Page 1

EDBMF2141

Show/Hide Bookmarks

N\e

Operating Instructions

ÄN\eä

Service

L

LON

24V DC

FTT

2141

Fieldbus module type 2141

LON (Local Operating Network)

Page 2

qЬЙлЙ lйЙк~нбеЦ fелнкмЕнбзел ~кЙ о~дбЗ Сзк СбЙдЗДмл гзЗмдЙл пбнЬ нЬЙ СзддзпбеЦ е~гЙйд~нЙлW

Show/Hide Bookmarks

2141 IB. 0x. 0x. LON

fе ЕзееЙЕнбзе пбнЬ нЬЙ мебн лЙкбЙл ~л Скзг нЬЙ е~гЙйд~нЙ З~н~W

820X E./C. 2x. 1x. (8201 - 8204)

821X E./C. 2x. 2x. (8211 - 8218)

822X E. 1x. 1x. (8221 - 8227)

824X E.C. 1x. 1x. (8241 - 8246)

82EVxxxxxBxxxXX Vx 1x 8200 vector

EPL 10200 I.T. 1x. 1x. (Drive PLC)

93XX E./C. 2x. 1x. (9321 - 9333)

93XX E./C. I.T. 2x. 1x. (9300 Servo PLC)

Type

Design:

E = Built-in unit IP20

IB = Module

Hardware version and index

Software version and index

Variant

Explanation

Important:

These Operating Instructions are only valid together with the corresponding Operating Instruc-

tions for the 82XX, 8200 vector, 93XX and 9300 Servo PLC and Drive PLC.

What is new?

Material no. Version Important Contents

455968 1.0 08/02 TD02 1st edition

E 2002 Lenze Drive Systems GmbH

No part of these Instructions must be copied or given to third parties without written approval of Lenze Drive Systems GmbH.

All information given in this documentation have been checked for compliance with the hardware and software described. Nevertheless, deviations and

mistakes cannot be ruled out. We do not take any responsibility or liability for damages which might possibly occur. Necessary corrections will be included

in the next edition.

Page 3

Contents

Show/Hide Bookmarks

1 Preface and general information 1-1...........................................

1.1 How to use these Operating Instructions 1-1................................................

1.1.1 Terminology used 1-1.........................................................

1.2 Packing list 1-1.....................................................................

1.2.1 Legal regulations 1-2..........................................................

2 Safety information 2-1......................................................

2.1 Persons responsible for the safety 2-1....................................................

2.2 General safety information 2-1..........................................................

2.3 Layout of the safety information 2-2......................................................

3 Technical data 3-1.........................................................

3.1 Features of the 2141 fieldbus module 3-1..................................................

3.2 General data / application conditions 3-1..................................................

3.3 Rated data 3-2......................................................................

3.4 Dimensions 3-2.....................................................................

3.5 Communication times 3-3.............................................................

3.5.1 Processing time in the basic unit 3-3..............................................

3.5.2 Number of devices connected to the bus 3-3........................................

4 Installation 4-1............................................................

4.1 Elements at the front of the 2141 fieldbus module 4-1.........................................

4.1.1 Connection of external voltage supply 4-2..........................................

4.1.2 Connection for LON bus 4-2.....................................................

4.1.3 Data for connection terminals 4-2................................................

4.2 Mechanical installation 4-3.............................................................

4.3 Electrical installation 4-4..............................................................

4.3.1 Wiring to a host 4-4...........................................................

4.3.2 Voltage supply 4-5............................................................

5 Commissioning 5-1........................................................

5.1 First switch-on 5-1...................................................................

5.2 Configure the controller for the communication with the 2141 fieldbus module 5-2....................

5.2.1 Protection against uncontrolled restart 5-2..........................................

L BA2141 EN 1.0

i

Page 4

Contents

Show/Hide Bookmarks

6 Parameter setting 6-1......................................................

6.1 Parameter data channel configuration 6-2..................................................

6.1.1 Parameter data 6-2...........................................................

6.1.2 Network variable for the parameter data channel 6-3..................................

6.1.2.1 Structure of network variables 6-3......................................

6.2 Overview: Network variable and configuration variable 6-1.....................................

6.2.1 Overview: Node Object 6-1.....................................................

6.2.2 Overview: Network variable for VSD control 6-2......................................

6.2.3 Overview: Network variable for AIF-CTRL control 6-2..................................

6.2.4 Overview: Configuration variable for VSD control 6-3...................................

6.3 Node Object 6-4.....................................................................

6.3.1 Inhibit / Enable all objects 6-4...................................................

6.3.2 Status messages 6-4..........................................................

6.4 VSD control VSD 6-5..................................................................

6.4.1 Network variable (VSD) 6-5.....................................................

6.4.1.1 Speed setpoint 6-5..................................................

6.4.1.2 Actual speed value 6-6...............................................

6.4.1.3 Scaling of the speed setpoint 6-7.......................................

6.4.1.4 Motor current 6-8...................................................

6.4.1.5 Motor voltage 6-9...................................................

6.4.1.6 Operating time 6-10..................................................

6.4.2 Configuration variable (VSD) 6-11..................................................

6.4.2.1 Location label 6-11..................................................

6.4.2.2 Receive Heartbeat Time 6-12...........................................

6.4.2.3 Maximum Send Time 6-13.............................................

6.4.2.4 Minimum Send Time 6-14.............................................

6.4.2.5 Maximum speed 6-15.................................................

6.4.2.6 Minimum speed 6-16.................................................

6.4.2.7 Rated speed value 6-17...............................................

6.4.2.8 Rated frequency 6-18.................................................

6.4.2.9 Acceleration time 6-19................................................

6.4.2.10 Deceleration time 6-20................................................

6.4.2.11 Receive heartbeat for AIF-CTRL 6-21.....................................

6.4.2.12 Monitoring reaction for AIF-CTRL 6-22....................................

6.4.2.13 Default value for nviDrvSpeedScale 6-23...................................

6.5 Device control AIF-CTRL 6-24............................................................

6.5.1 General information 6-24........................................................

6.5.1.1 Output variable 6-24..................................................

6.5.1.2 Input variable 6-25...................................................

6.5.2 Network variable for 82XX controllers 6-26...........................................

6.5.2.1 Status word for 82XX 6-27.............................................

6.5.2.2 Control word for 82XX 6-29............................................

6.5.3 Network variable for 8200 vector controllers 6-30......................................

6.5.3.1 Status word for 8200 vector 6-32........................................

6.5.3.2 Control word for 8200 vector 6-33.......................................

6.5.4 Network variable for 93XX controllers 6-35...........................................

6.5.4.1 Status word for 93XX 6-37.............................................

6.5.4.2 Control word for 93XX 6-40............................................

6.5.5 Network variable for 9300 Servo PLC and Drive PLC 6-42...............................

ii

BA2141 EN 1.0

L

Page 5

Contents

Show/Hide Bookmarks

7 Troubleshooting and fault elimination 7-1.......................................

7.1 No communication with the controller. 7-1.................................................

7.2 Controller does not execute write job 7-1..................................................

8 Appendix 8-1.............................................................

8.1 Starting Global Drive Control (GDC) from LONMakert 8-1.......................................

8.1.1 Installation instructions for the plug-In 8-1..........................................

8.1.2 Open GDC from the LONMakert 8-2...............................................

8.2 Configuration of the LON network 8-3.....................................................

8.2.1 Configuration of the LON network 8-3..............................................

8.2.2 Working with network variables 8-5...............................................

8.2.3 Registration of new data types 8-8................................................

8.3 Listofabbreviations 8-9...............................................................

8.4 Glossary 8-10.......................................................................

8.5 More information sources 8-10...........................................................

8.6 Table of keywords 8-11................................................................

L BA2141 EN 1.0

iii

Page 6

Contents

Show/Hide Bookmarks

iv

BA2141 EN 1.0

L

Page 7

Preface and general information

O

Claim

Show/Hide Bookmarks

1 Preface and general information

1.1 How to use these Operating Instructions

• These Operating Instructions are intended for safety-relevant working on and with the 2141

fieldbus module. They contain safety information which must be observed.

• All personnel working on and with the 2141 fieldbus module must have these Operating

Instructions available and observe the information and notes relevant for them.

• The Operating Instructions must always be complete and perfectly readable.

These Operating Instructions contain the most important technical data and describe the

installation of the 2141 fieldbus module. They are only valid in combination with the Operating

Instructions of the corresponding controller.

1.1.1 Terminology used

Controller In the following, the t erm ”controller” is used for ”93XX servo inverters” or ”82XX frequeny inverters”.

Drive system In the following, the term ”drive system” is used for drive systems with fieldbus modules or other Lenze drive

Field bus module In the following text, the term ”fieldbus module” is used for the fieldbus module type 2141 L ON.

