Page 1

EDB9200_E/GB

S

9

00375316

Antriebstechnik

Operating Instructions

ervo controller

200 series

Page 2

These Operating Instructions are valid for the controllers with the nameplate data:

9212 E.5x

9215 E.5x

9217 E.5x

9222 E.5x.5x

9223 E.5x.5x

9224 E.5x.5x

9225 E.5x.5x

9226 E.5x.5x

9227 E.5x.5x

9228 E.5x.5x

Controller type

Enclosure IP20

Hardware version + index

Software version + index

Corresponds to the German edition of 05/18/1995

Edition of: 05/18/1995

Date of print: 05/29/1995

Page 3

How to use these Operating

Instructions...

These Operating Instructions are divided into three parts:

•

Planning and installation

This part comprises the technical data of the supply modules,

the axis modules and of accessories available for the 9200

series (e. g. motors), instructions for installation and wiring and

descriptions of the drive connections.

•

Parameter setting

Describes the basics of parameter setting and informs about

commissioning, important functions and the operation via serial

interface. At the end of this part you will find a comprehensive

code table and a signal flow chart.

•

Service

Explains error messages and gives hints for trouble-shooting.

To locate information on specific topics, simply refer to the table of

contents at the beginning and to the index at the end of the

operating instructions.

A series of different symbols provide quick reference and highlight

important items.

Note

This symbol refers to items of information intended to facilitate

operation.

Caution

Notes which should be observed to avoid possible damage to or

destruction of equipment.

Warning

Notes which should be observed to avoid health risks to the

operating personnel.

Fehler! Es

ist nicht

möglich,

durch die

1

Page 4

Safety information

for electrical equipment used in industrial power installations.

The electrical devices and machines described are equipment to be

used in industrial power installations. This equipment incorporates

hazardous parts that are live, moving or rotating during operation.

Severe personal injury or damage to equipment may occur if e. g.

any required enclosures or covers are inappropriately removed or

the equipment is insufficiently serviced.

The personnel responsible for the safety of the equipment must

therefore ensure that:

•

only qualified personnel are permitted to install, operate and

maintain the devices

•

these Operating Instructions and any other documentation

about the equipment are consequently observed and always

available to the personnel working with the equipment.

•

non-qualified personnel is prohibited from working with the

equipment or in its vicinity.

•

the system is installed in accordance with local regulations.

A qualified person must by training be familiar with all relevant

standards and safety regulations and therefore be authorized to

perform the required work (For further details cf. IEC 364).

These safety instructions do not claim to be exhaustive. Should any

questions or problems occur, please contact your nearest Lenze

representative.

The information given in these Operating Instructions refer to the

specified hardware and software versions of the equipment.

The specifications, processes and ciruitry described in these

Operating Instructions are for guidance only and must be adapted

to your specific application.

Lenze cannot be held responsible for the applicability of the

processes and circuitry indicated.

The specifications in these Operating Instructions describe, not

guarantee the features of the equipment.

Hardware, software and documentation of the equipment have

been carefully checked by Lenze. Faultlessness cannot be

guaranteed.

Subject to technical alterations.

2

Page 5

Content

Planning and Installation

1. Features 5

2. Technical data 6

2.1. General data 6

2.2. Unit-specific data 6

2.2.1. Rated data of supply modules 6

2.2.2. Rated data of axis modules 7

2.3. Dimensions 8

2.4. Extension of delivery 8

2.5. Application as directed 8

2.6. Manufacturer's certification 9

3. Installation 10

3.1. Mechanical installation 10

3.2. Electrical installation 11

3.2.1. Combination of several axis modules with one supply module 12

3.2.2. Screening and earthing 14

3.2.3. Radio interference suppression 16

4. Drive connections 17

4.1. Power connections 17

4.1.1. Mains and motor connection 17

4.1.2. External brake resistor 18

4.2. Control connections of supply module 20

4.2.1. Overheat of internal brake resistor (9210 X1) 20

4.2.2. Mains and DC-bus monitoring (9210 X3) 20

4.2.3. State bus 21

4.3. Control connections axis module 22

4.3.1. Control terminals 22

4.3.2. Analog input and outputs 22

4.3.3. Digital inputs and outputs 23

5. Application examples 26

5.1. Variant with integrated positioning module 2211PP 26

5.2. Wiring with positioning control SX-1 28

5.2.1. Diagram 1: Mains supply 28

5.2.2. Diagram 2: Control circuit 230V 29

5.2.3. Diagram 3: Control circuit 24V 30

5.2.4. Diagram 4: Control connections 9200 - SX1 31

5.2.5. Diagram 5: Control connections SX1 32

6. Accessories 33

6.1. External brake resistors 33

6.2. Mains chokes 33

6.3. RFI filter 34

6.4. External fuses 34

6.5. System cables 34

6.5.1. System cables for control terminal block X5 34

6.5.2. System cables for master frequency selection X2 and incremental encoder output

X4 35

6.5.3. System cables for resolver X3 36

6.5.4. System cables for power supply of servo motors 37

6.5.5. System calbes for supply fo fan and brake 38

6.6. Motors 39

3

Page 6

1. LCD display 40

1.1. Key functions 40

1.2. Plain-text display 40

2. Basics of parameter setting 41

2.1. Change parameters 41

2.2. Save parameters 42

2.3. Load parameter 42

2.4. Examples 43

3. Commissioning 45

3.1. Basic parameter setting 45

3.2. Input of motor nameplate data 47

3.3. Setting of operating parameters 48

4. Additional functions 50

4.1. Mains failure detection with DC-bus control 50

4.1.1. Requirements 50

4.1.1. Wiring 52

4.1.2. Setting 53

4.2. Homing mode 56

4.3. Further additional functions 57

5. Serial interfaces 58

5.1. LECOM1 interface X1 58

5.2. LECOM status messages 59

5.3. Table of attributes 60

6. Code table 63

7. Signal flow chart axis modules 72

1. Monitoring messages 74

1.1. Monitoring without activating pulse inhibit 74

1.2. Monitoring with activating pulse inhibit 74

1.3. Monitoring with TRIP setting 74

2. LED displays 78

2.1. LED supply module 78

2.2. LED axis module 78

3. Checking the power stage 79

3.1. Checking the mains rectifier 79

3.2. Checking the output stage 79

Index

4

83

Page 7

Planning and installation

1. Features

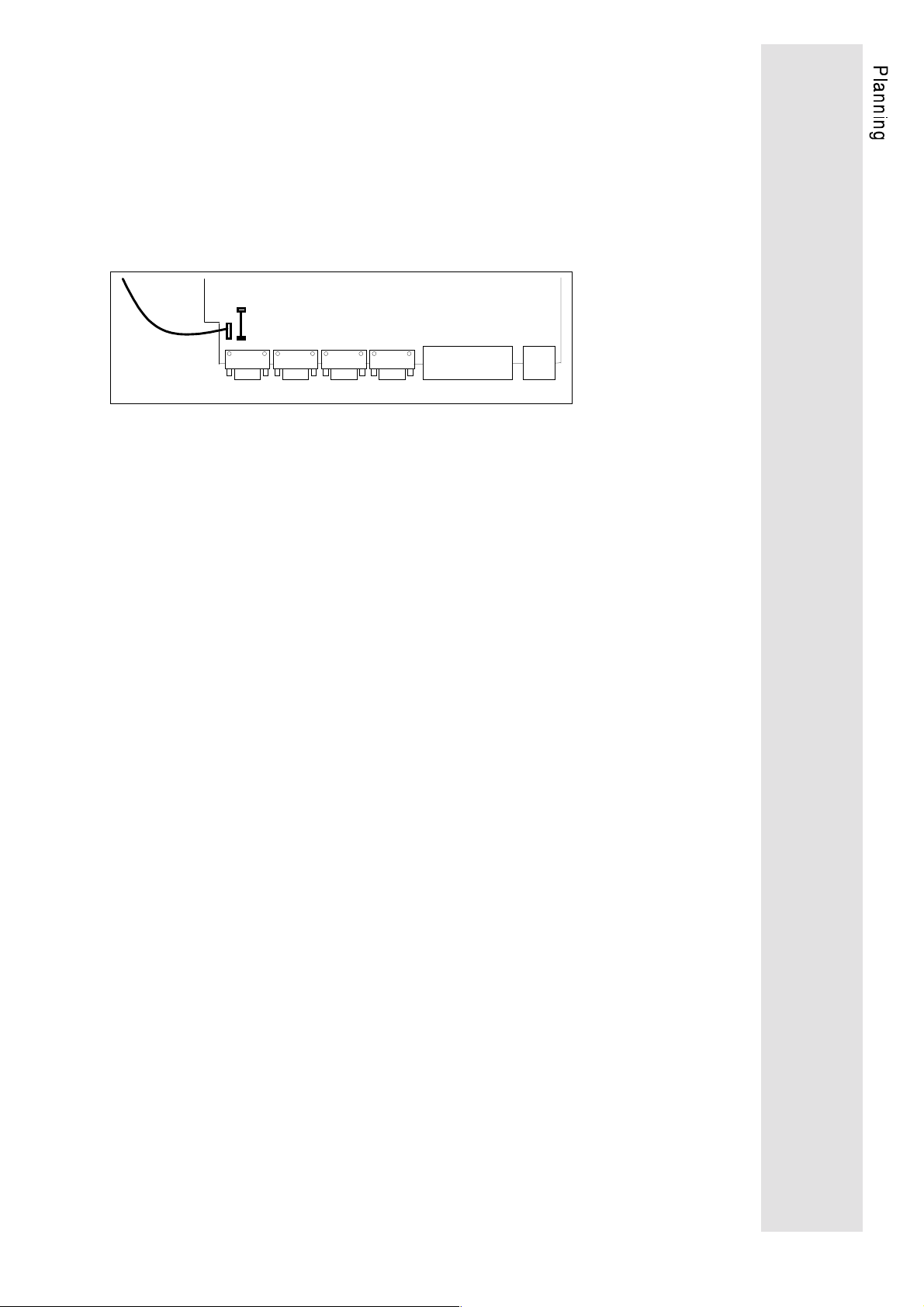

The 9200 controller series comprises 3 supply modules (types

9212, 9215 and 9217) and 7 servo modules (types 9222-9228 with

motor peak currents ranging from 8 to 82 A) for asynchronous

servo motors.

•

Digital control by 16-bit microcontroller and 3 ASICs

•

Field-orientated vector controlled current

•

Four-quadrant operation, any speed and torque direction

•

Inverter with IGBTs

•

Selectable chopper frequency either low noise 8kHz or silent

16kHz

•

Supply and axis modules can be combined for single or multiaxis operation

•

Efficient energy exchange by means of DC-bus for multi-axis

operation

•

Controlled operation even during mains interruption.

•

Supply modules with integrated brake chopper and brake

resistors

•

Short-circuit protected inverter outputs

•

When using the specified mains chokes, the units comply with

the overvoltage class 2 according to VDE 0160

•

I x t monitoring as overload protection for the inverter

•

Parameter setting and diagnosis via keypad and 2-line LCD

display in plain text German, English, and French language

•

Control parameters can be modified ON-LINE

•

Isolated digital inputs and outputs for 24V-PLC level

•

Electronic incremental encoder simulation for use by other

drives

•

Master frequency input for positioning, master/slave operation

or angular synchronization

•

Drift free standstill in the case of master frequency input or

quick stop QSP

•

Serial interface LECOM A/B (RS232 and RS 485) for

parameter setting, control and diagnosis

•

Enclosure IP20

•

Variants with additional modules are available

•

Approvals: UL 508, File no. 132659

VDE 0160, VDE reg. no. 1799

5

Page 8

2. Technical data

2.1. General data

Enclosure

Noise immunity:

Influence of installation height on

rated current:

Ambient temperature

Permissible humidity

Permissible pollution

Steel sheet housing, IP20 to DIN 40050

Severity 4 to IEC 801-4

1000 m: 100% rated current

2000 m: 95% rated current

3000 m: 90% rated current

4000 m: 85% rated current

0 °C...+45 °C during operation

-25 °C...+55 °C during storage

-25 °C...+70 °C during transport

relative humidity 80%, no condensation

Pollution strength 2 to V DE 0110, part 2.

Do not expose units to corrosive or explosive gases .

2.2. Unit-specific data

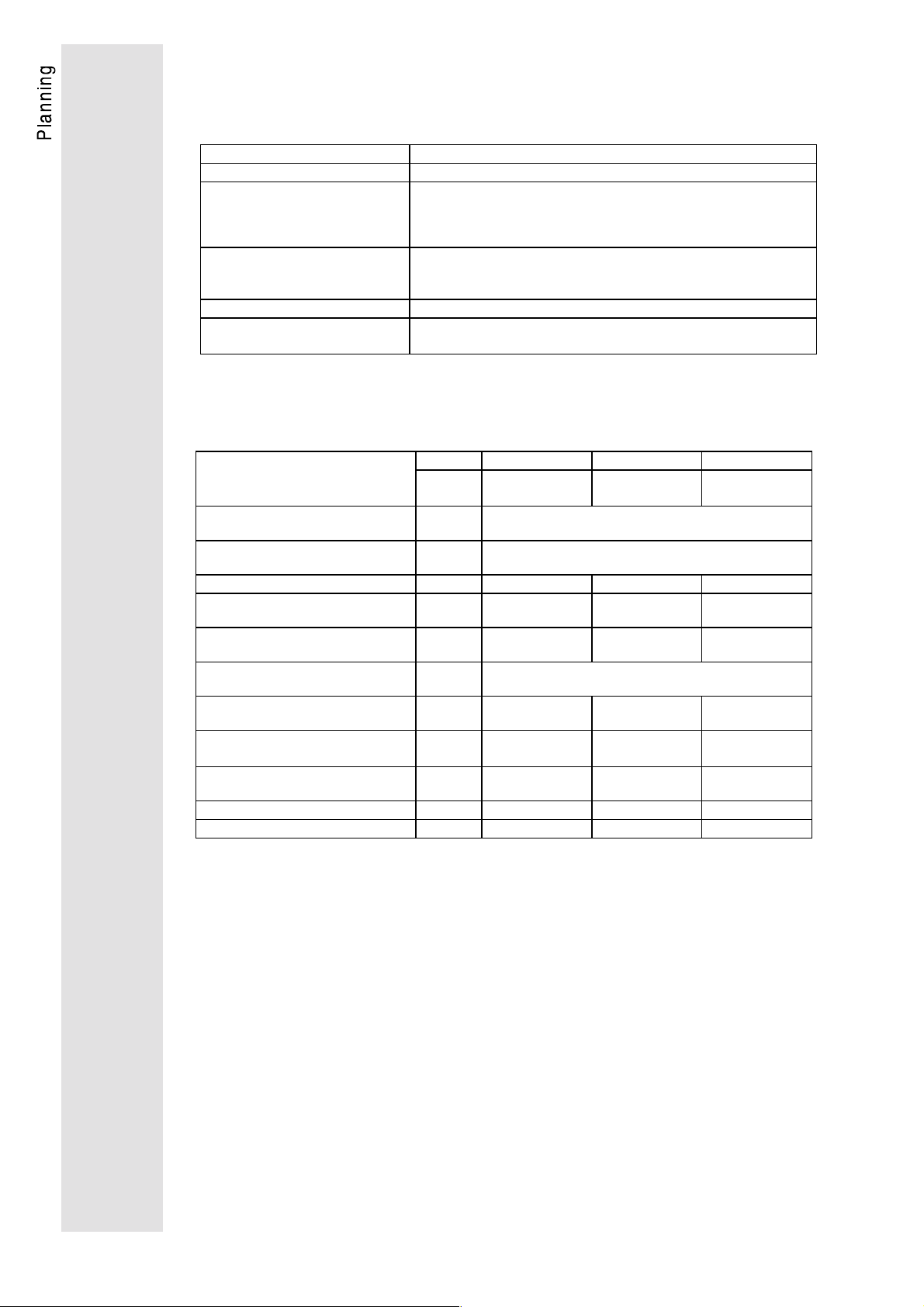

2.2.1. Rated data of supply modules

Supply module type 9212_E 9215_E 9217_E

Order no. 33.9212_E 33.9215_E 33.9217_E

Mains voltage

DC-bus voltage

(at rated current)

