Page 1

©

KROHNE 05/2006 7025942100

Supplementary

Installation and Operating

Instructions

Optiflux IFC300

Converter

with HART Interface

• HART/Field Communicator 275/375

• Asset Management Solutions (AMS)

• Process Device Manager (PDM)

• Field Device Tool/Device Type Manager (FDT/DTM)

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 1/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 2

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

1 General Information 3

2 IDs and Revision numbers 5

3 HART Communicator 275 (HC275), Field Communicator 375 (FC375) 6

3.1 Installation 6

3.2 Operating 6

4 Asset Management Solutions (AMS) 6

4.1 Installation 6

4.2 Operating 6

5 Process Device Manager (PDM) 7

5.1 Installation 7

5.2 Operating 7

6 Field Device Tool Device Type Manager (FDT DTM) 7

6.1 Installation 7

6.2 Operating 7

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 2/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 3

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

1 General Information

The IFC 300 is a “four-wire” transmitter with 4...20mA current output and HART® capability. Dependent on jumper

setting and wiring the current output can operate as active or passive output.

General characteristics of the IFC 300 HART® interface:

• Multidrop Mode is supported

• Burst Mode is not supported

Electrical connection: Refer to section “Electrical connection: outputs and inputs” of the following manual:

• “Handbook IFC 300 signal converter” (KROHNE)

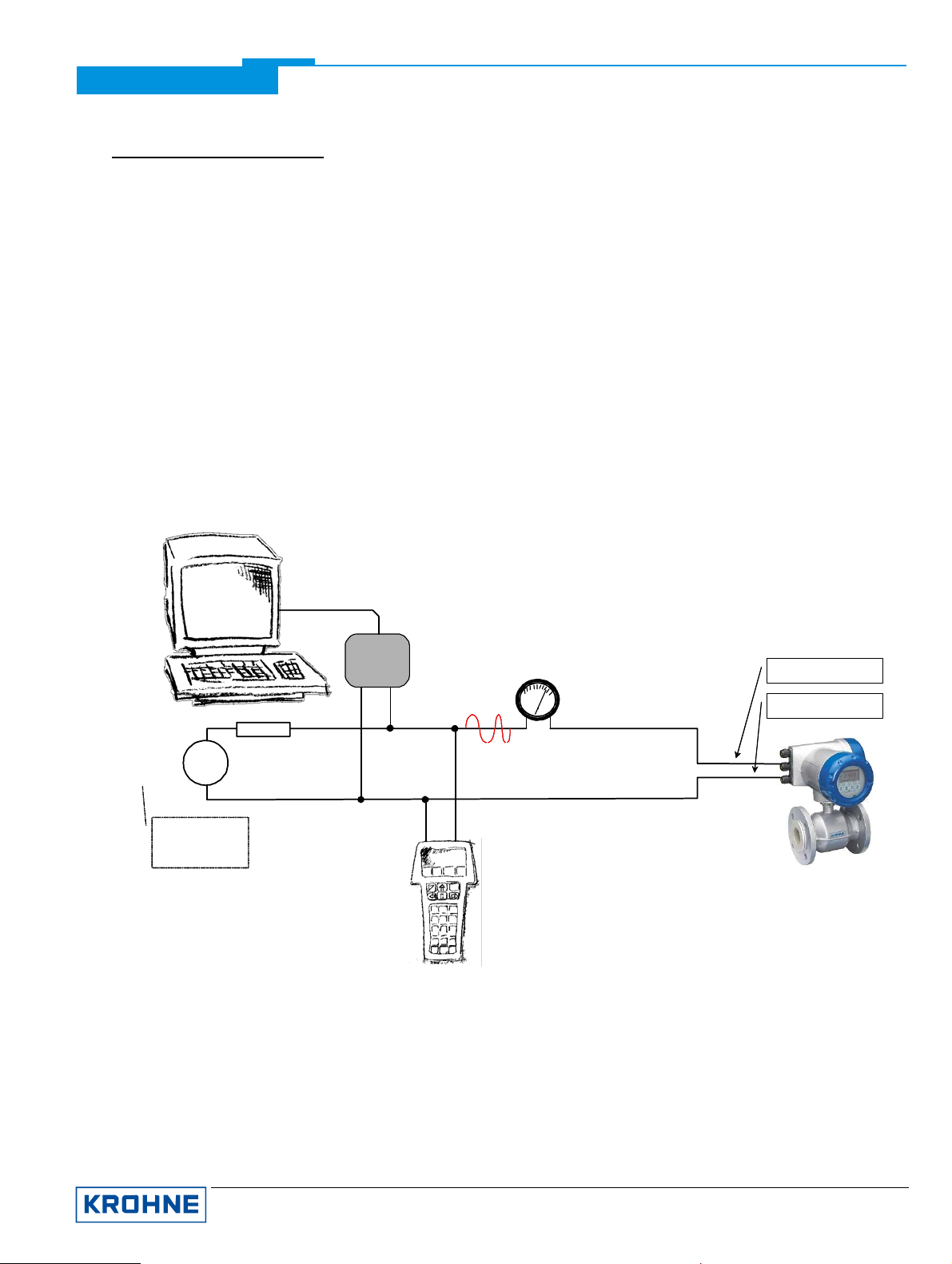

There are two ways of using the HART® communication:

a) As a point-to-point connection between the IFC 300 and the HART® master equipment. The instrument's current

output may be active or passive.

