Page 1

EDS84DMOTCAN

13395082

Ä.HSsä

L-force Communication

Communication Manual

8400 motec

E84DGFCCxxx

CANopen communication unit

L

Page 2

2 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 3

Communication manual 8400 motec CANopen

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Document history

1.2 Conventions used

1.3 Terminology used

1.4 Notes used

2 Safety instructions

2.1 General safety and application instructions

2.2 Device and application-specific safety instructions

2.3 Residual hazards

3 Product description

3.1 Application as directed

3.2 Product features and variants

3.3 Connections and interfaces

4 Technical data

4.1 General data and operating conditions of the CANopen

4.2 Supported protocols

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Communication time

5 Installation

5.1 Mechanical installation

5.2 Electrical installation

6 Commissioning

6.1 Before initial switch-on

6.2 Configuring the host (master)

6.3 Possible settings via DIP switch

6.4 Settings in the Lenze »Engineer«

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.1 Network topology

5.2.2 Bus termination

5.2.3 Specification of the bus cable

5.2.4 Bus cable length

5.2.5 CANopen connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.1 Setting the baud rate

6.3.2 Setting the CAN node address

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5 Initial switch-on

EDS84DMOTCAN EN 3.0 - 11/2011 L 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 4

Communication manual 8400 motec CANopen

Contents

7 Data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 Structure of the CAN data telegram

7.1.1 Identifier

7.1.2 User data

7.2 Communication phases/network management

7.2.1 State transitions

7.2.2 Network management telegram (NMT)

7.2.3 Parameterising the Inverter Drives 8400 motec as CAN master

8 Process data transfer

8.1 Access to process data / PDO mapping

8.2 Port interconnection of the process data objects (PDO)

8.3 Identifiers of the process data objects

8.4 Transmission type

8.5 PDO synchronisation via sync telegram

9 Parameter data transfer

9.1 Identifiers of the parameter data objects

9.2 User data

9.2.1 Command

9.2.2 Addressing by means of index and subindex

9.2.3 Data 1 ... data 4

9.2.4 Error messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3 Parameter data telegram examples

9.3.1 Reading parameters

9.3.2 Write parameters

9.3.3 Reading block parameters

10 Monitoring

10.1 Monitoring of the RPDOs for data reception

10.2 Integrated error detection

10.3 Heartbeat protocol

10.4 Emergency telegram

11 Diagnostics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.3.1 Telegram structure

10.3.2 Parameter setting

10.3.3 Commissioning example

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 5

Communication manual 8400 motec CANopen

Contents

12 Parameter reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.1 Communication-relevant parameters of the operating system

12.2 Parameters for CANopen communication

12.3 Table of attributes

13 Implemented CANopen objects

14 DIP switch positions for setting the CAN node address

15 Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

EDS84DMOTCAN EN 3.0 - 11/2011 L 5

Page 6

Communication manual 8400 motec CANopen

About this documentation

1 About this documentation

Contents

This documentation exclusively describes the system bus (CAN) and the CANopen-specific

functions of the Inverter Drive 8400 motec.

Note!

This documentation supplements the mounting instructions and the hardware

manual "Inverter Drives 8400 motec" supplied with the controller.

The features of the system bus (CAN) and CANopen-specific functions for the Inverter Drive

8400 motec are described in detail.

Typical applications are explained with the help of examples.

This documentation also contains ...

the most important technical data for CAN communication;

information on the installation and commissioning of the CAN network;

information on CAN data transfer, CAN monitoring functions, communication-relevant

parameters and implemented CAN objects.

The theoretical concepts are only explained to the level of detail required to understand

the function of CAN communication with Inverter Drives 8400 motec.

Depending on the software version of the controller and of the »Engineer« software

installed, the screenshots in this documentation may vary from the »Engineer«

representation.

This documentation does not describe the software of other manufacturers. No

responsibility is taken for corresponding information given in this documentation.

Information on how to use the software can be obtained from the documents of the host

(master).

All brand names used in this documentation are trademarks of their respective owners.

Tip!

Detailed information about the system bus (CAN) can be found on the website of

the CAN user organisation CiA (CAN in Automation):

www.can-cia.org

6 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 7

Communication manual 8400 motec CANopen

About this documentation

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking and remote service of a machine.

Tip!

Information and software updates for Lenze products can be found in the

Download area at:

www.Lenze.com

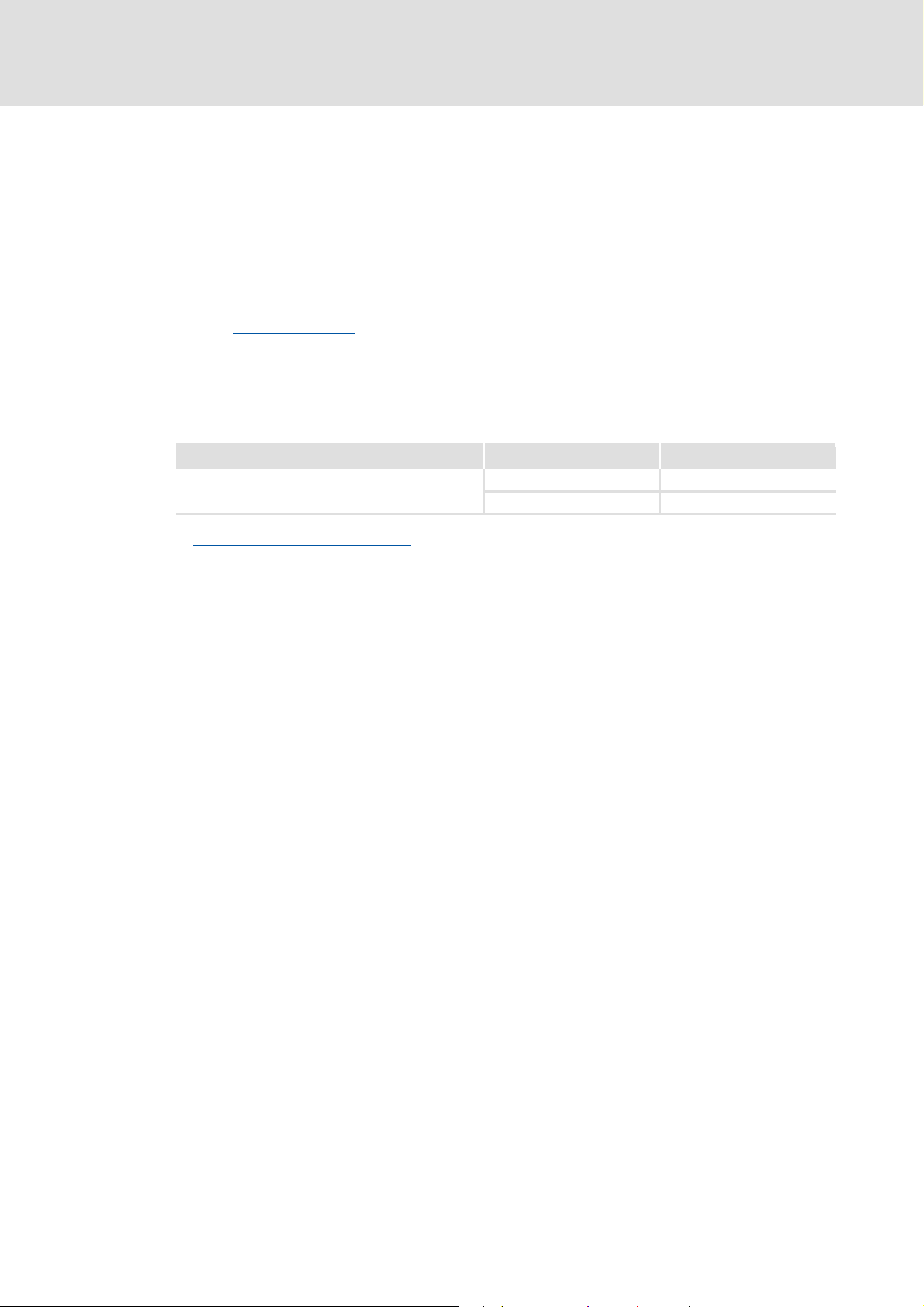

Information regarding the validity

The information given in this documentation is valid for the following devices:

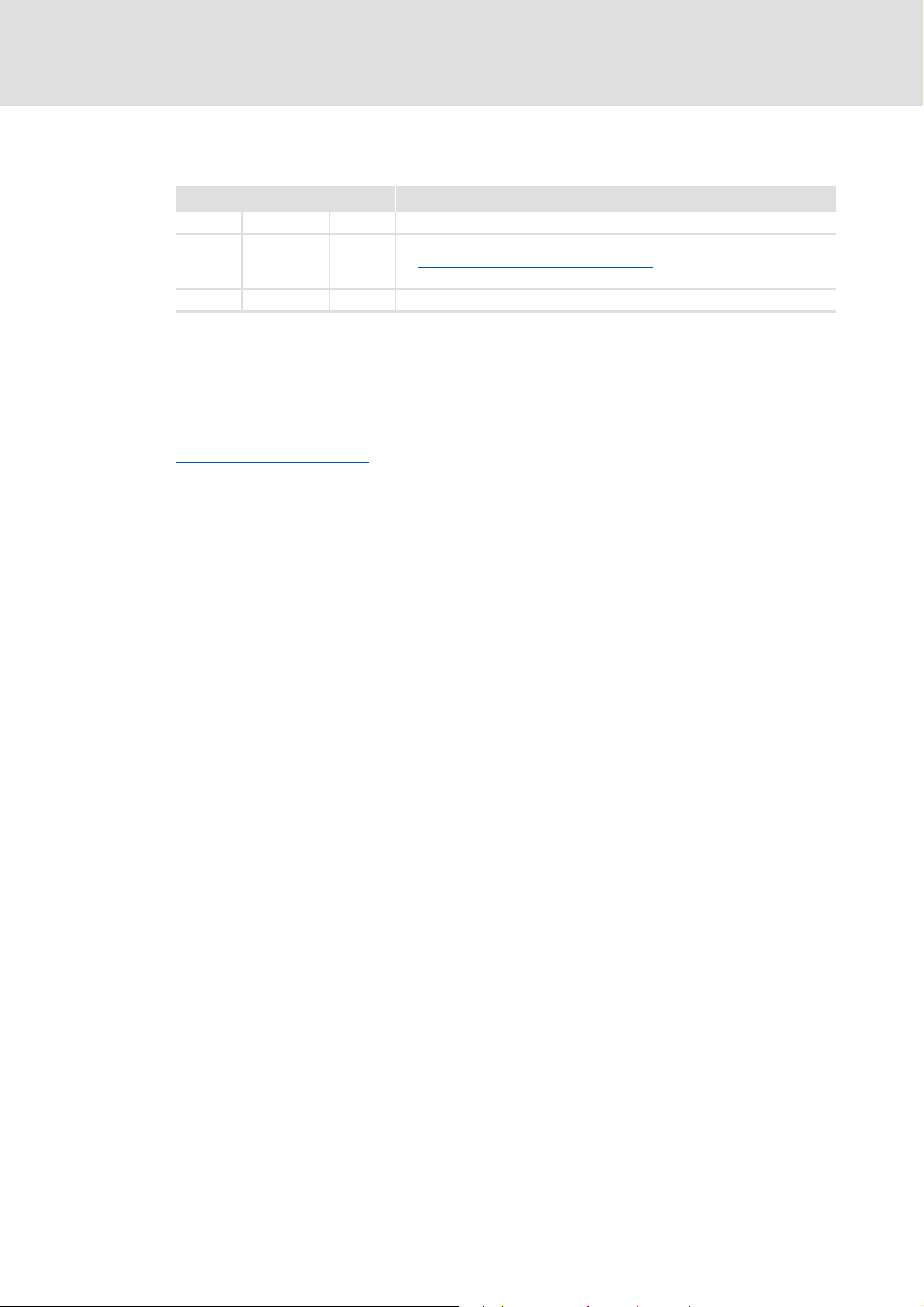

Product series Type designation Variant

Inverter Drives 8400 motec

CANopen communication unit

Product features and variants

E84DGFCCxNx CANopen

E84DGFCCxJx CANopen + safety

( 15)

EDS84DMOTCAN EN 3.0 - 11/2011 L 7

Page 8

Communication manual 8400 motec CANopen

About this documentation

Document history

1.1 Document history

Version Description

1.0 09/2010 TD17 First edition

2.0 01/2011 TD17 Update of the ...

