Page 1

Accessories

AS-Interface

(AS-i)

Inverter Drives 8400 motec

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

E84DGFCAxxx

Communication Manual EN

Ä.MLxä

13444387

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.4 Notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.1 General safety and application notes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.2 Device and application-specific safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2.3 Residual hazards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

3 Product description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.1 Application as directed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.2 Features and variants _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.3 Connections and interfaces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

4 Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.1 General data and operating conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.2 Protocol data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.3 Communication time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

5Installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

5.1 Mechanical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

5.2 Electrical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

5.2.1 Bus cable specification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

5.2.2 AS-i connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5.2.3 Voltage supply _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

6 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

6.1 Before initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

6.2 How to configure the host (master) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

6.3 Settings for AS-i communication in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

6.3.1 Addressing the AS-i slaves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

6.3.2 All parameters for setting the AS-i communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

6.4 Initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

7 Data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

7.1 AS-i messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

7.2 AS-i cycle _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

7.3 Synchronisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

7.4 AS-i concept of the Communication Unit _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

7.5 Data transmission slave 1 (AS-i profile 7.A.5) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

7.6 Data transmission slave 2 (AS-i profile 7.A.E) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

8 Process data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

8.1 Accessing process data / PDO mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

8.2 Port interconnection of process data objects (PDO) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

2 Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Parameter data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

9.1 CTT2: Read parameter value _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

9.2 CTT2: Write parameter value _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

9.3 CTT2: Read code number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

9.4 CTT2: Write code number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

9.5 CTT2: Block parameter transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

9.5.1 Read mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

9.5.2 Write mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

9.6 CTT2: Standard error codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

9.7 CTT2: Acyclic device error codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

10 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

10.1 LED status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

10.2 Diagnostics with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

11 Error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

11.1 Short overview of AS-i error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

11.2 Possible causes and remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

12 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

12.1 Communication-relevant parameters of the operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

12.2 Parameters relevant for AS-i communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

12.3 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 3

Page 4

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Contents

This documentation exclusively contains descriptions of the AS-Interface (AS-i) bus system for the

Inverter Drive 8400 motec.

Note!

This documentation supplements the mounting instructions supplied with the

Communication Unit and the "Inverter Drives 8400 motec" hardware manual.

The hardware manual contains safety instructions that must be observed!

The properties and functions of the AS-Interface for the Inverter Drive 8400 motec are described in

detail.

Examples illustrate typical applications.

The theoretical contexts are only explained to the level of detail required to understand the function

of the Communication Unit.

This documentation does not describe the software of other manufacturers. No responsibility is

taken for corresponding information given in this documentation. Information on how to use the

software can be obtained from the documents of the host (PLC, master).

All brand names used in this documentation are trademarks of their respective owners.

Tip!

Detailed information about the AS-Interface can be found on the website of the ASInterface user organisation:

www.as-interface.net

4 Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 5

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Target group

This documentation addresses persons who configure, install, commission, and maintain the

networking and remote servicing of a machine.

Tip!

Current documentation and software updates for Lenze products can be found in the

download area at:

www.Lenze.com

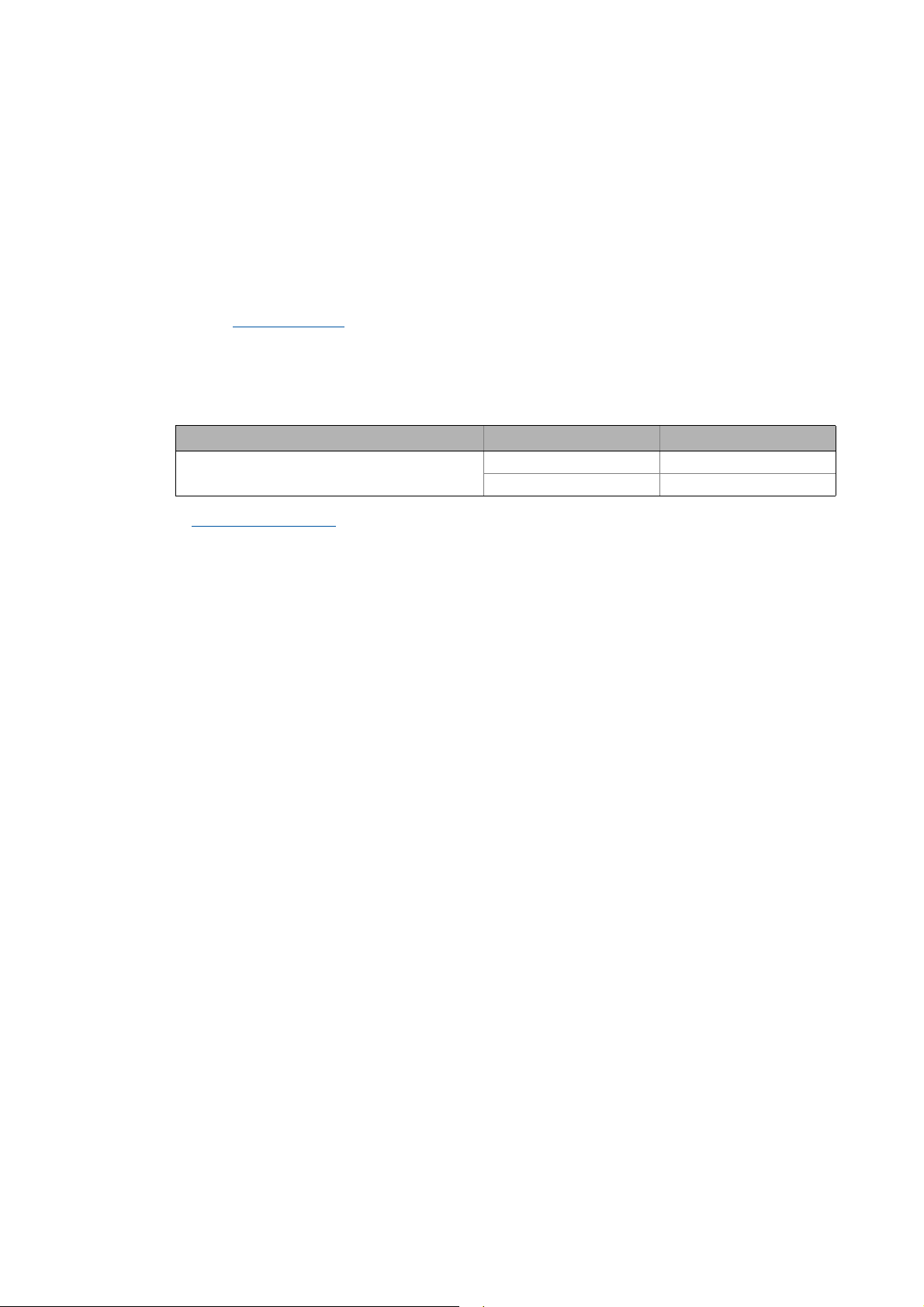

Validity

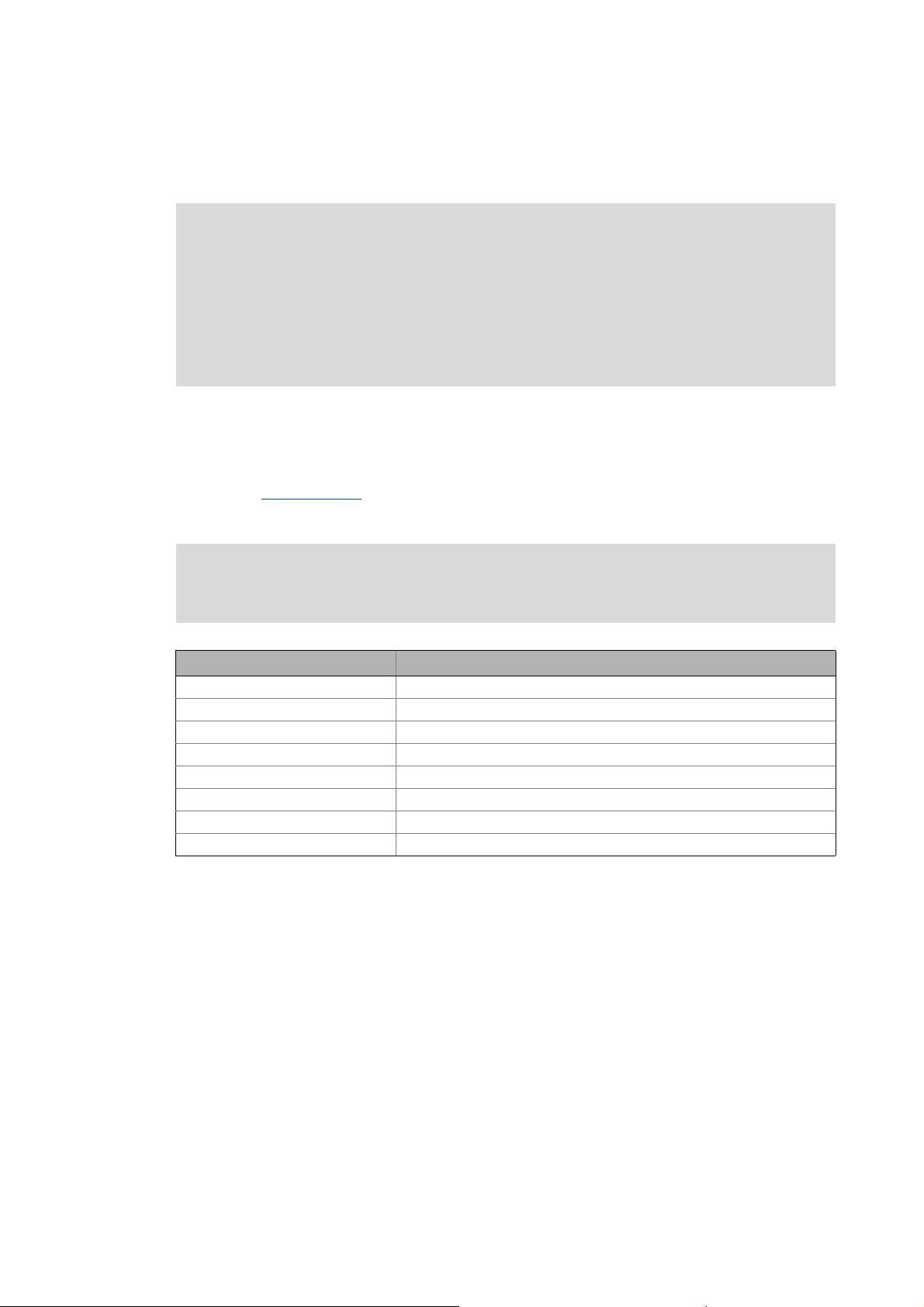

The information given in this documentation is valid for the following devices:

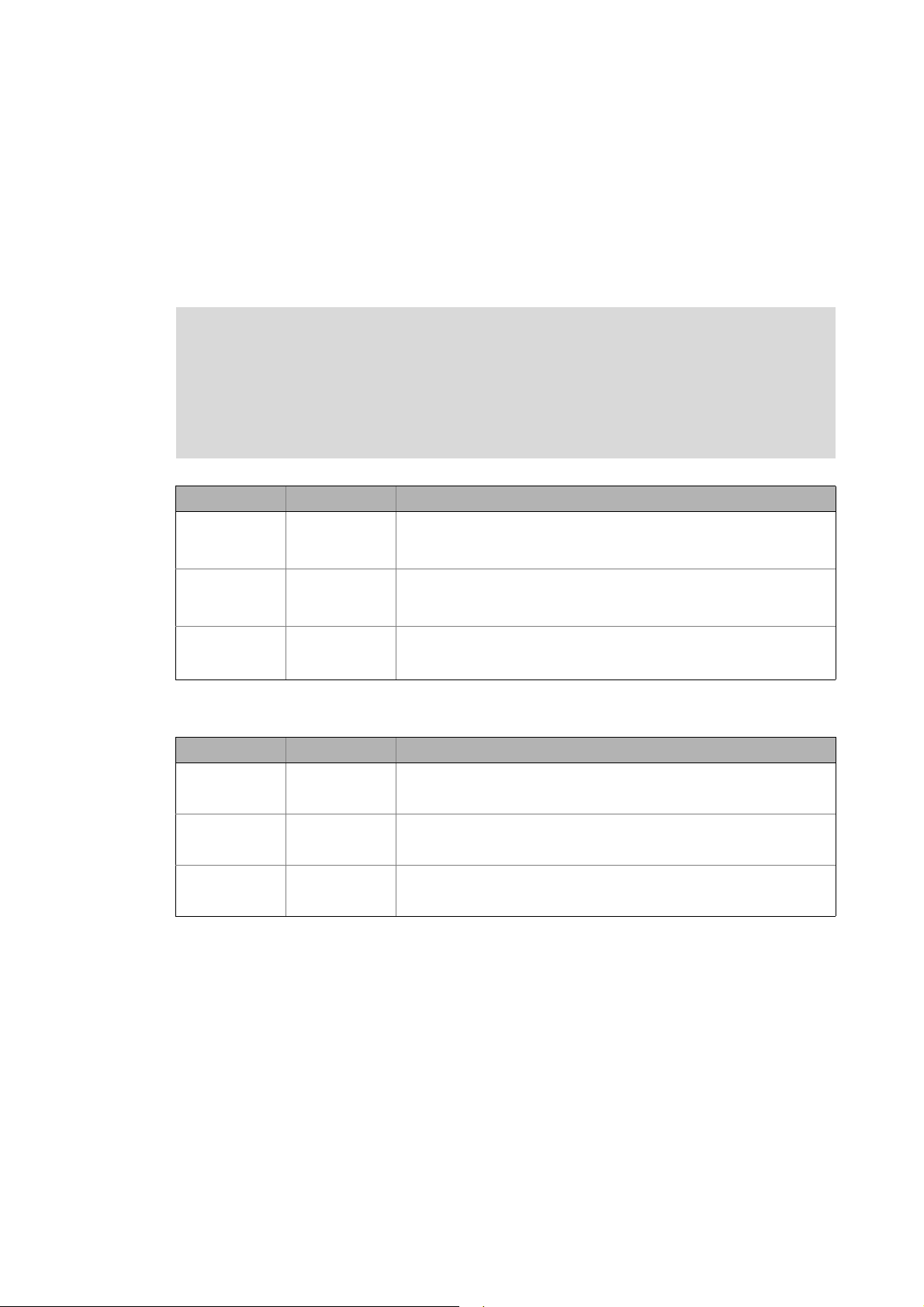

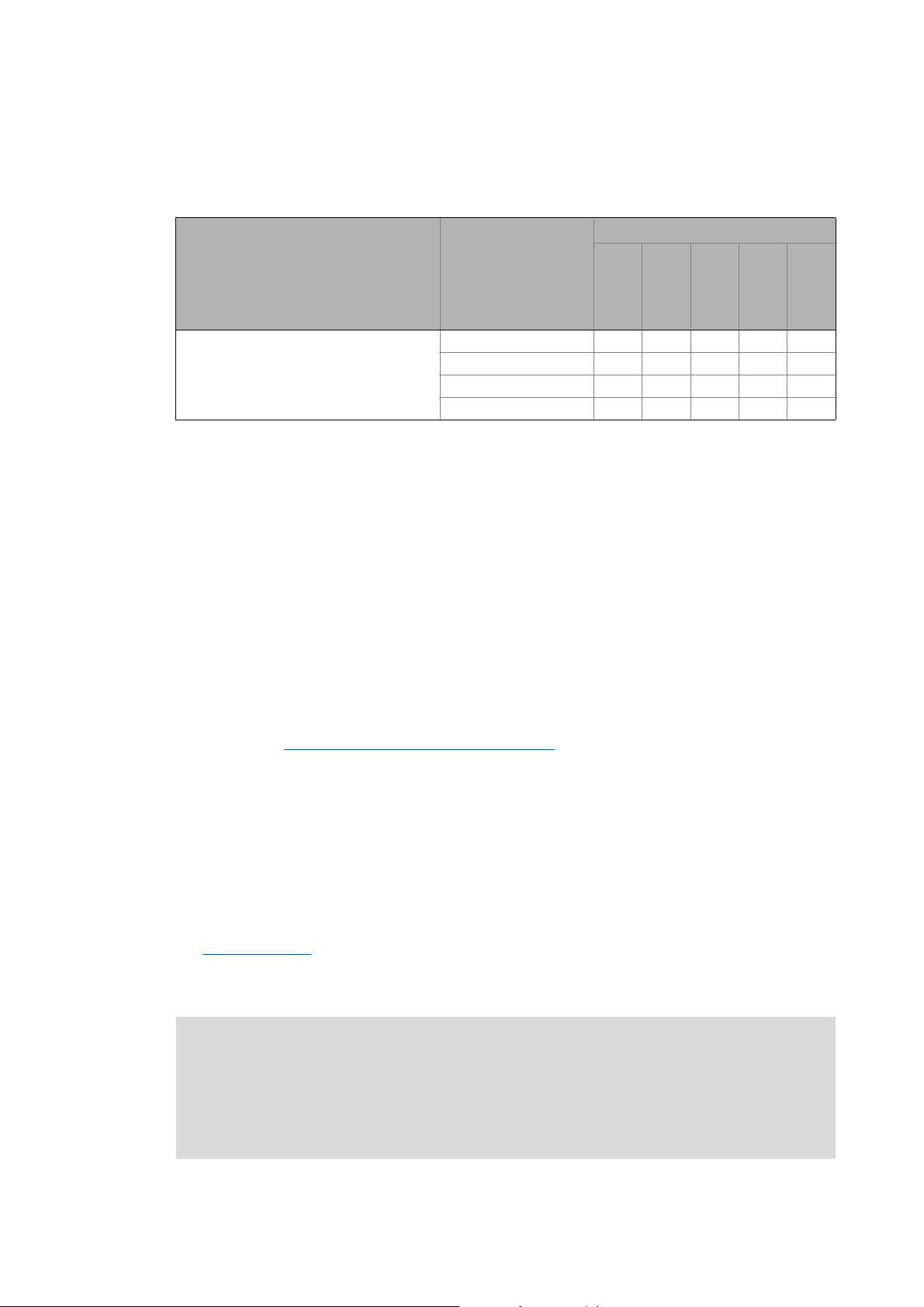

Product series Type designation Version

Inverter Drives 8400 motec

Communication Unit AS-Interface

E84DGFCAxNx AS-i V3

E84DGFCAxJx AS-i V3 + Safety

Features and variants

Screenshots/application examples

All screenshots provided in this documentation are application examples. Depending on the

firmware version of the field devices and the software version of the installed Engineering tools

(»Engineer«), the screenshots in this documentation may differ from the screens.

( 13)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 5

Page 6

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Document history

Version Description

1.0 12/2010 TD17 First edition

2.0 01/2011 TD17 Update:

• Low-voltage supply via the AS-i-bus cable

•I/O configuration

• Error messages

• Parameter descriptions

3.0 01/2012 TD17 General revision

4.0 09/2013 TD17 • General revision

•New layout

6

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 7

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This manual uses the following conventions to distinguish between different types of information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal Normal spelling Example: 1234

Decimal separator Point The decimal point is generally used.

For example: 1234.56

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Text

Program name » « PC software

Control element bold The OK button... / The Copy command... / The

Hyperlink Underlined

Icons

Page reference ( 7) Optically highlighted reference to another page. Can

Step-by-step instructions

0b[0, 1] Example: ’0b0110’

Example: ’0b0110.0100’

Example: Lenze »Engineer«

Properties tab... / The Name input field...

Optically highlighted reference to another topic. Can

be activated with a mouse-click in this

documentation.

be activated with a mouse-click in this

documentation.

Step-by-step instructions are indicated by a

pictograph.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 7

Page 8

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

AS-Interface The AS-Interface (actuator/sensor interface) ...

AS-i

Inverter Lenze frequency inverter of the "Inverter Drives 8400 motec" product series

Standard device

Drive Unit

Communication unit

Wiring Unit

»Engineer« Lenze PC software which supports you in "engineering" (parameter setting,

Code Parameter which serves to parameterise or monitor the inverter. In general

Subcode If a code contains several parameters, these are stored in "subcodes".

Lenze setting This setting is the default factory setting of the device.

Basic setting

HW Hardware

SW Software

CTT2 transmission

(Combined Transaction Type 2)

Data set transmission In the case of CTT2 transmission, data records are transmitted between the

Process image In the case of the Inverter Drive 8400 motec, 4 bits of control data (PAA) are

Parameter echo (diagnostics via

parameter data channel)

ICs Circuits which efficiently perform the described tasks of a slave.

MCU Microcontroller

ASIC Application specific integrated circuit

• is an international standard for fieldbus communication.

• is used in decentralised applications as fieldbus communication on the

lowest control level.

The Inverter Drive 8400 motec has a modular structure. It consists of the

following modules: "Drive Unit", "Communication Unit" and "Wiring Unit".

• The drive unit is available in different power settings.

• The Communication Unit is available in the following versions:

•No fieldbus

• AS-i option

• CANopen option

•PROFIBUS option

•PROFINET option

•EtherCAT option

• EtherNet/IP option

• The wiring unit provides flexible connection possibilities for a simple

integration into the power supply of the machine.

diagnosing, and configuring) during the entire life cycle, i.e. from planning to

maintenance of the commissioned machine.

linguistic usage, this term is also referred to as "index".

In this documentation, a slash "/" is used as a separator between code and

subcode (e.g. "C00118/3").

The term is usually called "subindex".

Serial data transmission is established between master and slave (clock in/out,

data in/out). This channel serves for ...

• acyclic transmission of data records;

• acyclic transmission of the extended process image.

master and the slave only on request. During acyclic data record transmission,

the cyclic transmission of the extended process image is interrupted.

transmitted to the slave every time the slave is called. The slave returns a

response containing 6 bits of information (PAE). The transmission is carried out

at least every 10 ms (AS-i cycle

assignment).

In the case of extended process images, continuous transmission of 4 bytes per

direction between the master and the slave takes place.

The "Write Parameter" AS-i command serves to transmit 4 parameter bits to the

slave.

In the response message, the slave returns 4 bits (16 bit combinations) of status

information.

( 31), depending on the addressing

8

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 9

1 About this documentation

1.4 Notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Notes used

The following signal words and icons are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another documentation

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 9

Page 10

Safety instructions

General safety and application notes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Note!

Always observe the specified safety measures to avoid severe injury to persons and

damage to material assets!

Always keep this documentation near the product during operation.

2.1 General safety and application notes

Danger!

If you ignore the following basic safety measures, severe injury to persons and damage

to material assets may be caused.

• Lenze drive and automation components ...

• must only be applied as directed.

Application as directed

• must never be commissioned in the event of visible damage.

• must never be technically modified.

• must never be commissioned unless they are completely mounted.

• must never be operated without the required covers.

• may have live, moving, or rotary parts during and after operation, depending on the degree

of protection. Surfaces may be hot.

• For Lenze drive components ...

• only use approved accessories.

• only use original spare parts from the manufacturer.

• Observe all specifications given in the attached and associated documentation.

• This is a precondition for ensuring safe, trouble-free operation and for achieving the stated

product features.

Features and variants

• The procedural notes and circuit details described in this document are only proposals. It is

up to the user to check whether they can be adapted to the particular applications. Lenze

does not take any responsibility for the suitability of the procedures and circuit proposals

described.

• Only qualified personnel may work with and on Lenze drive and automation components.

According to IEC 60364 and CENELEC, these are persons ...

• who are familiar with the installation, assembly, commissioning, and operation of the

product.

• who have the qualifications required for their occupation.

• who know all the accident prevention regulations, directives and laws applicable on site and

are able to apply them.

( 12)

( 13)

10

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 11

Safety instructions

Device and application-specific safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Device and application-specific safety instructions

• During operation, the Communication Unit must be connected to the Wiring Unit and the Drive

Unit.

• Only use cables that comply with the listed specifications.

Bus cable specification

( 21)

Documentation of "Inverter Drives 8400 motec", control system, plant/machine

All other measures prescribed in this documentation must also be implemented.

Observe the safety instructions and application notes specified in the documentation.

2.3 Residual hazards

Device protection

• The communication unit contains electronic components that can be damaged or destroyed by

electrostatic discharge.

Installation

( 19)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 11

Page 12

Product description

Application as directed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Product description

3.1 Application as directed

The AS-Interface Communication Unit ...

• is a unit that can only be used in conjunction with the following modules:

Product series Type designation

Inverter Drives 8400 motec

Drive Unit

Inverter Drives 8400 motec

Wiring Unit

• is a device intended for use in industrial power systems.

• should only be used under the operating conditions prescribed in this documentation.

• can only be used in AS-i networks.

E84DGDVxxxxxxxx

E84DGVNxx

• can also be used without being connected to the AS-i network.

Any other use shall be deemed inappropriate!

12

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 13

Product description

Features and variants

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.2 Features and variants

The AS-Interface Communication Unit is available in the following versions:

Product series Type designation Product features

Enclosure

IP 65

AS-Interface

M12

I/O: Terminal

Inverter Drives 8400 motec

Communication Unit AS-Interface

• The AS-Interface Communication Unit is ...

• mounted on top of the Wiring Unit (E84DGVNxx);

• supplied internally by the Drive Unit (E84DGDVxxxxxxxx) and externally by the AS-i bus.

• The I/O connections can be brought into the device via M12 connectors or cable glands.

• Devices without an integrated safety system (safety option) have no analog input and no relay

output.

E84DGFCAANP

E84DGFCA9NP

E84DGFCAAJP

E84DGFCA9JP

I/O: M12

Safety

• The integrated safety system can be used on machines for the protection of persons.