Point-to-Point Analog/Digital Mode

Primary Master

Power

Supply

For slaves with

passive current

output (2 wire)

HART

Modem

HART

≥ 250 Ω

Secondary Master

Analog

mA

420

Term inal A (C)

Terminal A- (C-)

4...20 mA

IFC 300

Addr. 0

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 3/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 4

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

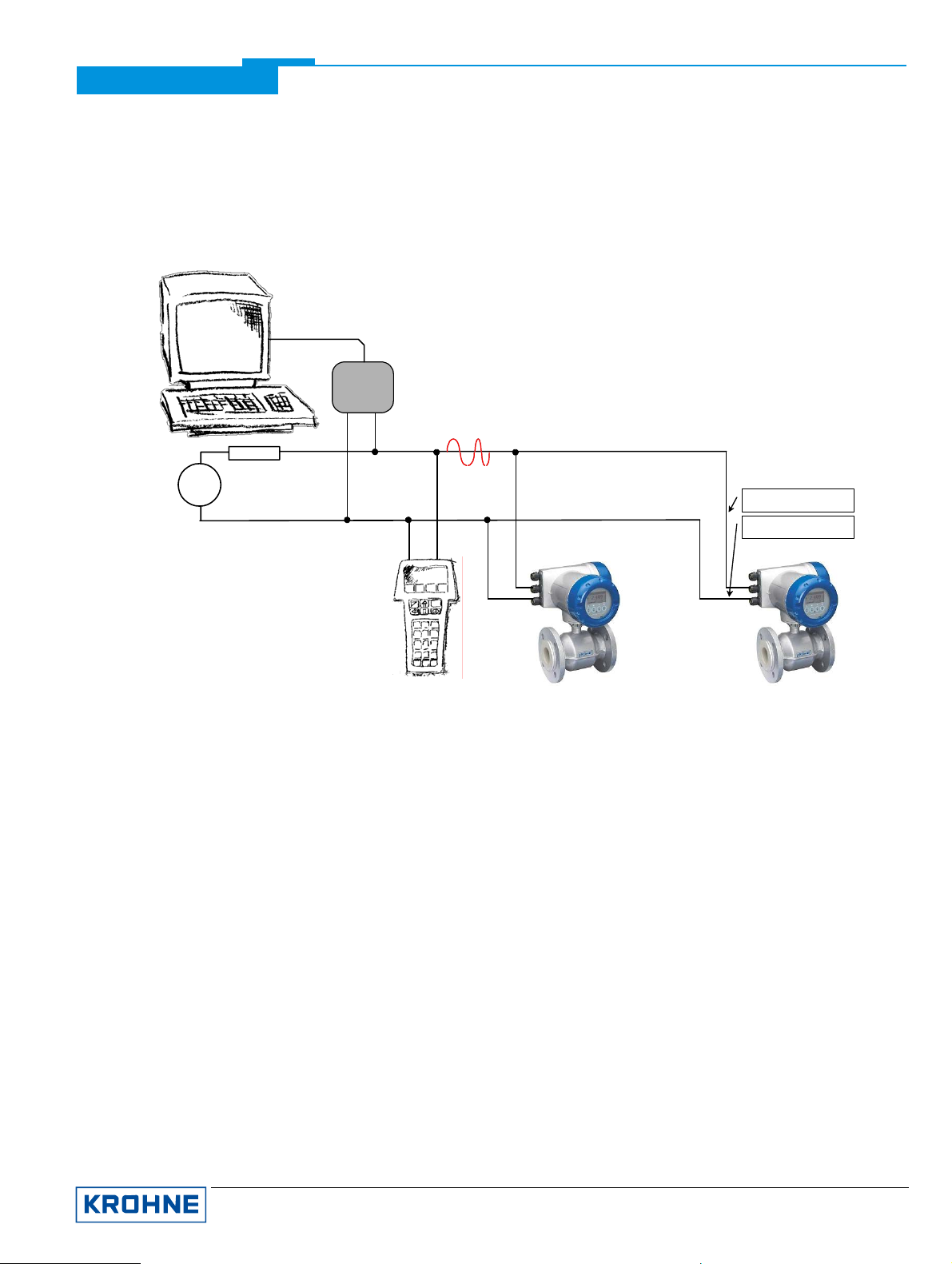

b) As a multipoint connection (multidrop) with up to 15 devices (IFC 300 or other HART® equipment) in parallel. The

instrument's current outputs must be passive.

Multidrop Mode

Primary Master

HART

Modem

HART

Power

Supply

≥ 250 Ω

Terminal A (C)

Terminal A- (C-)

4 mA 4 mA

. . .

Secondary Master Up to 15

Slaves

. . .

IFC 300

Addr. > 0

(passive current output)

IFC 300

Addr. > 0

(passi ve curr ent output)

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 4/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 5