• Parameters for CANopen communication

• »Engineer« screenshots

3.0 11/2011 TD17 General revision

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e-mail us to:

feedback-docu@Lenze.de

Thank you for your support.

( 76) (version 02.00)

Your Lenze documentation team

8 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 9

1.2 Conventions used

This manual uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Numbers

Decimal Standard notation Example: 1234

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Decimal separator Point The decimal point is always used.

Text

Program name » « PC software

Control element Bold The OK button... / The Copy command... / The

Hyperlink Underlined

Symbols

Page reference ( 9) Optically highlighted reference to another page. Can

Step-by-step instructions

Communication manual 8400 motec CANopen

About this documentation

Conventions used

In inverted commas

Point

Example: ’100’

Example: ’0110.0100’

Example: 1234.56

Example: Lenze »Engineer«

Properties tab... / The Name input field...

Optically highlighted reference to another topic. Can

be activated with a mouse-click in this

documentation.

be activated with a mouse-click in this

documentation.

Step-by-step instructions are indicated by a

pictograph.

EDS84DMOTCAN EN 3.0 - 11/2011 L 9

Page 10

Communication manual 8400 motec CANopen

About this documentation

Terminology used

1.3 Terminology used

Term Meaning

Controller Lenze frequency inverter of the "Inverter Drives 8400 motec" product series

Standard device

The 8400 motec controller consists of the following modules: "drive unit",

"communication unit", and "wiring unit".

• The drive unit is available in various power classes.

• The communication unit is available in the following versions:

–No fieldbus

–AS-i option

–CANopen option

–PROFIBUS option

–PROFINET option

–EtherCAT option

• The wiring unit provides flexible connection options for an easy integration

into the power supply of the machine.

diagnosing, and configuring) during the entire life cycle, i.e. from planning to

maintenance of the commissioned machine.

usage, the term is usually referred to as "Index".

"subcodes".

In this documentation a slash "/" is used as a separator between the code and

subcode (e.g. "C00118/3").

In normal usage, the term is also referred to as "Subindex".

Drive unit

Communication unit

Wiring unit

»Engineer« PC software from Lenze which supports you in "engineering" (parameter setting,

Code Parameter which serves to parameterise and monitor the controller. In normal

Subcode If a code contains more than one parameter, these parameters are stored in

Lenze setting These are settings with which the device is preconfigured ex works.

Basic setting

HW Hardware

SW Software

Note!

Some of the terms used originate from the CANopen protocol.

10 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 11

1.4 Notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and suggests how to avoid the danger)

Pictograph Signal word Meaning

Communication manual 8400 motec CANopen

About this documentation

Danger! Danger of personal injury through dangerous electrical voltage

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Danger! Danger of personal injury through a general source of danger

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Stop! Danger of property damage

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Notes used

Application notes

Pictograph Signal word Meaning

Note! Important note for trouble-free operation

Tip! Useful tip for simple handling

Reference to other documents

EDS84DMOTCAN EN 3.0 - 11/2011 L 11

Page 12

Communication manual 8400 motec CANopen

Safety instructions

General safety and application instructions

2 Safety instructions

Note!

Always observe the specified safety measures to avoid severe injury to persons

and damage to property!

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety and application instructions

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets.

Lenze drive and automation components ...

– must only be used as directed.

Application as directed

– must never be commissioned in the event of visible damage.

– must never be technically modified.

– must never be commissioned before they have been completely mounted.

– must never be operated without the covers required.

– can - depending on the degree of protection - have live, movable or rotating parts

during operation and after operation. Surfaces can be hot.

For Lenze drive components ...

– use only the accessories approved.

– use only original spare parts from the manufacturer.

Observe all specifications given in the attached and associated documentation.

– This is the precondition for safe and trouble-free operation and for achieving the

specified product features.

Product features and variants

– The procedural notes and circuit details described in this document are only

proposals. It is up to the user to check whether they can be adapted to the particular

applications. Lenze does not take any responsibility for the suitability of the

procedures and circuit proposals described.

( 14)

( 15)

12 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 13

Communication manual 8400 motec CANopen

Device and application-specific safety instructions

Only qualified personnel may work with and on Lenze drive and automation

components. In accordance with IEC 60364 and CENELEC, these are persons ...

– who are familiar with the installation, assembly, commissioning, and operation of

the product.

– who have the corresponding qualifications for their work.

– who know all regulations for the prevention of accidents, directives and laws

applicable on site and are able to apply them.

2.2 Device and application-specific safety instructions

During operation, the communication unit must be connected to the wiring unit and

the drive unit.

With external voltage supply, always use a separate power supply unit, safely

separated in accordance with EN 61800-5-1 in every control cabinet ("SELV"/"PELV").

Only use cables that correspond to the given specifications.

Specification of the bus cable

( 26)

Safety instructions

Documentation of "Inverter Drives 8400 motec", control system, plant/machine

All other measures prescribed in this documentation must also be implemented.

Observe the safety instructions and application notes specified in the

documentation.

2.3 Residual hazards

Device protection

The communication unit contains electronic components that can be damaged or

destroyed by electrostatic discharge.

Installation

( 22)

EDS84DMOTCAN EN 3.0 - 11/2011 L 13

Page 14

Communication manual 8400 motec CANopen

Product description

Application as directed

3 Product description

3.1 Application as directed

The CANopen communication unit ...

is a unit that can only be used in conjunction with the following modules:

Product series Type designation

Inverter Drives 8400 motec

Drive unit

Inverter Drives 8400 motec

Wiring unit

is a device intended for use in industrial power systems.

may only be operated under the operating conditions specified in this documentation.

E84DGDVxxxxxxxx

E84DGVNxx

may only be used in CANopen networks.

can also be used without being connected to the CANopen network.

Any other use shall be deemed inappropriate!

14 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 15

3.2 Product features and variants

The CANopen communication unit is available in the following versions:

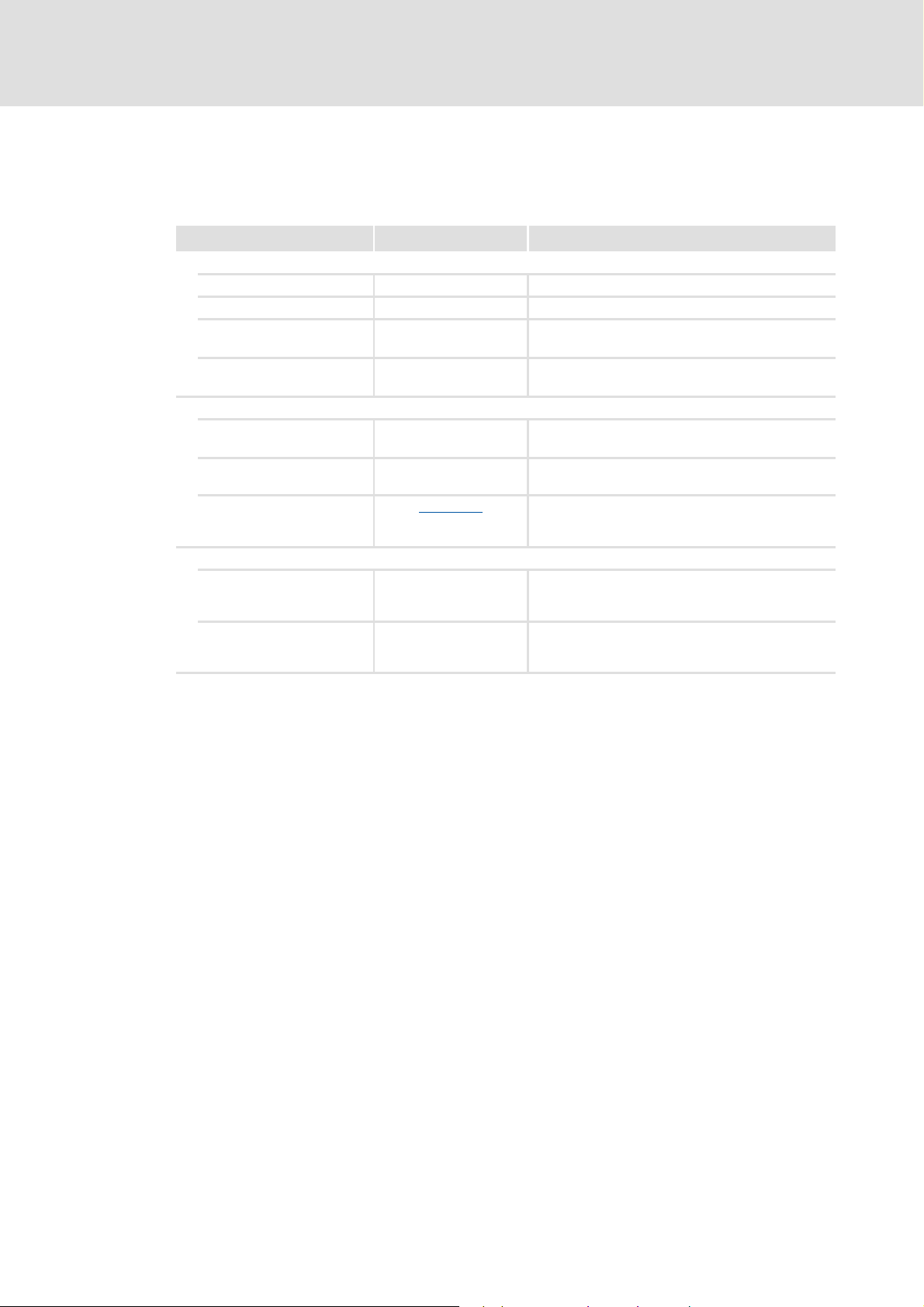

Product series Type designation Features

Inverter Drives 8400 motec

CANopen communication unit

The CANopen communication unit ...

– is mounted on the wiring unit (E84DGVNxx);

– is exclusively supplied internally by the drive unit (E84DGDVxxxxxxxx).

Communication manual 8400 motec CANopen

Product description

Product features and variants

Enclosure

IP 65

CANopen

M12

I/O: Terminal

E84DGFCCANP zz z

E84DGFCC9NP zzz

E84DGFCCAJP zz zz

E84DGFCC9JP zzz z

I/O: M12

Safety

The I/O connections can be led into the device via M12 connectors or by means of cable

glands.

In the E84DGFCC9xx version, a maximum of four digital inputs is conducted on M12

connectors (see "Inverter Drives 8400 motec" hardware manual).

Devices without an integrated safety system (safety option) have no analog input and

no relay output.

In the case of the E84DGFCCxJx communication units, the integrated safety system can

be used for the protection of persons on machines.

Setting of the CAN node address and baud rate is possible via DIP switch or code.

Communication with the Lenze »Engineer« (access to all Lenze parameters) is

preferably carried out via the CAN bus. Furthermore communication can be effected via

the diagnostic interface of the drive unit.

"Inverter Drives 8400 motec" hardware manual

Here you'll find detailed information on the integrated safety system (safety

option).

Software manual / »Engineer« online help "Inverter Drives 8400 motec"

Here you will find detailed information on how to configure the safety system

(safety option).

