Page 1

OPTISENS PAS 2000

OPTISENS PAS 2000

OPTISENS PAS 2000OPTISENS PAS 2000

pH and ORP sensors

Handbook

Handbook

HandbookHandbook

Page 2

: IMPRINT

:::::::::::::::::::::::::::::::::::::::::::::::::::::

OPTISENS PAS 2000

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH & Co. KG.

Subject to change without notice.

Copyright 2008 by KROHNE Messtechnik GmbH & Co.KG - Ludwig-Krohne-Straße 5 - 47058

Duisburg

2

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 3

OPTISENS PAS 2000

1 Safety instructions......................................................................... 5

1.1 Intended use......................................................................................................... 5

1.2 Safety instructions from the manufacturer......................................................... 5

1.2.1 Copyright and data protection................................................................................... 5

1.2.2 Disclaimer.................................................................................................................. 5

1.2.3 Product liability and warranty ...................................................................................6

1.2.4 Information concerning the documentation .............................................................6

1.2.5 Display conventions................................................................................................... 7

1.3 Safety instructions for the operator .................................................................... 7

2 Device description ......................................................................... 8

2.1 Scope of delivery .................................................................................................. 8

2.2 Device description................................................................................................ 9

2.3 Nameplates........................................................................................................ 10

2.3.1 OPTISENS PAS 2000 pH sensor .............................................................................. 10

2.3.2 OPTISENS PAS 2000 ORP sensor............................................................................ 11

CONTENTS

3 Installation................................................................................... 12

3.1 Notes on installation.......................................................................................... 12

3.2 Storage & Transport .......................................................................................... 12

3.3 Installing the sensor .......................................................................................... 13

3.3.1 Basic installation instructions................................................................................. 13

3.3.2 Mounting to MAA 2000 telescopic rod immersion holder ...................................... 13

3.3.3 MAA 2000 sensor holder and telescopic rod...........................................................16

3.3.4 Assembly of PAS 2000 to MAA 2000 slide rail immersion holder .......................... 17

3.3.5 Cable connections ................................................................................................... 18

3.4 Mounting the electrode...................................................................................... 18

4 Electrical connections ................................................................. 20

4.1 Safety instructions ............................................................................................. 20

4.2 Cable connections.............................................................................................. 20

5 Operation ..................................................................................... 21

5.1 Sensor display.................................................................................................... 21

5.2 Menu for sensors ............................................................................................... 21

5.2.1 Menu for PAS 2000 pH............................................................................................. 21

5.2.2 Menu for PAS 2000 ORP ..........................................................................................23

5.3 Calibration.......................................................................................................... 24

5.3.1 Calibrating pH.......................................................................................................... 25

5.3.2 Adjusting ORP..........................................................................................................26

5.4 Scaling................................................................................................................ 26

6 Service......................................................................................... 27

6.1 Maintenance....................................................................................................... 27

6.1.1 Broken electrode..................................................................................................... 27

www.krohne.com11/2008 • MA PAS 2000 R04 en

3

Page 4

CONTENTS

6.1.2 Error messages .......................................................................................................27

6.1.3 Incorrect measurements......................................................................................... 28

6.1.4 Cleaning of the flushing nozzle ............................................................................... 28

6.2 Cleaning ............................................................................................................. 28

6.3 Spare parts availability ...................................................................................... 30

6.4 Availability of services........................................................................................ 30

6.5 Returning the device to the manufacturer ........................................................ 31

6.5.1 General information ................................................................................................ 31

6.5.2 Form (for copying) to accompany a returned device .............................................. 32

6.6 Disposal.............................................................................................................. 32

7 Technical data ............................................................................. 33

7.1 Measuring principle ........................................................................................... 33

7.2 Data table ........................................................................................................... 34

7.3 Dimensions & Weight......................................................................................... 36

OPTISENS PAS 2000

8 Appendix...................................................................................... 38

8.1 pH as a function of mV ....................................................................................... 38

8.2 pH temperature dependency ............................................................................. 39

8.3 Support information form.................................................................................. 40

8.4 Setup information form ..................................................................................... 41

9 KROHNE measuring technology - Product overview................... 44

4

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 5

OPTISENS PAS 2000

1.1 Intended use

The OPTISENS PAS 2000 Sensors are used to measure pH value or ORP potential in water and

wastewater treatment plants and other industrial applications.

1.2 Safety instructions from the manufacturer

1.2.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to German copyright. Contributions from

third parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

SAFETY INSTRUCTIONS 1

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.2.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect, incidental, punitive and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

www.krohne.com11/2008 • MA PAS 2000 R04 en

5

Page 6

1 SAFETY INSTRUCTIONS

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

1.2.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

OPTISENS PAS 2000

1.2.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

6

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 7

OPTISENS PAS 2000

1.2.5 Display conventions

The following symbols are used to help you navigate this documentation more easily:

DANGER!

This symbol designates safety advice on handling electricity.

WARNING!

These warning signs must be observed without fail. Even only partial disregarding such

warnings can result in serious health damage, damage to the device itself or to parts of the

operator

CAUTION!

These warnings must be observed without fail. Even only partial disregarding such warnings can

lead to improper functioning of the device.

’

s plant.

SAFETY INSTRUCTIONS 1

LEGAL NOTICE!

This symbol designates information on statutory directives and standards.

NOTE!

This symbol designates important information for the handling of the device.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i CONSEQUENCE

CONSEQUENCE

CONSEQUENCECONSEQUENCE

This symbol designates all important consequences of the previous actions.

1.3 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com11/2008 • MA PAS 2000 R04 en

