Page 1

EDS82ZAFVCxxx

.IFõ

Ä.IFõä

L−force Communication

Communication Manual

DeviceNet

E82ZAFVC001 / E82ZAFVC010

Function module

l

Page 2

Contentsi

1 About this documentation 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Device− and application−specific safety instructions 9 . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Product features 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connections and interfaces 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Operating conditions 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Protective insulation 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Connection terminals 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Communication time 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Dimensions 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Mechanical installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Wiring according to EMC (CE−typical drive system) 20 . . . . . . . . . . . . . . . . .

5.2.2 Wiring with a host (master) 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Voltage supply 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Terminal assignment 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Cable cross−sections and screw−tightening torques 27 . . . . . . . . . . . . . . . . .

5.2.6 Bus cable length 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 Use of plug connectors 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Commissioning steps 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Controls and displays 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Possible settings using the front switch 31 . . . . . . . . . . . . . . . . . . . . . . . . . .

l 2

EDS82ZAFVCxxx EN 4.0

Page 3

Contents i

7 Diagnostics 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 LED status displays 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Troubleshooting and fault elimination 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Codes 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Appendix 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Data transfer 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Overview of the implemented objects for the function module 55 . . . . . . .

10 Index 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDS82ZAFVCxxx EN 4.0

l 3

Page 4

About this documentation1

0Fig. 0Tab. 0

1 About this documentation

Contents

This documentation exclusively contains descriptions regarding the E82ZAFVC001

(DeviceNet) and E82ZAFVC010 (DeviceNet PT) function modules.

) Note!

This documentation supplements the mounting instructions supplied with the

function module and the documentation for the standard devices used.

The mounting instructions contain safety instructions which must be

observed!

ƒ The features and functions of the function module are described in detail.

ƒ Typical applications are explained by means of examples.

ƒ Moreover, this documentation contains the following:

– Safety instructions which must be observed.

– The essential technical data of the function module

– Information on versions of the Lenze standard devices to be used

– Notes on troubleshooting and fault elimination

The theoretical concepts are only explained to the level of detail required to understand

the function of the function module.

Depending on the software version of the controller and the version of the »Engineer«

software installed, the screenshots in this documentation may deviate from the

»Engineer« representation.

This documentation does not describe any software provided by other manufacturers. No

liability can be accepted for corresponding data provided in this documentation. For

information on how to use the software, please refer to the host system (master)

documents.

All brand names mentioned in this documentation are trademarks of their respective

owners.

Validity information

The information given in this documentation is valid for the following devices:

Function module Type designation from hardware version from software version

DeviceNet E82ZAFVC001 Vx 0x

DeviceNet PT E82ZAFVC010 Vx 0x

4

l

EDS82ZAFVCxxx EN 4.0

Page 5

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking and remote service of a machine.

I Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

1.1 Document history

Material no. Version Description

− 1.0 06/2004 TD06 First edition

.IFõ 4.0 03/2012 TD29 General revision

About this documentation

Document history

1

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e−mail us to:

feedback−docu@Lenze.de

Thank you for your support.

Your Lenze documentation team

EDS82ZAFVCxxx EN 4.0

l

5

Page 6

1

About this documentation

Conventions used

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Decimal Standard notation For example: 1234

Hexadecimal 0x[0 ... 9, A ... F] For example: 0x60F4

Binary

l Nibble

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

Point In general, the decimal point is used.

For instance: 1234.56

In quotation marks

Point

For example: ´100´

For example: ´0110.0100´

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

1.3 Terminology used

Term Meaning

PROFIBUS The term stands for the PROFIBUS−DP variant according to IEC 61158/IEC 61784. A

Standard device

Controller

Frequency inverter

Master PROFIBUS station which takes over the master function in the fieldbus system.

Slave PROFIBUS station which acts as a slave in the fieldbus system.

Code "Container" for one or more parameters which can be used to parameterise or

Subcode If a code contains more than one parameter, these parameters are stored in

POW Process output data word

PIW Process input data word

different PROFIBUS variant is not described in this manual.

Lenze controllers/frequency inverters for which the function module can be used.

^ 10

monitor the controller.

"subcodes".

In this documentation, a slash "/" is used as a separator when specifying a code and

its subcode (e.g. "C00118/3").

6

l

EDS82ZAFVCxxx EN 4.0

Page 7

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

About this documentation

Notes used

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

1

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

EDS82ZAFVCxxx EN 4.0

l

7

Page 8

2

Safety instructions

General safety information

2 Safety instructions

) Note!

It is absolutely vital that the stated safety measures are implemented in order

to prevent serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety information

} Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

8

l

EDS82ZAFVCxxx EN 4.0

Page 9

Device− and application−specific safety instructions

2.2 Device− and application−specific safety instructions

ƒ During operation, the function module must be firmly connected to the standard

device.

ƒ With external voltage supply, always use a separate power supply unit, safely

separated to EN 61800−5−1 ("SELV"/"PELV"), in every control cabinet.

ƒ Only use cables corresponding to the given specifications (¶ 21).

, Documentation for the standard device, control system, system/machine

All other measures prescribed in this documentation must also be

implemented. Observe the safety instructions and application notes stated in

the documentation.

2.3 Residual hazards

Safety instructions

2

Protection of persons

ƒ If the controllers are used on a phase earthed mains with a rated mains voltage

³ 400 V, protection against accidental contact is not ensured without implementing

external measures. (See chapter "4.3", ^ 16)

Device protection

ƒ The module contains electronic components that can be damaged or destroyed by

electrostatic discharge.

EDS82ZAFVCxxx EN 4.0

l

9

Page 10

3

Product description

Application as directed

3 Product description

3.1 Application as directed

The E82ZAFVC001 function module ...

ƒ is an accessory module for use in conjunction with the following Lenze standard

devices:

Product range Device designation from hardware version

Frequency inverter 8200 vector Vx14

Motor starter starttec Vx1x

ƒ is a device intended for use in industrial power systems.

Any other use shall be deemed inappropriate!

8200 motec Vx14

The E82ZAFVC010 function module ...

ƒ is an accessory module for use in conjunction with the following Lenze standard

devices:

Product range Device designation from hardware version

Frequency inverter 8200 vector Vx14

ƒ is a device intended for use in industrial power systems.

Any other use shall be deemed inappropriate!

10

l

EDS82ZAFVCxxx EN 4.0

Page 11

Product description

APPLICATION

010 / 3A22

Identification

3

3.2 Identification

APPLICATION

010/ 3A22

Product range

DeviceNet

Generation

Variant:

001: Coated design

010: PT design

Hardware version

Software version

L

Type

Id.-No.

Prod.-No.

Ser.-No.

E82AF000P0B201XX

E82ZAFX005

E82ZAF V C 0xx Vx 0x

EDS82ZAFVCxxx EN 4.0

l

11

Page 12

3

3.3 Product features

Product description

Product features

The E82ZAFVC0xx function module (DeviceNet / DeviceNet PT) connects the basic device

to the serial communication system DeviceNet.

Basic devices can be retrofitted.

The function module adds functions to the controller, e.g.

ƒ Parameter selection/remote parameter setting

ƒ Connection to external controls and hosts

The function module is provided with a DIP switch. This DIP switch serves to set the

following:

ƒ Address

ƒ Baud rate

ƒ Compatibility to the Lenze E82ZAFD000Vx04 function module

Besides using the DIP switch, the device address and baud rate can also be set via software.

In this mode, the function module can either automatically or manually detect the baud

rate.

The function module must always be supplied externally.

