Page 1

Handbook

Handbook

OPTISENS IND 1000

OPTISENS IND 1000

OPTISENS IND 1000OPTISENS IND 1000

HandbookHandbook

Inductive conductivity sensor

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 2

:

IMPRINT

:::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2016 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 3

OPTISENS IND 1000

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Safety instructions from the manufacturer ..................................................................... 5

1.2.1 Copyright and data protection ................................................................................................ 5

1.2.2 Disclaimer ............................................................................................................................... 6

1.2.3 Product liability and warranty ................................................................................................ 6

1.2.4 Information concerning the documentation........................................................................... 6

1.2.5 Warnings and symbols used................................................................................................... 7

1.3 Safety instructions for the operator................................................................................. 7

2 Device description 8

2.1 Scope of delivery............................................................................................................... 8

2.2 Device description ............................................................................................................ 9

2.2.1 Sensor types............................................................................................................................ 9

2.3 Nameplate ...................................................................................................................... 11

3 Installation 12

3.1 General notes on installation ......................................................................................... 12

3.2 Storage and Transport ................................................................................................... 12

3.3 Installation procedure .................................................................................................... 12

3.4 Pre-installation requirements ....................................................................................... 13

3.5 Safety instructions.......................................................................................................... 14

3.5.1 Connecting the sensor cable to the signal converter MAC 100 ........................................... 14

3.6 Calibrating the sensor.................................................................................................... 15

3.7 Installing the sensor....................................................................................................... 16

3.7.1 General installation instructions.......................................................................................... 16

3.7.2 Mounting to a flow through assembly .................................................................................. 17

3.7.3 Mounting sensor with immersion assembly ........................................................................ 17

3.8 Examples of a typical measuring point.......................................................................... 18

4 Operation 19

4.1 Menu mode structure..................................................................................................... 19

4.2 Function tables ............................................................................................................... 20

4.2.1 Menu A, quick setup.............................................................................................................. 20

4.2.2 Menu B, test .......................................................................................................................... 20

4.2.3 Menu C, setup ....................................................................................................................... 21

4.3 Calibration ...................................................................................................................... 23

4.3.1 Temperature compensation .................................................................................................23

4.3.2 Calibrating the temperature measurement......................................................................... 25

4.3.3 Calibrating measurement..................................................................................................... 26

4.3.4 Calibration log....................................................................................................................... 30

4.4 Troubleshooting.............................................................................................................. 30

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

3

Page 4

CONTENTS

OPTISENS IND 1000

5 Service 31

5.1 Maintenance ................................................................................................................... 31

5.1.1 Cleaning ................................................................................................................................ 31

5.2 Spare parts availability...................................................................................................31

5.3 Availability of services .................................................................................................... 31

5.4 Returning the device to the manufacturer..................................................................... 31

5.4.1 General information.............................................................................................................. 31

5.4.2 Form (for copying) to accompany a returned device............................................................ 32

5.5 Disposal .......................................................................................................................... 32

6 Technical data 33

6.1 Measuring principle........................................................................................................33

6.1.1 Inductive conductivity measurement.................................................................................... 33

6.2 Technical data................................................................................................................. 34

6.3 Dimensions ..................................................................................................................... 35

7 Notes 38

4

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 5

OPTISENS IND 1000

1.1 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

The intended use of OPTISENS IND 1000 conductivity sensor is the measurement of conductive

liquids. The sensor is suitable for connection to the MAC 100 signal converter.

1.2 Safety instructions from the manufacturer

1.2.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

SAFETY INSTRUCTIONS

1

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

5

Page 6

1

SAFETY INSTRUCTIONS

1.2.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

1.2.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

OPTISENS IND 1000

1.2.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

6

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 7

OPTISENS IND 1000

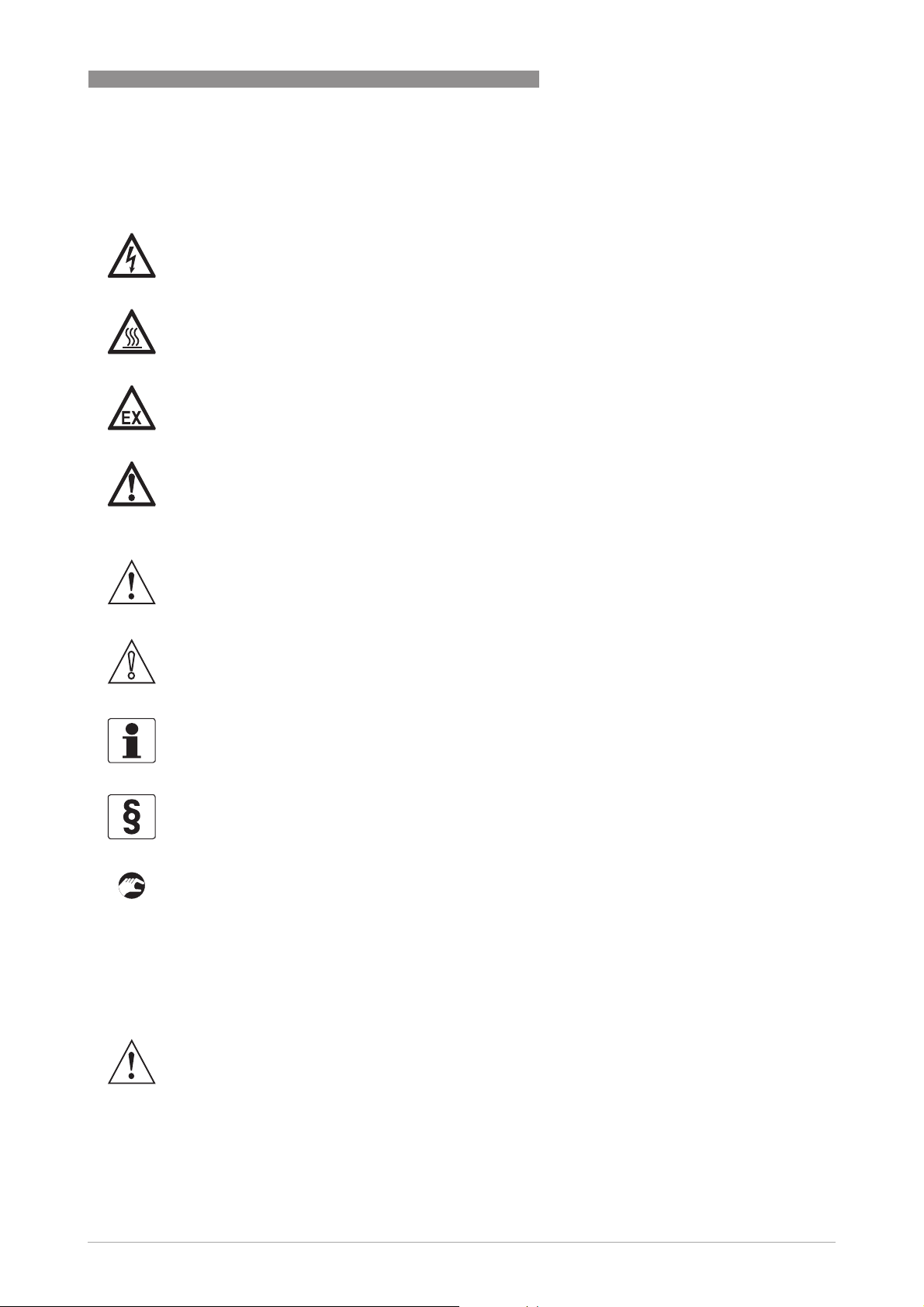

1.2.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS

1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.3 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