7

Page 8

2 DEVICE DESCRIPTION

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISENS PAS 2000

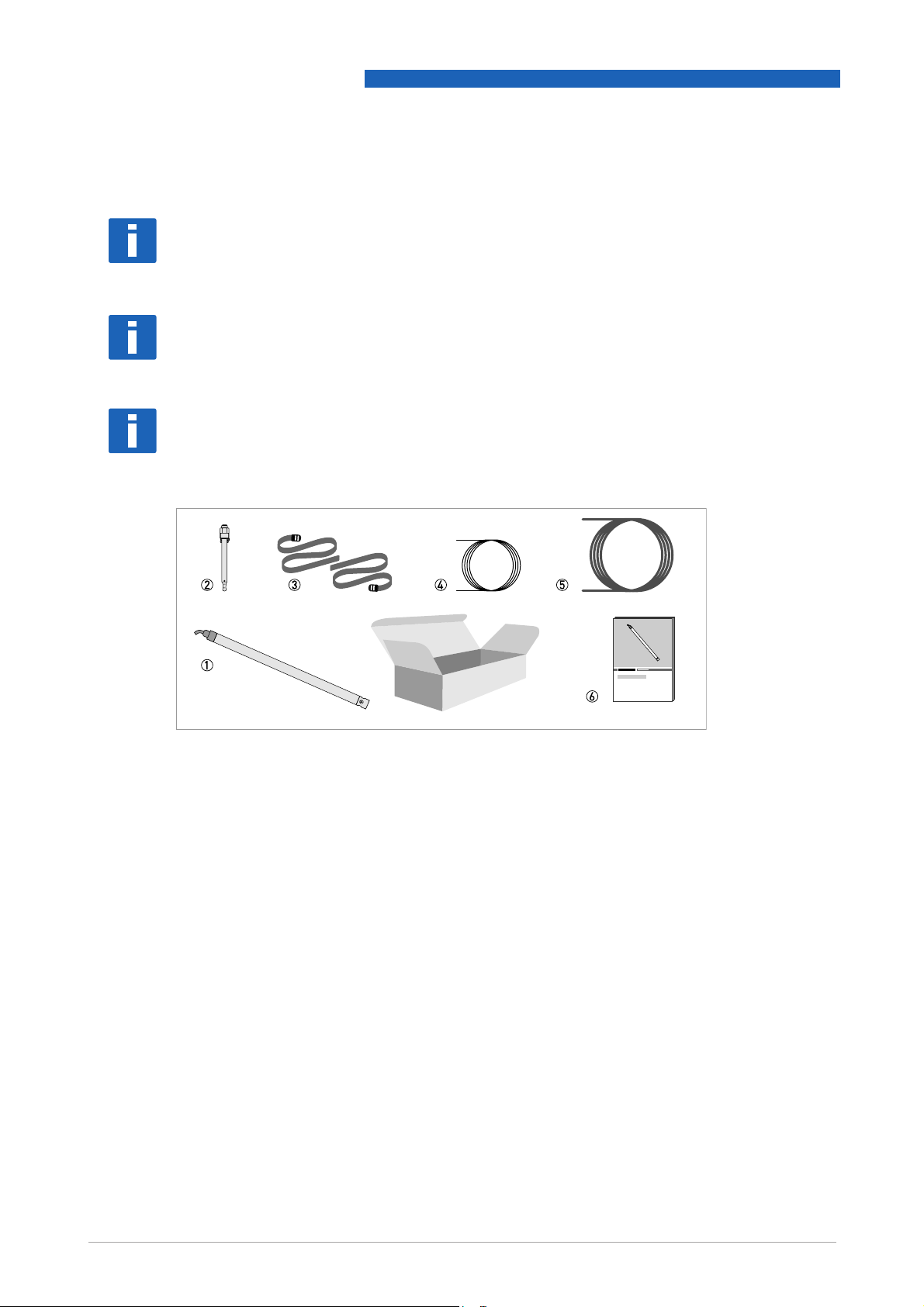

Figure 2-1: Standard scope of delivery for PAS 2000 pH sensor

1 PAS 2000 pH sensor

2 Gel-filled pH combination electrode

3 2 straps

4 10 m / 33 ft cable

5 10 m / 33 ft flush hose

6 Complete documentation

8

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 9

OPTISENS PAS 2000

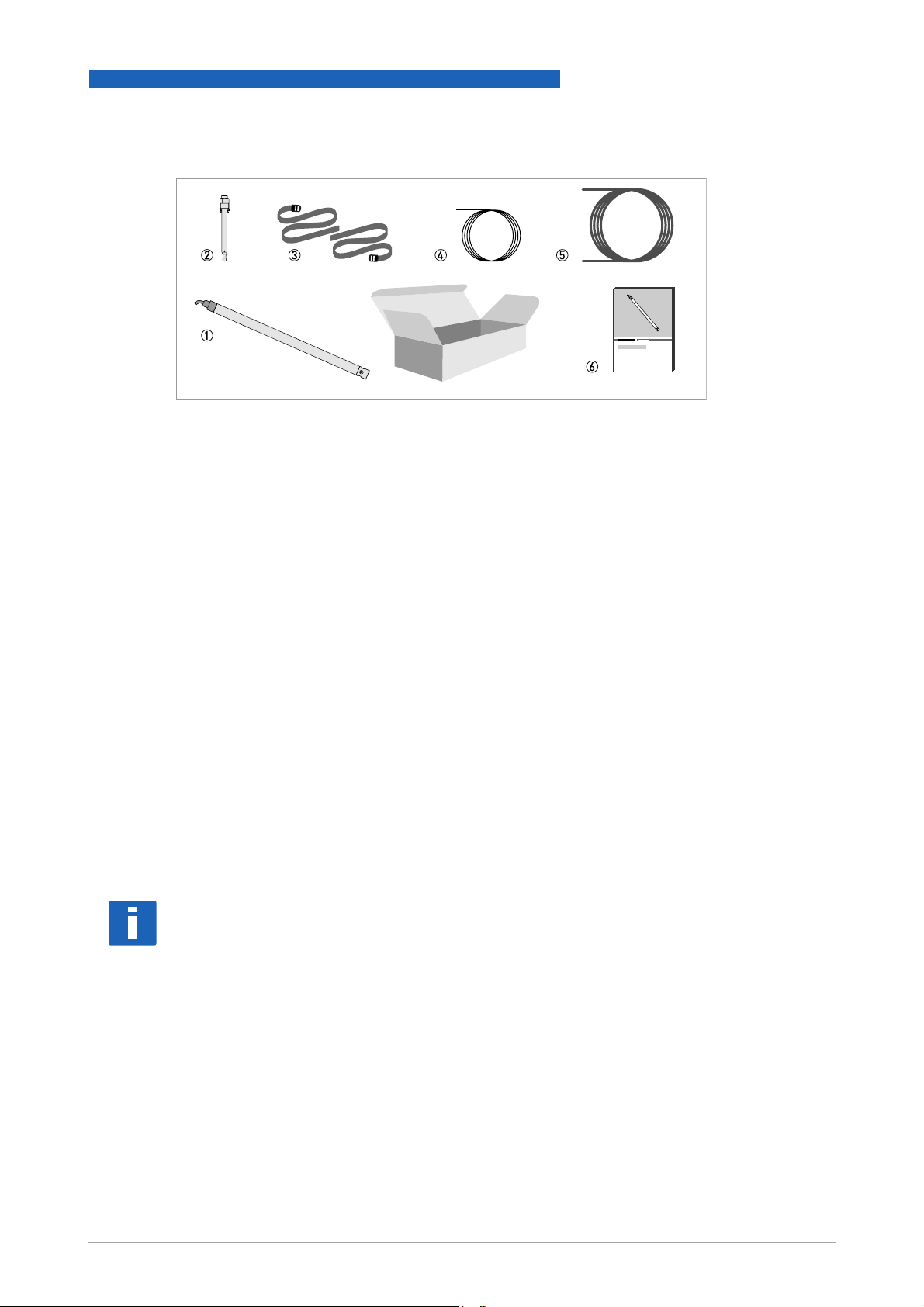

Figure 2-2: Standard scope of delivery for PAS 2000 ORP sensor

1 PAS 2000 ORP sensor

2 Gel-filled ORP combination electrode

3 2 straps

4 10 m / 33 ft cable

5 10 m / 33 ft flush hose

6 Complete documentation

DEVICE DESCRIPTION 2

Accessories available for PAS 2000 sensors

• MAA 2000 Insertion Holder, Telescopic Rod for PAS 2000 (inclusive telescopic rod plus rod

holder, handrail mounting bracket, sensor adapter)

• MAA 2000 Side Wall Mounting for PAS 2000

• Signal cable extension for OPTISENS 2000 sensors, 10 m / 33 ft

• Signal cable extension for OPTISENS 2000 sensors, 10 m / 33 ft

Consumables/Spare parts available for PAS 2000 sensors

• pH - electrode PAS 2000 pH

• ORP- electrode PAS 2000 ORP

2.2 Device description

INFORMATION!

This manual details installation procedures and operational features of the KROHNE

OPTISENS 2000 pH and ORP sensors. Menu navigation and technical data for the MAC 080

converter can be found in the OPTISENS MAC 080 manual.

The PAS 2000 sensors are manufactured in SIS2343 (316SS) stainless steel and PVC. The

sensors are mounted onto the MAA 2000 Adjustable telescopic rod holder using a POM adapter.

An adjustable stainless steel slide rail holder is available as an option. All PAS 2000 sensors

incorporate automatic cleaning as standard. The electronics is protected in the rugged casing,

ensuring its reliability in very demanding environments.

www.krohne.com11/2008 • MA PAS 2000 R04 en

9

Page 10

2 DEVICE DESCRIPTION

The sensor has a fixed, shielded 10 m / 33 ft cable used for signal transmission between the

sensor and the MAC 080 converter. The cable sheath is made of Hytrel and is highly resistant to

aggressive materials and fluids.

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.3.1 OPTISENS PAS 2000 pH sensor

OPTISENS PAS 2000

Figure 2-3: Nameplate OPTISENS PAS 2000 ph sensor

1 Manufacturer

2 Device type

3 Order code

4 Serial number

5 Sensor information

10

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 11

OPTISENS PAS 2000

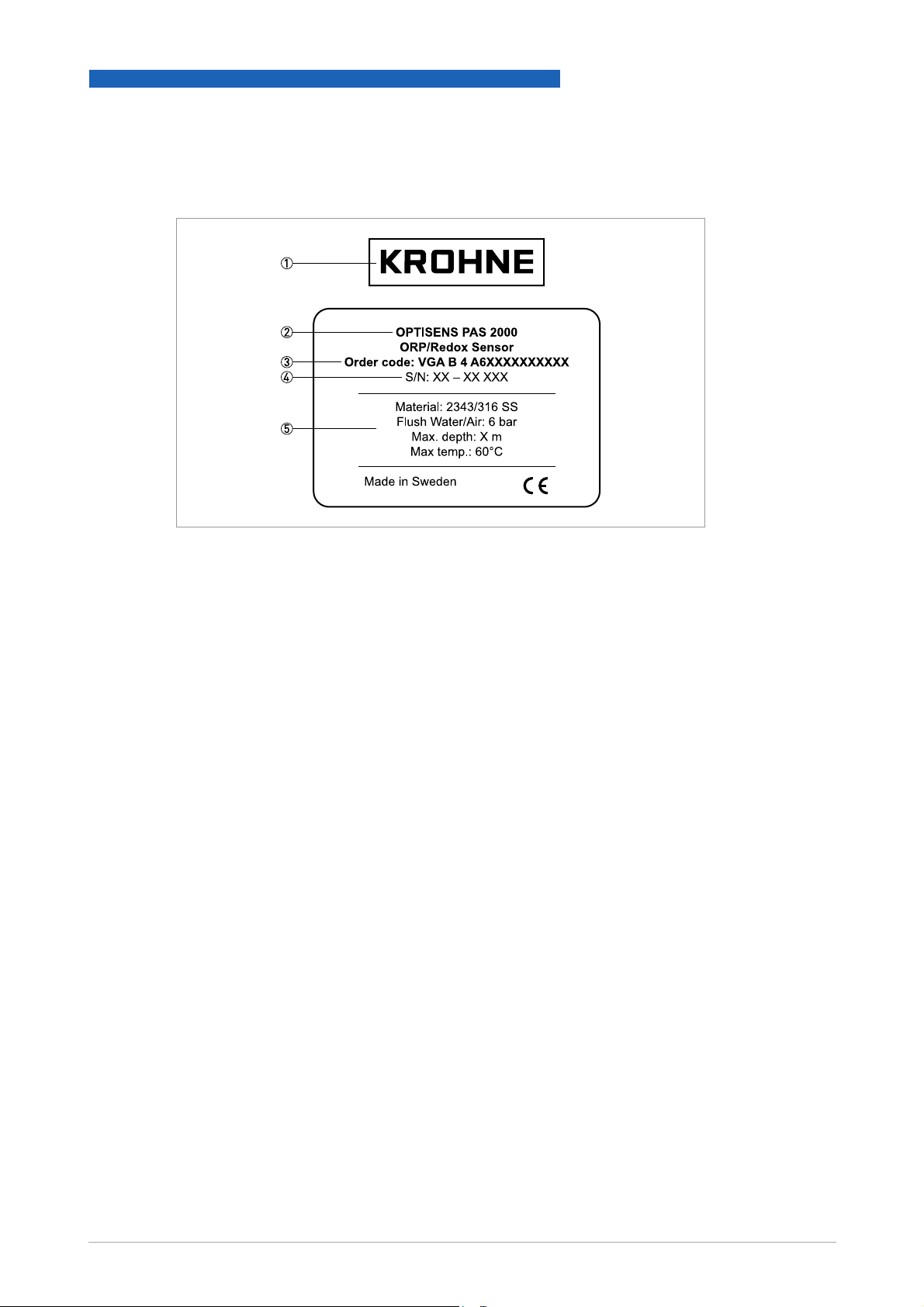

2.3.2 OPTISENS PAS 2000 ORP sensor

DEVICE DESCRIPTION 2

Figure 2-4: Nameplate OPTISENS PAS 2000 ORP

1 Manufacturer

2 Device type

3 Order code

4 Serial number

5 Sensor information

www.krohne.com11/2008 • MA PAS 2000 R04 en

11

Page 12

3 INSTALLATION

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage & Transport

OPTISENS PAS 2000

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• The original packaging is designed to protect the equipment. It has to be used if you the

device is transported or send back to the manufacturer.

