KROHNE OPTIFLEX 2200 C/F Specifications

Technical Datasheet

Technical Datasheet

OPTIFLEX 2200 C/F

OPTIFLEX 2200 C/F

OPTIFLEX 2200 C/FOPTIFLEX 2200 C/F

Technical DatasheetTechnical Datasheet

Guided Radar (TDR) Level Transmitter for storage and

process applications

•

Modular design of housing and sensor ensures suitability for a variety of mounting

positions and applications

•

Universal measurement device for liquids and solids

•

SIL2-compliant according to IEC 61508 for safety-related systems

© KROHNE 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

CONTENTS

OPTIFLEX 2200 C/F

1 Product features 3

1.1 The modular TDR level transmitter ................................................................................. 3

1.2 Overview............................................................................................................................ 5

1.3 Applications ...................................................................................................................... 7

1.4 Application table for probe selection ............................................................................... 9

1.5 Measuring principle........................................................................................................10

2 Technical data 11

2.1 Technical data................................................................................................................. 11

2.2 Minimum power supply voltage ..................................................................................... 21

2.3 Pressure / flange temperature graph for probe selection............................................ 22

2.4 Measurement limits ....................................................................................................... 24

2.5 Dimensions and weights ................................................................................................ 30

3 Installation 44

3.1 Intended use ................................................................................................................... 44

3.2 How to prepare the tank before you install the device.................................................. 44

3.2.1 General information for nozzles........................................................................................... 44

3.2.2 Installation requirements for concrete roofs....................................................................... 46

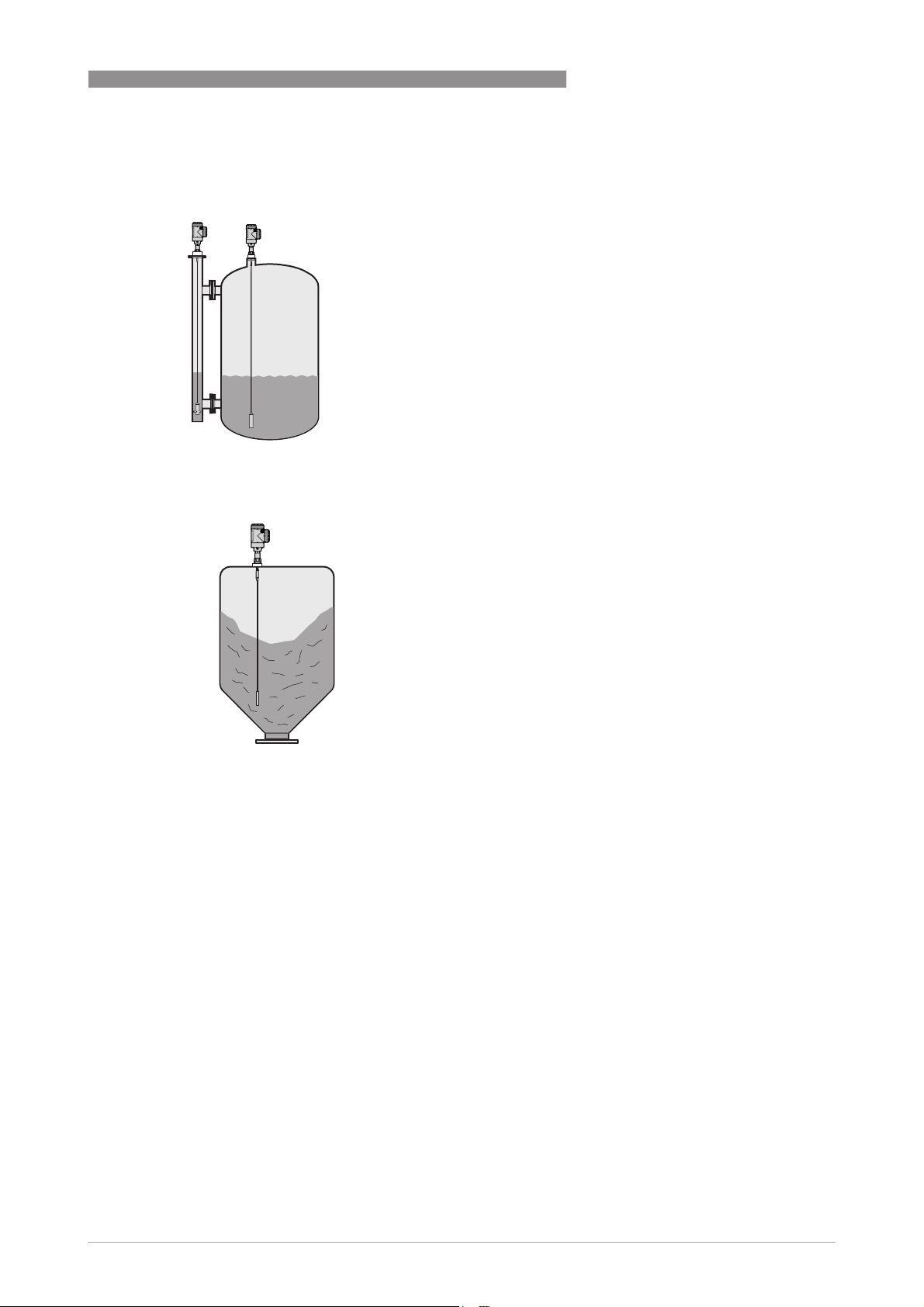

3.3 Installation recommendations for liquids...................................................................... 47

3.3.1 General requirements .......................................................................................................... 47

3.3.2 Installation in standpipes (stilling wells and bypass chambers) ......................................... 48

3.4 Installation recommendations for solids....................................................................... 50

3.4.1 Nozzles on conical silos........................................................................................................ 50

3.4.2 Traction loads on the probe.................................................................................................. 51

4 Electrical connections 52

4.1 Electrical installation: 2-wire, loop-powered ................................................................ 52

4.1.1 Compact version ................................................................................................................... 52

4.1.2 Remote version ..................................................................................................................... 52

4.2 Non-Ex devices............................................................................................................... 53

4.3 Devices for hazardous locations .................................................................................... 54

4.4 Networks ........................................................................................................................ 54

4.4.1 General information.............................................................................................................. 54

4.4.2 Point-to-point networks ....................................................................................................... 54

4.4.3 Multi-drop networks ............................................................................................................. 55

4.4.4 Fieldbus networks................................................................................................................. 56

5 Order information 58

5.1 Order code ...................................................................................................................... 58

6 Notes 69

2

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

1.1 The modular TDR level transmitter

This device is a TDR level transmitter for measuring distance, level, volume and mass. Its

modular design makes it an economical and reliable solution for common applications.

PRODUCT FEATURES

1

1 Large choice of probes to cover a vast range of applications, including a hygienic version for the food and beverage

industry

2 Optional remote converter can be installed up to 100 m / 328 ft away from the probe

3 Wall support

4 Horizontal / vertical housings and segmented probe options makes the device suitable for many applications and for

installation in a variety of positions

5 Aluminium or stainless steel housing

6 2-wire level transmitter

7 Optional LCD display with 4-button keypad

8 Converter is rotatable and removable under process conditions

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

3

1

PRODUCT FEATURES

Optional integrated display

The display can be ordered with the device or as an accessory. It shows measurement data on a

128 × 64 pixel screen. The configuration menu permits the device to be set up in a small number

of intuitive steps.

OPTIFLEX 2200 C/F

Highlights

• 2-wire loop-powered HART® TDR level transmitter for liquids and solids

• DPR (Dynamic Parasite Rejection): the software dynamically eliminates false reflections

caused by environmental disturbances and product build-up

• Quick coupling system permits removal of the converter under process conditions and 360°

rotation to make the display screen easier to read

• Horizontal and vertical housing position to suit every installation

• The remote converter can be installed up to 100 m / 328 ft from the probe

• Display keypad is directly accessible without opening the cover

• Measuring range up to 40 m / 131 ft

• Hygienic probe for processes where stringent hygiene standards must be obeyed

• Converter backwards compatible with all flange systems of current (OPTIFLEX 1300 C) and

previous (BM 100 A, BM 102) generation TDR level transmitters from KROHNE

• SIL2-compliant according to IEC 61508 for safety-related systems

• The device has FDT1.2 DTM certification.

Industries

• Chemical market

• Oil & Gas

• Power

• Food

• Wastewater

• Pulp & Paper

• Metals, Minerals & Mining

• Food and beverage

4

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

Applications

• Liquid level measurement in process tanks for various chemical products

• Liquid and solid volume measurement for storage tanks

1.2 Overview

OPTIFLEX 2200 C – Compact / Vertical version

PRODUCT FEATURES

This version makes it easier to read and operate

devices installed on a tank roof or in a recess.

1

OPTIFLEX 2200 C – Compact / Horizontal version

This version is ideal for installation in locations

with low roofs.

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

5

1

PRODUCT FEATURES

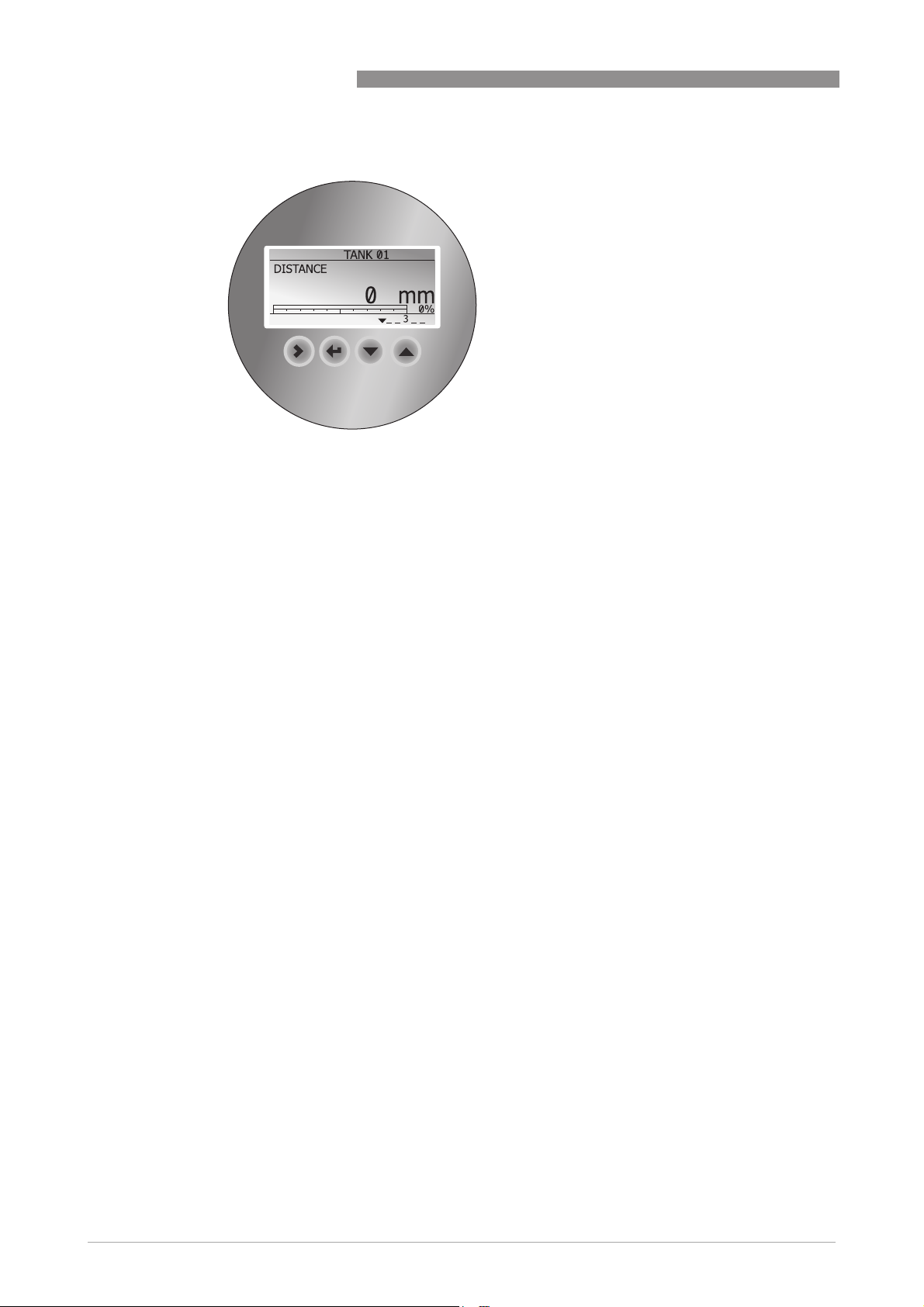

OPTIFLEX 2200 F – Remote version

OPTIFLEX 2200 C/F

This version has a separate converter with a

display which can be mounted and read off at the

bottom of the tank or even at a distance of up to

100 m / 328 ft from the sensor.

