KROHNE IFC 300 Specifications

Technical Datasheet

Technical Datasheet

IFC 300

IFC 300

IFC 300IFC 300

Technical DatasheetTechnical Datasheet

Signal converter for electromagnetic flowmeters

•

All-round signal converter matches almost any application requirement

•

Reliable measurements with extensive diagnostics of device and application

•

Wide range of communication options including PROFINET

The documentation is only complete when used in combination with the relevant

documentation for the flow sensor.

© KROHNE 08/2017 - 4000295604 - TD IFC 300 R07 en

CONTENTS

IFC 300

1 Product features 4

1.1 The versatile solution ....................................................................................................... 4

1.2 Options and variants......................................................................................................... 6

1.3 Possible scope of delivery for signal converter / flow sensor......................................... 9

1.4 Measuring principle........................................................................................................10

2 Technical data 11

2.1 Technical data................................................................................................................. 11

2.2 Dimensions and weight .................................................................................................. 24

2.2.1 Housing ................................................................................................................................. 24

2.2.2 Mounting plate of field housing ............................................................................................ 25

2.2.3 Mounting plate of wall-mounted housing ............................................................................ 25

2.3 Flow tables ..................................................................................................................... 26

2.4 Measuring accuracy (except TIDALFLUX 2000) ............................................................. 28

2.5 Measuring accuracy (only TIDALFLUX 2000) ................................................................. 29

3 Installation 30

3.1 Intended use ................................................................................................................... 30

3.2 Installation specifications .............................................................................................. 30

3.3 Mounting of the compact version................................................................................... 30

3.4 Mounting the field housing, remote version .................................................................. 31

3.4.1 Pipe mounting ....................................................................................................................... 31

3.4.2 Wall mounting....................................................................................................................... 32

3.5 Mounting the wall-mounted housing, remote version .................................................. 33

3.5.1 Pipe mounting ....................................................................................................................... 33

3.5.2 Wall mounting....................................................................................................................... 34

4 Electrical connections 35

4.1 Important notes on electrical connection...................................................................... 35

4.2 Preparing the signal and field current cables (except TIDALFLUX) ............................. 35

4.2.1 Signal cable A (type DS 300), construction........................................................................... 35

4.2.2 Length of signal cable A........................................................................................................ 36

4.2.3 Signal cable B (type BTS 300), construction......................................................................... 37

4.2.4 Length of signal cable B ....................................................................................................... 38

4.3 Connecting the signal and field current cables (except TIDALFLUX) ........................... 39

4.3.1 Connection diagram for flow sensor, field housing ............................................................. 39

4.3.2 Connection diagram for flow sensor, wall-mounted housing ............................................. 40

4.3.3 Connection diagram for flow sensor, 19" rack-mounted housing (28 TE) .......................... 41

4.3.4 Connection diagram for flow sensor, 19" rack-mounted housing (21 TE) .......................... 42

2

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

IFC 300

CONTENTS

4.4 Electrical connection only for TIDALFLUX 2000 ............................................................ 43

4.5 Connecting power - all housing variants ....................................................................... 43

4.6 Inputs and outputs, overview ......................................................................................... 46

4.6.1 Combinations of the inputs/outputs (I/Os) ........................................................................... 46

4.6.2 Description of the CG number .............................................................................................. 47

4.6.3 Fixed, non-alterable input/output versions.......................................................................... 48

4.6.4 Alterable input/output versions............................................................................................ 50

5 Notes 51

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

3

1

PRODUCT FEATURES

1.1 The versatile solution

The IFC 300

IFC 300 is a very complete signal converter, featuring a wide range of variants and options to

IFC 300IFC 300

match almost any application requirements in process industries.

The robust and reliable signal converter is compatible with almost any flow sensor in the

OPTIFLUX and WATERFLUX range. Its measurement performance is excellent even in more

difficult applications like mediums with low conductivity or mediums with high solid content or

entrained air, corrosive and or abrasive mediums. The signal converter is approved to a wide

range of custody transfer regulations (OIML, MID).

The IFC 300 is designed according to the unified General Device Concept (GDC) that is used for

the volume flow, mass flow and analysis converters. The design concept offers an uniform user

interface and menu structure and also an uniform electronics suitable for various housings,

uniform device and process diagnostics functions and uniform communication interfaces. This

offers great time and cost benefits with regard to procurement, engineering, operation and

servicing.

The IFC 300

IFC 300 signal converter provides a largest variety of flowmeter and process diagnostic

IFC 300IFC 300

functions guaranteeing reliable measurements. Detection of deposits or coating on the

electrodes, temperature and conductivity changes in the medium, gas bubbles or solids, and an

empty pipe are good examples of process diagnostics functions. The flow velocity and volume

can be read from the display or in analogue form via the current output (4...20 mA) as well as by

frequency or pulse outputs. Measuring values and diagnostic information can be transmitted via

field bus interfaces including HART

PROFINET IO.

®

, RS485 Modbus, FOUNDATION™ Fieldbus, PROFIBUS

IFC 300

®

and

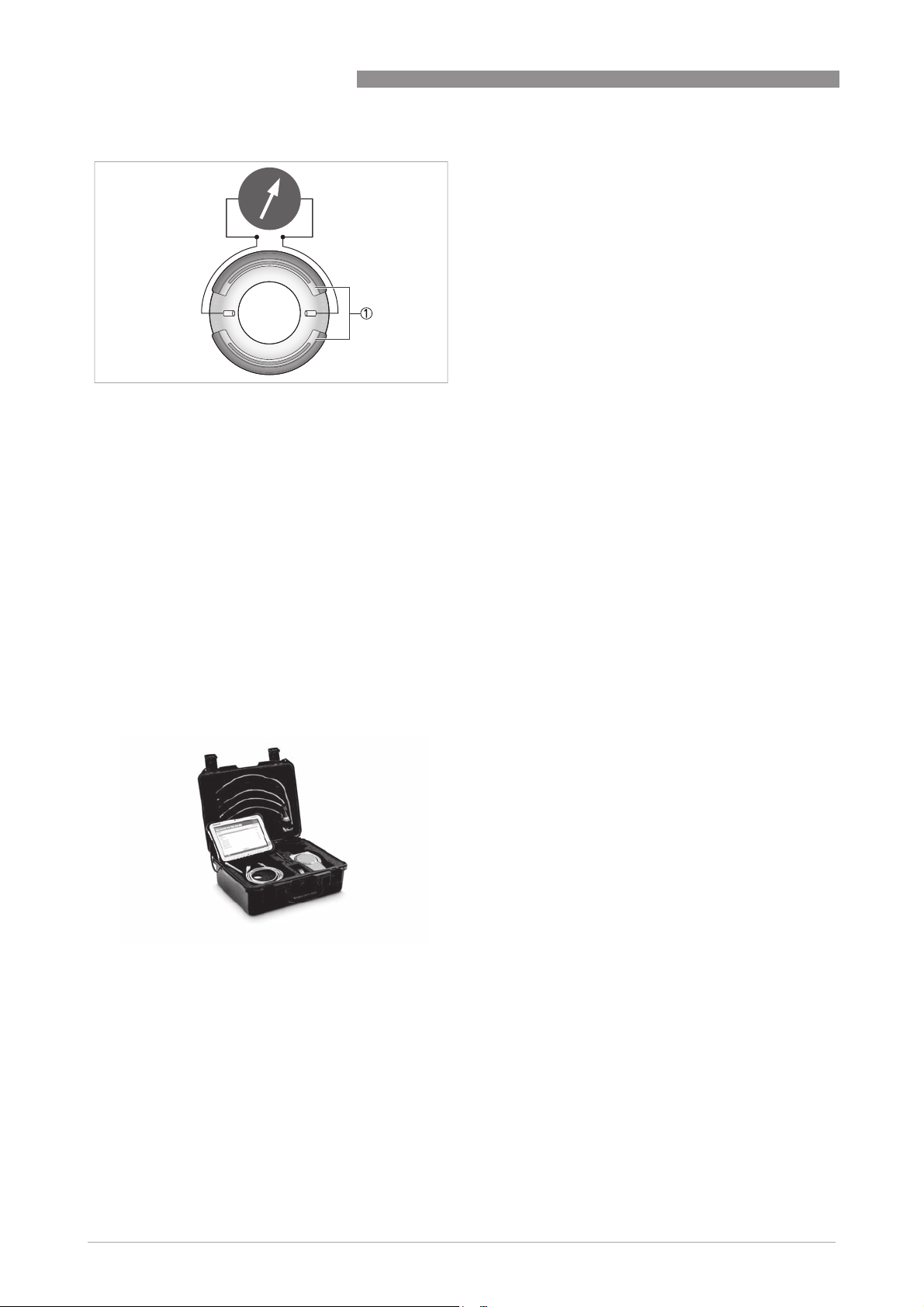

(signal converter in compact housing)

1 Large graphic display with backlit with graphics

2 Configuration with infrared interface for reading and writing all parameters (option)

3 Optical buttons (4) for operator control without opening the housing

4 Intuitive navigation and quick setup menu in 18 operating languages

5 Any combination of up to 4 outputs and inputs

6 Communication interfaces including HART

4

®

, Modbus, FOUNDATION™ Fieldbus, PROFIBUS

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

®

and PROFINET IO

IFC 300

PRODUCT FEATURES

Highlights

• For operation with complete OPTIFLUX and WATERFLUX flow sensor line

• For flow sensors over a diameter range of DN2.5...3000 / 1/10…120"