Mains current

Permanent power

(at V

Peak power

(t=5 s)

Permanent brake power (with int.

brake resistor)

Permanent brake power (with

appropriate ext. brake resistor)

Peak brake power

with int. or ext. brake resistor

min. permissible resistance for int.

or ext. brake resistor

Power loss (without brake resistor)

Weight

mains

= 3 x 480 V)

1)

[V] 3 x 480; 50 - 60 Hz

permissible range 3 x 330...528 ± 0%;

[V] 1.35 x V

[A

]

eff

[kW] 4.9 16.5 33

[kW] 12 37 60

[W] 250

[kW] 4.9 16.5 33

[kW] 19.4 51.1 66.1

[Ω]

[W] 110 110 110

[kg] 9.0 10.5 11.0

62040

29 11 8.5

mains

1)

With low mains voltages , the permissible permanent power is reduced to P

zul

6

= P

V

⋅

n

mains

/ 480 V

Page 9

2.2.2. Rated data of axis modules

Axis module type 9222_E 9223_E 9224_E 9225_E

Order no. 33.9222_E 33.9223_E 33.9224_E 33. 9225_E

Output current

(f

= 8 kHz)

ch

Output current

= 16 kHz)

(f

ch

Peak current

(for t = 5 s at f

for t = 2.5 s at f

= 8 kHz;

ch

= 16 kHz)

ch

Permanent power

(V

= 3 x 480 V and f

A

= 8 kHz)

ch

Permanent power

(V

= 3 x 480 V and f

A

= 16 kHz)

ch

Peak power

= 3 x 480 V)

(V

A

Output voltage V

A

Field frequency

Speed

Power loss at permanent power

Power loss at controller inhibit

Weight

] 4.5 5.5 13.5 18

[A

eff

] 2.3 2.9 6.9 9.5

[A

eff

[A

] 8 10 24 33

eff

[kVA] 3.7 4.5 11.2 14.9

[kVA] 1.9 2.4 5.7 7.9

[kVA] 6.6 8.3 19.9 27.4

[V] 3 x 0...V

mains

[Hz] 0... ± 300

-1

] 0... ± 8000

[min

[W] 200 250 340 510

[W]454545125

[kg] 9.2 9.5 9.5 20.5

Type 9226_E 9227_E 9228_E

Order no. 33.9226_E 33.9227_E 33.9228_E

Output current

(f

= 8 kHz)

ch

Output current

= 16 kHz)

(f

ch

Peak current

(for t = 5s at f

for t = 2.5 s at f

= 8kHz;

ch

ch

= 16kHz)

Permanent power

(V

= 3 x 480 V and f

A

= 8 kHz)

ch

Permanent power

(V

= 3 x 480 V and f

A

= 16 kHz)

ch

Peak power

= 3 x 480 V)

(V

A

Output voltage V

A

Field frequency

Speed

Power loss at permanent power

Power loss at controller inhibit

Weight

[A

]25 32 46

eff

] 13 16.5 23.5

[A

eff

[A

]45 57 82

eff

[kVA] 20.2 26.6 38.2

[kVA] 10.8 13.7 19.5

[kVA] 37.4 47.3 68.1

[V] 3 x 0...V

mains

[Hz] 0... ± 300

-1

] 0... ± 8000

[min

[W] 640 800 1000

[W] 125 125 125

[kg] 21 22 22

7

Page 10

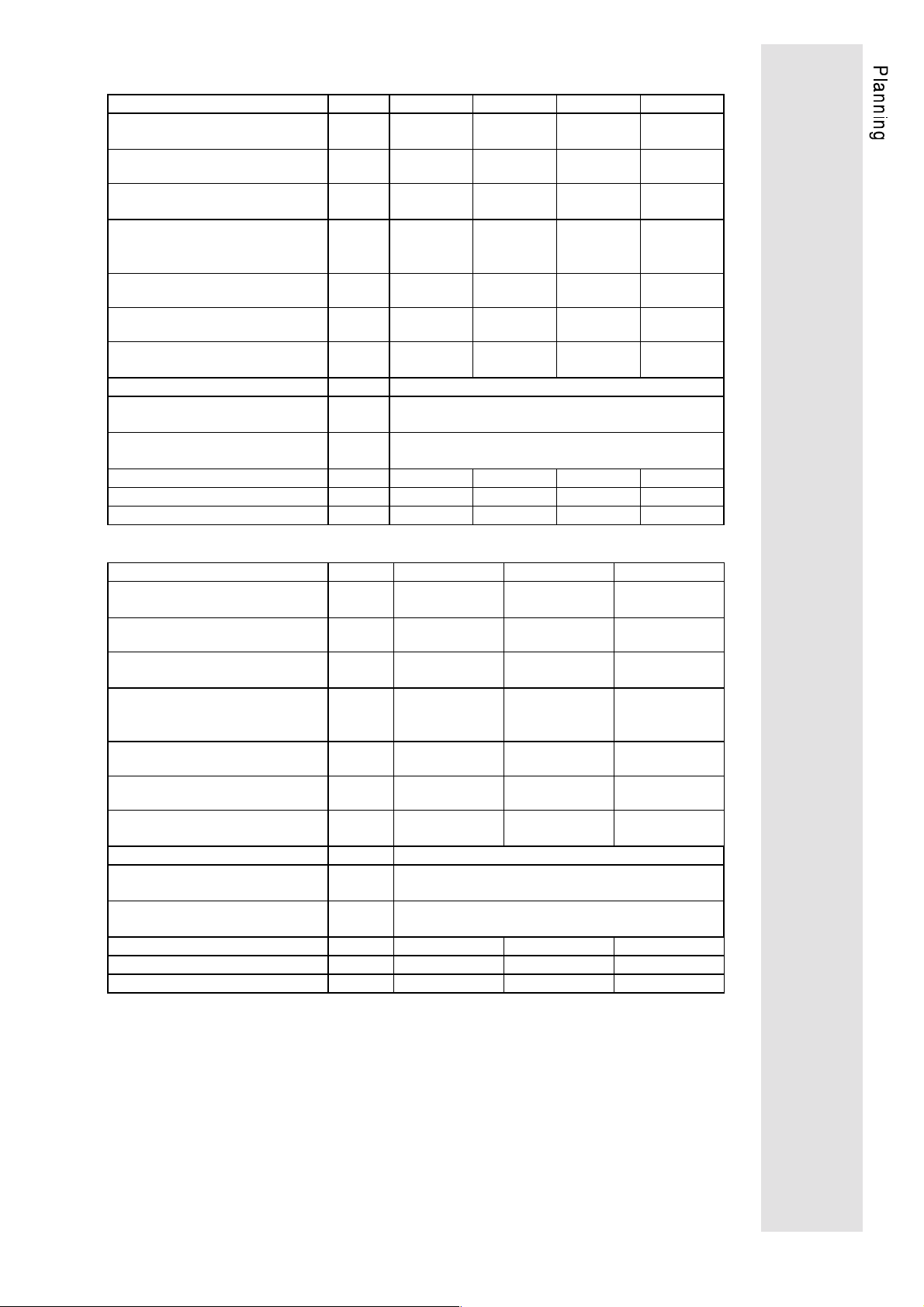

2.3. Dimensions

Type a

[mm]b[mm]c[mm]d[mm]e[mm]g[mm]

9212 - 9217

9222 - 9224

9225 - 9228

125 440 95 425 300 5

290 440 250 425 300 5

2.4. Extension of delivery

Axis module or supply module

•

Accessory kit (busbars, State-bus line, control terminals)

•

Operating Instructions

•

2.5. Application as directed

The units of the 9200 series are electrical units which are designed

for the application in control cabinets in industrial power

installations. They are designed for variable speed operations with

three-phase AC motors.

8

Page 11

2.6. Manufacturer's certification

We hereby certify that the below listed electronic controllers are

control components for variable speed motors intended for the

assembly into machines or together with other components to form

a machine. According to the "Council directive ... relating to

machinery" 89/392/EWG, our controllers are no machines.

The Operating Instructions supplied together with the controllers

give advice and recommendations for the installation and use of the

electronic equipment.

As long as the conformity with the protection and safety

requirements of the "Council directive ... relating to machinery"

89/392/EWG and its amendment 91/368/EWG is not proved,

operation of the machine is prohibited.

The measures required for typically configurated controllers to

comply with the EMC limit values are indicated in the Operating

Instructions. The electromagnetic compatibility of the machine

depends on the method and accuracy of the installation. The user

is responsible for the compliance of the machine with the "Council

directive ... relating to electromagnetic compatibility" 89/336/EWG

and its amendment 92/31/EWG.

Considered standards and regulations:

•

Electronic equipment for use in electrical power installations and

their assembly into electrical power installations: DIN VDE 0160,

5.88 (pr EN 50178)

•

Standards for the erection of power installations:

DIN VDE 0100

•

IP - enclosures: EN 60529, 10.91

•

Base material for printed circuits:

DIN IEC 249 part 1, 10.90; DIN IEC 249 part 2-15, 12.89

•

Printed circuits, printed boards:

DIN IEC 326 part 1, 10.90; EN 60097, 9.93

•

Creepage distances and clearances:

DIN VDE 0110 part 1-2, 1.89; DIN VDE 0110 part 20, 8.90

•

Electrostatic discharge (ESD):

prEN 50082-2, 8.92, IEC 801-2, 9.87 (VDE 0843, part 2)

•

Electrical fast transient interference (Burst):

prEN 50082-2, 8.92, IEC 801-4, 9.87 (VDE 0843, part 4)

•

Surge immunity requirements: IEC 801-5,10.93

•

Radio interference suppression of electrical equipment and

plants:

EN 50081-2, 3.94; EN 55011 (VDE 0875, part 11,7.92)

•

Radio interference suppression of radio frequency equipment

for industrial purposes: VDE 0871, 6.78

9

Page 12

3. Installation

3.1. Mechanical installation

•

The units are designed as housing units with enclosure IP20.

•

Install the units vertically with the power terminals at the top.

•

Ensure a free space of 100 mm at both the bottom and the top.

Caution!

When working with the maximum brake power, the temperature of the output air of

the supply modules can reach up to 120°C.

•

The axis modules should be installed at the same height at the righthand side of

the supply module:

−

If the axis modules have different power outputs, the more

powerful axis module must be placed directly next to the

supply module.

•

The interface connectors X1 to X4 and other terminals must be

covered with the supplied dust protectors or unused connectors

when not used.

10

Page 13

3.2. Electrical installation

•

The breakaway torque for the power terminals is 2.3 Nm

(20 lb in). Marking of terminals:

at 921X: +U

at 922X: +U

Supply modules

•

Without additional protective measures (e.g. zeroing) the units

may not be connected to a mains with e.l.c.b. (VDE

0160/05.88). In the event of an earth fault, a DC component in

the fault current can prevent the release of the e.l.c.b.

•

Operate the supply module with assigned mains choke.

•

Power input

Recommended cable diameter and number of cores

Supply module 9212 9215 9217

Number of cores

Cable diameter [mm²]

or

AWG

Protect input cables according to their diameter with adapted

cable protection fuses.

•

Protection of the input rectifier:

−

Total protection with external very quick acting fuses in the

mains input (see chapter "Accessories")

−

If total protection is not required:

The normal cable protection fuses or miniature circuit

breakers which are adapted to the cable diameter offer

sufficient protection.

•

The peak power of the supply module must be equal to or

higher than the total peak power of the connected axis modules

and the rated power of the suply module must also be equal to

or higher than the total permanent power of the axis module

(see chap. 3.2.1).

, -UG, RBr, L1, L2, L3

G

, -UG, U, V, W

G

4

(L1,L2,L3,PE)4(L1,L2,L3,PE)4(L1,L2,L3,PE)

1,5 4 10

14/15 10/11 6/7

Note

The supply modules 921x hardware version E.4x onwards described in these

Operating Instructions may only be used in combination with the axis modules of

the hardware version E.4x and higher.

Axis modules

•

Connect only one motor to each axis module.

•

The cable diameter of the motor cables must correspond to the

rated current of the motor.

Protection by means of:

−

cable protection fuses or

−

adapted motor protection relay

•

Ensure motor protection:

−

use motor protection relay and monitor the thermostat of the

motor.

•

The connected motor may not be operated when the controller

is enabled, except for safety shutdown.