Weather protection

A weather protection option can also be ordered with the device. It is recommended for outdoor

applications.

• Must be ordered with the device.

• Can be ordered for both compact versions of the

device and the probe housing of the remote

version.

• Easily opened and closed.

6

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

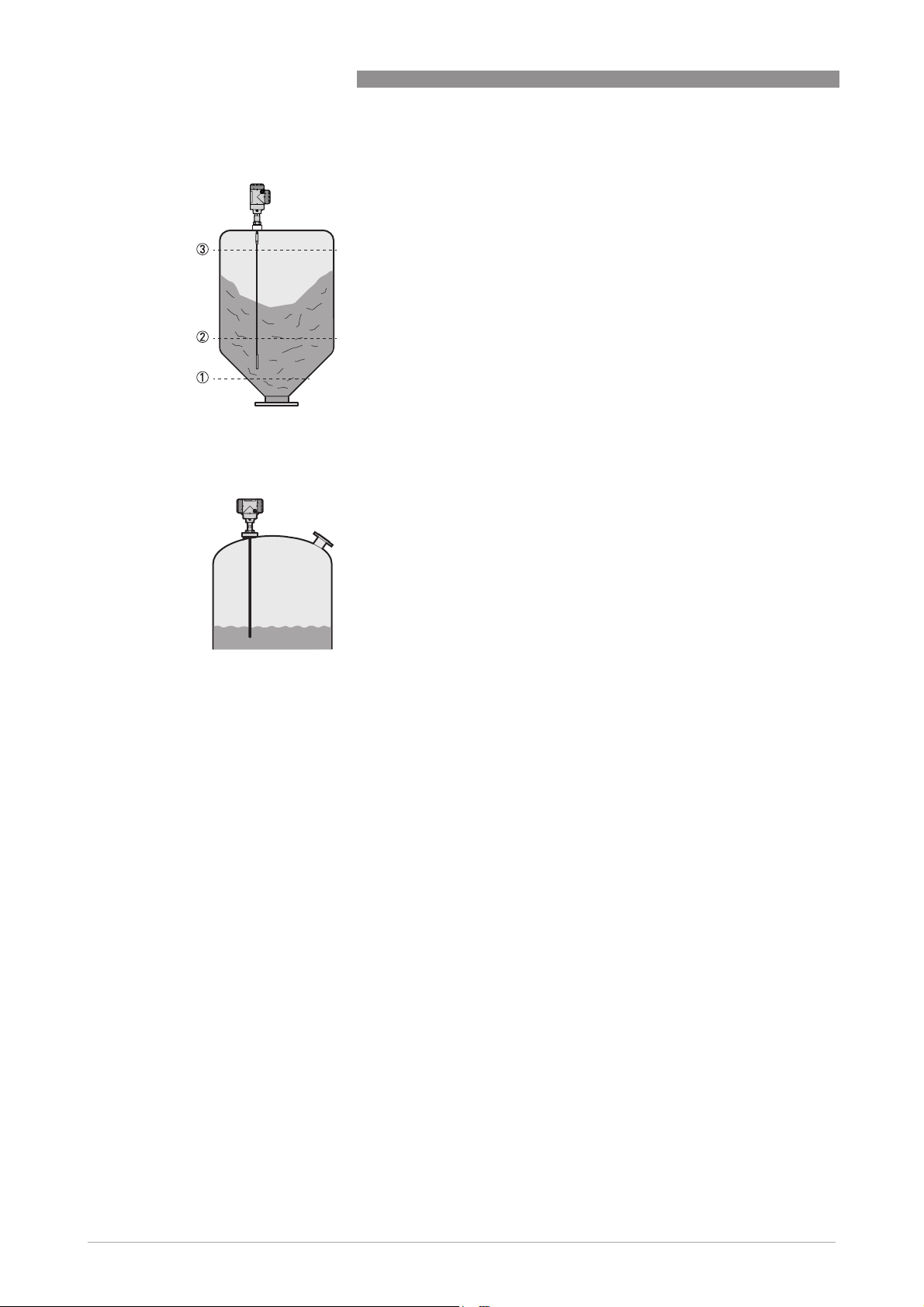

1.3 Applications

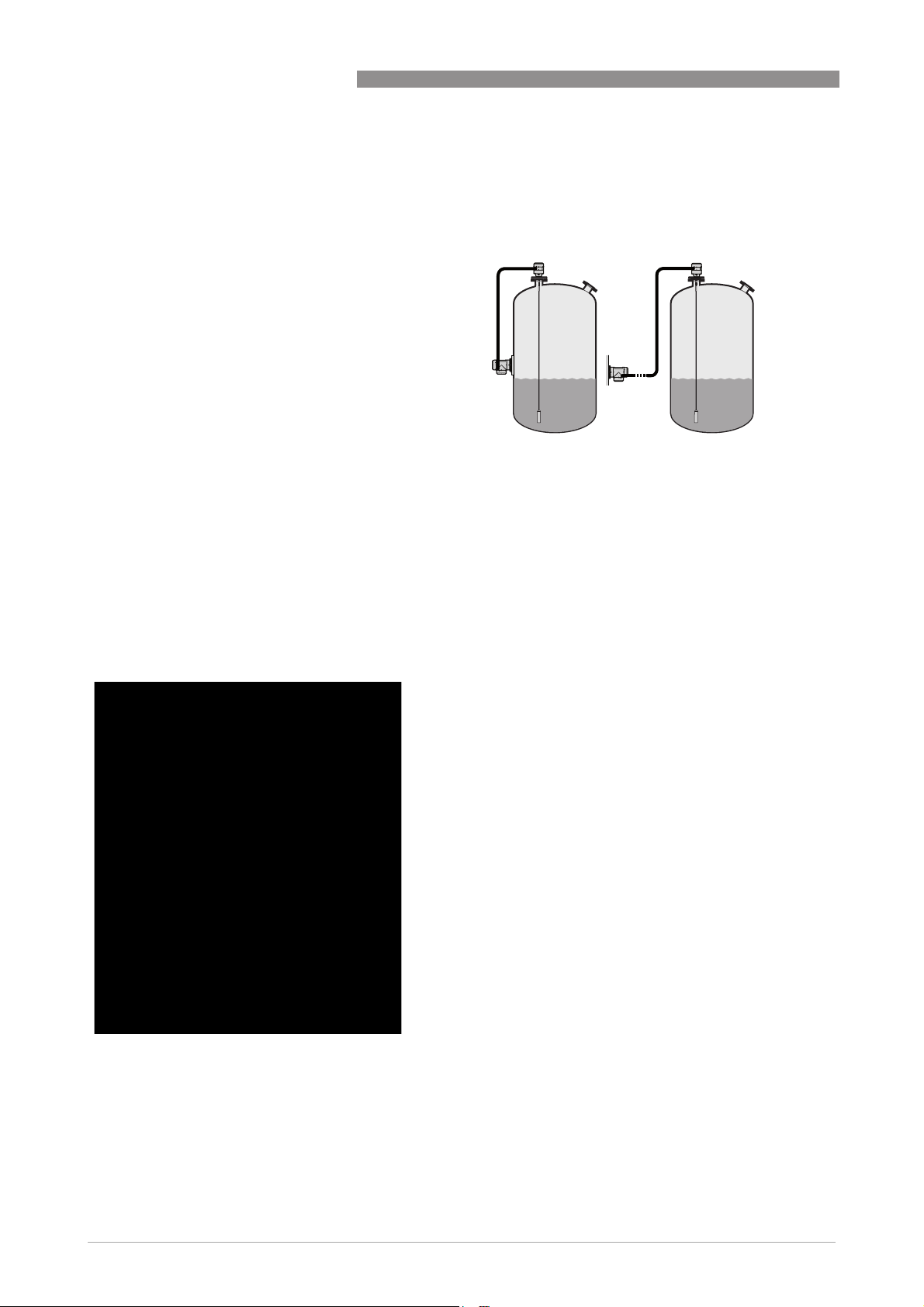

1. Level measurement of liquids

2. Level measurement of solids

PRODUCT FEATURES

The level transmitter can measure the level of a

wide range of liquid products on a large variety of

installations within the stated pressure and

temperature range. It does not require any

calibration: it is only necessary to adapt the probe

length and do a short configuration procedure.

The level transmitter has a Ø4 mm / 0.16¨ single

cable probe for measuring powders and granulates

in silos up to 20 m / 65.6 ft high. It does not require

any calibration: it is only necessary to adapt the

probe length and do a short configuration

procedure.

1

For silos up to 40 m / 131.2 ft, the level transmitter

also has a Ø8 mm / 0.32¨ single cable probe.

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

7

1

PRODUCT FEATURES

3. Volume measurement

4. Measurement of liquids with a hygienic probe

OPTIFLEX 2200 C/F

A conversion table (strapping table) function is

available in the configuration menu for volume or

mass measurement. Up to 30 volume values can be

related to level values. For example:

Level 1= 2 m / Volume 1= e.g. 0.7 m³

Level 2= 10 m / Volume 2= e.g. 5 m³

Level 3= 20 m / Volume 3= e.g. 17 m³

This data permits the device to calculate volumes

between strapping table entries.

The hygienic probe option is made of materials that

agree with FDA and European Union regulations. It

is suitable for level measurement in processes that

require hygienic equipment (such as the food,

beverage and pharmaceutical industries). It is also

suitable for CIP and SIP cycles.