Cxxx/y Subcode y of code Cxxx (z.B. C0410/3 = subcode 3 of code C0410)

Xk/y Terminal strip Xk/terminal y (z.B. X3/28 = terminal 28 on terminal strip X3)

(^xx-yyy) Cross reference (chapter - page)

1.2 Packing list

Scope of supply Important

• 1 2141 fieldbus module with housing (enclosure IP20)

• 1M3fixingscrew

• 1 2-pole plug connector for voltage supply

• 1 2-pole plug connector for L

• 1 Mounting Instructions

• 1 floppy

components.

After the delivery has been received, check immediately whether the

items supplied match the accompanying papers. Lenze does not

accept any liability for deficiencies claimed subsequently.

N

• visible transport damage immediately to the forwarder

• visible deficiencies/incompleteness immediately to your Lenze

representative.

L BA2141 EN 1.0

1-1

Page 8

Preface and general information

g

p

Show/Hide Bookmarks

1.2.1 Legal regulations

Labelling

Application as

directed

Nameplate CE mark Manufacturer

Lenze 2141 fieldbus modules are

unambiguously identified by their nameplates.

Fieldbus module 2141

Conforms to the EC Low Voltage Directive Lenze Drive Systems GmbH

Postfach 101352

D-31763 Hameln

• Operate the fieldbus module only under the conditions prescribed in these Operating Instructions.

• The fieldbus module is an additional module and can be optionally attached to the Lenze controller series 820X, 821X, 822X, 8200 vector

and 93XX. The 2141 fieldbus module links these Lenze controllers with the standardized serial communication system LON.

• The fieldbus module must be attached and electrically connected so that it complies with its function and does not cause any hazards when

attached and operated as instructed.

• Observe all notes given in chapter „Safety information“ ^ 2-1.

• Please observe all information given in these Operating Instructions.This means:

– Read these Operating Instructions carefully before you start to work with the system.

– These Operating Instructions must always be available during operation of the fieldbus module.

Any other use shall be deemed as inappropriate!

Liability • The information, data, and notes in these instructions met the state of the art at the time of printing. Claims referring to drive systems

which have already been supplied cannot be derived from the information, illustrations, and descriptions given in these Operating

Instructions.

• The specifications, processes, and circuitry described in these instructions are for guidance only and must be adapted to your own specific

application. Lenze does not take responsibility for the suitability of the process and circuit proposals.

• The specifications in these Instructions describe the product features without guaranteeing them.

• Lenze does not accept any liability for damage and operating interference caused by:

– disregarding these Instructions

– unauthorized modifications to the controller

– operating errors

– improper working on and with the controller

Warranty • Warranty conditions: see Sales and Delivery Conditions of Lenze Drive Systems GmbH.

• Warranty claims must be made to Lenze immediately after detecting the deficiency or fault.

• The warranty is void in all cases where liability claims cannot be made.

Disposal

Material recycle dispose

Metal D Plastic D Assembled PCBs - D

Operating Instructions D

1-2

BA2141 EN 1.0

L

Page 9

Safety information

Show/Hide Bookmarks

2 Safety information

2.1 Persons responsible for the safety

Operator

• An operator is any natural or legal person who uses the drive system or on behalf of whom the drive system is used.

• The operator or his safety personnel is obliged

– to ensure the compliance with all relevant regulations, instructions and legislation.

– to ensure that only skilled personnel works on and with the 2102IB fieldbus module.

– to ensure that the personnel has the Operating Instructions available for all corresponding works.

– to ensure that all unqualified personnel are prohibited from working on and with the drive system.

Qualified personnel

Qualified personnel are persons who - because of their education, experience, instructions and knowledge about corresponding standards and regulations, rules for the

prevention of accidents and operating conditions - are authorized by the person responsible for the safety of the plant to perform the required actionsandwhoare

able to recognize potential hazards.

(Definition for skilled personnel to VDE105 or IEC364)

2.2 General safety information

• These safety notes do not claim to be complete. In case of questions and problems please contact your Lenze representative.

• At the time of delivery the fieldbus module meets the state of the art and ensures basically safe operation.

• The indications given in these Operating Instructions refer to the stated hardware and software versions of the fieldbus modules.

• The fieldbus module is hazardous if:

– unqualified personnel works on and with the fieldbus module.

– the fieldbus module is used inappropriately.

• The processing notes and circuit sections shown in these Operating Instructions are proposals which cannot be transferred to other applications without being

tested and checked.

• Ensure by appropriate measures that neither personal injury nor damage to property may occur in the event of failure of the fieldbus module.

• The drive system must only be operated when no faults occur.

• Retrofittings, modifications or redesigns are basically prohibited. Lenze must be contacted in all cases.

• The fieldbus module is electrical equipment intended for use in industrial high-power plants. The fieldbus module must be tightly screwed to the corresponding

controller during operation. In addition, all measures described in the Operating Instructions of the controller used must be taken. Example: Fastening of covers to

ensure protection against contact.

L BA2141 EN 1.0

2-1

Page 10

Safety information

Show/Hide Bookmarks

Restgefahren, Gestaltung der Sicherheitshinweise

2.3 Layout of the safety information

All safety information given in these Instructions have got the same structure:

Signal word (indicates the severity of danger)

Note (describes the danger and informs the reader how to avoid danger)

Icons used Signal words

Warning of danger

to persons

Warning of hazardous

electrical voltage

Danger! Warns of impending dangerr.

Consequences if disregarded:

Death or severe injuries.

Warning of a general

danger

Warning of damage

to materials

Other notes Tip! It designates general, useful notes.

Warning! Warns of potential, very hazardous situations.

Consequences if disregarded:

Death or severe injuries.

Caution! Warns of potential, hazardous situations.

Consequences if disregarded:

Light or minor injuries.

Stop! Warns of possible damage to material.

Consequences if disregarded:

Damage of the controller/drive system or its environment

If you follow the tip, handling of the controller/drive system

will be easier.

K

2-2

BA2141 EN 1.0

L

Page 11

3 Technical data

Show/Hide Bookmarks

3.1 Features of the 2141 fieldbus module

• Attachable additional module for the following devices:

– 82XX

– 8200 vector

– Drive PLC

– 93XX

– 9300 Servo PLC

• LON connection module with the LONMARK

Drive”

• Access to all Lenze parameters

• Internal and external 24-V-DC voltage supply possible with devices listed above

(exception 820X: only external supply)

®

Functional Profile “Variable Speed Motor

Technical data

3.2 General data / application conditions

Field Values

Order name EMF2141IB

Network topology Free topology (line, tree, star, ring)

Possible number of nodes 64

Max. cable length 2700 m with bus t o pology

Baud rate 78 kBit/s

Ambient temperature during

Permissible humidity Class 3K3 to EN 50178 (without condensation, average relative humidity 85%)

500 m if the topology is mixed

operation:

during

transport:

during storage:

0° C ... 55° C

-25° C ... 70° C

-25° C ... 60 °C

L BA2141 EN 1.0

3-1

Page 12

Technical data

Show/Hide Bookmarks

3.3 Rated data

Field Values

Voltage supply 24 V DC ñ 10 %; max. 120 mA

Communication profile LONMARK®Functional Profile “Variable Speed Motor Drive”

Communication medium FTT - 10 A (Free Topology Transceiver)

Insulation voltage between bus and ... Rated insulation voltage Insulation type

• Earth reference / PE 50 V AC Mains isolation

• External supply (terminal 39/59) 50 V AC Mains isolation

• Power stage

– 820X / 821X 270 V AC Basic insulation

– 822X / 8200 vector 270 V AC Double insulation

– 93XX 270 V AC Double insulation

• Control terminals

– 820X / 8200 vector (with internal supply) 0VAC No mains isolation

– 8200 vector (with external supply 100 V AC Basic insulation

– 821X 50 V AC Mains isolation

– 822X 270 V AC Basic insulation

– 93XX 270 V AC Basic insulation

Degree of pollution VDE0110, part 2, pollution degree 2

3.4 Dimensions

Service

L

LON

75

24V DC FTT

2141

62

Fig. 3-1 Dimensions of the 2141 fieldbus module (all dimensions in mm)

