Page 1

EDB2112UB

Show/Hide Bookmarks

00414276

Operating Instructions

INTERBUS-Loop

IN OUT

2112

Fieldbus module type 2112

INTERBUS-LOOP

Page 2

These Operating Instructions are valid for fieldbus modules with the following nameplates:

Show/Hide Bookmarks

2112 IB. VA. 0.1 (INTERBUS-Loop)

In connection with the unit series as from the nameplate data:

820X E. 2x. 1x. (8201 - 8204)

820X E./C. 2x. 1x. Vxxx (8201 - 8204)

821X E. 2x. 2x. (8211 - 8218)

821X E./C. 2x. 2x. Vxxx (8211 - 8218)

822X E. 1x. 1x. (8221 - 8225)

822X E. 1x. 1x. Vxxx (8221 - 8227)

82EV VA 0x 8200 vector

82EV 1x 0x 8200 vector

93XX E. 2x. 1x. (9321 - 9333)

93XX E./C. 2x. 1x. Vxxx (9321 - 9333)

Typ e

Design:

E = Built-in unit IP20

IB = Module

Hardware version and index

Software version and index

Va ri a nt

Explana tion

Important:

These Operating Instructions are only valid together with the corresponding Instructions for

82XX, 8200 vector or 93XXcontrollers.

.

1998 Lenze GmbH &Co KG

Without written approval of Lenze Lenze GmbH & Co KG no part of these Instructions must be copied or given to third parties.

All information given in this documentation have been checked for compliance with the hardware and software described. Nevertheless, deviations and

mistakes cannot be ruled out. We do not take any responsibilityorliability for damages which might possibly occur. Necessarycorrections will be included

in the next edition.

Version 1.0 03/00

Page 3

Contents

Show/Hide Bookmarks

1 Preface and general information 1-1...........................................

1.1 About these Operating Instructions 1-1....................................................

1.1.1 Terminology used 1-1.........................................................

1.2 Items supplied 1-1...................................................................

1.2.1 Legal regulations 1-2..........................................................

2 Safety information 2-1......................................................

2.1 Persons responsible for safety 2-1.......................................................

2.2 General safety information 2-1..........................................................

2.3 Layout of the safety information 2-2......................................................

3 Technical data 3-1.........................................................

3.1 Features 3-1.......................................................................

3.2 General data and application conditions 3-1................................................

3.3 Rated data 3-2......................................................................

3.4 Dimensions 3-2.....................................................................

3.5 Protocol data 3-2....................................................................

3.6 Communication data 3-3..............................................................

3.6.1 Processing time of the controller 3-3..............................................

3.6.2 Number of participants 3-3.....................................................

4 Installation 4-1............................................................

4.1 Connections of the fieldbus module 2112 4-1...............................................

4.2 Mechanical installation 4-2.............................................................

4.3 Electrical installation 4-2..............................................................

4.3.1 Voltage supply 4-2............................................................

4.3.2 Features: 4-2................................................................

5 Commissioning 5-1........................................................

5.1 Configuration of the host for communication with the 2112 fieldbus module 5-1......................

5.2 Commissioning of 2112 fieldbus modules 5-1...............................................

5.3 Drive control via INTERBUS-Loop 5-2.....................................................

5.4 Enable controller via INTERBUS-Loop 5-3..................................................

5.4.1 Standard unit control 5-3.......................................................

5.4.2 DRIVECOM control 5-4.........................................................

5.4.2.1 Create DRIVECOM compatibility (C0009 ` 11, 12) 5-4.......................

5.4.3 User defined control profile 5-5..................................................

5.5 Special features with 82XX, 8200 vector und 93XX 5-5........................................

BA2112EN

i

Page 4

Contents

Show/Hide Bookmarks

6 Parameter setting 6-1......................................................

6.1 Process data 6-1....................................................................

6.1.1 Process data assignment 6-1....................................................

6.1.1.1 General information 6-1..............................................

6.1.1.2 Process-data assignments for 82XX 6-2..................................

6.1.1.3 Process-data assignment for 8200 vector 6-3..............................

6.1.1.4 Process-data assignment for 93XX 6-4...................................

6.1.2 Unit control (C0009 = 11) 6-8...................................................

6.1.2.1 Control word 6-8...................................................

6.1.2.2 Status word 6-10....................................................

6.1.3 DRIVECOM control (C0009 ` 11, 12) 6-12...........................................

6.1.3.1 DRIVECOM status machine 6-12.........................................

6.1.3.2 Control word 6-16...................................................

6.1.3.3 Status word 6-17....................................................

6.1.4 User defined control profile (C0009 = 12) 6-18.......................................

6.2 Process data monitoring 6-18............................................................

6.2.1 Process data monitoring time 6-18.................................................

6.2.2 Process data monitoring selection code 6-18.........................................

7 Troubleshooting and fault elimination 7-1.......................................

7.1 Controller is inhibited 7-2..............................................................

7.2 Check INTERBUS-Loop 7-4.............................................................

7.3 Activate fieldbus module 7-5...........................................................

7.4 Reset fault (TRIP) 7-6.................................................................

8 Appendix 8-1.............................................................

8.1 Accessories 8-1.....................................................................

8.2 List of abbreviations 8-2...............................................................

8.3 Glossary 8-3.......................................................................

8.4 Table of keywords 8-4................................................................

ii

BA2112EN

Page 5

Preface and general information

t

emssupplie

dmatchtheaccomp

anyingpapers.L

enzedoesno

t

•

1M3fixingscre

w

items

suppliedmatchtheaccompanyingpaper

s.Lenzedoesno

t

1Mo

i

onsClaim

v

oyour

L

Show/Hide Bookmarks

1 Preface and general information

1.1 About these Operating Instructions

• These Operating Instructions are intended for safety-relevant working on and with the 2112

fieldbus module. They contain safety information which must be observed.

• All personnel working on and with the 2112 fieldbus module must have these Operating

Instructions available and observe the information and notes relevant for them.

• The Operating Instructions must always be complete and perfectly readable.

TheseOperating Instructions inform about themost important technicaldataand theinstallation of

the 2112 fieldbus module. They are only valid in combinationwith theOperating Instructions of the

corresponding controller.

1.1.1 Terminology used

Controller In the following, the t erm ”controller” is used for ”93XX servo inverters” or ”82XX frequency inverters”.

Drive system In the following the term ”drive system” is use d for drive systems with f ieldbus modules and other Le nze

Fieldbus module In the f ollowing t ext, the te rm ”fieldbus module” is used for the fieldbus module type 2112 INTERBUS-Loop.

(xx-yyy) Cross reference (chapter - page)

1.2 Items supplied

Items supplied Important

• 1 2112 fieldbus module with housing (enclosure IP20)

•

• 2 2-pole connection plugs for INTERBUS-Loop connection

•

untingInstruct

drive compone nts.

After the delivered has been received, check immediately whether the

i

accept any liability for deficiencies claimed subsequently.

• visible transport damage immediately to the forwarder

•

isible deficiencies/incompleteness immedia telyt

representative.

enze

BA2112EN

1-1

Page 6

Preface and general information

g

p

Show/Hide Bookmarks

1.2.1 Legal regulations

Labelling

App lication as

directed

Nameplate CE mark Manufacturer

Lenze 2112 fieldbus modules a re

unambiguously identified by their nameplates.

2112 fieldbus module

Conforms to the EC Low Voltage Directive Lenze GmbH & Co KG

Postfach 101352

D-31763 Hameln

• Operate the fieldbus module only under the conditions prescribed in the se Operating Instructions.

• The fieldbus module is an additiona l module and can be optionally attached to the Le nze controlle r series 82XX, 8200, and 93XX. The 2112

fie ldbus module links Lenze controllers wi th the fast serial communication syste m INTERBUS.

• The fie ldbus module must be attached and electrica lly connecte d so that it complies with its function and does not cause any hazards when

being attached a nd opera ted as inst ructed.

• Observe a ll notes given in cha pter “ Safety information“ (

2-1) ).

• Plea se obse rve all information give n in these Operating Instructions.Thi s means:

– Read these Operating Instructions carefully be fore you start to work with the system.

– These Opera ting Instructions must always be available during operation of the fieldbus module .

Any other use shall be deemed inappropriate!

Liabilit y • The information, data, and notes in the se instructions met t he state of the a rt at t he time of pri nting. Claims referri ng to drive syst ems

which have a lready bee n supplie d cannot be derived from the inf ormation, illustrations, and descriptions given in these Operating

Instruct ions.

• The specifica tions, processes, and circuitry described in these Operating Instructions are for guidance only and must be adapted to your

own spe cific application. Lenze does not take responsibility for the suitability of the process and circuit proposals.

• The indications given in these Operating Instructions describe the features of the product without warranting them.

• Lenze does not accept any liability for damage and operating interference caused by:

– disregarding these Instructions

– unauthorized modifications to the controller

– operating faults

– improper working on and with the controlle r

Warranty • Warranty conditions: see Sales and Delivery Conditions of Lenze GmbH & Co KG.

• Warranty claims must be made to Lenze immediately after detecting the deficiency or fault.

• The warranty is void in all cases where liability claims cannot be made .

Disposal

Material recycle dispose

Me ta l

Pla sti c

Printe d-board asse mblies

Short Instructions/Operating Instructions

-

-

-

-

-

-

-

1-2

BA2112EN

Page 7

Safety information

Show/Hide Bookmarks

2 Safety information

2.1 Persons responsible for safety

Operator

• An ope rator is a ny natural or legal person who uses the drive system or on behalf of whom t he drive system is used.

• The operator or his safety personne l is oblige d

– to ensure the compliance wi th all re levant re gulations, instructions a nd legislat ion.

– to ensure that only skilled personnel work s on and with the2102IB fieldbus module.

– to ensure that the pe rsonnel ha s the Opera ting Instructions ava ilable for all corresponding work .

– to ensure that a ll unqualified personne l are prohibited from work ing on a nd with the drive system.

Qualified p ersonnel

Qualified personnel are pe rsons who - be cause of their e ducation, experie nce, instructions, and knowledge about corresponding sta ndards a nd regulations, rules for

the prevention of accidents, a nd opera ting conditions - are authoriz ed by the person responsible for the sa fety of the plant to perform the require d actions a nd who are

able to recognize pot ential ha zards.

(Definition for qua lifie d personne l to VDE 105 or IEC 364)

2.2 General safety information

• These safety note s do not claim t o be complete. In case of questions and problems please contact your Lenz e representat ive.

• At the time of delivery the fieldbus module meets the sta te of the a rt and ensures ba sically safe opera tion.

• The indications given in the se Operating Instructions refer to the st ated hardware and software versions of the fieldbus module s.

• The fieldbus module is hazardous if:

– unqualified personnel works on and with t he fieldbus module.

– the fieldbus module is used ina ppropriately.

• The processing notes and circuit sections shown in the se Operating Instructions are proposa ls which ca nnot be transferred to other applica tions without being

tested and checked.

• Ensure by a ppropriate me asures that neither personal injury nor damage to property ma y occur in the event of failure of the fieldbus module.

• The drive syste m must only be operated when no faults occur.

• Retrofitti ngs, modificat ions, or redesigns are basically prohibite d.Lenze must be contacted in all case s.

• The fieldbus module is electrica l equipment intended for use in industria l high- power plants. The fieldbus module must be tightly screwed to the corresponding

controller during operation. In addition, all measures described in the Operating Instructions of the controller used must be taken. Example: Fasten cove rs to ensure

protection aga inst contact.

