Page 1

Operating Manual

Leica CM1950, V 1.1 English – 05/2007

Always keep this manual near the instrument.

Read carefully prior to working with the instrument!

Leica CM1950

Cryostat

Page 2

Page 3

1. NOTE

The information, numerical data, notes and value

judgments contained in this manual represent the

current state of scientific knowledge and stateof-the-art technology as we understand it following thorough investigation in this field. We are

under no obligation to update the present manual periodically and on an ongoing basis according to the latest technical developments, nor to

provide our customers with additional copies,

updates etc. of this manual.

For erroneous statements, drawings, technical

illustrations etc. contained in this manual we exclude liability as far as permissible according to

the national legal system applicable in each individual case. In particular, no liability whatsoever

is accepted for any financial loss or consequential damage caused by or related to compliance

with statements or other information in this

manual.

Statements, drawings, illustrations and other

information as regards contents or technical

details of the present manual are not to be

considered as warranted characteristics of our

products.

These are determined only by the contract provisions agreed between ourselves and our

customers.

Leica reserves the right to change technical specifications as well as manufacturing processes

without prior notice. Only in this way is it possible

to continuously improve the technology and manufacturing techniques used in our products.

This document is protected under copyright laws.

All copyrights to this documentation are held by

Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods – including any electronic systems and media – requires

express prior permission in writing by

Leica Biosystems Nussloch GmbH.

For the instrument serial number and year of manufacture, please refer to the name plate at the

back of the instrument.

© Leica Biosystems Nussloch GmbH

Published by:

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 (62 24) 143-0

Fax: +49 (62 24) 143-200

eMail: histo_info@leica-microsystems.com

Internet: http://www.histo-solutions.com

Leica CM1950 – Cryostat

3

Page 4

Table of contents

1. Important Information ......................................................................................................................... 6

1.1 Symbols Used in This Manual and Their Meaning ................................................................ 6

1.2 Qualification of Personnel.......................................................................................................... 6

1.3 Designated Use............................................................................................................................ 6

1.4 Instrument Type ........................................................................................................................... 6

2. Safety and Design ................................................................................................................................ 7

2.1 General Safety Instructions ....................................................................................................... 7

2.2 Unpacking and Installation ........................................................................................................ 7

2.3 Safety Features .......................................................................................................................... 10

2.4 Securing/Locking the Handwheel .......................................................................................... 11

2.5 Cleaning, Disinfection – Turning the Instrument Back On.................................................. 12

2.6 Handling Specimens – Defrosting .......................................................................................... 13

2.7 Removal of the Microtome....................................................................................................... 13

2.8 Maintenance .............................................................................................................................. 13

3. Technical Data ................................................................................................................................... 14

4. Standard Delivery .............................................................................................................................. 16

5. General Overview .............................................................................................................................. 18

5.1 Control Panel Fields and Cryostat Chamber.......................................................................... 19

6. Installation ........................................................................................................................................... 20

6.1 Site Requirements ..................................................................................................................... 20

6.2 Transport to the Site ................................................................................................................. 21

6.3 Assembling the Handwheel, Centering the Handwheel (Optional) ................................... 22

6.3.1 Locking/Unlocking the Handwheel......................................................................................... 23

6.3.2 Installing the Footswitch Dummy (Instruments with Cutting Motor) ................................ 23

6.4 Connection to Power Supply System ..................................................................................... 24

6.5 Installing Accessories/Inserting Chamber Accessories .................................................... 25

6.5.1 Installing the Adjustable Footrest (Optional) ........................................................................ 25

6.5.2 Installing the Storage Systems (Optional) ............................................................................. 26

6.5.4 Inserting the Section Waste Tray ...........................................................................................26

6.5.3 Shelf, Movable (Optional)......................................................................................................... 26

6.5.5 Installing the Heat Conductor Block, Stationary (Optional) ............................................... 27

6.5.6 Installing the Knife/Blade Holder and Adjusting the Clearance Angle............................. 27

4

Operating Manual V 1.1 – 05/2007

Page 5

7. Instrument Controls ........................................................................................................................... 30

7.1 Control Panel Fields on the CM1950 – Control Panel Field 1 .............................................. 30

Control Panel Field 2 – Electric Coarse Feed, Sectioning

and Trimming Thickness Display ............................................................................................ 32

Control panel 3 – Motorized sectioning (optional) ............................................................... 34

8. Working with the Instrument ......................................................................................................... 36

8.1 Preparing Cutting Tools, Specimen Discs and Preparation Aids ...................................... 36

8.2 Turning the Instrument On ....................................................................................................... 36

8.3 Configuring the Parameters..................................................................................................... 37

8.4 Working with the Precooled Cryostat .................................................................................... 42

8.4.1 Preparatory Work ...................................................................................................................... 42

8.4.2 Trimming with Extraction – Anti-roll Guide Installed ........................................................... 43

8.4.3 Cutting with Extraction – Anti-roll Guide Installed ............................................................... 45

9. Troubleshooting ................................................................................................................................. 48

9.1 Problems During Work ............................................................................................................. 48

10. Temperature Selection Chart (in minus °C) .............................................................................. 52

11. Optional Accessories ....................................................................................................................... 53

11.1 Ordering Information ................................................................................................................. 53

12. Maintenance and Cleaning ............................................................................................................ 66

12.1 General Maintenance ............................................................................................................... 66

12.2 Changing Fuses .......................................................................................................................... 67

12.3 Replacement of the Lamp/UVC Lamp ..................................................................................... 68

13. Decontamination Certificate (master) ........................................................................................ 70

14. EC Declaration of Conformity ........................................................................................................ 72

15. Warranty and Service ...................................................................................................................... 73

16. Peoles Republic of China ................................................................................................................ 74

Leica CM1950 – Cryostat

5

Page 6

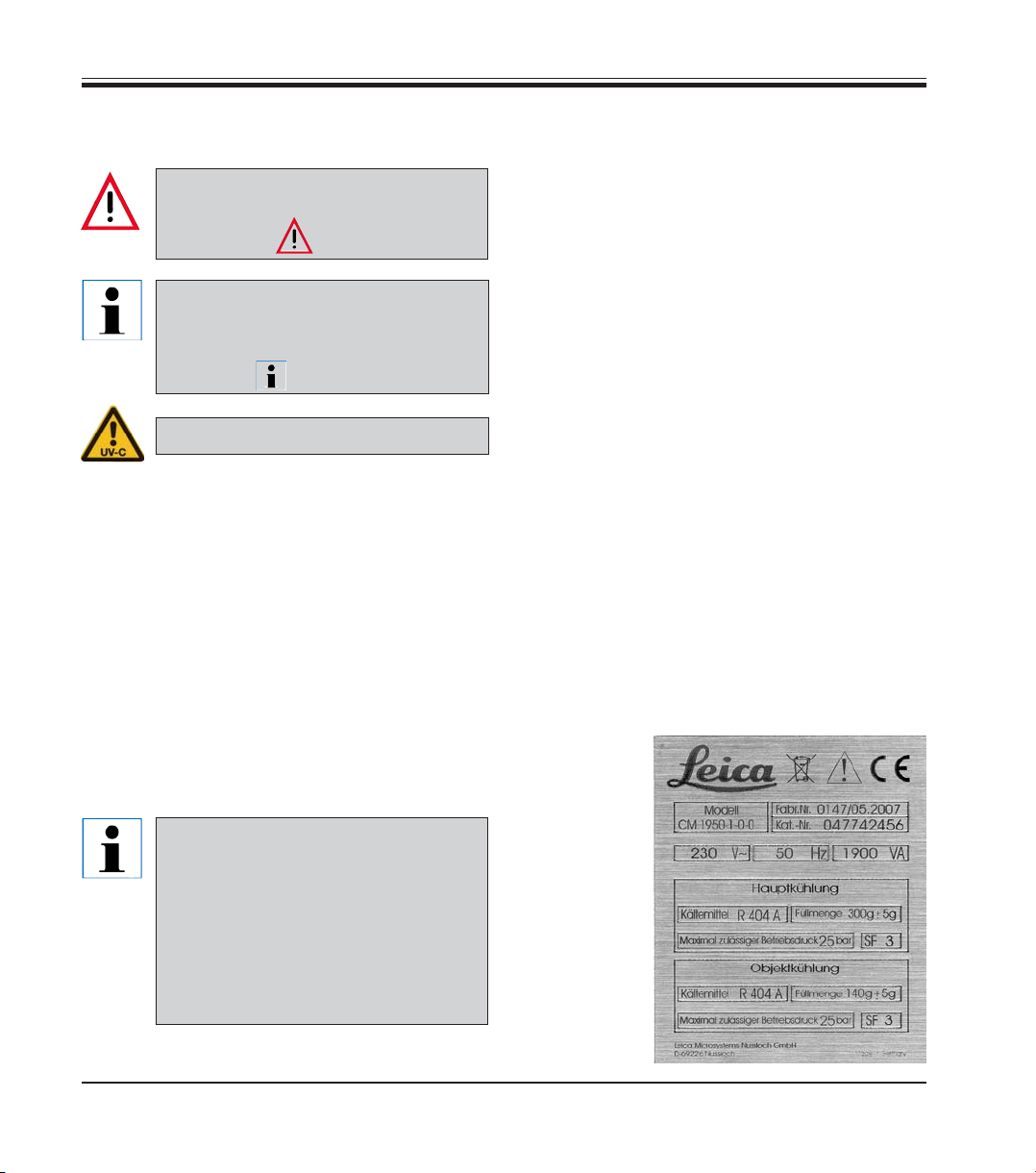

1. Important Information

1.1 Symbols Used in This Manual and

Their Meaning

Warnings

appear in a gray box and are marked

by a warning triangle.

Notes

i.e. important user information appear

in a gray box and are marked by an information symbol.

Caution – UVC radiation!

(5)

(Fig.5)

Figures in brackets refer to item numbers in drawings or to the drawings

themselves.

1.2 Qualification of Personnel

The Leica CM1950 may be operated by trained

laboratory personnel only.

All laboratory personnel designated to operate

the instrument must carefully read the present

instruction manual prior to starting work with the

instrument.

1.3 Designated Use

The CM1950 is a high-performance cryostat with

an encapsulated microtome and separate specimen cooling. It features a UV disinfection system,

an (optional) integrated extraction system for section waste and an (optional) motor for motorized

sectioning.

The cryostat is designed to produce frozen sections

for biological, medical and industrial applications.

The CM1950 is suitable for in-vitro diagnostic

(IVD) applications.

The instrument may only be operated within the

scope of its designated use as described above

and as per the instructions given in this manual.

Any other use of this instrument is considered

as improper operation.

1.4 Instrument Type

All information given in this instruction manual

applies only to the instrument type indicated on

the title page.

A name plate, indicating the instrument serial

number, is attached to the back of the instrument.

Despite chemical and/or UV-light disinfection, personal safety precautions

as per the applicable laboratory regulations must still be taken (i.e. safety

goggles, gloves, laboratory coat and

mask must be worn).

This type of disinfection reduces the

number of germs by at least 99.99%.

Fig. 1

6

Operating Manual V 1.1 – 05/2007

Page 7

2.1 General Safety Instructions

The CM1950 is a cryostat with an encapsulated microtome and separate

specimen cooling. It is primarily used for work in the area of fast-cut diagnostics. The displays and instrument controls are easy to operate due to

their largely self-explanatory symbols. LED displays make it easy to read.