• Continuous measurement of volume flow and flow velocity

Integrated conductivity measurement, mass flow (at constant density) and coil temperature

• High measuring accuracy and long-term stability: ±0.15% of measured value ± 1 mm/s

• Optimal zero point stability independent from product properties

• Power supply via 100…230 VAC (standard) or 24 VDC or 24 VAC/DC (optional)

• Superior process reliability thanks to standard integrated diagnostics: testing of device

functions, check for compliance with specifications and application testing

®

• Available inputs and outputs: Current output (including HART

status output, control input and current input

• Communication interfaces for integration into third party systems via HART

®

Modbus, FOUNDATION™ Fieldbus, PROFIBUS

• Wide range of custody transfer approvals including OIML R 49 and R 117-1, MI-001, MI-004

and MI-005

and PROFINET IO

), pulse/frequency output,

®

(as standard),

1

Industries

• Chemicals

• Water & Wastewater

• Machinery

• Pulp & Paper

• Minerals & Mining

• Food & Beverage

• Oil production & Refineries

• HVAC, energy management

Applications

• Volume flow measurements, process control and monitoring, blending, batching

• Mediums with low conductivity, high solid content or entrained air

• Sudden change in pH value

• Pulsating or turbulent flows

• Abrasive sludge and slurries, pastes

• Wide range of corrosive chemicals

• (Sea)Water flow measurements in a wide range of industries

• Well water injection

• Custody transfer

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

5

1

PRODUCT FEATURES

1.2 Options and variants

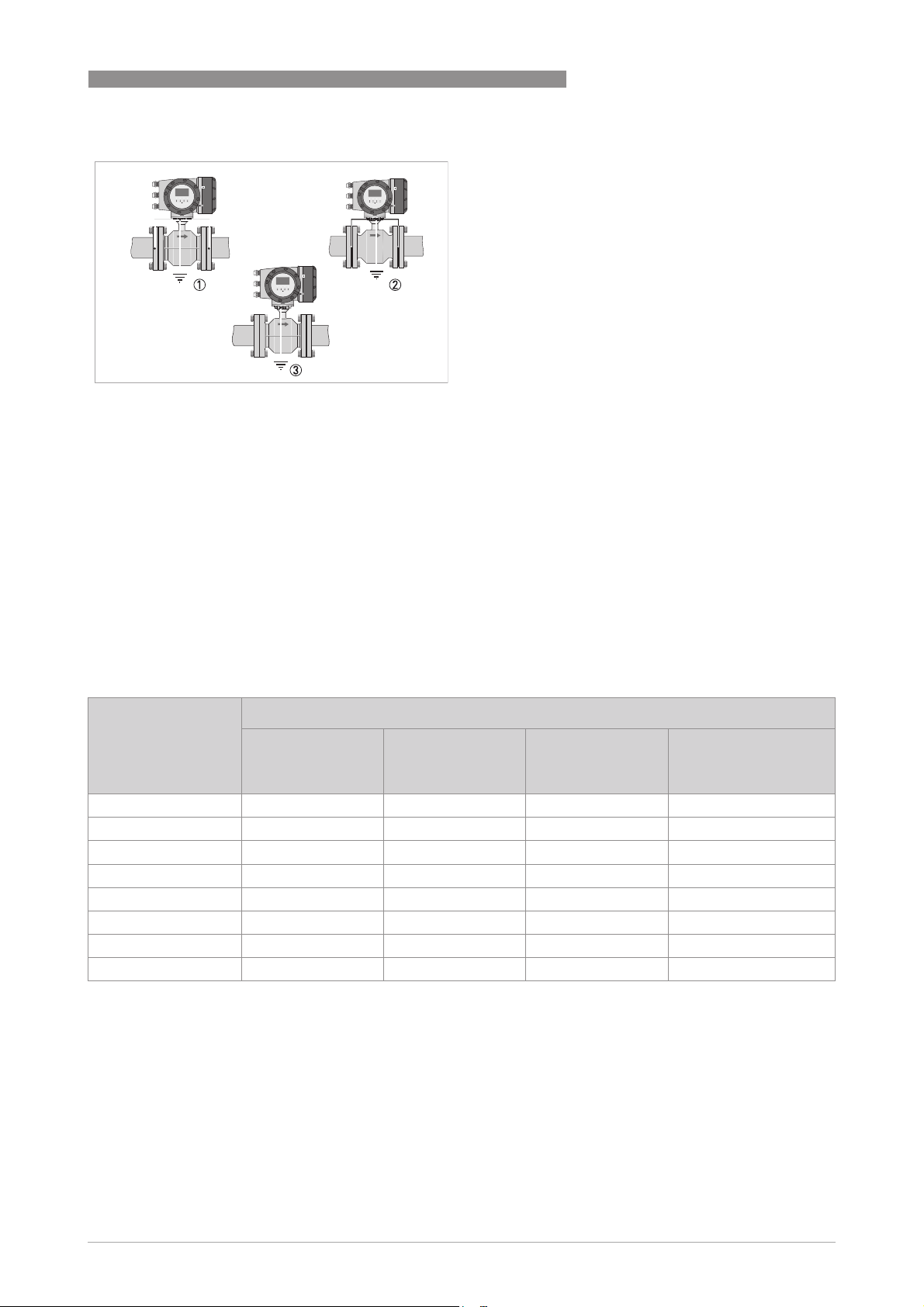

IFC 300

Compact or remote housing variants

Compact or remote housing variants

Compact or remote housing variantsCompact or remote housing variants

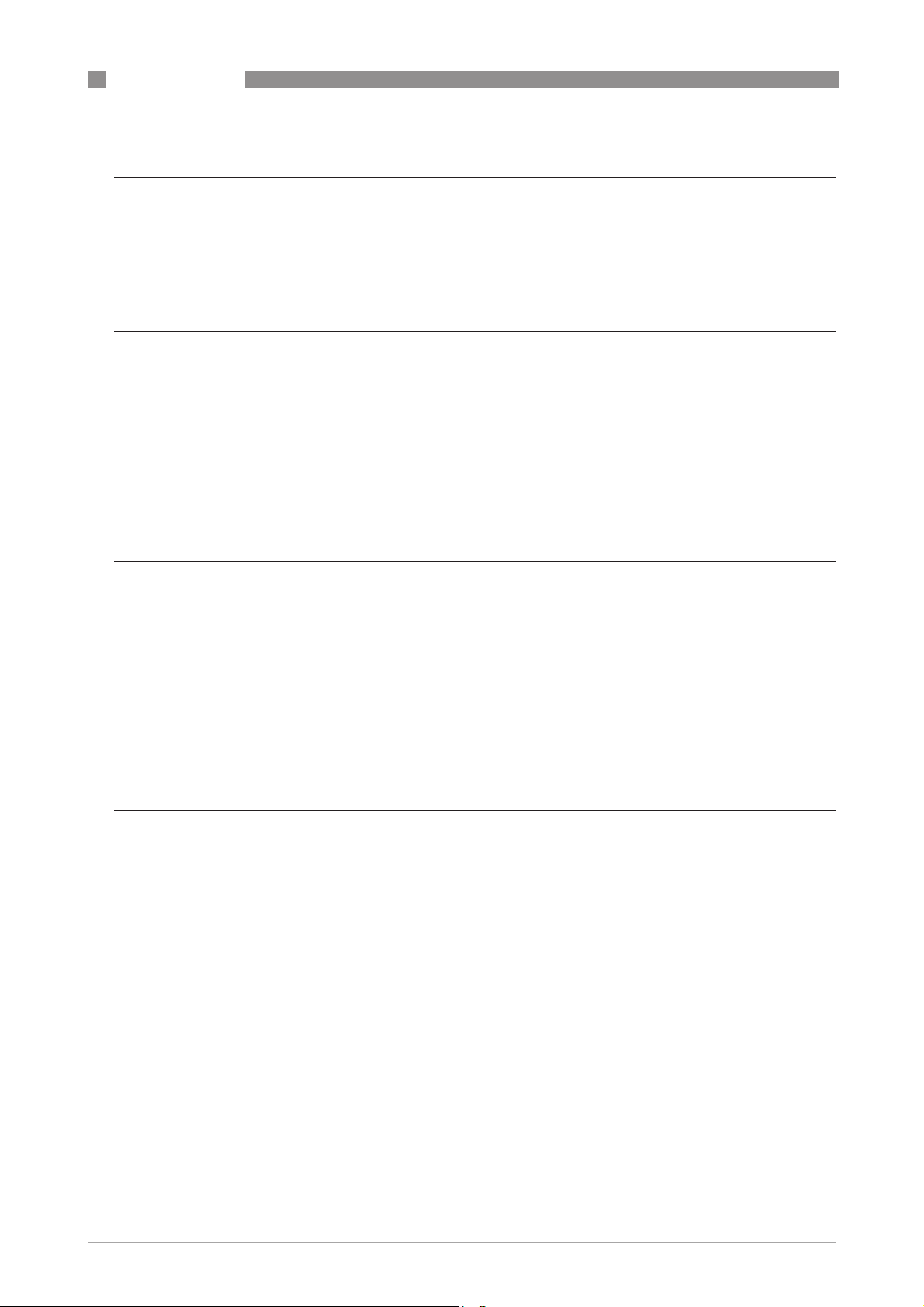

The IFC 300 signal converter is available in four housing

variants, of which one compact design and three remote

designs.

