Page 1

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Contents

5 2111 INTERBUS fieldbus module

5.1 Contents

5.2 General information 5.2-1........................................................

5.3 Technical data 5.3-1............................................................

5.3.1 General data and application conditions 5.3-1................................

5.3.2 Rated data 5.3-1.....................................................

5.3.3 Protocol data 5.3-1...................................................

5.3.4 Communication times 5.3-2.............................................

5.3.5 Dimensions 5.3-4.....................................................

5.4 Installation 5.4-1..............................................................

5.4.1 Components of the fieldbus module 5.4-1...................................

5.4.2 Mechanical installation 5.4-2............................................

5.4.3 Electrical installation 5.4-3.............................................

5.1

5.5 Commissioning 5.5-1...........................................................

5.5.1 Before switching on 5.5-1...............................................

5.5.2 Configuration of the INTERBUS master for communication with the fieldbus module 5.5-1

5.5.3 Start up of the 2111 fieldbus module 5.5-2..................................

5.5.4 Prepare controller for INTERBUS operation 5.5-3..............................

5.5.5 Controller enable via DRIVECOM 5.5-4.....................................

5.5.6 DRIVECOM compatibility 5.5-5...........................................

5.5.7 Special features when using 82XX, 8200 vector and 93XX 5.5-6..................

5.6 Data transfer 5.6-1.............................................................

5.6.1 Process data channel configuration 5.6-3...................................

5.6.2 Process data signals of Lenze controllers 5.6-7...............................

5.6.3 Process data preconfiguration depending on L-C0009 5.6-24......................

5.6.4 Examples for the configuration of PI/PO data 5.6-26............................

5.6.5 Device control 5.6-28..................................................

5.6.6 DRIVECOM control 5.6-30................................................

5.6.7 DRIVECOM profile parameters 5.6-33.......................................

5.6.8 Configuration of the parameter data channel (PCP communication) 5.6-47............

5.7 Troubleshooting 5.7-1...........................................................

5.7.1 Controller is inhibited 5.7-1.............................................

5.7.2 Check INTERBUS 5.7-3.................................................

5.7.3 Reset error (TRIP) 5.7-4................................................

5.7.4 DRIVECOM error codes 5.7-5............................................

L

5.8 Appendix 5.8-1...............................................................

5.8.1 Code table 5.8-1......................................................

5.9 Index 5.9-1..................................................................

EDSIBS-1.0-06/ 2003

5.1-1

Page 2

Show/Hide Bookmarks

Page 3

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

General information

5.2 General information

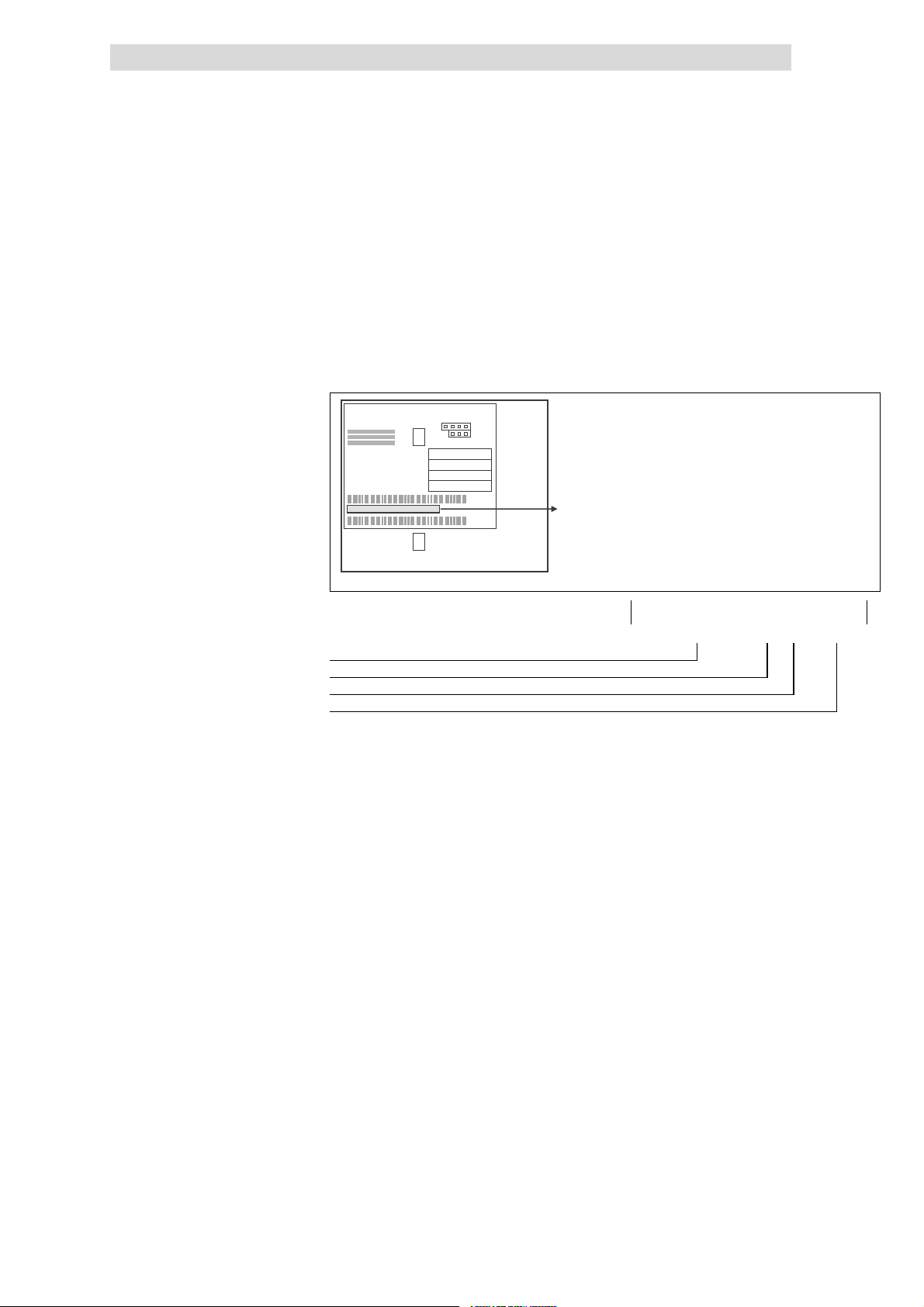

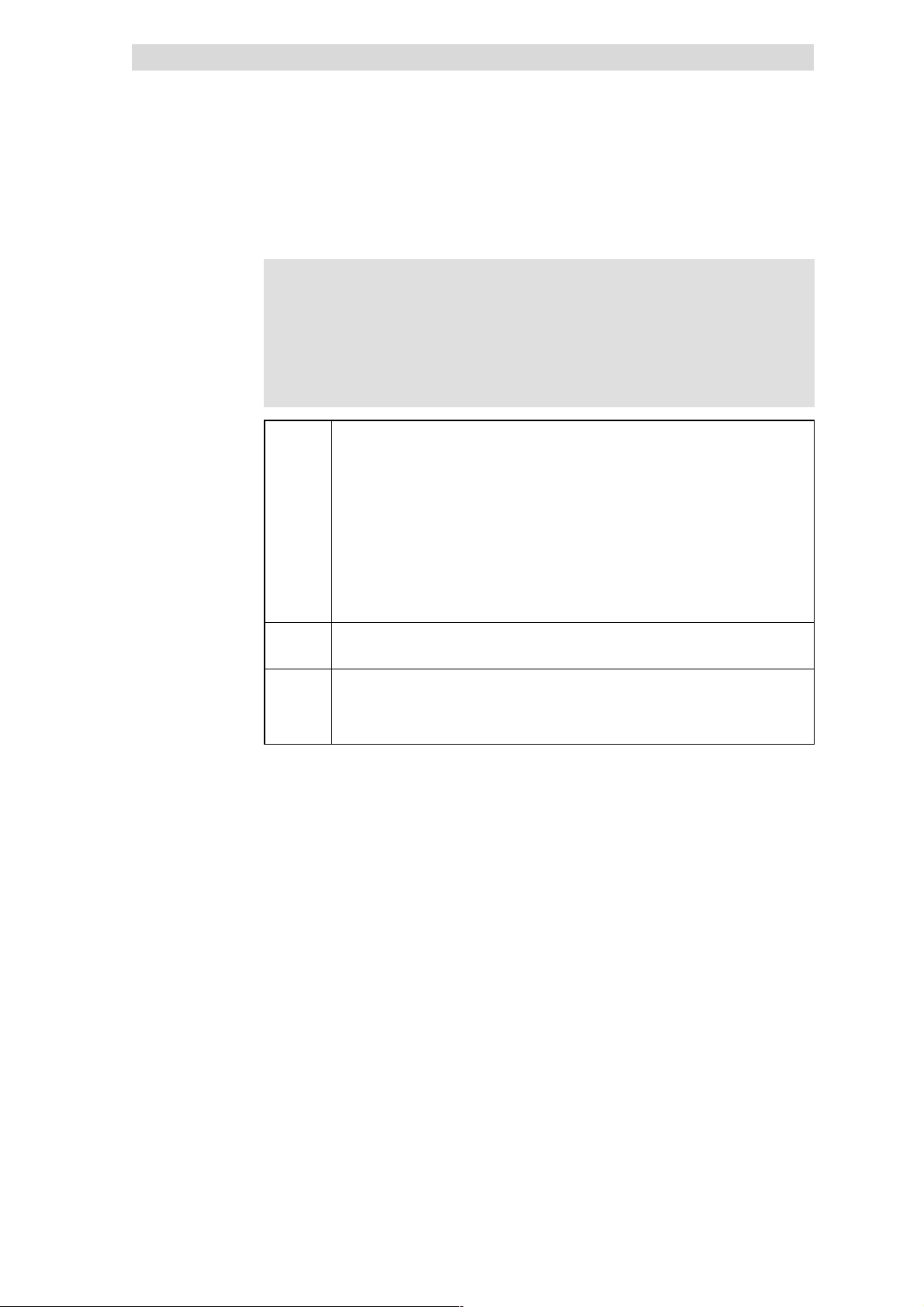

Validity of the Instructions 1

Identification

These Instructions are only valid

l for fieldbus modules as of nameplate data 2111IB.2x.4x.

l only together with the documentation for the basic devices permitted for

the application.

L

Type

Id.-No.

Prod.-No.

Ser.-No.

E82AF000P0B201XX

5.2

Type code 33.2111IB 2x 4x

Type series INTERBUS

Hardware version

Software version

Variant

29 9371BC013

L

EDSIBS-1.0-06/ 2003

5.2-1

Page 4

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.2

Application range

General information

The fieldbus module can be used together with devices with the following

nameplate data:

820X E./C. 2x. 1x. Vxxx (8201 - 8204)

821X E./C. 2x. 2x. Vxxx (8211 - 8218)

822X E. 1x. 1x. Vxxx (8221 - 8227)

824X E./C. 1x. 1x. Vxxx (8241 - 8246)

82EVxxxxxBxxxXX Vx 13 (8200 vector)

82CVxxxxxBxxxXX Vx 13 (8200 vector, Cold plate)

EPL 10200 I./T. 1x 1x (Drive PLC)

93XX Ex/Cx 2x 1x (9321 - 9332)

93XX E.C. I./T. 2x 1x (Servo PLC 9300)

Type

Design:

Ex = Built-in unit IP20

Cx = Cold plate

I=ServoPLC

xK = Cam profiler

xP = Positioning controller

xR = Register controller

xS = Servo inverter

Features

Hardware version

Software version

Variant

Explanation

The 2111 INTERBUS fieldbus module is an attachable intelligent additional

module with a 16-bit micro-processor.

The 2111 INTERBUS fieldbus module enables the following:

l Communication of 82XX, 8200 vector, 93XX controllers and 9300 servo PLC

via INTERBUS.

l Communication of 82XX, 8200 vector, 93XX controllers and 9300 servo PLC

via INTERBUS.

l Communication of Lenze Drive PLCs via INTERBUS.

l Bus connection via remote bus according to standard RS485.

l Access to all Lenze parameters.

l Access to standardised parameters and functions according to the

DRIVECOM drive profile 21 or AIF-CTRL device control.

5.2-2

EDSIBS-1.0-06/ 2003

L

Page 5

2111 INTERBUS fieldbus module

Baud

00kBit/

Show/Hide Bookmarks

5

Technical data

General data and application conditions

5.3 Technical data

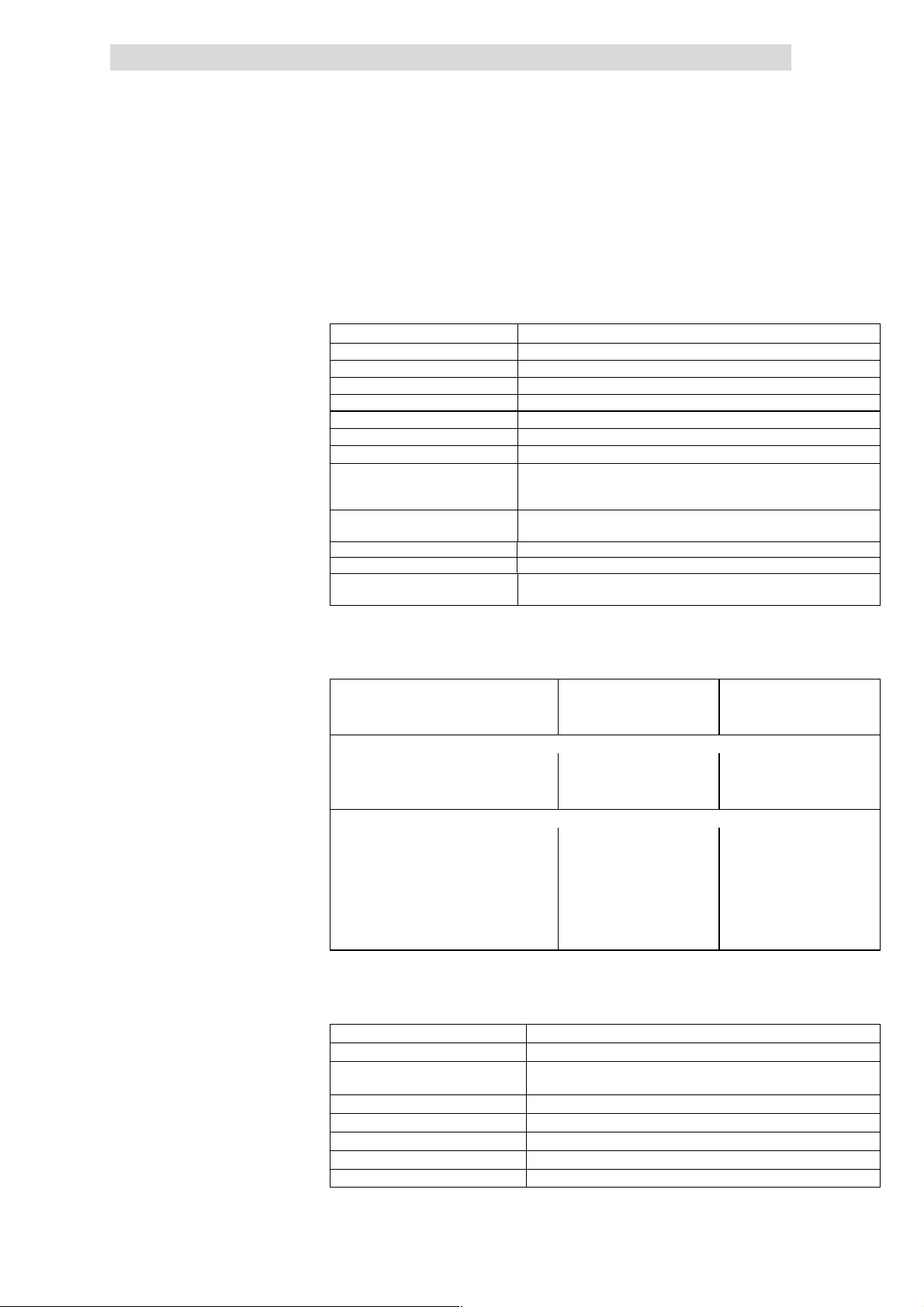

5.3.1 General data and application conditions

Field Values

Order number EMF 2111IB

Communication media RS485

Network topology Ring

INTERBUS participant Slave

Communication profile PCP 1.5

Drive profile DRIVECOM profile 21

rate 5

Ambient temperature during operation:

Permissible humidity Class 3K3 to EN 50178

Degree of pollution VDE0110, part 2, pollution degree 2

Enclosure IP 20

Voltage supply (internal / external),

^ 5.4-5

see

during transport:

during storage

(without condensation, average relative humidity 85%)

External supply via separate power supply unit

(+24 V DC ±10 %, ma x. 150 mA)

5.3

5.3.1

s

-25

-25

0 °C

°C

°C

to

to

to

55 °C

70 °C

60 °C

5.3.2 Rated data

5.3.3 Protocol data

Insulation voltage between bus and ... Rated insulation voltage Type of insulation

• Earth reference / PE 50 V AC Mains isolation

• External supply (terminal 39/59) 0VAC No mains isolation

• Power stage

– 820X / 821X 270 V AC Basic insulation

– 822X / 8200 vector 270 V AC Double insulation

– 93XX 270 V AC Double insulation

• Control terminals

– 820X / 8200 vector

(with internal supply)

– 8200 vector

(with external supply)

– 821X 50 V AC Mains isolation

– 822X 270 V AC Basic insulation

– 93XX 270 V AC Basic insulation

Field Values

Maximum number of participants 62

Process data words (PD) L-C1910 = 4: 2 words (32 bit)

Parameter data words (PCP) 1(16bit)

Maximum number of data words The maximum number of data words (PD + PCP) is 4.