7

Page 8

2

DEVICE DESCRIPTION

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISENS IND 1000

Figure 2-1: Standard scope of delivery

1 Ordered sensor with fixed cable 10 m / 33 ft

2 Documentation

Optional accessories

• SENSOFIT FLOW 1000 flow-through assembly (T-piece)

8

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 9

OPTISENS IND 1000

2.2 Device description

2.2.1 Sensor types

DEVICE DESCRIPTION

2

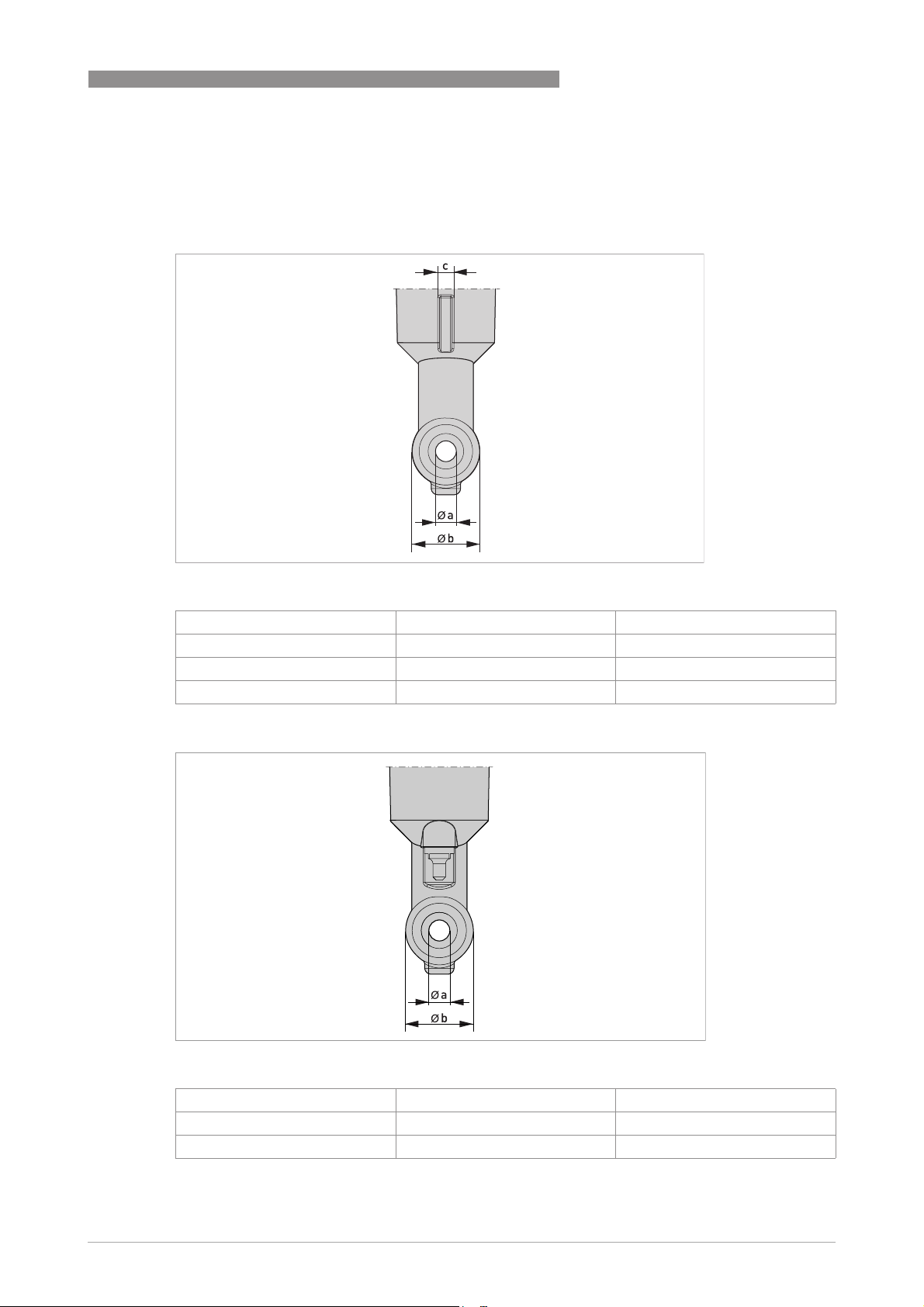

Figure 2-2: Sensor rear view with guide slot

Dimension [mm] Dimension [inch]

a 6.7 0.26

b 22 0.87

c 4 0.16

Figure 2-3: Sensor front view with exposed temperature sensor (standard sensor)

Dimension [mm] Dimension [inch]

a 6.7 0.26

b 22 0.87

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

9

Page 10

2

DEVICE DESCRIPTION

Figure 2-4: Sensor front view with internal temperature sensor

a 6.7 0.26

b 22 0.87

OPTISENS IND 1000

Dimension [mm] Dimension [inch]

The OPTISENS IND 1000 sensor features a compact and extremely rugged design as well as a

wide measuring range. The meaurement coils are completely enclosed and there is no direct

contact of the measurement coils to the medium. This feature makes it corrosion resistant and

suitable for measurement mediums with a high dirt load.

The body is either out of PP or PVDF. The sensor features an exposed or internal Pt1000

temperature sensor which reading is used for the temperature compensation of the conductivity.

Combined with a signal converter, an extremely reliable and cost-effective measuring systems

can be created. Inductive measurement systems are very well suited for conductivity

measurements in severely contaminated and aggressive media in all industries.

10

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 11

OPTISENS IND 1000

Thanks to its compact design, the sensor can be installed in pipelines with relatively small

diameters. The immersion depth from screw fitting to sensor tip is just 81 mm and such suitable

for DN50 pipes. The measurement field requires a minimum of 20 mm free space around the

sensor coils to not have an impact onto the cell factor.