EDS84DMOTCAN EN 3.0 - 11/2011 L 15

Page 16

Communication manual 8400 motec CANopen

Product description

Product features and variants

The system bus (CANopen) of the Inverter Drives 8400 motec is the advanced version of the

system bus (CAN) and includes the following features:

Full compatibility according to CANopen DS301, V4.02.

Support of the "Heartbeat" NMT slave function (DS301, V4.02).

Number of parameterisable server SDO channels:

– Max. 2 channels with 1 ... 8 bytes

– Because of the 2 server SDO channels, the address range from 1 ... 63 is available.

Number of parameterisable PDO channels:

– Max. 2 transmit PDOs (TPDOs) with 1 ... 8 bytes (adjustable)

– Max. 2 receive PDOs (RPDOs) with 1 ... 8 bytes (adjustable)

All PDO channels are functionally equivalent.

Monitoring of the RPDOs for data reception

Adjustable error response to ...

– physical CAN errors (frame, bit, ACK error)

– bus-stop, bus-working

– missing PDOs

Telegram counters for SDOs and PDOs

Bus status diagnostics

Boot-up telegram generation

Emergency telegram generation

Reset node telegram generation (in the case of master configuration)

Sync telegram generation and response to sync telegrams:

– Data transmission/reception

– Device-internal time base synchronisation

Abort codes

Object directory (all mandatory functions, optional functions, indexes)

16 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 17

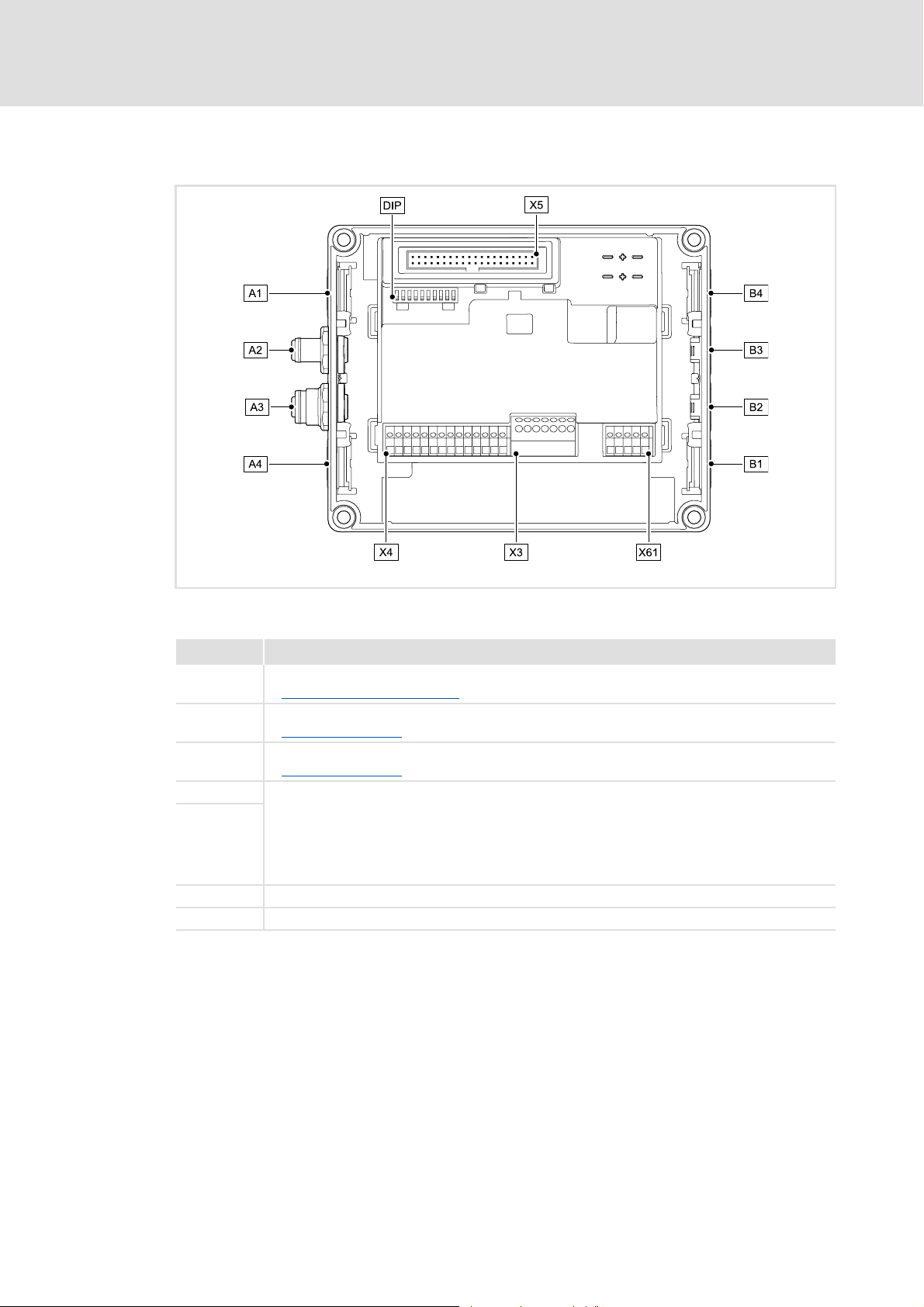

3.3 Connections and interfaces

Communication manual 8400 motec CANopen

Product description

Connections and interfaces

[3-1] CANopen communication unit

Pos. Description

DIP DIP switch

Possible settings via DIP switch

A2 CANopen input (M12 pins, 5-pole)

CANopen connection

A3 CANopen output (M12 socket, 5-pole)

CANopen connection

A1 / A4 Positions for further freely designable inputs and outputs:

B1 ... B4

X3 / X4 / X61 Terminal strips for wiring the connectors at A1 ... A4 and B1 ... B4

X5 Plug connector for connection to the drive unit

• Digital inputs

•Digital output

• Analog input (only for E84DGFCCxJx)

• Relay output (only for E84DGFCCxJx)

• Connection of safety system "Safety Option" (only for E84DGFCCxJx)

E84DG002

( 32)

( 29)

( 29)

EDS84DMOTCAN EN 3.0 - 11/2011 L 17

Page 18

Communication manual 8400 motec CANopen

Product description

Connections and interfaces

By default, the CANopen connectors are already pre-assembled and wired with the

terminal strip X3.

The CANopen connections and further connections (e.g. digital inputs) can be freely

designed at the positions A1 ... A4 and B1 ... B4..

The connections can be equipped with 5-pole M12 connectors, or optionally with cable

glands (cable cross-section max. 1.0 mm

The M12 connectors, cable glands and prefabricated system cables can be obtained

from various manufacturers.

Wire the M12 connectors or cable glands used to the corresponding contacts of

terminal strips X3, X4, and X61.

2

, AWG 18).

"Inverter Drives 8400 motec" hardware manual

Observe the notes and wiring instructions given in the documentation.

18 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 19

Communication manual 8400 motec CANopen

General data and operating conditions of the CANopen

4 Technical data

"Inverter Drives 8400 motec" hardware manual

Here you will find the ambient conditions and information on the

electromagnetic compatibility (EMC) that also apply to the communication unit.

4.1 General data and operating conditions of the CANopen

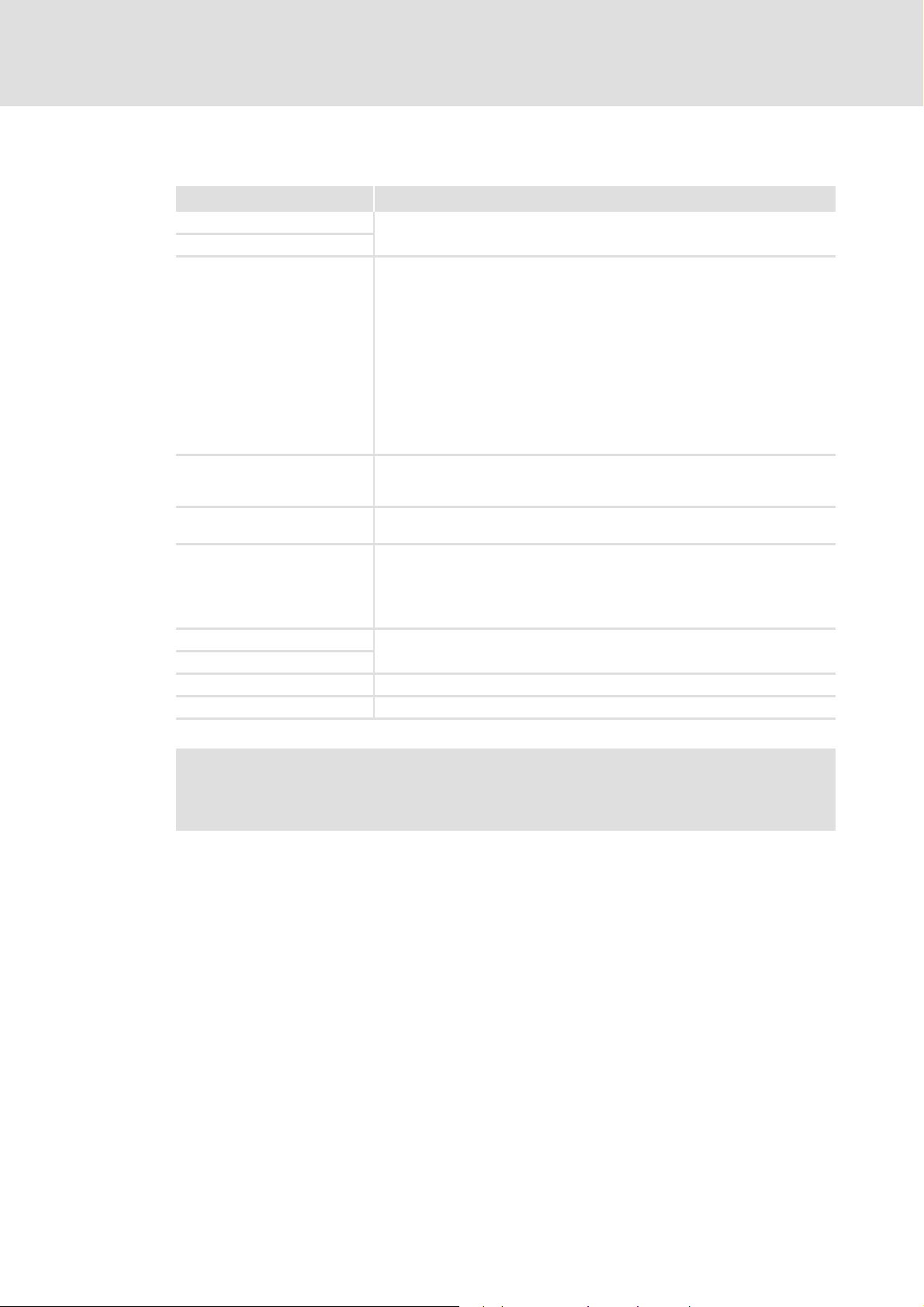

Field Values

Order designation • E84DGFCCxNx (CANopen)

• E84DGFCCxJx (CANopen + Safety)

Communication profile CANopen, DS301 V4.02

Communication medium DIN ISO 11898

Interface • CANopen input: M12 pins, 5-pole, A-coded

• CANopen output: M12 socket, 5-pole, A-coded

Network topology Line terminated on both sides

Adjustable node address 1 ... 63 (can be set via DIP switch or code C00350

Max. number of nodes 63

Baud rate [kbps] 20, 50, 125, 250, 500, 800, 1000 kbps, adjustable via DIP switches or code

C00351

Process data • Max. 2 transmit PDOs (TPDOs) with 1 ... 8 bytes (adjustable)

• Max. 2 receive PDOs (RPDOs) with 1 ... 8 bytes (adjustable)

Parameter data Max. 2 server SDO channels with 1 ... 8 bytes

Transmission mode for TPDOs • With change of data

• Time-controlled, 1 to x ms

• After the reception of 1 to 240 sync telegrams

Conformities, approvals • CE

•UR / cUR

Technical data

)

EDS84DMOTCAN EN 3.0 - 11/2011 L 19

Page 20

Communication manual 8400 motec CANopen

Technical data

Supported protocols

4.2 Supported protocols

Protocols

Standard PDO protocols PDO write

PDO read

SDO protocols SDO download

SDO download initiate

SDO download segment

SDO upload

SDO upload initiate

SDO upload segment

SDO abort transfer

SDO block download

SDO block download initiate

SDO block download end

SDO block upload

SDO block upload initiate

SDO block upload end

NMT protocols Start remote node (master and slave)

Stop remote node (slave)

Enter pre-operational (slave)

Reset node (slave and local device)

Reset communication protocol (slave)

Monitoring protocols Heartbeat (heartbeat producer and heartbeat consumer)

• 1 Heartbeat Producer can be monitored.