12

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 13

OPTISENS PAS 2000

3.3 Installing the sensor

3.3.1 Basic installation instructions

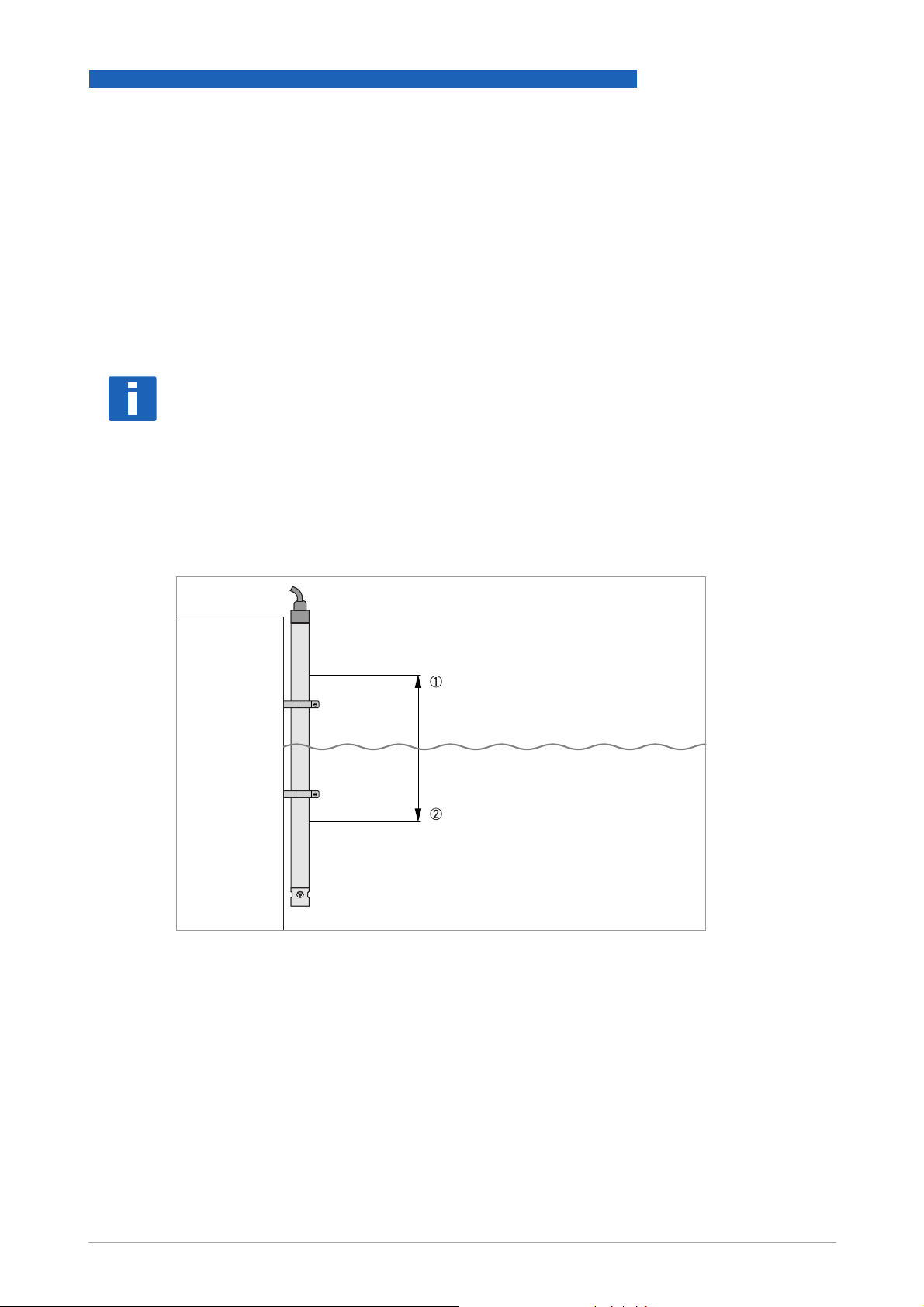

The electrode should be placed deep enough so that it always stays in the measuring media,

even when the level varies (see figure 3-1). The measuring ability of the electrode is influenced

negatively if the column of liquid to be measured is too large. For optimal results the column

should not exceed 300 mm / 12".

NOTE!

To protect the sensor from damage, the sensor should never be fully submerged into water.

Therefore a maximal immersion depth of 800 mm / 31" has to be maintained.

The sensor should be mounted in a vertical position. In some applications it may be desirable to

mount at a certain angle. In this case the angle from the horizontal plane should be greater than

or equal to 45°.

INSTALLATION 3

Figure 3-1: Installing the PAS 2000 in a flume

3.3.2 Mounting to MAA 2000 telescopic rod immersion holder

The mounting bracket of the telescopic rod is mounted to a handrail or a separate holder.

In case a handrail is not available, a mounting post with a vertical bar for sensor mounting can be

purchased from the manufacturer.

www.krohne.com11/2008 • MA PAS 2000 R04 en

13

Page 14

3 INSTALLATION

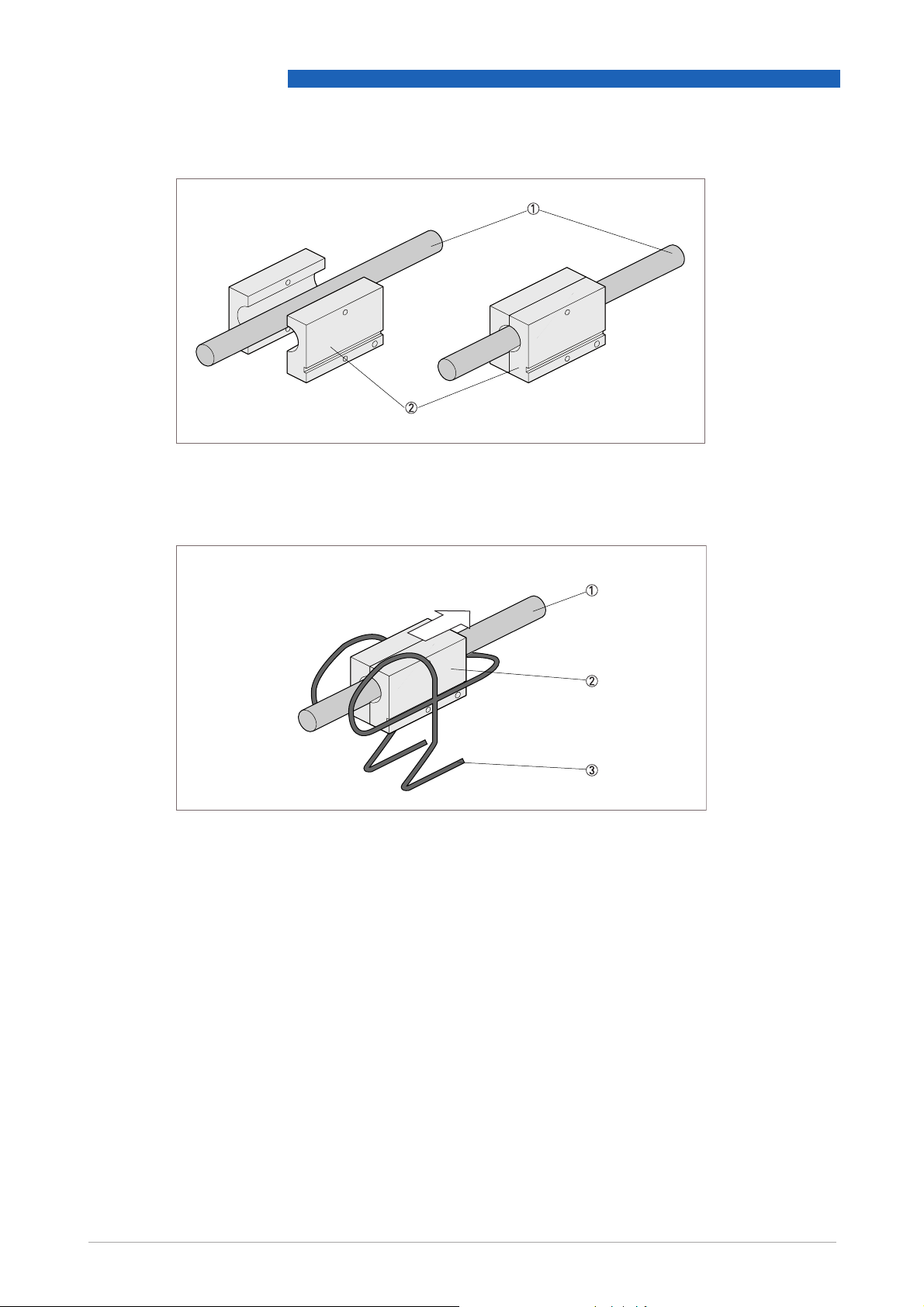

Figure 3-2: Placing the rod holder around the rod

1 Telescopic rod

2 Rod holder

OPTISENS PAS 2000

14

Figure 3-3: Inserting the rod holder into the mounting bracket

1 Telescopic rod

2 Rod holder

3 Mounting bracket

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 15

OPTISENS PAS 2000

INSTALLATION 3

Figure 3-4: OPTISENS MAA 2000 Telescopic rod immersion holders

1 Telescopic rod

2 Sensor holder

3 Handrail with mounting bracket attached

4 Rod holder

5 Mounting bracket

CAUTION!