BA2112EN

2-1

Page 8

Safety information

Show/Hide Bookmarks

2.3 Layou t of the safety information

• All safety information has a uniform layout:

– The icon characterizes the type of danger.

– The signal word characterizes the severity of danger.

– The note text describes the danger and gives information on how to prevent dangerous

situations.

Signal word

Note

Icons used Signal words

Wa rn i ng o f

damage to

persons

Wa r n i n g o f

hazardous e lectrical

volta ge

Danger! Wa r n s o f impending dangeU.

Consequences if disregarded:

Death or severe injuries.

Warning of a general

danger

Wa rn i ng o f

damage to

material

Other no tes Tip! This note de signates general, use ful not es.

Warning! Wa r ns of potential, very hazardous situations.

Possible consequences if disregarded:

Death or severe injuries.

Caution! War n s o f potential, hazardous situations.

Possible consequences if disregarded:

Light or minor injuries.

Stop! Wa r n s o f potential damage to material.

Possible consequences if disregarded:

Damage of the controller/drive system or its environment.

If you observe it, handling of the cont roller/drive system i s made

easier.

2-2

BA2112EN

Page 9

Technical data

Show/Hide Bookmarks

3 Technical data

3.1 Features

• Attachable additional module for Lenze controller series 82XX, 8200 vector, and 93XX

• Bus connection via remote bus to RS485 standard

• Maximum distance between participants: 20 m

• Max. loop length: 200 m

• Variable process d ata configuration

3.2 General data and application conditions

Field Values

Order designation EMF2112IB

INTERBUS pa rticipa nt Slave

Drive profile DRIVECOM profile 20

Baud rate 500 kbit/s

Ambient temperature During operation: 0Cto55C

Transport: -25

Storage: -25

Permissible humidity Class 3K3 to EN 50178 (without conde nsation, average relative humidity 85%)

Cto 70C

Cto 60C

BA2112EN

3-1

Page 10

Technical data

Show/Hide Bookmarks

3.3 Rated data

Field Values

Communication me dium ASIC LPCII

Supply voltage Voltage supply via INTERBUS- Loop.

Insulat ion voltage - bus systems:

• to PE 50 V AC

• to e xternal supply (terminal 39/59) 0V (no electrical isolation)

• to power stage

– 820X / 821X 270 V AC (single basic insulation)

– 822X / 93XX / 8200 vector 270 V AC (double basic insulation)

• to the control terminals

– 8200 vector 100 V AC (single basic insulation)

– 820X 0V (no electrical isolation)

– 821X 50 V AC (electrical isolation)

– 822X / 93XX 270 V AC (single basic insulation)

• to e xternal bus system 0V (no electrical isolation)

Degree of pollution VDE 0110 part 2 pollution degree 2

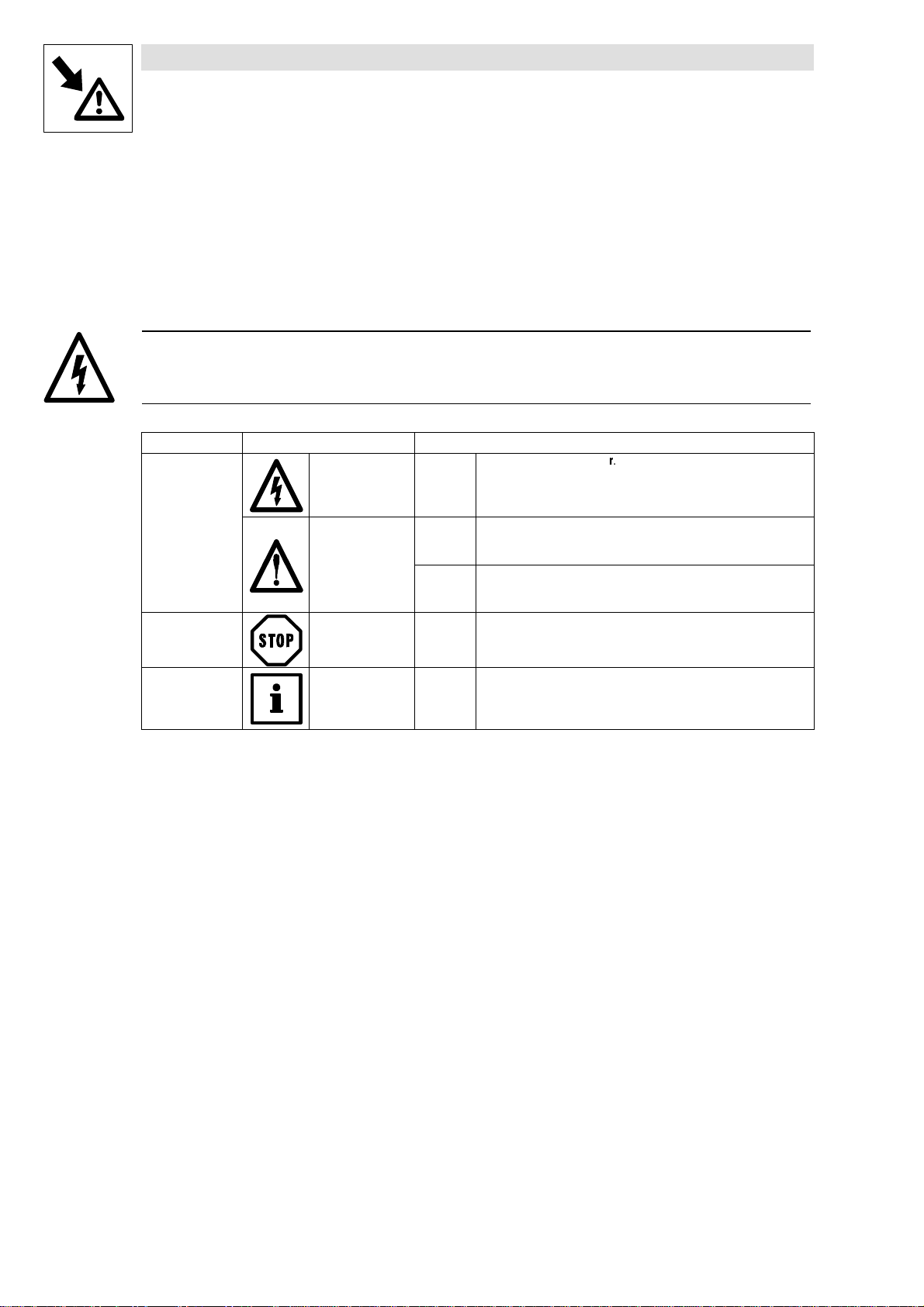

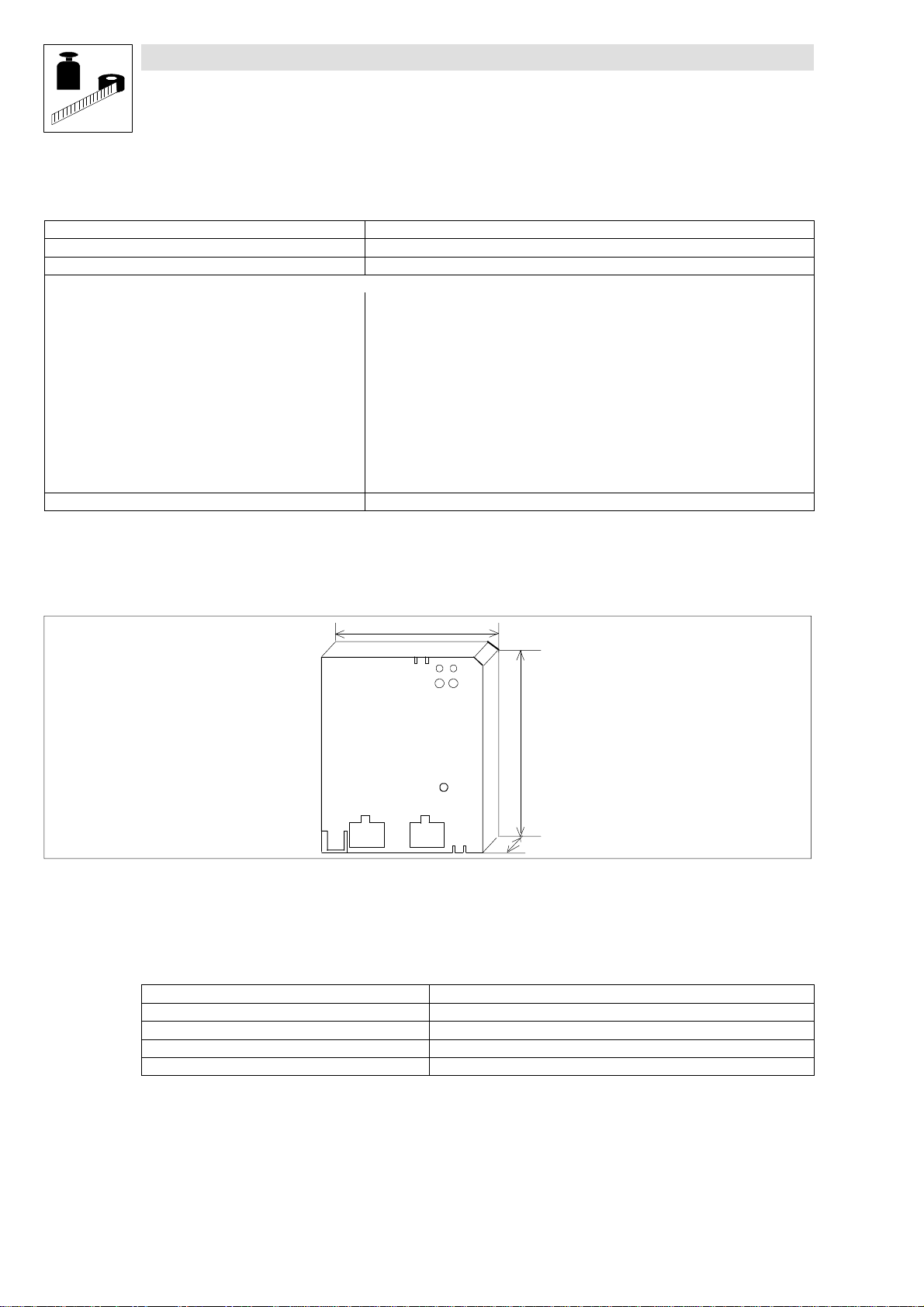

3.4 Dimens ions

Fig. 3-1 Dimensions of the 2112 fieldbus module

3.5 Protocol data

Field Values

Maximum number of controllers with InterBus-Loop 2112 36

Process- data words (PCD): 2 words (32 bit)

INTERBUS-Loop identification 179 (decimal) or B3 (hex)

Baud rate 500 kbit/s

61.8

INTERBUS loop

IN OUT

75.2

2112

18

3-2

BA2112EN

Page 11

3.6 Communication data

Show/Hide Bookmarks

3.6.1 Processing time of the controller

The INTERBUS transfer time or cycle time is added to the processing time in the controller.

The processing time of the controller depends on the controller series and type. Thecycle time of

the bus system is independent of the processing time of the controller.

Processing time 820X

For the 820X series several processing steps are required. These steps are processed cyclically.

