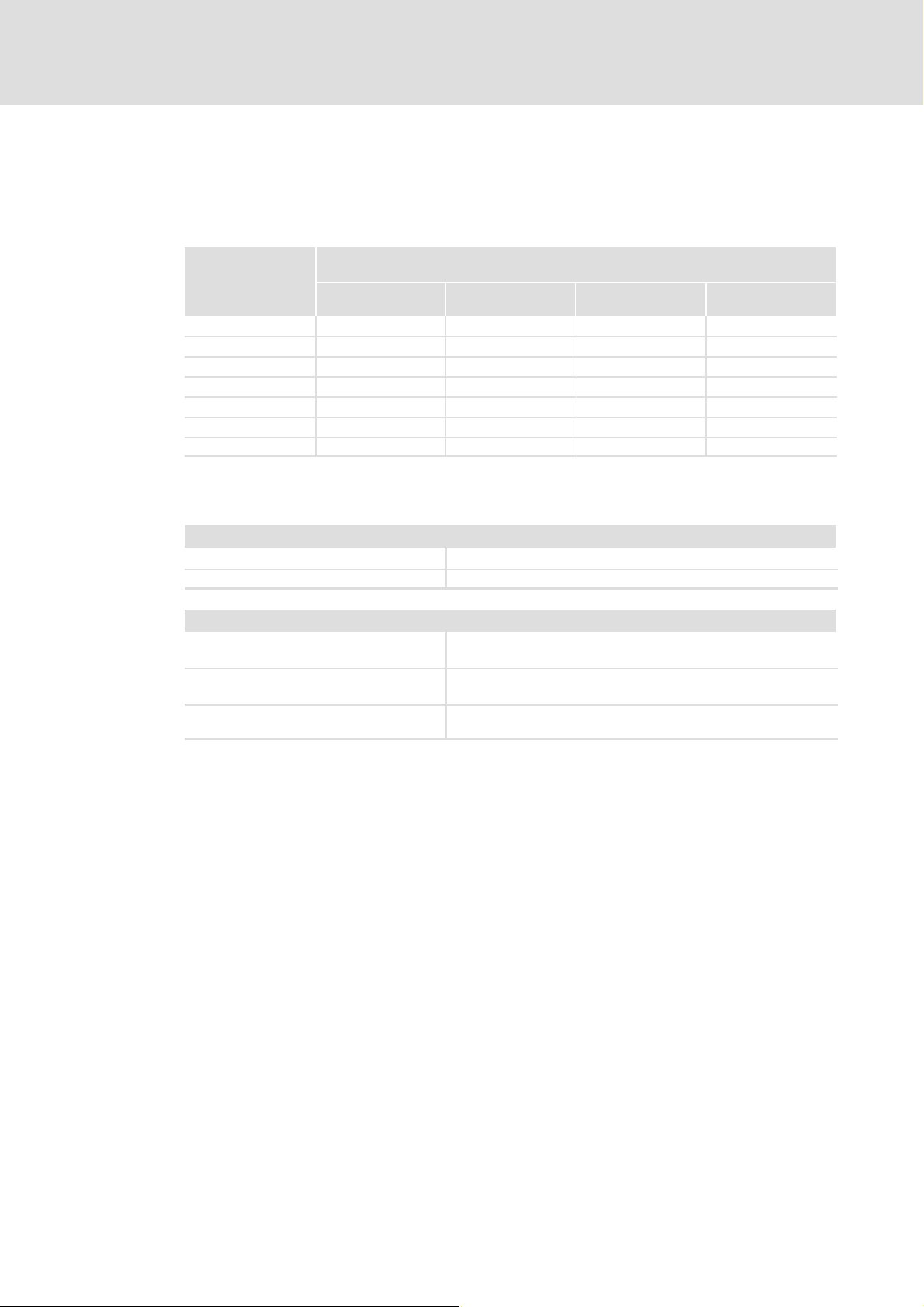

DIP switch settings

) Note!