12

l

EDS82ZAFVCxxx EN 4.0

Page 13

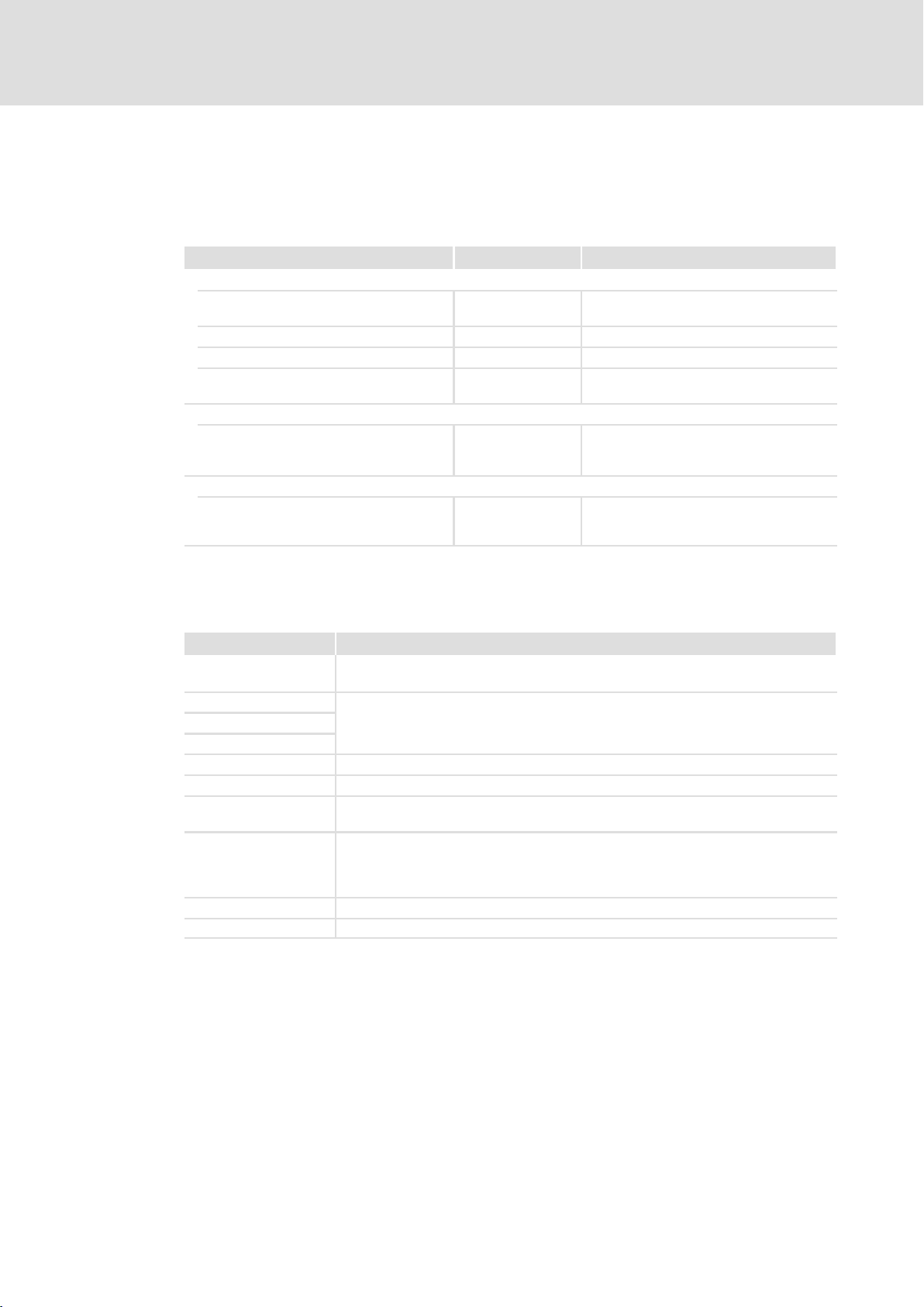

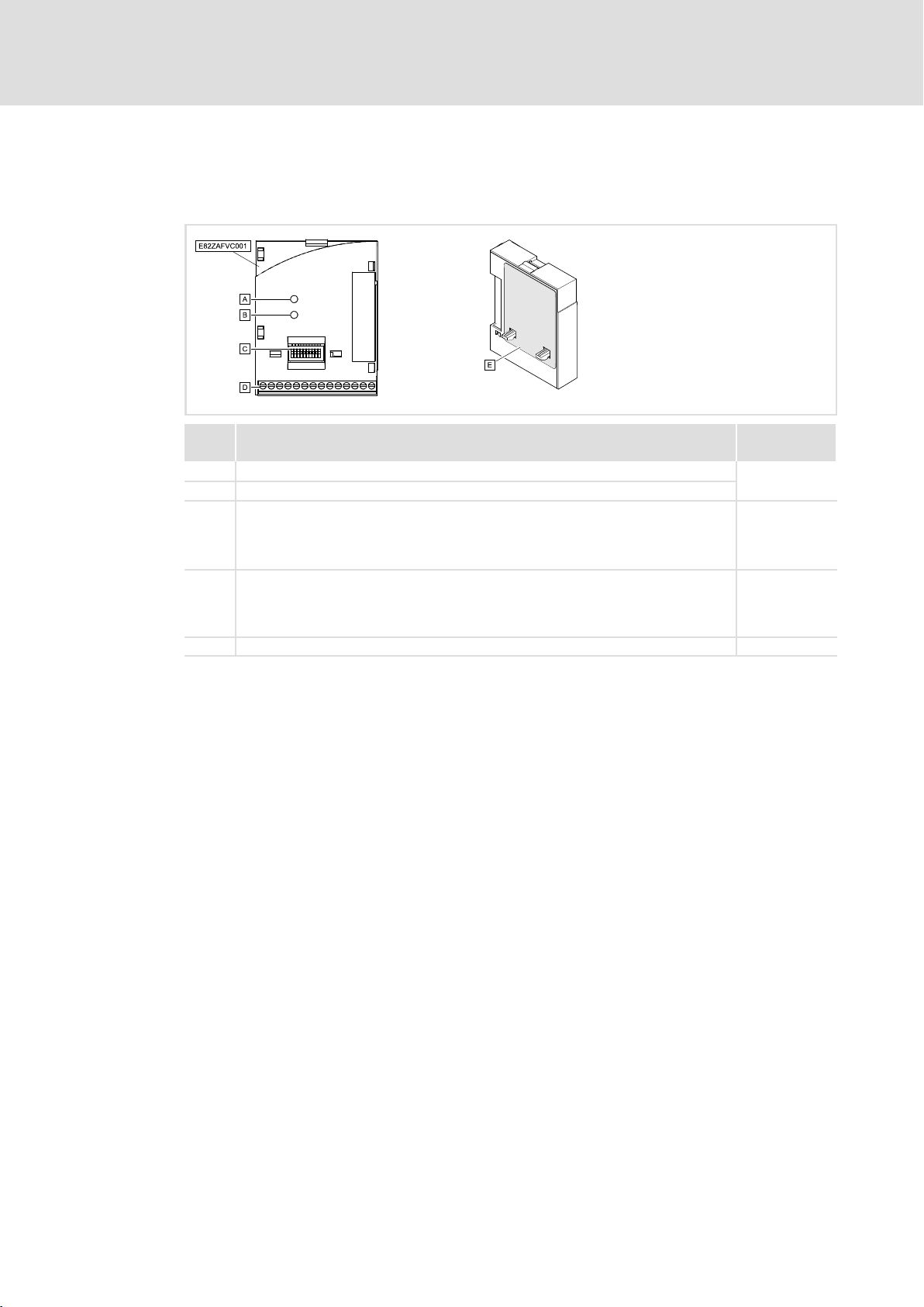

3.4 Connections and interfaces

Function module E82ZAFVC001

Product description

Connections and interfaces

3

E82ZAFV001E

Pos. Description Detailed

0

1

2

3

4

Status display (two−colour green / red), connection to the standard device

Status display (two−colour green / red), connection to the bus

DIP switches for setting

l Node address ("Address")

l Baud rate ("Bd")

l Compatibility with Lenze function module E82ZAFD (DeviceNet)

Terminal strip X3, connections for

l DeviceNet

l Controller inhibit (CINH)

l External voltage supply (via DeviceNet cable)

Nameplate ^ 11

information

^ 34

^ 31

^ 25

EDS82ZAFVCxxx EN 4.0

l

13

Page 14

3

Product description

Connections and interfaces

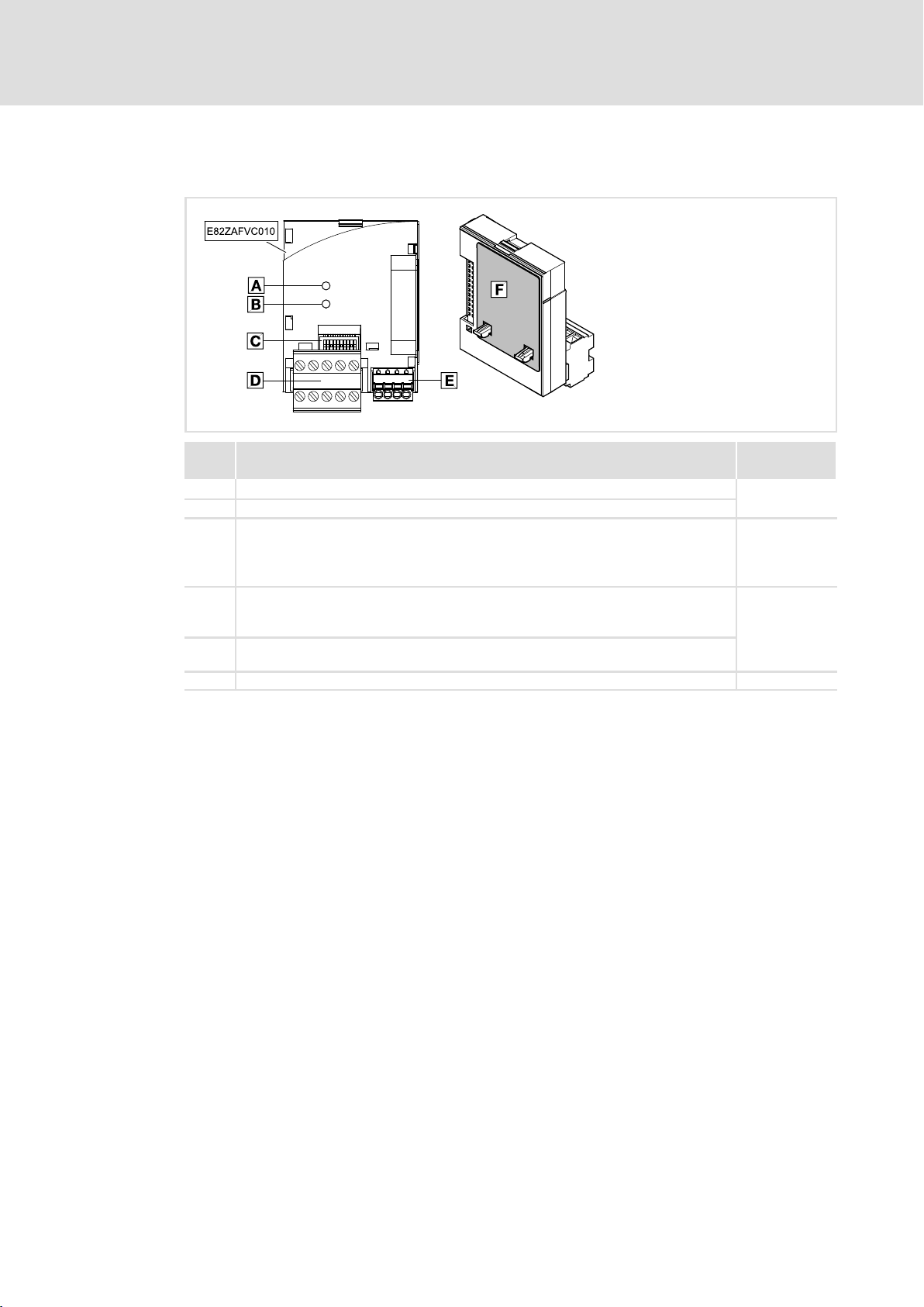

Function module E82ZAFVC010

E82ZAFD101A

Pos. Description Detailed

0

1

2

3

4

5

Status display (two−colour green / red), connection to the standard device

Status display (two−colour green / red), connection to the bus

DIP switches for setting

l Node address ("Address")

l Baud rate ("Bd")

l Compatibility with Lenze function module E82ZAFD (DeviceNet)

Plug connector with double screw connection X3.1, connections for

l DeviceNet

l External voltage supply (via DeviceNet cable)

Plug connector with spring connection X3.2, connections for

l Controller inhibit (CINH)

Nameplate ^ 11

information

^ 34

^ 31

^ 27

14

l

EDS82ZAFVCxxx EN 4.0

Page 15

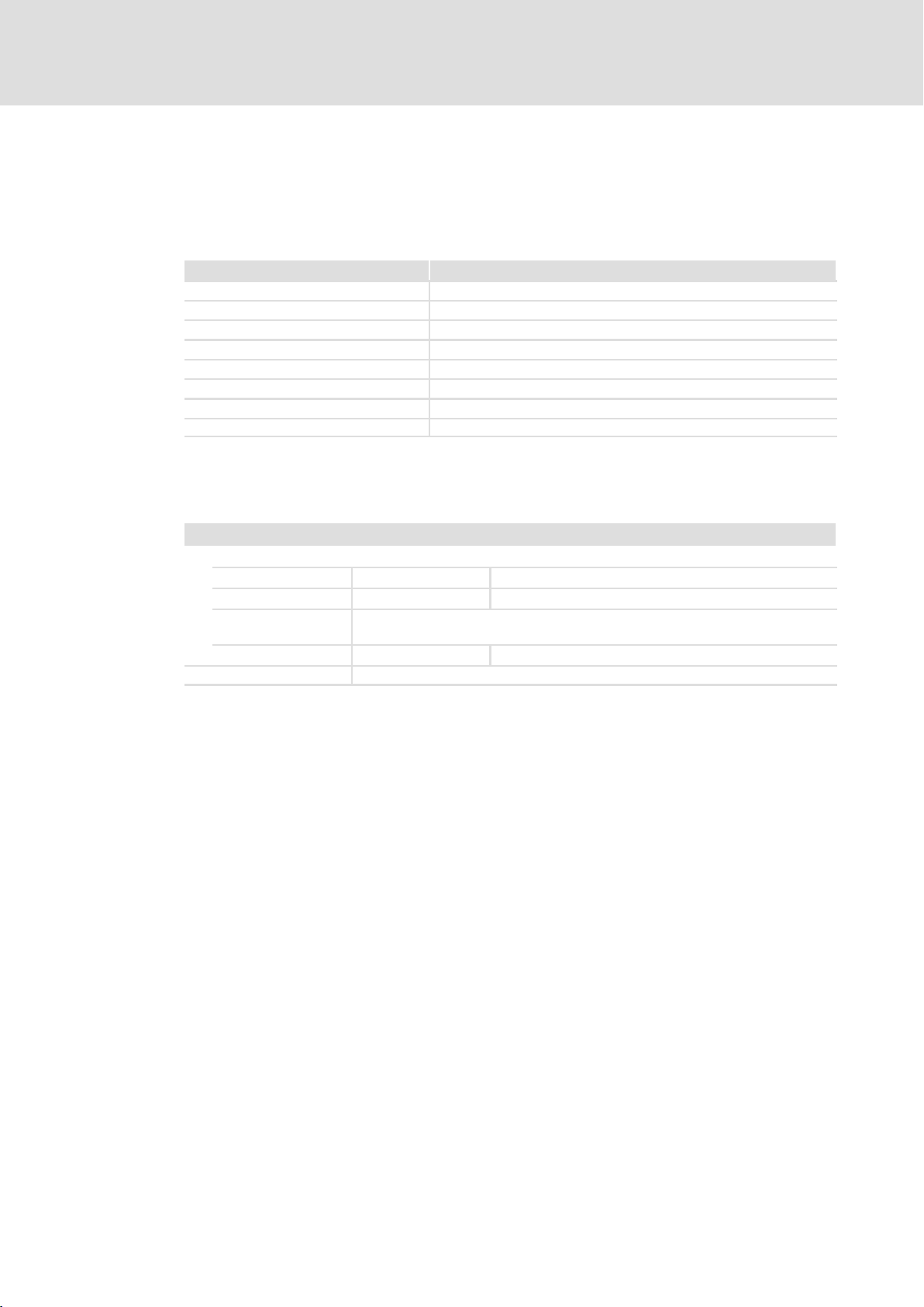

4 Technical data

4.1 General data

Field Values

Communication profile DeviceNet

Communication medium DIN ISO 11898

Network topology Line terminated at both ends (R = 120 Ohms)

Max. number of devices 63

DeviceNet device Slave

Baud rate [kbit/s] 125, 250, 500

Achievable bus cable length Depending on the cable used, see ^ 28

External voltage supply See^ 24

4.2 Operating conditions

Technical data

General data

4

Ambient conditions

Climate

Storage

Transport IEC/EN 60721−3−2 2K3 (−25 to +70 °C)

Operation Corresponding to the data of the Lenze standard device used (see documentation

Pollution EN 61800−5−1 Degree of pollution 2

Degree of protection IP20 (protection against accidental contact according to NEMA 250 type 1)

IEC/EN 60721−3−1 1K3 (−25 to +60 °C)

of the standard device).