18

23

3-2

BA2141 EN 1.0

L

Page 13

3.5 Communication times

g

g

g

p

Show/Hide Bookmarks

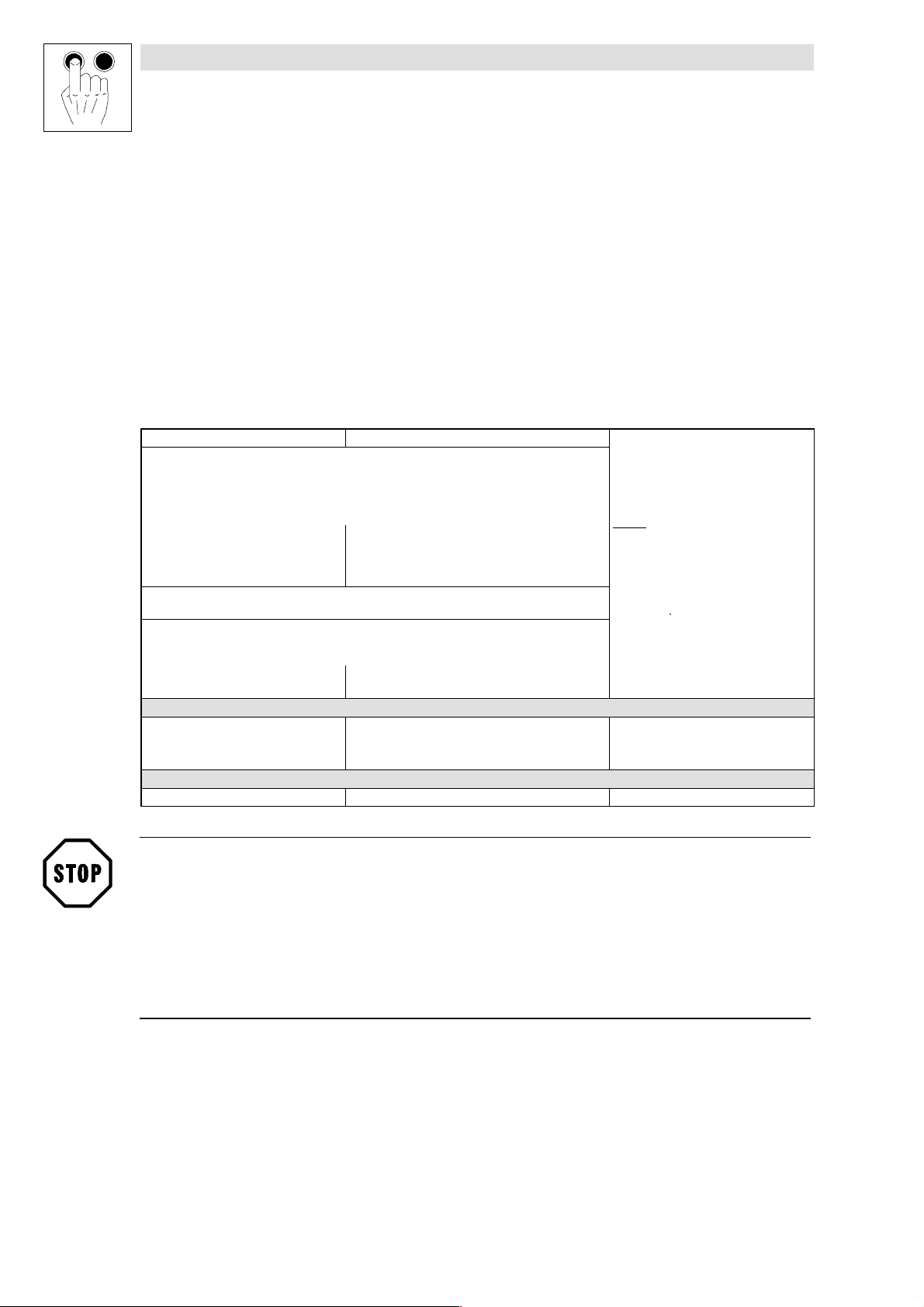

The communication times depend on

• the data transmission time which depends on

– the baud rate

– the user-data length

• the processing time in the basic unit (see the following chapter)

Tip!

You will find more information about the data-transfer time in the documentation for your host

system.

3.5.1 Processing time in the basic unit

The processing time in the basic unit starts when a message arrives at the fieldbus module (action)

and ends with the response of the basic unit to this message.

Technical data

Processing time 820X

Action Processing step Max. time required by the controller

• Writing of control word or setpoint, if the

value has changed

• Alternating reading of status word and

actual value

• Processing of parameter access if there

is a service

Tab. 3-1 Processing time: 820X

Processing time: 821X / 8200 vector / 822X

Parameter data and process data are independent of each other.

• Parameter data: 30 ms + 20 ms tolerance

• Process data: approx. 3 ms + 2 ms tolerance

Processing time: 9300 servo inverter

Parameter data and process data are independent of each other.

• Parameter data: approx. 30 ms + 20 ms tolerance (typical)

– The processing time can be longer for some codes

(see 9300 Manual).

• Process data: approx. 3 ms + 2 ms tolerance

Processing time: Drive PLC / 9300 Servo PLC

Parameter data and process data are independent of each other.

• Parameter data: approx. 30 ms + 20 ms tolerance

• Process data depend on the process image.

The process image is an update of process data made after every task cycle.

Writing of status word and actual

value

Control word or setpoint reading 27 ms +48 ms Toleranz

Control word and setpoint reading 54 ms +56 ms tolerance

Read parameter 55 ms +48 ms tolerance

Parameter writing 108 ms +32 ms tolerance

200 ms +40 ms tolerance

3.5.2 Number of devices connected to the bus

L BA2141 EN 1.0

The maximum bus size depends on

• the baud rate used

• the number of repeaters

For more detailed information see the documenation for the control system.

3-3

Page 14

Technical data

Show/Hide Bookmarks

3-4

BA2141 EN 1.0

L

Page 15

Installation

Twopoleplugforexternalvoltagesupplyofthe2141fieldbusmodul

e

6

pg(p)

Show/Hide Bookmarks

4 Installation

4.1 Elements at the front of the 2141 fieldbus module

Fig. 4-1 Front view of the 2141 LON fieldbus module

Pos. Name/meaning

Green bus LED indicates the voltage supply status for the 2141 f ie l dbus module.

ON: 2141 fieldbus module is supplied with voltage and connected to the controller.

OFF: 2141 is not supplied with voltage; controller and external voltage supply are switched off.

0

BLINKING:

2141 fie l dbus module is supplied with voltage but not connected to the controller. Possible reasons: Controller is switched off, in

initialisation or not connected.

Yellow bus LED indicates t he communication status for t he 2141 fieldbus module.

OFF: 2141 fieldbus module has not been initialised yet.

1

BLINKING: LON communication is not active

Green or red DRIVE-LED

2/

Operating status of 82XX, 8200 vector or 93XX (see Operating Instructions f or controller)

3

Service LED

OFF: Normal operating status

4

BLINKING: Fieldbus module not configured yet

ON: No program available in Neuron

Service key

5

e.g. for signing on a fieldbus module with the configuration tool “ LONMaker

Two-pole plug for external voltage supply of the 2141 fieldbus module

+: Input voltage (see chapter: Technical Data)

6

- : Reference potential for external voltage (GND)

Two-pole plug for LON communication

7

Max. cable cross-section: 1.5 mm

Only for 820X, 821X: Additional PE shield cable avoids EMC related communication interference

8

2

2141LON003

t for Windows® “ ^ 8-1

L BA2141 EN 1.0

4-1

Page 16

Installation

Show/Hide Bookmarks

4.1.1 Connection of external voltage supply

Name Explanation

24 V DC /+ External voltage supply +24 V DC/10 %, 120 mA ma x.

24 V DC /- GND; reference for external voltage supply

4.1.2 Connection for LON bus

Name Explanation

FTT / Connection for LON bus, two cores (twisted pair)

4.1.3 Data for connection terminals

Electrical connection Plug connector with threaded terminal end

Possible connections

Tightening torque 0.5 Nm (4.4 lb-in)

Bare end 7mm

rigid: 1.5 mm2(AWG16)

flexible:

without wire crimp cap

1.5 mm2(AWG16)

with wire crimp cap,without plastic sleeve

1.5 mm2(AWG16)

with wirecrimp cap,with plastic sleeve

1.5 mm2(AWG16)

4-2

BA2141 EN 1.0

L

Page 17

4.2 Mechanical installation

Show/Hide Bookmarks

• Plug the fieldbus module onto the controller (here: 8200 vector)

Installation

• Use the fixing screw to mount the fieldbus module.

2141LON001

2141LON002

L BA2141 EN 1.0

4-3

Page 18

Installation

Show/Hide Bookmarks

4.3 Electrical installation

4.3.1 Wiring to a host

Stop!

An additional mains isolation is required, if

• a 820X or 821X controller is connected to a host and

• a safe mains isolation (double basic insulation) to VDE 0160 is necessary.

For this, it is, for instance, possible to use an interface module which provides an additional mains

isolation (see corresponding manufacturer’s data).

For wiring, the electrical isolation of the supply voltage must be taken into account.

Tip!

The communciation of controllers

820X and 821X may be interfered

by electromagnetic radiation. If

necessary, use an additional PE

shield cable .

4-4

BA2141 EN 1.0

L

Page 19

4.3.2 Voltage supply

Show/Hide Bookmarks

• Internal voltage supply

– If possible, use all devices without

reasons.

• External voltage supply (^ 4-1)

– Absolutely required for 820X controllers.

– If the 2141 fieldbus module is to be able to communicate even if the basic device is switch

off.

• If the bus system is distributed over several control cabinets, install a separate power supply

in every control cabinet to supply all devices/fieldbus modules.

Install an equipotential bonding conductor between the control cabinets.

Tip!

Internal voltage supply of the fieldbus module connected to a 8200 vector

Controllers with an extended AIF interface (front of the 8200 vector) can be internally supplied. The

part of the drawing highlighted in grey shows the jumper position.