On the EMF2178IB communication module, the switch S1 = OFF(Lenze setting)

must remain set. (An address setting > 63 was not possible for EMF2172IB.)

L

1 - 3

ON

OFF

CAN

4 - 9

addressbaud

OFF

ON

Address

- -WS1 = OFF

S9 S2

W

S4 S7

W

Baudrate

S3 S8

W

S1 S10

W

Address Bd

1

78

10

L

CANopen

2178CAN011

Switch Value

Example

EMF2172IB EMF2178IB Switch position CAN node address

−S164 OFF

S9 S2 32 OFF

S8 S3 16 ON

S7 S4 8 OFF

16 + 4 + 2 + 1 = 23

S6 S5 4 ON

S5 S6 2 ON

S4 S7 1 ON

40

l

EDSMF2178IB EN 3.0

Page 41

Replacing the EMF2172IB communication module (CAN) 7

Activate the 2. SDO channel

Depending on the standard device used, set code C1865/1 or C2365/1 to activate the

2. SDO channel.

Settings via the GDC/XT keypad for these standard devices:

EVS 93xx−ES

EVS 93xx−EP

EVS 93xx−EK

EVS 93xx−ER

EVF 93xx−EV

E82EVxxx

1. Plug the EMF2178IB communication module onto

the standard device.

2. Use the GDC to set code C1865/1 = 1.

The setting is saved with mains failure protection

directly in the communication module.

When using the standard devices specified above,

the setting can also be carried out beforehand.

EVS 93xx−EI

EVS 93xx−ET

EPL−10200

ECSxS/P/M/A

Use the GDC or XT keypad to set standard device code

C2365/1 = 1 and save it with mains failure protection.

After mains connection of one of the standard devices

specified above, or after plugging on the EMF2178IB

communication module, the contents of C2365 are

written to the communication module.

EDSMF2178IB EN 3.0

l

41

Page 42

8

Data transfer

Structure of the CAN telegram

8 Data transfer

Master and controller communicate with each other by exchanging data telegrams via the

CAN bus.

The user data area of the CAN telegram either contains network management data, process

dataor parameter data (^ 44).

Different communication channels are assigned to parameter and process data in the

controller:

ƒ Process data are transferred via the process data channel.

ƒ Parameter data are transferred via the parameter data channel.

8.1 Structure of the CAN telegram

Control field CRC delimit. ACK delimit.

Start RTR bit CRC sequence ACK slot End

Identifier User data (0 ... 8 bytes)

l Network management

1 bit 11 bits 1 bit 6 bits 15 bits 1 bit 1 bit 1 bit 7 bits

Fig. 8−1 Basic structure of the CAN telegram

l Process data

l Parameter data

I Tip!

The identifier and the user data will be explained in more detail in this

documentation.

The other signals refer to the transfer characteristics of the CAN telegram

which are not described in this documentation.

For more information please refer to the homepage of the CAN user

organisation CiA (CAN in Automation):

http://www.can−cia.org

42

l

EDSMF2178IB EN 3.0

Page 43

Data transfer

Structure of the CAN telegram

Identifier (COB−ID)

The principle of the CAN communication is based on a message−oriented data exchange

between a transmitter and various receivers. Here, all nodes can quasi simultaneously

transmit and receive messages. In case of CANopen, a node orientation is achieved by

having only one transmitter for each message.

The control which node is to receive a transmitted message is executed via the identifierin

the CAN telegram, also called COB−ID(Communication Object Identifier). In addition to the

addressing, the identifier contains information on the priority of the message and the type

of user data.

With the exception of the network management and the sync telegram, the identifier

consists of a basic identifier and the node address of the node to be addressed:

Identifier (COB−ID) = basic identifier + adjustable node address (Node−ID)

The identifier assignment is defined in the CANopen protocol.

Basic identifier

8

The basic identifier is preset as default with the following values according to the CANopen

specification:

Object

NMT 0 0x000

Sync 128 0x080

Emergency X 128 0x080

PDO1

(Process data channel 1)

PDO2

(Process data channel 2)

PDO3

(process data channel 3)

SDO1

(Parameter data channel 1)

SDO2

(parameter data channel 2)

Lenze setting: not active.