INTERBUS ID (module ID) 227

Maximum PDU length 64 byte

Supported PCP services Initiate, abort, status, identify, Get-0V-long, read, write

0VAC No mains isolation

100 V AC Basic insulation

L-C1910 = 6: 3 words (48 bit)

=E3

dec

hex

à Lenze setting

PCP 1 word

L

EDSIBS-1.0-06/ 2003

5.3-1

Page 6

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.3

5.3.4

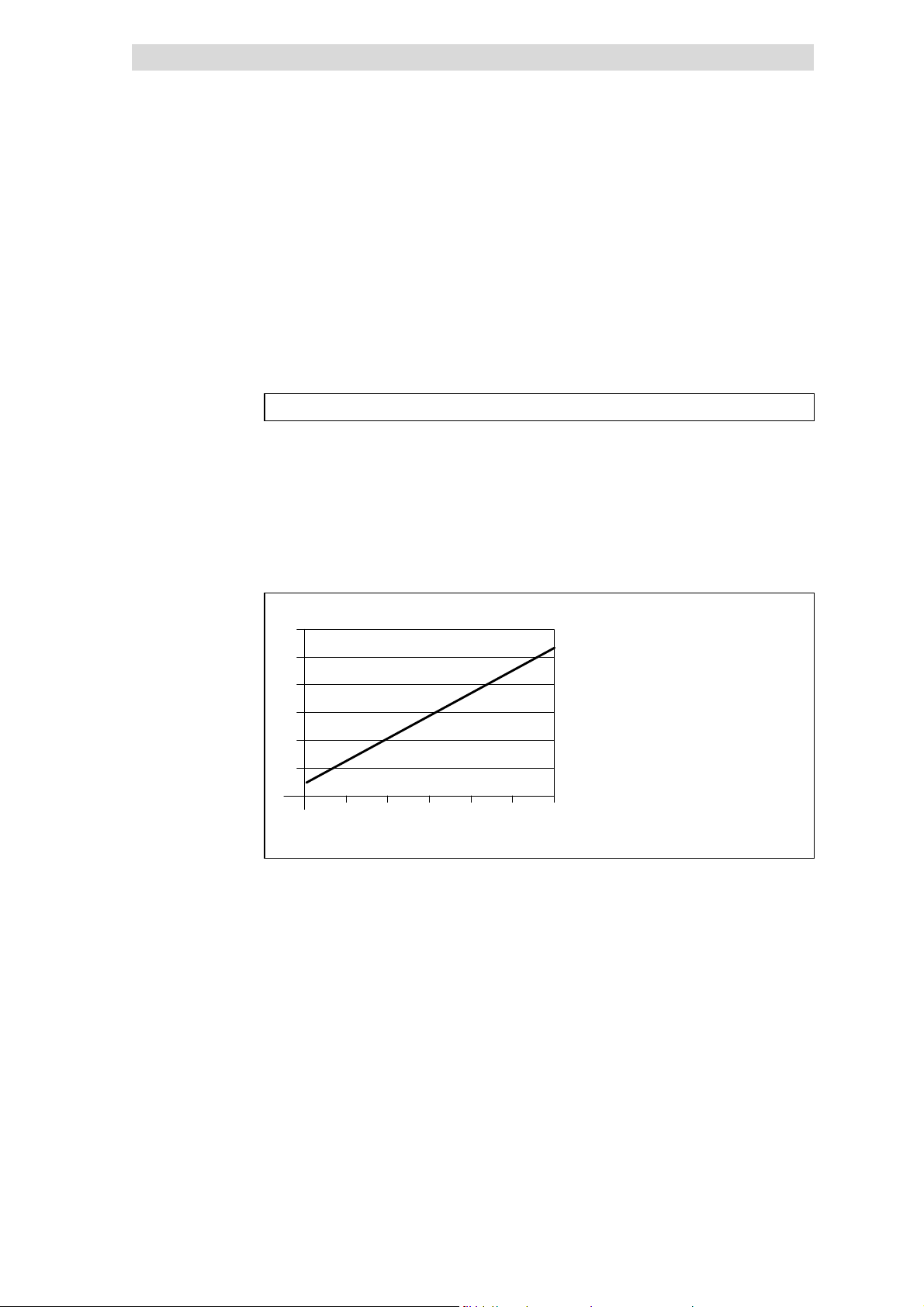

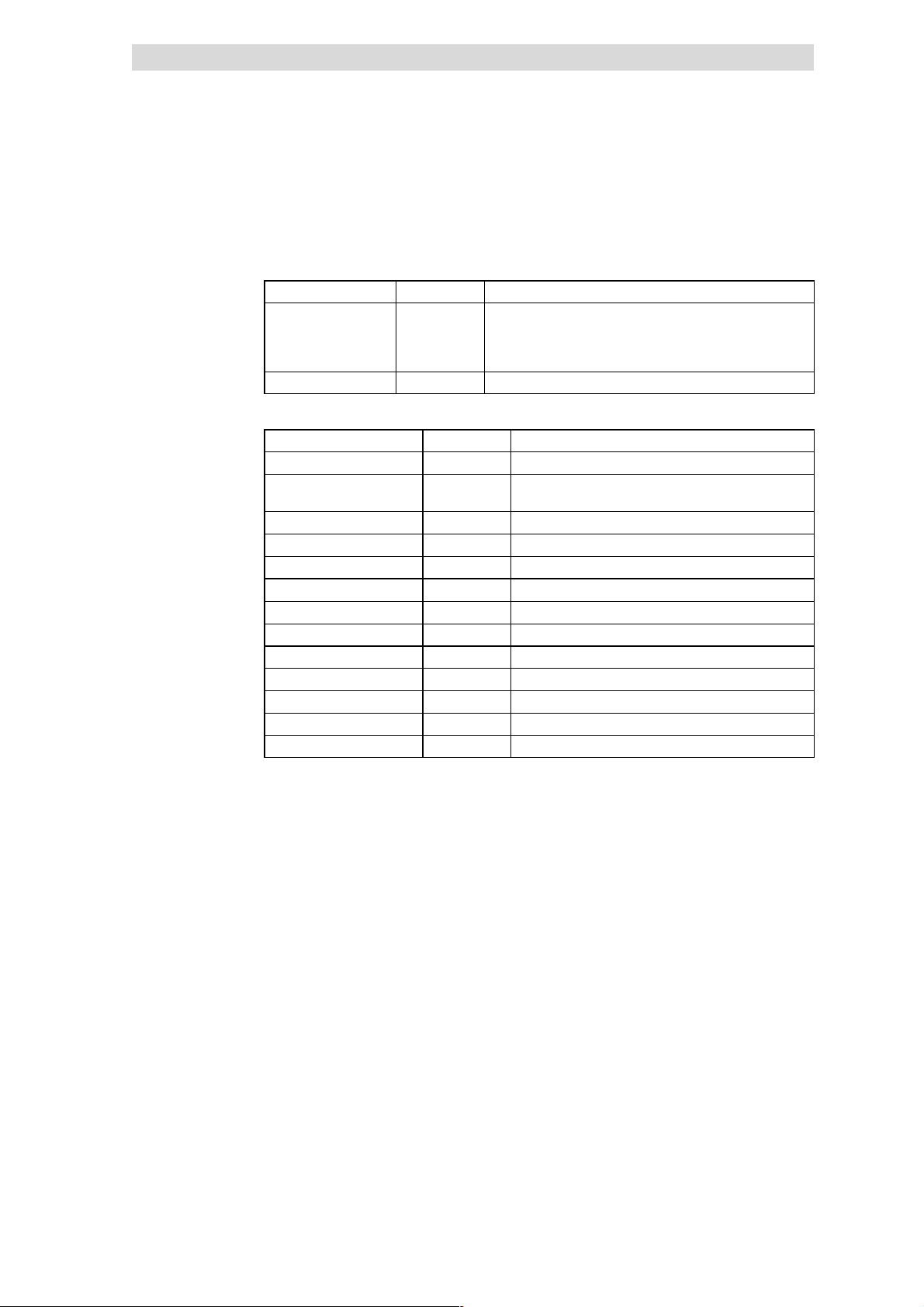

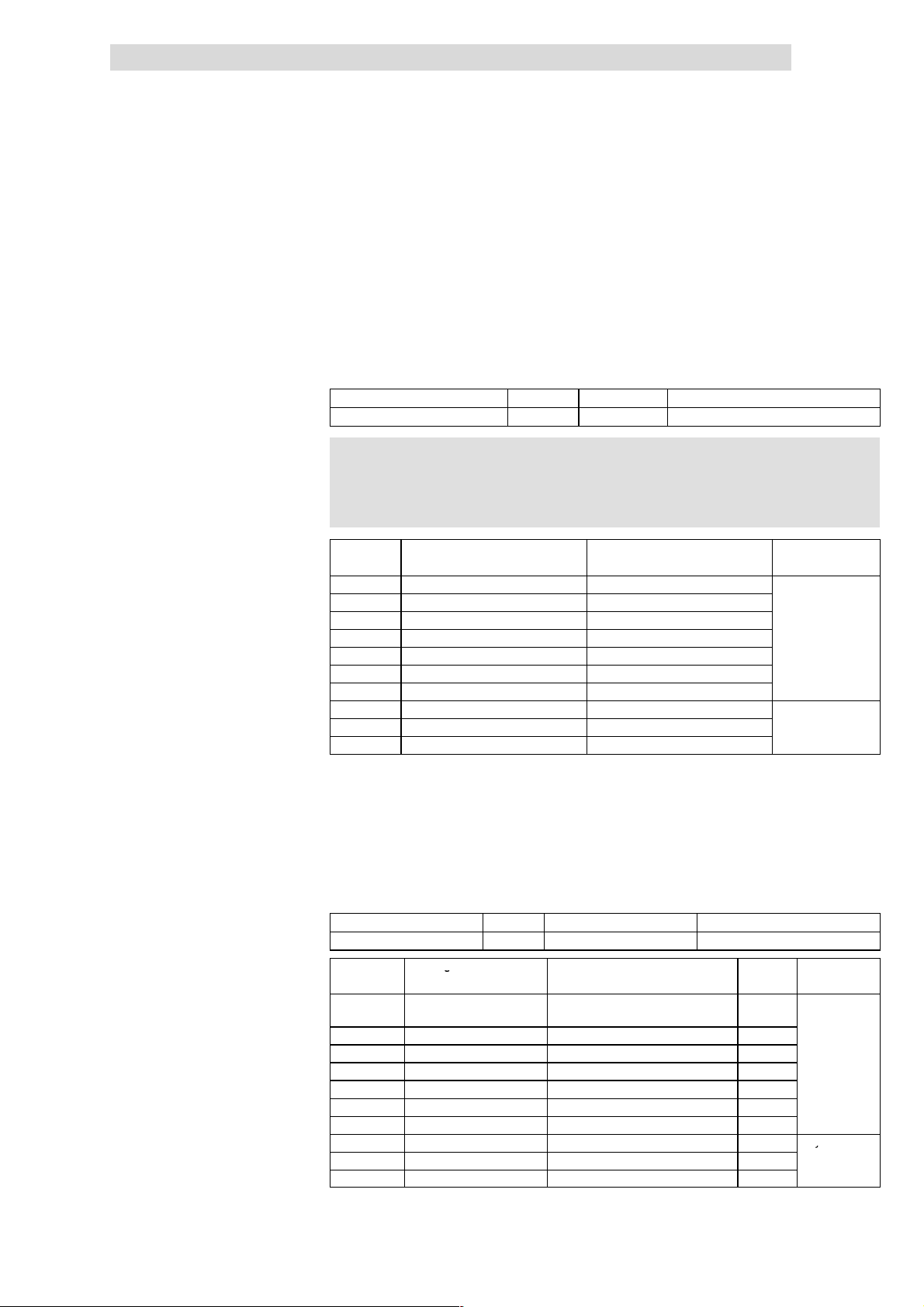

5.3.4 Communication times

5.3.4.1 Cycle time

The cycle time of a communication system is the time needed to exchange all

process data

to the bus.

It depends on the communication system data and is calculated as follows

(example: baud rate of 500 kbit/s):

í

= Eå + QU + P × _hF × PKPR × NM−P+ MKOQ × i + MKO

ÅóÅä

Fig. 5.3-1 is shows the ratio between cycle time and number of connected

controllers.

The indicated values refer to the connection of Lenze controllers (e. g. 2XX) with

48 data bits (1 parameter data word + 2 process data words, see

Technical data

Communication times

(¶ 5.6-6) between the INTERBUSmaster and the devices connected

t

cycl

n Sum of all data b it in the INTERBUS ring

BT Number of b us terminals

L Length of remote bus cable in [km]

Cycletimein[ms]

(¶ 5.3-1).

Cycletime[ms]

NO

NM

U

S

Q

O

N

NM

Number of devices connected to the bus

Fig. 5.3-1 INTERBUS cycle time for controllers

OM

PM QM

RM SM

5.3-2

EDSIBS-1.0-06/ 2003

L

Page 7

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Technical data

Communication times

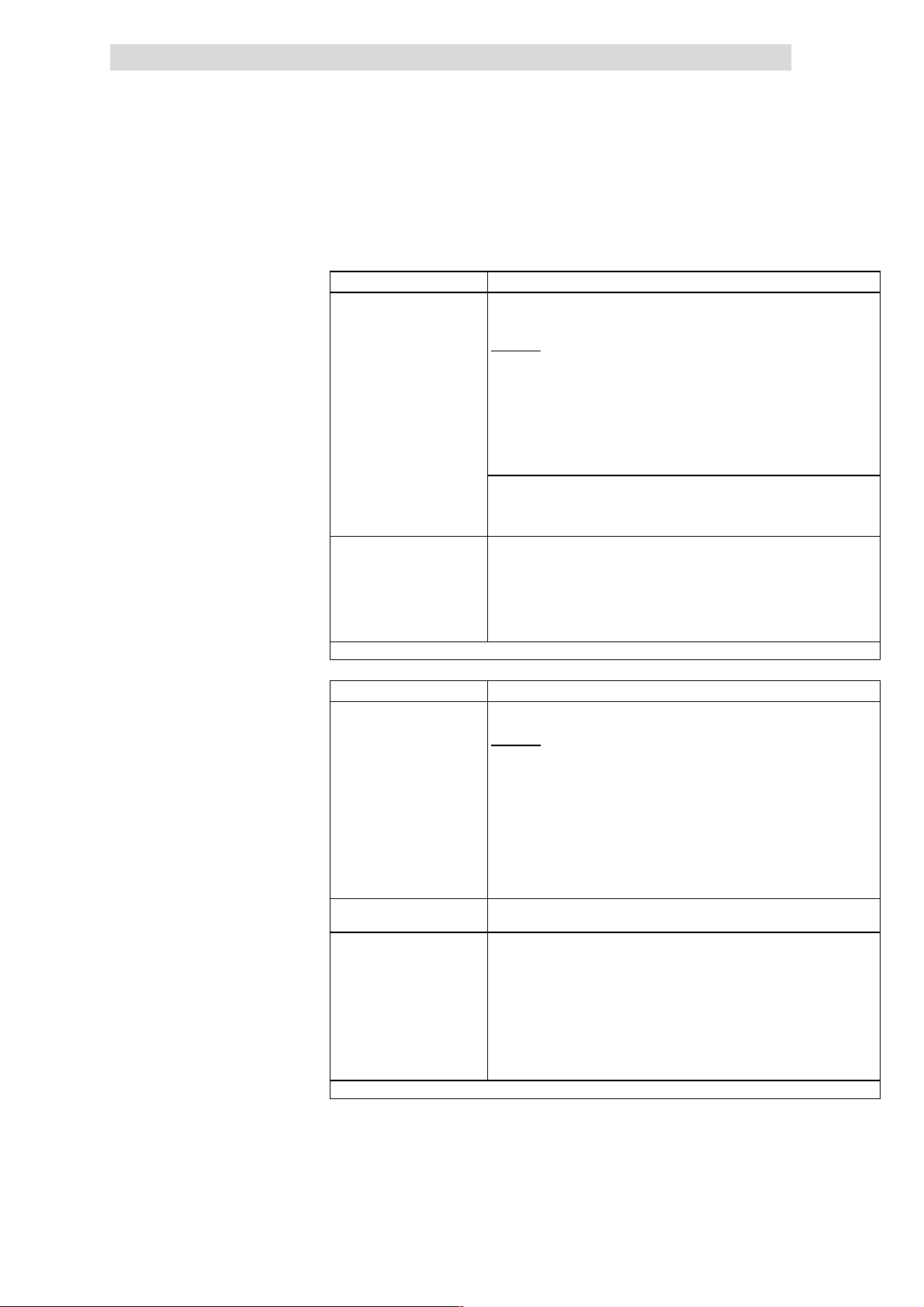

5.3.4.2 Processing time in the controller

The processing time of the controller is added to the INTERBUS cycle time.

