Page 1

Supplementary instructions

Supplementary instructions

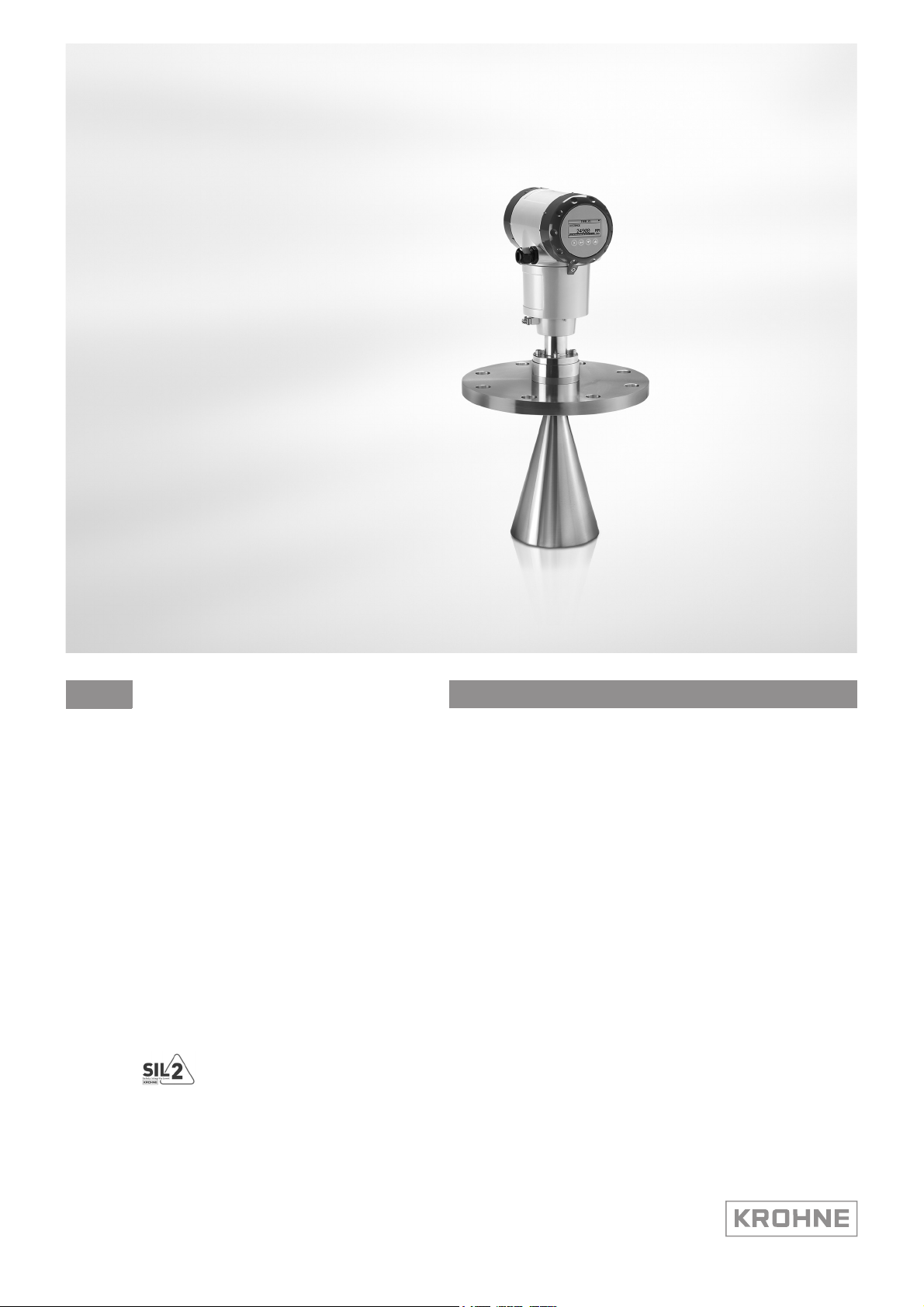

OPTIWAVE 5200 C

OPTIWAVE 5200 C

OPTIWAVE 5200 COPTIWAVE 5200 C

Supplementary instructions Supplementary instructions

2-wire / 10 GHz Radar (FMCW) Level Meter

Safety manual

Safety manual

Safety manualSafety manual

© KROHNE 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 2

CONTENTS

OPTIWAVE 5200 C

1 Introduction 4

1.1 Scope of the document..................................................................................................... 4

1.2 Revision history ................................................................................................................ 4

1.3 Device description ............................................................................................................ 5

1.4 Related documentation .................................................................................................... 5

1.5 Terms and definitions....................................................................................................... 6

2 System description 7

2.1 Peripheral equipment ...................................................................................................... 7

2.2 Software for use with the device...................................................................................... 7

3 Installation 8

4 Electrical connection 9

5 Start-up 10

5.1 General notes ................................................................................................................. 10

5.2 Device parameters ......................................................................................................... 10

6 Specification of safety function 11

6.1 Preliminary requirements.............................................................................................. 11

6.2 Safety function definition................................................................................................ 11

6.2.1 General notes........................................................................................................................ 11

6.2.2 Limits of application.............................................................................................................. 11

6.2.3 Safety function characteristics............................................................................................. 12

7 Operation 13

7.1 Conditions of use ............................................................................................................ 13

7.2 Failure state ................................................................................................................... 13

7.3 Operation mode .............................................................................................................. 14

7.4 Error conditions.............................................................................................................. 15

7.5 User parameters ............................................................................................................16

7.5.1 Limits for supervisor menu functions related to antenna configuration ............................ 16

7.5.2 Limits for supervisor menu functions related to device configuration ............................... 17

8 Service 20

8.1 Periodic maintenance..................................................................................................... 20

8.2 Keep the device clean..................................................................................................... 20

8.3 Availability of services .................................................................................................... 20

8.4 Proof tests ...................................................................................................................... 20

2

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 3

OPTIWAVE 5200 C

CONTENTS

8.5 Calibration procedure .................................................................................................... 23

8.5.1 General notes........................................................................................................................ 23

8.5.2 Current output check............................................................................................................ 24

8.5.3 Measuring range check (in process conditions) .................................................................. 25

8.6 Troubleshooting.............................................................................................................. 26

8.7 Returning the device to the manufacturer..................................................................... 26

8.7.1 General information.............................................................................................................. 26

8.7.2 Form (for copying) to accompany a returned device............................................................ 27

9 Technical data 28

9.1 General notes ................................................................................................................. 28

9.2 Assumptions ................................................................................................................... 28

9.3 Characteristics for the device safety function ............................................................... 29

9.4 SIL-specific technical data ............................................................................................. 29

9.5 Support for SIL-approved devices.................................................................................. 31

10 Appendix 32

10.1 Start-up report ............................................................................................................. 32

10.2 Proof test report form (for copying) ............................................................................. 33

11 Notes 34

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

3

Page 4

1 INTRODUCTION

1.1 Scope of the document

This document supplies functional safety data about the device. This data agrees with the

IEC 61508 standard.