• The Communication Unit AS-Interface supports the services of the AS-i version 3.0:

• cyclic reading and writing of single parameters

•cyclic drive control

• acyclic reading and writing of parameter sets

• acyclic query of diagnostic data

• Two AS-i slaves are contained in the Communication Unit. Thus, two AS-i addresses are

assigned. AS-i concept of the Communication Unit

• The acyclic communication via the AS-i bus and the slave 2 are available for the read and write

access to parameters.

• The AS-i slaves can be addressed ...

• via a programming unit or from the master or

• by means of parameters (e.g. via »Engineer«, keypad or EPM).

• Up to 31 standard slaves can be connected to an AS-i network. In this case the max. cycle time

is 5 ms. Up to 62 so-called A/B slaves can be connected if extended addressing is used. In this

case the max. cycle time is 10 ms.

• Synchronisation

• Communication with the Lenze »Engineer« (access to all Lenze parameters) is executed via the

diagnostic interface of the Drive Unit.

( 32) of input and output data is possible.

( 33)

"Inverter Drives 8400 motec" hardware manual

Here you will find detailed information on the integrated safety system (safety option).

Software manual / »Engineer« online help "Inverter Drives 8400 motec"

Here you will find detailed information on how to configure the safety system (safety

option).

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 13

Page 14

Product description

Connections and interfaces

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Connections and interfaces

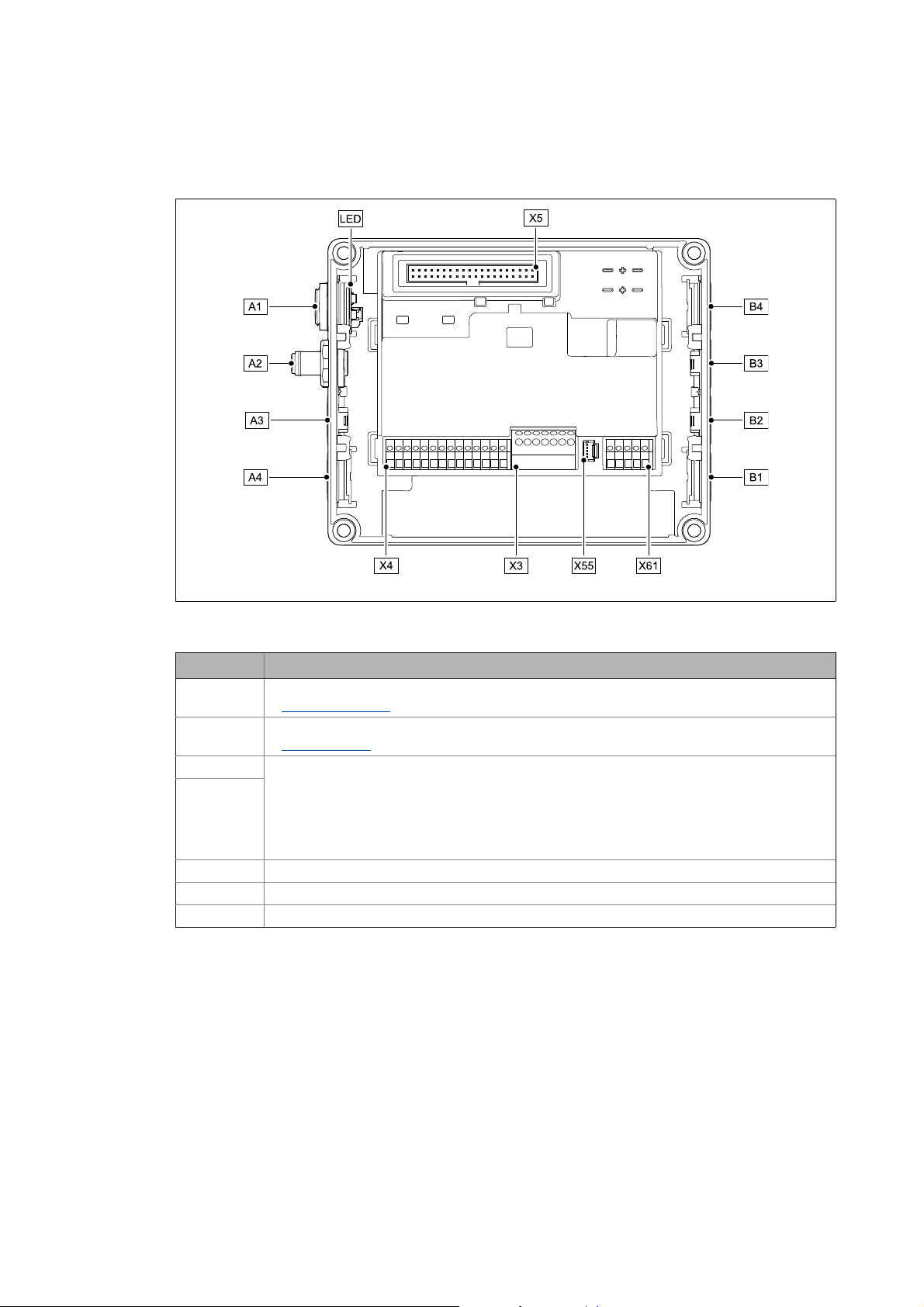

[3-1] Communication Unit AS-Interface

Pos. Description

A1 / LED Position of LEDs for AS-i status display

LED status displays

A2 AS-i terminal (M12 pins, 5-pole)

AS-i connection

A3 / A4 Positions for further freely designable inputs and outputs:

B1 ... B4

X3 / X4 / X61 Terminal strips for wiring the terminals at A2 ... A4 and B1 ... B4

X5 Plug connector for connection to the Drive Unit

X55 Plug connector for the wiring of the LEDs to A1

• Digital inputs

•Digital output

• Analog input (only for E84DGFCAxJx)

• Relay output (only for E84DGFCAxJx)

• Connection of "Safety Option" safety system (only for E84DGFCAxJx)

E84DG018

( 53)

( 22)

14

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 15

Product description

Connections and interfaces

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• By default, the AS-i terminal and the LEDs for the AS-i status displays are already mounted and

wired:

• AS-i connection to terminal strip X3

• LEDs on plug connector X55

• The positions A1 ... A4 and B1 ... B4 serve to freely connect the AS-i terminals, the LEDs for the

AS-i status displays and other connections (e.g. digital inputs).

• For the connections, 5-pin M12 connectors or - alternatively - cable glands (cable cross-section

max. 1.0 mm

• The M12 connectors, cable glands and prefabricated system cables can be obtained from

various manufacturers.

• Wire the M12 plugs or cable glands used with the corresponding contacts of the terminal strips

X3, X4 and X61.

2

, AWG 18) can be used.

"Inverter Drives 8400 motec" hardware manual

Observe the notes and wiring instructions contained in this documentation.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 15

Page 16

Technical data

General data and operating conditions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Technical data

"Inverter Drives 8400 motec" hardware manual

Here you will find the ambient conditions and information on the electromagnetic

compatibility (EMC) that also apply to the Communication Unit.

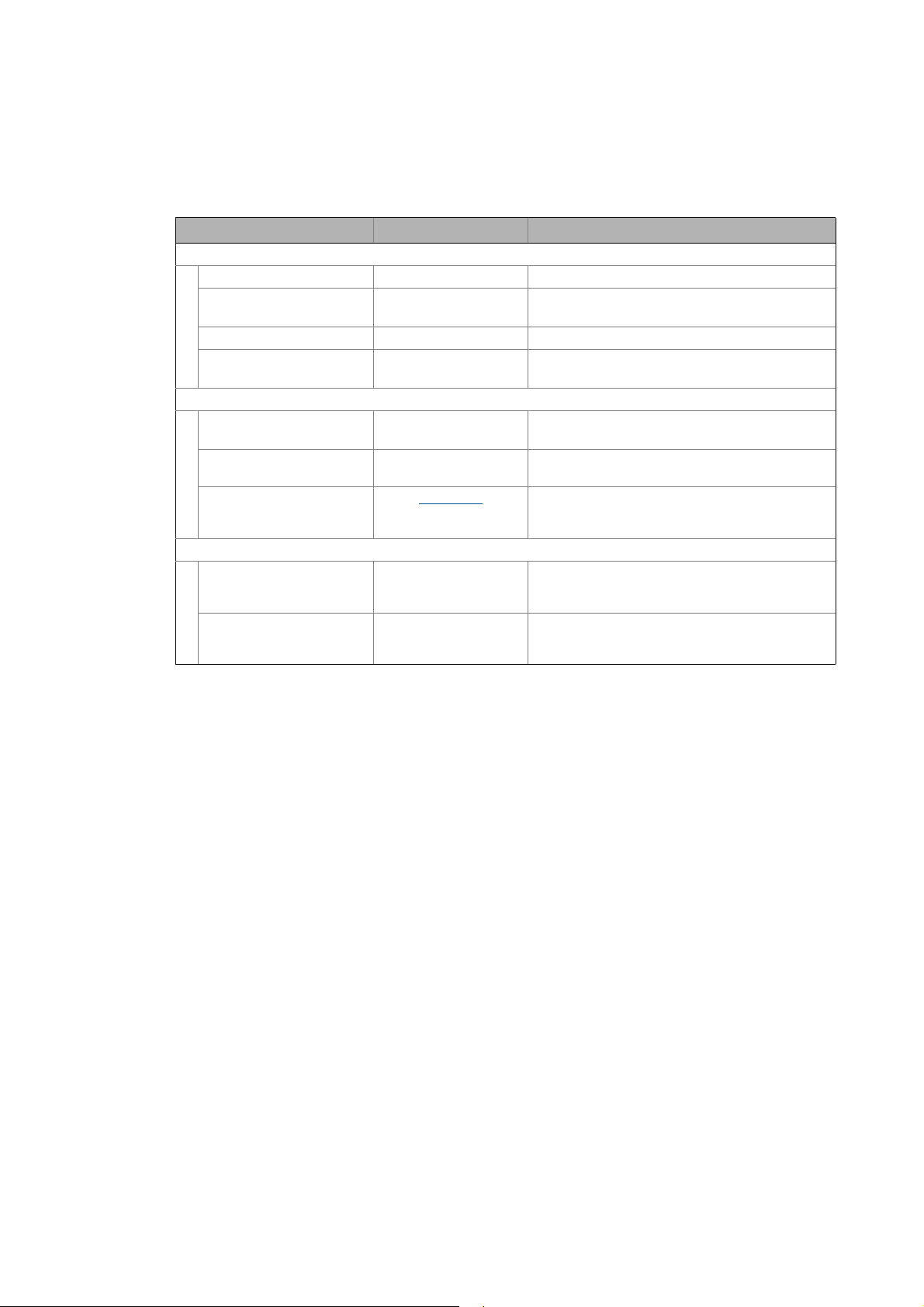

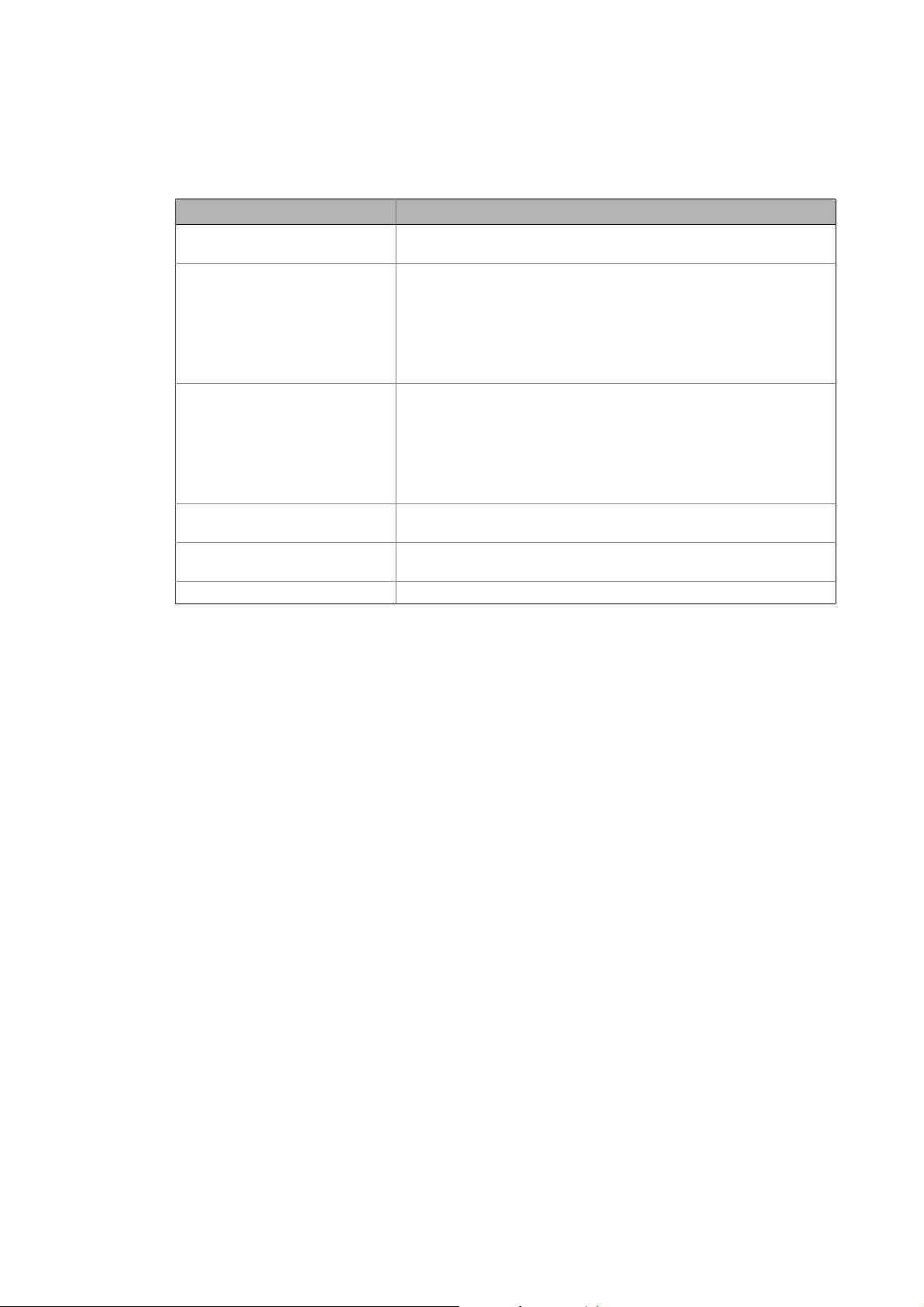

4.1 General data and operating conditions

Range Values

Order designation • E84DGFCAxNx (AS-i V3)

