Page 1

OPTIMASS

MFC 010 Converter

•• FFoorr bbootthh OOPPTTIIMMAASSSS aanndd OOPPTTIIGGAASS fflloowwmmeetteerrss

•• FFoorr ddiirreecctt mmeeaassuurreemmeenntt ooff mmaassss ffllooww rraattee,, ddeennssiittyy aanndd pprroodduucctt tteemmppeerraattuurree

•• MMOODDBBUUSS pprroottooccooll

•• SSooffttwwaarree vveerrssiioonn 22..33..xx

Page 2

Page 3

1

Contents

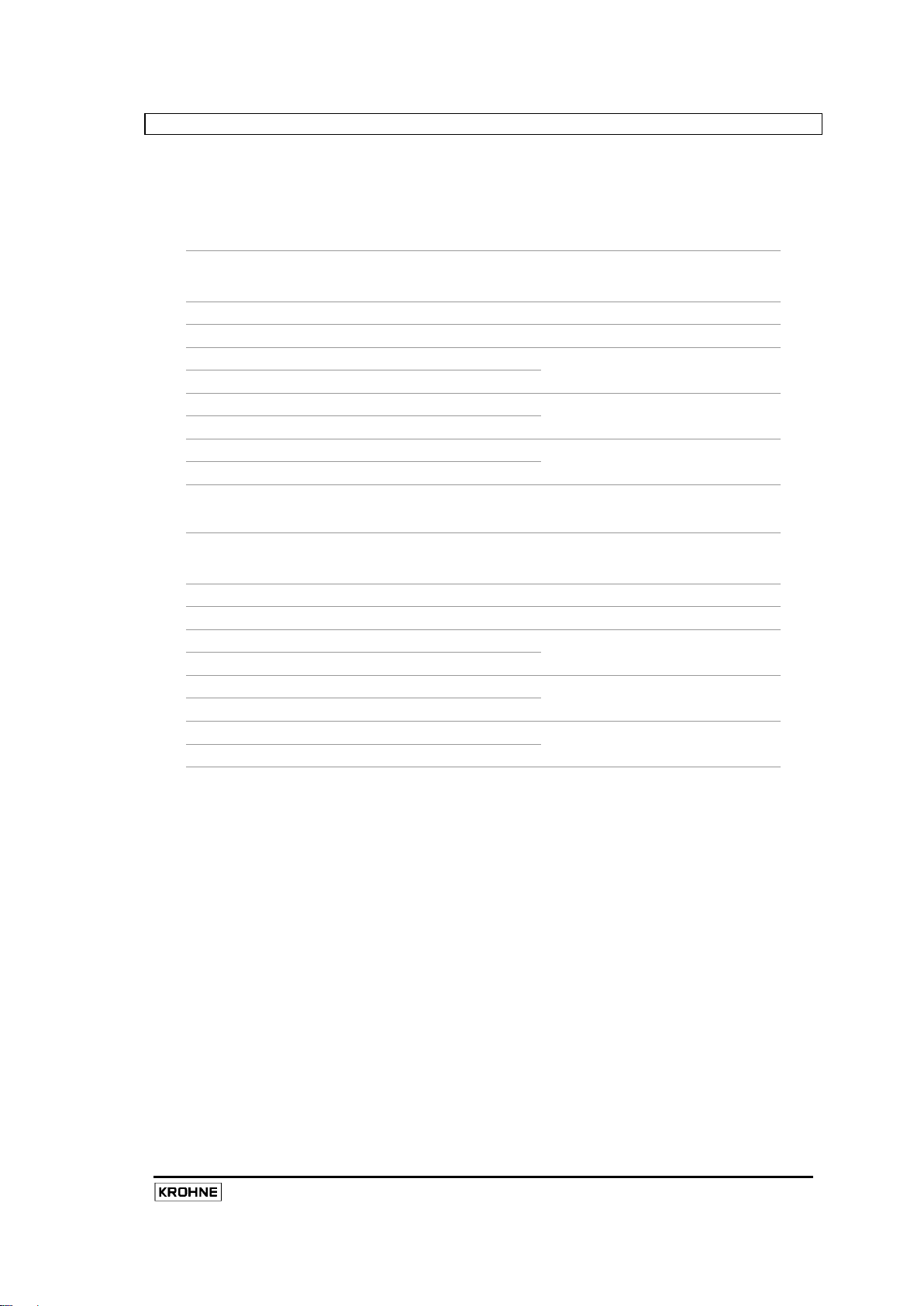

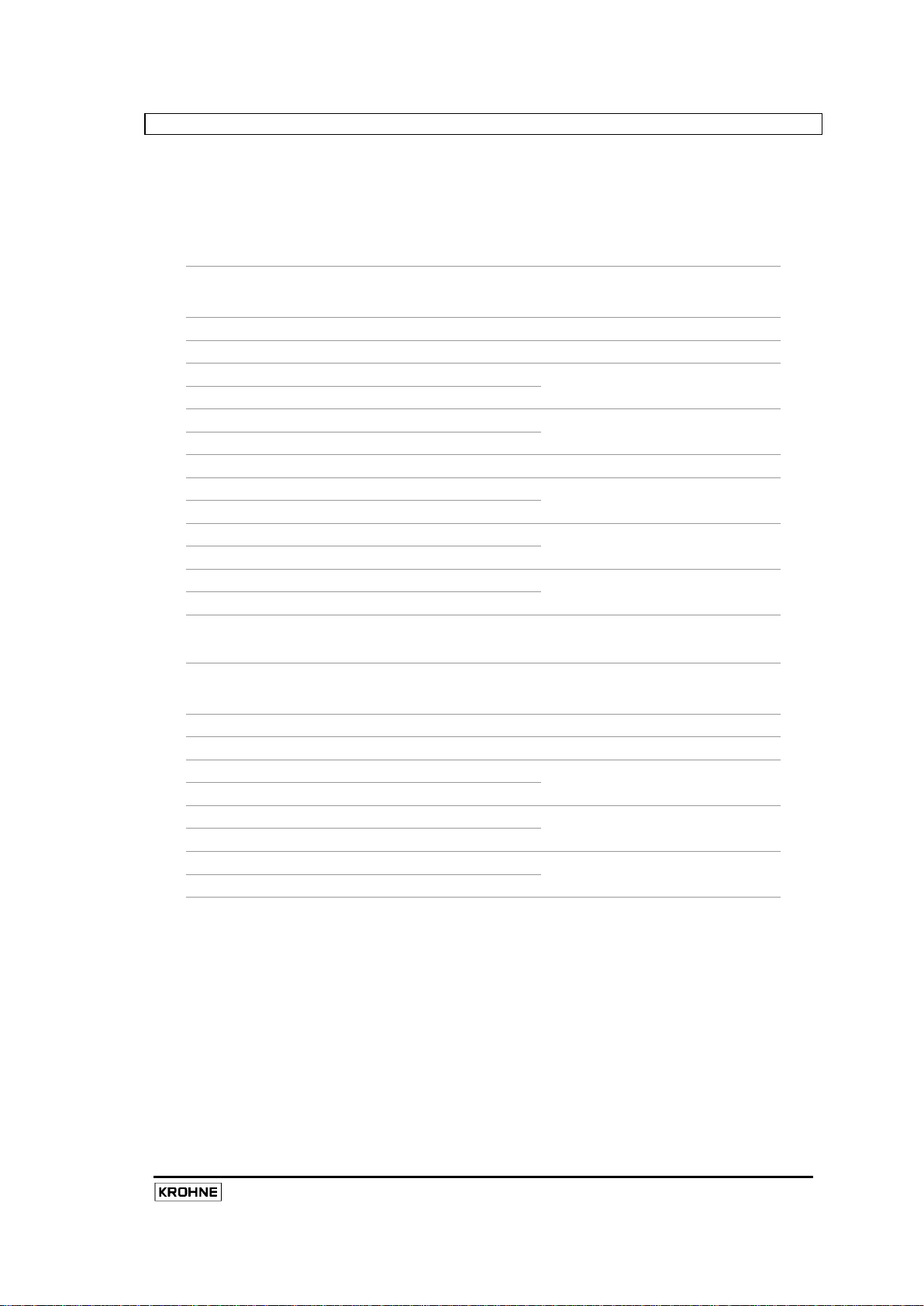

1. Introduction 5

2. Mechanical Installation 5

3. Electrical Installation 6

3.1 Electrical Input Specifications for the MFC010 6

3.2 Recommended Cable Specification 7

3.3 Connection to the MFC010 8

3.4 Connection to the Modbus Bus 10

3.5 Installation Guidelines for Electromagnetic Compatibility 12

4. Installation in Hazar d o u s Area Applications 13

4.1 Power Supply Barrier Devices 15

4.2 Modbus Barrier Devices 16

4.3 Connection To The Modbus Bus 17

5. Modbus Protocol Interface 19

5.1 Character Transmission Format 19

5.2 Modbus Telegram Format 20

5.3 Data Types in Modbus 20

5.4 Multidrop Operation 21

5.5 Calculating Data Transmission Rates 21

5.6 Error Messages in Modbus 22

6. Modbus Functions Supported by the MFC010 23

6.1 01 (0116): Read Coil Status 23

6.2 02 (0216): Read Discrete Input 24

6.3 03 (0316): Read Holding Registers 25

6.4 04 (0416): Read Input Registers 26

6.5 05 (0516): Force Single Coil 27

6.6 06 (0616): Preset Single Register 28

6.7 07 (0716): Read Exception Status 29

6.8 08 (0816): Diagnostics 30

6.9 11

6.10 16

(0B

): Fetch Comm. Event Counter 30

16

(10

): Preset Multiple Registers 31

16

6.11 17 (1116): Report Slave ID 32

7. MFC010 Modbus Data Model 33

7.1 MFC010 Register Structure 33

7.2 Discrete Status Output “Coil” Registers 39

7.3 Discrete Input (Binary) Status Registers 41

7.4 Input Registers 43

7.5 Holding Registers 49

8. MFC010 Operations 71

8.1 Mass Flow Zero Calibration 71

8.2 Density Calibration 72

8.3 Fixed and Referred Density Operation 75

8.4 Concentration Measurement 76

8.5 Using the System Protection Passwords 76

8.6 Saving and Restoring Configuration settings 77

8.7 Implementing User Defined Units 77

8.8 Using the Internal Process Control Mechanism 78

8.9 Custody Transfer Applications 78

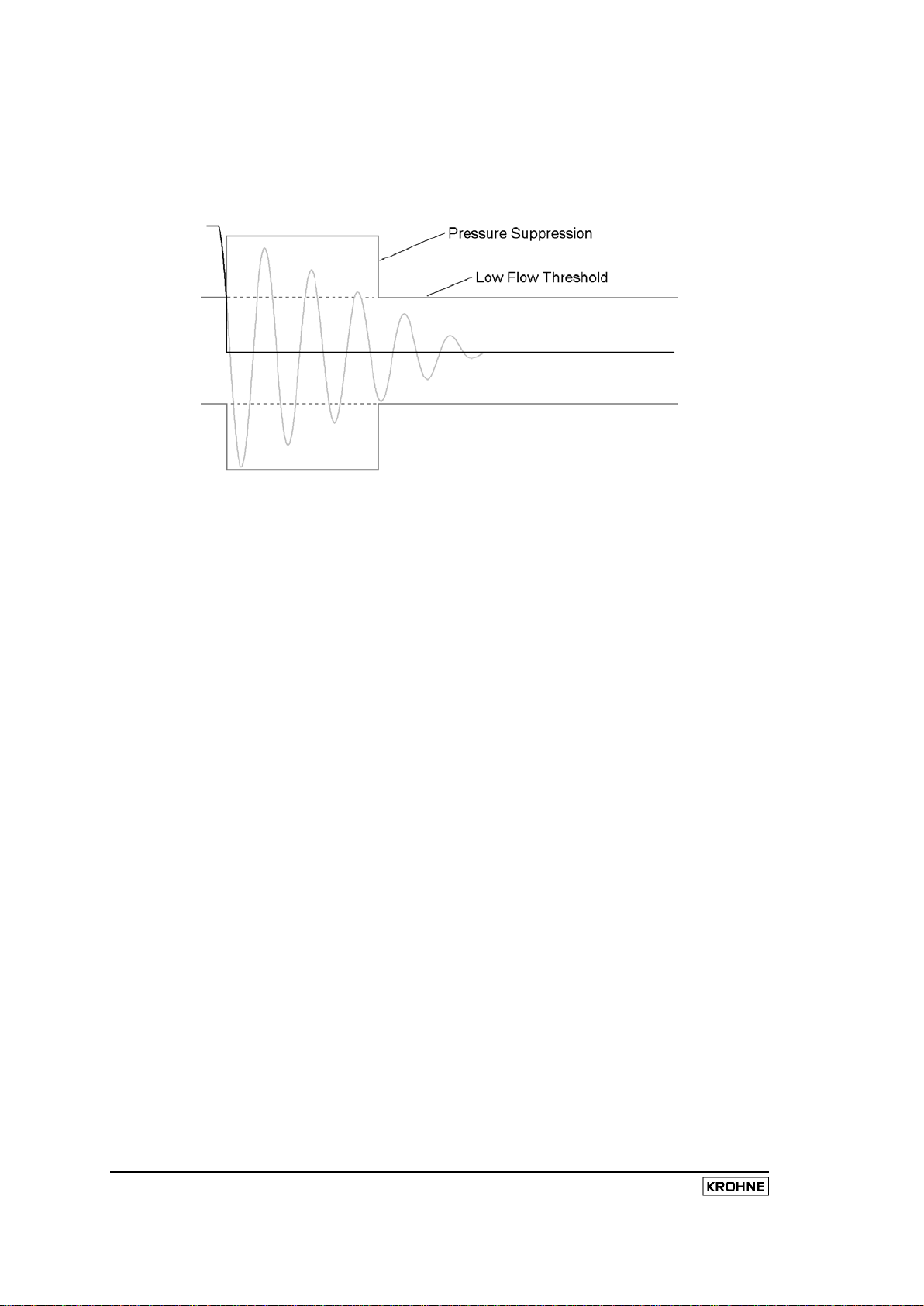

8.10 Pressure Suppression 79

MFC010 Interface Manual

Page 4

2

MFC010 Interface Manual

9. Error and Warning Messages 81

9.1 System Errors 81

9.2 Process Warnings 85

10. Trouble Shooting 88

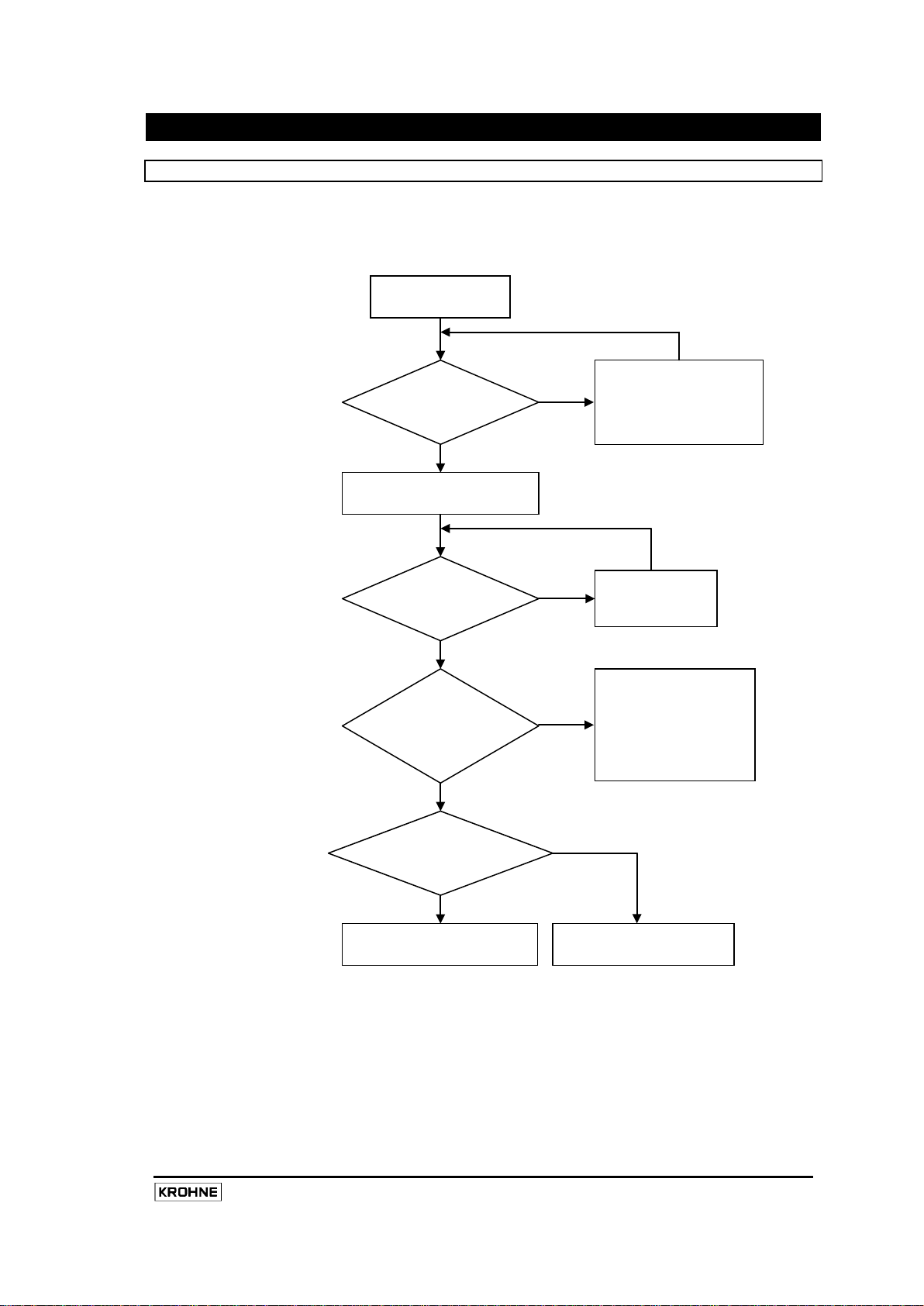

10.1 “No Response to Modbus Requests” 88

10.2 “Communication Errors” 88

10.3 “The MFC010 is responding with an Illegal Modbus Function Message” 89

10.4 “The MFC010 is responding with an Illegal Data Message” 89

10.5 “The MFC010 is responding with an Illegal Address Message” 89

Appendix A : Modbus CRC Checksum Calculation 90

Appendix B : Hexadecimal and Binary Notation 92

Appendix C : Decoding Floating Point Numbers 93

Single Precision Floating Point Numbers (“Floats”) 93

Double Precision Floating Point Numbers (“Doubles”) 94

Appendix D : Sensor Sizes and Associated Default Register Setti n g s 95

Appendix E : Installation of Power Supplies in MFC010 Applications 97

Appendix F: MFC010 Toolbox 100

Page 5

3

Product Liability and Warranty

The MFC010 mass flow sensor electronics are an integral part of the OPTIMASS a nd OPTIGAS m ass

flowmeter families des igned f or t he direct measurement of mass flow rate, product density and product

temperature, and also indirectly enables the measurement of par ameters s uch as m ass t otal,

concentration and volume flow.