The processing time of the controller depends on the series and version:

Processing t ime 820X

For the 820X series several processing steps are required. These steps are

processed cyclically.

A processing cycle consists of:

l Writing of c ontrol word or setpoint, if the value has changed

l Alternating reading of status word and actual value

l Processing of PCP parameter access, if there is a service.

)

) Note!

))

A change of the setpoint signal results in writing the control word.

5.3

5.3.4

Processing t ime 821X /

8200 vector / 822X

If the time tolerances caused by cyclic reading of the status word/ actual value are

too large, the alternating reading of the status word and the actual value can be

suppressed. This is controlled by bit 15 (PE inhibit) of the DRIVECOM control

(¶ 5.6-35).

word:

A suppression of the processing of parameter access is not necessary, since this

is controlled by the user.

In the following table you will find a list of the processing times:

Processing step Max. processing time

Parameter 70 -8 Setpoint 35 -8 180

Control word 35 -8 180

Actual value 35 -8 180

Status word 35 -8 180

Setpoint + control word 70 -16 180

Setpoint + control word + actual

value + status word

The parameter data (transmission via PCP channel) and process data are

independent of each other.

l Parameter data (PCP): approx. 30 ms + 20 ms tolerance

l Process data (PD): approx. 3 ms + 2 ms tolerance

[ms]

140 -32 180

Processing tolerance

[ms]

Additional parameter

[ms]

Processing t ime 9300 servo

inverter

Processing t ime Drive PLC / 9300

Servo PLC

L

The parameter data (transmission via PCP channel) and process data are

independent of each other.

l Parameter data (PCP): approx. 30 ms + 20 ms tolerance

l Process data (PD): approx. 2 ms + 1 ms tolerance

l Parameter data (PCP): 30 ms + 20 ms tolerance

l Process data (PD): depending on process image

EDSIBS-1.0-06/ 2003

5.3-3

Page 8

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.3

5.3.5

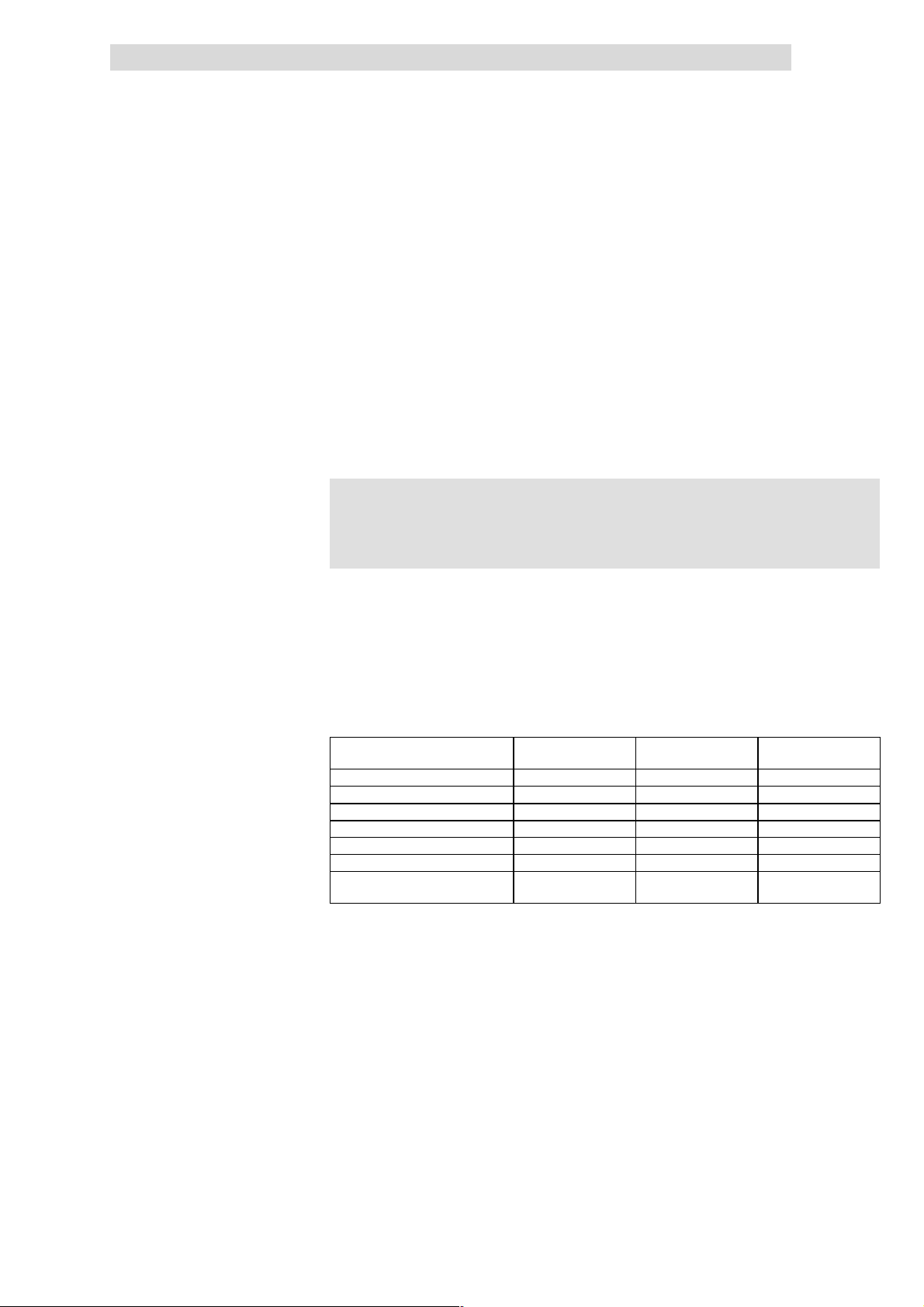

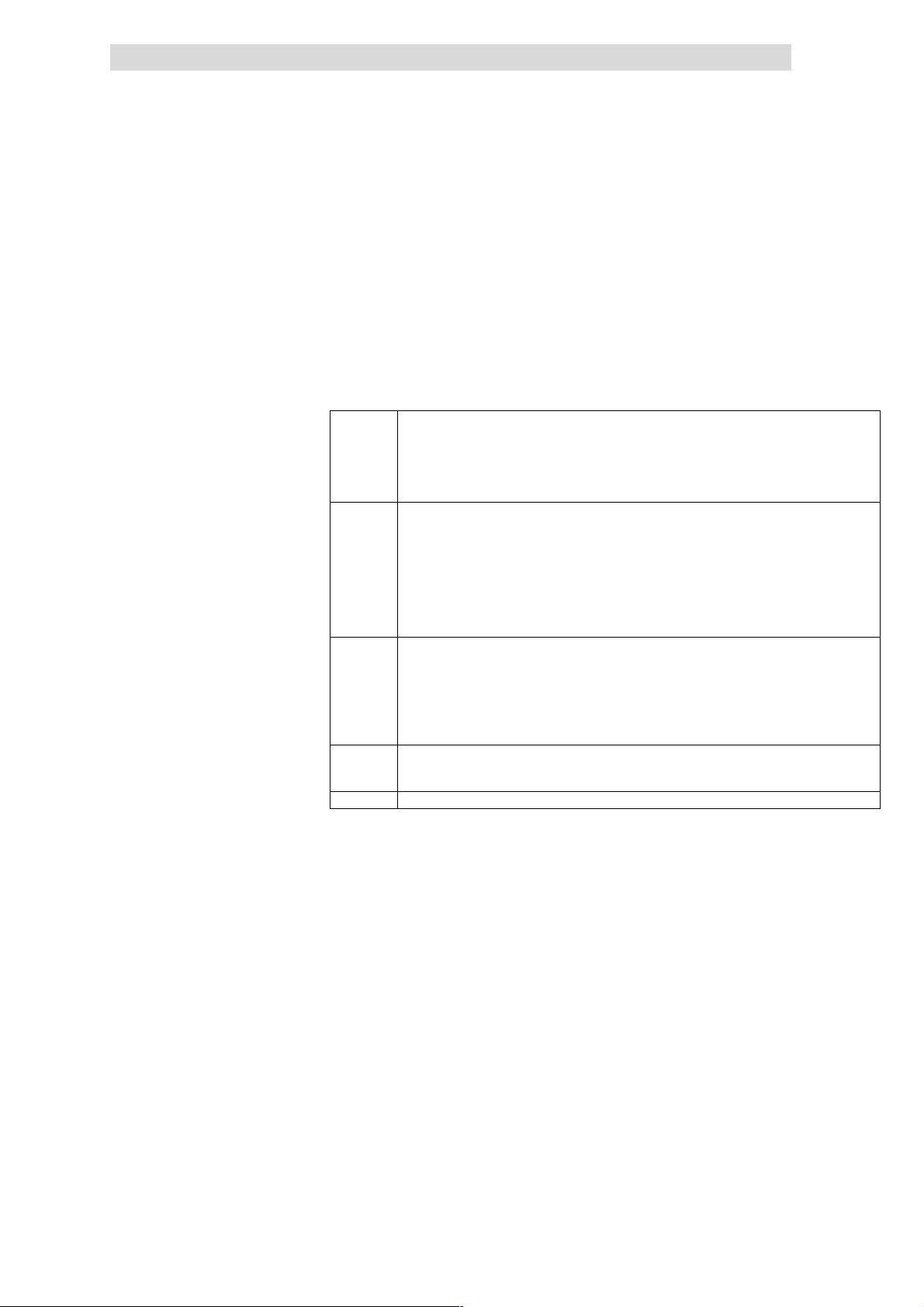

5.3.5 Dimensions

DRIVE

BUS

b

24V DC

+

a61mm

b75mm

e28mm

e1 18 mm

L

INTERBUS S

IN

OUT

_

2111

a

18

Technical data

Dimensions

e1

e

2111IBU005

5.3-4

EDSIBS-1.0-06/ 2003

L

Page 9

2111 INTERBUS fieldbus module

0

1

Show/Hide Bookmarks

5

Installation

Components of the fieldbus module

5.4 Installation

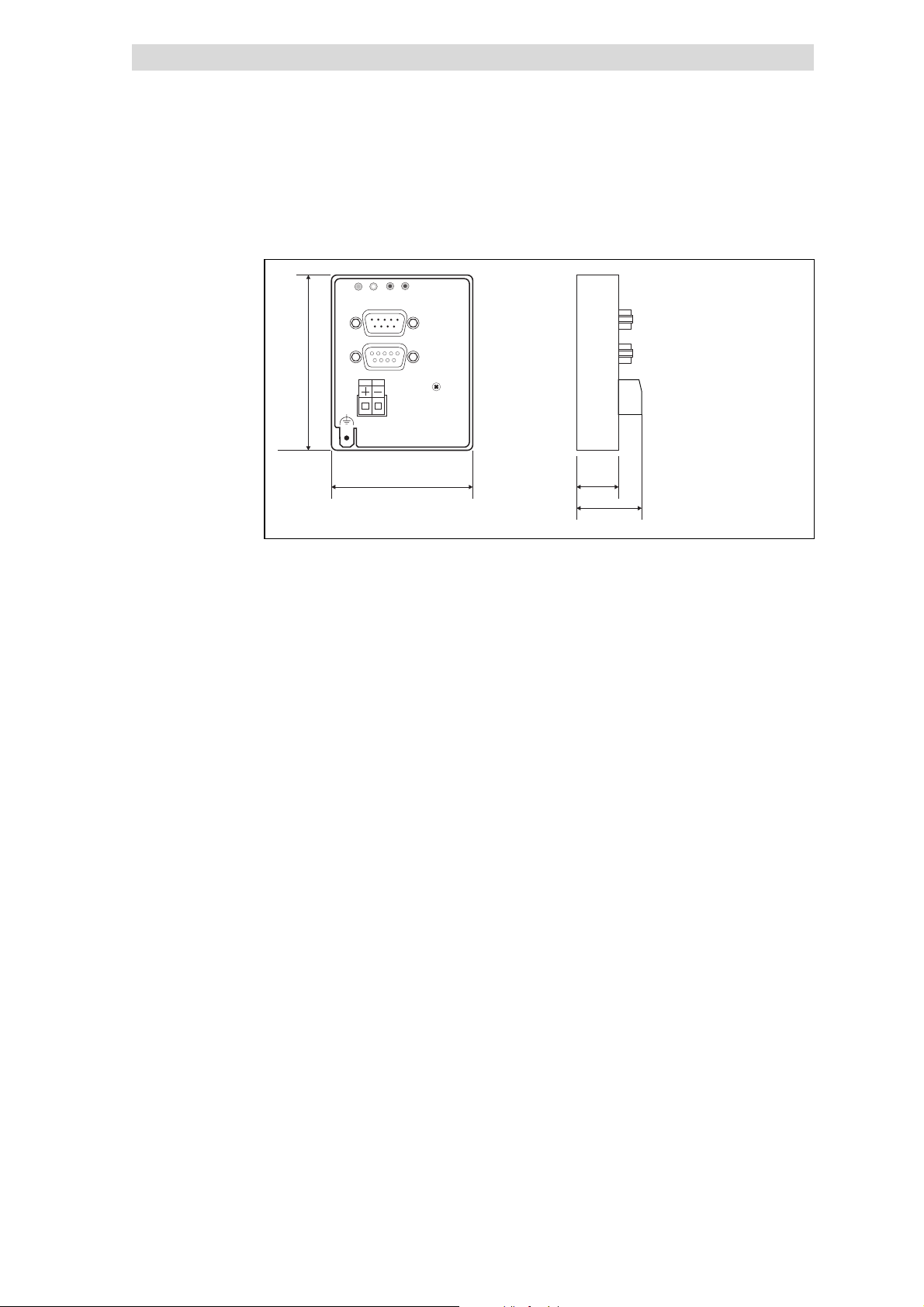

5.4.1 Components of the fieldbus module

2

1

0

DRIVE

BUS

L

INTERBUS S

IN

3

4

5

24V DC

+

_

OUT

6

Fig. 5.4-1 Components of the fieldb us module

5.4

5.4.1

7

2111

2111IBU004

Pos LED statu s Explanation 3

0

1

2

3

4

5

6

7

Green bus LED (voltage supply)

ON The fieldbus module is supplied with voltage and is connected to the drive controller.

OFF The fieldbus module is not supplied with voltage. The drive controller or external

voltage supply is switched off.

BLINKING The fieldbus module is supplied with voltage, but it is not connected to the drive

controller, because

• the fieldbus module was not plugged on the drive controller correctly

• the data transfer of/to the drive controller is not possible (e. g. the drive controller

is in the initialisation phase).

Yellow bus LED (communication)

ON Fieldbus module is initialised,

inactive INTERBUS communication of the master

OFF Fieldbus module is not initialised yet

BLINKING Active INTERBUS communication

• SLOW (1 Hz): process data and PCP communication.

• FAST (4 Hz): only process data

Red and green drive LED indicate the operating mode of the drive controller 82XX or 93XX (see the

Operating Instructions of the drive controller)

INTERBUS input (IN), Sub-D plug connector, 9-pole

INTERBUS output (OUT), Sub-D socket connector, 9-pole

Plug connector, connection for external voltage supply

PE connection

Fixing screw

^ 5.4-6

^ 5.4-7

^ 5.4-5

see note

L

)

) Note!

))

Only for 820X and 821X: If required use an additional PE screen

cable which avoids EMC-related communication interference in

surroundings with interferences.