EDS82ZAFVCxxx EN 4.0

l

15

Page 16

4

Technical data

Protective insulation

4.3 Protective insulation

{ Danger!

Dangerous electrical voltage

If Lenze controllers are used on a phase earthed mains with a rated mains

voltage ³ 400 V, protection against accidental contact is not ensured without

implementing external measures.

Possible consequences:

ƒ Death or serious injury

Protective measures:

ƒ If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged device modules, ...

– a double isolating distance must exist.

– the components to be connected must be provided with the second

E82ZAFVC001

function module

Protective insulation between bus and ... Type of insulation (acc. to EN 61800−5−1)

l reference earth / PE (X3/SH) Functional insulation

l external supply (X3/V+) No electrical isolation

l supply for CINH (X3/20) No electrical isolation

l controller inhibit, CINH (X3/28) Functional insulation

l power section

– 8200 vector Reinforced insulation

– 8200 motec Reinforced insulation

– starttec Reinforced insulation

l control terminals

– 8200 vector Functional insulation

– 8200 motec Functional insulation

isolating distance.

16

E82ZAFVC010

function module

Protective insulation between bus and ... Type of insulation

l Reference earth / PE (X3.1/SH) Functional insulation

l External supply (X3.1/V+) No functional insulation

l Supply for CINH (X3.2/20) No functional insulation

l Controller inhibit, CINH (X3.2/28) Functional insulation

l 8200 vectorpower unit Double insulation

l 8200 vector control terminals Functional insulation

l

EDS82ZAFVCxxx EN 4.0

Page 17

Technical data

Connection terminals

4

4.4 Connection terminals

E82ZAFVC001

function module

X3/

V+

7 Reference potential 1

39 Reference potential 2 of the controller inhibit (CINH) at X3/28

28 Controller inhibit

20 + 20 V internal for CINH, reference potential 1, load capacity: I

E82ZAFVC010

function module

X3.1/

V+

X3.2/

7

39 Reference potential 2 of controller inhibit (CINH) at X3.2/28

28 Controller inhibit

20 + 20 V internal for CINH, reference potential 1, load capacity: I

External DC voltage supply of the function module:

+24 V DC ±10 %, max. 80 mA

The current flowing via terminal V+ during looping through of the

supply voltage to other devices, is to amount to a maximum of 3 A.

l Start = HIGH (+12 V ... +30 V)

l Stop = LOW (0 V ... +3 V)

Input resistance: 3.3kW

30 mA

External DC voltage supply of the function module:

+24 V DC ±10 %, max. 80 mA

The current flowing via terminal V+ during looping through of the

supply voltage to other devices, is to amount to a maximum of 3 A.

Reference potential 1

l Start = HIGH (+12 V ... +30 V)

l Stop = LOW (0 V ... +3 V)

Input resistance: 3.3kW

30 mA

max

max

=

=

EDS82ZAFVCxxx EN 4.0

l

17

Page 18

4

Technical data

Communication time

4.5 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times depend on ...

ƒ the processing time in the controller

ƒ the transmission delay time

– the baud rate

– the telegram length

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The CAN bus communication times depend on ...

ƒ the processing time in the controller (see documentation of the controller)

ƒ Telegram runtime

– baud rate

– telegram length

ƒ the data priority

ƒ the bus load

18

l

EDS82ZAFVCxxx EN 4.0

Page 19

Technical data

Dimensions

4

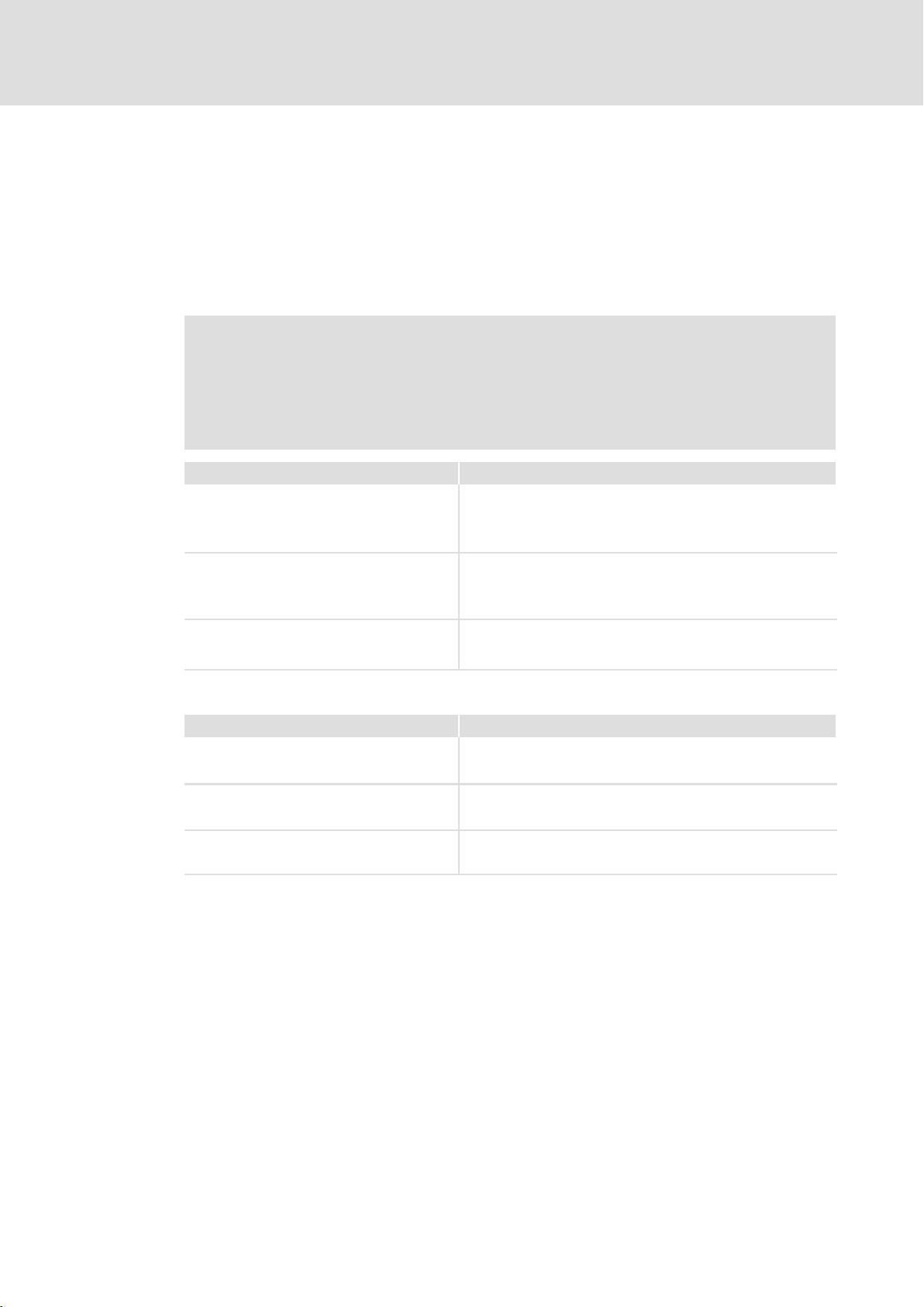

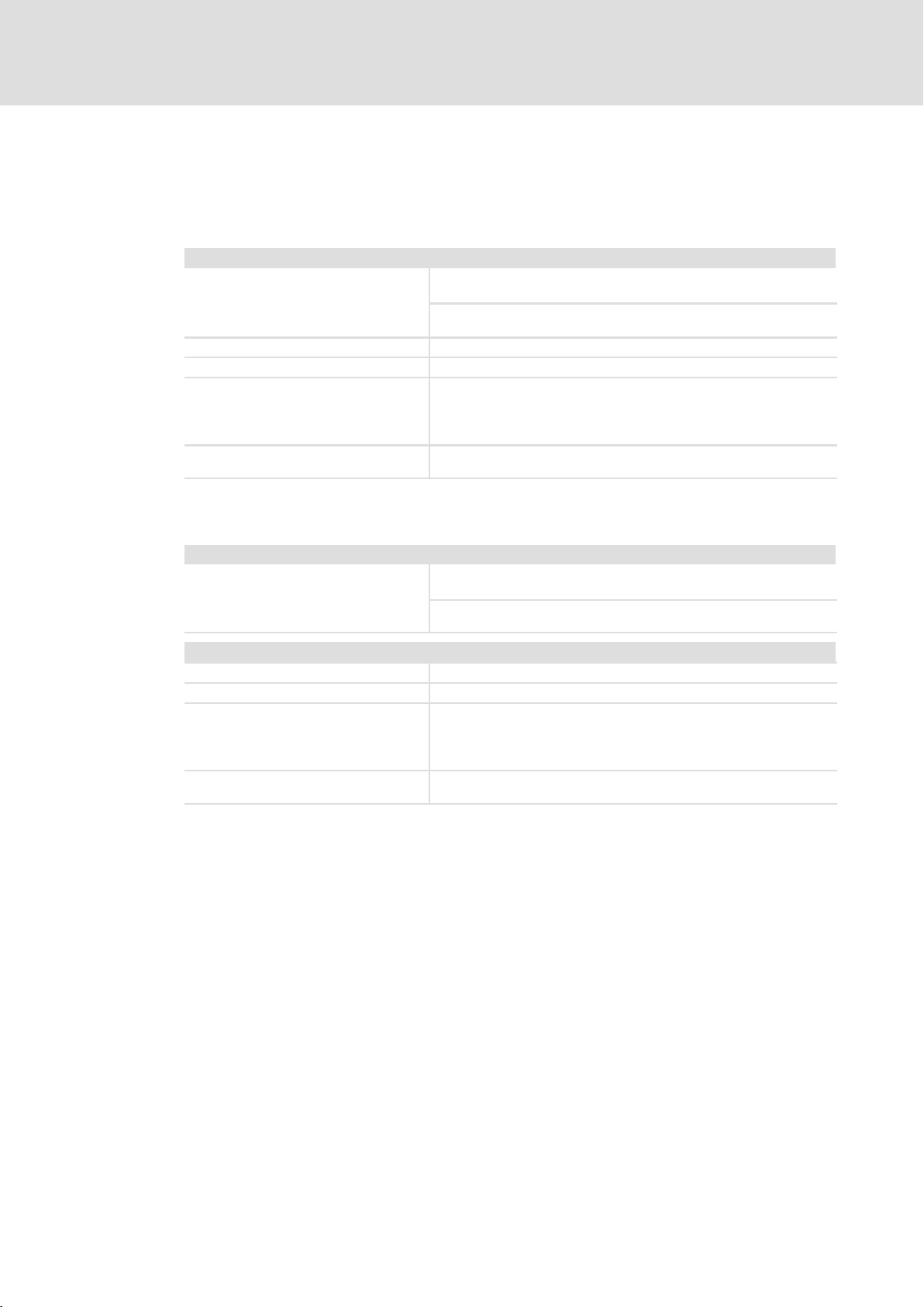

4.6 Dimensions

E82ZAFVC001

function module

E82ZAFVC010

function module

E82ZAFD001E

a51 mm

b 64 mm

c 15 mm

a51 mm

b 72 mm

b1 64 mm

e 30 mm

E1 15 mm

E82ZAFD101B

EDS82ZAFVCxxx EN 4.0

l

19

Page 20

5

Installation

Mechanical installation

Wiring according to EMC (CE−typical drive system)

5 Installation

} Danger!

