Page 1

Handbook

Handbook

OPTISENS OAS 2000

OPTISENS OAS 2000

OPTISENS OAS 2000OPTISENS OAS 2000

HandbookHandbook

Suspended solids sensor

Software version: 1.00

The documentation is only complete when used in combination with the relevant

documentation for the converter.

© KROHNE 07/2010 - MA OAS 2000 R02 en

Page 2

: IMPRINT ::::::::::::::::::::::::::::::::::

OPTISENS OAS 2000

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2010 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 3

OPTISENS OAS 2000

CONTENTS

1 Safety instructions 5

1.1 Software history ............................................................................................................... 5

1.2 Intended use ..................................................................................................................... 5

1.3 Certifications .................................................................................................................... 5

1.4 Safety instructions from the manufacturer ..................................................................... 5

1.4.1 Copyright and data protection ................................................................................................ 5

1.4.2 Disclaimer ............................................................................................................................... 6

1.4.3 Product liability and warranty ................................................................................................ 7

1.4.4 Information concerning the documentation........................................................................... 7

1.4.5 Warnings and symbols used................................................................................................... 8

1.5 Safety instructions for the operator................................................................................. 8

2 Device description 9

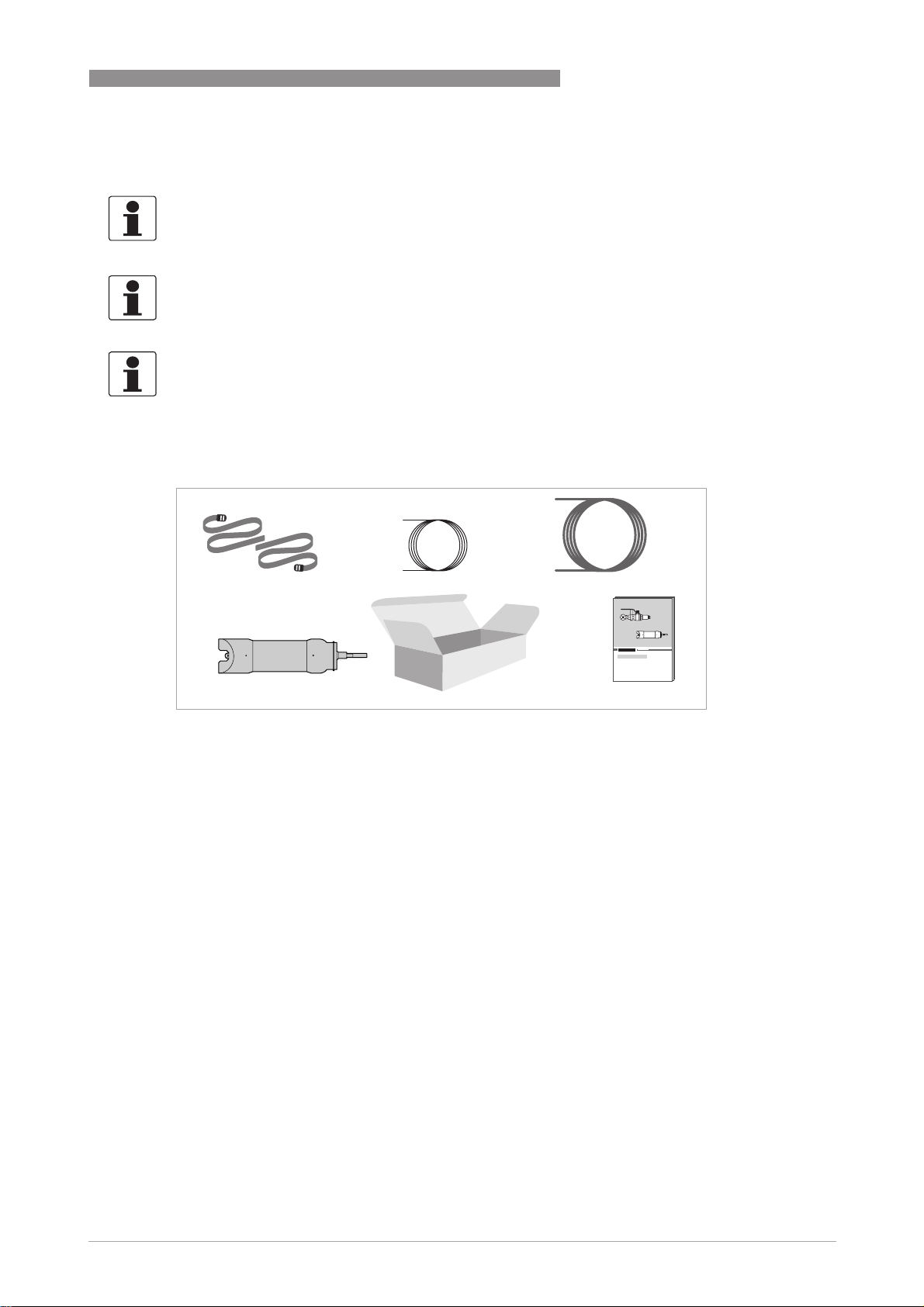

2.1 Scope of delivery............................................................................................................... 9

2.1.1 Scope of delivery .....................................................................................................................9

2.1.2 Scope of delivery ................................................................................................................... 10

2.2 Device description .......................................................................................................... 10

2.2.1 Design.................................................................................................................................... 11

2.3 Nameplates .................................................................................................................... 11

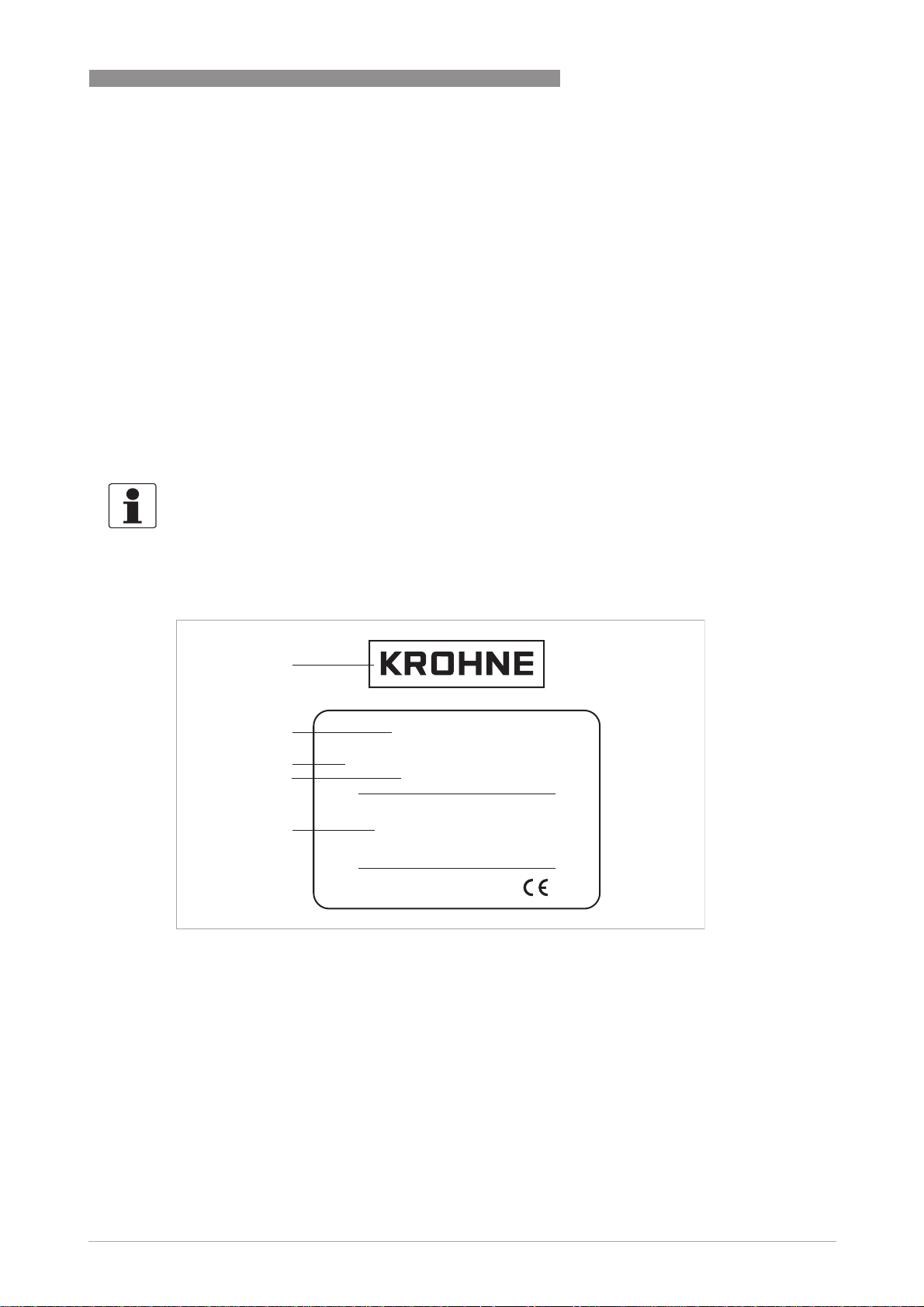

2.3.1 OPTISENS OAS 2000 ............................................................................................................. 11

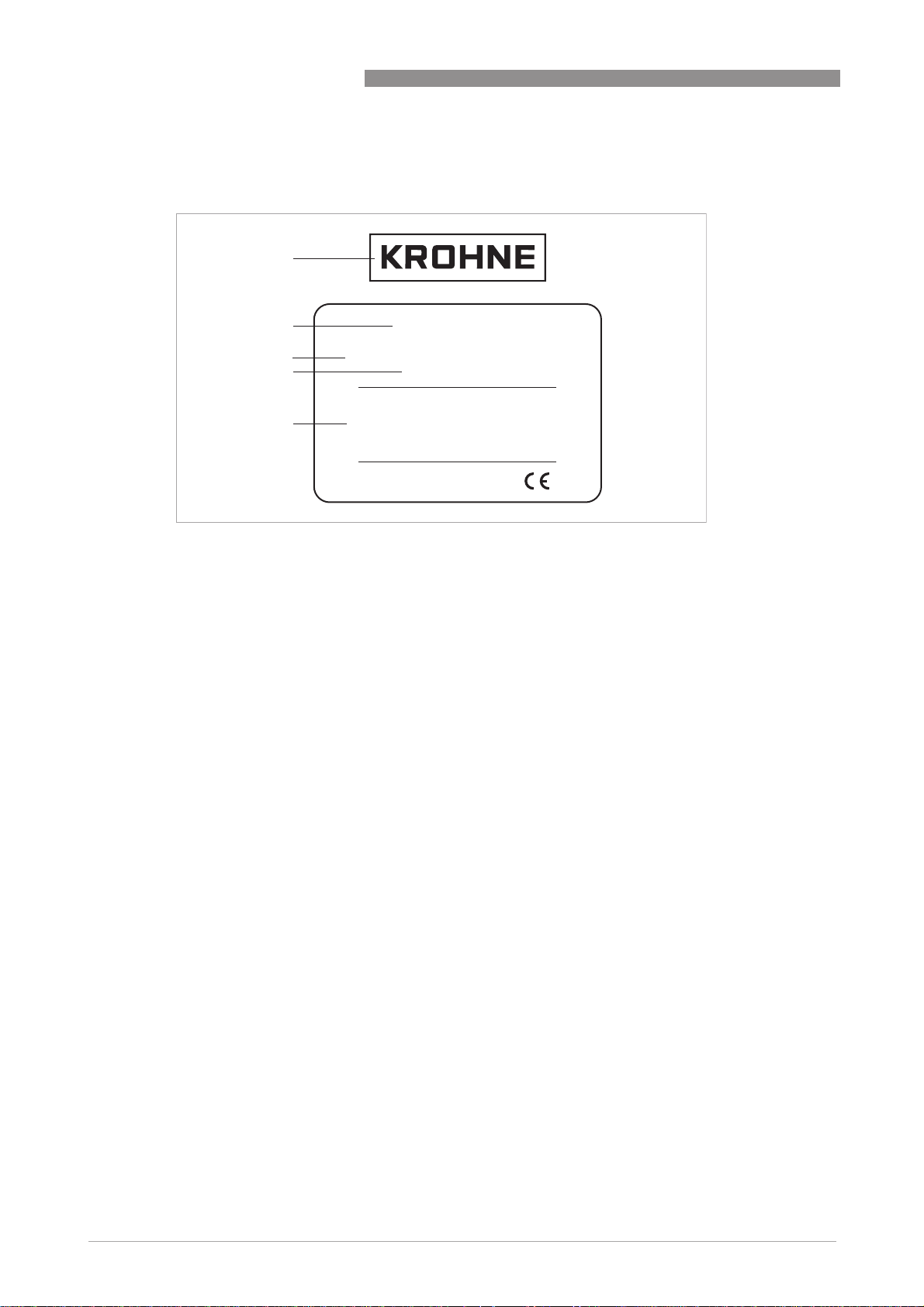

2.3.2 OPTISENS OAS 2000 ............................................................................................................. 12