11

Page 14

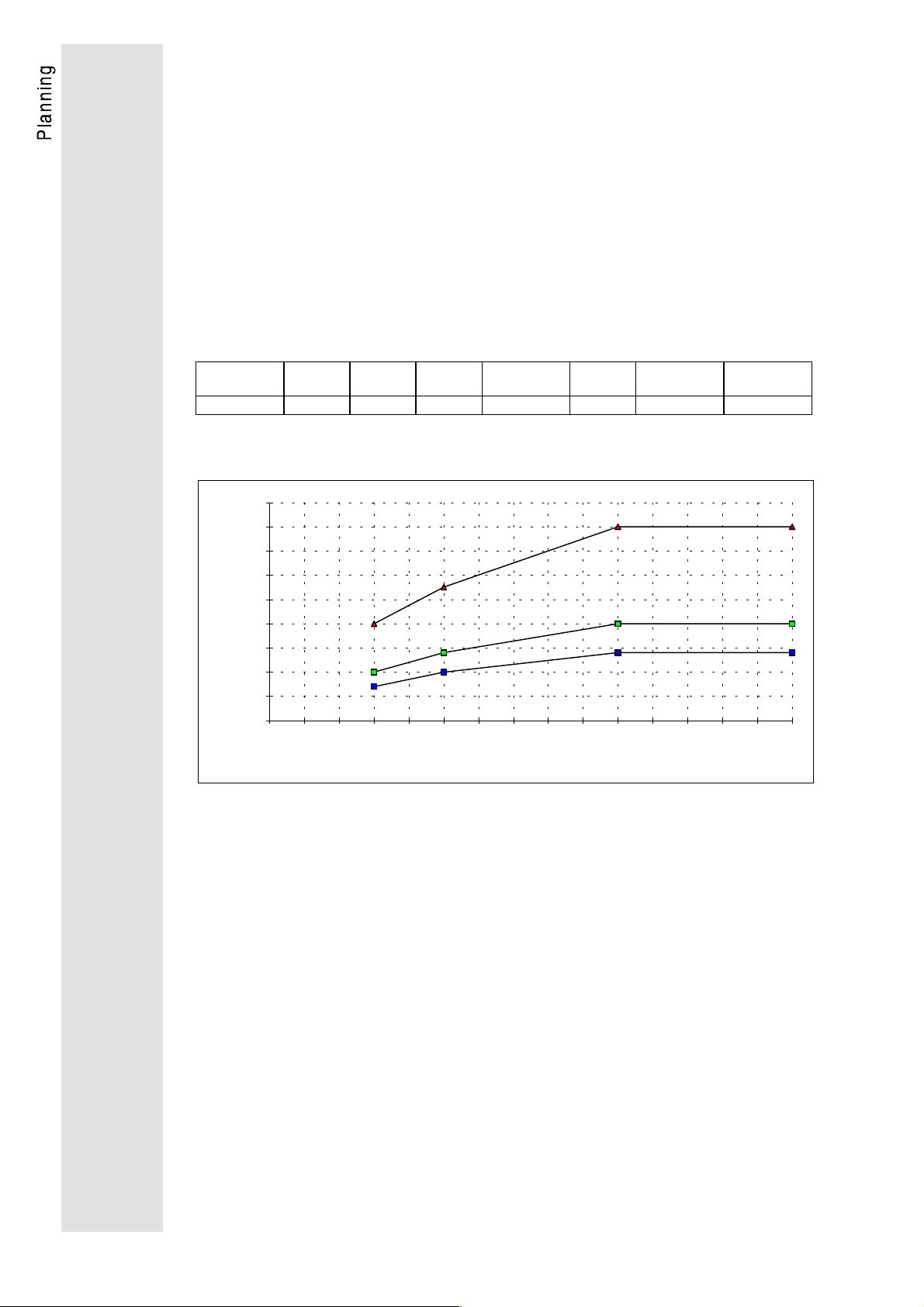

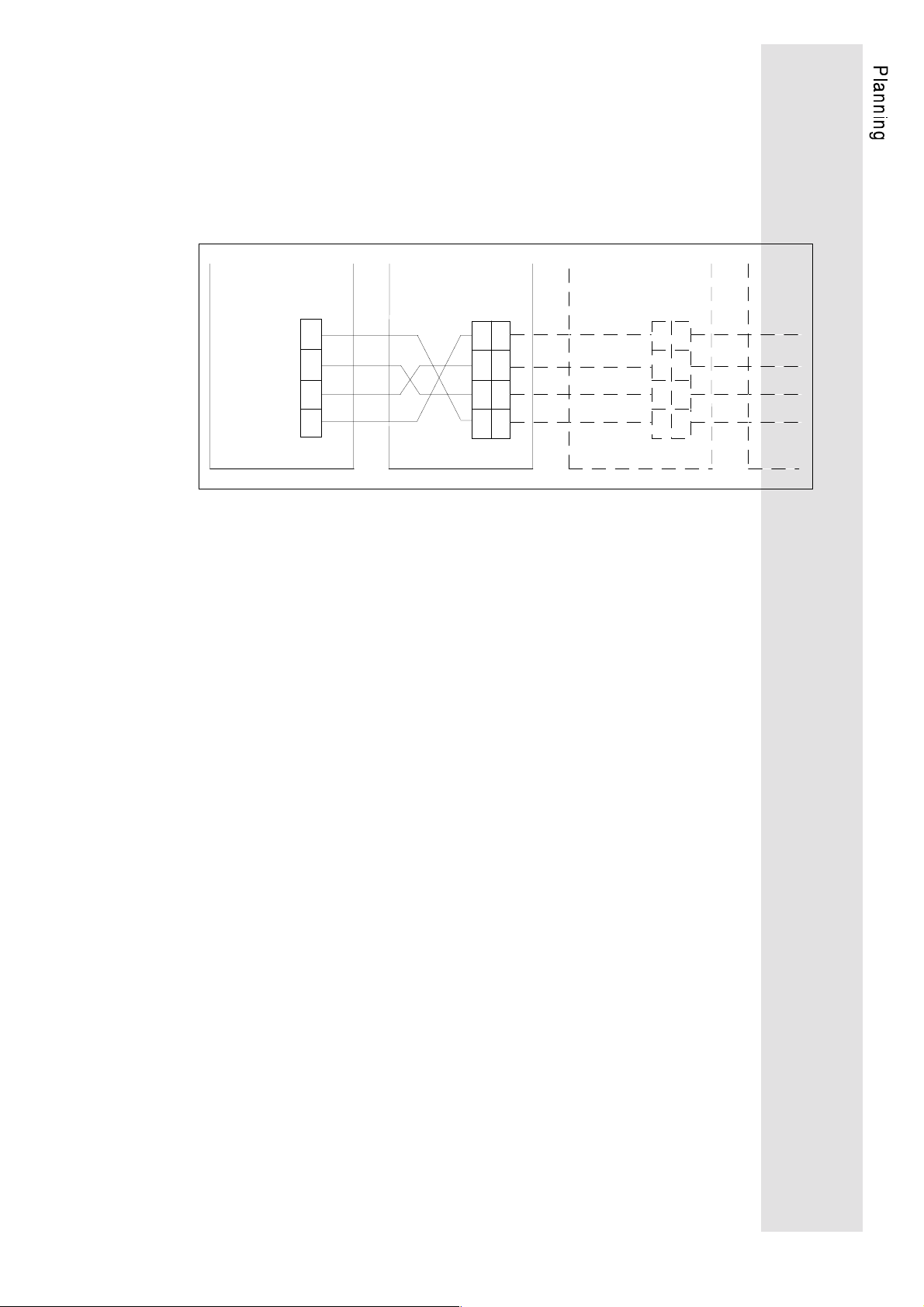

3.2.1. Combination of several axis modules with one supply module

µ

Please note the following conditions when combining several axis

modules with one supply module:

•

The State-bus (X6) can supply max. 10 axis modules.

•

The sum of the total capacity of the DC-bus may not exceed a

certain value (see chart):

The permissible total capacity depends on the interval between

two closing operations and the mains voltage. The total capacity

is the sum of the capicities of the supply module and the axis

modules.

−

For intervals between two closing operations longer than

15 min, the max. permissible capacities are applied.

DC-bus capacities of the 9200 series

Type 9212 9215 9217 9222

9223

F]

C

ZK

[

235 705 1175 235 340 1100 2200

9224 9225

9226

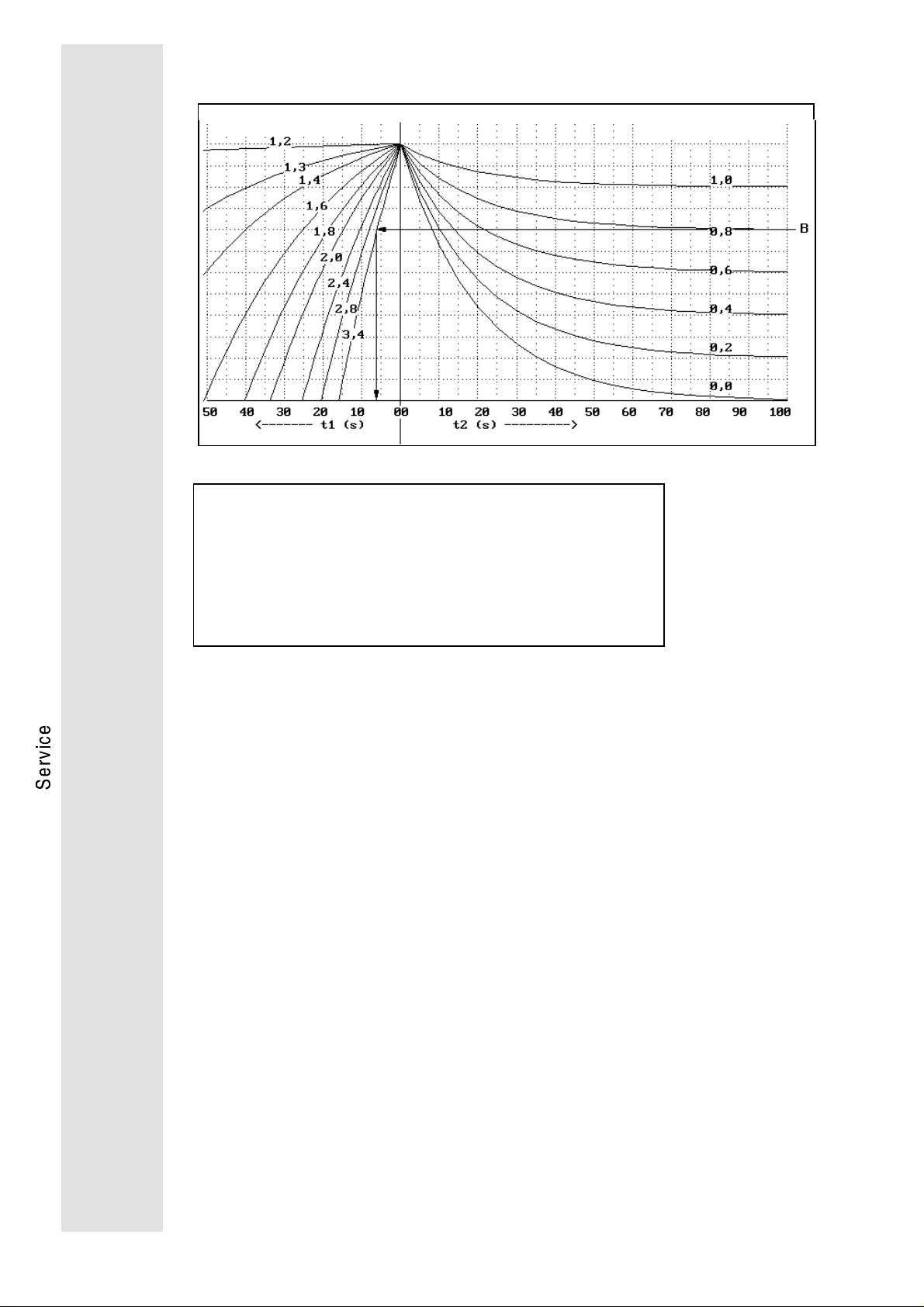

Permissible total capacity depending on the interval between two closing

operations and the mains voltage

9000

8000

7000

6000

5000

4000

C (total) / µF

3000

2000

1000

0

0 1 2 3 4 5 6 7 8 9 101112131415

Switch-on distance / min

9215; 9217

V mains=400V-480V

9212

V mains=400V

9212

V mains=480V

9227

9228

12

Page 15

•

When selecting the power of the supply module, proceed as

follows to find out about the required input power.

1. Determine the power profile of all axis modules connected to

the DC-bus by means of the process profile and the load

torques during a system cycle.

2. The power losses are stated in the technical data, for units

the losses are stated during rated power and for motors the

power loss during rated operation. These losses are

assumed to be constant during the whole cycle.

3. Find out the resultant powr by adding the power losses and

the power profiles:

calculate a positive motor power

and a negative generator power.

4. Determin e the effective power during the system cycle:

Do not calculate a negative resultant power (generator

power). These ranges can taken into consideration when

calculating the effective brake power.

5. Select the supply module according to the effective power

during a system cycle:

Please note that the supply module must have enough

capacity to supply the effective peak power and that, in the

event of mains voltage reductions, the permissible power of

the supply module will be reduced according to the reduction

of the mains voltage.

6. If the calculated effective permanent power exceeds the

permissible value of the supply module 9217:

Subdivide the DC-bus sets and install further supply

modules.

13

Page 16

3.2.2. Screening and earthing

In order to avoid radio interference, care must be taken with the design and

connection of digital drives to avoid EMC disturbances during operation.

Digital drives are not more vulnerable to interference than analog drives, but the

effect is generally different. Interference of analog devices becomes obvious as

irregularities in speed. Interference of digital drives may cause

program errors; therefore it is important that the drives are inhibited

immediately when interference occurs. This is done by setting the

TRIP function (CCr).

In order to avoid these problems, care must be taken with ground

(GND), protective earth (PE) connections as well as screening.

•

Screen control cables and motor cables.

•

Ensure effective screening:

−

a non-earthed conductior should be used to maintain screen

integrity where cahbles are interrupted (terminal strips,

relays, fuses).

Caution!

To increase the EMC (electromagnetic compatibility), the reference GND is

connected to the protective earth (PE) inside the drive.

Fehler! Es

ist nicht

möglich,

durch die

To ensure an optimum interference suppression, the screening and the GND-PEconnection is made differently for single drive and multi drive

networks.

Single drive

•

Connect the screen of the control cables to PE of the drive at

one end to avoid earth loops.

•

GND and PE are connected by a jumper inside the drive.

•

In case of firmly installed computer connections, a mains

isolation (e.g. Lenze Converter 2101) is mandantory between

computer and axis module.

•

The screens of the motor cables

−

should be as large as possible.

−

connected to the two sides.

14

Page 17

Multi drive networking

•

When laying the ground cables, care must be taken that there

are no ground loops. To ensure this, the GND-PE connection

must be removed in every drive. For the 9200 drives, turn the

four screws on the cover one haft turn CCW and pull out the

control board. Remove the jumper PE-BR on the board 9220

MP. CAUTION: Ensure that the mains has been disconnected

and the drive has been switched off at least 5 minutes before

removing any parts.

cable

PE

BR-PE

Control board 9220MP

X1 X2 X3 X4

SubD-plugs

•

All ground cables must then be lead to external, insulated

X5

Control terminals

central points, centralized again from there and connected to

PE in the central supply. The PE-GND reference is necessary

as the electronics insulation (SubD plug) does not allow

voltages >50V~ AC at PE.

•

In case of firmly installed computer connections, a mains

isolation (e.g. Lenze Converter 2101) is mandatory between

computer and axis module.

•

The individual cable screens must be connected to external

insulated centreal points, which are then connected to the PE

potential at one point.

•

The screens of the motor cables

−

should be as large as possible.

−

should be connected to the two sides.

X6

15

Page 18

3.2.3. Radio interference suppression

According to § 13 and § 14 of the legislation of the European

Community relating to the electromagnetic compatibility of devices

(EMVG v. 09.11.92) the national standards and regulations are only

interim standards vilid until December 31, 1995. In addition, the

harmonized European standards can be fulfilled following the

recommendations below. Measures against radio interference

suppression depend on the site of the device to be installed:

Previous national standards

The application without radio interference suppression in electrical

systems within connected working areas or industrial premises can

only be allowed if, outside the industrial premises, the limit values

according to VDE 0871/6.78, class B are not exceeded (General

allowance according to the standard on the operation of highfrequency devices of December 14, 1984, official no. 1045/1046).

For operation within residential areas or when exceeding the limit

value class B outside of industrial premises, radio interference

suppression according to VDE 0871, limit value class B is required.

Future hormonized standards

The standard prEN 50081-2 is valid for the radio interference

suppression.

It refers to standard EN 55011 (VDE 0875, part 11, limit value class

A and B).

•

Within industrial premises, which are not connected to the public

low-voltage supply, the limit values to EN 55011, limit value

class A apply.

•

Within residential areas or industrial premises, which are

connected to the plublic low-voltage supply, the limit values to

EN 55011, limit value class B apply.

Radio interference suppression to EN 55011, limit value class

A or B, can be achieved by:

•

Using a suitable mains filter and screening of motor cables,

brake resistor cables and the power cable between mains filter

and inverter (for recommended mains filters see "Accessories").

16

Page 19

4. Drive connections

4.1. Power connections

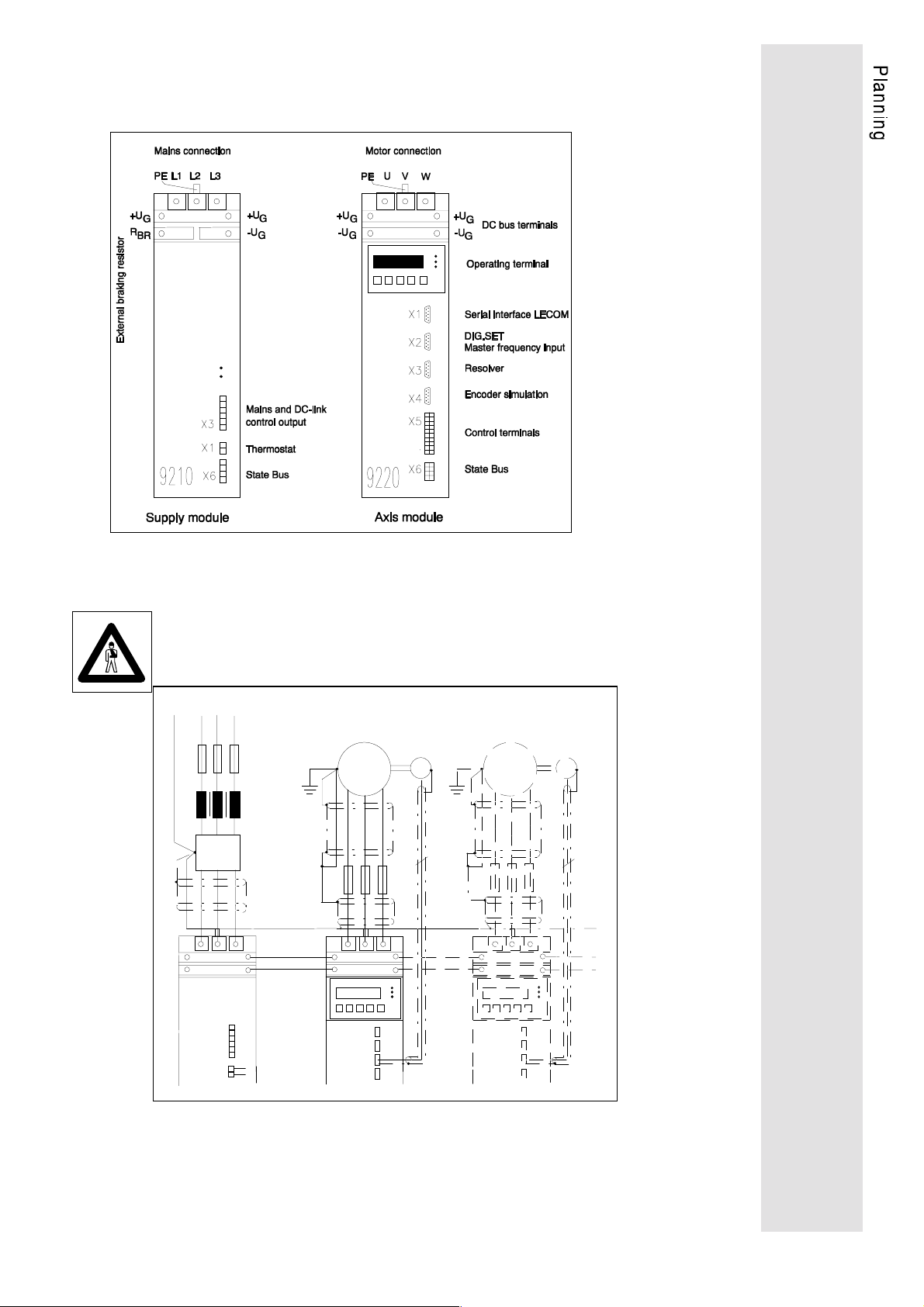

4.1.1. Mains and motor connection

Caution!