WARNING!

The data in this supplement only contains the data applicable to the SIL approval. The technical

data for the standard version in the handbook (document [N1]) shall be valid in its current

version, provided that it is not rendered invalid or replaced by this supplement.

INFORMATION!

Installation, commissioning and maintenance may only be carried out by approved personnel.

1.2 Revision history

Edition Date Description

1 January 31, 2013 First issue.

2 February 25, 2013 Firmware version (converter) changes from 1.00.05 to 1.00.06.

OPTIWAVE 5200 C

4

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 5

OPTIWAVE 5200 C

1.3 Device description

This device is a 2-wire level transmitter that uses FMCW (Frequency Modulated Continuous

Wave) / Radar technology. Radar is a non-contact technology. It measures the distance, level,

mass, volume, flow rate and reflection of liquids, pastes and slurries .It is particularly suitable

for the level measurement of corrosive and viscous products.

Measurements are given through a 4...20 mA current output and can be displayed via a DTM

(device type manager) for remote communication or an integrated display screen with wizarddriven set-up and online help functions. Only the 4...20 mA current output is used as the safety

function.

INFORMATION!

The manufacturer designed and developed the device for safety integrity level (SIL) 2.

Data for the SIL approval is not taken from field experience (i.e. it is not

this method can give unrealistic data if assumptions are too optimistic.

When the device detects a measurement error, it supplies an output current less than 3.6 mA.

Although the device can be set to a high error value (≥ 21 mA), some hardware failures can cause

the device to give a low error value (≤ 3.6 mA). For more data, refer to

menu functions related to device configuration

INTRODUCTION 1

“

proven in use”) because

Limits for supervisor

on page 17 (2.4.2 RANGE I).

Refer also to "Device description" in the handbook (document [N1]).

1.4 Related documentation

[N1] OPTIWAVE 5200 Handbook

[N2] IEC 61508-1 to 7:2010 Functional safety of electrical / electronic / programmable

electronic safety-related systems

[N3] NAMUR Recommendation NE 043 Standardization of the Signal Level for the Failure

Information of Digital Transmitters

[N4] NAMUR Recommendation NE 053 Software of Field Devices and Signal Processing

Devices with Digital Electronics

[N5] OPTIWAVE 5200 Supplementary Instructions for ATEX applications

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

5

Page 6

1 INTRODUCTION

1.5 Terms and definitions

OPTIWAVE 5200 C

DC

D

Diagnostic Coverage of dangerous failures

Firmware Software embedded in the device.

FIT

Failure In Time (1×10-9 failures per hour)

FMCW Frequency-Modulated Continous-Wave. The measuring principle. For more

data, refer to “Technical Data” in the handbook (document [N1]).

FMEDA Failure Modes, Effects and Diagnostics Analysis

HFT Hardware Fault Tolerance

High demand or

continuous mode

Where the frequency of demands for operation made on a safety-related system

is greater than one time per year

I/O Input / output

λ

DD

λ

DU

λ

SD

λ

SU

Rate for dangerous detected failure

Rate for dangerous undetected failure

Rate for safe detected failure

Rate for safe undetected failure

Low demand mode Where the frequency of demands for operation made on a safety-related system

is no greater than one time per year

MTBF Mean Time Between Failures

MTTF Mean Time To Failure

MTTR Mean Time To Recovery

PFD

AVG

Average Probability of Failure on Demand

PFH Probability of a dangerous Failure per Hour

SFF Safe Failure Fraction

SIL Safety Integrity Level

SIS Safety Integrated System

TBF Tank bottom following. A device measurement mode. For more data, refer to

“Technical Data” in the handbook (document [N1]).

Type A system "Non-complex" system (all failure modes are well defined). For more data, refer

to subsection 7.4.3.1.2 of IEC 61508-2.

Type B system "Complex" system (all failure modes are not well defined). For more data, refer

to subsection 7.4.3.1.2 of IEC 61508-2.

T[Proof] Proof Test Interval

T[Repair] Time to Repair

T[Test] Internal Diagnostics Test Interval

1oo1 1 out of 1 channel architecture (single architecture performs the safety function)

1oo1D 1 out of 1 channel architecture with diagnostics

6

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 7

OPTIWAVE 5200 C

2.1 Peripheral equipment

You can use the device with the equipment that follows:

• A logic solver that can read 4...20 mA current input and low error alarm signals

• A PC or workstation (this is used only to change parameters)

• A HART

For more data, refer to "Start-up" in the handbook (document [N1]).

®

Handheld Controller (this is used only to change parameters)

2.2 Software for use with the device

You can change device parameters with the software that follows:

• PACTware™

• AMS™ Device Manager

For more data, refer to "Start-up" in the handbook (document [N1]).

SYSTEM DESCRIPTION 2

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

7

Page 8

3 INSTALLATION

WARNING!

If the device is to agree with the requirements for functional safety given in IEC 61508, you must

obey the installation instructions given in the handbook (document [N1]). The device must be

installed by approved personnel.

If the device is delivered with an antenna extension, antennas for stilling wells (DN80, DN100,

DN150 and DN200 Metallic Horn antennas) or the Wave Guide antenna, refer to the "Installation"

and "Operation" chapters in the handbook. Make sure that the values for menu items 2.3.5

STILLWELL D., 2.3.6 STILLWELL H. and 2.3.7 ANTENNA.EXT are correct.

Calibrate the device to make sure that the safety function operates correctly if:

• the device was delivered without an antenna, or

• the device is delivered with an antenna extension, antenna types for stilling wells (DN80,

DN100, DN150 and DN200 Metallic Horn antennas) or the Wave-Guide antenna

This maintenance task must be done and recorded by approved personnel. For more data, refer

to

Calibration procedure

For more data, refer to "Installation" in the handbook (document [N1]).

OPTIWAVE 5200 C

on page 23.

8

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 9

OPTIWAVE 5200 C

WARNING!

If the device is to agree with the requirements for functional safety given in IEC 61508, you must

obey the electrical connection instructions given in the handbook (document [N1]). The device

must be installed by approved personnel.

DANGER!

If the device is for use in potentially explosive atmospheres, you must obey the electrical

connection instructions given in the supplementary instructions for ATEX applications

(document [N5]). We recommend that you use a galvanically-isolated power supply.

If the device was delivered without an antenna, then calibrate the device to make sure that the

safety function operates correctly. This maintenance task must be done and recorded by

approved personnel. For more data, refer to

For more data, refer to “Electrical connection” in the handbook (document [N1]).

ELECTRICAL CONNECTION 4

Calibration procedure

on page 23.

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

9

Page 10

5 START-UP

5.1 General notes

DANGER!

Before you energize the device, make sure that the polarity and the supply voltage are correct.

DANGER!

Make sure that the device and the installation agree with the requirements of the Ex certificate

of compliance. For more data, refer to the supplementary instructions for Ex approvals.