3 Installation 13

3.1 Notes on installation ......................................................................................................13

3.2 Storage and transport .................................................................................................... 13

3.3 Configuration of a measuring point ............................................................................... 13

3.3.1 Single parameter measuring point ...................................................................................... 14

3.3.2 Two parameter measuring point .......................................................................................... 15

3.3.3 Four parameter measuring point......................................................................................... 16

3.4 Mounting of submersible version .................................................................................. 17

3.4.1 Mounting to MAA 2000 telescopic rod immersion holder.................................................... 17

3.4.2 Mounting to MAA 2000 slide rail immersion holder............................................................. 20

3.5 Installation of flushing.................................................................................................... 21

3.6 Mounting of inline version .............................................................................................. 23

4 Electrical connections 27

4.1 Safety instructions.......................................................................................................... 27

4.2 Cable connections ..........................................................................................................27

5 Operation 28

5.1 Sensor display ................................................................................................................ 28

5.2 Menu for OAS 2000 sensor ............................................................................................. 28

5.3 Calibration ...................................................................................................................... 30

5.3.1 Calibration Points ................................................................................................................. 31

www.krohne.com07/2010 - MA OAS 2000 R02 en

3

Page 4

CONTENTS

5.3.2 Negative values..................................................................................................................... 31

5.3.3 Calibration screen................................................................................................................. 32

5.3.4 Automatic adjustment of the calibration.............................................................................. 33

5.3.5 Statistic adjustment .............................................................................................................. 34

5.3.6 Zero calibration..................................................................................................................... 34

5.3.7 Calibration with samples ...................................................................................................... 35

OPTISENS OAS 2000

5.4 Scaling ............................................................................................................................ 36

6 Service 37

6.1 Cleaning the flushing nozzle .......................................................................................... 37

6.2 Spare parts availability...................................................................................................37

6.3 Spare parts and accessories.......................................................................................... 37

6.4 Availability of services .................................................................................................... 38

6.5 Returning the device to the manufacturer..................................................................... 38

6.5.1 General information.............................................................................................................. 38

6.5.2 Form (for copying) to accompany a returned device............................................................ 39

6.6 Disposal .......................................................................................................................... 39

7 Technical data 40

7.1 Measuring principle........................................................................................................40

7.2 Technical data................................................................................................................. 41

7.3 Dimensions and weight .................................................................................................. 43

8 Appendix 45

8.1 Setup information form .................................................................................................. 45

8.2 Support information form .............................................................................................. 46