Next to a field housing there is a wall-mounted housing

and a 19" rack mounted housing.

The wall mounted signal converter can be installed

remotely for locations where the flow sensor is difficult to

access, or ambient temperature conditions or vibrations

prevent a compact variant.

(signal converter in compact housing)

(signal converter in field housing)

The signal converter in the 19" built rack mounted housing

is typically used in a central control room.

IFC 300 for hazardous areas

IFC 300 for hazardous areas

IFC 300 for hazardous areasIFC 300 for hazardous areas

The compact and field housing versions of the IFC 300

signal converter are available in a variant suitable for

hazardous areas with approvals to for example ATEX, IEC,

IA, FM, CSA, NEPSI and INMETRO.

IFC 300 in stainless steel housing (option)

IFC 300 in stainless steel housing (option)

IFC 300 in stainless steel housing (option)IFC 300 in stainless steel housing (option)

Whereas the standard housing material for the IFC 300 is

die-cast aluminium with a polyester topcoat, the compact

and the field version of the IFC 300 can optionally be

ordered in a stainless steel housing. The robust housing is

suitable for many applications in more harsh process

environments.

(signal converter in wall-mounted housing)

(signal converter in 19" rack-mounted

housing;

option 28 TE or 21 TE)

6

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

IFC 300

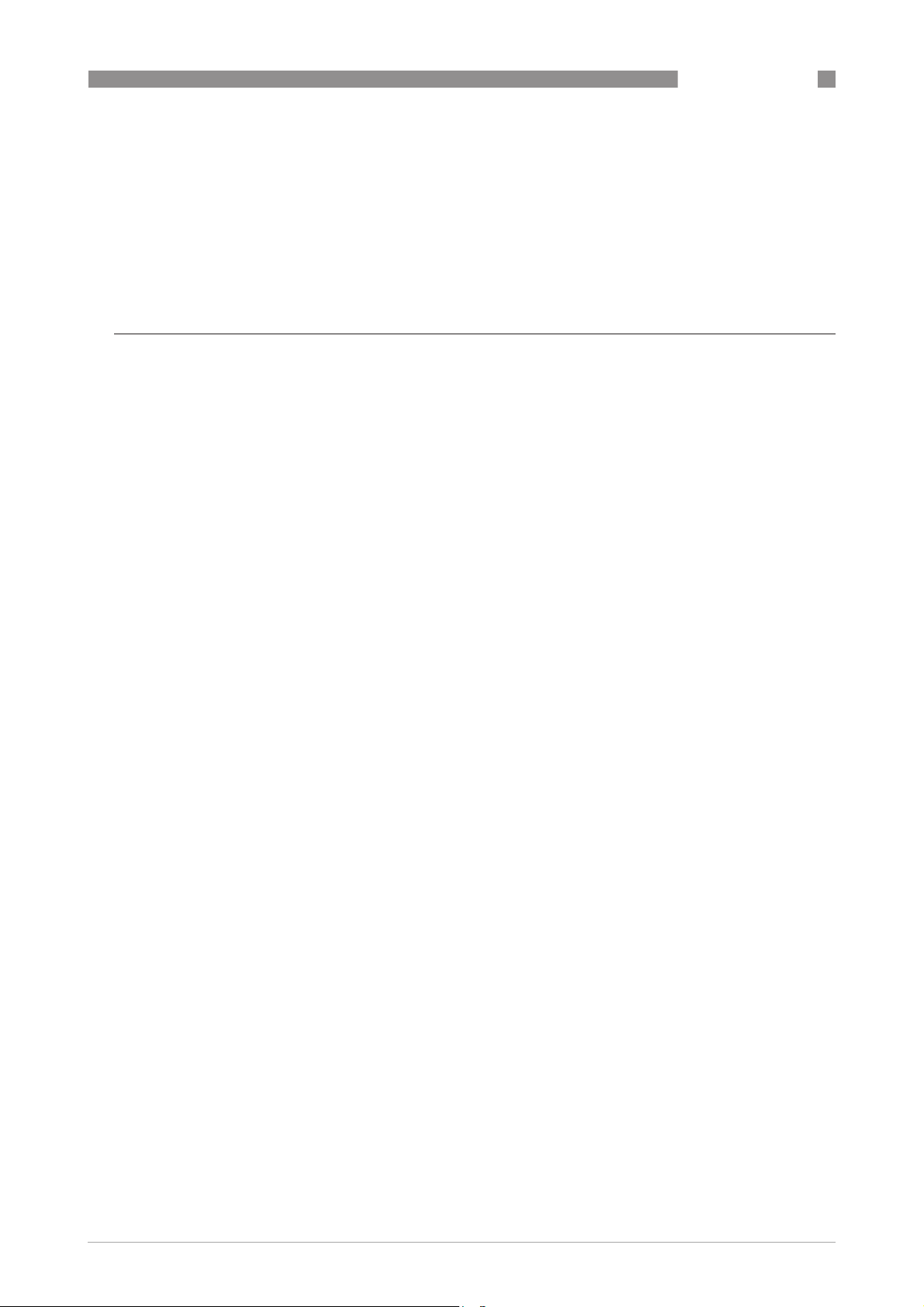

1 Monitoring system

2 Gateway

3 Flowmeter

PRODUCT FEATURES

Communication options

Communication options

Communication optionsCommunication options

The basic signal converter variant covers a current

®

output including HART

status output, control input and a current input.

The modular input/output variant allows for any

combination of up to four inputs and outputs. All

inputs and outputs are galvanically isolated from

each other and from the rest of the electronic

equipment. Inputs and outputs can be passive or

active.

In addition, the electronics can be equipped with

fieldbus functionality including Foundation Fieldbus,

Profibus PA/DP, Modbus or PROFINET IO to enable

communication to any third party system.

, pulse/ frequency output,

1

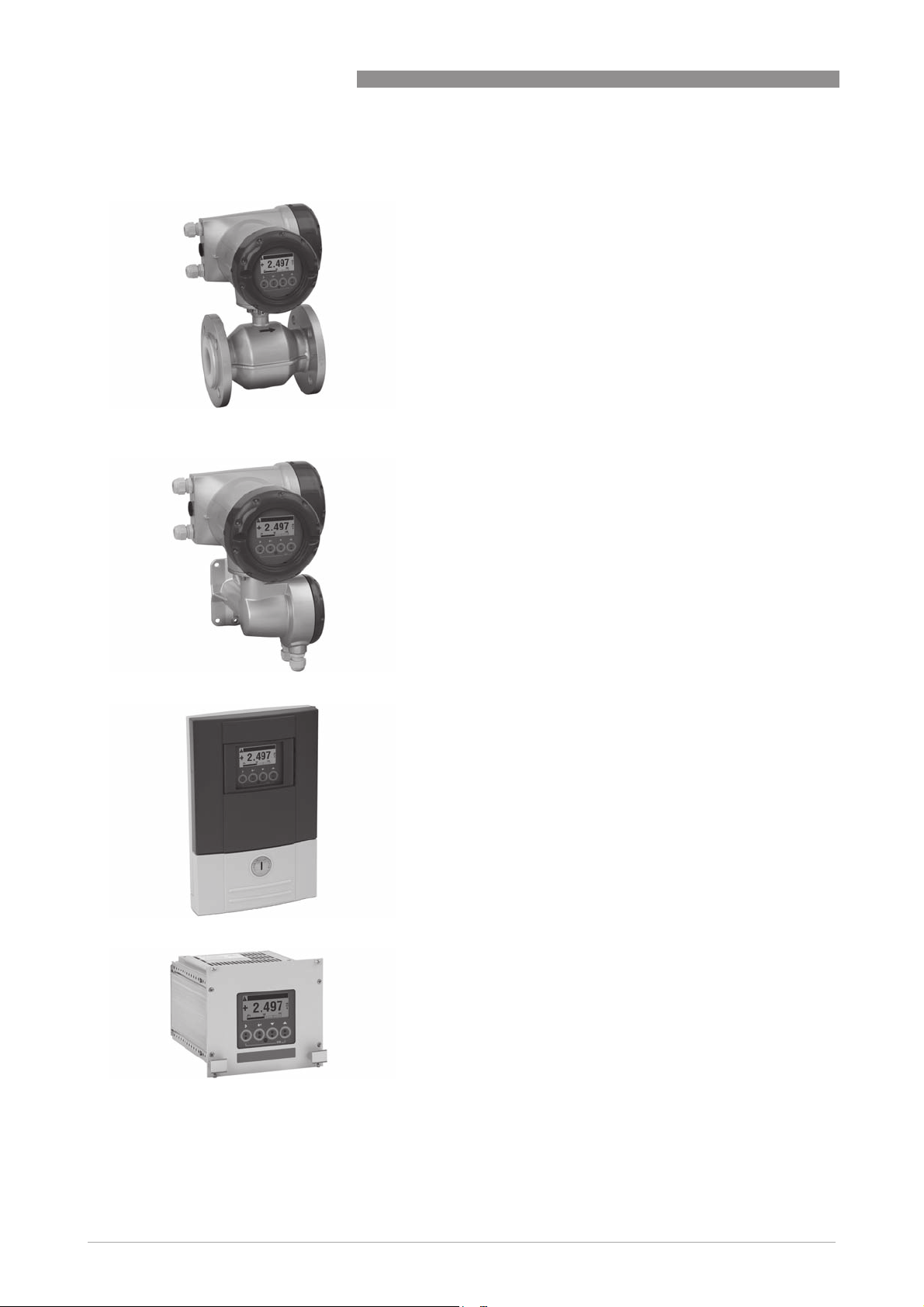

(1. point-to-point or star communication)

New: PROFINET IO option

New: PROFINET IO option

New: PROFINET IO optionNew: PROFINET IO option

With PROFINET IO, real time Ethernet can be

connected to IoT scenarios.