DEVICE DESCRIPTION

2

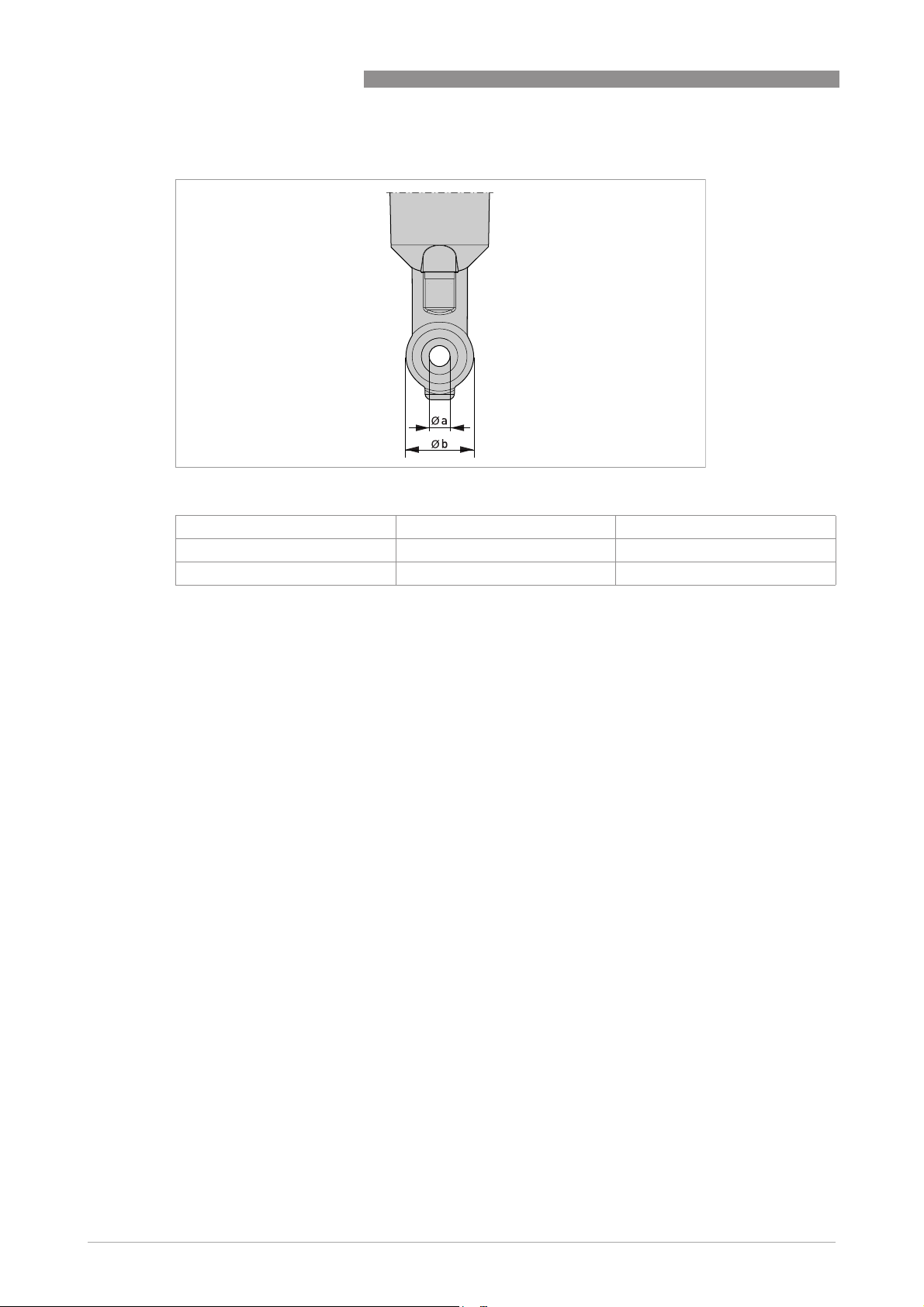

Figure 2-5: Sensor overview

1 Cable gland

2 Union nut PVC (optional stainless steel)

3 Exposed temperature sensor Pt1000

4 Primary coil

5 Secondary coil

2.3 Nameplate

Figure 2-6: Example of a nameplate

1 Device name

2 Manufacturer

3 Matrix code of the serial number

4 Cell factor

5 Serial number

6 Articel number

7 Order code

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

11

Page 12

3

INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage and Transport

• Store the conductivity measuring system in its original packaging in a dry and dust-free

location. Keep it away from dirt.

• The original packaging serves the protection of the equipment. Therefore always use it for

transport or return to the manufacturer.

OPTISENS IND 1000

3.3 Installation procedure

Most new inductive sensors get installed not needing a further calibration and adjustment of the

cell factor. However, it is good practice to calibrate a sensor at time of installation into its final

measuring location. The cell factor might vary ±15%. Follow the installation order:

1. Unpack the sensor.

2. Connect the sensor to the signal converter.

3. Program the cell factor of the inductive sensor used (PP version c=6.25, PVDF version c=4.65)

4. Adjust the cell factor against a known value after the following step or calibrate the sensor in

a standard solution (e.g. 25 mS/cm). Make sure the coils are minimum 20 mm away from any

surface and fully immersed in the solution.

5. Install the sensor into its final measuring location.

The required steps are explained in the following sections.

12

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 13

OPTISENS IND 1000

3.4 Pre-installation requirements

CAUTION!

•

Unpack the sensor carefully!

•

Make sure that the sensor is clean.

INFORMATION!

•

Nothing shall block the measurement hole within the sensor.

•

Consider a large enough distance from metal or plastic pipe walls!

The sensor can be installed into the SENSOFIT FLOW 1000 assembly which is available in DN32,

DN40 and DN50.

If installed into small diameter pipes like DN32 and DN40 the minimal free diameter of 20 mm

around the sensor coils can not be kept. In these cases the cell factor has to be adjusted. The

best method is to do an inline calibration against a reference measurement. In case this is not

possible try to achive similar dimensions and materials in a calibration beaker. In case both is

not possible you can adjust the cell factor by multiplying it by a factor. Every sensor coil is

different or might vary in its characteristics. A multiplier can only be given as an approximate

indication. Within a SENSOFIT FLOW 1000 with DN32 you do have ~8mm and with DN 40 ~14mm

free space around the sensor available, both being less then 20mm. Mentioned multipliers are

approximates only. Therefore the recommendation is to install in a pipe equal or bigger then

DN50.

INSTALLATION

3

Multipliers for cell factor correction depending on pipe dimensions

SENSOFIT FLOW 1000 Free space around the sensor coil Approximate multiplier for cell

DN32 ~8 mm ~1.09 (non conductive pipe)

DN40 ~14 mm ~1.05 (non conductive pipe)

DN50 ~21 mm ~1.00

factor correction

~0.97 (conductive pipe).

~0.98 (conductive pipe).

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

13

Page 14

3

INSTALLATION

3.5 Safety instructions

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

DANGER!

All work on the electrical connections may only be carried out with the power disconnected.

