Page 1

Data sheet

Liquid Level Switch

Type LLS 4000/4000U

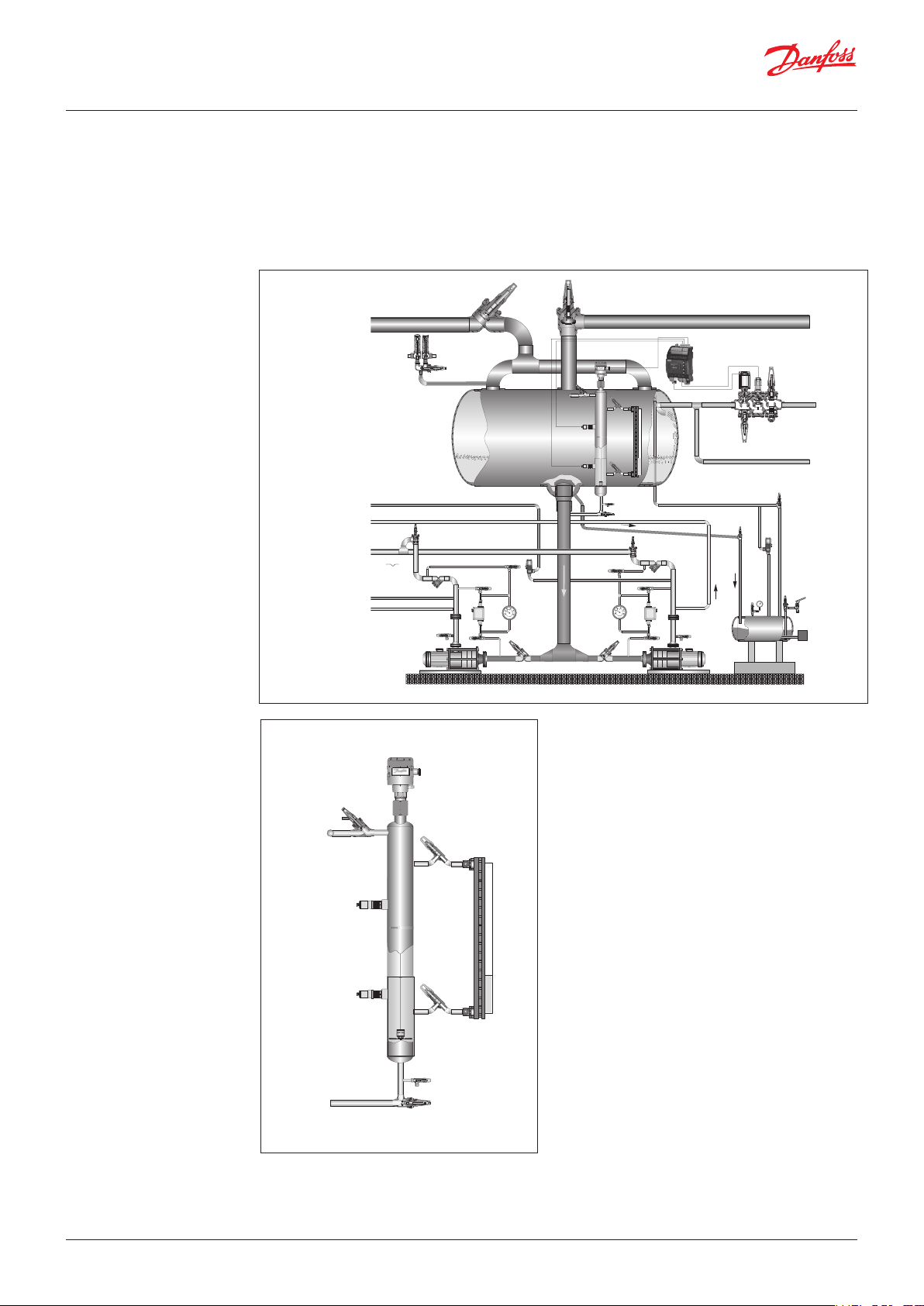

The LLS 4000/4000U liquid level switch is

designed to detect the state (gas or liquid) of the

refrigerant in front of the sensing head, while

installed in a wide range of refrigeration

applications.