A processing cycle consists of:

• Writing the control word or setpoint, if the value has changed

• Alternating reading of status word and actual value

If the time tolerances caused by cyclic reading of the status word/actual value are too large, the

alternating readingof thestatusword and theactual valuecan be suppressed. This is controlled by

the bit 15 (PEinhibit) of the DRIV ECOM control word:

• PEinhibit = 0: S tatus and actual-value update active

• PEinhibit = 1: S tatus and actual-value update inactive

In the following table you will find a list of the processing times:

Processing step Max. processing time in ms Processing tolerance in ms

Setpoint

Control word

Actual value

Status word

Setpoint + control word 70 -16

Setpoint + control word +

actual value + status word

35 -8

140 -32

Technical data

Note:

A change of the setpoint signal results in writing the control word.

Processing time 821X / 8200 vector / 822X

• Process data: approx. 3 ms + 2 ms tolerance

Processing time 93XX

• Process data: approx. 3 ms + 2 ms tolerance

3.6.2 Number of participants

• The maximum number of participants in the INTERBUS-Loop is 63.

Tip!

The maximum number of participants is not always possible. The number of fieldbus modules

(participants)taking part in the communication is limited by the sum of their partial currents.

The sum current limit is I

Example

The INTERBUS-Loop is loaded with approx. 50 mA per controller connected.

Here the sum current of I

max

max

=1.8A.

= 1.8 A is reached when 36 controllers are connected.

BA2112EN

3-3

Page 12

Technical data

Show/Hide Bookmarks

3-4

BA2112EN

Page 13

4 Installation

1

Show/Hide Bookmarks

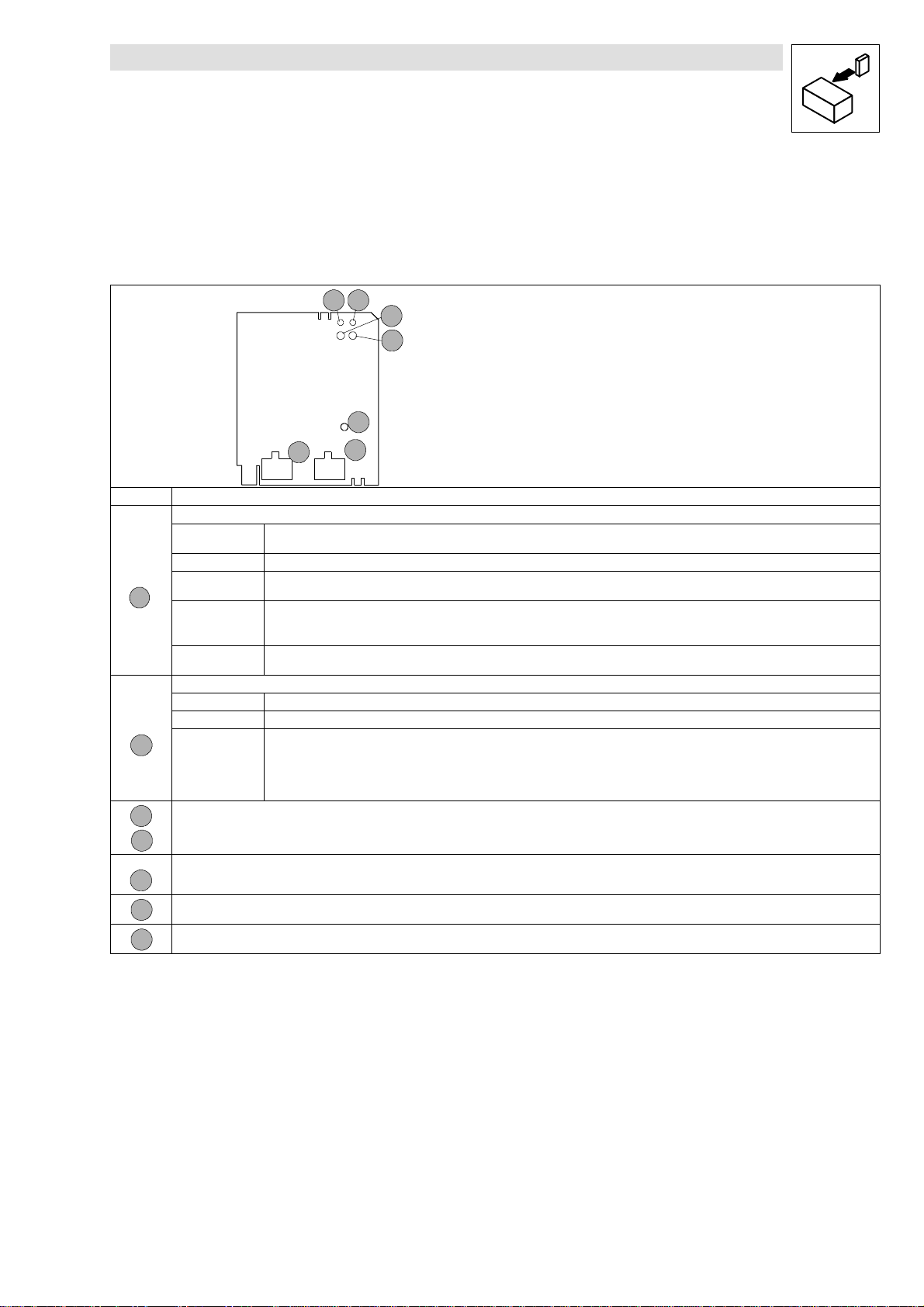

4.1 Connections of the fieldbus module 2112

2

No. Name/Meaning

Yellow b us LED Stat us: Bus c ommunicati on

ON Fie ldbus module 2112 has been initialized

OFF Fie ldbus module 2112 is not supplied wi th volt age yet.

BLINKING

(4 Hz )

BLINKING

(2 Hz )

BLINKING

(0. 5 Hz )

Green LED

ON 2112 fieldbus module is suppli ed wi th volt age a nd is conne cted to the cont rolle r.

OFF The 2112 fieldbus modul e is suppl ied via INTERBUS-Loop.X

BLINKING 2112 fieldbus module is suppli ed wi th volt age but i s not c onnected t o the cont roller.

2

1

INTERBUS loop

IN OUT

6

INTERBUS communi cation w ith the mast er is possibl e.

Periphe ral f ault/ open cir cuit

Voltage s upply from t he INTERBUS-Loop, but no INTERBUS communica tion.

Voltage s upply if INTERBUS communic ation is a ctive . Error t elegra ms caused by, e. g. open ci rcuit, a re ge nerat ed.

• Module not connecte d to t he contr oller or

• initializationactive.

Voltage s upply (5 V) from INTERBUS-Loop, but no INTERBUS communica tion.

Control ler i s

• switched-off,

• be ing init ializ ed or

• not a vailable

5

7

2112

3

4

Fig. 4-1 Name/meaning of the module elements

Installation

3

Green LED or red LED

Operating status of the controllers 82XX, 8200 vector and 93XX. (See Operating Instructions for the controller)

4

Fixing screw for fieldbus module

5

INTERBUS-Loop input (IN)

6

INTERBUS-Loop out put (OUT)

7

BA2112EN

4-1

Page 14

Installation

Show/Hide Bookmarks

4.2 Mechanical installation

• If necessary, remove the keypad which was previously attached to the controller before.

• Plug the 2112 fieldbus module into the corresponding interface of the controller and fasten it

with the fixing screw (see Fig. 4-1).

Tighten t he screws t o ensure a good PEconnection.

4.3 Electrical installation

Tip!

Thecommunciationof 820X and 821Xcontrollers may be disrupted by electromagnetic radiation.

If necessary, use an additional PE screen cable.

4.3.1 Voltage supply

No special or external voltage supplies necessary. The 2112 fieldbus module is supplied via

INTERBUS-Loop.

4.3.2 Features:

Communication me dium INTERBUS-Loop

Network topology Ri ng

Possible number of controllers – Max. load capacity of the loops: 1.8 A

Max. loop length 200 m

Distance between fieldbus modules 20 m

Maximum baud rate 500 kbit/s

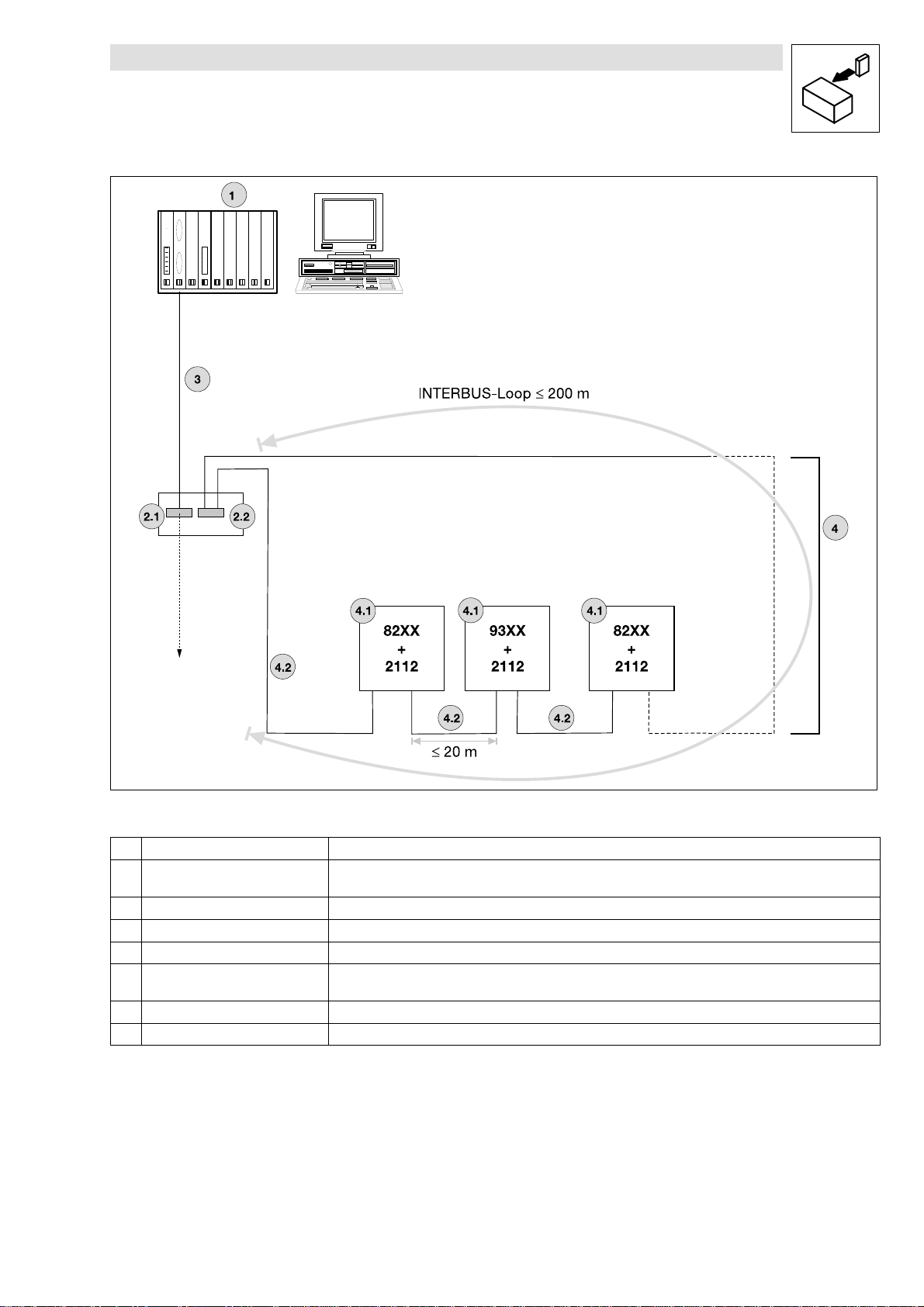

For an example of the INTERBUS structure, see the drawing ( Fig. 4-2). The accessories required

(I NTERBUS Loop terminal) are listed in chapter 8.