Node guarding / heartbeat X 1792 0x700

TPDO1

RPDO1

TPDO2

RPDO2

TPDO3

RPDO3

from the drive to the drive dec hex

Direction Basic identifier

X 384 0x180

X 512 0x200

X 640 0x280

X 768 0x300

X 896 0x380

X 1024 0x400

X 1408 0x580

X 1536 0x600

X 1472 0x5C0

X 1600 0x640

Node address (node ID)

Each node of the CAN network must be assigned with a node address (also called node ID)

within the valid address range for unambiguous identification.

EDSMF2178IB EN 3.0

ƒ A node address must not be assigned more than once within a network.

ƒ The node address of the controller is configured under code C1850/C2350 or via DIP

switch(^ 33).

l

43

Page 44

8

Data transfer

Structure of the CAN telegram

User data

The user data area of the CAN telegram either contains network management data, process

dataor parameter data:

ƒ Network management data (NMT data)

Network management data contain information on the establishment of

communication via the CAN network (^ 45).

ƒ Process data (PDO, Process Data Objects)

– Process data are transferred via the process data channel (see also chapter "Process

data transfer", ^ 48).

– Process data serve to control the controller (slave).

– Process data are transferred between the host and the controllers to ensure a

continuous exchange of current input and output data.

– The host has direct access to process data. In the PLC, the data are, for instance,

directly assigned to the I/O area. An exchange between host and controller is

required as fast as possible. Small amounts of data can be transferred cyclically.

– Process data are not saved in the controller.

– Process data are, for instance, control words, status words, setpoints and actual

values.

ƒ Parameter data (SDO, Service Data Objects)

– Parameter data are transmitted as SDOs via the parameter data channel and

acknowledged by the receiver, i.e.the sender gets a feedback about the

transmission being successful or not (see also chapter "parameter data transfer",

^ 69).

– The parameter data channel enables access to all Lenze codes and CANopen

indices.

– The parameters for instance are set for the initial system set−up during

commissioning or when material is changed on the production machine.

– In general, the parameter data transfer is not time−critical.

– Parameter changes are automatically stored in the controller.

– Parameter data for example are operating parameters, diagnostics information,

and motor data.

44

l

EDSMF2178IB EN 3.0

Page 45

Data transfer

CAN communication phases / network management (NMT)

8.2 CAN communication phases / network management (NMT)

Regarding communication, the controller knows the following statuses:

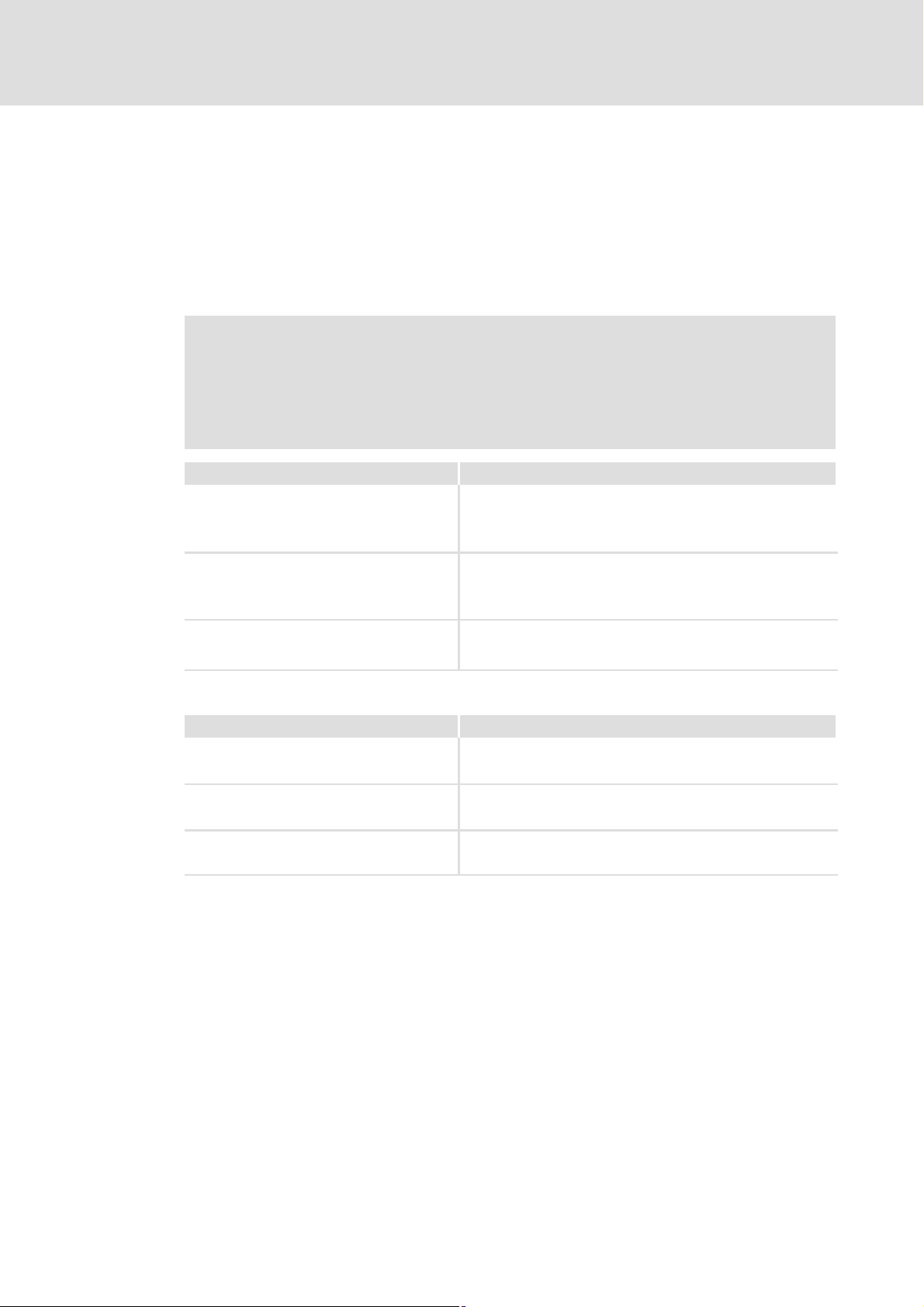

Status Description

"Initialisation" After the controller is switched on, the initialisation phase is run through.

During this phase, the controller is not involved in the data exchange on the

bus.

A part of the initialisation or the complete initialisation can be run through

again in every NMT status by transmitting different telegrams (see "state

transition"). Here, all parameters are written with their set values.

After completing the initialisation, the controller automatically adopts the

"Pre−Operational" status.

"Pre−Operational" The controller can receive parameter data.

The process data are ignored.

"Operational" The controller can receive parameter data and process data.

"Stopped" Only network management telegrams can be received.

8

EDSMF2178IB EN 3.0

l

45

Page 46

8

Data transfer

CAN communication phases / network management (NMT)

Network management (NMT)

The telegram structure used for the network management contains the identifier and the

command included in the user data which consists of the command byte and the node

address.

Telegrams with the identifier "0" and 2 byte user data are used to change between the

different communication phases.

Identifier User data

Value = 0

11 bits

Fig. 8−2 Telegram for switching over the communication phases

A bus node, the network master, carries out the changes between the communication

phases for the whole network.

With code C1852 / C2352 (¶ 125) you can set up the communication module for master

or slave operation.

After an adjustable boot−up time in C1856/1 / C2356/1 in master operation, (¶ 130) the

NMT command Start_Remote_Node is transmitted, which puts all nodes into the

"Operational" status.

Only contains command

2bytes

) Note!

Only a change to "Operational" status enables communication via the process

data!