Emergency telegram (to master)

20 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 21

4.3 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times in a CANopen network depend on ...

the processing time in the controller;

the telegram runtime (baud rate / telegram length);

the nesting depth of the network.

Processing time in the controller

Data Processing time

Process data Approx. 2 ms

Parameter data Approx. 30 ms + 20 ms tolerance (typical)

Communication manual 8400 motec CANopen

Technical data

Communication time

update cycle

+ 0 ... 1 ms

+ 1 ... x ms

• For some codes, the processing time may be longer (see software

manual/»Engineer« online help "Inverter Drives 8400 motec").

processing time in the module

application task runtime of the technology application used

(tolerance)

There are no interdependencies between parameter data and process data.

EDS84DMOTCAN EN 3.0 - 11/2011 L 21

Page 22

Communication manual 8400 motec CANopen

Installation

5 Installation

Stop!

Electrostatic discharge

Electronic components within the communication unit can be damaged or

destroyed by electrostatic discharge.

Possible consequences:

• The communication unit is defective.

• Communication via the fieldbus is not possible or faulty.

• I/O signals are faulty.

• The safety function is faulty.

Protective measures

• Discharge electrostatic charges before touching the communication unit.

22 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 23

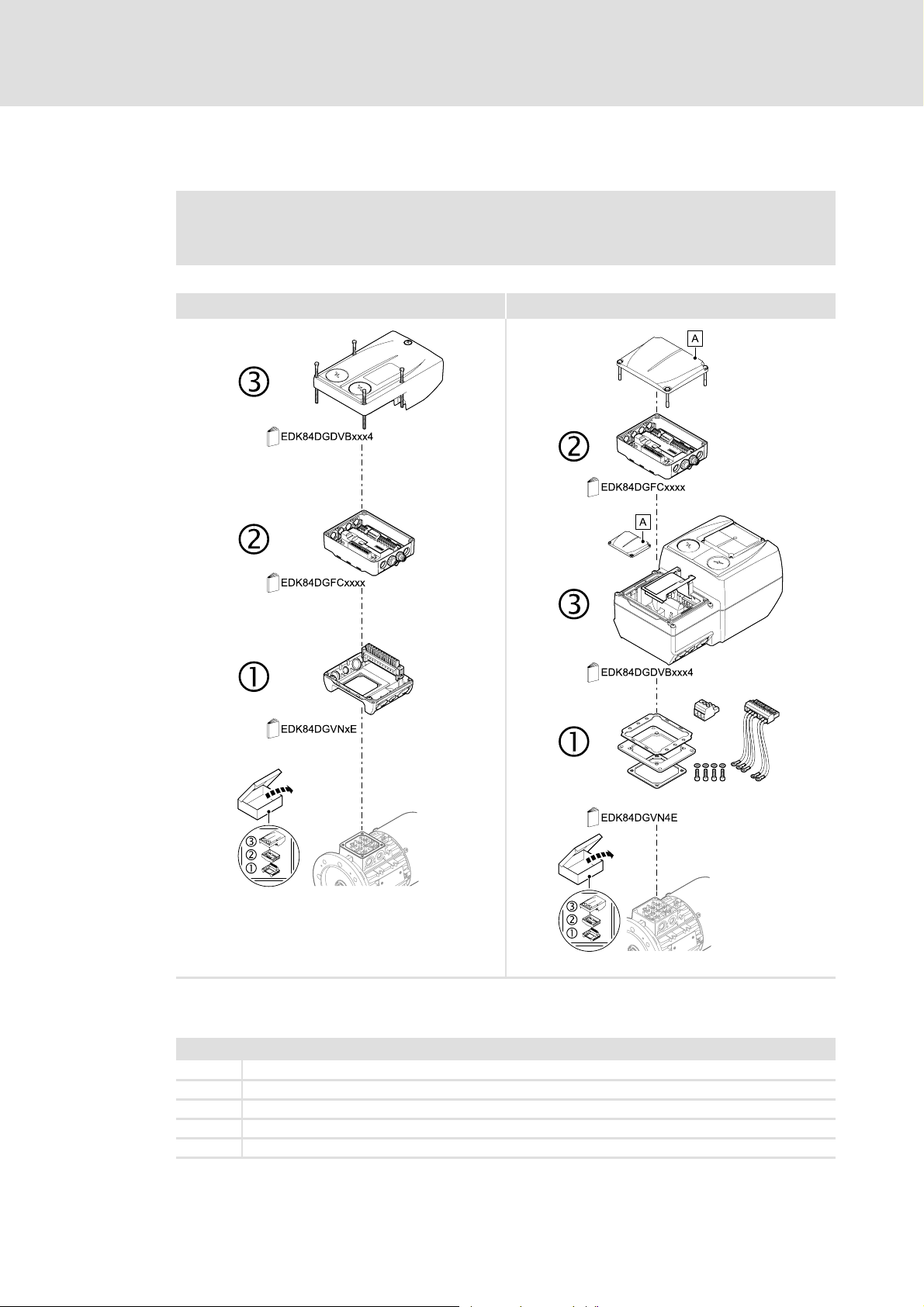

5.1 Mechanical installation

Mounting instructions for "Inverter Drives 8400 motec"

Here you will find detailed information on the installation.

0.37 ... 3.0 kW 4.0 ... 7.5 kW

Communication manual 8400 motec CANopen

Installation

Mechanical installation

[5-1] Mechanical installation of the 8400 motec components

Legend for Fig. [5-1]

1 Drive unit

2 Communication unit

3 Wiring unit

A Cover of the drive unit

EDK84DG... Mounting instructions for the drive unit, communication unit, wiring unit

E84DG023a

E84DG023b

EDS84DMOTCAN EN 3.0 - 11/2011 L 23

Page 24

Communication manual 8400 motec CANopen

Installation

Electrical installation

5.2 Electrical installation

"Inverter Drives 8400 motec" hardware manual

Here you'll find detailed information on ...

• the digital and analog inputs and outputs;

• the relay output;

• the integrated safety system (safety option);

• the wiring of the connections.

Observe the notes and wiring instructions given in the documentation.

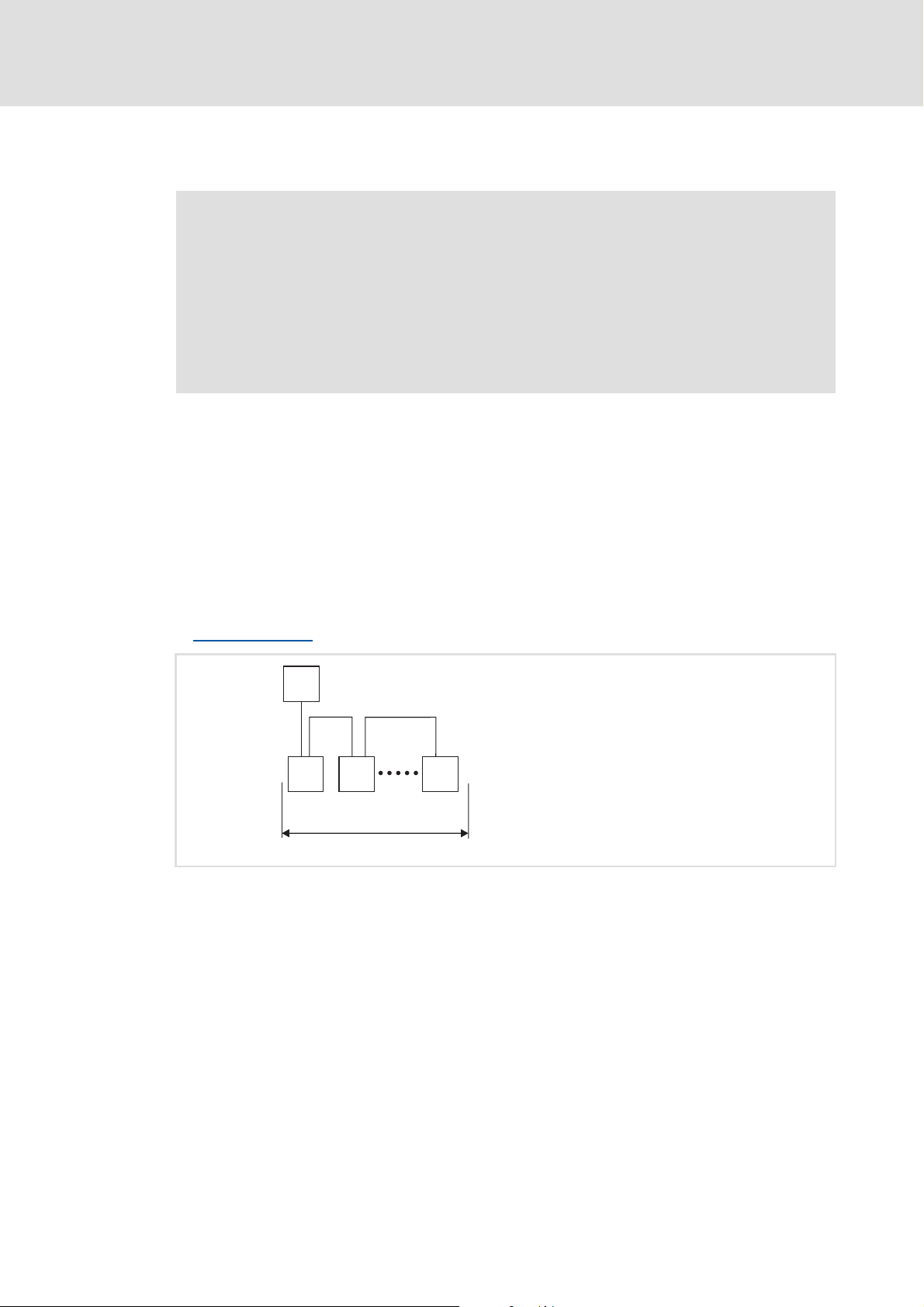

5.2.1 Network topology

The following examples show two simple CAN networks.

Each segment of the network must be terminated at both ends by resistors (120 Ω)

between CAN-Low and CAN-High. The bus terminators of the system bus (CAN) are marked

with a "Z" in the following examples.

A CAN network consisting of only one segment starts with the CAN master (M) with

integrated bus termination, whereas the last CAN node (S) has to be terminated by a bus

terminating resistor.