– Current consumption per 2112 fieldbus

module:

Å

Max. number of participa nts: 36

50 mA

4-2

BA2112EN

Page 15

Installation

Show/Hide Bookmarks

Fig.4-2 Wiring examplefor the bus system INTERBUS-Loop

Pos . Element Function

1 Host (e.g. PC or PLC) with INTERBUS

master interface module

2.1 Bus terminal Connects a remote bus to the INTERBUS-Loop terminal

2.2 INTERBUS- Loop terminal Start / end of INTERBUS-Loop

3 Remote bus Connects the INTERBUS master module with t he bus termina l and/or other remote bus modules.

4 INTERBUS-Loop INTERBUS-Loop terminal and periphera l bus participants

4.1 INTERBUS- Loop fie ldbus module Bus participant in the INTERBUS-Loop; e .g. Le nze controlle r with INTERBUS-Loop module 2112

4.2 INTERBUS- Loop cable Conne ction in the loop

Ma ste r

(Max. numbe r of participa nts: 63, ma x. sum current < 1.8 A)

2112IBL001

BA2112EN

4-3

Page 16

Installation

Show/Hide Bookmarks

4-4

BA2112EN

Page 17

Commissioning

Show/Hide Bookmarks

5 Commissioning

Stop!

• Before switching on the mains voltage, check the wiring for completeness, earth fault and

short circuit.

• Keep to the switch-on sequence! (Chapters 5.1 to 5.4)

5.1 Configuration of the host for communication with the 2112 fieldbus module

With INTER BUS-Loop the master does not have to be configured. Please observe that a 4th

generation master is used for the communication between host and 2112 fieldbus module.

5.2 Commissioning of 2112 fieldbus modules

1. Plug the 2112 fieldbus module into the front automation interface (AIF)of the controller (see

Operating Instructions for the controller)

2. Supply INTERBUS-Loop terminal (see Fig. 4-2, pos. 2.2) with voltage.

– The green LED for voltage supply (

– An internal initialization between controller and 2112 fieldbus module follows as soon as the

fieldbus module is connected to the controller. The initialization time is up to 3s.

3. Initialization is completed when

– the green LED (

4. ActivateINTERBUS

– the yellow bus LED is on permanently

5. It is now possible to communicate with the drive.

If the LED is not on or blinking, see chapter 7 ”Troubleshooting and fault elimination”.

(4-1) , pos. 1) is on permanently

Tip !

(I f the DRIVE CO M-Profile (C0009 ≠ 11, 12 (

When attaching the fieldbus module to the 93XX controller, the controller is inhibited and the

DRIV ECOM status switch-on inhibit is set. For enabling the controller, the status OPERAT I O N

ENABLE must be set once with the DRIVECOM control word.

can be controlled as usual, e.g. via terminals.

(4-1) pos.1)must be on or blinking.

5-4) ) is selected under C009)

(5-3) . Afterwards, the controller

BA2112EN

5-1

Page 18

Commissioning

Show/Hide Bookmarks

5.3 Drive control via INTERBUS-Loop

82XX /

8200 vector

93XX 1. For drive control via INTERBUS set the Lenze parameter Signal Configuration (C0005) to a value xxx3 using the 9371 keypad. For the first

1. For drive control via INTERBUS, change the setting of the Lenze parameter operating mode (C0001) from 0 to 3.

2. Determina tion of the control mode

– DRIVECOM control (C0009 ≠ 11, 12)

– Unit control (C0009 = 11)

– User defined control profile (C0009 = 12)

Note: Impermissible f or 82XX cont rollers, see

3. Termina l 28 (ctrl. enable ) is always active and must be set to HIGH level during INTERBUS opera tion (see the Operating Instructions for the

controller).

– Otherwise, the controller cannot be e nabled by the INTERBUS (DRIVECOM/standard unit status ”OPERATION ENABLED”).

– With 821x and 822x the QSP function (quick stop) is always active. If QSP is assigned to an input t erminal (default setting: not assigned),

this terminal must be at HIGH le vel during INTERBUS- Loop opera tion (see the corresponding Opera ting Instructions).

The controller now a ccepts control data from the InterBus-Loop.

commissioning, select the signal configuration 1013.

2. Determina tion of the control mode

– DRIVECOM control (C0009

– Unit control (C0009 = 11)

– User defined control profile (C0009 = 12)

3. Set the parameter Start Option (C0142) to 0.

4. Termina l 28 (ctrl. enable ) is always active and must be set to HIGH level during INTERBUS opera tion (see the Operating Instructions for the

controller).

– Otherwise, the controller cannot be e nabled by the INTERBUS (DRIVECOM/standard unit status ”OPERATION ENABLED”).

– With the signal configuration C0005= 1013, the QSP function (quick stop) and the CW/CCW changeover are assigned to the input terminals

E1 a nd E2, and are thus always active. For INTERBUS opera tion E1 must be set to HIGH level (see Operating Instructions 93xx).

The controller now a ccepts control data from t he INTERBUS- Loop.

≠ 11, 12)

5-5 !

5-2

BA2112EN

Page 19

5.4 Enable controller via INTERBUS-Loop

y

p

off

Show/Hide Bookmarks

The2112fieldbusmoduleofferstheuserthepossibilityto operatethe controllerwithdifferentcontrol

modes:

• Standard unit control

• DRIVECOM control

• User defined control profile

The bit assignment of the control and status word depends on the control mode selected. The

selection between the control modes “Standard unit control” and “DRIVECOM control” is effected

via the paramter C0009 of the basic unit and canbe adjusted directly at the controller by meansof

the corresponding keypad.

Auserdefinedcontrol profile canbe generated bysettingC0009 = 12.It isthus possible to map the

2 process data words of the INTERBUS-Loop to the words W1 and W2 of 93XXand 8200 vector

controllers.

Commissioning

C0009 Ty pe Status

11 82XX / 8200 vector / 93XX

12 93XX / 8200 vector

How toenable thecontrollerdependsonthecontrolmode selected and is decribed in thefollowing.

5.4.1 Standard unit control

1. Controller settings as described in chapter 5.3

2. Preselection of standard unit control: Parameter C0009 = 11

3. Input for unit control word: “0000 0000 0000 0000

Å Status change to: “OPERATION ENABLED“

4. The controller is enabled.

Danger!

Ifaspeedhas beenselected in process dataword 2,the drivestarts immediatelywhenthemodule

is being attached.

DRIVECOM:

Process data assignment

PCD 1 PCD 2

Unit control word C0135 or

unit status word C0150

AIF-IN.W1 or

AIF-OUT.W1

bin(0hex

AIF-IN.W1 or

AIF-OUT.W1

AIF-IN.W2 or

AIF-OUT.W2

)”

BA2112EN

5-3

Page 20

Commissioning

Show/Hide Bookmarks

5.4.2 DRIVECOM control

Tip !

• Assoon asthefieldbusmodule isattached to the 93XXcontroller, the c ontroller isinhibited.

DRIVECOM sets the status SWITCH-ON INHIBIT.

• Points 1. to 5. (see below):

– For enabling the controller, the status OPERATION ENABLE must be set once through the

DRIVECOM control word.

– The controllers 821X, 8200 vector and 822X need a speed setpoint to be enabled. These

controllers should therefore have a speed setpoint preselected via the corresponding

process data assignment before they are enabled through 7E

1. Controller settings as described in chapter 5.3

2. DRIVECOM unit control preselection under parameter C0009 ≠ 11, 12

3. Change to status „READY FOR SWITCH ON“

DRIV ECOM control word = 0000 0000 0111 1110

4. Change to the status „OPERATION ENABLED“

DRIV ECOM control word = 0000 0000 0111 1111

(waiting for OPERATION ENABLED)

5. The controller is enabled.

bin

bin

(7E

(7F

hex

hex

hex

or 7F

hex

.

).

)

5.4.2.1 Create DRIVECOM compatibility(C0009 ≠11, 12)

The unit control is described in t he DRIVECOM profile 20. In the following, you will find the changes require d for the Le nze controllers.

820X 821X,

8200 vector

and 822X

93XX Set a DRIVECOM speed signal configuration under code C0005, e. g.:

The automatic DC-injection brake must be deactivated in all parameter sets, i. e.

• C0106=0

• C2106=0

• C4106=0 (only 8200 vector)

• C6106=0 (only 8200 vector)

If the automatic DC-injection brake is not deactivated (holding time of the DC-injection brake C0106 unequal 0), the controller automatically

switches from the status ”OPERATION ENABLED” to the status ”SWITCHED ON” when the spe ed is 0 a nd the holding time of the DC-injection

brak e is elapsed. If the setpoint is higher than 0, the controller is automatically reset to the status ”OPERATION ENABLED”.

• C0005=1013

This configuration corresponds to the signa l configuration 1000 with the following changes:

• Setpoint se lection via INTERBUS- Loop

• Unit control via INTERBUS-Loop

• Output X5.A1 is se lected a s volta ge output for the internal supply of the digital inputs.

• Actual va lues a nd status signa ls for INTERBUS-Loop

For t he detailed description of the signal configuration, see 93XX Manual.

5-4

BA2112EN

Page 21

Commissioning

Show/Hide Bookmarks

5.4.3 Userdefined control profile

The controllers 93XX and 8200 vector offer the possibility to link the process data words 1 and 2

through the AIF block (see Process Data Assignment for 93XX and 8200 vector):

1. Controller settings as described in chapter 5.3

2. Selection of user defined control profile with C0009 = 12

3. Automatic enabling.

Danger!

User-defined control is only allowed for 93XXand 8200 vector controllers!

Ifaspeed hasbeenselected viathe corresponding process dataword,the drivestartsimmediately

when the module is being attached.

5.5 Special features with 82XX, 8200 vector und 93XX

Please note

• For sa fe ope ration it is absolutely necessary to observe the notes f or the controlle rs given in this chapter.

820X • Para me ter se tting only by using the k eypad a nd when the controller is inhibited (DRIVECOM controller sta tus not “OPERATION ENABLED“).

8200 vector • Digital and ana log input and output signals can be freely configured (see Operating Instructions for 8200 vector; codes C0410, C0412, C0417

93XX • Instead of operating mode L-C0001, set signal configuration C0005= xxx3.

• A TRIP must only be reset through INTERBUS Loop:

If the controller is set to the status TRIP while being operated with INTERBUS control (C0001 = 3) and if the TRIP is reset via terminal 28, the

drive might start for a short t ime. When resetting a fault via INTERBUS, this does not occur.

• Afte r the command „TRIP reset“ the 820X controller is basically initialized. During this time the controller does not accept any services.

• Always send the direction of rotation with a low setpoint before the new setpoint:

If the setpoint and the direction of rotation are changed at the sa me time via the DRIVECOM spe ed setpoint, the spe ed ca n change to the

wrong direction or rota tion for a short time. This is because the setpoint is sent to the controlle r as unipola r value before the informat ion about

the direction of rotation is sent.

and C0421)

• Process data words are preconfigured in the controller with C0001 = 3

• A change of code C0005 to xxx3 sta rts the pre configuration of the process da ta words in the controlle r

• Set the parameter C0142 = 0 (auto start lock), to avoid a brief start of the drive during the initialization phase.