When used in hazardous areas, special codes and r egulations are applicable which are specified in the

section on H azardous ar ea appl ications i n t his doc ument. Please note t hat haz ardous area approved

meters must ALWAYS be c onnected using appropriate barriers, even when used outside the hazardous

area, else the approval is void.

Responsibility as to suitability and intended use of the equipment rests solely with the purchaser.

KROHNE does not accept any liability resulting from misuse of the equipment by the customer.

Improper installation and operation of the flow meters may lead to loss of warranty. Warranty is also null

and void if the instrument is damaged or interfered with in any way.

In addi tion, t he “ General C onditions of S ale”, w hich f orm t he bas is of t he pur chase agr eement, are

applicable.

If you need to return OPTIGAS or OPTIMASS flow meters to KROHNE, please complete the form on the

last page of the Sensor manual and return it with the meter to be repaired. KROHNE regrets that it

cannot repair or check returned equipment unless accompanied by the completed form.

Standards and Approvals

The M FC010 c onverter i s t ested and c ertified, w hen i nstalled according to the directions

contained i n t his doc ument, t o m eet al l of the r equirements of t he E U-EMC a nd PED

directives and hence bears the CE symbol.

The MFC010 c onverter in association with the OPTIGAS and O PTIMASS s ensor systems is

approved f or oper ation i n H azardous ar ea i nstallations according to the harmonized

European Standards (ATEX).

Approvals for Hazardous area i nstallations c ompliant w ith t he F M and C SA

standards are pending.

Copies of all of the certificates of conformity f or t he appr ovals l isted abov e ar e av ailable f rom t he

download centre of the KROHNE website at www.krohne.com.

THE CONTENT OF THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

MFC010 Interface Manual

Page 6

4

MFC010 Interface Manual

Page 7

5

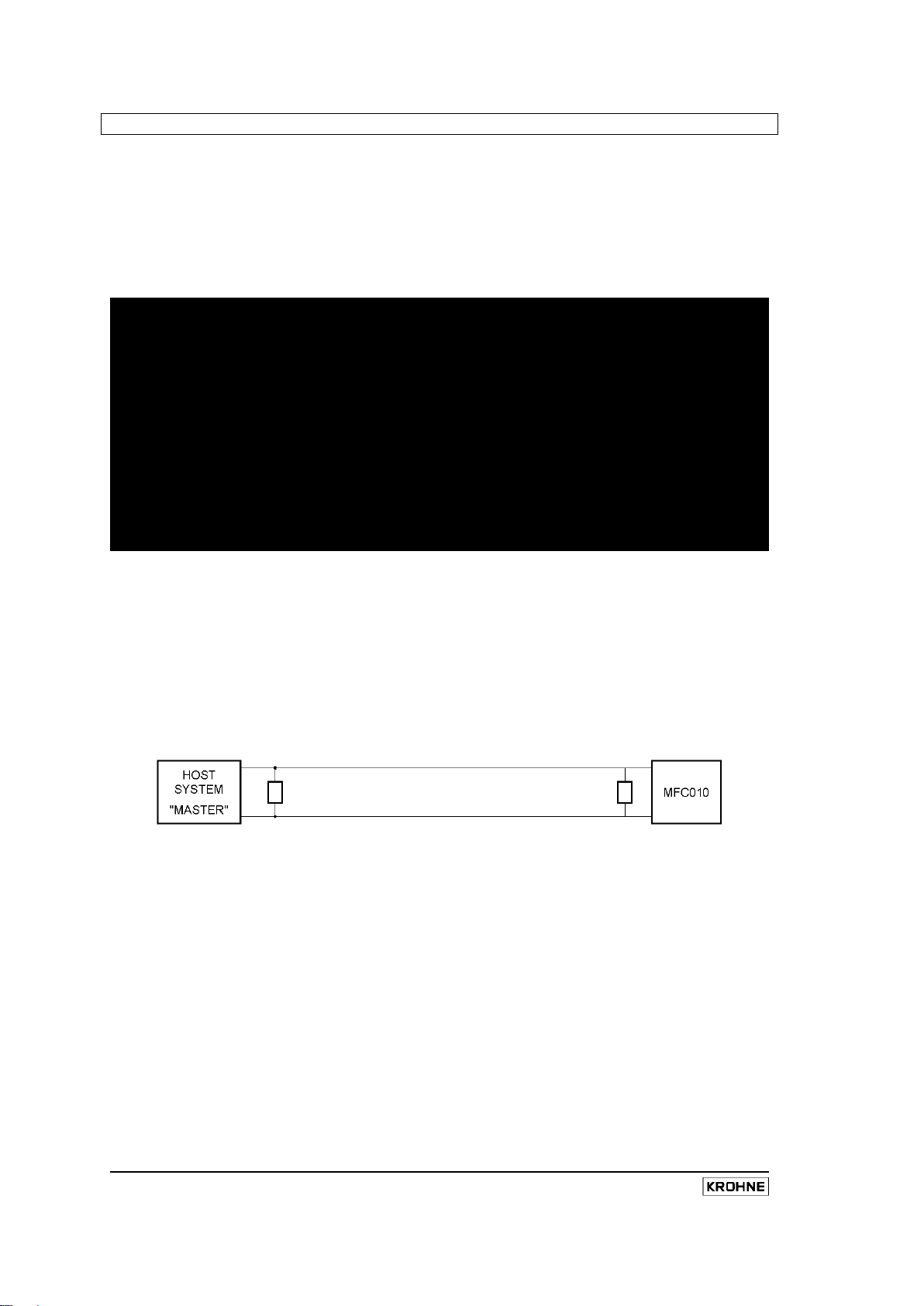

1. Introduction

The MFC010 is a s tand al one s ignal c onverter des igned t o di rectly i nterface t he O PTIMASS and

OPTIGAS f amilies of C oriolis m ass f lowmeters into c ontrol s ystems us ing t he M odbus R TU protocol

where t here i s no r equirement f or t he ex tensive out put c ontrol features provided by more expensive

converter solutions.

The MFC010 performs three primary direct measurements, Mass flow, Density and Temperature. Using

these primary measurements the MFC010 is able t o c alculate an ar ray of s econdary v alues s uch as

Volume Flow, Velocity and Concentration.

Mass Flow – Mass flow measurement doesn’t come any simpler, once installed just perform a “ Zero

Calibration”, “ Reset” t he “ Totalisers” and aw ay y ou go. W here P rocess noi se i s a nui sance use the

“Measurement T ime C onstant”, “ Low F low T hreshold” and “ Pressure S uppression” features to provide

reliable and repeatable results.

Density – Using the inverse relationship between the Density of the process product and the oscillation

frequency of the measuring tube, the MFC010 can provide a v ery accurate and r eliable Density reading.

In or der t o m aximise t he ex cellent per formance o f the MFC010 the user s hould per form a dens ity

calibration after installation. T he MFC010 provides t wo forms of Density C alibration, the simple “Single

Point Calibration” and t he more accurate “Two Point Calibration”. U sing the “Density Averaging” feature

the user can reduce noisy readings caused by process installation and noise. NB. Density measurement

is not available with the OPTIGAS 5000 meters.

Concentration – Using the “Density” and “Temperature” m easurements t he M FC010 i s c apable of

calculating the concentration of a pr oduct in the pr ocess medium, from one of a num ber of pre-defined

industry standards, such as “ °Brix” a nd “ °Baumé”, as w ell as us er def ined m ixtures us ing t he

programmable coefficients. Concentration measurement is a f unction that comes with a c omprehensive

manual and a Coefficient calculation software package w hich will take the users own process data and

convert it into compatible coefficients to permit the MFC010 to automatically calculate the concentration of

the target process.

Velocity – Using the measured mass flow and density, the velocity of the product is calculated using the

“Pipe Diameter” setting. By default this is set to the measuring tube internal diameter to calculate the

velocity of the product passing through the sensor, but it can be set to calculate the velocity in a section of

the connecting pipe work.

Process Control – Where precise process conditions are required, the “Process Control” function can be

used t o det ect adv erse v ariations i n t he “ Density” or “ Temperature” m easurements and, as well as

indicating the condition, it can take one of a num ber of pr edefined ac tions ac cording t o t he us ers

requirements.

2. Mechanical Installation

Refer t o t he i nstallation gui delines and i nstructions f or m ounting t he s ensor i n t he process pipe work

provided in the handbook on the CD supplied with the sensor.

MFC010 Interface Manual

Page 8

6

MFC010 Interface Manual

3. Electrical Installation

The MFC010 is provided with four electrical terminal connections.

V+ The power supply input terminal.

V- The power supply return path and “Common” for the Modbus interface.

A The inverting (RS485-) terminal for the Modbus interface.

B The non-inverting (RS485+) terminal for the Modbus interface.

These terminals can be accessed in the terminal compartment of the sensor.

3.1 Electrical Input Specifications for the MFC010

NB all voltages, unless otherwise stated, are with reference to the “V-” terminal.

V+ Terminal

Min. Input Voltage 11.4V DC

Max. Input Voltage 12.6V DC

Max. Input Current 200mA DC

A & B *

Min. Input Voltage -7V DC

Max. Input Voltage +11.8V DC

Min. Output Voltage -6V DC

Max. Output Voltage +6V DC

*The M odbus pr otocol r equires t hat t he c ommunications i nterface t o t he MFC010 complies with the

limitations of the EIA/TIA-485 (RS485) specification.

For a standard, non hazardous area, sensor the input impedance of the MFC010 is equivalent to 1/8 of a

standard RS485 load, i.e. an input impedance of >96kΩ, permitting it to be connected to the Modbus bus

in accordance with the Modbus requirements. However, when installed in a Hazardous area the MFC010

requires that suitable barrier devices must be fitted between the MFC010 and the Modbus main bus, see

sections 4.1 & 4.2 for det ails of s uggested bar rier devices and c onnection. I f t he main Modbus Bus is

configured f or m ultidrop oper ation, a M odbus c ompatible R S485 r epeater i s r equired to connect the

barrier devices to the bus, see section 4.3 for further details.

Page 9

7

3.2 Recommended Cable Specification

The c able us ed t o c onnect t he M FC010 t o t he M odbus m aster c ontrol s ystem should be an overall

screened t wisted pai r c able, w ith t wo t wisted pai rs of a m inimum 20 AWG conductor. The total cable

capacitance s hould not ex ceed 50nF and t he c onductor inductance should not exceed 200μH. The

external cable insulation should be specified appropriately for the environment into which the device is to

be installed. The outside diameter of the cable should be between 6.5 mm and 9.5 mm to ensure proper

sealing is achieved when passed through the cable gland entry.

KROHNE c an supply suitable cable that can be or dered to the required l ength, the part numbers are as

follows

External Insulation Colour Grey - KROHNE Part No. X5871059989

External Insulation Colour Blue - KROHNE Part No. X5871069989

(For hazardous area installations)

The maximum cable length from the MFC010 to the bus “Master” device is 300m when using the default

Modbus transmission speed of 19200 Baud. There are further limitations on the cable length when

installing the system into a Hazardous area, refer to section 4.3 on page 17 for details.

MFC010 Interface Manual

Page 10

8

MFC010 Interface Manual

Terminal

Input Connection

12V

V+ - V-

A

A (RS485-)

B

B (RS485+)

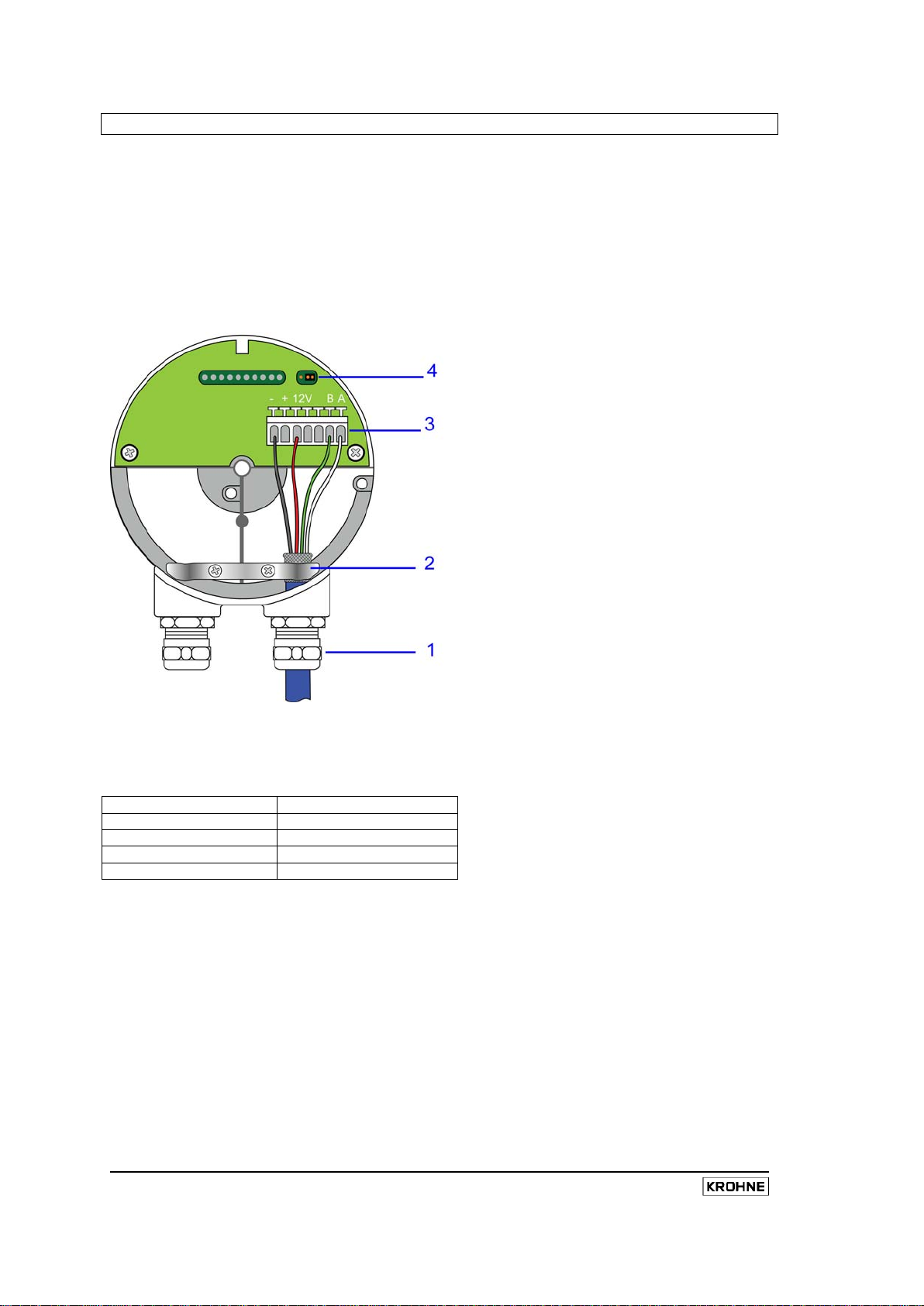

3.3 Connection to the MFC010

1. Unscrew the fixing screw on the junction box cover.

2. Release the two fixing screws holding the cable grip in place and remove the grip.

3. Strip approx. 50mm/2” of the outer casing of the signal cable.

4. Split the screen away from the cores and fold it back on the outer cable.

5. Fit the cable grip and secure, making sure that the screen is gripped under the grip.

6. Connect the four cores to the terminals marked A,B, 12V, - as shown

NOTE: The spring loaded connections are released by depressing the white lever above each

connection

1 Cable Gland

2 Cable Grip/Earth

3 Terminal connections

4 Jumper for EOL resistor (not supplied) – off in position as shown, on in other position

Page 11

9

MFC010 Interface Manual

Page 12

10

MFC010 Interface Manual

3.4 Connection to the Modbus Bus

The MFC010 is designed to be connected as a Slave device onto the 2-wire bus implementation of the

Modbus physical layer definition. In this configuration the receiver and transmitter lines for each device

are c onnected t ogether, Transmitter A t o R eceiver A and T ransmitter B t o Receiver B, and operated in

Half Duplex mode, where the master transmits a request and only after receiving it does the nominated

slave device transmit a reply. When not responding to a direct request from the Master device, the Slave

devices r emain passive, m onitoring the bus and aw aiting a suitable request from the Master device. In

addition to the A and B signal lines the bus MUST include a “Common” signal line to act as a ground

reference point for the A and B signals.