The LLS level switch comes in 2 variants, LLS 4000

and LLS 4000U. They are identical except for the

connector thread interface to the system. The LLS

4000 is provided with G3/4" thread, while the LLS

4000U is provided with NPT 3/4" thread.

The LLS 4000/4000U liquid level switch is based

on the proven reflectometry measuring

technology(microwave level measurement)

adapted specifically for the new LLS 4000/4000U

switch.

LLS 4000/4000U liquid level switches can be used

to control the liquid level of many different

refrigerants in vessels, accumulators, receivers,

standpipes, etc.

The switches are normally installed in a pair of

two, controlling the upper liquid level and the

lower liquid level.

The level switch includes a relay that switches by

change in refrigerant state. The on site

configuration of the LLS allows the normally

open/closed relay setting depending on the

desired correlation.

Features

• Plug and play liquid level switch

• Easy installation and minimum or no need for

configuration

• Convenient communication with all units via

Bluetooth and a Danfoss app

• SIL2 compliant version

• 2 commonly used connection variants

• Maintenance free

• Replacement of electronic part without

removing mechanical part (no opening to

refrigerant)

• Applicable for ammonia and commonly used

H(C)FCs

• Well proven reflectometry measuring principle

For SIL applications a SIL2 version is available

with blocked configuration (not configurable).

All configuration and readings from the LLS

switch are performed through Bluetooth and a

downloadable special Danfoss app.

• Approvals: CE, PED, EMC, RED, ROHS, SIL2, FCC,

( EAC, IC pending)

• Conforms to:

Telecommunications Directive RED 2014/53/EU.

Low voltage directive 2014/35/EU.

EMC directive 2014/30/EU.

ROHS 2011/65/EU

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 1

Page 2

Contents

Data sheet | Liquid Level Switch, type LLS 4000/4000U

Features .............................................................................. 1

uct concept/applications ........................................................... 3

Prod

Connection types ...................................................................... 4

Measuring principle..................................................................... 4

e

ctrical installation/connection......................................................... 5

El

LED light indicators .................................................................... 5

Configurable parameters .... .. ..... .. ..... ... ..

Ordering ................

Dimensions and weights .................................................................7

Maintenance/service & calibration precautions............... ............................. 8

Bluetooth communication .............................................................. 8

Bluetooth configuration ................................................................ 9

Technical data .................................

Safety/ Approvals .......................................................................11

.. ... ..... ... .. .. ... ..... .. ... . 5

..... ... .... .. .... ... ..... ... .... ... ..... .. ..... .. ... 7

........................................10

2 | AI323832972563en-000101

© Danfoss | DCS (ms) | 2020.02

Page 3

Product concept/

Data sheet | Liquid Level Switch, type LLS 4000/4000U

applications

To control if a liquid level is within predened

allowed limits, two LLS 4000 are installed in an

upper and a lower limit position respectively. By

this setup the liquid level is between the two

level switches and the lower switch will sense

liquid, while the upper will sense gas.

In case the liquid level moves outside the limits,

one of the switches will sense opposite and

switch the built-in relay. This relay switch function

should be used for alarm settings. This is made

easy when connected to the system PLC.

SFA

+DSV

FIA

SNV

SCA-X

SVA

SNV

RT

260A

SNV

SVA

BSV

LLG

LLS 4000

LLS 4000

SVA

SVA

AKS 4100

LLG

SCA-X

SNV

SVA

SVA

260A

EKE

347

ICF 25-6-5A

SVA

SNV

SVA

BSV

SNV

SVA

QDV

15

FIA

SNV

RT

SNV

The LLS can be used wherever liquid levels of

ammonia and certain H(C)FC refrigerants must

be controlled.