Inappropriate handling of the function module and the standard device can

cause serious injuries to persons and damage to material assets.

Observe the safety instructions and residual hazards included in the

documentation of the standard device.

( Stop!

The device contains components that can be destroyed by electrostatic

discharge!

Before working on the device, the personnel must ensure that they are free of

electrostatic charge by using appropriate measures.

5.1 Mechanical installation

Follow the notes given in the Mounting Instructions for the standard device for the

mechanical installation of the function module.

The Mounting Instructions for the standard device ...

5.2 Electrical installation

5.2.1 Wiring according to EMC (CE−typical drive system)

ƒ are part of the scope of supply and are enclosed with each device.

ƒ provide tips to avoid damage provide tips to avoid damage through improper

handling.

ƒ describe the obligatory order of installation steps.

For wiring according to EMC requirements observe the following points:

) Note!

ƒ Separate control cables/data lines from motor cables.

ƒ Connect the shields of control cables/data lines at both ends in the case of

digital signals.

ƒ Use an equalizing conductor with a cross−section of at least 16mm

(reference:PE) to avoid potential differences between the bus nodes.

ƒ Observe the other notes concerning EMC−compliant wiring given in the

documentation for the standard device.

2

20

l

EDS82ZAFVCxxx EN 4.0

Page 21

Installation

123 456789 10

123 456789 10

Electrical installation

Wiring with a host (master)

5

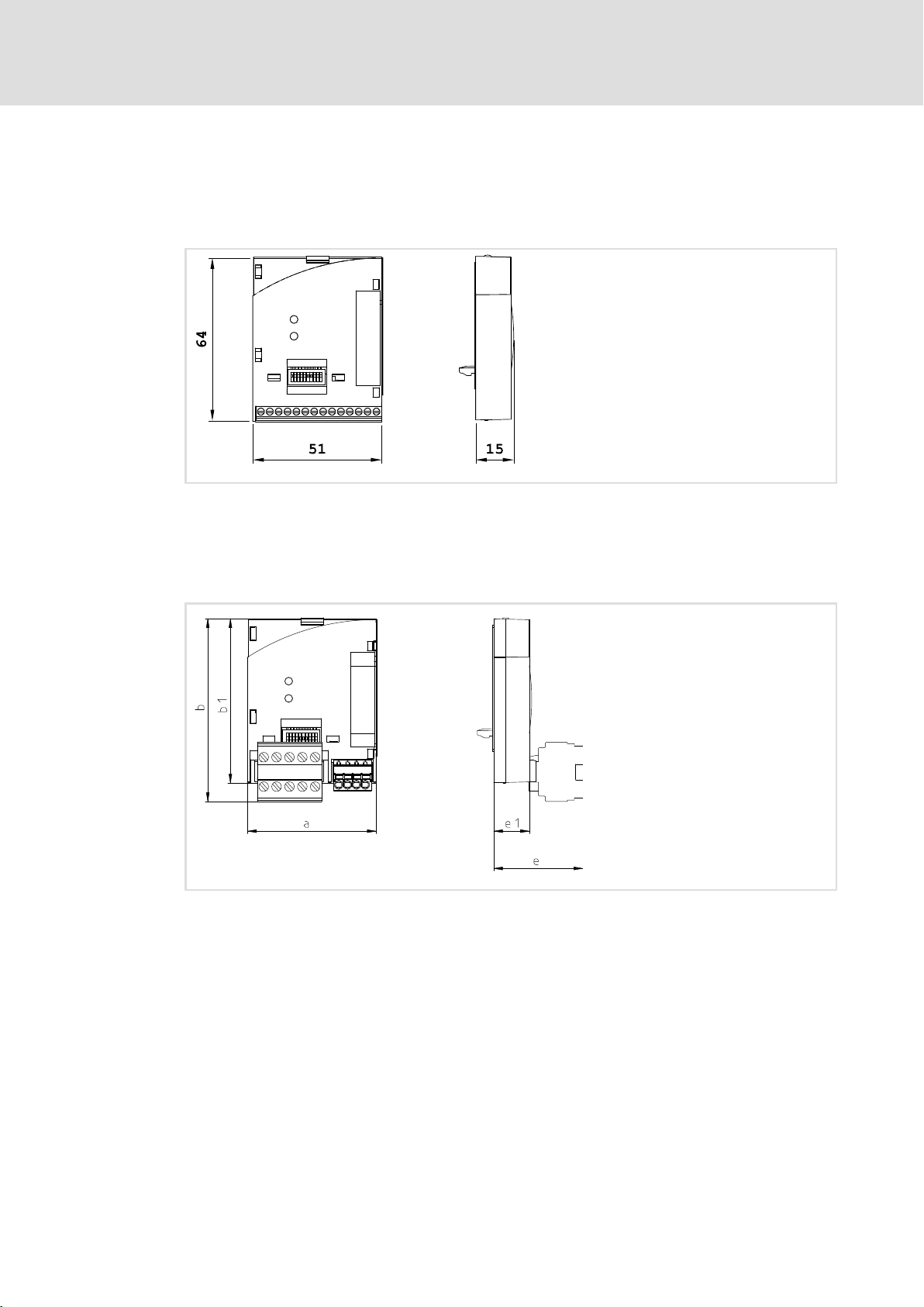

5.2.2 Wiring with a host (master)

The following figure shows the cable routing for the function module:

Adress

V-

CL

SHCHV+

D

Bd

V

V-

SH

20

CL

CH V+

39

7

28

DeviceNet

D

Adress

Bd

V

V-

CL

SHCHV+

V-

SH

20

CL

CH V+

39

7

28

For integrating the function modules a PC with installed configuration software is used.

Specification of the transmission cable

The nodes on the bus system have to be wired with a fieldbus cable (DeviceNet thick or thin

cable ) complying with the DeviceNet specification (DeviceNet Adaption of CIP, Edition 1.1,

Volume Three).

Manufacturers of DeviceNet thick and thin cables for example are Belden Inc., Lapp Group,

C&M Corp., and Madison Cable Corp.

V-

CL

SH

V+

CH

V-

20

39

7

28

20

39

7

28

CL

SH

V+

CH

DeviceNet

E82ZAFD019 E82ZAFD102

Colour code for the DeviceNet cable

Fig. 5−1 DeviceNet wiring with the E82ZAFVC001 function module

Connection Name Colour

V− Reference potential for external voltage supply Black

CL CAN−LOW Blue

SH SHIELD (shining)

CH CAN−HIGH White

V+ External supply voltage Red

E82ZAFD001D

EDS82ZAFVCxxx EN 4.0

l

21

Page 22

5

Installation

Electrical installation

Wiring with a host (master)

Properties of the "Thick Cable" in accordance with DeviceNet specification

General features

Structure Two shielded balanced lines, common axis with drain wire in the centre

Total shielding 65% coverage

Drain wire At least copper 18; at least 19 cores (individually tinned)

Outer diameter 10.41 ... 12.45 mm

Concentricity The radius deviation has to be within 15 % of half the outside diameter.

Cable sheath labelling Name of vendor, part no., and additional labelling

Spec. DC resistance (braid, wrapping, leakage) 5.74 W/km (nom. up to 20 °C)

Certifications (U.S. and Canada) NEC (UL), CL2/CL3 (min.)

Bend radius 20 x diameter (installation) / 7 x diameter (fixed)

Ambient temperature (operation) −20 ... +60 °C at 8 amperes;

Storage temperature −40 ... +85 °C

Pull tension 845.5 N

Features of the data line

Conductor pair At least copper 18; at least 19 cores (individually tinned)

Insulation diameter 3.81 mm (nom.)

Colours Light blue, white

Pair windings / m Approx. 10

Shielding/conductor pair 2000/1000, Al/Mylar, Al side on the outside, w/shorting fold (for tensile load)

Impedance 120 W +/− 10 % at 1 MHz

Capacitance between conductors 39.37 pF/m at 1 kHz (nom.)

Capacitance between one conductor and another which is

connected to the shield.

Capacitive assymetry 3937 pF/km at 1 kHz (nom.)

Spec. DC resistance at 20 °C 22.64 W/km (max.)

Damping 0.43 dB/100 m at 125 kHz (max.)

AWG 36 (at least 0.12 mm) of tin−coated copper braid (individually tinned)

linear current derating to zero at 80 °C

max

78.74 pF/m at 1 kHz (nom.)

0.82 dB/100 m at 500 kHz (max.)

1.31 dB/100 m at 1.00 MHz (max.)

Features of the voltage line

Conductor pair At least copper 15; at least 19 cores (individually tinned)

Insulation diameter 2.49 mm (nom.)

Colours Red / black

Pair windings / m Approx. 10

Shielding/conductor pair 1000/1000, Al/Mylar, Al side on the outside, with w/shorting fold (for tensile load)

Spec. DC resistance at 20 °C 11.81 W/km (max.)

Properties of the "Thin Cable" in accordance with DeviceNet specification

General features

Structure Two shielded balanced lines, common axis with drain wire in the centre

Total shielding 65% coverage

Drain wire At least copper 22; at least 19 cores (individually tinned)

Outer diameter 6.096 ... 7.112 mm

Concentricity The radius deviation has to be within 20 % of half the outside diameter.

Cable sheath labelling Name of vendor, part no., and additional labelling

Spec. DC resistance (braid, wrapping, leakage) 10.5 W/km (nom. at 20 °C)

Certifications (U.S. and Canada) NEC (UL), CL2 (min.)

Bend radius 20 x diameter (installation) / 7 x diameter (fixed)

Ambient temperature (operation) −20 ... +70 °C at 1.5 amperes;

Storage temperature −40 ... +85°C

Pull tension 289.23 N

AWG 36 (at least 0.12 mm) of tin−coated copper braid (individually tinned)

linear current derating to zero at 80 °C

max

22

l

EDS82ZAFVCxxx EN 4.0

Page 23

Installation

Electrical installation

Wiring with a host (master)

Features of the data line

Insulation diameter 1.96 mm (nom.)

Conductor pair At least copper 24; at least 19 cores (individually tinned)

Colours Light blue, white

Pair windings / m Approx. 16

Shielding/conductor pair 1000/1000, Al/Mylar, Al side on the outside, with w/shorting fold (for tensile load)

Impedance 120 W +/− 10 % at 1 MHz

Runtime 4.46 ns/m (max.)

Capacitance between conductors 39.37 pF/m at 1 kHz (nom.)