9 Notes 47

4

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 5

OPTISENS OAS 2000

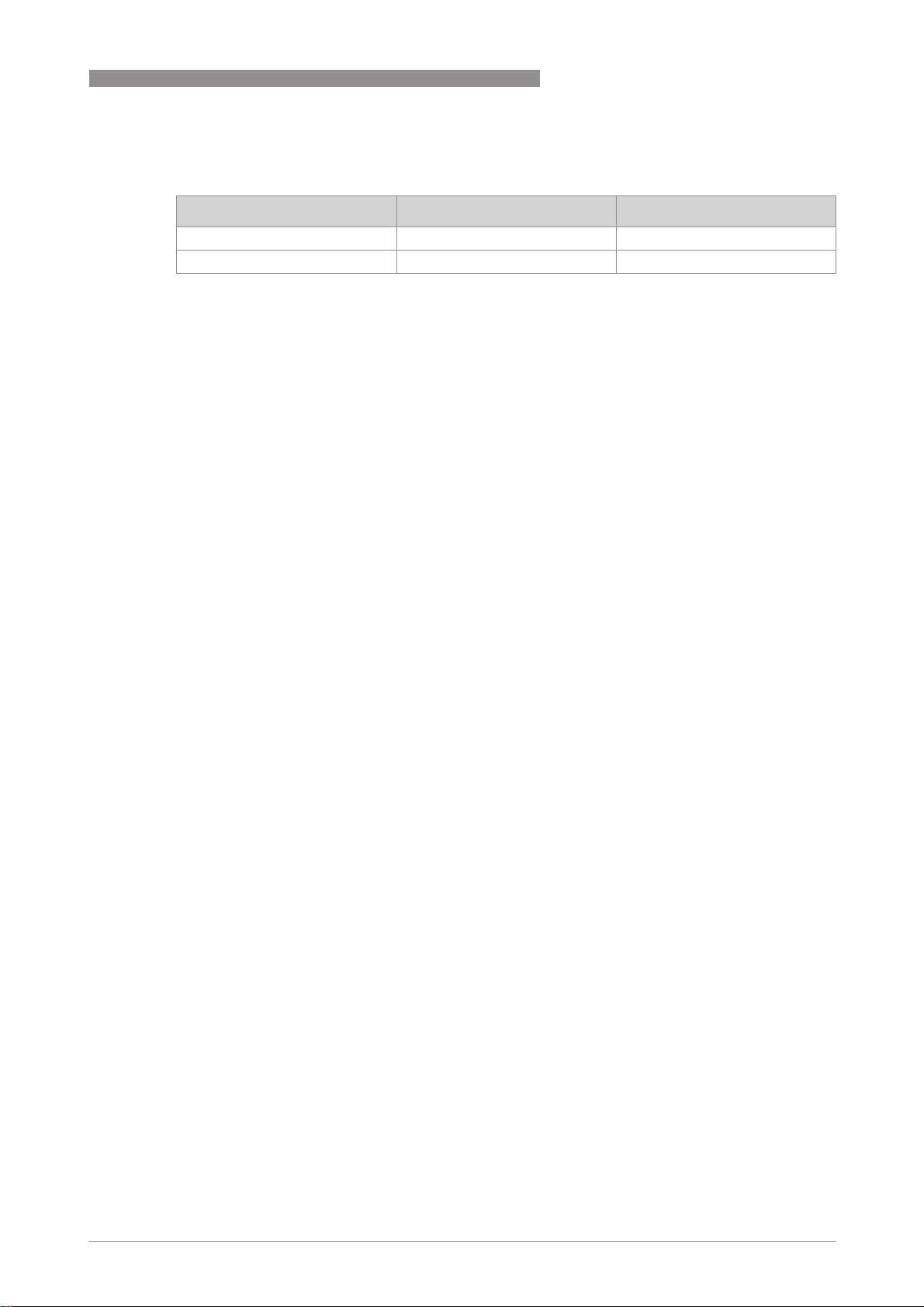

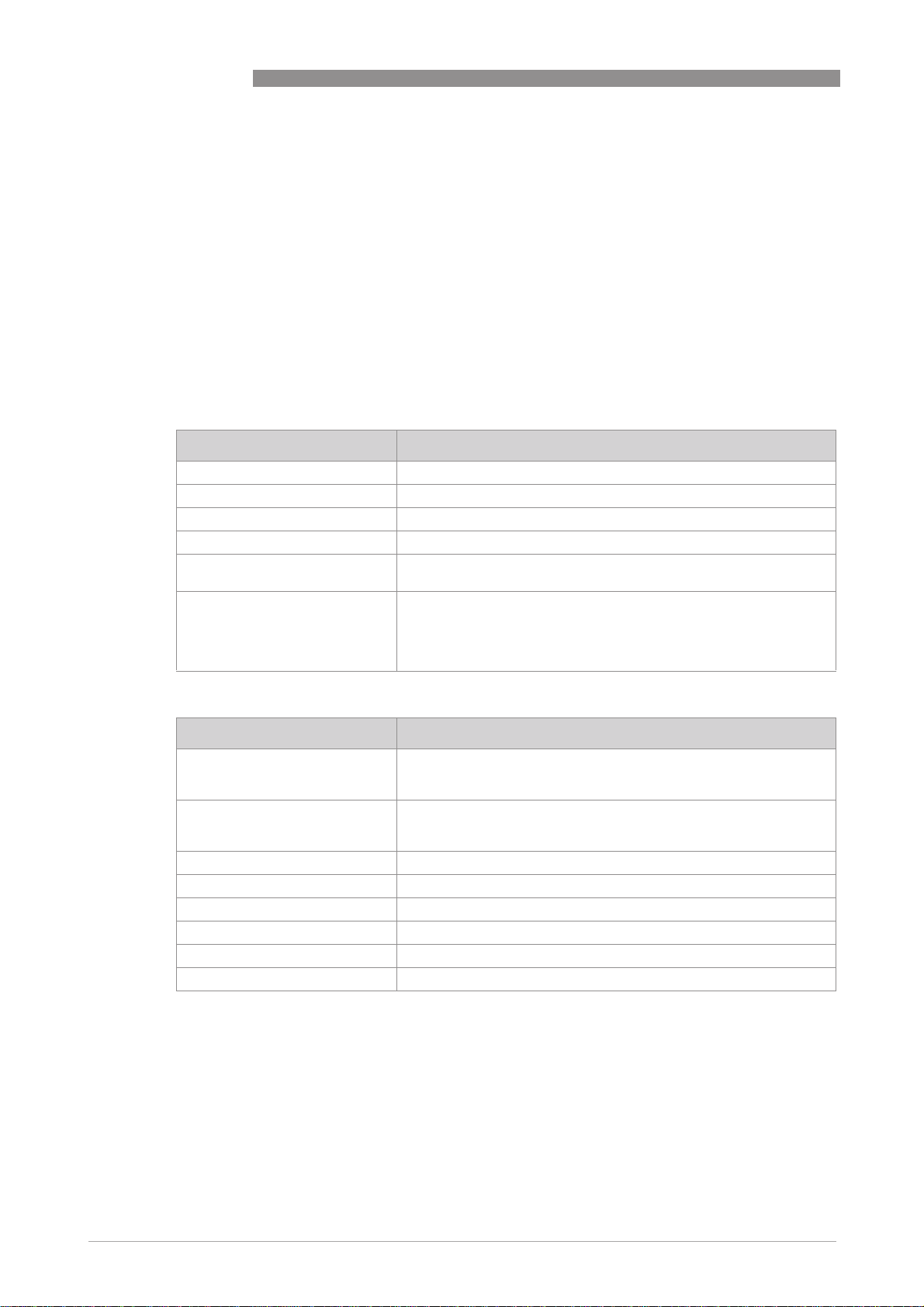

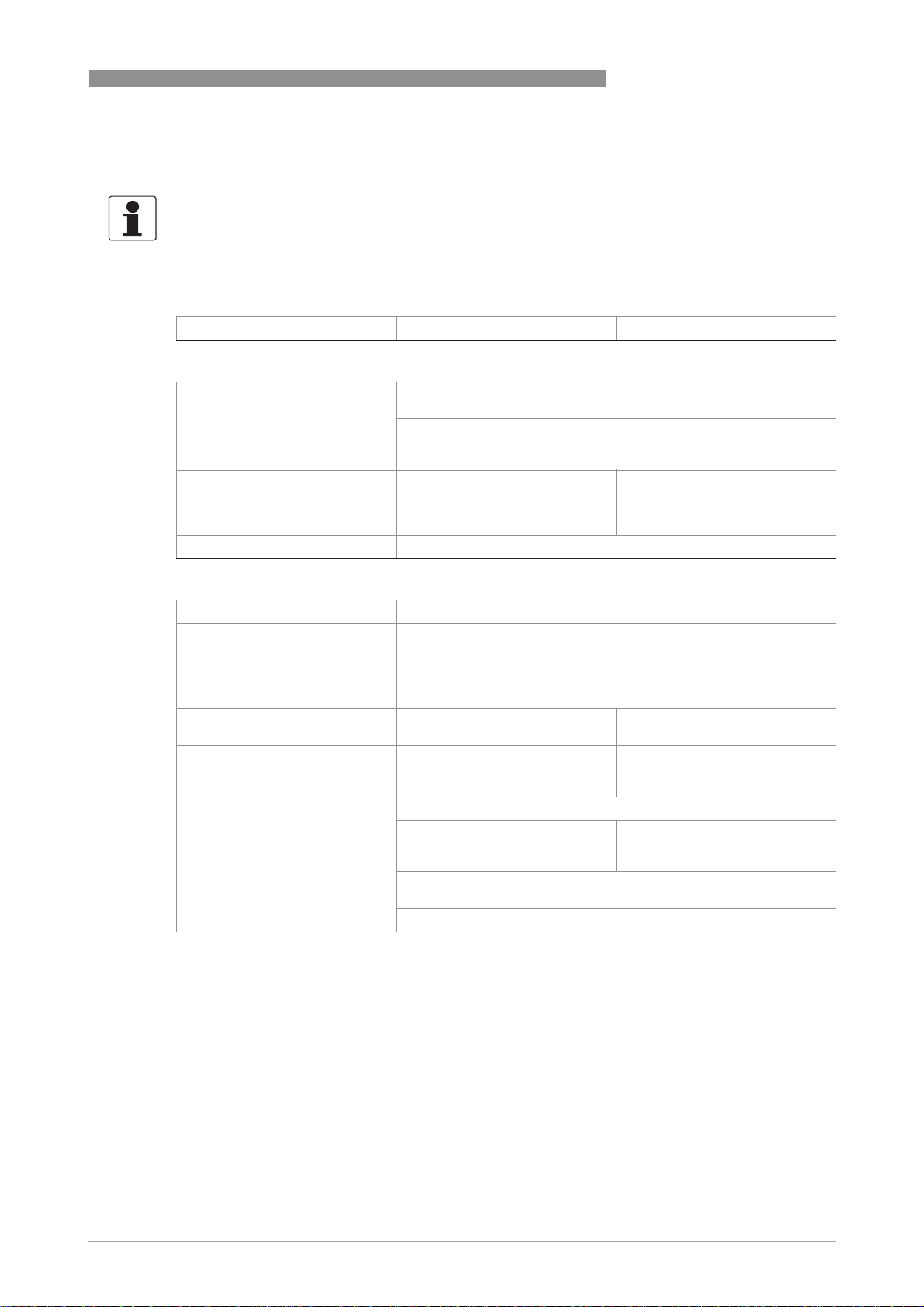

1.1 Software history

Release date Software version Documentation

05/2008 1.00 MA OAS 2000 R01

10/2009 1.00 MA OAS 2000 R02

1.2 Intended use

The sensors are used to measure suspended solids in water and wastewater treatment plants

and other industrial applications. They are designed to be combined with the MAC 080 converter.

1.3 Certifications

CE marking

SAFETY INSTRUCTIONS 1

The device fulfils the statutory requirements of the following EC directives:

• Electromagnetic compatibility (EMC) in accordance with:

EN 61000-6-4:2001: Emission standard for industrial environments

EN 61000-6-2:2001: Immunity for industrial environments

• Low Voltage Directive:

Safety requirements for electrical equipment for measurement, control and laboratory use in

accordance with EN 61010-1:2001.

The manufacturer certifies successful testing of the product by applying the CE marking.

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to German copyright. Contributions from

third parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

www.krohne.com07/2010 - MA OAS 2000 R02 en

5

Page 6

1 SAFETY INSTRUCTIONS

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect, incidental, punitive and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

OPTISENS OAS 2000

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

6

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 7

OPTISENS OAS 2000

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com07/2010 - MA OAS 2000 R02 en

7

Page 8

1 SAFETY INSTRUCTIONS

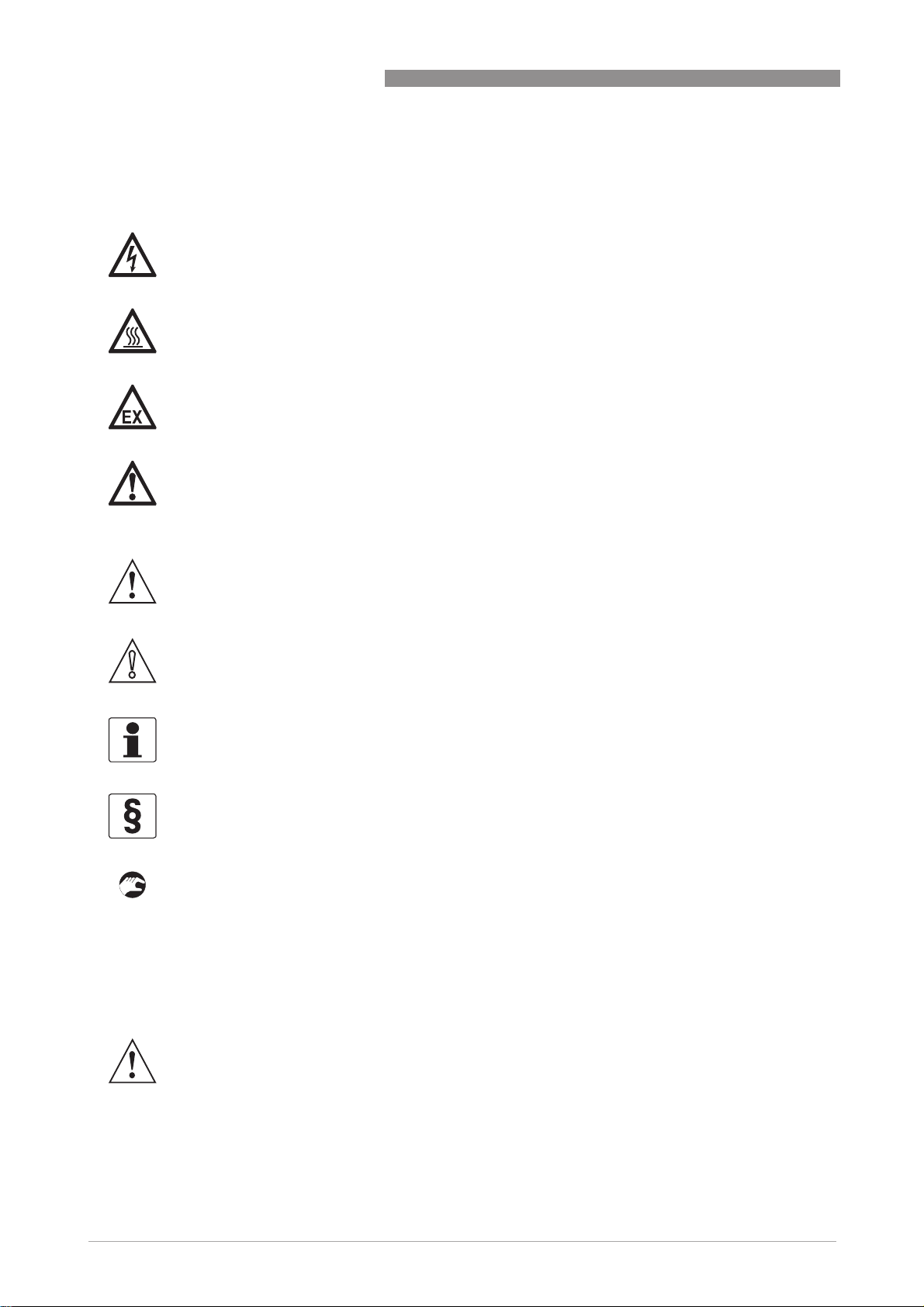

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTISENS OAS 2000

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 9

OPTISENS OAS 2000

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.1.1 Scope of delivery

DEVICE DESCRIPTION 2

234

1

Figure 2-1: Scope of delivery OAS 2000 submersible version

1 OAS 2000 suspended solids sensor (submersible version)

2 2straps

3 10 m / 33 ft signal cable

4 10 m / 33 ft flush hose

5 Handbook

5

Optional accessories for OAS 2000 submersible version (if ordered)

• MAA 2000 insertion holder, telescopic rod for OAS/AAS 2000 (incl. telescopic rod plus rod

holder, handrail mounting bracket and sensor adapter)

• MAA 2000 side wall mounting for OAS/AAS 2000

• Signal cable extension for OPTISENS 2000 sensors (10 m / 33 ft)

• Signal cable extension for OPTISENS 2000 sensors (30 m / 98 ft)

www.krohne.com07/2010 - MA OAS 2000 R02 en

9

Page 10

2 DEVICE DESCRIPTION

2.1.2 Scope of delivery

234

OPTISENS OAS 2000

1

Figure 2-2: Scope of delivery OAS 2000 inline version

1 OAS 2000 suspended solids sensor (inline version), connection valve, but weld end R 1½" for pipe mounting.

Optional: OAS 2000 suspended solids sensor (inline version) without connection valve and but weld end.

2 2straps

3 10 m / 33 ft signal cable

4 10 m / 33 ft flush hose

5 Handbook

Optional accessories for OAS 2000 inline version (if ordered)

• Signal cable extension for OPTISENS 2000 Sensors (10 m / 33 ft)

• Signal cable extension for OPTISENS 2000 Sensors (30 m / 98 ft)

• OAS 2000 inline connection valve

• OAS 2000 inline but weld end R 1 ½" for pipe mounting

• OAS 2000 inline 1/12" NPT nipple

• Sealing kit for OAS 2000 inline-version: flush membrane, o-ring between valve and adapter

48 x 2 EP70, o-ring in the adapter 33.3 x 2.4 EP70, o-ring on OAS 2000 inline 29 x 2.5 EP70

2.2 Device description

The sensor is designed to measure suspended solids concentrations in liquids. Combined with

the MAC 080 converter, the sensor is used to measure suspended solids content as a function of

the ability of suspended materials to absorb and reflect NIR-light (Near Infrared). The sensor is

available in two versions, for inline mounting and for submersion.

5

10

This manual details installation procedures and operational features of the sensor. Menu

navigation and technical data for the converter can be found in the converter manual.

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 11

OPTISENS OAS 2000

2.2.1 Design

The sensor is manufactured with 316SS (SS2343) Stainless Steel. The head of the sensor is

designed to achieve the highest self-cleaning effect, providing an exact and reliable

measurement with the least possible maintenance under critical applications. The measuring

lenses within the housing are made of glass. The electronics and optics are protected in the

rugged casing, ensuring its reliability in very demanding environments.

The sensor has a fixed, shielded 10 m / 33 ft cable used for signal transmission between the

sensor and the converter. The cable sheath is made of Hytrel and is highly resistant to

aggressive materials and fluids.