BA2112EN

5-5

Page 22

Commissioning

Show/Hide Bookmarks

5-6

BA2112EN

Page 23

6 Parameter setting

ByteN

POW1Uni

tcontro

lwordC0135DRIVECO

Mcontro

lwordLink:W1toAIF-I

N

POW282XX/8200vector:Speedsetpoint

L

ink:W2toAIF-I

N

Show/Hide Bookmarks

Tip!

PCP communication is not supported.

Parameter data (= Lenze codes)can be changed through a keypad which can be attached to the

controller.

6.1 Process data

6.1.1 Processdata assignment

6.1.1.1 General information

Parameter setting

Process data are cyclically exchanged between the controller and the master.

They are subdivided into

• Process output data (PO data)

• Process input data (PIdata)

Here the data flow starts from the master, i.e. the PO data of the master are input data for the

controller.

The controllergets the controlinformation from themaster and returns status information.

Control word and status word

The controller status, such as READY FOR OPERATION, OPERATION ENABLED, etc. a re cont rolled and monitore d via the cont rol and sta tus

words. The range s are subdivided as follows:

• Control word

– The control word is sent from the ma ster t o the controller. It includes sta tus information such as OPERATION ENABLED (see cha pter 5.4).

• Status word

– The status word is se nt from the controller to the ma ster. It provide s all a ctual controller state s, such as ERROR.

INTERBUS-Loop can transfer a maximum of 32 bit, which are interpreted by the 2112 fieldbus

moduleastwo process data words. Theassignment of the processdata words can bepreselected

under code C0009.

Assignment of process output data words

o.

1 HIGH byte ; bit 8- 15

2 LOW byte; bit 0-7

1 HIGH byte ; bit 8- 15

2 LOW byte; bit 0-7

Uni t co ntrol DRIVECOM control User defined

C0009 = 11 C0009 ≠ 11, 12 C0009 = 12

82XX / 8200 vector: Speed setpoint

93XX: Freely configurable

control profile

(only 8200 vector and 93XX)

-

-

BA2112EN

6-1

Page 24

Parameter setting

PIW1DRIVECO

Mstat

ordDRIVECOMstat

ordLink:W1toAIF-OUT

PIW282XX/8200vector:Actualspeed

L

ink:W2toAIF-OUT

Show/Hide Bookmarks

Assignment of process input data words

Byte No.

1 HIGH byte; bi t 8-1 5

2 LOW byte; bit 0-7

1 HIGH byte; bi t 8-1 5

2 LOW byte; bit 0-7

82XX / 8200 vector: Actual speed

93XX: Freely configurable

6.1.1.2 Process-data assignments for 82XX

Structure of t he PO-data response (data to drive)

Byte 1 Byte 2 Byte 3 Byte 4

Control word

High byte

Uni t co ntrol

C0009 = 11

us w

Control word

Low byte

Meaning for

DRIVECOM c ont rol

C0009

us w

Setpoint

High byte

≠ 11, 12

User defined

control profile

C0009 = 12

(only 8200 vector / 93XX)

Setpoint

Low byte

Control w o rd: see chapter 6.1.3.2

Setpoint: frequency setpoint

Here the frequency setpoint is preselected as process data word. The normalization is here

indicated as signed value with

á

24000 =á480 Hz.

Structure of the PI data response (data from drive)

Byte 1 Byte 2 Byte 3 Byte 4

Status word

High byte

Status word

Low byte

Actual value

High byte

Actual value

Low byte

Status word: see chapter 6.1.3.3.

Actual value: act. frequency value

á

The actual frequency value is provided as signed normalization

24000 =á480 Hz.

6-2

BA2112EN

Page 25

Parameter setting

Show/Hide Bookmarks

6.1.1.3 Process-data assignment for 8200 vect or

Digitaland analog inputand output signal canbeconfigured freely (seeOperatingInstructions“8200

vector”: Codes C0410, C0412, C0417 and C0421).

The change of the code C0001 to 3 starts the preconfiguration of the process data words in the

controller (see chapter 5.3,

Structure of t he PO-data response (data to drive)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Control word

High byte

Control word

Low byte

Control w o rd: see chapter 6.1.3.2.

AIF-IN.Wx see C0412.

Structure of the PI data response (data from drive)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Status word

High byte

Status word

Low byte

(5-2) ).

AIF-IN.W1

High byte

AIF-OUT.W1

High byte

AIF-IN.W1

Low byte

AIF-OUT.W1

Low byte

AIF-IN.W2

High byte

AIF-OUT.W2

High byte

AIF-IN.W2

Low byte

AIF-OUT.W2

Low byte

Status word: see chapter 6.1.3.3.

AIF-OUT.Wx see C0421.

Tip!

• Frequency and speed are normalized with á24000 á480 Hz.

• Torque is normalized with 16384 100%.

BA2112EN

6-3

Page 26

Parameter setting

Show/Hide Bookmarks

6.1.1.4 Process-data assignment for 93XX

Withthe 93XXcontroller theprocess dataassignmentcanbechanged by reconfiguring thefunction

blocks AIF-IN and AIF-OUT.

Structure of the PO data response

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Control word

High byte

AIF-IN.W1 to AIF-IN.W2 depend on the signal configuration selected under C0005.

For detailed description of the 93XX signal configuration see the Operating Instructions for 93XX

(only the main configurations: 1000, 4000, 5000, etc.) or the Manual 93XX.

In the controller, other signals can be assigned to AIF-IN.W1 to AIF-IN.W2. For this, the

function-block configuration - described in the Manual 93XX- is used. The function block AIF-IN

determines the input data of the controller as data interface for the 2112 fieldbus module.

For more detailed information about the function block AIF-IN, see the Manual 93XX.

Speed control 1003 / 1013 / 1113 NSET-N

Torque control 4003 / 4013 / 4113 MCTRL-MADD

DF ma ster 5003 / 5013 / 5113 NSET-N

DF-slave bus 6003 / 6013 / 6113 DFSET- A-TRIM

DF- slave cascade 7003 / 7013 / 7113 DFSET-VP-DIV

Cam profiler 1xxx3 YSET1-FACT Re se rv ed

Positioning 2xxx3 Re se rv ed Res er ve d

vector control 1xx3 / 2xx3 / 3xx3 / 5xx3 / 100x3 NLIM-IN1 Res er ve d

vector control 4xx3 NCTRL-MADD Res er ve d

vector control 6xx3 DFSET- A-TRIM DFSET-N-TRIM

vector control 7xx3 / 8xx3 / 9xx3 DFSET-VP-DIV DFSET-A-TRIM

vector control 100x3 NLIM- IN1 Res er ve d

vector control 110x3 Re se r ve d Re se rv ed

Control word

Low byte

Signal configuration (C0005) AIF-IN.W1 AIF-IN.W2

AIF-IN.W1

High byte

AIF-IN.W1

Low byte

Speed setpoint

100 % = 16383

Torque se tpoint

100 % = 16383

Speed setpoint

100 % = 16383

Phase trimming

DF fa ctor

AIF-IN.W2

High byte

AIF-IN.W2

Low byte

Re se rv ed

Re se rv ed

Re se rv ed

DFSET-N-TRIM

Speed trimming

DFSET-A-TRIM

Phase trimming

6-4

BA2112EN

Page 27

Parameter setting

. . .. . .

. . .. . .

Show/Hide Bookmarks

A IF -IN *

)

AIF-CTRL.B3

AIF-CTRL.B8

AIF-CTRL.B9

AIF-CTRL.B10

AIF-CTRL.B11

Bit 0

16 B it

C ontrol w ord

Bit 15

B y te 3 ,4

X1

B y te 5 ,6

B y te 7 ,8

16 B it

16 B it

16 B it

C 0855/1

16 binary

signals

C 0855/2

16 binary

signals

16 B it

Low W ord

16 B it

H igh W ord

C 0856/1

C 0856/2

C 0856/3

QSP

DISABLE

CINH

TRIP-SET

TRIP-RESET

AIF-C TRL.B0

AIF-C TRL.B1

AIF-C TRL.B2

AIF-C TRL.B4

AIF-C TRL.B5

AIF-C TRL.B6

AIF-C TRL.B7

AIF-CTRL.B12

AIF-CTRL.B13

AIF-CTRL.B14

AIF-CTRL.B15

AIF-IN.B0

AIF-IN.B2

AIF-IN.B14

AIF-IN.B15

AIF-IN.B16

AIF-IN.B17

AIF-IN.B30

AIF-IN.B31

C 0857

Fig. 6-1 Function block AIF-IN and AIF-IN

AIF-IN*)is available for the 9300 technology variants: servo inverter, positioning controller and cam profiler as of software

version 2.0). AIF-IN.D2 is new.

AIF-IN

DCTRL

A IF -IN .W 1

A IF -IN .W 2

A IF -IN .W 3

AIF-IN.D1

*)

AIF-C TRL.B3

AIF-C TRL.B8

AIF-C TRL.B9

AIF-C TRL.B10

AIF-C TRL.B11

Bit 0

16 B it

C ontrol w ord

Bit 15

C 0136/3

B y te 3 ,4B y te 5 ,6

X1

B y te 7 ,8

16 B it

16 B it

16 B it

C 0855/1

16 binary

signals

C 0855/2

16 binary

signals

16 Bit

Low W ord

16 Bit

H igh W ord

16 Bit

Low W ord

16 Bit

H igh W ord

C 0856/1

C 1197

C 0856/2

C 0856/3

C 0857

DCTRL

QSP

DISABLE

CINH

TRIP-SET

TRIP-RESET

AIF-C TRL.B0

AIF-C TRL.B1

AIF-C TRL.B2

AIF-C TRL.B4

AIF-C TRL.B5

AIF-C TRL.B6

AIF-C TRL.B7

AIF-CTRL.B12

AIF-CTRL.B13

AIF-CTRL.B14

AIF-CTRL.B15

AIF-IN.W 1

AIF-IN.D2

A IF -IN .W 2

AIF-IN.W 3

A IF -IN .B 0

A IF -IN .B 2

A IF -IN .B 1 4

A IF -IN .B 1 5

A IF -IN .B 1 6

A IF -IN .B 1 7

A IF -IN .B 3 0

A IF -IN .B 3 1

AIF-IN.D1

2111IBU003

BA2112EN

Tip!

Please observe that bytes 7 and 8 shown in the diagram above cannot be accessed via

INTERBUS-Loop.

6-5

Page 28

Parameter setting

Show/Hide Bookmarks

Structure of the PI data response (data from drive)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

DRIVECOM

Status word

High byte

AIF-OUT.W1 to AIF-OUT.W2 depend on the signal configuration selected under C0005.

For detailed description of the 93XX signal configuration see the Operating Instructions for 93XX

(only the main configurations: 1000, 4000, 5000, etc.) or the Manual 93XX.

In the controller, other signals can be assigned to AIF-OUT.W1 to AIF-OUT.W2. For this, the

function-block configuration- described in the Manual 93XX- is used. The function block AIF-OUT

determines the controller output data as data interface for the 2112 fieldbus module.

For more detailed information about the function block AIF-OUT, see the Manual 93XX.