All power terminals carry mains potential up to 5 minutes

after mains disconnection.

The DC-bus terminals +UG -UG and the PE terminals of the supply

and axis module must be connected by means of busbars

(accessory kit).

17

Page 20

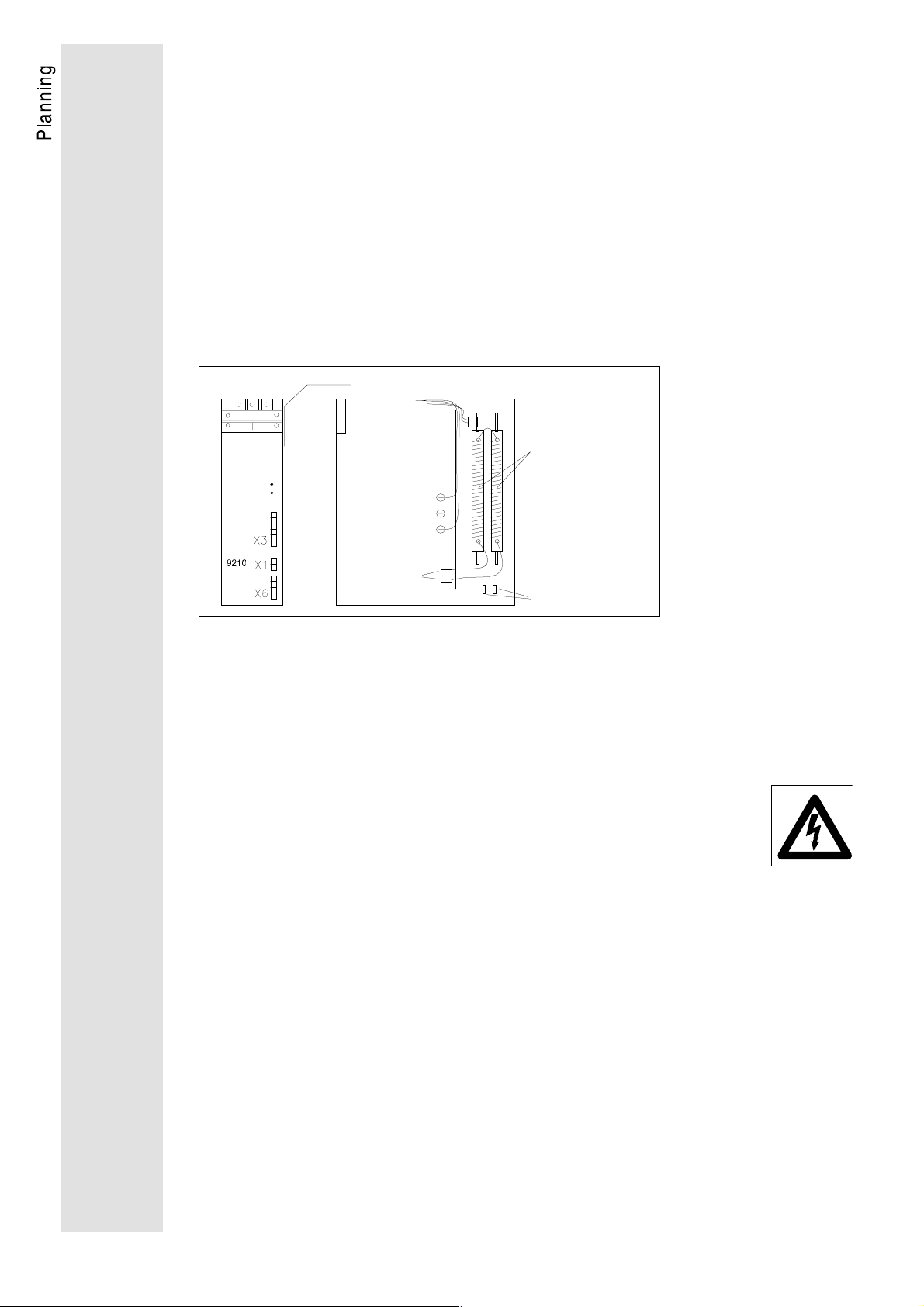

4.1.2. External brake resistor

To increase the permanent brake power, an external brake resistor

with a higher permanent power can be installed instead of the

internal resistor. In this case, the internal brake resistor must be

disconnected.

Disconnection of the internal resistor:

1. Remove right side of the supply module housing 9210, when

no voltage is applied.

2. Disconnect spade plug.

3. Connect spade plugs to tabs on the housing.

4. Close housing again.

1.

4.

in t er nal

brake resistor

2.

3.

The external brake resistor must be connected to the power

connections +U

recommended to exclusively use resistors with integrated overload

protection which disconnect the mains supply in case of overload

(for recommended resistors see chapter "Accessories"). The

surface temperature of the resistor may reach 360°C.

Caution!

When using brake resistors without overload protection, the resistors may burn due

to a fault (e.g. mains overvoltages >528V, application specific overload or internal

faults).

and RBR at the supply modules 9210. It is

G

18

Page 21

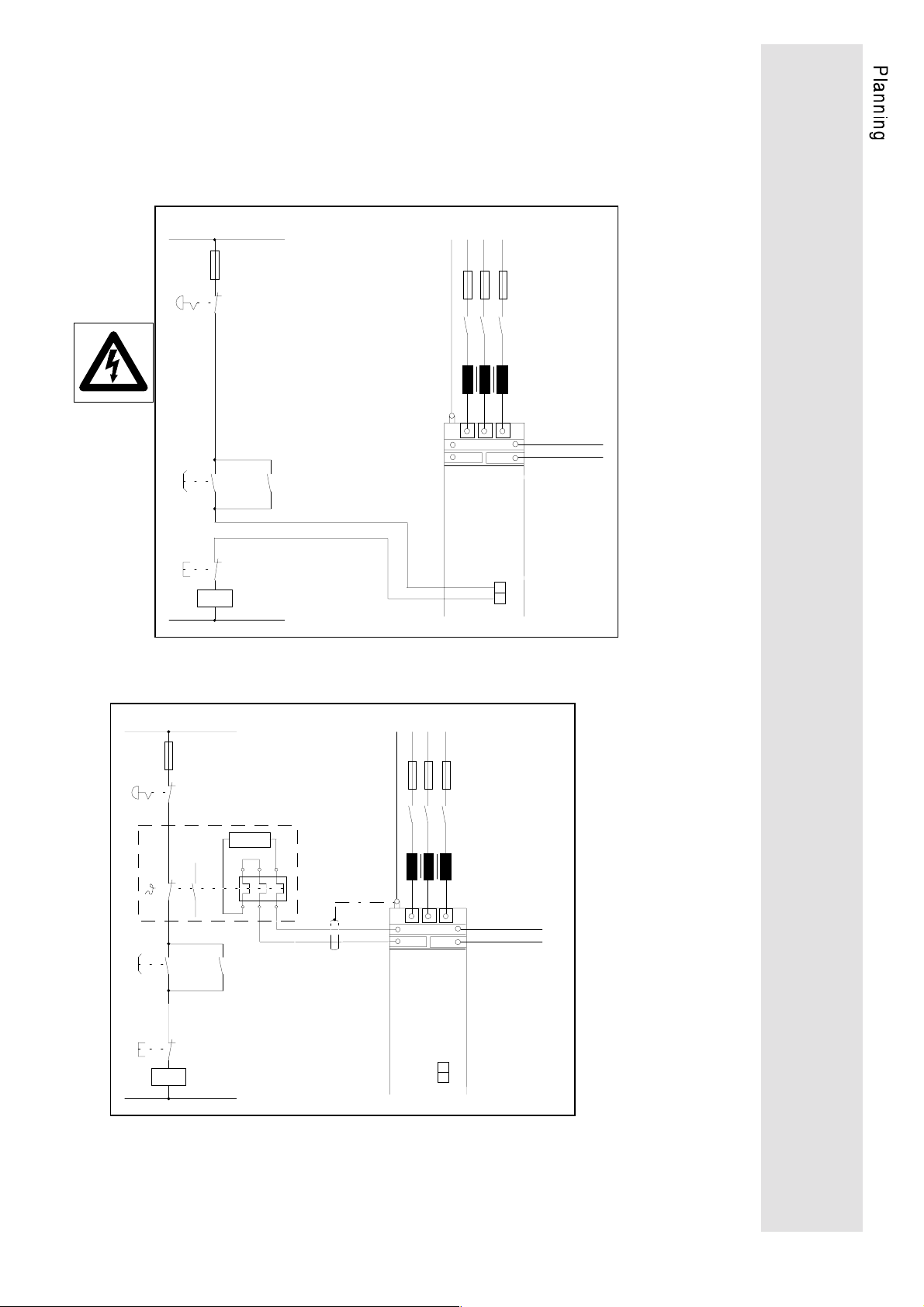

Wiring of brake resistor

Caution

K1 must additionally set controller enable!

Wiring when using the internal brake resistor

Wiring when using the external brake resistor

19

Page 22

4.2. Control connections of supply module

4.2.1. Overheat of internal brake resistor (9210 X1)

The thermal contact (capacity 230V/10A) of the internal brake

resistor can be accessed via the connector X1 of the supply

module. It can be used to switch off the mains in case of overload

of the internal brake resistor (see also: External brake resistor).

Caution!

Unlike previous models of this series, the connector X1 of the supply module does

not have to be bridged any more. This connector cannot be used for the monitoring

of an external thermal contact and the like! To protect the inverter, wiring according

to figure "Wiring using the internal brake resistor" (page 19) is necessary.

4.2.2. Mains and DC-bus monitoring (9210 X3)

At X3 of the power supply module several signals are available,

that give information about the status of the mains. The wiring of

this terminal is not necessary to make the device work. If the

software feature mains failure with DC-bus controlling is required,

the terminals X3,1 and X3,3 must be wired. By using an external 24

V supply there is an optoisolated signal of mains failure at terminal

X3,5.

For further information see: Parameter setting, page 50.

20

Page 23

4.2.3. State bus

By means of the state bus X6, the supply module gives status

information like ready, overvoltage, and heat sink or resistor

overtemperature to the connected axis modules. The four state bus

cables must be taken from the supply module to the axis modules.

The terminals in the axis module which are next to each other are

internally bridged.

9210

State Bus

X6 X6 X6

9220 9220

State Bus State Bus

GND

Temp

RDY

Umax

When the modules are ready to operate, the following levels are

applied at the terminal of the state bus:

•

Temp -> GND : approx. 0...2 V

•

RDY -> GND : approx. 0...2 V

•

V

GND : more than 2 V

max

These levels can only be measured when the state bus is

connected between the supply module and the axis modules.

Umax

RDY

Temp

GND

Umax

RDY

Temp

GND

21

Page 24

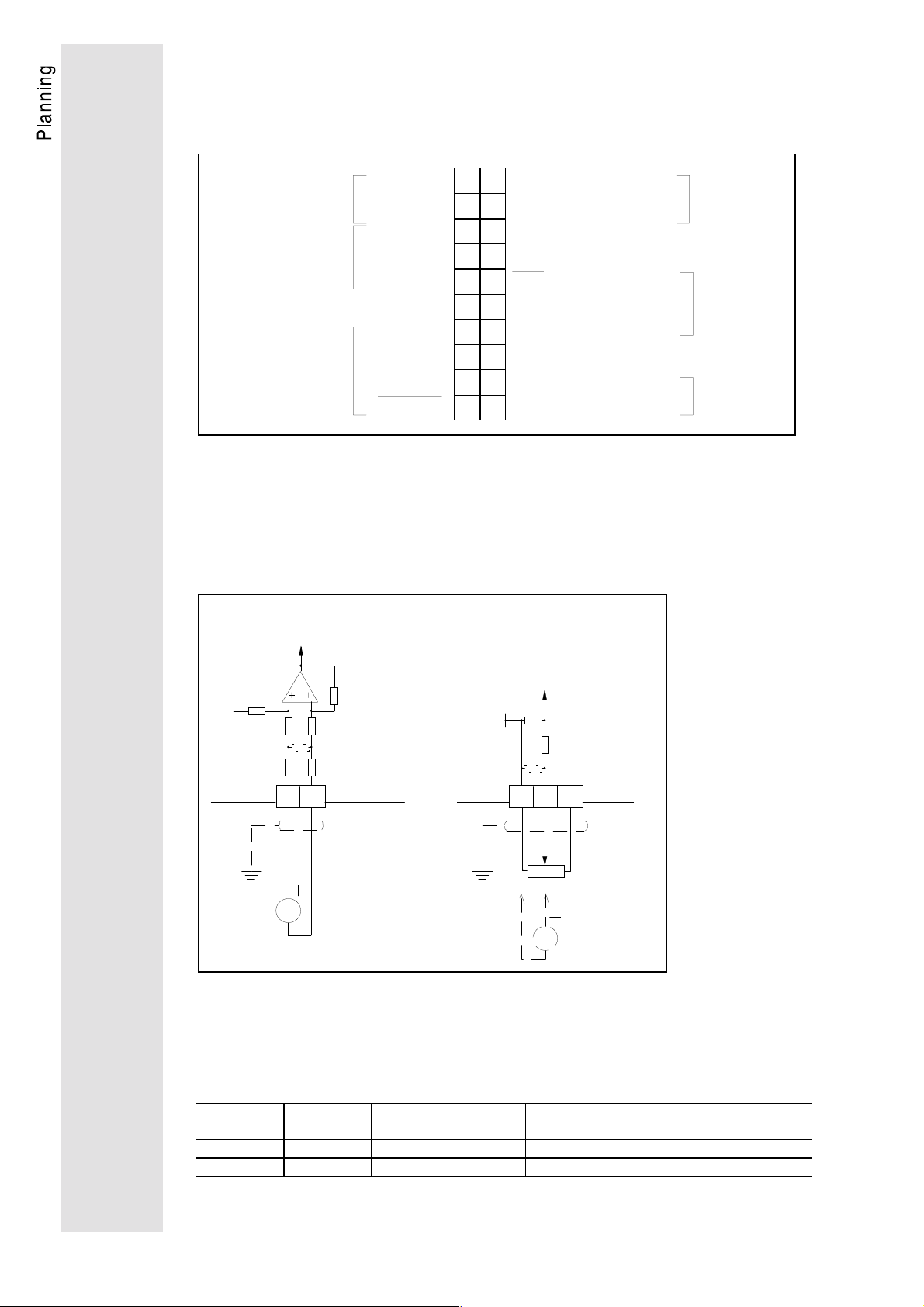

4.3. Control connections axis module

4.3.1. Control terminals

Pin assignment of the control terminal block X5

4.3.2. Analog input and outputs

Analog set value selection

For analog set value provision, two inputs are available, either as

speed or torque set value provision (for selection see C005

configuration). The bipolar input is a differential input..

a) bipolar set value selection b) unipolar set value selection

82kOhm

68kOhm

100kOhm

12

-

82kOhm

68kOhm

R304

100kOhm

X5 X5

Master voltage

-10...+10V

44kOhm

44kOhm

R306

9

8

7

S

A

-

Set value

potentio-

E

meter

10 kOhm/lin.