Do a check of the device and tank before you energize the device:

• Are all the wetted components (antenna, flange and gaskets) resistant to the product in the

tank?

• Does the information on the signal converter nameplate agree with the operating data? Does

the order code on the nameplate show the SIL option (xF50xxx1xxxxxx or xF50xxx5xxxxxx)?

• Are the process temperature and pressure in the limits for operation of the device?

• Did you correctly install the device on the tank?

• Do the electrical connections agree with the national electrical codes?

OPTIWAVE 5200 C

Complete the start-up report on page 32.

WARNING!

If the device was delivered without an antenna, then do a device calibration to make sure that the

safety function operates correctly. For more data about the procedure, refer to Calibration

procedure on page 23

The manufacturer offers a range of services to support the customer. These services include

repair, maintenance, technical support and training.

5.2 Device parameters

WARNING!

The device agrees with the data given in the customer order. If you change the configuration of

the device after its delivery, the manufacturer does not accept responsibility for the incorrect

configuration of the SIL-approved version of the device. Use device parameters that are

applicable to the application, because conditions at the plant can have an effect on the functional

saftey of the measuring system.

For more data about device configuration, refer to the "Start-up" and "Operation" chapters in the

handbook (document [N1]). Also refer to

.

User parameters

on page 16.

10

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 11

OPTIWAVE 5200 C

6.1 Preliminary requirements

WARNING!

The data in this supplement only contains the data applicable to the SIL approval. The technical

data for the standard version in the handbook (document [N1]) shall be valid in its current

version, provided that it is not rendered invalid or replaced by this supplement.

6.2 Safety function definition

6.2.1 General notes

The device contains a safety function that agrees with the standard (document [N2]). This safety

function operates if there is a large difference between the level measurement and the level

shown as a current output.

If the device senses that there is a difference of more than 2.5% between the level measurement

and the level shown as a current output, then the current output changes to an error signal

(≤ 3.6 mA) in less than 30 seconds. The safety integrity level of this safety function is SIL2.

SPECIFICATION OF SAFETY FUNCTION 6

INFORMATION!

If menu item 2.4.5 ERROR DELAY = 0 s, then the current output changes to an error signal

(≤ 3.6 mA) in less than 10 seconds. If menu item 2.4.5 ERROR DELAY is more than 0 seconds,

then the current output changes to an error signal (≤ 3.6 mA) in 10 seconds + 2.4.5 ERROR

DELAY.

6.2.2 Limits of application

This version of the device has the restrictions that follow:

• Distance is measured in Direct mode

• Only the compact version (the signal converter is attached directly to the antenna) can be

used.

• It is a 2-wire loop-powered device.

• Use DN80 and DN100 Metallic Horn antenna only in stilling wells as specified in the handbook

(document [N1]).

For more data, refer to

Direct mode (only one product in the tank is permitted).

Direct modeDirect mode

SIL-specific technical data

on page 29.

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

11

Page 12

6 SPECIFICATION OF SAFETY FUNCTION

6.2.3 Safety function characteristics

The safety function uses only a 4...20 mA analog output signal to measure the level and give the

device status. The analog output signal has an accuracy of ±2.5%.

WARNING!

The device must have the applicable options and settings for the application. The ambient and

process conditions must agree with the technical data given in the handbook (document [N1])

and this document (safety manual). You must obey the installation instructions given in the

handbook (document [N1]).

CAUTION!

We recommend that the 4 and 20 mA limits of the measuring range are not in the top dead zone

(100 mm / 3.9

The shape of the tank bottom can have a large effect on the accuracy when the tank is almost

empty. We recommend that device is not used to measure the liquid when it is less than 300 mm

from the bottom of the tank.

For more data about the top dead zone, refer to the "Operation" and "Technical Data" chapters in

the handbook (document [N1]).

¨

below the antenna).

OPTIWAVE 5200 C

Function input

Function input None

Function inputFunction input

Function output

Function output 4…20 mA

Function outputFunction output

If the device finds a fault:

Error signal

Error signal ≤ 3.6 mA

Error signalError signal

If a logic solver is used, it must use low error alarm signals (current input ≤ 3.6 mA ) to set itself

to a fail-safe condition.

12

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 13

OPTIWAVE 5200 C

7.1 Conditions of use

WARNING!

Only approved personnel can change device settings. Keep a report of changes to the device

settings. These reports must include the date, the menu item (e.g. 2.3.1 TANK HEIGHT), the old

parameter and the new parameter.

The configuration is protected with a password. For more data on password protection and

device configuration, refer to the “Operation” chapter in the handbook (document [N1]).

7.2 Failure state

For any type of safe or dangerous detected failure, the device sets the current output to less than

3.6 mA. Although this value can also be set to a high error value (≥ 21 mA), some hardware

failures will always cause the device to give a low error value (≤ 3.6 mA). Thus, the output signal

for the fail-safe condition is less than 3.6 mA. For more data, refer to

functions related to device configuration

OPERATION 7

Limits for supervisor menu

on page 17 (2.4.2 RANGE I).

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

13

Page 14

7 OPERATION

7.3 Operation mode

In operational conditions, the device continuously measures the distance between the tank

connecting flange face / thread stop and the surface of the product.

The operation mode of the device is shown in the flow chart that follows:

OPTIWAVE 5200 C

1 Initial state (start the device / new measurement)

2 Make sure that sufficient energy is available

3 Is there sufficient energy?

3a No. There is not sufficient energy.

3b Yes. There is sufficient energy.

4 The device does an auto-diagnostic check at

intervals of 24 hours

5 Is there an error condition?

5a Yes. There is an error conditon.

5b No. There is not an error condition.

6 Distance measurement

7 Is a correct measurement available?

7a No. A correct meaurement is not available.

7b Yes. A correct meaurement is available.

8 Error mode state

9 Current output (distance value or a derived

measurement value)

10 Is the current output setting correct?

10a No. The current output setting is incorrect.

10b Yes. The current output setting is correct.

14

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 15

OPTIWAVE 5200 C

OPERATION 7

8 Error mode state

9 Current output (error value)

10 Is the current output setting correct?

10a No. The current output setting is incorrect.

10b Yes. The current output setting is correct.

11 Is a new correct measurement available?

11a No. A correct measurement is not available.

11b Yes. A correct measurement is available.

1 Initial state (new measurement)

7.4 Error conditions

The device can sense the error conditions in the table that follows. When the device detects a

measurement error, it supplies an output current less than 3.6 mA.

Error condition Cause

Device does not start

immediately

The current output is incorrectly

calibrated

Component hardware errors Memory failure

Ambient temperature is too high The ambient temperature is more than +80°C / +176°F.

Ambient temperature is too low The ambient temperature is less than -40°C/ -40°F.

Incorrect measurement signal

(e.g. level lost)

Overfill The level is in the blocking distance. If menu item 2.5.3 OVERFILL EN.