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

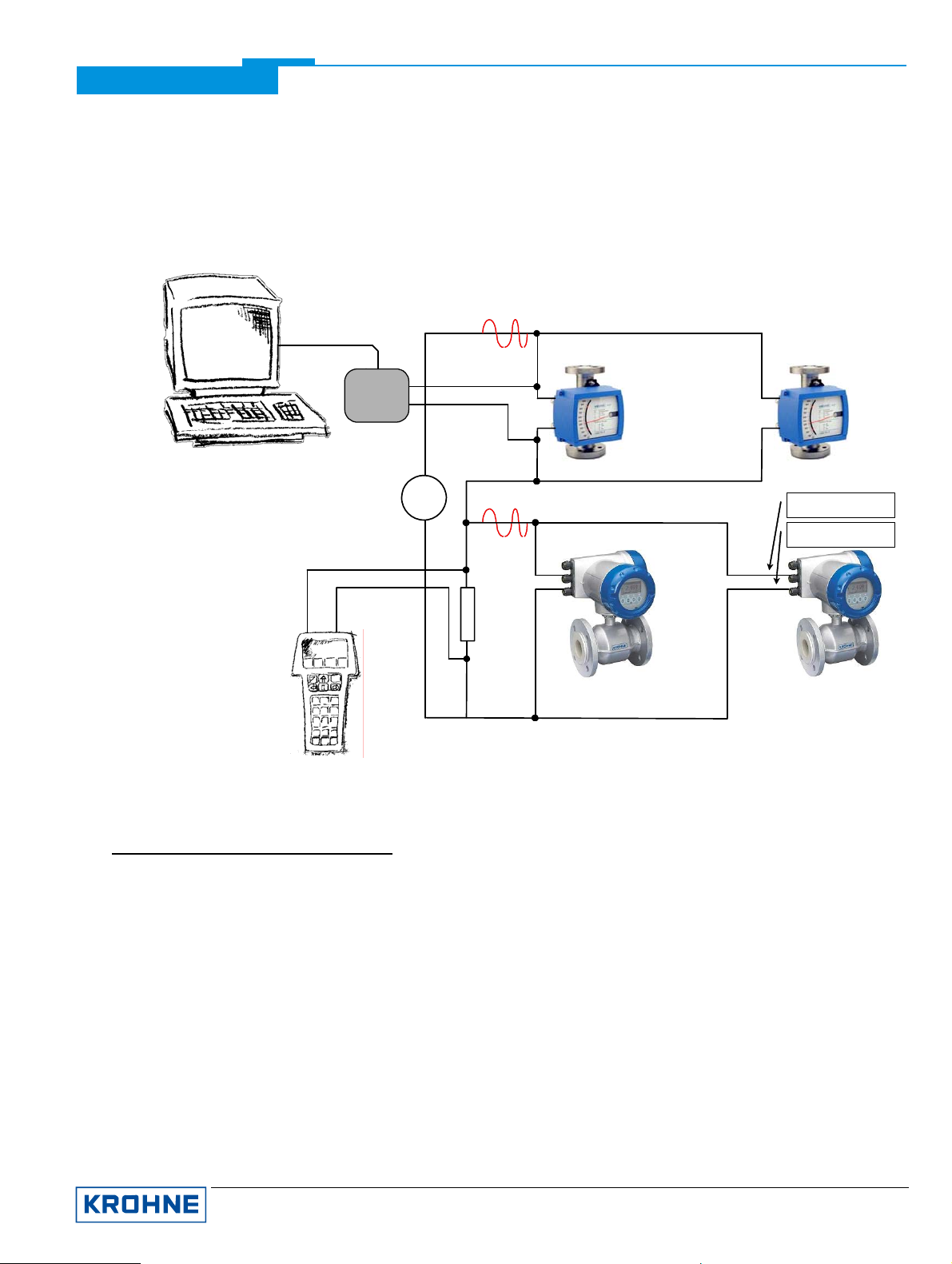

In case that the IFC 300's current output shall work continuously active a 'third wire' is needed to properly connect it

together with two-wire loop powered devices in the same network.

Multidrop Mode (‘three-wire’)

(Connecting two-wire and four-wire devices in the same network)

Secondary Master

Primary Master

HART

Mode m

Power

Supply

HART

HART

≥ 250 Ω

4 mA

two-wire

loop powered

devices

4 mA

. . .

Addr. > 0 Addr. > 0

Terminal A (C)

4 mA

IFC 30 0

Addr. > 0

4 mA

four-wire

active

source

devices

. . .

Terminal A- (C-)

IFC 300

Addr. > 0

2 IDs and Revision numbers

The HART Device Descriptions described in this document have the following IDs and revision numbers:

Manufacturer ID: 69 (0x45)

Device Type: 227 (0xE3)

Device Revision: 1

DD Revision: 2

HART Universal Revision: 5

HC 275 OS Revision: ≥ 4.9

FC 375 System SW Rev.: ≥ 1.8

AMS Version: ≥ 6.0

PDM Version: ≥ 5.2

FDT Version: ≥ 1.2

For information about Transmitter Revisions and related Device Descriptions refer to the KROHNE HART Device

List.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 5/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 6

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

3 HART Communicator 275 (HC275), Field Communicator 375 (FC375)

3.1 Installation

The IFC 300 HART Device Description has to be installed on the HC275 and FC375 respectively. Otherwise the user

will work with the instrument as a generic one thus loosing opportunity for entire instrument control.

For installing DDs on the HC275 a ‘HART Communicator Module Programmer’ is needed (se e details in the ‘Module

Programmer User’s Guide’).

For installing DDs on the FC375 the ‘Easy Upgrade Programming Utility’ is needed and the FC375 must have a

System Card with ‘Easy Upgrade’ option (see details in the ‘375 Field Communicator User’s Manual’).

3.2 Operating

Refer to the IFC 300 Menu Tree HC275 / FC375 (Attachment A).

The IFC 300 operation via HC275 / FC375 is made quite close to the manual instrument control via keypad with the

restriction that parameters of the device's "service" menu are not supported and simulation is possible only for

current outputs. The online help of each parameter contains its function number as a reference to the device’s local

display and the “Handbook”.

Parameter protection for custody transfer is the same as on the device's local display. Other specific protection

mechanisms like "password quick setup" and "password setup" are not supported via HART.

The set of parameters of the HC275 “standard configuration” is only a partial set. However th e HC275 “full

configuration” contains a complete set of supported parameters. Both types of configurations can be transferred to

AMS.

The FC375 always creates a “full” configuration for interaction with AMS. Still the FC375 considers only a partial

parameter set (like the HC275 “standard configuration”) when sending it to a device.

4 Asset Management Solutions (AMS)

4.1 Installation

If the IFC 300 Device Description is not already installed on the AMS System a so called Installation Kit IFC 300

HART AMS is needed (available as download from KROHNE ‘Download Centre’ on the internet or on floppy disk /

CD-ROM from KROHNE).

For installing the DD with the Installation Kit refer to the “AMS Intelligent Device Manager Books Online" section

"Basic AMS Functionality /Device Configurations / Installing Device Types / Procedures /Install device types from

media”. Please read also the “readme.txt”, which is also contained in the Installation Kit.