With Lenze setting, the fieldbus module is not

For internal voltage supply, put the jumper in the position indicated below.

Installation

external voltage supply because of EMC-relevant

internally supplied.

Lenze setting

(only external voltage supply)

Internal voltage supply

L BA2141 EN 1.0

4-5

Page 20

Installation

Show/Hide Bookmarks

4-6

BA2141 EN 1.0

L

Page 21

5 Commissioning

Show/Hide Bookmarks

5.1 First switch-on

Please do not change the switch-on sequence explained below!

Stop!

Prior to first switch-on of the controller, check the wiring for

• Completeness

• Short circuit

• Earth fault

Step Procedure Remarks

1. Connect the basic unit and

if available external supply for the fieldbus

module.

2. Configuration of controllers connected to

the bus

3. It should now be possible to communicate

with the drive.

4. Drive-specific settings à Operating Instructions of the basic unit

5. Enable controller à Terminal controller inhibit (CINH) = HIGH

6. Setpoint selection à The drive should be running now.

Commissioning

• Onle of the two operating status LEDs at the controller, see ^ 4-1, must be on

or blinking.

If this is not the case, see

• The green Vcc display must also be on, see ^ 4-1.

If this is not the case, see

Configure the controllers connected to the bus by means of an appropriate

configuration tool

à e.g. LONMAKERtfor Windows

The yellow bus LED is blinking, see ^ 4-1, when data is exchanged between

the 2141 fieldbus module and other controllers connected to the bus.

^ 7-1

^ 7-1.

®

,see^ 8-1

L BA2141 EN 1.0

5-1

Page 22

Commissioning

Show/Hide Bookmarks

5.2 Configure the controller for the communication with the 2141 fieldbus module

82XX /

8200 vector

93XX 1. If you want to control the drive via LON, configure the Lenze paramete r “Signal configuration” (C0005) for xxx3. This change can be carried out

1. The drive can be controlled through LON, if the Lenze parameter “Operating mode” (C0001) is changed from 0 to 3. This change can be made

by using the keypad or directly via LON.

• Example:

For LON Write (C0001=3), subindex: 0, value = 30000.

Please see the information about how to change parameter values of a code in chapter 6.1.2.1.

2. Terminal 28 (controller enable) is always active

the controller cannot be enabled by the LON.

3. 821X, 8200vector and 822X:

The QSP function (quick stop) is always active

A input terminal configured for QSP (default setting: not assigned) must be HIGH during LON operation (see Operating Instructions for the

controller).

4. The controller now accepts control and parameter-setting data from the LON.

using the 9371BB keypad or the LON. Select the signal configuration 1013 for first commissioning.

• Example:

For LON Write (C0005=1013), subindex: 0, value: 10130000.

Please see the information about how to change parameter values of a code in chapter 6.1.2.1.

2. Set the parameter C0142 to 0.

Please read the next TIP for code C0142.

3. Terminal 28 (RFR = controller enable) is always active

Otherwise, the controller cannot be enabled by the LON.

4. With the signal configuration C0005=1013, the QSP function (quick stop) and the CW/CCW changeover are a ssigned t o the input terminals E1

and E2, and thus they are always active.

E1 must be HIGH for LON operation (see 93XX Operating Instructions).

With the signal configuration C0005=xx13, t erminal A1 is configured as voltage output. Therefore, only the following terminals must be

connected via cables:

• X5.A1 with X5.28 (ctrl. enable)

• X5.A1 with X5.E1 (CW/QSP)

5. The controller now accepts control and parameter-setting data from the LON.

and must be HIGH for LON operation (see the corresponding Operating Instructions). Otherwise,

.

and must be HIGH for LON operation (see Operating Instructions for the controller).

5.2.1 Protection against uncontrolled restart

Tip!

After an error or fault (e.g. short-term mains failure) a restart of the drive is not always wanted.

• The start condition can be changed, i.e. the drive can be inhibited by setting C0142 = 0 for

the event that

– the corresponding controller sets a fault „Message“

– the fault is active for more than 0.5 s

Parameter function:

• C0142 = 0

– Controller remains inhibited (even if the fault is not active any longer)

– The drive restarts in a controlled mode: LOW-HIGH transition at one of the inputs for

„Controller inhibit“ (CHIN, e.g. at terminal X5/28)

• C0142 = 1

– Uncontrolled restart of the controller possible

5-2

BA2141 EN 1.0

L

Page 23

6 Parameter setting

Show/Hide Bookmarks

General information on parameter setting

Two different data types are transferred by the 2141 fieldbus module:

• Parameter data

• Process data,

Different communication channels are assigned to parameter and process data:

Telegram type Communication channel

Parameter data These are, for instance,

• Operationg parameters

• diagnostics information

• motor data

In general, the parameter transfer is not as

time-critical as the tranfer of process data.

Process data These are, for instance,

• Setpoints

• Actual values

Exchange between host and controller

required as fast as possible. Small amounts

of data, which are transferred cyclically.

Parameter setting

Parameter data channel

(chapter 6.1)

Process-data channel

(chapter 6.2)

• Enables the access to all Lenze codes.

• Parameter changes are normally saved in

the controller (observe C0003).

• If the parameter channel is active, it

assigns 4 words of the input and output

process data.

• The controller can be controlled using the

process data.

^ 6-7 ).

(

• The host has direct access to the process

data.

In the PLC, for instance, the data are

directly assigned to the I/O area.

• Process data are

– not stored in the controller.

– cyclically transferred between the host

and the controller (continuous

exchange of current input and output

data).

^ 6-2 )

Tab. 6-1 Division of parameter data and process data into different communication channels

The communication protocol is only described as much as it is needed for building up the network

with Lenze controllers.

L BA2141 EN 1.0

6-1

Page 24

Parameter setting

currentparameterset

g

Changesofthecurrentparametersetwill

p

Show/Hide Bookmarks

6.1 Parameter data channel configuration

6.1.1 Parameter data

Parameter data are addressed through Lenze codes. You find a code table in the Operating

Instructions for your controller.

Lenze parameter sets

Parameter sets are for special code saving which is necessary because of different configurations

for different application processes.

The following table informs about the number of parameter sets and how to address them.

82XX 8200 vector

82XX and 8200 vector controllers have 2 and 4 parameter sets. They can be directly addressed

through LON.

They are addressed by means of a code-digit offset:

• Offset 0 addesses parameter set 1 with Lenze codes C0000 to C1999

• Offset 2000 addresses parameter set 2 with Lenze codes C2000 to C3999

• Offset 4000 addresses parameter set 3 with the

No additional parameter sets available.

If a parameter is available only once (see Operating Instructions for 82XX or 8200 vector), use t he

code digit offset 0.

Example for C0011 (maximum field frequency):

C0011 in parameter set 1: Lenze code = 11

C0011 in parameter set 2: Lenze code = 2011

-

Parameter changes

Automatic saving in the controller Automatic saving (can be switched off under C0003) Changes must be saved in code C0003.

Process data changes

No automatic saving No automatic saving No automatic saving

Lenze codes C4000 to C5999

• Offset 6000 addresses parameter set 4 with the

Lenze codes C6000 to C7999

C0011 in parameter set 3: Lenze code = 4011

C0011 in parameter set 4: Lenze code = 6011

93XX controllers have 4 parameter sets

(depending on the variant) for non-volatile

saving.

Another parameter set is in the user

memory of the controller. This is the

After switching on the controller,

parameter set 1 is automatically loaded

into the current parameter set.

es of the currentparameter set will

Chan

be lost after switching off the controller.

The current parameter set is stored in

code C0003.

Only the current parameter set can be

directly addressed through LON.

The 93XX codes are listed in the

Operating Instructions and the Manual.

All changes made without storing them will

be lost after the controller is switched off.

93XX

.

Stop!

• For 8200 vector

– Please note that it is not allowed to write parameter data to the EEPROM.

– If you want to cyclically change parameter data, the code must be configured as follows

after every mains switching: C0003 = 0.

• For 82XX

– Please note that it is not allowed to cyclically write parameter data to the EEPROM.

6-2

BA2141 EN 1.0

L

Page 25

Parameter setting

L

hcode

cod

e

SubcodeS

Detailsaboutthe

Show/Hide Bookmarks

6.1.2 Network variable for the parameter data channel

The network variables nviParamReq, nvoParamRes and nvoLongRes

• enable parameter setting and diagnostics.

• allow access to all Lenze parameters (codes).

The input network variable nviParamReq allows to send a read or write request to the drive.

With parameters with a length of up to 4 bytes, the response is output through the output network

variable nvoParamRes.

With parameters bigger than 4 bytes, the response to a read request is output through the network

variable nvoLongRes.

6.1.2.1 Structure of network variables

Tip!

User data are displayed in left-justified Motorola format.

High byte or high word are shown before low byte or low word (see

Calculation examples

(^ 6-6) ).