• E84DGFCAxJx (AS-i V3, Safety)

Communication profile AS-Interface V3.0

Standards / specifications • EN 50295 / IEC 62026-2

• Safety engineering: EN 954-1, EN 13849-1, IEC 61508

(up to safety category 4)

2

Communication medium Two-wire cable for data and auxiliary power, 2 x 1.5 mm

(without shielding, without terminating impedance)

Interface for communication M12 pins, 5-pole, A-coded

• Contacting of the AS-i cable with penetration technique

• Cable with M12 socket, 5-pole, A-coded

Max. cable length • Max. 100 m without repeater/extender

• Max. 300 m with 2 repeaters/extenders

• Max. 500 m only for star topology with repeater/extender

Bus termination Only required for cable lengths > 100 m

Bus terminating resistors are required at the first and last AS-i node

(implemented in the connector of the bus cable)

Network topology Free topology (line, ring, tree, star)

Type of node Single slave or dual slave

Slave node number • Max. 31 standard slaves

• Max. 62 A/B slaves

Node address area 1 ... 31

Cycle time • max. 5 ms with maximum configuration

• 10 ms when A/B technique is used

• profile-specific with spec 3.0 slaves

Baud rate 167 kbps (gross)

53 kbps (net; data transfer efficiency = 32 %)

Voltage supply External supply via AS-i bus cable

• U = 29.5 ... 31.6 V (according to AS-i specification)

•I

= 400 mA

max

Available digital inputs • 5 dig. inputs with mains supply

• 4 dig. inputs with supply via AS-i bus and missing mains

Conformities, approvals • CE

•UR / cUR

(see also hardware manual)

16

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 17

Technical data

Protocol data

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Protocol data

Range Values

AS-i device profiles • Slave 1: 7.A.5 (CTT2)

• Slave 2: 7.A.E

Process image, standard Slave 1:

•DI0...3 = 4bits

• DO0 ... 3 = 4 bits

Slave 2:

•DI0/1 = 2 bits

•DO3/4 = 2 bits

Total: 6 input bits / 6 output bits

Process image, A/B technique Slave 1:

•DI0...3 = 4bits

• DO0 ... 2 = 3 bits

Slave 2:

•DI0/1 = 2 bits

•DO3 = 1 bits

Total: 6 input bits / 4 output bits

Cyclic parameter data channel

(AS-i spec. V2.0 and V3.0)

Acyclic parameter data channel

(AS-i spec. V3.0)

AS-i user data length max. 64 bytes

4 words (8 bytes)

max. 16 double words (64 bytes)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 17

Page 18

Technical data

Communication time

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Communication time

The communication time defines the time between the start of a request and the arrival of the

corresponding response.

The communication times in an AS-i network depend on the ...

• processing time in the inverter;

• telegram runtime (baud rate / telegram length);

• nesting depth of the network.

Processing time in the inverter

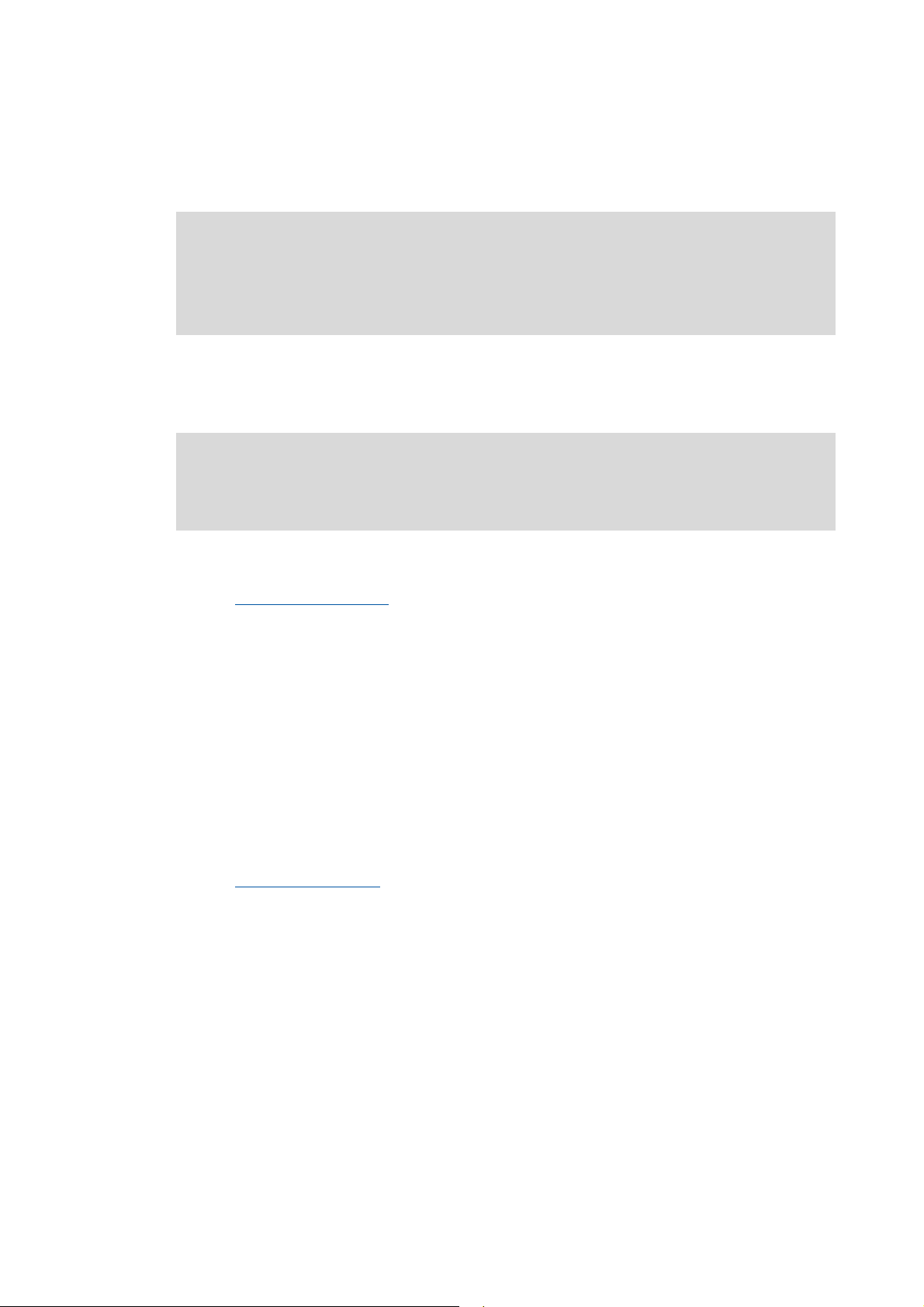

Data Processing time

Process data approx. 2 ms

+ 0 ... 1 ms

+ 1 ... x ms

Parameter data approx. 30 ms + a tolerance of 20 ms (typically)

For some codes, the processing time may be longer (see software manual/

»Engineer« online help "Inverter Drives 8400 motec").

Update cycle

Processing time in the module

Application task runtime of the use technology application

(tolerance)

There are no interdependencies between parameter data and process data.

18

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 19

Installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Installation

Stop!

Electrostatic discharge

Electronic components within the Communication Unit can be damaged or destroyed by

electrostatic discharge.

Possible consequences:

• The Communication Unit is defective.

• Fieldbus communication is not possible or faulty.

• I/O signals are faulty.

• The safety function is faulty.

Protective measures

Discharge electrostatic charges before touching the Communication Unit.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 19

Page 20

Installation

Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

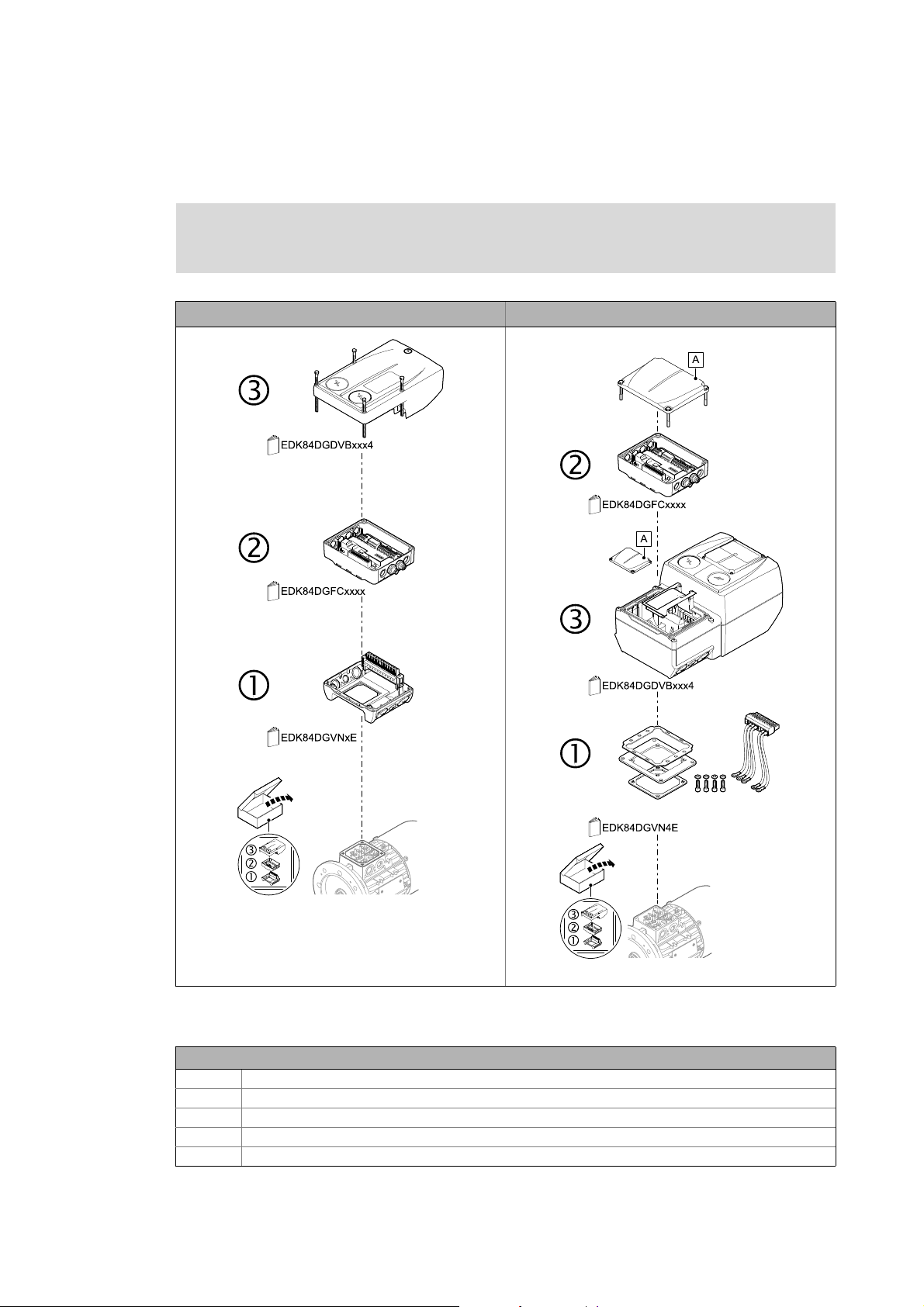

5.1 Mechanical installation

"Inverter Drives 8400 motec" mounting instructions

Here you will find detailed information on the installation.