This error occurs if more than 20 seconds are necessary to start the

device.

Do a current output check. For the procedure, refer to

check

on page 24. If the values do not agree with the tolerances given

in the procedure, speak to the supplier.

Voltage failure

No signal

Microwave failure

The signal peak is not found within the measuring window that filters

the signals received by the antenna. The measurement is not correct.

is set to "YES", there is a risk that the product will overflow and cover

the antenna.

Current output

For more data, refer to the "Status and error messages" section in the handbook (document

[N1]).

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

15

Page 16

7 OPERATION

7.5 User parameters

INFORMATION!

If you change a parameter set in one or more of the menu items that follow, this will have an

effect on the safety function.

7.5.1 Limits for supervisor menu functions related to antenna configuration

WARNING!

If the device was delivered without an antenna, then calibrate the device to make sure that the

safety function operates correctly. For more data, refer to Calibration procedure on page 23

CAUTION!

This section gives data on the modification of a small number of parameters in the 2.0.0

SUPERVISOR menu. If it is necessary to change parameters in the 3.0.0 SERVICE menu or the

4.0.0 MASTER menu, contact your supplier.

If you change the values of one or more of the parameters given in the "User parameters"

section, this can have an unwanted effect on the safety function. Do a check of the safety

function after you change a parameter.

OPTIWAVE 5200 C

.

INFORMATION!

Safety function check

Safety function check

Safety function checkSafety function check

Make sure that the 4...20mA measurement range is correctly calibrated.

LEGAL NOTICE!

The manufacturer declines all responsibility for the correct operation of the safety function if

these parameters in the 3.0.0 SERVICE or 4.0.0 MASTER menus are changed by the customer.

Menu

No.

2.3.4 STILLWELL EN. If this menu item is set to "YES",

2.3.5 STILLWELL D. The inner diameter of the stilling

2.3.6 STILLWELL H. The height of the stilling well. If the

2.3.7 ANTENNA.EXT Optional antenna extensions.These

Function Function description Selection list Default value

and comments

then you must give the stilling well

height and inner diameter in menu

items 2.3.5 STILLWELL D. and 2.3.6

STILLWELL H..

well. If the device is installed in a

stilling well or has a Wave-Guide

antenna, enter the diameter. The

device will use this data if you set

2.3.4 STILLWELL EN. to "YES". This

menu item is not shown if you set

2.3.4 STILLWELL EN. to "NO".

device is installed in a stilling well

or has a Wave-Guide antenna,

enter the height. The device will

use this data if you set 2.3.4

STILLWELL EN. to "YES". This

menu item is not shown if you set

2.3.4 STILLWELL EN. to "NO".

are attached between the flange

and the antenna.

YES, NO NO

min-max:

22...999 mm /

0.9...39.3¨

min:

500 mm / 19.7¨

max:

2.3.1 TANK HEIGHT

min:

0mm/ 0¨ or

2.3.6 ANTENNA.EXT

max:

2000 mm / 78.7¨ or

2.3.1 TANK HEIGHT

1

1

1

16

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 17

OPTIWAVE 5200 C

OPERATION 7

Menu

Function Function description Selection list Default value

No.

2.3.8 ANTENNA.TYP Type of antenna. For more data,

refer to the "Technical data"

chapter in the handbook.

2.3.9 DIST.PIECE Optional distance piece between

the converter and the process

connection. This is for hightemperature applications more

than +150°C / +302°F. The distance

piece is 120 mm / 4.7¨ long. For

more data, refer to the "Technical

data" chapter in the handbook.

1 This value is given in the customer order data

PP Horn,

PTFE Horn,

Metal. Horn,

Wave Stick,

Wave Guide

min:

0mm/ 0¨

max:

2.3.1 TANK HEIGHT

7.5.2 Limits for supervisor menu functions related to device configuration

CAUTION!

Make sure that you have the device configuration that follows:

•

2.6.1 HART ADDRESS is set to "0". If it is not set to "0", the safety function will not operate

correctly.

•

2.4.2 RANGE I is set to "4-20 / 3.6E" or "3.8-20.5 / 3.6E". If the error signal is set to "22 mA" or

"Hold", the safety function will not operate correctly.

•

2.5.4 MEASUR.MODE is set to "Direct". If the error signal is set to "TBF Partial" or "TBF Full",

the safety function will not operate correctly.

•

2.2.1 SET OUTPUT is not shown on the device display or in PACTware. If SET OUTPUT is

shown, the output will change to the set test value, independent of the measured value. The

current output will go back to the measured value when the user makes the display or

PACTware go back to the menu level.

and comments

1

1

Menu

Function Function description Selection list Default value

No.

2.3.1 TANK HEIGHT The distance from the tank

2.4.1 OUTPUT FUNC. The output function. Select an

2.4.2 RANGE I This parameter sets the range of

connecting flange face / thread

stop down to the tank bottom.

output function to scale the current

values in relation to a given point

(usually the device process

connection or the tank bottom). The

output current value is shown on a

bar graph in normal mode if the

measurement name is the same as

the output function. Conversion

parameters are shown if there is

volume or mass data in 2.8.1 INPUT

TABLE.

the output current with

(3.8...20.5 mA) or without

(4...20 mA) over-run values. It also

tells the device what to do if an

error occurs. For example, the

device will change to an error value

of 3.6 mA if you set RANGE I to

"3.8-20.5/3.6E".

min-max:

1…30 m /

3.3…98.4 ft

Distance, Level,

Distance

conversion,

Level conversion

4-20, 4-20 / 22E,

4-20 / 3.6E,

3.8-20.5 / 22E,

3.8-20.5 / 3.6E

and comments

Default value

agrees with the

customer

order

Default value

agrees with the

customer

order

3.8-20.5 / 3.6E

1

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

17

Page 18

7 OPERATION

OPTIWAVE 5200 C

Menu

Function Function description Selection list Default value

No.

2.4.3 SCALE 4mA This gives a measurement value to

2.4.4 SCALE 20mA This gives a measurement value to

2.4.5 ERROR DELAY The time after which the current

2.5.4 MEASUR.MODE The device uses the dielectric

2.5.5 OVERF. ENAB. If this function is in operation, the

4mA.

20 mA.

output changes to an error value.

The error value shows that there is

a measurement error.

MN=minutes and S=seconds.

constant (εr) of the tank contents to

monitor level. In direct mode (if the

dielectric constant is high), the

level signal is a reflection on the

surface of the tank contents. If the

dielectric constant is low, the

device uses TBF mode. The device

in TBF mode uses the radar

reflection on the bottom of the

tank (the signal goes through the

tank contents). The tank must have

a flat bottom for the device to

operate correctly in TBF mode.

This menu item is set by default to

"Direct" for tank contents with an

>1.8. If εr is very low (<1.6), use

ε

r

"TBF Full". If εr is low (εr=

1.5...1.7), use "TBF Partial" mode.