The m aster bus m ust be t erminated at i ts phy sical end poi nts by suitable termination networks

connected between the A (D0) and B (D1) signal lines. When not using bus-biasing resistors, see next

paragraph, each termination network may consist of a single 150 O hm, 0.5W r esistor. H owever, when

bus-biasing resistors are required, a more suitable termination network would consist of a 1nF capacitor in

series with a 120 Ohm, 0.25W resistor. NB It is common that the Host system “Master” is physically at

one end of the bus, so one of the termination resistors is fitted at its terminals, but it should be r ealised

that this is not always the case and care should be taken to ensure that the termination network is at the

physical end of the bus. In a point-to-point configuration, when only one Slave device is fitted to the bus,

then the terminating networks can simply be situated at the connecting terminals of the master and s lave

devices.

Some slave devices require that Bus-Biasing resistors are fitted to ensure that the bus is in a defined

state w hen none of t he t ransmitting devices are active. The MFC010 does NOT require Bus-Biasing

resistors t o be f itted but is compatible with their presence on t he bus i f one or more of the other slave

devices on the bus require them to be fitted, as long as they comply with the Line Polarization

requirements of the Modbus specification.

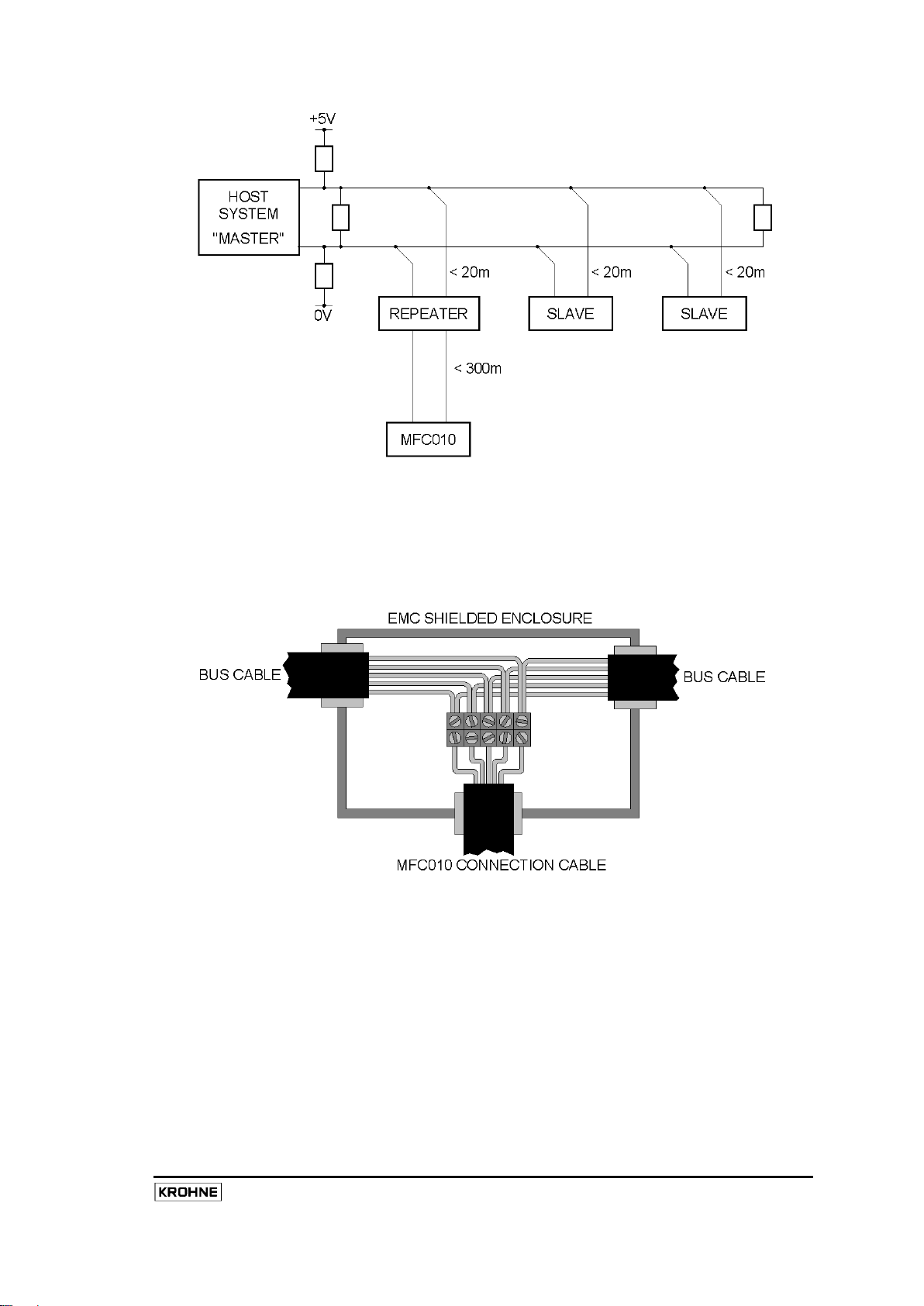

In a m ultidrop bus c onfiguration t he s lave dev ices ar e c onnected t o t he m ain bus cable by branch

connections at intervals along the length of the main bus. T he branch connections, Derivations as they

are termed in the Modbus specification, must be l ess than 20m in length from the main bus cable to the

slave device. Some slave devices permit direct connection to the main bus, known as “Daisy Chaining”,

in some cases by providing extra terminals and c able ac cess poi nts. H owever, as i ndicated i n t he

previous s ections, ac cess t o t he t erminal c ompartment of t he M FC010 i s limited; therefore i t i s not

practical to directly connect the MFC010 to the main bus. Instead, the installation should utilise a short

branch c onnection. I f a greater length of cable is required between the MFC010 device and the main

Modbus bus, the user should install a suitable RS485 repeater between the MFC010 and the bus (refer to

the diagram below).

Page 13

11

Because the connection to the bus requires exposing the signal wires, t he connection to the main bus

should be made within a suitable EMI shielded enclosure. This connection should include the “Common”

signal connection, the power supply connection (if a suitable one is provided by the bus), and the drain

wire when available. Each of the cable screens must be properly terminated to the enclosure by means of

appropriate EMC cable glands. For example:

If t he Bus does not provide a s uitable power s upply for the MFC010, a separate suitable power supply

connection should be made at this point.

An RS485 Repeater can be used to extend the length of the Bus and the number of slave devices that are

attached t o t he bus ( refer t o t he f igure bel ow). H owever, if the bus is extended in such a fashion,

termination and polarization networks should be fitted according to the same rules as used for the main

bus (see descriptions above).

MFC010 Interface Manual

Page 14

12

MFC010 Interface Manual

NB For H azardous A rea appl ications t he us er s hould r efer t o s ection 4.3, on page 17, f or c onnection

details.

NB For multidrop systems, ensure cycle times are properly calculated to ensure bus speeds are adequate

for the application.

3.5 Installation Guidelines for Electromagnetic Compatibility

Whilst t he M FC010 and i ts as sociated s ensor has been des igned, t ested and c ertified t o m eet the

requirements on international s tandards of E lectromagnetic C ompatibility ( EMC), i t i s t he us ers

responsibility to ensure that the connection guidelines described in this document are followed. In addition

the user should use recognised good practise in the location and cable routing of the MFC010 in relation

to its surrounding environment. The us er should consider t he following suggestions w hen installing an

MFC010 into a system.

1. Every effort should be made to avoid significant lengths (>50mm) of unshielded signal wire

when connecting to the system, any terminal connections should be housed in a suitably

shielded enclosure.

2. Avoid routing the cable in groups with or alongside other power carrying cables.

3. Avoid locating the MFC010 or routing the connection cable in close proximity to large

electrically powered equipment, such as pumps, inverters etc.

4. If necessary, route the connection cable through a suitably earthed metal conduit.

Page 15

13

i

i

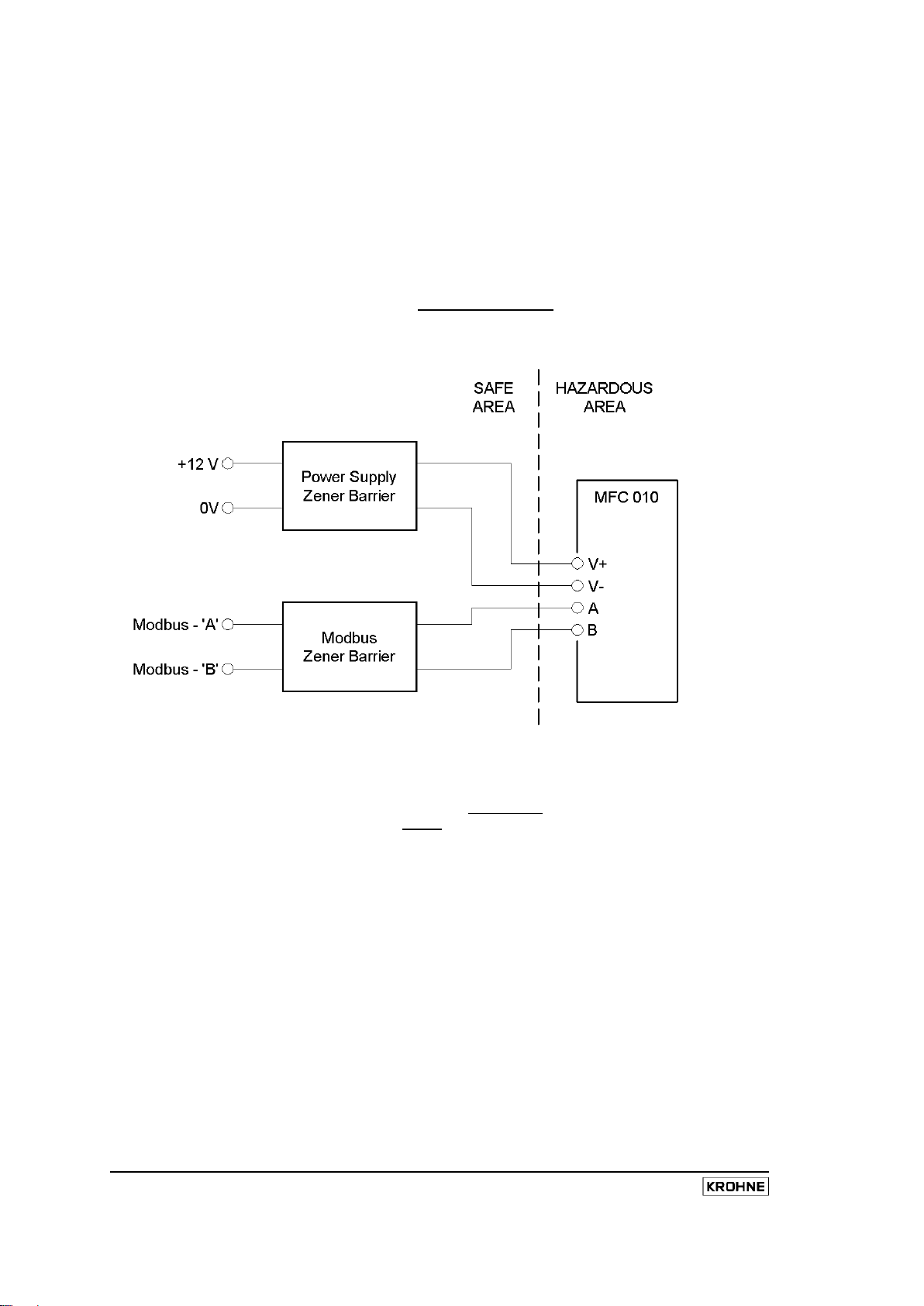

4. Installation in Hazardous Area Applications

Before installation the user MUST ENSURE that the equipment to be installed is the Hazardous ar ea

approved equipment.

Copies of the appropriate certificates can be found on the KROHNE website at www.krohne.com.

Before installation the user MUST refer to the hazardous area installation document, supplied w ith this

equipment, and strictly adhere to the relevant installation instructions indicated therein.

When the MFC010 is used in Hazardous area installations, suitable barrier devices MUST be fitted. The

Safety Parameters for the MFC010 are as follows. All interface and barrier devices must be appropriately

certified to meet these parameters.

ATEX

V+ & V-

Input Voltage, U

Input Current, I

Input Power, P

Input Capacitance, C

Input Inductance, L

i

i

i

i

i

16.5V

340mA

1.3W

35nF

10µH

A & B

FM

V+ & V-

Input Voltage, U

Input Current, I

Input Power, P

Input Capacitance, C

Input Inductance, L

i

i

i

Input Voltage, U

Input Current, I

Input Power, P

Input Capacitance, C

Input Inductance, L

i

i

i

i

i

11.8V

40mA

120mW

35nF

10µH

16.2V

317mA

1.28W

35nF

10µH

A & B

Input Voltage, U

Input Current, I

Input Power, P

i

i

i

Input Capacitance, C

Input Inductance, L

i

i

11.8V

34mA

90mW

35nF

10µH

MFC010 Interface Manual

Page 16

14

MFC010 Interface Manual

The output safety par ameters of t he bar rier dev ices m ust not ex ceed t he V oltage, P ower and C urrent

limits set out above. T he output Capacitance parameter for the barrier devices must exceed the sum of

the M FC010 i nput C apacitance, s pecified abov e, and t he m aximum c able Capacitance. The output

Inductance par ameter f or t he bar rier dev ices m ust ex ceed t he sum of the MFC010 input Inductance,

specified above, and maximum cable Inductance. To summarise:

Uo Barrier < U

Barrier < I

I

o

Barrier < P

P

o

Barrier > C

C

o

Barrier > L

L

o

MFC010

i

MFC010

i

MFC010

i

+ C

cable

cable

MFC010

i

+ L

MFC010

i

NB The In-line resistance of the Modbus barrier MUST NOT EXCEED 1000 Ohms for each of the A and

B Input terminals.

The Z ener barrier devices must be i nstalled in an E MI s hielded enc losure and t he cable screen(s) kept

intact right up to the barrier terminals as far as is practical. The cable screen(s) should be terminated to

the enclosure, chassis Earth connection, and kept SEPARATE from t he i ntrinsically s afe E arth

connections of the Barrier devices. The user MUST adhere to the barrier manufacturer’s instructions for

connecting the intrinsically safe Earth connection to the barrier devices.