0.37 ... 3.0 kW 4.0 ... 7.5 kW

E84DG023a

E84DG023b

[5-1] Mechanical installation of the 8400 motec components

Legend for fig. [5-1]

1Drive Unit

2 Communication unit

3 Wiring Unit

A Cover of the Drive Unit

EDK84DG... Mounting instructions of the Drive Unit, Communication Unit, Wiring Unit

20

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 21

Installation

Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2 Electrical installation

"Inverter Drives 8400 motec" hardware manual

Here you can find detailed information on ...

• the digital and analog inputs/outputs;

•the relay output;

• the integrated safety system (safety option);

• the wiring of the terminals.

Observe the notes and wiring instructions contained in this documentation.

5.2.1 Bus cable specification

The AS-i bus cable serves as ...

•external Voltage supply

• a means for data transmission to and from the inverter.

( 23) of the Communication Unit;

Note!

Only use cables that comply with the listed specifications.

Range Values

Cable type Two-wire cable, insulated and shielded

Core cross-section 1.5 mm

Cable resistance < 90 m/m, (f = 3 ... 20 MHz)

Inductance 400 ... 1300 nH/m

Capacitance per unit length < 80 pF/m

Electrical master value < 5 μS/m

Surge impedance 70 ... 140

Group runtime < 8.3 ns/m

Tip!

These data are also met by several other standardised cables. An AS-i network can also be

set up with different cables. Multi-core cables (e.g. DeviceNet Thick Cable, DESINA cable/

light conductor) or busbars can be used for the setup of AS-i networks, too. In case of doubt,

consult a specialist in the planning phase.

Prefabricated system cables can be obtained from diverse manufacturers.

2

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 21

Page 22

Installation

Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

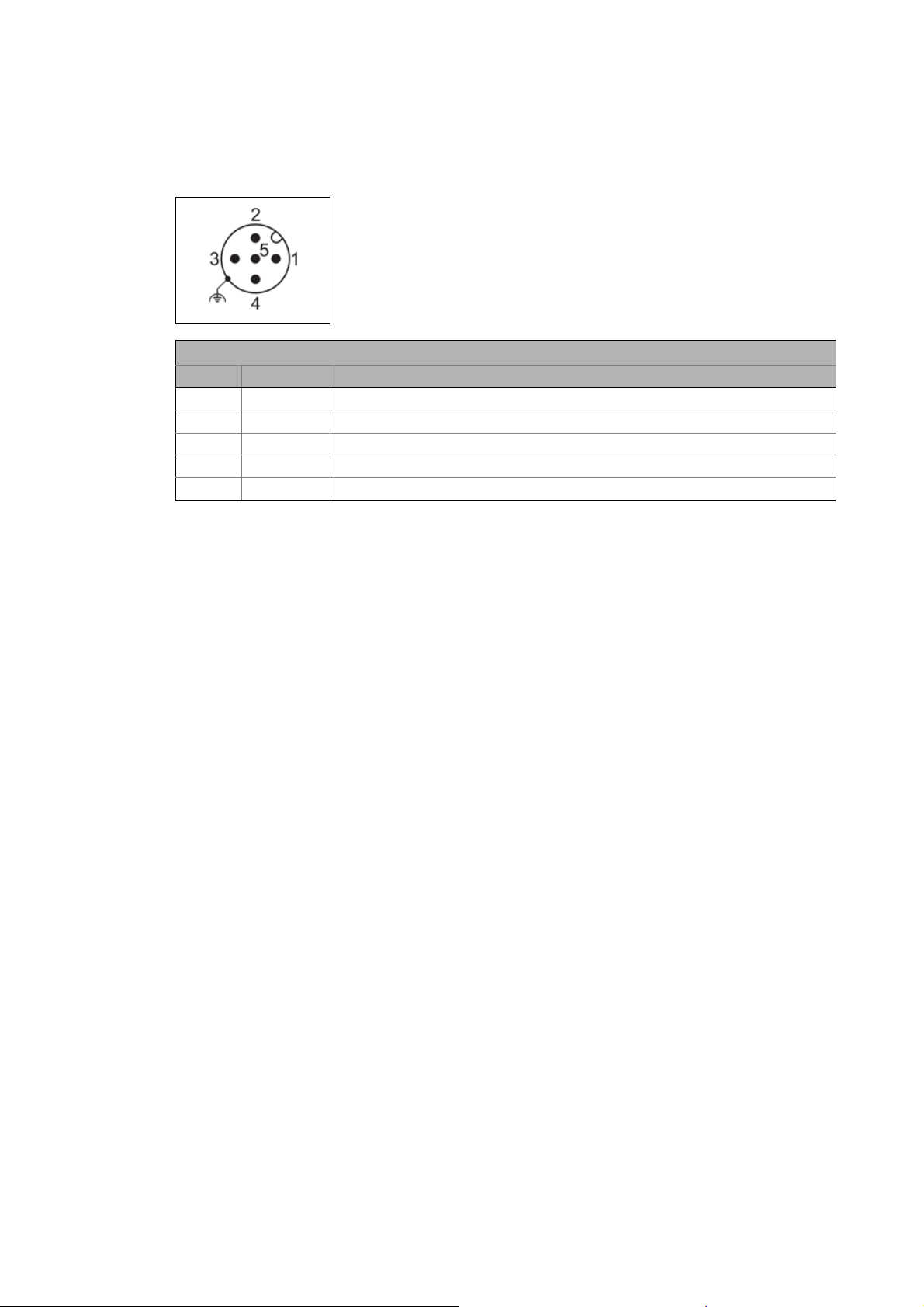

5.2.2 AS-i connection

• M12 pins, 5-pole, A-coded

• Wiring of terminal strip X3

AS-i connection

Pin Signal Description

1 ASi+ AS-i data line, positive

2 - Not assigned

3 ASi- AS-i data line, negative

4 - Not assigned

5 - Not assigned

22

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 23

Installation

Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.3 Voltage supply

• The Communication Unit is supplied with voltage via the AS-i bus cable.

• Access to parameters of a device that is disconnected from the mains is not possible.

• Permissible voltage (DC) / max. current:

• U = 29.5 ... 31.6 V (according to AS-i specification)

•I

= 400 mA

max

Low-voltage supply via the AS-i-bus cable

In case of low-voltage supply via the AS-i bus cable, communication with the slaves is still possible

if no mains voltage is available.

• A previous mains connection (400 V) is not required.

• The digital inputs DI1 ... DI5, RFR and the analog input can still be evaluated.

• The AS-i input ports DI0 ... DI3 represent the digital inputs DI1 ... DI4 (see AS-i concept of the

Communication Unit ( 33)). The current status of these inputs can be called.

• All digital input and output data which can be selected by the inverter are deleted or invalid..

• External sensors are also supplied via the AS-i bus cable.

"Inverter Drives 8400 motec" hardware manual

Here you can find detailed information on how to wire the Communication Unit.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 23

Page 24

Commissioning

Before initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Commissioning

During commissioning, system-related data such as motor parameters, operating parameters,

responses, and parameters for fieldbus communication are defined for the drive. For Lenze devices,

this is done via the codes.

The codes of the drive and communication are saved non-volatilely as a data set in the memory

module.

In addition to codes for the configuration, there are codes for diagnosing and monitoring the nodes.

Parameter reference

6.1 Before initial switch-on

Stop!

Before you switch on the inverter for the first time, check the entire wiring for

completeness, short circuit, and earth fault.

( 60)

24

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 25

Commissioning

How to configure the host (master)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2 How to configure the host (master)

For communication with the inverter, the host (master) must be configured first.

Defining the user data length

• The AS-Interface Communication Unit supports the configuration of max. 8 process data words

(max. 64 bytes).

• The user data length is defined during the initialisation phase of the master.

• The user data lengths for process input data and process output data are identical.

Note!

Observe the direction of the information flow.

• Process input data (Rx data):

Process data from the inverter (slave) to the host (master)

• Process output data (Tx data):

Process data from the host (master) to the inverter (slave)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 25

Page 26

Commissioning

Settings for AS-i communication in the »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3 Settings for AS-i communication in the »Engineer«

6.3.1 Addressing the AS-i slaves

Addressing is usually carried out automatically via the master or an external addressing unit.

The AS-Interface Communication Unit uses two slaves (see AS-i concept of the Communication Unit

( 33)) which must be initialised with unique addresses.

Note!

• If the same address is used for slave 1 and slave 2, the address of slave 2 is set to '0'.

• If address '0' is assigned to slave 1 and slave 2, slave 2 is switched "offline" (basic

settings remain intact).

•The setting C13200/x

visible in the AS-i network).

/ C13202/x = 64 serves to deactivate the slave (not active or

The parameters for addressing the AS-i slaves can be found in the »Engineer« on the "Settings" tab.

Setting / parameters Code

Slave 1: Address EPM value C13202/1

Slave 1: Address EPM value C13202/2

Override slave addresses C13204

26

Override of the slave addresses during

initialisation

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

C13205

Page 27

Commissioning

Settings for AS-i communication in the »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3.2 All parameters for setting the AS-i communication

All parameters for setting the AS-i communication can be found in the »Engineer« on the "All

parameters" tab.

Save the changed settings with the device command C00002/11 (save all parameter sets).

Addressing the AS-i slaves

Parameters relevant for AS-i communication

( 26)

( 61)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 27

Page 28

Commissioning

Initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4 Initial switch-on

Establishing communication

• To establish a communication, the Inverter Drive must be supplied with mains voltage.

• For AS-i communication, the Communication Unit has to be supplied with voltage. If this is not

the case, the error message "CE04: MCI communication error" (error no. 01.0127.00002) is

output.

•The Voltage supply

case of a main supply failure.

• During mains connection, all parameters (codes) are read.

• Addressing can be carried out automatically via the master, an external addressing unit or

manually via codes in the »Engineer«.

Addressing the AS-i slaves

( 23) via the AS-i bus cable serves to maintain the AS-i communication in

( 26)

28

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 29

Data transfer

AS-i messages

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer

The AS-Interface transmits parameter data, configuration data, diagnostic data, alarm messages

and process data between the host (master) and the inverters (slaves) participating in the fieldbus.

Depending on their time-critical nature, the data are transmitted via different communication

channels.

The bus access method of the AS-Interface is a master-slave method with cyclic polling.

• The master transmits a frame (master call) with a specific slave address.

• The slave triggered with this address responds within the allowed time (acknowledgement of

the message).

• When the response has been received correctly from the master, the message is deemed to be

transmitted successfully.

• If the master does not receive any response or the response cannot be decoded without errors

for the master, the frame can be repeated.

7.1 AS-i messages

An AS-i message consists of ... a master call, a short pause, a slave response, and a short pause again.

• All master calls have a length of 14 bit times (1 bit time = 6 μs).

• All slave responses have a length of 7 bit times.

• The 1st pause has a typical duration of 16 μs (synchronised slave) and must not be longer than

the expected slave response.

If during this time the master does not receive the start of a slave response, no response will

arrive anymore. Now the master may start with the next call.

• At the end of the slave response, there is a short pause again with a typical duration of approx.

9…12μs.

The master needs this time to check the slave response and decide what should happen next

(repeat the transmitted call or continue with the next call).

Broadcast call of the master

An exception to this message structure is a broadcast request of the master. A broadcast

transmission corresponds to broadcasting to all nodes (simultaneous transmission from the master

to all slaves). It can only be effected in one direction. Broadcast transmissions cannot be

acknowledged. Hence, it is not ensured that all slaves have received the message correctly.

Master call Pause 1 Slave response Pause 2

14 bits 7 bits

84 μs 16 μs 42 μs9...12μs

151 ... 154 μs

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 29

Page 30

Data transfer

AS-i messages

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Structure of the master call

Structure in the standard addressing mode for up to 31 slaves:

ST SB Address Information PB EB

1 bit 1 bit 5 bits 5 bits 1 bit 1 bit

Structure in the advanced addressing mode for up to 62 slaves:

ST SB Address Information PB EB

1 bit 1 bit 5 bits 1 bit Select

Bit field Description

ST The start bit marks the start of the master call.

•0: Valid start bit

•1: Not permitted

SB The control bit designates the call of data, parameters, addressing or commands.

• 0: Data/parameter/addressing call

•1: Command call

Address • 5 address bits contain the address of the slave to be called.

• Valid address range: 1 ... 31

Information Depending on the call type, the information bits contain the information that is transmitted

to the slave.

• 5 information bits in standard addressing mode

• 4 information bits in advanced addressing mode

Advanced addressing mode:

• For the advanced addressing mode (for up to 62 slaves), an additional select bit has been

defined.

• This has been defined in order that an A slave behaves the same as a standard slave. An

A slave can also be operated in networks where the master cannot distinguish between

A and B slaves. A/B slaves can be recognised by the hexadecimal ID code "0xA".

• Valid address range: 1A ... 31A, 1B ... 31B

PB Parity bit: The sum of all 1 bit states in the master call must be even.