EDSIBS-1.0-06/ 2003

5.4-1

Page 10

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.4

5.4.2

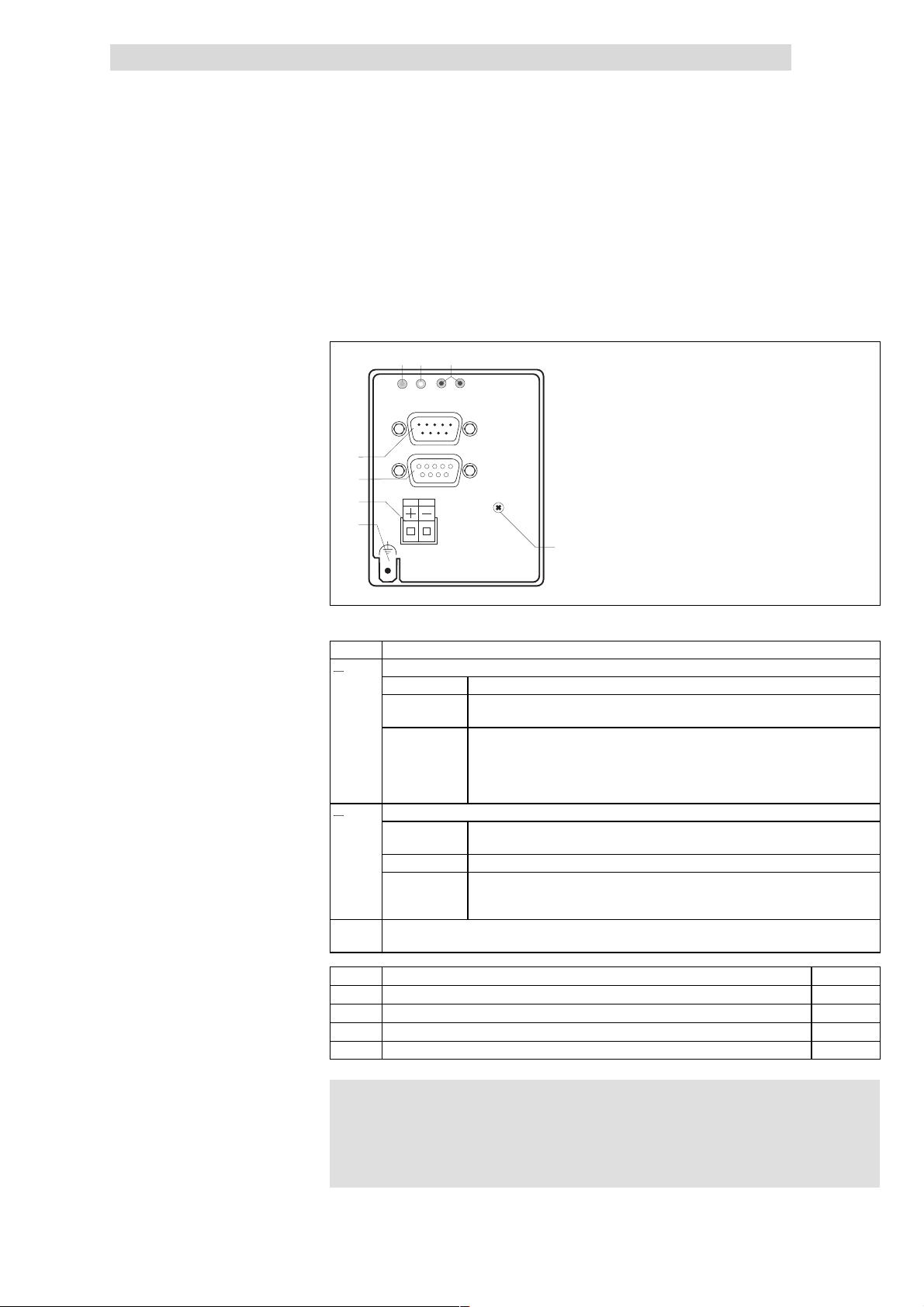

5.4.2 Mechanical installation

l Plug the fieldbus module onto the basic device (here: 8200 vector).

l Fasten the fieldbus module with the fixing screw onto the basic device to

ensure a good PE connection.

Installation

Mechanical installation

4 2102LEC014

)

) Note!

))

For the internal supply of the fieldbus module through the 8200

vector frequency inverter the interface of the jumper must be

adapted (see illustration above). Please observe the notes

^ 5.4-5.

5.4-2

EDSIBS-1.0-06/ 2003

L

Page 11

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Installation

Electrical installation

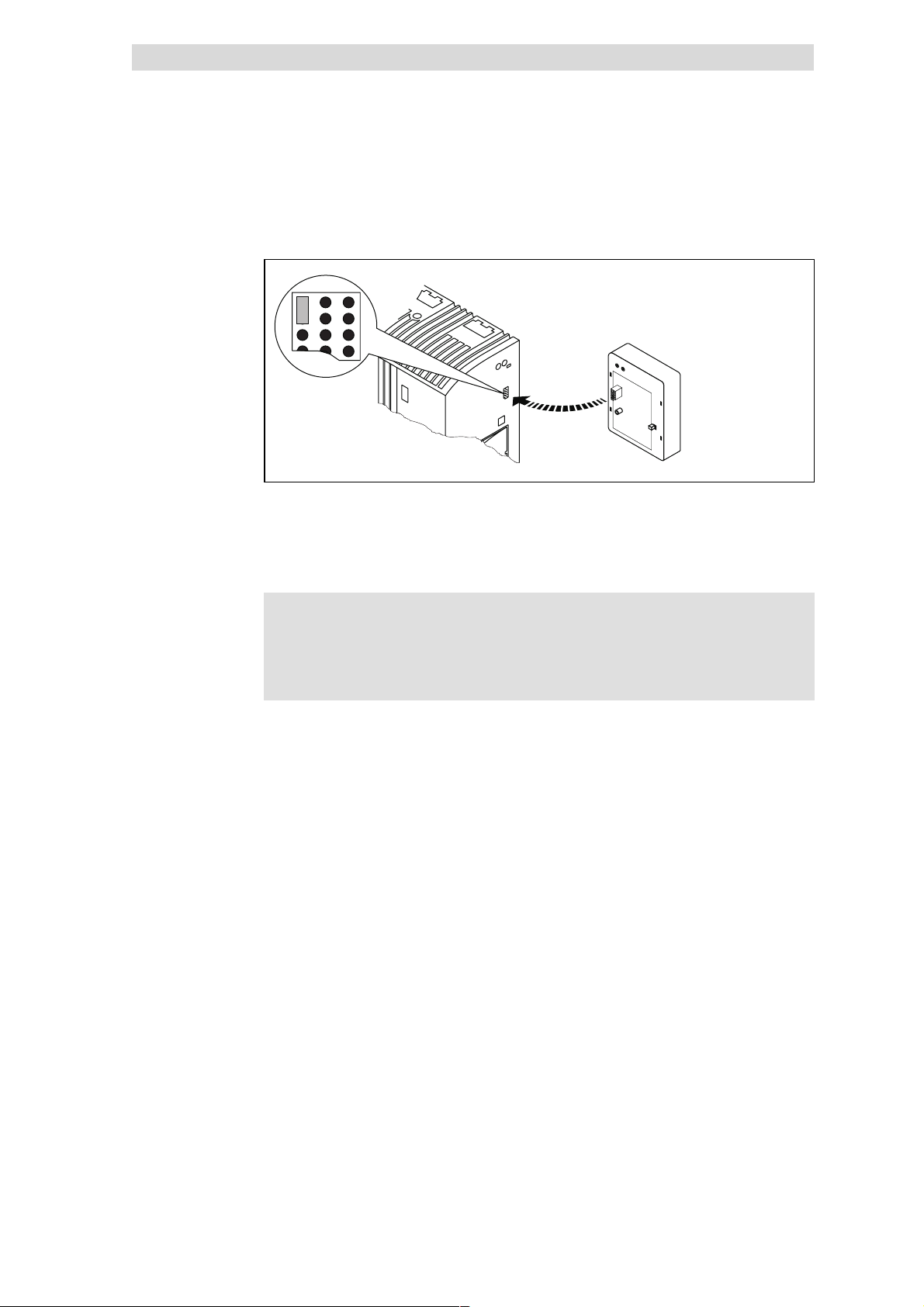

5.4.3 Electrical installation

Wiring to the INTERBUS master

)

) Note!

))

l The bus system must be designed as a ring.

l Go-and-return lines are both in the same bus cable.

l The ring connec ts the INTERBUS master with all devices connected to the

bus.

5.4

5.4.3

An additional mains isolation is required, if

l a 820X or 821X is connected to an INTERBUS master and

l a safe mains isolation (double basic insulation) is required

according to VDE 0160.

Use e.g. a bus terminal or an interface module for the INTERBUS

master with an additional mains isolation (see the corresponding

information of the manufacturer).

L

EDSIBS-1.0-06/ 2003

5.4-3

Page 12

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.4

5.4.3

Wiring example

Installation

Electrical installation

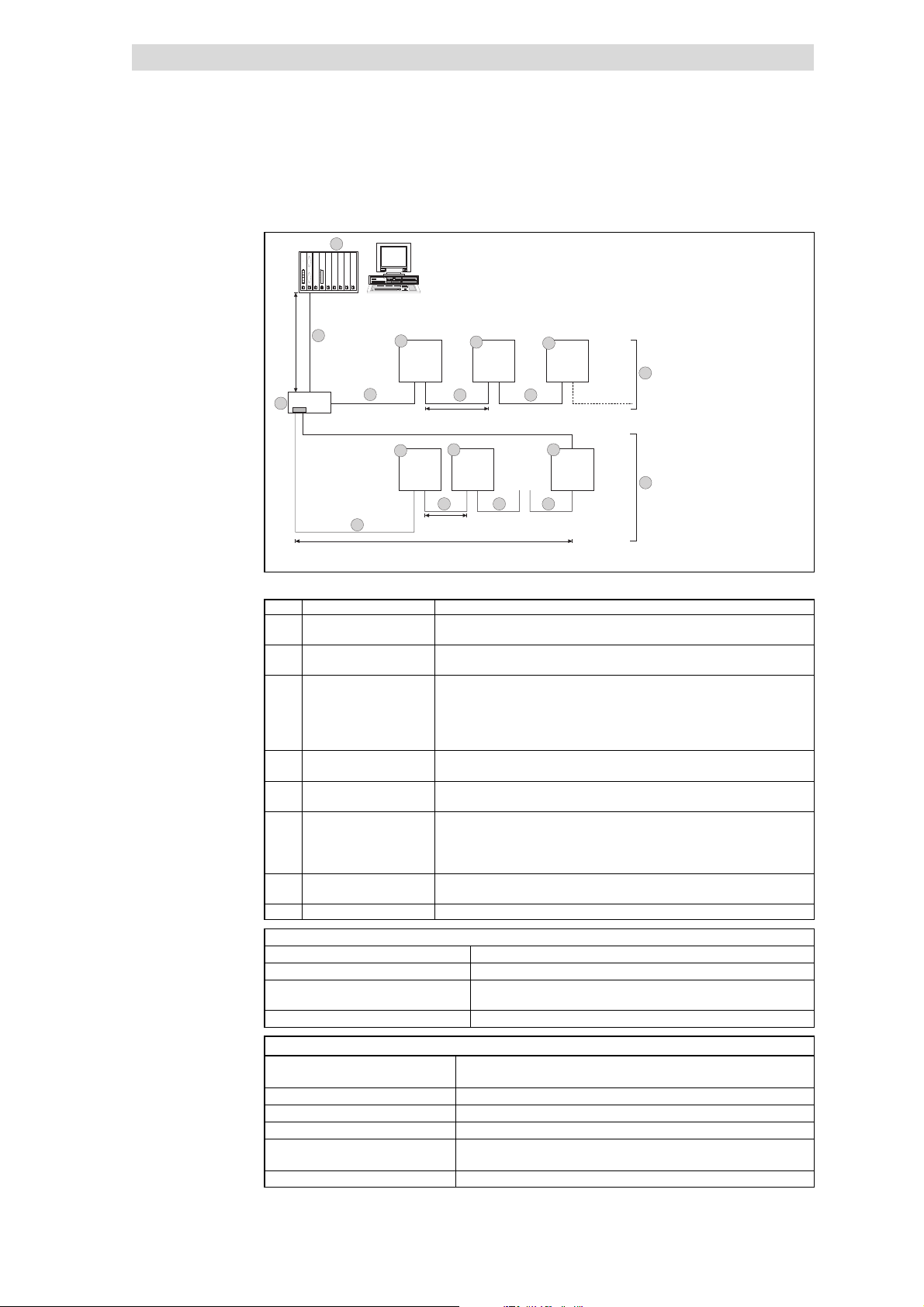

1

3.2

400 m

2

Fig. 5.4-2 Wiring examp le, INTERBUS (baud rate 500 kb it/ s)

Pos. Element Explanation

1 INTERBUS master with

interface module

2 INTERBUS loop bus

terminal

3 Remote bus

Fig. 5.4-2 Pos. 3

3.1 Long distance bus module Bus participant in the long distance bus; e.g. Lenze controller with INTERBUS

3.2 Remote bus cable Connects the INTERBUS master interface module with the bus terminal and/or

4 INTERBUS loop, peripheral

bus

Fig. 5.4-2 Pos. 4

4.1 INTERBUS loop module Bus participant in the INTERBUS loop; e.g. Lenze controller with INTERBUS loop

4.2 INTERBUS loop cable Connection within the loop

Features:

Communication medium RS485

Network topology Ring

Maximum number of controllers 62

4.2

3.2

INTERBUS-Loop 100 m

3.1

8200 vector

+

2111

4.1

82XX

+

2112

3.1

400 m

93XX

+

2112

4.2 4.24.2

10 m

93XX

2111

3.1

3.23.2

82XX

+

2111

4.14.1

8200 vector

+

2112

3

4

+

The bus system is a master-slave system, i.e. an INTERBUS master is connected

to several field devices (slaves).

The bus terminal connects a long distance bus to a peripheral bus.

The following connections are possible with remote buses:

• the INTERBUS master interface module and first bus terminal or first 2111

fieldbus module.

• the bus terminal and the 2111 fieldbus module

• two 2111 fieldbus modules

module (slave). Networking does not require bus terminals.

the long distance bus modules.

Connection in a peripheral-bus station

A peripheral-bus station consists of:

• a bus terminal (Fig. 5.4-2 pos. 2)

• up to eight peripheral bus modules (Fig. 5.4-2 pos. 3)

module 2112

2111IBU001

5.4-4

Baud rate / cable length 500 kbit/s / 400 m

Specification of INTERBUS remote bus cable 5

Cable type Yard goods:

IBS RBC Meter-T, order No. 28 06 28 6 (Fa. Phoenix Contact)

Number of conductors 3 x 2, paired with common shielding

Conductor cross-section >0.2mm

2

DC cable resistance <96Ω/km

Impedance, characteristic 120 Ω±20 % (f = 64 kHz)

Ω±15 Ω (f > 1 MHz)

100

Capacitance per unit length < 60 nF/km (f = 800 Hz)

EDSIBS-1.0-06/ 2003

L

Page 13

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Installation

Electrical installation

External DC voltage supply 6

Connection terminals 7

5.4.3

If necessary, supply the 2111 fieldbus module with a separate supply voltage

24 V DC via the two-pole plug connector ±10 %.

Plug connector Name Explanation

+ Vcc24 External supply 24 V DC ± 10 %, 150 mA

- GND24 Reference potential for external voltage supply

Use a separate power supply unit in each control cabinet.

Controller External voltage supply

820X Always required

821X / 822X / 824X and

93XX

8200 vector See information in “internal DC voltage supply”

Electrical connection Plug connector with threaded terminal end

Possible connections

Tightening torque 0.5 ... 0.6 Nm (4.4 ... 5.3 lb-in)

Bare end 6mm

Only necessary if the mains which supply the corresponding controllers is to be switched

off but the communication must not be interrupted.

rigid: 1.5 mm2(AWG 16)

flexible:

without wire crimp cap

2

(AWG 16)

1.5 mm

with wire crimp cap, without plastic sleeve

2

(AWG 16)

1.5 mm

with wire crimp cap, with plastic sleeve

2

(AWG 16)

1.5 mm

5.4

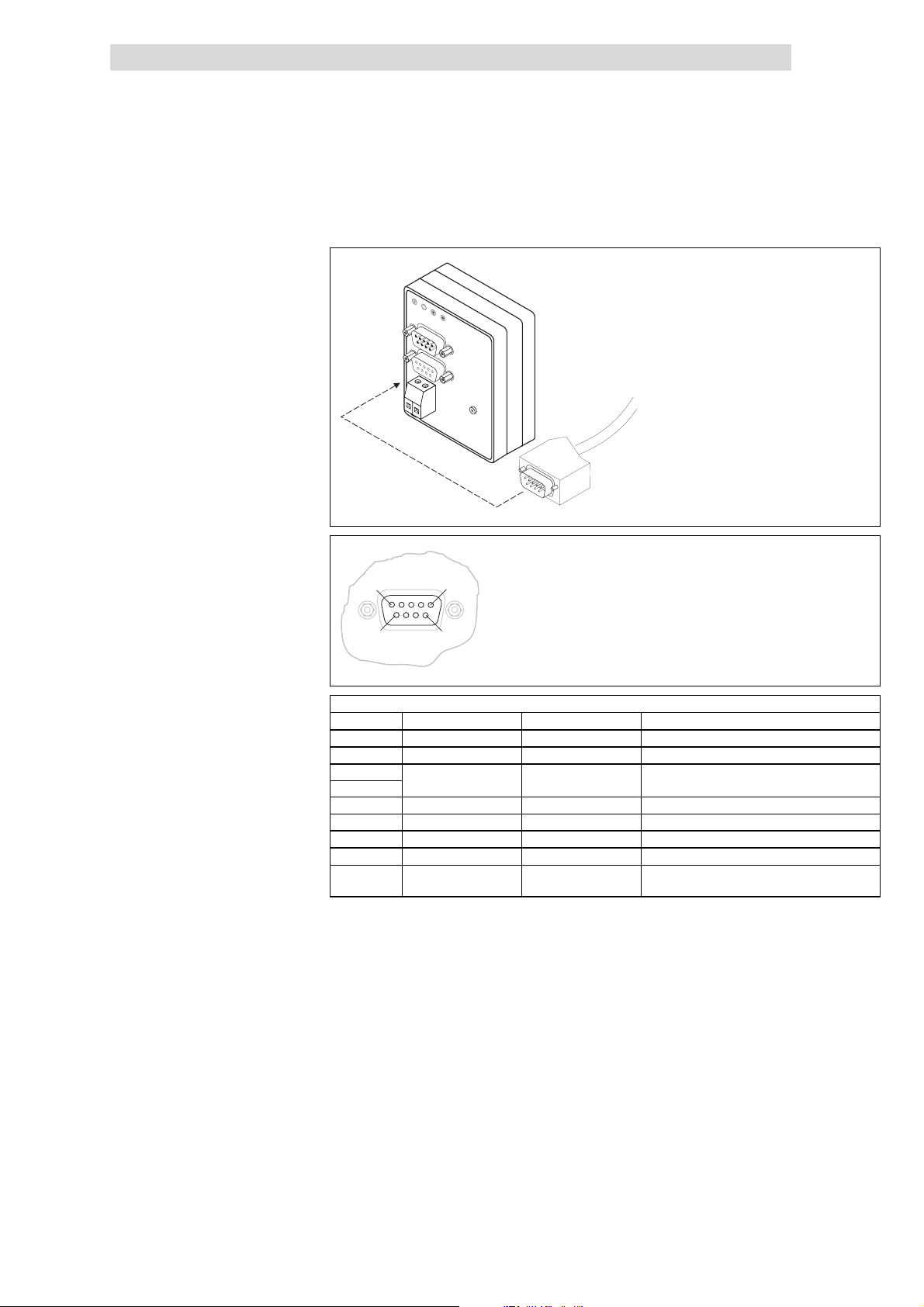

Internal DC voltage supply 8

)

) Note!