Upper

LLS 4000/U

Lower

LLS 4000/U

The LLS comes in 2 versions:

- A standard version, which is applicable for most

refrigeration or processing plants, and is fully

configurable regarding type of liquid and relay

setting.

- A SIL2 version applicable for SIL compliant

process plants. This version is non-configurable

regarding relay setting (see section: Configurable

parameters) and is intended specific as the upper

level switch.

Liq. Level

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 3

Page 4

Data sheet | Liquid Level Switch, type LLS 4000/4000U

Connection types

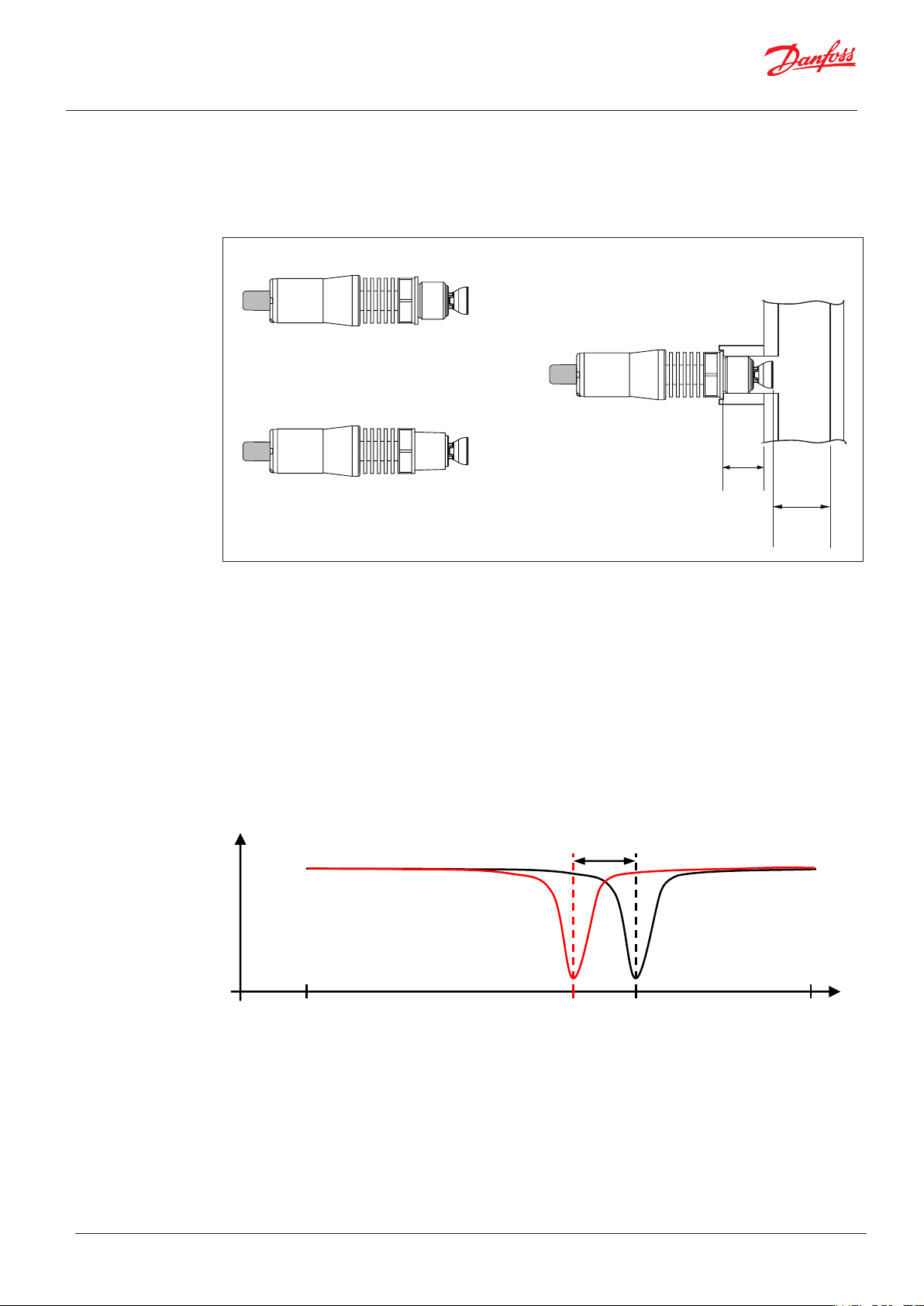

Beside the 2 versions the LLS also comes with 2

different thread types , LLS 4000 and LLS 4000U.

They are identical except for the connector

thread for installation to the system. The LLS

4000 is provided with G¾" thread, while the LLS

4000U is provided with NPT ¾" thread.

LLS 4000

LLS 4000U

G ¾”

NPT ¾”

For connection to the actual part of the system

appropriate weld connectors are needed. NPT

connectors are widespread available, while

Danfoss offers weld connectors for G3/4" thread

as accessory.

Please note geometric restrictions below.

Weld

connector

max

45 mm

1.8 in

min

25 mm

1 in

Measuring principle

The measurement principle of the LLS is based

on reflectometry with a 4.9 GHz to 6.2 GHz

linear sweep (Microwave switch technology).

The reflected signal is characterized by a

resonance frequency. The resonance frequency

in air is taken as a reference (fref). When the

sensing element is in contact with the liquid,

the resonance frequency is shifting to a lower

frequency. This is due to the change of the

dielectric constant of the medium.

P

R

4.9 GHz 6,2GHz

with

liquid

The point level switch monitors the resonance

frequency and indicates whether the sensing

element is surrounded by liquid or gas.

The figure below shows the reference frequency