Capacitance between one conductor and another which is

connected to the shield.

Capacitive assymetry 3.94 pF/km at 1 kHz (max.)

Spec. DC resistance at 20 °C 91.86 W/km (max.)

Damping 0.95 dB/100 m at 125 kHz (max.)

Features of the voltage line

Conductor pair At least copper 22; at least 19 cores (individually tinned)

Insulation diameter 1.4 mm (nominal)

Colours Red, black

Pair windings / m Approx. 16

Shielding/conductor pair 1000/1000, Al/Mylar, Al side on the outside, with w/shorting fold (for tensile load)

Spec. DC resistance at 20 °C 57.41 W/km (max.)

78.74 pF/m at 1 kHz (nom.)

1.64 dB/100 m at 500 kHz (max.)

2.30 dB/100 m at 1.00 MHz (max.)

5

EDS82ZAFVCxxx EN 4.0

l

23

Page 24

5

Installation

Electrical installation

Voltage supply

5.2.3 Voltage supply

) Note!

DeviceNet communication modules from Lenze are only supplied via the

external DeviceNet cable!

Internal wiring of the bus terminals

V

cc

3

5

1

4

8

7

6

2

V

cc

V+

CAN-HIGH

Shield

CAN-LOW

V-

2175DeN007

24

l

EDS82ZAFVCxxx EN 4.0

Page 25

Installation

Electrical installation

Terminal assignment

5

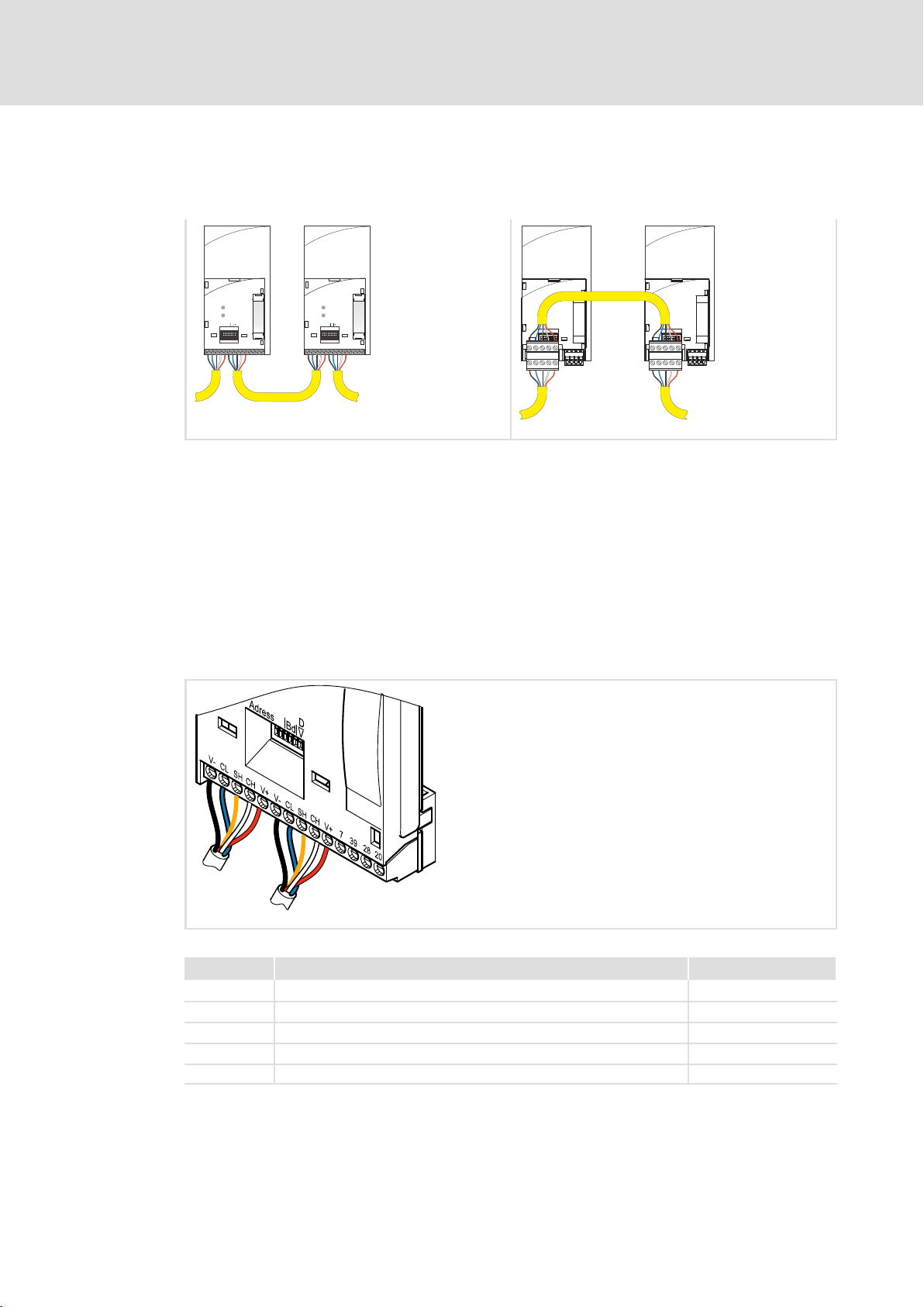

5.2.4 Terminal assignment

Function module E82ZAFVC001

Supply of the controller inhibit (CINH) via the internal voltage source (X3/20)

V-

SH SHCH CH

CLCLV-

X3

_

+

Supply of the controller inhibit (CINH) via the external voltage source

X3

_

+

V+ V+

SH SHCH CH

CLCLV-

V-

V+ V+

GND1

GND2

20

28397

GND1

GND2

28397

20

_

+

Min. wiring required for operation

E82ZAFD003

E82ZAFD006

X3/

V− Reference potential for external voltage supply

CL CAN−LOW CAN data line (LOW)

SH SHIELD Shield

CH CAN−HIGH CAN data line (HIGH)

V+ External supply voltage Please observe notes concerning

7 GND1 Reference potential for X3/20

39 GND2 Reference potential for controller inhibit (CINH) at X3/28

28 CINH Controller inhibit l Start = HIGH (+12 V ... +30 V)

20 DC voltage supply for internal supply of

Name Function Level

external supply!

l Stop = LOW (0 ... +3 V)

+20 V (ref.: GND1)

controller inhibit (CINH)

) Note!

Use the Thin" cable to wire the function module ^ 22.

EDS82ZAFVCxxx EN 4.0

l

25

Page 26

5

Installation

Electrical installation

Terminal assignment

Function module E82ZAFVC010

Controller inhibit (CINH) supply via internal voltage source

GND1

GND2

20

GND1

GND2

_

28397

E82ZAFD110

20

28397

X3.1

V-

V+

CHCL SH

X3.2

+

_

Controller inhibit (CINH) supply via external voltage source

X3.1

V-

V+

CHCL SH

X3.2

+

_

+

E82ZAFD112

Min. wiring required for operation

X3.1/

Designation Function Level

V− Reference potential for external supplyvoltage

CL CAN−LOW CAN data line (LOW)

SH SHIELD Shield

CH CAN−HIGH CAN data line (HIGH)

V+ External supply voltage Please see the notes for external

supply voltage!

X3.2/ Designation Function Level

7 GND1 Reference potential for X3.2/20

39 GND2 Reference potential for controller inhibit (CINH) at X3.2/28

28 CINH Controller inhibit l Start = HIGH (+12V...+30V)

l Stop = LOW (0 ... +3 V)

20 DC voltage source for internal supply of

+20 V (ref.: GND1)

controller inhibit (CINH)

26

l

EDS82ZAFVCxxx EN 4.0

Page 27

Installation

Electrical installation

Cable cross−sections and screw−tightening torques

5

5.2.5 Cable cross−sections and screw−tightening torques

Function module E82ZAFVC001

Range Values

Electrical connection Terminal strip with screw connection

Possible connections

Tightening torque 0.22 ... 0.25 Nm (1.9 ... 2.2 lb−in)

Bare end 5 mm

rigid:

1.5 mm

flexible:

without wire end ferrule

1.0 mm

with wire end ferrule, without plastic sleeve

0.5 mm

with wire end ferrule, with plastic sleeve

0.5 mm

Function module E82ZAFVC010

Field Values

Electrical connection Plug connector with double screw connection

Possible connections

Tightening torque 0.5 ... 0.6 Nm (4.4 ... 5.3 lb−in)

Stripping length 10 mm

rigid:

1.5 mm

flexible:

without wire end ferrule

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

2

(AWG 16)

2

(AWG 18)

2

(AWG 20)

2

(AWG 20)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

Field Values

Electrical connection 2−pin plug connector with spring connection

Possible connections

Stripping length 9 mm

EDS82ZAFVCxxx EN 4.0

rigid:

flexible:

l

2

1.5 mm

without wire end ferrule

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

27

Page 28

5

Installation

Electrical installation

Bus cable length

5.2.6 Bus cable length

Depending on the baud rate and the cable type used (thick cable/thin cable), the following

bus cable lengths are possible:

Baud rate [kbps]

125

250

500

If both thick and thin cable types are used, the maximum cable lengths can be defined

according to the baud rates as follows:

Baud rate [kbps] Max. bus cable length

125 500 m = L

250 250 m = L

500 100 m = L

L

: thick cable length

thick

L

: thin cable length

thin

) Note!

Select a baud rate in dependency of the data volume, cycle time and number

of nodes just high enough to suit your application.

Bus cable lengths [m]

Thick cable Thin cable

500

250

100

thick

thick

thick

+ 5 L

+ 2.5 L

+ L

thin

thin

thin

100

5.2.7 Use of plug connectors

( Stop!

Observe the following to prevent any damage to plug connectors and

contacts:

ƒ Only pug in / unplug the plug connectors when the controller is

disconnected from the mains.

ƒ Wire the plug connectors before plugging them in.

ƒ Unused plug connectors must also be plugged in.

Use of plug connectors with spring connection

E82ZAFX013

28

l

EDS82ZAFVCxxx EN 4.0

Page 29

6 Commissioning

During commissioning, system−dependent data as e.g. motor parameters, operating

parameters, responses and parameters for fieldbus communication are selected for the

controller.

In Lenze devices, this is done via codes. The codes are stored in numerically ascending order

in the Lenze controllers and in the plugged−in communication/function modules.

In addition to these configuration codes, there are codes for diagnosing and monitoring

the bus devices.

6.1 Before switching on

( Stop!

Before you switch on the basic device with the function module for the first

time, check

ƒ the entire wiring for completeness, short circuit and earth fault.

ƒ whether the bus system is terminated by terminating resistors at the first

and last bus station.

Commissioning

Before switching on

6

6.2 Commissioning steps

) Note!

ƒ For software version < 3.5 of the basic devices:

If you keep to the switch−on sequence decribed in the following table (basic

device must be switched on before the function module), a communication

error is indicated by the basic device.

This error message can be

– avoided by switching on the function module first and then the basic

device.

– automatically deleted by activating the function "Automatic trip reset" via

code C1566 (see chapter "Code table").

ƒ For software versions ³ 3.5 of the basic devices:

Keep to the switch−on sequence described in the commissioning steps (table

below).

EDS82ZAFVCxxx EN 4.0

l 29

Page 30

6

Commissioning

Commissioning steps

Step Procedure see

1. If necessary, set the software compatibility

2. Set the node address

3. Set the baud rate

4. Inhibit the standard device via terminal 28 (CINH).

Terminal 28 on LOW potential.

The standard device can be inhibited and enabled via the bus

5. Connect mains voltage

6. Connect the separate voltage supply for the function module

(Switch on the DeviceNet).