The cryochamber is made of seamlessly welded, high-quality stainless steel

that is free of difficult-to-access corners and thus easy to clean and disinfect.

This instrument has been built and tested in accordance with the following

safety regulations on electrical measuring, control, regulating and laboratory devices. In order to maintain this condition and to ensure safe operation, the operator must observe the instructions and warnings contained in

this instruction manual.

For current information about applicable standards, please refer to the

CE declaration of conformity on our Internet site:

2.2 Unpacking and Installation

• To ensure proper function of the instrument, it must be set up with a

minimum distance on all sides from walls and furniture (see ‘Site

Requirements’, p. 20)

• The instrument may only be transported in an upright or slightly inclined

position.

• To ensure a safe transport with a fork lift 3 people are required: one operating the fork lift, and the other 2 holding the instrument on either

side to prevent it from sliding down.

• Before connecting to the power supply system, please check if the local

voltage complies with the power rating specified on the name plate of

the instrument (see also ‘Technical data’)!

• Never connect the instrument to a power socket that does not have a

protective conductor terminal.

Length of power cable: up to 3.5 m extension possible: no

2. Safety and Design

www.histo-solutions.com

After transporting, wait at least 4 hours before turning the instrument on. This waiting period is

necessary to allow the compressor oil, which may have been displaced during transport, to return

into its original position. Any condensation on electrical parts that has formed due to temperature differences during transport must be allowed to dry completely. Failure to comply with this

can cause severe damage to the instrument!

Leica CM1950 – Cryostat

7

Page 8

2. Safety and Design

Fig. 2

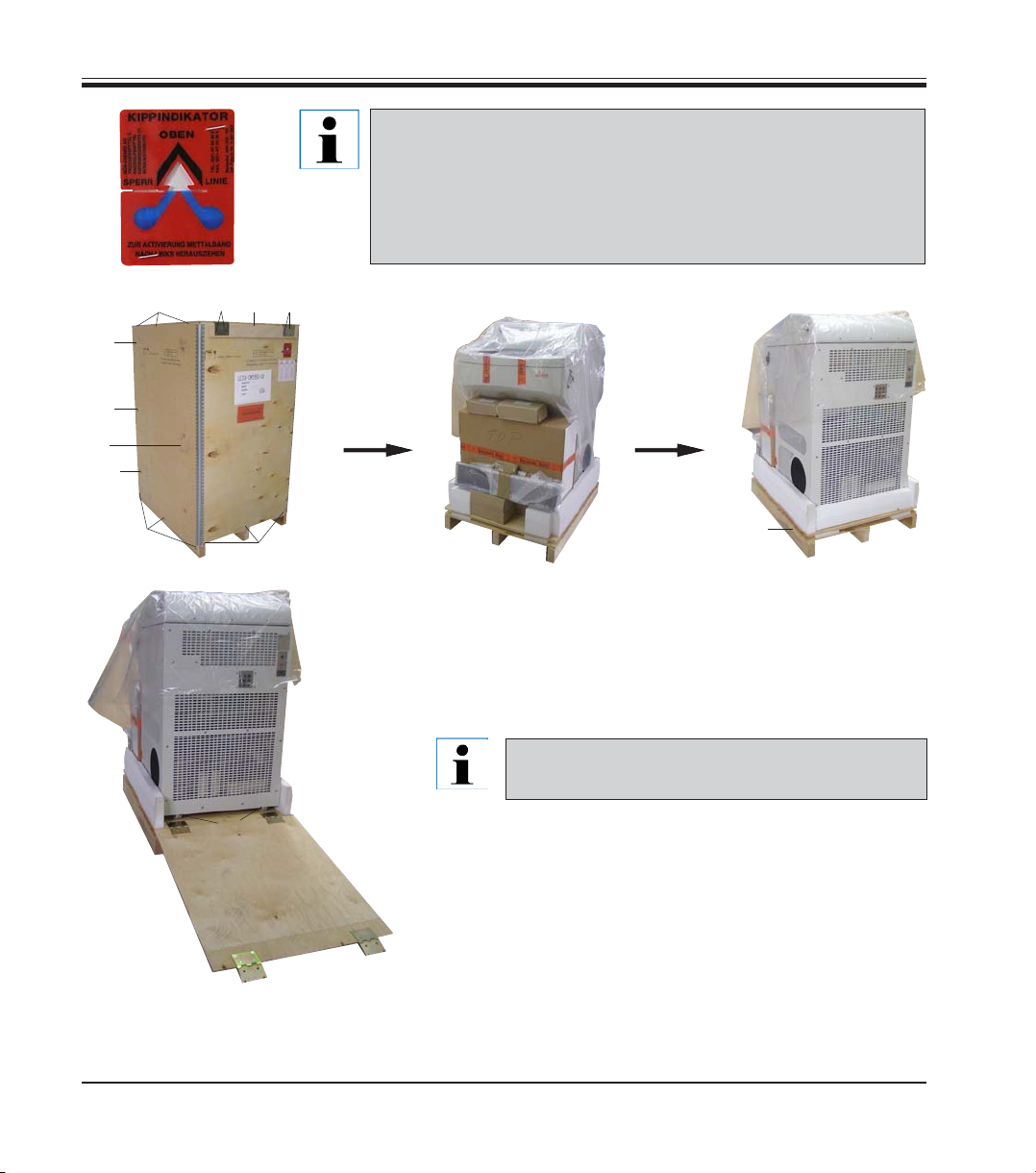

When the instrument is delivered, check the tilt indicators on the

packaging.

If the arrowhead is blue, the shipment was transported laying flat,

was tilted at too great an angle or fell over during transport.

Note this on the shipping documents and check the shipment for

possible damage.

1

5

5

7

5

4

22

3

8

8

8

8

8

11

4

9

10

11

Opening the packaging

1. Remove the 3 screws (1) on each of the two sides of the

box (7) at the top.

9

14

17

Cover = ramp

2. Remove the 2 screws on each of the 4 hinges (2) on the

front and rear side of the box.

Do NOT remove the screws of the hinges on the top

lid!

3. Remove 1 screw (3) between the two hinges on the front

and rear side of the box.

4. Remove the 3 screws (4) at the bottom on all four sides

of the box.

5. Of the two vertical rows of screws (5), remove one on

either side (which side does not matter) entirely.

Fig. 3

8

Operating Manual V 1.1 – 05/2007

Page 9

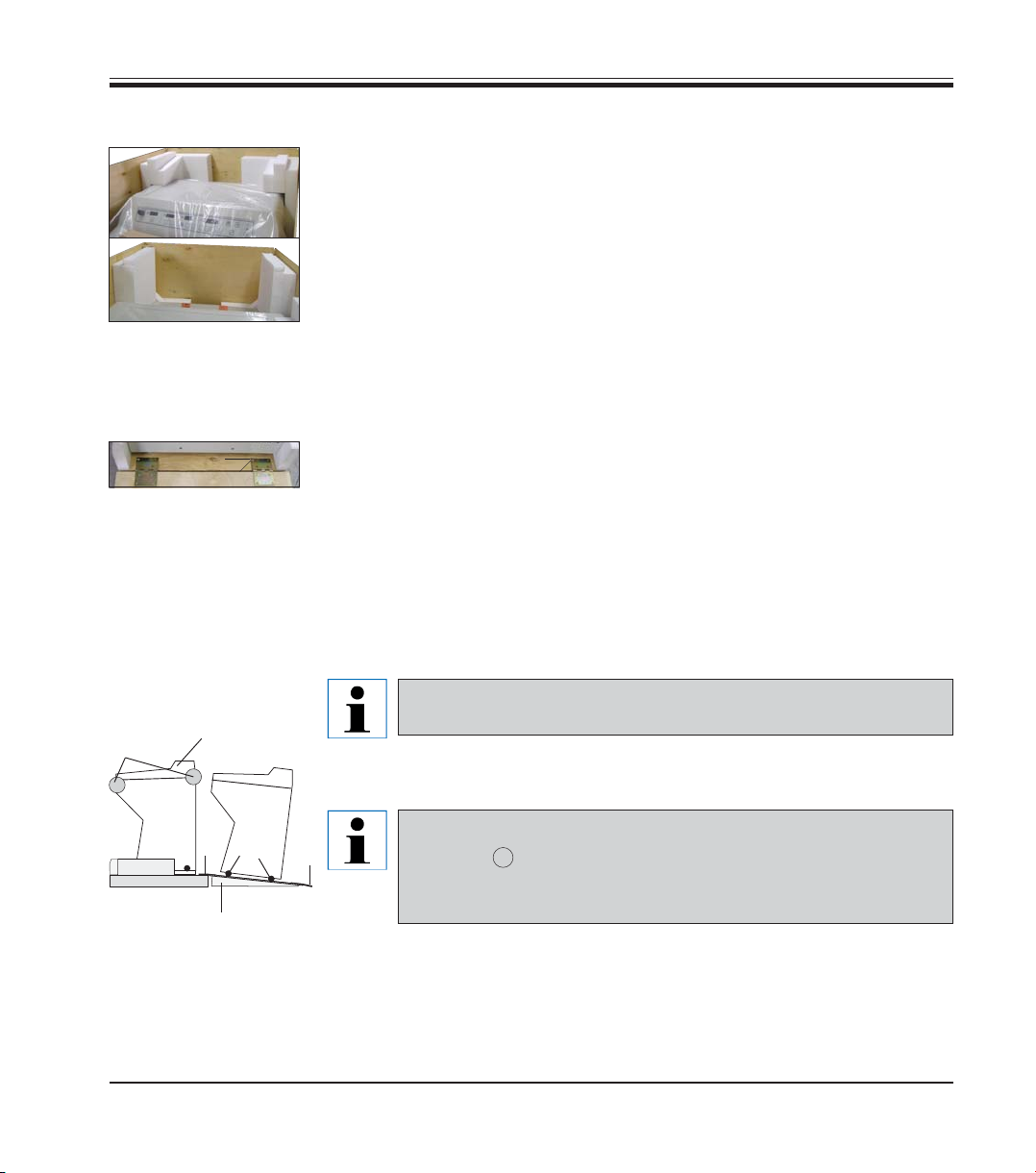

Removing the packaging

2. Safety and Design

6

6

1. Remove the cover (17) and place it on the floor with the foam parts facing

downwards. - The cover will be used as a ramp later.

2. Remove the 4 foam parts (6) by pulling them upwards.

3. Open the box (7) on its side hinges like an accordion partition and remove

it.

66

4. Remove the accessories carton (8) and operating manual on the front of

the instrument.

Fig. 4

5. Pull off the dust cover (9) by pulling upwards.

6. Take off the foam strip (10) on the bottom rear.

Ramp assembly

13

12

Fig. 5

1. After the foam strip (10) is removed, 2 screws (12) are visible on the

baseplate.

2. Swing out the cover hinges (2) at the front and rear.

3. Attach the cover (17) from the rear on the transport pallet (11).

The notches (13) of the hinges (2) must be pointing towards the instrument.

4. Move the cover towards the left so that the notches (13) of the hinges

slide beneath the heads of the screws (12).

Transport to the Installation Location

The instrument must be transported in an upright position.