The inline version of the sensor has a M12 connector to connect a standard

OPTISENS 2000 cable to the converter.

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

2.3.1 OPTISENS OAS 2000

1

2

3

4

5

Figure 2-3: Nameplate OPTISENS OAS 2000 submersible version

1 Manufacturer

2 Device type

3 Order code

4 Serial number

5 Sensor information

OPTISENS OAS 2000

Suspended Solids/TS Sensor

Order code: VGA R 4 A112AA4A13A0

S/N: XX XX XXX

Material: 2343/316 SS

Flush Water/Air: 6 bar

Max. depth: 10 m

Max temp.: 60C

Made in Sweden

www.krohne.com07/2010 - MA OAS 2000 R02 en

11

Page 12

2 DEVICE DESCRIPTION

2.3.2 OPTISENS OAS 2000

1

OPTISENS OAS 2000

2

3

4

5

Figure 2-4: Nameplate OPTISENS OAS 2000 inline version

1 Manufacturer

2 Device type

3 Order code

4 Serial number

5 Sensor information

Order code: VGA R 4 A2A2BA4A13A0

OPTISENS OAS 2000

Suspended Solids/TS Sensor

S/N: XX XX XXX

Material: 2343/316 SS

Flush Water/Air: 8 bar / 120 psi

Max. pressure: 6(10) bar / 90(120) psi

Max temp.: 60 ”C / 140 F

Made in Sweden

12

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 13

OPTISENS OAS 2000

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage and transport

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• The original packing is designed to protect the equipment. It has to be used if the device is

transported or sent back to the manufacturer.

INSTALLATION 3

3.3 Configuration of a measuring point

A complete measuring point consists of at least three parts:

• MAC 080 converter

• OPTISENS 2000 sensor (including cable)

• MAA 2000 sensor holder

If automatic flushing is installed, an optional solenoid valve is necessary as well.

Examples of typical measuring points are listed in the following sections.

www.krohne.com07/2010 - MA OAS 2000 R02 en

13

Page 14

3 INSTALLATION

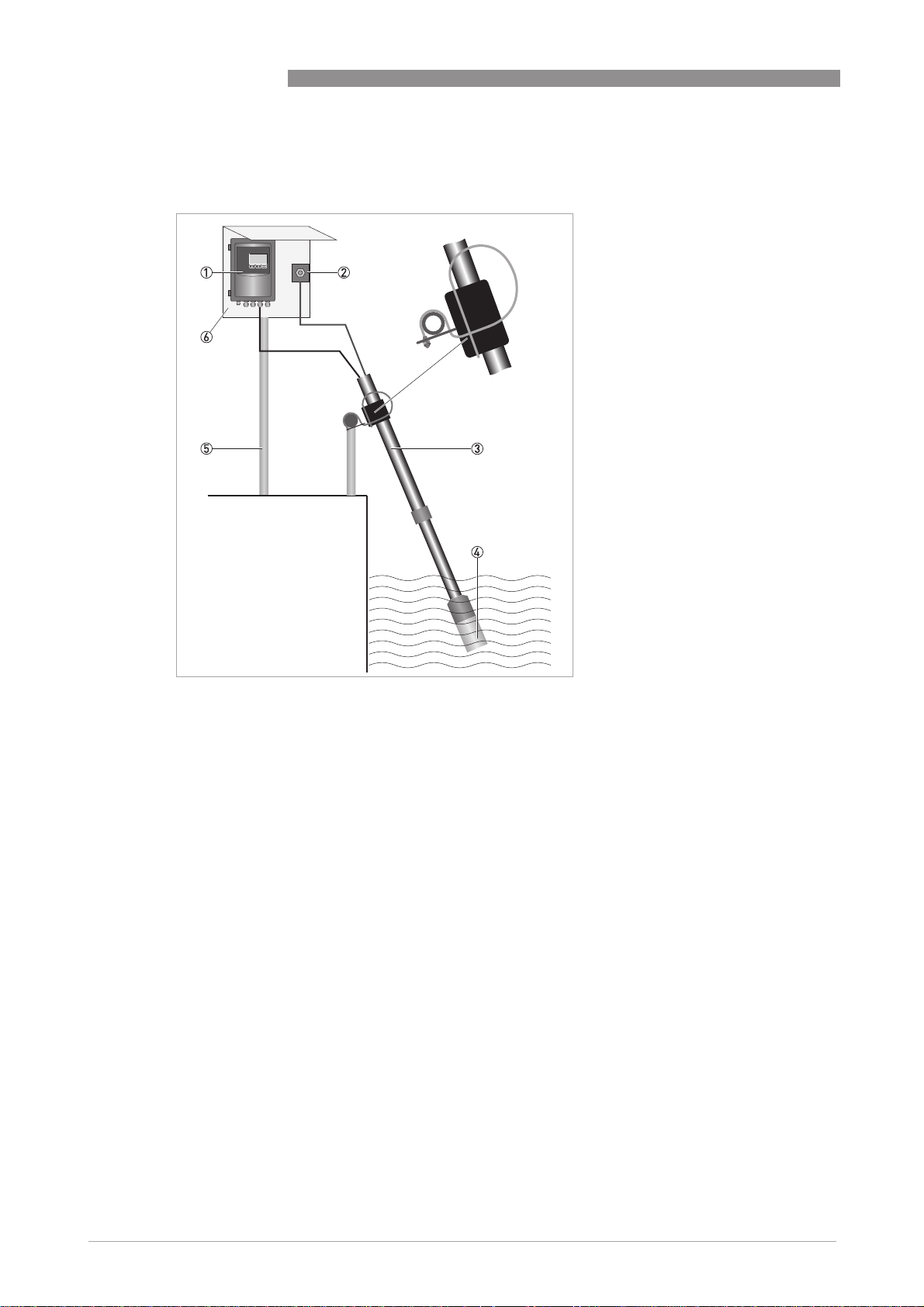

3.3.1 Single parameter measuring point

OPTISENS OAS 2000

1 Converter

2 Solenoid valve for flushing (to be ordered with converter)

3 Mounting assembly

4 Sensor incl. 10 m / 33 ft cable and flush hose

5 Mounting post

6 Mounting plate with sun shield

The figure above shows a single parameter measuring point consisting of one converter 1, one

sensor 4 with a telescopic rod immersion assembly as sensor holder 3 and one solenoid valve

2 for flushing.

The spring loaded mounting bracket for installation of the telescopic rod sensor holder on the

handrail is included in the delivery of the holder and can be used for round and square hand rails

with a maximum diameter of 50 mm / 2".

The signal cable to the sensor and the flush hose are provided with the sensor.

The mounting plate with sun shield and the mounting post are available optional.

14

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 15

OPTISENS OAS 2000

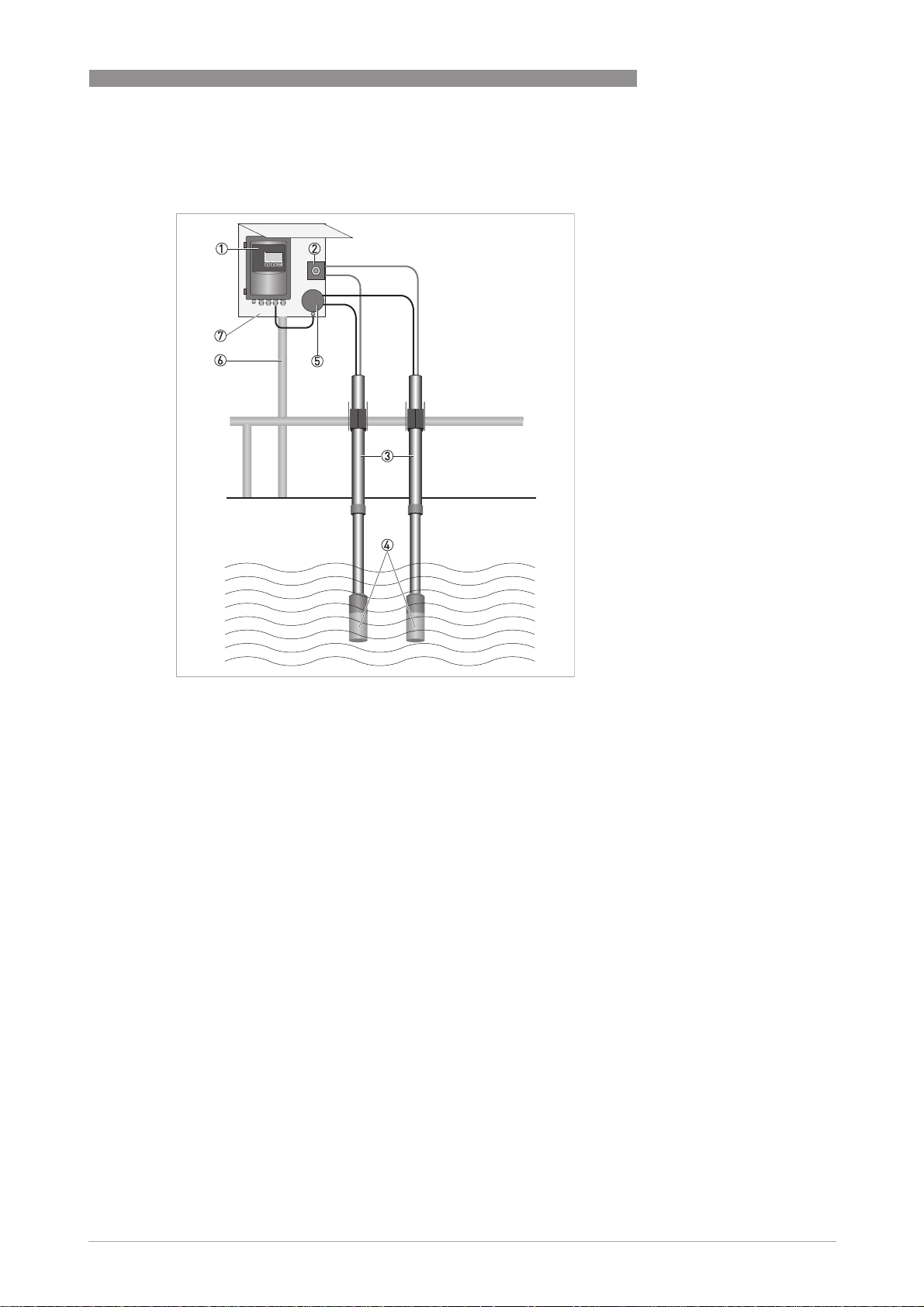

3.3.2 Two parameter measuring point

INSTALLATION 3

1 Converter

2 Solenoid valve for flushing (to be ordered with converter)

3 Mounting assembly

4 Sensor incl. 10 m / 33 ft cable and flush hose

5 Junction box for connection of up to 4 sensors (to be ordered with converter)

6 Mounting post

7 Mounting plate with sun shield

The figure above shows a two parameter measuring point consisting of one converter 1, two

sensors 4 with a telescopic rod immersion assembly as sensor holder 3 and one solenoid valve

2 for flushing.

Both sensors are flushed via one solenoid valve using an optional Y-splitter.

For connection of two sensors to the converter an optional junction box is needed.

www.krohne.com07/2010 - MA OAS 2000 R02 en

15

Page 16

3 INSTALLATION

3.3.3 Four parameter measuring point

OPTISENS OAS 2000

1 Converter

2 Solenoid valve for flushing (to be ordered with converter)

3 Mounting assembly

4 Sensor incl. 10 m / 33 ft cable and flush hose

5 Junction box for connection of up to 4 sensors (to be ordered with converter)

6 Mounting post

7 Mounting plate with sun shield

The figure above shows a four parameter measuring point consisting of one converter 1, four

sensors 4 with a telescopic rod immersion assembly as sensor holder 3 and two solenoid

valves 2 for flushing.