Master voltage

0...+10V

Monitor outputs

The terminals 62 and 63 of the control terminals block X5 transform

internal digital control signals into analog output signals. The

resolution is 8 bit. The signals are updated every 2ms. The

maximum monitor output current capacity is 2mA.

22

Output Terminal Signal Range Level

Monitor 1

Monitor 2

X 5 62 Actual s peed v alue adjustable via C153/C154 -10V...+10V

X 5 63 Torque set value -M

max

...+M

max

-10V...+10V

Page 25

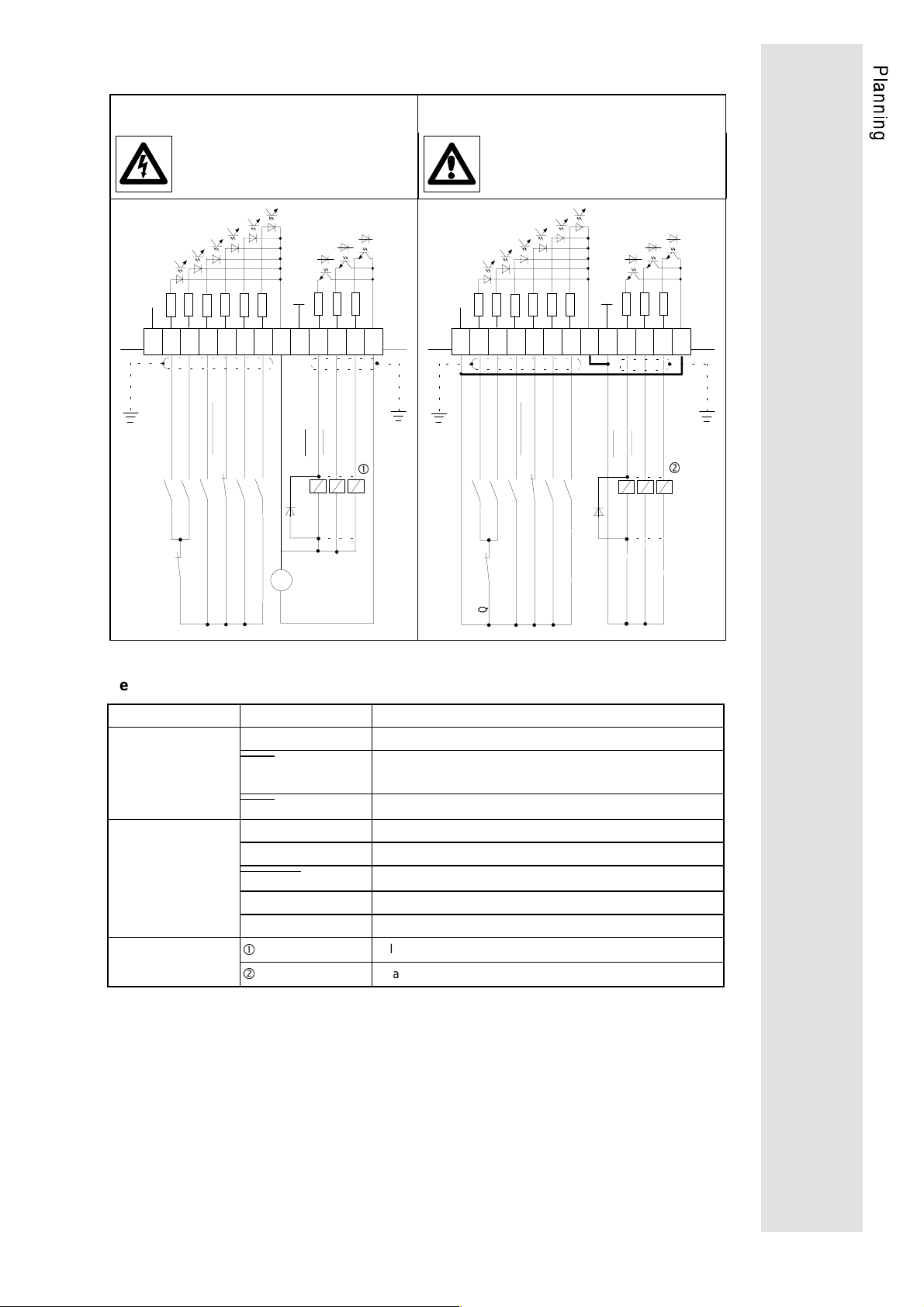

4.3.3. Digital inputs and outputs

External 24 V supply Internal 15 V supply

Caution!

GND is internally connected to PE

via jumper BR-PE.

+Vcc

20 21 22 24 26 27 28 39 40 41 42 44 59

2k2

2k2

R

2k2

2k2

TRIP SET

JOG

L

2k2

2k2

TRIP RESET

RFR

GND

-

56R

56R

TRIP

Qmin

56R

RDY

c

X5

Caution!

Bridge signals X5,39 and X5,40.

+Vcc

2k2

2k2

20 21 22 24 26 27 28 39 40 41 42 44 59

R

2k2

2k2

TRIP SET

JOG

L

2k2

2k2

TRIP RESET

RFR

GND

TRIP

56R

56R

Qmin

56R

X5

RDY

d

QSP

+

Legend

Marking Function at signal = HIGH

Digital outputs

I 7 50mA

Digital inputs

(active at 13 ... 30 V) TRIP RESET Fault reset

I 7 10mA

Relay

RDY Ready

Qmin

Motor speed > value of C017 (fact ory Setting)

The function depends on C117

TRIP

No faults

RFR Controller enable

TRIP SET

No fault switch-off (Motor thermostat)

JOG Internal set value

QSP No quick stop with this switch position

c

d

Relay 24 V, R

Relay 15 V, R

QSP

1 kΩ, e.g. order no. EK00326005

≥

i

600 Ω, e.g. order no. EK00326850

≥

i

23

Page 26

Comment on QSP function

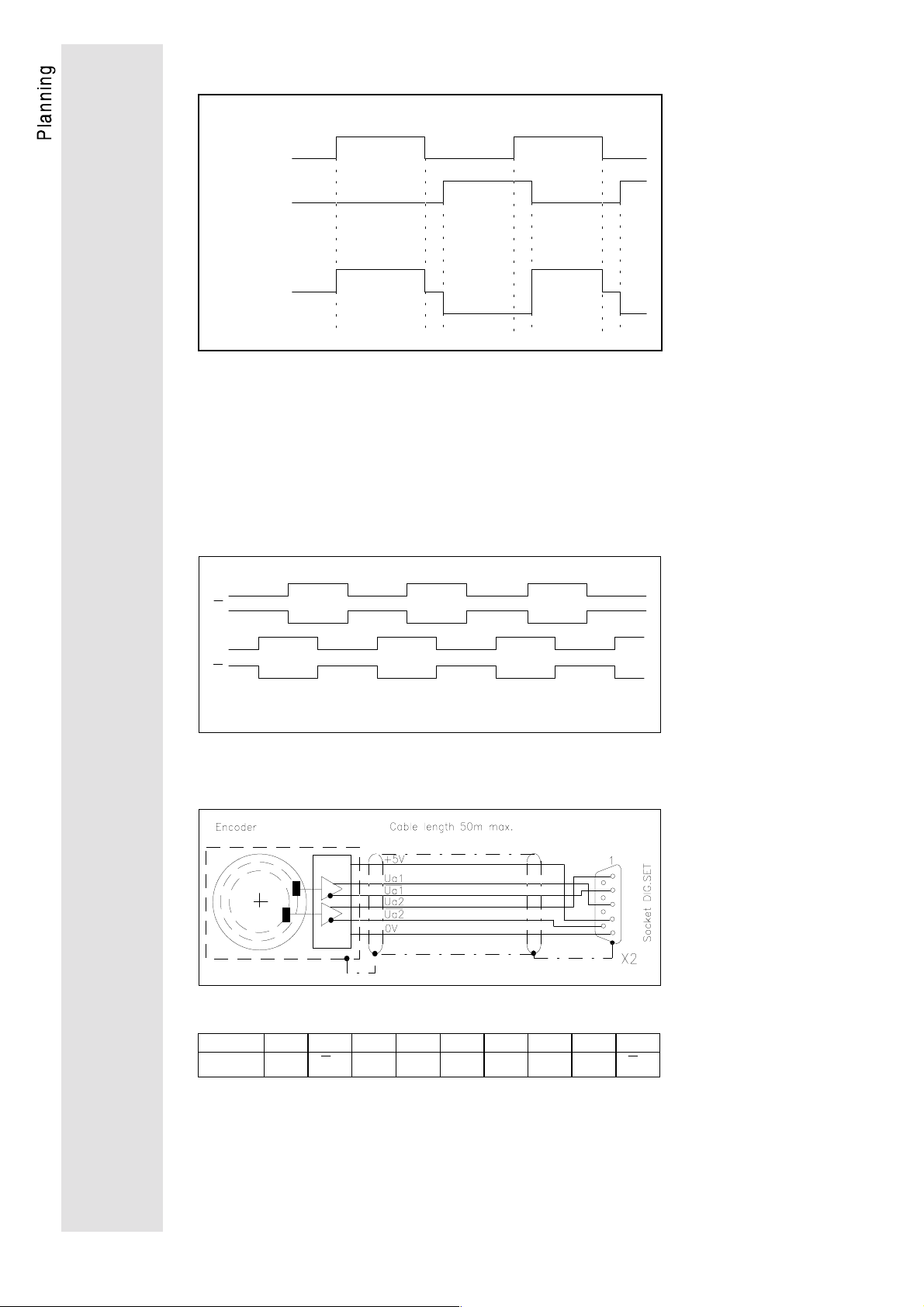

Master frequency selection

For speed set value selection by means of a master frequency, the

9-pole SubD Dig.Set (X2) is used. As master frequency signal

either the simulated encoder signal of the master drive or an

incremental signal source with two TTL complementary signals

shifted by 90° el. can be used. The zero track of the master

endcoder will not be evaluated. The maximum input frequency is

300 kHz. The current consumption per channel is 6 mA.l.

A

A

B

B

T T L /0 ...3 0 0 k Hz

a) Master frequency input by incremental encoder

Pin assignment X2 male plug Dig.Set

24

Pin 123456789

Signal

U

a2

U

U

a1

+ 5V GND -- -- --

a1

U

a2

Page 27

b) Master frequency input by encoder output signal of the

master drive

Pin assignment X2 male Dig.Set

Pin 123456789

Signal

BB

AA + 5V GND -- -- --

AA

BB

Encoder simulation

The encoder socket (X4) is used as an output for the encoder

simulation. Two TTL complementary signals (V

_ 2,5V, V

high

low

_

0,5V at I = 20mA) shifted by 90°C with 256, 512, 1024 or 2048

increments are generated per revolution (adjustable via C030). This

output is used for actual value feedback for closed-loop control

(positioning control) or as a set value for slaves (master/slave

operation). The current capacity is 20 mA per channel.

Pin assignment X4 encoder socket

Pin 123456789

Signal

B

A+ 5VGND

A

Z

ZLC

B

Resolver

2-pole resolvers (V=10V,f=5kHz) are fitted as standard. The Lenze

servo motors are already equiped with the corresponding resolvers.

The resolver is connected by means of a 9-pole socket (X3). The

resolver supply cable and the resolver are monitored for open

circuit (fault indication Sd2).

Pin assignment X3 resolver female plug

Pin 123456789

Signal

+REF -REF GND +COS−COS +SIN−SIN -- --

25

Page 28

5. Application examples

5.1. Variant with integrated positioning module 2211PP

Easy positioning tasks can be solved by applying the positioning

module 2211PP. Thus, you sometimes do not need a PLC or at

least reduce the load of the PLC. The positioning module can be

integrated into the unit and adapted to several applications.

Different designs are available, e.g. the basic module with or

without a terminal extension and alternatively a field bus module as

Interbus-S.

Lenze

Servo 9200

26

Page 29

Features of the positioning module 2211PP:

•

32 freely assignable digital inputs with 8 or 28 via terminals

according to variant

•

32 freely assignable digital outputs with 4 or 16 via terminals

according to variant

•

Absolute or relative measuring system

•

32 program sets, each with the following functions:

point to point positioning

point to point positioning with velocity profile

positioning to an interrup-input

acceleration, deceleration, traversing and final speed adjustable

waiting for input

switching of several outputs

homing according to 6 different modes

adjustable waiting time

adjustable number of pieces for repeat function

program branching depending on inputs

jump to following program set

•

32 adjustable positions

•

32 adjustable speeds

•

32 adjustable acceleration and deceleration values

•

32 adjustable number of pieces

•

32 waiting time

•

Manual and program operation

•

Input and display via the operating unit of the 9200 basic unit

•

Parameter setting and programming via the serial interface

LECOM A/B of the basic unit by means of the PC program

Lemoc2 (via menu)

•

Connection of a BCD switch possible

•

Connection of an absolute encoder possible

•

Control, parameter setting, and programming via Interbus-S or

Profibus possible

•

The function Winding calculator is available as alternative

system software on the same hardware basis as the positioning

module.

Note:

Please additionally note the Operating Instructions of the

positioning system.

27

Page 30

5.2. Wiring with positioning control SX-1

5.2.1. Diagram 1: Mains supply

28

Page 31

5.2.2. Diagram 2: Control circuit 230V

29

Page 32

5.2.3. Diagram 3: Control circuit 24V

30

Page 33

5.2.4. Diagram 4: Control connections 9200 - SX1

Ω

31

Page 34

5.2.5. Diagram 5: Control connections SX1

32

Page 35

6. Accessories

(All listed components must be ordered separately)

6.1. External brake resistors

9212

9215

9217

R

[Ω]Pn[kW]

29 1,1 ERBD029R01k1 120 430 510 92 64

11 1,1 ERBD011R01k1 120 430 510 92 64

8,5 1,1 ERBD009R01k1 120 430 510 95 64

Order no. H

6.2. Mains chokes

[mm]M[mm]O[mm]R[mm]U[mm]

[mH]I[A]

9212

9215

9217

3 x 2,5 3 x 7 ELN3_0250H007 120 61 84 45 130 105 73 6.0 11

3 x 1,2 3 x 25 E LN3_0120H025 150 76 140 61 180 140 95 5.0 10

3 x0,75 3 x 45 ELN3_0075H045 180 91 161 74 225 165 120 6.3 11

L

Part no. a

[mm]b[mm]c[mm]d[mm]e[mm]f[mm]k[mm]m[mm]n[mm]

33

Page 36

6.3. RFI filter

For radio interference suppression according to EN 55011, limit

value class A or B.

Assigned RFI filters for mains voltage of 400 V

Supply module type 9212 9215 9217

Mains current RFI filter

Order no. mains filter

8 A 25 A 50 A

EZF3_008A001 EZF3_025A001 EZF3_050A004

Filter for mains voltages of up to 460 V: please contact

manufacturer

6.4. External fuses

Semiconductor protection

External fast acting fuses in the mains input protect the input

rectifier in the supply module.

Recommended semiconductor protection fuses (at mains side):

Supply module 9212 9215 9217

Mains input with

rectifier protection

Order no.