15

16

The cover (17) now forms a ramp on which the instrument can now be rolled

down off the transport pallet.

2

14

Fig. 6

Leica CM1950 Cryostat

17

Do not push the device by its hood (16). Use the transport grip

2

points (15 ).

The rollers (14) must run over the cover hinges (2) at the front and

rear. Danger of tipping!

1. Carefully roll the instrument backwards from the pallet.

2. Push the instrument to the installation location on the castors (14).

9

Page 10

2. Safety and Design

2.3 Safety Features

The instruction manual includes important information related to the operating

safety and maintenance of the instrument.

The Operating Manual is an important part of the product, and must be read

carefully before startup and use and must always be kept near the instrument.

If additional requirements on accident prevention and environmental

protection apply in the country of operation, this Operating Manual must be

supplemented by appropriate instructions to ensure compliance with such

requirements.

The instrument is equipped with the following safety devices: an emergency stop switch (motorized instruments only), a handwheel lock and centering system (motorized instruments only), knife guard on the blade and knife

holder, and a blade ejector.

The consistent use of these safety features and strict observation of the warnings and cautions in this manual, will safeguard the operator from accidents

and/or personal injury to a great extent.

To prevent adverse health effects from UV radiation, the UV disinfection cycle can be started only after the sliding window has been properly closed. Closing the window activates the corresponding safety

features.

Microtome knives

10

• Take care when handling microtome knives/disposable blades. The

cutting edge is extremely sharp and can cause severe injury!

• Never leave knives and dismounted knife holders with a knife/blade

mounted lying around!

• Do not place a knife on a table with the cutting edge facing upwards!

We strongly recommend using the safety gloves included with the

standard delivery!

• Never try to catch a falling knife!

• Prior to manipulating the knife and specimen or changing the specimen,

always lock the handwheel and cover the cutting edge with the knife

guard!

• Avoid contact with cold parts of the instrument as this can cause frostbite!

Operating Manual V 1.1 – 05/2007

Page 11

Knife guard

Prior to manipulating the knife and specimen, changing the specimen or knife, or taking a break, always lock the handwheel and

cover the cutting edge with the knife guard.

The CE, CN and CN-Z knife holders feature knife guards; the glass anti-roll

plate of the CE knife holder also serves as a knife guard.

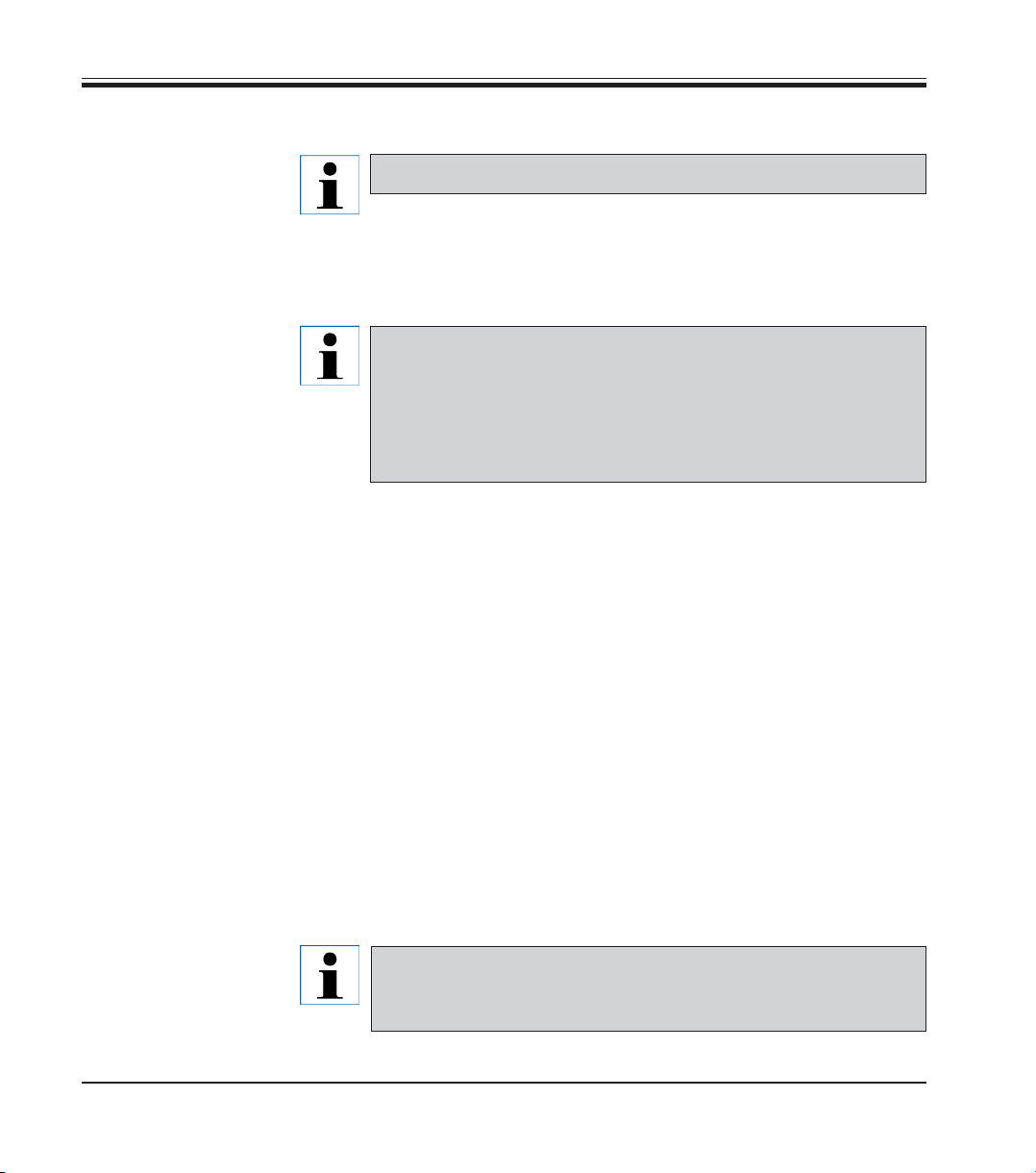

2.4 Securing/Locking the Handwheel

Always lock the handwheel and cover the cutting edge with the

12 o’clock

position

6 o’clock

position

1

2

Fig. 7

To lock the handwheel, press the lever (1) outward. Continue turning the

handwheel slowly until the grip is in the upper or lower position and the

handwheel is locked. Press the lever fully outward; gently rock the handwheel until the locking mechanism clicks into place noticeably.

To release the handwheel, press the lever (2) on the handwheel toward the

cryostat housing.

knife guard prior to manipulating the knife or specimen, changing

the specimen, or taking a break.

2. Safety and Design

Fig. 8

Fig. 9

Leica CM1950 – Cryostat

Centering of the handwheel (motorized instruments only)

Pull out the handwheel’s handle and position it in the middle of the

handwheel. The handle automatically engages in this position.

An important safety device on the cryostat is the centering of the

handwheel for motorized instruments.

Rotate the handwheel only if the refrigeration system is on and the

cryochamber is cold.

11

Page 12

2. Safety and Design

2.5 Cleaning, Disinfection – Turning the Instrument Back On

It is not necessary to remove the microtome for disinfection.

• The instrument has been designed for UV disinfection! Spray disinfection with Leica Cryofect is also possible, thanks to the special insulation

of the microtome. (Cryofect is not available in all countries!)

Remove section waste after EVERY sectioning operation and BEFORE changing specimens. Remove the section waste using a paper towel soaked in Cryofect or an alcohol-based disinfectant) or

remove the waste using the extraction nozzle (optional). Do not

start the disinfection until after folding the section stretcher to the

side! Each new specimen is a potential source of contamination.

• When disinfecting the instrument, take appropriate protective measures

(gloves, mask, protective clothing, etc.).

• When using detergents and disinfectants please comply with the safety

precautions of the disinfectant manufacturer.

• The integrated glass anti-roll guide of the blade holder CE, CN and CN-Z

can be cleaned either with acetone or alcohol.

• Dispose of waste liquid according to the waste disposal regulations!

• Do not use external heaters for drying the cryochamber. This can cause

damage to the cooling system!

• Do not turn the instrument on before the cryochamber is completely dry!

Frost formation!

• All components removed from the cryostat must be carefully dried before returning them to the cryochamber!

• The front panel and the slit cover of the microtome must be completely

dry before turning on the instrument!

12

For more detailed information about disinfection, visit the Leica

Microsystems website at

www.histo-solutions.com

Operating Manual V 1.1 – 05/2007

Page 13

2.6 Handling Specimens – Defrosting

• When working with contaminated or infected material, the general safety

guidelines for laboratories must be applied.

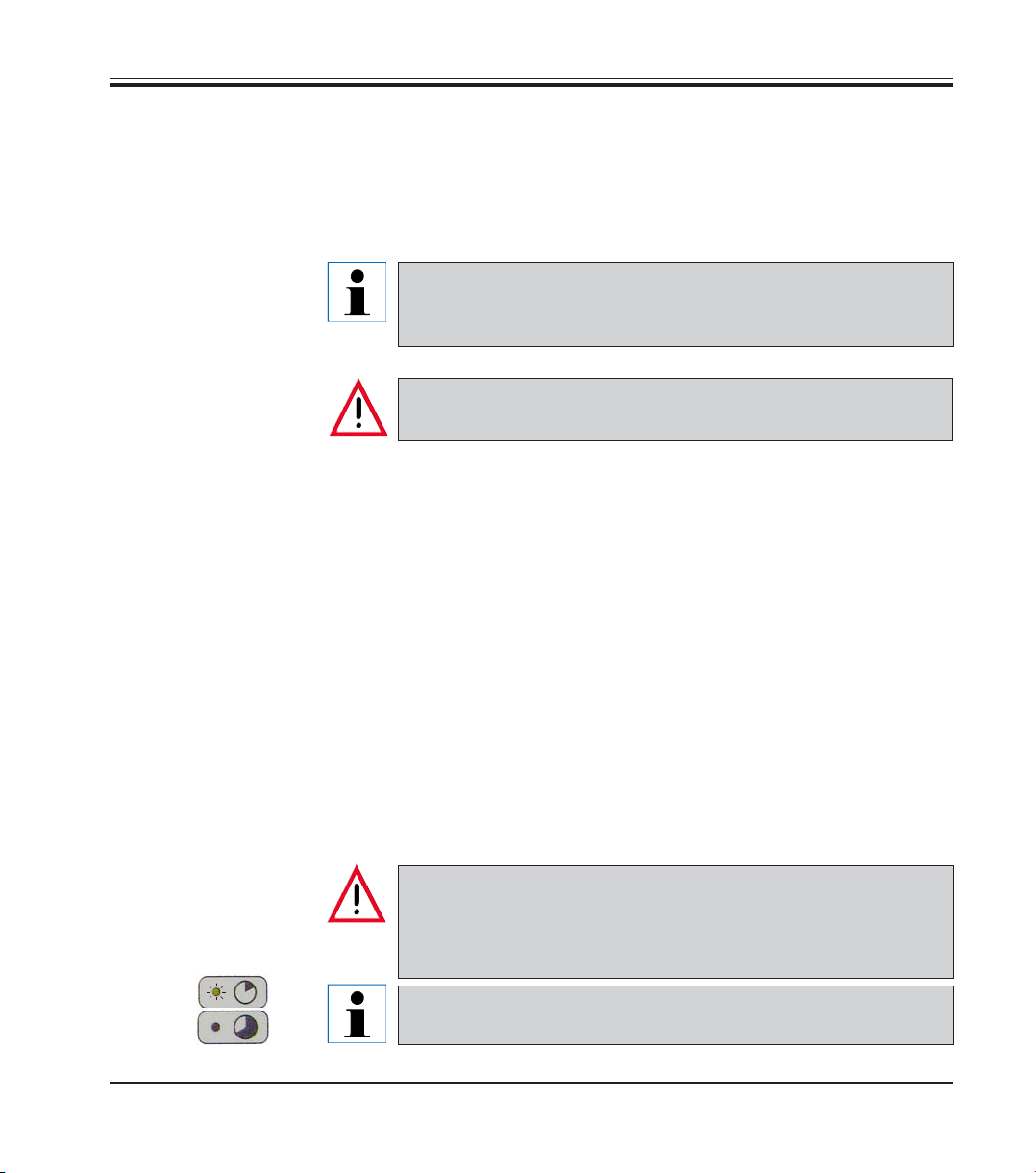

• Before defrosting the cryochamber remove all samples!