"TBF Partial" is an automatic mode

that lets the device make a

selection between "Direct mode

and "TBF" mode. If you use "TBF

Full" or "TBF Partial", enter the

dielectric constant in menu item

2.5.3 Er PRODUCT.

device will monitor the level even if

it is in the blocking distance. The

reading shown on the display stays

fixed at the blocking distance if the

level is higher than the blocking

distance. The output will show that

the tank is full. An error is

recorded by default.

If this function is not in operation,

the device looks for the largest

signal between the process

connection and the tank bottom.

and comments

min.-max: 2 Default value

min.-max: 2 Default value

0 S, 10 S, 20 S, 30 S,

1 MN, 2 MN,

5MN,15MN

Direct, TBF Partial,

TBF Full

YES, NO NO 4

agrees with the

customer

order

agrees with the

customer

order

0S 3

Direct Do not

Do not

Do not Do not

change.

change.

change.change.

18

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 19

OPTIWAVE 5200 C

OPERATION 7

Menu

No.

2.5.6 MULT.REF.EN. Multiple reflections will cause the

2.5.7 EMP.SPEC.EN. The supervisor can start or stop the

2.5.9 HART ADDRESS

2.8.1 INPUT TAB. The device uses the conversion

1 Use only "4-20 / 3.6E" or "3.8-20.5 / 3.6E"

2 Units and range depend on the output function, length unit and volume unit selected

3 If the safety function must immediately give a result, we recommend that you do not change this value

4 This menu item does a continuous check for radar reflections between the blocking distance (value set in menu item

2.3.2) and the flange. But condensation or other sources of parastic signals can cause an "overfill" error. If you set this

menu item to "YES", make sure that there are no sources of parasitic signals near to the flange.

Function Function description Selection list Default value

and comments

device to display smaller level

readings. Objects in the tank, sharp

corners, installation of the device

on a large nozzle or at the centre of

a dome roof, and low dielectric

products (εr= 1.8...5) can cause

multiple reflections. A very calm

surface or a tank with a small

convex or flat roof can also cause

multiple reflections.

If this function is in operation, the

device looks for the first signal

peak below the process

connection. This signal peak is then

used to measure the level of the

tank contents. If this function is not

in operation, the device looks for

the largest signal below the

process connection.

empty spectrum filter.

Any HART® address more than 0

will activate HART

mode.

Multidrop mode is not permitted

Multidrop mode is not permitted

Multidrop mode is not permitted Multidrop mode is not permitted

for SIL-approved devices.

for SIL-approved devices.

for SIL-approved devices.for SIL-approved devices.

table to convert distance or level

measurements to volume and

mass readings. The readings are

shown in normal mode.

®

multidrop

YES, NO NO

YES, NO NO

min-max:

0…63

min-max:

0…30 conversion

pairs

0.

Do not change.

Do not change.

Do not change.Do not change.

0

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

19

Page 20

8 SERVICE

8.1 Periodic maintenance

You must obey the maintenance instructions given in the handbook (document [N1]).

8.2 Keep the device clean

For more data, refer to “Service” in the handbook (document [N1]).

8.3 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

8.4 Proof tests

OPTIWAVE 5200 C

It is neccessary to do proof tests to make sure that the safety function is applicable to the full

measuring range.

• The device settings must be correct. If a parameter is incorrect, the device will not measure

correctly.

• The electronic components must not be defective.

• The software programs (firmware etc.) must operate correctly.

• The antenna must correctly transmit and receive the measurement signal. Parasitic signals

must not have an effect on the performance of the device.

We recommend that you do a proof test immediately after you install and start the device.

WARNING!

SIS engineers must calculate the interval of proof tests. The minimum time between proof tests

must be less than 5 years, but the interval between proof tests must also agree with the safety

system used on site.

Prepare the device for the proof tests. Do a check of the device parameters.

CAUTION!

•

Proof tests done by the customer must be equivalent or more difficult than the tests given in

this section.

•

Keep a report of each proof test. These reports must include the date, the tests results

(performance of the safety function or faults found), a list of approved personnel who did the

test and the report revision number. These reports must be put into storage and made easily

available. A proof test report form (for copying) is available on page 33

•

The location of the device and how it is installed on the tank can have an effect on the

.

performance. Make sure that you obey the installation instructions given in the handbook.

20

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 21

OPTIWAVE 5200 C

Equipment needed:

• Device with the integrated display option

• Process measurement and device configuration software (e.g. the DTM for PACTware™), if

the device does not have the integrated display option

• Ammeter

• Reference device: an approved level meter or indicator

Do a check of the 4 mA and the 20 mA settings:

• Find the data for the 4 mA and the 20 mA settings in the SIS specification.

• Enter the supervisor menu. For more data on how to get access to the supervisor menu, refer

to the "Operation" chapter of the handbook (document [N1]).

• Push [>>>>] to go to menu item COMMISSION. (2.1.1). Push 4 × [>>>>] to see the SCALE 4mA value

i If the 4mA scale does not agree with the SIS specification, make sure that this data is

• Push [>>>>] to see the SCALE 20mA value.

i If the 20mA scale does not agree with the SIS specification, make sure that this data is

SERVICE 8

correct. If necessary, change the value and record the new value in the proof test report.

correct. If necessary, change the value and record the new value in the proof test report.

Do a check of the tank height:

• Measure the height of the tank (or the depth of the pit).

• Enter the supervisor menu. For more data on how to get access to the supervisor menu, refer

to the "Operation" chapter of the handbook (document [N1]).

• Push [>>>>] to go to menu item COMMISSION. (2.1.1). Push [>>>>] to see the TANK HEIGHT value.

i Make sure that the value shown agrees with the tank height. If necessary, change the value

and record the new value in the proof test report.

CAUTION!

Did you change the values of the supervisor menu functions given in the "User parameters"

Did you change the values of the supervisor menu functions given in the "User parameters"

Did you change the values of the supervisor menu functions given in the "User parameters" Did you change the values of the supervisor menu functions given in the "User parameters"

section?

section?

section?section?

If you change the values in supervisor menu items 2.4.2 RANGE I and 2.6.1 HART ADDRESS, the

manufacturer cannot guarantee that the safety function will operate correctly. For more data,

contact your supplier.

Do a check of the device settings:

• Enter the supervisor menu. For more data on how to get access to the supervisor menu, refer

to the "Operation" chapter of the handbook (document [N1]).

• Push [], [], [], [>>>>] and [] to go to menu item RANGE I (2.4.2). Push [>>>>] to see the value.

i Make sure that the current output range is set to "4-20 / 3.6E" or "3.8-20.5 / 3.6E". If

necessary, change the value and record the new value in the proof test report.

• Push [^^^^], [^^^^], [], [>>>>], [], [] and [] to go to menu item MEASUR.MODE (2.5.4). Push [>>>>]

to see the parameter.

i Make sure that the measurement mode is set to "Direct". If necessary, change the

parameter and record the new parameter in the proof test report.