Response of the front LED display:

Directly after the voltage supply for the function module has been connected, both

LEDs at the front light up for a short time in the following order:

l The LED Status of connection with bus" changes its colour from green to red

before it goes off.

l The LED "Status of the connection to the standard device" changes its colour

from green to red before it goes off.

l The LED Connection status to the bus" at the front of the function module is

blinking (only visible in case of 8200 vector).

l The green LED Status of connection with standard device" at the front of the

function module is on (only visible in case of 8200 vector).

l Keypad: dc(if attached)

7.

Configure the host system for communicating with the function module with

configuration software:

l With explicit messages" all parameters can be read or written from the drive

and/or function module.

l Actual values can be read (e.g. status word) or setpoints can be written (e.g.

frequency setpoint) via the I/O data.

^ 31

Manual of the

standard device

^ 24

^ 34

Response

l The LED Status of connection with the bus" at the front of the function module

changes from blinking to the constantly ON state.

8. Configure process data channel of the standard device (see "application range") for

operation with the function module.

Recommendation

Set code C0005 = 200 after the Lenze setting has been loaded (C0002).

C0005 = 200 preconfigures the device for the operation with a function module.

Control and status words are already linked.

Continue with step 12.

9. If required, assign the process output data of the master/scanner via C1511 to the

input signals of the standard device.

10. If required, assign the process input words of the master/scanner to the output

signals of the standard device via C1510.

11. If the configuration in step 9. or step 10. has been changed:

Enable process output data with C1512 = 65535.

12. Enable standard device with terminal 28 (CINH) (terminal 28 on HIGH).

13. Send setpoint via a selected process data output word.

The drive is now running.

14. Inhibit the standard device via the bus (e.g. control word bit 9) or terminal 28 (CINH).

Manual of the

standard device

^ 44

^ 41

^ 47

l 30

EDS82ZAFVCxxx EN 4.0

Page 31

Possible settings using the front switch

6.3 Controls and displays

6.3.1 Possible settings using the front switch

) Note!

Settings via GDC, operating module or configuration software

The settings of device address and baud rate via GDC, the operating module or

the configuration software only become valid when the DIP switches S7 and

S8 are in the "ON" position.

Settings via front switch

The Lenze setting of all switches is OFF.

The device address and baud rate set via DIP switch will only be active after a

renewed mains connection.

The switch S9 is ineffective.

The following settings can be easily carried out via the front DIP switch of the function

module:

Commissioning

Controls and displays

6

ƒ Software compatibility of E82ZAFVC / E82ZAFD function module with S10

ƒ Device address with S1 − S6

ƒ Baud rate with S7 / S8

Adjustment of software compatibility

) Note!

Set the baud rate with S8/S9 if the controller is compatible with the E82ZAFD

function module (S10=ON).

ON

1627438

Fig. 6−1 Software compatibility setting

Compatibility S10

E82ZAFVC0xx OFF

E82ZAFD

For the description of the function

module see the E82ZAFD Mounting

Instructions

5

910

ON

OFF

E82ZAFD005

ON

EDS82ZAFVCxxx EN 4.0

l

31

Page 32

6

Commissioning

Controls and displays

Possible settings using the front switch

Setting of the device address

) Note!

The device address must be set via software, when the switches S7 and S8 are

in ON position.

In this case the switches S1 to S6 are ineffective.

ON

1627438

Fig. 6−2 Address assignment via DIP switch

5

910

ON

OFF

) Note!

The addresses of all controllers connected to the network must differ from

each other.

The device address (decimal number) is calculated by inserting the positions of the

switches S1 ... S6 (’0’ = OFF and ’1’ = ON) into the following equation:

Address

= S6 · 20 + S5 · 21 + S4 · 22 + S3 · 23 + S2 · 24 + S1 · 2

dec

The equation also allows you to calculate the valency of a confirmed switch. The sum of

valencies results in the device address to be set:

Switch Valency

S1 32 ON

S2 16 ON

S3 8 ON

S4 4 OFF

S5 2 OFF

S6 1 OFF

Switch position Address

5

Example

32 + 16+ 8 = 56

32

l

EDS82ZAFVCxxx EN 4.0

Page 33

Baud rate setting

) Note!

The baud rate must be the same for all devices and the scanner.

ON

Commissioning

Controls and displays

Possible settings using the front switch

ON

6

1627438

Fig. 6−3 Baud rate setting

Baud rate S7 S8

125 kbits/s OFF OFF

250 kbits/s OFF ON

500 kbits/s ON OFF

Setting of baud rate (and node address) via software

configuration.

The baud rate can be

l set manually via software or

l automatically detected.

5

910

OFF

ON ON

) Note!

Set the baud rate with S8/S9 if the controller is compatible with the E82ZAFD

function module (S10=ON).

EDS82ZAFVCxxx EN 4.0

l

33

Page 34

7

Diagnostics

LED status displays

7 Diagnostics

7.1 LED status displays

Function module E82ZAFVC001 Function module E82ZAFVC010

E82ZAFD001A* E82ZAFD101A*

Pos Colour Status Notes

1

green

red

2

green

red

off Function module is not supplied with voltage,

external voltage supply is switched off

blinking Function module is supplied with voltage but not connected to the controller.

Reason:

Standard device is

l switched off

l is being initialised

l not available

on Function module is supplied with voltage and is connected to the standard

device

blinking Internal error, Lenze setting has been loaded

on Internal error of the function module

off l No connection to the master

l Function module is not supplied with voltage.

blinking Dup_Mac_ID" test phase. Not yet connected to master (scanner).

on DeviceNet connection established.

blinking No communication due to time−out

on Critical bus error

l 34

EDS82ZAFVCxxx EN 4.0

Page 35

Protection against uncontrolled restart

) Note!

Establishing communication

If communication is to be established via an externally supplied

communication module, initially the standard device must also be switched

on.

After communication has been established, the externally supplied module is

independent of the power on/off state of the standard device.

Protection against uncontrolled restart

After a fault (e.g. short−term mains failure), a restart of the drive is not always

wanted and − in some cases − even not allowed.

The restart behaviour of the controller can be set in C0142:

ƒ C0142 = 0 (Lenze setting)

– The controller remains inhibited (even if the fault is no longer active).

– The drive starts up in a controlled manner by explicit controller enable:

93XX: Set terminal 28 to HIGH level.

ECSXX: Set terminals X6/SI1 and X6/SI2 to HIGH level.

ƒ C0142 = 1

– An uncontrolled restart of the drive is possible.

Diagnostics

LED status displays

7

EDS82ZAFVCxxx EN 4.0

l 35

Page 36

7

Diagnostics

Troubleshooting and fault elimination

7.2 Troubleshooting and fault elimination

No communication with the controller.

Possible causes Diagnostics Remedy

Is the controller switched on? One of the operating status LEDs of

Is the communication module

supplied with voltage?

Does the controller receive

telegrams?

the basic device must be on.

The LED "Connection status to the

basic device" must be lit or blinking

green.

The LED "Connection status to the

bus" at the communication module

must be blinking green when

communicating with the master

computer.

Supply controller with voltage.

Check the external voltage supply.

The measured voltage value at the

terminals for external voltage

supply of the communication

module must be in the range of 24V

± 10%.

The communication module has not

yet been initialised with the

controller.

Possibility 1: controller not switched

on

Possibility 2: check the connection to

the controller

Check your wiring (see ^ 20).

Check whether your master

computer sends telegrams.

Check the data assignment in the

scan list (I/0 mapping).

Is the available device address

already assigned?

Check the setting of the other nodes

on the DeviceNet.

l 36

EDS82ZAFVCxxx EN 4.0

Page 37

8 Codes

How to read the code table

Column Meaning

Code

Subcode Subcode

Name Designation of the Lenze code

Index Index under which the parameter is addressed.

Lenze

Values

Access R = read access (reading permitted)

Data type l FIX32: 32−bit value with sign; decimal with 4 decimal positions

Codes 8

(Lenze) code

l The parameters of a configurable code marked with an asterisk (<Code>*) can only be accessed

via the communication module.

l The value of a configurable code marked with a double asterisk (<Code>**) is not transmitted

with the parameter set transfer.

Lenze setting of the code

g Display code

Configuration of this code is not possible.

Fixed values determined by Lenze (selection list) or a value range:

Minimum value [Smallest increment/unit] Maximum value

W = write access (writing permitted)

l U16: 2 bytes bit−coded

l U32: 4 bytes bit−coded

l VS: visible string, character string with defined length

EDS82ZAFVCxxx EN 4.0

l

37

Page 38

Codes8

C0002: Parameter set management

(extract from code table)

Possible settings

Code Subcode

C0002 0 0 FIX32

Parameter set management (selection 0):

Selection Important

0 Ready PAR1 ... PAR4:

Lenze Selection

l Parameter sets of the controller

l PAR1 ... PAR4

FPAR1:

l Module−specific parameter set of the DeviceNet function

module

l FPAR1 is stored in the function module

Data type

Restoring the delivery state:

Selection Important

1 Lenze setting ðPAR1

2 Lenze setting ðPAR2

3 Lenze setting ðPAR3

4 Lenze setting ðPAR4

31 Lenze setting ðFPAR1 Restoring the delivery state in the function module

61 Lenze setting ðPAR1 + FPAR1

62 Lenze setting ðPAR2 + FPAR1

63 Lenze setting ðPAR3 + FPAR1

64 Lenze setting ðPAR4 + FPAR1

Restoring the delivery state in the selected parameter set

Restoring the delivery state in the selected parameter set of

the controller and the function module

38

l

EDS82ZAFVCxxx EN 4.0

Page 39

Transmitting the parameter sets with the keypad:

Selection Important

Using the keypad, you can transmit the parameter sets to the other controllers.

During the transmission the access to the parameters via other channels is inhibited!

Keypad ð controller

70 with DeviceNet function module

10 (other)

Keypad ð PAR1 (+ FPAR1)

71 with DeviceNet function module

11 (other)

Keypad ð PAR2 (+ FPAR1)

72 with DeviceNet function module

12 (other)

Keypad ð PAR3 (+ FPAR1)

73 with DeviceNet function module

13 (other)

Keypad ð PAR4 (+ FPAR1)

74 with DeviceNet function module

14 (other)

Controller ð keypad

80 with DeviceNet function module

20 (other)

Keypad ð function module

40 only with DeviceNet function module

Function module ð keypad

50 only with DeviceNet function module

Overwrite all available parameter sets (PAR1 ... PAR4, or if

required FPAR1) with the corresponding keypad data

Overwrite the selected parameter set and, if necessary, FPAR1

with the corresponding keypad data

Copy all available parameter sets (PAR1 ... PAR4, or if required

FPAR1) into the keypad

Only overwrite the module−specific parameter set FPAR1 with

the keypad data

Only copy the module−specific parameter set FPAR1 into the

keypad

Codes 8

Save own basic settings:

Selection Important

9 PAR1 ð own basic setting You can store an own basic setting for the controller

5 Own basic setting ðPAR1

6 Own basic setting ðPAR2

7 Own basic setting ðPAR3

8 Own basic setting ðPAR4

parameters (e. g. the delivery state of your machine):

1. Ensure that parameter set 1 is active

2. Inhibit the controller

3. Set C0003 = 3, confirm with v

4. Set C0002 = 9, confirm with v, the own basic setting is

stored

5. Set C0003 = 1, confirm with v

6. Enable the controller

With this function you can simply copy PAR1 into the

parameter sets PAR2 ... PAR4

Restoring the own basic setting in the selected parameter set

EDS82ZAFVCxxx EN 4.0

l

39

Page 40

Codes8

C1500:

Software product code

Possible settings

Code Subcode

C1500 − g − VS

The code contains a strings which is 14 bytes long. The product code will be output, e.g.

82SAFV0C_XXXXX.