The use of existing, legacy, industry-grade devices

(e.g. PROFINET flow sensors, actuators and

Programmable Logic Controllers (PLC’s)) enables a

new architecture to be used across the Internet.

An unique network topology:

1. Working with point-to-point or star

communication using a single Ethernet port and an

external switch.

2. Using ring or line communication there are two

Ethernet ports available controlled by an internal

switch.

(2. ring or line communication)

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

7

1

PRODUCT FEATURES

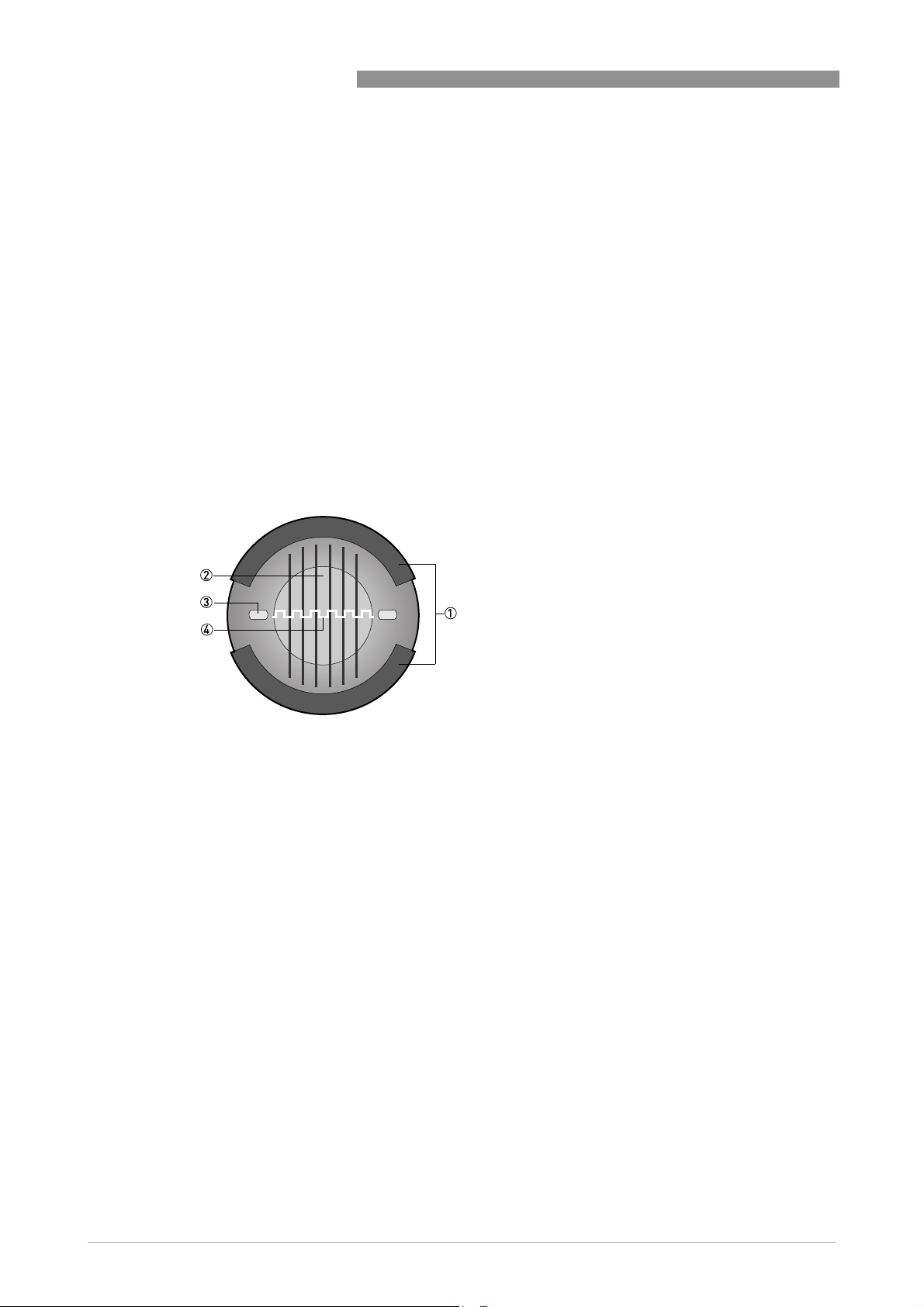

(Resistance measurement)

1 Coils

IFC 300

Extensive diagnostics of the device and application

Extensive diagnostics of the device and application

Extensive diagnostics of the device and applicationExtensive diagnostics of the device and application

The primary focus of a user for a flowmeter is that it

delivers reliable and robust measurements.

To achieve this all electromagnetic flowmeters are

calibrated before leaving the factory.

In addition, KROHNE was one of the first to introduce

extensive diagnostic features.

The IFC 300 provides a wide range diagnostic

functions on the flow sensor, signal converter and

process integrated in the signal converter.

The IFC 300 automatically performs an online

cyclical verification to determine whether the

measuring device is still within its specifications

regarding accuracy and linearity.

Potential problems that may occur in the process

including gas bubbles, solids, electrode corrosion,

deposits on electrodes, conductivity changes, empty

pipe, partial filling of the sensor, disrupted flow

profiles.

(Suitcase with OPTICHECK and all cables and

accessories)

External magnetic fields can be detected by the

IFC 300 diagnostics features.

Diagnostic info available via local display, status

outputs, Fieldbuses, Pactware or the OPTICHECK.

OPTICHECK tool for on-site verification

OPTICHECK tool for on-site verification

OPTICHECK tool for on-site verificationOPTICHECK tool for on-site verification

The OPTICHECK provides an inline health check of

the device under test by an external tool.

When the tool is connected on site, it gathers

measuring data to ensure that the flowmeter

performs within 1% of its factory calibration.

The baseline can be historic repair data from the

factory or on-site test results after performing a full

verification.

A hard copy of the verification report can be printed

for every flowmeter. The verification data are

digitally stored.

Contact us for more information or for an on-site

service visit.

8

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

IFC 300

1 Metal pipes

2 Non metal pipes

3 Virtual reference option

PRODUCT FEATURES

Virtual reference option simplifies installation

Virtual reference option simplifies installation

Virtual reference option simplifies installationVirtual reference option simplifies installation

Based on a special method, developed by KROHNE,

called virtual reference or grounding,

electromagnetic flowmeters can be installed in any

type of pipeline, without grounding rings or

electrodes.

The virtual reference option on the IFC 300 provides

complete isolation of the signal converters input

amplifier and coil power circuits.

It is ideal for applications in the water and

wastewater industry where large diameters are

common or in case of abrasive or corrosive

application that require rings of expensive materials.

In these case the costs for grounding rings can be

substantial.

Virtual reference also increases safety as it

decreases the number of potential leakage points.

1

Furthermore it is no longer necessary to select the

right grounding ring (material) and reduces the risk

of wrong installation of grounding rings and gaskets.