Two sensors each are flushed via one solenoid valve using an optional Y-splitter.

For connection of four sensors to the converter an optional junction box is needed.

16

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 17

OPTISENS OAS 2000

3.4 Mounting of submersible version

The sensor can be mounted in two ways:

• On a telescopic fibreglass rod placed in a mounting bracket that fastens to a handrail (see

next section).

• To an adjustable slide rail holder (see next section but one).

Installation tips

• When the sensor measures in a flume, it is important to find a place where the suspended

solids concentration is representative.

• Make sure the flushing nozzle is downstream from the lenses pointing against the stream.

This will avoid disturbances of the measurement by turbulence from the nozzle. At the same

time it will produce a shield around the nozzle, due to a constant over pressure, preventing

particles from getting in.

• Adjust the rod so that the sensor is at least 30 cm / 11.8" below the liquid surface or the

lowest water level in decant applications to prevent the sensor from coming out of the liquid.

• In an aeration tank, ensure that the sensor is not directly above a diffuser head. It should be

installed on the backside of the rolling diffuser effect.

• Flushing may not be required if the tank is well agitated. To verify the need for flushing,

remove the sensor from the liquid after it has been in the liquid for several days.

• When installing in a clarifier, compressed air flushing is required due to no agitation of liquid

and to remove oil and grease film on lens. This is especially applicable in primary clarifiers.

• When using the sensor for influent applications, always install the unit after the bar screen. If

the bar screen spacing is larger than 6 mm / 0.24", then a baffle or diffuser plate should be

installed in front of the sensor to prevent rags from catching on the sensor head. On influent

applications, compressed air flushing is recommended due to the oil or grease in the liquid.

INSTALLATION 3

3.4.1 Mounting to MAA 2000 telescopic rod immersion holder

The mounting bracket of the telescopic rod is mounted to a handrail or a separate holder.

In case a handrail is not available, a mounting post with a vertical bar for sensor mounting can be

purchased from the manufacturer.

www.krohne.com07/2010 - MA OAS 2000 R02 en

17

Page 18

3 INSTALLATION

Figure 3-1: Placing the rod holder around the rod

1 Telescopic rod

2 Rod holder

OPTISENS OAS 2000

Figure 3-2: Pulling the cable/hose through the rod

1 Cable/hose

2 Telescopic rod

3 Sensor holder

4 Sensor

Figure 3-3: Inserting the rod holder into the mounting bracket

1 Telescopic rod

2 Rod holder

3 Mounting bracket

18

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 19

OPTISENS OAS 2000

INSTALLATION 3

1 Telescopic rod

2 Sensor holder

3 Handrail with mounting bracket attached

4 Rod holder

5 Mounting bracket

CAUTION!

Do not extend the rod sections beyond the black lines. This could lead to rod damage.

INFORMATION!

°

For best measurement, the rod shall be mounted in an angle (5...30

from vertical).

www.krohne.com07/2010 - MA OAS 2000 R02 en

19

Page 20

3 INSTALLATION

Mounting to telescopic rod immersion holder

• Mount the flexible mounting bracket on an existing handrail or on a separate holder, diameter

32...50 mm / 1.3...2.0" or square 28...42 mm / 1.1...1.7". The bent lip on the mounting plate

shall be on top and faced toward the liquid or tank.

• Adjust the mounting bracket to the correct angle and tighten the nuts.

i The bracket shall be fixed to the rail and must not be able to rotate around it.

• Disassemble the rod holder and place it around the telescopic rod.

• Use the SS screws on the rod holder to tighten the rod holder to the rod.

• Pull the cable and hose through the sensor holder and rod.

• Connect the sensor to the rod with the two piece black PVC sensor holder.

• Tighten the adapter halves until snug, which will leave about 1.5 mm / 0.06" gap.

The gap is required so the water can drain from the rod.

• Adjust the length of the telescopic rod as necessary by twisting the nuts while holding the rod.

Do not extend the rod sections beyond the black lines. This could lead to rod damage.

• Insert the PVC rod holder with the telescopic rod into the mounting bracket. Make sure that

the guide tracks of the rod holder are properly seated in the bracket.

• Fasten the safety-locking clamp.

• Check that the mounting bracket is safely fixed to the rail for the spring to work the way it is

intended.

OPTISENS OAS 2000

3.4.2 Mounting to MAA 2000 slide rail immersion holder

Figure 3-4: Mounting to MAA 2000 slide rail immersion holder

1 Slide rail immersion holder

2 Sensor

3 66 mm / 2.60" clamp

4 Adjustable stop

20

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 21

OPTISENS OAS 2000

CAUTION!

In order to avoid large air bubbles which can affect the measurement please make sure that the

slide rail immersion holder is mounted in a certain angle to the vertical position. The angle

should be slightly off from vertical position (approx. 20

Mounting to MAA 2000 slide rail immersion holder

• Mount the slide rail immersion holder to the side wall of the basin or open channel using the

two predrilled holes. The adjustable stop should be on the bottom and the two sliding clamps

above.

• Take the two sliding clamps off from the slide rail and mount them around the sensor housing.

Make sure that the clamps are placed on the two elevated ends of the sensor housing (one on

the upper part and one on the lower part, see figure above).

The two guide tracks have to line-up in one straight line to each other.

• Slide the sensor with the two clamps into the slide rail. Make sure that the guide tracks of the

two clamps are properly seated.

• Adjust the sensor position as necessary and fasten the adjustable stop.

3.5 Installation of flushing

INSTALLATION 3

°

), but not more than 90°.

The sensor is equipped with built-in flushing nozzles. The nozzles are used to direct the cleaning

medium (compressed air or water) via a flushing hose that is connected to the top of the sensor

housing. A solenoid valve that is wired to a relay in the converter controls the air or liquid (see

converter manual).

Compressed air is recommended for most applications.

CAUTION!

For the submersible sensor the highest allowed flushing pressure is 6 bar / 87 psi. When using

air, 2 bar / 29 psi is usually sufficient.

CAUTION!

For the inline sensor the highest allowed flushing pressure is 8 bar / 116 psi. Inline sensors

require a flushing pressure at least 2 bars / 29 psi above the process pressure.

INFORMATION!

Pay attention to the requirements for protection against backflow, according to the

EN 1717 standard for drinking water devices. If possible, use plant reuse water or effluent water

for cleaning.

www.krohne.com07/2010 - MA OAS 2000 R02 en

21

Page 22

3 INSTALLATION

Figure 3-5: Flushing system

1 Flushing

2 Flushing tube

INFORMATION!

In order to clean the sensor, flushing must be activated in the Settings

There are two different ways of cleaning a sensor: The sensor can either be cleaned as a master

or as a slave. Both options are described in the following instructions.

OPTISENS OAS 2000

Settings menu of the converter.

SettingsSettings

Cleaning the sensor as a master (sensor has its own relay)

• Select the sensor in the main menu by using ↑ or ↓.

• Press ^ for approximately 5 seconds to enter the sensor menu.

• Use ↑ or ↓ to select Cleaning

• In the Cleaning

Cleaning submenu, select Cleaner

CleaningCleaning

• Then specify the cleaning interval in minutes (Interval min

(Length sec

Length sec).

Length secLength sec

Cleaning and press ^.

CleaningCleaning

Cleaner and set it to Flush

CleanerCleaner

Flush.

FlushFlush

Interval min) and the flush time in seconds

Interval minInterval min

• Specify the relay to be used according to the wiring inside the converter. For example, if the

solenoid is wired to relay #1, set Relay

• For sensors configured as masters, Next time

Relay to #1

RelayRelay

#1 for flushing.

#1#1

Next time displays that the next time flush will be

Next timeNext time

activated. Pushing ^ will set it to current time and thus start cleaning.

• If needed, specify the extra freeze time in seconds (Freeze sec

Freeze sec).

Freeze secFreeze sec

Cleaning the sensor as a slave (along with another sensor)

• Select the sensor in the main menu by using ↑ or ↓.

• Press ^ for approximately five seconds to enter the sensor menu.

• Use ↑ or ↓ to select Cleaning

• The parameters Cleaner

sensor being the master.

• Set Relay

Relay to Along #1

RelayRelay

Along #1 or Along #2

Along #1Along #1

• If needed, specify the extra freeze time in seconds (Freeze sec

Cleaning and press ^.

CleaningCleaning

Cleaner, Interval min

CleanerCleaner

Interval min and Length sec

Interval minInterval min

Along #2 depending on what relay the master sensor uses.

Along #2Along #2

Length sec in the Cleaning

Length secLength sec

Freeze sec).

Freeze secFreeze sec

Cleaning submenu are set for the

CleaningCleaning

22

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 23

OPTISENS OAS 2000

3.6 Mounting of inline version

CAUTION!

Be aware that the force may be strong when the sensor is mounted under pressure.

CAUTION!

If the following instructions cannot be fulfilled in all parts, the sensor should not be mounted or

dismounted under process pressure.

The inline sensor is mounted through a ball valve to make it possible to remove the sensor

under pressure. Make sure there is at least 260 mm / 10.2" free space to remove the sensor

from the valve. The sensor shall be mounted in a place where the process pressure is at least

1 bar. In horizontal pipes the sensor shall be mounted from the side or from below to avoid

disturbance from air bubbles.

The sensor is designed to be mounted in a right angle to the process flow. The smallest process

pipe diameter to mount the sensor is 80 mm / 3.1". The measure gap must be at least 5 mm /

0.2" from the pipe wall. If a sample outlet is used it must reach at least 20 mm / 0.8" into the

pipe.

INSTALLATION 3

Place the sensor at a location where there is no risk for it to get damaged. When the OAS 2000

inline is used outdoors, it shall be mounted with a sun and rain protective hood.

Figure 3-6: Mounting of sensor and sample outlet

1 Inline sensor with ball valve

2 Process pipe

3 Sample outlet

Dimensions [mm] Dimensions [inches]

a min. 80 mm min. 3.1"

b min. 5 mm min. 0.2"

c min. 20 mm min. 0.8"

www.krohne.com07/2010 - MA OAS 2000 R02 en

23

Page 24

3 INSTALLATION

Figure 3-7: Mounting of weld end with strip iron

1 Weld end

2 Weld

3 Process pipe

4 Stabilizing weld

OPTISENS OAS 2000

Ø [mm] Ø [inches]

a 48.5 1.91

Mounting the weld end (see previous figure)

• Open a Ø 48.5 mm / 1.91" hole in the process pipe.

• Cut the weld end to get the sensor head at least 5 mm / 0.2" from the pipe wall.

• Weld the weld end to the pipe.

• Stabilize the weld end using 3 mm / 0.1" strip iron according to the figure above.

Mounting the optional threaded nipple in a saddle

• Mount the saddle on the pipe according to the saddle manufacturer's instructions.

• Thread the nipple into the saddle.

• Use flaxen hair and joint paste. Be aware to get the correct distance from the pipe wall to the

valve.

24

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 25

OPTISENS OAS 2000

Figure 3-8: Mounting of sensor in ball valve

1 Flush hose

2 Sensor nut

3 Adapter

4 Weld end nipple or 1½" NPT threaded nipple

5 Ball valve

6 Lockring

7 O-ring 48 x 2 mm / 1.9 x 0.1"

8 O-ring 33.3 x 2.4 mm / 1.3 x 0.1"

9 O-ring 29 x 2.5 mm / 1.1 x 0.1"

INSTALLATION 3

Mounting the ball valve (see previous figure)

• Thread the valve end on the but weld end or nipple (use sealing tape or flaxen hair and joint

paste).

INFORMATION!

Don not pull the valve end to the bottom. The valve handle plane shall have the same direction as

the pipe. If the valve is turned the wrong way, the measuring gap will not be in line with the flow,

resulting in faulty measurement.