Bus termination

( 25)

M

Z

Z

S SS

1

[5-2] CAN network with one segment

E94YCPM012a

24 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 25

Communication manual 8400 motec CANopen

Installation

Electrical installation

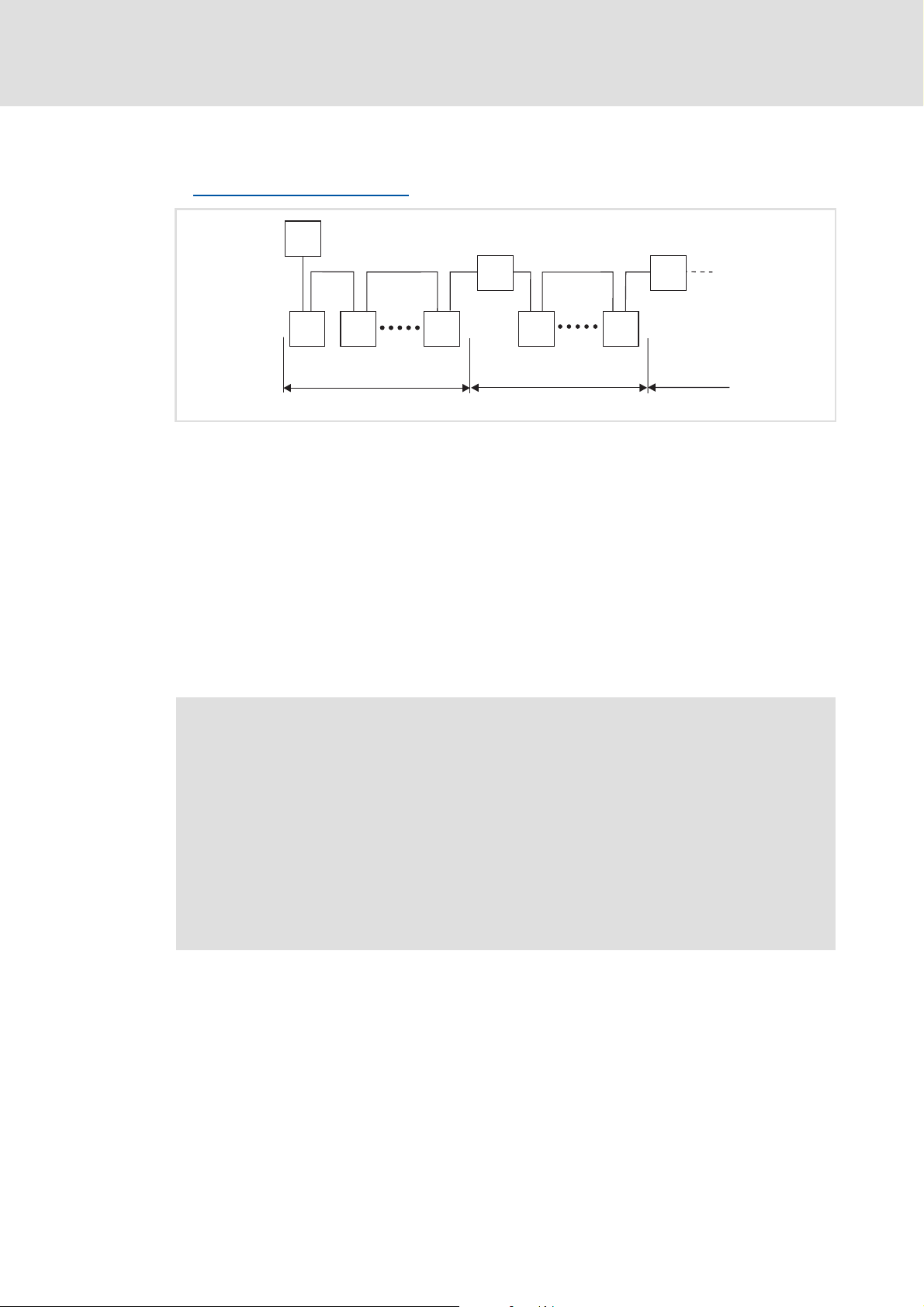

A CAN network consisting of several segments contains repeaters (R) for connecting the

segments. The repeaters are provided with integrated bus terminations.

Consider the use of repeaters

( 28)

M

Z

Z

Z

R

Z

Z

R

Z

[5-3] CAN network with repeaters

If no repeater is to be used at the end of the segment, the bus must be terminated by a bus

terminating resistor at the last node (S). The bus termination is supplied by the node itself.

5.2.2 Bus termination

The system bus (CANopen) must be terminated through a bus terminating resistor at the

first and last physical node (120 Ω).

In the case of the communication unit, the bus terminating resistor can only be installed

externally at the M12 connector. This has the advantage that the presence of the resistor

can be identified on the closed device.

Note!

• The CANopen terminals (input and output) must be installed so that they are

closed. For this purpose either use a connecting cable, a closed terminating

resistor plug (M12 pins, 5-pole, A-coded), or a cap.

• The connecting cable and terminating resistor plug can be procured freely

from various cable manufacturers (e.g. Lapp or Turck).

• If you want to disconnect individual nodes, ensure that the bus terminations

at the cable ends remain active. Otherwise the bus may become instable.

• Observe that the bus terminator is no longer active when the terminating

resistor plug has been removed.

S SS

S S

1 23

E94YCPM012b

EDS84DMOTCAN EN 3.0 - 11/2011 L 25

Page 26

Communication manual 8400 motec CANopen

Installation

Electrical installation

5.2.3 Specification of the bus cable

We recommend the use of CAN cables in accordance with ISO 11898-2:

CAN cable in accordance with ISO 11898-2

Cable type Paired with shielding

Impedance 120 Ω (95 ... 140 Ω)

Cable resistance/cross-section

Cable length ≤ 300 m

Cable length 301 ... 1000 m

Signal propagation delay ≤ 5 ns/m

≤ 70 mΩ/m / 0.25... 0.34 mm

≤ 40 mΩ/m / 0.5 mm

2

(AWG20)

2

(AWG22)

Observe the notes provided on the Bus cable length

5.2.4 Bus cable length

Note!

• It is absolutely necessary to comply with the permissible cable lengths.

• Please take into account the reduction of the total cable length due to the

• Mixed operation refers to different nodes being connected to the same

Total cable length

• If the total cable lengths of the nodes are different at the same baud rate, the

1. Check that the total cable length is not exceeded.

The total cable length is determined by the baud rate.

( 26)!

signal delay of the repeater.

Consider the use of repeaters

( 28)

network.

smaller value must be used to determine the maximum cable length.

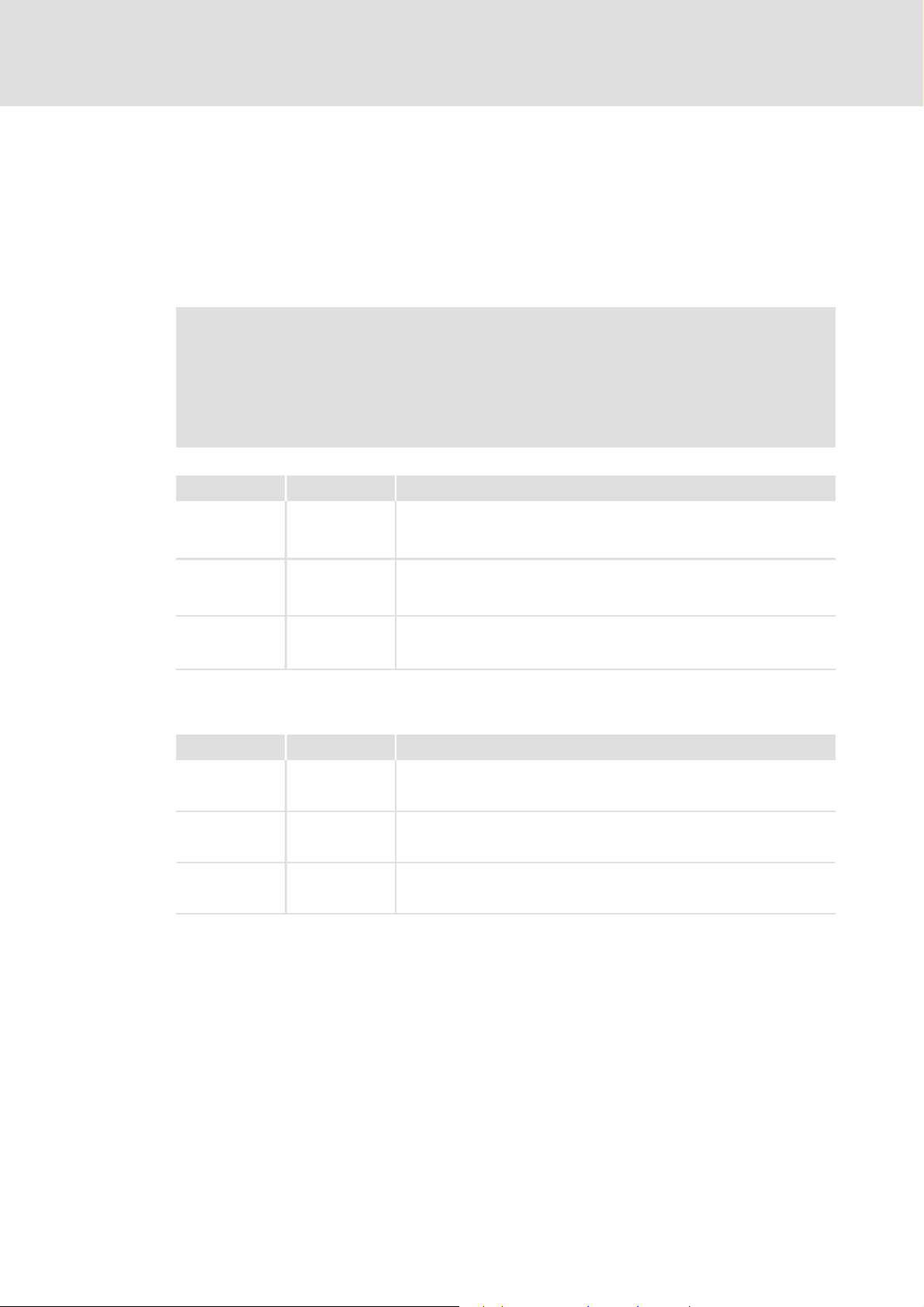

Baud rate [kbps] Max. bus length [m]

20 4013

50 1575

125 600

250 275

500 113

800 38

1000 13

[5-1] Total cable length

26 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 27

Communication manual 8400 motec CANopen

Segment cable length

2. Check that the segment cable length is not exceeded

The segment cable length is determined by the number of nodes and the cable

cross-section used. Without a repeater, the segment cable length corresponds to

the total cable length.

Installation

Electrical installation

Maximum number of

nodes per segment

2 240 m 430 m 650 m 940 m

5 230 m 420 m 640 m 920 m

10 230 m 410 m 620 m 900 m

20 210 m 390 m 580 m 850 m

32 200 m 360 m 550 m 800 m

63 170 m 310 m 470 m 690 m

[5-2] Segment cable length

3. Compare both values.

If the value determined from the Segment cable length

the required total cable length Total cable length

Repeaters divide the total cable length into segments.

Selection example

Given

• Cable cross-section: 0.5 mm

• Number of nodes: 63

• Repeater: Lenze repeater, type 2176 (cable reduction: 30 m)

Cable cross-section

0.25 mm

2

0.5 mm

2

0.75 mm

2

1 mm

[5-2] table is smaller than

[5-1], repeaters must be used.

2

, according to Specification of the bus cable ( 26)

2

Based on the given specifications, the following cable lengths/number of repeaters result

for a maximum of 63 nodes:

Baud rate [kbps] 20 50 125 250 500 800 1000

Max. cable length [m] 4013 1575 600 275 113 38 13

Segment cable length [m] 270 270 270 270 113 38 13

Number of repeaters 15621- - -

EDS84DMOTCAN EN 3.0 - 11/2011 L 27

Page 28

Communication manual 8400 motec CANopen

Installation

Electrical installation

Consider the use of repeaters

Note!