Do not extend the rod sections beyond the black lines. This could lead to rod damage.

CAUTION!

The sensor should be mounted in a vertical position. In some applications it may be desirable to

mount at a certain angle. In this case the angle from the horizontal plane should be greater than

or equal to 45

°

.

www.krohne.com11/2008 • MA PAS 2000 R04 en

15

Page 16

3 INSTALLATION

Mounting to telescopic rod immersion holder

• Mount the flexible mounting bracket on an existing handrail or on a separate holder, diameter

32...50 mm / 1.3...2.0" or square 28...42 mm / 1.1...1.7". The bent lip on the mounting plate

shall be on top and faced toward the liquid or tank.

• Adjust the mounting bracket to the correct angle and tighten the nuts.

i The bracket shall be fixed to the rail, and must not be able to rotate around it.

• Adjust the length of the telescopic rod as necessary by twisting the nuts while holding the rod.

Do not extend the rod sections beyond the black lines. This could lead to rod damage.

• Insert the PVC rod holder with the telescopic rod into the mounting bracket. Make sure that

the guide tracks of the rod holder are properly seated in the bracket.

• Fasten the safety-locking clamp.

• Check that the mounting bracket is safely fixed to the rail for the spring to work the way it is

intended.

3.3.3 MAA 2000 sensor holder and telescopic rod

OPTISENS PAS 2000

In standard applications the PAS 2000 telescopic rod version gets delivered pre-assembled. In

case the assembly needs to be done on side, the sensor is inserted into the telescopic rod and

fixed with two POM half shells, which additionally integrate the flushing system (see chapter 8).

NOTE!

To ensure easy access to the electrode in case of maintenance, make sure that the removable

part of the electrode holder is fixed clearly outside of the POM sensor holder.

16

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 17

OPTISENS PAS 2000

INSTALLATION 3

3.3.4 Assembly of PAS 2000 to MAA 2000 slide rail immersion holder

As an alternative way of mounting the sensor, an adjustable slide rail holder is available.

1 Slide rail

2 Sensor

3 28 mm / 1.10" clamp

NOTE!

Please make sure that the assembly is mounted in a vertical position. In some applications it

may be desirable to mount at a certain angle. In this case the angle from the horizontal plane

should be greater than or equal to 45

°

.

Mounting instructions:

• Mount the slide rail assembly to the side wall of the basin or open channel using the two

predrilled holes. The adjustable limit stop should be on the bottom and the two sliding clamps

above.

• Take the two clamps off from the slide rail and mount them around the sensor housing. Please

make sure the two guide tracks line-up in one straight line to each other. See figure 3-4!

• Slide the sensor with the two clamps into the slide rail and make sure that the guide tracks of

the two clamps are properly seated.

• Adjust the sensor position as necessary (see chapter 3.3.2.) and fasten the limit stop.

www.krohne.com11/2008 • MA PAS 2000 R04 en

17

Page 18

3 INSTALLATION

3.3.5 Cable connections

Connect the sensor to the MAC 080 converter using the connector on the end of the attached

sensor cable. In the event that two sensors are to be connected to the same MAC 080 converter,

use the optional junction box.

See MAC 080 handbook for details.

3.4 Mounting the electrode

NOTE!

If the electrode has been in the cap for an extended period of time, salt crystals may need to be

rinsed away with water.

NOTE!

If the electrode cannot be immersed into the measuring media before it is put to use, the

electrode's small, plastic protective cover should be filled with a buffer solution of pH 7.

OPTISENS PAS 2000

• Connect the supply voltage. Remove the protective cap from the electrode probe.

• In order to mount an electrode the electrode holder at the lower end of the sensor must be

taken off.

• The electrode is mounted in the electrode holder by taking the enclosed nut, washer and O-

ring and threading them onto the electrode.

Note: Adjust the electrode position so that the diaphragm on the lower part of the electrode is

in contact with the measuring media.

• Tighten the nut with your hand.

• Remove the protective cover over the connector on top of the electrode and plug in the cable

coming from the electronic inside the sensor rod.

• Feed the cable into the sensor rod. It is easier to get the cable in place if the holder is turned

so the cable gets curled. Be careful not to damage the sealing or the cable.

• Mount the electrode holder back into the tube. Be careful not to damage the sealing.

18

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 19

OPTISENS PAS 2000

INSTALLATION 3

Figure 3-5: Mounting the electrode

1 Diaphragm

2 Electrode

3 Nut

4 Washer

5 O-ring

www.krohne.com11/2008 • MA PAS 2000 R04 en

19

Page 20

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

OPTISENS PAS 2000

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Cable connections

INFORMATION!

Please refer to the MAC 080 manual for detailed information.

Connect the sensor to the MAC 080 converter using the connector on the end of the attached

sensor cable. In the event that two sensors are to be connected to the same converter, use the

optional junction box.

20

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 21

OPTISENS PAS 2000

5.1 Sensor display

By simultaneously pressing ↓ and ^ you alter between MAC 080 main menu and the sensor

information display for the selected sensor. PAS 2000 has two information pages. The first one

shows in addition to the measured value maximum, minimum and average values for the last

24 hours. The values are based on hour values which means they may jump when a new hour

starts and the oldest is skipped.

The second information display shows the date of the last calibration (PAS 2000 pH only) and the

date the electrode was changed.

5.2 Menu for sensors

Use ↑ or ↓ to select the sensor in the main display. The menu for the selected sensor is accessed

by pressing ^ for five seconds. If the selected sensor is not active (the text No transmitter

shown) a warning is displayed that asks you to make another choice in order to show the sensor

menu.

OPERATION 5

No transmitter is

No transmitterNo transmitter

5.2.1 Menu for PAS 2000 pH

Menu "Settings"

Submenu Description

Tag

Tag Name of the sensor (10 characters) shown in the main display.

TagTag

I-Time

I-Time Integration time or dampening - can be set up to 999 seconds. Normal value is 5-10

I-TimeI-Time

Decimals

Decimals "1 or "2", number of decimals to show the measured value (only pH).

DecimalsDecimals

Reset day

Reset day "Yes" or "No", Yes resets the day calculation of min- max- and average.

Reset dayReset day

Analog

Analog "None" , "Out1", "Out2", "Out3", "Out4", "Out1+2", or "Out3+4". Pick which analog

AnalogAnalog

seconds.

output(s) to be used with sensor.

Menu "Calibrate"

Submenu Description

Take sample

Take sample "No", "Smart", or "manual". Refer to chapter 10 for details.

Take sampleTake sample

Cal Temp

Cal Temp Temperature at which calibration was done.

Cal TempCal Temp

Measure Temp

Measure Temp Temperature of measured media.

Measure TempMeasure Temp

Slope %

Slope % Shows the current condition of the electrode. A value between 93 % and 102 % is

Slope %Slope %

Sample 1 pH

Sample 1 pH Actual pH for the first buffer.

Sample 1 pHSample 1 pH

Sample 2 pH

Sample 2 pH Actual pH for the second buffer.

Sample 2 pHSample 2 pH

Calibrated

Calibrated Date of last air calibration.

CalibratedCalibrated

New electr.

New electr. Date when electrode was last changed. Push ^ to edit the date, then ^ again to store

New electr.New electr.

acceptable.

it.

www.krohne.com11/2008 • MA PAS 2000 R04 en

21

Page 22

5 OPERATION

Menu "Cleaning"

Submenu Description

Press ^ to go to the cleaning program

Cleaner

Cleaner "None", "Flush" or "Brush". Do not select “Brush” since this does not exist for this

CleanerCleaner

Interval min

Interval min 0...999 minutes, time between cleaning cycles.

Interval minInterval min

Length sec

Length sec 0...999 seconds, duration of flushing cycle.

Length secLength sec

Freeze sec

Freeze sec 0...999 seconds, extra freeze time of output signal after a flushing cycle.

Freeze secFreeze sec

Relay

Relay "-", "1", "2", "Along 1", or "Along 2". Select relay to operate solenoid for flush cycle if

RelayRelay

Next time

Next time The next scheduled cleaning time. Pushing ^ on this line will set the time to current

Next timeNext time

Menu "Scale / Alarm"

OPTISENS PAS 2000

sensor.

this sensor is a master with its own relay, or relay used by master if this sensor is a

slave. These are the same relays used for “Alarm relay

time and start a cleaning cycle. This could be used to test the "Flush" cycle.