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

OPTISENS IND 1000

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

3.5.1 Connecting the sensor cable to the signal converter MAC 100

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

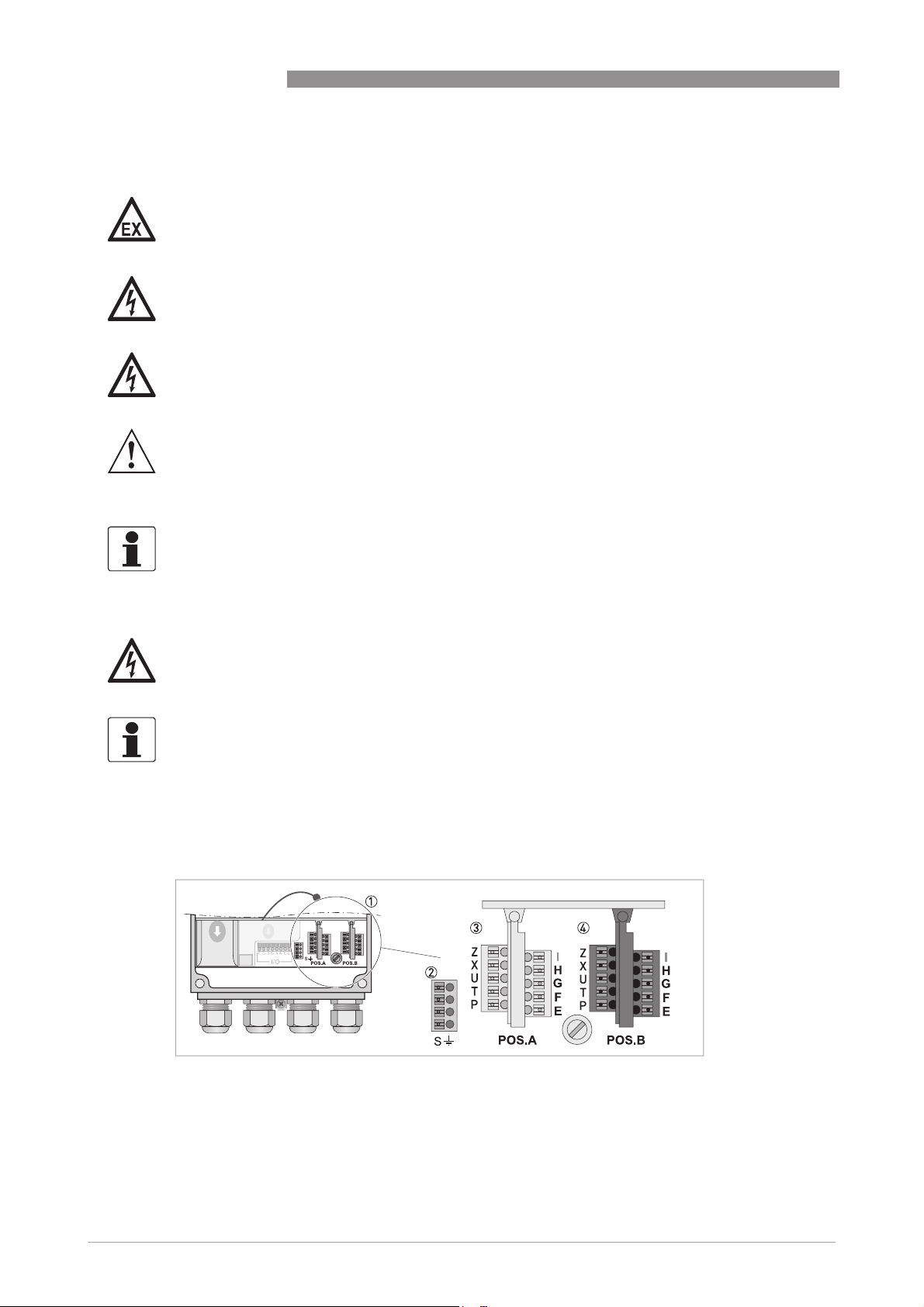

When ordering the single channel version, only the interface "Pos.A" is populated. In the version

with dual channels the interfaces "Pos.A" and "Pos.B" are populated.

14

Figure 3-1: Terminal compartment overview

1 Sensor connection terminals

2 Terminal block S (protective earth)

3 Terminal block A : terminal for sensor

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 15

OPTISENS IND 1000

Figure 3-2: Connection of the sensor cable

The following instructions describe the connection of the sensor cable

Connecting the sensor cable to the signal converter

• Thread the sensor cable through the middle right cable gland (1).

• Push the wire (9) into the terminal block Pos A as described in the chart.

• To remove a cable, press down the white clip (10) on the corresponding terminal and pull the

cable out.

INSTALLATION

3

Wire Terminal block A or B

Shield (2) S

Yellow - Pt1000 (3) X

Green - Pt1000 (4) P

Shield from pink (5) H

Pink (6) G

White (7) F

Brown (8) E

3.6 Calibrating the sensor

It is good practice to calibrate an inductive sensor before installation. For further information

refer to

Calibrating measurement

on page 26. Then continue with the installation procedure.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

15

Page 16

3

INSTALLATION

3.7 Installing the sensor

3.7.1 General installation instructions

WARNING!

Ensure that the pipe is without pressure before installing or removing a sensor!

INFORMATION!

Be sure that the tube is completely filled with water, otherwise the measuring reading is wrong.

INFORMATION!

During installation you should fix a shut-off valve in front of and behind the instrument so that

the sensor can be taken out of the bypass in case of check.

INFORMATION!

To achieve reliable measuring results, note the following items:

•

Always install the sensor in the designated flow through assembly or ensure that the pipe

diameter is large enough.

•

The sensor must always have full contact with the measuring medium.

OPTISENS IND 1000

16

Figure 3-3: Installation requirements

1 Flow direction

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 17

OPTISENS IND 1000

3.7.2 Mounting to a flow through assembly

WARNING!

Ensure that the pipe is without pressure before installing or removing a sensor!

INFORMATION!

The flow through assembly is an optional accessory and not part of the standard scope of

delivery. It has to be installed vertically to the flow direction.

INSTALLATION

3

Figure 3-4: Mounting to a flow-through assembly

1 Sensor

2 Flow-through assembly (T-piece)

• Screw the sensor 1 into the flow through assembly 2 and tighten the sensor by hand.

3.7.3 Mounting sensor with immersion assembly

Figure 3-5: Sensor in immersion version

1 Sensor with attached cable

2 Immersion assembly

3 Clamps onto immersion assembly

4 Cap with cable gland

The Sensor is also available as immersion version with 1000 or 2000 mm length. The sensor is

already installed and sealed inside the assembly. The assembly is equipped with retaining

clamps.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

17

Page 18

3

INSTALLATION

3.8 Examples of a typical measuring point

The following examples each show the signal converter, a sensor with integrated temperature

sensor, and the flow-through or immersion assembly.