The use of an additional repeater is recommended as:

• Service interface

– Advantage: Trouble-free connecting during ongoing bus operation is

possible.

• Calibration interface

– Advantage: Calibration/programming units remain electrically isolated.

Given

• Baud rate: 125 kbps

• Cable cross-section: 0.5 mm

• Number of nodes: 28

• Cable length: 450 m

2

Steps Cable length See

1 Total cable length at 125 kbps: 600 m Table Total cable length

2 Segment cable length for 28 nodes and a

cable cross-section of 0.5 mm

3 Comparison: The value determined in

step 2 is smaller than the required cable

length of 450 m.

2

:

360 m Table Segment cable length

( 27)

Conclusion:

A cable length of 450 m is not possible without installing a repeater.

After 360 m (step 2), a repeater must be installed.

Result:

The Lenze repeater, type 2176 (cable reduction: 30 m), is used

Calculation of the max. cable length:

– First segment: 360 m

– Second segment: 360 m (according to the table Segment cable length

[5-2] ( 27))

minus 30 m (cable reduction when a repeater is used)

Max. possible cable length with one repeater: 690 m

– Now the required cable length is possible.

[5-1] ( 26)

[5-2]

28 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 29

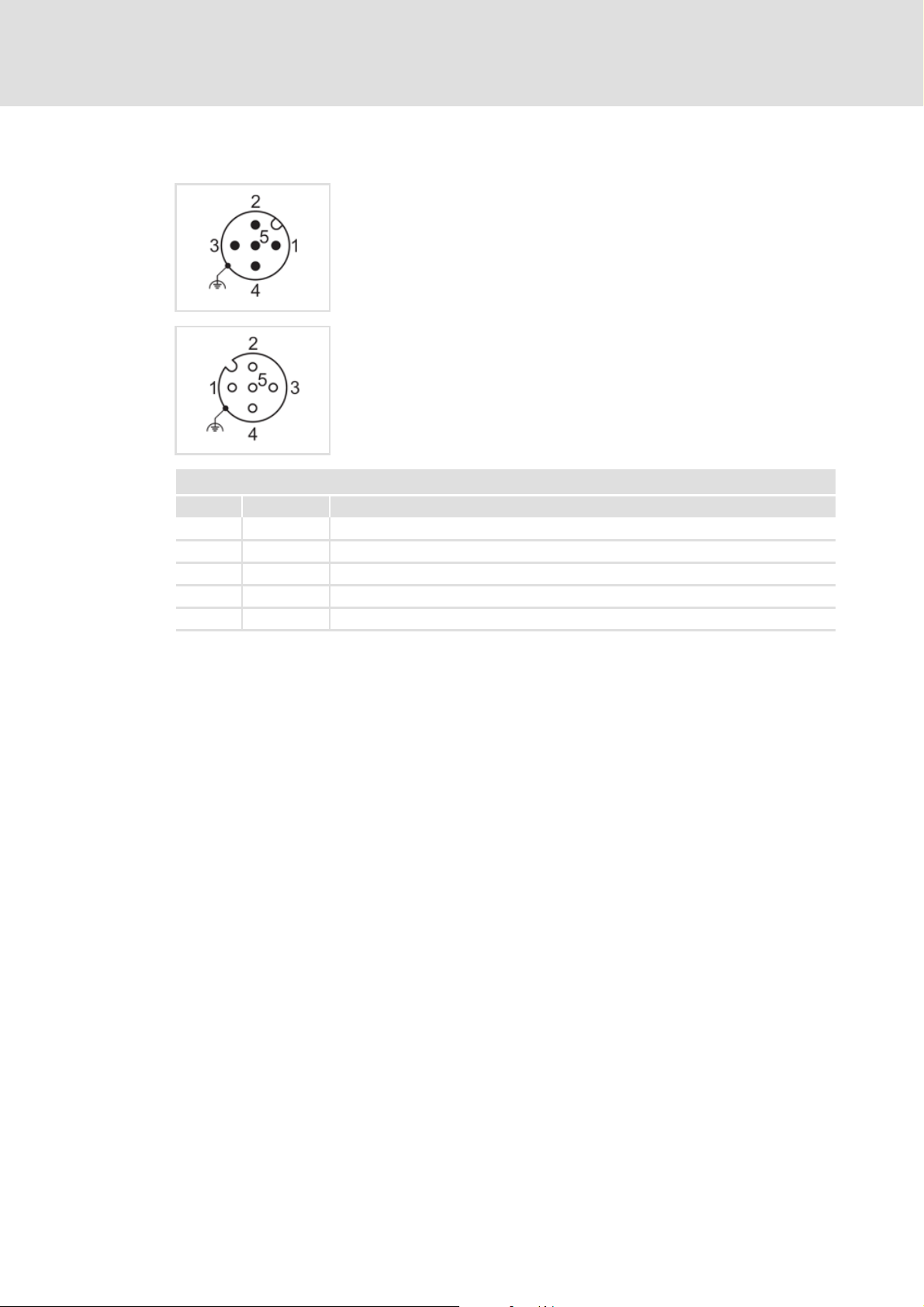

5.2.5 CANopen connection

CANopen connection

Pin Signal Description

1 - Not assigned

2 - Not assigned

3CG CAN GND potential

4 CH CAN-High data line

5CL CAN-Low data line

Communication manual 8400 motec CANopen

Installation

Electrical installation

Input: M12 pins, 5-pole, A-coded

Wiring at terminal strip X3

Output: M12 socket, 5-pole, A-coded

Wiring at terminal strip X3

EDS84DMOTCAN EN 3.0 - 11/2011 L 29

Page 30

Communication manual 8400 motec CANopen

Commissioning

Before initial switch-on

6 Commissioning

During commissioning, system-related data such as motor parameters, operating

parameters, responses, and parameters for fieldbus communication are defined for the

controller. For Lenze devices, this is done via the codes.

The codes of the controller and communication are saved non-volatilely as a data set in the

memory module.

In addition, other codes are also available for diagnosing and monitoring the nodes.

Parameter reference

6.1 Before initial switch-on

Stop!

Before switching on the device for the first time, please check ...

• the entire wiring for completeness, short circuit, and earth fault.

• whether the bus system is terminated through a bus terminating resistor at

the first and last physical node.

Bus termination

( 75)

( 25)

30 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 31

6.2 Configuring the host (master)

First you have to configure the host (master) for the communication with the controller.

Defining the user data length

The CANopen communication unit supports the configuration of max. 8 process data

words (max. 64 bytes).

The user data length is defined during the initialisation phase of the master.

The user data lengths for process input data and process output data are the same.

Note!

The CANopen process data objects are designated as seen from the node's view:

• Receive PDO (RPDOx): Process data object received by a node

• Transmit PDO (TPDOx): Process data object sent by a node

Communication manual 8400 motec CANopen

Commissioning

Configuring the host (master)

EDS84DMOTCAN EN 3.0 - 11/2011 L 31

Page 32

Communication manual 8400 motec CANopen

Commissioning

Possible settings via DIP switch

6.3 Possible settings via DIP switch

The DIP switches serve to ...

[6-1] DIP switch

Note!

• The DIP switches can only be accessed when the drive unit is detached from

the communication unit. Loosen the four fixing screws at the drive unit.

Observe the notes in the mounting instructions.

• Switch off the voltage supply of the controller and the external supply of the

communication unit before starting with the dismounting of the drive unit.

• The DIP switches are only read in when the device is switched on.

6.3.1 Setting the baud rate

The baud rate ...

must be the same for all networked CANopen nodes;

Setting the baud rate

( 32) (switches: a ... c)

Setting the CAN node address

(switches: 1 ... 64)

Lenze setting: All switches OFF

( 33)

can be set via the DIP switches a...c or via the »Engineer« (code C00351

DIP switch position Baud rate

c b a

ON OFF ON 20 kbps

OFF ON ON 50 kbps

OFF ON OFF 125 kbps

OFF OFF ON 250 kbps

OFF OFF OFF 500 kbps

ON ON OFF 800 kbps

ON OFF OFF 1000 kbps

Settings in the Lenze »Engineer«

( 34)

).

32 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 33

6.3.2 Setting the CAN node address

The node addresses must differ from each other in the case of several networked CANopen

nodes.

The node address can be set via DIP switches 1...64 or via the »Engineer« with code

C00350

.

Communication manual 8400 motec CANopen

Commissioning

Possible settings via DIP switch

For the setting with C00350

DIP switches 1...64must be set toOFF.

Note!

• The valid address range is 0 ... 63.

• If DIP switch 64 = ON (node address > 63), always node address 63 is used.

DIP switch Node address

64 32 16 8 4 2 1

OFF OFF OFF OFF OFF OFF OFF Value from C00350

OFF OFF OFF OFF OFF OFF ON 1

OFF ... ... ... ... ... ... ...

OFF ON ON ON ON ON ON 63

ON ... ... ... ... ... ...

The labelling on the housing corresponds to the values of the individual DIP switches for

determining the node address.

DIP switch 64 32 16 8 4 2 1

Switch position OFF OFF ON OFF ON ON ON

Value 00

Node address = Sum of the values = 16 + 4 + 2 + 1 = 23

16 0 4 2 1

The current address setting of the DIP switches is displayed in C00349

DIP switch positions for setting the CAN node address

Settings in the Lenze »Engineer«

( 34)

( 106)

.

EDS84DMOTCAN EN 3.0 - 11/2011 L 33

Page 34

Communication manual 8400 motec CANopen

Commissioning

Settings in the Lenze »Engineer«

6.4 Settings in the Lenze »Engineer«

The following settings can be made in the »Engineer« under the Settings tab:

CAN node address (C00350

– The node address can only be parameterised if the node address "0" is set via the DIP

switches.

– A change of the node address will only become effective after a CAN reset node.

CAN node is slave or master (C00352

Deceleration during status change from "Boot-up" to "Operational" (C00356/1

Time to the first transmission of CANx_OUT in the "Operational" state (C00356/4)

)

)

)

Save changed settings with the device command C00002/11 (save all parameter sets).

34 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 35

6.5 Initial switch-on

Establishing communication

To establish communication, the controller must be supplied with mains voltage.

All parameters (codes) and DIP switch settings are read in when the device is switched

on.

If an error occurs, the error message "CE04: MCI communication error" (error no.

01.0127.00002) is output.

The positions of the DIP switches define whether the CAN node address and the baud

rate are selected via the DIP switches or via codes C00350

Possible settings via DIP switch

Communication manual 8400 motec CANopen

Commissioning

Initial switch-on

and C00351.

( 32)

EDS84DMOTCAN EN 3.0 - 11/2011 L 35

Page 36

Communication manual 8400 motec CANopen

Data transfer

Structure of the CAN data telegram

7 Data transfer

Via the system bus interface, for instance process data and parameter values can be

exchanged between the nodes. In addition, the interface enables the connection of

additional modules such as distributed terminals, keypads and input devices or external

control systems and hosts (masters).

The system bus interface transfers CAN objects following the CANopen communication

profile (CiA DS301, version 4.02) developed by the umbrella organisation of CiA (CAN in

Automation) in conformity with the CAL (CAN Application Layer).

7.1 Structure of the CAN data telegram

6WDUW 575ELW

,GHQWLILHU 8VHUGDWD

%LW %LW %LW %LW %LW %LW %LW %LW %LW

[7-1] Basic structure of the CAN telegram

&RQWUROILHOG

&5&VHTXHQFH

%\WH

1HWZRUNPDQDJHPHQW

3URFHVVGDWD

3DUDPHWHUGDWD

&5&GHOLPLWHU $&.GHOLPLWHU

$&.VORW (QG

The following subchapters provide a detailed description of the identifier and the user

data. The other signals refer to the transfer characteristics of the CAN telegram the

description of which is not included in the scope of this documentation.