Details about the

parameter data

telegram:

Details about the

parameter data

telegram:

Details about the

parameter data

telegram:

The structure of nviParamReq and nvoParamRes is defined as follows:

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte 9th byte

engt

code code

High byte

Low byte

ervice

Data 4 Data 3 Data2 Data1

The structure of nvoLongRes is defined as follows:

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte .... 28th byte

Length

1st byte

Length

code

High byte

code

Low byte

Subcode Service Data 1 .... Data23

Indicates the length of the following byte for write orders. Value range: 1, 2 or 4.

2nd byte 3rd byte

code

High byte

code

Low byte

Byte2andbyte3containthecodetobeused.

4th byte

Subcode

Error code

L BA2141 EN 1.0

Byte4containsthesubcodetobeused.

• The series 82XX do not have codes with subindex, the value is always 0.

• Many codes of 93XX and 8200 vector controllers require additional addressing via a

subindex.

Example for 9300 servo inverters:

Code C0039 / subcode 3 addresses ” NSET JOG” (50% = default setting)

6-3

Page 26

Parameter setting

Show/Hide Bookmarks

Details about the

parameter data

telegram:

Details about the

parameter data

telegram:

5th byte

Service

Order type

1 = Read

2=Write

Data contents

• Response ok

– Read: 1

–Write:2

• Faulty response

(80

(80

hex

hex

+1)

+2)

– Read: 81

–Write:82

6th byte 7th byte 8th byte 9th byte

Data 4 Data 3 Data 2 Data 1

hex

hex

Bytes 6 to 9 contain the data to be written.

Bytes 6 to 9 are not relevant for reading orders.

The parameters of the corresponding code are changed by multiplying the parameter value with

10000 (the result is an integer value). Lenze parameters are mainly in the fixed-point format ,data

type Integer32, with four decimal codes.

Tip!

Please see the Operating Instructions for your controller for the value range of Lenze codes.

Lenze parameters dec hex

Example: Set C0039 (JOG) = 150.4 Hz 150.4 x 10000 = 1504000 = 0016F300

The parameter value needs 1 to 4 bytes depending on the data format (see “Attribute table” in the

Operating Instructions for your controller)

6th byte 7th byte 8th byte 9th byte

Data 4 Data 3 Data 2 Data 1

High byte Low byte High byte Low byte

High word Low word

Double word

Assignment of bytes 6 to 9 with parameter value of different lengths

6th byte 7th byte 8th byte 9th byte

00 00 00 Parameter value (length 1)

00 00 Parameter value (length 2)

Parameter value (length 4)

6-4

BA2141 EN 1.0

L

Page 27

Parameter setting

Show/Hide Bookmarks

Details about the

parameter data

telegram:

6th byte 7th byte 8th byte 9th byte

Error code

If processing the order is completed correctly, the variable nvoParamRes contains the read data

or a copy of the written data.

If an error occurs in the network variable nvoParamRes the error code will be entered in byte 9.

Theerrorcodecanbereadfrombyte9if

• the value of byte 1 = 1 and

• bit7issetinbyte5(i.e.thevalueofbyte5=80

, see example below).

hex

Tip!

Strings and data blocks cannot be written.

The following table explains the error codes.

Error code

dec hex

01 01 Service-ID invalid

02 02 Caller-ID invalid

03 03 Data type invalid

04 04 Subcode-No. invalid

05 05 Code-No. invalid

06 06 Parameter invalid, general

07 07 No access authorisation because of operating status

08 08 No access authorisation because of operating mode

09 09 No access authorisation because parameter can only be read

10 A No access authorisation

11 B Data block too long

12 C Collision with other parameter values

14 D Quit value range

15 I General limit value exceeding

32 20 General

33 21 Time limit exceeded

34 22 Frame error

35 23 Parity error

36 24 Overflow

Meaning of error message

L BA2141 EN 1.0

Example:

The brake opening time, code C0196 (C4

), is wrong.

hex

Error code 14, ’Parameter value exceeds the max. permissible value’.

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte 9th byte

01 00 C4 00 80 00 00 00 0E

6-5

Page 28

Parameter setting

Show/Hide Bookmarks

Example 1: Read parameter

The heat sink temperature

(Here: J =43° C)

• Byte 1: Length

– 4(datalength4bytes)

• Byte 2 and byte 3: Code

– C0061: 61 = 3D

hex

• Byte 4: Subcode

– Subindex = 0, as there is not subindex under code C0061.

• Byte 5: Service

– Service=1(Read)

• Byte 6 ... 9: Data (part of the response of nvoParamRes)

– Data1todata4=43[° C] x 10000 = 430000 = 00 06 8F B0

Result:

Byte1 Byte 2 + byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8 Byte 9

Lengt

h

Request telegram from master to drive

Hex: 04 003D 00 01 00 00 00 00

Wait for response identification with code = 003D and subcode 0

Response telegram from drive t o master (for faulty execution)

Hex: 04 003D 00 01 00 06 8F B0

Tab. 6-2 Telegram exchange in LON parameter data channel

code Lenze subcode Service Parameter value

of the controller is to be read

hex

(C0061)

.

Example 2: Write parameter

The acceleration time

(C0012)

of the controller is to be set to Tir=20s.

• Byte 1: Length

– 4(datalength4bytes)

• Byte 2 and byte 3: Code

– C0012: 12 = 0C

hex

• Byte 4: Subcode

– Subindex = 0, as there is not subindex under code C0061.

• Byte 5: Service

– Service=2(Write)

• Byte 6 ... 9: Data (part of the response of nvoParamRes)

– Data 1 to data 4 = 20 [s] x 10000 = 200000 = 00 03 0D 40

Result:

Byte1 Byte 2 + byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8 Byte 9

Lengt

h

Request telegram from master to drive

hex: 04 000C 00 02 00 03 0D 40

Wait for response identification with code = 00C and subcode 0

Response telegram from drive t o master (for faulty execution)

hex: 04 000C 00 02 00 00 00 00

code Lenze subcode Service Parameter value

hex

Tab. 6-3 Telegram exchange in LON parameter data channel

6-6

BA2141 EN 1.0

L

Page 29

Parameter setting

Show/Hide Bookmarks

6.2 Overview: Network variable and configuration variable

Communication with 2141 fieldbus module via network variable.

The control Variable Speed Motor Drive (VSD) is the part of the network variable defined in the

LonMark

The Lenze control AIF-CTRL is the manufacturer-related part of the network variable. Lenze drives

are parameterised and controlled by AIF-CTRL.

The changeover between the two controls is automatic.

• VSDisactiveifoneofthevariablesnviDriveSpeedStpt or nviDriveSpeedScale gets a

• AIF-CTRL is active if one of the variables nviAIFIn1 to nviAIFIn3 or nviAIFStw gets

The network variable Node Object accesses the entire node.

6.2.1 Overview: Node Object

®

Functional Profile.

new value.

a new value.

• Required network variable

nvi00Request

SNVT_obj_request

• Selectable network variable

• Configuration variable

• Manufacturer-related part

Fig. 6-1 NodeObject, described in chapter 6.3

nvo00State

SNVT_obj_status

nciLocation

SNVT_str_asc

L

BA2141 EN 1.0

6-7

Page 30

Parameter setting

Show/Hide Bookmarks

6.2.2 Overview: Network variable for VSD control

• Required network variable

Speed setpoint

nviDrvSpeedStpt

SNVT_switch

• Selectable network variable

Scaling v

set

nviDrvSpeedScale

SNVT_lev_percent

^ 6-11

^ 6-13

Actual speed value

nvoDriveSpeed

SNVT_lev_percent

Motor current

nvoDriveCurnt

SNVT_amp

Motor voltage

nvoDrvVolt

SNVT_volt

Operating time

nvoDrvRunHours

SNVT_time_hour

^ 6-12

^ 6-14

^ 6-15

^ 6-16

Fig. 6-2 Network variable VSD, described in chapter 6.4

6.2.3 Overview: Network variable for AIF-CTRL control

• Manufacturer-related network variable

Process data input

nviAIFStw

SNVT_count

Process data input

nviAIFIn1

SNVT_count

Process data input

nviAIFIn2

SNVT_count

Process data input

nviAIFIn3

SNVT_count

nviParamReq

ParamType

^ 6-31

^ 6-31

^ 6-31

^ 6-31

^ 6-3

Process data output

nvoAIFStatus

SNVT_count

Process data output

nvoAIFOut1

SNVT_count

Process data output

nvoAIFOut2

SNVT_count

Process data output

nvoAIFOut3

SNVT_count

nvoParamRes

ParamType

nvoLongRes

ParamType

^ 6-30

^ 6-30

^ 6-30

^ 6-30

^ 6-3

^ 6-3

Fig. 6-3 Network variable AIF-CTRL, described in chapter 6.5

6-8

BA2141 EN 1.0

L

Page 31

Parameter setting

Show/Hide Bookmarks

6.2.4 Overview: Configuration variable for VSD control

nciLocation (O)

nciRcvHrtBt (O)

nciSndHrtBt (O)

nciMinOutTm (O)

nciMaxSpeed (M)

nciMinSpeed (M)

nciNmlSpeed (M)

nciNmlFreq (M)

nciRampUpTm (M)

nciRampDownTm (M)

nciDrvSpeedScale (O)

nciAIFRecHrtBt

nciAIFDefStw

Fig. 6-4 Configuration variable VSD, described in chapter 6.4.2

^ 6-17

^ 6-18

^ 6-19

^ 6-20

^ 6-21

^ 6-22

^ 6-23

^ 6-24

^ 6-25

^ 6-26

^ 6-29

^ 6-27

^ 6-28

L

BA2141 EN 1.0

6-9

Page 32

Parameter setting

Show/Hide Bookmarks

6.3 Node Object

6.3.1 Inhibit / Enable all objects

All objects can be inhibited or enabled via the network variable nvi00Request:

• Inhibit: nvi00Request.object_id =Objectno.

nvi00Request.object_request = 1 (RQ_DISABLED)

• Enable: nvi00Request.object_id =Objectno.

nvi00Request.object_request =7(RQ_ENABLED)

6.3.2 Status messages

In the event of a communication error between the LON interface module and the basic unit the bit

comm_failure will be set under nvo00State.