• Push [^^^^], [^^^^], [] and [>>>>] to go to menu item HART ADDRESS (2.6.1). Push [>>>>] to see the value.

i Make sure that this menu item is set to 0

not operate correctly.

0. If the value is not set to 0000, the safety function will

00

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

21

Page 22

8 SERVICE

Do a check of the low error alarm signal:

• Enter the supervisor menu. For more data on how to get access to the supervisor menu, refer

to the "Operation" chapter of the handbook (document [N1]).

• Push [] and [>>>>] to go to menu item SET OUTPUT (2.2.1).

• Do a functional test of the low error alarm signal. Set the menu item SET OUTPUT (2.2.1) to

3.5 mA

3.5 mA.

3.5 mA3.5 mA

i The output will change to 3.5 mA. This output is not related to the measured value. Does the

INFORMATION!

The device is set to the "low" error alarm signal before delivery.

Measure the level and current output of the product in the tank at 3 points (example

procedure given):

• Find the data for the 4 mA and the 20 mA settings in the SIS specification.

• Fill the tank to the maximum level (without overfill). Measure the level of the product in the

tank with an approved level meter or indicator (reference device).

• Measure the output current with an ammeter.

i If the menu item OUTPUT FUNC. (2.4.1) is set to Level

• Remove the product from the tank until it is 50% full. Measure the level of the product in the

tank with an approved level meter or indicator (reference device).

• Measure the output current with an ammeter.

i Make sure the output current value is 12 mA.

OPTIWAVE 5200 C

device give a "low error" alarm signal? If there is no alarm signal, the safety function will

not operate correctly.

Level, make sure the output current value

LevelLevel

is 20 mA. If the menu item OUTPUT FUNC. (2.4.1) is set to Distance

current value is 4 mA.

Distance, make sure the output

DistanceDistance

• Remove the product from the tank to the minimum level. Measure the level of the product in

the tank with an approved level meter or indicator (reference device).

• Measure the output current with an ammeter.

i If the menu item OUTPUT FUNC. (2.4.1) is set to Level

is 4 mA. If the menu item OUTPUT FUNC. (2.4.1) is set to Distance

current value is 20 mA.

Level, make sure the output current value

LevelLevel

Distance, make sure the output

DistanceDistance

INFORMATION!

Make sure that the current output value linearly decreases from 20 mA to 4 mA, if the menu

item OUTPUT FUNC. (2.4.1) is set to Level

increases from 4 mA to 20 mA, if the menu item OUTPUT FUNC. (2.4.1) is set to Distance

Level. Make sure that the current output value linearly

LevelLevel

Distance.

DistanceDistance

The distance between 2 points in the tank must be as large as possible. We recommend that

there is a space of at least 1 m / 3.3 ft between 2 points in the tank.

You can adapt this procedure to special conditions. For example, if you use the safety function to

prevent an overfill, it is not necessary to remove the product from the tank to the minimum level.

It is only necessary to measure the level and current output of the product in the tank when it is

full (without overfill). and 50% full.

22

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 23

OPTIWAVE 5200 C

8.5 Calibration procedure

8.5.1 General notes

If the antenna is not in the same customer order as the signal converter, it is necessary to

calibrate the device.

Equipment needed

• A device with the integrated display option.

• Process measurement and device configuration software (e.g. the DTM for PACTware™), if

the device does not have the integrated display option.

• An ammeter.

• Reference device: an approved level meter or indicator

Requirements

• The ammeter must be correctly calibrated and connected directly to device.

• You must have 2 reference points (levels) in the tank given by a different measurement

solution. These points are identified as "ref_pt1" and ref_pt2".

SERVICE 8

CAUTION!

Do not connect the ammeter across the safety system PLC because this configuration can open

the circuit breaker.

Make sure that the 2 reference points are not in the top or bottom dead zones.

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

23

Page 24

8 SERVICE

8.5.2 Current output check

Do a check of the current output value: 4 mA

• Energize the device.

• Enter the Supervisor menu.

• Push [>>>>], [] and [>>>>] to go to menu item 2.2.1 SET OUTPUT. Push [>>>>] and then push [] or []

to move up or down the list to set the output to 4 mA.

i The output will change to the set value after 5 seconds, as an alternative to the measured

value. The current ouput stays at this value while you are in this menu item.

• Measure the current output at the terminals with an ammeter. Does the ammeter show a

current output of 4 mA ± 400 µA?

• Push [^^^^] to go back to the menu list.

i The current output goes back to the measured value.

• End of the procedure.

Do a check of the current output value: 12 mA

• Push [>>>>] and then push [] or [] to move up or down the list in menu item 2.2.1 SET OUTPUT

to set the output to 12 mA.

i The output will change to the set value after 5 seconds, as an alternative to the measured

value. The current ouput stays at this value while you are in this menu item.

• Measure the current output at the terminals with an ammeter. Does the ammeter show a

current output of 12 mA ± 400 µA?

• Push [^^^^] to go back to the menu list.

i The current output goes back to the measured value.

OPTIWAVE 5200 C

• End of the procedure.

Do a check of the current output value: 20 mA

• Push [>>>>] and then push [] or [] to move up or down the list in menu item 2.2.1 SET OUTPUT

to set the output to 12 mA.

i The output will change to the set value after 5 seconds, as an alternative to the measured

value. The current ouput stays at this value while you are in this menu item.

• Measure the current output at the terminals with an ammeter. Does the ammeter show a

current output of 12 mA ± 400 µA?

• Push [^^^^] to go back to the menu list.

i The current output goes back to the measured value.

• End of the procedure.

CAUTION!

If the values do not agree with the tolerances, then the data supplied by device will not be

correct. For a solution to the problem, speak to the supplier.

24

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 25

OPTIWAVE 5200 C

8.5.3 Measuring range check (in process conditions)

The complete device (the signal converter, the process connection and the antenna) is installed

on the tank in process conditions. We recommend that you use this procedure to do a measuring

range check.

For more data, refer to the "How to replace device components" section in the handbook.

CAUTION!

Make sure the the accuracy of the calibrated device agrees with the safety loop requirement. The

accuracy of the device must also agree with the reference conditions given in the "SIL-specific

technical data" section.

Procedure

• Attach the signal converter to the antenna. For more data, refer to the "How to replace device

components" section in the handbook.

• Change the level of the tank contents until you have level reference point 1 (ref_pt1

test device to make sure that you have level reference point 1. We recommend that the

location of this point is 33% of the measuring range (from the bottom of the tank).

• Measure the level at reference point 1 with the reference device (refer to "Equipment needed"

on page 23). Record the value (meas_pt1

• Change the level of the tank contents until you have level reference point 2 (ref_pt2

test device to make sure that you have level reference point 2. We recommend that the

location of this point is 66% of the measuring range (from the bottom of the tank).