Tip!

Please visit the homepage of the CAN user organisation CiA (CAN in automation)

for further information:

http://www.can-cia.org

36 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 37

7.1.1 Identifier

The principle of CAN communication is based on a message-oriented data exchange

between a transmitter and many receivers. All nodes can virtually transmit and receive

simultaneously.

The identifier, also called COB-ID (abbr. for communication object identifier), is used to

control which node is to receive a transmitted message. In addition to the addressing, the

identifier contains information on the priority of the message and the type of user data.

The identifier consists of a basic identifier and the node address of the node to be

addressed:

Identifier (COB-ID) = basic identifier + node address (node ID)

Communication manual 8400 motec CANopen

Data transfer

Structure of the CAN data telegram

Exception:

management and sync telegrams is freely assigned by the user (either manually or

automatically by the network configurator), or is permanently assigned.

Node address (node ID)

For unambiguous identification, a node address (also called node ID) within the valid

address range (1 ... 63) must be assigned to every node of the system bus network.

A node address may not be assigned more than once within a network.

The own node address can be configured via the DIP switches or via code C00350

Setting the CAN node address

Identifier assignment

The system bus is message-oriented instead of node-oriented. Every message has an

unambiguous identification, the identifier. For CANopen, node-oriented transfer is

achieved by the fact that every message has only one transmitter.

The basic identifiers for network management (NMT) and sync as well as the basic SDO

channel (SDO1) are defined in the CANopen protocol and cannot be changed.

In the Lenze setting, the basic identifiers of the PDOs are preset according to the

"Predefined connection set" of DS301, V4.02 and can be changed via parameters/

indexes, if required.

The identifier for process data/heartbeat/emergency objects as well as network

.

( 33)

Identifiers of the process data objects

EDS84DMOTCAN EN 3.0 - 11/2011 L 37

( 51)

Page 38

Communication manual 8400 motec CANopen

Data transfer

Structure of the CAN data telegram

Object Direction Lenze-Base-ID CANopen-Base-ID

from device to device dec hex dec hex

Network management (NMT) 0 0 0 0

1)

Sync

Emergency

PDO1

(Process data channel 1)

PDO2

(Process data channel 2)

SDO1

(Parameter data channel 1)

SDO2

(Parameter data channel 2)

Heartbeat z 1792 700 1792 700

Boot-up z 1792 700 1792 700

1)

TPDO1

RPDO1

TPDO2

RPDO2

TSDO1

RSDO1

TSDO2

RSDO2

z 128 80 128 80

z 384 180 384 180

z 640 280 640 280

z 1408 580 1408 580

z 1472 5C0 1472 5C0

128 80 128 80

z 512 200 512 200

z 641 281 768 300

z 1536 600 1536 600

z 1600 640 1600 640

1) If you set the sync transmit/receive identifier manually, observe the use of the emergency telegram, since it has the same

COB-ID.

38 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 39

7.1.2 User data

All nodes communicate by exchanging data telegrams via the system bus. The user data

area of the CAN telegram either contains network management data, or parameter data,

or process data:

Network management data

(NMT data)

Control information on start, stop, reset, etc. of communication to specific nodes or to

all nodes of the CAN network.

Process data

(PDOs – process data objects)

Process data are transferred via the process data channel.

Process data can be used to control the controller.

Communication manual 8400 motec CANopen

Data transfer

Structure of the CAN data telegram

Process data are not

Process data are transmitted between the host (master) and controllers (slaves) to

ensure a continuous exchange of current input and output data.

Process data usually are unscaled/scalable raw data.

Process data are, for instance, setpoints and actual values.

The exact meaning of the PDO file contents is determined via the function block editor

(FB Editor) in the I/O level or via the PDO mapping.

Parameter data

(SDOs – service data objects)

Parameter data are the CANopen indexes or, in the case of Lenze devices, the codes.

Parameters are, for instance, used for one-off plant setting during commissioning or

when the material on a production machine is changed.

Parameter data are transmitted as SDOs via the parameter data channel. They are

acknowledged by the receiver, i.e. the sender gets a feedback about whether the

transmission was successful or not.

The parameter data channel enables access to all Lenze codes and CANopen indexes.

Parameter changes are automatically saved to the controller until mains switching.

saved to the controller.

Generally the parameter transfer is not time-critical.

Parameter data are, for instance, operating parameters, diagnostic information, and

motor data.

EDS84DMOTCAN EN 3.0 - 11/2011 L 39

Page 40

Communication manual 8400 motec CANopen

Data transfer

Communication phases/network management

7.2 Communication phases/network management

With regard to communication via the system bus, the controller distinguishes between

the following states:

Status Explanation

"Initialisation"

(Initialisation)

"Pre-operational"

(before being ready for operation)

"Operational"

(ready for operation)

"Stopped"

(stopped)

After switch-on, an initialisation run is carried out.

• During this phase, the controller is not involved in the data exchange via

the bus.

• The standard values are re-written to all CAN-relevant parameters.

• After initialisation is completed, the controller is automatically set to the

"Pre-operational" status.

Parameter data can be received, process data are ignored.

Parameter data and process data can be received!

Only network management telegrams can be received.

Communication object Initialisation Pre-operational Operational Stopped

PDO z

SDO zz

Sync zz

Emergency zz

Boot-up z

Network management (NMT) zzz

Code C00359

serves to display the status of the CAN bus.

Tip!

Part of the initialisation or the entire initialisation can be carried out again in every

status by transmitting the corresponding network management telegrams.

40 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 41

7.2.1 State transitions

[7-2] NMT state transitions in the CAN network

Communication manual 8400 motec CANopen

Data transfer

Communication phases/network management

,QLWLDOLVDWLRQ

3UH2SHUDWLRQDO

2SHUDWLRQDO

6WRSSHG

Transition NMT command Status after

Effects on process/parameter data after status change

change

(1) - Initialisation Initialisation starts automatically at mains connection.

• During initialisation, the controller is not involved in the

data exchange.

• After the initialisation is completed, the node sends a

boot-up message with an individual identifier and

automatically changes to the "Pre-operational" status.

(2) - Pre-operational In this phase, the master determines the way in which the

node(s) takes/take part in communication.

From here, the master changes the states for the entire network.

• A target address included in the NMT command defines the receiver(s).

• If the controller is configured as CAN master, the status is automatically changed to

"Operational" after a waiting time has expired (C00356/1

) and the command 0x0100 NMT

("Start Remote Node") is transmitted to all nodes.

• Data can only be exchanged via process data objects if the status is "Operational"!

(3), (6) 0x01 xx

Start remote node

Operational Network management/sync/emergency telegrams as well

as process data (PDO) and parameter data (SDO) are active.

Optional: When the status is changed, event- and time-

controlled process data (PDOs) are transmitted once.

(4), (7) 0x80 xx

Enter Pre-operational

(5), (8) 0x02 xx

Stop remote node

(9), (10), (11) 0x81 xx

Reset node

(12), (13), (14) 0x82 xx

Reset communication

Pre-operational Network management/sync/emergency telegrams and

parameter data (SDO) are active.

Stopped Only network management telegrams can be received.

Initialisation All CAN-relevant parameters (CiA DS 301) are initialised with

the saved values.

All CAN-relevant parameters (CiA DS 301) are initialised with

the saved values.

Meaning of the node address in the NMT command:

• xx = 0x00: If this assignment is selected, the telegram addresses all nodes (broadcast telegram).

The status of all nodes can be changed at the same time.

• xx = Node ID: If a node address is specified, only the status of the node with the corresponding

address changes.

EDS84DMOTCAN EN 3.0 - 11/2011 L 41

Page 42

Communication manual 8400 motec CANopen

Data transfer

Communication phases/network management

7.2.2 Network management telegram (NMT)

The telegram for the network management contains the identifier "0" and the command

included in the user data, which consists of the command byte and the node address:

,GHQWLILHU 8VHUGDWD%\WH

&2%,'

%LW %LW %LW %LW %LW %LW %LW %LW %LW

[7-3] Network management telegram for changing over the communication phases

Command specifier (cs) NMT command

dec hex

1 0x01 Start remote node

20x02Stop remote node

128 0x80 Enter Pre-operational

129 0x81 Reset node

130 0x82 Reset communication

FRPPDQG

VSHFLILHU

FV

QRGH

DGGUHVV

QRGH,'

The change-over of the communication phases for the entire network is carried out by one

node, the CAN master. The function of the CAN master can also be carried out by the

controller.

Parameterising the Inverter Drives 8400 motec as CAN master

( 43)

Example:

Data can only be exchanged via process data objects if the status is "Operational". If the

CAN master is supposed to switch all nodes connected to the bus from the "Preoperational" communication status to the "Operational" communication status, the

identifier and user data in the transmission telegram must be set as follows:

Identifier: 0x00 (network management)

User data: 0x0100 ("Start remote node" NMT command to all nodes)

42 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 43

Communication manual 8400 motec CANopen

Communication phases/network management

7.2.3 Parameterising the Inverter Drives 8400 motec as CAN master

If the initialisation of the system bus and the associated status change from "Preoperational" to "Operational" is not effected by a higher-level host, the Inverter Drive 8400

motec can instead be defined to be a "quasi" master to execute this task.

Data transfer

The controller is configured as CAN master in C00352

Being the CAN master, the controller sets all

telegram) to the "Operational" communication status with the "Start remote node"

NMT telegram. Only in this communication status data can be exchanged via process

data objects.

A delay time can be set in C00356/1

the controller transmits the "Start remote node" NMT telegram.

Parameter Info Lenze setting

C00352 CAN slave/master Slave

C00356/1

CAN delay boot-up - Operational 3000 ms

, which must expire after mains switching before

.

nodes connected to the bus (broadcast

Value Unit

Note!

The changes of the master/slave operation in C00352 will not be activated until

• another mains switching of the controller

or

• the "Reset node" or "Reset communication" NMT telegram has been

transmitted to the controller.

The "CAN reset node" device command (C00002/26) is provided as an alternative

to the "Reset node" NMT telegram for the reinitialisation of the CAN-specific

device parameters.

Tip!

Master functionality is only required during the initialisation phase of the drive

system.

EDS84DMOTCAN EN 3.0 - 11/2011 L 43

Page 44

Communication manual 8400 motec CANopen

Process data transfer

8 Process data transfer

[8-1] PDO data transfer from / to the higher-level host (master)

The CANopen communication unit is provided with two separate process data channels

(PDO1 and PDO2) for transmitting process data. Each process data channel can transmit up

to four words (8 bytes) at a maximum.

The system bus (CANopen) transmits parameter data, configuration data, diagnostic data,

alarm messages and process data between the host (master) and the controllers (slaves)

participating on the fieldbus. Depending on their time-critical nature, the data are

transmitted via different communication channels.

Process data are transmitted via the process data channel.

The process data serve to control the controller.

Transferring process data is time-critical.

Process data are transferred cyclically between the master and the slaves participating

on the fieldbus (continuous exchange of current input and output data).

The master can directly access the process data. In the PLC, for instance, the data are

directly assigned to the I/O area.

Process data are not saved in the controller.

Process data are, for instance, setpoints, actual values, control words and status words.

44 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 45

Communication manual 8400 motec CANopen

Process data transfer

Definitions

Process data telegrams between the host (master) and the controllers (slaves) are

distinguished in terms of direction as follows:

– Process data telegrams to

– Process data telegrams from

The CANopen process data objects are designated as seen from the node's view:

– Receive PDOs (RPDOx): Process data object received by a node

– Transmit PDOs (TPDOx): Process data object sent by a node

the device (RPDO)

the device (TPDO)

Note!

Data can only be exchanged via process data objects if the status is

"Operational"!