• Before defrosting the specimen head, remove all samples!

Never leave samples in the cryochamber! - The instrument is not

suitable for storing frozen specimens, as the refrigeration dehydrates the specimens!

The quick freeze shelf can become very hot during the defrosting

process. Do not touch it during defrosting.

2.7 Removal of the Microtome

• The microtome is encapsulated and therefore does not require removal

by the user.

2.8 Maintenance

Replacing the fuses

• Turn the instrument off and disconnect the power plug before replacing

the fuses.

• Use only the fuse types specified in chapter 3, "Technical Data." Failure

to comply with this can cause severe damage to the instrument!

2. Safety and Design

Replacing the fluorescent lamp/UVC lamp

• Turn the instrument off and disconnect the power plug before replacing

the lamps.

Leica CM1950 Cryostat

It is possible to break the UVC lamp during replacement. If this

happens, the lamp change must be completed by Technical Service. If any metallic mercury is released, handle it carefully and

dispose of it properly.

If both disinfection indicator lights are blinking alternately, the

UV tube must be replaced!

13

Page 14

3. Technical Data

All specifications related to temperature are valid only up to an ambient temperature of 18°C

to 35°C and a relative humidity of no more than 60%.

Type

Nominal voltage (±10 %)

Nominal frequency

Power draw

Max. start-up current for 5 sec.

Protective class

Circuit breaker:

(MDA made by Schurter)

Pollution degree

Overvoltage installation category

Heat emission (max.)

Approval

② according to IEC-1010; UL 3101

②

-1 -2 -3

100 VAC 120 VAC 230 VAC

50/60 Hz 60 Hz 50 Hz

1900 VA 1900 VA 1900 VA

35 A eff. 35 A eff. 25 A eff.

III

15A M3 15A M3 15A M3

222

II II II

1900 J/s 1900 J/s 1900 J/s

CE/c_CSA_us CE/c_CSA_us CE/c_CSA_us

Microtome

Type: Rotary microtome,

encapsulated

Section thickness range 1 to 100 μm

Trimming range:

Clinic 10 - 40μm

Research 1 - 600 μm

③

③

Total specimen feed 25 mm + 1mm

Vertical stroke 59 mm ±0.5mm

Specimen retraction 20μm (can be deactivated)

Maximum specimen size 50 x 80 mm

Cutting speed Slow: 0-50 strokes/min

Fast: 0-85 strokes/min

Vmax: 85-90 strokes/min

Specimen orientation 8° (x, y-axis)

③ For additional details, see p. 32

Electric coarse feed

Slow 300μm/s

Fast 900 μm/s

For "Site Requirements," refer to item 6.1

(page 20).

Lamp

50/60 Hz-Version: Osram DULUX L 18 W/840

Cryostat

Dimensions:

Width (w/o handwheel) 700 mm

Width (with handwheel) 835 mm

Depth (cabinet only) 850 mm

Height (total) 1215 mm

Working height (armrest) 1025 mm

Weight:

Weight (w/motor and suct.) 193 kg

Weight (w/motor, w/o suct.) 185 kg

Weight (w/o motor, w/ suct.) 183 kg

Weight (w/o motor, w/o suct.) 175 kg

Weight (w/ specimen head cool.) 165 kg

Weight (w/o specimen head cool.) 145 kg

General information

Operating temperature range: 18 °C to 35 °C

Temperature range

during storage: +5 °C to +55°C

Relative humidity: max. 60 %,

non-condensing

Storage humidity: < 60 %

14

Operating Manual V 1.1 – 05/2007

Page 15

3. Technical Data

Refrigeration system CM1950 , 50 Hz CM1950, 60 Hz

Cryochamber

Temperature range 0°C to -35°C ± 5 K, adjustable in 1K increments, 0 °C to -35°C ± 5 K, adjustable in 1K increments

Cooling time to -25°C approx. 5 h approx. 5 h

Cooling time to -35°C approx. 8 h approx. 8 h

Refrigeration capacity ① 690 W 690 W

Cut-out pressure 25 bar 25 bar

Safety factor 3 3

Refrigerant* 300 g (± 5 g) refrigerant R -404A* 300 g (± 5 g) refrigerant R -404A*

Compressor oil* 0.6 l EMKARATE RL22S, ICI* 0.6 l EMKARATE RL22S, ICI*

Defrosting of cryochamber

Automatic defrosting

Programmable: Yes (hot gas defrost) Selectable time Yes (hot gas defrost) Selectable time

Defrosting intervals 1 defrost in 24 h 1 defrost in 24 h

Defrost time: 12 minutes 12 minutes

Automatic shutoff Defrost: at -5 °C chamber temperature at -5 °C chamber temperature

Quick-freeze shelf

Minimum temperature: - 42 °C (+ 5 K), at chamber temp. -35°C - 42 °C (+ 5 K), at chamber temp. -35°C

Number of freezing stations: 15+2 15+2

Defrost Manual hot-gas defrost Manual hot-gas defrost

Peltier element

Number of freezing stations: 2 2

Max. temperature difference: 17 K, at chamber temp. of -35°C 17 K, at chamber temp. of -35°C

at ambient temperature of 20°C ambient temperature of 20°C

or manual hot gas defrost or manual hot gas defrost

Specimen cooling

Temperature range -10 to -50 °C ± 3 K -10 to -50 °C ± 3 K

Refrigeration capacity① 320 W 320 W

Cut-out pressure 25 bar 25 bar

Safety factor 3 3

Refrigerant and quantity at 230 V/50 Hz 140 g (± 5 g), refrigerant R-404A* at 120 V/60 Hz 110 g (± 5 g), refrigerant R-404A*

at 100V/50/60 Hz 110 g (± 5 g), refrigerant R-404A*

Compressor oil* 0.4 l alpha 22, Kyodo* 0.4 l alpha 22, Kyodo*

Defrosting of specimen head

Automatic defrost: No No

Manual defrost

Defrost time 15 min. 15 min.

*) Refrigerant and compressor oil must be replaced by qualified, authorized service personnel only.

① acc. to CECOMAF: liquid temperature 45 °C, evaporation temperature: -25 °C

Leica CM1950 – Cryostat

15

Page 16

4. Standard Delivery

Basic instrument WITHOUT motor/WITHOUT extraction, in the specific voltage variant

1 handwheel, manual .........................................................................................0477 41346

5 specimen discs, 30 mm ...................................................................................0477 40044

1 section waste tray ...........................................................................................0477 40062

1 position holder for freeze shelf ..................................................................... 0477 40080

1 freeze shelf cover ............................................................................................0477 43763

1 tool set ............................................................................................................... 0436 43463

- 1 brush, fine ................................................................................................0183 28642

- 1 Leica brush w/magnet ........................................................................... 0183 40426

- 1 Allen key, No. 1.5 ..................................................................................... 0222 10050

- 1 Allen key, No. 2.5 ..................................................................................... 0222 04137

- 1 Allen key, No. 3.0 ..................................................................................... 0222 04138

- 1 Allen key, No. 4.0 ..................................................................................... 0222 04139

- 1 Allen key with dome head, No. 4.0 ....................................................... 0222 32131

- 1 Allen key, No. 5.0 ..................................................................................... 0222 04140

- 1 key with handle, No. 5.0 .........................................................................0194 04760

- 1 Allen key, No. 6.0 ..................................................................................... 0222 04141

- 1 Single-head wrench, No. 13 .................................................................0330 33149

- 1 Single-head wrench, No. 16 .................................................................0330 18595

1 power cable .........................................................................................................................

1 bottle of cryostat oil, type 407, 50 ml ............................................................0336 06098

1 bottle of OCT freezing compound, 125 ml ....................................................0201 08926

1 pair of safety gloves, size M, * for cryosectioning ....................................0340 29011

1 user manual plus language CD ..................................................................... 0708 37115

* Note: for the Japanese version: 100V, 50/60 Hz; 1 pair of safety gloves, size S

(0340 40859) is included.

Basic instrument WITHOUT motor and WITH extraction,

Standard scope of delivery as above,

plus:

1 accessory set (extraction) .............................................................................0477 43300

- Hose adapter 1 ...........................................................................................0477 40293

- Hose adapter 2 ...........................................................................................0477 40294

- Suction nozzle ............................................................................................ 0477 40295

- Silicone hose .............................................................................................. 0477 43302

- Silicone stopper .........................................................................................0477 43304

- Chamber suction nozzle ........................................................................... 0477 43779

- Set of filters (5 pieces) .............................................................................. 0477 43792

Compare the delivered components with the parts list and your order. Should you

find any discrepancies, please contact your Leica sales office without delay.

A choice of different knife holders is available for the CM1950.

16

Operating Manual V 1.1 – 05/2007

Page 17

4. Standard Delivery

Basic instrument WITH motor/WITHOUT extraction, in the specific voltage variant

1 handwheel, motorized .................................................................................... 0477 41347

5 specimen discs, 30 mm ...................................................................................0477 40044

1 section waste tray ...........................................................................................0477 40062

1 position holder for freeze shelf ..................................................................... 0477 40080

1 freeze shelf cover ............................................................................................0477 43763

1 tool set ............................................................................................................... 0436 43463

- 1 brush, fine ................................................................................................0183 28642

- 1 Leica brush w/magnet ........................................................................... 0183 40426

- 1 Allen key, No. 1.5 ..................................................................................... 0222 10050

- 1 Allen key, No. 2.5 ..................................................................................... 0222 04137

- 1 Allen key, No. 3.0 ..................................................................................... 0222 04138

- 1 Allen key, No. 4.0 ..................................................................................... 0222 04139

- 1 Allen key with dome head, No. 4.0 ....................................................... 0222 32131

- 1 Allen key, No. 5.0 ..................................................................................... 0222 04140

- 1 key with handle, No. 5.0 .........................................................................0194 04760

- 1 Allen key, No. 6.0 ..................................................................................... 0222 04141

- 1 Single-head wrench, No. 13 ................................................................. 0330 33149

- 1 Single-head wrench, No. 16 ................................................................. 0330 18595

1 power cable .........................................................................................................................