8

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

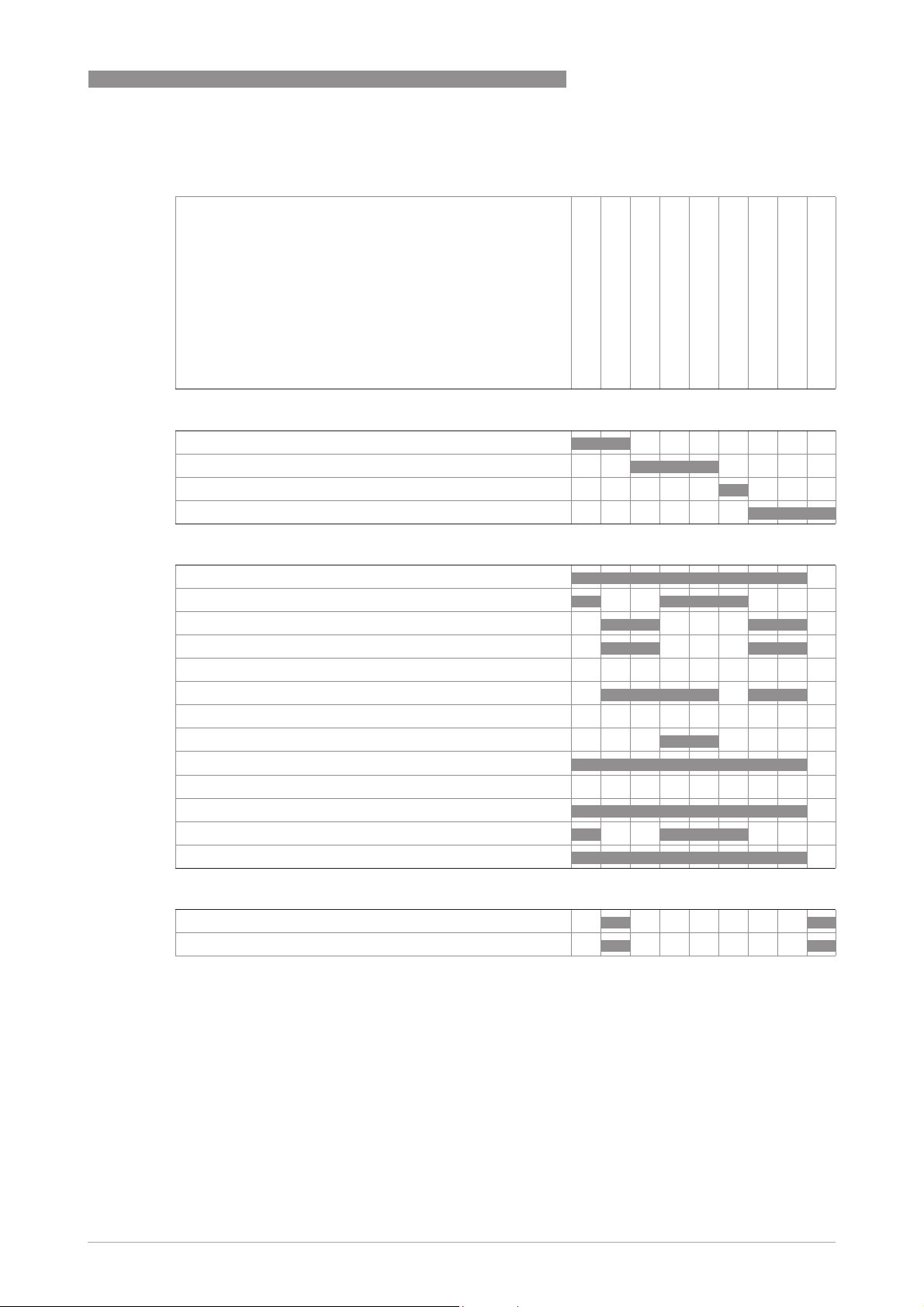

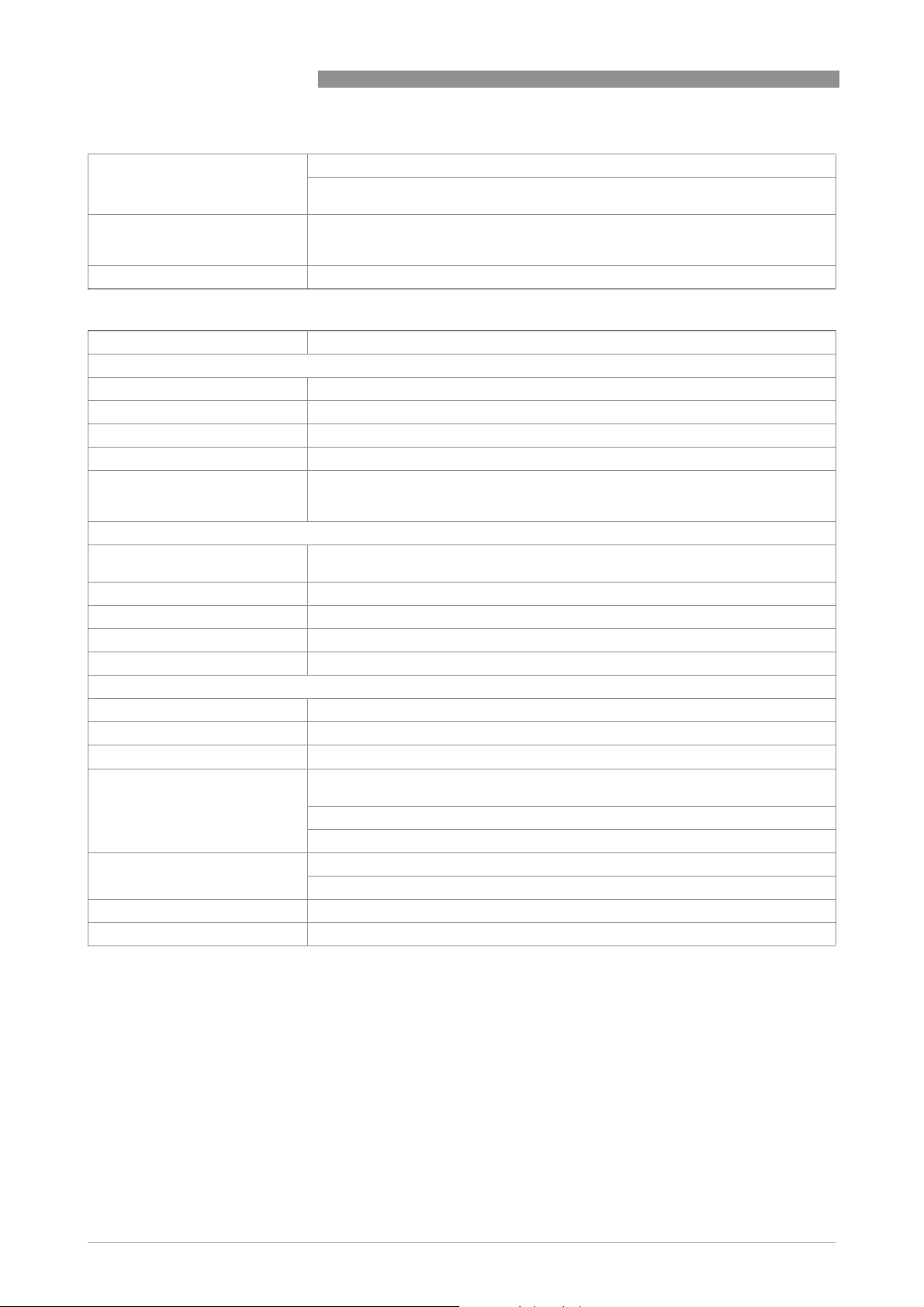

1.4 Application table for probe selection

Maximum probe length, L

4m/ 13ft

6m/ 20ft

28 m / 92 ft

40 m / 131 ft

PRODUCT FEATURES

Double rod

Single rod

Single rod (segmented)

Coaxial

Coaxial (segmented)

Double cable

Single cable Ø4 mm / 0.15¨

Single cable Ø2 mm / 0.08¨

1

Single cable Ø8 mm / 0.32¨

Liquids

Liquid application

LPG, LNG

Highly viscous liquids

Highly crystallising liquids

Highly corrosive liquids

Foam

Agitated liquids

Spray in tank

Storage tanks

Hygienic applications

Installation in bypass chamber

Small diameter nozzles and long nozzles

Stilling wells

1 1 1 1

2 3 3

4 4 4 4 4 4 4 4

1 1 1 1

5

4 4 4 4

Solids

Powders

Granules, <5 mm / 0.2¨

J standard J optional U on request

1 Install the device in a stilling well or a bypass chamber

2 Use a probe with a PTFE, PVDF or PP protective sheath

3 Use a probe made of HASTELLOY® C-22®

4 Use this probe with an anchor fitting. For more data, refer to the handbook.

5 Use a welded probe with a surface roughness, Ra <0.76 µm. The wetted part materials agree with FDA 21 CFR

177.2600, Regulation (EC) No 1935/2004, Commission Regulation (EC) No 2023/2006 and Commission Regulation (EU)

No 10/2011.

6 Max. length is 20 m / 65.5 ft, more on request

6

6

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

9

1

PRODUCT FEATURES

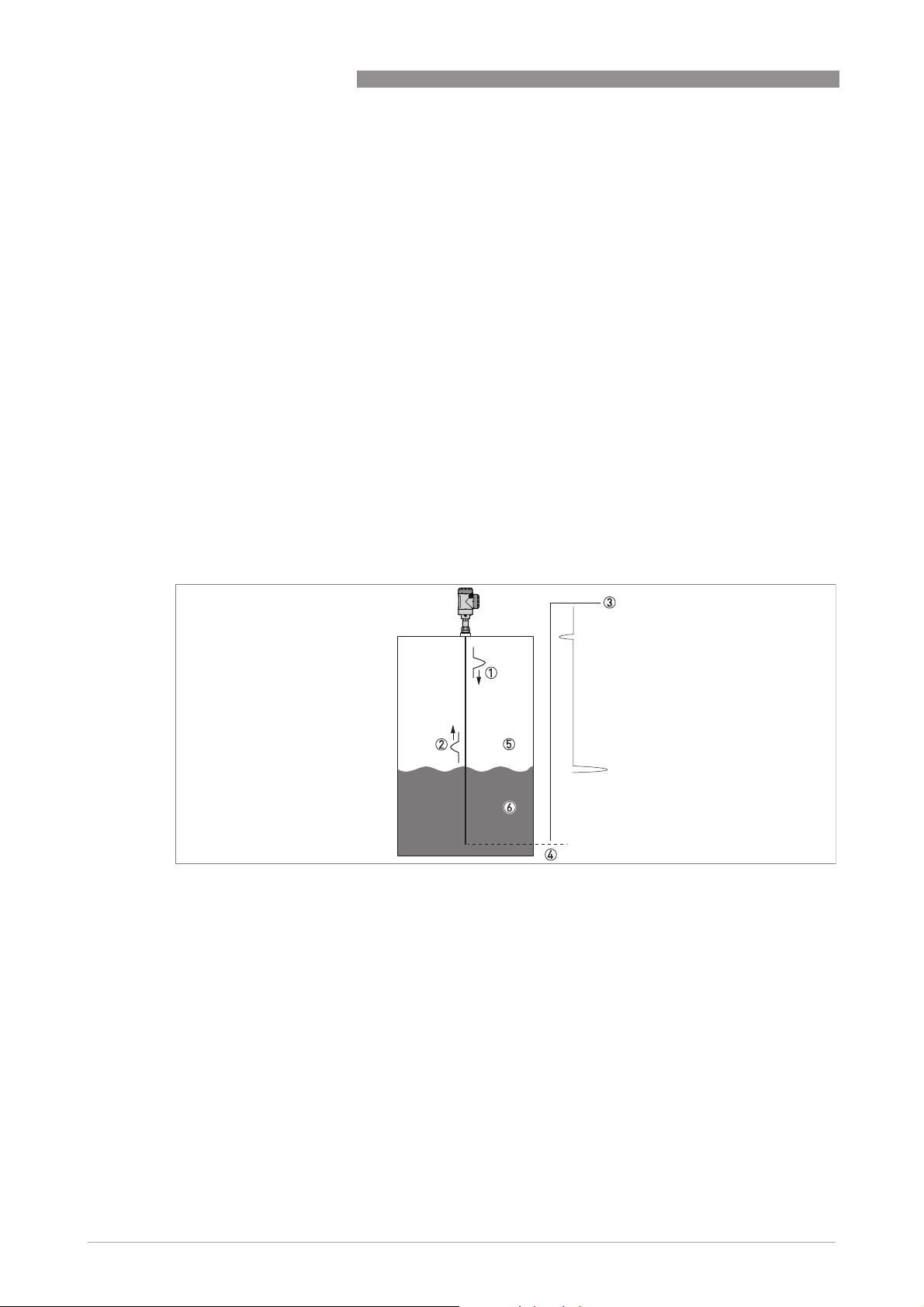

1.5 Measuring principle

This Guided Radar (TDR) level transmitter has been developed from a proven technology called

Time Domain Reflectometry (TDR).

The device transmits low-intensity electromagnetic pulses of approximately one nanosecond

width along a rigid or flexible conductor. These pulses move at the speed of light. When the

pulses reach the surface of the product to be measured, the pulses are reflected back to the

signal converter.

The device measures the time from when the pulse is emitted to when it is received: half of this

time is equivalent to the distance from the reference point of the device to the surface of the

product. The time value is converted into an output current of 4...20 mA.

Dust, foam, vapour, agitated surfaces, boiling surfaces, changes in pressure, changes in

temperature, changes in dielectric constant and changes in density do not have an effect on

device performance.

The illustration that follows shows a snapshot of what a user would see on an oscilloscope, if the

level of one product is measured.