Figure 3-6: Bypass installation with signal converter

1 Bypass measurement

2 Outlet measurement

3 Shut-off valve

4 Flow-through assembly (T-piece) with sensor

5 Bypass pipe

6 Main pipe

OPTISENS IND 1000

18

Figure 3-7: Installation with signal converter

1 Single channel version

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 19

OPTISENS IND 1000

4.1 Menu mode structure

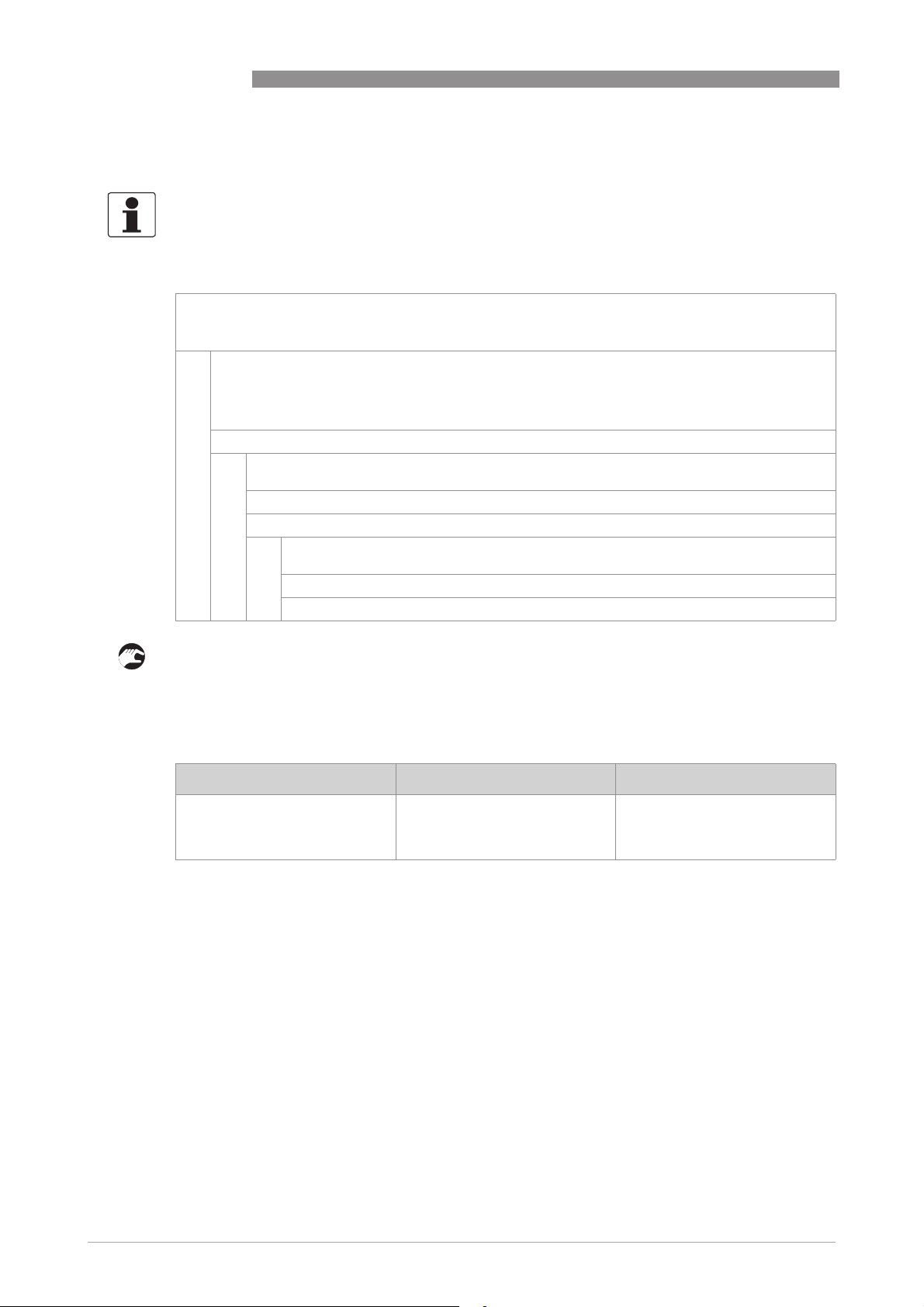

INFORMATION!

The following table just presents an overview. When programming the device, always consult the

function tables additionally as they contain further information!

Only the sensor relevant menus are shown in the following tables. For detailed information

about the general setting refer to the MAC 100 signal converter manual.

OPERATION

4

Measurnig

mode

3 or 4

pages,

scrolling

with ↓ or ↑

Main menu Submenu Parameter

>2.5s^A quick

A quick

A quick A quick

setup

setup

setupsetup

B test

B test B1 sim. process

B testB test

C setup

C setup C1 process input A C1.1 parameter

C setupC setup

↓↑ ↓↑ ↓↑

>^A6 analog outputs A6.1 measurement >^For

A6.2 spec. conductivity

A6.3 range

A6.4 time constant

input A

B4 actual values B4.2 process input A

B6 information B6.2 process input A

B1.1 temperature

B1.2 spec. conductivity

B1.3 spec. resistance

B4.2.1 temperature

B4.2.2 spec. conductivity

B4.2.3 Meg. Ohm

B4.2.5 pH

B4.2.8 generator volt.

B4.2.9 CPU temp.

B4.2.10 range

B4.2.11 electrode volt.

C1.2 cell constant

C1.14 time constant

C1.15 temperature

C1.23 cell calibration

further

informatio

n see

function

tables.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

19

Page 20

4

OPERATION

4.2 Function tables

To enter the menu from the measurement display point press > for more than 2.5 seconds, then

release the button. You are in the main menu level. Press up and down until the relevant menu

point is highlighted. Enter the menu point by pressing >

4.2.1 Menu A, quick setup

INFORMATION!

Note that the appearance of some sub-menus depends on the hardware setting and the used

sensor(s). Also only the sensor relevant menus and submenus are shown here in detail. For all

other menu functions refer to the MAC 100 signal converter manual.

A 6.1 measurement:

A 6.1 measurement:

A 6.1 measurement: A 6.1 measurement:

Value used for driving the current output C. Choose between:

• spec. conductivity

• temperature

• concentration % (function is choosable, but not implemented)

OPTISENS IND 1000

A 6.2 spec. conductivity

A 6.2 spec. conductivity

A 6.2 spec. conductivityA 6.2 spec. conductivity

Unit for the current output range. Choose between:

• µS/cm

• mS/cm

• free unit

4.2.2 Menu B, test

INFORMATION!

Note that the appearance of some sub-menus depends on the hardware setting and the used

sensor(s). Also only the sensor relevant menus and sub-menus are shown here in detail. For all

other menu functions refer to the MAC 100 signal converter manual.

The procedure to start the simulation process is the same for all functions:

• Choose the function with the help of ↓ or ↑ and press ^.

i You see the two options "set value" (opens the editor to enter the simulation value) and

"break" (exits the menu without simulation).

• Choose the desired option with the help of ↑ or ↓ and press ^.

i If you chose "set value", the device asks "start simulation" and offers the options "no" (exits

the menu without simulation) or "yes" (starts the simulation finally).

• Choose the desired option with the help of ↑ or ↓ and press ^.

i If you chose "yes", the simulation starts.

20

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 21

OPTISENS IND 1000

OPERATION

B1,sim.process inp.A

B2,sim.process inp.B

Level Designation / function Settings / descriptions

B1.1

B1.1 temperature In this menu the temperature can be simulated.

B1.1B1.1

B1.2

B1.2 spec. conductivitiy In this menu the conductivity can be simulated.

B1.2B1.2

B1.3

B1.3 spec. resistance In this menu the resistance can be simulated.

B1.3B1.3

B4, actual values

Level Designation / function Settings / descriptions

This menu groups several functions which allow to display the corresponding actual reading. The shown measurements

are depending on the device configuration.

B4.2

B4.2 process input A In this menu the measurements from process input A can be read.

B4.2B4.2

B4.3

B4.3 process input B In this menu the measurements from process input B can be read.

B4.3B4.3

For 2 channel version only.

B6, information

4

Level Designation / function Settings / descriptions

This menu groups several other menus which contain device specific information. The build-up of the display is the

same for all menus:

B6.1

B6.1 C number Identifies the types of electronics, is also located on the converter

B6.1B6.1

B6.2

B6.2 process input A Gives information about the electronical part of process input A.

B6.2B6.2

B6.3

B6.3 process input B Gives information about the electronical part of process input B.

B6.3B6.3

B6.4

B6.4 SW.REV.MS Gives information about the main software of the electronics.

B6.4B6.4

B6.5

B6.5 SW.REV.VIS Gives information about the user interface of the device.

B6.5B6.5

B6.6

B6.6 Electronic Revision ER Reference identification number, electronic revision and production date of

B6.6B6.6

nameplate.

For 2 channel version only.

the device; includes all hardware and software changes.

4.2.3 Menu C, setup

INFORMATION!

The signal converter MAC 100 has a dual process input, A and B. Each process input has an own

submenu in this main menu. Process input A is always present, i.e. there is always a board in the

interface "Pos.A" in the connection area. The interface of process input B only has a board with

the dual channel signal converter. Be aware that the definition which kind of measurement a

process input can do is defined when ordering the device. The configuration cannot be changed

later.

INFORMATION!

Note that the appearance of some submenus depends on the hardware setting and the used

sensor(s).

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

21

Page 22

4

OPERATION

C1, process input A

C1, process input A

C1, process input AC1, process input A

C2, process input B

C2, process input B

C2, process input BC2, process input B

OPTISENS IND 1000

Level Designation / function Settings / descriptions

Process input A and B can be either a sensor 1 or a sensor 2. Further information about the type of sensor 1 or 2 please

refer to the signal converter manual "Sensor input combinations". Process input A is always present, process Input B

can be present.

Note: The exchange of a sensors 1 with a sensor 2, or vice versa, can only be done by the manufacturer!

Depending on the sensor which is connected to a slot A or B the menu changes.

C1.1

C1.1 parameter (cond. ind.) This menu item is for selecting the probe which is connected to process

C1.1C1.1

C1.2

C1.2 cell constant Enter cell constant.

C1.2C1.2

C1.14

C1.14 time constant Enter time constant.

C1.14C1.14

C1.15

C1.15 temperature Menu for temperature measurement. Available for sensor 1 and sensor 2.

C1.15C1.15

C1.15.1 probe Options:

C1.15.2 manual Only available if C1.15.1 is set to "manual".

C1.15.3 correction Offset correction for temperature measurement. Not available if C1.15.1 is

C1.15.4 limitation Measuring ranges for temperature measurement.

C1.15.5 temp. comp. Menu for activating the temperature compensation parameters for the

C1.15.6 temp. coefficient If you have chosen “linear” enter the temperature coefficient.

C1.15.7 ref. temperature If you have chosen “linear” enter the reference temperature.

C1.23

C1.23 cell calibration For detailed information refer to Calibration refer to

C1.23C1.23

C1.23.1 temp. comp. Menu for temperature measurement.

C1.23.2 temperature Menu for setup of manual temperature (manual temperature

C1.23.3 temp. coefficient Menu for setup of temperature coefficient (manual temperature

C1.23.4 spec. conductivity Enter the conductivity of the calibration fluid.

C1.23.5 cell constant Enter cell constant.

input A/B. The entries of this selection depends on the chosen device

configuration. The device configuration is customer specific and set during

production.

•

manual: used if no internal or external temperature sensor is connected to

the signal converter

•

Pt1000: used if an external Pt1000 temperature sensor is connected to the

signal converter

set to "manual". If you have chosen “Pt 1000” enter the temperature

correction.

measurement.

Options:

•

Linear: linear temperature compensation.

•

Off: temperature compensation is disabled.

Calibrating

measurement

Options:

•

off: temperature measurement is disabled.

•

manual: temperature value has to be entered manually.

•

automatic: temperature measurement is performed as configured

measurement).

measurement).

Menu for preparation of measurement:

•

Put probe into calibration fluid

•

Wait until measurement is stable.

•

Press enter to proceed.

Wait until concentration is measured.

Check slope, press enter, decide whether to store or to discard calibration

parameter.

on page 26

22

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 23

OPTISENS IND 1000

CAUTION!

If you choose for measurement the temperature compensation "linear" than choose between

"automatic" or "manual" for the temperature compensation during calibration. If you choose for

measurement the temperature compensation "off" than choose also "off" for the temperature

compensation during calibration.

4.3 Calibration

4.3.1 Temperature compensation

There are three basic options for temperature compensation within the submenu probe in the

cell calibration menu:

• automatic:

automatic: the signal converter will automatically compensate temperature influences using

automatic:automatic:

the information of a Pt1000 temperature sensor.

• manual:

manual: the signal converter will compensate temperature influences using a manually

manual:manual:

entered value; this option only makes sense if the temperature of the measured medium is

quite constant.

• off:

off: temperature compensation is disabled.

off:off:

OPERATION

4

INFORMATION!

If you choose no compensation, the measured conductivity will most likely deviate from the

actual conductivity. The reason is that the conductivity of a specific medium varies depending on

the temperature of the medium.

The menu for temperature within the menu process input (A or B) offers the following options:

• Pt1000

Pt1000: choose this option if there is an external Pt1000 temperature sensor connected to the

Pt1000Pt1000

signal converter.

• manual

manual: choose this option if there is no internal or external temperature sensor connected

manualmanual

to the signal converter.

After starting-up the signal converter, the measuring screen appears. This is the standard

screen which is displayed automatically in the normal operating mode. If you are in this mode

and you want to choose the temperature compensation, you have to perform the following step:

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

23

Page 24

4

OPERATION

Step 1: choosing the temperature compensation for the measurement

•

Press >>>> for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu quick setup

•

Press or until the main menu setup

OPTISENS IND 1000

quick setup is highlighted.

quick setupquick setup

setup is highlighted.

setupsetup

MAIN MENU

A quick setup

B test

> C setup

> C setup

> C setup> C setup

D service

•

Press >>>> to enter the chosen menu.

You are on the first submenu level. In the upper line of the display "setup" and "c1" appears,

beneath the submenu process input A

•

Press or to select process input A

•

Press >>>> to enter the chosen menu.

You are on the second submenu level. In the upper line of the display "process input A"

and "c1.1"appears beneath the submenu parameter

•

Press or to select temperature

•

Press >>>> to enter the chosen menu.

You are on the third submenu level. In the upper line of the display "temperature"

and "C1.15.1" appears, beneath the submenu probe

•

Press or to select temp. comp.

•

Press >>>> to enter the chosen menu.

process input A is highlighted.

process input Aprocess input A

process input A.

process input Aprocess input A

parameter is highlighted.

parameterparameter

temperature

temperaturetemperature

temp. comp.

temp. comp.temp. comp.

probe is highlighted

probeprobe

• Now you can set up the temperature compensation. Press or to select off

off or linear

offoff

^ to confirm the entered value.

linear. Press

linearlinear

24

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 25

OPTISENS IND 1000

4.3.2 Calibrating the temperature measurement

This section is only required if the measured temperature is not correct.

The temperature is commonly measured with the integrated temperature probe and therefore

step 2a does apply in most cases. In rare cases of a process being very stable in temperature

manual compensation is used and step 2b applies.

Step 2: correcting the temperature measurement

OPERATION

4

Step 2a: probe Pt1000

Read the currently measured temperature of the Pt1000 temperature sensor from the measurement

screen and write it down.

Measure the temperature with a reference thermometer and check if it deviates from the temperature

measured by the Pt1000.

•

•

probe Pt1000

probe Pt1000probe Pt1000

Press >>>> for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu setup

Press or until the main menu setup

MAIN MENU

A quick setup

B test

> C setup

> C setup

> C setup> C setup

D service

•

Press >>>> to enter the chosen menu.

You are on the first submenu level. In the upper line of the display "setup" and "c1" appears,

beneath the submenu process input A

pH is configurated.

•

Press or to select process input A

•

Press >>>> to enter the chosen menu .

You are on the second submenu level. Press or until the submenu temperature

highlighted.

•

Press >>>> to enter the chosen menu.

You are on the third submenu level. Press or until the submenu correction

highlighted.

•

Press >>>> to enter the chosen menu.

•

Press or and to change the reading.

•

Press ^ to confirm the value

setup is highlighted.

setupsetup

process input A is highlighted. Choose process input A or B where ever

process input Aprocess input A

process input A.

process input Aprocess input A

setup is highlighted.

setupsetup

temperature is

temperaturetemperature

correction is

correctioncorrection

• If necessary, enter the temperature correction in Kelvin so that the signal converter shows the

same temperature as the reference thermometer. Press ^ to confirm the entered value. The

temperature sensor has been adjusted.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

25

Page 26

4

OPERATION

OPTISENS IND 1000

Step 2b: probe manual

Measure the temperature of the measuring medium.

•

•

probe manual

probe manualprobe manual

Press >>>> for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu setup

Press or until the main menu setup

MAIN MENU

A quick setup

B test

> C setup

> C setup

> C setup> C setup

D service

•

Press >>>> to enter the chosen menu.

You are on the first submenu level. In the upper line of the display "setup" and "c1" appears,

beneath the submenu process input A

•

Press or to select process input A

•

Press >>>> to enter the chosen menu process input A

You are on the second submenu level. Press or until the submenu temperature

highlighted.

•

Press >>>> to enter the chosen menu. The submenu probe

•

Press or until the submenu manual

•

Press ^ to enter the chosen menu

setup is highlighted.

setupsetup

process input A is highlighted.

process input Aprocess input A

process input A.

process input Aprocess input A

process input A.

process input Aprocess input A

setup is highlighted.

setupsetup

probe is highlighted.

probeprobe

manual is highlighted.

manualmanual

temperature is

temperaturetemperature

• Enter the measured temperature. Press ^ to confirm the entered value. The manually

measured temperature will now be used for temperature compensation.

4.3.3 Calibrating measurement

Verification and in case of need calibration is necessary in regular intervals or good practice

when installing a new sensor. A sensor should be recalibrated if the verification within a

standard solution shows a too high difference in actual reading.

When calibrating a conductivity measurement, keep in mind that the measuring system as a

whole is calibrated, and not only the electrode.

To avoid alarms on the distrubted control system (DLC) when temporarily removing the sensor

(i.e. for maintenance), the converter has a hold function. This function "freezes" all outputs (i.e.

the display and the current outputs) of the last measured value.

INFORMATION!

As an indication that the manual hold function is active, the "warning sign" in the upper left

corner of the display appears. Meanwhile the status messages show "checks in progress". For

more details about how to select the manual hold function refer to the signal converter manual.

26

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 27

OPTISENS IND 1000

After starting-up the signal converter, the measuring screen appears. This is the standard

screen which is displayed automatically in the normal operating mode. If you are in this mode

and you want to initiate a calibration, you have to activate the manual hold function in the first

step.

Step 1: activating the manual hold function

•

Press >>>> for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu quick setup

•

Press or until the main menu quick setup

•

MAIN MENU

> A quick setup

> A quick setup

> A quick setup> A quick setup

B test

Csetup

D service

Press >>>> to enter the chosen menu.

You are on the first submenu level. In the upper line of the display "quick setup" and

A1" appears, beneath the submenu language

•

Press or until the submenu manual hold

•

Press >>>> to enter the chosen menu.

You are on the second submenu level. In the upper line of the display

"manual hold" appears, beneath the option off

•

•

quick setup is highlighted.

quick setupquick setup

quick setup is highlighted.

quick setupquick setup

language is highlighted.

languagelanguage

manual hold is highlighted.

manual holdmanual hold

Press or to choose the option on

Press ^ to confirm the entered value.

OPERATION

off is highlighted

offoff

4

• You have activated the manual hold function. To go to the next step and prepare the calibration

procedure. You have to return to the measuring mode.

• Press ^ until you reach the measuring mode again

Step 2: preparing the calibration procedure

• If you re-calibrate an existing sensor, remove the sensor from its respective assembly

(for further information refer to

Calibrating measurement

Mounting to a flow through assembly

on page 26).

• If you calibrate a sensor, make sure that the sensor is correctly connected to the converter.

• Check the sensor for damages or dirt deposits.

• During the calibration procedure, you will have to dip the sensor into a standard solution.

Provide a suitable vessel.

After activating the manual hold function and the preparative measures, you can get access to

the calibration procedure from the measuring mode via the main menu setup

on page 17 or refer to

setup (step 3).

setupsetup

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

27

Page 28

4

OPERATION

OPTISENS IND 1000

Step 3: accessing the calibration menu via the main menu setup

•

Press >>>> for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu quick setup

•

Press or until the main menu setup

MAIN MENU

A quick setup

B test

> C setup

> C setup

> C setup> C setup

D service

•

Press >>>> to enter the chosen menu.

You are on the first submenu level. In the upper line of the display "setup" and "c1"

appears, beneath the submenu process input A

•

Press or to select process input A

•

Press >>>> to enter the chosen menu.

setup is highlighted.

setupsetup

process input A is highlighted.

process input Aprocess input A

process input A is highlighted.

process input A process input A

You are on the second submenu level. In the upper line of the

display "process input A" and "C1.1" appears, beneath the

submenu parameter

•

•

parameter is highlighted.

parameterparameter

Press or until the submenu cell calibration

Press >>>> to enter the chosen menu.

setup

setupsetup

quick setup is highlighted.

quick setupquick setup

cell calibration is highlighted.

cell calibrationcell calibration

• You can start the calibration procedure now as described in "Step 4".

28

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 29

OPTISENS IND 1000

Put sensor into the calibration solution!

Step 4: calibration procedure

• After choosing the submenu cell calibration

pressing >>>>.

i The signal converter demands to choose the kind of temperature compensation for the

calibration. You have the options "off", "automatic" and "manual" (for detailed information

refer to

temperature compensation for the calibration as for the measurement. Recommended and

most common setting for this type of measurement with integrated temperature sensor is

"automatic".

• If you chose "automatic", just press ^^^^. If you chose "manual", first enter the temperature of

the measured medium using or and then press ^^^^.

i On the screen the message spec.conductivity

• Enter the specific conductivity in mS/cm (or µS/cm if chosen as unit). Using

the single digits and >>>> to move right.

i Ones the value of the used standard (calibration solution) is displayed correctly press ^

• The signal converter performs directly a cell factor calibration which takes 25 seconds.

i On the screen the message cell constant appears

cell calibration (step 3) in the previous step, continue by

cell calibrationcell calibration

Temperature compensation

spec.conductivity appears.

spec.conductivityspec.conductivity

OPERATION

on page 23). Please select the same kind of

or to change

^.

^^

4

• The newly calculated cell constant is shown. Press ^^^^ to confirm

i The signal converter now asks store cal. value?

• Choose yes

• Press ^^^^ to confirm.

yes to store the calibration values. Choose no

yesyes

no to discard the results.

nono

i You have completed the calibration.

• If you want to return to the measuring mode, press ^^^^ several times until you reach this mode.

i You might get asked "Save configuration?" and choose either yes

• Press ^^^^ to confirm.

yes or no

no.

yesyes

nono

i You are back in the meaurement mode.

INFORMATION!

The "stored value" is a calculated value based on the actual measurement. The signal converter

calculates this value depending on the compensation methods (temperature compensation)

chosen for the calibration. Do not change the compensation method in the time between the

measurement of the "stored value" and the input of the reference value. Otherwise this could

result in a wrong calibration.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

29

Page 30

4

OPERATION

4.3.4 Calibration log

INFORMATION!

In order to show the history of the calibrations, the converter has a calibration logbook function.

Up to 64 entries of the calibration history are stored including date and time.