Page 17

15

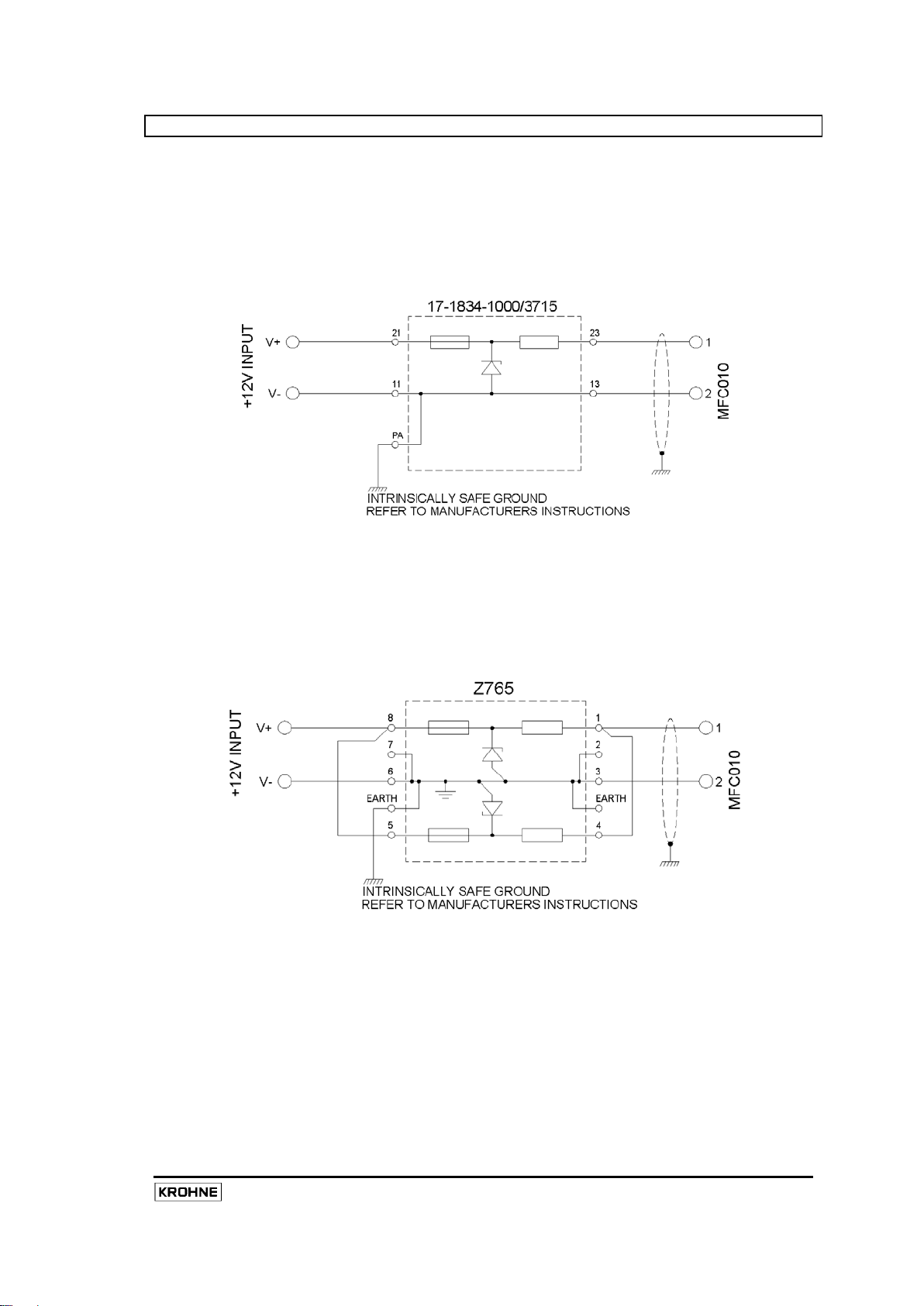

4.1 Power Supply Barrier Devices

The following Zener Barrier devices are those that are recommended for use on the V+ & V- power supply

input connections to the MFC010.

Manufacturer : Bartec

Part Number : 17-1834-1000/3715

Ex Approvals : EEx ia/ib IIC

Connection :

Manufacturer : Pepperl & Fuchs

Part Number : Z765

Ex Approvals : EEx ia IIC

FM and CSA Approved

Connection :

Note: For Optimass 2000 the supply voltage to the barrier should be +14V to ensure maximum voltage is

supplied to the meter.

MFC010 Interface Manual

Page 18

16

MFC010 Interface Manual

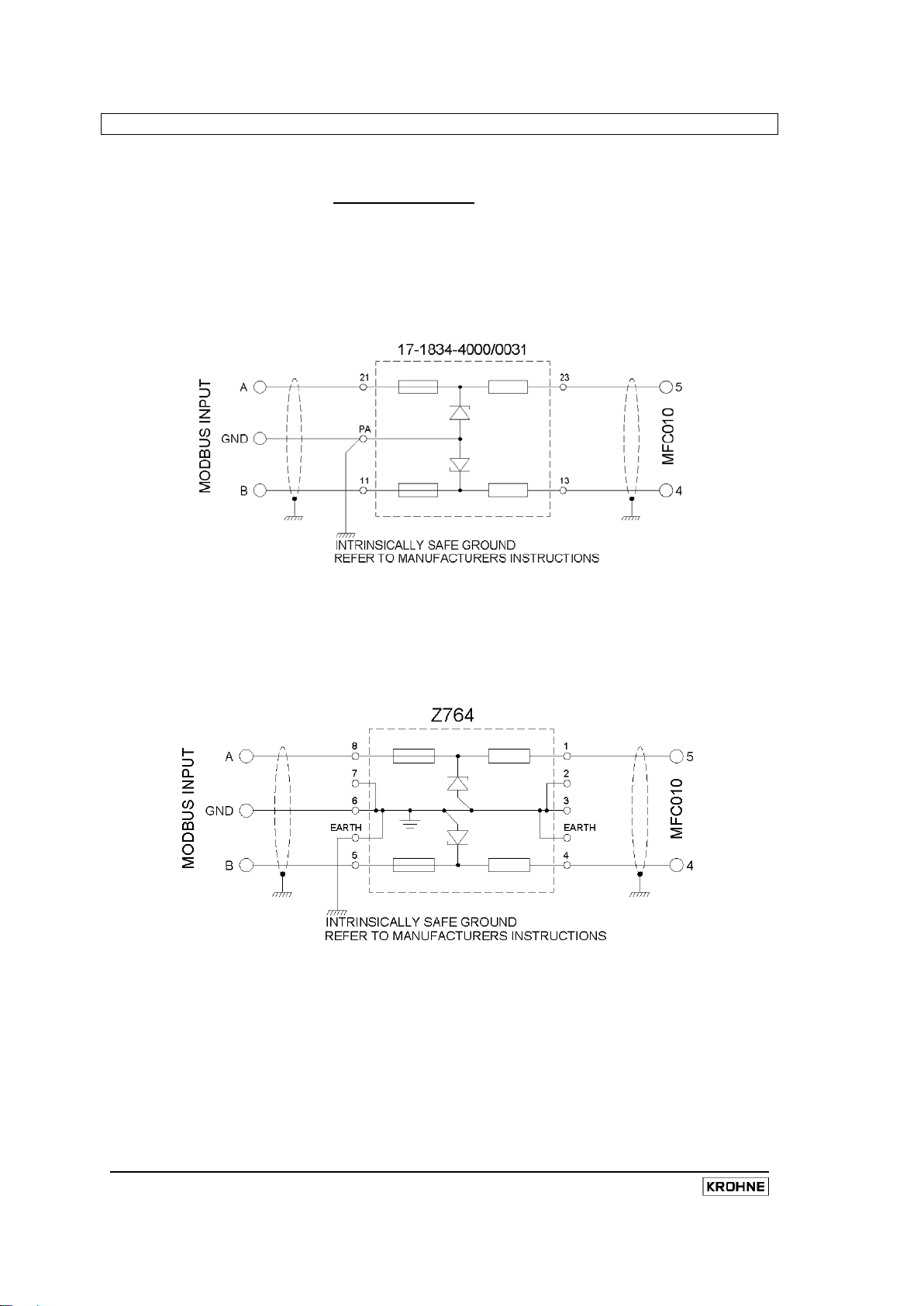

4.2 Modbus Barrier Devices

The following Zener Barrier devices are those that are recommended for use on the A & B Modbus input

connections to t he M FC010. W hen s pecifying al ternate dev ices t he us er m ust ens ure t hat t he i n-line

resistance of t he M odbus bar rier DOES NOT EXCEED 1000 O hms f or eac h of t he A and B I nput

terminals.

Manufacturer : Bartec

Part Number : 17-1834-4000/0031

Ex Approvals : EEx ia/ib IIC

Connection :

Manufacturer : Pepperl & Fuchs

Part Number : Z764

Ex Approvals : EEx ia IIC

FM and CSA Approved

Connection :

Page 19

17

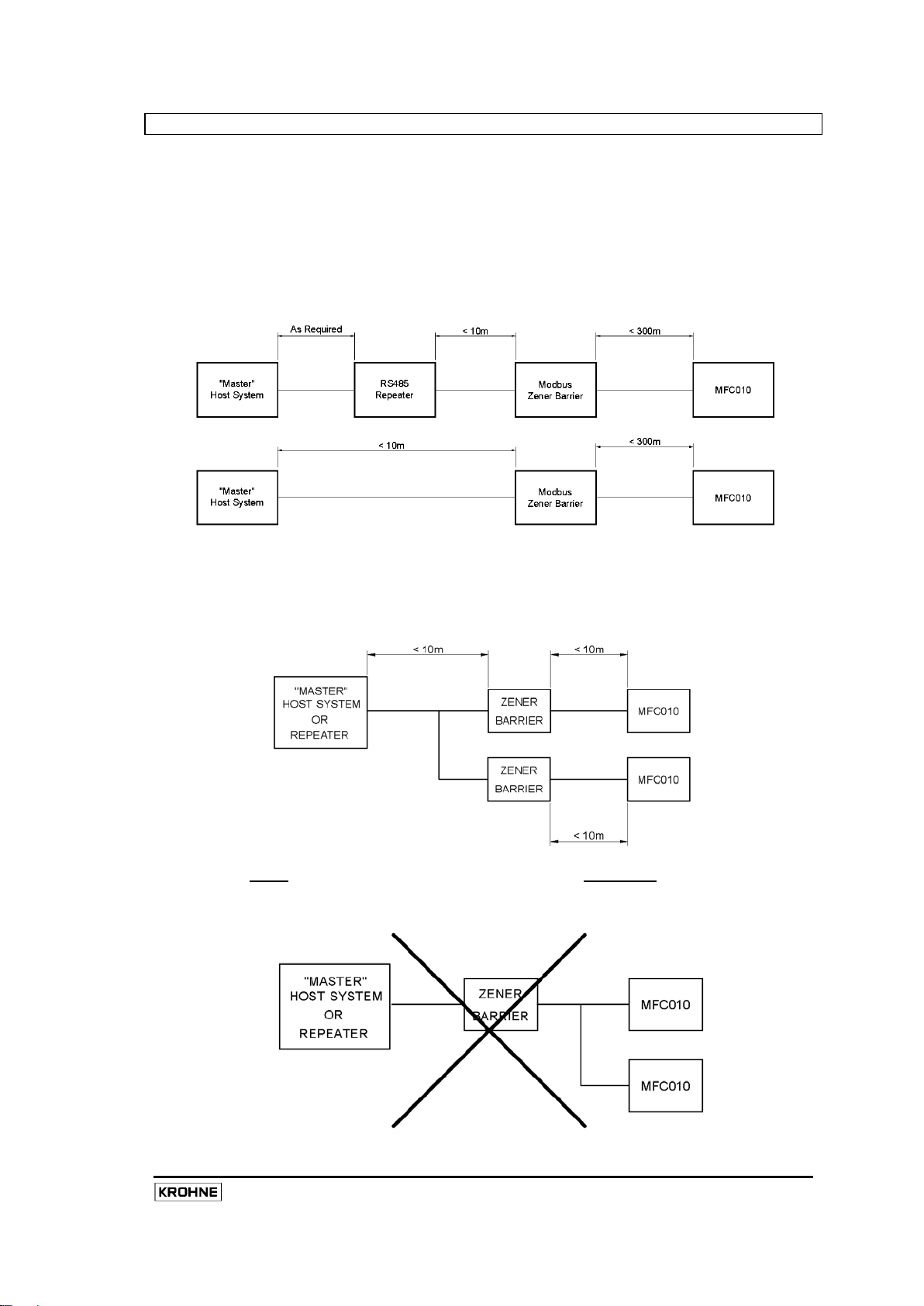

4.3 Connection To The Modbus Bus

When installed in hazardous area application the MFC010 i nterface i s not di rectly c ompatible w ith t he

Modbus interface standard due to the presence of the required Zener Barrier devices.

In a poi nt-to-point configuration, when the MFC010 is the only device on the bus, the cable length from

the barriers to the “Master” host system must not exceed 10m in length. If a greater distance is required,

the us e of a s uitable R S485 repeater is recommended, in which case the repeater connection to the

Zener B arrier dev ices s hould not ex ceed 10m i n l ength. T he m aximum c able l ength bet ween t he

Repeater and the “Master” host system is determined by the operating limits of those two devices. T he

cable length from the Modbus barrier device to the MFC010 must be less than 300m i.e.

Where the distance from the barrier device to the MFC010 is less than 10m, two barrier devices may be

connected in parallel to the “Master” host system, or the repeater if one is being used, refer to the diagram

below. The overall cable length from the Host/repeater to the barrier devices must still be less than 10m

as described previously. If more than two devices are required to be connected then a dedicated repeater

should be used for each.

Each MFC010 MUST have its own dedicated barrier interface; they MUST NOT be connected in parallel

on the hazardous area side of the system.

MFC010 Interface Manual

Page 20

18

MFC010 Interface Manual

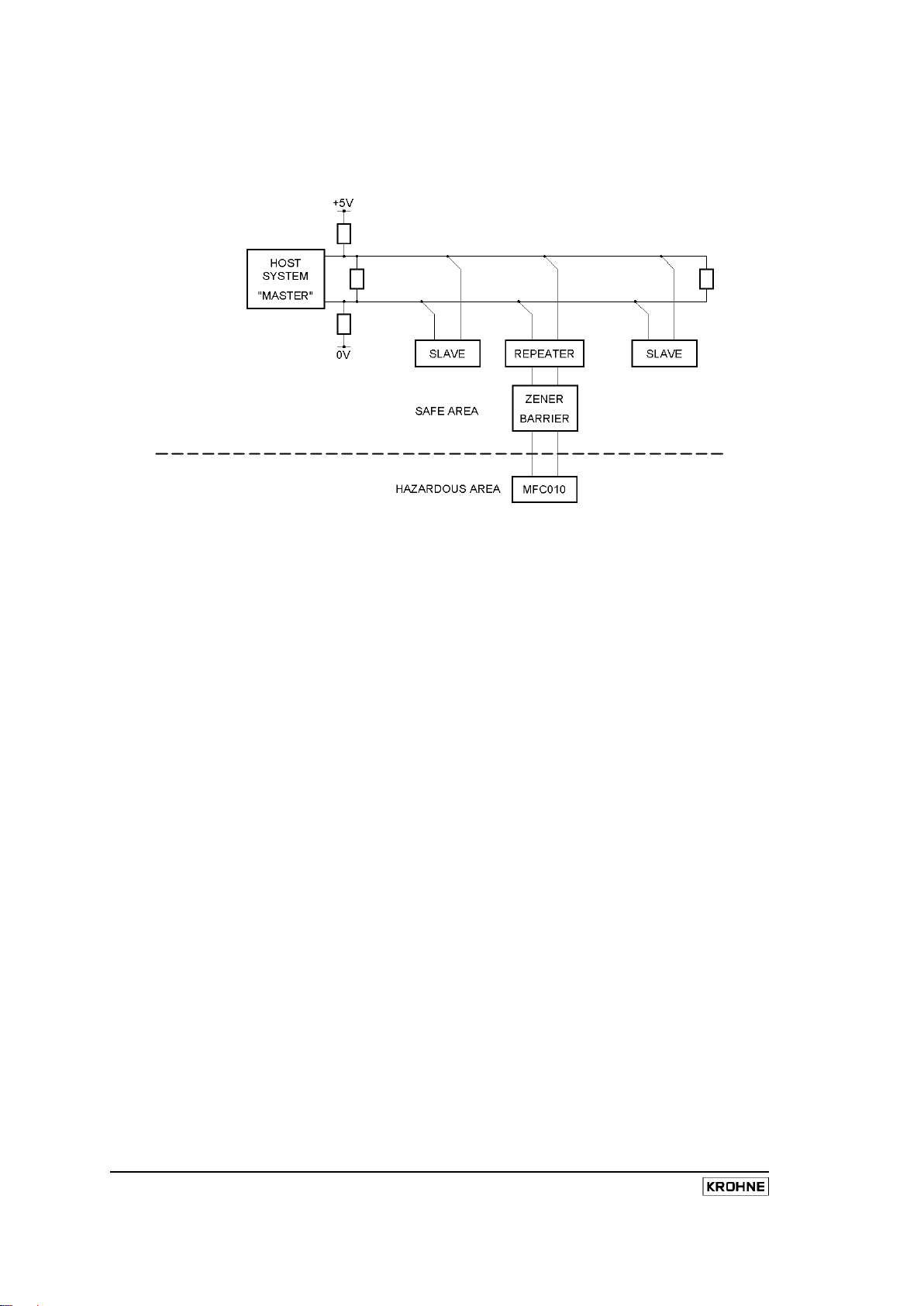

In a multidrop installation, see figure below, the Zener Barrier devices must be connected to the bus using

a s uitable R S485 repeater, with the c onnecting c able bet ween the Barrier devices and t he repeater not

exceeding 10m. The connection of the repeater to the Modbus bus must then follow the rules and

restrictions of the Modbus protocol as indicated previously in section 3.4.

Page 21

19

5. Modbus Protocol Interface

The interface to the MFC010 is implemented in the Modbus RTU communications pr otocol, and i s done

so in accordance with the specification and requirements of the “Modbus Protocol Reference Guide” (PIMBUS-300 R ev J ). The phy sical el ectrical par ameters of t he M odbus s pecification are def ined by the

EIA/TIA-485 (RS485) standard and t he “ Modbus ov er S erial Li ne - Specification and I mplementation

Guide V1.0” interface definition.