Speed control 1003 / 1013 / 1113 MCTRL-NACT

Torque control 4003 / 4013 / 4113 MCTRL-MSET2

DF ma ster 5003 / 5013 / 5113 MCTRL-NACT

DF-slave bus 6003 / 6013 / 6113 MCTRL-NACT

DF- slave cascade 7003 / 7013 / 7113 MCTRL-NACT

Cam profiler 1xxx3 MCTRL- NACT

Positioning 2xxx3 MCTRL-NACT

vector control 1xx3 / 4xx3 / 5xx3 / 10xx3 MCTRL-NACT

vector control 6xx3 / 7xx3 / 8xx3 / 9xx3 MCTRL- NACT

vector control 110x3 Re se r ve d Re se rv ed

DRIVECOM

Status word

Low byte

Signal configuration (C0005) A IF- OUT.W1 AI F-OUT.W2

AIF-OUT.W1

High byte

AIF-OUT.W1

Low byte

Actual speed

100 % = 16383

Torque display

100 % = 16383

Actual speed

100 % = 16383

Actual speed

100 % = 16383

Actual speed

100 % = 16383

Actual speed

100 % = 16383

Actual speed

100 % = 16383

Actual speed

100 % = 16383

Actual speed

100 % = 16383

AIF-OUT.W2

High byte

AIF-OUT.W2

Low byte

MCTRL-MSET2

Torque display

100 % = 16383

MCTRL- NACT

Act. speed in %

100 % = 16383

MCTRL-MSET2

Torque display

100 % = 16383

MCTRL- PHI-ACT

Actua l phase

MCTRL- PHI-ACT

Actua l phase

Re se rv ed

Re se rv ed

MCTRL- IACT

MCTRL- PHI-ANA

For more detailed information about the function block AIF-OUT, see the Manual 93XX.

6-6

BA2112EN

Page 29

Parameter setting

Show/Hide Bookmarks

AIF-O UT

C 0156/1

C 0156/6

C 0156/7

STAT

STAT.B0

DCTRL-IM P

...

STAT.B14

STAT.B15

16 Bit

B it 0

B it 1 5

B it 0

C 0850/1

C 0850/2

C 0850/3

C 0116/1

C 0116/16

C 0116/17

C 0116/32

C 0851

FDO -0

...

FDO -15

FDO -16

...

FDO -31

AIF-O U T.D 1

C 0858/1

C 0858/2

C 0858/3

FDO

C 0859

AIF-O U T.W 1

AIF-O U T.W 2

AIF-O U T.W 3

16 Bit

Low W ord

16 Bit

H igh W ord

16 Bit

Low W ord

16 Bit

H igh W ord

C 0852

0

1

2

C 0853

0

1

2

B it 1 5

B it 0

B it 3 1

Fig. 6-2 Function block AIF-OUT and AIF-OUT

AIF-OUT*)is available for the 9300 technology variants: servo inverter, positioning controller and cam profiler as of

software version 2.0). AIF-OUT.D2 is new.

AIF-O UT *

STAT

STAT.B0

C 0156/1

DCTRL-IM P

...

STAT.B14

C 0156/6

STAT.B15

Status w ord

B y te 3 ,4

:

B y te 5 ,6

B y te 7 ,8

C 0156/7

C 1195

C 0850/1

C 0850/2

C 0850/3

C 0116/1

C 0116/16

C 0116/17

C 0116/32

C 0851

AIF-O U T.D 2

C 1196

AIF-O U T.W 1

C 0858/1

C 0858/2

C 0858/3

FDO -0

...

FDO -15

FDO -16

...

FDO -31

AIF-O U T.D 1

C 0859

FDO

16 Bit

16 Bit

Low W ord

16 Bit

H igh W ord

AIF-O U T.W 2

AIF-O U T.W 3

16 Bit

Low W ord

16 Bit

H igh W ord

16 Bit

Low W ord

16 Bit

H igh W ord

C 0854

C 0852

C 0853

)

B it 0

Status w ord

B it 1 5

B it 0

0

3

0

1

2

3

0

1

2

B it 1 5

B it 0

B y te 3 ,4

:

B y te 5 ,6

B y te 7 ,8

B it 3 1

2111IBU002

*)

Tip!

Please observe that bytes 7 and 8 shown in the diagram above cannot be accessed via

INTERBUS-Loop.

BA2112EN

6-7

Page 30

Parameter setting

820X821x,822x

1

1=JOG3(C0039)active1

1=JOG3(C0039)activ

U

y

our

o

UseC0410tosetyourow

n

Show/Hide Bookmarks

6.1.2 Unit control (C0009 = 11)

In the following the bit assignment of control and status word is under C0009 = 11:

6.1.2.1 Control word

Control word for 82XX and 8200 vector

820X 821x,822x

Factory setting:

C0001=3 if C0007 < 52

0

JOG1, J OG2, J OG3

00 = C0046 active

01 = JOG1 (C0037) active

10 = JOG2 (C0038) active

1

2 CW/CCW (CW rotation/CCW rotation)

0 = CW rotation

1 = CCW rotation

3 QSP (quick stop)

0 = QSP not active

1=QSPactive

4 Re se r ve d RFG stop (stop of the ra mp function

5 Re se r ve d RFG zero (deceleration along the T i f

6 Re se r ve d UP function for motor potentiometer

7 Re se r ve d DOWN function for motor

8 Re se r ve d Re se rv ed Re se rv ed

9 Ctrl. inhibit (controller inhibit)

0 = controlle r not inhibited

1 = controlle r inhibited

10 Re se r ve d Re se rv ed No function

11 Re se r ve d TRIP rese t

12 PAR1 (Parameter set changeover)

0 -> 1 = Parameter set

1 -> 0 = Parameter set

13 Re se r ve d Re se rv ed DCTRL1-PAR3/4

14 DC brake (DC injection brake)

0 = DC brake not active

1 = DC brake active

15 Re se r ve d Re se rv ed Re se rv ed

JOG1, J OG2, J OG3

00 = C0046 active

01 = JOG1 (C0037) active

10 = JOG2 (C0038) active

e

CW/CCW (CW rotation/CCW rotation)

0 = CW rotation

1 = CCW rotation

QSP (quick stop)

0 = QSP not active

1=QSPactive

generator)

0 = RFG stop not active

1=RFGstopactive

ramp C0013)

0 = RFG zero not active

1=RFGzeroactive

0 = UP not active

1=UPactive

potentiometer

0 = DOWN not a cti ve

1 = DOWN a ctive

Ctrl. inhibit (controller inhibit)

0 = controlle r not inhibited

1 = controlle r inhibited

0 - > 1 = Edge from 0 to 1

PAR1 (Parameter set changeover)

0 -> 1 = Parameter set

1 -> 0 = Parameter set

DC brake (DC injection brake)

0 = DC brake not active

1 = DC brake active

NSET1 -JOG1 /3

00 = C0046 active

01 = JOG1 (C0037) active

10 = JOG2 (C0038) active

11 = JOG3 (C0039) active

NSET1 -JOG2 /3

DCTRL1-CW/CCW

0 = not active

1=active

AIF-CTRL- QSP

0 = not active

1=active

NSET1 -RFG1 -STOP

0 = not active

1=active

NSET1-RFG1-0

0 = not active

1=active

MPOT1 -UP

0 = not active

1=active

MPOT1- DOWN

0 = not active

1=active

AIF-CTRL- CINH

0 = not active

1=active

AI F- CT RL- TRIP -RE SET

0 - > 1 = Edge from 0 to 1

DCTRL1-PAR2/4

0 = not active

1=active

0 = not active

1=active

MCTRL1-DCB

0 = not active

1=active

8200vector

Factory setting:

C001=3 if C0007 > 51

The default setting (see below) is

accepted with setting C0007 > 51

se C0410 toset

configurations.

wn

6-8

BA2112EN

Page 31

Control word for 93XX

Show/Hide Bookmarks

Parameter setting

9300 9300 Servo 9300

C0005 1xx3 4xx3 5xx3 6xx3,7xx3 2xxx3 xxx3 1xxx, 2xxx,

0 NSET-JOG*1 Re se r ve d NSET- JOG*1 Re se rv ed Res er ve d CSEL1-CAM*1 NSET-J OG*1 Re se rv ed Re se r ve d

1 NSET-JOG*2 Re se r ve d NSET- JOG*2 Re se rv ed Res er ve d CSEL1-CAM*2 NSET-J OG*2 Re se rv ed Re se r ve d

2 NSET-N- INV NSET- N-INV NSET-N-INV NS ET-N- INV Re se rve d CSEL1-CAM*4 NSET-N- INV Re se rv ed Re se r ve d

3 AIF-CTRL.QSP AIF-CTRL.QSP AIF- CTRL.QSP AIF-CTRL.QSP AIF- CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF- CTRL.QSP

4 NSET-RFG-

STOP

5 NSET-RFG-0 NS ET-RF G-0 NSET-RF G-0 NSET -RFG- 0 POS-PRG-STOP CDATA-CYCLE NSET-RF G-0 NSE T-RFG- 0 Re se rv ed

6 Re se rv ed Re se r ve d Re se rve d Re se r ve d Res er ve d CSEL1- LOAD Re se r ve d Res er ve d Re se rv ed

7 Re se rv ed Re se r ve d Re se rve d Re se r ve d POS-PRG-RESE T CSEL1- LOAD Re se rv ed Res er ve d Re se rv ed

8 Re se rv ed Re se r ve d Re se rve d Re se r ve d Res er ve d Re se r ve d Re se r ve d Res er ve d Re se rv ed

9 AIF- CTRL.CINH AIF-CTRL.CINH AIF- CTRL.CINH AIF-CTRL.CINH AIF- CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF- CTRL.CINH AIF-CTRL.CINH

10 AIF-CTRL.TRIP-

SET

11 AIF-CTRL.TRIP-

RES ET

12 DCTRL-PAR*1 DCTRL-PAR*1 DCTRL-PAR*1 DCTRL-PAR*1 POS-PS-CANCEL Re se r ve d DCTRL- PAR*1 DCTRL-PAR*1 DCTRL-PAR*1

13 DCTLR-PAR-

LOAD

14 NSET-Ti*1 NSET -JOG*1 REF - ON REF - ON POS- LOOP-ONH Re se rv ed NSET- Ti*1 NSET- JOG*1 Re se r ve d

15 NSET-Ti*2 NSET -JOG*2 NSET-Ti*1 Rese r ve d POS-STBY-STP Re se r ve d NSET- Ti*2 NSET- JOG*2 Re se rv ed

NSET- RFGSTOP

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRES ET

DCTLR-PARLOAD

NSET- RFGSTOP

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRES ET

DCTLR-PARLOAD

NSET- RFGSTOP

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRES ET

DCTLR-PARLOAD

Pos ition ing

controller

POS-PRG- START CSEL1- EVENT NSET-RFG-

AIF-CTRL.TRIPSET

AI F- CT RL. TRIP- RE

SET

POS -PA RAM- RD Re se rv ed DCTLR-PAR-

9300

Cam profiler

AIF-CTRL.TRIPSET

AI F- CT RL. TRIP- RE

SET

3xxx, 5xxx,

10xxx, 11xxx

STOP

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRES ET

LOAD

9300 Vector

4xx3 6xx3,7xx3

NSET- RFGSTOP

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRES ET

DCTLR-PARLOAD

Re se rv ed

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRES ET

DCTLR-PARLOAD

Tip!

Thesinglebit control commandsof the control word depend onother bit positions. Chapter6.1.3.1

describes the bits required to effect the command.