4.2 Operating

Refer to the IFC 300 Menu Tree AMS (Attachment B).

Due to AMS requirements and conventions the IFC 300 operation differs to some extent from operation with HC275 /

FC375 and via local keypad. Furthermore parameters of the device's "service" menu are not supported and

simulation is possible only for current outputs. The online help of each parameter contains its function number as a

reference to the device’s local display and the “Handbook”.

Parameter protection for custody transfer is the same as on the device's local display. Other specific protection

mechanisms like "password quick setup" and "password setup" are not supported via HART.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 6/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 7

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

5 Process Device Manager (PDM)

5.1 Installation

If the IFC 300 Device Description is not already installed on the PDM System a so called Device Install IFC 300

HART PDM is needed (available as download from KROHNE ‘Download Centre’ on the internet or on floppy disk /

CD-ROM from KROHNE).

For installing the DD on PDM V 5.2 refer to the “PDM Manual” section 11.2:”Device Install / Integrating Devices in

SIMATIC PDM with 'Device Install'".

For installing the DD on PDM V 6.0 refer to the “PDM Manual” section 13:”Integrating Devices”.

Please read also the “readme.txt”, which is also contained in the Device Install.

5.2 Operating

Refer to the IFC 300 Menu Tree PDM (Attachment C).

Due to PDM requirements and conventions the IFC 300 operation differs to some extent from operation with HC275 /

FC375 and via local keypad. Furthermore parameters of the device's "service" menu are not supported and

simulation is possible only for current outputs. The online help of each parameter contains its function number as a

reference to the device’s local display and the “Handbook”.

Parameter protection for custody transfer is the same as on the device's local display. Other specific protection

mechanisms like "password quick setup" and "password setup" are not supported via HART.

6 Field Device Tool Device Type Manager (FDT DTM)

6.1 Installation

If the IFC 300 Device Type Manager is not already installed on the Field Device Tool container a setup is needed

(available as download from KROHNE ‘Download Centre’ on the internet or on CD-ROM from KROHNE).

For installing the DTM with the setup refer to the setup’s accompanying documentation.

6.2 Operating

The IFC 300 operation via DTM is made quite close to the manual instrument control via keypad. Refer to the

device’s local display and the “Handbook”.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 7/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 8

Attachment A

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree HC275 / FC375

1 dynamic

variables

2 quick setup

3 test

4 setup

Designations:

Opt

Optional, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Loc al HC275/FC375,

affects only HC275/FC375 vie ws

1 measuredvalues

1 volum eföw

2 mass flow

3 flow speed

4 conductivity

5 coiltemperature

6 counter 1

7 counter 2

2 in/out puts

1 A

2 % range A

3 B

4 % rangeB

5 C

6 % rangeC

7 D

8 % rangeD

1 language

2 tag

3 reseterrors

4 unit A/C

5 range A/C mi n

6 range A/C max

7 time constant A/C

8 lfc threshold A/C

9 lfchysteresis A/C

7 pulse val. unit

8 pulse valueD

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

1 simul. current/frequency A

2 simul. current/frequencyB

3 simul. current C

4 simul. frequency D

Opt

Opt

1 calibration

1 process input

2 filter

3 self test

4 information

5 sensorlimits

2 I/O

2

3 comm unication

4 device

3

Opt

Opt

Opt

Opt

Opt

Opt

Opt

Opt

Opt

Opt

1 zero calibration

2 zero set

Cust

3 size

4 GK selection

5 GK / GKH

Opt, Cust

6 GKL

7 coilresist. Rsp

8 density

9 targe tconductivity

10 EF electr. factor

11 num. of elec trodes

12 field frequency

13 select settling

14 settling time

15 linefrequency

Opt

Opt

1 limitation min

2 limitation max

3 flow directi on

4 time constant

5 pulse filter

6 pulse width

7 pulse limitation

8 noise filter

9 noise leve l

10 n. sup pression

11 lfc threshold

12 lfchysteresis

1 liner

2 electrodematerial

Cust

Cust

Cust

Opt, Cust

Opt, Cust

Cust

Opt, Cust

Cust

Opt, Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

Cust

Cust

Cust

Cust

1 empty pipe

2 limitempty pipe

3 fullpipe

4 limitfull pipe

5 linearity

6 gain

7 coil current

8 flow profile

Cust

Opt, Cust

Opt, Cust

Cust

Cust

Cust

Cust

9 limit flow profile

10 elect rode noise

11 limit elect. noise

12 settling of field

Opt, Cust

Opt, Cust

Cust

Opt, Cust

Cust

1 volum eflow

2 mass flow

3 flowspee d

4 conductivity

1 uppersnsr limit

2 lowersnsr limit

3 minimum span

Rd

Rd

Rd

5 coiltemperature

KROHNE IFC 300 HA 45e30102 (1/3)

06/05

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 8/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 9

1 dynamic

variables

2 quick setup

3 test

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree HC275 / FC375

1

4 setup

1 process input

2 I/O

1

1 hardware

2 A

3 B

4 C

5 D

1 terminals A

2 terminalsB

3 terminalsC

4 terminalsD

current output

1 range0%

2 range100%

3 ext. ra nge min

4 ext. ra nge max

5 errorcurrent

6 errorcondition

7 measurement

8 rangemin

9 rangemax

10 polarity

11 limitmin

12 limi tmax

13 lfc threshold

14 lfchysteresis

15 time constant

16 special function

17 rc threshold

18 rc hysteresis

frequency output

1 pulse shape

2 pulse width

3 100% pul se rate

4 measurement

5 rangemin

6 rangemax

7 polari ty

8 limitmin

9 limitmax

10 lfc threshold

11 lfchysteresis

13 time constant

14 invert signal

Cust

Cust

Cust

Cust

Opt

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

15 special function

16 phas eshift w. B

:

Opt

Cust

:

Cust

Opt, Cust

Opt, Cust

Cust

Opt

:

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

pulse ou tput

1 pulse shape

2 pulse width

3 max pulse rate

4 measurement

5 pulse valueunit

6 value p. pulse

7 polari ty

8 lfc threshold

9 lfchysteresis

10 time constant

11 invert signal

12 special functio n

13 phaseshift w. B

statusoutput

1 mode

2 outputA

output B

output C

output D

Opt

:

Opt

Opt

Opt

Opt

3 invert signal

Opt

limit switch

:

1 measurement

2 threshold

3 hysteresis

4 polari ty

5 time constant

6 invert signal

Cust

Opt

:

controlinput

1 mode

2 invert signal

Cust

Opt, Cust

Opt, Cust

Designations:

Opt

Optional, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Loc al HC275/FC375,

affects only HC275/FC375 vie ws

3 comm unication

4 device

6 counter1

7 counter2

3

1 functi on

2 measurement

3 lfc threshold

4 lfchysteresis

5 time constant

6 presetvalue

Cust

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

KROHNE IFC 300 HA 45e30102 (2/3)

06/05

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 9/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 10

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree HC275 / FC375

1 dynamic

variables

2 quick setup

3 test

4 setup

1

1 process input

2 I/O

3 communication

1

2

1 HART

1 address

2 D/A trim

3 apply values

Cust

Cust

4 message

5 descriptor

6 deviceinformatio n

7 dynamic variables

settings

8 preambles

9 master reset

1 manufa cturer

2 model

3 deviceID

Rd

Rd

Rd

3 tag

4 date

5 write protect

Rd

6 final assemblyno.

7 sensorserial no.

8 revision nos.

1 universal rev.

2 devicerev.

3 software rev.

4 hardware rev.

1 PV is

Rd

Rd

Rd

Rd

Rd

2 SV is

3 TV is

4 4V is

1 request preams

Rd

2 response preams

Designations:

Opt

Optional, depend ent on device

implementation / configuration

Rd

Read-only

Cust

Custody Lock prote ct ed

Loc

Loc al HC275/FC375,

affects only HC275/FC375 views

4 device

1 deviceinfo

2 display

3 1. meas. page

4 2. meas. page

3 special functions

4 units (device)

5 units (HART)

6 formats(HART)

7 circuit board info

1 tag

2 C number

Rd

1 language

2 default display

1 list errors

2 reset errors

1 volume flow

2 mass flow

Cust

3 flow speed

4 conductivity

5 temperature

6 volume

7 mass

8 density

Cust

Cust

Cust

1 volume flow

2 mass flow

3 flow speed

4 conductivity

5 temperature

6 counter 1

7 counter 2

Cust

Cust

Cust

Cust

1 functi on

2 meas urem. 1. line

3 rangemin

4 rangemax

5 limitation min

6 limitation max

7 lfc threshold

8 lfchystereis

Cust

9 time constant

10 format 1. line

11 meas urem. 2. line

12 format 2. line

13 meas urem. 3. line

14 format 3. line

KROHNE IFC 300 HA 45e30102 (3/3)

06/05

Cust

Cust

Cust

Cust

Cust

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 10/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 11

Attachment B

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree AMS

Configure

Compare

Clear Offline

-----------------------------------

Status/Conditions

Process Variables

Scan Device

-----------------------------------

CalibrationManagement

Diagnostics and Test

Calibrate

Reset

----------------------------------Rename

Unassign

Assign / Replace

----------------------------------Audit Trail

Record Manual Event

Drawings / Notes ...

Help ...

quick setup

device:

•language

•tag

pulse output D:

• pulse va lue unit

• value p. puls e D

4

5

input calibration

• zero set

•size

5

• GK selection

•GK / GKH

•GKL

• coil resist. Rsp

•density

input filter

• limitation max

• limitation min

•flow direction

• time constant

• pulse filter

• pulse width

• pulse lim itation

Cust

Opt, Cust

Cust

Cust

Cust

Opt, Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

Cust

current output A/C:

•unit A/C

• range A/C max

• range A/C min

Cust

Cust

Cust

• time constant A/C

• lfc threshold A/C

• lfc hysteresis A/C

• target conductivity

• EF electrode factor

• num. of electrodes

• field frequency

• select settling

• settlin g time

• line frequency

• noise filter

• n o i s e level

Cust

Cust

Opt, Cust

Cust

Cust

Cust

• noise suppression

• lfc threshold

• lfc hysteresis

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

sensor

volume flow sensor limits:

• upper sensor limit

• lower sensor limit

• minimum span

Rd

Rd

Rd

mass fl ow sensor limits:

...

flow spee d sensor limits:

...

conductivity sensor limits:

...

coil temperature snsr limits:

...

Designations:

Opt

Opti onal, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Local AMS, affects only AMS views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 11/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

self test / info

self test:

•empty pipe

• limit empty pipe

• full pipe

• limit fu ll pipe

•linearity

•gain

• coil current

Cust

Opt, Cust

Opt, Cust

Cust

Cust

Cust

Opt, Cust

self test:

• flow pr of i le

• limit flow pro f ile

• electrode noise

• limit elec t. no ise

• settling of field

Cust

Cust

Cust

information:

•liner

•electrode material

Opt, Cust

Opt, Cust

KROHN E IFC 300 HA 45e30102 (1/5)

06/05

Page 12

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree AMS

I/O terminals A/B/C/D

•terminals

Cust

Cust

Cust

Opt

Cust

Cust

Cust

Cust

Cust

Cust

:

• range 100%

• range 0%

• ext. range max

• ext. range min

• error cu rr ent

• error condition

• special function

• rc threshold

•rchysteresis

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

current output

• measurement

• limitation max

• limitation min

• time constant

•polarity

•lfcthreshold

• lfc hysteresis

• range max

• range min

Configure

Compare

Clear Offline

-----------------------------------

Status/Conditions

Process Variables

Scan Device

-----------------------------------

CalibrationManagement

Diagnostics and Test

Calibrate

Reset

----------------------------------Rename

Unassign

Assign / Replace

----------------------------------Audit Trail

Record Manual Event

Drawings / Notes ...