1 bottle of cryostat oil, type 407, 50 ml ............................................................0336 06098

1 footswitch dummy ........................................................................................... 0443 30420

1 bottle of OCT freezing compound, 125 ml ....................................................0201 08926

1 pair of safety gloves, size M, * for cryosectioning ....................................0340 29011

1 operating instructions plus language CD .................................................... 0708 37115

* Note: for the Japanese version: 100V, 50/60 Hz; 1 pair of safety gloves,

size S (0340 40859) is included.

Basic instrument WITH and WITH extraction, in the specific voltage variant

Standard scope of delivery as above,

plus:

1 accessory set (extraction) .............................................................................0477 43300

- Hose adapter 1 ...........................................................................................0477 40293

- Hose adapter 2 ...........................................................................................0477 40294

- Suction nozzle ............................................................................................ 0477 40295

- Silicone hose .............................................................................................. 0477 43302

- Silicone stopper .........................................................................................0477 43304

- Chamber suction nozzle ........................................................................... 0477 43779

- Set of filters (5 pieces) .............................................................................. 0477 43792

Leica CM1950 – Cryostat

Compare the delivered components with the parts list and your order. Should you

find any discrepancies, please contact your Leica sales office without delay.

A choice of different knife holders is available for the CM1950.

17

Page 18

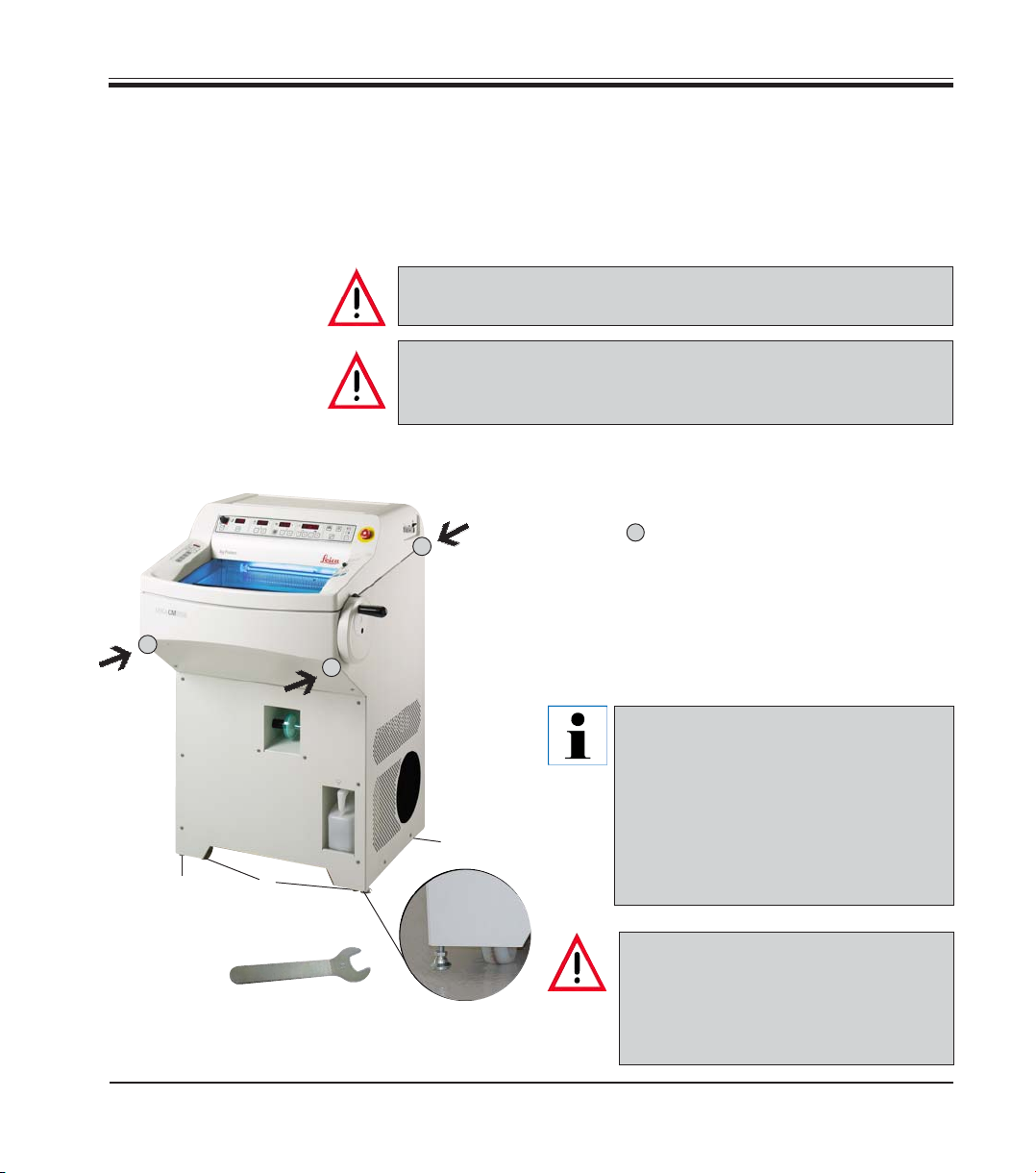

5. General Overview

Cryostat chamber

(with activated

UV disinfection)

Bacterial filter

(optional, only for

instruments with filter)

Emergency-stop

switch (motorized

instruments only)

On/off switch, also circuit

breaker

Footswitch dummy

(motorized

instruments only)

Handwheel in

12 o’clock

position

Unscrew and align

adjusting feet after

transport

18

Catch tank for

condensate

Fig. 10

Castors for safe transport

over short distances

Align adjusting feet for secure

upright position

Operating Manual V 1.1 – 05/2007

Page 19

5. General Overview

5.1 Control Panel Fields and Cryostat Chamber

1 - Control panel field 1: Extraction, temperature and time control, illumination, UV disinfection

2 - Control panel field 2: Electric coarse feed (sectioning and trimming thickness adjustment)

3 - Control panel field 3: Motorized sectioning cutting, optional (adjustment of stroke type, cutting speed etc.)

1

7

4

2

6

10a

5

10b

15

16

10

11

10c

14

3

8

9

4 - Heat conductor block, stationary (optional)

5 - Peltier element (with 2 stations)

6 - Freeze shelf, 15 positions

7 - Position holder on freeze shelf

8 - Heat and cold extractor, mobile (opt.)

9 - Shelf, movable (optional)

10 - Blade holder CE with blade ejector (a)

10b- Finger rest on the blade holder CE

Leica CM1950 – Cryostat

13

12

10c- Knife guard on the blade holder CE

11 - Extraction nozzle on the extraction hose

12 - Extraction hose for section waste

13 - Brush shelf (optional)

14 - Adapter piece for extraction hose

(the coarse filter insert is behind it)

15 - Object head, directional

16 - Waste tray

Fig. 11

19

Page 20

6. Installation

6.1 Site Requirements

The place of installation must meet the following requirements:

• No direct sunlight.

• Power supply at a distance no greater than approx. 3 m.

• No drafts (air condition outlets etc.).

• Even floor.

• Vibration-free floor.

• The instrument is designed for indoor use only.

• Obstruction-free access to the handwheel.

• The power switch/circuit breaker must be freely and easily accessible.

• Room temperature always approx. 22°C.

• The relative humidity must not exceed 60%.

To ensure proper function of the instrument, it must be set up while

maintaining a minimum distance from walls and furniture.

• Distance to walls and furniture, calculated from the cabinet:

- rear: 15 cm

- right side: 30 cm

- left side: 15 cm

• No heat dissipating appliances around.

20

High room temperatures and excessive air humidity affect the

cooling capacity of the cryostat and lead to ice forming in the

instrument!

• Plug the instrument into power sockets with ground only.

Power cable length: up to 3.5 m

Extendable: no

Operating Manual V 1.1 – 05/2007

Page 21

6.2 Transport to the Site

• First, check if the location meets the conditions specified in "Site

• Transport the instrument to the desired location.

• Observe the following:

requirements".

The instrument must be transported in an upright position or slightly tilted (max. 30°)!

When tilting the instrument 2 people must counterbalance from the

front side to prevent the instrument from falling down and causing

severe injury!

6. Installation

• When transporting the instrument on wheels

(2) grip the cabinet only at the marked locations (

• To do so, unscrew the adjustable feet using

the No. 13 open-end wrench (when subsequently transporting the instrument on castors, screw the feet back in as far as they will

go). To ensure a secure upright position at its

intended location, align both adjusting feet (1).

).

1

Fig. 12

Leica CM1950 – Cryostat

2

2

1

2 (covered)

Before transport or relocation, remove

the filter bag from the chamber. If you

fail to do this, the filter bag will thaw,

then freeze solid when the instrument

is reconnected. When subsequently

removed, the filter will be destroyed,

causing section waste to get into the

bacteria filter. (Refer to p. 26.)

When not using the extraction for a long

period, tightly close the opening for the

extraction hose using the silicone stopper (5, page 28) included in the scope of

delivery.

