Page 1

Installation and

Operating Instructions

LS 72xx

Conductive mono-rod level sensor

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems and solutions

Switches, counters, displays and recorders

Heat metering

© KROHNE 02/2013 Pressure and temperature

Page 2

Contents

Items supplied .................................................................................................................................... 3

System description ............................................................................................................................ 3

Product liability and warranty ............................................................................................................. 3

CE / EMC / Standards / Approvals ..................................................................................................... 3

1 Installation ............................................................................................................................... 4

1.1 Mechanical installation .............................................................................................................. 4

1.2 Process connection ................................................................................................................... 4

1.3 Mounting of 3A marked products ............................................................................................... 5

2 Electrical connection .............................................................................................................. 6

2.1 Connection plan ........................................................................................................................ 7

2.2 Initial start-up ............................................................................................................................. 7

2.3 Operator control ........................................................................................................................ 7

3 Fault diagnosis and corrective actions ................................................................................. 7

4 Technical data ......................................................................................................................... 8

4.1 Technical data table .................................................................................................................. 8

4.2 Dimensions ............................................................................................................................... 9

5 Type code .............................................................................................................................. 10

5.1 Ordering code ......................................................................................................................... 10

5.2 Spare parts .............................................................................................................................. 10

5.3 Accessories ............................................................................................................................. 10

6 Product description .............................................................................................................. 11

6.1 Applications ............................................................................................................................. 11

6.2 Functional principle ................................................................................................................. 11

6.3 Construction ............................................................................................................................ 11

6.4 Features .................................................................................................................................. 11

7 Notes ...................................................................................................................................... 12

If you need to return a device for testing or repair to KROHNE ....................................................... 15

02/2013 LS 72xx 2

Page 3

Items supplied

6\VWHP_GHVFULSWLRQ_

• Measuring instrument

• Hygienic adapter

• Installation and operating instructions

System description

Inputting physical quantities into an SPC or PLC or other computer and control systems requires

accurate and reliably working sensors. The sensor is a detecting element that converts physical

quantities, such as temperature, level, pressure, conductivity, turbidity and flow, into an electrical

signal. Locally further processed, usually by an integrated microcontroller, the measuring signal can

be transmitted by analogue (e.g. 4...20mA loop) or digital (e.g. Profibus PA) means.

The conductive mono-rod-level sensors of the LS Series are designed to detect the level of

conductive liquids. Since the rod electrodes can be shortened to any required length, this allows

flexibility in the choice of the operating point.

Product liability and warranty

The instrument is designed solely for detecting the interface between conductive liquids.

Responsibility as to suitability and intended use of this instrument rests solely with the operator.

Improper installation and operation of the instrument / system may lead to loss of warranty.

In addition, all claims are subject to the “General terms and conditions of sale” under which this

instrument was purchased.

If a meter or instrument needs to be returned to KROHNE, please note the information given on the

last-but-one page of these Instructions.

KROHNE regrets that it cannot repair or check your instruments unless accompanied by a fully

completed Service and Repair sheet.

CE / EMC / Standards / Approvals

(applicable only with integrated electronic evaluator)

The product bears the CE marking on account of compliance with and application of the following

standards:

EMCG (89/336/EEC)

EN 50081-1 EN 55022 Class B

EN 61000-6-2 EN 61000-4-2 ESD 4/8 kV

EN 61000-4-3 RF radiated 10 V/m

EN 61000-4-4 Burst 4 kV

EN 61000-4-5 Surge 1 kV sym., 2 kV unsym.

EN 61000-4-6 RF cable 10 V

02/2013 LS 72xx 3

Page 4

1 Installation

1.1 Mechanical installation

• Use only the recommended sleeves or adapters. If other systems are used, no guarantee can

be given for proper functioning or leak-tightness.

• The connection thread must have direct electrical contact with the threaded sleeve and the

metal vessel.

• Do not use Teflon or paper gaskets.

• The stub electrode can be used in electrically non-conducting vessels (e.g. plastic tanks) if

the screw-in sleeve has a metal surface that can be used as reference ground.

• The tightening torque for the sleeve should be between 10 and

20 Nm.

• The rod electrodes can be shortened to any required length (by clipping, sawing, etc). Make

sure not to damage the coating or the insulating part.

• Insulated rods: remove about 10 mm of the coating from the end of the rod, using an abrasive

disc, a sanding belt or a sharp knife.

• Make absolutely sure that the rod electrode cannot come into contact with the pipe or tank

wall. Also take into consideration the fact that the rod may be deflected by movement in the

liquid product. If necessary, select a more favourable mounting location.