BA2112EN

6-9

Page 32

Parameter setting

Show/Hide Bookmarks

6.1.2.2 Status word

Status word for 82XX and 8200 vector

820X 821x,822x 8200vector

0 Res er ve d Actual parameter set

1 IMP (pulse i nhibit)

0 = Pulses for power stage enabled

1 = Pulses for power stage inhibited

2 I

3 Res er ve d fd=f

4 fd=f

5 Qmin (f

6 fd= 0 (act. frequency = 0)

7 Ctrl. inhibit (controller inhibit)

8...11 Uni t s ta tu s

(current limit reached)

max

0 = Curre nt limit not re ached

1 = current limit reached

dset

0=f

≠ f

d

dset

1=fd=f

dset

≤ f

)

d

d

d

dQmin

≠ 0

=0

0 = Qmin not active

1=Qminactive

0=f

1=f

0 = controlle r not inhibited

1 = controlle r inhibited

0 = No error

8 = Error active

0=Parameterset1or3active

1=Parameterset2or4active

IMP (pulse inhibit)

0 = Pulses for power stage enabled

1 = Pulses for power stage inhibited

I

(current limit reached)

max

0 = Curre nt limit not re ached

1 = current limit reached

dset

0=f

≠ f

d

dset

1=fd=f

dset

RF G on = RF G of f

0=RFGon

1 = RF G o n = RF G ou t

Qmin (f

0 = Qmin not active

1=Qminactive

fd= 0 (act. frequency = 0)

0=f

1=f

Ctrl. inhibit (controller inhibit)

0 = controlle r not inhibited

1 = controlle r inhibited

Uni t st a tu s

0 = Controller initialization

1 = Switch on inhibit

3 = Operation inhibited

4 = Flying-restart circuit active

5 = DC brake active

6 = Operation enabled

7 = Messa ge a ctive

8 = Fault active

d

d

d

≠ 0

=0

≠ RF G o ff

≤ f

dQmin

)

Lenz e setting

DCTRL-PAR- B0

DCTRL1-IMP

MCTRL1-IMAX

MCTRL1-RFG1= NOUT

NSET1-RFG1-I= 0

PCTRL1-QMIN

DCTRL1-NOUT=0

DCTRL1-CINH

Uni t st a tu s

0 = Controller initialization

1 = Switch on inhibit

3 = Operation inhibited

4 = Flying-restart circuit active

5 = DC brake active

6 = Operation enabled

7 = Messa ge a ctive

8 = Fault active

12 Overtemperature warning ( ϑ

0=Nowarning

1=Warning

13 U

14 Direction of rotation

15 Ready for ope ration

(DC-bus overvoltage)

Gma x

0 = No overvoltage

1 = overvoltage

0 = CW rotation

1 = CCW rotation

0 = not ready f or opera tion

1 = ready for ope ration

max

-10°C)

Overtemperature warning

0=Nowarning

1=Warning

U

(DC-bus overvoltage)

Gma x

0 = No overvoltage

1 = overvoltage

Direction of rotation

0 = CW rotation

1 = CCW rotation

Ready for operation

0 = not ready f or opera tion

1 = ready for ope ration

DCTRL1-OH- WARN

DCTRL1-OV

DCTRL1-CCW

DCTRL1-RDY

6-10

BA2112EN

Page 33

Status word for 93XX

8...1

1

Show/Hide Bookmarks

Parameter setting

9300 Ser vo Servo

C0005 1xx3 4xx3 5xx3 6xx3,7xx3 2xxx3 1xxx3 xxx, 2xxx,

0 DCTRL- PAR1-0 DCTRL-PAR1- 0 DCTRL-PAR1-0 DCTRL-PAR1-0 Re se rv ed CERR1 - ERR DCTRL-PAR1- 0 DCTRL-PAR1-0 DCTRL-PAR1-0

1 DCTRL- IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP

2 MCTRL-IMAX MCTRL-IMAX REF -O K REF - OK POS- REF- OK MCTRL-IMAX MCTRL-IMAX MCTRL-IMAX MCTRL-IMAX

3 MCTRL- MMAX Re se r ved MCT RL -MMAX Re se r ve d Re se r ve d MCT RL -MMAX MC TRL- MMAX MCTRL-IMAX

4 NSET- RFG-I= 0 MCTRL-IMAX

5 QMIN QMIN REF-BUSY REF- BUSY POS-IN-TARGET CDATA-X0 QMIN QMIN QMIN

6 DCTRL- NACT=0DCTRL-NACT=0DCTRL-NACT=0DCTRL-NACT=0DCTRL-NACT=0DCTRL-NACT=0DCTRL-NACT=0DCTRL-NACT=0DCTRL-NACT=

7 DCTRL- CINH DCTRL- CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL- CINH DCTRL- CINH DCTRL-CINH

8 ... 11 Controller status:

12 DCTRL- WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN

13 DCTRL-MESS DCTRL- MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS

14 DCTRL-CW/

CCW

15 DCTRL- RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL- RDY DCTRL-RDY DCTRL-RDY

negated

DCTRL-CW/

CCW

NSET- RFG- I= 0 MCTRL-IMAX

DCTRL-CW/

CCW

negated

Re se rv ed DCTRL-AIFL-

positioning

controller

MCTRL -MMAX

negated

0=

Unit initialization

1=

Switch-on inhibit

3=

Operation inhibited

4=

Flying-restart circuit active

5=

DC-injection brake active

6=

Operation enabled

7=

Message a ctive

8=

Fault active

10 =

Fail-QSP (only 9300 servo positioning controller)

QSP

Serv o cam

profiler

3xxx, 5xxx,

10xxx, 11xxx

DCTRL-TRIP NSET-RF G-I= 0 NSET- RFG- I=0 NSET- QSP-OUT

DCTRL-CW/

CCW

DCTRL-CW/

CCW

vector

4xxx 6xxx, 7xxx,

negated

DCTRL-CW/

CCW

MCTRL -MMAX

0

DCTRL-CW/

CCW

8xxx, 9xxx

Tip!

Thecurrent controller status canonly be clarified by combining thebits with the status information

(bit 0, 1, 2, 3, 4, 5 and 6). This is shown in chapter 6.1.3.1.

BA2112EN

6-11

Page 34

Parameter setting

Show/Hide Bookmarks

6.1.3 DRIVECOM control (C0009≠ 11, 12)

6.1.3.1 DRIVECOM status machine

Controllers 82XX, 8200 vector (C0001 ½ 3)

For standard control you enter the control information via the corresponding control inputs

(terminal):

Information about the current unit status (Fig. 6-3, see below) (rectangles) are available in the

DRIVECOM parameter “status word“. Commands in theDRIVECOM parameter “control word“ are

switched offandcannotchangethecontrollerstatus.Thecommandsto changethecontrollerstatus

are entered via the corresponding control inputs. These commands are marked by arrows in the

following diagram.

Switch on unit

NOT READY TO SWITCH ON

Status word xxxx xxxx x0xx 0000

automatically when

the initialization is

completed

READY TO SWITCH ON

Status word xxxx xxxx x01x 0001

automatically

SWITCHED ON

Status word xxxx xxxx x01x 0011

Ctrl. enable** Ctrl. inhibit**

OPERATION ENABLED

Status word xxxx xxxx x01x 0111

QSP**

TRIP (fault)

Fault

Status word xxxx xxxx x0xx 1000

TRIP reset**

Note:

The terms marked with ** are

commands

Fig. 6-3 Status diagram for standard unit control

Status Meaning

NOT READY TO SWITCHONThe controller is being initialized a nd is not yet re ady to operate.

READYTOSWITCHON The controller is inhibite d and waits for the powe r stage to be cha rged. It the n automatically switches to the sta tus “SWITCHED ON“.

SWITCHED ON The controlle r is inhibited a nd waits for controlle r ena ble.

OPERATION ENABLED The controlle r is e nabled. In t his status, a pulse inhibit can be set a utomatically.

FAULT The controller is in the status “FAULT“ (T RIP).

6-12

It then automatically switches to the status READY TO SWITCH ON.

BA2112EN

Page 35

Parameter setting

Show/Hide Bookmarks

Controllers 82XX and 8200 vector (C0001 = 3) and 93XX

With INTERBUS-DP control(82XX:Lenze parameter C0001 = 3; 93XX: always)and whenusing the

2112fieldbusmodule, theLenzecontrollerstatusis normalizedaccordingtotheDRIV ECOM-Profile

20.

Information about the current unit status (Fig. 6-4 rectangles in the status diagram)are available in

theDRIVECOM parameter “Status word“. Commands in the DRIV ECOM parameter control word

can change thecontrollerstatus.Thesecommandsaremarked byarrowsinthe following diagram.

Example:

Status information by means of

„status word“

Bit 15 ... bit 0 (binary display)

Switch on unit

FAULTREACTION ACTIVE

Status word xxxx xxxx x0xx 1111

13

Malfunction was recognized

automatically, if the error reaction is over

NOTREADY TO SWITCH ON

Status word xxxx xxxx x0xx 0000

automatically when

initializing is completed

SWITCH ON INHIBIT

Status word xxxx xxxx x0xx 0000

9

Inhibit voltage

xxxx xxxx xxxx xx0x

Status word xxxx xxxx x01x 0001

8

Standstill

xxxx xxxx xxxx

x110

Status word xxxx xxxx x01x 0011

Operation enable

xxxx xxxx xxxx 1111 and

act. speed value

Status word xxxx xxxx x01x 0111

2

Standstill

xxxx xxxx

xxxx x110

READY TO SWITCH ON

3

Switch on

xxxx xxxx

xxxx x111

SWITCHED ON

45

≠0*

OPERATION ENABLED

Inhibit RFG is mapped to

quick stop

Fig. 6- 4 Statusdiagram DRIVECOM unit control

Status word xxxx xxxx x0xx 1000

10

Inhibit voltage

xxxx xxxx xxxx xx0x

Quick stop

xxxx xxxx xxxx x01x

7

6

Standstill

xxxx xxxx xxxx x110

Operation inhibit

xxxx xxxx xxxx 0111 or act.

speed value = 0*

QUICK STOP ACTIVE

Status word xxxx xxxx x01x 0111

11

Quick stop

xxxx xxxx xxxx x01x

Note :

* only valid for 821X, 8200 vector when the automatic

DC-injection brake is active (C0106, C2106

Fault

14

Reset fault

xxxx xxxx 0xxx xxxx

xxxx xxxx 1xxx xxxx

12

Inhibit voltage

xxxx xxxx xxxx xx01

or

quick stop completed

≠ 0)

Status Mea ning

NOTREADYTOSWITCHON The controller is being initialize d and is not yet ready to ope rate. It then automatically switches to the sta tus READY TO SWITCH ON.

SWITCH ON INHIBIT The controller is inhibited and waits f or command 2 (shut down).

READYTOSWITCHON The controller is inhibited and waits f or command 3 (switch on).

SWITCHED ON The controller is inhibited and waits for command 4 (enable opera tion).

OPERATION ENABLED The controller is ena bled. In this status, a pulse inhibit can be set a utomatically.

FAULT REACTION ACTIVE A fault (TRIP) was re cognized and a fa ult re sponse initia ted.

FAULT The controller is in the status “FAULT“ (TRIP).

QUICK ST OP ACTIVE While being in the status “OPERATION ENABLED“ the comma nd “Quick stop“ was set. The controller is decelerated in a controlled

BA2112EN

way (quick- stop ra mp). Afte r deceleration, the controller automatically changes to the controller sta tus “SWITCH ON INHIBIT“.