EB The end bit marks the end of the master call.

•0: Not permitted

• 1: Valid end bit

bit

3 bits 1 bit 1 bit

30

Structure of the slave response

ST Information PB EB

1 bit 4 bits 1 bit 1 bit

Bit field Description

ST The start bit marks the start of the slave response.

•0: Valid start bit

•1: Not permitted

Information The 4 information bits contain the information that is transmitted to the master.

PB Parity bit: The sum of all 1 bit states in the slave response must be even.

EB The end bit marks the end of the slave response.

•0: Not permitted

• 1: Valid end bit

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 31

Data transfer

AS-i cycle

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2 AS-i cycle

The complete AS-i cycle consists of:

• AS-i messages

Max. 31 messages (sum of the standard slaves connected to the network or the maximum of A

and B slaves)

• 1 management call

Consists of a parameter exchange or a command to a slave and an optional response.

• 1 call from the recording phase

Search for new slave addresses and optional response

• 1 reserve message (if required)

Cycle time

• The cycle time results from the following formula:

Cycle time = messages per cycle x max. message duration

• When the maximum cycle time is determined, 33 messages are maximally estimated. Hence:

Max. cycle time = 33 messages x 154 μs = 5.08 ms

• Thus, approx. 200 cycles are passed per second.

• Thus, a standard slave can be provided 200 times per second with new output data and can

transmit its input data to the master.

Note!

Wherever A and B slaves are operated on one address, the cycle time is twice as long.

Medium response time

• The medium response time results from the following formula:

Medium response time = 0.5 x max. cycle time + max. message duration

Medium response time = 0.5 x 5.08 ms + 154 μs= 2.7ms

•The jitter, which is the fluctuation around the medium response time, amounts to ...

• ± 2.5 ms for standard slaves;

•±5.0 ms for A/B slaves.

Note!

Wherever A and B slaves are operated on one address, the medium response time is

twice as long (5.4 ms).

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 31

Page 32

Data transfer

Synchronisation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.3 Synchronisation

The synchronisation serves to read in or output all input and output data exactly at the same time

and independent of the slave address. The jitter of the outputs can be reduced from ± 2.5 ms to

±154μs.

In a standard data exchange, the outputs of each slave that receives a data call from the master are

updated immediately and the input information are read in. For the 1st slave, this occurs approx.

154 μs before the 2nd slave and for this slave again approx. 154 μs before the 3rd etc.

If all the slaves are in a synchronised state, the information at their inputs and outputs is only

synchronised once at the beginning of the cycle. Since each slave can recognise when a new AS-i

cycle starts, no special additional synchronisation command is required. Thus, the information

exchange within the cycle remains the same. In order that the synchronisation works, not every

slave has to be in a synchronised state.

32

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 33

Data transfer

AS-i concept of the Communication Unit

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

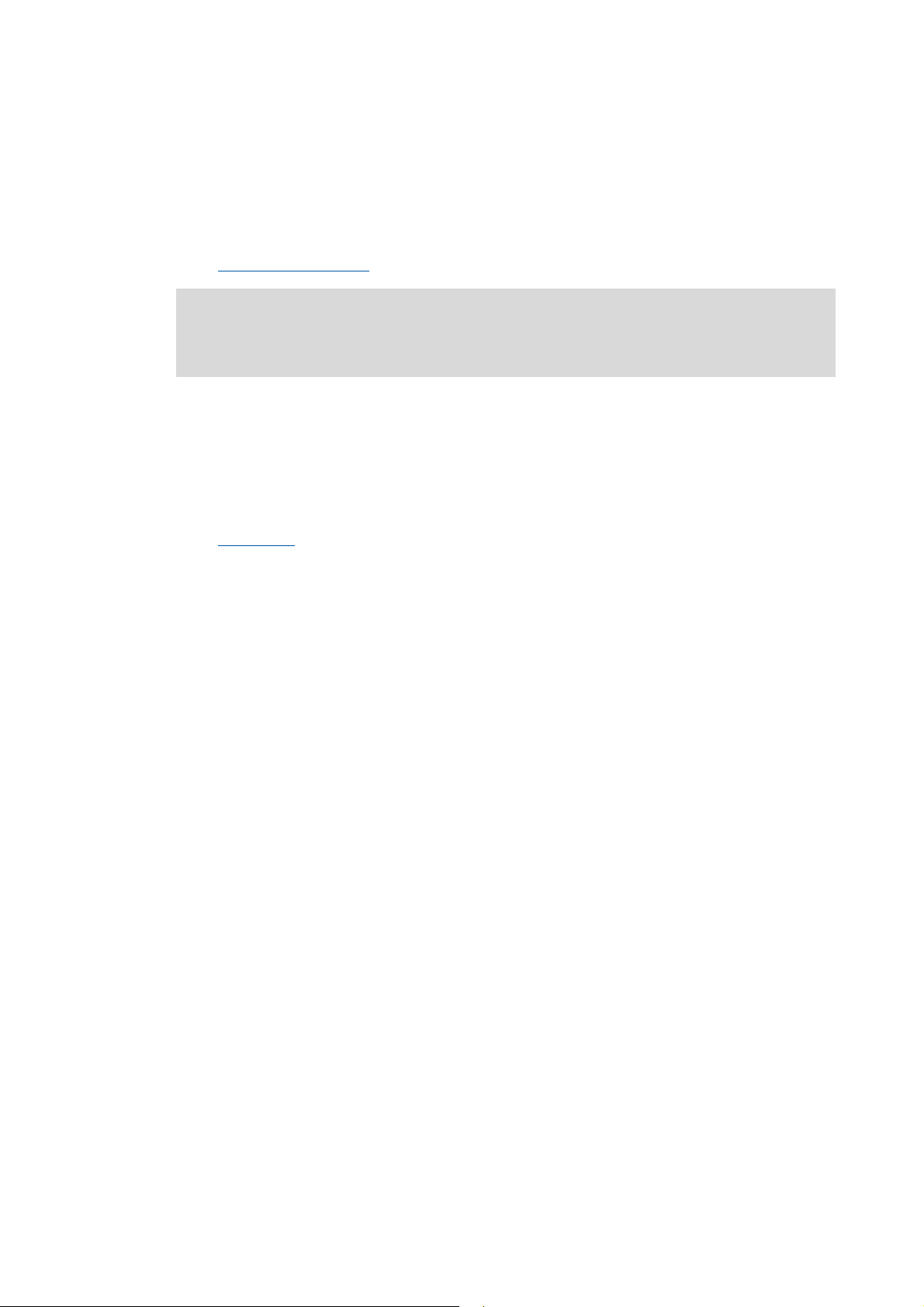

7.4 AS-i concept of the Communication Unit

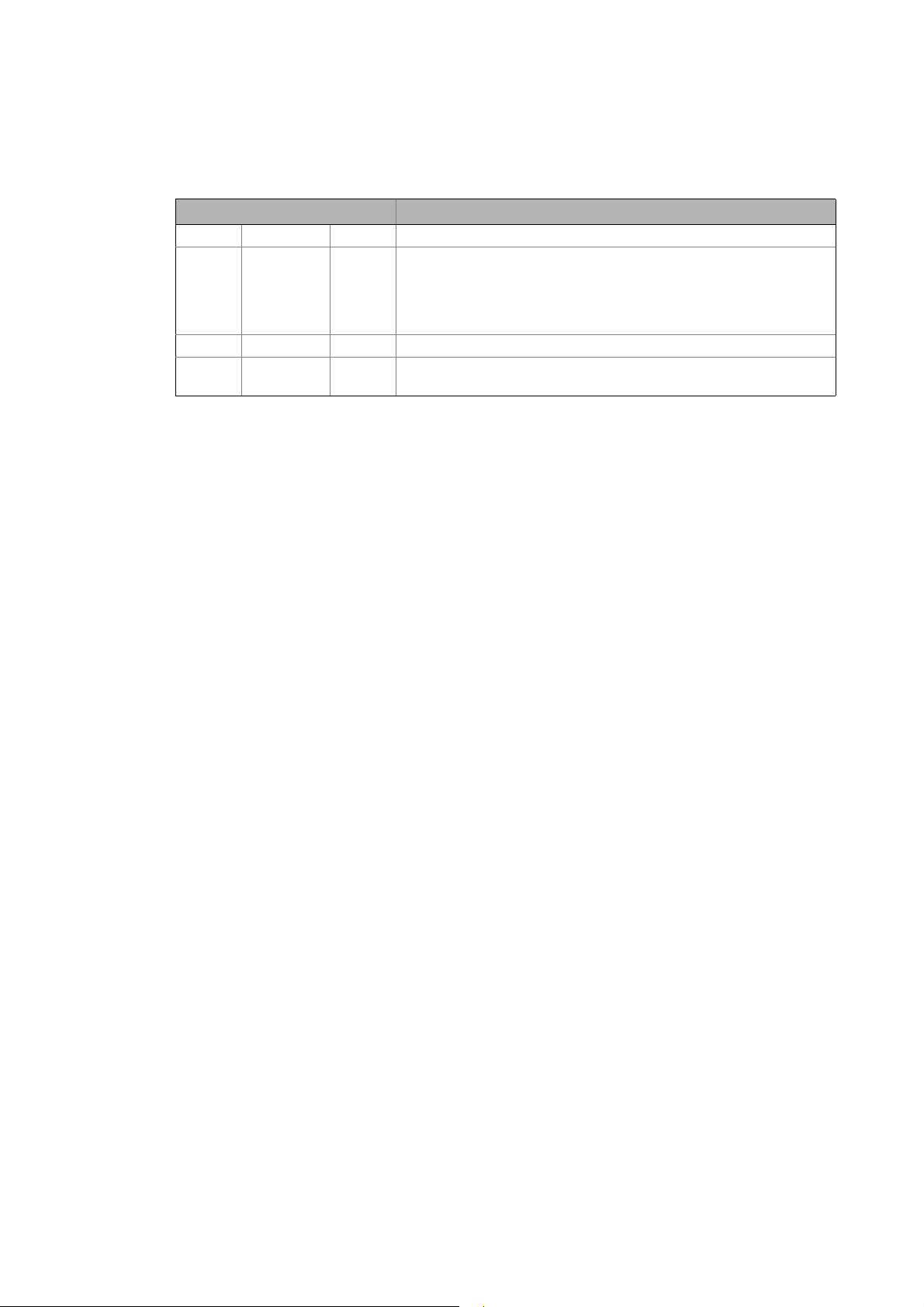

The AS-Interface Communication Unit supports the following device profiles:

AS-i profile Slave Data transmission Data / parameter bits

7.A.5 1 Cyclic process image DI0/1, DO2/3

Serial data transmission (CTT2):

Acyclic transmission of data records and cyclic transmission

of the extended process image

Extended process image for slave 1

7.A.E 2 Cyclic process image DI0 ... 3, DO0 ... 3

Diagnostics via parameter data channel (parameter echo) P0 ... P3

( 35)

DI2/3, DO0/1

[7-1] AS-i concept of the Communication Unit

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 33

Page 34

Data transfer

Data transmission slave 1 (AS-i profile 7.A.5)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.5 Data transmission slave 1 (AS-i profile 7.A.5)

Accessing the data bits

Bits Signal / I/O mapping Description / standard connection with ...

Inputs

DI0 DigIn_bIn2 The function of these inputs cannot be selected in the

DI1 DigIn_bIn4

DI2 Serial Clock In Intended for CTT2 transmission.

DI3 Serial Data In

Outputs

DO0 Serial Clock Out Intended for CTT2 transmission.

DO1 Serial Data Out

DO2 LP_Network_In: MCI_bCtrl_B3 C00701/3: not connected

DO3 Reserved Reserved for AS-i A/B addressing

»Engineer«.

Can be used to monitor the digital inputs if the Drive Unit is

in the "offline" status.

Accessing the parameter bits

Bits Signal / I/O mapping Description

P0 Reserved Selection of the process image:

• 0: Data of the extended (cyclic) process image 1

• 1: Data of the extended (cyclic) process image 2

Extended process image for slave 1

P1 Reserved

P2 Reserved

P3 Reserved Reserved for AS-i A/B addressing

( 35)

34

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 35

Data transfer

Data transmission slave 1 (AS-i profile 7.A.5)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Extended process image for slave 1

Extended process image 1 - PR0 = 0

Position Signal / I/O mapping

Master Slave (2 x 16 bits/word)

Word 1 MCI_wIn2/CAN1_wIn2

Word 2 MCI_wIn5/CAN2_wIn1

Slave Master (2 x 16 bits/word)

Word 1 MCI_wOut2/CAN1_wOut2

Word 2 MCI_wOut5/CAN2_wOut1

Extended process image 2 - PR0 = 1

Position Signal / I/O mapping Description

Master Slave (2 x 16 bits/word)

Word 1 MCI_wIn2/CAN1_wIn2

Word 2 MCI_wIn5/CAN2_wIn1

Slave Master (2 x 16 bits/word)

Word 1 MCI_wOut2/CAN1_wOut2

Word 2:

Bits 0 ... 9

Word 2:

Bit 10

Word 2:

Bit 11

Word 2:

Bit 12

Word 2:

Bit 13

Word 2:

Bit 14

Word 2:

Bit 15

0...10V

(Voltage at analog input)

DI3 0: Active

DI4

DI5

Reserved

I/O status information 0: Invalid data in word 1, word 2

Status of the drive (Drive Unit) 0: Drive (Drive Unit) is "offline"

10 V = 1000

1: Not active

1: Valid data in word 1, word 2

1: Drive (Drive Unit) is "online"

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 35

Page 36

Data transfer

Data transmission slave 2 (AS-i profile 7.A.E)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.6 Data transmission slave 2 (AS-i profile 7.A.E)

Accessing the data bits

Bits Signal / I/O mapping Description / standard connection with ...