Alarm relay” below.

Alarm relayAlarm relay

Submenu Description

Max

Max Measured value corresponding to 100 %, equal to 20 mA output signal (or 4 mA if 20-

MaxMax

Min

Min Measured value corresponding to 0 %, equal to 4 mA output signal (or 20 mA if 20-4 mA

MinMin

Hi-Alarm

Hi-Alarm Level that activates an alarm when exceeded, 0 = not in use.

Hi-AlarmHi-Alarm

Low-Alarm

Low-Alarm Level that activates an alarm when underpassed, 0 = not in use.

Low-AlarmLow-Alarm

Alarm Relay

Alarm Relay "-", "1", "2" or "1 and 2". Check that the relay is not being used for cleaning.

Alarm RelayAlarm Relay

4mA is used).

is used).

22

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 23

OPTISENS PAS 2000

Menu "System"

Submenu Description

Type

Type Type of sensor, read only.

TypeType

Serial

Serial Serial number of the sensor, read only.

Serial Serial

SoftW

SoftW Software version of the sensor, read only.

SoftWSoftW

Press ^ to go to "info" read only menu. This menu is for KROHNE internal use.

Info

Info

InfoInfo

MS 1 mV Millivolt value for the first calibration point.

MS 2 mV Millivolt value for the second calibration point.

pH 1 pH for the first calibration point.

pH 2 pH for the second calibration point.

RV 0 mV Raw value for 0 mV.

RV 200 mV Raw value for 200 mV.

Ch1 Raw value.

MS mV Electrode output in millivolt.

pH Current measure value.

Samp/s Number of samples per second.

Service

Service Not accessible for users.

ServiceService

OPERATION 5

5.2.2 Menu for PAS 2000 ORP

Menu "Settings"

Submenu Description

Tag

Tag Name of the sensor (10 characters) shown in the main display.

TagTag

I-Time

I-Time Integration time or dampening - can be set up to 999 seconds. Normal value is 5-10

I-TimeI-Time

Analog

Analog "None", "Out1", "Out2", "Out3", "Out4", "Out1+2" or "Out3+4". Pick which analog

AnalogAnalog

seconds.

output(s) to be used with sensor.

Menu "Calibrate"

Submenu Description

Adjust

Adjust "No", "Reset" or "Set". Automatic offset adjustment.

AdjustAdjust

Offset

Offset Offset for the electrode.

OffsetOffset

@Buffer

@Buffer Buffer used for adjustment, saved during the automatic offset adjustment.

@Buffer@Buffer

ORP mV

ORP mV Current reading.

ORP mVORP mV

New electr.

New electr. Date when electrode was last changed. Push ^ to edit the date, then ^ again to store it.

New electr.New electr.

www.krohne.com11/2008 • MA PAS 2000 R04 en

23

Page 24

5 OPERATION

Menu "Cleaning"

Submenu Description

Press ^ to go to the cleaning program

Cleaner

Cleaner "None", "Flush" or "Brush". Do not select "Brush" since this does not exist for this

CleanerCleaner

Interval min

Interval min 0...999 minutes, time between cleaning cycles.

Interval minInterval min

Length sec

Length sec 0...999 seconds, duration of flushing cycle.

Length secLength sec

Freeze sec

Freeze sec 0...999 seconds, extra freeze time of output signal after a flushing cycle.

Freeze secFreeze sec

Relay

Relay "-", "1", "2", "Along 1" or "Along 2". Select relay to operate solenoid for flush cycle if

RelayRelay

Next time

Next time The next scheduled cleaning time. Pushing ^ on this line will set the time to current

Next timeNext time

Menu "Scale / Alarm"

OPTISENS PAS 2000

sensor.

this sensor is a master with its own relay, or relay used by master if this sensor is a

slave. These are the same relays used for "Alarm relay"

time and start a cleaning cycle. This could be used to test the "Flush" cycle.

"Alarm relay" below.

"Alarm relay""Alarm relay"

Submenu Description

Max

Max Measured value corresponding to 100 %, equal to 20 mA output signal (or 4 mA if 20-

MaxMax

Min

Min Measured value corresponding to 0 %, equal to 4 mA output signal (or 20 mA if 20-4 mA

MinMin

Hi-Alarm

Hi-Alarm Level that activates an alarm when exceeded, 0 = not in use.

Hi-AlarmHi-Alarm

Low-Alarm

Low-Alarm Level that activates an alarm when underpassed, 0 = not in use.

Low-AlarmLow-Alarm

Alarm Relay

Alarm Relay "-", "1", "2" or ”1 and 2”. Check that the relay is not being used for cleaning.

Alarm RelayAlarm Relay

4mA is used).

is used).

Menu "System"

Submenu Description

Type

Type Type of sensor, read only.

TypeType

Serial

Serial Serial number of the sensor, read only.

Serial Serial

SoftW

SoftW Software version of the sensor, read only.

SoftWSoftW

Press ^ to go to "info" read only menu. This menu is for KROHNE internal use.

Info

Info

InfoInfo

RV 0 mV Raw value for 0 mV.

RV 1000 mV Raw value for 1000 mV.

Ch1 Raw value.

ORP mV Current reading in millivolt.

Samp/s Number of samples per second.

Service

Service Not accessible for users.

ServiceService

5.3 Calibration

The sensor is shipped pre-calibrated, but since all electrodes are different, the sensor must be

calibrated with its electrode to give a good measurement. The electrode degrades by time and

calibrations shall be done regularly following a maintenance schedule.

24

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 25

OPTISENS PAS 2000

The time between calibrations varies with the application, it is usually between one and ten

weeks. It is important that the sensor has been switched on for about 30 minutes prior to the

calibration in order to stabilize.

5.3.1 Calibrating pH

For a pH calibration there are two alternatives: smart or manual. Irrespective of the type of

calibration you chose, you need two pH buffers which both have a common, known temperature.

For a smart calibration you need two different buffer solutions with pH 4.00, 7.00, or 10.00. For a

manual calibration, two different buffer solutions can be used irrespective of the buffer value.

Remove the sensor and, if necessary the electrode as well, but make sure that the electrode is

still connected to the signal amplifier. Make sure that you have at least 2 standard buffers

available with pH 4 00, 7.00 or 10.00 of a known temperature (it is best to pour the buffers into

plastic cups). Now do the steps that follow:

OPERATION 5

• Enter the sensor menu. The output is frozen when the menu is opened.

• Open the "Calibrate" menu, select "Calibrate", then "Smart" or "Manual" and press ^.

• A window pops up and asks for the buffer temperature. Enter the temperature and press ^.

• MAC 080 will say "Put the electrode in buffer 1". Spray the electrode using clean water, then

immerse it in the first buffer, and press ^.

• The text will say "Waiting for stable signal xxx,x mV" (xxx,x is the millivolt signal from the

electrode). By pressing ^ you can select to abort the calibration or to accept the value shown.

• If smart calibration is used and MAC 080 recognizes the buffer, MAC 080 will suggest a pH

value showing the text "Accept smart calibration pH X.X". You can choose to accept the value

or to change it manually.

• If manual calibration is used MAC 080 will always ask for the value of the buffer, enter the

value and press ^.

• MAC 080 will now tell you "Put the electrode in buffer 2". Spray the electrode using clean

water, then immerse it in the second buffer, and press ^.

• The text will say "Waiting for stable signal xxx,x mV" (xxx,x is the millivolt signal from the

electrode). By pressing ^ you can select to abort the calibration or to accept the value shown.

• If smart calibration is used and MAC 080 recognizes the buffer, MAC 080 will suggest a pH

value showing the text "Accept smart calibration pH X.X". You can choose to accept the value

or to change it manually.

• If manual calibration is used MAC 080 will always ask for the value of the buffer, enter the

value and press ^.

• The second buffer is not accepted if it is less than 1 pH from buffer 1, if so the second

calibration will be repeated.

• When the calibration is finished the slope is shown in the display ("Slope XX%"). This gives an

indication of the shape of the electrode. A good electrode has a slope between 93 and 102 %.

• Press ^ to finish the calibration.

www.krohne.com11/2008 • MA PAS 2000 R04 en

25

Page 26

5 OPERATION

5.3.2 Adjusting ORP

The ORP sensor is not re-calibrated, an offset adjustment is done instead. The offset adjustment

can be done in two ways: automatic or manual. Irrespective of the way you chose, you need a

buffer with a known potential.

Remove the sensor and, if necessary the electrode as well, but make sure that the electrode is

still connected to the signal amplifier. Wipe clean the electrode before adjustment. Now do the

steps that follow:

• Spray the electrode using clean water, then immerse it in the first buffer, and wait for a stable

reading.

• Enter the sensor menu. The output is frozen when the menu is opened.

• Open the "Calibrate" menu, then select "Adjust", choose "Set" and press ^.

• A window pops up asking for the ORP potential. Enter it and then press ^. MAC 080 will

calculate the difference and use it as offset.

OPTISENS PAS 2000

5.4 Scaling

The Scale / Alarm

low boundaries for a 4...20 mA output signal. In addition, this menu allows the user to set high

and low alarm values to switch a relay when solids have reached critical points.