Help ...

4

5

5

frequency output

• measurement

• limitation max

• limitation min

• time constant

•polarity

Cust

•lfcthreshold

• lfc hysteresis

• range max

• range min

pulse output

Cust

Cust

Opt

• measurement

• time constant

•polarity

Cust

•lfcthreshold

• lfc hysteresis

status output

Opt

•mode

Opt

limit switch

:

• measurement

• time constant

•polarity

• threshold

•hysteresis

control input

•mode

Opt

Cust

Cust

Cust

Opt

:

Cust

Cust

Cust

• pulse shape

• pulse width

• 100% pulse rate

•invert signal

• special function

Cust

:

Cust

• phase shift wrt. B

• pulse va lue unit

• value p. puls e

• pulse shape

• pulse width

Cust

• max pu ls e rat e

•invert signal

• special function

• phase shift wrt. B

:

•output A

•output B

•output C

•output D

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt, Cust

Opt, Cust

Opt

Opt

Opt

Opt

•invert signal

•invert signal

:

•invert signal

Designations:

Opt

Opti onal, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Local AMS, affects only AMS views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 12/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

counter

counter 1:

• function

• measurement

•lfcthreshold

• lfc hysteresis

• time constant

•preset value

Cust

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

counter 2:

• function

Cust

• measurement

• lfc threshold

• lfc hysteresis

• time constant

•preset value

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

KROHN E IFC 300 HA 45e30102 (2/5)

06/05

Page 13

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree AMS

device

Configure

Compare

Clear Offline

-----------------------------------

Status/Conditions

Process Variables

Scan Device

-----------------------------------

CalibrationManagement

Diagnostics and Test

Calibrate

Reset

----------------------------------Rename

Unassign

Assign / Replace

----------------------------------Audit Trail

Record Manual Event

Drawings / Notes ...

Help ...

device info:

•tag

• C number

display:

•language

• default displa y

1./2. meas page

• function

• measurem. 1. line

• limitation max

• limitation min

4

• time constant

• lfc threshold

5

• lfc hysteresis

• range max

• range min

• format 1. line

HART

identification:

5

• manufacturer

•model

•device ID

•address

•tag

•date

•message

• descriptor

• write protect

•final assembly no.

•sensor serial no.

HART units

display formats:

•volume flow

•mass flow

•flow speed

• conductivity

•temperature

• counter 1

• counter 2

units:

Rd

•volume flow

•mass flow

Cust

Cust

•flow speed

• conductivity

Cust

Cust

Cust

Cust

Cust

Rd

Rd

Rd

Rd

Loc

Loc

Loc

Loc

Loc

Loc

Loc

•temperature

•volume

•mass

•density

• measurem. 2. line

• format 2. line

• measurem. 3. line

• format 3. line

revision numbers:

•universal rev.

•device rev.

• software rev.

• hardw a re rev.

Cust

Cust

Cust

Cust

Cust

Rd

Rd

Rd

Rd

preambles:

• request preambles

• respon s e pr eambles

units:

•volume flow

•mass flow

•flow speed

• conductivity

•temperature

• counter 1

• counter 2

Cust

Cust

dynamic variables settings:

•PV is

•SV is

•TV is

•4V is

Rd

Rd

Designations:

Opt

Opti onal, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Local AMS, affects only AMS views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 13/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

KROHN E IFC 300 HA 45e30102 (3/5)

06/05

Page 14

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree AMS

Configure

1,2,3

Compare

Clear Offline

-----------------------------------

Status/Conditions

Process Variables

5

Scan Device

-----------------------------------

CalibrationManagement

Diagnostics and Test

Calibrate

5

Reset

----------------------------------Rename

Unassign

Assign / Replace

----------------------------------Audit Trail

Record Manual Event

Drawings / Notes ...

Help ...

Overview

Standard:

• Primary variable out of

limits

• Non -primary va riable ou t

of limit s

• Primary variable analog

output satur at ed

• Primary variable analog

output fixed

•Cold start

• Configuratio n changed

• Field device malfunction

Application error

•application error

•empty pipe

• flow rate too h igh

• field frequency too high

•DC offset

• open circuit A

• open circuit B

• open circuit C

Uncertain

• uncertain measurement

• pipe not full

•empty pipe

•linearity

• flow pr of i le

•electrode noise

•gain error

• elect ro de s ymmetry

Failure in device

• error in device

•IO1

• parameter

•IO2

• configuration

•display

• sensor electronic

•sensor global

•sensor local

• over range A (current)

• over range B (current)

• over range C (current)

• over rang e A (pu lse)

• over range B (pulse)

• over rang e D (pu lse)

• active settings

• factory settings

• backup 1 settings

• backup 2 settings

• field coil br ok en

• field coil br id ged

• field cu rr en t devia tion

• field frequency too high

• electronic temperature

• coil temperature

• overflow counter 1

• overflow counter 2

• backplane invalid

• field current loca l

• current output A

• current output B

• current output C

• software user interface

• hardware settings

• hardwa re d ete ction

•RAM/ROM error IO 1

•RAM/ROM error IO 2

Check req. & Info rmation

check request:

• checks in progress

• test sensor

information:

• counter 1 stopped

• counter 2 stopped

• power fail

• contro l input A act iv e

• contro l input B activ e

• over range display 1

• over range display 2

• backpl ane se nsor

• backplane settings

• backplane difference

• optical interface

Designations:

Opt

Opti onal, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Local AMS, affects only AMS views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 14/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

KROHN E IFC 300 HA 45e30102 (4/5)

06/05

Page 15

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree AMS

Configure

Compare

Clear Offline

-----------------------------------

Status/Conditions

Process Variables

Scan Device

-----------------------------------

CalibrationManagement

Diagnostics and Test

Calibrate

Reset

----------------------------------Rename

Unassign

Assign / Replace

----------------------------------Audit Trail

Record Manual Event

Drawings / Notes ...