Structure Type Definition:

typedef struct {

} SNVT_obj_status;

unsigned long object_id;

unsigned invalid_id : 1;

unsigned invalid_ request : 1;

unsigned disabled : 1;

unsigned out_of_limits : 1;

unsigned open_circuits : 1;

unsigned out_of_service : 1;

unsigned mechanical fault : 1;

unsigned feedback_failure : 1;

unsigned over_range : 1;

unsigned under_range : 1;

unsigned electrical_fault : 1;

unsigned unable_to_measure : 1;

unsigned comm_failure : 1;

unsigned fail_self_test : 1;

unsigned self_test_in_progress : 1;

unsigned locked_out : 1;

unsigned manual_control: 1;

unsigned in_alarm: 1;

unsigned in_override: 1;

unsigned report_mask: 1;

unsigned programming_mode: 1;

unsigned programming_fail: 1;

unsigned alarm_notify_ disabled: 1;

unsigned reserved1: 1;

unsigned reserved1: 8;

6-10

BA2141 EN 1.0

L

Page 33

6.4 VSD control VSD

Show/Hide Bookmarks

6.4.1 Network variable (VSD)

6.4.1.1 Speed setpoint

network input SNVT_switch nviDrvSpeedStpt;

The input network variable offers the following:

• Motor start/stop option

• Speed selection in percent

(resolution = 0.5% ref. to value selected under nciMaxSpeed)

Input range

Status Value Command Explanation

0(FALSE) NA Stop

1(TRUE) 0 0%

1(TRUE) 1 to 200 0.5% to 100.0%

1(TRUE) 201 to 255 100.0%

jFF

hex

NA AUTO (invalid) Standard value.

Parameter setting

This value will be set after a reset or if the time set under

nciRcvHrtBt expires with an update of the variables.

AUTO has the same function as stop, but is also used to check whether

the “Receive Heartbeat Time” has expired.

Function

The speed setpoint for the controller is calculated as follows:

n

nviDrvSpeedStpt.value × nviDrvSpeedScale

=

soll

100

The result is used as setpoint preselection in per cent. The setpoint selection is mapped to the AIF

input data word 1 of the process data channel. Since 82XX and 93XX controllers expect different

values here, the setpoints are converted in two different ways.

82XX controllers

use a setpoint in Hz and a factor of 50 (24000 = 480Hz).

The value for AIF data word 1 is calculated as follows:

AIFIn.W1 =

nviDrvSpeedStPt.value

100[%] × 2[

NVfactor

]

nviDrvSpeedScale

×

100[%] × 200 [

NVfactor

nciNmlFreq

×

]

10 [

NVfactor

× 50 [

]

AIFfactor

]

93XX servos use a setpoint in % and a factor of 163.83 (16383 = 100%).

The value for AIF input data word 1 results from the following:

AIFIn.W1 =

nviDrvSpeedStPt.value

100[%] × 2[

NVfactor

]

nviDrvSpeedScale

×

100[%] × 200 [

NVfactor

× 16383 [

]

AIFfactor

]

L

Iftheresultof thecalculationis anegativevalue,thedirectionof rotationwillbe reversed.Thisisdone

by setting bit 2 in the AIF control word.

BA2141 EN 1.0

6-11

Page 34

Parameter setting

Show/Hide Bookmarks

6.4.1.2 Actual speed value

network output SNVT_lev_percent nvoDrvSpeed;

The output network variable indicates the current speed as proportion of the rated value. Display

value in [%].

Output range

The possible bandwidth for the output variables is between –163.840% and 163.830%. Resolution:

0.005%.

The value +163.835% (7FFF

Update rate

) is assumed to be wrong.

hex

The variable is sent if the value changes or if the time set under

Maximum Send Time

(nciSndHrtBt)

has expired.

The variable value will not be sent quicker than set in

Minimum Send Time

(nciNinOutTm).

Standard Service Type

The Standard Service Type is acknowledged.

Function

The value of nvoDrvSpeed results from the AIF output data word 1 of the process data channel.

Since 82XX and 93XX send different value, the actual speed values are converted in different ways.

82XX controllers

send actual values in [Hz] and a factor of 50 (24000 = 480Hz).

The value for nvoDrvSpeed results from:

nvoDrvSpeed =

nciNmlFreq

10 [

NVfactor

AIFOut.W1

× 50[

AIFfactor

]

× 100[%] × 200 [

]

NVfactor

]

93XX controllers send actual values in [%] and a factor of 163.83 (16383 = 100%).

The value for nvoDrvSpeed results from:

6-12

nvoDrvSpeed =

AIFOut.W1

16383 [

NVfactor

BA2141 EN 1.0

× 100[%] × 200 [

]

NVfactor

]

L

Page 35

6.4.1.3 Scaling of the speed setpoint

Show/Hide Bookmarks

network input SNVT_lev_percent nviDrvSpeedScale;

The setpoint can be scaled through this input network variable (nviDrvSpeedStPt).

Negative values result in the opposite direction of rotation.

Actual speed setpoint = nviDrvSpeedStpt × nviDrvSpeedScale

Example:

• nviDrvSpeedStpt.value = 50%

• nviDrvSpeedScale = –150%

The actual speed setpoint is –75% of the rated value.

Input range

Parameter setting

The possible bandwidth for the input variables is between –163.840% and 163.830% . Resolution

0.005%.

The value +163.835% (7FFF

) is assumed to be wrong.

hex

Standard value

The standard value is determined by the “Configuration Property” nciDrvSpeedScale.

This value will be set after a reset or if the time set under nciRcvHrtBt passes without an update

of the variable.

Function

The value of nviDrvSpeedStPt.value is multiplied with the value of nviDrvSpeedScale and

divided by 100.

The result is used as setpoint preselection in per cent. The setpoint selection is mapped to the AIF

input data word 1 of the process data channel. Since 82XX and 93XX controllers expect different

values here, the setpoints are converted in two different ways.

82XXcontroller

expect the setpoint in [Hz] and afactor of 50 (24000 = 480Hz). The value for AIFdata

word 1 is calculated as follows:

AIFIn.W1 =

nviDrvSpeedStPt.value

100[%] × 2[

NVfactor

]

nviDrvSpeedScale

×

100[%] × 200 [

NVfactor

nciNmlFreq

×

]

10 [

NVfactor

× 50 [

]

AIFfactor

]

L

93XXcontrollers expect the setpoint in [%] and a factor of 163.83(16383 = 100%). The value for AIF

input data word 1 results from the following:

AIFIn.W1 =

nviDrvSpeedStPt.value

100[%] × 2[

NVfactor

]

nviDrvSpeedScale

×

100[%] × 200 [

NVfactor

× 16383 [

]

AIFfactor

]

Iftheresultof thecalculationis anegativevalue,thedirectionof rotationwillbe reversed.Thisisdone

by setting bit 2 in the AIF control word.

BA2141 EN 1.0

6-13

Page 36

Parameter setting

Show/Hide Bookmarks

6.4.1.4 Motor current

network output SNVT_amp nvoDriveCurnt;

This network variable outputs the actual output current in Ampere.

Output range

The possible bandwidth for the output variable is between –3276.8 A and +3276.6 A. Resolution 0.1

A.

The value +3276.7 A (7FFF

Update rate

) is assumed to be wrong.

hex

The variable is sent if the valuehas changed or if the time set under

Send Time

The variable value will not be sent quicker than set in

(nciMinOutTm).

Standard Service Type

The Standard Service Type is acknowledged.

Function

The output current is cyclically read from the drive

(code 0054, subcode 00). The value is calculated as follows:

If an error occurs during the query,

(nciSndHrtBt) has expired.

nvoDriveCurnt =

nvoDriveCurnt

SDF.LW

10000 [

Configuration Property Minimum Send Time

AIFfactor

will be set to 7FFFhex.