Max

Max sets the 20 mA point output

MaxMax

Min

Min sets the 4 mA point output (may be negative for special applications)

MinMin

Hi-Alarm

Hi-Alarm sets the high alarm set point; the value zero inactivates the alarm

Hi-AlarmHi-Alarm

Low-Alarm

Low-Alarm sets the low alarm set point; the value zero inactivates the alarm

Low-AlarmLow-Alarm

Scale / Alarm menu (see the OPTISENS MAC 080 manual) allows the user to set the high and

Scale / AlarmScale / Alarm

26

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 27

OPTISENS PAS 2000

6.1 Maintenance

PAS 2000 sensors are easy to maintain. An electrode maintenance schedule should be kept,

listing when it is removed and cleaned. When this is done, the electrode should be checked

against a known buffer solution. If the control value does not match, a re-calibration should be

made.

Regularly check that the sensor does not get damp or wet inside during cleaning and other

activities. Also check that the electrode is correctly mounted in its holder to avoid leaking.

CAUTION!

Use distilled water for cleaning, otherwise the calibration and in worst case the total life time of

the electrode might be compromised.

6.1.1 Broken electrode

SERVICE 6

Lightning or static discharges during thunder storms may cause damage to the electrode, and

could also damage the signal amplifier. The electrode is the most exposed point since it is in

direct contact with the water and, consequently, the ground connection for a discharge.

Physical damage to the electrode usually makes measuring impossible. Make sure that neither

electrode nor cable is damaged.

6.1.2 Error messages

Display text Explanation Cause Solution

Unkown buffer The smart calibration

Same buffer During calibration the

does not recognize the

current buffer from the

signal of the electrode.

PAS 2000 pH does not

perceive a difference of

buffers.

Unknown buffers have

been used.

Broken sensor,

damaged electronic

components or bad

cable connection.

Same buffers have been

used.

The electrode or the

electronic components

in the sensor may be

broken.

Use standard buffers

4.00, 7.00 and 10.00.

Check or reseat cable

connection. Inspect

electrode and exchange

it if damaged.

Make sure that you use

two different buffers

during calibration.

Inspect electrode and

exchange it if damaged.

www.krohne.com11/2008 • MA PAS 2000 R04 en

27

Page 28

6 SERVICE

6.1.3 Incorrect measurements

Problem Solution

Dirty electrode Clean with distilled water

Insufficient or poor reference solution in the

electrode

Change of "slope" due to age Recalibration

Old electrode which gives slope <93 % Change electrode

6.1.4 Cleaning of the flushing nozzle

If the flushing nozzle becomes plugged, it can usually be cleaned by back flushing it with clean

water. Before attempting to backflush, close the valve for the flush water source and disconnect

the sensor flushing hose from the solenoid valve. Then, place a 12 mm hose over the flush

nozzle and carefully open the water valve.

OPTISENS PAS 2000

Refill/change reference solution (only for refillable

electrodes)

The pressure should clear the line of solids. If backflushing does not work initially, try cleaning

the flushing nozzle with a needle. Try backflushing the nozzle again as described above until

clean water comes out at the solenoid valve end of the hose.

6.2 Cleaning

The sensor is equipped with a flushing nozzle. The nozzle is used to direct the cleaning liquid

supplied through a 6 mm hose that is mounted along the sensor housing to flush the electrode. A

solenoid valve that is wired to a relay in the MAC 080 converter controls the air or liquid (see

handbook OPTISENS MAC 080).

Compressed air is recommended for most applications.

CAUTION!

For PAS 2000 submersible sensor the highest allowed flushing pressure is 6 bar / 87 psi. When

using air, 2 bar / 29 psi is usually sufficient.

NOTE!

Pay attention to the requirements for protection against backflow, according to the

EN 1717 standard for drinking water devices. If possible, use plant reuse water or effluent water

for cleaning.

28

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 29

OPTISENS PAS 2000

Figure 6-1: Flushing system

1 Flush nozzle for automatic cleaning

NOTE!

In order to clean the sensor, flushing must be activated in the Settings

converter

SERVICE 6

Settings menu in the MAC 080

SettingsSettings

There are two different ways of cleaning a sensor: The sensor can either be cleaned as a master

or as a slave. Both options are described in the following instructions.

Cleaning the sensor as a master (sensor has its own relay)

• Select the sensor in the main menu by using ↑ or ↓.

• Press ^ for approximately five seconds to enter the sensor menu.

• Use ↑ or ↓ to select Cleaning

• In the Cleaning

Cleaning submenu, select Cleaner

CleaningCleaning

• Then specify the cleaning interval in minutes (Interval min

(Lenght sec

Lenght sec).

Lenght secLenght sec

Cleaning and press ^.

CleaningCleaning

Cleaner and set it to Flush

CleanerCleaner

Flush.

FlushFlush

Interval min) and the flush time in seconds

Interval minInterval min

• Specify the relay to be used according to the wiring inside the MAC 080 converter. For

example, if the solenoid is wired to relay #1, set Relay

• For sensors configured as masters, Next time

Next time displays the next time flush will be activated.

Next timeNext time

Relay to #1

RelayRelay

#1 for flushing.

#1#1

Pushing ^ will set it to current time and thus start cleaning.

• If needed, specify the extra freeze time in seconds (Freeze sec

Freeze sec).

Freeze secFreeze sec

www.krohne.com11/2008 • MA PAS 2000 R04 en

29

Page 30

6 SERVICE

Cleaning the sensor as a slave (along with another sensor)

• Select the sensor in the main menu by using ↑ or ↓.

• Press ^ for approximately five seconds to enter the sensor menu.

• Use ↑ or ↓ to select Cleaning

• The parameters Cleaner

the sensor being the master.

• Set Relay

Relay to Along #1

RelayRelay

• If needed, specify the extra freeze time in seconds (Freeze sec

Along #1 or Along #2

Along #1Along #1

Cleaning and press ^.

CleaningCleaning

Cleaner, Interval min

CleanerCleaner

6.3 Spare parts availability

The manufacturer adheres to the basic principle that operational spare parts for each device or

each important accessory part will be kept available for a period of 10 (ten) years after delivery of

the last production run for that device.

OPTISENS PAS 2000

Interval min and Lenght sec

Interval minInterval min

Along #2 depending on what relay the master sensor uses.

Along #2Along #2

Lenght sec in the Cleaning

Lenght secLenght sec

Freeze sec).

Freeze secFreeze sec

Cleaning submenu are set for

CleaningCleaning

Operational spare parts are defined as parts that are subject to faults in normal operation.

6.4 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, technical support and training.

NOTE!

For more precise information, please contact your local representative.

30

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 31

OPTISENS PAS 2000

6.5 Returning the device to the manufacturer

6.5.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

SERVICE 6

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

www.krohne.com11/2008 • MA PAS 2000 R04 en

31

Page 32

6 SERVICE

6.5.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

OPTISENS PAS 2000

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

6.6 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

32

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 33

OPTISENS PAS 2000

7.1 Measuring principle

The pH value is normally measured with an electrode where pH is expressed as a function of

voltage. Today's electrodes often contain both a measuring electrode and a reference electrode,

which in combination provide a voltage in linear proportion to the pH value. Electrodes internally

combined with a reference and measuring cell are divided into two categories: gel electrodes

and refillable electrodes. The gel electrode is the simpler and less expensive type. There are a

number of different types of refillable electrodes for different applications, each with different

internal solutions that are to be added at regular intervals. KROHNE provides gel-filled glass

electrodes.

To compensate for the temperature dependence of the electrode, the temperature of the media

is measured by the transmitter and compensated automatically via the MAC 080 software. The

temperature can also be read in the MAC 080 converter and used as secondary value when a

transmitter is configured to use two analogue outputs.

TECHNICAL DATA 7

NOTE!

The build in temperature measurement is not a precision measurement, but shall be seen as an

indication.

The temperature compensation can also be set manually to a fixed value via the MAC 080 menu.

All settings are made in the MAC 080 converter using a self-instructing menu controlled by just

three keys. The output signal is frozen when you switch to menu mode so that the output signal

will not change during procedures such a re-calibration.