Accessing the calibtration log

•

Press >>>> for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu quick setup

•

Press or until the main menu test

MAIN MENU

A quick setup

> B test

> B test

> B test> B test

C setup

D service

Press >>>> to enter the chosen menu.

OPTISENS IND 1000

quick setup is highlighted.

quick setupquick setup

test is highlighted.

testtest

You are on the first submenu level. In the upper line of the display "test" and "B1" appears,

beneath the submenu sim.process input A

Press or until the submenu logbooks

Press >>>> to enter the chosen menu.

You are on the second submenu level. In the upper line of the display "logbooks" and

"B5.1" appears, beneath the submenu status log

Press or until the submenu calibration log

Press >>>> to enter the chosen menu.

sim.process input A is highlighted.

sim.process input Asim.process input A

logbooks is highlighted.

logbookslogbooks

status log is highlighted.

status logstatus log

calibration log is highlighted.

calibration logcalibration log

• You are on the data level and you see the calibration history. With the help of or you can

scroll through the different entries.

• If you want to return to the measuring mode press ^^^^ several times until you reach this mode.

4.4 Troubleshooting

Problem Possible cause Remedy

Signal converter shows:

application error sensor in

electronic A/B.

Sensor in air or not in solution

with correct conductivity range.

Put the sensor into a solution

with a minimum conductivity of:

cell factor * 100 µS/cm. This is

for the sensor in PP > 625 µS/cm.

30

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 31

OPTISENS IND 1000

5.1 Maintenance

5.1.1 Cleaning

• Clean the sensor surface with water and brush.

• Slight dirt residues or dust: Rinse the sensor with water and clean it with a cloth or tissue.

• Oily and greasy coatings: Remove with a warm soap solution and rinse with water.

• Hardness deposits or metal hydroxide deposits: Remove with 10% citric acid or diluted

hydrochloric acid and rinse with water.

5.2 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

SERVICE

5

5.3 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

5.4 Returning the device to the manufacturer

5.4.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of the personnel, the manufacturer may only handle, test and repair returned devices

that have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, radioactive, flammable or water-endangering

products, you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

31

Page 32

5

SERVICE

5.4.2 Form (for copying) to accompany a returned device

CAUTION!

To avoid any risk for our service personnel, this form has to be accessible from outside of the

packaging with the returned device.

Company: Address:

Department: Name:

Tel. no.: Fax no. and/or Email address:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

This medium is: radioactive

water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such substances.

We have flushed out and neutralized all cavities in the device.

OPTISENS IND 1000

We hereby confirm that there is no risk to persons or the environment through any residual media contained in the

device when it is returned.

Date: Signature:

Stamp:

5.5 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:

Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:

Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:

According to the directive 2012/19/EU, the monitoring and control instruments marked with the

WEEE symbol and reaching their end-of-life must not be disposed of with other waste

The user must dispose of the WEEE to a designated collection point for the recycling of WEEE or

send them back to our local organisation or authorised representative.

must not be disposed of with other waste.

must not be disposed of with other wastemust not be disposed of with other waste

32

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 33

OPTISENS IND 1000

6.1 Measuring principle

6.1.1 Inductive conductivity measurement

The inductive measurement method enables largely maintenance-free acquisition of specific

conductivity, even in the toughest media conditions. In the principle of inductive measurement,

the sensor consists of a sender-recipient-coil.

When a magnetic field is generated by an electrical coil and a second electrical coil is placed

next to it, a certain amount of electric energy will be transferred to it. In an inductive conductivity

sensor, the process media flows directly through the middle of both coils. The amount of energy

transferred from the primary to the secondary coil is directly proportional to the electrical

resistance of the solution.

TECHNICAL DATA

6

Figure 6-1: Inductive measurement

1 Flow direction

2 Sinusoidal AC voltage supply

3 Induced voltage measurement

4 Exposed temperature sensor Pt1000

5 Measuring medium

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

33

Page 34

6

TECHNICAL DATA

6.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle Inductive conductivity - toroidal

Measuring range 0.625…2000 mS/cm (if c=6.25)

Lowest detection limit Cell factor x 100 µS/cm

Design

Construction PP or PVDF - body material

Cell constant c= 6.25 1/cm (PP), c= 4.65 1/cm (PVDF)

Process connection pipe

installation

Process connection open

channel installation

Temperature sensor Pt1000

OPTISENS IND 1000

G1½ (PVC or stainless steel)

Immersion assembly (only PP version)

PP version: exposed or sealed Pt1000

PVDF version: only sealed Pt1000

Measuring accuracy

Conductivity accuracy ≤ 1% (measuring range)

Temperature accuracy ≤ 0.5% (measuring range)

Operating conditions

Temperature range PP version: -10…+60°C / +14…+140°F

Max. operating pressure PP version:

Max. 15 min. at 100°C

PVDF version: -10…+100°C / +14…+212°F

Max. 15 min. at 110°C

PVC process connection: -10…+60°C / +14…+140°F

min. -0.1 bar at -10°C...+80°C / min. -1.45 psi at +14°F...+176°F

10 bar at +20°C / 145 psi at +68°F

6bar at +50°C / 87 psi at 122°F

0bar at +60°C / 0 psi at 140°F

PVDF version:

min. -0.1 bar at -10°C...100°C / min. -1.45 psi at 14°F...212°F

10 bar at +20°C / 145 psi at +68°F

6bar at +60°C / 87 psi at 140°F

4bar at +80°C / 58 psi at 176°F

0 bar at +100°C / 0 psi at 212°F

Installation conditions

Process connection Pipe installation with G1½ PVC or stainless steel union nut

Immersion version

34

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 35

OPTISENS IND 1000

Electrical connection

Cable Attached cable

Cable options Core end sleeves

Cable length 10 m / 33 ft

6.3 Dimensions

9.2 m / 30 ft. (1 meter immersion version)

8.2 / 26 ft. ( 2 meter immersion version)

TECHNICAL DATA

6

Figure 6-2: Sensor

a 145 5.7

b 118 4.65

c 81 3.2

d 67 2.64

e 44.5 1.75

f 41 1.6

g 36.5 1.44

Dimensions [mm] Dimensions [inch]

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

35

Page 36

6

TECHNICAL DATA

Figure 6-3: Flow-through assembly (T-piece)

OPTISENS IND 1000

DN a [mm / inch] øb [mm / inch] Material Max. Temp.

32 88 / 3.46 40 / 1.57 PP +60°C / +140°F

40 102 / 4.02 50 / 1.97

50 124 / 4.88 63 / 2.48

36

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 37

OPTISENS IND 1000

TECHNICAL DATA

6

Figure 6-4: Immersions assembly

Dimensions [mm] Dimensions [inch]

a 21 0.83

b 120 +/- 10 4.72 +/- 0.4

c 1000 / 2000 39.37 / 78.74

d 44.5 1.75

e 40 1.57

f 40 1.57

g 22 0.87

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

37

Page 38

7

NOTES

OPTISENS IND 1000

38

www.krohne.com 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

Page 39

OPTISENS IND 1000

NOTES

7

www.krohne.com12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en

39

Page 40

KROHNE – Process instrumentation and measurement solutions

•

Flow

•

Level

•

Temperature

•

Pressure

•

Process Analysis

•

Services

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.: +49 203 301 0

Fax: +49 203 301 10389

info@krohne.com

© KROHNE 12/2016 - 4001969202 - MA OPTISENS IND 1000 R02 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...