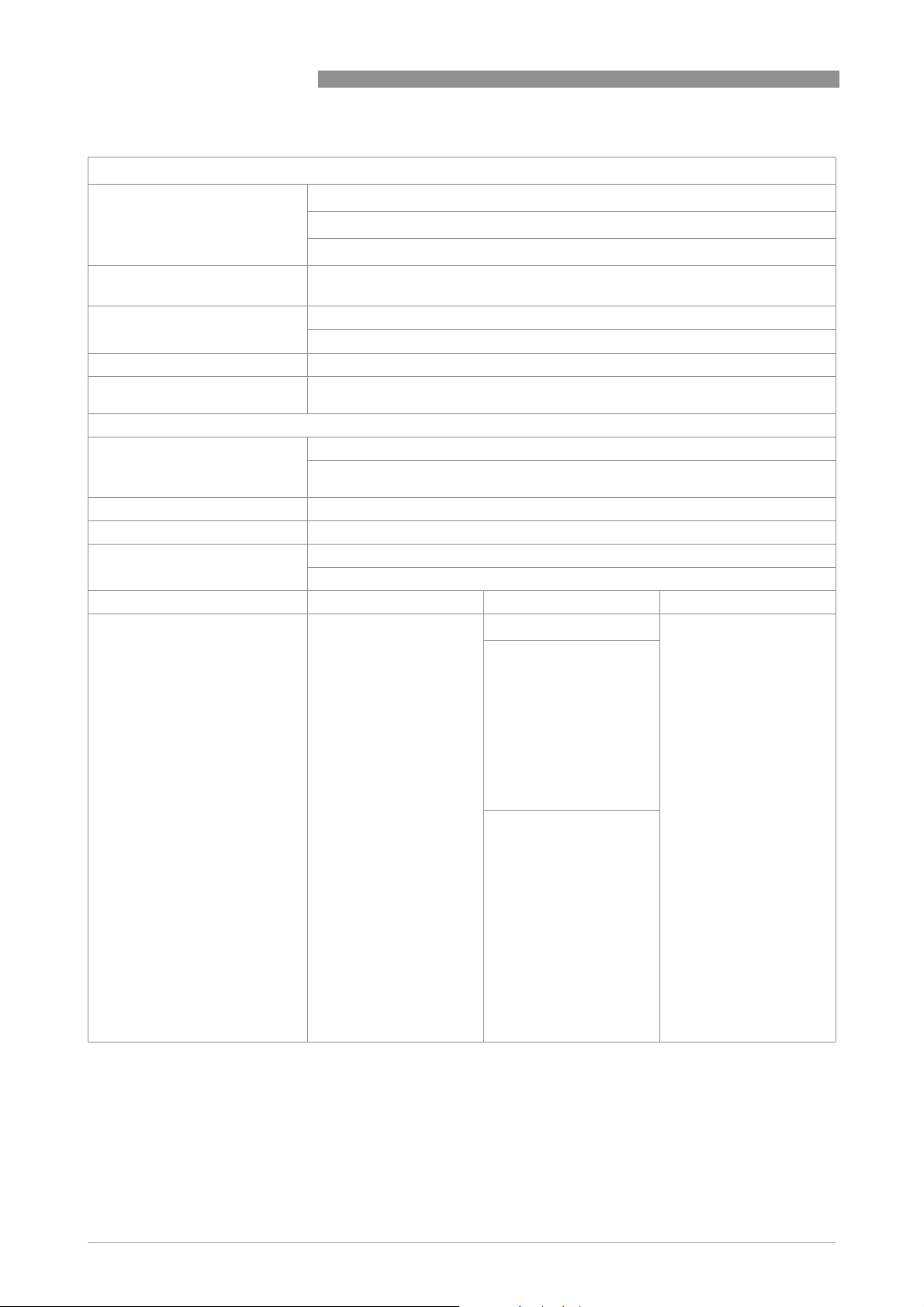

1.3 Possible scope of delivery for signal converter / flow sensor

Flow sensor Flow sensor + signal converter IFC 300

Compact Remote field

housing

OPTIFLUX 1000 OPTIFLUX 1300 C OPTIFLUX 1300 F OPTIFLUX 1300 W OPTIFLUX 1300 R

OPTIFLUX 2000 OPTIFLUX 2300 C OPTIFLUX 2300 F OPTIFLUX 2300 W OPTIFLUX 2300 R

OPTIFLUX 4000 OPTIFLUX 4300 C OPTIFLUX 4300 F OPTIFLUX 4300 W OPTIFLUX 4300 R

OPTIFLUX 5000 OPTIFLUX 5300 C OPTIFLUX 5300 F OPTIFLUX 5300 W OPTIFLUX 5300 R

OPTIFLUX 6000 OPTIFLUX 6300 C OPTIFLUX 6300 F OPTIFLUX 6300 W OPTIFLUX 6300 R

OPTIFLUX 7000 OPTIFLUX 7300 C - - -

WATERFLUX 3000 WATERFLUX 3300 C WATERFLUX 3300 F WATERFLUX 3300 W WATERFLUX 3300 R

TIDALFLUX 2000 - TIDALFLUX 2300 F - -

Remote wallmounted housing

Remote rack-mounted

housing

R (28 TE) or (21 TE)

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

9

1

PRODUCT FEATURES

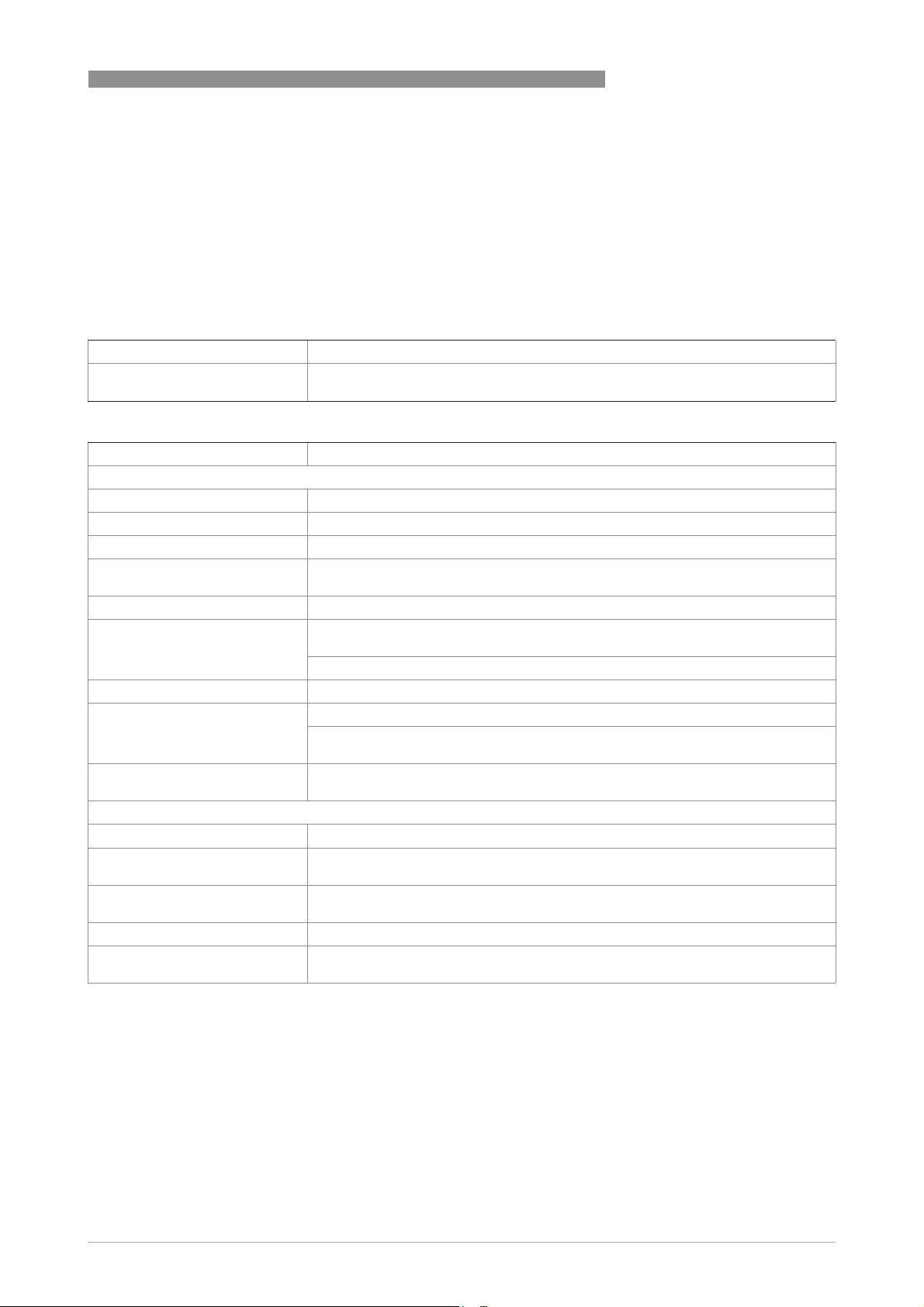

1.4 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils.

Inside of the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flowmeter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate Q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalizing, recording and output processing.