The sensor is mounted in the valve using an adapter. The adapter serves two purposes:

1. A thread for the sensor nut to keep the sensor in place.

2. A stop for the lockring to prevent the sensor from coming loose when the sensor nut is loos-

ened.

www.krohne.com07/2010 - MA OAS 2000 R02 en

25

Page 26

3 INSTALLATION

CAUTION!

Be careful that the sensor is inserted straight. If the sensor is not straight, it can jam and so

cause damages on the transmitter or valve.

CAUTION!

If the transmitter is hard to mount and you suspect something that is stuck or the transmitter is

not mounted straight, crank out and check that everything is OK.

CAUTION!

The Sensor nut can release big forces. Do not ever loosen the nut without holding the sensor in

place at the same time.

Mounting the sensor (see previous figure)

• Make sure that the o-rings in the adapter between the sensor and the valve and on the sensor

below the sensor nut are in a faultless condition.

• Use silicon grease or soup to grease the o-rings before mounting the adapter.

• If the adapter is separated from the sensor, check and grease the o-ring inside the adapter.

Then push the adapter over the sensor head having the smaller thread towards the sensor

housing.

• Mount the lockring on the sensor head.

• Thread the adapter into the valve.

i The sensor is now fixed to the valve.

OPTISENS OAS 2000

• When the adapter is tightened, open the valve.

• Push the sensor in place. If the process pressure is high, considerable force may be needed to

push the sensor in place.

• Screw the sensor nut in place, but do not tighten it yet.

• Align the sensor in parallel with the process flow.

• Tighten the sensor nut.

i The sensor is mounted.

26

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 27

OPTISENS OAS 2000

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Cable connections

The sensor is equipped with a fixed 10 m / 33 ft cable, which has a M12 connector attached.

Connect the sensor to the converter using the M12 connector. In the event that two or more

sensors should be connected to the same converter, use the optional junction box.

Power requirements:

• The sensor requires 24 VDC power, which is supplied from the converter via the sensor cable.

• The maximum current during operation is 45 mA.

www.krohne.com07/2010 - MA OAS 2000 R02 en

27

Page 28

5 OPERATION

5.1 Sensor display

By simultaneously pressing ↓ and ^ you alter between the converter main menu and the sensor

information display for the selected sensor. The sensor information display shows the sensor's

calibration curve.

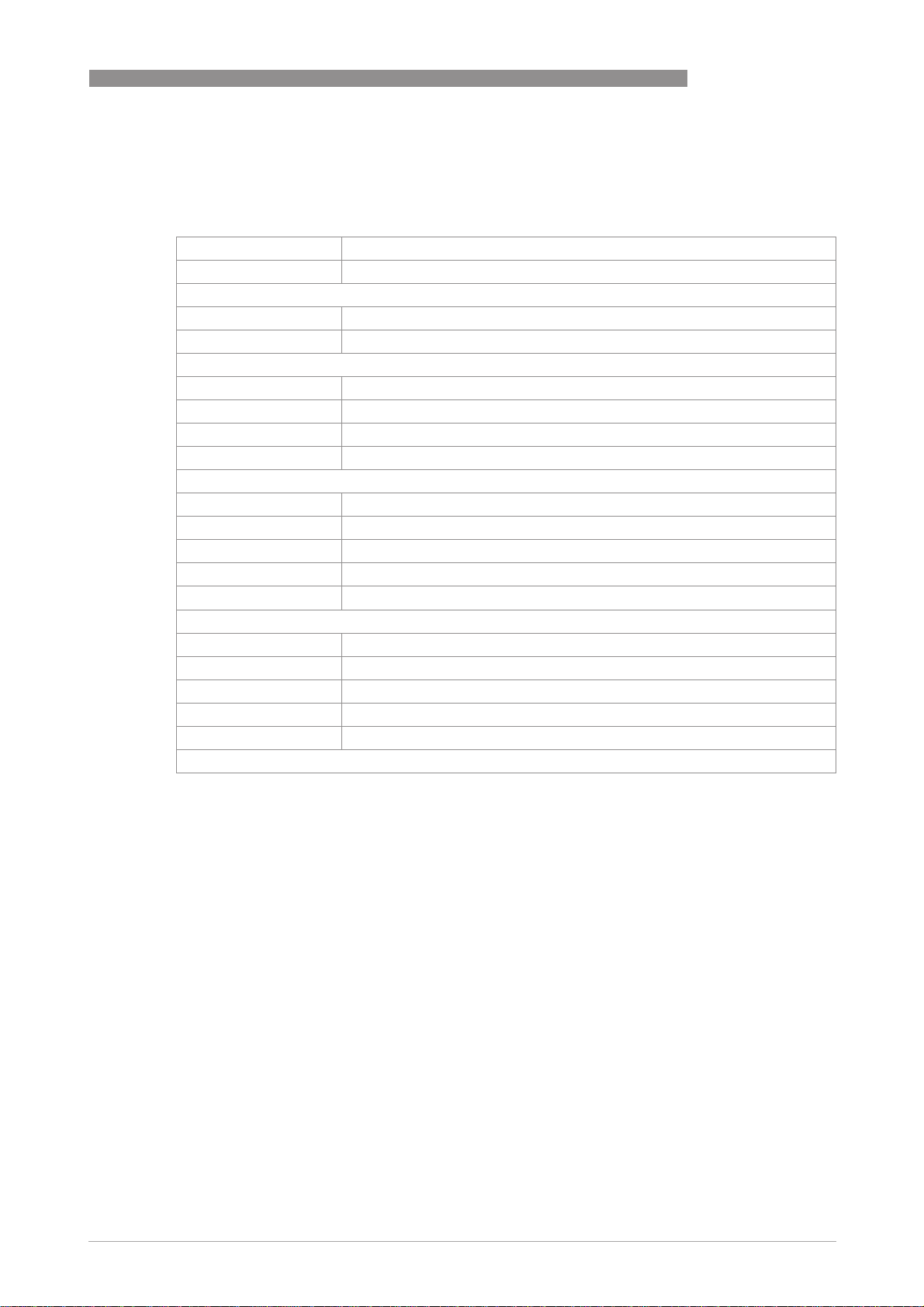

5.2 Menu for OAS 2000 sensor

Use ↑ or ↓ to select the sensor in the main display. The menu for the selected sensor is accessed

by pressing ^ for five seconds. If the selected sensor is not active (the text No transmitter

shown) a warning is displayed that asks you to make another choice in order to show the sensor

menu.

Menu "Settings"

Submenu Description

Tag

Tag Name of the sensor shown in the main display (10 characters).

TagTag

I-Time

I-Time Integration time or dampening (can be set up to 999 seconds).

I-TimeI-Time

Unit

Unit "%", "ppm", "g/l", "mg/", NTU, FNU

UnitUnit

Decimals

Decimals "Std" or "Extra". Number of decimals for the reading.

DecimalsDecimals

Analog

Analog "None" , "Out1", "Out2", "Out3", "Out4", "Out1+2" or "Out3+4". Pick

AnalogAnalog

Second

Second "Temp" or "=Prim". If two analog outputs are chosen above, the first

SecondSecond

OPTISENS OAS 2000

No transmitter is

No transmitterNo transmitter

which analog output(s) should be used with sensor.

will always give the primary value according to the sensors selected

scale. The second will either give the temperature scaled 0...100°C/

32...212°F, or the same signal as the first channel. The temperature

is additional information, not a precision measurement.

Menu "Calibrate"

Submenu Description

Adjust

Adjust "No", "Store" or "Lab". Stores the reading of the meter when a

AdjustAdjust

Take sample

Take sample "No", "Zero", "1", "2", "3", "4", "5". Sensor stores current MS (light)

Take sampleTake sample

Con

Con Current concentration (same as shown in the main menu).

ConCon

Sample 1

Sample 1 Lab test (suspended solids value for Sample 1)

Sample 1Sample 1

Sample 2

Sample 2 Lab test (suspended solids value for Sample 2)

Sample 2Sample 2

Sample 3

Sample 3 Lab test (suspended solids value for Sample 3)

Sample 3Sample 3

Sample 4

Sample 4 Lab test (suspended solids value for Sample 4)

Sample 4Sample 4

Sample 5

Sample 5 Lab test (suspended solids value for Sample 5)

Sample 5Sample 5

sample is taken and can then automatically adjust the sample value

when the sample analysed by lab is different to the reading.

value in memory and you enter a lab solids value below to complete

calibration.

28

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 29

OPTISENS OAS 2000

Menu "Cleaning"

Submenu Description

Press ^ to go to the cleaning program

Cleaner

Cleaner "None", "Flush" or "Brush". Do not select "Brush" since this does not

CleanerCleaner

Interval min

Interval min 0...999 minutes, time between cleaning cycles (only for master).

Interval minInterval min

Length sec

Length sec 0...999 seconds, duration of flushing cycle (only for master).

Length secLength sec

Freeze sec

Freeze sec 0...999 seconds, extra freeze time of output signal after a

Freeze secFreeze sec

Relay

Relay "-", "1", "2", "Along 1" or "Along 2". Select relay to operate solenoid

RelayRelay

Next time

Next time The next scheduled cleaning time. Pushing ^ on this line will set the

Next timeNext time

Menu "Scale / Alarm"

OPERATION 5

exist for this sensor (only for master).

flushing cycle.

for flush cycle if this sensor is a master with its own relay, or relay

used by master if this sensor is a slave. These are the same relays

used for Alarm relay

time to current time and start a cleaning cycle. This could be used to

test the flush cycle (only for master).

Alarm relay below.

Alarm relayAlarm relay

Submenu Description

Max

Max 0...99.9 % or 0...99999.9 ppm, mg/l or g/l (units selected in the menu

MaxMax

Min

Min 0...99.9 % or 0...99999.9 ppm, mg/l or g/l (units selected in the menu

MinMin

Hi-Alarm

Hi-Alarm 0...99.9 % or 0...99999.9 ppm, mg/l or g/l (units selected in the menu

Hi-AlarmHi-Alarm

Low-Alarm

Low-Alarm 0...99.9 % or 0...99999.9 ppm, mg/l or g/l (units selected in the menu

Low-AlarmLow-Alarm

Alarm Relay

Alarm Relay "-" "1", "2", or "1 and 2". Check that the relay is not being used for

Alarm RelayAlarm Relay

"Settings"

"Settings"), equal to 20 mA output signal.

"Settings""Settings"

"Settings"

"Settings"), equal to 4 mA output signal.

"Settings""Settings"

"Settings"

"Settings"), the value zero inactivates the alarm.

"Settings""Settings"

"Settings"

"Settings"), the value zero inactivates the alarm.

"Settings""Settings"

cleaning.

www.krohne.com07/2010 - MA OAS 2000 R02 en

29

Page 30

5 OPERATION

Menu "System"

Submenu Description

Type

Type Type of sensor (read only)

TypeType

Serial

Serial Serial number of the sensor (read only)

Serial Serial

SoftW

SoftW Software version of the sensor (read only)

SoftWSoftW

Temp

Temp Sensor temperature (read only)

TempTemp

MaxTemp

MaxTemp The highest temperature the sensor has been exposed to (read only)

MaxTempMaxTemp

Samples

Samples Press ^ to view SA values and suspended solids values.

SamplesSamples

SA 0 SA value for zero sample

SA 1 SA value for sample 1

Cons 1 Lab test (suspended solids value for sample 1)

... SA and Cons repeated for samples 2 to 5

Info

Info Press ^ to go to menu "Info"

InfoInfo

MS Linearised light signal, which are SA values in calibration chart.

Con Unit value in %, ppm, mg/l or g/l after MS value has been converted to

SA 0 SA value for zero sample

SA 1 SA value for sample 1

Cons 1 Lab test (suspended solids value for sample 1)

Ch1a Raw value for channel 1

Ch1 Raw value for channel 1, compensated for changed intensity.