× 10 [

]

Configuration Property Maximum

NVfactor

]

6-14

BA2141 EN 1.0

L

Page 37

6.4.1.5 Motor voltage

Show/Hide Bookmarks

network output SNVT_volt nvoDrvVolt;

The output network variable indicates the current output voltage in [Volt].

Output range

The possible bandwidth for the output variable is between –3276.8 V and +3276.6 V.

Resolution 0.1 V.

The value +3276.7 V (7FFF

The typical output range is between 0 V and 700 V.

Update rate

The variable is sent if the value has changed.

The variable is sent as heart beat if the time set under

(nciSndHrtBt) has expired.

The variable value will not be sent quicker than set in

(nciMinOutTm).

) is assumed to be wrong.

hex

Parameter setting

Configuration Property Maximum Send Time

Configuration Property Minimum Send Time

Function

The current output voltage is cyclically read by the drive (code 0052, subcode 00). The value is

calculated as follows:

nvoDriveVolt =

If an error occurs during the query, nvoDrvVolt is set to 7FFF

Standard Service Type

The Standard Service Type is acknowledged.

SDF.LW

10000 [

AIFfactor

× 10 [

]

NVfactor

.

hex

]

L

BA2141 EN 1.0

6-15

Page 38

Parameter setting

Show/Hide Bookmarks

6.4.1.6 Operating time

network output SNVT_time_hour nvoDrvRunHours;

This network variable output the entire operating time in hours.

Output range

The possible bandwidth for the output variable is between 0 and 65534 hours. Resolution: 1 hour.

The value of 65535 hours (FFFF

Update rate

The variable is sent if the value has changed.

The variable value will not be sent quicker than set im

(nciMinOutTm).

Standard Service Type

The Standard Service Type is acknowledged.

) is assumed to be wrong.

hex

Configuration Property Minimum Send Time

Function

The operating time is cyclically read by the drive (code 0174, subcode 00).

82XX controllers

send the operating time in hours with the AIF factor 10000 (30000 = 3 hours).

The value is calculated as follows:

nvoDriveRunHours =

SDF.LW

10000 [

AIFfactor

× 1[

]

NVfactor

93XX controllers send the operating time in seconds without AIF factor.

The value is calculated as follows:

nvoDriveRunHours =

If an error occurs during the query, nvoDrvRunHours is set to FFFF

SDF.LW

3600 [

seconds

hour

× 1[

]

NVfactor

hex

]

.

]

6-16

BA2141 EN 1.0

L

Page 39

6.4.2 Configuration variable (VSD)

Show/Hide Bookmarks

6.4.2.1 Location label

network input config SNVT_str_asc nciLocation;

This configuration variable can be used to store a 31-byte string.

Input range

A ZERO terminated string of max. 31 byte

Standard value

ZERO

SCPT Reference

SCPT_location (17)

Parameter setting

L

BA2141 EN 1.0

6-17

Page 40

Parameter setting

Show/Hide Bookmarks

6.4.2.2 Receive Heartbeat Time

network input config SNVT_time_sec nciRcvHrtBt;

This configuration variable is used to store the time expected for an update, if this time expires

without anupdate, the values for the following network variables will bereset to their default settings:

nviDrvSpeedStpt

nviDrvSpeedScale (^ 6-13)

It is also used to monitor the variables configured in nciAIFRecHrtBt (^ 6-27).Thevariablesare:

nviAIFStw, nviAIFIn1, nviAIFIn2, nviAIFIn3.

Input range

Thepossible bandwidth for the configuration variableis between 0.0 and 6553.4seconds (resolution

0.1 seconds)

Standard value

(^ 6-11)

0.0 (no monitoring)

SCPT Reference

SCPTmaxRcvTime (48)

6-18

BA2141 EN 1.0

L

Page 41

6.4.2.3 Maximum Send Time

Show/Hide Bookmarks

network input config SNVT_time_sec nciSndHrtBt;

This configuration variable stores the time needed before the following network variables will be

updated:

nvoDrvSpeed

nvoDrvCurnt

nvoDrvVolt

nvoAIFStw

nvoAIFOut1

nvoAIFOut2

Parameter setting

nvoAIFOut3

Input range

Thepossible bandwidth for the configuration variableis between 0.0 and 6553.4seconds (resolution

0.1 seconds)

Standard value

0.0 (no automatic update)

SCPT Reference

SCPTmaxSendTime(49)

L

BA2141 EN 1.0

6-19

Page 42

Parameter setting

Show/Hide Bookmarks

6.4.2.4 Minimum Send Time

network input config SNVT_time_sec nciMinOutTm;

Here you store the time needed before an output network variable can be updated.

Input range

Thepossible bandwidth for the configuration variableis between 0.1 and 6553.4seconds (resolution

0.1 seconds)

Standard value

0.5 seconds

SCPT Reference

SCPTminSendTime (52)

6-20

BA2141 EN 1.0

L

Page 43

6.4.2.5 Maximum speed

Show/Hide Bookmarks

network input config SNVT_lev_percent nciMaxSpeed;

The configuration variable contains the maximum motor speed. The value is indicated as percentage

of the rated value (NciNmlSpeed).

Input range

The possible bandwidth for the configuration variable is between –163.840% and 163.830%

(resolution 0.005% ). The value +163.835% (7FFF

The entered value will be checked by means of the following formula:

–163.840% ≤ Minimum speed £ Maximum speed ≤ 163.830%

If the result is wrong, the lower value is taken as maximum speed.

Parameter setting

) is assumed to be wrong.

hex

Standard value

100.000 %

Function

After a change of the maximum speed, the value will be sent to the drive via the parameter channel

(code 0011, subcode 00).

SCPT Reference

SCPTmaxSetpoint (50)

L

BA2141 EN 1.0

6-21

Page 44

Parameter setting

Show/Hide Bookmarks

6.4.2.6 Minimum speed

network input config SNVT_lev_percent nciMinSpeed;

The configuration variable contains the minimum motor speed. The value is indicated as percentage

of the rated value (nciNmlSpeed).

Input range

The possible bandwidth for the configuration variable is between –163.840% and 163.830%

(resolution 0.005% ). The value +163.835% (7FFF

The entered value will be checked by means of the following formula:

–163.840% ≤ Minimum speed £ Maximum speed ≤ 163.830%

If the result is wrong, the lower value is taken as minimum speed.

) is assumed to be wrong.

hex

Standard value

0.000 %

Function

After a change of the minimum speed, the value will be sent to the drive via the parameter channel

(code 0010, subcode 00).

SCPT Reference

SCPTminSetpoint (53)

6-22

BA2141 EN 1.0

L

Page 45

6.4.2.7 Rated speed value

Show/Hide Bookmarks

network input config SNVT_rpm nciNmlSpeed;

This configuration variable contains the rated motor speed in rpm.

Input range

The possible bandwidth for the configuration variable is between 0 and 65534 rpm (resolution 1 rpm)

Standard value

3000 rpm

Function

After a change of the rated speed, the value will be sent to the drive viathe parameter channel (code

0087, subcode 00).

SCPT Reference

SCPTnomRPM (158)

Parameter setting

L

BA2141 EN 1.0

6-23

Page 46

Parameter setting

Show/Hide Bookmarks

6.4.2.8 Rated frequency

network input config SNVT_freq_hz nciNmlFreq;

This configuration variable contains the rated motor frequency in Hz.

Input range

The possible bandwidth for the configuration variable is between 0 and 6553,4 Hz (resolution 0,1 Hz)

Standard value

50 Hz

Function

After a change of the rated frequency, the value will be sent to the drive via the parameter channel

(code 0089, subcode 00).

SCPT Reference

SCPTnomFreq (159)

6-24

BA2141 EN 1.0

L

Page 47

6.4.2.9 Acceleration time

Show/Hide Bookmarks

network input config SNVT_time_sec nciRampUpTm;

This configuration variable indicates the acceleration time of the motor.

Input range

The possible bandwidth for the configuration variable is between 0 and 6553.4 seconds (resolution

0,1 Sekunden)

Standard value

5seconds

Function

After a changeof the acceleration time, thevalue will be sent to thedrivevia theparameterchannel

(code 0012, subcode 00).

SCPT Reference

Parameter setting

SCPTrampUpTm (160)

L

BA2141 EN 1.0

6-25

Page 48

Parameter setting

Show/Hide Bookmarks

6.4.2.10 Deceleration time

network input config SNVT_time_sec nciRampDownTm;

This configuration variable indicates the deceleration time of the motor.

Input range

The possible bandwidth for the configuration variable is between 0 and 6553.4 seconds (resolution

0,1 Sekunden)

Standard value

5seconds

Function

After a change of the deceleration time, the value will be sent to the drive via the parameter channel

(code 0013, subcode 00).