Help ...

1,2,3

process values:

• volume flow

•mass flow

•flow speed

• conductivity

• coil temperature

4

Device:

Rd

•tag

• descriptor

Rd

Simulat ion cu rr ent output A/C

Simulation current/frequency output A

Simulation current/frequency output B

Simulation frequency output D

Circuit Board Info

Autom. zero calibration

D/A trim

Apply va lu es

Cust

Cust

Cust

Master Reset

Reset Errors

Reset C onfiguration Changed Flag

counter:

• counter 1

• counter 2

HART:

• Polling Address

•Device ID

Opt, Cust

Opt, Cust

Opt, Cust

Opt, Cust

outputs:

Opt

Opt

Rd

Rd

Opt

•A

• % range A

Opt

•B

• % range B

Opt

•C

• % range C

Opt

•D

• % range D

Opt

Opt

Opt

Opt

Designations:

Opt

Opti onal, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Local AMS, affects only AMS views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 15/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

KROHN E IFC 300 HA 45e30102 (5/5)

06/05

Page 16

Attachment C

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree PDM

Menu Bar

File Device View Options Help

Communication Pa th

----------------------------------Load To Device

Load To PG/PC

----------------------------------Set Addres s

-----------------------------------

Test

Reset

Calibration

-----------------------------------

Parameter Protection

2,3

Test

• simuation. current/frequency A

• simuati on current/f requency B

• simuation current C

Opt, Cust

• simuation frequency D

Opt, Cust

Opt, Cust

Reset

•<master reset>

• <reset errors>

• <reset configuration changed flag>

Calibration

• automatic zero calibration

•D/A trim

• apply values

Cust

Cust

Cust

Opt, Cust

-----------------------------------

HART

Designations:

Opt

Opti onal, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Loc k pr ote cted

Loc

Local PDM, affects only PDM views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 16/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

HART

preambles

• request preambles

• respon se preambles

dynamic variables settings

Rd

•PV is

•SV is

•TV is

•4V is

Rd

KROHN E IFC 300 HA 45e30102 (1/5)

06.05

Page 17

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree PDM

Menu Bar

1

File Device View Options Help

Display

Yt Diagram

Outputs

Measured Values

• volume flow

•mass flow

•flow speed

• conductivity

• coil tem pe ra tu re

• devic e status

Y t Diagram

• volume flow

•mass flow

Outputs

curren t/f r eq uency o. A

•measured value

Opt

•A

•% range A

curren t/f r eq uency o. B

•measured value

Opt

•B

•% range B

Opt

Opt

Opt

Opt

Counters

• counter 1

• counter 2

Opt

:

current output C

• meas u r e d value

Opt

•C

•% range C

Opt

:

frequency output D

• meas u r e d value

Opt

•D

•% range D

Opt

Opt

Opt

:

Opt

Opt

Opt

:

Opt

Opt

Device St at us

Circuit Board I nfo

----------------------------------Toolbar

Status Bar

----------------------------------Update

Designations:

Opt

Optional, dependent on device

implementation / configuratio n

Rd

Read-only

Cust

Custod y Lo ck prot ect ed

Loc

Local PDM, affects only PDM views

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 17/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

3

KROHNE IFC 300 HA 45e30102 (2/5)

06.05

Page 18

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree PDM

Menu Bar

1

File Device View Options Help

Display

Yt Diagram

3

Outputs

Device Status

Circuit Board Info

----------------------------------Toolbar

Status Bar

----------------------------------Update

device

• C number

HART:

•tag

• manufacturer

Rd

•model

•device ID

• universal revision

• device revision

• software revision

• hardware revision

• date

Rd

• writ e protec t

• final assembly no.

Rd

• sensor serial no.

failure / application

failure in device:

• error in device

•IO1

• parameter

•IO2

• configuration

•display

• sensor electronic

• sensor global

uncertain / checks / info

uncertain:

• unc ertain measurement

• pipe not full

•empty pipe

•linearity

• flow pr of il e

•electrode noise

•gain error

• electrode symmetry

•field coil broken

• field coil bridged

• field current deviation

Rd

Rd

Rd

Rd

Rd

Rd

Rd

Rd

failure in device:

• sens or local

• field current local

• current output A

• current output B

• current output C

• soft ware user interface

• hardwa re s ettings

• hardwa re d et ec tion

•RAM/ROM error IO 1

•RAM/ROM error IO 2

• field frequency too high

• elect ronic temperature

• coil temperat u r e

• overflow counter 1

• overflow counter 2

• backplane invalid

check request:

• checks in progress

•test sensor

standard

overview:

• Primary variable out of li mits

• Non-primary variable out of limits

• AO outside the operating ra ng e limits

• Analog Output in fixe d mode

•Cold start

• Configuration changed

• Field device malfunction

application error:

• application error

• empty pi pe

•flow rate too high

• field freq uenc y too hi gh

•DC offset

•open circuit A/B/C

• over range A/B/C (current)

• over range A/B/D (pulse)

• active settings

•factory settings

• backup 1/2 settings

information:

• counter 1 stopped

• counter 2 stopped

•power fail

• control input A active

• control input B ac tive

• over ra nge display 1

• over ra nge display 2

• backpl ane sensor

• backpl ane settings

• backplane difference

•optical interface

Designations:

Opt

Optional, dependent on device

imple me ntation / configura tion

Rd

Read-only

Cust

Custo d y Lock protecte d

Loc

Local PDM, affects only PDM views

KROHNE IFC 300 HA 45e30102 (3/5)

06.05

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 18/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 19

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree PDM

Parameter Table

identification

operation unit

device

-----------------------------------

input

calibration

filter

self test

information

measuring limits

-----------------------------------

IO

Opt

A

Opt

B

Opt

C

Opt

D

counter 1

counter 2

-----------------------------------

human interface

local display

units (device)

units (HART)

formats(HART)

5

5

identification

operation unit

•tag

• descriptor

•message

device

•C number

• manufacturer

•model

•device ID

Rd

Rd

Rd

• universal revision

• device revision

• software revision

• hardware revision

• date

• final assembly no.

• sensor serial no.

input

calibration

•zero set

•size

• GK selection

•GK/GKH

•GKL

•density

Cust

Opt,

Cust

Cust

Cust

Opt,

Cust

Cust

• target conductivity

• EF electrod e fa ct o r

• number of electro des

• field frequency

• select settling

• settling time

Cust

Opt,

• line frequency

filter

• limitation min

• limitation max

• flow direction

• time constant

• pulse filter

•pulse width

• pulse limitation

• noise filter

• noise level

• noise suppression

•lfcthreshold

•lfchysteresis

Cust

Cust

Opt,

Opt,

Cust

Cust

Cust

...

Cust

Cust

Cust

Cust

Cust

Rd

Cust

Cust

Opt,

input

...

self test

• empty pipe

• limit empty pipe

• full pipe

• limit full pipe

•linearity

•gain

• coil current

• flow profile

Rd

Rd

Rd

Rd

• limit flow profile

• electrode noise

• limit elect. noise

• settling of field

information

Cust

Cust

Cust

Cust

Cust

Cust

Opt,

Cust

Cust

Opt,

Cust

Opt,

Opt,

Cust

Cust

Cust

•liner

• elect rode materia l

measuring limits

volum e flow

• upper sensor limit

• lower sensor limit

•minimum span

Rd

Rd

Rd

mass flow

• ...

flow spe ed

Cust

Cust

• ...

conductivity

• ...

coil temper ature

• ...

...

Cust

Opt,

Cust

Designations:

Opt

Optional, dependent on device

imple me ntation / configura tion

Rd

Read-only

Cust

Custo d y Lock protecte d

Loc

Local PDM, affects only PDM views

KROHNE IFC 300 HA 45e30102 (4/5)

06.05

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 19/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Page 20

Supplementary Installation and Operating Instructions IFC 300 HART

HC275, FC375, AMS, PDM, FDT DTM

IFC 300 HART Menu Tree PDM

Parameter Table

identification

operation unit

device

-----------------------------------

input

calibration

filter

self test

information

measuring limits

-----------------------------------

IO

Opt

A

Opt

B

Opt

C

Opt

D

counter 1

counter 2

-----------------------------------

human i nterface

local display

units(device)

units(HART)

formats (HART)

Designations:

Opt

Optional, dependent on device

implementation / configuration

Rd

Read-only

Cust

Custod y Lo ck prot ected

Loc

Local PD M , affect s only PDM views

4

4

output

•terminals A

•terminals B

•terminals C

•terminals D

A/B/C/D

current output

• range 0%

Cust

Cust

Cust

Cust

Opt

Cust

• range 100%

• ext. range min

• ext. range max

• error current

• error condition

• measurement

• range min

• range ma x

•polarity

•limit min

•limit max

Cust

Cust

Cust

Cust

Cust

• lfc threshold

• lfc hysteresis

• time co nstant

• special function

• rc threshold

•rchysteresis

frequency output

• pulse shape

•pulse width

• 100% pulse rate

• measurement

• range min

• range ma x

•polarity

•limit min

•limit max

Cust

Cust

Cust

Cust

Cust

• lfc threshold

• lfc hysteresis

• time co nstant

• invert signal

• special function

• phase s hift wrt. B

pulse output

Opt

• pulse shape

•pulse width

• max pulse rate

• measurement

• puls e v alu e unit

• value p. pulse

•polarity

Cust

• lfc threshold

• lfc hysteresis

• time co nstant

• invert signal

• special function

• phase s hift wrt. B

...

Opt,

Cust

Cust

Cust

Cust

Opt

Cust

Cust

Cust

Opt,

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

:

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Cust

Opt

...

status output

•mode

•output A

•output B

•output C

•output D

:

• invert signal

limit switch

Opt

:

Opt

Opt

Opt

Opt

Opt

:

•measurement

•threshold

•hysteresis

•polarity

• time constant

• invert signal

Cust

Opt

:

control input

•mode

• invert signal

human interface

Cust

Cust

:

Cust

local display

•language

• default display

units (device)

•volume flow

•mass flow

Cust

• flo w speed

• conductivity

• temperature

•volume

•mass

•density

Cust

Cust

Cust

Cust

Cust

units (HART)

•volume flow

•mass flow

• flo w speed

• conductivity

Opt,

Opt,

Cust

Cust

• temperature

• counter 1

• counter 2

Cust

Opt,

Opt,

formats ( HART)

•volume flow

•mass flow

• flow speed

• conductivity

• temperature

• count er 1

• count er 2

Cust

Cust

Loc

Loc

Loc

Loc

Loc

Loc

Loc

KROHNE IFC 300 HA 45e30102 (5/5)

06.05

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 20/20

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Loading...

Loading...