1.2 Process connection

The hygienic ½” process sleeve is easy to weld in into tanks or pipes. The kind of assembly allows

installation in conformity with standards of hygiene (to EHEDG, FDA). The G1/2” and G1”

connections can be mounted in any counter thread acc. to ISO 228.

Various hygienic adapter sleeves (refer to chapter “Accessories”) are available for fitting to other

process connections. For more information refer to data sheet “Accessories”

02/2013 LS 72xx 4

Page 5

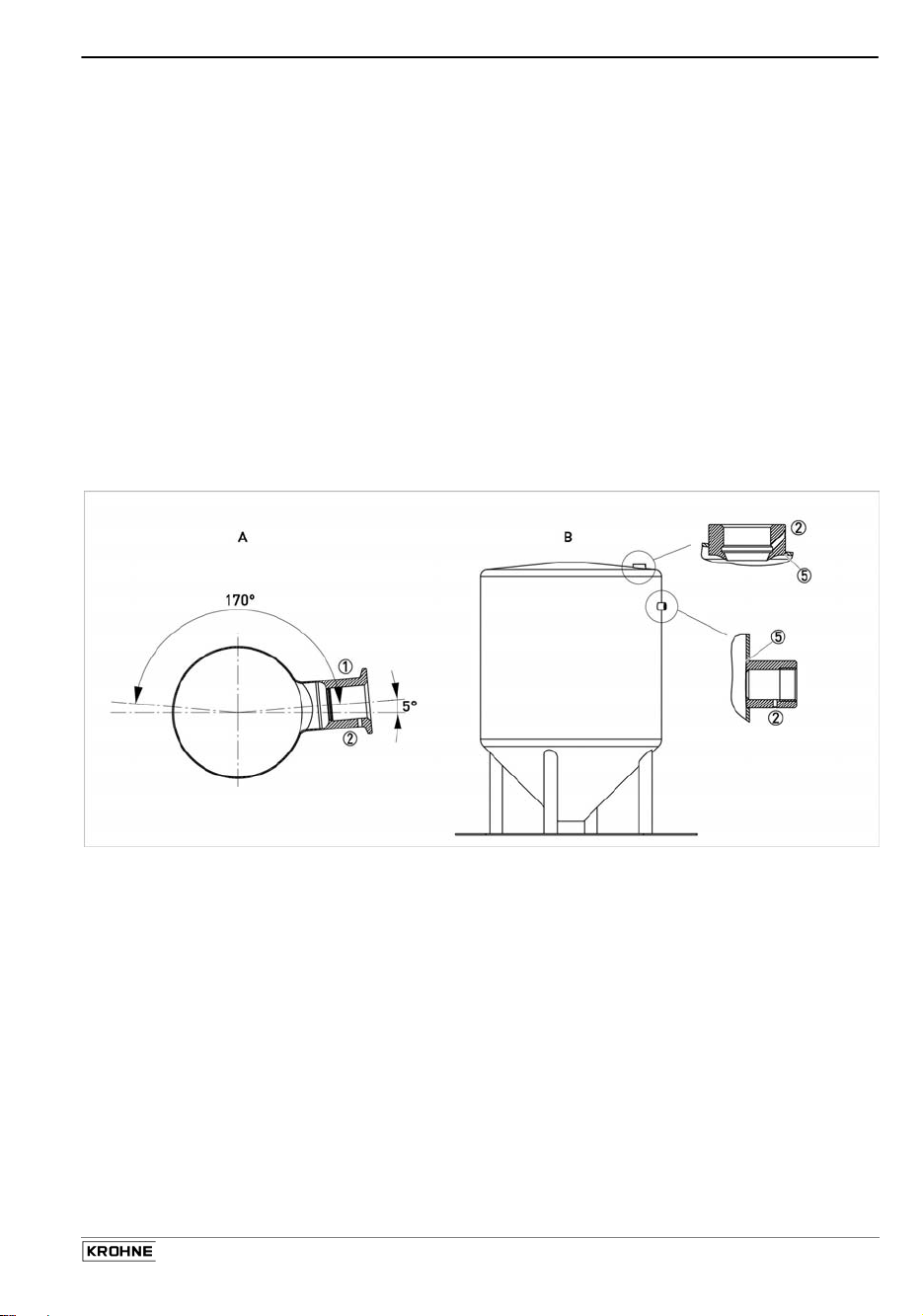

1.3 Mounting of 3A marked products

The 3A mark is valid only when the product is mounted in a 3A marked counterpart and installed acc.

to the installation manual. Use also a 3A marked O-ring or gasket if relevant.

The 3A marked products conforms to the 3A sanitary standards criteria. Materials and surfaces fulfil

the FDA demands and are certified by EHEDG.

EPDM O-rings supplied with 3A marked products are conform to sanitary standards class II (8% milk

fat).

1) Use only 3A approved counterparts

2) The inspection hole should be visible and drained. Face it downwards that leaking can be

observed.

3) Mount the device in a self-drained position.

4) Level the inner surface of the pipe with the counterpart.

5) Weld from the inside of the tank, if possible. Welds shall be free from cracks, crevices

and grooves. Weldings should be grinded to Ra= 0.8

Mounting of 3A products in pipe installations (A) or tank installations (B)

02/2013 LS 72xx 5

Page 6

2 Electrical connection

External level converter module

Terminal 1 is for the electrode potential, terminal 2 for ground (housing). Wire these two

connections to the appropriate terminals of your evaluation unit (see also “Accessories“). The pin

assignment for the M12 plug connection is shown in the connection diagram. Make absolutely

sure that the sensor has no DC voltage, as this could damage the sensor or tank! The most

suitable devices are evaluators with a frequency higher than 200 Hz. Do not use devices with an

r.m.s. voltage of more than 5 V. Also pay regard to currently valid installation regulations.

With integrated level converter module

Terminals 1 and 2 are used for supplying a DC voltage of 18...36 V. According to polarity, the

output switches to active or inactive when the electrode is immersed (see connection diagram).

The terminal wired to the negative pole is connected to the housing via an internal protective

diode. The maximum power consumption is 10 mA (without load switched). This value should be

taken into account for the recommended fuse. An active switching output (pnp) is available at

terminal 3. The switching voltage is a minimum of 1 V below the supply voltage. The maximum

output current is 50 mA. At higher loads, the current is limited accordingly. Damage through

shorting cannot occur. At terminal 4 (connection “R“) the sensitivity can be set in three stages,

either by fixed wiring or by external activation for changeover in the case of product changes (see

Table). The pin assignment for the M12 plug connection is shown in the connection diagram.

Please pay regard to the respectively valid installation regulations.

R Operating point Examples

L

open

L+

200 Ω

2 kΩ

20 kΩ

acids, alkalis

beer, juice, yoghurt

(pure) water Connection diagram

02/2013 LS 72xx 6

Page 7

2.1 Connection plan

2.2 Initial start-up

• Check the leak-tightness at the sleeve.

• Make sure that the cable gland is tight or, as the case may be, the M12 plug is properly

screwed down.

• After powering the unit, check for correct switching function.

2.3 Operator control

External level converter module

Refer to the directions for the appropriate evaluator and set the sensitivity level accordingly.

With integrated level converter module

• The red LED in the evaluator module lights up when the electrode is immersed in the liquid

product of adequate conductivity.

• According to the polarity of the supply voltage (see “Electrical connection“) the output

operates in the active or inactive mode.

• Should the module fail to switch, check the sensitivity setting (see “Electrical connection“).

3 Fault diagnosis and corrective actions

Fault Cause Action/elimination

No indication of level Electrode not in product o.k.

Measure continuity,

02/2013 LS 72xx 7

Page 8

Wire break

Sensitivity too low

Insufficient electrode area

Constant level indication Short-circuit to ground, sensor

Short-circuit

Sensitivity too high (possibly

deposits)

connections

Select higher sensitivity

Strip more insulation from

electrode

Replace sensor

Check power leads, power

cable

Select lower sensitivity

With integrated level converter module

LED not “on” Supply voltage < 18 V Measure voltage at pin 1, 2

No switching output Wire break

Supply polarity incorrect

Short-circuit

Check continuity of wires

Reverse terminals 1, 2

Check wiring

4 Technical data

4.1 Technical data table

Connection head Stainless steel V2A 1.4305; 55 mm dia.

Electrical connection Cable gland M16; M12 connector

Process connection Threaded socket G1/2“h; V4A 1.4571

Type of protection IP 67

Insulating part PEEK

Electrode 4 mm dia.; V4A 1.4571

(Option: PTFE coating)

Ambient temp. range –20...+60 °C

Process temp. range –20...+140 °C

Operating pressure max. 16 bar

Mounting position Rod electrode: above; stub electrode: any

With integrated level converter module

Indicating elements 1 LED red (level)

Power supply 18...36 V DC; 10 mA max. (no load switched)

Output min. Ub – 1 V, (50 mA max. short-circuit-proof)

Switching function full / empty polarity of supply power

Response time Damping 0.5 s

Sensitivity

With electrode output for level converter module

Output electrode connection, ground connection

200 Ω, 2 kΩ, 20 kΩ via control signal

02/2013 LS 72xx 8

Page 9

4.2 Dimensions

02/2013 LS 72xx 9

Page 10

5 Type code

5.1 Ordering code

Parts code VGP1 0 x y 000 z

x: Type

2 Stub, integr. level converter module

3 Rod bare, electrode/ground connection

4 Rod bare, integr. level converter module

5

6

y: Rod length

1 200 mm, bare

2 500 mm, bare

3 850 mm, bare

4 1000 mm, bare

5 200 mm, coated

6 500 mm, coated

7 850 mm, coated

8 1000 mm, coated

z: Electrical connection

2 Plug M12

1 Stub, electrode/ground connection

Rod coated, electrode/ground connection

Rod coated, integr. level converter module

0 Stub

1 Cable gland M16

5.2 Spare parts

Should a replaceable part of the probe be lost or damaged, replacements can be

ordered on the basis of the part number.

Designation Type

Housing lid KMD.008.055.100

Cable gland M16 KVV.M16.010.008

Connector insert M12 4-pin KVV.100.004.000

Integrated level converter module LKP.100

5.3 Accessories

Designation Type

Weld-in sleeve, HWN 200 V GP7 010000

Liquiphanten adapter thread G1", HGA 200 V GP7 050000

Sanitary pipe assembly kit DN 25, HMT 225 V GP7 0A0000

Sanitary pipe assembly kit DN 50, HMT 250 V GP7 0B0000

Varivent flange version N, HVF 250 V GP7 0C0000

Tri-Clamp flange DN 32/DN 40, 2"; HTC 250 V GP7 0D0000

External level converter module,2-channel, 24VDC, LEM 202 V GP0 100090

External level converter module,24VDC, 4-channel, LEM 204 V GP0 100080

External level converter module, 230 V, LEM 100 V GP0 100070

02/2013 LS 72xx 10

Page 11

6 Product description

6.1 Applications

The conductive mono-rod-level sensors of the LS Series are designed to detect the

level of conductive liquids. Since the rod electrodes can be shortened to any

required length, this allows flexibility in the choice of the operating point.

6.2 Functional principle

Conductive measuring sensors pick up the electrical resistance of the tank product

when the electrode is immersed in the product. This causes a small alternating

current to flow which is measured by the electronic unit in the converter module. The

wall of the vessel or pipe acts as reverse potential. The switching position is defined

by the length or mounting position of the sensor.

6.3 Construction

The weldable process sleeve is made of stainless steel and ensures installation in

keeping with hygiene requirements. Various level converter modules (see

Accessories) are available for evaluation purposes. The integrated evaluator module

in the connection head allows direct connection to an SPC or PLC via a short-circuitproof 24-V switching signal.

6.4 Features

• Sensor for hygienic installation, no elastomers

• Compact design

• Rod electrode can be shortened to any length

• Optimized flow geometry

• Precise, constant operating point

• Rejection of foam and deposits (coated electrode)

• Insensitive to vibration

• Materials in conformity with food standards

• Maintenance-free

• Installation in pipelines DN 25 and higher

• Direct connection to an SPC or PLC (with integrated electronics)

• Hygienic adapter sleeves for other process connections

02/2013 LS 72xx 11

Page 12

7 Notes

02/2013 LS 72xx 12

Page 13

02/2013 LS 72xx 13

Page 14

02/2013 LS 72xx 14

Page 15

If you need to return a device for testing or repair to KROHNE

Your instrument has been carefully manufactured and tested. If installed and operated in

accordance with these operating instructions, it will rarely present any problems. Should you

nevertheless need to return an instrument for servicing or repair, please pay strict attention to the

following points:

Due to statutory regulations on environmental protection and safeguarding the health and safety of

our personnel, KROHNE may only handle, test and repair returned instruments that have been in

contact with liquids if it is possible to do so without risk to personnel and environment.

This means that KROHNE can only service your instrument if accompanied by the following

certificate confirming that the instrument is safe to handle. If the instrument has been operated with

toxic, caustic, flammable or water-endangering liquids, you are kindly requested

to check and ensure, if necessary by rinsing or neutralising, that all cavities in the instrument are

free from such dangerous substances.

(Directions on how you can find out whether the primary head has to be opened and flushed out or

neutralised are obtainable from KROHNE on request.)

to attach a certificate to the instrument confirming that the instrument is safe to handle and stating

the liquid used.

We cannot service your instrument unless accompanied by such a certificate.

Specimen certificate

Company: Address:

Department: Name:

Tel. No.: Fax No.:

The enclosed instrument

Type: .:

KROHNE Order No. or Series No

has been operated with the following process liquid

Because this process liquid is

water-hazardous toxic caustic flammable

*

we have

checked that all cavities in the instrument are free from such substances *

flushed out and neutralised all cavities in the instrument *

We confirm that there is no risk to humans or environment through any residual liquid contained in

the instrument.

Date: Signature Signature:

Company stamp:

02/2013 LS 72xx 15

Loading...

Loading...