with air (dielectric constant εr=1) in front of the

sensing element and with a liquid dielectric

constant εr> 1.35.

∆f ~ ε

r

without

liquid

f

liquid

f

ref

f

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 4

Page 5

Data sheet | Liquid Level Switch, type LLS 4000/4000U

1

2

3

4

+ Red

- White

Green

Black

Relay: 30 V DC

200 mA

24 V DC

+/- 25%

Electrical installation/

connection

The LLS 4000 level switch must be installed as

one unit (mechanical and electrical assembled)

without disassembly to avoid the need for

recalibration.

For powering the device, a low power source

(LPS) must be used with safety extra low

voltage output (SELV) and current limited to 8A

maximum

After connecting the M12 female cable to the

power supply and relay circuit the M12 plug can

be installed on the M12 male connector and the

power can be switched on.

At this stage the green light LED will turn on and

be visible through the transparent housing.

The LLS is now ready for configuration via the

Danfoss Bluetooth app (see section: Configurable

parameters).

Danfoss M12 cables (ordered separately)

M12 cable female x 2 meter

M12 cable female x 8 meter

1

2

4

3

LED light indicators

Configurable parameters

Red light LED

Yellow light LED

Green light LED

There are 3 LED indicators inside the LLS 4000

behind the transparent cover.

• Green indicates the state of power to the

switch.

If flashing: Bluetooth connection is

established

• Yellow indicates if liquid is in front of switch.

• Red indicates if alarm is present.

The set-up of the LLS 4000 is easy and simple,

since only few parameters in the LLS software are

configurable. These are:

Green

Black

Relay: 30 V DC

200 mA

- White

24 V DC

+/- 25%

+ Red

For plants where factory defaults are valid, the

installation and set-up is simply Plug & play.

| AI323832972563en-000101

5

• Media type - Ammonia or Freon (H(C)FC).