IFC 300

Figure 1-1: Measuring principle

1 Field coils

2 Magnetic field

3 Electrodes

4 Induced voltage (proportional to flow velocity)

10

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

IFC 300

TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

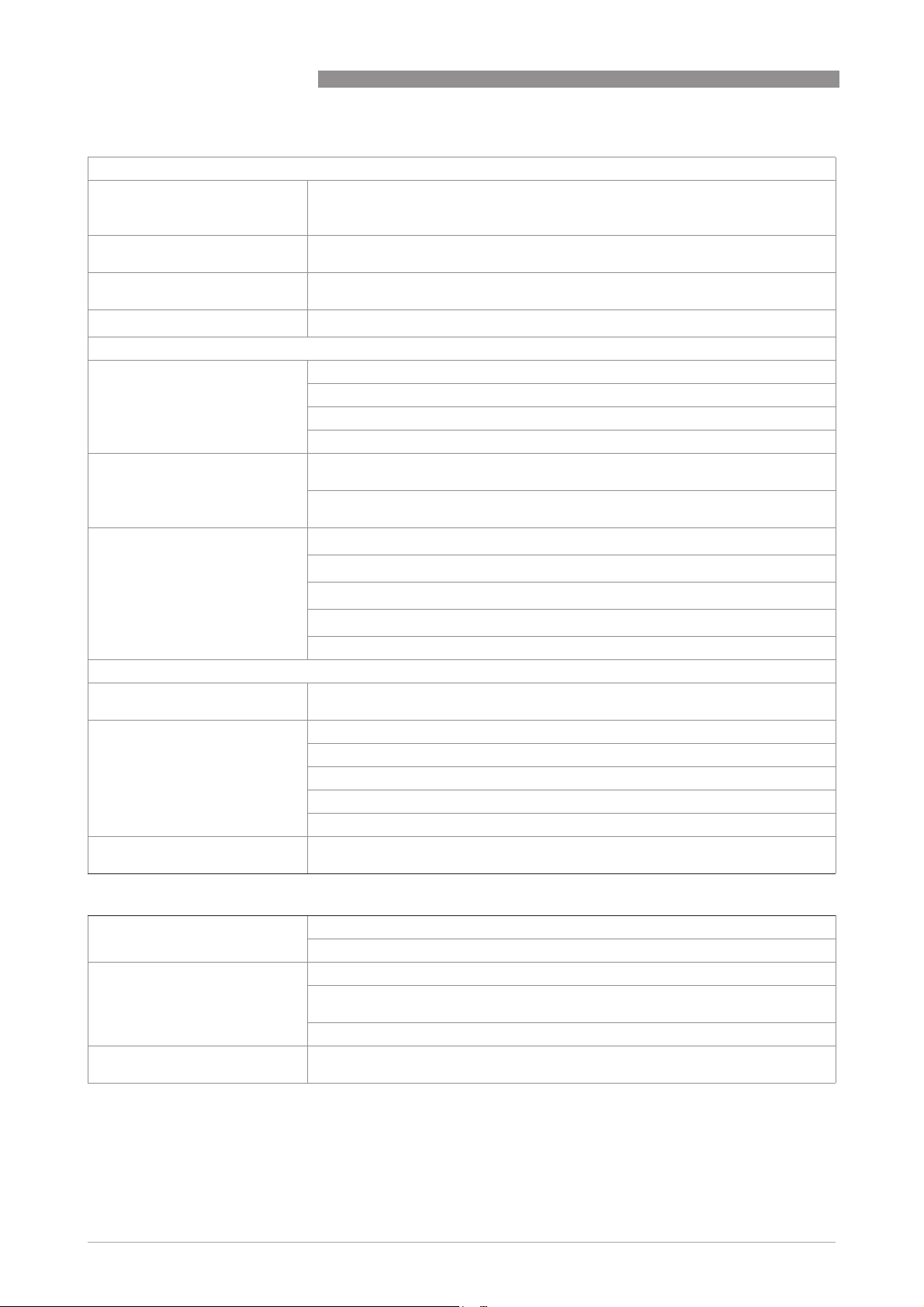

Measuring system

Measuring principle Faraday's law of induction

Application range Continuous measurement of current volume flow, flow velocity, conductivity, mass

Design

Modular design The measuring system consists of a flow sensor and a signal converter.

Flow sensor

Flow sensor

Flow sensorFlow sensor

OPTIFLUX 1000 DN10...150 / 3/8…6"

OPTIFLUX 2000 DN25...3000 / 1…120"

OPTIFLUX 4000 DN2.5...3000 / 1/10…120"

OPTIFLUX 5000 Flange: DN15...300 / 1/2…12"

OPTIFLUX 6000 DN2.5...150 / 1/10…6"

OPTIFLUX 7000 Flange: DN25...100 / 1…4"

WATERFLUX 3000 DN25...600 / 1...24"

TIDALFLUX 2000 DN200...1600 / 8...64"

Signal converter

Signal converter

Signal converterSignal converter

Compact version (C) OPTIFLUX x300 C (x = 1, 2, 4, 5, 6, 7) or WATERFLUX 3300 C

Field housing (F) remote version

Wall-mounted housing (W) remote version

19" rack-mounted housing (R) remote version

flow (at constant density), coil temperature of the flow sensor

Sandwich: DN2.5...100 / 1/10…4"

Sandwich: DN25...100 / 1…4"

This capacitive flowmeter is only available as compact version (OPTIFLUX 7300 C).

This flow sensor for measurements in partly filled pipelines is only available as a

remote field housing version (TIDALFLUX 2300 F).

With the exception of the OPTIFLUX 1000, TIDALFLUX 2000 and WATERFLUX 3000

all flow sensors are also available as Ex versions.

IFC 300 F

IFC 300 W

Compact and field housing versions are also available as Ex versions.

IFC 300 R

2

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

11

2

TECHNICAL DATA

Options

Options

OptionsOptions

Outputs / inputs

Totalizer 2 (optional 3) internal counters with a max. of 8 counter places (e.g. for counting

Verification Integrated verification, diagnostic functions: measuring device, process, measured

Communication interfaces

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Graphic display LC display, backlit white.

Operating elements 4 optical keys for operator control of the signal converter without opening the

Remote control

Current output (including HART®), pulse output, frequency output and/or status

output, limit switch and/or control input or current input (depending on the I/O

version)

volume and/or mass units)

value, empty pipe detection, stabilisation

HART®, Foundation Fieldbus, Profibus PA and DP, PROFINET IO, Modbus

Size: 128 x 64 pixels, corresponds to 59 x 31 mm = 2.32" x 1.22"

Display can be rotated in 90° increments.

Ambient temperatures below -25°C/ -13°F, may affect the readability of the display.

housing.

Infrared interface for reading and writing all parameters with IR interface (option)

without opening the housing.

PACTwareTM (including Device Type Manager (DTM))

IFC 300

HART® Hand Held Communicator from Emerson Process

AMS® from Emerson Process

PDM® from Siemens

All DTMs and drivers are available free of charge from the manufacturer's website.

Display functions

Display functions

Display functionsDisplay functions

Operating menu Setting the parameters using 2 measured value pages, 1 status page, 1 graphics

Language display texts (as

language package)

Units Metric, British and US units selectable as required from lists for volume / mass flow

page (measured values and graphics are freely adjustable)

Standard: English, French, German, Dutch, Portuguese, Swedish, Spanish, Italian

Eastern Europe: English, Slovenian, Czech, Hungarian

Northern Europe: English, Danish, Polish

China: English, German, Chinese

Russia: English, German, Russian

and counting, flow velocity, electrical conductivity, temperature, pressure

Measuring accuracy

Reference conditions Depending on the flow sensor version.

Refer to technical data for the flow sensor.

Maximum measuring error ±0.15% of the measured value ±1 mm/s, depending on the flow sensor

For detailed information and accuracy curves, refer to chapter "Measuring

accuracy".