Ch2 Raw value for channel 2

Intensity Currently used intensity

Zero Int Intensity for clear water, set during zero calibration.

I-offset Intensity offset, set during zero calibration.

Samp/s Number of samples per second

Service

Service Not accessible for users

ServiceService

OPTISENS OAS 2000

"Info" (read only). This menu is for KROHNE

internal use, it may change without notice.

units due to sample values. This is displayed on main screen.

"Info""Info"

5.3 Calibration

The MAC 080 has a self-optimizing calibration algorithm able to handle several calibration

points in order to give maximum measuring precision in difficult applications. However, a single

point calibration is usually preferred.

After a calibration has been carried out, make it a habit to look at the calibration curve in the

sensor information screen to make sure it represents a smooth line without any sharp bends.

• Leave the instrument turned on for about 30 minutes prior to calibration so that the sensor

and electronics can stabilize.

• Please check that the correct unit is selected for the application. In the sensor menu, select

Settings > Unit

Settings > Unit.

Settings > UnitSettings > Unit

30

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 31

OPTISENS OAS 2000

5.3.1 Calibration Points

To calculate the consistency or concentration out of the loss of light the sensor uses a calibration

curve. The curve is built up of the zero calibration point and at least one calibration point.

Each point has a sample value and a consistency value. To be used a point needs both values.

The sample value is set by Calibrate > Take sample

value is manually entered in the same menu after having analysed the actual consistency at the

time the sample was taken.

A calibration point can be disabled by setting the consistency value to zero. In most applications

one calibration point in addition to the zero sample is the best solution, adding more samples

then just confuses the measurement. Only in the following cases a multipoint calibration is

needed:

1. The measurement turns out to be non linear.

2. The sensor needs to be very accurate at widely separated consistencies.

The zero calibration defines the zero point used as a reference for all other calibration points.

The other points define the relation between loss of light and real consistency.

OPERATION 5

Calibrate > Take sample in the calibration menu. The consistency

Calibrate > Take sampleCalibrate > Take sample

Figure 5-1: Example of a calibration curve

1 Loss of light

2 Consistency

5.3.2 Negative values

The sensor continuously compares the loss of light to its calibrated points. If, for some reason,

the loss of light is less than when the sensor was zero-calibrated, the sensor shows a negative

consistency. This is not a fault, it just indicates the liquid in the sensor absorbs less light than the

liquid used as zero reference. Please contact the manufacturer if this is a problem for you.

1

0

2

www.krohne.com07/2010 - MA OAS 2000 R02 en

31

Page 32

5 OPERATION

5.3.3 Calibration screen

The sensor information menu is the calibration curve screen. To change between the main menu

and the calibration screen, press ↓ and ^ simultaneously.

The converter uses at least a zero sample and one sample (single point calibration). Up to five

samples may be used to create a calibration curve (multipoint calibration).

INFORMATION!

The sample number itself does not change, only the order in which the samples are used.

The calibration menu displays sample values placed in a graph.

OPTISENS OAS 2000

Figure 5-2: Calibration screen

1 Single point calibration

2 Multi point calibration

• The X-scale displays consistency/suspended solids, where min

on the left and max

max value (20 mA output) is shown on the right.

maxmax

min value (4 mA output) is shown

minmin

• The Y-scale displays the light loss due to solids from the sensor light source. The converter

uses the light loss values to calculate which measuring signal corresponds to minconsistency/suspended solids and max-consistency/suspended solids.

• The actual measuring value is indicated with an arrow that moves up and down to the left of

the Y-scale axis.

• Samples that are not within the chosen scale of the active sensor are not displayed on the

calibration screen. However, these samples are still used in the calculations. If you want to

see a point outside the sensor scale, then you may temporarily change the scale in the sensor

menu Scale/Alarm.

Scale/Alarm.

Scale/Alarm.Scale/Alarm.

If the sample values are switched or the lab result is incorrectly performed, then the calibration

curve will be incorrect. Such a mistake is easy to discover on the calibration screen since a part

of the calibration curve will go in the wrong direction. Different measuring values should never

correspond to the same consistency/suspended solids.

32

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 33

OPTISENS OAS 2000

Figure 5-3: Incorrect calibration

In the above figure the curve goes backwards because two samples have been exchanged when

entering the lab results. A higher Y-value must have a higher X-value. The curve must continue

upwards and to the right.

5.3.4 Automatic adjustment of the calibration

OPERATION 5

The function Adjust

easy way using an offset value. When a sample is taken to be analysed by lab, the converter

stores the reading. When the sample has been analysed, the result is keyed in to the converter.

The converter will compare it to the stored reading and calculate a new setting for the sample

value.

Automatic adjustment (offset) only works for single point calibrations and is primarily intended

as an easy way to get started with a new sensor. Once the automatic adjustment is done and the

sensor gives a sensible reading, we recommend using a statistical adjustment to get a higher

accuracy over time (see next section).

Adjust in the Calibrate

AdjustAdjust

Calibrate menu is used to automatically adjust the calibration in an

CalibrateCalibrate

CAUTION!

Even though the sensors have daylight-filters, they are sensitive to the infrared parts of the

sunlight. Always cover the sensor and the bucket before calibration.

Running an automatic adjustment

• Fill a bucket with a sample of the liquid you intend to measure.

• Submerge the sensor into the liquid.

• Select the sensor to be calibrated in the menu by using ↑ or ↓.

• Press ^ for approximately 5 seconds to enter the sensor menu.

• Select Calibrate > Adjust

• Select Take sample

• Take the bucket to the lab for analysis. Note the concentration of the sample determined at

• Select Calibrate > Adjust

• Press ^.

• Press ^ to use the stored reading or ↑ to key in a value.

• Key in the result of the lab analysis, then press ^.

Calibrate > Adjust and then Store

Calibrate > AdjustCalibrate > Adjust

Take sample and stir the sample in the bucket until the measuring is finished.

Take sampleTake sample

the lab.

Calibrate > Adjust and then Lab

Calibrate > AdjustCalibrate > Adjust

Store using ↑ and ↓.

StoreStore

Lab using ↑ and ↓.

LabLab

i MAC 080 will show the current value and the suggested new value for "Sample 1".

• Acknowledge the change by pressing ^ or abort using ↑ or ↓.

www.krohne.com07/2010 - MA OAS 2000 R02 en

33

Page 34

5 OPERATION

5.3.5 Statistic adjustment

Statistic adjustment of the lab sample value is a much better way to good measurement than

frequent calibration. This is done comparing the lab results with the instrument reading over

time. If a systematic discrepancy is detected, change accordingly the value of the lab sample

used in the converter by using the Adjust

If, for example, several lab results for a period of time in average show 5 % more than the

instrument, the sample value in the converter shall be increased by 5% of its value. E.g. if the

sample value is 10000 mg/l, it shall be changed to 10500 mg/l.

Using the statistic method will increase the accuracy and reliability of the measurement as time

passes while new calibrations will start from scratch. An Excel sheet to help doing statistical

adjustment of the calibration can be obtained from the manufacturer.

Running a statistic adjustment

• Select the sensor to be calibrated in the menu by using ↑ or ↓.

• Press ^ for approximately 5 seconds to enter the sensor menu.

• Select Calibrate > Adjust

• Press ^.

• Press ↑ to key in a value.

• Key in the result of the statistical calculation, then press ^.

i The converter will show current and suggested new value for "Sample 1".

Calibrate > Adjust and then Lab

Calibrate > AdjustCalibrate > Adjust

Adjust function in the calibration menu.

AdjustAdjust

Lab using ↑ and ↓.

LabLab

OPTISENS OAS 2000

• Acknowledge the change by pressing ^ or abort using ↑ or ↓.

5.3.6 Zero calibration

CAUTION!

Even though the sensors have daylight-filters, they are sensitive to the infrared parts of the

sunlight. Always cover the sensor and the bucket before calibration.

The sensor is zero-calibrated at the factory and does not often need to be zero-calibrated.

Before doing a zero calibration, always check that it is really needed. Make sure the lenses are

clean, and use clean de-aerated water to check the sensor reading. Tap water is best de-aerated

by leaving the water in an open bucket for at least two hours.

34

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 35

OPTISENS OAS 2000

Running a zero calibration

• Remove the sensor from the process and clean the sensor head.

• Dip the sensor in a bucket of clean water.

• Select the sensor to be calibrated in the menu by using ↑ or ↓.

• Press ^ for approximately 5 seconds to enter the sensor menu.

• Select Calibrate > Take sample

• Select Zero

• To acknowledge that you really want to change the zero calibration, select Yes

^.

i The converter will ask you to put the sensor in clean water.

• Submerge the sensor head into the clean water and cover it from direct sunlight.

• Press ^.

• Wait for the zero calibration to finish. It will take approximately 30 seconds before the unit

returns to the menu.

INFORMATION!

Detailed procedures for navigating the converter software can be found in the converter manual.

Calibrate > Take sample and then press ^.

Calibrate > Take sampleCalibrate > Take sample

Zero by using ↑ or ↓ and then press ^.

ZeroZero

OPERATION 5

Yes and then press

YesYes

5.3.7 Calibration with samples

CAUTION!

Even though the sensors have daylight-filters, they are sensitive to the infrared parts of the

sunlight. Always cover the sensor and the bucket before calibration.

Calibration with sample in a bucket

• Fill a bucket with a sample of the liquid you intend to measure.

• Submerge the sensor into the liquid.

• Select the sensor to be calibrated in the menu by using ↑ or ↓.

• Press ^ for approximately five seconds to enter the sensor menu.

• Select Calibrate > Take sample

• Press ^ and stir the sample in the bucket until the calibration is finished. It will take

• Take the bucket to the lab for analysis. Note the concentration of the sample determined at

• Enter sample #1 concentration by selecting Calibrate > Sample #1

• Press ^.

• Use ↑ and ↓ to change the values and ^ to go to the next digit. Some special applications may

Calibrate > Take sample and then #1

Calibrate > Take sampleCalibrate > Take sample

approximately 30 seconds.

the lab.

need additional sample points. Do not enter samples that are identical in concentration or

less than 10% from initial values.

#1 using ↑ and ↓.

#1#1

Calibrate > Sample #1 in the calibration menu.

Calibrate > Sample #1Calibrate > Sample #1

www.krohne.com07/2010 - MA OAS 2000 R02 en

35

Page 36

5 OPERATION

Calibration of submersible sensor in a basin or channel

• Calibration can be done without the use of a bucket. Make sure that the sensor is at least

30 cm / 11.8" below the lowest liquid level.

• Follow the steps 3 to 5 of the above procedure "Calibration with a sample bucket".

• While the OAS 2000 is calibrating, grab a sample of the liquid with a dip bucket. Make sure to

grab a sufficiently large sample volume for low solids applications.

• Take the sample to the lab for analysis. Note the concentration of the sample determined at

the lab.

• Follow the steps 8 to 10 of the above procedure "Calibration with a sample bucket".

Calibration of inline sensor in a pipe

• Inline sensors are easiest calibrated if the pipe has a sample outlet.

• Follow the steps 3 to 5 of the above procedure "Calibration with a sample bucket".

• While the OAS 2000 is calibrating, open the sample valve and fill a bucket with process liquid.

• Take the sample to the lab for analysis. Note the concentration of the sample determined at

the lab.

• Follow the steps 8 to 10 of the above procedure "Calibration with a sample bucket".

5.4 Scaling

OPTISENS OAS 2000

The menu Scale / Alarm

Scale / Alarm (see converter manual) allows the user to set the high and low

Scale / AlarmScale / Alarm

boundaries for a 4...20 mA output signal. In addition, this menu allows the user to set high and

low alarm values to switch a relay when solids have reached critical points.