In a serial communications system such as the Modbus protocol, data is transmitted as a series of voltage

levels along the connecting data wires. A “bit”, or binary digit, value is determined by the logical level

(high or low) of the connecting interface over a set time period. The time period for each bit is determined

by the transmission speed, known as the baud rate. For a baud r ate of 9600, the bit period is 1/9600 =

104.2 m icroseconds. T he MFC010 supports Baud r ates of 1200, 2400, 4800, 9600, 19200, 38400 and

57600 baud (see the Baud rate setting in Holding Register No. 1005). The higher transmission speeds

require careful attention to the cable installation in order to function reliably and error free (see Section 3.2

on page 7 for installation details).

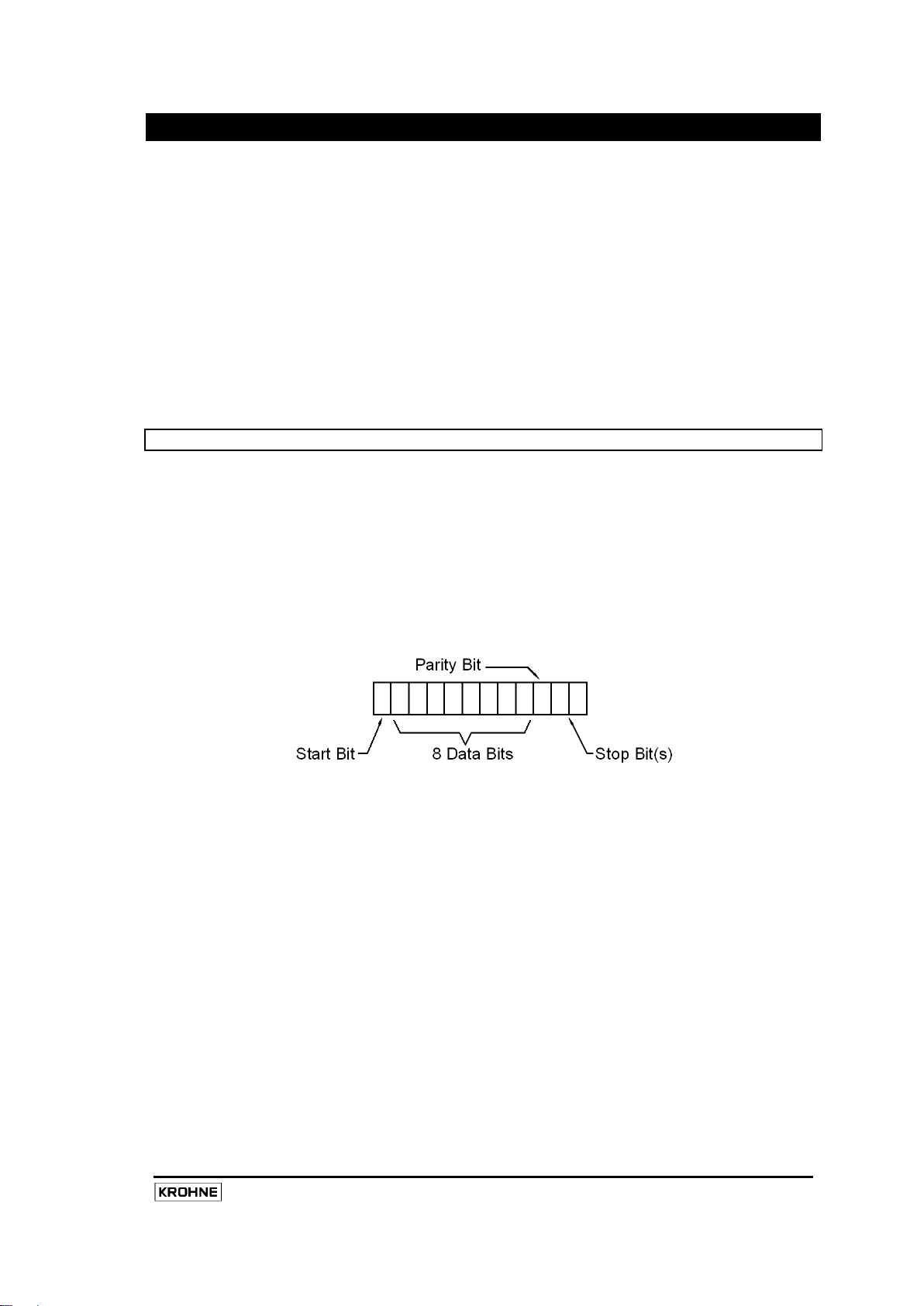

5.1 Character Transmission Format

Data is transmitted in sets of 8 bit data blocks, known as “Bytes” or “Characters”. Each character i s

preceded and followed by framing bits that permit the correct detection of the transmitted character. The

first “Bit” transmitted will be the “Start” bit, this permits the receiving device to detect that a character is

being transmitted. The “Start” bit is then followed by the 8-bit data byte. A “Parity” bit may then follow the

8-bit character. T his “Parity” bit is optional (see the Transmission format setting in Holding Register No.

1004), it allows the system to validate the c ontents of the 8-bit data byte to ensure that no er rors have

occurred during transmission. Following the “Parity” bit is the “Stop” bit that indicates the end of the

transmitted character to the receiving device. If no parity bit is used, two stop bits must be implemented,

this ensures a consistent character length of 11 bits is maintained.

The 8 dat a bits are annotated from bit 0 ( the least significant bit, LSB) to bi t 7 ( the most significant bit,

MSB). The character is transmitted “MSB first”, i.e. the first bit after the start bit, is bit 7 of the data byte.

See appendix B for more details on binary coding.

MFC010 Interface Manual

Page 22

20

MFC010 Interface Manual

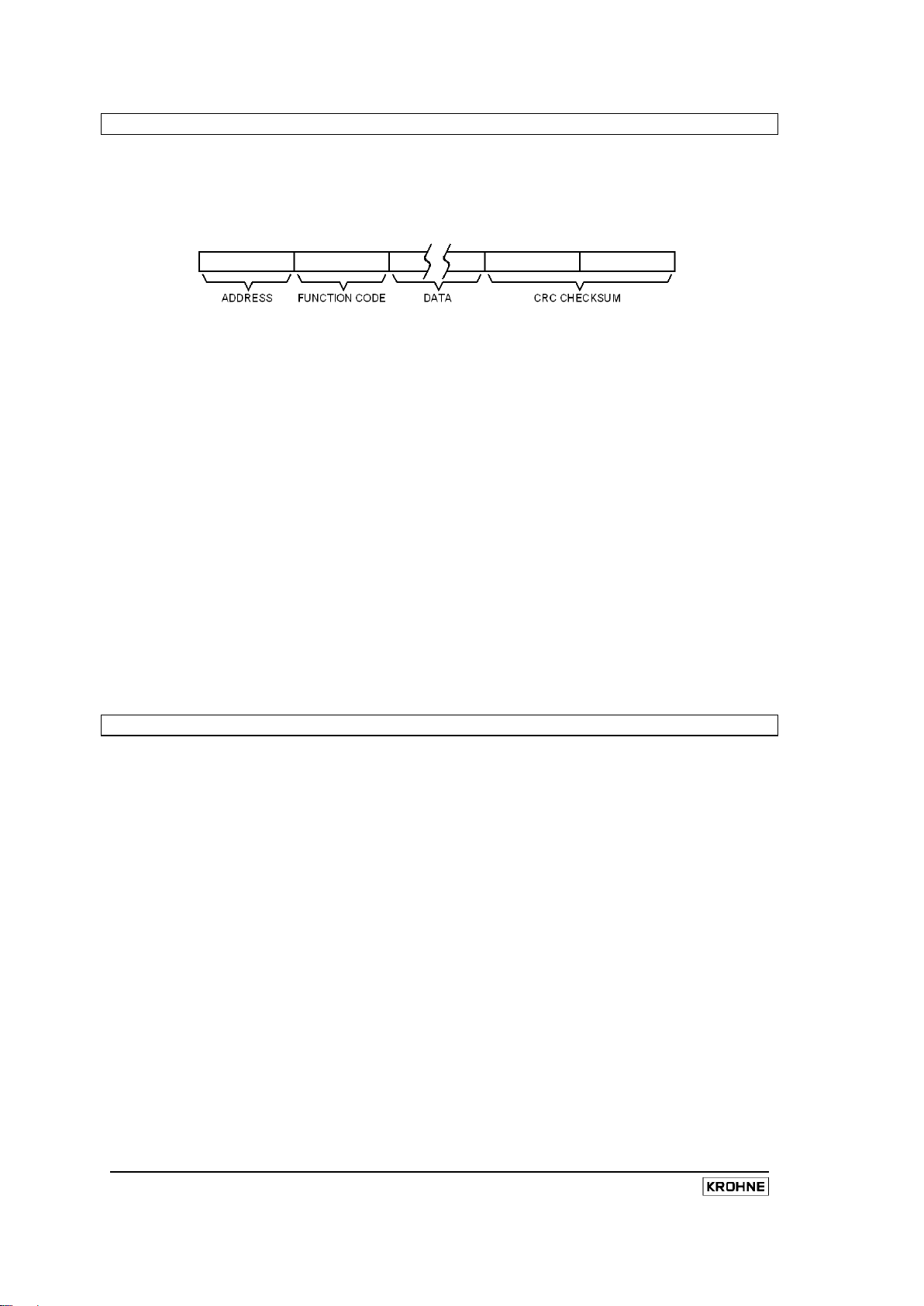

5.2 Modbus Telegram Format

The messages between the Modbus master and slave devices are transmitted as groups of characters,

as des cribed abov e, c ollectively k nown as t elegrams. E ach t elegram i s preceded and followed by a

“Quiet” period on t he Modbus bus of 3½ character periods. T he “Quiet” period following the telegram is

used to indicate the end of the telegram.

The first character received in the telegram identifies the slave device to which or from which the telegram

is bei ng t ransmitted. T his f irst c haracter i s k nown as t he S lave I D or S lave A ddress. In multidrop

configurations (see Section 5.4 below) this address character is used by the master device to individually

communicate with one of the instruments on the bus connection. T he Slave device returns this value to

indicate to the master the source of the response telegram. The Slave Address value for the MFC010 can

be set using Holding register No. 1006 (see Section 7.5).

The s econd character received in the telegram is the function command code r equested by the master

device. A list of the function codes supported by the MFC010 can be f ound in Section 6 (See Page 23)

along with a description of each.

The last two characters received form a 16 -bit checksum value. T his checksum value is used to ensure

that t he dat a r eceived i n t he t elegram has not been c orrupted. T he c hecksum i s calculated and

appended to the telegram by the transmitting device (Slave or Master) and the receiving device compares

the received checksum value against the value it calculates from the received data. If the data has been

corrupted in some way during transmission, then the checksum calculated by the receiving device will be

different than that which it received with the telegram. The receiving device will then ignore the telegram

knowing t hat t he dat a w ithin i s unr eliable. S ee A ppendix A for information on the Modbus Checksum

calculation.

Between t he function code character and t he CRC checksum at the end of the telegram is the telegram

data. The contents and format of these data characters is dependant upon the function code requested.

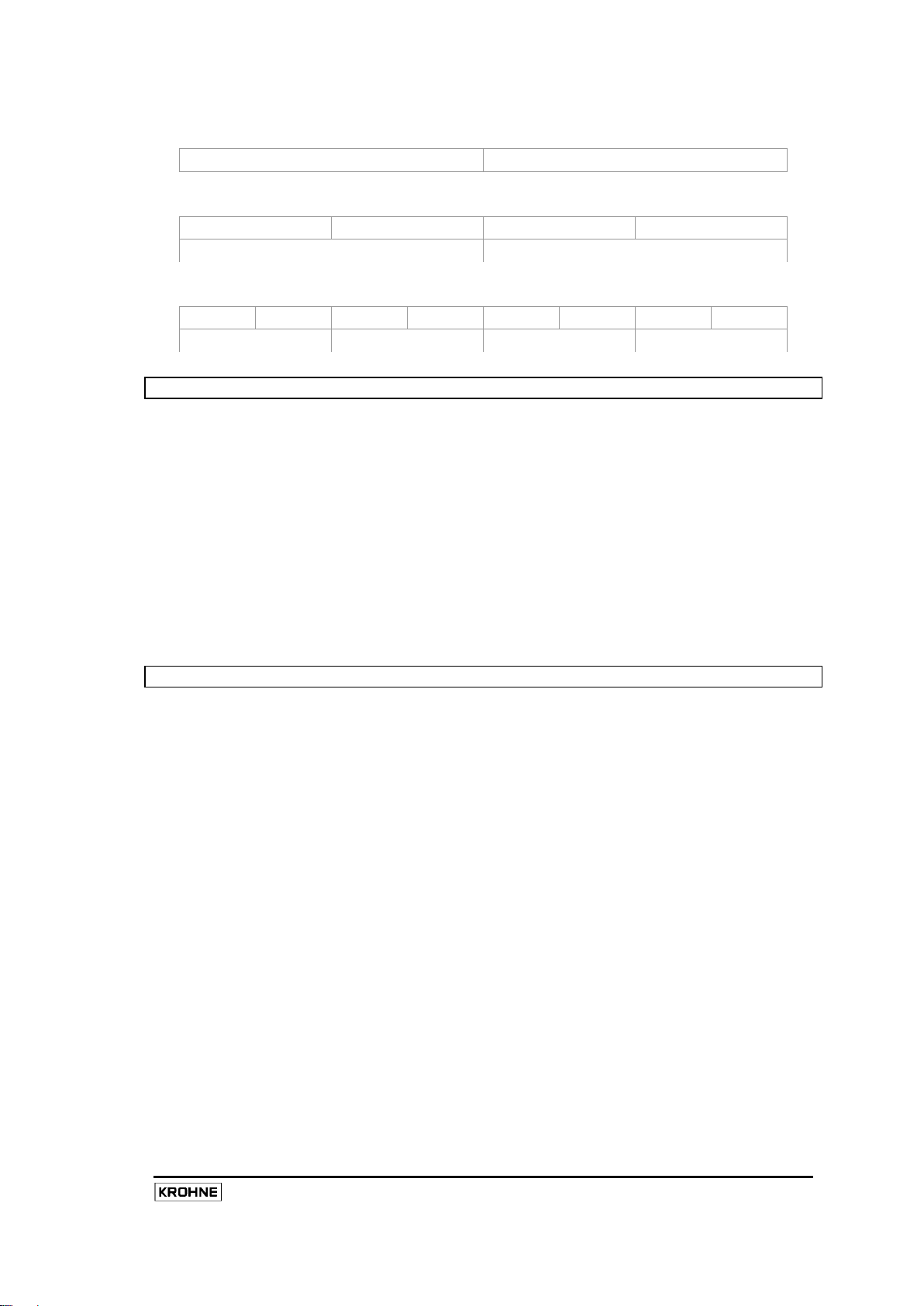

5.3 Data Types in Modbus

There are two data types used to transmit information on a Modbus data bus, the “Bit” and the “Register”.

The “Bit” represents a s ingle binary state, whether as an output or an input condition. The “Register” is a

16-bit integer transmitted as two 8-bit c haracters. U sing multiple “ Registers” the Modbus interface c an

transmit higher accuracy values such as “Floating Point” and “Double Precision Floating Point” numbers.

“Bit” variables are packed into 8 bit bytes, so each character sent or received can contain up t o 8 “ Bit”

variables. The Master and Slave devices use only as many 8 bit data characters as are required to

transmit the information. Any unused bits in the data characters are ignored. The bit that is first indexed

by the Master request address is transmitted in the LSB, Bit 0, of the first data character. T he next “Bit”

value i s t ransmitted i n t he nex t bi t, B it 1, of t he f irst dat a c haracter. T his c ontinues until the last bit

location, Bit 7, of the first data character is used. The next “Bit” value is then transmitted in the LSB, Bit 0,

of the following data character, this continues until all of the requested values have been transmitted. Any

unused bit locations in the last data character are filled out with “0”s

For simple single register variables the Most Significant Character of the register is transmitted first, with

the Least Significant character following i mmediately after. H owever, f or variables that r equire m ultiple

registers, i.e. the “Floating Point” and “Double Precision Floating Point” variables, the transmission order

is a little more complicated. i.e.