Current output electronics: ±5 µA

Repeatability ±0.06% according to OIML R117

Not valid for WATERFLUX 3000, OPTIFLUX 7000 and TIDALFLUX 2000

12

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

IFC 300

TECHNICAL DATA

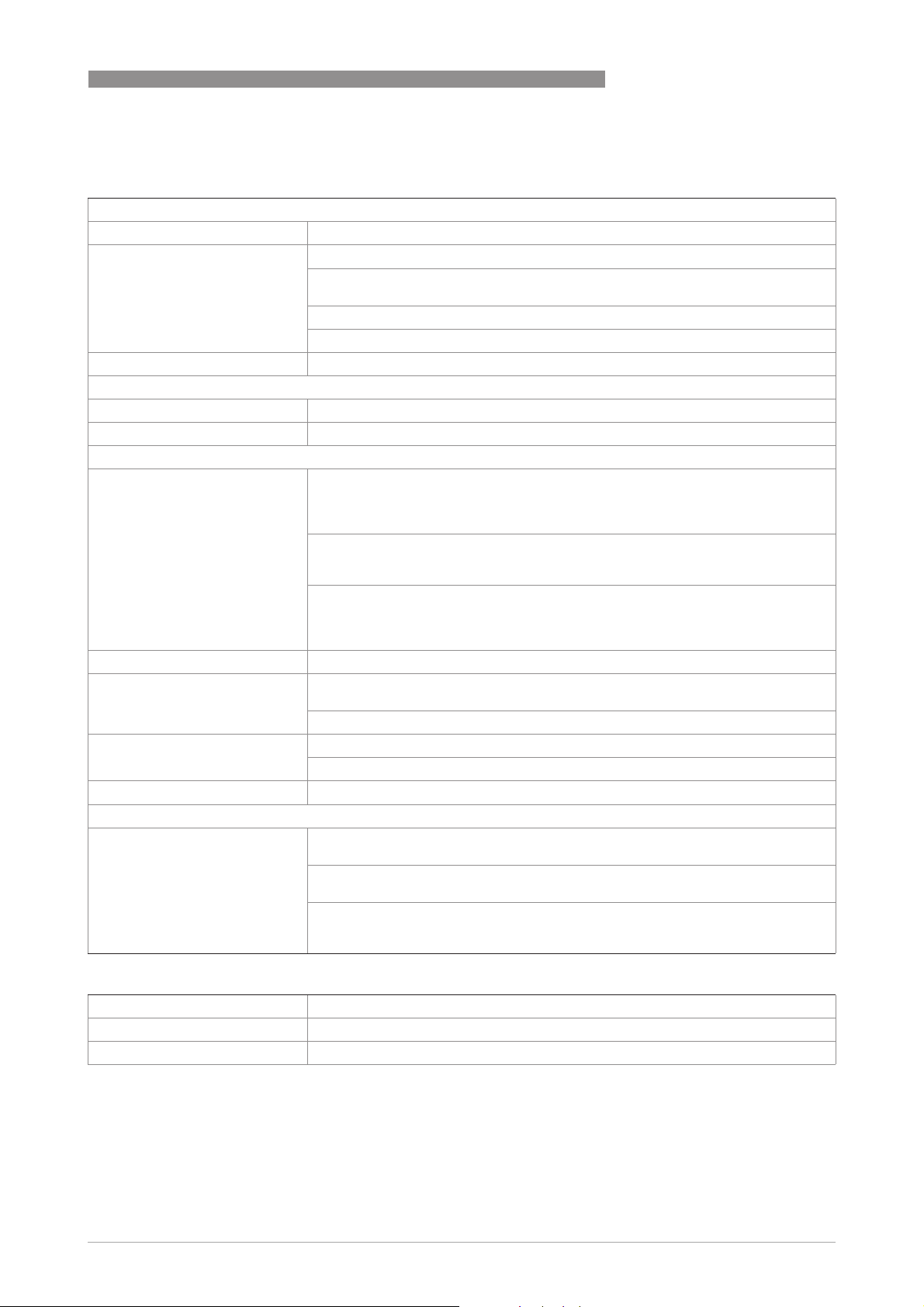

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Refer to technical data for the flow sensor.

Ambient temperature Depending on the version and combination of outputs.

It is a good idea to protect the converter from external heat sources such as direct

sunlight as higher temperatures reduce the life cycle of all electronic components.

-40…+65°C/ -40…+149°F

Ambient temperatures below -25°C/ -13°F, may affect the readability of the display.

Storage temperature -50…+70°C/ -58…+158°F

Pressure

Pressure

PressurePressure

Medium Refer to technical data for the flow sensor.

Ambient pressure Atmosphere: Height up to 2000 m / 6561.7 ft

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Electrical conductivity Standard

Physical condition Conductive, liquid media

Solid content (volume) Can be used up to ≤ 70% for OPTIFLUX flow sensors and ≤ 20% for TIDALFLUX 2000

Gas content (volume) Can be used up to ≤ 5% for OPTIFLUX and TIDALFLUX 2000 flow sensors

Flow For detailed information, refer to chapter "Flow tables".

Other conditions

Other conditions

Other conditionsOther conditions

Ingress protection according to

IEC 60529

Standard

StandardStandard

All media except for water: ≥ 1 µS/cm

(also refer to the technical data for the flow sensor)

Water: ≥ 20 µS/cm

TIDALFLUX 2000

TIDALFLUX 2000

TIDALFLUX 2000TIDALFLUX 2000

All media: ≥ 50 µS/cm

(also refer to the technical data for the flow sensor)

OPTIFLUX 7000

OPTIFLUX 7000

OPTIFLUX 7000OPTIFLUX 7000

All media except for water: ≥ 0.05 µS/cm

(also refer to the technical data for the flow sensor)

Water: ≥ 1 µS/cm

flow sensors

The greater the solid content, the less accurate the measurements!

The greater the gas content, the less accurate the measurements!

C (compact version) & F (field housing):

IP66/67 (according to NEMA 4/4X/6)

W (wall-mounted housing):

IP65/66 (according to NEMA 4/4X)

R (19" rack-mounted housing (28 TE) or (21 TE)):

IP20 (according to NEMA 1);

Use: Indoor only, level of pollution 2 and relative humidity < 75%

2

Installation conditions

Installation For detailed information, refer to chapter "Installation".

Inlet/outlet runs Refer to technical data for the flow sensor.

Dimensions and weight For detailed information refer to chapter "Dimensions and weight".

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

13

2

TECHNICAL DATA

Materials

Signal converter housing Standard

Flow sensor For housing materials, process connections, liners, grounding electrodes and

Standard

StandardStandard

Version C and F: die-cast aluminium (polyurethane coated)

Version W: polyamide - polycarbonate

Version R (28 TE): aluminium, stainless steel and aluminium sheet, partially

polyester-coated

Version R (21 TE): aluminium and aluminium sheet, partially polyester-coated

Option

Option

OptionOption

Versions C and F: stainless steel 1.4408 / 316 L

gaskets, refer to technical data for the flow sensor.

Electrical connection

General Electrical connection is carried out in conformity with the VDE 0100 directive

Power supply Standard: 100…230 VAC (-15% / +10%), 50/60 Hz

Power consumption AC: 22 VA

Signal cable Only for remote versions.

Interface cable

(only TIDALFLUX 2000)

Cable entries (except

TIDALFLUX 2000)

Cable entries (only

TIDALFLUX 2000)

"Regulations for electrical power installations with line voltages up to 1000 V" or

equivalent national regulations.

240 VAC + 5% is included in the tolerance range.

Option 1: 12...24 VDC (-55% / +30%)

12 VDC - 10% is included in the tolerance range.

Option 2: 24 VAC/DC (AC: -15% / +10%, 50/60 Hz; DC: -25% / +30%)

12 V is not

not included in the tolerance range.

notnot

DC: 12 W

DS 300 (type A)

DS 300 (type A)

DS 300 (type A)DS 300 (type A)

Max. length: 600 m / 1968 ft (depending on electrical conductivity and flow sensor

version)

BTS 300 (type B)

BTS 300 (type B)

BTS 300 (type B)BTS 300 (type B)

Max. length: 600 m / 1968 ft (depending on electrical conductivity and flow sensor

version)

Type LIYCY (only FM, Class 1 Div. 2)

Type LIYCY (only FM, Class 1 Div. 2)

Type LIYCY (only FM, Class 1 Div. 2)Type LIYCY (only FM, Class 1 Div. 2)

Max. length: 100 m / 328 ft (depending on electrical conductivity and flow sensor

version)

Type LIYCY

Type LIYCY

Type LIYCYType LIYCY

Max. length: 600 m / 1968 ft (3 x 0.75 mm

Standard: M20 x 1.5 (8...12 mm) for C, F and W version;

Terminal strip for R-version

Option: 1/2 NPT, PF 1/2 for C, F and W version

Standard: 2x M20 x 1.5 + 2x M16 x 1.5 EMC type

Option: 1/2 NPT

2

shielded cable)