Factory default: Ammonia

• Relay NO (normally open) or NC (normally

closed)

Factory default: Normally closed

Below table shows possible configurations, relay

state for given configuration/liquid level and LED

indications

© Danfoss | DCS (ms) | 2020.02

Page 6

Data sheet | Liquid Level Switch, type LLS 4000/4000U

High Level

sensor

High Level

sensor

Low Level

sensor

Low Level

sensor

Level

LLS

4000/4000U

NO mode*

LLS

4000/4000U

NC mode*

SIL2 fixed

configura

tion

Voltage

connected

Green LED Yellow LED Red LED

Level

detection

LLS Fault

Voltage

supply

outside

spec.

LLS

4000/4000U

fault**

* Configuration dependent. Non-SIL2 fully configurable. SIL2 fixed configuration and only applicable

for High Level sensor

** For complete list of failure types refer to failure type section

*** Fault can be detected at any detected level, ie. 2 or all 3 lights on

–

***

–

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 6

Page 7

Data sheet | Liquid Level Switch, type LLS 4000/4000U

Ordering

LLS 4000/4000U

Description Code Number

LLS 4000 liquid level switch (excl. welding connector & M12 cable) G 3/4"

LLS 4000 SIL2 liquid level switch (excl. welding connector & M12 cable) G 3/4"

LLS 4000U liquid level switch (excl. welding connector & M12 cable) NPT 3/4"

LLS 4000U SIL2 liquid level switch (excl. welding connector & M12 cable) NPT 3/4"

Spare parts/Accessories

Description Code Number

Weld connector 3/4”G

LLS 4000/U Electronic top part, non SIL2

M12 Danfoss female cable, 2 meter (6.6 ft) 034G7073

M12 Danfoss female cable, 8 meter (26.2 ft) 034G7074

LLS 4000/U Inspection sealing kit

84H6001

0

84H6002

0

0

84H6003

84H6004

0

084H6012

084H601

0

84H6011

0

Dimensions and weights

LLS 4000

19,5

LLS 4000U

0.6

20 15

G3/4

34

H32

142,4

(mm)

5.6

71,3 2

M12x1

36

Weight: approx. 350 g / 0.77 lbs

2.80.78

7 | AI323832972563en-000101

0.77

3/4 NPT

H32

(in)

M12x1

1.4

Weight: approx. 350 g / 0.77 lbs

© Danfoss | DCS (ms) | 2020.02

Page 8

Maintenance/service &

Data sheet | Liquid Level Switch, type LLS 4000/4000U

calibration precautions

The LLS 4000 is considered maintenance free,

but there are a few precautions that needs

attention.

The fins shall be kept free of dirt, dust, paint

and oil etc. that potentially reduces the

thermal heat transfer from the fins to the air.

Ice build-up on the LLS switch reduces the

accessibility for the Bluetooth connection.

- 10 cm icecap reduces the distance from

app device to the LLS to 1 meter.

- 20 cm icecap is considered as the

maximum to be able to connect.

For LLS cleaning use soft cloth dry or wet or

compressed air.

If the electronic part is separated from the

mechanical part during installation, service or

maintenance, the ingress of any foreign

substances to the electronic or mechanical

part shall be avoided.

Generally the separating of electronic and

mechanical parts should be avoided due to

calibration, and the mixing of mechanical and

electronic parts from different switches must

be avoided. In case of the incident mixing of

mechanical and electronic parts from different

switches, subsequent recalibration might be

required.

Prior to calibration the following must be

ensured:

The LLS must be out of liquid state (in gas

phase), otherwise the calibration might end

up incorrect.

This can be secured by either emptying the

actual vessel or uninstall the LLS to ambient

air.

While in "dry" surroundings, connect power to

the LLS switch and perform the calibration.

Ice as such do not impact the functionality

of the product as far as the minimum

ambient temperature is respected.

Bluetooth

communication

The danfoss LLS app includes the calibration

possibility.

- A special Danfoss LLS app can be

downloaded from Android google play or IOS

app store.