Page 23

21

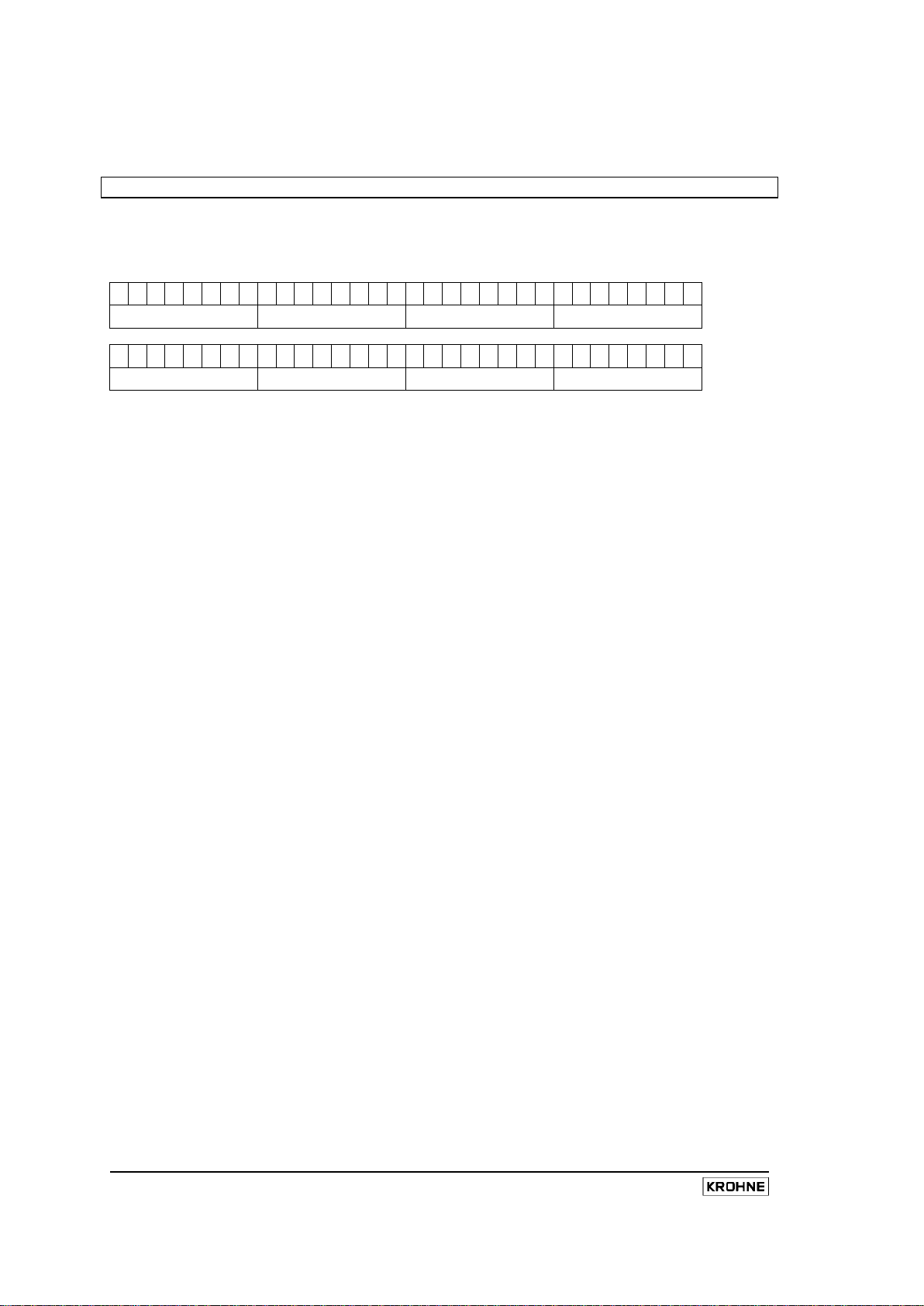

Single 16 Bit Register Variables, Data Transmission Order

Byte 1, MS Byte Byte 0, LS Byte

Long Integer & Floating Point Variables, Data Transmission Order

Byte 1 Byte 0, LS Byte Byte 3, MS Byte Byte 2

Requested Register Requested Register + 1

Double Precision Floating Point Variables, Data Transmission Order

1 0 3 2 5 4 7 6

Requested Register Register + 1 Register + 2 Register + 3

5.4 Multidrop Operation

A “Master” dev ice, s uch as a P C or P LC, c an be us ed t o control and i nterrogate a num ber of “ Slave”

devices, such as an MFC010, connected to the Modbus bus in a “Multidrop” configuration. The “Master”

device always initiates the communication interchange with the “Slave” devices, each of which waits for

instructions or requests from the “Master” before transmitting dat a on t he bus i n r esponse t o t he

instruction. Although the Modbus specification allows for up to 247 “Slave” devices to be physically

connected to the bus at any time, the Master device can only request information from one “Slave” device

at a time. A unique ID number or “Address” is allocated to each of the “Slave” devices to allow the

“Master” to differentiate between them. Although it does not matter in which order the “Slave” devices are

interrogated, the “Master” must wait for the response, or for a suitable period after the request, before

making a request to any other of the slave devices on the bus.

Under some limited conditions, i.e. when the instruction to the “Slave” device does not require a detailed

response, the “Master” device can send a “Broadcast” command, indicated by a “Slave” ID Address of “0”,

to all of the slave devices simultaneously.

5.5 Calculating Data Transmission Rates

Careful attention should be made to ensuring that the bus installation can support the amount and rate of

data t ransmission r equired. C onsideration of t he l imitations of the physical installation, as previously

described, s hould not be i gnored. T he m aximum us able t ransmission s peed, baud r ate, w ill depend

entirely upon the installation.

The transmission format also needs to be carefully considered. In the Modbus standard, each transmitted

character is 11 bi ts long, depending upon t he setting of the transmission f ormat. A t the Modbus default

transmission speed of 19200 baud, each character will have a transmission period of 573 microseconds.

For a simple data transfer of one Input value (see section 6.4 on page 26 for details) between the master

and slave will require an 8 character (+ 2 x 3½ character “Quiet” periods) telegram in the request from the

master, and a 9 character (+ 2 x 3½ character “Quiet” periods) telegram in the response from the slave. If

the Slave responds immediately the cycle from the Master sending the request to receiving the response

will be at least 31 characters long, or 17.8 milliseconds at 19200 baud. T herefore the maximum rate of

data requests that could be made is 56 every second.

In m ost c ases f ar m ore dat a w ill be required, and i n m ultidrop s ystems t he m aster dev ice m ay be

requesting data from up to 64 units. In these circumstances the user must ensure that there is sufficient

time i nterval bet ween r equests f or t he m easured v alues t o be received without overlapping the Master

request telegram with the previous slave reply telegram.

To achieve the required update rates the user may have to consider whether, in a multidrop configuration,

the number of devices on a bus must be l imited or whether the cable installation will support one of the

higher data transmission speeds which are available.

This is especially important where fast response is required (such as batch filling operations).

MFC010 Interface Manual

Page 24

22

MFC010 Interface Manual

5.6 Error Messages in Modbus

When t he M FC010 det ects an error i n t he r equest r eceived i n a pr operly f ormatted t elegram, i t w ill

respond with an error message. The error message response telegram is formatted as follows.

Address Function Error Code CRC CRC

The most significant bit of the requested function code is set (add 128, 80

) in the response telegram to

16

indicate that an error has been detected. For example, if an error were detected in a Function 1 request,

then the returned function code would be 81

(129).

16

The single data character in the response telegram will indicate the type of error detected. These are as

follows.

1 Illegal Function The requested function code is not supported by

the MFC010 or is not valid due to the current

settings of the device.

2 Illegal Data Address The Register requested is not valid.

3 Illegal Data Value The requested data (in Write operations only) is

invalid for the register being written.

6 Slave Device Busy The MFC010 is unable to process the requested

command because an EEPROM save is in progress.

Errors due t o c ommunications f aults ( CRC er rors, P arity er rors et c) ar e logged but no response is

returned because the data in the received telegram is deemed unreliable. T he Master system can read

the error logs by using the diagnostic command (Function 08, see Section 6.8).

Page 25

23

6. Modbus Functions Supported by the MFC010

6.1 01 (0116): Read Coil Status

This f unction permits the user to read the state of a number of consecutive Discrete Outputs, or “Coil”,

registers. Within the MFC010 the majority of the Discrete Outputs are used to initiate command functions;

when read, response will be “ 1” w hilst c ommand i s bei ng processed and “ 0 when t he c ommand i s

completed (See Section 7.2 on page 39 for details of the individual Status Output registers). The format

of the Master request telegram for this function should be as follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 0116 “Read Coil Status”

3 Start Address Hi 0316

4 Start Address Lo E916

5 No of Points Hi 0016

6 No of Point Lo 0516

7 CRC Lo 2D16

8 CRC Hi B916

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

Start Address = 1002

No. of Points = 5

( “Coils” 1002 – 1006 )

CRC Checksum

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0116 “Read Coil Status”

3 Data Bytes in Response 0116 1 byte (5 States requested < 8 Bits)

4 Data Byte 1 1516 Data = 000101012

5 CRC Lo 9016

6 CRC Hi 4716

The number of data bytes in the response will depend upon the number of Discrete Outputs requested.

The appropriate bit in each of the data bytes received will indicate each Discrete Output state requested.

Therefore, each data byte in the response will contain a maximum of 8 Discrete Output “Coil” states. For

example, if 19 Discrete Outputs are requested, then three data characters will be r eturned, with the first

group of 8 out put states encoded in the first data byte, the second group of 8 out put states coded in the

second data byte, and the last 3 output s tates coded in the first three bit locations of the last data byte.

Bit 0 of the first response data byte will c orrespond t o t he “ Start A ddress” D iscrete O utput r egister

specified by the request telegram. B it 0 of the second response data byte will correspond to the “Start

Address” + 8 Discrete Output register and so on.

In the example above, 5 Discrete Outputs are r equested, s o onl y one dat a by te i s r equired i n t he

response. The response data value shown above i ndicates t hat r egisters 1002, 1004 and 1006 ar e

active, and that registers 1003 and 1005 are inactive.

CRC Checksum

MFC010 Interface Manual

Page 26

24

MFC010 Interface Manual

6.2 02 (0216): Read Discrete Input

This function permits the user to read the state of a number of consecutive Discrete Input registers. (See

Section 7.3, on page 41, for details of the individual registers). The format of the Master request telegram

for this function should be as follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 0216 “Read Discrete Input”

3 Start Address Hi 0316

4 Start Address Lo E816

5 No of Points Hi 0016

6 No of Point Lo 0C16

7 CRC Lo F816

8 CRC Hi 7F16

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

Start Address = 1001

No. of Points = 12

( “Inputs” 1001 – 1011 )

CRC Checksum

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0216 “Read Discrete Input”

3 Data Bytes in Response 0216 2 bytes

4 Data Byte 1 CD16 Data = 110011012

5 Data Byte 2 0916 Data = 000010012

6 CRC Lo 2D16

7 CRC Hi 2E16

The num ber of dat a by tes i n t he r esponse will depend upon the number of Discrete Inputs requested.

The appropriate bit in each of the data bytes received will indicate each Discrete Input state requested.

Therefore, each data by te i n t he r esponse w ill c ontain a m aximum of 8 di screte i nput s tates. F or

example, if 19 Discrete Inputs are requested, then three data characters will be returned, with the first

group of 8 input states encoded in the first data byte, t he s econd gr oup of 8 i nput states c oded i n t he

second data byte, and the last 3 input states coded in the first three bit locations of the last data byte. Bit

0 of the first response data byte will correspond to the “Start Address” Discrete Input register specified by

the request telegram. B it 0 of the second response data byte will correspond to the “Start Address” + 8

Discrete Input register and so on.

In the example above, 12 Discrete Inputs are requested, so two data bytes are required in the response.

CRC Checksum

Page 27

25

6.3 03 (0316): Read Holding Registers

This f unction per mits t he us er t o r ead t he v alue of a number of consecutive Holding registers. (See

Section 7.5 on page 49 for details of the individual registers). The format of the Master request telegram

for this function should be as follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 0316 “Read Holding Registers”

3 Start Address Hi 0316

4 Start Address Lo FE16

5 No of Points Hi 0016

6 No of Point Lo 0316

7 CRC Lo 6416

8 CRC Hi 7F16

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

Start Address = 1023

No. of Points = 3

( Input Registers 1023 – 1025 )

CRC Checksum

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0316 “Read Holding Registers”

3 Data Bytes in Response 0616 6 bytes ( 3 x 2 Byte Registers )

4 Data Byte 1 3F16

5 Data Byte 2 4916

6 Data Byte 3 0216

7 Data Byte 4 D416

8 Data Byte 5 F116

9 Data Byte 6 2216

10 CRC Lo 7D16

11 CRC Hi BD16

Register 1023 = 16201

Register 1024 = 724

Register 1025 = 61730

CRC Checksum

MFC010 Interface Manual

Page 28

26

MFC010 Interface Manual

6.4 04 (0416): Read Input Registers

This function permits the user to read the value of a number of consecutive Input registers. (See Section

7.5 on page 493 for details of the individual registers). The format of the Master request telegram for this

function should be as follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 0416 “Read Input Registers”

3 Start Address Hi 0B16

4 Start Address Lo B816

5 No of Points Hi 0016

6 No of Point Lo 0216

7 CRC Lo F316

8 CRC Hi CA16

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

Start Address = 3001

No. of Points = 2

( Input Registers 3001 – 3002 )

CRC Checksum

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0416 “Read Input Registers”

3 Data Bytes in Response 0416 4 bytes ( 2 x 2 Byte Registers )

4 Data Byte 1 9416

5 Data Byte 2 7B16

6 Data Byte 3 4216

7 Data Byte 4 9616

8 CRC Lo 1716

9 CRC Hi 6316

In t he ex ample abov e t he I nput r egister r equested c ontains a f loating poi nt num ber and needs to be

accessed as a pai r of r egisters ( 3001/3002). T he r esulting 4 by tes i n t he dat a r esponse c an t hen be

decoded into a floating-point number (See Section 5.3 on page 20 and Appendix C on page 93 for further

details on encoding and decoding floating point numbers).

Register 3001 / 3002 = 75.29

CRC Checksum

Page 29

27

6.5 05 (0516): Force Single Coil

This function permits the user to set the state of a single Discrete Output “Coil” register. (See Section 7.2

on page 39 for det ails of t he i ndividual r egisters). I n t he M FC010 implementation, these registers are

used t o i nitiate c ommands and functions. S etting t he O utput s tate i nitiates t he f unction, at tempting t o

clear t he O utput s tate w ill r esult i n a dat a er ror. The format of the Master request telegram for this

function should be as follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 0516 “Force Single Coil”

3 Coil Address Hi 0316

4 Coil Address Lo E816

5 Force Data Hi FF16

6 Force Data Lo 0016

7 CRC Lo 0C16

8 CRC Hi 4A16

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

Coil Address = 1001

Set Coil “Active”

CRC Checksum

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0516 “Force Single Coil”

3 Coil Address Hi 0316

4 Coil Address Lo E816

5 Force Data Hi FF16

6 Force Data Lo 0016

7 CRC Lo 0C16

8 CRC Hi 4A16

The MFC010 (slave) response telegram should be an exact duplicate of the master request telegram.

Coil Address = 1001

Set Coil “Active”

CRC Checksum

MFC010 Interface Manual

Page 30

28

MFC010 Interface Manual

6.6 06 (0616): Preset Single Register

This function permits the user to set the value of a single Holding register. For this reason this command

cannot be used to write to variables that occupy multiple consecutive registers such as floating point and

long integer v ariables (See Section 7.5 on page 49 for details of the individual registers). The format of

the Master request telegram for this function should be as follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 0616 “Preset Single Register”

3 Register Address Hi 0316

4 Register Address Lo FB16

5 Preset Data Hi 0016

6 Preset Data Lo 2316

7 CRC Lo B916

8 CRC Hi A616

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

Register Address = 1020

Set Register 1020 = 35

CRC Checksum

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0616 “Preset Single Register”

3 Register Address Hi 0316

4 Register Address Lo FB16

5 Preset Data Hi 0016

6 Preset Data Lo 2316

7 CRC Lo B916

8 CRC Hi A616

The MFC010 (slave) response telegram should be an ex act dupl icate of t he m aster r equest

Register Address = 1020

Set Register 1020 = 35

CRC Checksum

Page 31

29

6.7 07 (0716): Read Exception Status

When the Master device requests this command function, the MFC010 will respond with a single 8 bit

data character summarizing the status of the instrument. The Master query telegram format is.

Request

Character

Field For Example

1 Slave Address 0116 Request to Slave ID 1

2 Function 0716 “Read Exception Status”

3 CRC Lo 4116

4 CRC Hi E216

CRC Checksum

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0716 “Read Exception Status”

3 Status 3D16 Data = 001111012

4 CRC Lo E316

5 CRC Hi E116

CRC Checksum

The Status character received in the response will be formatted as follows :

Bit 0

(LSB)

Bit 1

System State : 00

01

10

11

= Measuring,

2

= Standby,

2

= Stop,

2

= Start-up.

2

Bit 2 EEPROM Save Status : 0 = All Data Saved to EEPROM

1= Data Write to EEPOM Pending

Bit 3 Process Control Status :

0 = Process Control Inactive (Control Condition Invalid)

1 = Process Control Active (Control Condition Valid)

Bit 4 Zero Calibration Status : 0 = Zero Calibration OK

1 = Zero Calibration Error

Bit 5 Density Calibration Status : 0 = Density Calibration OK

1 = Density Calibration Error

Bit 6 Process Warning Status : 0 = No Process Warning Flag(s) Detected

1 = Process Warning Flag(s) Detected

Bit 7 (MSB) System Error Status : 0 = No System Error Flag(s) Detected

1 = System Error Condition Flag(s) Detected

MFC010 Interface Manual

Page 32

30

MFC010 Interface Manual

6.8 08 (0816): Diagnostics

This command function permits the user to per form one of s everal di agnostic oper ations, s uch as

retrieving t he er ror and ev ent l ogs. F or f urther det ails on t his c ommand function, refer to the Modbus

specification.