C1501: Software date

Code Subcode

C1501 − g − VS

The code contains a string which is 17 bytes long. The date and time the software have

been written will be output, e.g. June 21 2000 12:31.

Lenze Selection

Possible settings

Lenze Selection

Data type

Data type

C1502:

Display of the software product code

Possible settings

Code Subcode

C1502 1 ... 4 g

Lenze Selection

−

Data type

U32

Display of code C1500 in 4 subcodes with 4 digits each.

C1503:

Display of the software date

Possible settings

Code Subcode

C1503 1 ... 4 g

Lenze Selection

−

Data type

U32

Display of code C1501 in 4 subcodes with 4 digits each.

C1509:

Setting of the node address

Possible settings

Code Subcode

C1509 − 63 1 [1] 63 FIX32

Lenze Selection

Data type

Only valid if switches S7 and S8 are in the ON position.

40

) Note!

Switch off and then on again the voltage supply of the function module to

activate the changed settings of the node address.

Please observe that the node addresses are not the same when using several

networked nodes.

l

EDS82ZAFVCxxx EN 4.0

Page 41

Codes 8

C1510:

Configuration of process input data

Possible settings

Code Subcode

C1510 FIX32

1 (PEW1) 1

2 (PEW2) 3

3 (PEW3) 4

4 (PEW 4) 5

5 (PEW 5) 6

6 (PEW 6) 7

7 (PEW 7) 8

8 (PEW 8) 9

9 (PEW 9) 10

10 (PEW 10) 11

11 (PEW11) 12

12 (PEW12) 13

Lenze Selection

See table below

Data type

The assignment of the bit status information or the actual values of the controller to the

max. 12 process data input words (PEW) of the master can be freely configured.

Selection Scaling

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

FIF status word 1 (FIF−STAT1)

FIF status word 2 (FIF−STAT2)

Output frequency with slip (MCTRL1−NOUT+SLIP)

Output frequency without slip (MCTRL1−NOUT)

Apparent motor current (MCTRL1−IMOT)

Actual process controller value (PCTRL1−ACT)

Process controller setpoint (PCTRL1−SET)

Process controller output (PCTRL1−OUT)

Controller load (MCTRL1−MOUT)

DC−bus voltage (MCTRL1−DCVOLT)

Ramp function generator input (NSET1−RFG1−IN)

Ramp function generator output (NSET1−NOUT)

FIF−OUT.W1

FIF−OUT.W2

FIF−OUT.W3

FIF−OUT.W4

16 bits

16 bits

±24000 º ±480 Hz

±24000 º ±480 Hz

214 º 100 % rated device current

±24000 º ±480 Hz

±24000 º ±480 Hz

±24000 º ±480 Hz

±214 º ±100 % rated motor torque

16383 º 565 VDC at 400 V mains

16383 º 325 VDC at 230 V mains

±24000 º ±480 Hz

±24000 º ±480 Hz

16 bits or 0 ... 65535

16 bits or 0 ... 65535

0 ... 65535

0 ... 65535

) Note!

ƒ FIF−OUT.W1 is digitally defined in the Lenze setting and assigned with the

16 bits of the controller status word 1 (C0417).

ƒ Before you assign an analog signal source (C0421/3 ¹ 255), the digital

assignment must be deleted (C0417/x = 255)! Otherwise the output signal

would be incorrect.

EDS82ZAFVCxxx EN 4.0

l

41

Page 42

Codes8

C0417/1

C0417/16

C0421/3

C0418/1

C0418/16

C0421/4

C0421/5

NSET1

PCTRL1

MCTRL1

DCTRL1

…...

…...

STAT 1

STAT1.B0

…...

STAT1.B15

STAT 2

STAT2.B0

…...

STAT2.B15

MCTRL1-NOUT+SLIP

MCTRL1-NOUT

MCTRL1-IMOT

PCTRL1-ACT

PCTRL1-SET1

PCTRL1-OUT

MCTRL1-MOUT

MCTRL1-DCVOLT

NSET1-RFG1-IN

NSET1-NOUT

FIF-OUT.W1.B0

…...

FIF-OUT.W1.B15

FIF-OUT.W2.B0

…...

FIF-OUT.W2.B15

FIF-STAT.B0

FIF-STAT.B1

…

FIF-STAT.B14

FIF-STAT.B15

FIF-STAT.B16

FIF-STAT.B17

…

FIF-STAT.B30

FIF-STAT.B31

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

FIF-OUT

Byte1

Byte 2

Byte 3

Byte 4

Byte 5, 6

Byte 7, 8

Byte 9, 10

Byte 11, 12

Byte 13, 14

Byte 15, 16

Byte 17, 18

Byte 19, 20

Byte 21, 22

Byte 23, 24

Byte 25, 26

Byte 27, 28

Byte 29, 30

FIF-STAT1

FIF-STAT2

FIF-OUT.W1

FIF-OUT.W2

FIF-OUT.W3

C1510/1 = 1

C1510/2 = 3

C1510/3 = 4

C1510/4 = 5

C1510/5 = 6

C1510/6 = 7

C1510/7 = 8

C1510/8 = 9

C1510/9 = 10

C1510/10 = 11

C1510/11 = 12

C1510/12 = 13

PEW1

PEW2

PEW3

PEW4

PEW5

PEW6

PEW7

PEW8

PEW9

PEW10

PEW11

PEW12

PEW1

PEW2

PEW3

PEW4

PEW5

CH

PEW6

CL

PEW7

PEW8

PEW9

PEW10

PEW11

PEW12

DeviceNet

SH

C0421/6

16 Bit

Byte 31, 32

FIF-OUT.W4

Fig. 8−1 Free configuration of the 12 process input words of the function module with Lenze setting

Symbol Meaning

Combination of signals in the Lenze setting

Fixed signal connection

Analog input (can be freely connected with an analog output which has the same labelling)

Analog output

Digital input (can be freely connected with a digital output which has the same labelling)

Digital output

8200vec513

42

l

EDS82ZAFVCxxx EN 4.0

Page 43

Codes 8

FIF status word 1 (FIF−STAT1) FIF status word 2 (FIF−STAT2)

Bit Assignment Bit Assignment

0 Current parameter set bit 0 (DCTRL1−PAR−B0) 0 Current parameter set bit 1 (DCTRL1−PAR−B1)

01Parameter set 1 or 3 active

Parameter set 2 or 4 active

1 Pulse inhibit (DCTRL1−IMP) 1 TRIP, Q

01Power outputs enabled

Power outputs inhibited

2 I

limit (MCTRL1−IMAX)

max

(If C0014 = 5: Torque setpoint)

01Not reached

Reached

3 Output frequency = frequency setpoint

(DCTRL1−RFG1=NOUT)

01False

True

4 Ramp function generator input 1 = ramp function

01False

5 Q

01Not reached

generator output 1

True

threshold (PCTRL1−QMIN) 5 C0054 < C0156 and NSET1−RFG1−I=O

min

Reached

(NSET1−RFG1−I=O)

6 Output frequency = 0 (DCTRL1−NOUT=0) 6 LP1 warning (fault in motor phase) active

01False

True

7 Controller inhibit (DCTRL1−CINH) 7 f < f

01Controller enabled

Controller inhibited

11...8 Device status (DCTRL1−STAT*1 ... STAT*8) 8 TRIP active (DCTRL1−TRIP)

Bit 11 10 9 8

00000100Controller initialisation

00011010Operation inhibited

0 1 0 1 DC−injection brake active

00111101Operation enabled

1 0 0 0 Fault active

1 1 1 1 Communication with basic device not

Switch−on inhibit

Flying−restart circuit active

Message active

possible

12 Overtemperature warning (DCTRL1−OH−WARN) 12

01No warning

− 10 C reached

J

max

13 DC−bus overvoltage (DCTRL1−OV) 13

01No overvoltage

Overvoltage

14 Direction of rotation (DCTRL1−CCW) 14 C0054 > C0156 and NSET1−RFG1−I=0

01CW rotation

CCW rotation

15 Ready for operation (DCTRL1−RDY) 15

01Not ready for operation (fault)

Ready for operation (no fault)

Tab. 8−1 Parameter structure FIF status word (FIF−STATx)

01Parameter set 1 or 2 active

Parameter set 3 or 4 active

or pulse inhibit active (DCTRL1−TRIP−QMIN−IMP)

min

01False

True

2 PTC warning active (DCTRL1−PTC−WARN)

01False

True

3

Reserved

Do not write to this bit!

4 C0054 < C0156 and Q

(DCTRL1−(IMOT<ILIM)−QMIN)

01False

True

(DCTRL1−(IMOT<ILIM)−RFG−I=O)

01False

True

(DCTRL1−LP1−WARN)

01False

True

(NSET1−C0010 ... C0011)

min

01False

True

01False

True

threshold reached

min

9 Motor is running (DCTRL1−RUN)

01False

True

10 Motor is running clockwise (DCTRL1−RUN−CW)

01False

True

11 Motor is running counter−clockwise (DCTRL1−RUN−CCW)

01False

True

Reserved

Reserved

(DCTRL1−(IMOT>ILIM)−RFG−I=O)

01False

True

Reserved

EDS82ZAFVCxxx EN 4.0

l

43

Page 44

Codes8

C1511:

Configuration of process output data

Possible settings

Code Subcode

C1511 FIX32

1 (PAW1) 1

2 (PAW2) 3

3 (PAW3) 4

4 (PAW 4) 5

5 (PAW 5) 6

6 (PAW 6) 7

7 (PAW 7) 8

8 (PAW 8) 9

9 (PAW 9) 10

10 (PAW 10) 11

11 (PAW11) 13

12 (PAW12) 14

Lenze Selection

See table below

Data type

The assignment of the process data output words (PAW) of the master to bit control

commands or setpoints of the controller can be freely configured with C1511.

Selection Scaling

1 FIF control word 1 (FIF−CTRL1)

2 FIF control word 2 (FIF−CTRL2)

3 Setpoint 1 (NSET1−N1)

4 Setpoint 2 (NSET1−N2)

5 Additional setpoint (PCTRL1−NADD)

6 Actual process controller value (PCTRL1−ACT)

7 Process controller setpoint (PCTRL1−SET1)

8 reserved

9 Torque setpoint / limit value (MCTRL1−MSET)

10 PWM voltage(MCTRL1−VOLT−ADD)

11 PWM angle (MCTRL1−PHI−ADD)

12 reserved

13 FIF−IN.W1

14 FIF−IN.W2

15 FIF−IN.W3

16 FIF−IN.W4

16 bits

16 bits

±24000 º ±480 Hz

±24000 º ±480 Hz

±24000 º ±480 Hz

±24000 º ±480 Hz

±24000 º ±480 Hz

214 º 100 % rated motor torque

(

Only for special applications. Please

contact Lenze!