Example:

If all nodes connected to the bus are to be switched from the

"Pre−Operational" communication status to the "Operational" communication

status via the CAN master, the identifier and the user data must have the

following values in the transmission telegram:

ƒ Identifier: 0x00 (broadcast telegram)

ƒ User data: 0x0100

46

l

EDSMF2178IB EN 3.0

Page 47

CAN communication phases / network management (NMT)

State transitions

(1)

Initialisation

(2)

(14)

Pre-Operational

(7)

(4)

(13)

(3)

(12)

Operational

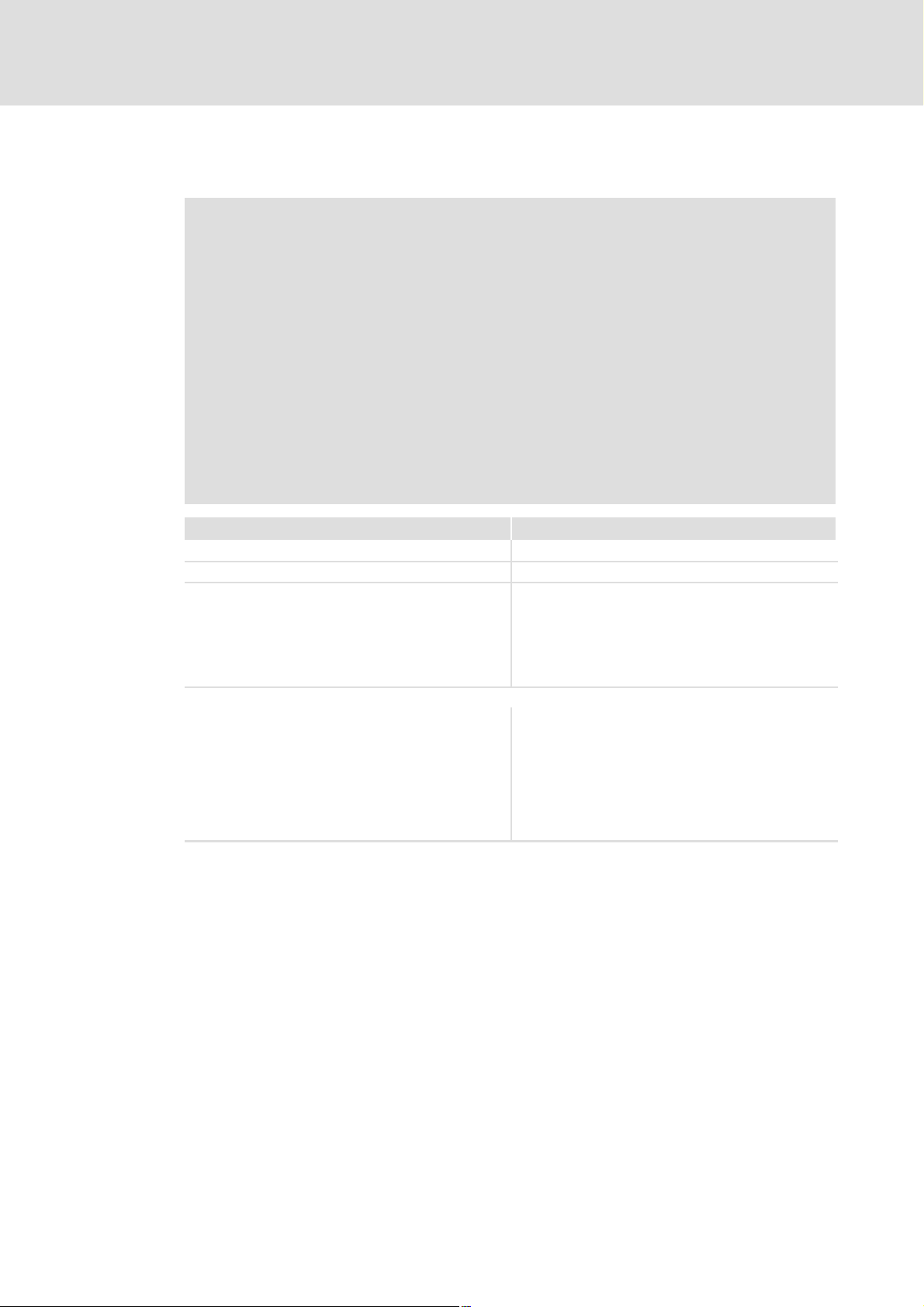

Fig. 8−3 State transitions in CAN network (NMT)