6.9 11 (0B16): Fetch Comm. Event Counter

This f unction allows the master device to det ermine i f r equest telegrams are being properly processed.

The Event count returned is a count of the number of request telegrams which have been received and

processed without errors occurring. By fetching the Event count before and after a series of messages the

master can determine whether the messages were handled normally. When the Master device requests

this command function the MFC010 will respond with a two character (16 bit) status value and a two

character event count. The Master request telegram should be formatted as follows.

Request

Character

Field For Example

1 Slave Address 0116 Request to Slave ID 1

2 Function 0B16 “Fetch Comm. Event Counter”

3 CRC Lo 4116

4 CRC Hi E716

CRC Checksum

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 0B16 “Fetch Comm. Event Counter”

3 Status Hi FF16

4 Status Lo FF16

5 Count Hi 1E16

6 Count Lo D316

7 CRC Lo EC16

8 CRC Hi 1216

Instrument Status

Event Count = 7891

CRC Checksum

The s tatus value is either FFFF

, i n w hich case the slave is still processing a c ommand, or 000016, i n

16

which case the slave is ready to receive the next command request.

Page 33

31

6.10 16 (1016): Preset Multiple Registers

This function permits the user to set the v alue of a num ber of c onsecutive H olding r egisters. T his

command function must be used to write to variables which occupy multiple consecutive registers such as

floating point and long integer variables (See Section 7.5 on page 49 for details of the individual

registers). Some of the Variables which occupy single (16 bit) registers c annot be s et us ing t his

command, the Password registers (1001-1003) in particular. Command Function 06 (06

) must be used

16

to set these registers. The format of the Master request telegram for this function should be as follows.

Request

Character

Field For Example

1 Slave Address 0116 Request to Slave ID 1

2 Function 1016 “Preset Multiple Registers”

3 Starting Address Hi 0316

4 Starting Address Lo FB16

5 No. of Registers Hi 0016

6 No. of Registers Lo 0216

Starting Register Address = 1020

Number of Registers = 2

7 Byte Count 0416 No of Bytes = 4 ( 2 x 2 )

8 Data Hi 0016

9 Data Lo 1116

10 Data Hi 0016

11 Data Lo 1216

12 CRC Lo 7916

13 CRC Hi A016

Set Register 1020 = 17

Set Register 1021 = 18

CRC Checksum

The MFC010 will respond to such a request with a telegram formatted as follows.

Response

Character

Field For Example

1 Slave Address 0116 Response from Slave ID 1

2 Function 1016 “Preset Multiple Registers”

3 Starting Address Hi 0316

4 Starting Address Lo FB16

5 No. of Registers Hi 0016

6 No. of Registers Lo 0216

7 CRC Lo 3016

8 CRC Hi 7D16

Starting Register Address = 1020

Number of Registers = 2

CRC Checksum

MFC010 Interface Manual

Page 34

32

MFC010 Interface Manual

6.11 17 (1116): Report Slave ID

The Report Slave ID command is useful to retrieve all of the identification information from the s ystem

with one simple short request. The master request telegram should be 4 bytes long and formatted as

follows.

Request

Character

1 Slave Address 0116 Request to Slave ID 1

2 Function 1116 “Report Slave ID”

3 CRC Lo C016

4 CRC Hi 2C16

The M FC010 r esponse t elegram w ill be 57 c haracters l ong (including the two CRC checksum bytes

appended to the telegram) and is structured as follows.

Response

Character

1 Slave Address 0116 Response from Slave ID 1

2 Function 1116 “Report Slave ID”

3 Byte Count 3416 “No of bytes in Reply “ = 52

4 Device ID 0016 00 = MFC010

5 Run Indicator FF16 0 = Off , FF16 = On

6 Sensor Type (See Holding Register No. 1012)

7 Sensor Size (See Holding Register No. 1013)

8 Sensor Material (See Holding Register No. 1014)

9 – 20 Software Version - 12 Character ASCII String

21 – 34 Software Number - 14 Character ASCII String

35 – 46 Software Compilation Date - 12 Character ASCII String

47 – 49 MFC010 Serial Number – 24 bit Integer (Most Significant Byte First)

50 – 52 Sensor Serial Number – 24 bit Integer (Most Significant Byte First)

53 - 55 System Serial Number – 24 bit Integer (Most Significant Byte First)

56 CRC Lo

57 CRC Hi

Field For Example

CRC Checksum

Field For Example

CRC Checksum

Page 35

33

7. MFC010 Modbus Data Model

7.1 MFC010 Register Structure

The register s tructure f or t he M FC010 begi ns w ith r egister 1001 in al l r egister t ypes ( Discrete O utput,

Discrete I nput, Input Register and H olding Register). T he di fferent variable types (integer, float, double

etc) have been arranged into groups of the same data type spread over the entire permitted register

address range.

It is not permissible, within this implementation of the MFC010 Modbus interface, to retrieve registers

containing different data types within the same request t elegram. A ttempts t o ac hieve t his w ill be

responded to with an “Illegal Data Address” exception error (See Section 5.6 on page 22).

Large gaps hav e been l eft bet ween t hese gr oups of dat a t ypes i n or der t o per mit ex pansion of the

MFC010 interface and compatibility with future high performance converters.

Data variables which require more than one register (e.g. a 4 byte “Float” requires two 2 byte registers to

transmit it) will occupy the number of consecutive registers needed to hold the variable. For example if a

floating point variable is contained in Register 3001, this will also fill register 3002. For this reason any

attempt t o r ead 3002 di rectly w ill be r esponded t o w ith an “Illegal Data Address” ex ception error ( See

Section 5.6 on page 22). This is the same for both Long Integers (which also require 2 consecutive 2 byte

registers to hold 4 bytes) and Double Precision Floating Point Numbers (which require 4 c onsecutive 2

byte registers to hold the 8 byte format of the Double Float).

In addi tion, w hen accessing these multi-register variables, the user must request the correct multiple of

registers. i .e. w hen ac cessing F loating P oint and Long i nteger v ariables, the number of registers

requested must be a multiple of 2, and when requesting Double Precision floating point variables the

number of registers requested must be a multiple of 4. Requesting variables with the incorrect multiple of

registers will again result in an “Illegal Data Address” exception error (See Section 5.6 on page 22). For

example if a request was made to a group of floating point variable register locations but only 3 registers

were requested, then the exception error would be returned.

Some of t he f ollowing r egisters ar e pr otected by t he “Service” password to prevent accidental or unauthorised changes to key configuration values, specifically the sensor calibration settings, these registers

are indicated by the following symbol.

.

For details on t he operation and de -activation of the Service Password see section 8.5

registers are protected by a Custody Transfer Password for use when the M FC010 is used in Custody

transfer applications, see section 8.9 on page 78. These registers are indicated by the CT symbol.

Holding registers marked RO are “Read Only”.

The following is a summary of the MFC010 register s tructure, t he details of which are explained in t he

following sections.

MFC010 Interface Manual

. S imilarly, some

Page 36

34

MFC010 Interface Manual

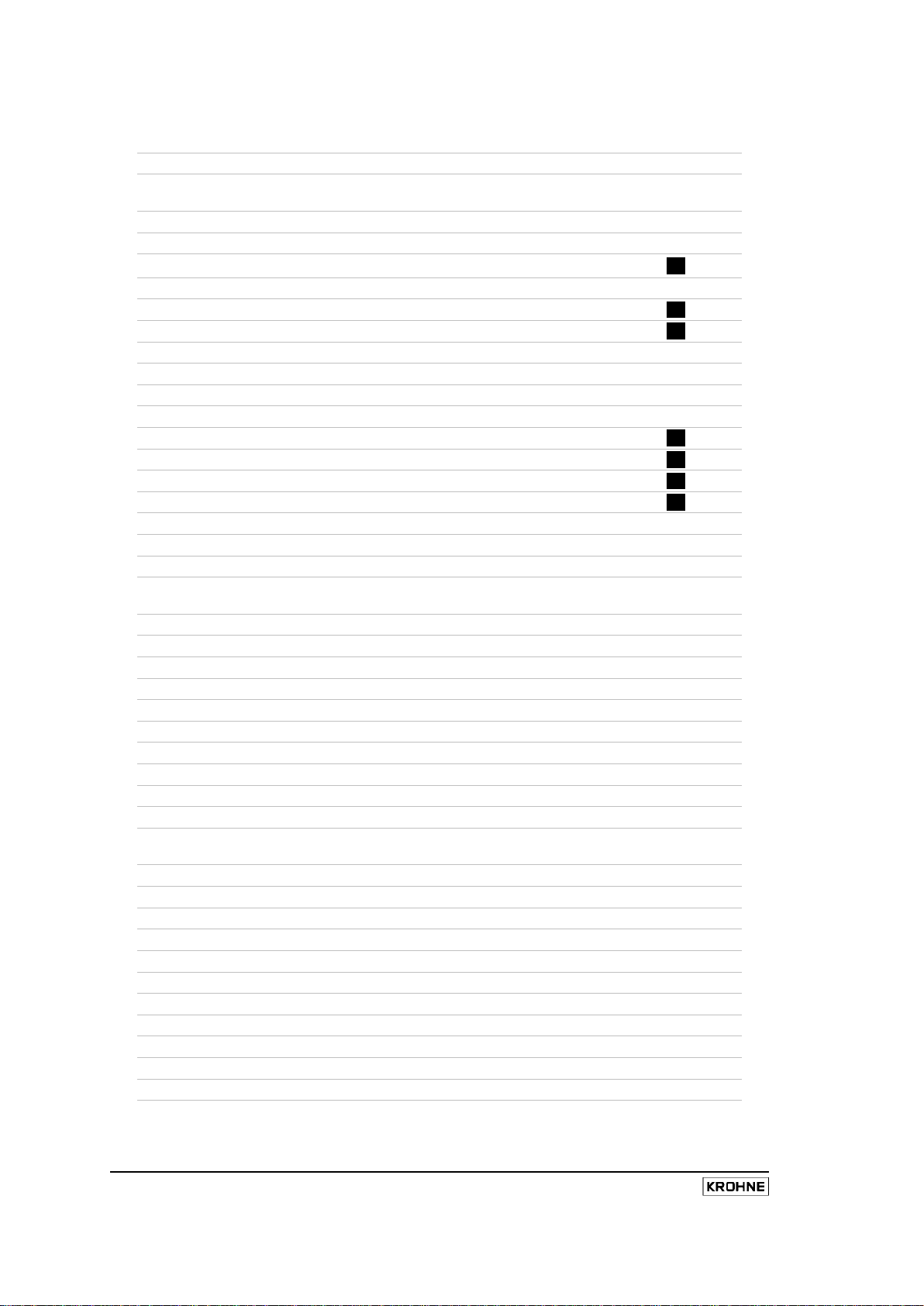

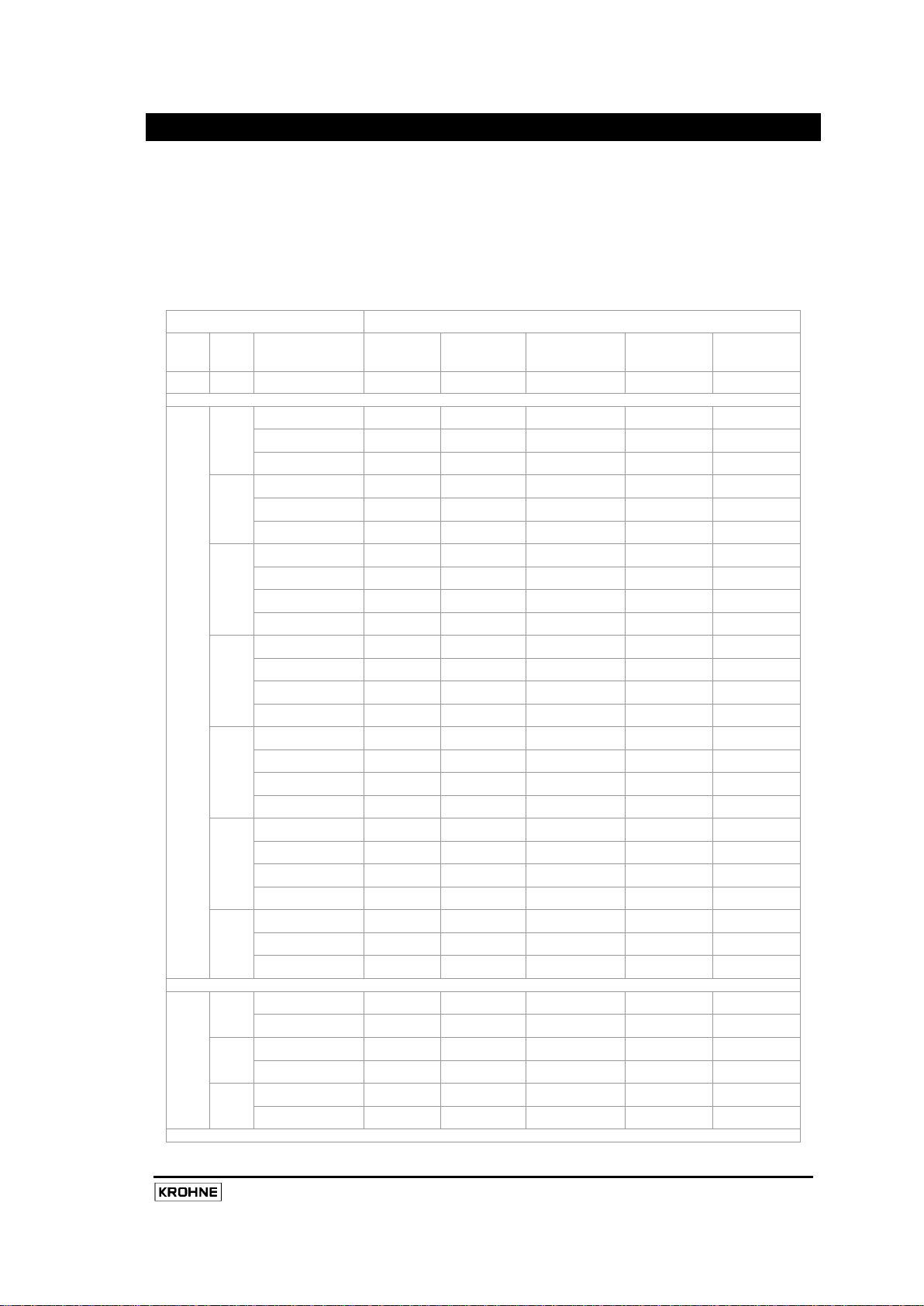

Discrete Output (Binary) States (and Commands)

0XXXX Registers, Accessed Using Commands 01 and 05

CT

CT

CT

CT

CT

CT

Discrete Input (Binary) States

1XXXX Registers, Accessed Using Command 02

Input Registers

3XXXX Registers, Accessed Using Command 04

Floating Point Values (Accessed in pairs of registers)

Register Description

1001 Save Changes to EEPROM

1002 Begin Zero Calibration

1003 Reset Totalisers

1004 Reset Additional Totaliser

1005 Request STANDBY Mode

1006 Request STOP Mode

1007 Request MEASURE Mode

1008 Reset Errors

1009 Reset W arnings

1010 Discard Previous Write Operations

1011 Initiate Single Point Density Calibration

1012 Initiate Two Point Density Calibration

1013 Continue Two Point Density Calibration

1014 Reset to Factory Density Calibration

1015 Save Changes to EEPROM with Mass Total

1016 Save Changes to EEPROM with Volume Total

CT

1001 Supervisor Lock Password State

1002 Service Lock Password State

1003 Custody Transfer Lock Password State

1004 Parameters Changed, Awaiting “Save Changes to EEPROM

1005 System Error Flag

1006 Process Warning Flag

1007 Density Calibration Status

1008 Mass Flow Zero Calibration Status

1009 Process Control Status

Single Registers (16 bit Integer Values)

1001 Sensor A Level

1002

1003

1004 System State

1005 DCF1

1006 DCF5

Sensor B Level

Drive Level

3001 Mass Flow

3003 Density

Page 37

35

Register Description

Holding Registers

4XXXX Registers, Accessed Using Commands 03, 06 and 16 (* Command 03 and 06 Only)

3005 Temperature

3007 Volume Flow

3009 Concentration 1 Flow

3011 Concentration 2 Flow

3013 Concentration 1

3015 Concentration 2

3017 Velocity

3019 Mass Total

3021 Volume Total

3023 Concentration 1 Total

3025 Concentration 2 Total

3027 Additional Total

3029 Tube Frequency

3031 Measuring Tube Strain

3033 Inner Cylinder Strain

3035 DCF2

3037 DCF3

3039 DCF4

3041 DCF6

3043 DCF7

3045 DCF8

3047 Zero Calibration Percent

3049 Maximum Instrument Temperature

3051

3053 2 Phase Signal

Double Precision Floating Point Values (Accessed in groups of four registers)