16 bits or 0 ... 65535

16 bits or 0 ... 65535

0 ... 65535

0 ... 65535

44

l

EDS82ZAFVCxxx EN 4.0

Page 45

Codes 8

PAW1

PAW2

PAW3

PAW4

PAW5

PAW6

PAW7

DeviceNet

PAW8

PAW9

PAW10

PAW11

PAW12

FIF-CTRL.B0

FIF-CTRL.B1

FIF-CTRL.B2

FIF-CTRL.B3

…

Byte 1

FIF-CTRL.B4

FIF-CTRL.B5

FIF-CTRL.B6

FIF-CTRL.B7

FIF-CTRL.B8

FIF-CTRL.B9

Byte 2

Byte 3

Byte 4

Byte 25, 26

Byte 27, 28

Byte 29,30

Byte 31,32

FIF-CTRL.B10

FIF-CTRL.B11

…

FIF-CTRL.B12

FIF-CTRL.B13

FIF-CTRL.B14

FIF-CTRL.B15

FIF-CTRL.B16

FIF-CTRL.B17

FIF-CTRL.B18

FIF-CTRL.B19

…

FIF-CTRL.B20

FIF-CTRL.B21

FIF-CTRL.B22

FIF-CTRL.B23

FIF-CTRL.B24

FIF-CTRL.B25

FIF-CTRL.B26

FIF-CTRL.B27

FIF-CTRL.B28

FIF-CTRL.B29

FIF-CTRL.B30

FIF-CTRL.B31

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

16 Bit

FIF-IN.W1.B0 … FIF-IN.W1.B15

FIF-IN.W2.B0 … FIF-IN.W2.B15

FIF-CTRL1

FIF-CTRL2

PAW1

C1511/1 = 1

PAW2

C1511/2 = 3

PAW3

C1511/3 = 4

PAW4

C1511/4 = 5

PAW5

PAW6

PAW7

PAW8

PAW9

PAW10

PAW11

PAW12

C1511/5 = 6

C1511/6 = 7

C1511/7 = 8

C1511/8 = 9

C1511/9 = 10

C1511/10 = 11

C1511/11 = 13

C1511/12 = 14

CH

CL

SH

Byte 5, 6

Byte 7, 9

Byte 9, 10

Byte 11, 12

Byte 13, 14

Byte 15, 16

Byte 17, 18

Byte 19, 20

Byte 21, 22

Byte 23, 24

FIF-IN.W1

FIF-IN.W2

FIF-IN.W3

FIF-IN.W4

QSP

CINH

TRIP-SET

TRIP-RESET

DCTRL

DCTRL

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-IN.W1

FIF-IN.W2

FIF-IN.W3

FIF-IN.W4

C0410/1 = 200

C0410/2 = 200

C0410/3 = 200

C0410/4 = 200

C0410/5 = 200

C0410/6 = 200

C0410/7 = 200

C0410/8 = 200

C0410/9 = 200

C0410/10 = 200

C0410/11 = 200

C0410/12 = 200

C0410/13 = 200

C0410/14 = 200

C0410/15 = 200

C0410/17 = 200

C0410/18 = 200

C0410/19 = 200

C0410/20 = 200

C0410/21 = 200

C0410/22 = 200

C0410/23 = 200

C0410/24 = 200

C0412/1 = 200

C0412/2 = 200

C0412/3 = 200

C0412/4 = 200

C0412/5 = 200

C0412/6 = 200

C0412/7 = 200

C0412/8 = 200

C0412/9 = 200

FIF-IN

NSET1-JOG1/3

NSET1-JOG2/3

DCTRL1-CW/CCW

DCTRL1-QSP

NSET1-RFG1-STOP

NSET1-RFG1-0

MPOT1-UP

MPOT1-DOWN

RESERVED

DCTRL1-CINH

DCTRL1-TRIP-SET

DCTRL1-TRIP-RESET

DCTRL1-PAR2/4

DCTRL1-PAR3/4

MCTRL1-DCB

DCTRL1-H/RE

PCTRL1-I-OFF

PCTRL1-OFF

RESERVED

PCTRL1-STOP

DCTRL1-CW/QSP

DCTRL1-CCW/QSP

DFIN1-ON

NSET1-N1

NSET1-N2

PCTRL1-NADD

PCTRL1-SET1

PCTRL1-ACT

MCTRL1-MSET

RESERVED

MCTRL1-VOLT-ADD

MCTRL1-PHI-ADD

C0410/x = 30 … 45

C0415/x = 60 … 75

C0417/x = 60 … 75

C0418/x = 60 … 75

C0412/x = 20

C0419/x = 50

C0421/x = 50

C0410/x = 50 … 65

C0415/x = 80 … 95

C0417/x = 80 … 95

C0418/x = 80 … 95

C0412/x = 21

C0419/x = 51

C0421/x = 51

C0412/x = 22

C0419/x = 52

C0421/x = 52

C0412/x = 23

C0419/x = 53

C0421/x = 53

Fig. 8−2 Free configuration of the 12 process output words of the function module with Lenze setting

8200vec512

Symbol Meaning

EDS82ZAFVCxxx EN 4.0

Combination of signals in the Lenze setting

Fixed signal connection

Analog input (can be freely connected with an analog output which has the same labelling)

Analog output

Digital input (can be freely connected with a digital output which has the same labelling)

Digital output

l

45

Page 46

Codes8

FIF control word 1 (FIF−CTRL1) FIF control word 2 (FIF−CTRL2)

Bit Assignment Bit Assignment

0 / 1 JOG values (NSET1−JOG2/3 | NSET1−JOG1/3) 0 Manual/remote changeover (DCTRL1−H/Re)

Bit 1 0

0001C0046 active

1101JOG2 (C0038) active

JOG1 (C0037) active

JOG3 (C0039) active

2 Current direction of rotation (DCTRL1−CW/CCW) 2 Switch off process controller (PCTRL1−OFF)

01Not inverted

Inverted

3 Quick stop (QSP) (FIF−CTRL1−QSP)

01Not active

Active (deceleration via QSP ramp C0105)

4 Stop ramp function generator (NSET1−RFG1−STOP) 4 Stop process controller (PCTRL1−STOP)

01Not active

Active

5 Ramp function generator input = 0 (NSET1−RFG1−0) 5 CW rotation/quick stop (QSP) (DCTRL1−CW/QSP)

01Not active

Active (deceleration via C0013)

6 UP function of motor potentiometer (MPOT1−UP) 6 CCW rotation/quick stop (QSP) (DCTRL1−CCW/QSP)

01Not active

Active

7 DOWN function of motor potentiometer (MPOT1−DOWN) 7 X3/E1 is digital frequency input (DFIN1−ON)

01Not active

Active

8

Reserved

9 Controller inhibit (FIF−CTRL1−CINH) 9

01Controller enabled

Controller inhibited

10 External fault (FIF−CTRL1−TRIP−SET) 10

11 Reset fault (FIF−CTRL1−TRIP−RESET)

0 Þ 1 Bit change resets TRIP

12 / 13 Parameter set changeover

(DCTRL1−PAR3/4 | DCTRL1−PAR2/4)

Bit 13 12

0001PAR1

1101PAR3

PAR2

PAR4

14 DC injection brake (MTCRL1−DCB)

01Not active

Active

15

Reserved

Tab. 8−2 Parameter structure of FIF control word (FIF−CTRLx)

01Not active

Active

1 Switch off I−component of process controller

(PCTRL1−I−OFF)

01Not active

Active

01Not active

Active

3

Reserved

Do not write to this bit!

01Not active

Active

01Not active

Active

01Not active

Active

01Not active

Active

8

11

12

13

14

15

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

46

) Note!

Use of bit 5 and bit 6 in FIF control word 2

Set codes C0410/22 (DCTRL1−CW/QSP) and C0410/23 (DCTRL1−CCW/QSP) to

"200".

l

EDS82ZAFVCxxx EN 4.0

Page 47

Codes 8

C1512:

I/O data enable

Possible settings

Code Subcode

C1512 ** − 65535

If C1511 is changed, the process output data is automatically inhibited to ensure data

consistency.

Use the decimal value in code C1512 to enable some or all process output words (PAW)

again:

ƒ 0 = Inhibit PAW

ƒ 1 = Enable PAW

Bit 15 ... 12 Bit 11 Bit 10 ... Bit 1 Bit 0

reserved PAW12 PAW 11 ... POW2 PAW 1

Lenze Selection

0

Data type

[1] 65535 FIX32

The bit settings 0 to 11 are each assigned to a process data word. The bit settings 12 to 15

are reserved.

Use the value 65535 (FFFF

) in code C1512 to release all process output data.

hex

) Note!

ƒ The release is required if the process output data configuration has been

changed.

C1516:

Baud rate setting

Possible settings

Code Subcode

C1516 0 see below FIX32

Selection Baud rate

0 125 kbits/s

1 250 kbits/s

2 500 kbits/s

255 Auto baud (automatic baud rate recognition)

Only valid if switches S7 and S8 are in the ON position.

Lenze Selection

Data type

) Note!

EDS82ZAFVCxxx EN 4.0

Switch off the voltage supply of the function module and then on again to

activate changed settings of the baud rate.

l

47

Page 48

Codes8

C1518:

I/O data length

Possible settings

Code Subcode

C1518 −

This code determines the number of words (I/O input data and I/O output data) being

currently exchanged with the scanner.

A change of the I/O data length must be sent to the scanner via the configuration program.

C1519:

Behaviour in idle state/in case of an error

Code Subcode

C1519 /1 ... /3 0 0 [1] 3 FIX32

Subcode Meaning

1 Setting of the reaction in the event of idle running of the DeviceNet communication.

2 Setting of the reaction if the communication is interrupted (time out)

3 Setting of the reaction if a bus error occurs (duplicateMAC-ID, Bus−Off).

Lenze Selection

4

Possible settings

Lenze Selection

1 [1] 12 FIX32

Data type

Data type

Selection Baud rate

0 No action

1 Fault (TRIP)

2 Controller inhibit

3 Quick stop

C1520:

Display of all words to scanner

Possible settings

Code Subcode

C1520 /1 ... /12 g 0 [1] 65535 U16

Lenze Selection

Data type

Display of the process data input words PEW1 to PEW12 in the corresponding subcodes.

C1521:

Display of all words from scanner

Possible settings

Code Subcode

C1521 /1 ... /12 g 0 [1] 65535 U16

Lenze Selection

Data type

Display of the process data output words 1 ... 12 of the scanner in the corresponding

subcodes.

48

l

EDS82ZAFVCxxx EN 4.0

Page 49

Codes 8

C1522:

Display of all process data words to the basic device

Possible settings

Code Subcode

C1522 1...16 g 0 [1] 65535 U16

Display of the process data words 1 ... 16, which are transferred from the function module

to the basic device:

Subcode Process data word

1 FIF control word 1 (FIF−CTRL1)

2 FIF control word 2 (FIF−CTRL2)

3 Setpoint 1 (NSET1−N1)

4 Setpoint 2 (NSET1−N2)

5 Additional setpoint (PCTRL1−NADD)

6 Actual process controller value (PCTRL1−ACT)

7 Process controller setpoint (PCTRL1−SET1)

8 Reserved

9 Torque setpoint or torque limit value (MCTRL1−MSET)

10 PWM voltage(MCTRL1−VOLT−ADD)

11 PWM angle (MCTRL1−PHI−ADD)

12 Reserved

13 FIF−IN.W1

14 FIF−IN.W2

15 FIF−IN.W3

16 FIF−IN.W4

Lenze Selection

Data type

EDS82ZAFVCxxx EN 4.0

l

49

Page 50

Codes8

C1523:

Display of all process data words from the basic device

Possible settings

Code Subcode

C1523 1...16 g 0 [1] 65535 U16

Display of the process data words 1 ... 16, which are transferred from the basic device to the

function module:

Subcode Process data word

1 FIF status word 1 (FIF−STAT1)

2 FIF status word 2 (FIF−STAT2)

3 Output frequency with slip (MCTRL1−NOUT+SLIP)

4 Output frequency without slip (MCTRL1−NOUT)

5 Apparent motor current (MCTRL1−IMOT)

6 Actual process controller value (PCTRL1−ACT)

7 Process controller setpoint (PCTRL1−SET)

8 Process controller output (PCTRL1−OUT)

9 Controller load (MCTRL1−MOUT)

10 DC bus voltage (MCTRL1−DCVOLT)

11 Ramp function generator input (NSET1−RFG1−IN)

12 Ramp function generator output (NSET1−NOUT)

13 FIF−OUT.W1

14 FIF−OUT.W2

15 FIF−OUT.W3

16 FIF−OUT.W4

Lenze Selection