(5)

(6)

Stopped

(8)

(11)

(10)

(9)

Data transfer

8

E82ZAFU004

Status

transition

(1) − Initialisation

(2) − Pre−operational

From that moment on, the master changes the states for the whole network. A target address, which is part of

the command, specifies the receiver(s).

(3), (6) 0x01yy Operational

(4), (7) 0x80yy Pre−operational

(5), (8) 0x02yy Stopped Only network management telegrams can be received.

(9)

(10)

(11)

(12)

(13)

(14)

Command

(hex)

0x81yy

0x82yy

Network status after

change

Initialisation

Effects on process and parameter data after the status

change

Initialisation starts automatically when the mains is

switched on.

During initialisation, the drive does not take part in the

data transfer.

After initialisation has been completed, the node sends a

boot−up message with an individual identifier on the

CAN bus and changes automatically to the status

"Pre−operational".

In this phase, the master determines the way in which

the controller takes part in the communication.

Network management telegrams, sync, emergency,

process data (PDOs) and parameter data (SDOs) active

(like "Start remote node")

Optional:

When the status is changed, event and time−controlled

process data (PDOs) will be sent once.

Network management telegrams, sync, emergency and

parameter data (SDOs) active (like "Enter pre−operational

state")

Initialises all parameters in the communication module

with the stored values (corresponds to "Reset node")

Initialises communication−relevant parameters (CIA DS

301) in the communication module with the stored

values (corresponds to "Reset communication")

EDSMF2178IB EN 3.0

yy = 00 In case of this assignment, the telegram addresses all devices connected. The

state of all devices can be changed at the same time.

yy = node ID If a node address is given, only the state of the device with the corresponding

address will be changed.

l

47

Page 48

9

Process data transfer

Available process data objects

9 Process data transfer

Agreements

ƒ Process data telegrams between host (master) and controller (slave) are

distinguished as follows with regard to their direction:

– Process data telegrams to the controller

– Process data telegrams from the controller

ƒ In CANopen, the process data objects are named from the node’s view:

– RPDOx: A process data object received by a node

– TPDOx: A process data object transmitted by a node

9.1 Available process data objects

Depending on the basic device used, up to 3 RPDOs and TPDOs can be available.

I Tip!

From the masters’s view, the following terms are used for process data

transfer with the standard device and the plugged communication module:

ƒ The master sends the process data output words (POWs) as process output

data to the standard device

ƒ The master receives the process data input words (PIWs) as process input

data from the standard device.

48

l

EDSMF2178IB EN 3.0

Page 49

Process data transfer

Available process data objects

Process data telegram to the controller (RPDO)

The identifier of the process data telegram includes the node address of the controller. The

telegram has a maximum user data length of 8 bytes. This chapter describes which user

data will be evaluated for the controllers.

The CAN bus is connected to the automation interface X1 via the communication module.

X1 is connected to the function block AIF−IN. Here, the user data is transformed into

corresponding signal types in order to use them for further function blocks. The control

word is especially important for the controller. It contains the drive setpoint in user data

bytes 1 and 2.

AIF−IN

Control word

Byte 1, 2 =

9

Byte 3, 4

Identifier

Fig. 9−1 Example: Process data telegram to controller

User data

8 bytes

X1 = AIF interface, e.g. 8200 vector

X1

AIF

X1

Process data telegram from the controller (TPDO)

For the cyclic process data telegrams from the controller, the function block to be used is

called AIF−OUT. The status word (bytes 1 and 2) included in the process data telegram is

transmitted on the CAN bus to the master via this function block.