FF

20A / 700V

14 x 51

EFSFF0200ARH EFSFF0630ARI EFSFF1000ARI

FF

63A / 700V

22 x 58

FF

100A / 700V

22 x 58

Input cables must be protected with standard fuses adapted to the

cross-sectional area of the cables.

6.5. System cables

Note

For best interference immunity results, cut the cables to the required length.

6.5.1. System cables for control terminal block X5

Fehler! Es

ist nicht

möglich,

durch die

34

Design for left X5 terminals right X5 terminals

Order no.

EW00340899 EW00340898

Page 37

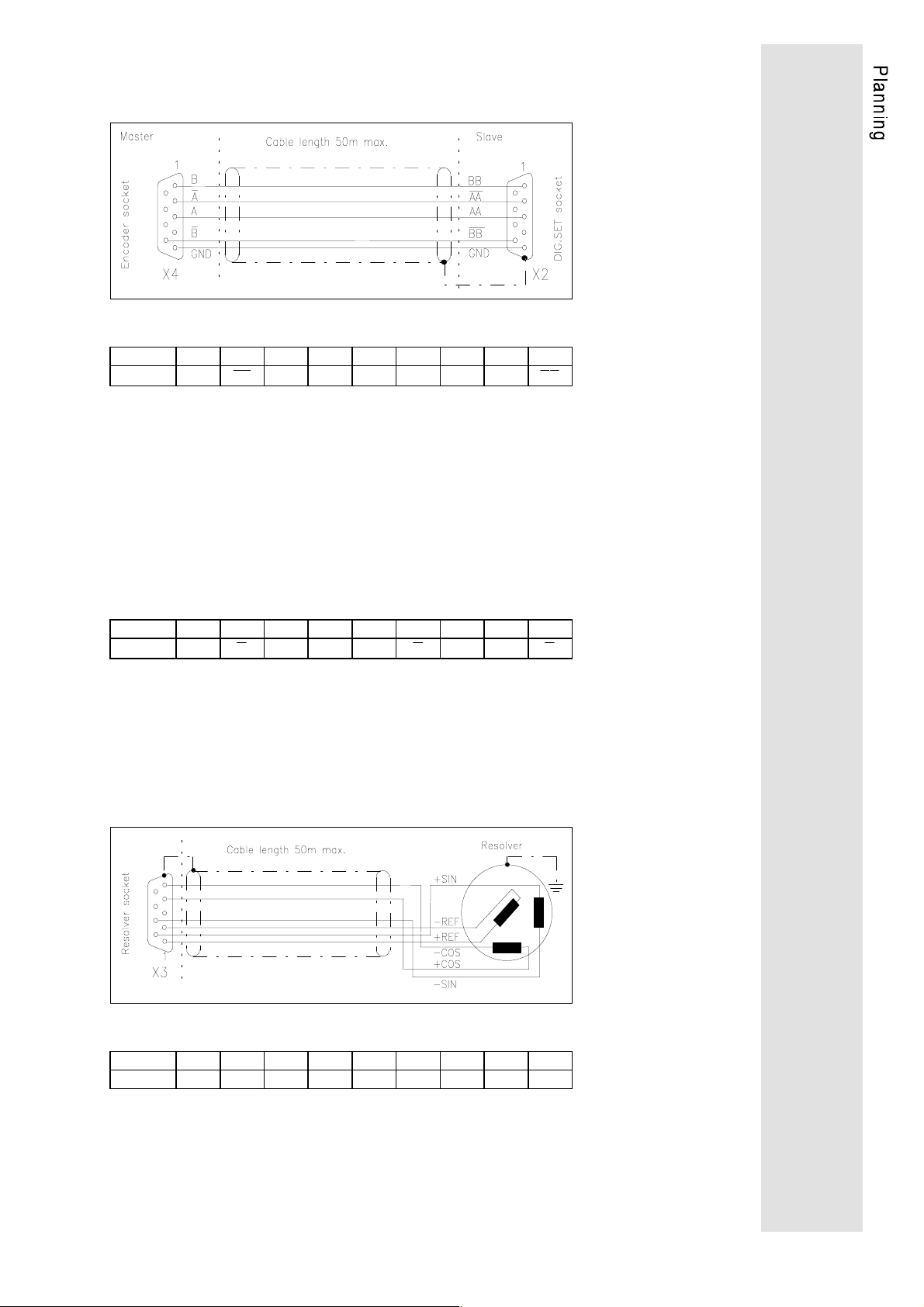

6.5.2. System cables for master frequency selection X2 and

incremental encoder output X4

green

black

black

red

black

yellow

black

white

P o s itio n in g c o n t ro lle r A x is m o d u le A x is m o du le m a st e r A x is mod ule s la v e

Design with plugs at both ends with single plug

Order no.

Fehler! Es

ist nicht

möglich,

Note:

The bridge beween pin 4 and pin 8 is necessary for the

operation with the SX1 positioning control.

EW00340900 EW00340906

durch die

35

Page 38

6.5.3. System cables for resolver X3

Various lengths

+REF white

- REF black

- SIN black

+SIN yellow

-COS black

+COS red

Order numbers of resolver cables

Length plugs at both ends plug at motor side plug at unit side

2.5 m

5 m

10 m

15 m

20 m

25 m

30 m

35 m

40 m

45 m

50 m

- - EW00340907

EWREB_______05 EW00345891 EWREB_______10 EW00340909 EWREB_______15 EW00345892 EWREB_______20 EW00345893 EWREB_______25 EW00345894 EWREB_______30 EW00345895 EWREB_______35 EW00345896 EWREB_______40 EW00345897 EWREB_______45 EW00345898 EWREB_______50 EW00345899 -

36

Page 39

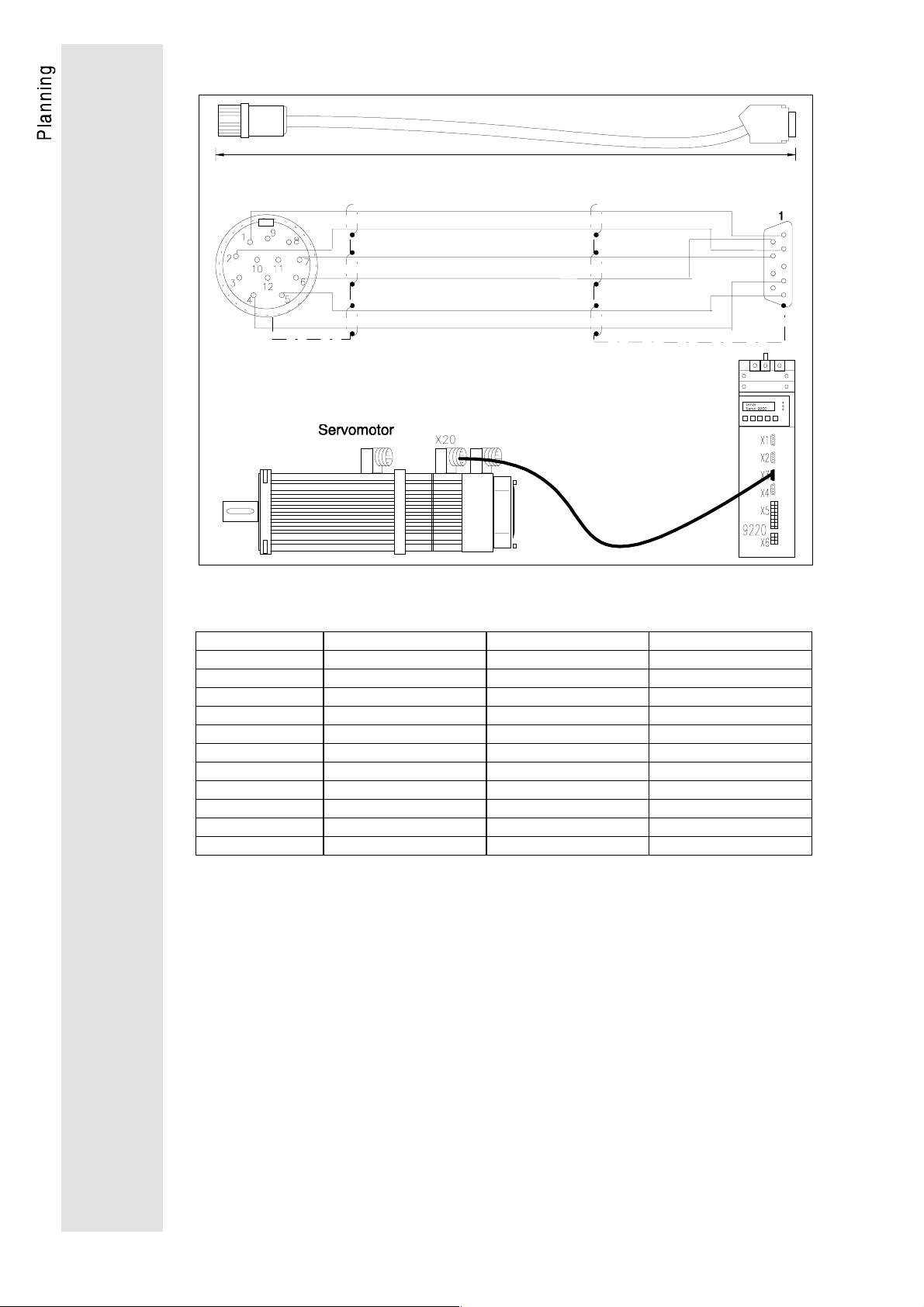

6.5.4. System cables for power supply of servo motors

Various lengths

white

brown

1

5

6

4

2

black 1

black 2

black 3

blank

12 456 PE

X11

U

V

W

0.5 mm

1.5 mm

or

2.5 mm

UVW

M

3

2

2

2

Order numbers of motor cables

Length 4 x 1.5 mm

2 x 0.5 mm

5 m

10 m

15 m

20 m

25 m

30 m

35 m

40 m

45 m

50 m

EWMOL056_01505 EWMOL056_02505 EWMOL100_04005 EWMOL112_10005

EWMOL056_01510 EWMOL056_02510 EWMOL100_04010 EWMOL112_10010

EWMOL056_01515 EWMOL056_02515 EWMOL100_04015 EWMOL112_10015

EWMOL056_01520 EWMOL056_02520 EWMOL100_04020 EWMOL112_10020

EWMOL056_01525 EWMOL056_02525 EWMOL100_04025 EWMOL112_10025

EWMOL056_01530 EWMOL056_02530 EWMOL100_04030 EWMOL112_10030

EWMOL056_01535 EWMOL056_02535 EWMOL100_04035 EWMOL112_10035

EWMOL056_01540 EWMOL056_02540 EWMOL100_04040 EWMOL112_10040

EWMOL056_01545 EWMOL056_02545 EWMOL100_04045 EWMOL112_10045

EWMOL056_01550 EWMOL056_02550 EWMOL100_04050 EWMOL112_10050

2

2

4 x 2.5 mm

2 x 0.5 mm

Cable cross section

2

2

4 x 4.0 mm

2 x 0.5 mm

2

2

4 x 10 mm

2 x 0.5 mm

2

2

37

Page 40

6.5.5. System calbes for supply fo fan and brake

Various length

black 1

black 2

brown

blue

green-yellow

X30X30

Servo motor

Dotted line: m otor with brake but without fan: DSV A BS X X

L1 fan

N fan

Y1 + brake

Y2 - brake

PE

Y1+ Y2- L1 N PE

Order numbers of fan and brake supply cables

Cable cross section

Length 5 x 0.5 mm

5 m

10 m

15 m

20 m

25 m

30 m

35 m

40 m

45 m

50 m

EWBLL_______05

EWBLL_______10

EWBLL_______15

EWBLL_______20

EWBLL_______25

EWBLL_______30

EWBLL_______35

EWBLL_______40

EWBLL_______45

EWBLL_______50

2

0.5 mm

2

38

Page 41

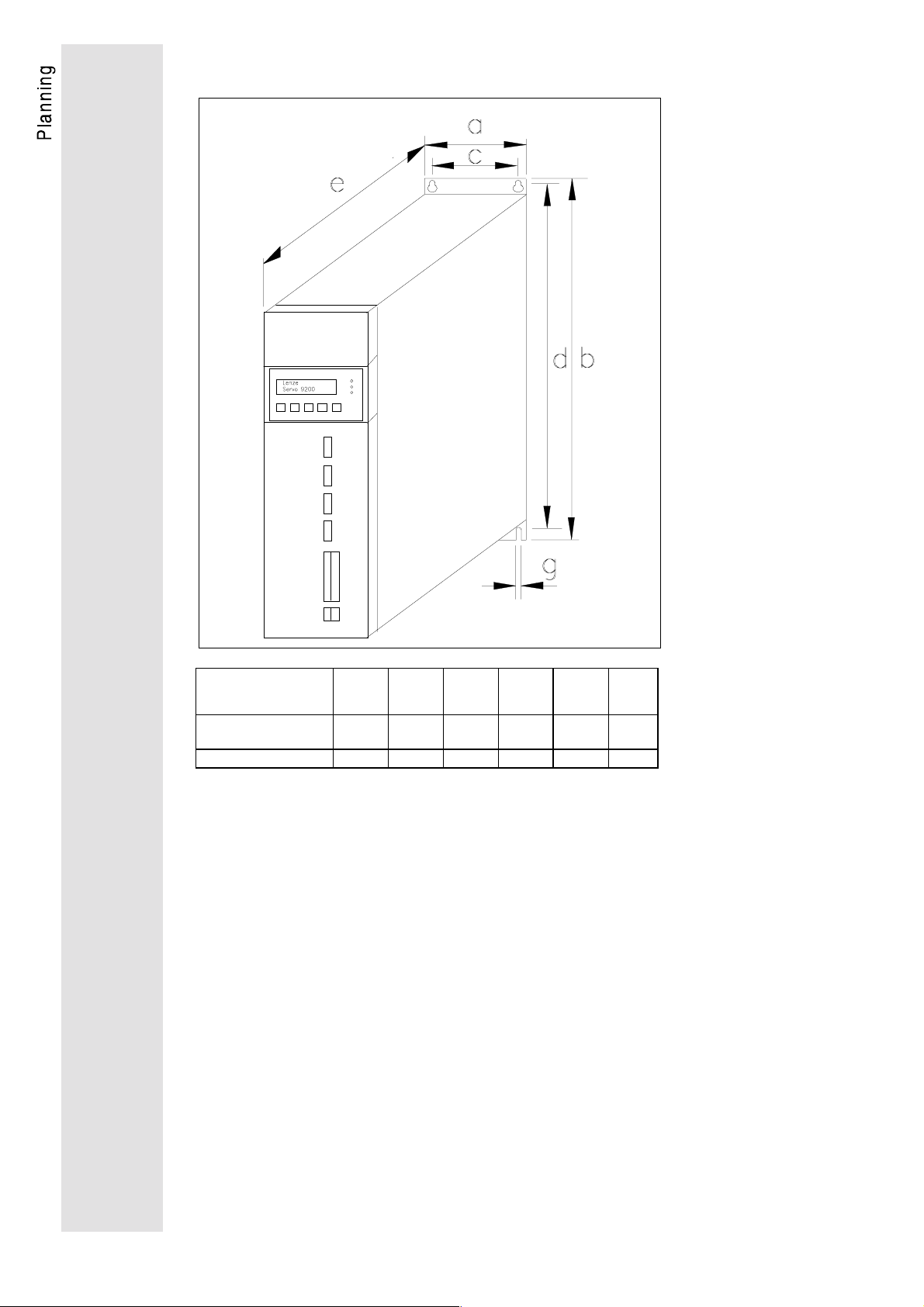

6.6. Motors

Asynchronous servo motors DSV/DFV series

Motor type Technical data of motors Standstill

brake

Vn = 205 V

DSVARS 56

DSVABS 56

DSVARS 71

DSVABS 71

DFVARS 71

DFVABS 71

DSVARS 80

DSVABS 80

DFVARS 80

DFVABS 80

DSVARS 90

DSVABS 90

DFVARS 90

DFVABS 90

DSVARS 100

DSVABS 100

DFVARS 100

DFVABS 100

DSVARS 112

DSVABS 112

DFVARS 112

DFVABS 112

n

M

2.0

2.0

4.0

4.0

6.3

6.3

5.4

5.4

10.8

10.8

9.5

9.5

19.0

19.0

12.0

12.0

36.0

36.0

17.0

17.0

55.0

55.0

n

PnV

0.8

0.8

1.7

1.7

2.2

2.2

2.3

2.3

3.9

3.9

4.1

4.1

6.9

6.9

5.2

5.2

13.2

13.2

7.4

7.4

20.3

20.3

n3~In

390

390

390

390

390

390

390

390

390

390

350

350

390

390

330

330

390

390

320

320

390

390

n

1

-

[min

] [Nm] [kW] [V] [A] [Hz] [kgcm2] [kg] [Nm] [A] [A]