The MAC 080 has two 4-20 mA outputs (extendable to four), and relay outputs for alarm and

cleaning of the electrode. The current pH/mV values and the temperature measurement of the

active sensor are continuously displayed in the MAC 080 display. Maximum, minimum and

average values for the last 24 hours can be obtained by pressing two buttons.

www.krohne.com11/2008 • MA PAS 2000 R04 en

33

Page 34

7 TECHNICAL DATA

7.2 Data table

Measuring system

Measuring principle Potentiometric measurement

Field of application Continuous measurement of pH

Modular design A typical measuring system

Measuring accuracy ± 1.5 % FS (Full scale) ± 1.5 % FS (Full scale)

Measuring range 0…14 pH -1500…+1500 mV (ORP)

OPTISENS PAS 2000

OPTISENS PAS 2000 pH OPTISENS PAS 2000 ORP

using combination electrodes

in waste water applications

consists of:

MAC 080 Multiparameter

Converter

1 (or up to 4) OPTISENS 2000

Sensors

Solenoid valves for flushing Solenoid valves for flushing

MAA 2000 mounting assemblies MAA 2000 mounting assemblies

Potentiometric measurement

using combination electrodes

Continuous measurement of ORP

in waste water applications

A typical measuring system

consists of:

MAC 080 Multiparameter

Converter

1 (or up to 4) OPTISENS 2000

Sensors

Operating conditions

Process temperature 0…60°C / 32…140°F 0…60°C / 32…140°F

Max. immersion depth 0.8 m / 2.6 ft 0.8 m / 2.6 ft

Calibration Two point calibration (smart or

manual) using two buffer

solutions

Offset calibration (automatic or

manual) using clean water and

one buffer solution

Installation conditions

PAS 2000 + MAA 2000 Telescopic

rod for immersion into basins

PAS 2000 + MAA 2000 Slide rail

for side wall mounting

Flushing With filtered air or clean water

Process connection Submerged in open channels/basins

The telescopic rod can be fixed to the handrail using a flexible spring

loaded mounting bracket

Fully extended: 2.7 m / 8.9 ft

Mounting bracket for:

- Round handrails ø = 32…50 mm / 1.3…2"

- Square cross-sections 28…42 mm / 1.1…1.7"

Installation on the side wall of basins; retractable holder with

adjustable stop

Pressure: 2…6bar / 29…87 psi

Hose: 1/4" external diameter; length: 10 m / 32.8 ft

Solenoid valve: available in 230 V and 117 V versions; up to 2 sensors

can be connected to one solenoid valve

34

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 35

OPTISENS PAS 2000

Materials

Enclosure 316SS 316SS

Cable feed through PVC PVC

Sensor holder for telescopic rod POM POM

Connection cable 5-pin M 12 contact; fixed on

Flush hose PE PE

Electrode Design: Combination electrode

TECHNICAL DATA 7

OPTISENS PAS 2000 pH OPTISENS PAS 2000 ORP

5-pin M 12 contact; fixed on

sensor side, shielded; 10 m /

32.8 ft long; insulation: Hytrel

12 mm / 0.47"; Length: 120 mm /

4.72"

PG13.5 threated cap PG13.5 threated cap

KCL-Gel KCL-Gel

Connector: KOAX Connector: KOAX

sensor side, shielded; 10 m /

32.8 ft long; insulation: Hytrel

Design: Combination electrode

12 mm / 0.47"; Length: 120 mm /

4.72"

Approvals

Protection class IP65 (Nema 4x)

Approval mark CE

EMC (89/336/EEC) Electromagnetic compatibility (EMC) in accordance with:

EN 61000-6-4:2001 Emission standard for industrial environments

EN 61000-6-2:2001 Immunity for industrial environments

Low Voltage Directive

(89/336/EEC)

Safety requirements for electrical equipment for measurement,

control, and laboratory use in accordance with EN 61010-1:2001

www.krohne.com11/2008 • MA PAS 2000 R04 en

35

Page 36

7 TECHNICAL DATA

7.3 Dimensions & Weight

OPTISENS PAS 2000

36

Dimensions [mm] Dimensions [inches]

a 1085 42.7

b 1000 39.4

c Ø28 Ø1.1

d 35 1.4

Weight [kg] Weight [lbs]

PAS 2000 length 1000 mm / 39.4" 1.8 4

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 37

OPTISENS PAS 2000

MAA 2000 sensor holder and telescopic rod

TECHNICAL DATA 7

1 Flexible telescopic rod

2 Large diameter sensor holder

3 Flush nozzle for automatic cleaning

Weight [kg] Weight [lbs]

MAA 2000 sensor holder 0.5 1.1

www.krohne.com11/2008 • MA PAS 2000 R04 en

37

Page 38

8 APPENDIX

8.1 pH as a function of mV

The pH-value is the negative logarithm of the hydrogen ion concentration, and it is directly

related to the proportion of hydrogen ions H

electrode measures excess or deficit of the hydrogen ions and gives a proportional millivolt

signal as output. The signal is 59.16 mV per 1 pH at 77°F. In clean water there is a total balance

between hydrogen ions and hydroxide ions, the output from the electrode is 0.0 mV and pH is 7.

The millivolt signal is measured by PAS 2000 pH and the corresponding pH is calculated in

MAC 080.

mV pH H+ ions, mol/l OH- ions, mol/l Example

414 0 1 0.00000000000001

355 1 0.1 0.0000000000001

296 2 0.01 0.000000000001 Coca Cola

237 3 0.001 0.00000000001

177 4 0.0001 0.0000000001 Orange juice

118 5 0.00001 0.000000001

59 6 0.000001 0.00000001 Milk

0 7 0.0000001 0.0000001 Clean water

-59 8 0.00000001 0.000001 Blood

-118 9 0.000000001 0.00001

-177 10 0.0000000001 0.0001

-237 11 0.00000000001 0.001

-296 12 0.000000000001 0.01

-355 13 0.0000000000001 0.1

-414 14 0.00000000000001 1 Sulfa

OPTISENS PAS 2000

+

to hydroxide ions OH- in the media. The pH-

38

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 39

OPTISENS PAS 2000

8.2 pH temperature dependency

The output from a pH-electrode varies with the temperature in a predictable way. The size of the

variation depends on both the temperature and the pH being measured.

°C °F pH pH pH pH pH pH pH pH pH pH pH pH

5 41 2.30 3.24 4.18 5.12 6.06 7.00 8.06 9.12 10.18 11.24 12.30 13.36

15 59 2.15 3.12 4.09 5.06 6.03 7.00 8.03 9.06 10.09 11.12 12.15 13.18

25 77 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00

35 95 1.85 2.88 3.91 4.94 5.97 7.00 7.97 8.94 9.91 10.88 11.85 12.82

45 113 1.70 2.76 3.82 4.88 5.94 7.00 7.94 8.88 9.82 10.76 11.70 12.64

55 131 1.55 2.64 3.73 4.82 5.91 7.00 7.91 88.2 9.73 10.64 11.55 12.46

65 149 1.40 2.52 3.64 4.76 5.88 7.00 7.88 8.76 9.64 10.52 11.40 12.28

75 167 1.25 2.40 3.55 4.70 5.85 7.00 7.85 8.70 9.55 10.40 11.25 12.10

85 185 1.10 2.28 3.46 4.64 5.82 7.00 7.82 8.64 9.46 10.28 11.10 11.92

95 203 0.95 2.16 3.37 4.58 5.79 7.00 7.79 8.58 9.37 10.16 10.95 11.74

APPENDIX 8

At pH 7 or 78°F the temperature error is zero. If temperature or pH changes the temperature

error is calculated using the following formula: 0.03 pH-difference / pH / 10°C. PAS 2000 pH has

a built in compensation for the temperature error provided that the correct temperature of

calibration buffers and measured media is entered.

www.krohne.com11/2008 • MA PAS 2000 R04 en

39

Page 40

8 APPENDIX

8.3 Support information form

Before calling the customer support, please collect the information in this form and have it at

hand.

Company:

Company: Name:

Company:Company:

Phone:

Phone: E-mail:

Phone:Phone:

Sensor type:

Sensor type: Position / Tag:

Sensor type:Sensor type:

Name:

Name:Name:

E-mail:

E-mail:E-mail:

Position / Tag:

Position / Tag:Position / Tag:

OPTISENS PAS 2000

First go to the converter menu by pressing ↑ and ^ simultaneously for five seconds. Then select System

and press ^. Write down the following information.

Version:

Version:

Version:Version:

Serial:

Serial:

Serial:Serial:

Box temp:

Box temp:

Box temp:Box temp:

Leave the converter menu by pressing ↑ and ^ simultaneously. Use ↑ and ↓ to select the sensor in the

main display. Go to the sensor menu by pressing ^ for five seconds. Then select System

Write down the following information.

Type:

Type: SoftW:

Type:Type:

Serial:

Serial:

Serial:Serial:

Select Info

Info, then press ^ to go to the Info menu.

InfoInfo

MS 1 mV

MS 1 mV 1 MS 2 mV

MS 1 mVMS 1 mV

pH 1

pH 1 1 pH 2

pH 1pH 1

RV 0 mV

RV 0 mV RV 200 mV

RV 0 mVRV 0 mV

RV 1000 mV

RV 1000 mV 2 Ch1

RV 1000 mVRV 1000 mV

MS mV

MS mV 1 ORP mV

MS mVMS mV

pH

pH 1

pHpH

Leave the menu by pressing ↑ and ^ simultaneously.

1 Only for PAS 2000 ph

2 Only for PAS 2000 ORP

SoftW:

SoftW:SoftW:

MS 2 mV 1

MS 2 mVMS 2 mV

pH 2 1

pH 2pH 2

RV 200 mV 1

RV 200 mVRV 200 mV

Ch1

Ch1Ch1

ORP mV 2

ORP mVORP mV

System and press ^.

SystemSystem

System

SystemSystem

40

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 41

OPTISENS PAS 2000

8.4 Setup information form

This form can be used to document the setup of the sensor.

Sensor type

Sensor type

Sensor typeSensor type

Position / Tag

Position / Tag

Position / TagPosition / Tag

In the System

System submenu of the sensor menu the following information can be collected:

SystemSystem

Serial

Serial

SerialSerial

SoftW

SoftW

SoftWSoftW

In the Settings

Settings submenu of the sensor menu the following parameters can be set:

SettingsSettings

I-time

I-time

I-timeI-time

APPENDIX 8

Decimals

Decimals

DecimalsDecimals

1

Analog

Analog

AnalogAnalog

In the Cleaning

Cleaning submenu of the sensor menu the following parameters can be set:

CleaningCleaning

Cleaner

Cleaner

CleanerCleaner

Cleaning interval

Cleaning interval

Cleaning intervalCleaning interval

Cleaning length

Cleaning length

Cleaning lengthCleaning length

Cleaning relay

Cleaning relay

Cleaning relayCleaning relay

In the Scale / Alarm

Scale / Alarm submenu of the sensor menu the following parameters can be set:

Scale / AlarmScale / Alarm

Max

Max

MaxMax

Min

Min

MinMin

High alarm

High alarm

High alarmHigh alarm

Low alarm

Low alarm

Low alarmLow alarm

Alarm relay

Alarm relay

Alarm relayAlarm relay

Leave the menu by pressing ↑ and ^ simultaneously.