))

Basic devices with extended AIF interface opening (8200 vector

front) can be internally supplied. The part of the drawing

highlighted in grey shows the jumper position.

l In the delivery state of the frequency inverter these are not

internally supplied.

l For internal voltage supply, put the jumper in the position

indicated below.

only external voltage supply

Lenze setting

Internal voltage supply

L

EDSIBS-1.0-06/ 2003

5.4-5

Page 14

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.4

5.4.3

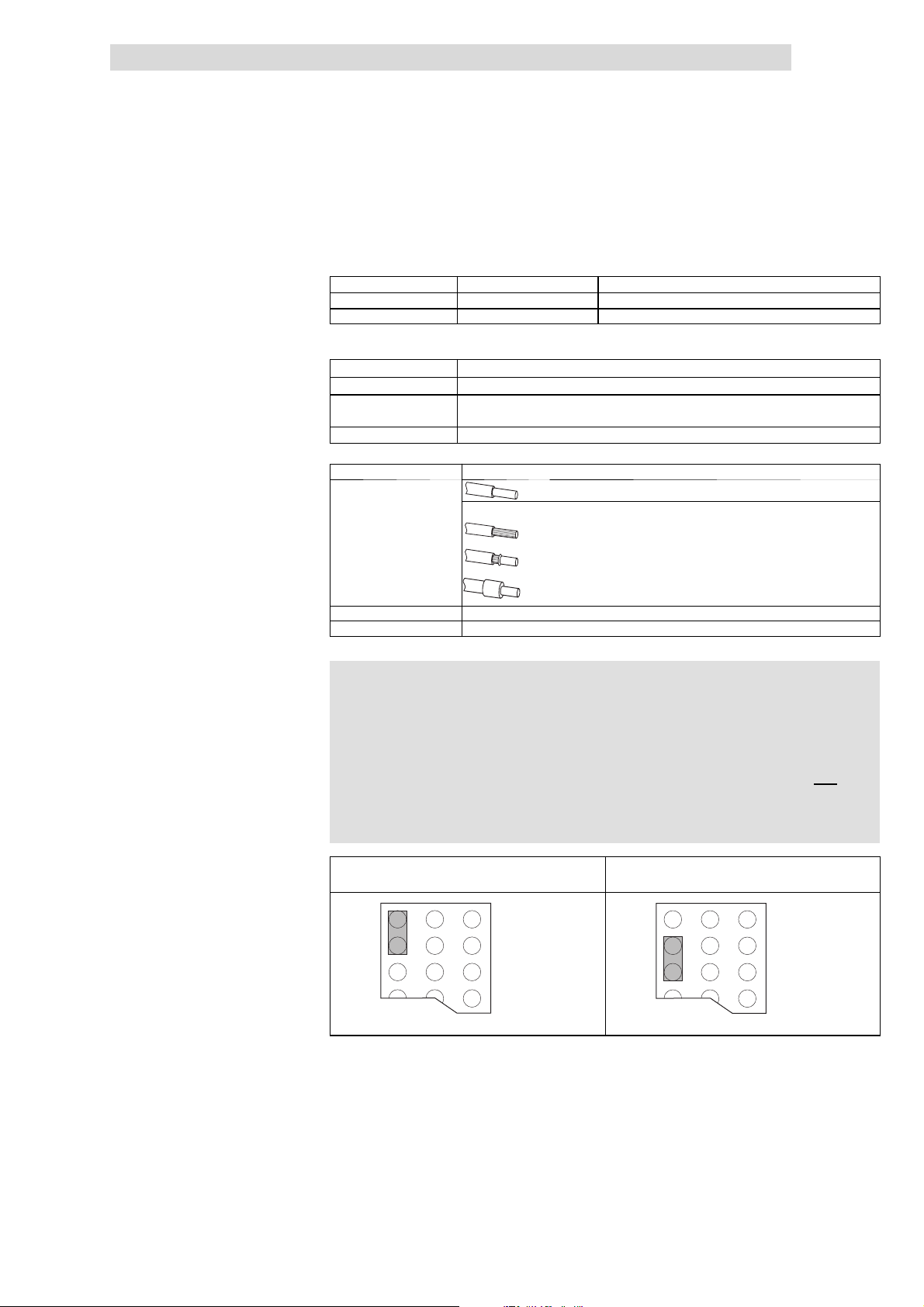

5.4.3.1 Connection from the INTERBUS

Installation

Electrical installation

BUS

DRIVE

L

INTERBUS S

IN

2

4

V

D

C

O

U

+

T

_

2

1

11

2111IBU006

5

9

IN

Sub-D pin connector (IN)

Pin Name Input/output Explanation

1 DO1 Input RS485: DO1 not i nverted

2 DI1 Output RS485: DI1 not inverted

3 GND Reference potential

4 free

5 Vcc5 5VDC

6 /DO1 Input RS485: DO1 inverted

7 /DI1 Output RS485: DI1 inverted

8 Vcc5 5VDC

9 free

Tab. 5.4-1 Pin assignment of the Sub -D pin connector (IN)

1

6

2113IBU012

5.4-6

EDSIBS-1.0-06/ 2003

L

Page 15

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Installation

Electrical installation

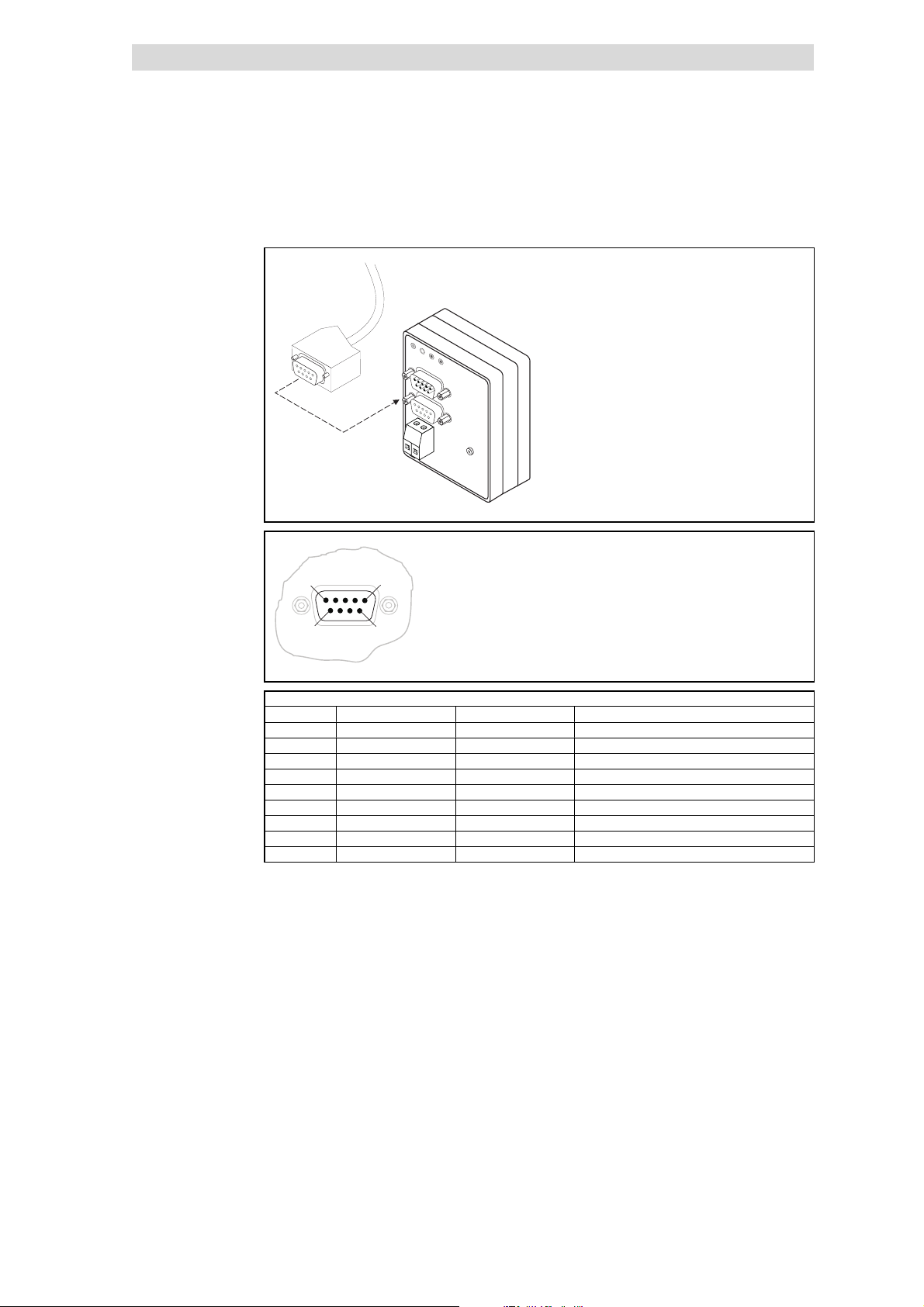

5.4.3.2 Connection to the INTERBUS

5.4

5.4.3

B

U

S

D

R

IV

E

L

INTERBUS S

IN

PC

2

4

V

D

C

OUT

+

_

2111

2111IBU006

5

9

OUT

1

6

2113IBU011

Sub-D socket connector (OUT)

Pin Name Input/output Explanation

1 DO2 Output RS485: DO2 not inverted

2 DI2 Input RS485: DI2 not inverted

3

4

GND Reference potential

5 Vcc5 Output 5VDC

6 /DO2 Output RS485: DO2 inverted

7 /DI2 Input RS485: DI2 i nverted

8 Vcc5 5VDC

9 RBST Message input The assignment of the Sub-D socket connector

(OUT) with a Sub-D plug is indicated.

Tab. 5.4-2 Pin assignment of the Sub -D socket c onnector (OUT)

L

EDSIBS-1.0-06/ 2003

5.4-7

Page 16

Show/Hide Bookmarks

Page 17

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Commissioning

Before switching on

5.5.1

5.5 Commissioning

5.5.1 Before switching on

(

( Stop!

((

Before switching on the mains voltage, check the wiring for

completeness, earth fault and short circuit.

)

) Note!

))

Do not change the switch-on sequence!

5.5.2 Configuration of the INTERBUS master for communication with the fieldbus

module

5.5

The program ”SYSSWT”

The host parameters (PC, PLC, etc.) are typically set via the PC program

” SYSSWT” of Phoenix Contact.

)

) Note!

))

mдЙ~лЙ зДлЙкоЙ нЬЙ беСзкг~нбзе ЦбоЙе бе нЬЙ ТpvpptqТ

йкзЦк~гK mкзЦк~г Ду mЬзЙебс `зен~ЕнK

1. Inst all „ SYSSWT“ on the host.

2. Start the program „ SYSSWT” .

3. Select „ Applications“ from the main menu.

4. Then select „ Planning“. A list for field assignment (field names) is displayed.

Please enter the following values:

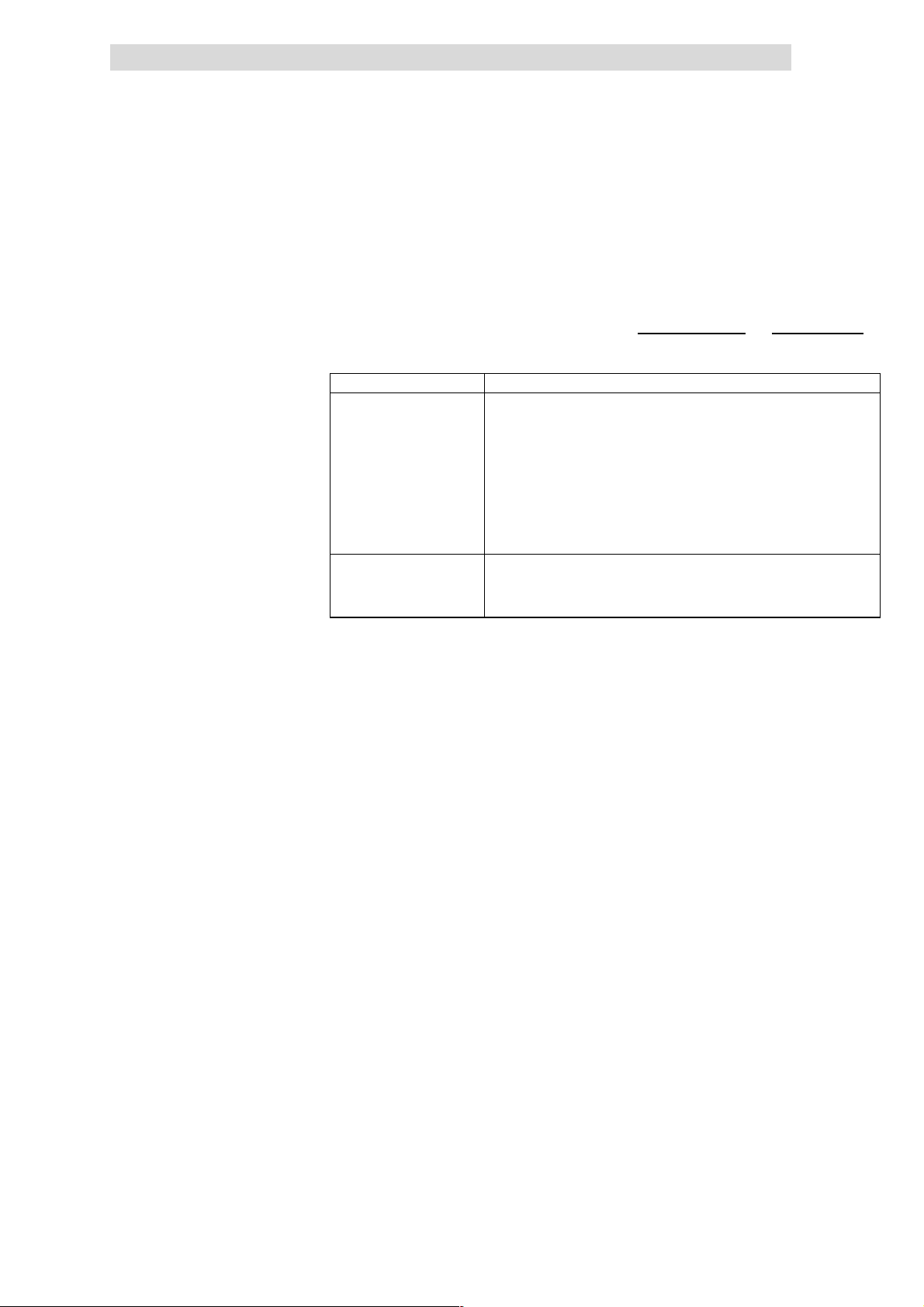

Field name Entry Explanation

Module/PD

length

Module ID 227 Module identification

CR 2 or higher Communication reference for PCP communication

5. Select the menu „ File“ .

2

2

3

Process-data length in words (16 bit each)

for 82XX

for 93XX Lenze sett i ng (L-C1910 = 4)

for 93XX, when code L-C1910 = 6

L

6. Then select the menu point „ Save planning data“.

– Before saving the new settings, mark the options not to be executed:

( ) NO bus start

( ) NO communication initialization

()NOtransferstop

Mark the options not to be executed.