3950

3950

4050

4050

3410

3410

4100

4100

3455

3455

4110

4110

3480

3480

4150

4150

3510

3510

4160

4160

3520

3520

2.4

2.4

4.4

4.4

6.0

6.0

5.8

5.8

9.1

9.1

10.2

10.2

15.8

15.8

14.0

14.0

28.7

28.7

19.8

19.8

42.5

42.5

fncos

140

140

140

140

120

120

140

140

120

120

140

140

120

120

140

140

120

120

140

140

120

120

0.70

0.70

0.76

0.76

0.75

0.75

0.75

0.75

0.80

0.80

0.80

0.80

0.80

0.80

0.78

0.78

0.80

0.80

0.80

0.80

0.80

0.80

ϕ

JmMnI

2.6

3.0

5.8

6.8

5.8

6.8

19.2

23.0

19.2

23.0

36.0

40.0

36.0

40.0

72.0

81.5

72.0

81.5

180.0

212.0

180.0

212.0

6.4

6.9--2.5--0.06----

10.4

11.2

12.0

12.9

15.1

16.9

16.9

18.7

22.9

25.0

25.5

27.1

44.7

47.4

48.2

50.9

60.0

66.5

63.5

70.0

--

11.0

--

11.0

--

12.0

--

12.0

--

22.0

--

22.0

--

40.0

--

40.0

--

80.0

--

80.0

=

0.08

0.08

0.09

0.09

0.09

0.09

0.11

0.11

0.18

0.18

Fan

230V

∼

50/60Hz

I

n

n

--

--

--

--

0.12

0.12

--

--

--

--

0.12

0.12

--

--

--

--

0.25

0.25

--

--

--

--

0.25

0.25

--

--

--

--

0.24

0.24

For further information about servo motors please see the

operating Instuctions "Three-phase servo motors".

39

Page 42

Parameter setting

1. LCD display

Ready (green)

Curr. limit I

max

Impulse inhibit

(ye llow )

(red)

SH

STPPRG

Keys

1.1. Key functions

Key Function

PRG Change between code and parameter level

▲

▲

+ SH

▼

▼

+ SH

SH + PRG Execute change. Reset after fault i ndi cation

STP Inhibit controller (see note below)

SH + STP Enable controller

Note

•

For the execution command SH+PRG and the enable command SH+STP first

press the SH key and hold, than press the PRG or STP key.

•

When inhibiting the controller by pressing the STP key, it must be enabled

again by using the SH+STP command. Only then can it be

enabled via terminal 28 or interface.

Increase displayed value

Rapid increase of displayed v al ue

Reduce displayed value

Rapid reduction of displayed v al ue

Fehler! Es

ist nicht

möglich,

durch die

40

1.2. Plain-text display

The LCD display constists of two lines of 16 characters each. In the

upper line, code no. and parameter are displayed. The arrow >

shows the present level (code or parameter level), which can be

changed when pressing the ▲ or ▼ key. In the lower line, the

codes or parameters are explained.

-Arrow for code level-

Code no.- -Parameter-

↓ -

>C001 - 0Operat i ng mode

-Explanatory text-

Page 43

2. Basics of parameter setting

The drive can be adapted to your specific applications by

parameter setting of the axis modules. The possible settings are

arranged in the form of codes, which are numbered in ascending

order and start with the letter "C". Each code provides several

parameters which can be selected according to the application.

Parameters can be direct values of a physical unit (e.g. 50Hz or

50% related to f

information (e.g. -0- = controller inhibited, -1- = controller enabled).

In cases where the parameters represent values of physical units, it

is possible to vary the increment.

Example: The acceleration and deceleration can be set in

increments of 0.01 s up to 1 s and in increments of 0.1 s from 1 s

upwards.

For codes with more than 5 digit values, the keypad operation is

different: In the parameter level, the cursor can be shifted to enter

large values. This is done by pressing SH+ ▲ and SH+▼ (see

example on page 44).

In some codes, parameters can only be read but not changed.

In the factory setting, only those codes are displayed which are

necessary for the most common applications. For activation of the

extended code set see code table C 000.

) or numerical codes giving certain status

dmax

2.1. Change parameters

Each code has a factory set parameter which can be changed.

There are three different ways of selecting and confirming a new

parameter, depending on the code:

Direct acceptance

The servo axis immediately accepts the new parameter, i.e. while

you change it using the ▲ or ▼-key. This is possible even when the

drive is running. Parameters which are immediately accepted are

marked with

Acceptance with SH + PRG

The axis accepts a new parameter when SH + PRG are pressed.

This is possible even with the drive running. First press SH and

then in addition PRG. The display shows --ok-- for 0.5 seconds.

The axis module now works with the new parameter. The key

combination SH and PRG can be compared to the "return" key on

your computer keyboard. If you have to set a parameter of a code

in this way, the code table shows the symbol

ON-LINE

in the code table.

SH + PRG

.

41

Page 44

Acceptance with SH + PRG with controller inhibit

The axis module accepts the new parameter when it has been

inhibited prior to pressing SH + PRG. Inhibit the controller e.g. by

pressing STP. First press SH and then in addition PRG. The

display shows --ok-- for 0.5 seconds. The axis module works with

the new parameter when the controller is released again. If you

have to set a parameter of a code in this way, the symbol

appears in the code table.

2.2. Save parameters

•

When commissioning for the first time, the parameter set 1 is

factory-set. After the acceptance, new parameters are saved in

the RAM, i.e. they are saved until the controller is disconnected

from the mains.

If you do not want to lose your setting when connecting the

controller to the mains, save them permanently:

1. Select code C003.

2. Select parameter set 1 by entering -1- .

3. Press SH first, and then additionally PRG. --ok-- will be

displayed.

4. Now you can disconnect the servo controller from the mains.

Your settings are permanently saved under "parameter set

1".

•

Password

The input of a password prevents unauthorized changes of

parameters or code levels.

2.3. Load parameter

If you only need one parameter set, you can permanently save

your changes under parameter set 1. After every mains connection,

parameter set 1 is loaded automatically.

42

Page 45

2.4. Examples

Change of the operating mode

1. enter Code C001 using ▲ or ▼ keys

-Arrow for code level ↓ -Code no.- -parameter-

>C001 - 0Operat i ng mode

-Explanatory text-

2. change from code level to parameter level using the PRG key

-Arrow for parameter level-

↓

C001> - 0-

Termi nal / keypad

-explanatory text for the selected parameter-

3. set parameter to -1- using the ▲ key

C001> - 1-

keypad

4. acknowledge with the keys SH + PRG and return to code level

C001> - 1-

Operat i ng mode

43

Page 46

Change of the ratio denominator.

For codes with more than 5 digit values, the keypad operation is

different: In the parameter level, the cursor can be shifted to enter

large values. This is done by pressing SH+▲ and SH+▼.

1. enter code C033 using ▼ or ▲ keys

-Arrow for code level ↓ -Code no.- -value- -exponent-

>C033 1. 000E- 01

Rat i o denomi nat .

-Explanatory text-

2. change from code level to parameter level using the PRG key

-Arrow for parameter level-

↓

C033>

0. 1000

-10-digit value-

3. position the cursor using the keys ▲ + SH

↑

-Cursor-

C033>

0. 1000

4. enter value using the key▼ or

▲

C033>

0. 3000

5. acknowledge with SH + PRG and return to the code level

>C033 3. 000E- 01

Rat i o denomi nat .

44

Page 47

3. Commissioning

The following notes on the commissioning do not explain all

possibilities of parameter settings. The code table at the end of the

chapter lists and describes all codes in detail.

Caution!

Before commissioning, check the wiring of the controller.

Typical faults are:

•

incorrect screening of the cables

•

earth or ground current loops

and if Lenze system cables are not used:

•

incorrect connection of the motor phases

•

incorrect connection of the resolver terminals

The axis modules are factory-set for terminal control and parameter

setting via keypad for speed control with asynchronous motor,

resolver feedback and analog set value provision at terminal 8

(C005 = 11). For this standard application, the basic parameters

are already programmed. Start entering the motor nameplate data

(see page 47) for commissioning.

For all other applications, the basic parameters must be selected.

3.1. Basic parameter setting

Before setting the parameters of the axis module, the controller

must be inhibited, i.e. terminal 28 open, RFR ENABLE switch open,

or STP key pressed.

•

C000 code set

All codes in the inverter are arranged in different code sets. With

factory setting, the standard code set is activated. It contains all

codes which are required for the most common applications.

By selecting the extended code set under code C000, the

keypad also shows those codes which are suitable for special

applications. There is also a service code set which is not

accessible in general.

If you want to protect your parameter settings from nonauthorized access you can enter a password in the form of a

three-digit number. By defining a password, the parameters of

the standard code set can only be read, but not changed when

the password is not entered. The parameters of the extended

code set can neither be read nor changed.

First enter the password under C094 and then set code C000 to

"standard code set read only". After this, the setting of code

C000 can only be changed when the programmed password is

entered.

45

Page 48

•

C001 Operating mode

Selection between keypad control or control via LECOM-A/B

interface or parameter setting via LECOM interface. For control

or parameter setting via LECOM interface, the drive must, in

addition, be given an address in code C009 (code set -2-).

To change the operating mode, open RFR switch (X5 terminal

28 open). The functions RFR ENABLE, QSP, Trip set and Trip

reset are not affected and can be controlled via terminals.

After selecting the control via Lecom (C001 = 3, 5, 6, 7) the

controller must be enabled via the selected interface. If

Lecom1 control (C001 = 3) has been selected, although the

interface is not connected, the controller can be enabled again

by selecting C001 = 1, and then C040 = 1. If LECOM 2 control

has been selected (C001 = 5, 6, 7) if the interface is not

connected, the controller remains inhibited even after changing

C001. To enable the controller again, select under C001 a

parameter other than 5, 6, 7 save the parameter and

disconnect the controller from the mains. After reconnection,

the controller can be enabled again.

•

C005 Configuration

Other control modes (e.g. torque control) or alternative methods

of producing the reference signal are available. The

configuration can only be changed whilst in code set -2-.

Caution!

When changing the configuration, control structure, motor and encoder and

terminal assignment are changed.

•

C025 Encoder

The set value and the actual value encoder can be selected

under C025 (PPR). Encoder constants are set under C026.

The master/slave ratio is set under C027.

•

Master frequency Dig.Set

The master frequency provision is set under C025 -3- via input

Dig.Set (X2); then the increments per revolution are set in code

C026. It is also possible to set the speed ratio between the

master and slave, this adjustment is made under code C027.

Under

Under

Another possibility to set the angular synchronization is given by

the gearbox factor. The gearbox factor is given as a fraction.

The numerator of the fraction in entered under

denominator of the fraction is entered under

C028,

a second ratio can be entered.

C140

, the required speed ratio is activated.

C032

C033.

, and the

46

Page 49

Beispiel:

given: f

required: encoder constant C026

100 kHz = 100.000 increments/s

3000 rpm = 50rps

C 026 =

Selectable are 512, 1024, 2048, 4096 inc rem ents/revolution

C026 = 2048

C027 = 2048/2000 = 1,024

C027 = 1,024

DIG.SET

100.000 increments / s

is chosen

is to adjust.

= 100 kHz

max

n

= 3000 rpm

max

encoder setting C027

50 / s

= 2000 increments/revolution

3.2. Input of motor nameplate data

To calculate the excitation and torque generating components of

the current vector, it is necessary to enter the motor nameplate

data correctly.

This is only possible if the controller is inhibited, i.e. RFR ENABLE

open, or the STP key pressed.

•

C081 Rated motor power

This parameter is only required for automation module

applications to calculate the absolute reference for the torque.

The rated motor power of the Lenze servo motor, which is best

adapted to the axis module, is factory-set.

•

C087 Rated motor speed

•

C088 Rated motor current

For M << M

CI

088

=⋅

rated

•

C089 Rated motor frequency

•

C091 cos ϕ motor

M

required

M

rated

ratedrequired

47

Page 50

3.3. Setting of operating parameters

T

The operating parameters must be adjusted according to the

specific application requirements. Operating parameters can be

modified ON-LINE during operation. However, a preadjustment of

the operating parameters before start-up of the motor is

recommended.

•

C022 Maximum current I

Factory set to the maximum controller current. An adjustment

of the maximum current limitation is only necessary if the maximum current must be smaller than the controller peak current.

•

C011 Maximum speed n

In the case of analog set value provision, the maximum motor

speed determines the motor speed at maximum set value. In

the case of digital set value provision, n

speed. If n

set

> n

max

directions, CW and CCW).

•

C012 Acceleration time T

The acceleration and deceleration times refer to a speed

change from 0 to n

max

adjusted as follows:

max

max

limits the motor

max

the speed is limited to n

, C013 deceleration time T

ir

(valid for both

max.

. The timesTir and Tif to be set can be

if

ir

⋅⋅

t n

ir max

=

n - n

22

1

T =

if

t n

if max

n - n

1

When moving large inertias with short deceleration times, it is

possible that the brake energy would not be dissipated by the

internal brake resistor. The axis module trips and the fault OUE

"overvoltage" or OH1 "overtemperature supply module" is

displayed. In this case it is necessary to increase the

deceleration time or to connect an external brake resistor.

•

C105 Quick stop deceleration time TQSP

The quick stop deceleration time is activated by the function

QSP quick stop.

•

C039 JOG speed

An internally stored speed set value can be activated via X5

terminal 24 or via C045. The JOG speed is set under C039.

48

Page 51

Speed controller setting

Set a low speed set value. Enable the controller release (close

RFR switch or apply a voltage of 13...30 V to X5 terminal 28). The

speed controller can now be set. In case of uncontrolled motor

running (oscillation etc.), the drive can be immediately stopped by

pressing the STP key. After reducing the gain adjustment V

pn

C070, release the controller again using SH+STP.

•

C070 Gain adjustment Vpn

I

ncrease V

LED I

max

drive operates smoothly. Read the V

until the drive becomes unstable (motor noise and

pn

illuminated), then reduce Vpn amplification until the

value and adjust to one

pn

third of the value.

Increase the speed set value. If the motor speed does not follow

the higher speed set value, but stays at 50...300 rpm, the drive

must be disconnected from the mains and after a period of 5

min, the motor connections U and V must be interchanged.

Switch on the mains and readjust the gain.

•

C071 Integral action time of the speed controller

Factory setting optimized to the torque loop. It may be

necessary to adjust higher values if the field weakening range

is completely used or if non-adapted motors are employed. For

higher time constants in the speed control loop (e.g. for chain

drives), it may also be necessary to readjust the integral action

time. To change the integral action time, select the extended

code set -2- under code C000. Increase T

stable. Read T

•

C072 Amplification of the difference component of the

and adjust to approx. double the value.

n

until the drive is

n

speed controller.

This adjustment is only necessary if the time has been set to a

larger time constant. The difference component of the the speed

controller is used for compensation of the time behaviour of the

torque control circuit. The adjustment of the difference

component is only possible in the extended code set -2-.

Change K

until achieving optimum control behaviour.

d

49

Page 52

4. Additional functions

4.1. Mains failure detection with DC-bus control

Purpose:

In the event of mains failure, this function prevents an uncontrolled

coasting of the drives as long as possible for the system.

Within this period of time the drives, a speed-controlled,

synchronous brake is possible.