EDSMF2178IB EN 3.0

l

49

Page 50

9

9.2 Configuring process data channel

Process data transfer

Configuring process data channel

Selection of the setpoint source

Drive controller 8200 vector

The selection of the setpoint source for these controllers is determined with code C0001

(index: 0x5FFE). For process data evaluation the code C0001 must be set to 3 when

operating the controller with the communication module.

The setpoint source is the process channel which overwrites the frequency setpoint

(C0046) and the control word (C0135) (see documentation for 8200 vector).

) Note!

Please observe that the setpoint source selection (C0001) must be set equally

in all parameter sets.

Drive controller 93XX

The 9300 controllers do not offer a setpoint source selection which can be set by one code

only. For this purpose, you only need to connect preconfigured function blocks in order to

adapt the controller to the drive task without being an expert in programming.

The user himself is able to carry out the interconnection. However, it is recommended to

use the preconfigurations provided by Lenze, which are saved in the read−only memory of

the controller. The Lenze preconfigurations (code C0005) define which source (terminal,

keyboard, communication module) overwrites the frequency setpoint and the control

word.

For operation via CAN bus, the value to be set under code C0005 must be set to "xxx3" (x =

wildcard for selected preconfiguration).

, 9300 system manual

Here, you can find more detailed information.

PLC devices: 9300 Servo PLC / Drive PLC / ECSxA

For communicating via a communication module (e.g. EMF2178IB), it is necessary that the

system blocks AIF−IN/OUT1 ... 3 and, if required, the AIF management are integrated into

the control configuration of the IEC61131 project.

50

Axis modules of the ECS series

, Operating instructions for the axis modules of the ECS series

Here you can find detailed information on the process data configuration.

l

EDSMF2178IB EN 3.0

Page 51

9.3 Cyclic process data objects

Synchronisation of cyclic process data

The "sync telegram" is used to ensure that the process data can be cyclically read by the

controller and will be accepted by the controller.

The sync telegram is the trigger point for accepting data in the controller and activates the

sending process from the controller. For cyclic process data processing, the sync telegram

must be generated accordingly.

Sync telegram Sync telegram

Process data transfer

Cyclic process data objects

9

Process data from

Controller

Fig. 9−2 Sync telegram

After the sync telegram has been received, the controllers send the cyclic process data to

the master. The master reads them as process input data.

When the sending process has been completed, the controllers receive the process output

data (from the master).

All other telegrams (e. g. parameters or event−controlled process data) are acyclically

accepted by the controllers after transmission has been completed.

Acyclic data have not been taken into account for the above figure. When selecting the

cycle time, they must be considered.

Process data to

Controller

Cycle time

EDSMF2178IB EN 3.0

l

51

Page 52

9

Process data transfer

Cyclic process data objects

Process data signals of Lenze controllers

9.3.1 Process data signals of Lenze controllers

9.3.1.1 Process data signals for 8200 vector frequency inverters

A change of code C0001 to 3 preconfigures the process data words in the controller.

) Note!

Frequency and speed values are normalised with "240005"480Hz.

Process data telegram to drive

User data (up to 8 bytes)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Control

word

Low byte

Byte description:

Byte Content Description

1 C0135

2 C0135

3 AIF−IN.W1, low byte

4 AIF−IN.W1, high byte

5 AIF−IN.W2, low byte

6 AIF−IN.W2, high byte

7 / 8 xx No evaluation of these data, any content possible

Control

word

High byte

Control word, low byte

Control word, high byte

AIF−IN.W1

Low byte

AIF−IN.W1

High byte

Bits 0 ... 7 of the control word under C0135 (^ 145) are entered here.

Bits 8 ... 15 of the control word under C0135 (^ 145) are entered

here.

AIF−IN.Wx is parameterised under code C0412.