– Save your settings

7. Close the program „ SYSSWT“.

EDSIBS-1.0-06/ 2003

5.5-1

Page 18

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.5

5.5.3

Different program

Commissioning

Start up of the 2111 fieldbus module

If you d o not use t he program ” SYSSWT” , the following settings must be mad e:

Name Entry Explanation

Module/PD length

2

2

3

Module ID 227 Module identification

Tab. 5.5-1 Process-data communication

Name Entry Explanation

COM_REF 2 or higher Communication reference (CR)

CONN_TYPE Acyclic

master/slave

CONN_ATTR Defined Connection attribute

Max PDU sending high prio 0 Sending history high priority

Max PDU sending low prio 64 Sending history low priority

Max PDU receiving high prio 0 Receiving history high priority

Max PDU receiving low prio 64 Receiving history low priority

Supported service request 803000

Supported Services Response 000000

Maximum SCC 1

Maximum RCC 0

Maximum SAC 0

Maximum RAC 0

Process-data length in words (16 bit each)

for 82XX

for 93XX Lenze sett i ng (L-C1910 = 4)

for 93XX, when code L-C1910 = 6

Connection type

hex

hex

Supported service, master request

Supported service, slave response

Tab. 5.5-2 PCP communication

5.5.3 Start up of the 2111 fieldbus module

1. The fieldbus module must be attached to the controller (¶ 5.4- 2).

2. Switch on the controller and, if required, the external voltage supply of the

2111 fieldbus module.

3. Check fieldbus module signals:

– The green bus LED indicates the operating status according to the

corresponding description

– The yellow bus LED indicates the communication status according to the

description

– If the signals are different in any way please see the chapter

“Troubleshooting and fault elimination” .

4. You can now communicate with the drive.

– With a PCP communication it is only possible to access the parameters of

the controller after having executed the PCP service ” Initiate“

5. It is then possible to access the parameters via the PCP services ”Read“

and ” Write“

(¶ 5.4-1) Pos. 1.

(¶ 5.6-49).

(¶ 5.4-1) Pos. 0.

(¶ 5.6-49).

5.5-2

EDSIBS-1.0-06/ 2003

L

Page 19

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Commissioning

Prepare controller for INTERBUS oper ation

5.5.4 Prepare controller for INTERBUS operation

82XX / 8200 vector

Preparation Notes

1. L-C0001 (operating mode):

Change value from “0” to “3”

.

2. Terminal 28 (controller

enable) must be HIGH during

INTERBUS operation.

Terminal 28 is always

active!

The controller is now ready to accept process and parameter data from the INTERBUS.

For this use

• the 8201BB for 82XX and

• the keypad for 8200 vector

Alternative

Direct access to the code via INTERBUS.

Example

Set code L-C0001 t o “3” (PCP write):

à For conversion formula and parameter value range see ^ 5.6-46

8200 vector (up to SW version 1.1)

à C0410/y (y = 1...16) must be assigned to the AIF control word (AIF-CTRL)

Otherwise, the controller cannot be enabled by the INTERBUS (DRIVECOM

controller status ”OPERATION ENABLED”, see Operating Instructions for the

controller).

821X, 8200vector und 822X

With these controllers the QSP function is always active. If QSP is assigned to an

input terminal (default setting: not assigned), this terminal must be at HIGH level

during INTERBUS operation (see the corresponding Operating Instructions).

:

– Index: 5FFE

– Subindex: 0

– Value: 30000

i.e. C0410/1 = 10, C0410/2 = 11 .... C0410/16 = 25 (see Operating

Instructions for 8200 vector).

hex

dec

(= 5FFF

− (L-C0001)

hex

hex

5.5

5.5.4

)

93XX controllers

Preparation Notes

1. L-C0005: Set “xxx3”. Use the 9371BB keypad

Alternative:

Direct access to the code via INTERBUS.

For the first commissioning you should select the signal configuration 1013 (speed

control).

Example

Set code L-C0005 to “1013” (PCP write):

– Index: 5FFA

– Subindex: 0

– Value: 10130000

à For conversion formula and parameter value range see ^ 5.6-46

2. L-C0142 (autostart lock):

Set “0”.

3. Terminal 28 (controller

enable) must be HIGH during

INTERBUS operation.

Terminal 28 is always

active!

The controller is now ready to accept process and parameter data from the INTERBUS.

Only necessary with DRIVECOM control

Otherwise, the controller cannot be enabled by the INTERBUS (DRIVECOM

controller status ”OPERATION ENABLED”, see Operating Instructions for 93XX).

à With the signal configuration L-C0005=1013, the function QSP (quick stop) and

the CW/CCW changeover are assigned to the digital input terminals E1 and E2

and thus they are always active. For INTERBUS operation E1 must be set to

HIGH level (see Operating Instructions 93XX).

à With the signal configuration L-C0005=xx13, terminal A1 is switched as

voltage output. Thus, only the following terminals can be connected via cables:

– X5.A1 with X5.28 (ctrl. enable)

– X5.A1 with X5.E1 (CW/QSP)

hex

(5FFF

dec

− (L-C0005)

hex

hex

)

L

EDSIBS-1.0-06/ 2003

5.5-3

Page 20

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.5

5.5.5

5.5.5 Controller enable via DRIVECOM

Controllers can be controlled with DRIVECOM proc ess data. The INTERBUS

master has direct access to the process data. In the INTERBUS master, data are

stored in the I/O area.

l Controller enable: DRIVECOM process data word ” Control word”

l Display of actual controller status: DRIVECOM process data word ” Status

word”.

The controller can be enabled by changing to OPERATION ENABLED by means

of the DRIVECOM control word.

Afterwards, the controller can be controlled as usual, e.g. via terminals.

)

) Note!

))

If DRIVECOM control is active and the fieldbus module

l in the controller

– 82XX / 8200 vector “ controller inhibit” will be activated if

L-C0001 = 3.

– 93XX “ Controller inhibit” will always be active.

l the fieldbus module sets SWITCH ON INHIBIT.

Commissioning

Controller enable via DRIVECOM

Enable the controller as follows:

1. Select speed setpoint (2nd process data word; PD2), value

2. Change to ” READY FOR SWITCH ON“

PD output word1 = 0000 0000 0111 1110

3. Wait for the status ” READY FOR SWITCH ON“.

PD input word1 = xxxx xxxx x01x 0001

4. Change to ” OPERTION ENABLED“

PD output word1 = 0000 0000 0111 1111

5. Wait for ” OPERATION ENABLED“.

PD input word1 = xxx xxx x01x 0111

bin.

bin.

bin

bin

(007E

(007F

hex

hex

).

).

≠ 0.

5.5-4

EDSIBS-1.0-06/ 2003

L

Page 21

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Commissioning

DRIVECOM compatibility

5.5.6 DRIVECOM compatibility

The DRIVECOM profile 21 is a specification of important parameters and unit

performance of several manufacturers. The DRIVECOM profile 21 mainly

describes the unit control and a speed operating mode. In addition to the

DRIVECOM specifications there are further Lenze-specific functions, e.g.

digital-frequency connection or DCinjection-brake. These manufacturer-specific

specifications require minor changes in the settings to comply with the desired

DRIVECOM compatibility. In the following, you will find the changes required for

the Lenze controllers.

820X With 820X controllers, parameters can only be set when the controller is inhibited.

821X,

8200 vector

and 822X

93XX Set the controller parameters for INTERBUS control, e.g. L-C0005=1013

9300 Servo

PLC

Drive PLC It is necessar y to use the device control for the DRIVE PLC.

5.5

5.5.6

The controller is inhibited in DRIVECOM status.

• ”SWITCH-ON INHIBIT”

• ”READY FOR SWITCH ON”

• ”SWITCHED ON”

• ”TRIP”

The automatic DC-injection brake must be deactivated in all parameter sets, i. e.

• L-C0106=0

• L-C2106=0

• L-C4106=0 (only 8200 vector)

• L-C6106=0 (only 8200 vector)

If the automatic DC-injection brake is not deactivated (holding time o f the DC-injection brake L-C0106

not 0), the controller automatically switches from the status ”OPERATION ENABLED” to the status

”SWITCHED ON” when the speed is 0 and the holding time of the DC-injection brake is elapsed. If the

setpoint is higher than 0, the controller is automatically reset to the status ”OPERATION ENABLED”.

This configuration corresponds to t he signal configuration 1000 with the following changes:

• Setpoint selection with INTERBUS

• Unit control with INTERBUS

• Output X5.A1 is selected as voltage output for the internal supply of the digital inputs.

• Actual values and status signals for INTERBUS

For the detailed description of the signal configuration, see 93XX Manual.

The following links must be made in the PLC program.

• AIF1_wDctrlCtrl W DCTRL_wAIF1Ctrl

• DCTRL_wStat W AIF1_wDctrlStat

L

EDSIBS-1.0-06/ 2003

5.5-5

Page 22

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.5

5.5.7

Special features when using 82XX, 8200 vector and 93XX

5.5.7 Special features when using 82XX, 8200 vector and 93XX

}

} Danger!

}}

Please note

l For safe operation it is absolutely necessary to observe the

notes for the controllers given in this chapter.

l Please observe the corresponding Operating Instructions of the

controllers.

820X • Parameter setting (codes except process data) is only possible when the controller is inhibited

8200 vector • Digital and analog input and output signals can be freely configured (see Operating Instructions for

93XX • Set the signal configuration L-C0005 = xxx3 instead of the operating mode L-C0001.

(DRIVECOM controller status unequal ”OPERATION ENABLED“). Parameters are accepted when the

controller is enabled, but they are not saved.

• A TRIP must only be reset through INTERBUS:

If the controller is set to the status TRIP while being operated with INTERBUS control

(L-C0001 = 3) and if the TRIP is reset through terminal 28, the drive can start for a short time.

When resetting a fault via INTERBUS, this does not occur.

• Aft er the command ”TRIP reset“ the 820X controller is basically initialized. During this time the

controller does not accept any services.

• Always send the direction of rotation with a low setpoint before the new setpoint:

If the setpoint and the direction of rotation are changed at the same time via the DRIVECOM speed

setpoint, the speed can change to the wrong direction or rotation for a short time. This is because

the setpoint is sent to the controller as unipolar value before and the information about the

direction of rotation is sent.

8200 vector; codes L-C0410, L-C0412, L-C0417 a nd L-C0421)

• A change of code L-C0001 to “3“ preconfigures the process data words in the controller.

• The change o f the code L-C0005 to xxx3 starts the preconfiguration of the process data words in

the controller

• Set the parameter L-C0142 = 0 (auto start lock), to avoid a short time start of the drive during the

initialization phase.

Commissioning

5.5-6

EDSIBS-1.0-06/ 2003

L

Page 23

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Data transfer

5.6 Data transfer

5.6

INTERBUS master and slave communicate by sending data telegrams via the

INTERBUS.

The user data of the data telegram contains parameter data

Different communication channels are assigned to parameter and process data:

Telegram type Communication channel

Process data,

• Setpoints

• Actual values

Parameter data

• Operating parameters

• diagnostics information

• moto r data

Tab. 5.6-1 Division of p arameter data and p rocess d ata into different c ommunication channels

The following describes the communication protocol only as much as needed for

networking Lenze controllers.

Process-data channel • Exchange between INTERBUS master and

Parameter data channel

or “PCP channel”

(PCP = Peripherials

Communication Protocol)

controller required as fast as possible. Small

amounts of data for cyclic data transfer.

• The INTERBUS master has direct access to the

process data.

• Process data can control the controller.

• Process data are

– not stored in the controller.

– exchanged between INTERBUS master and

controllers to ensure a constant update of

input and output data.

• In general, the parameter transfer is not as

time-critical as the tranfer of process data.

• Enables access to all Lenze codes and indexes.

or process data.

L

EDSIBS-1.0-06/ 2003

5.6-1

Page 24

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.1

5.6.1 Process data channel configuration

5.6.1.1 Process data transfer

Process data telegrams between INTERBUS master and the controllers

connected to the INTERBUS are divided into:

l Process data telegrams from drive (PI)

l Process data telegrams to drive (PO)

)

) Note!

))

As agreed, the data flow is described from the INTERBUS

master’s view:

l PI data of the INTERBUS master are output data for the

controller.

l PO data of the INTERBUS master are input data for the

controller.

Data transfer

Process data channel configuration

Process data telegram from

drive

Process data telegram to

drive

For the cyclic process data telegram from

is called AIF-OUT. The status word included in the process data telegram (byte

1 and byte 2) is sent to the INTERBUS master via this function block.

For the cyclic process data telegram to

is called AIF-IN. The control word included in the process data telegram (byte 1

and byte 2) is sent to the INTERBUS master via this function block.

the drive, the func tion block to be used

the drive, the function block to be used

5.6-2

EDSIBS-1.0-06/ 2003

L

Page 25

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Data transfer

Process data channel configuration

5.6.1.2 Setpoint source selection

82XX controllers

Controller 8200 vector

The setpoint source selection for these controllers is determined under code

L-C0001 (5FFE

is set to ”3” when the controller is operated together with the fieldbus module. The

process data channel which describes the frequency setpoint (L-C0046) and the

control word (parameter channel, L-C0135) is the setpoint source

)

) Note!

))

The setpoint source selection for these controllers is determined under code

L-C0001 (5FFE

is set to ”3” when the controller is operated together with the fieldbus module. The

process data channel which describes the frequency setpoint (L-C0046) and the

control word (parameter channel, L-C0135) is the setpoint source

5.6.1

).An evaluation of process data is only possible if code L-C0001

hex

.

Please ensure that the setpoint source (L-C0001) is the same for

all parameter sets used.

).An evaluation of process data is only possible if code L-C0001

hex

.

5.6

93XX controllers

Servo PLC 9300 / Drive PLC

Check in L-C0412/ x whether the assignment of setpoint source and analog signal

is correct and change, if necessary.

)

) Note!

))

Please ensure that the setpoint source selection (L-C0001) is the

same for all parameter sets used.

The value in code C0005 must be set to ” xxx3” for bus operation (x = selected

preconfiguration).

Communication requires that AIF-IN 1 ... 3 or AIF-OUT 1 ... 3 and if available

AIF management are part of the control configuration of the IEC61131 project.

the

L

EDSIBS-1.0-06/ 2003

5.6-3

Page 26

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.1

5.6.1.3 Process data configuration

Some data important for the process must be transmitted as quickly as possible.

These data are called process data and stored in the I/O area of the controller for

access from the INTERBUS master.

The process data are cyclically exchanged between the controller and the

INTERBUS master.

Theprocess data of a Process-data configuration have a certain ”Process data

structure“.

The process-data structure is subdivided into

l Process input data (PI data, index = 6000

l Process output data (PO data, index = 6001

The controller receives control information from the INTERBUS master and sends

status information to the master.

The Lenze setting for the process-data length is 4 byte.

The PD length is set under code L-C1910.

Data transfer

Process data channel configuration

, (¶ 5.6-5))

hex

, (¶ 5.6-5))

hex

)

) Note!

))

The assignment of the AIF-CTRL control word to PO data is only

useful, if the Drivecom status machine is switched off. This is

achieved by entering “0” under L-C1911.

Different controller signals can be assigned to the PI and PO data

words (see

(¶ 5.6-6)).

5.6-4

EDSIBS-1.0-06/ 2003

L

Page 27

2111 INTERBUS fieldbus module

M

g

y

Show/Hide Bookmarks

5

Data transfer

Process data channel configuration

PI data description (6000

hex

)9

The parameter describes the process data which are sent from the controller to

the INTERBUS master (input data for the INTERBUS master). Parameters of the

described process data assignment of Lenze controllers can be assigned to the

subindex values (see

changed.

Ensure that the parameters of the process data channel are only used once, i.e.

double assigment must be avoided (example: DC speed and speed setpoint are

sent via AIF-W1).

Parameter name (Index) Subindex Data structure Data type

PI data description (6000

)

) Note!

))

Subindex

1 Number of process data [byte] 04

2 Index PI data word 1 6041

3 Subindex PI data word 1 00

4/5 No entry 00

6 Index PI data word 2 6044

7 Subindex PI data word 2 00

8/9 No entry 00

10 Index PI data word 3 5CA5

11 Subindex PI data word 3 03

12/13 No entry 00

(¶ 5.6-6)). Exception: The value for subindex 1 cannot be

) 1 ... 13 R PBS(20

hex

hex

)

Only the valid subindex is displayed with the parameter 6000

It is determined by PD!

eaning

Value

Lenze setting Notes

hex

DRIVECOM status word

hex

DRIVECOM speed

hex

AIF-OUT.W2

hex

Of if code

L-C1910 = 6

5.6.1

hex

5.6

.