• Measure the level at reference point 2 with the reference device (refer to "Equipment needed"

on page 23). Record the value (meas_pt2

• End of the procedure.

meas_pt1).

meas_pt1meas_pt1

meas_pt2).

meas_pt2meas_pt2

SERVICE 8

ref_pt1). Use the

ref_pt1ref_pt1

ref_pt2). Use the

ref_pt2ref_pt2

The tolerance is ±5mm/ 0.2¨ in reference conditions. If the difference between ref_pt1

meas_pt1

meas_pt1 and between ref_pt2

meas_pt1meas_pt1

results of the test are satisfactory. If the 2 values do not agree with the tolerance, then the

results of the test are unsatisfactory. To change the device settings to get satisfactory results,

speak to the supplier.

For more data about reference conditions, refer to

ref_pt2 and meas_pt2

ref_pt2ref_pt2

meas_pt2 agrees with the safety loop tolerance, then the

meas_pt2meas_pt2

SIL-specific technical data

ref_pt1 and

ref_pt1ref_pt1

on page 29.

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

25

Page 26

8 SERVICE

8.6 Troubleshooting

INFORMATION!

•

Modifications to the device are not permitted.

•

Only approved personnel can repair the device.

If you find a problem, please contact your local representative. If the device must go back to the

manufacturer, refer to "Returning the device to the manufacturer" in this supplement.

8.7 Returning the device to the manufacturer

8.7.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

OPTIWAVE 5200 C

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

26

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 27

OPTIWAVE 5200 C

8.7.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 8

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

27

Page 28

9 TECHNICAL DATA

9.1 General notes

The device agrees with these conditions in the IEC 61508 standard:

Condition Description

OPTIWAVE 5200 C

The device operates in high

demand or continuous mode of

operation 1

The device is a type B system The device uses programmable electronics embedded in complex

The device has a hardware fault

tolerance of zero (HFT = 0)

1 This agrees with IEC 61508 Part 4, section 3.5.16

9.2 Assumptions

FMEDA is applicable for the conditions that follow:

• Use of the device agrees with its design and performance characteristics. This includes

ambient and process conditions.

• Installation of the device must agree with the instructions and the requirements of the

application.

• We can ignore wear of mechanical parts. Failure rates are constant.

• Failures that follow one after the other are put in the same group as the failure that is the

source of the problem.

• The HART

used during safety operation mode.

• All components that are not part of the safety function and cannot influence the safety

function (feedback immune) are not included.

• Only the analog output (4…20 mA) is used for safety applications.

• The Mean Time to Recovery after safe failure is 72 hours (MTTR = 72 h).

• If necessary, the device can operate as a safety-related system in a low-demand mode of

operation.

• External power failure rates are not included.

The device continuously measures the distance to the surface of the

product in the tank. If electrical power is not available or is not

sufficient, the device will not measure. The safety function is

continuously available to keep the device in a safe state.

components (a microcontroller). It is not possible to find all the

failure modes for this type of component.

The device does not have hardware redundancy.

®

protocol is only used for set-up, calibration and diagnostic purposes. It is not

28

INFORMATION!

The FMEDA of the device was calculated with the exida

exida tool FMEDA v7.1.17, with the

exidaexida

configuration that follows:

•

Database SN 29500

•

Ambient temperature is 40°C

•

T[Proof] is from 1 to 10 years (87600 hours)

•

T[Repair] is 72 hours

•

T[Test] is 24 hours (all internal test functions are done a minimum of one time during this

period)

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 29

OPTIWAVE 5200 C

9.3 Characteristics for the device safety function

Version Non-Ex / Ex i Ex d

Firmware version Converter: 1.00.06; Sensor: 1.00.06

Board version Converter: 4000678801B;

Sensor: 4001105601B

Systematic capability 2 2

Architecture 1oo1D (daily auto-diagnostic checks)

PFH

9.0×10

-8

SFF 91.8% 90%

λ

λ

λ

λ

DC

SD

SU

DD

DU

D

-8

2.1×10

-7

5.37×10

-7

5.13×10

-8

9.0×10

85% 82%

MTBF 97 years 82 years

Converter: 4000678801B;

Sensor: 4001105601B

Ex d barrier: 4000633801A

1.34×10

9.6×10

8.37×10

6.24×10

1.34×10

TECHNICAL DATA 9

-7

-8

-7

-7

-7

If it is necessary to use the device in a low demand mode (as specified in document [N2]), refer to

the table below. For example, the device can be used to give a warning if an error signal occurs.

The table shows the change of PFD

with a T[Proof] between 1 to 10 years:

AVG

Year: 1 2 3 4 5 6 7 8 9 10

PFD

AVG

(Non-Ex / Ex i)

PFD

AVG

(Ex d)

3.99

×10

5.89

×10

7.96

-4

×10

-4

1.17

-4

×10

-3

For more data, refer to

1.19

-3

×10

1.76

-3

×10

Proof tests

1.59

-3

×10

2.34

-3

×10

on page 20.

1.98

×10

2.93

×10

2.38

-3

×10

3.51

-3

×10

2.77

-3

×10

4.09

-3

×10

3.17

-3

×10

4.67

-3

×10

3.56

-3

×10

-3

×10

5.26

-3

×10

-3

×10

9.4 SIL-specific technical data

INFORMATION!

This data is for SIL-approved devices only. For more data about device characteristics and

performance, refer to

(document [N1]).

Measuring system

Measuring principle 2-wire loop-powered level transmitter; X-band (10 GHz) FMCW radar

Application range Level measurement of liquids, pastes and slurries

Primary measured value Distance and reflection measurement of 1 product

Secondary measured value Distance, level, volume, mass and flow rate

“

Technical data” in the technical datasheet, quick start or handbook

3.96

-3

5.84

-3

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

29

Page 30

9 TECHNICAL DATA

OPTIWAVE 5200 C

Design

Antenna options All basic antenna options

Interface languages English, German, French, Italian, Spanish, Portuguese, Japanese, Chinese

(Mandarin) and Russian

Accuracy

Resolution 1mm/ 0.04¨

Repeatability ±1mm/ ±0.04¨

Accuracy ±5mm/ ±0.2¨, when distance < 10 m / 33 ft;

Reference conditions acc. to EN 61298-1

Reference conditions acc. to EN 61298-1

Reference conditions acc. to EN 61298-1Reference conditions acc. to EN 61298-1

Temperature +15...+25°C / +59...+77°F

Pressure 1013 mbara ±50 mbar / 14.69 psia ±0.73 psi

Relative air humidity 60% ±15%

Target Metal plate in an anechoic chamber (0...7 m / 0...23 ft)

±0.05% of measured distance, when distance > 10 m / 33 ft

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature -40…+80°C/ -40…+175°F (according to the temperature limits of the gasket

Pressure

Pressure

PressurePressure

Operating pressure PP Wave Horn antenna:

Other conditions

Other conditions

Other conditionsOther conditions

Dielectric constant (εr) Direct mode: ≥1.8

material. Refer to "Materials" in this table.)