1 Only for PAS 2000 pH

www.krohne.com11/2008 • MA PAS 2000 R04 en

41

Page 42

8 APPENDIX

OPTISENS PAS 2000

42

www.krohne.com 11/2008 • MA PAS 2000 R04 en

Page 43

OPTISENS PAS 2000

APPENDIX 8

www.krohne.com11/2008 • MA PAS 2000 R04 en

43

Page 44

OPTISENS PAS 2000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

KROHNE measuring technology - Product overview

• Electromagnetic flowmeters • Level measuring instruments

• Variable area flowmeters • Temperature measuring instruments

• Mass flowmeters • Pressure measuring instruments

• Ultrasonic flowmeters • Analysis

• Vortex flowmeters • Oil and gas industry

• Flow controllers

Addresses:

Great Britain

Germany

Northern sales office

KROHNE Messtechnik GmbH & Co. KG

Bremer Str. 133

D-21073 Hamburg

Phone:+49 (0)40 767 3340

Fax:+49 (0)40 767 33412

nord@krohne.com

ZIP code: 10000 - 29999, 49000 - 49999

Western and middle sales office

KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Straße

D-47058 Duisburg

Phone:+49 (0)203 301 4416

Fax:+49 (0)203 301 10416

west@krohne.com

ZIP code: 30000 - 34999, 37000 48000, 50000 - 53999, 57000 - 59999,

98000 - 99999

Southern sales office

KROHNE Messtechnik GmbH & Co. KG

Landsberger Str. 392

D-81241 Munich

Phone:+49 (0)89 121 5620

Fax:+49 (0)89 129 6190

sued@krohne.com

ZIP code: 0 - 9999, 80000 - 89999,

90000 - 97999

Southwestern sales office

KROHNE Messtechnik GmbH & Co. KG

Rüdesheimer Str. 40

D-65239 Hochheim/Main

Phone: +49(0)6146) 827 30

Fax:+49 (0)6146 827 312

rhein-main@krohne.com

ZIP code: 35000 - 36999, 54000 56999, 60000 - 79999

Instrumentation and control

equipment catalog

TABLAR Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg

Phone:+49 (0)2 03 305 88 0

Fax:+49 (0)2 03 305 8888

kontakt@tablar.de; www.tab lar.de

KROHNE sales

companies

International

Australia

Australia

AustraliaAustralia

KROHNE Australia Pty Ltd

Quantum Business Park 10/287

Victoria Rd Rydalmere NSW 2116

Phone: +61 2 8846 1700

Fax: +61 2 8846 1755

krohne@krohne.com.au

Austria

Austria

AustriaAustria

KROHNE Gesellschaft m.b.H.

Modecenterstraße 14

A-1030 Vienna

Phone:+43 (0)1/203 45 32

Fax:+43 (0)1/203 45 32 99

info@krohne.at

Belgium

Belgium

Belgium Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

Phone:+32 (0)2 4 66 00 10

Fax:+32 (0)2 4 66 08 00

krohne@krohne.be

Brazil

Brazil

Brazil Brazil

KROHNE Conaut Controles

Automaticos Ltda.

Estrada Das Águas Espraiadas, 230

C.P. 56 06835 - 080 EMBU - SP

Phone:+55 (0)11-4785-2700

Fax:+55 (0)11 4785-2768

conaut@conaut.com.br

China

China

ChinaChina

KROHNE Measurement Instruments

(Shanghai) Co. Ltd., (KMIC)

9th Floor, Puyuan Science Park,

Building A

396 Guilin Road

Shanghai 200233

Tel.: +86 (021) 6470 5656

Fax: +86 (021) 6451 6408

info@krohne-asia.com

Czech Republic

Czech Republic

Czech RepublicCzech Republic

Krohne CZ, spol. s r.o.

Sobìsická 156

63800 Brno

Phone: +420 (0)545.242 627

Fax: +420 (0)545 220 093

brno@krohne.cz

France

France

FranceFrance

KROHNE S.A.S.

Les Ors BP 98

F-26103 ROMANS Cedex

Phone:+33 (0)4 75 05 44 00

Fax:+33 (0)4 75 05 00 48

info@krohne.fr

Great Britain

Great BritainGreat Britain

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough

Northants NN8 6AE

Phone:+44 (0)19 33 408 500

Fax:+44 (0)19 33 408 501

info@krohne.co.uk

CIS

CIS

CISCIS

Kanex KROHNE Engineering AG

Business Centre "POLLARS", office

164

Derbenevskaya nab., 11-B

113114 Moscow/Russia

Tel. / Fax: +7 (0)495 913-68-41

Tel. / Fax: +7 (0)495 913-68-42

Tel. / Fax: +7 (0)495 913-68-43

Tel. / Fax: +7 (0)495 913-68-44

krohne@krohne.ru

India

India

IndiaIndia

Krohne Marshall Ltd.

A-34/35, M.I.D.C. Industrial Area,

H-Block

Pimpri Poona 411018

Phone:+91 (0)202 744 2020

Fax:+91 (0)202 744 2020

pcu@vsnl.net

Iran

Iran

IranIran

KROHNE Liaison Office

North Sohrevardi Ave. 26,

Sarmad St., Apt. #9

Tehran 15539

Phone: +9821 8874 5973

Fax: +9821 8850 1268

krohne@krohneiran.com

Italy

Italy

ItalyItaly

KROHNE Italia Srl.

Via V. Monti 75

I-20145 Milan

Phone:+39 02 4300 661

Fax:+39 02 4300 6666

info@krohne.it

Korea

Korea

KoreaKorea

KROHNE Korea

Room 508 Miwon Bldg 43

Yoido-Dong Youngd eungpo-Ku

Seoul, Korea

Phone: 00-82-2-782-1900

Fax: 00-82-2-780-1749

mail@krohne.co.kr

Netherlands

Netherlands

NetherlandsNetherlands

KROHNE Nederland B.V.

Kerkeplaat 14

NL-3313 LC Dordrecht

Phone:+31 (0)78 630 6200

Fax:+31 (0)78 630 6405

Service Direct: +31 (0)78 630 6222

info@krohne.nl

Norway

Norway

NorwayNorway

KROHNE Norway A.S.

Ekholtveien 114

NO-1521 Moss

Phone:+47 (0)69 264 860

Fax:+47 (0)69 267 333

postmaster@krohne.no

Poland

Poland

PolandPoland

KROHNE Polska Sp.z.o.o.

ul. Stary Rynek Oliwski 8a

80-324 Gdansk

Phone: +48 (0)58 520 9211

Fax.:+48 (0)58 520 9212

info@krohne.pl

Switzerland

Switzerland

SwitzerlandSwitzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

Phone:+41 (0)61 638 30 30

Fax:+41 (0)61 638 30 40

info@krohne.ch

Singapore

Singapore

SingaporeSingapore

Tokyo Keiso - KROHNE (Singapore)

Pte. Ltd.

14, International Bus iness Park,

Jurong East

Chiyoda Building, #01-01/02

Singapore 609922

Phone: (65) 6567 4548

Fax : (65) 6567 9874

tks@tokyokeiso-krohne.com.sg

Republic of South Africa

Republic of South Africa

Republic of South AfricaRepublic of South Africa

KROHNE Pty. Ltd.

Bushbock Close

Corporate Park South

Midrand, Gauteng

P.O. Box 2069

Midrand, 1685

Tel.: +27 (0)11 314 1391

Fax: +27 (0)11 314 1681

midrand@krohne.co.za

Spain

Spain

SpainSpain

I.I. KROHNE IBERIA, S.r.l.

Poligono Indust rial Nilo

Calle Brasil, nº. 5

28806 Alcalá de Henares Madrid

Phone: +34 (0)91 883 2152

Fax: +34 (0)91 883 4854

krohne@krohne.es

USA

USA

USAUSA

KROHNE, Inc.

7 Dearborn Road

Peabody, MA 01960

Phone: +1 (800) FLOWING

Phone: +1 (978) 535 6060 (in MA)

info@krohne.com

Representatives

Algeria

Argentina

Cameroon

Canada

Chile

Columbia

Croatia

Denmark

Ecuador

Egypt

Finland

Gabon

Ghana

Greece

Hong Kong

Hungary

Indonesia

Iran

Ireland

Israel

Ivory Coast

Japan

Jordan

Kuwait

Libya

Lithuania

Malaysia

Mauritius

Mexico

Morocco

New Zealand

Peru

Portugal

Romania

Saudi Arabia

Senegal

Slovakia

Slovenia

Sweden

Taiwan

Thailand

Tunisia

Turkey

Venezuela

Yugoslavia

Other countries

KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Str. 5

D-47058 Duisburg

Phone:+49 (0)203 301 0

Fax:+49 (0)203 301 389

export@krohne.com

© KROHNE 11/2008 MA PAS 2000 R04 en Subject to change without notice

www.krohne.com

Loading...

Loading...