Advantages:

•

Material cracks can be avoided.

•

External UPSs may not be necessary

4.1.1. Requirements

•

The axis module 922x and the supply module 921x must be

wired according to the charts on page 52.

Pin assignment of the plug X3 at the supply module

X3 Function Condition Level

1GND

2VG*

3

NA&U

424V

5

NA

6GND

Reference potential for analog

signals U

Monitor signal of the DC-bus

voltage V

*

Combined signal from X3,2 and

G

X3,5.

External supply for t he

ext

potential-free output X3,5

Potential-free output signal for

mains failure.

Reference point for terminal

ext

X3,4 and X3,5.

* and

G

.

Z

NA&U

*

G

≤ 900 V 0.01 ⋅ V

0 V ≤ V

Z

X3,5 = HIGH and V

X3,5 = LOW or V

> 320 V ± 3.5 % and

V

mains

V

> 440 V ± 3 %

Z

≤

V

320 V ± 3,5 % or

mains

≤

440 V ± 3 %

V

Z

> 440 V ± 3 %

Z

≤ 440 V ± 3 %

Z

Z

10 V

0.01 ⋅ V

Z

+ 24 V (13 ... 30 V)

HIGH (13 ... 30 V)

LOW (0 V)

0 V of the external

supply

•

Configuration C005

Setting

C005

-11-, -21- Terminals X5,1 and X5,2

-12-, -13-, -30- Terminals X5,7 and X5,8

-20-, -33- Mains failu re det ection with DC-bus control im possible

Input of the combined signals

NA&UG* at the axis module

Note:

For drive control via LECOM interface, terminals X5,7 and X5,8 are automatically

the control terminals evaluating the combined signal, no matter which configuarion

had been selected under C005.

50

Page 53

•

Parameter setting of the mains failure detection:

The following codes affect the drive properties in case of mains

failure:

C079

Proportional gain of the DC-bus vol t age controller (V

signal flow chart p.55)

C080

Integral-action component of the Vz-controller

C228

Acceleration integrator for the set value of the DC-bus voltage

C229

Activation of mains failure detection

C229 = -1- : Mains failure detect i on activated

C236

C237

(Vz-controller).

V

setl

Ater the detection of a mai ns fialure and the activati on of the DC-bus

control, the value of C237 is the set value of the Vz-controller

This code indirectly det erm i nes the possible speed decrease during a

controller cycle.

•

In drive configuration with several controllers and DC-bus

-controller) (see

z

connection (one master drive and one or several slave

drives), the mains failure detection with DC-bus control may

only be activated for the master drive.

51

Page 54

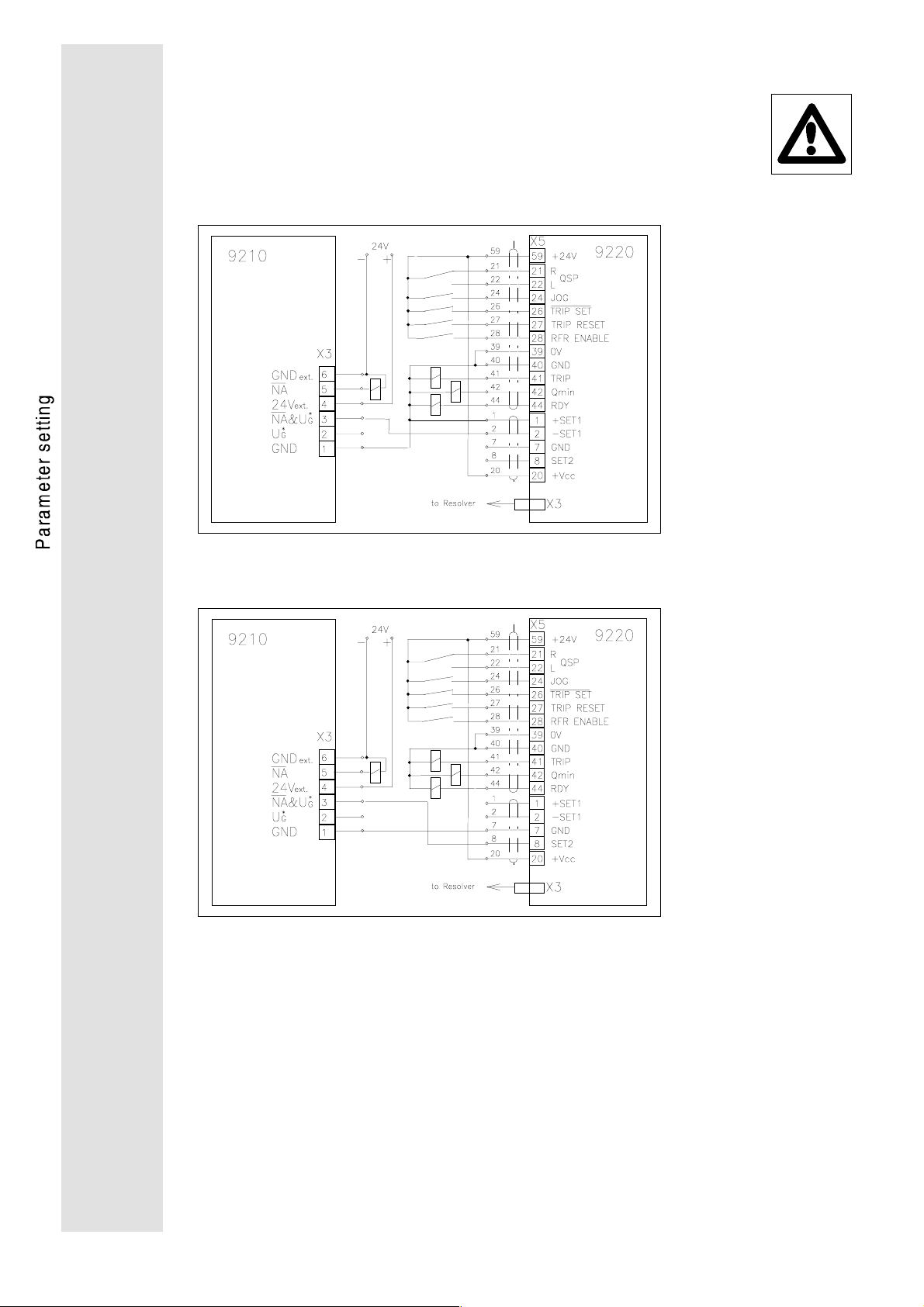

4.1.1. Wiring

Note

•

For radio interference suppression, all relays have to be equipped with freewheeling diodes!

•

all relays: R

a) Wiring for C005 = 11 und 21

< 1K

i

Ω

b) Wiring for C005 = 12, 13, 30 and for interface control

52

Page 55

4.1.2. Setting

These setting instructions are meant as guideline and must not

always decelerate the machine to standstill before reaching the

undervoltage threshold. The parameter setting of the codes, which

influences the DC-bus control during mains failure detection (C079,

C080, C228, C236, C237), depend on the size of the drive

configurations and the mechanical features of the system.

There are minimum speeds at which the energy of the mechanical

system is not high enough to compensate the losses which occur

during the controlled deceleration (switched-mode power supplies,

inverter, machines).

Aim:

•

The aim is to have a controlled speed deceleration that allows a

DC-bus voltage value which remains higher than the

undervoltage threshold for as long as possible.

As soon as the value falls below this threshold, pulse inhibit will

be set and the drive will coast to standstill.

•

The brake chopper should not be activated during the controlled

deceleration of the speed.

Therefore, the parameter setting of the DC-bus control should

be "softly". It is not very important whether the DC-bus can be

loaded to the voltage set under C236.

Required measuring units:

•

Oscilloscope,

at least 2 channels, if possible with memory.

Test set-up:

•

Connect channel 1 of the oscilloscope with X5,62 of the axis

module (speed monitor).

•

Connect channel 2 of the oscilloscope with X3,2 of the supply

module (DC-bus monitor).

•

If available, connect channel 3 of the oscilloscope with X5,44 of

the axis module (RDY-output).

Presettings:

1. Set the speed controller of the axis module drive configuration

as usual.

2. Activate the mains failure detection of the master drive (C229 =

-1-).

If the function is activated, the RDY-output changes from the

HIGH level to the LOW level. As soon as the speed is

decelerated to 0, the RDY-output re-changes to HIGH.

3. The relevant codes must be set as follows:

Code Presetting

C079

C080

C228

C229

C236

C237

-1150 s

1/10...1/20 of the natural slow-down time of the machine at

maximum operating speed

-1680 V

1000 rpm or more

53

Page 56

Setting course:

1. Select a medium speed as set value according to the occuring

speed range of the system.

2. Switch-off the mains.

The oscillogramme shows the reaching of the undervoltage

threshold on channel 2, the DC-bus voltage decreases slowly

(see fig. 1)

t1 = Start of the DC-bus control

= Undervoltage t hreshold

c

U

V

Br

C236

*

G

c

Vmin

t

1

fig. 1: Start of the setting

DC-bus voltage during DC-bus control

3. Increase C079 to reach the undervoltage threshold at a speed

as low as possible. For very small final speed values, you may

reduce C228.

4. Repeat steps 1.) to 3.) at maximum and minimum system

speed.

5. Reduce C080 at maximum system speed until the DC-bus

voltage does no longer overshoot the brake-chopper threshold

(see fig. 2).

You may also reduce C237 to limit the speed decrease during

deceleration.

reached

U

V

Br

C236

*

G

t1 = Start of DC-bus control

= Undervoltage t hreshold

c

c

Vmin

t

1

fig. 2: Real sett i ng

DC-bus voltage during DC-bus control

6. The increase of the Vz acceleration integrator C228 prolongs the

deceleration period.

7. Save the setting under C003.

reached

54

Page 57

Signal fow chart DC-bus control

55

Page 58

4.2. Homing mode

•

C250 Homing mode

In the homing mode (C250 = -0-) the increments of the master

frequency at the DIG.SET input are processed as a relative

change of angle. By activating the homing mode (C250 = -1-) it

is possible to refer to an absolute angle position of the motor

shaft. The homing mode can only be activated if the controller is

inhibitied. It is initiated by means of JOG function.

Functional sequence:

Start the homing mode by means of the JOG function enable.

The RDY signal indicates "not ready". The drive runs at the

selected JOG speed. After blocking the JOG signal (e.g. by

means of a proximity switch), the drive continues to run to the

home position and stops. The RDY signal indicates "ready".

If controller inhibit or QSP are activated during homing, the RDY

signal remains "not ready" until the homing process is finished.

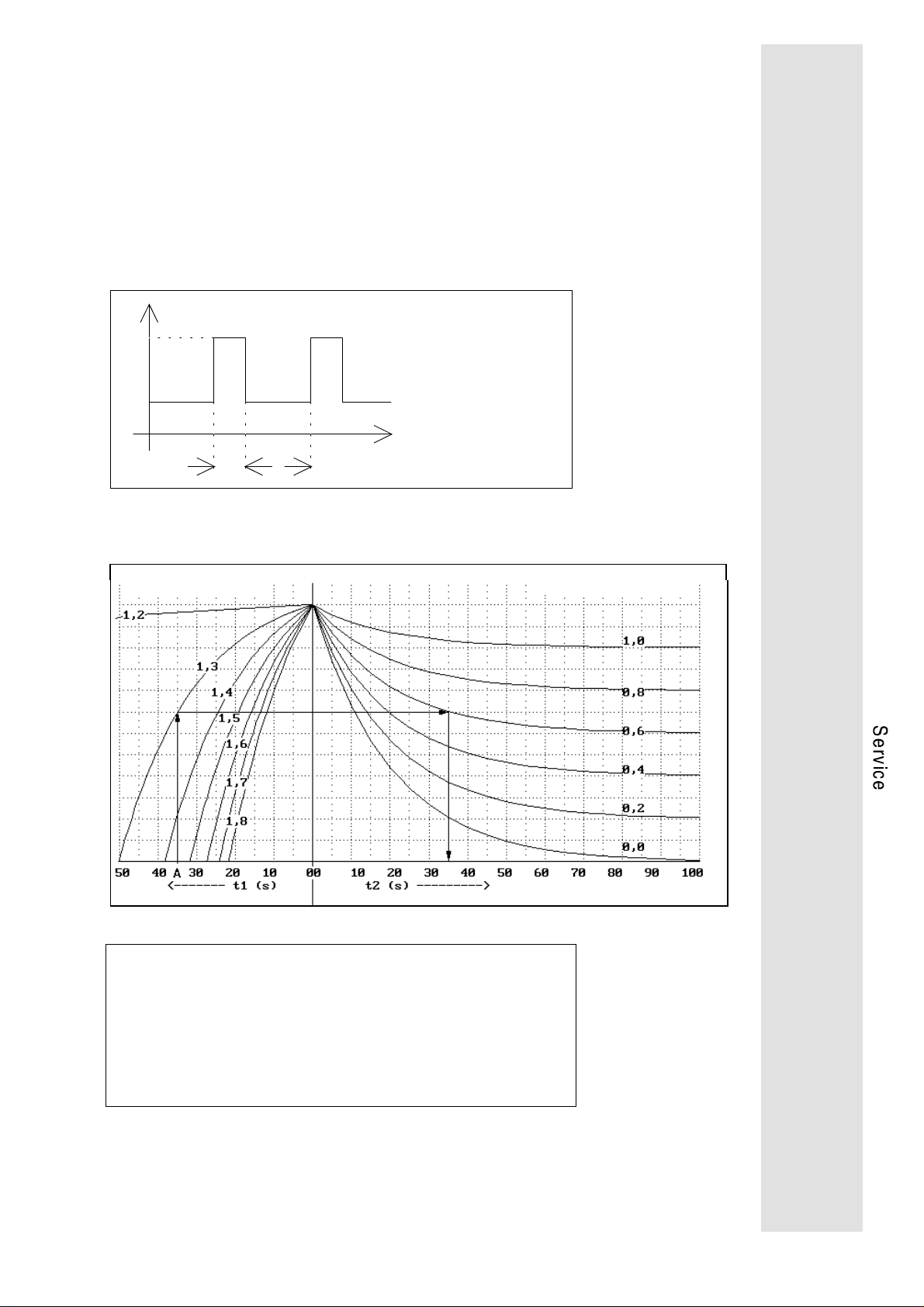

Input signal JOG

Motor speed

Motor shaft

position

Output signal RDY

•

C252 Angle offset

JOG speed

0

o

360

Home position

any position

o

0

The shift range of the home position is one revolution of the

motor shaft. 360° is resolved into 2048 steps. The adjustment

can be made ON-LINE when the motor is running. The zero

pulse of the encoder emulation X4 is also resolved in 256 steps.

•

C254 Amplification of the angle controller

The angular controller is active when using a master frequency

DIG.SET input or if the homing mode is active. By selecting

Vpw=0, the angular controller is deactivated. In this case, the

master frequeny is processed as speed set value and not as set

angle increments. Before adjusting the amplification of the

angular controller, the speed controller must be optimized.

•

C159 Homing OK

C159 displays whether the homing was successful or not:

C159 = -1- homing successfully completed

C159 = -0- homing not completed

C159 may also be used for simulating a homing mode:

Set C159 = -1- and manually activate the angle offset under

C252.

t

56

Page 59

4.3. Further additional functions

•

C004 Switch-on display

Entering a code number under C004 determines which

parameter is to be displayed after switching-on.

•

C018 Chopper frequency

The chopper frequency determines the noise level. The chopper

frequency can either be 8 or 16 kHz. Changing the chopper

frequency changes the admissible permanent load of the axis

module.

•

C255 Following error limit

If an following error exceeds the value entered under C255

during master frequency operation (C005 = -13- or -21-) and an

amplification of the angle controller of C254 > 0, an internal

signal will be generated for the error status >>Following error

limit exceeded<< . If this signal is applied to the terminal Q

(X5,42) via C117, the Q

HIGH to LOW as soon as the set limit value is exceeded.

For following errors of more than 3188 increments, also the

RDY message will be set to LOW and >>following error<< will

be displayed.

(see page 74)