Kyocera FS-2100 Service Bulletin 2LV 0002 C291 TCSD

(Revised Issue 1) (Page.1/3)

Subject

Measures against the Erroneous Detection of the Top Tray

Paper Full

Model l:

FS-4300DN, FS-4200DN, FS-4100DN

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measure:

When the message below is mistakenly displayed, please check whether the message is cleared by lifting up

the actuator once. (If it cannot be cleared, please investigate another cause.)

If it can be reset by the operation above, please check the state of the sponge (X) after detaching the top

cover assembly. When the sponge is fallen between the ribs (same as the wrong state below), please reaffix it

to the PORON(R) sheet (No.1) according to the alignment.

Serial Nos. of the Affected Machines:

(Stocked machines at the sales companies)

(-->) PORON (R) was reaffixed at the warehouse. -> Please refer to the Excel file

“SN_of_Reworked_Machines_C291.

(Machines manufactured after this)

Please refer to the following.

Service Bulletin Ref. No. 2LV-0002 (C291)

<Date> November 19, 2012

* The following phenomenon is not expected on FS-2100DN and FS-2100D since the shape of

the ribs at their exit frame differs from the high-end models.

This time, the description with (-->) was revised from the previous information.

<Number of changes: 1> The serial numbers of the reworked machines were added.

Phenomenon

Although paper was not full on the top tray, the message “Top tray is full of paper. Remove the paper” might be

displayed.

Cause

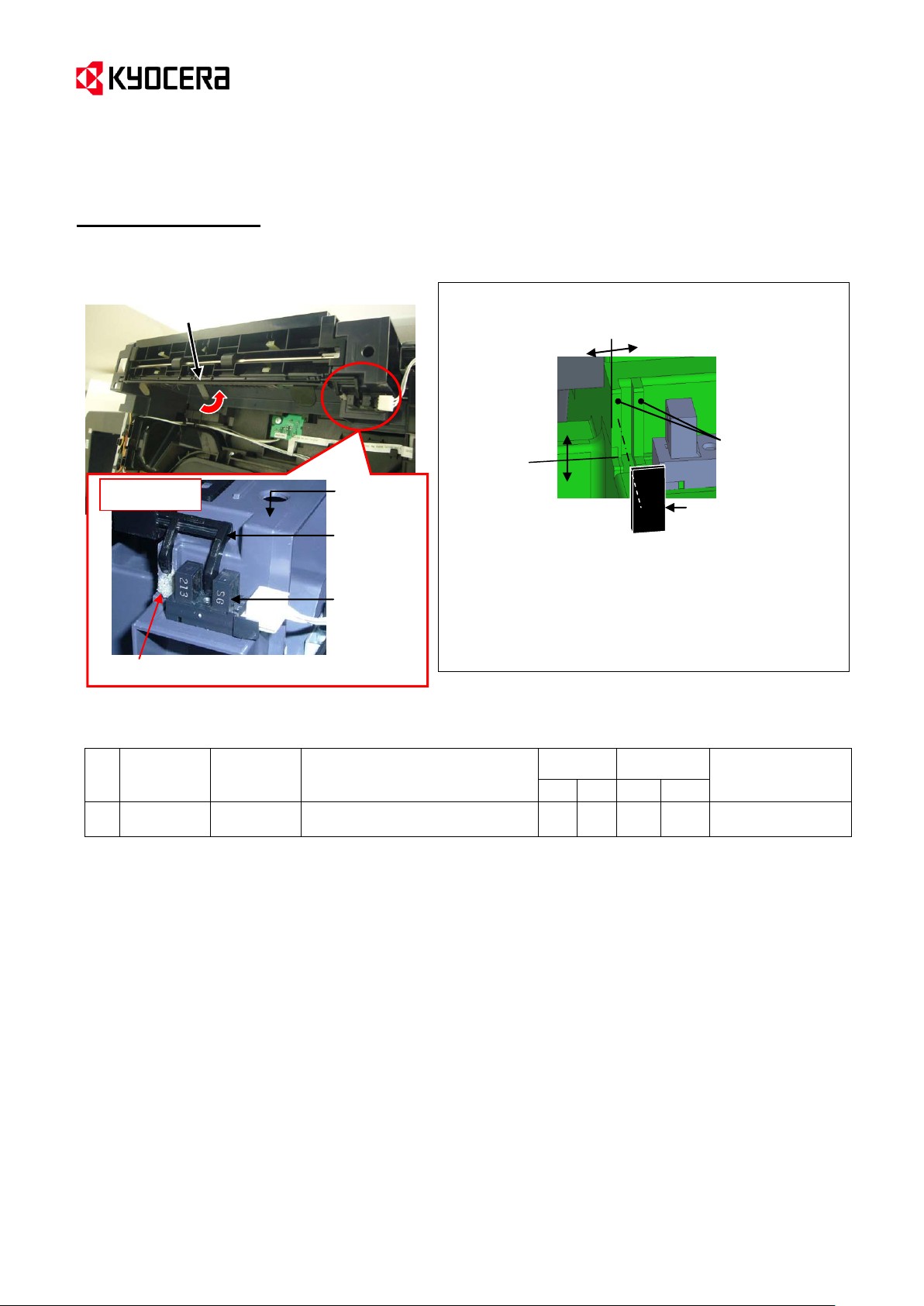

If the actuator (302LV2814_) to switch the eject full sensor was strongly pressed with hand or by the bundled

items toward the exit frame side (arrow A direction in the figure below) during packing the machine, the sponge

(X) might fall between the ribs (Y). As a result, the sensor light interruption of the actuator overrunning toward the

eject frame side might be out of the detectable range of the eject full sensor, which causes the erroneous top tray

paper full detection.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

(Revised Issue 1) (Page.2/3)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

1

------------

302LV28460

2LV28460

SEAL EXIT C

-

1

-

O

Actuator switching the eject

full sensor

Sensor light

interruption

part of the

actuator

Eject full

sensor

Sponge (X): Fell between the ribs

Wrong state

立ちリブ(Y)

A

A

A

<Alignment>

(View without the parts such as the actuator)

[Note]

- Please make sure to wear anti-static band when

executing this work.

- Please completely remove the sponge (X) and its

double-sided tape, and clean the affixing side with

alcohol.

Align to the edge of the inner rib.

0 mm

1 mm

Align to the

bottom of

the ribs.

0.5 mm

0 mm

PORON (R) parts

(No.1): 11x6 mm

(Thickness of 1.0 mm)

Eject frame

Ribs (Y)

Service Bulletin Ref. No. 2LV-0002 (C291)

Corrective Measures

The sponge (X) was changed to the PORON(R) sheet in order to prevent the part from falling between the ribs.

(Eject section without the top cover assembly)

<Date> November 19, 2012

* The sponge (X) is not individually supplied for field.

Technical Customer Service Division (TCSD)

KYOCERA Document Solutions Europe

Loading...

Loading...