- All communication with all LLS installed in a

plant is done by use of this app.

Communication can only happen with one

LLS at a time.

- Each LLS switch includes its own serial

number, which will appear in the app when

connected. At the same time the green light

LED in the actual connected LLS will be

flashing.

Bluetooth® word mark and logos are

registered trademarks of Bluetooth SIG Inc.

Android and Google Play are registered

trademark of Google LLC. App Store is

registered trademarks of Apple Inc.

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 8

Page 9

Data sheet | Liquid Level Switch, type LLS 4000/4000U

Bluetooth

configuration

The first time parameter setting of an

individual LLS switch is done by opening

of the app and performing a scan for

devices. The app will get a list of LLS that

are present at the actual location.

will include a name and the matching

serial number for each of the present LLS.

1.

Choose the first item on the list and

observe which LLS' green LED is

flashing.

2.

Log-in with the provided PIN code.

(For safety reason the PIN code should

be changed afterwards).

3.

Touch the Menu Icon.

4.

Touch the Log-in.

5.

Enter the Password provided.

6.

Rename the device to an up to 24

symbol name (8 symbols visible).

7.

Check the parameter settings and if

needed change one or both parameters

Media type/ Switch state.

8.

Note the ID: Name, serial number, media

type and switch state.

9.

Close the app and observe that the

green light stops flashing.

10. This LLS is now ready for operation.

11.

If more LLS are present choose the next

item on the list and repeat steps 1 to 10.

The list

The name and configurable parameters

of any LLS can be changed at any time.

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 9

Page 10

Data sheet | Liquid Level Switch, type LLS 4000/4000U

Technical data

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 10

Page 11

Data sheet | Liquid Level Switch, type LLS 4000/4000U

Safety/

Approvals

Warning! This is a Class A device.

This device may cause radio

interference in residential areas.

In case o

may be required to take

appropriate measures.

This instrument has to be mounted

on a metallic tank.

The device is intended to be used in

industrial areas.

f interference, the operator

General Warnings/precautions

- Every use that is not described in this

data sheet is considered incorrect and is

not authorized by the manufacturer.

- The LLS device should only be used with

approved media listed under Technical

data. Use with other media must be

validated by Danfoss before installation.

- Verify that the installation and operating

conditions of the device respect those

specified in this sheet, especially concerning

the supply voltage and environmental

conditions.

- All service and maintenance operations

must be performed by qualified personnel.

- Installation must comply with local

standards and legislation.

- Before carrying out any maintenance

operations on the device, disconnect the

device from the main power supply.

- Before unscrewing the LLS device from the

pipe or tank ensure that pipe or tank is

empty and not under pressure.

- Liability for injury or damage caused by

incorrect use of the device lies solely with

the user.

- Depending on the application, the metallic

part of the instrument may be hot or cold.

- If media detection or non-detection by

the level switch could generate a hazard

the SIL version and specific instructions

described in the safety manual (periodic

proof test) should be used. The SIL safety

manual can be downloaded from the

Danfoss web site.

USA/Canada:

This device complies with Part 15 of the

FCC Rules and with RSS-210 of Industry

Canada. Operation is subject to the

following two conditions. (1) this device

may not cause harmful interference, and

(2) this device must accept any

interference received, including

interference that may cause undesired

operation. Changes or modifications not

expressly approved by the party

responsible for compliance could void the

user's authority to operate the equipment.

This device complies with FCC and ISED RF

radiation exposure limits set forth for

general population. This device must be

installed to provide a separation distance

of at least 20cm from all persons and must

not be co-located or operating in

conjunction with any other antenna or

transmitter.

The Product Marketing name of the

instrument is ‘LLS 4000 series’.

Read and apply safety instructions contained in product documentation.

Contact : Danfoss A/S, 6430 Nordborg, Denmark

© Danfoss | DCS (ms) | 2020.02

AI323832972563en-000101 | 11

Loading...

Loading...