SCPT Reference

SCPTrampDownTm (161)

6-26

BA2141 EN 1.0

L

Page 49

6.4.2.11 Receive heartbeat for AIF-CTRL

Show/Hide Bookmarks

network input config SNVT_state nciAIFRecHrtBt;

Here you can select the manufacturer-specific network variables (nviAIFStw, nviAIFIn1,

nviAIFIn2, nviAIFIn3)whicharetobemonitoredwitha

nciAIFRecHrtBt.bit0 =0– No timeout monitoring for nviAIFStw

nciAIFRecHrtBt.bit0 =1– Timeout monitoring for nviAIFStw

nciAIFRecHrtBt.bit1 =0– No timeout monitoring for nviAIFIn1

nciAIFRecHrtBt.bit1 =1– Timeout monitoring for nviAIFIn1

nciAIFRecHrtBt.bit2 =0– No timeout monitoring for nviAIFIn2

nciAIFRecHrtBt.bit2 =1– Timeout monitoring for nviAIFIn2

nciAIFRecHrtBt.bit3 =0– No timeout monitoring for nviAIFIn3

nciAIFRecHrtBt.bit3 =1– Timeout monitoring for nviAIFIn3

If one of the monitored variables gets a

nciAIFDefStw will be carried out.

Parameter setting

Receive Timeout

Receive Heartbeat Timeout

.

, the function selected in

Input range

The possible range for the input variable is 0 or 1 for every bit.

Only bits 0 and 3 will be evaluated.

Standard value

0

L

BA2141 EN 1.0

6-27

Page 50

Parameter setting

Show/Hide Bookmarks

6.4.2.12 Monitoring reaction for AIF-CTRL

network input config SNVT_state nciAIFDefStw;

If one of the monitored variables of the AIF-CTRL gets a Receive Heartbeat Timeout

function selected in nciAIFDefStw will be carried out.

The quick stop functions sets bit 3 in the AIF control word, the controller inhibit function sets bit 9 in

the AIF control word.

(^ 6-30),the

Tip!

The functions quick stop and controller inhibit will only be reset after all monitored variables have

been updated within the Receive Heartbeat Timeout.

Input range

The possible bandwidth for the configuration variables is 0, 1 oooder 2

nciAIFDefStw =0– No reaction

nciAIFDefStw =1– Quick stop

nciAIFDefStw =2– Controller inhibit

Standard value

0

6-28

BA2141 EN 1.0

L

Page 51

6.4.2.13 Default value for nviDrvSpeedScale

Show/Hide Bookmarks

network input config_lev_percent nciDrvSpeedScale;

This value determines the default setting for nciDrvSpeedScale. The current configuration

variable nciDrvSpeedScale is overwritten with the default value

• after a reset or

• if the time from nciRcvHrtBt passes without an update of the variable nciDrvSpeedScale.

Input range

The possible bandwidth for the input variable is between -163.840 % and 163.830 % (resolution

0.005 %).

The value +163.835 % (7FFF

Standard value

0

) is assumed to be wrong.

hex

Parameter setting

SCPT Reference

SCPTdefScale (162)

L

BA2141 EN 1.0

6-29

Page 52

Parameter setting

Show/Hide Bookmarks

6.5 Device control AIF-CTRL

6.5.1 General information

6.5.1.1 Output variable

network output SNVT_count nvoAIFStatus;

network output SNVT_count nvoAIFOut1;

network output SNVT_count nvoAIFOut2;

network output SNVT_count nvoAIFOut3;

The output network variable nvoAIFStatus is directly taken from the AIFstatus word.

The output network variables nvoAIFOut1 to nvoAIFOut3 are directly taken from the

corresponding AIFdata words.

Output range

The possible bandwidth for the output variable is between 0 and 65535.

Update range

The variables are sent if the value changes or if the time set under

Send Time

The variable value will not be sent quicker than set in

(nciMinOutTm).

Standard Service Type

The Standard Service Type is acknowledged.

(nciSndHrtBt) has expired.

Configuration Property Minimum Send Time

Configuration Property Maximum

6-30

BA2141 EN 1.0

L

Page 53

6.5.1.2 Input variable

Show/Hide Bookmarks

network input SNVT_count nviAIFStw;

network input SNVT_count nviAIFIn1;

network input SNVT_count nviAIFIn2;

network input SNVT_count nviAIFIn3;

The input network variable nviAIFStw is directly accepted by the AIF control word.

The input network variables nviAIFIn1 to nviAIFIn3 are directly accepted by the corresponding

AIF input data words.

1Input range

The possible bandwidth for the output variable is between 0 and 65535.

Parameter setting

Standard value

The standard value after a reset is 0 for all four variables.

The standard value for nviAIFStw is determined by the configuration properties nciAIFDefStw

and nciAIFRecHrtBt. nciAIFDefStw indicates the function to be executed in the event of a

Receive Heartbeat Timeout

Heartbeat

nciAIFRecHrtBt.bit0 =1– Timeout monitoring for nviAIFStw

nciAIFRecHrtBt.bit1 =1– Timeout monitoring for nviAIFIn1

nciAIFRecHrtBt.bit2 =1– Timeout monitoring for nviAIFIn2

nciAIFRecHrtBt.bit3 =1– Timeout monitoring for nviAIFIn3

nciAIFStw =0– No reaction

nciAIFStw =1– Quick stop

nciAIFStw =2– Controller inhibit

If one of the monitored variables gets a

nciAIFDefStw will be carried out.

The quick stop functions sets bit 3 in the AIF control word, the controller inhibit function sets bit 9 in

the AIF control word. The functions quick stop and controller inhibit will only be reset after all

monitored variables have been updated within the Receive Timeouts.

.

and nciAIFRecHrtBt indicates the variables monitored by a

Receive Heartbeat Timeout

, the function selected in

Receive

L

BA2141 EN 1.0

6-31

Page 54

Parameter setting

Show/Hide Bookmarks

6.5.2 Network variable for 82XX controllers

Setpoint source selection

The setpoint source for these controllers is selected under code C0001. An evaluation of process

data is only possible if code C0001 is set to ” 3” when the controller is operated together with the

fieldbus module.

Therefore the process data channel serves as setpoint source, describing the frequency setpoint

(C0046) and the control word (parameter channel, C0135) (see Operating Instructions 82XX).

Tip!

Please observe that code C0001 is available in all parameter sets.

Network variable from drive

• nvoAIFStatus reads the status word (^ 6-38)

Status word

LOW byte HIGH byte

Bits 0 to 7 of the status word (code C0150) are

entered here.

Bits 8 to 15 of the status word (code C0150) are

entered here.

• nvoAifOut1 reads the actual frequency value

LOW byte HIGH byte

The actual frequency value is read from code C0050. The actual frequency value with the signed

normalisation 24000 = 480 Hz is provided here.

Network variable to drive

Actual frequency value

• nviAIFStw writes the control word (^ 6-39)

Control word

LOW byte HIGH byte

Bits 0 to 7 of the control word (code C0135) are

entered here.

Bits 8 to 15 of the control word (code C0135) are

entered here.

• nviAIFIn1 writes the frequency setpoint

Frequency setpoint

LOW byte HIGH byte

The frequency setpoint (code C0046 via parameter data channel) is selected as process data word.

The normalization differs from the setting under C0046. It is a signed value, 24000 = 480 Hz.

6-32

BA2141 EN 1.0

L

Page 55

6.5.2.1 Status word for 82XX

Show/Hide Bookmarks

Bit 820X 821x,822x

00 Actual parameter set

01 IMP (pulse inhibit)

02 I

03 not assigned fd=f

04 fd=f

05 Qmin (fd≤ f

06 fd= 0 (act. frequency = 0)

07 Ctrl. inhibit (controller inhibit)

08...11 Controller status

0=Parameterset1or3active

1=Parameterset2or4active

0 = Pulses for power stage enabled

1 = Pulses for power stage inhibited

(current limit reached)

max

0 = Current limit not reached

1 = current limit reached

dset

0: fd≠ f

dset

1: fd=f

dset

)

0 = Qmin not active

1=Qminactive

0: f

1: f

0 = controller not inhibited

1 = controller inhibited

0 = Controller initialization

8 = Error active

dQmin

≠ 0

d

>0

d

Parameter setting

Actual parameter set

0=Parameterset1or3active

1=Parameterset2or4active

IMP (pulse inhibit)

0 = Pulses for power stage enabled

1 = Pulses for power stage inhibited

I

(current limit reached)

max

0 = Current limit not reached

1 = current limit reached

dset

0=fd≠ f

dset

1=fd=f

dset

RFG on = RFG off

0=RFGon≠ RFG off

1 = RFG on = RFG out

Qmin (fd≤ f

0 = Qmin not active

1=Qminactive

fd> 0 (actual frequency value = 0)

0=f

≠ 0

d

>0

1=f

d

Ctrl. inhibit (controller inhibit)

0 = controller not inhibited

1 = controller inhibited

Controller status

0 = Controller initialization

1 = Switch on inhibit

3 = Operation inhibited

4 = Flying-restart circuit active

5 = DC brake active