IFC 300

14

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

IFC 300

TECHNICAL DATA

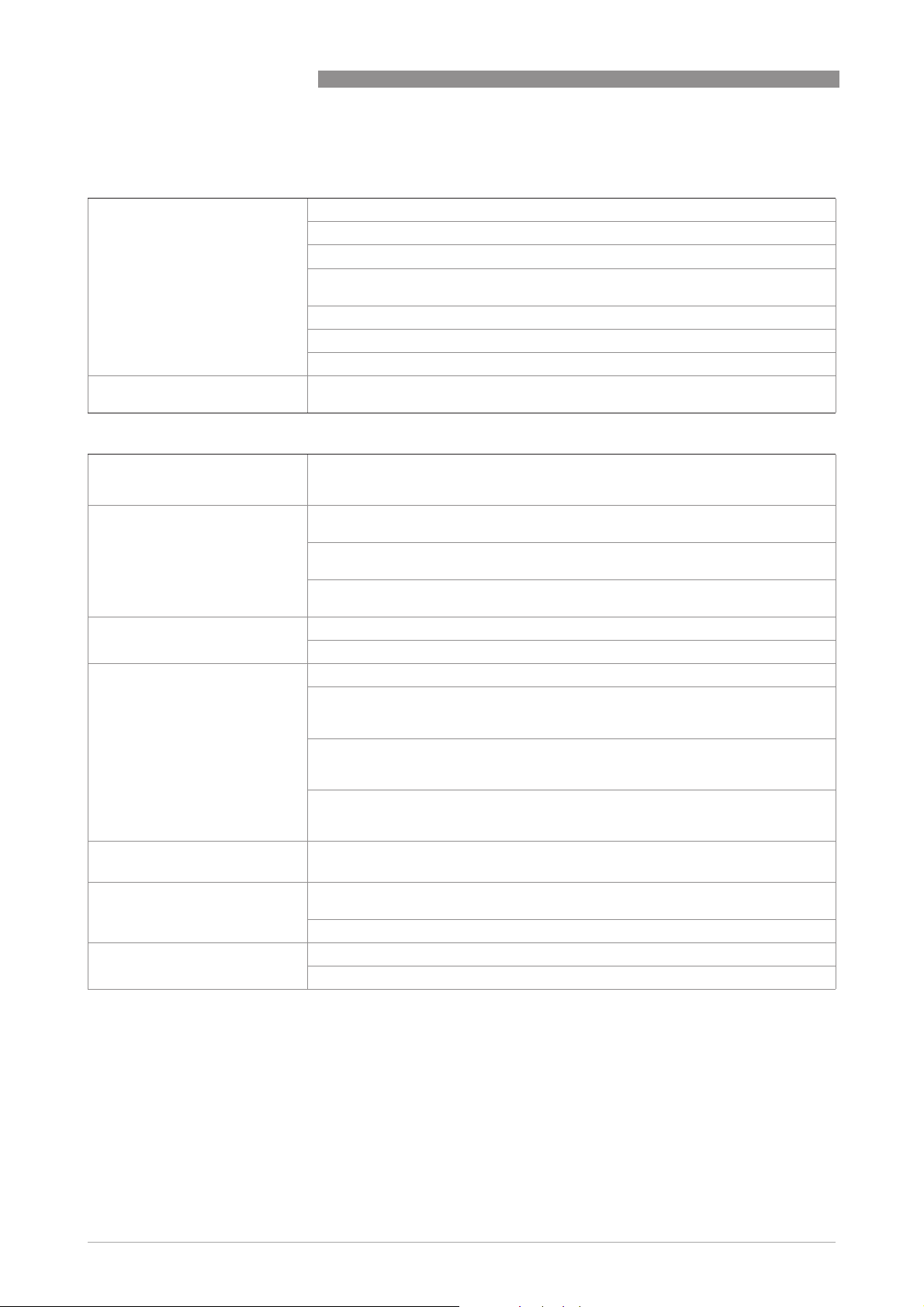

Inputs and outputs

General All outputs are electrically isolated from each other and from all other circuits.

All operating data and output values can be adjusted.

Description of used abbreviations U

Current output

Current output

Current outputCurrent output

Output data Volume flow, mass flow, diagnostic value, flow velocity, coil temperature,

Settings

Operating data Basic I/Os

Active U

= external voltage; RL = load + resistance;

ext

= terminal voltage; I

U

o

= nominal current

nom

Safety limit values (Ex i):

Ui = max. input voltage; Ii = max. input current; Pi = max. input power rating;

= max. input capacity; Li = max. input inductivity

C

i

conductivity

Without HART

Without HART

Without HARTWithout HART

®

Q = 0%: 0…15 mA; Q = 100%: 10…20 mA

Error identification: 3…22 mA

With HART

With HART

With HARTWith HART

®

Q = 0%: 4…15 mA; Q = 100%: 10…20 mA

Error identification: 3.5…22 mA

Basic I/Os Modular I/Os

Basic I/OsBasic I/Os

=24VDC

int, nom

Modular I/Os Ex i I/Os

Modular I/OsModular I/Os

Ex i I/Os

Ex i I/OsEx i I/Os

U

int, nom

=20VDC

2

Passive U

I ≤ 22 mA

≤ 1kΩ

R

L

≤ 32 VDC

ext

I ≤ 22 mA

U0≥ 1.8 V

≤ (U

R

L

ext-U0

)/I

max

I ≤ 22 mA

≤ 450 Ω

R

L

U0=21V

I0=90mA

=0.5W

P

0

C0= 90 nF / L0=2mH

=110nF/ L0=0.5mH

C

0

Linear characteristics

U

≤ 32 VDC

ext

I ≤ 22 mA

U0≥ 4V

≤ (U

R

L

ext-U0

)/I

max

Ui=30V

Ii= 100 mA

=1W

P

i

Ci=10nF

~0mH

L

i

www.krohne.com08/2017 - 4000295604 - TD IFC 300 R07 en

15

2

TECHNICAL DATA

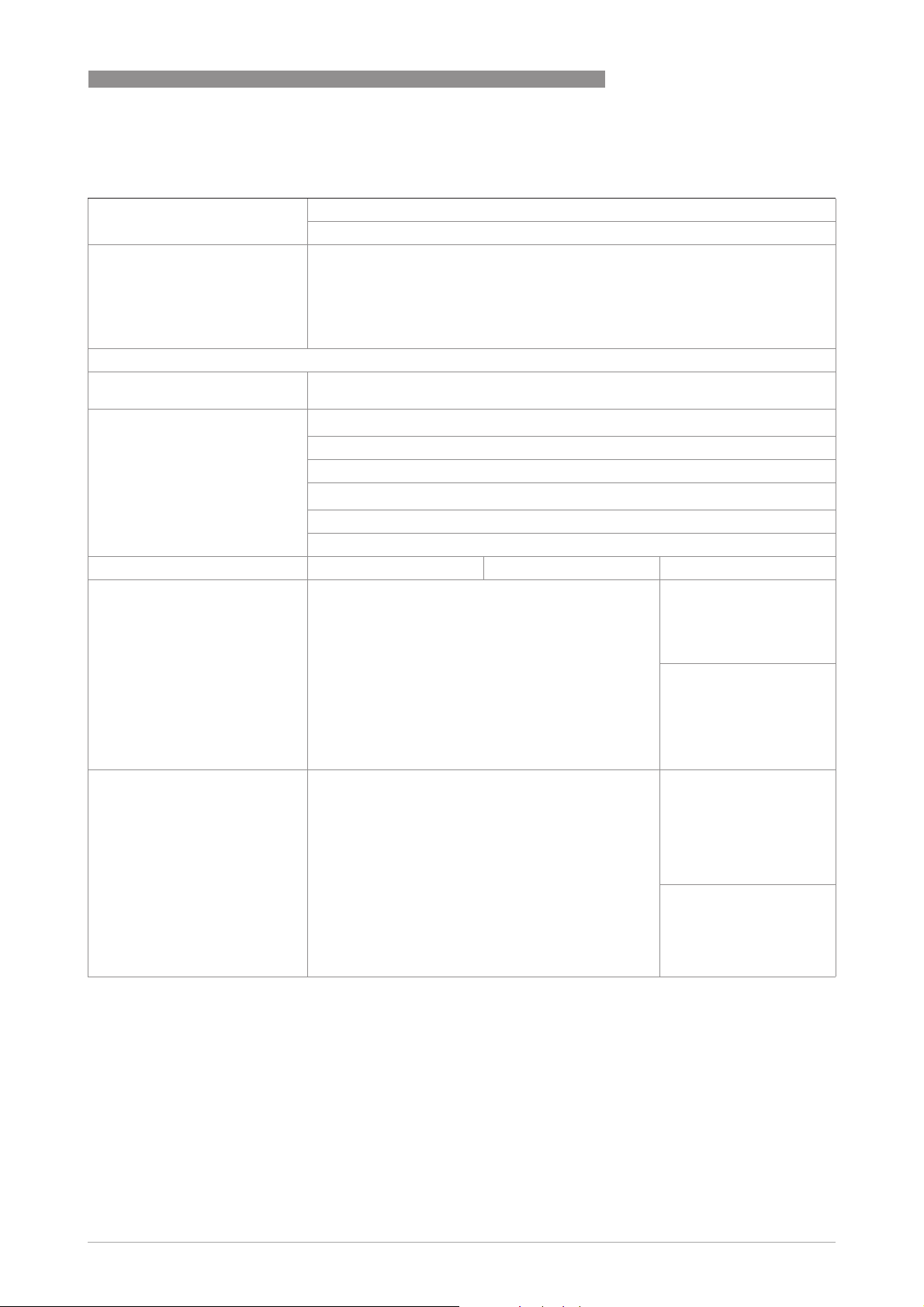

®

HART

HART

HARTHART

Description

HART® protocol via active and passive current output

HART® version: V5

Universal HART® parameter: completely integrated

Load

≥ 230 Ω at HART® test point;

Note maximum load for current output!

Multi-Drop operation Yes, current output = 4 mA

Multi-Drop address adjustable in operation menu 1…15

Device drivers Available for FC 375/475, AMS, PDM, FDT/DTM

Registration (HART

Yes

Communication Foundation)

Pulse output or frequency output

Pulse output or frequency output

Pulse output or frequency outputPulse output or frequency output

Output data Pulse output: volume flow, mass flow

Frequency output: volume flow, mass flow, diagnostic value, flow velocity, coil

temperature, conductivity

Function Adjustable as pulse or frequency output

Pulse rate/frequency Adjustable final value: 0.01...10000 pulse/s or Hz

Settings Pulses per volume or mass unit or max. frequency for 100% flow

Pulse width: setting automatic, symmetric or fixed (0.05...2000 ms)

Operating data Basic I/Os

Active - U

Basic I/Os Modular I/Os

Basic I/OsBasic I/Os

Modular I/Os Ex i I/Os

Modular I/OsModular I/Os

=24VDC -

nom

f

in operating menu set

max

Ex i I/Os

Ex i I/OsEx i I/Os

to

f

≤ 100 Hz:

max

I ≤ 20 mA

IFC 300

open:

I ≤ 0.05 mA

closed:

=24V

U

0, nom

at I = 20 mA

f

in operating menu set

max

to

100 Hz < f

max

≤ 10 kHz:

I ≤ 20 mA

open:

I ≤ 0.05 mA

closed:

= 22.5 V

U

0, nom

at I = 1 mA

U

= 21.5 V

0, nom

at I = 10 mA

=19V

U

0, nom

at I = 20 mA

16

www.krohne.com 08/2017 - 4000295604 - TD IFC 300 R07 en

Loading...

Loading...