Ex: see supplementary operating instructions or approval certificates

PP Wave Horn antenna:

PP Wave Horn antenna:PP Wave Horn antenna:

-1…16 barg / -14.5…232 psig.

For more data refer to "Technical Data / Pressure Ratings" in the handbook.

PTFE Wave Horn antenna:

PTFE Wave Horn antenna:

PTFE Wave Horn antenna:PTFE Wave Horn antenna:

-1…40 barg / -14.5…580 psig.

For more data refer to "Technical Data / Pressure Ratings" in the handbook.

Metallic Horn antenna / Wave Guide antenna:

Metallic Horn antenna / Wave Guide antenna:

Metallic Horn antenna / Wave Guide antenna:Metallic Horn antenna / Wave Guide antenna:

Standard: -1…40 barg / -14.5…580 psig;

subject to the process connection used and the flange temperature. Higher

pressure on request.

TBF mode: ≥1.1

Refer also to "Technical data: Antenna selection".

Material

Housing

(compact version only)

Wetted parts, including antenna PTFE Wave Horn antenna: PTFE

Process connection PP Wave Horn antenna: PP

30

Standard: Aluminium with a polyester topcoat

Option: Stainless steel (1.4404 / 316L)

PP Wave Horn antenna: PP

Metallic Wave Horn and Wave Guide antennas: Stainless steel (1.4404 / 316L) and

PTFE - refer also to "Gaskets"

PTFE Wave Horn antenna: Stainless steel (1.4404 / 316L) with a PTFE plate / lining

Metallic Horn antenna: Stainless steel (1.4404 / 316L); other materials on request

Wave Guide antenna: Stainless steel (1.4404 / 316L)

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 31

OPTIWAVE 5200 C

TECHNICAL DATA 9

Electrical connections

Power supply Terminals output - Non-Ex / Ex i:

Terminals output - Non-Ex / Ex i:

Terminals output - Non-Ex / Ex i:Terminals output - Non-Ex / Ex i:

12…30 VDC; min./max. value for an output of 22 mA at the terminal

Terminals output - Ex d:

Terminals output - Ex d:

Terminals output - Ex d:Terminals output - Ex d:

16…36 VDC; min./max. value for an output of 22 mA at the terminal

Input and output

Current output

Current output

Current outputCurrent output

Resolution ±3 µA

Error signal Low: ≤ 3.6 mA acc. to NAMUR NE 43

Error tolerance If an error is >2.5% of the output signal, this error has a "dangerous undetected

®

HART

HART

HARTHART

Description

Point-to-point operation

Multidrop operation Multidrop operation is not permitted because the current output (safety function)

PROFIBUS PA

PROFIBUS PA

PROFIBUS PAPROFIBUS PA

Description Not yet available. This option is not permitted.

FOUNDATION

FOUNDATION™ Fieldbus

FOUNDATIONFOUNDATION

Description Not yet available. This option is not permitted.

Modbus

Modbus

ModbusModbus

Description Not yet available. This option is not permitted.

Other data

Other data

Other dataOther data

Response time (errors) Response time = value given in supervisor menu item 2.4.5 ERROR DELAY

Diagnostic test frequency 1 time / day (firmware does an auto-diagnostic test)

Fieldbus

Fieldbus Fieldbus

failure" status.

HART® protocol via passive current output 1

Yes. Current output = 4 mA. HART® Address = 0. Output current data that is

transmitted in less than 1 ms is ignored (this data filter agrees with HART

requirements).

must be set to 4 mA. Thus, the safety function cannot supply data about the device

status.

If electrical power is not sufficient for correct operation of the device (worst

conditions for operation), the error is shown in less than 30 seconds.

®

protocol

Approvals and certification

SIL SIL 2 2

Agrees with IEC 61508:2010 Parts 1 to 7

1 HART® is a registered trademark of the HART Communication Foundation

2 When only one liquid is in the tank

9.5 Support for SIL-approved devices

If the manufacturer makes a modification that has an effect on the safety function of the device,

the manufacturer will tell you about the modification immediately.

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

31

Page 32

10 APPENDIX

10.1 Start-up report

WARNING!

Complete the start-up checklist before you energize the device.

Please complete this start-up checklist and return it to the manufacturer.

Are the polarity and the supply voltage correct?

Ex-approved devices only: does the device and the installation agrees with the

requirements of the Ex certificate of compliance?

Are all the wetted components (antenna, flange and gaskets) resistant to the product in the

tank?

Does the information on the signal converter nameplate agree with the operating data?

OPTIWAVE 5200 C

Yes

Yes No

No

YesYes

NoNo

Are the process temperature and pressure in the limits for operation of the device?

Did you correctly install the device on the tank?

Do the electrical connections agree with the national electrical codes?

I hereby confirm that I have completed the start-up checklist.

Date: Signature:

Stamp:

32

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 33

OPTIWAVE 5200 C

10.2 Proof test report form (for copying)

CAUTION!

Complete the report form that follows when you do a proof test.

APPENDIX 10

For more data, refer to

Recorded by: Date:

Unique device ID (e.g. serial number):

Proof tests

on page 20.

Parameter value check

Proof tests results

Recorded value Correct value Approved

2.3.1 TANK HEIGHT Correct tank height [Yes] [No]

2.4.3 SCALE 4mA 4.000 mA ± 1 μA [Yes] [No]

2.4.4 SCALE 20mA 20.000 mA ± 1 μA [Yes] [No]

2.4.2 RANGE I Error value= 3.6 mA 1 [Yes] [No]

2.6.1 HART ADDRESS HART address= 0 2 [Yes] [No]

1 The error value is correct if the menu item is set to "4-20/3.6E" or "3.8-20.5/3.6E"

2 Multidrop is not permitted for SIL-approved devices

Functional check

Proof tests results

Recorded value Correct value Approved

Error alarm signal < 3.6 mA <3.6mA [Yes] [No]

Current output= 4 mA 1 4mA ± 400 μA [Yes] [No]

Current output= 12 mA 2 12.000 mA ± 400 μA [Yes] [No]

Current output= 20 mA 3 20.000 mA ± 400 μA [Yes] [No]

1 The tank is full when menu item 2.4.1 OUTPUT FUNC.= Distance. The tank is empty when menu item 2.4.1 OUTPUT

FUNC.= Level.

2 The tank is 50% full.

3 The tank is full when menu item 2.4.1 OUTPUT FUNC.= Level. The ta nk i s em pty whe n me nu ite m 2.4. 1 OUTP UT F UNC.=

Distance.

Conclusion

Does the device operate satisfactorily in safety-related systems? [Yes] [No]

Signature:

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

33

Page 34

11 NOTES

OPTIWAVE 5200 C

34

www.krohne.com 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

Page 35

OPTIWAVE 5200 C

NOTES 11

www.krohne.com02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en

35

Page 36

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

© KROHNE 02/2013 - 4001906202 - AD SIL OPTIWAVE 5200 R02 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...