Inputs

DI0 LP_Network_Out: MCI_bState_B0 C00621/30: not connected

DI1 LP_Network_Out: MCI_bState_B1 C00621/31: not connected

DI2 Digin_bln1 The function of these inputs cannot be selected in the

DI3 Digin_bln3

Outputs

DO0 LP_Network_In: MCI_bCtrl_B0 C00701/1: not connected

DO1 LP_Network_In: MCI_bCtrl_B1 C00701/6: not connected

DO2 LP_Network_In: MCI_bCtrl_B2 C00701/5: not connected

DO3 Reserved Reserved for AS-i A/B addressing

»Engineer«.

Can be used to monitor the digital inputs if the Drive Unit is

in the "offline" status.

36

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 37

Data transfer

Data transmission slave 2 (AS-i profile 7.A.E)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Accessing the parameter bits

Parameter bits P0 ... P3 provide diagnostic information to the master for slave 2. Here, P0 ... P2

define whether a status query of code C00150 or an error/warning diagnostics is returned as slave

response to the master.

The values of P0 ... P3 are transmitted to the master via the "Write_Parameter" command.

Bits Signal / I/O mapping Description

P0 Diagnostic information

P1

P2

P3

(slave master):

• 4 status bits of the status word

C00150

• Error messages / warnings (see

below)

Error messages and warnings

Values P0 - P1 - P2:

• 0 - 0 - 0: Query C00150/Bits 0 ... 3

• 0 - 0 - 1: Query C00150/Bits 4 ... 7

• 0 - 1 - 0: Query C00150/Bits 8 ... 11

• 0 - 1 - 1: Query C00150/Bits 12 ... 15

• 1 - 0 - 0: Active error

• 1 - 0 - 1: Active warning

Note!

No error message / warning is ever provided other than the one with the highest priority.

As long as this error message / warning is pending, no other can be provided.

Values Error message Warning

P0 P1 P2 P3

0 0 0 0 No failure No warning

0001"OC1" - Short circuit "OC5" - Device load warning

0010"OC2" - Ground fault "OC6" - Overload warning

0011 "OH" - High temperature Heat sink temperature high warning

0 1 0 0 "US02" - User error #1 "US01" - User warning #1

0 1 0 1 "OU" - High bus voltage Brake resistor overload

0 1 1 0 "LU" - Low bus voltage error "LU" - Low bus voltage warning

0 1 1 1 "OC6" - Overload error Motor identification active

1 0 0 0 "Su02" - Single phasing "Su02" - Single phasing

1 0 0 1 "US02" - User error #2 "US02" - User warning #2

1 0 1 0 "dbF" - Dynamic brake fault AutoStartLock

1 0 1 1 "PS0x" - EPM failure Motor phase failure

1 1 0 0 "DF0x" - Internal failure AIN current < 4 mA

1101"OH3" - PTC fault Reserved (unused)

1 1 1 0 Drive Unit "offline" Reserved (unused)

1111Other failure Other warnings

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 37

Page 38

Process data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8 Process data transfer

• Process data are transmitted via the process data channel.

• The process data serve to control the inverter.

• The transmission of process data is time-critical.

• Process data are cyclically transferred between the master and the slaves participating in the

fieldbus (continuous exchange of current input and output data).

• The master can directly access the process data. In the PLC, for instance, the data are directly

assigned to the I/O area.

• Process data are not saved in the inverter.

• Process data are e.g. setpoints, actual values, control words, and status words.

Note!

Observe the direction of the information flow.

• Process input data (Rx data):

Process data from the inverter (slave) to the host (master)

• Process output data (Tx data):

Process data from the host (master) to the inverter (slave)

38 Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 39

Process data transfer

Accessing process data / PDO mapping

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.1 Accessing process data / PDO mapping

Process data are transferred via the MCI/CAN interface.

• The process data is accessed via the LP_Network_In and LP_Network_Out port blocks.

• Up to 8 words (16 bits/word) per direction can be exchanged.

• The port/function blocks of the process data objects (PDO) are interconnected via the Lenze

»Engineer«.

[8-1] Outer and inner data transfer between bus system, drive and application

Software manual / »Engineer« online help for the Inverter Drive 8400 motec

Here you will find detailed information on the port/function block interconnection in

the »Engineer« and on the port blocks.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 39

Page 40

Process data transfer

Port interconnection of process data objects (PDO)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.2 Port interconnection of process data objects (PDO)

How to configure the port interconnection in the »Engineer«:

1. Go to the Application parameters tab to make the default setting of the I/O configuration.

Select the "Network (ASi)" control mode (C00007).

2. The Process data objects tab of the AS-i interface displays the preset I/O configuration.

40

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 41

Process data transfer

Port interconnection of process data objects (PDO)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Open the "Assignment Signal --> Function Block" dialog window using the buttons.

Here, tick (

) the signals that are sent from the PLC (AS-i master) to the inverter.

4. Confirm the selection with OK.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 41

Page 42

Process data transfer

Port interconnection of process data objects (PDO)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5. The codes C00620/21, C00620/24, C00621/30 and C00621/31 serve to

select the signals that are sent from the inverter to the PLC (AS-i master).

6. Use code C00002 to execute the command "11: Save all parameter sets".

The changed settings are activated and saved safe against mains failure.

42

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 43

Parameter data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Parameter data transfer

• Parameter data are acyclically transmitted via the parameter data channel.

• The parameter data channel provides access to all Lenze codes.

• In general, the transmission of parameter data is not time-critical.

• Parameter data are, for instance, operating parameters, diagnostic information, and motor

data.

• Parameter data transfer of the AS-Interface Communication Unit is done acyclically by means

of serial CTT2 transmission (combined transaction type 2).

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 43

Page 44

Parameter data transfer

CTT2: Read parameter value

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.1 CTT2: Read parameter value

• Acyclic read request from the master to the slave:

Byte Contents / value

0 CTT2: Code

•Index 0x12 (18): Acyclic read request

1 CTT2: Index

•Index 0x10 (16): Read parameter value

2 CTT2: Number of bytes

• Value depends on the master.

• Response from slave to master is OK:

Byte Contents / value

0 CTT2: Code

•Index 0x52 (82): Acyclic read request is OK.

1 Data type / number of bytes

Bit 7 = 0 Octet string (text)

• Bits 0 ... 6 = Number of string characters

Bit 7 = 1 Number (4 data bytes):

• Bits 0 ... 2 = Number of valid bytes

(1 = 1 byte, 2 = 2 bytes, 3 = 3 bytes, 4 = 4 bytes)

2 1st character of the character string or data byte 1 (MSB)

3 2nd character of the string or data byte 2

4 3rd character of the string or data byte 3

5 4th character of the string or data byte 4 (LSB)

6 5th character of the string

... ...

n n-th character of the string

• Response from slave to master has failed:

Byte Contents / value

0 CTT2: Code

•Index 0x92 (146): Acyclic read request is not OK.

1 CTT2: Standard error code

CTT2: Standard error codes

2Error code (MSB)

3Error code

4Error code

5Error code (LSB)

CTT2: Acyclic device error codes

( 51)

( 52)

44

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 45

Parameter data transfer

CTT2: Write parameter value

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.2 CTT2: Write parameter value

• Acyclic write request from master to slave:

Byte Contents / value

0 CTT2: Code

•Index 0x13 (19): Acyclic write request

1 CTT2: Index

•Index 0x18 (24): Write parameter value

2 CTT2: Number of bytes

• 0x8 (8)

3Index high

byte

4Index low

byte

5Subindex

6 Data type / number of bytes

Bit 7 = 0 Number (4 data bytes):

Bit 7 must be "0". Writing the string is not supported.

7 Data byte 1 (MSB)

8 Data byte 2

9 Data byte 3

10 Data byte 4 (LSB)

Index = 0x5FFF (code to be written)

• Bits 0 ... 2 = Number of valid bytes

(1 = 1 byte, 2 = 2 bytes, 3 = 3 bytes, 4 = 4 bytes)

• Response from slave to master is OK:

Byte Contents / value

0 CTT2: Code

•Index 0x53 (83): Acyclic write request is OK.

• Parameter value was written.

• Response from slave to master has failed:

Byte Contents / value

0 CTT2: Code

•Index 0x93 (147): Acyclic write request is not OK.

1 CTT2: Standard error code

CTT2: Standard error codes

2Error code (MSB)

3Error code

4Error code

5Error code (LSB)

CTT2: Acyclic device error codes

( 51)

( 52)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 45

Page 46

Parameter data transfer

CTT2: Read code number

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.3 CTT2: Read code number

• Acyclic read request from the master to the slave:

Byte Contents / value

0 CTT2: Code

•Index 0x12 (18): Acyclic read request

1 CTT2: Index

•Index 0x12 (18): Read code number

2 CTT2: Number of bytes

• Value depends on the master.

• Response from slave to master is OK:

Byte Contents / value

0 CTT2: Code

•Index 0x52 (82): Acyclic read request is OK.

3Index high

byte

4Index low

byte

5Subindex

6 Reserved

Index = 0x5FFF (code of the inverter)

• Response from slave to master has failed:

Byte Contents / value

0 CTT2: Code

•Index 0x92 (146): Acyclic read request is not OK.

1 CTT2: Standard error code

CTT2: Standard error codes

2Error code (MSB)

3Error code

4Error code

5Error code (LSB)

CTT2: Acyclic device error codes

( 51)

( 52)

46

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 47

Parameter data transfer

CTT2: Write code number

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.4 CTT2: Write code number

• Acyclic write request from master to slave:

Byte Contents / value

0 CTT2: Code

•Index 0x13 (19): Acyclic write request

1 CTT2: Index

•Index 0x11 (17): Write code number

2 CTT2: Number of bytes

• 0x4 (4)

3Index high

byte

4Index low

byte

5Subindex

6 Reserved

Index = 0x5FFF (code of the inverter)

• Response from slave to master is OK:

Byte Contents / value

0 CTT2: Code

•Index 0x53 (83): Acyclic write request is OK.

• Code number was written.

• Response from slave to master has failed:

Byte Contents / value

0 CTT2: Code

•Index 0x93 (147): Acyclic write request is not OK.

1 CTT2: Standard error code

CTT2: Standard error codes

2Error code (MSB)

3Error code

4Error code

5Error code (LSB)

CTT2: Acyclic device error codes

( 51)

( 52)

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 47

Page 48

Parameter data transfer

CTT2: Block parameter transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.5 CTT2: Block parameter transfer

In the case of the CTT2 block parameter transfer, parameter sets with a fixed length of 64 bytes are

transmitted.

Note!

In order to guarantee that a fixed data length of 64 bytes is transmitted, all the

parameters are transmitted as 32-bit values (16 x 32-bit parameters).

If required, the data lengths or formats of the parameters must be adjusted accordingly.

Parameter data smaller than 32 bits are not extended to 32 bits.

9.5.1 Read mode

• Acyclic read request from the master to the slave:

Byte Contents / value

0 CTT2: Code

•Index 0x12 (18): Acyclic read request

1 CTT2: Index

•Index 0x20 (32): Read parameter

2 CTT2: Number of bytes

• Value depends on the master.

• Response from slave to master is OK:

Byte Contents / value

0 CTT2: Code

•Index 0x52 (82): Acyclic read request is OK.

• All the parameters were read.

1 Reserved

2 Reserved

3 Reserved

4 ... 7 Double word 1

• Value of the parameter in code C13214/1

... ...

64 ... 67 Double word 16

• Value of the parameter in code C13214/16

48

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 49

Parameter data transfer

CTT2: Block parameter transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• Response from slave to master has failed:

Byte Contents / value

0 CTT2: Code

•Index 0x92 (146): Acyclic read request is not OK.

• Read exception list (index 0x21 (33))

1 CTT2: Standard error code

CTT2: Standard error codes

2Error code (MSB)

3Error code

4Error code

5Error code (LSB)

CTT2: Acyclic device error codes

• After the acyclic read request (index 0x12 (18)) has failed, the master sends error codes.

• Then the read request from master to slave with the index 0x21 (33) is repeated.