Communication phases/network management

( 40)

EDS84DMOTCAN EN 3.0 - 11/2011 L 45

Page 46

Communication manual 8400 motec CANopen

Process data transfer

Access to process data / PDO mapping

8.1 Access to process data / PDO mapping

The process data are transferred via the MCI/CAN interface.

Max. 8 words (16 bits/word) per direction can be exchanged.

– 2 x 4 words via the input ports CAN1_IN and CAN2_IN

– 2 x 4 words via the output ports CAN1_OUT and CAN2_OUT

The process data are accessed via the port blocks LP_Network_In and

LP_Network_Out. These port blocks are also called process data channels.

The port/function block interconnection of the process data objects (PDO) takes place

via the Lenze »Engineer«.

[8-2] External and internal data transfer between the bus system, controller, and application

Software manual / »Engineer« online help "Inverter Drives 8400 motec"

Here you will find detailed information on port blocks and port/function block

interconnection in the »Engineer«.

46 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 47

Communication manual 8400 motec CANopen

Port interconnection of the process data objects (PDO)

8.2 Port interconnection of the process data objects (PDO)

Note!

The »Engineer« screenshots shown on the following pages are only examples for

the setting sequence and the resulting screens.

Depending on the software version of the controller and of the »Engineer«

software installed, the screenshots may deviate from your »Engineer«

representation.

The preconfigured port interconnection of the process data objects is activated by setting

code C00007 = 40: Network (MCI/CAN).

How to freely configure the port interconnection in the »Engineer«:

1. Under the Process data object tab, click the Go to application button.

Process data transfer

2. The Ports tab displays the port blocks CAN1_IN/CAN2_IN and CAN1_OUT/

CAN2_OUT.

EDS84DMOTCAN EN 3.0 - 11/2011 L 47

Page 48

Communication manual 8400 motec CANopen

Process data transfer

Port interconnection of the process data objects (PDO)

3. Click the port to be configured and press the Edit port ... button.

48 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 49

Communication manual 8400 motec CANopen

Process data transfer

Port interconnection of the process data objects (PDO)

4. Via the button, you can assign signals to the process data words in the Signal

assignment --> Function Block dialog box.

Select the signals and then confirm the selection with the OK button.

EDS84DMOTCAN EN 3.0 - 11/2011 L 49

Page 50

Communication manual 8400 motec CANopen

Process data transfer

Port interconnection of the process data objects (PDO)

For some process data words, you can also assign signals to the individual bits via

the and buttons.

Select the signals and then confirm the selection with OK.

The current interconnection is only displayed if the following has been set for the

control mode in code C00007 = 40: Network (MCI/CAN).

50 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 51

Communication manual 8400 motec CANopen

8.3 Identifiers of the process data objects

In the Lenze setting, the identifier for the process data objects PDO1 and PDO2 consists of

a basic identifier (CANBaseID) and the node address set in C00350

Identifier (COB-ID) = basic identifier + node address (node ID)

The basic identifiers of the PDOs comply with the "Predefined connection set" of

DS301, V4.02.

Process data transfer

Identifiers of the process data objects

:

Alternatively, define via code C00353

that the identifiers of the PDOs are to be assigned

according to Lenze definition or that individual settings are to be made.

–If C00353

= "2: COBID = C0354/x", the identifiers of the PDOs can be set individually

via the Lenze codes and CANopen indexes listed in the table below. That way,

identifiers independent of the node address can be set for specific PDOs.

– If identifiers are assigned individually, all PDOs must have basic identifier values in

the range of 385 ... 1407.

Process data object Basic identifier Individual setting

dec hex Lenze code CANopen index

PDO1

RPDO1 512 0x200 C00354/1

TPDO1 384 0x180 C00354/2 I-1800/1

PDO2

RPDO2 768 0x300 C00354/3

TPDO2 640 0x280 C00354/4 I-1801/1

I-1400/1

I-1401/1

Note!

After a node address change (C00350) and a subsequent CAN reset node, the

subcodes of C00354

respective basic identifier and the node address set.

automatically resume the values which result from the

Short overview: Parameters for setting the identifiers

Parameter Info Lenze setting

Value Unit

C00353/1 COBID source CAN1_IN/OUT 0: COBID = C0350 + CANBaseID

C00353/2

C00354/1

C00354/2

C00354/3

C00354/4

EDS84DMOTCAN EN 3.0 - 11/2011 L 51

COBID source CAN2_IN/OUT 0: COBID = C0350 + CANBaseID

COBID CAN1_IN 0x00000201

COBID CAN1_OUT 0x00000181

COBID CAN2_IN 0x00000301

COBID CAN2_OUT 0x00000281

Page 52

Communication manual 8400 motec CANopen

Process data transfer

Transmission type

8.4 Transmission type

Process data objects can be transmitted in an event-controlled or time-controlled manner.

The below table shows that it is possible to combine the different methods by means of

logic operations (AND, OR):

Event-controlled

The PDO is sent when a certain device-internal event has occurred, e.g. when the data

contents of the TPDO have changed or when a transmission cycle time has elapsed

Synchronous transmission

A TPDO (or RPDO) is sent (or received) after the device has received a sync telegram

(COB-ID 0x80).

Cyclic transmission

The cyclic transmission of PDOs takes place when the transmission cycle time has

elapsed.

Polled via RTR

A TPDO is sent when another device requests it by means of a data request telegram

(RTR remote transmit request). For this purpose, the data requester (e.g. the master)

sends the data request telegram with the COB-ID of the TPDO requested to be sent. The

receiver recognises the RTR and transmits the corresponding PDO.

Transmission type PDO transmission Logic combination of

cyclic synchronous event-controlled

0 zzAND

1 ... 240 zz AND

254 zzOR

Transmission type Description

0 Synchronous and acyclic:

The PDO is transmitted on an event-controlled basis with every sync (e.g. when a bit change

occurs in the PDO).

1 ... 240 Synchronous and cyclic (sync-controlled with response):

• Selection n = 1: The PDO is transmitted with every

• Selection 1 < n ≤ 240: The PDO is transmitted with every n-th

241 ... 251 Reserved

252, 253 RTR-controlled manner is not permissible.

254 Event-controlled with cyclic transmission:

If this value is entered, the PDO is transferred in an event-controlled or cyclic manner. (The

values "254" and "255" are equivalent).

For a cyclic transmission, a cycle time must be set for the respective PDO. In this case, cyclic

transmission takes place in addition to event-controlled transmission.

255 Not permissible

sync.

different

transmission types

sync.

52 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 53

Communication manual 8400 motec CANopen

Process data transfer

Transmission type

The communication parameters such as the transmission mode and cycle time can be set

freely for every PDO and independently of the settings of other PDOs:

Parameter Info Lenze setting

Value Unit

C00322/1 Transmission mode CAN1 OUT 254

C00322/2

C00323/1

C00323/2

C00324/1

C00324/2

C00324/3

C00356/5

C00356/2

Transmission mode CAN2 OUT 254

Transmission mode CAN1 IN 254

Transmission mode CAN2 IN 254

Inhibit time for emergency telegrams 0 ms

CAN1_OUT inhibit time 0 ms

CAN2_OUT inhibit time 0 ms

CAN1_OUT cycle time 0 ms

CAN2_OUT cycle time 0 ms

Tip!

The setting can also be carried out via the following CANopen objects:

• I-1400

• I-1800

/ I-1401: Communication parameter for RPDO1 and RPDO2

/ I-1801: Communication parameter for TPDO1 and TPDO2

EDS84DMOTCAN EN 3.0 - 11/2011 L 53

Page 54

Communication manual 8400 motec CANopen

Process data transfer

PDO synchronisation via sync telegram

8.5 PDO synchronisation via sync telegram

During cyclic transmission, one or more PDOs are transmitted/received in fixed time

intervals. An additional specific telegram, the so-called sync telegram, is used for

synchronising cyclic process data.

The sync telegram is the trigger point for the transmission of process data from the

slaves to the master and for the acceptance of process data from the master in the

slaves.

For sync-controlled process data processing, the sync telegram must be generated

accordingly.

The response to a sync telegram is determined by the selected transmission type.

Transmission type

Basic workflow

n Sync cycle time

[8-3] Sync telegram

A. After the sync telegram has been received, the slaves transmit the synchronous process

data to the master (TPDOs). The master reads them as process input data.

B. When the transmission process is completed, the slaves receive (RPDOs) the process

output data (of the master).

– All other telegrams (e.g. parameters or event-controlled process data) are accepted

acyclically by the slaves after the transmission is completed.

–Illustration [8-3]

when dimensioning the cycle time.

( 52)

SYNC SYNC

01 2

does not include acyclic data. However, they need to be considered

C. The data are accepted in the slave with the next sync telegram if the Rx mode is set to

1 ... 240. If the Rx mode is 254 or 255, the data are accepted in the next device cycle,

irrespective of the sync telegram.

Short overview: Parameters for the synchronisation via sync telegram

Parameter Info Lenze setting Assignment

Value Unit Sync

C00367 CAN sync Rx identifier 128 z

C00368

C00369

54 L EDS84DMOTCAN EN 3.0 - 11/2011

CAN sync Tx identifier 128 z

CAN sync transmission cycle time 0 ms z

master

Sync

slave

Page 55

9 Parameter data transfer

Communication manual 8400 motec CANopen

Parameter data transfer

[9-1] Parameter data transfer via the available parameter data channels

Parameters are values stored in codes on Lenze controllers.

Two parameter data channels are available for parameter setting, enabling the

simultaneous connection of different devices for configuration purposes.

Parameter data are transmitted via the system bus as SDOs (Service Data Objects) via the

system bus (CANopen) and are acknowledged by the receiver. The SDO enables read and

write access to all device parameters and to the CANopen object directory integrated in the

device. Indexes (e.g. 0x1000) enable access to device parameters and functions included in

the object directory. To transfer SDOs, the information contained in the user data must

comply with the CAN-SDO protocol.

EDS84DMOTCAN EN 3.0 - 11/2011 L 55

Page 56

Communication manual 8400 motec CANopen

Parameter data transfer

Identifiers of the parameter data objects

9.1 Identifiers of the parameter data objects

In the Lenze setting, the basic identifiers of the SDOs are preset according to the

"Predefined Connection Set".

The identifiers for the parameter data objects SDO1 and SDO2 are generated from the

basic identifier and the node address set in code C00350

Identifier = basic identifier + node address

Object Direction Lenze-Base-ID CANopen-Base-ID

from device to device dec hex dec hex

SDO1

(Parameter data channel 1)

SDO2

(Parameter data channel 2)

Heartbeat z 1792 700 1792 700

Boot-up z 1792 700 1792 700

TSDO1

RSDO1

TSDO2

RSDO2

z 1408 580 1408 580

z 1472 5C0 1472 5C0

:

z 1536 600 1536 600

z 1600 640 1600 640

Note!

Please observe that the parameter data channels 1 and 2 are active in the factory

setting.

56 L EDS84DMOTCAN EN 3.0 - 11/2011

Page 57

9.2 User data

Structure of the user data of the parameter data telegram

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Command Index Subindex Data 1 Data 2 Data 3 Data 4

Note!

For the user data, the Motorola format is used.

Communication manual 8400 motec CANopen

Parameter data transfer

User data

Low byte High byte Low word High word

Low byte High byte Low byte High byte

Parameter data telegram examples

The following subchapters provide detailed information on user data.

9.2.1 Command

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Command Index Subindex Data 1 Data 2 Data 3 Data 4

The following commands can be transmitted or received for writing and reading the

parameters:

Command 1st byte Data length Info

Write request 0x23 35 4 bytes Writing of a parameter to the controller.

Write response 0x60 96 4 bytes Controller acknowledges a write request.