AIF−IN.W2

Low byte

AIF−IN.W2

High byte

xx xx

Process data telegram from drive

User data (up to 8 bytes)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Status word

Low byte

Status word

High byte

AIF−OUT.W1

Low byte

AIF−OUT.W1

High byte

AIF−OUT.W2

Low byte

AIF−OUT.W2

High byte

xx xx

Byte description:

Byte Content Explanation

1 C0150

Status word, low byte

2 C0150

Status word, high byte

3 AIF−OUT−W1

Low byte

4 AIF−OUT.W1

High byte

5 AIF−OUT−W2

Low byte

6 AIF−OUT.W2

High byte

7 / 8 xx No evaluation of these data, any content possible

Bits 0 ... 7 of the status word are entered here under C0150 (^ 145).

Bits 8 ... 15 of the status word are entered here under C0150 (^ 145).

AIF−OUT.Wx is parameterised under code C0421.

52

l

EDSMF2178IB EN 3.0

Page 53

Process data transfer

Cyclic process data objects

Process data signals of Lenze controllers

Device control word AIF−CTRL for 8200 vector (C0135, index 0x5F78)

9

Bit

0 / 1 JOG values

2

3

4

5

6

7 DOWN function motor potentiometer

Assignment (Lenze setting)

C0001 = 3 with C0007 £ 51 C0001 = 3 with C0007 > 51

Freely configurable 1

Bit 1 0

0 0 00 = C0046 active

0 1 01 = NSET1−JOG1 (C0037) active

1 0 10 = NSET1−JOG2 (C0038) active

1 1 11 = NSET1−JOG3 (C0039) active

Current direction of rotation (DCTRL1−CW/CCW)

01Not active

Active

Freely configurable 3

Quick stop (QSP) (AIF−CTRL−QSP) Quick stop (QSP) (AIF−CTRL−QSP)

01Not active

Active

Stop ramp function generator (NSET1−RFG1−STOP)

01Not active

Active

Ramp function generator input = 0

(NSET1−RFG1−0)

01Not active

Active

UP function motor potentiometer (MPOT1−UP)

01Not active

Active

01Not active

Active

Freely configurable 5

Freely configurable 6

Freely configurable 7

Freely configurable 8

(MPOT1−DOWN)

Set under

C0410/...

2

4

8 Freely configurable Freely configurable 9

9

10

11 Reset fault

12

13

14

Controller inhibit (AIF−CTRL−CINH) Controller inhibit (AIF−CTRL−CINH)

01Not active

Active

01Not active

Active

External fault (AIF−CTRL−TRIP−SET) External fault (AIF−CTRL−TRIP−SET)

01Not active

Active

01Not active

Active

Reset fault

(AIF−CTRL−TRIP−RESET)

0 −> 1 Edge from 0 to 1 0 −> 1 Edge from 0 to 1

Change over parameter set (DCTRL1−PAR2/4)

01Not active

Active

Change over parameter set (DCTRL1−PAR3/4)

01Not active

Active

DC injection brake (MCTRL1−DCB)

01Not active

Active

(AIF−CTRL−TRIP−RESET)

Freely configurable 13

Freely configurable 14

Freely configurable 15

10

11

12

15 Freely configurable Freely configurable 16

EDSMF2178IB EN 3.0

l

53

Page 54

9

Process data transfer

Cyclic process data objects

Process data signals of Lenze controllers

DCTRL

...

...

...

DCTRL

...

...

...

AIF-IN

AIF-IN.W1

AIF-IN.W2

C0410/x = 10

C0410/x = 11

C0410/x = 12

C0410/x = 22

C0410/x = 25

C0412/x = 10

C0412/x = 11

AIF

AIF-CTRL

16 Bit

16 Bit

16 Bit

.B0

.B1

.B2

.B3

.B4

.B8

.B9

.B10

.B11

.B12

.B15

QSP

...

...

...

CINH

TRIP-SET

TRIP-RESET

...

...

...

Fig. 9−3 System block AIF−IN in 8200 vector (freely configurable assignment)

2141LON011

54