PO data description (6001

hex

)10

The parameter describes the process data which are sent to the controller from

theINTERBUSmaster (output data for the INTERBUS master).Parameters of the

described proc ess data of Lenze controllers can be assigned to subindex values

(¶ 5.6-6)). Exception: The value for subindex 1 cannot be changed.

(see

Ensure that the parameters of the process data channel are only used once, i.e.

double assigment must be avoided (example: DC speed and speed setpoint are

sent via AIF-W1).

Parameter name (Index) Subindex Data structure Data type

PO data description (6001

Subindex Meaning

1 Number of process data

[byte]

2 Index PO data word 1 6040

3 Subindex PO data word 1 00

4/5 No entry 00 1

6 Index PO data word 2 6042

7 Subindex PO data word 2 00

8/9 No entry 00 3

10 Index PO data word 3 5CA7

11 Subindex PO data word 3 03

12/13 No entry 00 5

) 1 ... 13 R PBS(20

hex

Lenze setting

Value

04

hex

DRIVECOM control word 0

hex

DRIVECOM speed setpoint 2

hex

AIF-IN.W2 4

hex

hex

)

hex

index

6002 / Bit

Notes

Only if

L-C1910 = 6

L

EDSIBS-1.0-06/ 2003

5.6-5

Page 28

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

5.6.2 Process data signals of Lenze controllers

5.6.2.1 Process data signals for frequency inverters 82XX

Process data telegram from

drive

ThefollowingparameterscanbeassignedtothePI-data:

Index Subindex Name Explanation Lenze setting:

6041 0 DRIVECOM status word PI data word 1 ^ 5.6-38

6044 0 DRIVECOM speed Actual speed [rpm] PI data word 2 ^ 5.6-41

6054 0 DRIVECOM actual

percentage value

5F69 0 Device status word

(L-C0150)

5CA5 1 AIF-OUT.W1 AIF word 1

Data transfer

Process data signals of Lenze controllers

see

^ 5.6-42

Table below

Actual speed [%]

100% = 16383

Index 6000

hex

5.6-6

EDSIBS-1.0-06/ 2003

L

Page 29

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

Device status word AIF- STAT for 82XX (Lenze code C0150, index 5F69

Bit 820X 821x, 822x

0 Actual parameter set 0=Parameterset1or3active

1=Parameterset2or4active

1 IMP (pulse inhibit) 0 = Pulses for power stage enabled

1 = Pulses for power stage inhibited

2 I

(current limit reached) 0 = Current limit not reached

max

1 = Current limit reached

3 not assigned fd=f

4 fd=f

5 Qmin (f

dset

≤ f

) 0 = Qmin not active

d

dQmin

6 fd+ 0 (act. frequency = 0) 0=f

0=f

≠ f

d

dset

1=fd=f

dset

1=Qminactive

≠ 0

d

+0

1=f

d

7 Ctrl. inhibit (controller inhibit) 0 = Controller not inhibited

1 = Controller inhibited

8...11 Controller status 0 = Unit initialisation

8 = Error active

12 Overtemperature warning 0=Nowarning

1=Warning

13 V

(DC-bus overvoltage) 0 = No overvoltage

Gmax

1 = Overvoltage

14 Direction of rotation 0 = CW rotation

1 = CCW rotation

15 Ready for operation 0 = Not ready for operation

1 = Ready for operation

)

hex

Actual parameter set 0=Parameterset1or3active

IMP (pulse inhibit) 0 = Pulses for power stage enabled

I

(current limit reached) 0 = Current limit not reached

max

dset

RFG on = RFG off 0=RFGon≠ RFG off

Qmin (f

d

fd+ 0 (act. frequency = 0) 0=f

Ctrl. inhibit (controller inhibit) 0 = Controller not inhibited

Controller status 0 = Controller initialization

Overtemperature warning 0=Nowarning

V

(DC-bus overvoltage) 0 = No overvoltage

Gmax

Direction of rotation 0 = CW rotation

Ready for operation 0 = Not ready for operation

1=Parameterset2or4active

1 = Pulses for power stage inhibited

1 = Current limit reached

0=f

1=fd=f

1 = RFG on = RFG out

≤ f

) 0 = Qmin not active

dQmin

1=Qminactive

1=f

1 = Controller inhibited

2 = Switch on inhibit

3 = Operation inhibited

4 = Flying-restart circuit active

5 = DC brake active

6 = Operation enabled

7 = Message active

8 = Error active

1=Warning

1 = Overvoltage

1 = CCW rotation

1 = Ready for operation

5.6

5.6.2

≠ f

d

dset

dset

≠ 0

d

+0

d

- / fd=fdset

fd=fdset / RFG

ctrl. inhibit

B11 B10 B9 B8

0

0

0

1

0

0

1

0

0

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

PAR

IMP

Imax

Qmin

fd>0

STAT

0

0

2

0

3

1

.

.

.

.

.

.

Vgmax

RDY

C0050

.

.

.

.

.

.

T

R/L

.B0

.B1

.B2

.B3

.B4

.B5

.B6

.B7

.B8

16 bits

.B9

.B10

.B11

ü

.B12

.B13

.B14

.B15

AIF

16 bits

2141LON012_en

Fig. 5.6-1 Read access to status word and actual frequency in 82XX (fixed assignment)

L

EDSIBS-1.0-06/ 2003

5.6-7

Page 30

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

Process data telegram to drive

Data transfer

Process data signals of Lenze controllers

ThefollowingparameterscanbeassignedtothePO-data:

Index Subindex Name Explanation Lenze setting:

6040 0 DRIVECOM control word PO data word 1 ^ 5.6-35

6042 0 DRIVECOM speed

6052 0 DRIVECOM percentage

5F78 0 Device control word

1 AIF-IN.W1 AIF word 1. See the

5CA7

)

) Note!

))

setpoint

setpoint

(L-C0135)

The assignment of the AIF-CTRL control word to PO data is only

useful, if the Drivecom status machine is switched off. This is

achieved by entering “0” under L-C1911.

Speed setpoint [rpm] PO data word 2 ^ 5.6-41

Speed setpoint [%]

100% = 16383

following description.

Index 6001

hex

see

^ 5.6-42

Table below

5.6-8

EDSIBS-1.0-06/ 2003

L

Page 31

2111 INTERBUS fieldbus module

0

0,0

1

01JOG1activeinC0037

R

d

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

Control w ord AIF- CTRL for 82XX (Lenze code C0135, index 5F78

Bit 820X 821x, 822x

00 = C0046 active

01 = JOG1 active in C0037

10 = JOG2 active in C0038

11 = JOG3 active in C0039

02 CW/CCW (CW rotation/

03 QSP (quick stop) 0 = QSP not active

04 RFG stop (stop of the ramp function generator) 0 = RFG stop not active

05 RFG zero (deceleration along the Tiframp C0013) 0 = RFG zero not active

06

07 DOWN function for motor potentiometer 0 = DOWN not active

08 Reserved

09 Ctrl. inhibit (controller inhibit) 0 = Controller not inhibited

10

11

12 PAR1 (Parameter set changeover) 0 -> 1 = Parameter set

13 Reserved Reserved

14 DC brake (DC injection brake) 0 = DC brake not active

15 Reserved Reserved

CCW rotation)

Reserved

eserve

0 = CW rotation

1 = CCW rotation

1=QSPactive

1 = Controller inhibited

1 -> 0 = Parameter set

1 = DC brake active

)

hex

00 = C0046 active

01 = JOG1 active in C0037

10 = JOG2 active in C0038

11 = JOG3 active in C0039

CW/CCW (CW rotation/CCW rotation) 0 = CW rotation

QSP (quick stop) 0 = QSP not active

UP function for motor potentiometer 0=UPnotactive

Ctrl. inhibit (controller inhibit) 0 = Controller not inhibited

Reserved

TRIP reset 0 -> 1 = Edge from 0 to 1

PAR1 (Parameter set changeover) 0 -> 1 = Parameter set

DC brake (DC injection brake) 0 = DC brake not active

1 = CCW rotation

1=QSPactive

1=RFGstopactive

1=RFGzeroactive

1=UPactive

1 = DOWN active

1 = Controller inhibited

1 -> 0 = Parameter set

1 = DC brake active

5.6

5.6.2

AIF

16 bits

16 bits

.B0

.B1

.B2

.B3

.B4

.B8

.B9

.B10

.B11

.B12

.B13

.B14

.B15

0

011

JOG/

C046

0101

QSP

...

...

...

CINH

TRIP-SET

TRIP-RESET

C0046

Fig. 5.6-2 Access to c ontrol word and actual frequency in 82XX (fixed assignment)

CW/

CCW

PAR

DC

brake

2141LON010_en

L

EDSIBS-1.0-06/ 2003

5.6-9

Page 32

5

C

A

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

5.6.2.2 Process data signals for 8200 vector frequency inverters

The function block AIF (AIF=automation interface) is the data interface between

the 8200 vector and the fieldbus module. The function block consists of AIF-OUT

and AIF-IN.

Process data telegram from

drive

ThefollowingparameterscanbeassignedtothePI-data:

Index Subindex Name Explanation Lenze setting:

6041 0 DRIVECOM status word PI data word 1 ^ 5.6-38

6044 0 DRIVECOM speed Actual speed [rpm] PI data word 2 ^ 5.6-41

6054 0 DRIVECOM actual

5F69 0 Device status word

1 AIF-OUT.W1 AIF word 1

5

5

2 AIF-OUT.W2 AIF word 2 PI data word 3

AIF-OUT.Wx is parameterised under code L-C0421.

percentage value

(L-C0150)

Process data signals of Lenze controllers

Actual speed [%]

100% = 16383

Index 6000

Data transfer

see

hex

^ 5.6-42

Table below

5.6-10

EDSIBS-1.0-06/ 2003

L

Page 33

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

Controller status word AIF-STAT for 8200 vector (Lenze code C0150, index 5F69

AIF-STAT.Bxx Lenze setting Adjustable in code L-0417/..

0 DCTRL-PAR-B0 1

1 DCTRL1-IMP 2

2 MCTRL1-IMAX 3

3 MCTRL1-RFG1=NOUT 4

4 NSET1-RFG1-I=0 5

5 PCTRL1-QMIN 6

6 DCTRL1-NOUT=0 7

7 DCTRL1-CINH 8

8...11 Controller status

0 = Controller initialization

2 = Switch on inhibit

3 = Operation inhibited

4 = Flying-restart circuit active

Reserved

5 = DC brake active

6 = Operation enabled

7 = Message active

8 = Error active

12 DCTRL1-OH-WARN 13

13 DCTRL1-OV 14

14 DCTRL1-CCW 15

15 DCTRL1-RDY 16

hex

)

5.6

5.6.2

C0417/1

DCTRL1-IMP

C0417/3

C0417/4

C0417/5

C0417/6

DCTRL1-NOUT=0

DCTRL1-CINH

DCTRL1-STAT*1

DCTRL1-STAT*2

DCTRL1-STAT*4

DCTRL1-STAT*8

DCTRL1-OH-WARN

DCTRL1-OV

C0417/15

C0417/16

C0421/1

C0421/2

STAT1

.B10

.B12

.B13

AIF-OUT.W1

AIF-OUT.W2

.B0

.B1

.B2

.B3

.B4

.B5

.B6

.B7

.B8

.B9

.B11

.B14

.B15

AIF-OUT

.B0

.B1

.B2

.B3

.B4

.B5

.B6

.B7

.B8

AIF-STAT

.B9

16 bits

.B10

.B11

.B12

.B13

.B14

.B15

16 bits

16 bits

Fig. 5.6-3 Function b loc k AIF-OUT in 8200 vector (freely p rogrammable assignment)

AIF

2141LON013_en

L

EDSIBS-1.0-06/ 2003

5.6-11

Page 34

5

C

A

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

Process data telegram to drive

Data transfer

Process data signals of Lenze controllers

ThefollowingparameterscanbeassignedtothePO-data:

Index Subindex Name Explanation Lenze setting:

6040 0 DRIVECOM control word PO data word 1 ^ 5.6-35

6042 0 DRIVECOM speed

6052 0 DRIVECOM percentage

5F78 0 Device control word

1 AIF-IN.W1 AIF word 1

5

7

2 AIF-IN.W2 AIF word 2

AIF-IN.Wx is parameterised under code L-C0412.

setpoint

setpoint

(L-C0135)

Speed setpoint [rpm] PO data word 2 ^ 5.6-41

Speed setpoint [%]

100% = 16383

Frequency and speed

are normalised with

24000 ≡ 480 Hz.

Frequency and speed

are normalised with

24000 ≡ 480 Hz.

Index 60001

PO data word 3

hex

see

^ 5.6-42

Table below

)

) Note!

))

The assignment of the AIF-CTRL control word to PO data is only

useful, if the Drivecom status machine is switched off. This is

achieved by entering “0” under L-C1911.

5.6-12

EDSIBS-1.0-06/ 2003

L

Page 35

2111 INTERBUS fieldbus module

00,

01NSET1JOG1(C0037)activ

e

1

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

Control w ord AIF- CTRL for 8200 vector (Lenze code C0135, index 5F78

AIF-CTRL.Bxx Default setting:

00,

01

02 DCTRL1-CW/CCW 0=notactive

03 AIF-CTRL-QSP 0=notactive

04 NSET1-RFG1-STOP 0=notactive

05 NSET1-RFG1-0 0=notactive

06 MPOT1-UP 0=notactive

07 MPOT1-DOWN 0=notactive

08 Freely configurable by user 9

09 AIF-CTRL-CINH 0=notactive

10 AIF-CTRL-TRIP-SET 0=notactive

11 AIF-CTRL-TRIP-RESET 0 -> 1 = Edge from 0 to 1 AIF-CTRL-TRIP-RESET 0 -> 1 = Edge from 0 to 1 12

12 DCTRL1-PAR2/4 0=notactive

13 DCTRL1-PAR3/4 0=notactive

14 MCTRL1-DCB 0=notactive

15 Freely configurable by user Freely configurable by user 16

00 = C0046 active

01 = NSET1-JOG1 (C0037) a ct ive

10 = NSET1-JOG2 (C0038) a ct ive

11 = NSET1-JOG3 (C0039) a ct ive

C0001=3 if C0007

≤ 51

1=active

1=active

1=active

1=active

1=active

1=active

1=active

1=active

1=active

1=active

1=active

)

hex

Default setting:

C0001=3 if C0007 > 51

Freely configurable by user

AIF-CTRL-QSP 0=notactive

Freely configurable by user

AIF-CTRL-CINH 0=notactive

AIF-CTRL-TRIP-SET 0=notactive

Freely configurable by user

1=active

1=active

1=active

5.6

5.6.2

Adjustable in L-C0410/..

1

2

3

4

5

6

7

8

10

11

13

14

15

AIF

AIF-CTRL

16 bits

16 bits

16 bits

.B0

.B1

.B2

.B3

.B4

.B8

.B9

.B10

.B11

.B12

.B15

AIF-IN

DCTRL

QSP

...

...

...

...

...

...

Fig. 5.6-4 Function b lock AIF-IN in 8200 vector (freely programmable assignment)

...

...

...

DCTRL

CINH

TRIP-SET

TRIP-RESET

...

...

...

AIF-IN.W1

AIF-IN.W2

2141LON011_en

L

EDSIBS-1.0-06/ 2003

5.6-13

Page 36

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

5.6.2.3 Process data signals for servo inverters 9300

The function block AIF (AIF = automation interface) is the data interface between

the 93XX controller and the fieldbus module. The function block consists of

AIF-OUT and AIF-IN.

With the 93XX controller the process data assignment can be changed by

reconfiguring the function blocks AIF-IN and AIF-OUT.

Data transfer

Process data signals of Lenze controllers

5.6-14

EDSIBS-1.0-06/ 2003

L

Page 37

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

Process data telegram from

drive

ThefollowingparameterscanbeassignedtothePI-data:

Index Subindex Name (same in

6041 0 DRIVECOM status word PI data word 1 ^ 5.6-38

6044 0 DRIVECOM speed Actual speed [rpm] PI data word 2 ^ 5.6-41

6054 0 DRIVECOM actual

5F69 0 Device status word

5CA5 1 AIF1-OUT.W1 AIF word 1

5CA5 2 AIF1-OUT.W2 AIF word 2 PI data word 3

5CA5 3 AIF1-OUT.W3 AIF word 3

5CA4 0 AIF1-OUT.D1 AIFdoubleword

The assignment of AIF-OUT depends on the signal configuration selected under

L-C0005:

Signal

configuration

(L-C0005)

Speed control

1003

1013

1113

Torque control

4003

4013

4113

DF master

5003

5013

5113

DF-slave bus

6003

6013

6113

DF-slave cascade

7003

7013

7113

Not equal to xxx3

(except self

configurations)

IEC1131)

percentage value

(AIF1_Stat)

AIF-OUT.W1 AIF-OUT.W2 AIF-OUT.W3 AIF-

MCTRL-NACT

Actual speed

100%=16383

MCTRL-MSET2

Torque display

100%=16383

MCTRL-NACT

Actual speed

100%=16383

MCTRL-NACT

Actual speed

100%=16383

MCTRL-NACT

Actual speed

100%=16383

MCTRL-NACT

Actual speed

100%=16383

Explanation Lenze setting:

Actual speed [%] ^ 5.6-42

MCTRL-MSET2

Torque display

100%=16383

MCTRL-NACT

Act. speed in %

100%=16383

MCTRL-MSET2

Torque display

100%=16383

MCTRL-PHI-ACT

Actual phase

MCTRL-PHI-ACT

Actual phase

MCTRL-MSET2

Torque display

100%=16383

Index 6000

hex

MCTRL-NSET2

Speed controller input

100%=16383

MCTRL-NSET2

Speed controller input

100%=16383

MCTRL-NSET2

Speed controller input

100%=16383

MCTRL-MSET2

Torque setpoint in %

100%=16383

MCTRL-MSET2

Torque setpoint in %

100%=16383

MCTRL-PHI-ACT

Actual phase

see

Table below

OUT.D1

not

assigned

not

assigned

not

assigned

not

assigned

not

assigned

not

assigned

5.6

5.6.2

L

For detailed description of the 93XX signal configuration see the Operating

Instructions for 93XX (only the main configurations: 1000, 4000, 5000, etc.) or the

Manual 93XX.