• The slave sends the parameter values in code C13214/1...16

( 51)

( 52)

again.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 49

Page 50

Parameter data transfer

CTT2: Block parameter transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.5.2 Write mode

• Acyclic write request from master to slave:

Byte Contents / value

0 CTT2: Code

•Index 0x13 (19): Acyclic write request

1 CTT2: Index

•Index 0x28 (40): Write parameter

2 CTT2: Number of bytes

• 0x41 (65)

3 Reserved

4 ... 7 Double word 1

• Value of the parameter in code C13213/1

... ...

64 ... 67 Double word 16

• Value of the parameter in code C13213/16

• Response from slave to master is OK:

Byte Contents / value

0 CTT2: Code

•Index 0x53 (83): Acyclic write request is OK.

• All the parameters were written.

• Response from slave to master has failed:

Byte Contents / value

0 CTT2: Code

•Index 0x93 (147): Acyclic write request is not OK.

• Read exception list (index 0x29 (41))

1 CTT2: Standard error code

CTT2: Standard error codes

2Error code (MSB)

3Error code

4Error code

5Error code (LSB)

CTT2: Acyclic device error codes

( 51)

( 52)

• After the acyclic write request (index 0x13 (19)) has failed, the master sends error codes.

• Then the write request from master to slave with the index 0x29 (41) is repeated.

• The slave sends the parameter values in code C13213/1...16

again.

50

Note!

Faulty writing of parameter sets can change single parameters.

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 51

Parameter data transfer

CTT2: Standard error codes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.6 CTT2: Standard error codes

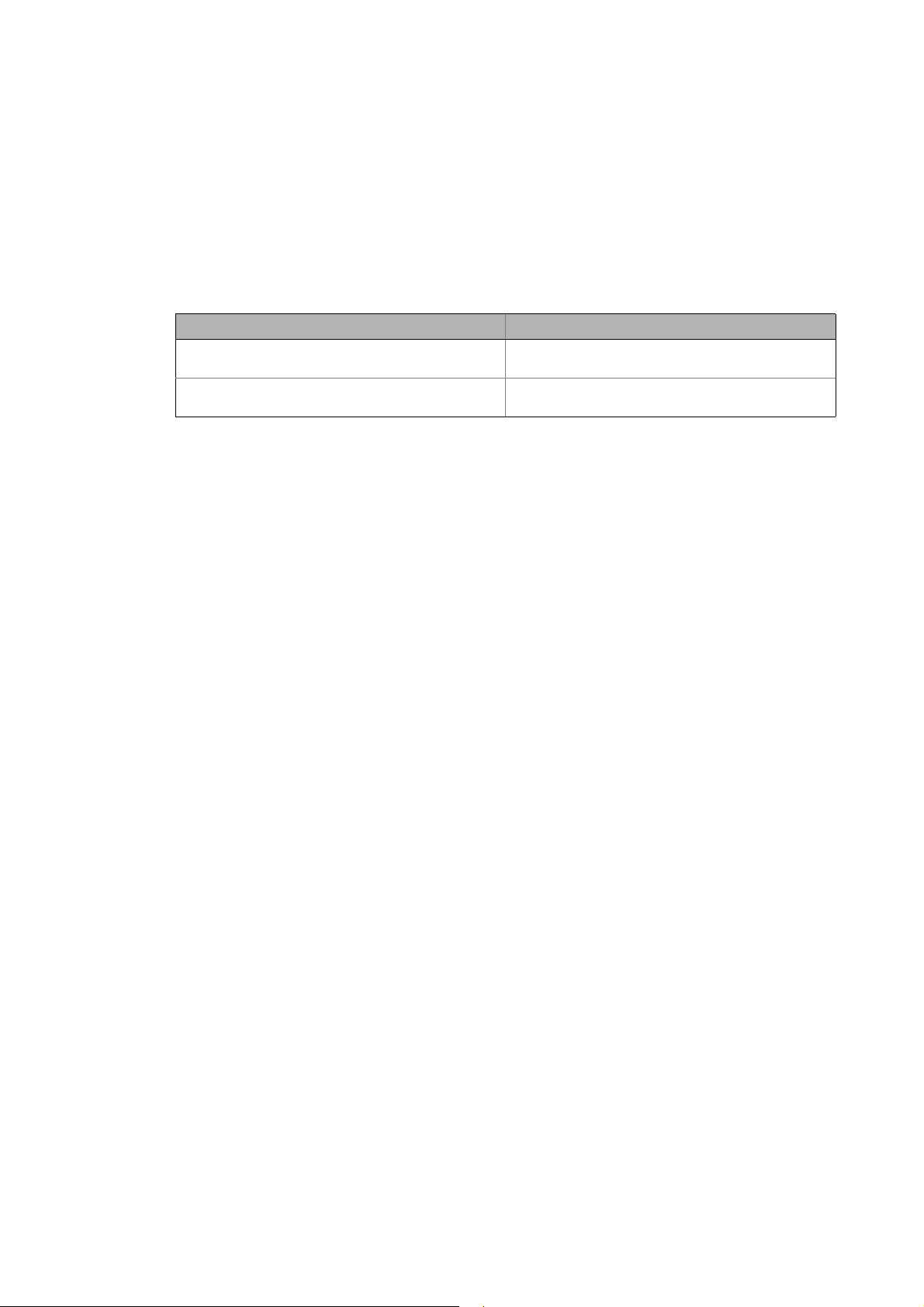

CTT2 error

code

0 No error / no CTT2 standard error

1Invalid index

2 Invalid length

3 Request not executed

4 In process (request not fully completed / new trial)

5 Last acyclic request not confirmed

6 Invalid subindex

7 Command "Selective read request" is missing

Description

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 51

Page 52

Parameter data transfer

CTT2: Acyclic device error codes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.7 CTT2: Acyclic device error codes

Error code [hex] Description

Byte 0

(MSB)

0x00 0x00 0x00 0x00 Transfer aborted

0x06 0x03 0x00 0x00 • No access rights

0x06 0x05 0x00 0x10 Invalid service

0x06 0x05 0x00 0x11 Invalid subindex

0x06 0x05 0x00 0x12 Data length too large

0x06 0x05 0x00 0x13 Data length too small

0x06 0x06 0x00 0x00 Object is no parameter

0x06 0x07 0x00 0x00 Object does not exist

0x06 0x08 0x00 0x00 Data (types) do not correspond

0x08 0x00 0x00 0x00 • Invalid function

0x08 0x00 0x00 0x20 Request cannot be executed at the moment

0x08 0x00 0x00 0x21 No operation due to local control

0x08 0x00 0x00 0x22 Request cannot be executed due to the device state

0x08 0x00 0x00 0x30 • Value beyond the range

0x08 0x00 0x00 0x31 Parameter value too high

0x08 0x00 0x00 0x32 Parameter value too low

0x08 0x00 0x00 0x33 Value range of the (sub)parameter exceeded

0x08 0x00 0x00 0x34 Value range of the (sub)parameter too high

0x08 0x00 0x00 0x35 Value range of the (sub)parameter too low

0x08 0x00 0x00 0x36 Maximum value lower than minimum value

0x08 0x00 0x00 0x41 Communication object cannot be displayed

0x08 0x00 0x00 0x42 Process data length exceeded

0x08 0x00 0x00 0x43 General value collision

0x08 0x00 0x00 0x50 • Block access has failed

0x08 0x00 0x00 0x80 Hardware error

Byte 1 Byte 2 Byte 3

(LSB)

• Invalid access

• Read-only object

• Request cannot be executed

•No operation

• Parameter can only be changed when the controller is inhibited

(CINH)

• One or several parameter accesses within the block have failed

• Read exception list for more details

52

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 53

Diagnostics

LED status displays

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10 Diagnostics

For diagnosing troubled AS-i communication, LEDs can be mounted to the Communication Unit.

The LEDs, in conjunction with a transparent cover, can be procured from Lenze.

Moreover, the current bus status can be queried via code C13211

status can be queried via code C13950

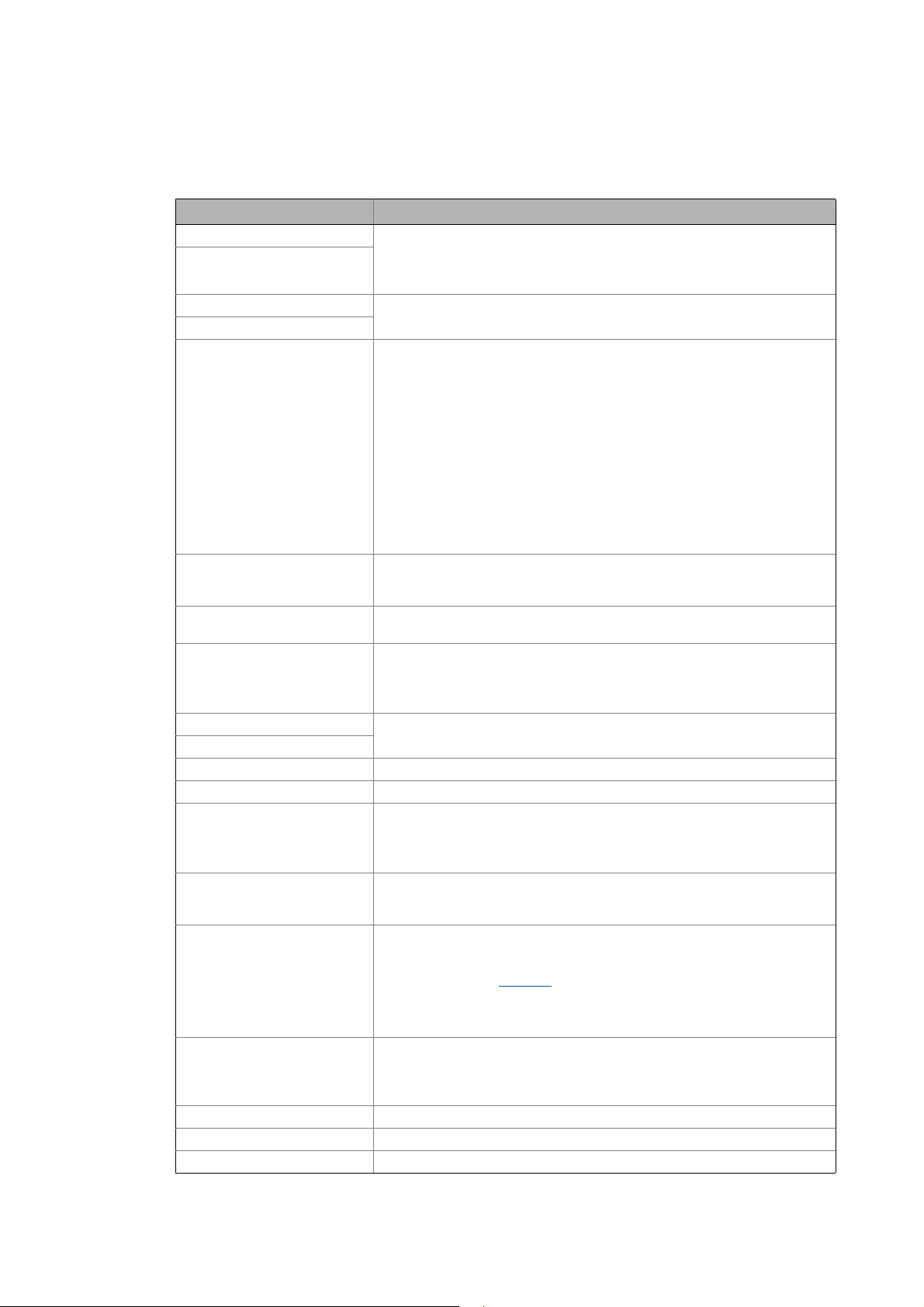

10.1 LED status displays

.

and the internal communication

E84DG057

LED statuses for slave 1 and slave 2 Description

Green LEDs Red LEDs

Off Off There is no AS-i voltage.

On Off Everything is alright

• AS-i communication is possible.

Off On The slave is switched off; data exchange with the

master is not possible.

On On "No data exchange"

• The Data_Exchange_Disable flag is set; data

exchange with the master is not possible.

• The IC is waiting for a "Write Parameter Request".

• The communication monitoring reports "No data

exchange" or the IC has been reset via "Watchdog

IC Reset".

Blinking (2 Hz) On "No data exchange"

• The slave is waiting for address assignment by the

master.

• Data exchange with the master is not possible.

Blinking (2 Hz) Blinking (2 Hz) Peripheral error

• A signal indicating a peripheral error is pending at

the FID input.

• The LEDs are blinking alternately.

On Blinking (2 Hz) Fatal peripheral error with reset

• Data sampling pulse = LOW for more than 44 μs

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013 53

Page 54

Diagnostics

Diagnostics with the »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10.2 Diagnostics with the »Engineer«

In the »Engineer« under the Diagnostics tab, you will find AS-Interface diagnostics information.

54

Lenze · Decentralised frequency inverter 8400 motec (AS-Interface option) · EDS84DMOTASI EN 4.0 - 09/2013

Page 55

Error messages

Short overview of AS-i error messages