5001 Mass Total

5005 Volume Total

5009 Concentration 1 Total

5013 Concentration 2 Total

5017 Additional Total

Long Integer Values (Accessed in pairs of registers)

7001 System Error Flags

7003 Process Warning Flags

7005 Stored System Error Flags

7007 Stored Process Warning Flags

Minimum Instrument Temperature

Single Registers (16 bit Integer Values)

1001 Supervisor Lock Password*

1002 Service Lock Password*

1003 Custody Transfer Lock Password*

1004 Modbus Communications Format

MFC010 Interface Manual

Page 38

36

MFC010 Interface Manual

Register Description

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

CT

RO

RO

CT

CT

CT

CT

CT

1005 Modbus Communications Baud rate

1006 Modbus Communications Address

1007 Flow Direction

1008 Flow Mode

1009 Internal Process Control Function

1010 Internal Process Control Condition

1011 Concentration 1 Function

1012 Sensor Type

1013 Sensor Size

1014 Sensor Material

1015 Tube Amplitude

1016 Concentration Type

1017 Concentration 1 Product

1018 Concentration Coefficient 5

1019 Density Mode

1020 Mass Flow Units

1021 Density Units

1022 Mass Total Units

1023 Volume Total Units

1024 Volume Flow Units

1025 Temperature Units

1026 Velocity Units

1027 Additional Totaliser Source

1028 Density Calibration Product Type

1029 Concentration 2 Function

1030 Concentration 2 Product

1031 CF25

1032 Year of Manufacture

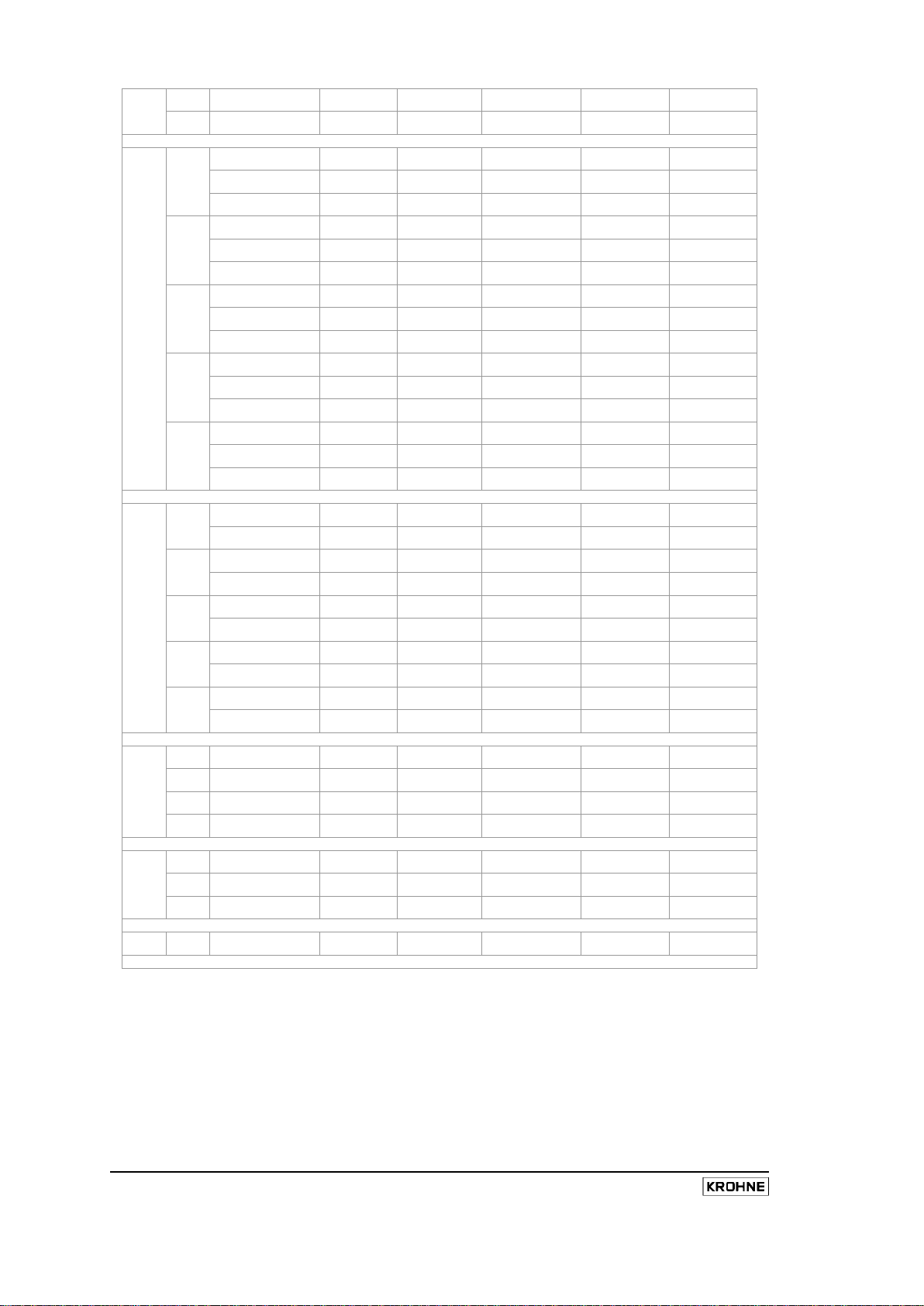

Floating Point Values (Accessed in pairs of registers)

3001 CF1

3003 CF2

3005 CF3

3007 CF4

3009 CF5

3011 CF6

3013 CF7

3015 CF8

3017 CF9

3019 CF10

3021 CF11

3023 CF12

3025 CF13

3027 CF14

3029 CF15

3031 CF16

CT

CT

CT

CT

Page 39

37

Register Description

CT

CT

CT

CT

CT

CT

CT

RO

CT

CT

CT

CT

CT

CT

CT

3033 CF17

3035 CF18

3037 CF19

3039 CF20

3041 Meter Correction

3043 Pipe Diameter

3045 Measurement Time Constant

3047 Low Flow Threshold

3049 User Flow Offset

3051 Internal Process Control Maximum Limit

3053 Internal Process Control Minimum Limit

3055

3057 Fixed Density Value

3059

3061

3063

3065

3067 Concentration Coefficient 6

3069

3071

3073

3075

3077 Concentration Coefficient 11

3079

3081

3083

3085

3087 User Defined Mass Flow Units Scaling

3089

3091

3093

3095 Temperature During Last Zero Calibration

3097 Maximum Sensor Temperature Specification

3099 Minimum Sensor Temperature Specification

3101 Pressure Suppression Duration

3103 Pressure Suppression Cut-off

3105 Density Averaging

3107 Concentration 2 Offset

3109 CF21

3111 CF22

3113 CF23

3115 CF24

3117 CF26

3119 CF27

3121 2 Phase W arning Level

Referred Density Reference Temperature

Referred Density Slope

Concentration Coefficient 2

Concentration Coefficient 3

Concentration Coefficient 4

Concentration Coefficient 7

Concentration Coefficient 8

Concentration Coefficient 9

Concentration Coefficient 10

Concentration Coefficient 12

Concentration 1 Offset

User Defined Mass Total Units Scaling

User Defined Volume Total Units Scaling

User Defined Volume Flow Units Scaling

User Defined Density Units Scaling

Calibration Density

CT

CT

MFC010 Interface Manual

Page 40

38

MFC010 Interface Manual

Register Description

CT

CT

CT

Long Integer Values (Accessed in pairs of registers)

7001 MFC010 Serial Number

7003 System Serial Number

7005 Meter Serial Number

7007 Enable Concentration Calculation

Page 41

39

CT

to any 1 of the 3 coils will clear the other 2.

7.2 Discrete Status Output “Coil” Registers

The discrete Status Output, or “Coil”, registers are used by the MFC010 to initiate special functions and

operations. When read, the values are meaningless and in most cases are just returned by the MFC010

as 0. Some of the oper ations r equire a m ore det ailed explanation; this c an be f ound l ater i n t his

document in Section 8.

Use Modbus command number 01 to read the state of these registers ( see section 6.1 on page 23 ) and

Modbus command number 05 to activate the output register/command ( see section 6.5 on page 27 ).

Register No.

1001

1002

1003

1004

1005

CT

1006

CT

Description

Save Changes to EEPROM

- Store the configuration changes made into the non-volatile memory. See Section

8.6 on page 77 for a more detailed explanation of saving and restoring configuration

settings.

Begin Zero Flow Calibration

– Initiate a calibration of the zero flow offset. See Section 8.1 on page 71 for further

details. Reads value “1” when zero calibration in process and “0” when complete.

Reset Totalisers

– Resets all Totaliser values.

Reset Additional Totaliser

– Reset the Additional Totaliser.

Request STANDBY Mode

– Place the instrument into “Standby” mode, where the meter oscillation continues

but the Mass flow reading is set to Zero. Valid Temperature and Strain

measurements continue to be made during the “Standby” mode. Reads “1” when set

Request STOP Mode

– Place the instrument into “Stop” mode, where the meter oscillation stops and all

mass flow measurement stops. Valid Temperature and Strain measurements

continue to be made during the “Stop” mode. Reads “1” when set

1007

1008

1009

Request MEASURE mode

– Place the instrument into “Measure” mode, all measurement and totalising restarts.

Reads “1” when set

NOTE: For above 3 registers, only 1 of the coils will be set at any one time. Writing

Reset Errors

– Clears the Stored System Error Flags (See Input Register No 7005). Will not reset

Custody sensitive errors when Custody Transfer lock is active, see section 8.9 on

page 78 for details.

Reset Warnings

– Clears the Stored Process Warning Flags (See Input Register No 7007). Will not

reset Custody sensitive warnings when Custody Transfer lock is active, see section

8.9 on page 78 for details.

MFC010 Interface Manual

Page 42

40

MFC010 Interface Manual

Register No. Description

is in progress, and “0” when complete.

1010

1011

CT

1012

CT

1013

CT

1014

CT

Discard Previous Write Operations

– Discard all of the configuration changes made since the last write to EEPROM

operation (see Coil Register 1001 above). See Section 8.6 on page 77 for a more

detailed explanation of saving and restoring configuration settings.

Initiate Single Point Density Calibration

– Initiate a single point calibration of the density measurement system according to

the settings of the Calibration Density Type ( See Holding Register 1028) and the

Calibration Density Value ( See Holding Register No 3093). See Section 8.2 on page

72 for further details.

Initiate Two Point Density Calibration

– Perform a calibration on the first of a two point density calibration according to the

settings of the Calibration Density Type (See Holding Register 1028) and the

Calibration Density Value (See Holding Register No 3093). See Section 8.2 on page

72 for further details.

Continue Two Point Density Calibration

– Perform a calibration on the second of a two point density calibration according to

the settings of the Calibration Density Type (See Holding Register 1028) and the

Calibration Density Value (See Holding Register No 3093). This will only be

permitted if the first point has been calibrated previously (See Output Register No.

1012). See Section 8.2 on page 72 for further details.

Reset to Factory Density Calibration

– Resets the instrument Density calibration to the settings determined at the point of

manufacture during initial instrument calibration. See Section 8.2 on page 72 for

further details.

1015

1016

NOTE: For registers 1010 to 1014, the value of the coil reads “1” when the process

Save Changes to EEPROM with Mass total

- Store the configuration changes made and the current Mass total into the nonvolatile memory. See Section 8.6 on page 77 for a more detailed explanation of

saving and restoring configuration settings.

Save Changes to EEPROM with Volume total

- Store the configuration changes made and the current Volume total into the nonvolatile memory. See Section 8.6 on page 77 for a more detailed explanation of

saving and restoring configuration settings.

Page 43

41

7.3 Discrete Input (Binary) Status Registers

The Discrete I nput S tatus r egisters ar e us ed t o i ndicate t o t he c ontrol s ystem t he c urrent s tate of t he

meter. From these values the user can access more detailed information in the other register groups.

Many of these states can also be accessed using the “Read Exception Status” command (Command No.

7).

Register No.

1001

1002

1003

1004

Description

Supervisor Lock Password State

- The current state of the Supervisor Password protection. For details on activation,

de-activation and operation of the Supervisor password refer to Section 8.5 on page

76 for further details.

Range : 0 = Password Protection is Inactive

1 = Password Protection is Active

Service Lock Password State

- The current state of the Service Password protection. For details on activation, deactivation and operation of the Service password refer to Section 8.5 on page 76 for

further details.

Range : 0 = Password Protection is Inactive

1 = Password Protection is Active

Custody Transfer Lock Password State

- The current state of the Custody Transfer Lock Password protection. For details on

activation, de-activation and operation of the Custody Transfer password refer to

Section 8.9 on page 78 for further information.

Range : 0 = Password Protection is Inactive

1 = Password Protection is Active

Parameter Changed – Awaiting “Save Changes to EEPROM”

– This state indicates when configuration changes have been made but not yet

saved to the non-Volatile memory (EEPROM). See Section 8.6 on page 77 for a

more detailed explanation of saving and restoring configuration settings.

Range : 0 = No new data to save

1 = Data has been written but not stored in EEPROM

1005

1006

System Error Flag

– This state indicates when the system has detected one or more error conditions

that may affect the operation of the meter. The individual System Error flags are

accessed from Input Register No 7001. (See Section 9 for more details on Errors

and Warnings)

Range : 0 = No system error flags detected

1 = One or more system error conditions are present

Process Warning Flag

– This state indicates when the system has detected one or more process conditions

that may affect the operation of the meter. The individual Process warning flags are

accessed from Input Register No 7005. ( See section 9 for more details on Errors

and Warnings).

Range : 0 = No process warning flags detected

1 = One or more process warning conditions are present

MFC010 Interface Manual

Page 44

42

MFC010 Interface Manual

Register No. Description

1007

1008

1009

Density Calibration Status

– This state indicates when the system has detected an error during the density

calibration. This will only be active for the latest attempt at a density calibration. If

this bit indicates that the latest density calibration failed, then the previous density

calibration will still be being used. See Section 8.2 on page 72 for further details on

Density calibration.

Range : 0 = The last Density Calibration was successful

1 = An error was detected during the last Density Calibration

Mass Flow Zero Calibration Status

– This state indicates when the system has detected an error during the mass flow

zero calibration. This will only be active for the latest attempt at a calibration. If this

bit indicates that the latest zero calibration failed, then the previous zero calibration

will still be being used. See Section 8.1 on page 71 for further details on Mass Flow

Zero Calibration.

Range : 0 = The last Mass Flow Zero Calibration was successful

1 = An error was detected during the last Zero Calibration.

Process Control Status

– This state indicates when the Internal process control mechanism is active. See

section 8.8 on page 78 for more details on the Internal Process control system

Range : 0 = Internal Process Control In-active

1 = Internal Process Control Active

Page 45

43

7.4 Input Registers

The input registers contain the measurement values and di agnostic data that the MFC010 produces. All

of these registers are read only.

Register No. Description

1001

1002

1003

1004

Sensor A Level

- The measured input level for Sensor A as a percentage of the maximum possible

input.

Format : Unsigned Integer

Range : 0% to 100%

Sensor B Level

– The measured input level for Sensor B as a percentage of the maximum possible

input.

Format : Unsigned Integer

Range : 0% to 100%

Drive Level

– The output power to the Drive coil as a percentage of the maximum possible

output.

Format : Unsigned Integer

Range : 0% to 100%

System State

- The current operating condition of the sensor system. This can be changed using

the “Request System State” commands (see Coil Register No’s 1005 – 1007).

Format : Unsigned Integer

Range : 1 = Stop

2 = Start-up

3 = Measuring

4 = Not Used

5 = Standby

6 = Zero Calibration

1005

1006

Density Calibration Coefficient DCF1

- The fluid type defined for the calibration of Density Point #1

Format : Unsigned Integer

Range : 0 = Empty

1 = Pure Water (998.2 kg/m

2 = Town Water (999.7 kg/m

3 = Other

Density Calibration Coefficient DCF2

- The fluid type defined for the calibration of Density Point #2

Format : Unsigned Integer

Range : 0 = Empty

1 = Pure Water (998.2 kg/m

2 = Town Water (997.7 kg/m

3 = Other

3

@ 20°C )

3

@ 20°C )

3

@ 20°C )

3

@ 20°C )

MFC010 Interface Manual

Page 46

44

MFC010 Interface Manual

Register No. Description

3001 / 3002

3003 / 3004

3005 / 3006

3007 / 3008

Mass Flow

- The measured mass flow rate after filtering. Proportional to the Phase shift

detected between the sensors. The value transmitted is scaled according to the

setting of the “Mass Flow Units” (see Holding Register No.1020)

Format : Floating Point

Range : Dependant on the sensor type and selected units

Density

- The measured density after filtering. Inversely proportional to the oscillation

frequency of the measuring tube. The value transmitted is scaled according to the

setting of the “Density Units” (see Holding Register No.1021). This value may be

fixed or referred according to the setting of the ”Density Mode” (see Holding Register

No.1019)

Format : Floating Point

Range : 0.05 kg/m³ to 3000 kg/m³

Temperature

- The measured temperature of the measuring tube. The value is scaled according