Max

Max Sets the 20 mA point output.

MaxMax

Min

Min Sets the 4 mA point output (may be negative for special applications).

MinMin

Hi-Alarm

Hi-Alarm Sets the high alarm set point (the value zero inactivates the alarm).

Hi-AlarmHi-Alarm

Low-Alarm

Low-Alarm Sets the low alarm set point (the value zero inactivates the alarm).

Low-AlarmLow-Alarm

36

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 37

OPTISENS OAS 2000

6.1 Cleaning the flushing nozzle

If the flushing nozzle becomes plugged, it can usually be cleaned by backflushing it with clean

water.

Cleaning the flushing nozzle on submersible sensors

• Before attempting to backflush, close the valve of the flush water source.

• Disconnect the sensor flushing hose from the solenoid valve.

• Place a 12 mm / 0.47" hose over the flush nozzle and carefully open the water valve.

i The pressure should clear the line of solids. If backflushing does not work initially, try

cleaning the three flushing nozzles with a needle. Try backflushing the nozzles again as

described above until clean water comes out at the solenoid valve end of the hose.

INFORMATION!

The nozzle of an inline sensor usually does not need to be cleaned. The nozzle works as a check

valve to avoid that process liquid is pressed up the flushing hose. It consists of a rubber

membrane held in place by a steel bracket.

SERVICE 6

Plugging the nozzle if flushing is not used

• Plug the nozzle by removing the membrane and the steel bracket, which is attached with two

screws to the sensor head.

• Fit a spotfaced M5x8 screw with soft thread retainer in the hole.

6.2 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are under normal operating conditions subjects

to wear and tear.

6.3 Spare parts and accessories

Order number Designation

XGA S 06010 OAS 2000 inline connection valve

XGA S 06020 OAS 2000 inline but weld end R 1½"

XGA S 06030 OAS 2000 inline 1/12" NPT nipple

XGA S 06040 Sealing kit for OAS 2000 inline version

XGA W 08010 Signal cable extension for OPTISENS 2000 sensor (10 m / 33 ft)

XGA W 08020 Signal cable extension for OPTISENS 2000 sensor (30 m / 98.4 ft)

www.krohne.com07/2010 - MA OAS 2000 R02 en

37

Page 38

6 SERVICE

6.4 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, technical support and training.

INFORMATION!

For more precise information, please contact your local representative.

6.5 Returning the device to the manufacturer

6.5.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

OPTISENS OAS 2000

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

38

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 39

OPTISENS OAS 2000

6.5.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 6

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

6.6 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com07/2010 - MA OAS 2000 R02 en

39

Page 40

7 TECHNICAL DATA

7.1 Measuring principle

The sensor measures transmitted light through the liquid. The measuring principle is based on

the suspended particles ability to absorb and reflect NIR (Near Infrared) light. The light source is

a light emitting diode that pulses and emits monochromatic light with a wavelength of 880 nm.

The detected measuring signal is inversely logarithmical proportional to the concentration of

suspended solids. Signal treatment or linearisation is done within the converter.

In addition, the temperature is measured to be used for temperature compensation of the

measured value. It can be read in the converter and used as secondary value when a sensor is

configured to use both analog outputs.

INFORMATION!

The built-in temperature measurement is not a precision measurement, but shall be seen as an

indication.

OPTISENS OAS 2000

1

4

Figure 7-1: Cross-section of measuring gap

1 Measuring gap

2 Light source (NIR-LED)

3 Monochromatic light beam

4 Detector

3

2

40

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 41

OPTISENS OAS 2000

7.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Transmitted light absorption principle, pulsed NIR 880 nm, with

Application range Continuous measurement of

Measured value Suspended solids concentration

TECHNICAL DATA 7

Submersible version Inline version

reference measurement, temperature-compensated.

Reflection and absorption of light on suspended solids and sludge

particles. The light passes the measured particles between the

emitter and the detector in a straight line.

suspended solids in waste water

and sludge (e.g. in aeration

basins).

Continuous measurement of

suspended solids in pump lines

for waste water and sludge (e.g.

in pump lines for return sludge).

Design

Modular construction

A typical measuring system consists of:

• MAC 080 multiparameter converter

• 1 (or up to 4) OPTISENS 2000 sensors

• Solenoid valves to control spray cleaning

Assemblies for submersion or

side wall installation.

Measuring range 0...20000 mg/l (ppm),

min. 0...100 mg/l (depending on

the sludge type)

Flushing Flushing using clean water or compressed air.

Pressure: 6 bar / 87 psi Pressure: 2 bar / 29 psi above

Solenoid valve: available in 220 V and 117 V versions, up to 2 sensors

can be operated on a single valve.

Flush hose: ¼" external diameter, PE, standard length: 10 m / 32.8 ft

Ball valve assembly for inline

installation.

0...5% suspended solids,

min. 0...100 mg/l (depending on

the sludge type)

process pressure, max. 10 bar /

145 psi

www.krohne.com07/2010 - MA OAS 2000 R02 en

41

Page 42

7 TECHNICAL DATA

Measuring accuracy

Reference conditions Medium: water

Maximum measuring error Typical ±2% of selected range, max. ±5% of selected range.

Display resolution

(in combination with MAC 080)

Calibration Pre-calibrated in the factory, calibration on site: software-supported

Operating conditions

Temperature Process temperature = ambient temperature

Process pressure Ambient Max. 6 bar / 87 psi with automatic

Max. immersion depth 10 m / 32.8 ft N/A

Protection category IP68 (Nema 6)

OPTISENS OAS 2000

Temperature: +25°C / +77°F

Pressure: 1 barg / 14.5 psig

Temperature: ±0.5°C/ 0.5°F

1 mg/l, extended mode: 0.1 mg/l

Temperature: 0.1°C/ 0.1°F

single or multipoint calibration using reference samples.

0…+60°C/ 32…140°F

cleaning

Max. 10 bar / 145 psi without

automatic cleaning (special

version)

Installation conditions

AAS 2000 + MAA 2000 fibreglass

telescopic rod for submersible

installations

AAS 2000 + MAA 2000 slide rail

mounting for side wall

installations

OAS 2000 inline version N/A Pipe installation using a butt

Dimensions and weights For detailed information see chapter "Dimensions and weights".

Process connection Open basins and channels 1½"ballvalve for inline

Installation on the handrail with

up to 4 m length-adjustable,

oscillating fibreglass assembly.

Handrail mounting for:

• Round handrails:

d = 32...50 mm / 1.3…2"

• Square cross-sections:

28...42 mm / 1.1…1.7"

Installation on side walls of

channels and basins using slide

rails for simple sensor removal.

N/A

N/A

weld end for holes of 48.5 mm /

1.9" diameter (standard scope of

delivery) or with an optional

1½" NPT nipple, on which a ball

valve is installed to fit the sensor.

Min. pipe diameter: 80 mm / 3.1".

installation

42

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 43

OPTISENS OAS 2000

Materials

Enclosure 316 SS

NIR diode GAS diode, 880 nm wavelength, pulsed

Connection cable to converter Insulation: Hytrel (5-pin M12 connector, fixed cable, shielded, 10 m /

Flush hose PE

Approvals and certifications

CE sign This device fulfils the statutory requirements of the EC directives.

Electromagnetic compatibility Interference emission to EN 61000-6-4:2001; immunity to EN 61000-

Low voltage directive Safety requirements for electrical equipment for measurement,

7.3 Dimensions and weight

TECHNICAL DATA 7

32.8 ft)

The manufacturer certifies successful testing of the product by

applying the CE mark.

6-2:2001.

control and laboratory use in accordance with EN 61010-1:2001.

Figure 7-2: Submersible version

Dimensions

[mm]

Dimensions

[inches]

Weight

[kg] [lbs]

a Ø66 Ø2.6 1.6 3.5

b 20 0.8

c 227 8.9

d 255 10.0

www.krohne.com07/2010 - MA OAS 2000 R02 en

43

Page 44

7 TECHNICAL DATA

3

OPTISENS OAS 2000

1

2

Figure 7-3: In-line version

1 1½" NPT

2 Welding end

3 Min. 283 mm / 11.1" (de)installation spacing

Dimension

[mm]

Dimension

[inches]

Weight

[kg] [lbs]

a 368 14.5 4.6 10.1

44

www.krohne.com 07/2010 - MA OAS 2000 R02 en

Page 45

OPTISENS OAS 2000

8.1 Setup information form

This form can be used to document the setup of the sensor.

Sensor type:

Sensor type:

Sensor type:Sensor type:

Position / Tag:

Position / Tag:

Position / Tag:Position / Tag:

In the System

System submenu of the sensor menu the following information can be collected:

SystemSystem

Serial:

Serial:

Serial:Serial:

SoftW:

SoftW:

SoftW:SoftW:

In the Settings

Settings submenu of the sensor menu the following parameters can be set:

SettingsSettings

I-time:

I-time:

I-time:I-time:

Unit:

Unit:

Unit:Unit:

Analog:

Analog:

Analog:Analog:

Second:

Second:

Second:Second:

In the Cleaning

Cleaning submenu of the sensor menu the following parameters can be set:

CleaningCleaning

Cleaner:

Cleaner:

Cleaner:Cleaner:

Cleaning interval:

Cleaning interval:

Cleaning interval:Cleaning interval:

Cleaning length:

Cleaning length:

Cleaning length:Cleaning length:

Cleaning freeze:

Cleaning freeze:

Cleaning freeze:Cleaning freeze:

Cleaning relay:

Cleaning relay:

Cleaning relay:Cleaning relay:

In the Scale / Alarm

Scale / Alarm submenu of the sensor menu the following parameters can be set:

Scale / AlarmScale / Alarm

Max:

Max:

Max:Max:

Min:

Min:

Min:Min:

High alarm:

High alarm:

High alarm:High alarm:

Low alarm:

Low alarm:

Low alarm:Low alarm:

Alarm relay:

Alarm relay:

Alarm relay:Alarm relay:

Leave the menu by pressing ↑ and ^ simultaneously.

APPENDIX 8

www.krohne.com07/2010 - MA OAS 2000 R02 en

45

Page 46

8 APPENDIX

8.2 Support information form

Company:

Company: Name:

Company:Company:

Phone:

Phone: E-mail:

Phone:Phone:

Sensor

Sensor

Sensor Sensor

type:

type:

type:type:

First go to the converter menu by pressing ↑ and ^ simultaneously for five seconds. Then select System

and press ^. Write down the following information.

Version:

Version:

Version:Version:

Serial:

Serial:

Serial:Serial:

Box temp:

Box temp:

Box temp:Box temp:

Leave the converter menu by pressing ↑ and ^ simultaneously. Use ↑ and ↓ to select the sensor in the

main display. Go to the sensor menu by pressing ^ for 5 seconds. Then select System

down the following information.

Type:

Type: SoftW:

Type:Type:

Serial:

Serial: Temp:

Serial:Serial:

Select System > Samples

System > Samples and press ^. Write down the following information.

System > SamplesSystem > Samples

SA 0:

SA 0:

SA 0:SA 0:

SA 1:

SA 1: Cons 1:

SA 1:SA 1:

SA 2:

SA 2: Cons 2:

SA 2:SA 2:

SA 3:

SA 3: Cons 3:

SA 3:SA 3:

SA 4:

SA 4: Cons 4:

SA 4:SA 4:

SA 5:

SA 5: Cons 5:

SA 5:SA 5:

Select System > Info

System > Info and press ^. Write down the following information.

System > InfoSystem > Info

MS:

MS: Con:

MS:MS:

SA0:

SA0: SA1:

SA0:SA0:

Cons 1:

Cons 1: Ch1a:

Cons 1:Cons 1:

Ch1:

Ch1: Intensity:

Ch1:Ch1:

Zero Int: