Page 1

CMD

Installation and

Operating Instructions

LEM 300

Double level control unit

for LS 7000 series

©

KROHNE 02/2006 7.02575.21.00

Subject to change without notice.

Electromagnetic flowmeters

Variable area flowmeters

Mass flowmeters

Ultrasonic flowmeters

Vortex flowmeters

Flow controllers

Level measuring instruments

Pressure and temperature

Heat metering

Communications technology

Switches, counters, displays and recorders

Engineering systems & solutions

Page 2

Contents

Description....................................................................................................................................3

Product liability and warranty .....................................................................................................3

1

Safety Instructions................................................................................................................. 4

2

Description ............................................................................................................................. 4

3

Technical data ........................................................................................................................ 5

4

Application Example.............................................................................................................. 6

4.1 Example 1 ............................................................................................................................6

4.2 Example 2 ............................................................................................................................7

4.3 Example 3 ............................................................................................................................8

4.4 Example 4 ............................................................................................................................9

4.5 Example 5 ..........................................................................................................................10

If you need to return a device for testing or repair to KROHNE............................................. 11

2 Installation and Operating Instructions LEM 300

Page 3

Description

The Double Level Control Unit has two independent, galvanically separated electrical circuits.

Each circuit controls a relay with Normally Open contacts. The status of each relay changes as a

function of the two resistance inputs.

The two inputs act with a hysteresis. The sensibility of the relay circuit can be adjusted from the

front of the module. LED´s indicates an activated relay.

The module can be used as an evaluation module for LS 7000 series sensors. Please refer to the

application example(s).

Product liability and warranty

Responsibility as to suitability and intended use of this instrument rests solely with the operator.

Improper installation and operation of the instrument / system may lead to loss of warranty.

In addition, all claims are subject to the “General terms and conditions of sale” under which this

instrument was purchased.

If a meter or instrument needs to be returned to KROHNE, please note the information given on

the last-but-one page of these Instructions.

KROHNE regrets that it cannot repair or check your instruments unless they are accompanied by

a fully completed Service and Repair sheet.

Installation and Operating Instructions LEM 300 3

Page 4

1 Safety Instructions

This instrument is built and tested according to the specifications and packed in technically safe

condition. In order to maintain this condition and to ensure safe operation, the user shall follow the

hints and warnings given in this instruction.

WARNING

During the installation the valid national rules have to be observed.

Ignoring the warnings may lead to severe personal injury or substantial damage

to property.

The product shall be operated by trained staff. Correct and safe operation of this equipment is

dependent on proper transport, storage, installation and operation.

All electrical wiring shall conform to local standards. In order to prevent stray electrical radiation,

we recommend twisted and shielded input cables, as also to keep mains supply cables separated

from the input cables. The connection shall be made according to the connecting diagrams.

2 Description

The Double Level Control Unit has two independent, galvanically separated electrical circuits.

Each circuit controls a relay with Normally Open contacts. The status of each relay changes as a

function of the two resistance inputs.

The two inputs act with a hysteresis. The sensibility of the relay circuit can be adjusted from the

front of the module. LED´s indicates an activated relay.

The module can be used as an evaluation module for LS 7000 series sensors. Please refer to the

application example(s).

4 Installation and Operating Instructions LEM 300

Page 5

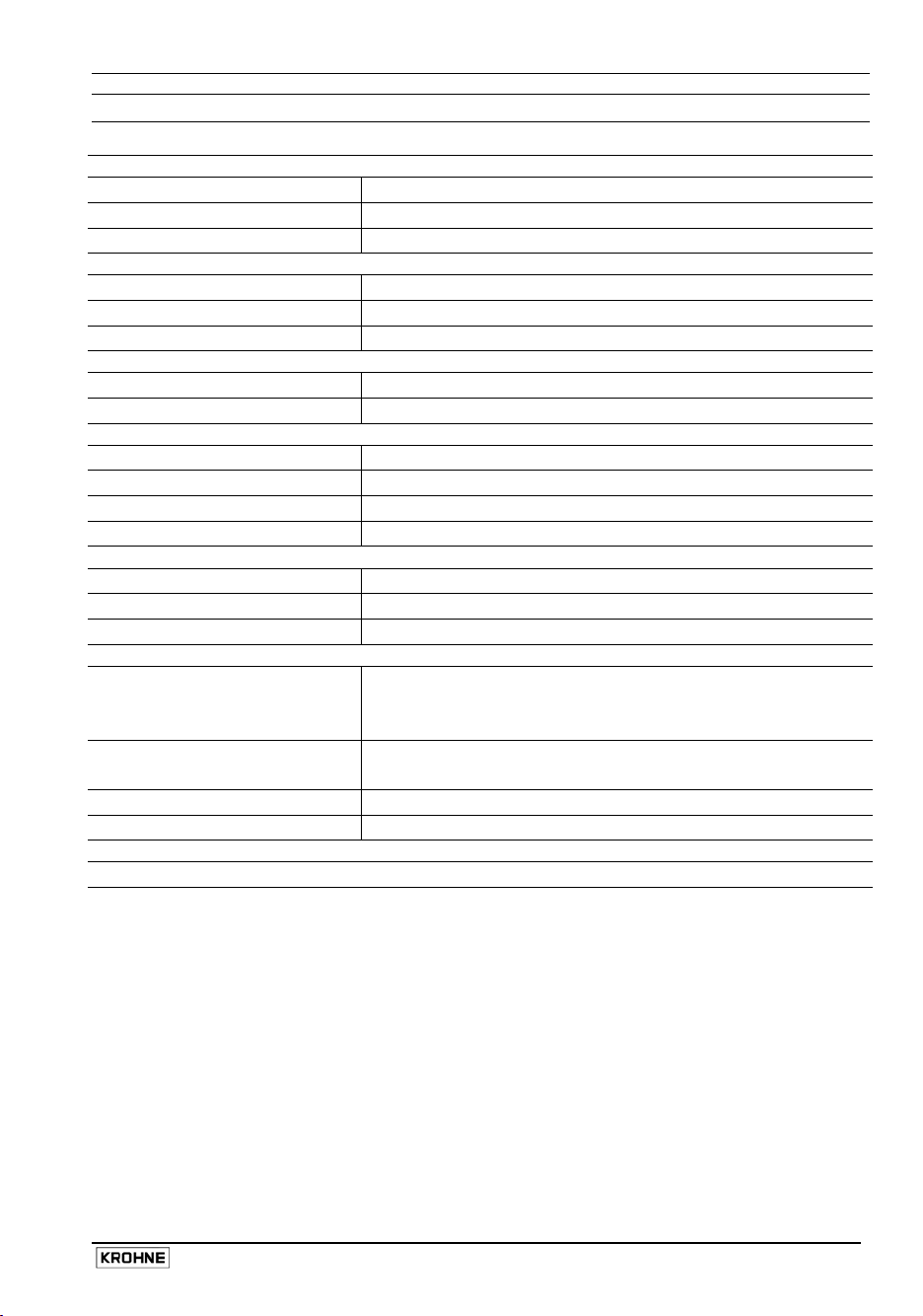

3 Technical data

Input

Range 7...100 KOhm (adjustable)

Probe voltage 24 V AC

Probe current 4 mA

Environmental conditions

Operating temperature -20...+50°C

Storage temperature -50...+85°C

Humidity <85% RH, non-condensing

EMC data

Generic standards EN 61000-6-3, EN 61000-6-2

LVD standards EN 61010-1, EN60204-1

Mechanical data

Dimensions 91.5 x 98 x 35 mm

DIN-rail mounting DIN 46277

Protection class Housing: IP 20

Weight 0.325 kg

Power supply

Supply range 230 V AC (+10 /-15%)

Frequency 50/60 Hz

Power consumption 15 mA

Output Relay

Resistive load AC: 250 V / 10 A

DC: 200 V / 0.4 A

DC: 24 V / 10 A

Inductive load AC: 250 V / 5 A

DC: 24 V / 5 A

Mechanical life cycle >30 x 106 operations

Operation voltage 250...440 V AC

Disposal of product and packing

According to national laws or by returning to KROHNE

Installation and Operating Instructions LEM 300 5

Page 6

4 Application Example

4.1 Example 1

A tank is being filled with waste water. Pump 1 is supplying a filter unit. Pump 2 is securing the

tank from overflowing.

Tank: Metal

Ground: Via the LS 72XX process connection

Instrument: LS 7240, 4 coated rods.

< Y1 level: Stop Pump 1

> Y2 level: Start Pump 1

< Y3 level: Stop Pump 2

> Y4 level: Start Pump 2

Y1

Y2

Y3

Y4

Switch (Pump 1)

Switch (Pump 2)

5

Z1

Y1

Y2

Y3

4

6

2

5

3

3

6

4

1 Switches »Normally open«

2 230 V AC

3 Pump 1

4 Pump 2

Max.

5

Min.

6

6 Installation and Operating Instructions LEM 300

Y4 A1

A2

1

11 14

21

34

Page 7

4.2 Example 2

Pump1 is filling a tank to a certain level. The alarm is securing the tank from overflowing.

Tank: Non-Metal

Ground: Via one uncoated rod

Instrument: LS 7240, 3 coated rods, 1 uncoated.

<Y1 level: Start Pump1

>Y2 level: Stop Pump1

Y3 + Y4 level: Alarm

1

5

1 Switches »Normally open«

2 230 V AC

3 Alarm

4 Reversing relay

5 Pump 1

Z1

Y1 Y2

2

Y3

A1 A2

Y4

3

11

14 21 34

4

Installation and Operating Instructions LEM 300 7

Page 8

4.3 Example 3

A tank is being filled with waste water. Pump 1 is supplying a filter unit. Pump 2 is securing the

tank from overflowing.

Tank: Non-metal

Ground: Via one uncoated rod

Instrument: LS 7240, 3 coated rods, 1 uncoated.

< Y1 + Y3 level: Stop Pump 1 + Pump 2

> Y2 level: Start Pump 1

> Y4 level: Start Pump 2

1

11

Z1 Y1 Y2

2

Y3

Y4

A1 A2

14

21

34

1 Switches »Normally open«

2 230 V AC

3 Pump 1

4 Pump 2

3

4

8 Installation and Operating Instructions LEM 300

Page 9

A

A

4.4 Example 4

Tank 1 is being filled with water and emptied via a water tap. Security valve1 is securing the tank

from overflowing.

Tank 1: Metal

Ground: Via the LS 72XX process connection.

Instrument: LS 7240, 2 coated rods.

< Y1 level: Close valve1

> Y2 level: Open valve1

Tank 2 is filled via pump 2 and emptied via a water tap.

Tank 2: Metal

Ground: Via the LS 72XX process connection.

Instrument: LS 7240, 2 coated rods.

< Y3 level: Start Pump 2

> Y4 level: Stop Pump 2

Z1

Y1 Y2

Y3

Y4

1

34

21

14

2 11

1

2

7

6

1 Switches »Normally open«

2 230 V AC

3 Reversing relay 2

4 Pump 2

5 Tank 2

6 Valve 1

7 Tank 1

3

4

5

Installation and Operating Instructions LEM 300 9

Page 10

A

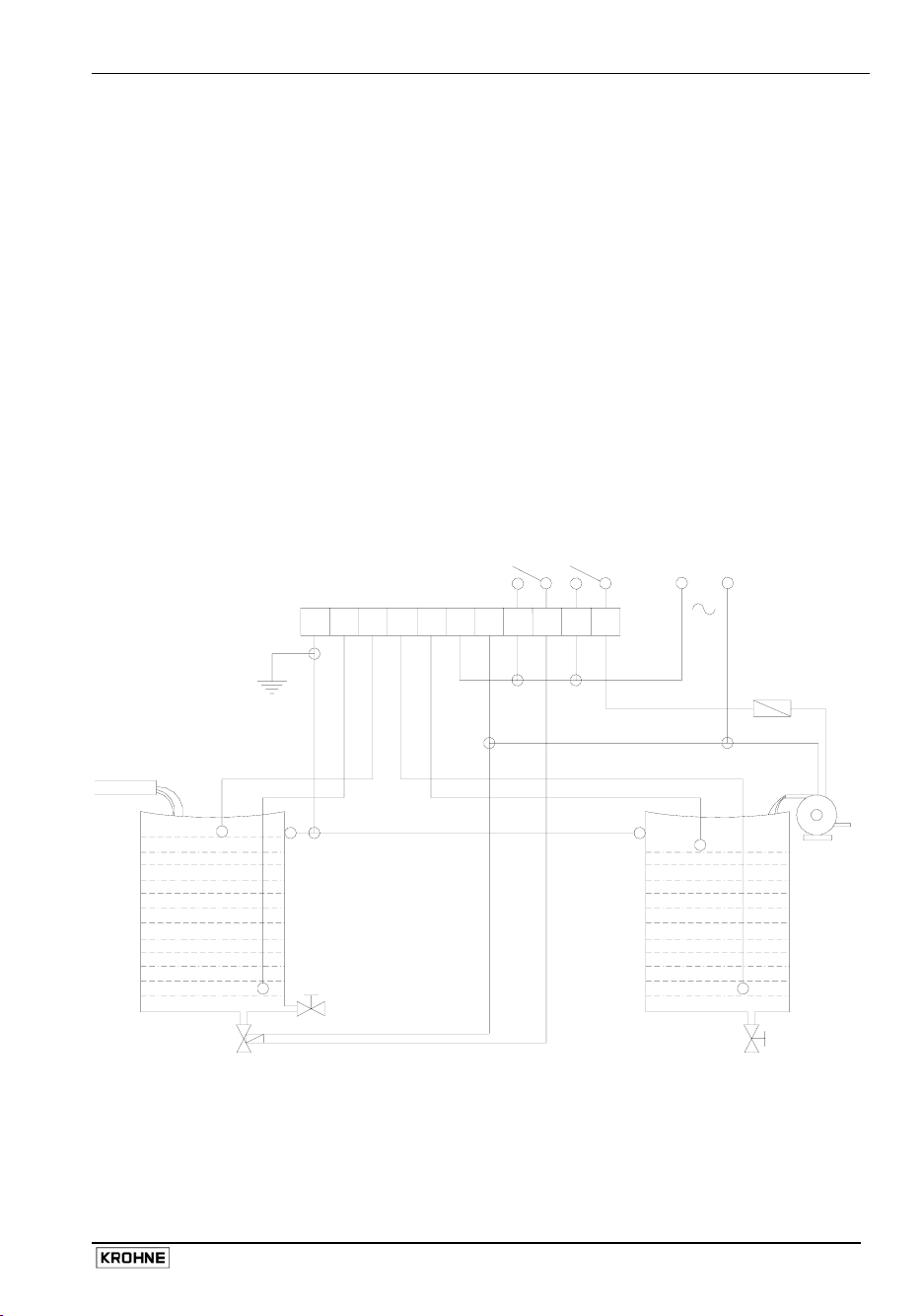

4.5 Example 5

Tank 1 and Tank 2 are being filled with water via Pump 1 and Pump 2.

Tank 1: Metal

Ground 1: Via the LS 72XX process connection

Instrument 1: LS 7200 - stub version.

Tank 2: Non-metal

Ground 2: Via one uncoated rod

Instrument 2: LS 7XXX- one coated rod - one uncoated rod.

Power on: Start Pump 1 and Pump 2

< Y1 + Y2 level: Start Pump 1

< Y3 + Y4 level: Start Pump 2

> Y1 + Y2 level: Stop Pump 1

> Y3 + Y4 level: Stop Pump 2

1

2

Z1

8

7

6

1 Switches »Normally open«

2 230 V AC

3 Reversing relay 2

4 Pump 2

5 Tank 2

6 Tank 1

7 Pump 1

8 Reversing relay 1

Y4 Y3 Y2 Y1

1

21 34 14 11 A2

3

4

5

10 Installation and Operating Instructions LEM 300

Page 11

If you need to return a device for testing or repair to KROHNE

Your instrument has been carefully

manufactured and tested. If installed and

operated in accordance with these operating

instructions, your instrument will rarely present

any problems. Should you nevertheless need

to return an instrument for checkout or repair,

please pay strict attention to the following

points:

Due to statutory regulations concerning

protection of the environment and

safeguarding the health and safety of our

personnel, KROHNE may only handle, test

and repair returned instruments that have

been in contact with liquids if it is possible to

do so without risk to personnel and

environment.

This means that KROHNE can only service

your instrument if it is accompanied by a

certificate in line with the following model

confirming that the instrument is safe to

handle.

S P E C I M E N certificate

Company: ……………………………………….. Address: ……………………………………………

Department: …………………………………….. Name: ………………………………………………

Tel. No.: ………………………………………….

The enclosed instrument

Type: …………………………………………………………………………………………………………

KROHNE Order No. or Series No ………………………………………………………………………...

has been operated with the following liquid: ……………………………………………………………..

Because this liquid is

water-endangering * / toxic * / caustic * / flammable *

we have

– checked that all cavities in the instrument are free from such substances *

– flushed out and neutralized all cavities in the flowmeter *

(* delete if not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in the

instrument.

Date: ………………………….. Signature: ……………………………………………………………..

Company stamp:

Installation and Operating Instructions LEM 300 11

If the instrument has been operated with toxic,

caustic, flammable or water-endangering liquids,

you are kindly requested

• to check and ensure, if necessary by rinsing

or neutralizing, that all cavities in the

instrument are free from such dangerous

substances.

(Directions on how you can find out whether

the primary head has to be opened and then

flushed out or neutralized are obtainable from

KROHNE on request.)

• to enclose a certificate with the instrument

confirming that the instrument is safe to

handle and stating the liquid used.

KROHNE regret that they cannot service your

instrument unless it is accompanied by such a

certificate.

Loading...

Loading...