OPTIFLEX 2200 C/F

TDR measurement of level

Figure 1-1: TDR measurement of level

1 Transmitted pulses

2 Reflected pulse

3 Pulse amplitude

4 Time of flight

5 Air, ε

6 ε

=1

r

≥ 1.4 in direct mode or εr≥ 1.1 in TBF mode

r

10

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

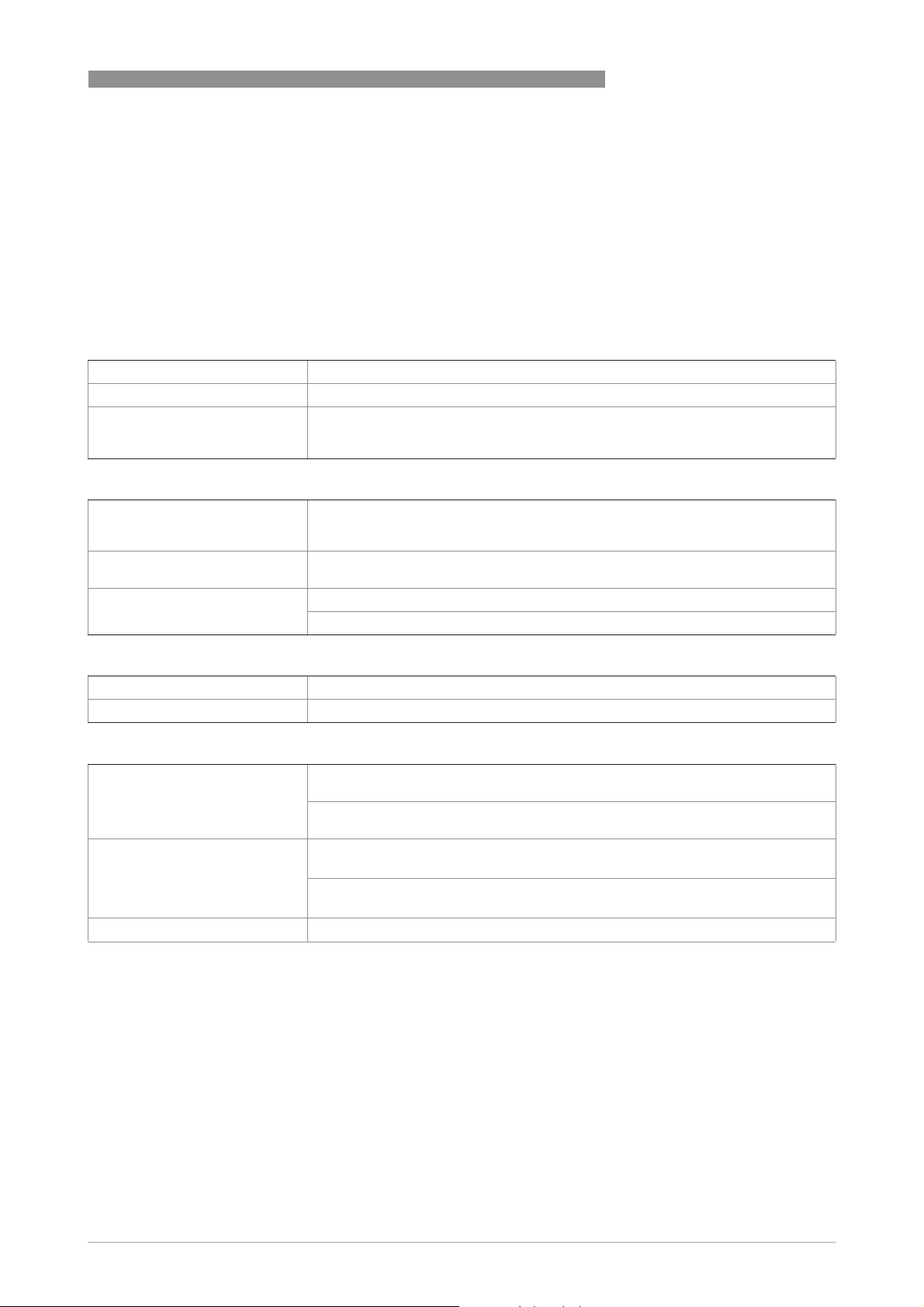

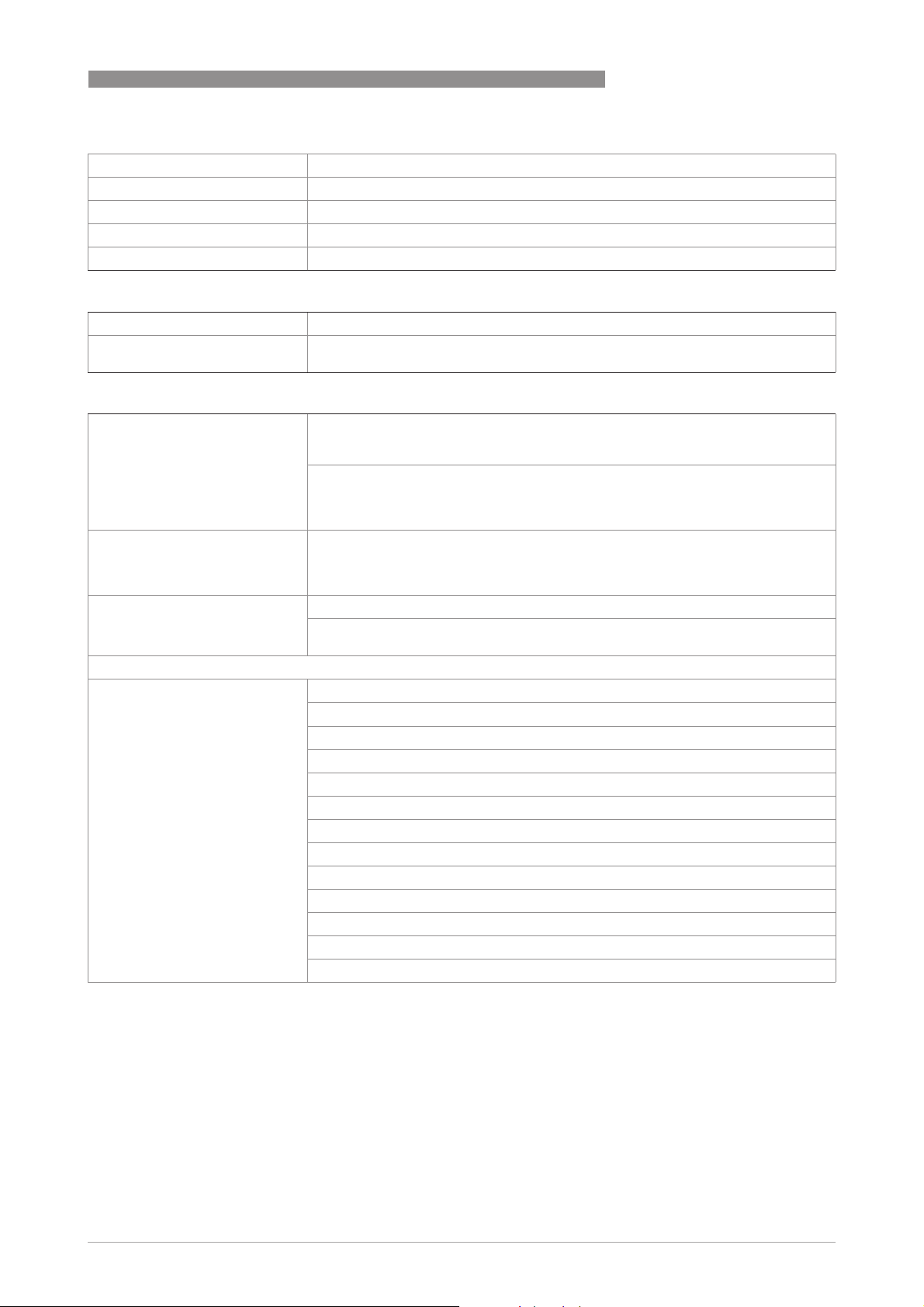

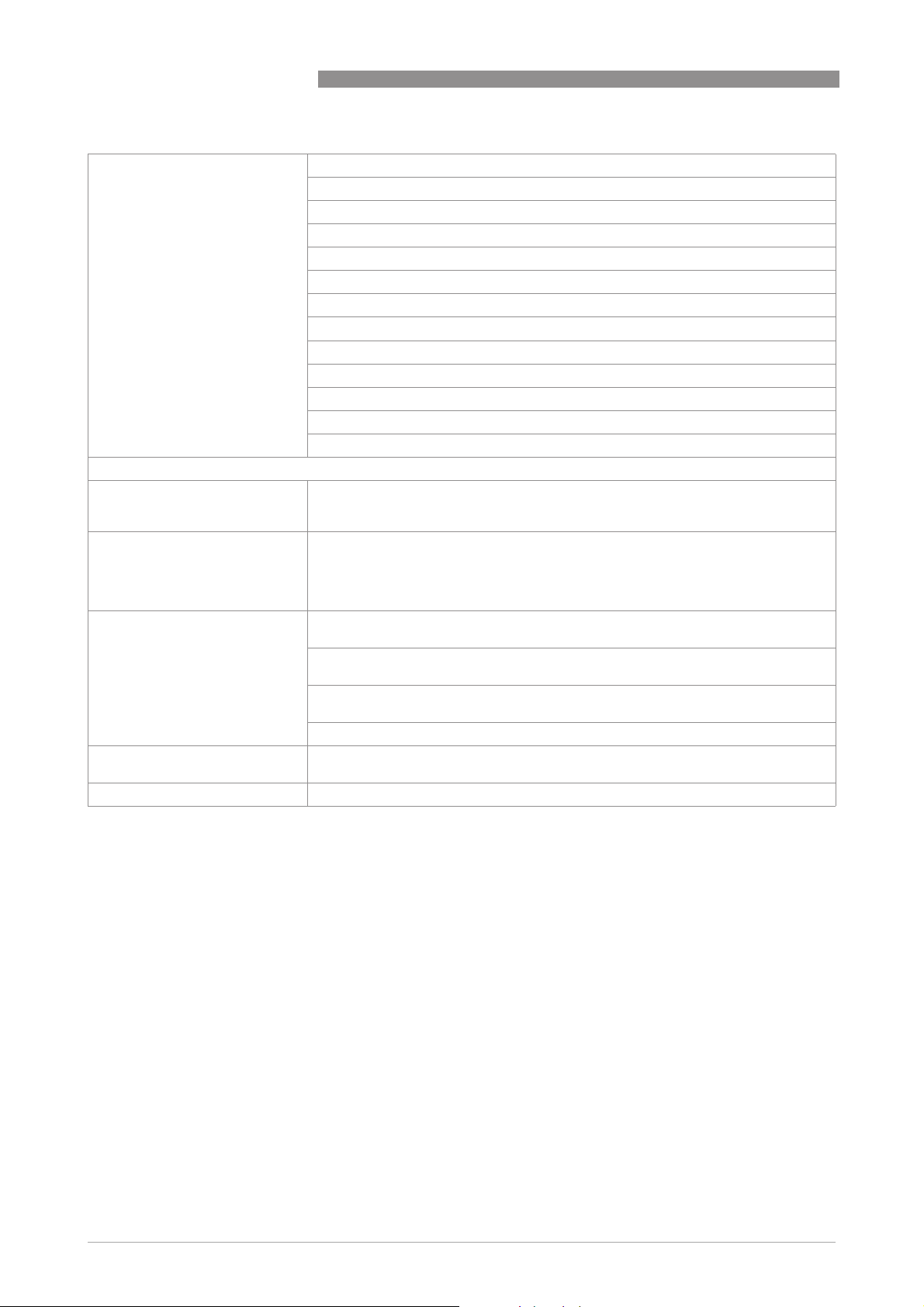

Converter

Measuring system

Application Level and volume measurement of liquids, pastes, powders and granulates

Measuring principle TDR (time domain reflectometry)

Construction Compact (C) version: Measuring probe attached directly to a signal converter

Operating conditions

Ambient temperature -40…+80°C/ -40…+176°F

Storage temperature -50…+85°C/ -60…+185°F (min. -40°C/ -40°F for devices with the integrated LCD

Ingress protection IEC 60529: IP66 / IP67

Remote (F) version: Measuring probe installed on a tank and connected by a signal

cable (max. length 100 m / 328 ft) to a signal converter

Integrated LCD display: -20...+60°C / -5...+140°F; if the ambient temperature is not

in these limits, the display switches off. The device continues to operate correctly.

display option)

NEMA 250: NEMA type 4X (housing) and type 6P (probe)

2

Materials

Housing Polyester-coated aluminium or stainless steel (1.4404 / 316L)

Cable entry Plastic; nickel-plated brass, stainless steel

Electrical connections

Power supply (terminals) Terminals output

Current output load Non-Ex / Ex i:

Cable entry M20×1.5; ½ NPT

Terminals output – Non-Ex / Ex i:

Terminals output Terminals output

11.5…30 VDC; min./max. value for an output of 22 mA at the terminal

Terminals output

Terminals output – Ex d:

Terminals output Terminals output

13.5…36 VDC; min./max. value for an output of 22 mA at the terminal

Non-Ex / Ex i: RL [Ω] ≤ ((U

Non-Ex / Ex i:Non-Ex / Ex i:

power supply voltage

Ex d:

Ex d: RL [Ω] ≤ ((U

Ex d:Ex d:

on page 21.

voltage

Non-Ex / Ex i:

Non-Ex / Ex i: Non-Ex / Ex i:

Ex d:

Ex d: Ex d:

-11.5 V)/22 mA). For more data, refer to

ext

on page 21.

-13.5 V)/22 mA). For more data, refer to

ext

Minimum

Minimum power supply

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

11

2

TECHNICAL DATA

Cable gland Standard: none

Options: M20×1.5 (cable diameter (non-Ex / Ex i: 6...7.5 mm / 0.24...0.30¨;

Ex d: 6...10 mm / 0.24...0.39¨); others are available on request

Signal cable – remote version None for non-Ex devices (4-wire shielded cable of max. length 100 m / 328 ft to be

Cable entry capacity (terminal) 0.5…2.5 mm²

supplied by the customer). Supplied with all Ex-approved devices. For more data,

refer to the handbook

OPTIFLEX 2200 C/F

Input and output

Measured variable Time between the emitted and received signal

Current output / HART

Current output / HART®

Current output / HARTCurrent output / HART

Output signal 4…20 mA HART® or 3.8…20.5 mA acc. to NAMUR NE 43

Resolution ±3 µA

Temperature drift (analog) Typically 50 ppm/K

Temperature drift (digital) Max. ±15 mm for the full temperature range

Error signal options High: 22 mA; Low: 3.6 mA acc. to NAMUR NE 43; Hold (frozen value – not available if

PROFIBUS PA

PROFIBUS PA

PROFIBUS PAPROFIBUS PA

Type PROFIBUS MBP interface that agrees with IEC 61158-2 with 31.25 kbit/s; voltage

Function blocks 1 × Physical Block, 1 × Level Transducer Block, 4 × Analog Input Function Blocks

Device power supply 9...32 VDC – bus powered; no additional power supply required

Polarity sensitivity No

Basic current 15 mA

FOUNDATION

FOUNDATION™ fieldbus

FOUNDATIONFOUNDATION

Physical layer FOUNDATION™ fieldbus protocol that agrees with IEC 61158-2 and FISCO model

Communication standard H1

ITK version 6.1

Function blocks 1 × Resource Block (RB), 3 × Transducer Blocks (TB), 3 × Analog Input Blocks (AI), 1

Device power supply Not intrinsically safe: 9...32 VDC

Basic current 14 mA

Maximum error current FDE 20.5 mA (= basic current + error current = 14 mA + 6.5 mA)

fieldbus

fieldbus fieldbus

the output agrees with NAMUR NE 43 or the device is approved for safety-related

systems (SIL))

mode (MBP = Manchester-Coded, Bus-Powered)

x Proportional Integral Derivative Block (PID)

Analog Input Block: 30 ms

Proportional Integral Derivative Block: 40 ms

Intrinsically safe: 9...24 VDC

1

12

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

Polarity sensitivity No

Minimum cycle time 250 ms

Output data Level, distance, ullage conversion, level conversion

Input data None

Link Active Scheduler Supported

TECHNICAL DATA

Display and user interface

User interface options LCD display (128 × 64 pixels in 8-step greyscale with 4-button keypad)

Languages 9 languages are available: English, German, French, Italian, Spanish, Portuguese,

Japanese, Chinese (simplified) and Russian

Approvals and certification

CE The device meets the essential requirements of the EU Directives. The

Vibration resistance EN 60721-3-4 (1...9 Hz: 3 mm / 10...200 Hz:1g; 10g shock ½sinus: 11 ms)

Conformity to sanitary

regulations

(for hygienic probe options only)

Explosion protection

Explosion protection

Explosion protectionExplosion protection

ATEX (Ex ia, Ex d or Ex tb)

DEKRA 11ATEX0166 X

manufacturer certifies successful testing of the product by applying the CE

marking.

For more data about the EU Directives and European Standards related to this

device, refer to the EU Declaration of Conformity. You can find this documentation

on the DVD-ROM supplied with the device or it can be downloaded free of charge

from the website (Download Center).

For coaxial probes:

<2 m / 6.56 ft, 0.5g or category 4M3 according to EN 60721-3-4

<6 m / 19.68 ft, 0.5g or category 4M1 according to EN 60721-3-4

FDA 21 CFR 177.2600

Regulation (EC) No 1935/2004, Commission Regulation (EC) No 2023/2006,

Commission Regulation (EU) No 10/2011

Compact version

Compact version

Compact versionCompact version

II 1/2 G, 2 G Ex ia IIC T6...T2 Ga/Gb or Ex ia IIC T6...T2 Gb;

II 1/2 D, 2 D Ex ia IIIC T90°C Da/Db or Ex ia IIIC T90°C Db;

II 1/2 G, 2 G Ex d ia IIC T6...T2 Ga/Gb or Ex d ia IIC T6...T2 Gb;

II 1/2 D, 2 D Ex ia tb IIIC T90°C Da/Db or Ex ia tb IIIC T90°C Db

Remote version, transmitter

Remote version, transmitter

Remote version, transmitterRemote version, transmitter

II 2 G Ex ia [ia Ga] IIC T6...T4 Gb;

II 2 D Ex ia [ia Da] IIIC T90°C Db;

II 2 G Ex d ia [ia Ga] IIC T6...T4 Gb;

II 2 D Ex ia tb [ia Da] IIIC T90°C Db

Remote version, sensor

Remote version, sensor

Remote version, sensorRemote version, sensor

II 1/2 G, 2 G Ex ia IIC T6...T2 Ga/Gb or Ex ia IIC T6...T2 Gb;

II 1/2 D, 2 D Ex ia IIIC T90°C Da/Db or Ex ia IIIC T90°C Db

2

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

13

2

TECHNICAL DATA

OPTIFLEX 2200 C/F

ATEX (Ex ic)

DEKRA 13ATEX0051 X

IECEx

IECEx DEK 11.0060 X

Compact version

Compact version

Compact versionCompact version

II 3 G Ex ic IIC T6...T2 Gc;

II 3 D Ex ic IIIC T90°C Dc

Remote version, transmitter

Remote version, transmitter

Remote version, transmitterRemote version, transmitter

II 3 G Ex ic [ic] IIC T6...T4 Gc;

II 3 D Ex ic [ic] IIIC T90°C Dc

Remote version, sensor

Remote version, sensor

Remote version, sensorRemote version, sensor

II 3 G Ex ic IIC T6...T2 Gc;

II 3 D Ex ic IIIC T90°C Dc

Compact version

Compact version

Compact versionCompact version

Ex ia IIC T6…T2 Ga/Gb or Ex ia IIC T6…T2 Gb or Ex ic IIC T6…T2 Gc;

Ex ia IIIC T90°C Da/Db or Ex ia IIIC T90°C Db or Ex ic IIIC T90°C Dc;

Ex d ia IIC T6...T2 Ga/Gb or Ex d ia IIIC T6...T2 Gb;

Ex ia tb IIIC T90°C Da/Db or Ex ia tb IIIC T90°C Db

Remote version, transmitter

Remote version, transmitter

Remote version, transmitterRemote version, transmitter

Ex ia [ia Ga] IIC T6…T4 Gb or Ex ic [ic] IIC T6…T4 Gc;

Ex ia [ia Da] IIIC T90°C Db or Ex ic [ic] IIIC T90°C Dc;

Ex d ia [ia Ga] IIC T6...T4 Gb;

Ex ia tb [ia Da] IIIC T90°C Db

Remote version, sensor

Remote version, sensor

Remote version, sensorRemote version, sensor

Ex ia IIC T6…T2 Ga/Gb or Ex ia IIC T6…T2 Gb or Ex ic IIC T6…T2 Gc;

Ex ia IIIC T90°C Da/Db or Ex ia IIIC T90°C Db or Ex ic IIIC T90°C Dc

14

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

TECHNICAL DATA

2

cFMus – Dual Seal-approved

(pending for hygienic probe

options)

NEPSI

(not available for hygienic probe

options)

NEC 500 (Division ratings)

NEC 500 (Division ratings)

NEC 500 (Division ratings)NEC 500 (Division ratings)

XP-AIS / Cl. I / Div. 1 / Gr. ABCD / T6–T1;

DIP / Cl. II, III / Div. 1 / Gr. EFG / T90°C;

IS / Cl. I, II, III / Div. 1 / Gr. ABCDEFG / T6–T1;

NI / Cl. I / Div. 2 / Gr. ABCD / T6–T1

NEC 505 and NEC 506 (Zone ratings)

NEC 505 and NEC 506 (Zone ratings)

NEC 505 and NEC 506 (Zone ratings)NEC 505 and NEC 506 (Zone ratings)

Cl. I / Zone 0 / AEx d [ia] / IIC / T6–T1;

Cl. I / Zone 0 / AEx ia / IIC / T6–T1;

Cl. I / Zone 2 / AEx nA / IIC / T6–T1;

Cl. I / Zone 2 / AEx ic / IIC / T6–T1 FISCO;

Zone 20 / AEx ia / IIIC / T90°C;

Zone 20 / AEx tb [ia] / IIIC / T90°C

Hazardous (Classified) Locations, indoor/outdoor Type 4X and 6P, IP66, Dual Seal

CEC Section 18 (Zone ratings)

CEC Section 18 (Zone ratings)

CEC Section 18 (Zone ratings)CEC Section 18 (Zone ratings)

Cl. I, Zone 0, Ex d [ia], IIC, T6–T1;

Cl. I, Zone 0, Ex ia, IIC, T6–T1;

Cl. I, Zone 2, Ex nA, IIC, T6–T1;

Cl. I, Zone 2, Ex ic, IIC, T6–T1 FISCO

CEC Section 18 and Annex J (Division ratings)

CEC Section 18 and Annex J (Division ratings)

CEC Section 18 and Annex J (Division ratings)CEC Section 18 and Annex J (Division ratings)

XP-AIS / Cl. I / Div. 1 / Gr. BCD / T6–T1;

DIP / Cl. II, III / Div. 1 / Gr. EFG / T90°C;

IS / Cl. I, II, III / Div. 1 / Gr. ABCDEFG / T6–T1;

NI / Cl. I / Div. 2 / Gr. ABCD / T6–T1

Ex ia IIC T2~T6 Gb or Ex ia IIC T2~T6 Ga/Gb DIP A20/A21 T

Ex d ia IIC T2~T6 Gb or Ex d ia IIC T2~T6 Ga/Gb DIP A20/A21 T

T90°C IP6X;

A

T90°C IP6X

A

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

15

2

TECHNICAL DATA

OPTIFLEX 2200 C/F

DNV / INMETRO

DNV 13.0142 X

(not available for hygienic probe

options)

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

SIL

– only for 4...20 mA output

EMC Electromagnetic Compatibility (EMC) directive. The device agrees with this directive

NAMUR NAMUR NE 21 Electromagnetic Compatibility (EMC) of Industrial Process and

CRN This certification is applicable for all Canadian provinces and territories. For more

Construction code On request: NACE MR0175 / ISO 15156; NACE MR0103

1 HART® is a registered trademark of the HART Communication Foundation

Compact version

Compact version

Compact versionCompact version

Ex ia IIC T6…T2 Ga/Gb or Ex ia IIC T6…T2 Gb or Ex ic IIC T6…T2 Gc;

Ex ia IIIC T90°C Da/Db or Ex ia IIIC T90°C Db or Ex ic IIIC T90°C Dc;

Ex d ia IIC T6...T2 Ga/Gb or Ex d ia IIIC T6...T2 Gb;

Ex ia tb IIIC T90°C Da/Db or Ex ia tb IIIC T90°C Db

Remote version, transmitter

Remote version, transmitter

Remote version, transmitterRemote version, transmitter

Ex ia [ia Ga] IIC T6…T4 Gb or Ex ic [ic] IIC T6…T4 Gc;

Ex ia [ia Da] IIIC T90°C Db or Ex ic [ic] IIIC T90°C Dc;

Ex d ia [ia Ga] IIC T6...T4 Gb;

Ex ia tb [ia Da] IIIC T90°C Db

Remote version, sensor

Remote version, sensor

Remote version, sensorRemote version, sensor

Ex ia IIC T6…T2 Ga/Gb or Ex ia IIC T6…T2 Gb or Ex ic IIC T6…T2 Gc;

Ex ia IIIC T90°C Da/Db or Ex ia IIIC T90°C Db or Ex ic IIIC T90°C Dc

Compact version only: SIL 2 – certified according to all the requirements in

EN 61508 (Full Assessment) and for high/low demand mode operation. HFT=0,

SFF=94.3% (for non-Ex / Ex i devices) or 92.1% (for Ex d devices), type B device

and its related standard if:

– the device has a coaxial probe or

– the device has a single / double probe that is installed in a metallic tank.

SIL 2-approved devices agree with EN 61326-3-1 and EN 61326-3-2.

Laboratory Control Equipment

NAMUR NE 43 Standardization of the Signal Level for the Failure Information of

Digital Transmitters

NAMUR NE 53 Software and Hardware of Field Devices and Signal Processing

Devices with Digital Electronics

NAMUR NE 107 Self-Monitoring and Diagnosis of Field Devices

data, refer to the website.

16

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

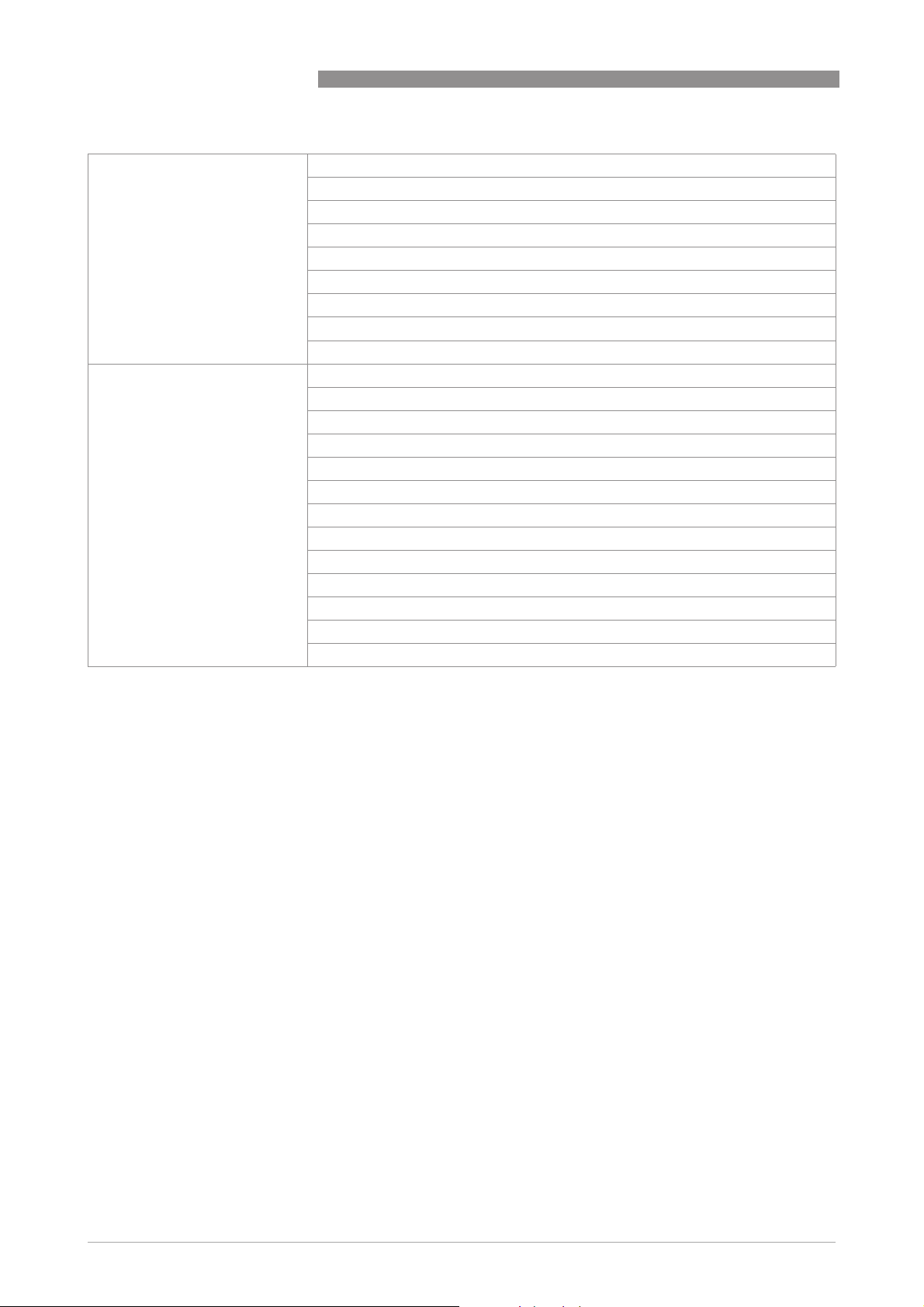

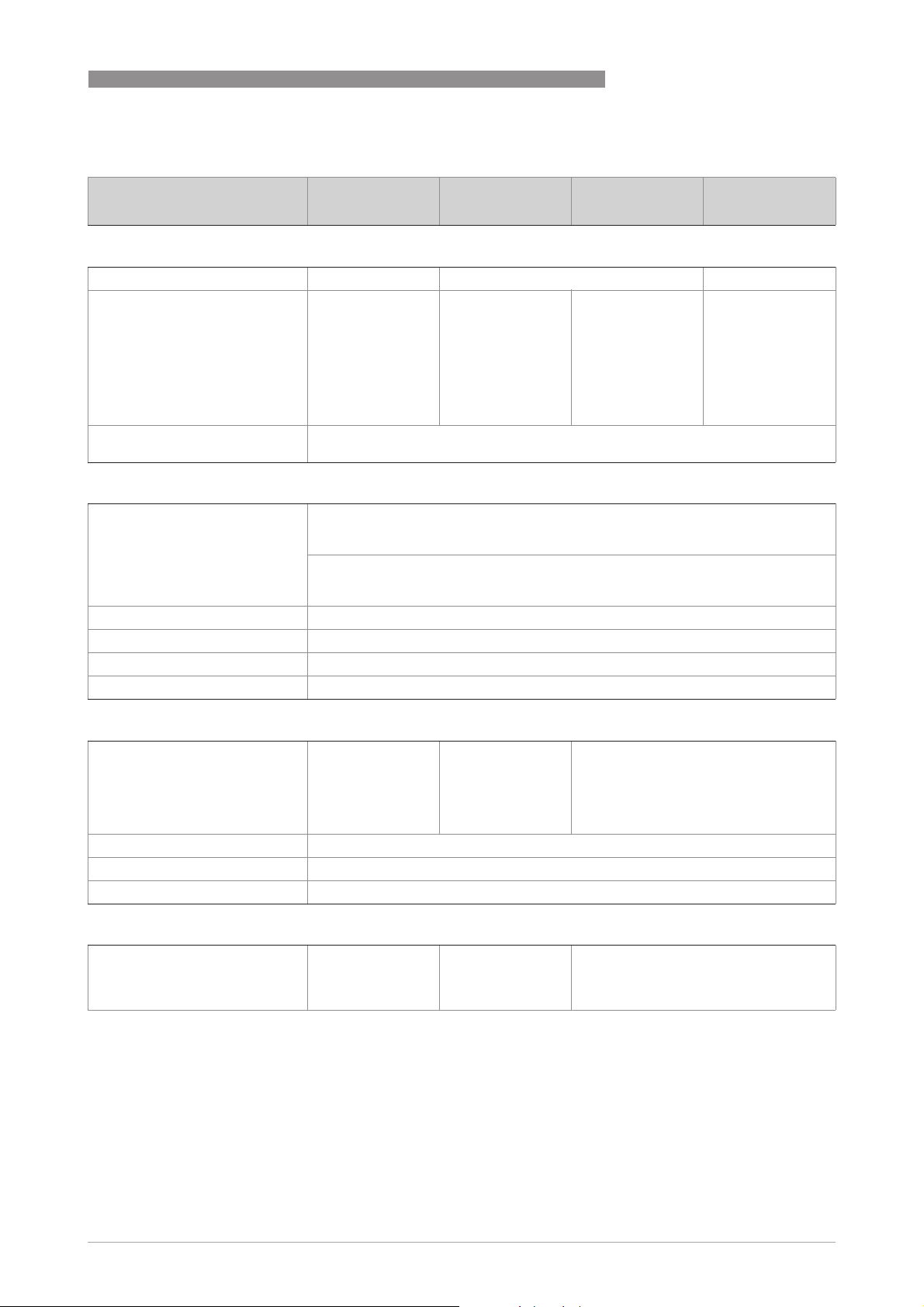

Probe options

TECHNICAL DATA

2

Single cable

Ø2 mm / 0.08¨

Single rod

Ø8 mm / 0.32¨

Single cable

Ø4 mm / 0.16¨

Measuring system

Application Liquids Liquids and solids Solids

Measuring range 1...40 m /

3.28...131.23 ft

Dead zone This depends on the type of probe. For more data, refer to

page 24.

Single-piece probe

(liquid, solids and

hygienic

applications):

1...4 m /

3.28...13.12 ft

Segmented probe

(liquids): 1...6 m /

3.28...19.69 ft

Liquids:

1...40 m /

3.28...131.23 ft

Solids:

1...20 m /

3.28...65.62 ft

1...40 m /

3.28...131.23 ft

Measurement limits

Measuring accuracy

Accuracy (in direct mode) Standard (liquids and solids):

Accuracy (in TBF mode) ±20 mm / ±0.8¨

Resolution 1mm/ 0.04¨

Repeatability ±1mm/ ±0.04¨

Maximum rate of change at 4 mA 10 m/min / 32.8 ft/min

Standard (liquids and solids):

Standard (liquids and solids):Standard (liquids and solids):

±10 mm / ±0.4¨, when distance ≤ 10 m / 33 ft;

±0.1% of measured distance, when distance > 10 m / 33 ft

Optional (liquids and solids):

Optional (liquids and solids):

Optional (liquids and solids):Optional (liquids and solids):

±3mm/ ±0.1¨, when distance ≤ 10 m / 33 ft;

±0.03% of measured distance, when distance > 10 m / 33 ft

Single cable

Ø8 mm / 0.32¨

on

Operating conditions

Min./Max. temperature at the

process connection (also

depends on the temperature

limits of the gasket material.

Refer to "Materials" in this table.)

Pressure -1…40 barg / -14.5…580 psig

Viscosity (liquids only) 10000 mPa·s / 10000 cP

Dielectric constant ≥ 1.8 in direct mode; ≥ 1.1 in TBF mode

-50…+300°C/

-58…+572°F

-50…+150°C/

-58…+302°F

(Hygienic

applications:

-45…+150°C/

-49…+302°F)

Materials

Probe Stainless steel

(1.4404 / 316L);

HASTELLOY®

C-22® (2.4602)

Stainless steel

(1.4404 / 316L);

PVDF (Ø16 mm /

0.64¨ PVDF sheath)

-50…+150°C/ -58…+302°F

Stainless steel (1.4401 / 316)

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

17

2

TECHNICAL DATA

OPTIFLEX 2200 C/F

Single cable

Ø2 mm / 0.08¨

Gasket (process seal) FKM/FPM

Process connection Stainless steel

Other wetted parts PTFE, PEEK PTFE PTFE

Surface roughness of metallic

wetted parts

(-40…+300°C/

-40…+572°F);

Kalrez® 6375

(-20…+300°C/

-4…+572°F);

EPDM

(-50...+250°C/

-58...+482°F)

(1.4404 / 316L);

HASTELLOY®

C-22® (2.4602)

— For hygienic

1

Single rod

Ø8 mm / 0.32¨

FKM/FPM

(-40…+150°C/

-40…+302°F);

Kalrez® 6375(

-20…+150°C/

-4…+302°F);

EPDM

(-50...+150°C/

-58...+302°F)

For hygienic

applications only:

FKM/FPM

(-20…+150°C/

-4…+302°F);

EPDM

(-45...+150°C/

-49...+302°F)

Also applicable to

CIP and SIP cycles

1

Stainless steel (1.4404 / 316L)

applications only:

Ra <0.76 µm

Single cable

Ø4 mm / 0.16¨

FKM/FPM (-40…+150°C/ -40…+302°F);

Kalrez® 6375 (-20…+150°C/

-4…+302°F); EPDM (-50...+150°C/

-58...+302°F)

—

Single cable

Ø8 mm / 0.32¨

1

Process connections

Thread For more data on options, refer to

Flange For more data on options, refer to

Hygienic — For more data on

options, refer to

Order code

page 58,

"Hygienic" table

1 Kalrez® is a registered trademark of DuPont Performance Elastomers L.L.C.

Order code

Order code

on

on page 58

on page 58

—

18

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

OPTIFLEX 2200 C/F

TECHNICAL DATA

2

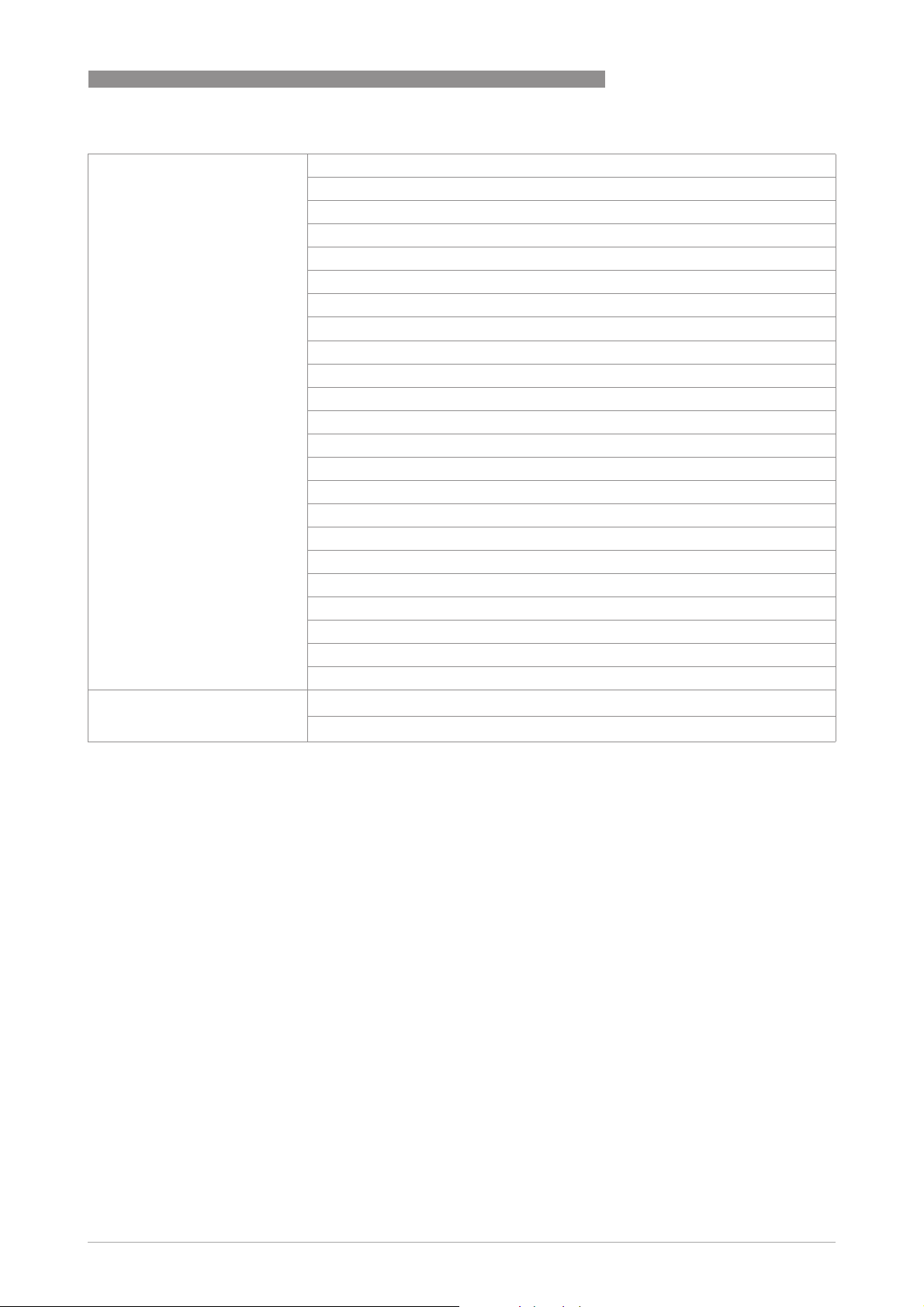

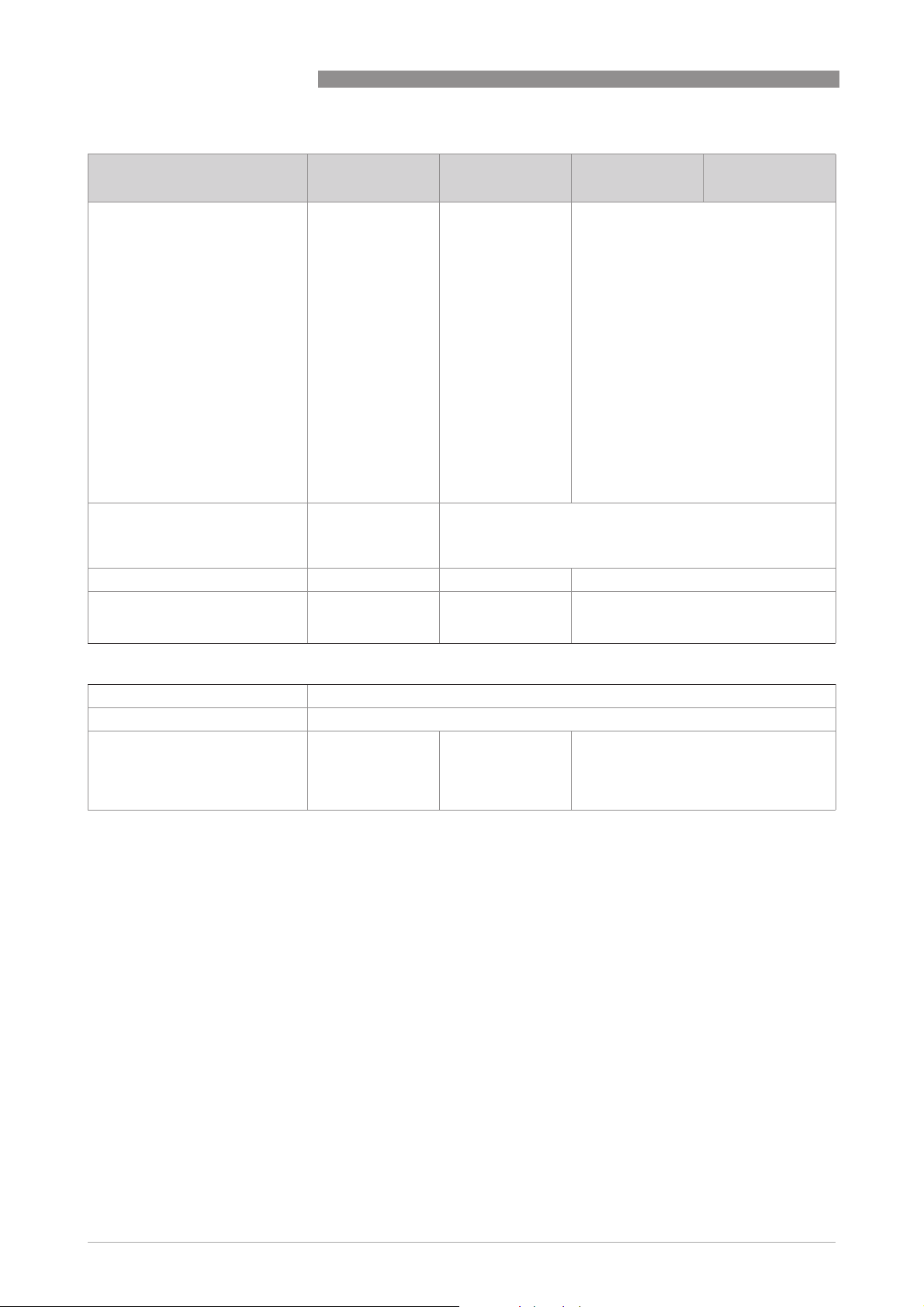

Double cable

2× Ø4mm/ 0.16¨

Double rod

2 × Ø8 mm / 0.32¨

Coaxial

Ø22 mm / 0.87¨

Measuring system

Application Liquids

Measuring range 1...28 m / 3.28...91.86 ft 1...4 m / 3.3...13.12 ft 0.6...6 m / 1.97...19.69 ft

Dead zone This depends on the type of probe. For more data, refer to

page 24.

Measurement limits

Measuring accuracy

Accuracy (in direct mode) Standard (liquids and solids):

Accuracy (in TBF mode) ±20 mm / ±0.8¨

Resolution 1mm/ 0.04¨

Repeatability ±1mm/ ±0.04¨

Maximum rate of change at 4 mA 10 m/min / 32.8 ft/min

Standard (liquids and solids):

Standard (liquids and solids):Standard (liquids and solids):

±10 mm / ±0.4¨, when distance ≤ 10 m / 33 ft;

±0.1% of measured distance, when distance > 10 m / 33 ft

Optional (liquids and solids):

Optional (liquids and solids):

Optional (liquids and solids):Optional (liquids and solids):

±3mm/ ±0.1¨, when distance ≤ 10 m / 33 ft;

±0.03% of measured distance, when distance > 10 m / 33 ft

Operating conditions

Min./Max. temperature at the

process connection (also

depends on the temperature

limits of the gasket material.

Refer to "Materials" in this table.)

Pressure -1…40 barg / -14.5…580 psig

Viscosity (liquids only) 10000 mPa·s / 10000 cP 1500 mPa·s / 1500 cP 500 mPa·s / 500 cP

Dielectric constant ≥ 1.6 in direct mode ≥ 1.4 in direct mode

-50…+150°C/ -58…+302°F

≥ 1.1 in TBF mode

on

Materials

Probe Stainless steel

Gasket (process seal) FKM/FPM (-40…+150°C/ -40…+302°F); Kalrez® 6375 (-20…+150°C/ -4…+302°F);

Process connection Stainless steel (1.4404 / 316L) Stainless steel

Other wetted parts PTFE, FEP PTFE PTFE

(1.4404 / 316L)

EPDM (-50...+150°C / -58...+302°F)

1

Stainless steel

(1.4401 / 316);

HASTELLOY® C-22®

(2.4602)

(1.4404 / 316L);

HASTELLOY®

C-22® (2.4602)

Process connections

Thread For more data on options, refer to

Flange For more data on options, refer to

1 Kalrez® is a registered trademark of DuPont Performance Elastomers L.L.C.

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

Order code

Order code

on page 58

on page 58

19

2

TECHNICAL DATA

Process connection options: flange facing finish

Type (flange facing) Flange facing finish, Ra (min...max)

[µm] [µin – AARH]

EN 1092-1

B1, E or F 3.2…12.5 125…500

B2, C or D 0.8…3.2 32…125

ASME B16.5

RF, FF, LF or LM 3.2...6.3 125...250

LG, LT, SF, ST or SM ≤ 3.2 ≤ 125

RJ ≤ 1.6 ≤ 63

JIS B2220

RF 3.2...6.3 125...250

OPTIFLEX 2200 C/F

ISO 2852 / DIN 32676 (Tri-Clamp®)

— ≤ 0.76 30

DIN 11851

— ≤ 0.76 30

20

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

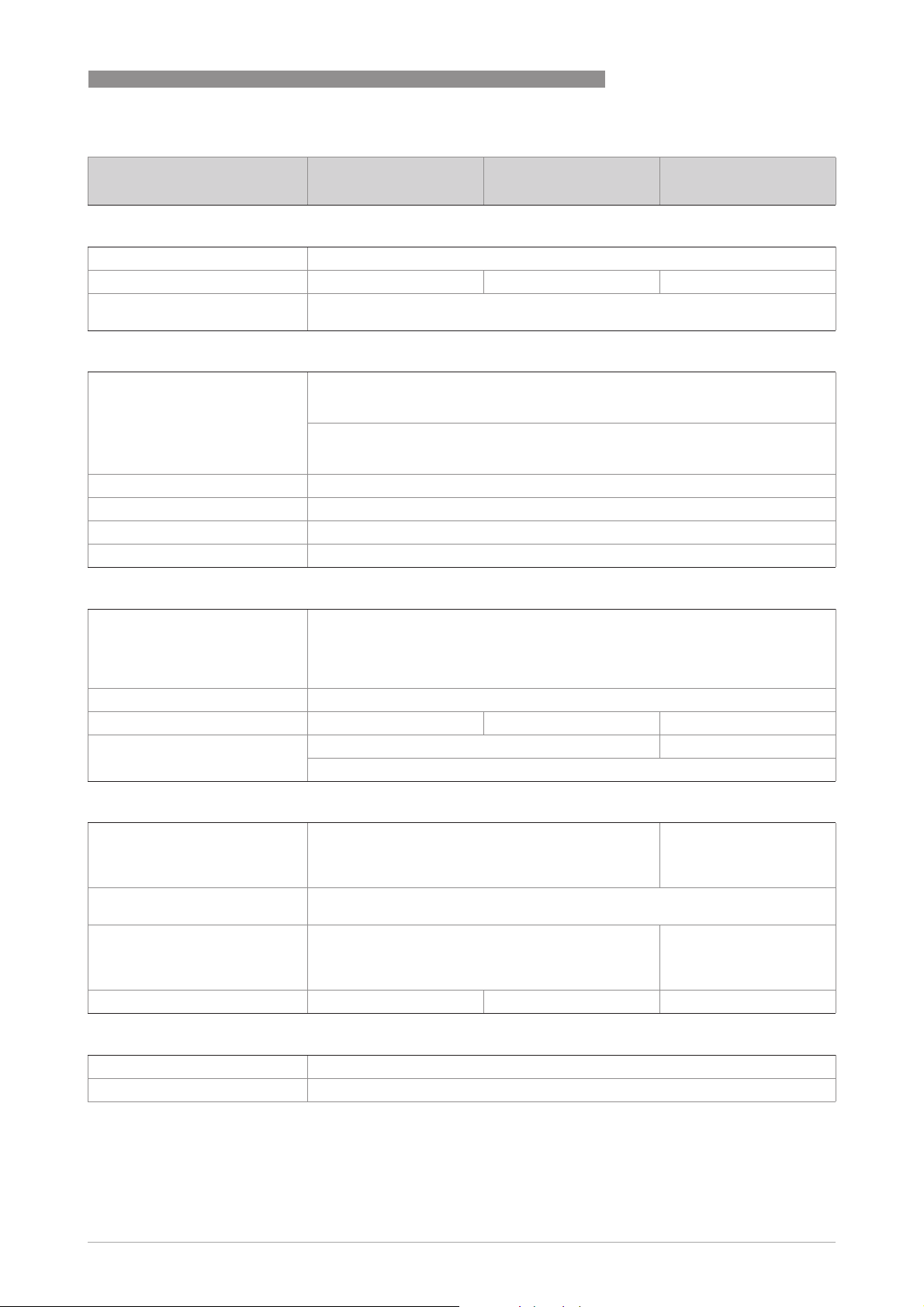

OPTIFLEX 2200 C/F

2.2 Minimum power supply voltage

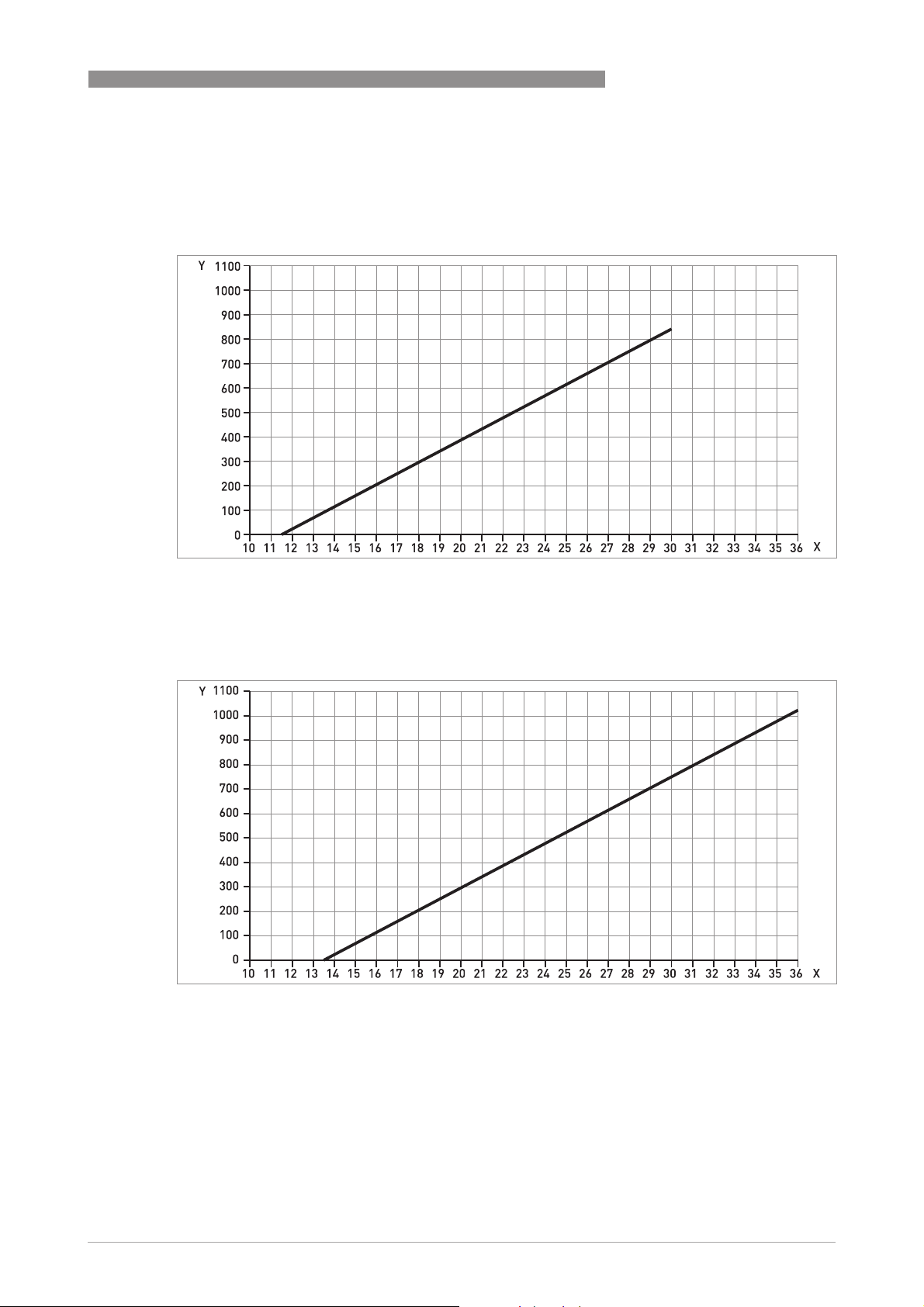

Use these graphs to find the minimum power supply voltage for a given current output load.

Non-Ex and Hazardous Location approved (Ex i / IS) devices

TECHNICAL DATA

2

Figure 2-1: Minimum power supply voltage for an output of 22 mA at the terminal (Non-Ex and Hazardous Location

approval (Ex i / IS))

X: Power supply U [VDC]

Y: Current output load R

L

[Ω]

Hazardous Location (Ex d / XP/NI) approved devices

Figure 2-2: Minimum power supply voltage for an output of 22 mA at the terminal (Hazardous Location approval (Ex d /

XP/NI))

X: Power supply U [VDC]

Y: Current output load R

L

[Ω]

www.krohne.com12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

21

2

TECHNICAL DATA

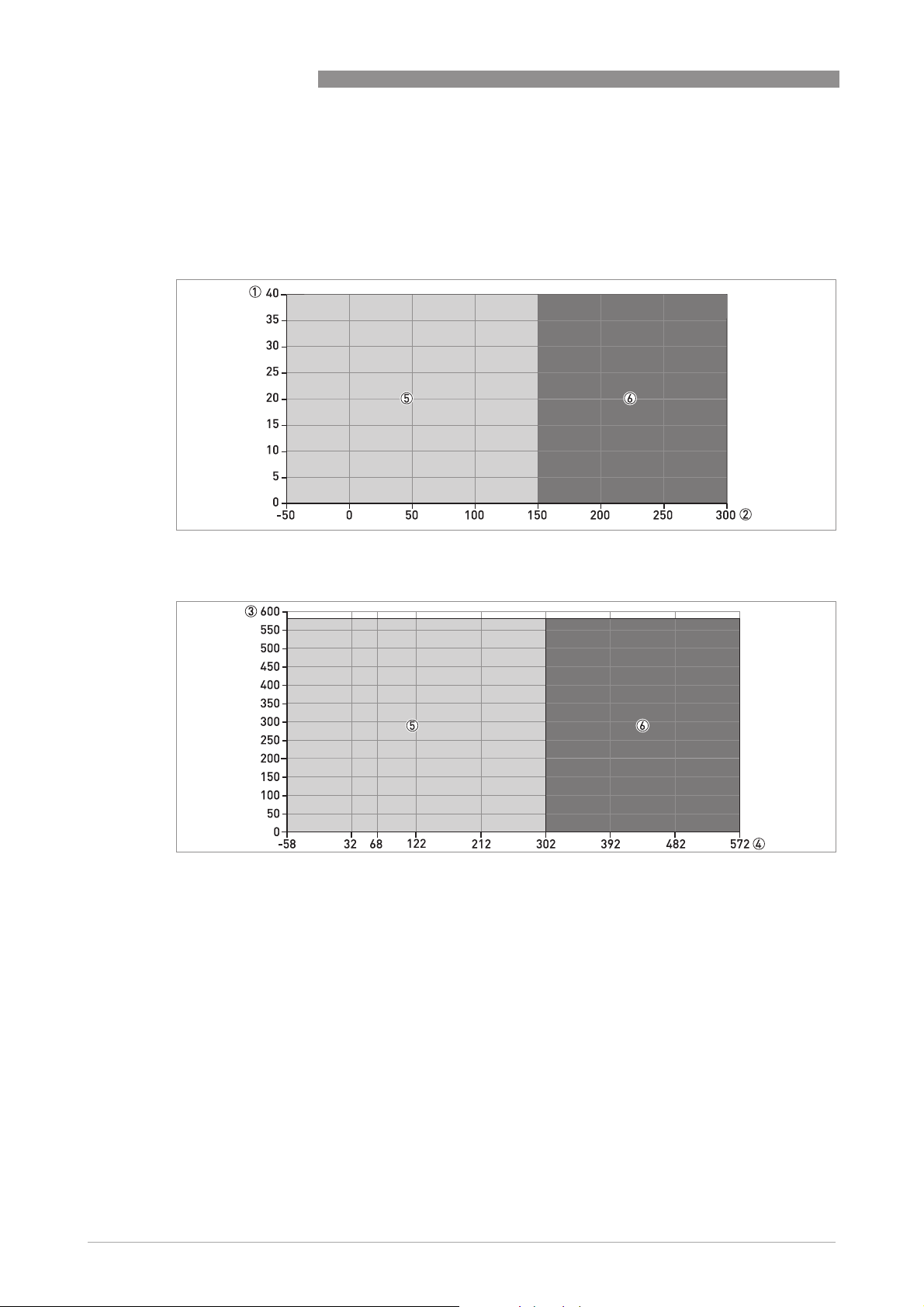

2.3 Pressure / flange temperature graph for probe selection

Make sure that the transmitters are used within their operating limits. Obey the temperature

limits of the process seal and the flange.

OPTIFLEX 2200 C/F

Figure 2-3: Pressure/temperature graph for probe selection in °C and barg

Figure 2-4: Pressure/temperature graph for probe selection in °F and psig

1 Process pressure, P

2 Process connection temperature, T [°C]

3 Process pressure, P

4 Process connection temperature, T [°F]

5 All probes

6 High-Temperature (HT) version of the Ø2 mm / 0.08¨ single cable probe

[barg]

s

[psig]

s

22

The minimum and maximum process connection temperature and the minimum and maximum

process pressure also depends on the gasket material selected. Refer to "Technical data" on

page 11

.

www.krohne.com 12/2016 - 4000621805 - TD OPTIFLEX 2200 R05 en

Loading...

Loading...