In the c ontroller, other signals can be assigned to AIF-OUT.W1 to AIF-OUT.W3.

For this, thefunction-block configuration - described in the Manual 93XX- is used.

The function block AIF-OUT determines the output data of the controller as data

interfac e for the 2133 fieldbus module.

For more detailed information about the function block AIF-OUT, see the Manual

93XX.

EDSIBS-1.0-06/ 2003

5.6-15

Page 38

5

8...1

1

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

Process data signals of Lenze controllers

Data transfer

Controller status word AIF-STAT for 93XX

9300 Servo 9300 POS 9300 CRV 9300 Vector

L-C0005:

1xxx, 2xxx,

Bit..

1xx3 4xx3 5xx3 6xx3,7xx3 2xxx3 xxx3

3xxx, 5xxx,

4xx3 6xx3,7xx3

10xxx, 11xxx

0 DCTRL-PAR1-0 DCTRL-PAR1-0 DCTRL-PAR1-0 DCTRL-PAR1-0 not assigned CERR1-ERR DCTRL-PAR1-0 DCTRL-PAR1-0 DCTRL-PAR1-0

1 DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP DCTRL-IMP

2 MCTRL-IMAX MCTRL-IMAX REF-OK REF-OK POS-REF-OK MCTRL-IMAX MCTRL-IMAX MCTRL-IMAX MCTRL-IMAX

3 MCTRL-MMAX not assigned MCTRL-MMAX not assigned not assigned MCTRL-MMAX MCTRL-MMAX MCTRL-IMAX

MCTRL-MMAX

negated

4 NSET-RFG-I=0 MCTRL-IMAX

negated

NSET-RFG-I=0 MCTRL-IMAX

negated

MCTRL-MMAX

negated

DCTRL-TRIP NSET-RFG-I=0 NSET-RFG-I=0 NSET-QSP-OUT

5 QMIN QMIN REF-BUSY REF-BUSY POS-IN-TARGET CDATA-X0 QMIN QMIN QMIN

6 DCTRL-

NACT=0

DCTRLNACT=0

DCTRLNACT=0

DCTRLNACT=0

DCTRLNACT=0

DCTRLNACT=0

DCTRLNACT=0

DCTRLNACT=0

DCTRL-

NACT=0

7 DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH DCTRL-CINH

8 ... 11

Controller status:

0=

Unit initialisation

2=

Switch-on inhibit

3=

Operation inhibited

4=

Flying-restart circuit active

5=

DC-injection brake active

6=

Operation enabled

7=

Message active

8=

Fault active

10 =

Fail-QSP (only 9300 servo positioning controller)

12 DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN DCTRL-WARN

13 DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS DCTRL-MESS

14 DCTRL-CW/

CCW

DCTRL-CW/

CCW

DCTRL-CW/

CCW

not assigned DCTRL-AIFL-

QSP

DCTRL-CW/

CCW

DCTRL-CW/

CCW

DCTRL-CW/

CCW

DCTRL-CW/

CCW

15 DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY DCTRL-RDY

C 0 1 5 6 / 1

C 0 1 5 6 / 6

C 0 1 5 6 / 7

C 1 1 9 5

C 0 8 5 0 / 1

C 0 8 5 0 / 2

C 0 8 5 0 / 3

C 0 1 1 6 / 1

C 0 1 1 6 / 1 6

C 0 1 1 6 / 1 7

C 0 1 1 6 / 3 2

C 0 8 5 1

S T A T

S T A T . B 0

D C T R L - I M P

. . .

S T A T . B 1 4

S T A T . B 1 5

A I F - O U T . D 2

C 1 1 9 6

A I F - O U T . W 1

C 0 8 5 8 / 1

C 0 8 5 8 / 2

C 0 8 5 8 / 3

F D O - 0

. . .

F D O - 1 5

F D O - 1 6

. . .

F D O - 3 1

A I F - O U T . D 1

C 0 8 5 9

F D O

1 6 b i t s

1 6 b i t s

L o w W o r d

1 6 b i t s

H ig h W o r d

A I F - O U T . W 2

A I F - O U T . W 3

1 6 b i t s

L o w W o r d

1 6 b i t s

H ig h W o r d

1 6 b i t s

L o w W o r d

1 6 b i t s

H ig h W o r d

A I F - O U T

B i t 0

S t a t u s w o r d

B i t 1 5

B i t 0

C 0 8 5 4

0

3

C 0 8 5 2

0

1

2

3

C 0 8 5 3

0

1

2

B i t 1 5

B i t 0

B i t 3 1

B y t e 3 , 4

:

B y t e 5 , 6

B y t e 7 , 8

2113IBU009_en

Fig. 5.6-5 Function b loc k AIF-OUT (function block extension on grey b ackground: available as

of software version 2.0 on)

5.6-16

EDSIBS-1.0-06/ 2003

L

Page 39

2111 INTERBUS fieldbus module

notassignednotassigne

d

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

Process data telegram to drive

ThefollowingparameterscanbeassignedtothePO-data:

Index Subindex Name Explanation Lenze setting:

6040 0 DRIVECOM control word PO data word 1 ^ 5.6-35

6042 0 DRIVECOM speed

6052 0 DRIVECOM percentage

5F78 0 Device control word

5CA7 1 AIF-IN.W1 AIF word 1

5CA7 2 AIF-IN.W2 AIF word 2 PO data word 3

5CA7 3 AIF-IN.W3 AIF word 3

5CA6 0 AIF-IN.D1 AIFdoubleword

)

) Note!

))

5.6.2

see

^ 5.6-42

Table below

setpoint

setpoint

(AIF1_CTRL)

Index 6001

Speed setpoint [rpm] PO data word 2 ^ 5.6-41

Speed setpoint [%]

100% = 16383

hex

The assignment of the AIF-CTRL control word to PO data is only

useful, if the Drivecom status machine is switched off. This is

achieved by entering “0” under L-C1911.

5.6

The assignment of AIF-IN.W1 to AIF-IN.W3 depends on the signal configuration

selected under L- C0005:

Signal configuration

(L-C0005)

Speed control

1003 / 1013 / 1113

Torque control

4003 / 4013 / 4113

DF master

5003 / 5013 / 5113

DF-slave bus

6003 / 6013 / 6113

DF-slave cascade

7003 / 7013 / 7113

not equal to xxx3 not assigned not assigned

AIF-IN.W1 AIF-IN.W2 AIF-IN.W3 AIF-IN.D1

NSET-N

Speed setpoint

MCTRL-MADD

Torque setpoint

NSET-N

Speed setpoint

DFSET-A-TRIM

Phase trimming

DFSET-VP-DIV

DF factor

not assigned

not assigned

not assigned

not assigned not assigned

DFSET-N-TRIM

Speed trimming

DFSET-A-TRIM

Phase trimming

For detailed description of the 93XX signal configuration see the Operating

Instructions for 93XX (only the main configurations: 1000, 4000, 5000, etc.) or the

Manual 93XX.

In the controller, other signals can be assigned to AIF-IN.W1 to AIF-IN.W3. For

this, the function-block configuration - described in the Manual 93XX - is used.

The function block AIF-IN determines the input data of the controller as data

interfac e for the 2133 fieldbus module.

For more detailed information about the function block AIF-IN, see the Manual

93XX.

L

EDSIBS-1.0-06/ 2003

5.6-17

Page 40

5

X

. . .. . .

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

Process data signals of Lenze controllers

Data transfer

Control word AIF- CTRL for 93XX

9300 Servo 9300 POS 9300 CRV 9300 Vector

L-C0005:

1xxx, 2xxx,

Bit

1xx3 4xx3 5xx3 6xx3,7xx3 2xxx3 xxx3

3xxx, 5xxx,

4xx3 6xx3,7xx3

10xxx, 11xxx

0 NSET-JOG*1 not assigned NSET-JOG*1 not assigned not assigned CSEL1-CAM*1 NSET-JOG*1 not assigned not assigned

1 NSET-JOG*2 not assigned NSET-JOG*2 not assigned not assigned CSEL1-CAM*2 NSET-JOG*2 not assigned not assigned

2 NSET-N-INV NSET-N-INV NSET-N-INV NSET-N-INV not assigned CSEL1-CAM*4 NSET-N-INV not assigned not assigned

3 AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP AIF-CTRL.QSP

4 NSET-RFG-STOP NSET-RFG-

STOP

NSET-RFGSTOP

NSET-RFGSTOP

POS-PRG-START CSEL1-EVENT NSET-RFG-

STOP

NSET-RFGSTOP

not assigned

5 NSET-RFG-0 NSET-RFG-0 NSET-RFG-0 NSET-RFG-0 POS-PRG-STOP CDATA-CYCLE NSET-RFG-0 NSET-RFG-0 not assigned

6 not assigned not assigned not assigned not assigned not assigned CSEL1-LOAD not assigned not assigned not assigned

7 not assigned not assigned not assigned not assigned POS-PRG-RESET CSEL1-LOAD not assigned not assigned not assigned

8 not assigned not assigned not assigned not assigned not assigned not assigned not assigned not assigned not assigned

9 AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH AIF-CTRL.CINH

10 AIF-CTRL.TRIP-SET AIF-CTRL.TRIP-

SET

11 AIF-CTRL.TRIP-

RESET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIPRESET

AIF-CTRL.TRIPSET

AIF-CTRL.TRIP-

RESET

12 DCTRL-PAR*1 DCTRL-PAR*1 DCTRL-PAR*1 DCTRL-PAR*1 POS-PS-CANCEL not assigned DCTRL-PAR*1 DCTRL-PAR*1 DCTRL-PAR*1

13 DCTLR-PAR-LOAD DCTLR-PAR-

LOAD

DCTLR-PARLOAD

DCTLR-PARLOAD

POS-PARAM-RD not assigned DCTLR-PAR-

LOAD

DCTLR-PARLOAD

DCTLR-PAR-

LOAD

14 NSET-Ti*1 NSET-JOG*1 REF-ON REF-ON POS-LOOP-ONH not assigned NSET-Ti*1 NSET-JOG*1 not assigned

15 NSET-Ti*2 NSET-JOG*2 NSET-Ti*1 not assigned POS-STBY-STP not assigned NSET-Ti*2 NSET-JOG*2 not assigned

A I F - I N

C 0 8 5 6 / 1

C 1 1 9 7

D C T R L

Q S P

D I S A B L E

C I N H

T R I P - S E T

T R I P - R E S E T

A I F - C T R L . B 0

A I F - C T R L . B 1

A I F - C T R L . B 2

A I F - C T R L . B 4

A I F - C T R L . B 5

A I F - C T R L . B 6

A I F - C T R L . B 7

A I F - C T R L . B 1 2

A I F - C T R L . B 1 3

A I F - C T R L . B 1 4

A I F - C T R L . B 1 5

A I F - I N . W 1

A I F - I N . D 2

A I F - I N . W 2

A I F - I N . W 3

A I F - I N . B 0

A I F - I N . B 2

A I F - I N . B 1 4

A I F - I N . B 1 5

A I F - I N . B 1 6

A I F - I N . B 1 7

A I F - I N . B 3 0

A I F - I N . B 3 1

A I F - I N . D 1

A I F - C T R L . B 3

A I F - C T R L . B 8

A I F - C T R L . B 9

A I F - C T R L . B 1 0

1 6 b i t s

C 0 1 3 6 / 3

1 6 b i t s

1 6 b i t s

1 6 b i t s

C 0 8 5 5 / 1

1 6

b i n a r y

s i g n a l s

C 0 8 5 5 / 2

1 6

b i n a r y

s i g n a l s

1 6 b i t s

L o w W o r d

1 6 b i t s

H i g h W o r d

A I F - C T R L . B 1 1

1 6 b i t s

L o w W o r d

1 6 b i t s

H i g h W o r d

C 0 8 5 6 / 2

C 0 8 5 6 / 3

C 0 8 5 7

B i t 0

C o n t r o l w o r r d

B i t 1 5

B y t e 3 , 4B y t e 5 , 6

1

B y t e 7 , 8

5.6-18

2113IBU008_en

Fig. 5.6-6 Function b loc k AIF-IN (grey: Extension available as of software version 2.0)

EDSIBS-1.0-06/ 2003

L

Page 41

2111 INTERBUS fieldbus module

Show/Hide Bookmarks

5

Data transfer

Process data signals of Lenze controllers

5.6.2.4 Process data signals for 9300 servo PLC and Drive PLC

Process data telegram from

drive

The following data can be assigned to the PE data:

Index Subindex Name/variable name Explanation Lenze setting: Ind ex 6000

6041 0 DRIVECOM status word PI data word 1

6044 0 DRIVECOM speed Actual speed [rpm] PI data word 2

6054 0 DRIVECOM actual percentage

value

5F69 0 Device status word

(AIF1_DctrlStat)

5CA5 1 AIF_nOutW1_a AIF word 1

5CA5 2 AIF_nOutW2_a AIF word 2 PI data word 3

5CA5 3 AIF_nOutW3_a AIF word 3

5CA5 4 AIF2_nOutW1_a AIF word 4

5CA5 5 AIF2_nOutW2_a AIF word 5

5CA5 6 AIF2_nOutW3_a AIF word 6

5CA5 7 AIF2_nOutW4_a AIF word 7

5CA5 8 AIF3_nOutW1_a AIF word 8

5CA5 9 AIF3_nOutW2_a AIF word 9

5CA5 10 AIF3_nOutW3_a AIF word 10

5CA5 11 AIF3_nOutW4_a AIF word 11

5CA4 0 AIF1_dnOutD1_p AIFdoubleword1

5.6

5.6.2

hex

Actual speed [%]

)

) Note!

))

9300 Servo PLC

Please execute the following logic operations in the PLC program

of the controller:

AIF1_wDctrlCtrl W DCTRL_wAIF1Ctrl

DCTRL_wStat W AIF1_wDctrlStat

Drive PLC

It is necessary to use the device control for the Drive PLC.

L

EDSIBS-1.0-06/ 2003

5.6-19

Page 42

5

Show/Hide Bookmarks

2111 INTERBUS fieldbus module

5.6

5.6.2

AIF1_wDctrlStat

AIF1_nOutW1_a

AIF1_nOutW2__a

AIF1_bFDO0_b

AIF1_bFDO15_b

AIF1_nOutW3_a

AIF1_bFDO16_b

AIF1_bFDO31_b

…

…

AIF1_dnOutD1_p

C0858/1

C0858/2

C0858/3

C0859

16 bits

16 bits

16 bits

C0151/4

16 binary

signals

16 bits

C0151/4

16 binary

signals

16 bits

Low Word

16 bits

High Word

Outputs_AIF1

Byte

Byte

Byte

Byte

Byte

Byte

Byte

Byte

Data transfer

Process data signals of Lenze controllers

AIF2_nOutW1_a

1

2

3

4

5

6

7

8

Automation

Interface

AIF2_bFDO0_b

...

AIF2_bFDO15_b

AIF2_nOutW2_a

AIF2_bFDO16_b

...

AIF2_bFDO31_b

AIF2_dnOutD1_p

AIF2_nOutW3_a

AIF2_nOutW4_a

16 bits

16 binary

signals

16 bits

16 binary

signals

16 bits

Low Word

16 bits

High Word

16 bits

16 bits

Outputs_AIF2

Byte

Byte

Byte

Byte

Byte

Byte

Byte

Byte

1

2

3

4

5

6

7

8

Automation

Interface

AIF3_nOutW1_a

AIF3_bFDO0_b

...

AIF3_bFDO15_b

AIF3_nOutW2_a

AIF3_bFDO16_b

...

AIF3_bFDO31_b

AIF3_dnOutD1_p

AIF3_nOutW3_a

AIF3_nOutW4_a

Fig. 5.6-7 Function b locks AIF-OUT1, AIF-OUT2 and AIF-OUT3

16 bits

16 binary

signals

16 bits

16 binary

signals

16 bits

Low Word

16 bits

High Word