21

Page 22

6. Installation

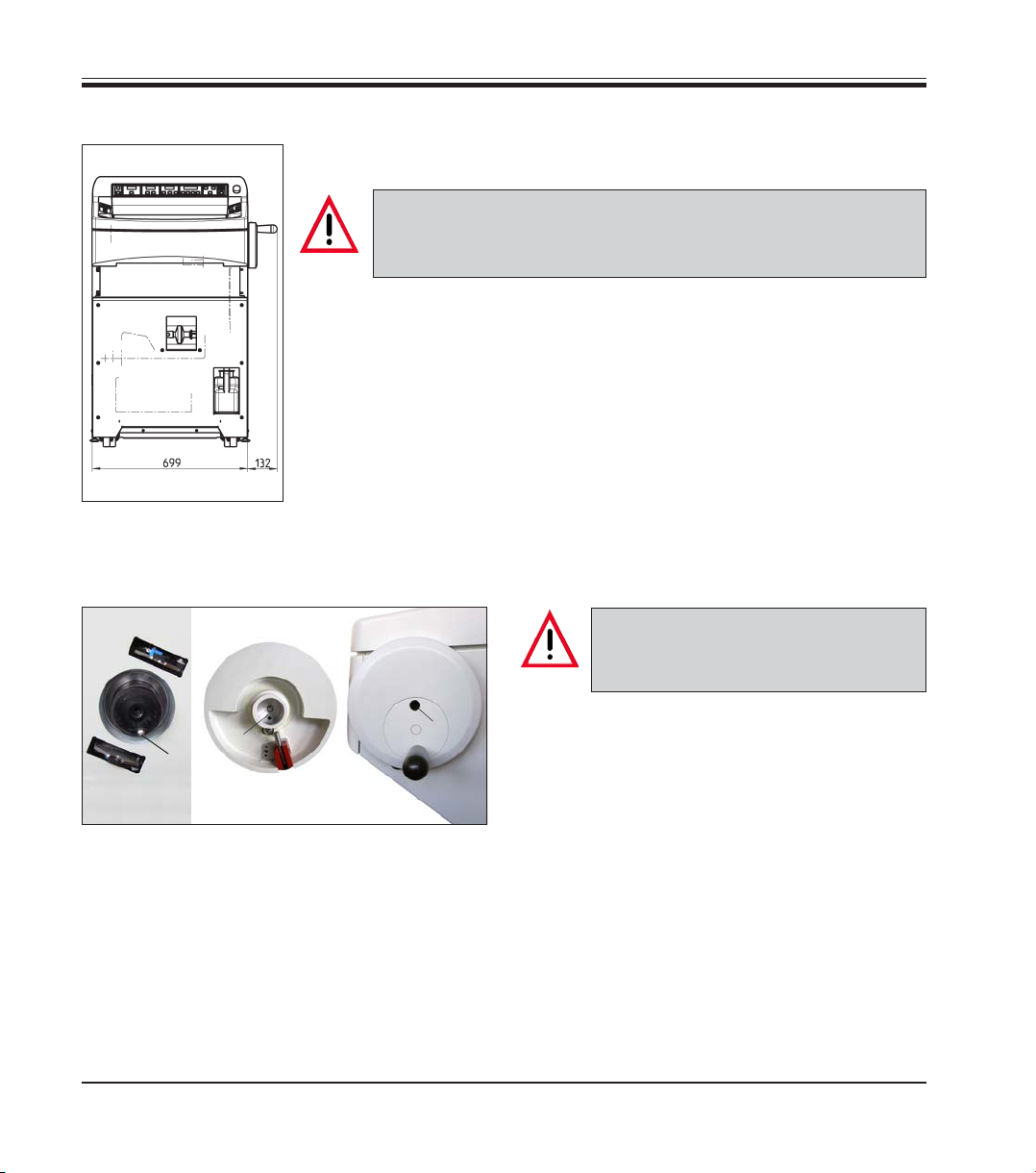

Transport with a fork lift

• The instrument can be transported with a fork lift.

• At the installation site, unscrew the adjustable feet (1) with the openend wrench No. 13 (see Fig. 12). This is absolutely necessary for a stable

stand.

Total width with handwheel

Fig. 13

6.3 Assembling the Handwheel

To ensure a safe transport with a fork lift 3 people are required:

one operating the fork lift, and the other 2 holding the instrument

on either side to prevent it from sliding down.

22

Rotate the handwheel only if the

refrigeration system is on and the

cryochamber is cold.

2

1

4

• Insert the pin (1) of the handwheel shaft into

the hole (2) of the handwheel.

• Tighten the screw (4) using the No. 6 Allen key.

• Place the protective cap on the screw (4).

Fig. 14

To dismount, proceed in reverse order.

Operating Manual V 1.1 – 05/2007

Page 23

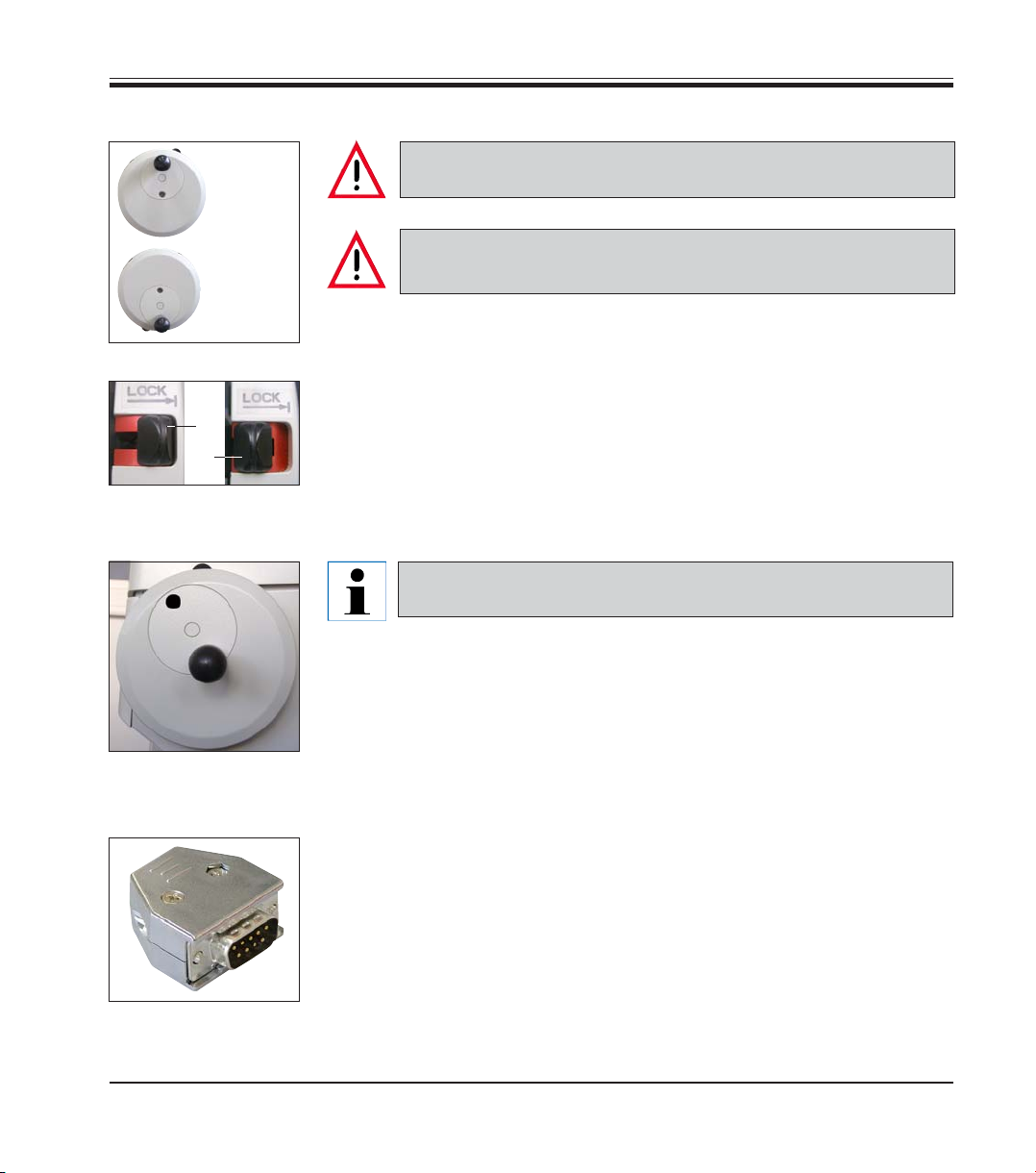

6.3.1 Locking/Unlocking the Handwheel

Only rotate the handwheel when the refrigeration system is on and

12 o’clock

position

6 o’clock

position

the cryochamber is cold!

Always lock the handwheel prior to manipulating the knife or

specimen, changing the specimen, or taking a break.

To lock the handwheel, move its handle to the 12 or 6 o’clock position. Press

Fig. 15

the lever (1) fully outward; gently rock the handwheel until the locking mechanism clicks into place noticeably.

To release the handwheel, press the lever (2) on the handwheel toward the

1

2

Fig. 16

cryostat housing.

Centering the Handwheel (Optional)

An important safety device on the cryostat is the feature for centering the handwheel in motorized sectioning mode.

6. Installation

To do so, pull out the handwheel’s handle and position it in the middle of the

handwheel. The handle automatically engages in this position.

Fig. 17

6.3.2 Installing the Footswitch Dummy (Instruments with Cutting Motor)

• The footswitch dummy must be installed on the outer right side of the

instrument (see page 16, General overview) if no footswitch (optional) is

used.

If the red LED in the E-STOP field in control panel field 3 is illuminated, either:

• emergency-stop function active, or

•

footswitch dummy (optional footswitch) connected incorrectly or not at all.

Fig. 18

Leica CM1950 Cryostat

23

Page 24

6. Installation

6.4 Connection to Power Supply System

After transporting, wait at least 4 hours before turning the instrument on. This waiting period is

necessary to allow the compressor oil, which may have been displaced during transport, to return into its original position. Furthermore, any condensation that has formed during this time

due to temperature fluctuations must be allowed to dry completely.

Failure to comply with this can cause severe damage to the instrument!

During the start-up of the compressor the nominal voltage must not drop below the values

specified in the "Technical Data".

Please note that the compressor requires a start-up current between 25 and 35 A.

Therefore, the electric circuit at the installation site must be inspected by an electrical

engineer to ensure that it meets the requirements for a smooth operation of the instrument.

Failure to comply with the above will cause severe damage to the instrument!

• Check mains voltage and mains frequency to comply with the specification on the type plate.

• Do not connect any other consumers to this electric circuit.

Never connect the instrument to a power socket that does not have a protective conductor

terminal.

Only for instruments sold in Japan

Selecting the frequency

• After unpacking the instrument and setting it up at its intended location,

use the lever (1) to select the frequency corresponding to the conditions of

1

Fig. 19

the existing power system.

Power plug

24

Operating Manual V 1.1 – 05/2007

Page 25

6.5 Installing Accessories/Inserting Chamber Accessories

6.5.1 Installing the Adjustable Footrest (Optional)

• To install the optional footrest, unscrew the

screws (1) using the No. 3 Allen key provided.

6. Installation

1

When installing the holder (2), ensure

that the cutout faces downwards so that

the support (3) can be hooked in.

• Attach the holders (2) for the footrest on the

left and right to the front wall of the housing.

To do so, use the Allen screws you used earlier. Ensure that the screws are tight.

• Hook the footrest (3) into the installed holder

2

according to individual requirements (height).

• Once installed, the user can adjust the height

of the footrest at any time by relocating it (3)

to the desired height on both sides in the

3

Fig. 20

holder (2).

Leica CM1950 – Cryostat

25

Page 26

6. Installation

6.5.2 Installing the Storage Systems (Optional)

2

Fig. 21

1

For reasons of

1

accessibility, the

(optional) storage

system must always

be installed first.

To do so, remove the insert (1), place the frame

(2) in front of the bore and tighten the screws/

washers on the cryostat housing using the No. 4

Allen key. Afterwards, insert the insert (1) into the

frame and fold it up.

6.5.3 Shelf, Movable (Optional)

Attach the rod for the shelf to the inner front side

of the cryostat housing using the provided screws

(1) and the No. 3 Allen key, then attach the caps

(3). (The rear side of the movable shelf has white

plastic screws (2) that prevent the interior of the

chamber from being scratched.) Now hook the

movable shelf into the guide rod.

3

2

6.5.4 Inserting the Section Waste Tray

Fig. 23

26

Fig. 22

Before installing the knife/

blade holder base, insert the

a

section waste tray with the

cutout (a) facing the user.

Operating Manual V 1.1 – 05/2007

Page 27

6.5.5 Installing the Heat Conductor Block, Stationary (Optional)

The holder (1, Fig. 24) of the heat conductor block

is screwed to the left housing wall using the

No. 4 Allen key provided. (Preferably, begin with

1

the bottom screw. Then, rotate the holder

upwards (see arrow) and insert and tighten the

top screw).

6. Installation

6.5.6 Installing the Knife/Blade Holder and Adjusting the Clearance Angle

3

1

2

4

Fig. 24

5

Now, attach the cover for the quick

freeze shelf to protect the shelf from

frost.

For temperature reasons, install the

knife/blade holder on an appropriate

base.

• Set the knife or blade holder (1, Fig. 25) on the

base (2), adjust the clearance angle (on the

left of the knife/blade holder) to approx. 2°-5°

and secure it in the bore (3) on the base (2)

using the No. 4 Allen key.

• Push the knife holder base (2) on the dovetail

guide (4) from the front and tighten it using the

clamping lever (5). To move the base, open the

clamping lever only a little to prevent accidental sliding in the direction of the specimen

head.

• If the clamping distance is not sufficient, the

clamping lever (3) can be moved. To do so, pull

the lever out and move it to the next position.

2

Leica CM1950 – Cryostat

When removing the knife holder base

(2) from the refrigerated cryostat

chamber, hold it by the grip points

a

Fig. 25

(a – front and rear) to keep your

fingers from freezing.

27

Page 28

6. Installation

6.5.7 Inserting/Changing the Bacteria Filter

Fig. 26

6.5.8 Assembling the Filter Bag

1

2

A

L

3a

3

The holder for the bacterial filter (optional) is

visible in the front of the instrument.

• To insert the filter, hold it with one hand, press

on the right of the socket, then guide the filter

into the tube from the left.

• To change the filter, follow the opposite procedure: press the filter to the right, then pull it to

the left and out of the tube.

• The filter must be changed approx. every

3 months (we recommend writing the date on

the filter using a marker).

The filter must be disposed of according to valid laboratory specifications.

• Set the mark (A) of the extraction opening (1)

and pull it out. Plug the filter (3) into the extraction hose connecting piece (3a) until there

is an audible click.

Now push the connected parts back into the

opening in the cryostat chamber (filter first) and

set it to the "closed" mark (2, Fig. 27).

28

Fig. 27

When not using the extraction, tightly

close the opening for the extraction

hose using the silicone stopper (E) included in the scope of delivery.

Reasons:

E

1. To prevent section waste from falling into the

opening.

2. To prevent cold from escaping from the

chamber.

3. To prevent moisture from penetrating into the

Fig. 28

chamber.

Operating Manual V 1.1 – 05/2007

Page 29

6. Installation

6.5.9 Installing the Section Extraction (Optional) – Use with Blade Holder CE Only

When the suction nozzles are changed, the adapt-

A

B

D

C

er (white) remains in the silicone hose. Pull off

the nozzle by rotating and pulling it gently and

firmly plug in the desired nozzle.

G

Fig. 29

• Silicone hose (A) with hose adapter 1 (B, to the filter

in the instrument), hose adapter 2 (C, for suction

nozzle D or F) and suction nozzle (D) – factory preassembled

• Silicone stopper (E)

• Chamber suction nozzle (F)

• Filter (G)

• Plastic clip (H), for parking the chamber suction

nozzle.

Mark for

suction

nozzle

C

H

Fig. 30

K

D

I

E

F

B

Ensure that the hose with the nozzle is

not installed against its "natural" curvature on the pressure plate of the

blade holder.

The tension acting on the hose can be minimized

by turning the red ring (Fig. 31, top right) clockwise so that the suction nozzle presses against

the pressure plate (I, Fig. 31).

Afterwards, fold the anti-roll guide (K) back onto

the pressure plate.

• The scope of delivery also includes 2 plastic

clips (H). These enable comfortable "parking"

of the chamber suction nozzle (F) during sectioning.

The clip must be glued in before switching on the

refrigeration. Before doing so, briefly degrease

the surface to ensure a secure hold.

Preferably, the clip should be attached outside

the working area, e.g. on the left inside wall of

the instrument.

If the extraction is not used for a long time, it is absolutely necessary to clean the extraction hose in order

to ensure maximum extraction capacity. To do so, place the hose in commercially available disinfectant or

alcohol. After several cleanings, the hose must be replaced (see order information on p. 49)!

Leica CM1950 – Cryostat

If the extraction nozzle (D) is not being

A

Fig. 31

used, it can be "parked" on one of the

two magnetic surfaces indicated in the

interior of the instrument.

29

Page 30

7. Instrument Controls

7.1 Control Panel Fields on the CM1950 – Control Panel Field 1

Display of actual and target chamber

temperatures

Fig. 32

Button to

enable/disable

vacuum

extractor,

Extraction

force intensity

selectable

from 1-5 (see

following page

for more

information)

Button to

enable/disable

the Peltier

element

Display of actual and target specimen

head temperatures

+/- buttons to

select

chamber

temperature

+/- buttons to

select

specimen

head

temperature

Max-Cool button to

select the maximum

low temperature of

the specimen head

directly (-50 °C)

+/- buttons to

select real

time

+/- buttons to

select defrost

Display of real time, defrost time

and error messages

"Melting

Snowflake"

button to

activate manual

defrost

time

ON/OFF button of

illumination

Press the key button to

lock/unlock the entire

keypad.

(Refer to following page

for activation of the

specimen head)

UVC

disinfection,

(short time 30 min,

long time 180 min)

30

EMERGENCY STOP switch to the right of control panel field 1 (motorized

instruments only)

For danger situations during motorized sectioning.

• Immediate stop of the sectioning process – motor stops – LED in E-Stop is

illuminated in red.

• Turning in direction of arrow cancels the stop – LED in E-Stop goes out.

• Select single stroke (Single) or continuous stroke (Cont.) operating

mode again.

Operating Manual V 1.1 – 05/2007

Page 31

7. Instrument Controls

A

• Press the "VAC" button to enable the vacuum extractor. The LED in the

"VAC" button is lit while the extractor is on. Press the button again to

12 o’clock

B

Position

6 o’clock

disable it.

• Use the knob to adjust the intensity of the vacuum.

A Optimal area for trimming and sectioning

• Trimming: Handwheel position 12 - 6 o’clock, valve open

Handwheel position 6 - 12 o’clock, valve closed

• Cutting: Handwheel position 12 - 3 o’clock, valve open all the way

Handwheel position 3 - 6 o’clock, valve half open

Handwheel position 6 - 12 o’clock, valve closed

B Optimal area for extraction from the chamber

• To clean the chamber, turn the knob to the red range.

The strength of the required extraction force depends on the following:

• Size of the specimen

• Sectioning speed

• Section thickness used

• The Peltier element provides additional cooling for the freezing stations.

After the button is pressed, the display changes from "PE" to 10",

indicating an additional cooling period of 10 minutes. The remaining cooling time is always shown in the display. Once only 4 minutes are remaining, a dot will appear after the "4". As of this time, the Peltier element may

be switched off early by pressing the button again.

Leica CM1950 Cryostat

Caution:

The specimen head and Peltier do not switch on until the chamber

temperature reaches -5°C, in order to prevent icing.

If the condenser (resting phase) is off and the Peltier is activated,

the digit 10 flashes until the condenser switches on again to prevent the Peltier from being destroyed when the condenser is not

running. When the condenser starts up, the flashing starts and the

10 minutes are counted down.

(For exact instructions for using the chamber, specimen head and

real time display fields, refer to the chapter on "Working with the

Instrument" on page 37 of this Operating Manual.)

31

Page 32

7. Instrument Controls

Control Panel Field 2 – Electric Coarse Feed, Sectioning and Trimming Thickness Display

Illuminates in

yellow when the

specimen is in

retraction.

Toggle TRIM and

SECT (LED

active).

Press approx. 3 sec.; "on" or

"off" appears (for the

retraction). Toggle using the

"+" or "-" key

Retraction: off = 0

on = 20 μm

In manual mode.

For motorized sectioning, the retraction value is fixed and cannot

be changed (see page 39 - lower

infobox).

In the "off" setting, there is

no retraction in manual,

automatic or rocking mode.

1

2

Fig. 33

For trimming values above a sec-

LED for trim

and section

thickness

display

Rocking mode – only in manual mode;

in rear area, i.e. approx. 12 - 3 o’clock position of

the handwheel (rock handwheel back and forth

a short distance)

Move specimen head backwards

quickly to home position (latched)

Move specimen head backwards slowly – pressing

briefly retracts the specimen 20 μm

Specimen head forwards – pressing briefly

advances the specimen 20μm

Specimen head fast

feed

tion thickness of 200 μm, the display flashes to expressly notify

the user of thick sections!

Setting section/trim thickness

Use the

- keys on control panel 2.

Range of section thickness: 1 - 100 μm

Values: 1.0μm - 5.0μm in 0.5μm steps

5.0μm - 20.0 μm in 1.0 μm steps

20.0μm - 60.0 μm in 5.0 μm steps

60.0μm -100.0 μm in 10.0 μm steps

32

Range of trim thickness: 1 - 600 μm

(Recommended for research applications)

Values: 1.0 μm - 10.0 μm in 1.0 μm steps

10.0μm - 20.0 μm in 2.0 μm steps

20.0μm - 50.0 μm in 5.0 μm steps

50.0 μm - 100.0 μm in 10.0 μm steps

100.0 μm - 600.0 μm in 50.0 μm steps

Trimming section thickness setting range:

(Recommended for clinical applications)

Values: 10μm, 20μm, 30 μm, 40 μm,

Operating Manual V 1.1 – 05/2007

Page 33

Coarse feed functions

The two-speed electric coarse feed is designed to quickly position the specimen in relation to the knife. The buttons with double arrows move the specimen at 900 μm/s; the buttons with single arrows move it at 300 μm/s.

Retracting the specimen head from the knife

• Pressing once starts the rapid backwards movement to the rear end

1

position (Home position).

The LED (1) flashes while the specimen head is in motion.

fast

The LED (1) lights up when the rear end position (Hp.) has been reached.

• The retraction can be stopped by pressing one of the coarse drive buttons.

• The rapid backwards movement to the rear end position (Hp.) starts.

The motion continues as long as the button is held.

• A brief press of the button retracts the specimen by 20μm.

slow

7. Instrument Controls

Advancing the specimen toward the knife

• Start the slow forwards movement to the knife.

To feed the specimen, press and hold the button.

slow

• Pressing the button briefly results in a feed motion of 20μm.

• Start the fast forwards movement to the knife.

2

• The LED (2) flashes while the specimen head is in motion.

The LED (2) lights up when the forward end position has been reached.

fast

Manual sectioning mode

Select ROCK operating mode (LED active) – retraction must be enabled!

• For sectioning, turn the handwheel a short distance (approx. 1/4 turn)

forwards and back (rocking mode) – only possible at rear (handwheel in

approx. 12 - 3 o'clock position).

Every change in rotation direction is electronically detected and automatically translated into a specimen feed or retraction movement.

Leica CM1950 – Cryostat

33

Page 34

7. Instrument Controls

Control panel 3 – Motorized sectioning (optional)

Switching the sectioning mode

("CUT MODE") from continuous

stroke ("CONT") to single stroke

("SINGLE") (active)

Motor speed controller (0-100%)

Hold the button to section

at maximum speed.

Release the button to continue section-

ing at the previously selected speed

(see controller, above).

Switch from slow speed

range to fast speed range:

while switching on the instrument, press and hold

down the Vmax button.

Speed ranges

Slow: 0-50 strokes/min

Fast: 0-85 strokes/min

Vmax: 85-90 strokes/min

Sectioning modes

The instrument can be used in manual and motorized modes.

The following settings are available:

• Single stroke (SINGLE) or continuous stroke (CONT.) in automatic mode,

as well as

• ROCK (sectioning using handwheel) in manual mode.

Fig. 34

If emergency stop has been activated, the cutting mode must be selected again.

The red LED in the E-STOP field indicates

either:

• emergency-stop function active, or

• footswitch dummy (optional footswitch)

connected incorrectly or not at all.

The mechanical handwheel brake is enabled

when the yellow LED is lit in the M-STOP field.

The handwheel must also be locked

when working on the specimen head.

Press to brake the handwheel electronically

(LED lit) – specimen stops in lower (6 o’clock)

position.

Can be used in any position.

1. Press the buttons at the same time to start

motorized sectioning.

2. To end the sectioning process, press RUN/STOP,

ENABLE or BRAKE.

- Specimen head stops at bottom (for BRAKE,

automatic electronic braking takes place).

3. For motorized sectioning, does not have to be

unlocked; continue working by pressing both

the RUN/STOP and ENABLE keys.

4. If, during manual work using handwheel, you have

braked using BRAKE also use BRAKE to release!

34

When switching the instrument on, no operating mode is active for

safety reasons.

Operating Manual V 1.1 – 05/2007

Page 35

7. Instrument Controls

Fig. 35

Disinfection

Duration - 30min

Duration - 180 min

UVC key - to activate / deactivate the disinfection cycle

and/or to acknowledge interruption of a disinfection

cycle.

The germicidal UV lamp is a simple and safe disinfection device

which considerably reduces the risk of infection.

Nevertheless, UV light disinfection cannot replace chemical

disinfection of the cryochamber at regular intervals.

UV light disinfection is effective only on those surfaces that are

directly illuminated.

Specimens and section waste must be thoroughly removed from

the cryochamber first (e. g. using the optional vacuum extractor, or

a paper towel soaked with Cryofect or alcoholic disinfectant).

Before UV disinfection, move the anti-roll guide to the side to

allow complete disinfection.

To start disinfection the sliding window must be

completely closed.

• Press UVC key once briefly to start the

30 min. mode

• Press UVC key once for a longer time

(approx. 4sec.) to start the 180 min. mode

Leica CM1950 – Cryostat

• Leica Cryofect is not available in all countries.

Opening the sliding window cancels the disinfection cycle. Press

the UVC key to acknowledge this.

When the keypad lock is activated (via the key button) the UV lamp

can be shut off only by opening the glass, as the UV keys are

locked.

The cancellation can be acknowledged only if the keypad lock is

disabled. Only then can the UV lamp be switched back on.

35

Page 36

8. Working with the Instrument

8.1 Preparing Cutting Tools, Specimen Discs and Preparation Aids

The knives are extremely sharp! Handle with care!

Never try to catch a falling knife!

• Place working materials such as the blade box or knives (in the knife case), brush, pincers or

preparation needles and, where applicable, specimen discs into the cryostat chamber.

• The necessary tools and preparation aids can

be precooled on the (optional) movable shelf,

making them available at all times in a convenient position for the user.

• In addition, specimen discs can be precooled

and stored in the storage system (see page 26,

Fig. 21).

8.2 Turning the Instrument On

The circuit breaker is used as power switch. The switch must be in the top

position for switching on and in the bottom position for switching off. The

switch must be accessible without obstruction.

• Close the sliding window.

Fig. 37

36

Fig. 36

The instrument must be switched on at least 5 hours before the

planned use.

To avoid frost formation always put the cover on the quick freeze

shelf.

Always cover the quick freeze shelf during breaks and overnight.

For installation of knife/blade holder

and installation in the chamber, refer

to optional accessories on page 50).

Operating Manual V 1.1 – 05/2007

Page 37

8.3 Configuring the Parameters

• Turn the lamp on or off.

• This button activates or deactivates the manual defrost of the cooling

chamber, specimen head or freeze shelf. (For more detailed handling

instructions, refer to the chapter on "Working with the Instrument" on

p. 39 of this Operating Manual.)

• Pressing the key button for approx. 5 sec. locks the entire keyboard

(the LEDs in the clock go out).

• Pressing the key button briefly, then the "-" key in the specimen head

control panel field, switches off the specimen head.

• Pressing the key button briefly, then the "+" key in the specimen head

control panel field, switches the specimen head back on.

8. Working with the Instrument

The instrument must be switched on at least 5 hours before the

planned use.

Leica CM1950 Cryostat

Programming the temperature of the cryochamber

• The temperature of the cryochamber is set and indicated on the control

panel marked with the cryostat symbol.

The actual temperature is the standard indication.

Briefly pressing the "+" or "-" button displays the target temperature.

Set the desired value via the "+" / "-" buttons. Pushing the "+" or "-" button

for more than 1 sec. increases or decreases the chamber temperature

continuously.

The actual value will be indicated 5 seconds after finishing the programming.

Refer to page 52 for a table with guide values. The temperature

values given there are based on long-term experience, but are

intended solely as guide values, as any tissue may require particular adjustments.

37

Page 38

8. Working with the Instrument

Programming the specimen temperature

• Select the desired temperature of the specimen.

• The specimen temperature is set and indicated on the control panel

marked with the specimen head symbol.

The actual temperature is the standard indication.

Briefly pressing the "+" or "-" button displays the target temperature.

Set the desired value via the "+" / "-" buttons. Pushing the "+" or "-" button

for more than 1 sec. increases or decreases the specimen temperature

continuously.

The actual value will be indicated 5 seconds after finishing the programming.

Caution:

The specimen head and Peltier do not switch on until the chamber

temperature reaches -5 °C, in order to prevent icing.

Specimen temperature - "Max-Cool" function

• The snowflake button for the Max-Cool function is in the panel with the

specimen head symbol.

Pressing the button sets the lowest possible specimen head temperature (-50°C) as the target temperature. The instrument adjusts the

maximum low temperature of the specimen head, i.e. -50°C.

• Push the snowflake button again to stop the "Max-Cool" function.

The temperature adjusts to the value programmed prior to activating the

"Max-Cool"-function.

• Alternate flashing of "LL" and the actual temperature indicates activation of the Max-Cool function.

38

Setting the time

• The clock time is set with the +/- buttons in the control panel marked

with the clock symbol.

To do so, set the current time using the "+" or "-" button below the small

clock symbol.

Pushing the "+" or "-" button for more than 1 sec. increases or decreases

the time continuously (auto-repeat function).

Operating Manual V 1.1 – 05/2007

Page 39

8. Working with the Instrument

Programming the defrost cycle

• Set the beginning of the automatic defrost cycle.

The automatic defrost cycle takes place once within 24 hours.

It is set with the "+"/"-" buttons on the right of the panel with the clock

.

symbol. The two buttons are marked by a melting snowflake

• Briefly press the "+" or "-" button for indication of the beginning of the

defrost cycle which has actually been set. At the same time, the LEDs

between the indication of hours and minutes are flashing.

• To change the beginning of the defrost cycle in steps of 15 minutes, push

the "+" or "-" key. When the "+" or "-" button is pushed for more than 1 s,

the defrost time value increases or decreases continuously.

Before starting the defrost cycle remove all samples from the

cryochamber!

• When the automatic defrost cycle begins, the specimen head tempera-

ture adjusts to a temperature between - 10°C and - 5°C (reduction of ice

formation). The specimen head cooling turns off. This is confirmed by the

flashing of the decimal points on the panel for the specimen cooling. The

specimen cooling (controlled to set value) automatically turns back on

after 4 hours, once the chamber temperature varies by less than 5 K from

the target temperature.

• If you want to turn the specimen cooling back on manually before the

automatic activation sets in, push the "+" or "-" button on the panel for the

specimen cooling and then the key button.

• The temperature of the specimen cooling first raises to +10°C and then

adjusts to the programmed specimen temperature.

Leica CM1950 Cryostat

Manual defrost for the freeze shelf (including Peltier element)

• Press the key for manual defrost

,

then the

key.

The manual defrost takes 12 min.

• Push the button and then the

After defrosting the freeze shelf, carefully wipe it out, as otherwise

a lot of water collects in the channel. Ice does not melt during

normal defrosting.

key again to stop the manual defrost.

39

Page 40

8. Working with the Instrument

Manual defrosting of the cryochamber

• Push the manual defrost button (with the melting snowflake) on the left

over the key button to activate the defrost cycle of the cryochamber on

demand.

• Activation is confirmed by an audible signal.

Then, push the "+" or "-" button on the panel for the cryochamber temperature.

•

• The manual defrost cycle (12 min.) is activated.

• There is a flashing indication of the temperature of the cryochamber

during the whole defrost cycle.

• If necessary, push the manual defrost button again to deactivate the

manual defrost cycle.

• When the manual defrost begins, the specimen head adjusts to a temperature between -10°C and -5°C (reduction of ice formation). The

specimen head cooling turns off. This is confirmed by the flashing of the

decimal points on the panel for the specimen cooling.

• Ten seconds after the manual defrost cycle has been completed, the

specimen cooling turns back on.

Before starting the defrost cycle, remove all specimens from the

cryochamber!

40

Manual defrosting of the specimen cooling

• Push the manual defrost button (with the melting snowflake) on the left

over the key button to activate the defrost cycle of the specimen head.

• Activation is confirmed by an audible signal.

• Then, push the "+" or "-" button on the panel for the specimen temperature.

• There is a flashing indication of the specimen temperature during the

defrost cycle.

• For 15 minutes, the specimen head is adjusted to a temperature of 45°C.

• Subsequently, the instrument adjusts to the specimen temperature which

has been programmed prior to the manual defrost cycle.

• If necessary, push the manual defrost button again to deactivate the

manual defrost cycle.

Press the key button, then the "+" button = specimen head on

Press the key button, then the "-" button = specimen head off

Operating Manual V 1.1 – 05/2007

Page 41

8. Working with the Instrument

Entering the trimming thickness

To switch from a trimming section thickness for research applications (1-600 μm) to a thickness for clinical applications (10, 20,

30 or 40 μm), press and hold down the TRIM/SECT key while

switching on the instrument.

• Press the TRIM/SECT button. TRIM mode is active if the LED at the top

right is illuminated.

• Set the desired trimming thickness using the "+" or "-" button in control

panel field 2. (Refer to page 32 for adjustable sequence of steps)

Entering the section thickness

• Press the TRIM/SECT button. SECT mode is active if the LED at the bot-

tom right is illuminated.

• Set the desired section thickness using the "+" or "-" button in control

panel field 2. (Refer to page 32 for adjustable sequence of steps)

Switching the retraction on or off in manual sectioning mode

• Press the TRIM/SECT button for approx. 3 sec. The LED in control panel

field 2 displays on or oFF .

Leica CM1950 Cryostat

• You can switch by pressing the "+" or "-" button.

• "Retraction on" means a specimen retraction of 20 μm in manual mode.

During motorized sectioning, the retraction value is speeddependent and cannot be changed by the user.

41

Page 42

8. Working with the Instrument

8.4 Working with the Precooled Cryostat

8.4.1 Preparatory Work

• Lock the handwheel in the top (12 o’clock) position.

• Cut the specimen to size outside of the cryostat.

• Select the precooled specimen disc, cover it with freezing compound,

then attach and orient the specimen.

• Attach the specimen disc and specimen to the Peltier position on the

freeze shelf. Activate the Peltier element and wait until the specimen is

completely frozen.

Specimens that have been frozen on the Peltier element are often