Theactualunit status canonly be clarified by combining theunit-status informationbits (bit 0 to 6).

This is shown in the following:

6-13

Page 36

Parameter setting

Show/Hide Bookmarks

Uni t st at us Bits of the status word

Bit 6 5 4 3 2 1 0

NOTREADYTOSWITCHON 0 0 0 0 0

SWITCH ON INHIBIT 1 0 0 0 0

READYTOSWITCHON 0 1 0 0 0 1

SWITCHED ON 0 1 0 0 1 1

OPERATION ENABLED 0 1 0 1 1 1

FAULT 0 1 0 0 0

FAULT REACTION ACTIVE 0 1 1 1 1

QUICK ST OP ACTIVE 0 0 0 1 1 1

Switch-on inhibit

Quic k st op

Voltage inhibit

Fault

Operation enabled

Switched on

Readytoswitchon

Command Meaning

COMMAND 2, 6, 8 (standstill)

Control word: bit 0 = 0

COMMA ND 3 (s wit ch o n) Command to change to the controller status “SWITCHED ON“.

COMMAND 4 (enable ope ration) Command to change to the controller status “OPERATION ENABLED“. The cont roller inhibit is deacti vated.

COMMAND 5 (inhibit operation) Command to change to the controller status “SWITCHED ON“. The controlle r inhibit is activated.

COMMAND 7, 9, 10, 12 (voltage inhibit)

Control word: bit 1 = 0

COMMAND 7, 10, 11 (quick stop)

Control word: bit 2 = 0

COMMAND 13 (FAULT/TRIP) The controller ha s recognized a malfunction. For some malfunction a controlle d dece leration ma y be ne cessary

COMMAND 14 (reset fault/TRIP)

A

Control word: bit 7 = 0

1

Command to change from different states to the status „READYTOSWITCHON“.

Command to change to the controller status “SWITCH ON INHIBIT“. The controlle r inhibit is activated.

Command to change to the controller status “SWITCH ON INHIBIT“. If the controller was enabled, it is decelerated in a

controlled way along the Le nze quick- stop ramp.

(depending on the controller). Once completed, the controller cha nges to the status FAULT.

With the series 821X, 8200 vector this command acknowledges a fault. The controller changes to the status “SWITCH ON

INHIBIT“ when a fault is no longer recognized.

6-14

BA2112EN

Page 37

Parameter setting

Show/Hide Bookmarks

The individual bit-control commands of the control word depend on other bit positions. In the

following you will find a description of the bits required to effect the command.

Controller status commands Bits of the control word

Bit 7 6 5 4 3 2 1 0

1 Standsti ll 1 1 0

2Switchon 1 1 1

3 Operation enable 1 1 1 1

4 Operation inhibit 0 1 1 1

5 Voltage inhibit 0

6 Quick st op 0 1

8Faultreset 01

Fault reset

RF G- ze ro

RF G- st op

RFG inhibit

Operation enable

Quic k st op

Voltage inhibit

Switch on

Detailed information on the tables:

0 =Bit statusis 0

1 =Bit statusis 1

no entry = Any bit status, no influence

BA2112EN

6-15

Page 38

Parameter setting

Show/Hide Bookmarks

6.1.3.2 Control word

Bit Name Meaning

0 Switch on 0 = command 2, 6, 8 (controller inhibit)

1 Voltage inhibit 0 = Voltage inhibit active

2 Quic k st op 0 = Quick stop active

3 Operation enable 0 = Operation inhibite d

4 RFG inhibit Inhibit of the ramp-funtion generator.

5 RF G- st op 820X: Reserved

6 RF G- ze ro 820X: Reserved

7 Fault reset Fault reset (TRIP). For this, a bit change from 0 to 1 is require d.

8..9 Rese r ve d

11 Manuf acturer 820X, 821x, 822x: Reserved

12 Manuf acturer 820X, 821x, 822x: Parameter set changeover:

13 Manuf acturer 820X, 821x, 822x: DC-injection brake:

14 Manuf acturer 820X, 821x, 822x: Reserved

15 Manuf acturer 820X: PI - inhibit

1 = command 3 (controller inhibit)

1 = voltage inhi bit not active

1 = Quick stop not active

1 = Operation enabled

Quick stop is activated without the cont roller leaving its sta tus.

0 = RFG inhibit (quick stop)

1 = RFG inhibit not active

821X, 822X: Output of the RFG (speed setpoint integrator) is ”frozen”.

0=RFGstop

1 = RFG stop not active

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B4 negated.

821X, 822X: Input of the ramp function gene rator (speed setpoint integrator) is set to 0. Thus

controlled deceleration along the ramp.

0=RFGzero

1 = RFG zero not active

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B5 negated.

For 82XX, the controller is initialized.

During this time, the controller doe s not a ccept any commands.

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B7 1) .

0 – 1= Parameterset2

1 – 0= Parameterset1

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B12 1) .

0 = DCB not a ctive

1=DCBactive

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B13 1) .

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B14 1) .

Inhibit the update of the PO data of the controller (input data for the ma ster).

Updates for sta tus and actual information of the process channel ca n be inhibited

to transfer control information timed more accurately (see chapter 3.6.2).

0 = Read status and actual value

1 = Do not read status and actual value

821X,822X: Reserved

8200 vector, 93XX: free. Mapping to bit AIF-CTRL.B15 1) .

Signal configuration C0005 Bit 5

Speed control 1003 / 1013 /

Torque

control

DF ma ster 5003 / 5013 /

DF-slave bus 6003 / 6013 /

DF- sla ve

cascade

Cam profiler 1xxx3 CSEL1- EVENT CDATA-CYCLE CSEL1-LOAD Re se rv ed Re se rve d Re ser ve d Re se r ve d

Positioning 2xxx3 POS-PRG-START POS- PRG-S TOP POS- PRG-

1113

4003 / 4013 /

4113

5113

6113

7003 / 7013 /

7113

(AIF-CTRL.B4)

NSET- RFG- STOP

(RFG stop)

NSET- RFG- STOP

(RFG stop)

NSET- RFG- STOP

(RFG stop)

Re se rv ed Re se rv ed Re se r ve d DCTRL-PAR*1 DCTRL-PAR-

Re se rv ed Re se rv ed Re se r ve d DCTRL-PAR*1 DCTRL-PAR-

6-16

Bit 6

(AIF-CTRL.B5)

NSET- RFG- 0

(RF G z e ro)

NSET- RFG- 0

(RF G z e ro)

NSET- RFG- 0

(RF G z e ro)

Bit 11

(AIF-CTRL.B7)

Re se rv ed DCTRL-PAR*1 DCTRL-PAR-

Re se rv ed DCTRL-PAR*1 DCTRL-PAR-

Re se rv ed DCTRL-PAR*1 DCTRL-PAR-

RES ET

Bit 12

(AIF-CTRL.B12)

POS-PS-CANCEL POS- PARA M- RD POS- LOOP-

Bit 13

(AIF-CTRL.B13)

LOAD

LOAD

LOAD

LOAD

LOAD

BA2112EN

Bit 14

(AIF-CTRL.B1

4)

NSETTI*1

NSET- JOG*1 NSET-J OG*2

REF - ON NSET-TI*1

REF - ON Re se rv ed

REF - ON Re se rv ed

INH

Bit 15

(AIF-CTRL.B15)

NSETTI*2

POS-STBY-STP

Page 39

Parameter setting

Show/Hide Bookmarks

Signal configuration C0005 Bit 15

vector control 1xx3 / 2xx3 / 3xx3

/ 5 xx3 / 10xx3

vector control 4xx3 NSET-RFG-STOP

vector control 6xx3 / 7xx3 / 8xx3

/ 9 xx3

vector control 11xx3 Re se rve d Re se rve d Re se r ve d Re se r ve d Re se rv ed Re se rv ed Res er ve d

Bit 5

(AIF-CTRL.B4)

NSET- RFG- STOP

(RFG stop)

(RFG stop)

Re se rv ed Re se rv ed Re se r ve d DCTRL-PAR*1 DCTRL-PAR-

Bit 6

(AIF-CTRL.B5)

NSET- RFG- 0

(RF G z e ro)

NSET- RFG- 0

(RF G z e ro)

Bit 11

(AIF-CTRL.B7)

Re se rv ed DCTRL-PAR*1 DCTRL-PAR-

Re se rv ed DCTRL-PAR*1 DCTRL-PAR-

Bit 12

(AIF-CTRL.B12)

Bit 13

(AIF-CTRL.B13)

LOAD

LOAD

LOAD

Bit 14

(AIF-CTRL.B1

4)

NSET-TI*1 NSET-TI*2

NSET- JOG*1 NSET-J OG*2

Re se rv ed Re se r ve d

(AIF-CTRL.B15)

6.1.3.3 Status word

Bit Name Meanin g

0 Readytoswitchon Controlle r status information

1 Rea dy for ope ration Controller status information

2 Operation enabled Controller status information

3 Fault Controller status information

4 Voltage inhibite d Information about command “Volta ge inhibit“

5 Qui ck stop Information about command “QUICK STOP“

6 Switch-on inhibit Controller sta tus information

7 Wa r n i n g Collective warning

8 Message Colle ctive messa ge. Automatic se tting a nd rese tting of pulse inhibit in the controller status ”OPERATION ENABLED”. Reasons for

9 Re mo te 82xx, 821x, 822x, 8200 vector: Bus access right depends on Lenze parameter ”Operating mode” (C0001)

10 Setpoint reached Status of spee d/freque ncy devia tion

11 Limit value Status of the DRIVECOM speed limitation

12 Res er ve d 820X, 821X, 822X: Reserved

13 Res er ve d 820X, 821x, 822x: Reserved

14 Manufacturer 820X, 821x, 822x: I max (current limit reached)

15 Manufacturer 820X, 821x, 822x: Q min (f d < dQmin )

0 = Sta tus lowe r than “READYTOSWITCHON“

1 = Status at least “SWITCHED ON“

0 = Sta tus lowe r than “READY F OR OPERATION“

1 = Status at least “READY F OR OPERATION“

0 = Sta tus lowe r than “OPERATION ENABLED“

1=Status“OPERATION ENABLED“

0 = No fault (TRIP))

1 = Fault (TRIP) occured

0 = Comma nd active

1 = Command not active

0 = Comma nd active

1 = Command not active

0 = Sta tus not “SWITCH-ON INHIBIT“

1=Status“SWITCH- ON INHIBIT“

0=Nowarning

1=warning

this can be undervolta ge or overvoltage a s well a s overcurrent (clamp).

0 = No me ssage

1 = Me ssa ge (IMP)

0 = C0001

93 XX:

0=RFGon

1 = RF Gon = RF Gof f

always 0

8200 vector, 93XX: Mapping to bit C0150.B14

8200 vector: Mapping to bit C0150.B15

93XX: Mapping to bit C0150.B3

8200 vector, 93XX: Mapping to bit C0150.B2

8200 vector, 93XX: Mapping to bit C0150.B5

1 = C0001 = 3

≠ RF G o ff

0 = Current limit not reached

1 = Current limit exceeded

0 = Q min not active

1=Qminactive

≠ 3

DOZD\V

BA2112EN

6-17

Page 40

Parameter setting

Show/Hide Bookmarks

6.1.4 Userdefined control profile (C0009= 12)

• Only useful with 93XXand 8200 vector (free configuration possible)

• When using a user-defined control profile, predefined control and status words are not

available.